Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

200 results about "Phase separation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase Separation. The process of phase separation, which takes place either as normal boiling or as brine condensation at supercritical pressures (see figure below), plays a crucial role in determining vent fluid composition.

Polyalkylene microporous diaphragm for lithiam ion battery and manufacturing method thereof

InactiveCN101000952AImprove securityImprove heat resistanceSynthetic resin layered productsCell component detailsPolyolefinPhase separation process

Owner:许贵斌

Membrane post treatment

InactiveUS7662212B2Low toxicityReduce riskSolid sorbent liquid separationPretreated surfacesHydrophilizationMicrofiltration membrane

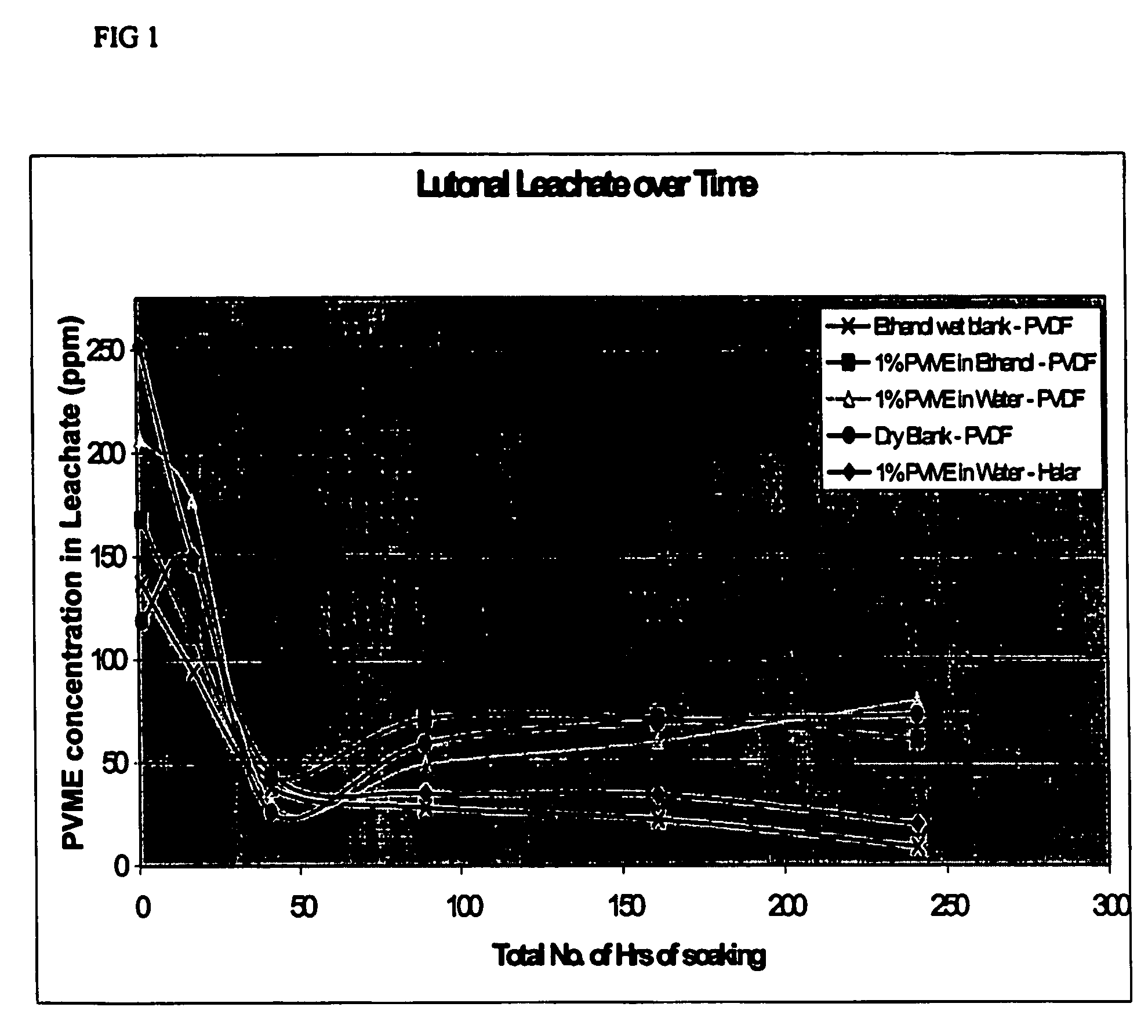

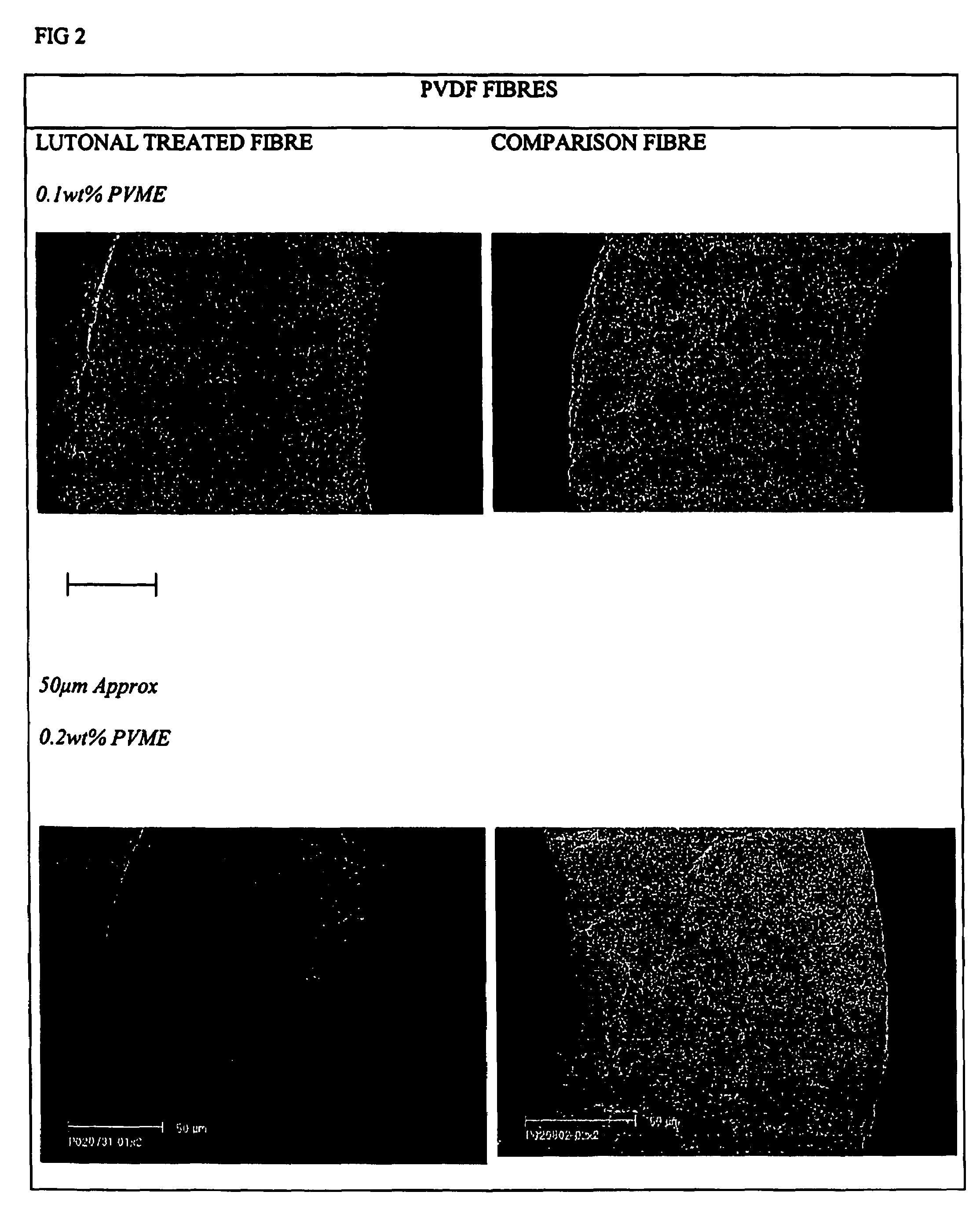

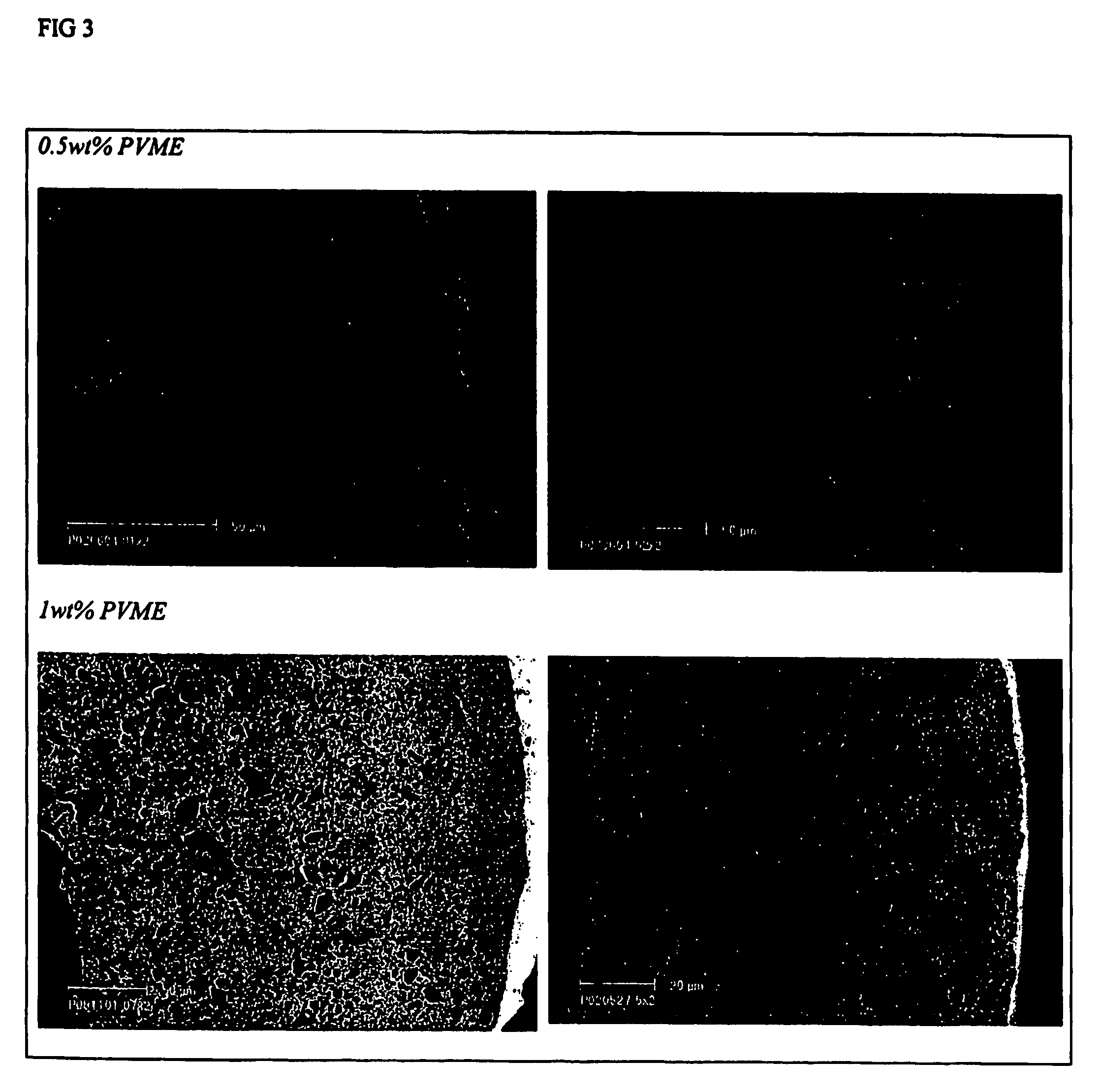

