Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1759 results about "Copper conductor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper has been used in electrical wiring since the invention of the electromagnet and the telegraph in the 1820s. The invention of the telephone in 1876 created further demand for copper wire as an electrical conductor.

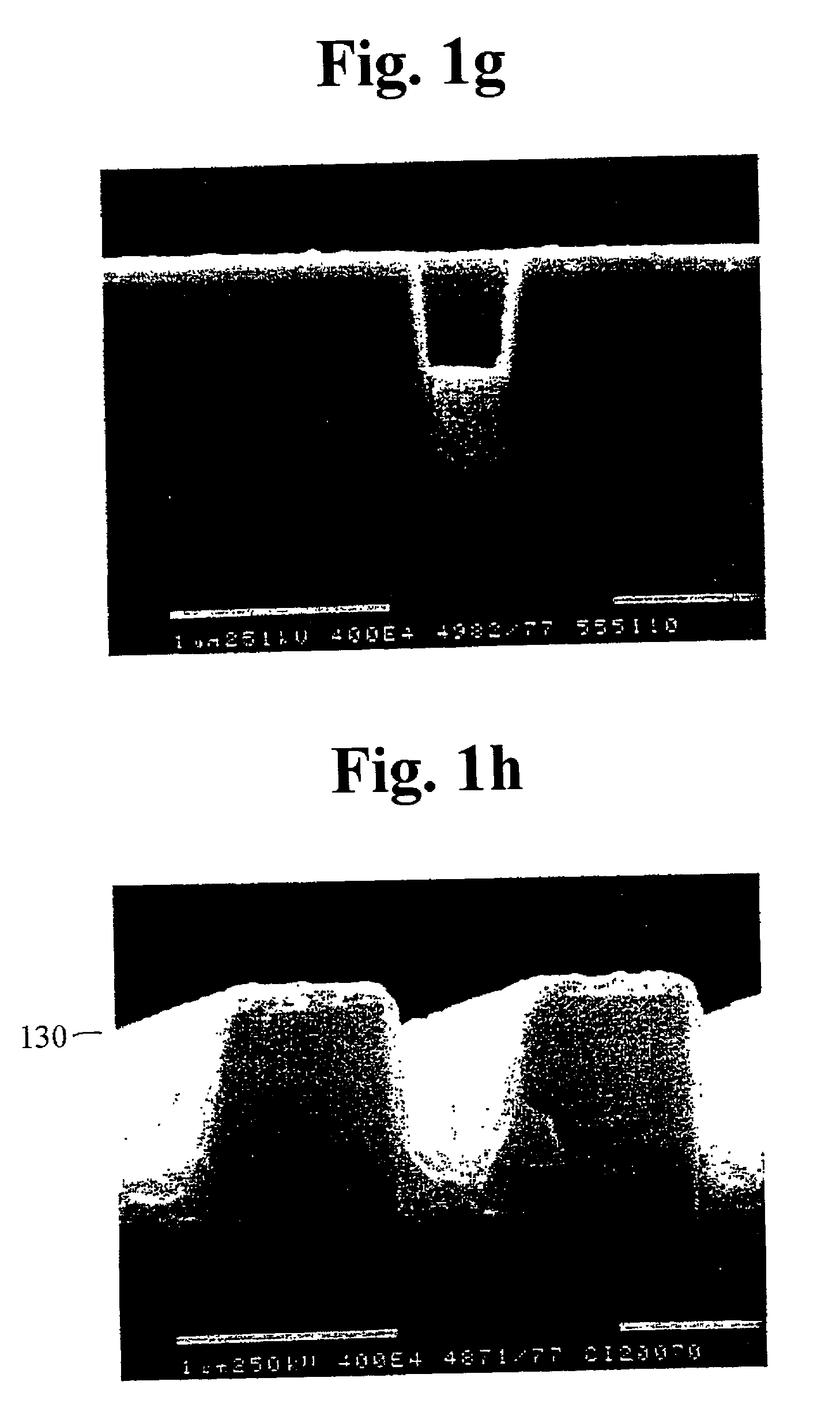

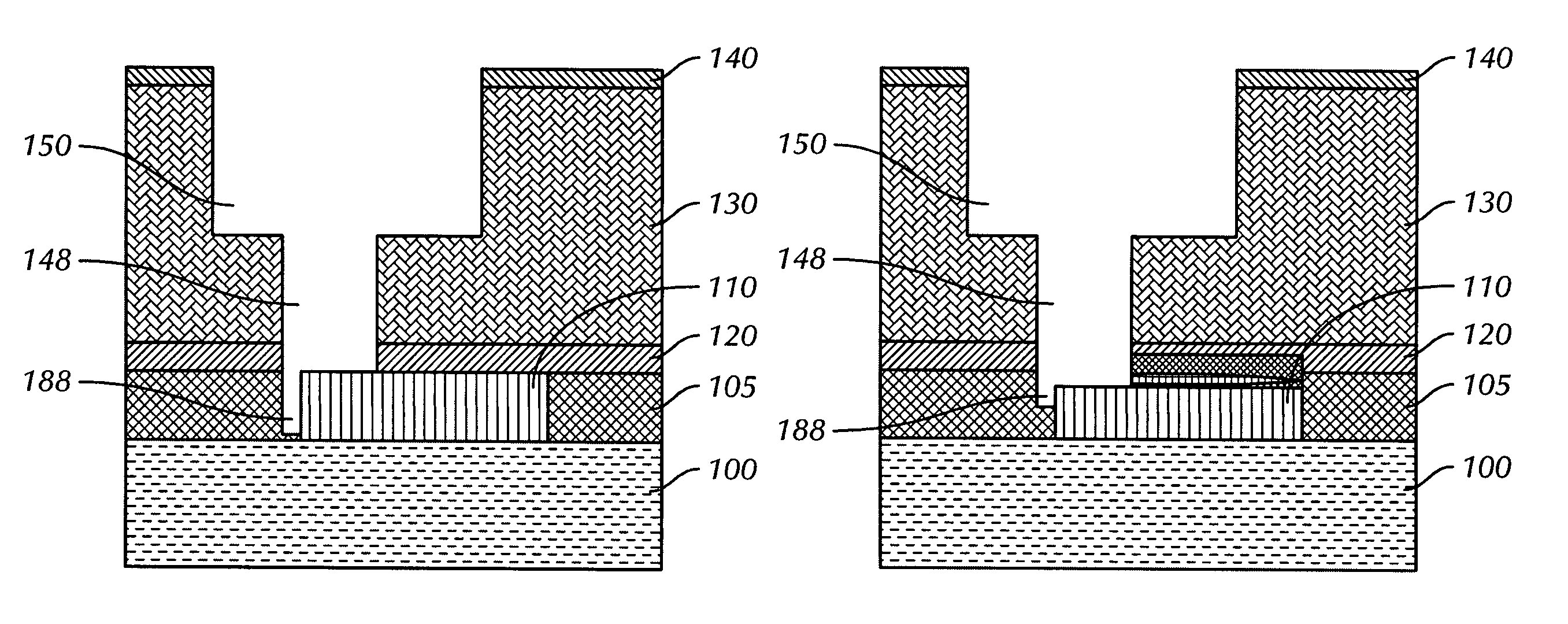

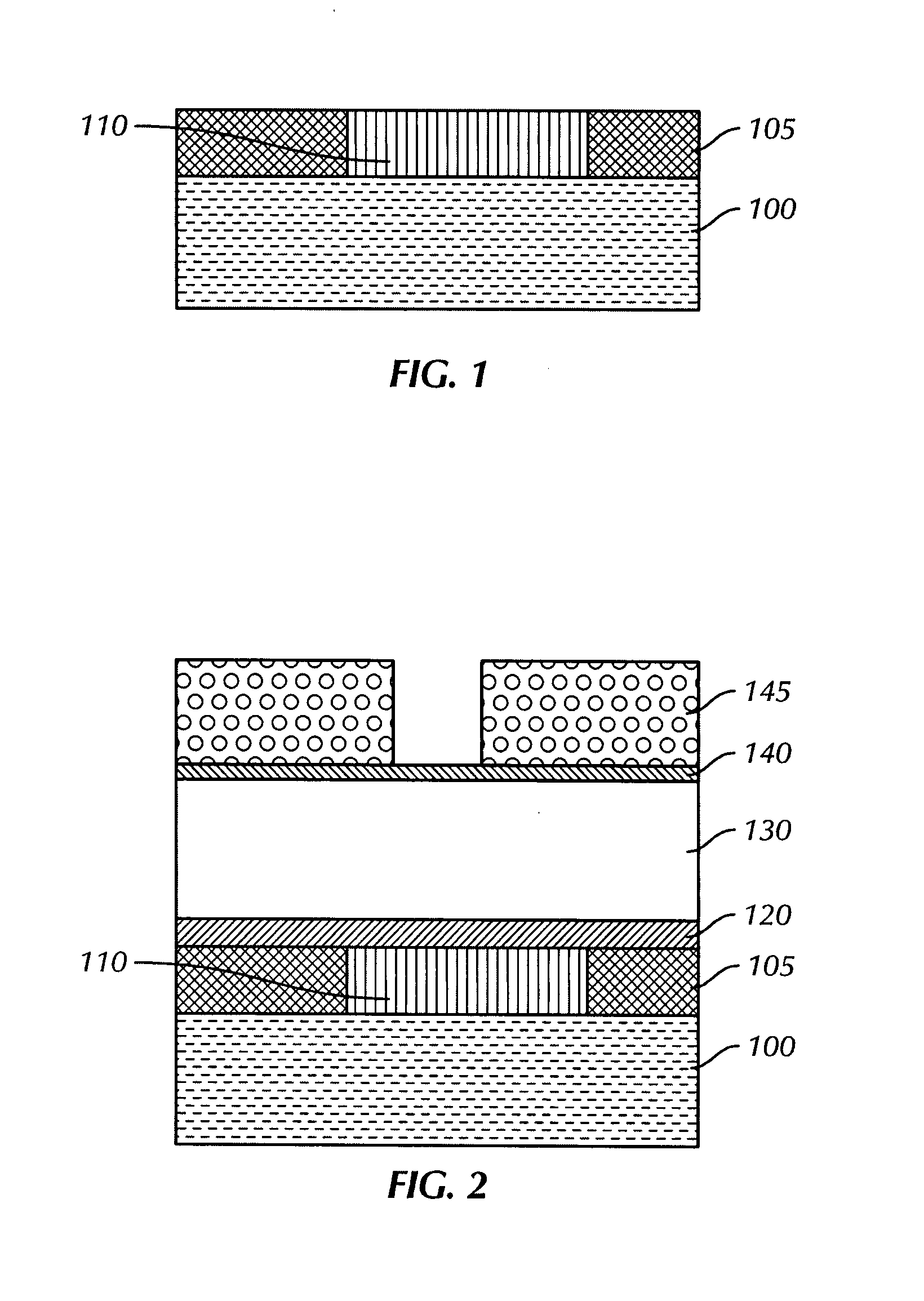

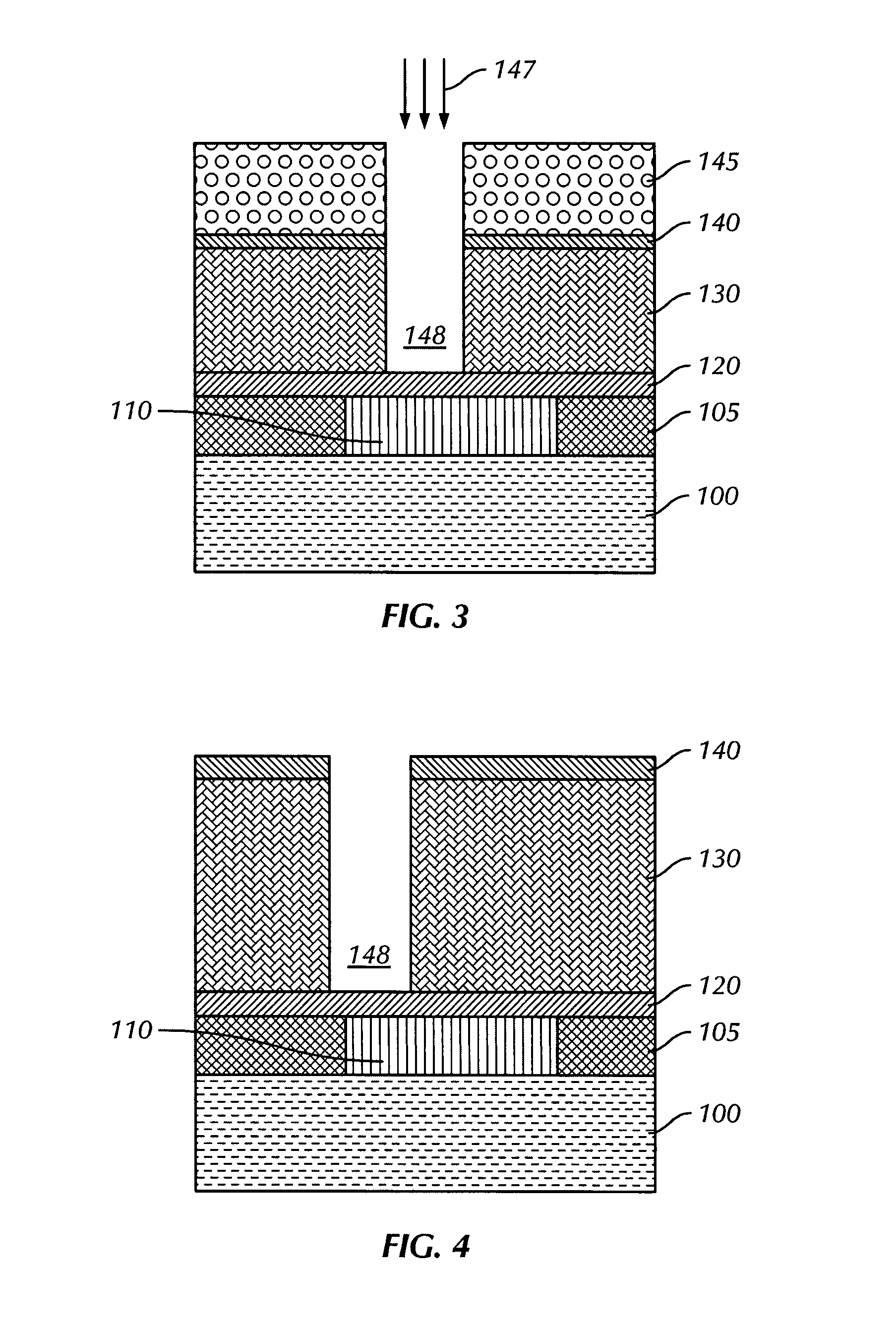

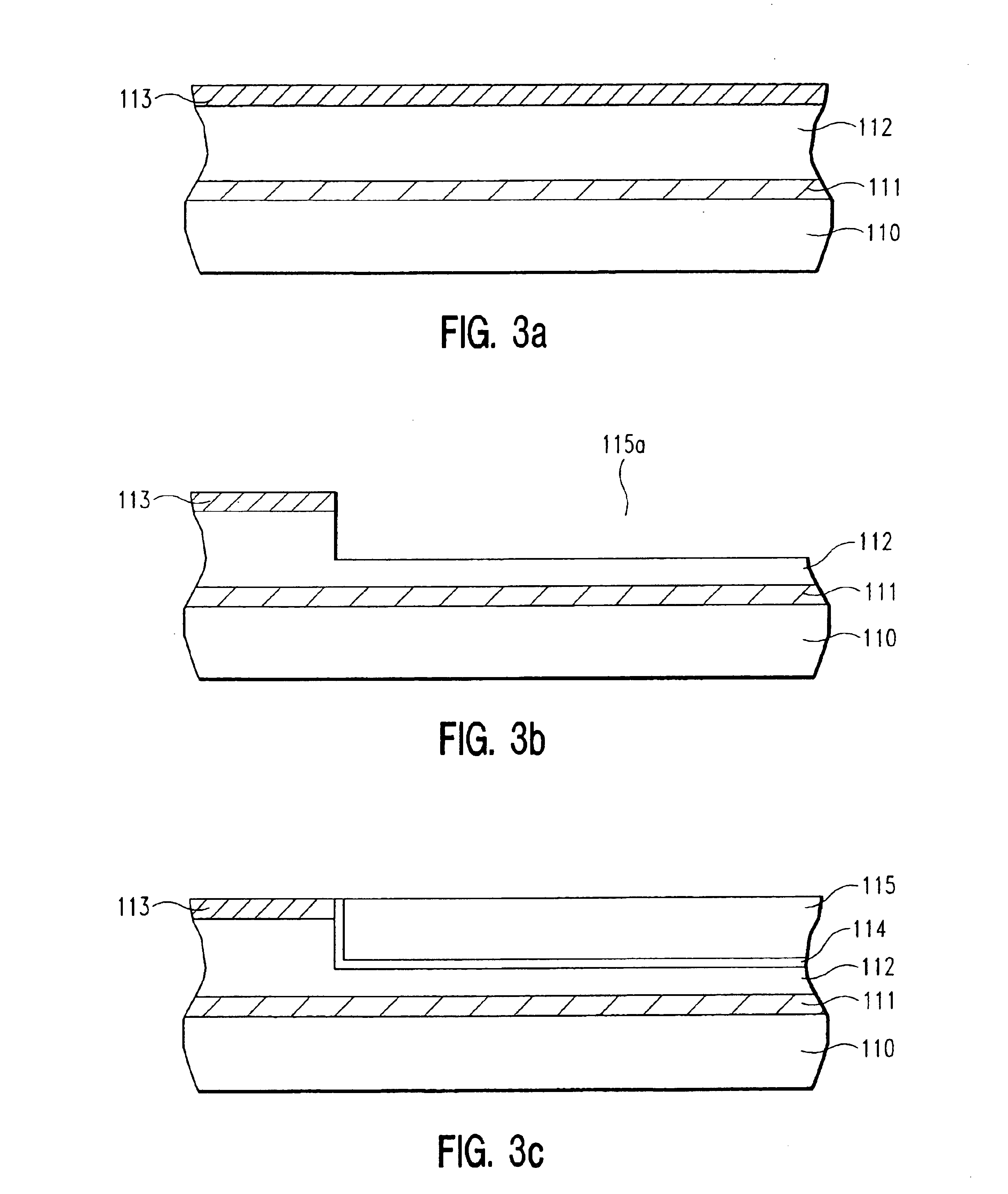

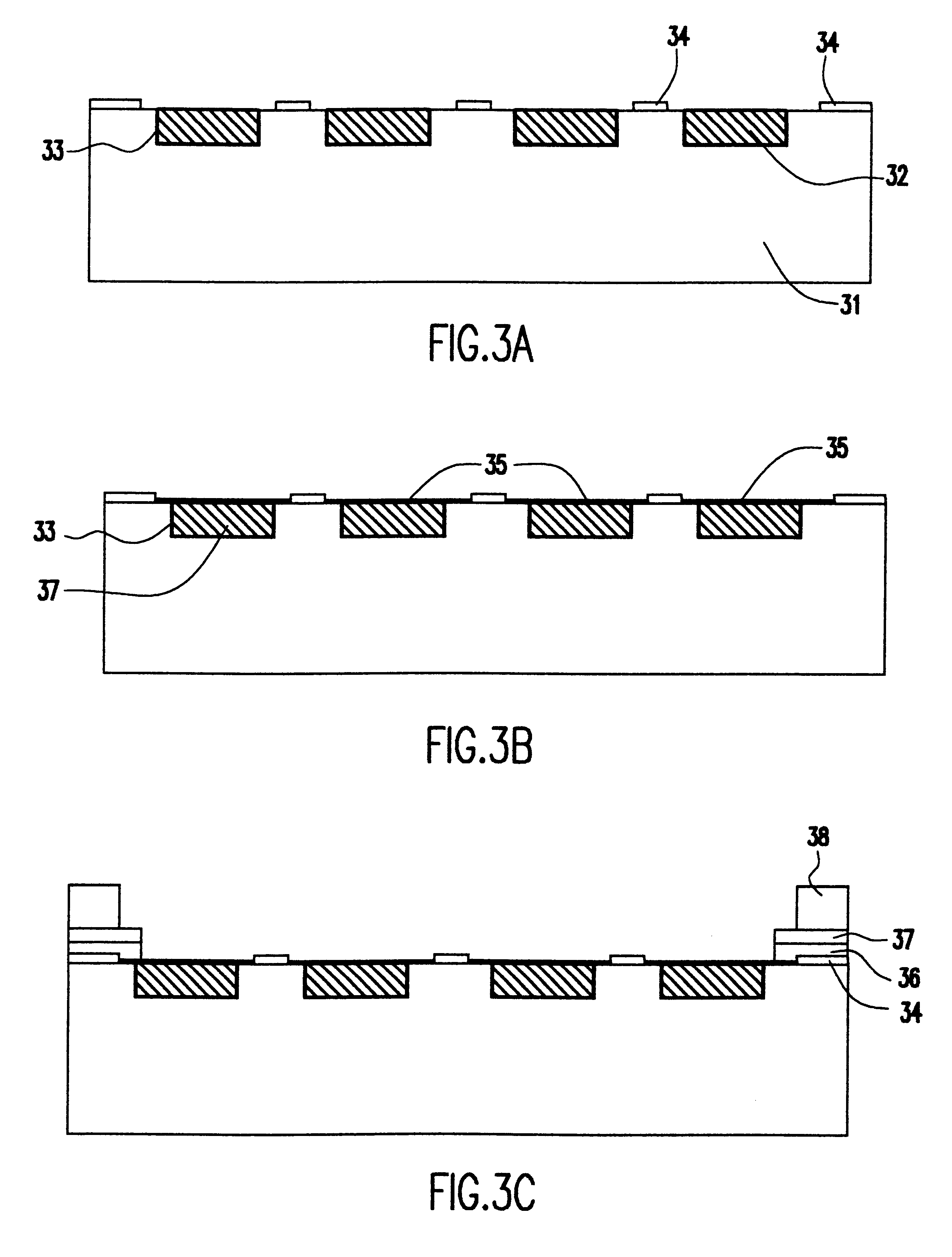

Copper conductor annealing process employing high speed optical annealing with a low temperature-deposited optical absorber layer

InactiveUS7335611B2Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesCopper conductorLow temperature deposition

