Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161 results about "Cooling bath" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cooling bath, in laboratory chemistry practice, is a liquid mixture which is used to maintain low temperatures, typically between 13 °C and −196 °C. These low temperatures are used to collect liquids after distillation, to remove solvents using a rotary evaporator, or to perform a chemical reaction below room temperature (see: kinetic control).

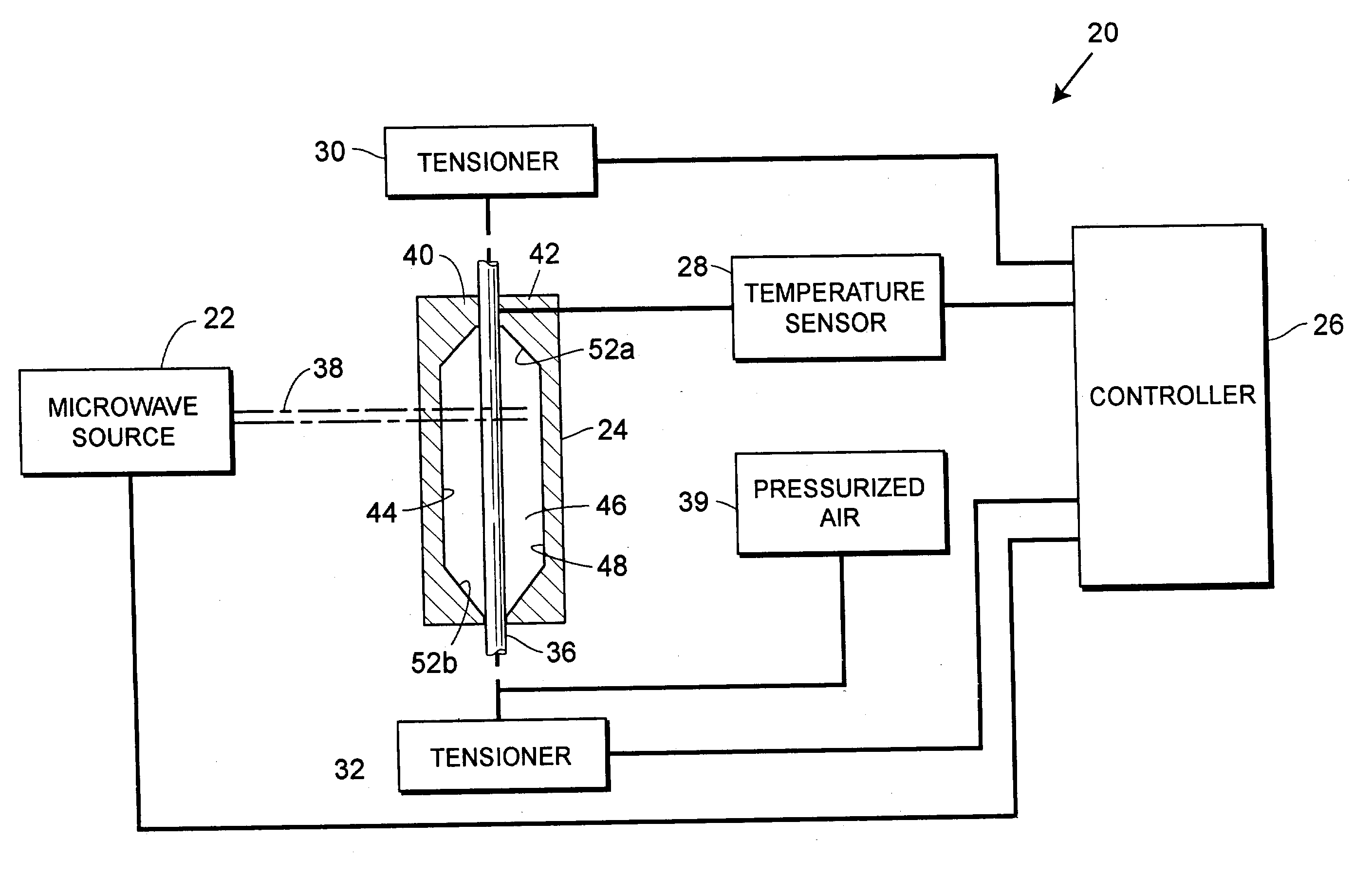

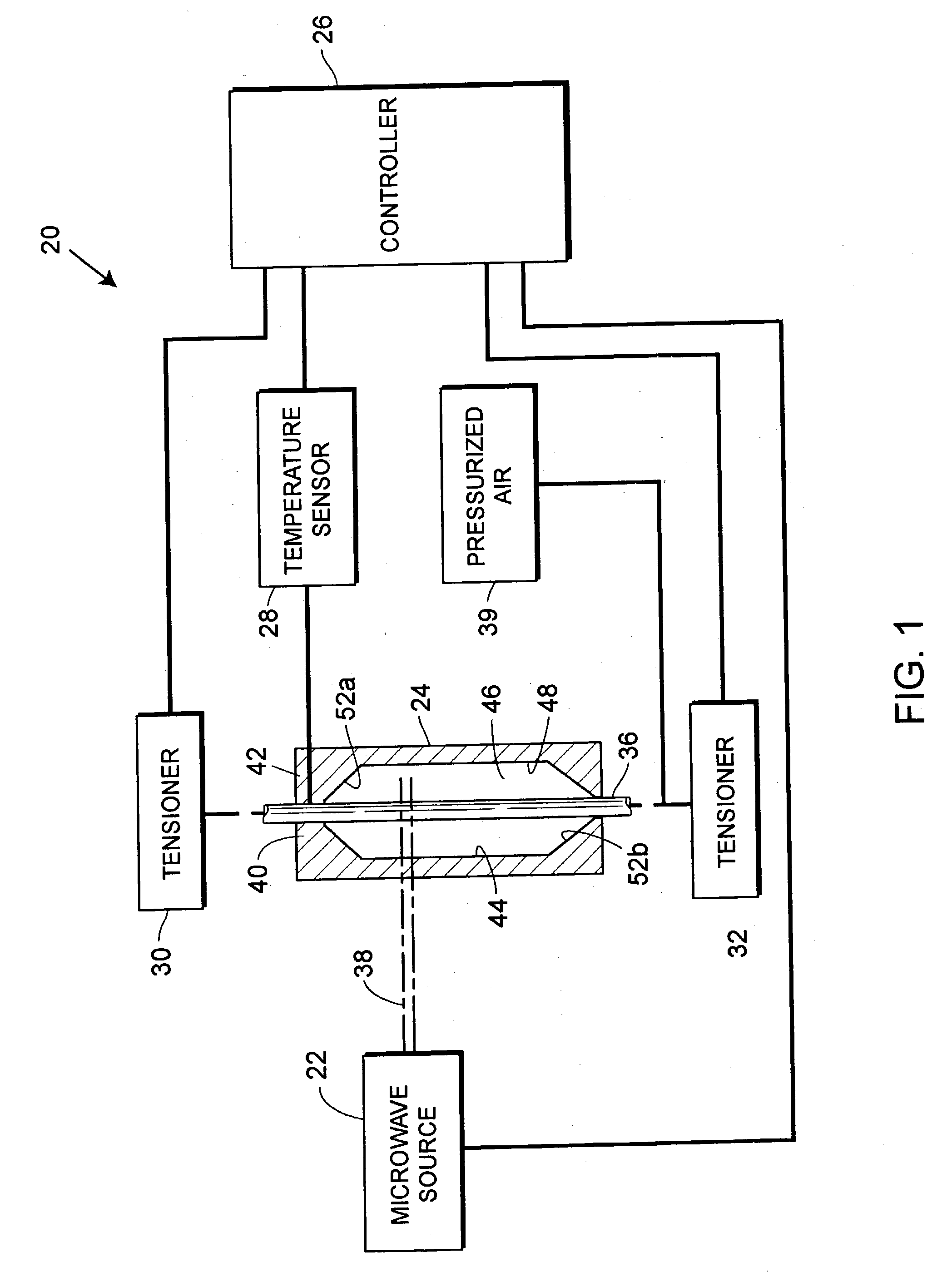

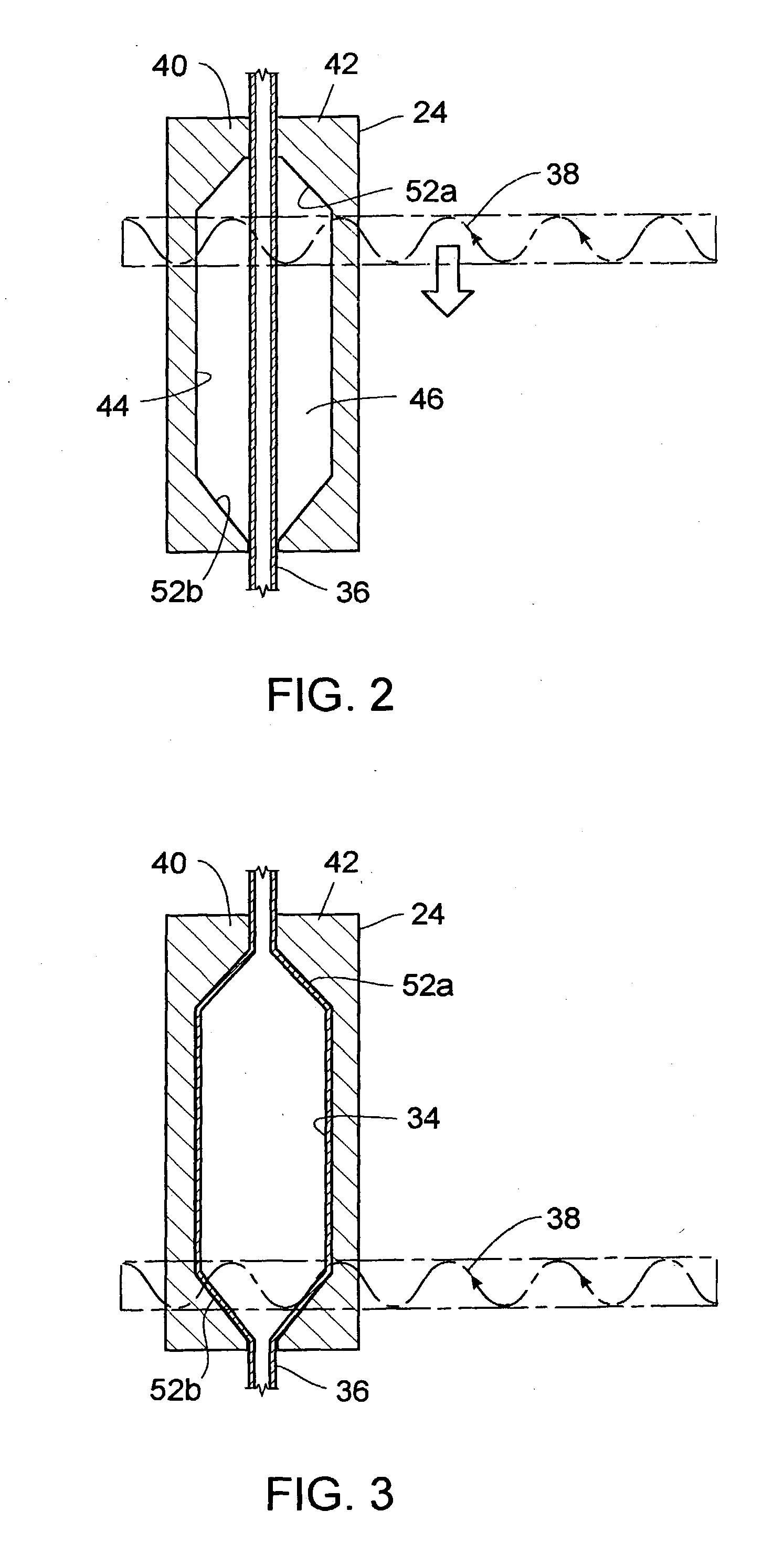

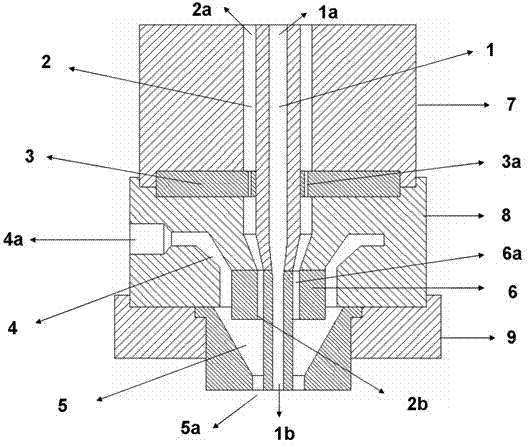

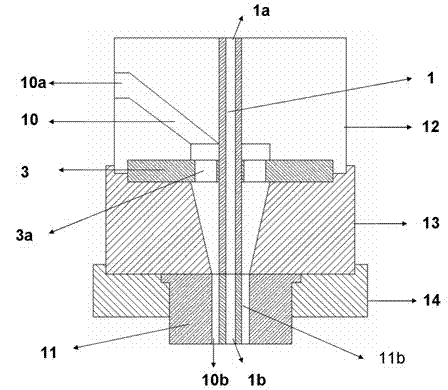

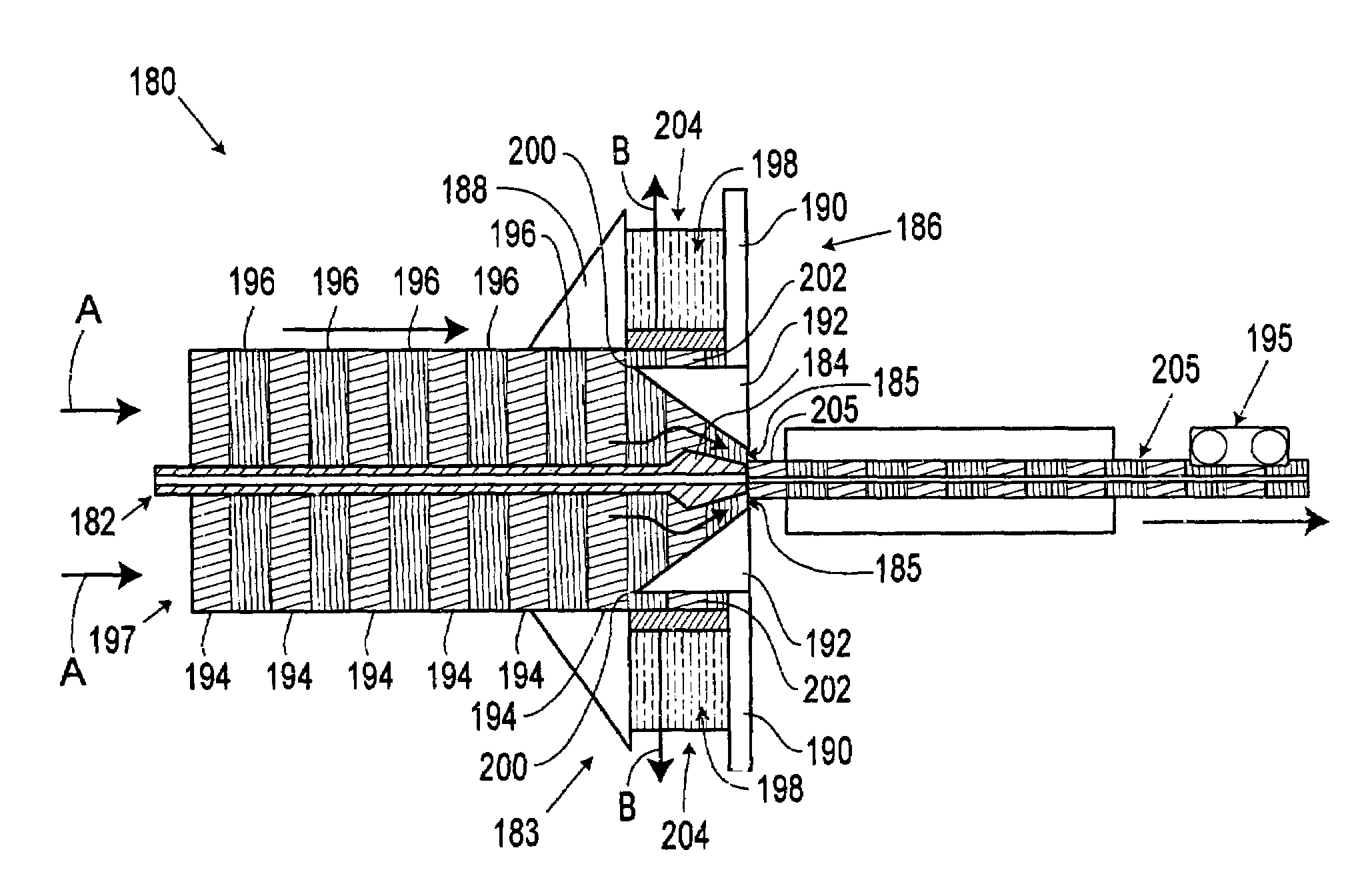

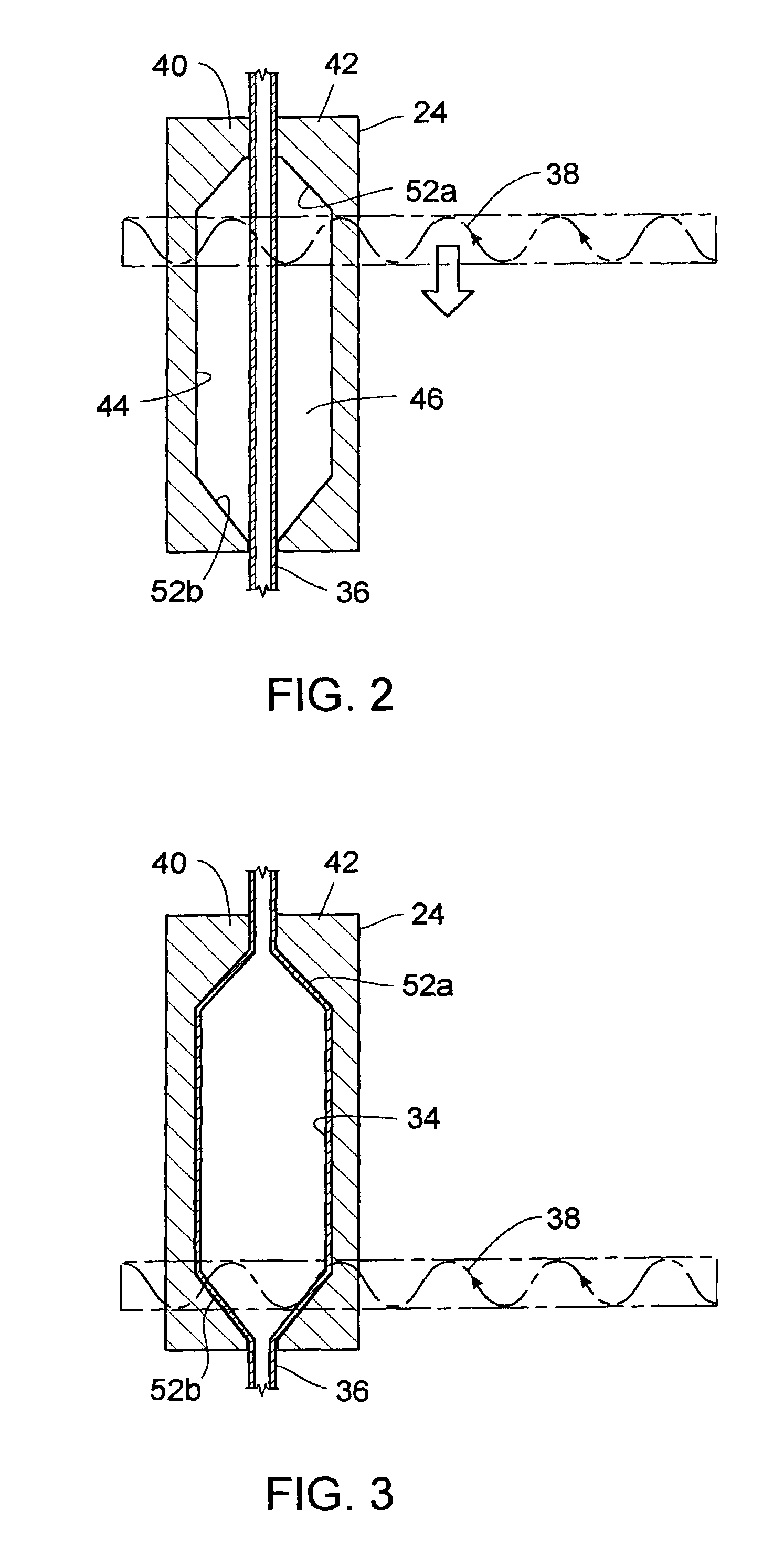

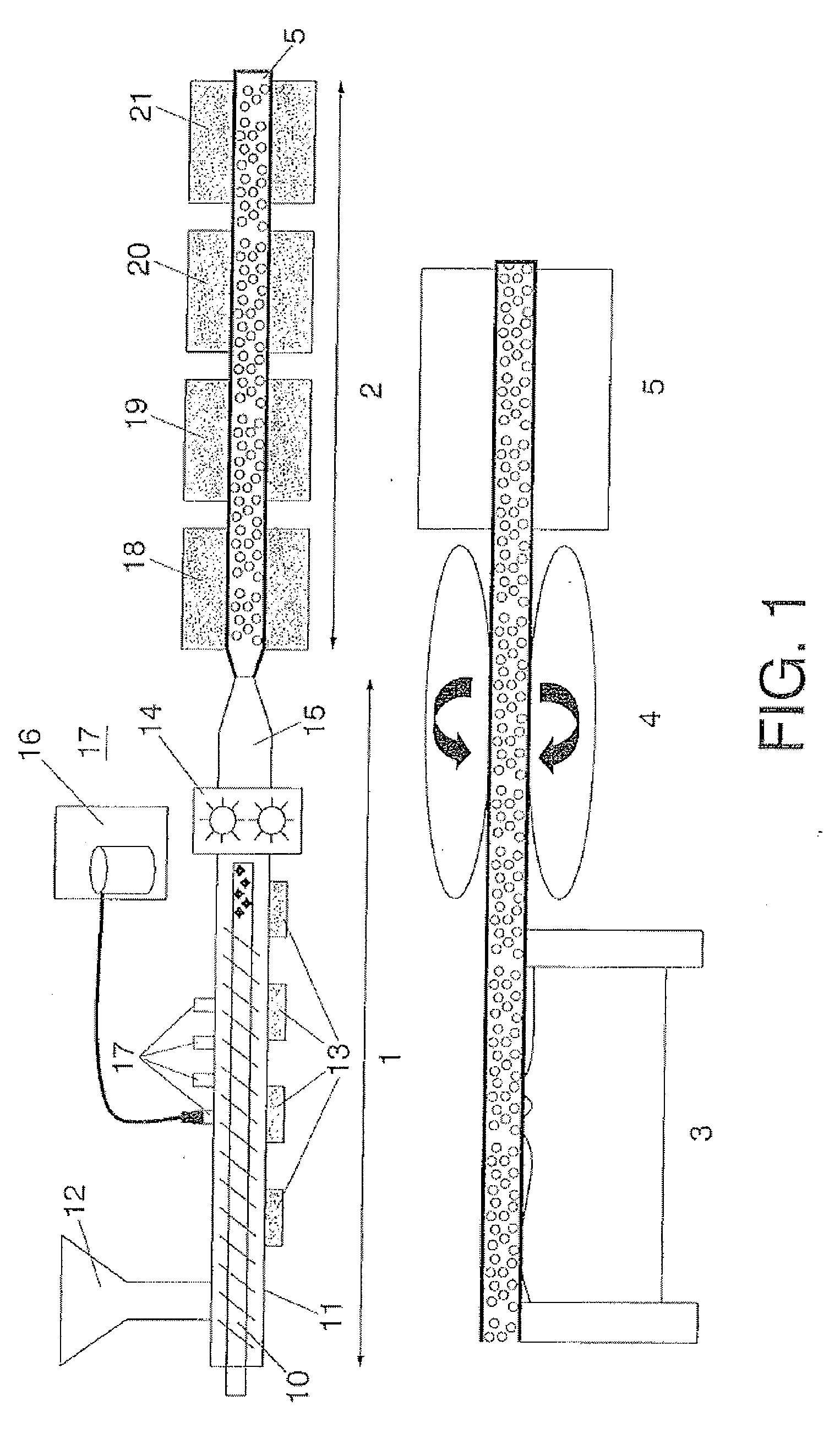

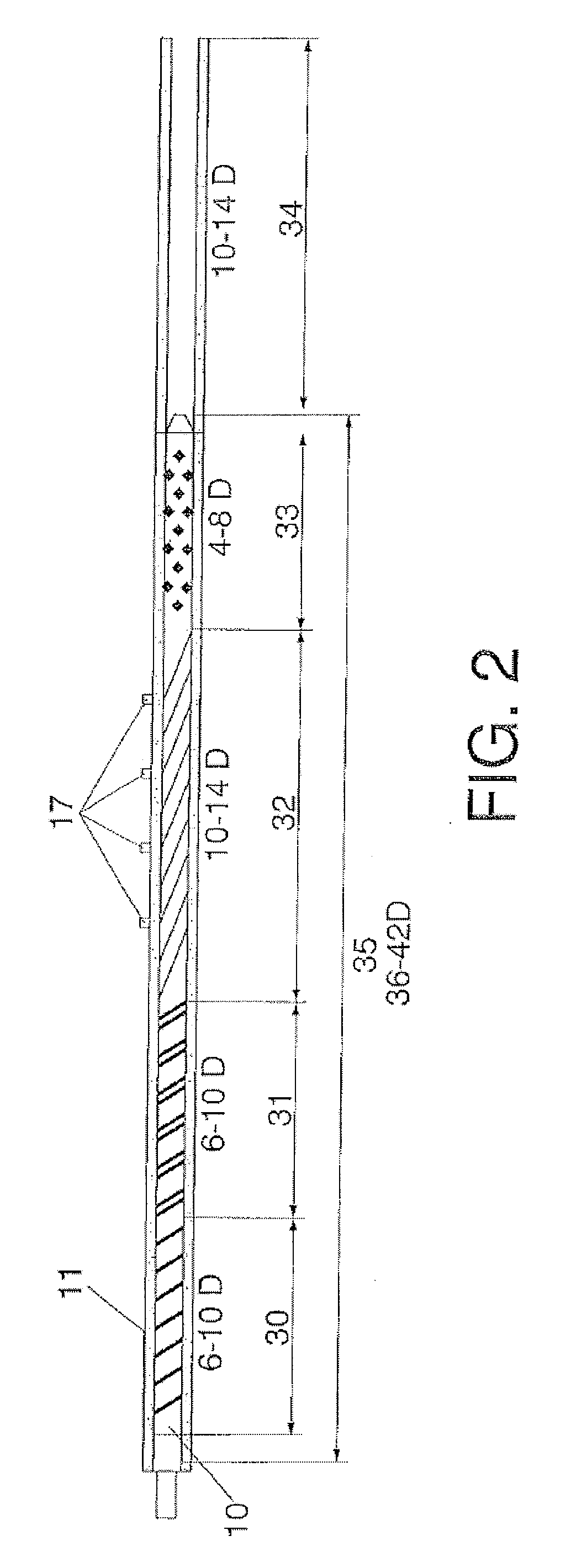

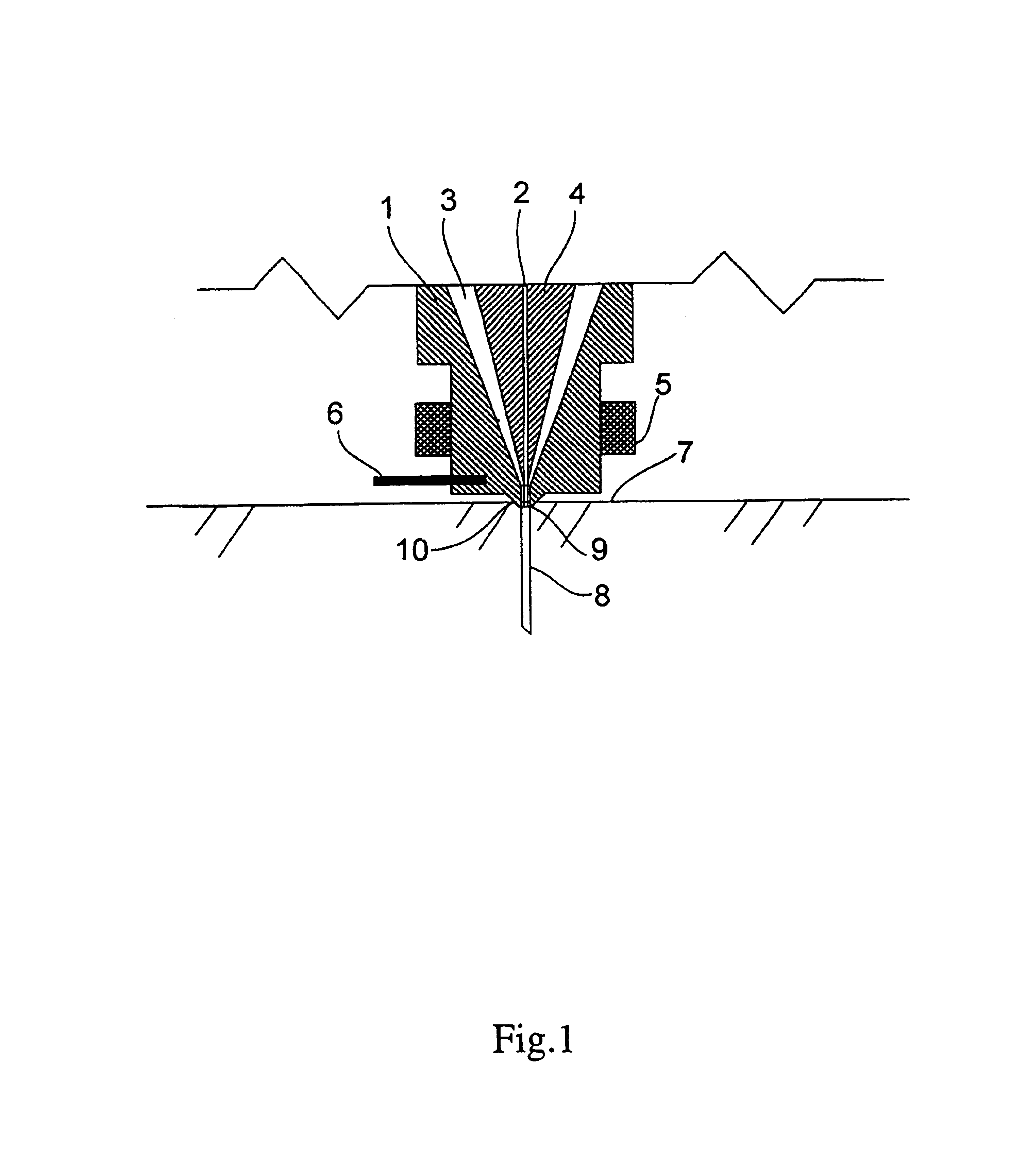

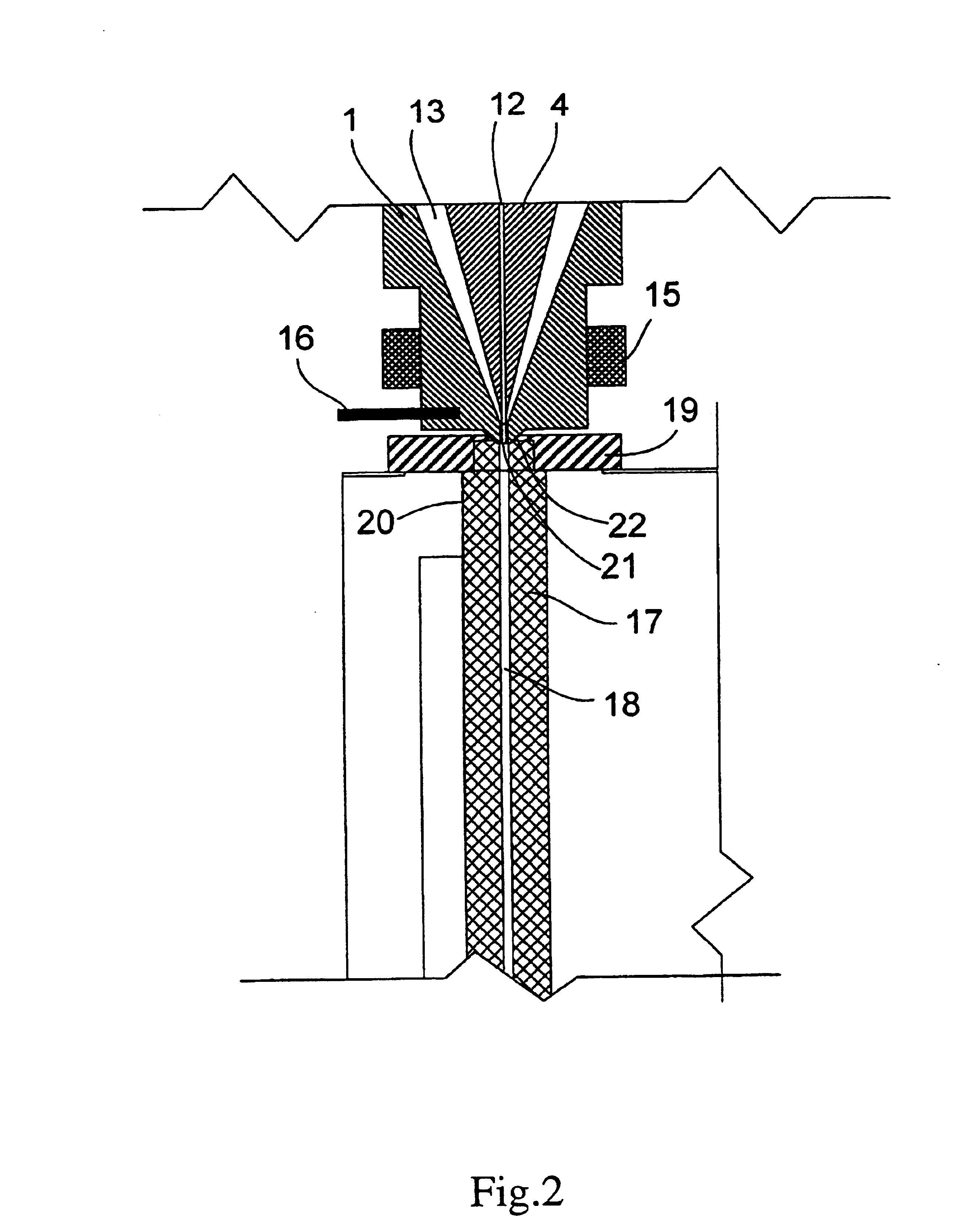

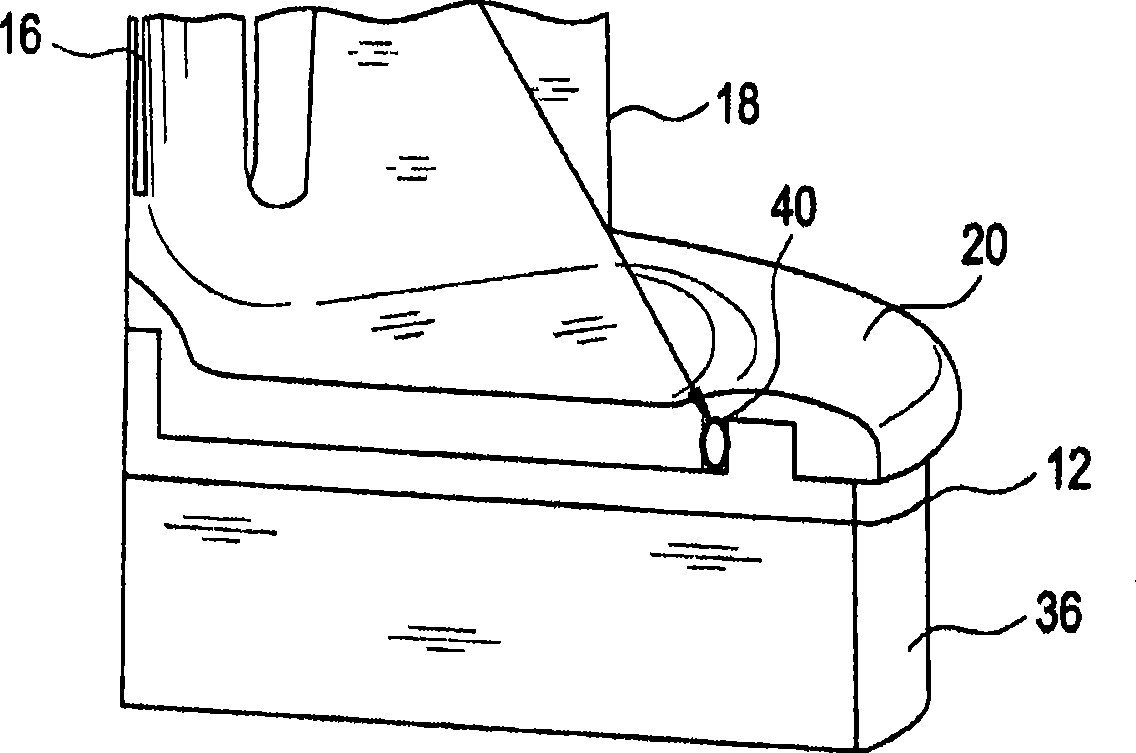

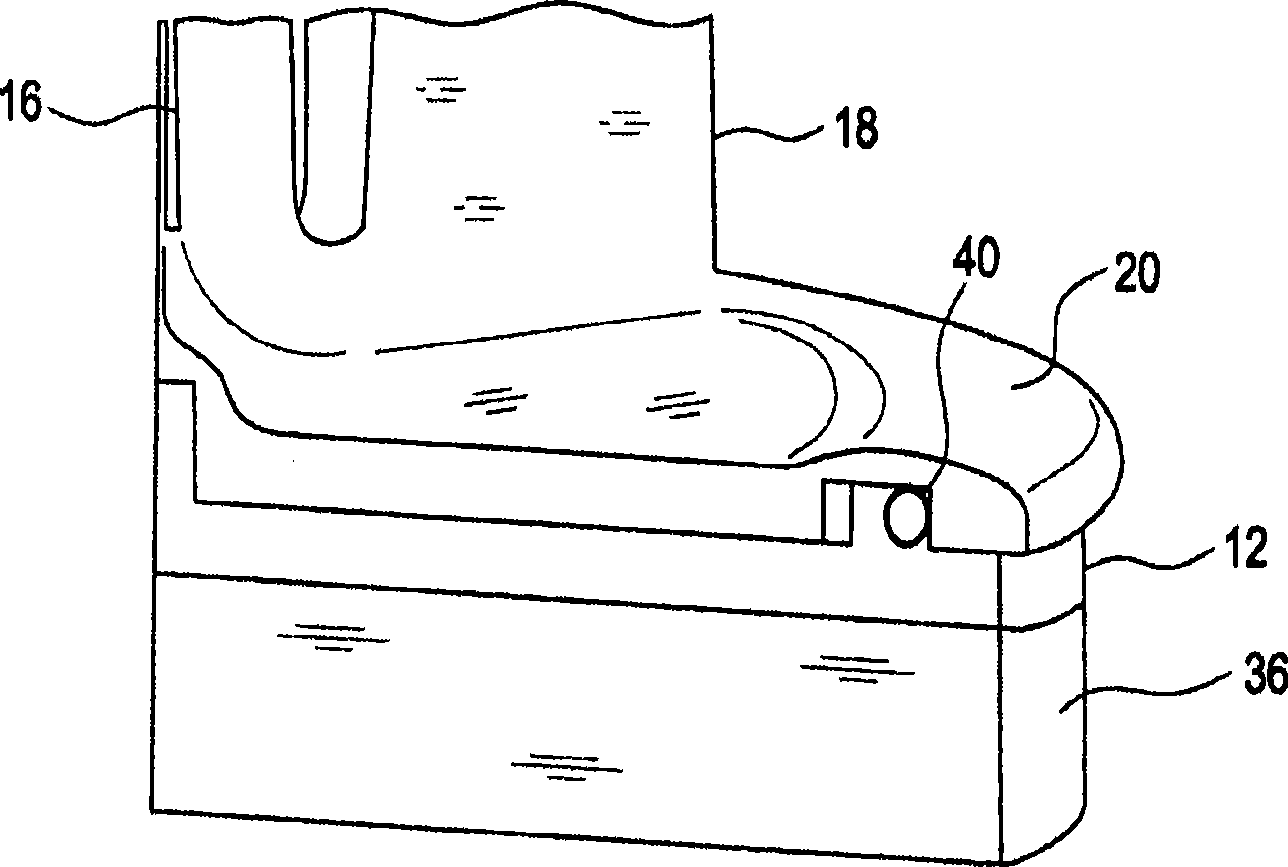

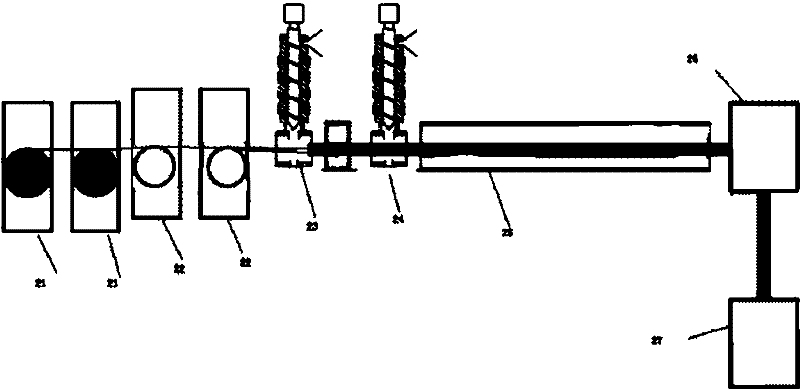

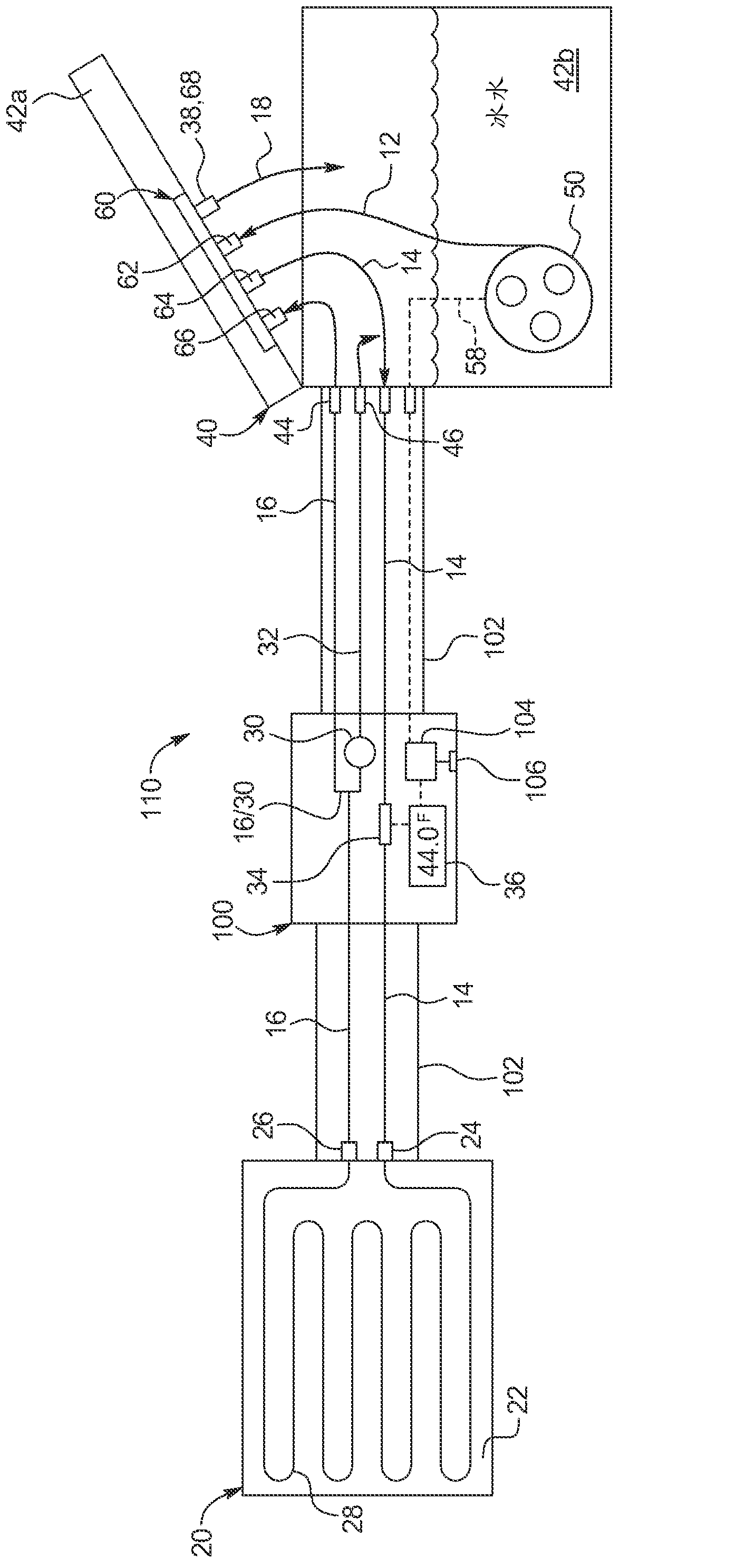

Method and apparatus for extruding polymers employing microwave energy

An apparatus and method for molding balloon catheters is disclosed. The balloon may be molded by providing a polymeric tube within a mold having an interior cavity in the shape of the desired balloon. Microwave energy, which may be generated by a gyrotron, may then be directed toward the mold, to heat the