Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178results about How to "Reliable filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

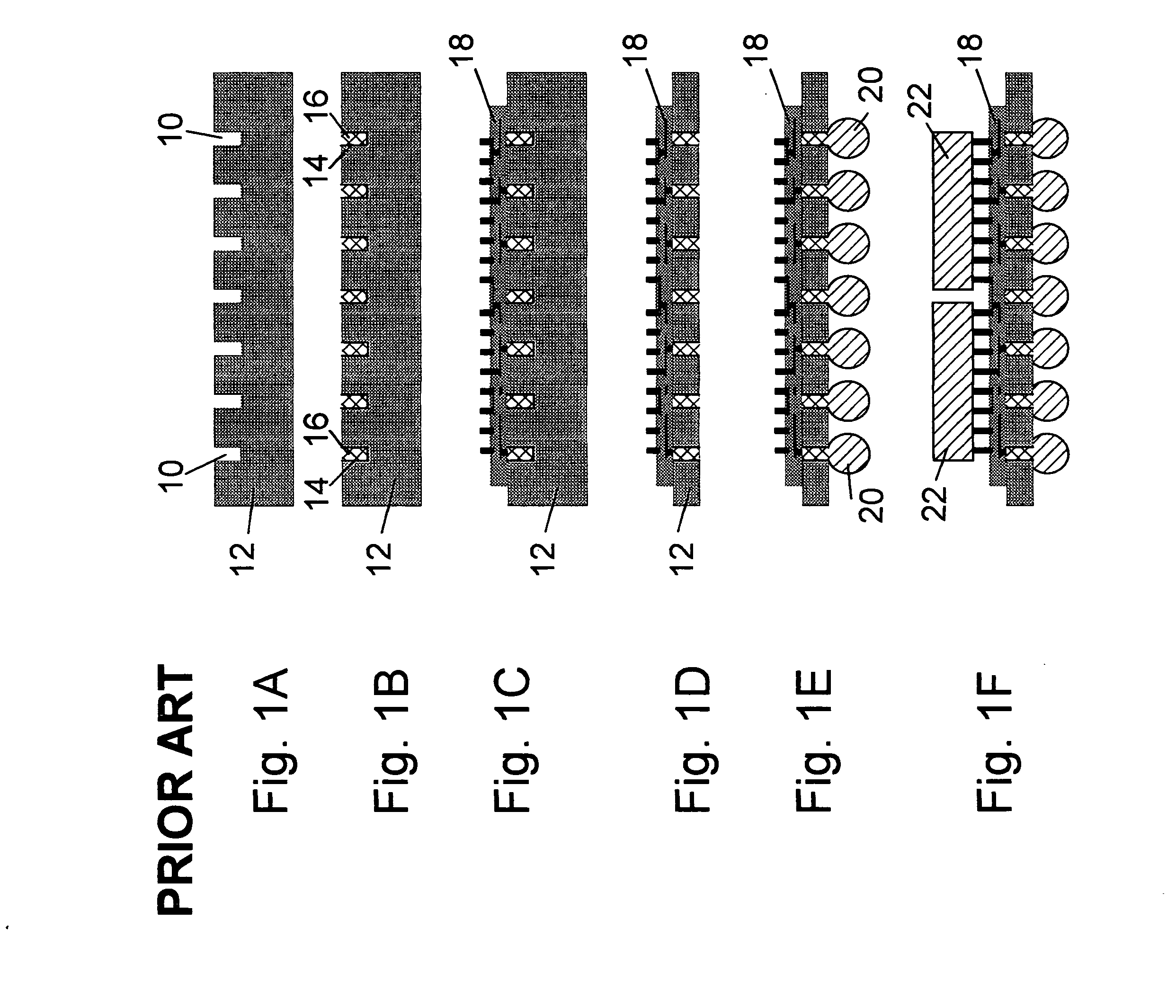

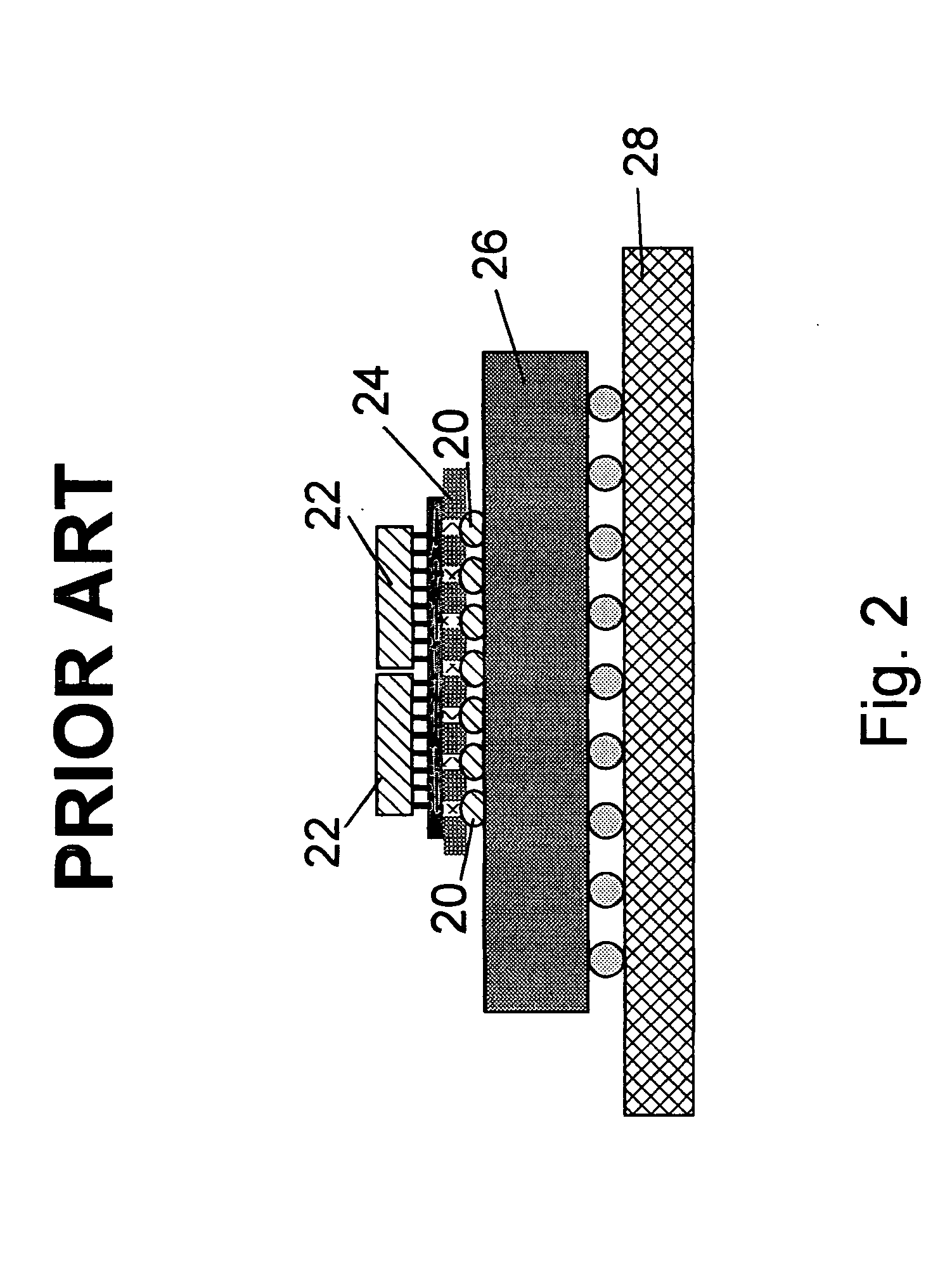

Method and apparatus for filling vias

ActiveUS20050106834A1Reliable fillingPrinted circuit assemblingLiquid surface applicatorsMechanical engineering

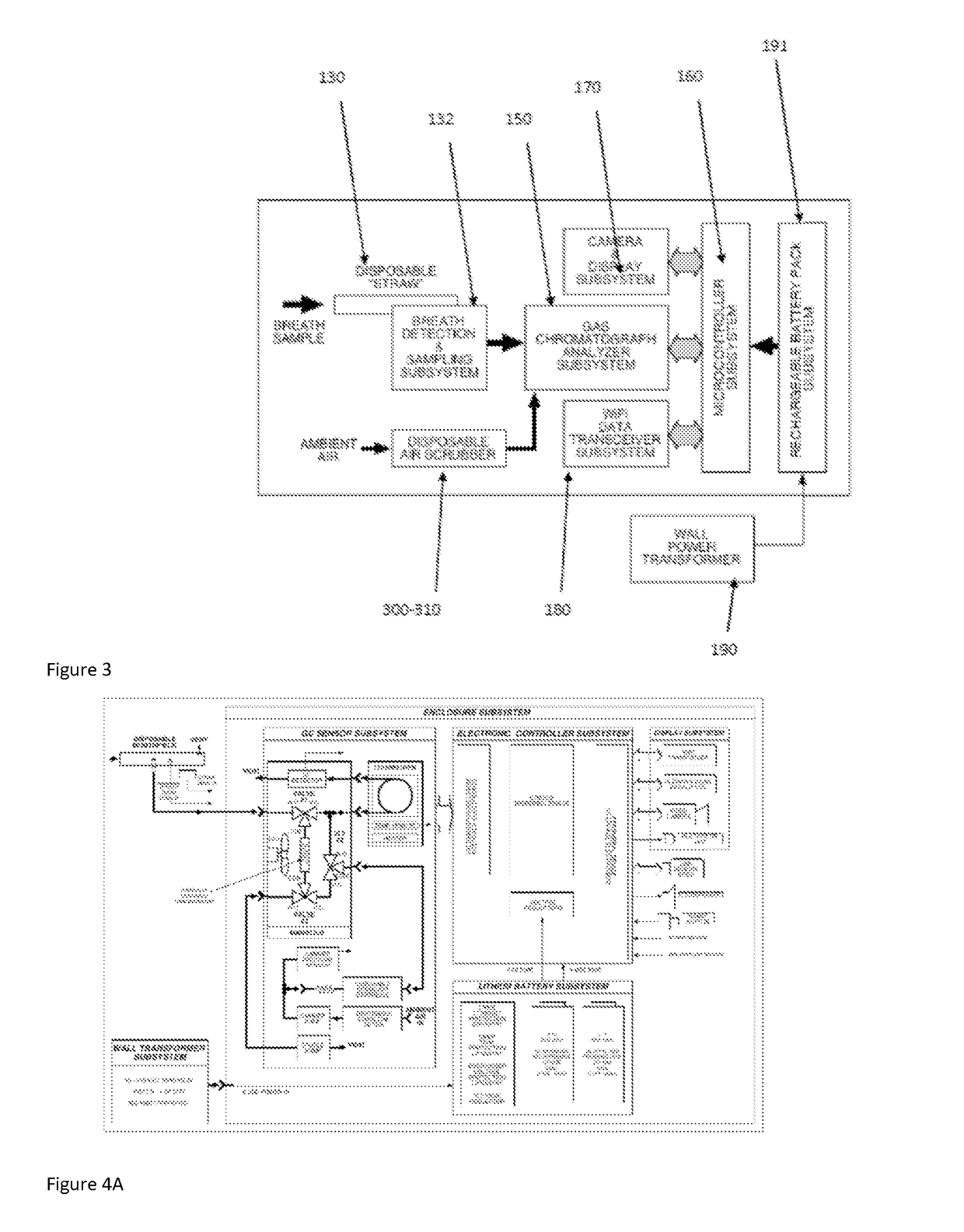

A method for filling vias, and in particular initially blind vias, in a wafer, and various apparatus for performing the method, comprising evacuating air from the vias; trapping at least a portion of the wafer and a paste for filling the vias between two surfaces; and pressurizing the paste to fill the vias.

Owner:GLOBALFOUNDRIES US INC

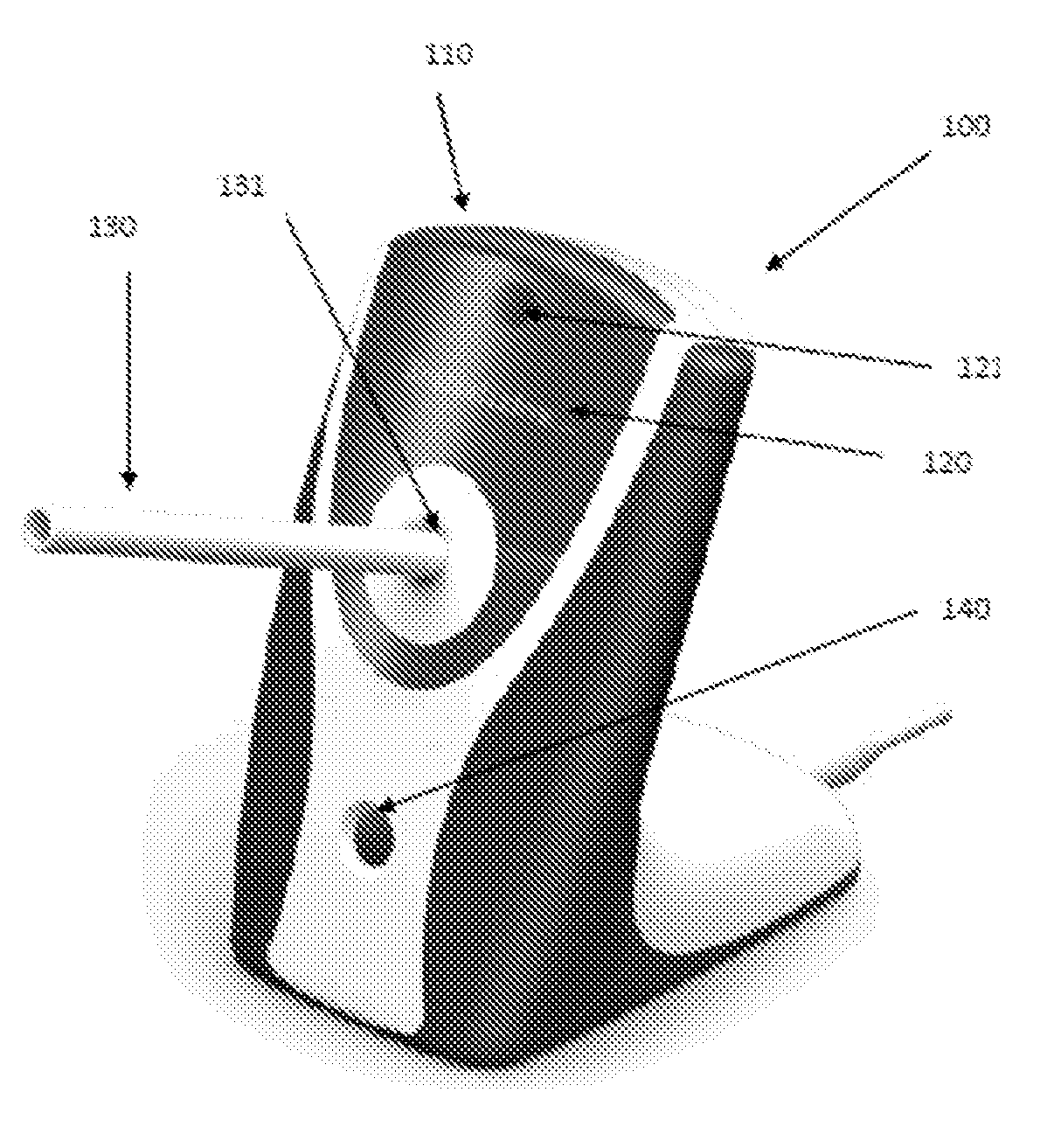

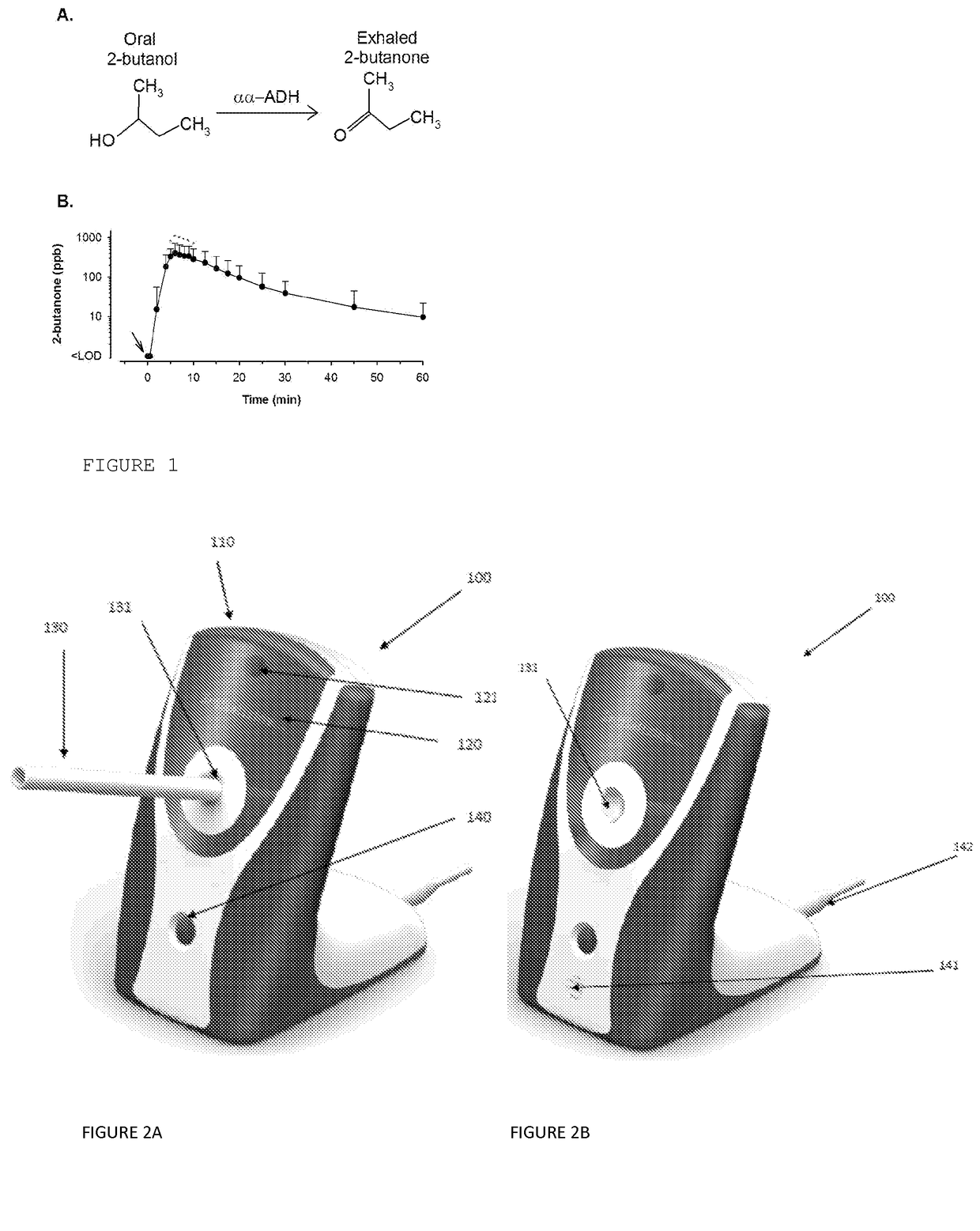

Medication adherence monitoring device

InactiveUS20170074857A1Promotes quick releaseAvoid lostComponent separationVaccination/ovulation diagnosticsMedication adherenceIntermediate term

A Self Monitoring And Reporting Therapeutics, SMART® composition, method, apparatus and system are provided which flexibly provide options, by combining different embodiments of the device with different embodiments of the composition, the ability to conduct definitive medication adherence monitoring over the short term (Acute Medication Adherence Monitoring, immediately up to an hour or so after taking a medication), intermediate term (Intermediate Medication Adherence Monitoring, IMAM, an hour or so to a day or so after taking a medication), and longer term (Chronic Medication Adherence Monitoring, CMAM, a day to several days after taking a medication).

