Light pipeline lead-in optical cable and manufacturing method thereof

A technology that introduces optical cables and manufacturing methods, applied in the field of optical cable manufacturing, can solve problems such as low tensile strength and inconvenient construction of optical cables, and achieve the effects of ensuring tensile performance, improving waterproof performance, excellent mechanical properties and environmental applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

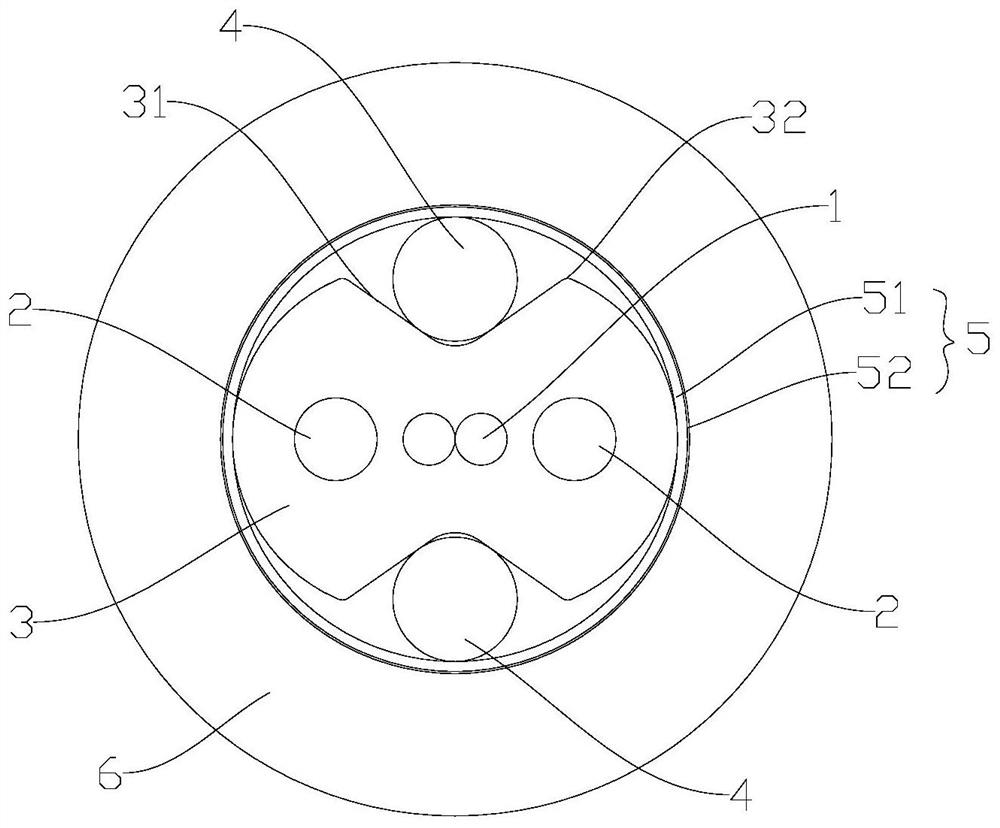

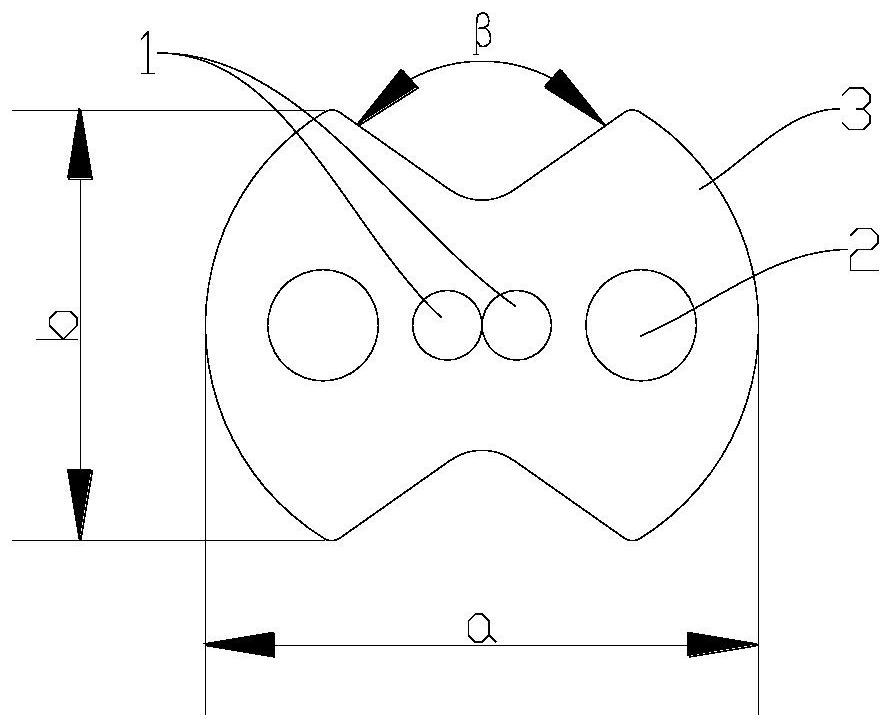

[0040] combine figure 1 and figure 2 As shown, this embodiment provides a light-duty pipe drop cable, which is mainly used in the home broadband communication system of newly built or old cells; the drop cable includes a butterfly cable subunit, a reinforcement 4, a water blocking layer 5 and an outer protective Layer 6, wherein the butterfly cable sub-unit includes a colored optical fiber 1, a butterfly sheath 3 wrapped in the colored optical fiber 1, and a strength member 2 embedded in the butterfly sheath 3, and the colored optical fiber 1 can be one or two , this embodiment takes two colored optical fibers 1 as an example to form an optical fiber ribbon; in this embodiment, a reinforcement 4 is respectively arranged between the gaps 31 of the