polymeric material without heating the mold. Once heated, pressurized fluid may be injected into the tube to blow the polymeric material against the interior cavity whereupon the material can cool to form the balloon or can be further heatset by additional microwave energy and be cooled to form the balloon. In accordance with one embodiment, microwave energy can also be used without a mold to form a medical device. A polymer extrusion apparatus is disclosed utilizing a microwave energy for heating polymer feedstock material within the extruder tip and die unit just prior to formation of the extrudate product. A cooling bath mechanism, which in one embodiment can also include a cooling tube member having a cooling medium forced therethrough, is also disclosed. An apparatus for preparing polymer disk members, to use as the polymer feedstock material for the microwave extrusion apparatus, is also disclosed. Apparatus for interconnecting and rotating the polymer disk members, the die tip, or the die, or any combination thereof, for creating angularity characteristics in the polymer extrudate, is also disclosed.

Owner:BOSTON SCI SCIMED INC

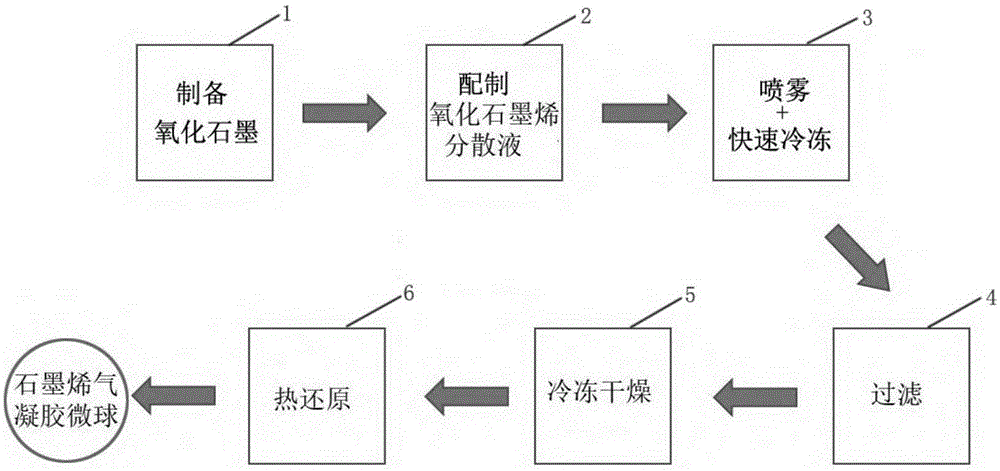

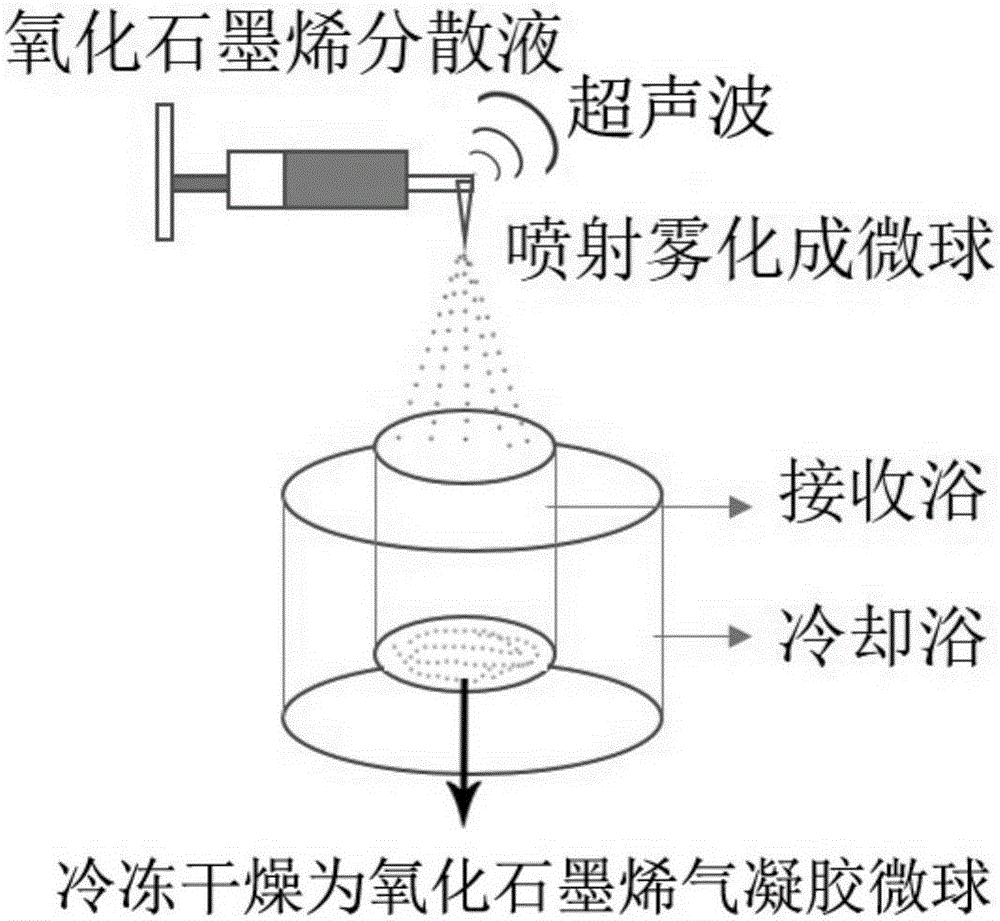

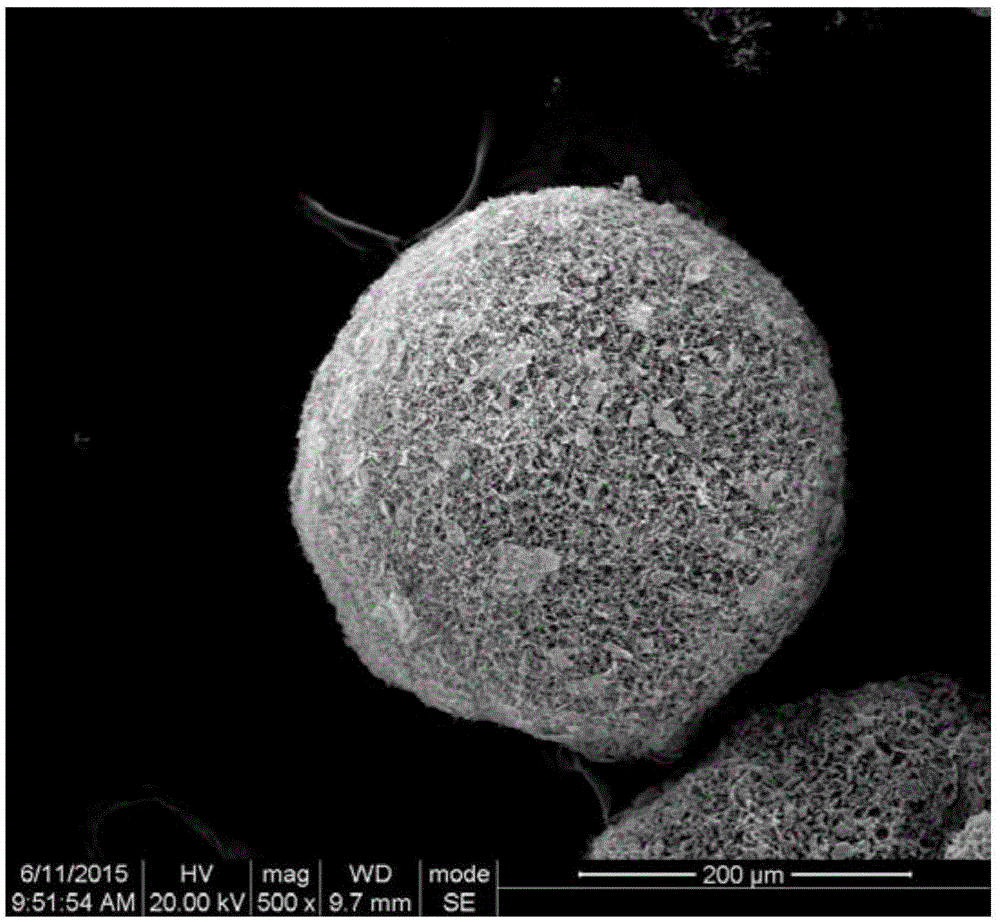

Graphene aerogel microspheres and preparation method and application thereof

ActiveCN105195067AParticle size controllableLarge specific surface areaIon-exchange process apparatusWater cleaningFreeze-dryingMicrosphere

