Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

304results about "Pen repairing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

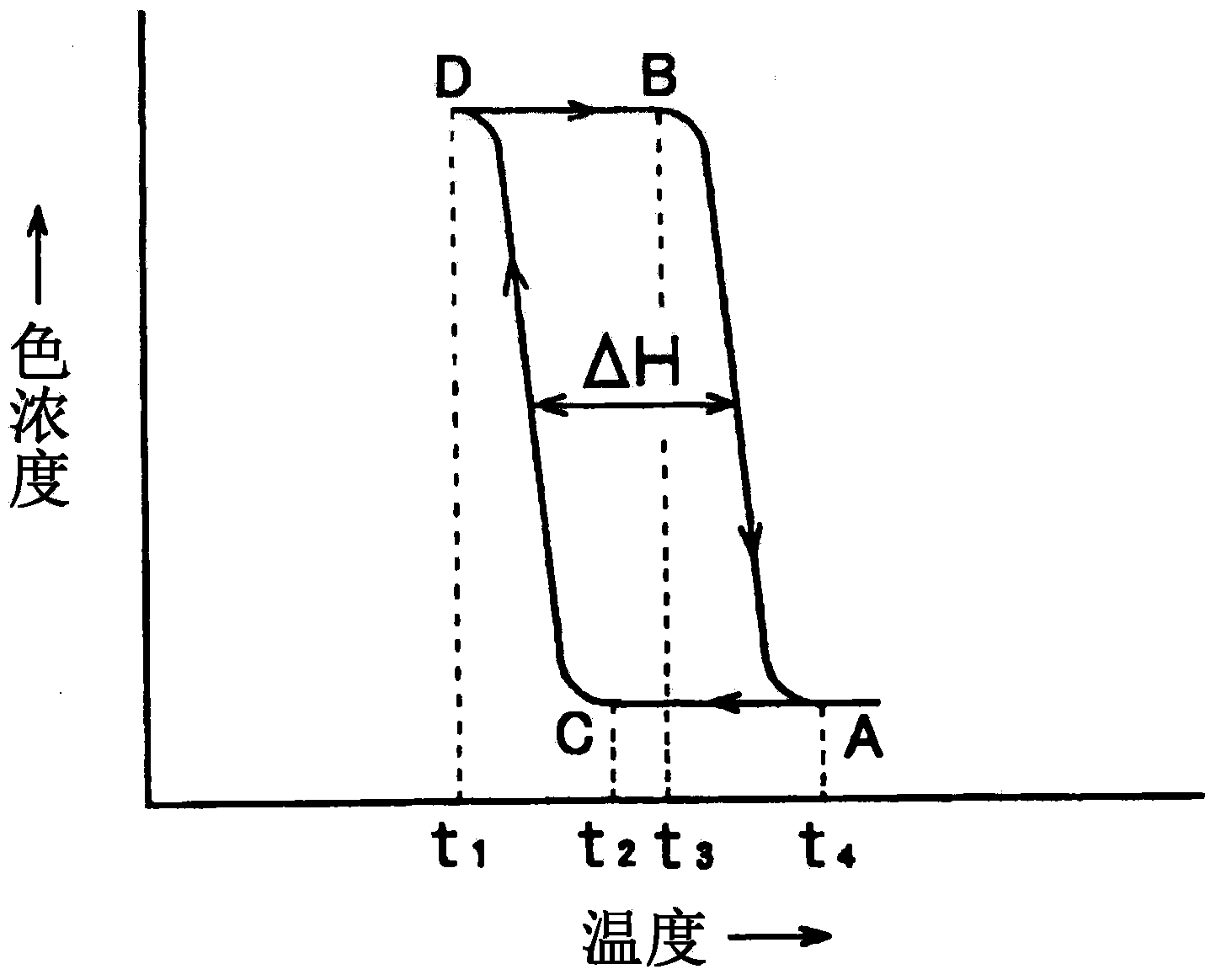

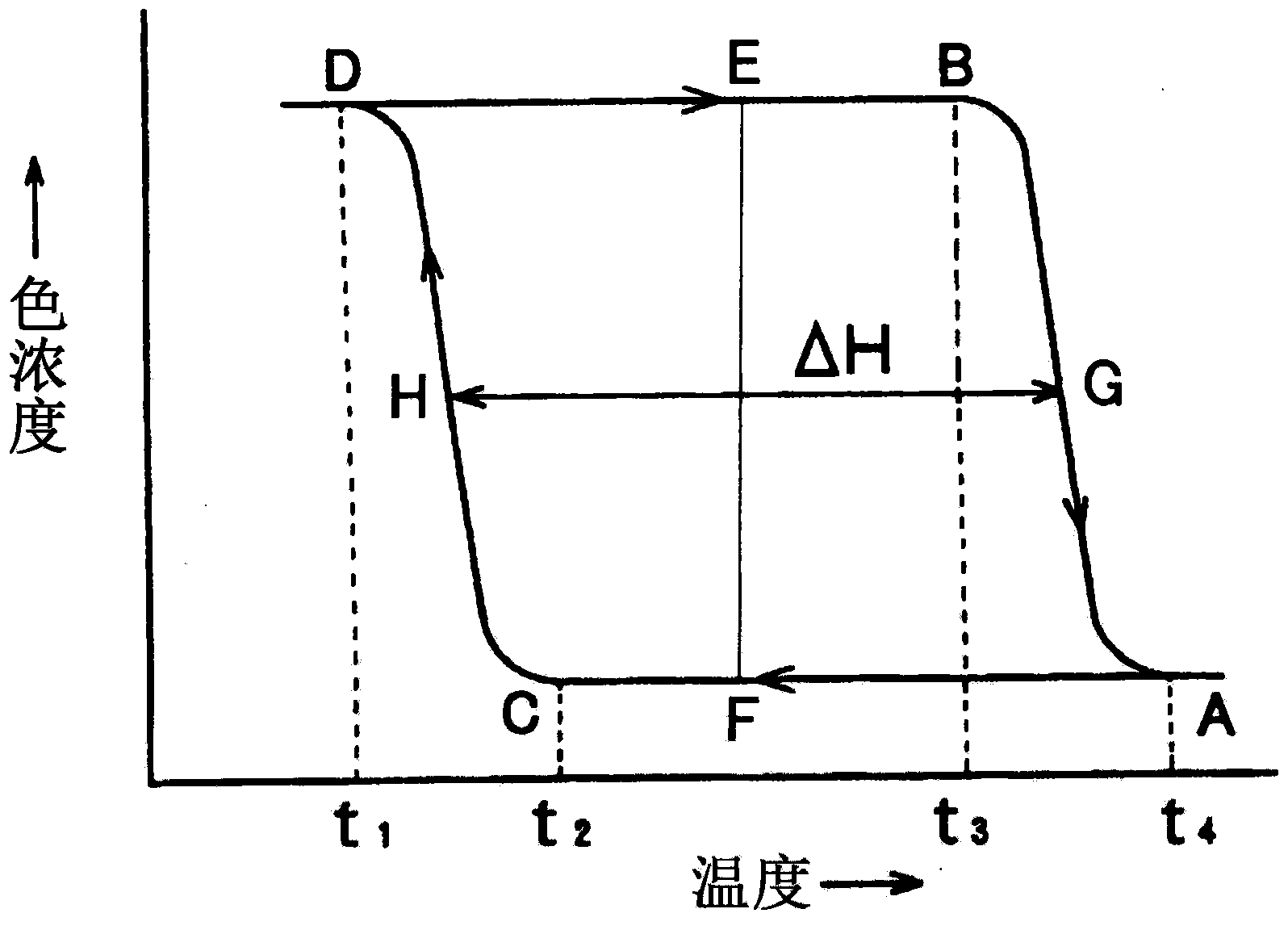

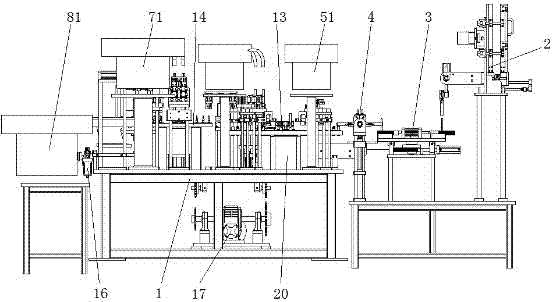

Reversibly thermochromic composition

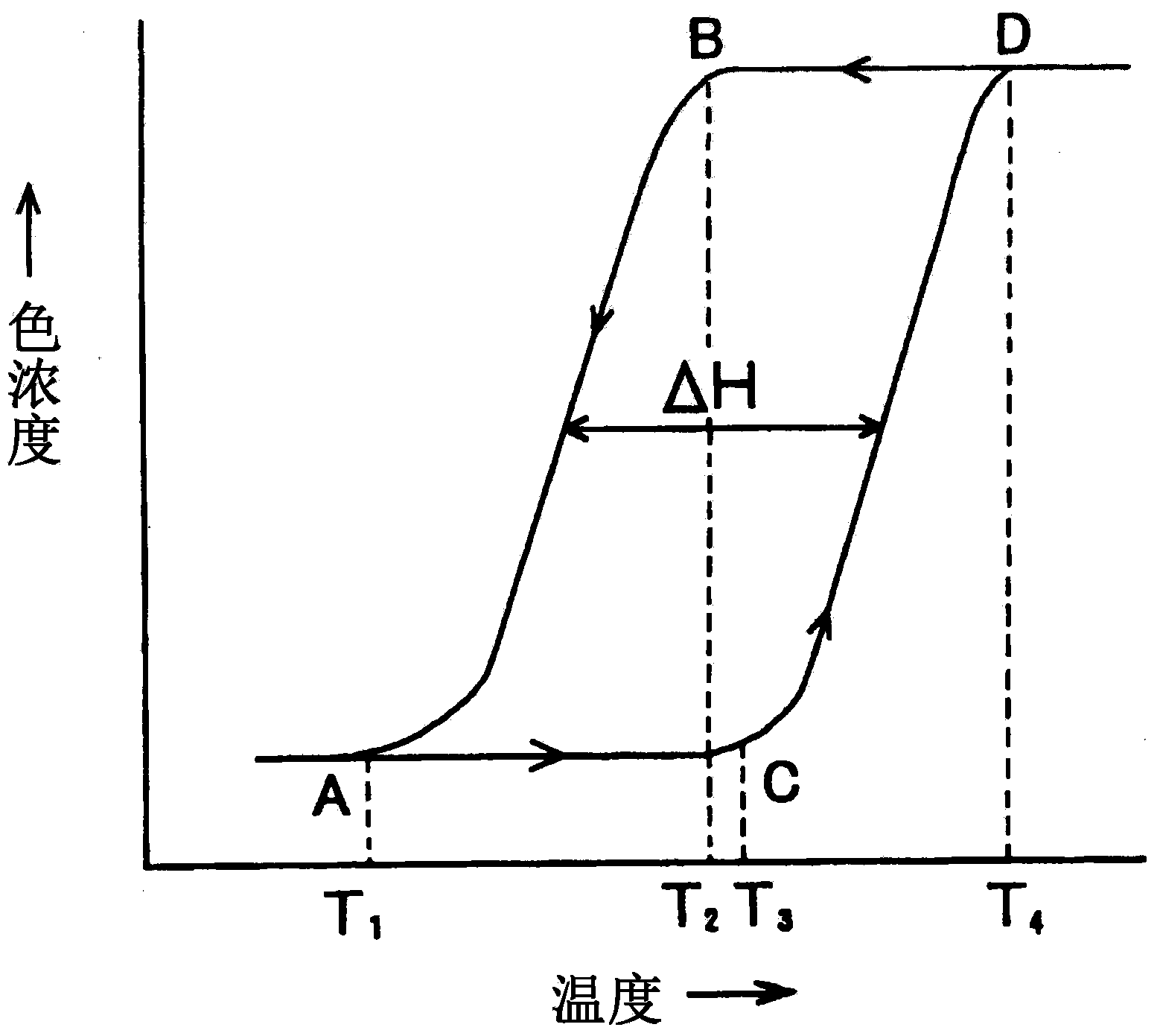

InactiveUS20140291585A1Improve visibilityGood effectConductive materialPen repairingThermochromismHeat conducting

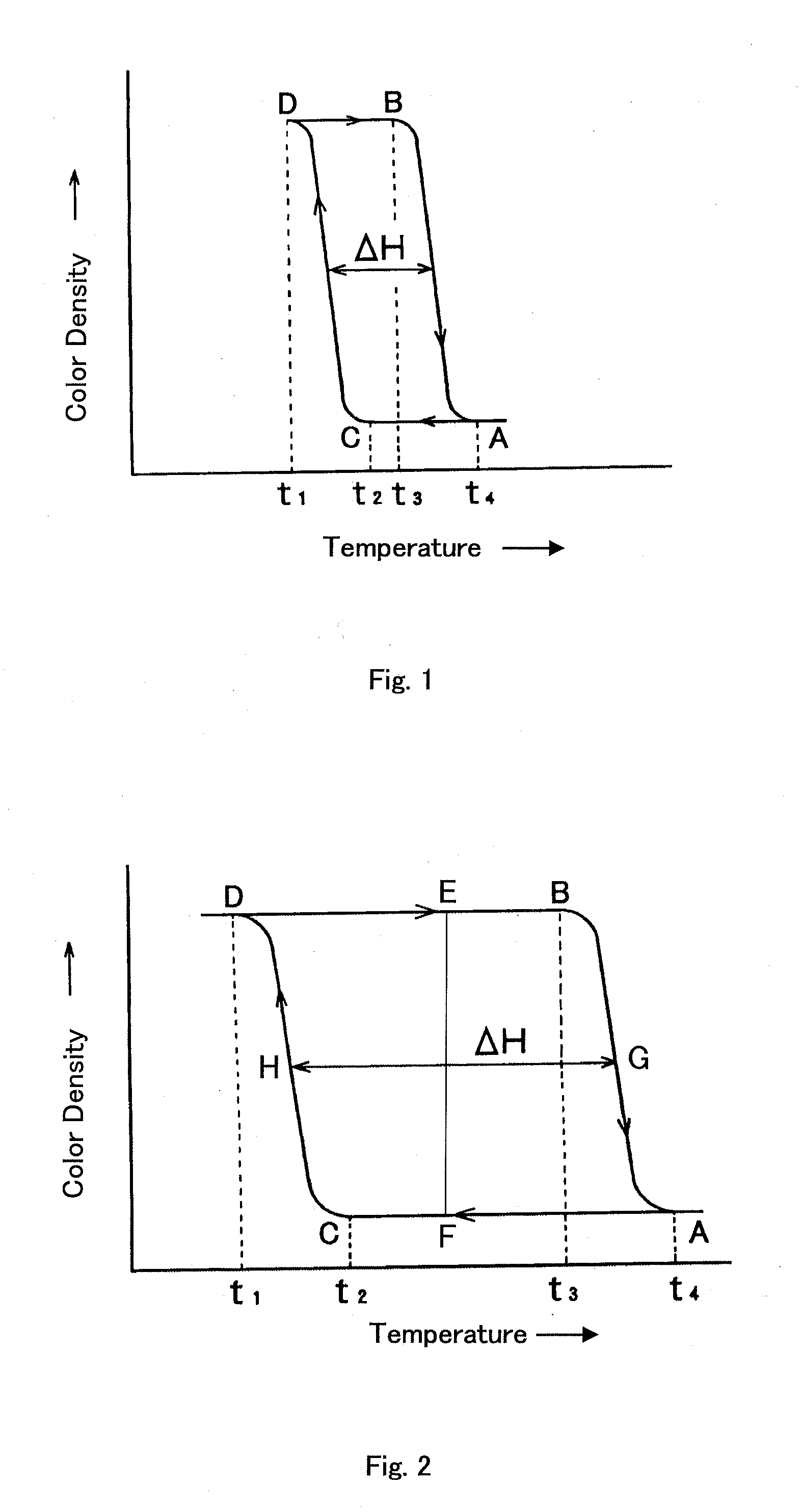

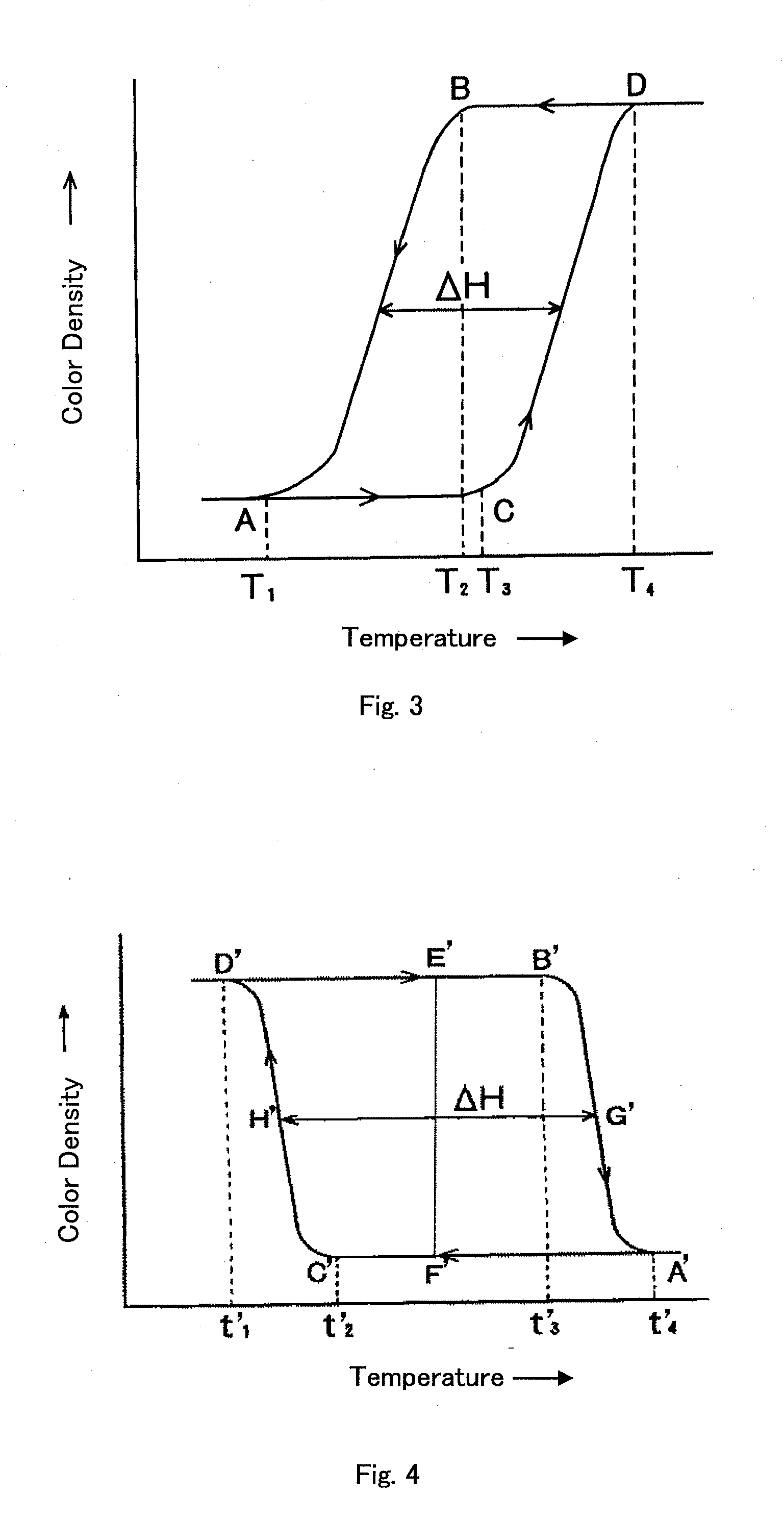

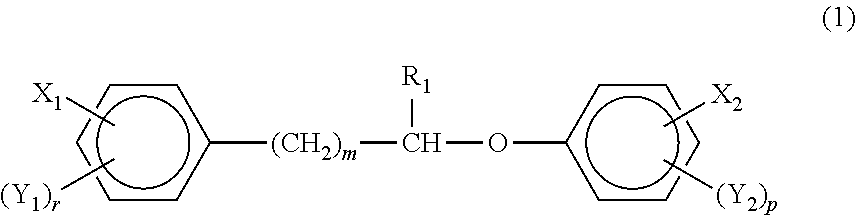

[Object] To provide a reversibly thermochromic composition free from accidental discoloration by heat conducting from the opposite side writing surface or by self-heating due to quick writing; and also to provide a solid writing material and a writing ink composition comprising that composition.[Means to solve the problem] A reversibly thermochromic composition comprising a combination of: (a) a reversibly thermochromic component capable of being discolored or decolored by heat and (b) a component for controlling heat conducting to the reversibly thermochromic component; and also a solid writing material and a writing ink composition comprising that composition.