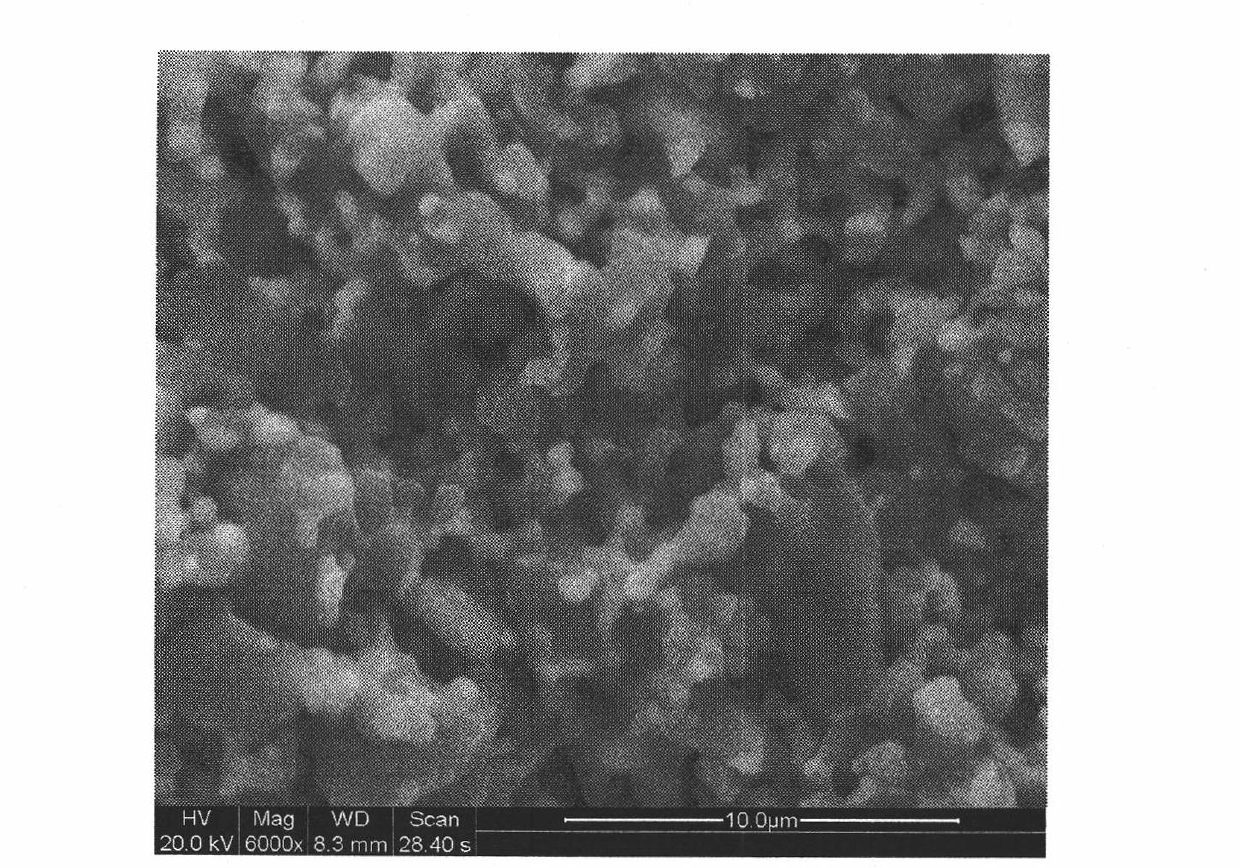

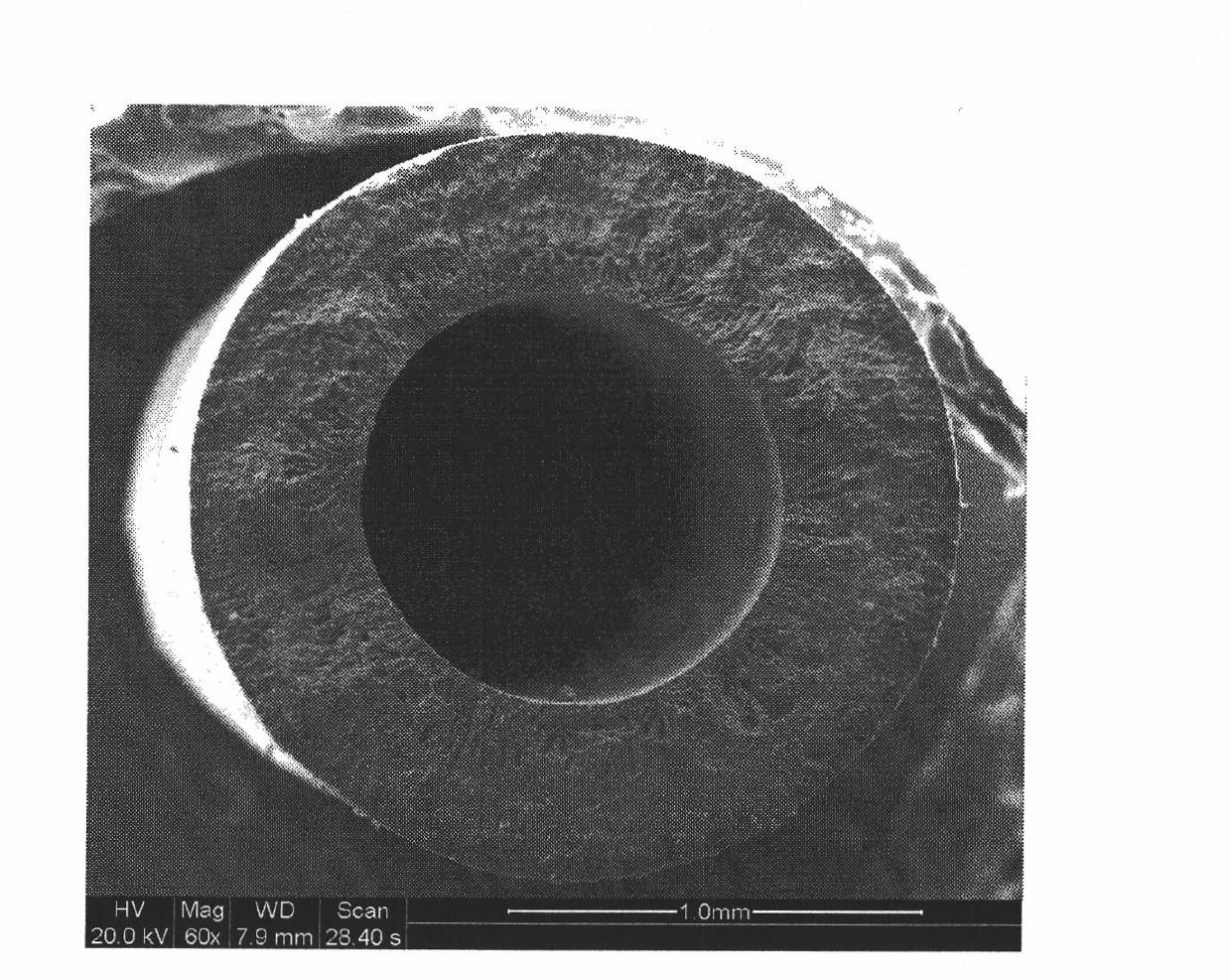

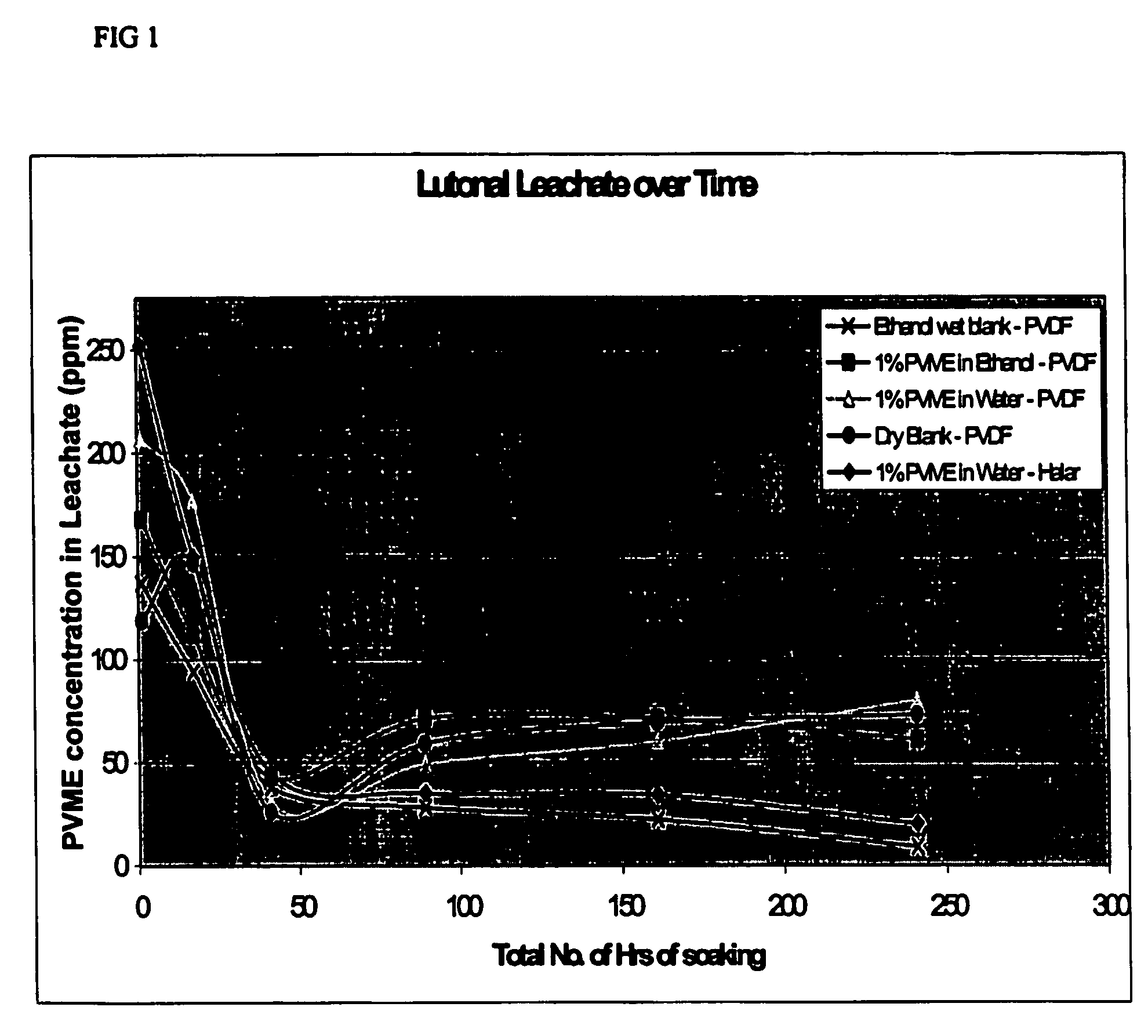

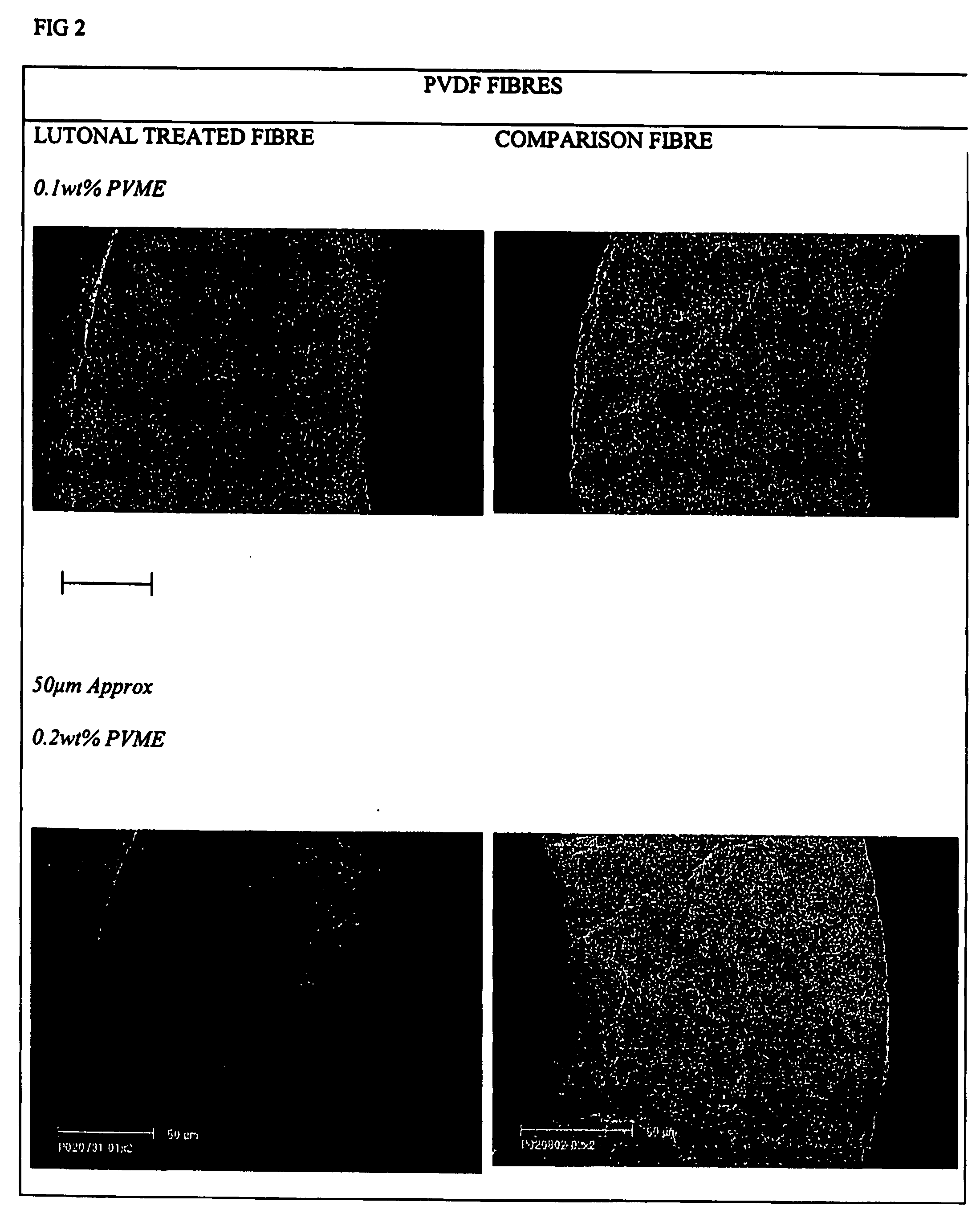

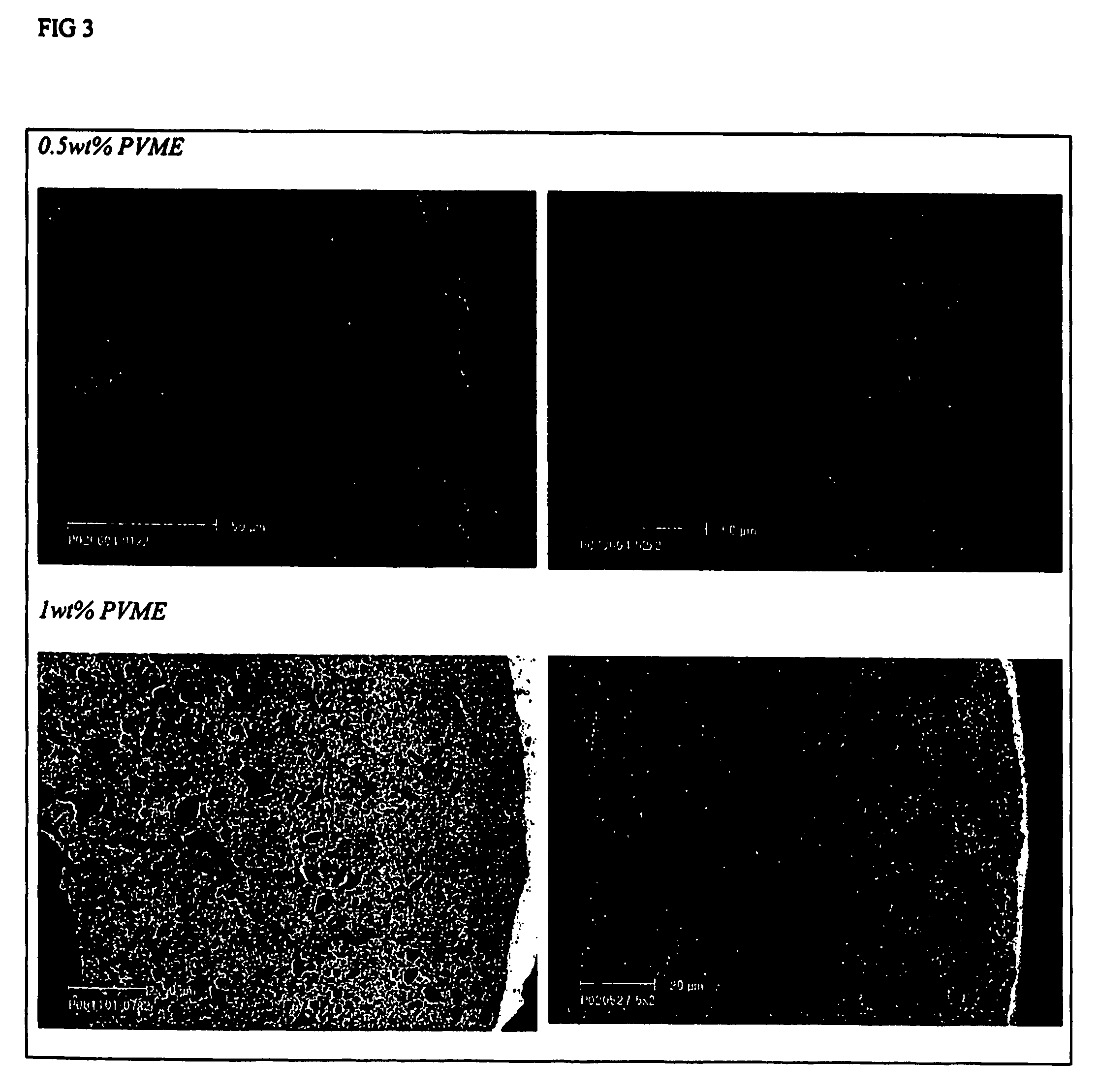

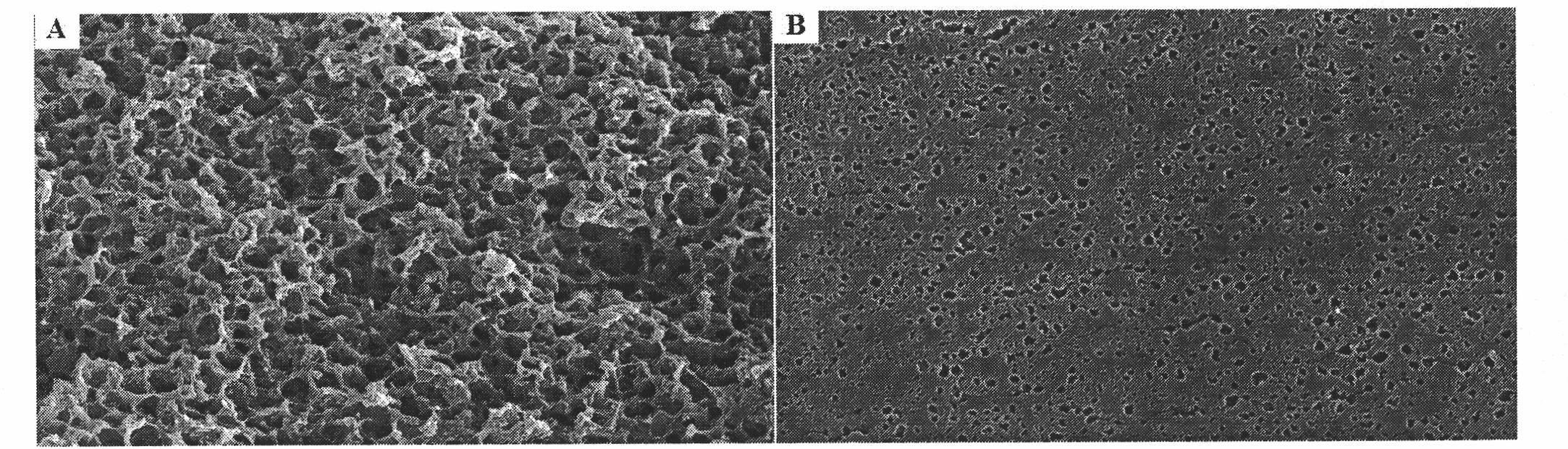

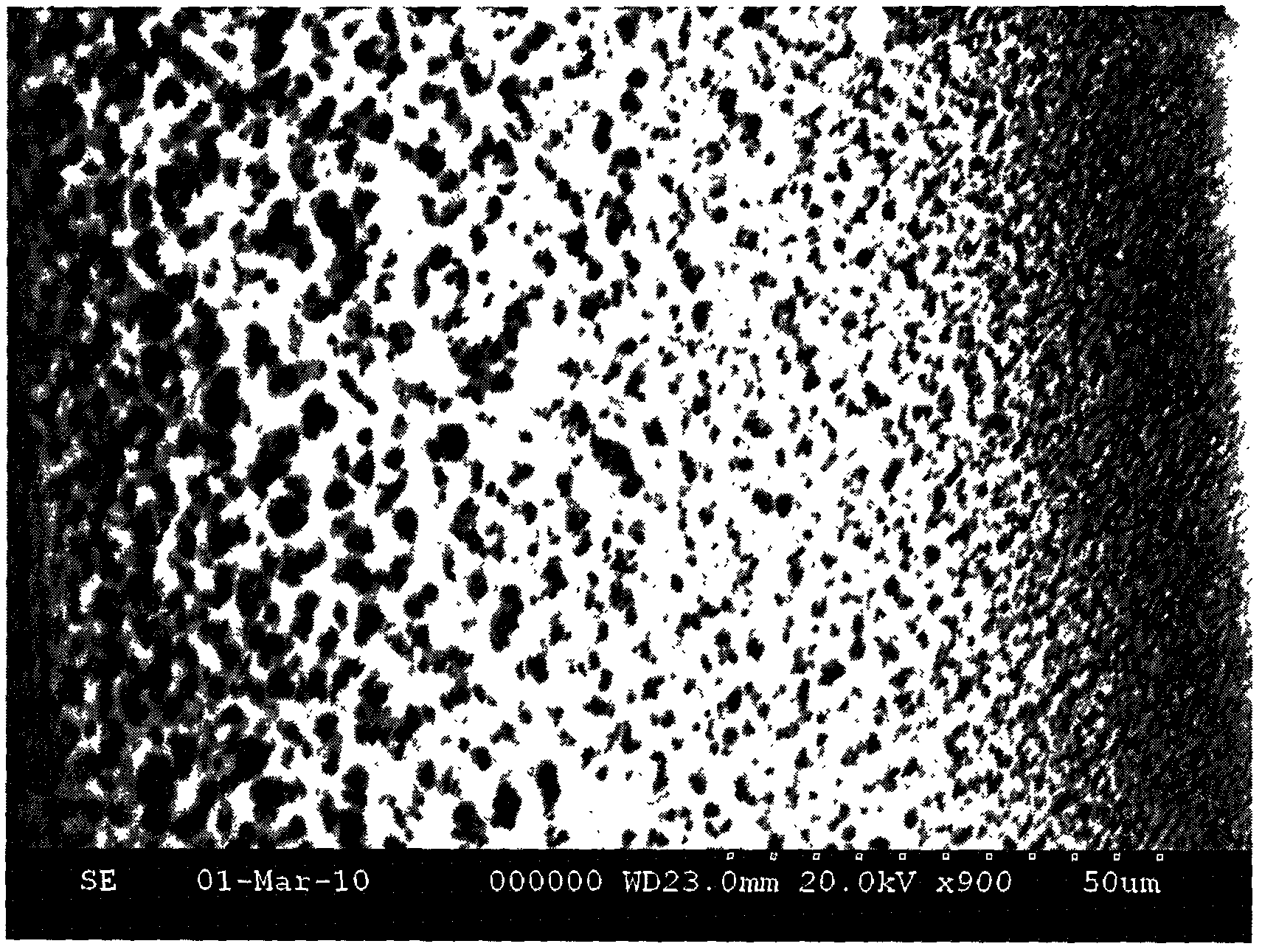

The invention relates to polymeric ultrafiltration or microfiltration membranes of, for instance, Halar, PVDF or PP, incorporating PVME or vinyl methyl ether monomers. The PVME may be present as a coating on the membrane or dispersed throughout the membrane or both. The membranes are preferably hydrophilic with a highly asymmetric structure with a reduced pore size and / or absence of macrovoids as a result of the addition of PVME. The PVME maybe cross-linked. The invention also relates to methods of hydrophilising membranes and / or preparing hydrophilic membranes via thermal or diffusion induced phase separation processed.

