Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5893results about "Insulating conductors/cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

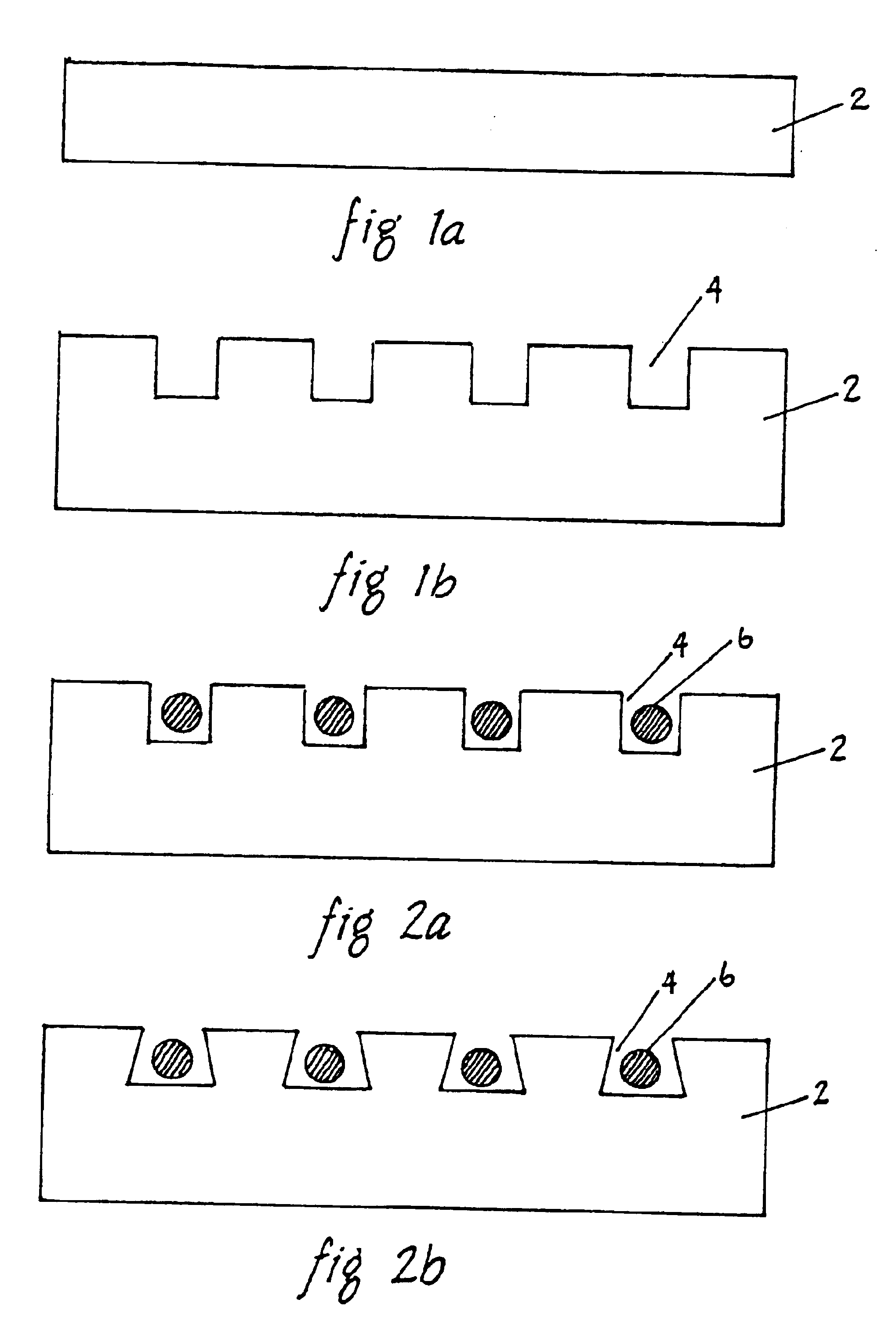

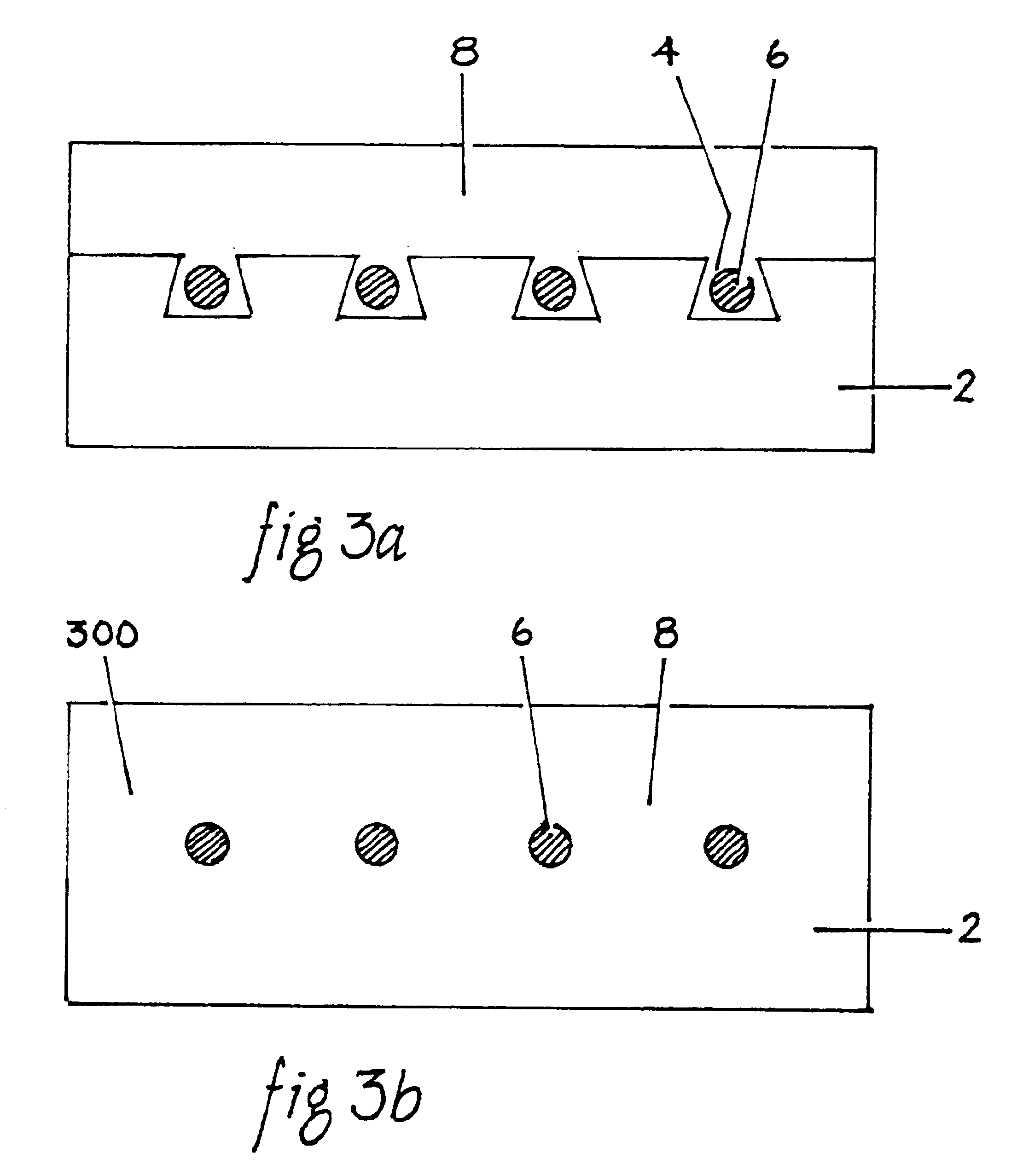

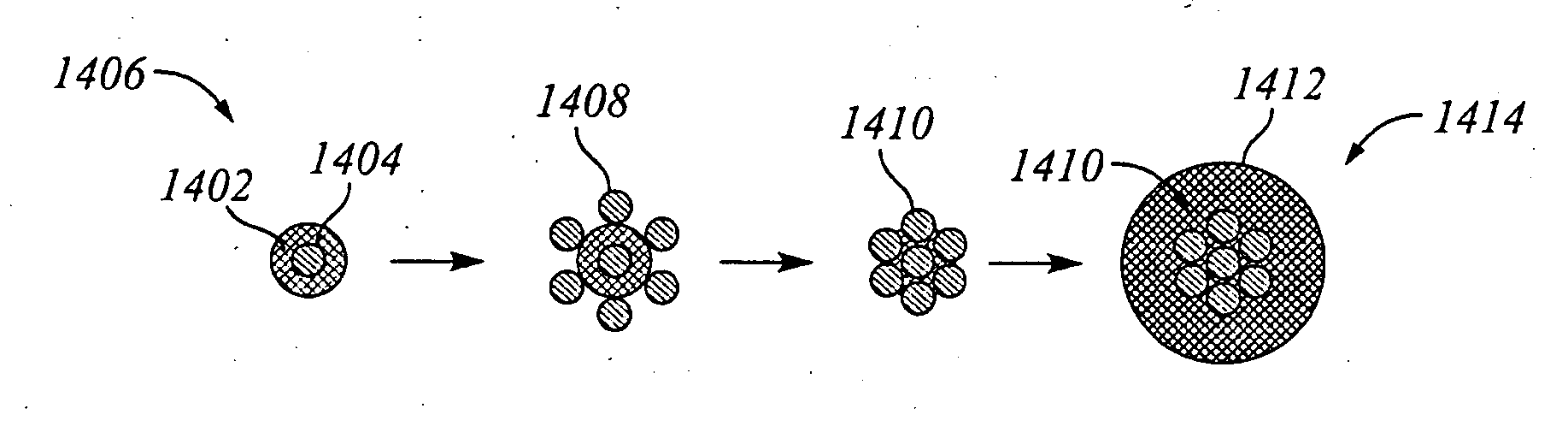

Methods of forming a coating for a prosthesis

InactiveUS6503556B2Increase the amount addedIncrease the number ofRadiation applicationsGlovesProsthesisImplanted device

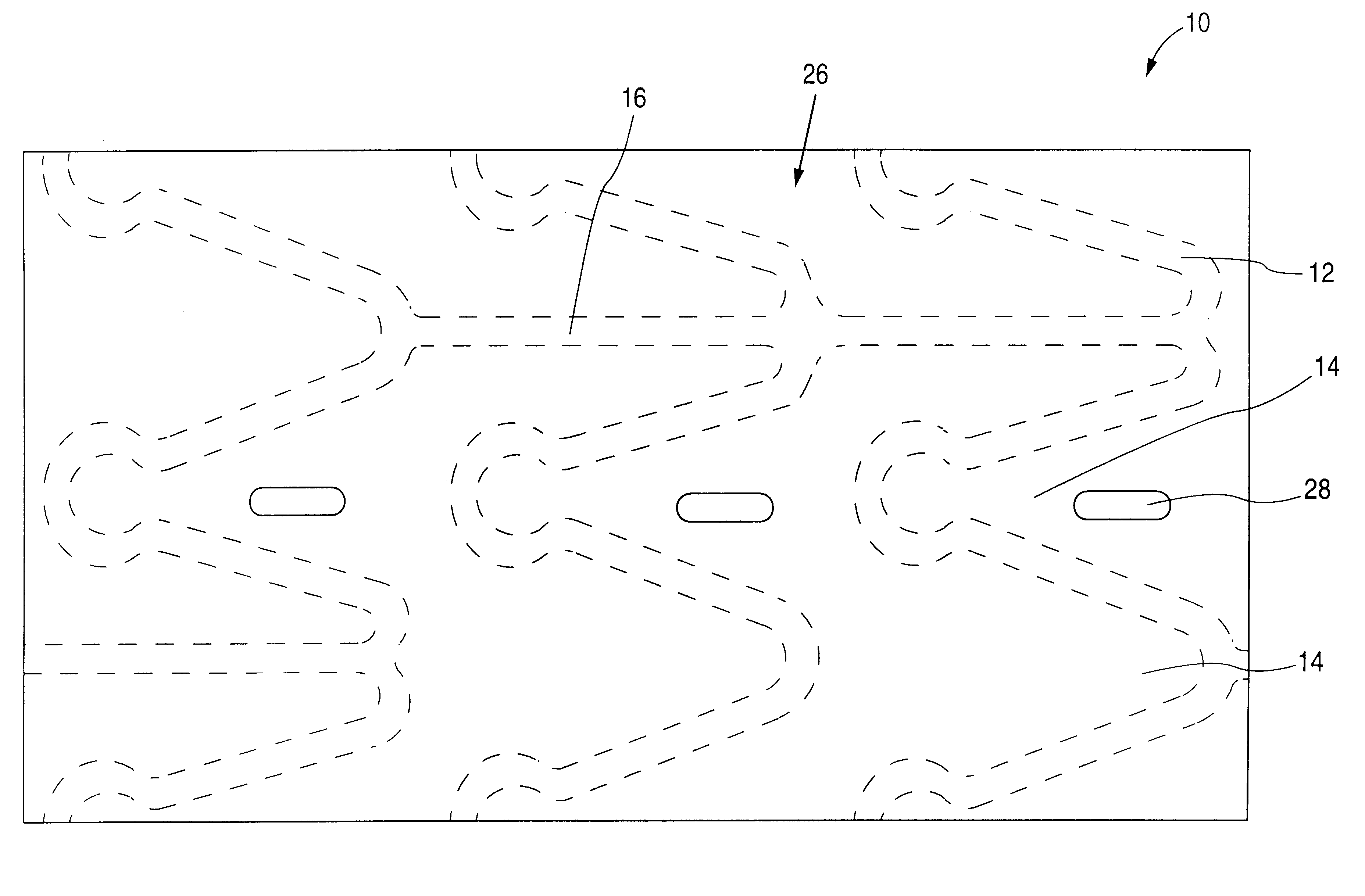

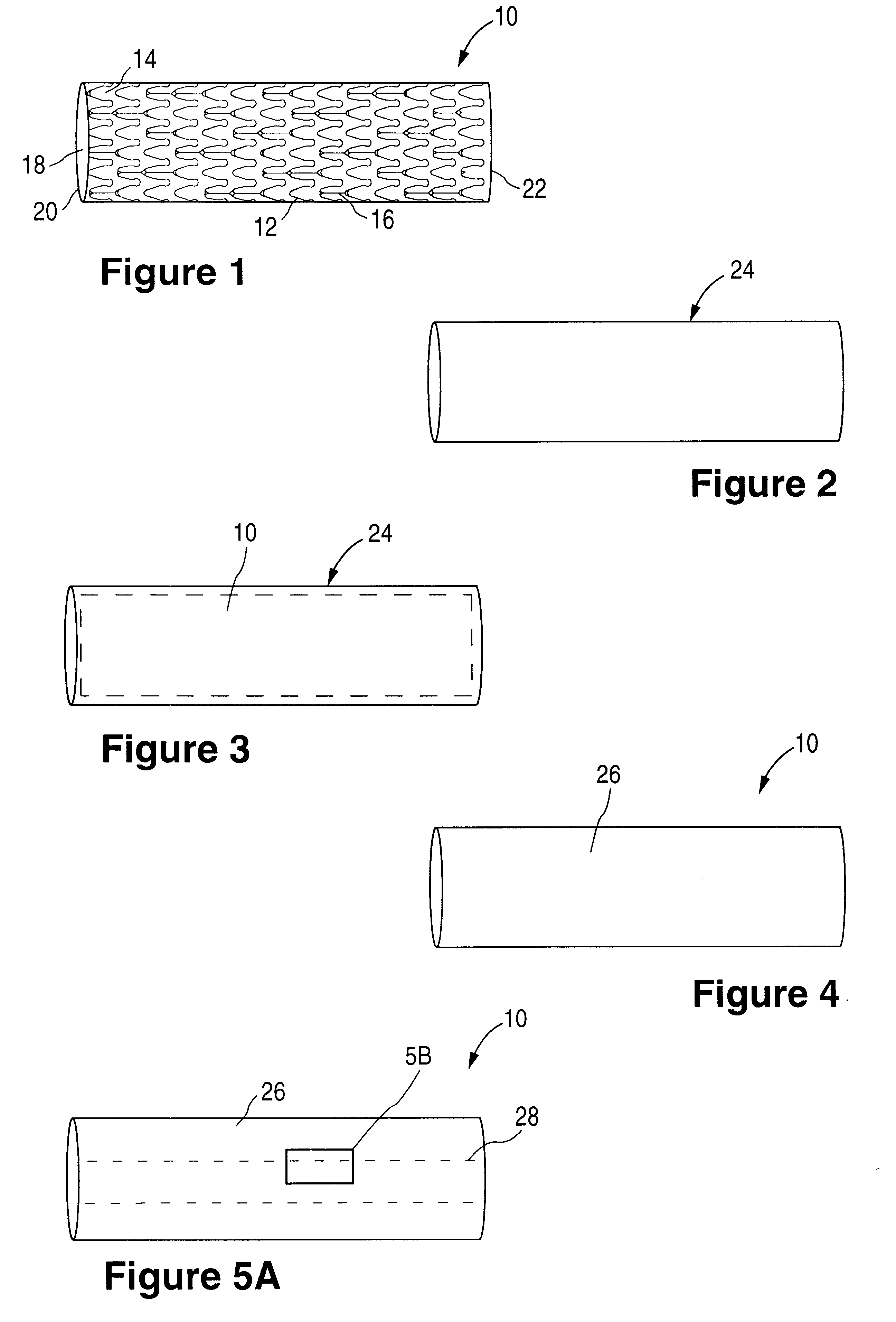

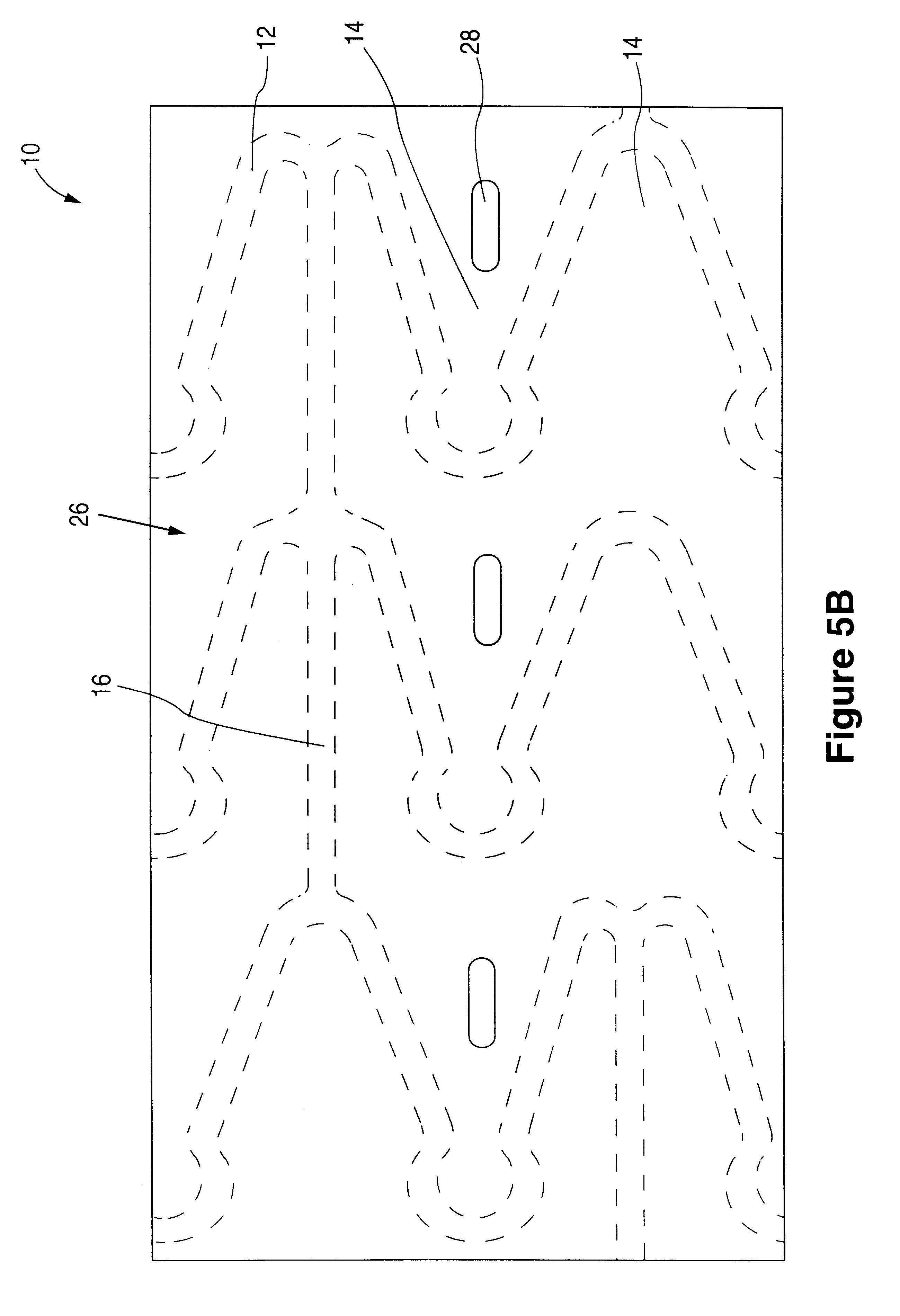

Methods of forming a coating onto an implantable device or endoluminal prosthesis, such as a stent, are provided. The coating may be used for the delivery of an active ingredient. The coating may have a selected pattern of interstices for allowing a fluid to seep through the coating in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

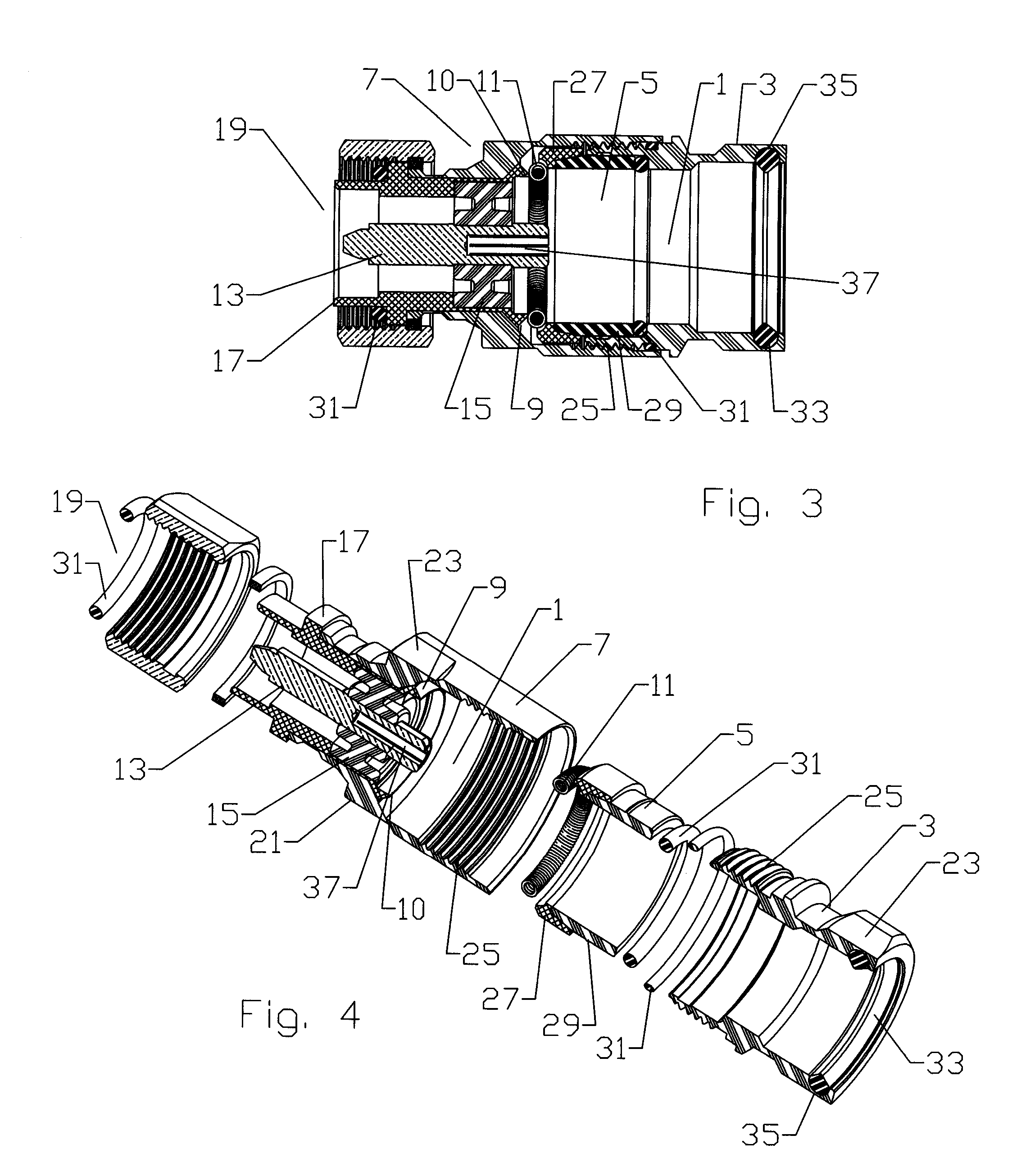

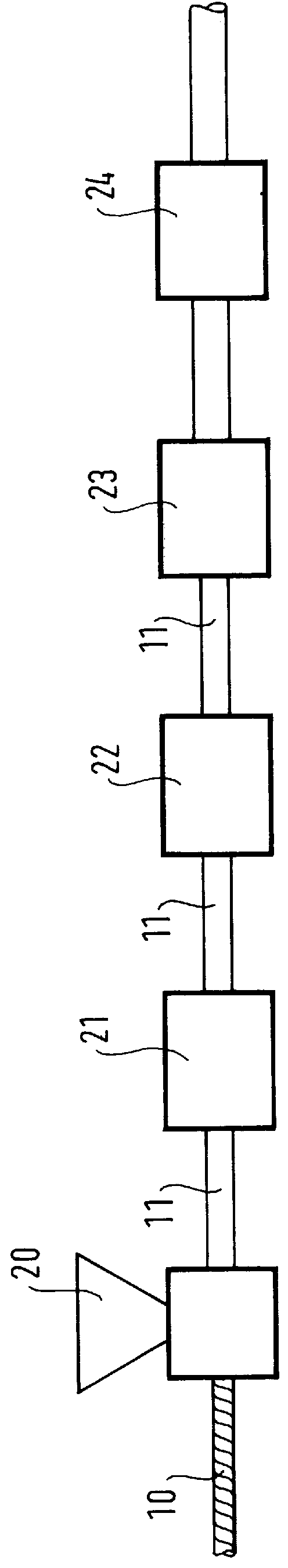

Coaxial waveguide microstructures and methods of formation thereof

ActiveUS7012489B2Printed circuit aspectsCircuit fluid transportElectrical conductorCoaxial waveguides

Provided are coaxial waveguide microstructures. The microstructures include a substrate and a coaxial waveguide disposed above the substrate. The coaxial waveguide includes: a center conductor; an outer conductor including one or more walls, spaced apart from and disposed around the center conductor; one or more dielectric support members for supporting the center conductor in contact with the center conductor and enclosed within the outer conductor; and a core volume between the center conductor and the outer conductor, wherein the core volume is under vacuum or in a gas state. Also provided are methods of forming coaxial waveguide microstructures by a sequential build process and hermetic packages which include a coaxial waveguide microstructure.