Owner:PILOT PEN CO LTD

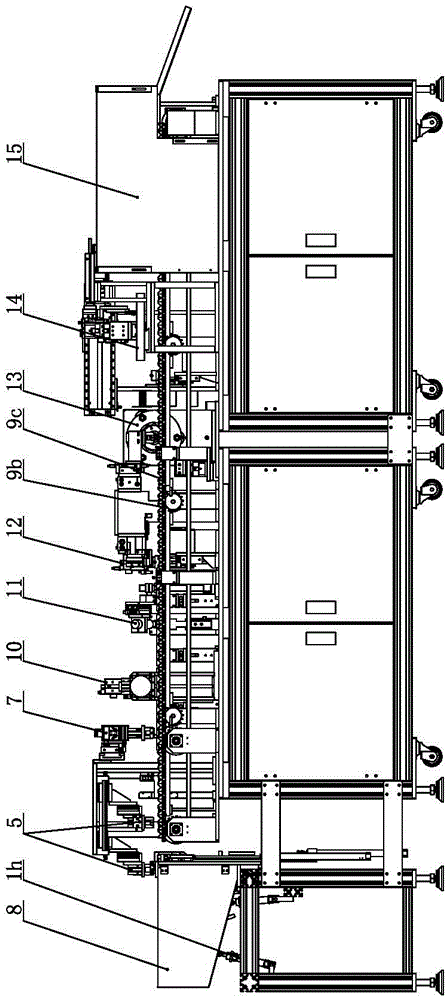

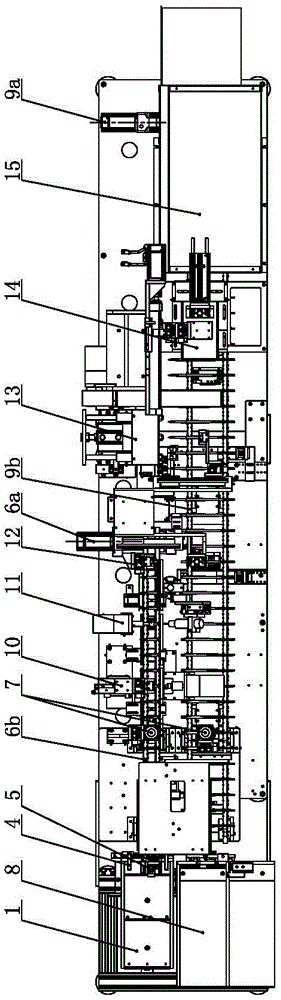

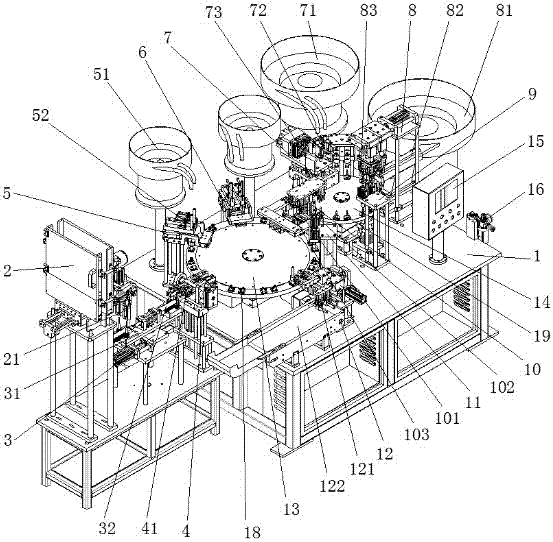

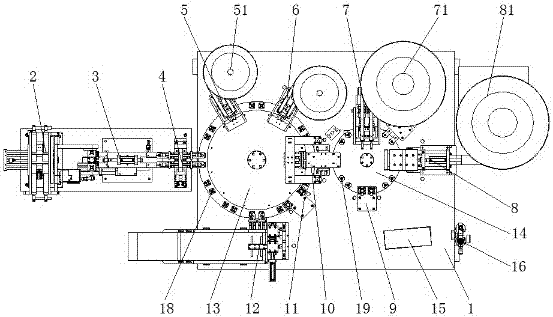

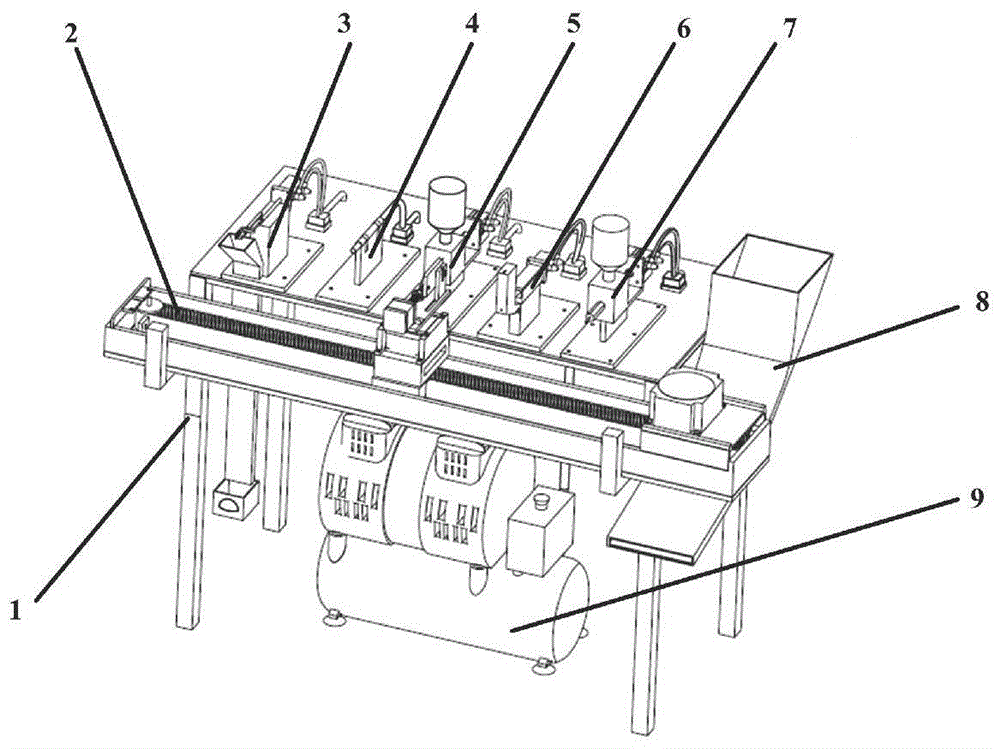

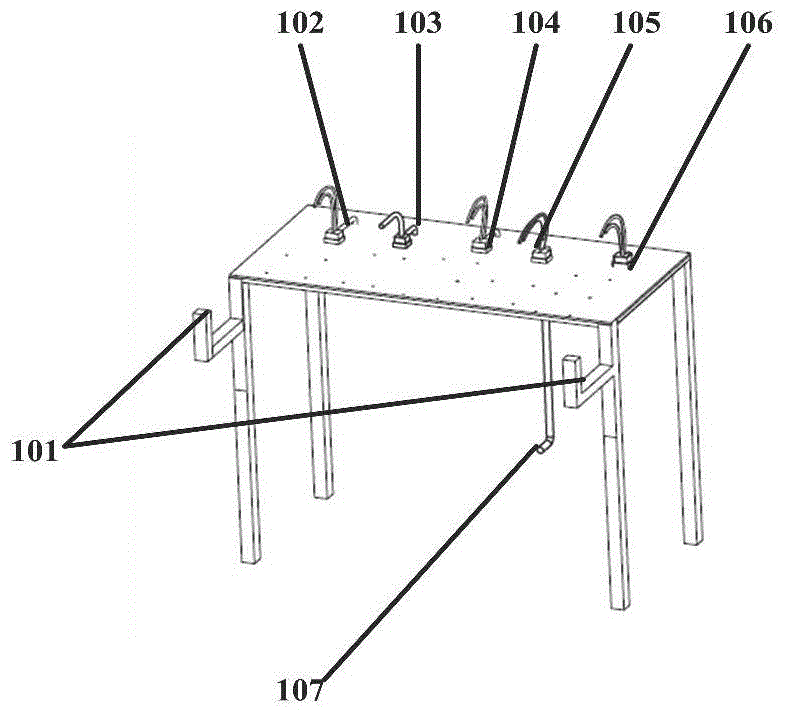

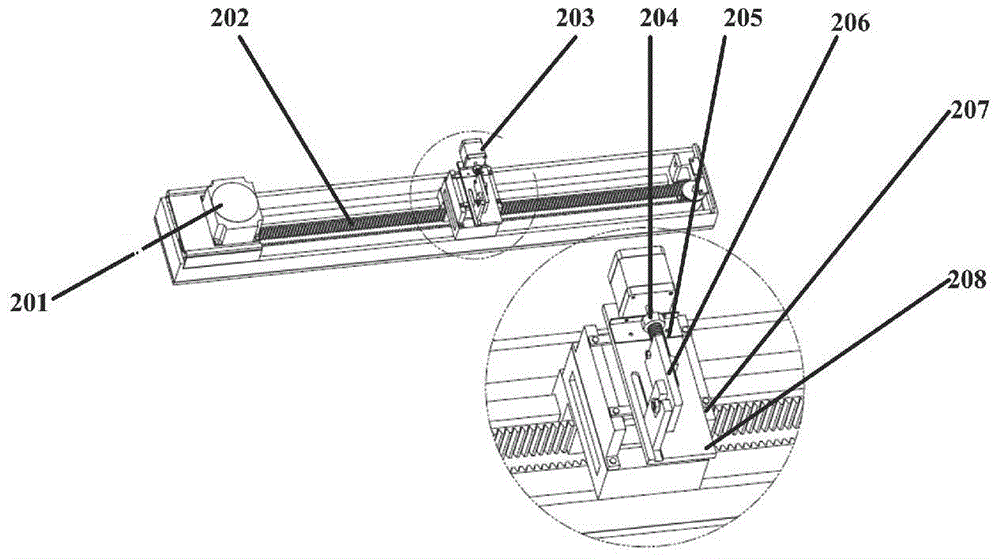

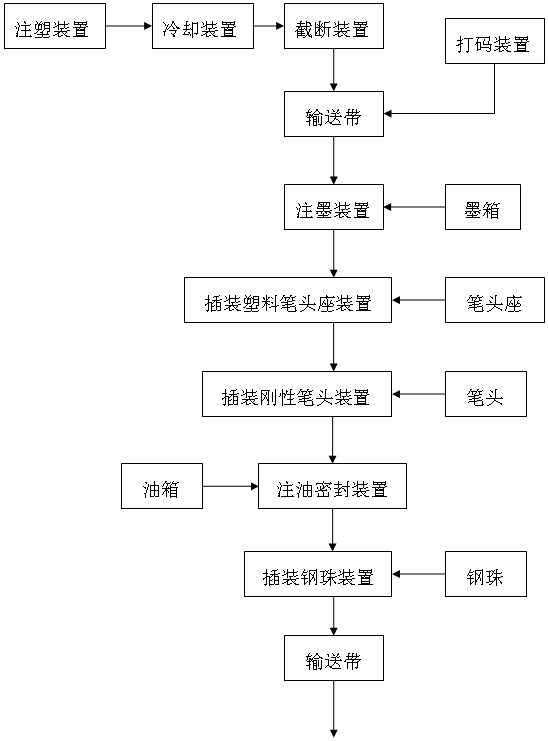

System and method for automatically assembling fountain pen

InactiveCN101830137AIncrease productivityImprove product qualityPen repairingMachine partsSoftware system

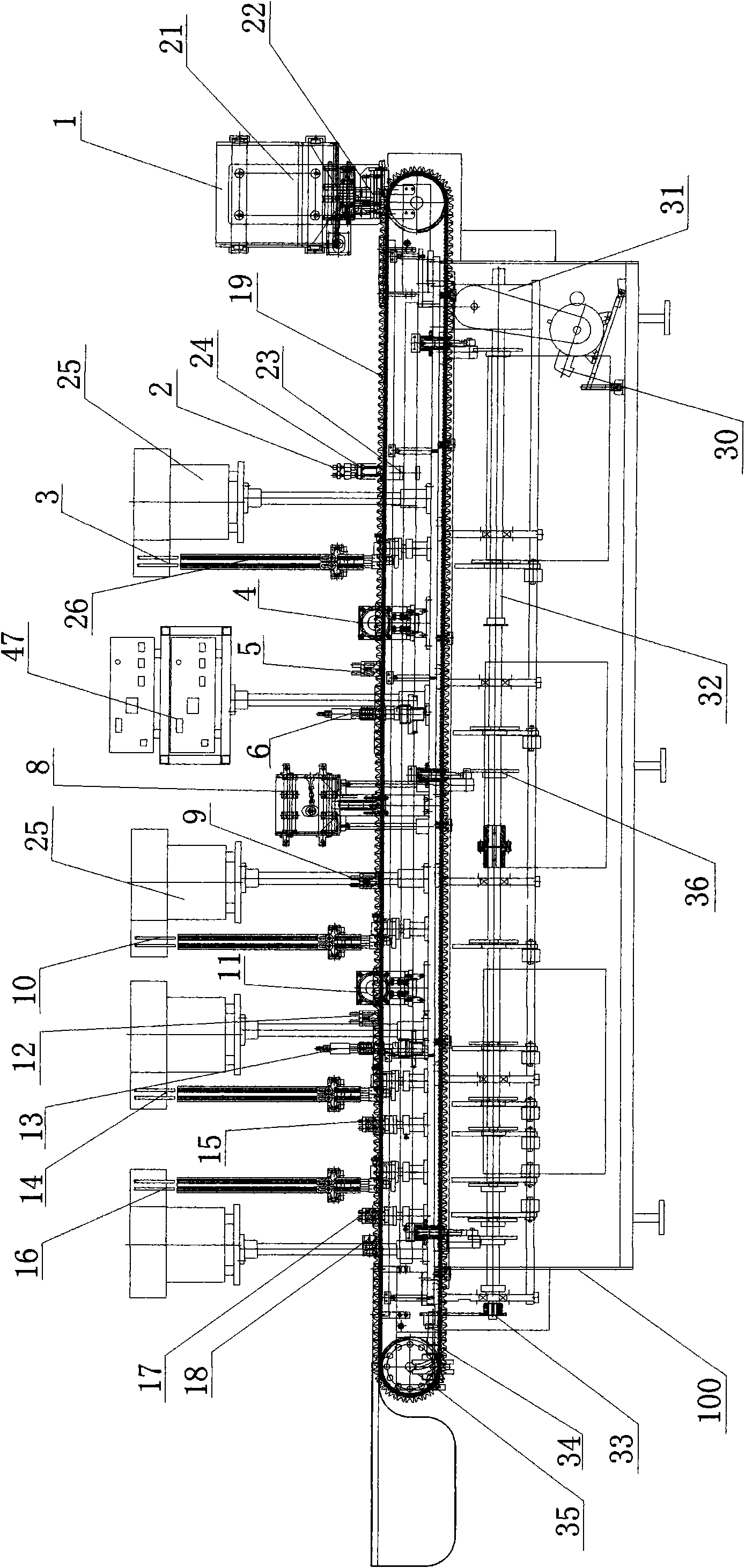

The invention relates equipment and method for assembling a fountain pen. The equipment comprises a plurality of operation units consisting of an electric machine part, a pneumatic machine part, a sensing element, a measuring element, an ultrasonic plastic welding electrical appliance and the like. The method comprises: simulating the manual operation methods of each working procedure in a manufacturing process flow; compiling an operational program software system; sending operation instructions to each operation unit; assembling all required fountain pen parts in sequence by adopting barrel cam control and a conveying chain stepping mode; automatically detect and screening the results of all operation units; and automatically segregating quality field products and non-qualified products. Thus, the method improves production efficiency, saves labor and cost, reduces labor intensity and improves product quality.

