Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3158results about "Multi-objective optimisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A System and Method for Modelling System Behaviour

ActiveUS20170147722A1Reduce the impactReduce impactMedical simulationDesign optimisation/simulationCollective modelModel system

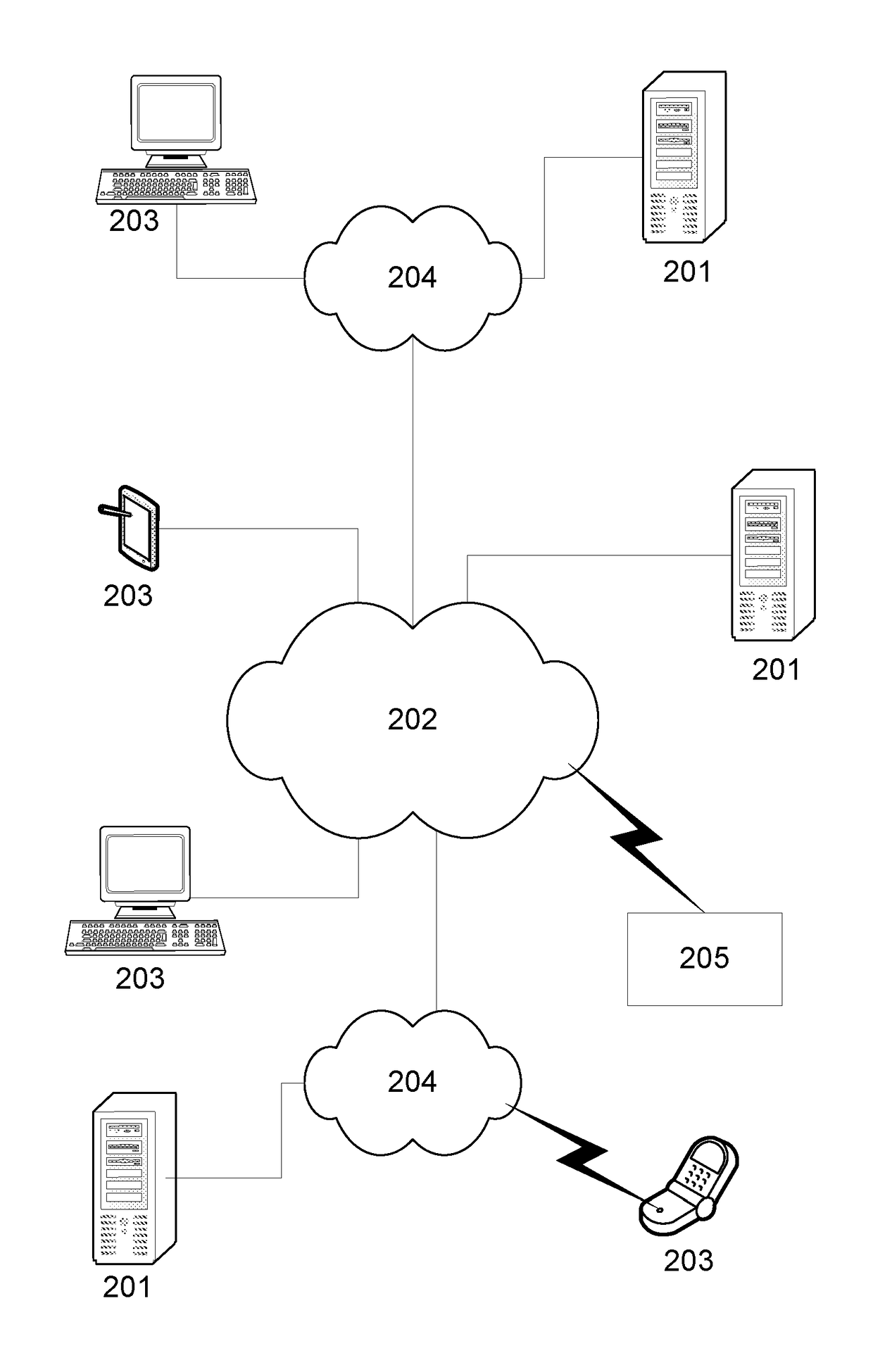

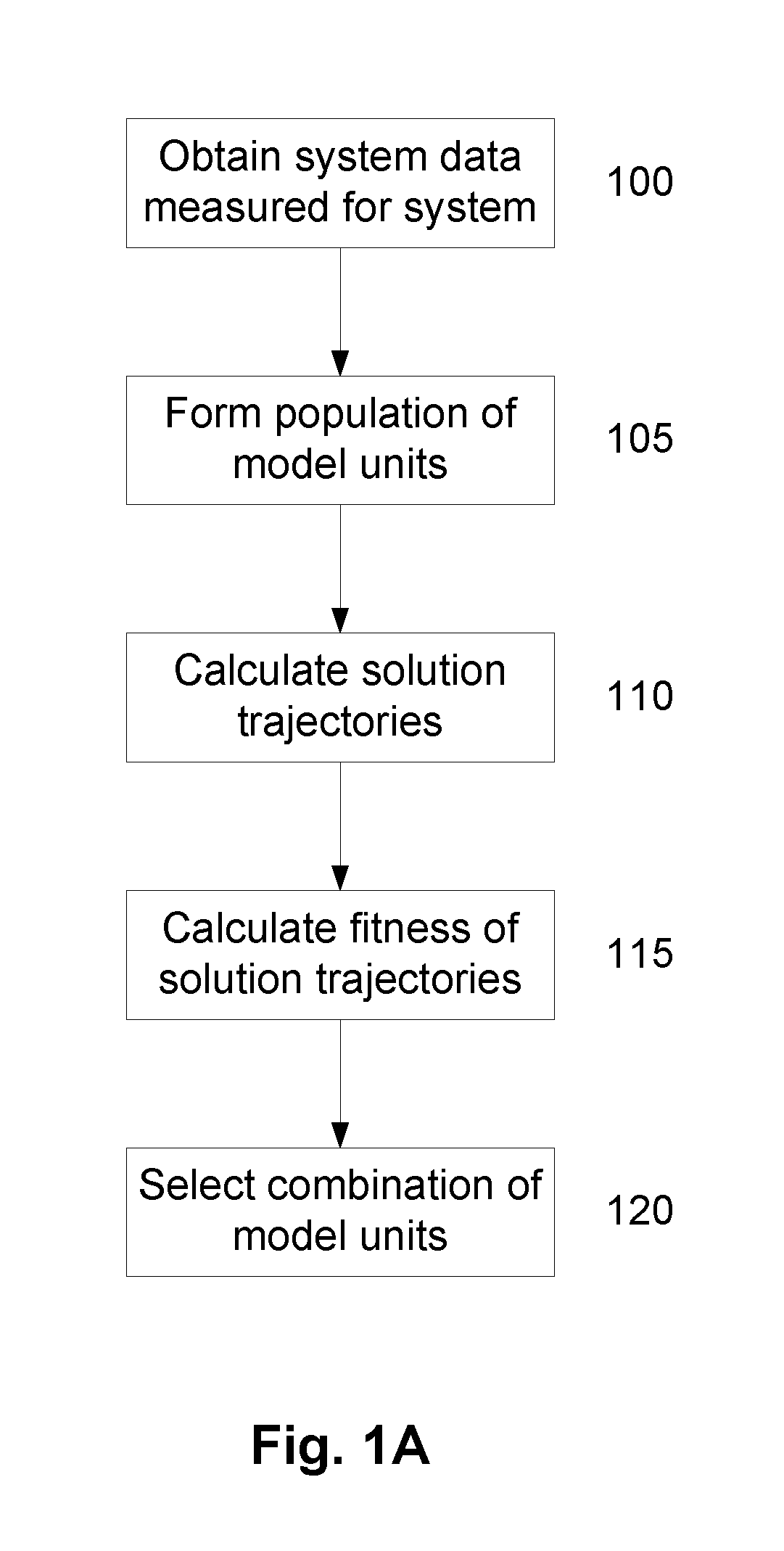

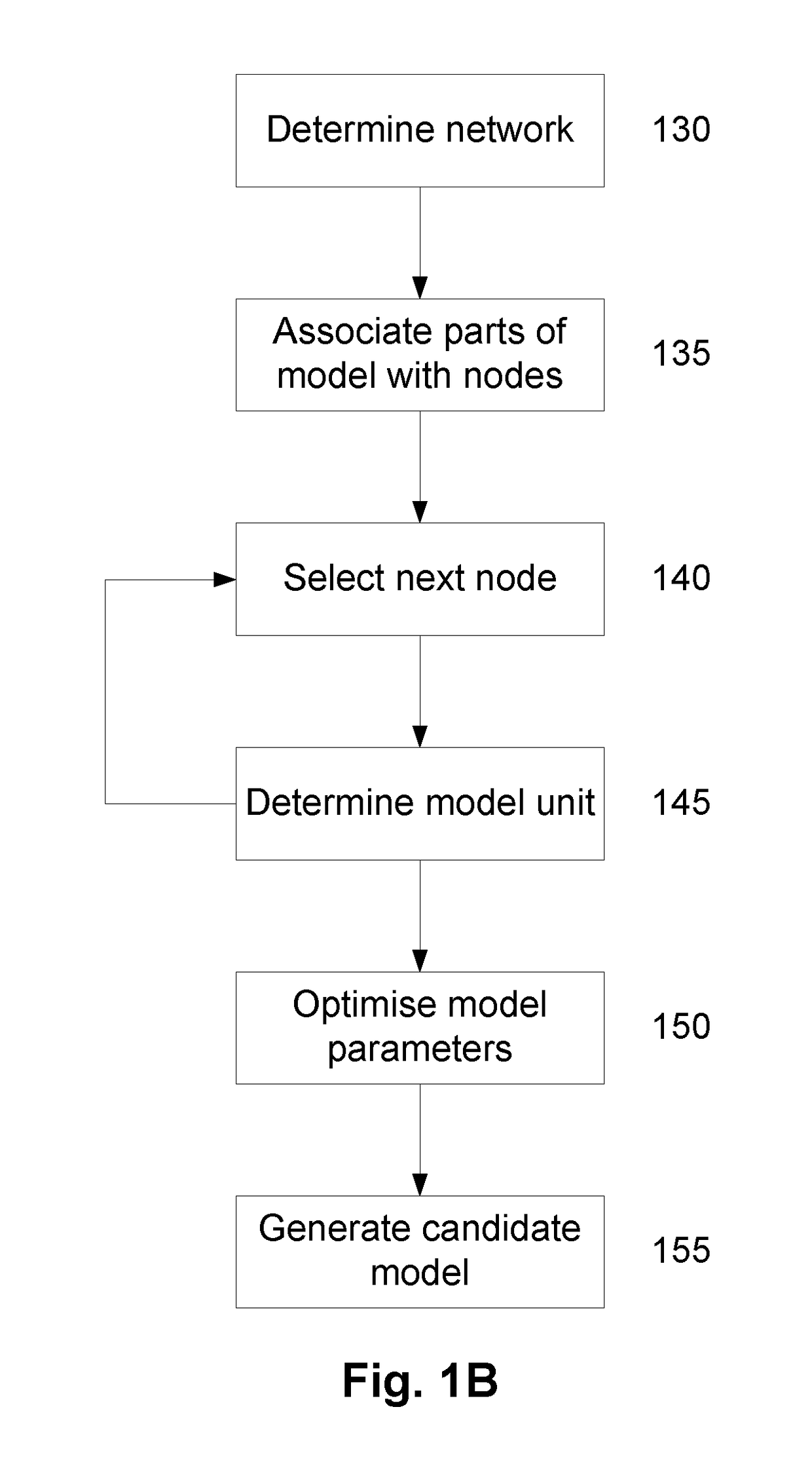

A method of modelling system behaviour of a physical system, the method including, in one or more electronic processing devices obtaining quantified system data measured for the physical system, the quantified system data being at least partially indicative of the system behaviour for at least a time period, forming at least one population of model units, each model unit including model parameters and at least part of a model, the model parameters being at least partially based on the quantified system data, each model including one or more mathematical equations for modelling system behaviour, for each model unit calculating at least one solution trajectory for at least part of the at least one time period; determining a fitness value based at least in part on the at least one solution trajectory; and, selecting a combination of model units using the fitness values of each model unit, the combination of model units representing a collective model that models the system behaviour.

Owner:EVOLVING MACHINE INTELLIGENCE

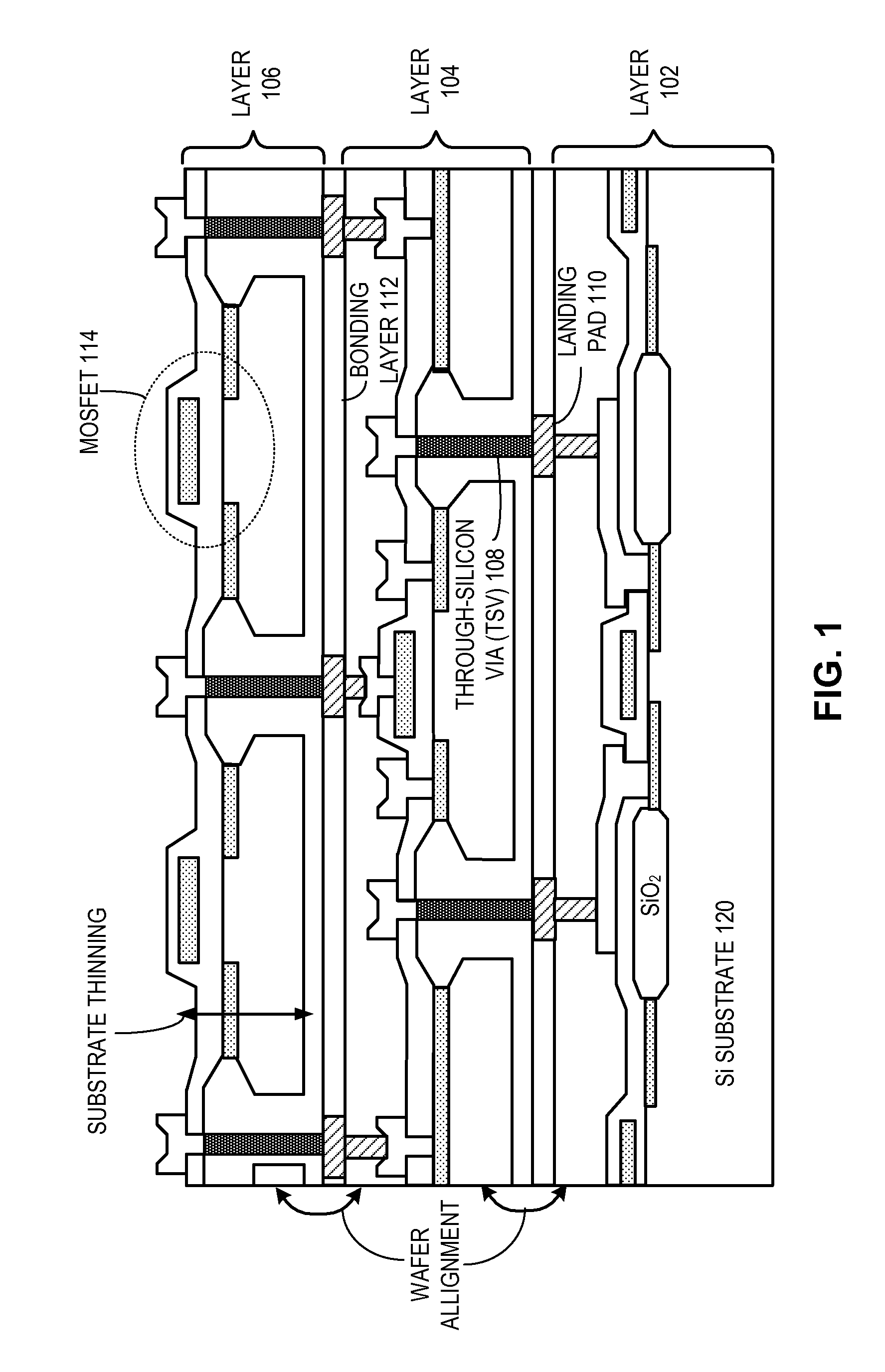

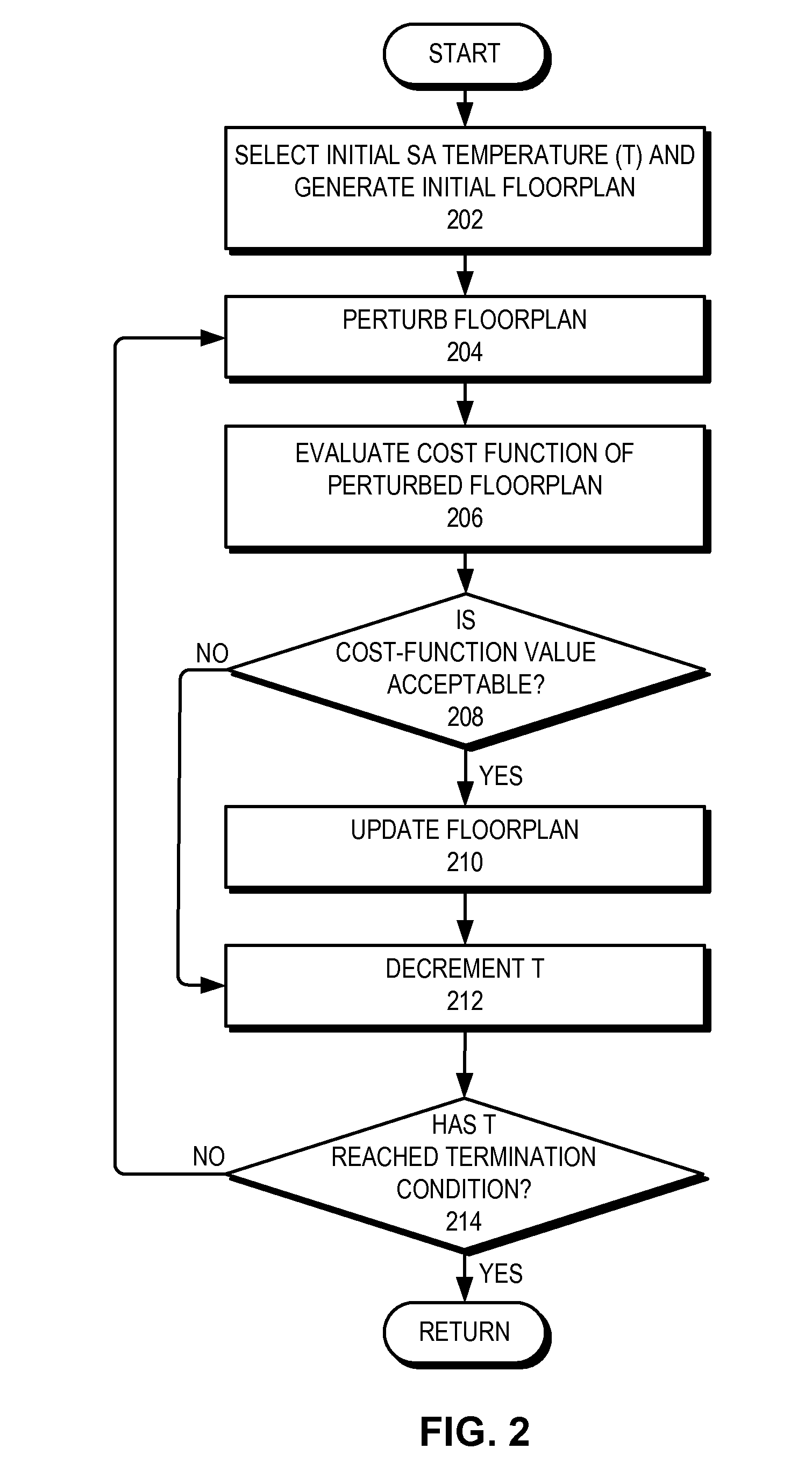

Method and system for facilitating floorplanning for 3D IC

ActiveUS20100031217A1Increase disturbanceMulti-objective optimisationSoftware simulation/interpretation/emulationComputer scienceIntegrated circuit

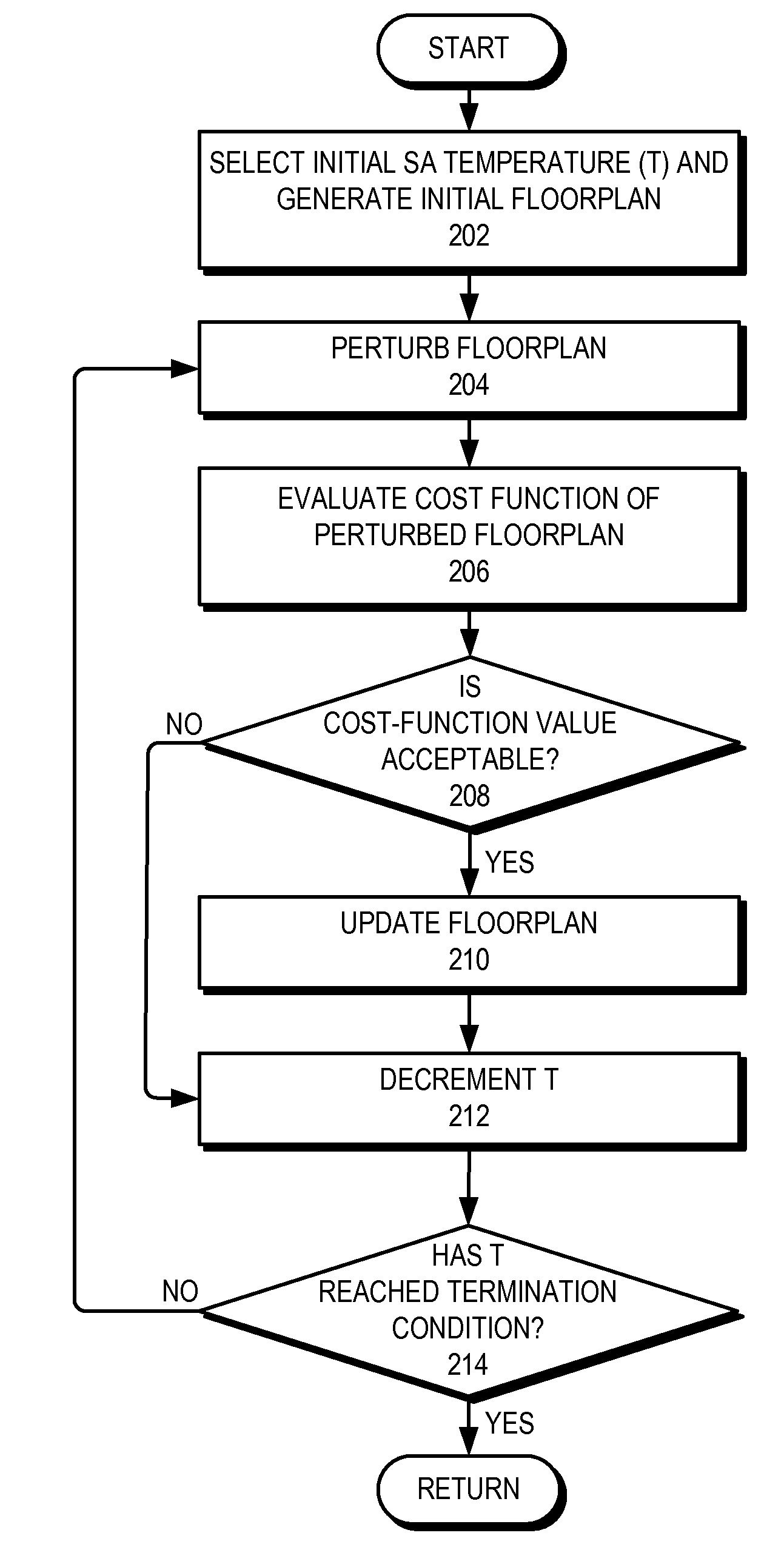

One embodiment of the present invention provides a system for facilitating floorplanning for three-dimensional integrated circuits (3D ICs). During operation, the system receives a number of circuit blocks. The system places the blocks in at least one layer of a multi-layer die structure and sets an initial value of a time-varying parameter. The system then iteratively perturbs the block arrangement until the time-varying parameter reaches a pre-determined value.

Owner:SYNOPSYS INC

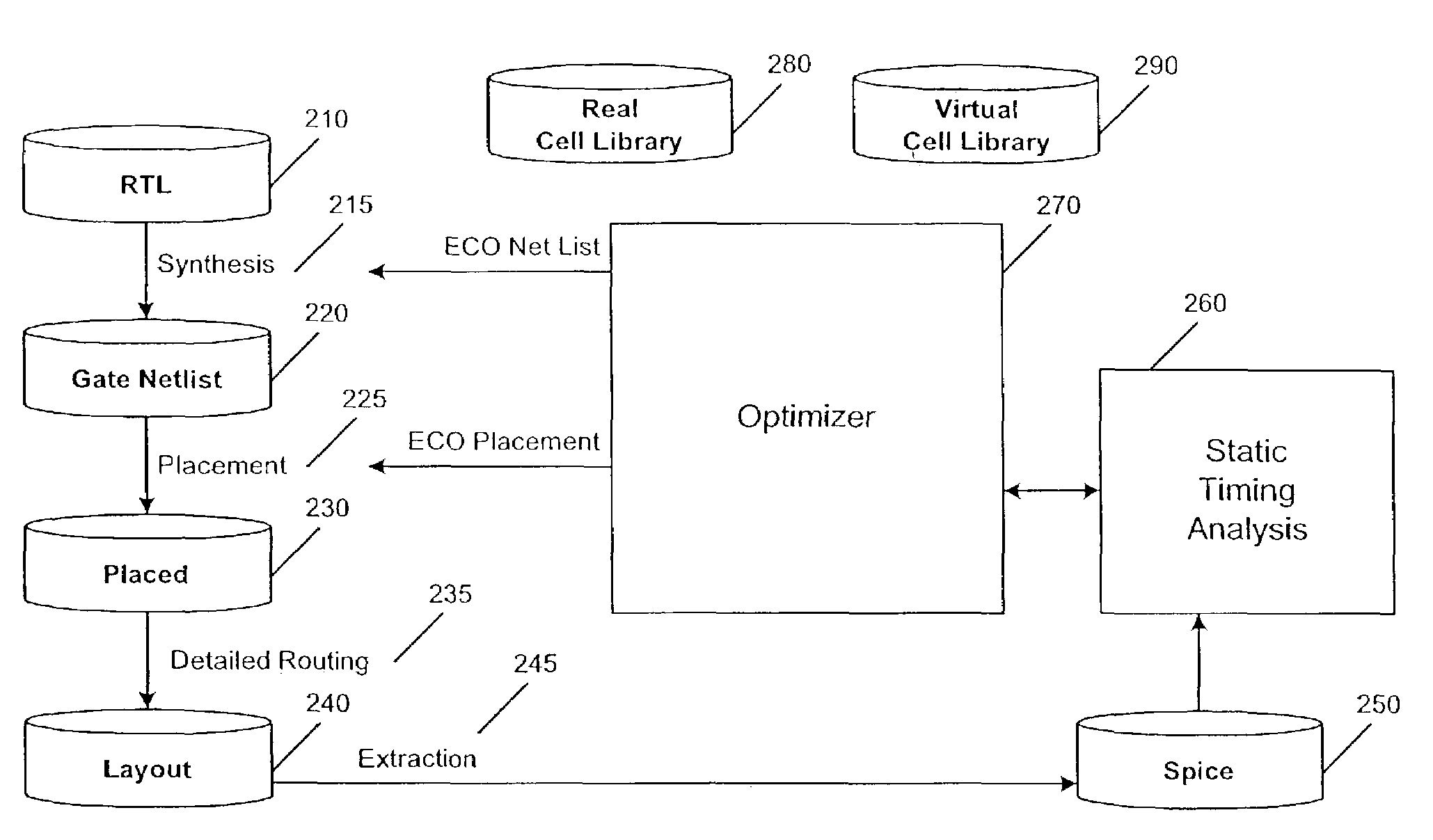

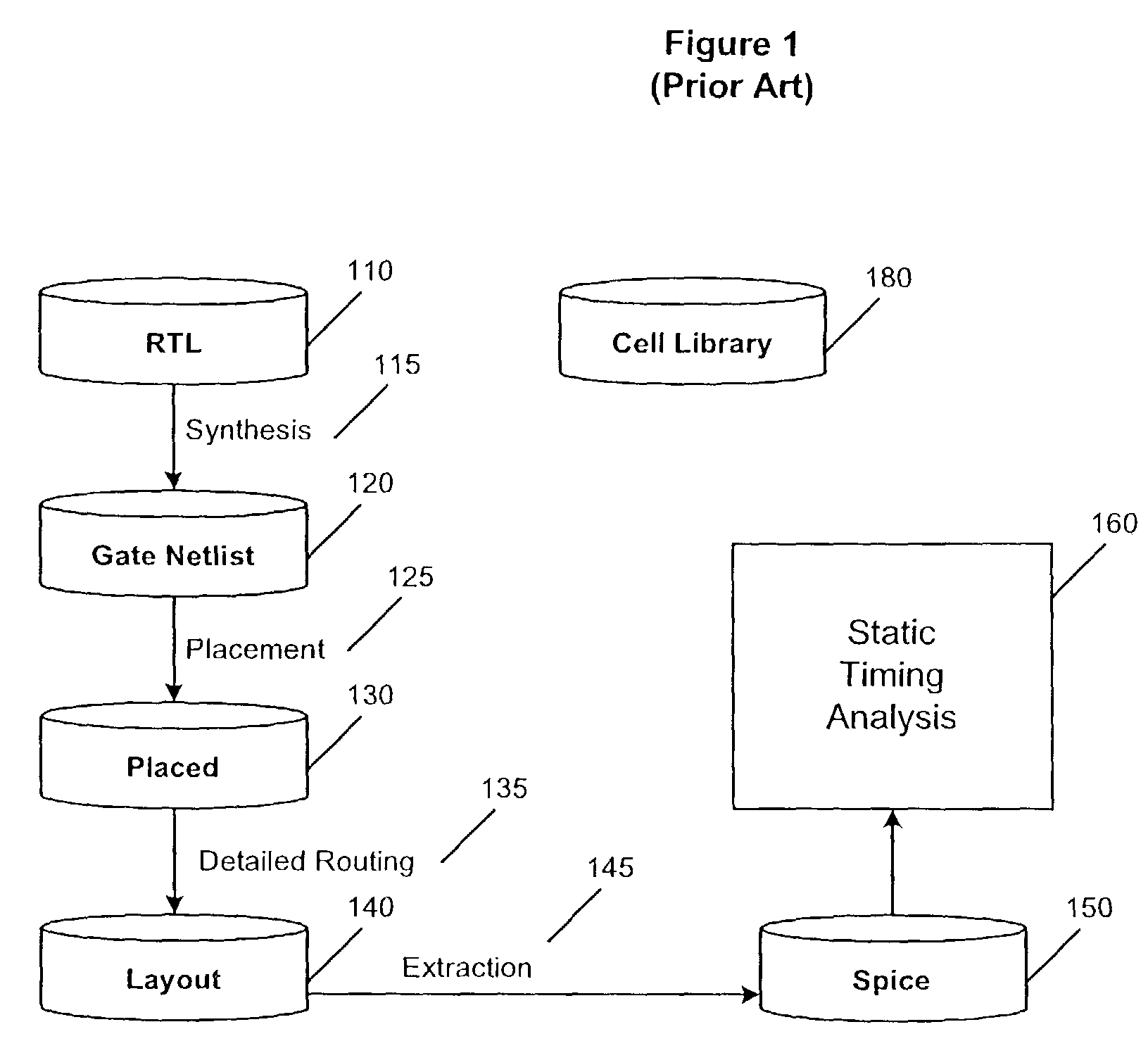

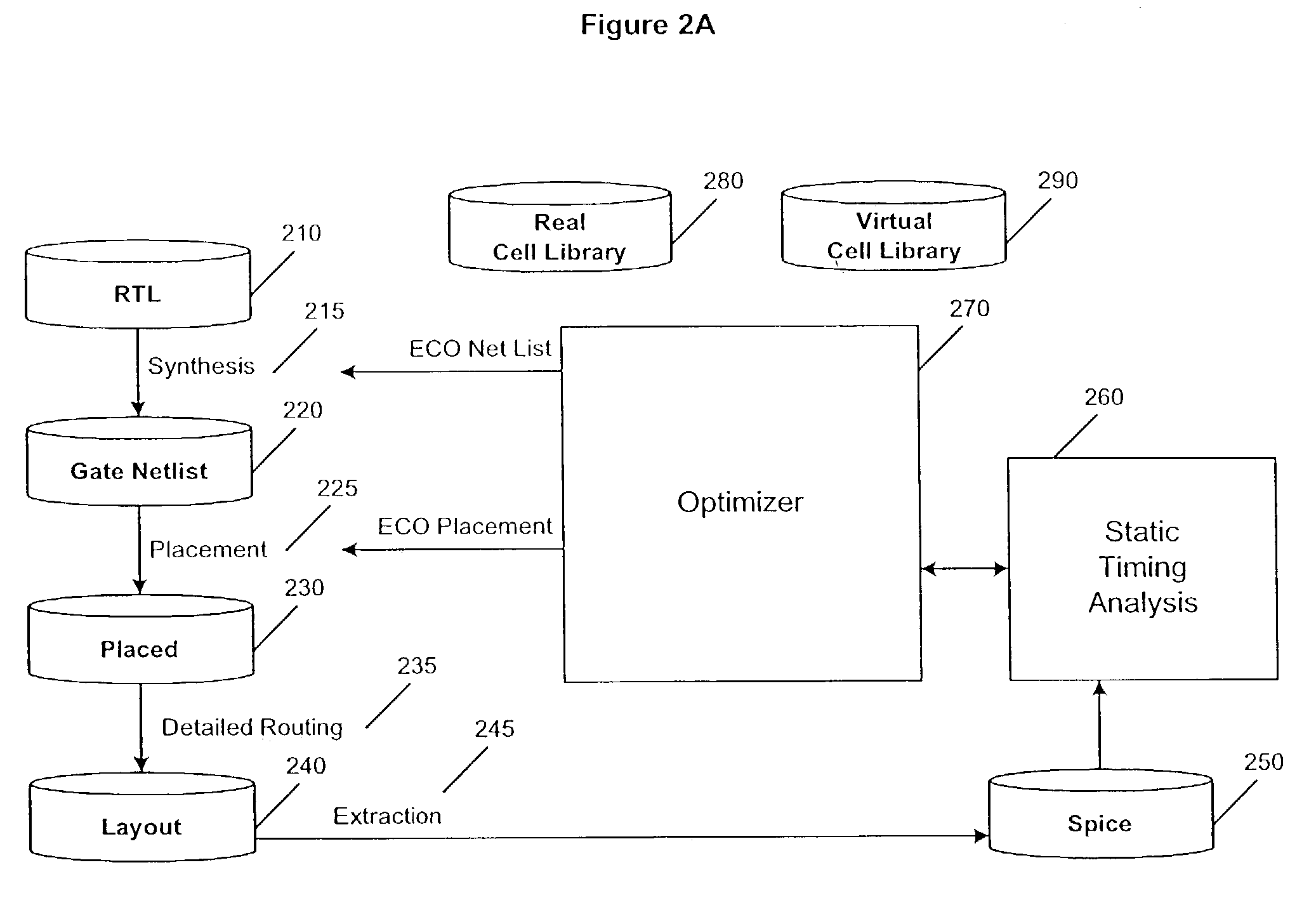

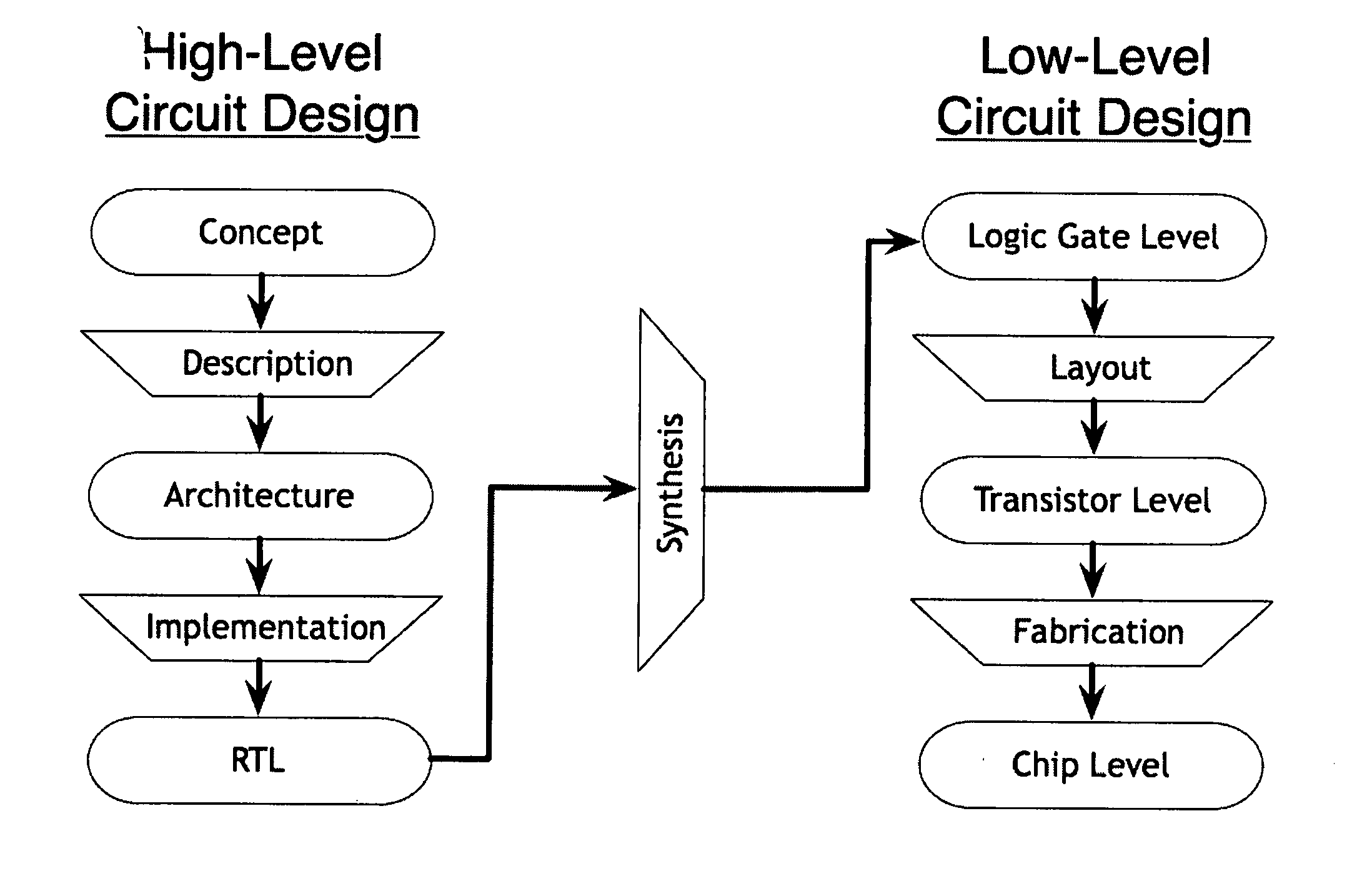

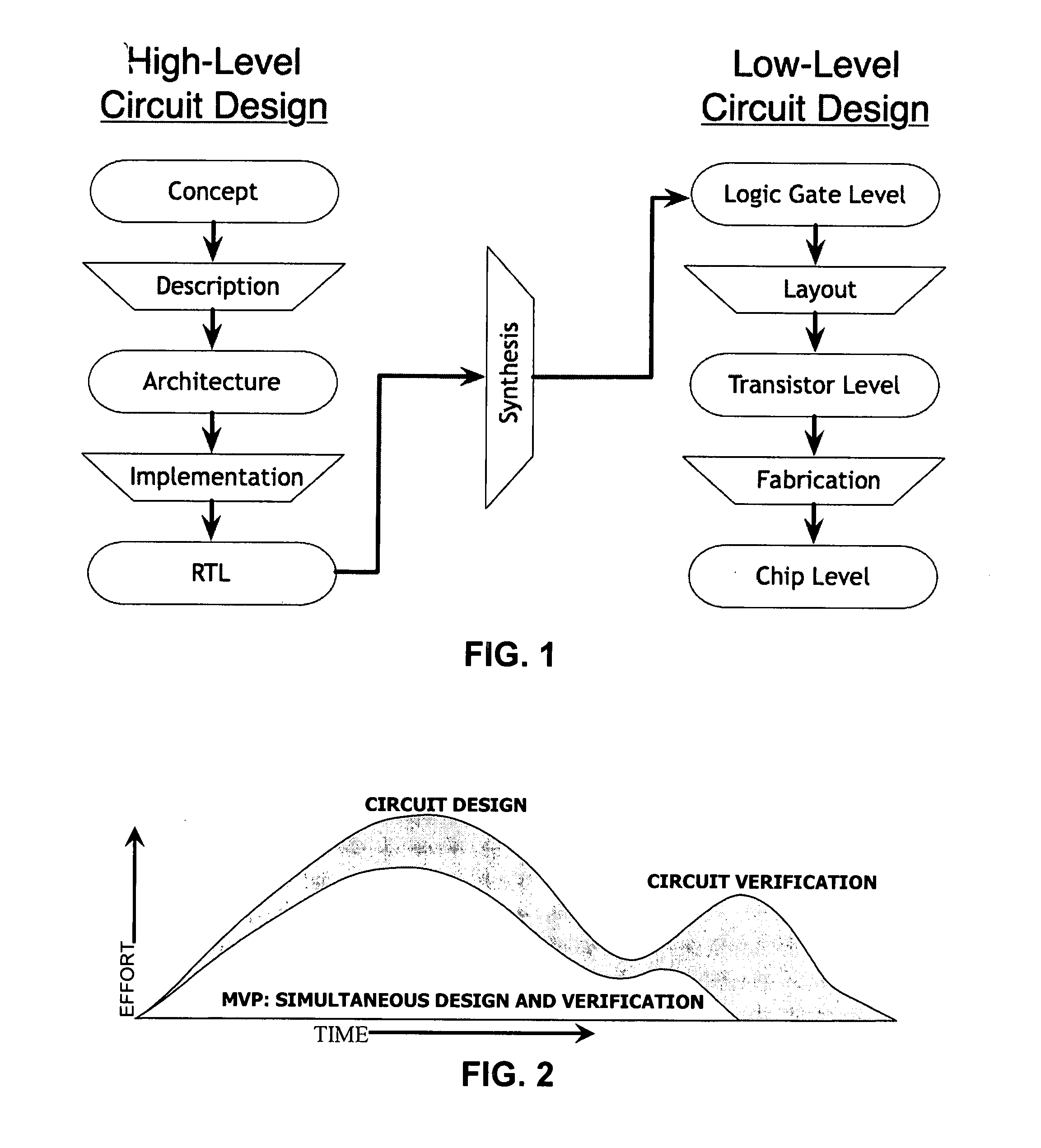

Optimization of circuit designs using a continuous spectrum of library cells

InactiveUS7107551B1Minimal impactSimple designMulti-objective optimisationSoftware simulation/interpretation/emulationVirtual cellSoftware engineering

A method and apparatus for optimizing a circuit design using a library of cells in which a continuous spectrum of cells are provided. A library containing real and virtual cells is used so that cells can be selected across a wide spectrum of a design parameter, such as drive strength. The cells are provided in discrete steps small enough that the effect of having a continuous spectrum of cells is achieved. After optimization, only the cells finally selected need be actually synthesized, and when these constitute a small percentage of the total number of cells, the impact to library size and final placement and routing is minimized. Thus the ability to optimize across a continuous spectrum is achieved while preserving a cell library based design flow.

