Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279results about "Refining with aqueous alkaline solutions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

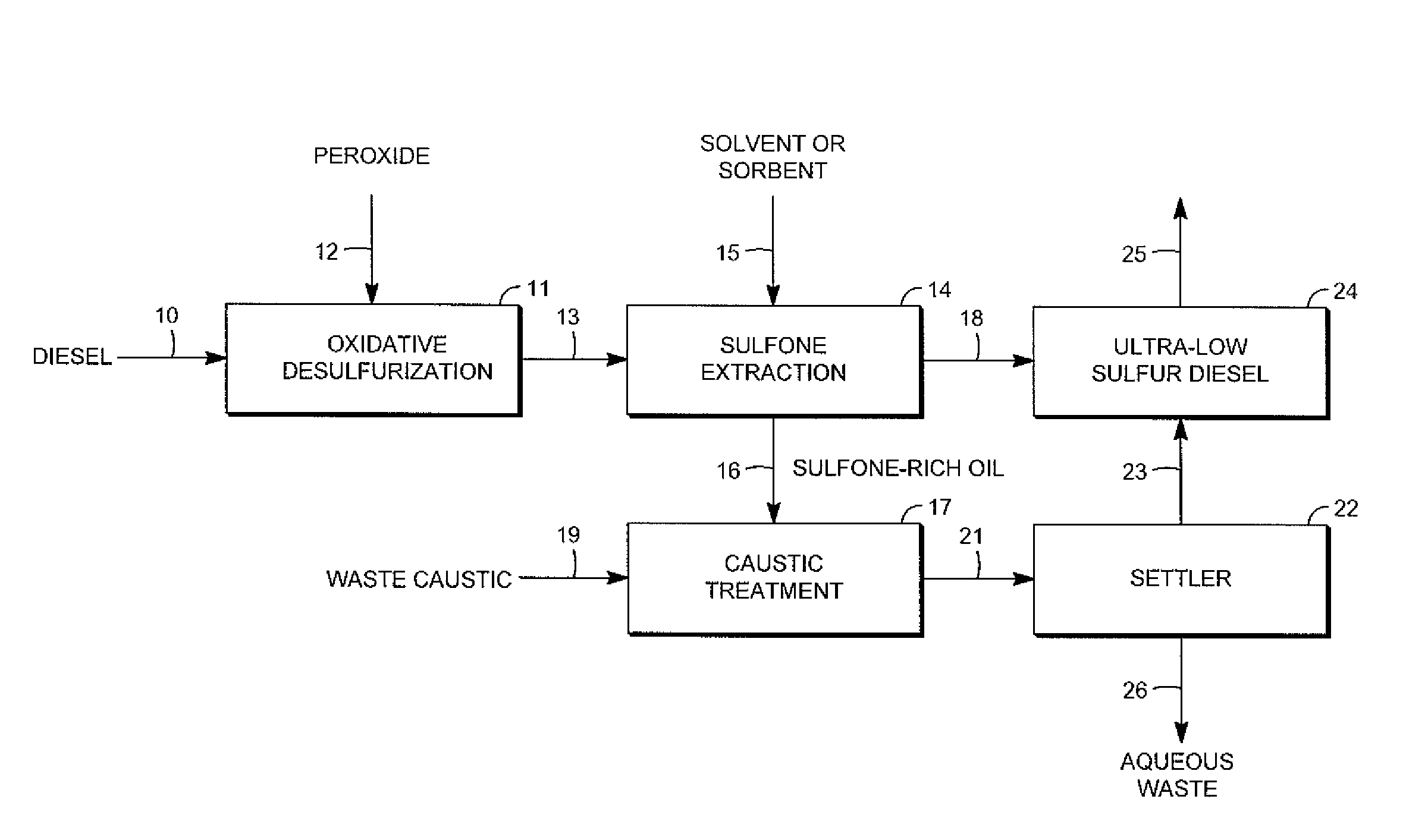