Owner:CUBIC CORPORATION

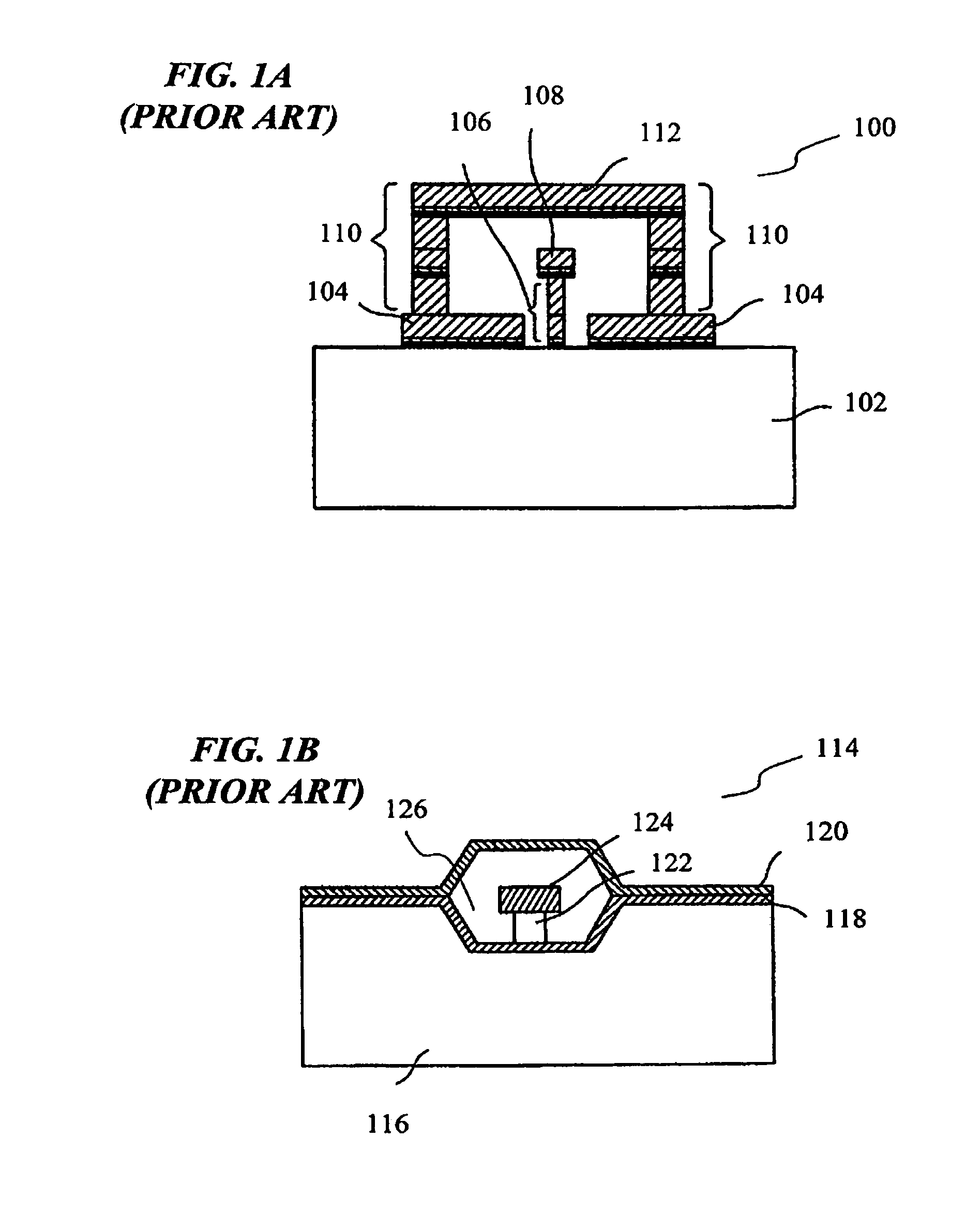

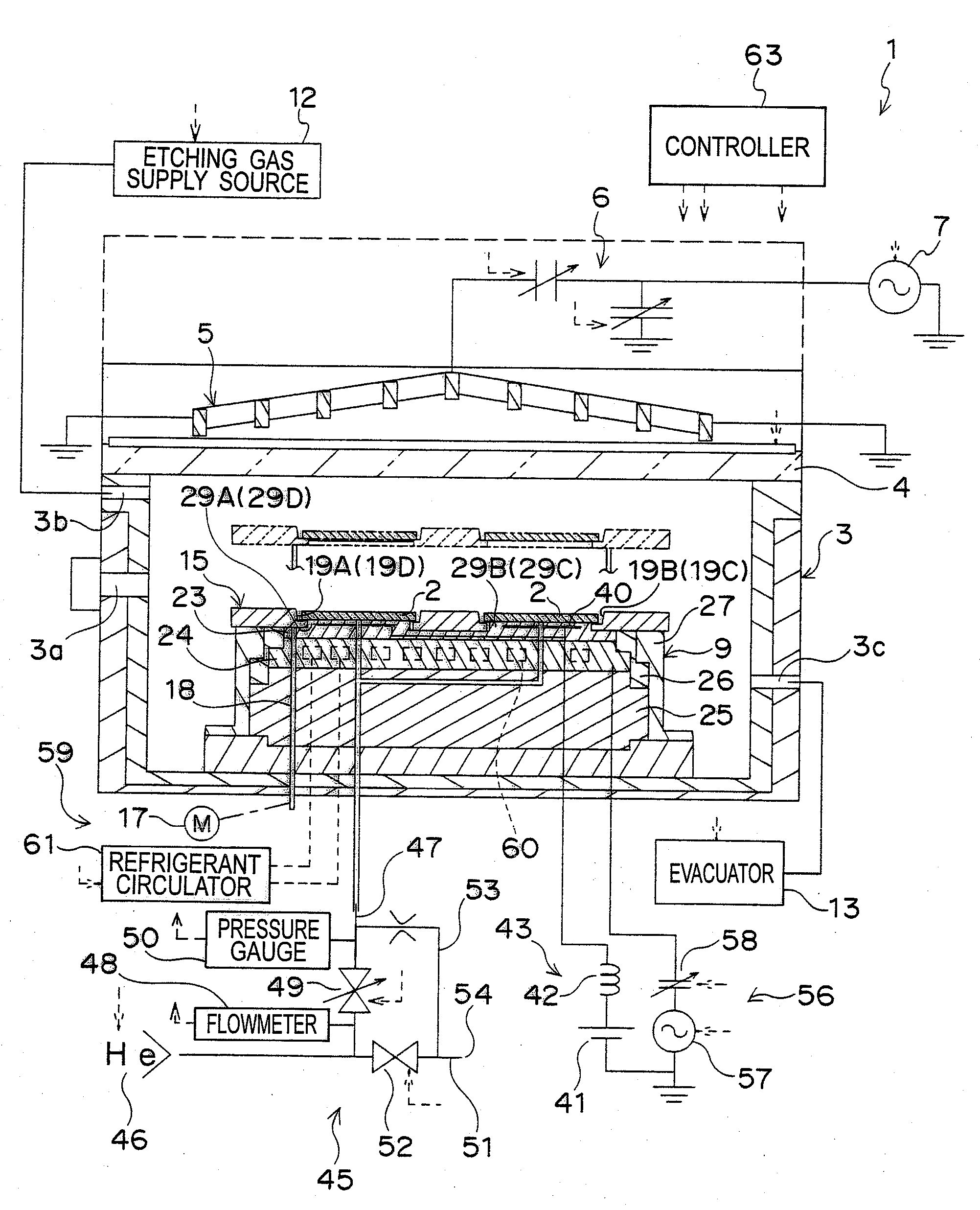

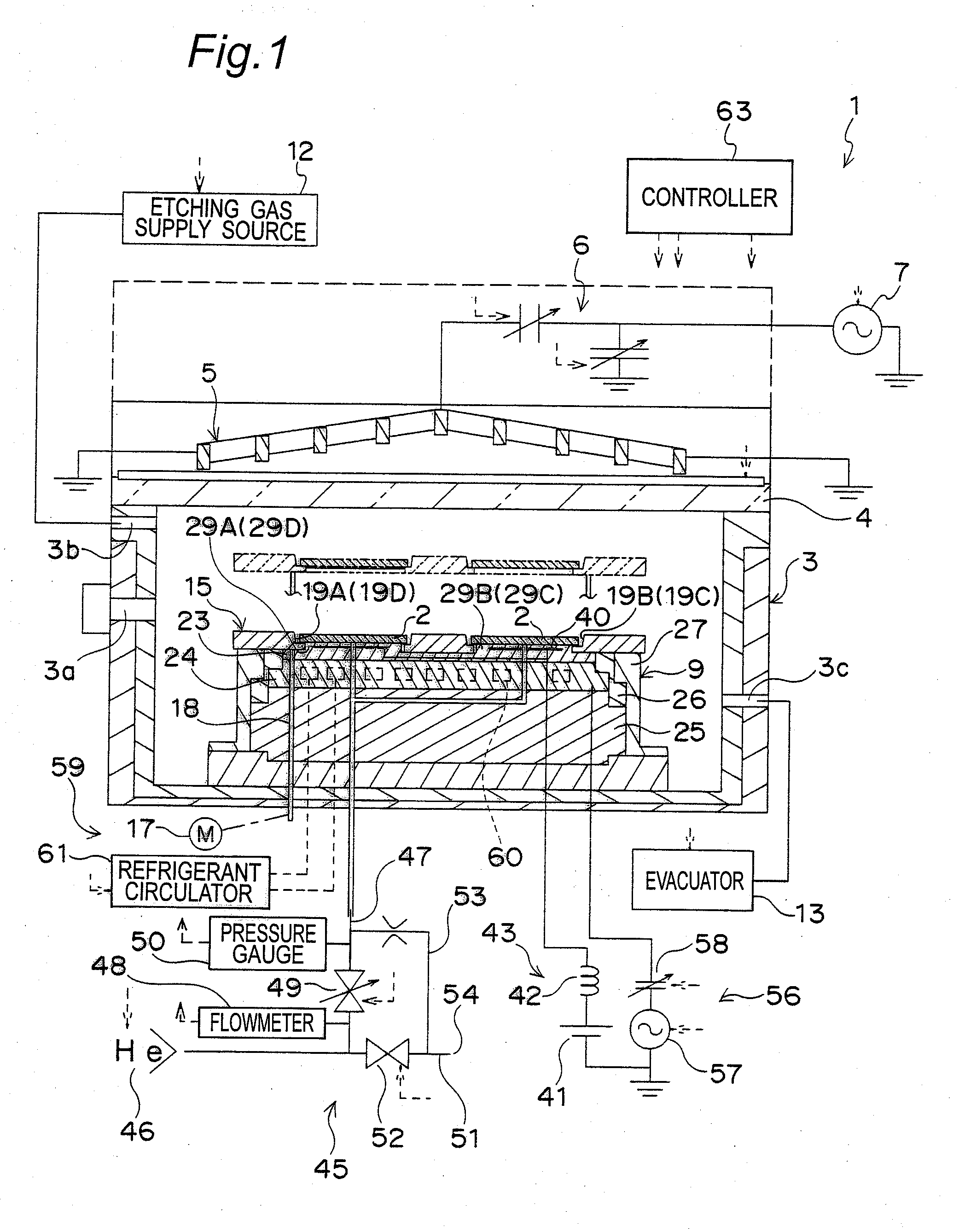

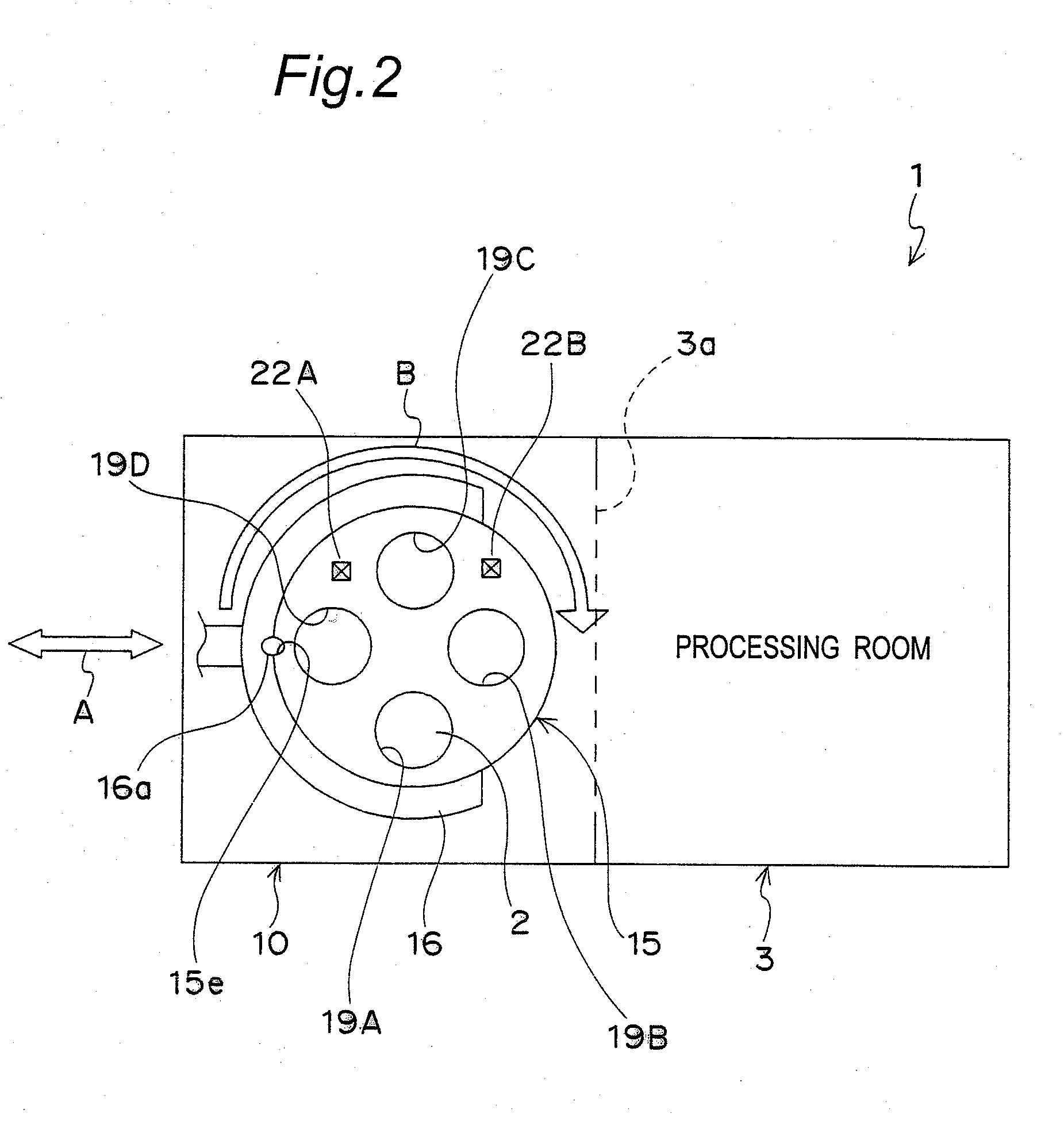

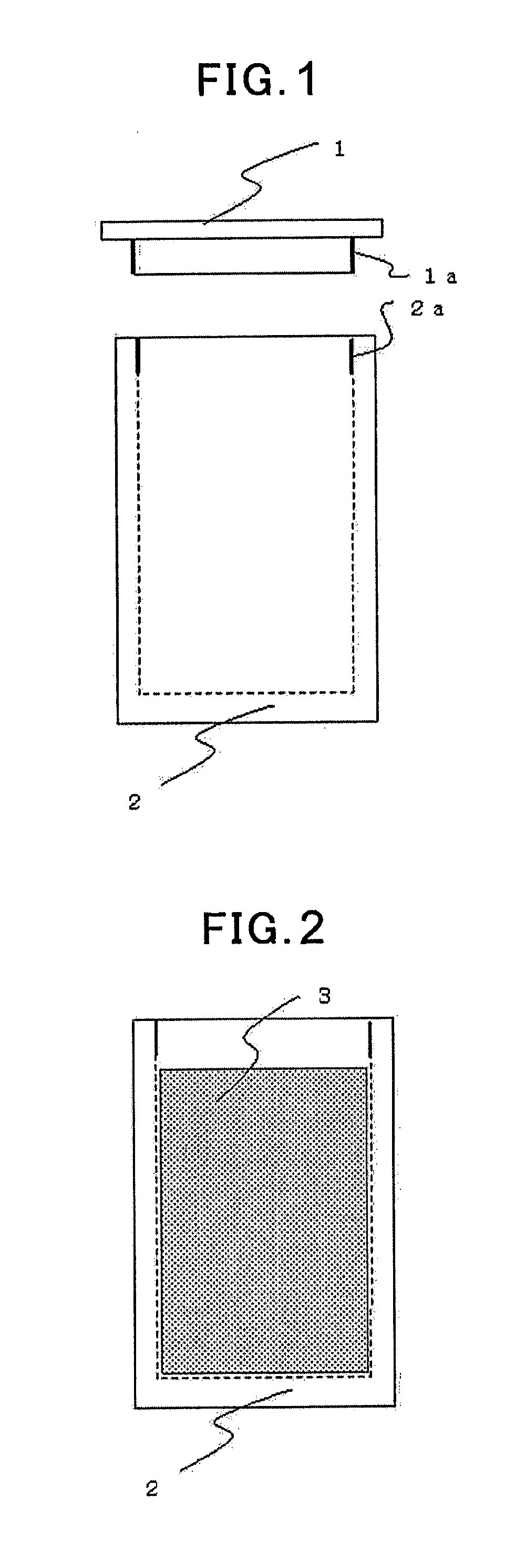

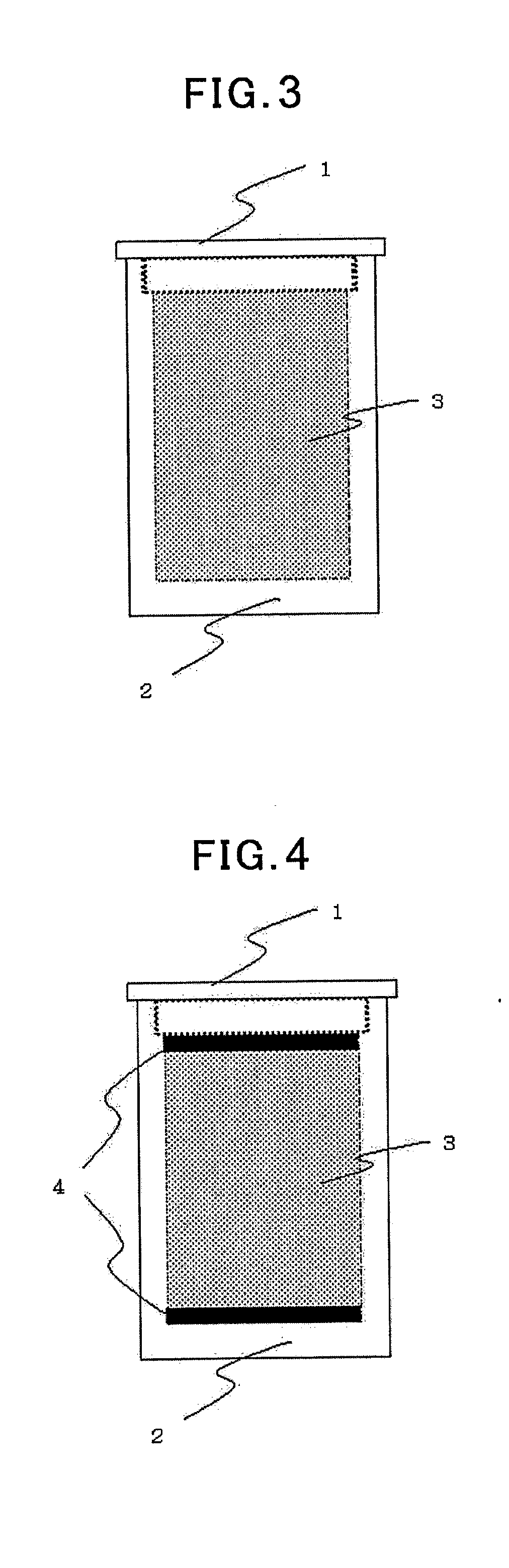

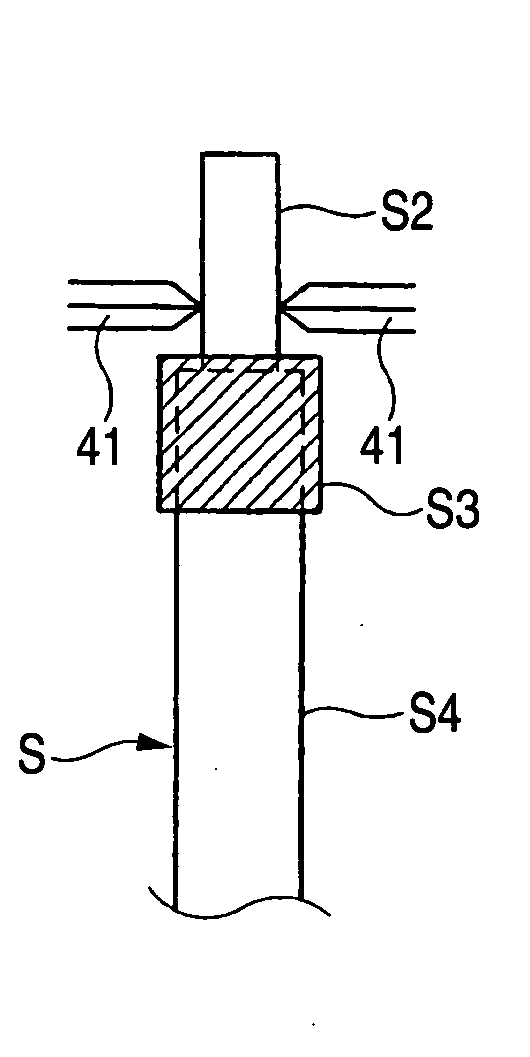

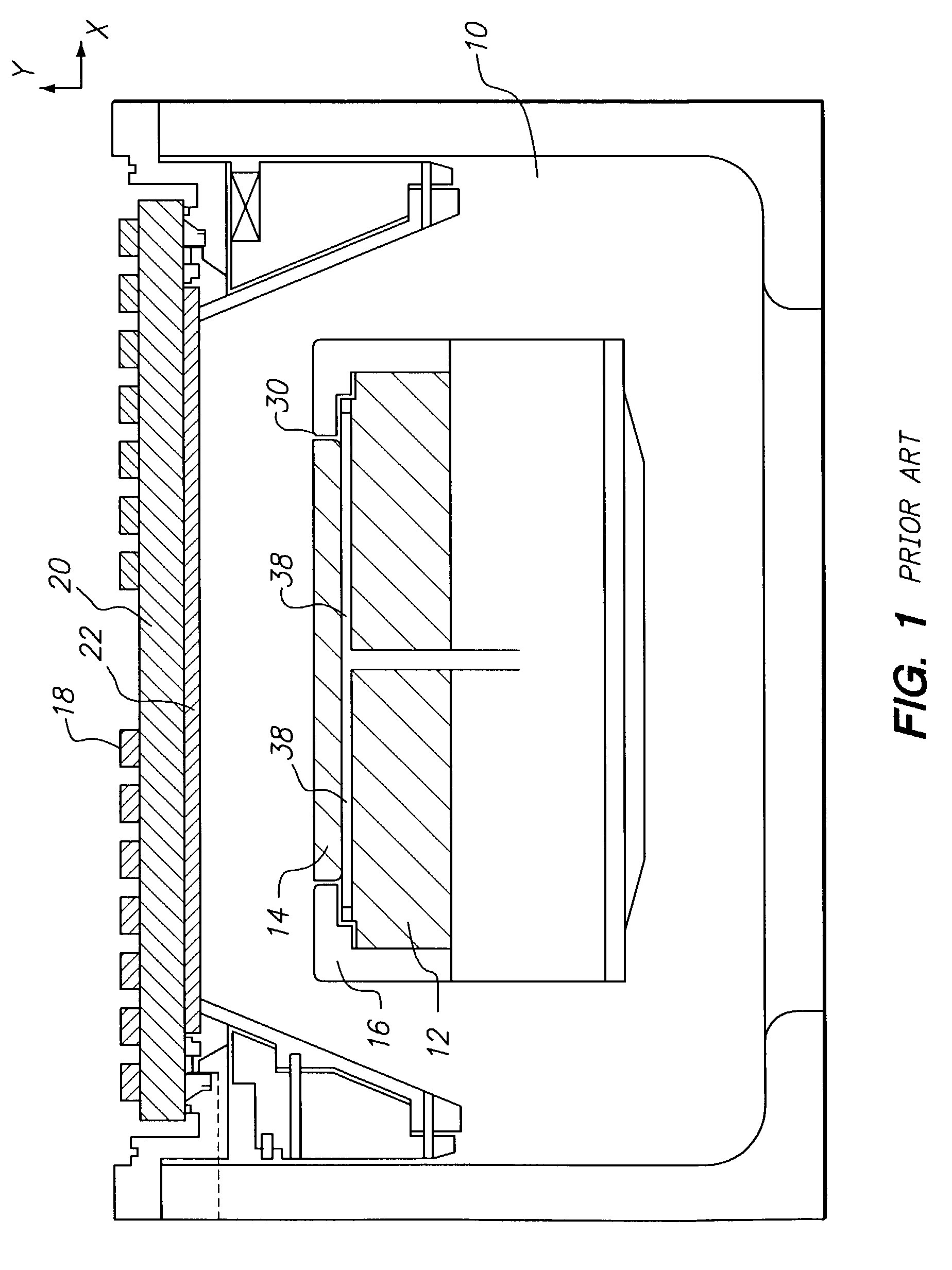

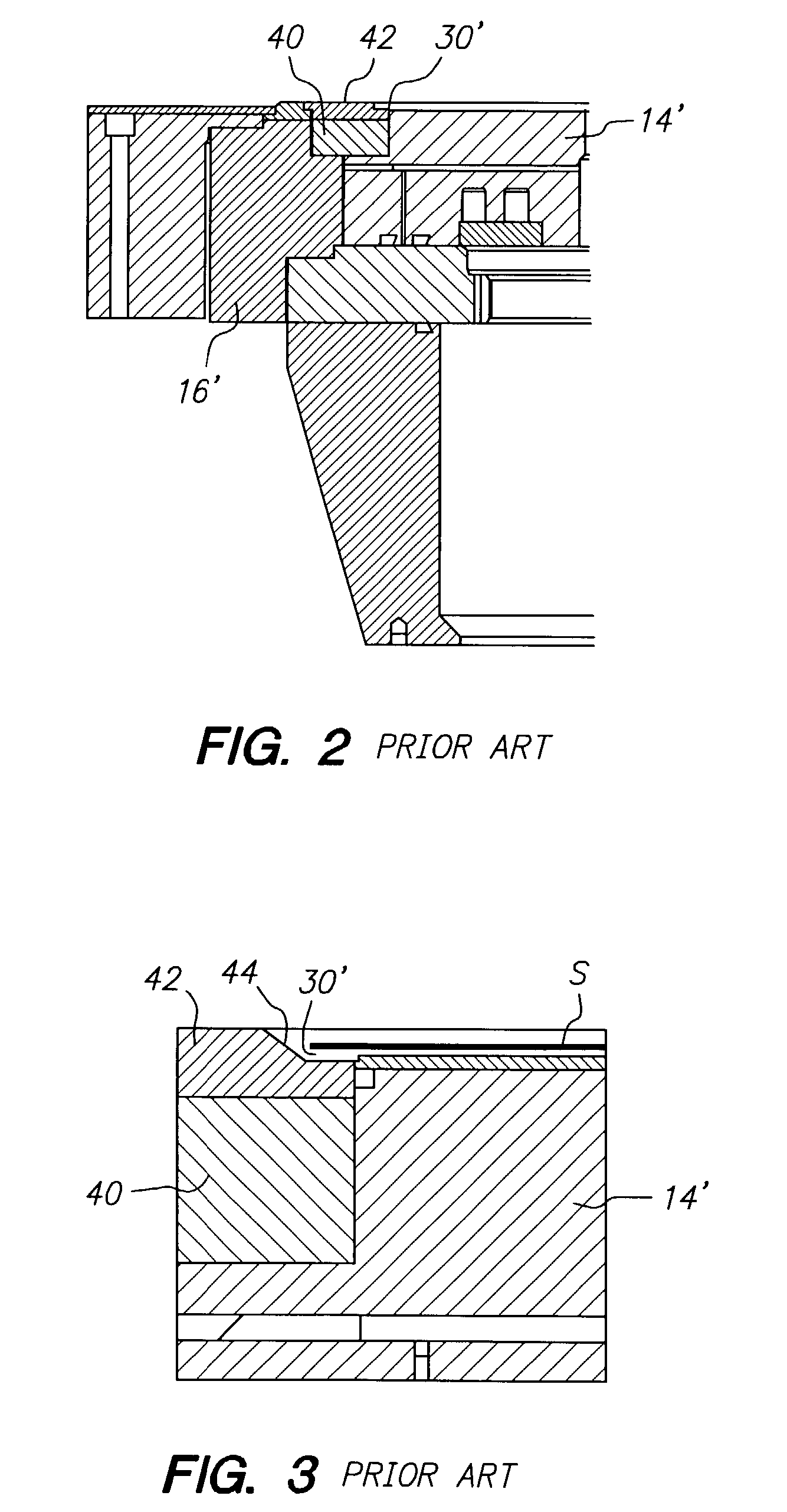

Plasma processing apparatus, plasma processing method, and tray

ActiveUS20090255901A1Uniform plasma treatmentImprove adhesionElectric discharge tubesDecorative surface effectsDielectric plateEngineering

A tray 15 for a dry etching apparatus 1 has substrate accommodation holes 19A to 19D penetrating thickness direction and a substrate support portion 21 supporting an outer peripheral edge portion of a lower surface 2a of a substrate 2. A dielectric plate 23 has a tray support surface 28 supporting a lower surface of the tray 15, substrate placement portions 29A through 29D inserted from a lower surface side of the tray 15 into the substrate accommodation holes 19A through 19D and having a substrate placement surface 31 at its upper end surface for placing the substrate 2. A dc voltage applying mechanism 43 applies a dc voltage to an electrostatic attraction electrode 40. A heat conduction gas supply mechanism 45 supplies a heat conduction gas between the substrate 2 and substrate placement surface 31. The substrate 2 can be retained on the substrate placement surface 31 with high degree of adhesion. This results in that the cooling efficiency of the substrate 2 is improved and processing is uniformed at the entire region of the substrate surface including the vicinity of the outer peripheral edge.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

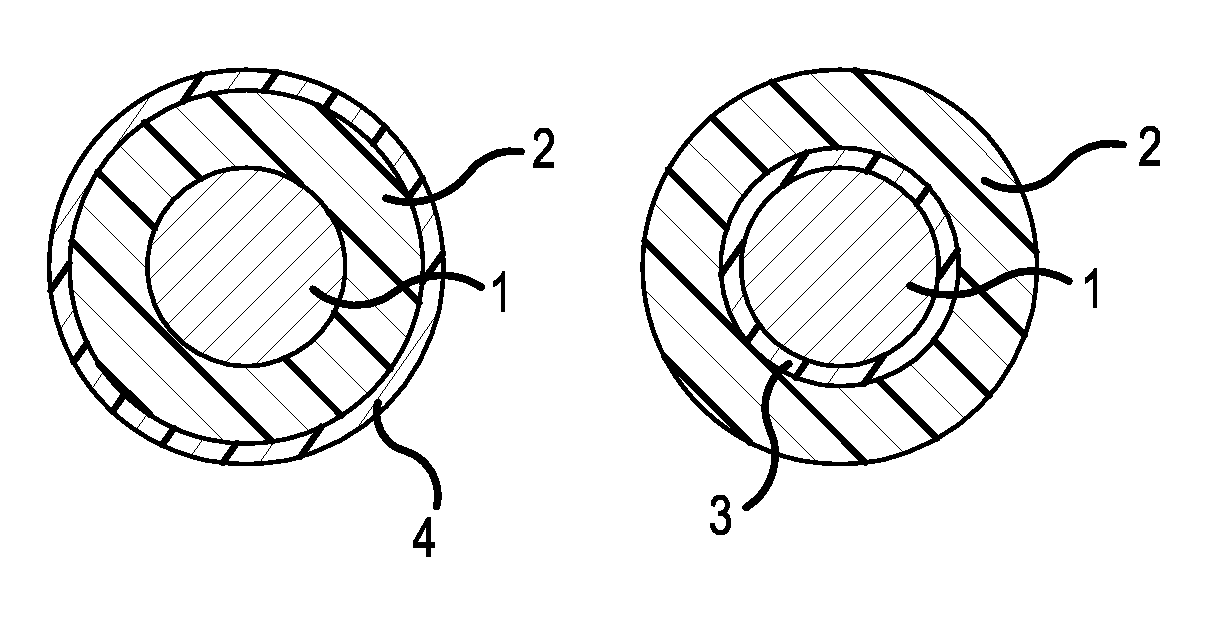

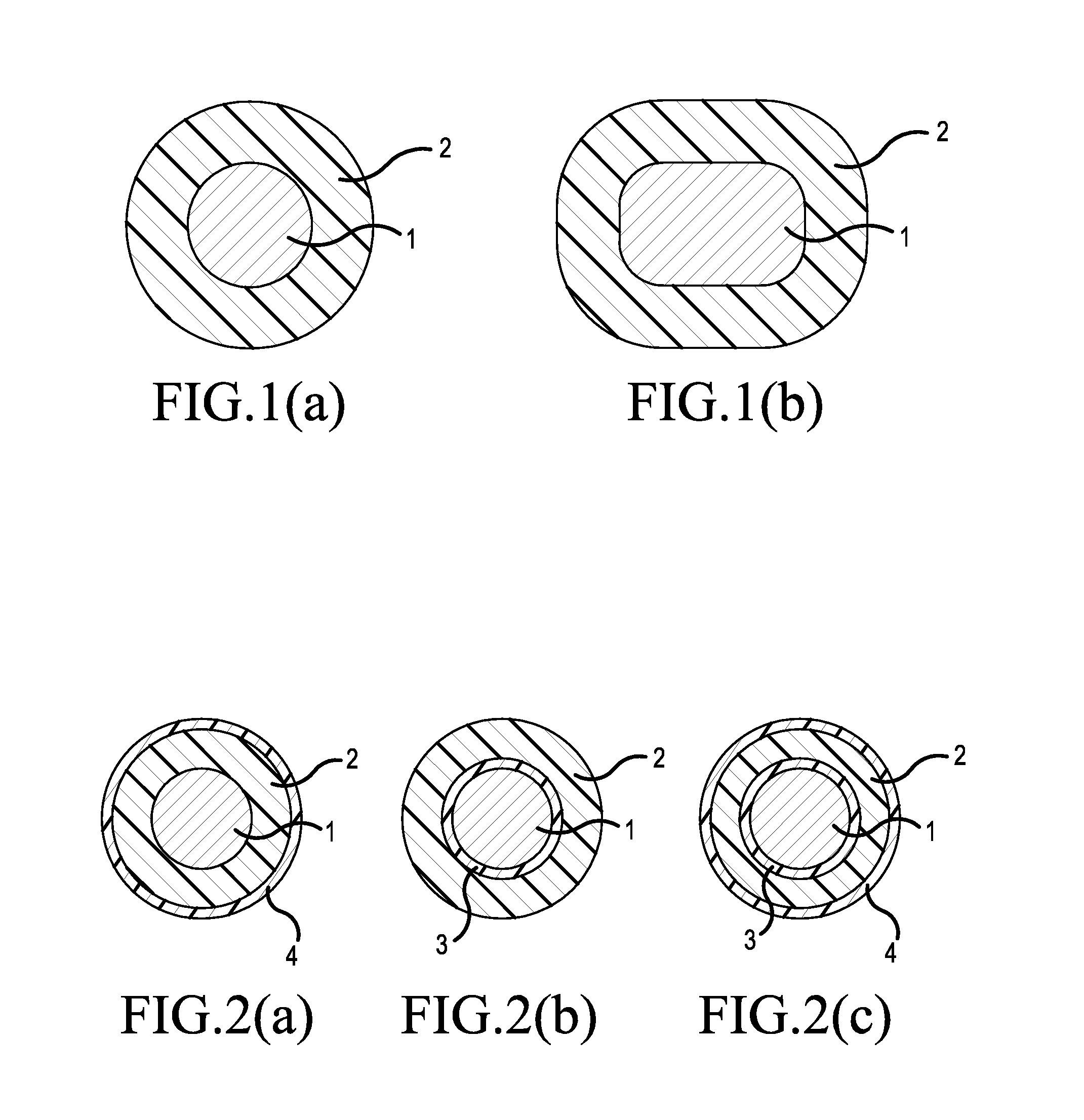

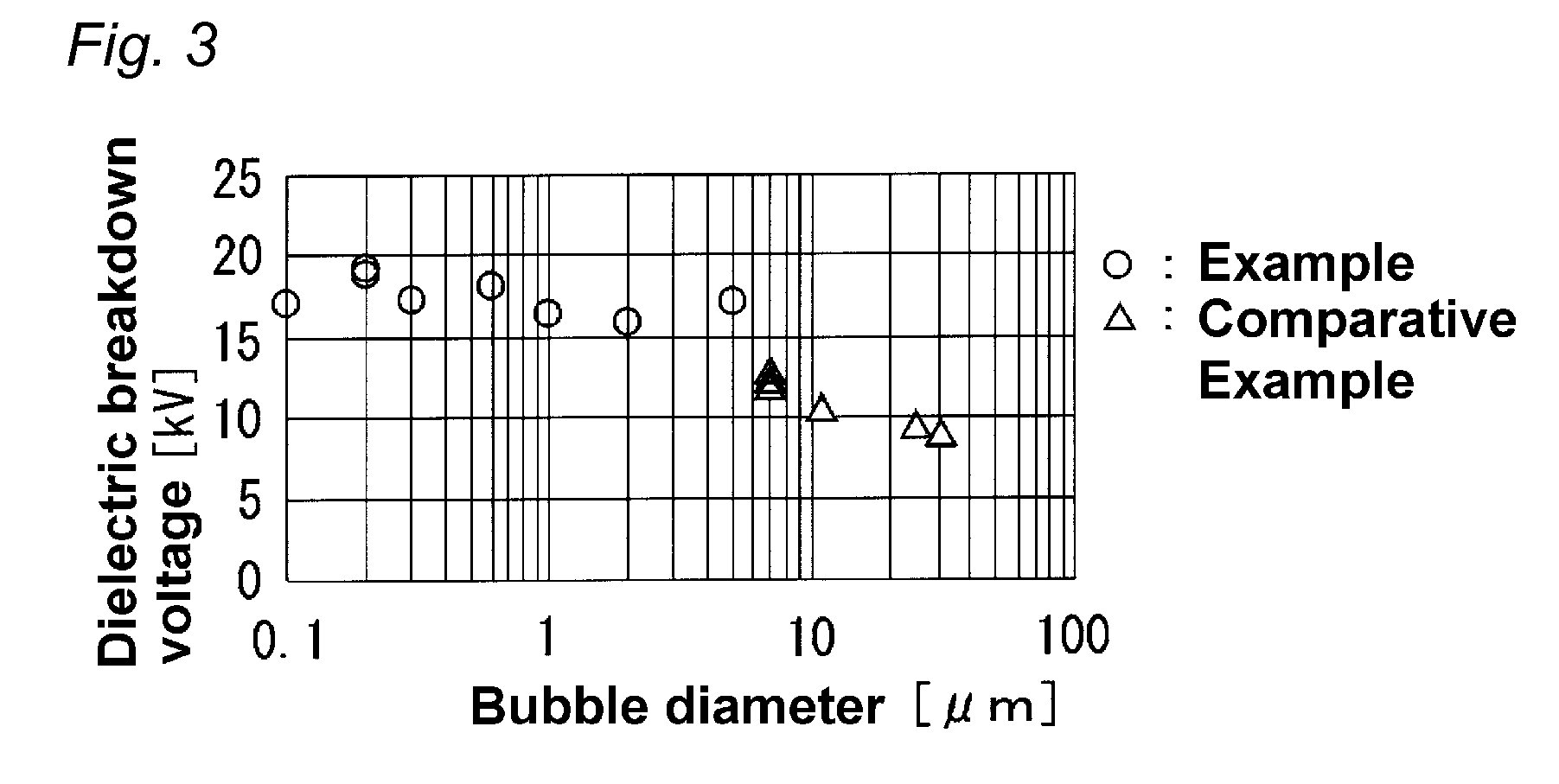

Foamed electrical wire and a method of producing the same

ActiveUS9142334B2Increase resistanceGood partitionPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorGlass transition

A foamed electrical wire, containing: a conductor; and a foamed insulating layer; in which the foamed insulating layer comprises a thermoplastic resin that is a crystalline thermoplastic resin having a melting point of 150° C. or more or a non-crystalline thermoplastic resin having a glass transition temperature of 150° C. or more, and the average bubble diameter of the foamed insulating layer is 5 μm or less.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