Owner:ARM INC

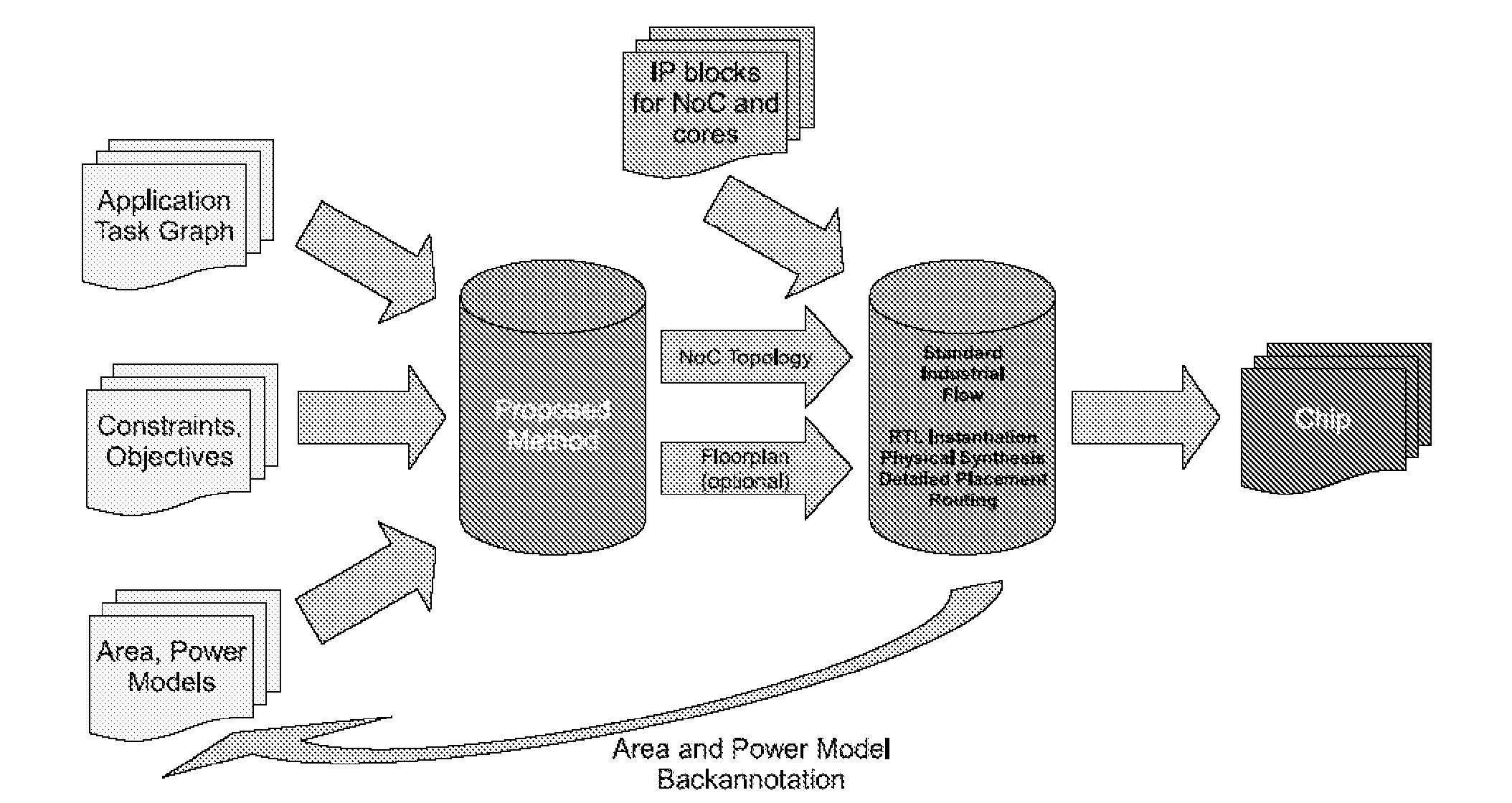

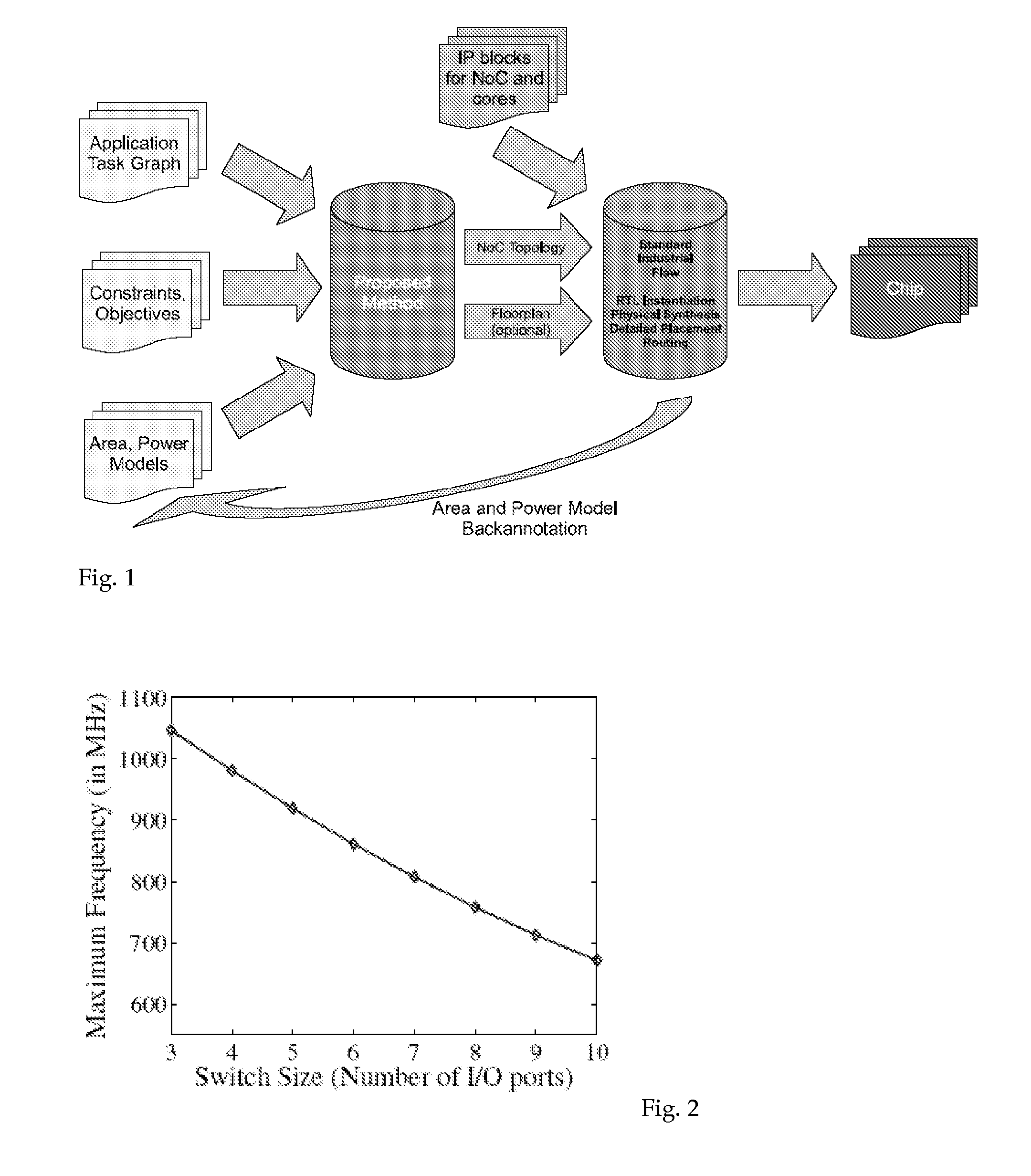

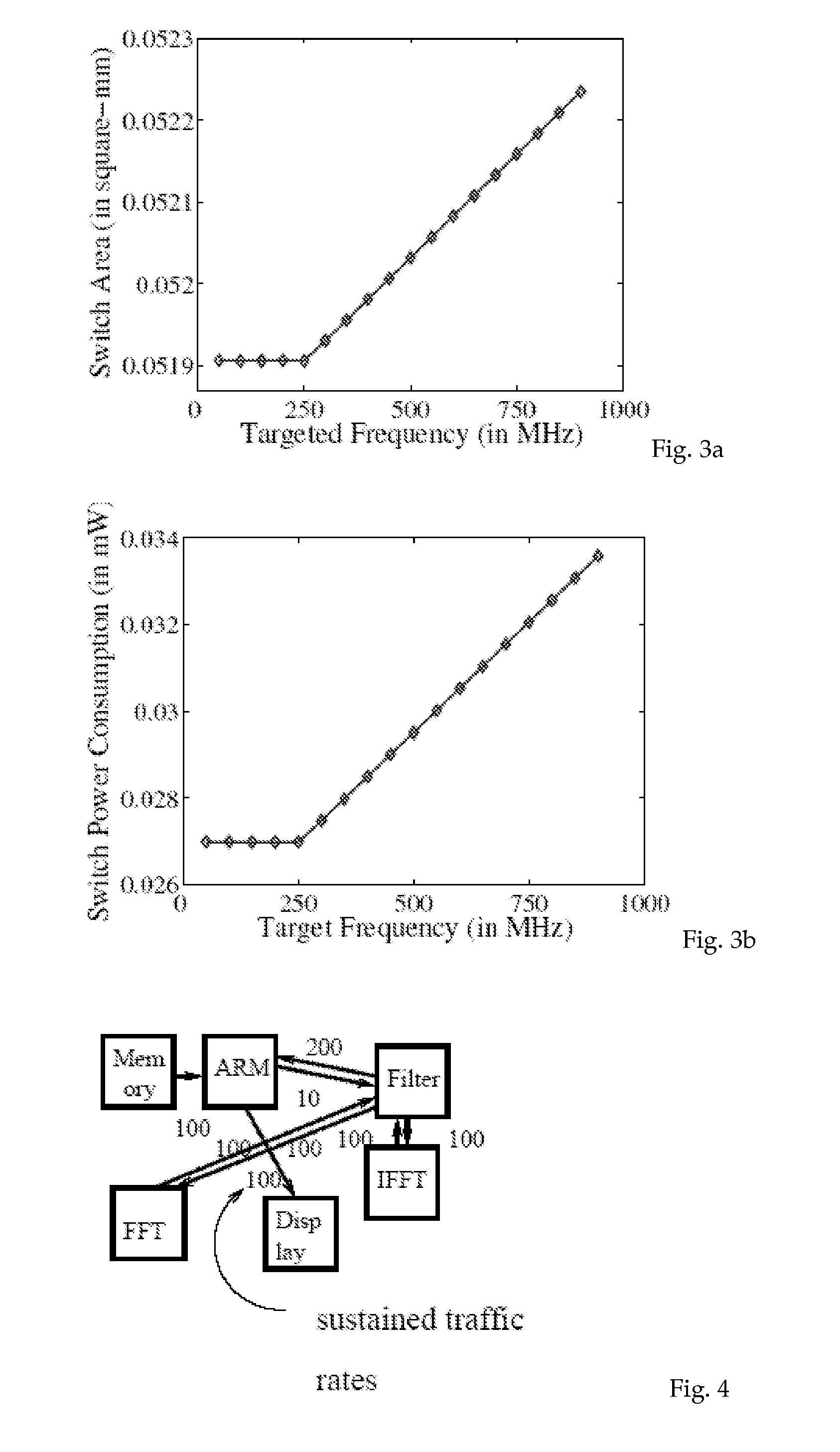

Method to design network-on-chip (NOC) - based communication systems

ActiveUS20090313592A1Error preventionFrequency-division multiplex detailsCommunications systemEngineering

A method to design a Networks on Chips (NoCs)-based communication system for connecting on-chip components in a multicore system, said system comprising several elements communicating through the communication system, said communication system comprising at least switches, said method comprising the steps of modelling the applications running on the multicore system, establishing the number and configuration of switches to connect the elements, establishing physical connectivity between the elements and the switches, for each two pairs of communicating elements: (a) a defining a communication path, (b) calculating metrics as affected by the need to render said path into physical connectivity, taking into account any previously defined physical connectivity, (c) iterating the steps a and b for a plurality of possible paths, (d) choosing the path having the optimal metrics, and (e) establishing any missing physical connectivity between the switches so that the selected optimal path occurs across physically connected switches.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

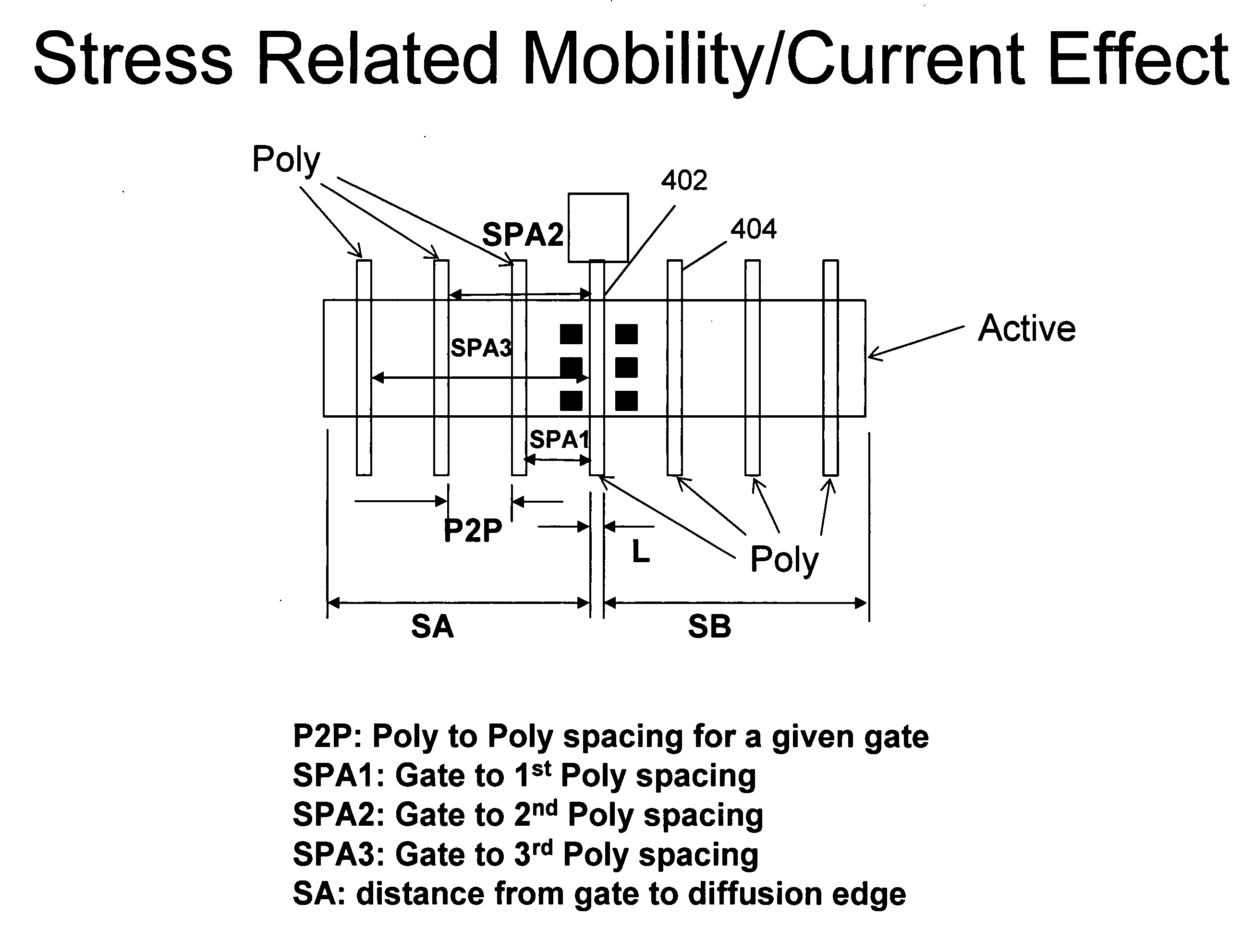

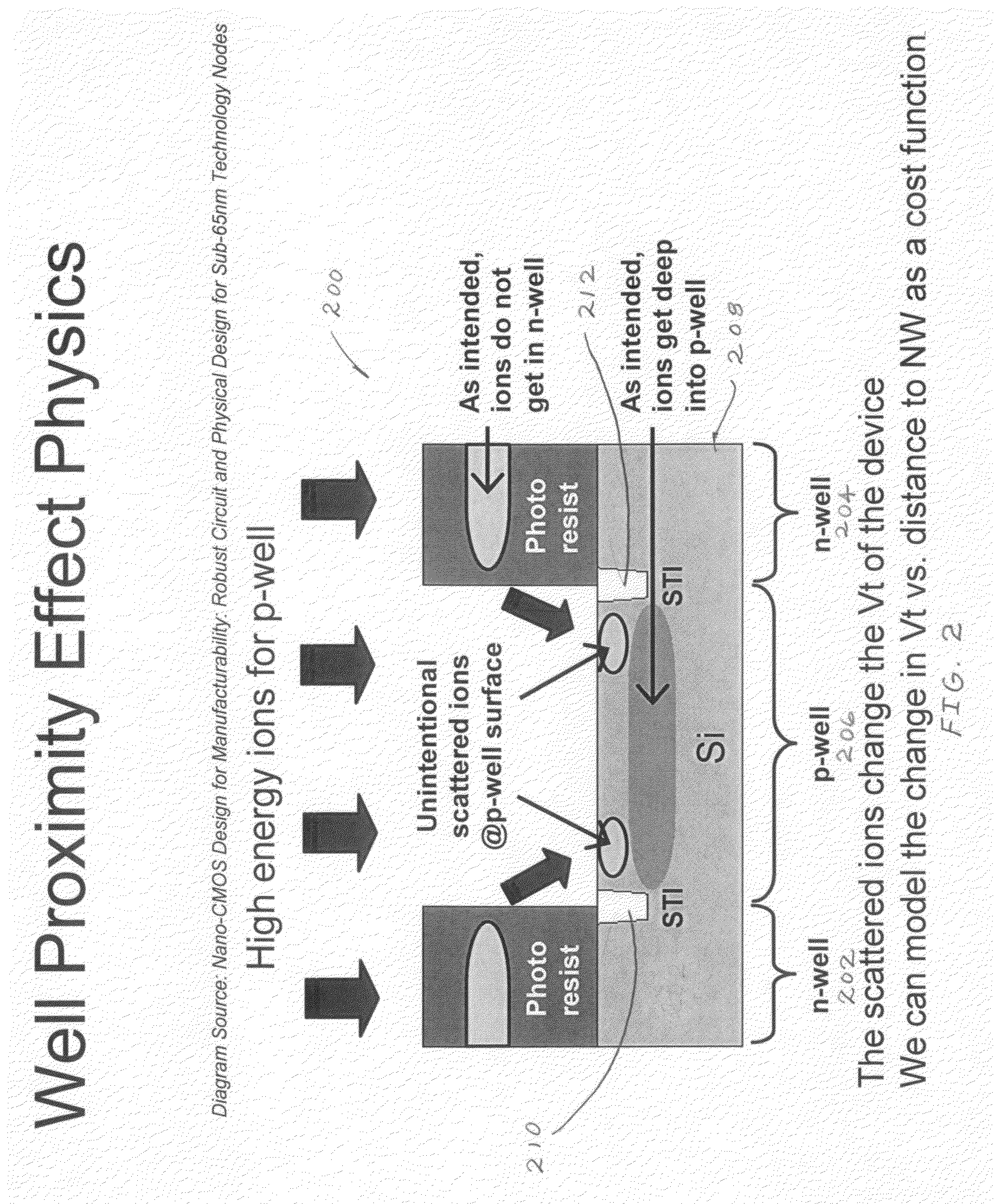

Automated optimization of an integrated circuit layout using cost functions associated with circuit performance characteristics

InactiveUS20100100856A1Low variabilityImprove performanceCAD circuit designMulti-objective optimisationLocal patternIntegrated circuit layout

An integrated circuit (IC) design system and method provide an optimization of a layout of an integrated circuit wherein an assessment is taken into account of the circuit performance characteristics and the layout of the IC design. The system and method assess associated circuit performance characteristics, each as a cost function of a local pattern of shapes in an initial circuit layout, aggregate cost functions of the associated circuit performance characteristics to derive an integral performance number associated to the initial global circuit layout, perturb the integral performance number by varying the global circuit layout, and select perturbations that optimize the performance number, so as to optimize the global circuit layout. Assessment is taken into account of the circuit performance characteristics based on the layout and the interdependence of the circuit performance characteristics for the IC design. The physical process related effects such as well proximity effect and stress / strain engineering and / or performance parameters such as the P-N transistor size ratio are taken into account to achieve optimization.

Owner:MITTAL ANURAG

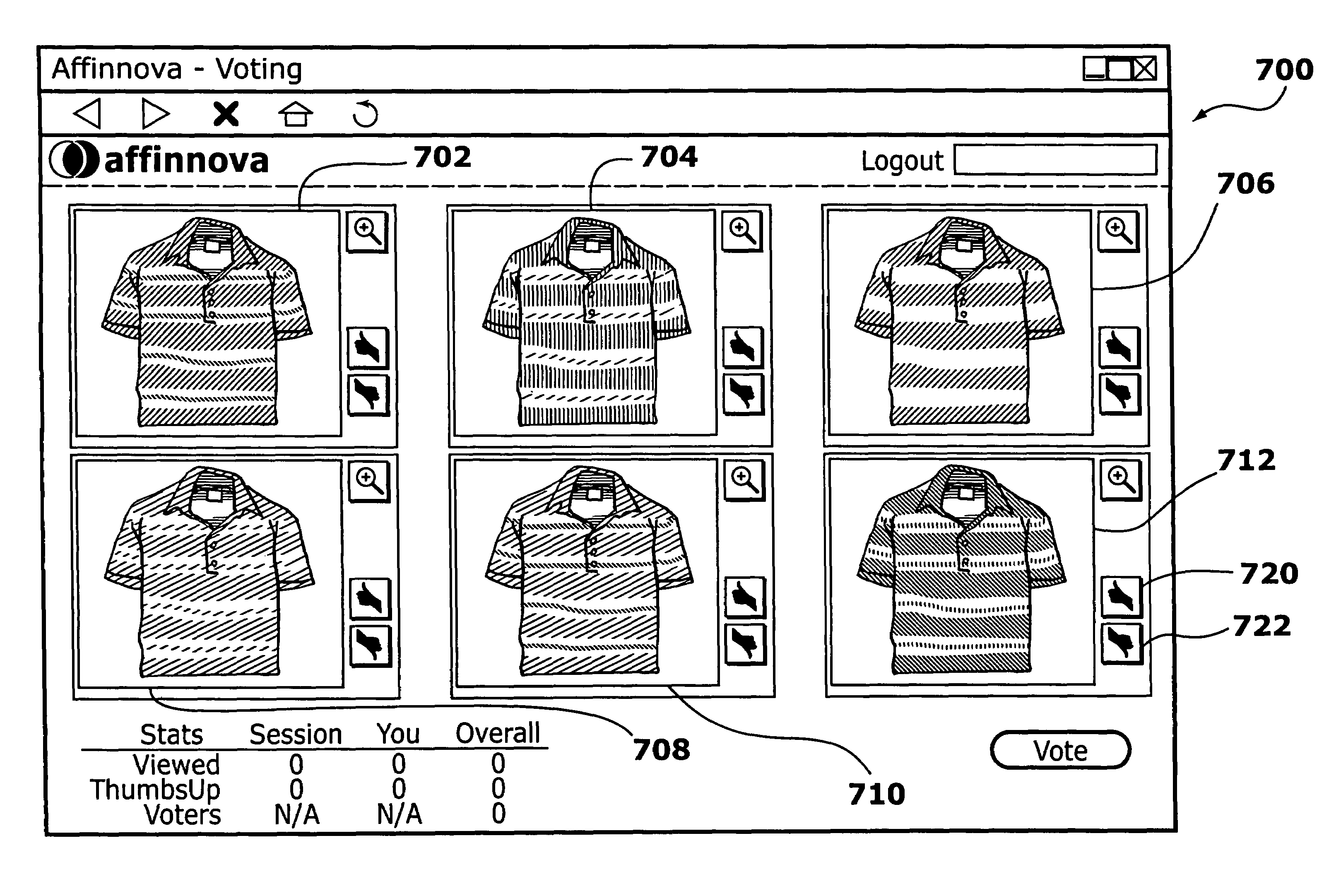

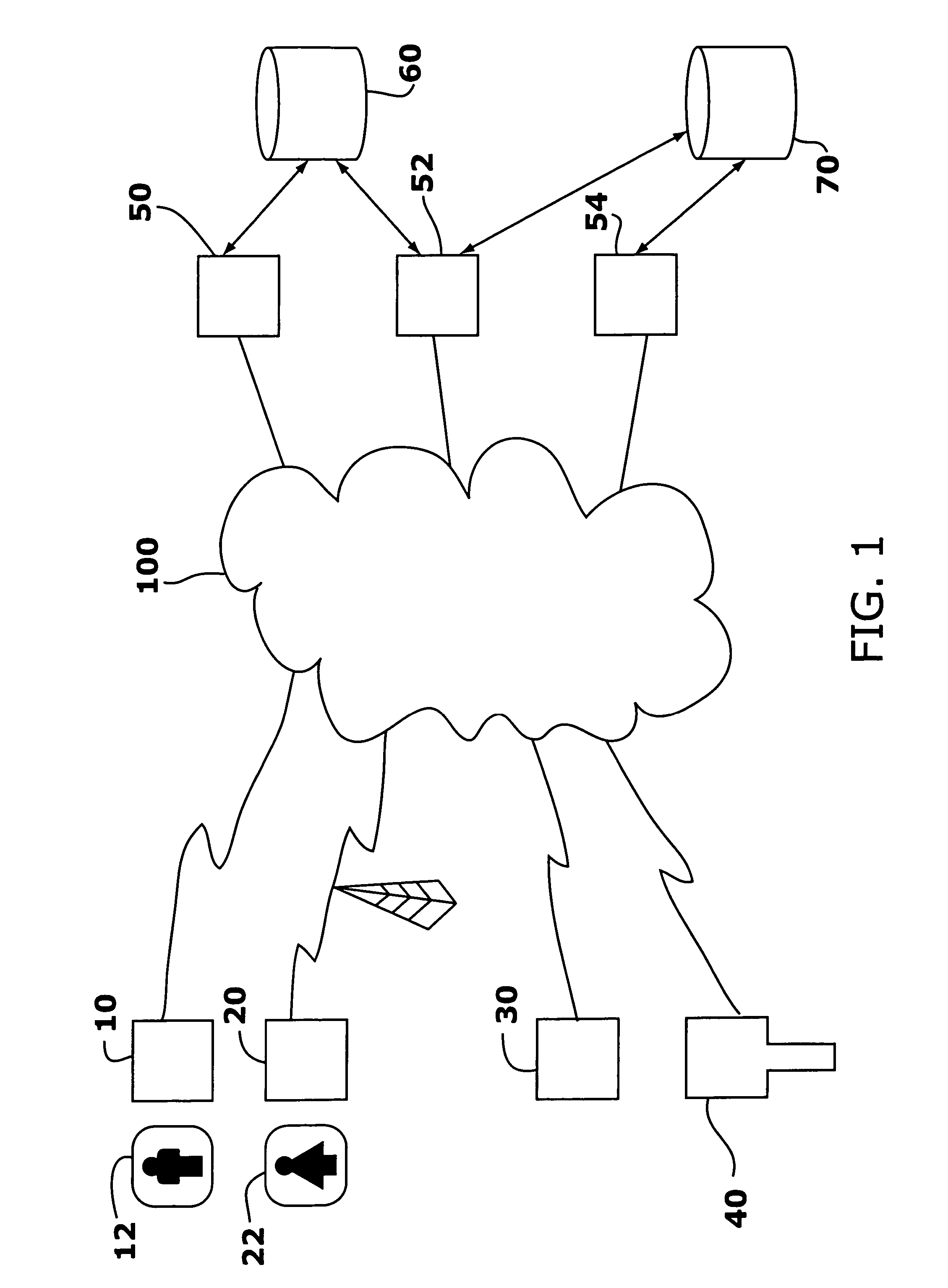

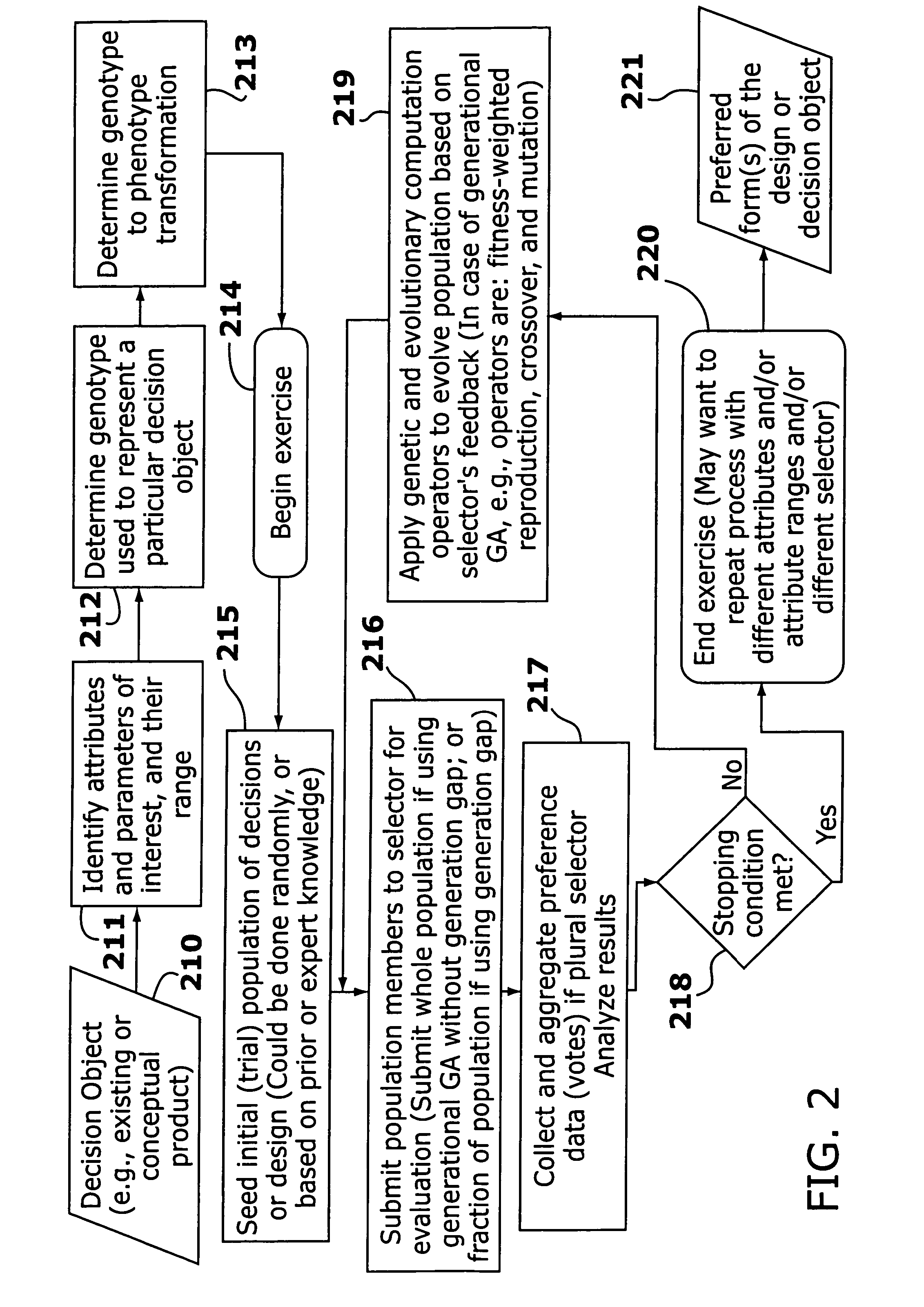

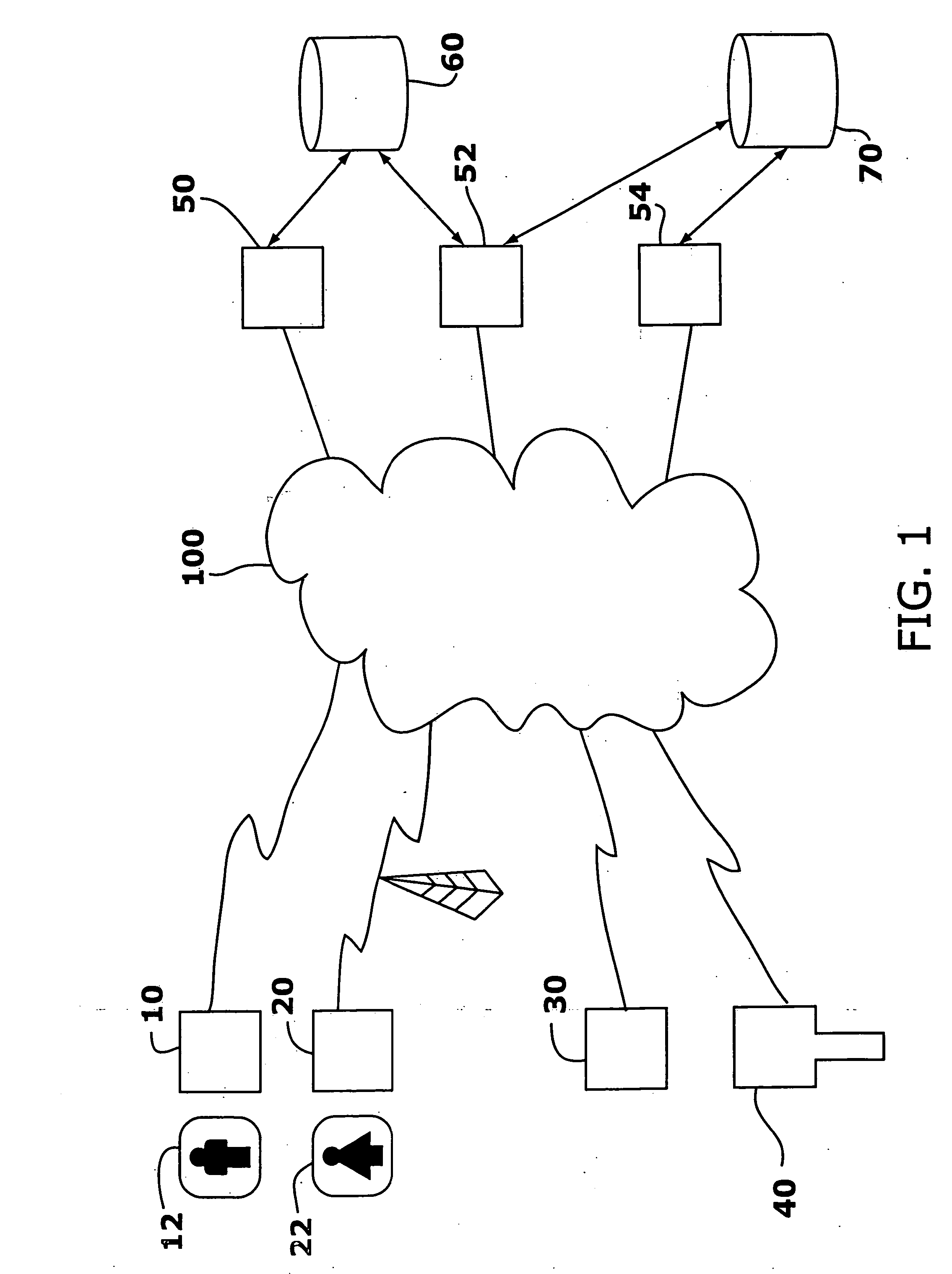

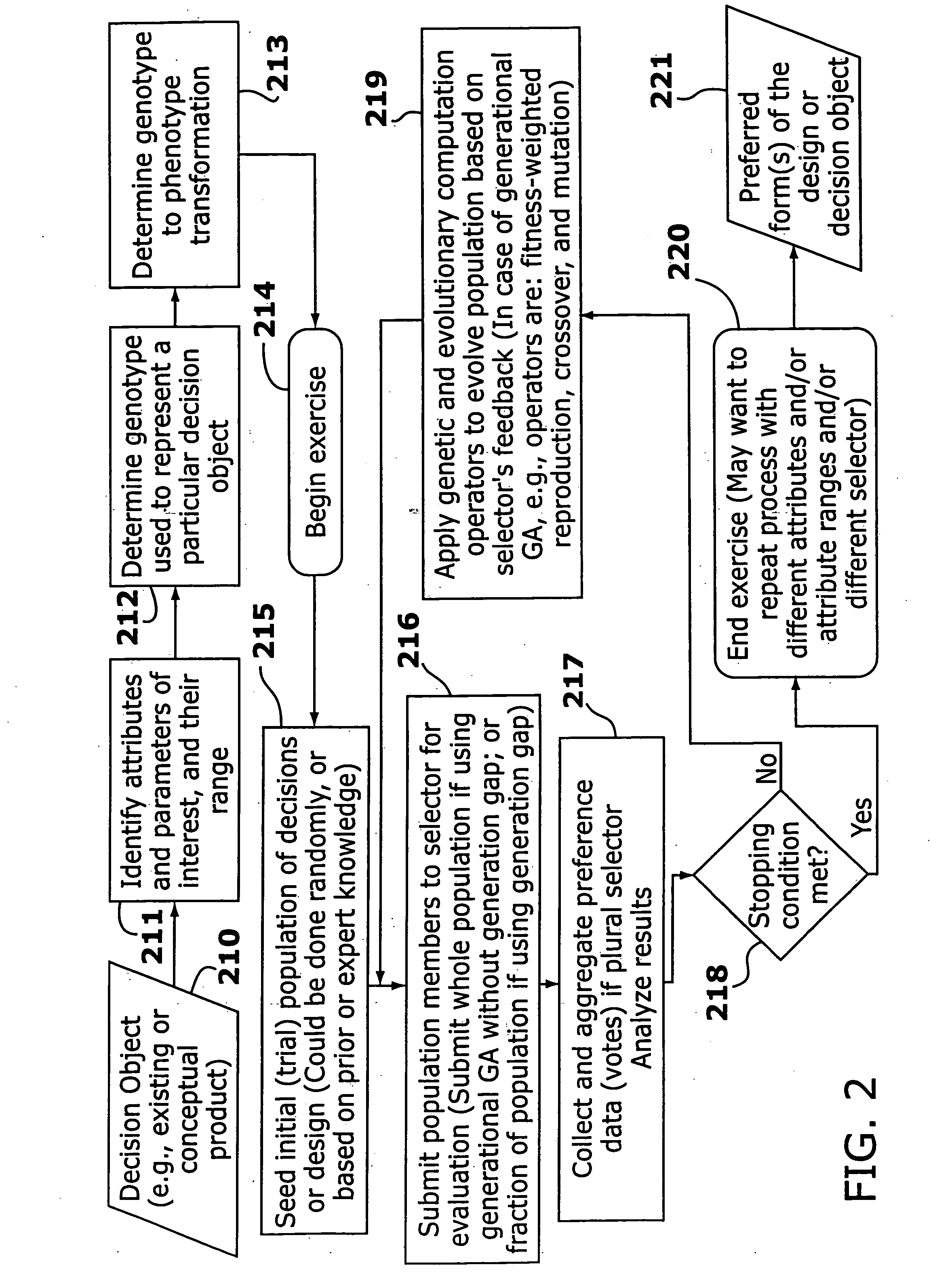

Method and apparatus for evolutionary design

InactiveUS7016882B2ConfidenceGreat confidenceDigital computer detailsProbabilistic networksEvolutionary computationComputer science

The invention involves generating and presenting, typically electronically, a number of design alternatives to persons who are participating in the design, selection, or market research exercise. The participants (referred to as “selectors”) transmit data indicative of their preferences among or between the presented design alternatives, and that data is used to derive a new generation of design alternatives or proposals. The new designs are generated through the use of a computer program exploiting a genetic or evolutionary computational technique. The process is repeated, typically for many iterations or cycles.