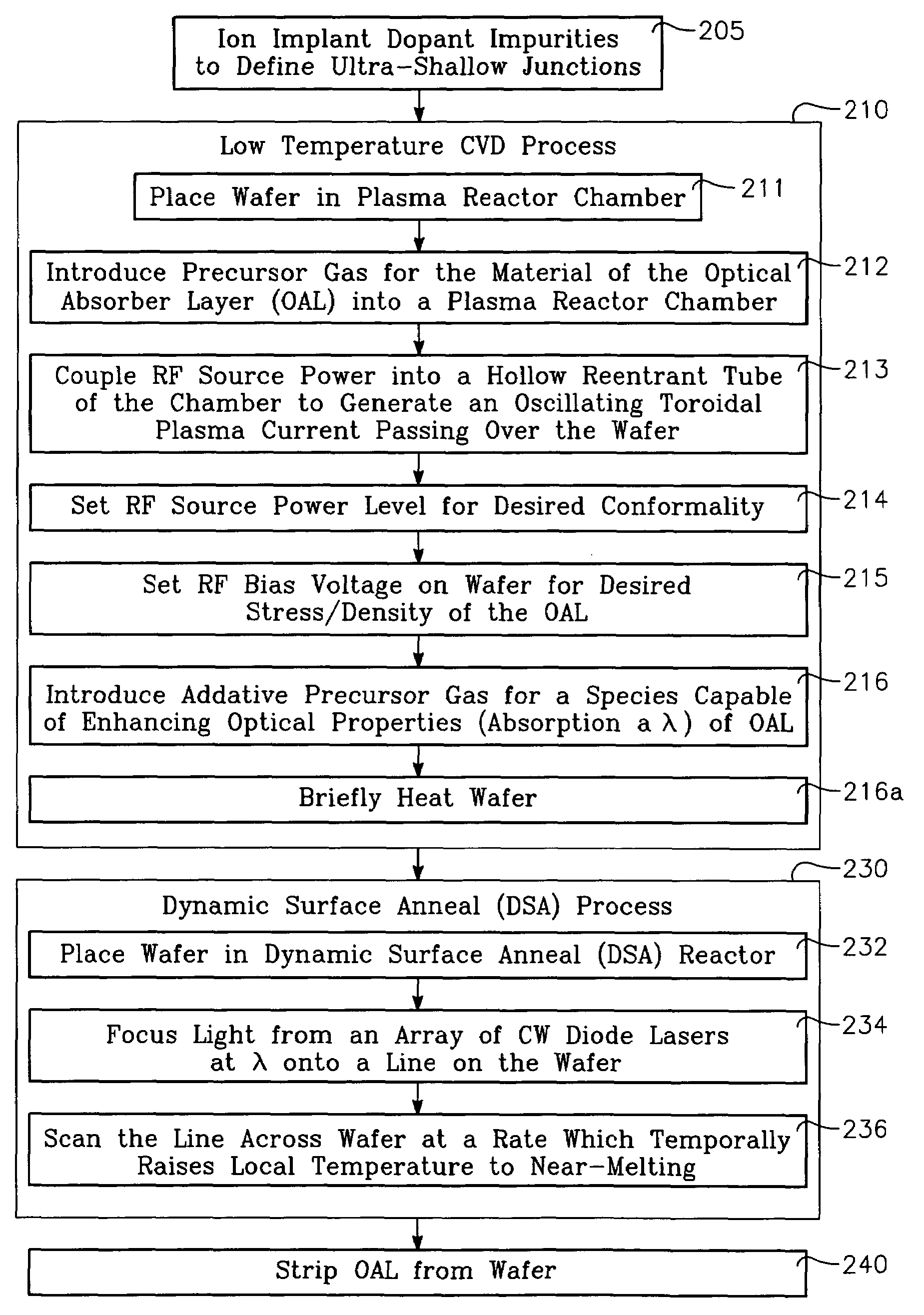

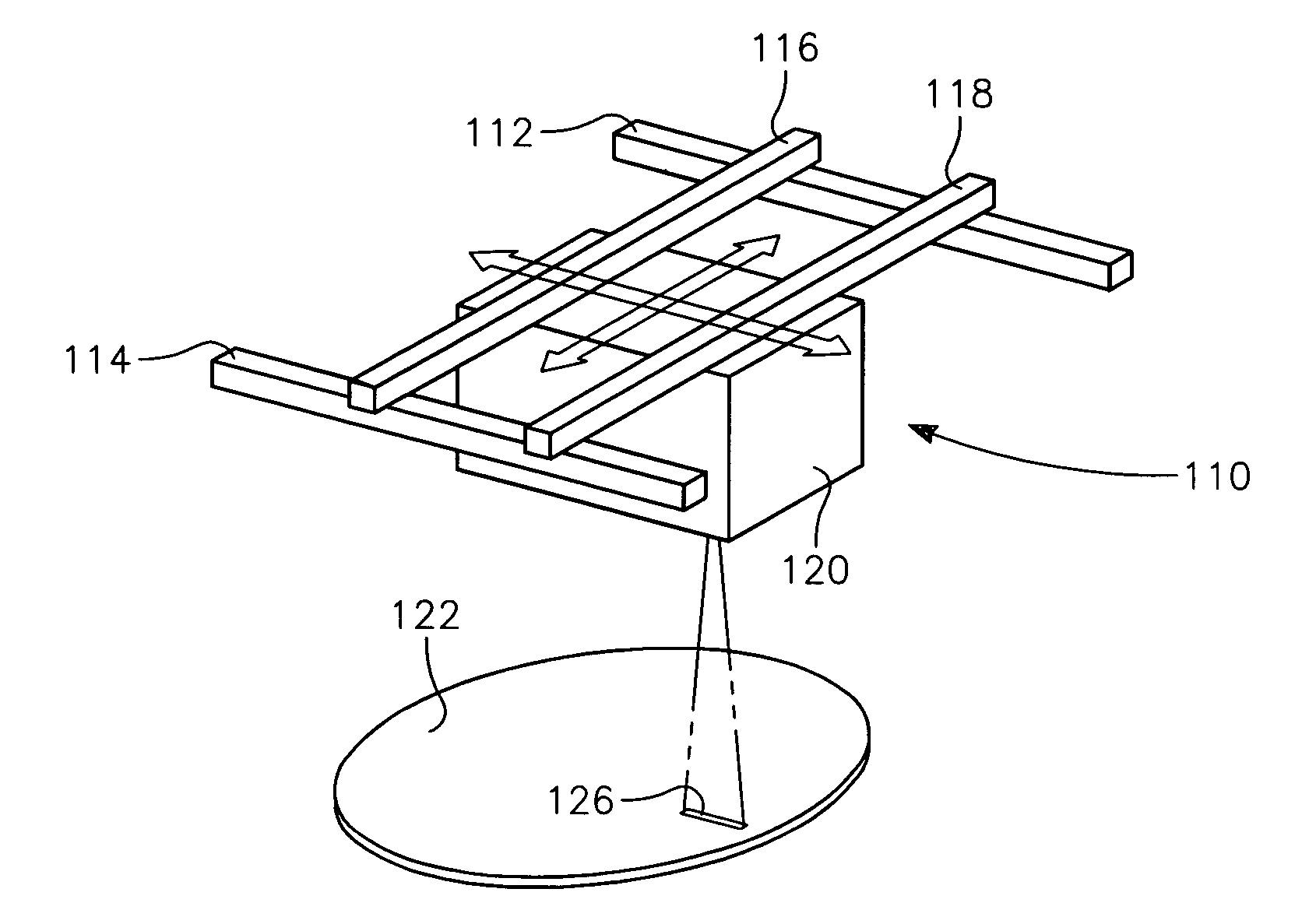

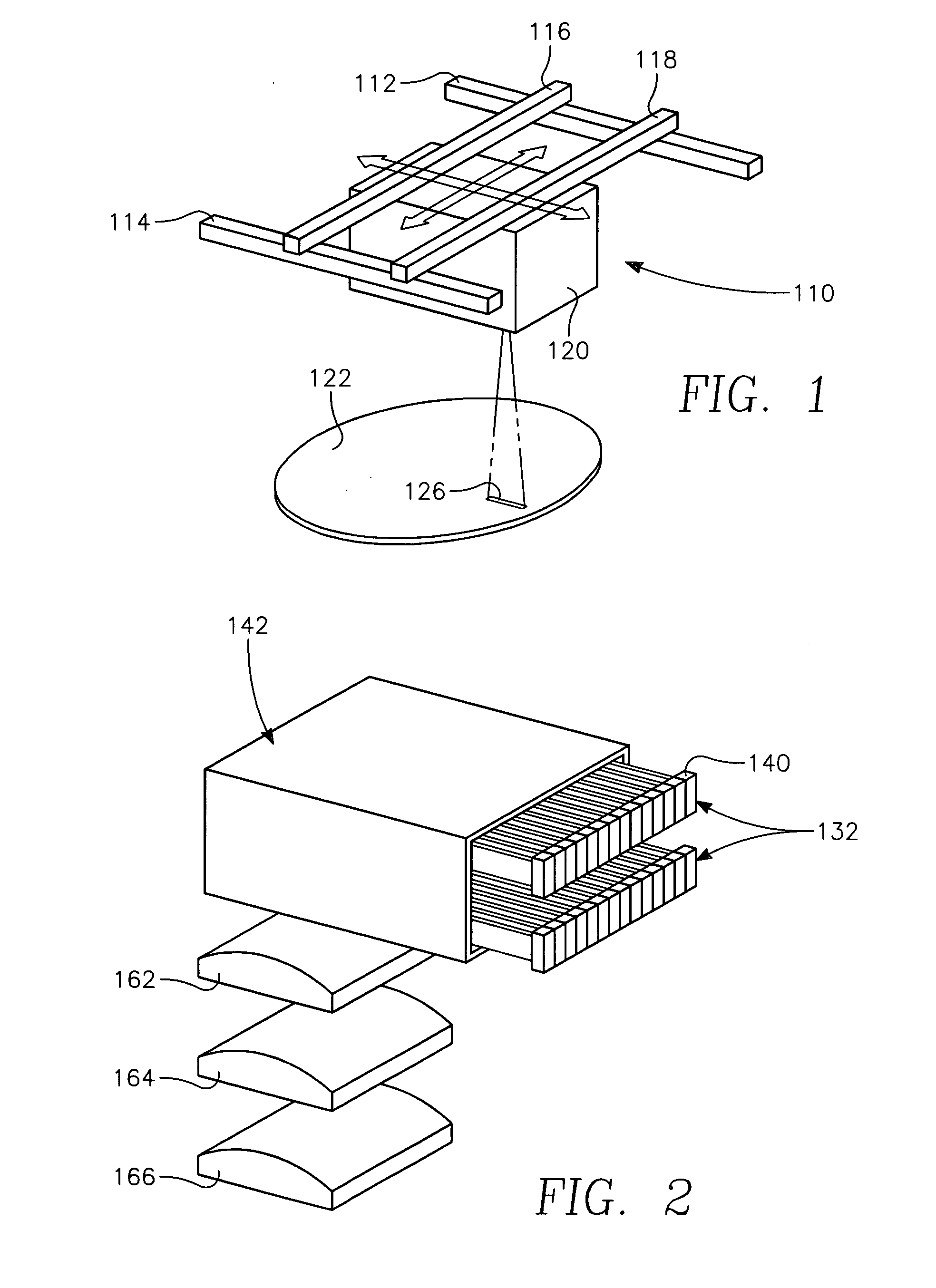

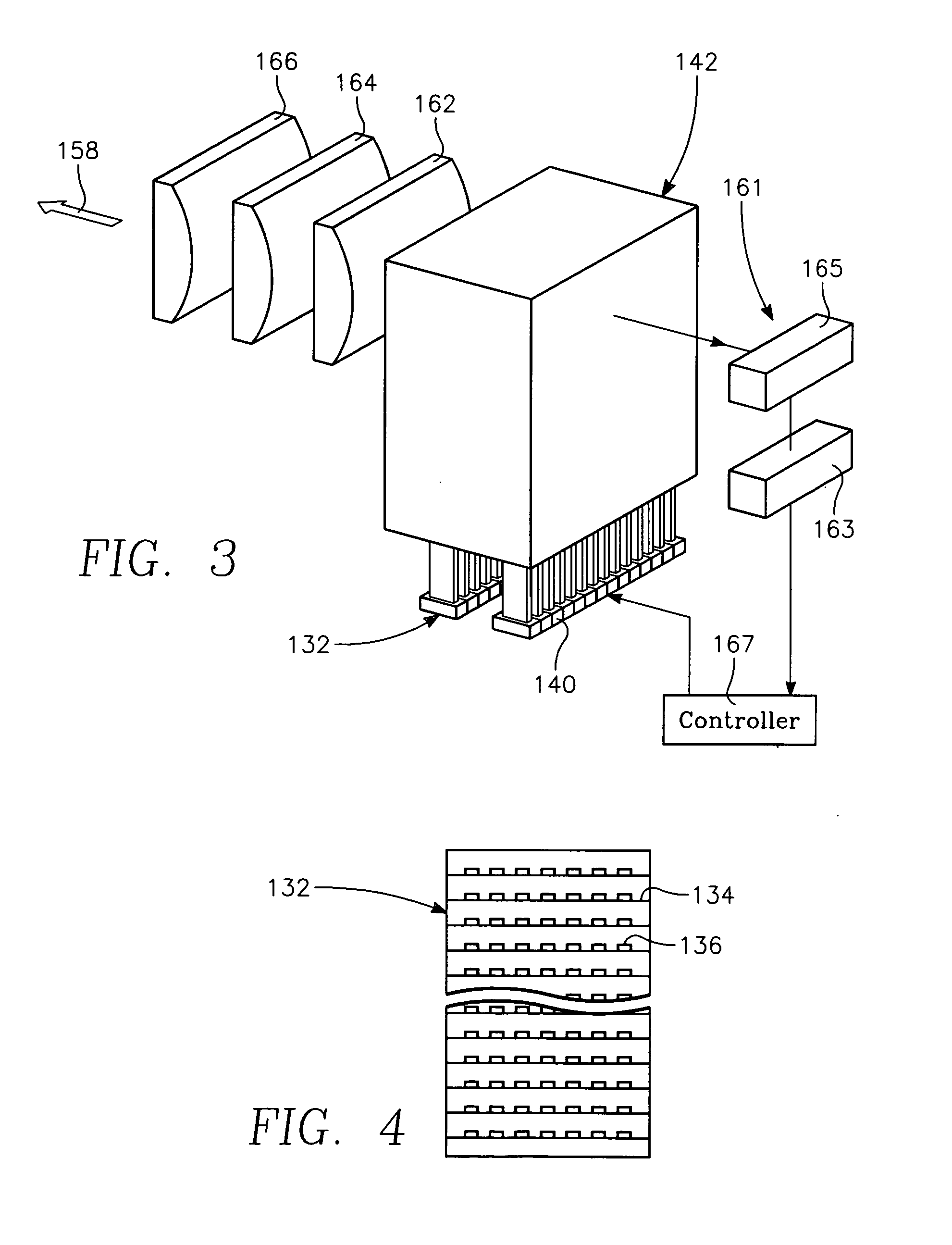

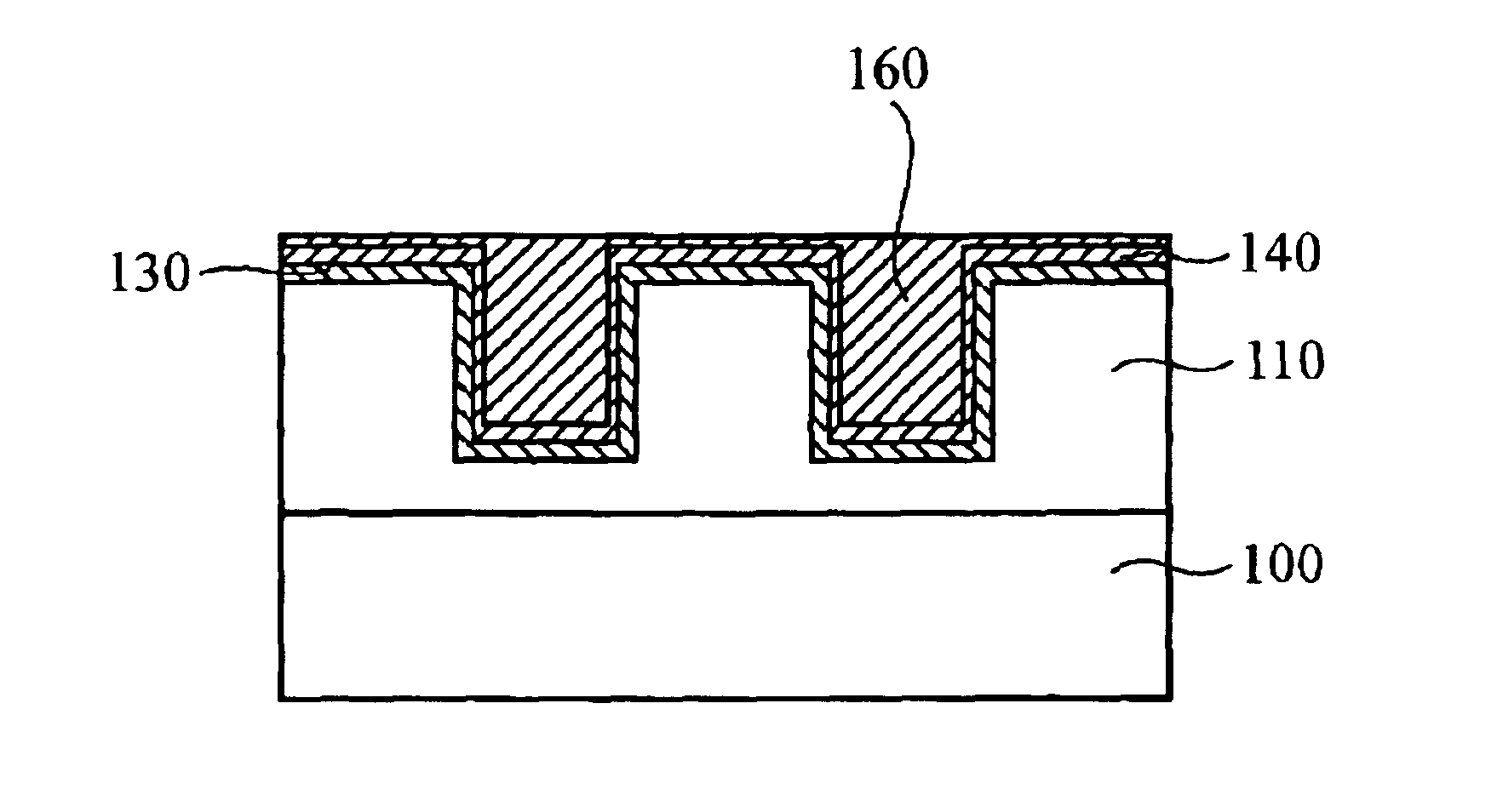

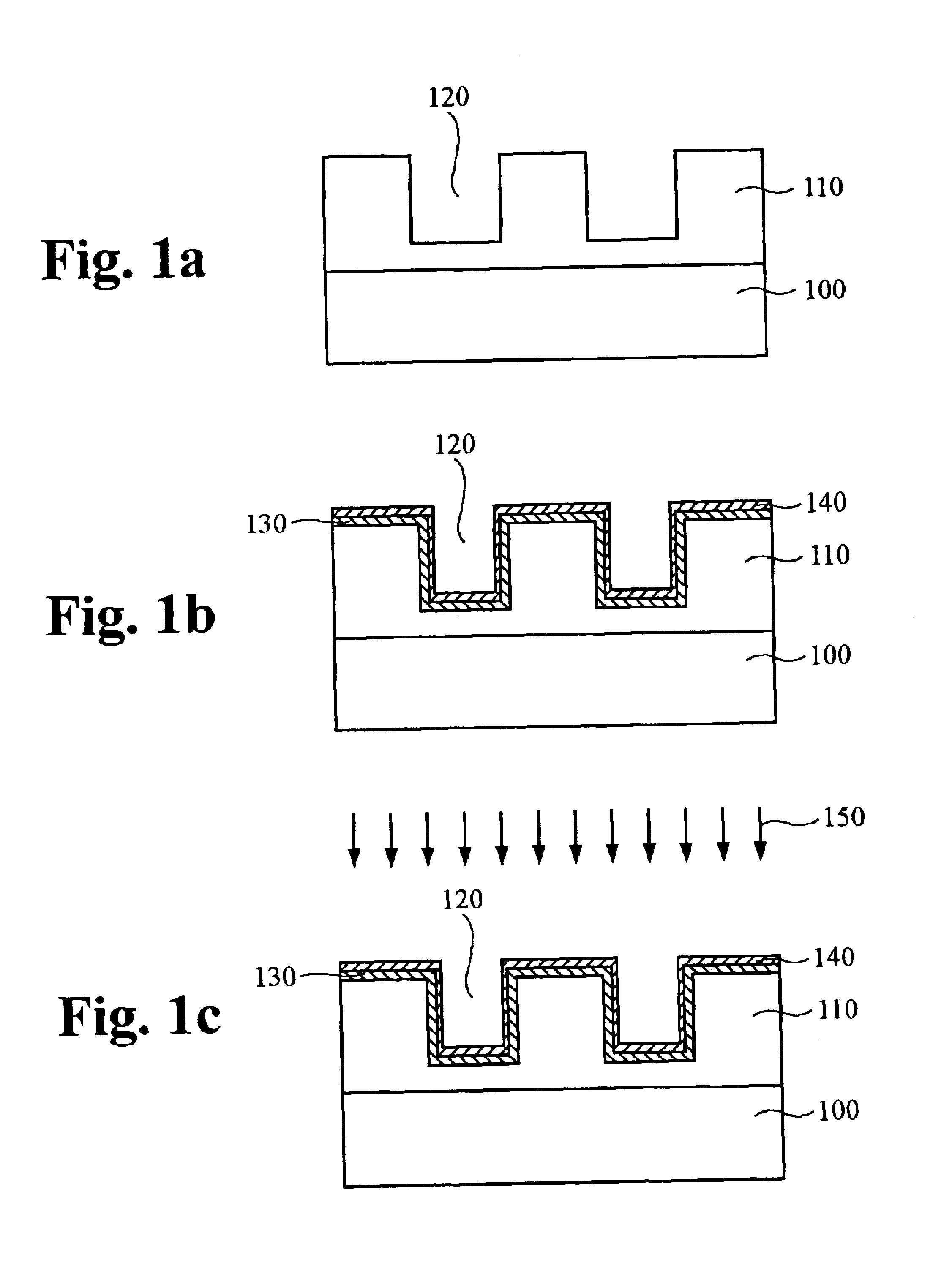

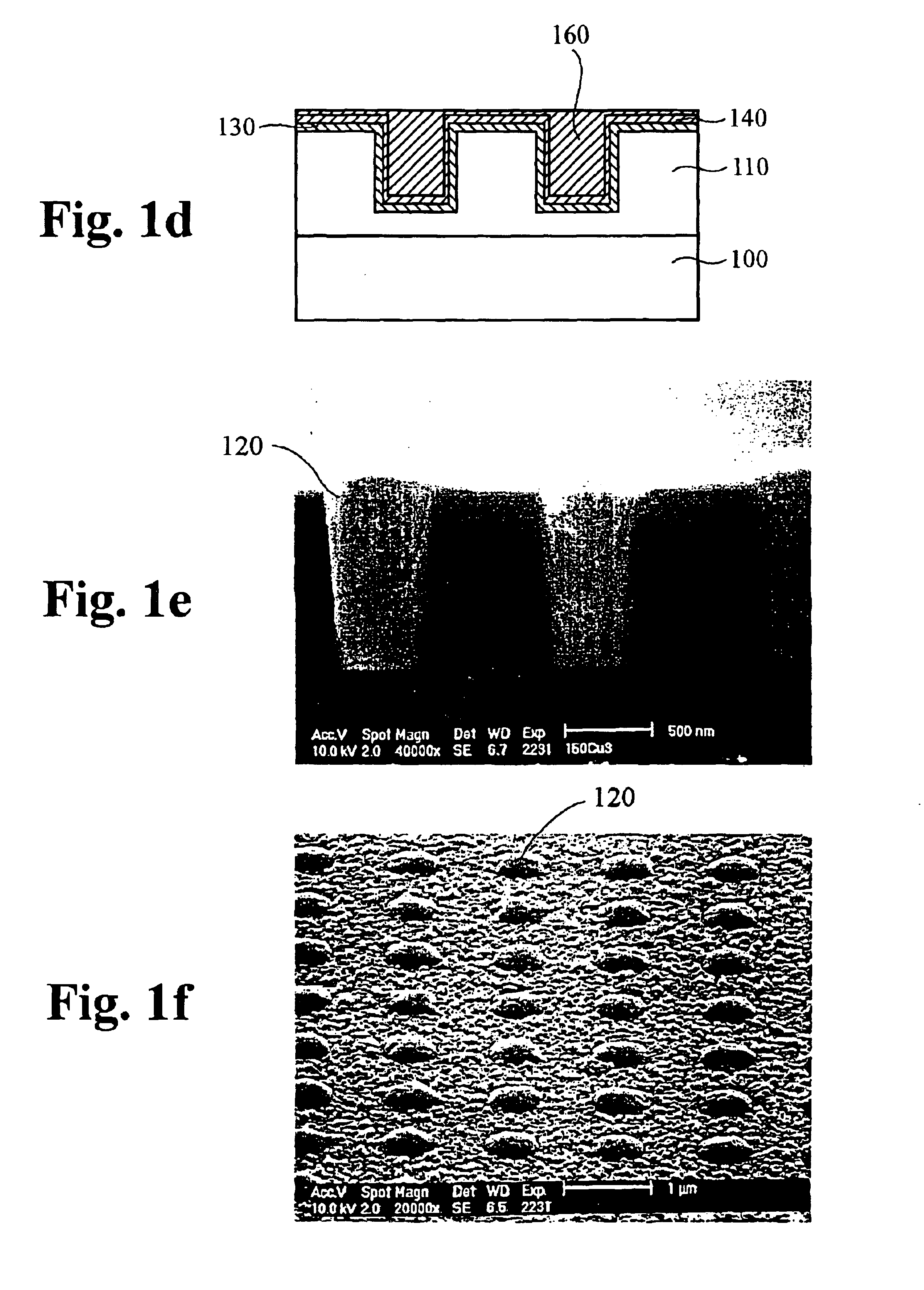

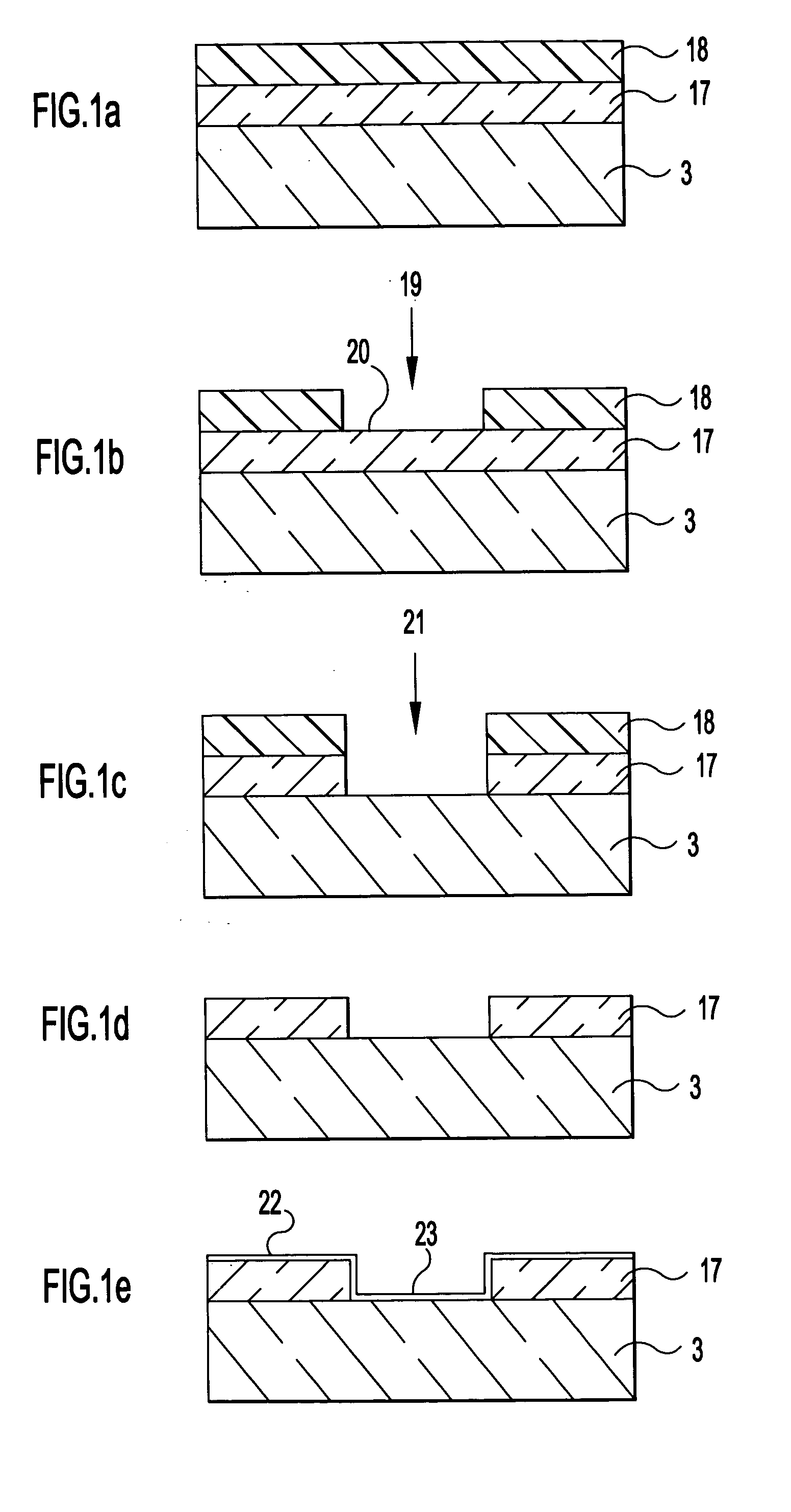

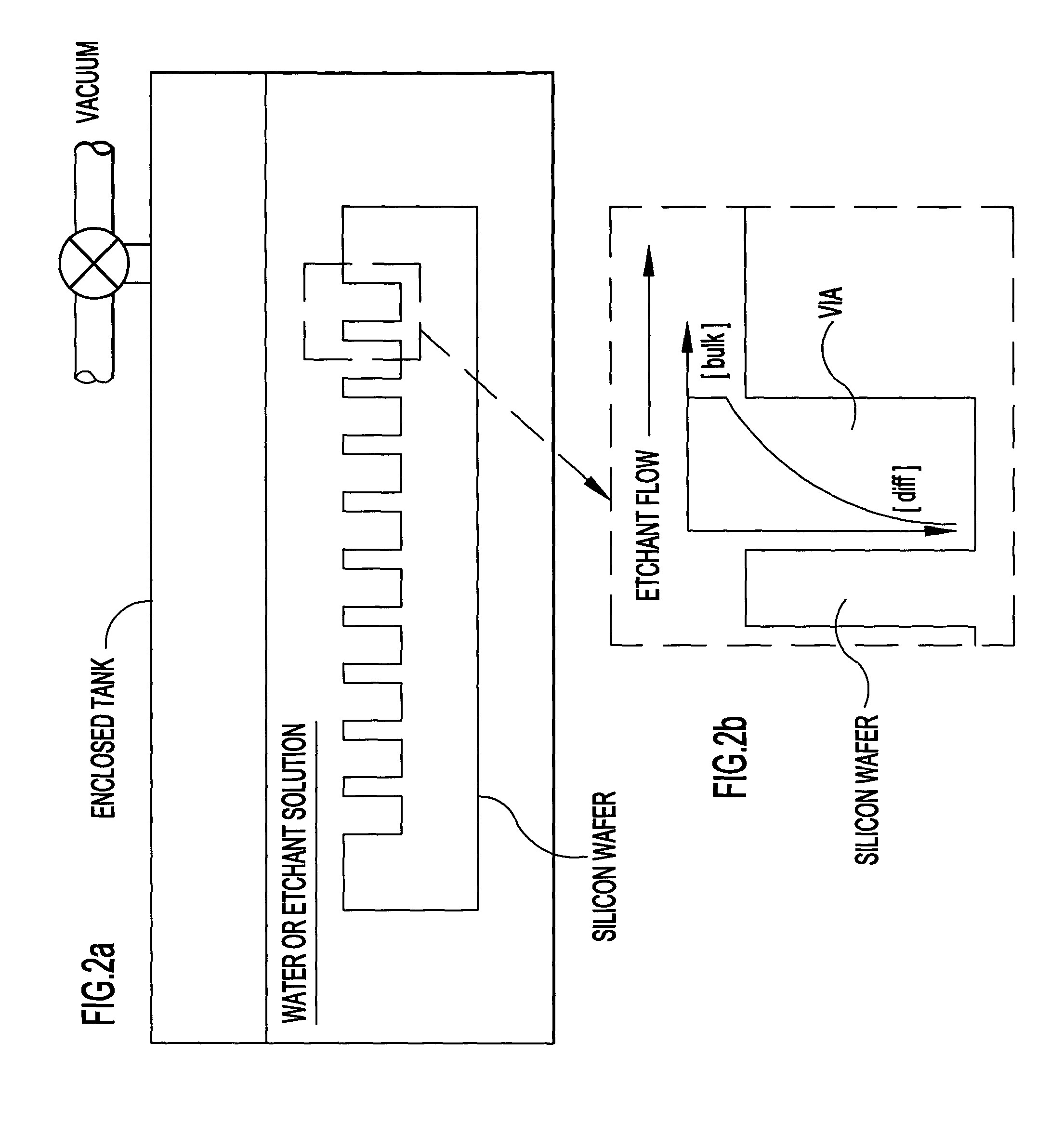

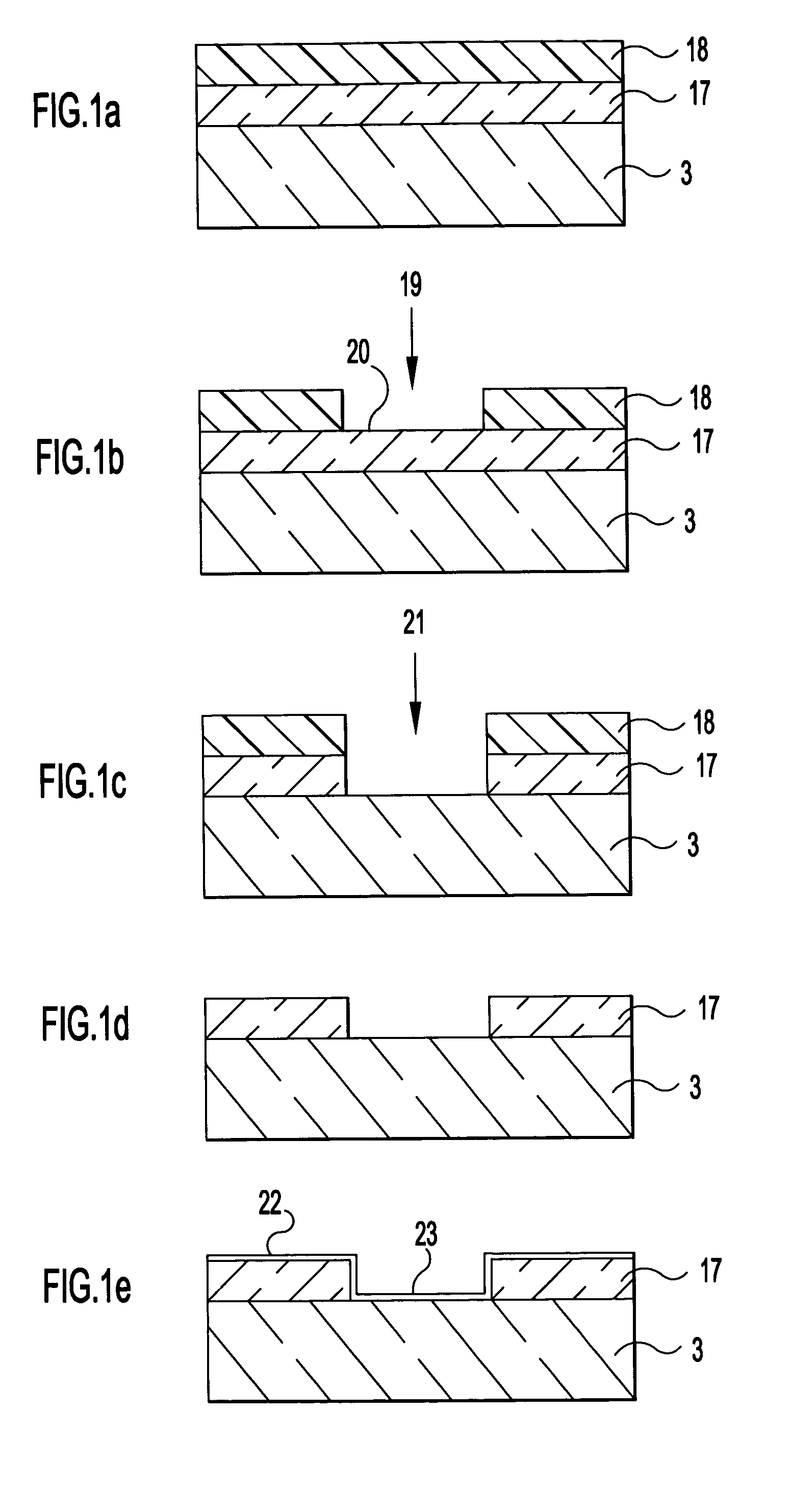

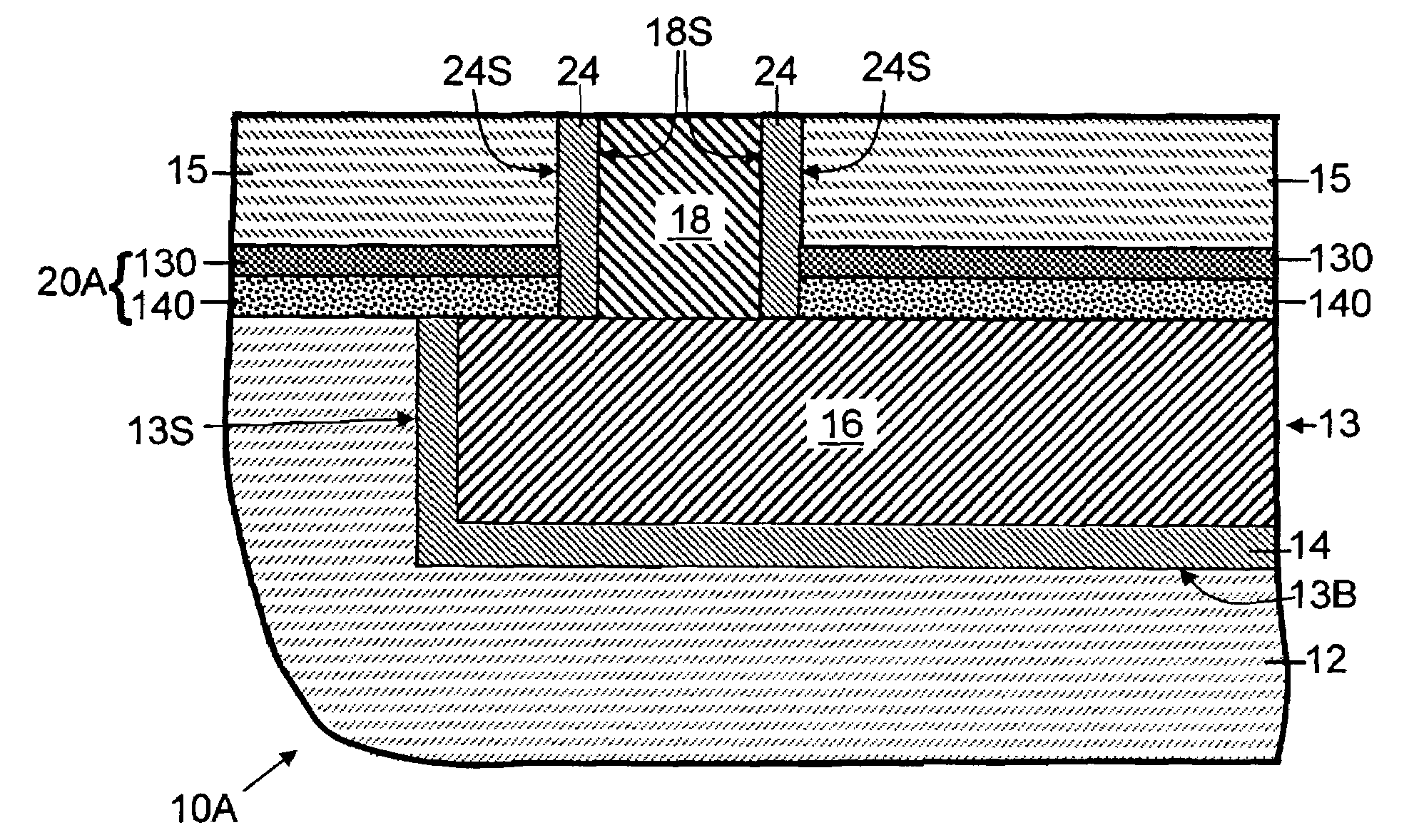

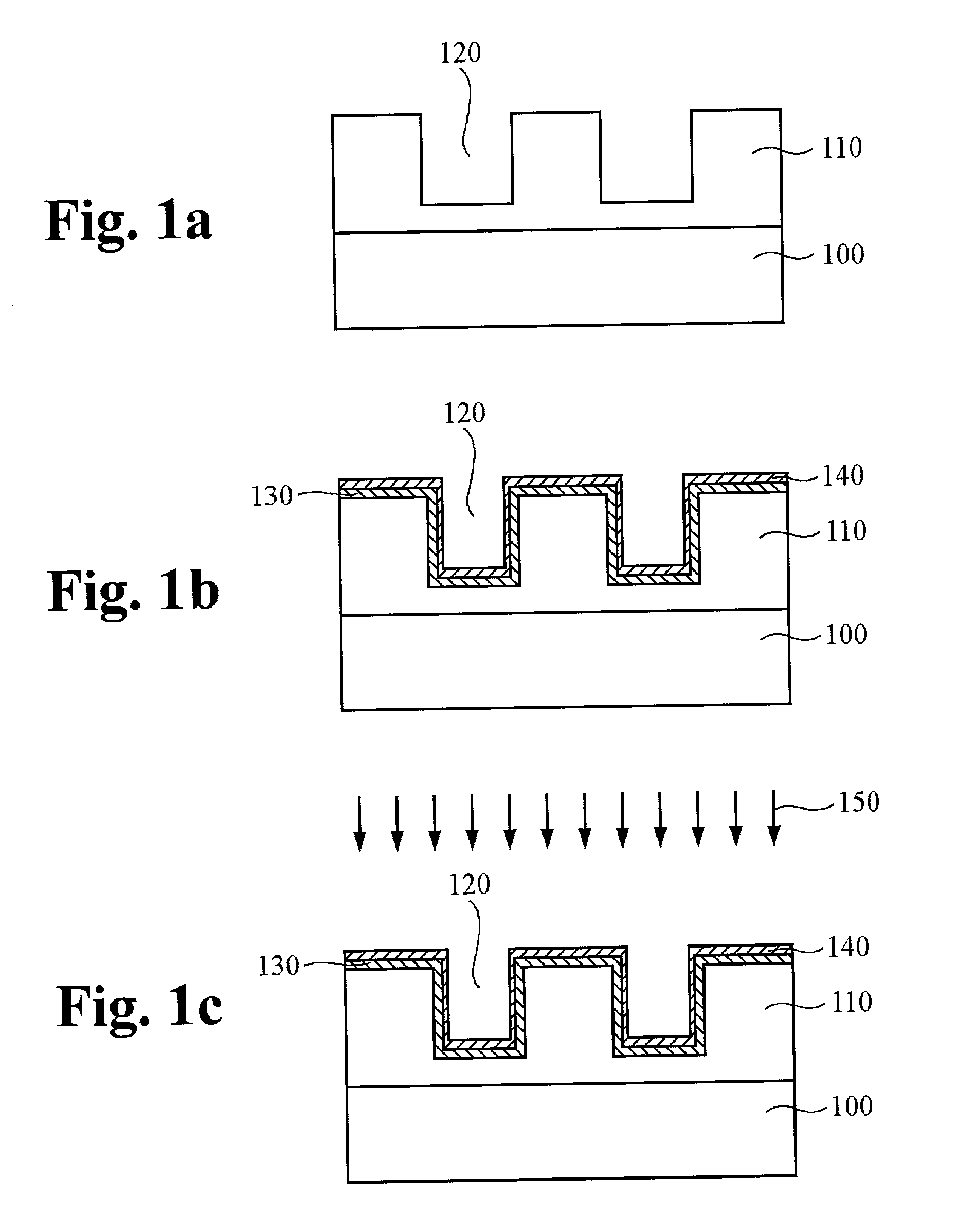

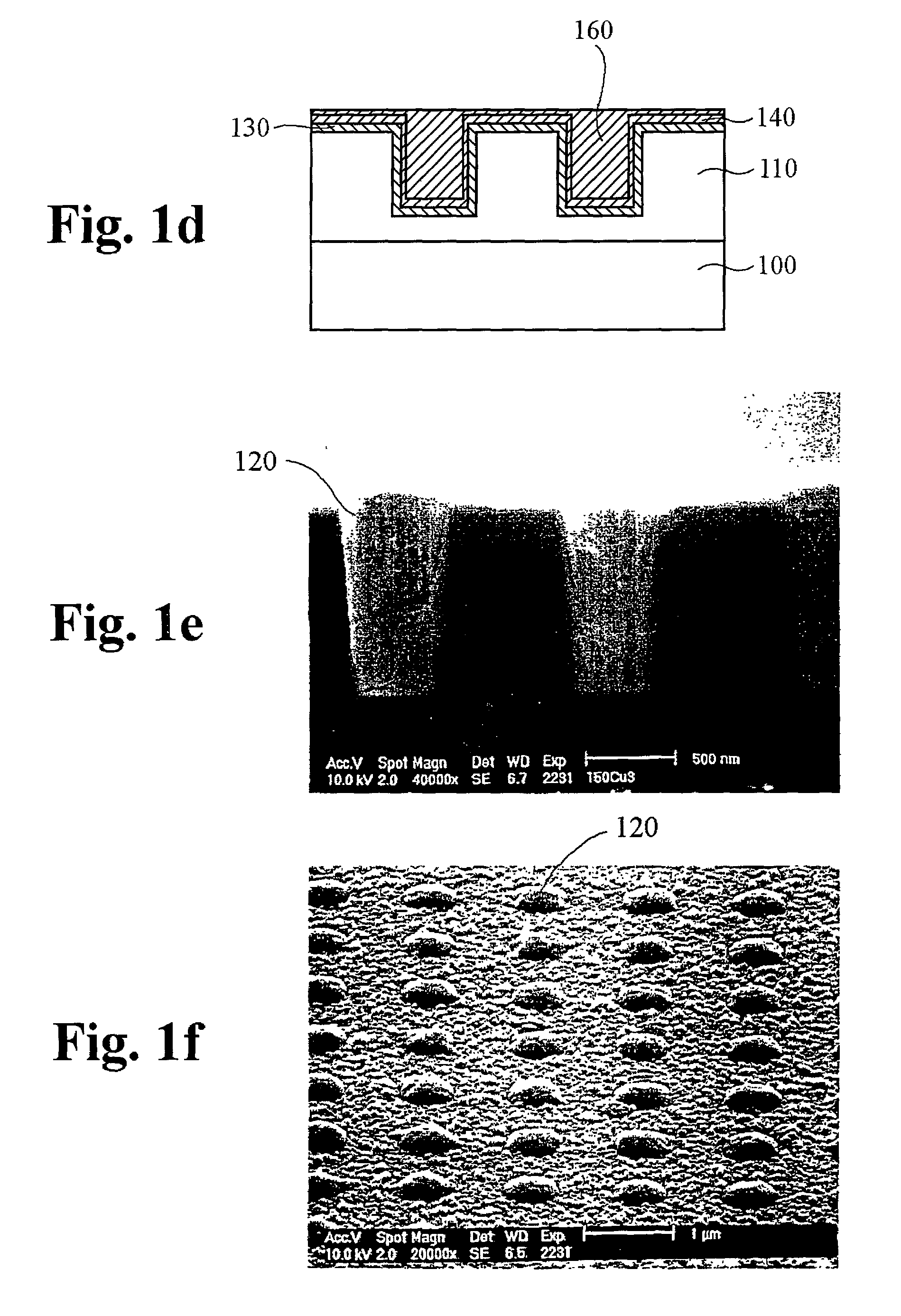

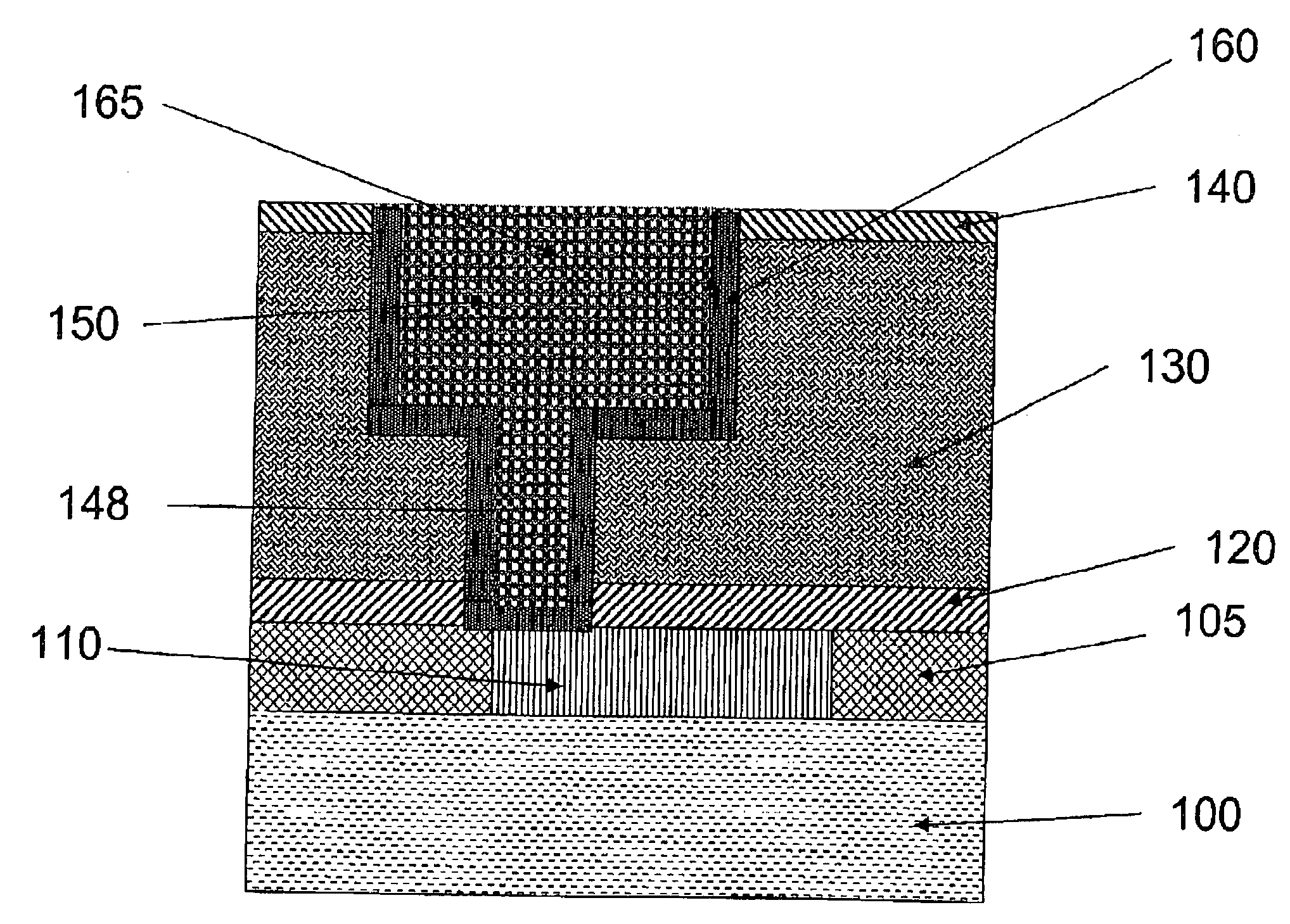

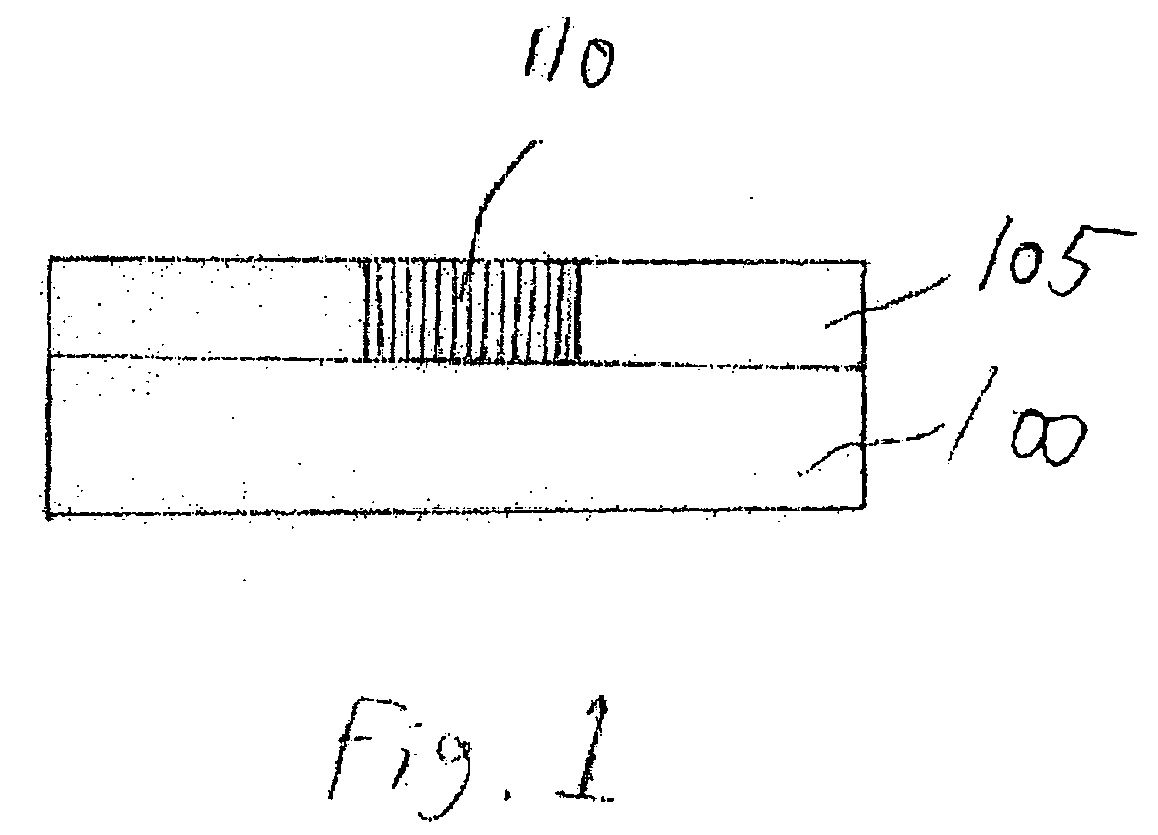

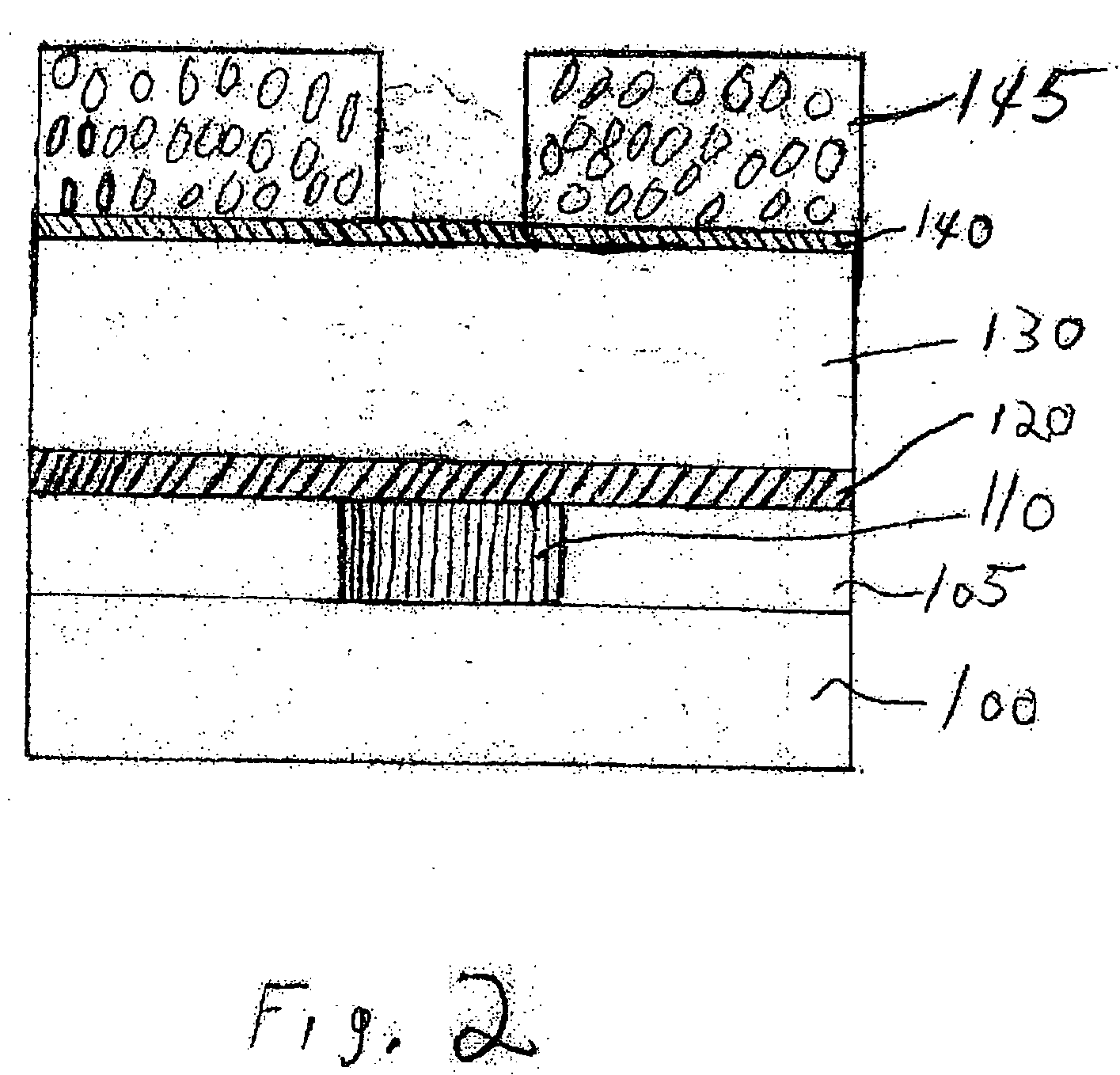

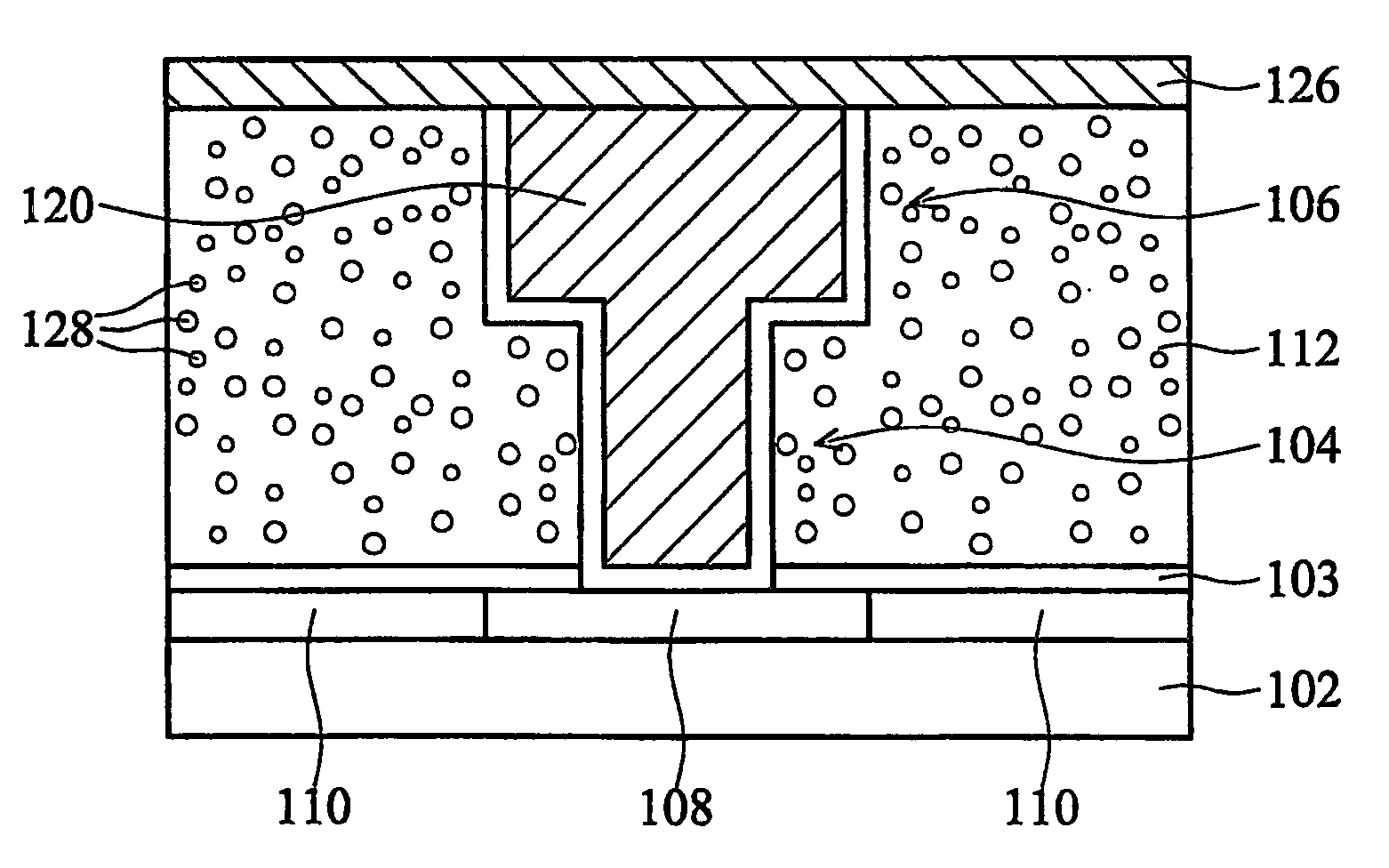

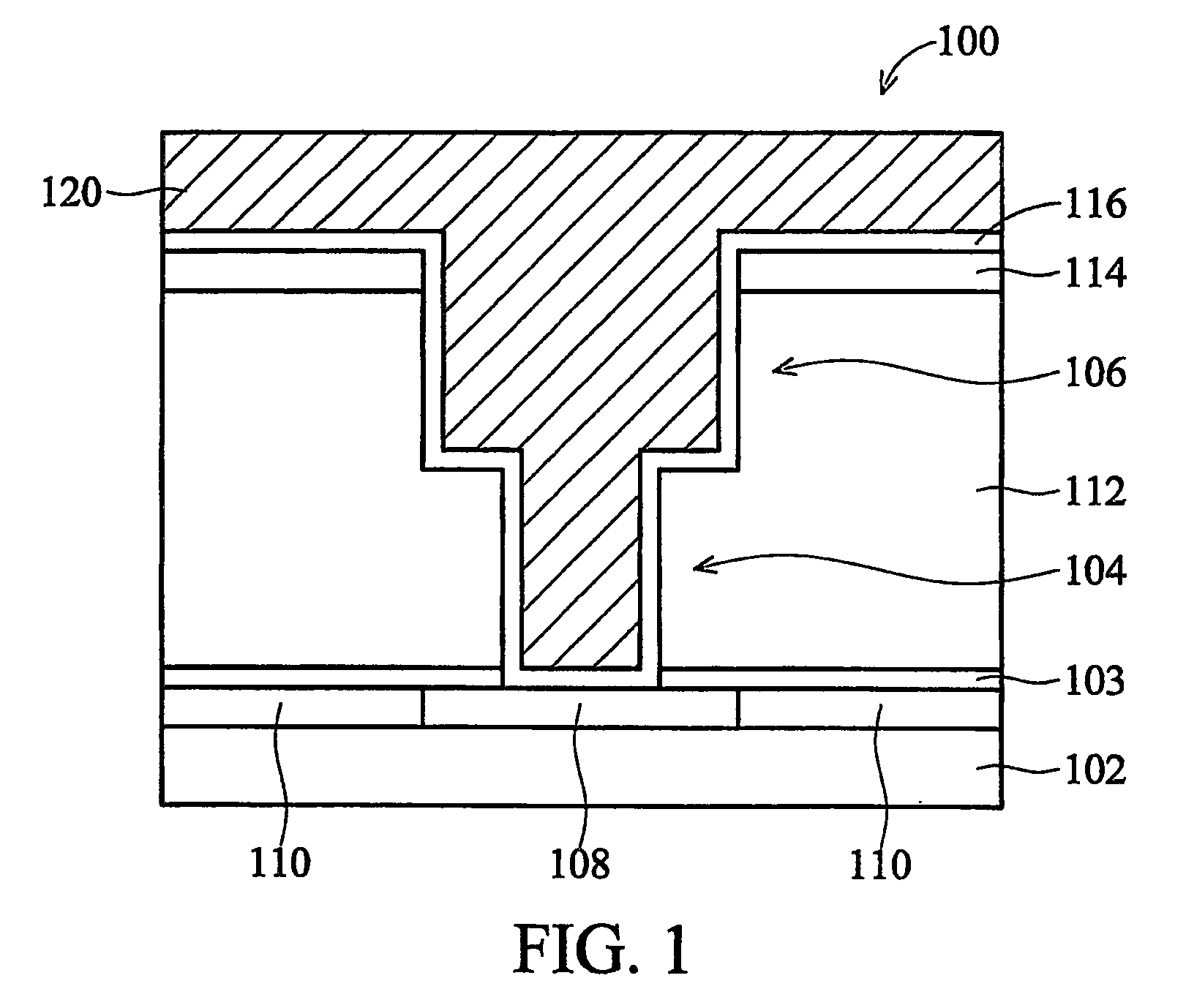

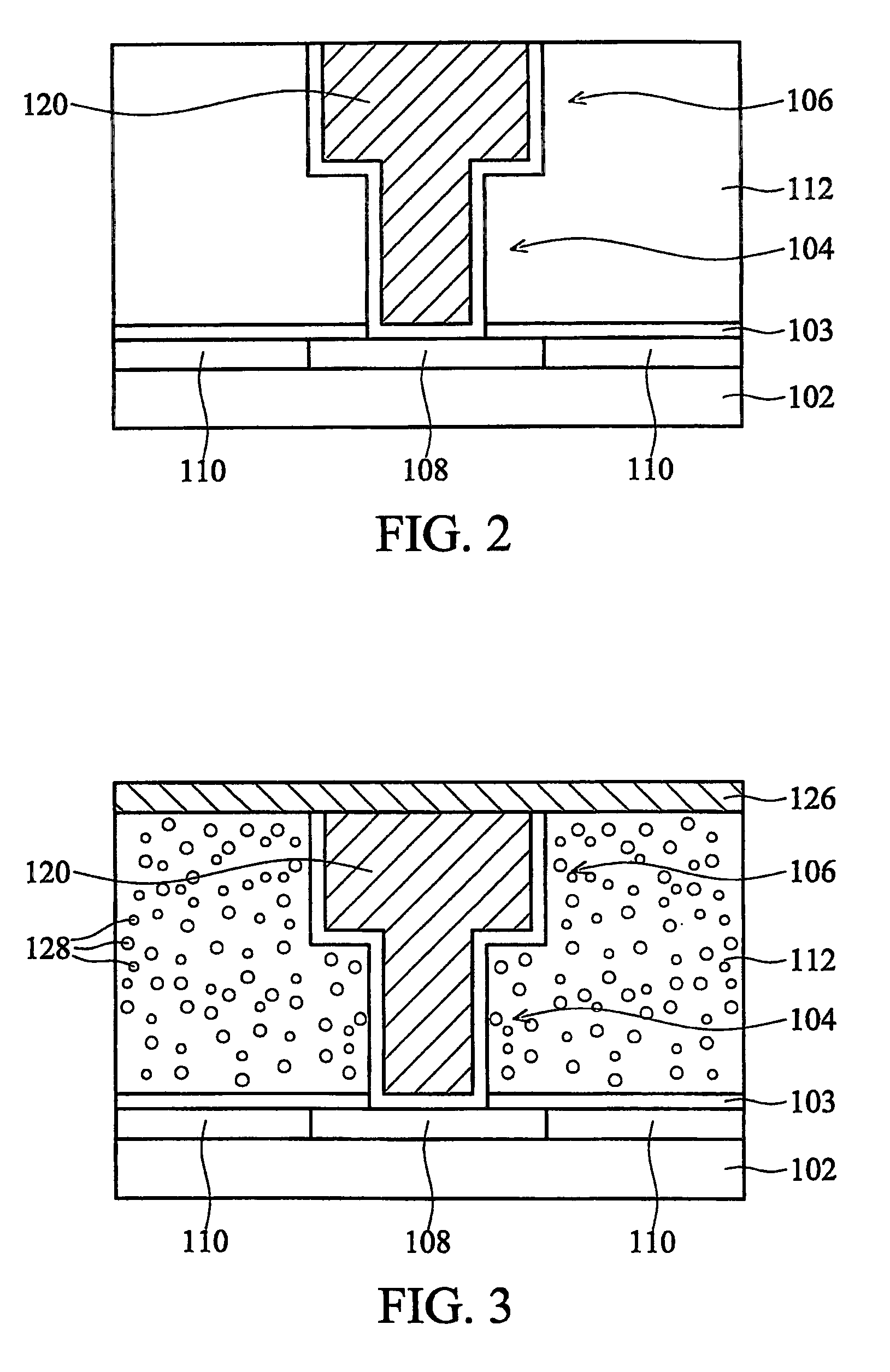

A method of forming a conductor in a thin film structure on a semiconductor substrate includes forming high aspect ratio openings in a base layer having vertical side walls, depositing a dielectric barrier layer comprising a dielectric compound of a barrier metal on the surfaces of the high aspect ratio openings including the vertical side walls, depositing a metal barrier layer comprising the barrier metal on the first barrier layer, depositing a main conductor species seed layer on the metal barrier layer and depositing a main conductor layer. The method further includes annealing the main conductor layer by (a) directing light from an array of continuous wave lasers into a line of light extending at least partially across the thin film structure, and (b) translating the line of light relative to the thin film structure in a direction transverse to the line of light. The method of Claim 1 further comprising, prior to the annealing step, depositing an amorphous carbon optical absorber layer on the main conductor layer. The step of depositing an amorphous carbon optical absorber layer includes introducing a carbon-containing process gas into a reactor chamber containing the substrate in a process zone of the reactor, applying RF source power to an external reentrant conduit of the reactor to generate a reentrant toroidal RF plasma current passing through the process zone and applying a bias voltage to the substrate.

Owner:APPLIED MATERIALS INC

Copper conductor annealing process employing high speed optical annealing with a low temperature-deposited optical absorber layer

InactiveUS20070032095A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesCopper conductorEngineering