Owner:EVOQUA WATER TECH LLC

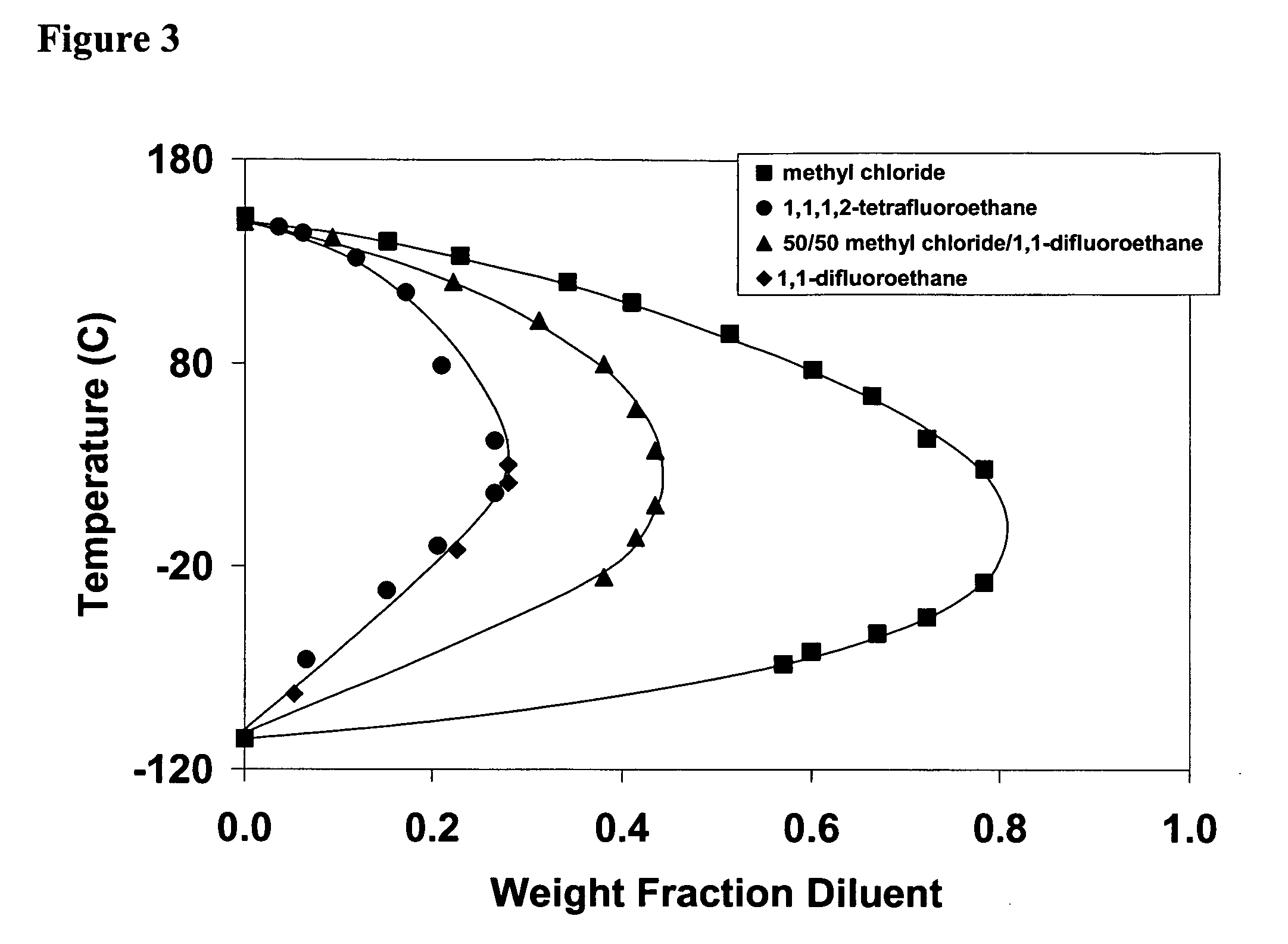

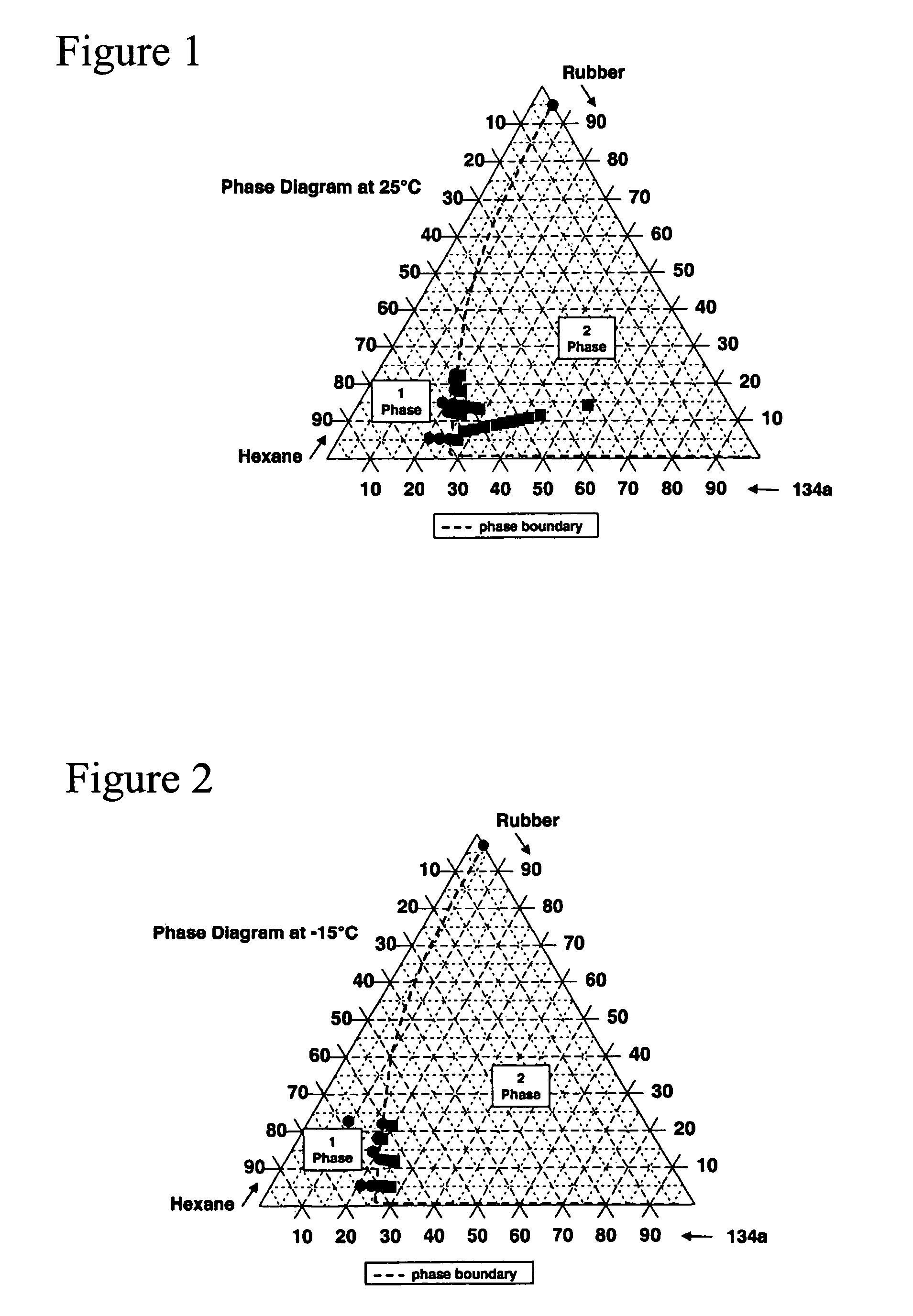

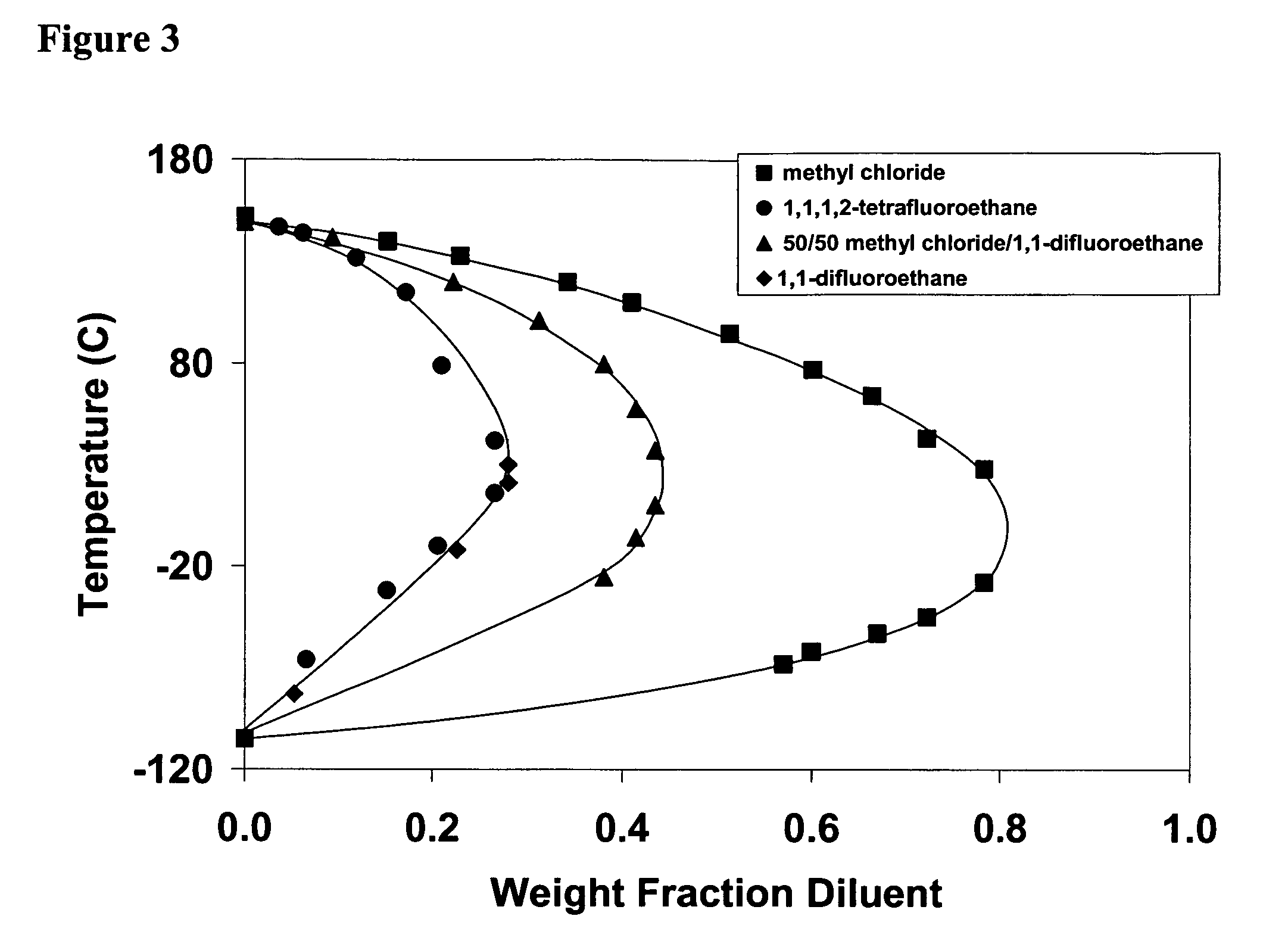

Phase separation process utilizing a hydrofluorocarbon

ActiveUS20070299161A1Easy to appreciateSpecial tyresMultistage water/sewage treatmentHydrocarbon solventsPhase separation process

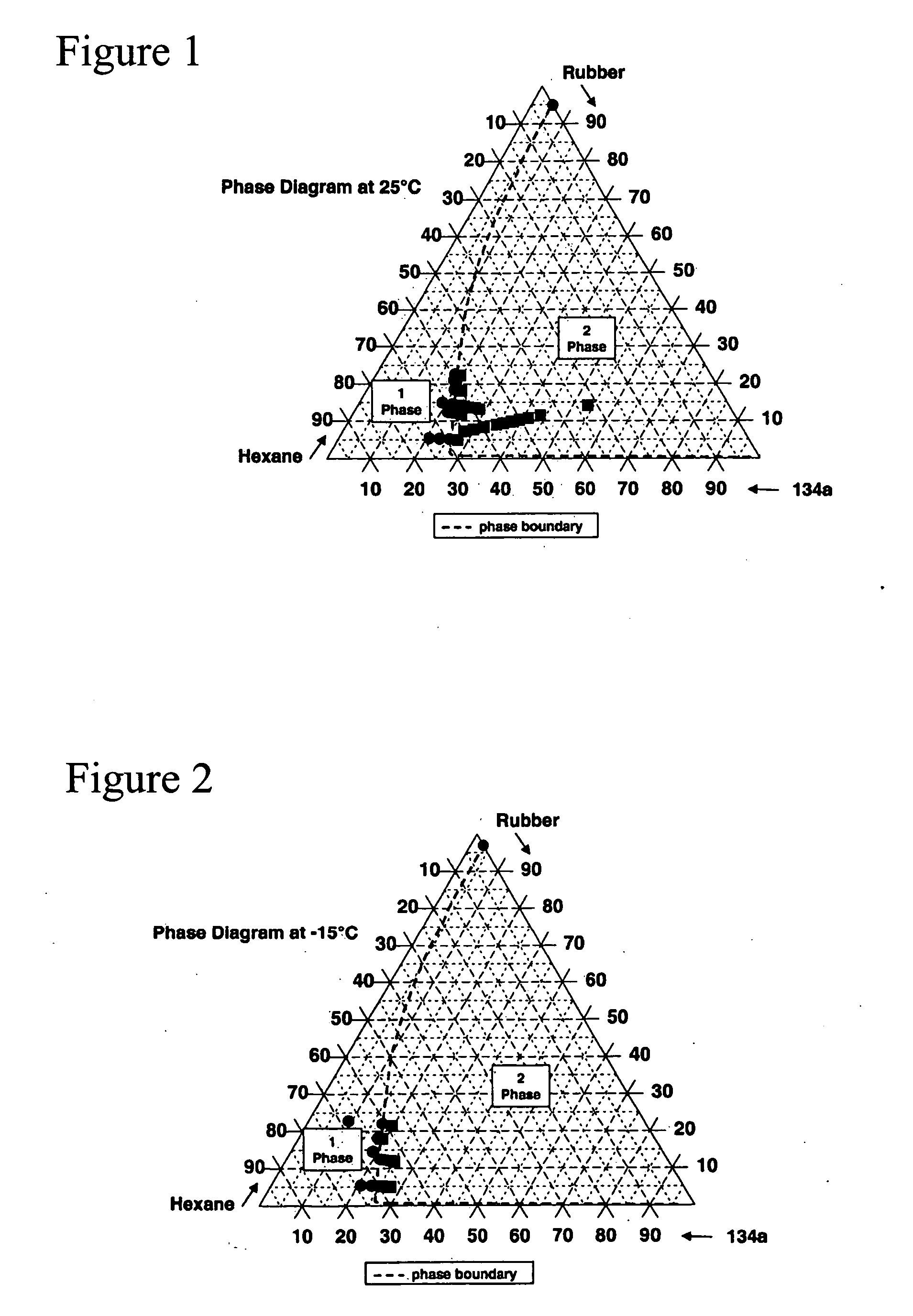

Provided for herein is a process for separating a hydrocarbon-rubber from a hydrofluorocarbon diluent comprising contacting a polymer slurry comprising the hydrocarbon-rubber dispersed within the hydrofluorocarbon diluent with a hydrocarbon solvent capable of dissolving the hydrocarbon-rubber, to produce a first liquid phase and a second liquid phase, and separating the first liquid phase from the second liquid phase.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing super-hydrophobicity surfaces

