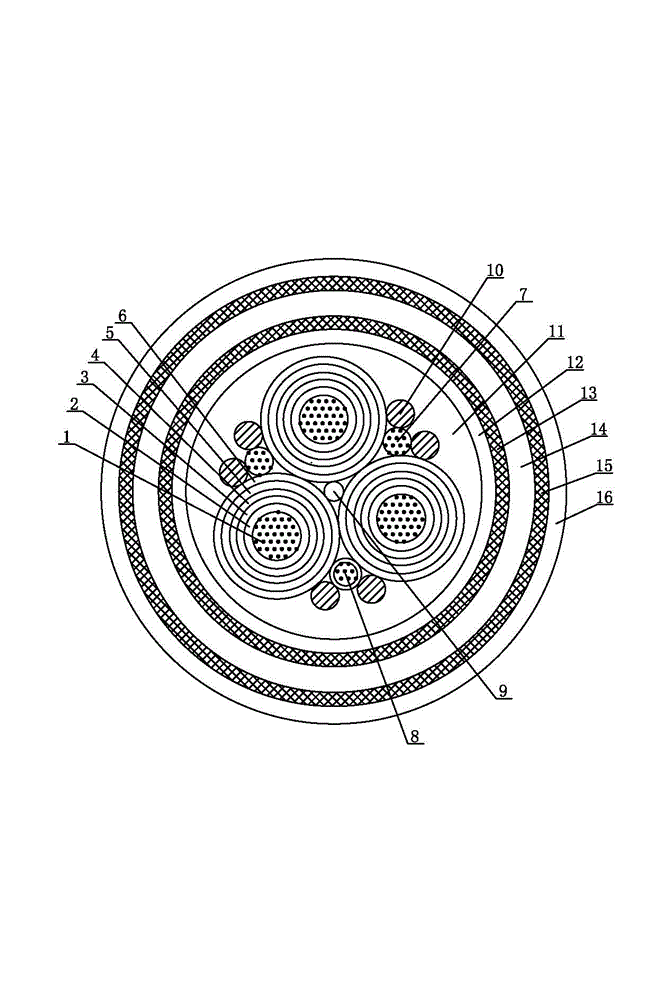

Medium and high-voltage cable for moving petrochemical device and manufacturing method thereof

A technology for medium and high voltage cables and petrochemical devices, which is used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve problems such as poor waterproof performance, and achieve the effects of good oil resistance and excellent shielding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First prepare the rubber required for the oil-resistant rubber inner sheath and the oil-resistant rubber outer sheath, the steps are as follows: (1) Prepare raw materials according to the following components and weight content, chlorinated polyethylene rubber CM352: 15 parts; chlorosulfonated polyethylene rubber H40: 15 parts; curing agent dicumyl peroxide: 0.4 parts; curing agent triallyl isocyanurate: 0.2 parts; active agent magnesium oxide: 1.0 parts; active agent polyethylene glycol: 1.0 parts Antiaging agent nickel dibutyl dithiocarbamate: 0.2 parts; Antiaging agent 4,4′-bis(α,α-dimethylbenzyl) diphenylamine: 0.1 parts; Plasticizer dioctyl sebacate : 2.0 parts; flame retardant antimony trioxide: 3 parts; filler carbon black: 2 parts; filler superfine talcum powder: 15 parts; processing aid light lead stearate: 0.1 parts; Knead chlorinated polyethylene rubber CM352 raw rubber on an internal mixer at a temperature of 70°C for 2 minutes, then add chlorosulfonated pol...

Embodiment 2

[0035] First prepare the rubber required for the oil-resistant rubber inner sheath and the oil-resistant rubber outer sheath, the steps are as follows: (1) Prepare raw materials according to the following components and weight content, chlorinated polyethylene rubber CM352: 15 parts; chlorosulfonated polyethylene rubber H40: 15 parts; vulcanizing agent dicumyl peroxide: 0.5 parts; vulcanizing agent triallyl isocyanurate: 0.25 parts; active agent magnesium oxide: 1.2 parts; active agent polyethylene glycol: 1.5 parts Antiaging agent nickel dibutyldithiocarbamate: 0.3 parts; Antiaging agent 4,4′-bis(α,α-dimethylbenzyl) diphenylamine: 0.15 parts; Plasticizer dioctyl sebacate : 3.0 parts; flame retardant antimony trioxide: 4 parts; filler carbon black: 3 parts; filler superfine talcum powder: 18 parts; processing aid light lead stearate: 0.2 parts; (2) first Knead chlorinated polyethylene rubber CM352 raw rubber on an internal mixer at a temperature of 75°C for 2.5 minutes, then a...

Embodiment 3

[0050] First prepare the rubber required for the oil-resistant rubber inner sheath and the oil-resistant rubber outer sheath, the steps are as follows: (1) Prepare raw materials according to the following components and weight content, chlorinated polyethylene rubber CM352: 15 parts; chlorosulfonated polyethylene rubber H40: 15 parts; curing agent dicumyl peroxide: 0.6 parts; curing agent triallyl isocyanurate: 0.3 parts; active agent magnesium oxide: 1.5 parts; active agent polyethylene glycol: 2.0 parts Antiaging agent nickel dibutyl dithiocarbamate: 0.4 parts; Antiaging agent 4,4′-bis(α,α-dimethylbenzyl) diphenylamine: 0.2 parts; Plasticizer dioctyl sebacate : 3.5 parts; flame retardant antimony trioxide: 5 parts; filler carbon black: 4 parts; filler superfine talcum powder: 20 parts; processing aid light lead stearate: 0.3 parts; (2) first Knead chlorinated polyethylene rubber CM352 raw rubber on an internal mixer at a temperature of 80°C for 3 minutes, then add chlorosulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com