Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3073results about "Route devices for controlling vehicles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

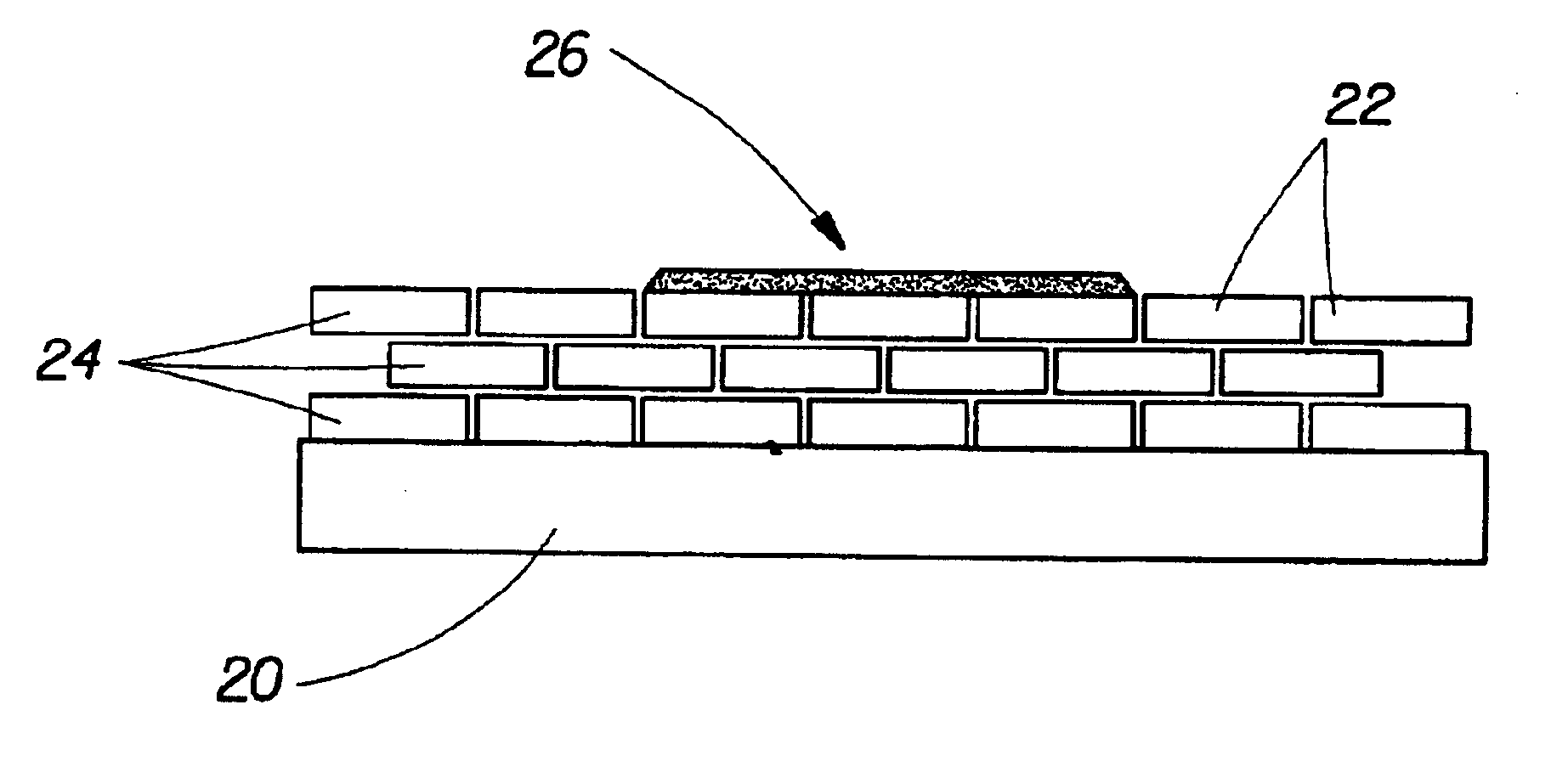

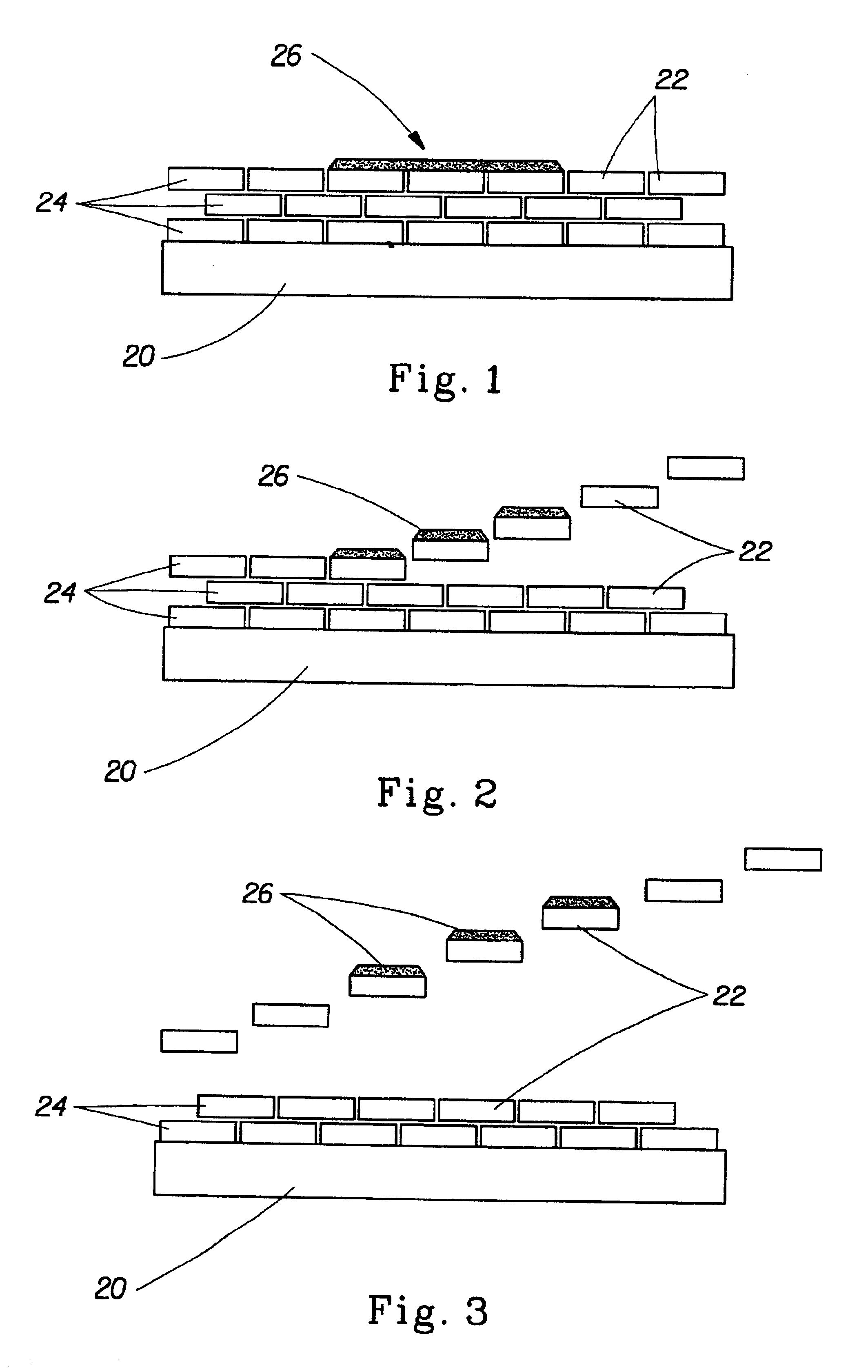

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

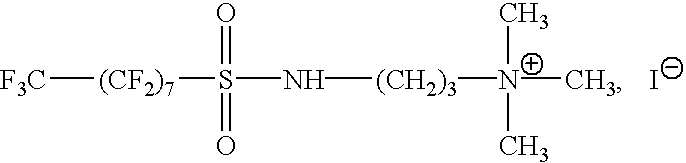

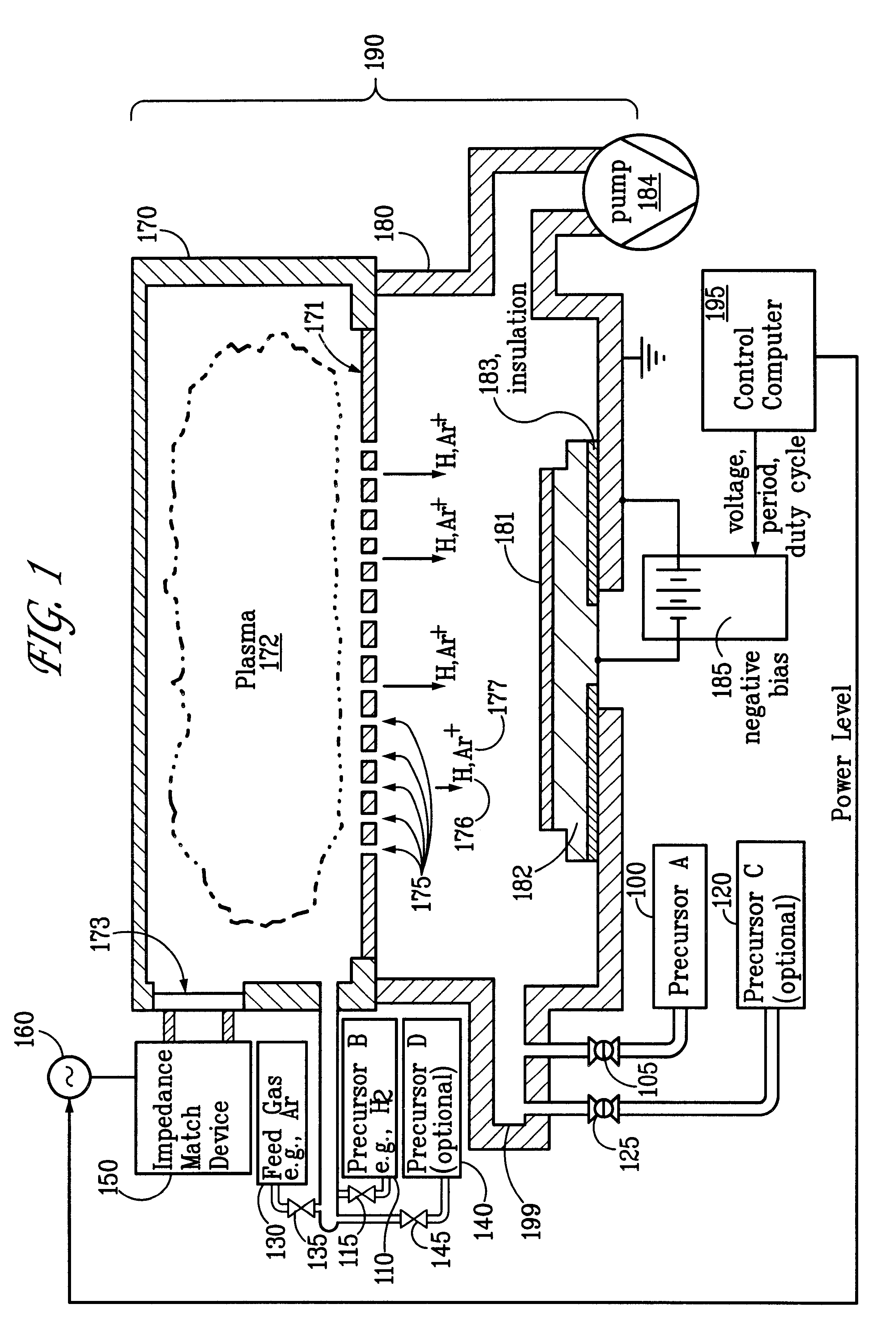

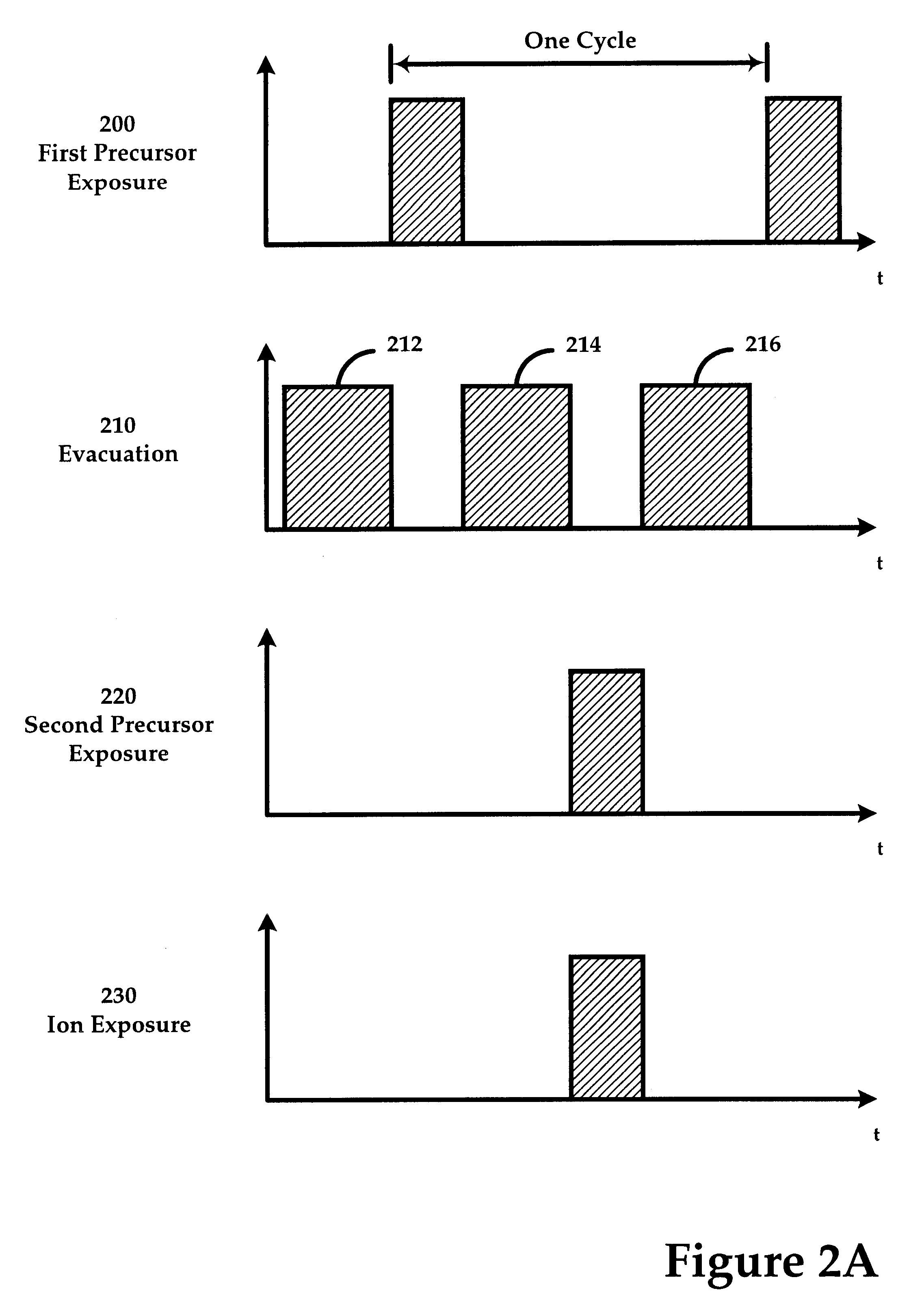

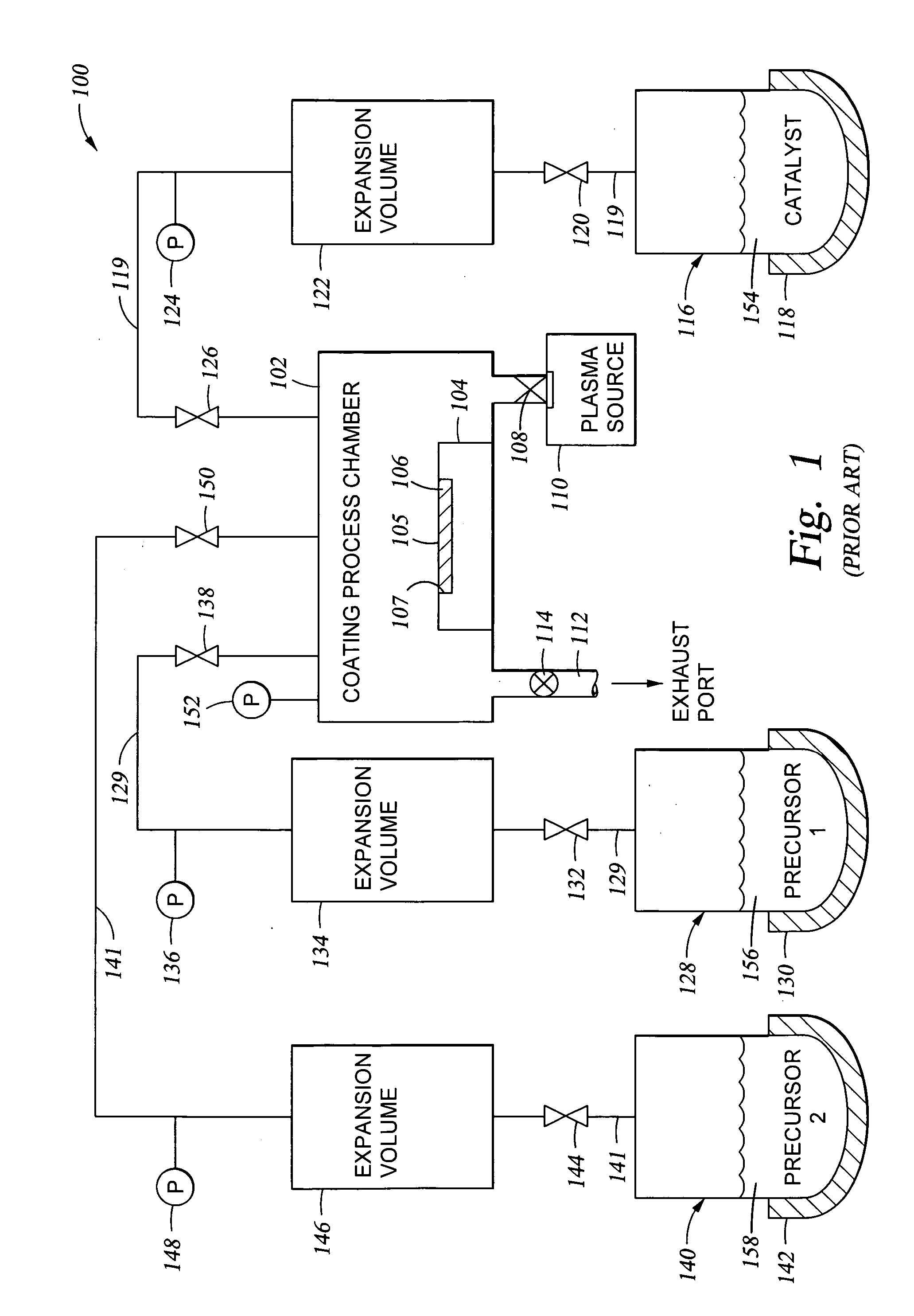

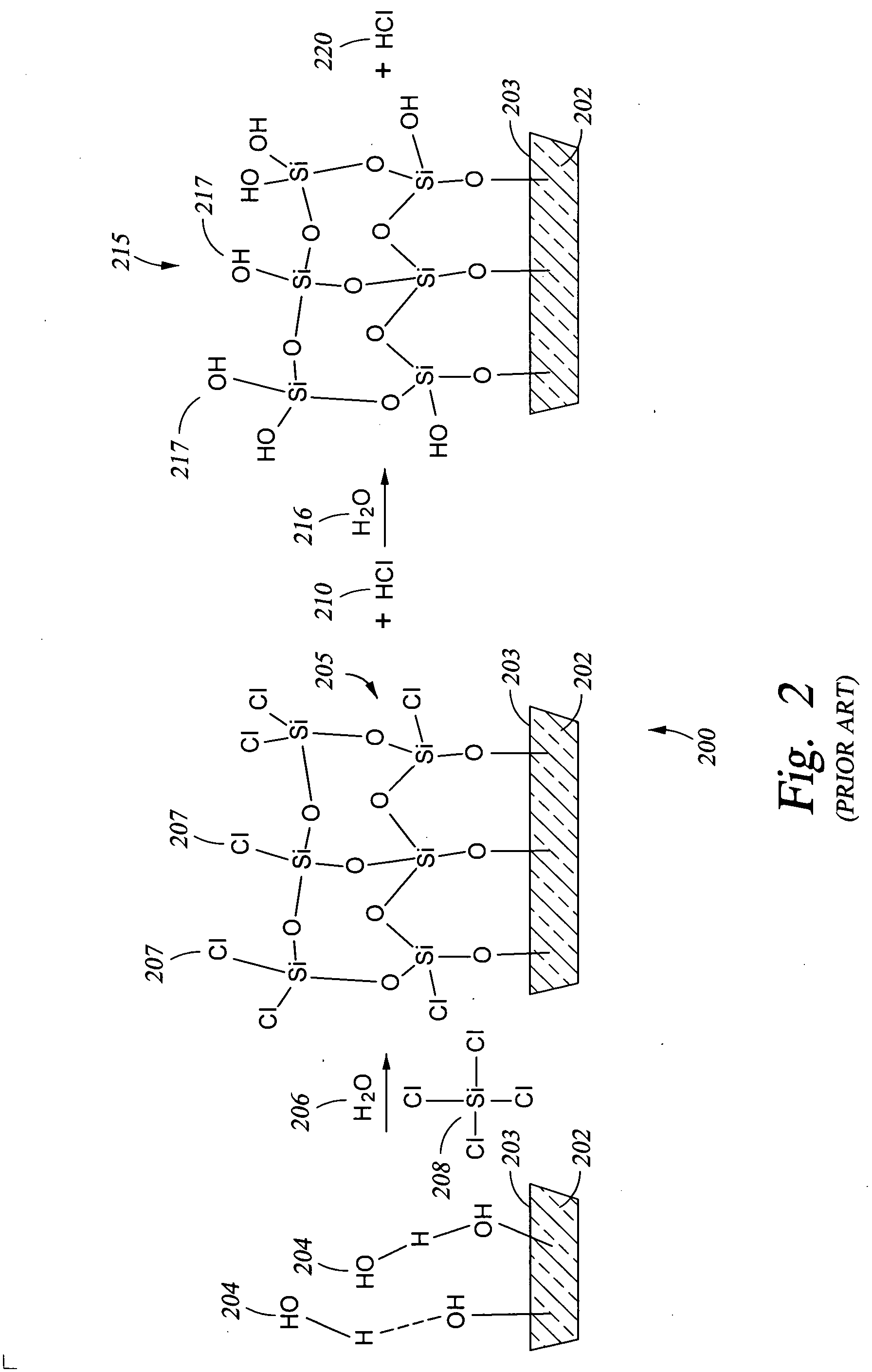

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

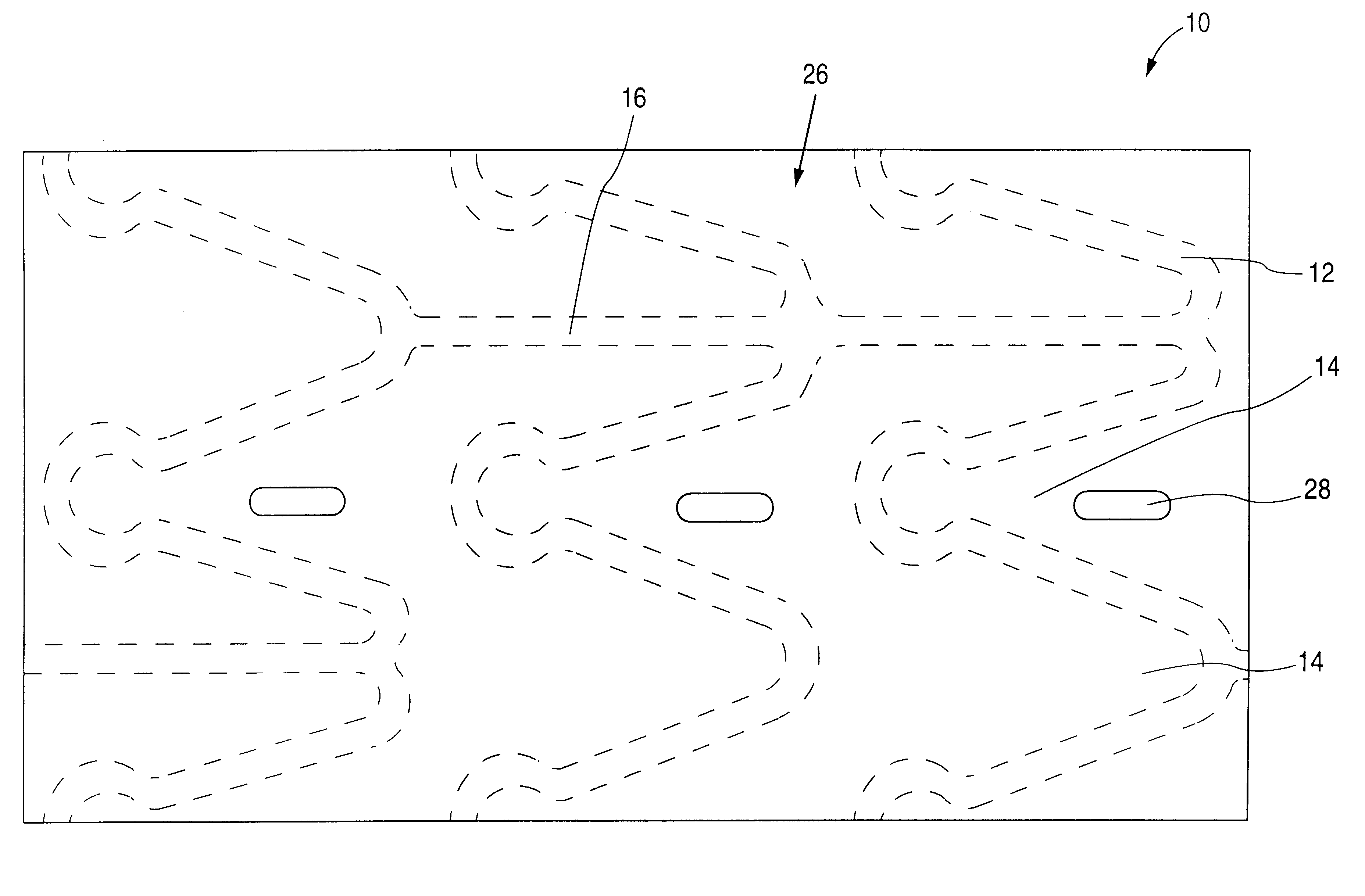

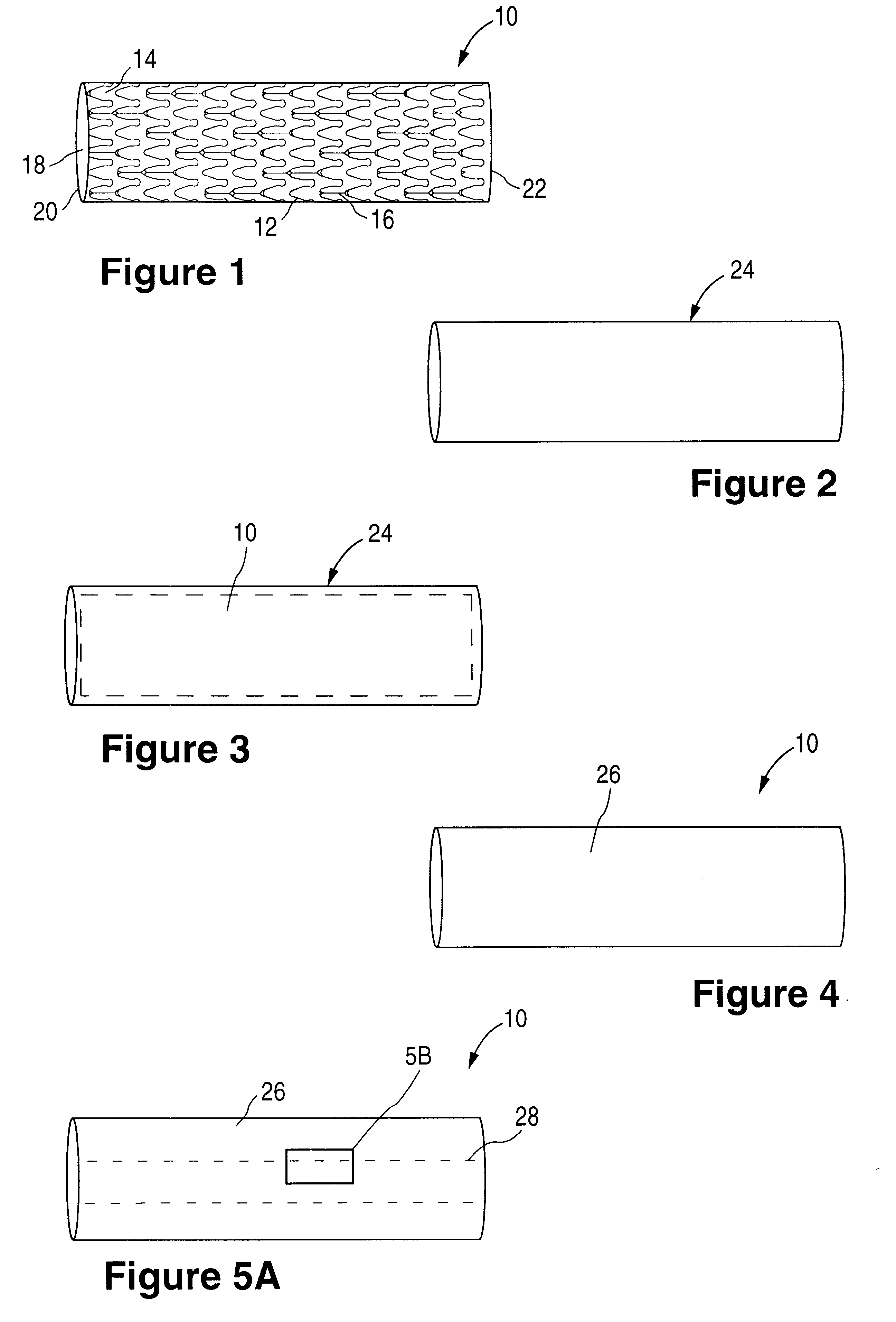

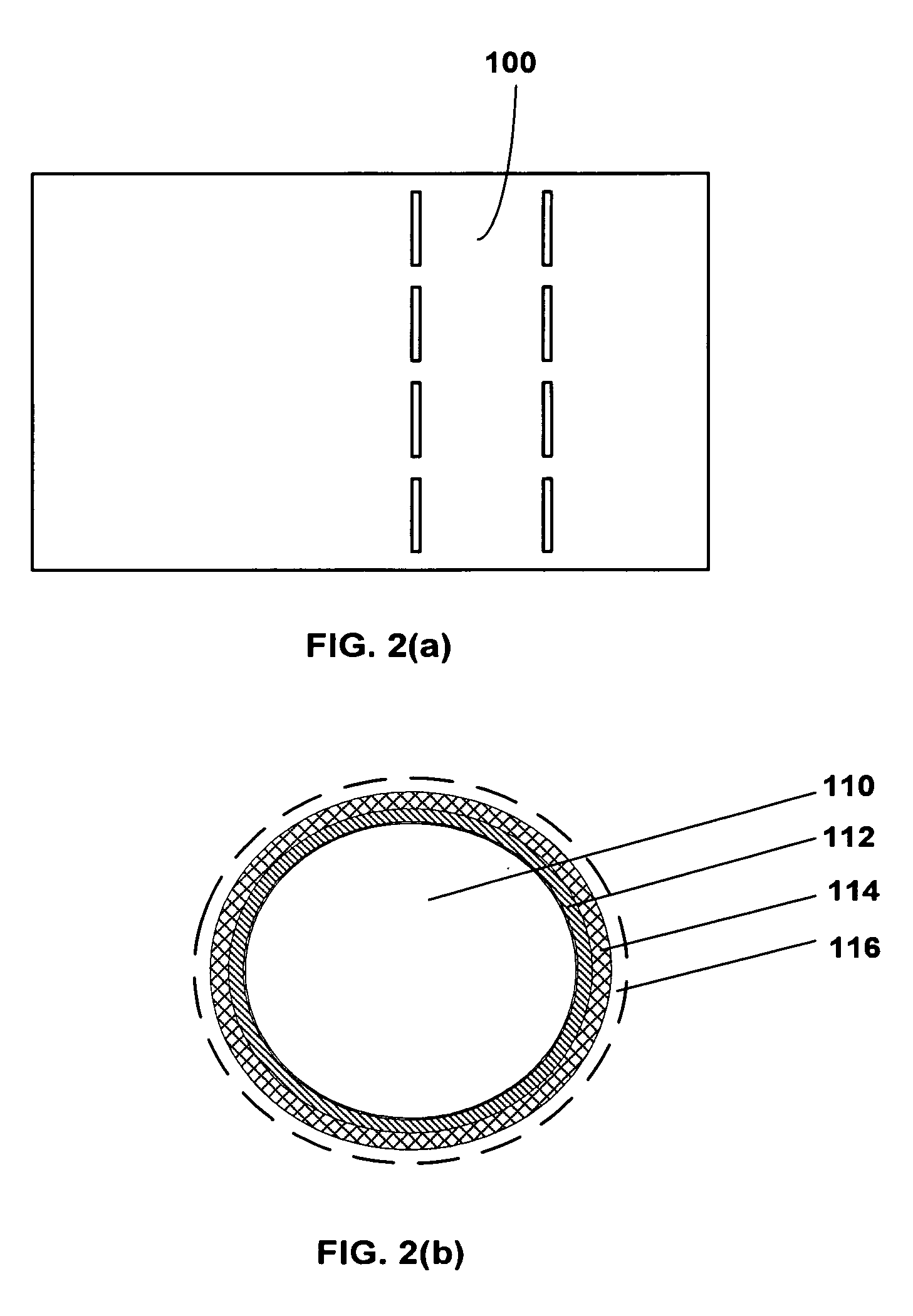

Methods of forming a coating for a prosthesis

InactiveUS6503556B2Increase the amount addedIncrease the number ofRadiation applicationsGlovesProsthesisImplanted device

Methods of forming a coating onto an implantable device or endoluminal prosthesis, such as a stent, are provided. The coating may be used for the delivery of an active ingredient. The coating may have a selected pattern of interstices for allowing a fluid to seep through the coating in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