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

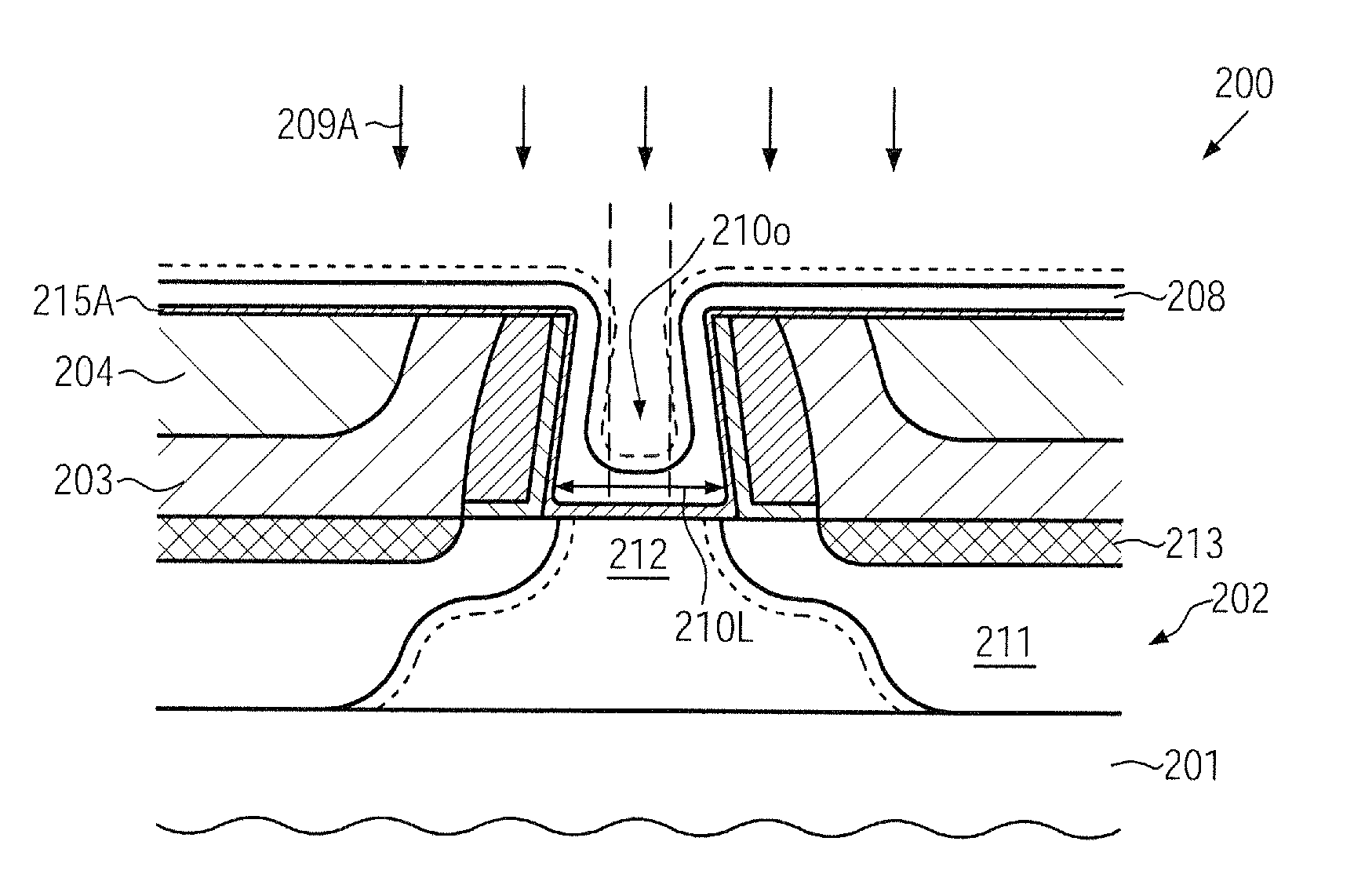

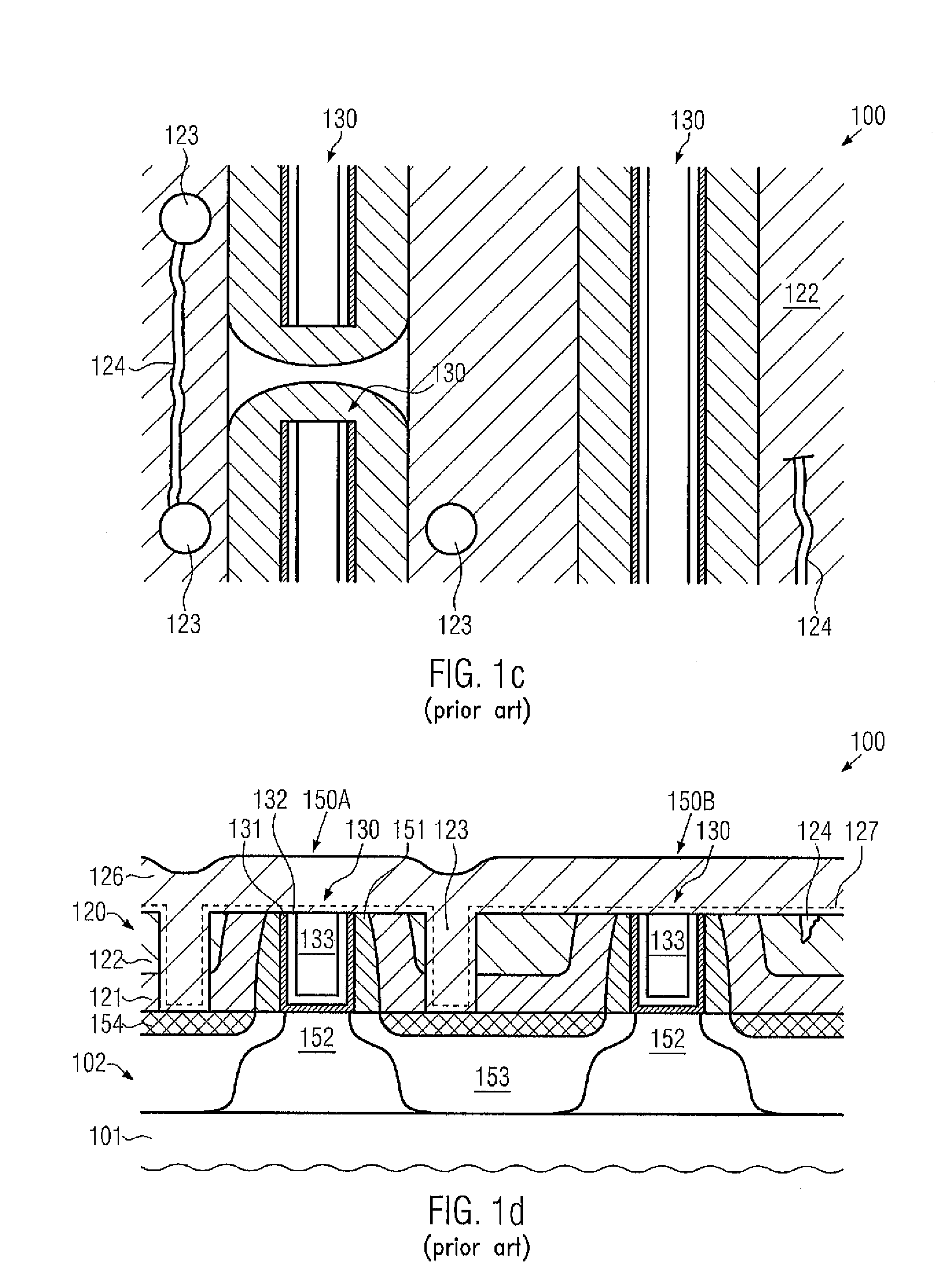

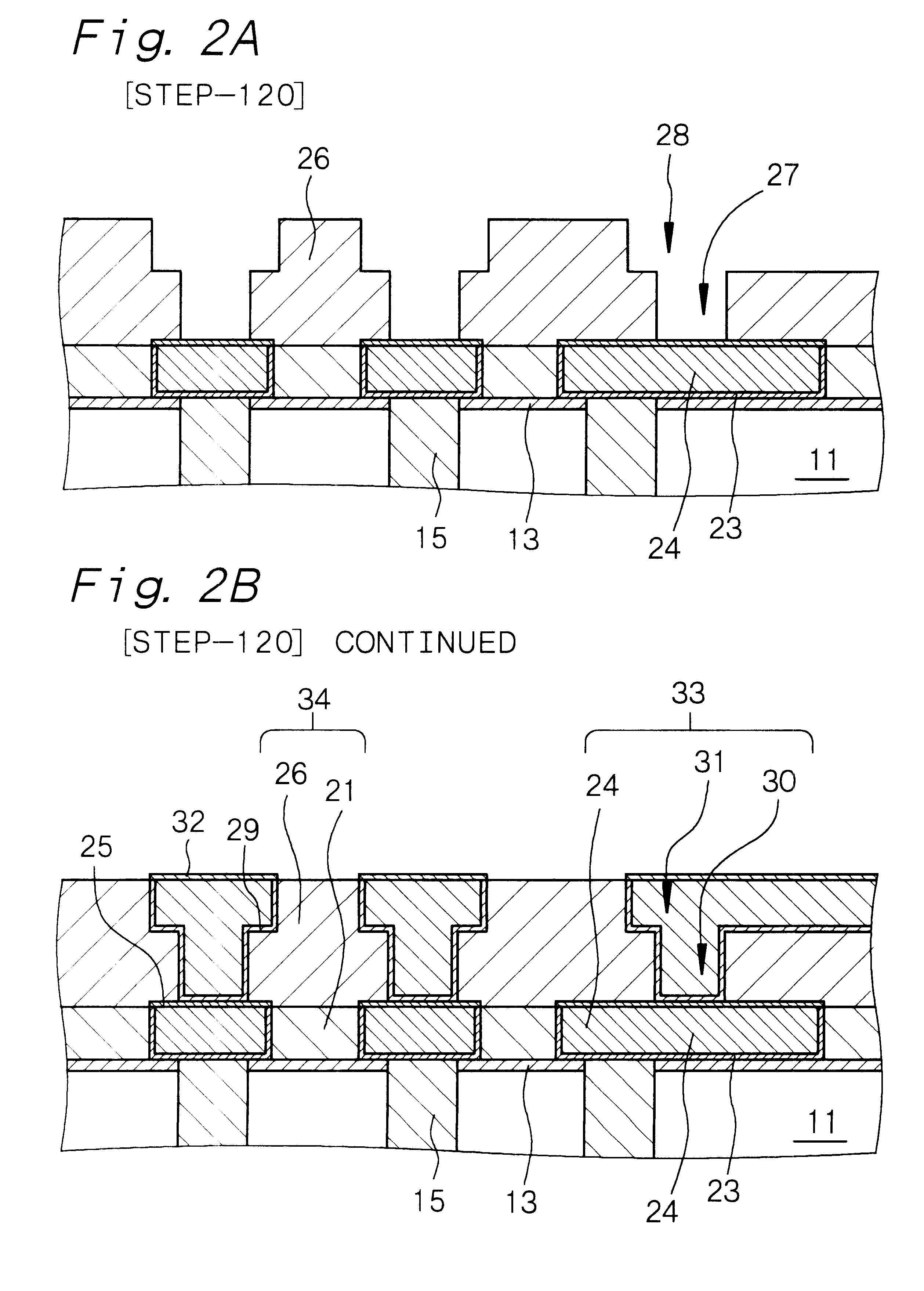

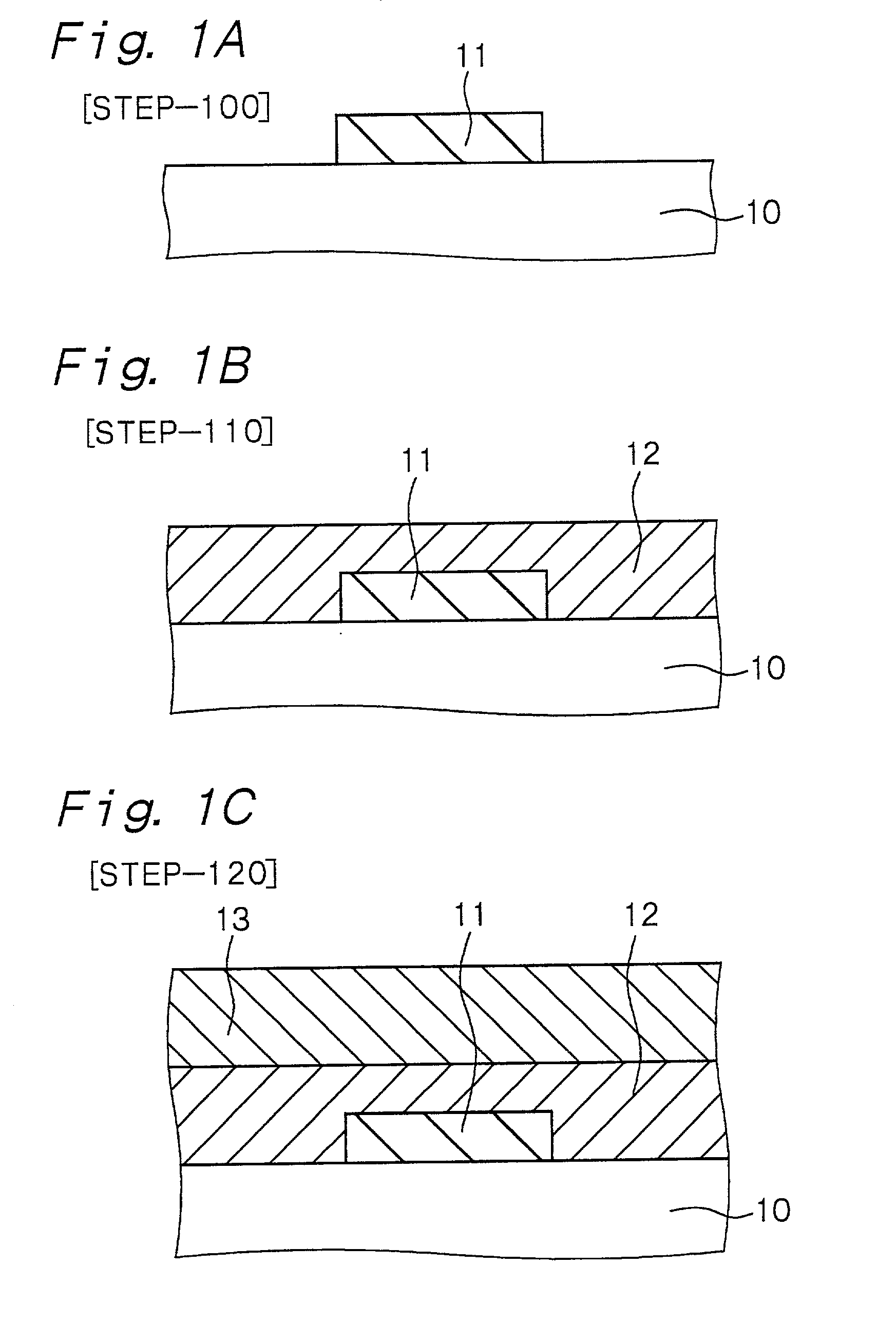

Technique for enhancing the fill capabilities in an electrochemical deposition process by edge rounding of trenches

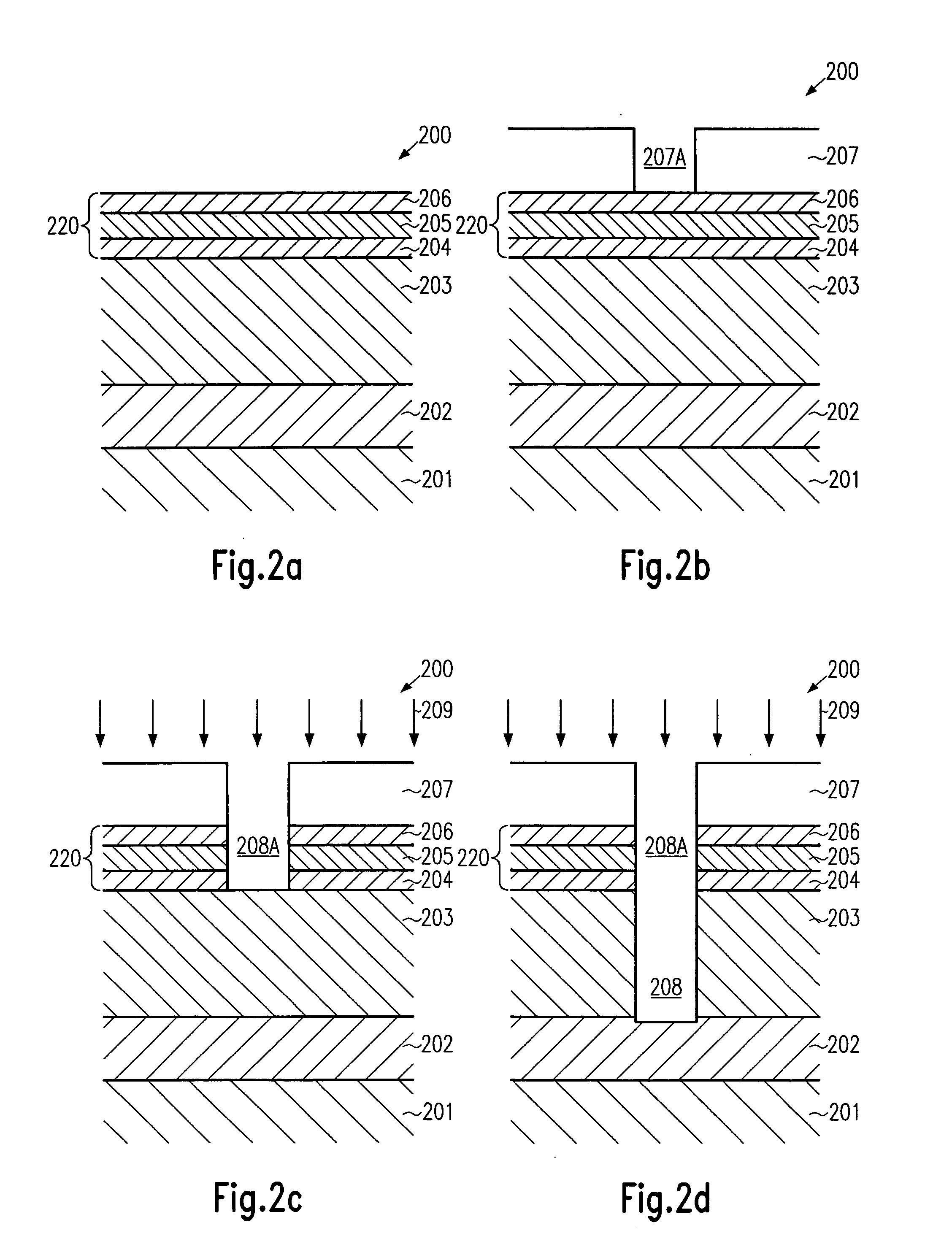

ActiveUS20060046495A1Reducing and avoiding formation of voidIncrease depositionSemiconductor/solid-state device manufacturingResistRounding

During the formation of a metal line in a low-k dielectric material, an upper portion of a trench formed in a capping layer and the low-k dielectric material is treated to provide enlarged tapering or corner rounding, thereby significantly improving the fill capabilities of subsequent metal deposition processes. In one particular embodiment, an additional etch process is performed after etching through the capping layer and the low-k dielectric layer and after resist removal.

Owner:ADVANCED MICRO DEVICES INC

Thin-film magnetic head structure, method of manufacturing the same, and thin-film magnetic head

ActiveUS20060103980A1Large coercivityReliable fillingRecord information storageHeads for perpendicular magnetisationsMagnetic polesEngineering

Owner:HEADWAY TECH INC

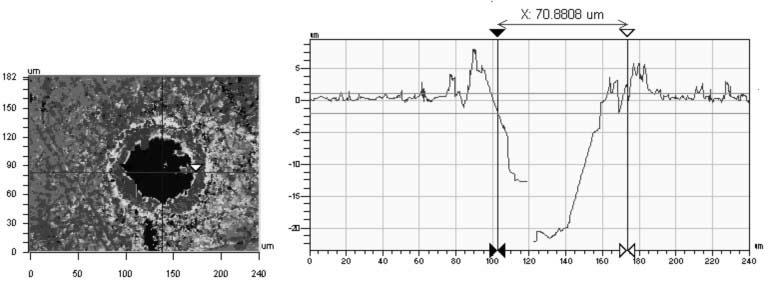

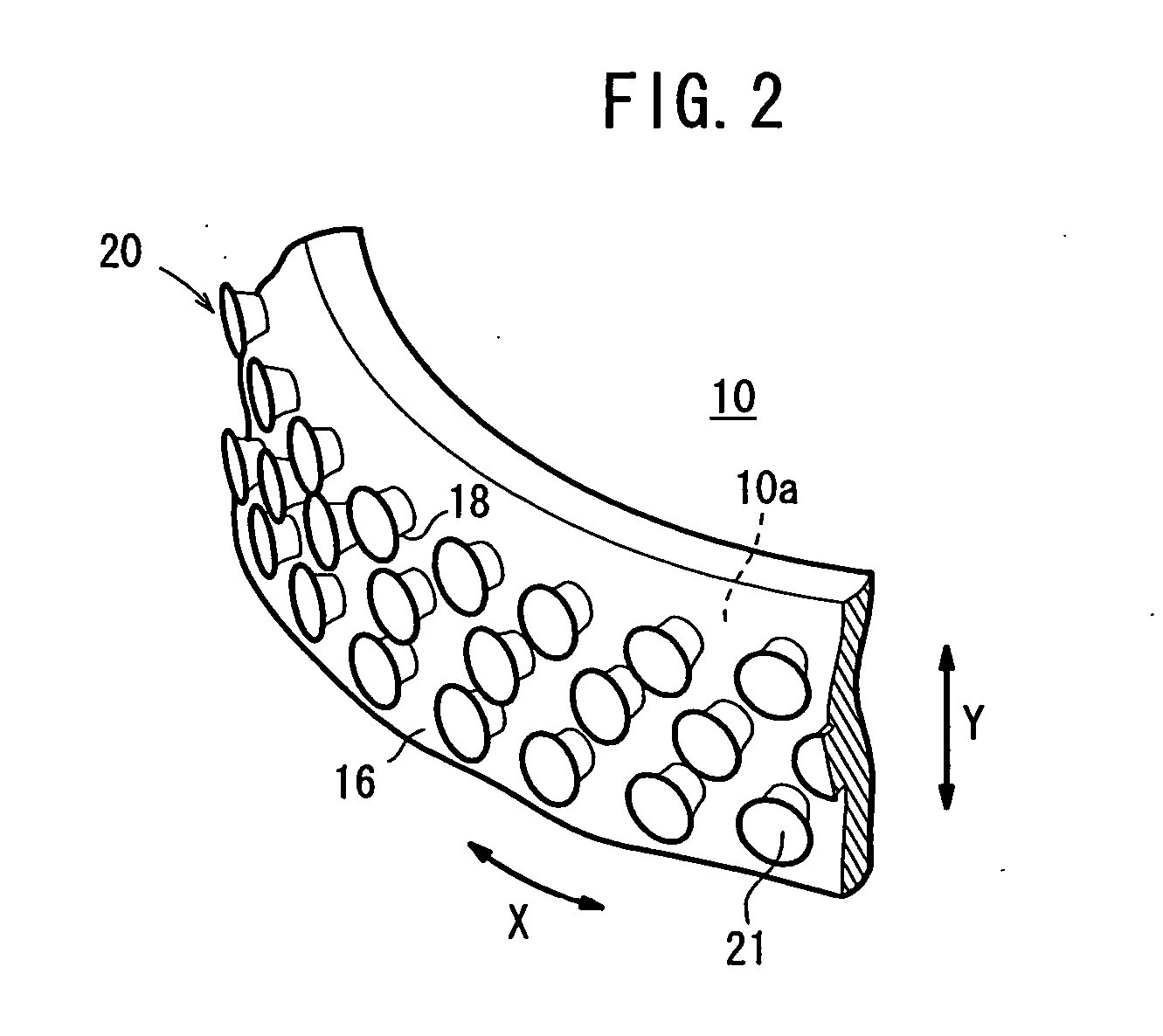

Micro-embedded self-lubricating texture on surfaces of gear and cam and preparation method thereof

InactiveCN102628544AImprove adaptabilityImprove lubrication and anti-wear performancePortable liftingBase-materialsLaser processingHexagonal boron nitride

The invention discloses a micro-embedded self-lubricating texture on the surfaces of a gear and a cam and a preparation method thereof. The preparation method comprises the following steps of: performing micro texture processing on the surfaces of the gear and the cam by an Nd: YAG laser processing technology; and embedding a solid lubricant into the micro texture on the surfaces of the gear and the cam by a molding bonding technology of a self-lubricating composite material. The self-lubricating composite material comprises the following formula components in percentage by mass: 15 to 85 percent of polyimide (PI), 0 to 85 percent of polytetrafluoroethylene (PTFE), 10 to 40 percent of MoS2, 0 to 15 percent of WS2, 0 to 16 percent of graphite fluoride, 5 to 15 percent of graphite, 0 to 12 percent of PbO, 0 to 6 percent of antimony trioxide, 0 to 10 percent of CaF2 or BaF2, 0 to 15 percent of hexagonal boron nitride, 0 to 15 percent of nano lubricant and 0 to 5 percent of additive. According to the micro-embedded self-lubricating texture, the self-lubricating texture is subjected to micro embedding on the surfaces of the gear and the cam to ensure that the solid lubricant on the friction surface is stably supplied and uniformly coated, so that the lubrication and anti-wear properties of friction pairs such as the gear and the cam under complicated and harsh operating conditions are improved.

Owner:JIANGSU UNIV

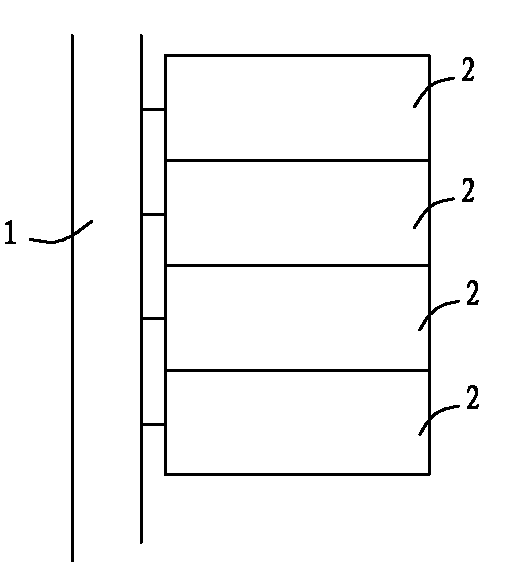

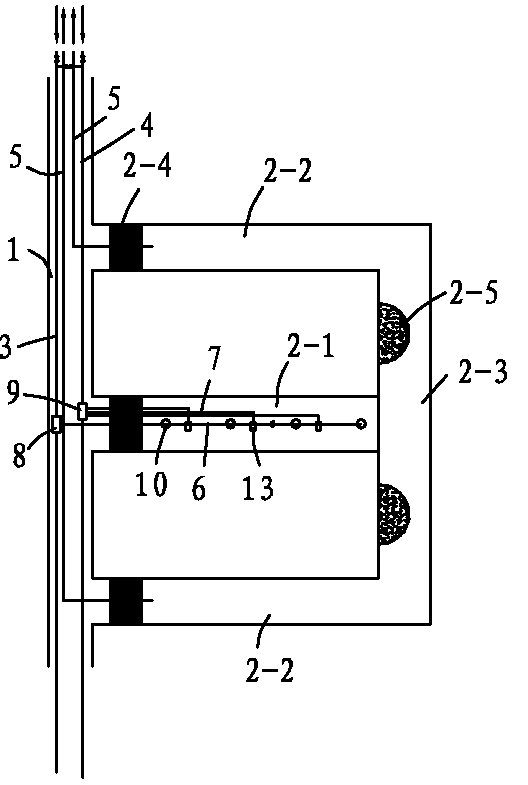

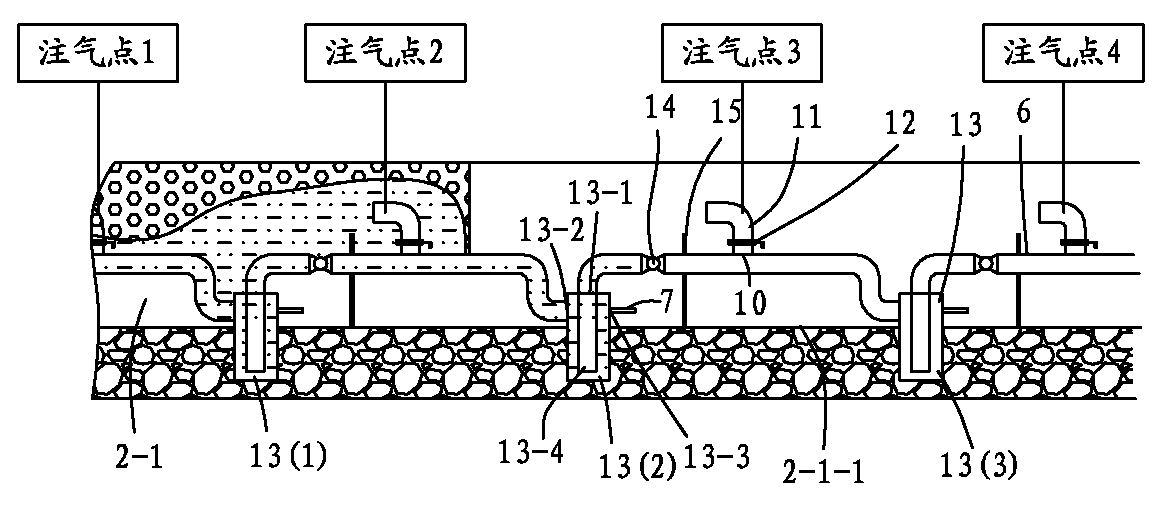

Gas injection point retreating type coal underground gasification system and process