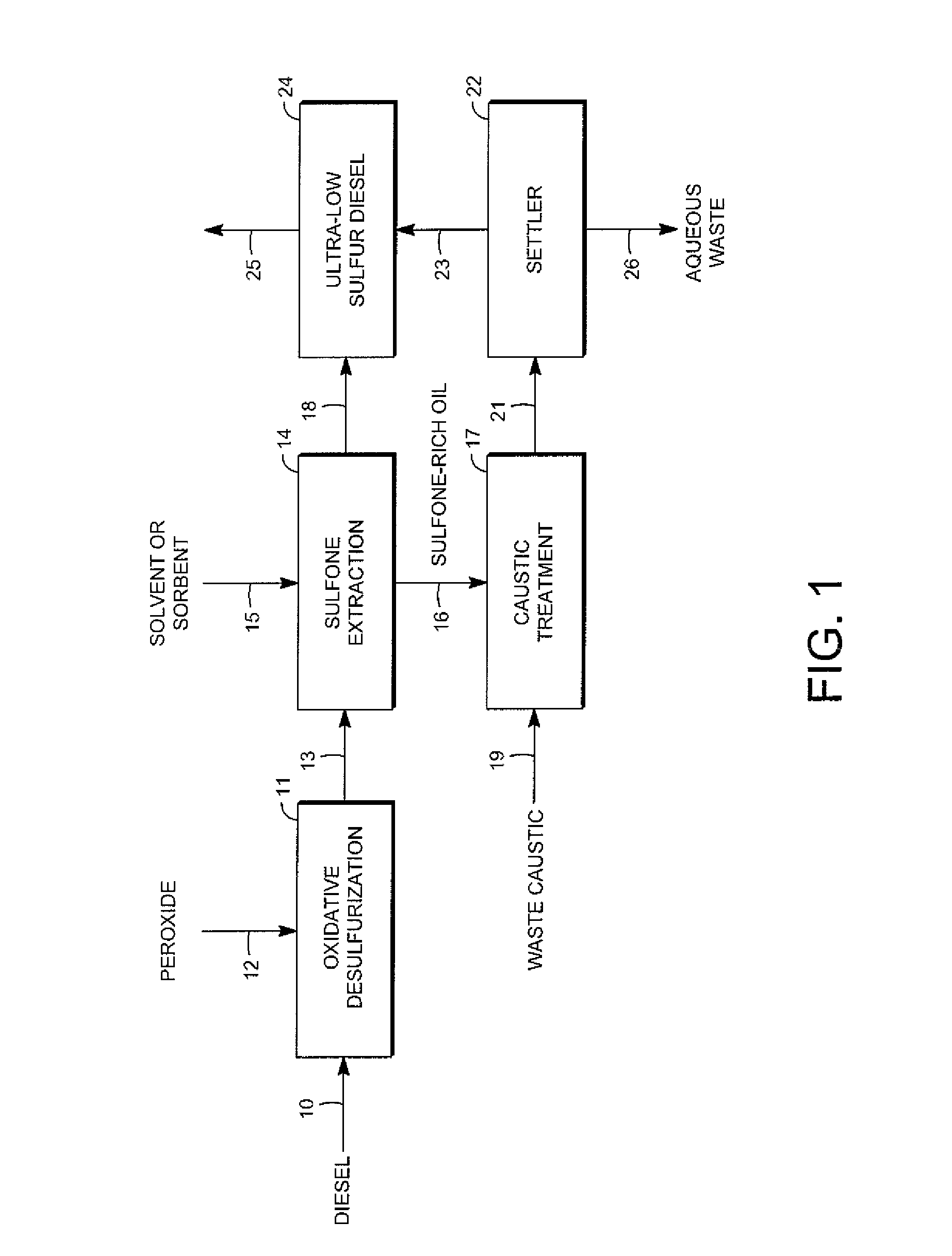

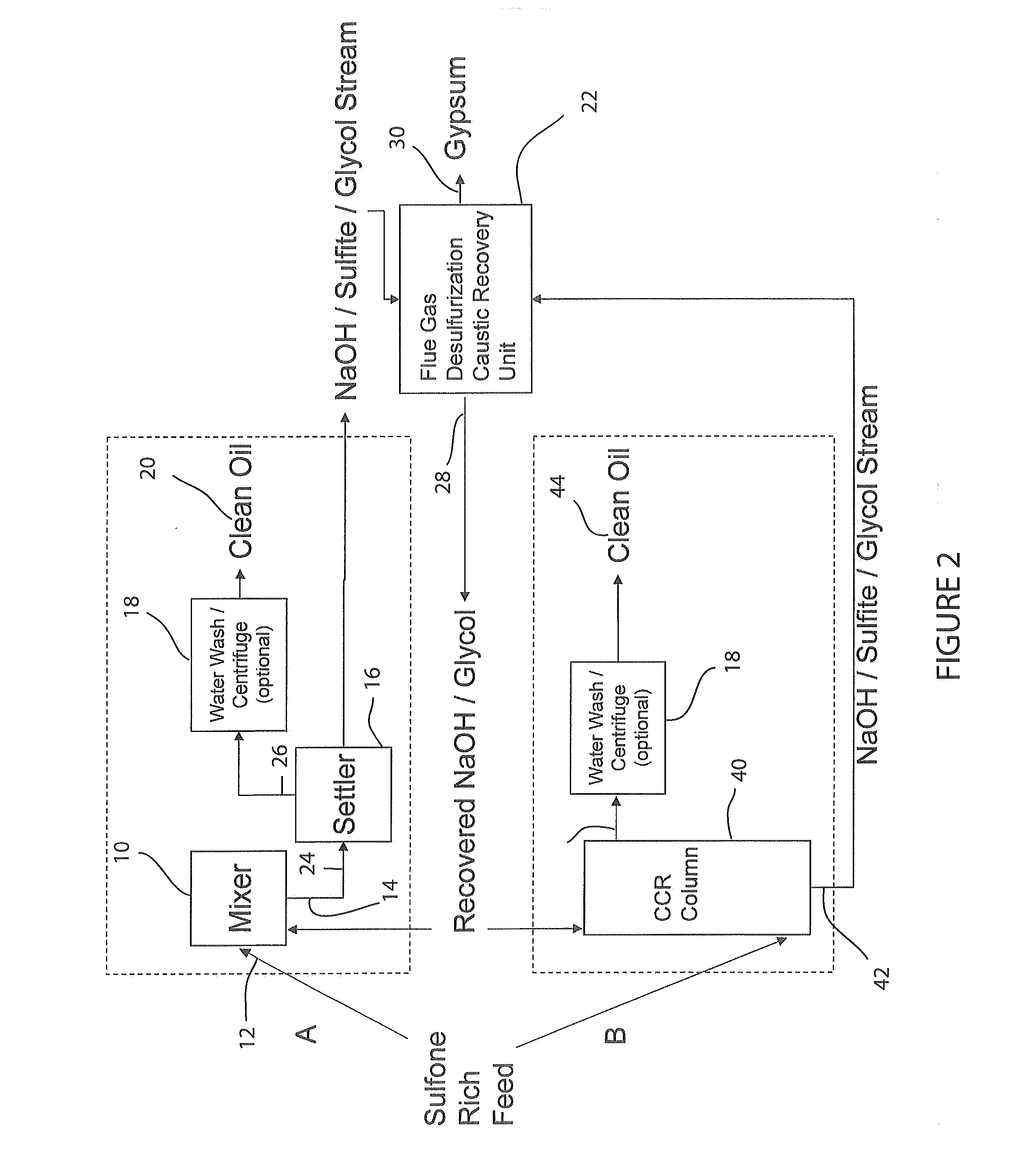