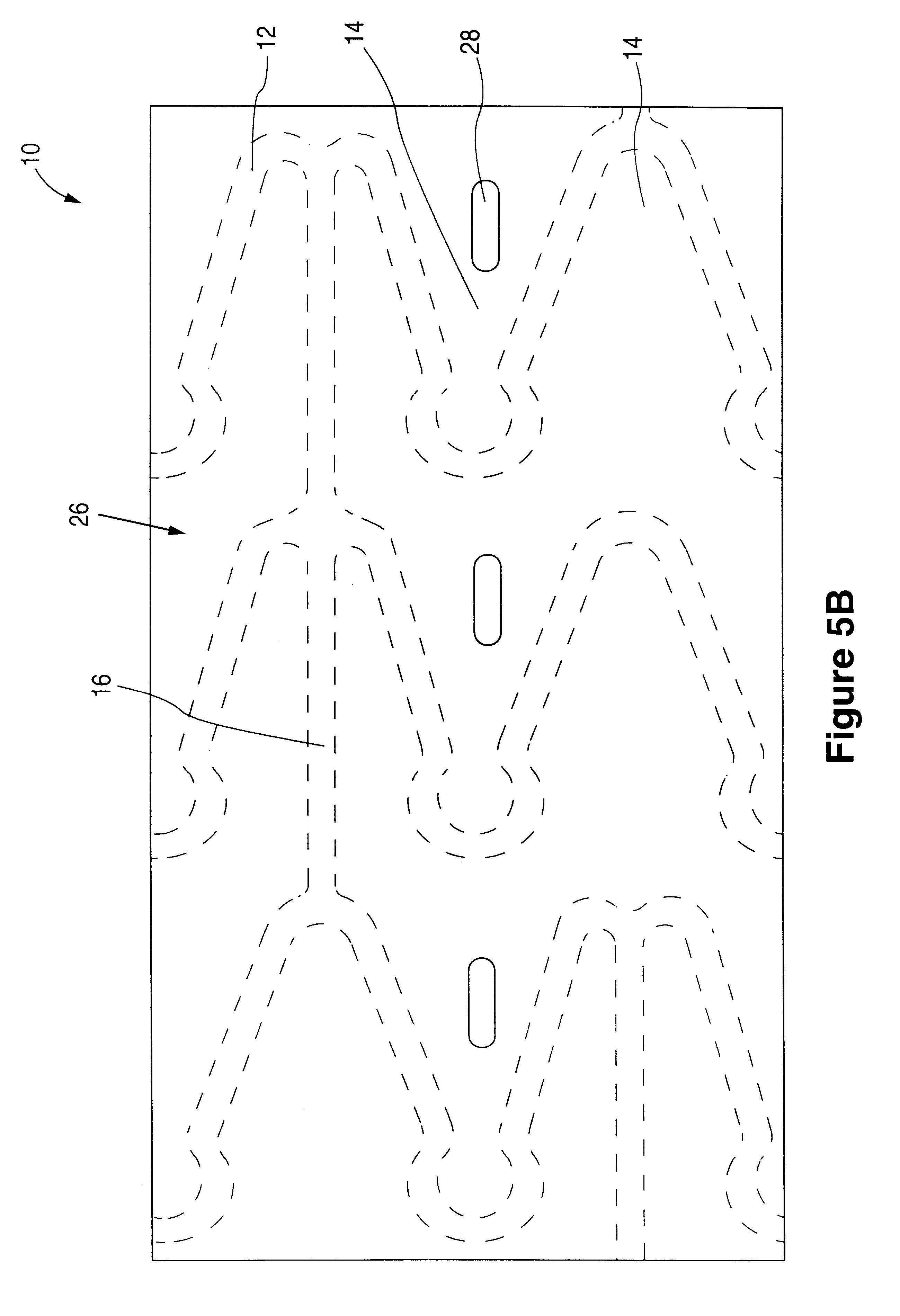

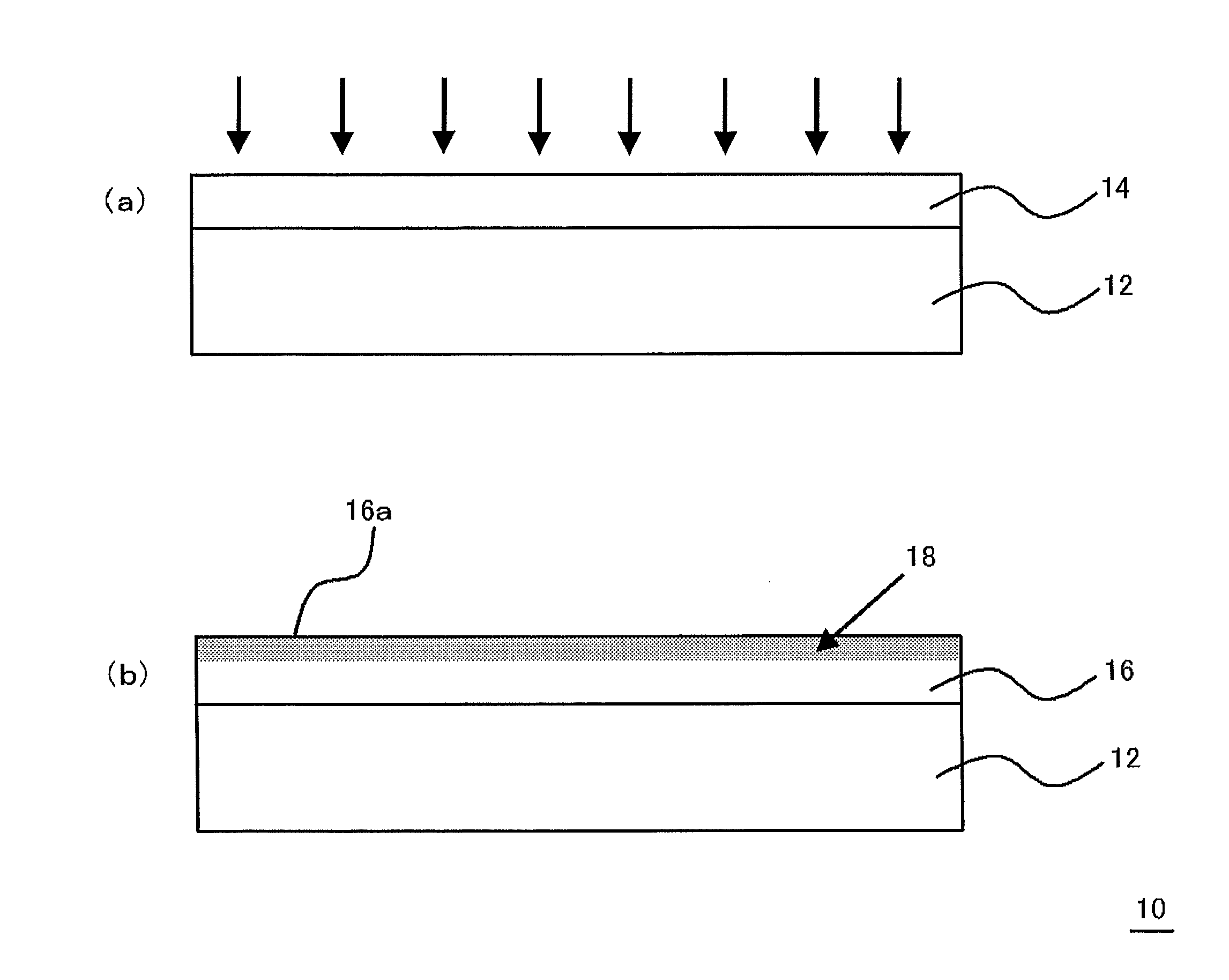

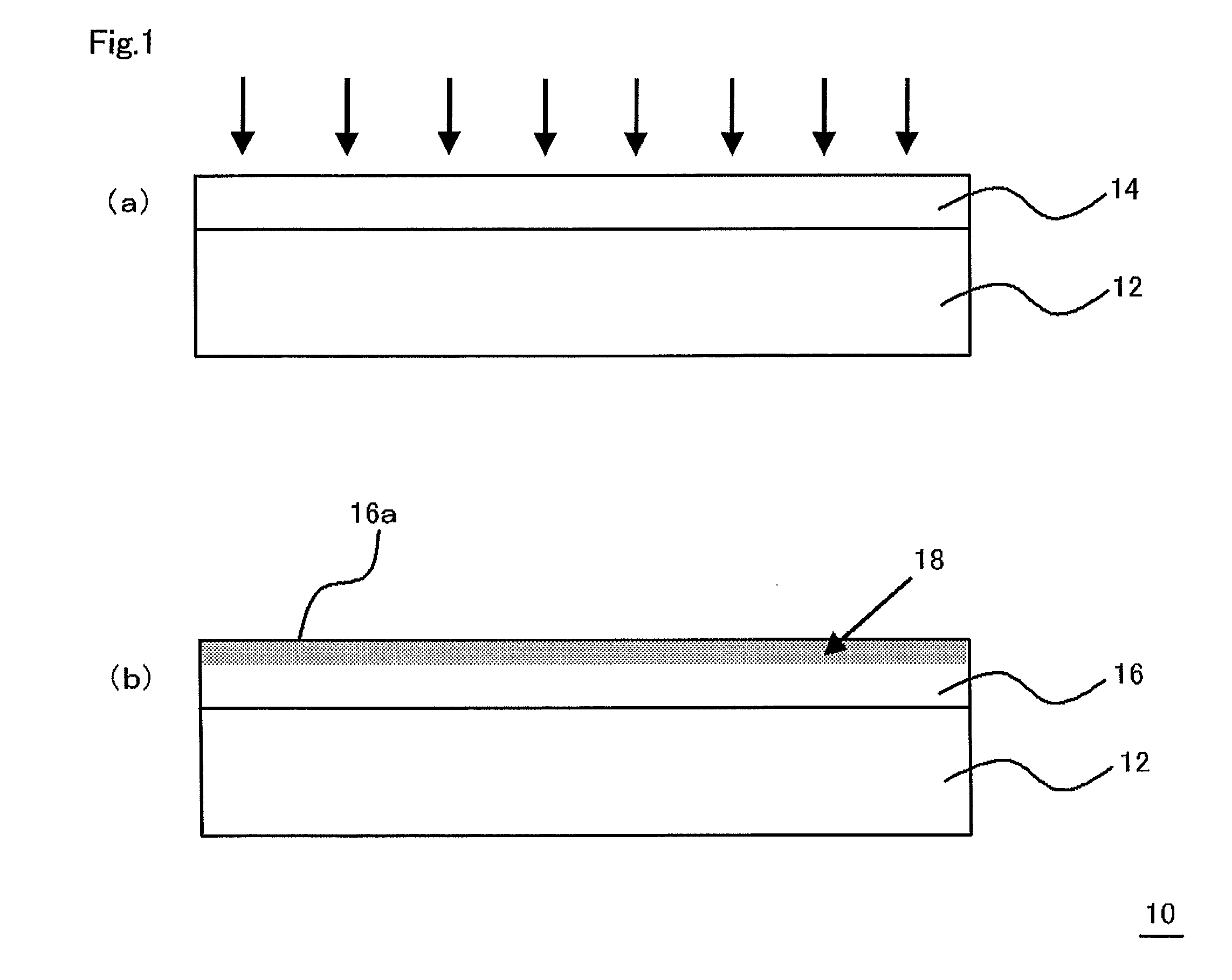

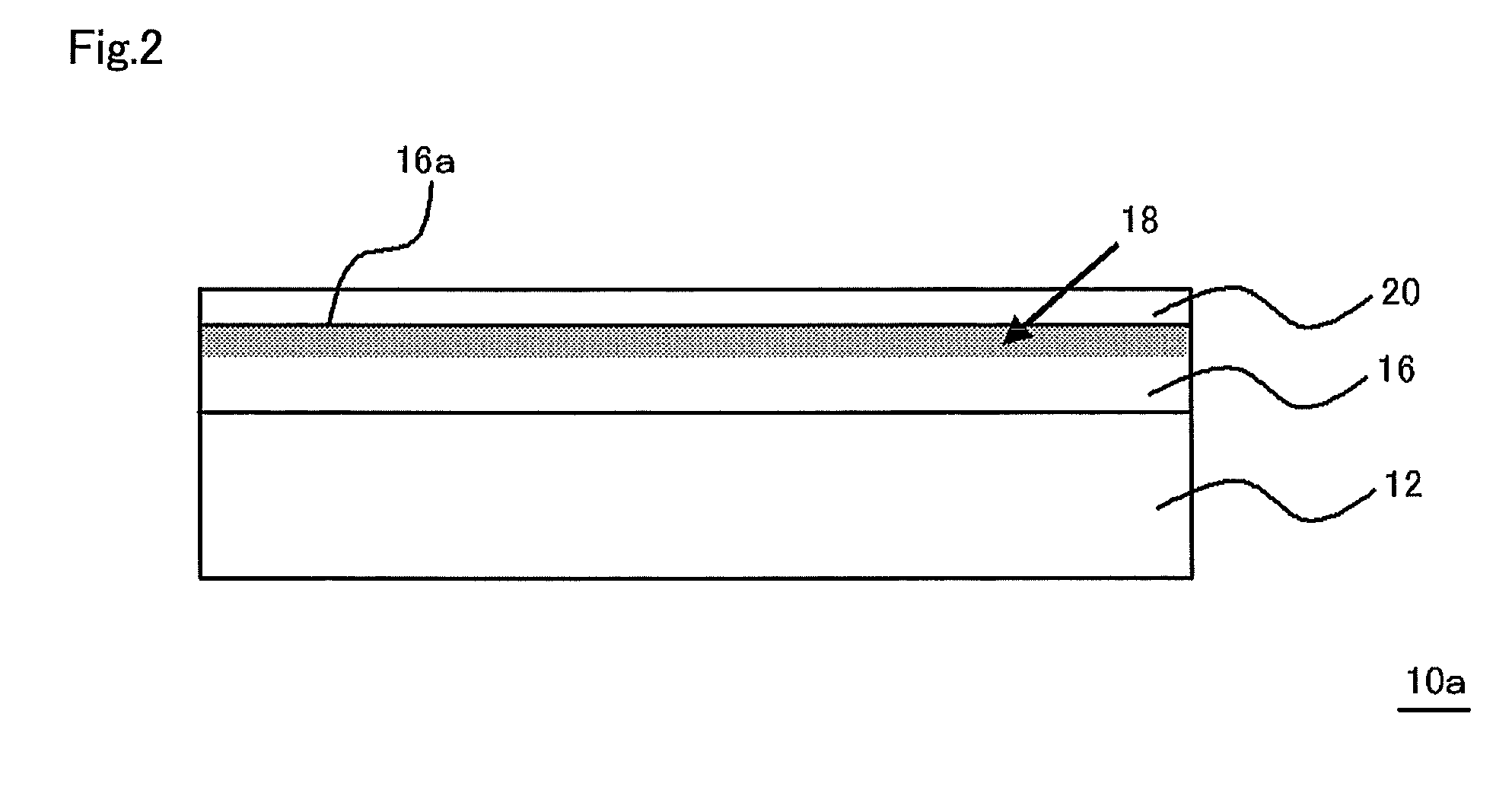

Multilayered material and method of producing the same

InactiveUS20120107607A1Reduce the impactIncrease production capacityRadiation applicationsPretreated surfacesWater vaporPolysilazane

A multilayered material is provided which includes a substrate and a silicon-containing film formed on the substrate, wherein the silicon-containing film has a nitrogen-rich area including silicon atoms and nitrogen atoms, or silicon atoms, nitrogen atoms, and an oxygen atoms and the nitrogen-rich area is formed by irradiating a polysilazane film formed on the substrate with an energy beam in an atmosphere not substantially including oxygen or water vapor and denaturing at least a part of the polysilazane film. A method of producing the multilayered material is also provided.

Owner:MITSUI CHEM INC

Sequential UV induced chemical vapor deposition

Ion-induced, UV-induced, and electron-induced sequential chemical vapor deposition (CVD) processes are disclosed where an ion flux, a flux of ultra-violet radiation, or an electron flux, respectively, is used to induce the chemical reaction in the process. The process for depositing a thin film on a substrate includes introducing a flow of a first reactant gas in vapor phase into a process chamber where the gas forms an adsorbed saturated layer on the substrate and exposing the substrate to a flux of ions, a flux of ultra-violet radiation, or a flux of electrons for inducing a chemical reaction of the adsorbed layer of the first reactant gas to form the thin film. A second reactant gas can be used to form a compound thin film. The ion-induced, UV-induced, and electron-induced sequential CVD process of the present invention can be repeated to form a thin film of the desired thickness.

Owner:NOVELLUS SYSTEMS

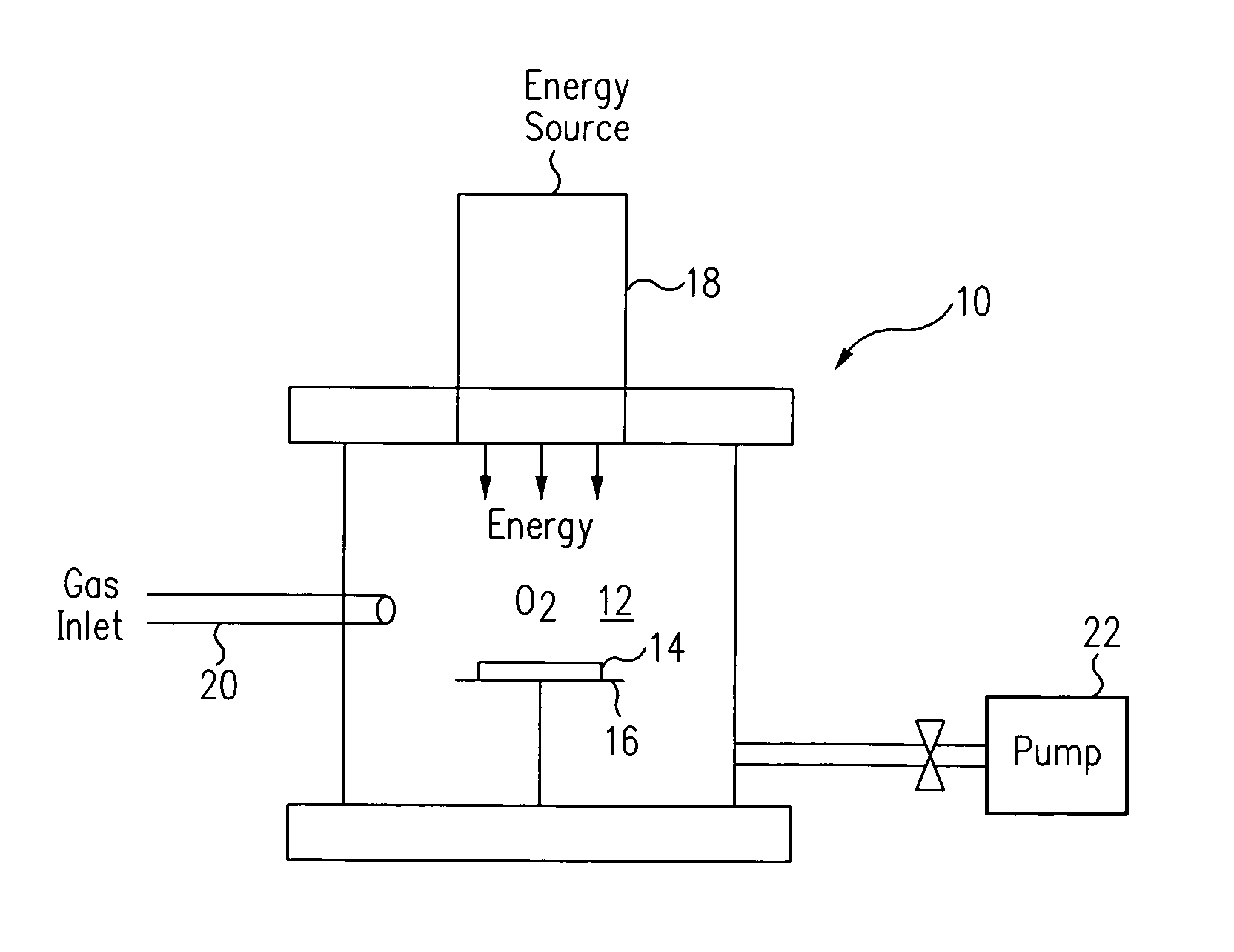

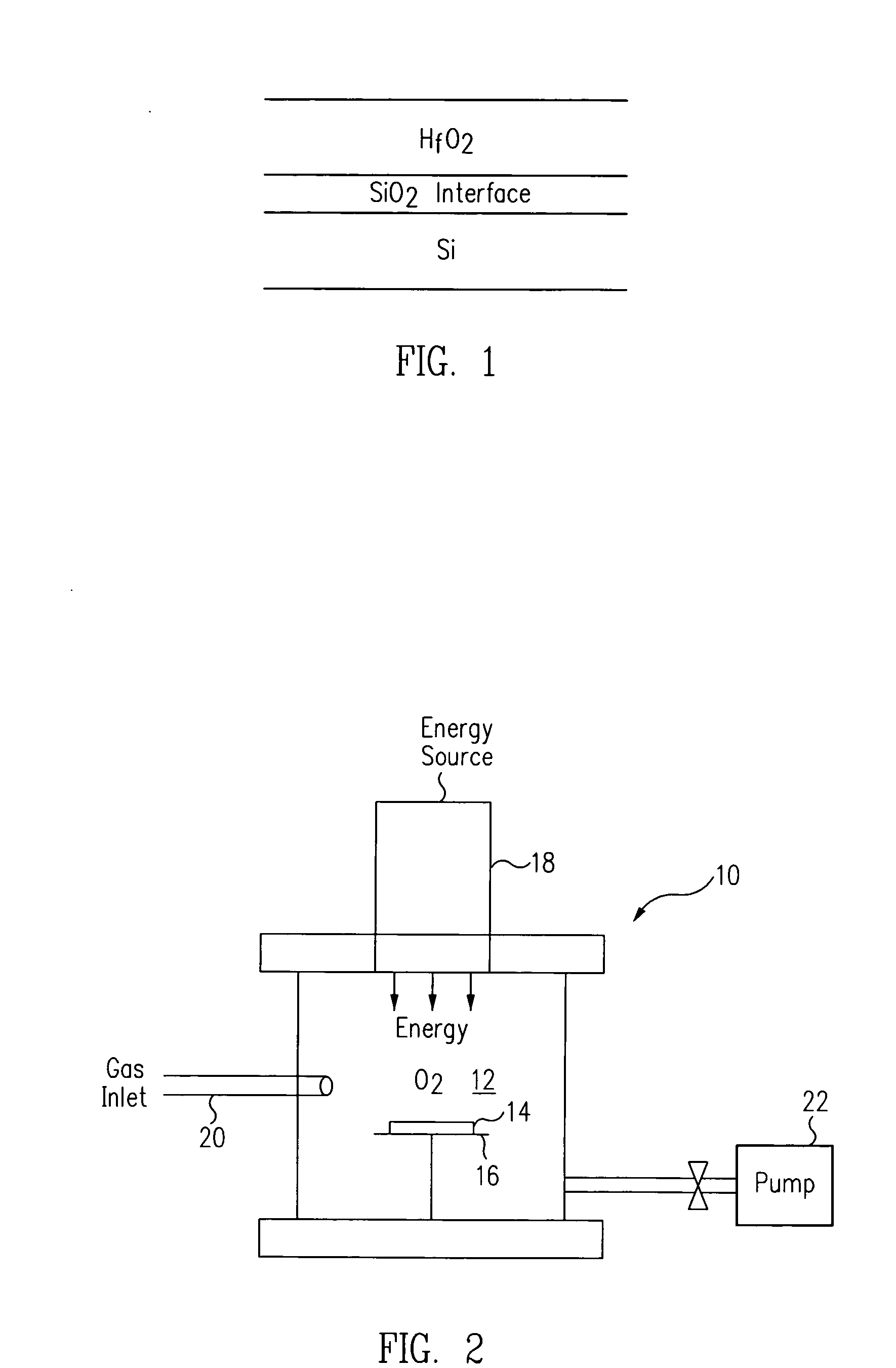

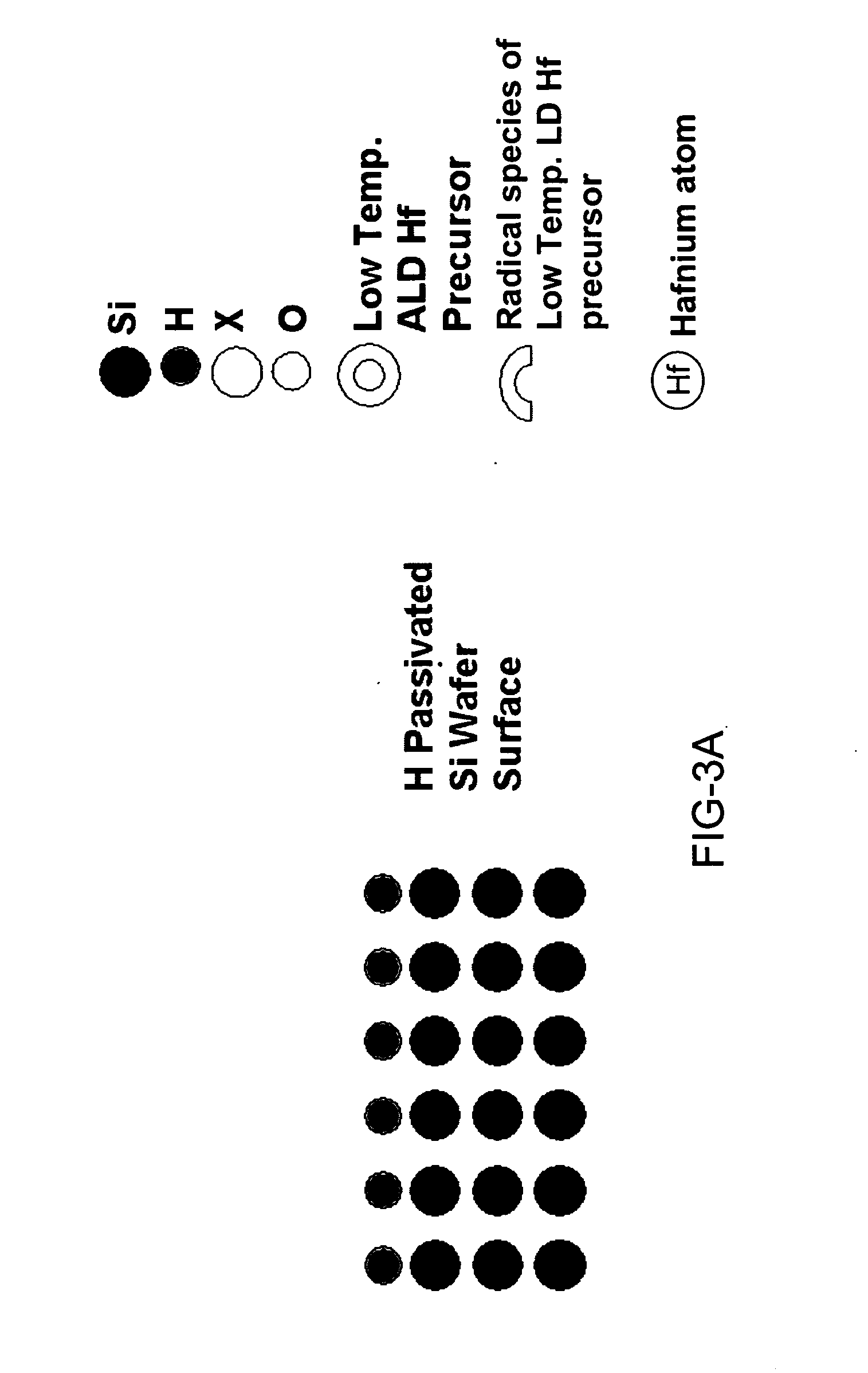

Method for energy-assisted atomic layer deposition and removal

InactiveUS20050175789A1High energyGood initiativeSemiconductor/solid-state device manufacturingPretreated surfacesProduct gasElectromagnetic radiation

A method for energy-assisted atomic layer deposition and removal of a dielectric film are provided. In one embodiment a substrate is placed into a reaction chamber and a gaseous precursor is introduced into the reaction chamber. Energy is provide by a pulse of electromagnetic radiation which forms radical species of the gaseous precursor. The radical species react with the surface of the substrate to form a radical terminated surface on the substrate. The reaction chamber is purged and a second gaseous precursor is introduced. A second electromagnetic radiation pulse is initiated and forms second radical species. The second radical species of the second gas react with the surface to form a film on the substrate. Alternately, the gaseous species can be chosen to produce radicals that result in the removal of material from the surface of the substrate.

Owner:HELMS JR AUBREY L +3

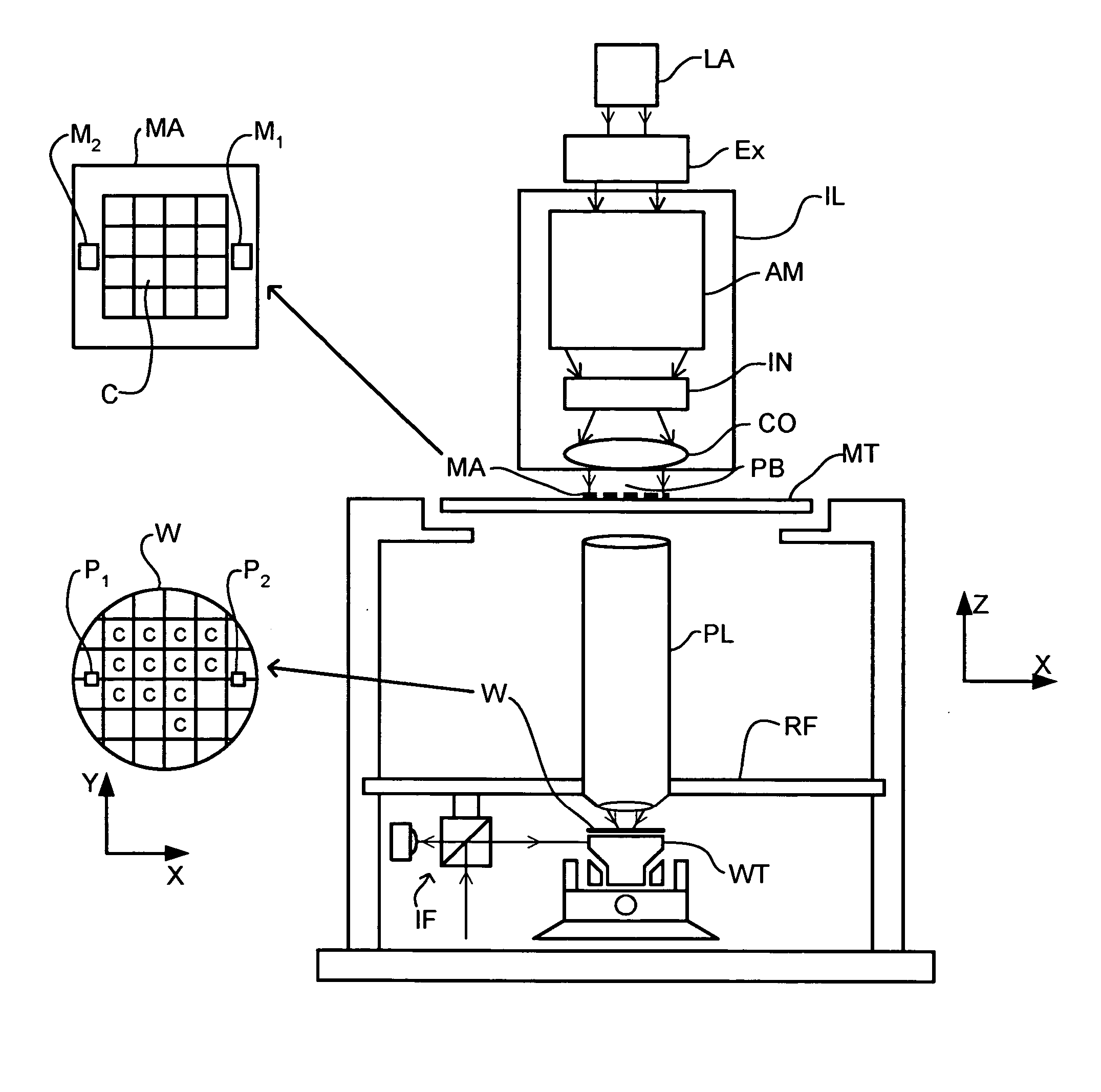

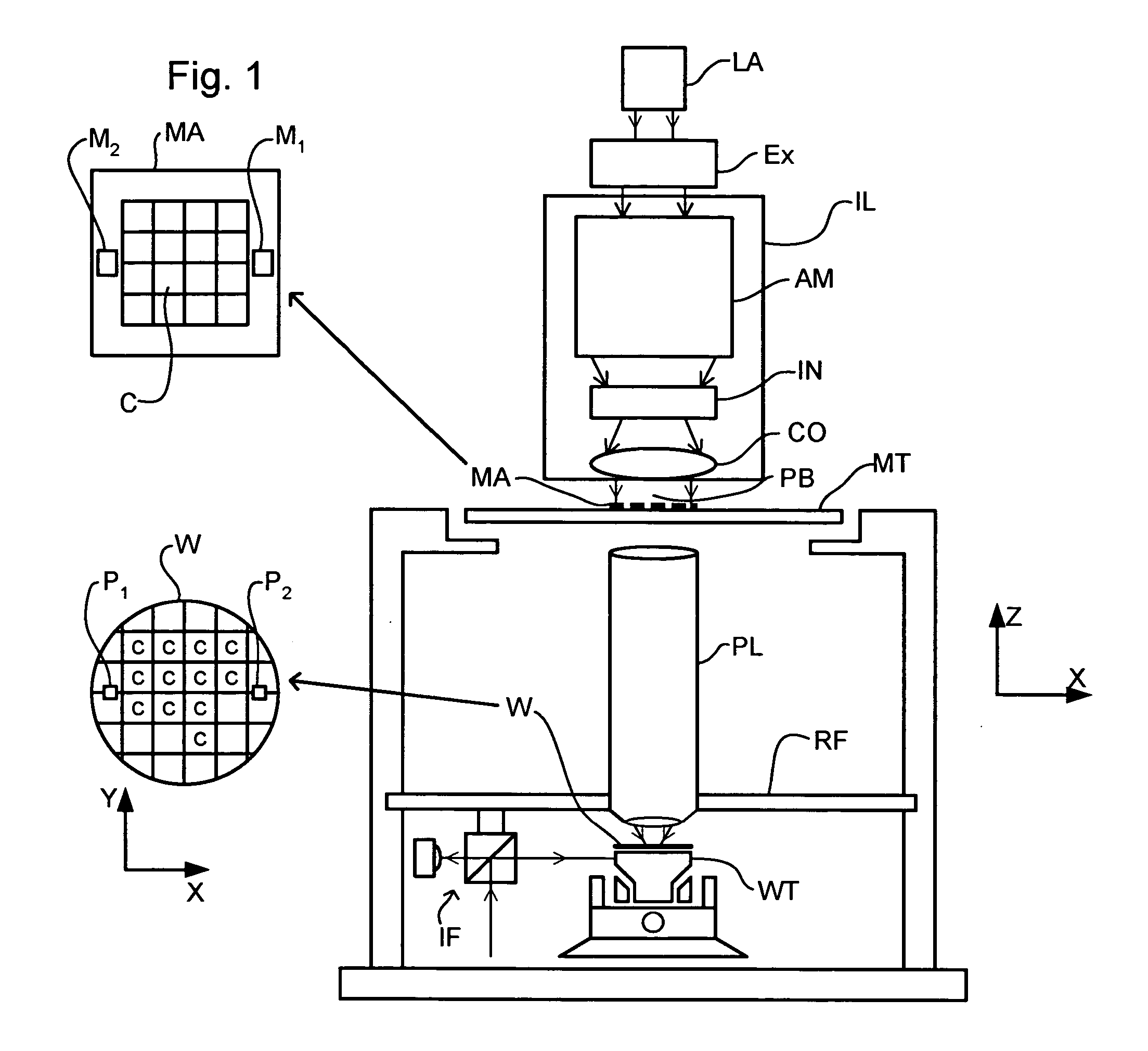

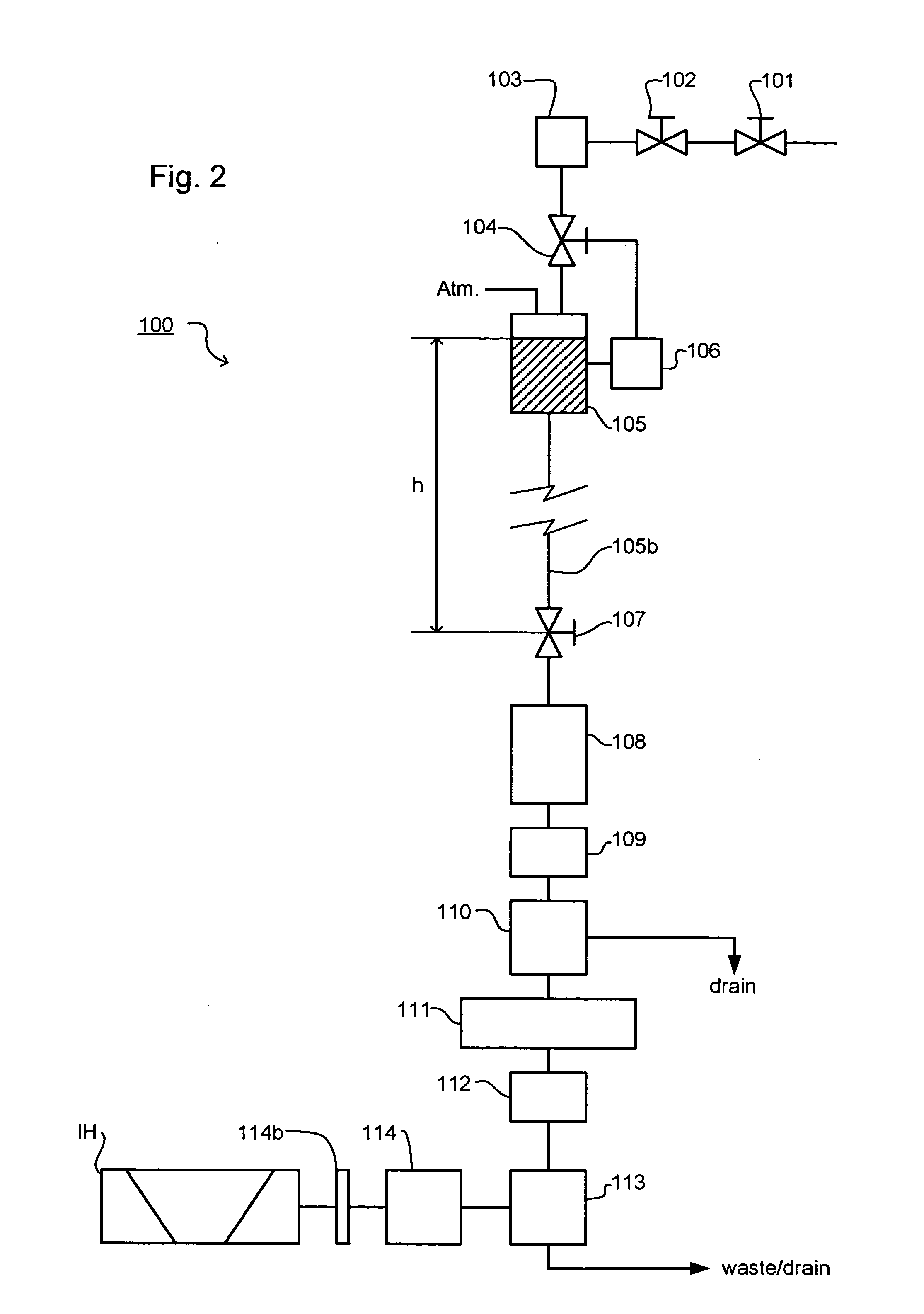

Lithographic apparatus and device manufacturing method

InactiveUS20050048220A1ConstantAvoid pollutionSemiconductor/solid-state device manufacturingPretreated surfacesEngineeringImmersion lithography

In an immersion lithography apparatus, the immersion liquid is supplied from a tank via a flow restrictor. The liquid held in the tank is maintained at a substantially constant height above the flow restrictor to ensure a constant flow of liquid.