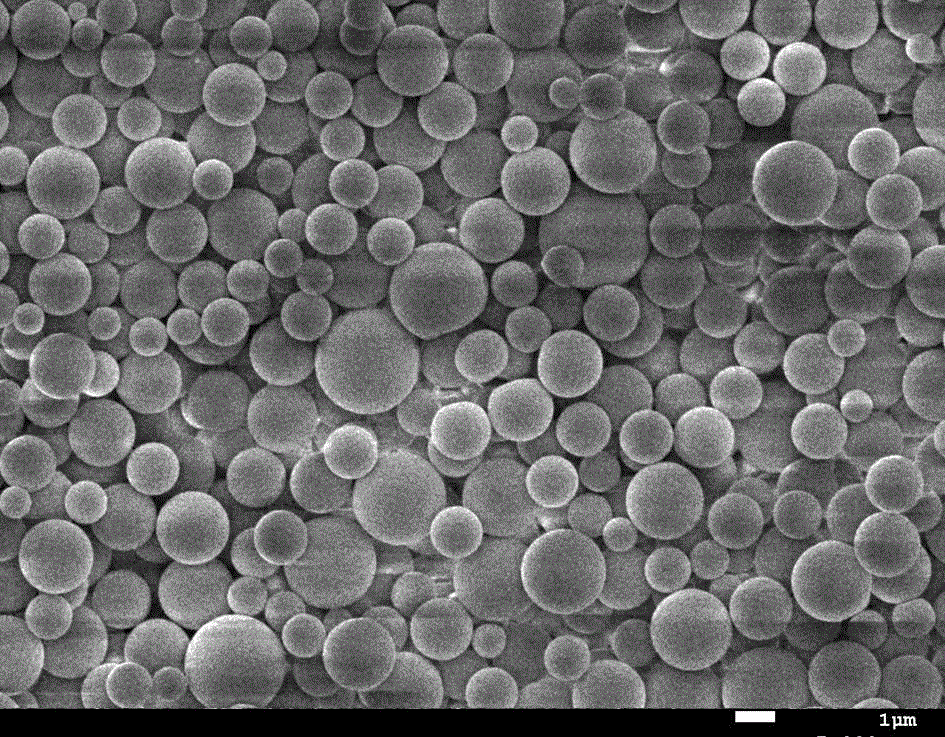

The invention discloses a method for preparing super-hydrophobicity surfaces. A silane coupling agent containing reactivity amino serves as a catalyst to prepare amino modified hollow silica nanometer microspheres; the amino modified hollow silica nanometer microspheres are reacted with epoxy group modified titanium dioxide nano particles to form nano composite particles in raspberry-shaped structures; and the nano composite particles in raspberry-shaped structures are modified through long-carbon-chain fluorine-containing substances to prepare the super-hydrophobicity surfaces. The method for preparing super-hydrophobicity surfaces is characterized in that templates are not needed in the preparing process of the amino modified hollow silica nanometer microspheres; and the chemical bonding reaction between the amino modified hollow silica nanometer microspheres and the epoxy group modified titanium dioxide nano particles is used for preparing the nano composite particles in raspberry-shaped structures. The super-hydrophobicity surfaces are hopeful for being applied to heavy metal ion absorption and separation, harmful gas absorption and decomposing and micro-carrier aspects in relevant separation processes.

Owner:QILU UNIV OF TECH

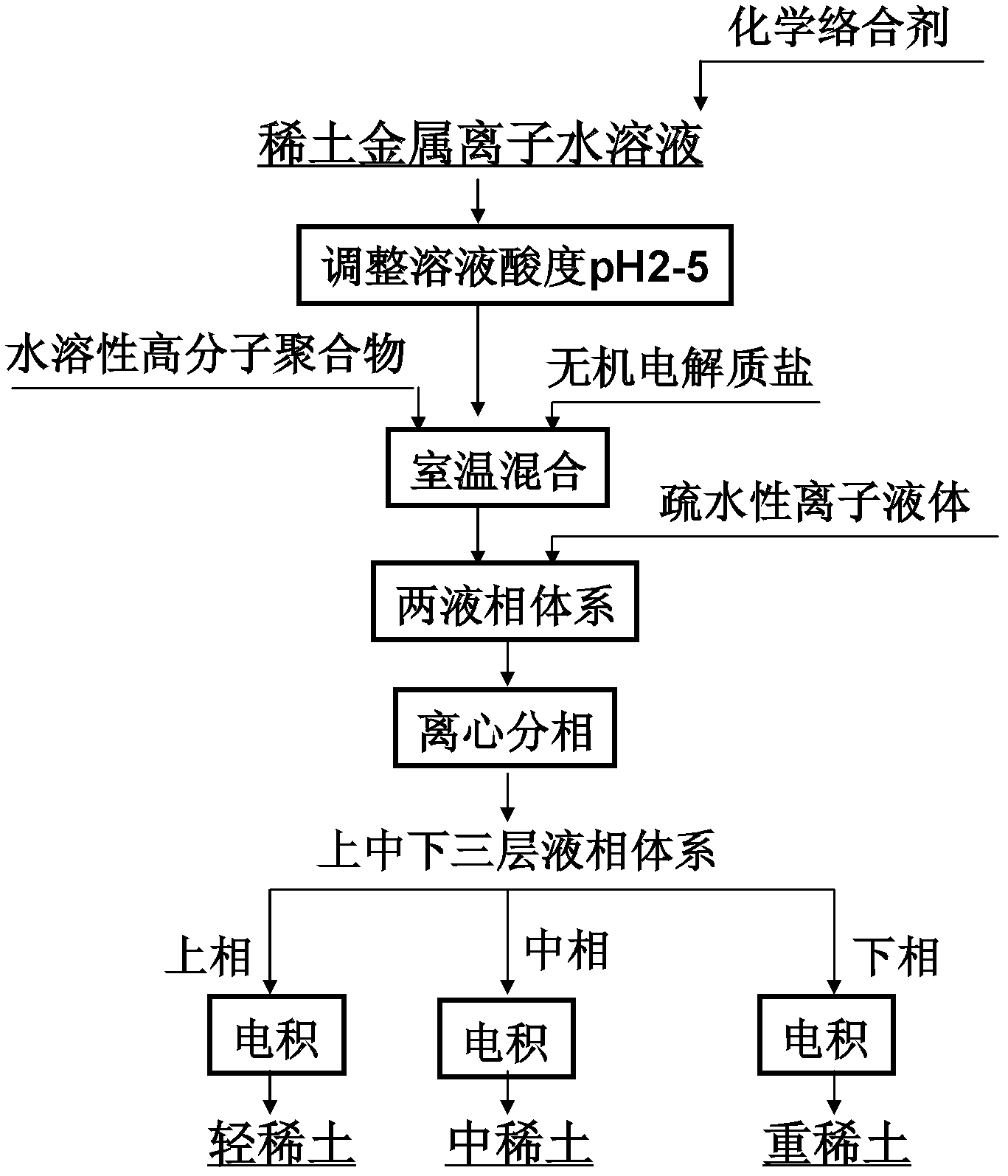

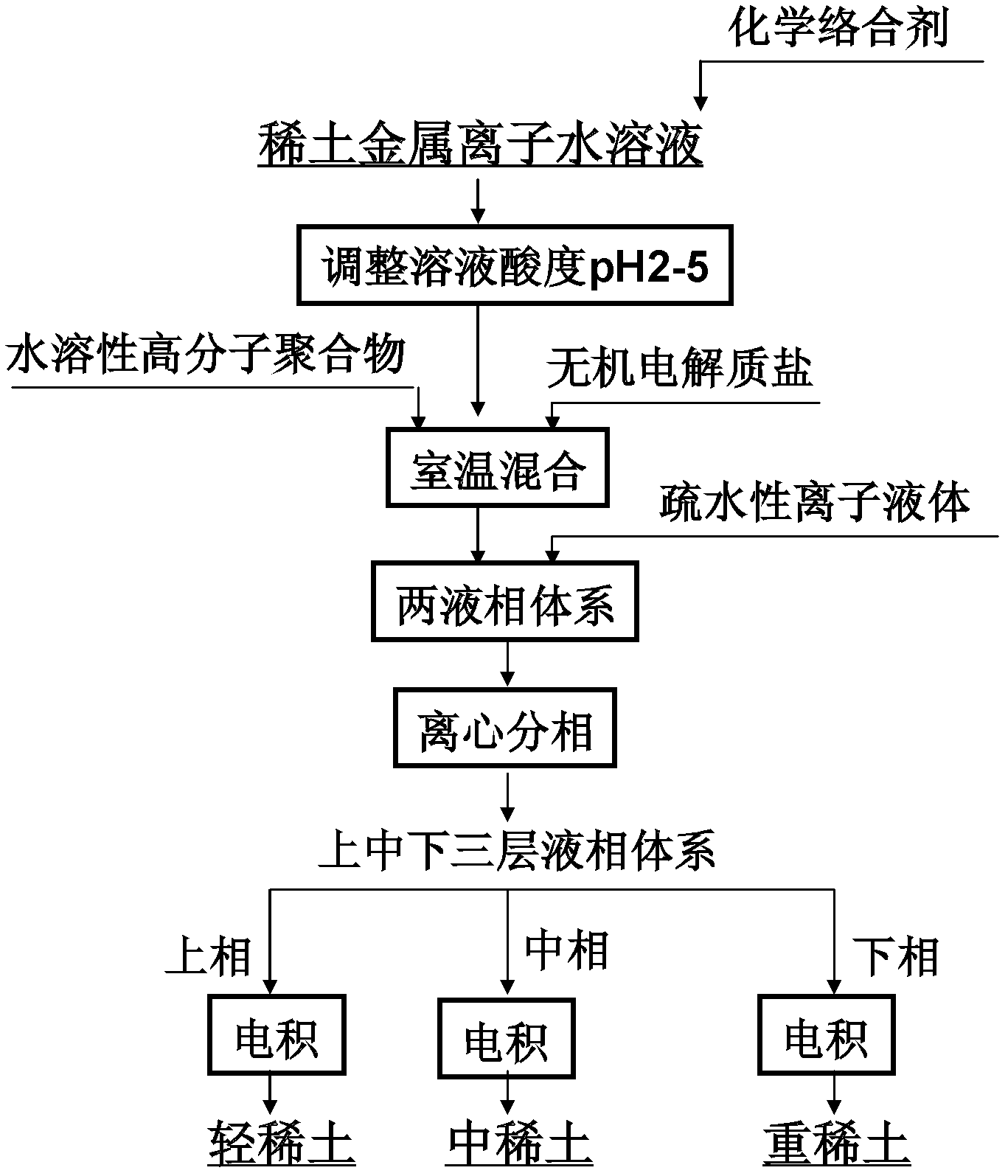

Method for separating rare earth ions by extraction of liquid-liquid-liquid three-phase system

InactiveCN102382982ASpeed up clarification and phase separationReduce usageProcess efficiency improvementSeparation technologyIonic liquid

The invention relates to a method for separating rare earth ions by extraction of a liquid-liquid-liquid three-phase system, and belongs to the technical field of rare earth extraction and separation. The method comprises the following steps of: adding a chemical complexing agent into an aqueous solution containing the rare earth ions, regulating the acidity of the solution, adding a water-soluble high polymer and an inorganic electrolyte salt, oscillating and mixing at room temperature, and obtaining a liquid phase system of upper and lower layers; adding a hydrophobic ionic liquid, fully mixing the solution at room temperature, and obtaining an insoluble three-liquid phase coexistence system of upper, middle and lower layers; and respectively taking the upper, middle and lower phases ofthe three-liquid phase system, and reclaiming the rare earth ions by using an electro-deposition method. According to the method, a volatile organic solvent is not used, so that the phase forming behavior and the phase separation process of the three-phase system are easily artificially controlled; and light, medium and heavy rare earth ions are selectively enriched or grouped and separated in three different liquid phases respectively. Compared with conventional oil-water two-phase separation, the method has the advantages that: the process flow is greatly simplified, the method is quick in phase separation and avoids emulsifying, and the hydrophilic and hydrophobic properties of the ionic liquid three-phase system are easily controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing super high molecular polythene porous membrane by thermally phase separation method

InactiveCN101164677ANarrow pore size distributionHigh porositySemi-permeable membranesPolymer sciencePhase separation process

The present invention relates to a preparation method of ultrahigh molecutar weight polyethylene porous membrane, specially, it relates to a method for preparing high-performance ultrahigh molecular weight polyethylene (UHMWPE) porous membrane by adopting thermal phase separation process. It is characterized by that it uses a high-temperature-resistant solvent-resistant high-strength ultrahigh molecular weight polyethylene resin as membrane material, under the action of diluting agent said invention makes the polyethylene resin membrane material undergo the processes of solution preparation, extrusion, drawing, cooling extraction and recovering extracting agent so as to obtain the invented ultrahigh molecular weight polyethylene porous membrane. The described diluting agent can be selected from white camphor oil, paraffin and paraffin oil.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polypropylene hollow fiber microporous membrane and preparation method thereof

ActiveCN101862601AHigh strengthUniform pore size distributionSemi-permeable membranesFiberHollow fibre

The invention discloses a polypropylene hollow fiber microporous membrane and a preparation method thereof. The hollow fiber microporous membrane comprises the following components in percentage by weight: 15-45% of polypropylene, 50-80% of thinner and 0.1-5% of additive. The preparation method of the hollow fiber microporous membrane is realized on the basis of a thermotropic phase separation process. The preparation method of the polypropylene hollow fiber microporous membrane is simple and easy to industrialize, and has low requirements on equipment, the prepared hollow fiber microporous membrane has the advantages of high strength, uniform pore diameter distribution, high porosity and the like, the pore diameter of the hollow fiber microporous membrane can be controlled between 0.1 and 0.45mu m, and the porosity is 60-85%, so the hollow fiber microporous membrane has large water flux, is not easy to block in use, can be widely used for feeding water treatment, and is particularly suitable for the membrane bioreactor technology and other water treatment fields.

Owner:三泰(青岛)膜科技有限公司

Antibacterial macromolecular ultra-filtration membrane and preparation method thereof

ActiveCN102205209AHas a long-term sustained release effectLong-term effective antibacterial abilitySemi-permeable membranesFiberNon solvent

The invention relates to a macromolecular ultra-filtration membrane having a long-term antibacterial effect and a preparation method thereof. The preparation method for the antibacterial macromolecular ultra-filtration membrane comprises the following steps: (a) preparing a macromolecular membrane-preparing solution; (b) adding antibacterial grains into the macromolecular membrane-preparing solution, wherein the antibacterial grains are prepared by compounding inorganic carriers and antibacterial agents and have a long-term slow-releasing function, the weight of the antibacterial grains is 0.01-0.1% of the weight of the macromolecules in the macromolecular membrane-preparing solution, and the grain size of the antibacterial grains is 0.01-10 mu m; and (c) preparing the antibacterial macromolecular ultra-filtration membrane by adopting a dry-wet or wet spinning method through a non-solvent induced phase separation process (NIPS) or a thermally induced phase separation process (TIPS). Afiber ultra-filtration membrane provided by the invention can be applied to the water filtration and purification and has the long-term antibacterial effect. The macromolecular ultra-filtration membrane can be widely applied to the drinking water treatment, the household water purifiers, and the filtration and purification for foods and medicines.

Owner:江苏美能膜材料科技有限公司

Phase separation process utilizing a hydrofluorocarbon

ActiveUS7629397B2Easy to appreciateSpecial tyresMultistage water/sewage treatmentHydrocarbon solventsPhase separation process

Provided for herein is a process for separating a hydrocarbon-rubber from a hydrofluorocarbon diluent comprising contacting a polymer slurry comprising the hydrocarbon-rubber dispersed within the hydrofluorocarbon diluent with a hydrocarbon solvent capable of dissolving the hydrocarbon-rubber, to produce a first liquid phase and a second liquid phase, and separating the first liquid phase from the second liquid phase.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing aluminum oxide-based ceramic hollow fibrous membrane

The invention relates to a method for preparing an enhanced aluminum oxide-based ceramic hollow fibrous membrane. The method comprises the following steps: performing ball milling and mixing a main membrane material aluminum oxide powder and a reinforcing agent, and then drying, grinding and sieving; preparing a polymer solution, adding the evenly mixed ceramic powder in the polymer solution and evenly dispersing to obtain a spinning solution with proper viscosity; after the spinning solution is subjected to deaeration treatment, extruding the spinning solution via a spinning jet, enabling the extruded spinning solution to enter into external coagulated bath by passing through a certain dry spinning procedure, and generating a phase separation process at the moment while forming a hollow fibrous membrane green body; soaking the membrane green body in the external coagulated bath to replace out residual organic solvents; and after naturally drying, processing the green body via a sintering technology to obtain the ceramic hollow fibrous membrane. The invention has simple and convenient technology and no expensive devices, the prepared aluminum oxide-based ceramic hollow fibrous membrane has favorable mechanical property, and the mechanical strength thereof is remarkably improved compared with the hollow fibrous membrane produced by pure aluminum oxide powder.