The invention discloses graphene aerogel microspheres and a preparation method and application thereof. The preparation method is characterized in that 1, graphite oxide is prepared; 2, graphene oxide aqueous dispersion is prepared; 3, the graphene oxide aqueous dispersion is atomized through a spraying method into graphene oxide liquid drop microspheres, and meanwhile the microspheres are collected through receiving liquid in a cooling bath; 4, the receiving liquid is filtered to obtain graphene oxide ice microspheres, and then freeze drying is performed on the microspheres to obtain graphene oxide aerogel microspheres; 5, the graphene oxide aerogel microspheres are subjected to thermal reduction to obtain the graphene aerogel microspheres. The preparation method is simple and convenient to implement, no environmental pollution is generated, and the obtained graphene aerogel microspheres are uniform in size and large in specific area, are of a stable center-divergence multi-porous-channel network structure and are used for adsorbing environmental pollutants.

Owner:SICHUAN UNIV

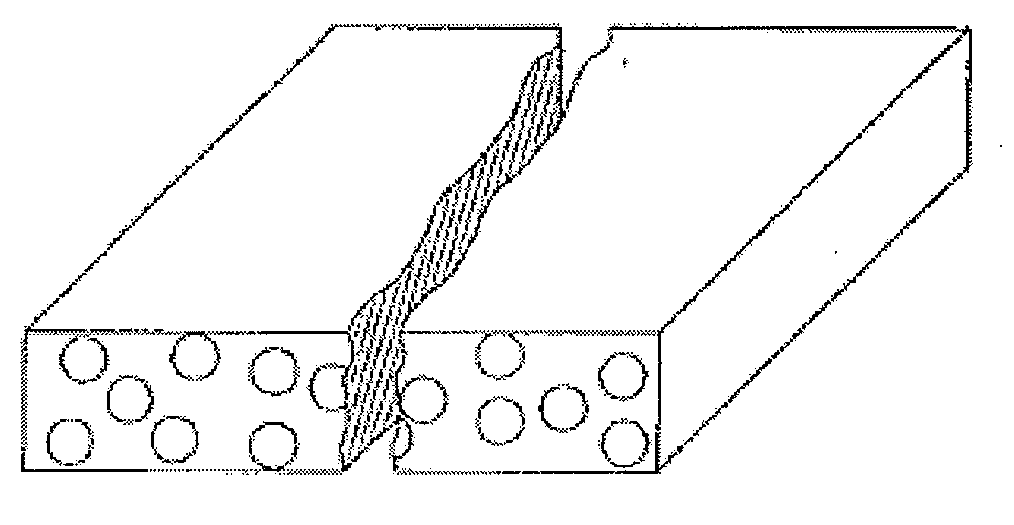

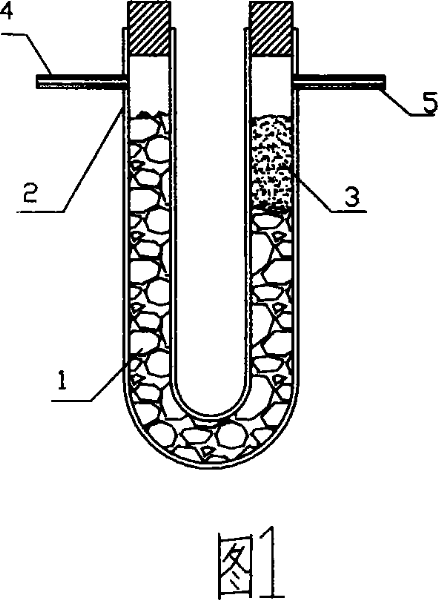

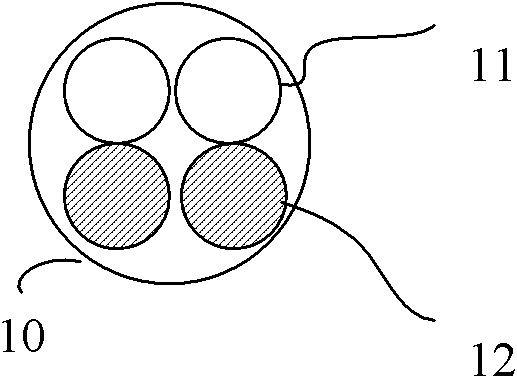

A kind of preparation method of long fiber reinforced hollow fiber membrane

ActiveCN102266726AContact priorityPrevent overflowMembranesSemi-permeable membranesWinding machineHollow fibre membrane

The invention discloses a method for preparing a long fiber reinforced hollow fibrous membrane. The method can be implemented in two ways: (1) adopting a spinning nozzle having a long fiber channel; introducing a long fiber into the long fiber channel; guiding the long fiber into a membrane casting solution and fiber compounding area via a fiber positioning plate; co-extruding the compounded long fiber and membrane casting solution; and forming a membrane under the action of core solution and external coagulating bath or cooling bath, and (2) adopting a spinning nozzle for co-extruding the long fiber and the membrane casting solution; guiding the long fiber out of a liquid material jar; guiding the long fiber to pass by a membrane casting solution pipeline and introducing the long fiber into the spinning nozzle from a membrane casting solution inlet of the spinning nozzle; co-extruding the long fiber and membrane casting solution after positioning the long fiber through the fiber positioning plate; forming the membrane under the action of core solution and external coagulating bath; and finally winding the membrane through a guide wheel and a winding machine. The long fiber reinforced compound membrane prepared by using the method has the advantages that the mechanical strength of the hollow fibrous membrane is increased by 3-5 times according to the quantity and variety of the long fiber in the hollow fibrous membrane, and the water flux, the rejection coefficient and the hydrophilicity are all obviously improved.

Owner:ZHEJIANG UNIV

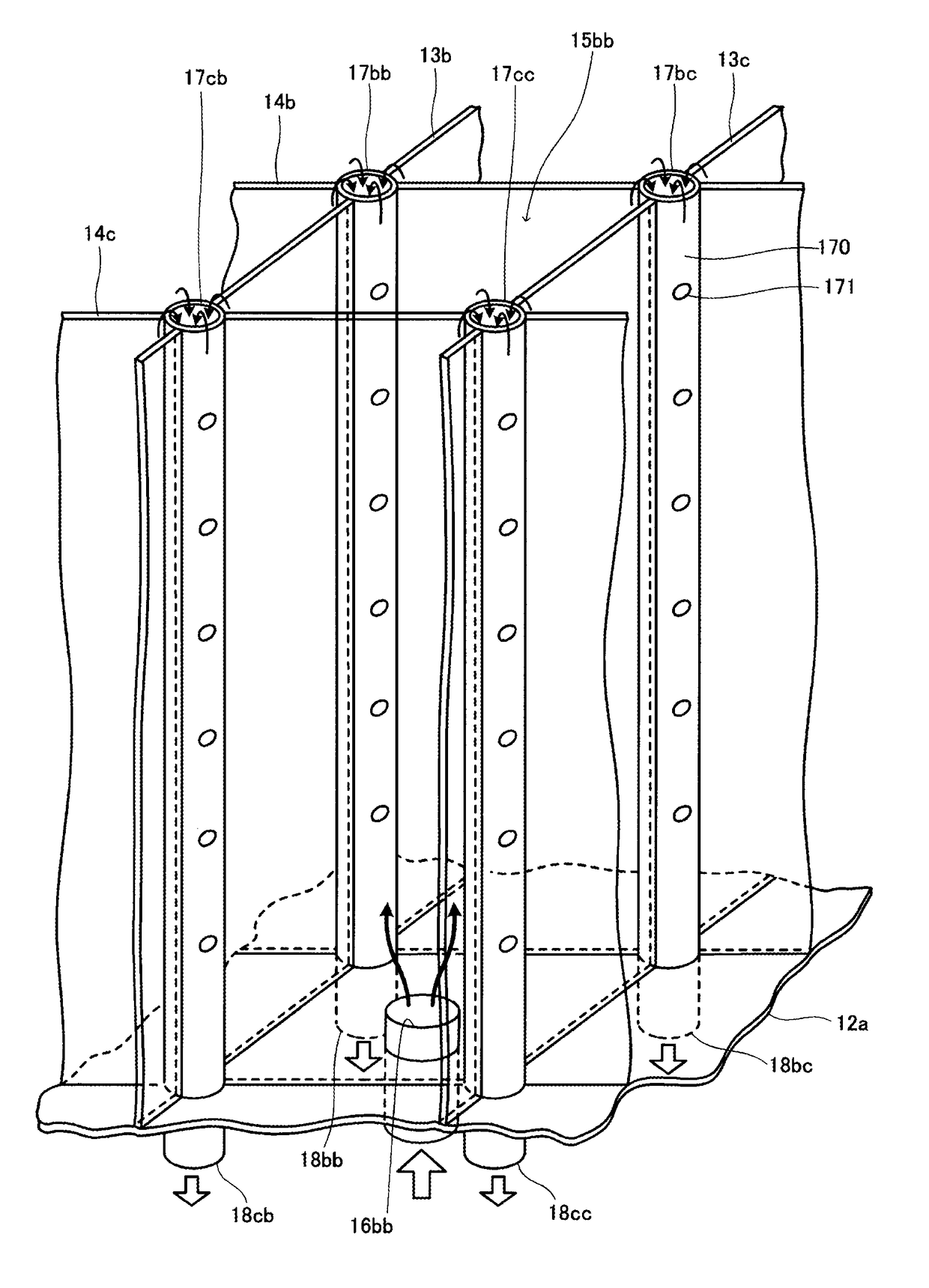

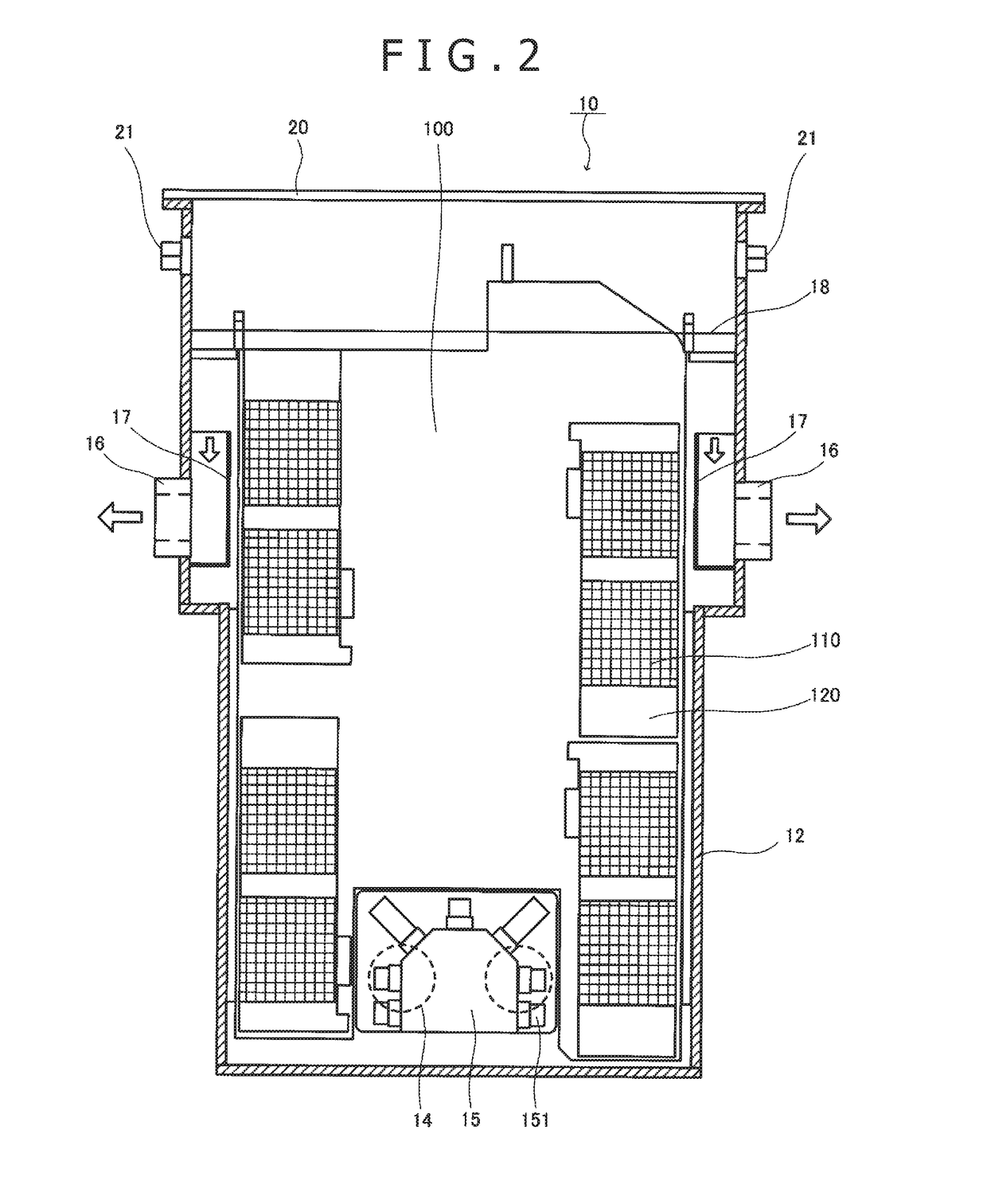

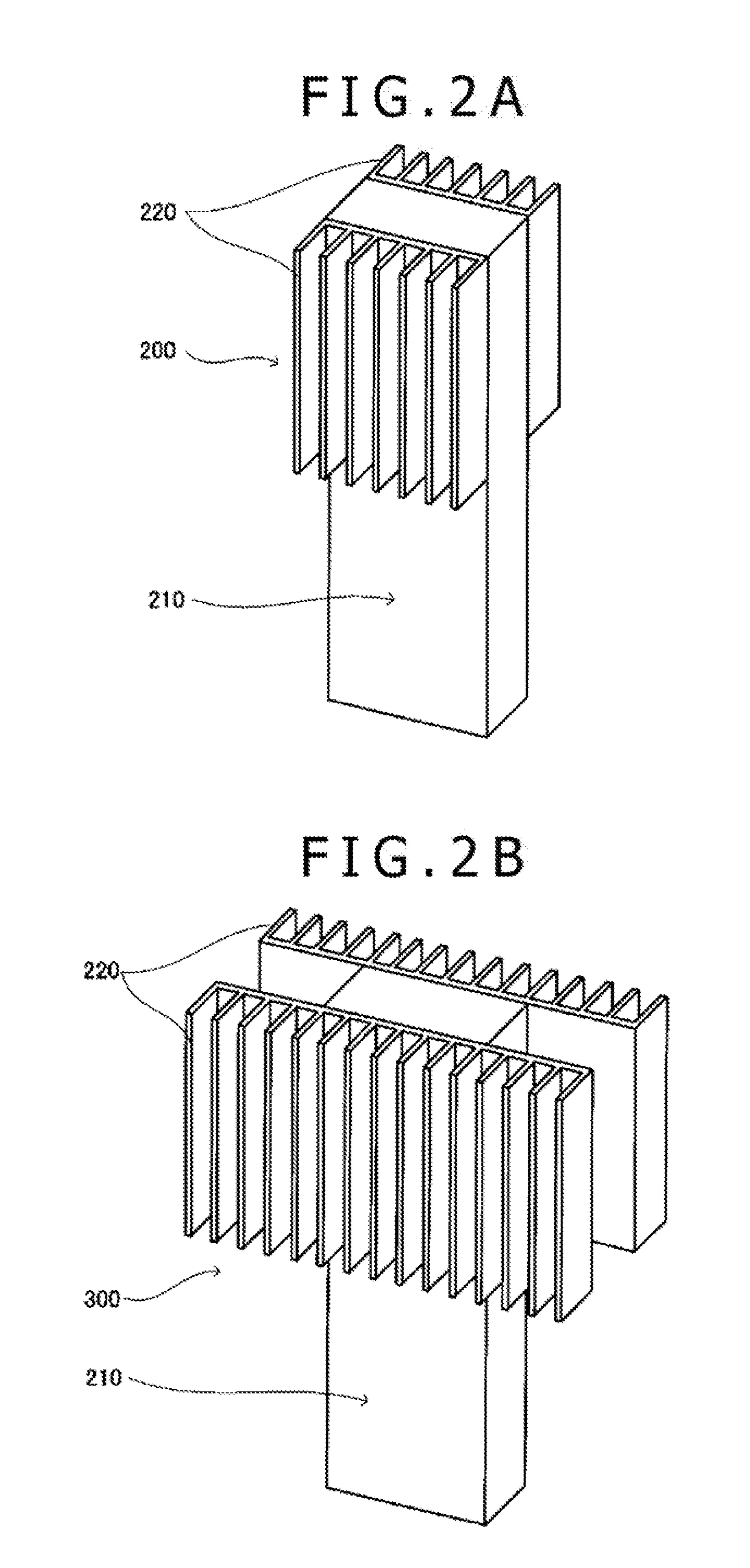

Cooling system for electronic device

InactiveUS20180246550A1Effective coolingLow costDigital data processing detailsSemiconductor/solid-state device detailsBoiling pointEngineering

A cooling system has a cooling bath. The open space of the cooling bath contains a second coolant having a boiling point, and having an electronic device that has a processor that is a heat generating component mounted on a board, and is immersed in the second coolant. A boiling cooling device is thermally connected to the processor, and encloses a first coolant having a boiling point. A first heat exchanger has a high-temperature side passage formed of a group of narrow gaps or a group of micro passages, through which the second coolant is passed, and a low-temperature side passage formed of a group of narrow gaps or a group of micro passages, through which a third cooling medium having a boiling point is passed. A pump is configured to pressurize and deliver the second coolant warmed in the cooling bath toward the inlet of the high-temperature side passage.

Owner:EXASCALER

Graphene nano particle compound aerogel microspheres and preparation method thereof

InactiveCN105498649AUniform sizeAvoid uneven loadAerogel preparationMicroballoon preparationFreeze-dryingMicrosphere

The invention relates to graphene nano particle compound aerogel microspheres and a preparation method thereof, and belongs to the field of functional materials. The graphene nano particle compound aerogel microspheres are prepared from, by weight, 100 parts of deionized water, 0.05-1.5 parts of graphite oxide and 0.1-5 parts of nano particles. The raw materials are subjected to 1,600W ultrasound wave irradiation for 60 min to 180 min after being mixed to be prepared into a graphene oxide nano particle dispersion solution, the graphene oxide nano particle dispersion solution is atomized into graphene oxide nano particle drop microspheres through a spraying method, the graphene oxide nano particle drop microspheres are put in a cooling bath for receiving liquid collection, graphene oxide nano particle cold microspheres are obtained through filtering, and graphene oxide nano particle compound aerogel microspheres are obtained after freeze drying; the graphene nano particle compound aerogel microspheres are obtained through a thermal reduction method or chemical reduction method. The products are uniform in size, are provided with a porous net structure, are evenly loaded with metal / inorganic nano particles, and are low in mass and small in density. Meanwhile, the preparation method is easy to operate, simple and efficient.