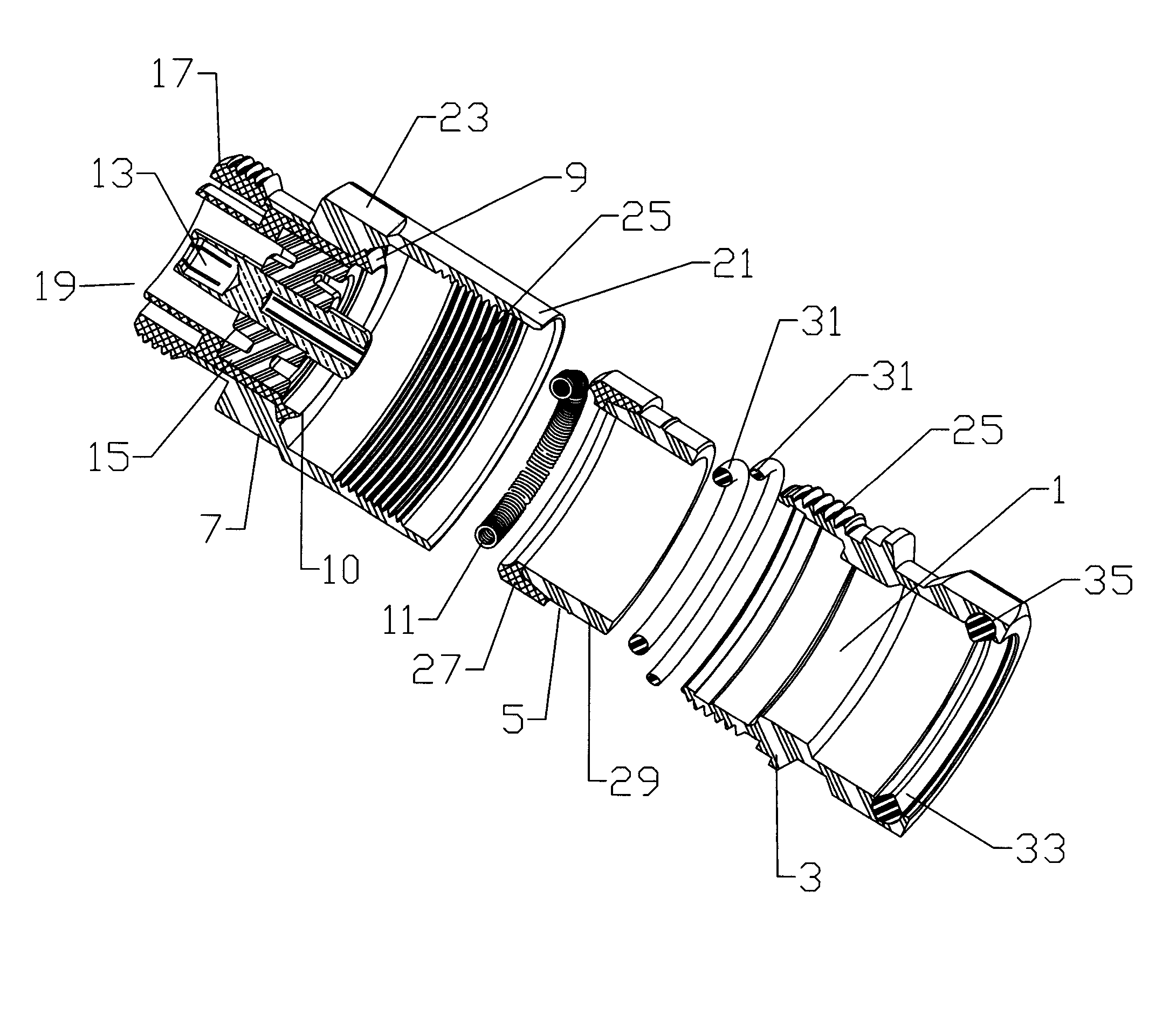

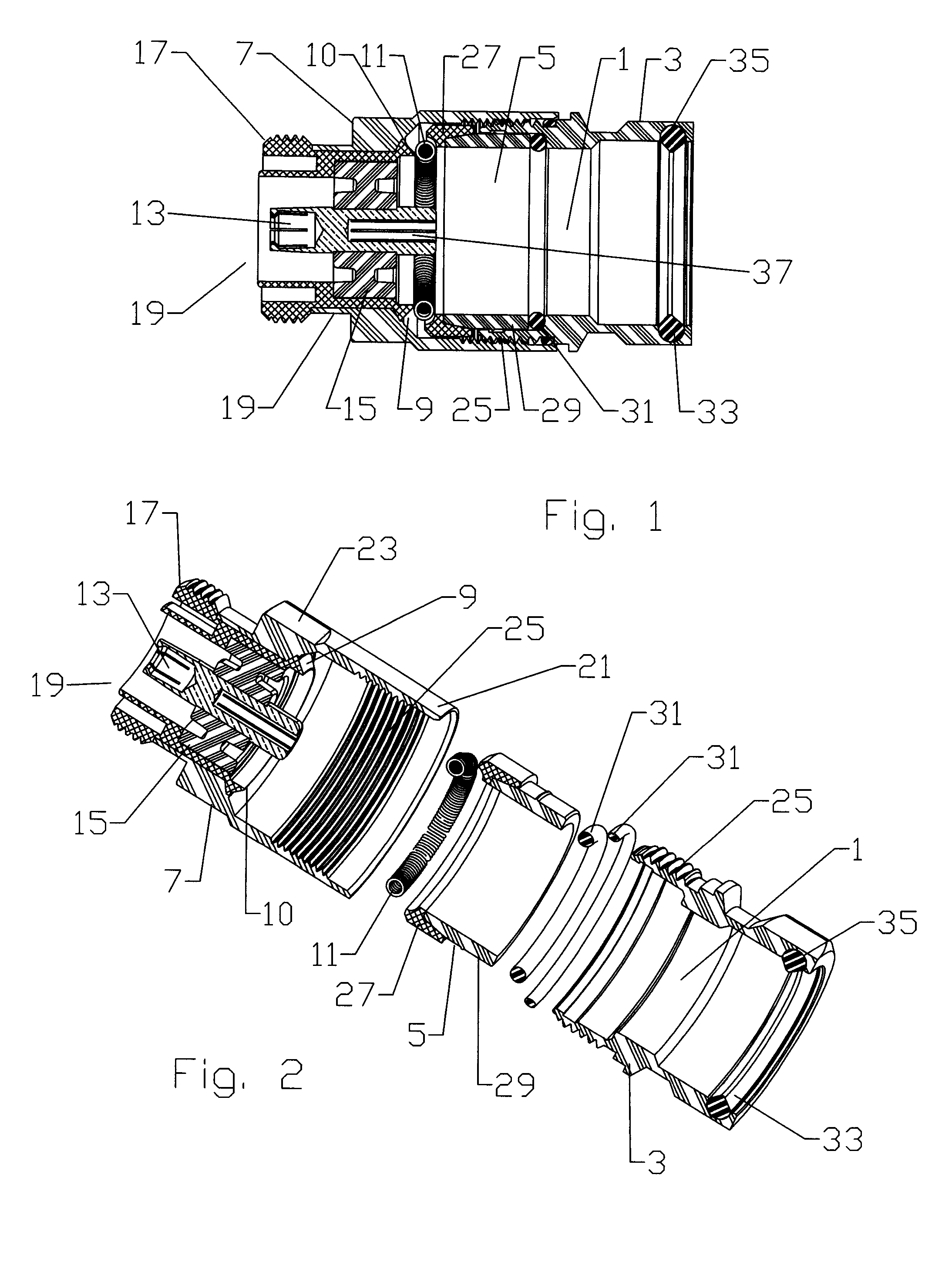

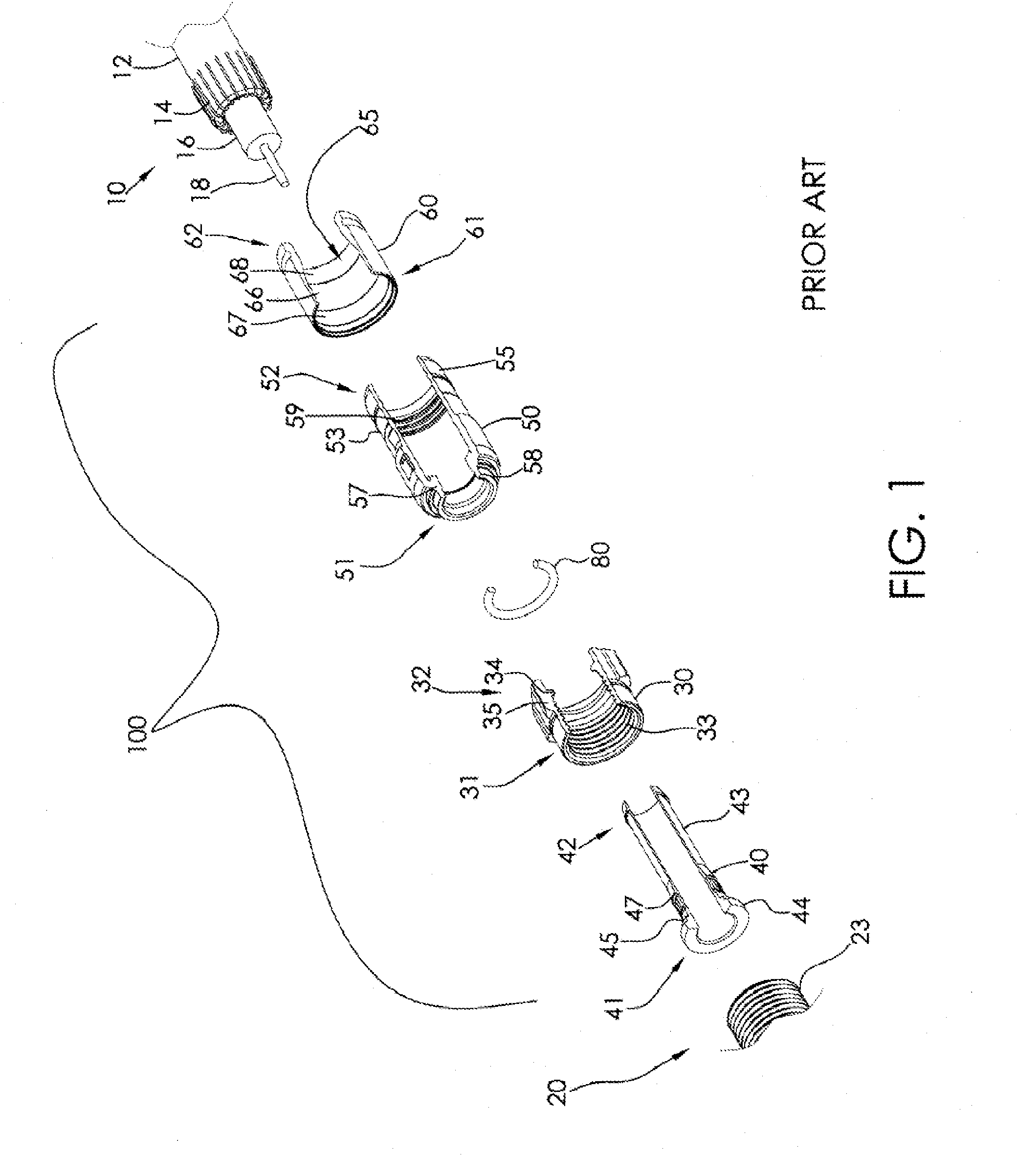

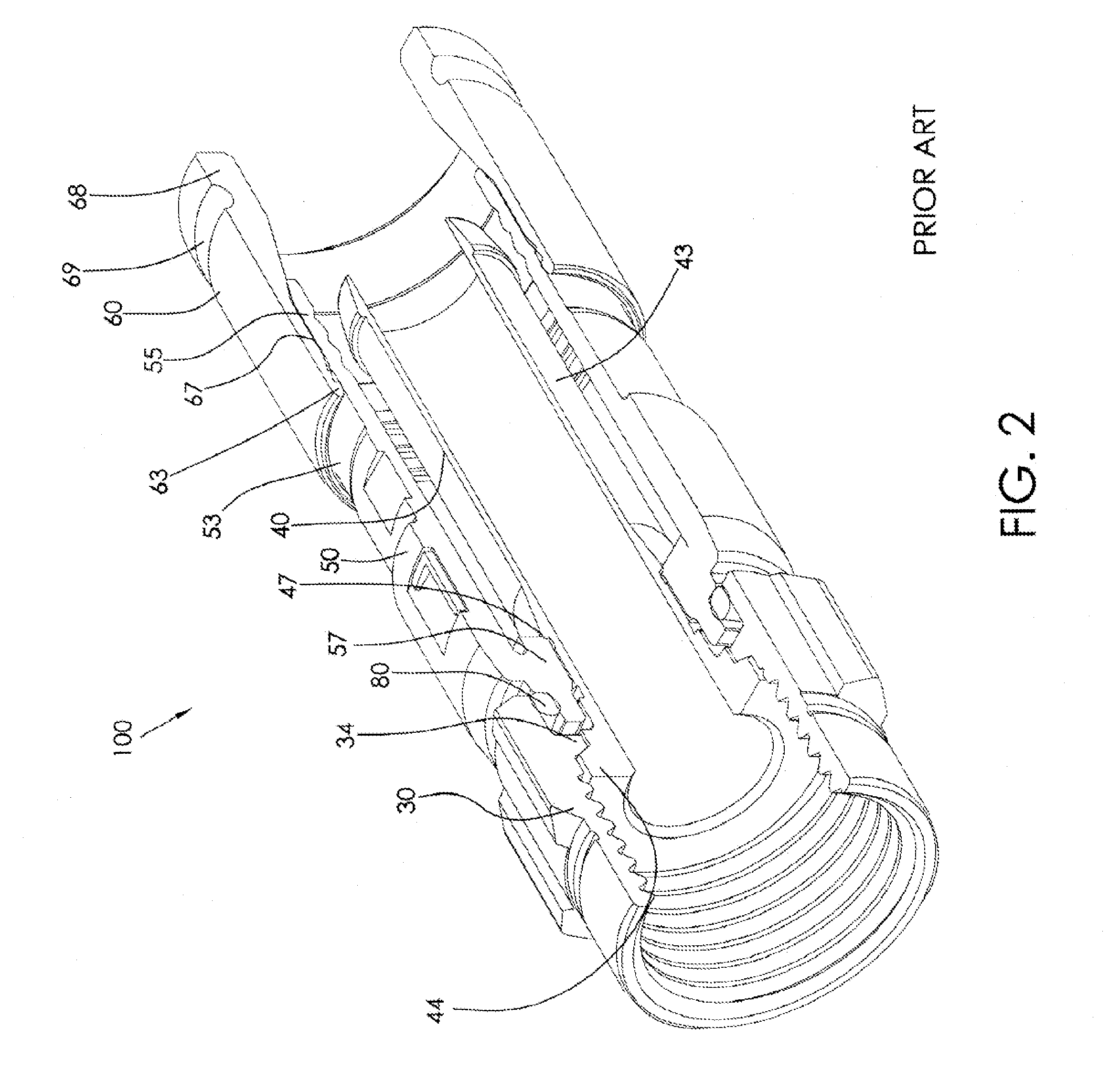

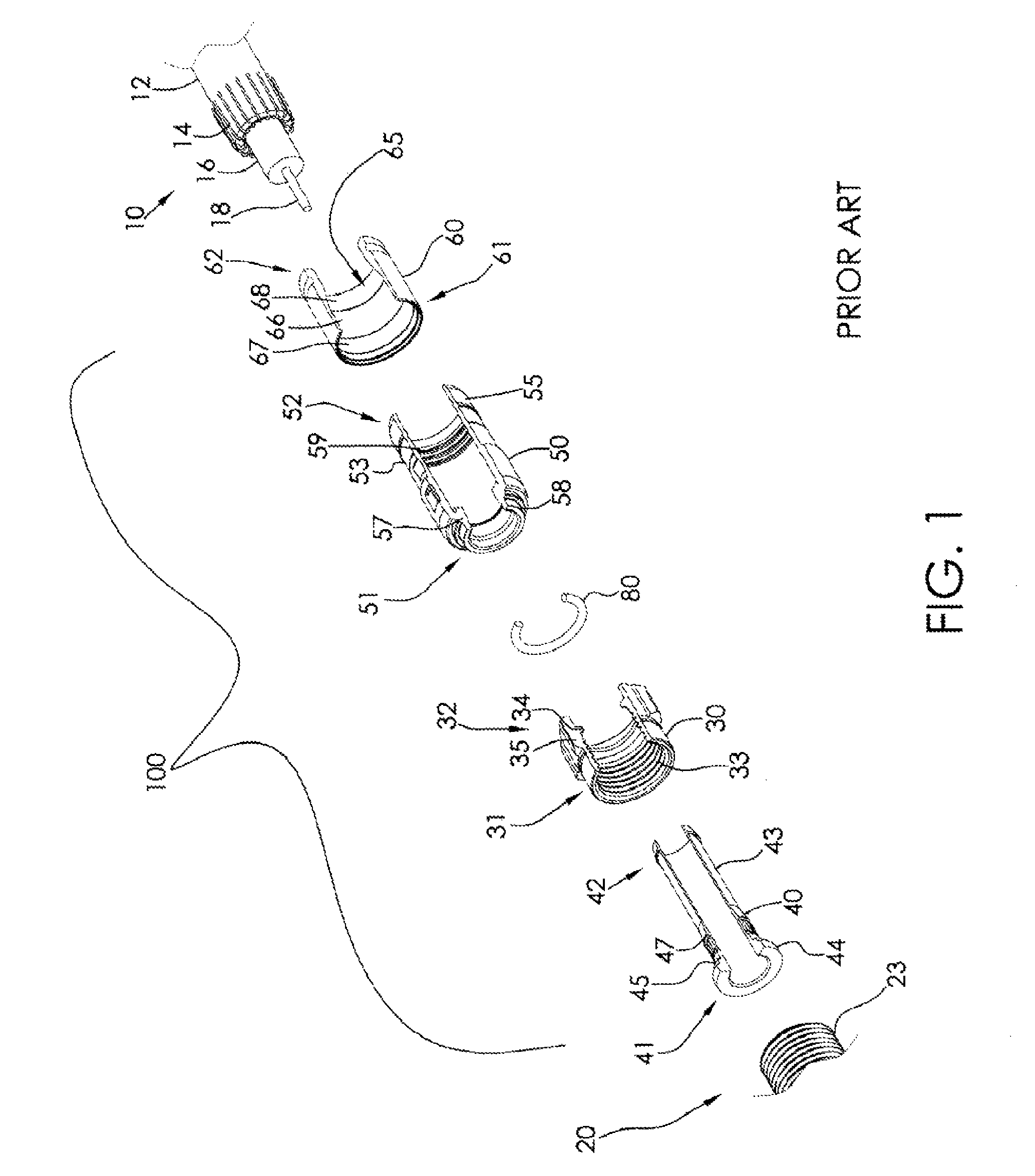

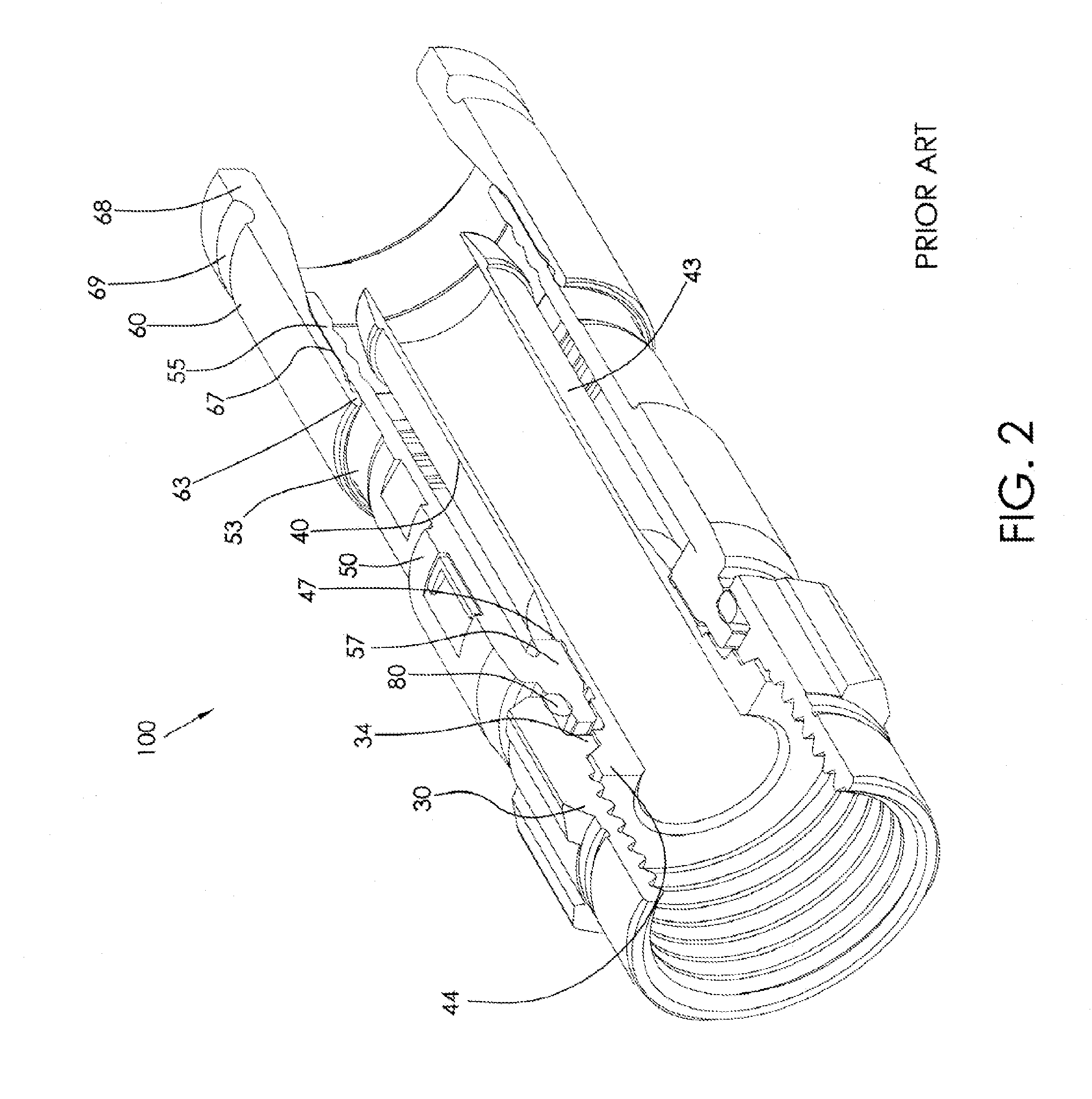

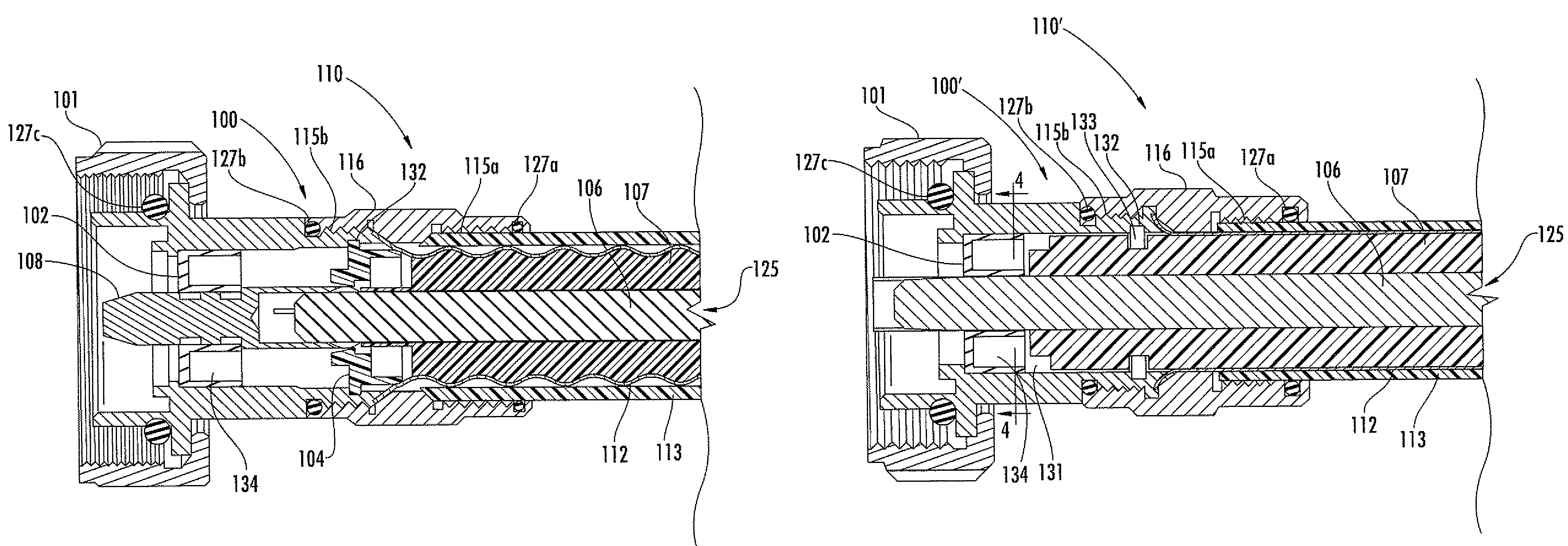

Multi-shot coaxial connector and method of manufacture

ActiveUS7607942B1Significant costSignificant materialElectrically conductive connectionsContact member cases/bases manufactureMultiple injectionCoaxial cable

A coaxial cable connector formed via multi-shot injection molding has a body formed by multiple injection molding layers of different injection moldable materials about a central inner contact to form an integral connector body. The connector body is provided with a coaxial dielectric spacer of dielectric polymer surrounding the inner contact; a coaxial inner body of injectable molded metal composition surrounding an outer diameter of the dielectric spacer; and an outer body of polymer surrounding the inner body. A range of different coupling bodies compatible with the connector body may also be formed via injection molding to provide connectors compatible with a range of different coaxial cable configurations.

Owner:COMMSCOPE INC

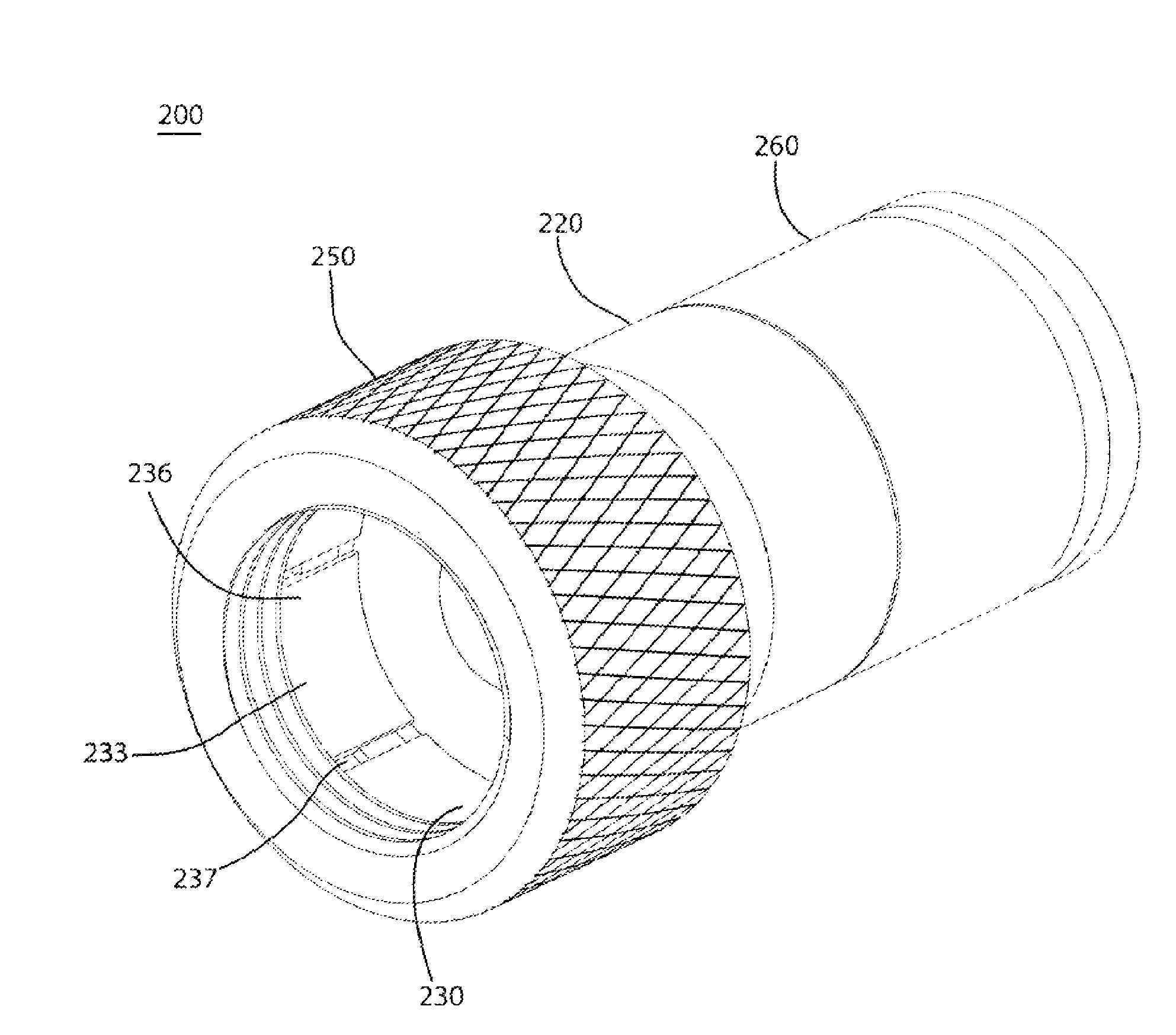

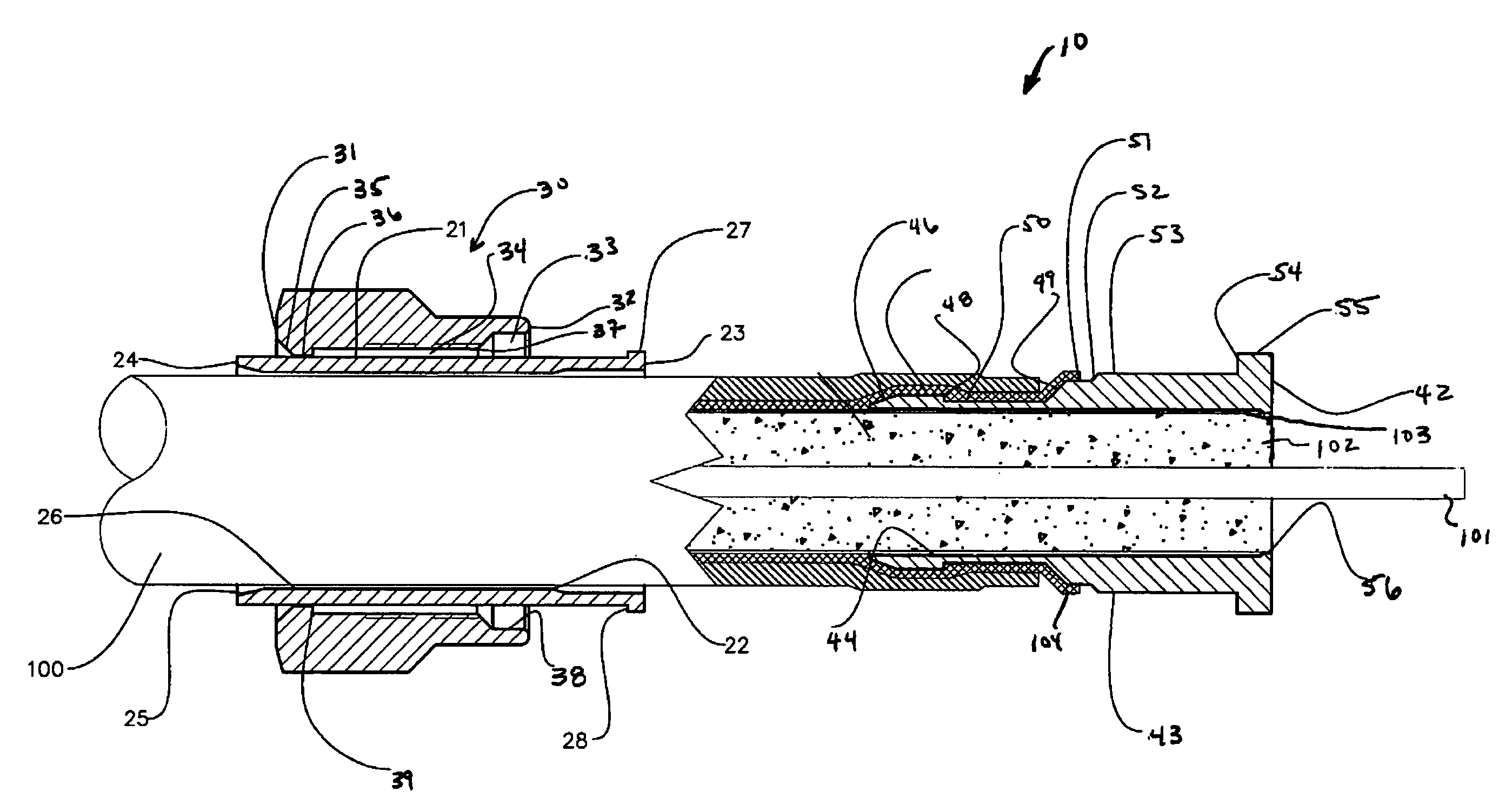

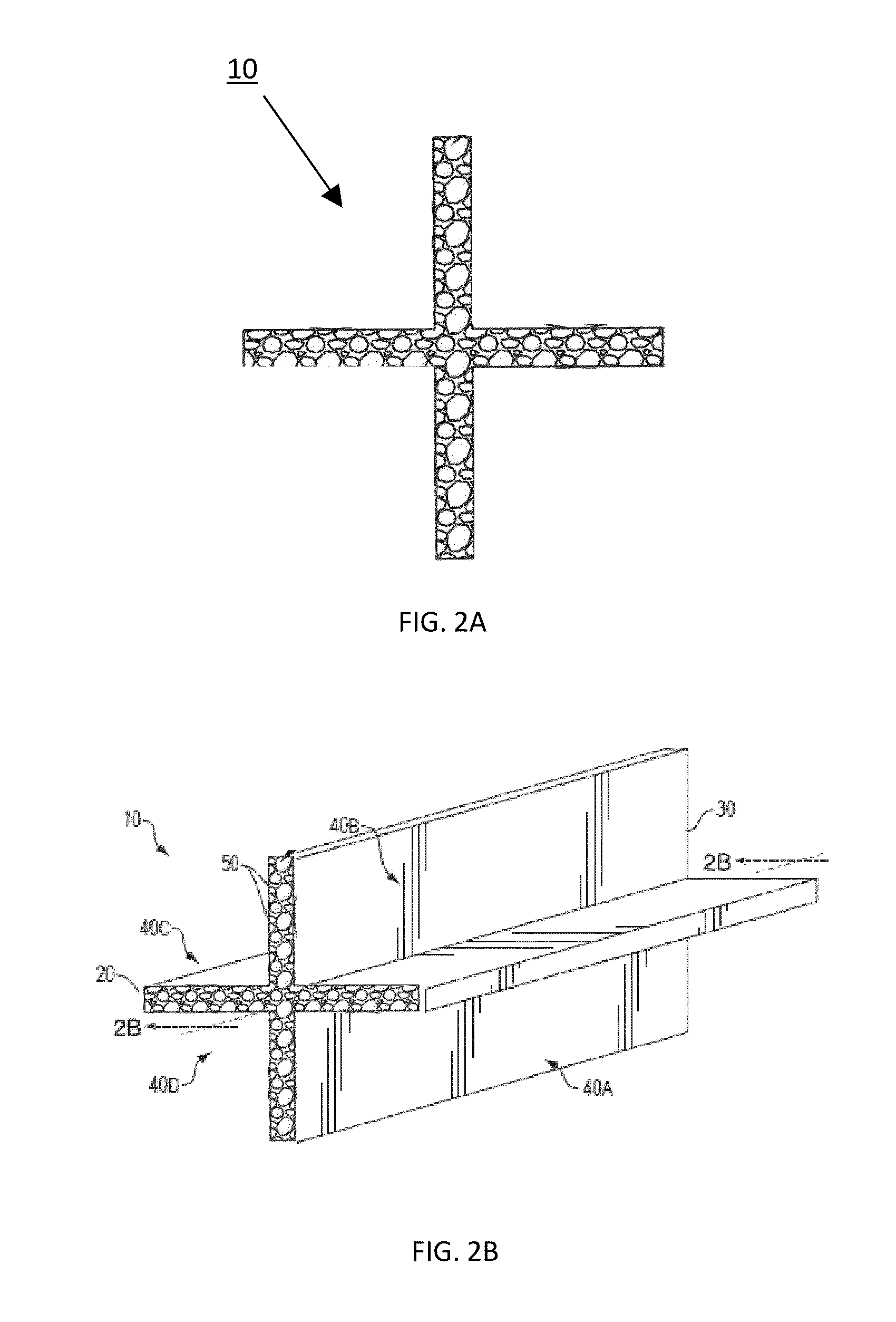

Coaxial transmission line microstructures and methods of formation thereof

Provided are coaxial transmission line microstructures formed by a sequential build process, and methods of forming such microstructures. The microstructures include a transition structure for transitioning between the coaxial transmission line and an electrical connector. The microstructures have particular applicability to devices for transmitting electromagnetic energy and other electronic signals.