InactiveCN103277082AAvoid cloggingPrevent backflowConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

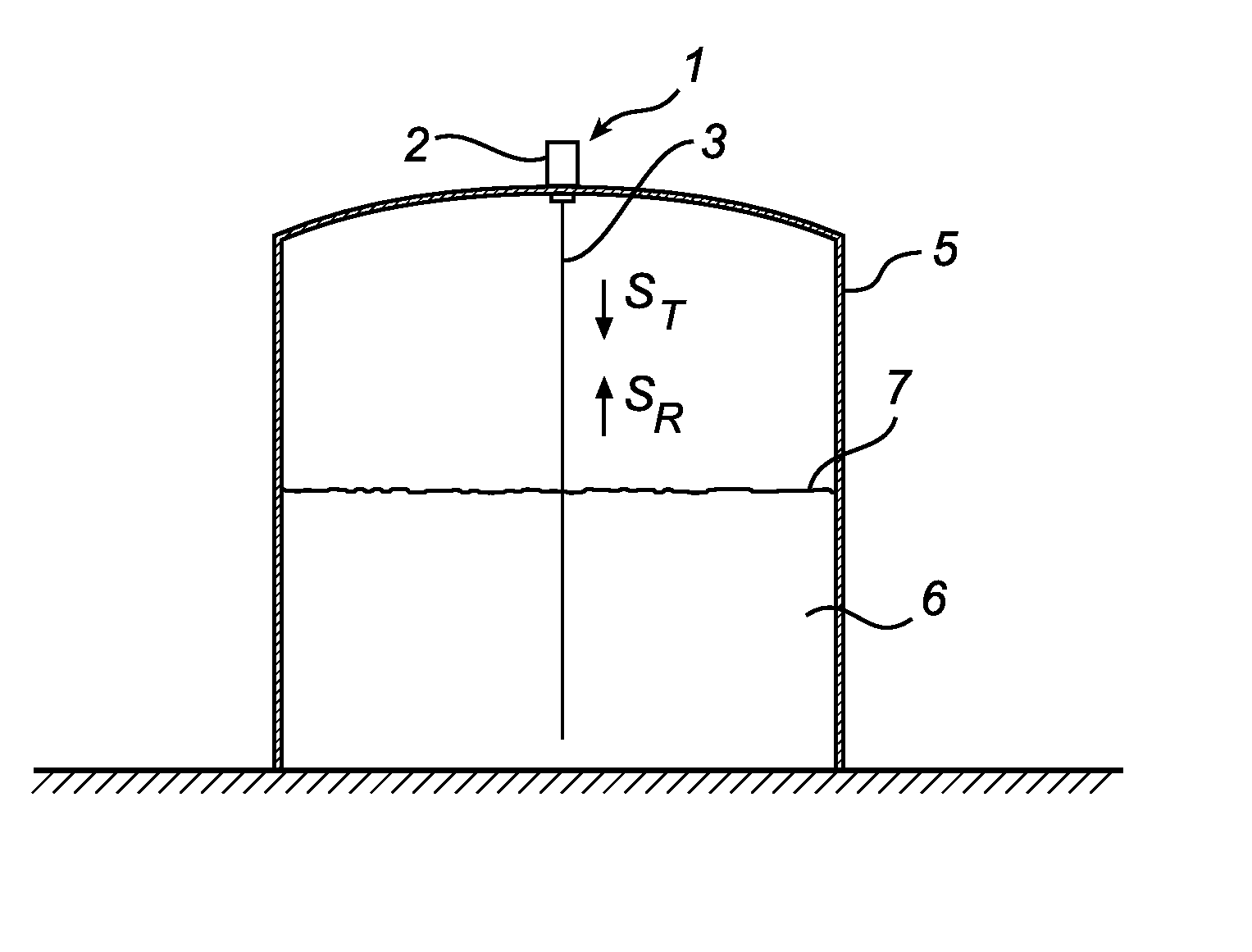

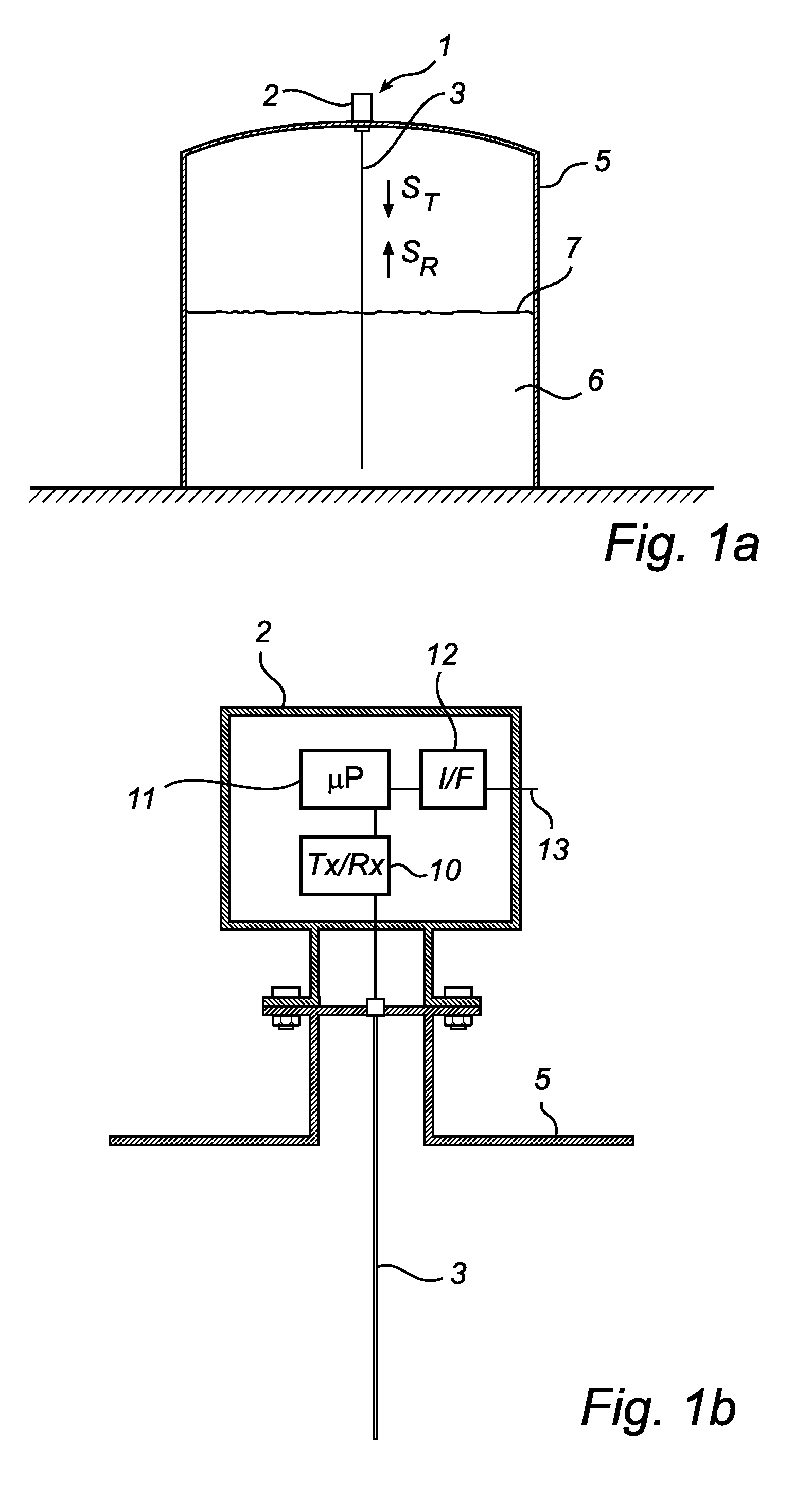

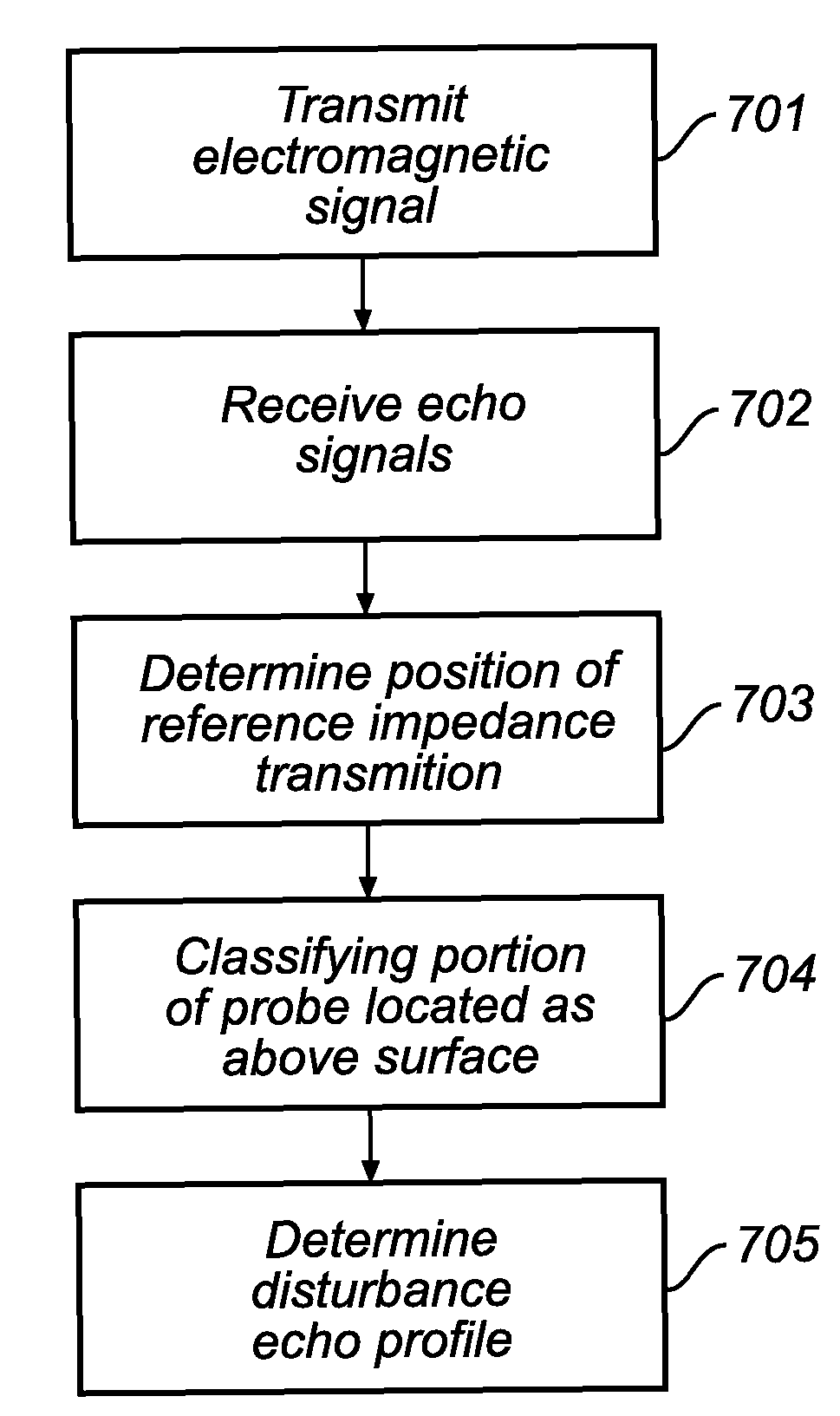

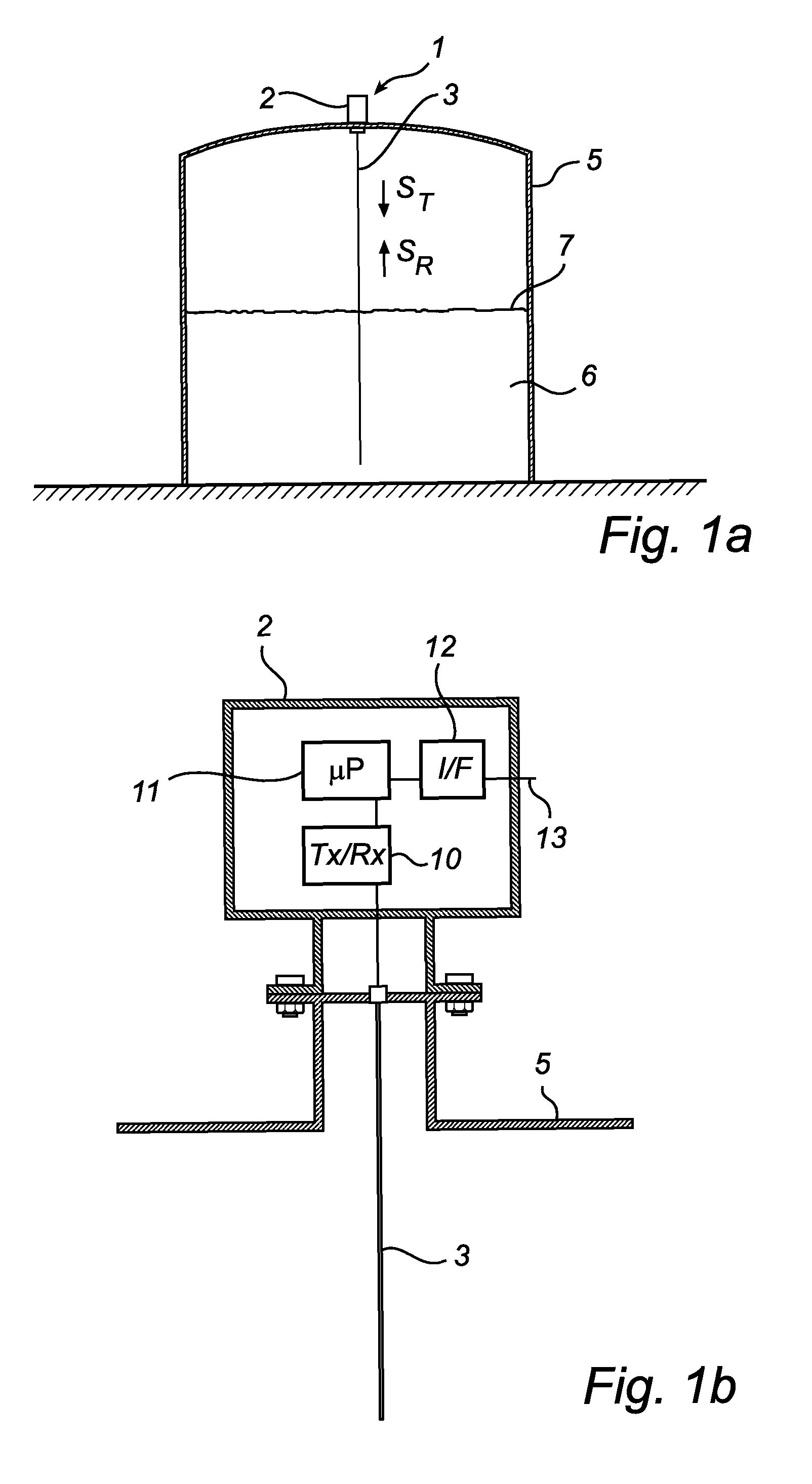

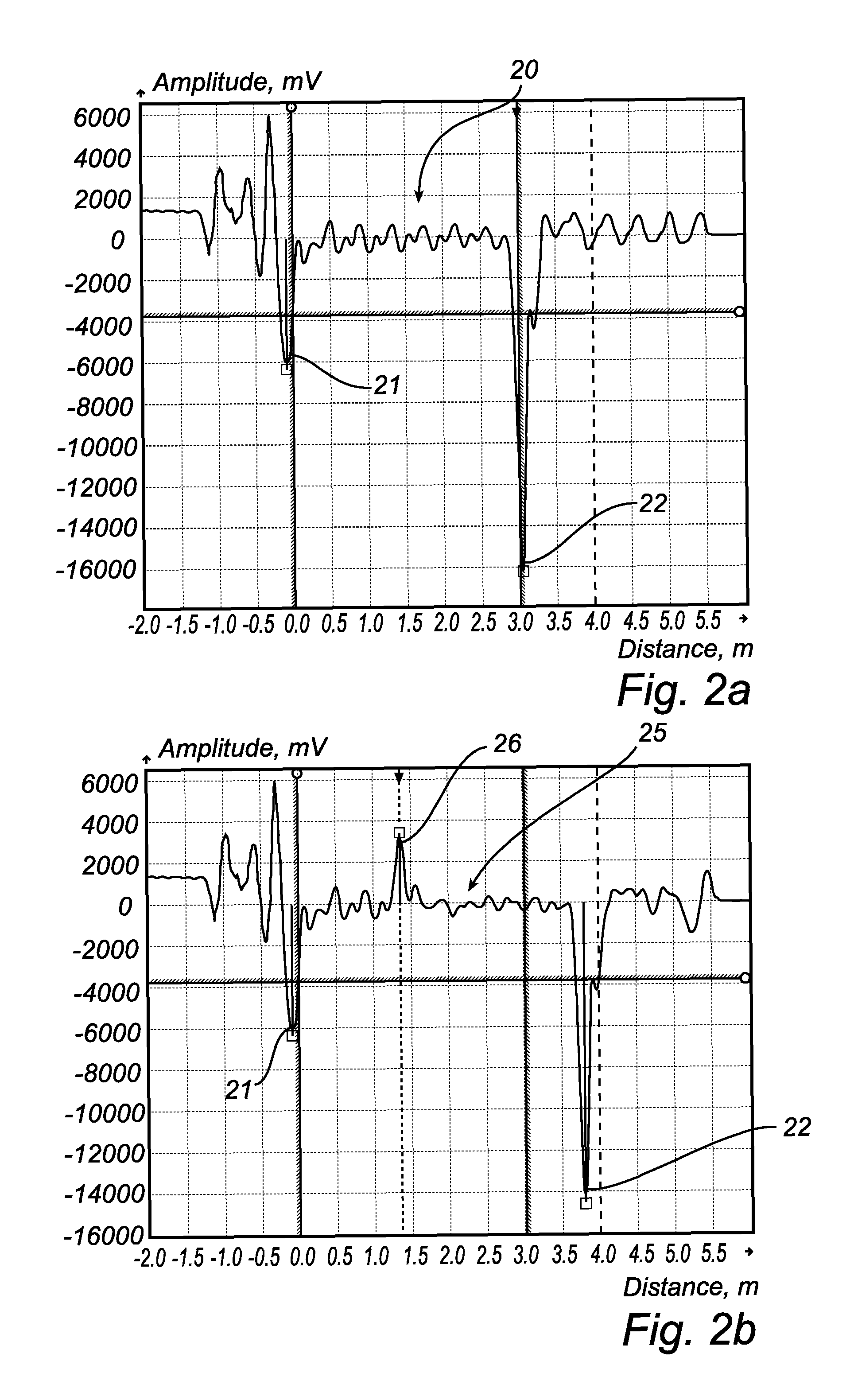

Method of determining a disturbance echo profile for a radar level gauge system

ActiveUS20090273506A1Reliable levelingEasy to identifyTesting/calibration apparatusMachines/enginesRadarElectromagnetic shielding

A method of determining a filling level of a product contained in a tank, the method comprising generating and transmitting electromagnetic signals; propagating the transmitted electromagnetic signals towards a surface of the product contained in the tank; receiving echo signals resulting from reflections at impedance transitions encountered by the transmitted electromagnetic signals, including a surface echo signal resulting from reflection at a surface of the product; determining a position of a reference impedance transition using a reference echo signal resulting from reflection of the transmitted electromagnetic signals at the reference impedance transition; determining an update level located above the surface, based on the determined position of the reference impedance transition and a known position of the reference impedance transition; determining a disturbance echo profile using at least one of the echo signals resulting from reflection of the transmitted signals at at least one impedance transition located above the update level; and determining the filling level based on the received echo signals and the disturbance echo profile.

Owner:ROSEMOUNT TANK RADAR

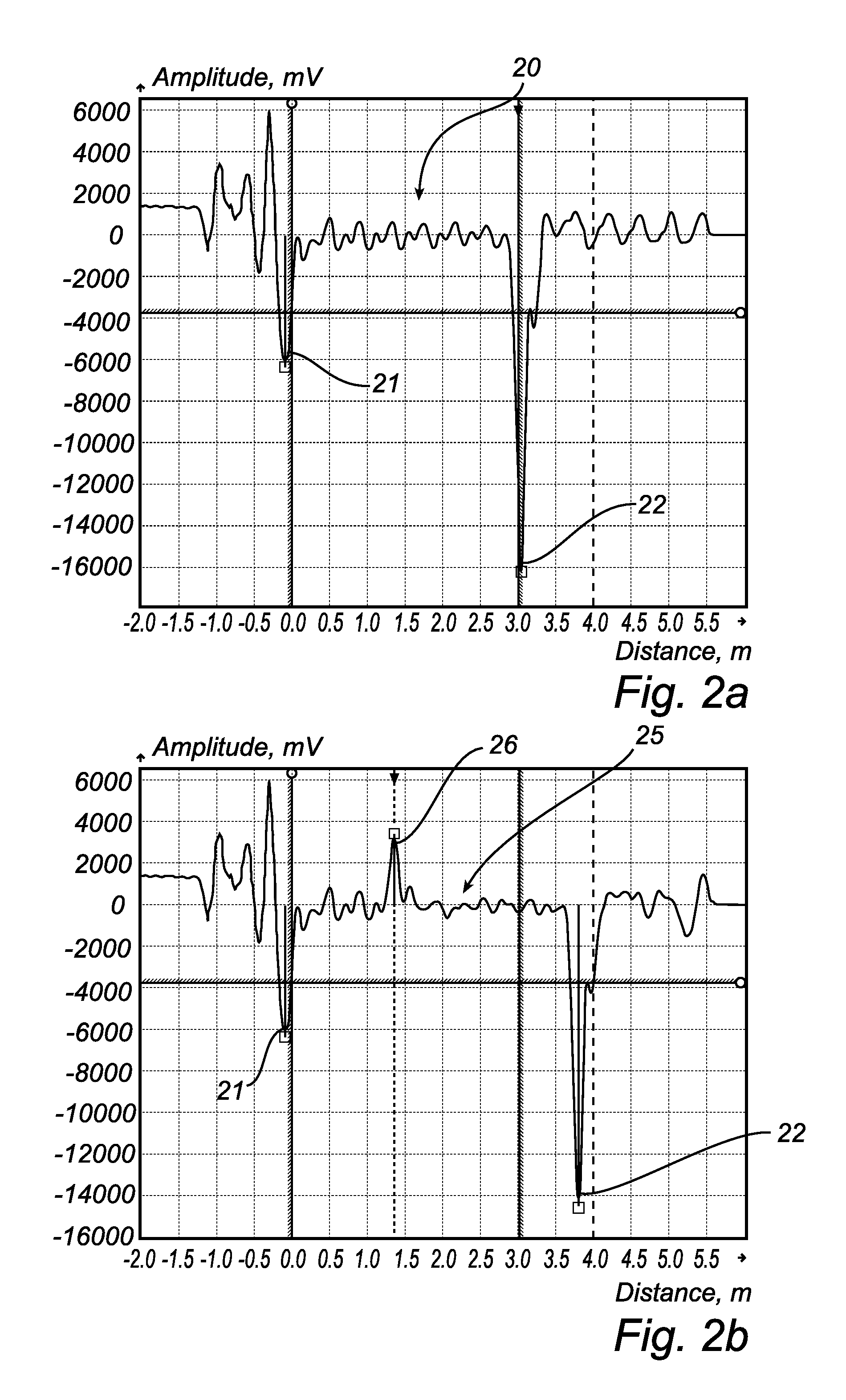

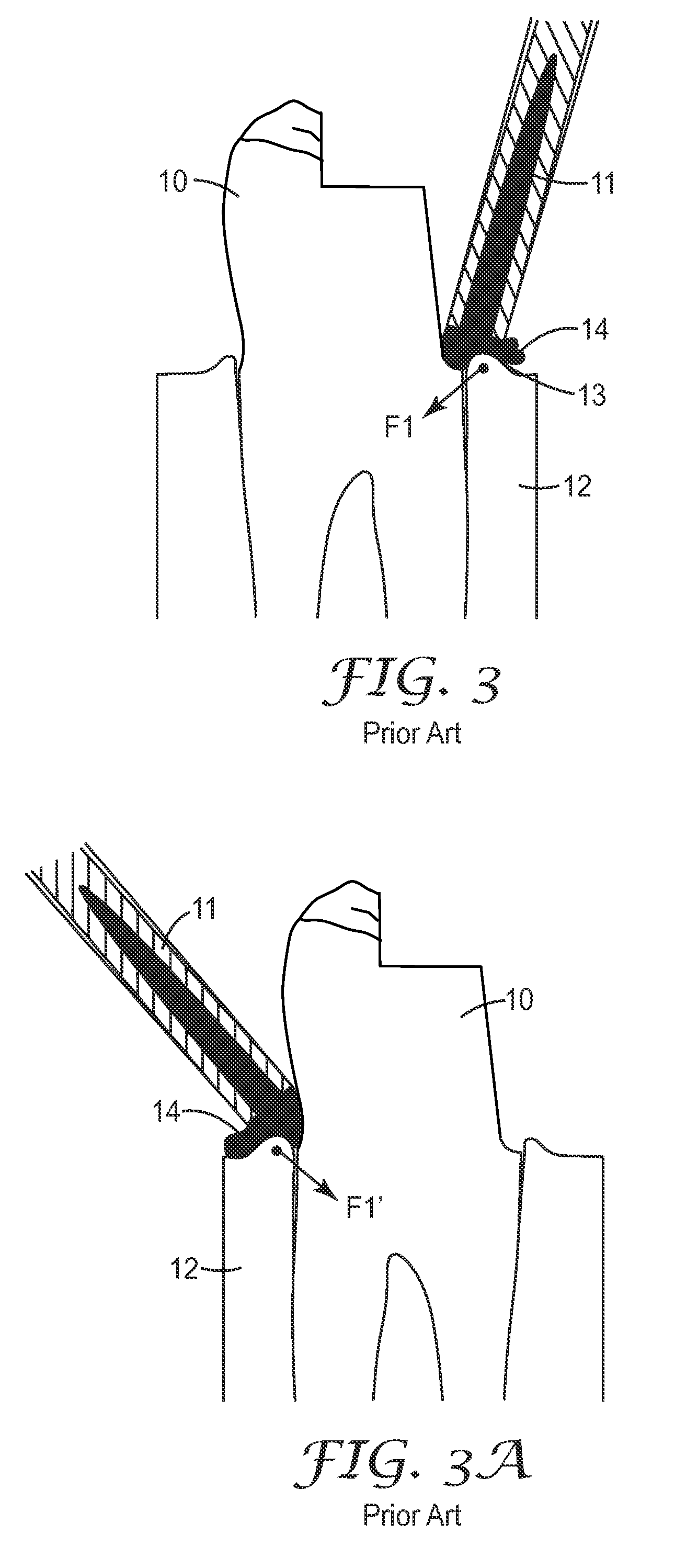

Device and a method for delivery of a dental composition

ActiveUS20110151403A1Reliably recognizeSave wasteImpression capsDental toolsGingival spaceTooth Supporting Structures

A device for use in retracting a gingiva from a human tooth by widening a gingival sulcus with a dental composition. The device comprises a cannula with a free end having an opening for dispensing the dental composition. The free end is shaped to be inserted with its front in the entry of the gingival sulcus, and to laterally displace the gingiva from the tooth as the cannula is moved in the gingival sulcus. The invention may help to achieve a reliable and cost effective gingival retraction treatment.