Owner:THE NIELSEN CO (US) LLC

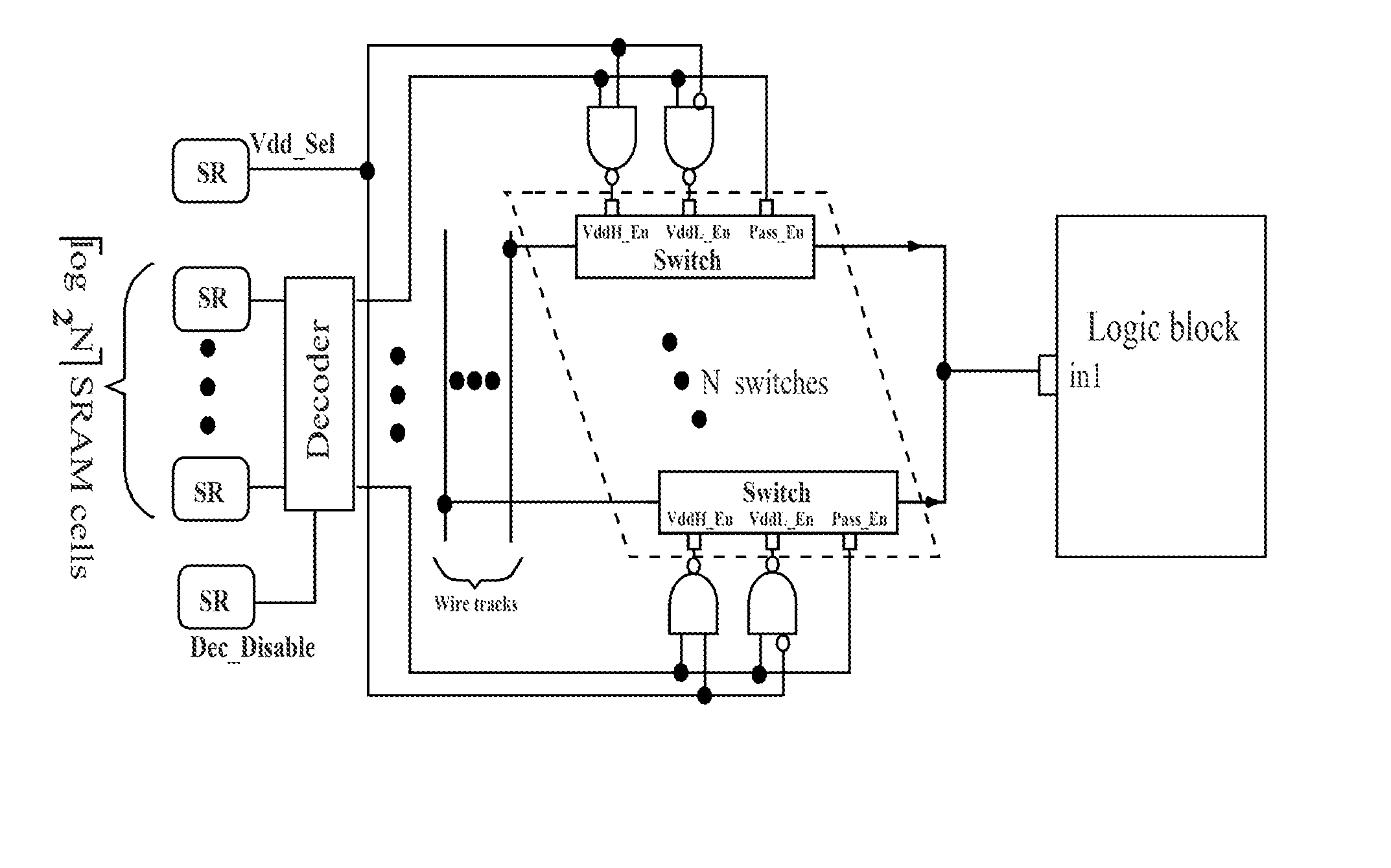

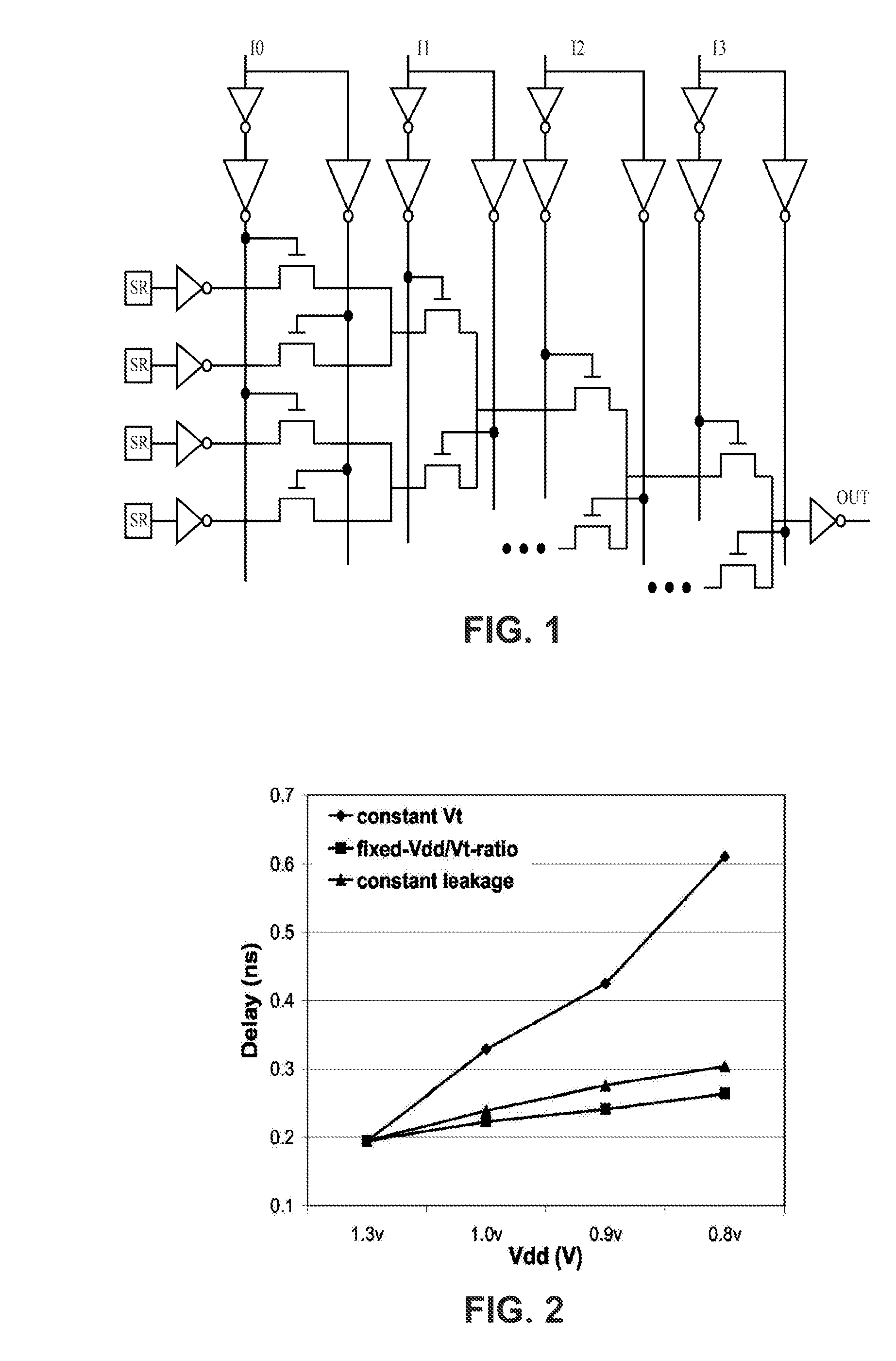

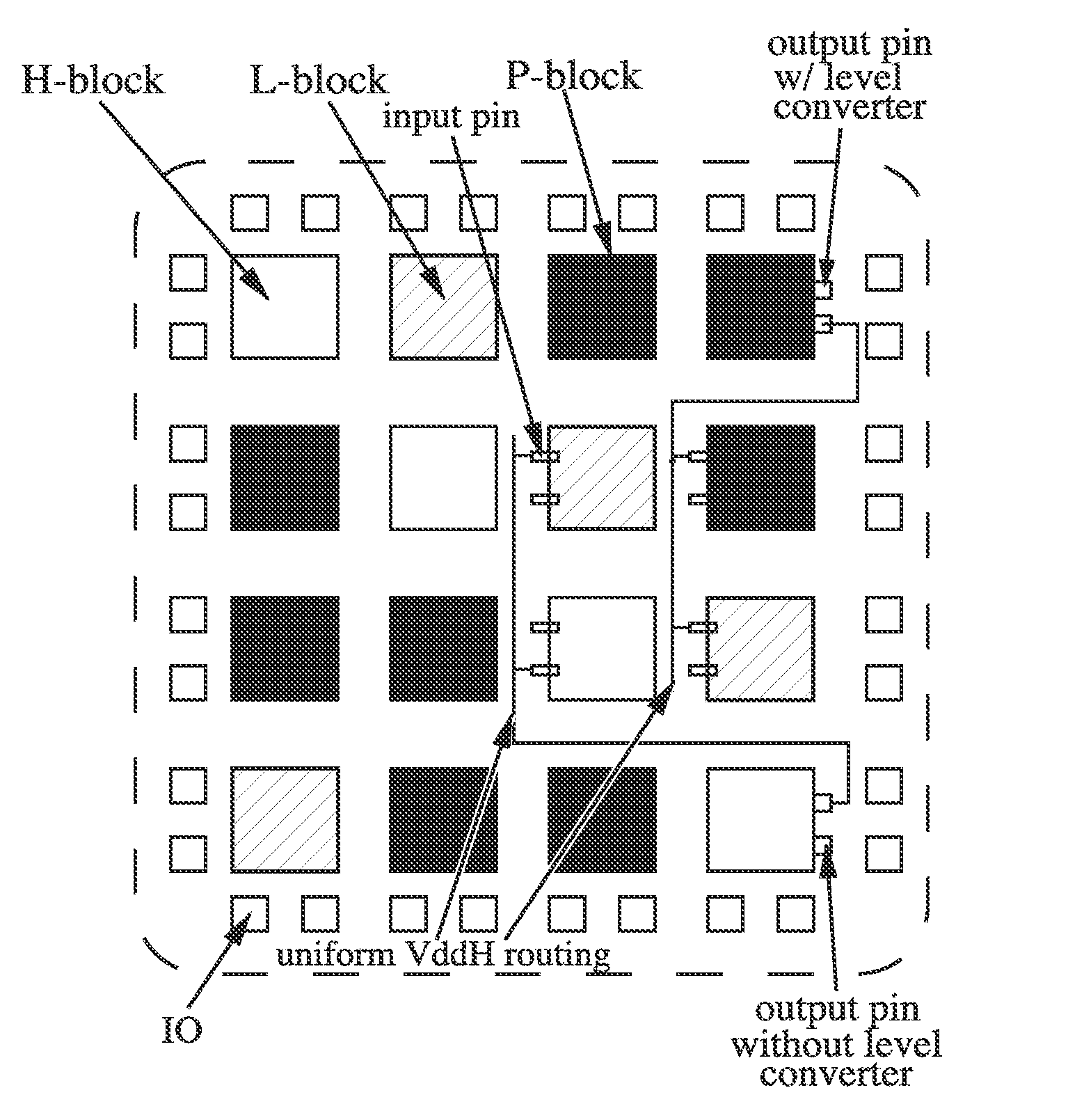

Low-power FPGA circuits and methods

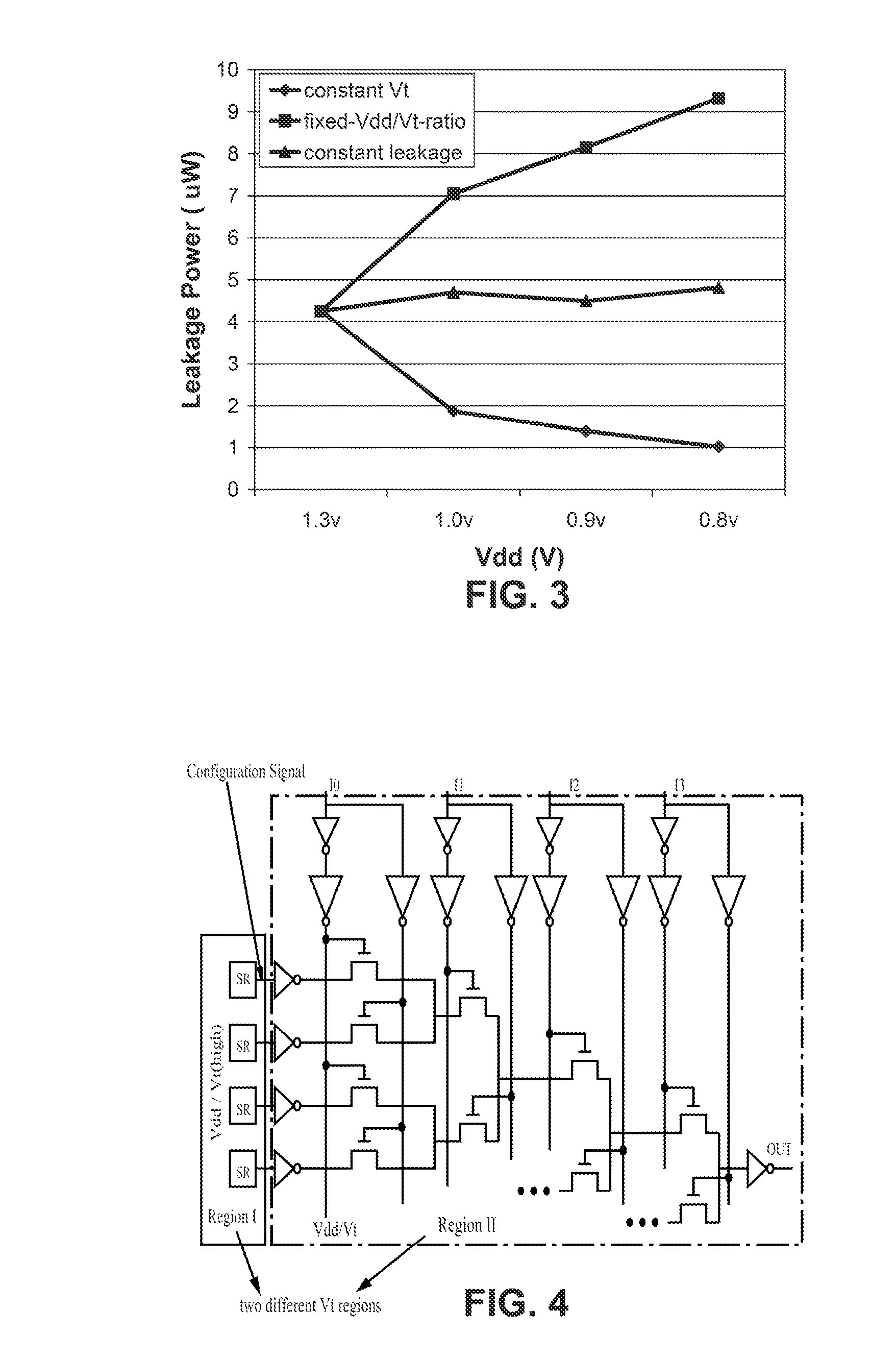

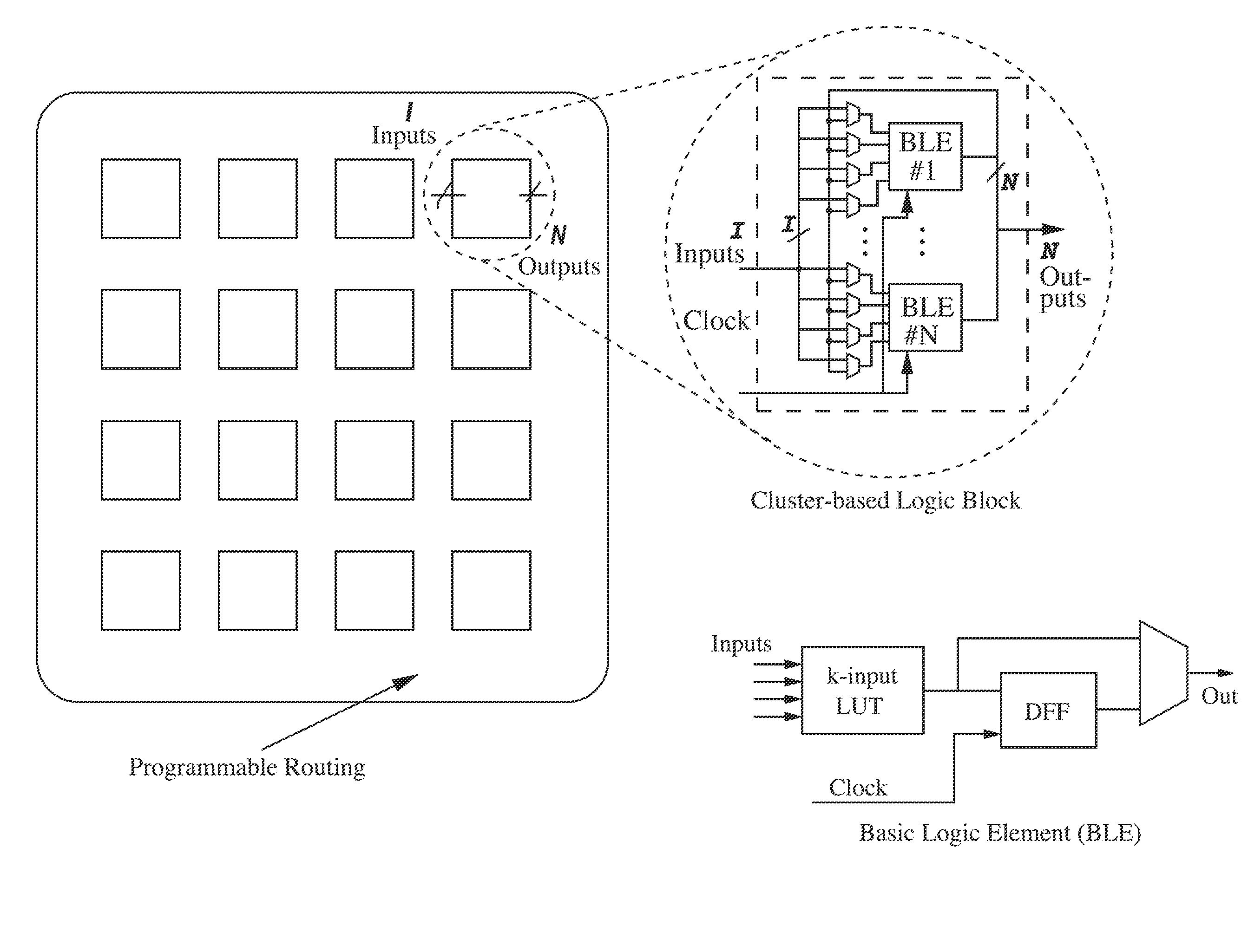

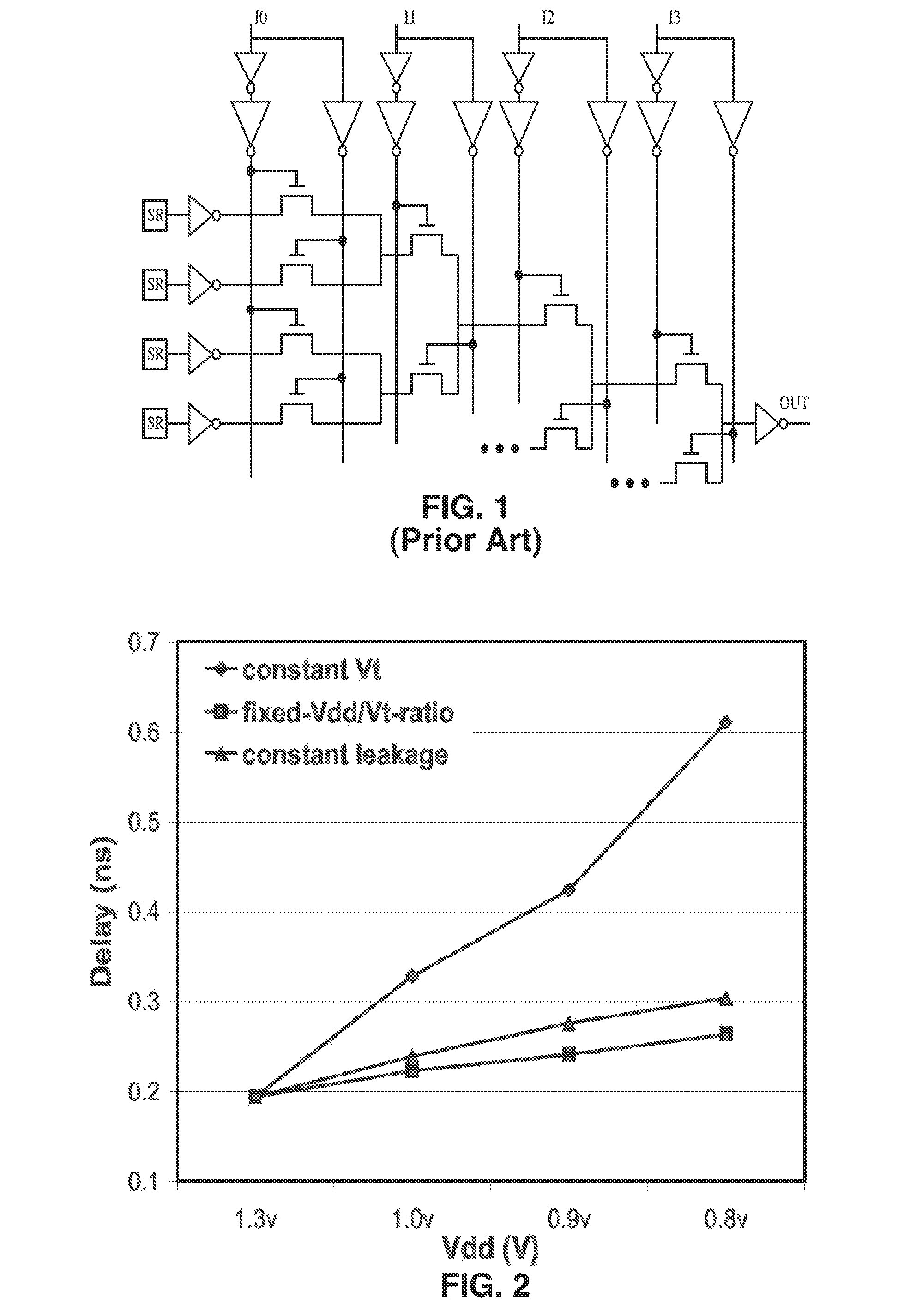

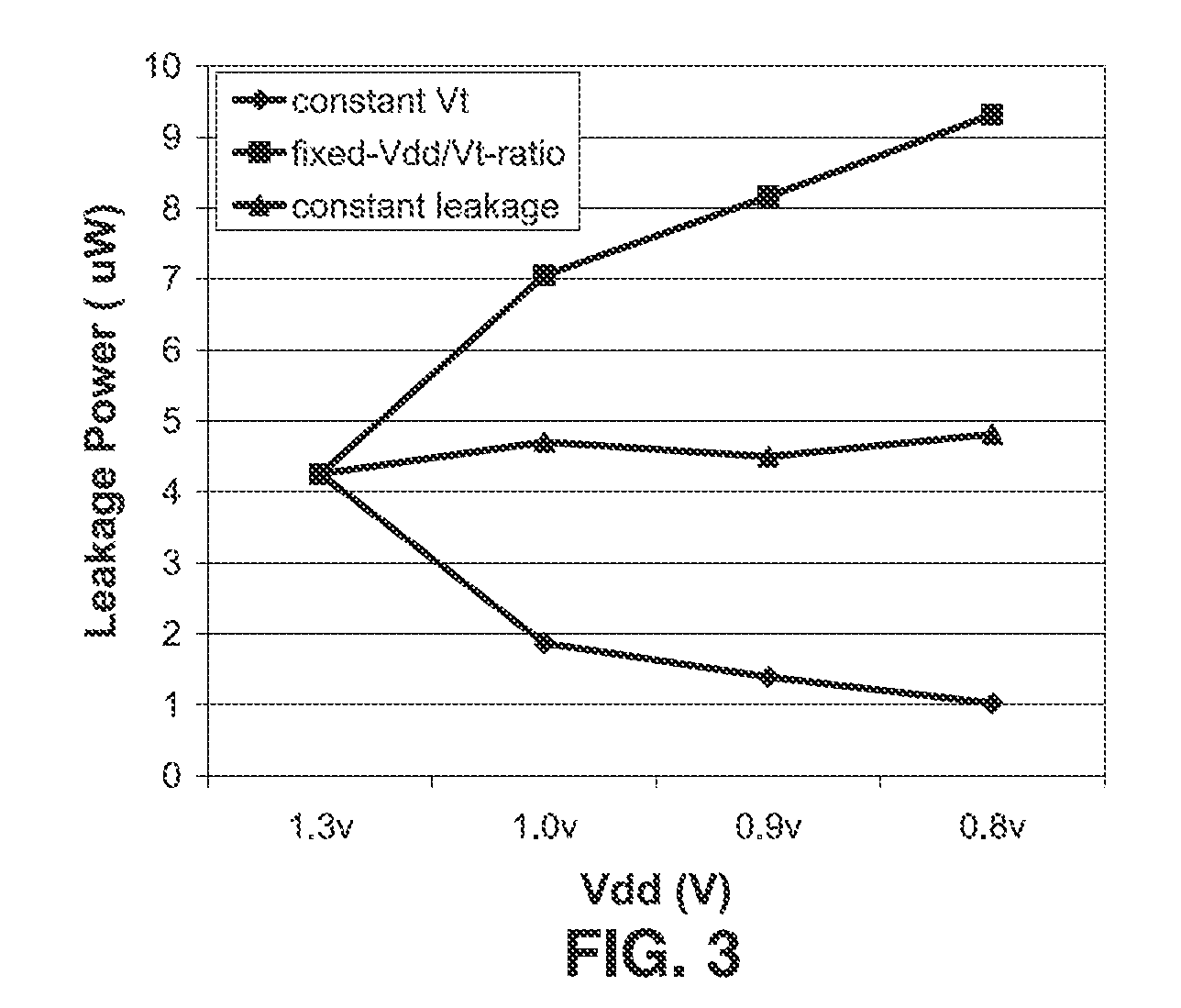

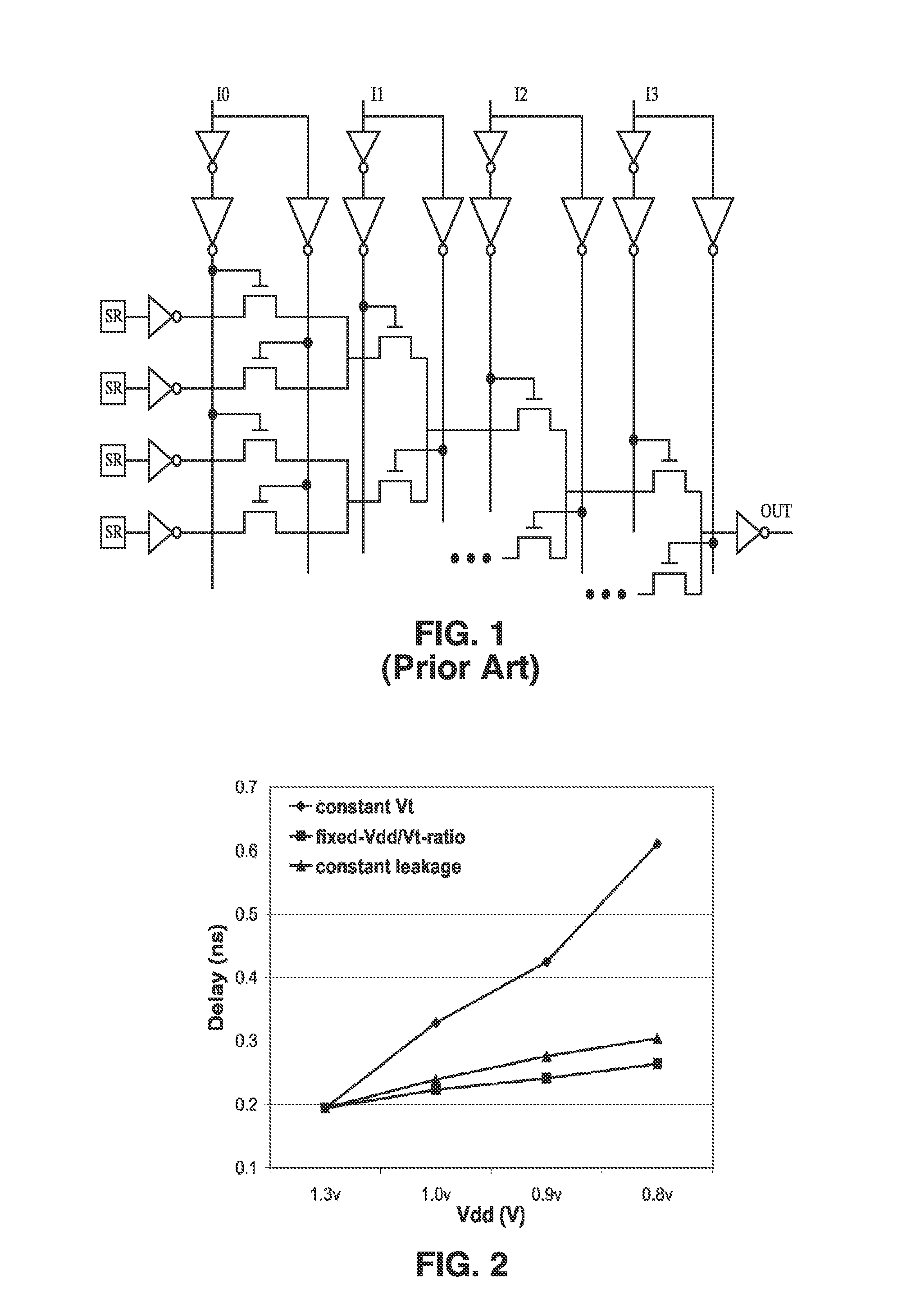

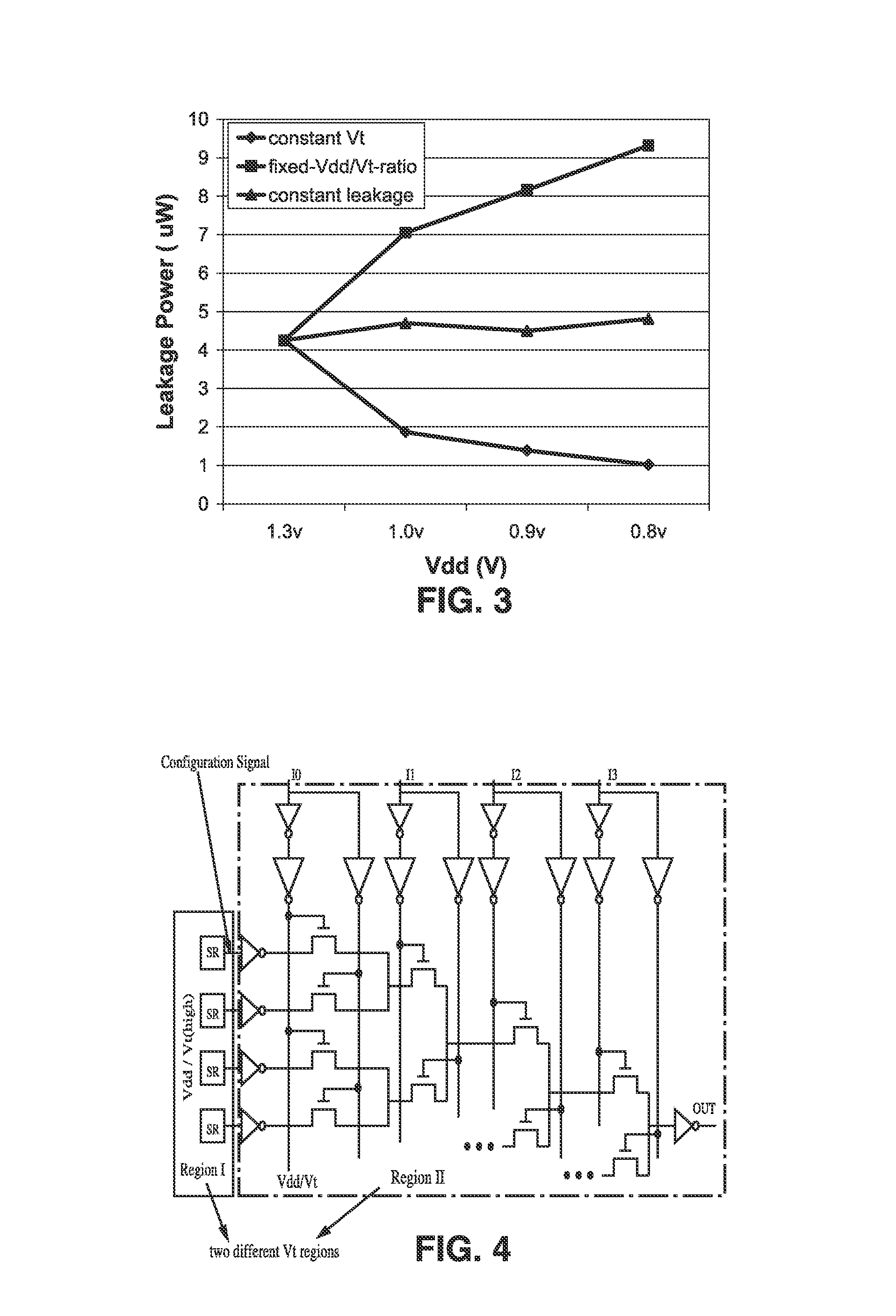

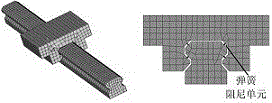

InactiveUS20070164785A1Increase profitReduce needSolid-state devicesCAD circuit designEngineeringLeakage power

Field Programmable Logic Arrays (FPGAs) are described which utilize multiple power supply voltages to reduce both dynamic power and leakage power without sacrificing speed or substantially increasing device area. Power reduction mechanisms are described for numerous portions of the FPGA, including logic blocks, routing circuits, connection blocks, switch blocks, configuration memory cells, and so forth. Embodiments describe circuits and methods for implementing multiple supplies as sources of Vdd, multiple voltage thresholding Vt, signal level translators, and power gating of circuitry to deactivate portions of the circuit which are inactive. The supply voltage levels can be fixed, or programmable. Methods are described for performing circuit CAD in the routing and assignment process on FPGAs, in particular for optimizing FPGA use having the power reduction circuits taught. Routing methods describe utilizing slack timing, power sensitivity, trace-based simulations, and other techniques to optimize circuit utilization on a multi Vdd FPGA.