Owner:CUBIC CORPORATION

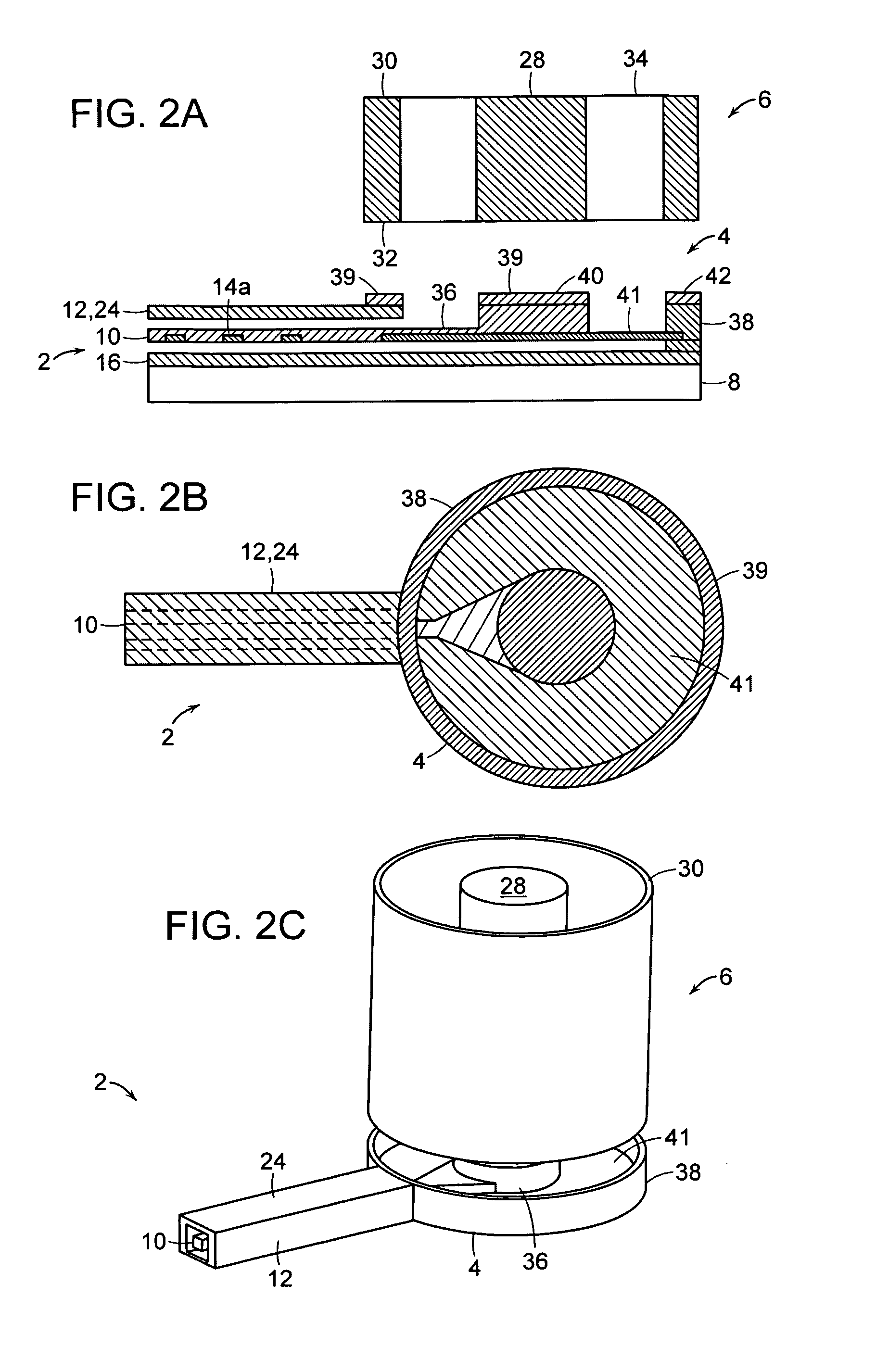

Port seizing cable connector nut and assembly

ActiveUS20120021642A1Minimal effortStability GuaranteeEngagement/disengagement of coupling partsTwo-part coupling devicesCoaxial cableEngineering

A coaxial cable connector includes a connector body having a first end and a second end, a coupling nut freely rotatable and disposed in relation to the first end of the connector body and a post having a first end and a second end, the post further including a open-ended port retaining portion. The coupling nut includes an internal threaded portion and is disposed in overlaying relation relative to the port retaining portion, which is configured for engaging an external port. The port retaining portion defines a locking collet that prevents loosening of the engaged port, while still guaranteeing electrical continuity without requiring excessive tightening of the connector.

Owner:PPC BROADBAND INC

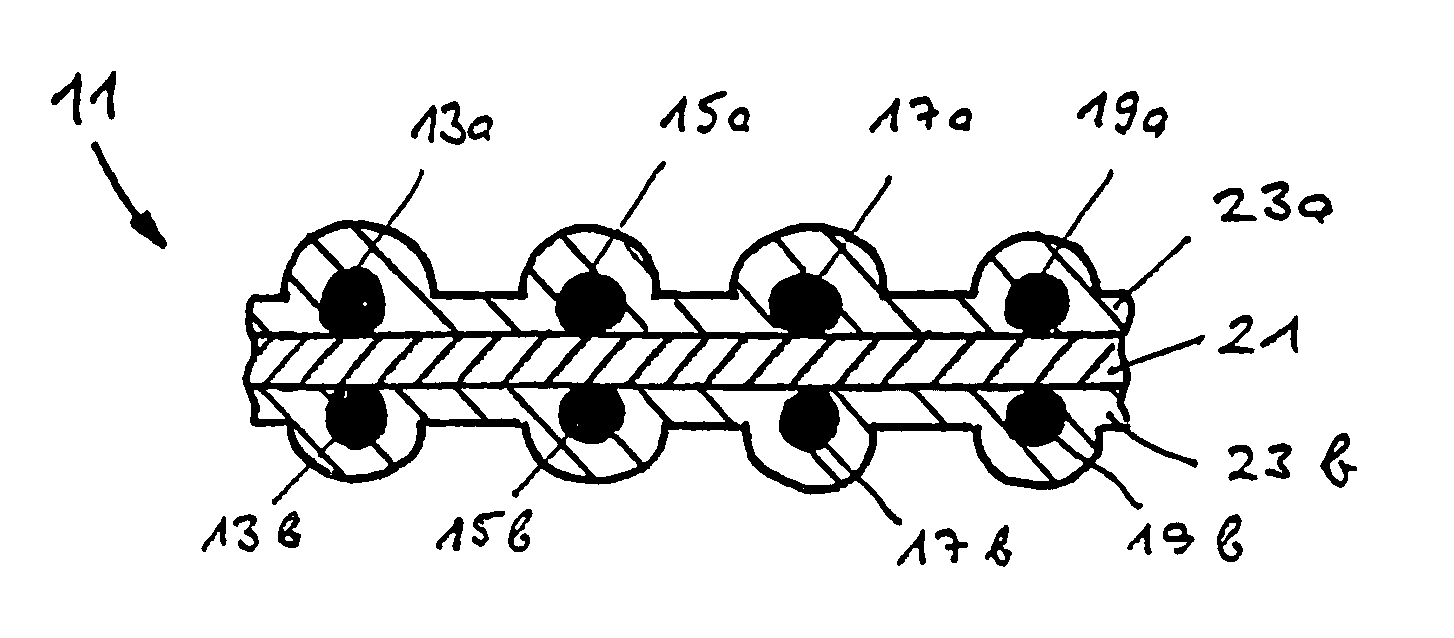

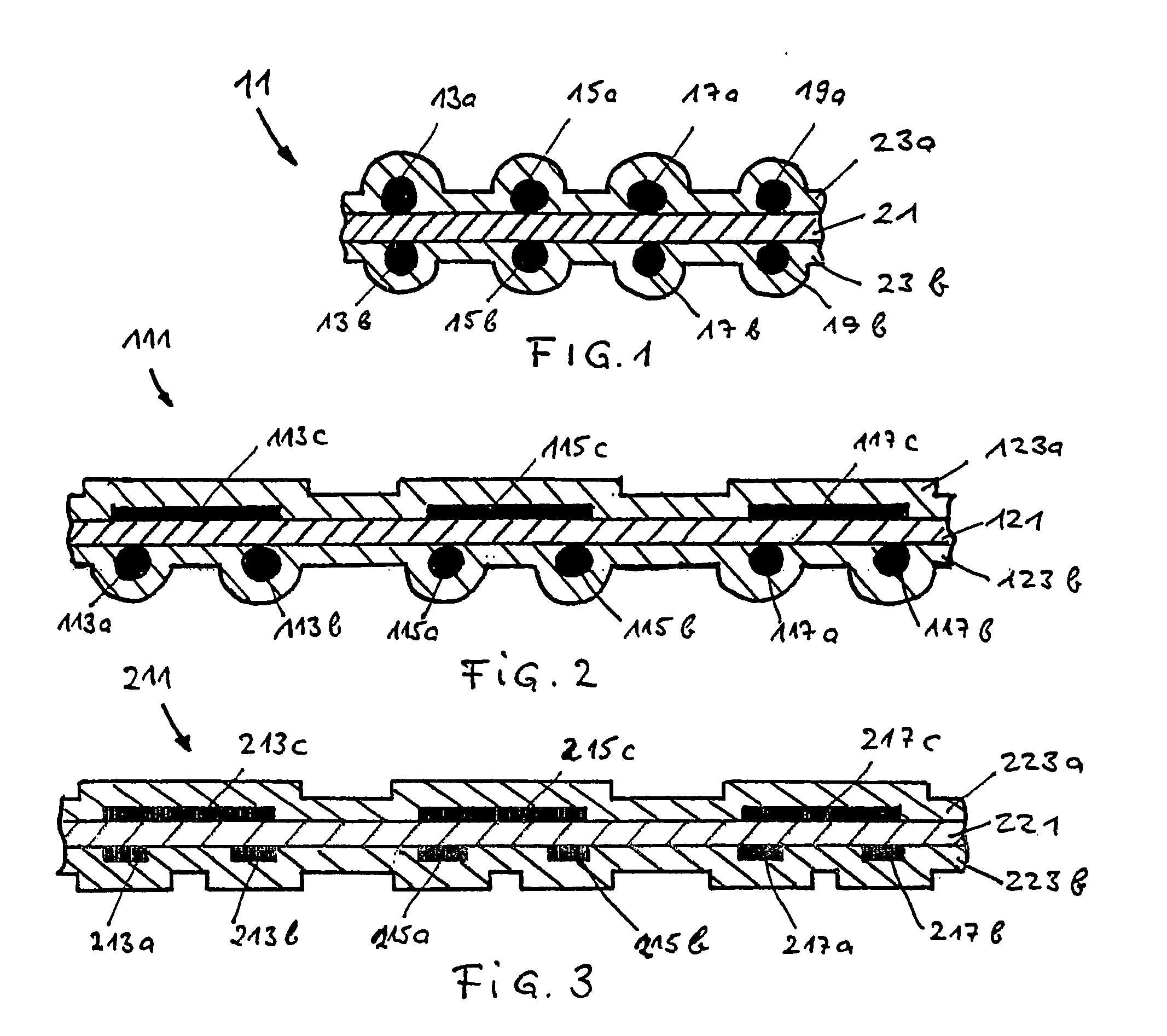

Flat Cable

ActiveUS20070240898A1Increased mechanical load capacityImprove bending performanceLine/current collector detailsFlat/ribbon cablesElectrical conductorInsulation layer

A flat cable having at least two conductor planes, in which a number of electrical conductors running in the longitudinal direction of the cable are arranged, in which the electrical conductors in the flat cable thickness direction and / or in the flat cable width direction are kept at a defined distance from each other by means of a central insulation layer of predetermined thickness acting as a spacer insulator and are electrically insulated and positioned relative to each other and to the flat cable exterior by means of an outer insulation layer.

Owner:W L GORE & ASSOC GMBH

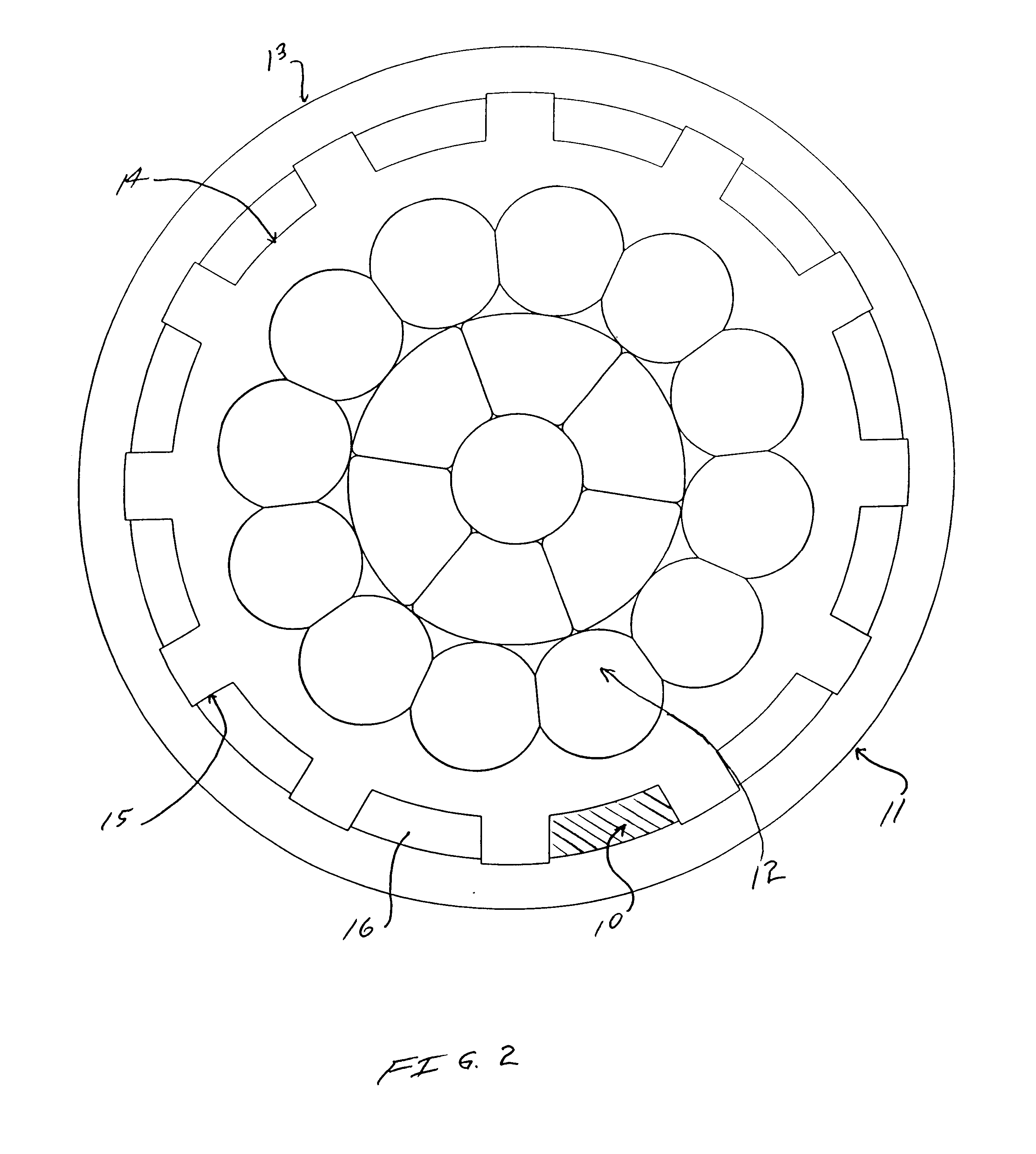

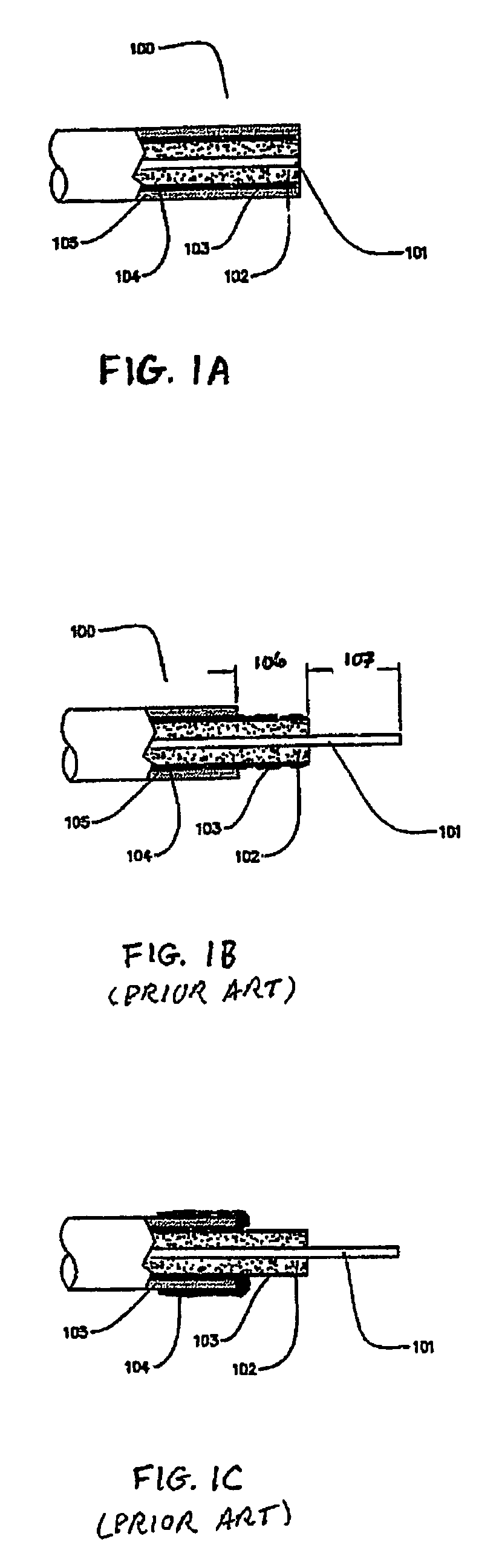

Self-sealing electrical cable having a finned inner layer

InactiveUS6573456B2Plastic/resin/waxes insulatorsClimate change adaptationElectrical conductorInsulation layer

An electrical cable and a method for manufacturing the electrical cable are provided in which a plurality of conductors have an inner protective layer extruded thereabout, a ribbed or finned surface exterior thereto which includes a plurality of longitudinally extending ribs or fins between which exist a plurality of channel regions, an outer insulation layer thereabout, and a material within the channel regions which provides self-sealing properties to the cable, all applied to the conductor as a combined multilayer, the inner layer and outer layer merging to form the fins therebetween.

Owner:SOUTHWIRE CO LLC

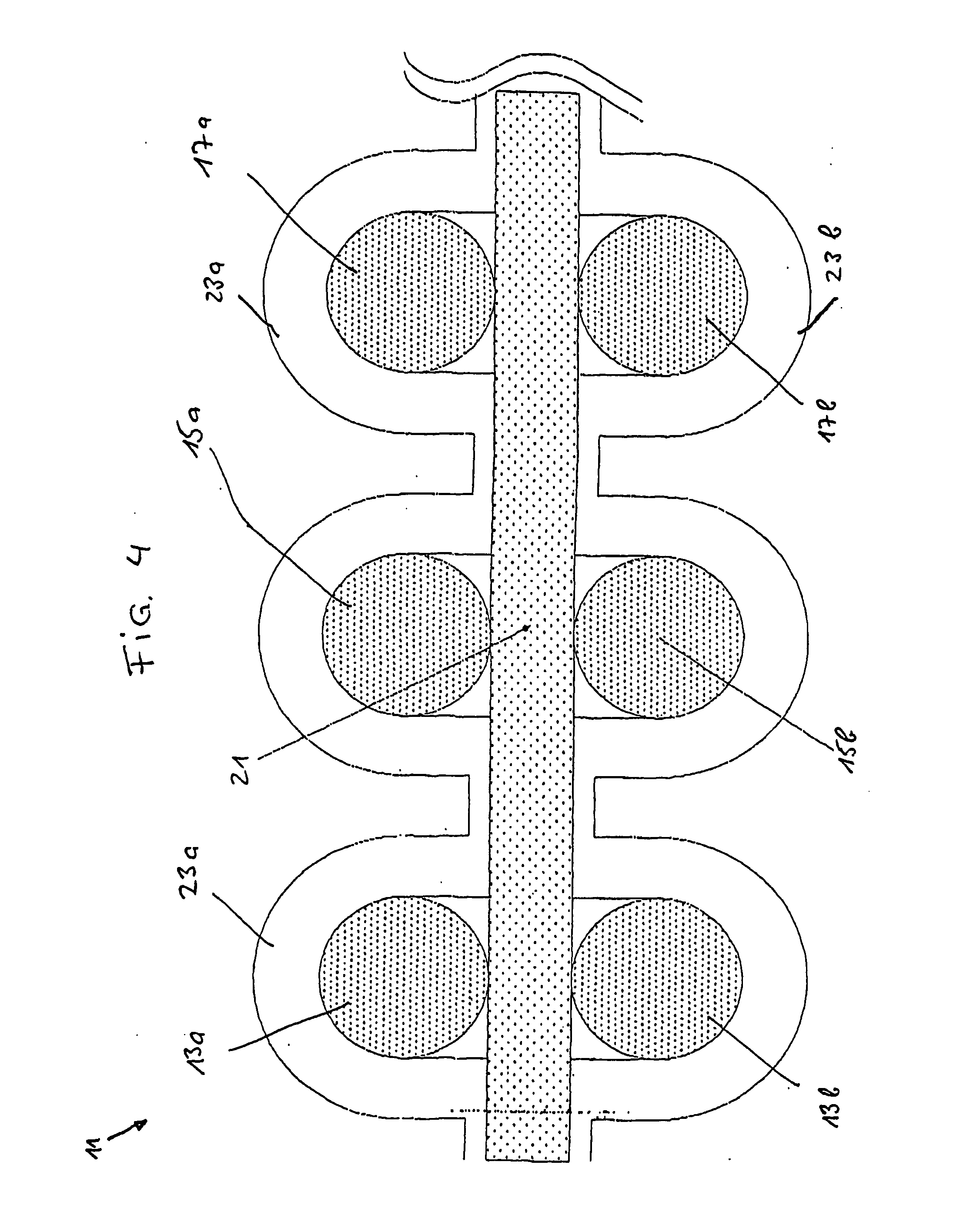

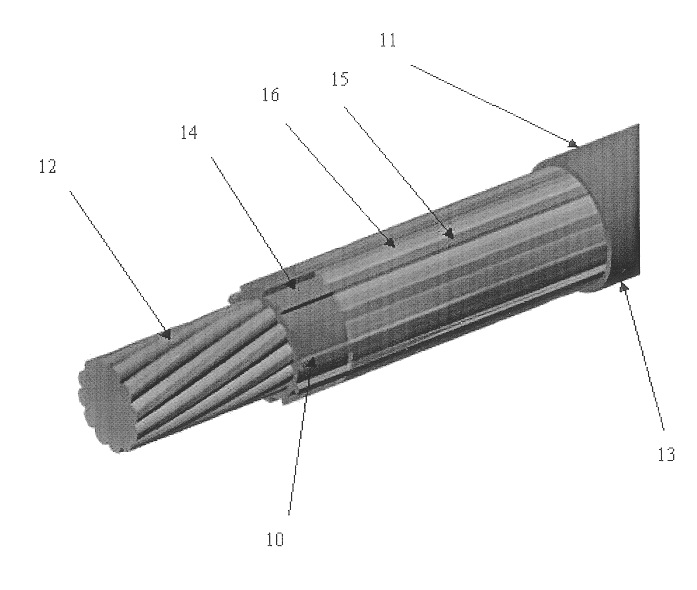

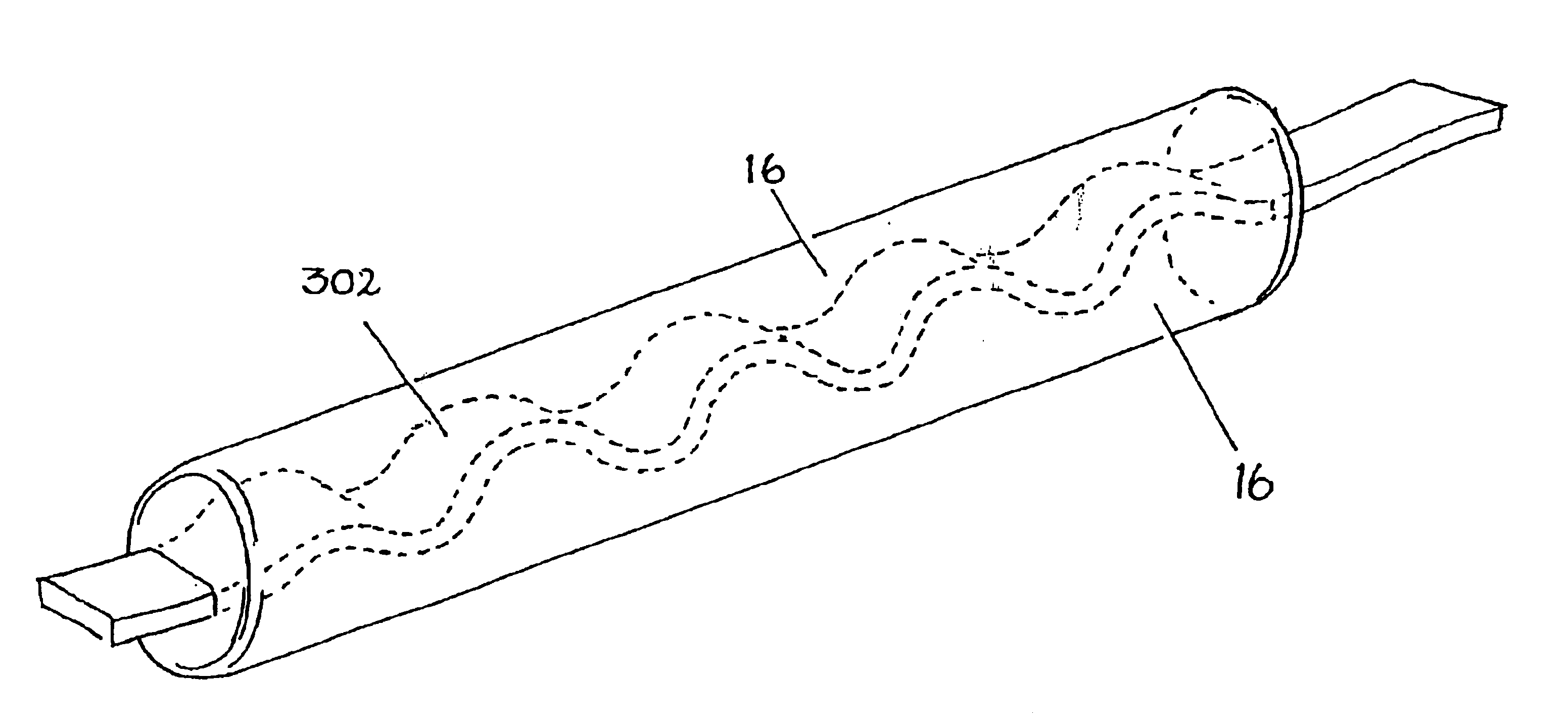

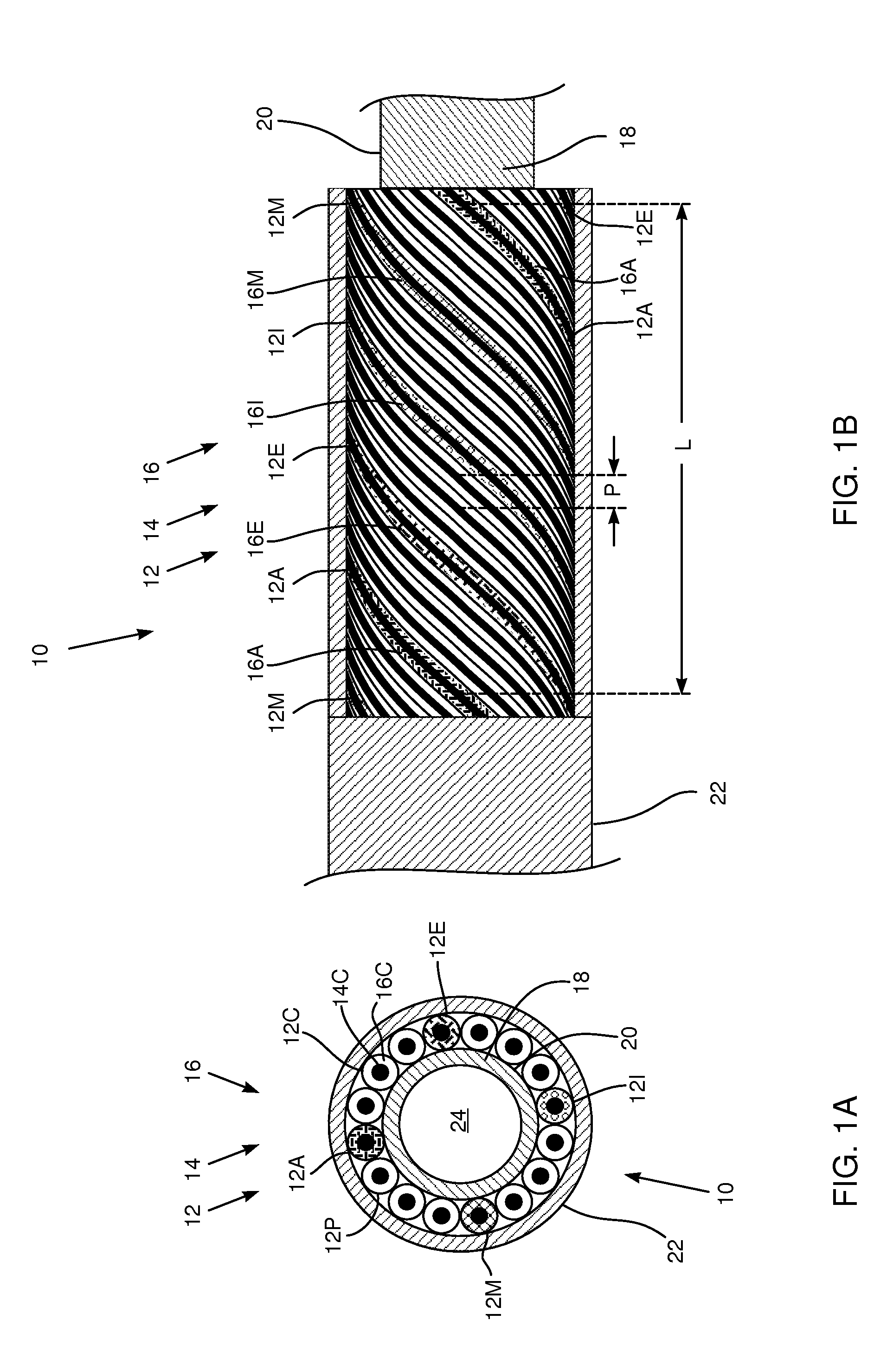

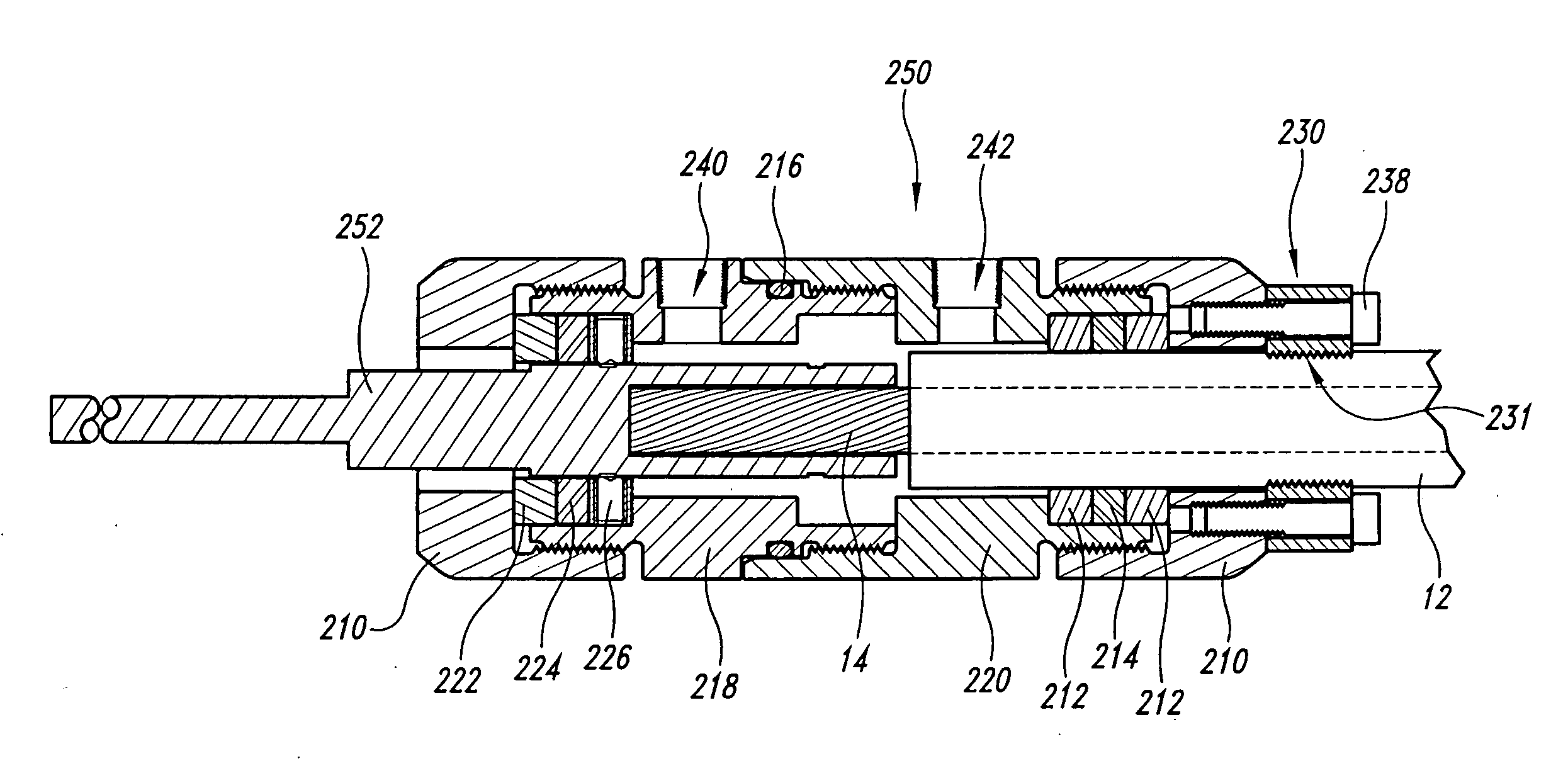

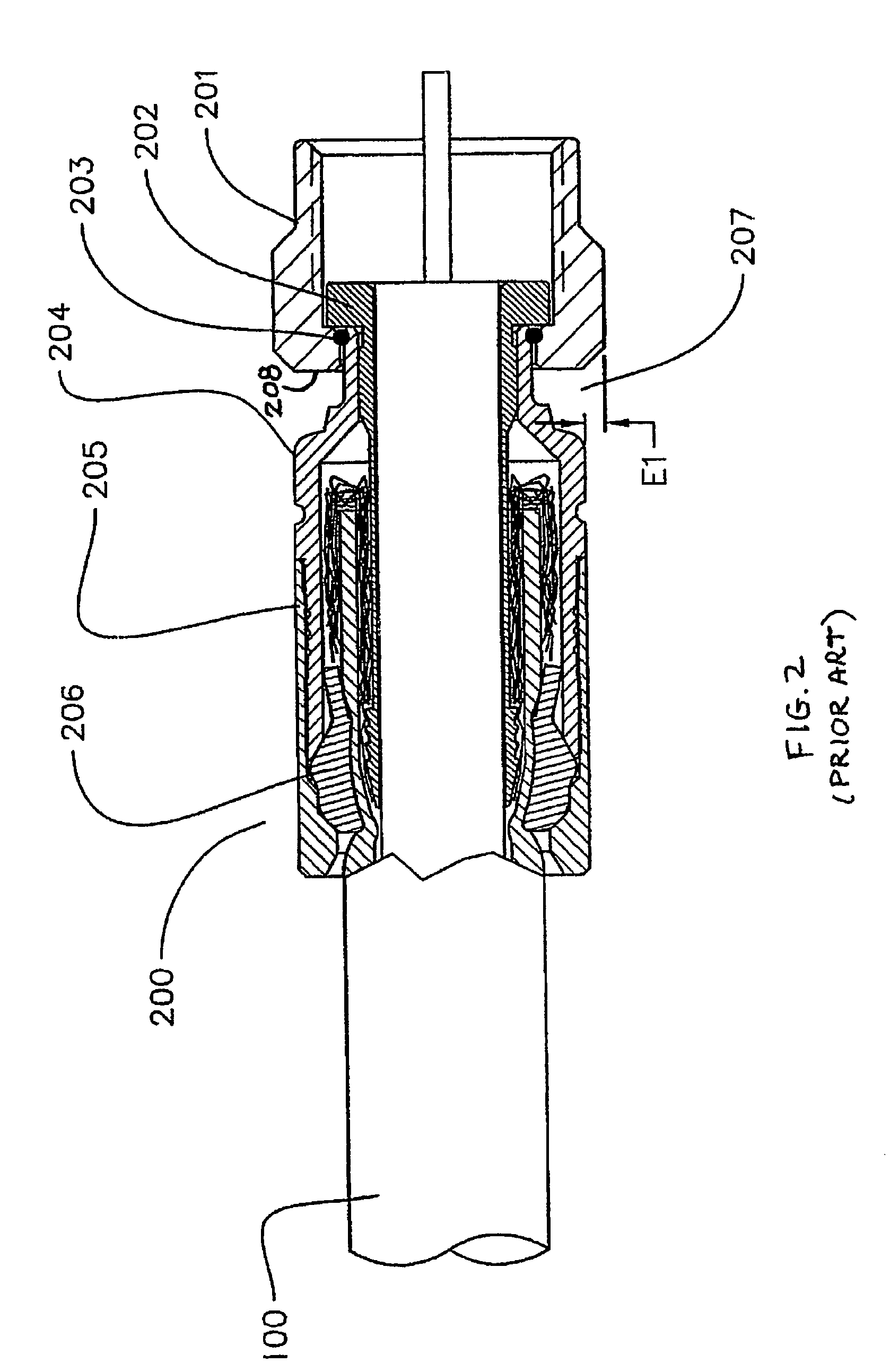

Implantable electrical cable and method of making

ActiveUS6843870B1The method is simple and reliableMechanical working/deformationInternal electrodesPliabilityFluoropolymer

The present invention is an implantable cable and a process to manufacture said implantable cable. The cable is composed of a biocompatible fluoropolymer, in which biocompatible conductor wires are embedded. The entire cable is heat treated at various stages to ensure the wires are securely embedded. The cable is then undulated to enhance its pliability and flexibility. Further treatment activates the outer surface of the cable, following which it may be encapsulated in silicone.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

Cable covered in solid lubricant

The invention relates to apparatus for depositing a lubricant coating on a cable, the cable including a sheath made by means of an extruder followed by a cooling vessel. Downstream from the cooling vessel, the apparatus includes a heater member followed by a deposition chamber for depositing a lubricant material.