A method of forming a conductor in a thin film structure on a semiconductor substrate includes forming high aspect ratio openings in a base layer having vertical side walls, depositing a dielectric barrier layer comprising a dielectric compound of a barrier metal on the surfaces of the high aspect ratio openings including the vertical side walls, depositing a metal barrier layer comprising the barrier metal on the first barrier layer, depositing a main conductor species seed layer on the metal barrier layer and depositing a main conductor layer. The method further includes annealing the main conductor layer by (a) directing light from an array of continuous wave lasers into a line of light extending at least partially across the thin film structure, and (b) translating the line of light relative to the thin film structure in a direction transverse to the line of light. The method of Claim 1 further comprising, prior to the annealing step, depositing an amorphous carbon optical absorber layer on the main conductor layer. The step of depositing an amorphous carbon optical absorber layer includes introducing a carbon-containing process gas into a reactor chamber containing the substrate in a process zone of the reactor, applying RF source power to an external reentrant conduit of the reactor to generate a reentrant toroidal RF plasma current passing through the process zone and applying a bias voltage to the substrate.

Owner:APPLIED MATERIALS INC

Method of forming copper interconnections and thin films using chemical vapor deposition with catalyst

InactiveUS6720262B2Semiconductor/solid-state device detailsSolid-state devicesCopper conductorSource material

A method of forming copper conductors for interconnecting active and passive elements as well as signal and power lines for circuits and devices on silicon wafers is disclosed. The method disclosed herein involves with using catalysts in conjunction with a chemical vapor deposition(CVD) process with typically using copper as a source material for forming interconnecting conductors. Interconnecting method for filling trenches, via holes, contacts, large trenches and holes for power devices and lines as well as for forming large passive elements is also disclosed. Disclosed herein are also a method of filling narrow and deep trenches and small in diameter and deep holes, and a method of forming very thin film on the flat top surface so that an etchback process, such as wet or dry etchback as well as plasma etchback processes, can be used for removing a thin film in preparation for subsequent processing steps, thereby rather expensive chemical mechanical polishing(CMP) process need not be used.

Owner:ASM KOREA LTD

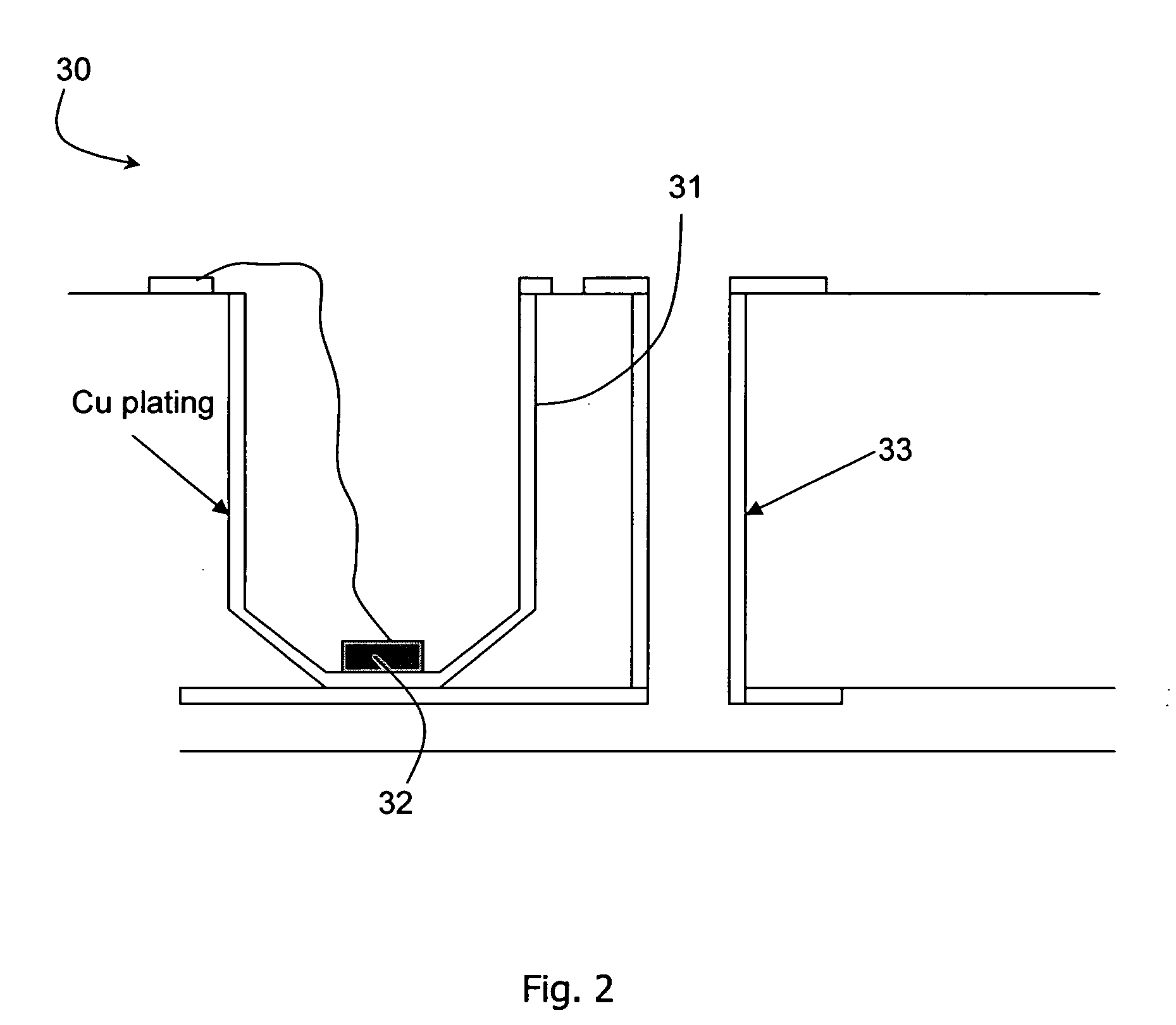

Deep filled vias

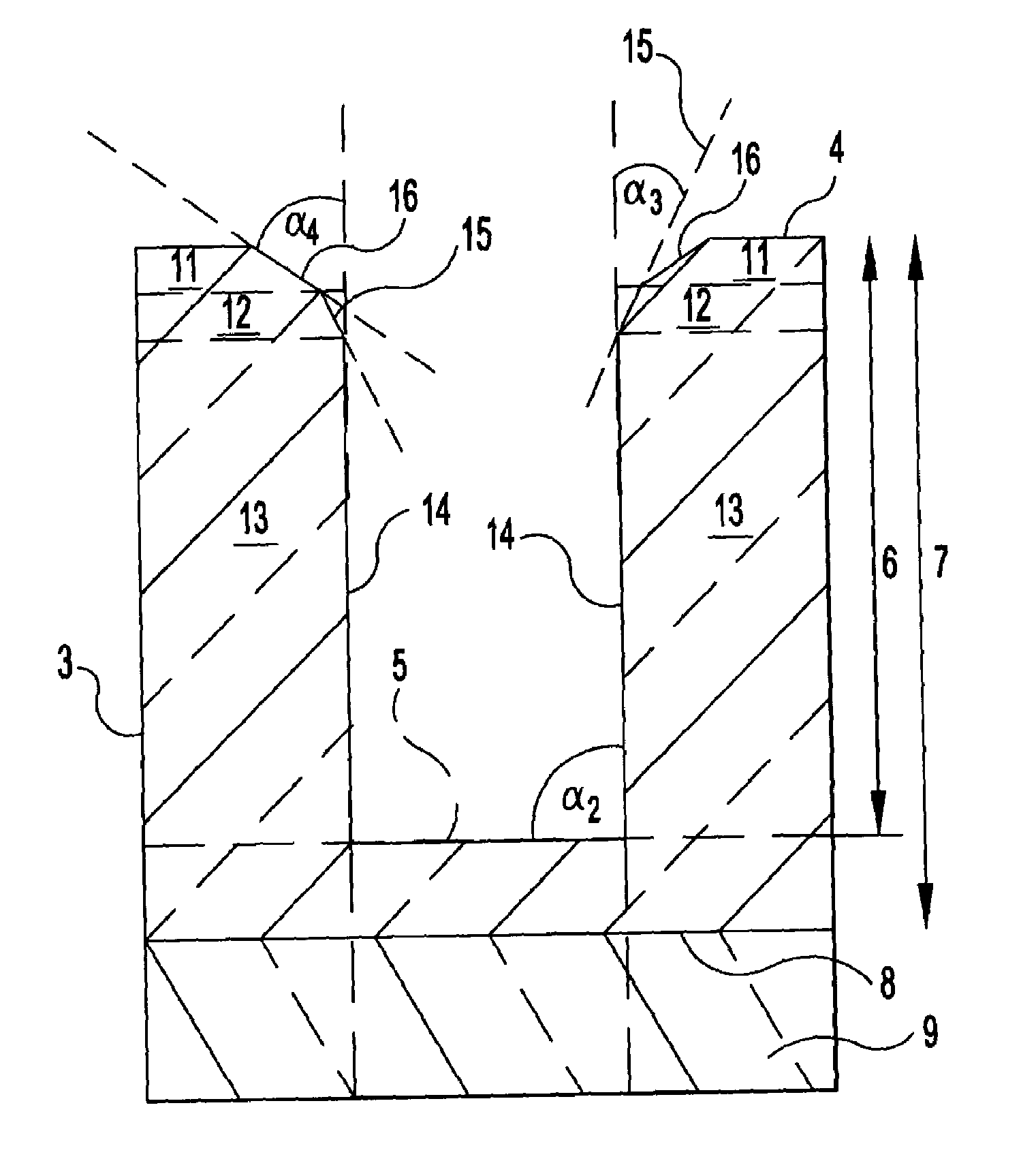

ActiveUS20050037608A1Maintain structural integrityReliable fillingSemiconductor/solid-state device manufacturingCopper conductorElectrical connection