Owner:张汉平

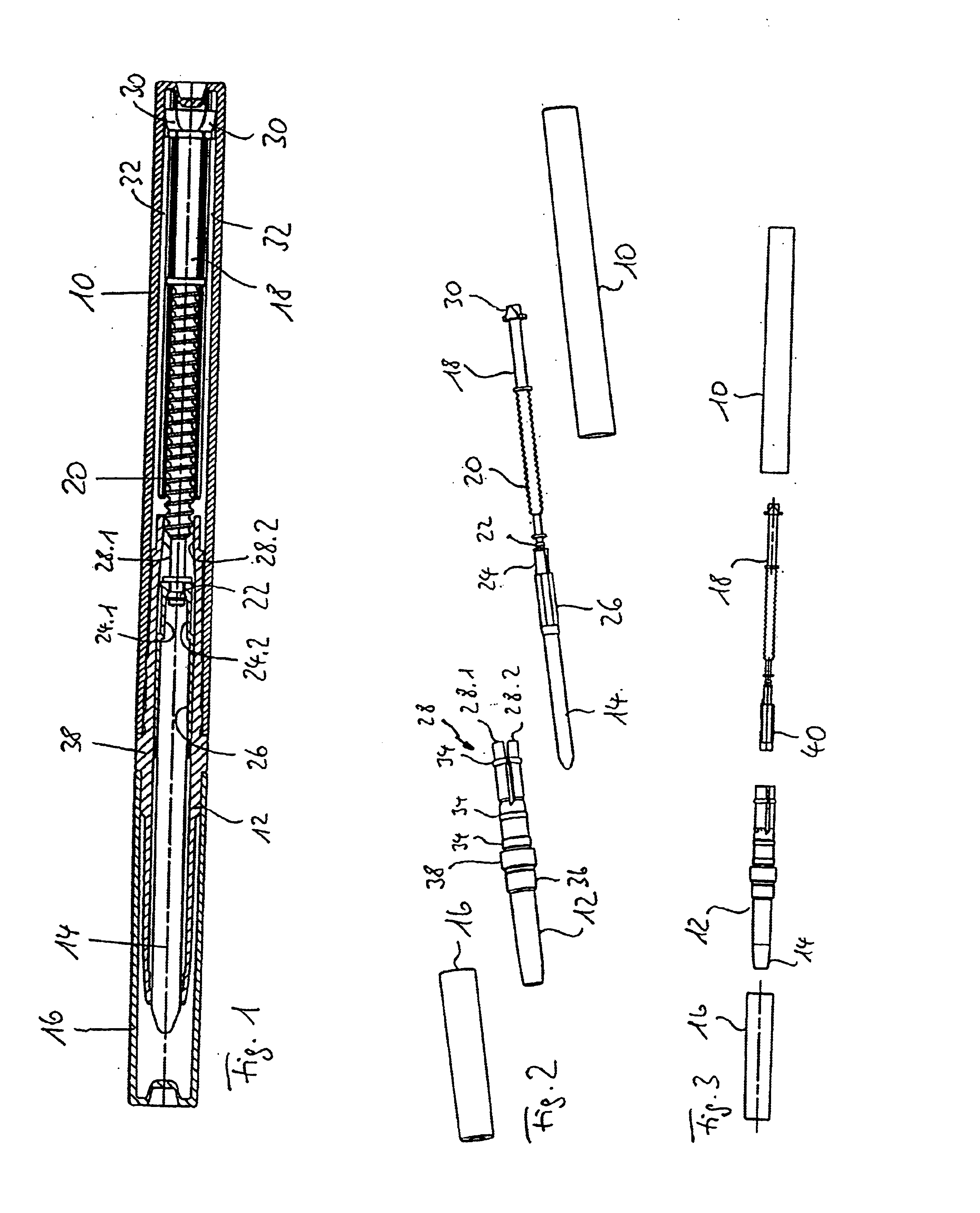

Crayon

A crayon comprising a holding portion, a cartridge for receiving a refill of a predetermined color and a cover characterized in that the cartridge is of the color of the refill, and a part of the cartridge is visible from the exterior, more specifically even when the cartridge is held by the holding portion and the cover is fitted on to the cartridge.

Owner:SCHWAN STABILO COSMETICS

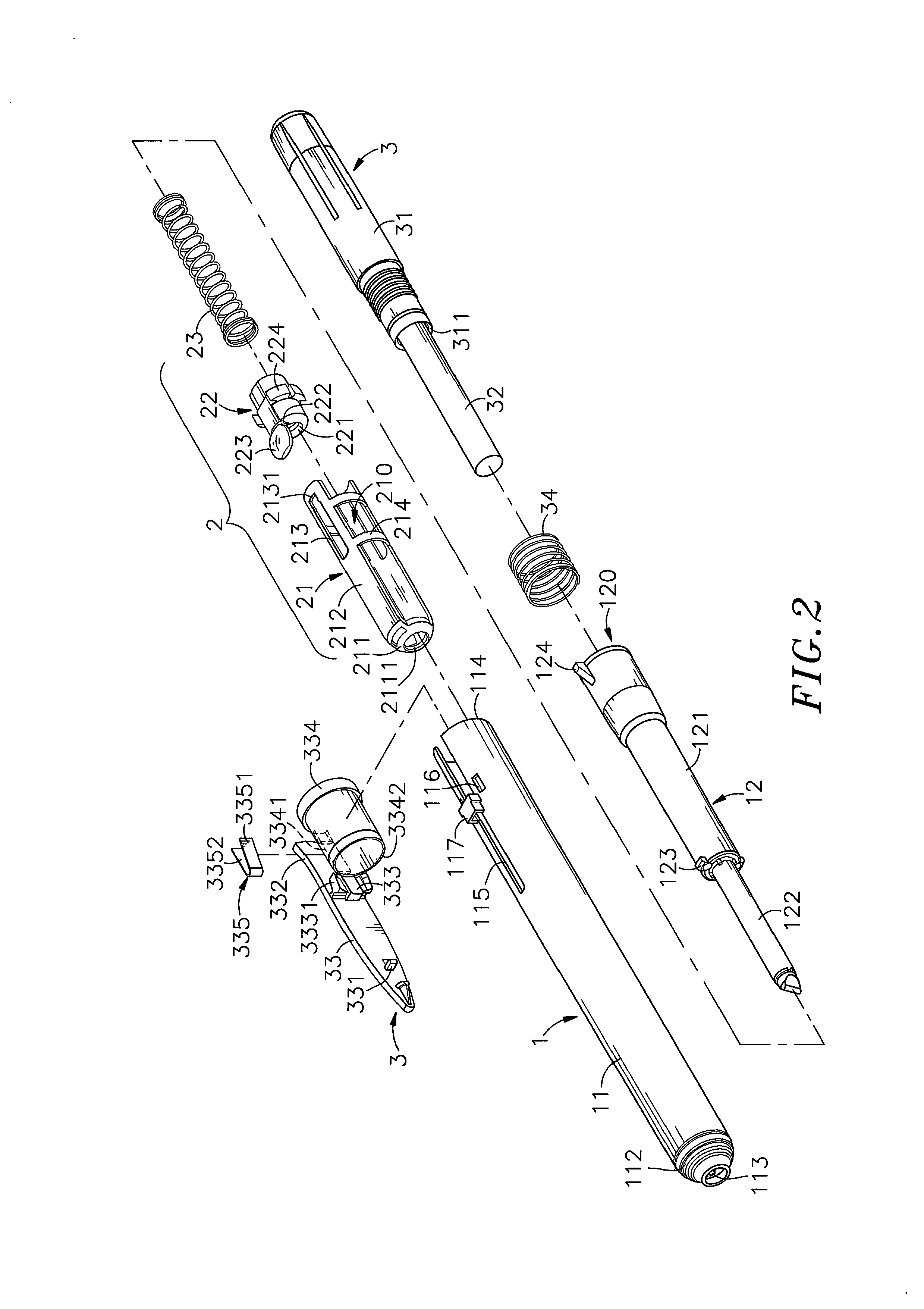

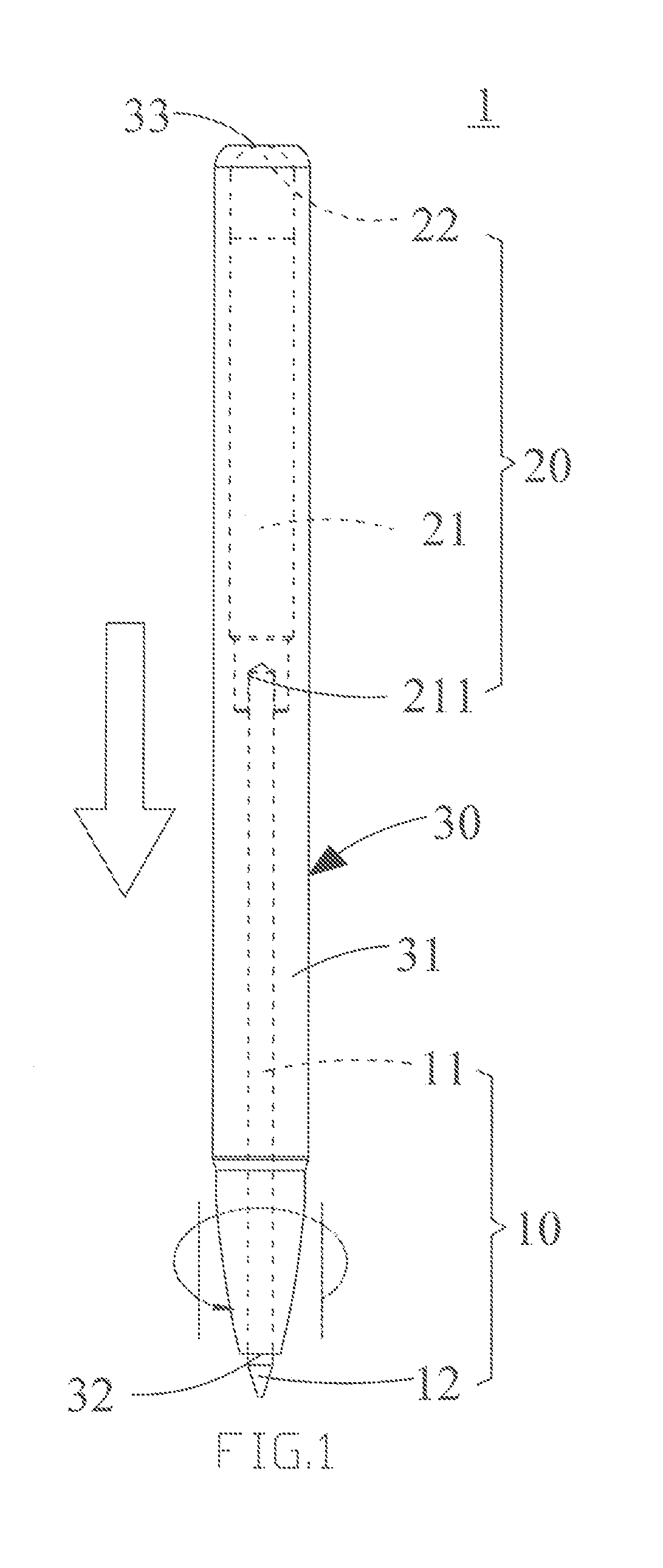

Retractable push button pen

InactiveUS20110103875A1Avoid noiseAvoid wear damagePen repairingBall-point pensEngineeringPush-button

A retractable push button pen includes a barrel, a pen refill, which has a refill body with hooks at the front side and a writing tip extended out of the front side of the refill body, an extending and retracting mechanism formed of a slide, a limiter and a spring member and received inside the barrel around the writing tip received in the barrel, and a press-control mechanism formed of an absorption rod, which is connected to the writing tip to supply an ink, a cylindrical cap holding the absorption rod and extending out of the rear side of the barrel for pressing by a user to move the writing tip out of the barrel for writing and a pen clip, which has a positioning protrusion engageable into the barrel to lock the pen refill in the extended position and a press portion for pressing by a user to unlock the positioning protrusion from the pen refill.

