Asymmetric polyvinylidene fluoride microporous membrane with high intensity and preparation method thereof

A polyvinylidene fluoride, microporous membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of inability to change pore size gradient and excellent strength unity, and limit the application of PVDF membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

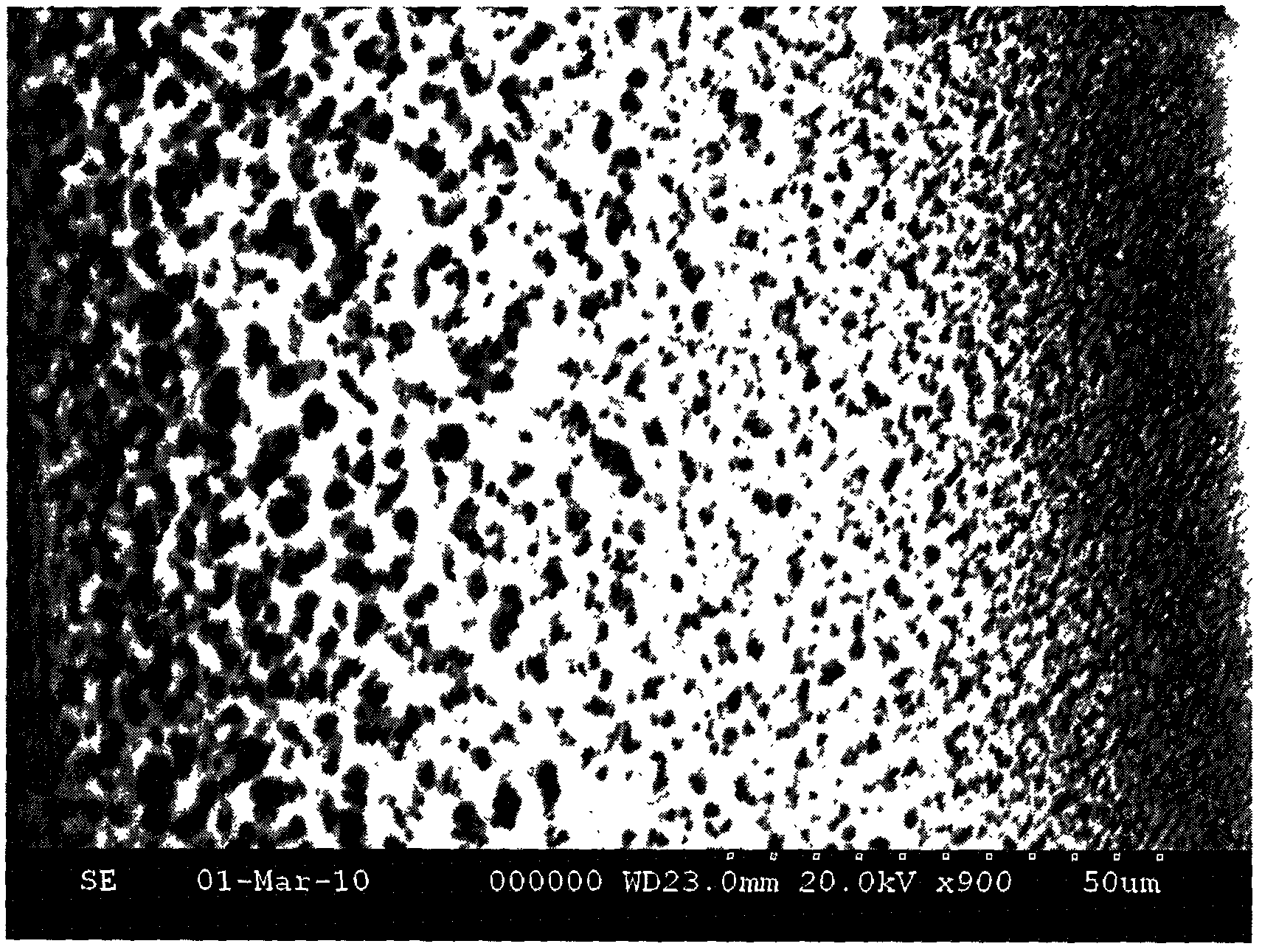

[0021] Example 1 PVDF microporous membrane with pore size gradient change in the thickness direction

[0022] We configured PVDF polymer HYLAR-461 with a weight content of 13.7%, fluorosurfactant FC-170 of 9.7%, water of 4%, LiCl of 1% and 71.6% of dimethylacetamide (DMAC) as solvent Casting stock solution. At 70°C, use a spatula with a thickness of 300 μm to evenly coat the polymer solution on a glass plate, stay in air with room temperature and humidity of 70% for 5 seconds, and then immerse in a water bath at 60°C for phase separation and solidification. After curing, the membrane was washed with pure water and then immersed in an aqueous solution with a weight content of 2% KOH and 2% hydrogen peroxide for 48 hours to make the membrane hydrophilic. The average pore diameter of the small pore surface of the membrane is about 0.1 μm, the average pore diameter of the large pore surface is about 15 μm, the thickness of the membrane is about 160 μm, the flow rate of water is 7...

Embodiment 2

[0024] Example 2 The PVDF microporous membrane with the pore diameter in the thickness direction increasing gradually and then tending to be consistent

[0025] We configured PVDF polymer HYLAR-461 with a weight content of 18.5%, 3% fluorosurfactant FC-170, 2% water, 0.5% LiCl and 78% dimethylacetamide (DMAC) as solvent Casting stock solution. At 70°C, use a spatula with a thickness of 300 μm to evenly coat the polymer solution on a glass plate, stay in air with room temperature and humidity of 70% for 5 seconds, and then immerse in a water bath at 60°C for phase separation and solidification. After curing, the membrane was washed with pure water and then immersed in an aqueous solution with a weight content of 2% KOH and 2% hydrogen peroxide for 48 hours to make the membrane hydrophilic. The average pore diameter of the small pore surface of the membrane is about 0.3 μm, the average pore diameter of the large pore surface is about 3 μm, the thickness of the membrane is about...

Embodiment 3

[0027] The influence of embodiment 3 polymer concentration

[0028] We configured PVDF polymer HYLAR-461 with a weight content of 12.5%, fluorosurfactant FC-170 with 2.5%, water with 4%, LiCl with 0.5% and 82% dimethylacetamide (DMAC) as solvent Casting stock solution. Then according to the steps of Example 2, we found that finger-shaped macropores appeared in the prepared membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com