Owner:ALCATEL LUCENT SAS

Port seizing cable connector nut and assembly

ActiveUS8152551B2Easy to fixMinimum of effortEngagement/disengagement of coupling partsTwo-part coupling devicesCoaxial cableMechanical engineering

A coaxial cable connector includes a connector body having a first end and a second end, a coupling nut freely rotatable and disposed in relation to the first end of the connector body and a post having a first end and a second end, the post further including a open-ended port retaining portion. The coupling nut includes an internal threaded portion and is disposed in overlaying relation relative to the port retaining portion, which is configured for engaging an external port. The port retaining portion defines a locking collet that prevents loosening of the engaged port, while still guaranteeing electrical continuity without requiring excessive tightening of the connector.

Owner:PPC BROADBAND INC

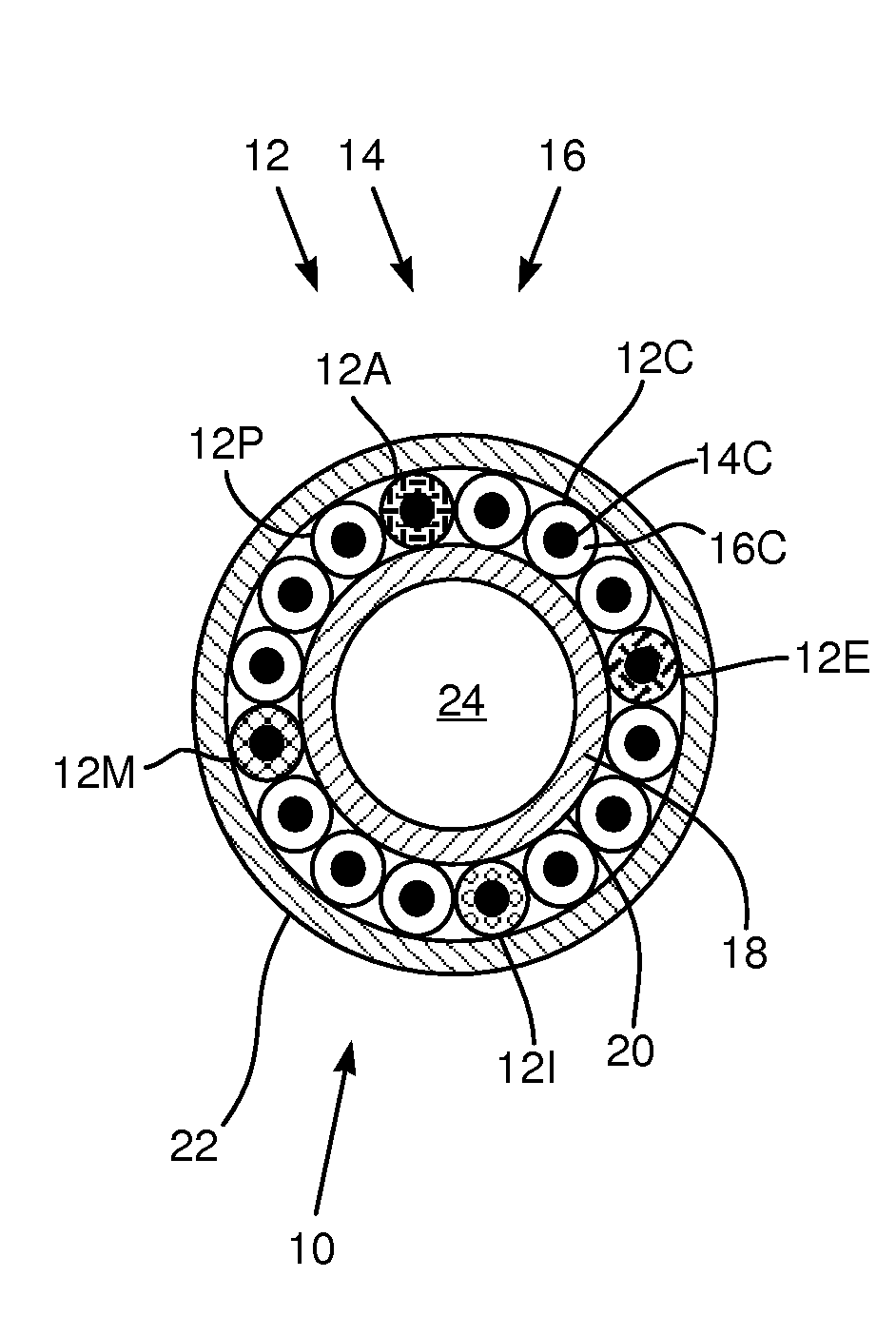

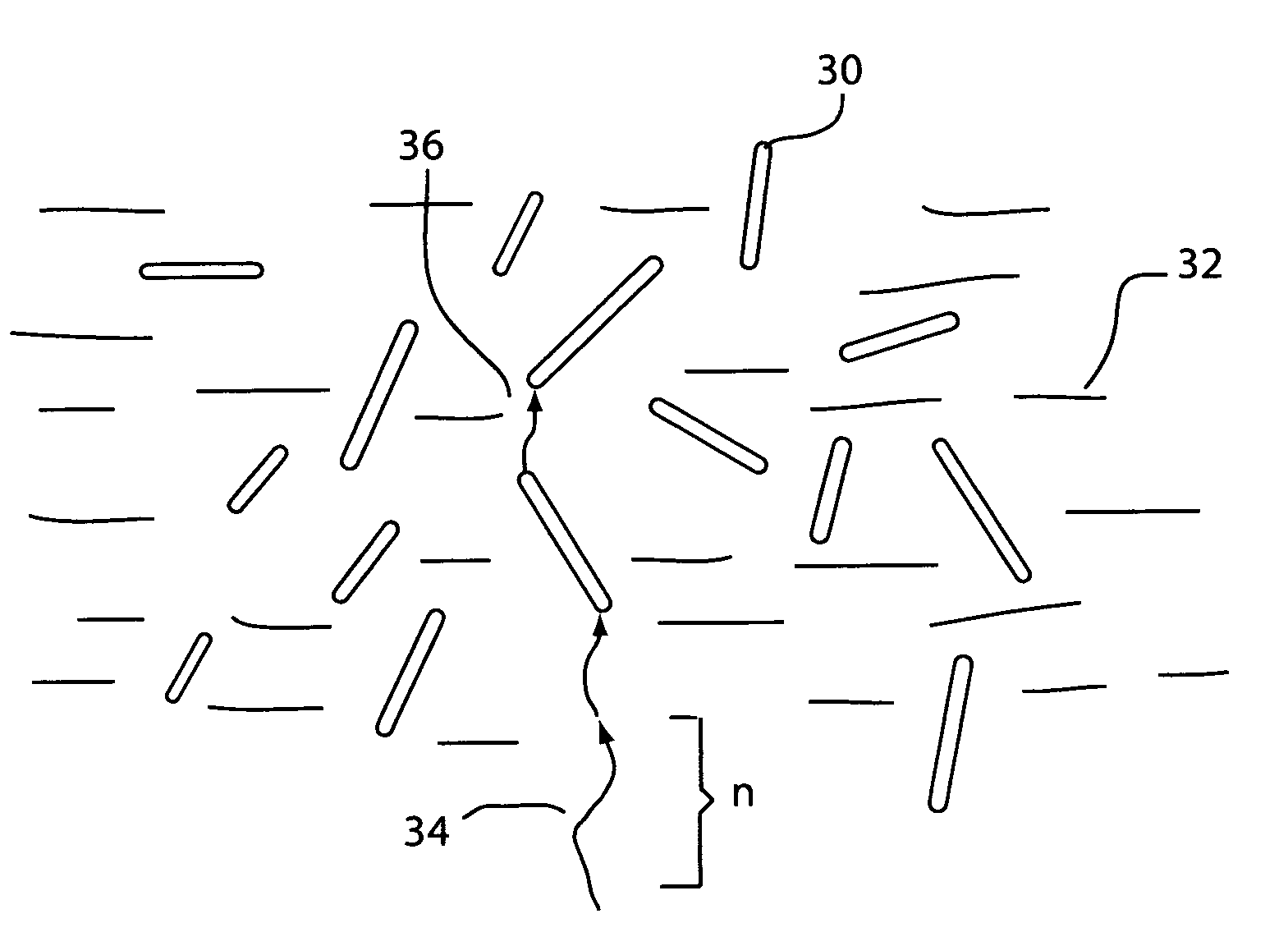

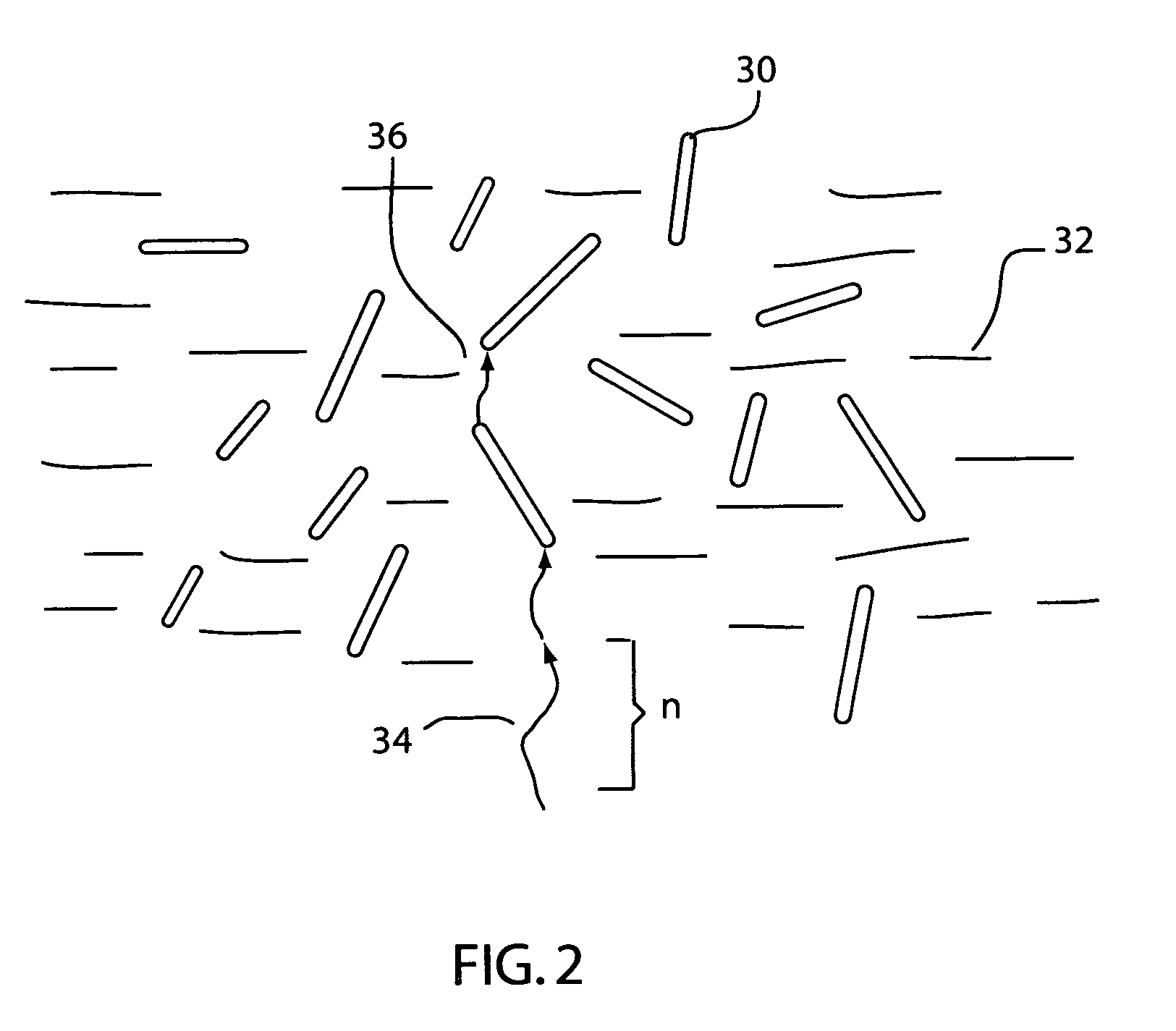

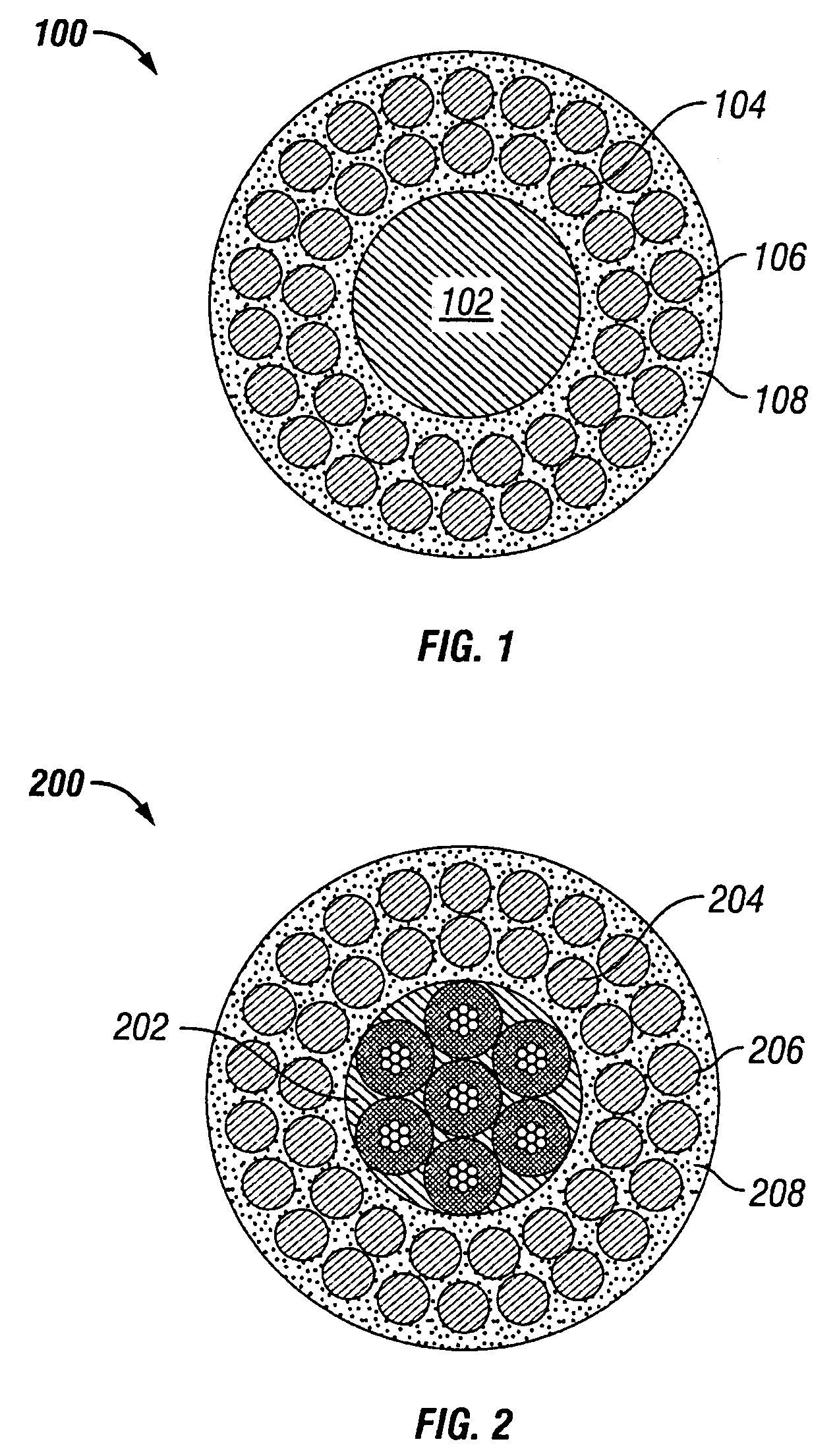

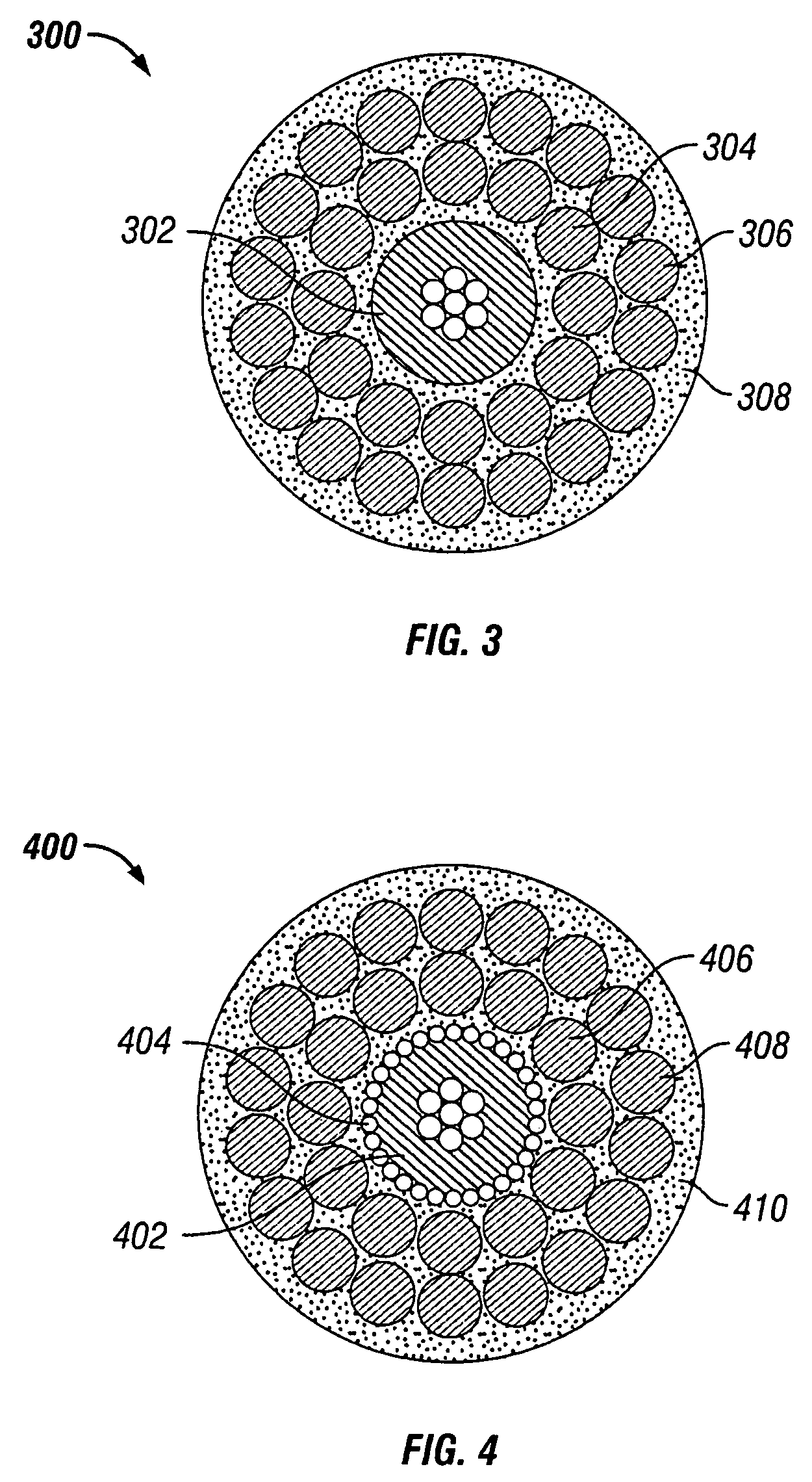

High density electrode structure

ActiveUS20140309512A1Line/current collector detailsTransvascular endocardial electrodesHigh densityEngineering

Electrode cabling, including a core and n wires coiled on the core in an arrangement topologically equivalent to an n-start thread configuration, wherein n is an integer greater than one. The cabling also includes a sheath covering the n wires and an electrode attached through the sheath to a given wire selected from the n wires.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

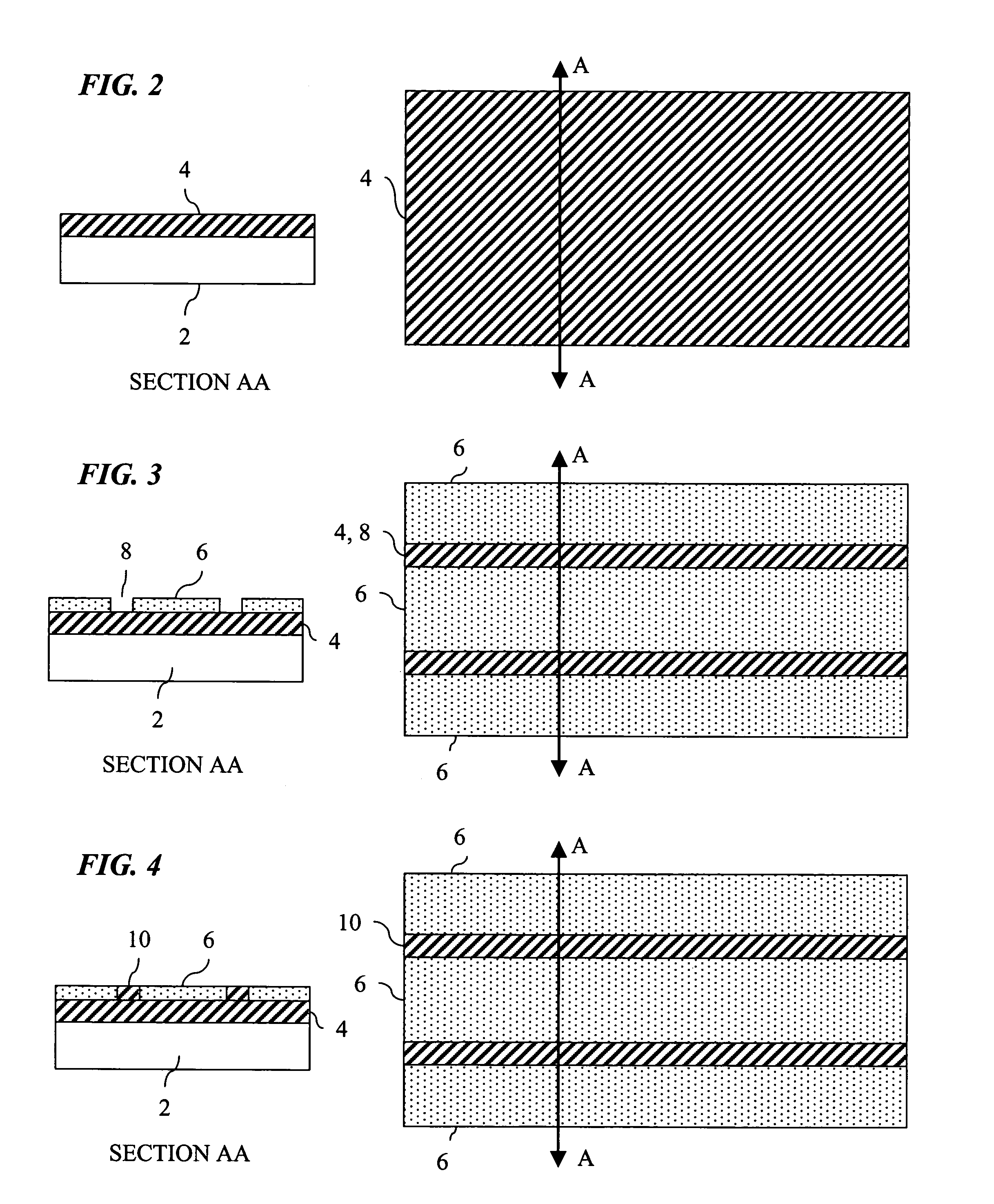

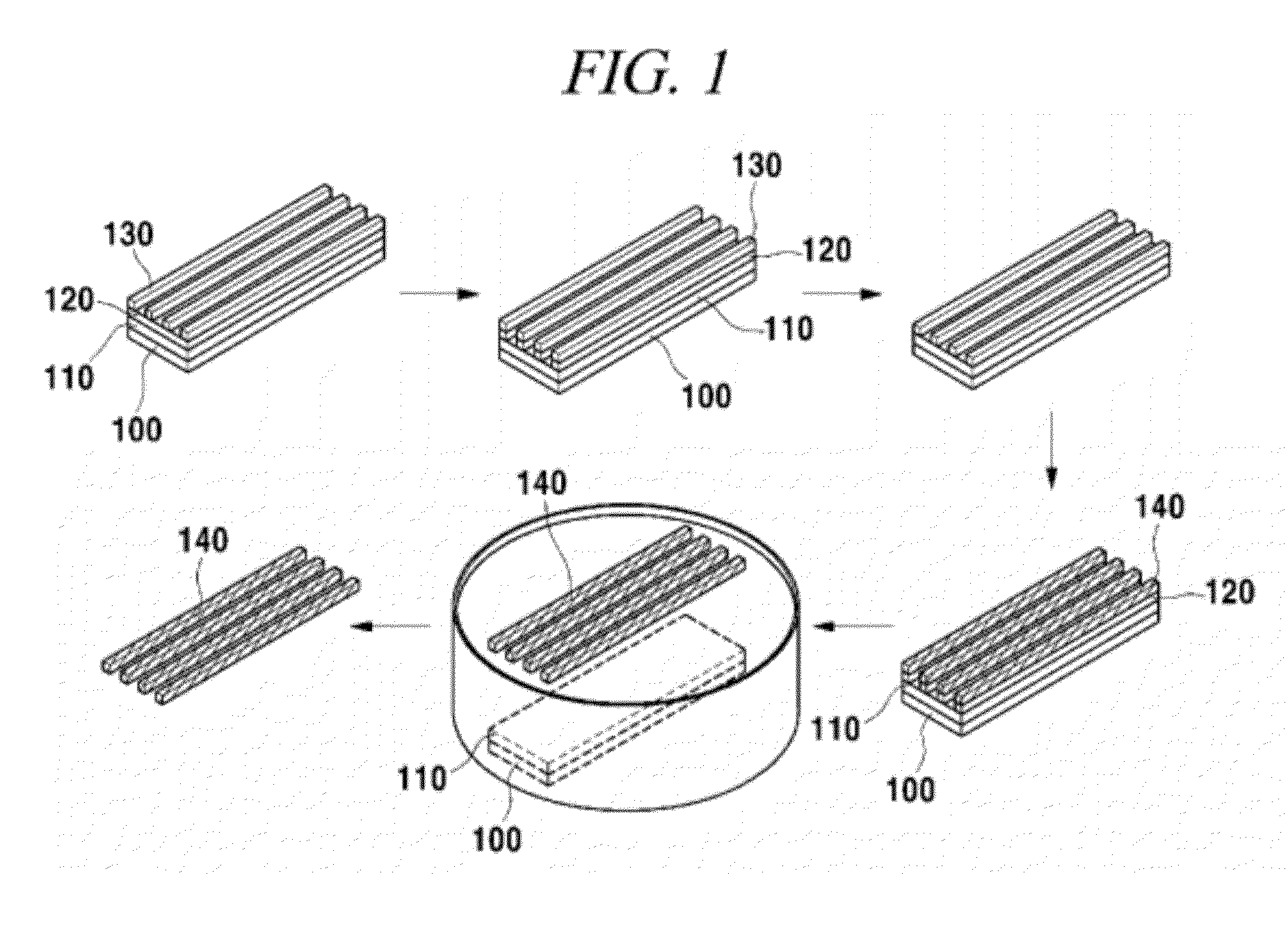

Method for producing multilayer graphene-coated substrate

ActiveUS20130065034A1Inexpensive heat-releasingLow costMaterial nanotechnologyLayered productsTransparent conducting filmEngineering

The present invention provides a method of producing a multi-layer graphene-laminated substrate which comprises laminating, on a substrate surface, multi-layer graphenes from a mass of multi-layer graphenes. The method of the present invention can provide an electrically conductive film and a transparent electrically conductive film made of graphenes more easily and stably.

Owner:INCUBATION ALLIANCE

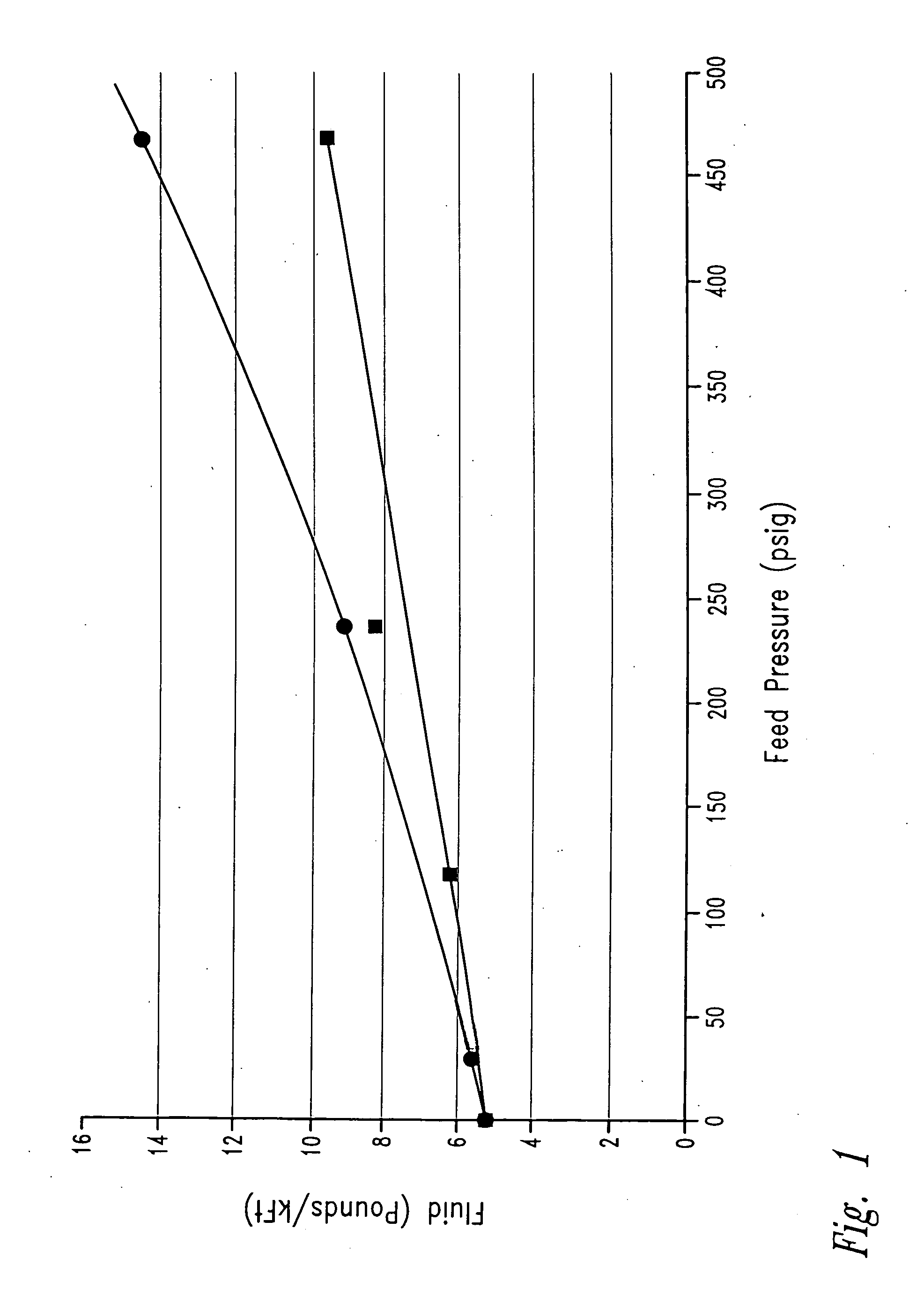

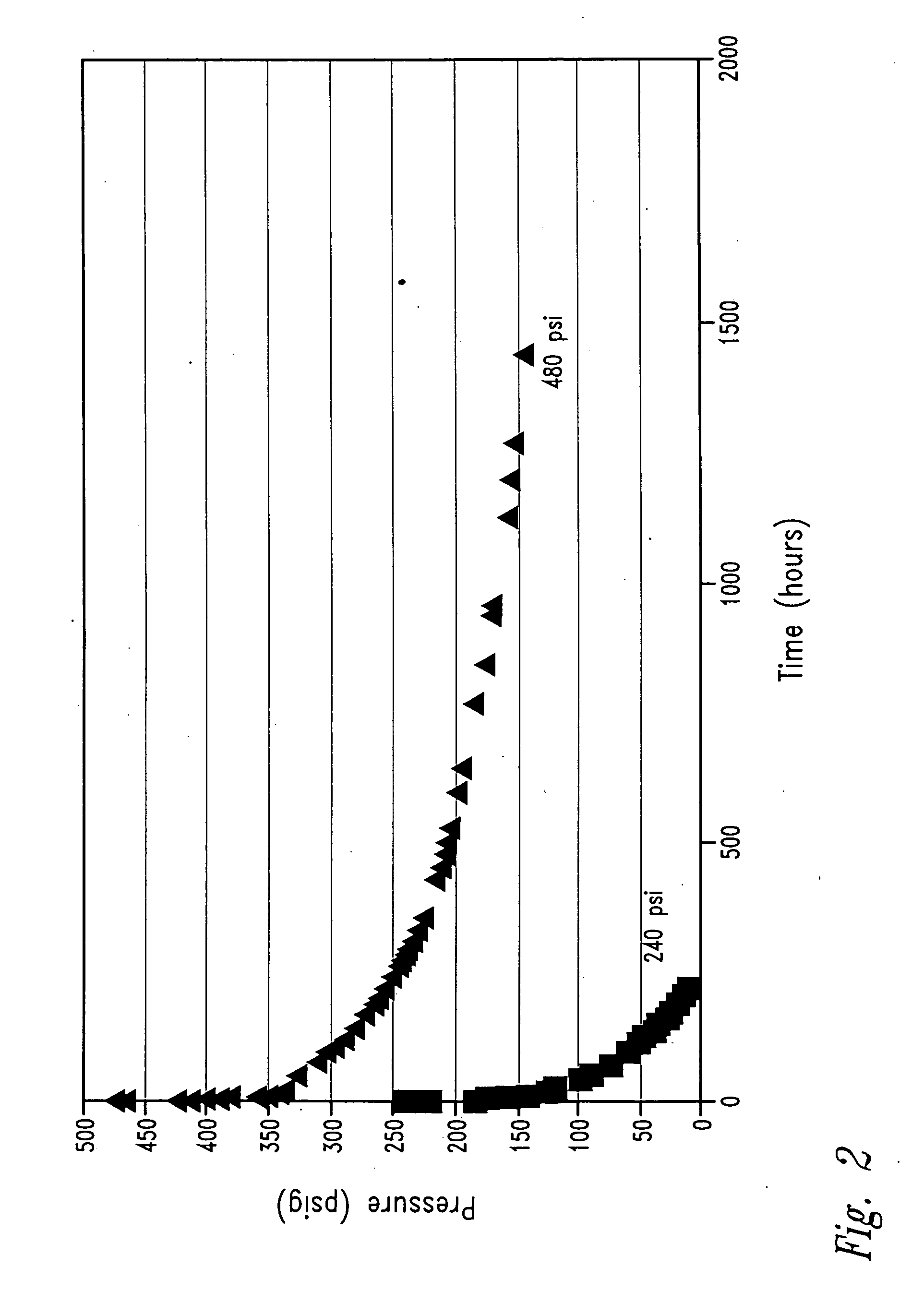

Method for treating electrical cable at sustained elevated pressure

ActiveUS20100095521A1Effective treatmentExcellent dielectric propertiesClimate change adaptationPower cables with screens/conductive layersElectrical conductorPolymer insulation

A method for enhancing the dielectric properties of an electrical cable segment having a central stranded conductor encased in a polymeric insulation jacket and an interstitial void volume in the region of the conductor, including filling the interstitial void volume with a dielectric property-enhancing fluid at a pressure below the elastic limit of the polymeric insulation jacket, and confining the fluid within the interstitial void volume at a residual pressure greater than about 50 psig, with the pressure being imposed along the entire length of the segment but below the elastic limit of the polymeric insulation jacket. Preferably, the residual pressure is sufficient to expand the interstitial void volume along the entire length of the cable segment by at least 5%.