Owner:3M INNOVATIVE PROPERTIES CO

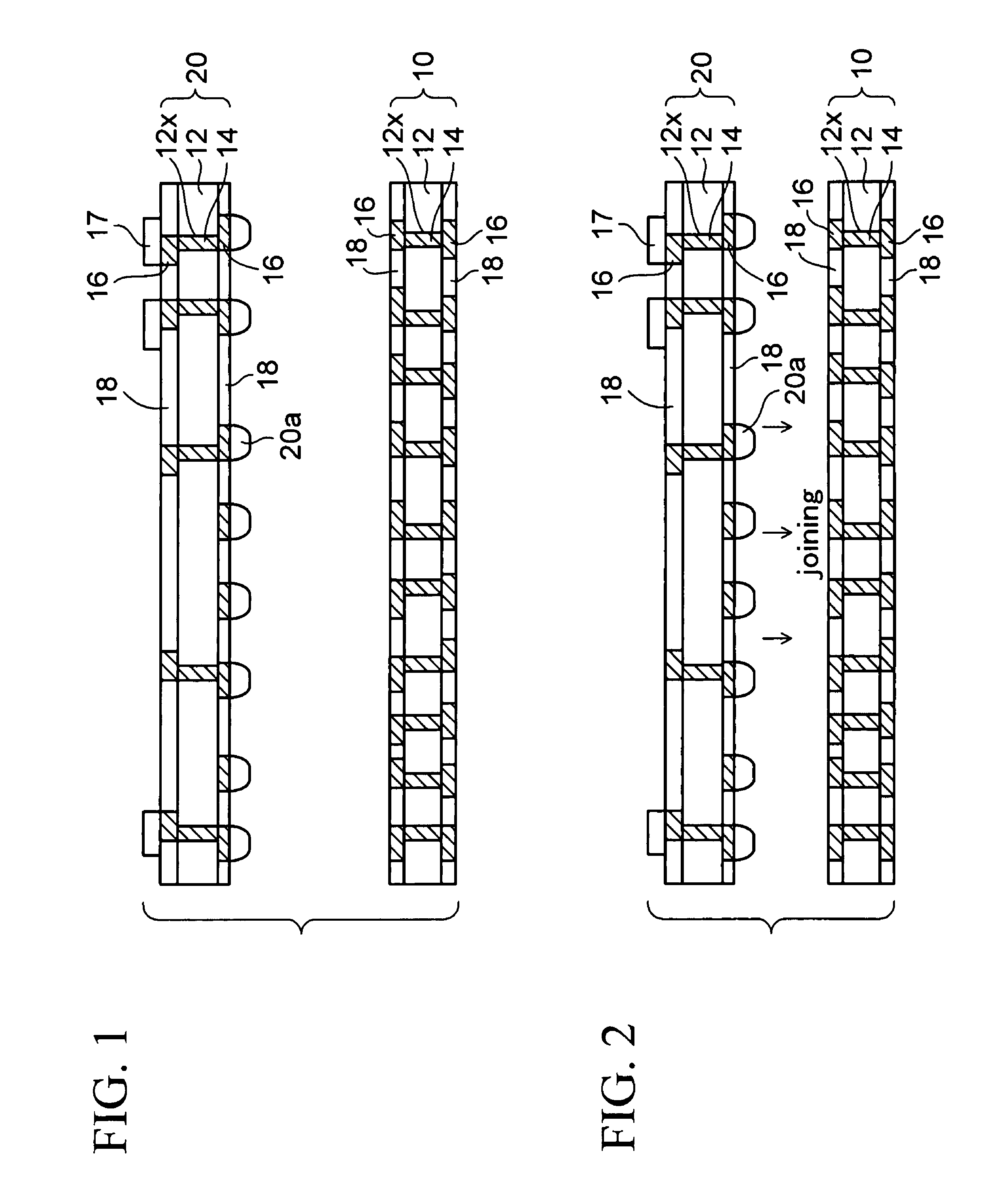

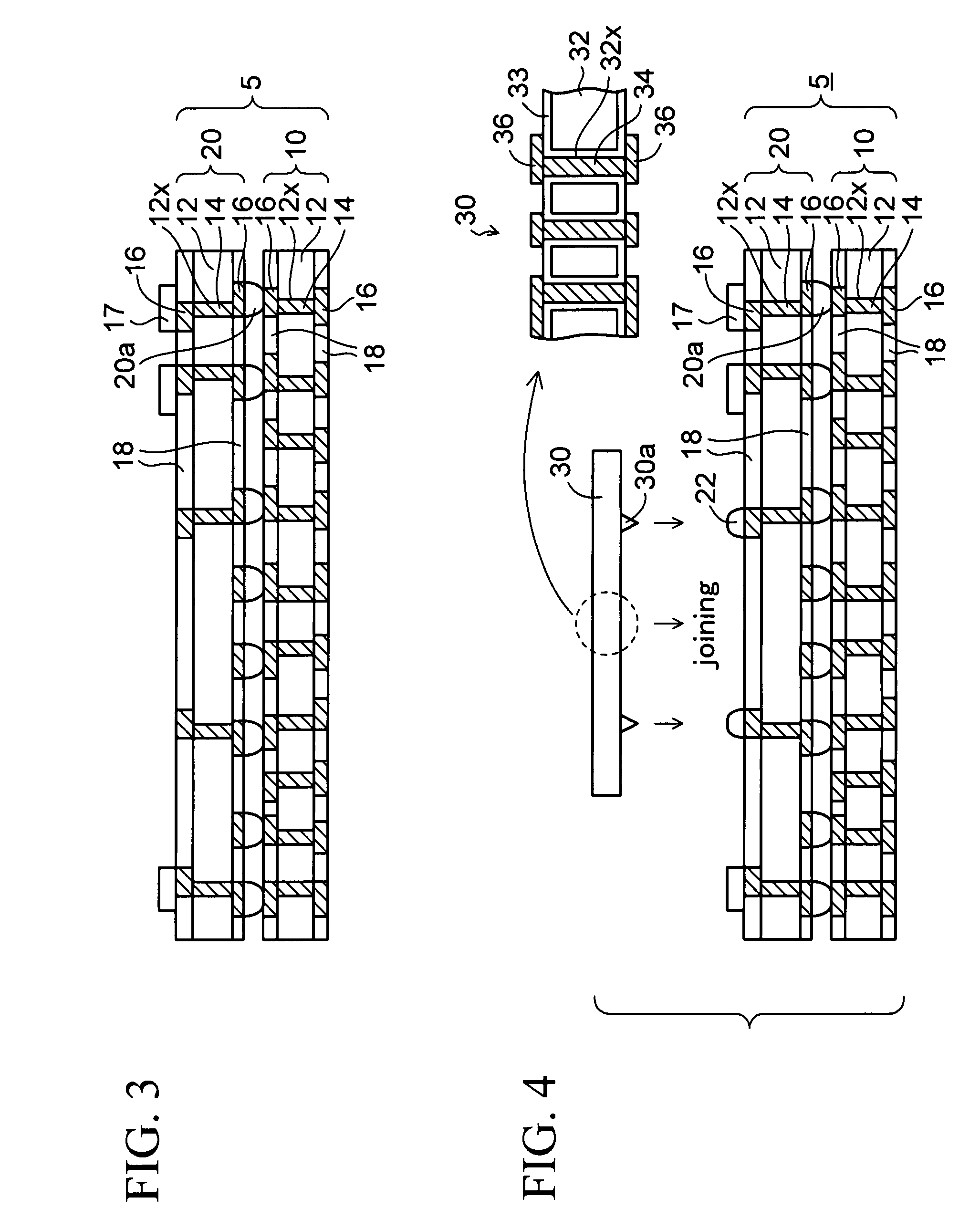

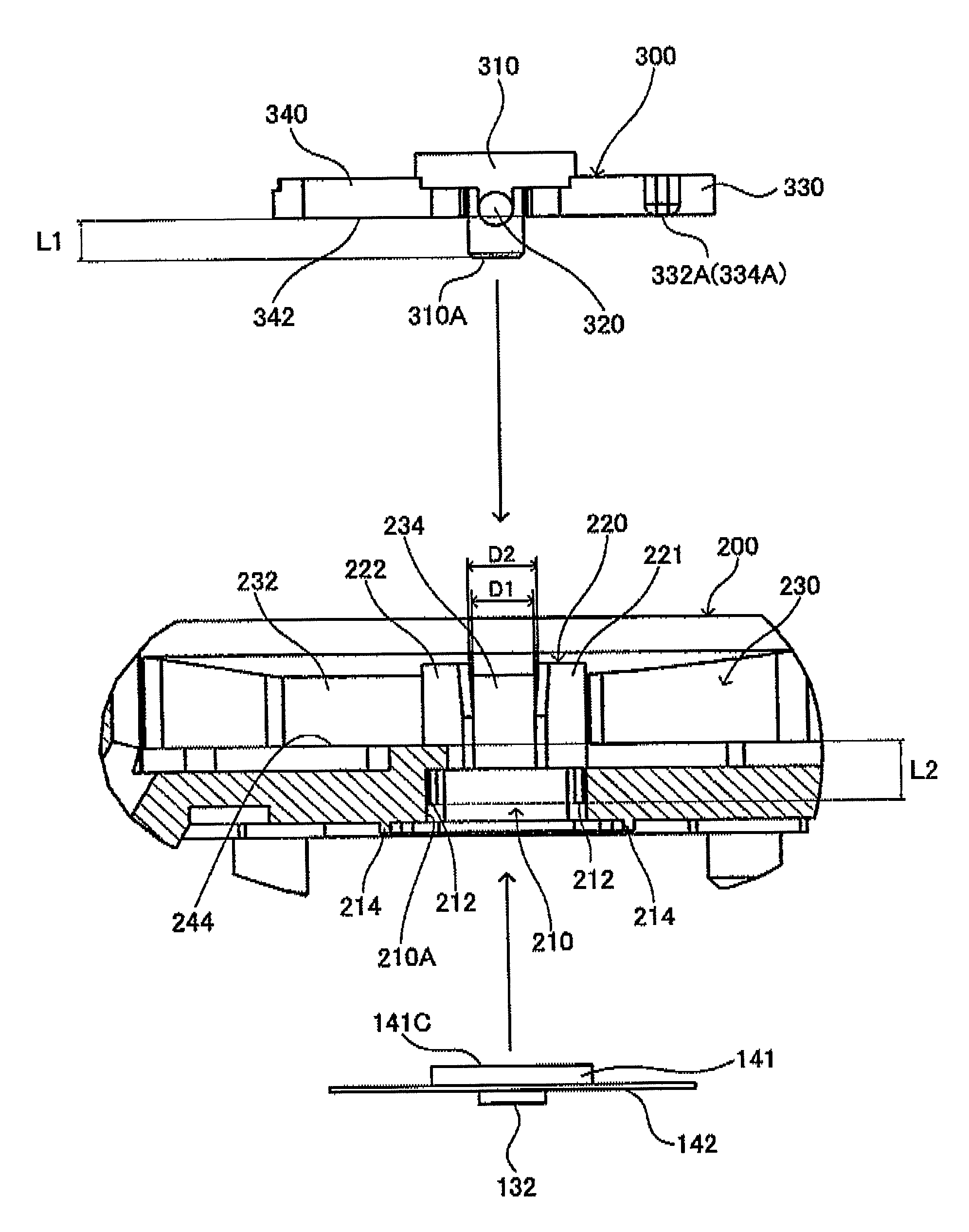

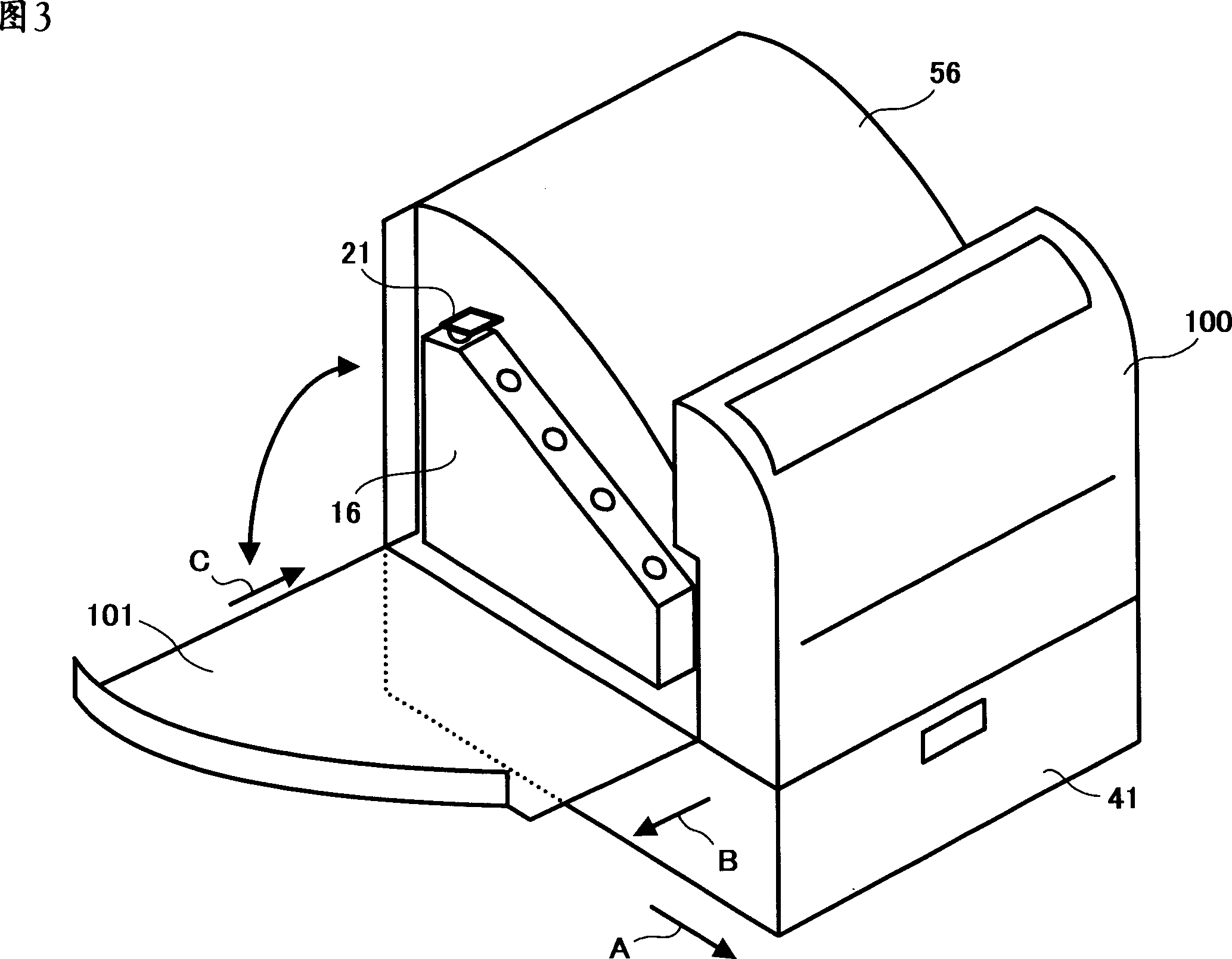

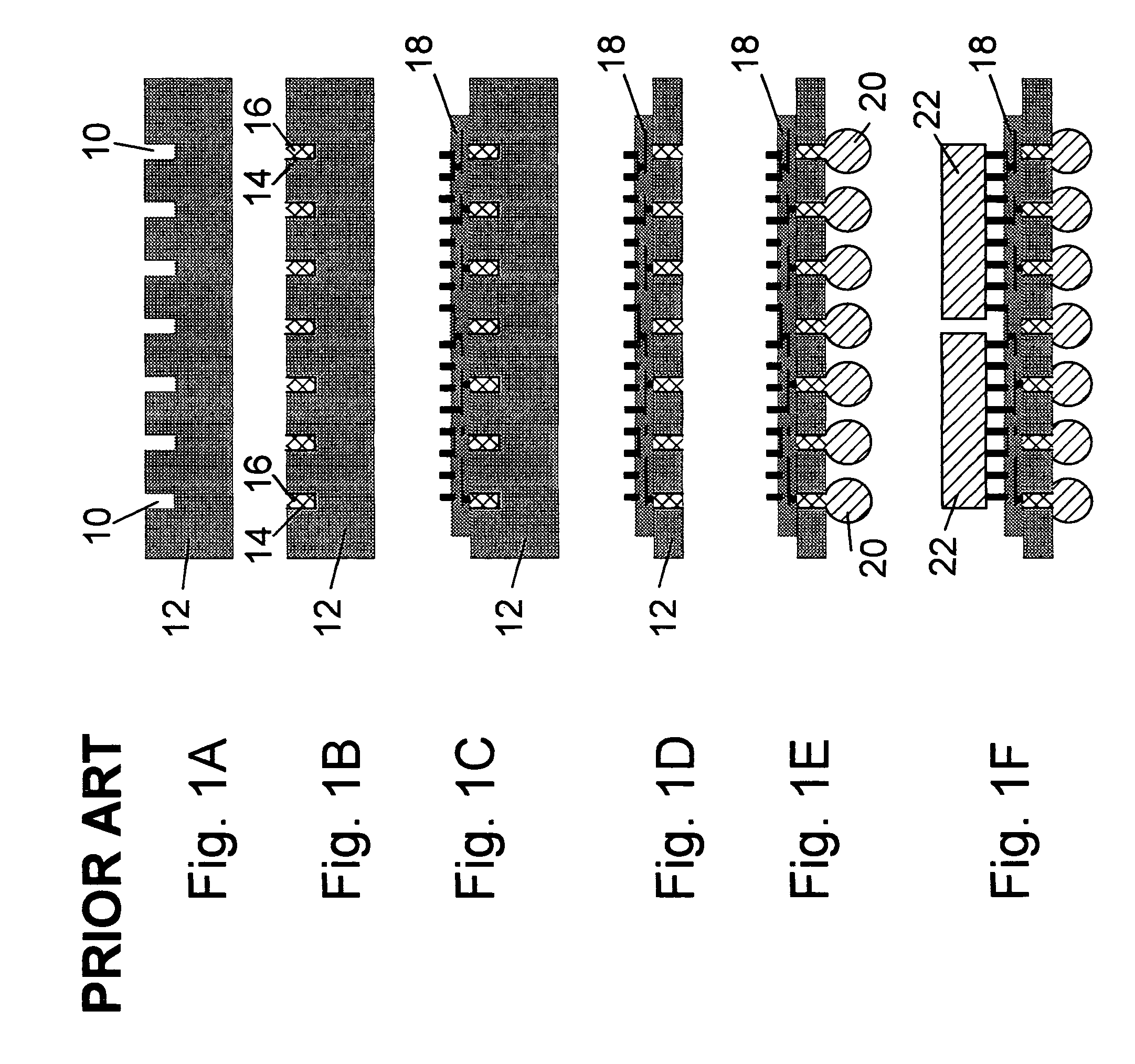

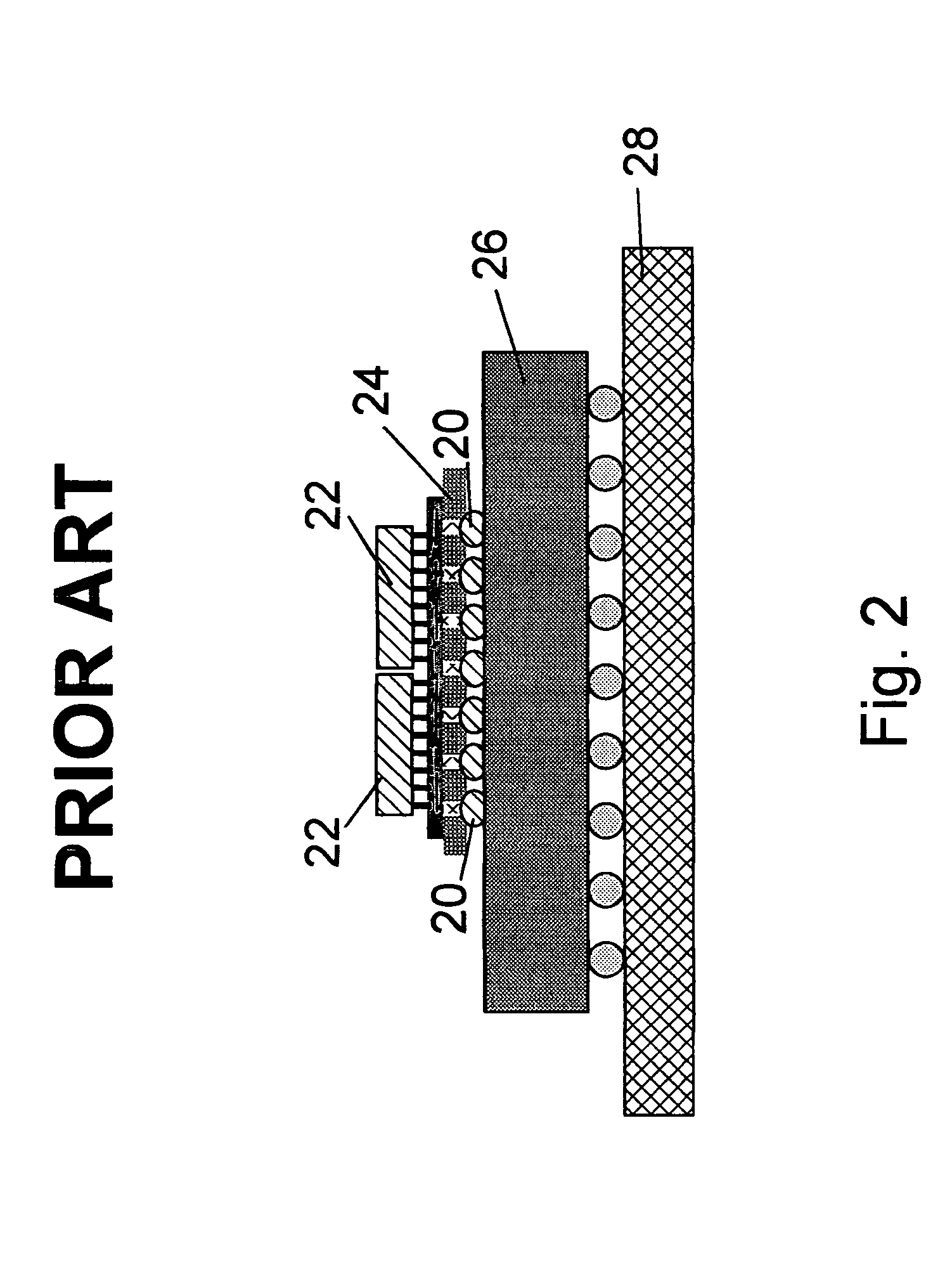

Method and apparatus for mounting conductive ball

InactiveUS20070130764A1Minimize effect of gapEasy to correctPrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

A method of mounting conductive balls comprises a step of setting, on a substrate, a mask that includes a plurality of apertures for disposing conductive balls on the substrate and a filling step. The filling step includes using a head that moves along a surface of the mask, holding a group of conductive balls in an area that is part of the surface of the mask, and moving the area so that parts of a path taken by the area overlap. By limiting the area where filling is carried out and moving the conductive balls while gathering the conductive balls in this area, it is possible to prevent losses for the conductive balls, to increase the filling efficiency, and to suppress the number of unfilled apertures.