Owner:SICHUAN UNIV

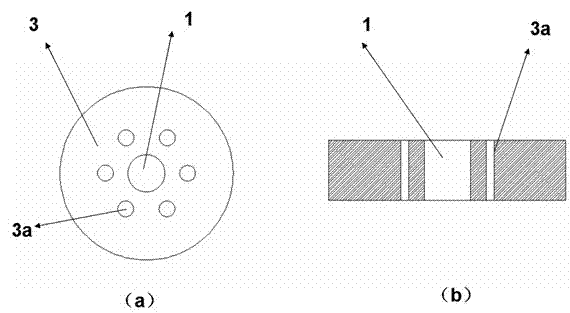

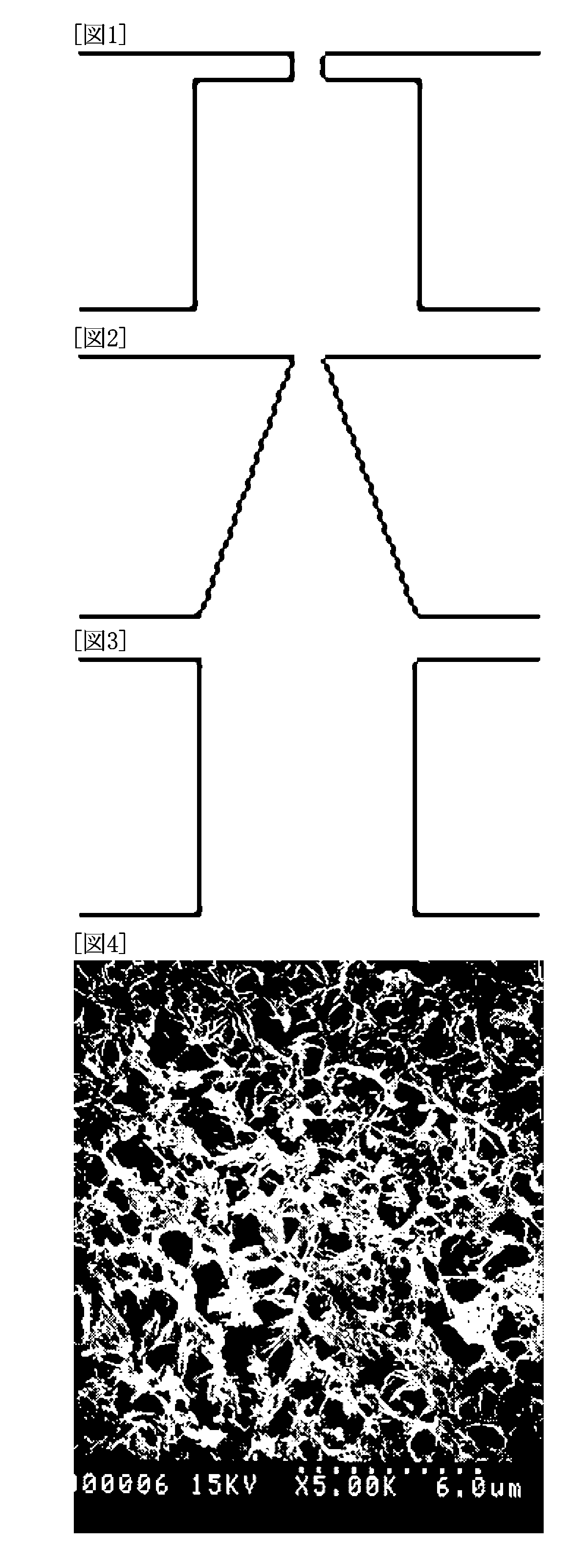

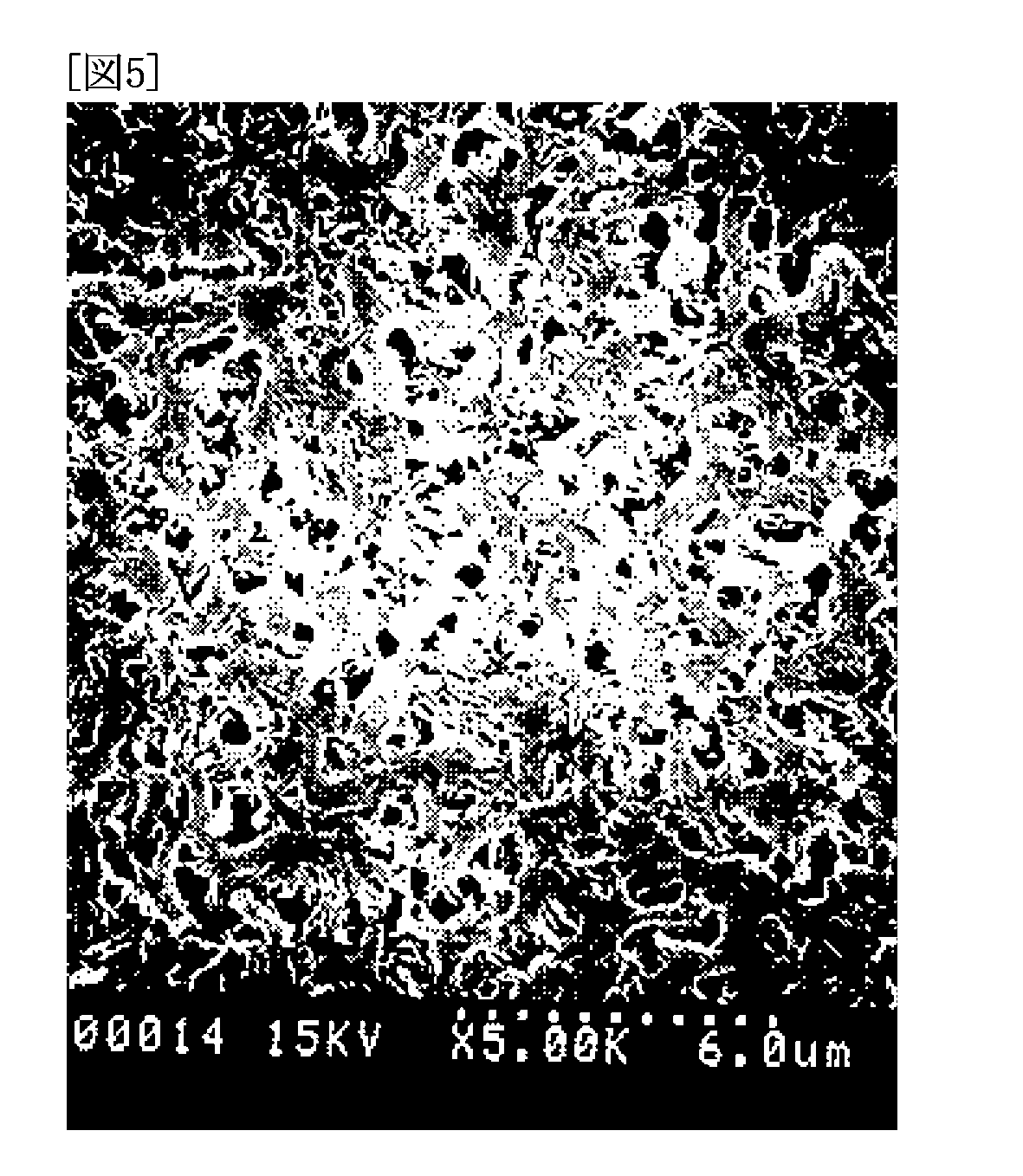

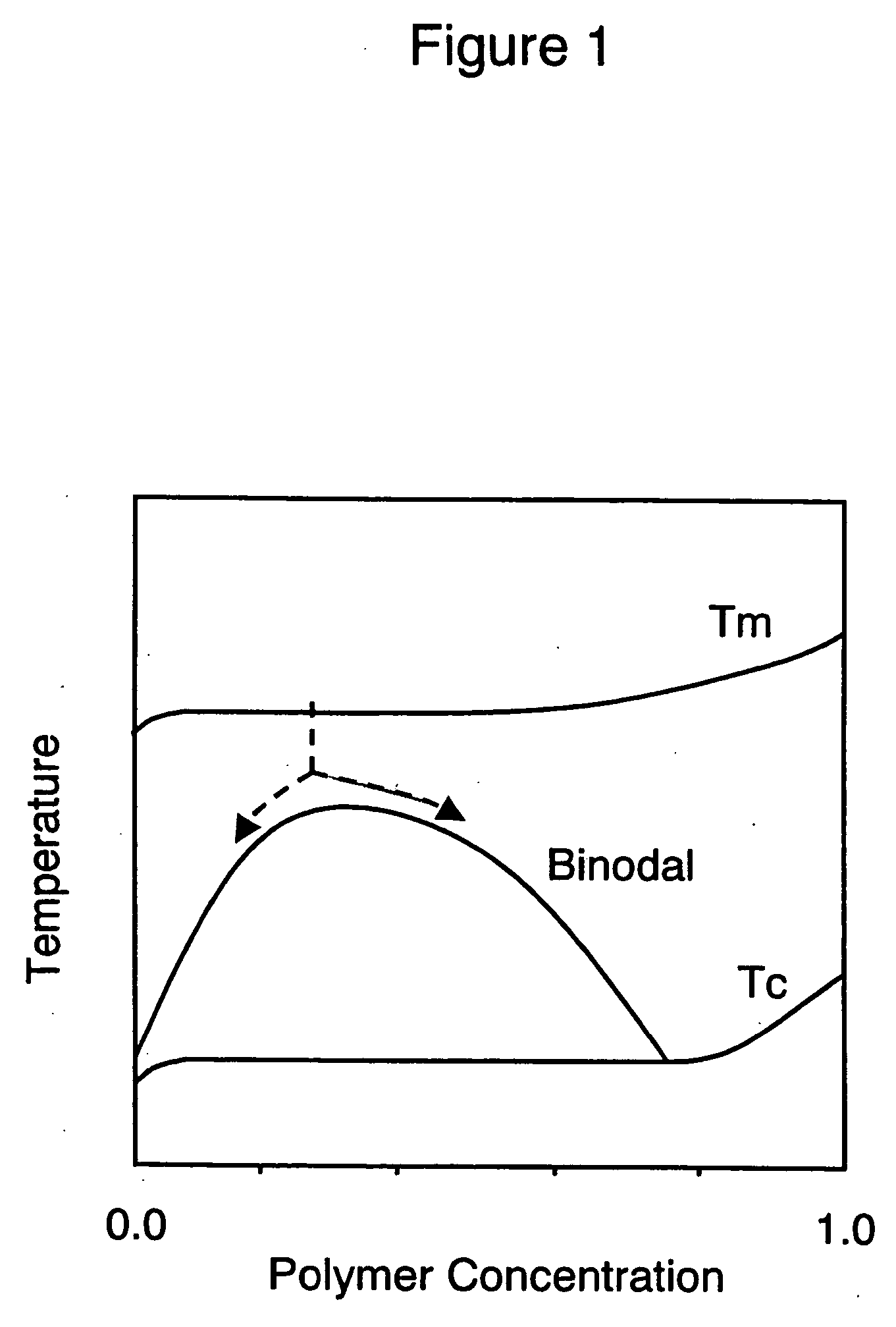

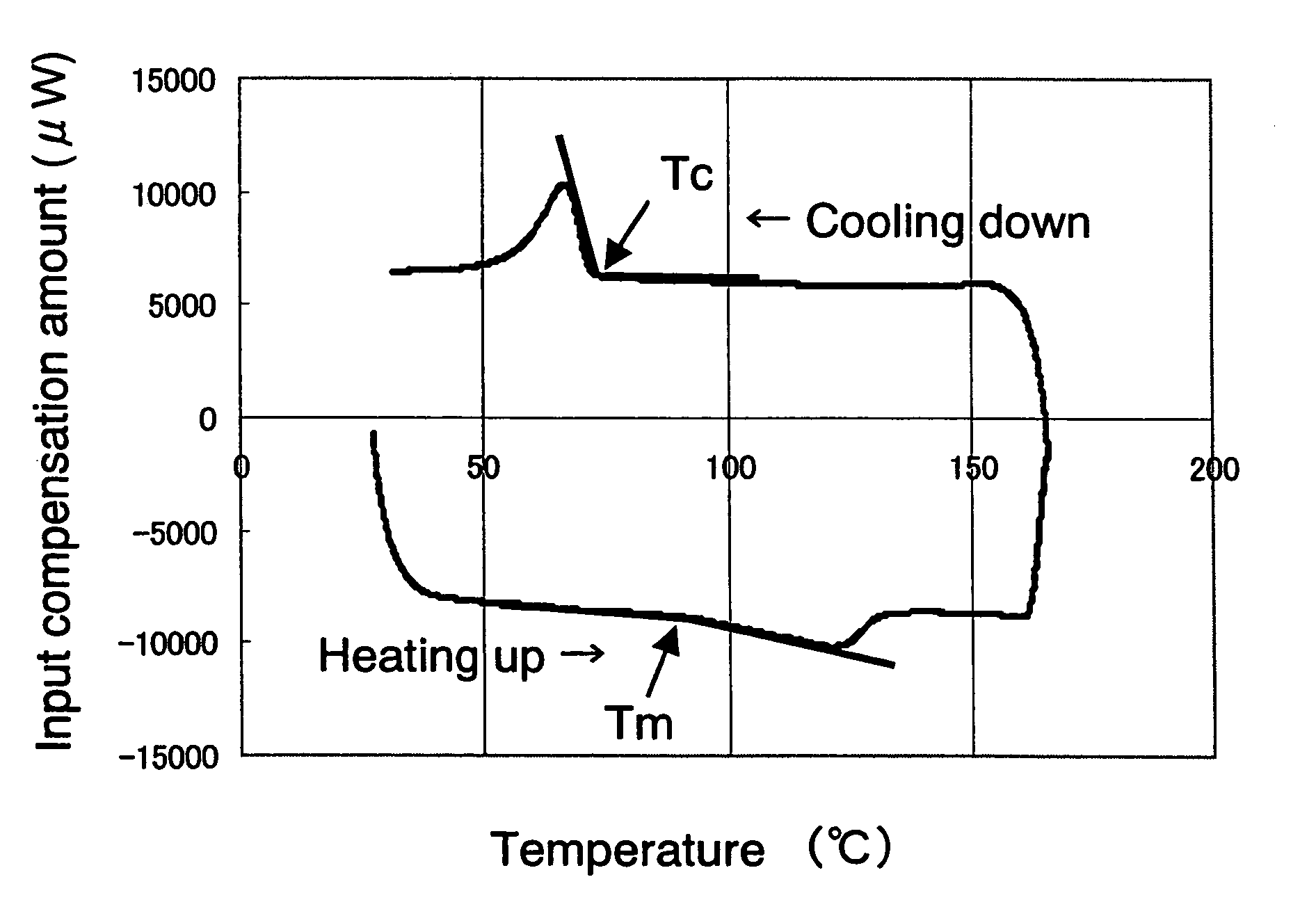

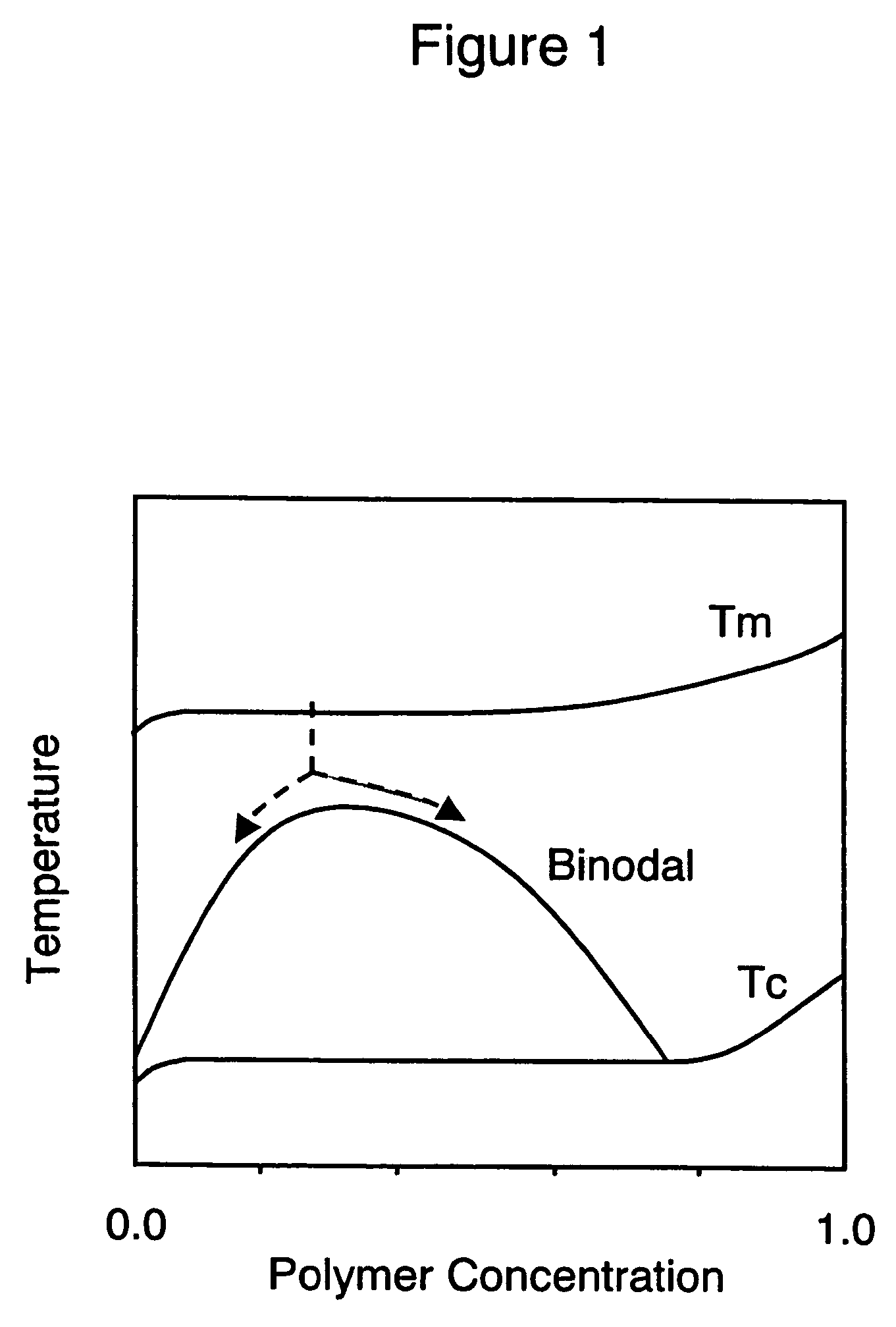

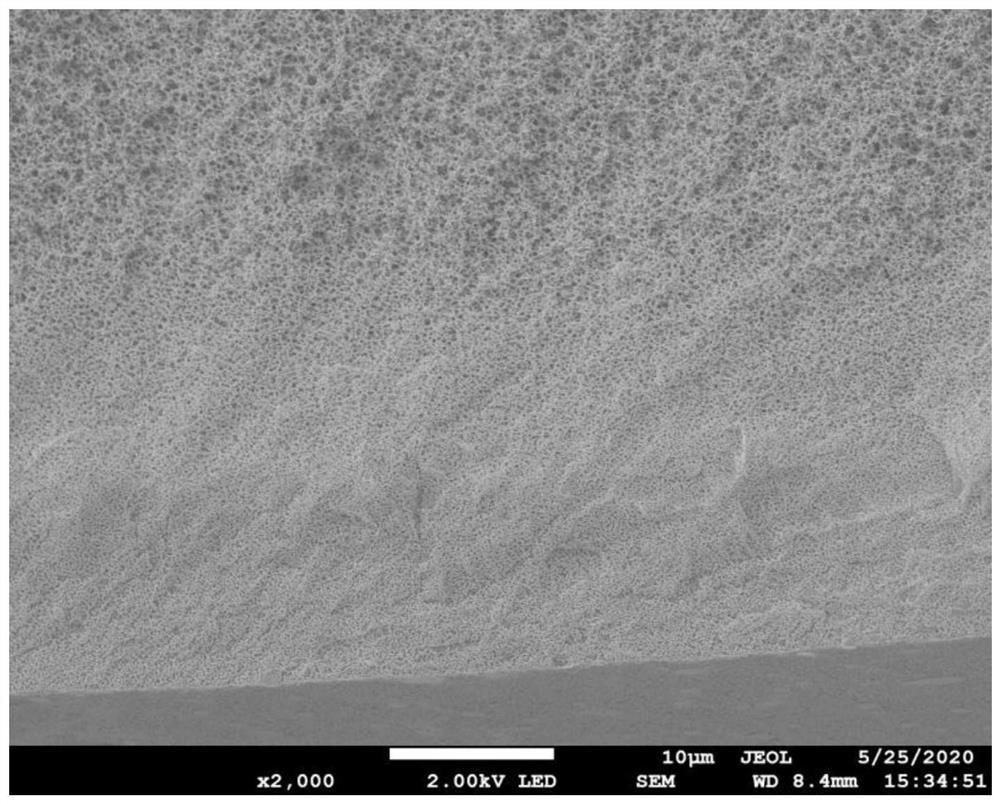

Polyvinylidene fluoride hollow yarn type microporous film and process for production of the same

InactiveUS20090283469A1Easy to separateImprove permeabilitySemi-permeable membranesMembranesYarnFiber

Problems: To provide a polyvinylidene fluoride microporous membrane which has high water permeability and separation performance and is excellent in mechanical and chemical strength; and a process for producing the film.Means for Solving Problems: An anisotropic polyvinylidene fluoride hollow fiber microporous membrane characterized in that the porosity of the cross-sectional bulk layer is higher than the membrane surface porosity of the outer layer and that in the cross section of the membrane, the dense microstructure of the outer surface changes substantially discontinuously into the coarse structure of the bulk layer. The microporous membrane can be produced by introducing by a dry-wet method a dope prepared by dissolving a polyvinylidene fluoride resin together with a water-soluble latent solvent at high temperature into a cooling bath consisting of water or a mixture thereof with a water-soluble latent solvent and subjecting the dope to membrane formation wherein the cross-sectional bulk layer is formed mainly by thermally-induced phase separation and the outer layer is formed mainly by nonsolvent-induced phase separation.

Owner:TOYO TOYOBO CO LTD

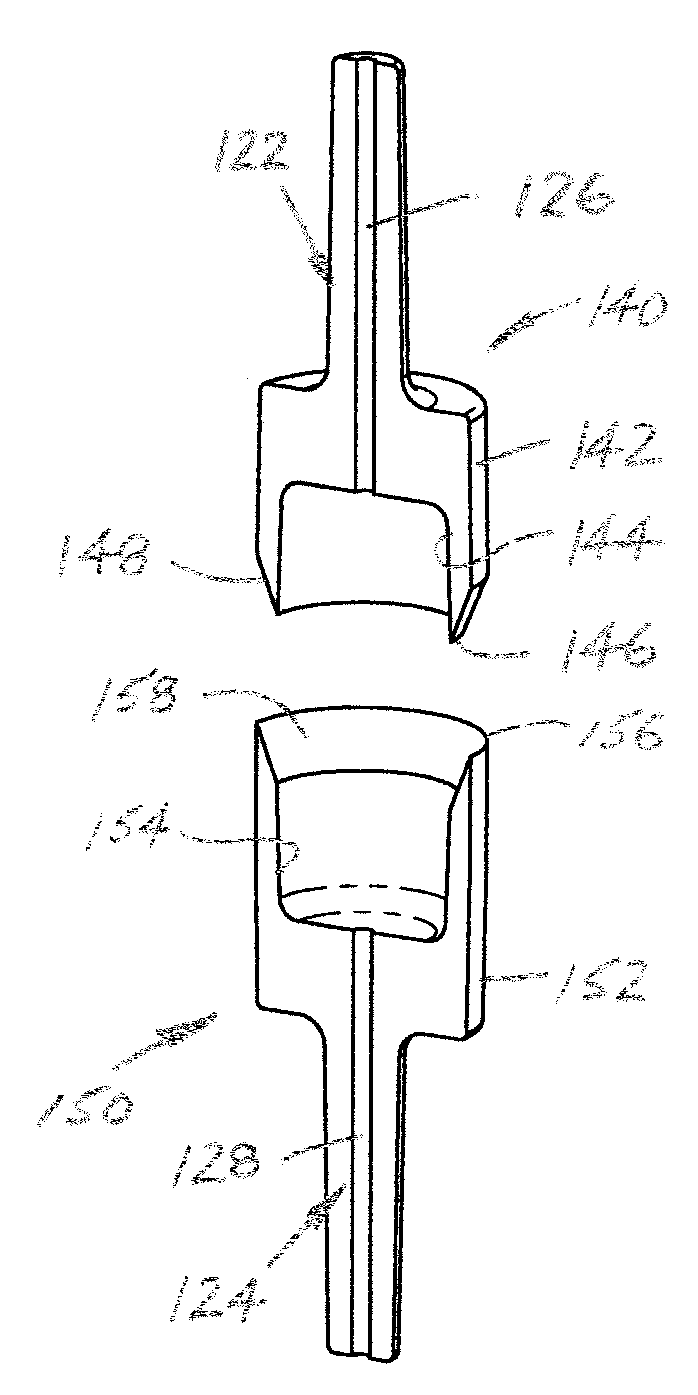

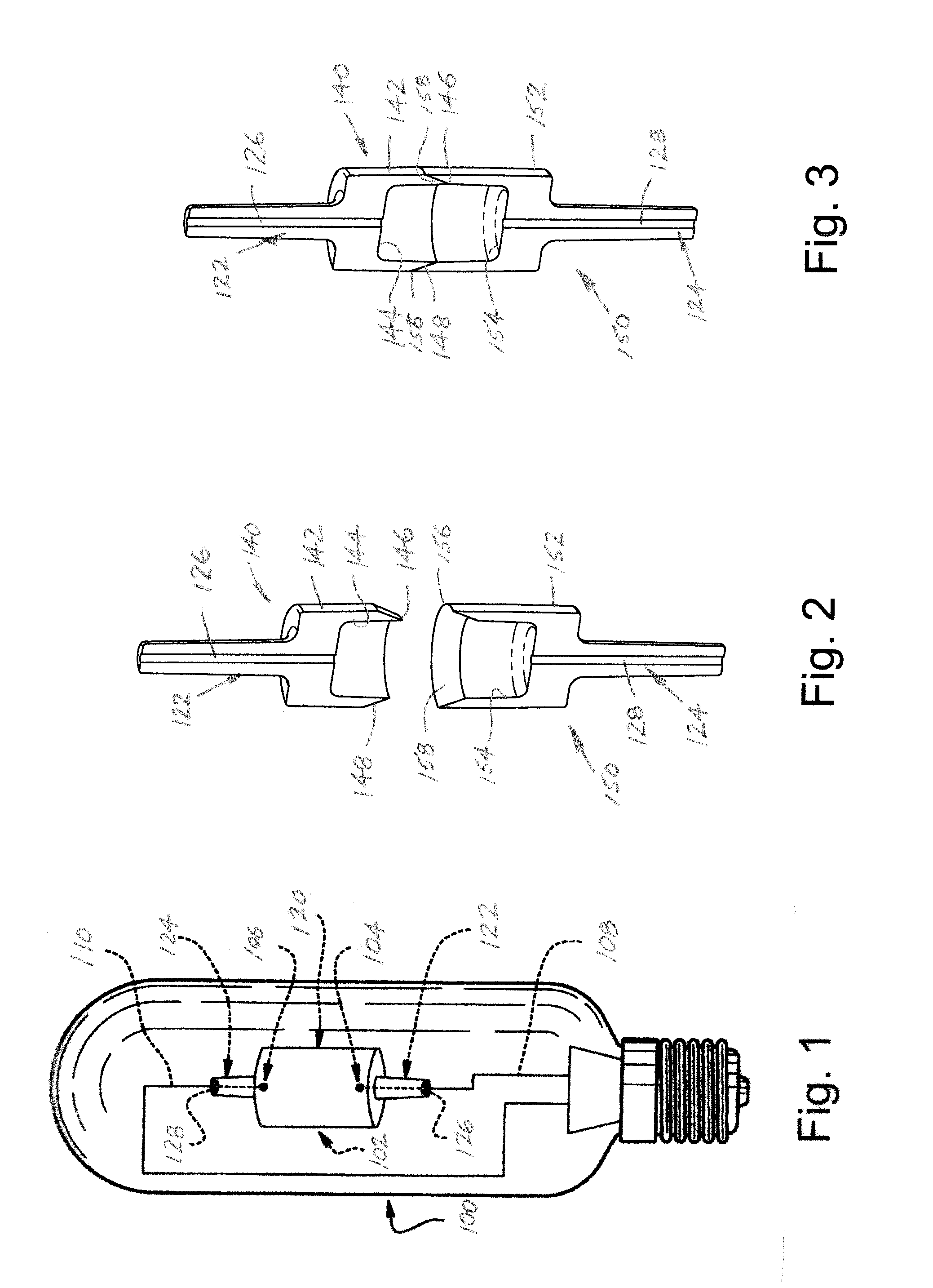

Method and apparatus for extruding polymers employing microwave energy

An apparatus and method for molding balloon catheters is disclosed. The balloon may be molded by providing a polymeric tube within a mold having an interior cavity in the shape of the desired balloon. Microwave energy, which may be generated by a gyrotron, may then be directed toward the mold, to heat the polymeric material without heating the mold. Once heated, pressurized fluid may be injected into the tube to blow the polymeric material against the interior cavity whereupon the material can cool to form the balloon or can be further heatset by additional microwave energy and be cooled to form the balloon. In accordance with one embodiment, microwave energy can also be used without a mold to form a medical device. A polymer extrusion apparatus is disclosed utilizing a microwave energy for heating polymer feedstock material within the extruder tip and die unit just prior to formation of the extrudate product. A cooling bath mechanism, which in one embodiment can also include a cooling tube member having a cooling medium forced therethrough, is also disclosed. An apparatus for preparing polymer disk members, to use as the polymer feedstock material for the microwave extrusion apparatus, is also disclosed. Apparatus for interconnecting and rotating the polymer disk members, the die tip, or the die, or any combination thereof, for creating angularity characteristics in the polymer extrudate, is also disclosed.