Owner:NANJING UNIV OF TECH

Membrane post treatment

InactiveUS20060157404A1Low toxicityReduce riskSolid sorbent liquid separationPretreated surfacesCross-linkPhase separation process

The invention relates to polymeric ultrafiltration or microfiltration membranes of, for instance, Halar, PVDF or PP, incorporating PVME or vinyl methyl ether monomers. The PVME may be present as a coating on the membrane or dispersed throughout the membrane or both. The membranes are preferably hydrophilic with a highly asymmetric structure with a reduced pore size and / or absence of macrovoids as a result of the addition of PVME. The PVME maybe cross-linked. The invention also relates to methods of hydrophilising membranes and / or preparing hydrophilic membranes via thermal or diffusion induced phase separation processed.

Owner:EVOQUA WATER TECH LLC

Bionic tissue engineering scaffold containing inner channel network and oriented pore structure as well as preparation method and application of bionic tissue engineering scaffold

ActiveCN105311683ASignificant biomimetic structural featuresIncrease planting densitySurgeryProsthesisRapid prototypingSmall hole

The invention discloses a bionic tissue engineering scaffold containing an inner channel network and an oriented pore structure as well as a preparation method and application of the bionic tissue engineering scaffold. The bionic tissue engineering scaffold comprises a scaffold main body and a channel network, wherein the channel network is arranged inside the scaffold main body; the scaffold main body has the oriented micro-pore structure, and oriented big holes of the oriented micro-pore structure are mutually communicated by virtue of transverse small holes; the channel network has a hierarchical multi-branch structure, and the branches of the channel network are mutually communicated; and the scaffold main body is made from a degradable natural high polymer material. The bionic tissue engineering scaffold disclosed by the invention, which combines a 'core' manufacturing process with an 'oriented pore' directional crystallization and thermally induced phase separation process on the basis of thinking from 'presetting' to 're-dissolving', can break through the technical bottleneck of a complex micro-channel structure which is directly formed. By virtue of a rapid forming technology or a mold casting method, and in particular by virtue of the rapid forming technology, a core forming structure becomes flexible, so that a complex channel structure in any morphologies are formed; and the channel structure is good in passing-through characteristic.

Owner:TSINGHUA UNIV

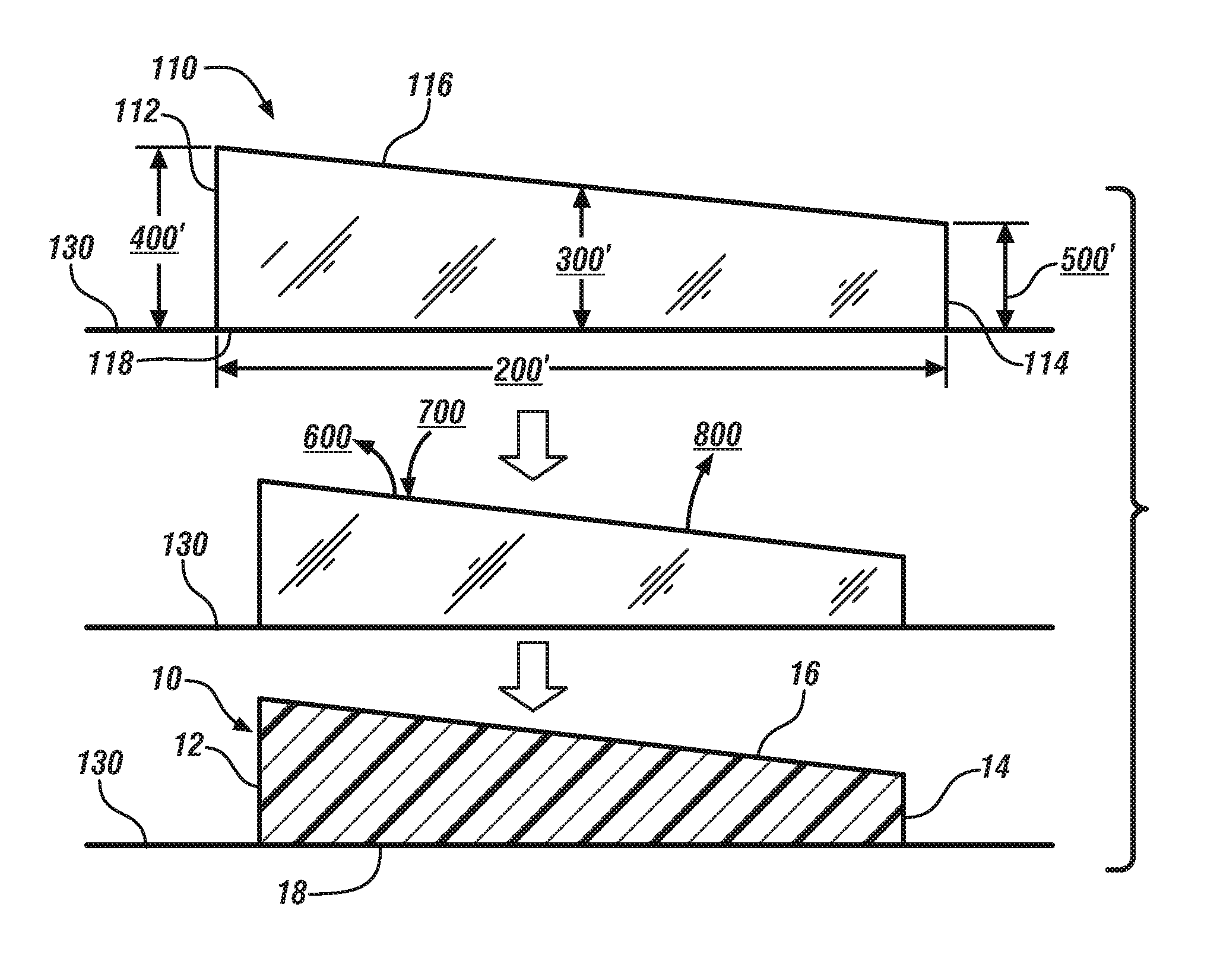

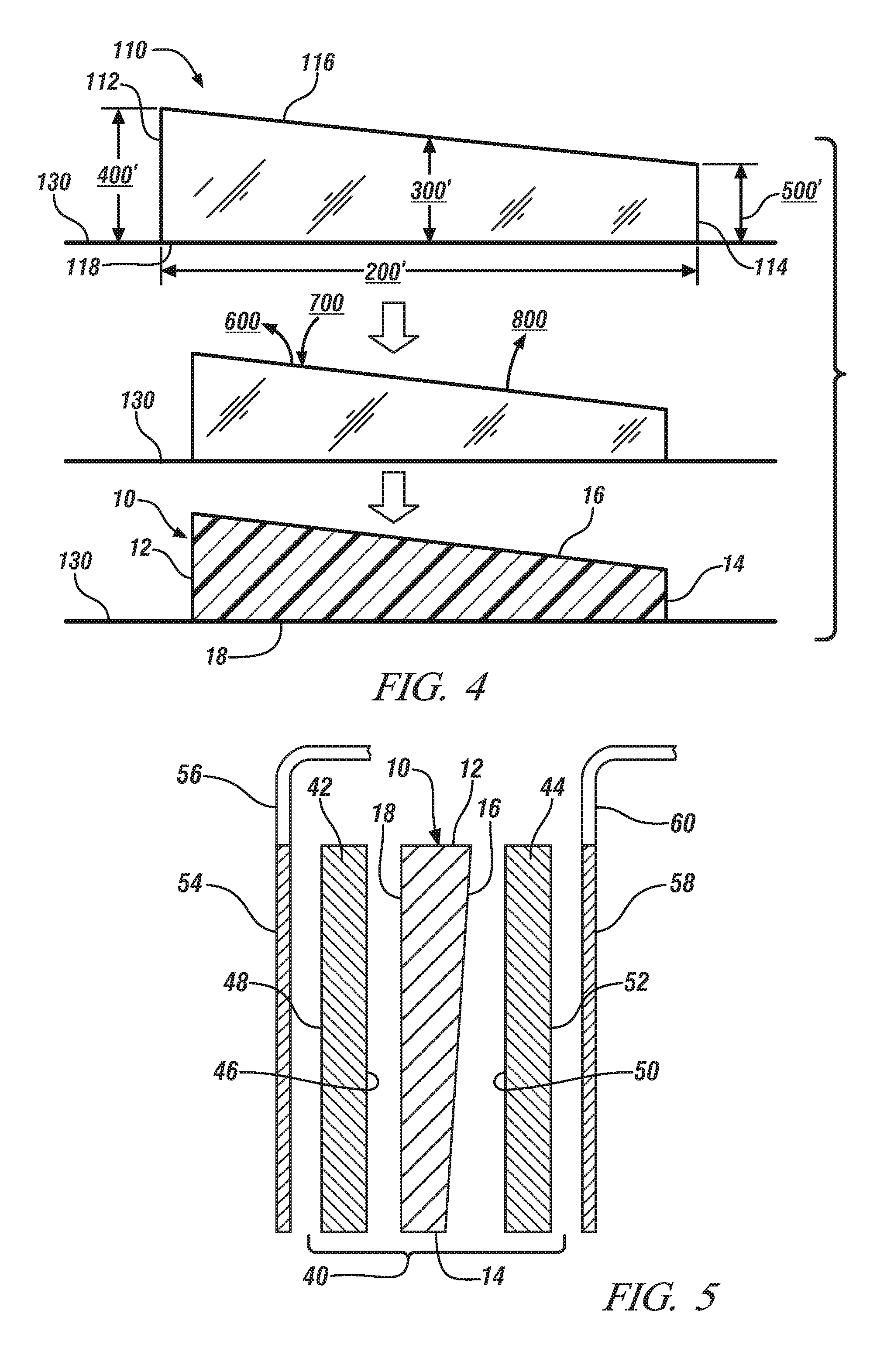

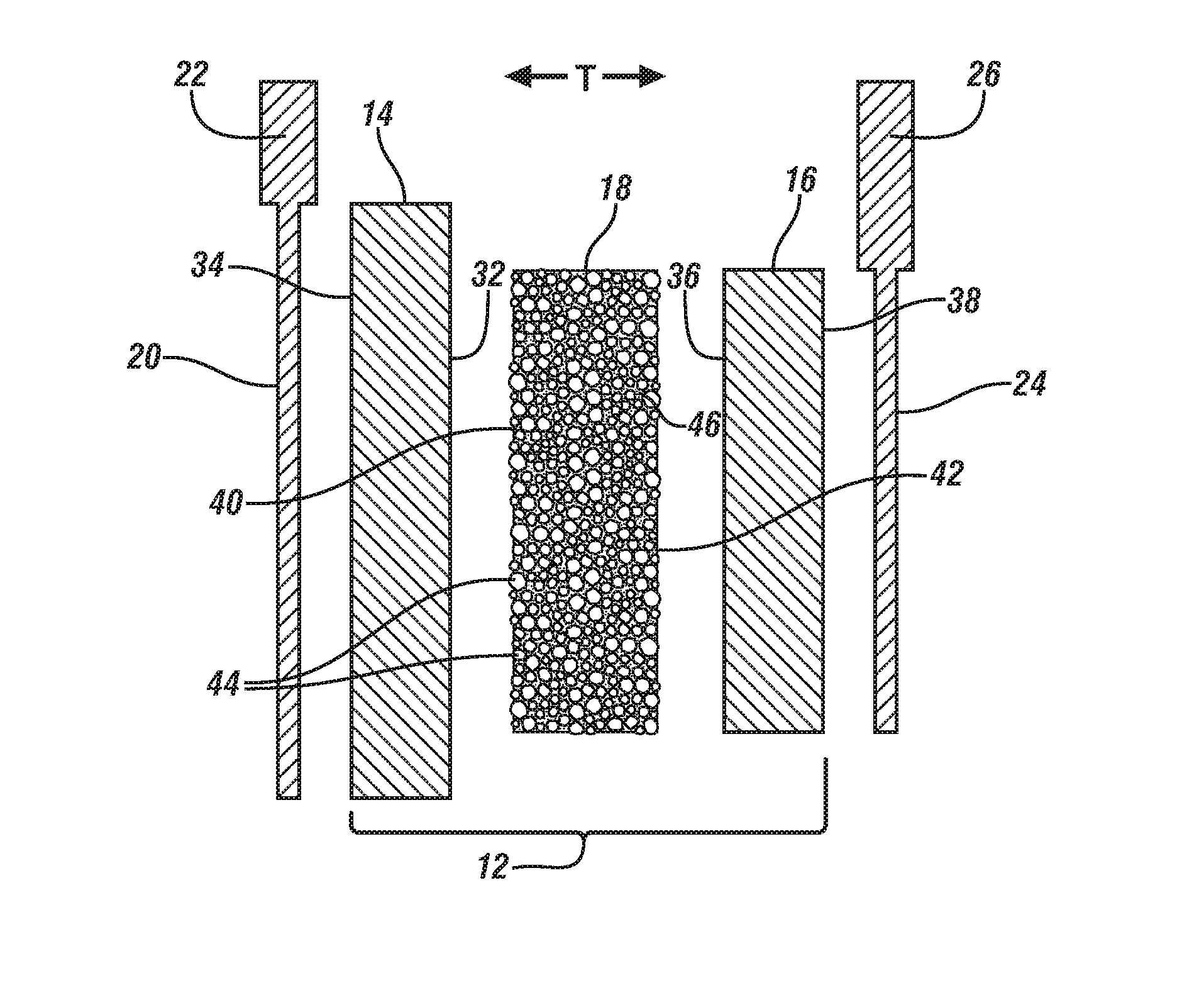

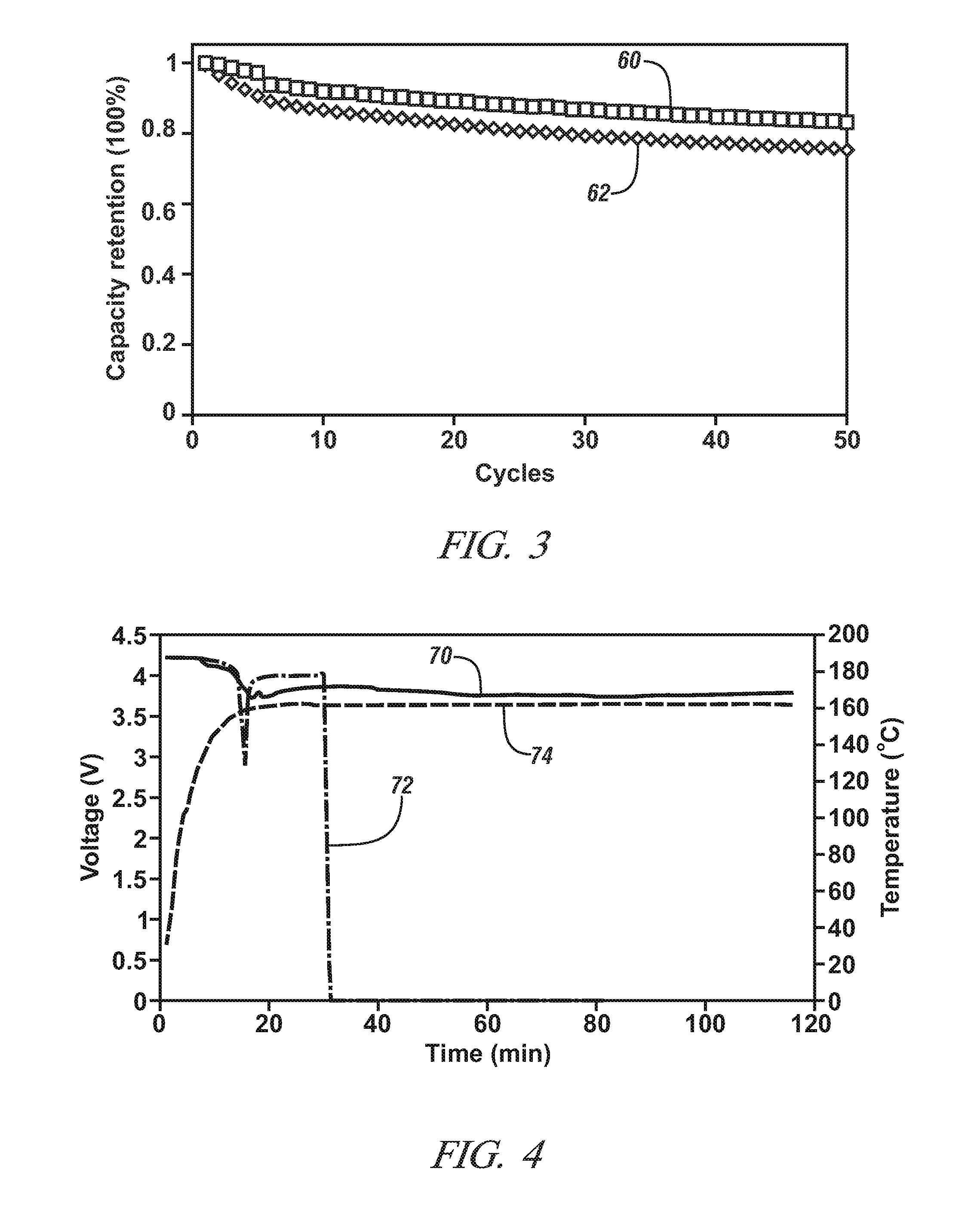

Porous polymer separator layer having a non-uniform cross sectional thickness for use in a secondary liquid electrolyte battery