Owner:SUNNY PRO +1

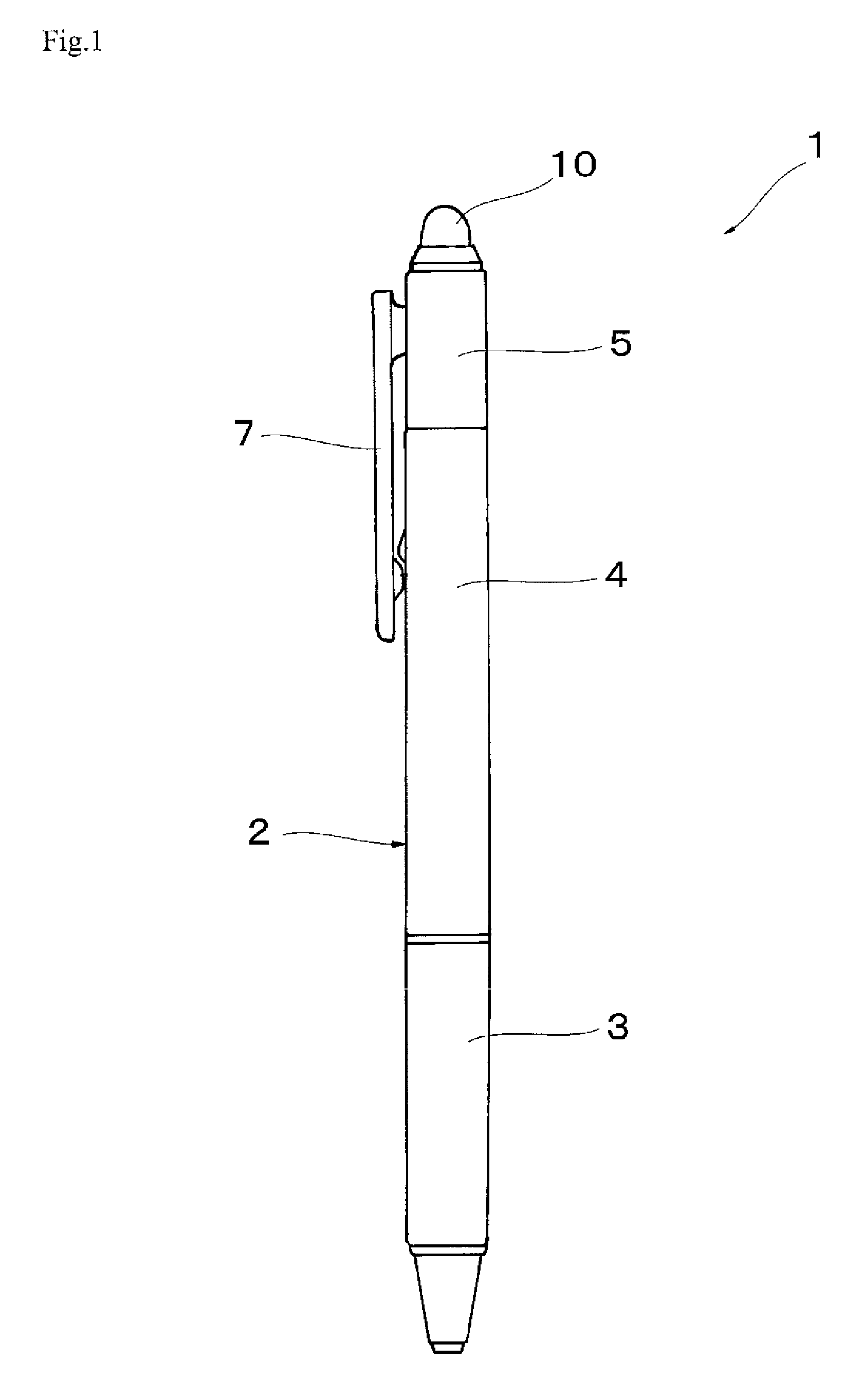

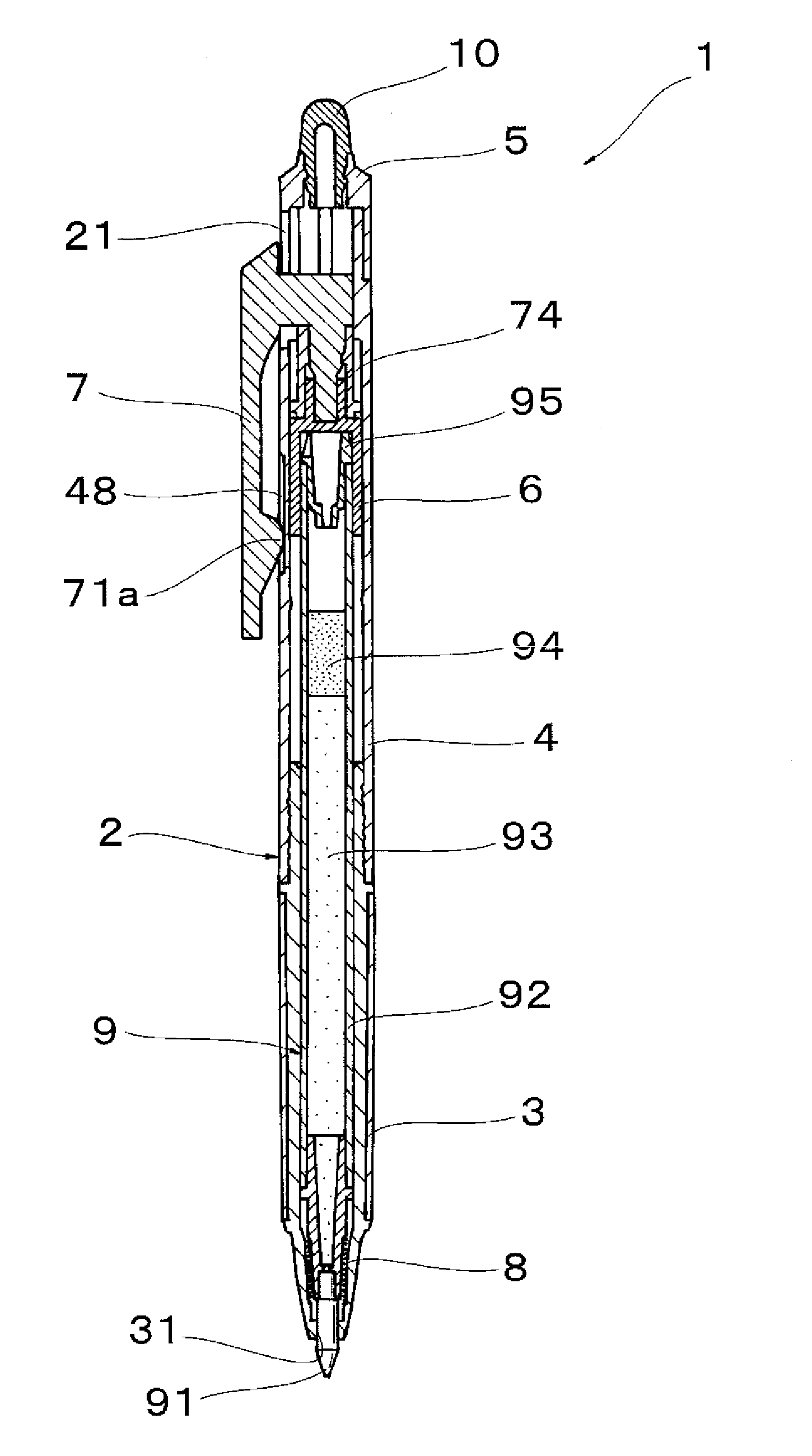

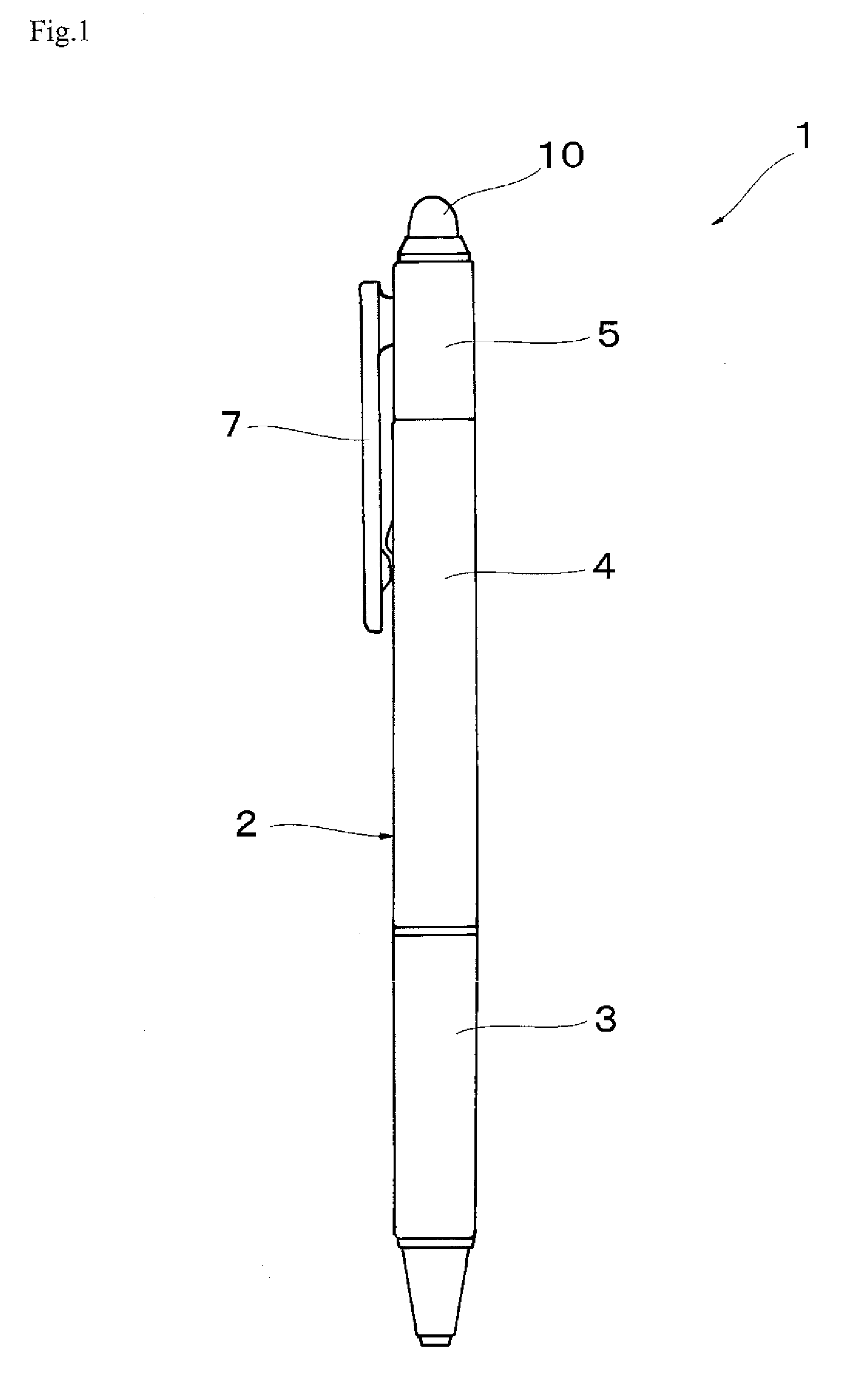

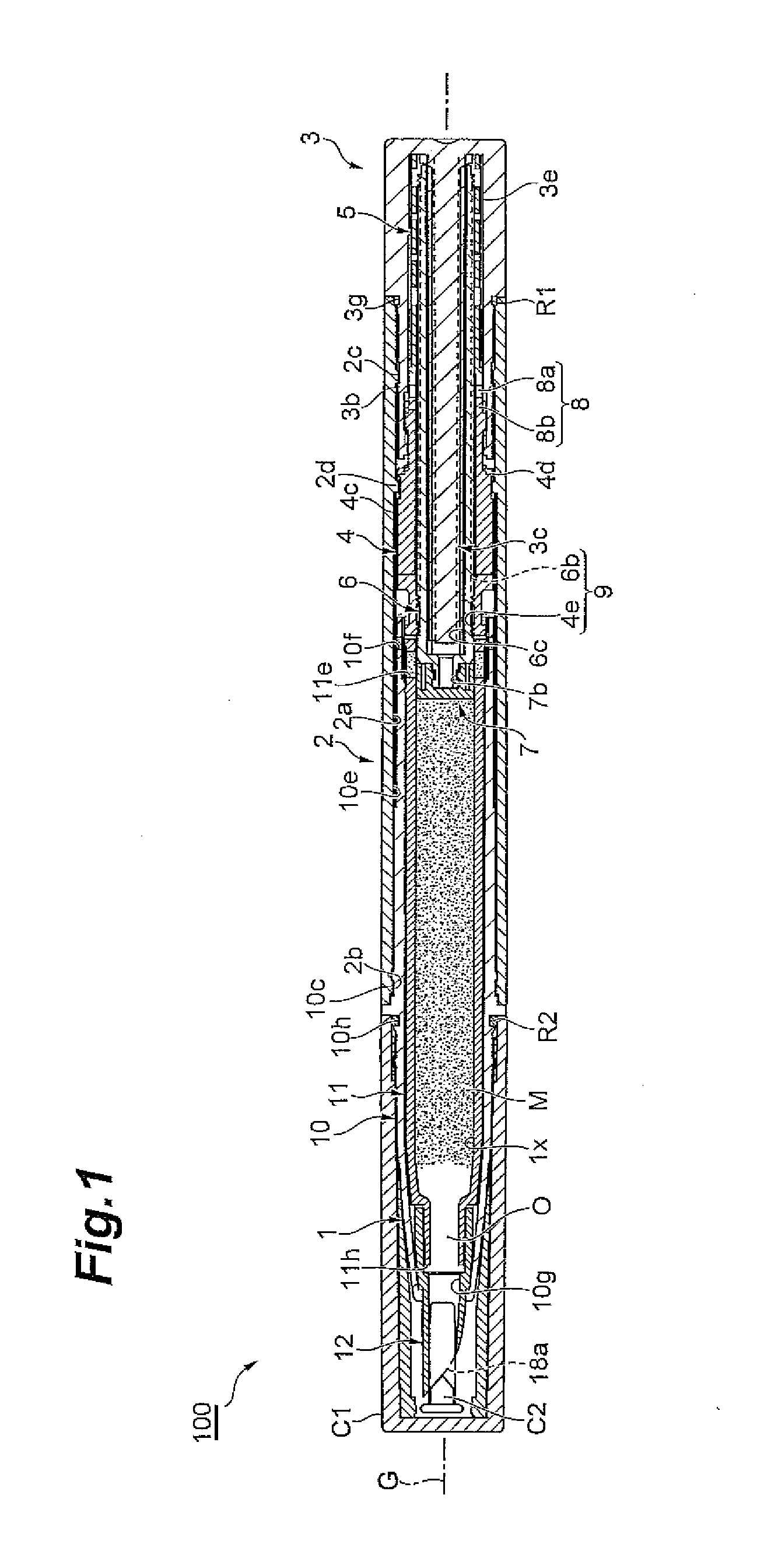

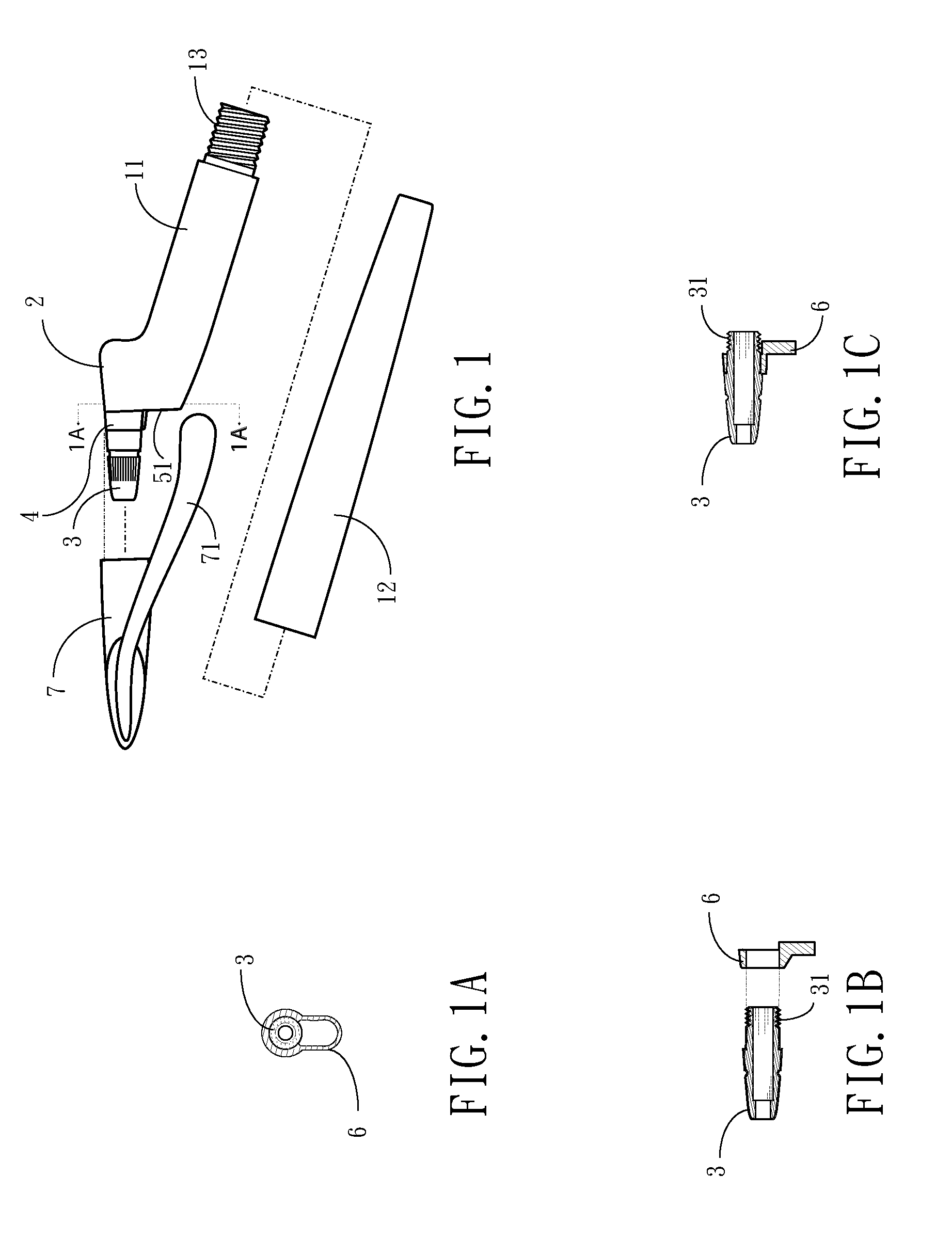

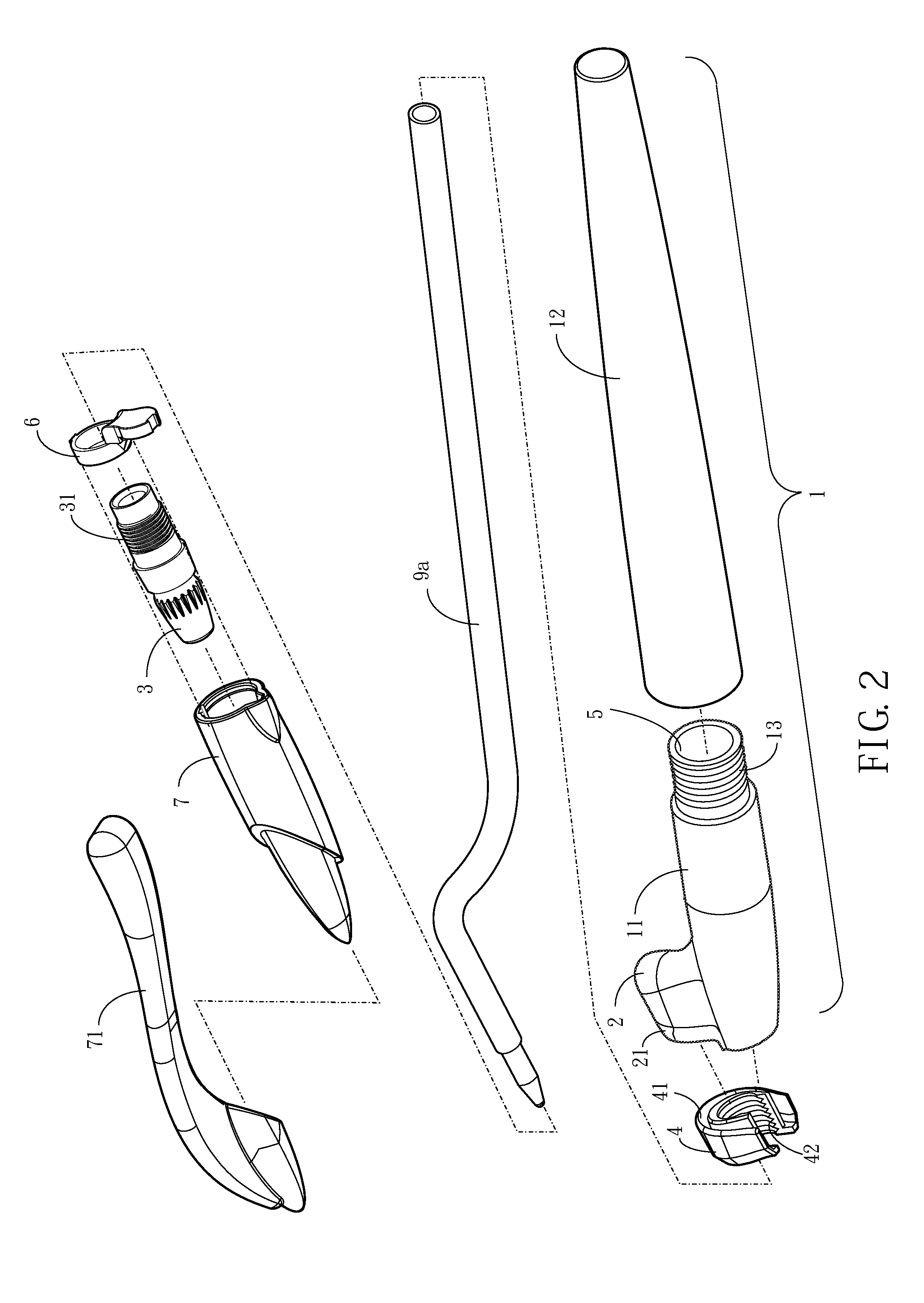

Writing instrument

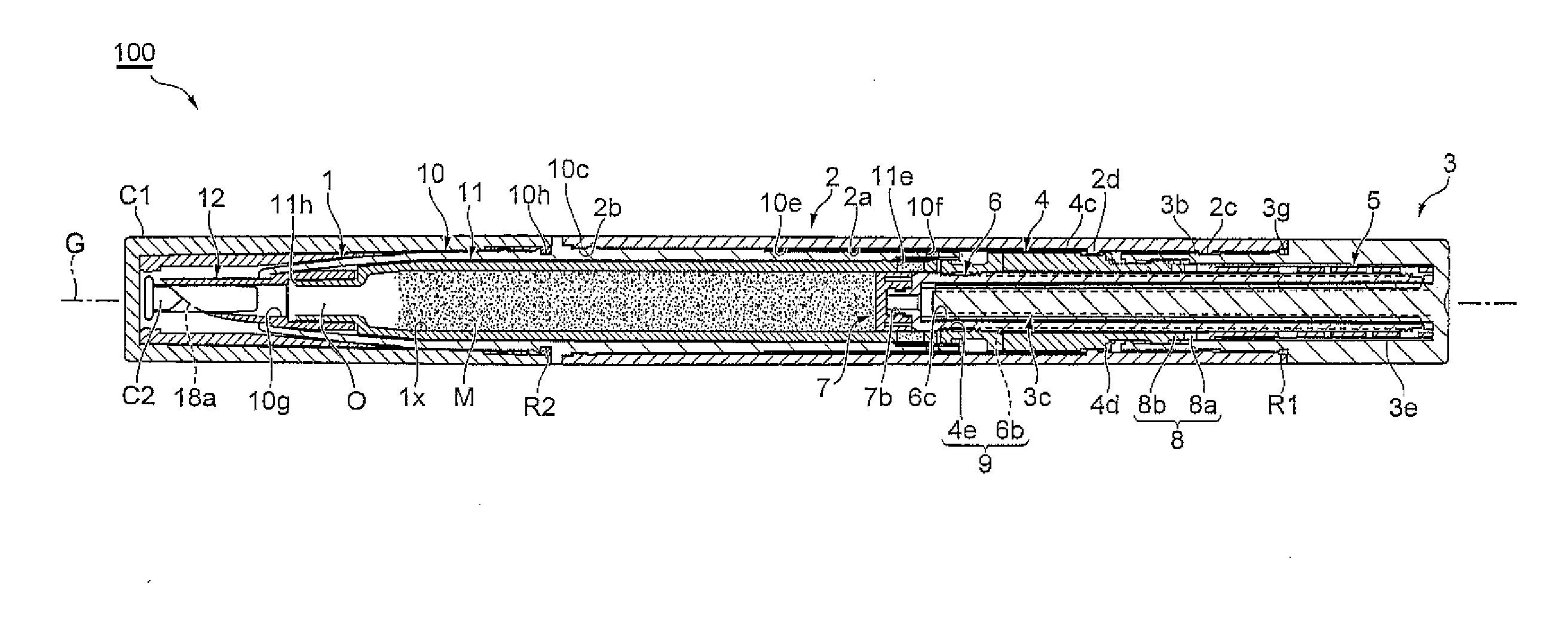

ActiveUS9108456B2Guaranteed uptimeAvoid pollutionWriting connectorsPen repairingHandwritingEngineering

A thermochromic writing instrument 1 including a writing body 9, storing a thermochromic ink therein, stored in a barrel 2; an operation body provided in the barrel 2 to be operated to longitudinally move the writing body 9; a nib 91 of the writing body 9 configured to be capable of appearing from a front end of the writing instrument, wherein the writing instrument 1 further includes a friction unit 10, for rubbing handwriting in the thermochromic ink and capable of thermally changing the color of the handwriting by frictional heat generated at that time, and at least one clip body 7 as the operation body, the friction unit 10 is provided at a rear end of the barrel 2, and the clip body 7 is provided in an area other than the rear end of the barrel 2.

Owner:THE PILOT INK CO LTD +1

Pen head and penholder assembling system

The invention relates to a pen head and penholder assembling system which comprises a pen head conveying chain and a penholder conveying chain. A pen head feeding device and a penholder feeding device are arranged on the left side of the pen head conveying chain and the left side of the penholder conveying chain correspondingly, and an assembling mechanism is arranged at the right end of the pen head conveying chain. A tightening mechanism, a transfer printing mechanism and a drying oven are arranged on the right side of the assembling mechanism. The assembling mechanism comprises a pen head control mechanism and a penholder control mechanism. The pen head control mechanism comprises an assembling clamping claw, a pen head assembling clamping claw cylinder and an assembling lifting rodless cylinder. The penholder control mechanism comprises V-shaped support feet, and the lower ends of the V-shaped support feet are connected to a penholder assembling jacking cylinder. A rubber pressing block is arranged above a penholder, a protruding block is arranged in the middle of the rubber pressing block and presses the penholder, the upper end of the rubber pressing block is connected to a pressing cylinder, and the V-shaped support feet are located in the same vertical plane with the central line of jaws of the assembling clamping claw. Stripping rods are arranged on the front side and the rear side of the protruding block of the rubber pressing block correspondingly and driven by a stripping rod cylinder. The pen head and penholder assembling system can automatically assemble pen heads and penholders.