Owner:BOSTON SCI SCIMED INC

Composition, process and installation for the continuous production of a foamed polymeric sheet and sheet thus produced

InactiveUS20100215934A1Improve melt strengthLow densitySynthetic resin layered productsDomestic articlesFoaming agentEngineering

The present invention describes a process and respective installation for continuous production of foamed polymeric sheets by extrusion, another object of the invention being the development and use of polypropylene-based formulations comprising linear polypropylenes and branched polypropylenes. The installation includes four stages: a first stage of extrusion foaming, in which a foaming agent, either of a chemical or physical nature, in the latter case introduced in supercritical conditions, is mixed with the polymeric mass melted previously in the first stages of the extruder, the material expanding exactly at the outlet of the lips of the planar extrusion head; a second stage of calibration and cooling of the foamed sheet, in which the expanded plastic material is cooled by contact in a system of vacuum calibrators and by contact with water in a cooling bath; a stage of collection of the foamed panel; and a final stage of cutting of the foamed sheet, defining the final dimensions thereof.

Owner:ULMA C Y E

Hollow fiber membrane and method of producing the same

InactiveUS20050258101A1Good water permeabilityHigh mechanical strengthMembranesHollow filament manufactureFiberHollow fibre membrane

A method of producing a hollow fiber membrane includes discharging a polyvinylidene fluoride solution comprising a polyvinylidene fluoride resin and a poor solvent at a temperature above a phase separation temperature into a cooling bath at a temperature below the phase separation temperature to coagulate the polyvinylidene fluoride resin. The hollow fiber membrane comprises a polyvinylidene fluoride resin having spherical structures that have an average diameter in the range of 0.3 to 30 μm.

Owner:TORAY IND INC

Method for preparing reinforced hollow fiber membrane of braided tube by using low-temperature thermal-induced phase separation method

The invention discloses a method for preparing a reinforced hollow fiber membrane of a braided tube by using a low-temperature thermal-induced phase separation method. The method comprises the following steps of: 1) mixing polymer with a diluting agent, heating and dissolving, and configuring polymer solution; 2) coating the polymer solution onto the surface of the braided tube; and 3) generating thermal-induced phase separation in cooling bath and successively removing the diluting agent in an extracting agent to prepare the reinforced hollow fiber membrane of the braided tube. The invention has the beneficial effects that as the diluting agent capable of dissolving the polymer at a lower temperature is adopted in the method, the destructive effect caused by high temperature required by the conventional thermal-induced phase separation method on a braided tube structure can be prevented; the invention provides a new process for preparing the reinforced hollow fiber membrane of the braided tube by using the thermal-induced phase separation method with good universality for braided tube materials; and the prepared reinforced hollow fiber membrane of the braided tube has high strength and is low in cost.

Owner:ZHEJIANG UNIV

Hollow fiber membrane and method of producing the same

InactiveUS7182870B2Good water permeabilityHigh mechanical strengthMembranesHollow filament manufacturePhysical chemistryPolyvinylidene difluoride

A method of producing a hollow fiber membrane includes discharging a polyvinylidene fluoride solution comprising a polyvinylidene fluoride resin and a poor solvent at a temperature above a phase separation temperature into a cooling bath at a temperature below the phase separation temperature to coagulate the polyvinylidene fluoride resin. The hollow fiber membrane comprises a polyvinylidene fluoride resin having spherical structures that have an average diameter in the range of 0.3 to 30 μm.

Owner:TORAY IND INC

Method for preparing hollow fiber microporous membrane by thermally-induced phase separation method

InactiveCN102107121AHigh mechanical strengthIncrease water productionSemi-permeable membranesFiberDiluent

The invention provides a method for preparing a hollow fiber microporous membrane by a thermally-induced phase separation method. The method for preparing the hollow fiber microporous membrane by the thermally-induced phase separation method comprises the following steps of: mixing 20 to 60 weight percent of polymer, 70 to 35 weight percent of compound diluent and 5 to 10 weight percent of out-of-phase particles in a mixing and stirring kettle at the high temperature of between 135 and 180 DEG C, and dissolving to form membrane liquid; leading the membrane liquid within the same temperature range into a screw rod extruder metering pump; putting a center pipe into core liquid by using a spinning component so as to spray a hollow fiber into a cooling bath, wherein the temperature of the cooling bath is controlled to be 10 to 60 DEG C; and coiling to obtain a hollow fiber microporous membrane product. The mechanical strength and the water generation amount of the prepared hollow fiber microporous membrane product are enhanced greatly.

Owner:林金建

Method for preparing hollow fiber nanofiltration membrane by using thermally induced phase separation/interface cross linking synchronization method

InactiveCN102824859AThickness is easy to controlAvoid the difficulty of high adhesiveness requirementsSemi-permeable membranesHollow filament manufactureFiberCross-link

The invention discloses a method for preparing a hollow fiber nanofiltration membrane by using a thermally induced phase separation / interface cross linking synchronization method; the preparation method comprises the following steps: 1) mixing polymer, a diluting agent and a cross linking agent to form a homogeneous phase membrane casting solution; 2) extruding the membrane casting solution and core solution, or the membrane casting solution and nitrogen by a ring-shaped spinning head, then conducting the thermally induced phase separation in a cooling bath so as to obtain a hollow primary membrane; 3) soaking the hollow primary membrane in extracting solution containing cross linking pre-polymer, conducting the interface cross linking at the same time with removing diluting agent, thereby obtaining a hollow fiber nanofiltration membrane. According to the method provided by the invention, the preparations of holing and separation layer is finished, and the difficulty point of high require of bonding property between a separation layer and a supporting layer of a combining method in the prior art can be avoided, and meanwhile the thickness and the evenness of the separation layer are easy to control; the simple new method for preparing the hollow fiber nanofiltration membrane with excellent property by using the thermally induced phase separation / interface cross linking synchronization method is provided; and the prepared nanofiltration membrane is little in defect, high in stability and high in controllability.

Owner:ZHEJIANG UNIV

Multi-bath apparatus and method for cooling superconductors

InactiveUS20070204632A1Superconductors/hyperconductorsRefrigeration devicesHigh-temperature superconductivityEngineering

A multi-bath apparatus and method for cooling a superconductor includes both a cooling bath comprising a first cryogen and a shield bath comprising a second cryogen. The cooling bath surrounds the superconductor, and the shield bath surrounds the cooling bath. The cooling bath is maintained at a first pressure and subcooled, while the shield bath is maintained at a second pressure and saturated. The cooling bath and the shield bath are in a thermal relationship with one another, and the first pressure is greater the second pressure. Preferably, the cryogens are liquid nitrogen, and the superconductor is a high temperature superconductor, such as a current limiter. Following a thermal disruption to the superconductor, the first pressure is restored to the cooling bath and the second pressure is restored to the shield bath in order to restore the superconductor to a superconductive state.

Owner:BOC GRP INC

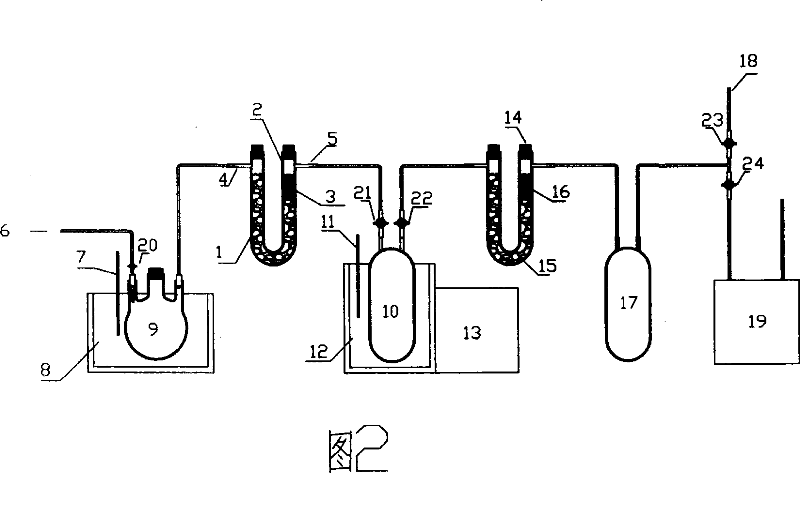

Preparation and purification method of hydrogen selenide

InactiveCN101041425ATake advantage ofReduce pollutionBinary selenium/tellurium compoundsPurification methodsSorbent

The invention discloses a purifying method to prepare hydrogen selenide, which comprises the following steps: reacting Al2Se3 and H2O; getting hydrogen selenide H2Se; removing water of H2Se gas through condensing; using Al2Se3 particle to adsorb remain water; entering into carboy to condense and liquefy; evacuating the carboy under the condition of cool bath; eliminating non-condensable gas impurity of solution in the liquid; closing the valve of carboy; getting purify hydrogen selenide; absorbing water; taking-up active solid of reacting with water as raw material; reacting Al2Se3 and H20; getting H2Se; reaching highly effective dewater effect.

Owner:DALIAN LIFANG CHEM TECH

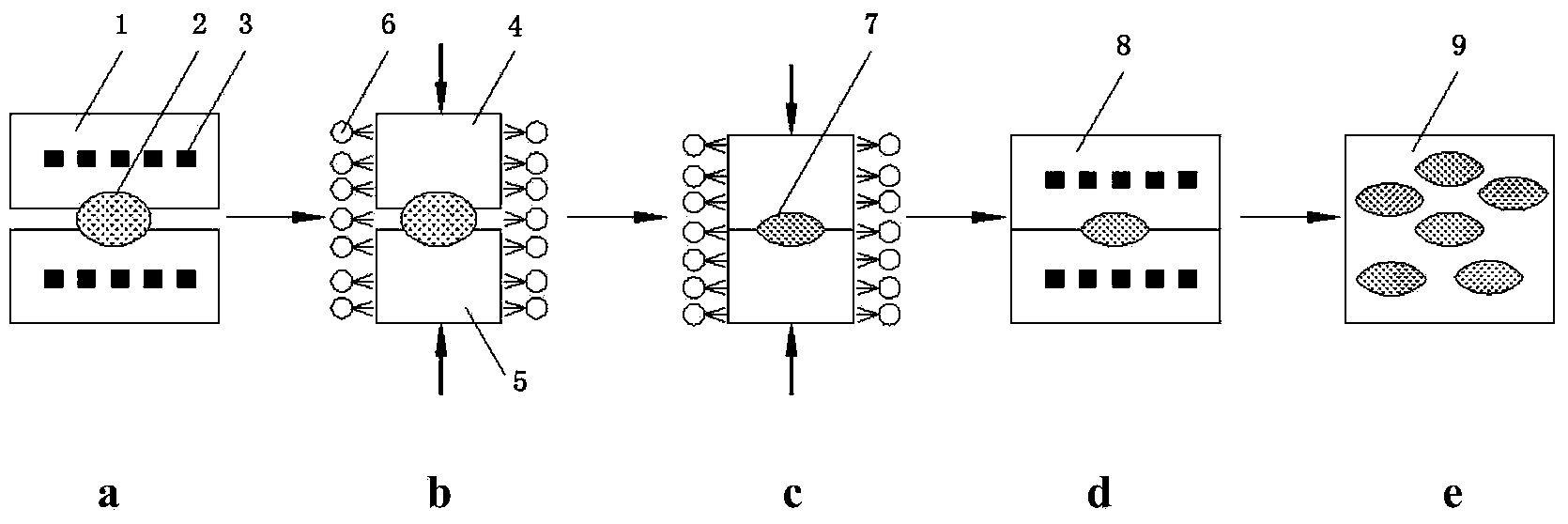

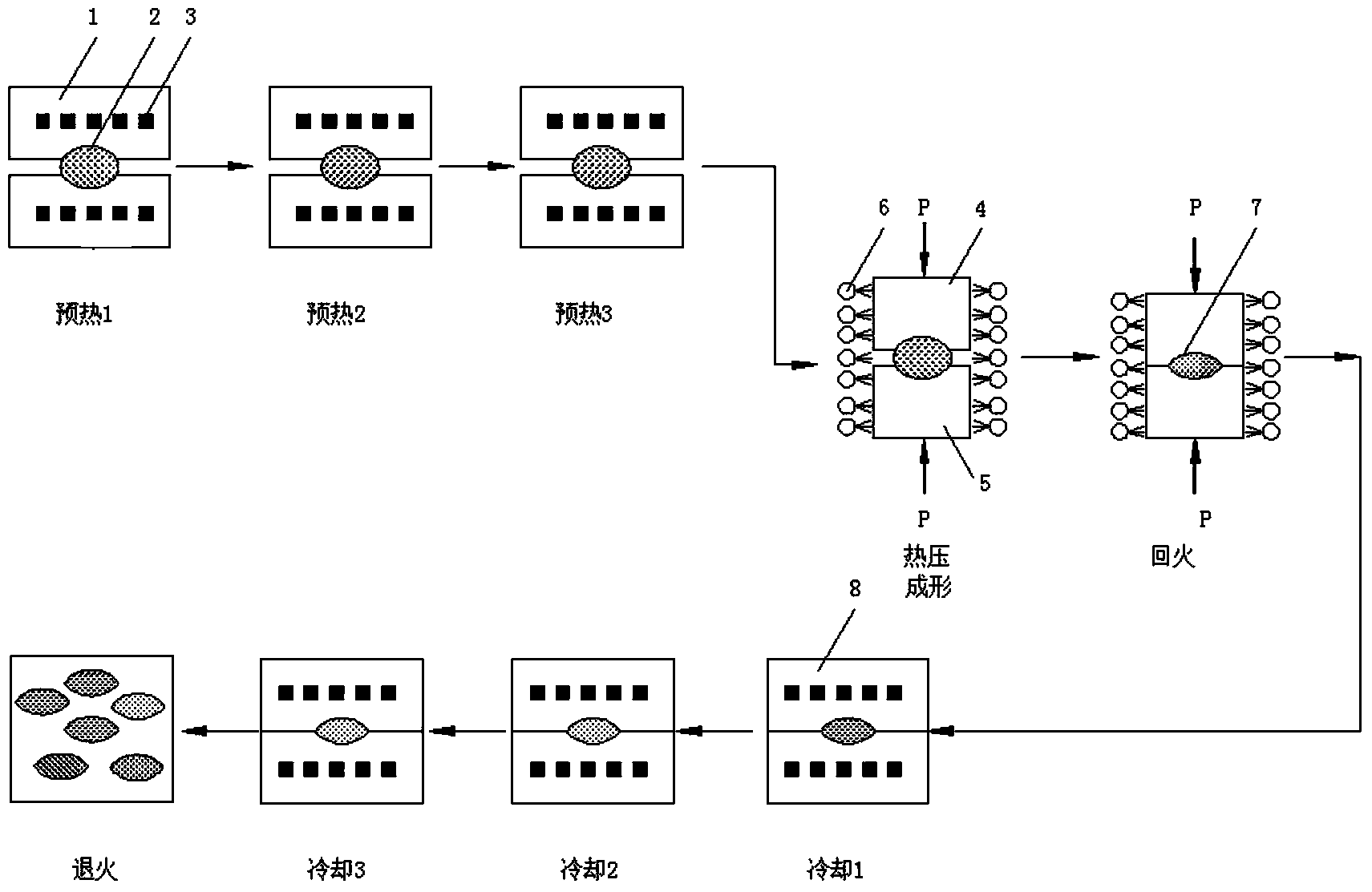

Forming method of chalcogenide glass aspherical lens

ActiveCN104310755AEfficient quality batch manufacturingEfficient batch manufacturingGlass pressing apparatusGlass press-moulding apparatusChalcogenide glassRoom temperature

A forming method of a chalcogenide glass aspherical lens is disclosed. The method includes: a) subjecting a chalcogenide glass prefabricated part to three times of heating in a preheating device to raise the temperature of the prefabricated part from room temperature to a temperature T1, with the temperature T1 being near the yield temperature At of the material; b) maintaining the temperature of a cavity and a core at T2 under the actions of heating elements, with the temperature T2 being 5-10 DEG C lower than the conversion temperature Tg of the material, transferring the prefabricated part having the temperature T1 into a mould pressing cavity formed by the cavity and the core; maintaining the temperature of the prefabricated part to be around the yield temperature At of the material, and applying a pressing force P1 on to the cavity and the core simultaneously for a time period of t1 to allow the prefabricated part to be turned into the chalcogenide glass aspherical lens by mould pressing; c) maintaining the pressing force P1 for a time period of t2, and cooling the temperature of the forming mould and the chalcogenide glass aspherical lens to a temperature T3; d) transferring the chalcogenide glass aspherical lens to a cooling bath, performing three times of cooling to cool the chalcogenide glass aspherical lens from the temperature T3 to room temperature, and taking the chalcogenide glass aspherical lens out; and e) putting the chalcogenide glass aspherical lens into a tempering device and tempering for 12-36 h.

Owner:沈奕芸

Cooling system for electronic equipment

InactiveUS20170273223A1Function increaseReduce evaporative lossDigital data processing detailsSemiconductor/solid-state device detailsNuclear engineeringPerfluorinated compound

A cooling system is adapted for reduction of evaporative loss of a liquid coolant and for efficient cooling of plural electronic devices densely accommodated in a cooling bath of a small volume. A cooling system accommodates plural electronic devices in an open space of a cooling bath provided with an inlet port and an outlet port for a liquid coolant. The cooling system is configured to directly cool the electronic devices by immersion of the electronic devices in the liquid coolant circulated in the open space. The liquid coolant contains a perfluorinated compound as a main component. The liquid coolant is adapted to exhibit a liquid weight loss percentage of 1.5% or less as determined by allowing 10 ml of the liquid coolant in a 10-ml measuring cylinder (opening diameter: 11.5 mm) to spontaneously evaporate under normal environment at a room temperature of 25° C. for 100 hours.

Owner:EXASCALER

Skinned hollow fiber membrane and method of manufacture

InactiveUS6921482B1Not prevent solvent evaporationPrevents formation of skinSemi-permeable membranesMembranesFiberHollow fibre membrane

Hollow fiber membranes having a skinned surface on one diameter, and a porous surface on the opposite diameter arm produced from perfluorinated thermoplastic polymers by extruding a heated solution of the polymer having a lower critical solution temperature directly into a cooling bath to form the porous membrane by liquid-liquid phase separation. Extrusion can be conducted either vertically or horizontally. The hollow fiber membranes are useful as ultrafiltration membranes and as membrane contactors.

Owner:ENTEGRIS INC +1

Liquid metal directional casting apparatus and process

Processes for directionally casting liquid metal to form an articles is disclosed, which includes compressing a seal intermediate a mold chill plate and a mold assembly, wherein the seal circumscribes a shell mold in the mold assembly; filling the shell mold in the mold assembly with molten metal; immersing the mold assembly into a liquid metal cooling bath from a bottom portion to a top portion of the mold assembly; and transmitting heat from the mold assembly to the liquid metal cooling bath to solidify the molten metal from the bottom portion to the top portion of the mold assembly. A device for directionally casting liquid metal is further provided.

Owner:GENERAL ELECTRIC CO

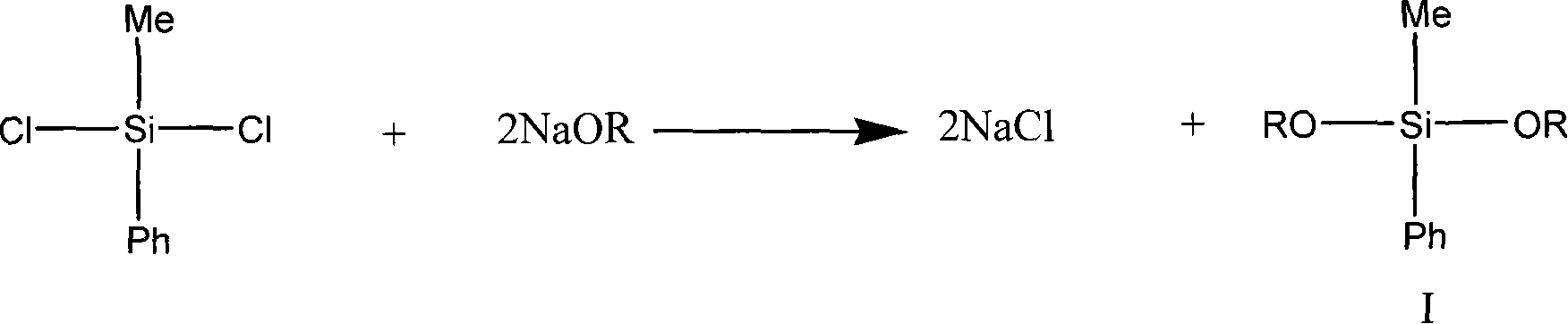

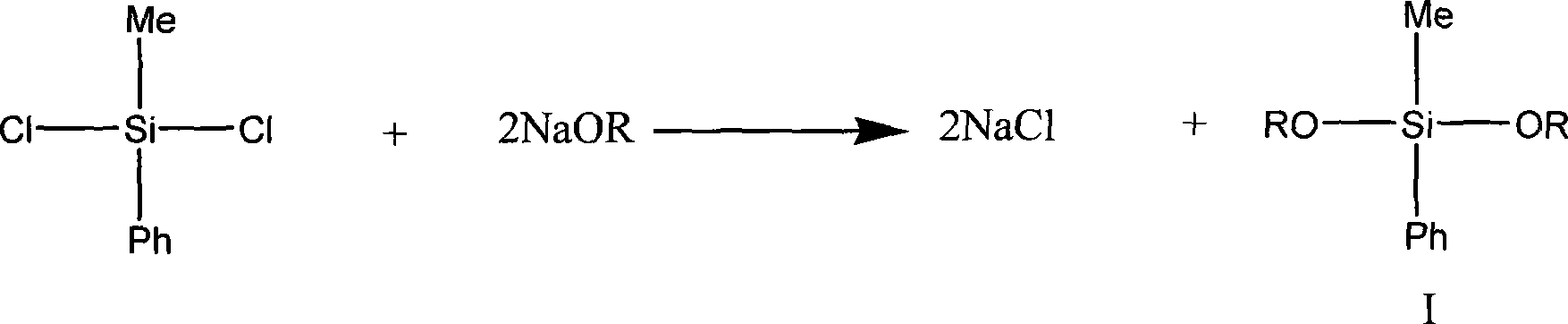

Safe separation method for increasing yield of methyl phenyl dialkoxy silicane

ActiveCN101058585AHigh yieldSafe and efficient separationGroup 4/14 element organic compoundsSlagNitrogen

The invention discloses a receiving rate improving method of methylbenzene dialkoxy silicane and safe separating method of methylbenzene alkoxy silicane, which comprises the following steps: adopting methylbenzene dichloro-silicane as neutralizing agent; adding the methylbenzene dichloro-silicane into the transmitting material of methylbenzene alkoxy silicane slowly protected by dried air or nitrogen to neutralize under normal temperature or cooling bath; controlling the pH value of composite material to 2-9; filtering slag after reacting; rectifying the filtrate; separating to recycling the solvent and non-reacted raw material; separating the high-purity methylbenzene dialkoxy silicane under certain reflux rate; increasing the receiving rate of methylbenzene dialkoxy silicane in the transmitting material of methylbenzene alkoxy silicane greatly; fitting for preparing the product of national defence, space aviation, architecture and rubber widely.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL

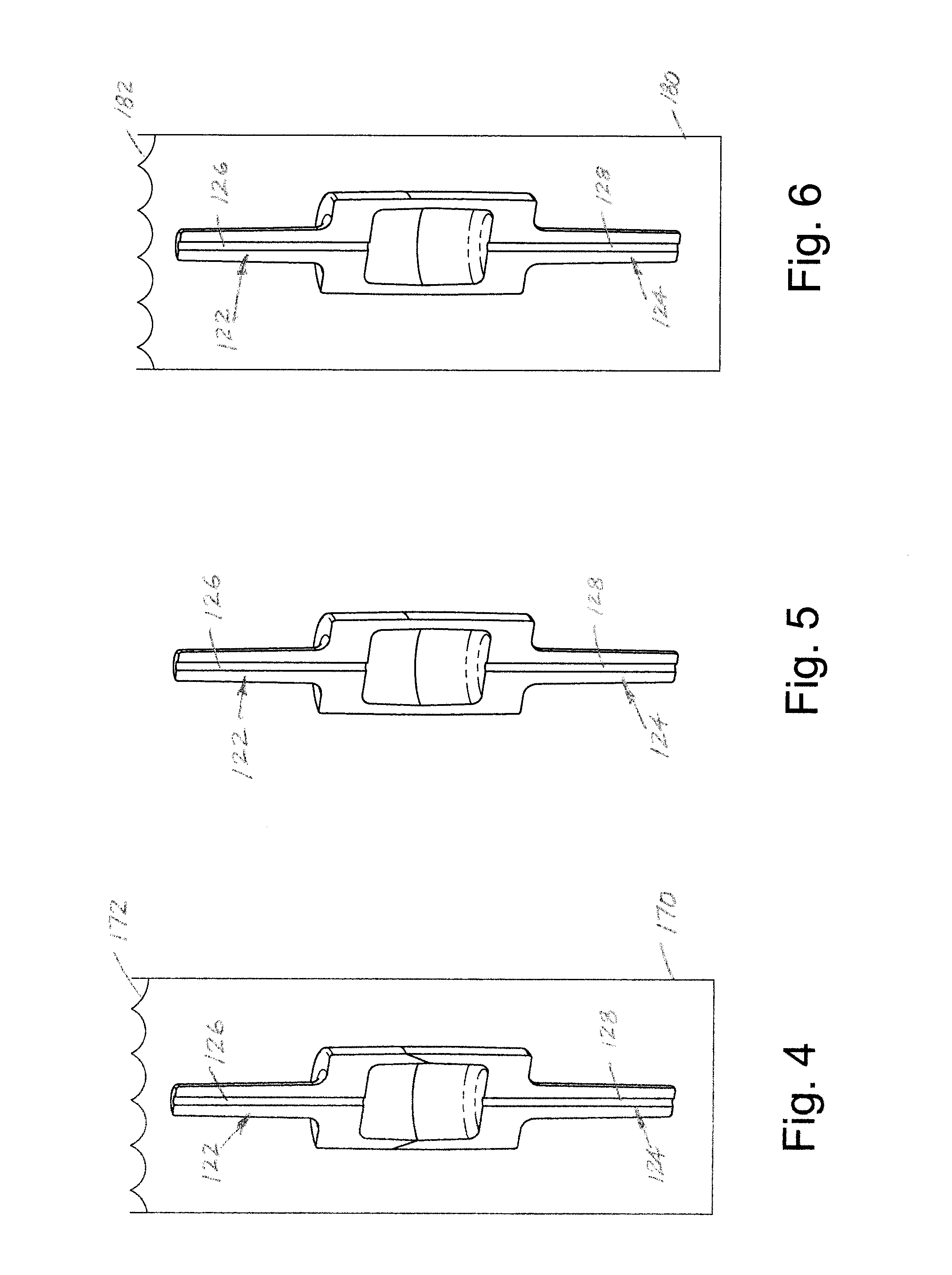

Green joining ceramics

InactiveUS20090130459A1Simple manufacturing processReduce the numberSolid cathodesLaminationCooling bathCeramic metal

A method of green joining ceramic components is disclosed, particularly for use in forming a discharge body for a ceramic metal halide lamp. The process includes providing a first green ceramic component having a male joining surface, and providing a second green ceramic component having a female joining surface dimensioned to matingly receive the first component. The first and second green ceramic components are assembled along the joining surfaces, the assembled components are uniformly heated to join the first and second components. The joined components are next cooled in a cooling bath that uniformly cools the joined components. Thereafter, the joined green part may be inserted in the furnace for debindering and sintering.