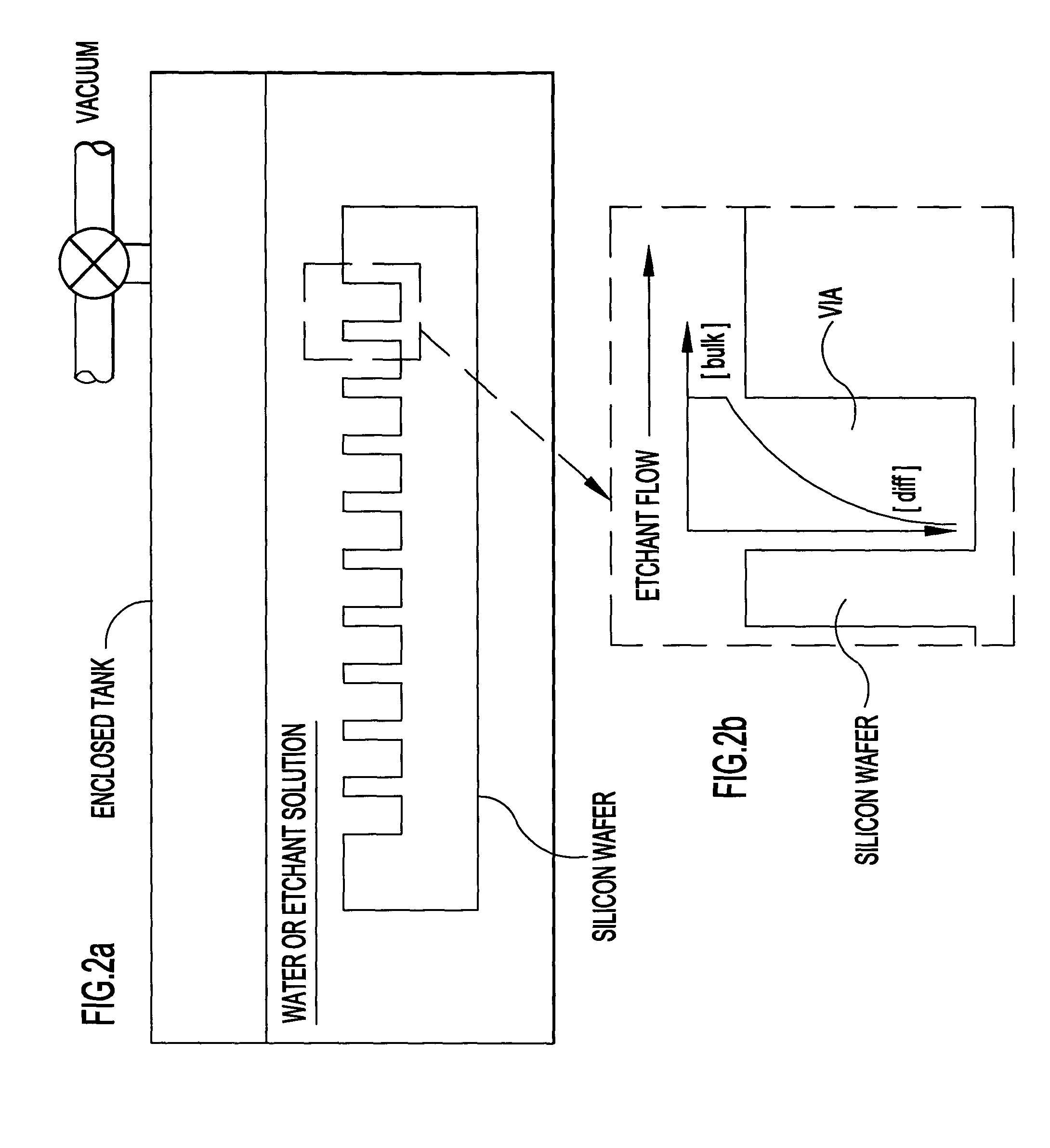

Flared and non-flared metallized deep vias having aspect ratios of about 2 or greater are provided. Blind vias have been fabricated in silicon substrates up to a depth of about 300 microns, and flared through vias have been fabricated up to about 750 microns, the approximate thickness of a silicon substrate wafer, enabling the formation of electrical connections at either or both ends of a via. In spite of the depth and high aspect ratios attainable, the etched vias are completely filled with plated copper conductor, completing the formation of deep vias and allowing fuller use of both sides of the substrate.

Owner:GLOBALFOUNDRIES US INC

Deep filled vias

Owner:GLOBALFOUNDRIES U S INC

Embedded NANO UV blocking barrier for improved reliability of copper/ultra low k interlevel dielectric electronic devices

InactiveUS20080122103A1Prevention of UV/e-beam modificationChange is minimalSemiconductor/solid-state device detailsSolid-state devicesDielectricCopper conductor

An interconnect in provided which comprises a copper conductor having both a top surface and a lower surface, with caps formed on the top surface of the metallic conductor. The cap is formed of dual laminations or multiple laminations of films with the laminated films including an Ultra-Violet (UV) blocking film and a diffusion barrier film. The diffusion barrier film and the UV blocking film may be separated by an intermediate film.

Owner:GLOBALFOUNDRIES INC

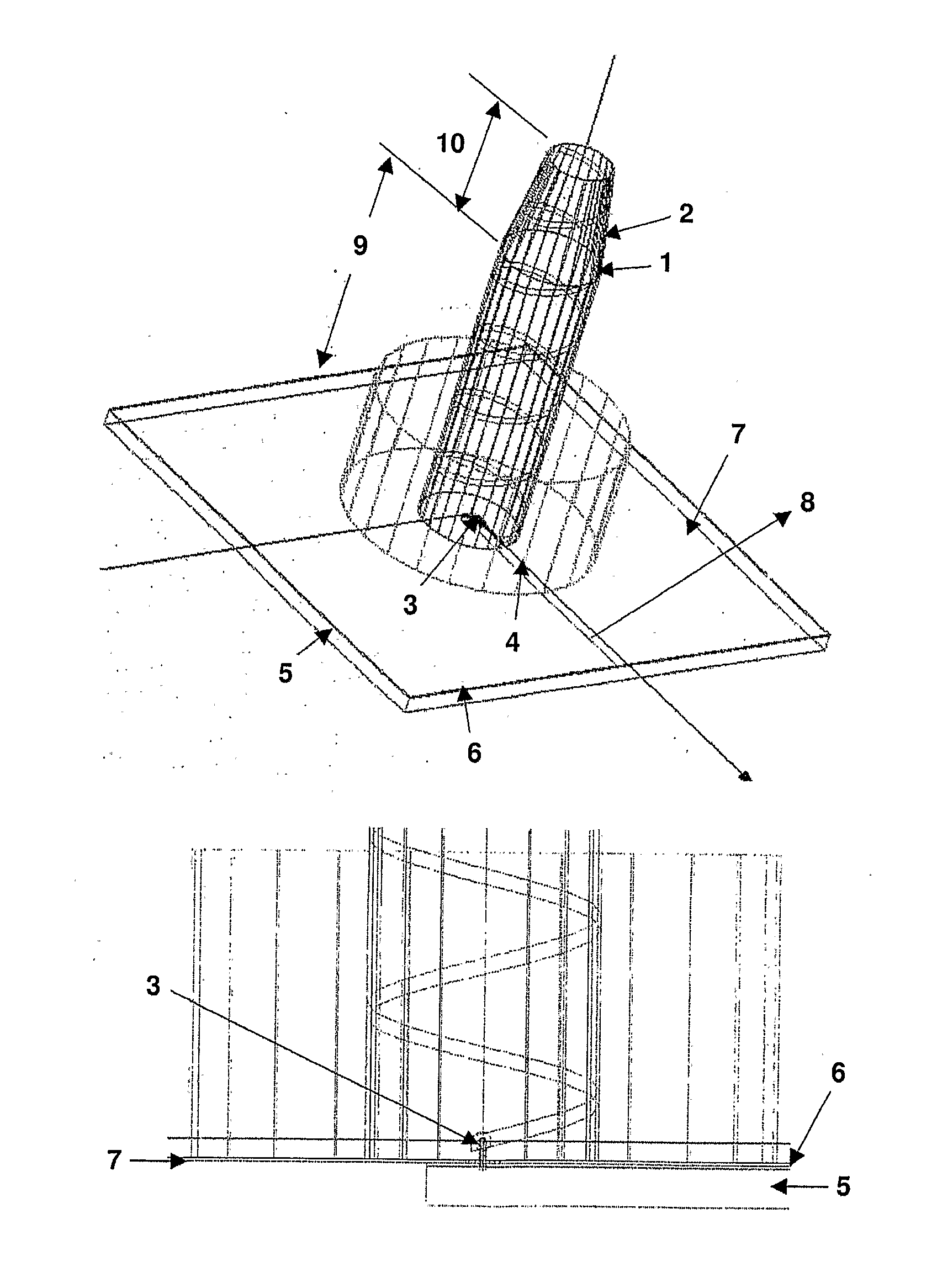

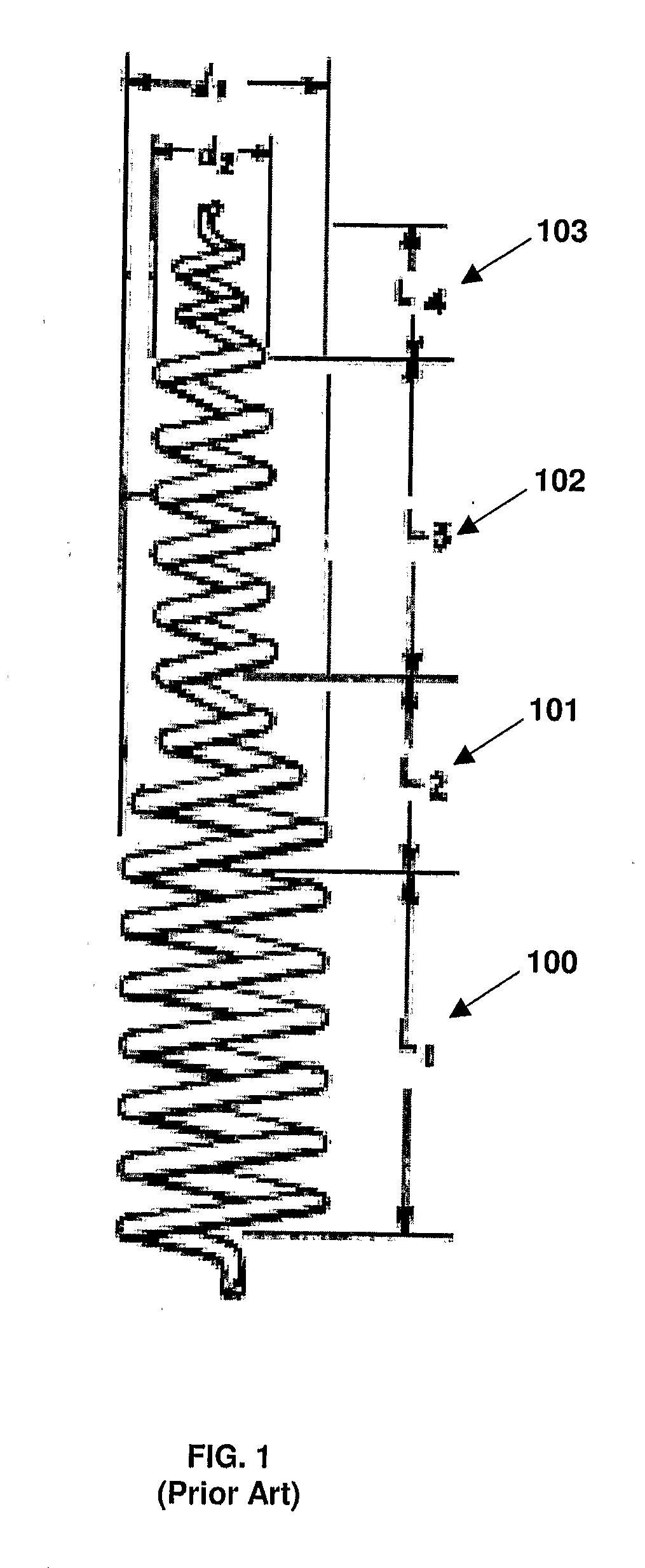

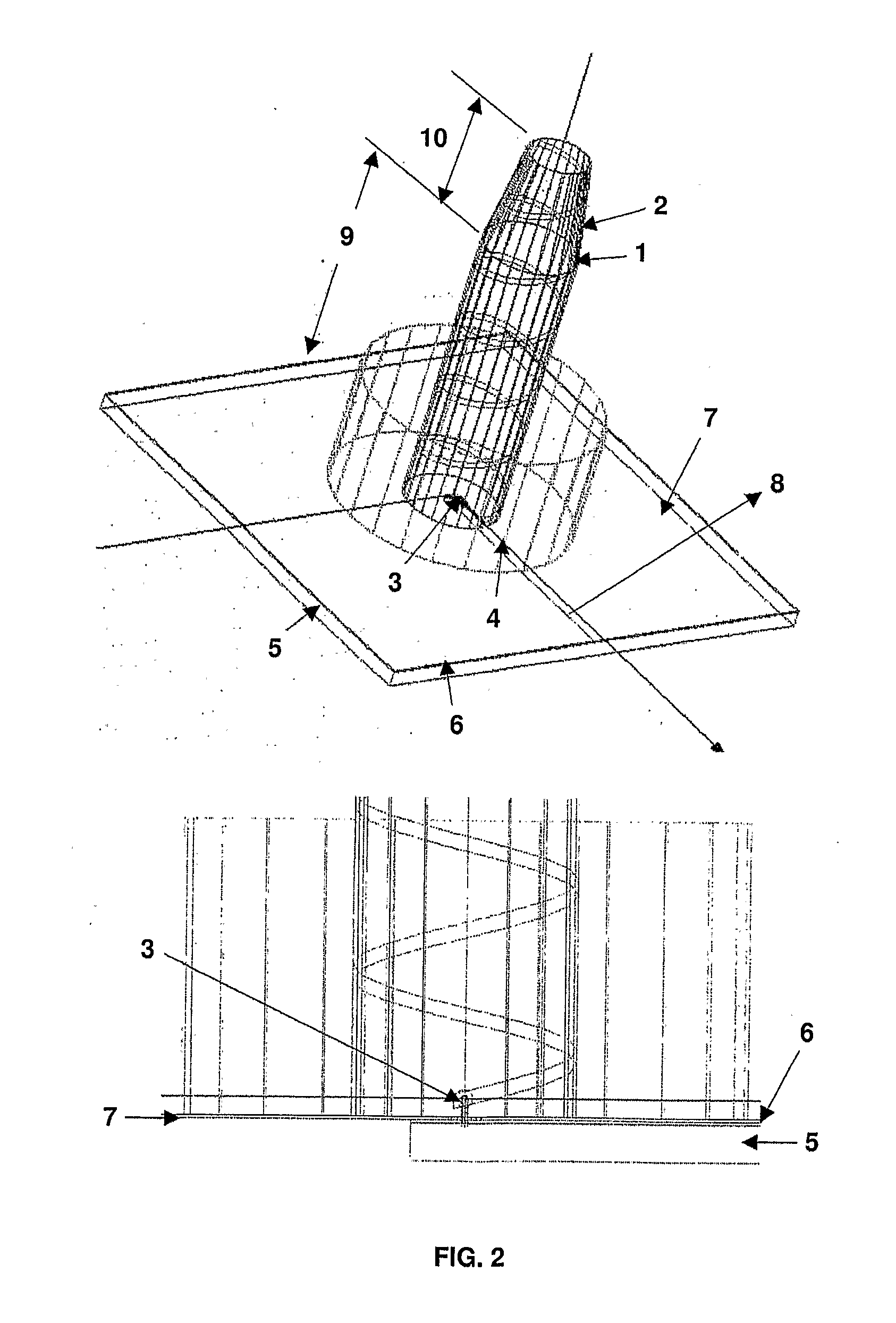

Printed quasi-tapered tape helical array antenna

ActiveUS20120188142A1Reduce decreaseMinimize couplingAntenna arraysElectrically long antennasCopper conductorAxial ratio

A printed quasi-tapered tape helical element and printed helical array antenna arc disclosed. The helical element comprises a thin helix conductor having a uniform section associated with a tapered section. The helix conductor can be printed on a thin dielectric sheet and bonded to a hollow composite dielectric support. A solid copper conductor is configured to provide electrical connection between a feeding point of the helix conductor and a microstrip line of a microstrip feed network. The uniform and tapered helix turns are respectively wrapped around the uniform and tapered sections, which enables impedance matching, axial mode excitation, gain and radiation patterns, and damping out of standing waves generated in current distribution over the helix conductor. Conductive composite cups surrounding each helical element reduces mutual coupling in array environment. Thus, the helical element and the array antenna achieve low on-axis and off-axis axial ratio performance over the wideband for global coverage.

Owner:INDIAN SPACE RES ORG OF ISRO

Silver coated copper conductor slurry for front electrode of solar battery and preparation method of silver coated copper conductor slurry

ActiveCN102610297ALow costImprove electrical performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureCopper conductorMetallurgy

The invention provides silver coated copper conductor slurry for a front electrode of a solar battery and a preparation method of the silver coated copper conductor slurry for the front electrode of the solar battery. The silver coated copper conductor slurry for the front electrode of the solar battery comprises a conductive phase, glass powder and an organic carrier, wherein the conductive phase is silver coated copper powder and silver powder which account for 68-85% of the total weight of the slurry, the glass powder is Bi-B-Zn-Si-Ti-Ba-Al-O glass powder which accounts for 5-10% of the total weight of the slurry, and the organic carrier accounts for 10-22% of the total weight of the slurry. The preparation method comprises the steps: mixing the silver coated copper powder, the silver powder and the glass powder; weighing the organic carrier to agitate adequately; then mixing the silver coated copper powder, the silver powder and the glass powder with the organic carrier; and then rolling the mixture to obtain the silver coated copper conductor slurry for the front electrode of the solar battery. According to the silver coated copper conductor slurry for the front electrode of the solar battery, the electric properties of the electrode greatly is improved, and the photoelectric conversion rate of the battery is enhanced. The maximum fineness of the silver coated copper conductor slurry for the front electrode of the solar battery is 15 microns, the average fineness of the silver coated copper conductor slurry is less than 7 microns, the solid content is 80-87%, and the viscosity is 200-100keps. The solar battery printed and sintered by the silver coated copper slurry has higher photoelectric conversion rate and low cost.

Owner:昆明高聚科技有限公司

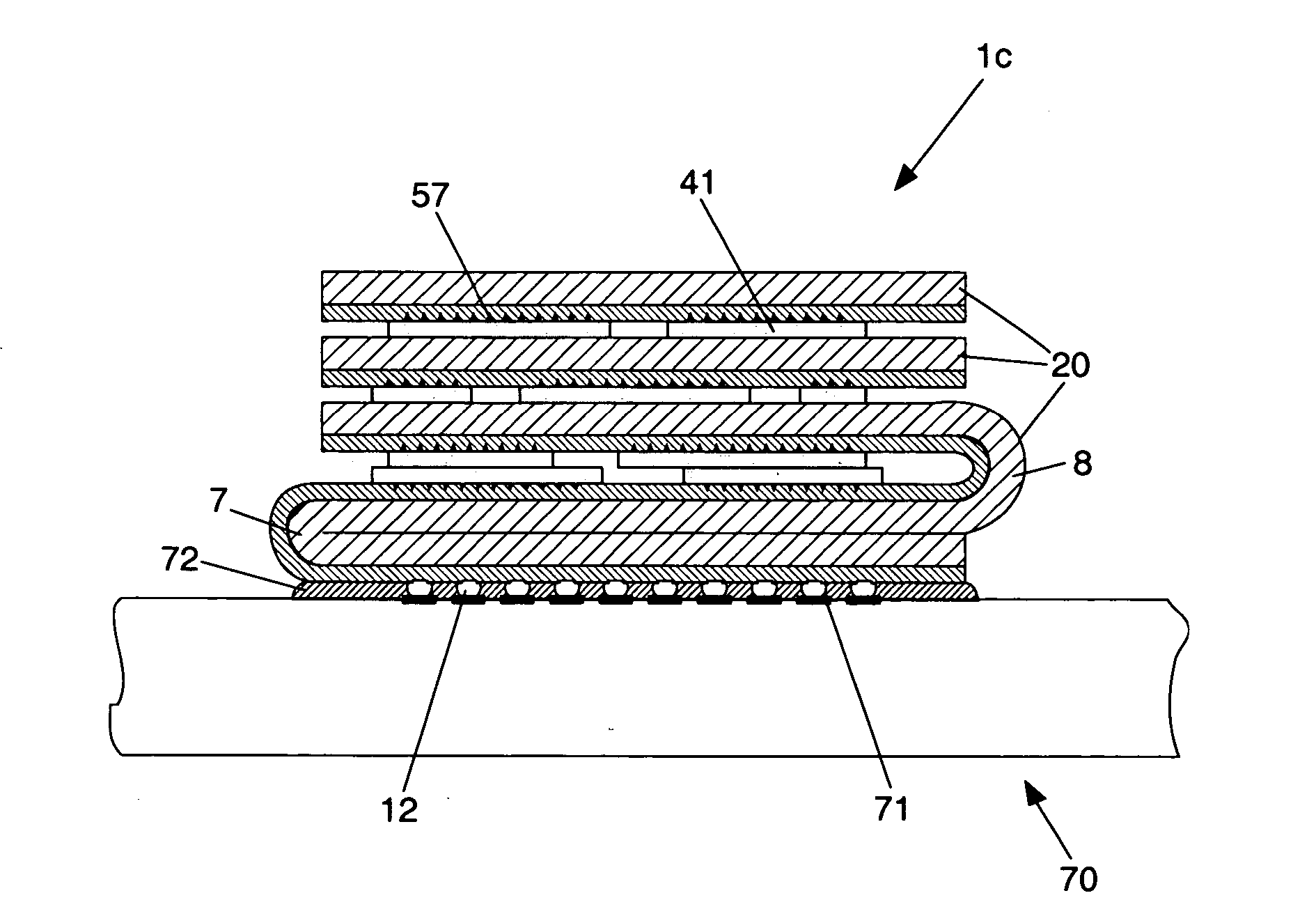

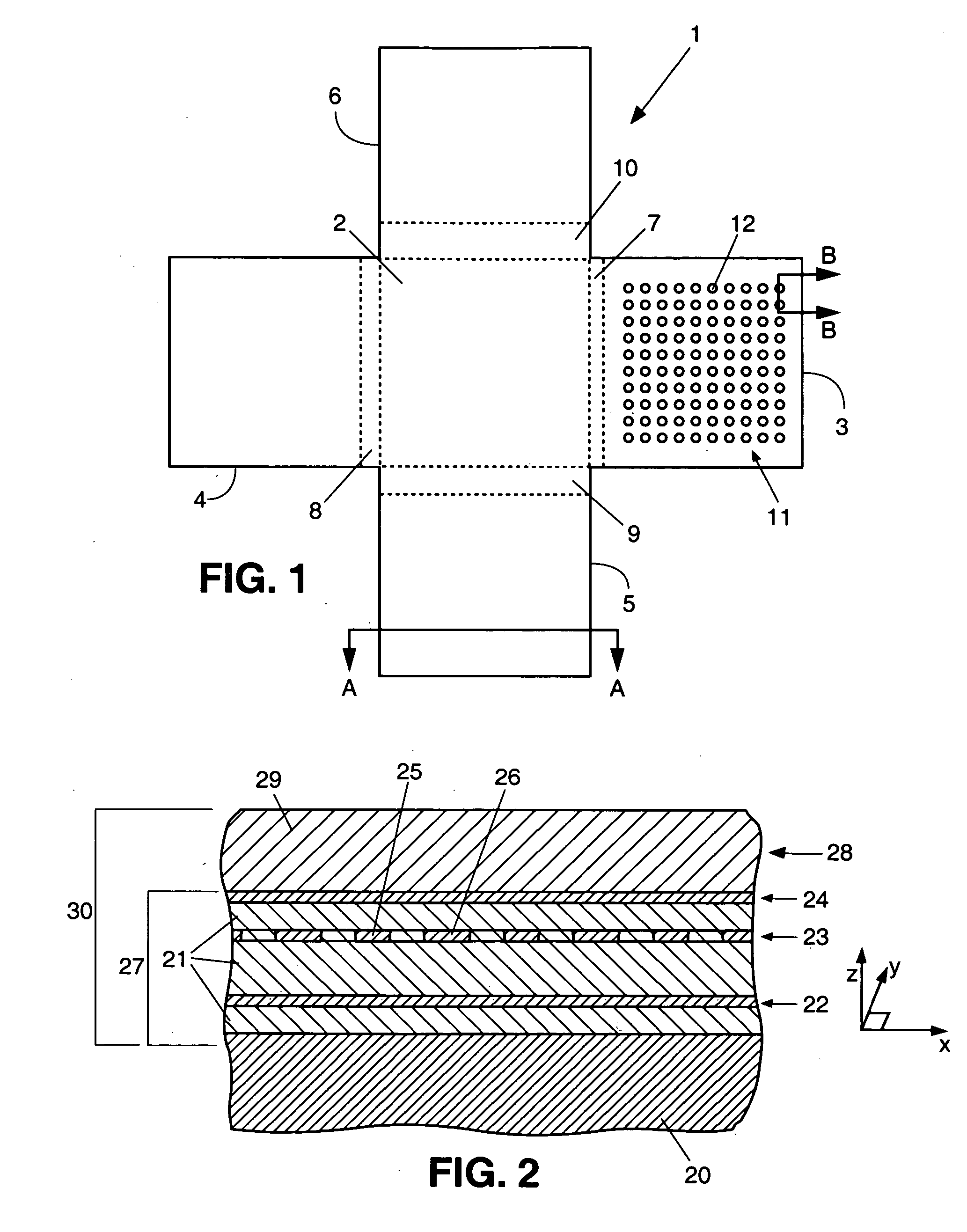

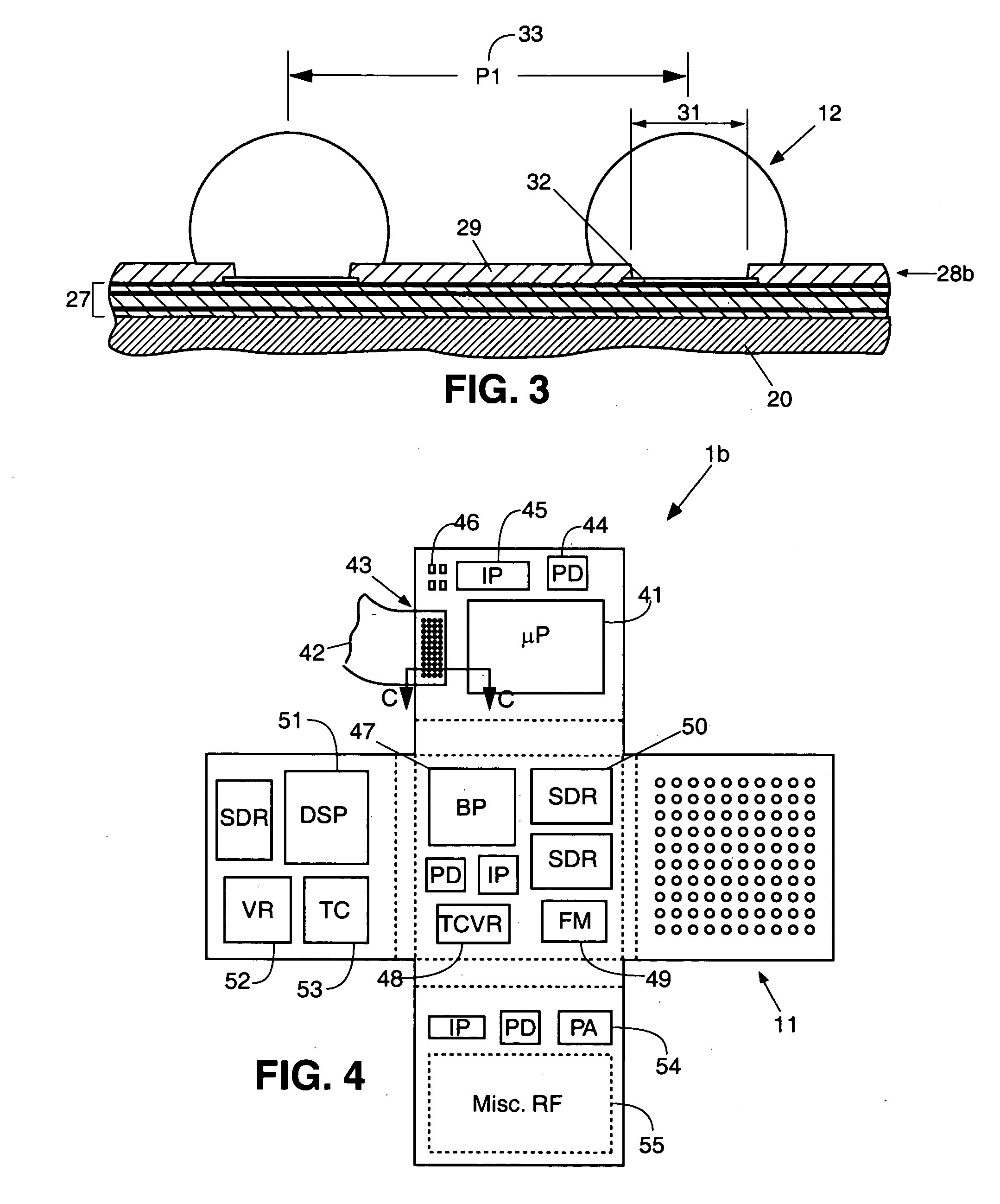

System in package

InactiveUS20050184376A1Improve cooling effectIncrease speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper conductorBand shape

A system in package (SIP) is fabricated on a sheet of copper foil. An interconnection circuit is fabricated on the foil using copper conductors and a dual damascene structure for each conductive layer. The preferred dielectric material is an amorphous fluorinated polymer called Cytop. Input / output traces of the interconnection circuit terminate in wells filled with solder. Chips are bumped and direct attached by inserting the bumps into the wells. The preferred bumps are gold stud bumps, and the preferred wells contain solder paste to a depth of approximately 15 microns. Imprinting is the preferred method for patterning; it enables 6-micron wide traces, 6-micron diameter vias, and a cost per well of around 0.02 cents. Stripline structures are described for a 4-layer stackup that can support operating frequencies of at least 10 GHz. New methods are proposed for testing the completed assembly and for rework of any chips that prove defective. After the assembly is fully tested and reworked in sheet form the copper foil is folded to form a stacked die package or system in package. 5-high and 9-high stacks are illustrated. The copper foil provides a low impedance thermal path for cooling every chip in the SIP.