Owner:RGT UNIV OF CALIFORNIA

Low-power FPGA circuits and methods

InactiveUS20100281448A1Improve utilizationEasy to controlCAD circuit designMulti-objective optimisationComputer architectureMemory cell

Field Programmable Logic Arrays (FPGAs) are described which utilize multiple power supply voltages to reduce both dynamic power and leakage power without sacrificing speed or substantially increasing device area. Power reduction mechanisms are described for numerous portions of the FPGA, including logic blocks, routing circuits, connection blocks, switch blocks, configuration memory cells, and so forth. Embodiments describe circuits and methods for implementing multiple supplies as sources of Vdd, multiple voltage thresholding Vt, signal level translators, and power gating of circuitry to deactivate portions of the circuit which are inactive. The supply voltage levels can be fixed, or programmable. Methods are described for performing circuit CAD in the routing and assignment process on FPGAs, in particular for optimizing FPGA use having the power reduction circuits taught. Routing methods describe utilizing slack timing, power sensitivity, trace-based simulations, and other techniques to optimize circuit utilization on a multi Vdd FPGA.

Owner:RGT UNIV OF CALIFORNIA

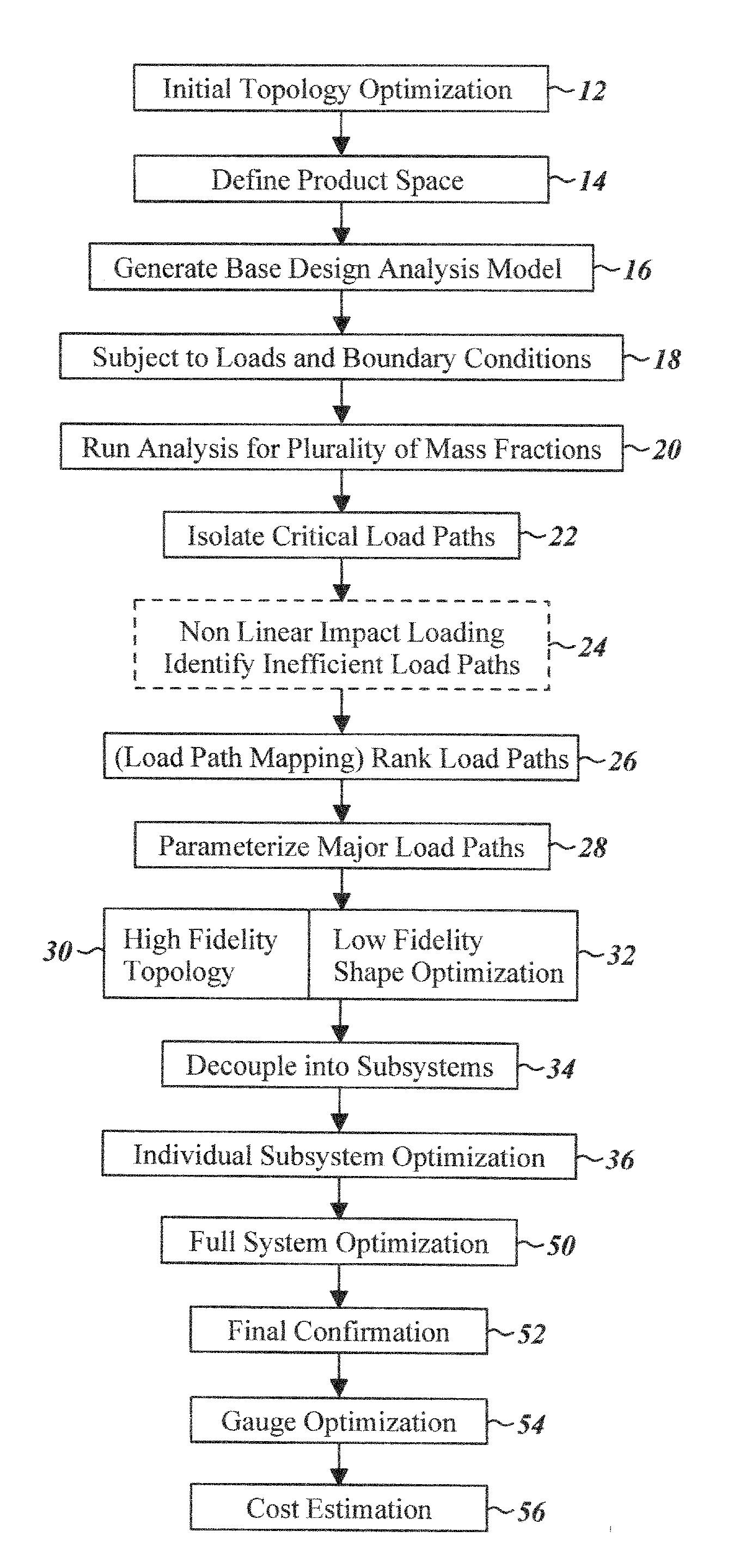

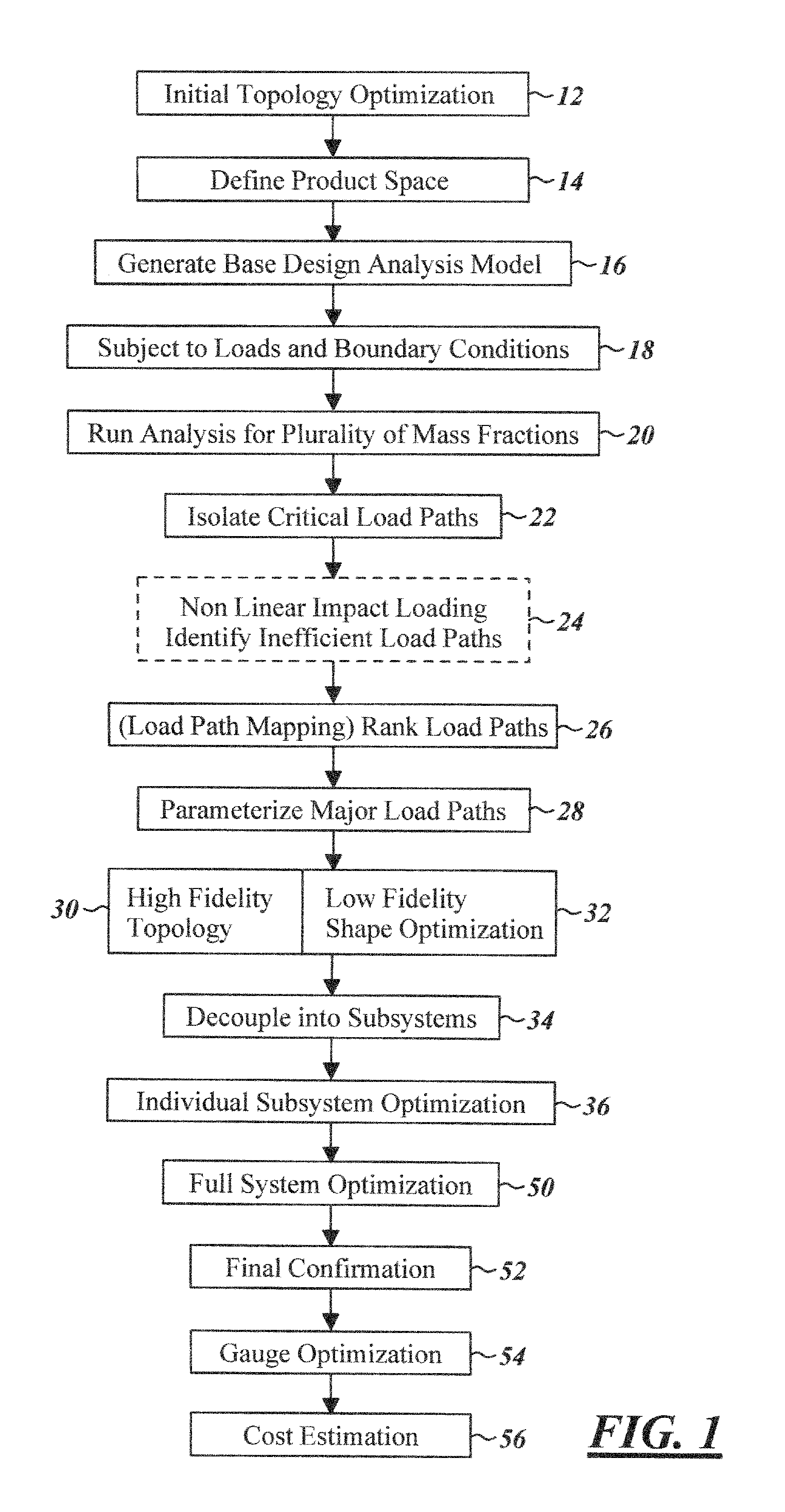

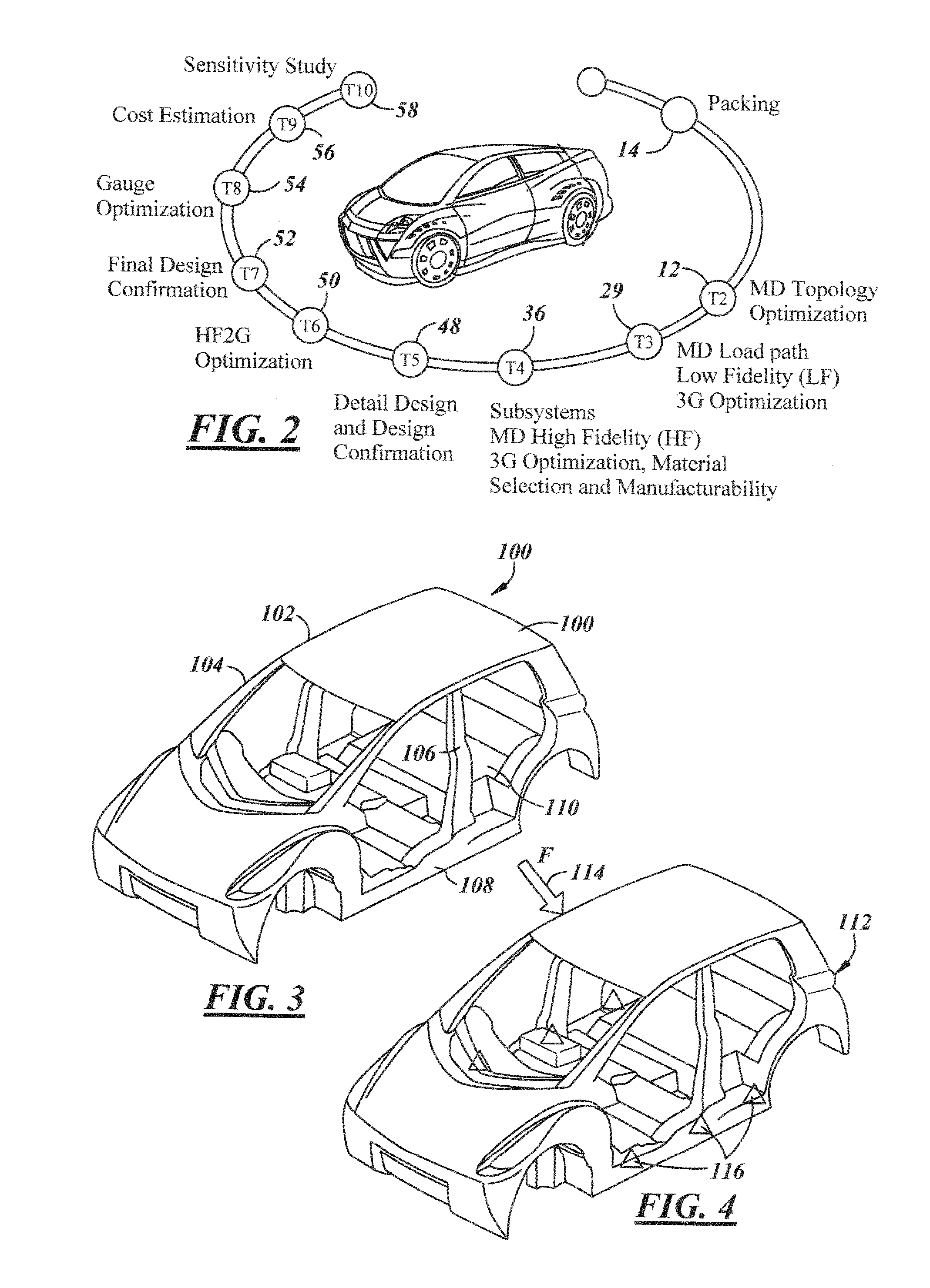

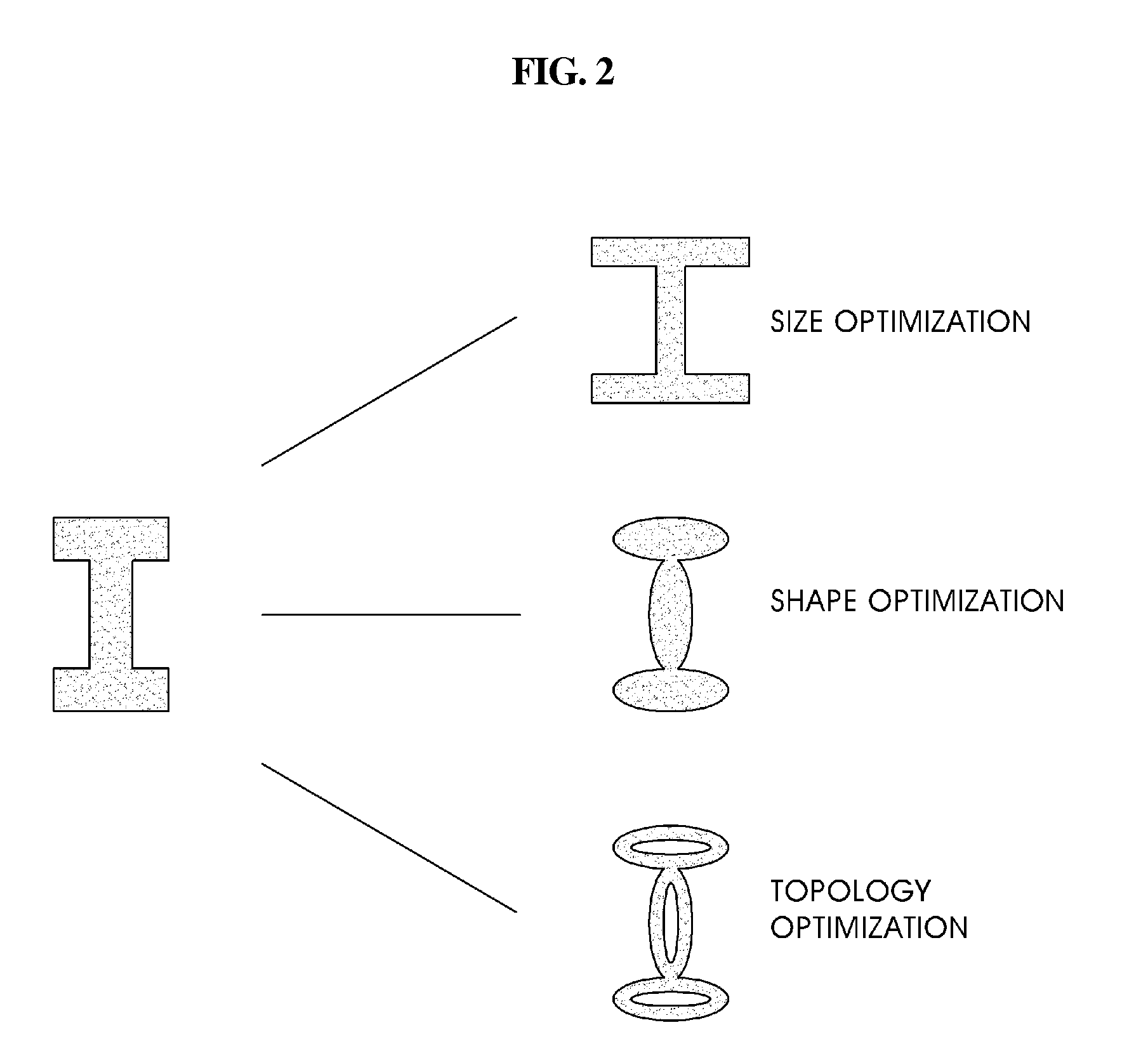

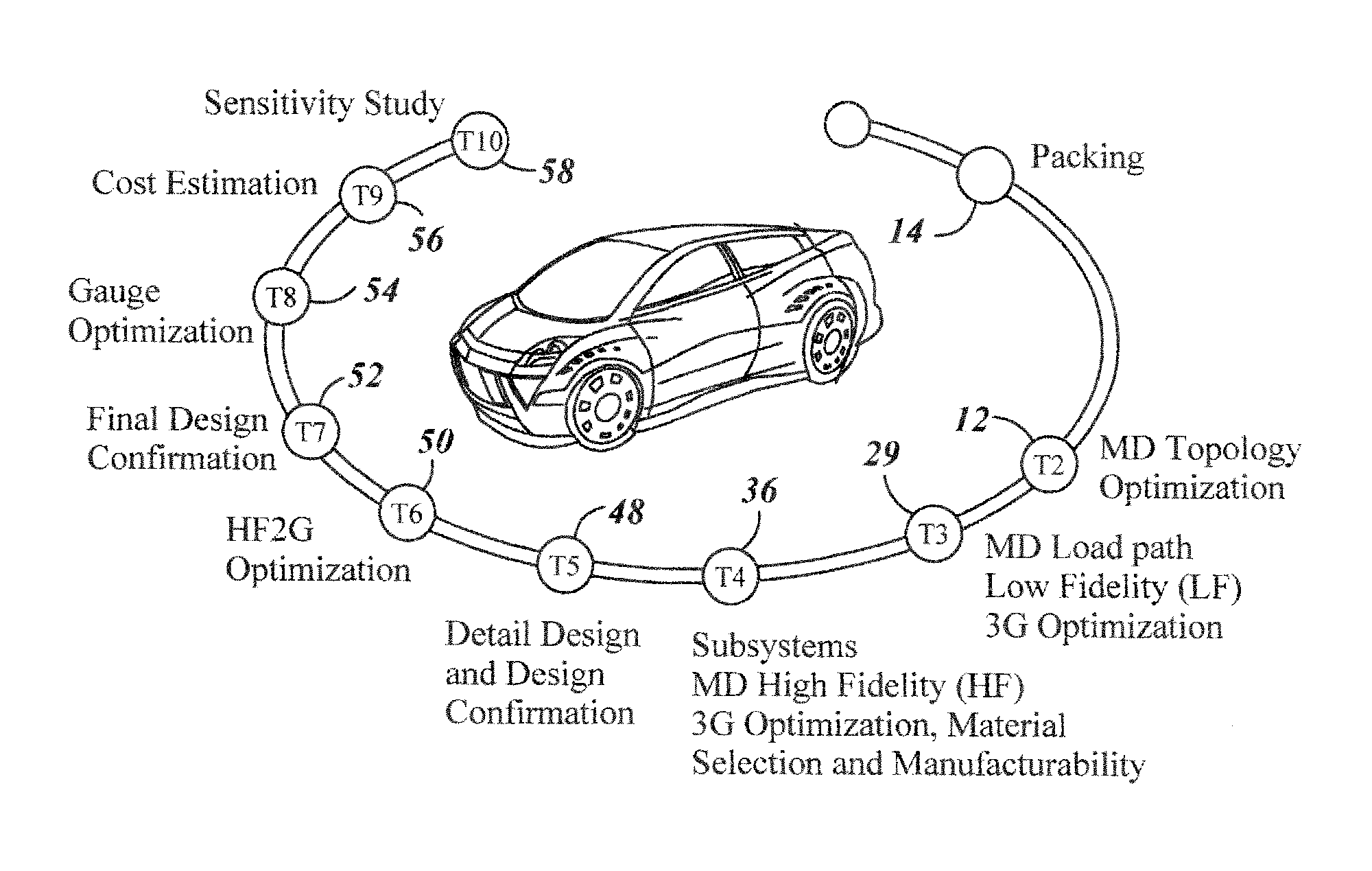

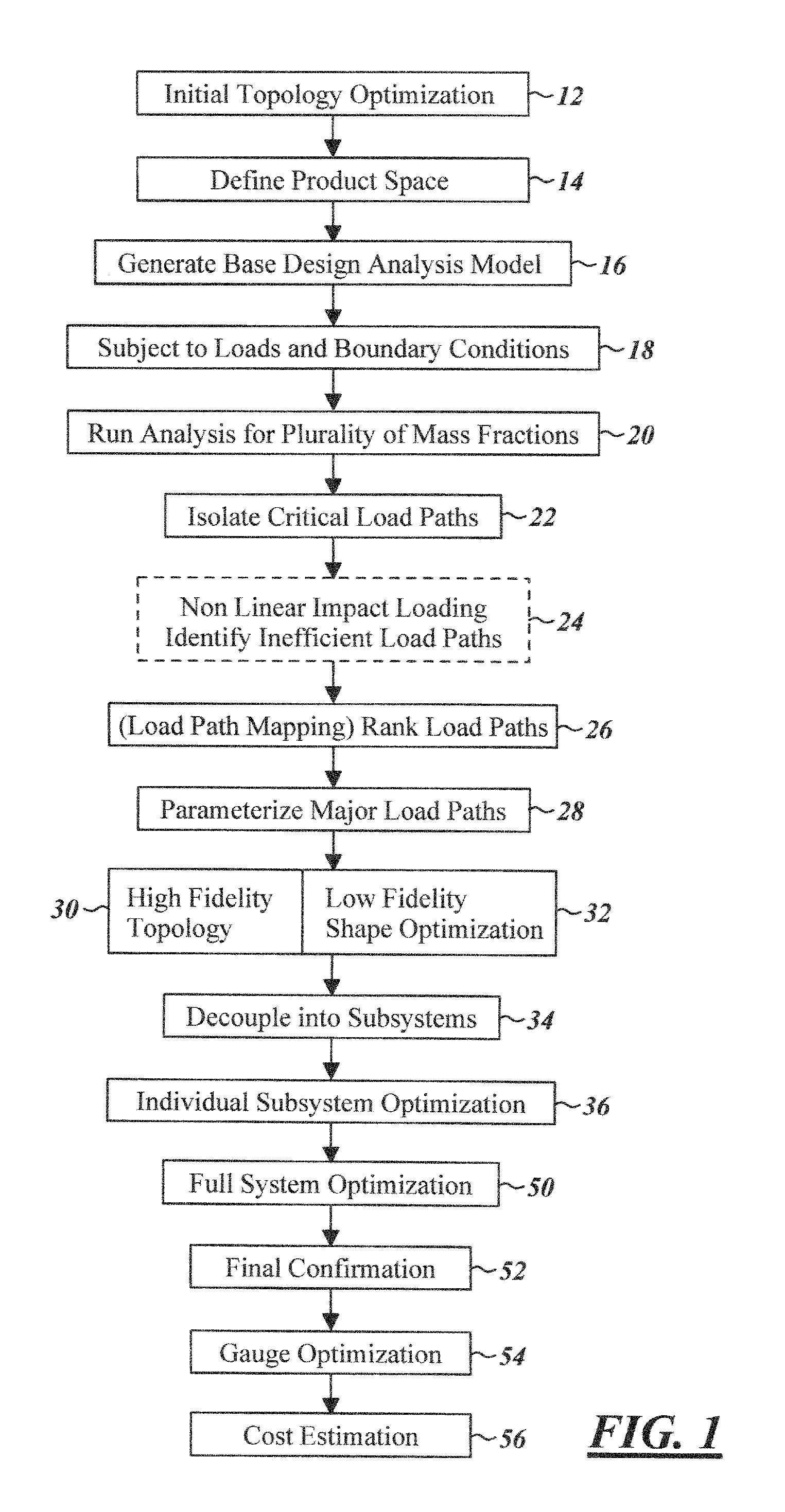

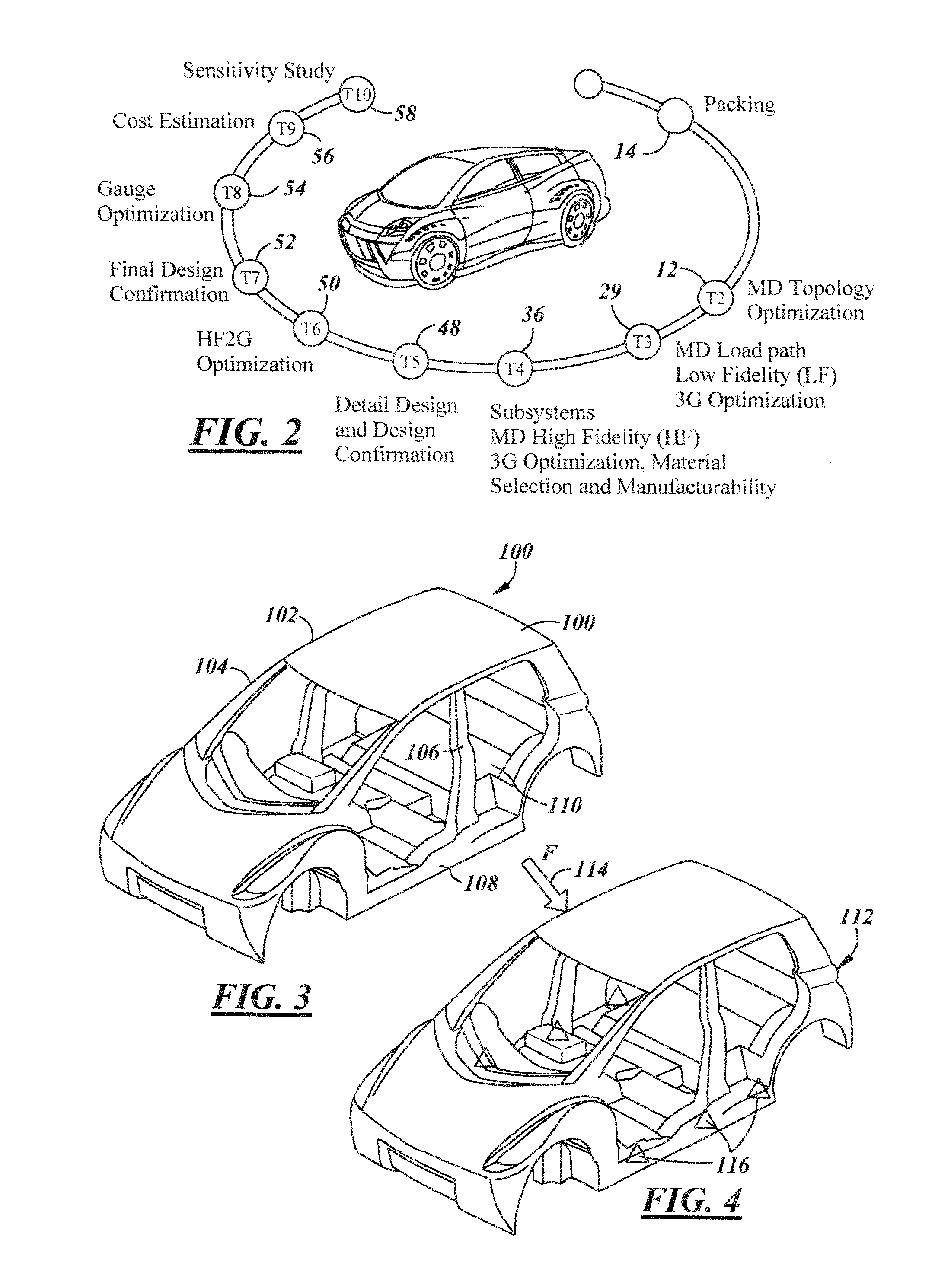

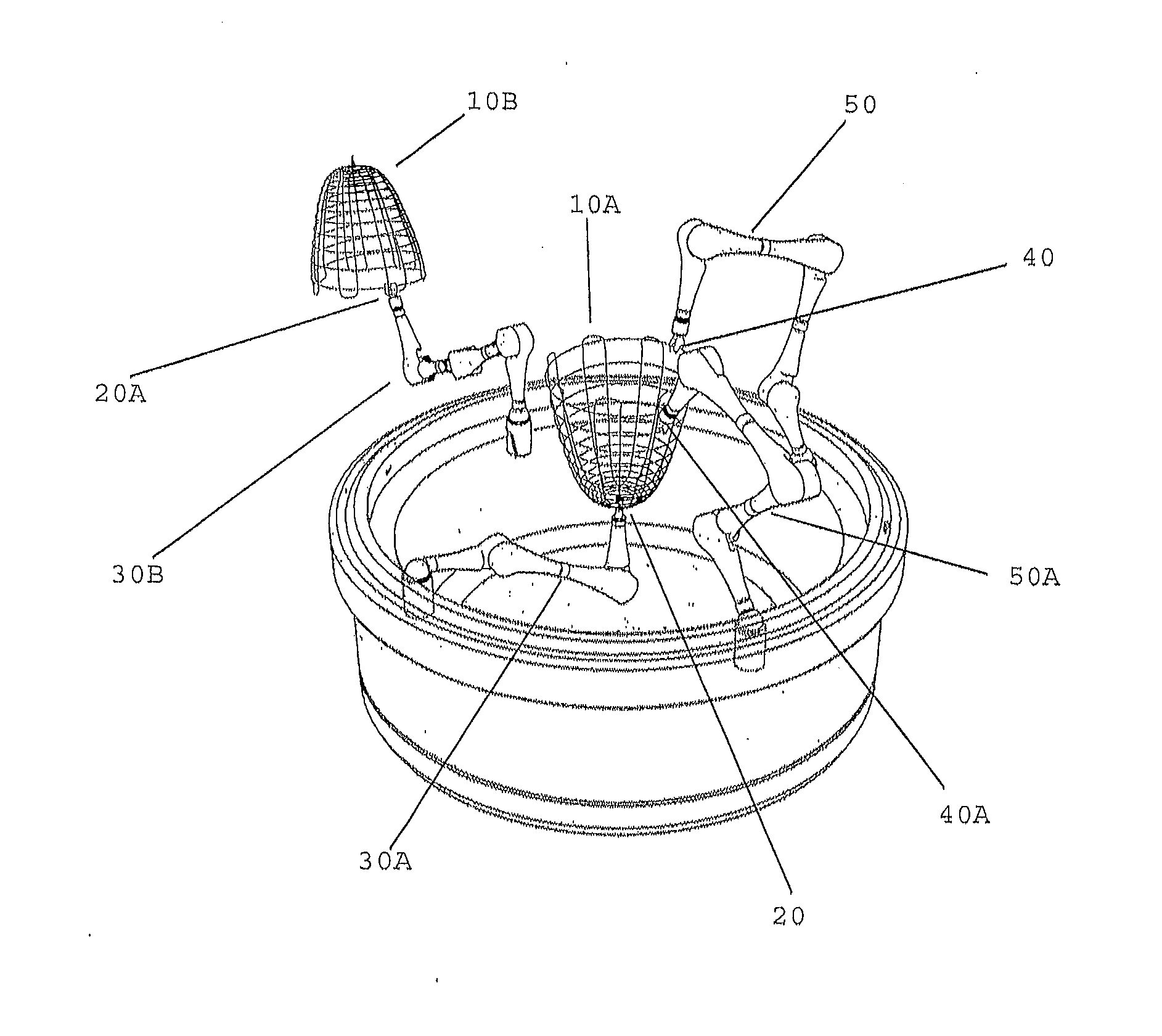

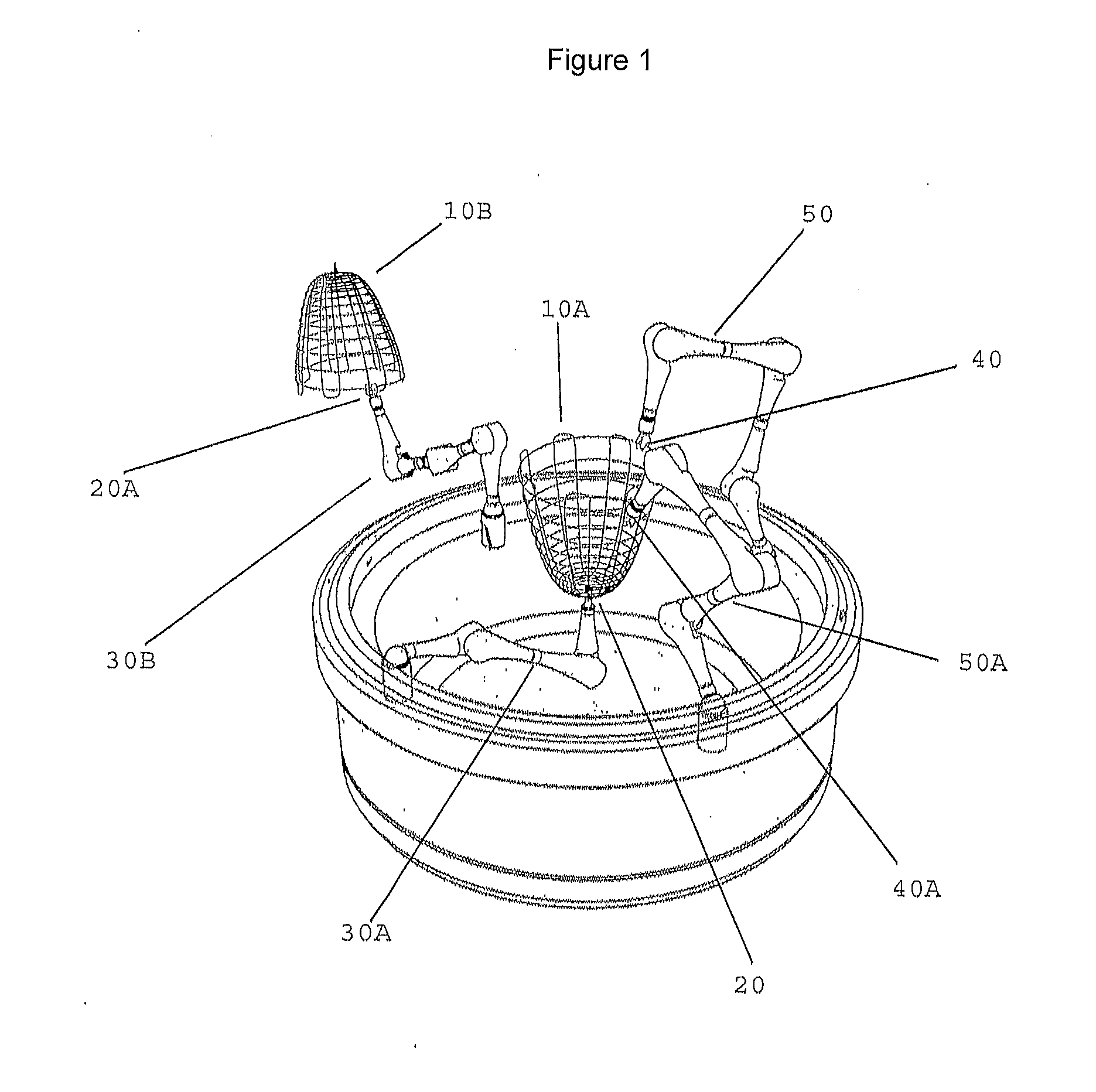

Design Optimization System

ActiveUS20110137443A1Geometric CADDesign optimisation/simulationCritical structureTopology optimization

In accordance with the objects of the present invention, a method of complex product design is provided. The method defines a product design space a base design analysis model is then automatically generated within the product design space. A topology optimization of the base design analysis model is performed including solving the topology optimization for multiple mass fractions to identify critical structure areas. The results of the topology optimizations are utilized to identify a plurality of load paths. An optimization of said plurality of load paths is performed to find the optimized load paths. Critical structure areas along the plurality of optimized load paths are then parameterized. An optimization is performed utilizing a multi-disciplinary optimization to optimize geometry, material and thickness along the optimized load paths. A manufacturing analysis of the shape optimized structure is performed and the shape optimized structure is modified to comply with manufacture requirements. An optimization is then performed using multi-disciplinary optimization comprising a gauge and grade optimization.