Removal of sulfur-containing compounds from liquid hydrocarbon streams

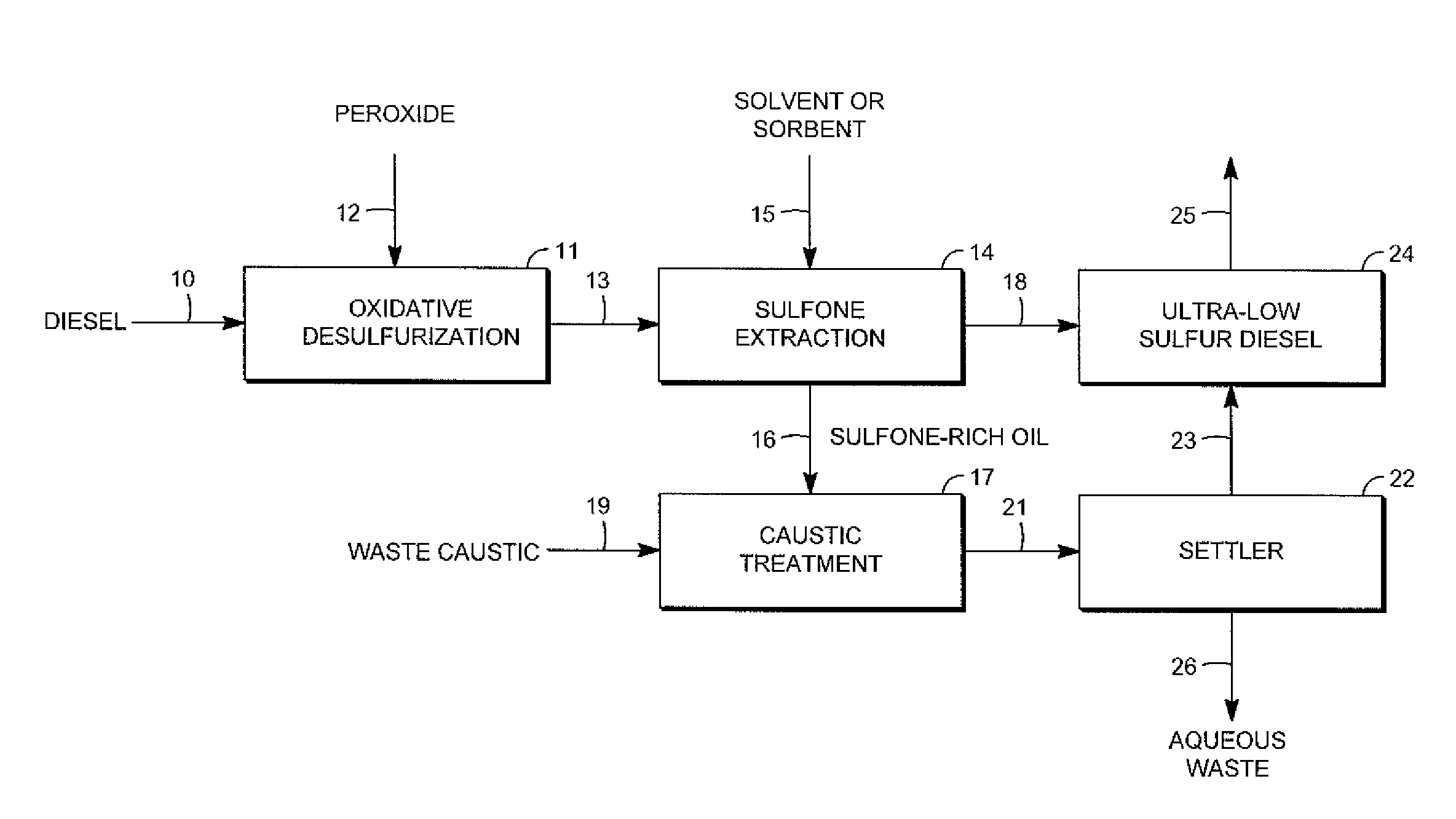

