Automatic passing phase separation control device and passing phase separation control system for multi-locomotives

An automatic over-phase separation and control device technology, which is applied to locomotives, motor vehicles, electric locomotives, etc., can solve the problems that the main control locomotive can not control the over-phase separation process at the same time, and it is not suitable for the application of heavy-duty locomotives, so as to increase reliability and safety. , the effect of effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

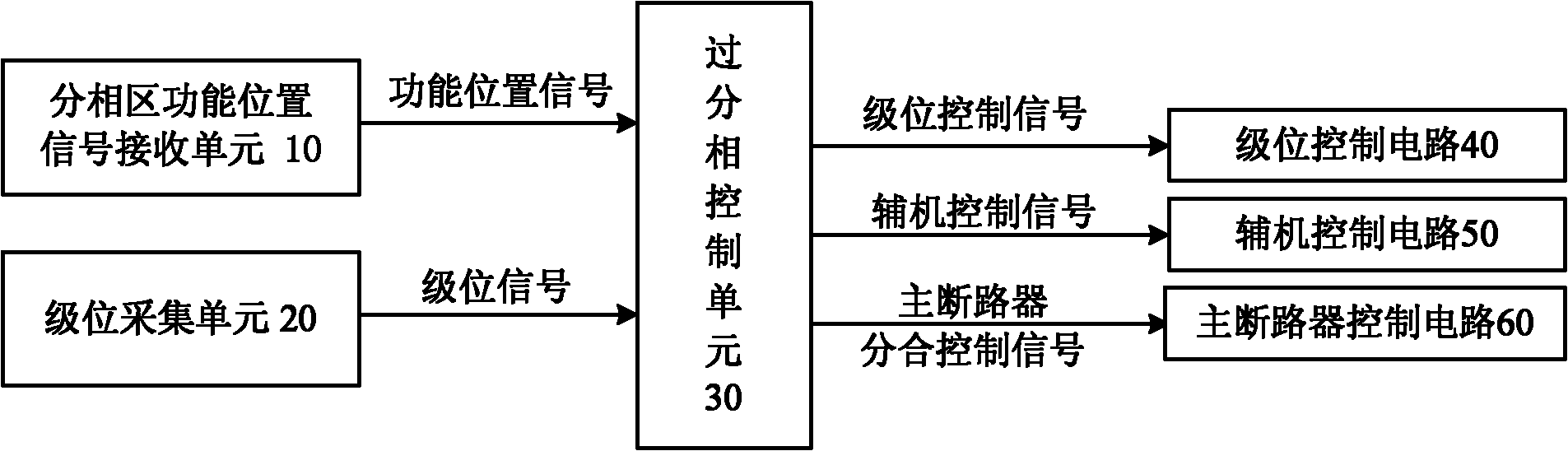

[0012] Such as figure 1 As shown, the present invention provides an automatic over-phase control device, which includes: a phase-splitting area functional position signal receiving unit 10 for receiving and identifying a phase-splitting area functional position signal; a level acquisition unit 20, Used to collect the joystick level signal; the excessive phase control unit 30 connected with the phase separation area functional position signal receiving unit 10 and the level acquisition unit 20, the excessive phase control unit 30 is used to receive the signal from the phase separation area function position signal 10 receiving the functional position signal of the phase-splitting area and the level signal from the level acquisition unit 20, and outputting a level control signal in the form of pulse width modulation based on the level signal according to the received functional position signal to control the rise and fall of the level, And output the auxiliary machine control si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com