Owner:NOVINIUM LLC

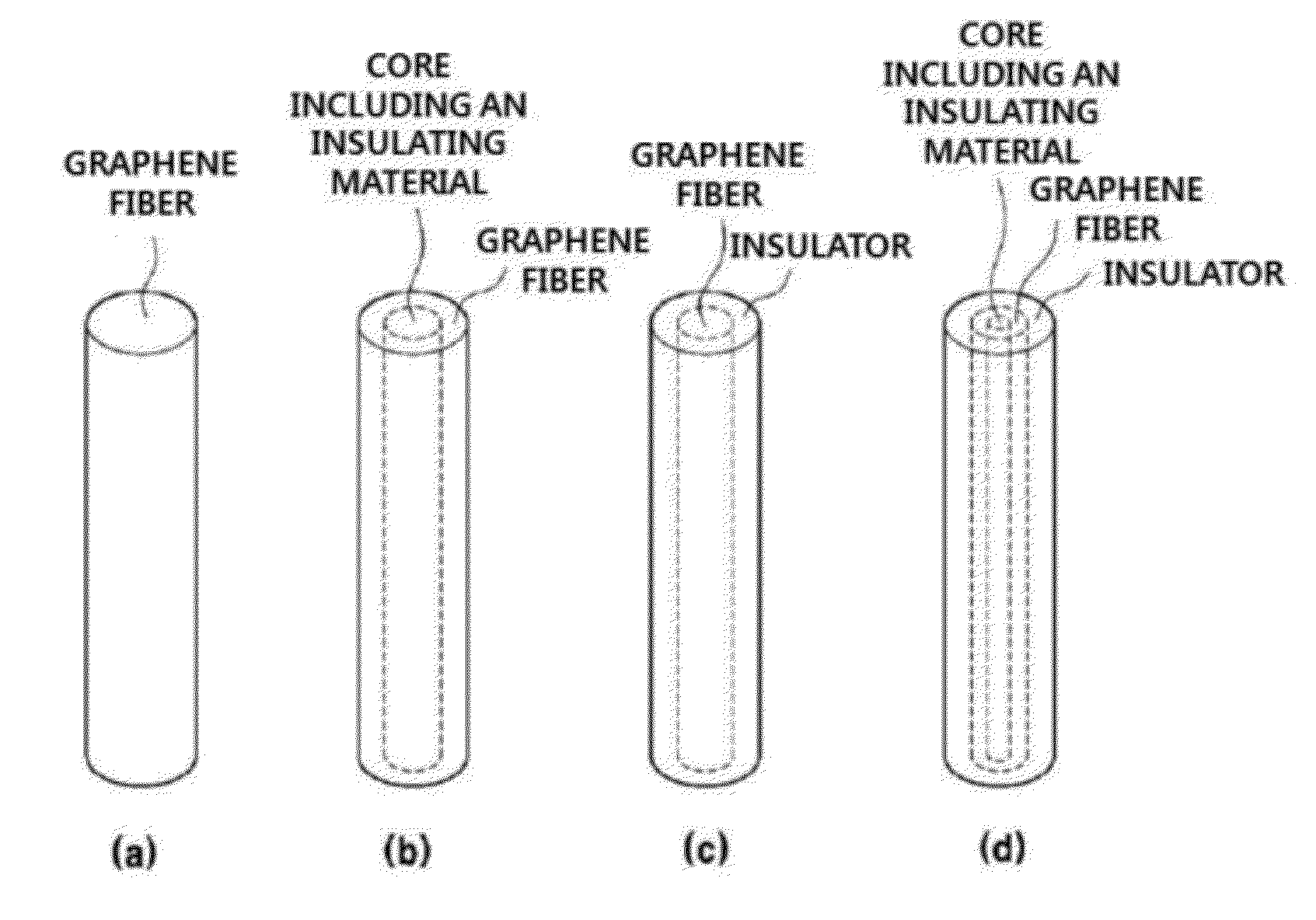

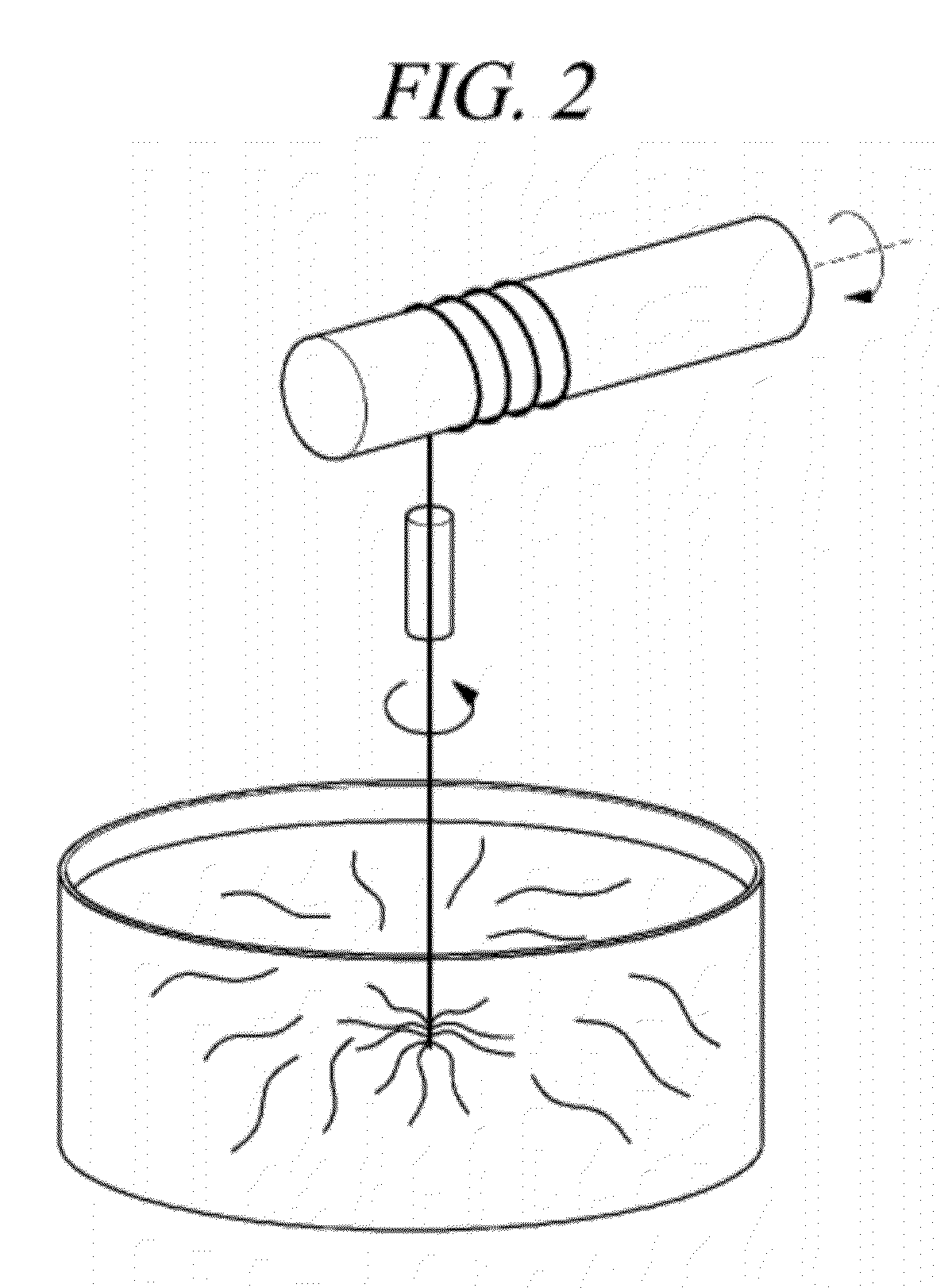

Graphene fiber, method for manufacturing same and use thereof

ActiveUS20120298396A1Quality improvementLow costCoaxial cables/analogue cablesMaterial nanotechnologyFiberCoaxial cable

The present disclosure relates to a manufacturing method of a graphene fiber, a graphene fiber manufactured by the same method, and use thereof. The graphene fiber formed by using graphenes of linear pattern can be applied to various fields such as an electric wire and coaxial cable.

Owner:GRAPHENE SQUARE

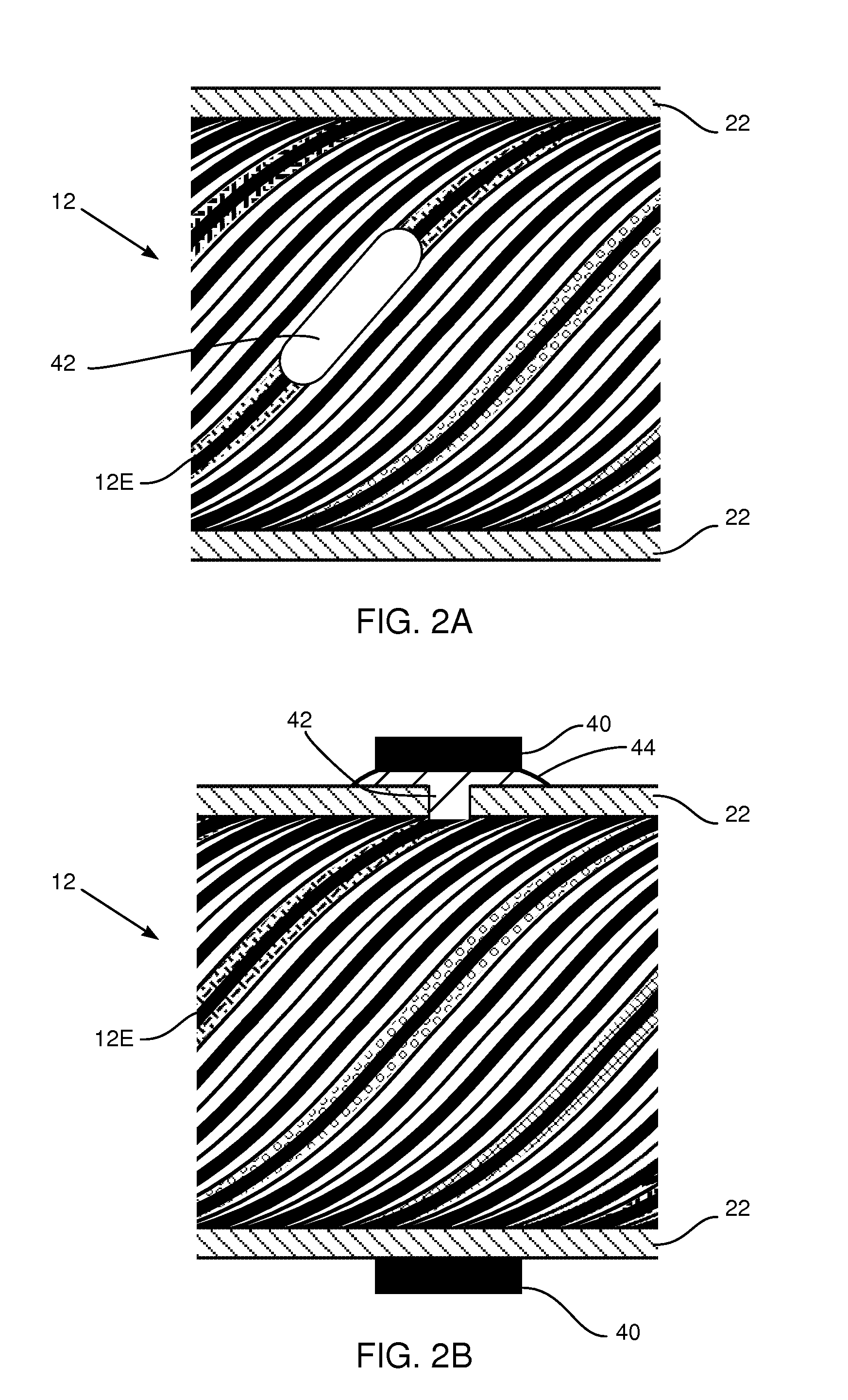

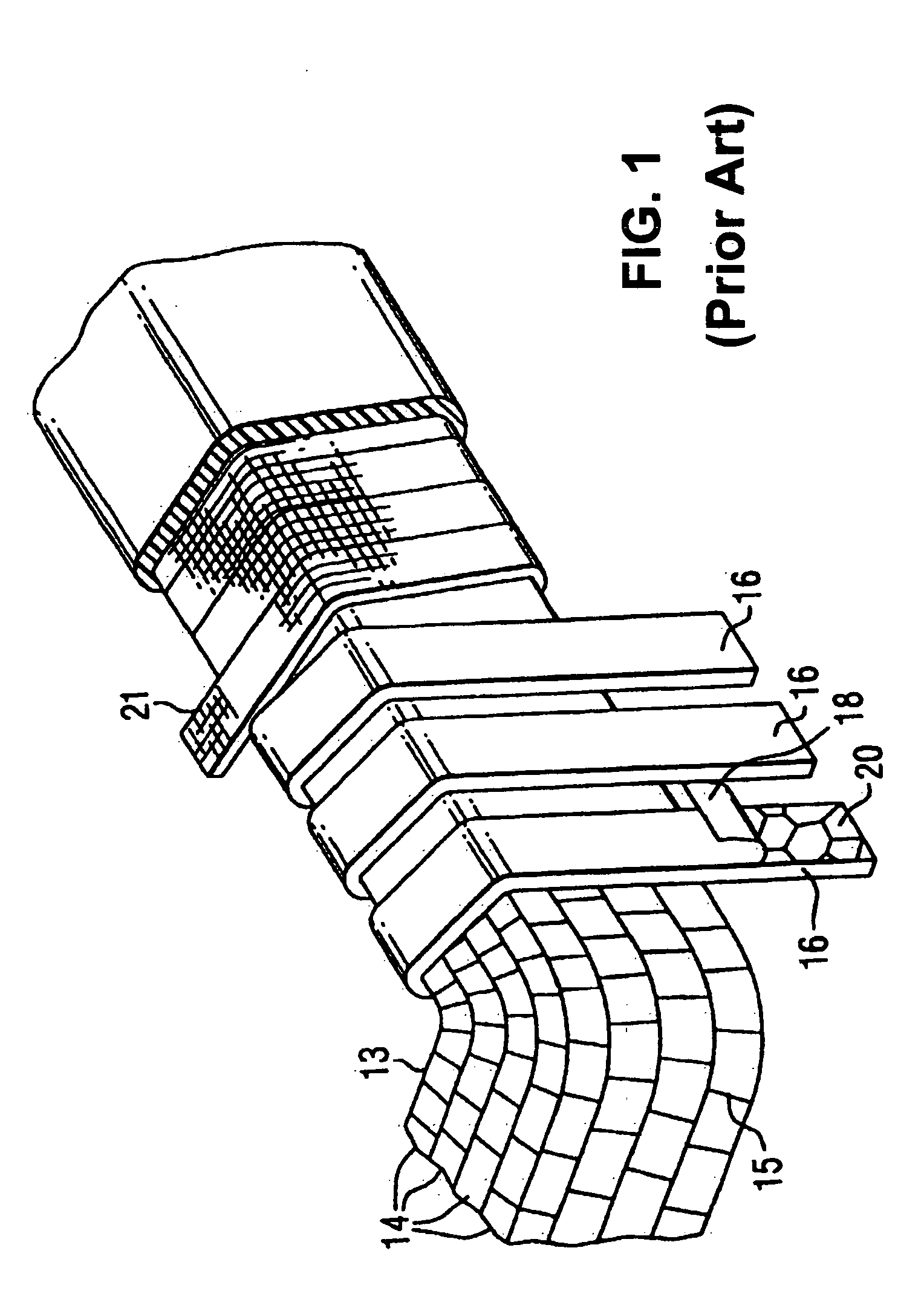

Compression of resin impregnated insulating tapes

ActiveUS20050274450A1Easy to disperseReduces phonon scatteringWindings insulation materialAdhesive processes with surface pretreatmentThermal conductivity

The present invention provides for a method of impregnating a matrix with a high thermal conductivity filled resin 32, which produces a resin impregnated matrix. The high thermal conductivity material 30 comprises 5-60% by volume of the resin 32. This is compressed by approximately 5-30%, and the distances between the high thermal conductivity materials loaded in the resin are reduced, and the resin is then cured.

Owner:SIEMENS ENERGY INC

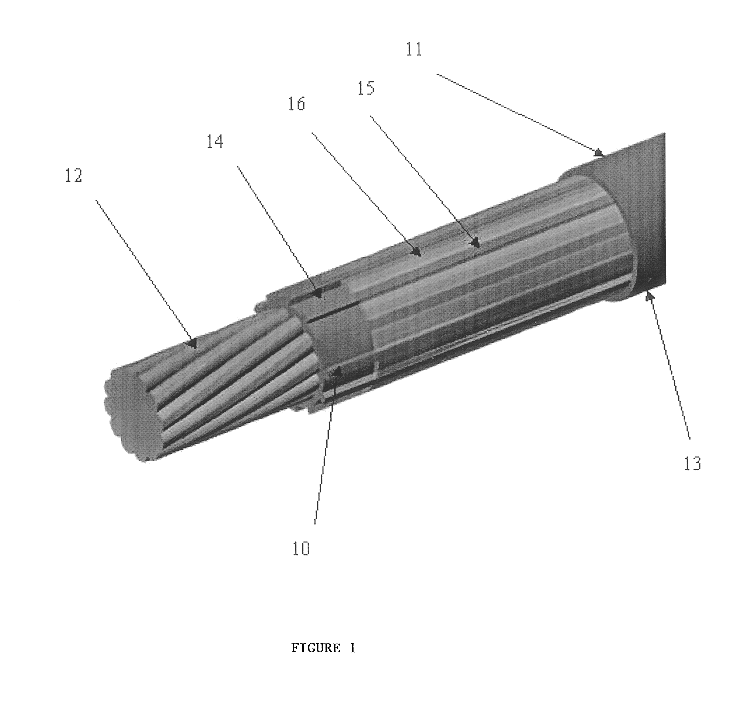

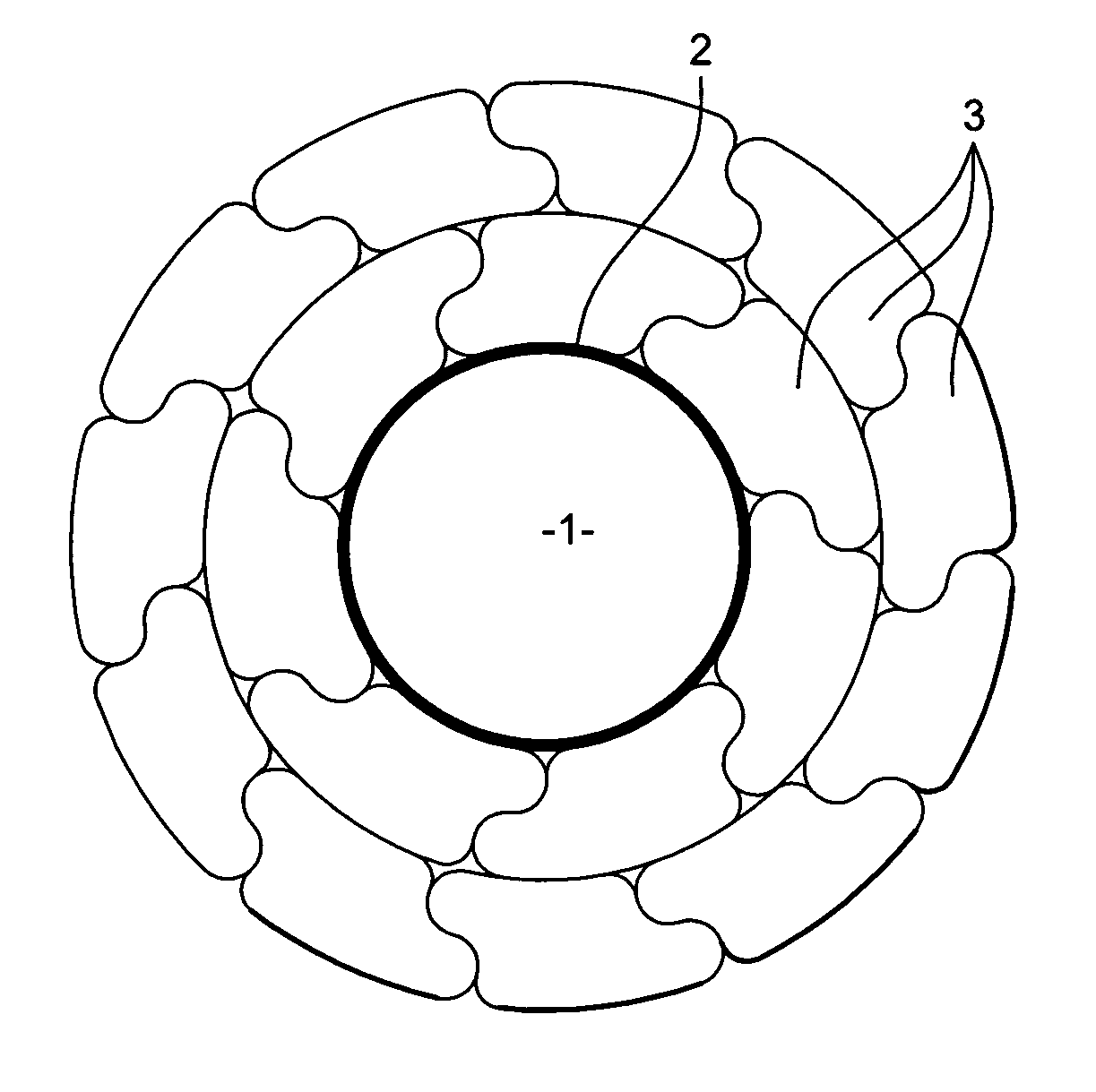

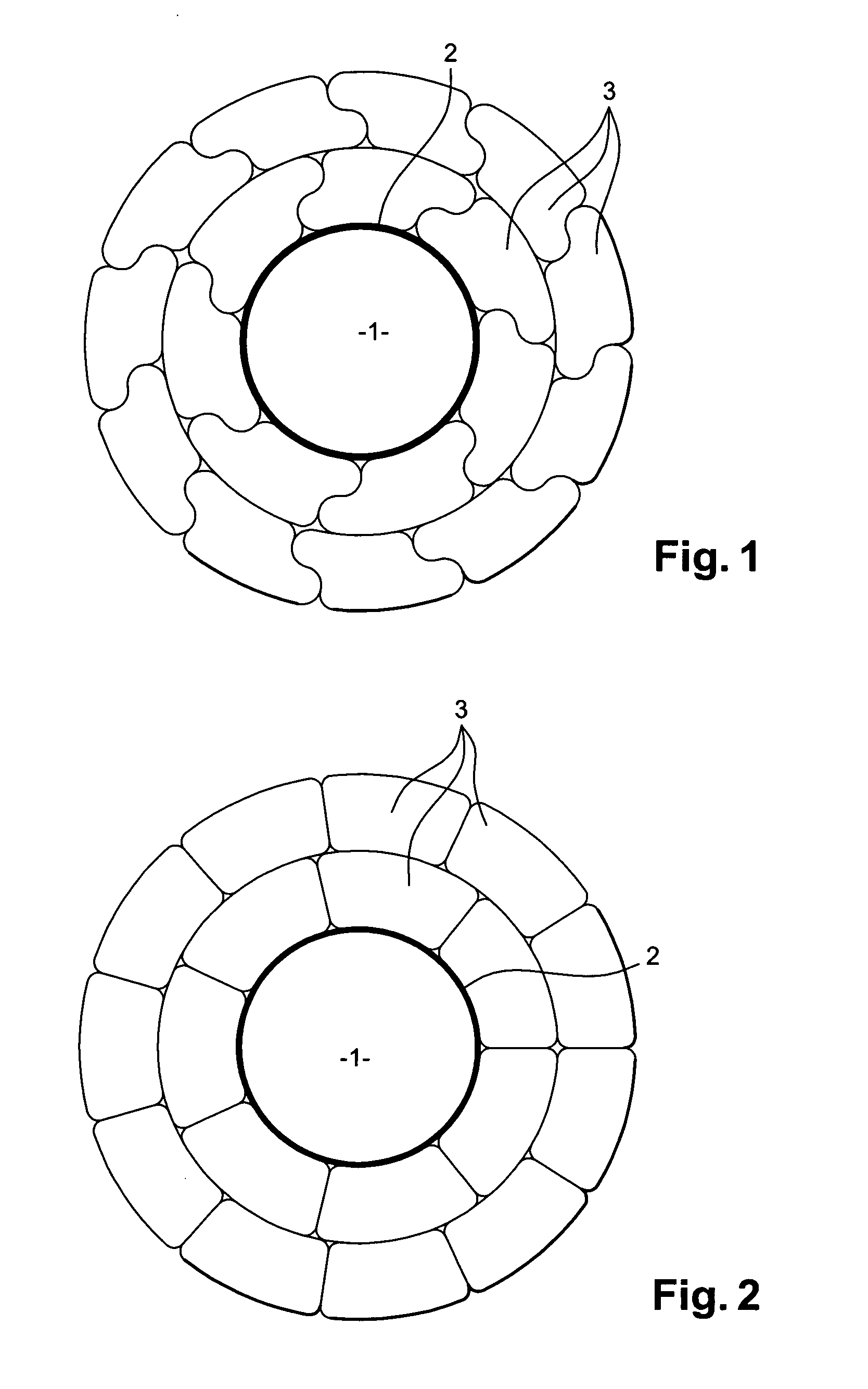

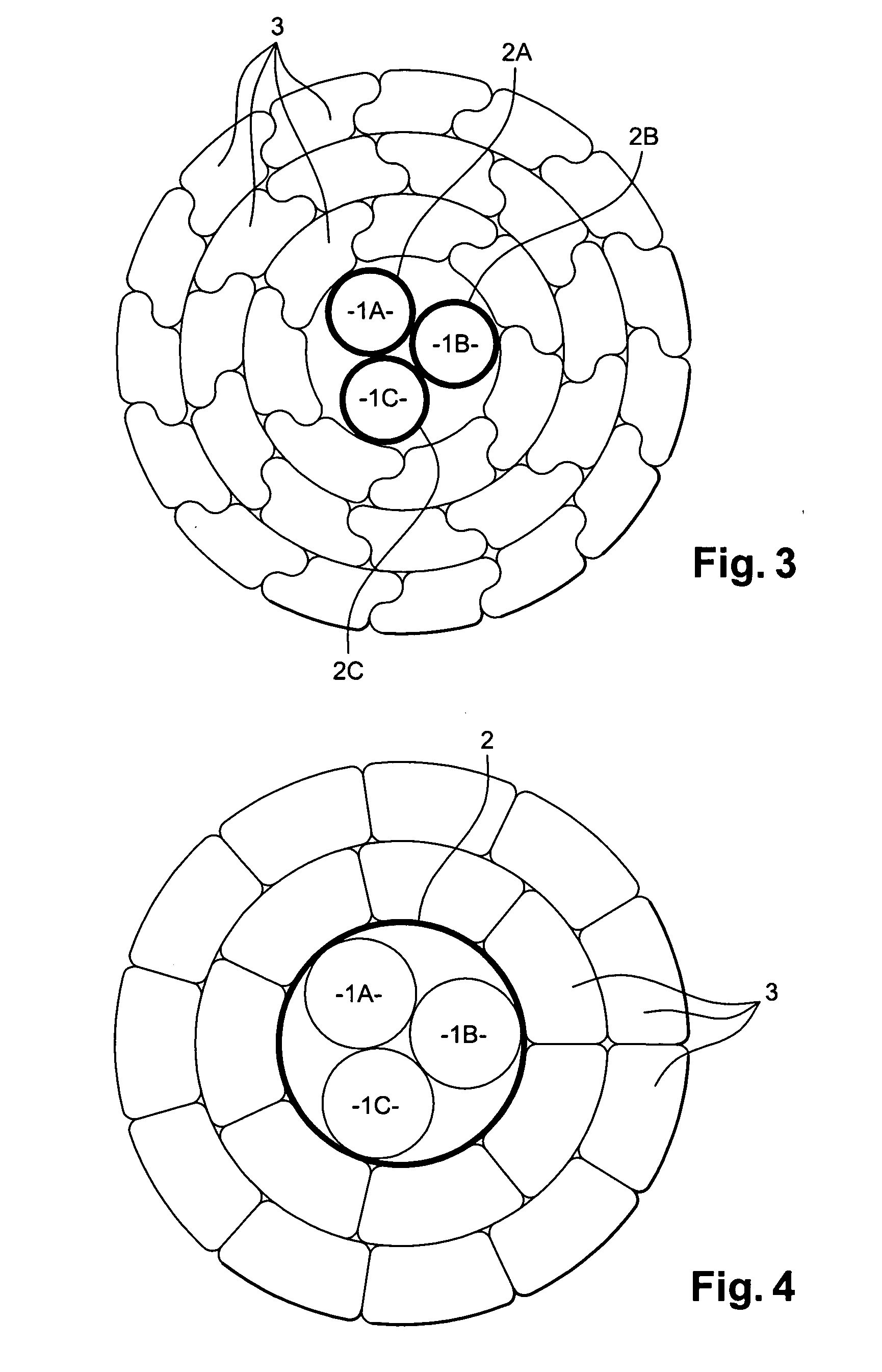

Electricity transport conductor for overhead lines

The invention relates to a method of fabricating an electricity transport conductor, in particular for overhead power lines, that are to operate at an operating temperature greater than or equal to 200° C., and comprising at least one composite central core 1 made of continuous fibers impregnated with an epoxy resin matrix, the core being covered in at least one layer of insulating material 2, and conductor wires 3 of aluminum or aluminum alloy being wound around the core. According to the invention, said insulating material is compatible with said operating temperature and is put into place on said core 1 without subsequent heating.

Owner:NEXANS

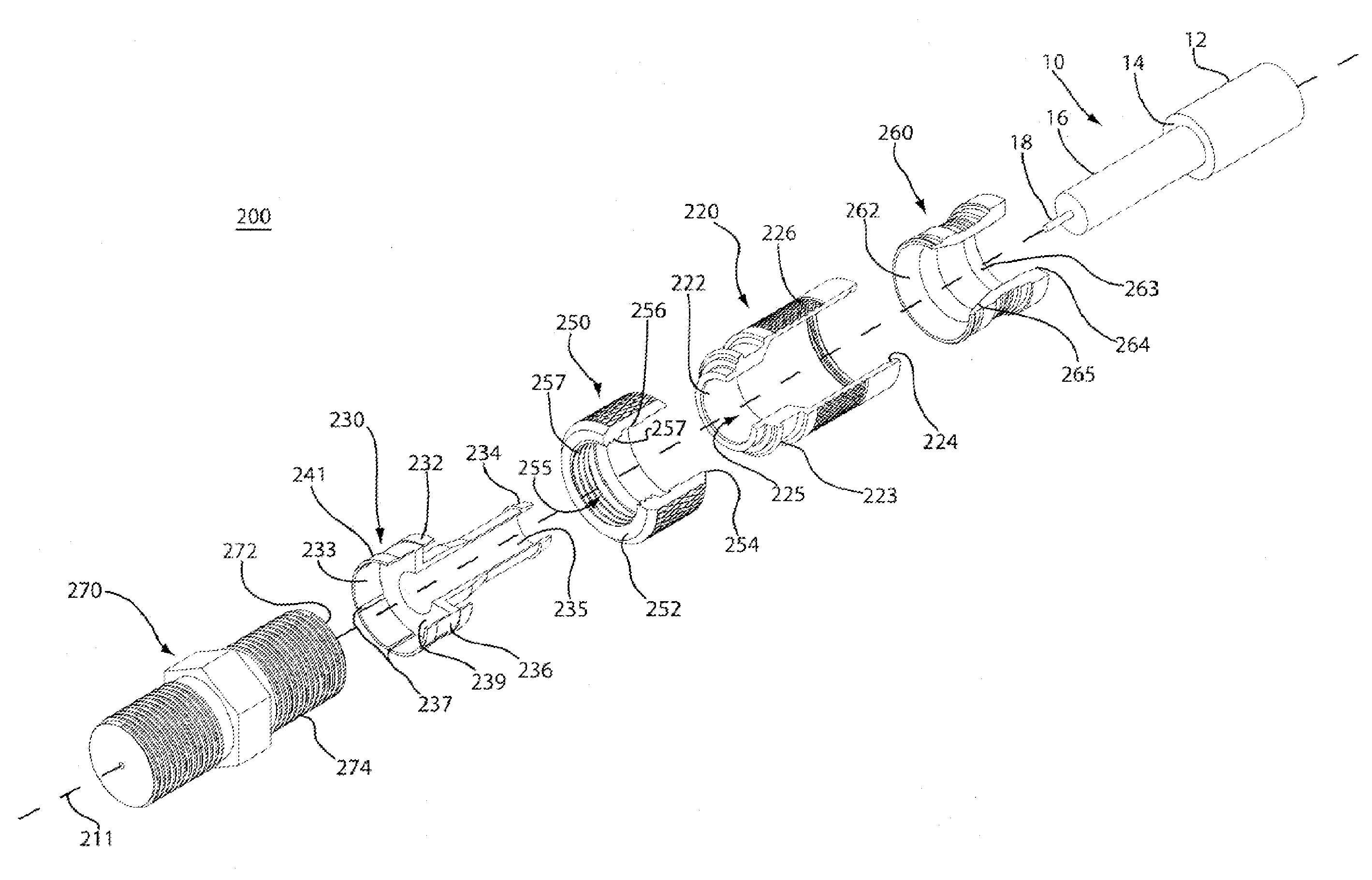

Coaxial connector and coaxial cable connector assembly and related method

ActiveUS7371112B2CostSufficient retentionElectrically conductive connectionsCoupling device detailsCoaxial cablePatch cable

A method of making a coaxial cable assembly is disclosed, the assembly comprising a coaxial cable and a connector, or connector termination, on at least one end of the cable. A connector, comprised of connector components, is also disclosed. The method comprises placing connector components into contact with the cable before the connector components are assembled into a connector. The connector is assembled simultaneously with securing the connector to the cable to make a coaxial cable assembly. A method of preparing coaxial cable in a manner suitable for making coaxial cable assemblies is also disclosed. The coaxial cable assembly can be a jumper, or a lead.