Owner:NITED STATES STEEL CORP +1

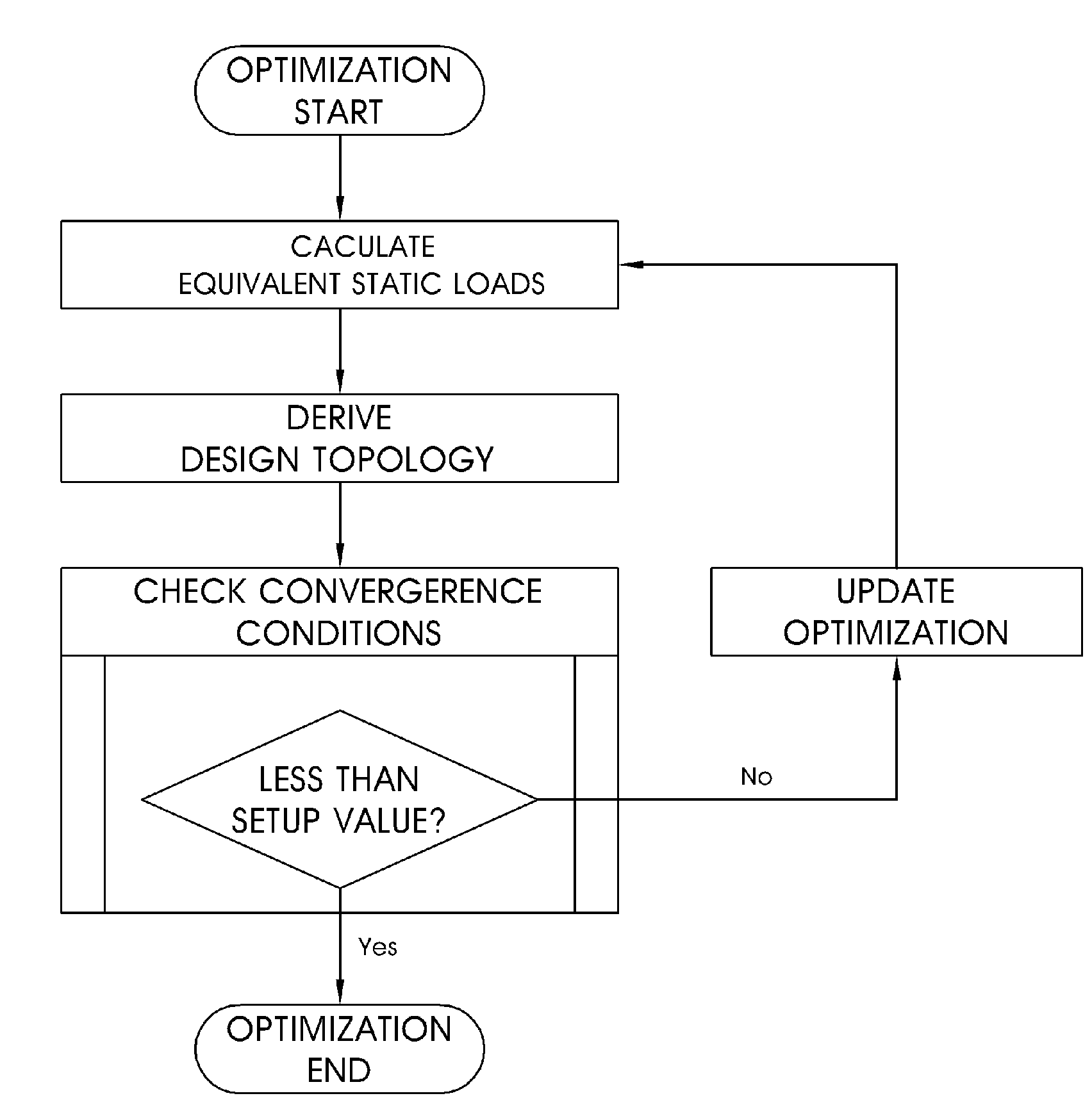

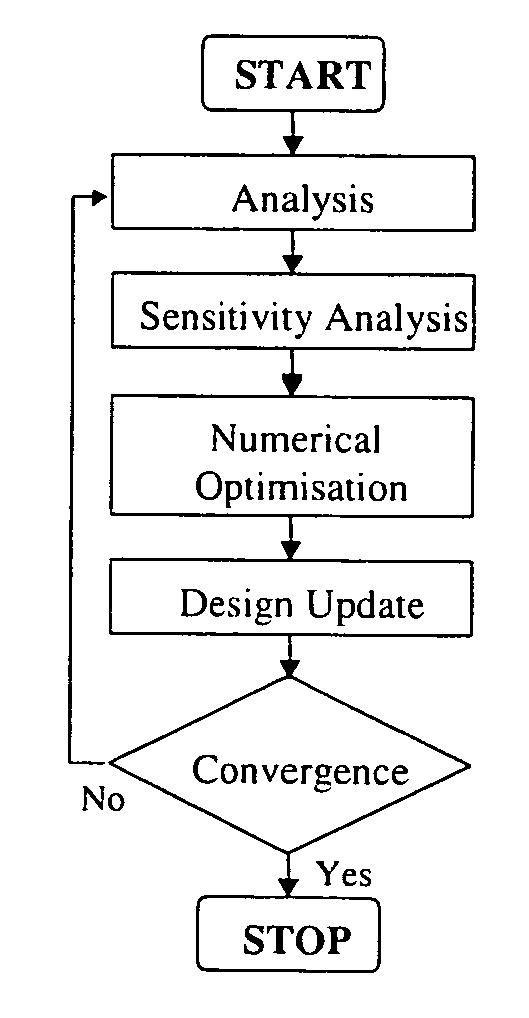

Topology optimization method using equivalent static loads

InactiveUS20100058257A1Accurate solutionReduce in quantityMulti-objective optimisationSoftware simulation/interpretation/emulationTopology optimizationEngineering

A topology optimization method. Characteristics of a structure to be designed are differentiated to calculate equivalent static loads. A relative fraction of material is adopted as a design variable. It is determined whether or not an element exists based on an objective function and constraints. Design topology is derived through a linear static analysis that processes the equivalent static loads as multiple loading conditions. Topology of the structure to be designed is compared with the design topology, and thereby the progress of optimization is determined. The topology optimization processes are terminated when a difference of the compared result is less than a setup value, and are returned to an initial step when the difference is greater than the setup value, and the equivalent static loads are calculated using the design topology as a new structure to be designed.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

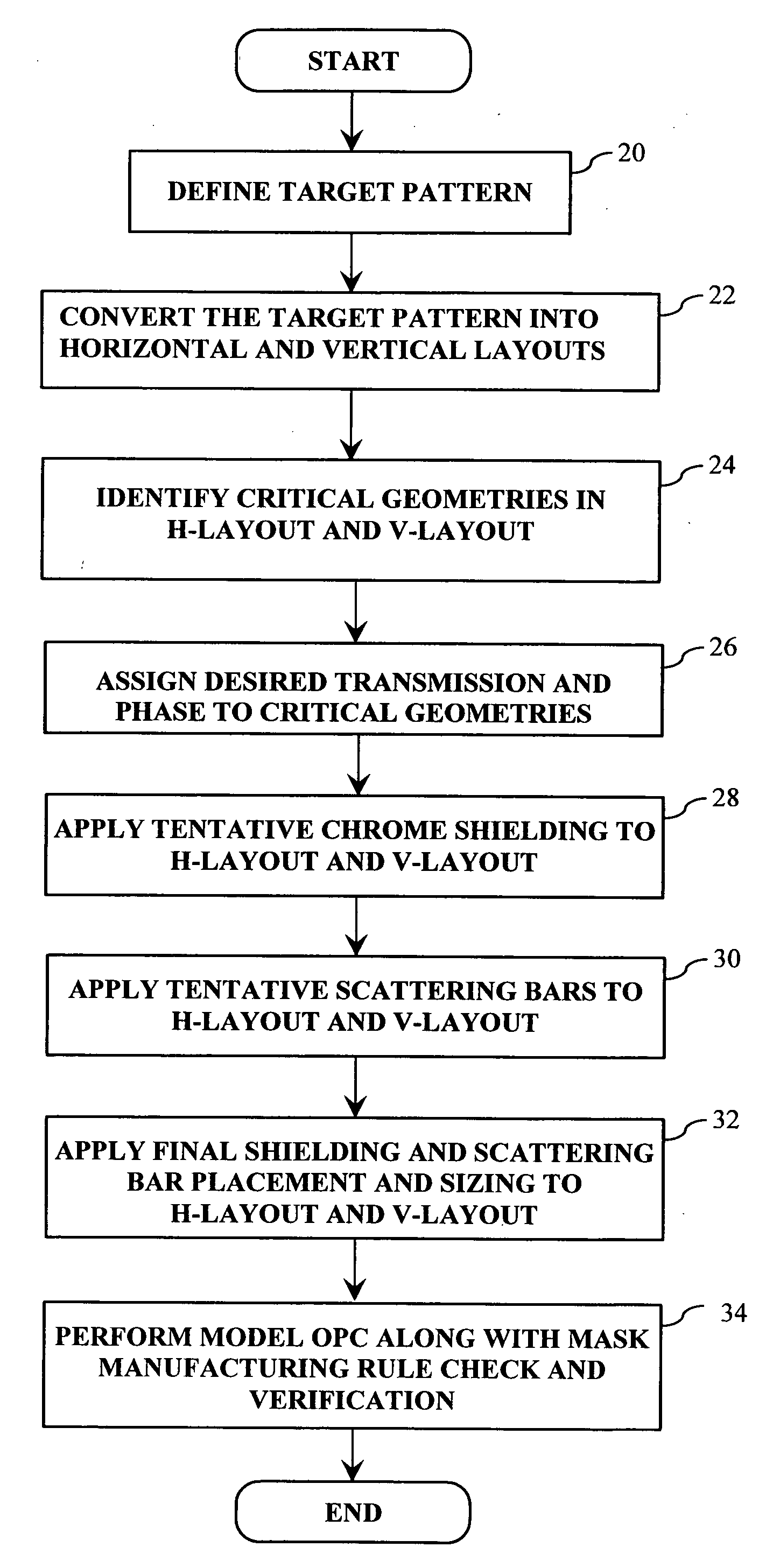

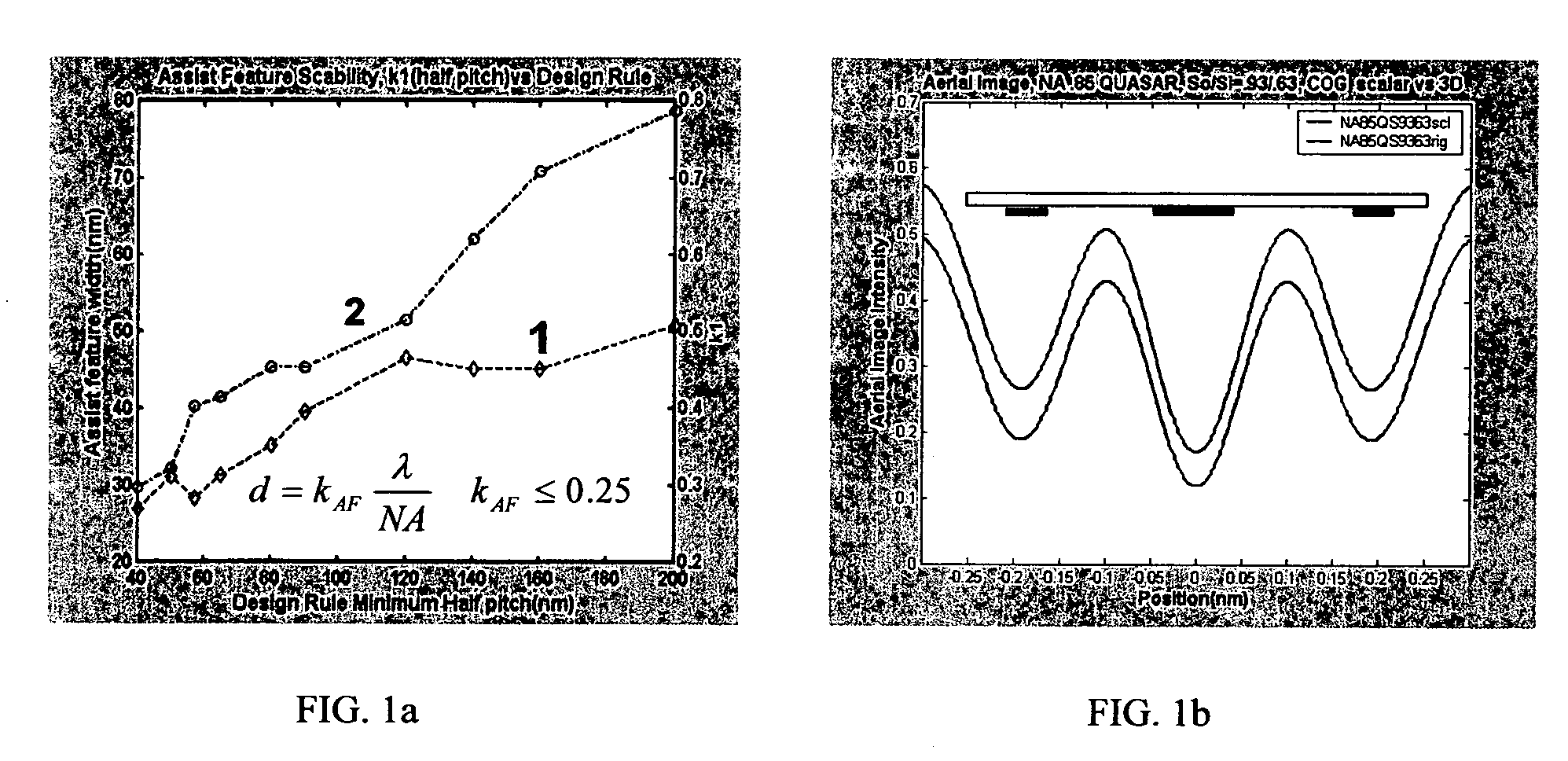

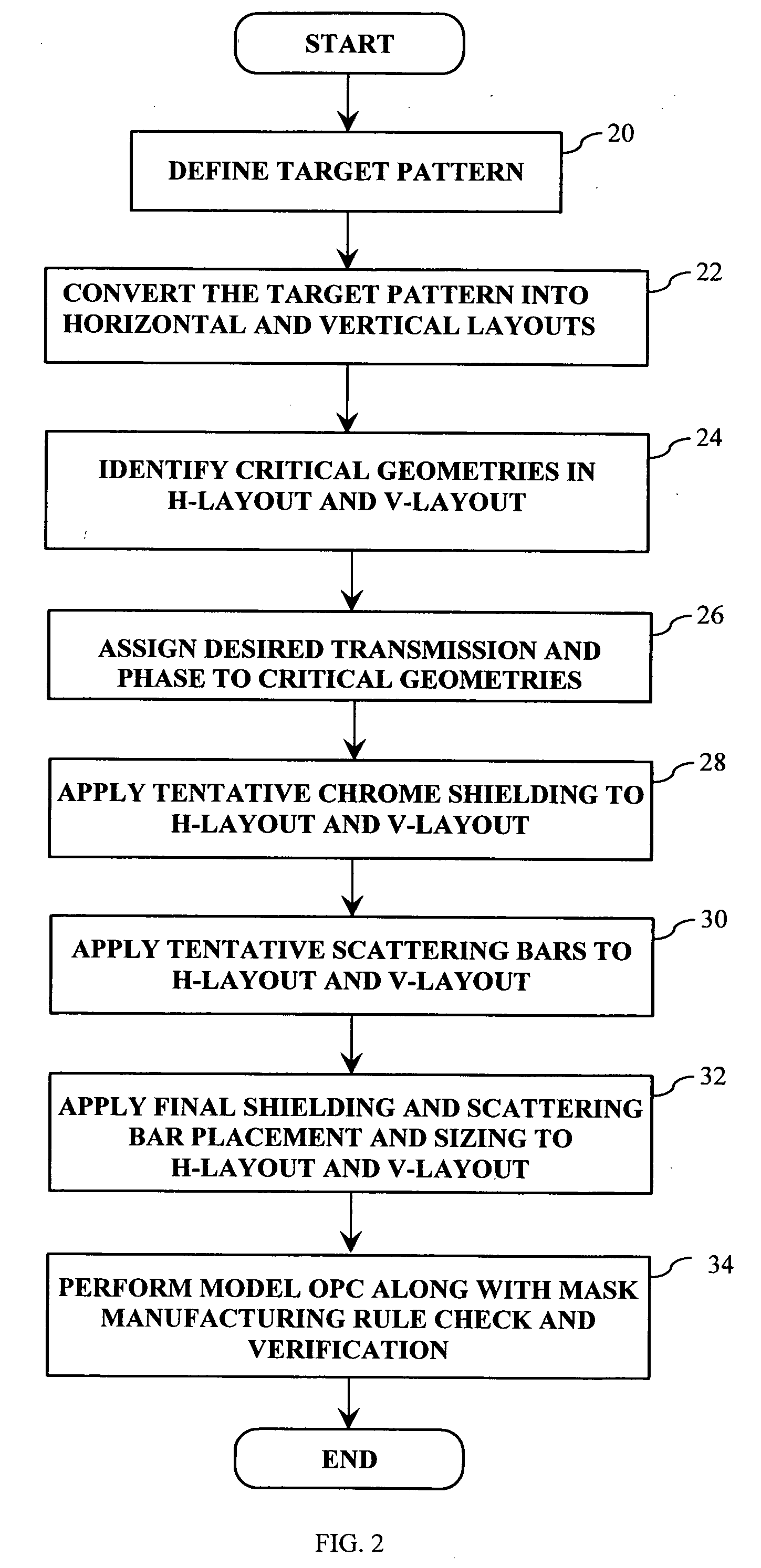

Method, program product and apparatus for performing double exposure lithography

InactiveUS20060277521A1Photomechanical apparatusSemiconductor/solid-state device manufacturingLithographic artistPhase shifted

A method of generating complementary masks based on a target pattern having features to be imaged on a substrate for use in a multiple-exposure lithographic imaging process. The method includes the steps of: defining an initial H-mask corresponding to the target pattern; defining an initial V-mask corresponding to the target pattern; identifying horizontal critical features in the H-mask having a width which is less than a predetermined critical width; identifying vertical critical features in the V-mask having a width which is less than a predetermined critical width; assigning a first phase shift and a first percentage transmission to the horizontal critical features, which are to be formed in the H-mask; and assigning a second phase shift and a second percentage transmission to the vertical critical features, which are to be formed in the V-mask. The method further includes the step of assigning chrome to all non-critical features in the H-mask and the V-mask. The non-critical features are those features having a width which is greater than or equal to the predetermined critical width. The non-critical features are formed in the H-mask and the V-mask utilizing chrome. The target pattern is then imaged on the substrate by imaging both the H-mask and V-mask.

Owner:ASML NETHERLANDS BV

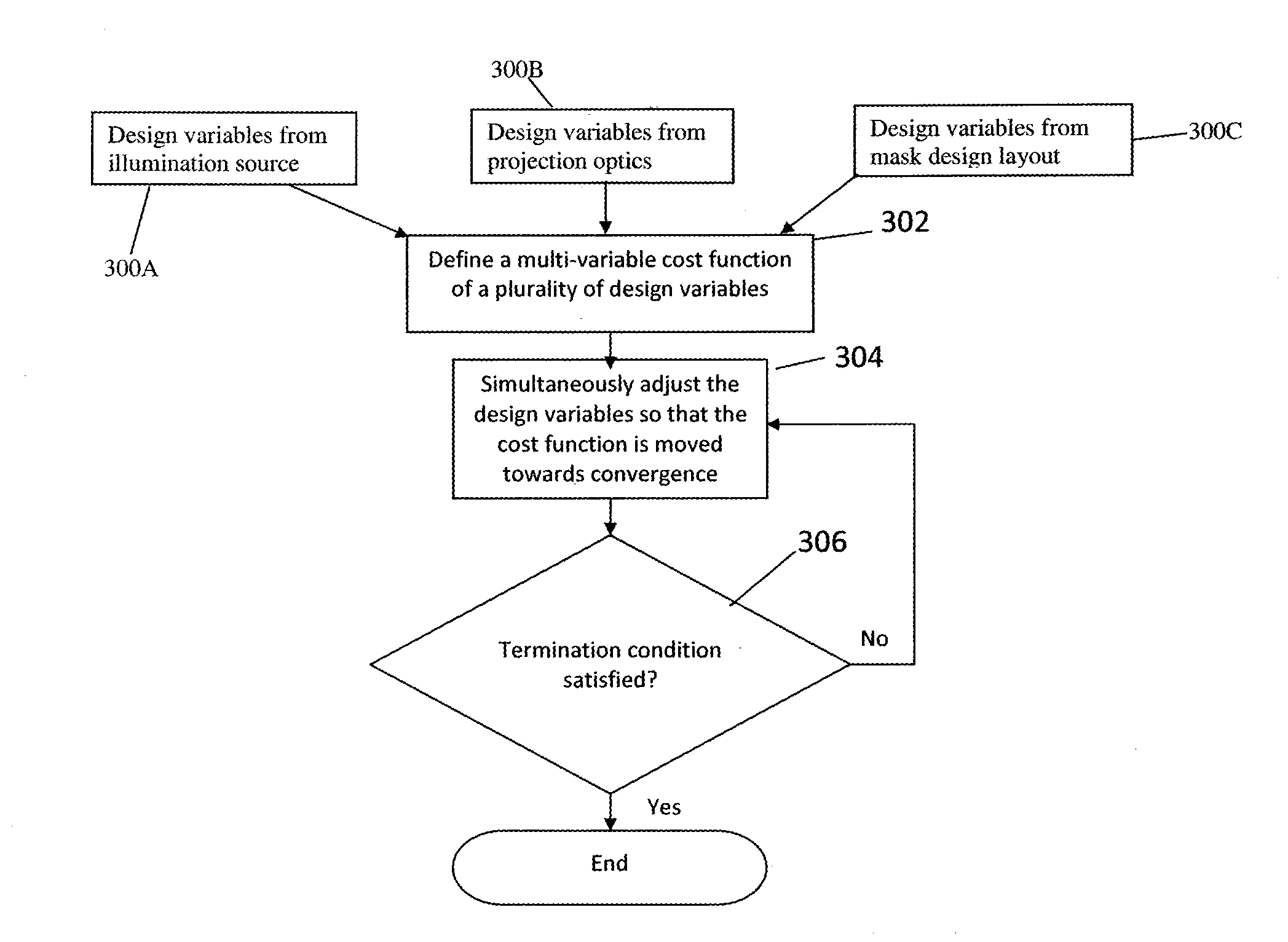

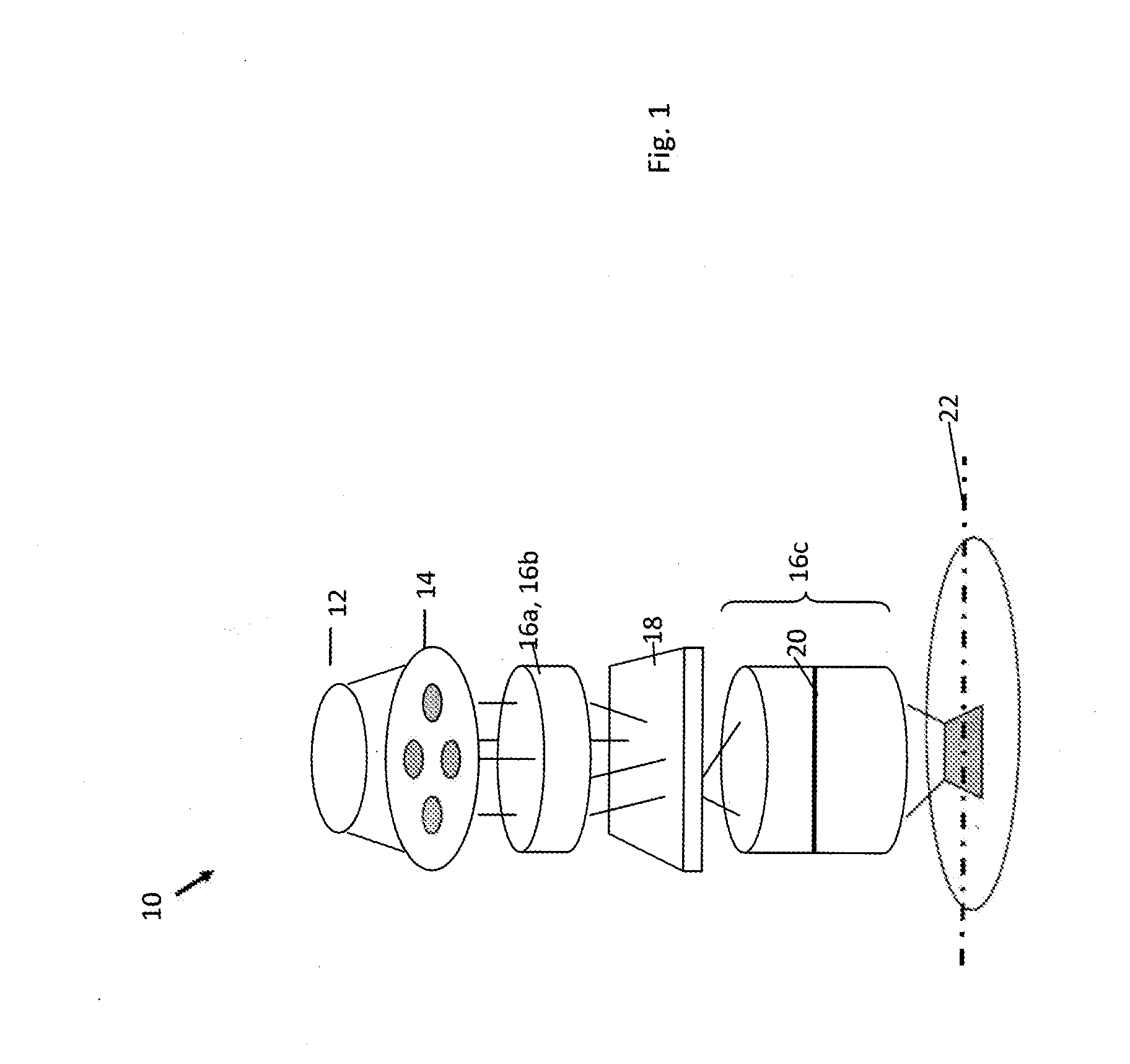

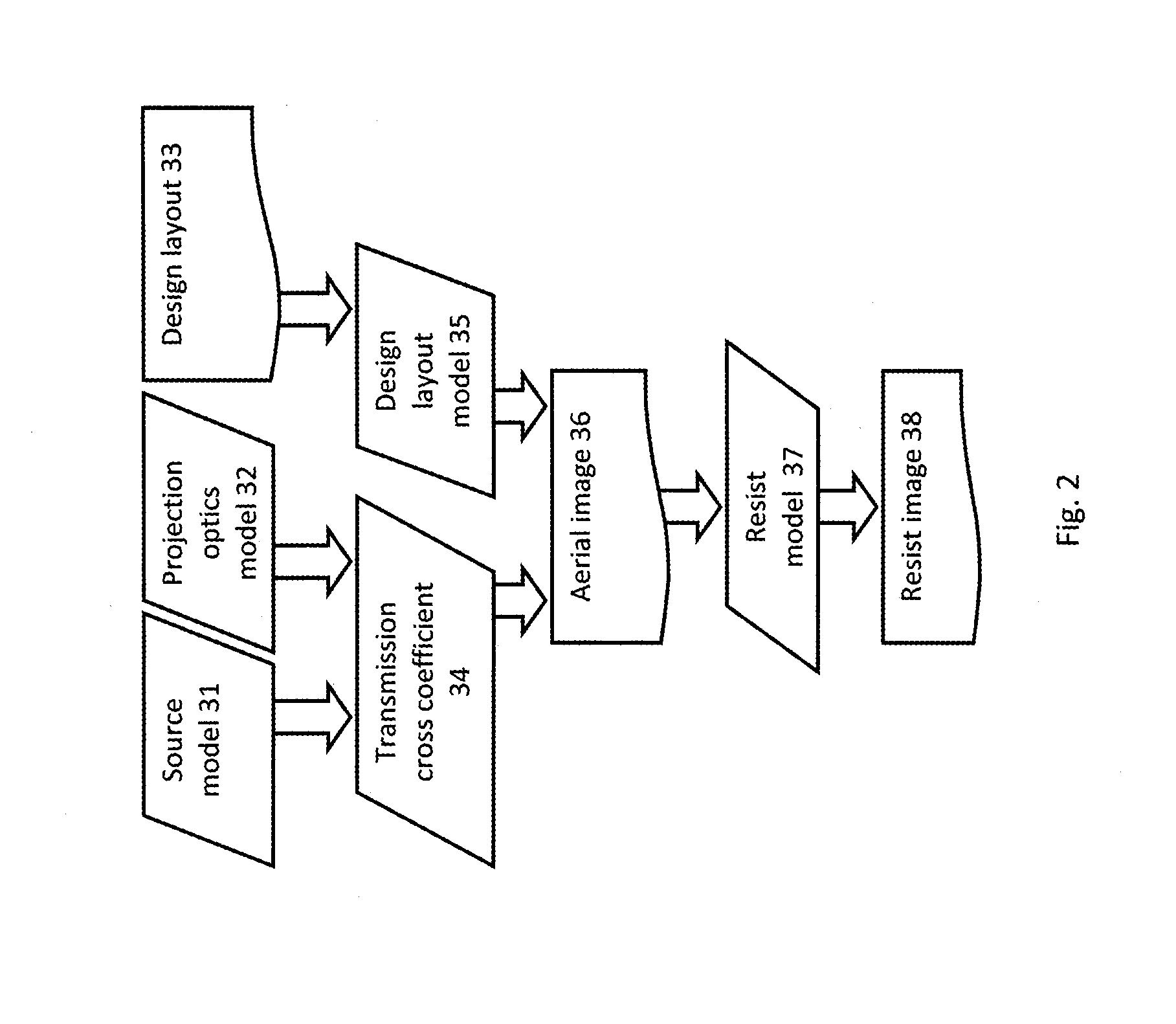

Optimization of Source, Mask and Projection Optics

ActiveUS20120117522A1Optimize and improveEasy to optimizePhotomechanical apparatusDesign optimisation/simulationProjection opticsWavefront

Embodiments of the present invention provide methods for optimizing a lithographic projection apparatus including optimizing projection optics therein, and preferably including optimizing a source, a mask, and the projection optics. The projection optics is sometimes broadly referred to as “lens”, and therefore the joint optimization process may be termed source mask lens optimization (SMLO). SMLO is desirable over existing source mask optimization process (SMO), partially because including the projection optics in the optimization can lead to a larger process window by introducing a plurality of adjustable characteristics of the projection optics. The projection optics can be used to shape wavefront in the lithographic projection apparatus, enabling aberration control of the overall imaging process. According to the embodiments herein, the optimization can be accelerated by iteratively using linear fitting algorithm or using Taylor series expansion using partial derivatives of transmission cross coefficients (TCCs).

Owner:ASML NETHERLANDS BV

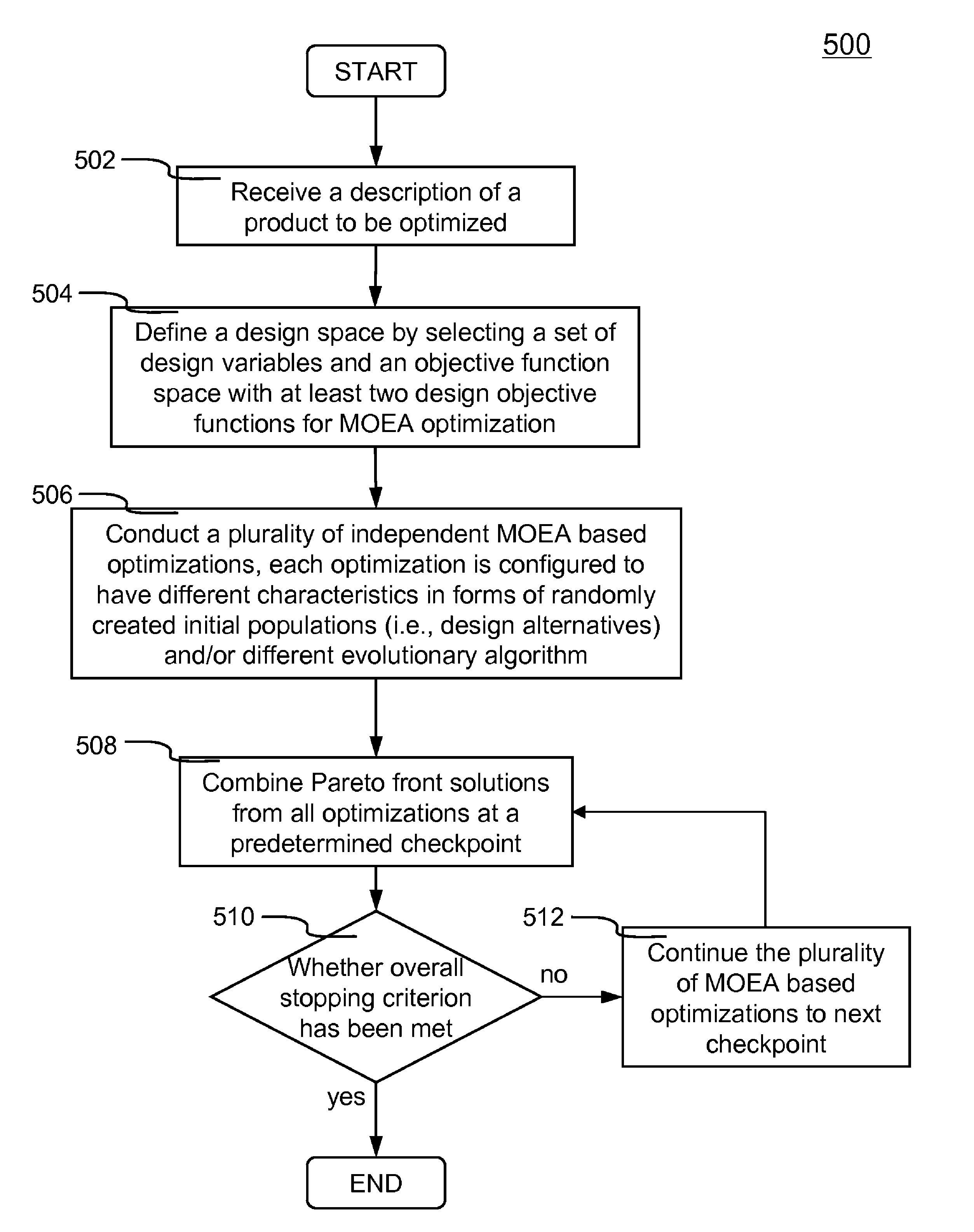

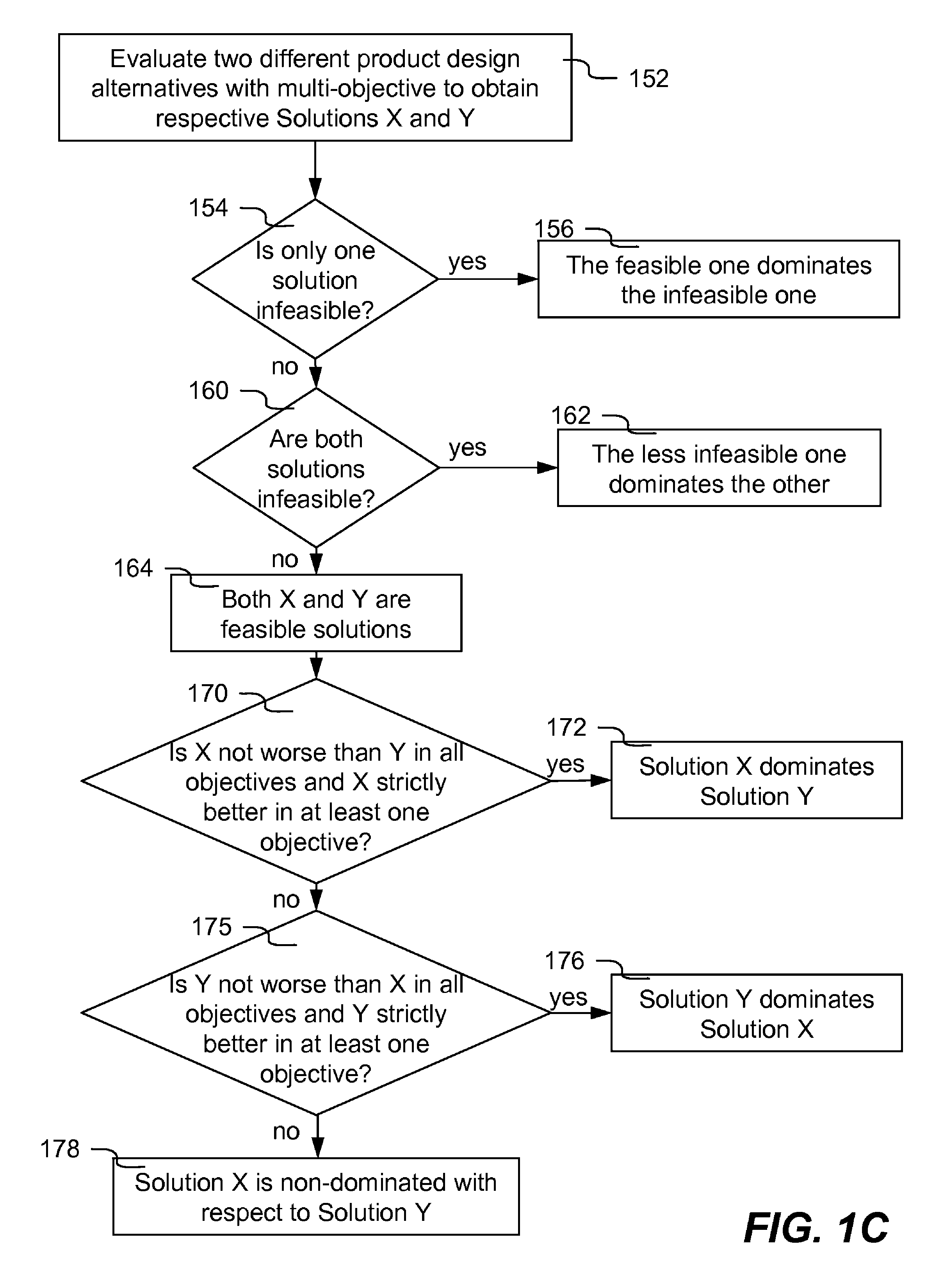

Multi-objective evolutionary algorithm based engineering design optimization

Systems and methods of obtaining a set of better converged and diversified Pareto optimal solutions in an engineering design optimization of a product (e.g., automobile, cellular phone, etc.) are disclosed. According to one aspect, a plurality of MOEA based engineering optimizations of a product is conducted independently. Each of the independently conducted optimizations differs from others with parameters such as initial generation and / or evolutionary algorithm. For example, populations (design alternatives) of initial generation can be created randomly from different seed of a random or pseudo-random number generator. In another, each optimization employs a particular revolutionary algorithm including, but not limited to, Nondominated Sorting Genetic Algorithm (NSGA-II), strength Pareto evolutionary algorithm (SPEA), etc. Furthermore, each independently conducted optimization's Pareto optimal solutions are combined to create a set of better converged and diversified solutions. Combinations can be performed at one or more predefined checkpoints during evolution process of the optimization.

Owner:ANSYS

Optimization system

A method for generating an optimized body structure is provided. A first topology optimization of a first body configuration is performed to generate a second body configuration. A subset of critical body components are identified based on load path values for the second body component and are parameterized. A second optimization is performed. The second optimization includes a low fidelity optimization for the geometry, the gauge and the grade of the critical body components, and a high fidelity optimization for the mass of each of the critical body components to generate an optimized set of critical body components. The optimized set of critical body components are combined with non-critical body components from the second body configuration to generate a final body configuration which is optimized for performance and weight.