Owner:SALMON TECH

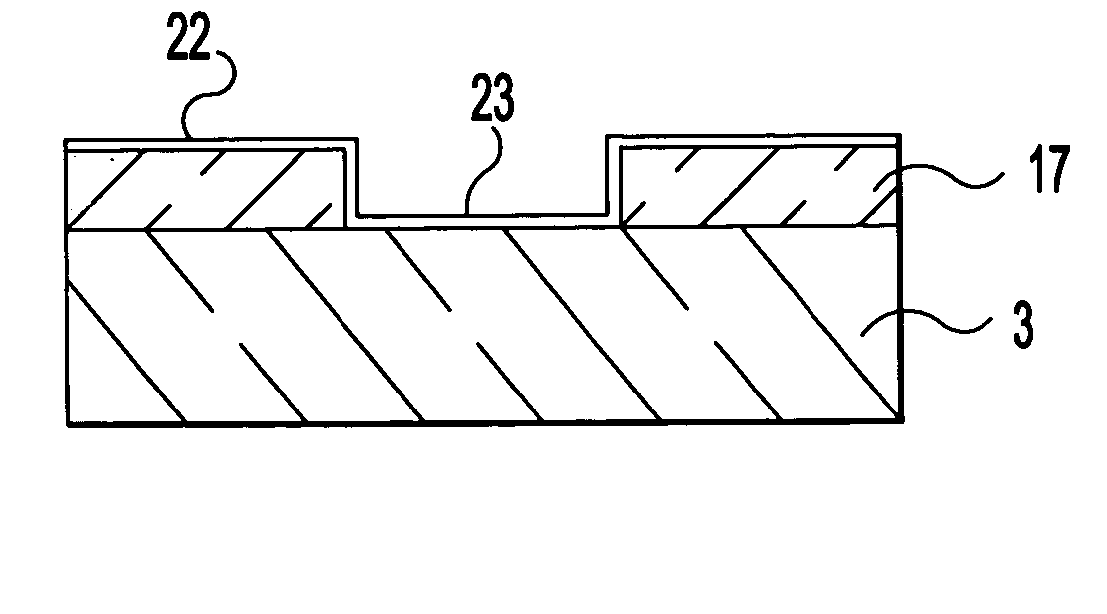

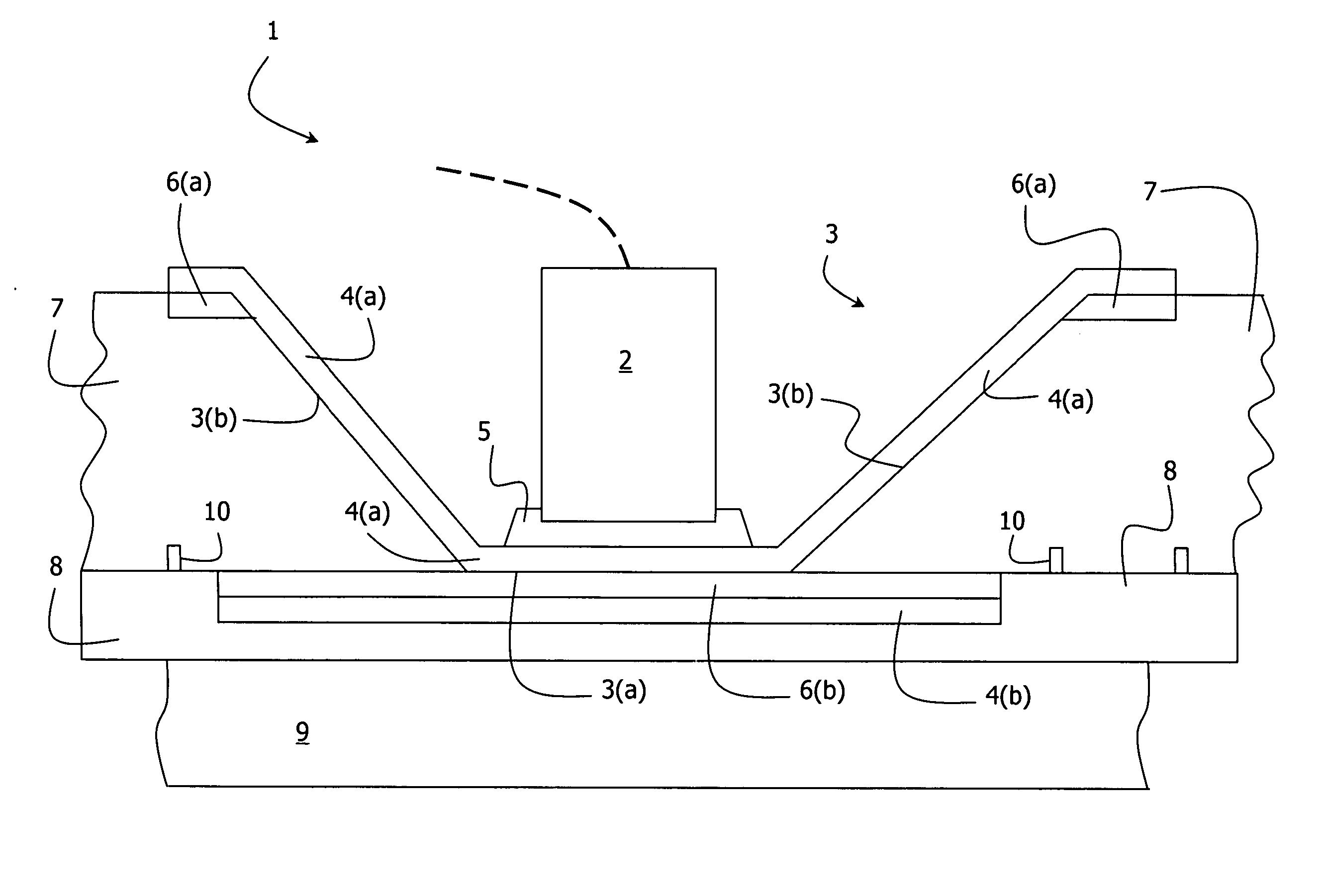

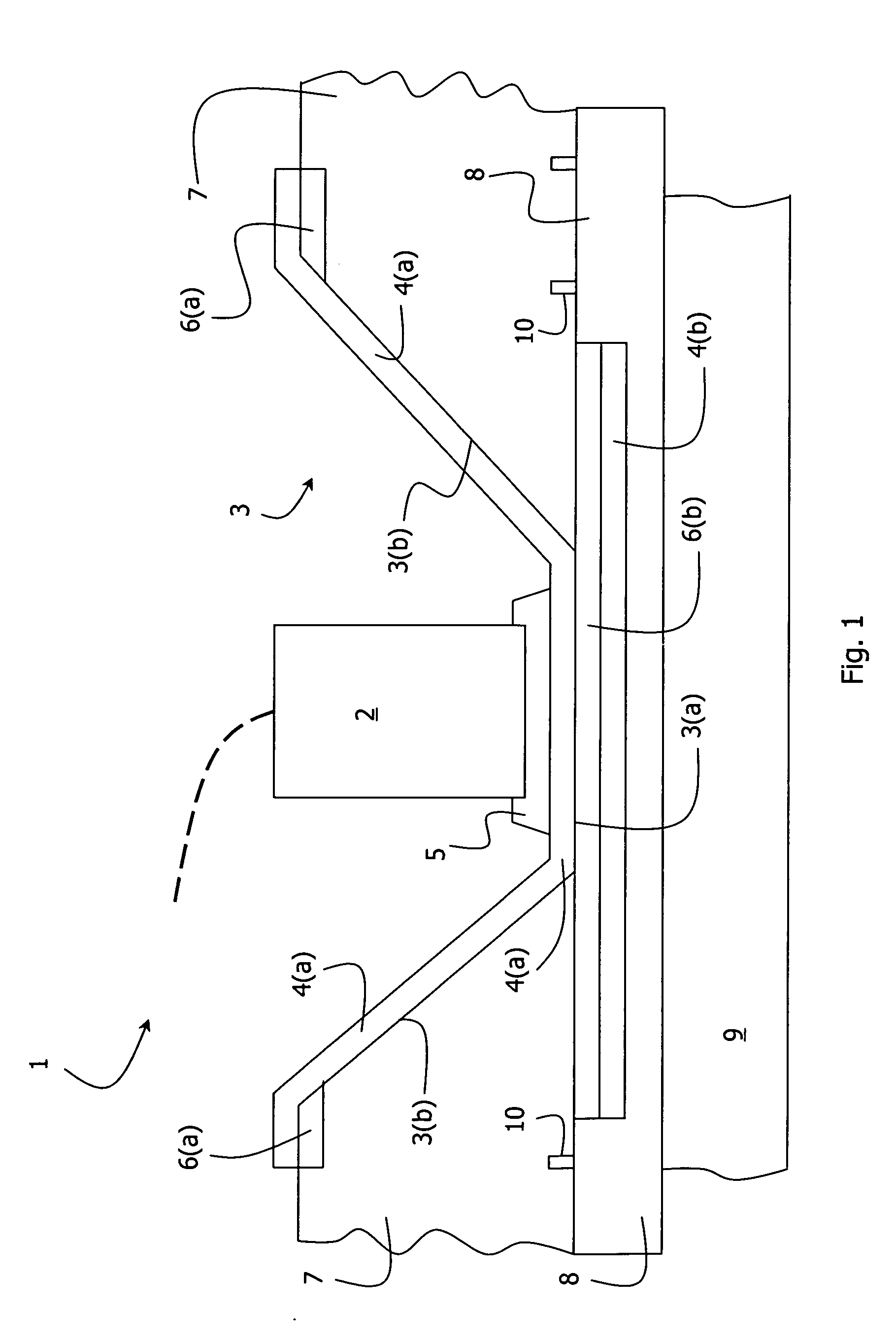

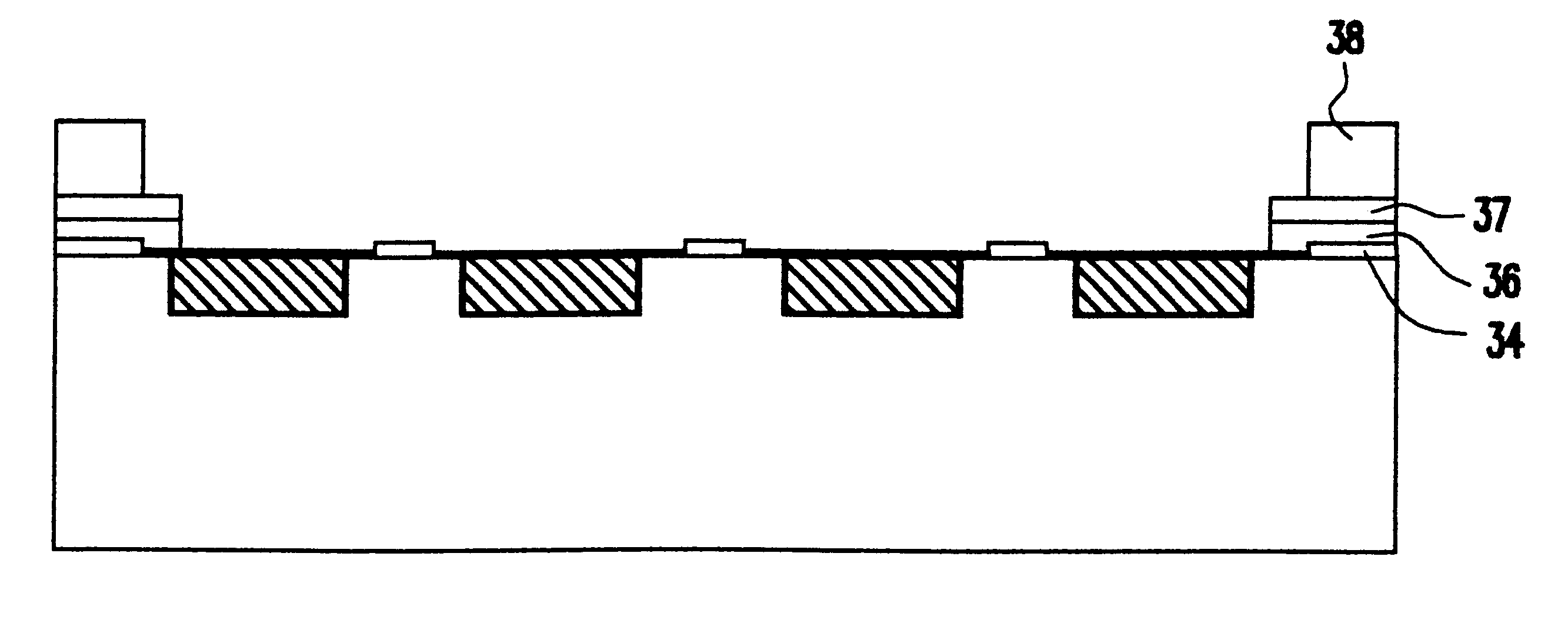

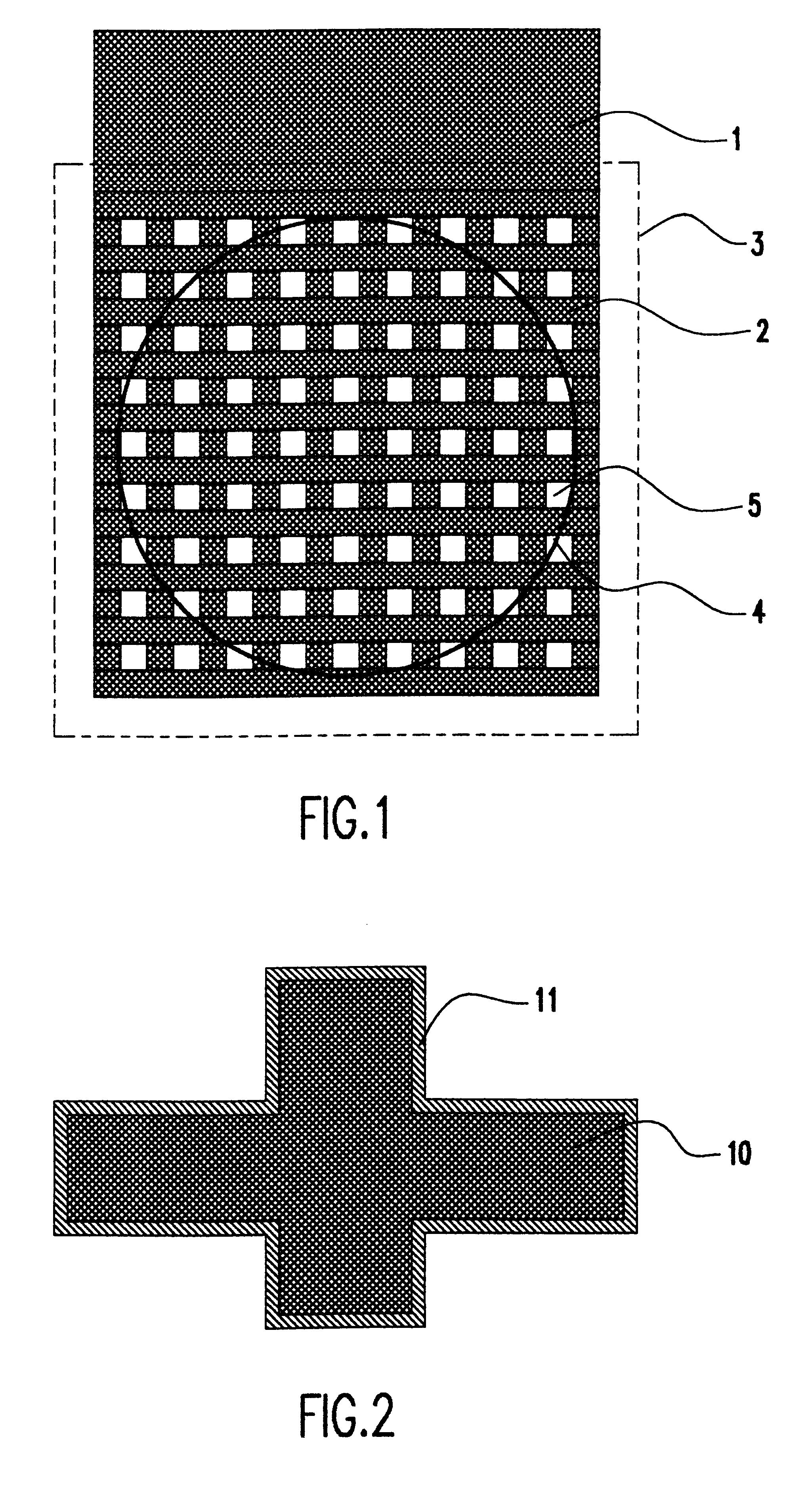

Illuminator and production method

InactiveUS20060018120A1Printed circuit detailsLighting heating/cooling arrangementsCopper conductorEngineering

An illuminator (1) has an array of cavities (3) are drilled in a substrate having an FR4 electrically insulating body (7) plated with copper conductors (6(a), 6(b)). Further patterning of the substrate provided electrical conductors (3(b)) in the cavities to act as both part of the light drive circuit and reflectors in the cavities. The drilling is performed to the full depth of the FR4 body (7) until underneath plating (6(b)) is reached. A further Cu plating (4(b)) is applied on the platings (6(b)) so that they together form a heat spreader under each cavity (3). A layer (8) of resin incorporating thermally conductive particles is bonded to the underside surfaces, both of the FR4 (7) and of the platings (4(b)). A heat sink (9) is bonded to the layer (8). Good optical efficiency and thermal dissipation is achieved, despite the fact that conventional PCT processing techniques are used.

Owner:STOCKERYALE IRL

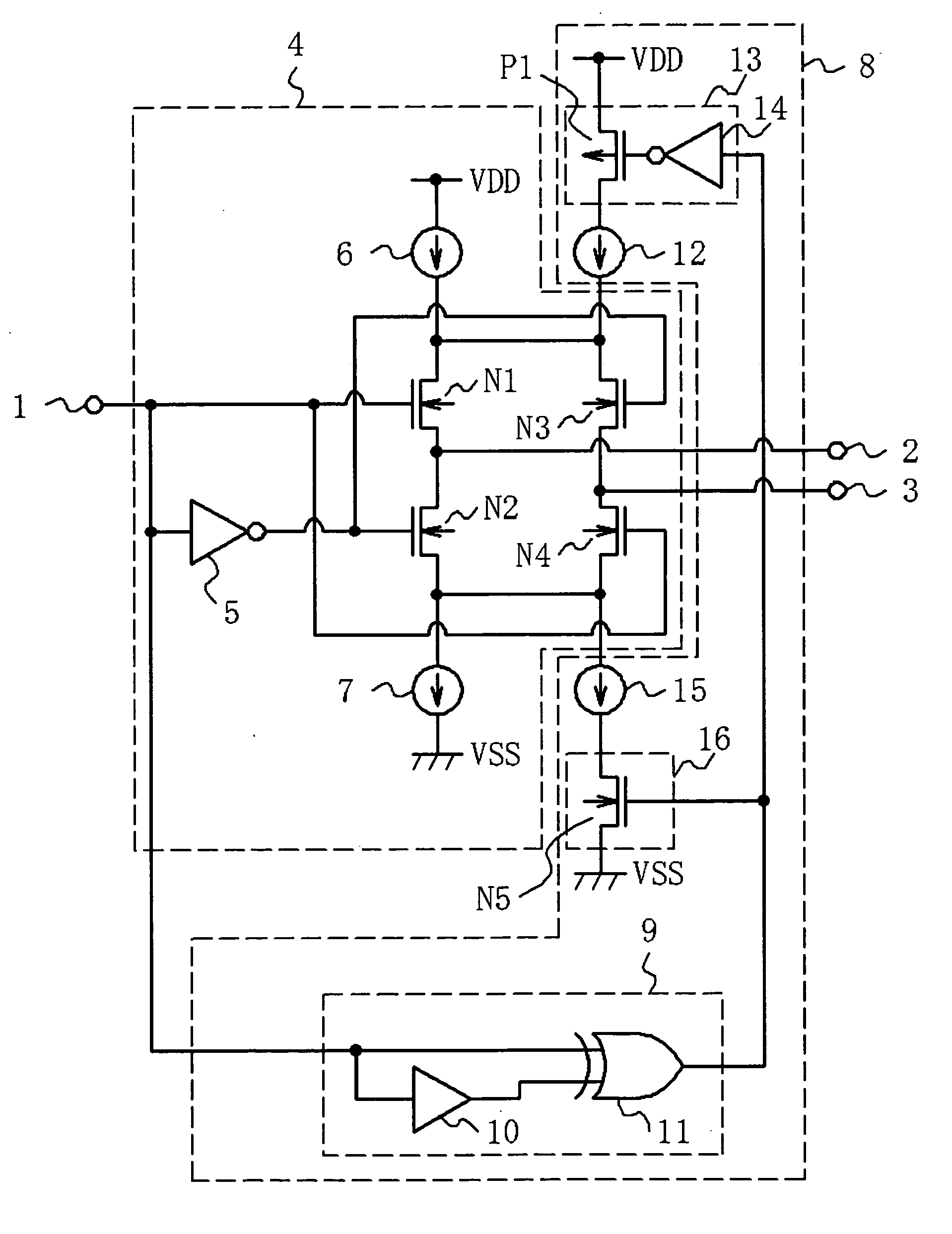

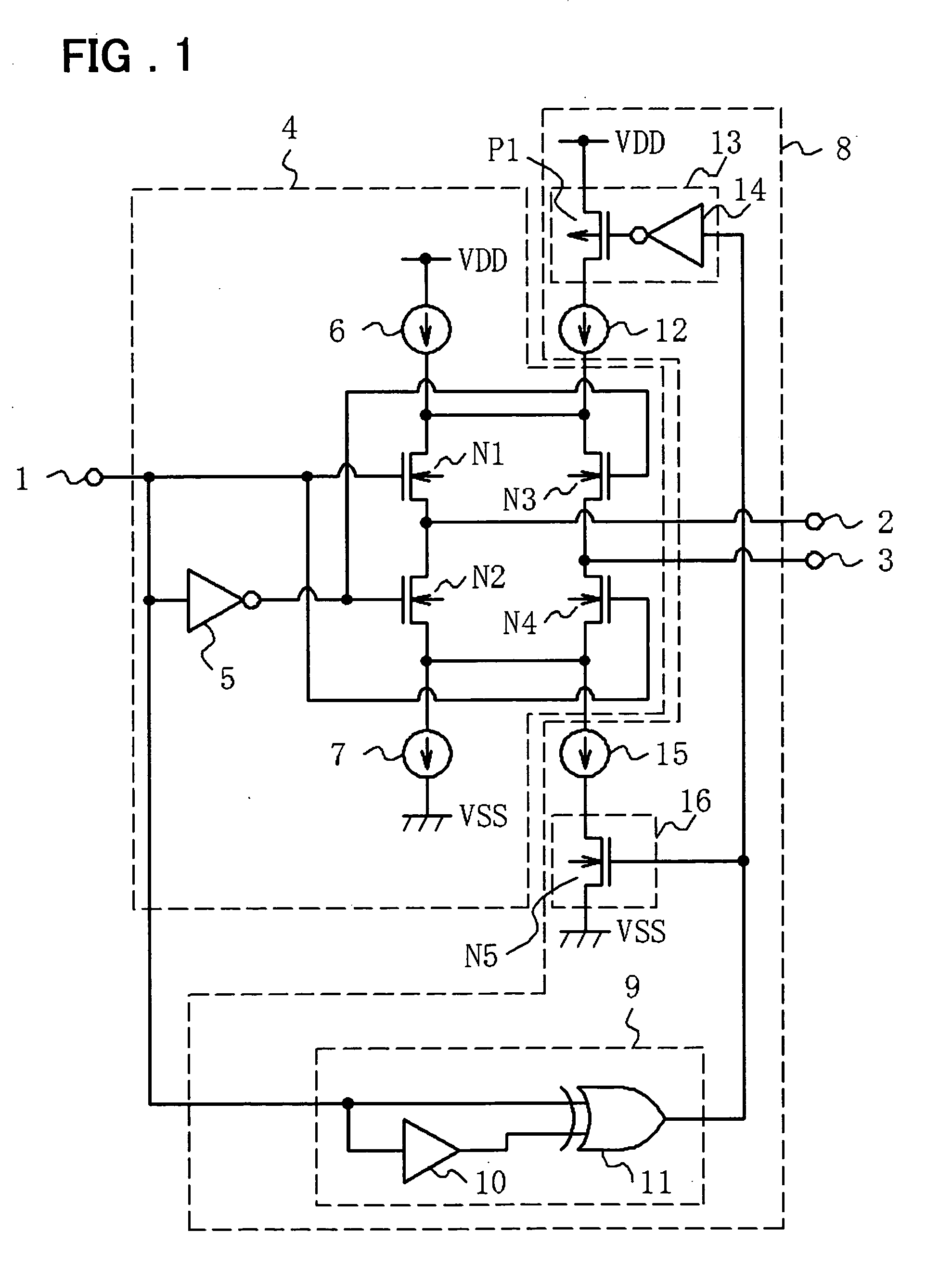

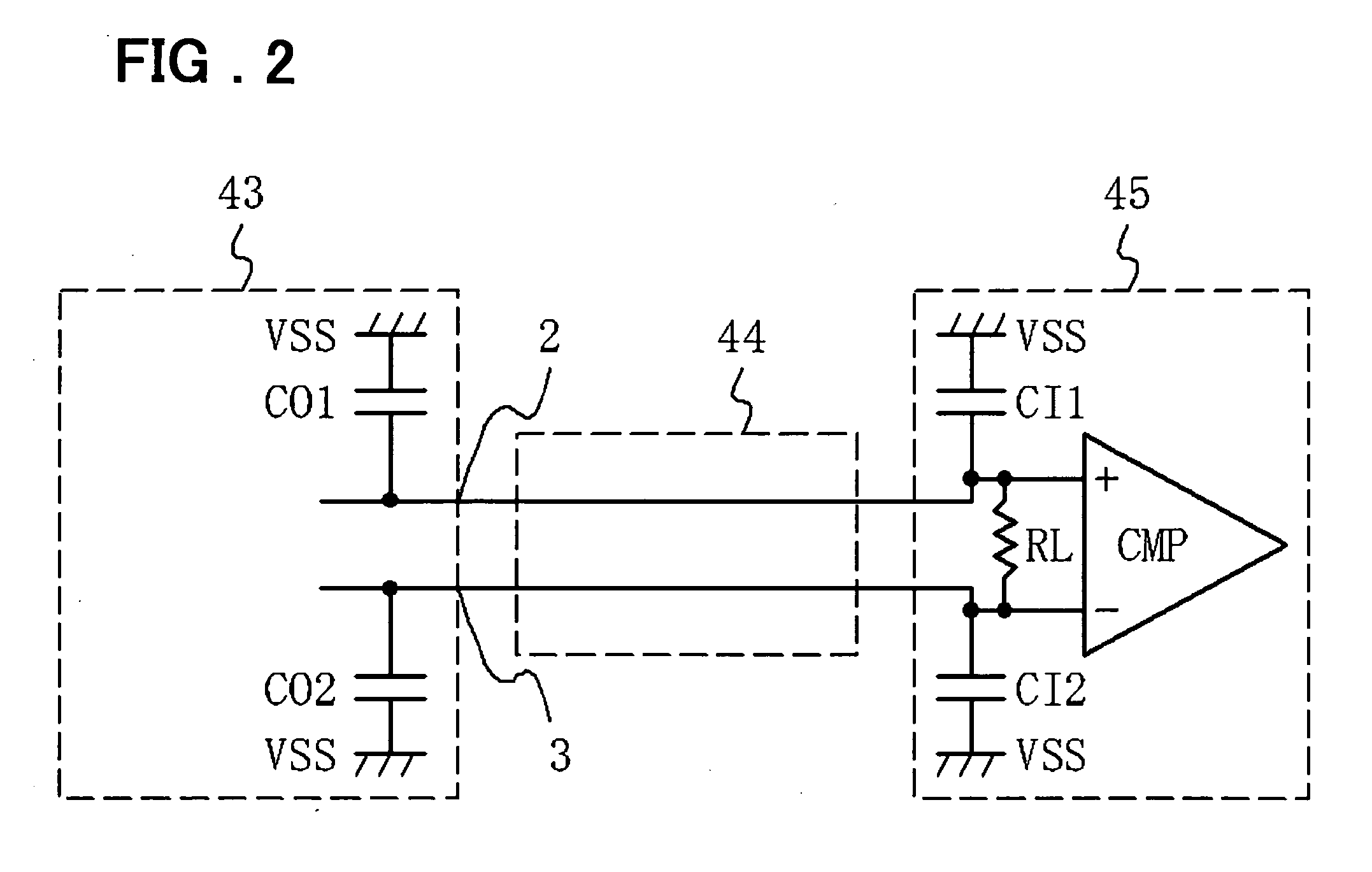

Transmitter circuit, transmission circuit and driver unit

InactiveUS20040242171A1Small sizeReduce weightResonant long antennasBaseband system detailsCopper conductorDriver circuit

A transmitter circuit for use in a display device of the type having a transmission line consisting of aluminum or copper conductor formed on a glass substrate includes a driver circuit, which has a non-inverting output terminal and an inverting output terminal, for outputting a signal current, which has a loop direction that changes based upon an input signal, to the non-inverting and inverting output terminals; and an output-waveform control circuit for detecting the edge of the waveform of the input signal and responding by increasing the signal current temporarily.

Owner:RENESAS ELECTRONICS CORP

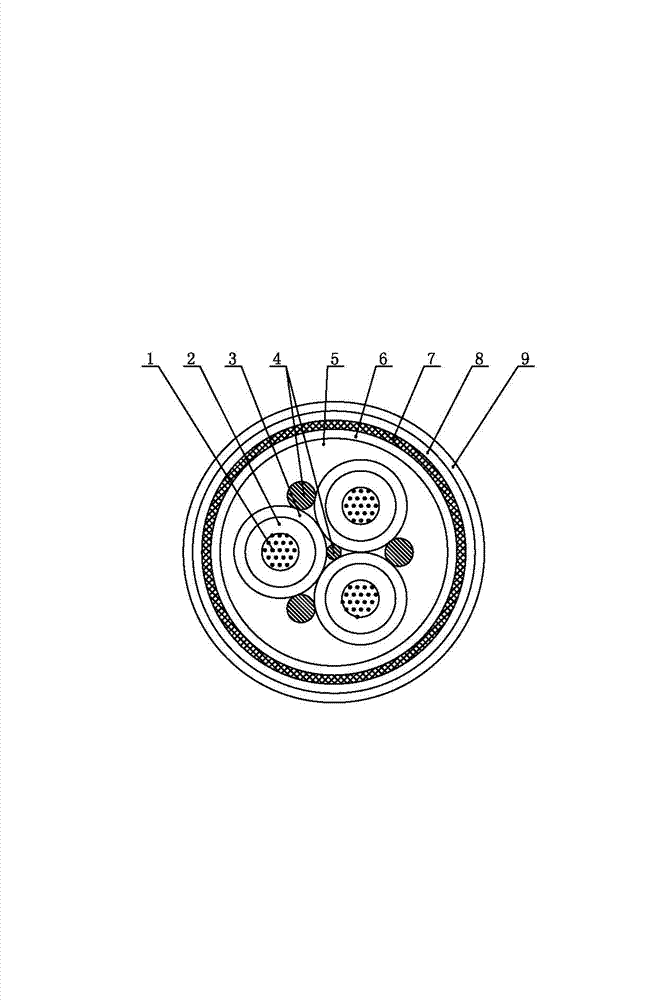

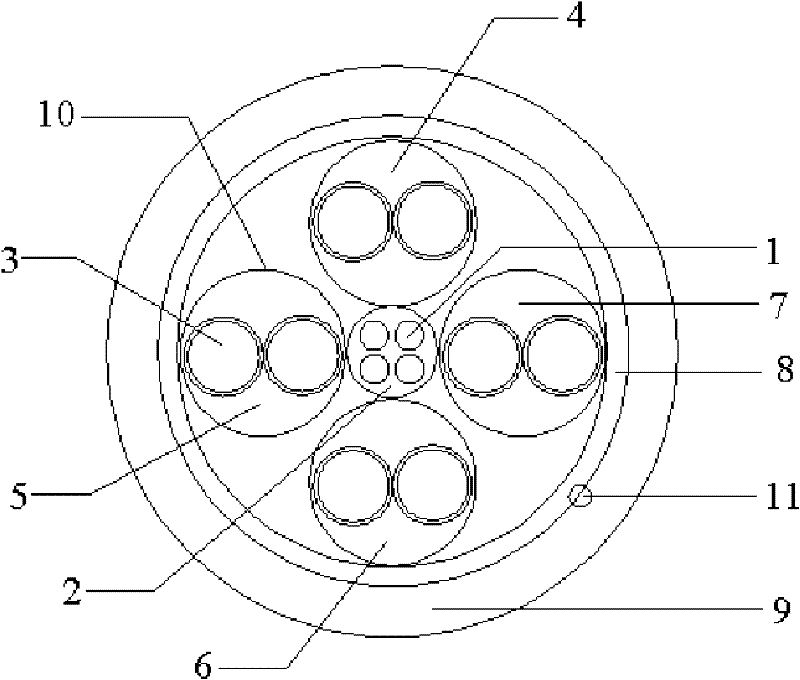

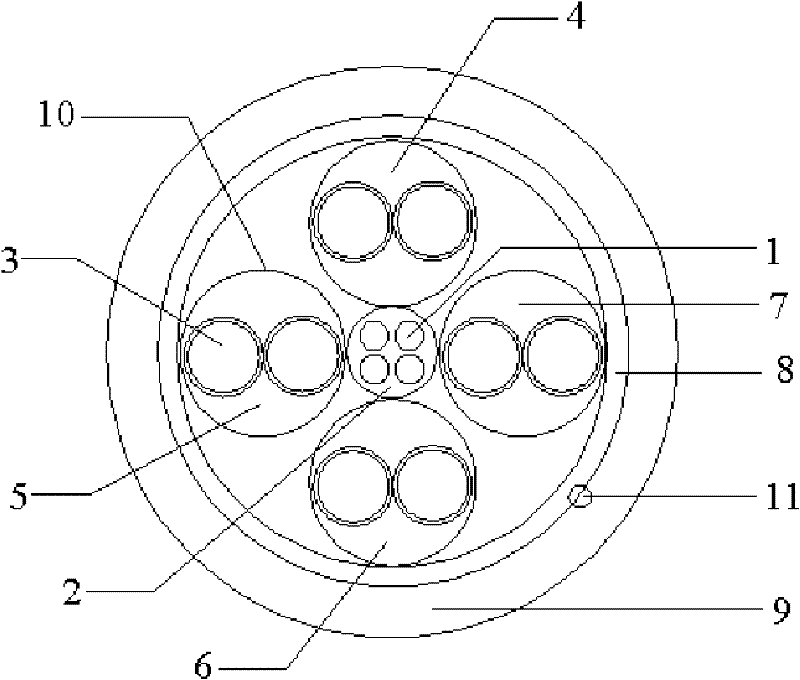

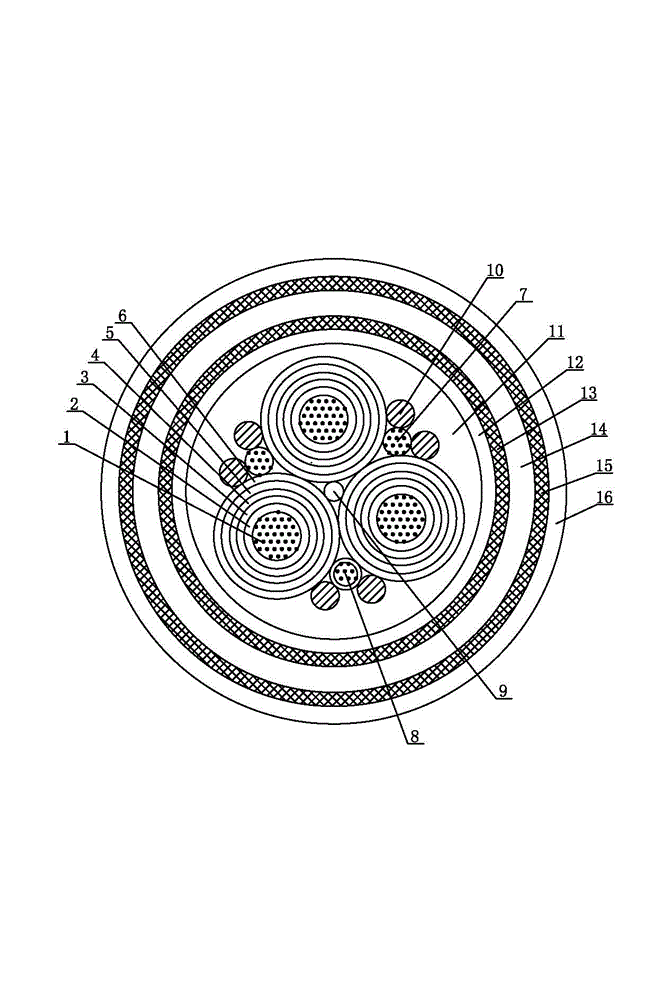

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

Reinforced tensile screening type vertical watertight degaussing cable for ship and manufacturing method thereof

InactiveCN102737760AEnsure watertight effectHigh tensile strengthNon-insulated conductorsSubmarine cablesCopper conductorVulcanization

The invention discloses a reinforced tensile screening type vertical watertight degaussing cable for a ship and a manufacturing method thereof. A twisted copper conductor is formed by soaking a plurality of tinned copper wires in a sealant and then twisting the tinned copper wires; a conductor sealant layer is soaked on the periphery of the twisted copper conductor; insulating rubber layers are extruded on the periphery of the conductor sealant layer; an aramid fiber reinforcing layer is weaved on the periphery of each insulating rubber layer so as to form an insulating core wire; chloroprene rubber filling strips are filled into gaps among the insulating core wires, and a cable core is integrally formed by twisting the insulating core wires; a cable core inner sealant layer is extruded on the periphery of the cable core; and an inner jacket rubber layer is extruded on the periphery of the cable core inner sealant layer. A plurality of seals are arranged on the periphery of a cable conductor, and the chloroprene rubber filling strips expand in a follow-up vulcanization process, thus entirely filling the gaps in the cable core; and one insulating core wire is not tangential to another insulating core wire. Therefore, when the cable core inner sealant layer is extruded, the sealant can permeate inside the cable core, so that the watertight effect can be ensured.