Owner:ATHLETE FA KK

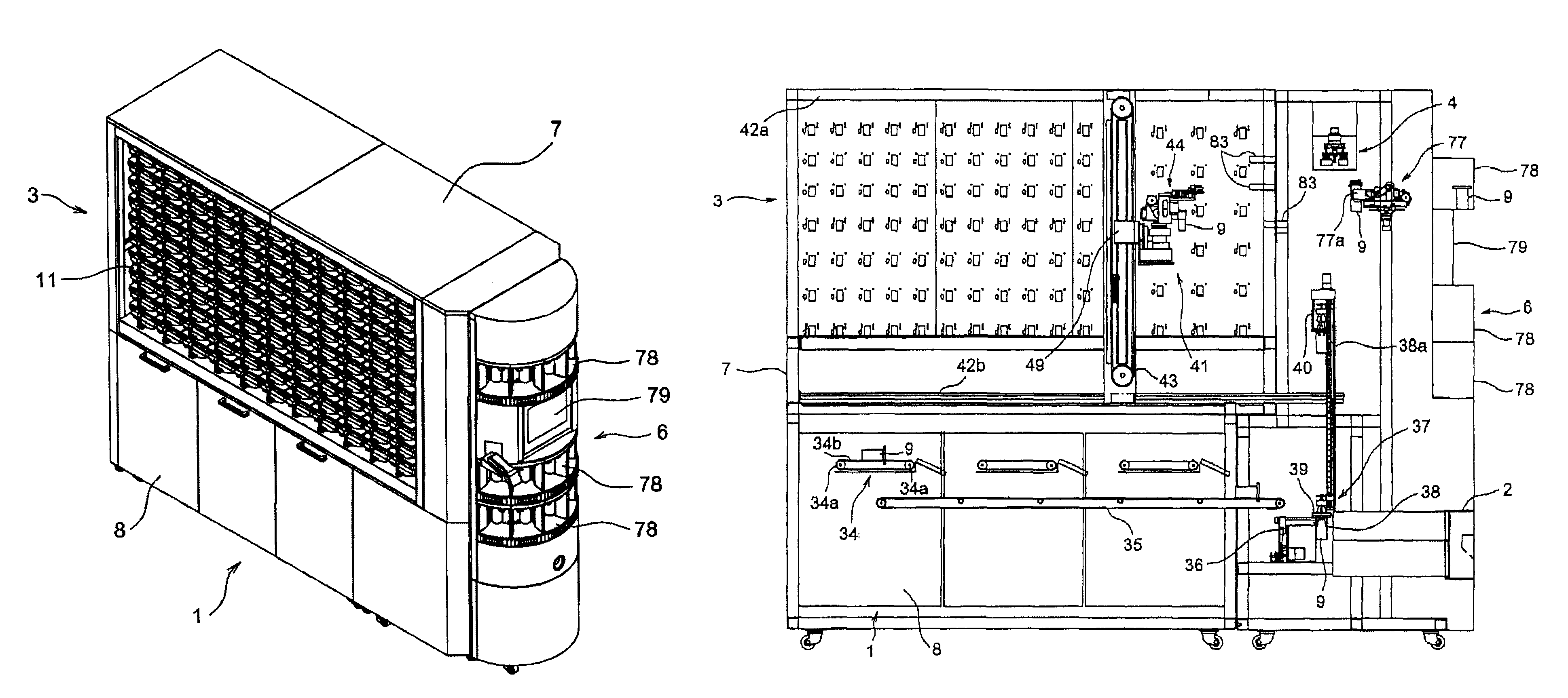

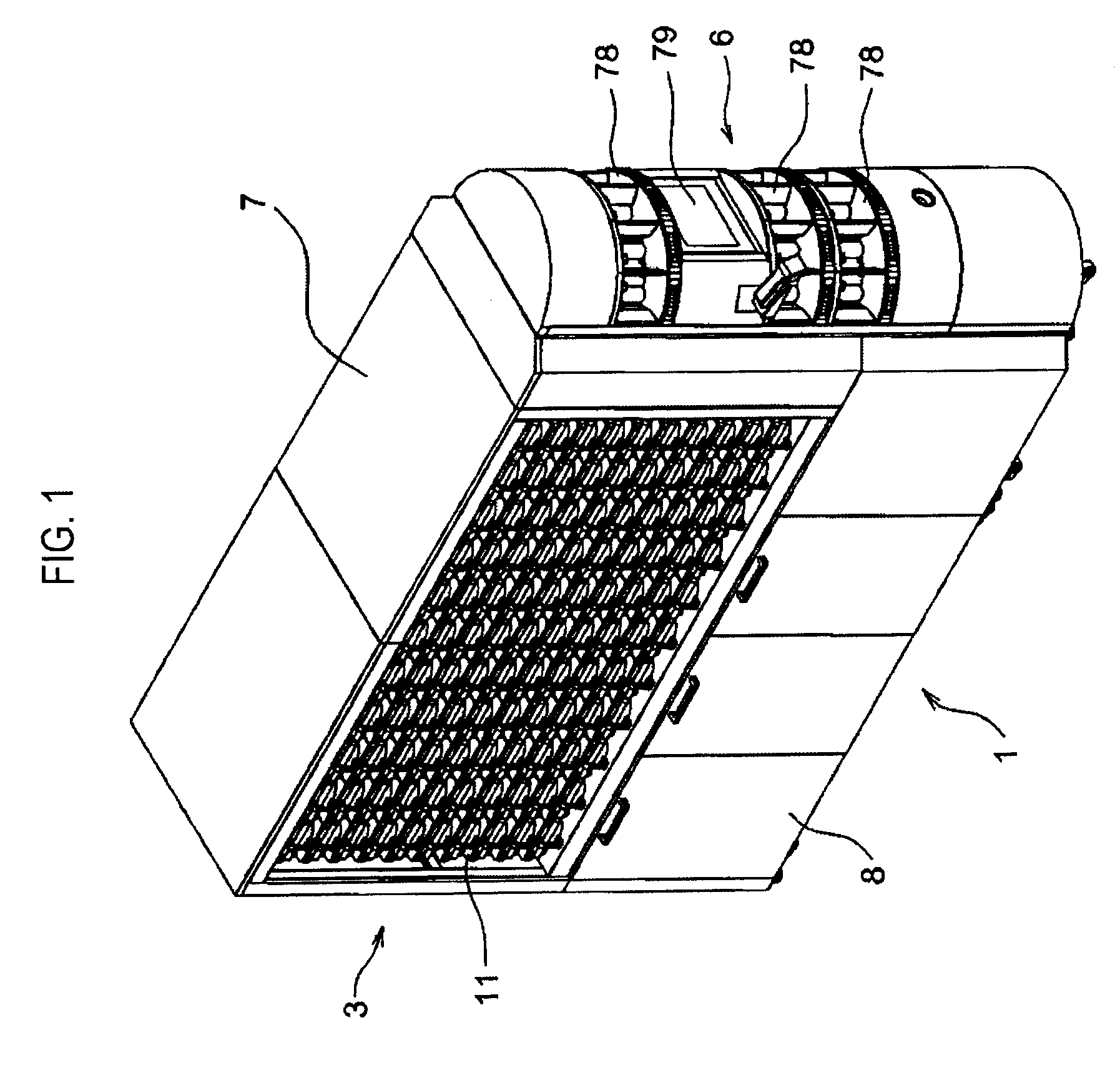

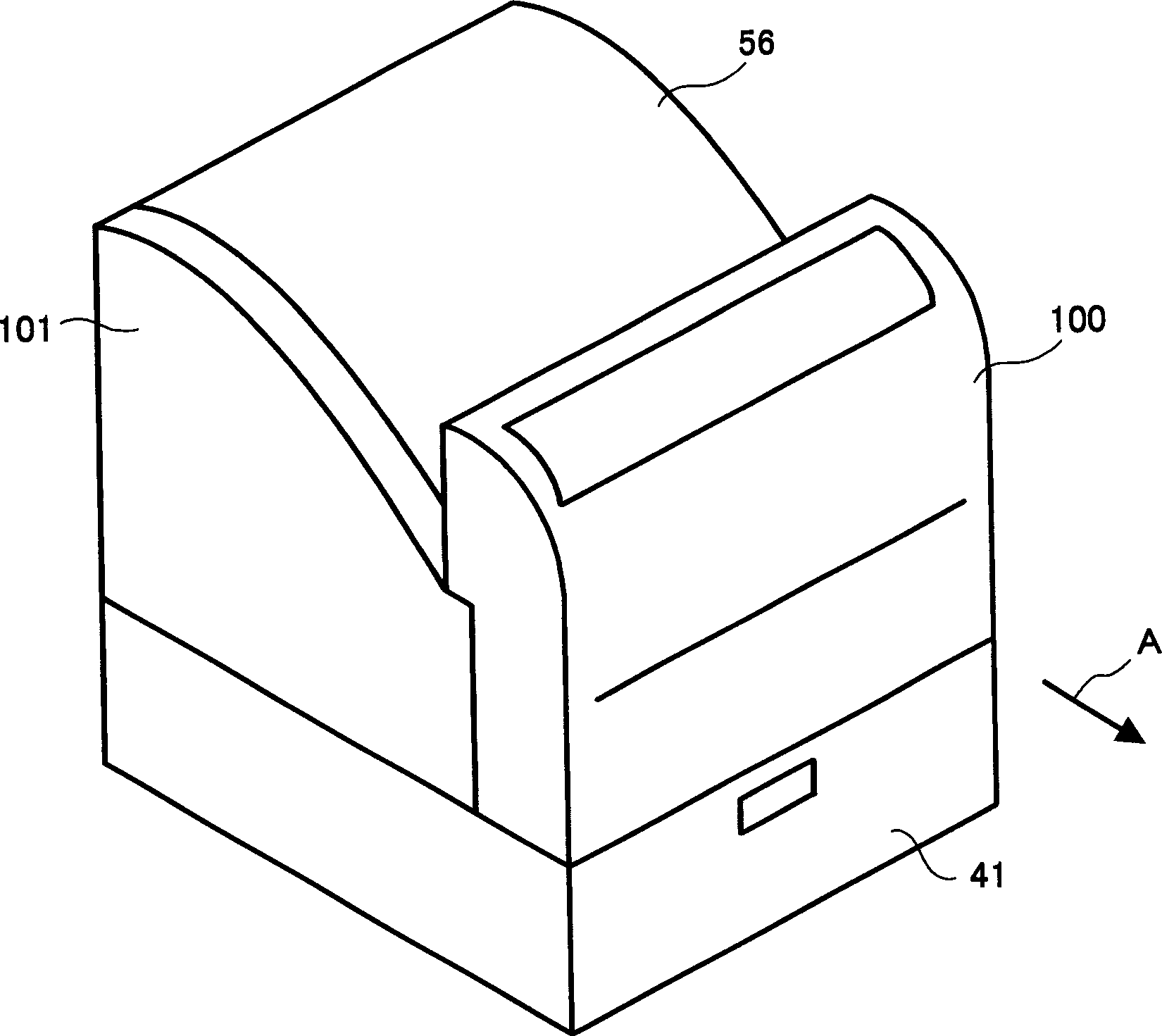

Tablet filling device

InactiveUS7721508B2Easy constructionReliable fillingLiquid fillingPharmaceutical product form changeMedicineHorizontal and vertical

A tablet filling device to convey a vial to a tablet cassette for receiving tablets easily and reliably. The tablet filling device includes: a detachable tablet feeding unit including a plurality of tablet feeders capable of discharging tablets one by one and arranged horizontally and vertically; and an arm unit that carries an empty vial, fills the vial with tablets discharged from a tablet feeder of the tablet feeding unit, and carries the vial filled with the tablets. The arm unit includes: a perpendicularly moving base movable horizontally and vertically along a horizontal rail and a vertical rail, respectively, the rails provided in directions in which the tablet feeders of the tablet feeding unit are arranged; an arm base on the perpendicularly moving base to be slidable in a horizontal direction perpendicular to the horizontal rail and horizontally rotatable; and an arm, on the arm base, capable of holding the vial.

Owner:YUYAMA MFG CO LTD

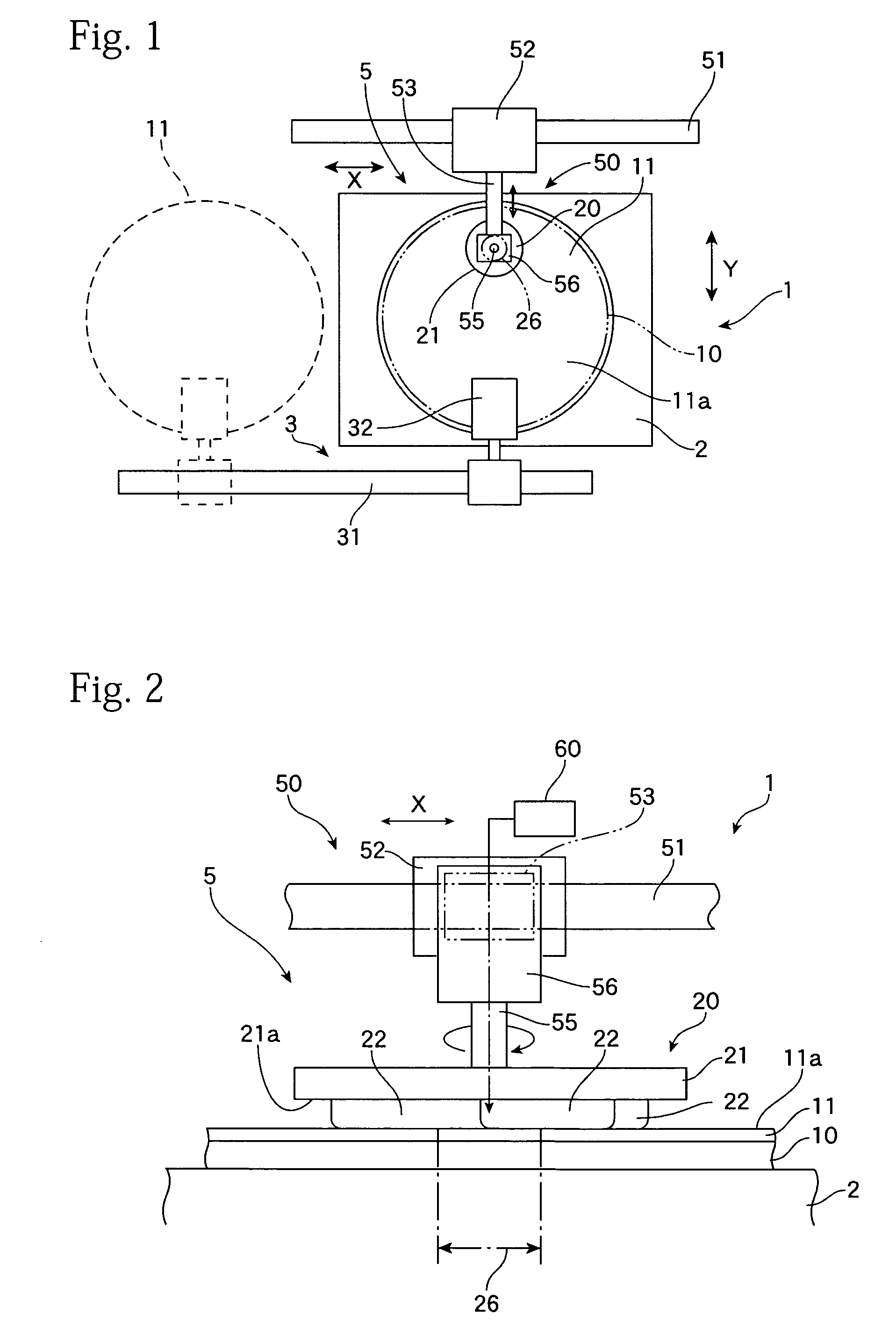

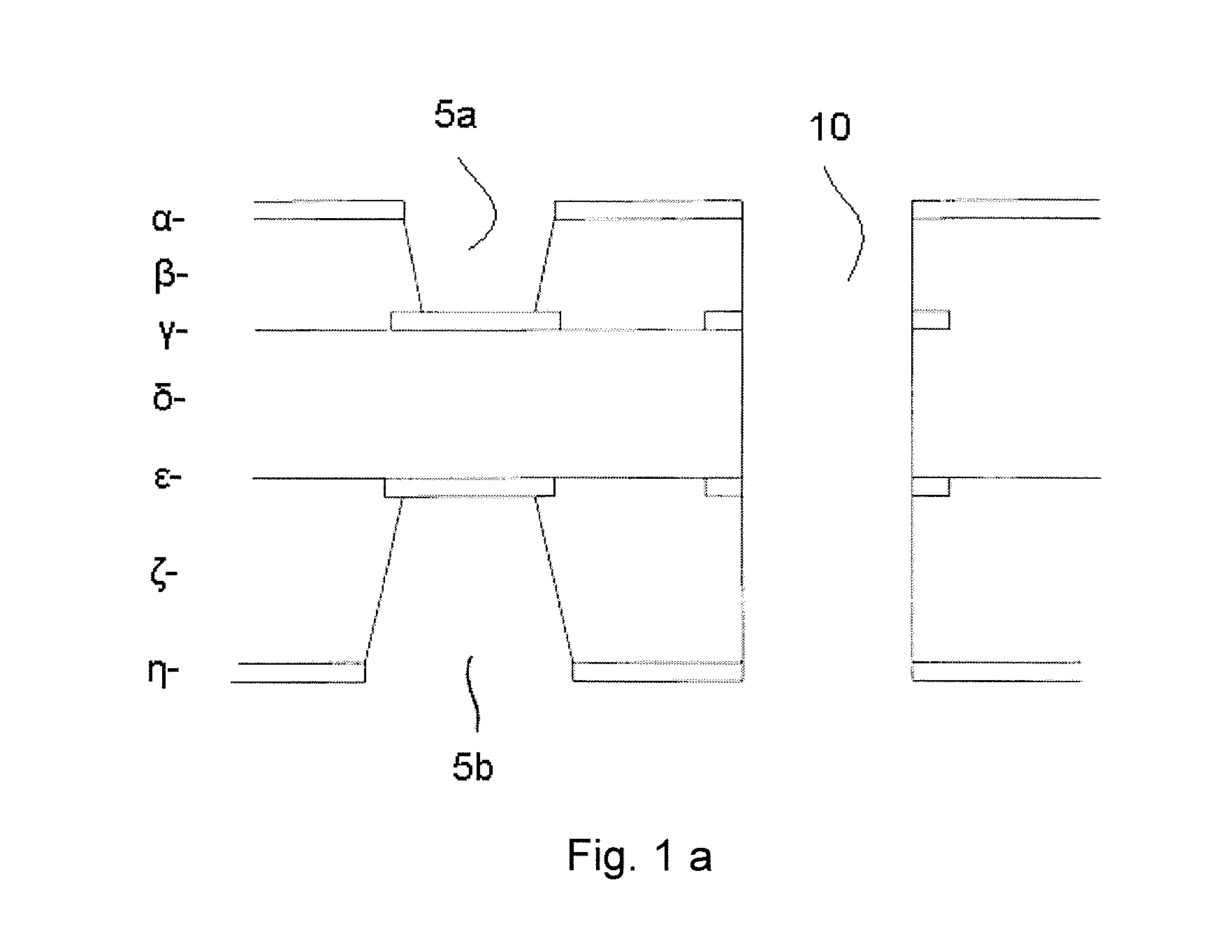

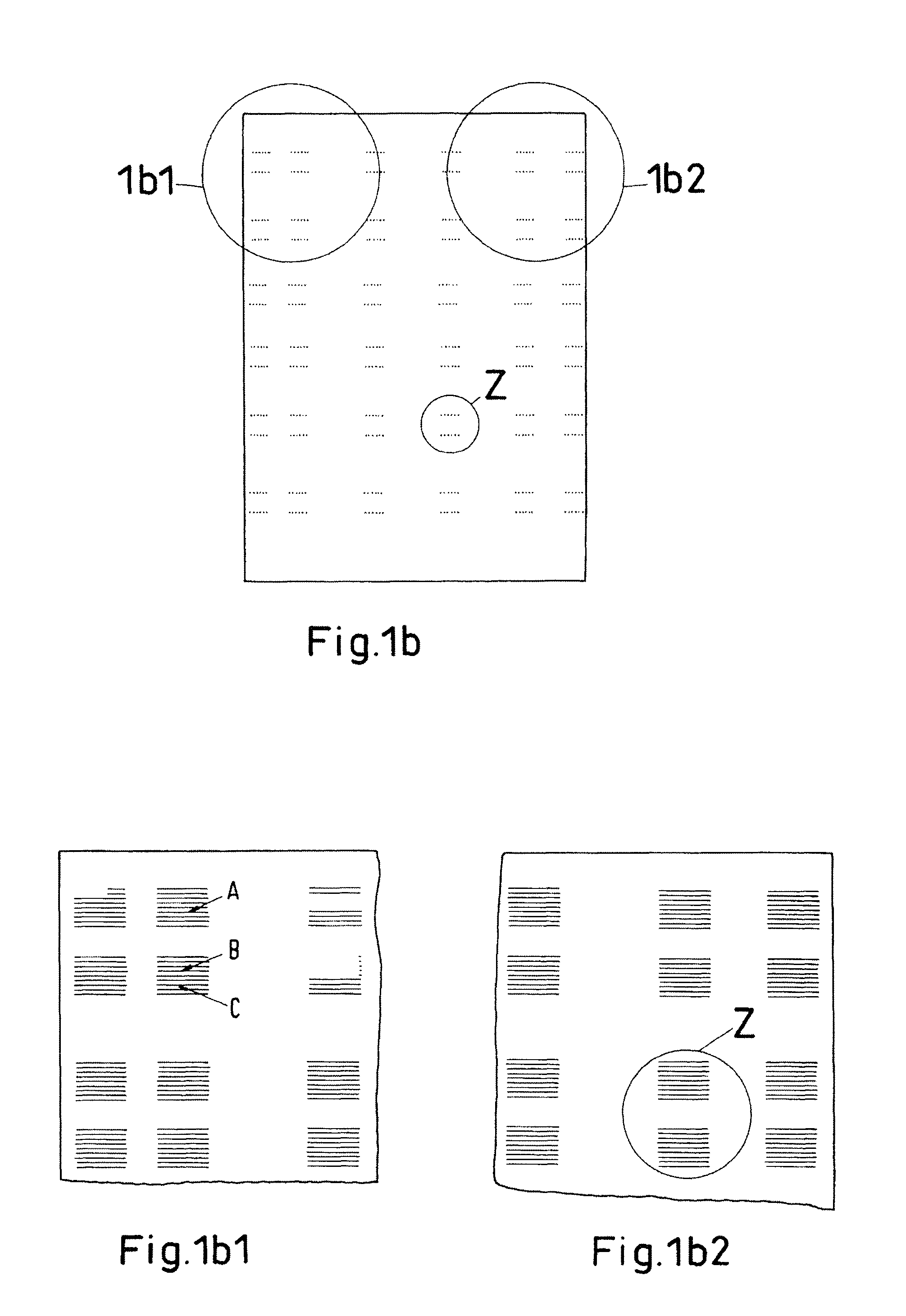

Biological sample discrimination device, biological sample discriminating method, and biological sample discriminating plate

InactiveUS20070148759A1The result is accurateShort timeBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringChannel pattern

There is provided a plate (10) on which a channel pattern (110) is formed, which channel pattern includes a first channel (116) into which a buffer agent is injected, and a second channel (117) having, in a portion thereof, a quantification part (117a) that has a portion common to the first channel and holds a predetermined amount of a biological sample, the biological sample being injected into the channel including the quantification part, and the plate (10) is rotated at a high speed by a filling unit (20) to fill the buffer agent in the first channel, and thereafter, the second channel is pressurized by a discrimination unit (30) to fill the biological sample in the second channel, and simultaneously, a predetermined amount of the biological sample is added into the buffer agent. Therefore, when performing discrimination of the biological sample, a discrimination result can be obtained accurately in a short time without the necessity of complicated preparation works.