Owner:ASML NETHERLANDS BV

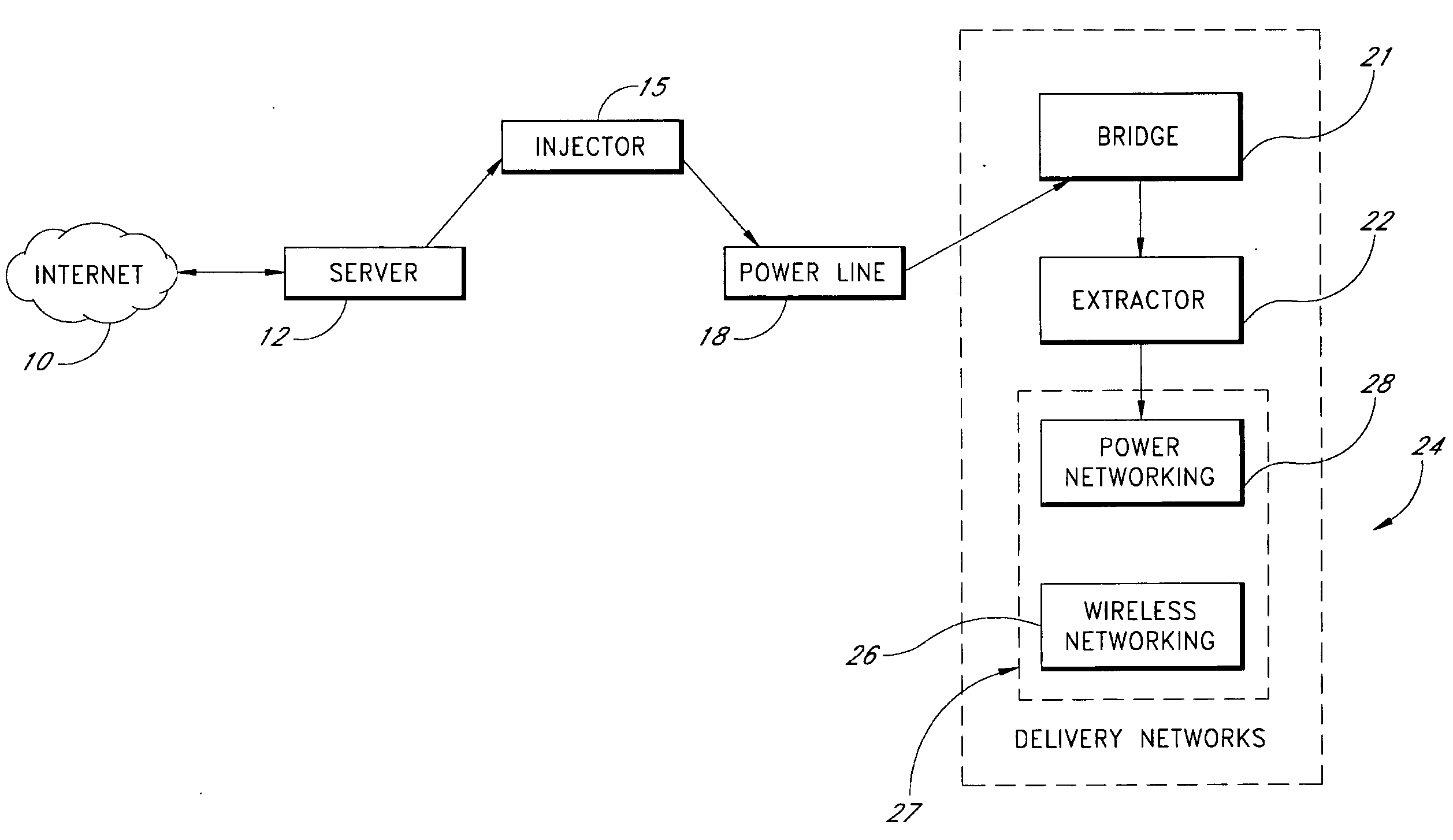

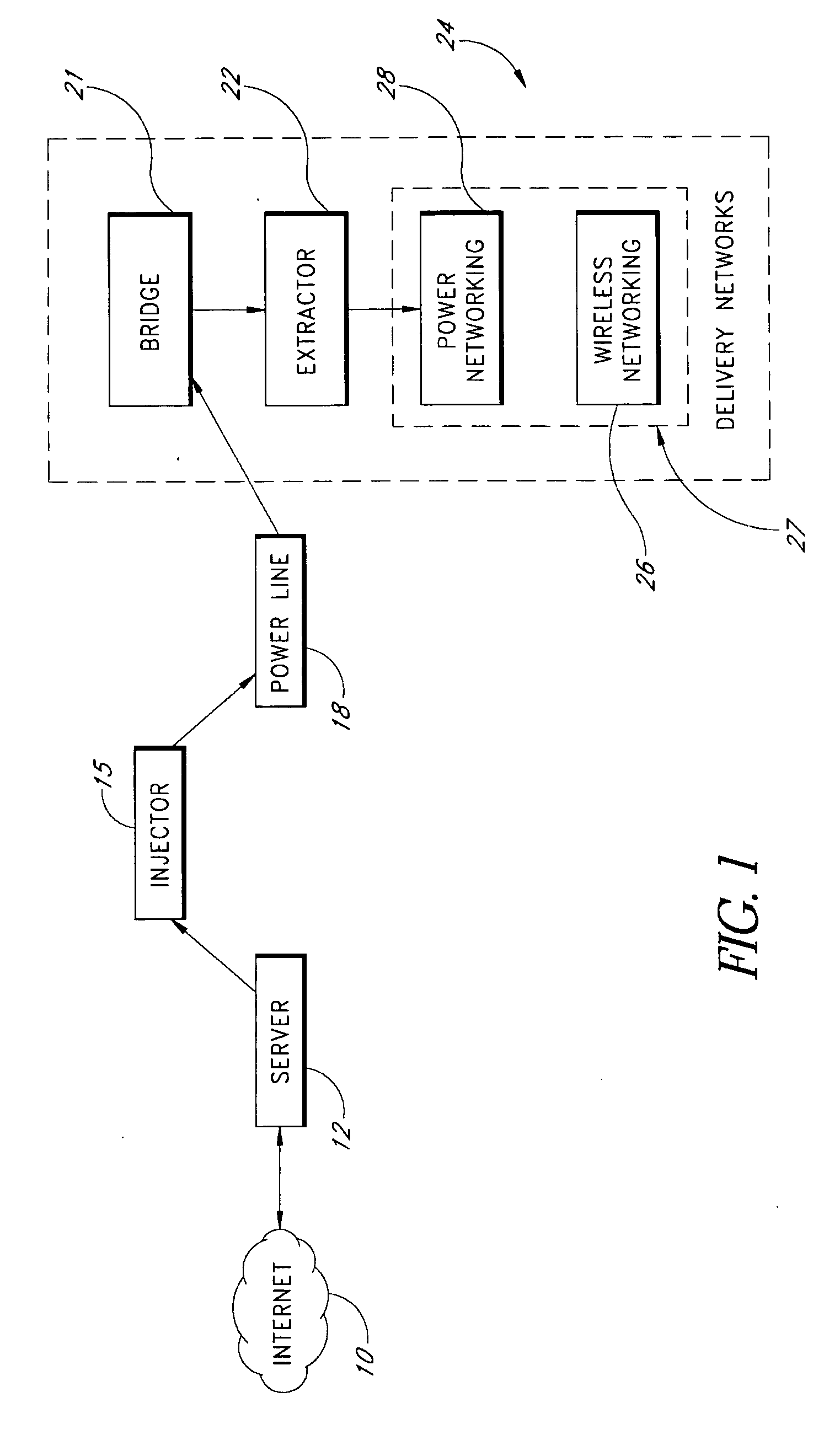

Broadband data services over vehicle power lines

InactiveUS20050143868A1Improving S/N for transmission/receivingDigital data processing detailsElectric forceMobile vehicle

A method of providing broadband data services over power lines for moving vehicles is provided herein. Using broadband over power line (BPL) networking, a data signal is connected to a vehicle that is connected to a transport power line. The signal is communicated from the transport power line to the vehicle. The signal is then demodulated for use aboard the vehicle. The data signal connection allows for access to wide area networks such as the Internet. Access points can wirelessly broadcast wide area network signals from stationary locations to define meshed wireless networks in metropolitan areas.

Owner:WHELAN ANTHONY

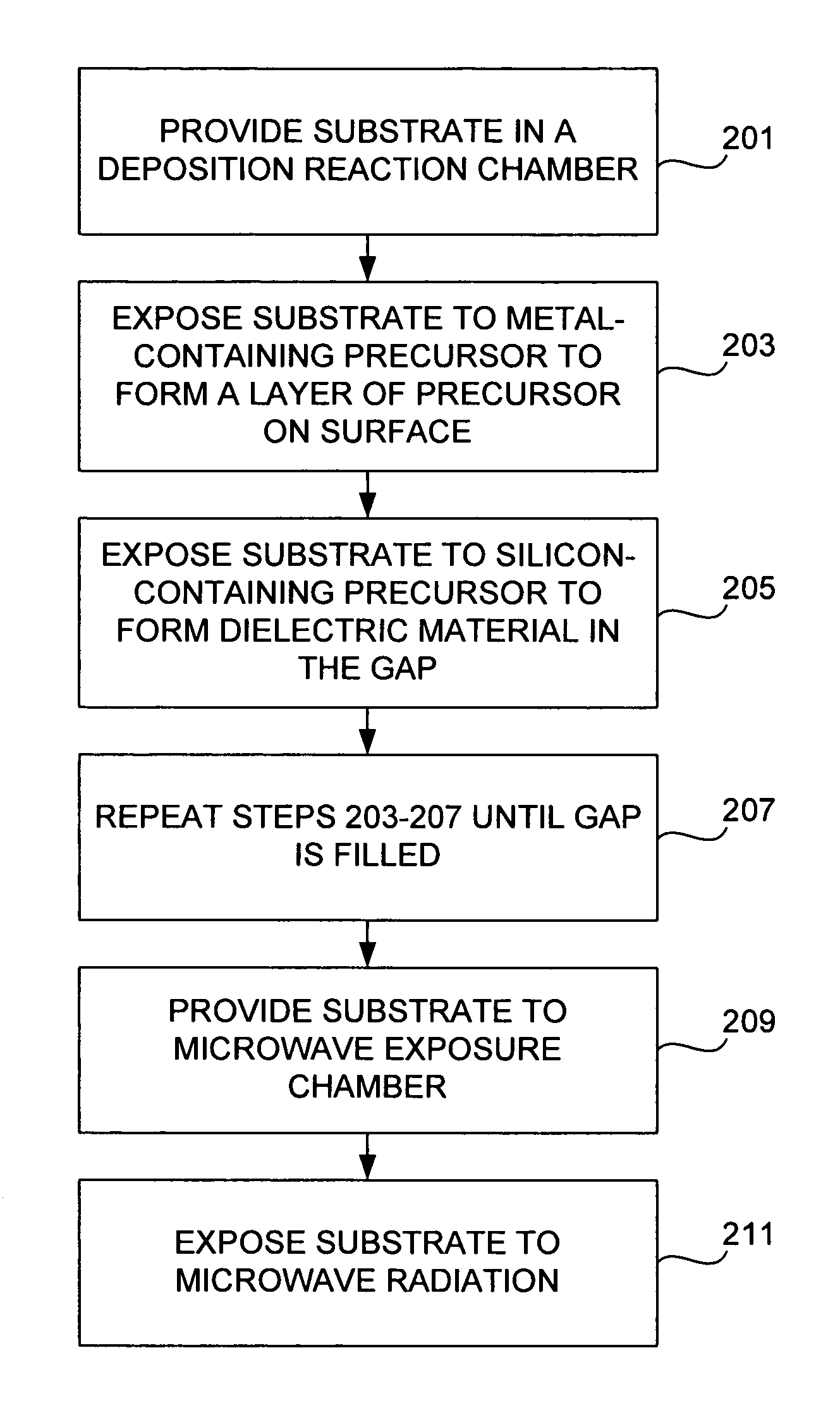

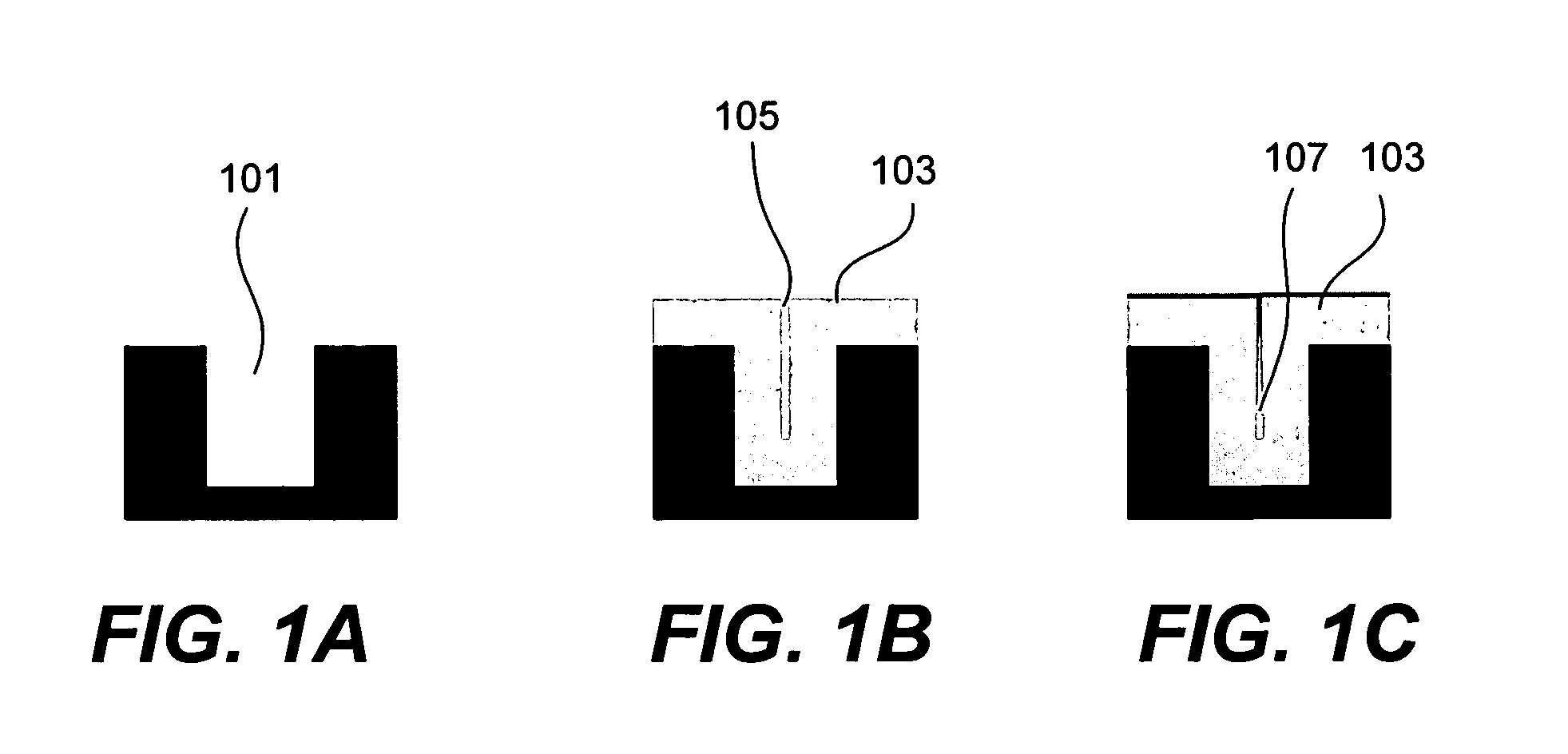

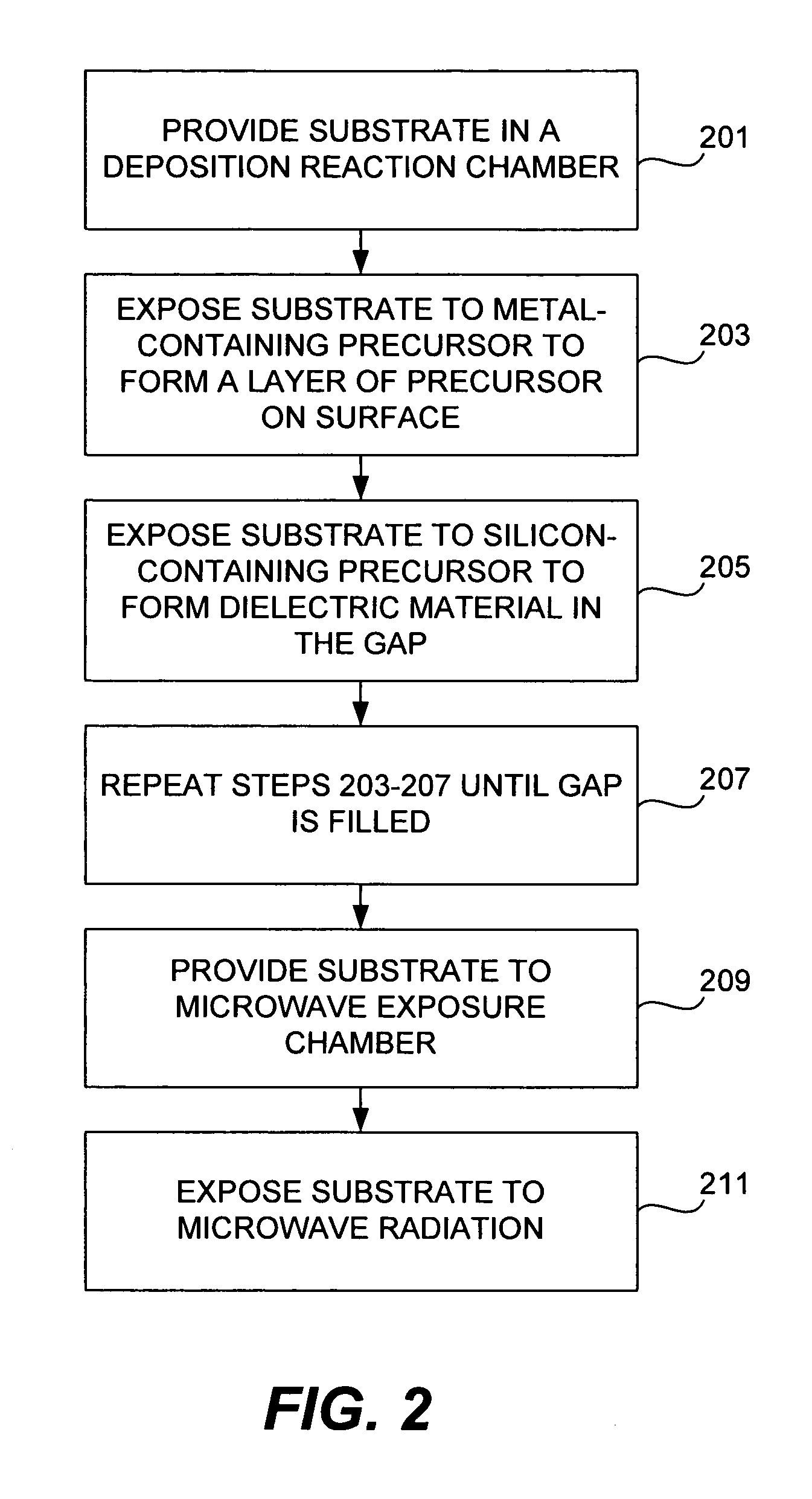

Hydroxyl bond removal and film densification method for oxide films using microwave post treatment

ActiveUS7589028B1High densityImprove film propertiesRadiation applicationsSemiconductor/solid-state device manufacturingDielectricMicrowave

Methods of forming dielectric films with increased density and improved film properties are provided. The methods involve exposing dielectric films to microwave radiation. According to various embodiments, the methods may be used to remove hydroxyl bonds, increase film density, reduce or eliminate seams and voids, and optimize film properties such as dielectric constant, refractive index and stress for particular applications. In certain embodiments, the methods are used to form conformal films deposited by a technique such as PDL. The methods may be used in applications requiring low thermal budgets.