Owner:PPC BROADBAND INC

Methods of manufacturing enhanced electrical cables

Owner:SCHLUMBERGER TECH CORP

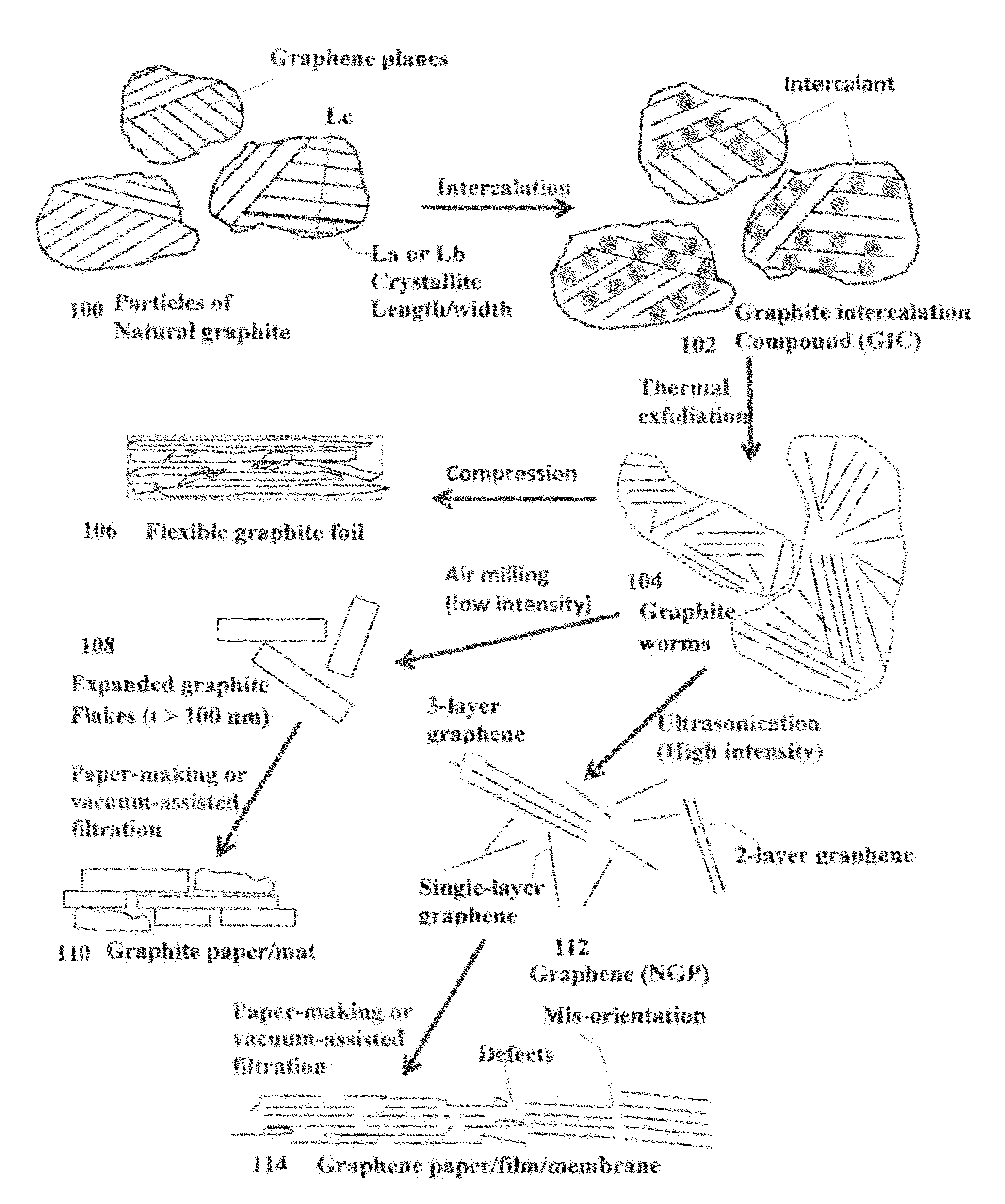

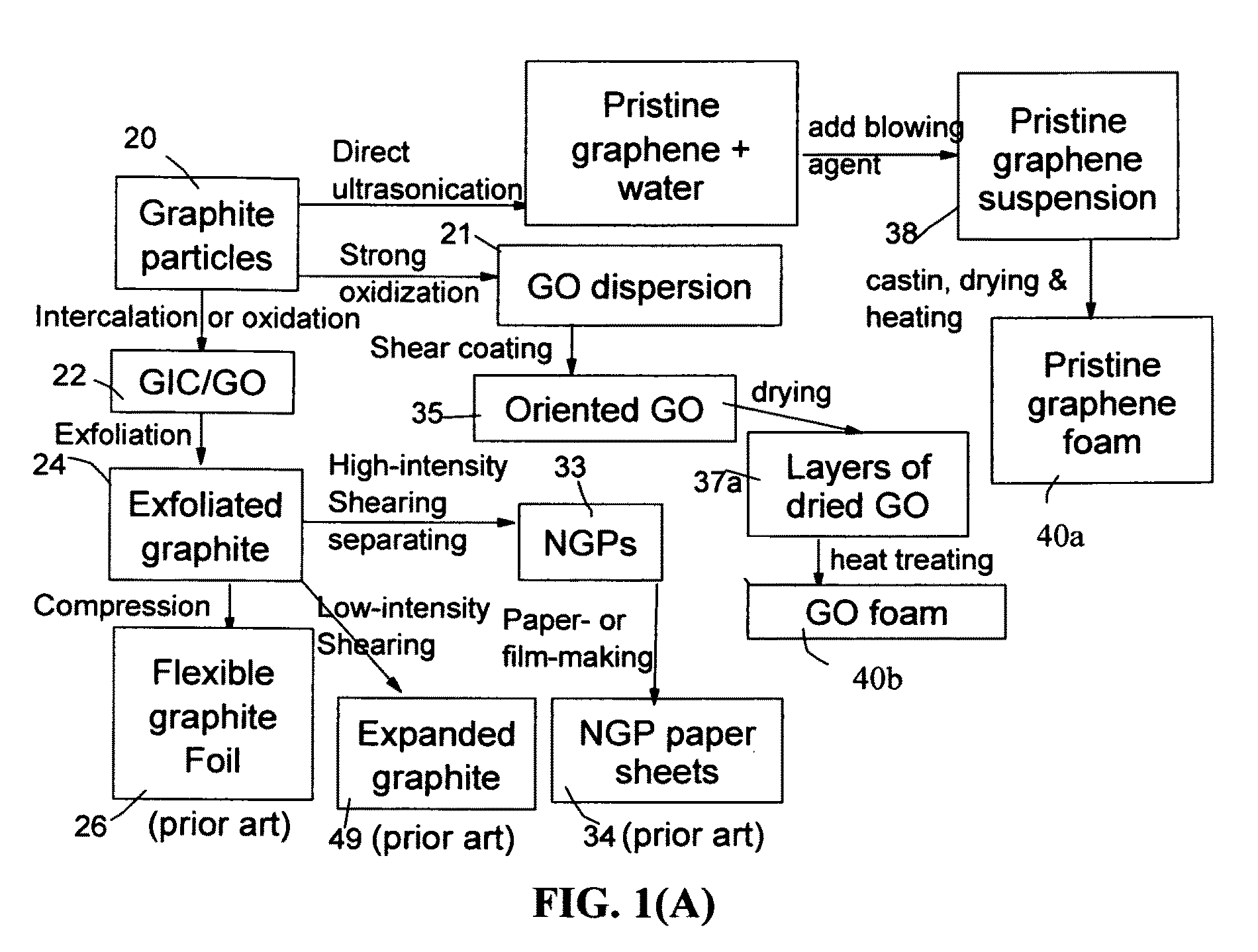

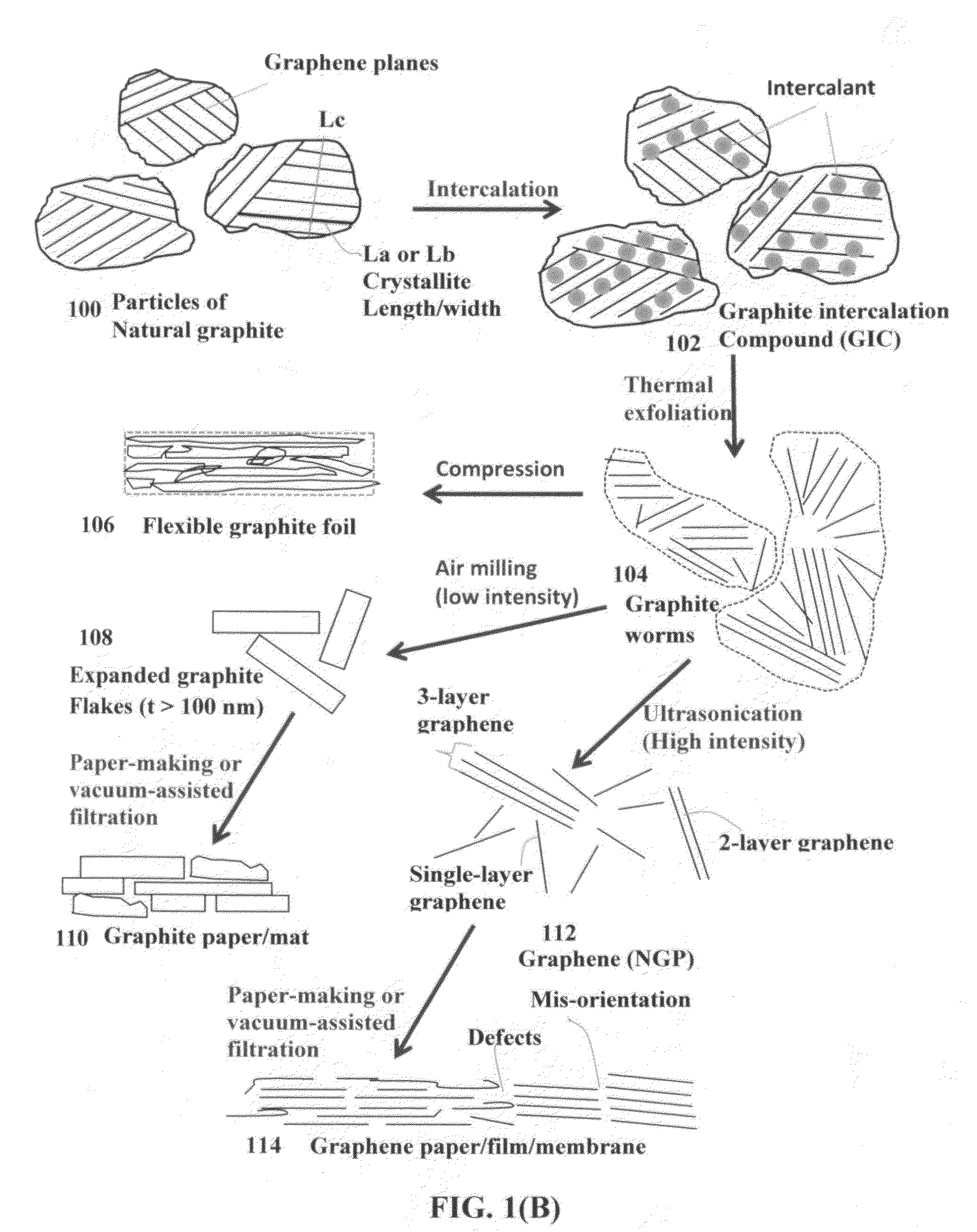

Highly conductive graphene foams and process for producing same

ActiveUS20160019995A1Effective orientation-inducing stressIncrease flexibilityNon-insulated conductorsGraphitePolymer scienceLiquid medium

A process for producing a solid graphene foam composed of multiple pores and pore walls The process comprises: (a) preparing a graphene dispersion having a graphene material dispersed in a liquid medium, which contains an optional blowing agent; (b) dispensing and depositing the graphene dispersion onto a supporting substrate to form a wet layer of graphene material having a preferred orientation; (c) partially or completely removing the liquid medium from the wet layer of graphene material to form a dried layer of graphene material having a content of non-carbon elements no less than 5% by weight (including blowing agent weight); and (d) heat treating the layer of graphene material at a first heat treatment temperature from 80° C. to 3,200° C. at a desired heating rate sufficient to induce volatile gas molecules from the non-carbon elements or to activate the blowing agent for producing the graphene foam having a density from 0.01 to 1.7 g / cm3 or a specific surface area from 50 to 3,000 m2 / g.

Owner:GLOBAL GRAPHENE GRP INC

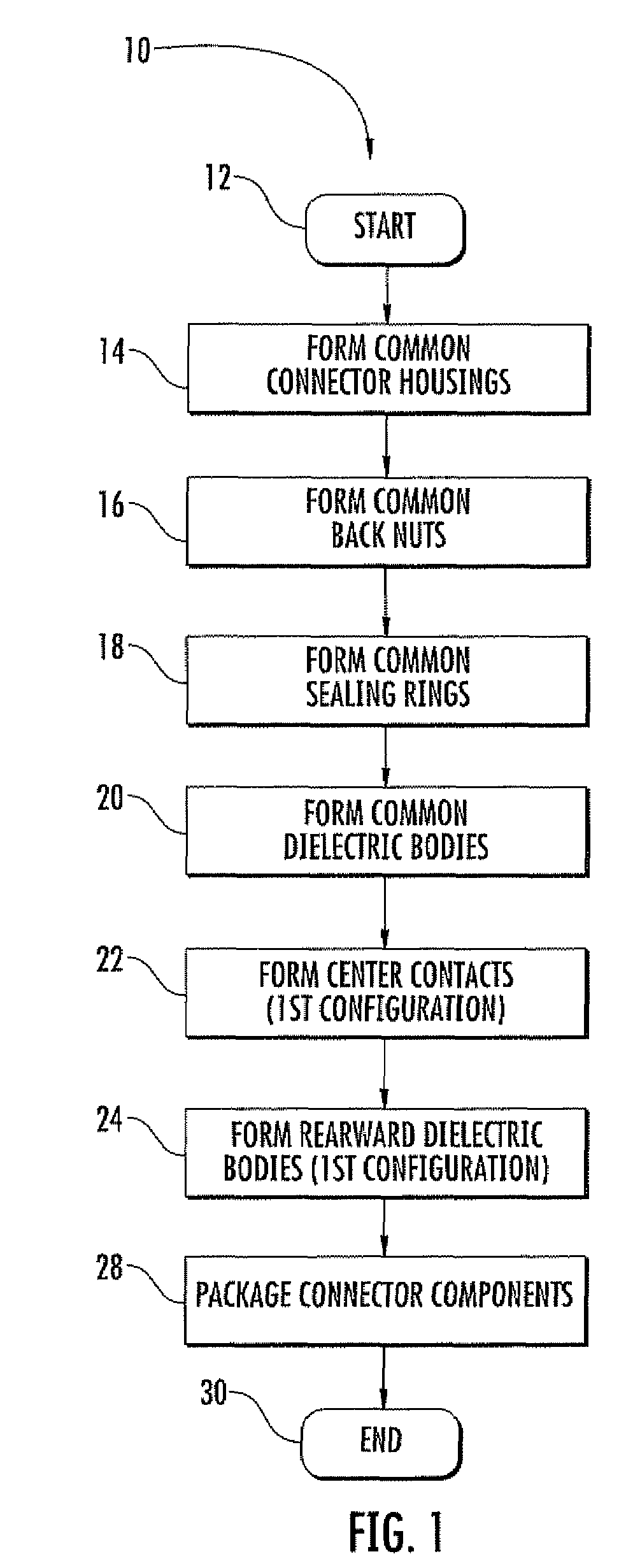

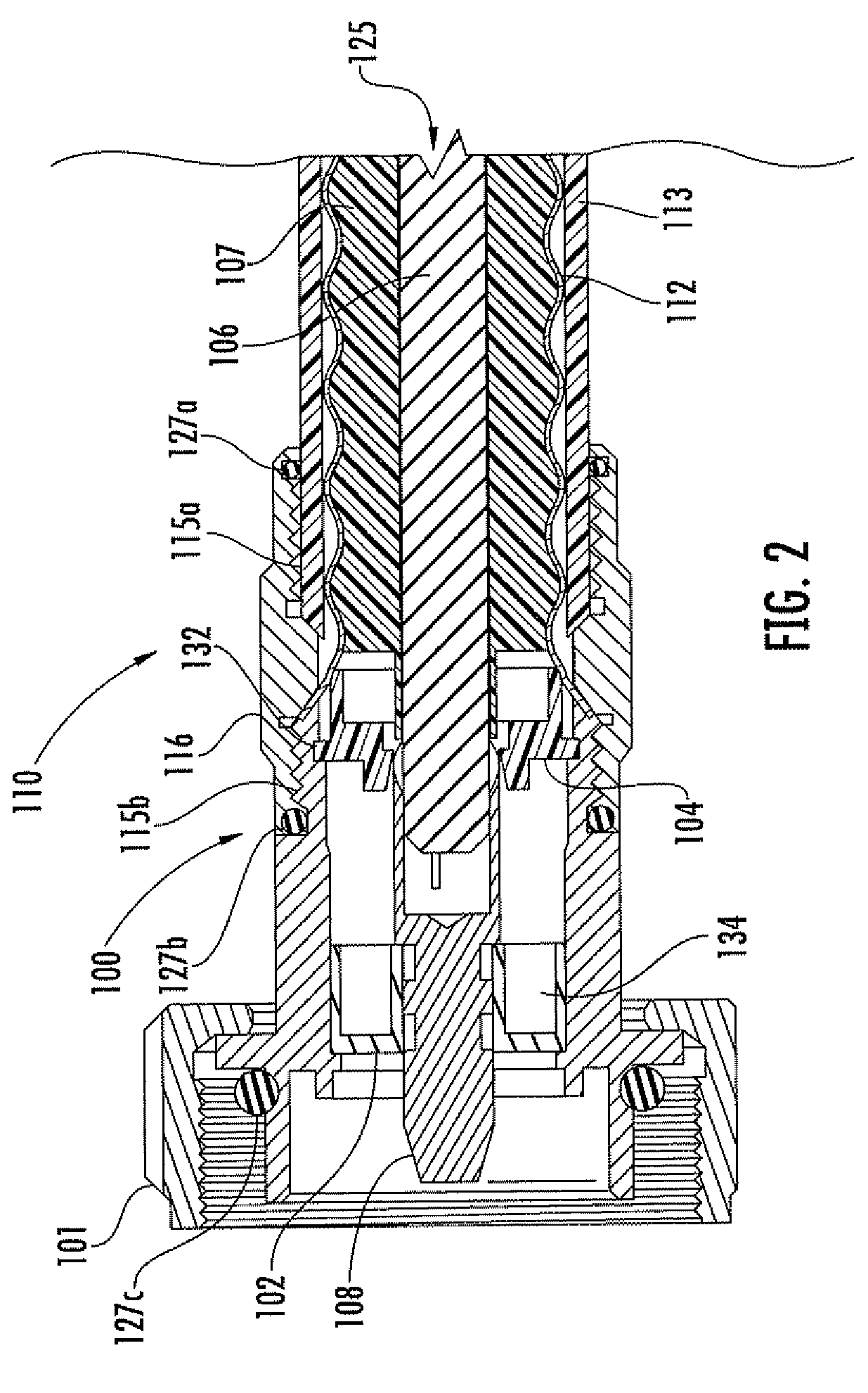

Method for making coaxial cable connector components for multiple configurations and related devices

ActiveUS7637774B1Easy to assembleEasy to manufactureElectrically conductive connectionsTwo pole connectionsCoaxial cableElectrical conductor

A method for making coaxial cable connector components for assembly into either first or second different connector configurations may include forming center contacts for the first connector configuration and forming common connector components for either the first or second connector configuration. The common connector components may include common connector housings; common back nuts, each for clamping a coaxial cable outer conductor in cooperation with a respective common connector housing; and common forward dielectric bodies, each having a passageway therethrough. The common forward dielectric body is for supporting a respective center contact for the first connector configuration, and for alternatively supporting a respective forward portion of a coaxial cable inner conductor for the second configuration. The common forward dielectric bodies may provide impedance matching with a coaxial cable for both the first and second connector configurations.

Owner:COMMSCOPE INC

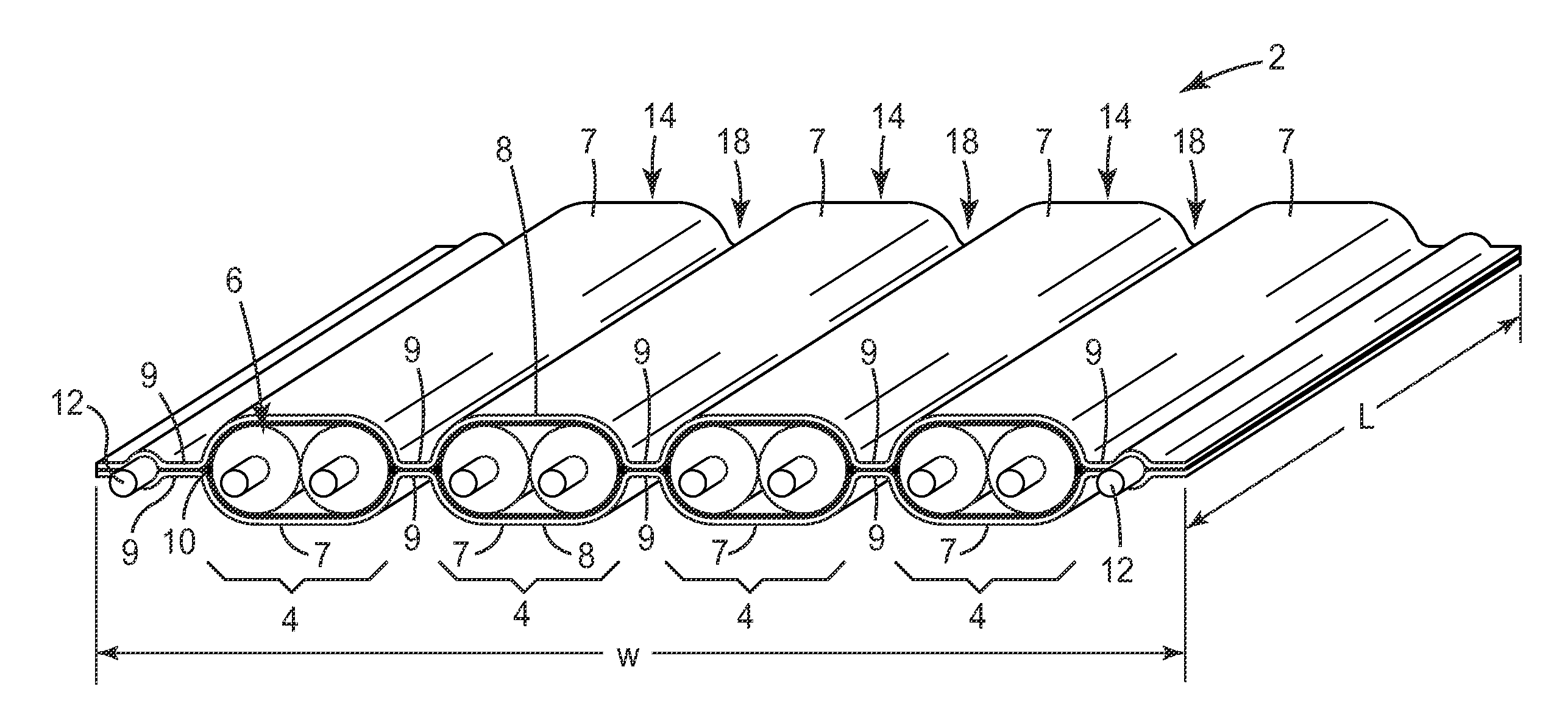

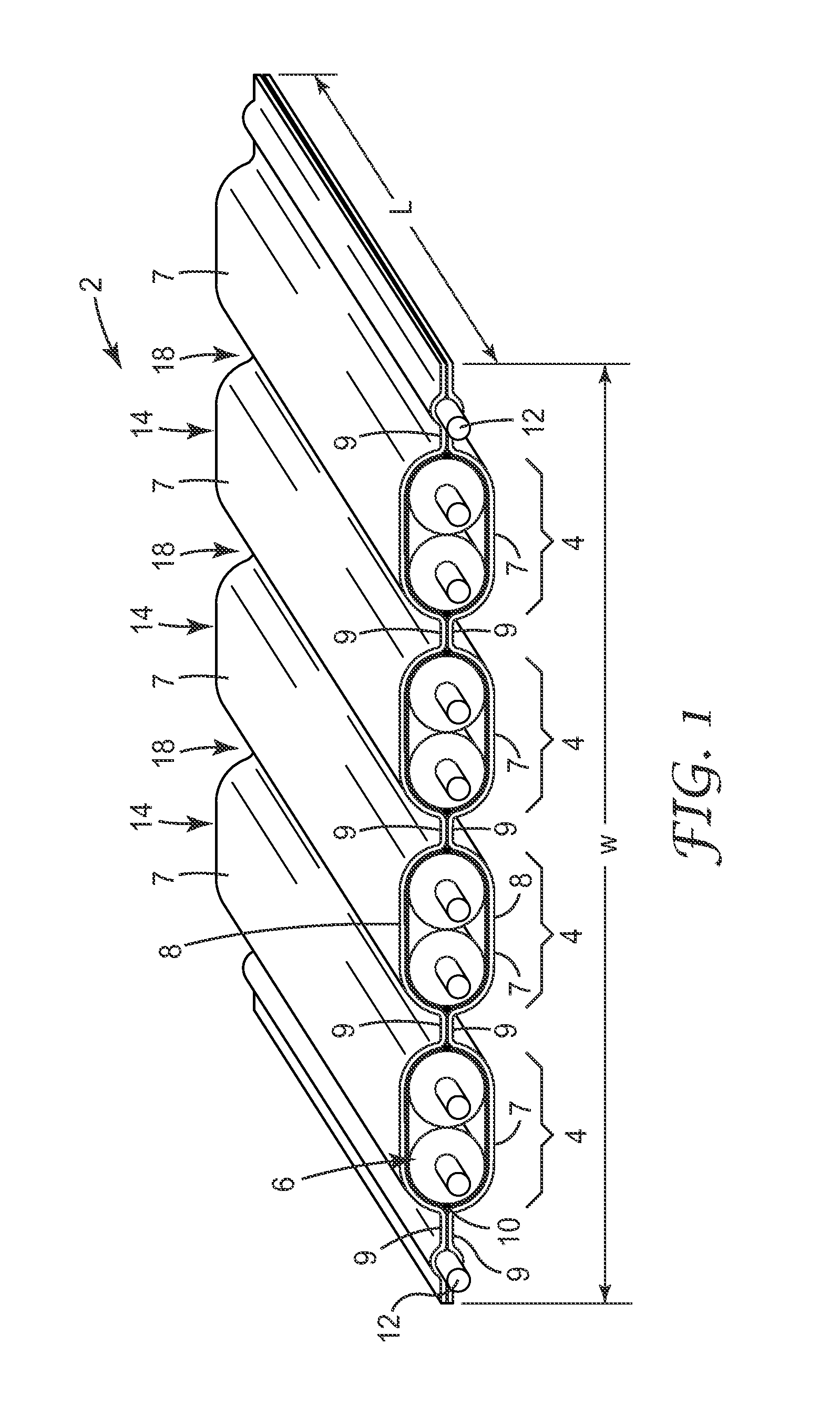

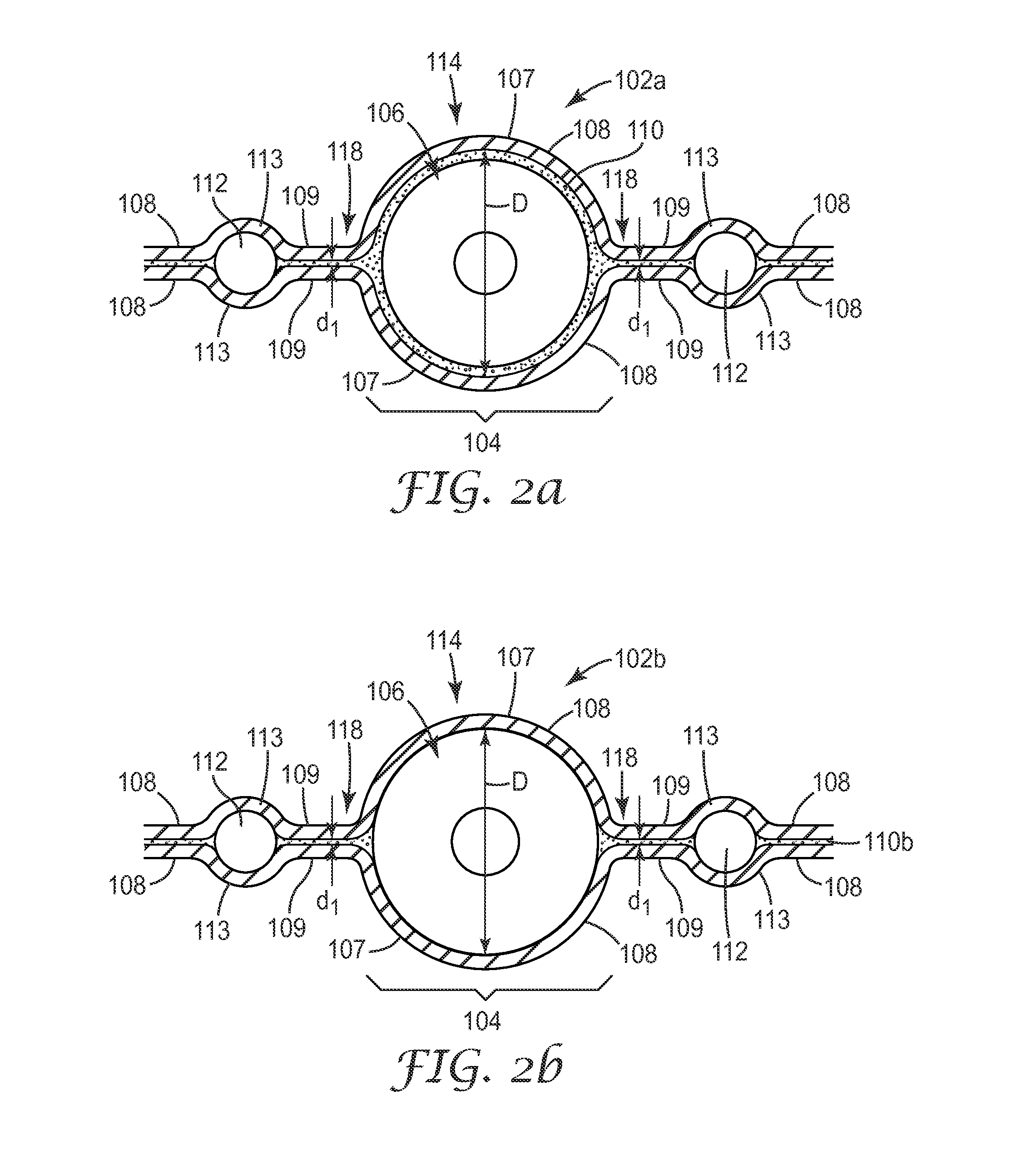

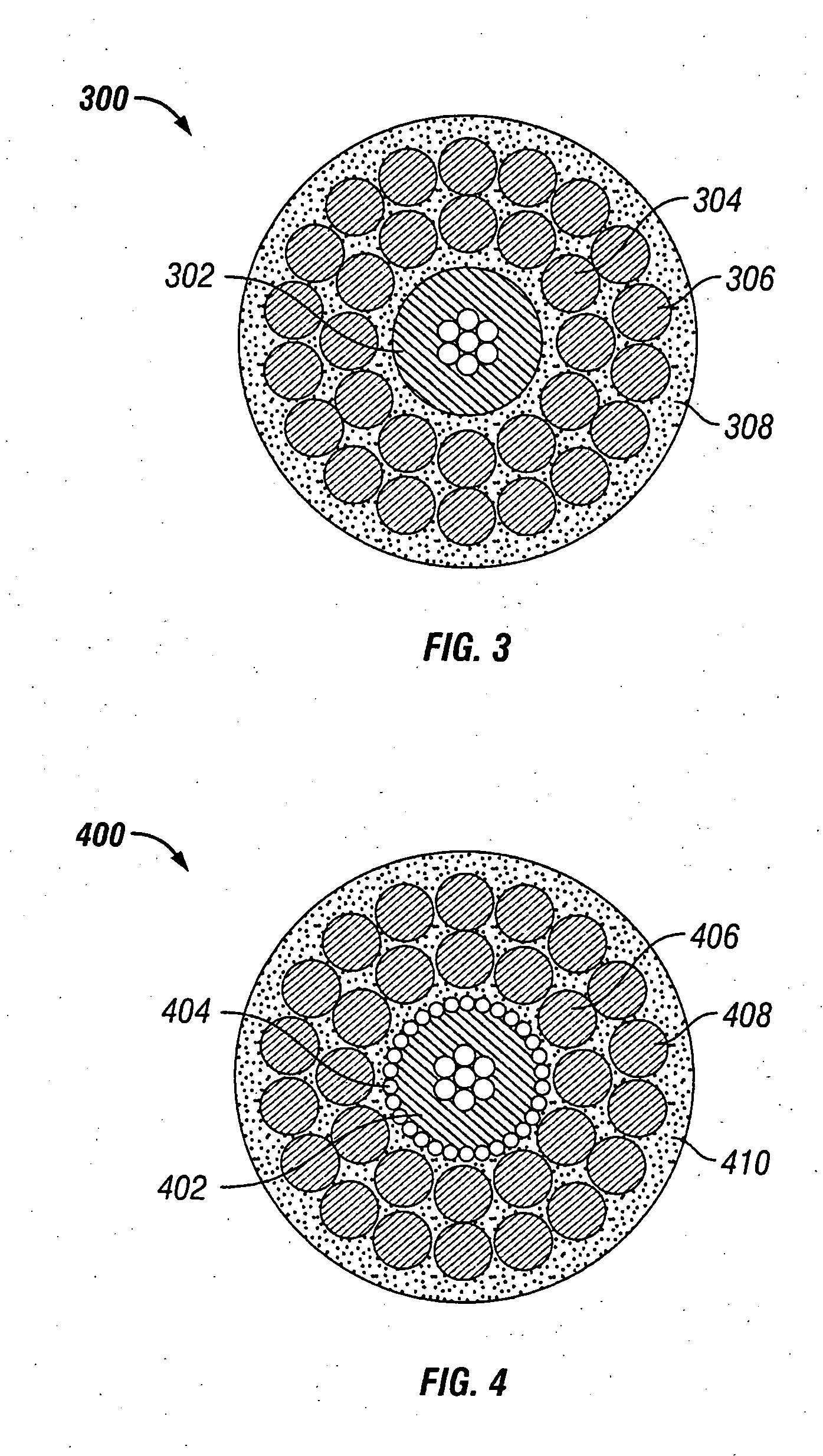

High density shielded electrical cable and other shielded cables, systems, and methods

ActiveUS20130146326A1Improve manufacturing speedReduce complexityQuad constructionsPower cables with screens/conductive layersShielded cableHigh density