Owner:PANASONIC CORP

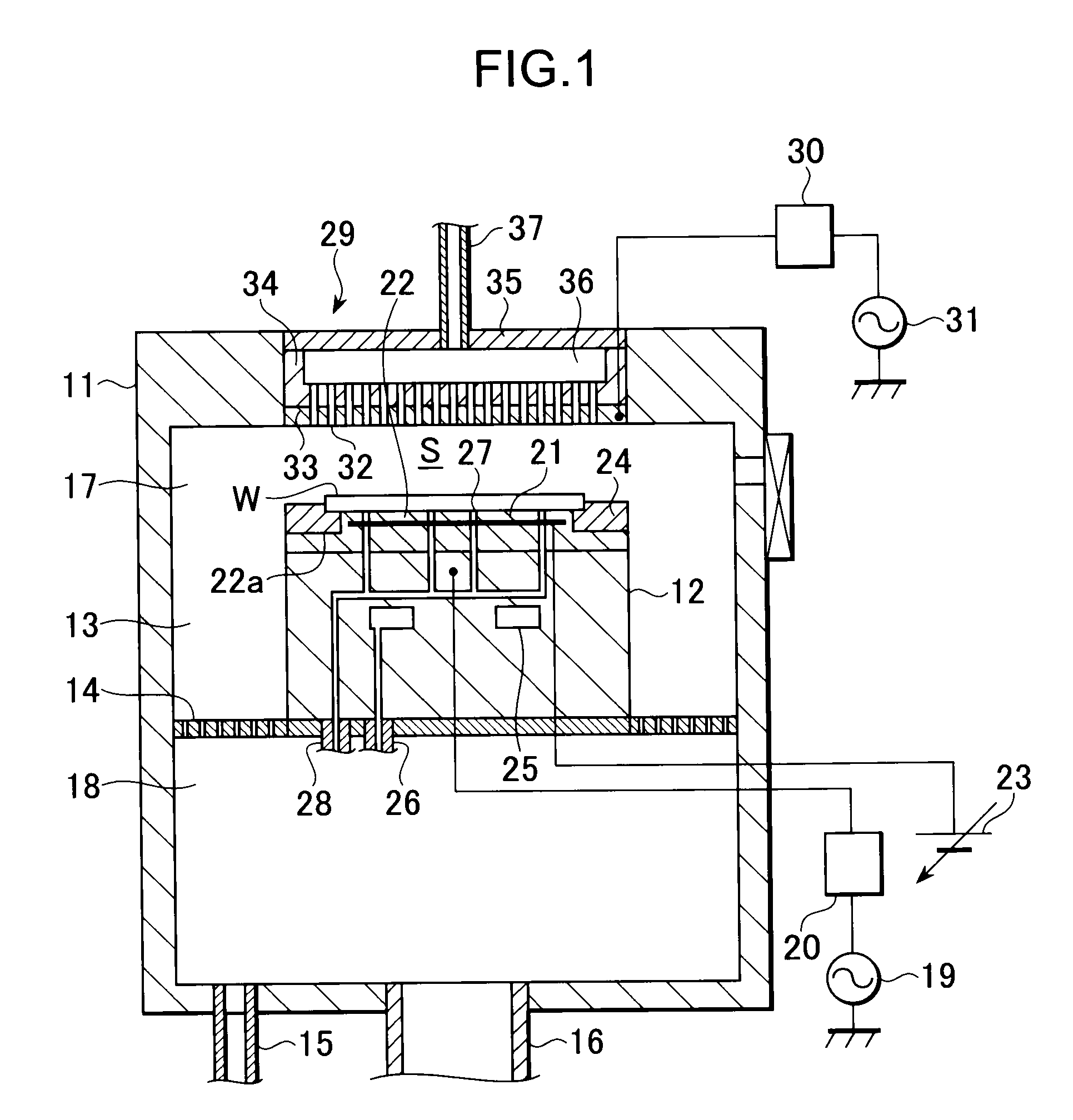

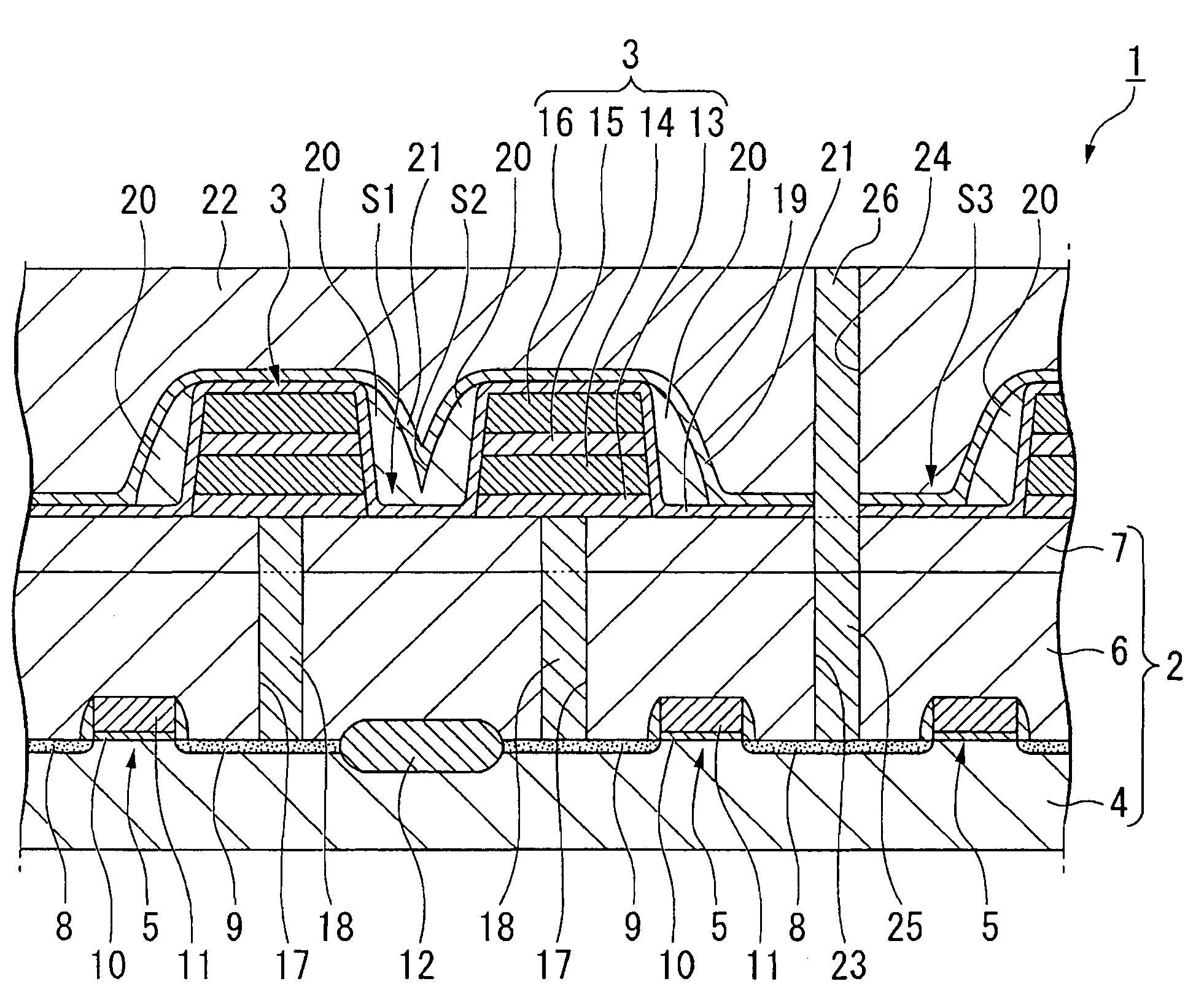

Substrate processing apparatus and substrate mounting stage on which focus ring is mounted

InactiveUS20080236746A1Inhibition of attachmentPrevent heat transferElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate processing apparatus that can prevent a heat transfer sheet from becoming attached to a focus ring mounting surface of a substrate mounting stage. The substrate mounting stage is disposed in a housing chamber of the substrate processing apparatus, and a substrate is mounted on the substrate mounting stage. A focus ring that surrounds a peripheral portion of the mounted substrate is mounted on the focus ring mounting surface. The heat transfer sheet is interposed between the focus ring and the focus ring mounting surface, and a fluorine coating is formed on the focus ring mounting surface.

Owner:TOKYO ELECTRON LTD

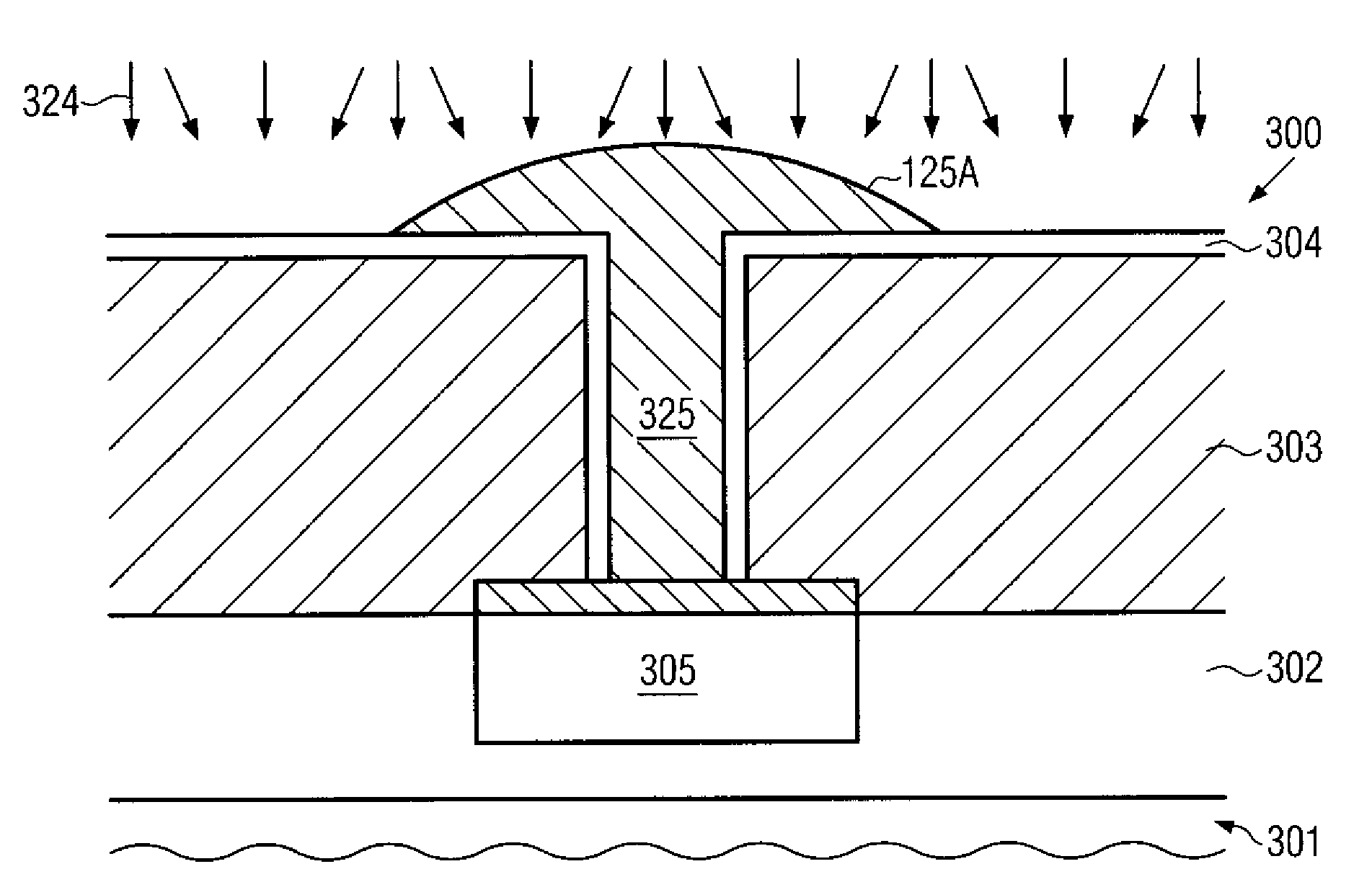

High-k gate electrode structure formed after transistor fabrication by using a spacer

ActiveUS20100133628A1Enhancing deposition conditionDegree of reductionTransistorSemiconductor/solid-state device manufacturingEngineeringMetal

During a replacement gate approach, the inverse tapering of the opening obtained after removal of the polysilicon material may be reduced by depositing a spacer layer and forming corresponding spacer elements on inner sidewalls of the opening. Consequently, the metal-containing gate electrode material and the high-k dielectric material may be deposited with enhanced reliability.

Owner:ADVANCED MICRO DEVICES INC

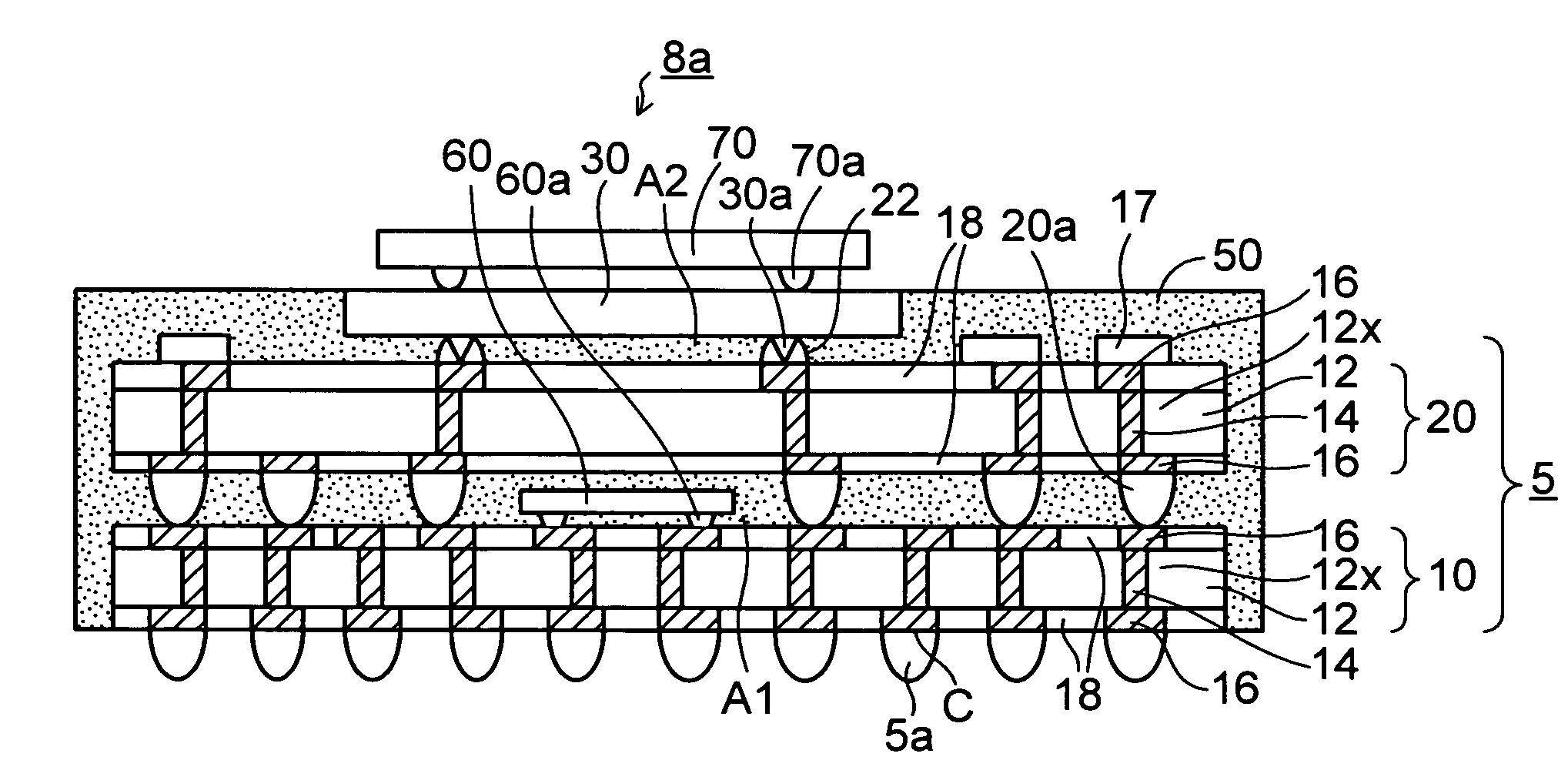

Wiring substrate, manufacturing method thereof, and semiconductor device

ActiveUS7901986B2Reduce manufacturing costHigh yieldPrinted circuit assemblingSemiconductor/solid-state device detailsSilicon interposerElectrical connection

In a wiring substrate according to the present invention, a base wiring board is constructed by stacking a plurality of unit wiring boards each having wiring patterns which enable an electrical connection between upper and lower sides, in a state that the plurality of unit wiring boards are connected to each other via a connection terminal, and a silicon interposer is stacked on the base wiring board via a connection terminal, and a resin portion is filled in a gap between the plurality of unit wiring boards as well as a gap between the base wiring board and the silicon interposer, and a resin portion serves as a substrate which integrates the base wiring board and the silicon interposer.

Owner:SHINKO ELECTRIC IND CO LTD

Manufacturing method for ferroelectric memory device

InactiveUS7642099B2High densityLower Reliability RequirementsSolid-state devicesSemiconductor/solid-state device manufacturingHydrogenChemical vapor deposition

A manufacturing method for a ferroelectric memory device includes: forming a ferroelectric capacitor on a substrate, the ferroelectric capacitor including a lower electrode, a ferroelectric film, and an upper electrode; forming a first hydrogen barrier film that covers the ferroelectric capacitor by a chemical vapor deposition method; forming a dielectric film on the first hydrogen barrier film; forming a sidewall composed of the dielectric film on a side of the ferroelectric capacitor by etching back the dielectric film; forming a second hydrogen barrier film on the first hydrogen barrier film and the sidewall by a chemical vapor deposition method; and forming an interlayer dielectric film on the second hydrogen barrier film.

Owner:FUJITSU SEMICON LTD

Method of determining a disturbance echo profile for a radar level gauge system

ActiveUS7924216B2Reliable levelingEasy to identifyTesting/calibration apparatusMachines/enginesRadarElectromagnetic shielding

A method of determining a filling level of a product contained in a tank, the method comprising generating and transmitting electromagnetic signals; propagating the transmitted electromagnetic signals towards a surface of the product contained in the tank; receiving echo signals resulting from reflections at impedance transitions encountered by the transmitted electromagnetic signals, including a surface echo signal resulting from reflection at a surface of the product; determining a position of a reference impedance transition using a reference echo signal resulting from reflection of the transmitted electromagnetic signals at the reference impedance transition; determining an update level located above the surface, based on the determined position of the reference impedance transition and a known position of the reference impedance transition; determining a disturbance echo profile using at least one of the echo signals resulting from reflection of the transmitted signals at at least one impedance transition located above the update level; and determining the filling level based on the received echo signals and the disturbance echo profile.