Owner:嘉兴君宏光学有限公司

Method of forming copper interconnections and thin films using chemical vapor deposition with catalyst

InactiveUS20010019891A1Semiconductor/solid-state device detailsSolid-state devicesCopper conductorGas phase

A method of forming copper conductors for interconnecting active and passive elements as well as signal and power lines for circuits and devices on silicon wafers is disclosed. The method disclosed herein involves with using catalysts in conjunction with a chemical vapor deposition(CVD) process with typically using copper as a source material for forming interconnecting conductors. Interconnecting method for filling trenches, via holes, contacts, large trenches and holes for power devices and lines as well as for forming large passive elements is also disclosed. Disclosed herein are also a method of filling narrow and deep trenches and small in diameter and deep holes, and a method of forming very thin film on the flat top surface so that an etchback process, such as wet or dry etchback as well as plasma etchback processes, can be used for removing a thin film in preparation for subsequent processing steps, thereby rather expensive chemical mechanical polishing(CMP) process need not be used.

Owner:ASM KOREA LTD

Method of manufacturing a 2-layered flexible substrate

InactiveUS6045713AImprove adhesionDecorative surface effectsVacuum evaporation coatingCopper conductorCopper plating

A method of manufacturing a 2-layered flexible substrate includes forming an underlying metal layer on an insulation film with a deposition layer formed by a dry plating method using at least one of nickel, copper-nickel alloy, chromium and chromium oxide and a copper deposition layer formed by a dry plating method on the noted deposition layer, then forming a primary electric copper plated deposition layer on the underlying metal layer, then applying a treatment using at least one alkaline solution selected from inorganic alkaline solutions and organic alkaline solutions, then forming an electroless copper plated deposition layer as an intermediate metal layer on the primary electric copper plated deposition layer and, finally, forming a secondary electric copper plated deposition layer on the intermediate metal layer, thereby finally forming a copper conductor layer of 1 to 35 mu m thickness on the insulation film.

Owner:SUMITOMO METAL MINING CO LTD

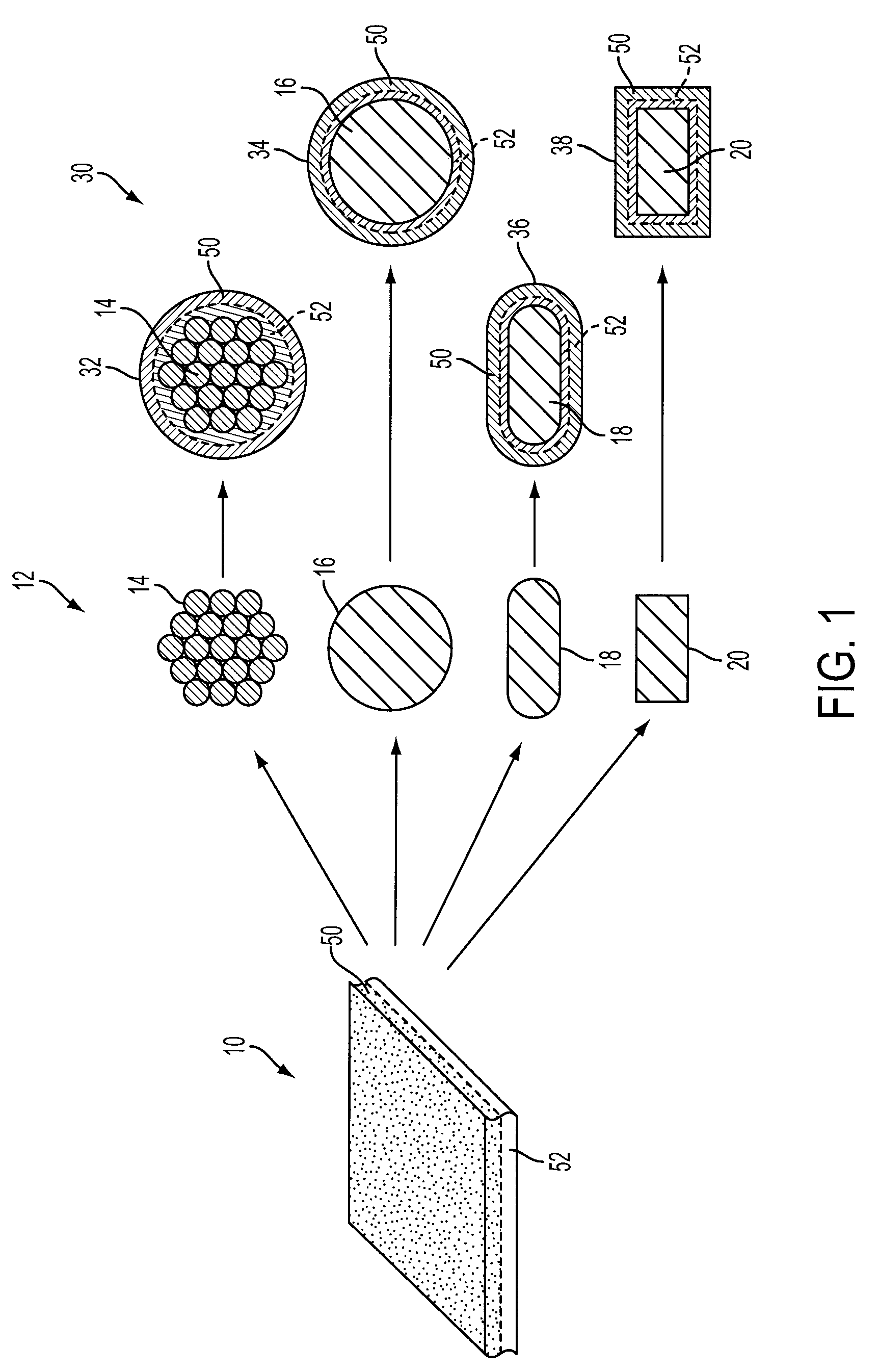

Photonic sintering of polymer thick film copper conductor compositions

ActiveUS20140367619A1Modifies its propertySuitable consistencyConductive materialPrinted circuit aspectsCopper conductorPolymer chemistry

This invention provides a method for using a polymer thick film copper conductor composition to form an electrical conductor in an electrical circuit, the method subjecting the deposited thick film copper conductor composition to photonic sintering. The invention also provides a method for reducing the resistance of an electrical conductor formed from a polymer thick film conductor composition, the method comprising the step of subjecting the electrical conductor to photonic sintering. The invention further provides devices containing electrical conductors made by these methods. The invention also provides a polymer thick film copper conductor composition.

Owner:DU PONT CHINA LTD

Cobalt tungsten phosphate used to fill voids arising in a copper metallization process

InactiveUS7317253B2Semiconductor/solid-state device detailsSolid-state devicesCopper conductorPhosphate

A semiconductor device includes a substrate, at least one layer of functional devices formed on the substrate, a first dielectric layer formed over the functional device layer and a first trench / via located in the first dielectric layer. A copper conductor fills the first trench / via. An electromigration inhibiting barrier layer is selectively located over a surface of the copper conductor and not any other remaining exposed surface. An insulating cap layer overlies the barrier layer and the remaining exposed surface. A second dielectric layer overlies the insulating cap layer. A second trench / via is located in the second dielectric layer and extends through the insulating cap layer and the barrier layer. A micro-trench is located within the first dielectric layer and is associated with the formation of the second trench / via. The micro-trench exposes a portion of the copper conductor. A filler fills the micro-trench. The filler is formed from a material used to form the electromigration inhibiting barrier layer.

Owner:SONY CORP +1

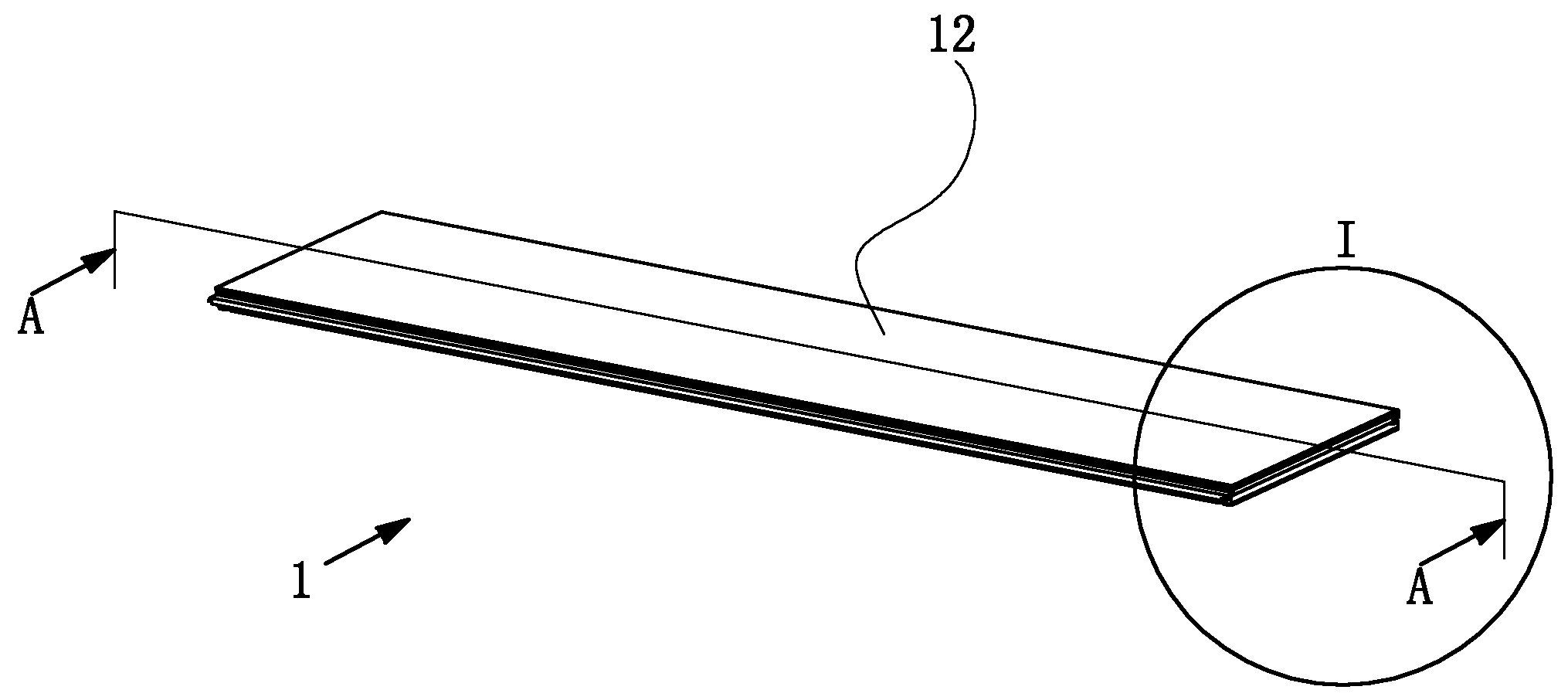

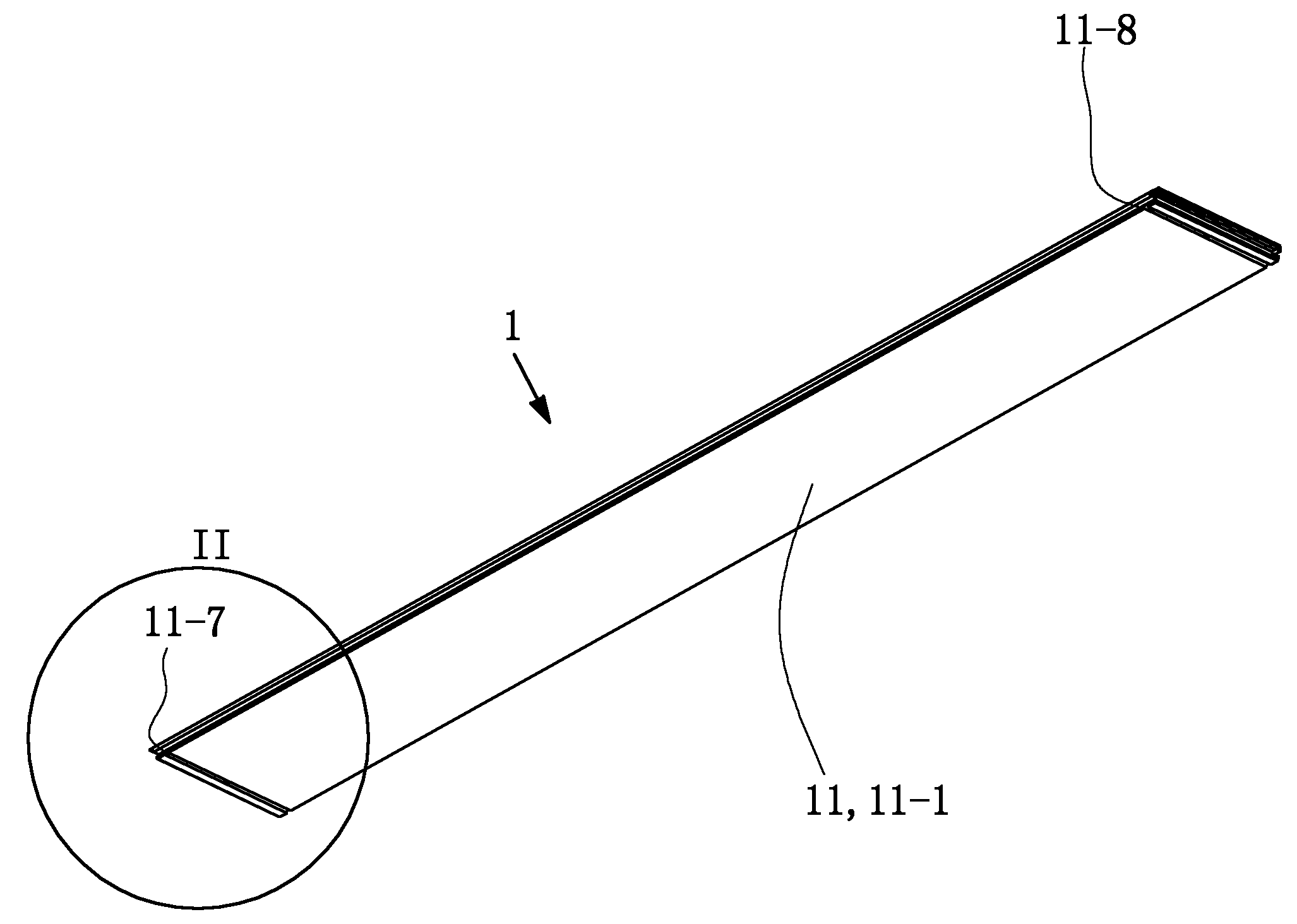

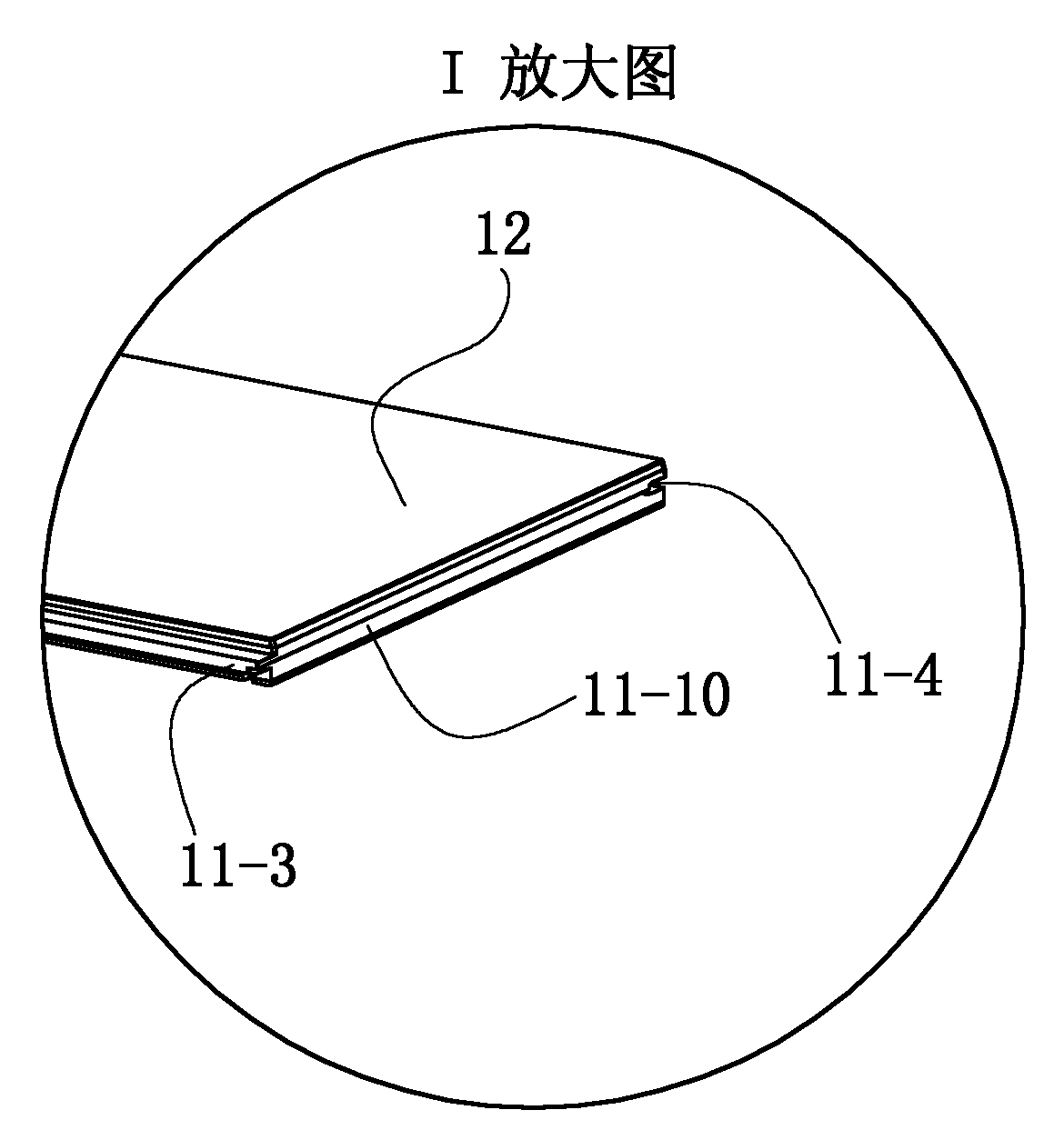

Non-nail clamped electric heating floor system and electric heating floors thereof

InactiveCN102042633AQuality improvementEasy to removeLighting and heating apparatusElectric heating systemCopper conductorKeel

The invention discloses a non-nail clamped electric heating floor system which is characterized by comprising electric heating floors, mounting bases, power supply keels, inserting piece clips, copper conductors, connecting pieces and connecting wires. The installation method of the non-nail clamped electric heating floor system comprises the following steps: firstly the power supply keels are laid on the floor along the side of the rear wall of the laid room in the length direction; the mounting bases are laid on the floor in the mode that the length direction of the mounting bases are perpendicular to that of the power supply keels, the mounting bases are parallel to one another, and plate-end transverse clamping parts and middle transverse locating parts of two neighboring mounting bases are correspondingly arranged at front and back positions; the electric heating floors are vertically fixed on the mounting bases; and finally the electric heating floors work in parallel, i.e. all the electric heating floors emit heat for warming purpose while switching on a power supply, and other electric heating floors are not affected even though certain floor is damaged.

Owner:葛跃进

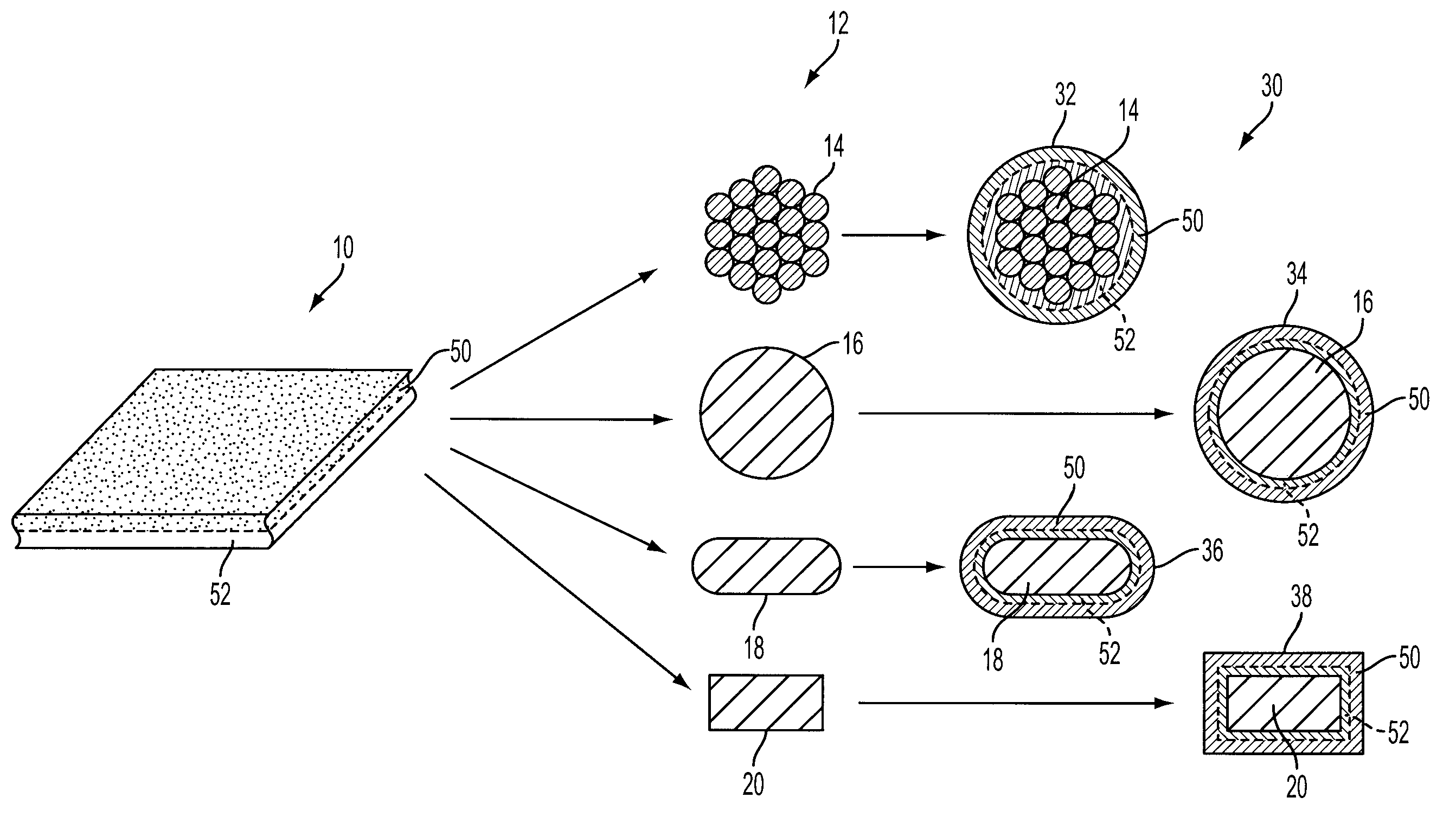

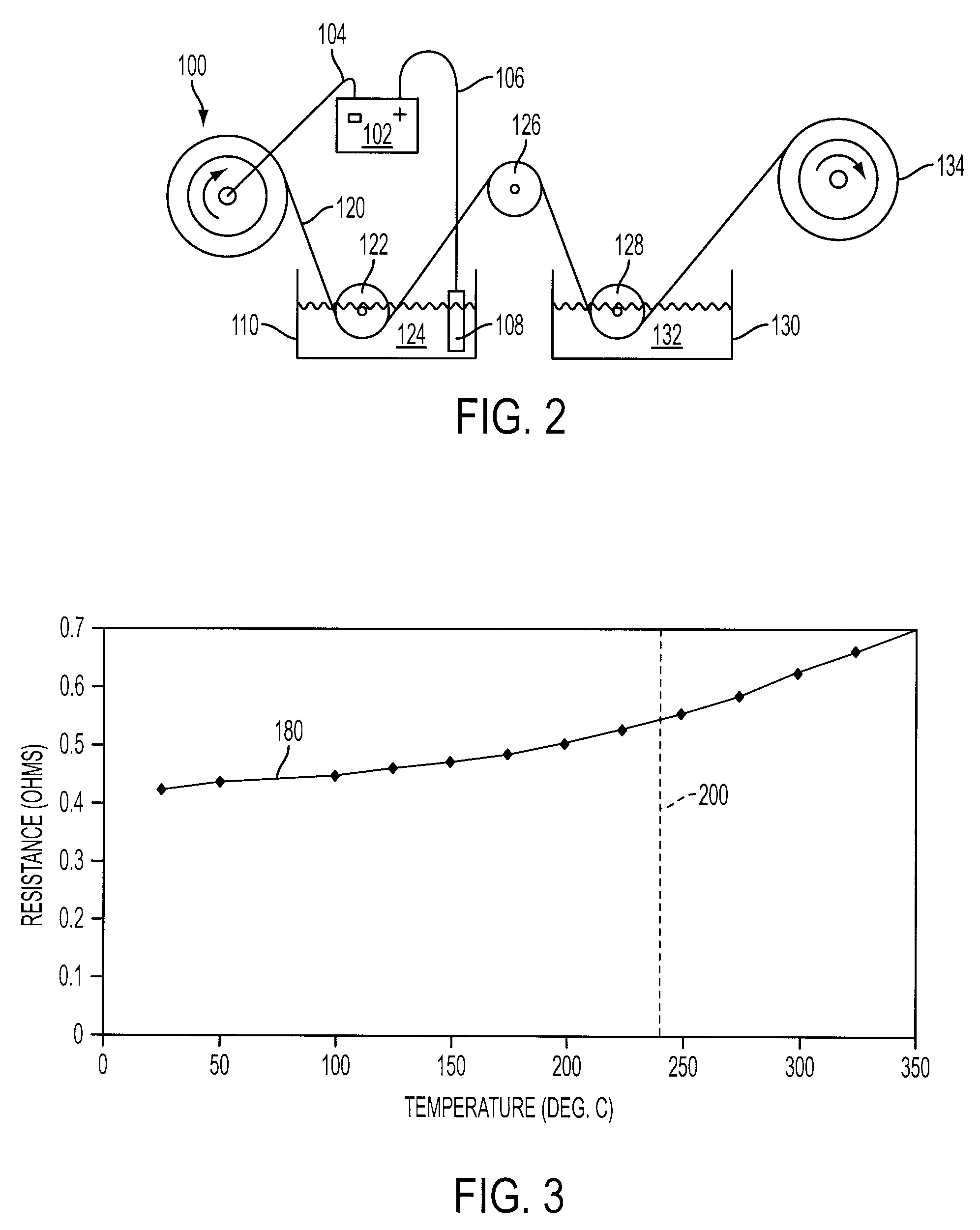

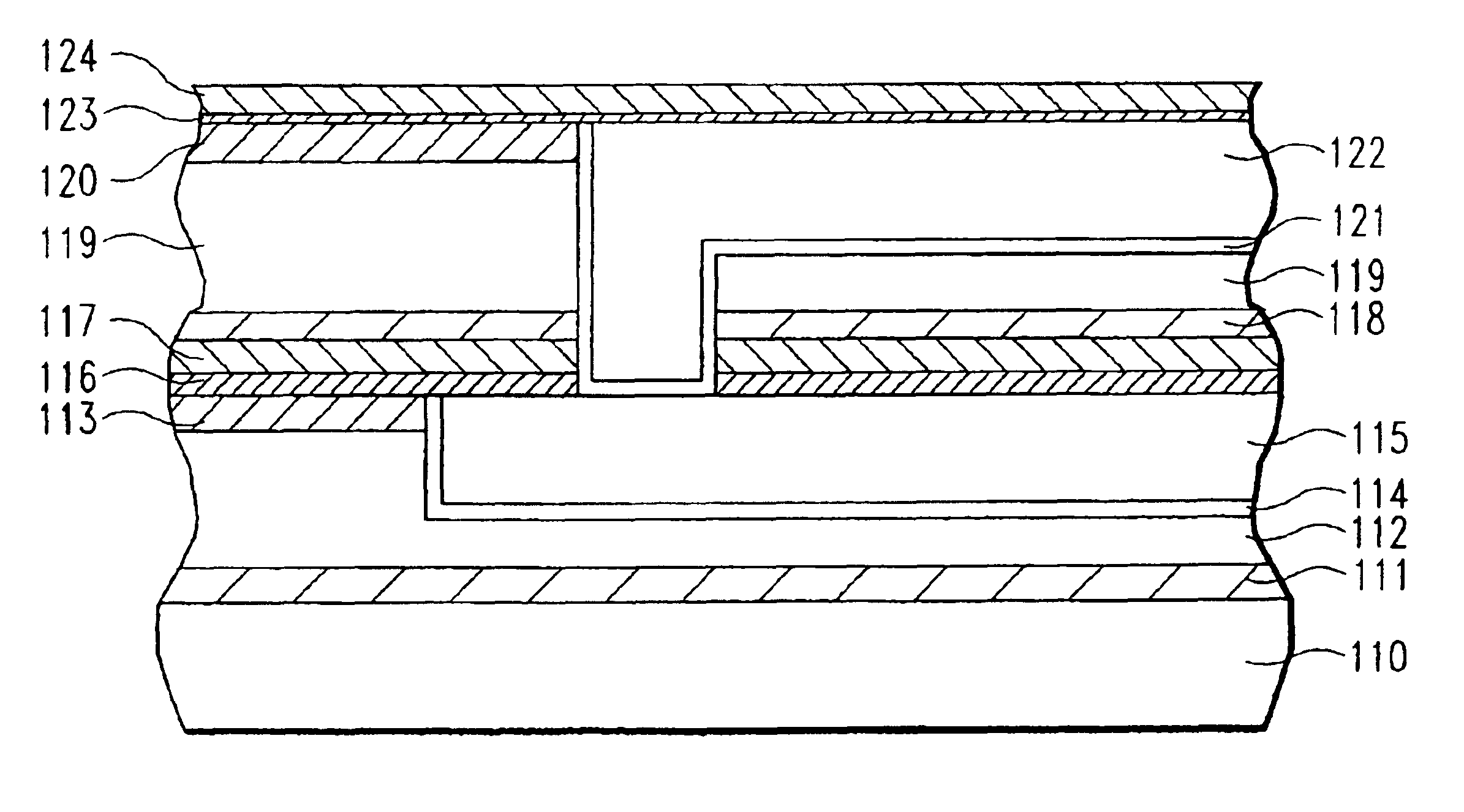

Copper conductor with anodized aluminum dielectric layer

ActiveUS7572980B2Reduce and eliminate any internal stressEconomically viable to produce in large quantities and long continuous lengthsInsulated cablesMetallic oxidesCopper conductorAlclad

An electrically insulated conductor for carrying signals or current includes a solid or stranded copper core of various geometries with only a single electrically insulating and thermally conductive layer of anodized aluminum (aluminum oxide). The device is made by forming a uniform thickness thin sheet or foil of aluminum to envelop the copper or copper alloy core. The aluminum has its outer surface partially anodized either before or after forming to the core in an electrolytic process to form a single layer of aluminum oxide.