Owner:NOVELLUS SYSTEMS

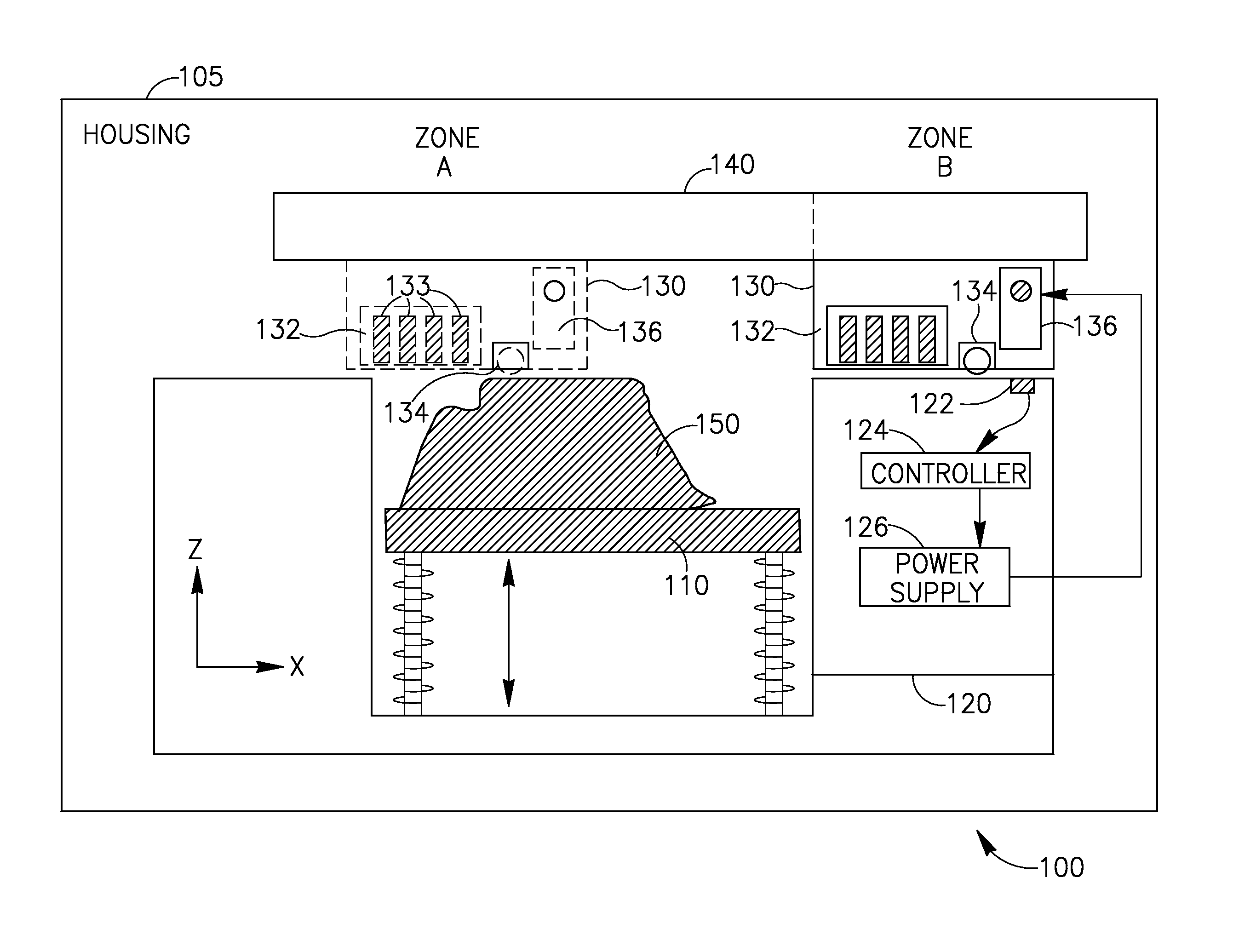

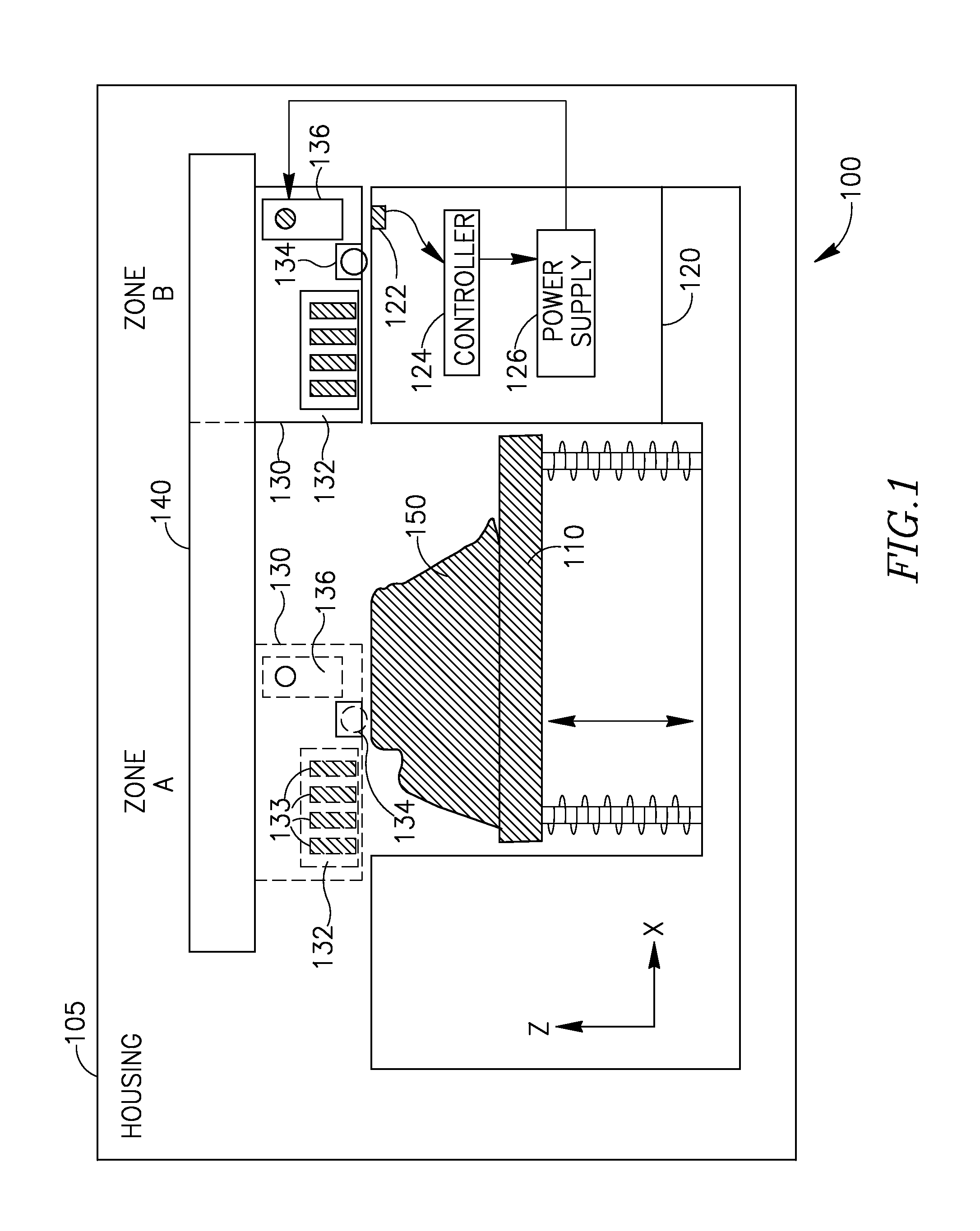

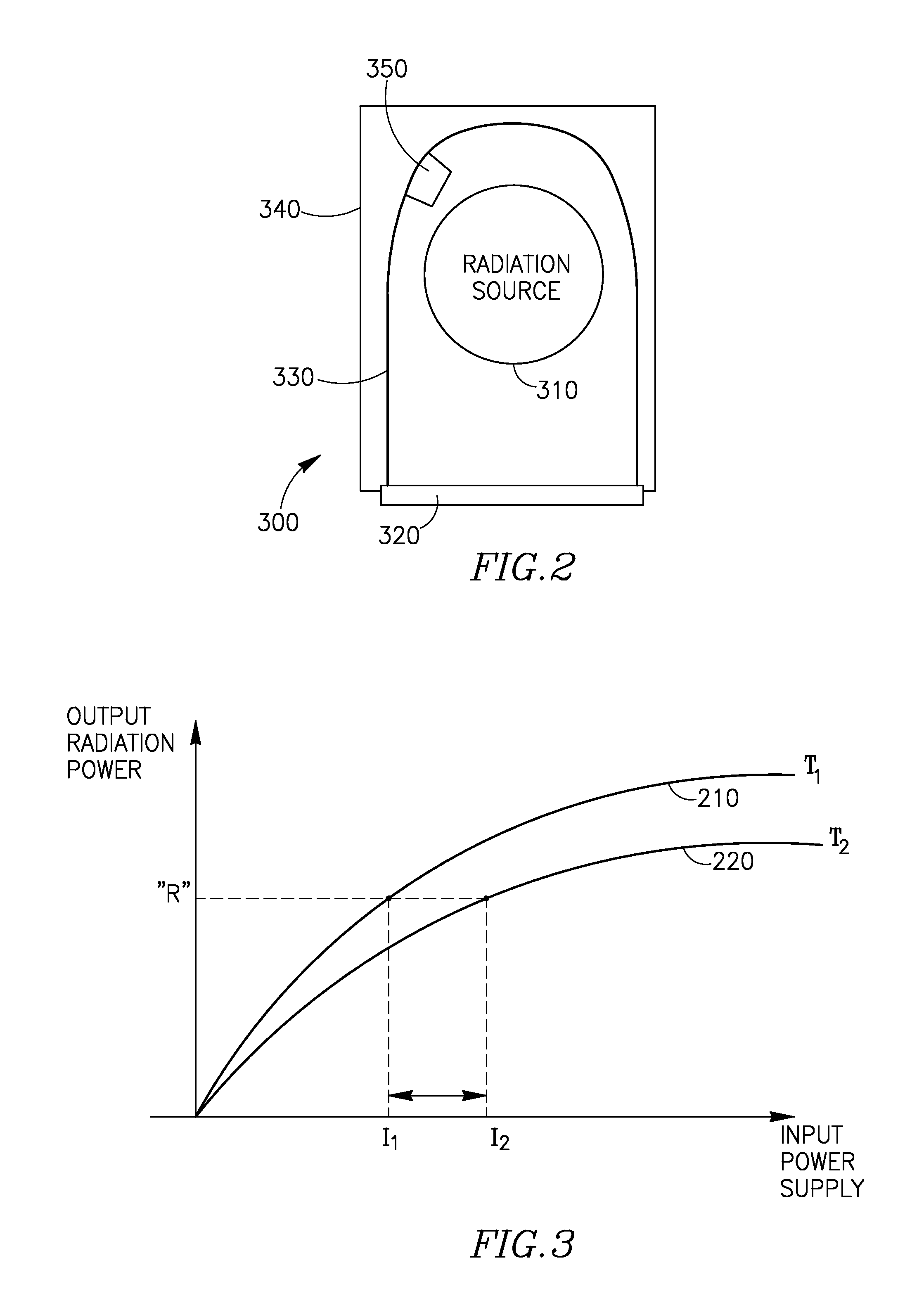

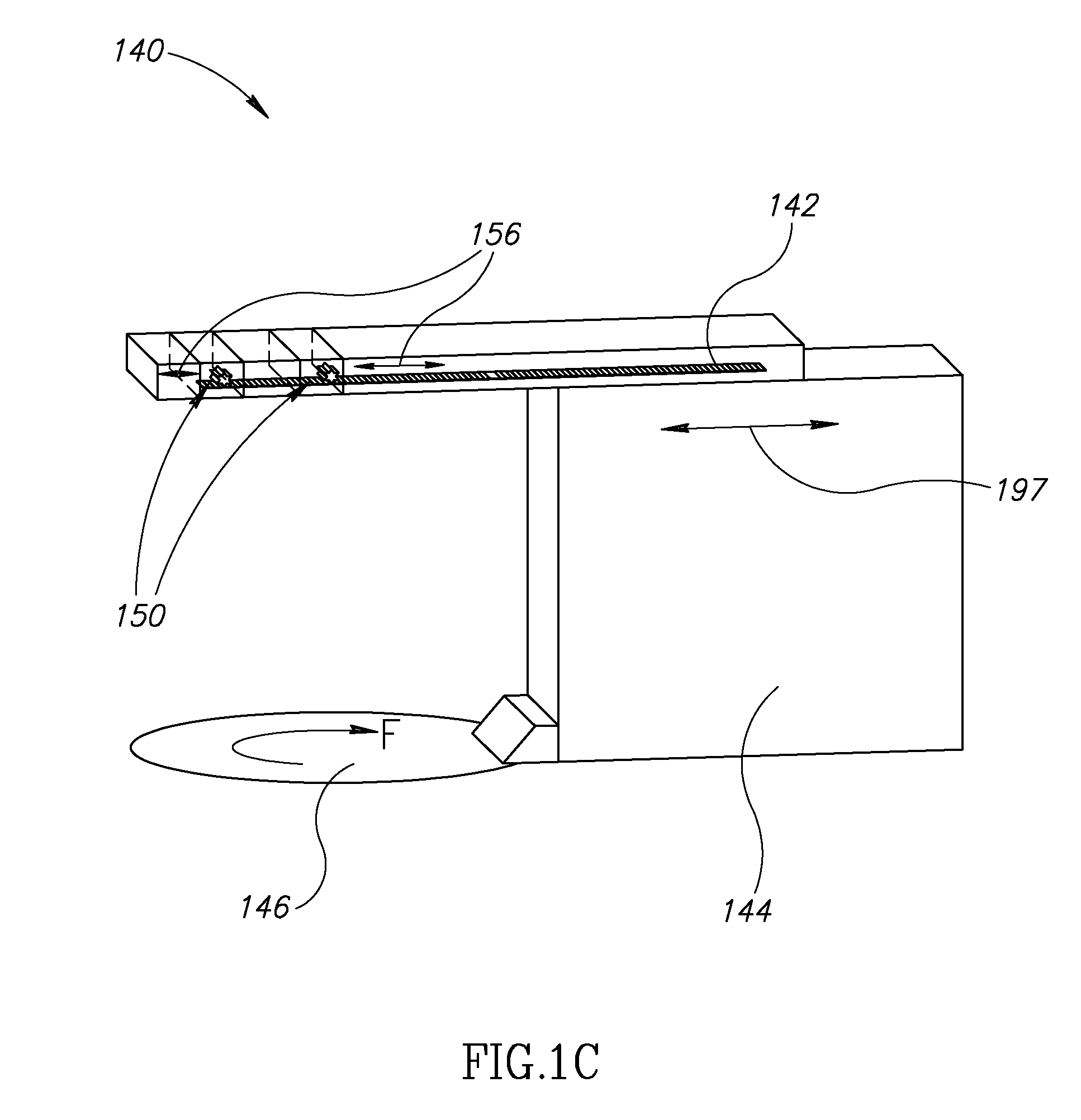

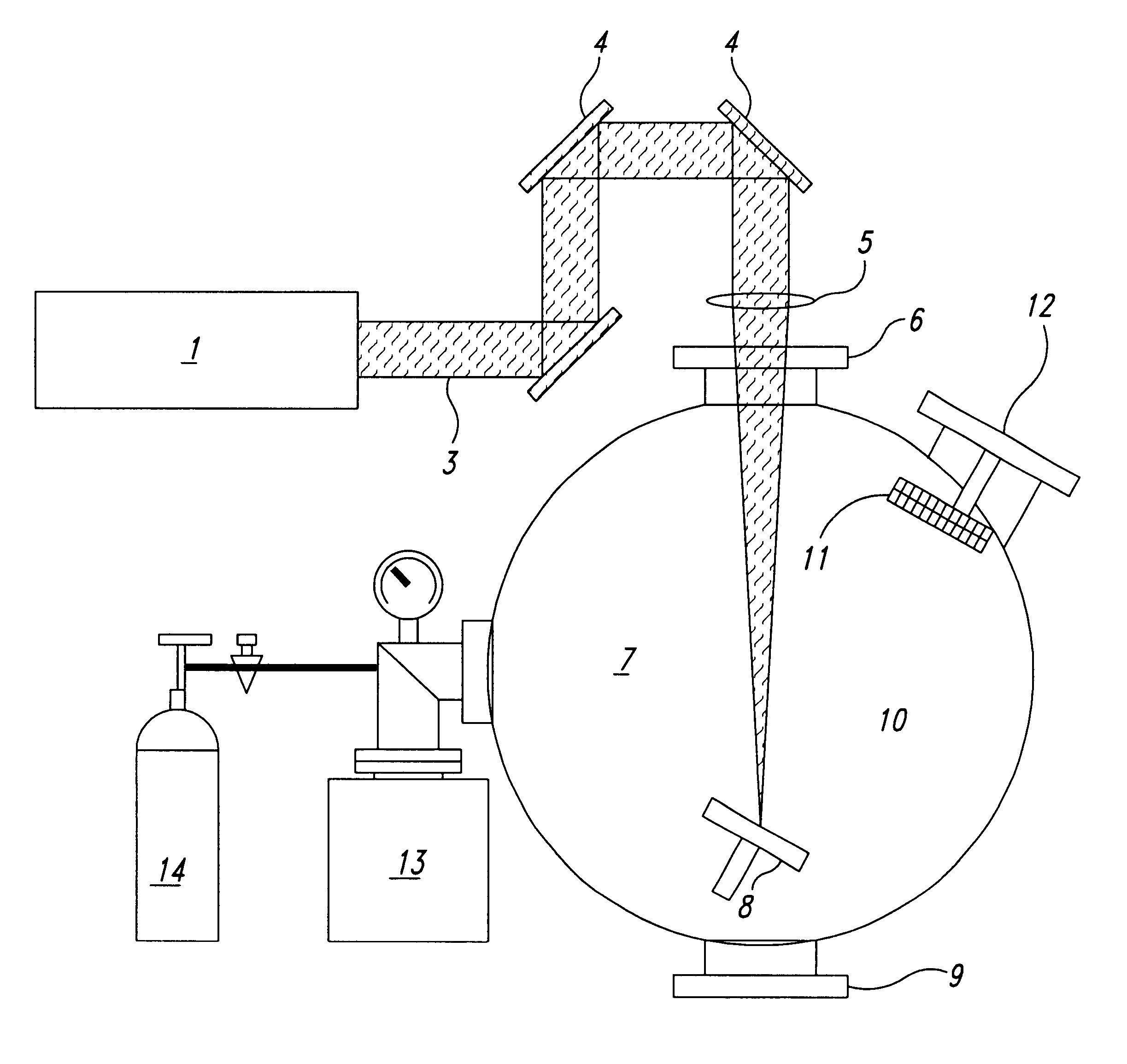

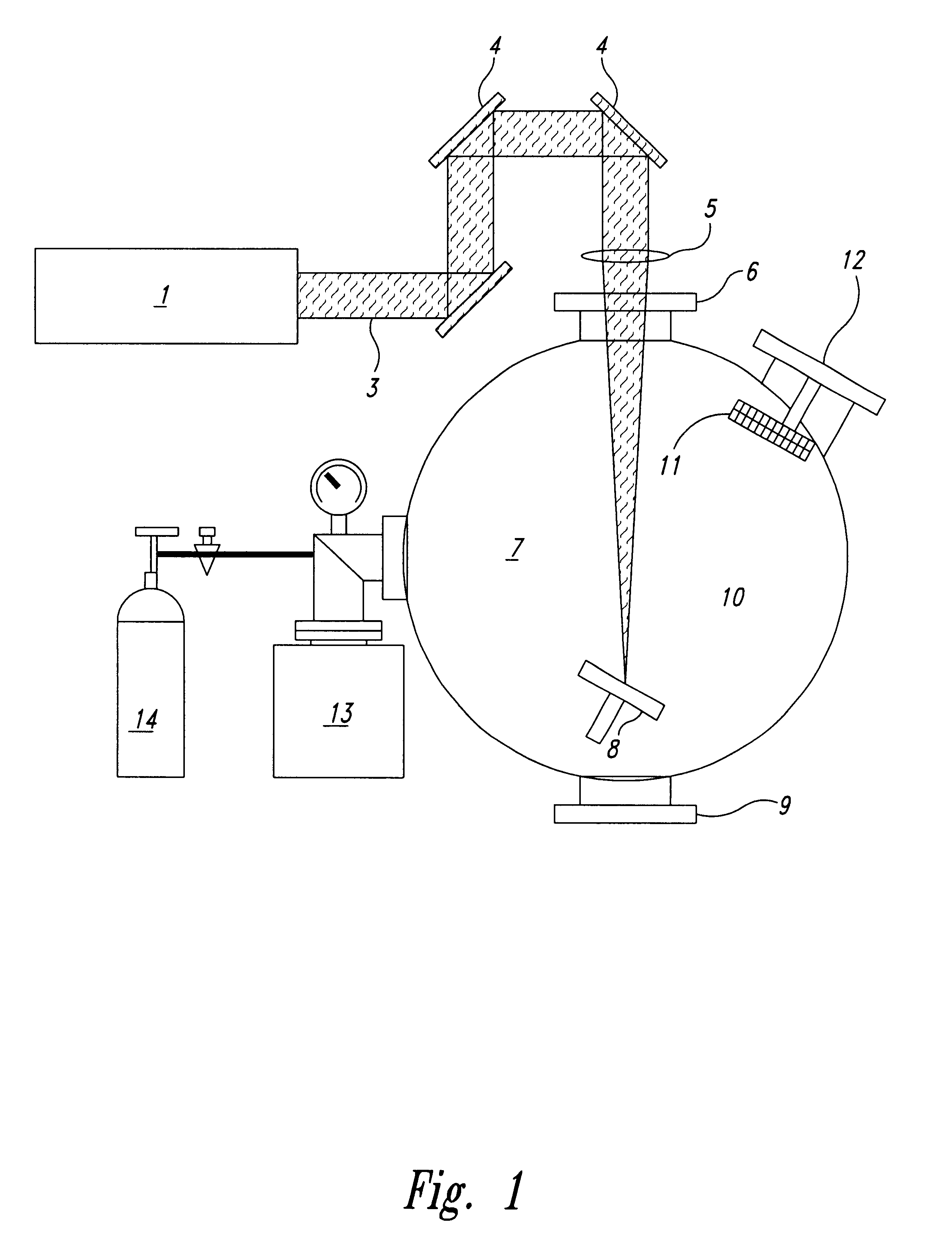

Method and apparatus for monitoring electro-magnetic radiation power in solid freeform fabrication systems

Owner:STRATASYS LTD

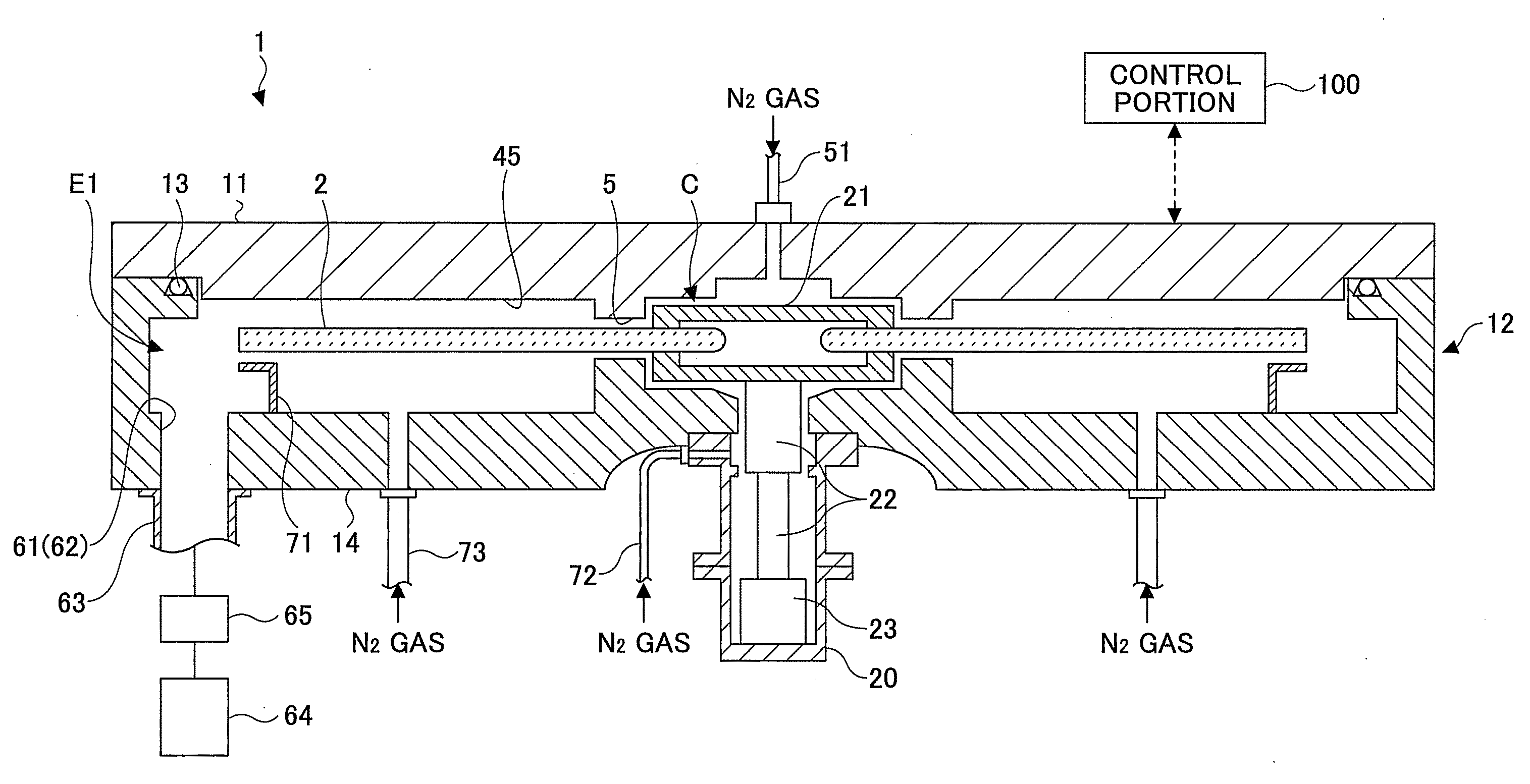

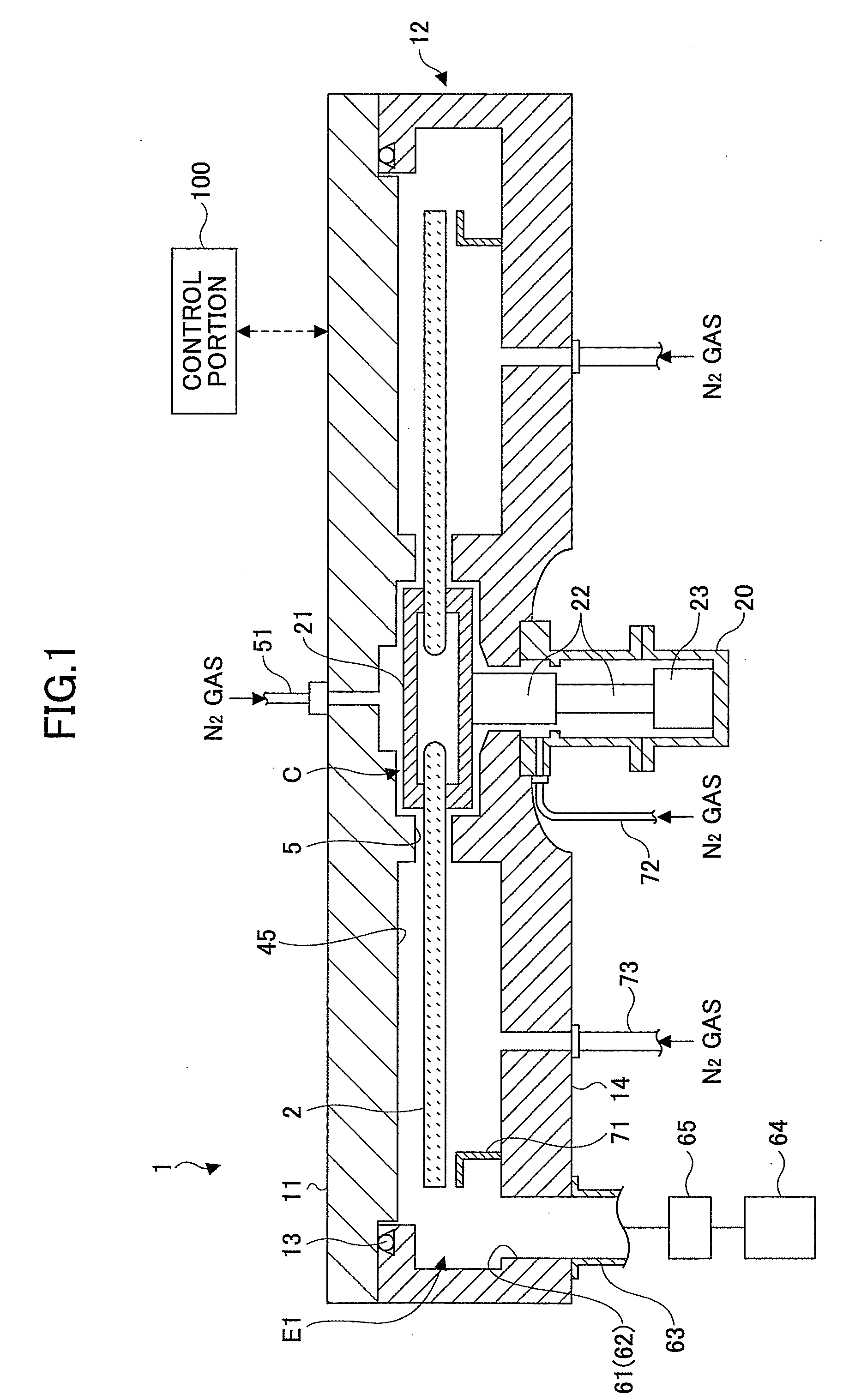

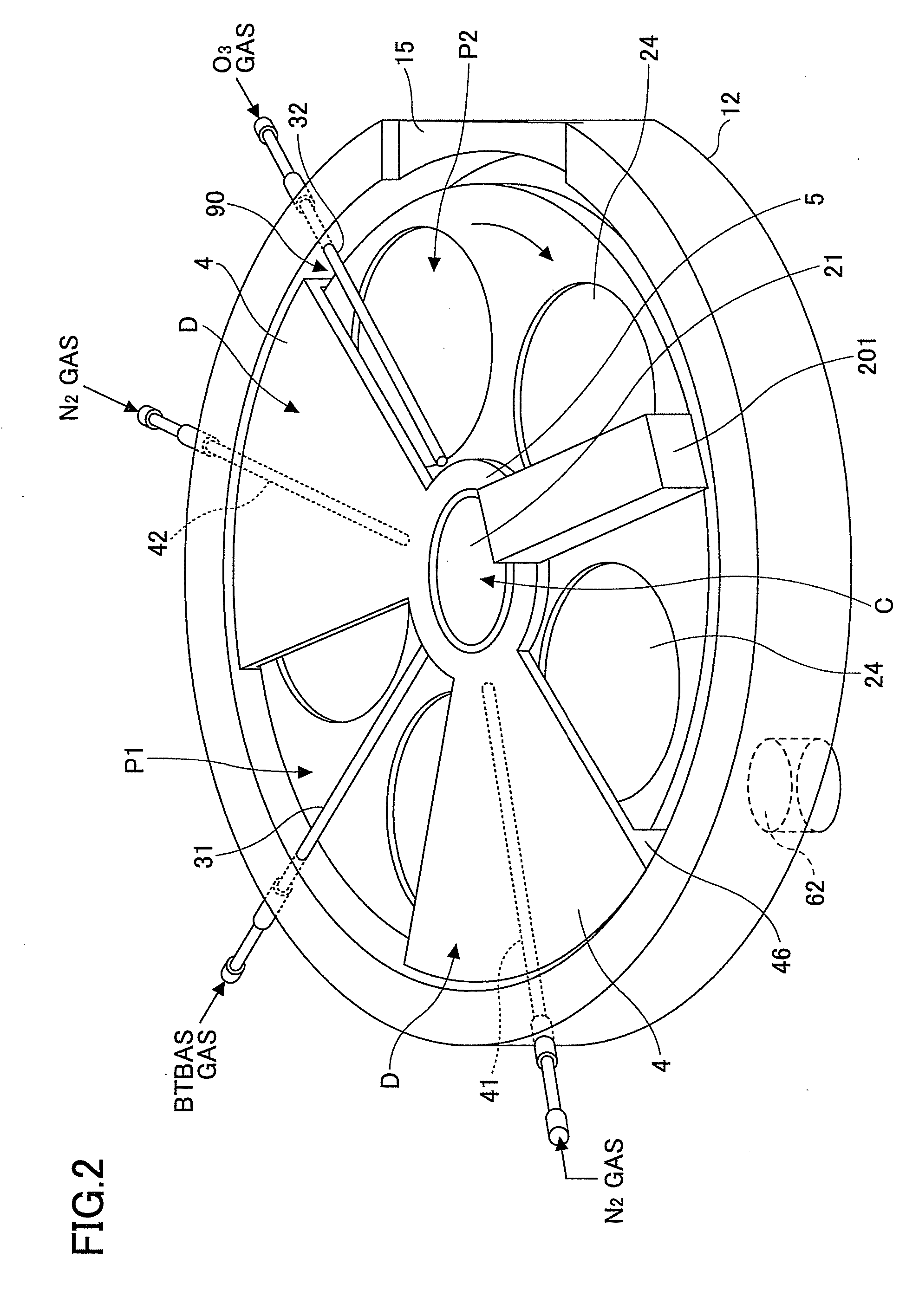

Film deposition apparatus, film deposition method, and storage medium

In a film deposition apparatus where bis (tertiary-butylamino) silane (BTBAS) gas is adsorbed on a wafer and then O3 gas is adsorbed on the wafer so that the BTBAS gas is oxidized by the O3 gas thereby depositing a silicon oxide film by rotating a turntable on which the wafer is placed, a laser beam irradiation portion is provided that is capable of irradiating a laser beam to an area spanning from one edge to another edge of a substrate receiving area of the turntable along a direction from an inner side to an outer side of the table.

Owner:TOKYO ELECTRON LTD

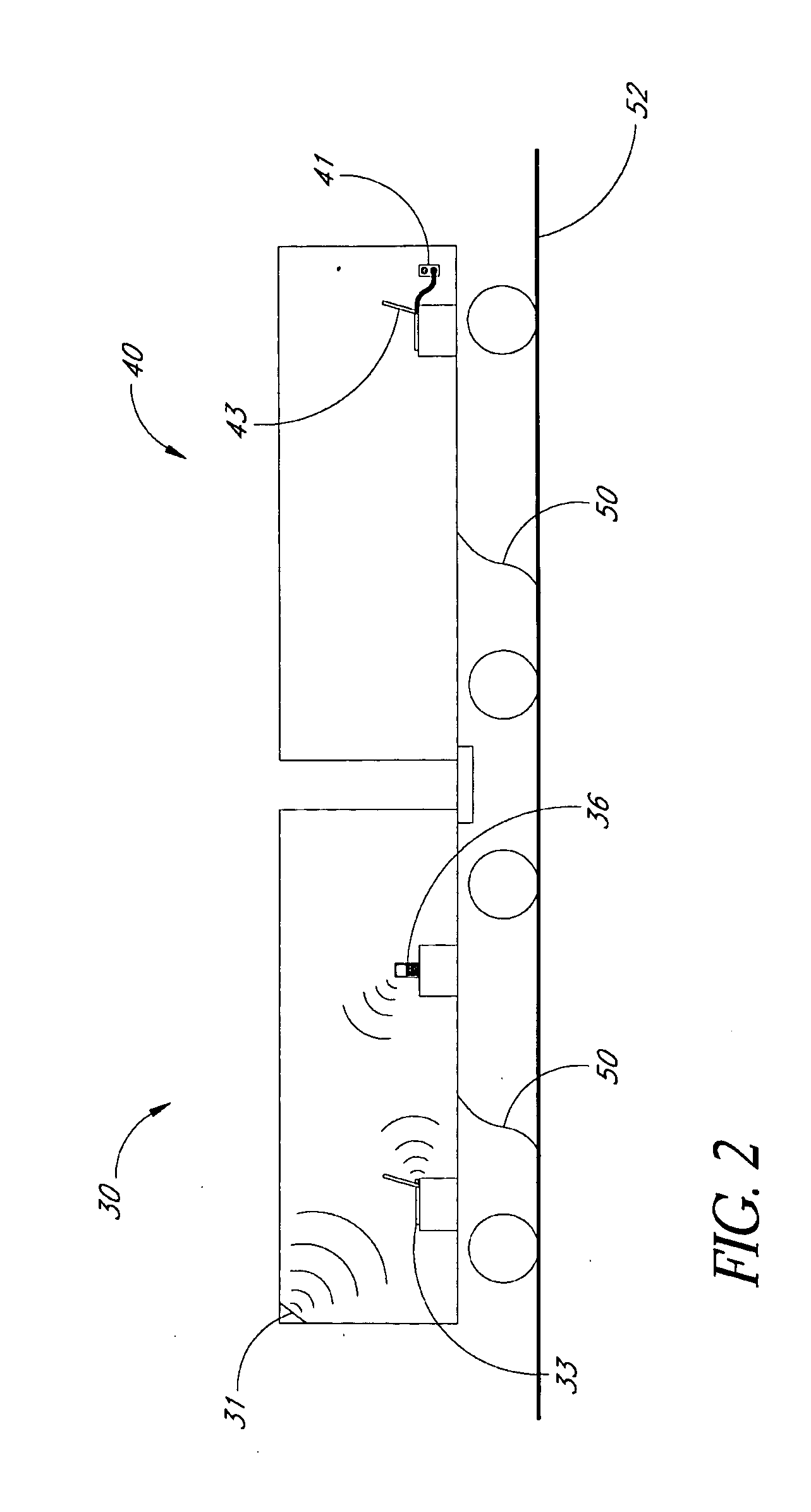

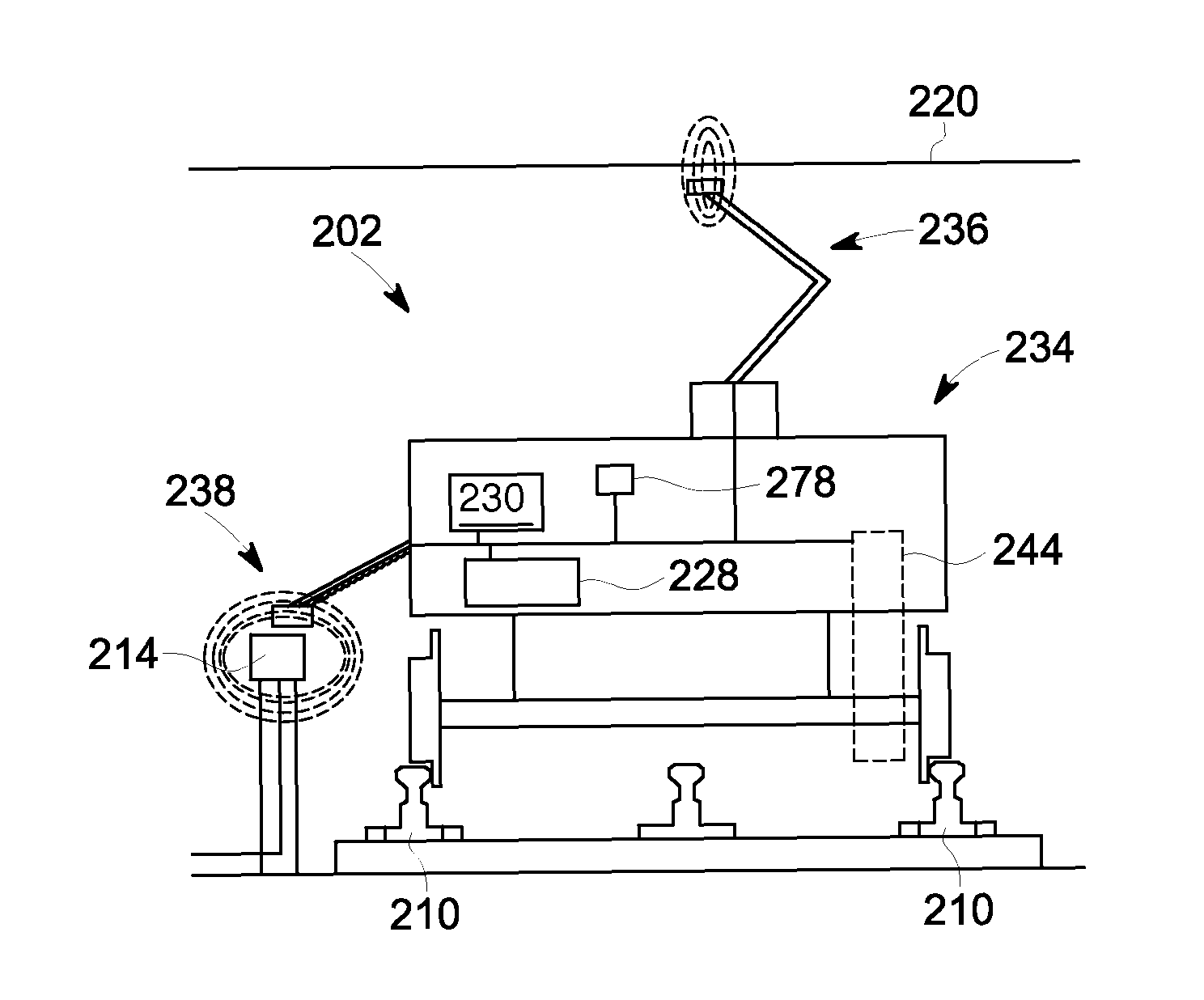

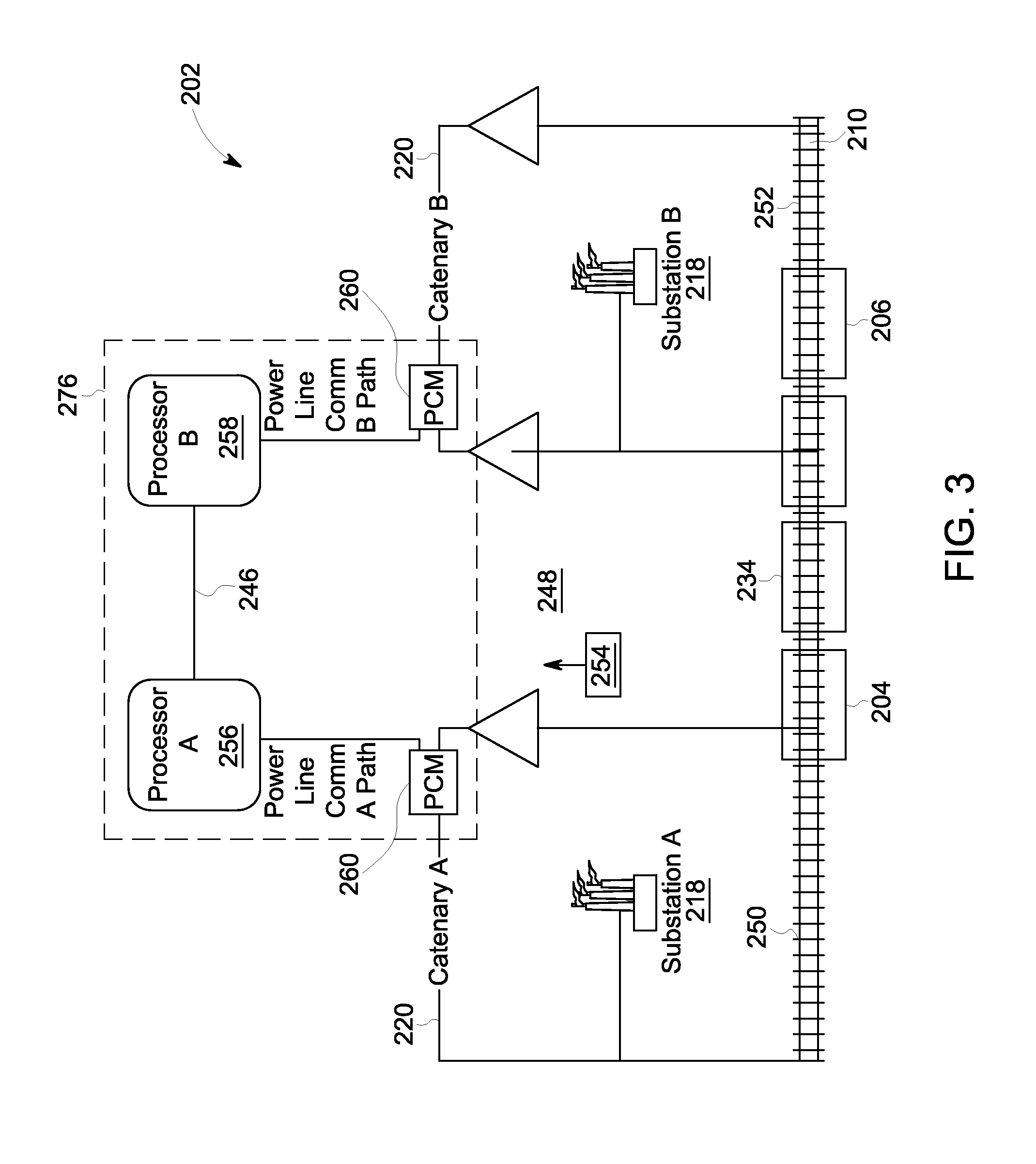

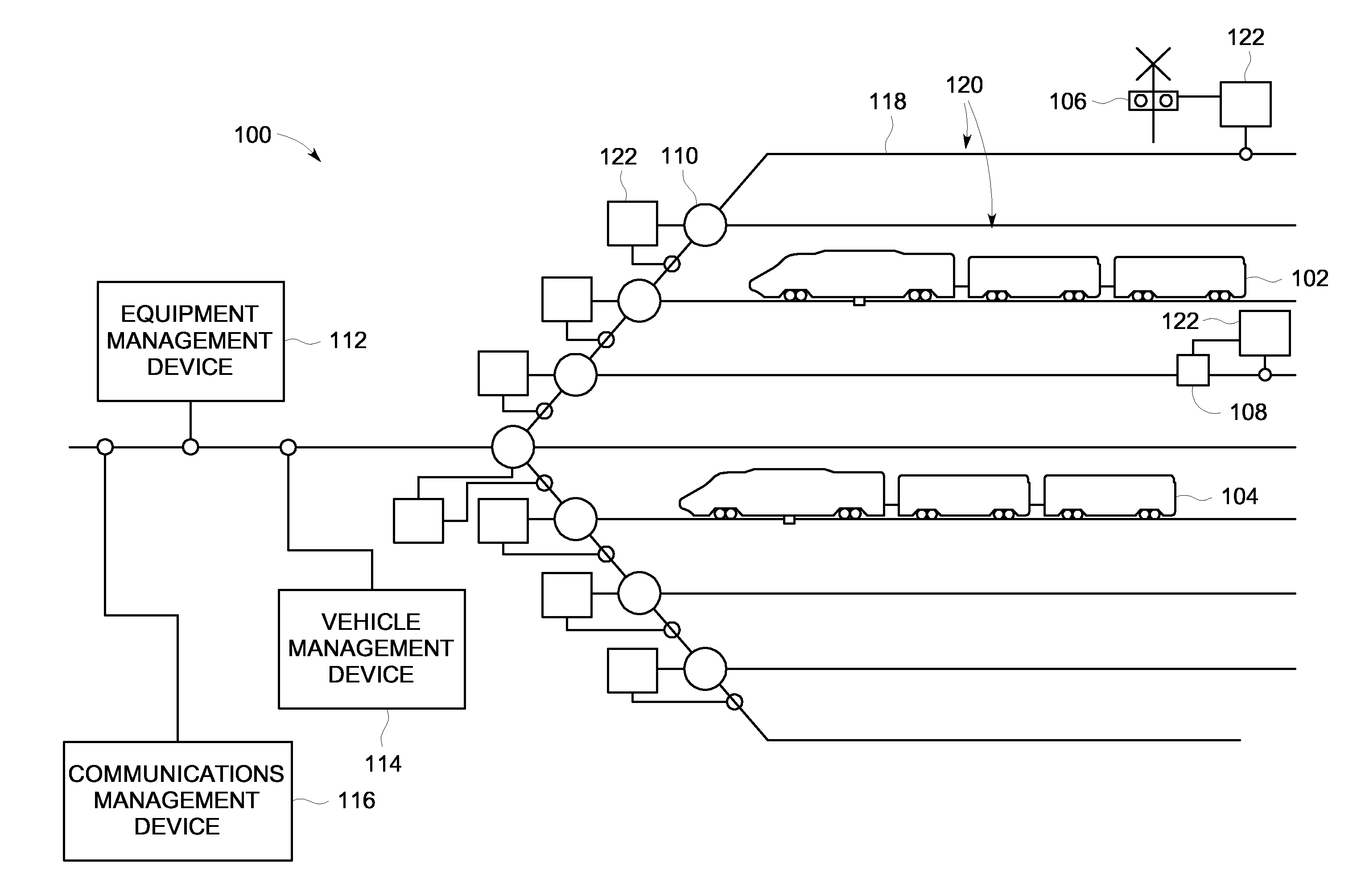

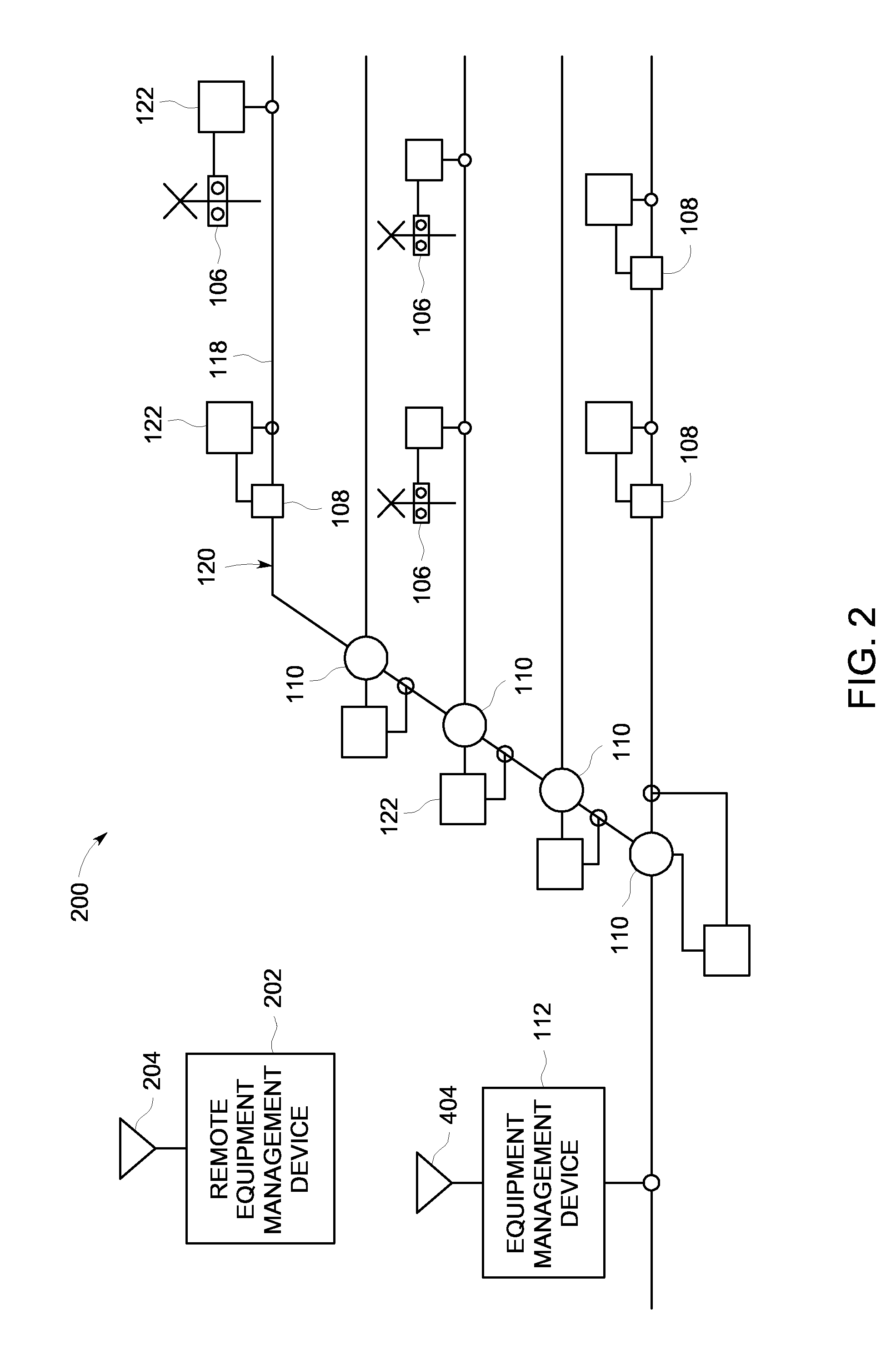

Communication system and method for a rail vehicle consist

ActiveUS8825239B2Digital data processing detailsSignalling indicators on vehicleCommunications systemElectrical conductor

A method for communicating data in a rail vehicle consist includes transmitting first data at a first rail vehicle of the consist over a power supply conductor to a second, different rail vehicle in the consist, where at least one rail vehicle of the consist receives direct electrical power from the power supply conductor. The method also includes monitoring the power supply conductor for second data at the first rail vehicle and receiving the second data over the power supply conductor at the first rail vehicle for use by a first system onboard the first rail vehicle. In one aspect, the transmitting step comprises transmitting the first data over one or more of a catenary line or a third rail that supplies the electrical power.