Owner:GENERAL ELECTRIC CO

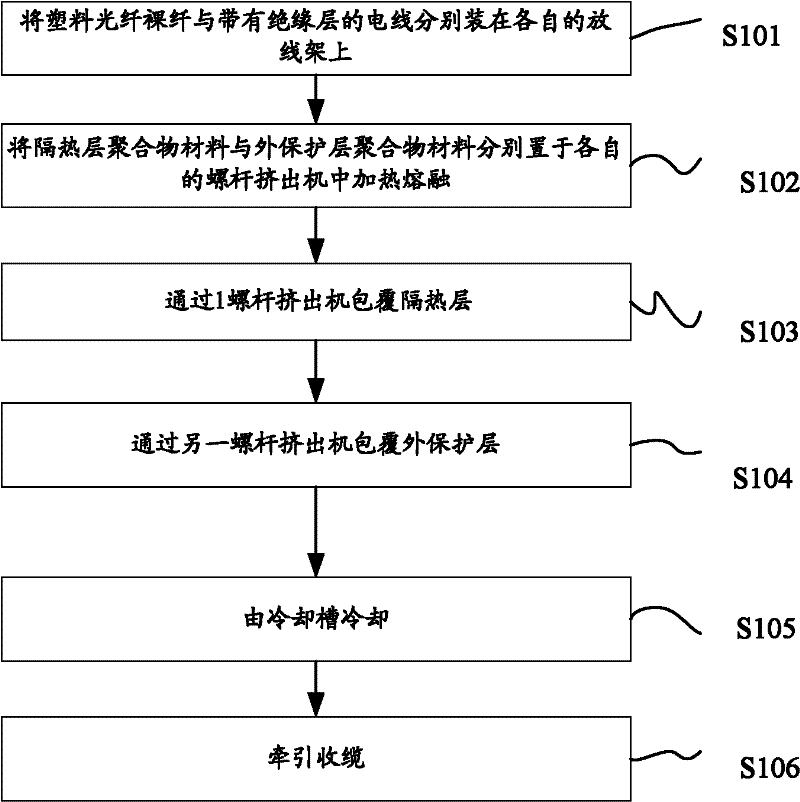

Production method and equipment of bunched optical cable

InactiveCN102254625AHigh toughness and low costResilience is low costPower cablesCable/conductor manufactureInsulation layerBare fiber

The invention provides a production method of a bunched optical cable, comprising the following steps of: respectively installing bare fiber of plastic optical fiber and an electric wire with an insulation layer on respective payoff racks; respectively placing a polymer material for a heat insulation layer and a polymer material for an outer protection layer in respective screw extruder, and heating and fusing; cladding the heat insulation layer through one screw extruder; cladding the outer protection layer through the other screw extruder; cooling through a cooling bath; and retracting the cable through traction. According to the bunched optical cable produced by utilizing the method, the plastic optical fiber with high tenacity and low cost and the electric cable for power transmission can be integrated in the same cable, optical signals and power can be simultaneously transmitted in the same cable erection network, and the erection of an intelligent grid can be facilitated; in addition, the bunched optical cable not only has the advantage of high bandwidth same as a glass optical fiber composite cable, but also has the advantages of convenience for connection, low cost, simpleness and feasibility for later maintenance, and the like.

Owner:BEIJING ZHONGKE HAITONG TECH

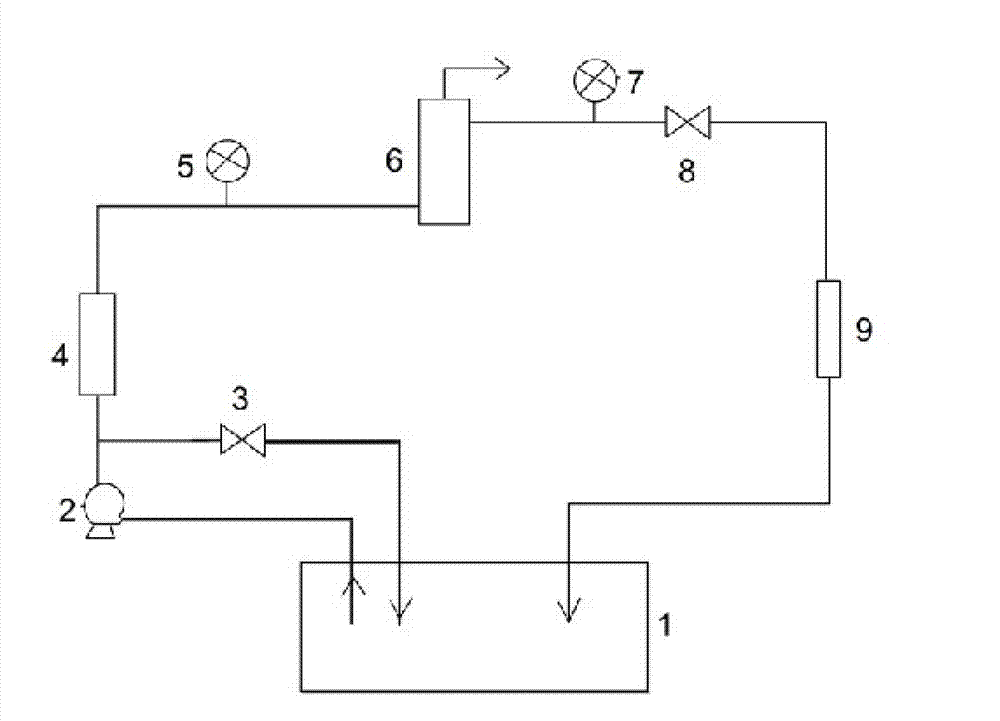

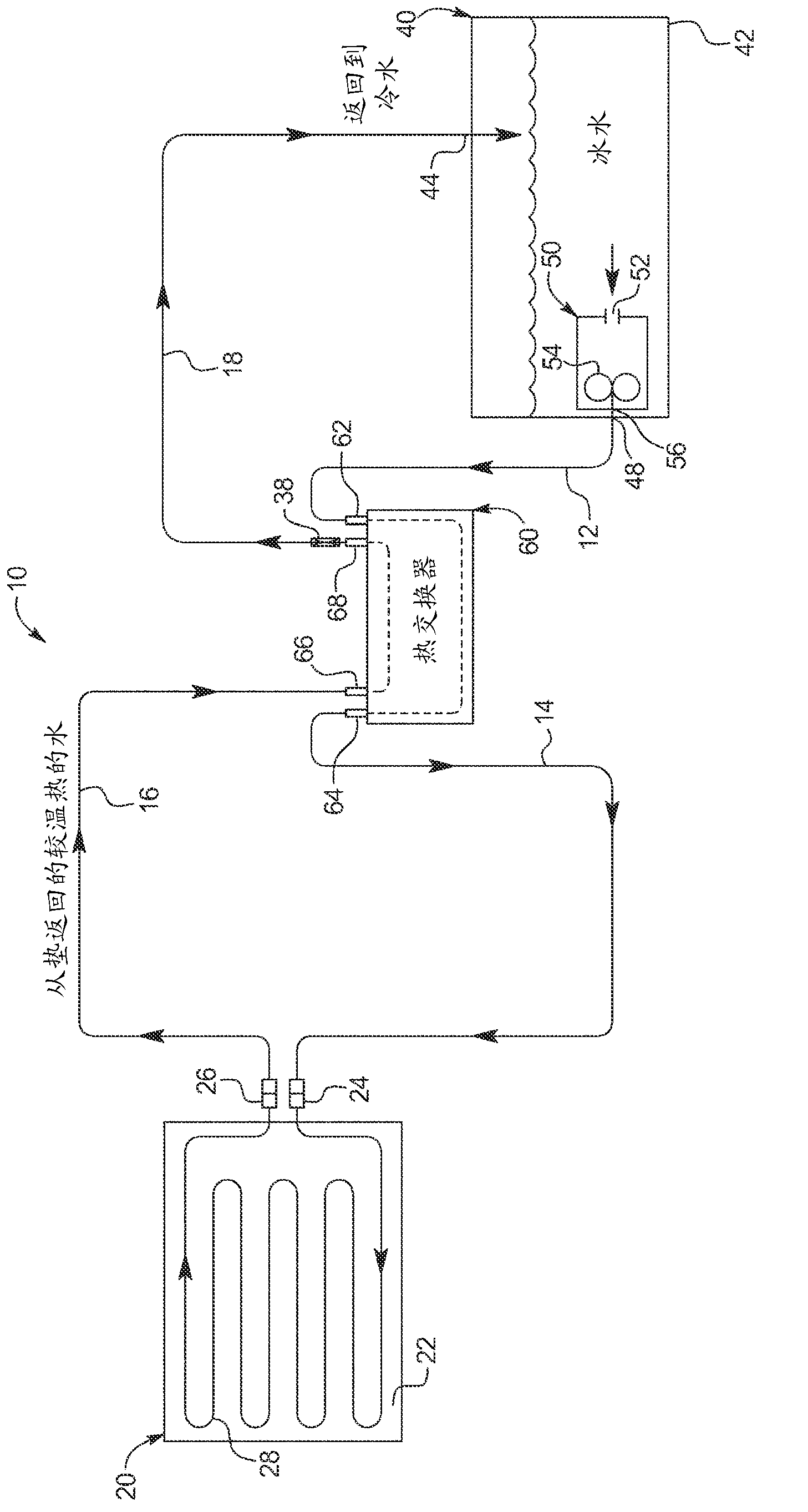

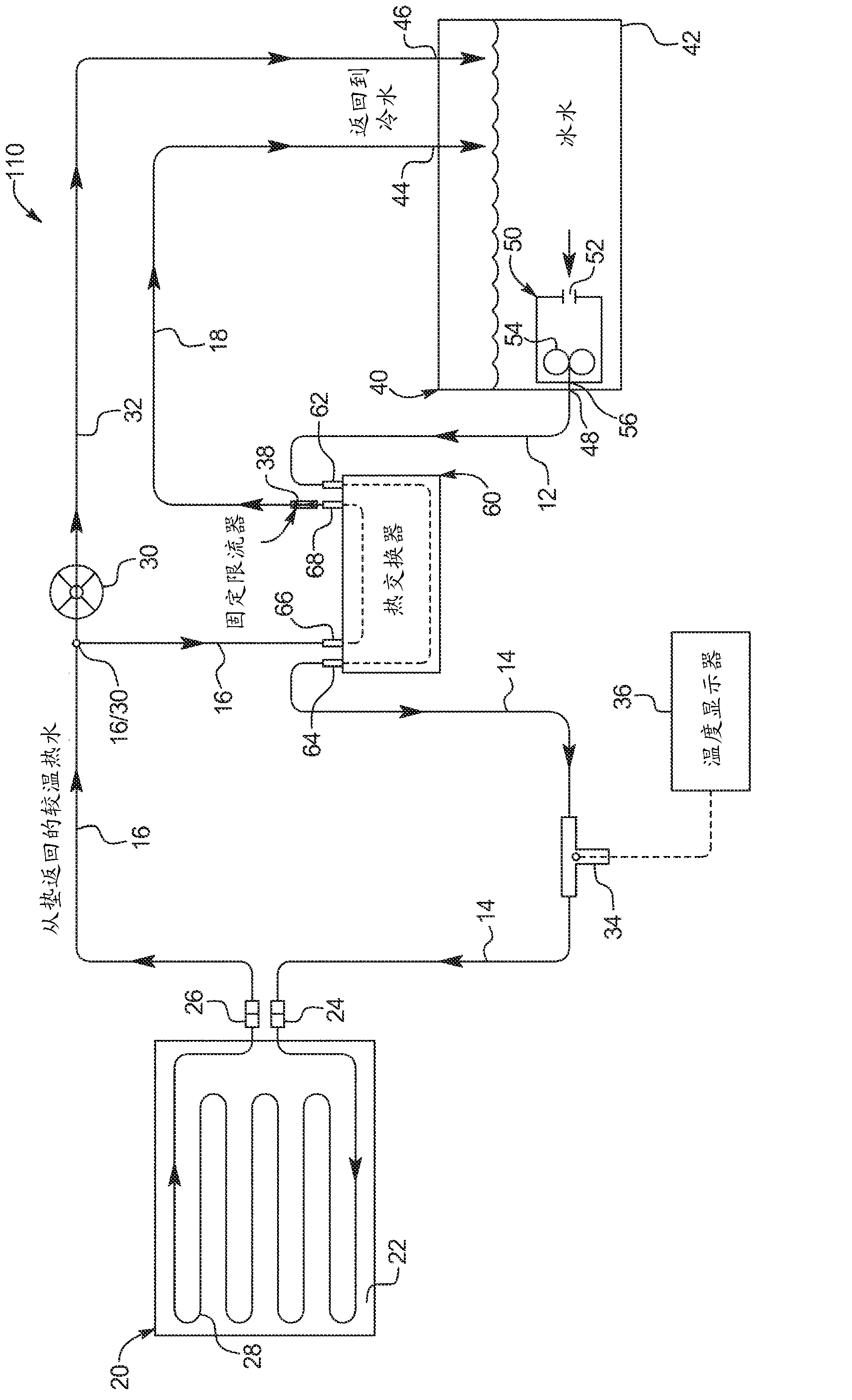

Cold therapy apparatus using heat exchanger

InactiveCN103338730AEffective and efficient combinationTherapeutic coolingTherapeutic heatingFirst pathwayEngineering

A cold therapy system includes a cooling bath; a therapy pad; a heat exchanger; a first pathway fluidly connecting the cooling bath to the heat exchanger; a second pathway fluidly connecting the heat exchanger to an inlet of the therapy pad; a third pathway fluidly connecting an outlet of the therapy pad to the heat exchanger; and a fourth pathway fluidly connecting an outlet of the heat exchanger to the cooling bath.

Owner:BREG

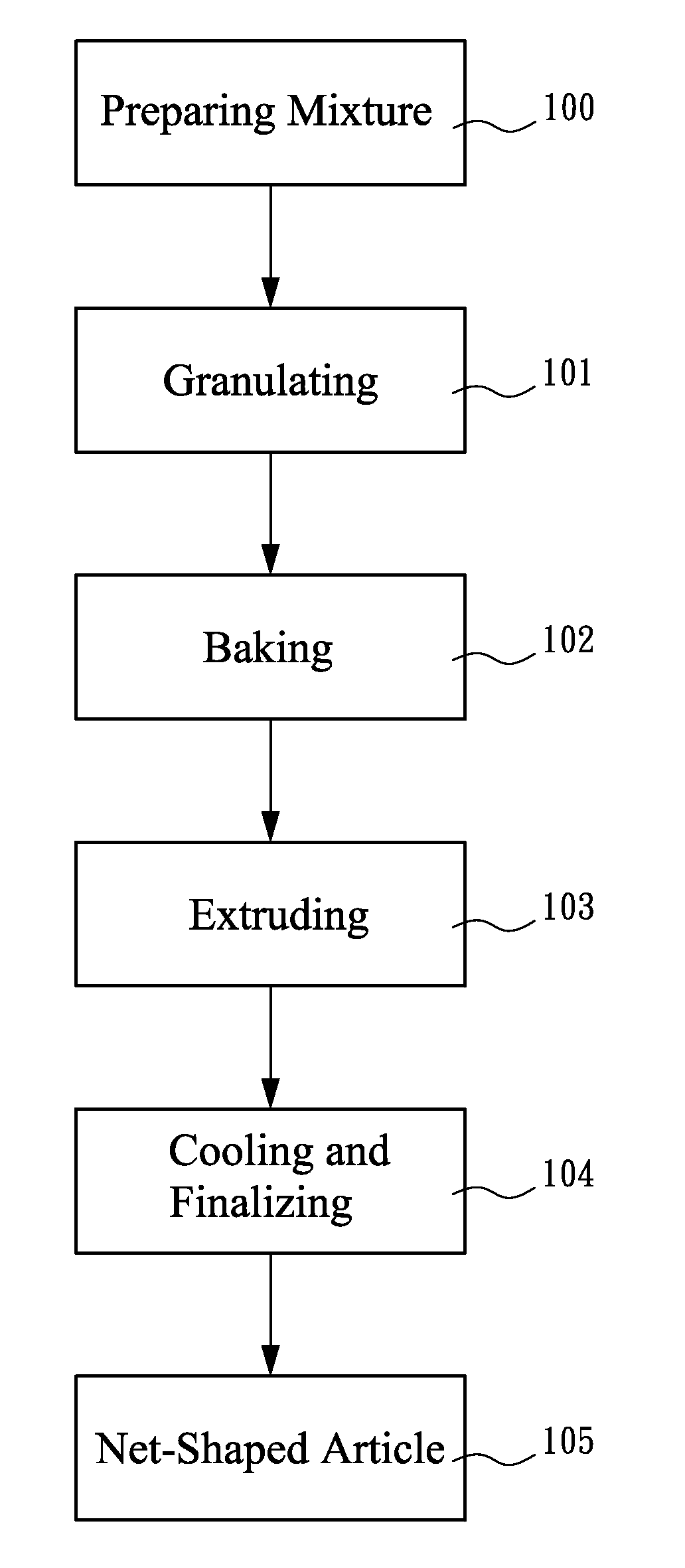

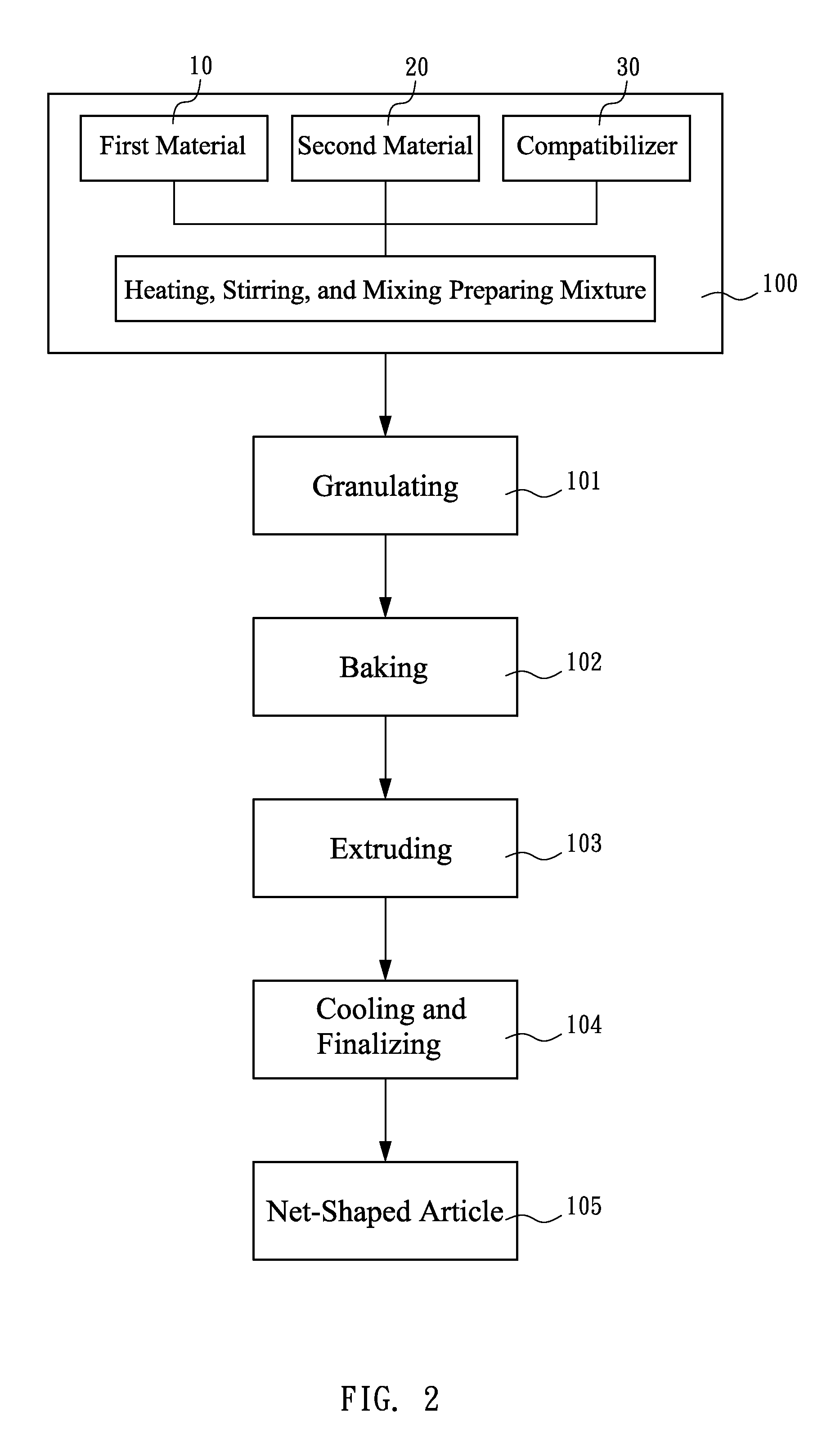

Manufacturing method of biodegradable net-shaped articles

ActiveUS20130147087A1Increased durabilityImprove heat resistanceFlexible coversWrappersMetallurgyCooling bath

A manufacturing method of biodegradable net-shaped articles includes: (a) preparing a biodegradable mixture; (b) granulating the mixture into plastic grains; (c) baking the plastic grains in an oven at 60° C. to 70° C. for 3 to 4 hours; (d) melting and extruding the plastic grains by a screw-type extruder so as to obtain a net-shaped preform; and (e) cooling and thereby finalizing the net-shaped preform in a cooling bath at 15° C. to 30° C. so as to obtain the net-shaped article.