A shielded electrical ribbon cable (2) includes conductor sets (4) each including one or more insulated conductors (6), and a first and second shielding film (8) on opposite sides of the cable. In transverse cross section, cover portions (7) of the shielding films (8) substantially surround each conductor set (4), and pinched portions (9) of the films (8) form pinched portions of the cable on each side of each conductor set (4). Dense packing is achieved while maintaining high frequency electrical isolation between conductor sets (4). When the cable (2) is laid flat, a quantity s / Dmin is in a range from 1.7 to 2, where S is a center-to-center spacing between nearest insulated conductors (6) of two adjacent conductor sets (4), and Dmin is the lesser of the outer dimensions of such nearest insulated conductors (6). Alternatively, a first and second conductor set each having only one pair of insulated conductors can satisfy a condition that Σ / σ1 is in a range from 2.5 to 3. Other shielded cables, systems, and methods, which may or may not utilize the dense packing, are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

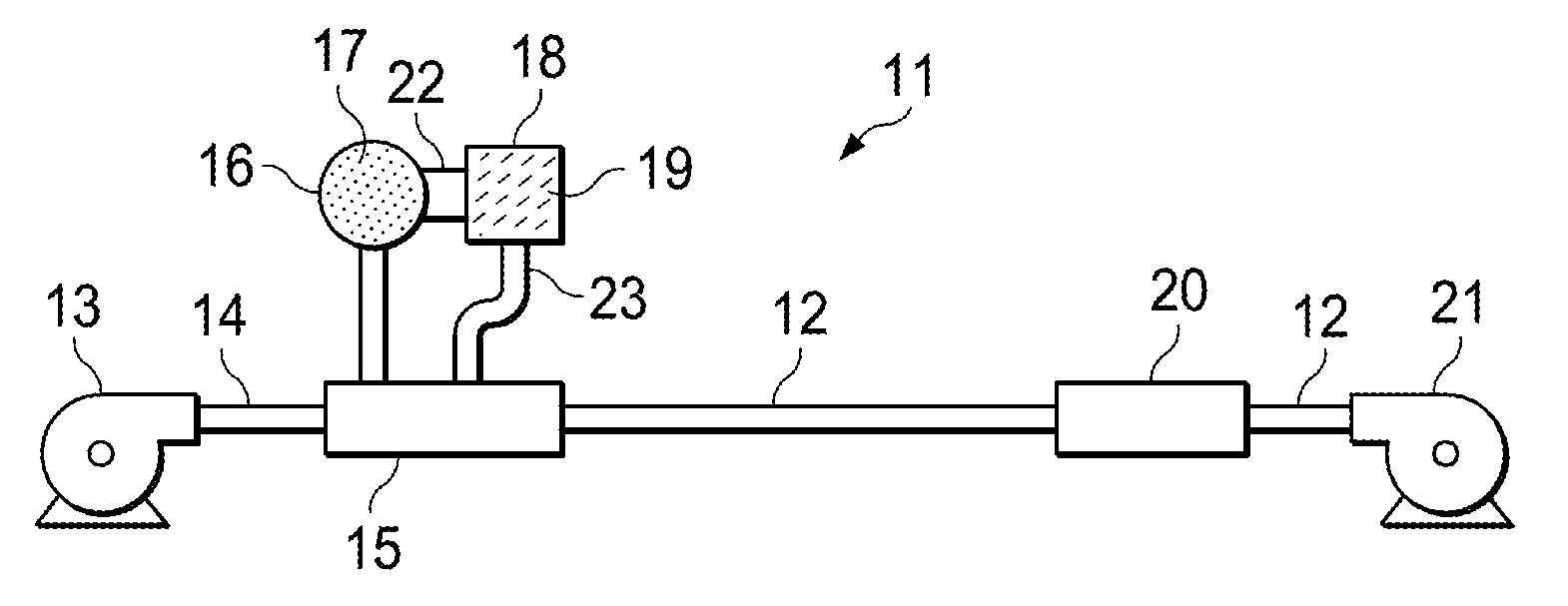

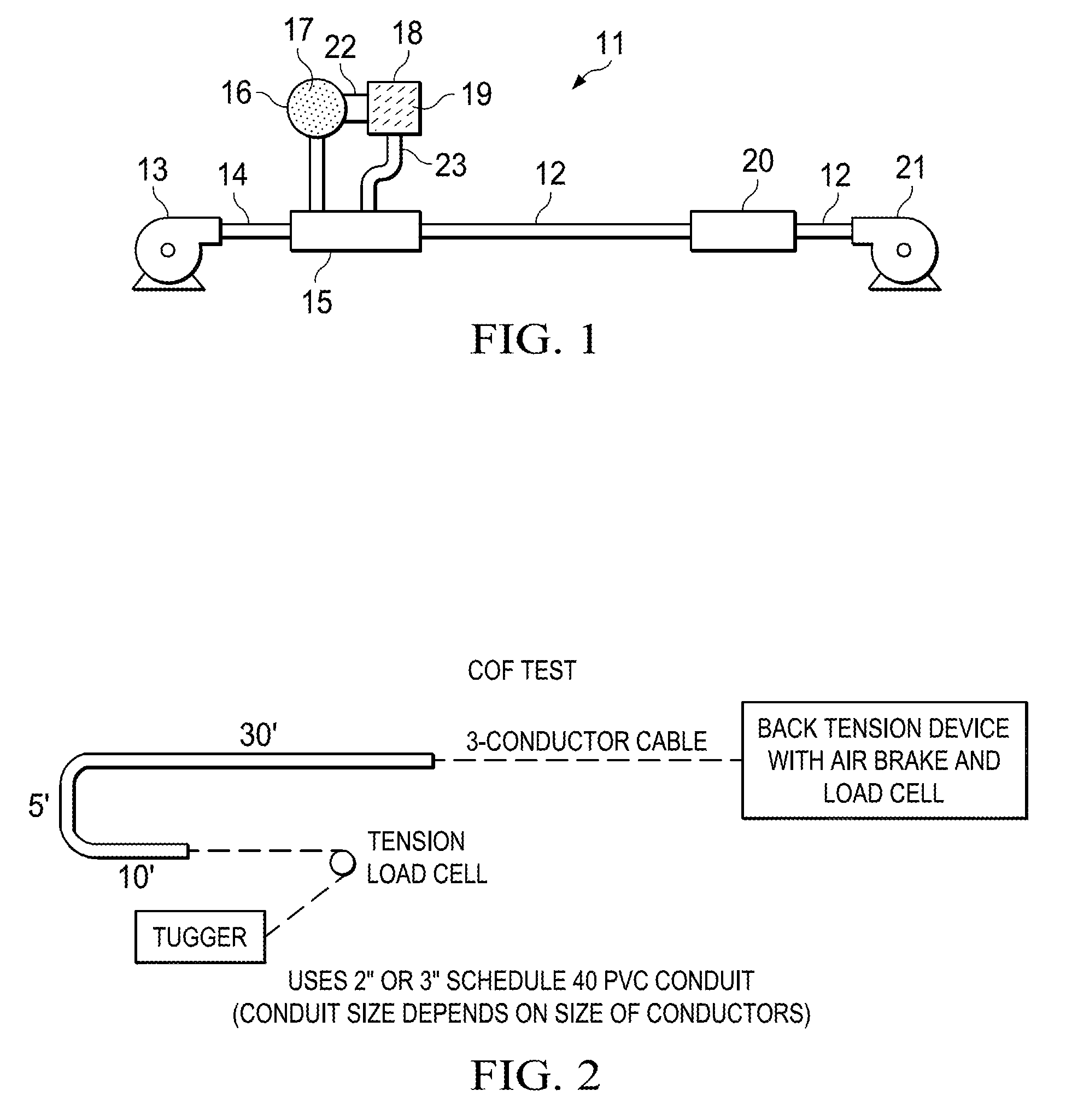

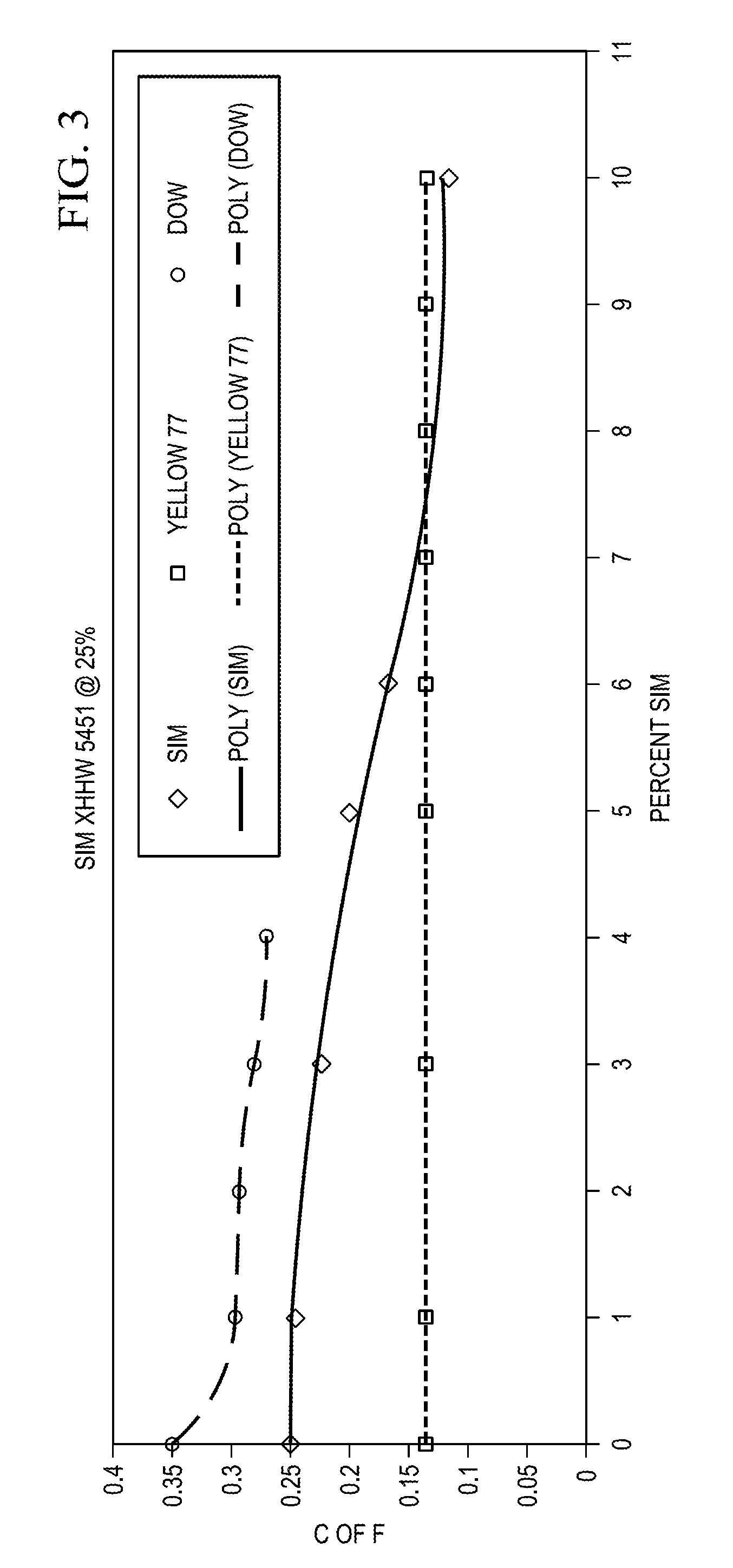

Electrical Cable Having Crosslinked Insulation With Internal Pulling Lubricant

ActiveUS20100236811A1Reduce tensionHigh viscosityPlastic/resin/waxes insulatorsBottlesElectrical conductorPower cable

Electrical power cable having a reduced surface coefficient of friction and required installation pulling force, and the method of manufacture thereof, in which the central conductor core, with or without a separate insulating layer, is surrounded by a sheath of crosslinked polyethylene. A high viscosity, high molecular weight silicone based pulling lubricant or fatty acid amide pulling lubricant is incorporated by alternate methods with the polyethylene to form a composition from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

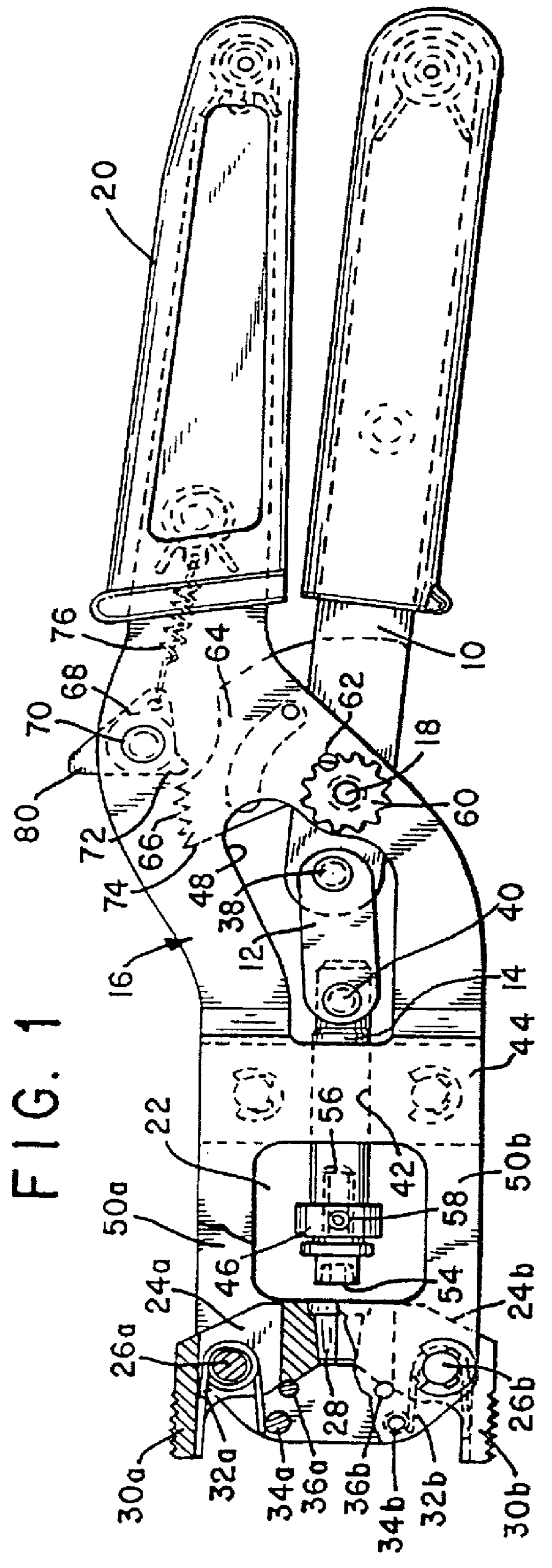

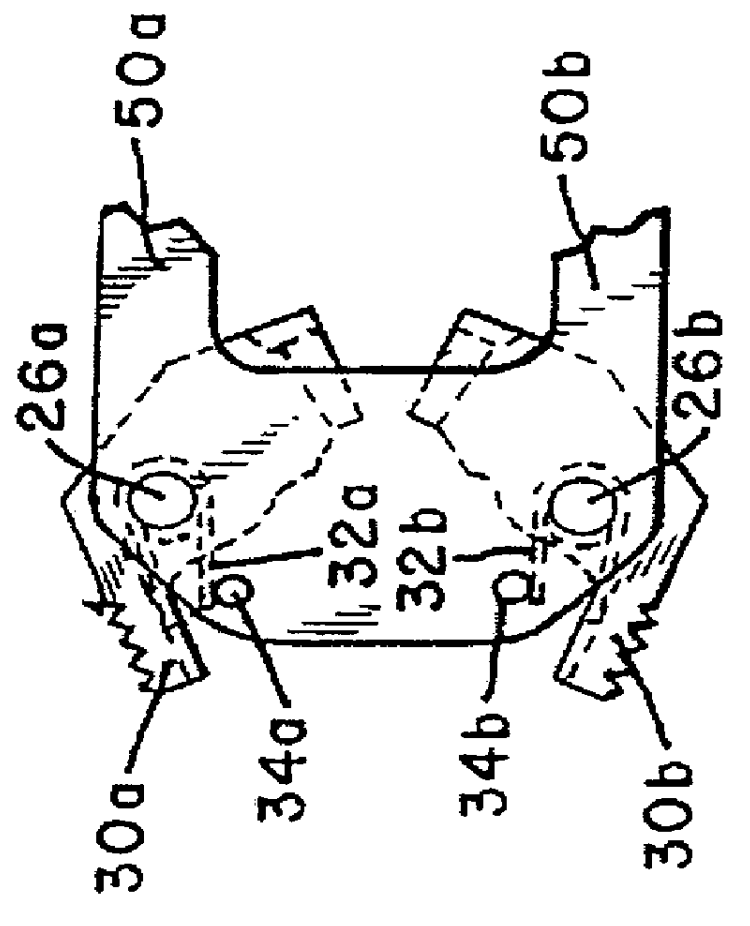

Radial taper tool for compressing electrical connectors

InactiveUS6112404ALight weightReduce material costsShaping toolsPliersElectrical connectorMechanical engineering

A tool for attaching a connector to an end of a cable by compressing the connector axially and driving it into a tapered cavity uses a light rigid O-frame. The tapered cavity is formed in a pair of die halves which are both pivoted to the frame and which are provided with oppositely mounted handles, allowing the dies to be opened by squeezing the handles together. Two different adjustment means are provided and the tool is provided with a full-cycle ratchet mechanism to ensure complete compression of the connector during each use.

Owner:RIPLEY TOOLS

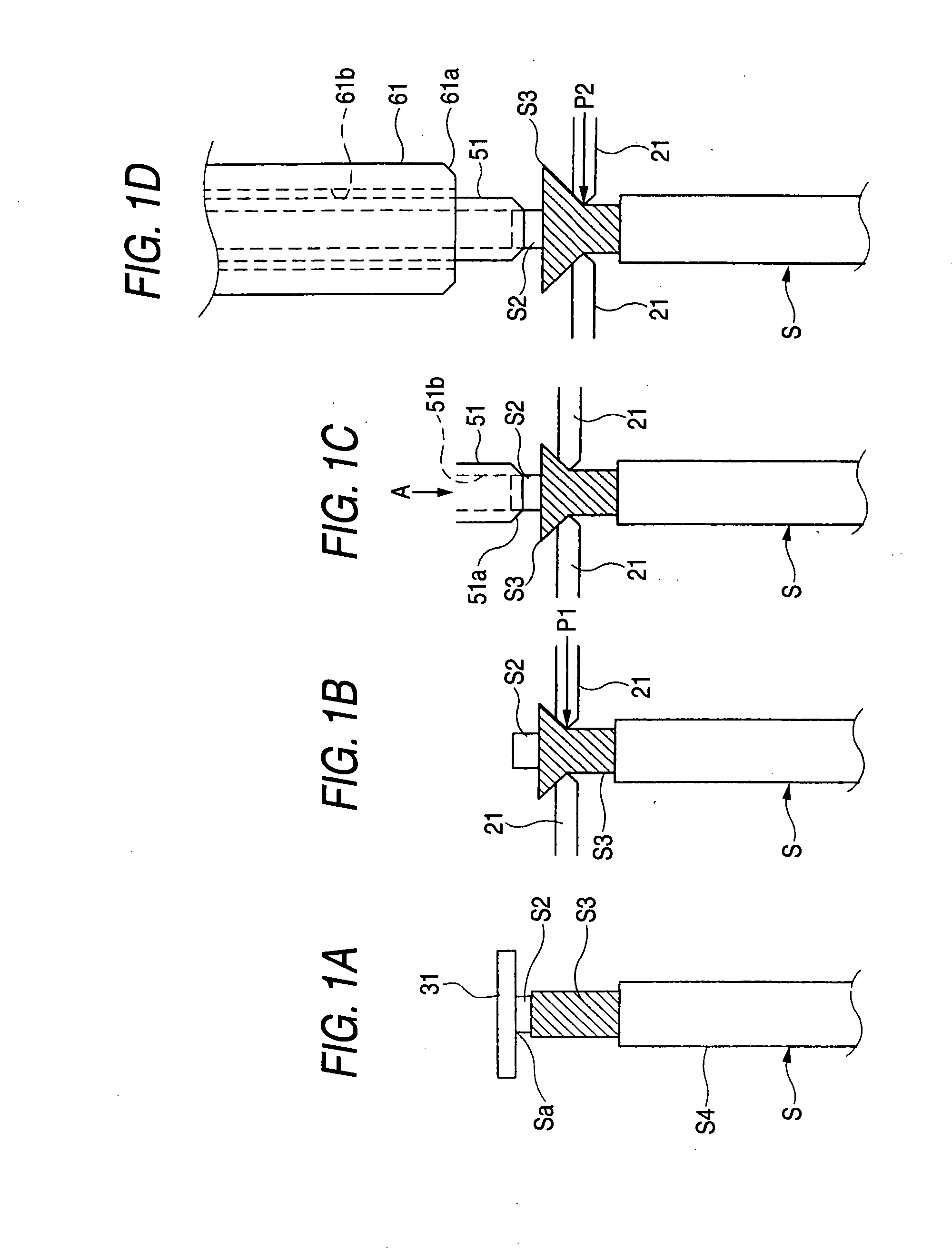

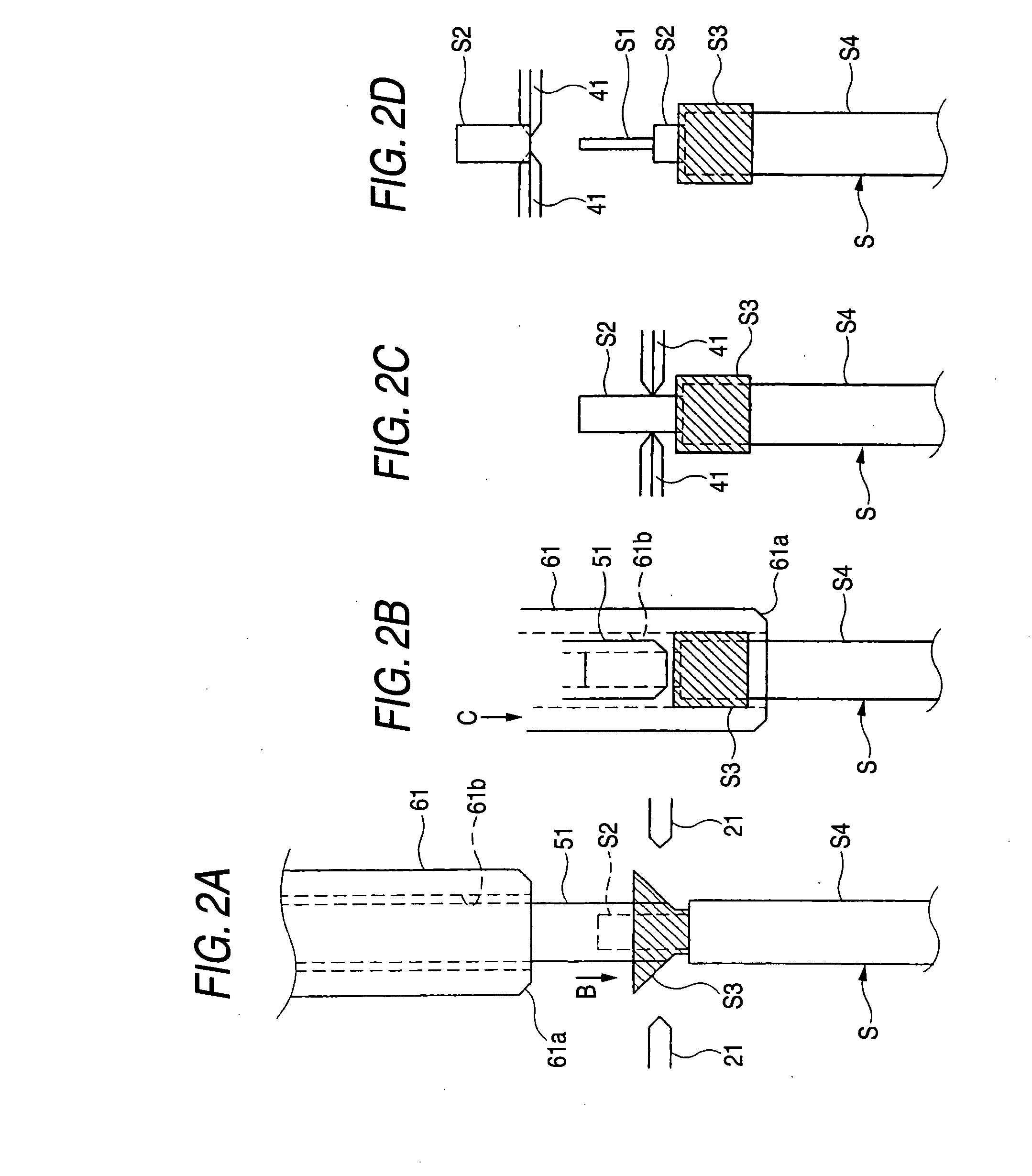

Method of processing end portion of shielded wire and end portion processing apparatus

ActiveUS20070173122A1Increase productionShaping toolsElectrically conductive connectionsEngineeringBraid

An end portion processing apparatus for processing an end portion of a shielded wire in which part of an outer sheath has been removed such that an exposed braid disposed between an inner sheath and the outer sheath extends from a distal end of the outer sheath, includes a wire clamp portion which positions the end portion of the shielded wire in an open condition of the wire clamp portion, and clamps the end portion of the shielded wire, a pair of claw portions which strikes against the exposed braid radially thereof at the clamped end portion of the shielded wire to expand the end portion of the braid, a first pipe portion which is disposed in a standby position on a line of extension of the clamped end portion of the shielded wire, and is fitted onto an outer periphery of the inner sheath, a second pipe portion which is provided on an outer periphery of the first pipe portion in concentric relation thereto, and is slid toward the shielded wire to fold back the expanded braid on the outer sheath, and a control portion which controls the operations of the claw portions, the first pipe portion and the second pipe portion.

Owner:YAZAKI CORP

Polyethylene crosslinkable composition

InactiveUS20020169238A1Plastic/resin/waxes insulatorsPower cables1,3,5-TriazineHindered amine light stabilizers

A composition comprising: (a) polyethylene; (b) as a scorch inhibitor, [1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione]; (c) a thioester; (d) a hindered amine stabilizer; and (e) an organic peroxide.

Owner:UNION CARBIDE CORP

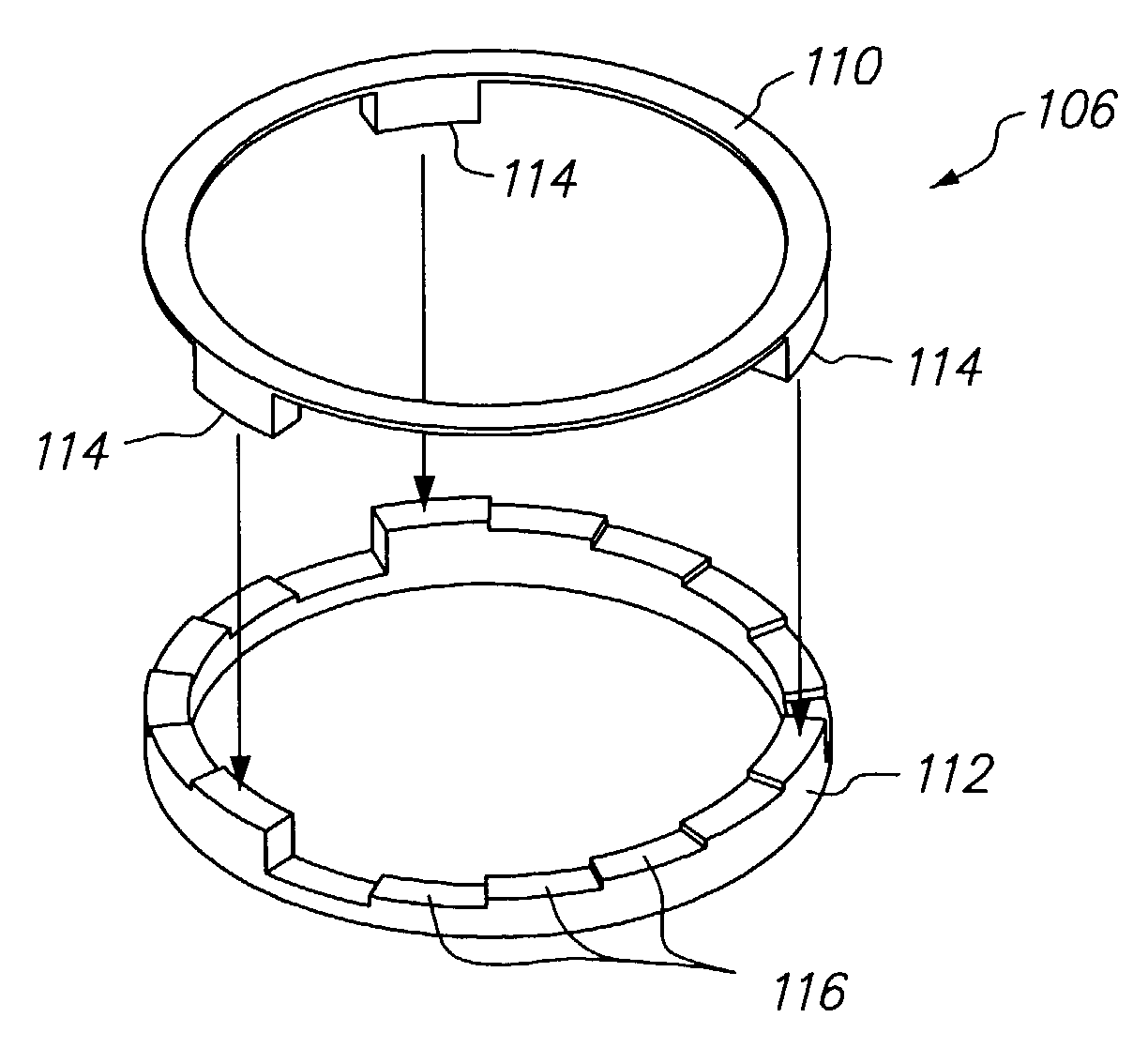

Apparatus for reducing polymer deposition on a substrate and substrate support

InactiveUS7252738B2Electric discharge tubesSemiconductor/solid-state device manufacturingCouplingEngineering

An adjustable RF coupling ring is capable of reducing a vertical gap between a substrate and a hot edge ring in a vacuum processing chamber. The reduction of the gap reduces polymer deposits on the substrate and electrostatic chuck and improves wafer processing.

Owner:LAM RES CORP

Methods of manufacturing enhanced electrical cables

Disclosed are methods of manufacturing electrical cables. In one embodiment of the invention, method for manufacturing a wellbore cable includes providing at least one insulated conductor, extruding a first polymeric material layer over the insulated conductor, serving a first layer of armor wires around the polymeric material and embedding the armor wires in the first polymeric material by exposure to an electromagnetic radiation source, followed by and extruding a second polymeric material layer over the first layer of armor wires embedded in the first polymeric material layer. Then, a second layer of armor wires may be served around the second polymeric material layer, and embedded therein by exposure to an electromagnetic radiation source. Finally, a third polymeric layer may be extruded around the second layer of armor wires to form a polymeric jacket.

Owner:SCHLUMBERGER TECH CORP

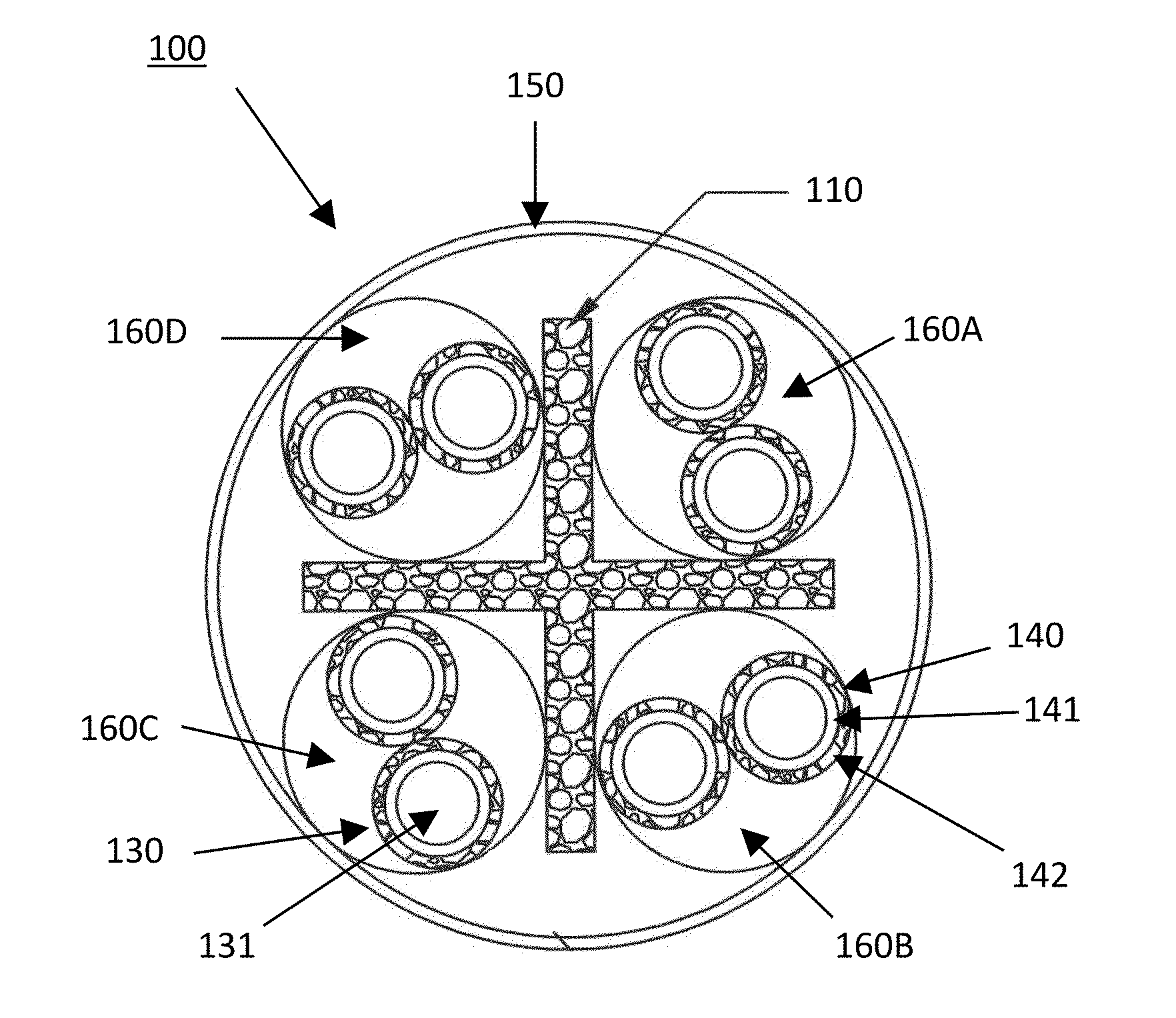

Compositions for compounding, extrusion and melt processing of foamable and cellular halogen-free polymers

ActiveUS20160133355A1Good flexibilityImprove electrical performanceInsulated cablesNon-conductive material with dispersed conductive materialFoaming agentTalc

Described herein are foamable compositions and methods of making foamed compositions. The foamable composition comprises at least one polymer and a foaming agent. The foaming agent comprises a talc or a talc derivative. The polymers described herein comprise a substantially non-halogenated polymer. One or more additives are added to render the compositions flame retardant and / or smoke suppressant. Also described are Power over Ethernet (PoE) cables, having at least one electrical conduit comprising an electrically conductive core, an insulation that at least partially surrounds said electrically conductive core and a polymeric separator extending from a proximal end to a distal end and having at least one channel adapted for receiving the at least one electrical conduit. The PoE cables are capable of carrying about 1 watt to about 200 watts of power.

Owner:CABLE COMPONENTS GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com