Lignin-based block copolymerization molecular-grade combined polyether, preparation method thereof and application of lignin-based block copolymerization molecular-grade combined polyether in preparation of polyurethane flexible foam material

A technology for block copolymerization and combination of polyethers is applied in the fields of its preparation, lignin-based block copolymerization of molecular-level combined polyethers, the preparation of polyurethane soft foam materials, and the preparation of combined polyethers, which can solve the structure of polyurethane soft-hard copolymerization. Can not fully meet the requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

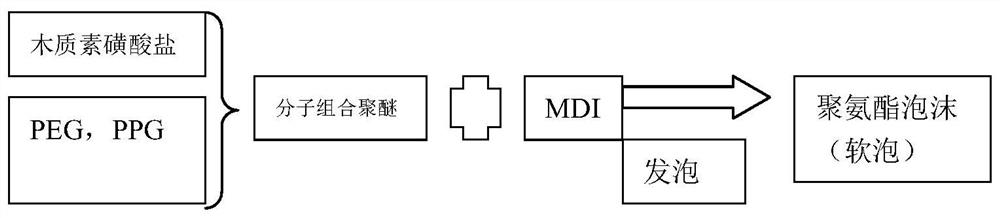

[0036] The core of the present invention is to provide a method for preparing a lignin-based block copolymerized molecular-level combination polyether, which is called Embodiment 1. The process flow diagram is shown in figure 1 , the method includes the following steps:

[0037] 1) Pretreatment of lignosulfonate:

[0038] Lignosulfonate and pretreatment reagent are mixed at a weight ratio of 1:2-10 at a temperature of 100-140 Pretreatment for 60-240 minutes at a pressure of 10-15MPa;

[0039] 2) Remove the pretreatment reagent:

[0040] The lignosulfonate obtained after the pretreatment is sloughed off the pretreatment reagent through vacuum distillation;

[0041] 3) Soft and hard copolymerization of lignosulfonate and polyether polyol:

[0042] Lignosulfonate and polyether polyol are copolymerized at a weight ratio of 1:1-5, and the copolymerization temperature is 120-180 The time is 1-4 hours, and the lignin-based block copolymerized molecular-level combination polyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com