Liquid metal directional casting apparatus and process

A technology of directional casting and liquid metal, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., and can solve problems such as damage to casting process reliability and molten metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

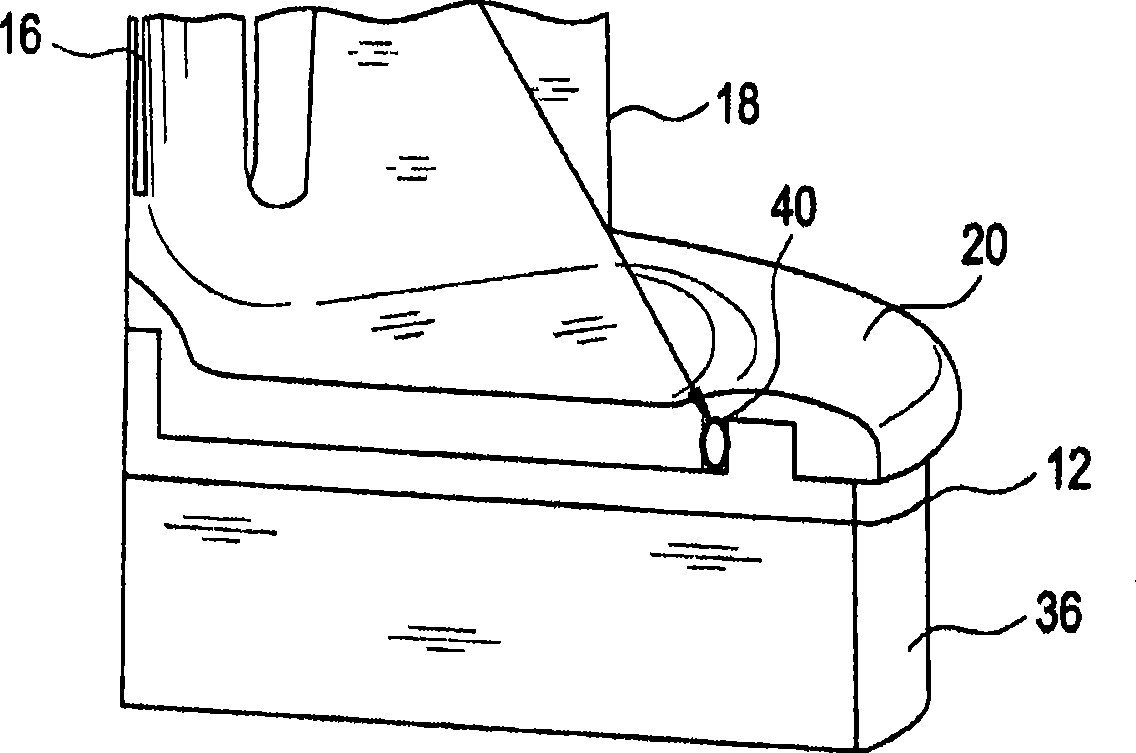

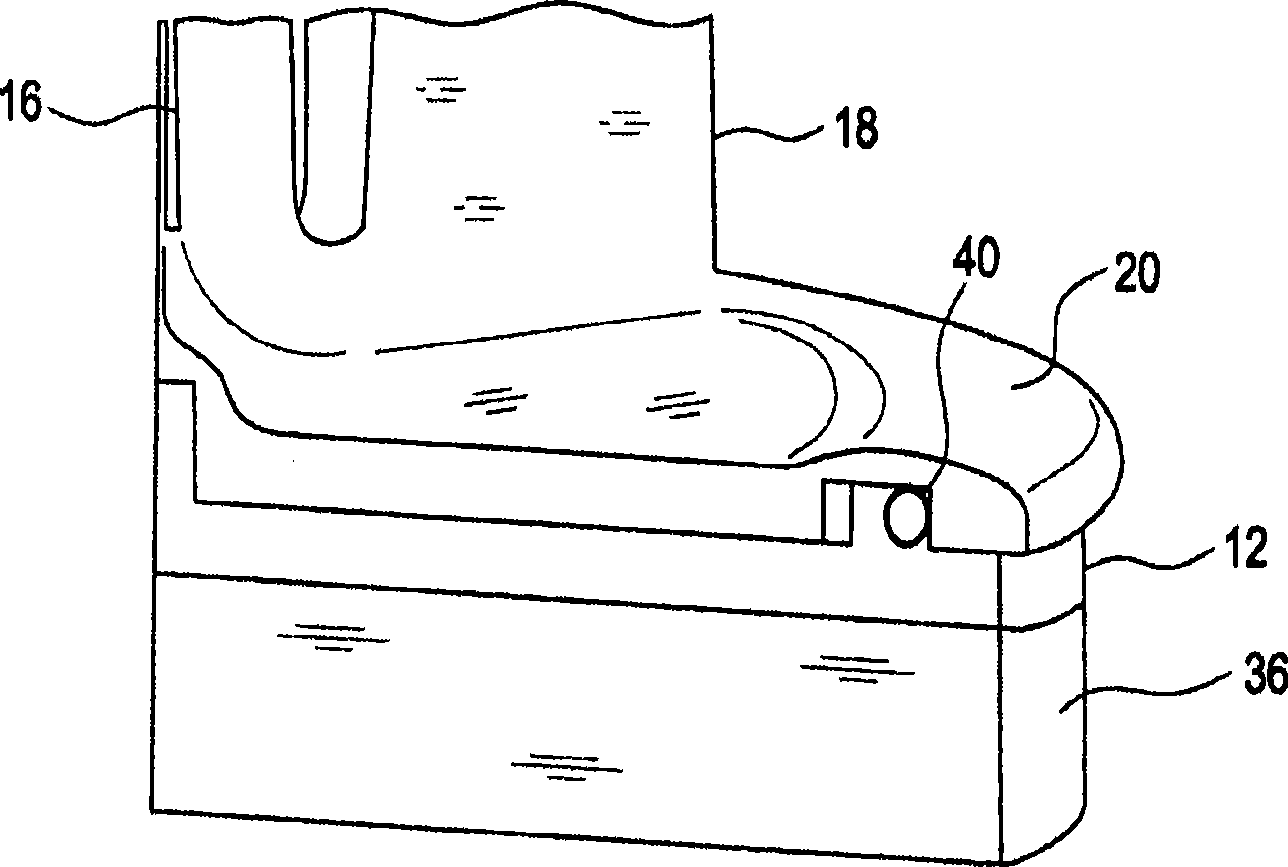

[0019] The present application discloses an apparatus and method for effectively sealing the interface between a shell mold and a chill plate in a casting pattern assembly. figure 1 A cutaway perspective view of the mold assembly 10 on a chill plate 12 is shown. Mold assembly 10 generally includes an opening 14 , eg, funnel-shaped, in fluid communication with a runner 16 that is in fluid communication with one or more shell molds 18 . The shell mold, or cavity, defines the shape of the part to be cast. A mold assembly having more than one shell mold is often referred to as a cluster mold assembly. A skirt 20 extends laterally across the bottommost portion of the mold assembly. A groove (ie channel) 22 is formed in the bottom surface of the skirt such that the shell mold 18 is contained within the perimeter defined by the groove, ie the channel defines the boundary of the shell mold.

[0020] In one embodiment, the chill plate 12 includes a generally planar surface 24 and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com