Owner:TAICANG CENTURY BRIDGE IND & COMMERCIAL OFFICE

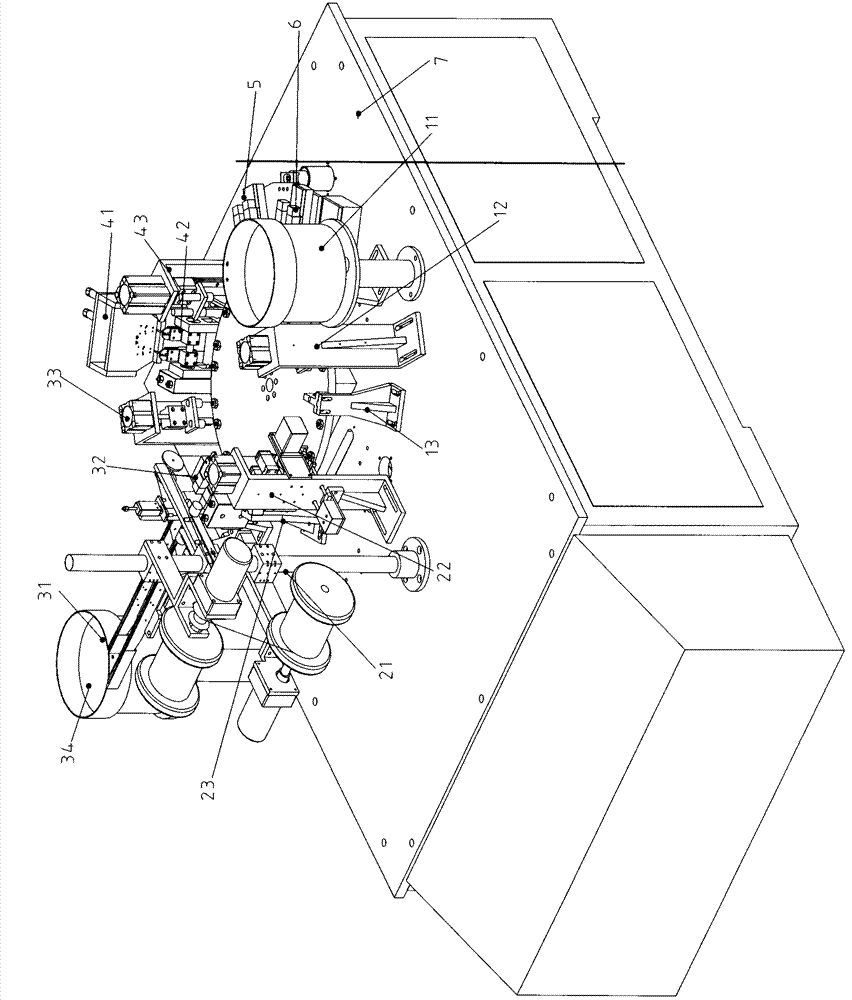

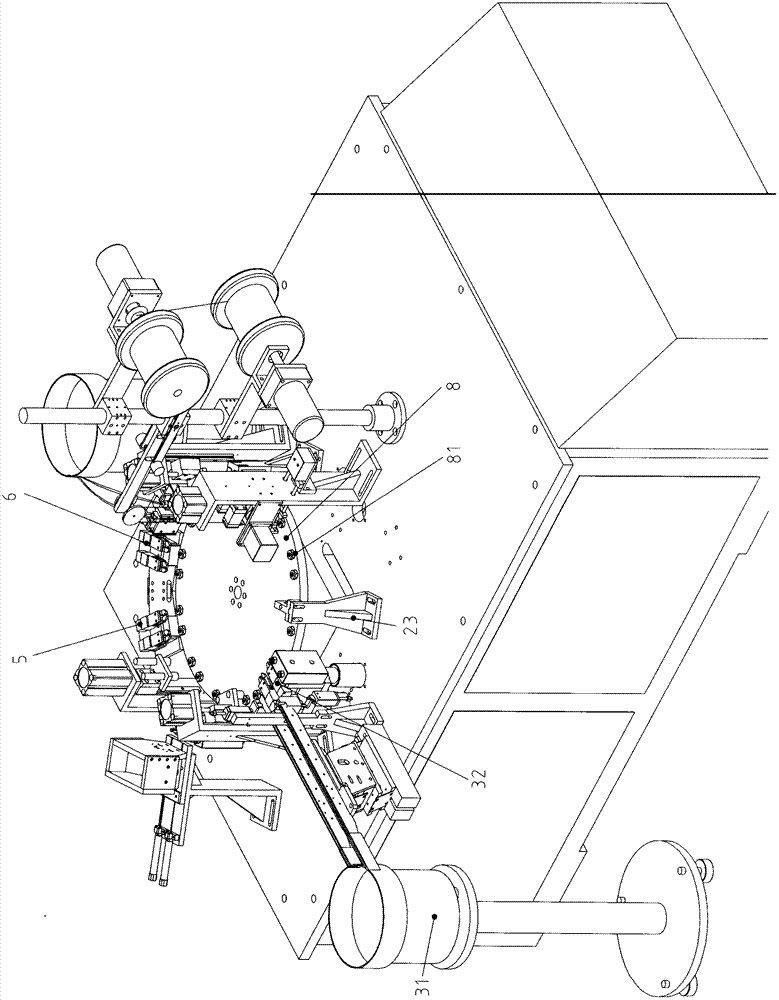

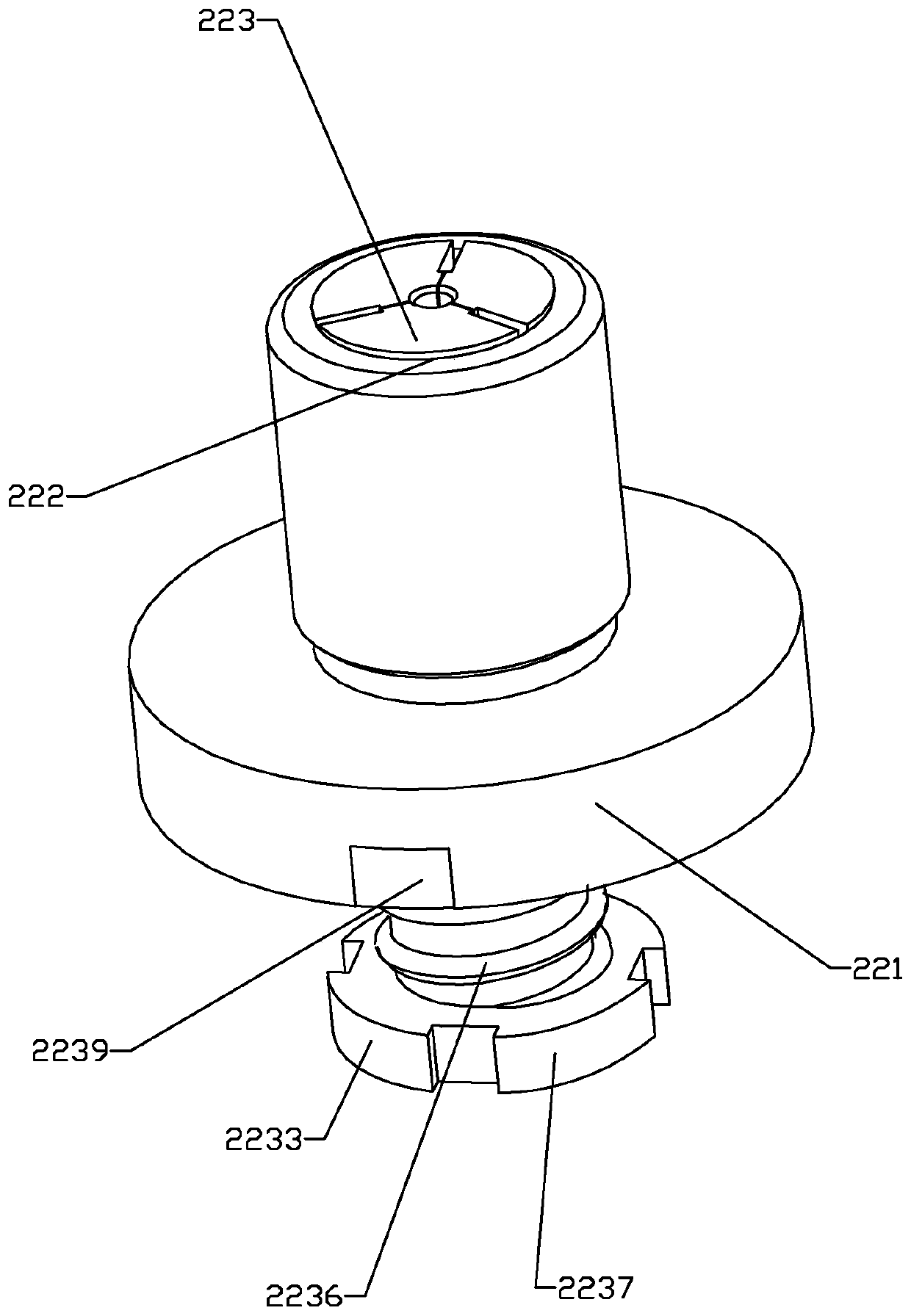

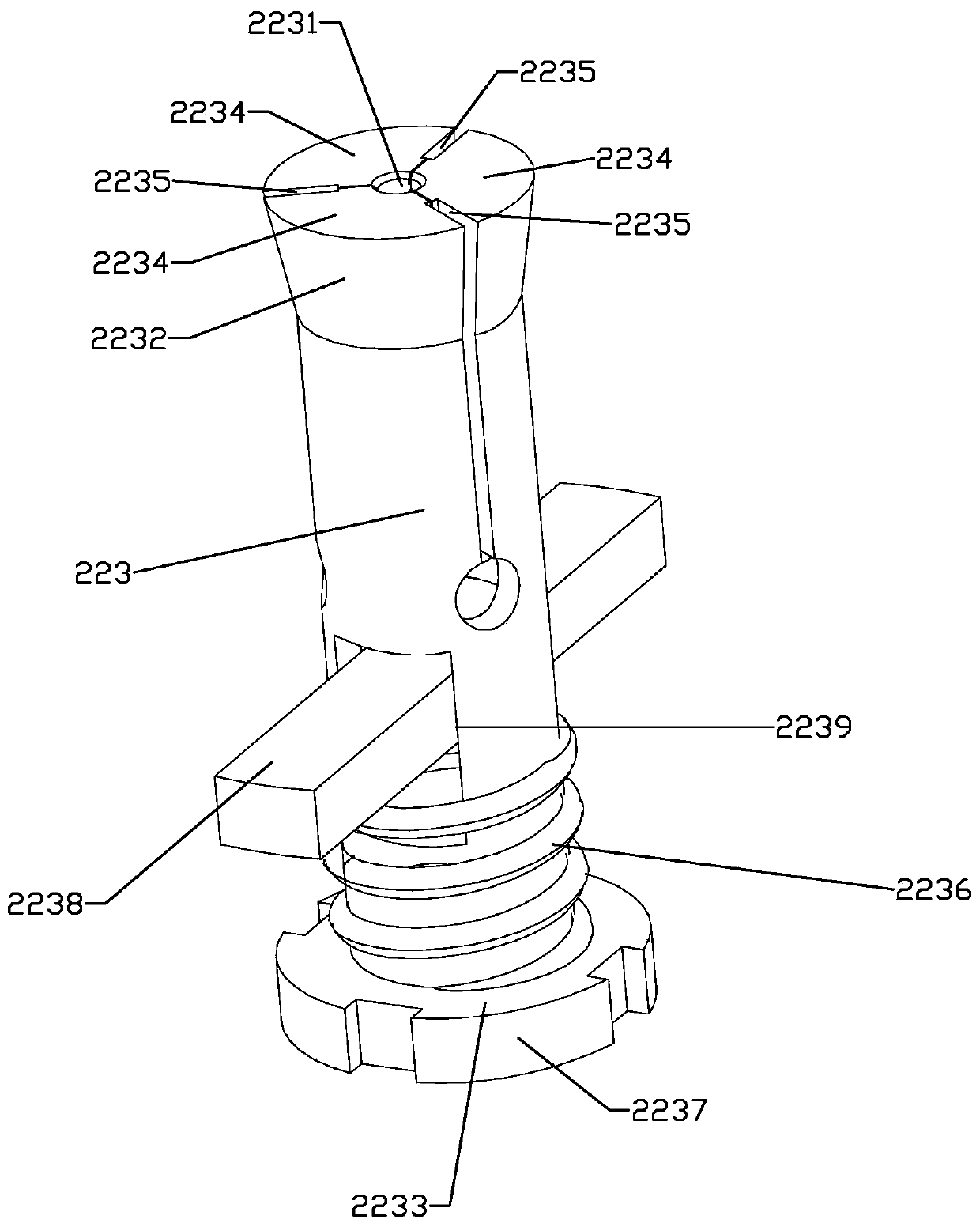

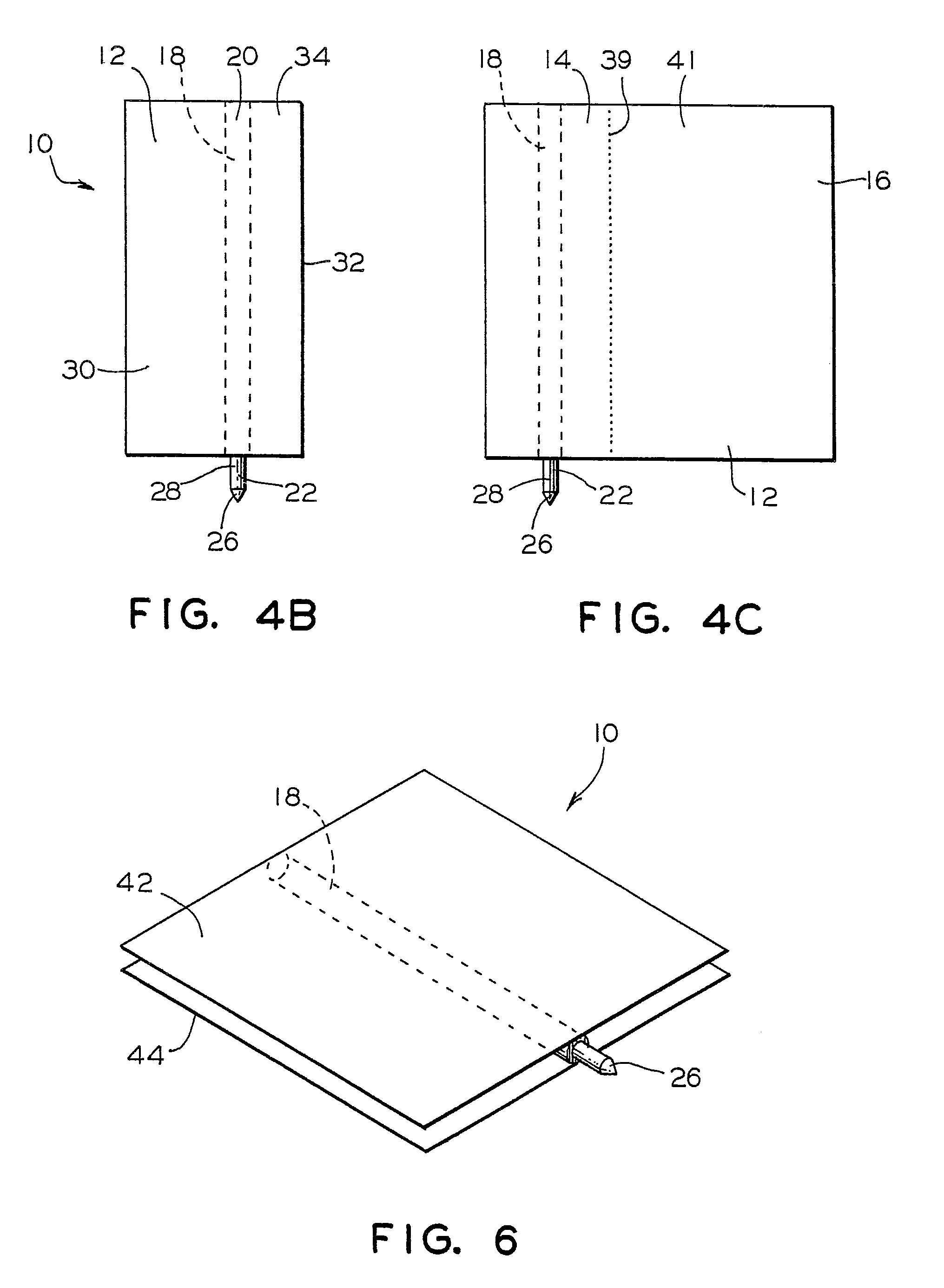

Automatic assembling system of pin type pen head component

InactiveCN102815127ASolve the softness problemSolve the clampingPen repairingFront loadingEngineering

The invention discloses an automatic assembling system of a pin type pen head component. The system comprises a machine frame, a power device and a part conveying system, wherein the machine frame forms an equipment support and a main body; the part conveying system is connected with the power device; and a pen head supplying mechanism, a pen head assembling mechanism, a pen head direction detection mechanism, an ink core supplying mechanism, an ink core cutting and assembling mechanism, an ink core assembly detecting mechanism, a front loading mechanism, a front assembling mechanism, a front assembly detecting mechanism, a relay core loading mechanism, a relay core assembling mechanism, a relay core assembly detecting mechanism, an unqualified product selecting mechanism and a finished product unloading mechanism are sequentially arranged in the movement direction of the part conveying system. By the automatic assembling system of the pin type pen head component, the problem that an ink core is not easy to clamp and cut because the ink core is relatively flexible and elastic is solved, and meanwhile, the technical scheme of automatic material supply, automatic assembly and automatic detection is adopted, so that each part is precisely assembled, and the stability in an assembling process is ensured.