Owner:ROSEMOUNT TANK RADAR

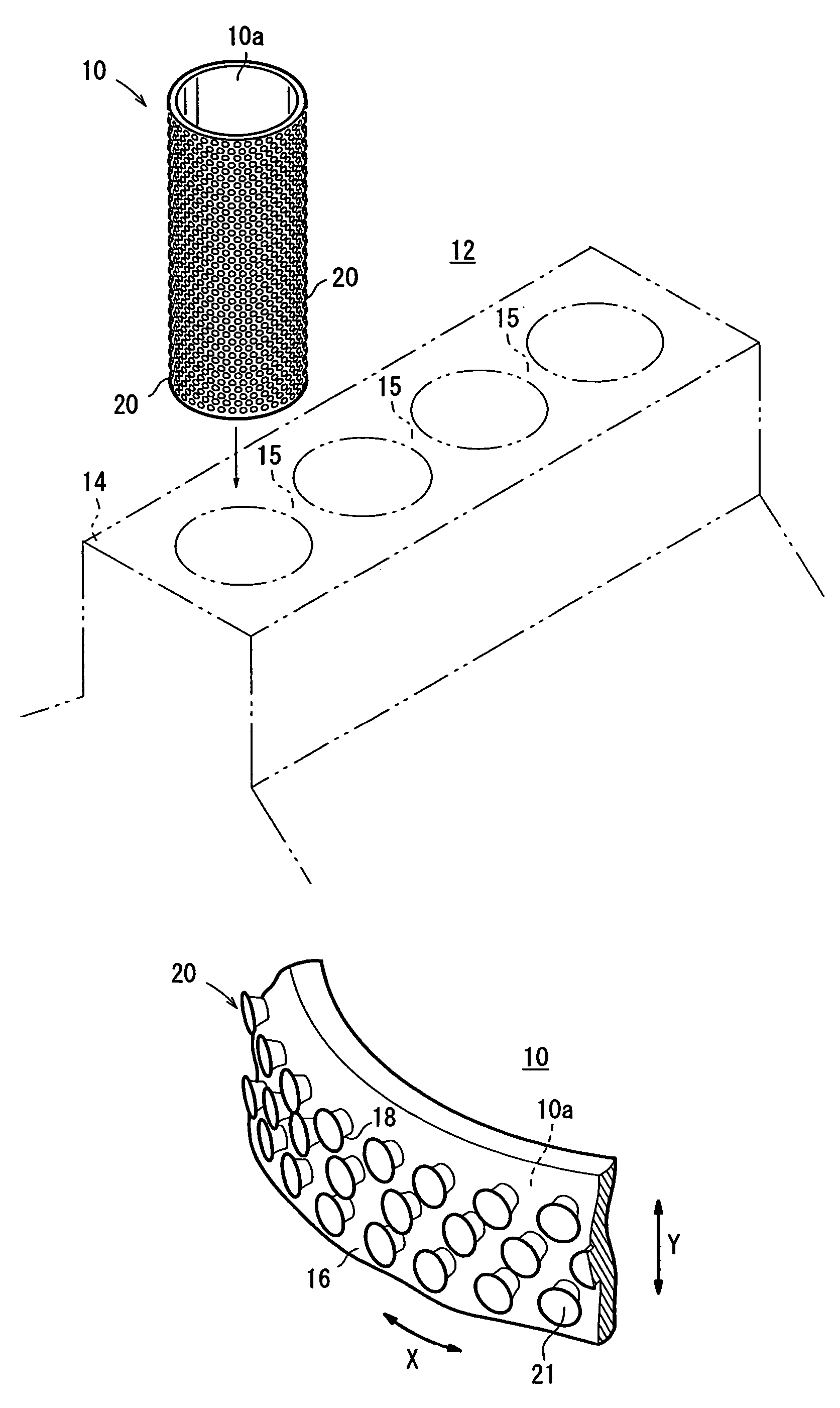

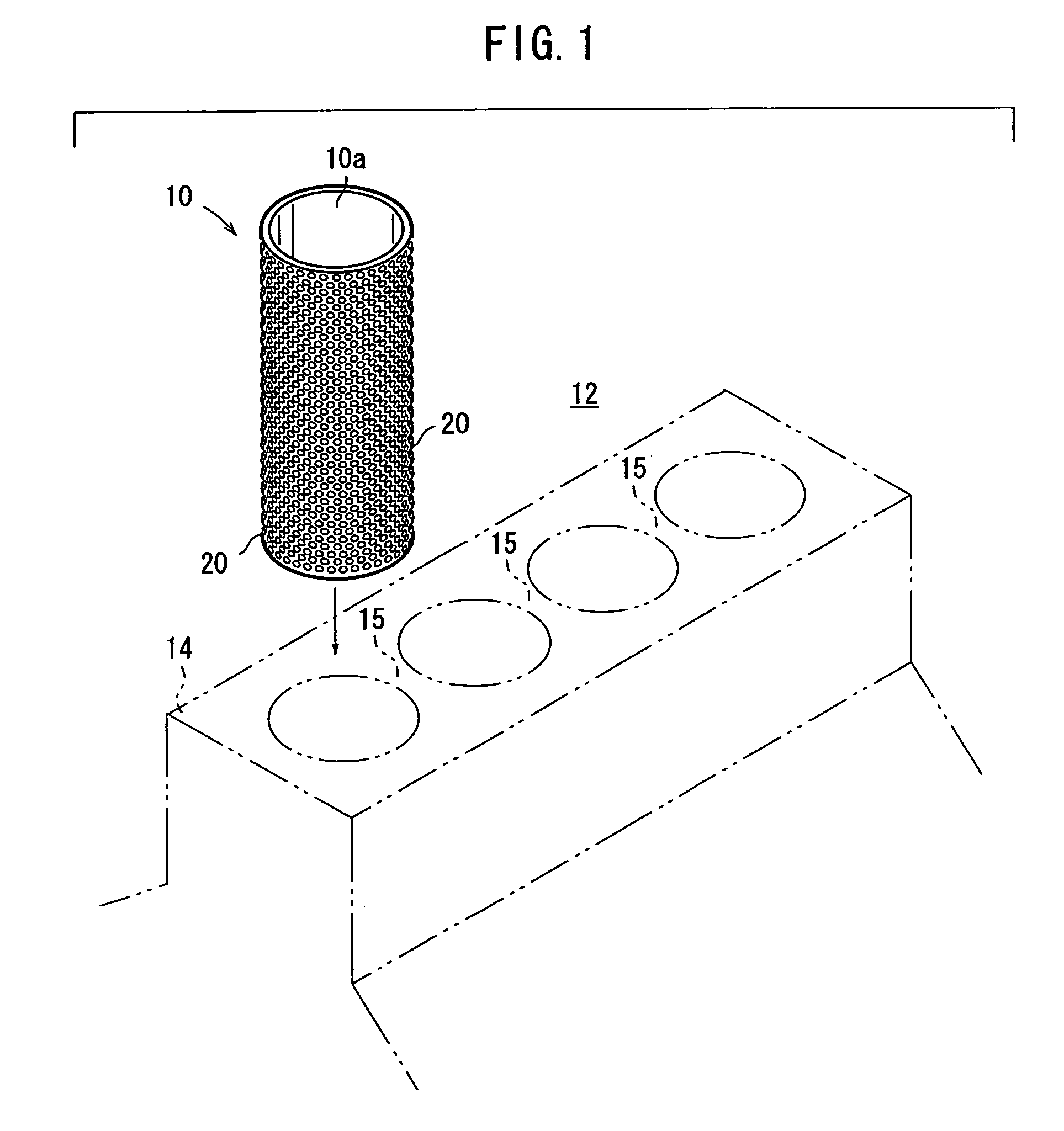

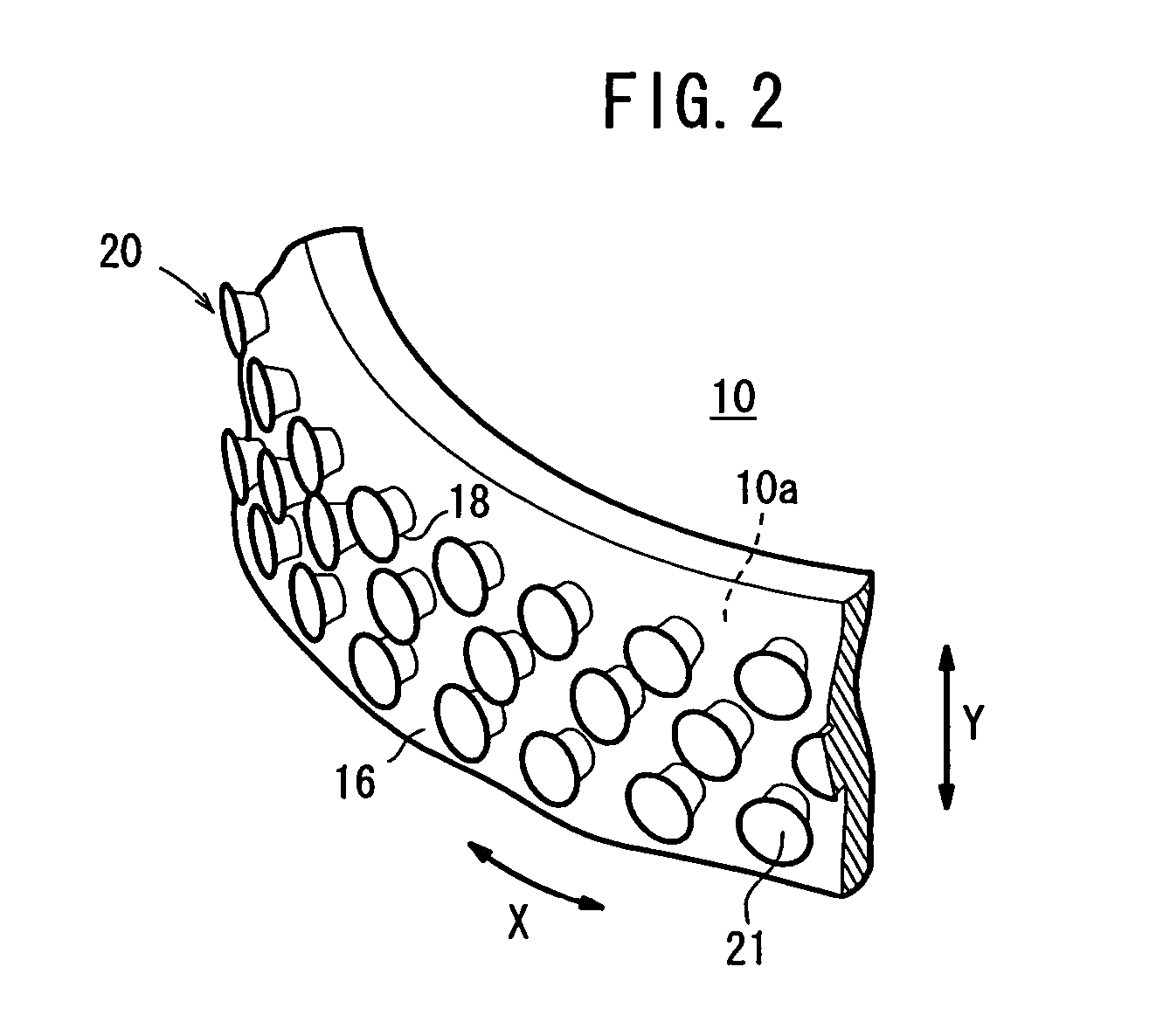

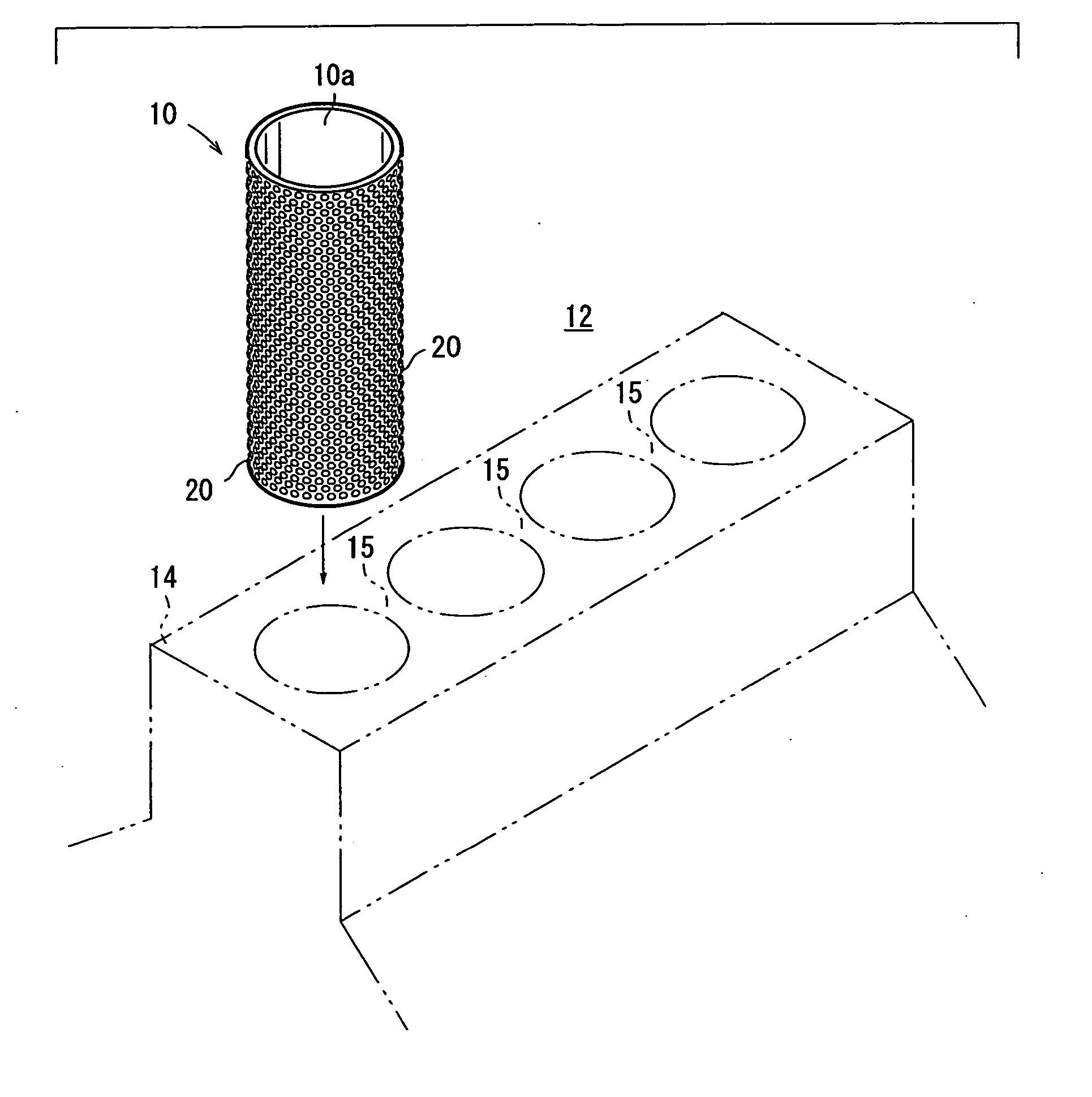

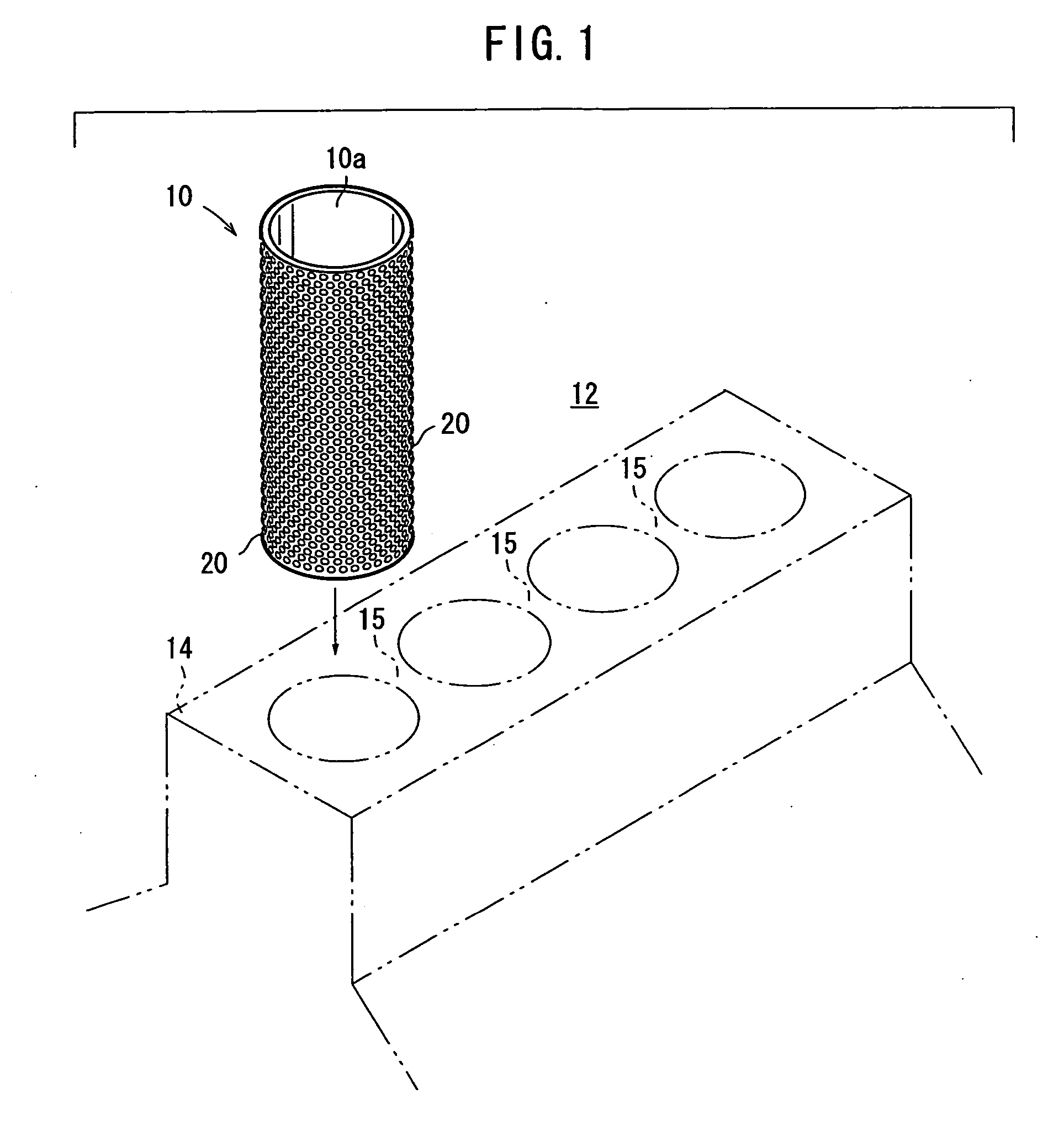

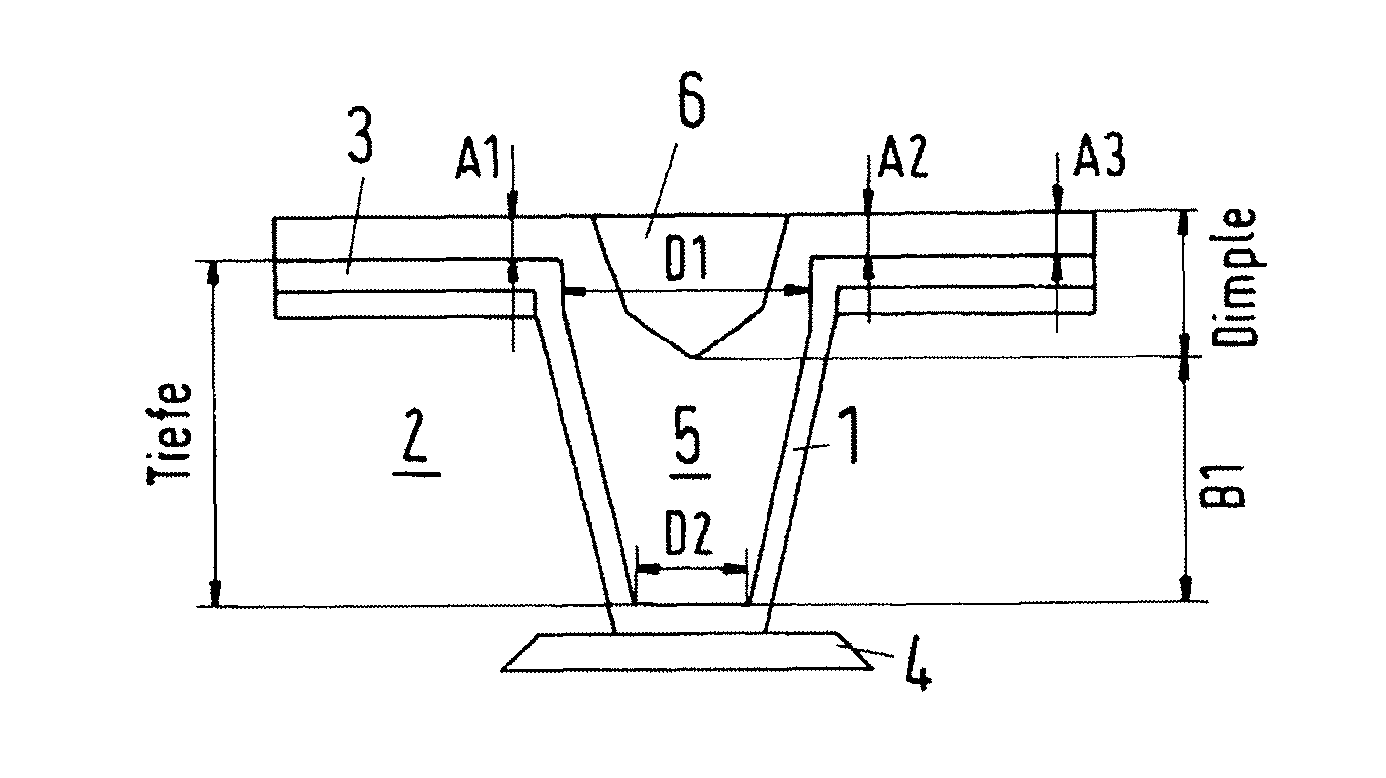

Cast-iron insert and method of manufacturing same

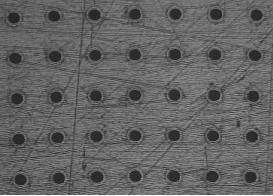

ActiveUS7226667B2Increase contactSimple processHot-dipping/immersion processesCasingsEngineeringConoid

A cylinder liner has an outer circumferential surface around which another metal is to be cast. The cylinder liner also has a plurality of protrusions disposed on the outer circumferential surface and having respective substantially conical undercuts or necks which are progressively spread outwardly from the outer circumferential surface. The protrusions have respective flat faces on the distal ends of the undercuts.

Owner:HONDA MOTOR CO LTD

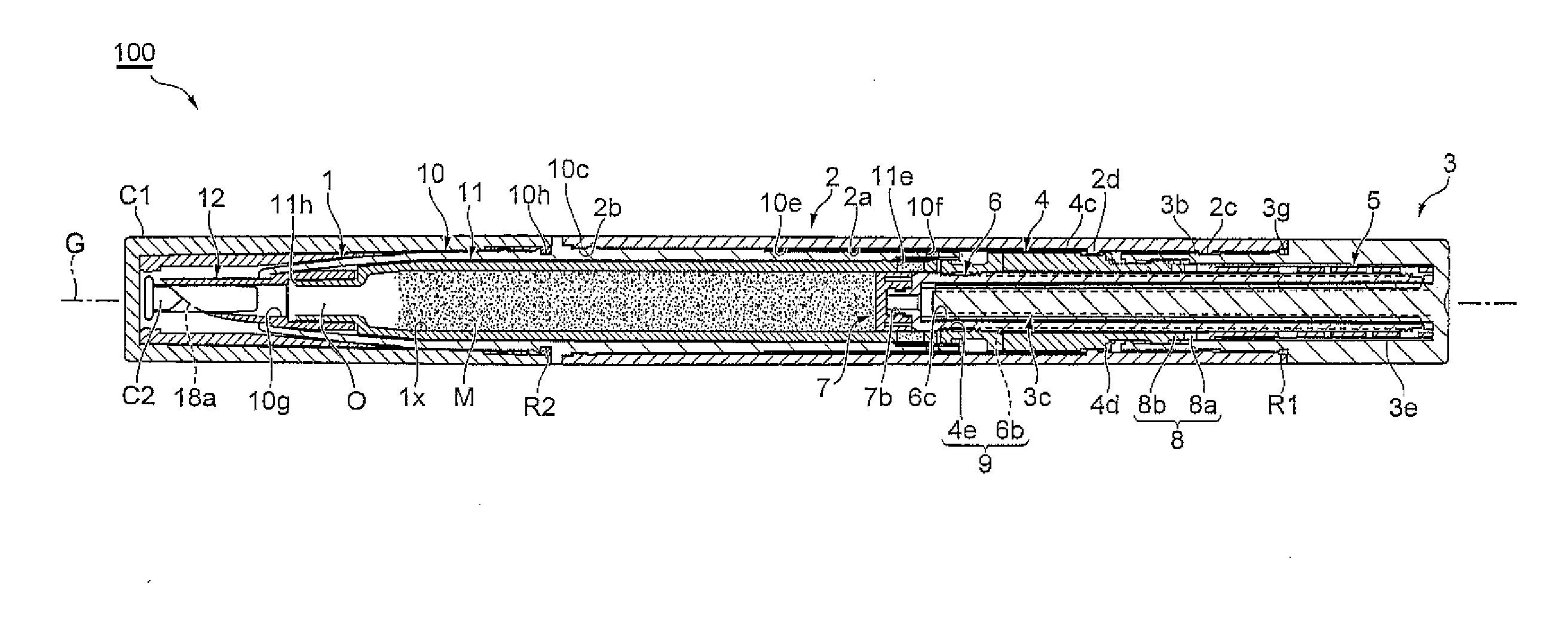

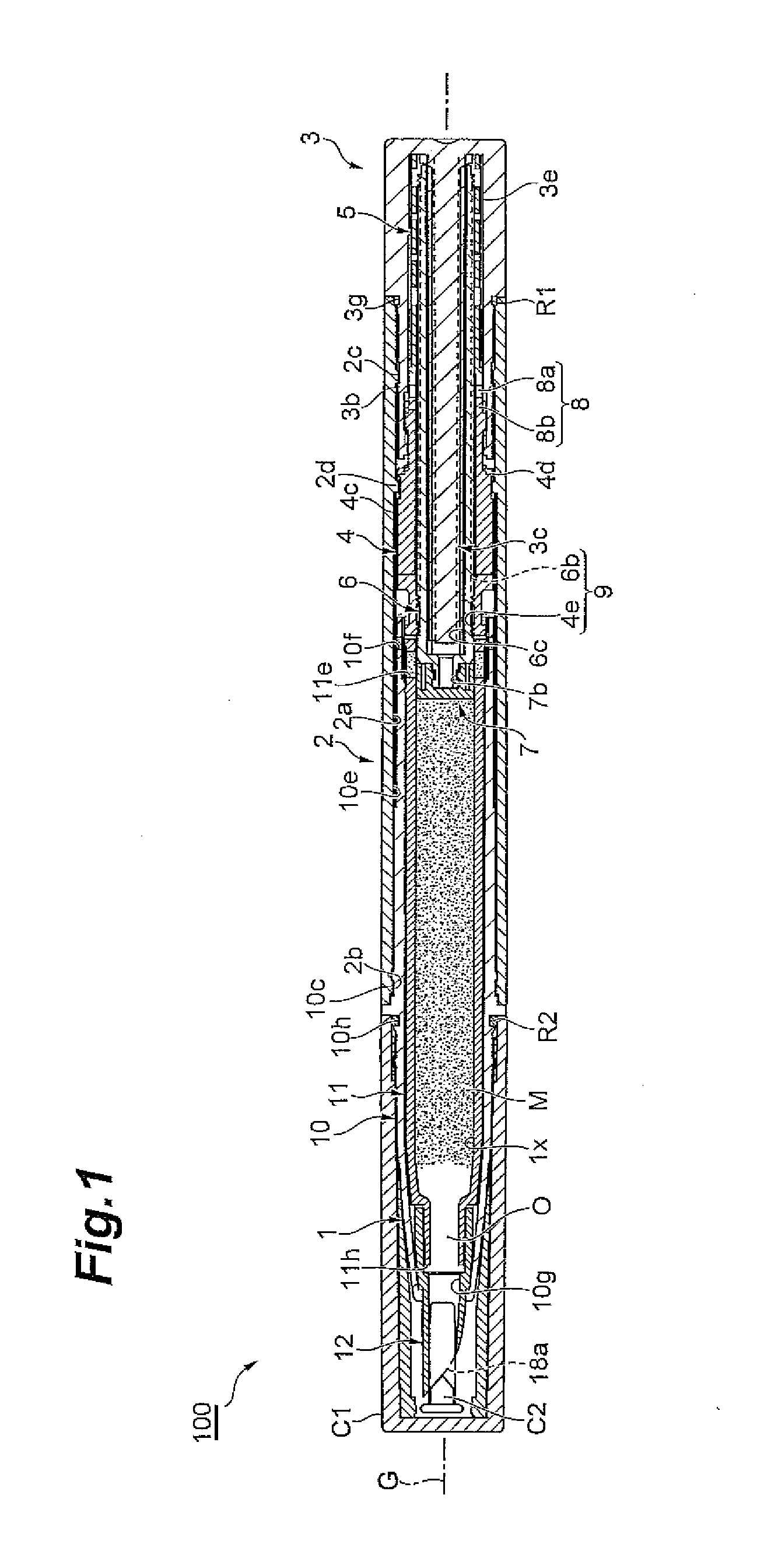

Liquid detecting device, liquid container, and liquid refilling method

InactiveUS20080148859A1Reliable fillingFluid pressure measurement using piezo-electric devicesPrintingLiquid pressure

A liquid container includes; a liquid containing portion for containing liquid therein; a unit case, including a liquid inlet communicating with the liquid containing portion, a liquid outlet for supplying the liquid outside, a flexible diaphragm that covers an upper opening of the unit case and that is displaceable depending on liquid pressure between the liquid inlet and the liquid outlet; a movable member attached to the flexible diaphragm and that has a pair of shafts formed to protrude from opposite sides of the movable member: a sensor assembly attached to a bottom opening formed in a bottom plate of the unit case and used for detecting that the liquid in the liquid containing portion is exhausted to a predetermined amount; and a pair of shaft receiving portions that is provided on the unit case for receiving the pair of the shafts to fix the movable member in a predetermined position in an initial state where the liquid has not flowed from the liquid inlet to the detection portion.