Owner:MINIMA TECH CO LTD

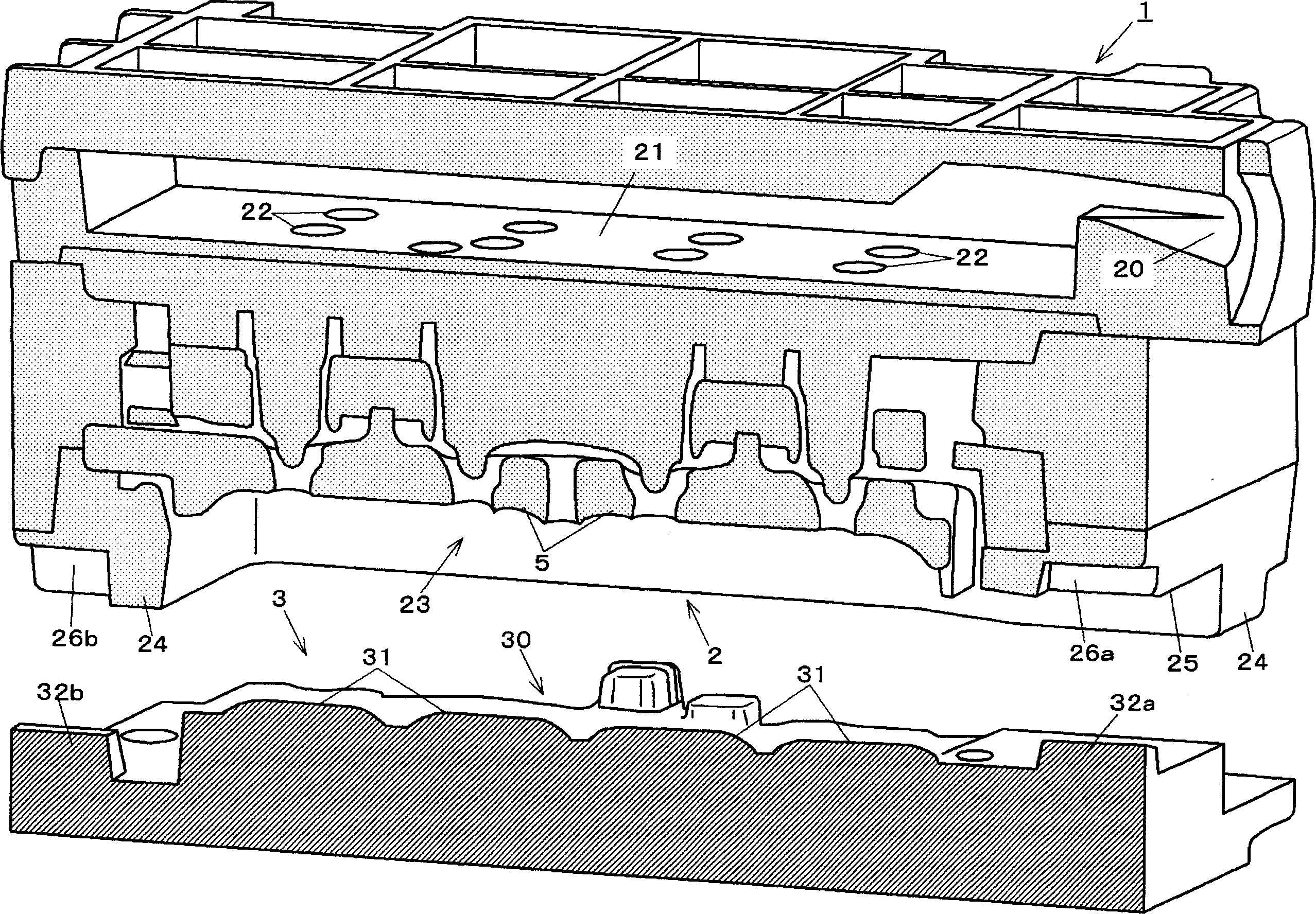

Casting mold device and method producing cast

InactiveCN1833796AWon't flow outExcellent mechanical propertiesFoundry mouldsFoundry coresCooling bathMolding sand

The invention provides a casting mold device and a method for manufacturing castings using the casting mold device. The casting mold device includes a metal mold and a sand mold (2), wherein the sand mold has: a riser formed on the opposite side of the metal mold. One side; the opening (25), which is sealed by a metal mold to form a mold cavity when forming a mold; The surface of the surrounding wall protrudes more toward the metal mold side, wherein a notch is provided on the surrounding wall to make the inner part (S) of the surrounding wall communicate with the outer part. The casting method includes the following steps: a molding process, The sand mold and the metal mold are combined to form a mold cavity; the casting process is to pour molten metal into the mold cavity; the mold opening process is to leave the casting (7) on one side of the sand mold and separate the sand mold from the metal mold; and In the cooling step, the sand mold with the casting left is immersed in a cooling tank with the opening side positioned on the lower side. With this method, when the sand mold and casting are immersed in cooling water in the cooling process, air bubbles (X) remaining in the inner portion (S) are discharged through the notch portion (25), and cooling or quenching can be efficiently performed.

Owner:MAZDA MOTOR CORP

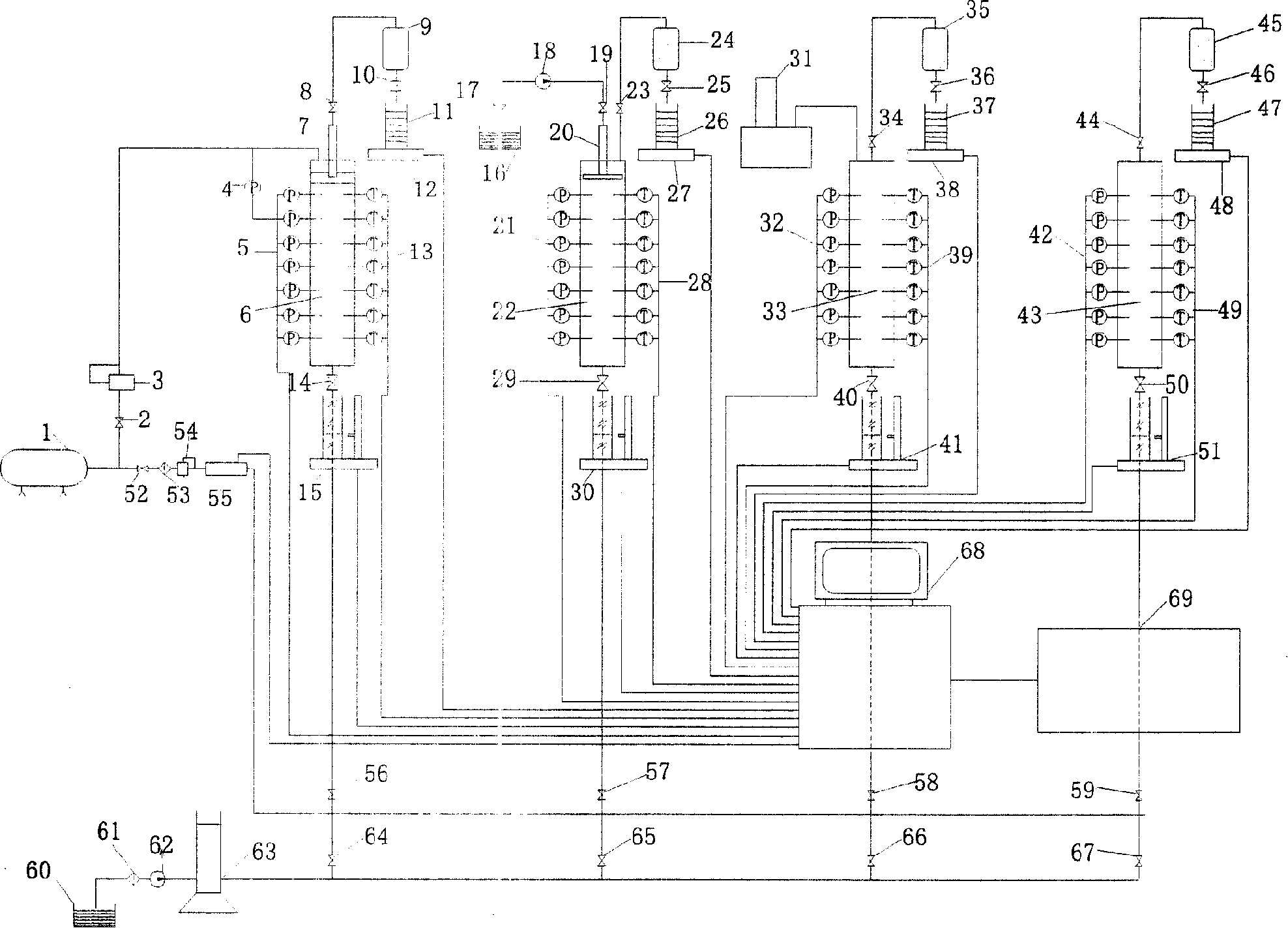

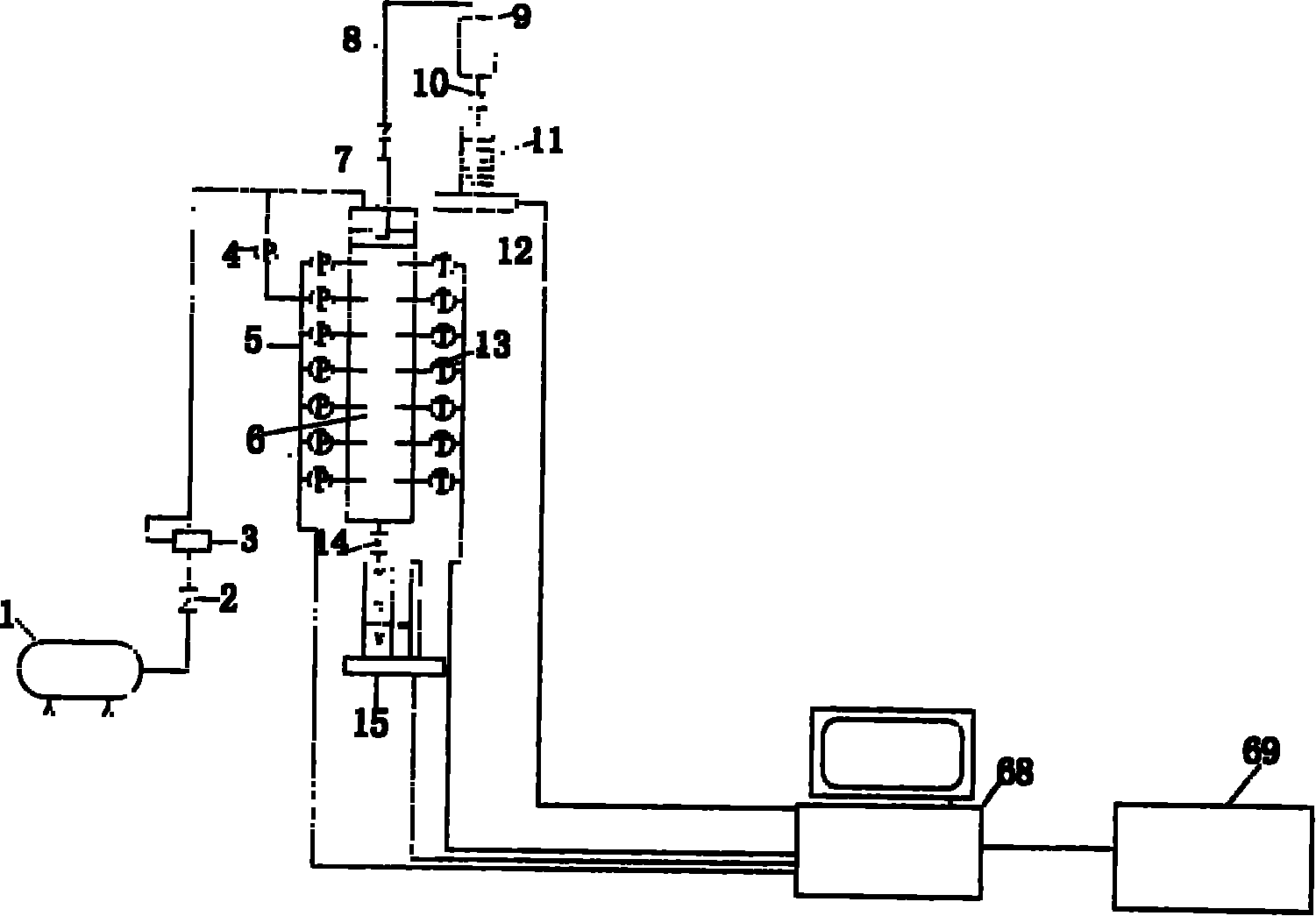

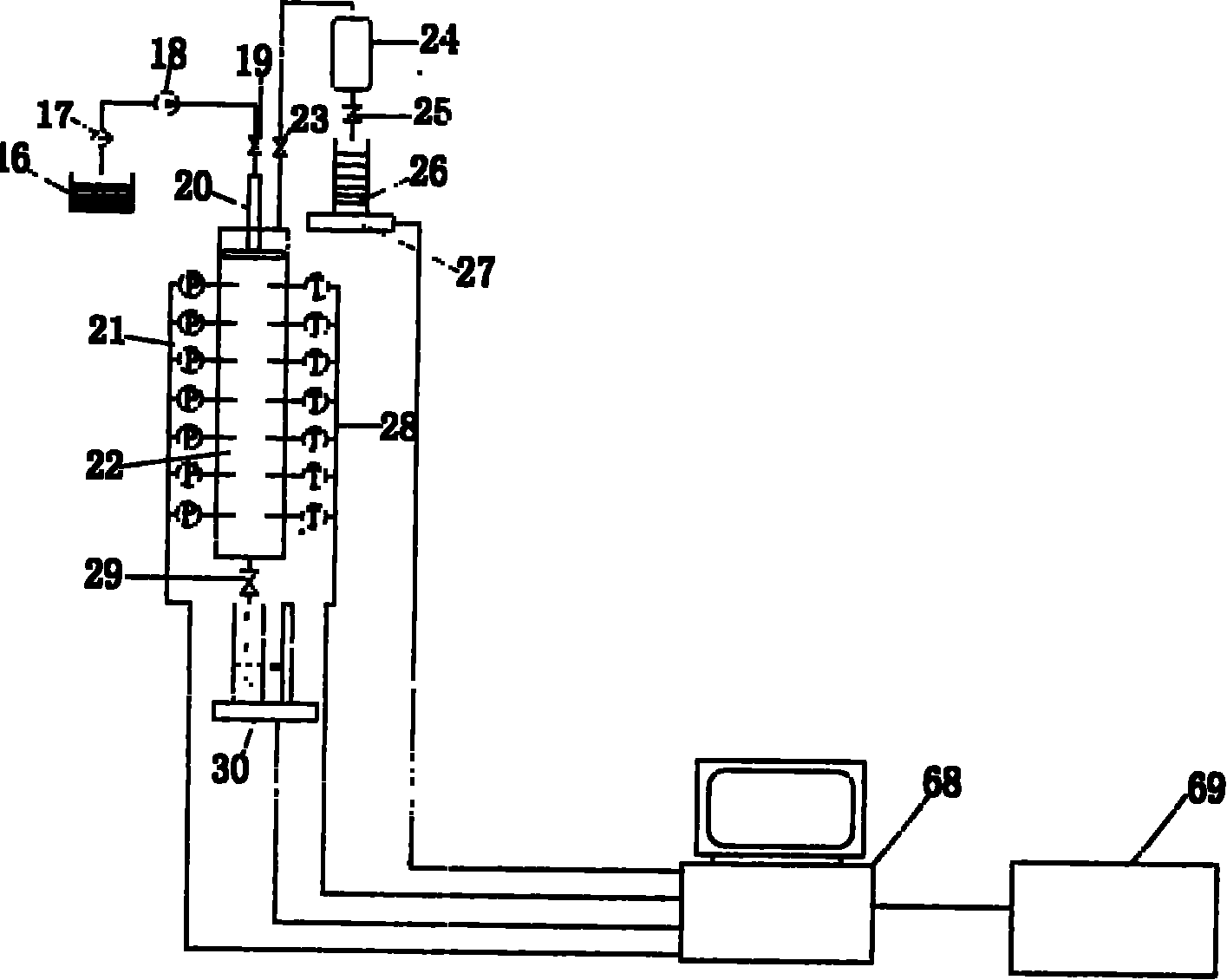

Monitoring test system for burying gas and leachate transmit process

ActiveCN101162220AShort cycleHigh-precision automatic collectionSurface/boundary effectTemperature controlTransfer procedure

The invention discloses a test system for monitoring the process of land fill gas and leachate transmission, comprising a pulsation-free pump, an air compressor, a pressure earth column, a rainfall earth column, a temperature control earth column, a natural earth column and a computer, wherein, a pressure transducer, a liquid volume metering vessel, a temperature pickup and a pair of scales are respectively connected with the computer; a valve is respectively connected with the air compressor and a filter; a gas mass flowmeter is respectively connected with the pair of scales and the computer; the pressure earth column is respectively connected with a piston and the valve; the rainfall earth column is respectively connected with the piston and the valve; the temperature control earth column is respectively connected with a piston heating bath and a piston cooling bath; the natural earth column is connected with the valve; a piston vessel is connected with the valve. The invention is simple in structure, convenient in operation and accurate in test data with shortened test period, high precision of test data and quick automatic data acquisition.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

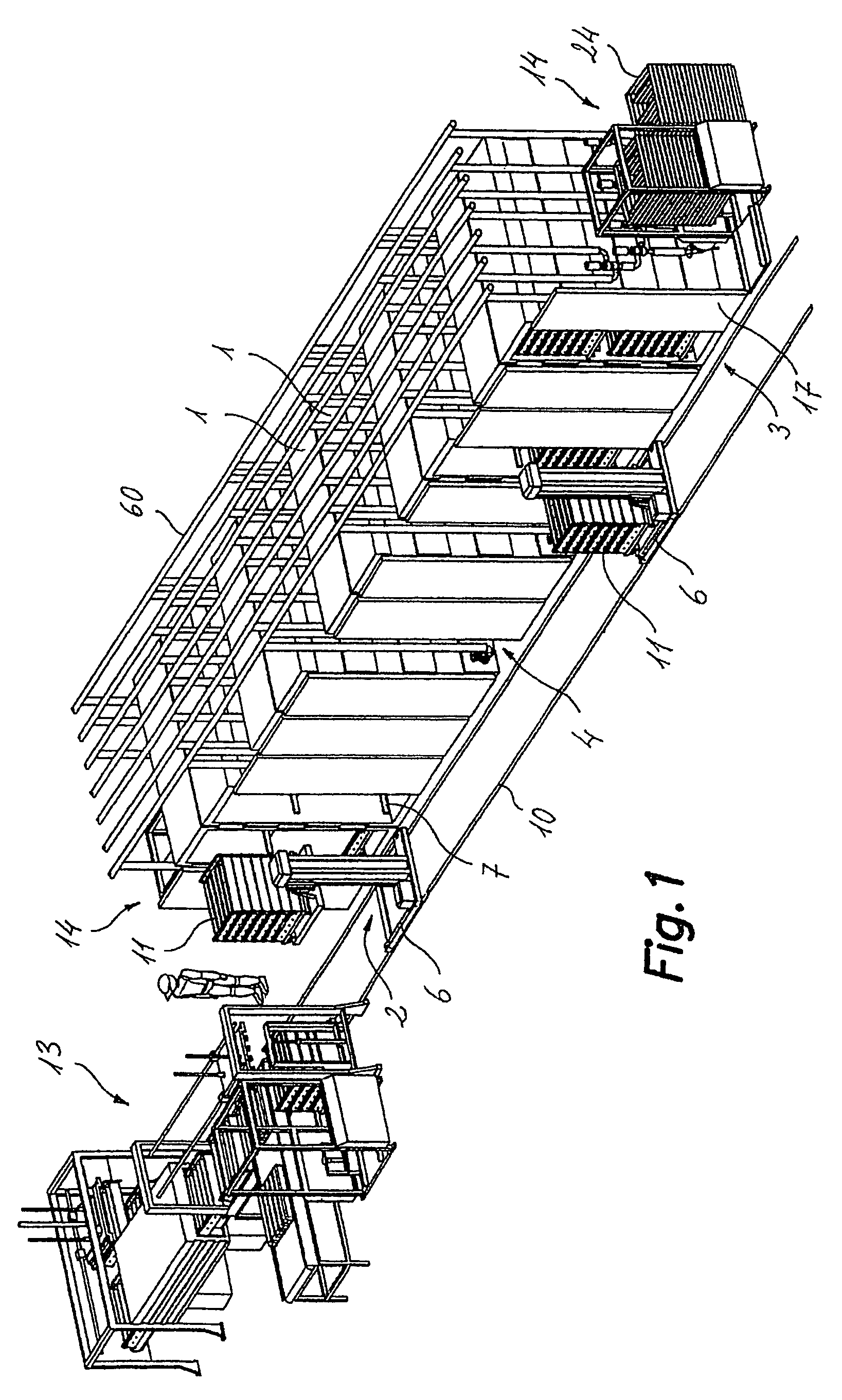

Food cooking installation

InactiveUS7654194B2Reduce riskHigh ceiling heightOil/fat bakingIndirect heat exchangersPipe waterEngineering

The invention relates to a food cooking installation comprising numerous cooking tanks which are used to receive the food items to be cooked; means of loading / unloading the food items into / from said cooking tanks; and means of conveying, driving and storing liquids, which are used to connect a heated liquid container, a cooled liquid container and a piped water delivery point with the aforementioned cooking tanks. In this way, the tanks can be filled and emptied independently and the food items contained therein can be subjected to successive baths for different periods of time and at different temperatures, at least one of the baths being a cooking bath and the other a cooling bath. According to the Invention, each of the aforementioned cooking tanks comprises at least one lateral opening which is equipped with impervious sealing means and which is used to load / unload the food items using the above-mentioned loading / unloading means.