Owner:QINGDAO CHANGLONG STATIONERY

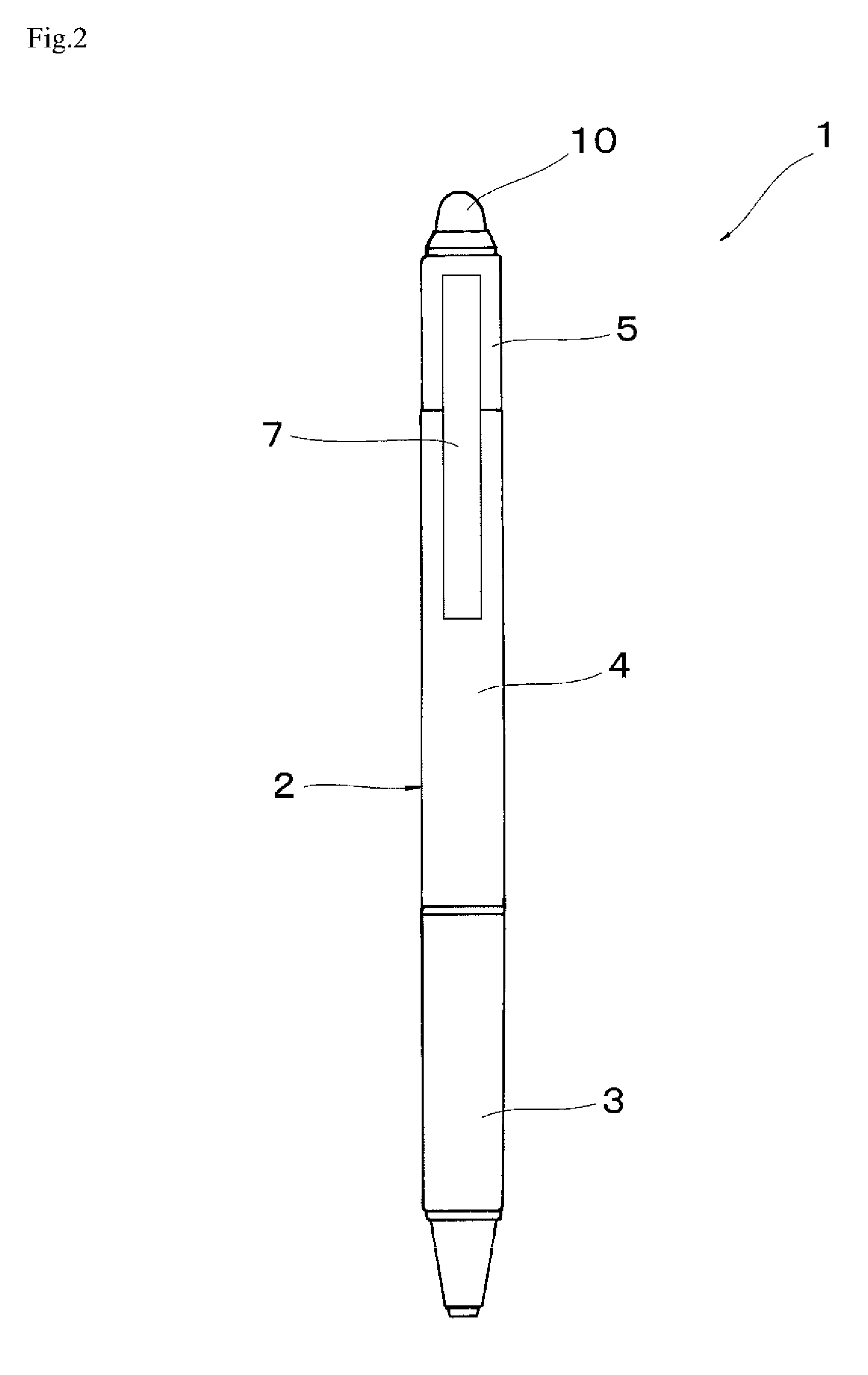

Writing instrument

ActiveUS20120308290A1Guaranteed uptimeAvoid pollutionWriting connectorsPen repairingHandwritingEngineering

Provided is a thermochromic writing instrument 1, comprising: a writing body 9, storing a thermochromic ink therein, stored in a barrel 2; an operation body provided in the barrel 2 to be operated to longitudinally move the writing body 9; a nib 91 of the writing body 9 configured to be capable of appearing from a front end of the writing instrument, wherein the writing instrument 1 further includes a friction unit 10, rubbing handwriting in the thermochromic ink and capable of thermally changing the color of the handwriting by frictional heat generated at that time, and at least one clip body 7 as the operation body, the friction unit 10 is provided at a rear end of the barrel 2, and the clip body 7 is provided in an area other than the rear end of the barrel 2.

Owner:THE PILOT INK CO LTD +1

Reversibly thermochromic composition

InactiveCN103998569AImprove visibilityGood effectErasing devicesPen repairingHeat conductingOrganic chemistry

[Object] To provide a reversibly thermochromic composition free from accidental discoloration by heat conducting from the opposite side writing surface or by self-heating due to quick writing; and also to provide a solid writing material and a writing ink composition comprising that composition. [Means to solve the problem] A reversibly thermochromic composition comprising a combination of: (a) a reversibly thermochromic component capable of being discolored or decolored by heat and (b) a component for controlling heat conducting to the reversibly thermochromic component; and also a solid writing material and a writing ink composition comprising that composition.

Owner:PILOT PEN CO LTD

Applicator

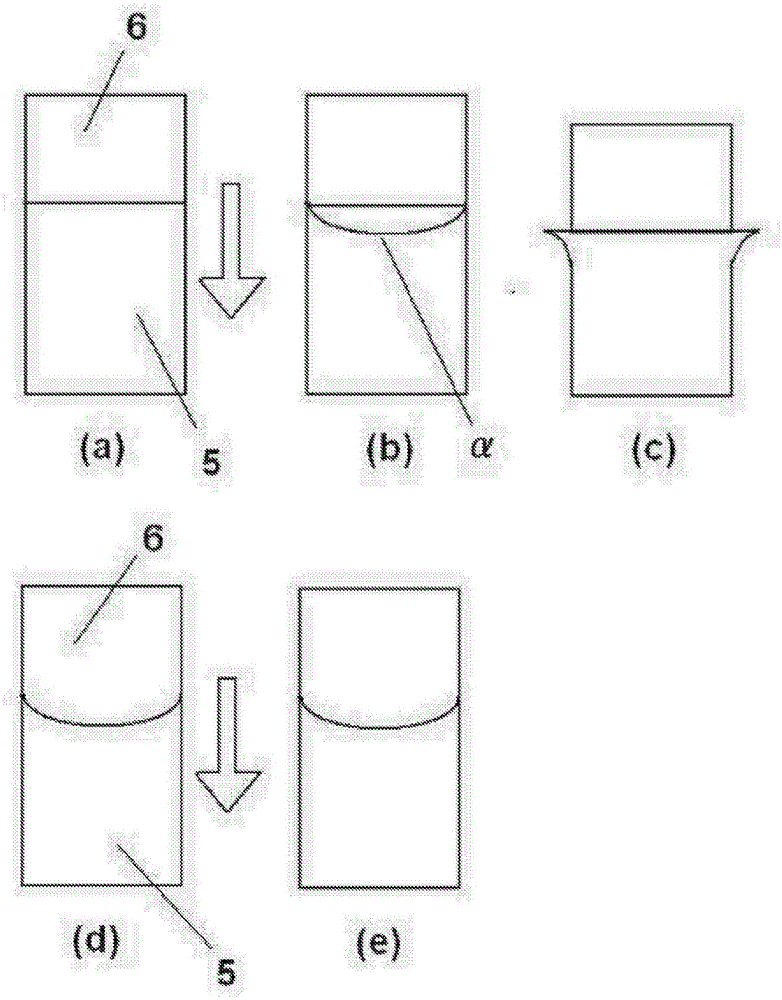

InactiveCN105072950APrevent variation in coating amountSmooth dischargeErasing devicesPen repairingBiomedical engineeringCoating

[Problem] Fluctuations or irregular increases / decreases in the discharged amount of a coating liquid may occur due to large variations in the discharged amount of coating liquid in the coating liquid container tube, or to failure of the curing oil to be uniformly pushed out in the course of using the applicator. [Solution] Provided are a coating liquid container tube and an applicator, the coating liquid container tube being furnished at the distal end with an applicator part, and filled in the interior thereof with a coating liquid for supply to the applicator part; being furnished also with a curing oil to the back of the coating liquid which fills the coating liquid container tube interior; and being further furnished to the back thereof with a pushing means for pushing the curing oil through the agency of a pushing member. The surface of the pushing means on the side facing the curing oil is formed as a convex surface.

Owner:SAKURA COLOR PRODUCTS CORPORATION

Method for manufacturing a coating instrument

ActiveUS20150231916A1Reliably prevent leakagePrevent leakageDispensing apparatusPen repairingEngineeringMechanical engineering

There is provided a method for manufacturing a coating instrument provided with a filling member having a filling region in which a coating material is filled and a body portion including an extruding portion inserted inside so as to be brought into close contact with the filling member and constituting a rear end of the filling region, in which the coating material is discharged from a discharge outlet on a tip end side of the filling member by advance of the extruding portion, including a step of filling the coating material into the filling region of the filling member from behind in a state in which a front side of the filling member is located below the rear side, a step of feeding a predetermined amount of air from the discharge outlet into the filling region so that a space is formed on the tip end side in the filling region after the coating material is filled, and a step of assembling the body portion to the filling member after the air is fed.

Owner:TOKIWA CORP

Ballpoint pen spring nib assembling device

ActiveCN111251749AQuality assuranceUniform deformationPen repairingBall-point pensElectric machineryEngineering

The invention relates to a ballpoint pen spring nib assembling device. The assembling device comprises an assembling platform, an assembling rotary disc and a rotary disc motor, wherein the edge of the assembling rotary disc is provided with conveying clamps for clamping nibs for conveying; and a nib feeding device for placing the nibs on the conveying clamps, a first nib detection device for detecting whether the nibs exist on the conveying clamps or not, a second nib detection device for detecting whether the nibs on the conveying clamps conform to the standard or not, a spring feeding device for placing springs on the nibs of the conveying clamps, a spring detecting device for detecting whether the springs are assembled in place or not, a waste discharging device for taking away unqualified nibs, a deformation device for extruding and deforming the side surfaces of the qualified nibs to limit the springs in the nibs, and a qualified product discharging device for taking away the deformed nibs are sequentially arranged at the position, close to the edge of the assembling rotary disc, of the assembling platform in the rotating direction. According to the technical scheme, the ballpoint pen spring nib assembling device improves the yield, improves the assembling efficiency and reduces the machining cost.

Owner:WENZHOU UNIVERSITY +1

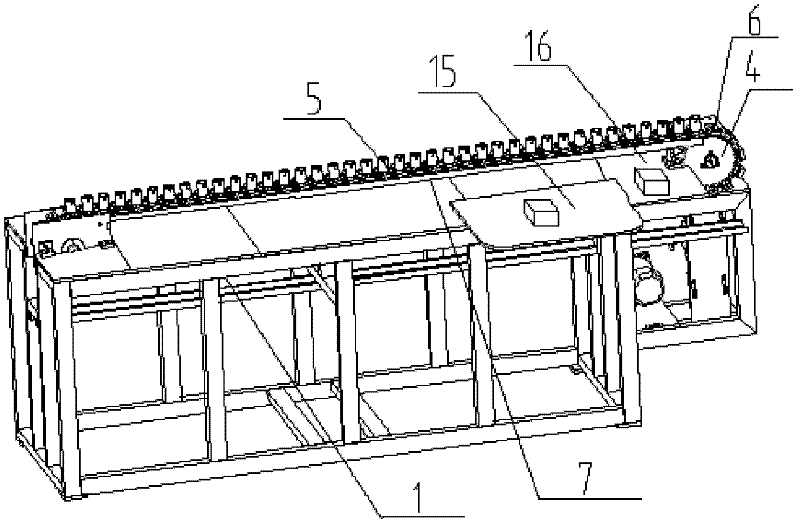

Flat pen automatic assembly line

The invention discloses a flat pen automatic assembly line which comprises a workbench, two driving chain wheels and a ring-shaped driving chain connecting the two driving chain wheels, wherein the two driving chain wheels are respectively installed at two ends of the workbench, the driving chain is sequentially provided with a plurality of clamps for inserting pen holders of flat pens, a transmission rail for supporting the driving chain is arranged between the two driving chain wheels and is fixed on the workbench, the workbench is sequentially provided with a pen cap assembling station and a pen cap pressing station and an automatic pen cap pressing machine is arranged at the pen cap pressing station. The flat pen automatic assembly line has the advantages that the pen cap assembling process and the pen cap pressing process are implemented on one workbench and are linked through the driving chain, and therefore the assembling time is saved, the assembling efficiency is improved; in addition, an automatic operation is applied to the pen cap pressing process step, the labor intensity is reduced further and the assembling efficiency is improved.

Owner:安徽新贝发制笔城有限公司

Offset pen structure for rapid assembling

InactiveUS7665921B2Easy to produceQuick assemblyErasing devicesLiquid surface applicatorsEngineeringMechanical engineering

Owner:LIU BAO SHEN

Gel pen assembly forming unit

PendingCN107323128ARealize automatic feeding processAchieve positioningPen repairingFinal product manufactureElectrical controlEngineering

The invention discloses a gel pen assembly forming unit comprising a base table, a lower penholder device, a penholder correction device, a penholder holding device, a lower button device, a lower rotary tooth device, a lower inner sleeve device, a lower pen clamp device, a pen clamp pressing device, a lower pen sleeve device, a pen sleeve pressing device, a discharge device, a large rotary disc, a small rotary disc, a control box and an electrical control element. The lower penholder device, the penholder correction device, the penholder holding device, the lower button device, the lower rotary tooth device, the lower inner sleeve device, the lower pen clamp device, the pen clamp pressing device, the lower pen sleeve device, the pen sleeve pressing device, the discharge device, the large rotary disc, the small rotary disc, the control box and the electrical control element are installed on the base table. The penholder correction device is located between the lower penholder device and the penholder holding device. The penholder holding device, the lower button device, the lower rotary tooth device, the lower pen sleeve device, the pen sleeve pressing device and the discharge device are distributed clockwise sequentially in the circumferential direction of the large rotary disc. The lower inner sleeve device, the lower pen clamp device, the pen clamp pressing device and the lower pen sleeve device are distributed clockwise sequentially in the circumferential direction of the small rotary disc. Full automation of the assembly forming process of a gel pen is achieved, production efficiency and product quality are promoted greatly, a large quantity of manpower resources and cost inputs are saved, and the gel pen assembly forming unit has good application and popularization value.

Owner:GUANGDONG GENVANA STATIONERY CO LTD

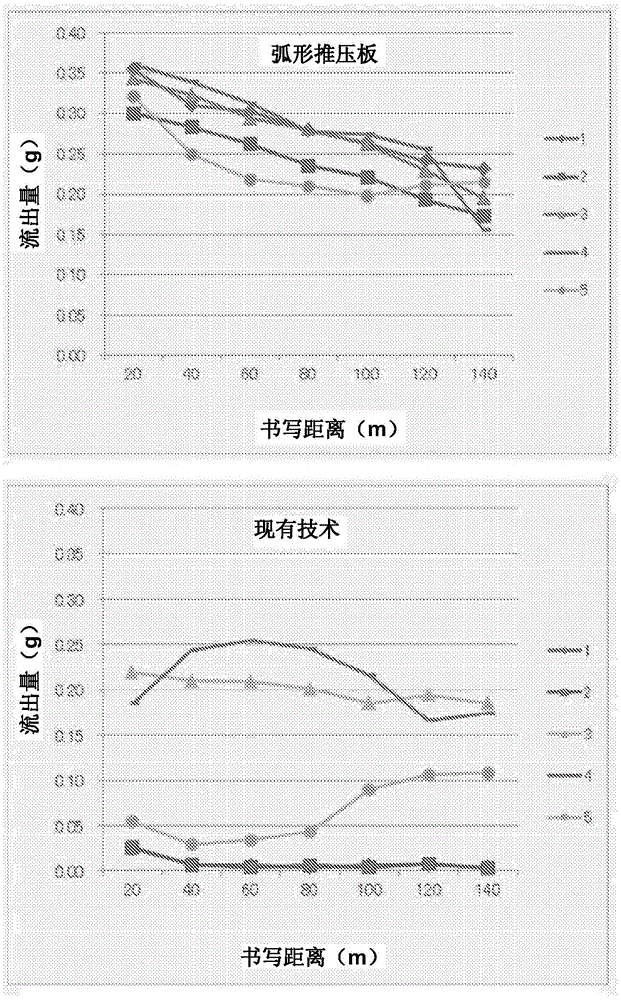

Ballpoint pen tip, ballpoint pen refill, and ballpoint pen

InactiveUS20120328356A1Reduce outflow resistancePreventing defective writingPen repairingBall-point pensMechanical engineeringEngineering

A ballpoint pen tip in which ink grooves are formed around an ink guide hole at equally distributed places, the ink guide hole connecting a ball house and a back hole of a holder for holding the writing ball, and the ink grooves radially penetrate through from the ball house side to the front end portion of the back hole. Inward protrusions are formed at positions which are respectively in contact with the rear ends of the ink grooves. If the inner diameter of the ink guide hole is A, the inner diameter of the front end portion of the back hole is B, the diameter of the circle circumscribing the ink grooves is C, and the diameter of the circle inscribing the inward protrusions is D, their relationships are A<B<C, and D<B.

Owner:MITSUBISHI PENCIL CO LTD

Method for bonding pen point and pen holder by glue A and glue B

The invention relates to a method for bonding a pen point and a pen holder by glue A and glue B. The method is characterized by comprising the following steps that a, hair selection: a cluster of screened pen hair is selected; b, pen point bonding: the cluster of pen hair is immersed in paste for 1s to 1.5s, is then taken out and is straightened; c, drying: a straightened pen hair is dried to form the pen point, the sharp end of the pen point is a head part, and the other end of the pen point is a tail part; d, pen holder manufacturing: a groove matched with the tail part of the pen point is formed in one end of the round-tube or cylindrical pen holder; e, glue preparation: the glue A and the glue B are proportionally mixed according to different indoor temperatures; f, bonding: the tail part of the pen point is immersed in the mixed glue A and B, or the mixed glue A and glue B are uniformly smeared on the tail part of the pen point, and then, the tail part of the pen point is inserted into the groove of the pen holder; g, fixation: the bonded pen point and pen holder are placed in a room for 5 minutes to 20 minutes.

Owner:湖州市练市善琏秦峰湖笔厂

Method for degreasing writing brush bristles

The invention discloses a method for degreasing writing brush bristles, relating to the technical field of production processes of writing brushes for traditional Chinese paintings. The method comprises the following steps of: putting raw bristles on animal skin into a baking oven of which the temperature is 110+ / -5 DEG C for treating for 30-45 minutes; kneading with rice hull ash; and removing the rice hull ash to obtain degreased brush bristles. According to the method, perfect scale tissues on the surface of raw bristles are kept, the surface of the brush bristles is smooth, grease is not contained, ink absorption is facilitated, and the writing and painting processes are smooth; and by adopting the method, bristle sclerotin is not damaged, the completeness of raw bristles is kept, crispness is avoided, and the service life of a writing brush is prolonged by over one time.