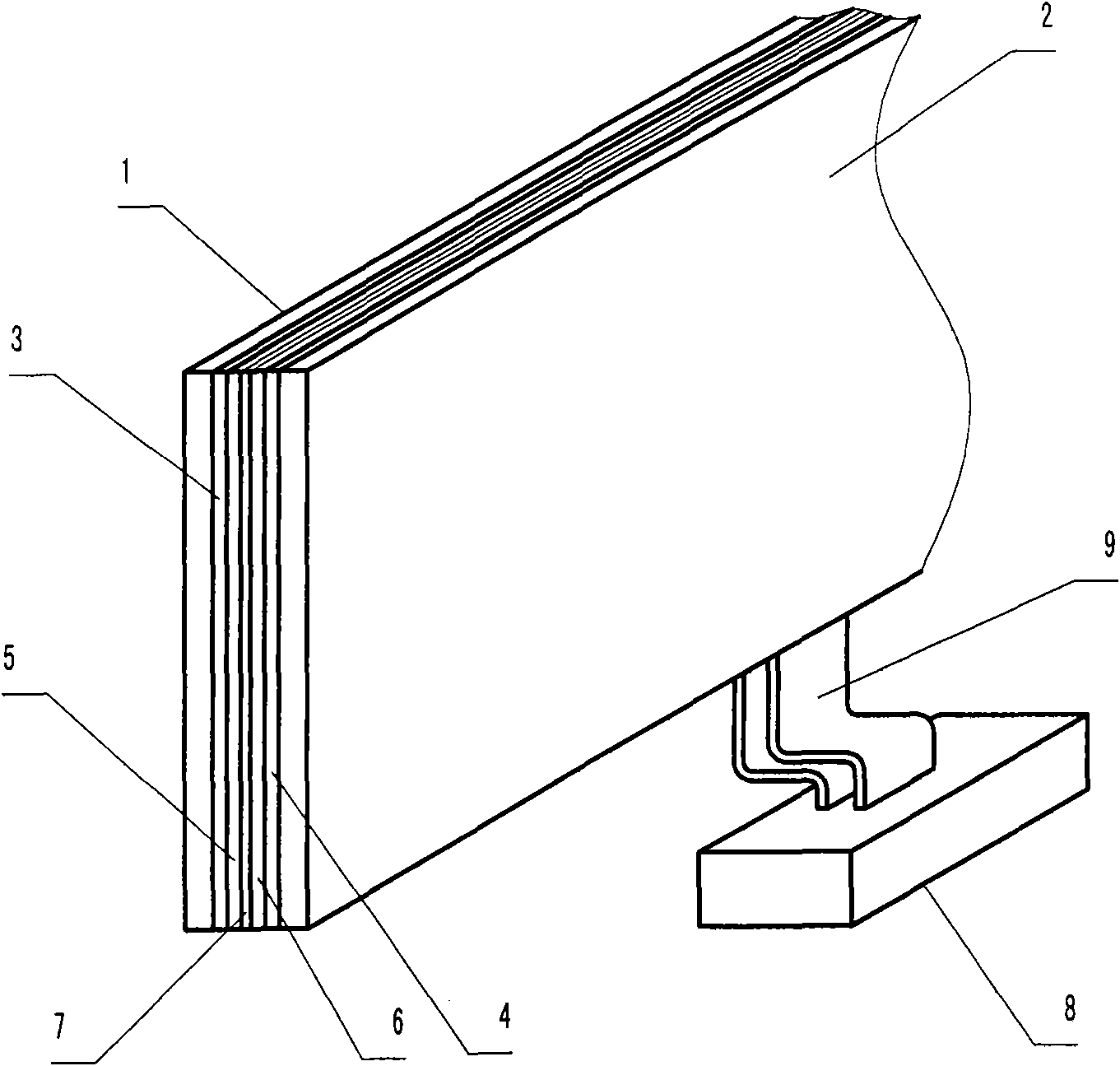

ActiveUS8455140B1Easy to transportSuitable propertyCell seperators/membranes/diaphragms/spacersLi-accumulatorsPower flowPhase separation process

A porous polymer separator layer that exhibits a non-uniform cross-sectional thickness and a method of making the same are disclosed. The porous polymer separator layer may be made by a phase-separation process. This process involves precipitating the porous polymer separator layer from a film having a non-uniform cross-sectional thickness similar to that sought to be imparted to the resultant separator layer. An electrochemical battery cell for a secondary liquid-electrolyte battery may incorporate the disclosed porous polymer separator layer between a negative electrode and a positive electrode in a way that that helps maintain a more evenly distributed current density within the cell.

Owner:GM GLOBAL TECH OPERATIONS LLC

Modified polyvinyl chloride hollow fiber microporous memebrane and method for providing the same

The invention discloses a hollow microporous membrane of a modified polychloroethylene and process for preparation. The hollow microporous membrane of the modified polychloroethylene has a spongy structure, the bore diameter of a microporous is 0.01-1.0 um, the porosity rate of the membrane is 40-80%, wall thickness of the membrane is 0.10-0.30 mm, and the external diameter of the membrane is 1.0-3.0mm, wherein the main components of the hollow microporous membrane of the modified polychloroethylene are polychloroethylene and toughening agent. The preparing method is realized on the basis of thermal separation process. The hollow microporous membrane of the improved polychloroethylene which is made by the invention has the advantages of narrow bore diameter distribution, high intensity, and good structural repeatability and the like, and the bore diameter is easy to be controlled. The invention is a filter membrane material for water process which has high performance, low cost and long service life.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

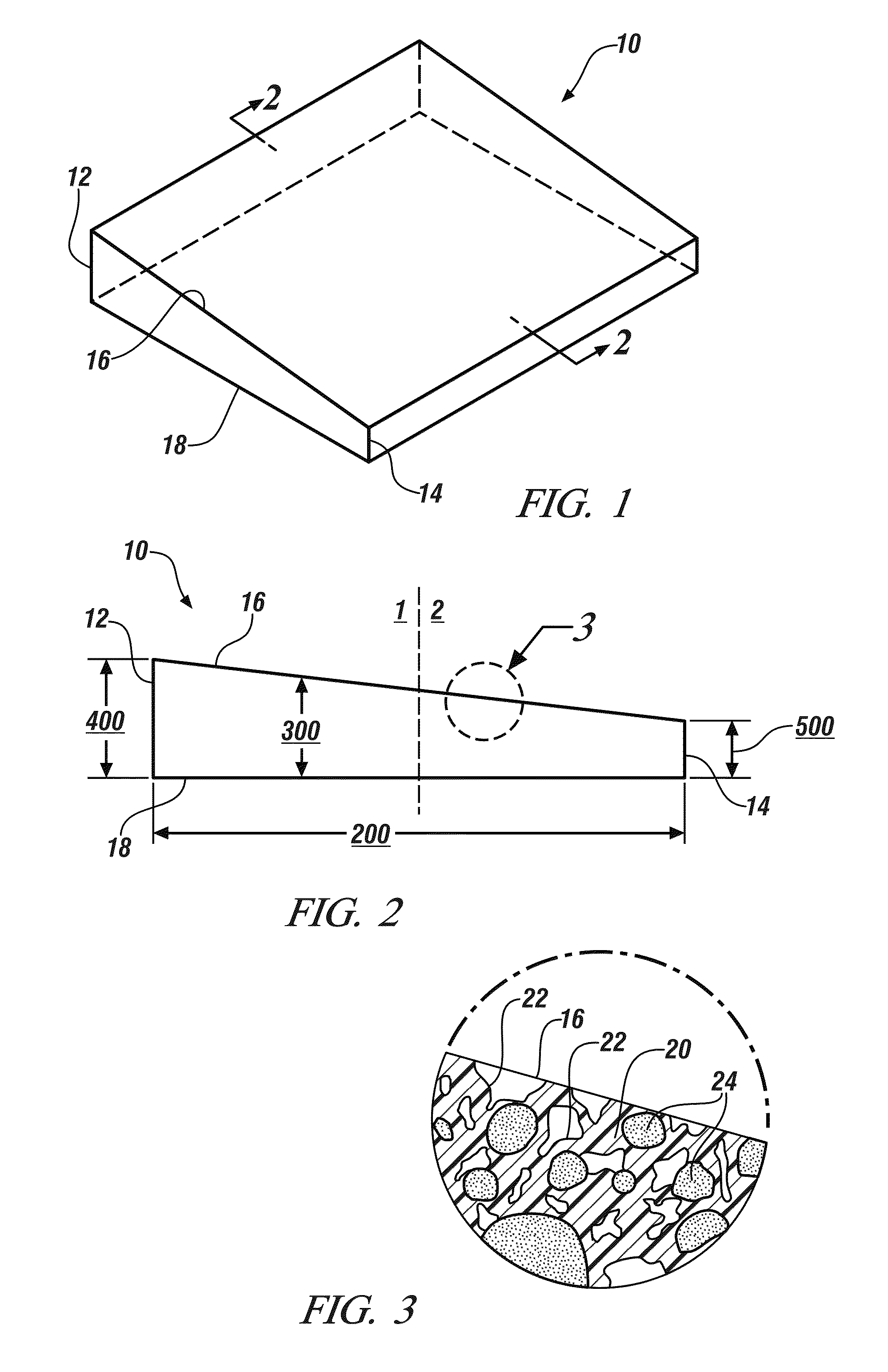

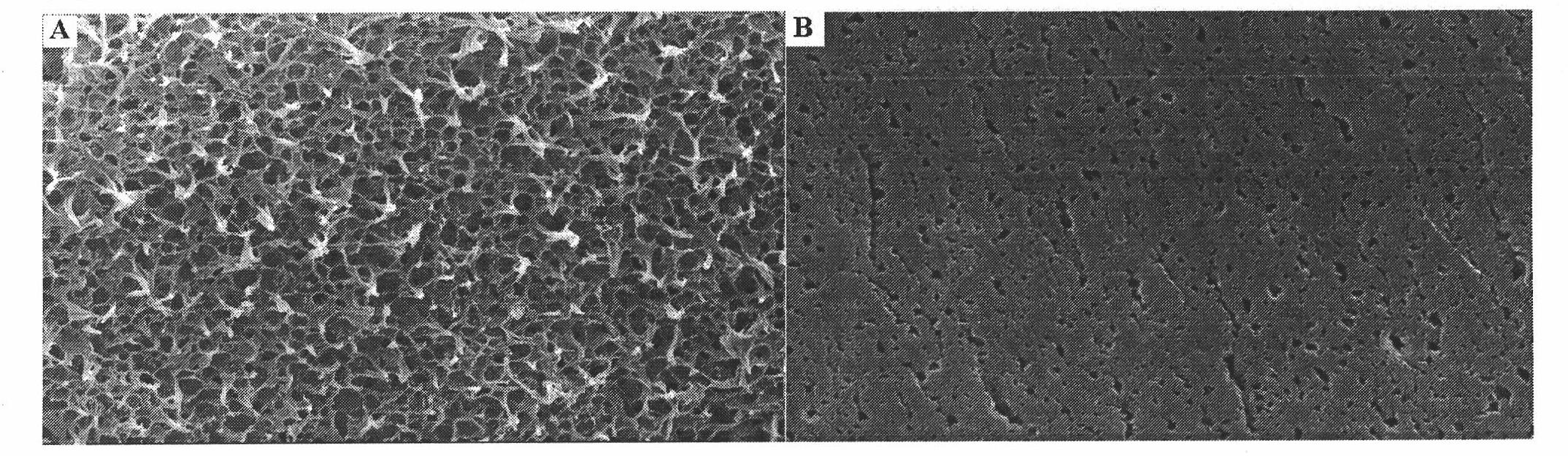

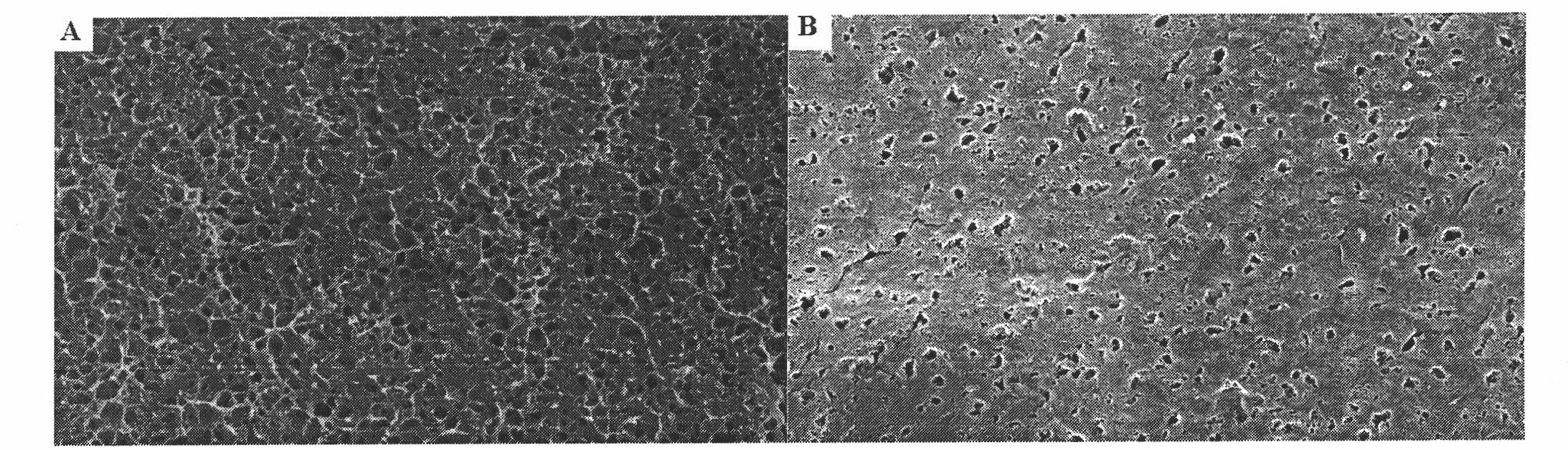

Separators for a lithium ion battery

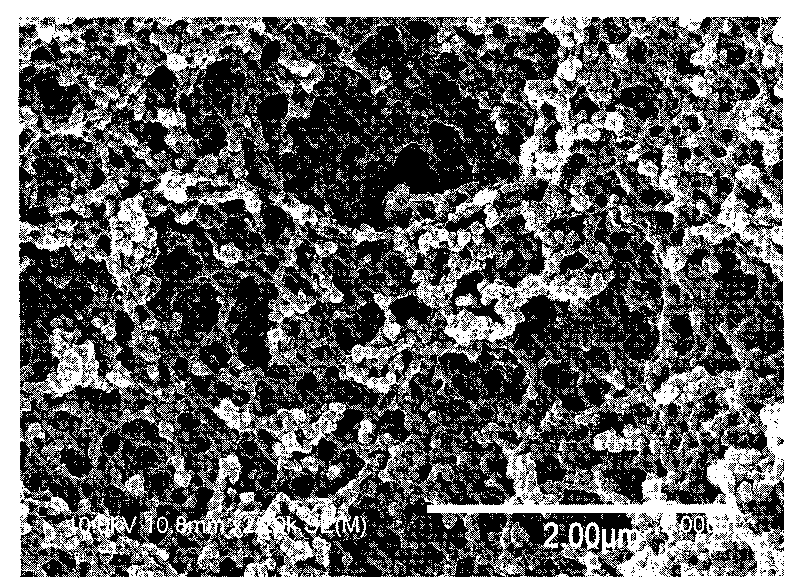

ActiveUS9287540B2Improve thermal stabilityEasy to openPrimary cell to battery groupingSecondary cellsPhase separation processThermal stability

A separator for use in a lithium ion battery to provide a physical and electrically insulative mechanical barrier between confronting inner face surfaces of a negative electrode and a positive electrode may be formed predominantly of heat-resistant particles. The heat-resistant particles, which have diameters that range from about 0.01 μm to about 10 μm, are held together as a thin-layered, handleable, and unified mass by a porous inert polymer material. The high content of heat-resistant particles amassed between the confronting inner face surfaces of the negative and positive electrodes provides the separator with robust thermal stability at elevated temperatures. Methods for making these types of separators by a phase-separation process are also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Polyester flat microporous membrane and preparation method thereof

InactiveCN101985085AAchieve hydrophilicAchieve hydrophilizationSemi-permeable membranesCell seperators/membranes/diaphragms/spacersPolyesterMicrometer

The invention discloses a polyester flat microporous membrane and a preparation method thereof. The microporous membrane comprises the following materials in percentage by mass: 60-99.9% of polyester and 0.1-40% of modifier; or 20-40% of non-woven fabric, 60-79.9% of polyester and 0.1-30% of modifier. The preparation method is realized on the basis of a thermally induced phase separation process and comprises the following steps: mixing the polyester, the modifier and diluter into a homogeneous solution at high temperature; scraping the homogeneous solution into a liquid membrane, cooling andcuring into a membrane so as to form a precursor membrane subject to microphase separation, and extracting to obtain a flat microporous membrane. The prepared polyester flat microporous membrane is in a spongeous structure with the pore diameter of 0.05-5.0 micrometers and the porosity of 30-80%, and has the advantages of narrow pore diameter distribution, uniform pore size, easily controlled pore size, high strength, symmetrical structure and the like, thereby being a filter membrane material for water treatment and a lithium ion battery diaphragm material with high performance, low cost andlong life.