Owner:FORD GLOBAL TECH LLC

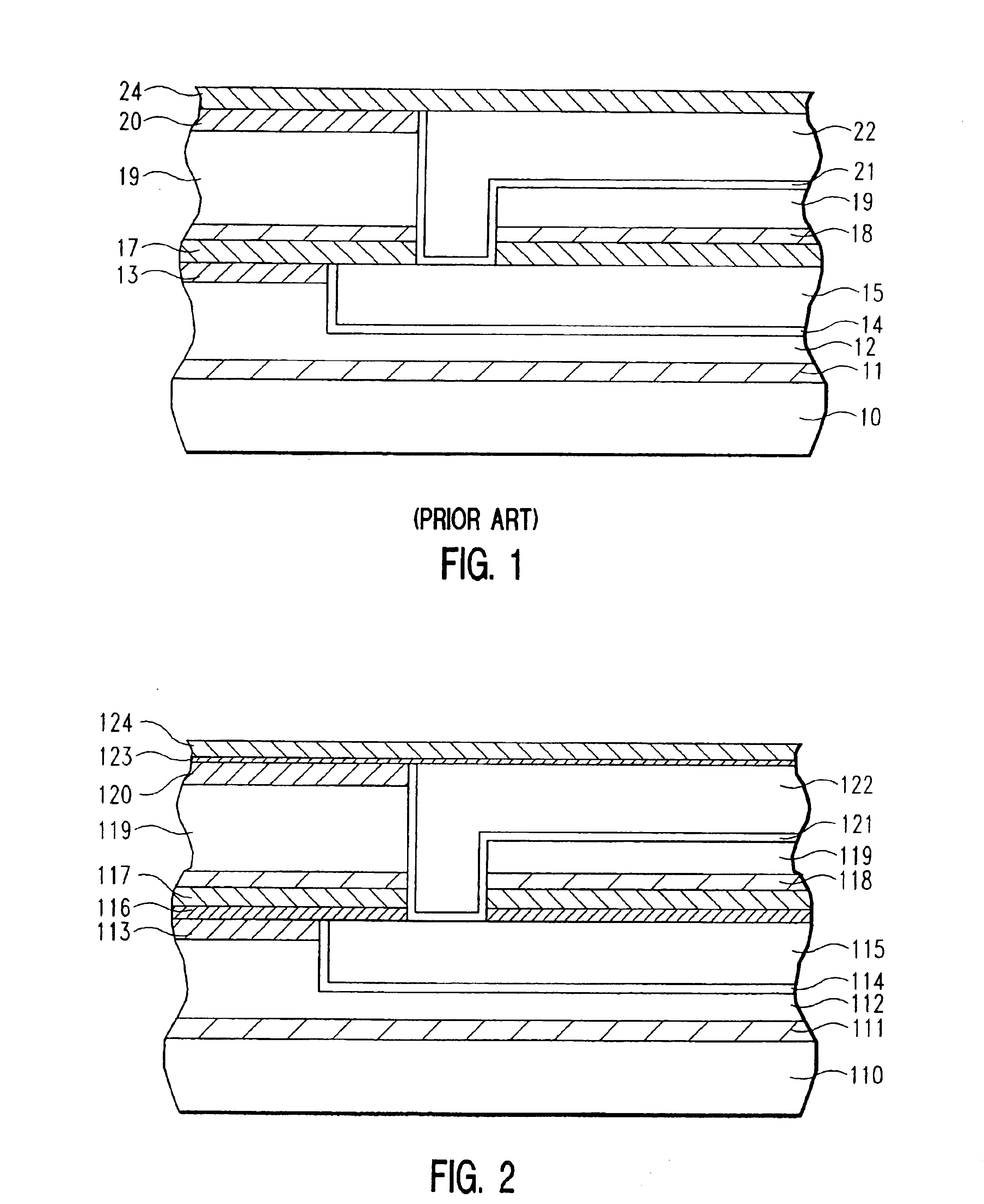

Advanced BEOL interconnect structures with low-k PE CVD cap layer and method thereof

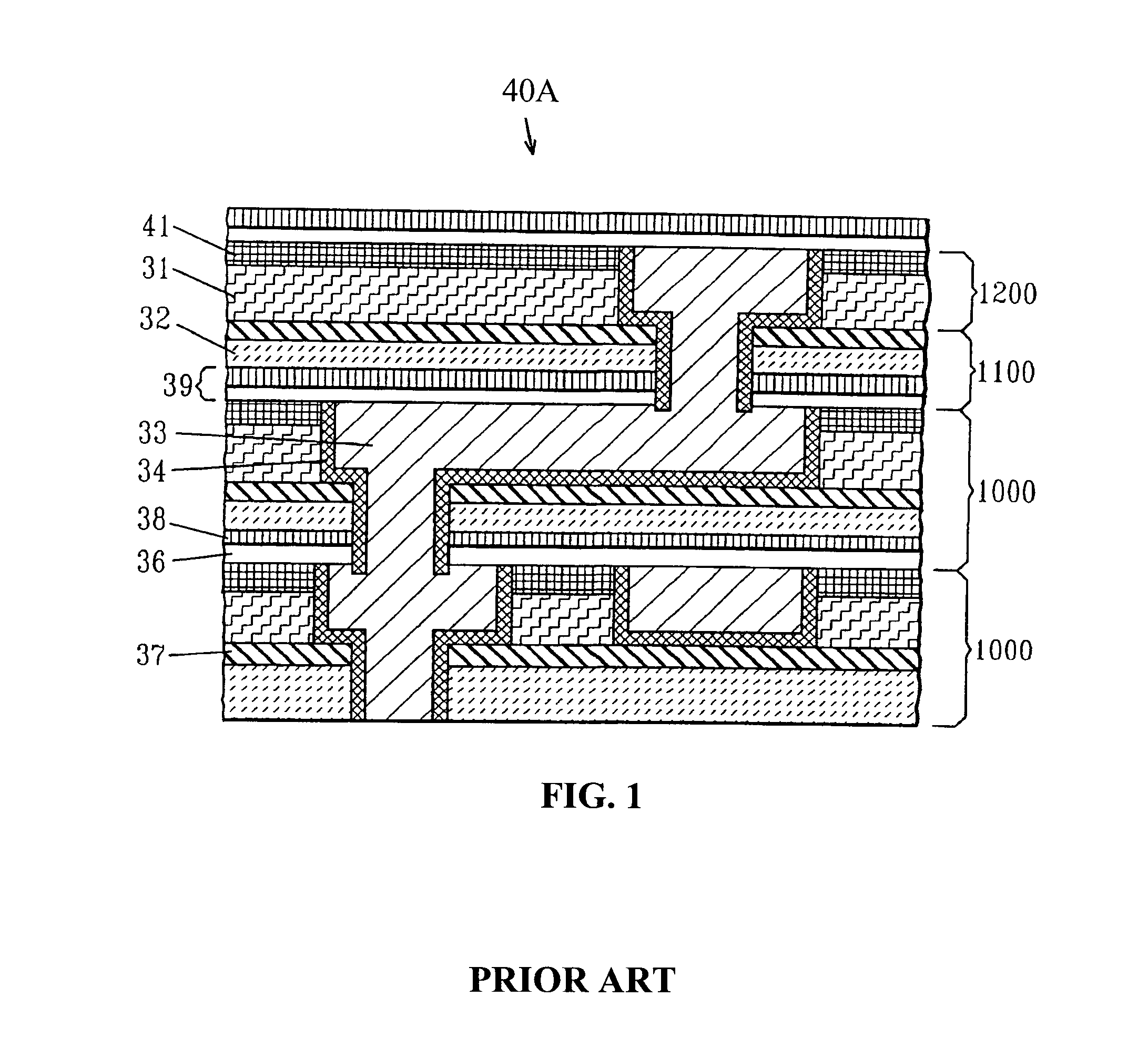

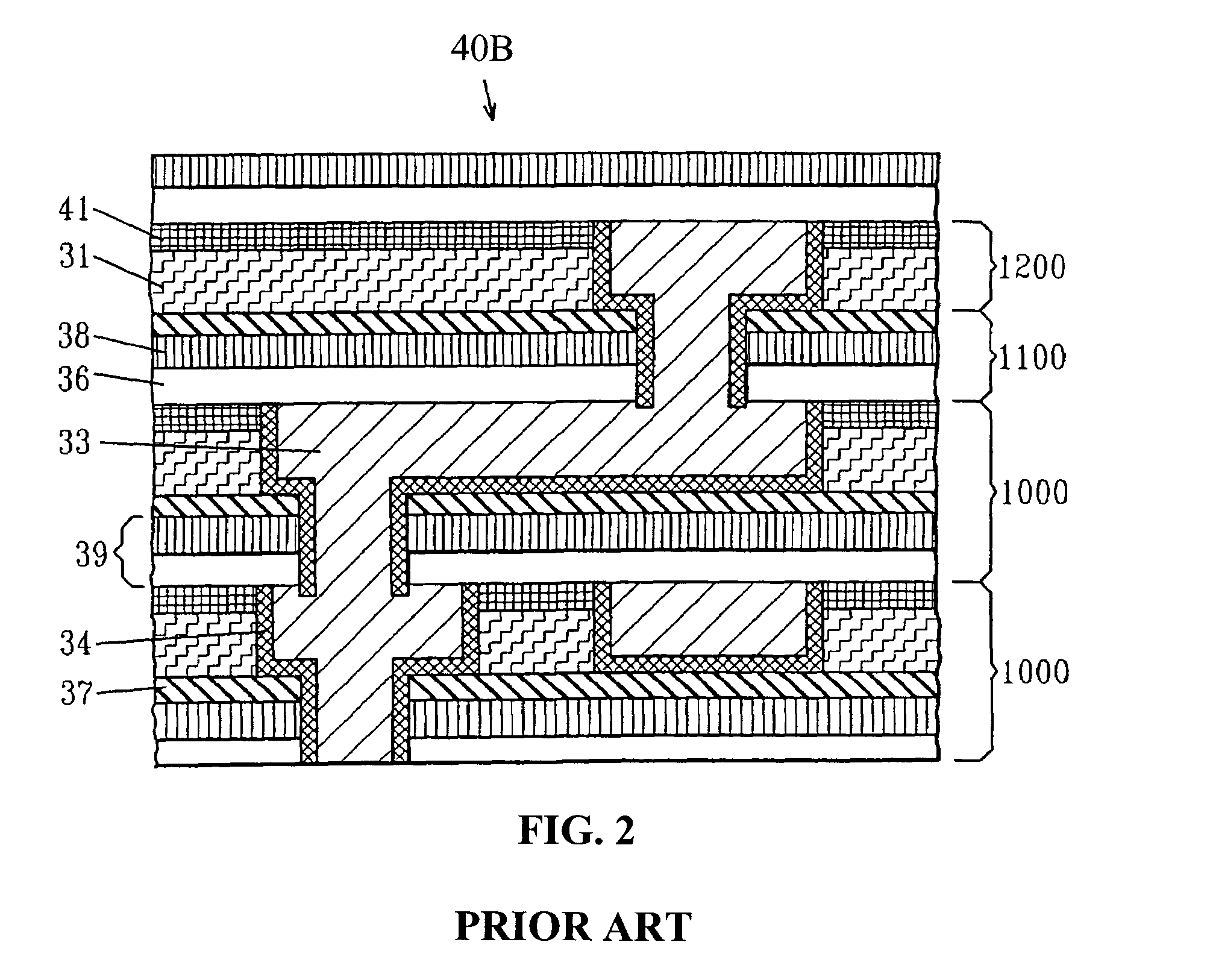

InactiveUS6939797B2Semiconductor/solid-state device detailsSolid-state devicesCopper conductorNoble gas

An advanced back-end-of-line (BEOL) metallization structure is disclosed. The structure includes a diffusion barrier or cap layer having a low dielectric constant (low-k), where the cap layer is formed of silicon nitride by a plasma-enhanced chemical vapor deposition (PE CVD) process. The metallization structure also includes an inter-layer dielectric (ILD) formed of a carbon-containing dielectric material having a dielectric constant of less than about 4, and a continuous hardmask layer overlying the ILD which is preferably formed of silicon nitride or silicon carbide. A method for forming the BEOL metallization structure is also disclosed. The method includes a pre-clean or pre-activation step to improve the adhesion of the cap layer to the underlying copper conductors. The pre-clean or pre-activation step comprises exposing the copper surface to a reducing plasma including hydrogen, ammonia, nitrogen and / or noble gases.

Owner:GLOBALFOUNDRIES INC

Low-voltage remote power supply cable for high-speed Ethernet switch

ActiveCN102364585AGuaranteed transfer characteristicsImprove transmission performanceInsulated cablesInsulated conductorsCopper conductorLow voltage

The invention discloses a low-voltage remote power supply cable for a high-speed Ethernet switch. The low-voltage remote power supply cable comprises four single-wire copper conductors for transmitting electric energy, wherein the four single-wire copper conductors are stranded into an electroconductive cable core in a star-quad manner; four pairs of stranded wires are uniformly and sequentially arrayed on the periphery of the electroconductive cable core in an anticlockwise manner; the pitches of the first stranded wire pair and the third stranded wire pair are larger than the pitches of the second stranded pair and the fourth stranded wire pair; the first stranded wire pair and the third stranded wire pair are arrayed by being alternated with the second stranded pair and the fourth stranded wire pair; the pitch of the first stranded wire pair is more than the pitch of the third stranded wire pair; and the pitch of the second stranded wire pair is larger than the pitch of the fourth stranded wire pair. According to the low-voltage remote power supply cable disclosed by the invention, on the basis of transmission characteristics of communication cables and the characteristics of power transmission cables, the communication cables and the power transmission cables are guaranteed to be composited and are prevented from mutual interferences at the same time, and communication signals and a DC-48V power supply needed by a building switch are simultaneously transmitted to a broadband box in each building.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

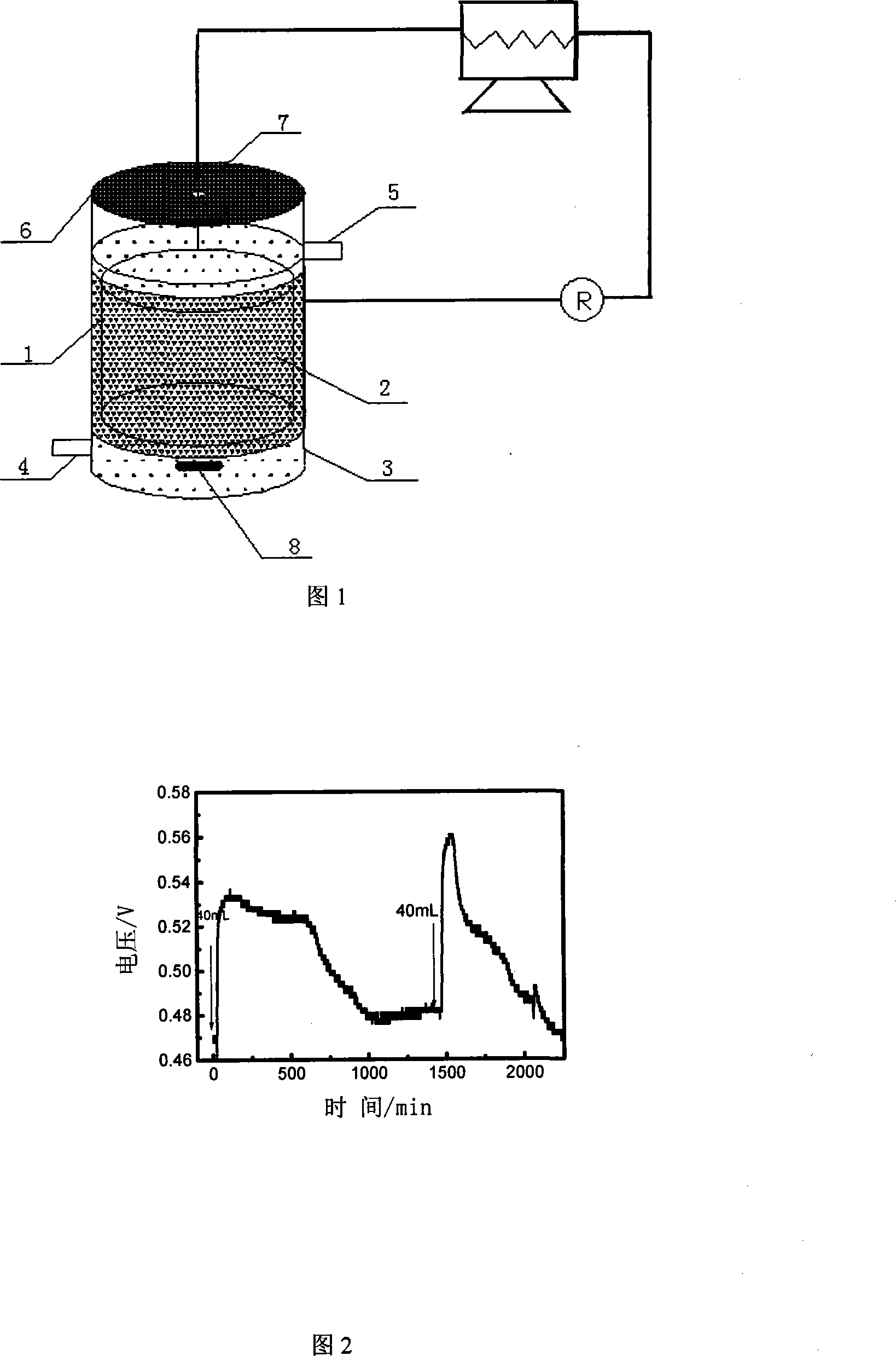

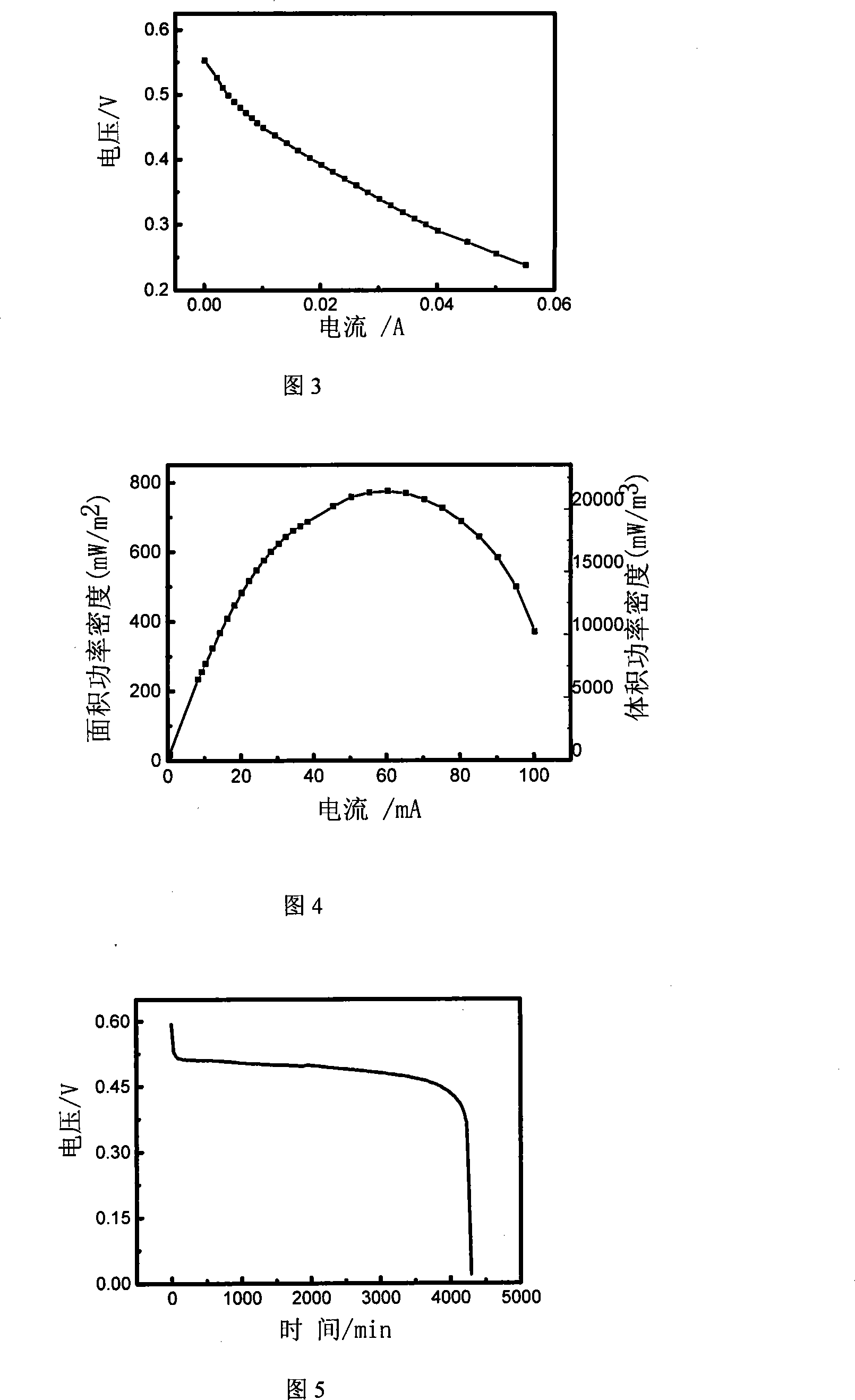

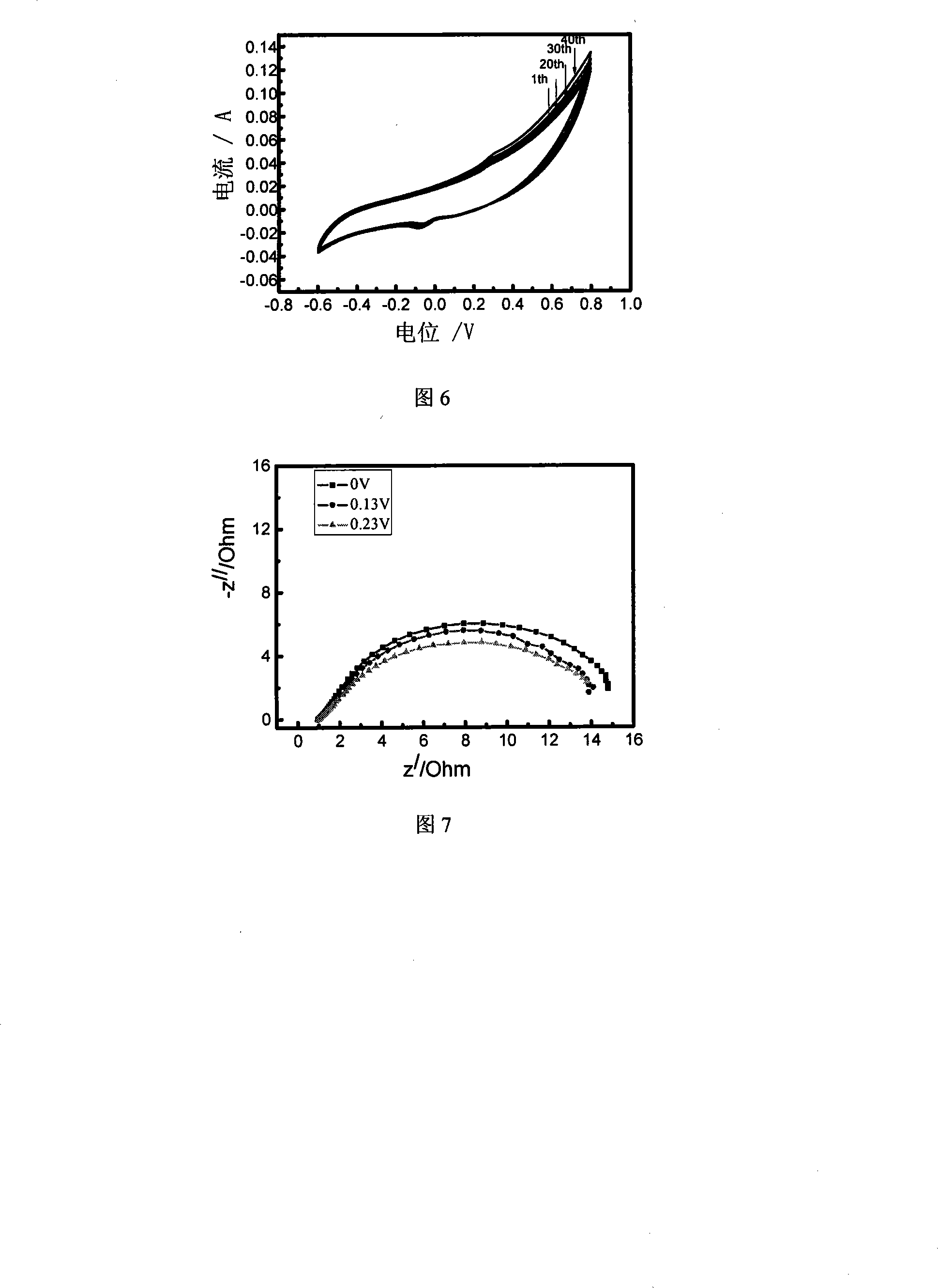

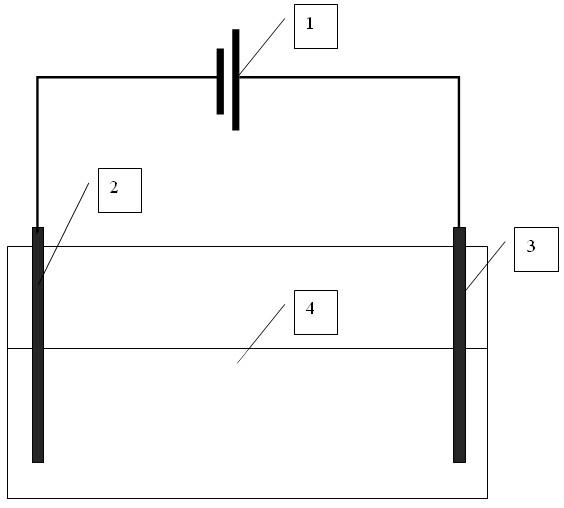

Single microbiological fuel cell with gaseous diffusion electrode as cathode

InactiveCN101207219ALow running costEasy to handleCell electrodesBiochemical fuel cellsCopper conductorClosed loop

The invention provides a single-chamber microbial fuel cell, which takes a gas diffusion electrode as the negative electrode. The invention comprises a container, a positive electrode and a negative electrode; wherein, the positive electrode adopts a foamed metal electrode, the negative electrode adopts a gas diffusion electrode containing metallic catalyst, such as Ag, the container adopts a cylindric glass container, a water inlet opening is arranged at the lower end of the container, a water outlet opening is arranged at the upper end, a sealing cover is arranged at the upper part of the container, a sampling opening is arranged at the middle part of the sealing cover, the positive electrode is positioned at the inner side of the container, the negative electrode is positioned at the outer side of the container, the positive electrode and the negative electrode are arranged along the circumference of the container, copper conductors are connected between the both electrodes, and the both electrodes are connected with a load to form a closed loop. The gas diffusion electrode adopted by the invention exposes in the air, the oxygen gas in the air can be directly utilized as electron acceptors, an extra aerating device is not required; therefore the running cost is reduced. Organism, such as dextrose and discharge water can be used as the fuel of the cell, chemical energy can be effectively converted into electric energy; simultaneously, better discharge water processing effect can be achieved.

Owner:HARBIN ENG UNIV

Self-aligned last-metal C4 interconnection layer for Cu technologies

InactiveUS6426557B1Reduce resistanceReduce mechanical stressSemiconductor/solid-state device detailsSolid-state devicesShunt DeviceCopper conductor

A controlled collapse chip connection (C4) structure having stronger resistance to failure is constructed for use with integrated circuit devices having copper wiring. Failure resistance is obtained by replacing the mechanically weak final passivation to copper interface. The weak interface is eliminated by use of a specific peg on peg structure together with a layer of shunt metal having excellent adhesion and barrier characteristics. A shunt metal, e.g., Ta or TaN, is placed between both the copper and final passivation and the copper and C4 metals such that it overlaps the edge of the peg defined wiring mesh to encase the copper. Overlap is obtained by the peg on peg structure where a SiO2 peg defines the copper wire mesh and a smaller Si3N4 peg placed on the SiO2 peg defines the overlap above the mesh wire and provides the ability to pattern the overlayer shunt without exposure of the copper conductor.

Owner:IBM CORP

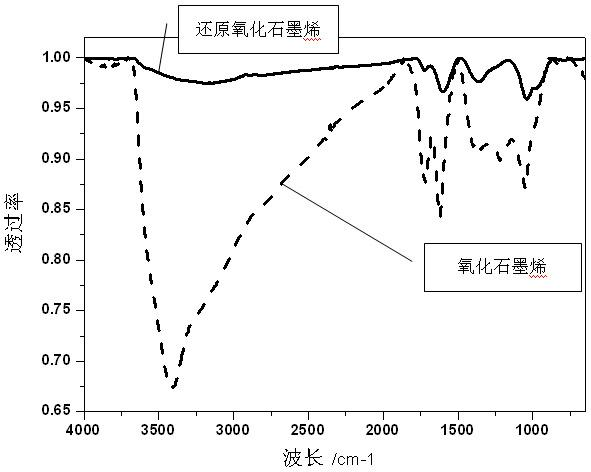

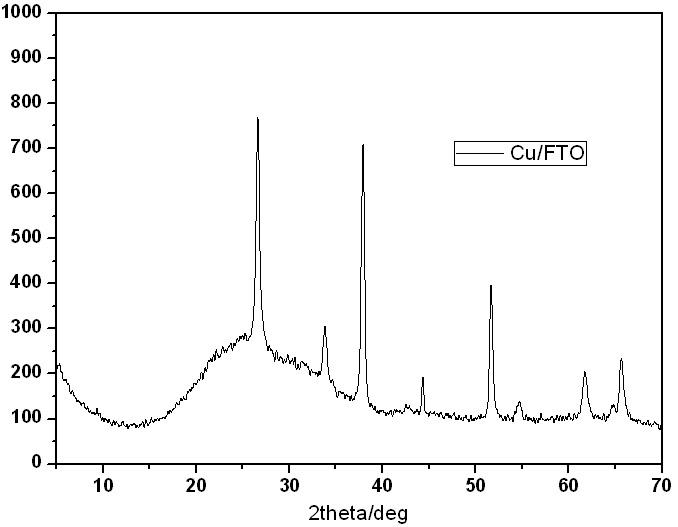

Graphene oxide for electrochemical reduction and preparation method of graphene

InactiveCN102181877AQuality improvementElectrochemical reduction is effectively realizedElectrolysis componentsCopper conductorGraphite

The invention belongs to the technical field of nano materials, and particularly relates to a graphene oxide for electrochemical reduction and a preparation method of graphene. The method comprises the following steps: dissolving graphite oxide in deionized water, and carrying out ultrasonic peeling to obtain a graphene oxide solution; cleaning electrodes and a glass container; adding the graphene oxide solution into the glass container; connecting one end of a copper conductor with cathode and anode materials, putting the electrodes into the graphene oxide solution, and respectively connecting the other end of the copper conductor with positive and negative poles of a direct-current stabilized voltage supply; switching on the direct-current stabilized voltage supply, wherein the voltage is controlled at 10-50V, and the temperature is controlled at 25-90 DEG C; and carrying out electrochemical reduction for 1-60 minutes, thereby obtaining the graphene. The graphene prepared by the method provided by the invention has the advantages of high quality; and the method is simple to operate, and has the advantages of low cost, high safety, no pollution, high-efficiency and the like.

Owner:TONGJI UNIV

Cobalt tungsten phosphate used to fill voids arising in a copper metallization process

InactiveUS20060237853A1Semiconductor/solid-state device detailsSolid-state devicesCopper conductorDevice form

A semiconductor device includes a substrate, at least one layer of functional devices formed on the substrate, a first dielectric layer formed over the functional device layer and a first trench / via located in the first dielectric layer. A copper conductor fills the first trench / via. An electromigration inhibiting barrier layer is selectively located over a surface of the copper conductor and not any other remaining exposed surface. An insulating cap layer overlies the barrier layer and the remaining exposed surface. A second dielectric layer overlies the insulating cap layer. A second trench / via is located in the second dielectric layer and extends through the insulating cap layer and the barrier layer. A micro-trench is located within the first dielectric layer and is associated with the formation of the second trench / via. The micro-trench exposes a portion of the copper conductor. A filler fills the micro-trench. The filler is formed from a material used to form the electromigration inhibiting barrier layer.