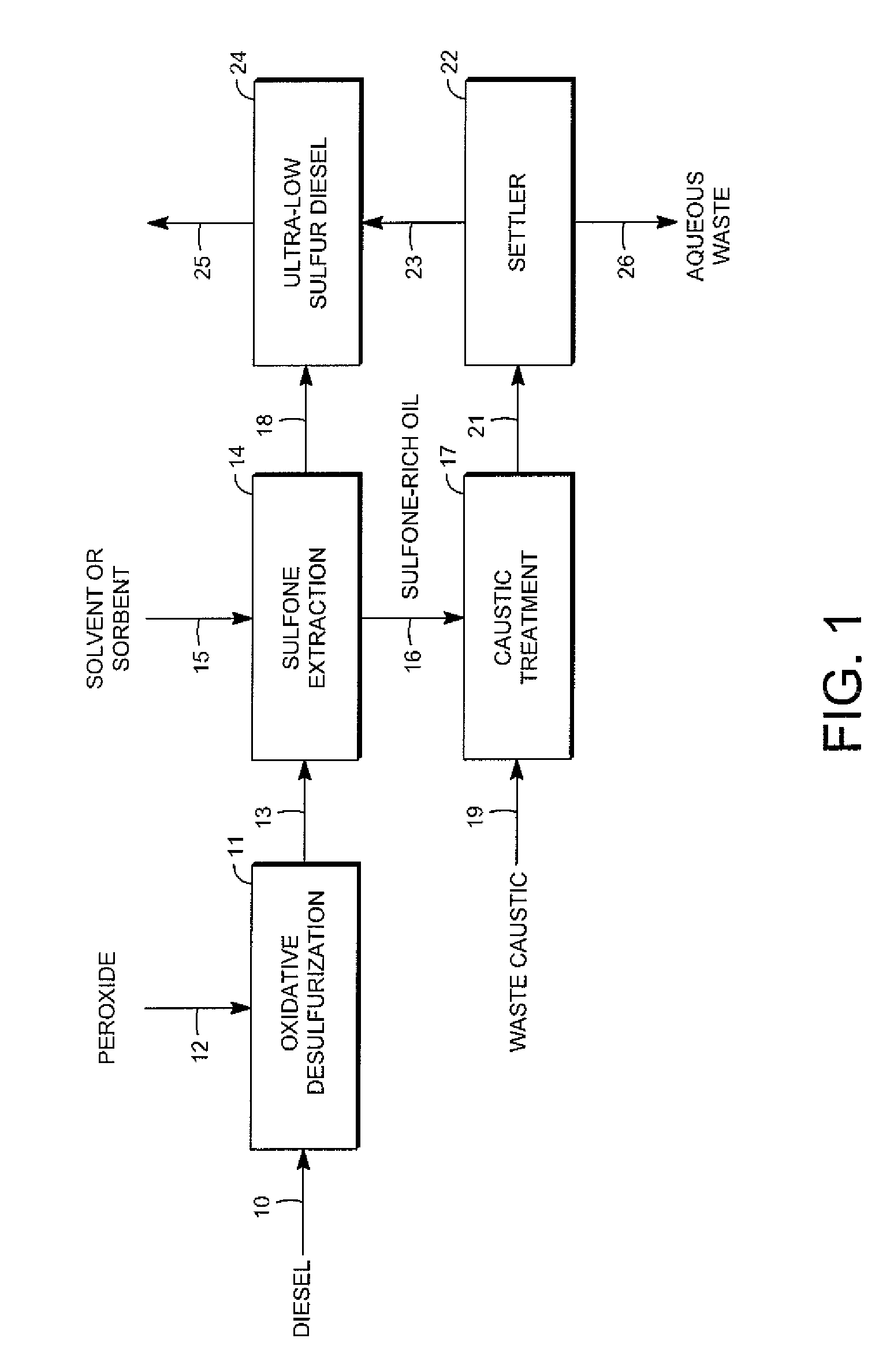

InactiveUS20090065399A1Easy to separateEasy