Owner:石庆鹏

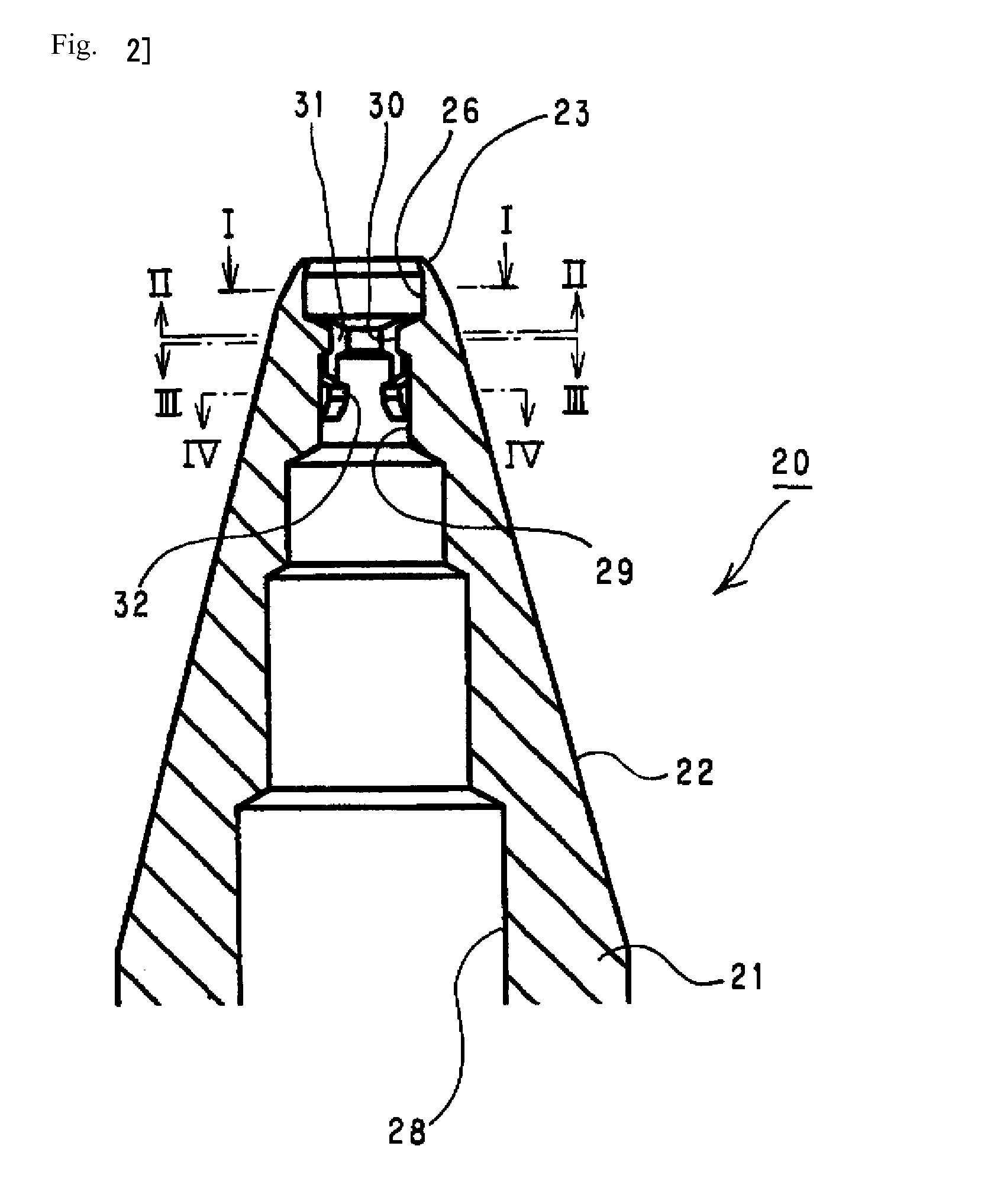

Sanitary disposable writing instrument, method of making and dispenser therefore

ActiveUS8944715B2Minimizing transferEasy to separateWriting connectorsWriting accessoriesEngineeringSupport surface

A sanitary disposable writing instrument for minimizing the transfer of bacteria, viruses and / or chemicals from one person to another including a strip of flexible holding material, a writing implement removably secured to the flexible holding material, and a writing tip associated with the writing implement. At least a second writing instrument can be provided to form a series of removably secured writing instruments wherein removal of one writing instrument from the series causes a next writing instrument to be positioned for removal from the series. Combination dispenser and holding members for dispensing the series of writing instruments in a sanitary manner is also provided. The holding members can be mounted on either a vertical or horizontal support surface and can receive replacement dispensers therein.

Owner:YODER TIMOTHY HOWARD

Method for fixing writing brush tip

InactiveCN102785507AEffective penetrationSolve the problem of mildew and rettingPen repairingYarnEngineering

The invention discloses a method for fixing a writing brush tip. The method includes the following steps of firstly, winding 6-10 circles of yarn at the end of the writing brush tip; secondly, sleeving a plastic sleeve which is equal to the writing brush tip in diameter below the yarn; thirdly, turning the bottom of the writing brush tip upward, and gluing the bottom of the writing brush tip; and fourthly, keeping the bottom of the writing brush tip horizontal and upward to stand for 24 hours to finish fixing of the writing brush tip. The defect that ink permeates to cause mildew and rotting of soft hair is overcome effectively, and the service life of a writing brush is prolonged. In addition, the problem of falling of hairs of the writing brush tip is solved, writing quality is improved greatly, and the service life of the writing brush is prolonged.

Owner:湖州善琏松鹤湖笔厂

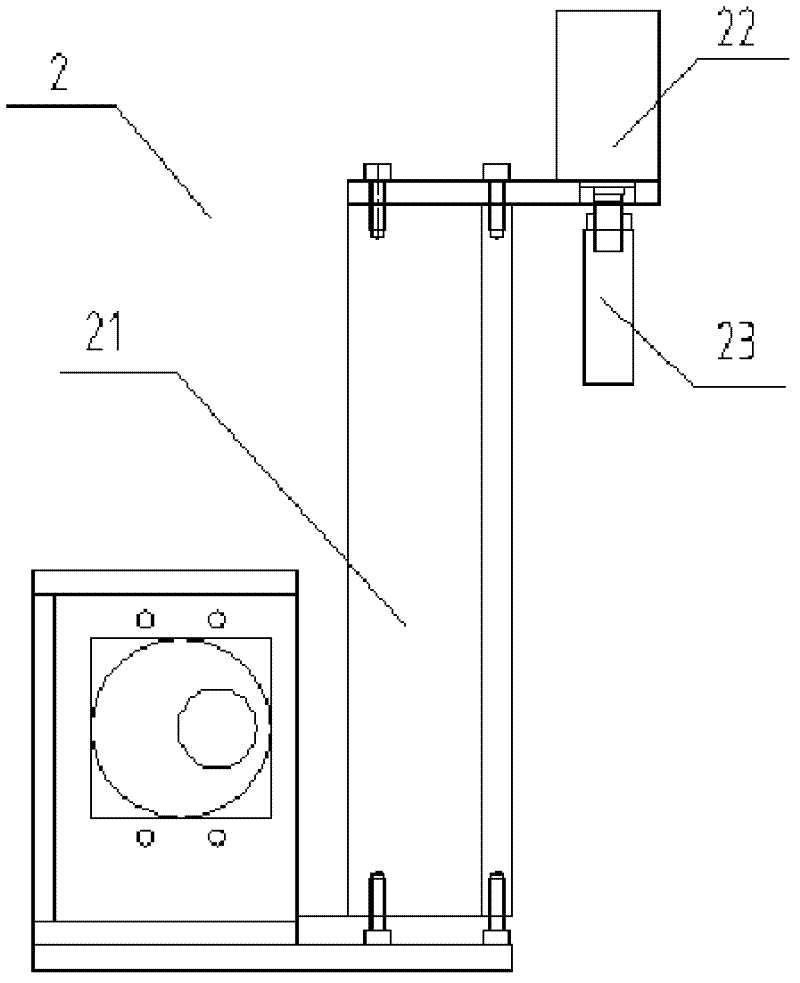

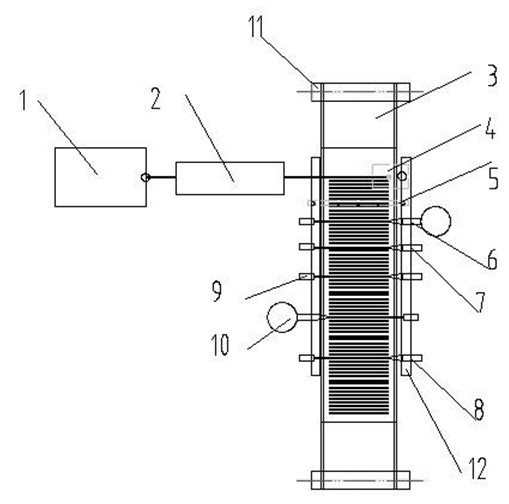

Selling device capable of adding ink into fountain pen refill and replacing pen point automatically

InactiveCN105856903AEfficient recyclingReduce pollutionPen repairingNib removersEngineeringAssembly line

The invention relates to a selling device capable of adding ink into a fountain pen refill and replacing a pen point, in particular to an assembly line type producing and selling device for adding ink into a waste fountain pen refill and replacing a pen point fully automatically. The selling device comprises a machine frame, a moving platform, a pulling-out mechanism, an air blowing mechanism, an ink adding mechanism, a pen point installation mechanism, a tail ink injection mechanism and a selling mechanism. According to the selling device, the overall structure is compact, and disassembly, assembly and maintenance are easy; the waste refill can be refilled with ink to be used repeatedly, effective recovery of the refill and tail ink can be achieved, and pollution of harmful substances in the refill and the tail ink to the living environment is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

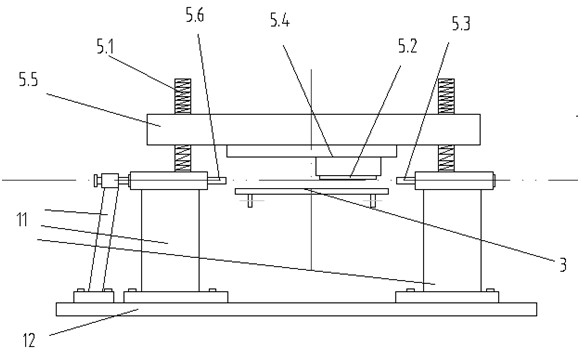

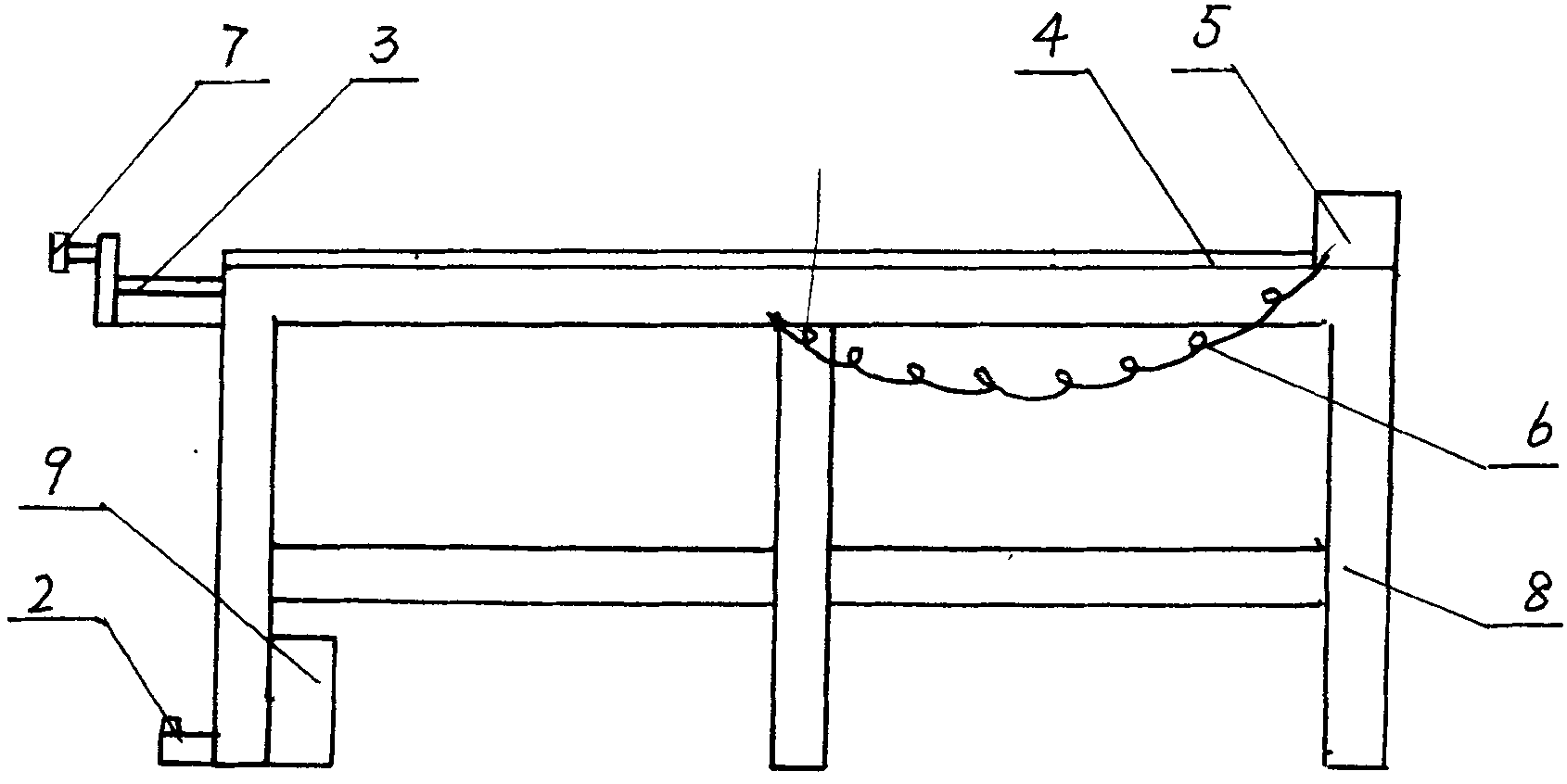

Neutral pen refill manufacturing device and method thereof

The invention discloses a neutral pen refill manufacturing device and a method thereof. The device comprises an injection molding machine, a cooling bath, a conveyer belt, a cutting device, a coding device, an ink filling device, a plastic pen head base inserting device, a steel ball inserting device, a rigid pen head inserting device, an oil filling sealing device, a bracket and a base, wherein the injection molding machine, the cooling tank and the conveyer belt are connected successively; and the cutting device, the coding device, the ink filling device, the plastic pen head base inserting device, the rigid pen head inserting device, the oil filling sealing device and the steel ball inserting device are arranged on the bracket at two sides of the conveyer belt successively. With the device, the pen refill tube injection molding procedure, the cutting procedure, the ink filling procedure, pen refill head and pen refill tube inserting procedure and other procedures are linked effectively; the production efficiency and the product quality are improved; and the device operates safely and reliably.

Owner:浙江创元文具制造有限公司

Components direction regulating mechanism for ball pen assembly and assembly system and method

The invention relates to a components direction regulating mechanism for ball pen assembly and an assembly system and method. The mechanism is provided with a runner plate, a combination brush pen propeller and a receiving member, wherein the combination brush pen propeller is located at the front end of the runner plate; the receiving member is arranged at the outlet end of the runner plate; and a runner surface engaged with a plurality of runners on the runner plate is formed on the contact surface between the combination brush pen propeller and the runner plate. The system is provided with stations from a first station to a seventh station, a movable type assembly platform, a highest position runner plate group and a components direction regulating mechanism, wherein the movable type assembly platform sequentially moves along seven-station movable rails of the assembly platform, the highest position runner plate group is arranged at one side of the seven-station movable rails of the assembly platform, and the components direction regulating mechanism is located at one side of the seven-station movable rails of the assembly platform. The method comprises the following steps of: preparing corresponding components according to pen types, and placing the same components on a corresponding runner plate; regulating the uniform direction of the same components; receiving and clamping the same components with a receiving type row clamp and a grabbing-type row clamp for later use; and sequentially assembling from the first station to the fifth station or the seventh station to complete the ball pen assembly. The components regulating mechanism for the ball pen assembly has a simple structure, low cost and high production efficiency.

Owner:罗金全

Assembling device for sealing rings of pens with center refills and method

The invention discloses an assembling device for sealing rings of pens with center refills and a method. The assembling device comprises a feeding device, a staggering device and a suction nozzle, the feeding device conveys a sealing ring, the suction nozzle sucks the sealing ring and is connected with a gas source, the staggering device consists of a material carrying seat and a second cylinder which pushes the material carrying seat to move in a staggered manner, the material carrying seat is positioned at one end of the feeding device, and the suction nozzle is arranged above the material carrying seat so as to suck the sealing ring which is arranged on the material carrying seat and needs to be sucked. The direction of staggered movement of the material carrying seat is perpendicular to the feeding direction of the feeding device. The sealing ring which is arranged on the material carrying seat and needs to be sucked moves relative to other sealing rings in a staggered manner, accordingly, the suction nozzle accurately and reliably sucks the sealing ring assuredly, and assembly efficiency of the sealing ring of a pen with a center refill is improved.