butterfly wings on both sides of the butterfly cable subunit, and the reinforcement 4 is in a columnar structure and is connected with The colored optical fibers 1 are arranged side by side, and each reinforcing member 4 is arranged...

Embodiment 2

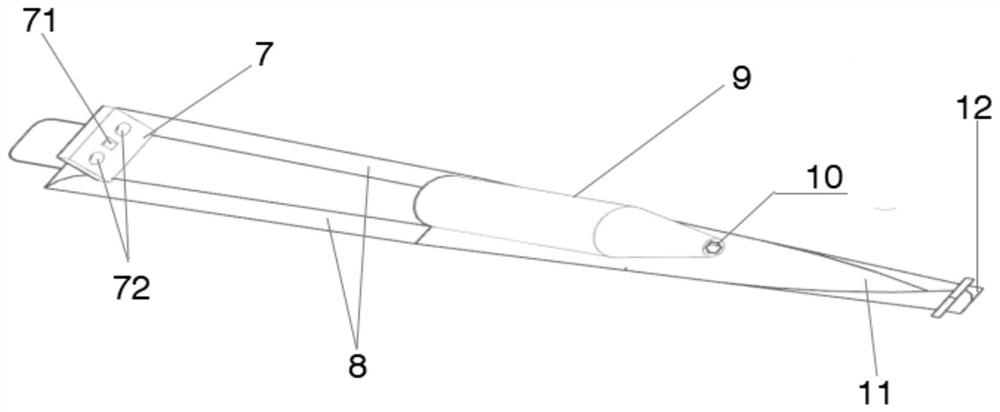

[0049] combine Figure 1 to Figure 4 As shown, this embodiment provides a manufacturing method of a light-duty duct drop cable, which is used to manufacture the light-duty duct drop cable in Embodiment 1. The manufacturing method at least includes the following steps:

[0050] colored fiber 1;

[0051] To make the butterfly cable unit, use the optical fiber and the strength member 2 to tightly sleeve the low-smoke and halogen-free fuel to form the butterfly cable unit; in this process, when the colored optical fiber 1 is tightly sleeved into the butterfly cable unit, it is necessary to strictly control the colored optical fiber 1 , The pay-off tension of the unit reinforcement 2; use a specific non-adjustable eccentric drawing tube mold to ensure that the optical fiber stripping force value can be stably maintained at 6N-9N;

[0052] A reinforcement 4 made of phosphating steel wire is respectively placed between the gaps 31 of the butterfly wings on both sides of the butterfl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com