Owner:GE GLOBAL SOURCING LLC

Rail communication system and method for communicating with a rail vehicle

ActiveUS20120078452A1Digital data processing detailsRailway traffic control systemsCommunications systemOn board

A rail communication system includes: a communication management device capable of being communicatively coupled with a conductive pathway that extends along a track; and an on-board communication device capable of being coupled with a rail vehicle that travels along the track and with the conductive pathway, the communication management device and the on-board communication device configured to communicate a data signal between each other through the conductive pathway, where the data signal includes network data. A method for communicating with rail vehicles includes: coupling a vehicle management device with a conductive pathway that extends alongside a track; and coupling an on-board communication device disposed on a rail vehicle that travels along the track with the conductive pathway; where the communication management device and the on-board communication device communicate a data signal that includes network data through the conductive pathway.

Owner:GE GLOBAL SOURCING LLC

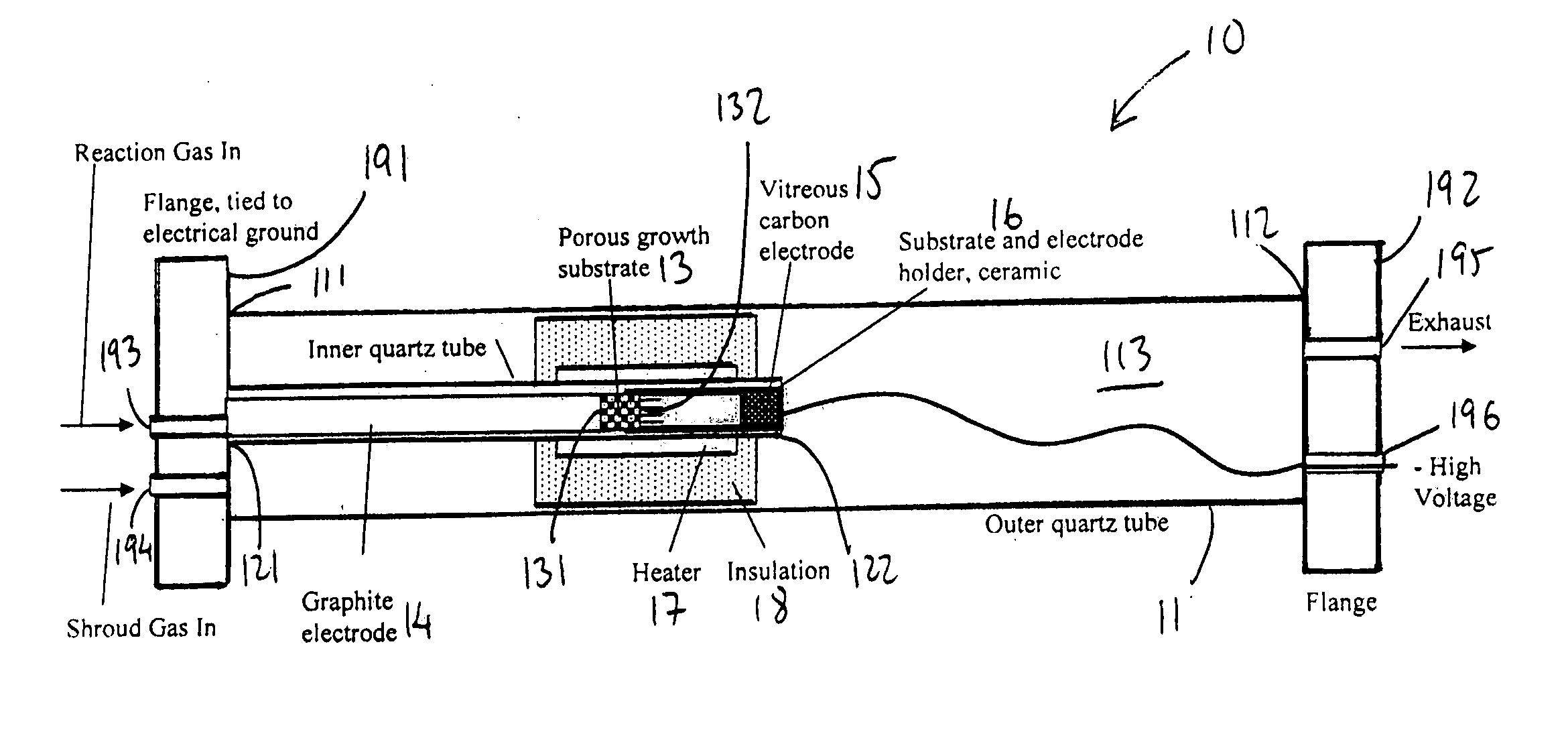

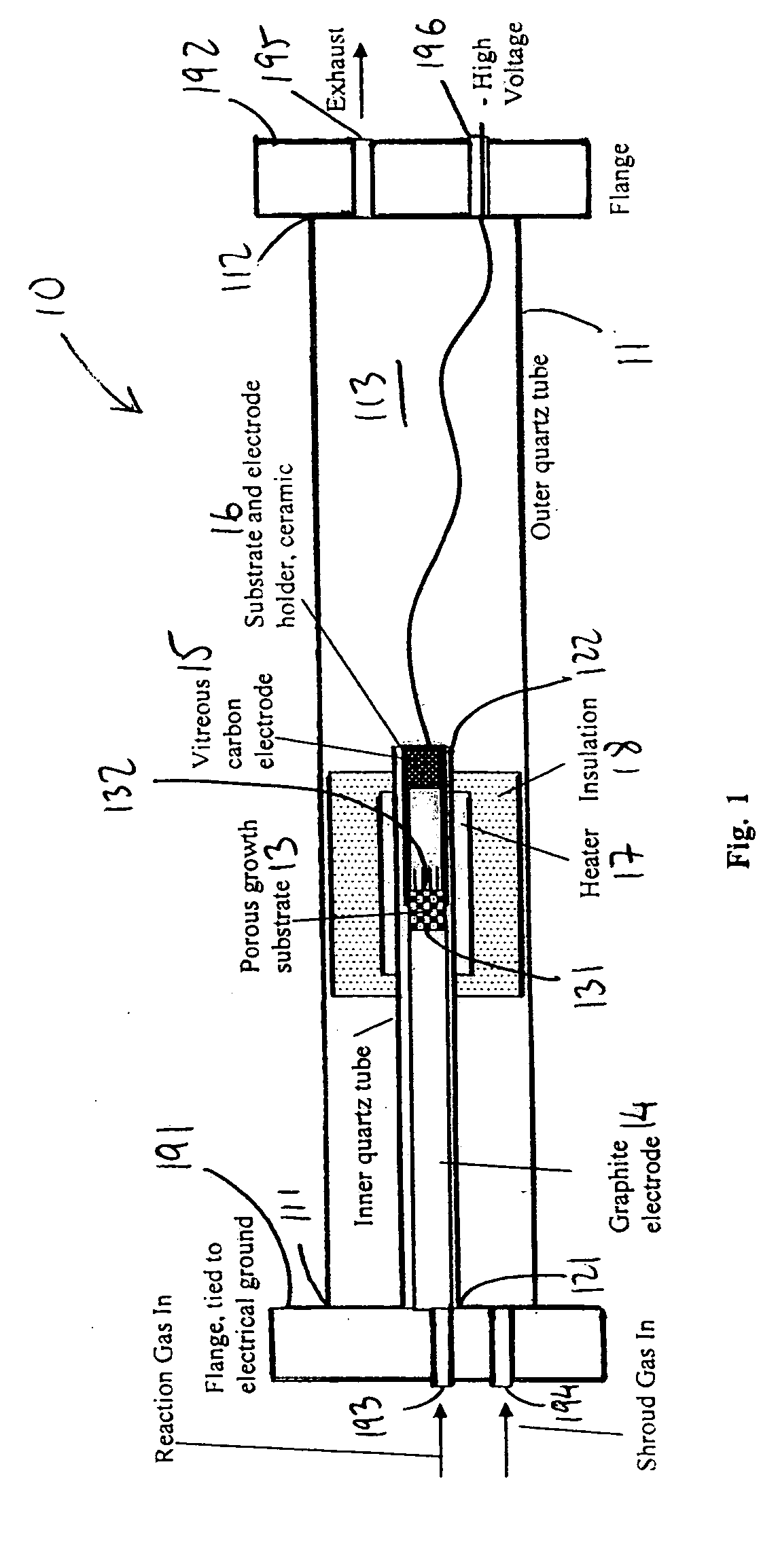

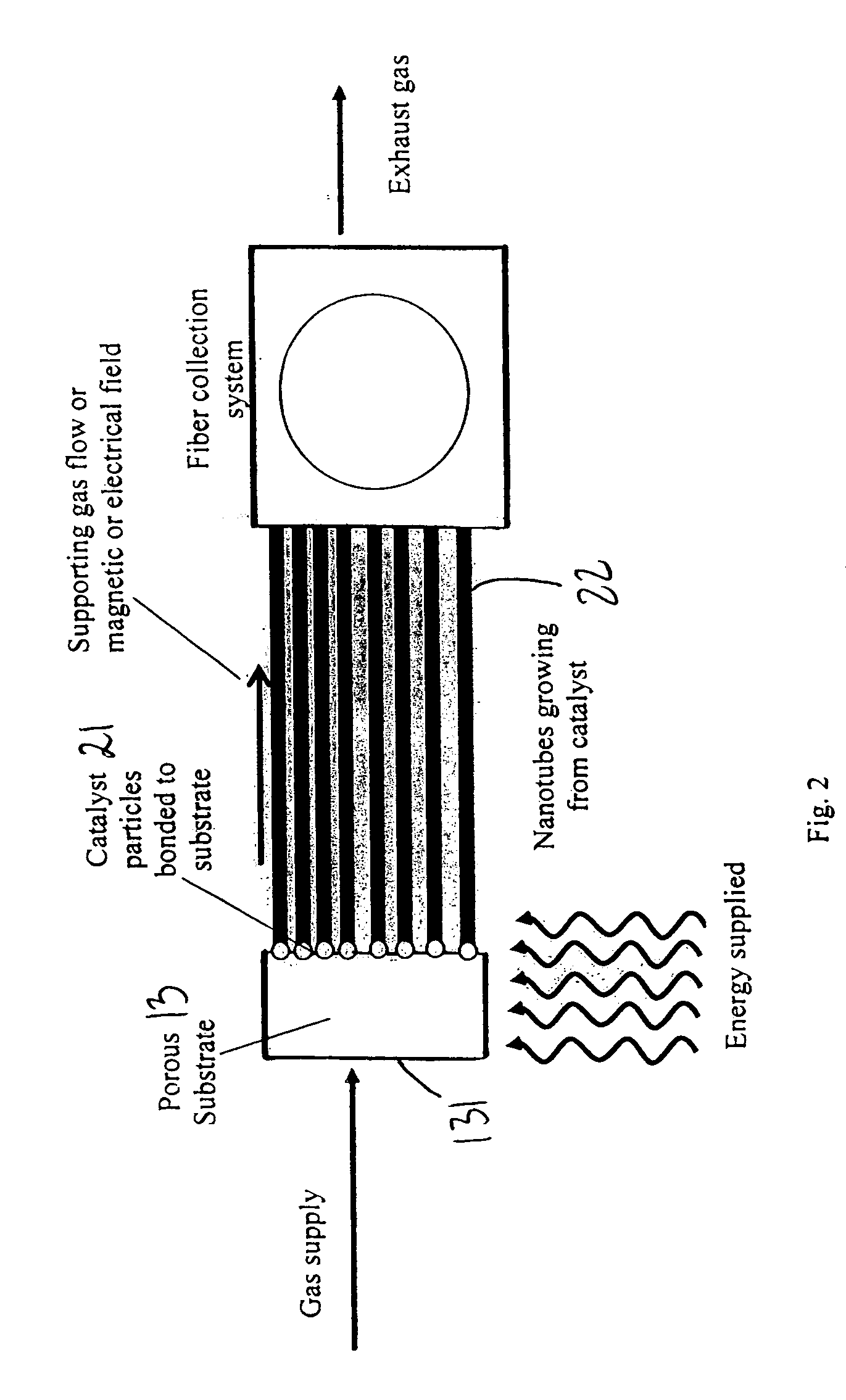

Systems and methods for synthesis of extended length nanostructures

ActiveUS20050170089A1Equally distributedMaterial nanotechnologyRadiation applicationsPorous substrateGas phase

A system for synthesizing nanostructures using chemical vapor deposition (CVD) is provided. The system includes a housing, a porous substrate within the housing, and on a downstream surface of the substrate, a plurality of catalyst particles from which nanostructures can be synthesized upon interaction with a reaction gas moving through the porous substrate. Electrodes may be provided to generate an electric field to support the nanostructures during growth. A method for synthesizing extended length nanostructures is also provided. The nanostructures are useful as heat conductors, heat sinks, windings for electric motors, solenoid, transformers, for making fabric, protective armor, as well as other applications.

Owner:NANCOMP TECHNOLOGIES INC

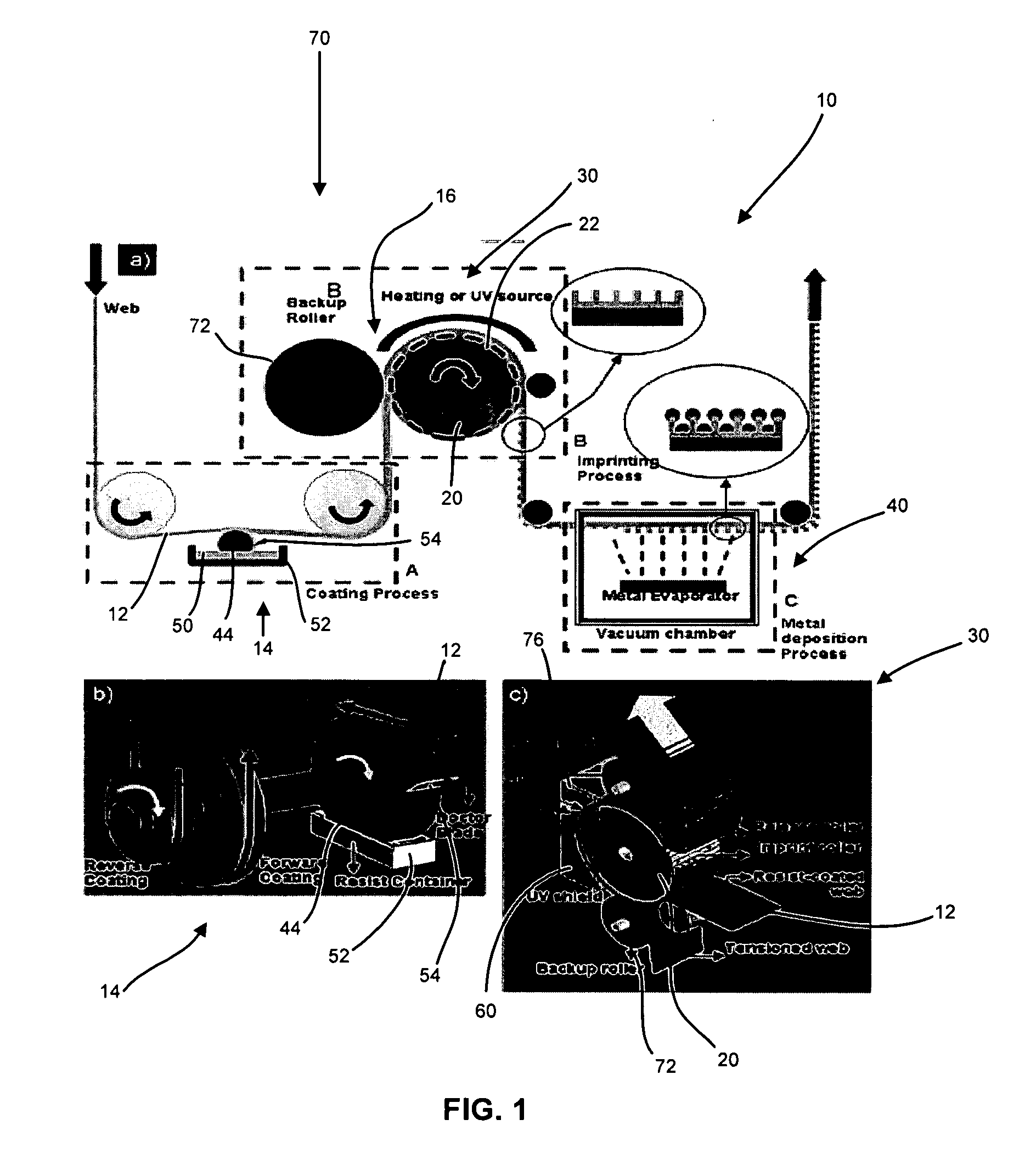

Roll to roll nanoimprint lithography

Apparatus and methods for a nano-patterning process to fabricate nanostructures. A roller type mold is used to continuously imprint nanostructures onto a flexible web or a rigid substrate. The process includes a coating and an imprinting module, which rotate the web synchronously. Liquid resist materials are used for imprinting and the patterns are set by thermal or UV curing. The process is used to produce bilayer metal wire-grid polarizers, organic solar cells, and organic light emitting diodes.

Owner:RGT UNIV OF MICHIGAN

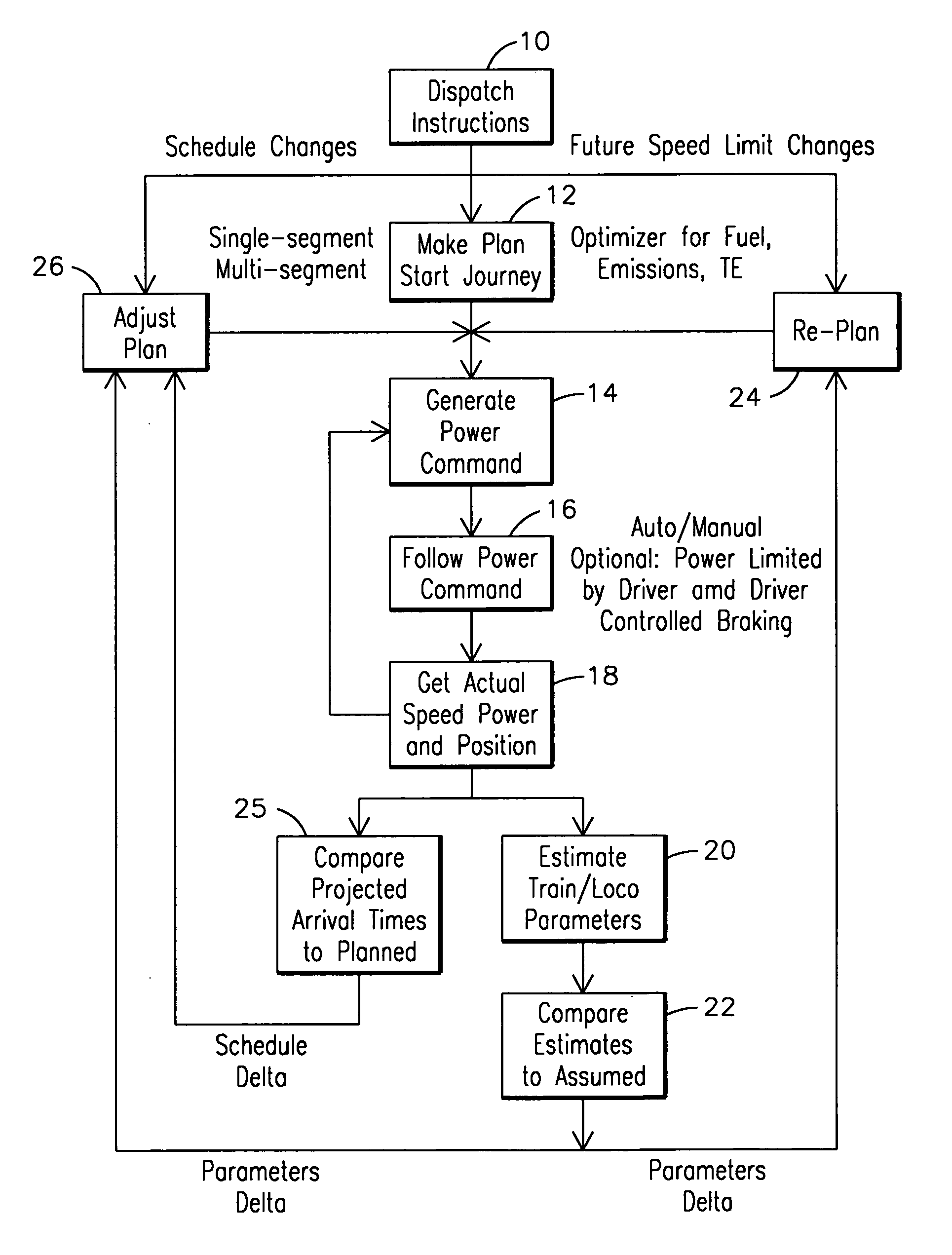

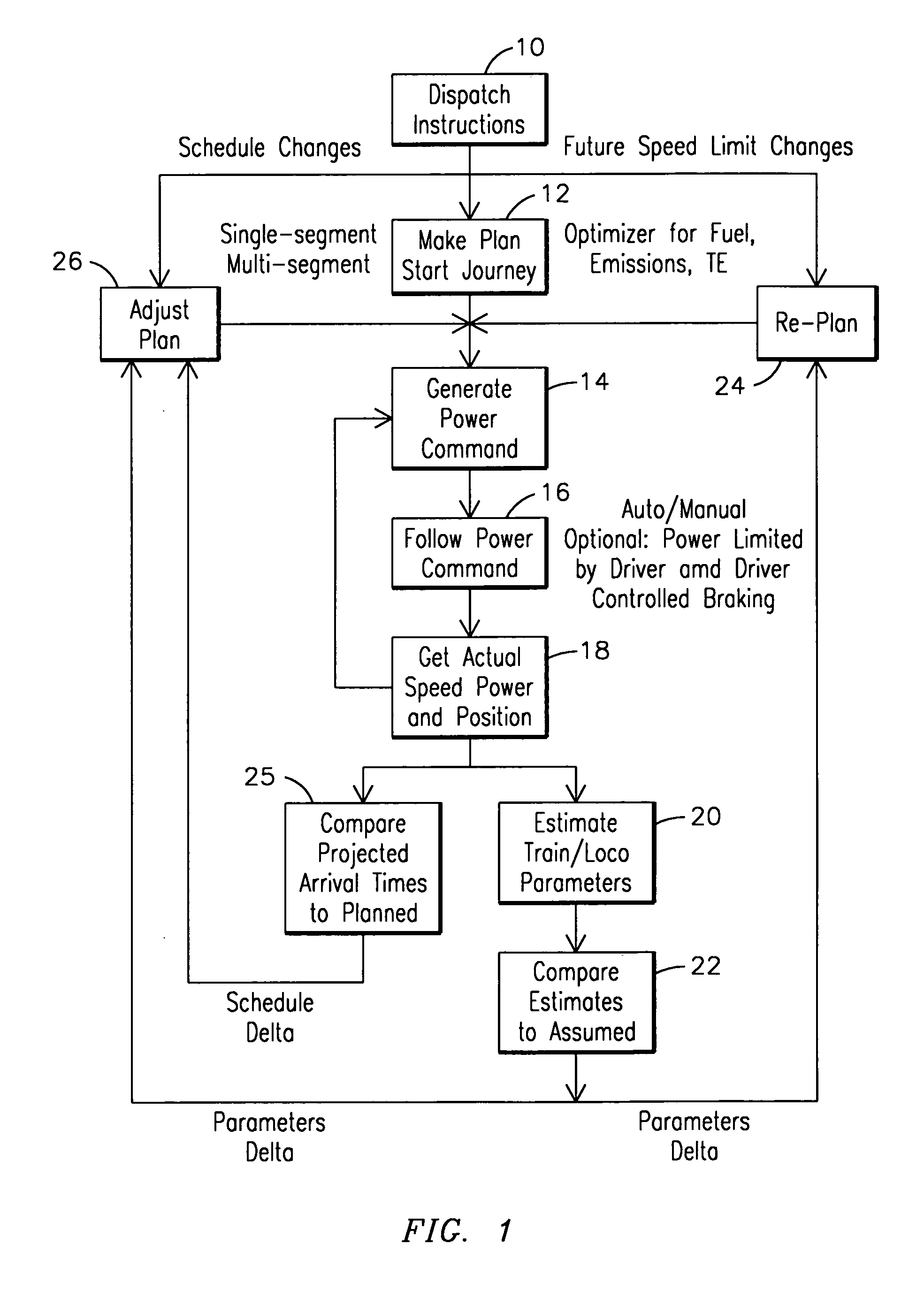

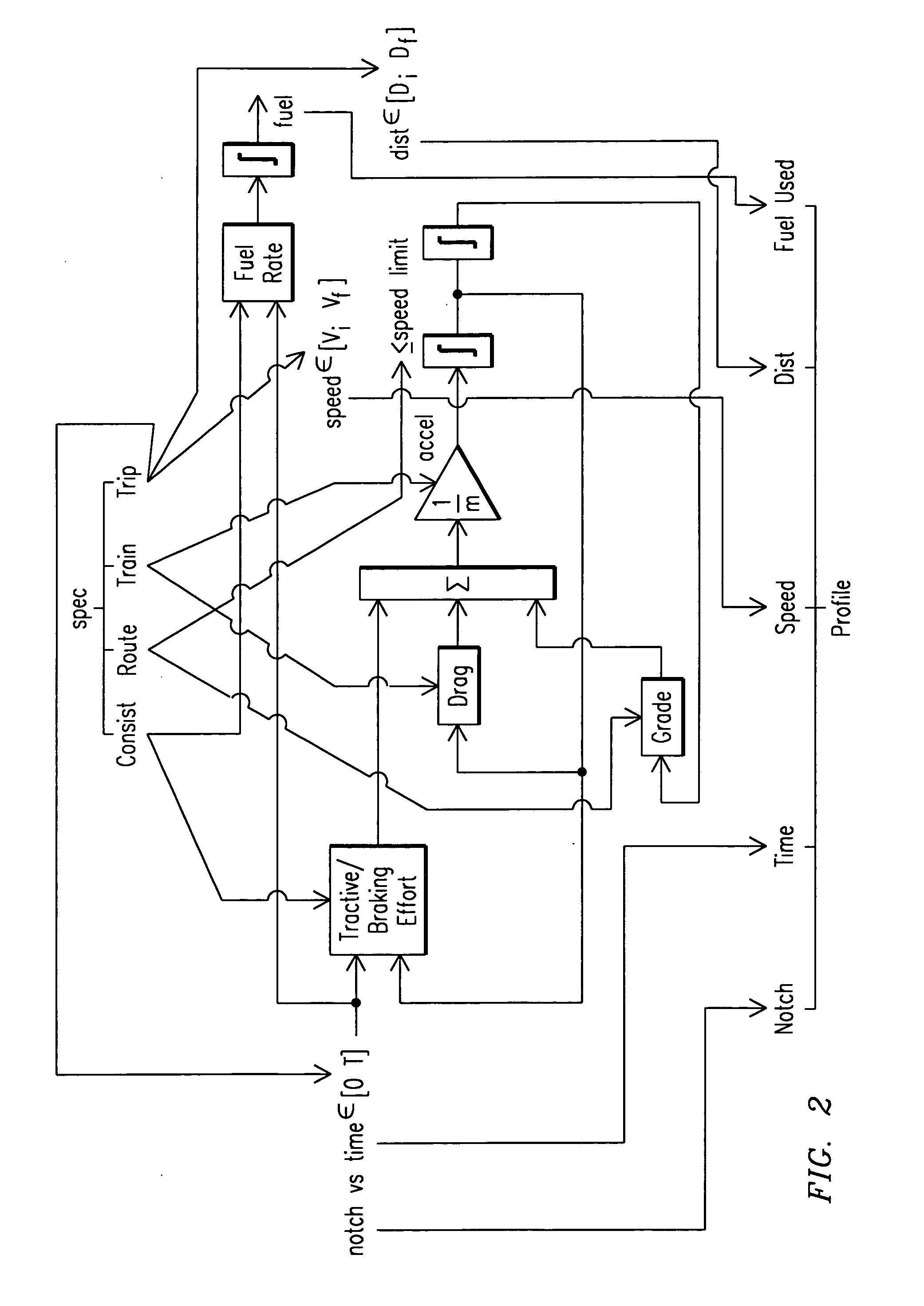

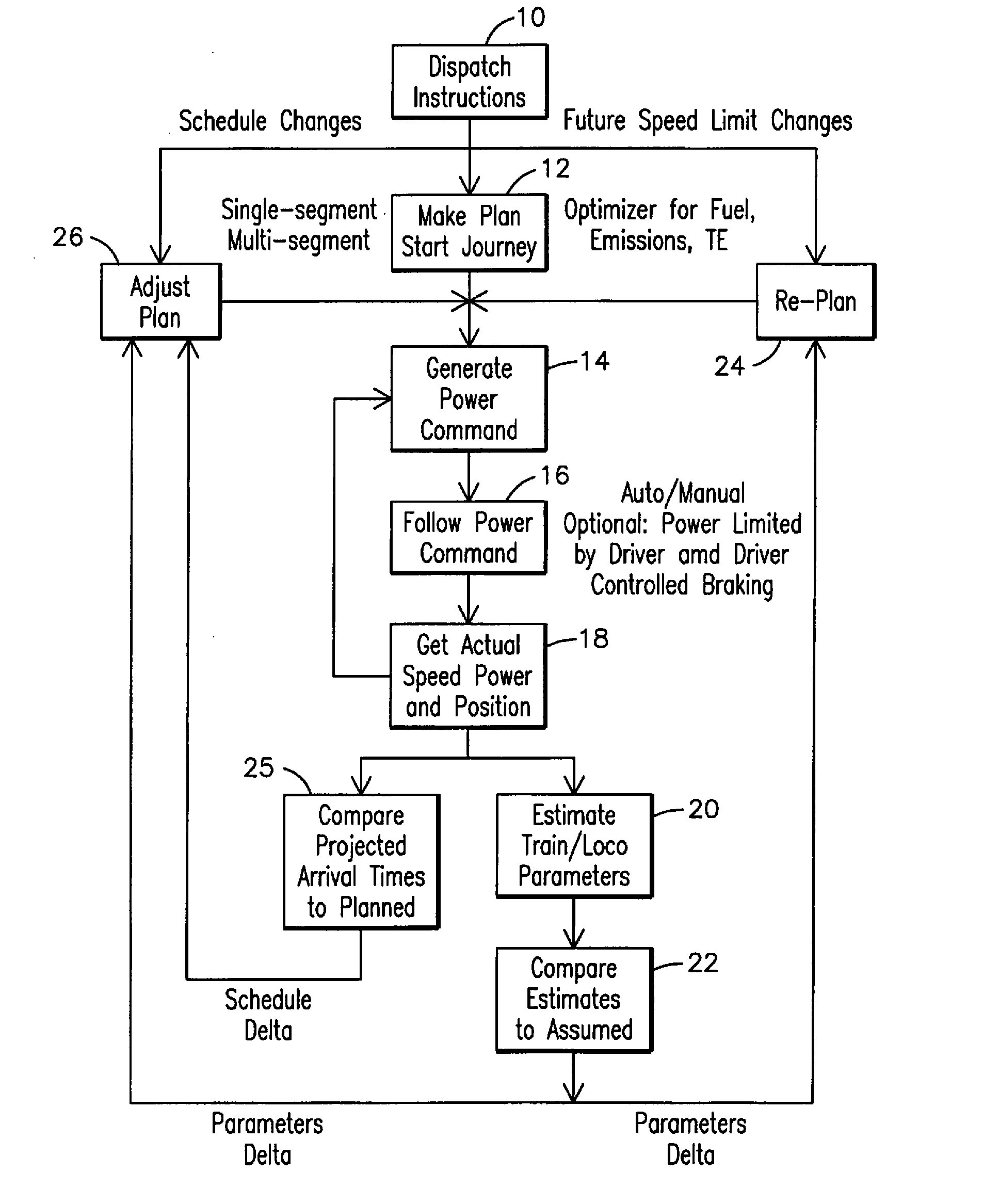

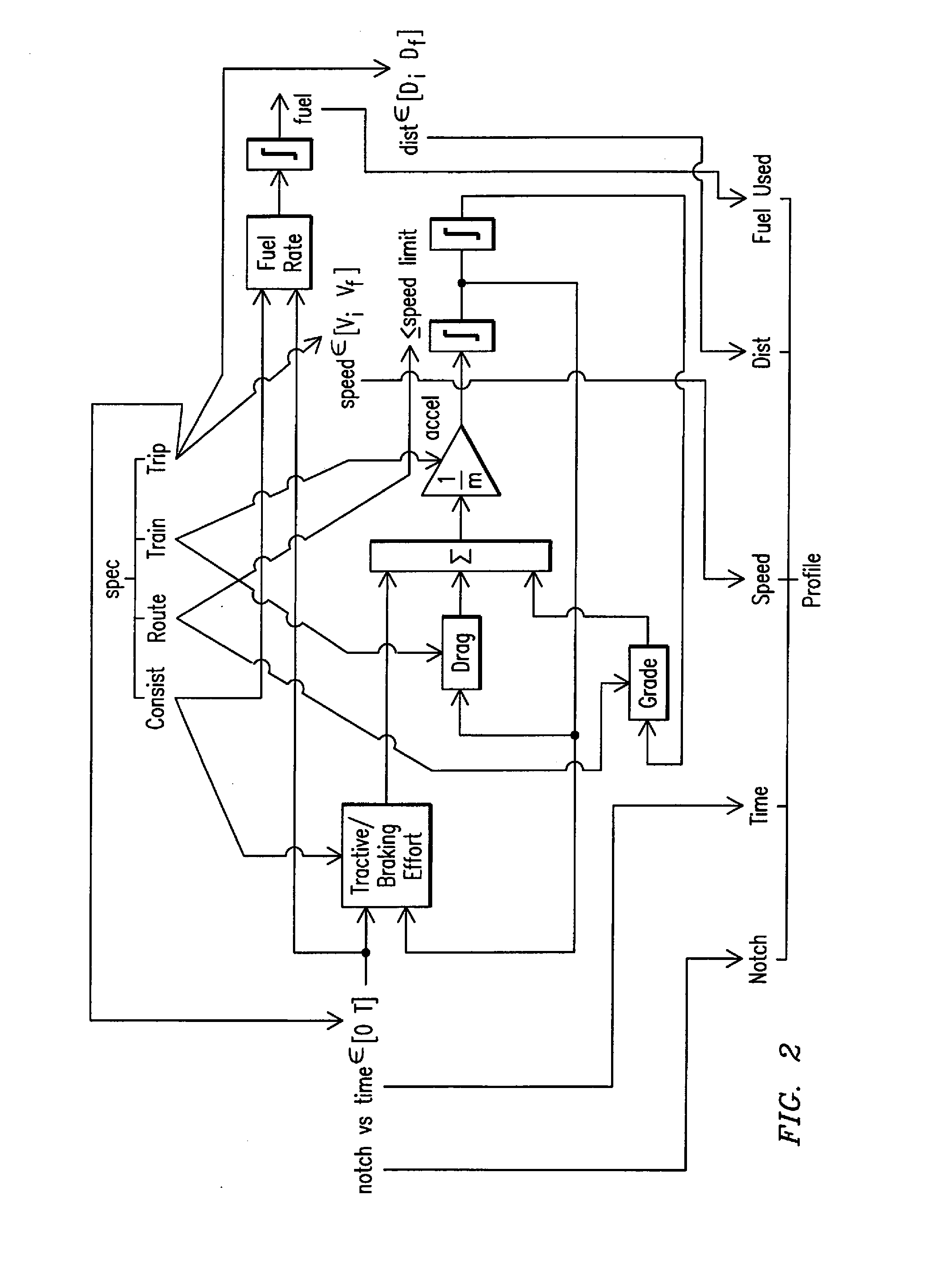

Trip optimization system and method for a train

ActiveUS20070219680A1Minimize consumptionDigital data processing detailsTraffic regulationEngineeringOptimization system

A system for operating a train having one or more locomotive consists with each locomotive consist comprising one or more locomotives, the system including a locator element to determine a location of the train, a track characterization element to provide information about a track, a sensor for measuring an operating condition of the locomotive consist, a processor operable to receive information from the locator element, the track characterizing element, and the sensor, and an algorithm embodied within the processor having access to the information to create a trip plan that optimizes performance of the locomotive consist in accordance with one or more operational criteria for the train.