Owner:NITED STATES STEEL CORP +1

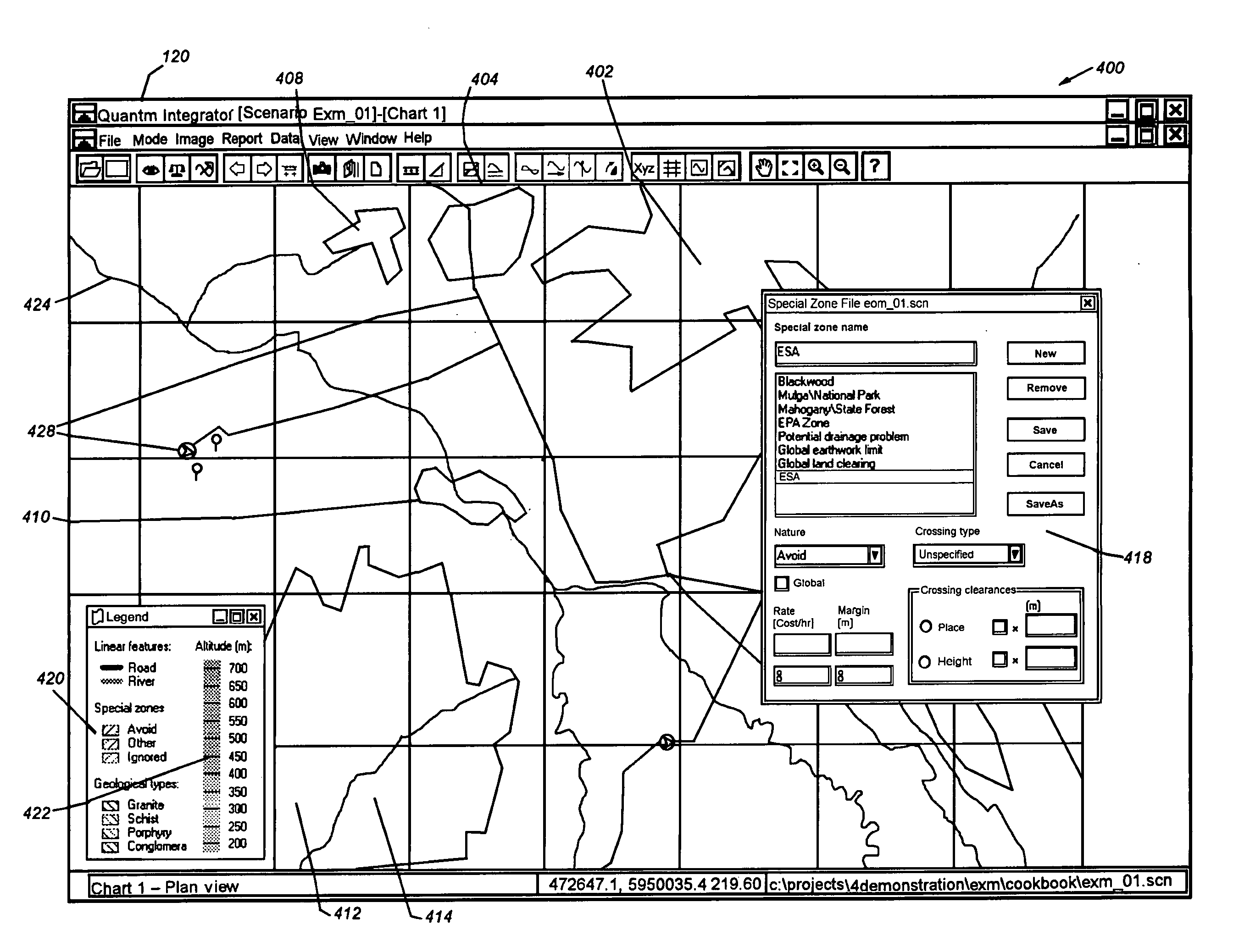

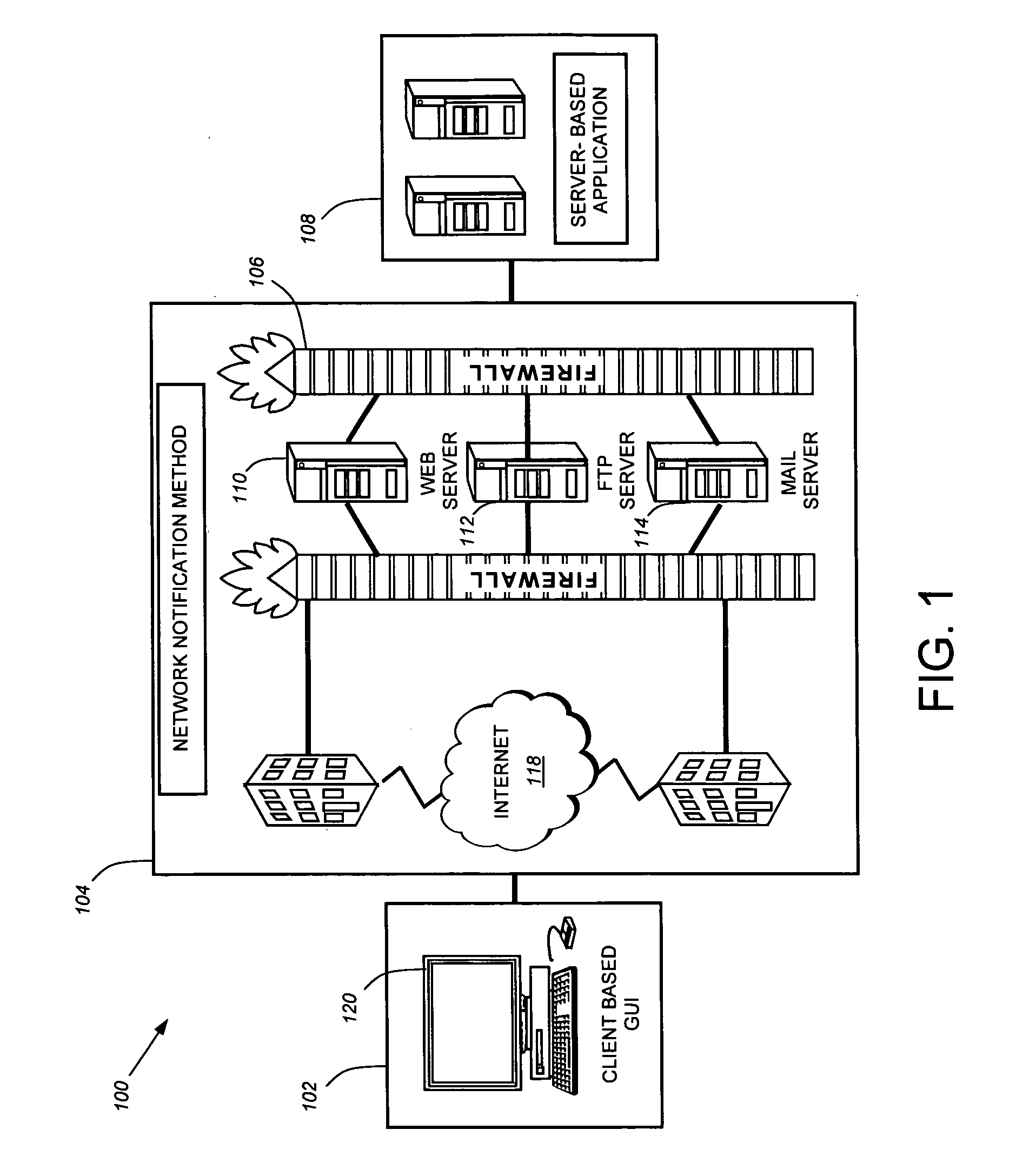

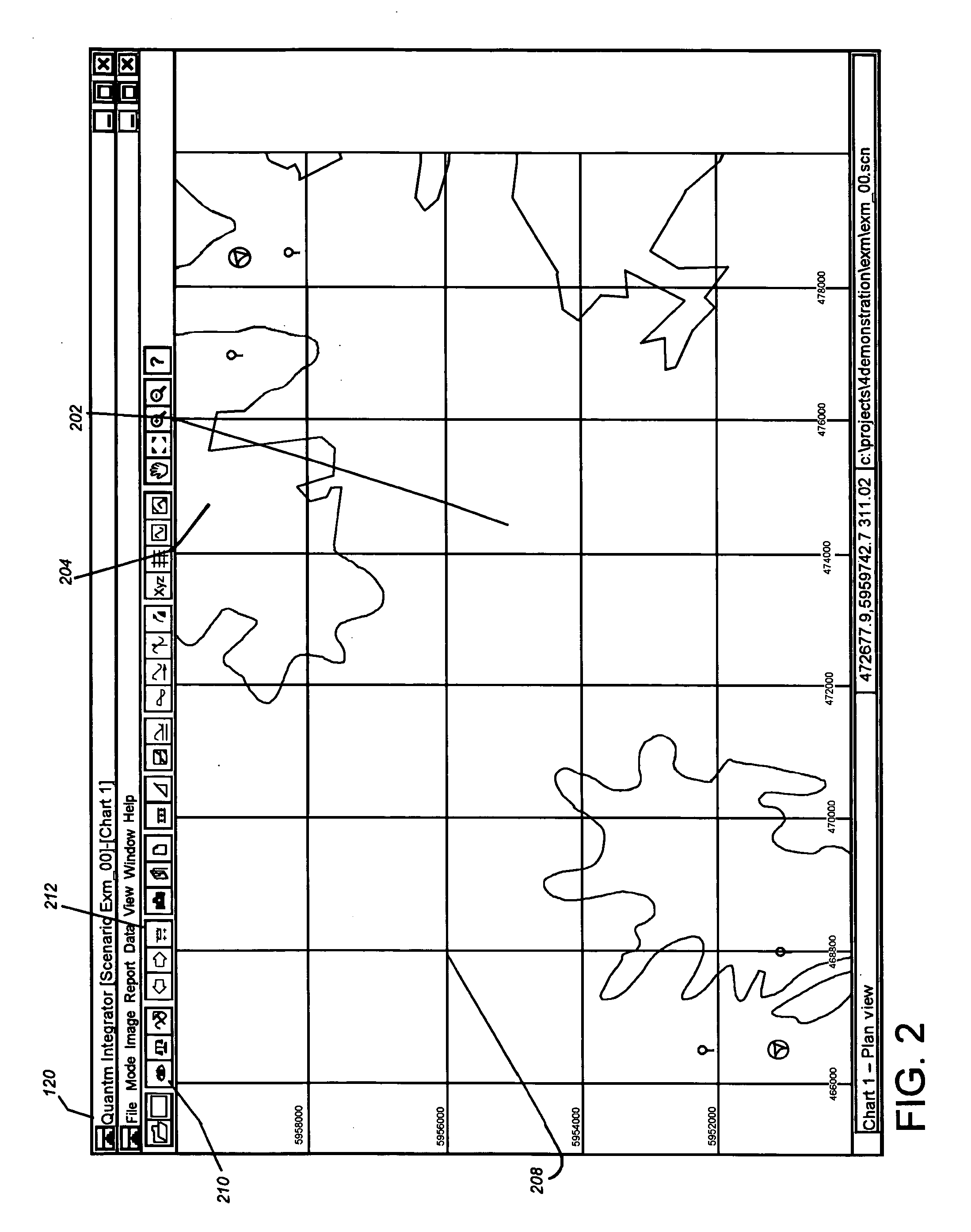

User interface for path determination system

InactiveUS20050268245A1Fast data transferGeometric CADError preventionGraphicsGraphical user interface

Aspects of the present invention relate to a client-based graphical user interface for infrastructure path determination. In embodiments, methods and systems are provided for a user interface and remote infrastructure planning. Methods and systems provide a user interface for allowing a user to select an object that relates to the determination of a path and upon selection of the object, triggering an action of a path determination system. Methods and systems are provided for establishing a connection to a portable computer device, accessing an infrastructure model remotely from the portable computer device, and interacting with the infrastructure model using the portable computer device.

Owner:TRIMBLE PLANNING SOLUTIONS

Optimization adjusting method and optimization adjusting apparatus

InactiveUS6148274AFast and efficient optimal solution estimationEffective estimateProgram control using stored programsDigital computer detailsTheoretical computer scienceComparative evaluation

At the start of a process, an information presenting section presents information expressed by a solution vector, while an auxiliary information presenting section presents information for facilitating comparative evaluation of multiple pieces of information being presented simultaneously. Based on these pieces of information, the user evaluates each solution vector. A model estimation executing section generates an evaluation model for an adjustment process from a user evaluation history, and thereafter, a model evaluation calculating section performs evaluation using the evaluation model. A fitness calculating section calculates fitness from the evaluation made by the user or by the model, and in accordance with the thus calculated fitness, a recombination operation section performs an arithmetical recombination operation. The above process is iteratively performed to carry out optimum adjustment of solution vectors.

Owner:PANASONIC CORP

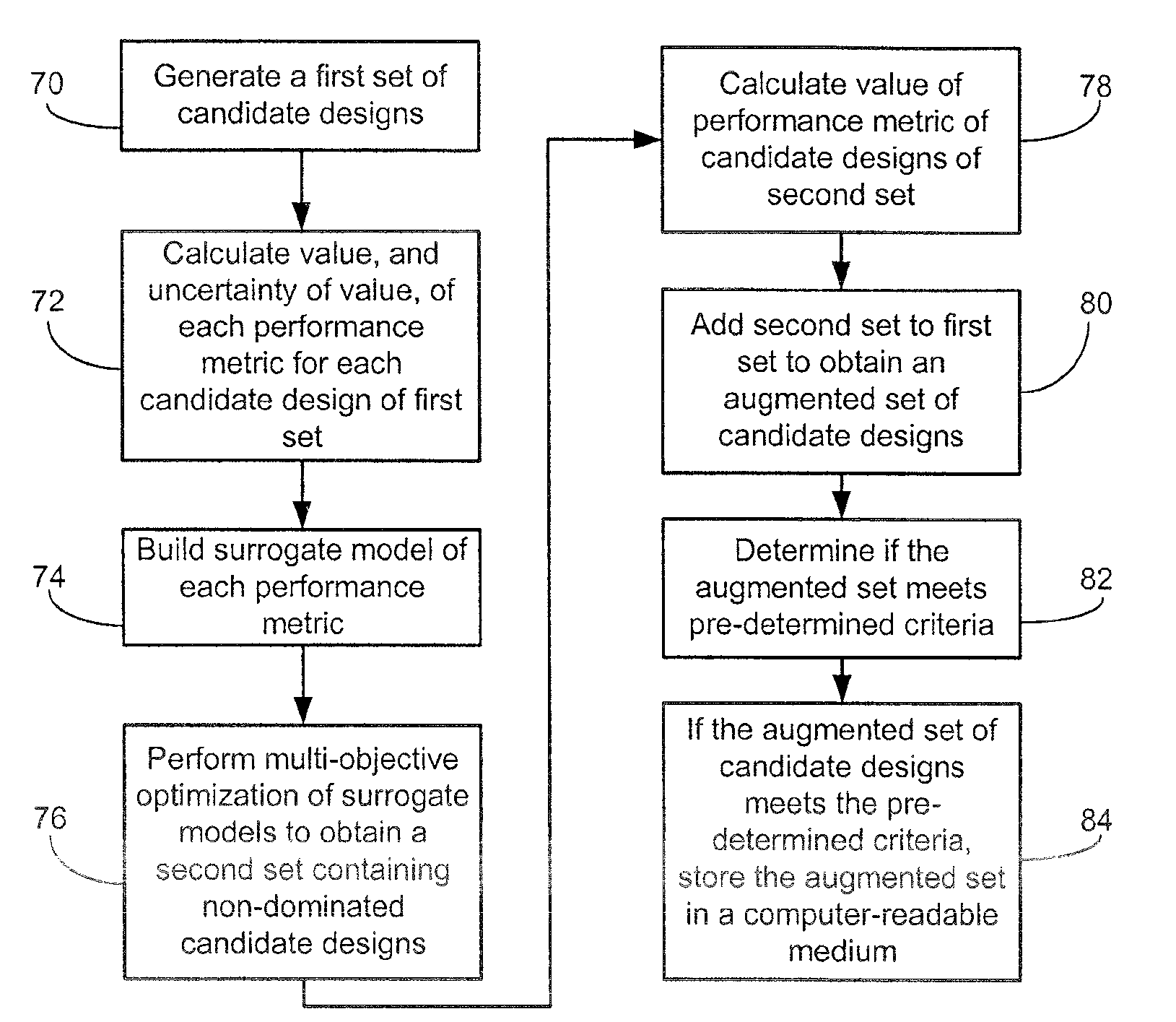

Model-building optimization

ActiveUS20090083680A1Maximizing the uncertainty of the surrogate modelIncrease computational costCAD circuit designMulti-objective optimisationAlgorithmSurrogate model

A method and system for performing multi-objective optimization of a multi-parameter design having several variables and performance metrics. The optimization objectives include the performance values of surrogate models of the performance metrics and the uncertainty in the surrogate models. The uncertainty is always maximized while the performance metrics can be maximized or minimized in accordance with the definitions of the respective performance metrics. Alternatively, one of the optimization objectives can be the value of a user-defined cost function of the multi-parameter design, the cost function depending from the performance metrics and / or the variables. In this case, the other objective is the uncertainty of the cost function, which is maximized. The multi-parameter designs include electrical circuit designs such as analog, mixed-signal, and custom digital circuits.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

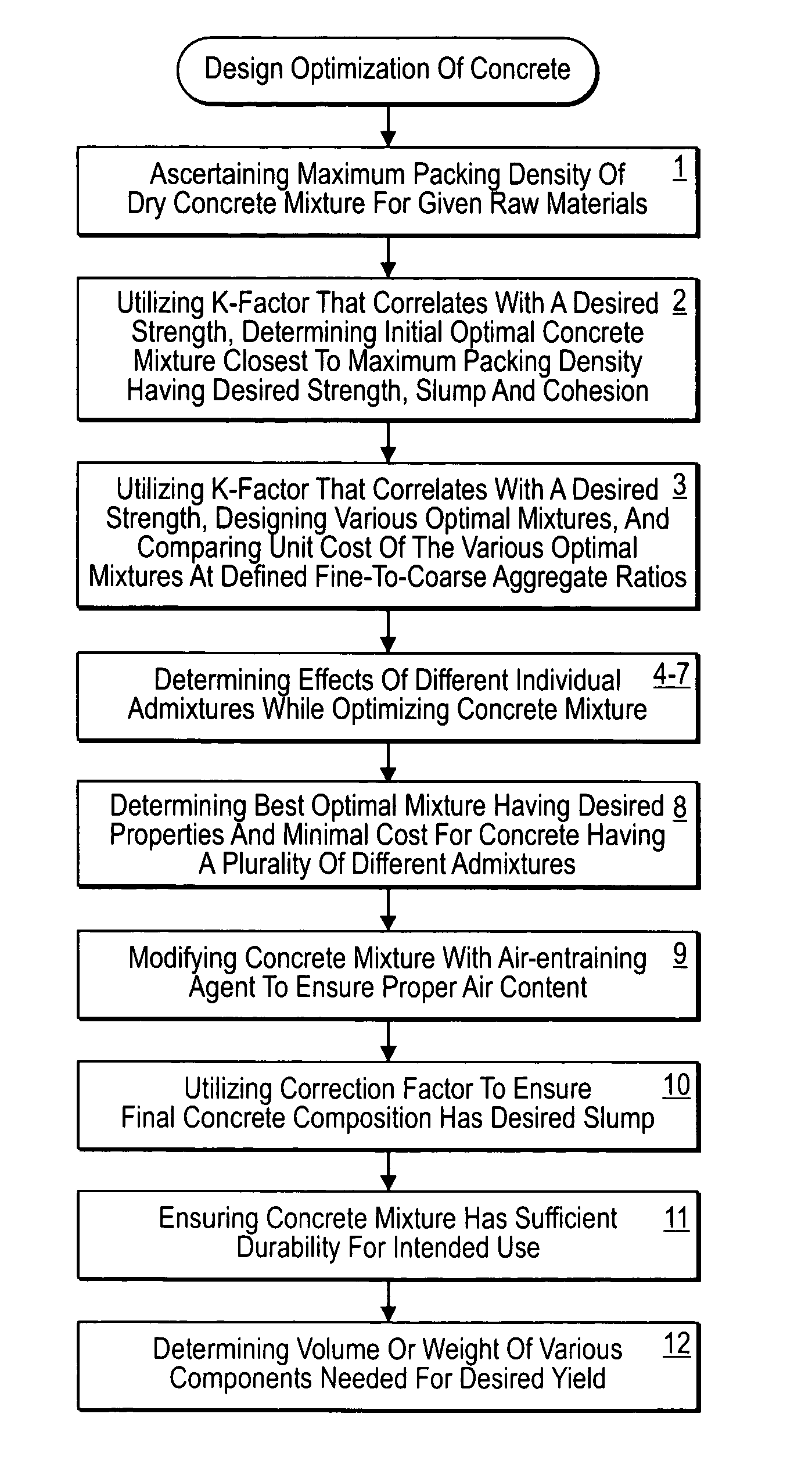

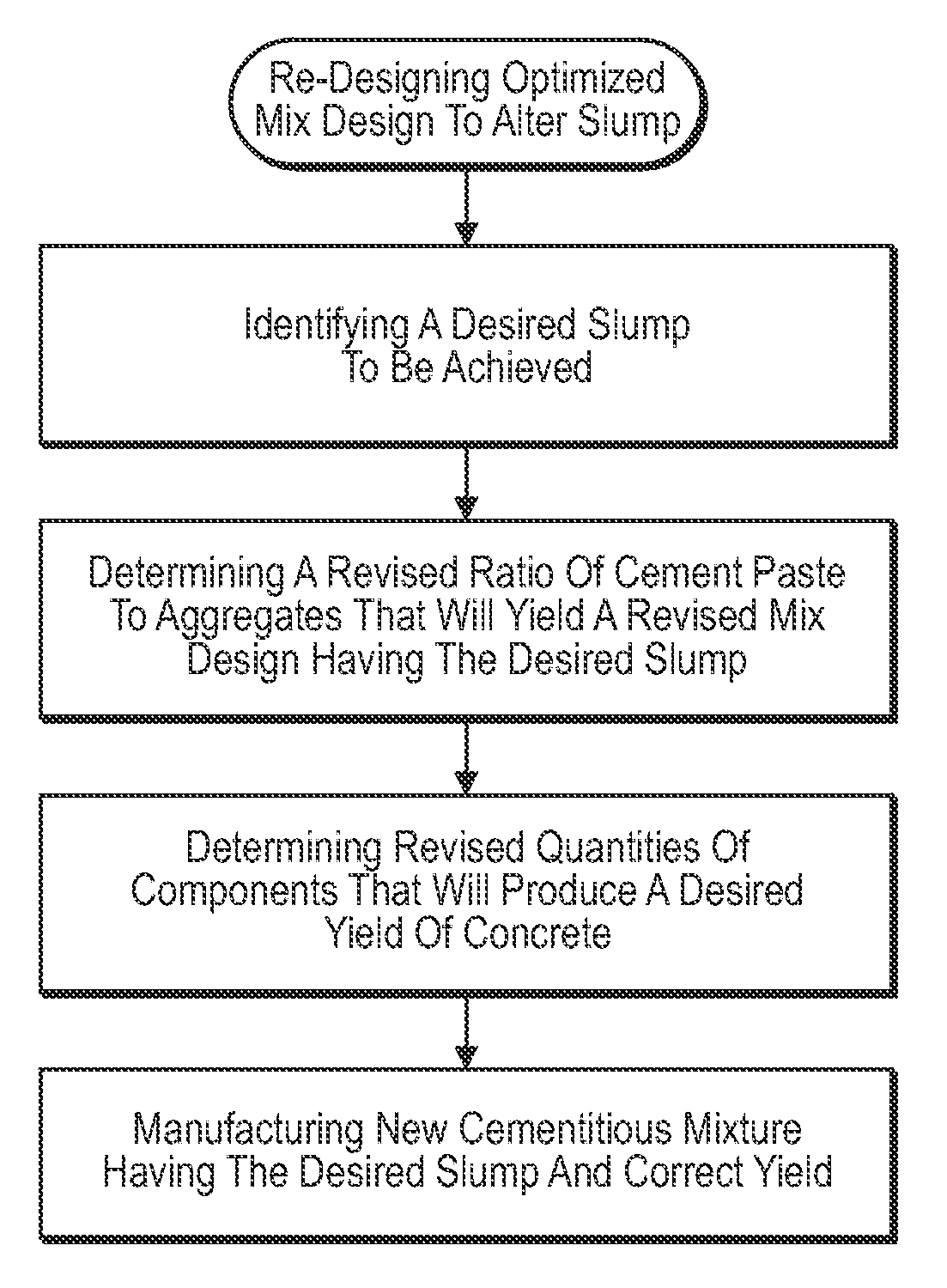

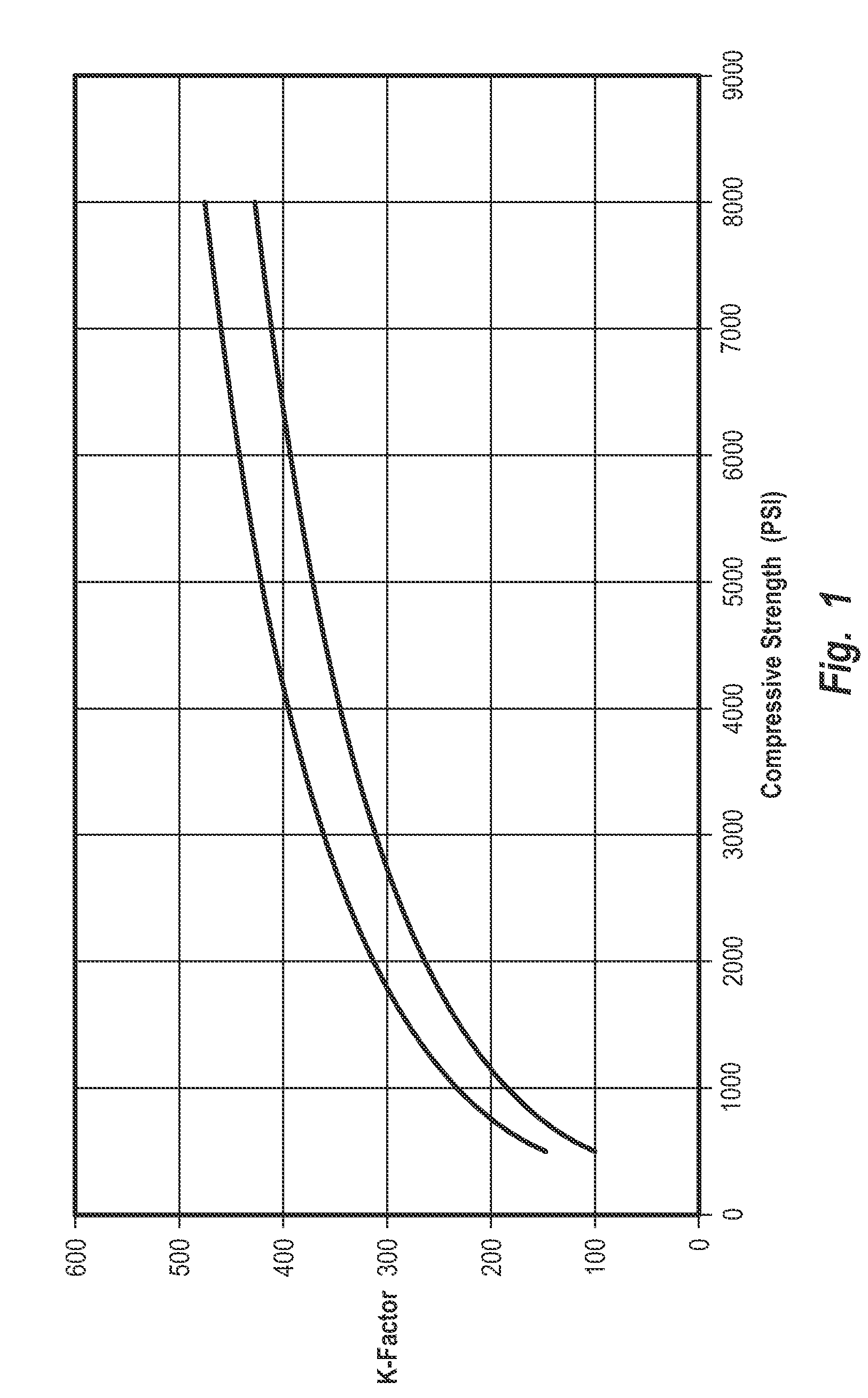

Methods and systems for redesigning pre-existing concrete mix designs and manufacturing plants and design-optimizing and manufacturing concrete

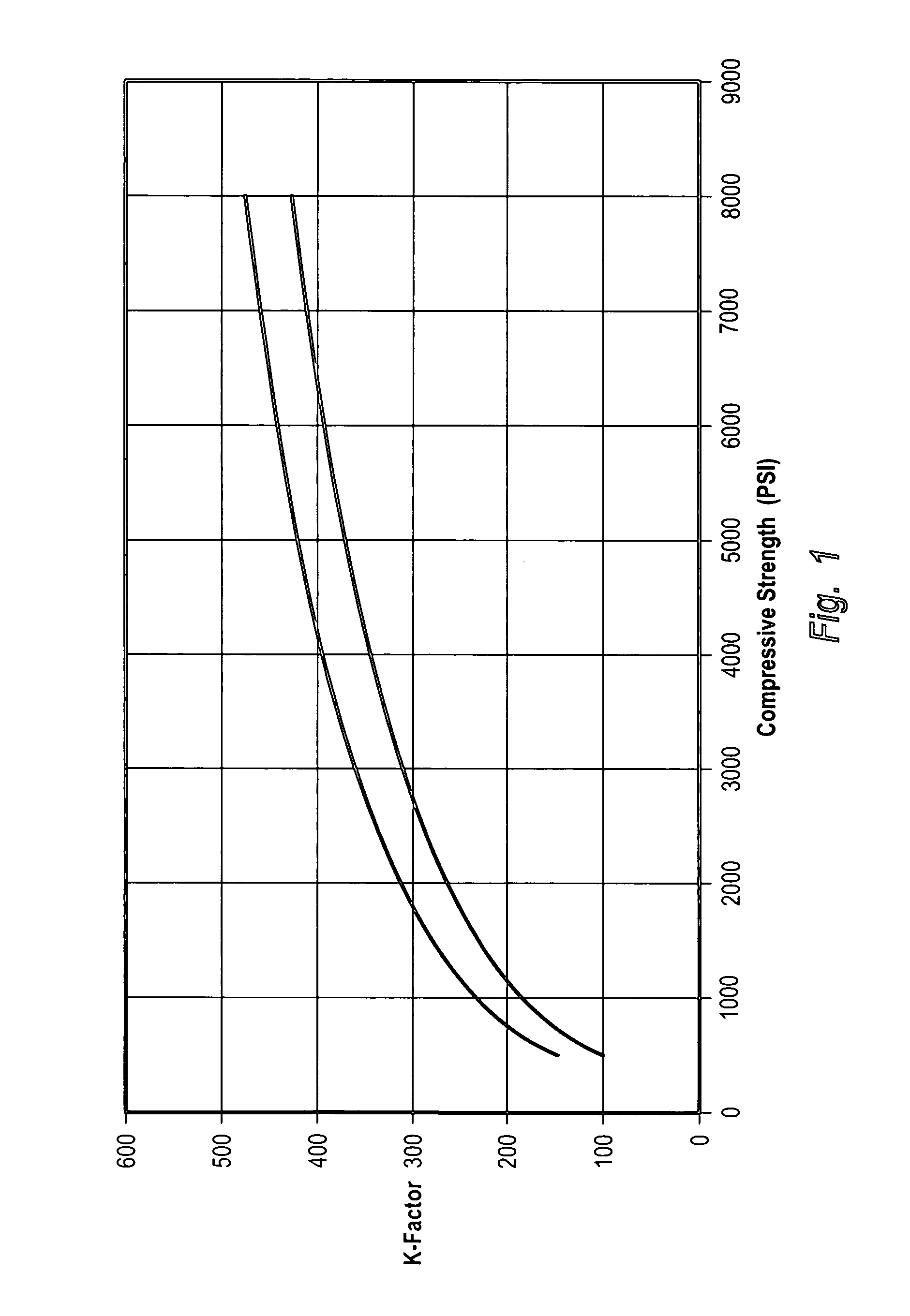

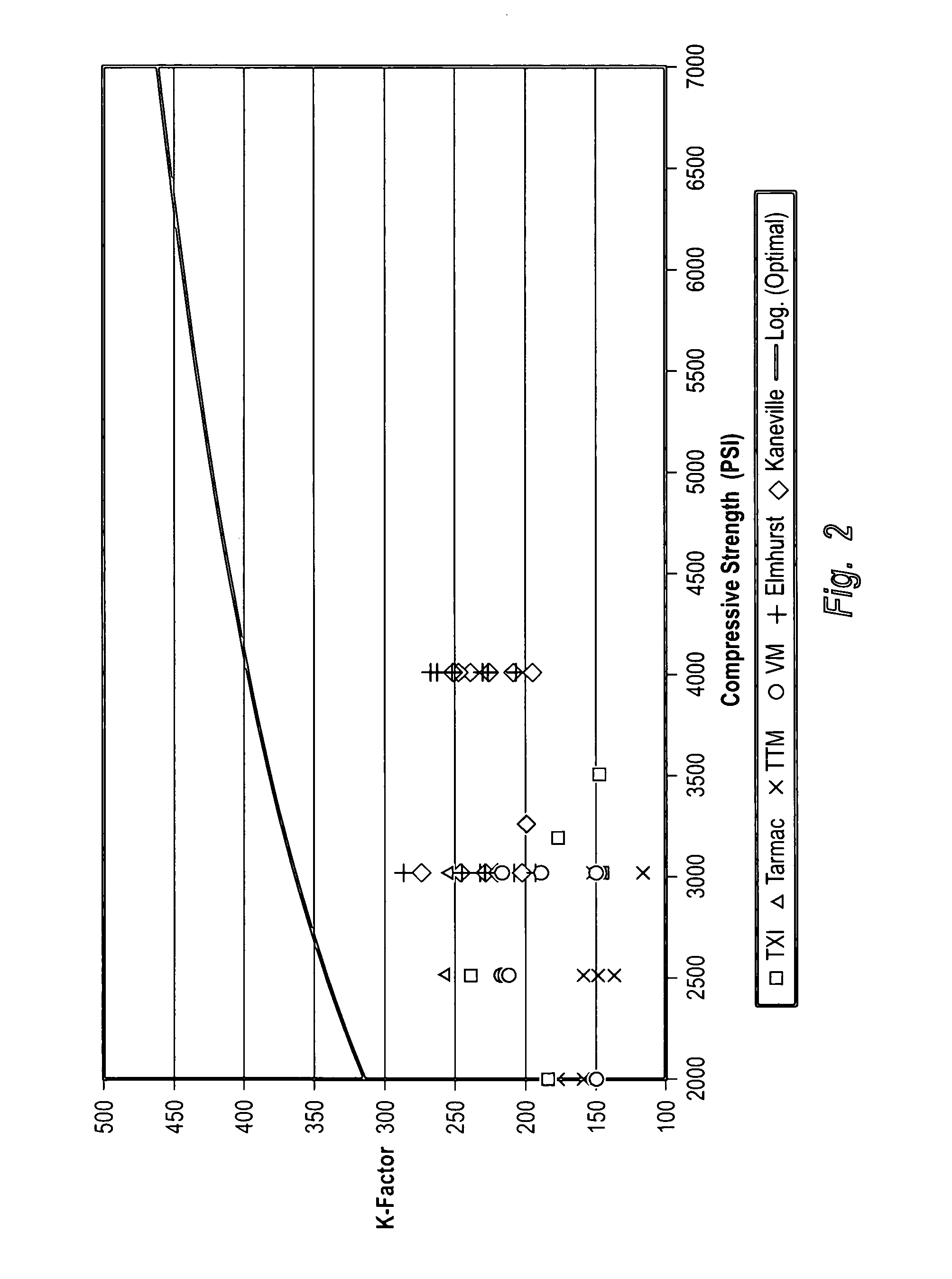

InactiveUS20060287773A1Accurate predictionEfficient identificationGeometric CADSampled-variable control systemsEngineeringMultiple case

Design optimization methods can be used to design concrete mixtures having optimized properties, including desired strength and slump at minimal cost. The design optimization methods use a computer-implemented process that is able to design and virtually “test” millions of hypothetical concrete compositions using mathematical algorithms that interrelate a number of variables that affect strength, slump, cost and other desired features. The design optimization procedure utilizes a constant K (or K factor) within Feret's strength equation that varies (e.g., logarithmically) with concrete strength for any given set of raw material inputs and processing equipment. That means that the binding efficiency or effectiveness of hydraulic cement increases with increasing concentration so long as the concrete remains optimized. The knowledge of how the K factor varies with binding efficiency and strength is a powerful tool that can be applied in multiple circumstances. A concrete manufacturing process may include accurately measuring the raw materials to minimize variation between predicted and actual strength, as well as carefully controlling water content throughout the manufacturing and delivery process.

