A kind of preparation method of long fiber reinforced hollow fiber membrane

A long-fiber and fiber membrane technology, which is applied in the field of preparation and reinforcement of polymer membrane materials, can solve problems such as weak adhesion, shedding of polymer membranes and braided tubes, weakening the strength of hollow fiber composite membranes, etc., and achieve high retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

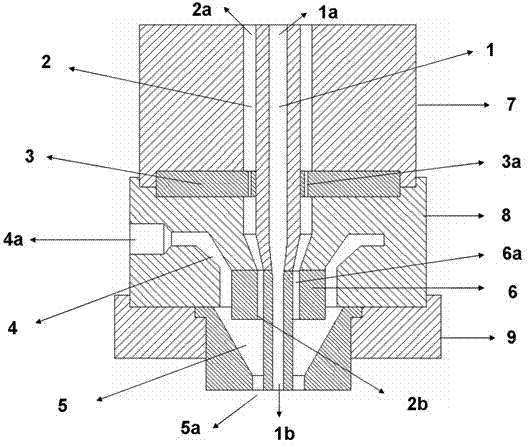

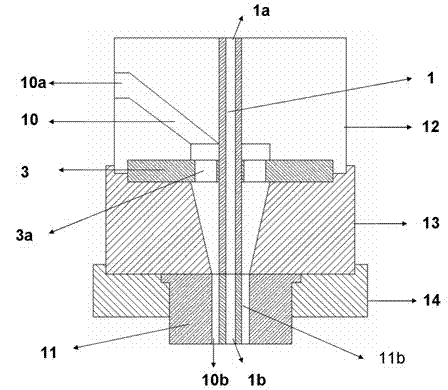

[0030] Such as figure 1 Shown, the steps of a kind of preparation method of long fiber reinforced hollow fiber membrane are as follows:

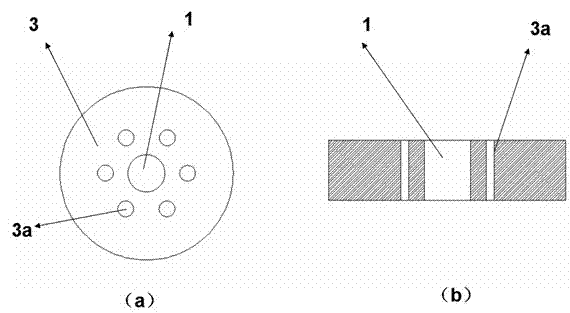

[0031] 1) The spinneret with fiber channel is adopted, and the spinneret with fiber channel includes core liquid pipe 1, core liquid pipe inlet 1a, core liquid pipe outlet 1b, long fiber channel 2, inlet 2a of long fiber channel, long fiber channel Outlet 2b, long fiber positioning plate 3, positioning channel 3a on the long fiber positioning plate, casting liquid channel 4, casting liquid inlet 4a, long fiber and casting liquid composite area 5, long fiber and casting liquid after compounding Co-extrusion outlet 5a, baffle plate 6 for preventing backflow of casting liquid, long fiber channel 6a on the baffle for preventing backflow of casting liquid, first upper module 7, first middle module 8 and first lower module 9; A long fiber positioning plate 3 is provided between the lower end of the first upper module 7 and the upper end of the fi...

Embodiment 1

[0041] 1) Blend polyethersulfone PES, additives, non-solvent and solvent, stir at 80°C for 12 hours, filter, and vacuum defoam to obtain a homogeneous casting solution. The components and concentrations of the casting solution are as follows:

[0042] The molecular weight of polyethersulfone is 5.3×10 5 , with a concentration of 18wt%

[0043] The additive is: polyvinylpyrrolidone PVP, the molecular weight is 3×10 5 , the concentration is 0.5wt%;

[0044] Polyethylene glycol PEG, molecular weight 6×10 2 , the concentration is 5wt%;

[0045] The non-solvent is: H 2 O, the concentration is 0.5wt%;

[0046] The solvent is: N,N-dimethylacetamide (DMAc), the concentration is 76wt%;

[0047] The ratio of each component is: PES / PVP / PEG / H 2 O / DMAc=18 / 5 / 0.5 / 0.5 / 76

[0048] 2) After the long polyester fiber is positioned into 4 from the entrance of the spinneret fiber channel through the fiber distribution plate, it enters the composite area with the casting solution;

[0049]...

Embodiment 2

[0054] Embodiment 2 preparation steps are the same as embodiment 1

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com