Owner:GE GLOBAL SOURCING LLC

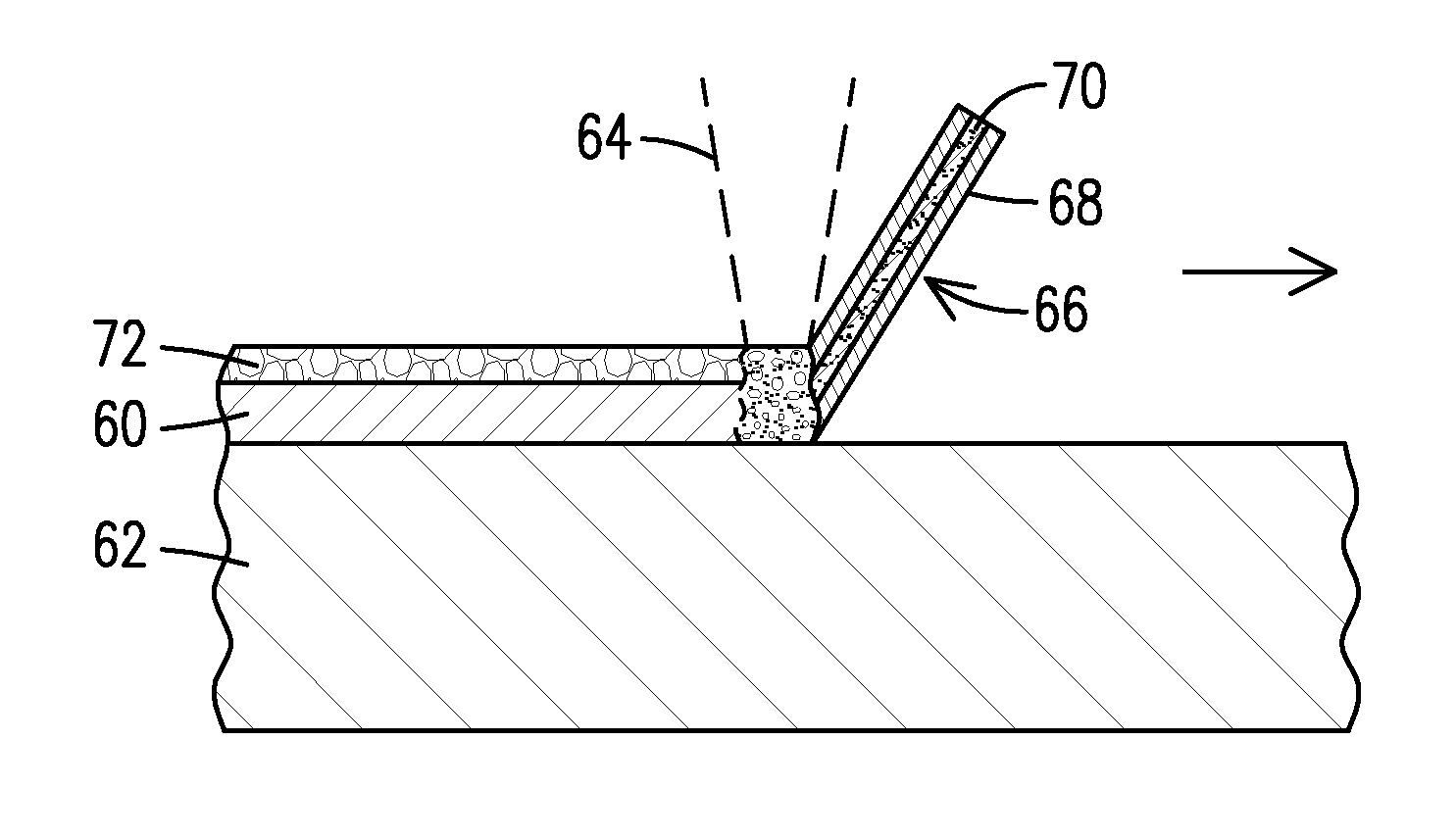

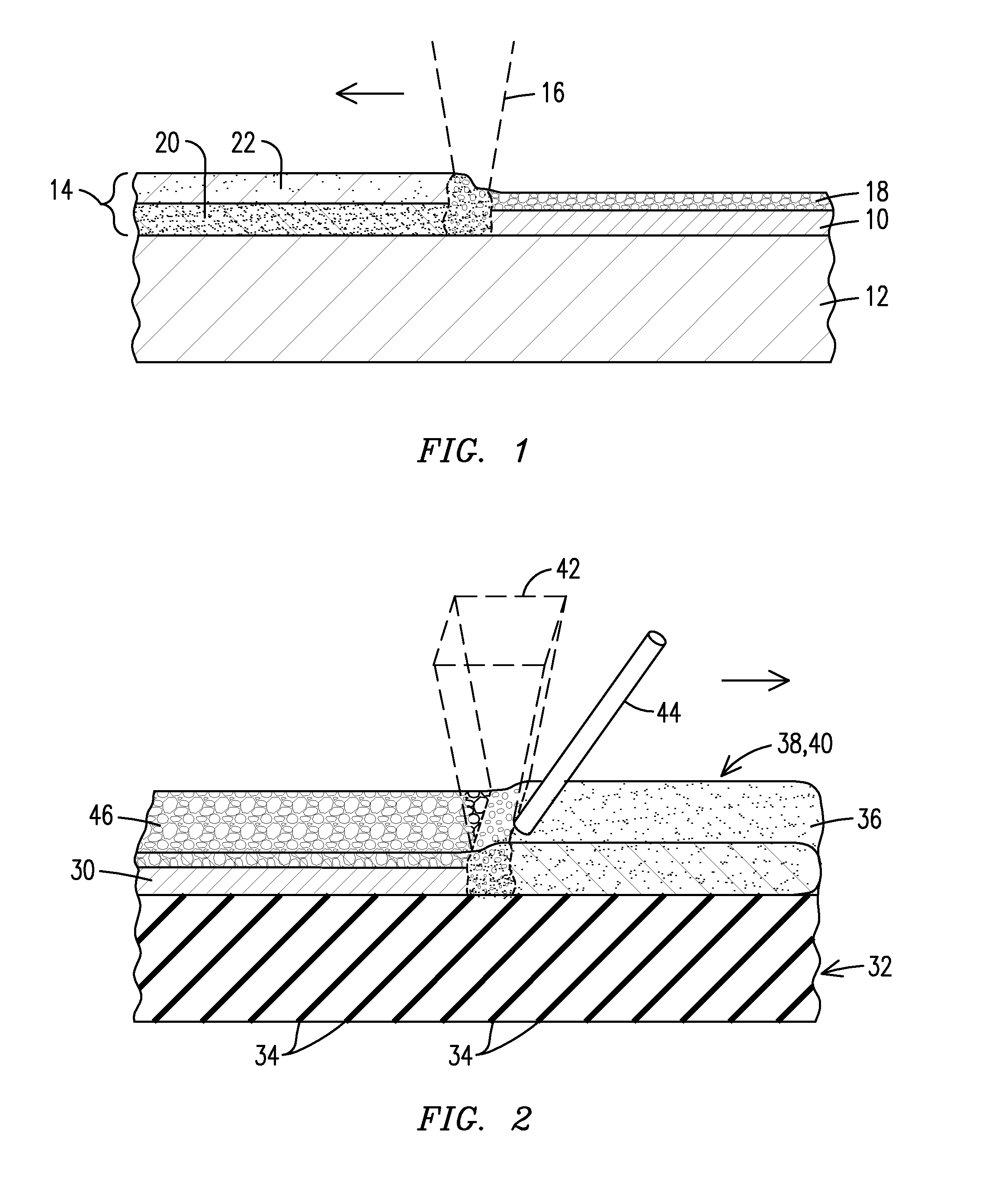

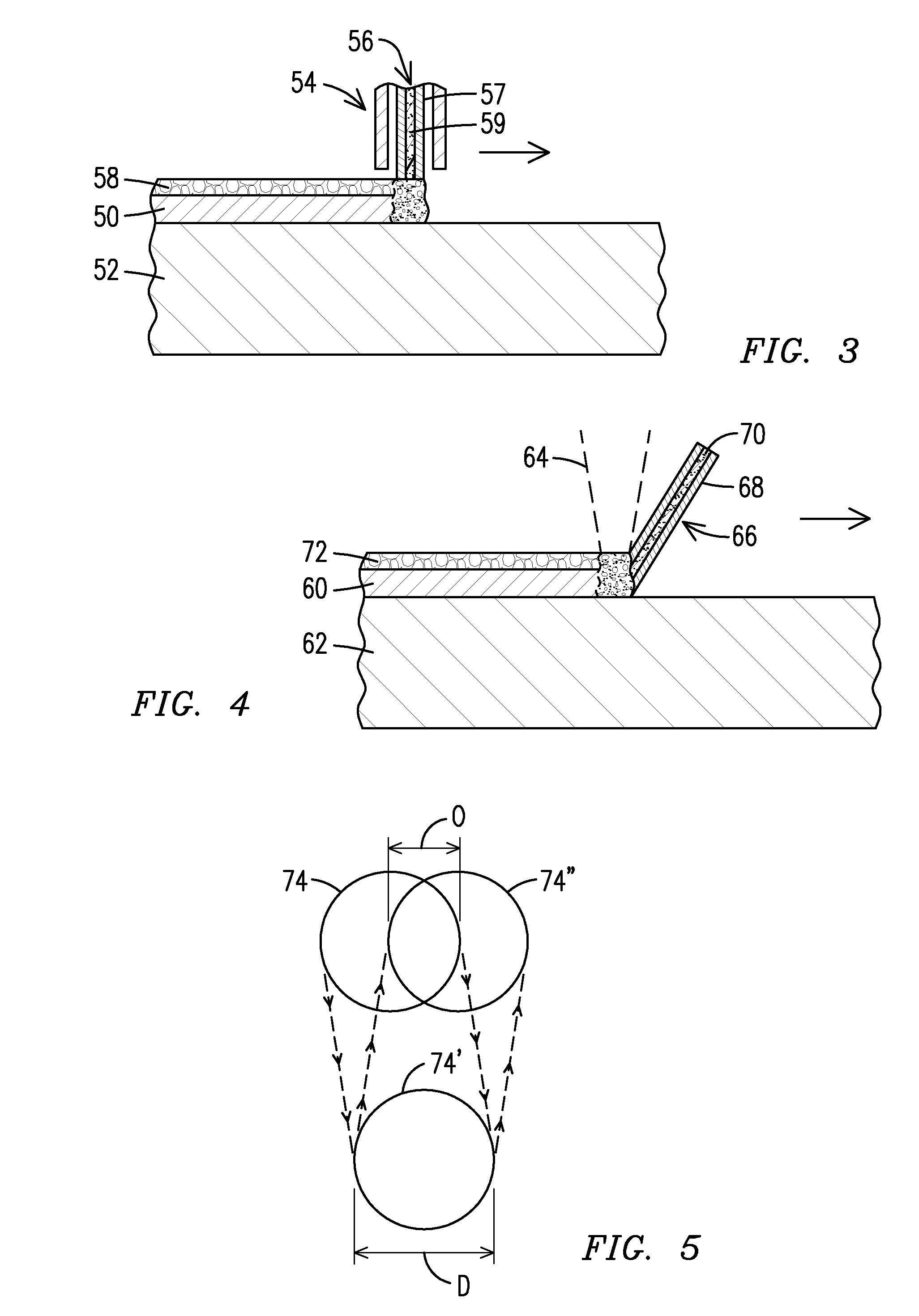

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

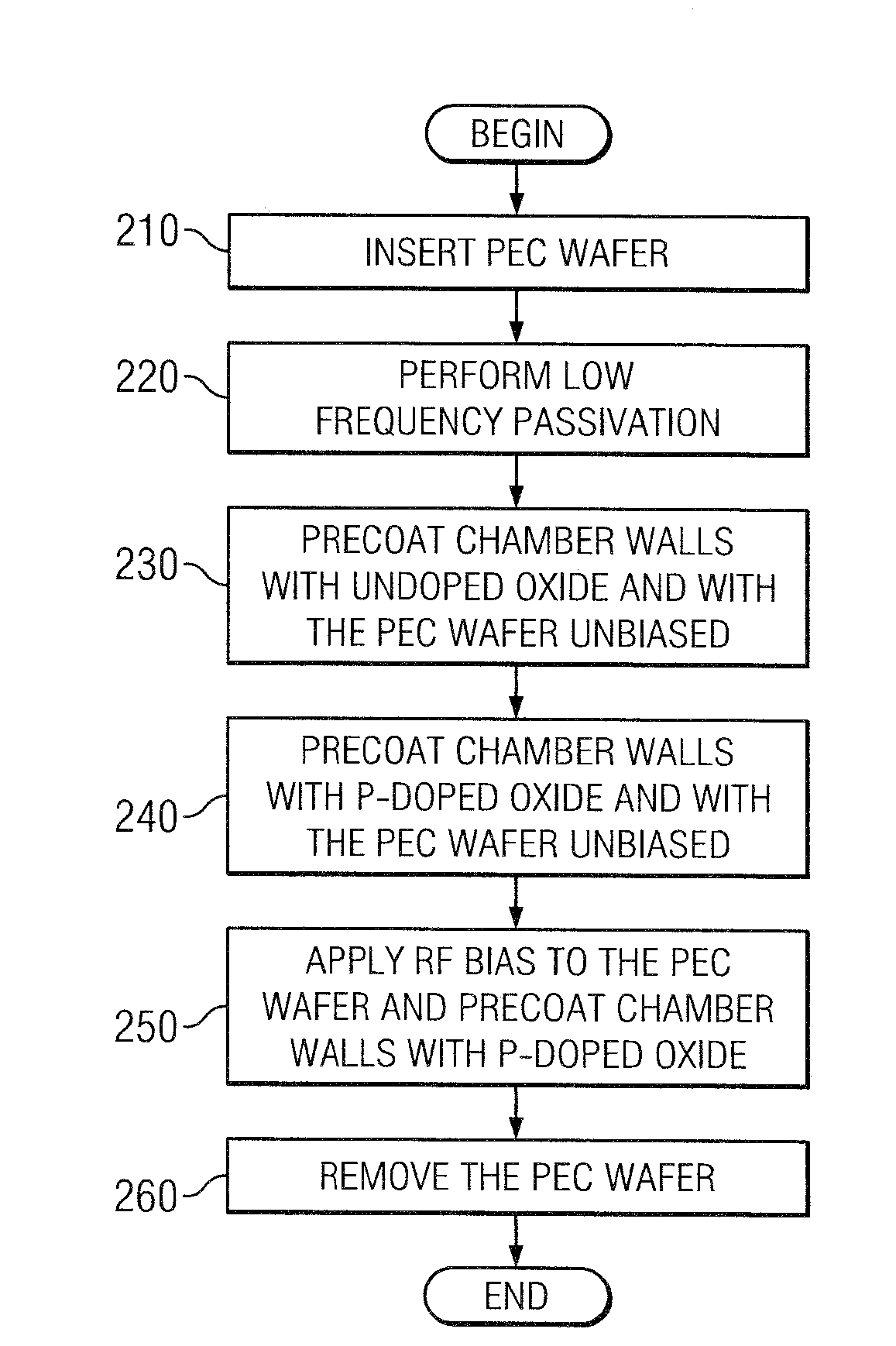

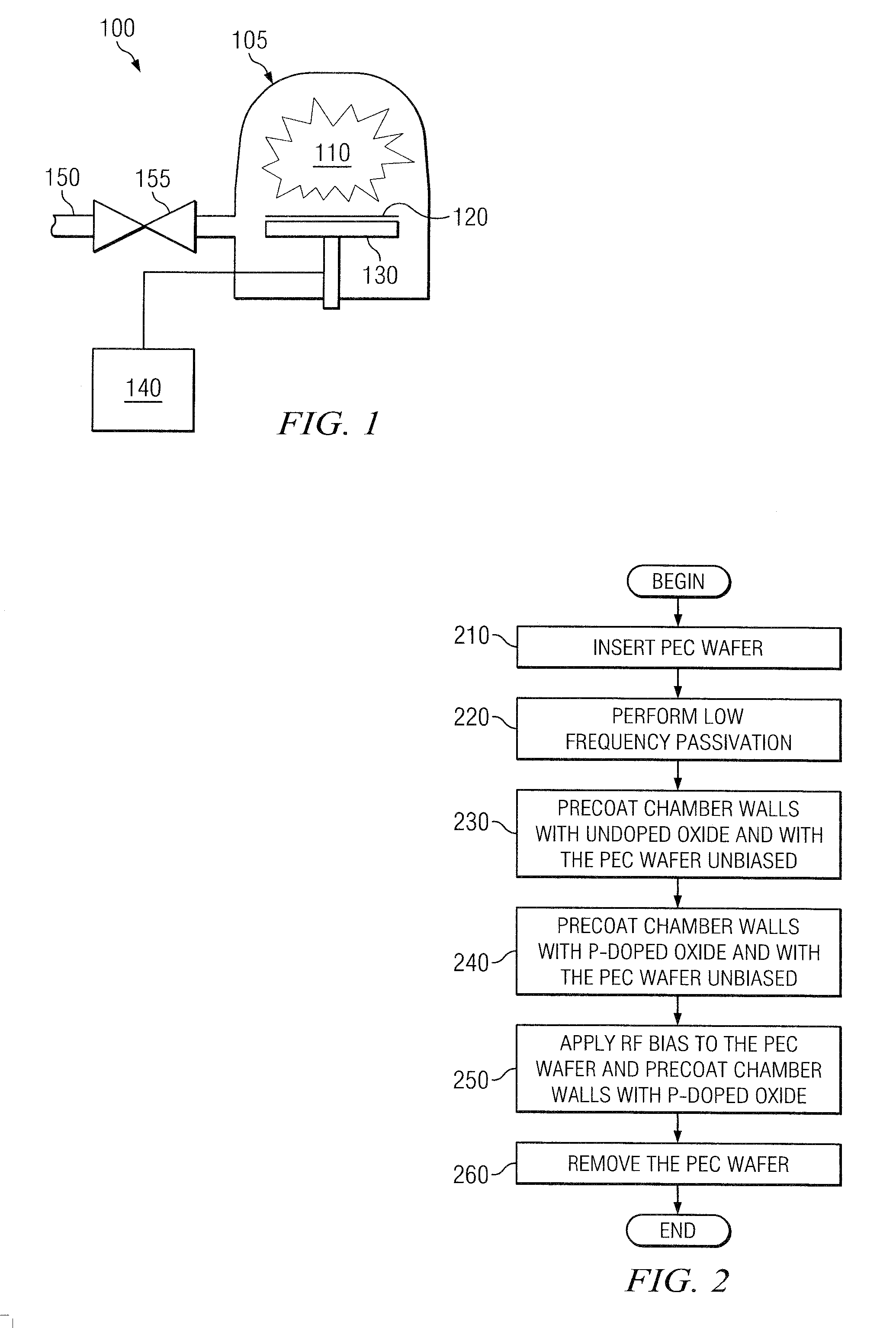

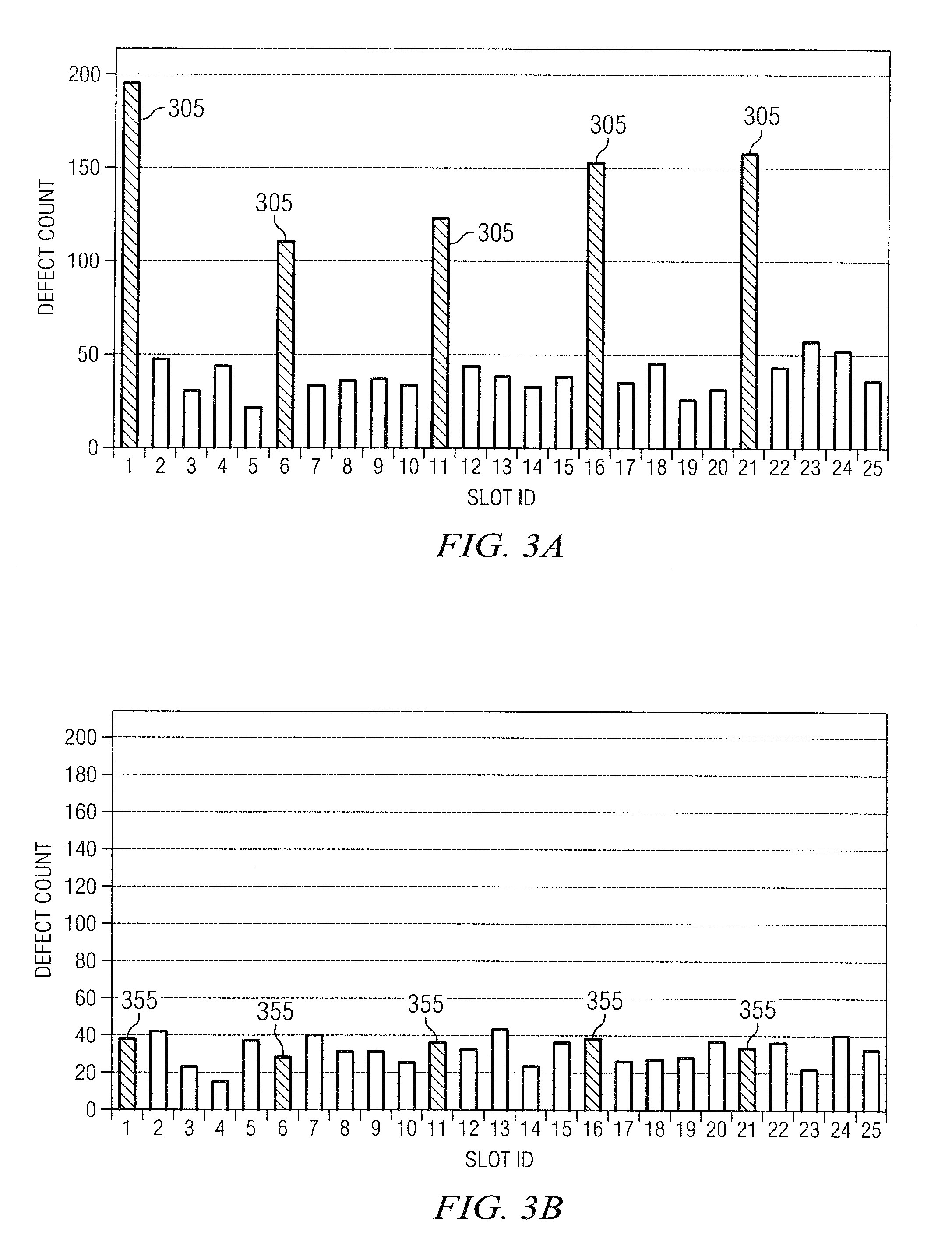

Use of a biased precoat for reduced first wafer defects in high-density plasma process

ActiveUS20100190352A1Minimizing yield lossReducing first wafer defectRadiation applicationsPretreated surfacesHigh densityGas phase

According to various embodiments, the present teachings include methods for reducing first wafer defects in a high-density plasma chemical vapor deposition process. In an exemplary embodiment, the method can include running a deposition chamber for deposition of film on a first batch of silicon wafers and then cleaning interior surfaces of the deposition chamber. The method can further include inserting a protective electrostatic chuck cover (PEC) wafer on an electrostatic chuck in the deposition chamber and applying power to bias the PEC wafer while simultaneously precoating the deposition chamber with an oxide. The exemplary method can also include re-starting the deposition chamber for deposition of film on a second batch of silicon wafers.

Owner:TEXAS INSTR INC

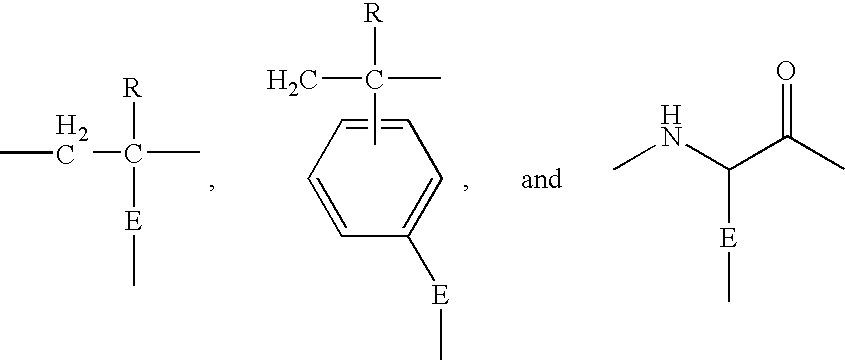

Raman-active taggants and their recognition

InactiveUS6610351B2Easy to useQuality improvementMaterial nanotechnologyRadiation applicationsMaximum dimensionActive component

An organic or organoelement, linear or branched, monomeric or polymeric composition of matter having a Raman-active component in the form of particles. The particles having a maximum dimension of 50 mum. The Raman-active compound is applied to a substrate. When the Raman-active compound is exposed to a laser light wavelength which is batochromically well beyond a spectral region of maximum absorbance of said Raman-active compound, Raman scattering can be detected.

Owner:QUANTAG SYST

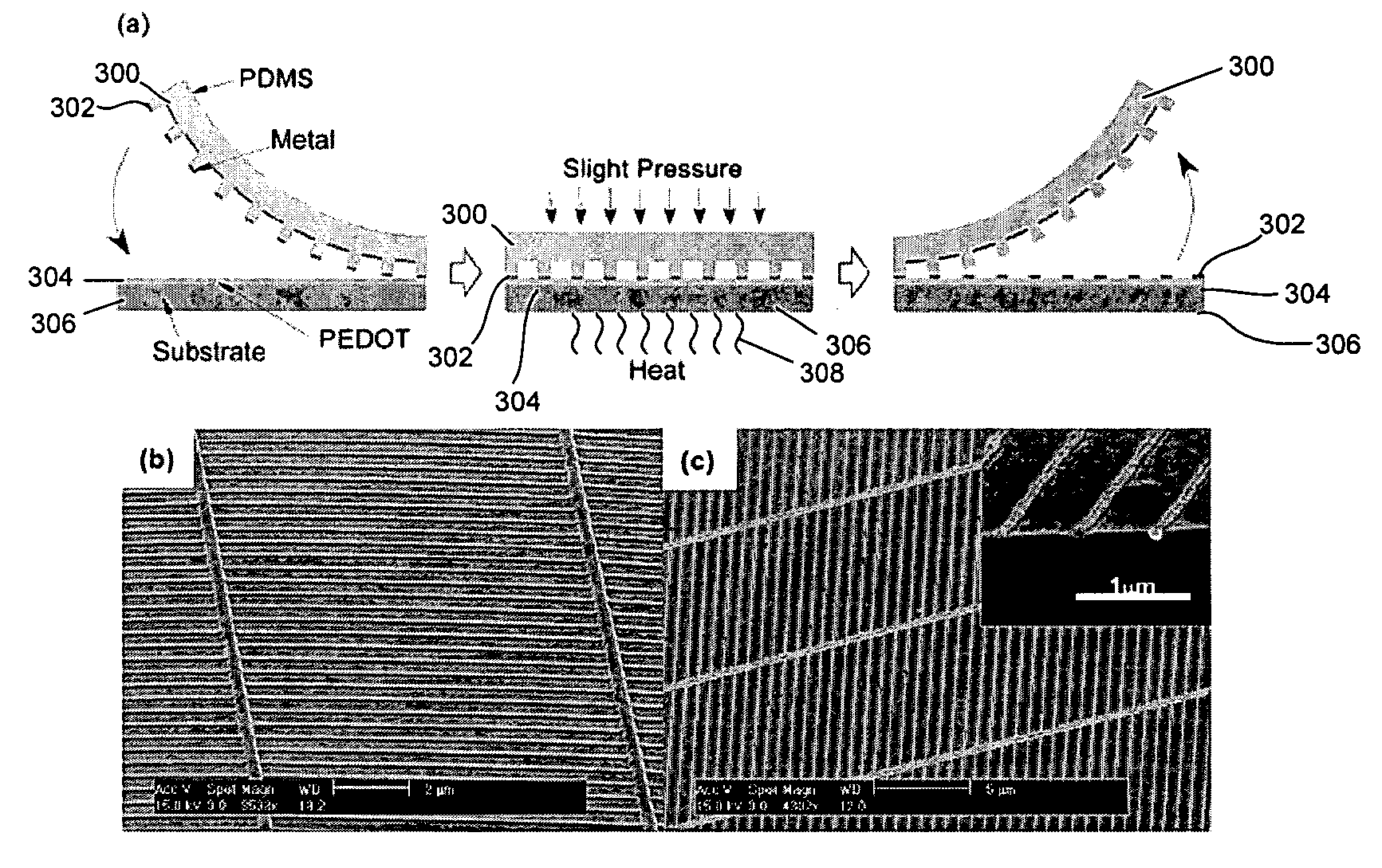

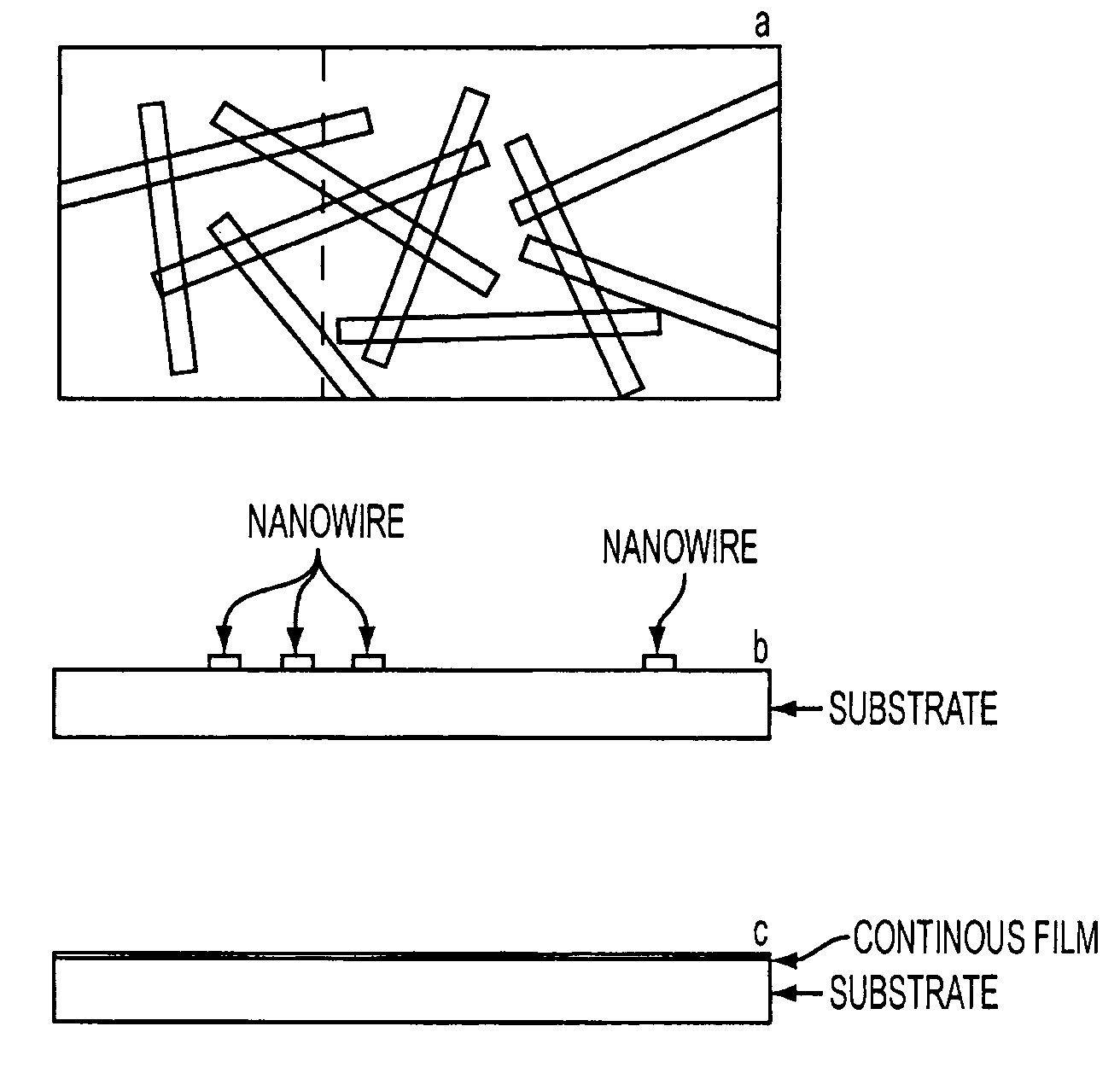

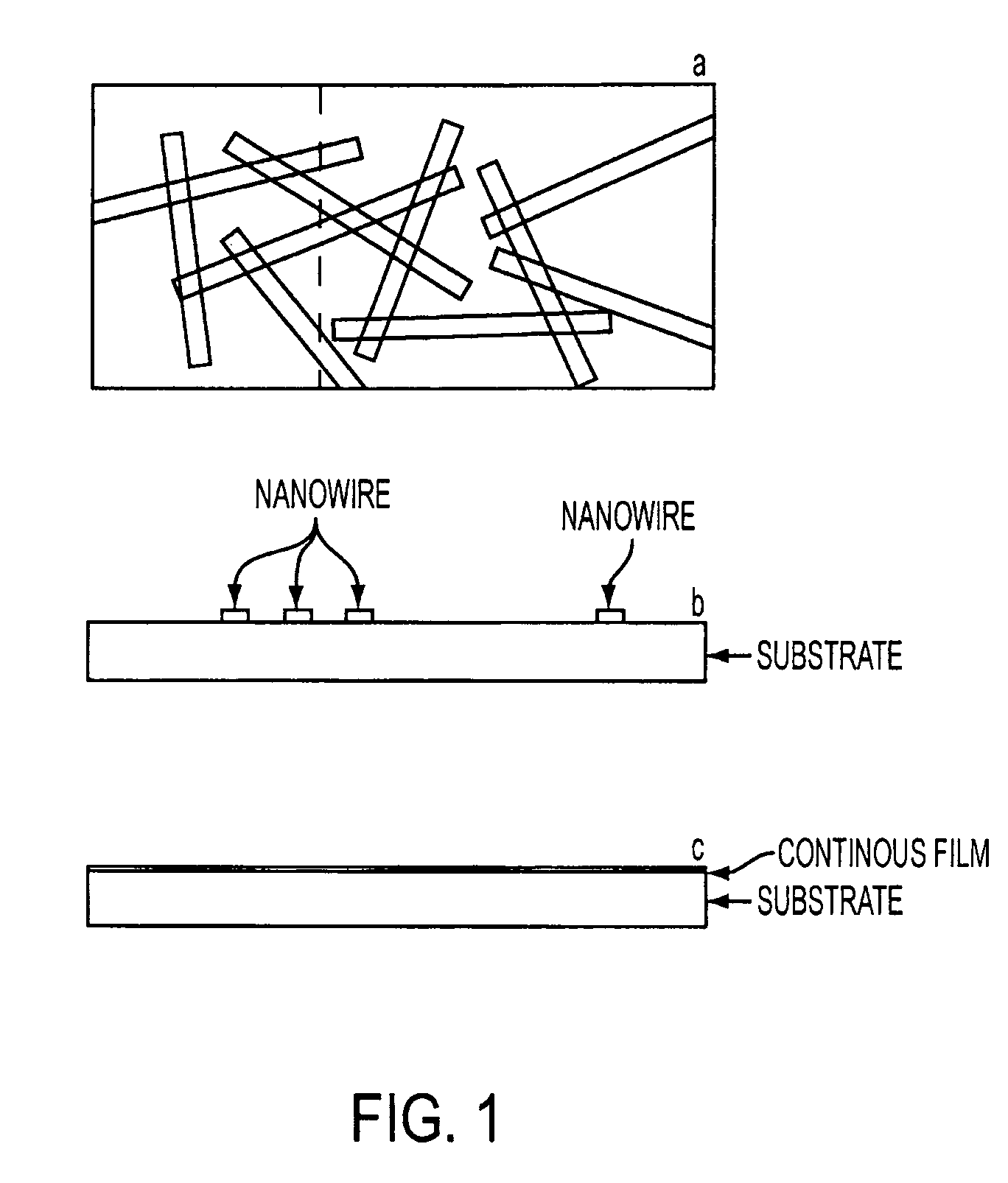

Electrically conducting and optically transparent nanowire networks

A network of nanowires has a plurality of interconnected nanowires. Each interconnected nanowire includes a metal in its composition. The network of nanowires is electrically conducting and substantially transparent to visible light. An electronic or electro-optic device has a network of nanowires. The network of nanowires has a plurality of interconnected nanowires, each interconnected nanowire including a metal in its composition. The network of nanowires is electrically conducting and substantially transparent to visible light. A metal-oxide nanowire has a metal oxide doped with a second metal in a composition thereof. The metal-oxide nanowire is electrically conducting and substantially transparent to visible light.