Owner:SUZHOU KAILEISHENG AUTOMATION TECH CO LTD

Combination-type pen

Owner:WU MAO SUNG

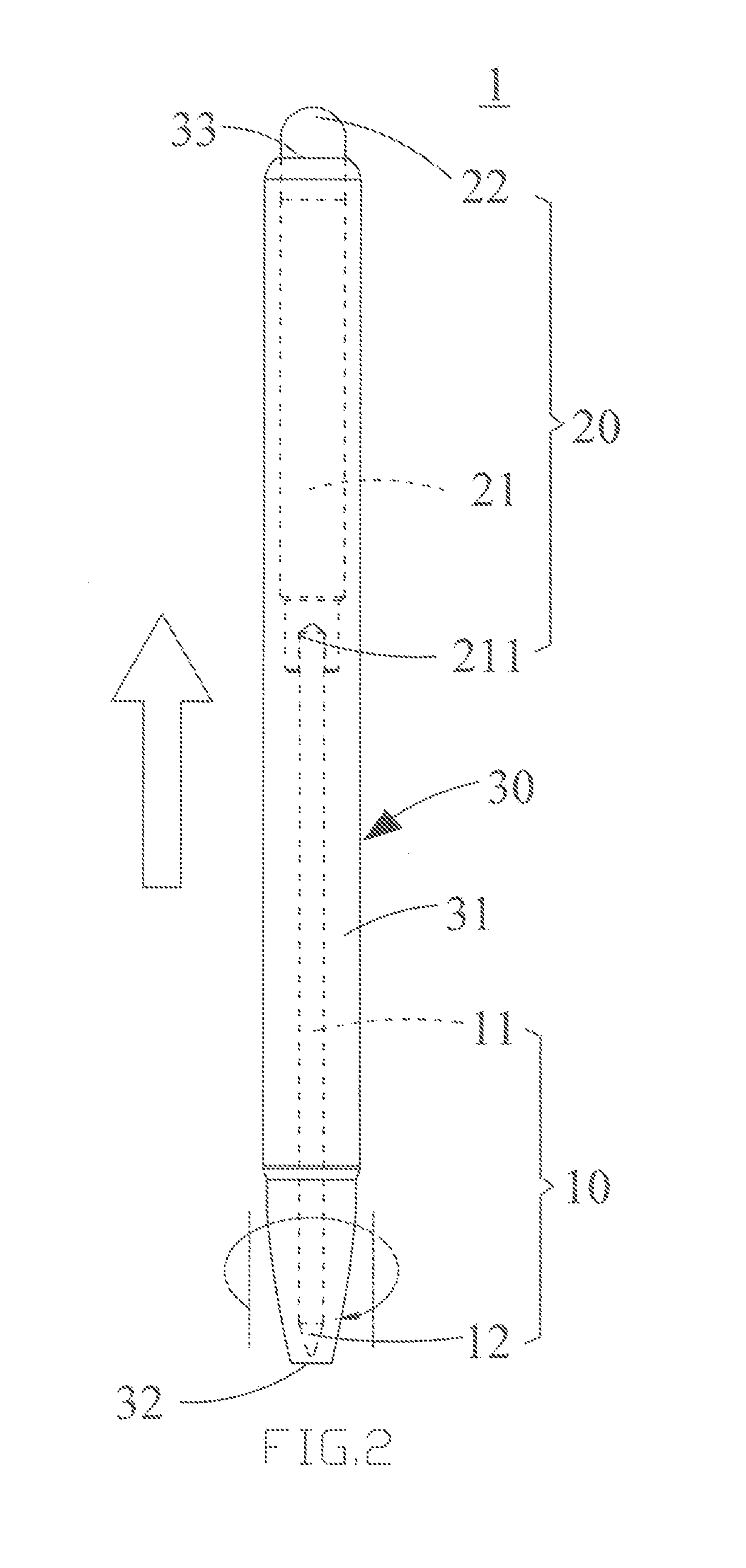

Pen and manufacturing method therefor

InactiveCN101367307AImprove comfortCorrect writing posturePen repairingBall-point pensEngineeringDrill bit

The invention discloses a pen and a manufacturing method thereof, wherein the sharp part on the front end of the pen is provided with a pen point; the front end of a penholder takes the shape of a circular platform; the diameter close to the pen point end is less than the diameter on the rear; the penholder is concave on the first web of a user; and the rear end of the penholder is provided with an air hole which is communicated with a refill and the outside. The manufacturing method for the pen comprises the following steps: wood is made into the shape of the penholder by a turning machine; a refill hole is drilled in the center of the penholder through a drill bit; and after the refill is loaded, a finished product is obtained. The pen has elegant and beautiful shape, comfortable use, high strength, low cost and strong feature of environmental protection, can correct poor writing posture and is favorable for culturing correct writing posture.

Owner:方汉旗

Nib brushing straightening device for ink brush manufacturing

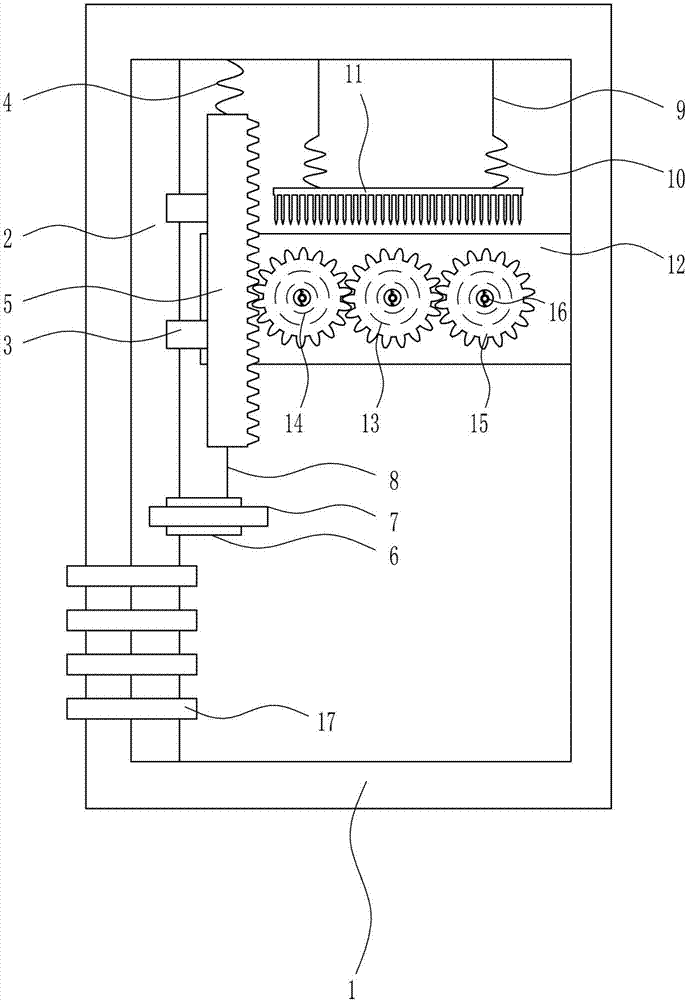

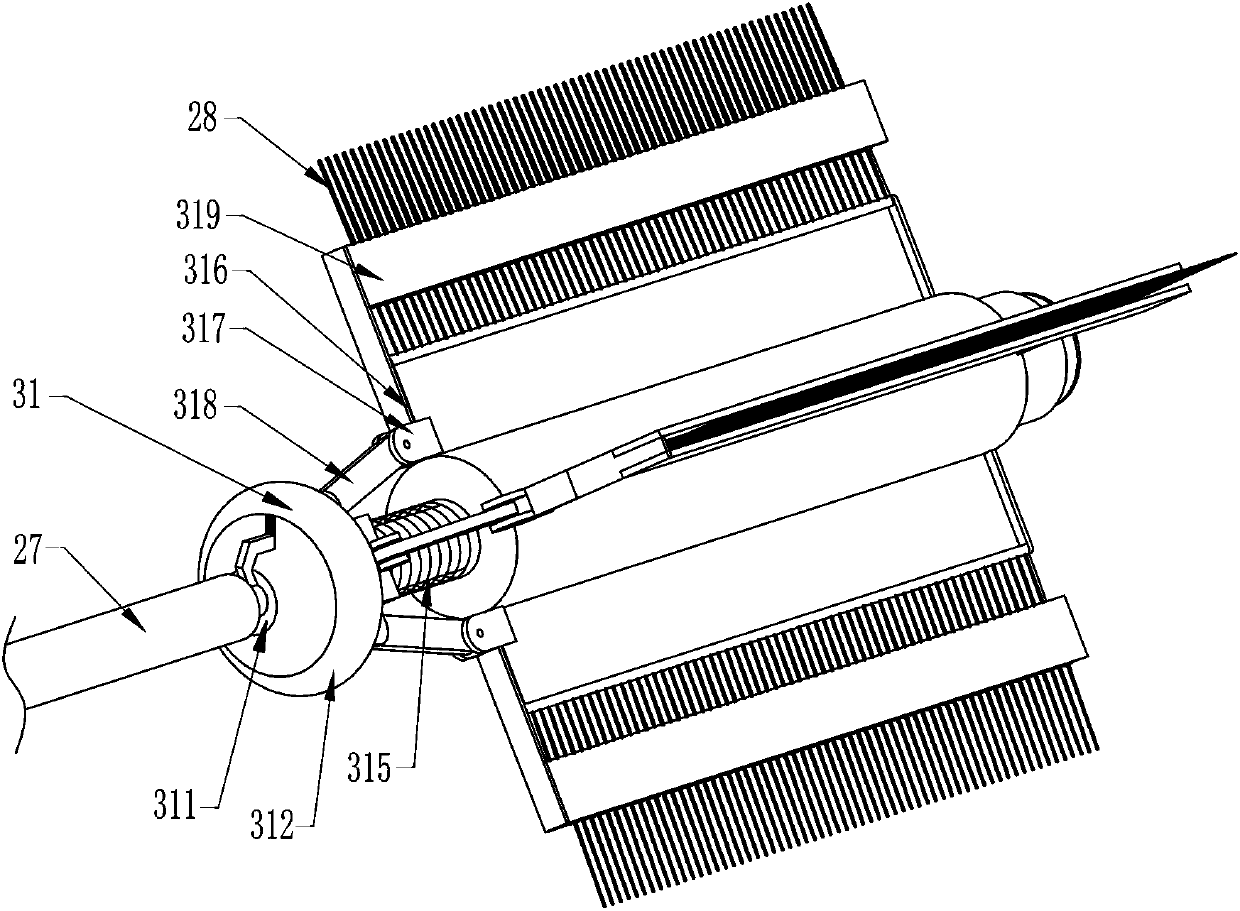

The invention relates to a nib brushing straightening device, particularly to a nib brushing straightening device for ink brush manufacturing, and provides the time-saving and effort-saving nib brushing straightening device for ink brush manufacturing. The nib brushing straightening device for ink brush manufacturing provided to solve the technical problem comprises a mounting rack, a slide rail, first sliding blocks, a first spring, a rack, a second sliding block, a pedal, a first stay wire, second stay wires, second springs, a comb, a mounting plate, and the like, wherein the slide rail is arranged on the inner left wall of the mounting rack; the first sliding blocks are connected on the right side of the slide rail in a sliding manner; the rack is arranged on the right sides of the first sliding blocks; the first spring is connected between the top end of the rack and the left side of the inner top of the mounting rack; and the second sliding block is connected on the right side of the slide rail in a sliding manner. According to the nib brushing straightening device, when the pedal is trod for multiple times, the rack and gears cooperate with each other to rotate multiple ink brushes, and nibs of the multiple ink brushes are straightened out through the comb.

Owner:嘉兴磊佳电子科技有限公司

Pen point brush aligning machine capable of removing bad brushes

InactiveCN110978862AEasy to operateReduce work intensityPen repairingOther pensElectric machineryElectric machine

The invention relates to a pen point brush aligning machine, in particular to a pen point brush aligning machine capable of removing bad brushes. According to the pen point brush aligning machine capable of removing the bad brushes, the work intensity of people can be reduced, and a lot of time and costs can be saved. The pen point brush aligning machine capable of removing the bad brushes comprises a supporting frame, a rack, a motor, a collecting box and the like; the supporting frame is connected with the rack, the motor is arranged at the bottom of the rack, and the collecting box is fixedly arranged on the right side in the rack. Brush pens can be continuously conveyed rightwards through movement of a conveying assembly, a combing assembly can automatically comb pen points of the brush pens, in this way, the multiple brush pens can be simultaneously combed smoothly and subjected to miscellaneous brush removing, operation is easy, the work intensity of people is reduced, the work efficiency is accelerated, and the lot of time and costs are reduced.

Owner:王亚婷

Antibacterial and mildew-proof fiber pen point and preparation method thereof

InactiveCN111361330AReduce dosageMeet the limit requirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveOrganosolv

The invention belongs to the technical field of pen manufacturing, and particularly relates to an antibacterial and mildew-proof fiber pen point and a preparation method thereof. Fibers are sequentially subjected to strand combining, shaping, gum dipping, curing, cutting and grinding forming, and then the fiber pen point is obtained; and a glue solution adopted by the gum dipping comprises the following components of an adhesive, an organic solvent and a mildew-proof bactericide. According to the antibacterial and mildew-proof fiber pen point and the preparation method thereof, the mildew-proof bactericide is added into the glue solution and permeates into the fiber pen point, the obtained fiber pen point contains the sterilization component (the existing pen point does not contain the sterilization component), then the dosage of the bactericide in the matched ink can be reduced, so that the limit requirement of the European Union on EN71-9 is met; and the prepared antibacterial and mildew-proof fiber pen point is long in effective antibacterial time, and the antibacterial effect can be maintained in the whole service life of a water-based marking pen.

Owner:WENZHOU UNIVERSITY

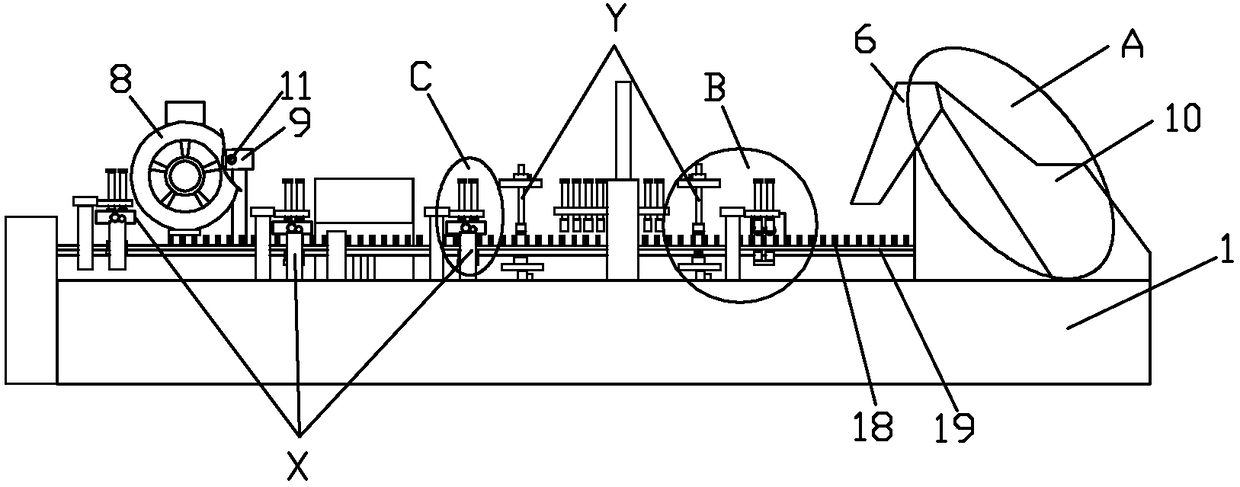

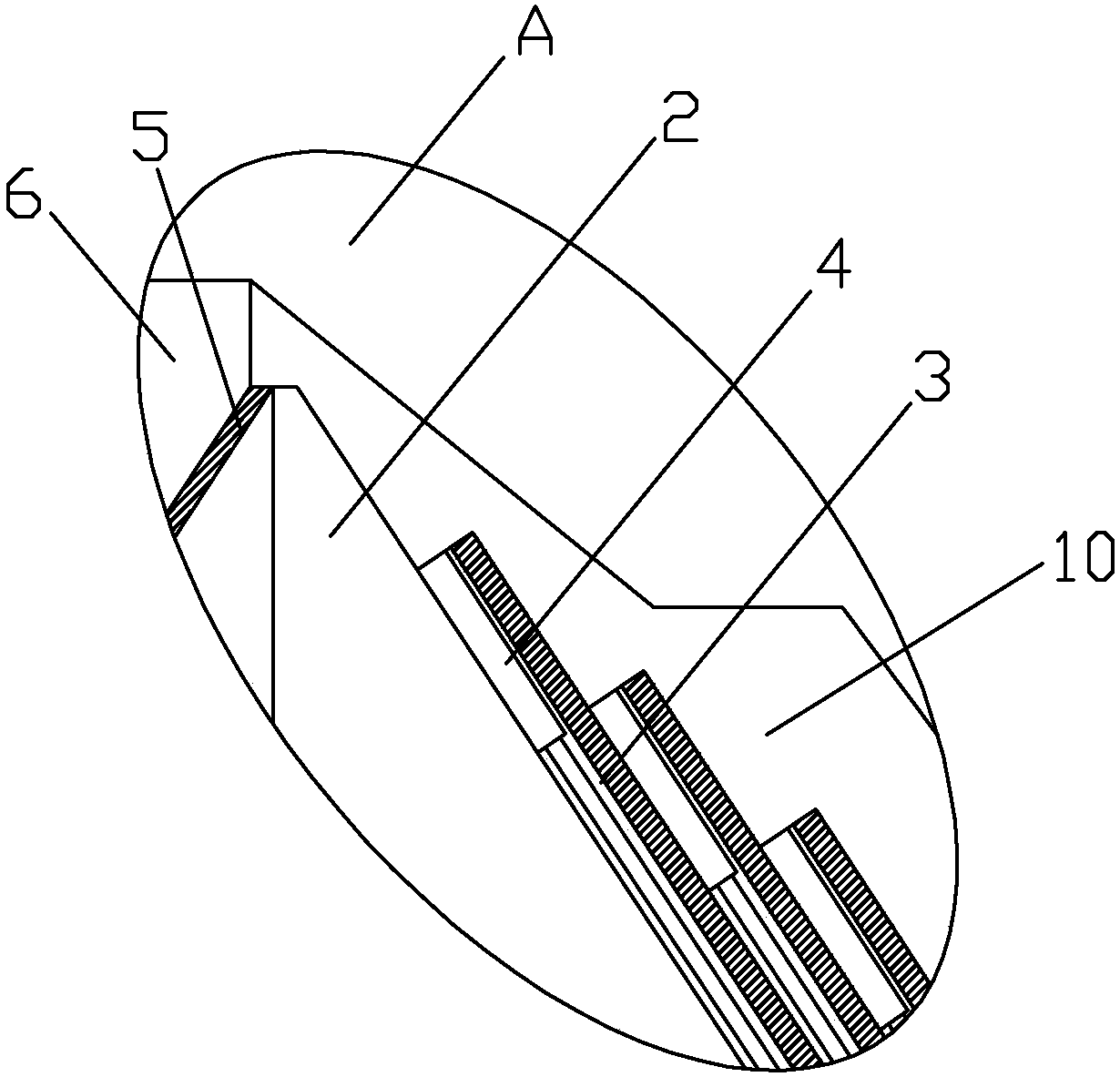

Full-automatic ball-point pen assembling machine

The invention relates to the technical field of ball-point pen production, in particular to a full-automatic ball-point pen assembling machine, which comprises an installation platform, a delivery mechanism, an outer shell feeding mechanism, a direction detection mechanism, a turnover mechanism Y, a pen cap feeding mechanism, a pen cap assembling manipulator, a pen refill assembling manipulator, apen refill feeding mechanism, a spring assembling manipulator, an inner shell feeding mechanism, an inner shell assembling manipulator, and a hydraulic clamping mechanism X. The horizontally arrangeddelivery mechanism is arranged on the installation platform; one end, close to the outer shell feeding mechanism, of the delivery mechanism, is arranged to be a feeding end; the other end, opposite to the outer shell feeding mechanism, of the delivery mechanism is arranged to be a discharging end; and the outer shell feeding mechanism is located on the right side of the delivery mechanism. The full-automatic ball-point pen assembling machine provided by the invention has the advantages of convenience in use and high production efficiency, is capable of automatically producing ball-point pens, has a time-saving and labor-saving effect, and is convenient for actual production and use.

Owner:WENZHOU FEIDA PEN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com