Owner:ZHEJIANG UNIV

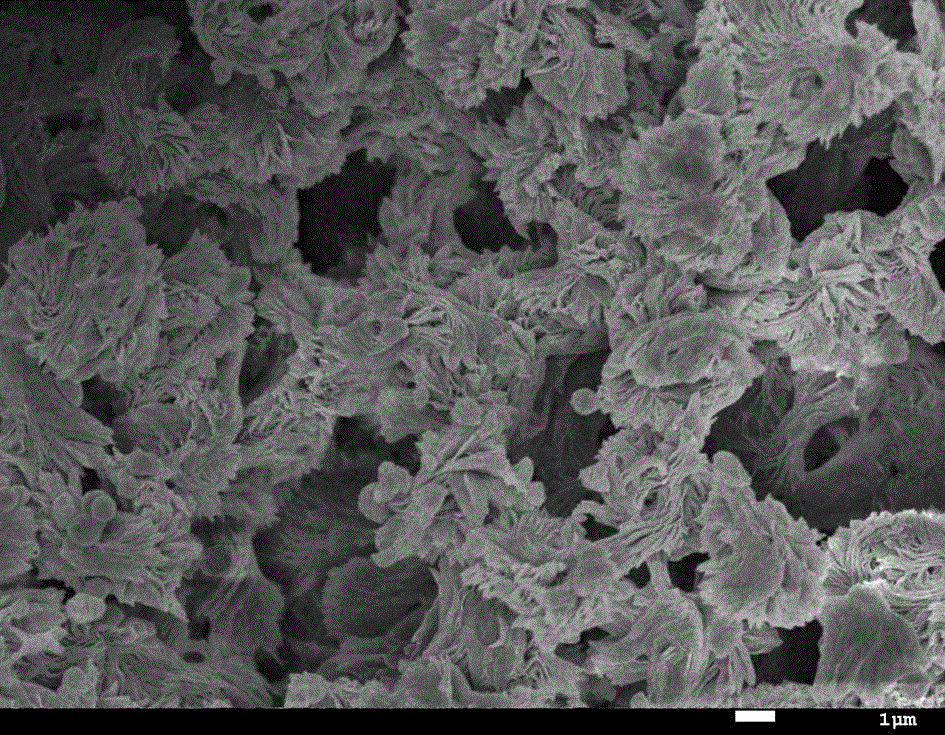

Porous polymer whole separating material and preparation method thereof

InactiveCN101735414AWide range of choicesRegular and orderly internal structureOther chemical processesPorosityPolymer science

The invention discloses a porous polymer whole material, a preparation method and application thereof. The porous polymer whole material has a regular three-dimensional network framework structure, and consists of a polymer framework and through holes, wherein the surface and / or inside of the polymer framework is provided with nanometer mesopores; the diameter of the through holes is between 0.2 and 5.0 mu m; the diameter of the mesopores is between 2 and 50nm; and the size of the framework is between 0.1 and 1.0 mu m. The preparation method adopts a free radical polymerization method, and regulates a phase separation process of a reaction system by adding two amphiphilic block copolymers into a common free radical polymerization system so as to obtain the polymer whole material with the three-dimensional network framework structure. The polymer whole material has regular and orderly structure and high porosity, and can be widely applied in the field of high-efficiency quick separation of biological macromolecules.

Owner:INST OF CHEM CHINESE ACAD OF SCI

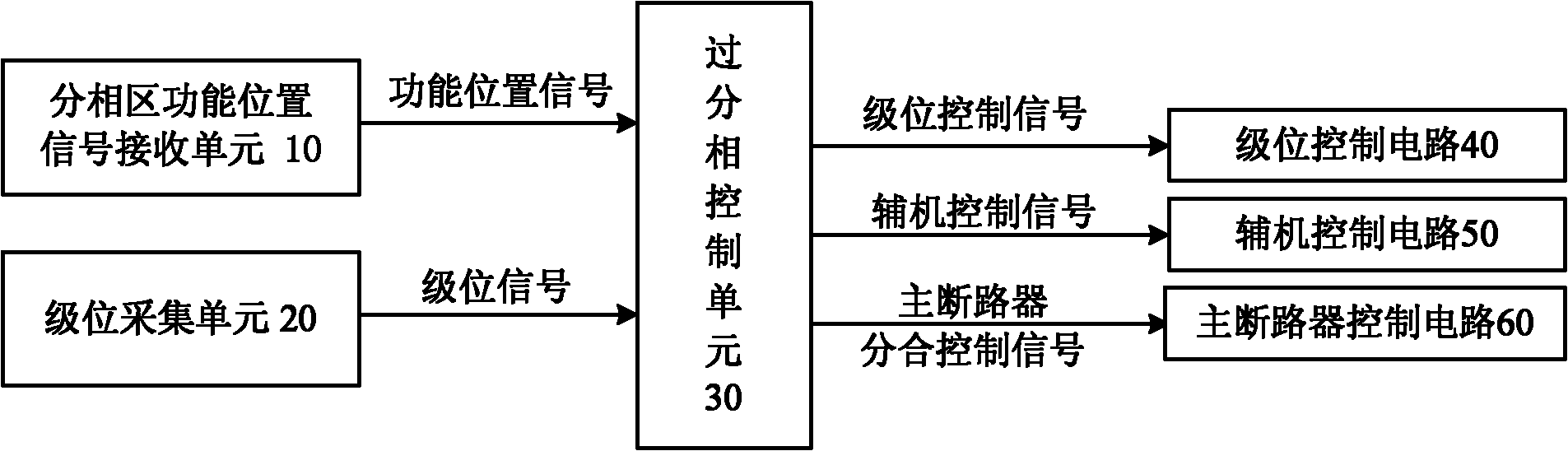

Automatic passing phase separation control device and passing phase separation control system for multi-locomotives

ActiveCN102039828ASafe and reliable controlEffective controlElectric locomotivesTrolley linesControl signalControl system

The invention provides an automatic passing phase separation control device and a passing phase separation control system for multi-locomotives. The automatic passing phase separation control device comprises a phase separation section functional position signal receiving unit (10) for receiving and recognizing a phase separation section functional position signal, a level acquiring unit (20) for acquiring a level signal of a control handle, and a passing phase separation control unit (30) for receiving the phase separation section functional position signal from the phase separation section functional position signal receiving unit (10) and receiving the level signal from the level acquiring unit (20), outputting a level control signal based on the pulse width modulating form of the level signal according to the received functional position signal to control lifting of the level, and outputting a secondary control signal and a main circuit breaker on / off control signal to respectively control starting and shutting of a secondary machine and the switch off and switch on of the main circuit breaker. The passing phase separation device and system are beneficial to stably finish passing phase separation processes of a single locomotive and the multi-locomotive.

Owner:CHINA SHENHUA ENERGY CO LTD +1

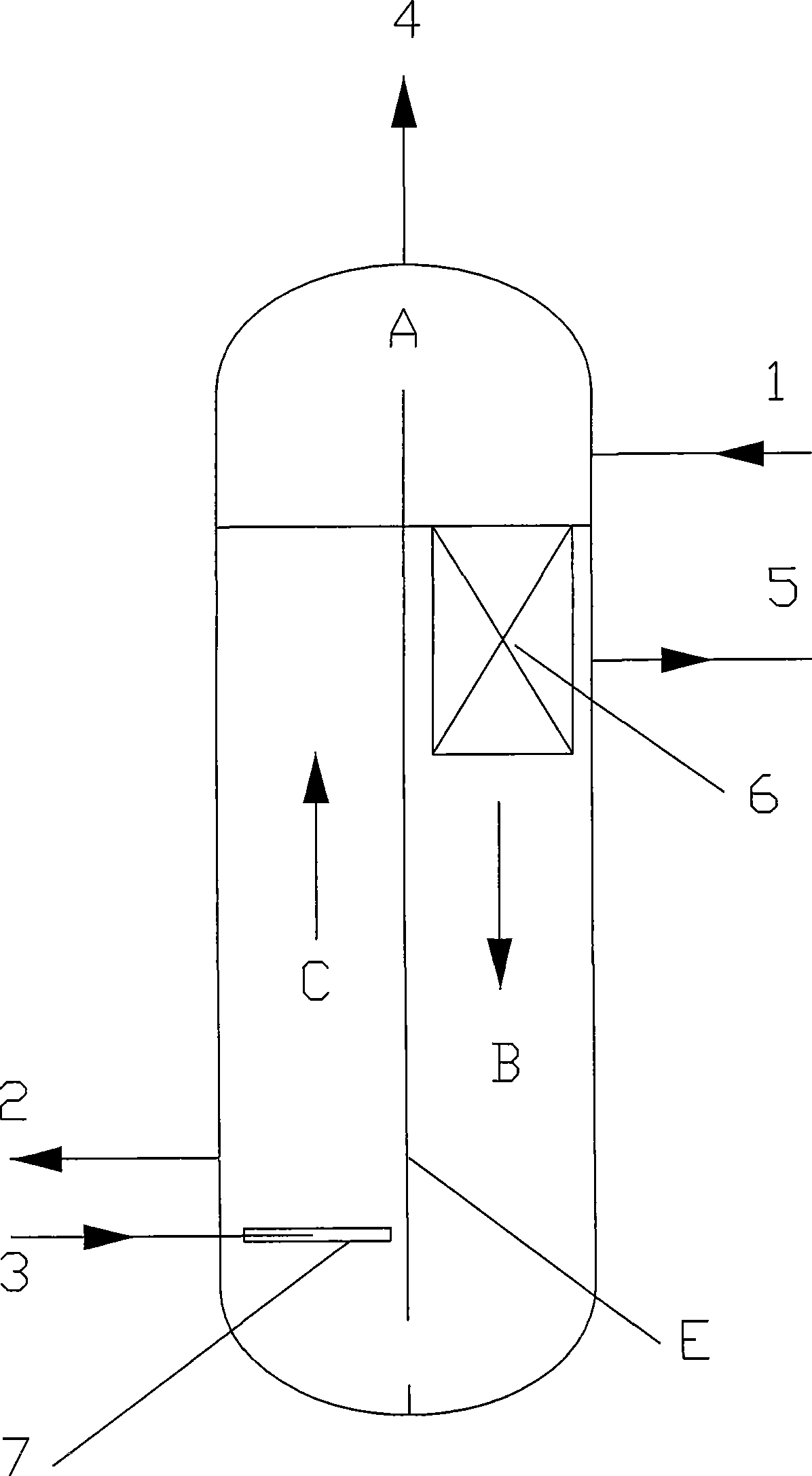

Oil-containing alkali liquor separation apparatus and method

ActiveCN101469276AImprove cleanlinessReduce contentLiquid separationRefining with aqueous alkaline solutionsBisulfidePhase separation process

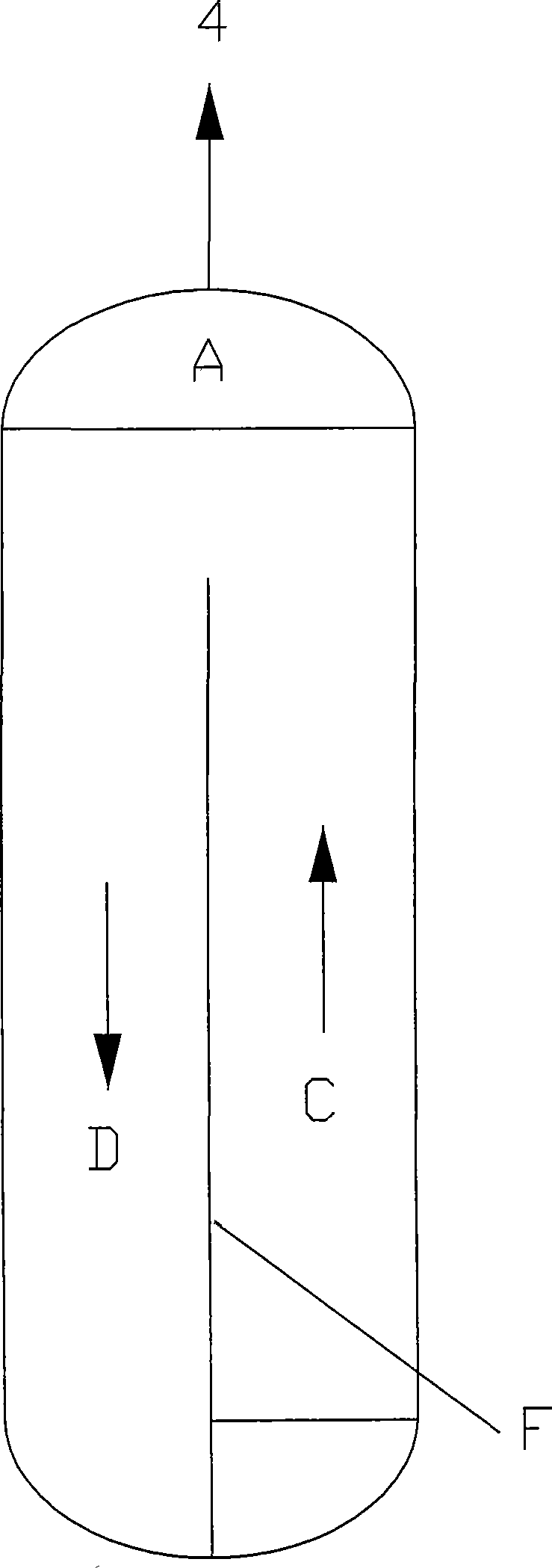

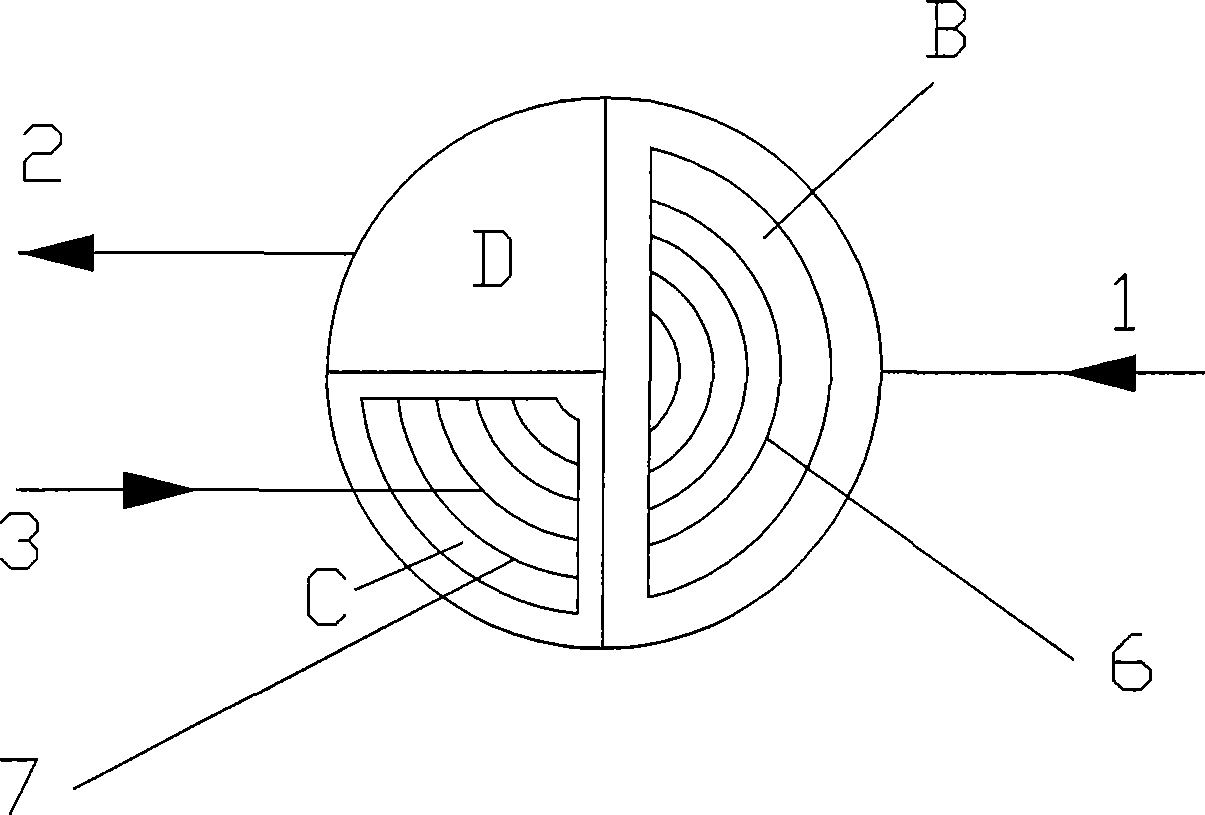

The invention relates to an oil-contained lye separating device, which at least comprises a device shell and is characterized in that the upper space of the device shell is a tail gas separation zone provided with a tail gas outlet, and the circumferential surface of the middle-lower space of the device shell is at least distributed with an oil-alkali separation zone provided with an oxidized lyeinlet and a gas stripping separation zone, wherein an oil phase aggregation separating device and an oil phase outlet are arranged in the oil-alkali separation zone which is communicated with the bottom of the gas stripping separation zone; a gas distributor and a gas stripping gas inlet connected therewith are arranged in the gas stripping separation zone; and the device shell is provided with aregenerated lye outlet. A method comprises the following steps: adopting the oil phase aggregation separating device to perform oil-alkali separation on the oxidized lye in the oil-alkali separation zone, and then using the gas distributor to perform gas stripping in the gas stripping zone so as to obtain the regenerated lye through a lye stabilization zone, wherein the tail gas zone is communicated with other zones so as to exhaust the tail gas after the treatment. The oil-contained lye separating device integrates the separation processes of the three phases including the tail gas generatedin the lye regeneration process, the lye and disulphide into a whole; the cleanliness of the lye obtained through separation is improved, the content of the disulphide is low, and the separation effect is good; besides, the oil-contained lye separating device has the advantages of more compact structure, small volume, and reasonable and practical process.