Owner:SEIKO EPSON CORP

Cast-iron insert and method of manufacturing same

ActiveUS20050161187A1Improve intimate contactDesired level of accuracyHot-dipping/immersion processesCasingsCast ironBiomedical engineering

A cylinder liner has an outer circumferential surface around which another metal is to be cast. The cylinder liner also has a plurality of protrusions disposed on the outer circumferential surface and having respective substantially conical undercuts or necks which are progressively spread outwardly from the outer circumferential surface. The protrusions have respective flat faces on the distal ends of the undercuts.

Owner:HONDA MOTOR CO LTD

Method of forming a metal layer over a patterned dielectric by electroless deposition using a selectively provided activation layer

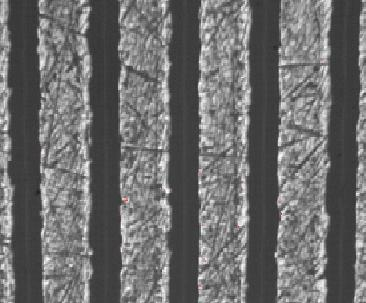

InactiveUS20080182409A1Effective controlHigh selectivitySemiconductor/solid-state device manufacturingDielectricElectroless deposition

By forming an activation / nucleation layer selectively at a bottom of an opening, efficient electroless deposition techniques may be used for forming contacts, vias and trenches of advanced semiconductor devices. By selectively providing the activation material, a self-aligned bottom-to-top fill behavior may be obtained.

Owner:GLOBALFOUNDRIES INC

Reduced Defectivity in Contacts of a Semiconductor Device Comprising Replacement Gate Electrode Structures by Using an Intermediate Cap Layer

ActiveUS20110269303A1Efficient overall process flowReduce or removeSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringDielectric

Superior contact elements may be formed in semiconductor devices in which sophisticated replacement gate approaches may be applied. To this end, a dielectric cap layer is provided prior to patterning the interlayer dielectric material so that any previously created cracks may be reliably sealed prior to the deposition of the contact material, while the removal of any excess portion thereof may be performed without an undue interaction with the electrode metal of the gate electrode structures. Consequently, a significantly reduced defect rate may be achieved.

Owner:GLOBALFOUNDRIES US INC

Method of forming buried wiring, and apparatus for processing substratum

InactiveUS6524429B1Improve reliabilityDamaged and brokenLiquid surface applicatorsSemiconductor/solid-state device detailsElectrical and Electronics engineeringRaw material

A method of forming a buried wiring comprising the steps of: (A) forming a wiring and a first insulating layer filled between the wirings on a substratum, (B) immersing the first insulating layer in a fluid which can dissolve the first insulating layer, to dissolve the first insulating layer into the fluid, (C) substituting, for the fluid, a raw material solution containing a raw material for forming a second insulating layer, without bringing the wiring into contact with a gas, and (D) filling a second insulating layer formed by gelation in the raw material solution at least between the wirings, and then, drying off the raw material solution, thereby to form the second insulating layer at least between the wirings.

Owner:KOBE STEEL LTD

Aqueous, acid bath and method for the electrolytic deposition of copper

ActiveUS8679316B2Good effectControl roughnessSemiconductor/solid-state device manufacturingPrinted circuit manufactureElectrolysisCopper

An aqueous, acid bath for the electrolytic deposition of copper contains at least one copper ion source, at least one acid ion source, at least one brightener compound, and at least one leveler compound, and generates a very uniform copper deposit in particular in blind micro vias (BMVs) and trenches. The leveler compound is selected from among synthetically produced non-functionalized peptides, synthetically produced functionalized peptides, and synthetically produced functionalized amino acids.

Owner:ATOTECH DEUT GMBH

Waste toner recovering apparatus and image forming apparatus

InactiveCN1493932AEfficient fillingExtended replacement cycleElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

Method for manufacturing a coating instrument

ActiveUS20150231916A1Reliably prevent leakagePrevent leakageDispensing apparatusPen repairingEngineeringMechanical engineering

There is provided a method for manufacturing a coating instrument provided with a filling member having a filling region in which a coating material is filled and a body portion including an extruding portion inserted inside so as to be brought into close contact with the filling member and constituting a rear end of the filling region, in which the coating material is discharged from a discharge outlet on a tip end side of the filling member by advance of the extruding portion, including a step of filling the coating material into the filling region of the filling member from behind in a state in which a front side of the filling member is located below the rear side, a step of feeding a predetermined amount of air from the discharge outlet into the filling region so that a space is formed on the tip end side in the filling region after the coating material is filled, and a step of assembling the body portion to the filling member after the air is fed.

Owner:TOKIWA CORP

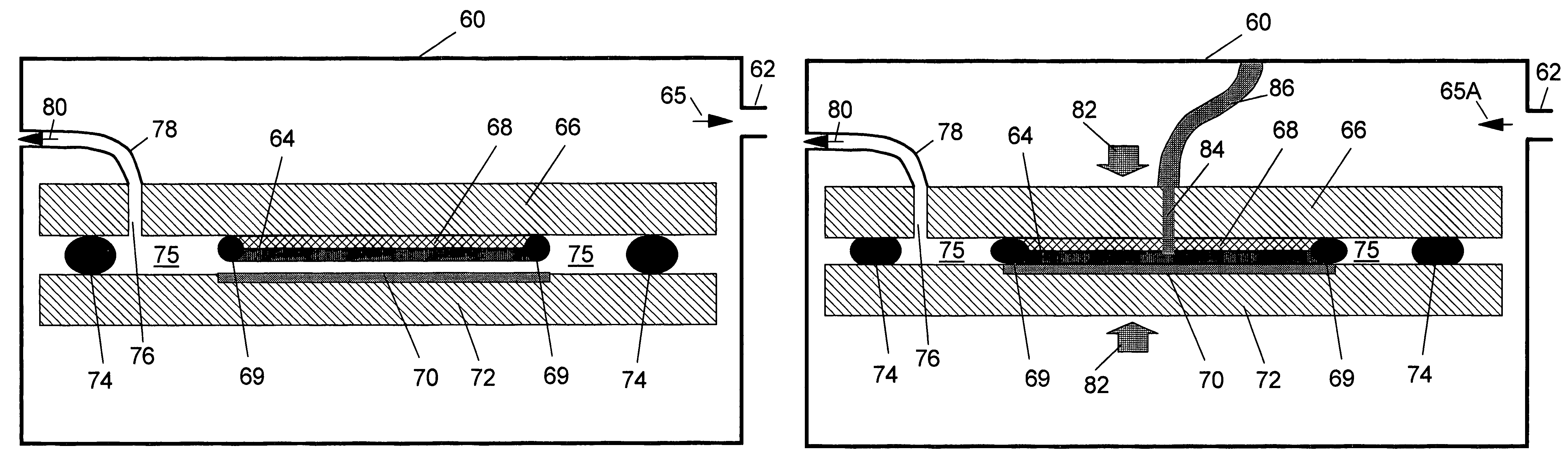

Method and apparatus for filling vias

ActiveUS7449067B2Reliable fillingPrinted circuit assemblingLiquid surface applicatorsEngineeringMechanical engineering

A method for filling vias, and in particular initially blind vias, in a wafer, and various apparatus for performing the method, comprising evacuating air from the vias; trapping at least a portion of the wafer and a paste for filling the vias between two surfaces; and pressurizing the paste to fill the vias.

Owner:GLOBALFOUNDRIES U S INC

Motor stator pouring and sealing method and motor stator pouring and sealing tooling

ActiveCN108183588AReliable fillingReduce poor pottingManufacturing dynamo-electric machinesEngineeringSealant

The present invention relates to a motor stator technology field, in particular to a motor stator pouring and sealing method and a motor stator pouring and sealing tooling. The plastic end cups sleevethe two ends of an assembled stator assembly, the stator assembly at the end parts of which the plastic end cups sleeve is clamped to a glue pouring tooling in a vacuumizing device, and the epoxy pouring sealant is poured into an inner hole of the stator assembly. The vacuumizing device vacuumizes, under a vacuum state, a core rod of which the diameter matches the inner hole of the stator assembly is inserted in the inner hole of the stator assembly from top to bottom, and under the extrusion of the core rod, the epoxy pouring sealant in the inner hole immerses and flows from inside to outside and from bottom to top along the inner slits of the stator assembly until the epoxy pouring sealant is poured full in all slits of the stator assembly and the space between the stator assembly and the plastic end cups. The stator is poured full by the pouring sealant from bottom to top and from inside to outside, so that the situation that the glue fills reliably is guaranteed, and under a vacuum environment, the bad pouring and sealing brought by the bubbles can be reduced.

Owner:常州精纳电机有限公司

Wiring structure in semiconductor device and method for forming the same

InactiveUS20020060362A1Avoid crackingGrowth inhibitionSemiconductor/solid-state device detailsSolid-state devicesDevice materialThin layer

Owner:SONY CORP

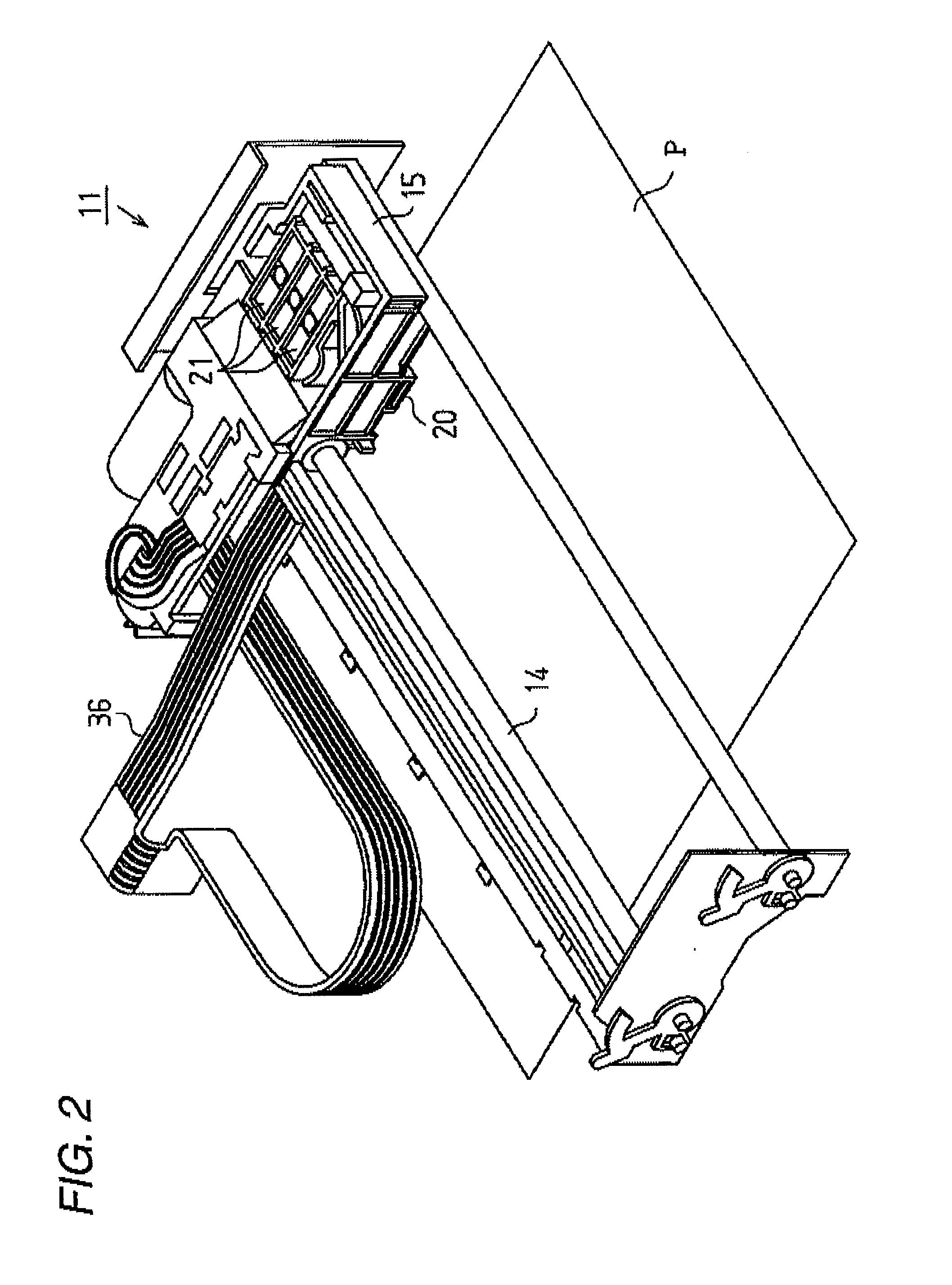

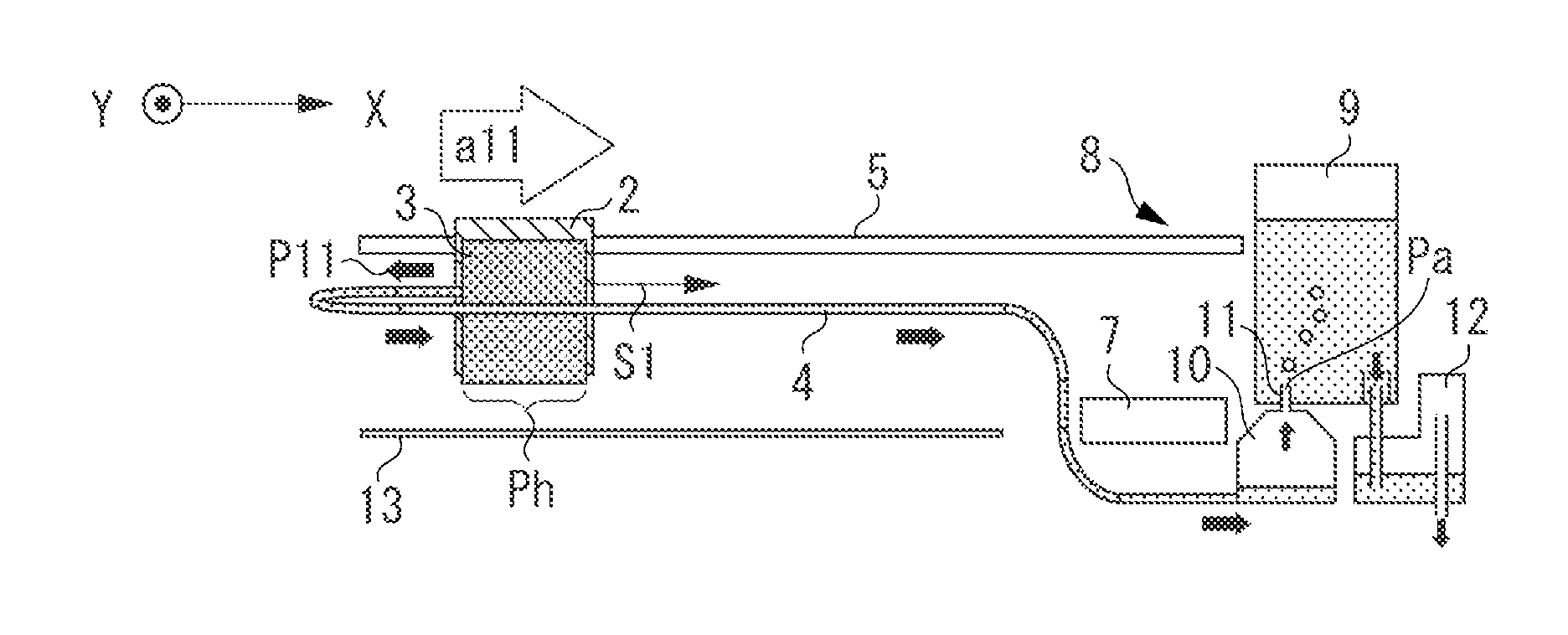

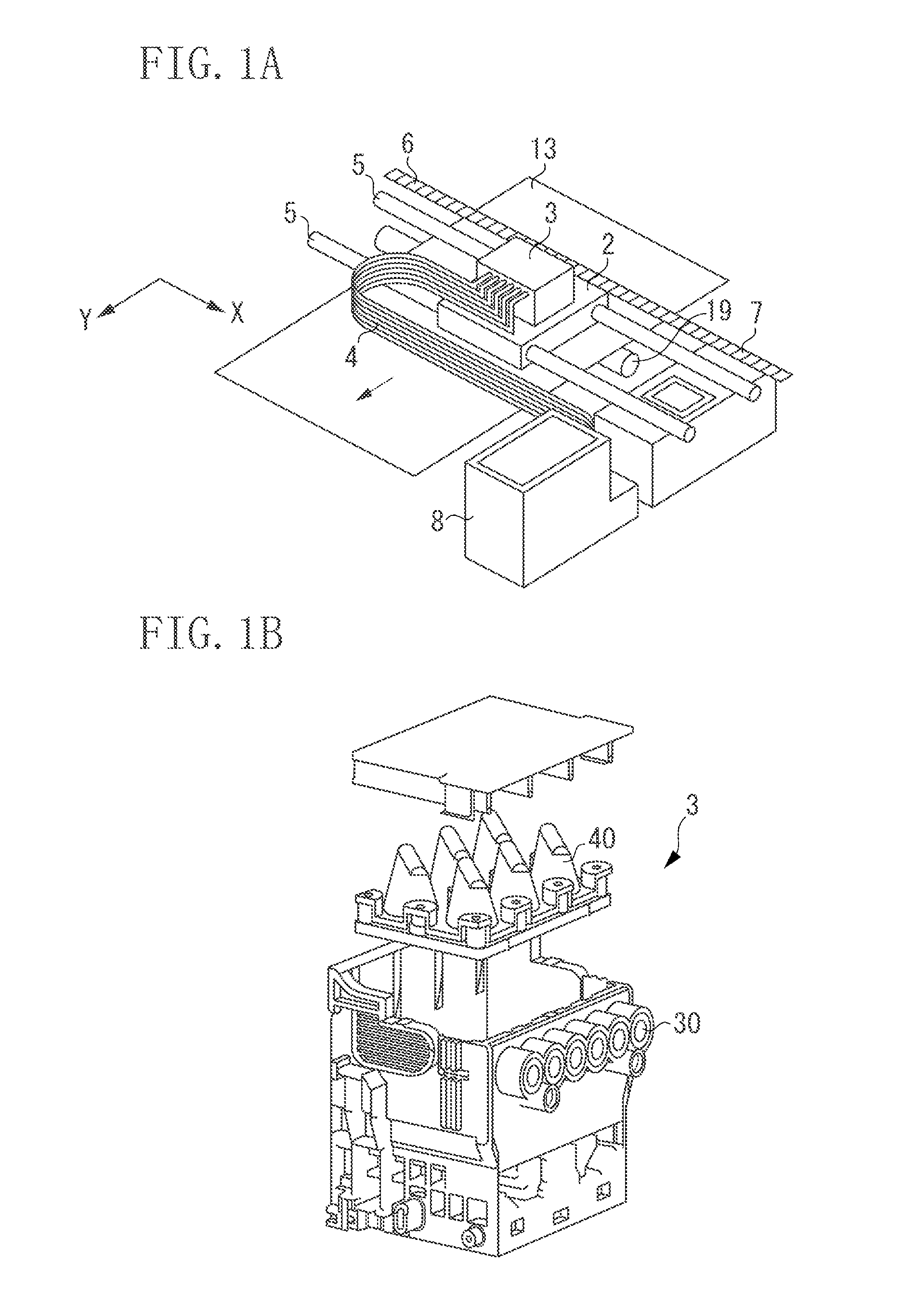

Ink filling method and inkjet recording apparatus

InactiveUS20130286065A1Decrease in recording efficiencyReliable fillingOther printing apparatusRecording headEngineering

An inkjet recording apparatus includes a recording head, a carriage with the recording head mounted thereon, a main tank, a sub-tank configured to be supplied with ink from the main tank via a tube, a supply tube configured to connect the recording head and the sub-tank, a supply unit connected to the supply tube and configured to supply ink from the main tank to the sub-tank, and a control unit configured to control acceleration of the carriage and to control the supply unit, wherein, when an empty volume in the sub-tank is greater than or equal to an ink volume in the main tank, the supply unit is controlled to supply ink to the sub-tank.

Owner:CANON KK

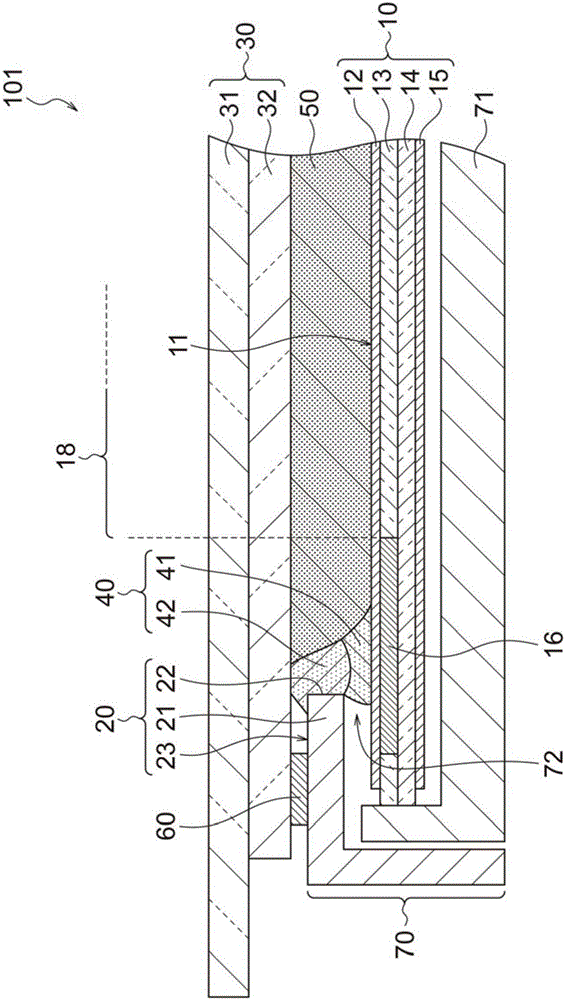

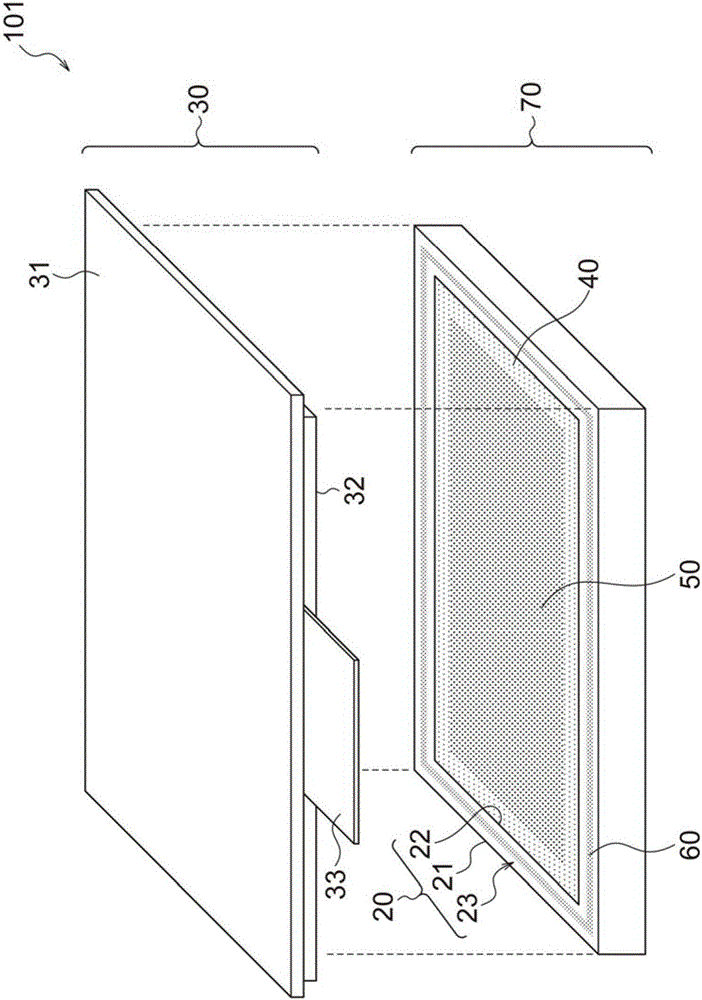

Display device and manufacturing method thereof

ActiveCN105938267AReliable fillingImprove qualityDigital data processing detailsNon-linear opticsDisplay deviceEngineering

The invention refers to a display device and a manufacturing method thereof. To provide a display device of high quality and high reliability by securely sealing the gap between the bezel and the display panel even when variation is generated in the gap. The display device includes: a display panel including a display face; a bezel which includes a frame part and an aperture end that is on the inner side of the frame part, and covers the fringe of the display panel on the display face side by the frame part; a frontal panel provided by sandwiching the bezel on the display face side of the display panel; and a resin member provided along the whole circumference of the aperture end of the bezel. The resin member has a first resin member formed on the display face and a second resin member formed to cover over the first resin member and a surface of the bezel opposing to the frontal panel.

Owner:TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com