Automatic assembling system of pin type pen head component

A technology of automatic assembly and pen head, which is applied in the repair of ink pens, printing, writing utensils, etc., can solve the problems of bending deformation, inaccessibility, unstable quality, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

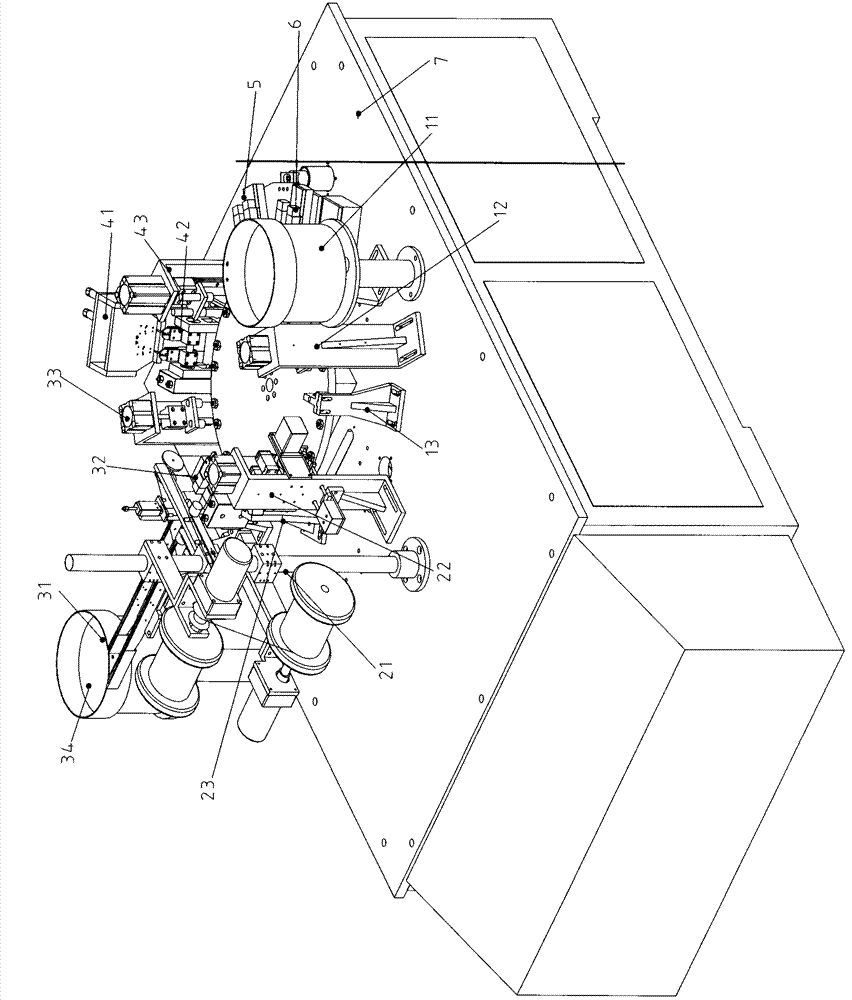

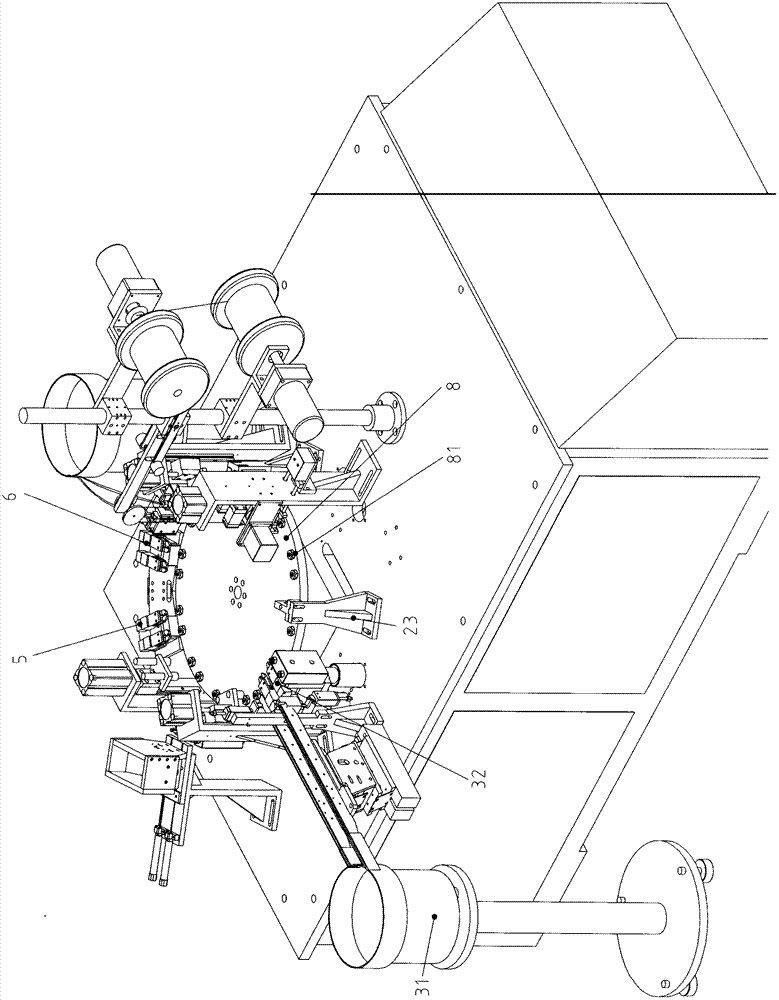

[0021] Example 1, such as figure 1 , as shown in 2, the present embodiment discloses an automatic assembly system for a needle-type nib assembly, including a frame 7 constituting the equipment support and the main body, a power unit and a parts transmission system connected thereto, which are arranged in sequence along the moving direction of the parts transmission system Nib supply mechanism 11, nib assembly mechanism 12, nib direction detection mechanism 13, water core supply mechanism 21, water core cutting and assembly mechanism 22, water core assembly detection mechanism 23, front feeding mechanism 31, front assembly mechanism 32, front assembly Detection mechanism 33 , relay core loading mechanism 41 , relay core assembly mechanism 42 , relay core assembly detection mechanism 43 , defective product selection mechanism 5 , finished product unloading mechanism 6 . The water diversion core assembly detection mechanism 23, the front assembly detection mechanism 33, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com