Owner:NINGBO ZHONGYI PETROCHEM TECH

Mixing and settling method and device in solvent extraction processes to recover high-purity products

ActiveUS7507343B2Easy to pourLower Level RequirementsFlow mixersRotary stirring mixersPhase separation processEngineering

The device of the invention includes the following 5 new elements in each mixer-settler: a) agitators with blunt edged turbines, b) decreasing degree of agitation throughout the series of mixing compartments, c) baffle with a central window in the settler interface, located after the flow buffers, and d) baffle without a window, centered in the settler interface, located after the baffle with a window. These elements allow for an operative method which inhibits secondary dispersion, reducing the formation of micro-droplets, without affecting the mass transfer between the phases. Consequently, this obtains a phase separation process with entrainments so small that it is possible to drastically increase the quality of the product, by obtaining an ultra-pure aqueous extract, simultaneously reducing the settling surface required.

Owner:TECH REUNIDAS SA

Thermoplastic polyurethane hollow fiber membrane and preparation method thereof

InactiveCN102000515AHigh strengthImprove throughputSemi-permeable membranesHollow filament manufactureFiltrationMelt extrusion

The invention discloses a thermoplastic polyurethane hollow fiber membrane and a preparation method thereof. The hollow fiber membrane is made of polyurethane and prepared by adopting a thermally induced phase separation process. The preparation method comprises the following steps of: mixing thermoplastic polyurethane, thinner, inorganic pore-forming agent and antioxidant uniformly by using a high-speed stirrer, melting and extruding the mixture into granules by using a double-screw extruder, then melting and extruding the granules into hollow fibers by using a single-screw extruder, performing cooling molding, and finally extracting the thinner and the inorganic pore-forming agent in the hollow fibers. The prepared thermoplastic polyurethane hollow fiber membrane has the advantages of high flux, tensile strength and compressive strength, good flexibility of membrane silks, high elongation of the membrane silks at break, good chemical tolerance, permanent hydrophilic property, dry storage and the like. The fiber membrane can be applied to filtration of household and commercial drinking water, filtration and purification of brewed wine, food and medicaments, municipal tap water and sewage treatment, industrial sewage treatment, sea water desalinization pretreatment and the like.

Owner:HUIZHOU QIXIN MEMBRANE PURIFICATION & ENVIRONMENTPROTECTION

Method for comprehensively processing brown coal and leonardite into humic fertilizers and preparations and into fuel briquettes, and mechanochemical reactor for processing highly-viscous media

ActiveUS20170036967A1Improve soil structureMaintain stabilityBio-organic fraction processingEnergy inputRaw materialPhase separation process

A method for comprehensively processing coal-type caustobiolites, predominantly brown coal and leonardite, into humic organic and organomineral fertilizers and intor preparations producing fuel briquettes, including carrying out main processes in a continuous flow; carrying out leaching processes based on aqueous solutions with hydromodules of close to 2, carrying out acidification processes with the formation of humic acid released from a liquid phase into a heavy phase of a coagulated pulp, carrying out mechanical phase separation processes in a centrifugal field, carrying out liquid-phase mechanoactivation and the dispersion of reaction compositions via grinding, using residual “water” in recycling, and including the production of water-soluble humic acids and fuel briquettes and allowing for the production of a wide range of products; preliminarily grinding raw materials to a 03 mm class, and cleaning and electrochemically softening water in preparing reaction aqueous solutions; using a liquid-phase raw material oxidation process, and using liquid-phase mechanoactivation and / or mechanochemical activation, with the dispersion of reaction compositions by means of grinding and by means of dynamically shifting layers having statistical shift rate components, of a medium to be processed, which range from single-digit meters per second to tens of meters per second; accompanying said mechanoactivation with the dosed input into said medium of 1040 MJ of mechanical energy per cubic meter, with the stabilization of said dosing regardless of the drift of all other parameters in said medium to be processed; wherein, said grinding and shifting processes are formed by means of statistical and dynamic characteristics; in this way, a dynamic hydro-pulse effect on a medium to be processed is carried out within a range of frequencies floating between infrasound and frequencies bordering on ultrasound, wherein the processing is carried out beginning with higher frequencies; in addition, providing for automatically maintaining maximum parameters for inputting mechanical energy into the medium to be processed, while automatically restricting same within a sub-cavitation zone in order to prevent the transition of the mechanochemical reactors into cavitation modes.

Owner:SEVASTYANOV VLADIMIR PETROVICH +3

Process of preparing polymer porous leg by separation and combination of paraffin microballons porous making agent and thermotropic phase

The production process of porous polymer rack includes suspending dispersion to prepare paraffin microballoon, mixing paraffin microballoon and polymer solution, lowering temperature to make polymer solution produce phase separation, and freeze drying to eliminate solvent, boiled hexane washing or extracting to eliminate paraffin microballoon. The said process concentrates the advantages of bothpore creating process and thermal phase separation process and the produced porous polymer rack has macro pores with size determined by the paraffin microballoon as pore creating agent and micro pores produced in thermal phase separation and distributed on wall of the macro pores. The porous polymer rack has controllable pore size, good communication and high porosity.

Owner:ZHEJIANG UNIV

Polyvinylidene fluoride hollow fiber microporous membrane and preparation method thereof

ActiveCN101862605AHigh strengthUniform pore size distributionSemi-permeable membranesBiological water/sewage treatmentFiberHollow fibre

The invention discloses a polyvinylidene fluoride hollow fiber microporous membrane and a preparation method thereof. The polyvinylidene fluoride hollow fiber microporous membrane comprises the following components in percentage by weight: 20-45% of polyvinylidene fluoride, 50-79.4% of thinner and 0.6-17% of additive. The preparation method of the hollow fiber microporous membrane is realized on the basis of a thermotropic phase separation process. The polyvinylidene fluoride hollow fiber microporous membrane has the characteristics of high strength, uniform pore diameter distribution, high porosity and the like, and has high inoxidizability, the pore diameter is generally between 0.1-0.5mu m, and the porosity is 60-85%, so the hollow fiber microporous membrane has large water flux, is not easy to block in use, can be widely used for feed water treatment, and is particularly suitable for the membrane bioreactor technology and other water treatment fields.

Owner:三泰(青岛)膜科技有限公司

Method for preparing polyvinylidene fluoride flat plate porous film by thermal phase separation process

InactiveCN1748844ANarrow pore size distributionSimple structureSemi-permeable membranesPhase separation processDiluent

The thermal phase separation process for preparing plate porous polyvinylidene fluoride film includes the following steps: mixing and heating polyvinylidene fluoride in 25-35 wt% and diluent in 65-75 wt% through stirring in high temperature reactor to obtain homogeneous polymer solution, debubbling and letting stand to obtain film casting liquid; preheating mold; pouring the film casting liquid into the mold and rolling to form; setting in cooling environment to cool and to crystallize polymer into film; setting the film inside extractant to eliminate diluent and obtain the plate porous polyvinylidene fluoride film. Prepared plate porous polyvinylidene fluoride film via the said process has narrow pore size distribution, various structure and powerful adaptability, and the preparation process is simple.

Owner:TSINGHUA UNIV

High-clearing-point electro-liquid-crystal atomized glass

InactiveCN101776819AThe phase separation process is sufficientHigh activityNon-linear opticsBright spotGlass sheet

The invention relates to high-clearing-point electro-liquid-crystal atomized glass, which comprises a plastic liquid-crystal membrane and a transparent glass plate, wherein a thermal-curing transparent adhesive layer is compounded between the transparent glass plate and the plastic liquid-crystal membrane, the plastic liquid-crystal membrane comprises a liquid-crystal-plastic core layer and two transparent conductive film surface layer, the transparent conductive film is provided with a bar-shaped electrode which can produce a homogenous electric field, epoxy resin which is used in the liquid-crystal-plastic core layer is of bisphenol A epoxy resin and hydrogenated bisphenol A epoxy resin, and the weight ratio of the bisphenol A epoxy resin and the hydrogenated bisphenol A epoxy resin is 0.1 to 0.2: 0.8 to 0.9. The phase separation process of the polymer is more adequate, and the activity of the high polymer is improved, so the clearing point of the electro-liquid-crystal atomized glass is improved by 20 percent, the adhesion between the transparent conductive film and the PDLC is strengthened, and the glue failure problem of the electro-liquid-crystal atomized glass is solved.

Owner:北京众智同辉科技有限公司

Preparation method of air filtering material capable of releasing fragrance

ActiveCN106582114AImprove air filtrationPreparation conditions are easy to controlMembrane filtersDeodrantsFiberAir filter

The invention provides a preparation method of an air filtering material capable of releasing fragrance. The method comprises the following steps: 1, preparing a solution: dispersing a fragrance releasing substance in a solvent, carrying out ultrasonic stirring to form a dispersion, adding a polymer to the dispersion, and carrying out ultrasonic mixing to form the spinning solution; and 2, carrying out electrostatic spinning: placing the solution prepared in step 1 in a liquid storage device, setting electrostatic spinning parameters, releasing etching steam in a range having a certain distance to a receiving base material, and using the etching steam to carry out in-situ etching in the phase separation process of spinning solution jet to form a micropore structure on the surface of fibers, which allows the fragrance releasing substance distributed in nano-fibers to be exposed in order to form the air filtering material capable of releasing fragrance. The fragrance release evaluation score of the prepared material is 24-40, the fragrance releasing stability is that the evaluation score in 300 d reduces by 0-10, the filtering efficiency of 0.3-10 [mu]m particles is 80-100%, and the resistance pressure drop is 10-100 Pa.

Owner:DONGHUA UNIV

Asymmetric polyvinylidene fluoride microporous membrane with high intensity and preparation method thereof

ActiveCN102198374AEnhanced mass transferReduce mass transferSemi-permeable membranesCross-linkSurface-active agents

The invention relates to an asymmetric polyvinylidene fluoride (PVDF) microporous membrane with high intensity and a preparation method thereof. Particularly the invention provides a method for preparing the polyvinylidene fluoride microporous membrane by adding a surface active agent, wherein the surface active agent is preferably a fluorocarbon surface active agent. In a non-solvent phase separation process, on the one hand, the surface active agent and polyvinylidene fluoride macromolecules are cross-linked and hybridized, therefore, the crystalline property of the polyvinylidene fluoride is reduced, the liquid-liquid phase separation is promoted, the crystals are effectively prevented from being agglomerated in the film-forming process of the polyvinylidene fluoride, and the intensityis improved; on the other hand, proved by accidental discovery, a thermodynamic mass transport process is changed by adding the surface active agent so that the asymmetric polyvinylidene fluoride microporous membrane can be prepared. The membrane disclosed by the invention is wide in application, such as clearing and filtering of food / beverage, sterilizing and filtering of medical preparation andthe like.

Owner:HANGZHOU COBETTER FILTRATION EQUIP

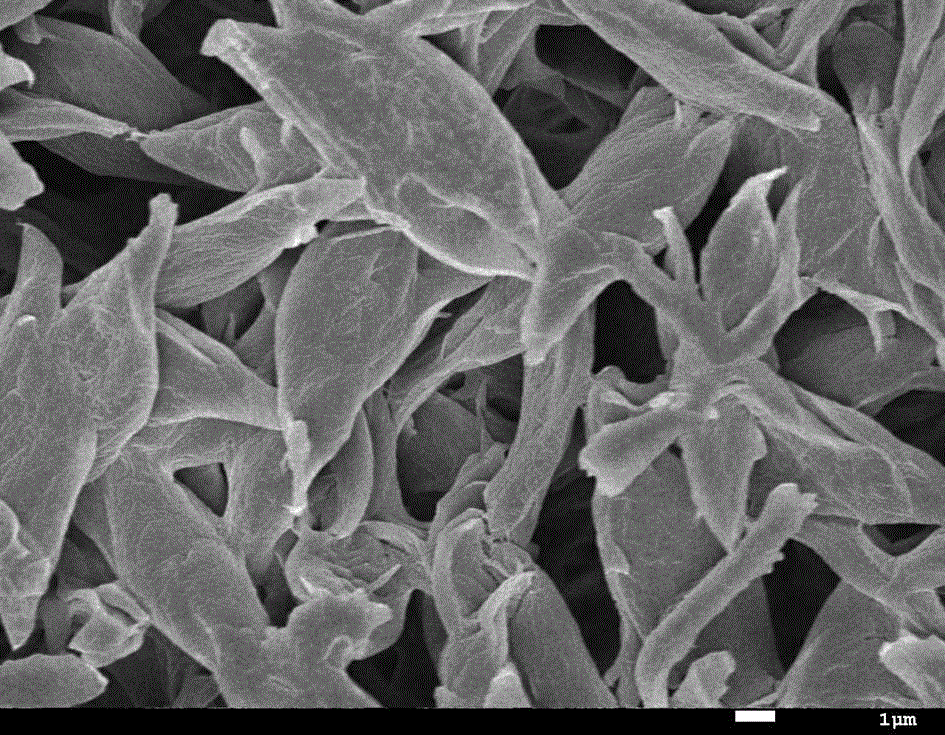

Method for preparing polylactic acid super-hydrophobic membranes by aid of phase separation process

The invention discloses a method for preparing polylactic acid super-hydrophobic membranes by the aid of a phase separation process, and belongs to the field of high-polymer materials. The method includes steps of (1), preparing pre-coating liquid, to be more specific, uniformly mixing poor solvents and good solvents with one another to prepare mixed solvents, and dissolving polylactic acid in the mixed solvents to obtain the pre-coating liquid; (2), preparing coating liquid, to be more specific, adding poor solvents in the pre-coating liquid, and uniformly stirring the poor solvents and the pre-coating liquid to obtain the coating liquid; (3), carrying smearing and drying, to be more specific, smearing the coating liquid on carriers, and drying the carriers to obtain the polylactic acid super-hydrophobic membranes. The method has the advantages that super-hydrophobic surfaces with micrometer-nanometer two-level structures are prepared by the aid of the non-solvent auxiliary process at one step, the method is easy to operate, conditions are mild, curing and steam inducing can be omitted in membrane forming procedures, gel procedures can be omitted, accordingly, the reaction time can be shortened, and the method is high in work efficiency; inorganic nanometer particles or substances with low surface energy can be omitted in super-hydrophobic membrane preparing procedures, and accordingly the polylactic acid super-hydrophobic membranes are low in manufacturing cost.

Owner:ZHENGZHOU UNIV

Method for preparing braided tube reinforced polyvinylidene fluoride porous membrane

InactiveCN102512989ASolution to short lifeHigh mechanical strengthSemi-permeable membranesFiberNeural information processing

The invention belongs to the membrane separation manufacturing field, and relates to a method for preparing polyvinylidene fluoride braided tube reinforced hollow fiber or capillary tube porous membrane (including a microfiltration membrane and a ultrafiltration membrane) by a composite thermal induced phase separation method (C-TIPS method), and the prepared porous membrane can be used in the fields such as environmental protection, water purification, sewage treatment and the like. The method is characterized in that dissolving polymer with weight percentage concentration of 10-45% and water-soluble composite diluent in a reaction kettle at the temperature of 110-170 DEG C, and making the dissolved solution into membrane-making liquid; then, squeezing the membrane-making liquid into composite cold quenching liquid with the temperature of 4-15 DEG C together with a braided tube (used for replacing inner core liquid) by a universal membrane-making mould within the temperature range of 110-170 DEG C, carrying out the composite phase separation process, and obtaining the braided tube reinforced capillary tube ultrafiltration membrane or microfiltration membrane through a series of post-processing. The mechanical strength of a coating layer coated by the C-TIPS method in the method is obviously higher than that coated by a neural information processing system (NIPS) method, so that the membrane does not easily fall off, is longer in service life and can be treated by backflushing through higher pressure; the temperature of coating liquid in the C-TIPS method is lower than the decomposition temperature of polyvinylidene fluoride, so that the problem that hydrogen fluoride is corroded can be prevented; and due to the reinforcing function of the braided tube, the capillary tube membrane is more durable in use.

Owner:北京坎普尔环保技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com