Owner:RGT UNIV OF CALIFORNIA

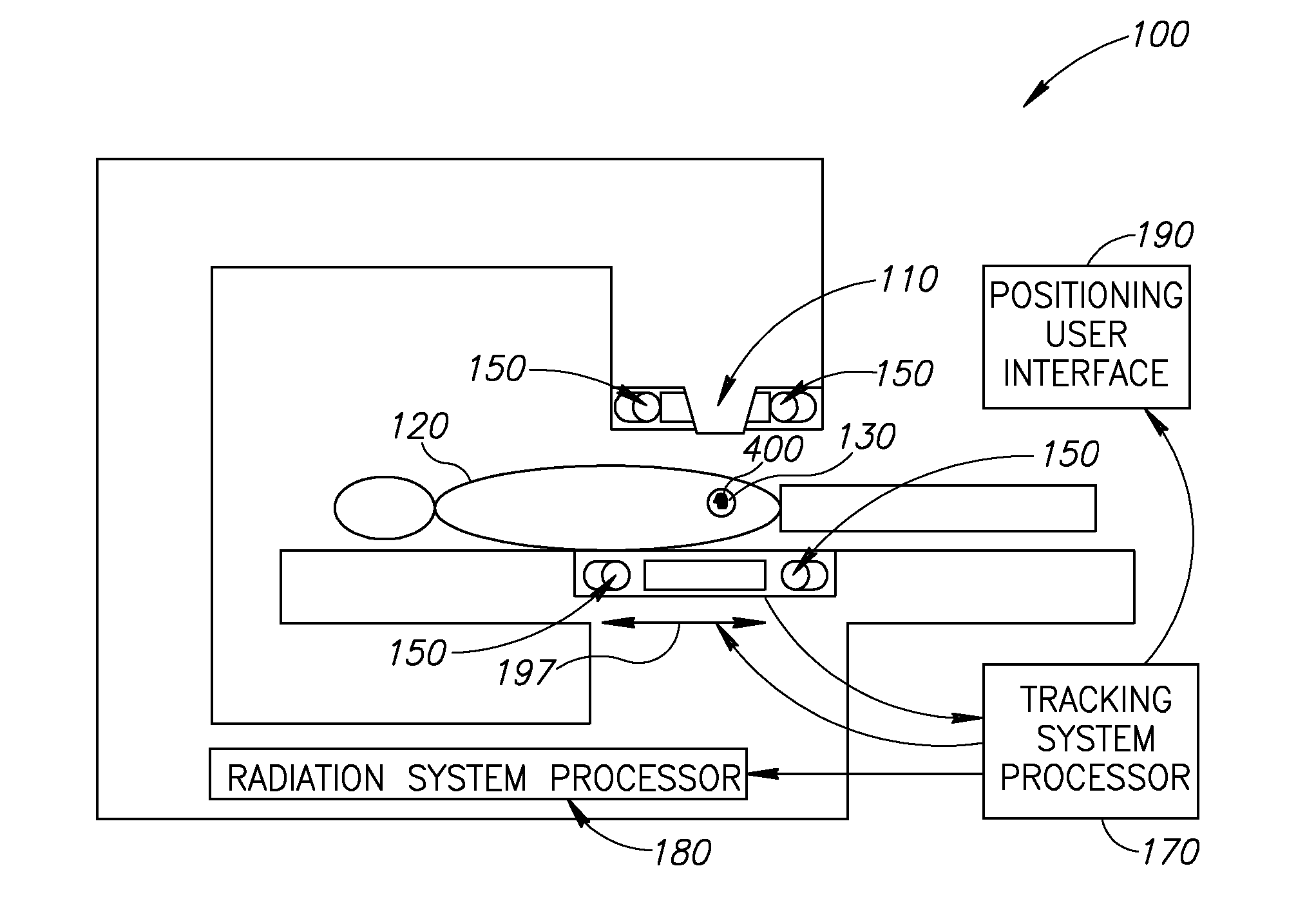

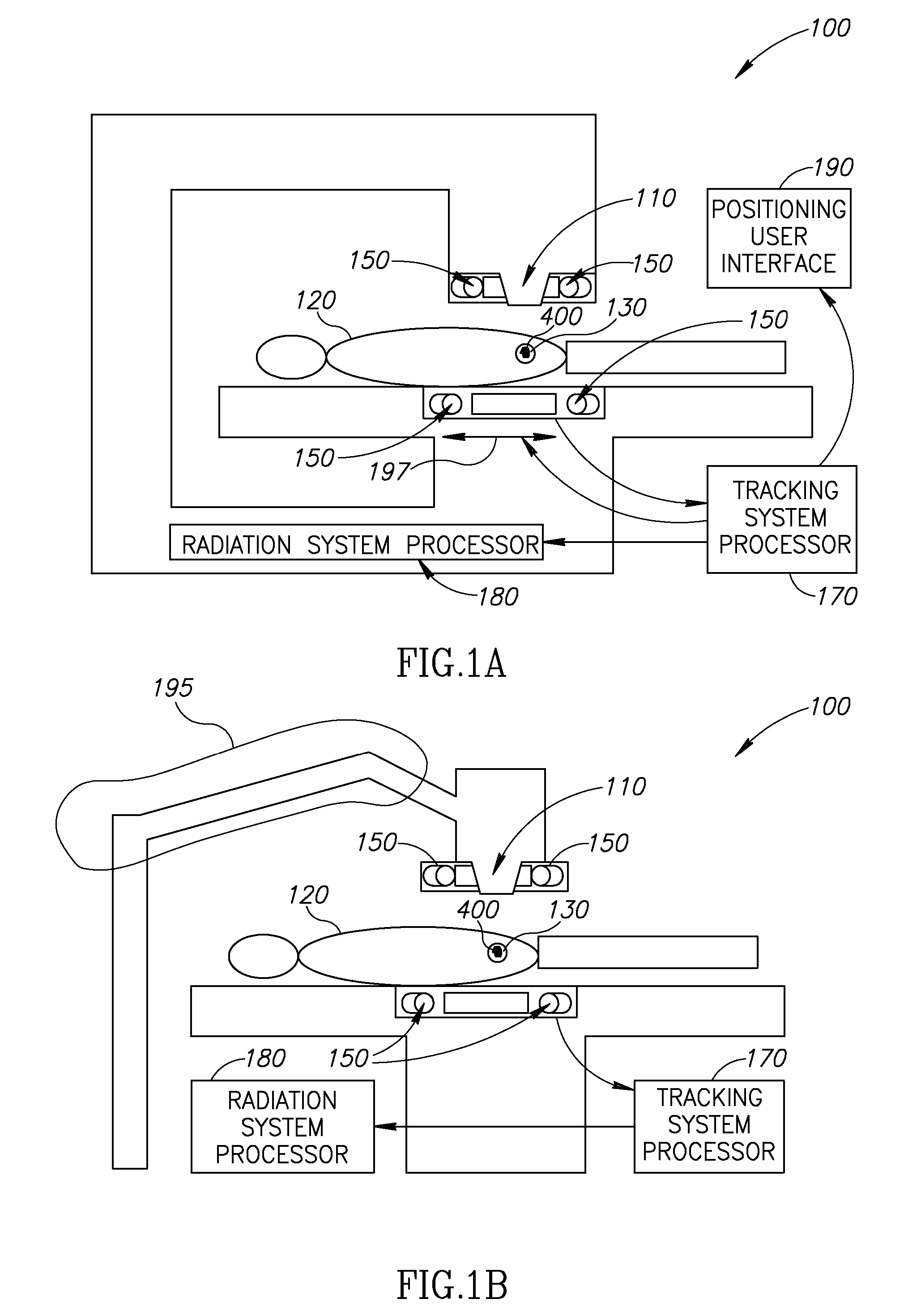

Medical Treatment System and Method

InactiveUS20070055144A1Inhibit migrationRadiation applicationsPretreated surfacesTarget tissuePosition sensor

A method of guiding a tool, the method comprising: (a) implanting a source of radioactivity at a position having a geometric relationship to a target tissue; (b) determining at least an indication of a location of said source using at least one radioactivity detecting position sensor; and (c) positioning a tool at a desired relative location with respect to said target tissue based on said determined location.

Owner:NAVOTEK MEDICAL

Method and apparatus for optimizing a train trip using signal information

One embodiment of the invention includes a system for operating a railway network comprising a first railway vehicle (400) during a trip along track segments (401 / 412 / 420). The system comprises a first element (65) for determining travel parameters of the first railway vehicle (400), a second element (65) for determining travel parameters of a second railway vehicle (418) relative to the track segments to be traversed by the first vehicle during the trip, a processor (62) for receiving information from the first (65) and the second (65) elements and for determining a relationship between occupation of a track segment (401 / 412 / 420) by the second vehicle (418) and later occupation of the same track segment by the first vehicle (400) and an algorithm embodied within the processor (62) having access to the information to create a trip plan that determines a speed trajectory for the first vehicle (400), wherein the speed trajectory is responsive to the relationship and further in accordance with one or more operational criteria for the first vehicle (400).

Owner:GE GLOBAL SOURCING LLC

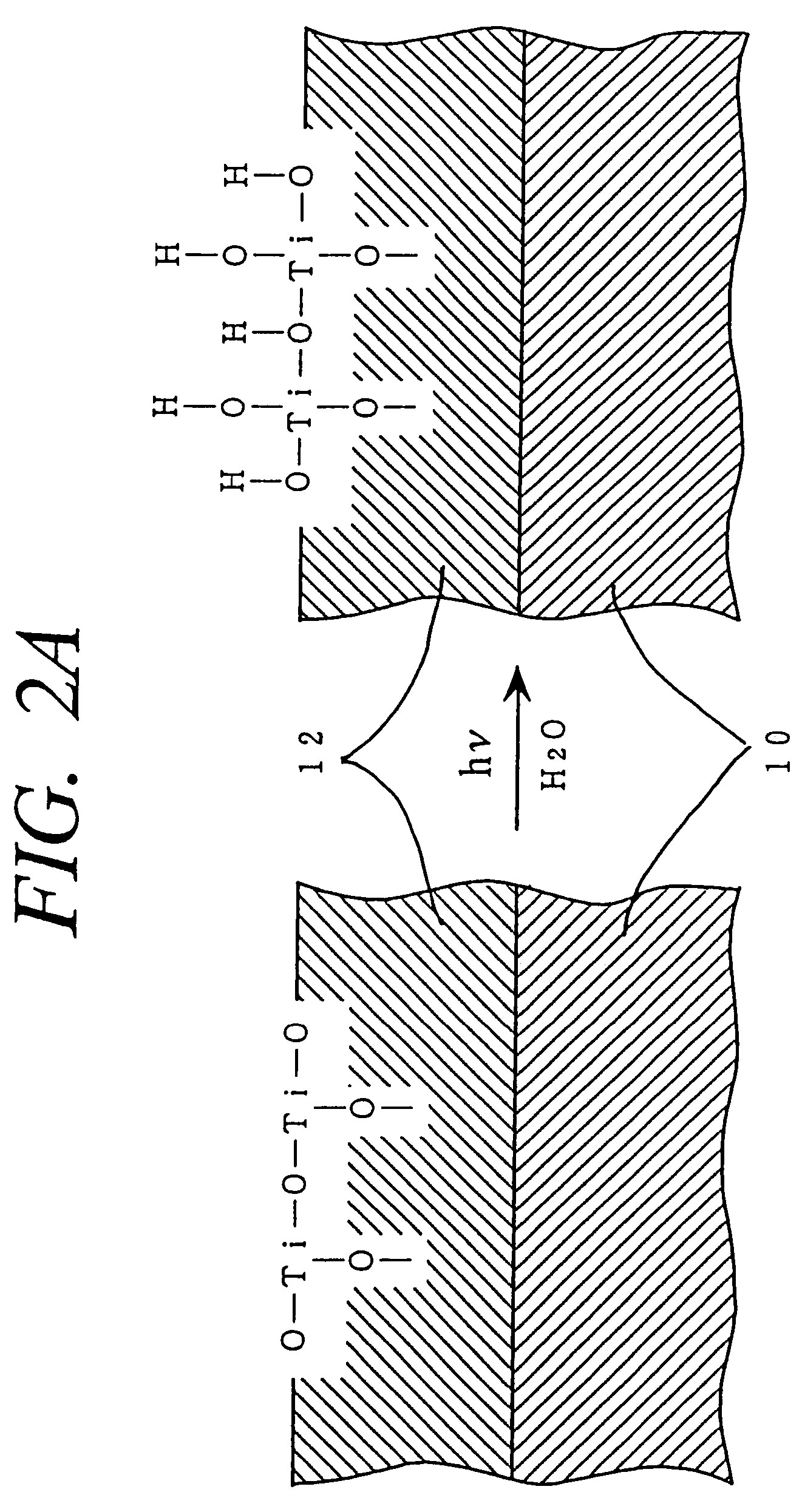

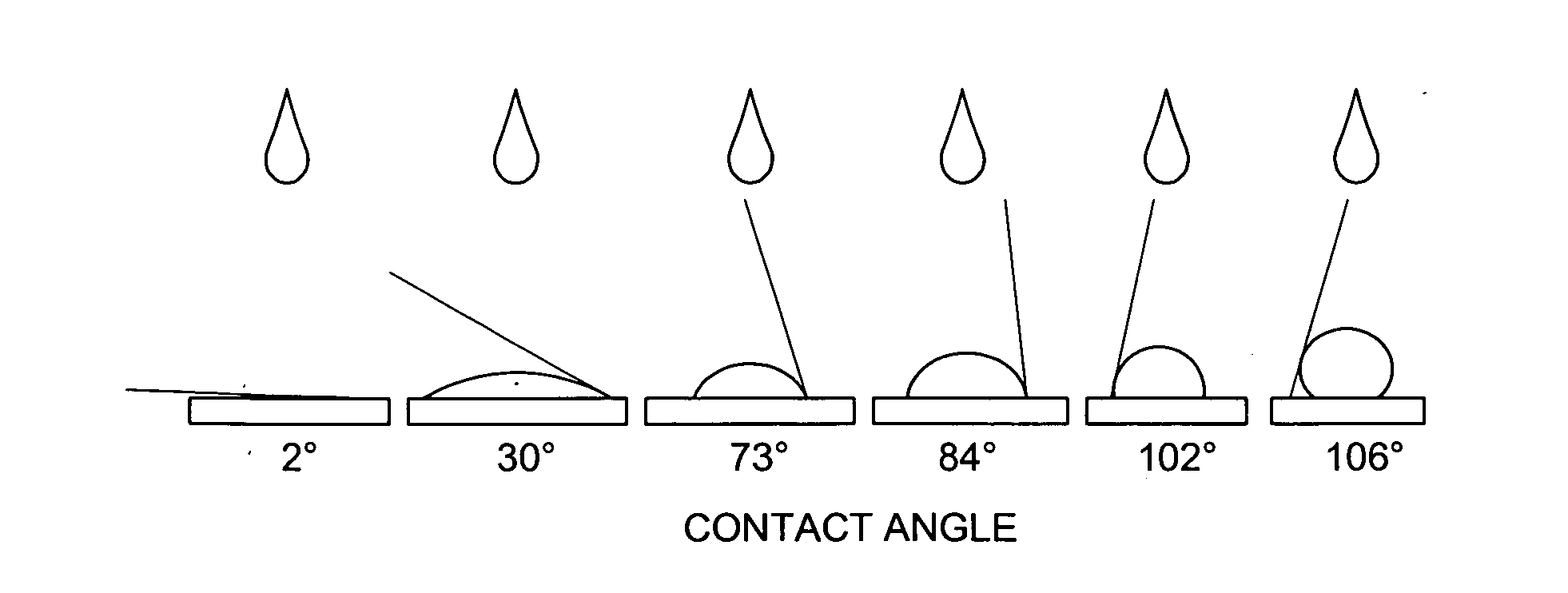

Method for photocatalytically rendering a surface of a substrate superhydrophilic, a substrate with superhydrophilic photocatalytic surface, and method of making thereof

A method of preventing or reducing fogging of a surface of a composite when subjected to humid conditions includes providing a composite with a surface. The composite includes a substrate and a photocatalytic surface layer. The photocatalytic surface layer includes a photocatalyst. The method further includes subjecting the photocatalyst to photoexcitation to render the surface of the composite hydrophilic, wherein, after the photoexcitation, the surface of the composite has a water wettability of less than 10° in terms of the contact angle with water. The method further includes subjecting the composite to humidity that is sufficient to induce fogging of the substrate if the photocatalytic surface layer were absent.

Owner:TOTO LTD

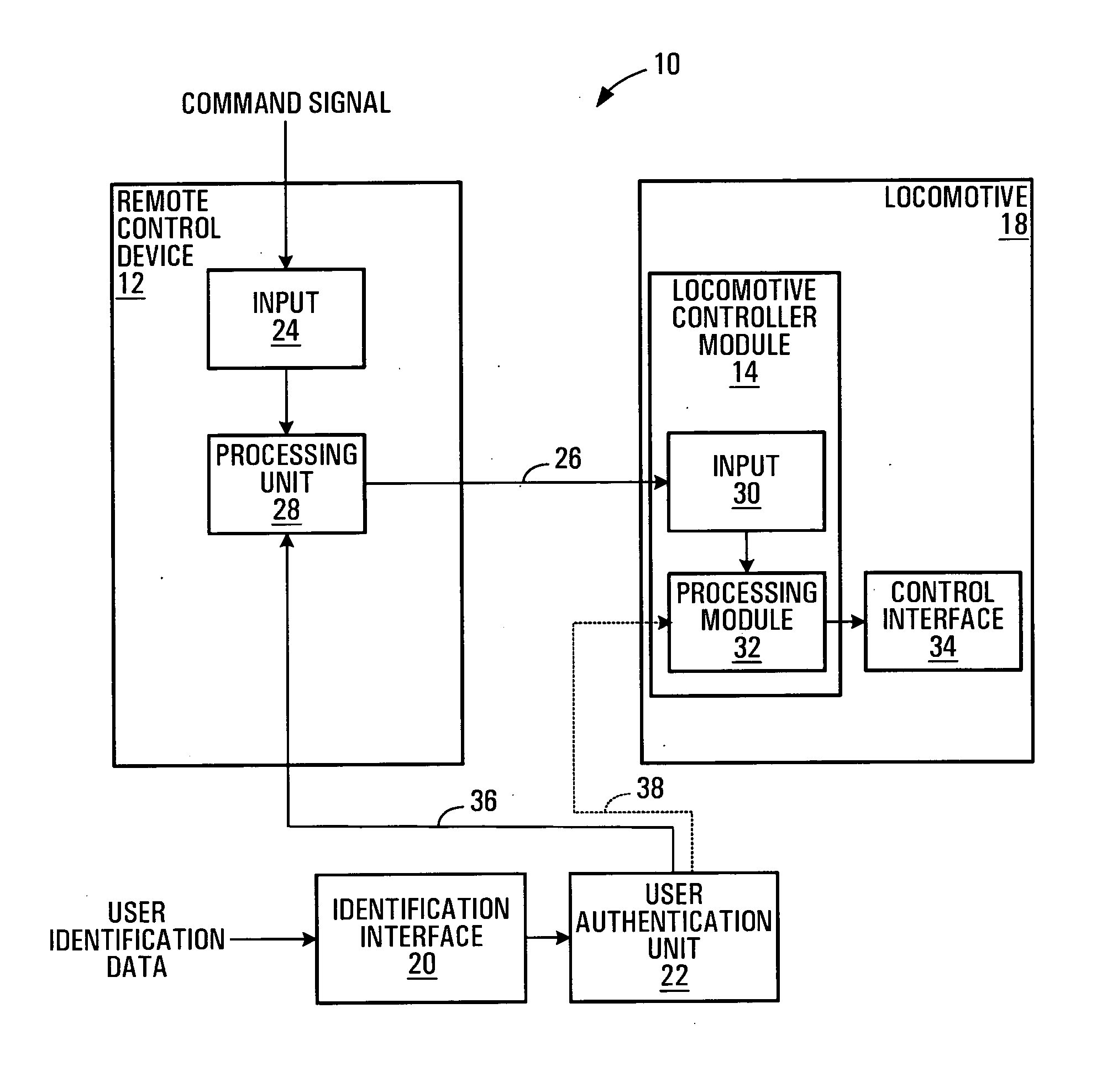

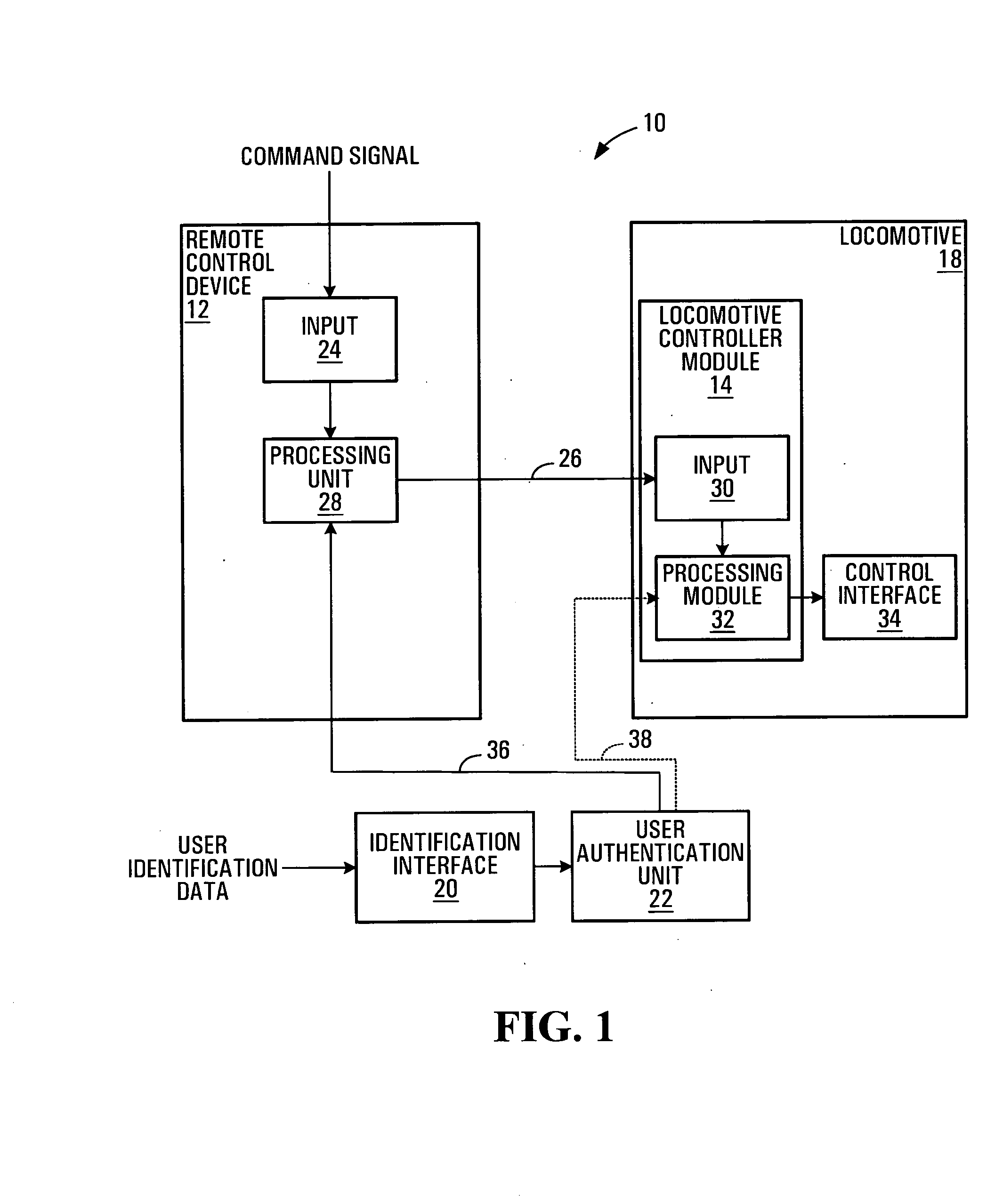

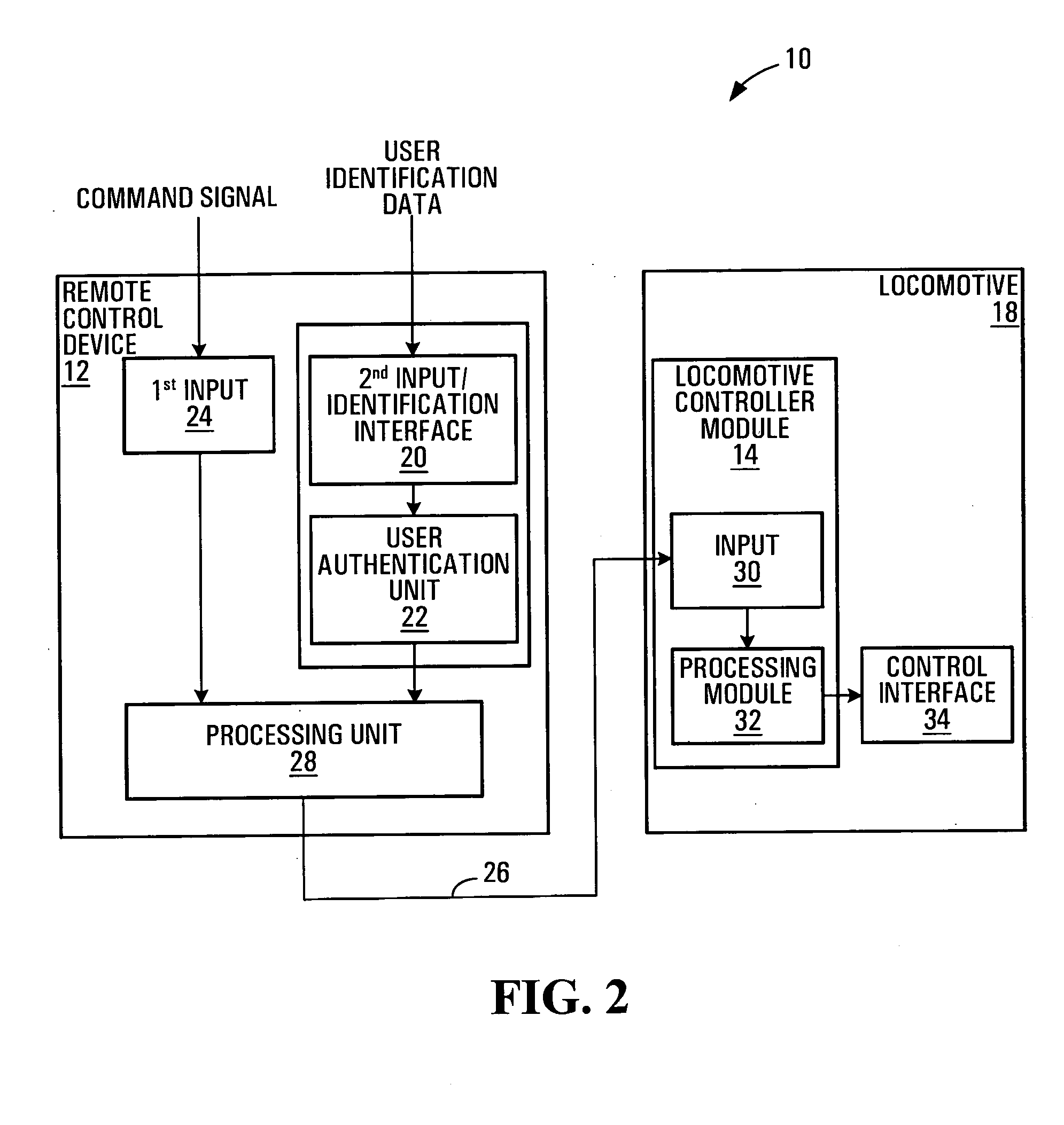

Remote control system for a locomotive having user authentication capabilities

InactiveUS20050075764A1Electric signal transmission systemsDigital data processing detailsRemote controlControl system

The present invention provides a remote control system for a locomotive. The remote control system comprises a remote control device, an identification interface and a locomotive controller module. The remote control device is operative for receiving a command signal indicative of an action to be executed by the locomotive. The identification interface is adapted for receiving user identification data from a user of the remote control device. The locomotive controller module is suitable for mounting at the locomotive and is adapted for generating local control signals. When the user identification data belongs to an authorized user, the locomotive controller module is operative to issue a local control signal for causing the locomotive to execute the action conveyed by the command signal received at the remote control device.