Owner:METALQUIMIA SA

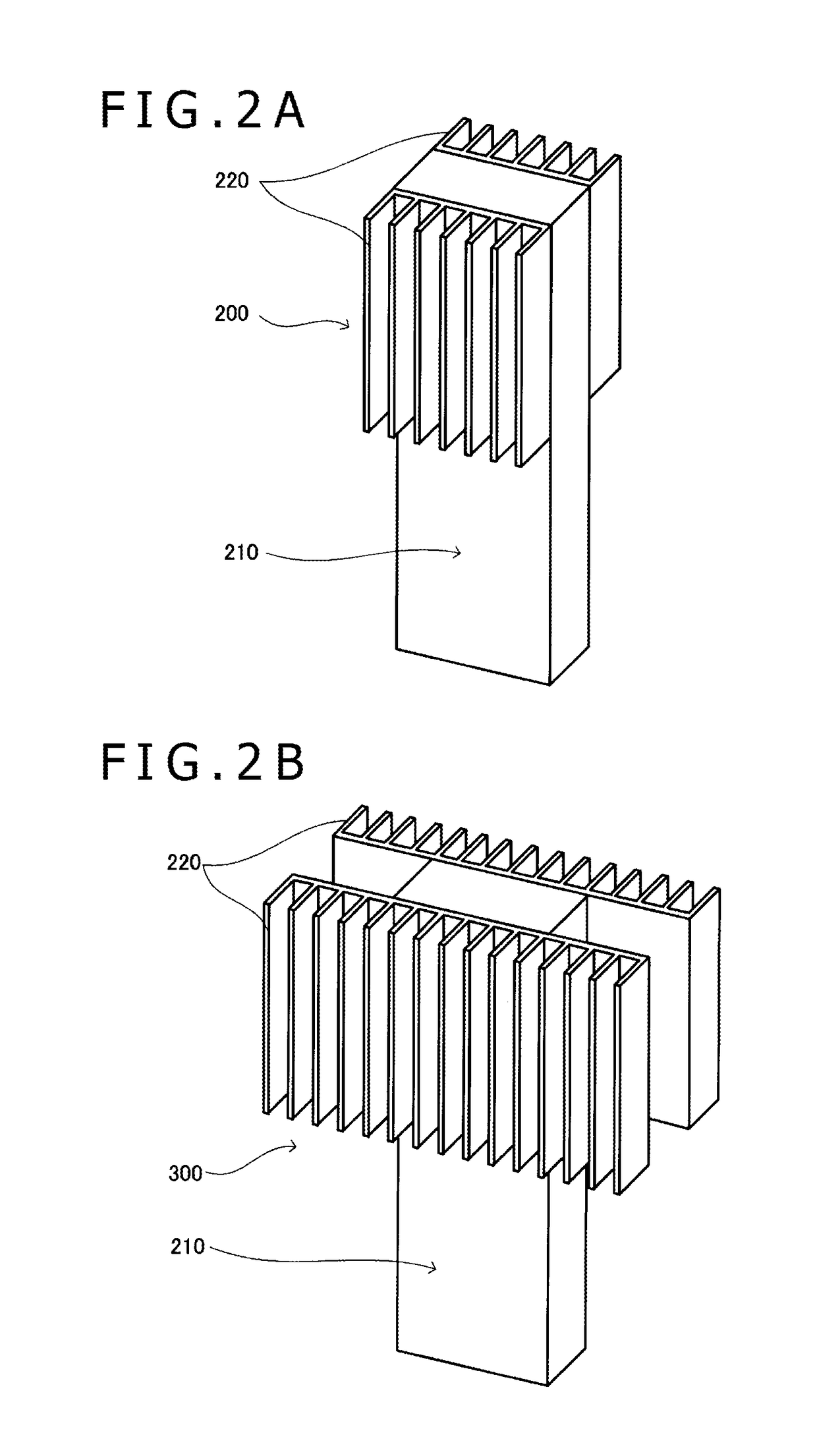

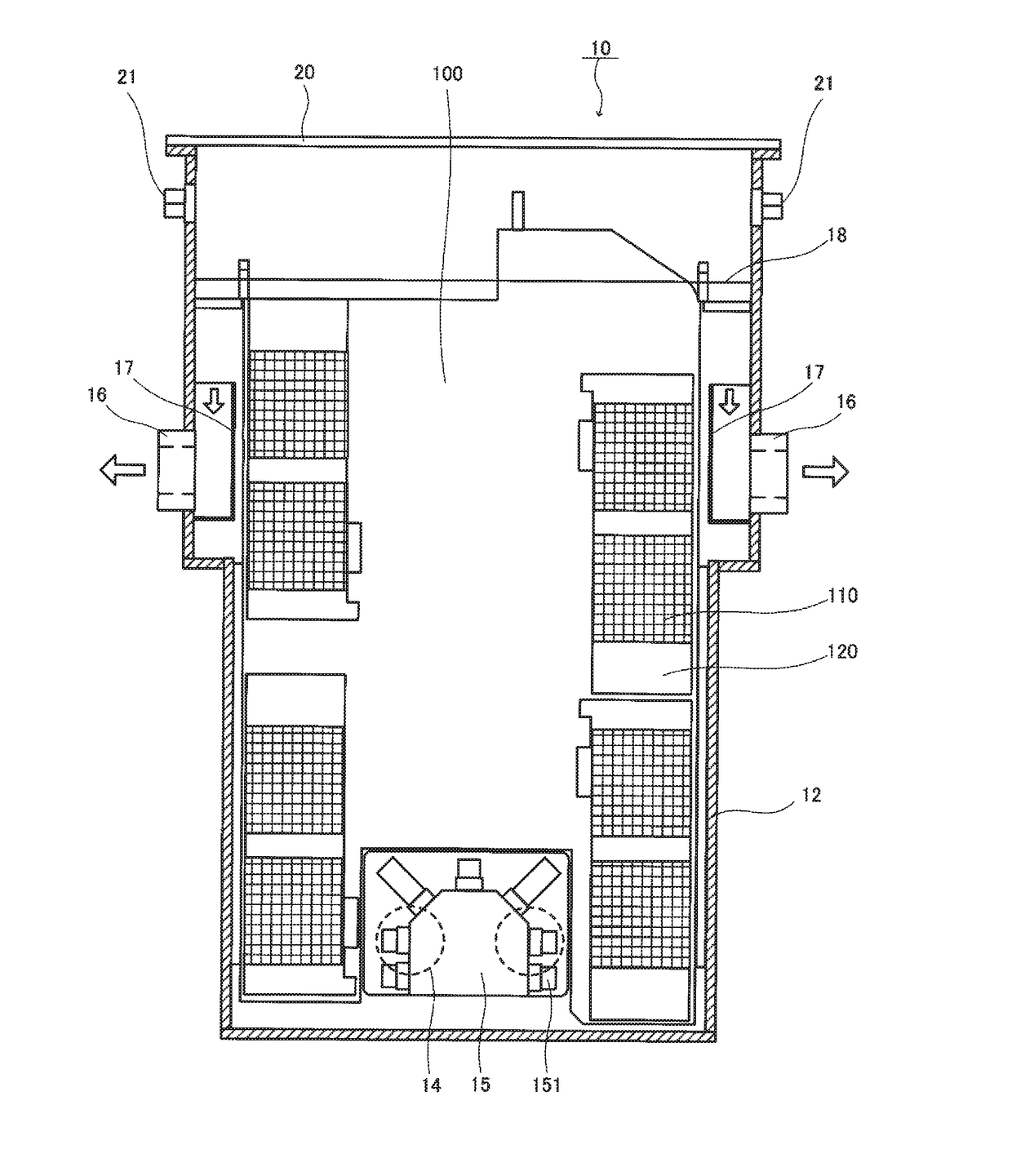

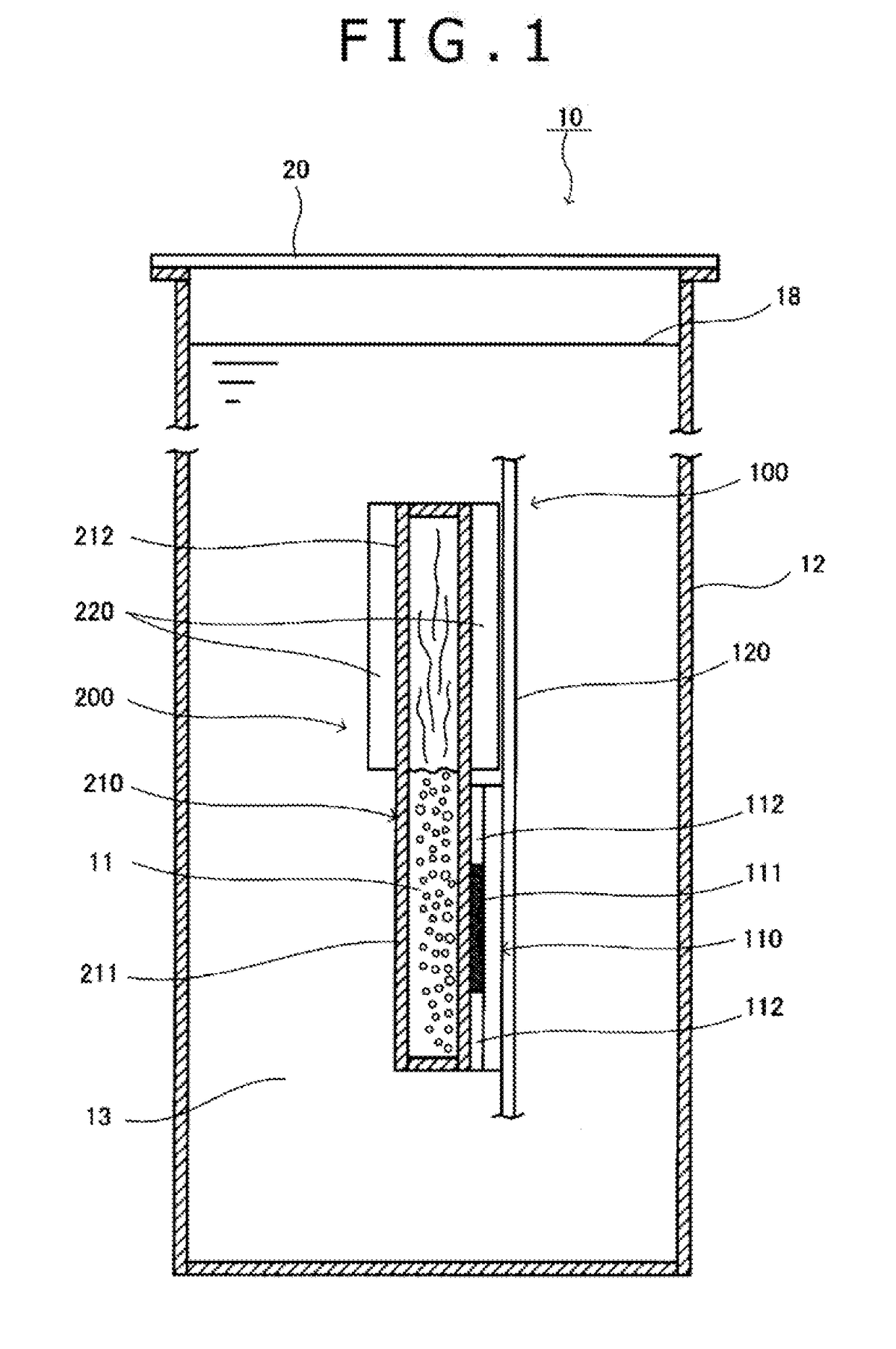

Cooling system and cooling method for electronic equipment

InactiveUS20170332514A1Reduce necessityReduce the volume occupiedDomestic cooling apparatusDigital data processing detailsNuclear engineeringBoiling point

There are provided a cooling system and a cooling method that are simple and efficient and improve cooling performances for an electronic device. A cooling system (10) includes a cooling bath (12). In the open space of the cooling bath (12), a second coolant (13) with a boiling point (T2) is contained. In the open space of the cooling bath (12), an electronic device (100) is housed. The electronic device (100) is mounted with a processor (110) as a heat generating component on a board (120). The electronic device (100) is immersed in the second coolant 13. A boiling cooling device (200) is a cooling device thermally connected to the processor (110), and encloses a first coolant 11 with a boiling point (T1) (where T2>T1).

Owner:EXASCALER

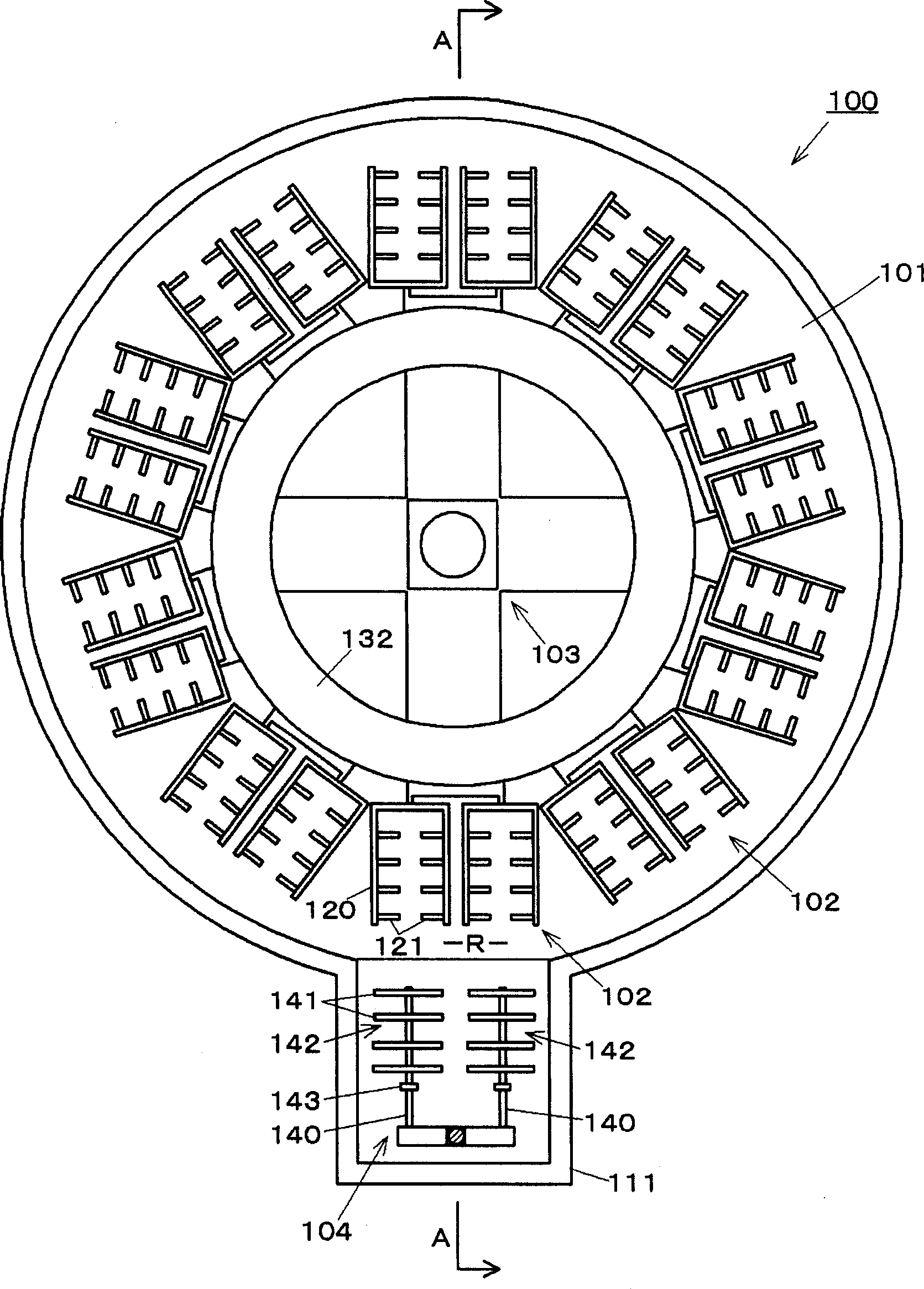

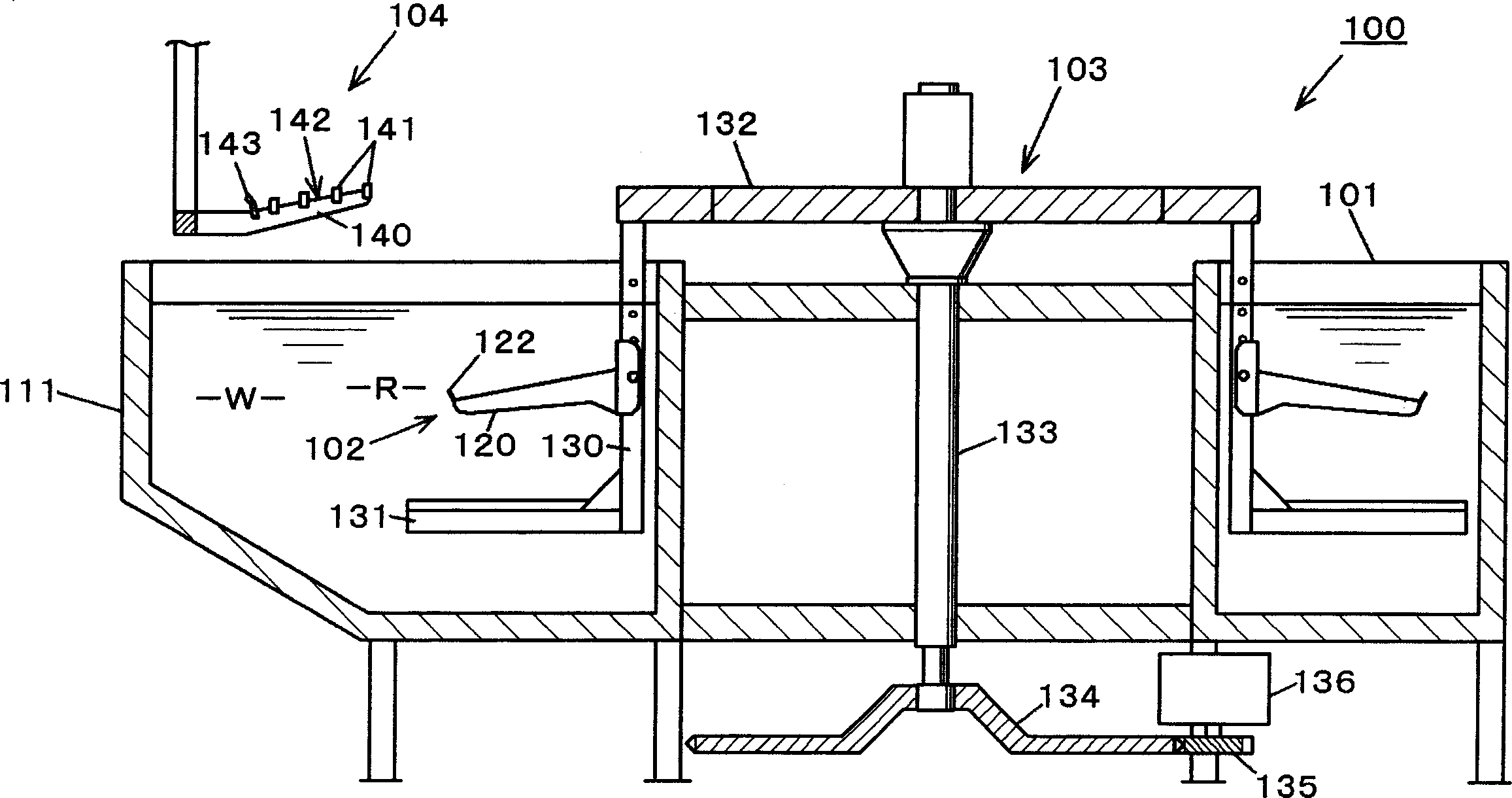

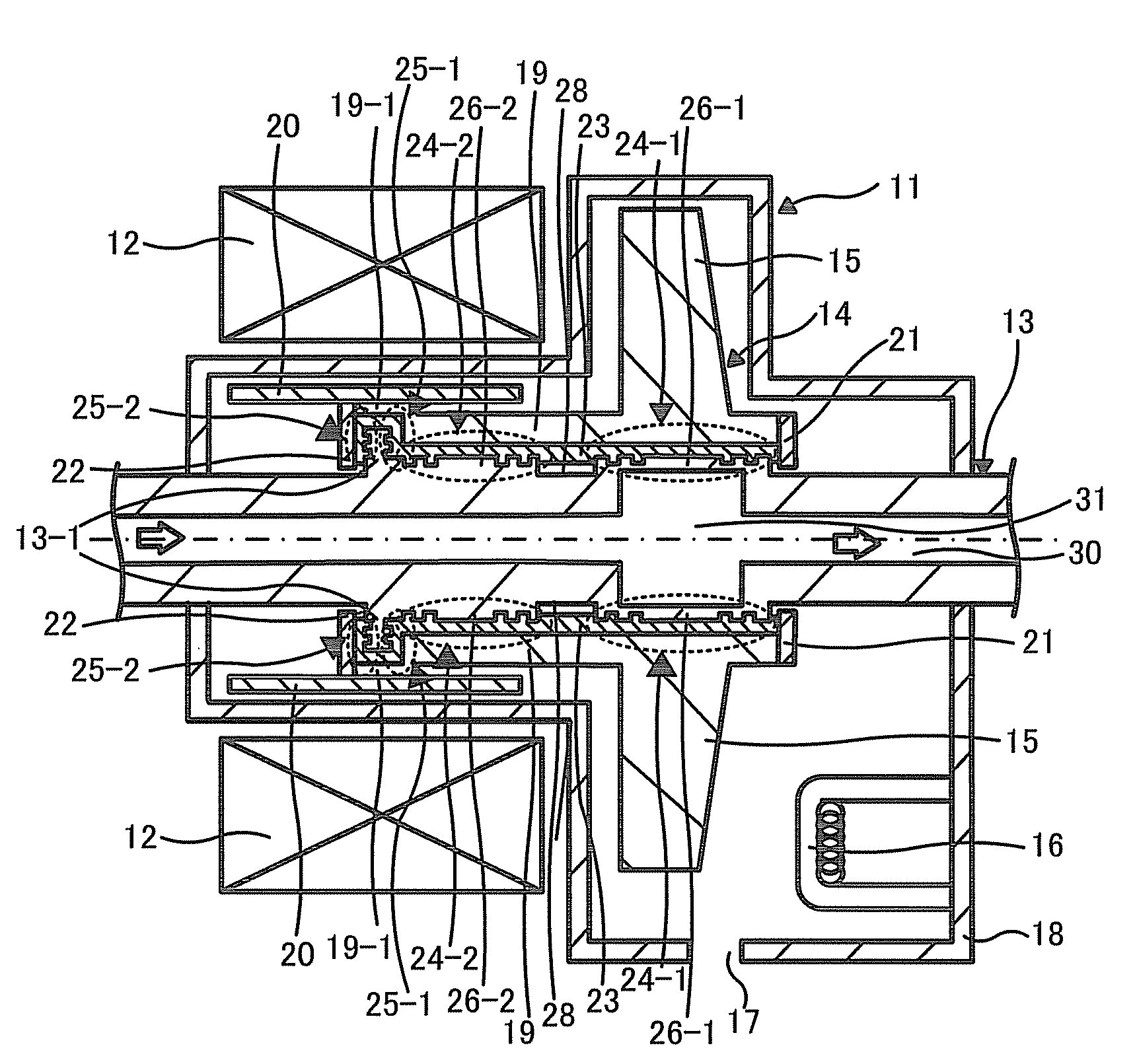

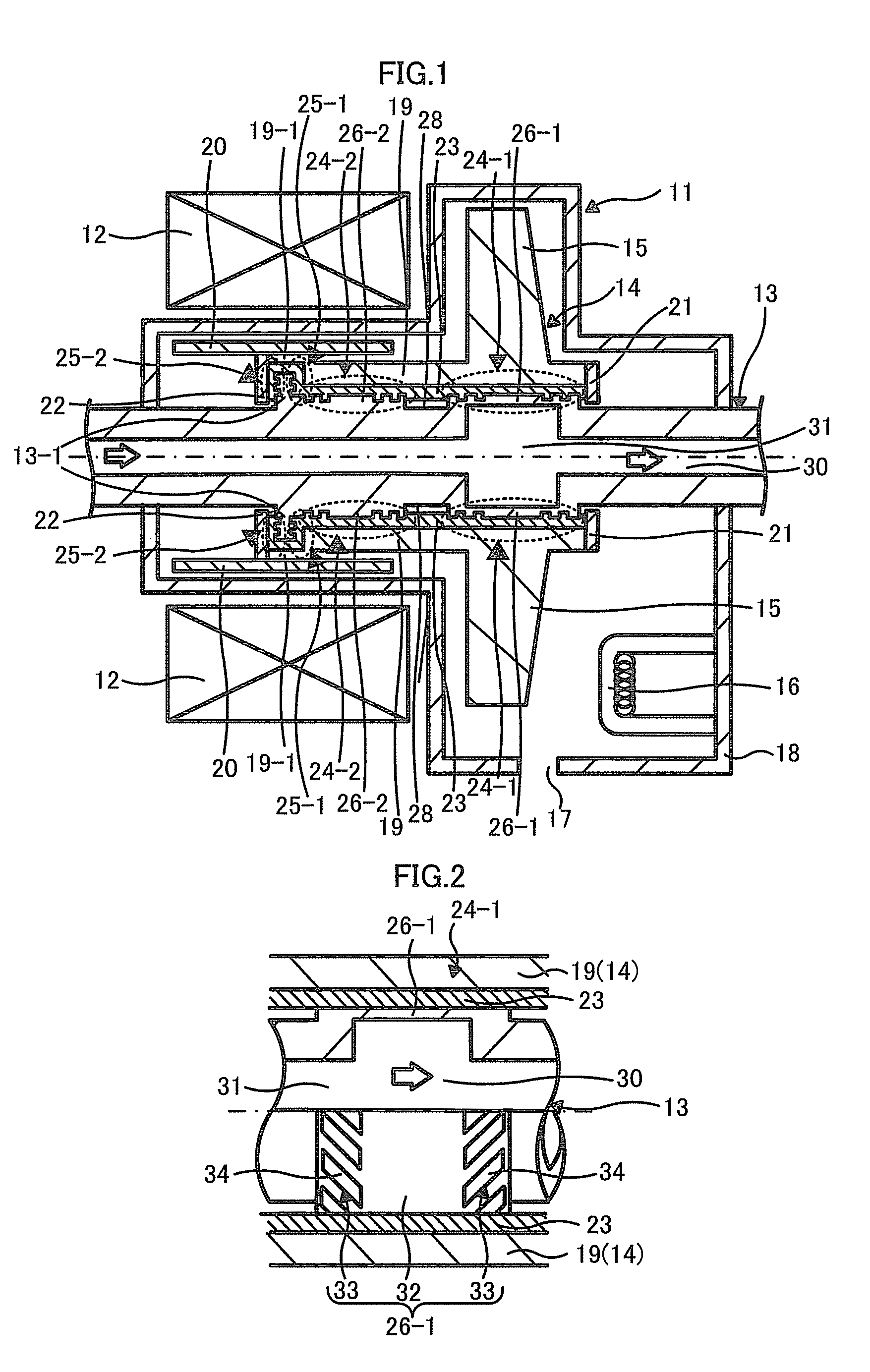

Rotary anode x-ray tube

A rotary anode X-ray tube apparatus according to an embodiment of the present invention includes a stationary shaft, a cooling bath that is provided in the stationary shaft, a rotary cylinder that is rotatably supported to the stationary shaft, a target that is provided in the rotary cylinder, a cathode that is disposed to face the target, and a vacuum enclosure that stores these components. The stationary shaft has a large-diameter portion provided in a portion thereof and is provided with a flow passage through which a cooling fluid flows. The cooling bath is provided by thinning the wall thickness of the large-diameter portion to increase the flow passage diameter of a portion of the flow passage. The rotary cylinder covers an area of the stationary shaft including the large-diameter portion through a liquid metal and is rotatably supported to the stationary shaft. The target has a hollow circular plate shape that is provided on an outer circumferential surface of the rotary cylinder. The vacuum enclosure stores the stationary shaft, the rotary cylinder, the target, and the cathode and supports the stationary shaft.

Owner:CANON ELECTRON TUBES & DEVICES CO LTD

Poly(4-methyl-1-pentene) hollow fiber membrane with gradient pore structure and preparation method thereof

ActiveCN112403289AExtended diluent screeningExpand the scope of the filterSemi-permeable membranesNon solventPolymer science

The invention provides a method for preparing a poly(4-methyl-1-pentene) hollow fiber membrane with a gradient pore structure through coupling of a thermally induced phase separation method and a non-solvent induced phase separation method. The method comprises the following steps: uniformly mixing poly(4-methyl-1-pentene) and a diluent at high temperature, and carrying out extrusion to realize one-shot molding; after the formed mixture passes through an air section, allowing the mixture to enter a cooling bath for cooling so as to realize thermally induced phase separation and non-solvent phase separation; and finally, extracting the diluent to obtain the hollow fiber membrane. The hollow fiber membrane prepared by the method provided by the invention has improved safety, and the thermally induced phase separation process and the non-solvent induced phase separation process in a poly(4-methyl-1-pentene) diluent system are easy to regulate and control, so the poly(4-methyl-1-pentene) membrane with better mechanical strength, gas permeability and plasma infiltration resistance is obtained. The invention also provides the poly(4-methyl-1-pentene) hollow fiber membrane and applicationthereof in the field of artificial membrane lungs.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com