Owner:SONY CORP +1

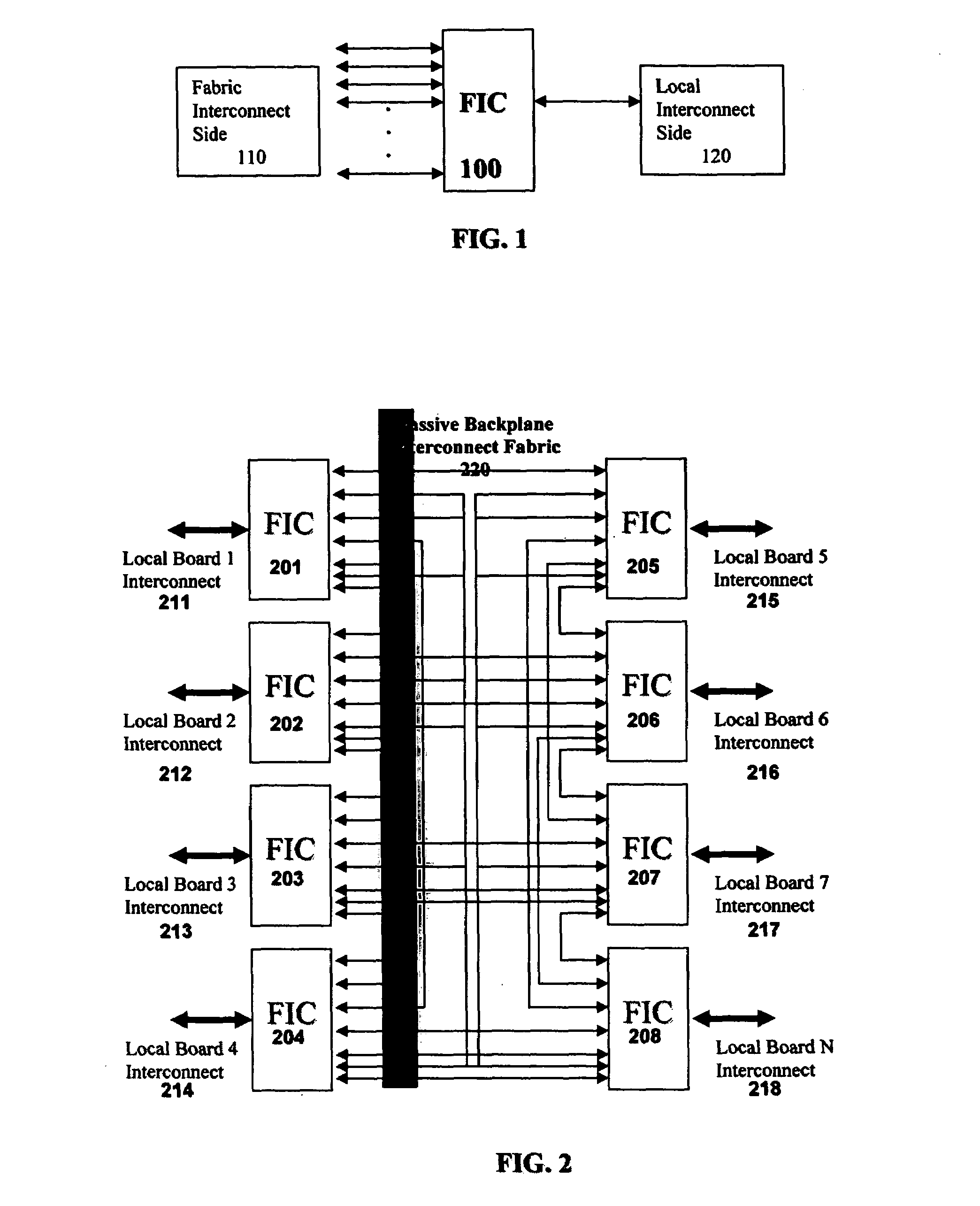

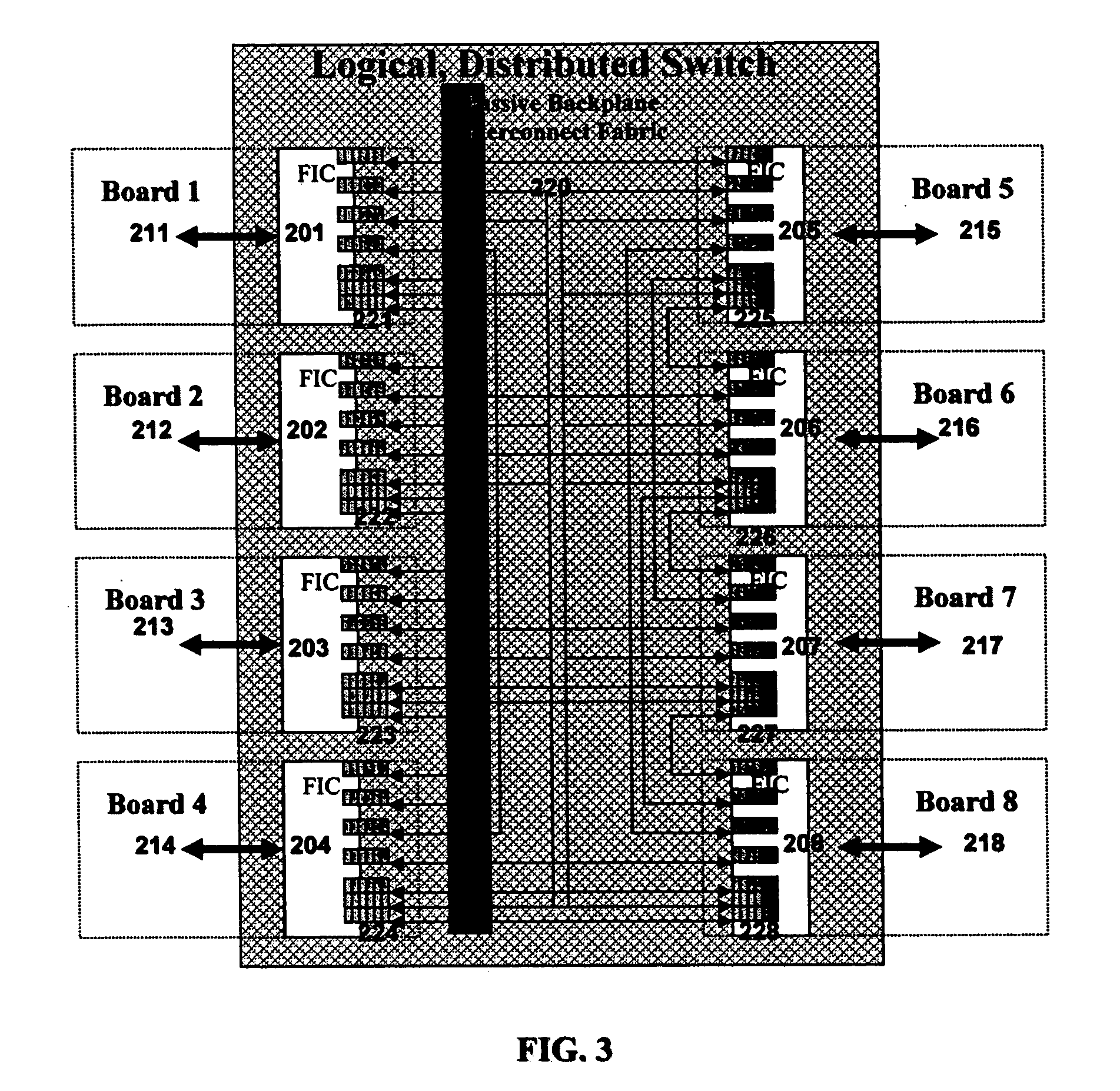

Multi-port high-speed serial fabric interconnect chip in a meshed configuration

InactiveUS7218640B2Store-and-forward switching systemsSupport structure mountingCopper conductorSystem configuration

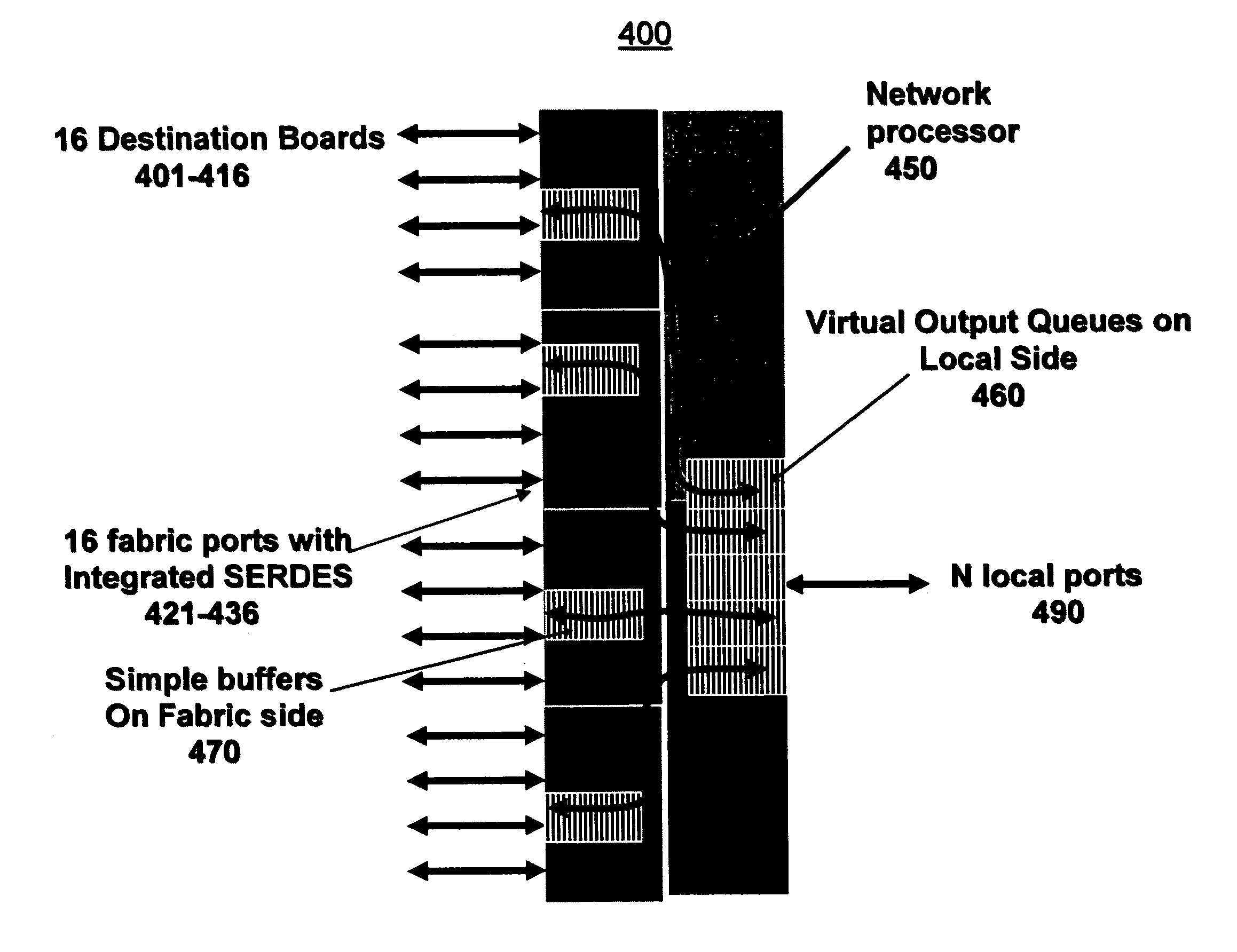

Multiple boards are connected within a chassis, using a multi-port Target Channel Adapter (TCA). Data is transported from a TCA on a board directly to a TCA on another board through a meshed backplane. The meshed backplane is equipped to mount boards via connectors and may consist of a fabric of copper conductors or optical fibers. Communication from TCA to TCA requires placing ports on each individual TCA along with the appropriate input and output buffering. A multi-port TCA capable of performing multiple bridging functions simultaneously i.e., bridging from a high speed serial meshed backplane to multiple local busses, i.e., Gigabit Ethernet, Fibre Channel, and TCP / IP devices, is referred to as a Fabric Interconnect Chip (FIC).

Owner:INTEL CORP

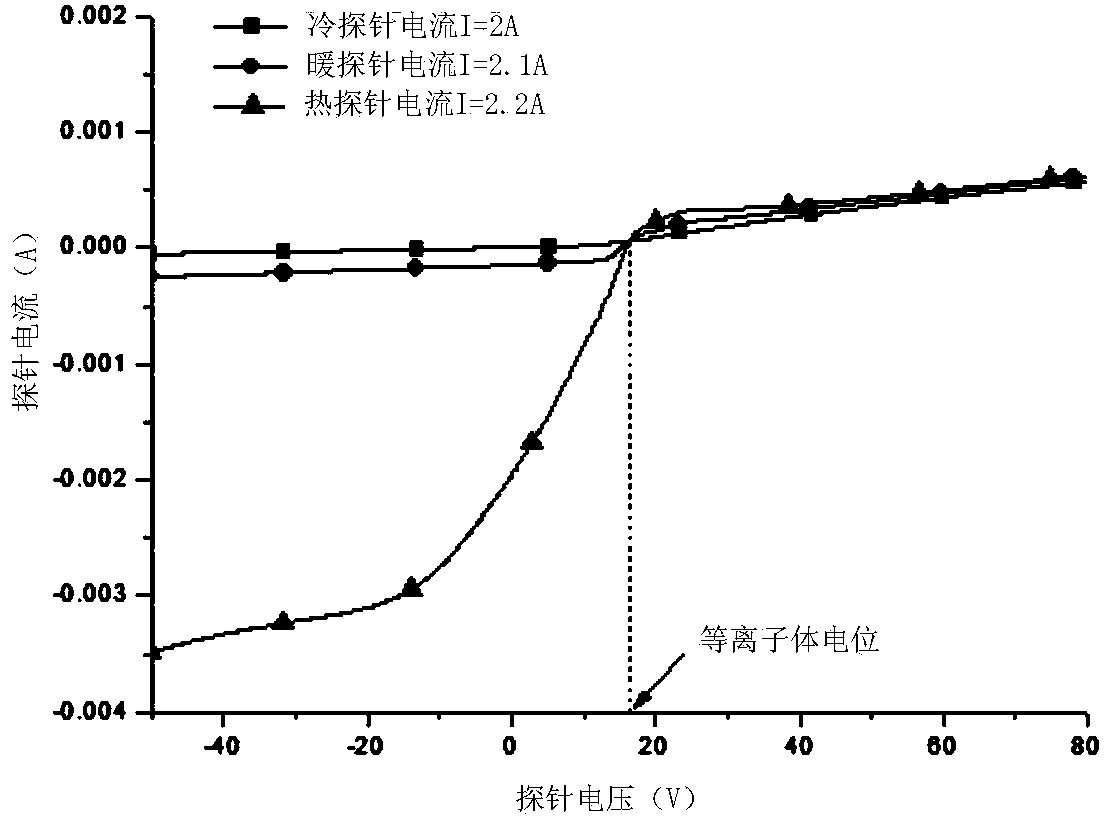

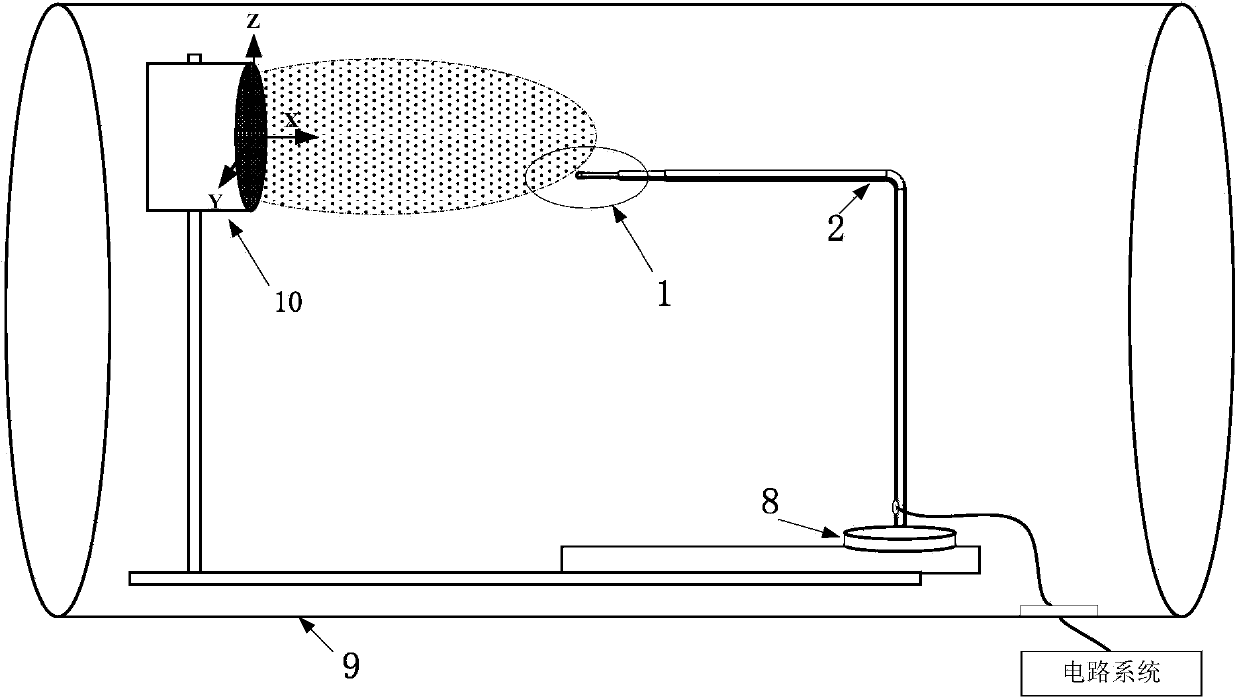

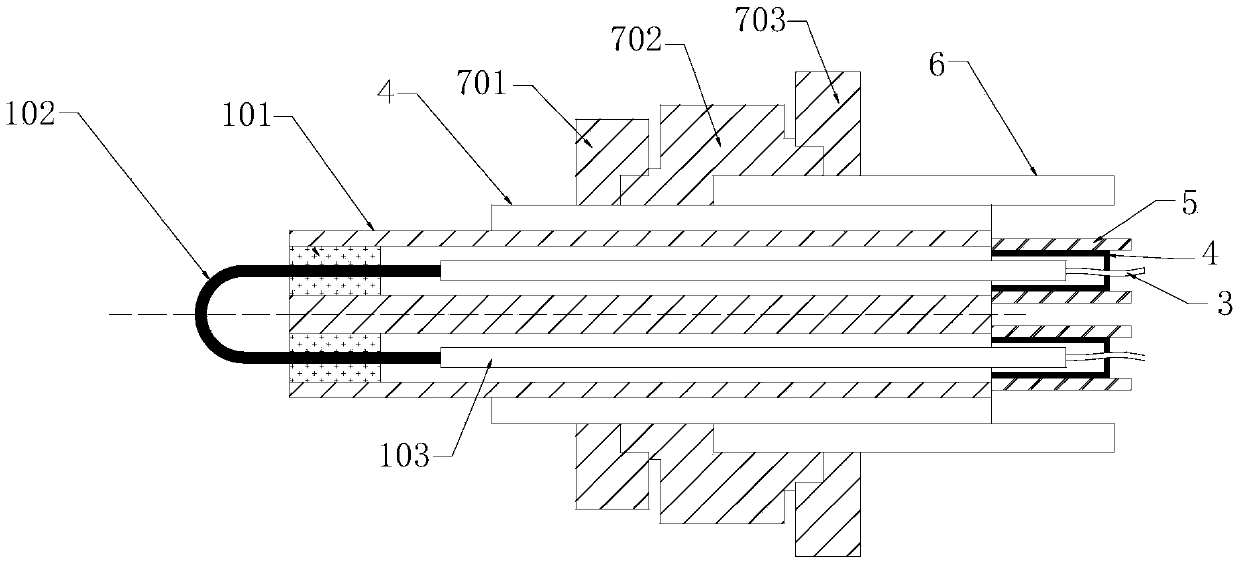

Langmuir emitting probe for plasma space potential diagnosing

InactiveCN104244555AAccurate measurementOptimize layoutPlasma techniqueCopper conductorSpatial positioning

The invention discloses a Langmuir emitting probe for plasma space potential diagnosing. The Langmuir emitting probe comprises a probe body and a probe support. The probe body is made of a 2% thoriated tungsten wire 0.1 in diameter. The thoriated tungsten wire is bent into a U shape. The tail of the thoriated tungsten wire is welded with a copper conductor. The tail of the copper conductor welded with the central signal line of a shielding coaxial cable. The central signal line of the shielding coaxial cable serves as a signal transmission line. Multiple layers of insulation and thermal insulation protective materials wrap the central signal line of the shielding coaxial cable. The probe body is supported by the tubular probe support which is bent into an L shape. The probe support is connected to a spatial positioning device in a threaded manner. The Langmuir emitting probe is small in size, high in signal to noise ratio of signal transmission, high in heat resistance, good in stability, convenient in spatial positioning, small in repeated positioning error, suitable for fast and accurate measuring of plasma feature parameter spatial distribution under various plasma environments, and widely applicable to plasma scientific research and industrial application.

Owner:BEIHANG UNIV

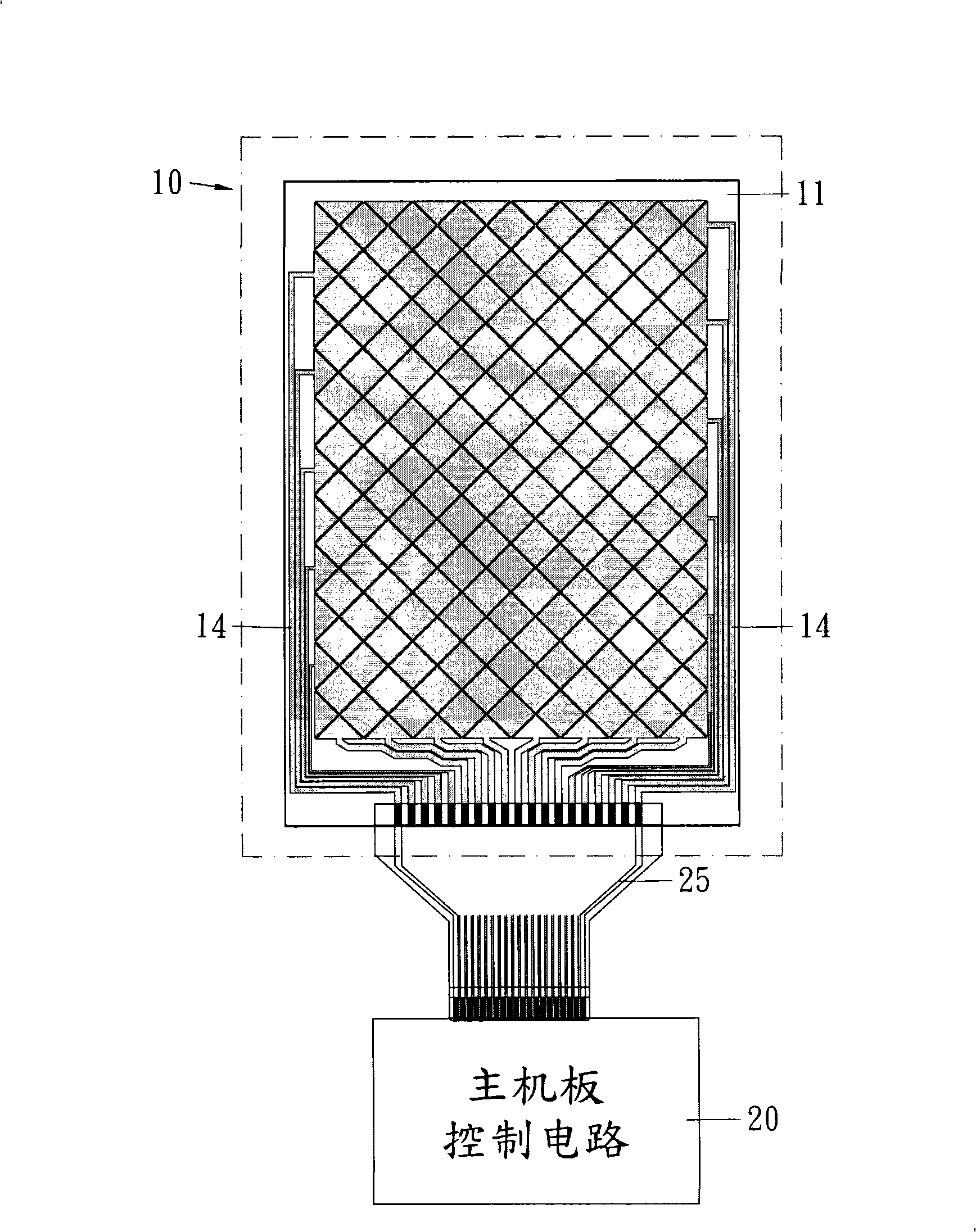

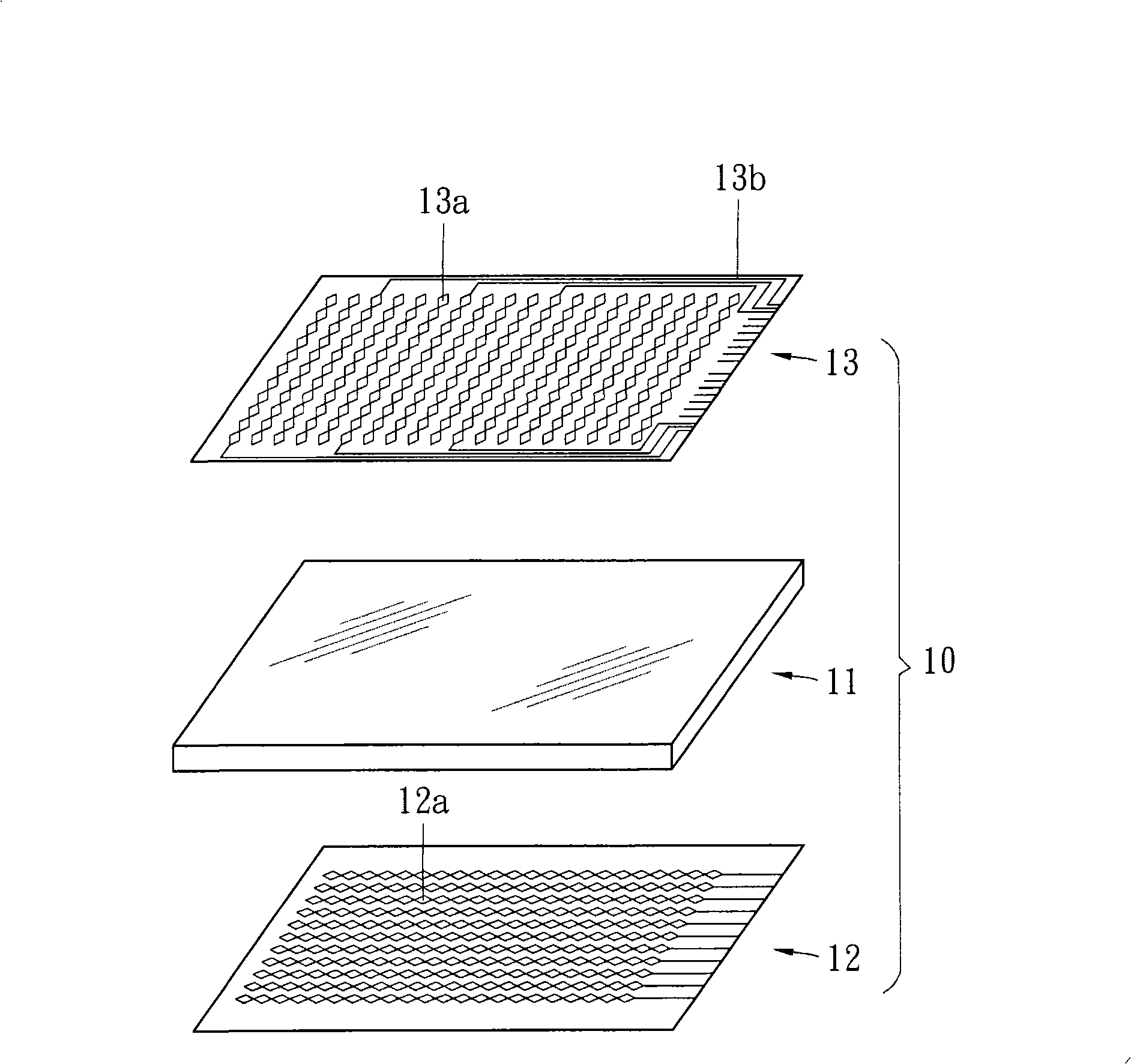

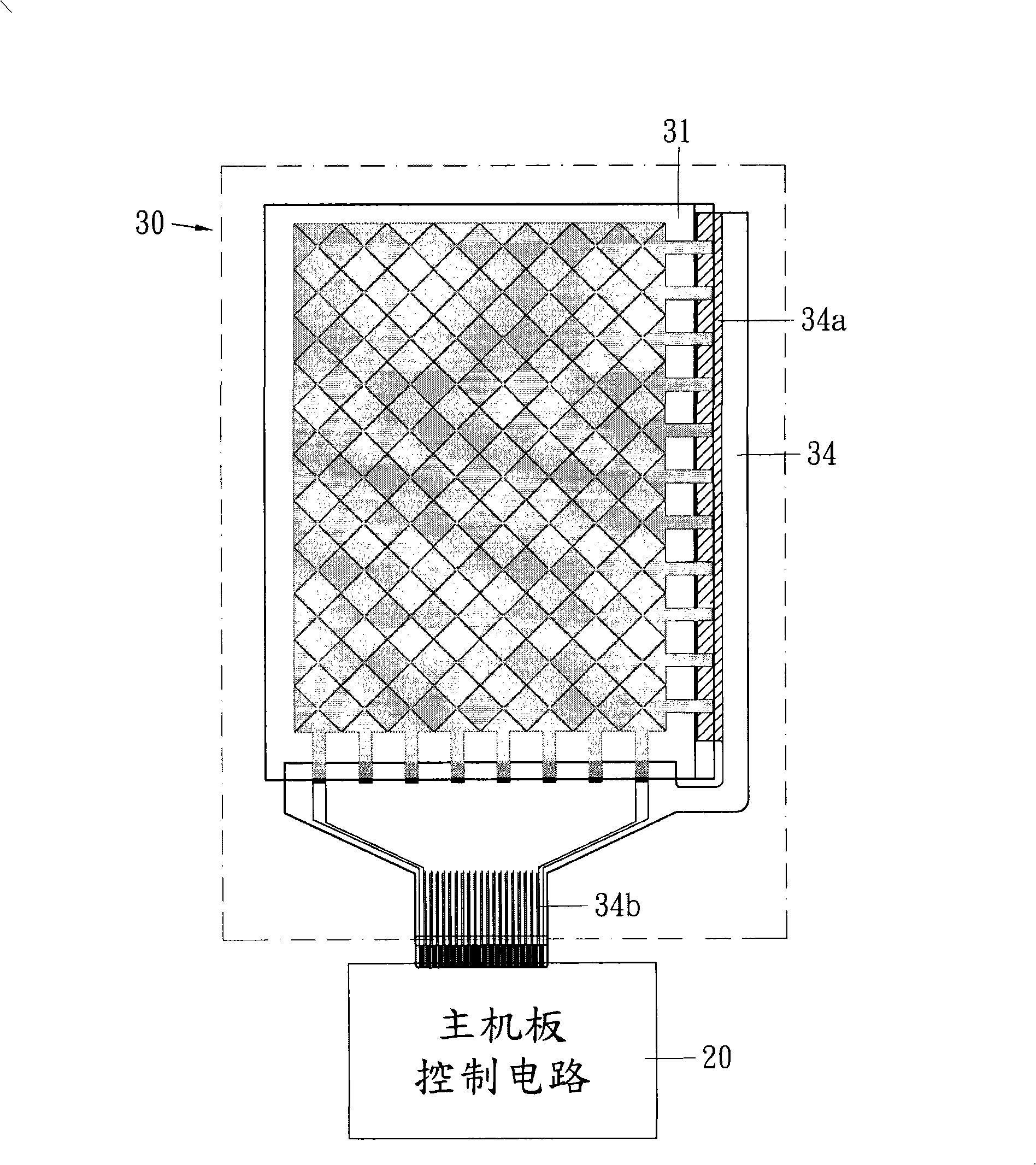

Condenser type touching control panel reducing line impedence by FPC

InactiveCN101344831ALower impedanceElectrical connection printed elementsInput/output processes for data processingCopper conductorEngineering

A capacitor touch panel which reduces line impedance by using FPC and comprises a glass base plate and a flexible printed circuit board, wherein, the upper and the lower surfaces of the glass base plate are respectively provided with an X-direction sensing line layer and a Y-direction sensing line layer. The Y-direction sensing line layer has no screen-printed single or multiple-layer metal wires, but copper conductor material of the flexible printed circuit board is made into metal wires, which are used for connecting the X-direction sensing line layer and the Y-direction sensing line layer. The capacitor touch panel reduces the impedance of the whole line through the flexible printed circuit board and has the characteristics of improving the output and lowering the cost.

Owner:NANYA PLASTICS CORP

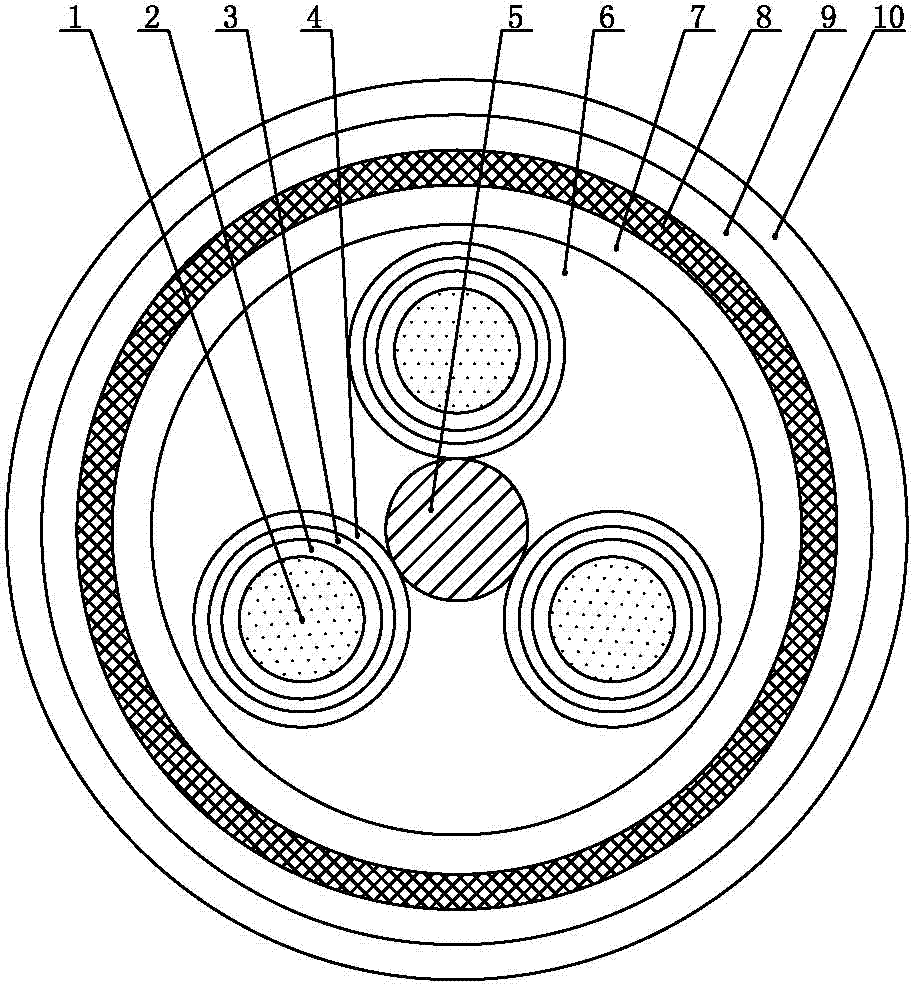

Medium and high-voltage cable for moving petrochemical device and manufacturing method thereof

ActiveCN102751013AHigh mechanical strengthMeet the use requirementsNon-insulated conductorsFlexible cablesCopper conductorCopper wire

The invention discloses a medium and high-voltage cable for moving a petrochemical device and a manufacturing method thereof. A semiconducting conductor shielding belt, a semiconducting conductor shielding extruding and wrapping layer, an oil-resistant rubber insulating layer, a semiconducting insulating shielding extruding and wrapping layer and an insulating shielding braiding reinforcing layer are sequentially arranged outside a stranded copper conductor; three insulating shielding phase wire cores are provided with central tensile components; three grounding wires and a plurality of tensile filling cores are integrally stranded into a cable core; and an oil-resistant rubber inner lining layer, an aluminum foil polyester composite belt shielding layer, a tin-coated copper wire braided shielding layer, an oil-resistant rubber inner sheath, an armored braided layer and an oil-resistant rubber outer sheath are sequentially arranged at the periphery of the cable core. A multiple shielding effect is achieved by the cable, and the oil-resistant rubber insulating layer, the oil-resistant rubber inner sheath and the oil-resistant rubber outer sheath achieve a triplex protection effect, so that the oil resistance of the cable is better. The central tensile components are arranged in the center of the three insulating shielding phase wire cores, and the tensile filling cores are arranged at the peripheries of the three insulating shielding phase wire cores, so that the cable can bear high tensile force.

Owner:嘉兴顾翔制冷设备有限公司

Post-ESL porogen burn-out for copper ELK integration

InactiveUS7217648B2Avoid dielectric shrinkageSolid-state devicesSemiconductor/solid-state device manufacturingCopper conductorSemiconductor

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com