Owner:CATTRON INTPROP CORP

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

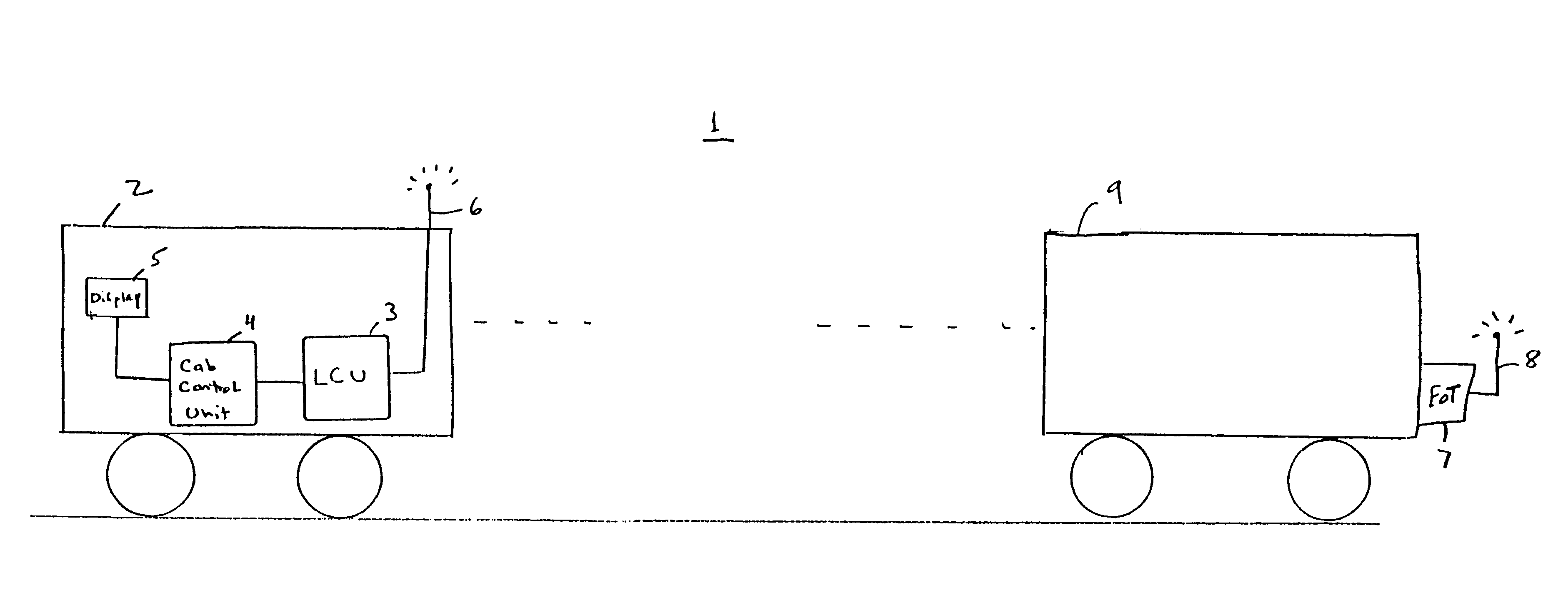

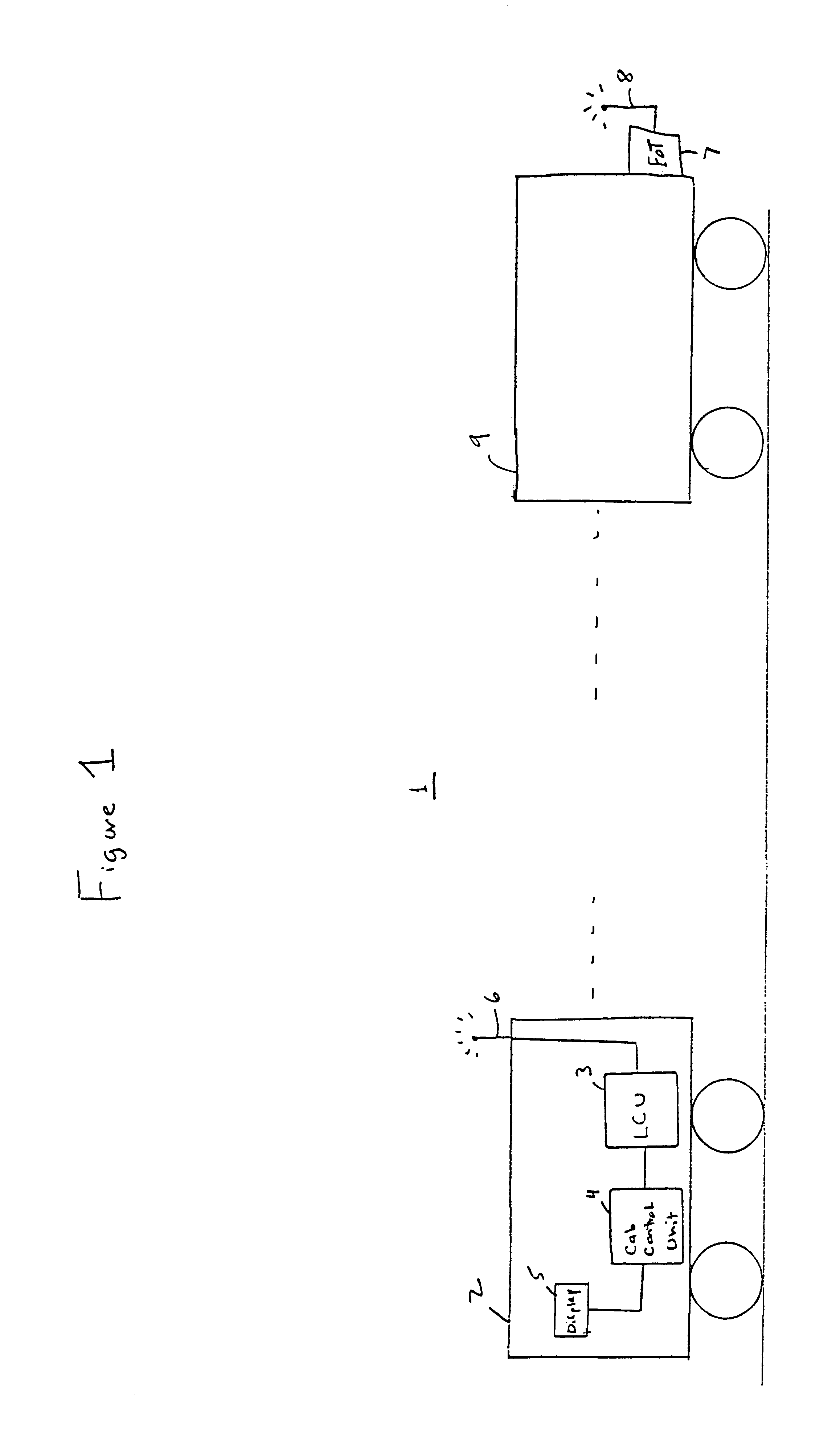

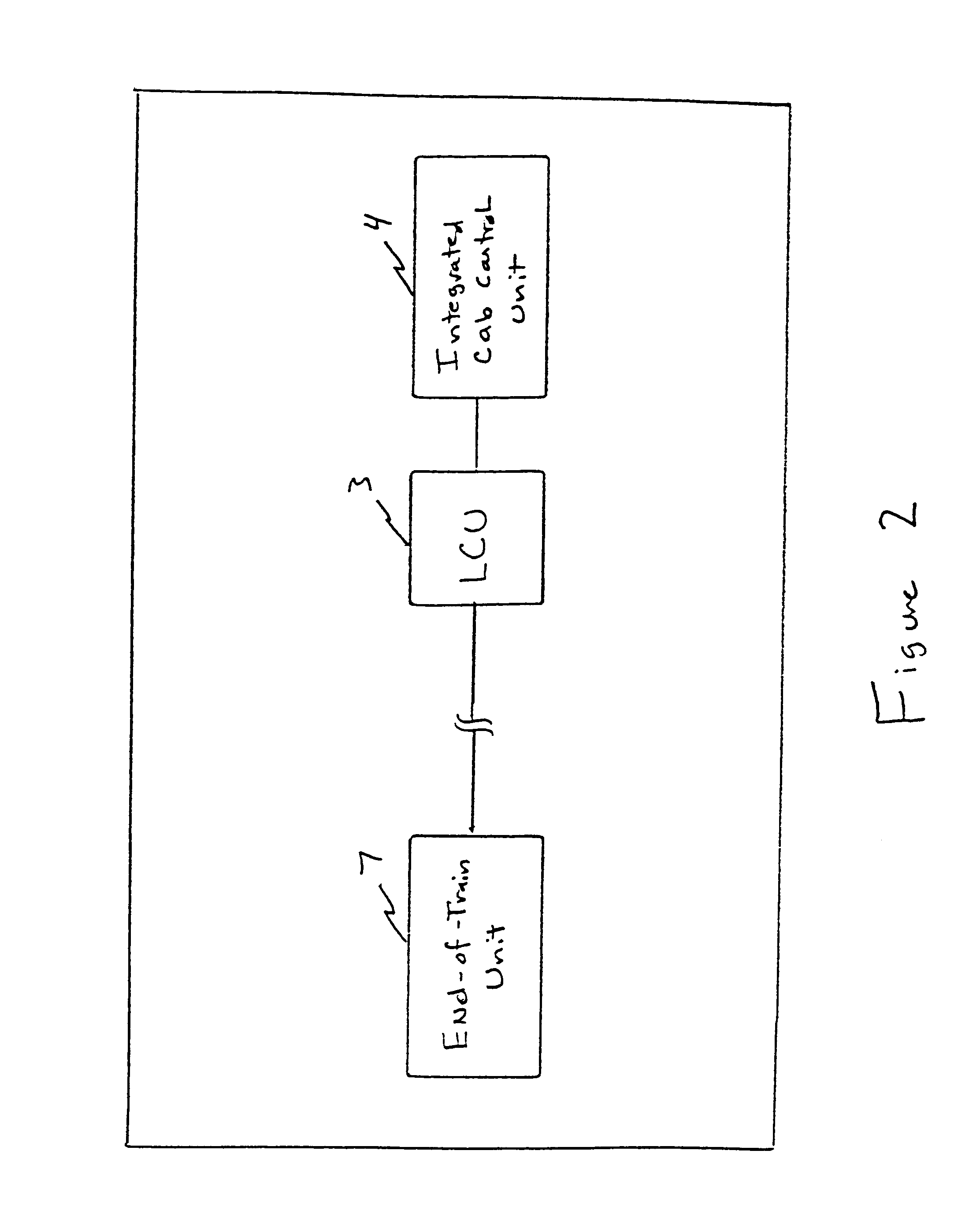

Dual-protocol locomotive control system and method

InactiveUS6322025B1Easy to operateImprove securityCircuit arrangementsSignalling indicators on vehicleCommunications systemTelecommunications link

An intra-train communication system includes a locomotive control unit (LCU) establishes a communications link between a lead unit and a remote unit which operate using different protocols and / or in different frequency bands. To accomplish this objective, the LCU automatically detects the type of lead unit and remote unit installed on the train. If the types are not the same, the LCU resolves any serial link protocol and arming differences that might exist in a manner virtually transparent to train operators. As a result, data is communicated between the lead and remote units in a way which requires less operator intervention and no software changes to the control computer of the head unit.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

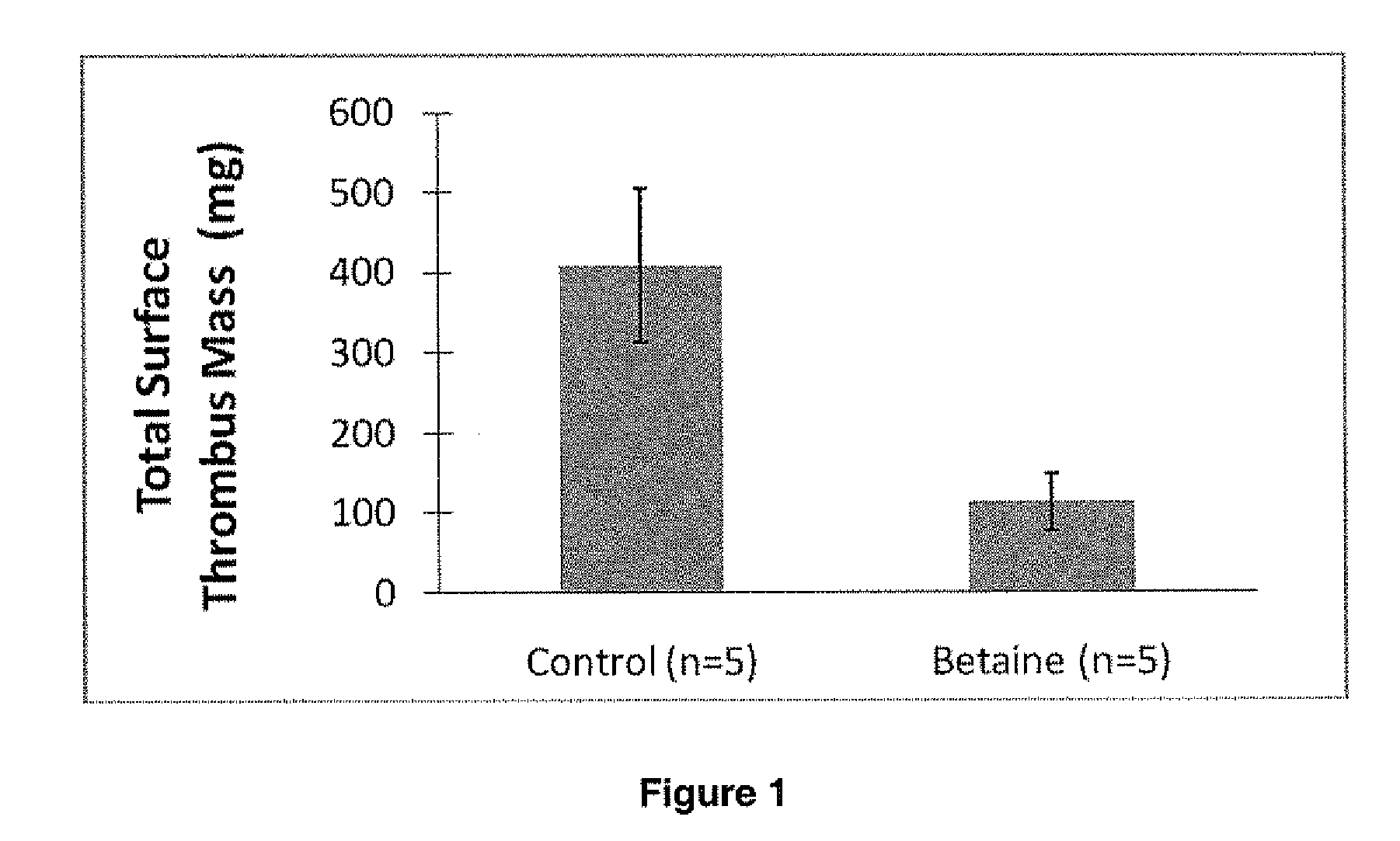

Non-fouling, Anti-microbial, Anti-thrombogenic graft-from compositions

InactiveUS20100152708A1Reduce penetrationRadiation applicationsSurgeryMicroorganismPolymer substrate

Substrates, optionally coated with an undercoating layer, having grafted there from one or more non-fouling materials are described herein. The non-fouling, polymeric material can be grafted from a variety of substrate materials, particularly polymeric substrates and / or polymeric undercoating layers. The graft-from techniques described herein can result in higher surface densities of the non-fouling material relative to graft-to formulations. Graft-from methods can be used to produce covalently tethered polymers. The compositions described herein are highly resistant protein absorption, particularly in complex media and retain a high degree of non-fouling activity over long periods of time. The compositions described herein may also demonstrate antimicrobial and / or anti-thrombogenic activity. The non-fouling material can be grafted from the substrate, or optionally from an undercoating layer on the substrate, preferably without significantly affecting the mechanical and / or physical properties of the substrate material.

Owner:ARROW INT INC

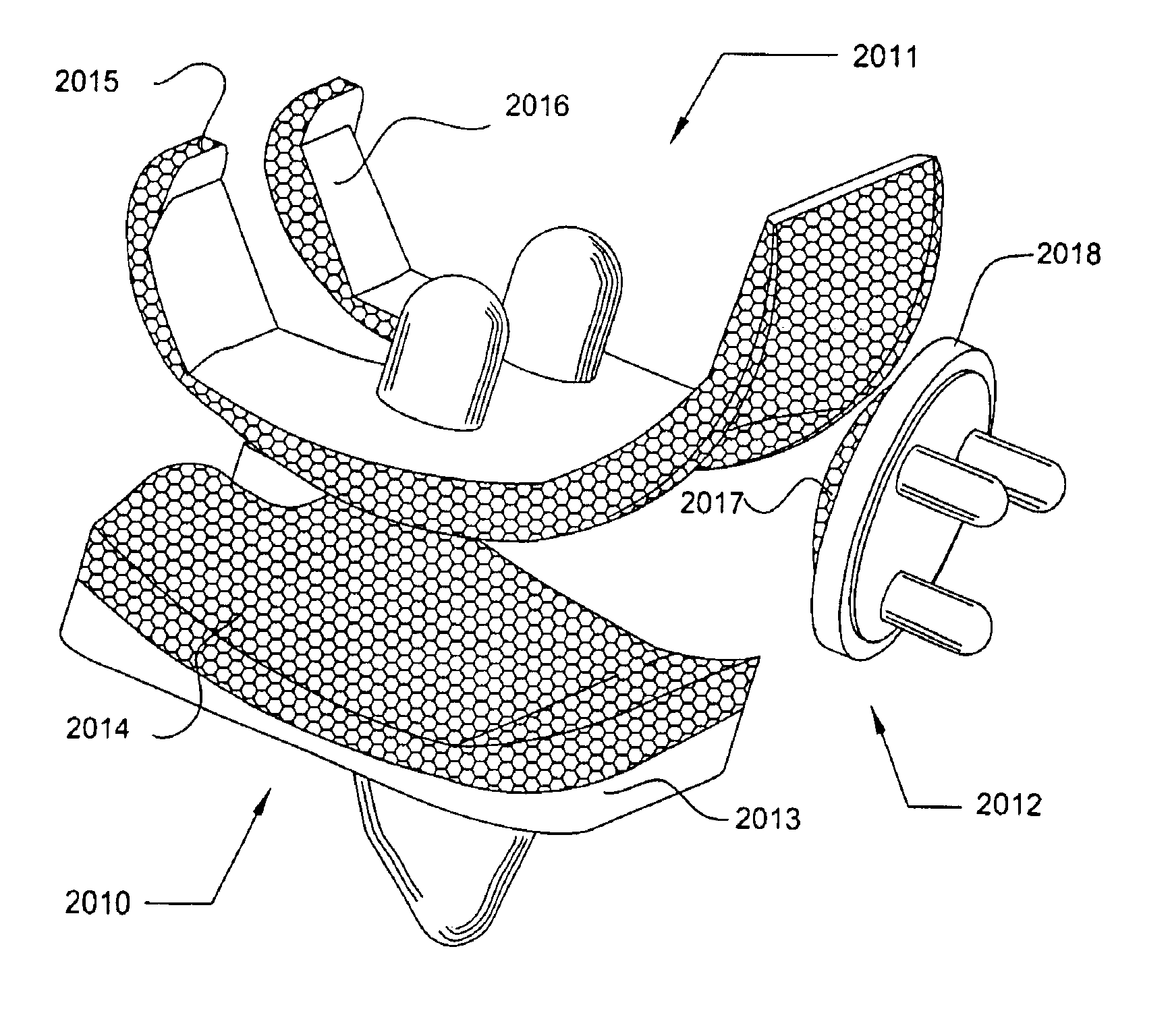

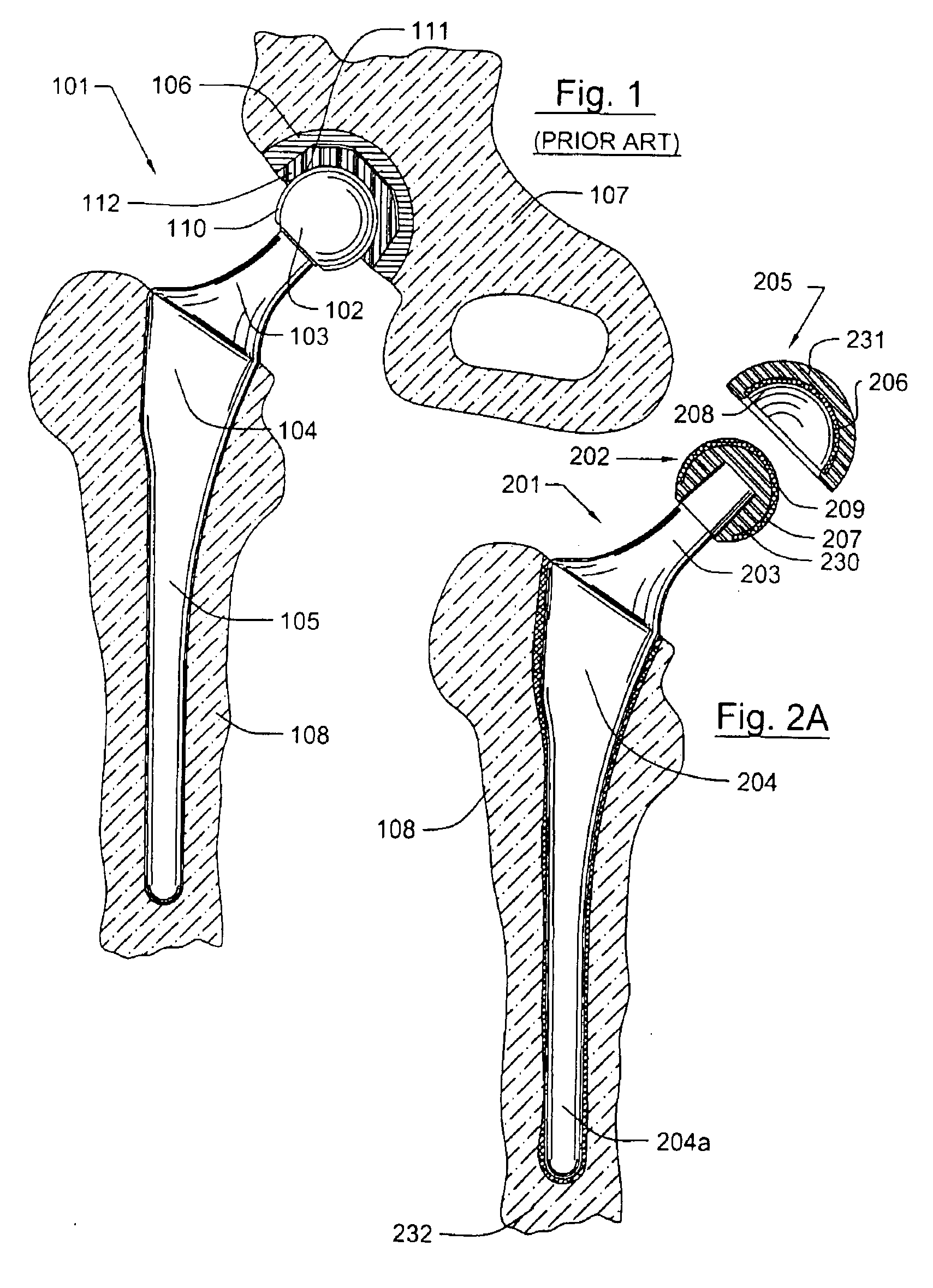

Prosthetic knee joint having at least one diamond articulation surface

InactiveUS7077867B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesKnee Joint

Owner:DIAMICRON

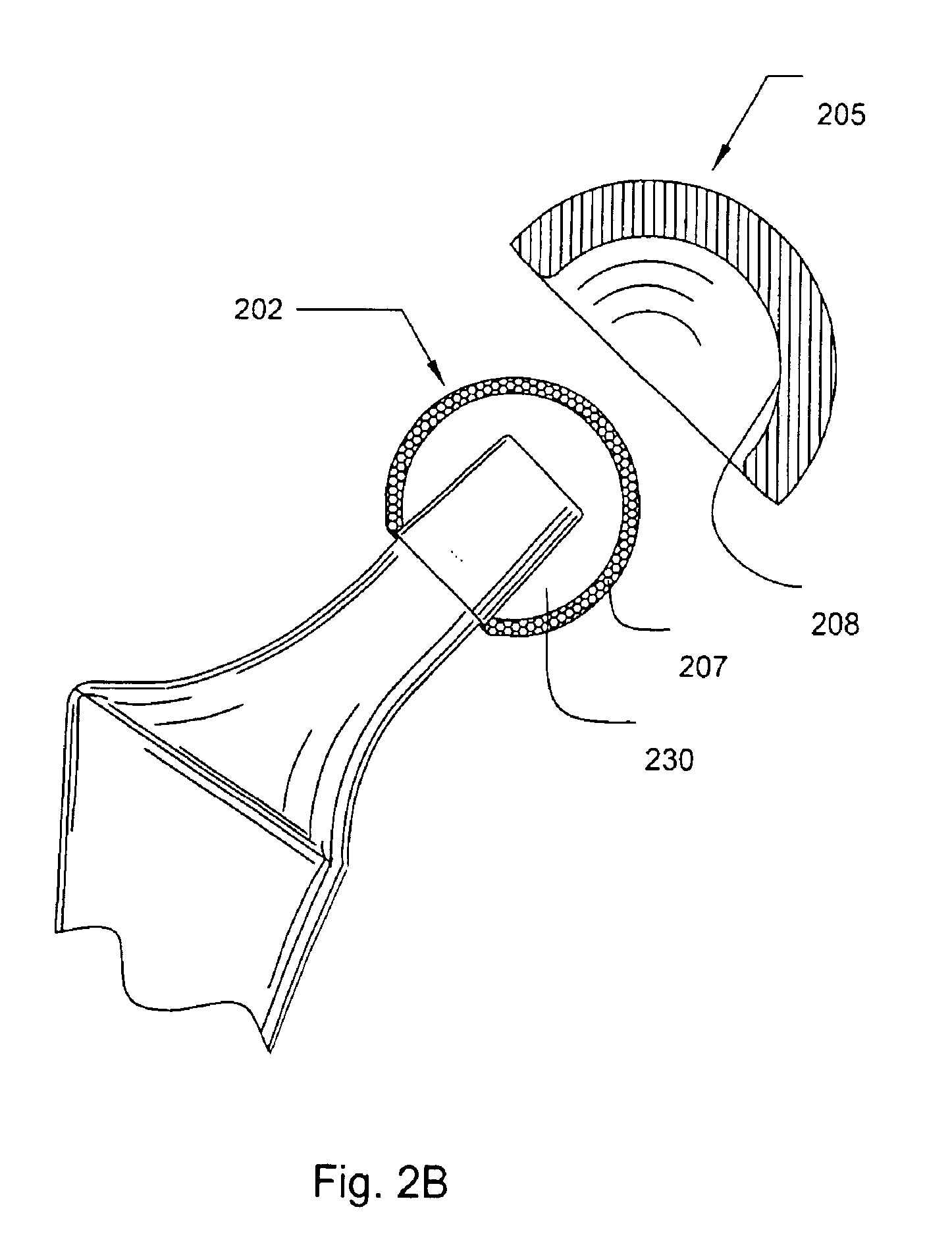

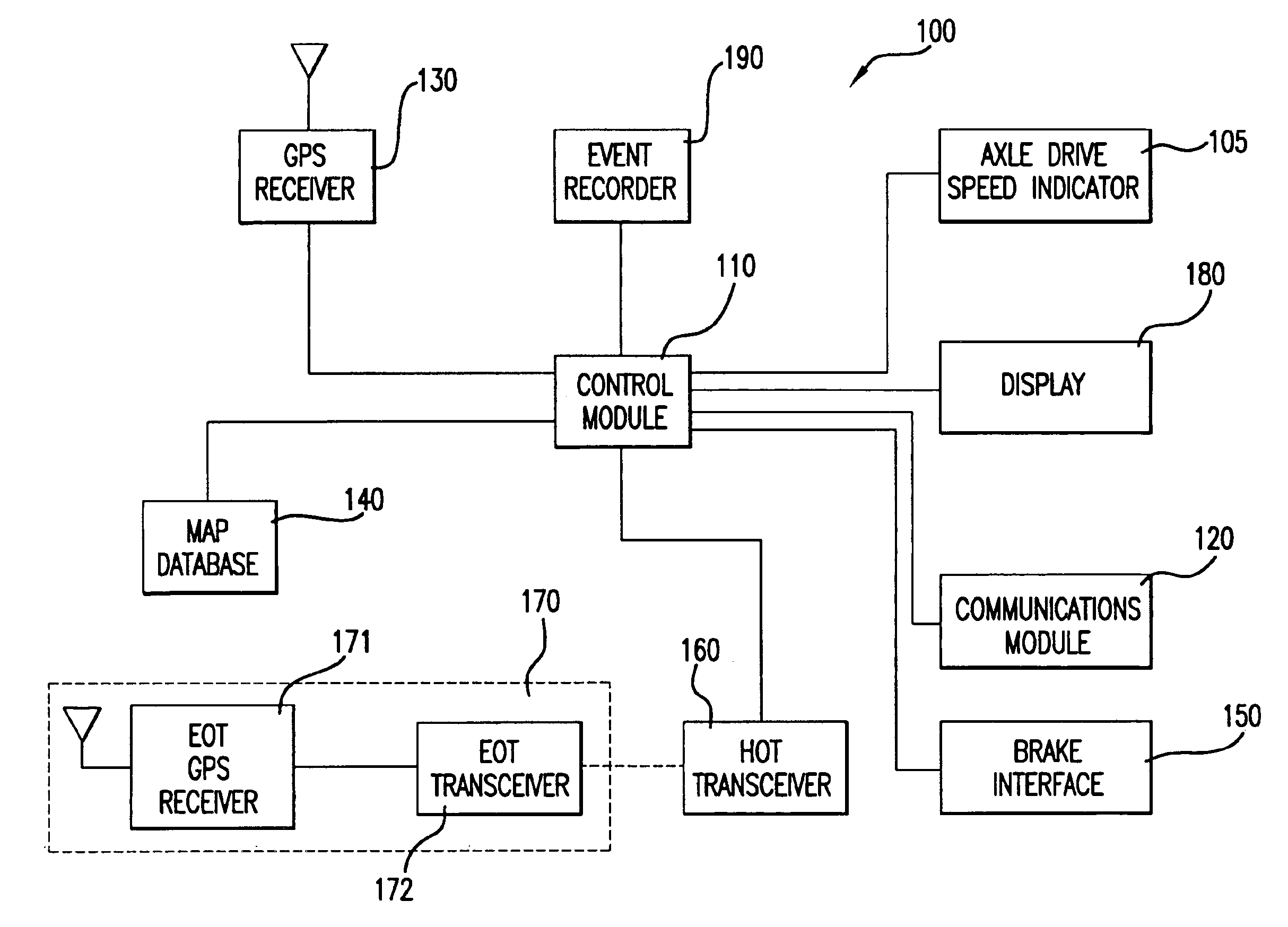

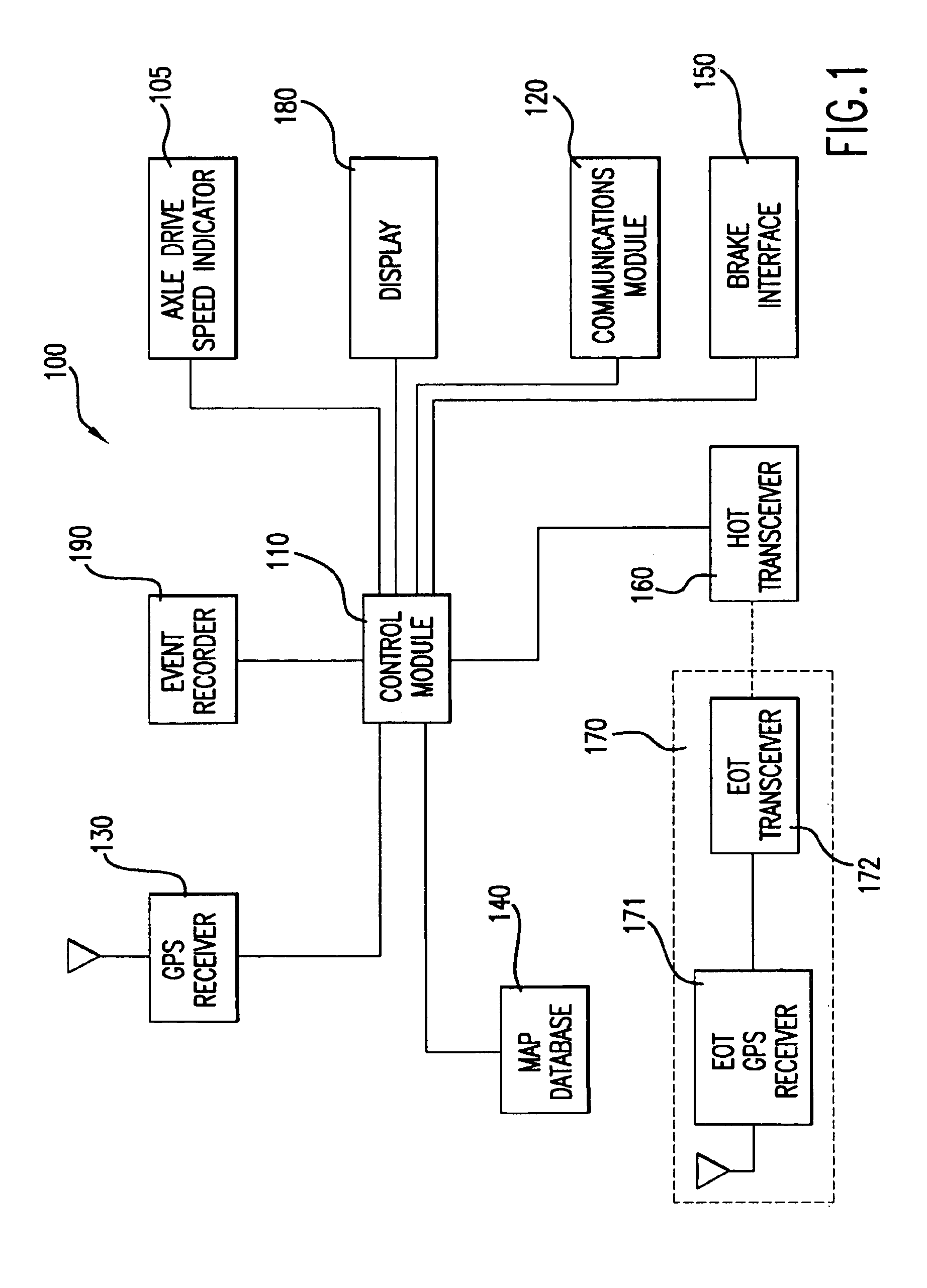

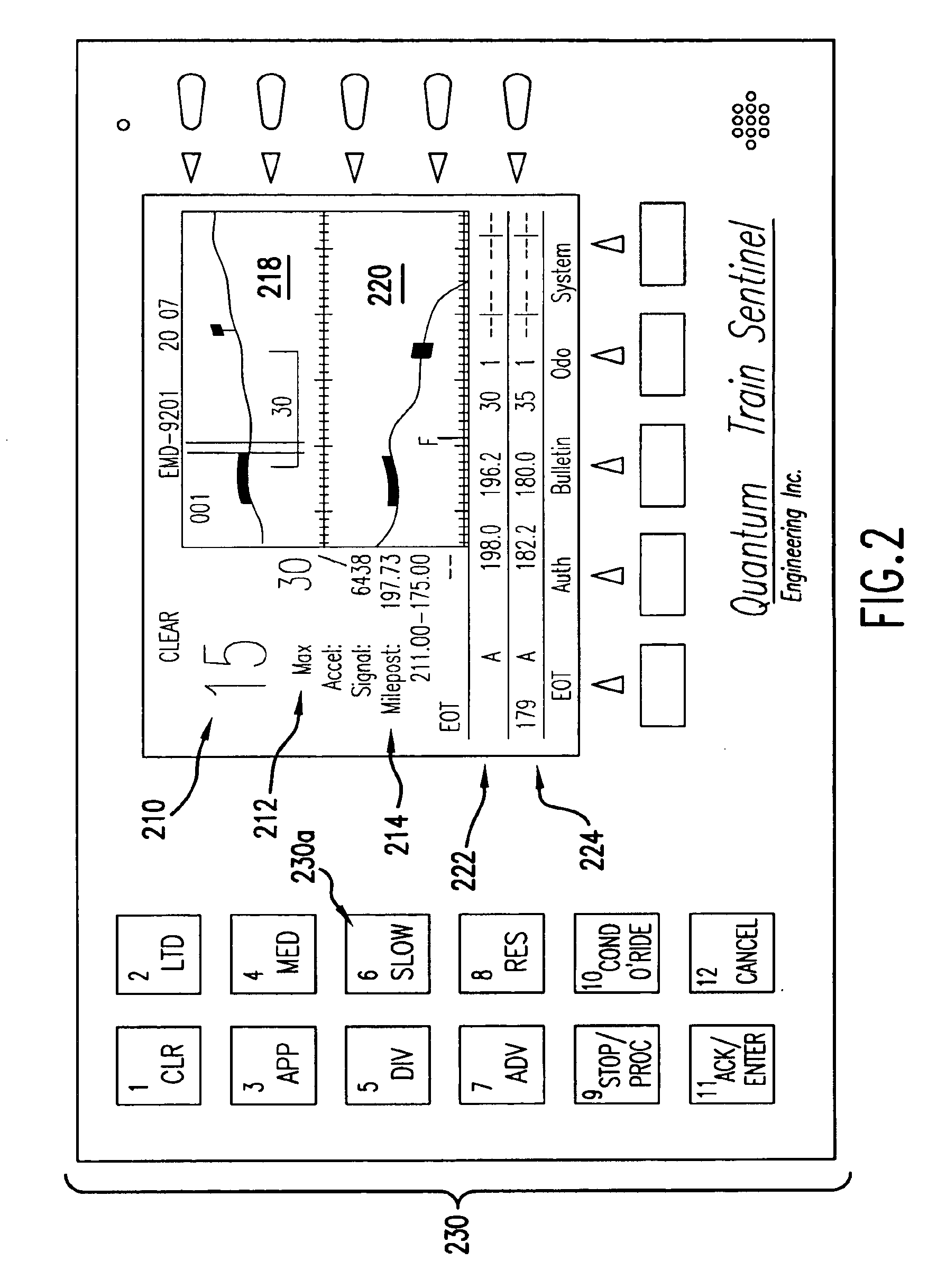

Train control system and method of controlling a train or trains

InactiveUS6865454B2Digital data processing detailsAnti-collision systemsElectrical conductorControl system

A train control system includes positioning systems at the end of the train and at the front of the train, allowing the conductor or engineer to unambiguously determine that no cars of the train have become detached. The positioning system at the end of the train is also used to verify that the entire train has cleared a block. This information can be relayed to a dispatcher, thereby eliminating the need for trackside sensing equipment. A control unit prevents the train from moving without an authorization that includes the train's current position.

Owner:SIEMENS MOBILITY INC

Controlled vapor deposition of biocompatible coatings over surface-treated substrates

ActiveUS20060088666A1Improve bindingThe surface is moreMaterial nanotechnologyRadiation applicationsGas phaseBiocompatible coating

We have developed an improved vapor-phase deposition method and apparatus for the application of layers and coatings on various substrates. The method and apparatus are useful in the fabrication of biofunctional devices, Bio-MEMS devices, and in the fabrication of microfluidic devices for biological applications. In one important embodiment, a siloxane substrate surface is treated using a combination of ozone and UV radiation to render the siloxane surface more hydrophilic, and subsequently a functional coating is applied in-situ over the treated surface of the siloxane substrate.

Owner:SPTS TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com