Owner:ICRETE LLC

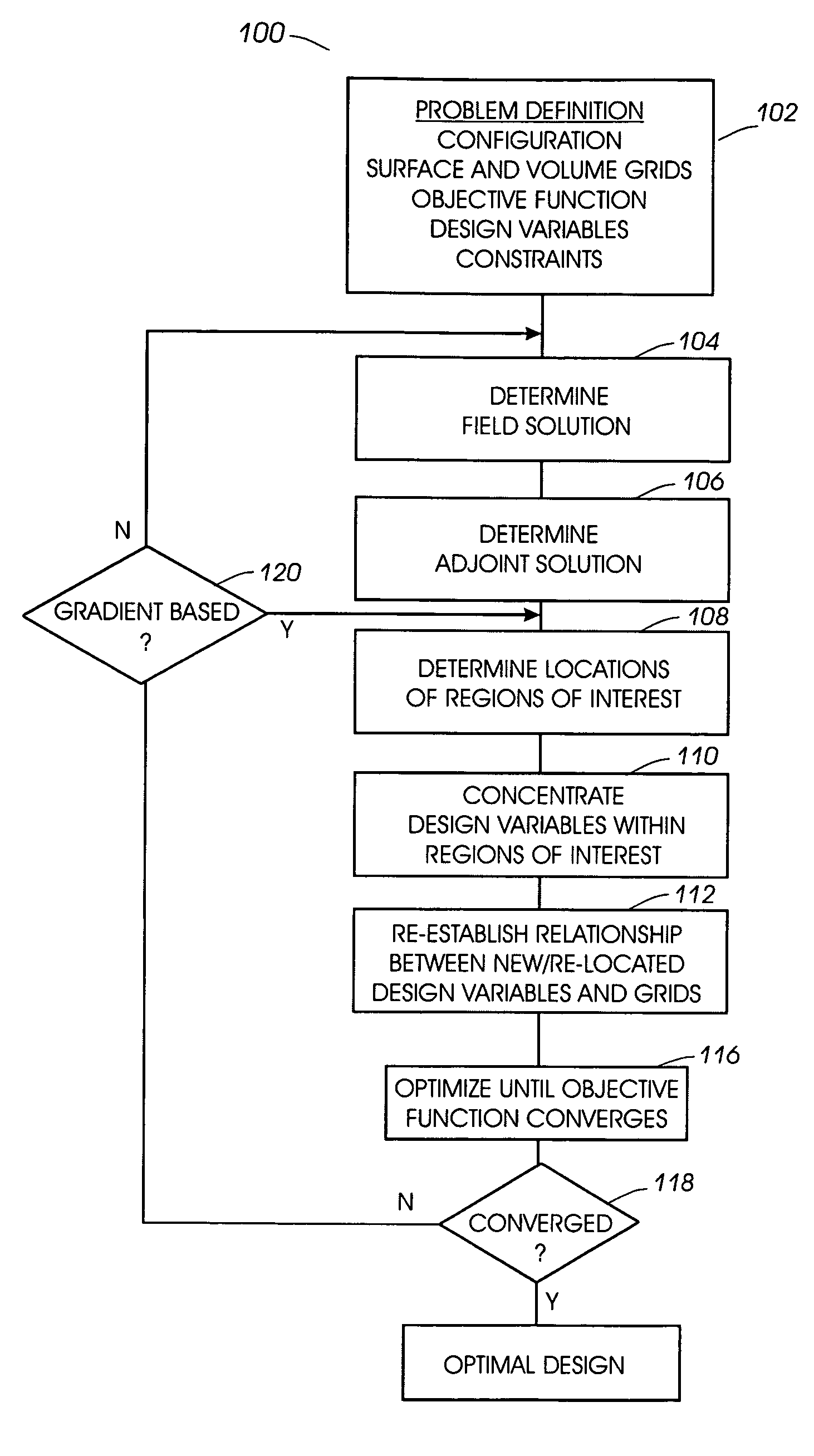

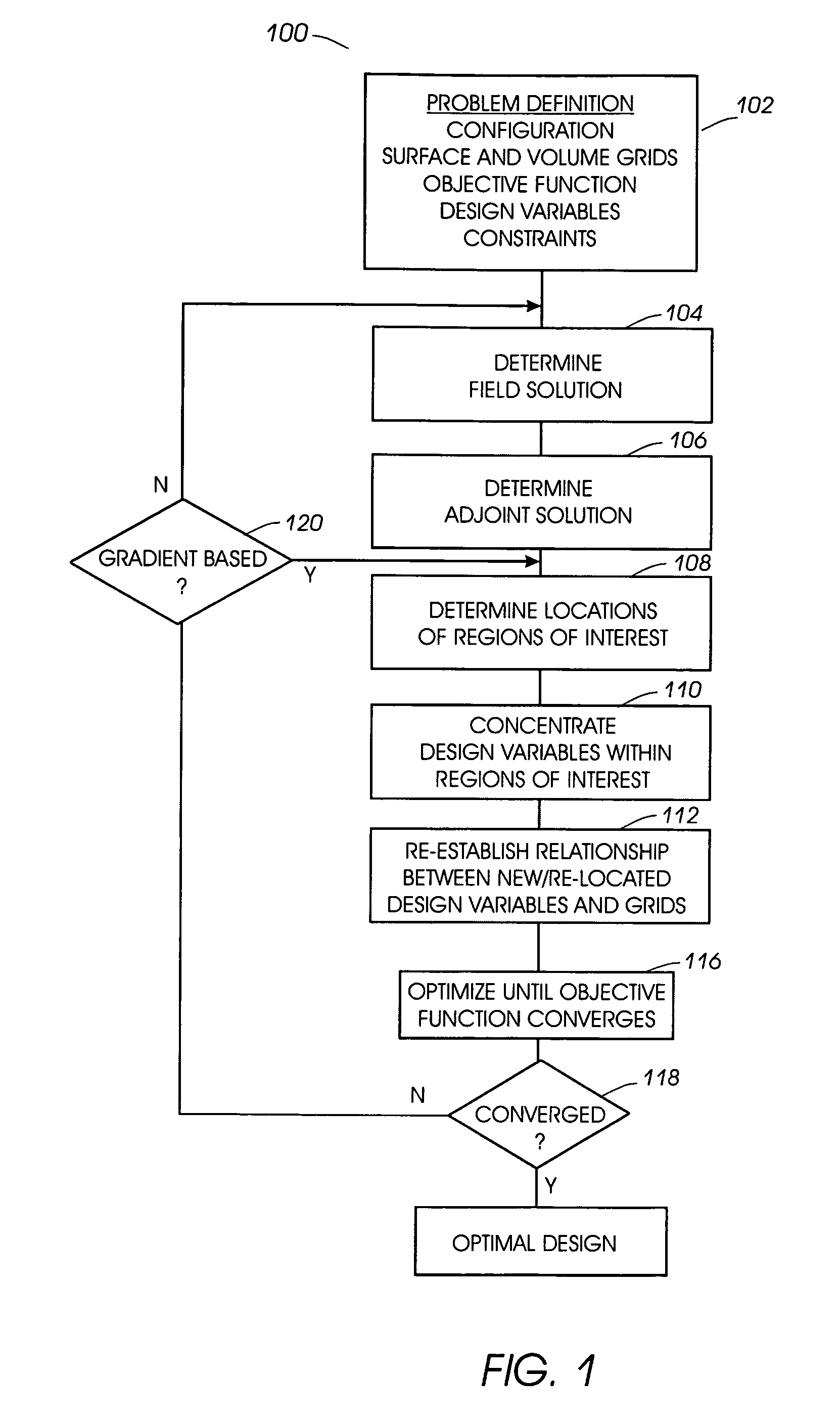

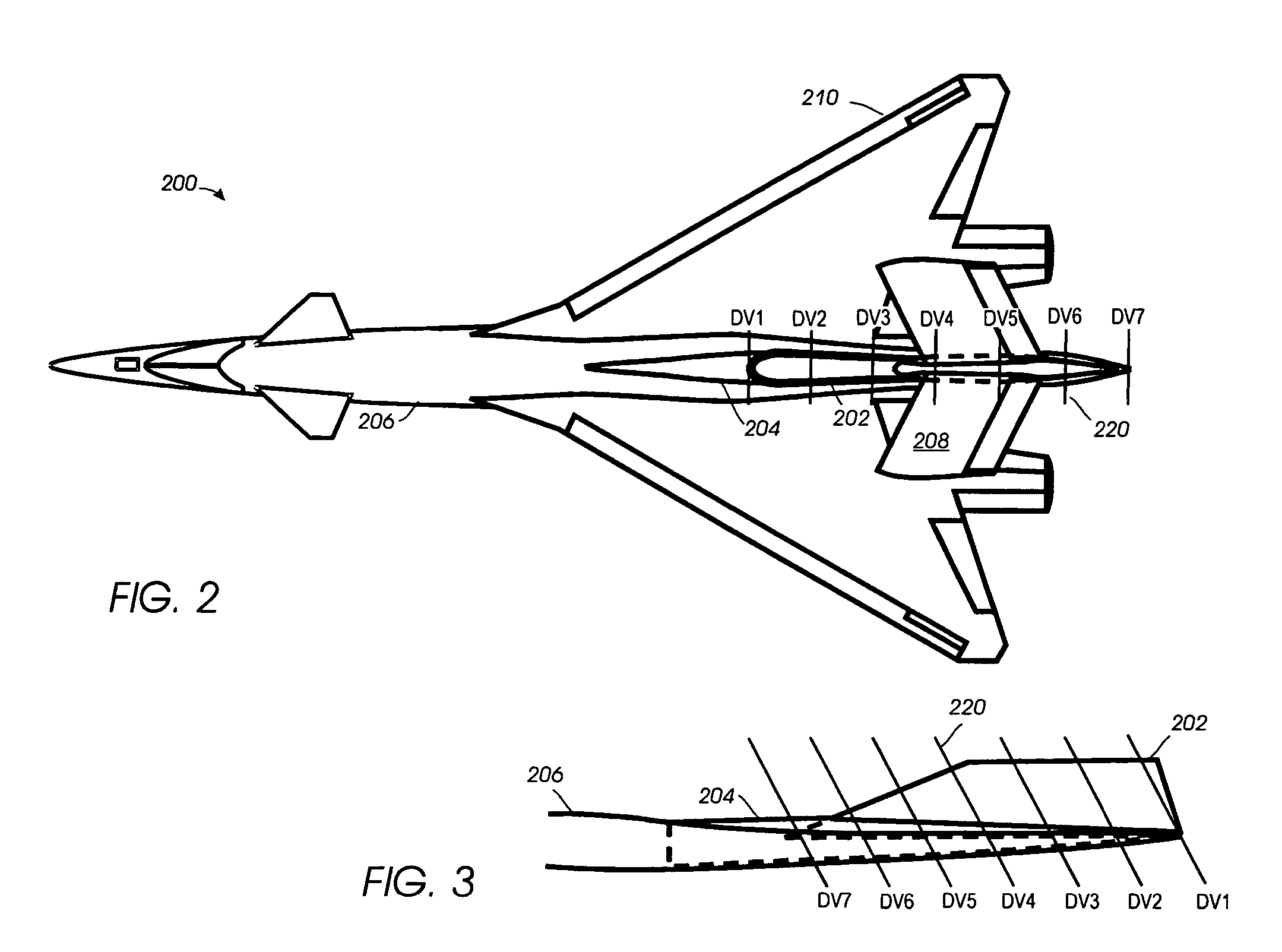

Adjoint-based design variable adaptation

InactiveUS20060058985A1Geometric CADComputation using non-denominational number representationEngineeringRegion of interest

Owner:SUPERSONIC AEROSPACE INT

Manufacturing system using topology optimization design software, novel three-dimensional printing mechanisms and structural composite materials

ActiveUS20150239178A1Adjusting operationGeometric CADProgramme controlThermoplasticComputer Aided Design

Owner:ARMSTRONG NATHAN

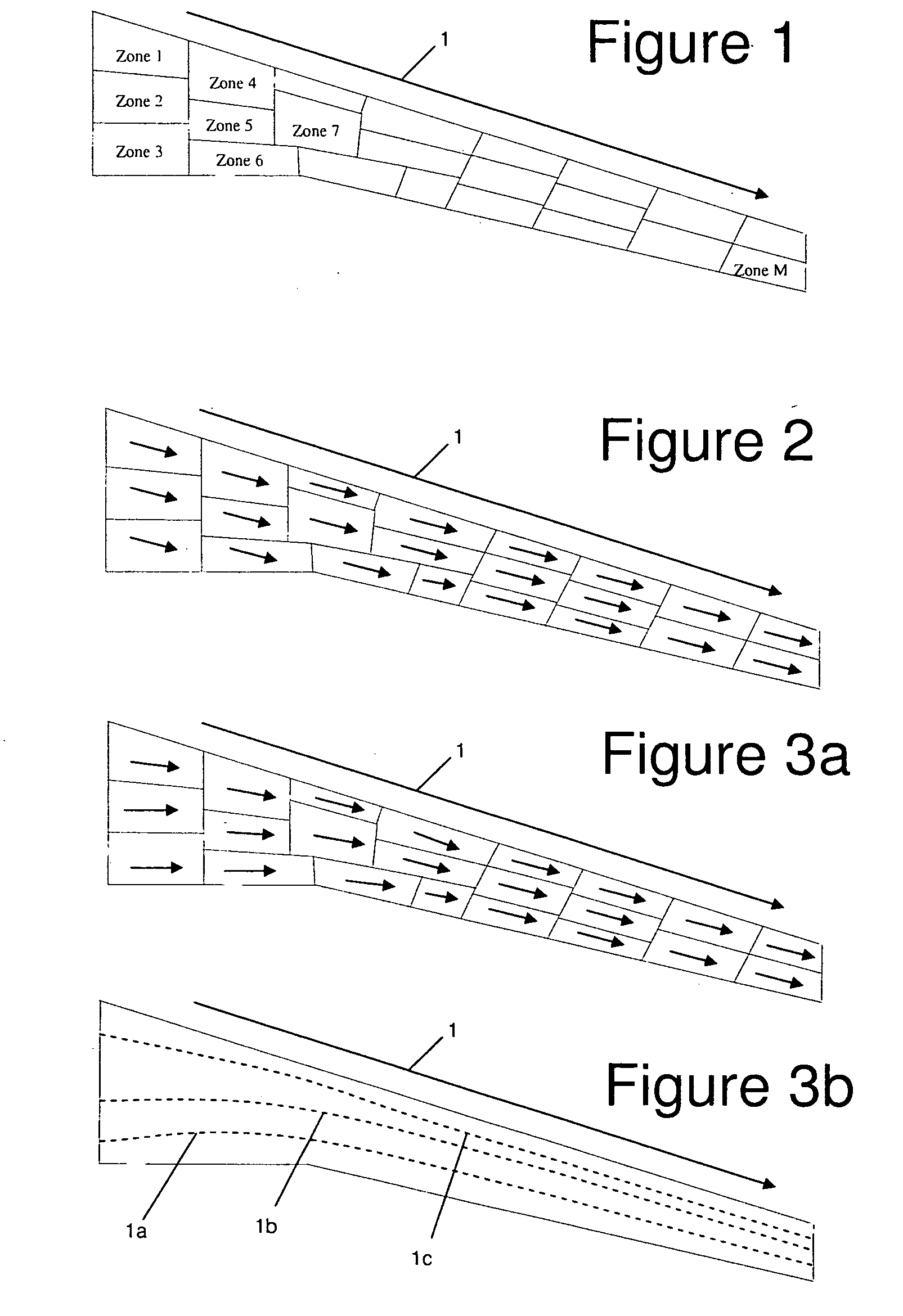

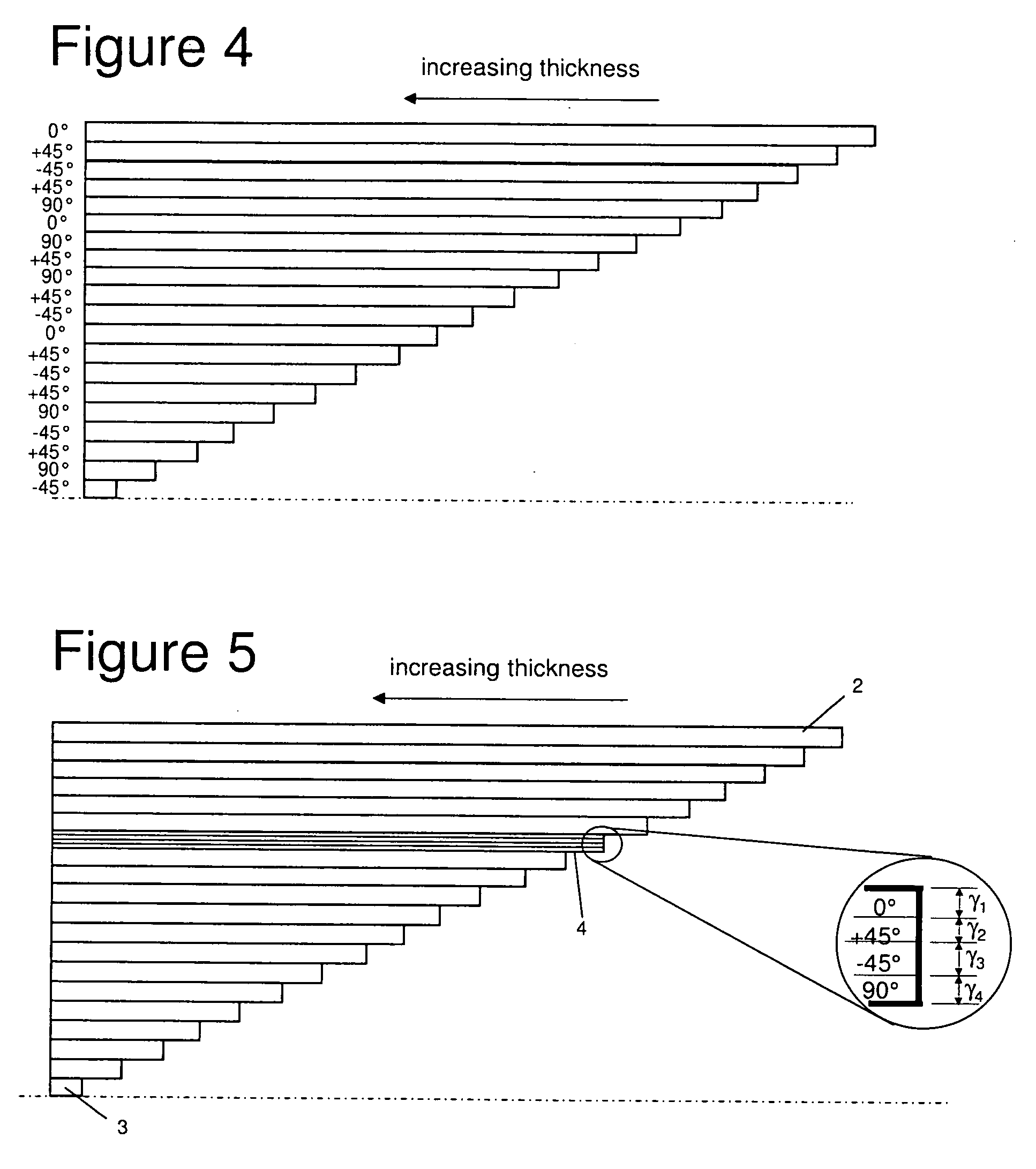

Method of designing a composite laminate

InactiveUS20100121625A1Sufficient capabilityHigh strengthGeometric CADComputation using non-denominational number representationComposite laminatesEngineering

A method of designing a composite laminate, the laminate comprising a plurality of zones, each zone comprising a plurality of plies of composite material, each ply in each zone having a respective ply orientation angle. A global stacking sequence is determined for the laminate, the global stacking sequence comprising a sequence of stacking sequence elements. A local laminate thickness is determined for each zone. A local stacking sequence is then determined for each zone by extracting a subsequence of stacking sequence elements from the global stacking sequence. The global stacking sequence and the local laminate thicknesses are determined together in an optimisation process in which multiple sub-ply selection variables are assigned to each stacking sequence element, each sub-ply selection variable representing the density or sub-ply thickness for a respective candidate ply orientation angle. Optimal values are determined for the sub-ply selection variables and the local laminate thicknesses. A single one of the sub-ply selection variables is assigned to each stacking sequence element thereby forcing a discrete choice of global ply orientation angle for each stacking sequence element.

Owner:AIRBUS OPERATIONS LTD

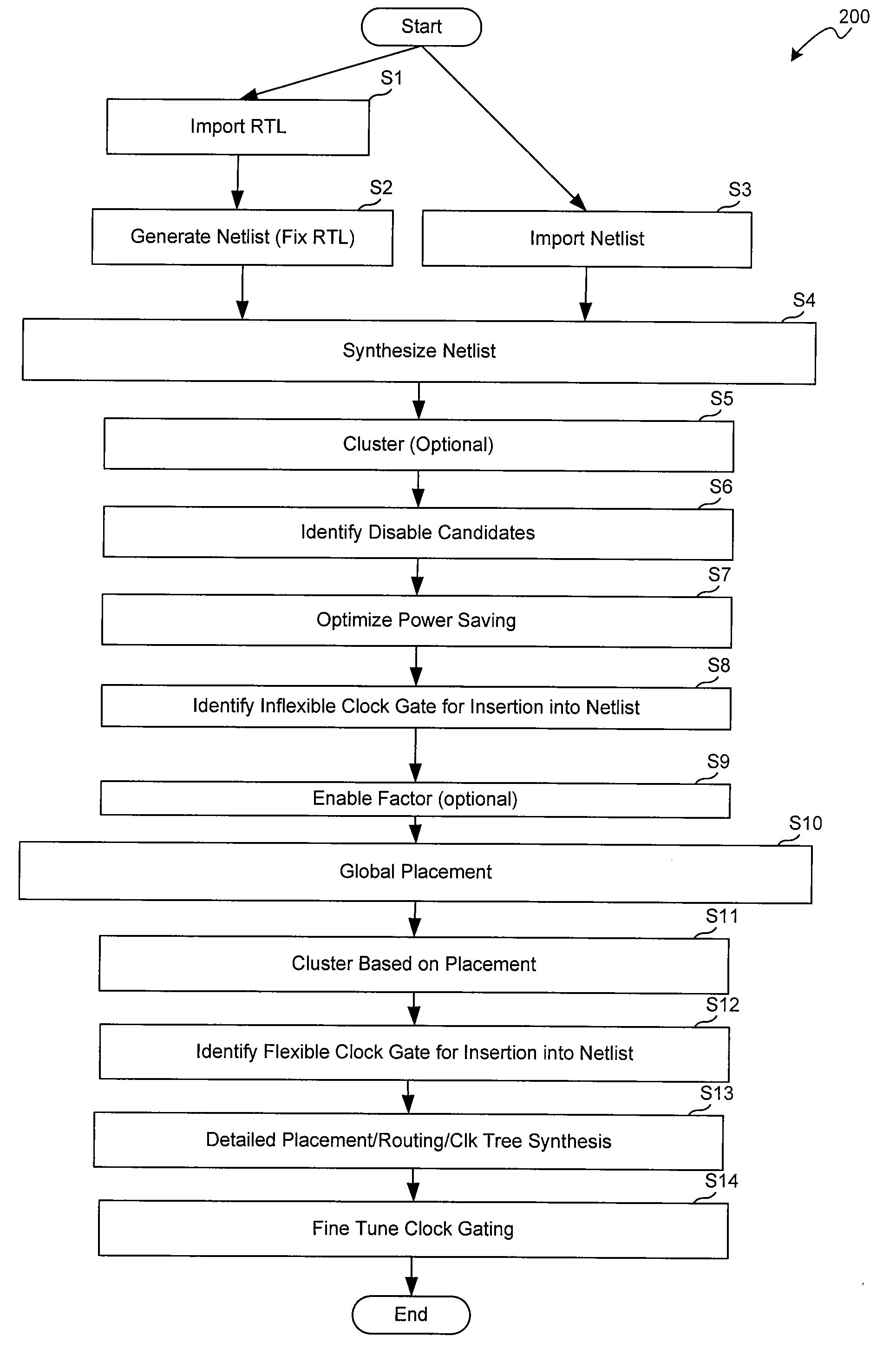

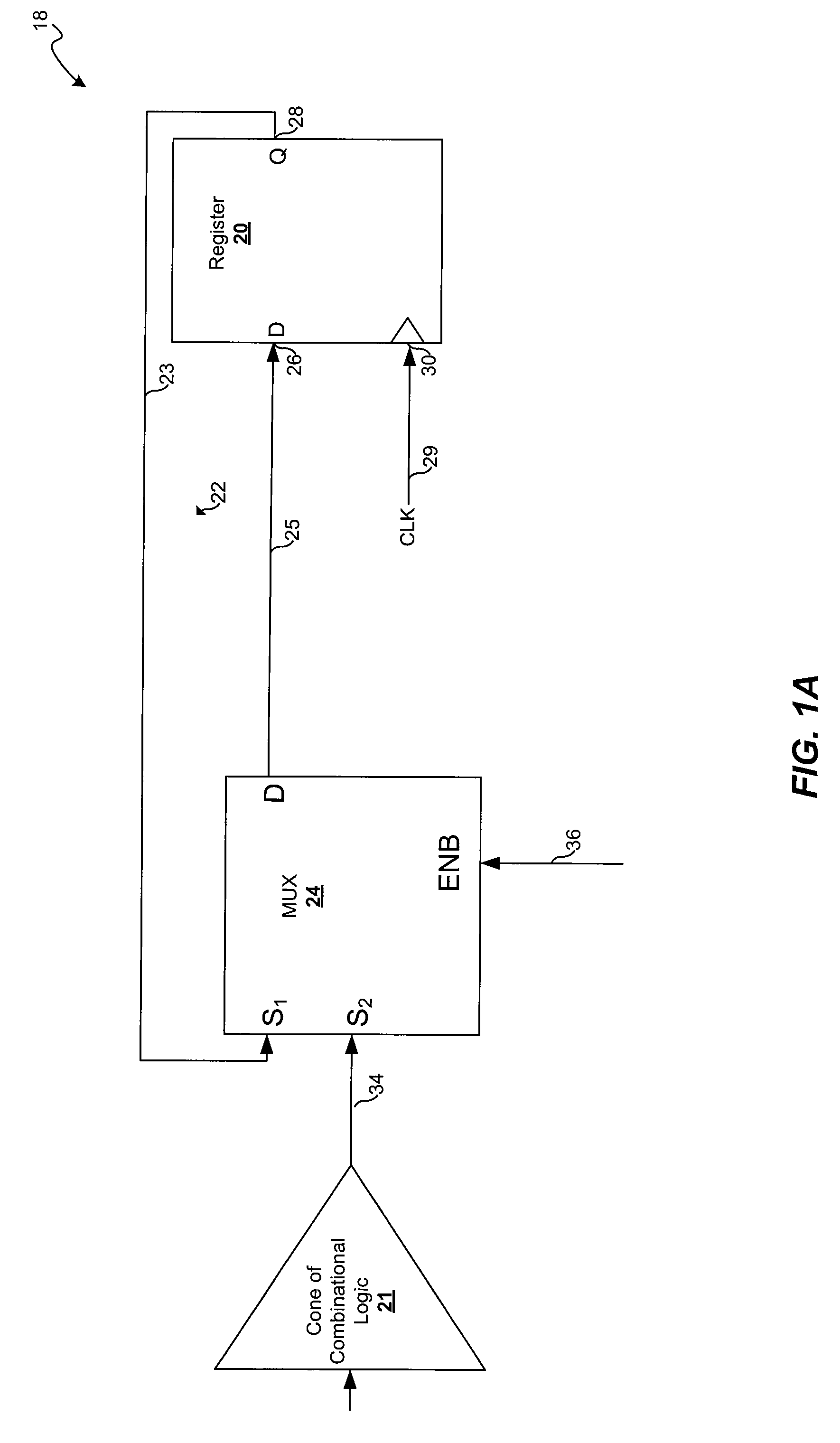

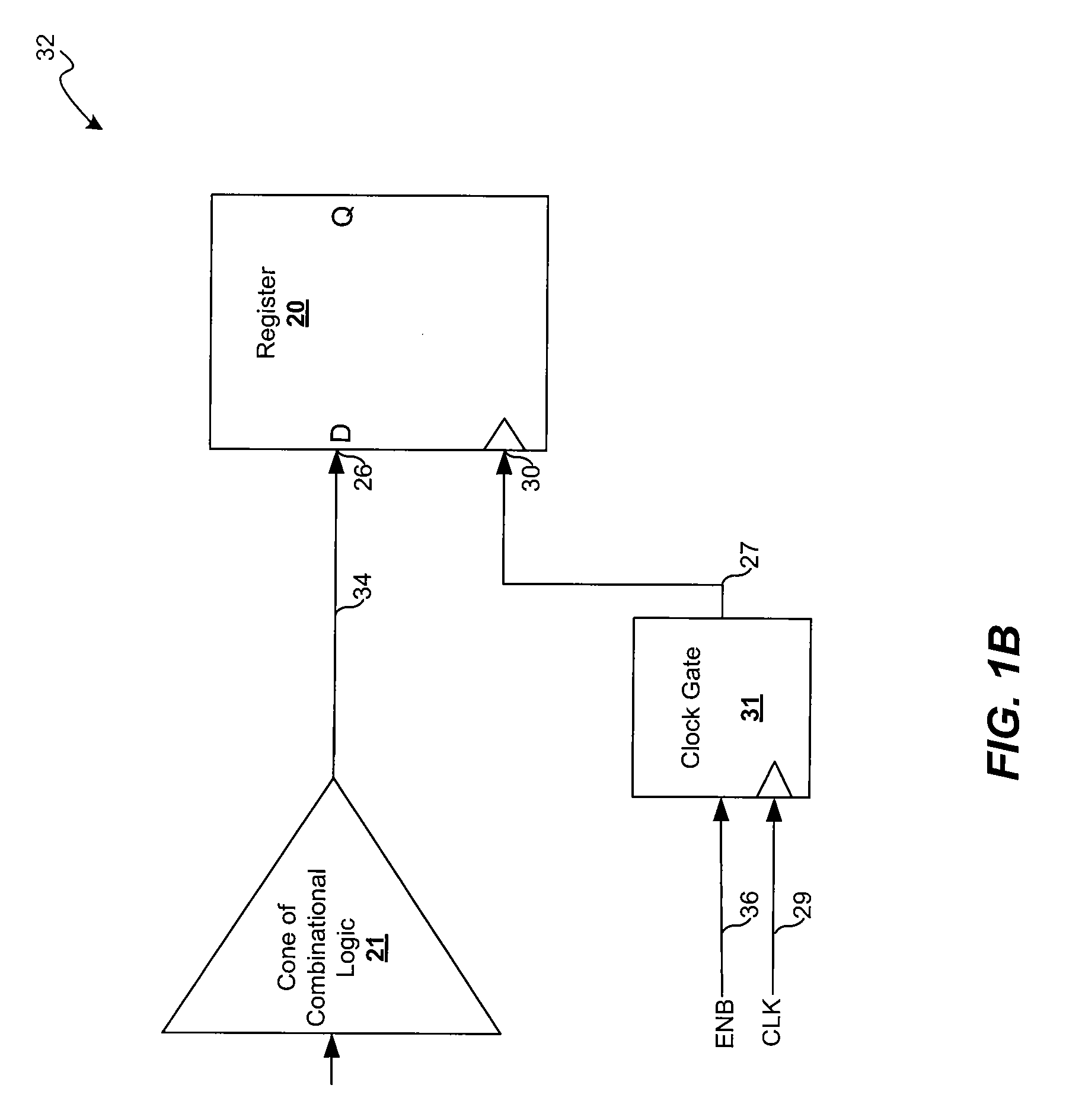

Method For Optimized Automatic Clock Gating

ActiveUS20080301594A1Reduce Switching Power ConsumptionConsumes less powerCAD circuit designMulti-objective optimisationComputer architectureCombinational logic

A method of optimizing clock-gated circuitry in an integrated circuit (IC) design is provided. A plurality of signals which feed into enable inputs of a plurality of clock gates is determined, where the clock gates gate a plurality of sequential elements in the IC design. Combinational logic which is shared among the plurality of signals is identified. The clock-gated circuitry is transformed into multiple levels of clock-gating circuitry based on the shared combinational logic.

Owner:SYNOPSYS INC

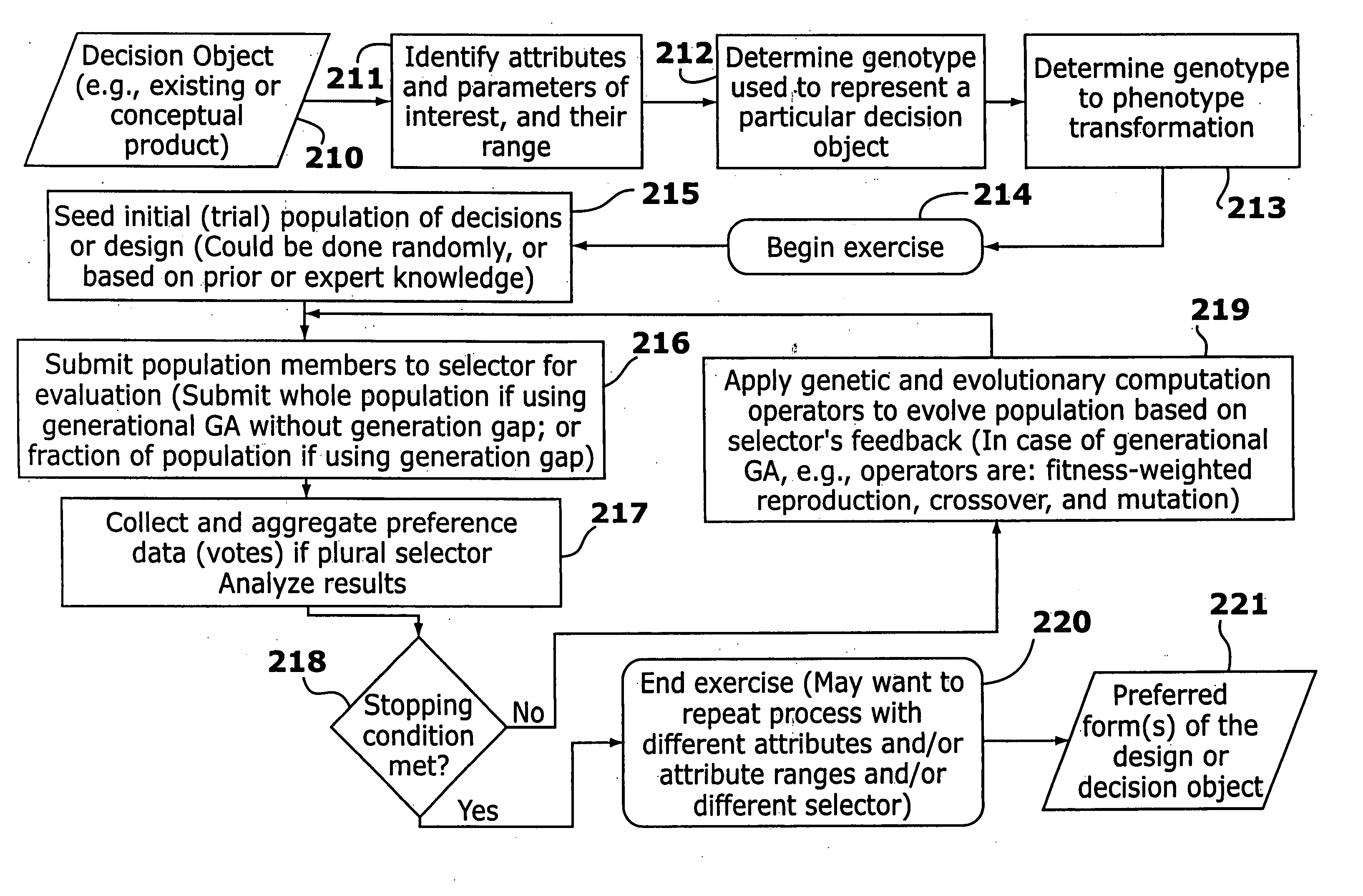

Method and apparatus for evolutionary design

InactiveUS20060080268A1Control the interpersonal dynamics among the participantsEasy time managementDigital computer detailsProbabilistic networksEvolutionary computationComputer science

The invention involves generating and presenting, typically electronically, a number of design alternatives to persons who are participating in the design, selection, or market research exercise. The participants (referred to as “selectors”) transmit data indicative of their preferences among or between the presented design alternatives, and that data is used to derive a new generation of design alternatives or proposals. The new designs are generated through the use of a computer program exploiting a genetic or evolutionary computational technique. The process is repeated, typically for many iterations or cycles.

