Neutral pen refill manufacturing device and method thereof

A technology for manufacturing devices and gel pens, which is applied in the repair of ink pens, printing, writing utensils, etc., can solve problems such as waste of resources, unstable ink injection, and low-quality refills, so as to improve production efficiency and product quality. The effect of safe and reliable equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

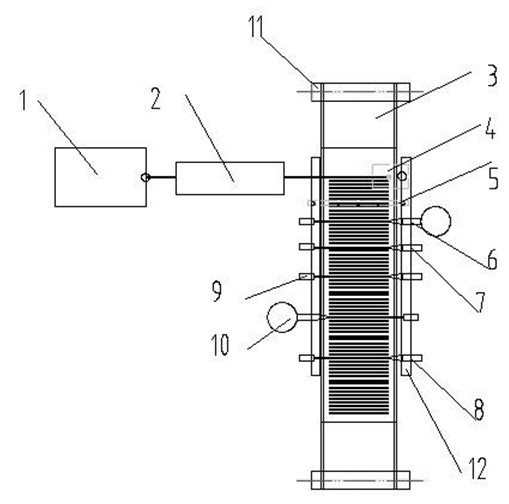

[0019] like figure 1 As shown, the gel pen refill manufacturing device includes an injection molding machine 1, a cooling tank 2, a conveyor belt 3, a cutting device 4, a coding device 5, an ink filling device 6, a plastic nib holder device 7, and a steel ball device 8 , Insert rigid nib device 9, oil filling sealing device 10, support 11, base 12; injection molding machine 1, cooling tank 2, conveyor belt 3 are connected in sequence, and the brackets on both sides of conveyor belt 3 are sequentially provided with shearing device 4, Coding device 5, ink filling device 6, plastic nib holder device 7, rigid nib device 9, oil filling sealing device 10, steel ball device 8;

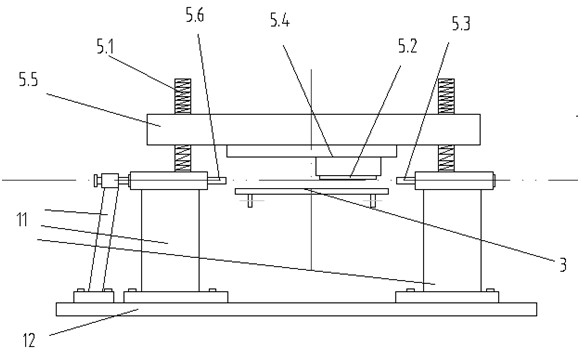

[0020] like image 3 As shown, the coding device 5 includes a threaded shaft 5.1, a coding mold 5.2, a fixed thimble 5.3, a coding mold base 5.4, a beam 5.5, a movable thimb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com