Owner:THE NIELSEN CO (US) LLC

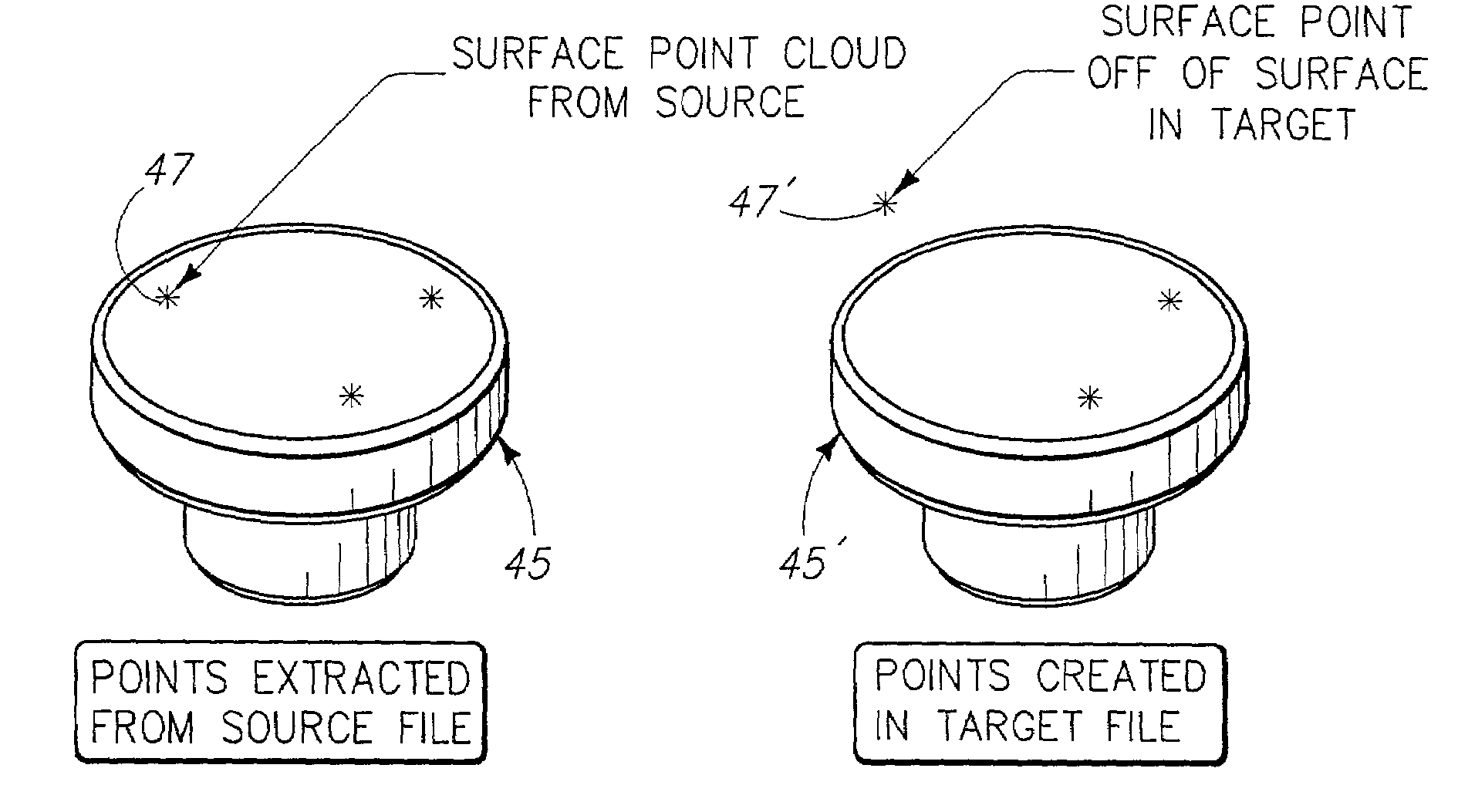

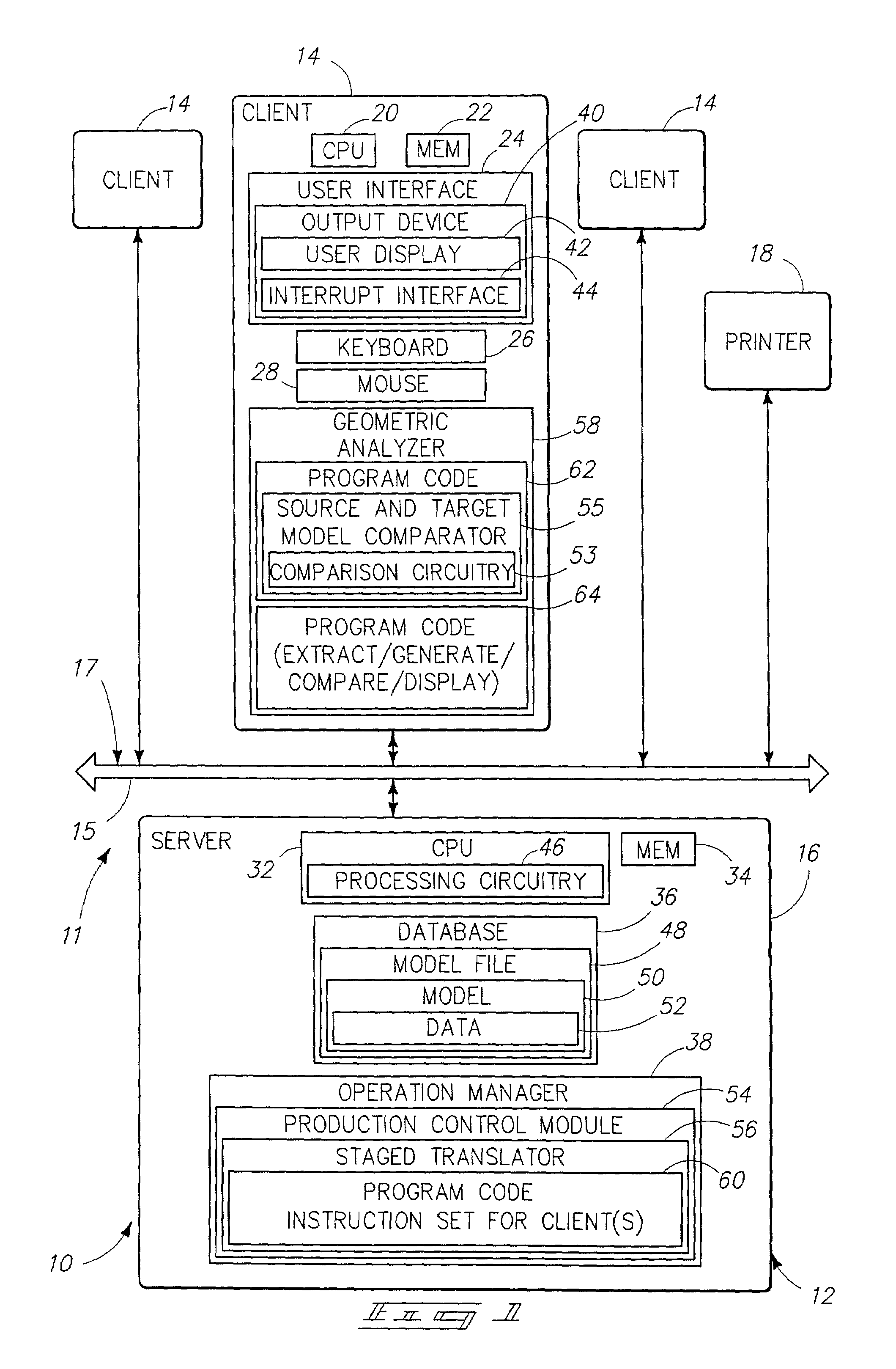

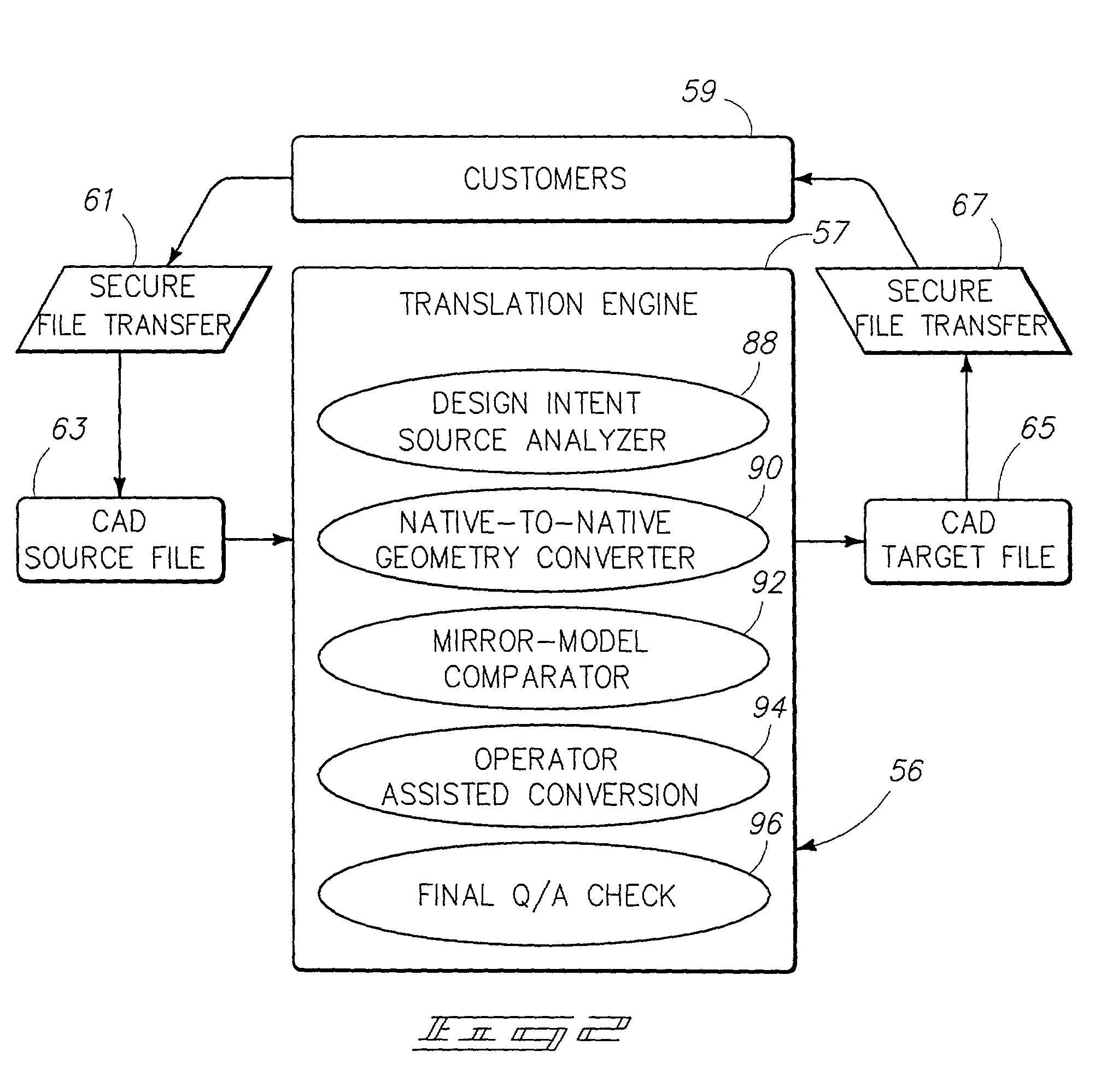

Geometric model comparator and method

InactiveUS7149677B2Increase speedMaterial analysis by optical meansProgram controlAlgorithmObjective model

A geometric model comparator is provided, which includes processing circuitry, memory, and comparison circuitry. The processing circuitry is configured to generate a target model from a source model. The memory is configured to store the source model and the target model. The comparison circuitry is configured to identify selected points from the source model, create corresponding selected points in a target model, and compare the selected points from the source model with the selected points from the target model to identify one or more selected points from the target model that fall outside of a predetermined tolerance range with the respective one or more points from the source model. A method is also provided.

Owner:TTI ACQUISITION CORP

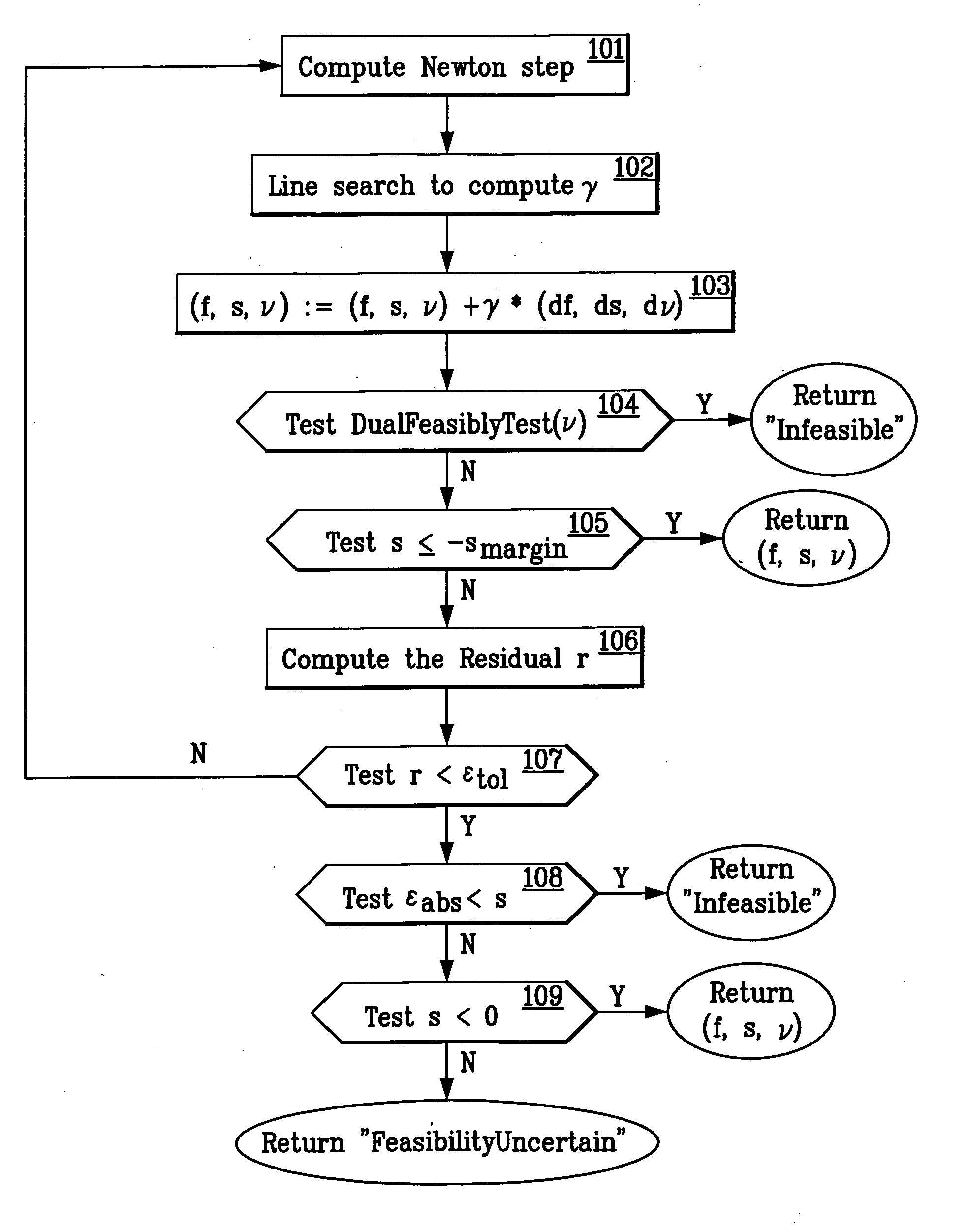

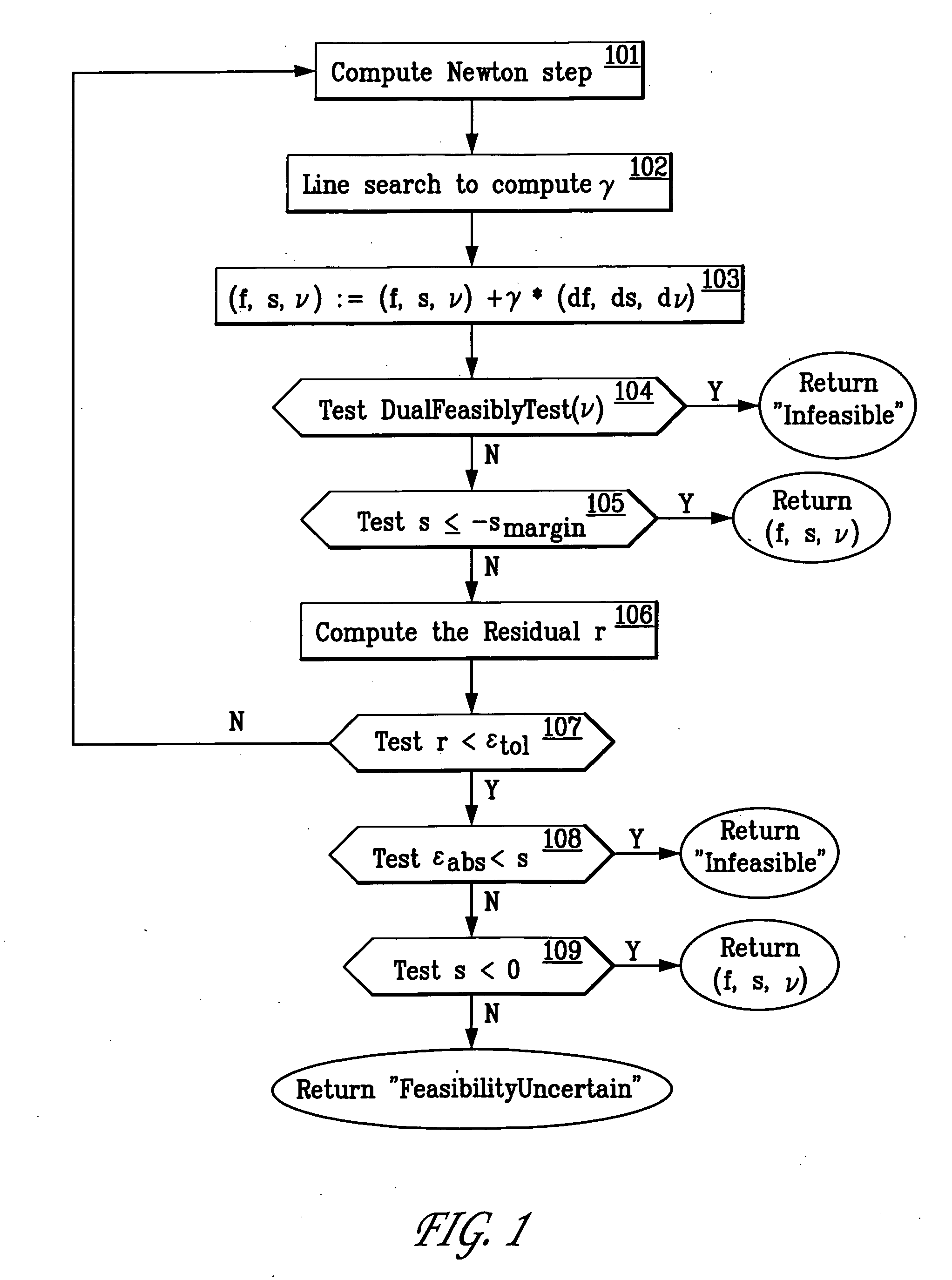

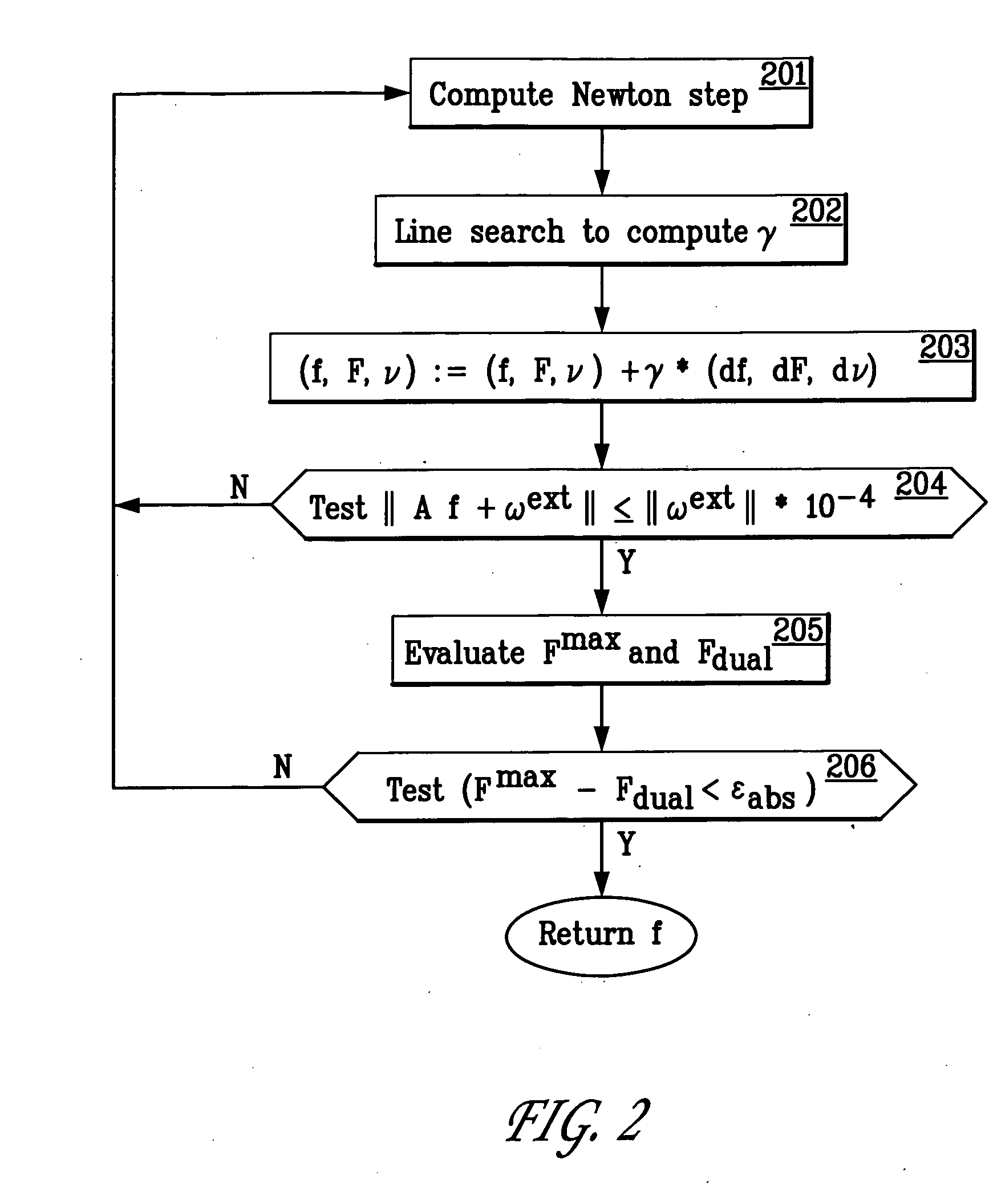

Method for fast computation of optimal contact forces

ActiveUS20080077361A1High feasibilityProgramme-controlled manipulatorMeasurement arrangements for variableContact forceOptimization problem

A method for rapidly determining feasibility of a force optimization problem and for rapidly solving a feasible force optimization problem is disclosed. The method comprises formulating the force optimization problem or force feasibility problem as a convex optimization problem, formulating a primal barrier subproblem associated with the convex optimization problem, and solving the primal barrier subproblem. The method and related methods may also be used to solve each problem in a set of force optimization problems, determine the minimum or maximum force required to satisfy any of a set of force optimization problems, solve a force closure problem, compute a conservative contact force vector, or solve a feasible force optimization problem with bidirectional forces.

Owner:STRIDER LABS

Computer-implemented methods for re-designing a concrete composition to have adjusted slump

InactiveUS20080027584A1Accurate predictionEfficient identificationGeometric CADSampled-variable control systemsEngineeringMultiple case

Design optimization methods can be used to design concrete mixtures having optimized properties, including desired strength and slump at minimal cost. The design optimization methods use a computer-implemented process that is able to design and virtually “test” millions of hypothetical concrete compositions using mathematical algorithms that interrelate a number of variables that affect strength, slump, cost and other desired features. The design optimization procedure utilizes a constant K (or K factor) within Feret's strength equation that varies (e.g., logarithmically) with concrete strength for any given set of raw material inputs and processing equipment. That means that the binding efficiency or effectiveness of hydraulic cement increases with increasing concentration so long as the concrete remains optimized. The knowledge of how the K factor varies with binding efficiency and strength is a powerful tool that can be applied in multiple circumstances. A concrete manufacturing process may include accurately measuring the raw materials to minimize variation between predicted and actual strength, as well as carefully controlling water content throughout the manufacturing and delivery process.

Owner:ICRETE LLC

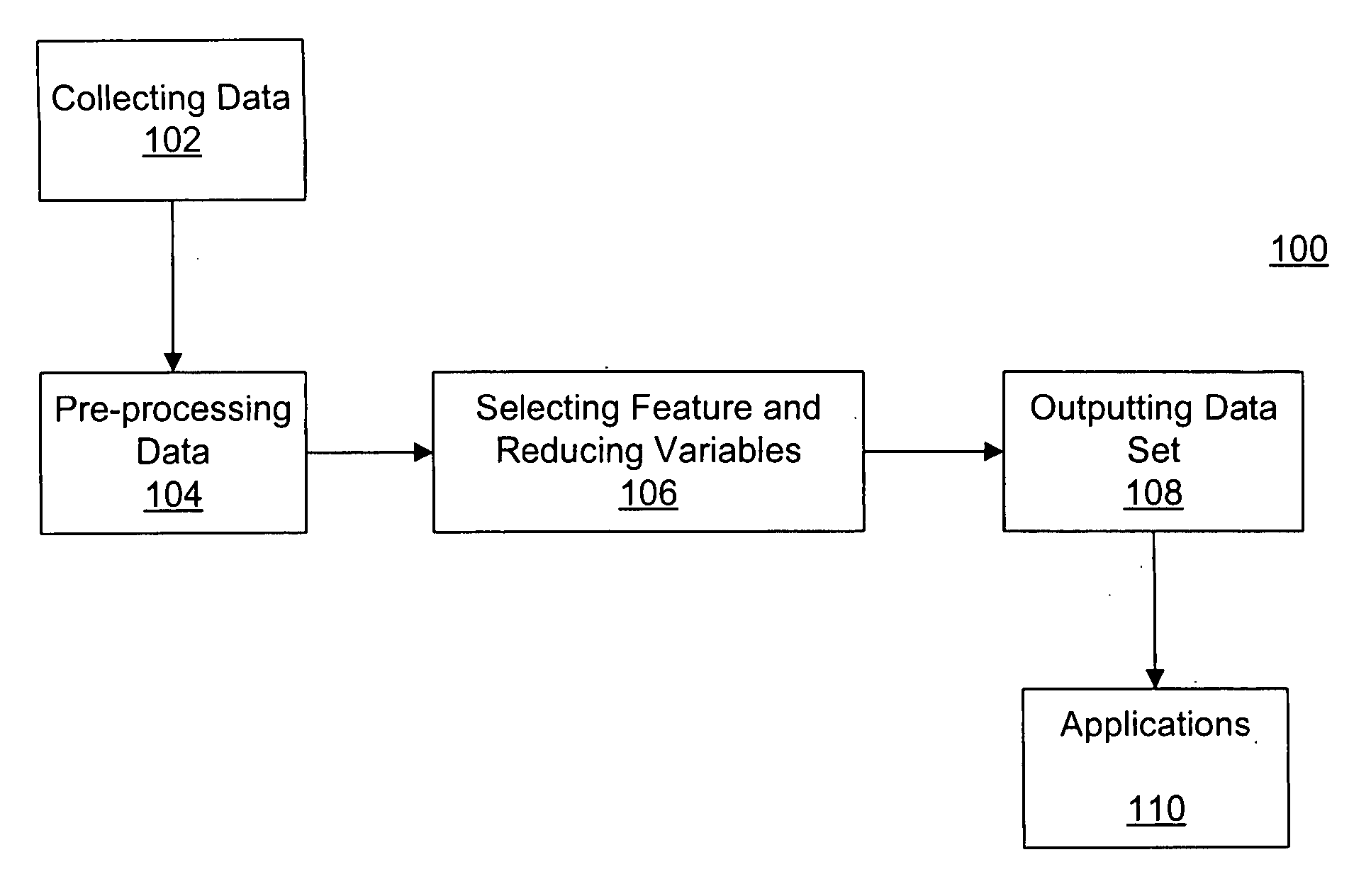

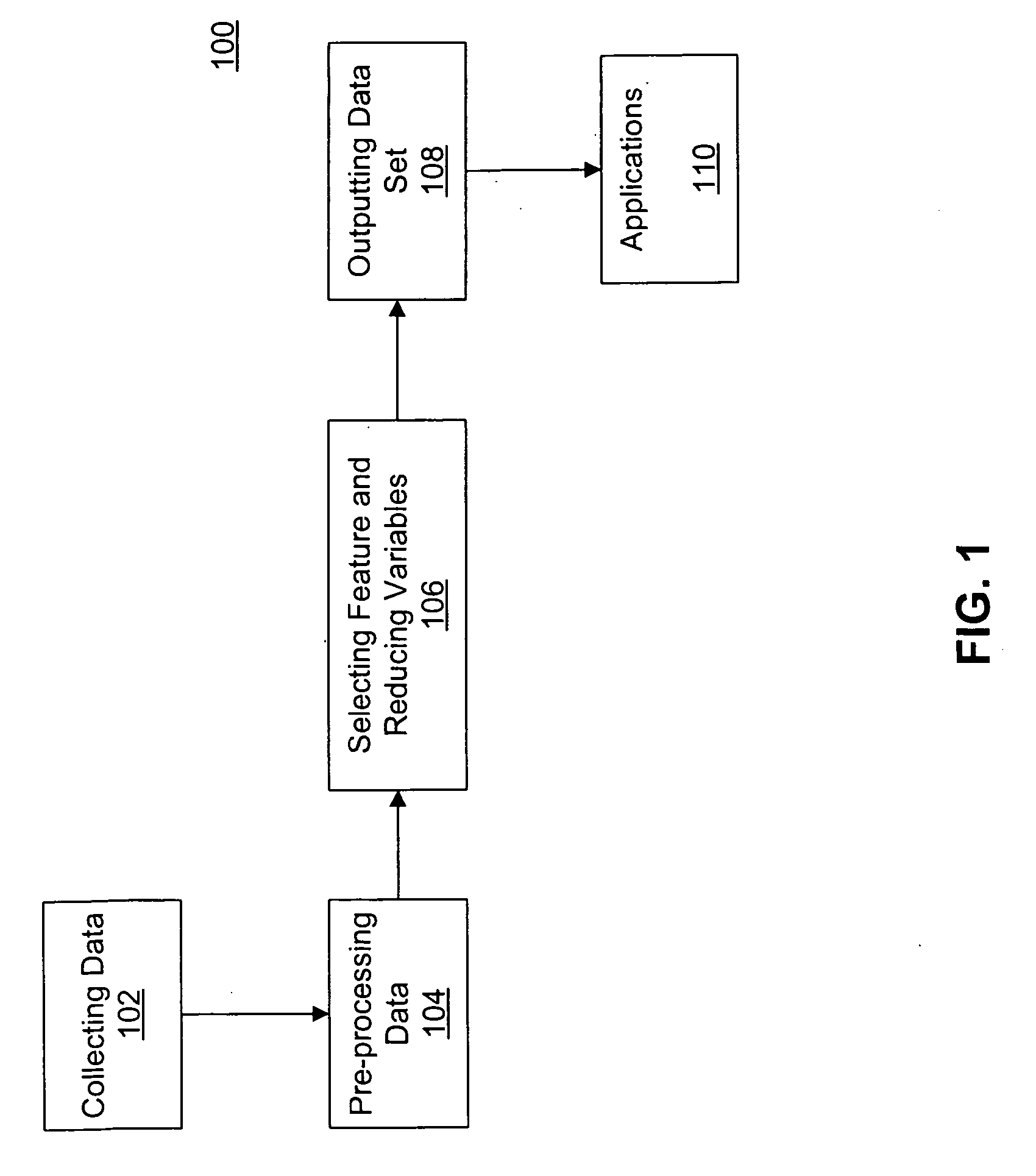

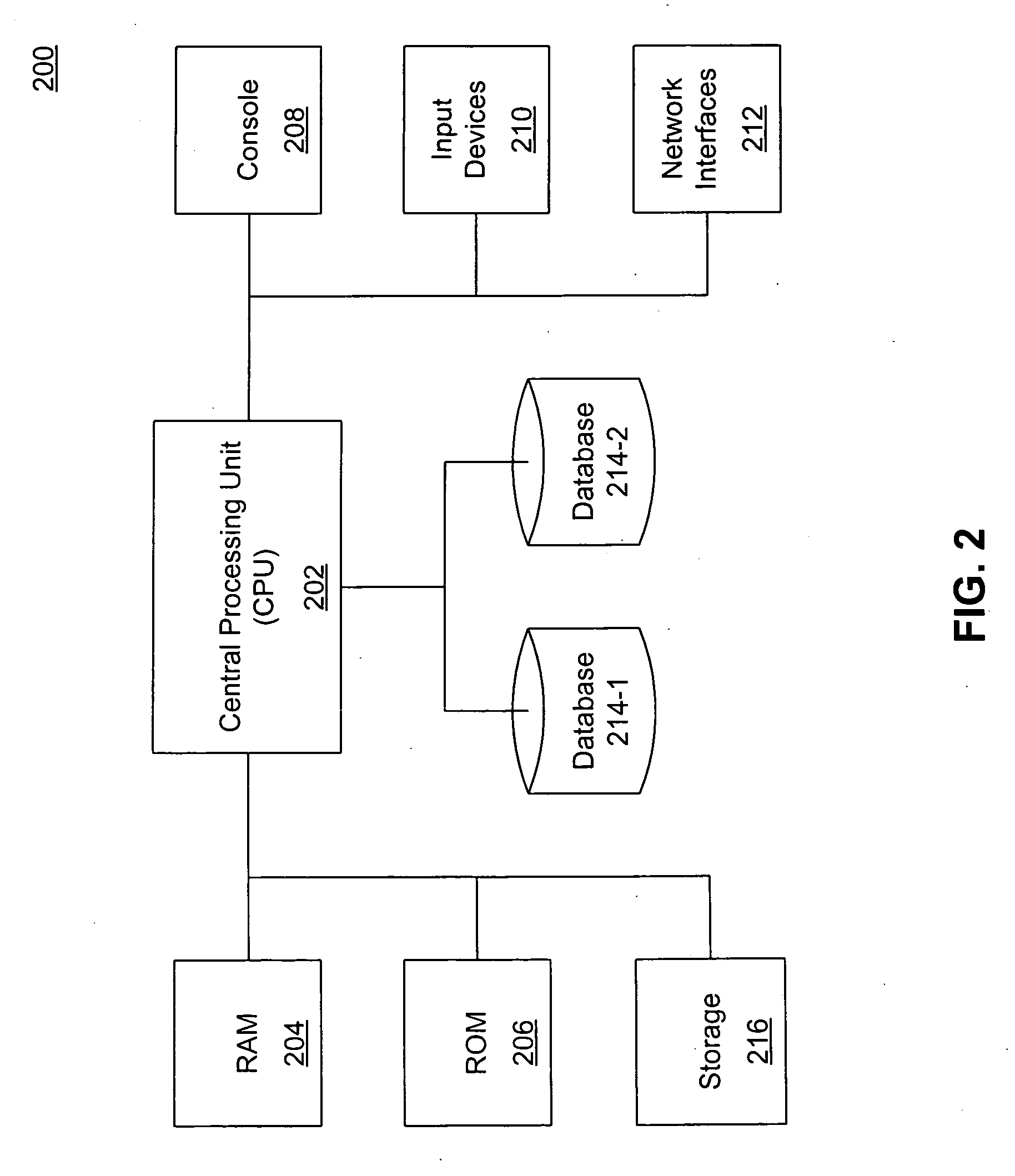

Mahalanobis distance genetic algorithm (MDGA) method and system

InactiveUS20060230018A1Design optimisation/simulationMulti-objective optimisationTheoretical computer scienceGenetic algorithm

A computer-implemented method to provide a desired variable subset. The method may include obtaining a set of data records corresponding a plurality of variables and defining the data records as normal data or abnormal data based on predetermined criteria. The method may also include initializing a genetic algorithm with a subset of variables from the plurality of variables and calculating Mahalanobis distances of the normal data and the abnormal data based on the subset of variables. Further, the method may include identifying a desired subset of the plurality of variables by performing the genetic algorithm based on the Mahalanobis distances.

Owner:CATERPILLAR INC

Low-power FPGA circuits and methods

InactiveUS7714610B2Increase profitEasy to controlSolid-state devicesCAD circuit designEngineeringLevel converter

Field Programmable Logic Arrays (FPGAs) are described which utilize multiple power supply voltages to reduce both dynamic power and leakage power without sacrificing speed or substantially increasing device area. Power reduction mechanisms are described for numerous portions of the FPGA, including logic blocks, routing circuits, connection blocks, switch blocks, configuration memory cells, and so forth. Embodiments describe circuits and methods for implementing multiple supplies as sources of Vdd, multiple voltage thresholding Vt, signal level translators, and power gating of circuitry to deactivate portions of the circuit which are inactive. The supply voltage levels can be fixed, or programmable. Methods are described for performing circuit CAD in the routing and assignment process on FPGAs, in particular for optimizing FPGA use having the power reduction circuits taught. Routing methods describe utilizing slack timing, power sensitivity, trace-based simulations, and other techniques to optimize circuit utilization on a multi Vdd FPGA.

Owner:RGT UNIV OF CALIFORNIA

Method for optimizing dynamic performance of entire numerical control machine tool

InactiveCN106815407AClarify the direction of optimizationImprove optimization calculation efficiencyGeometric CADDesign optimisation/simulationNumerical controlDynamic models

The invention discloses a method for dynamic modeling on an entire numerical control machine tool based on kinetic parameters of a joint part and analyzing and optimizing dynamic performance and an implementation scheme. The method disclosed by the invention takes a certain type of a vertical machining center as an example, dynamic model building and parameter identification are carried out on a bolt joint part, a guide rail sliding block joint part, a ball screw joint part and a bearing joint part, the dynamic performance of the entire numerical control machine tool is analyzed by combining finite element analysis software, an optimization object is established on the basis, a multi-objective optimization model is constructed, and the best optimization configuration is solved, so that the dynamic performance of the entire numerical control machine tool is optimized. Achievements of the method disclosed by the invention can be used for solving problems finite element analysis and optimization on the dynamic performance of the entire numerical control machine tool, and technical support is provided for improving processability of the numerical control machine tool.

Owner:SICHUAN UNIV

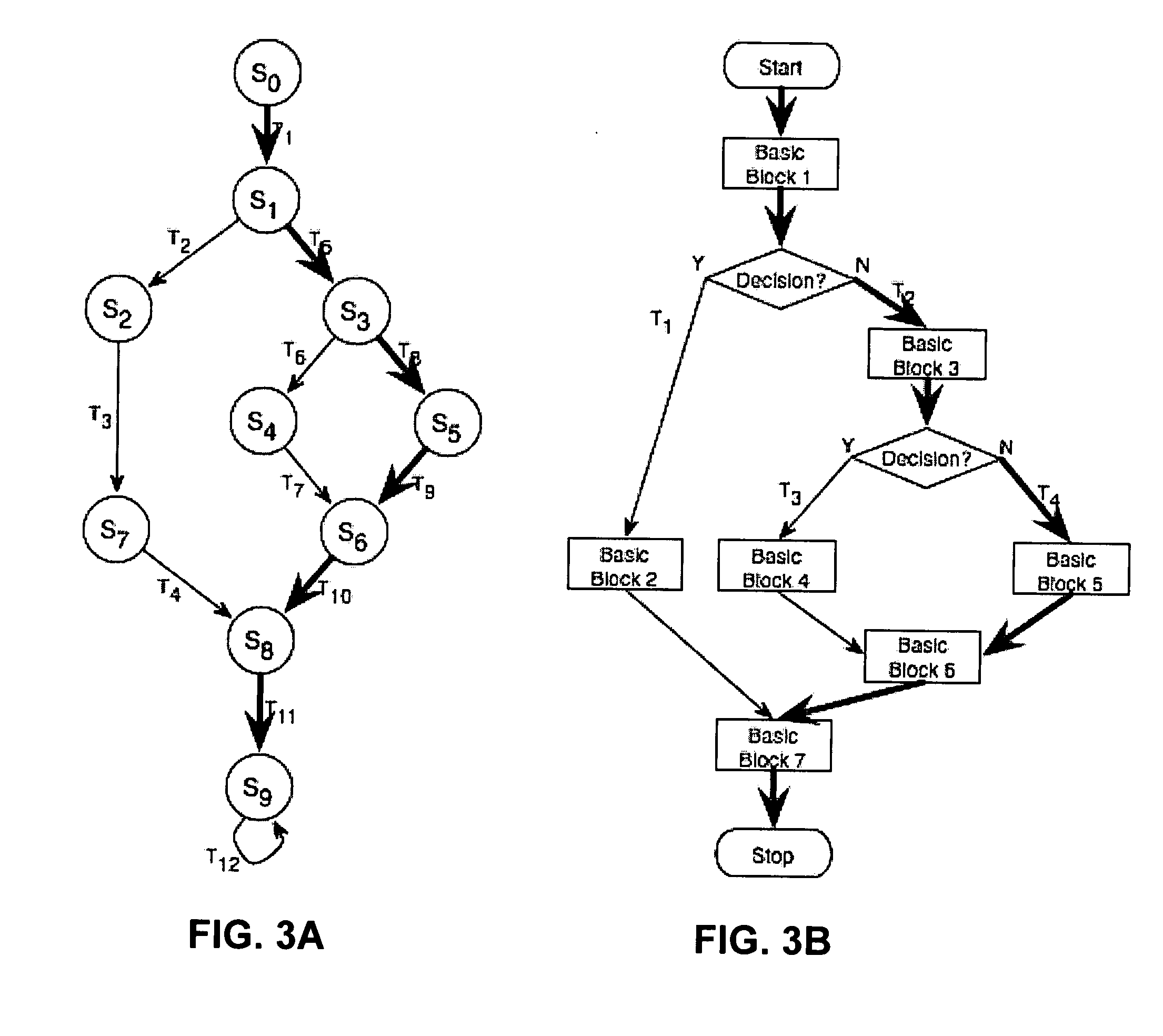

Automatically generating an input sequence for a circuit design using mutant-based verification

InactiveUS20070294655A1Facilitates appending additional constraintFacilitates user verificationDetecting faulty computer hardwareDigital storageAnalog circuit designControl signal

One embodiment of the present invention provides a system that automatically generates an input sequence for a circuit design using mutant-based verification. During operation, the system receives a description of the circuit design. Next, the system determines a target value for a control signal in the description and a mutant value for the control signal. The system then determines if an input sequence exists for the circuit design that stimulates the control signal to the target value and causes the effects of the target value and the effects of the mutant value to reach an observation point in the circuit such that the effects of the target value and the effects of the mutant value differ at the observation point. If such an input sequence exists, the system then simulates operation of the circuit design using the input sequence. During simulation, the system generates two sets of signal outputs for the circuit design. The first set of signal outputs is affected by the target value for the control signal, while the second set of signal outputs is affected by the mutant value for the control signal.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com