extractionRefining with oxygen compoundsTreatment with plural serial refining stagesLiquid hydrocarbonsImproved method

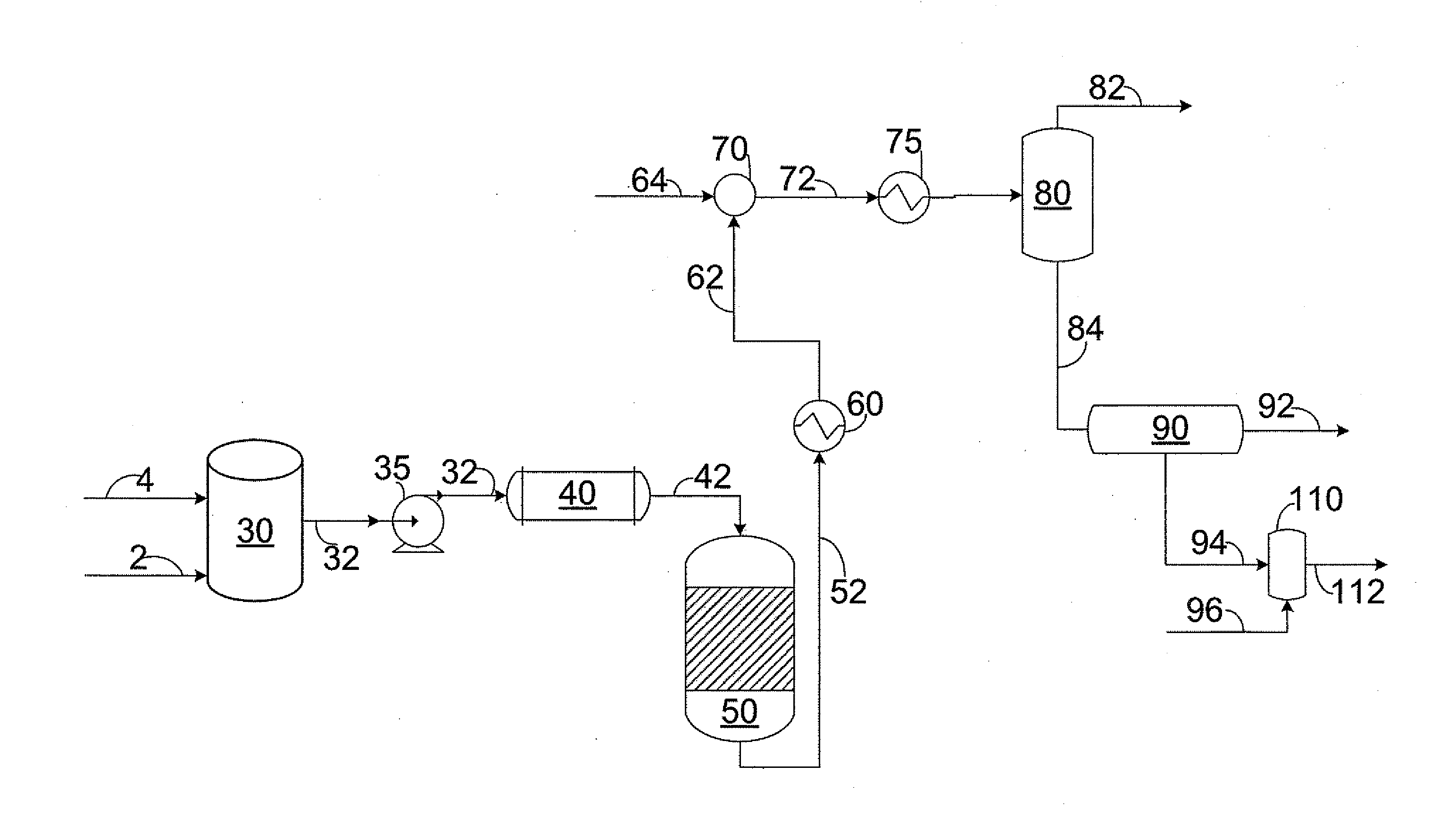

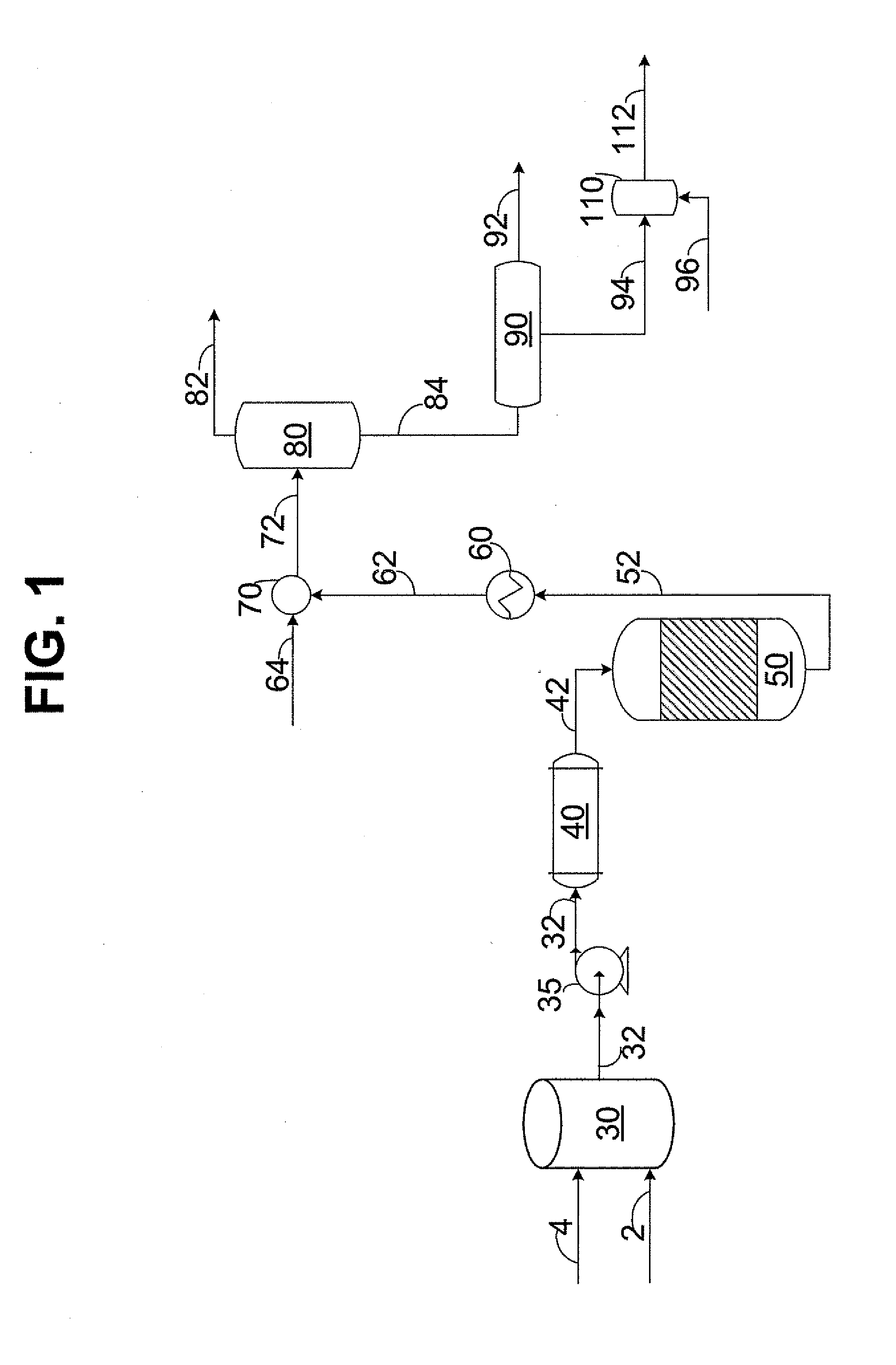

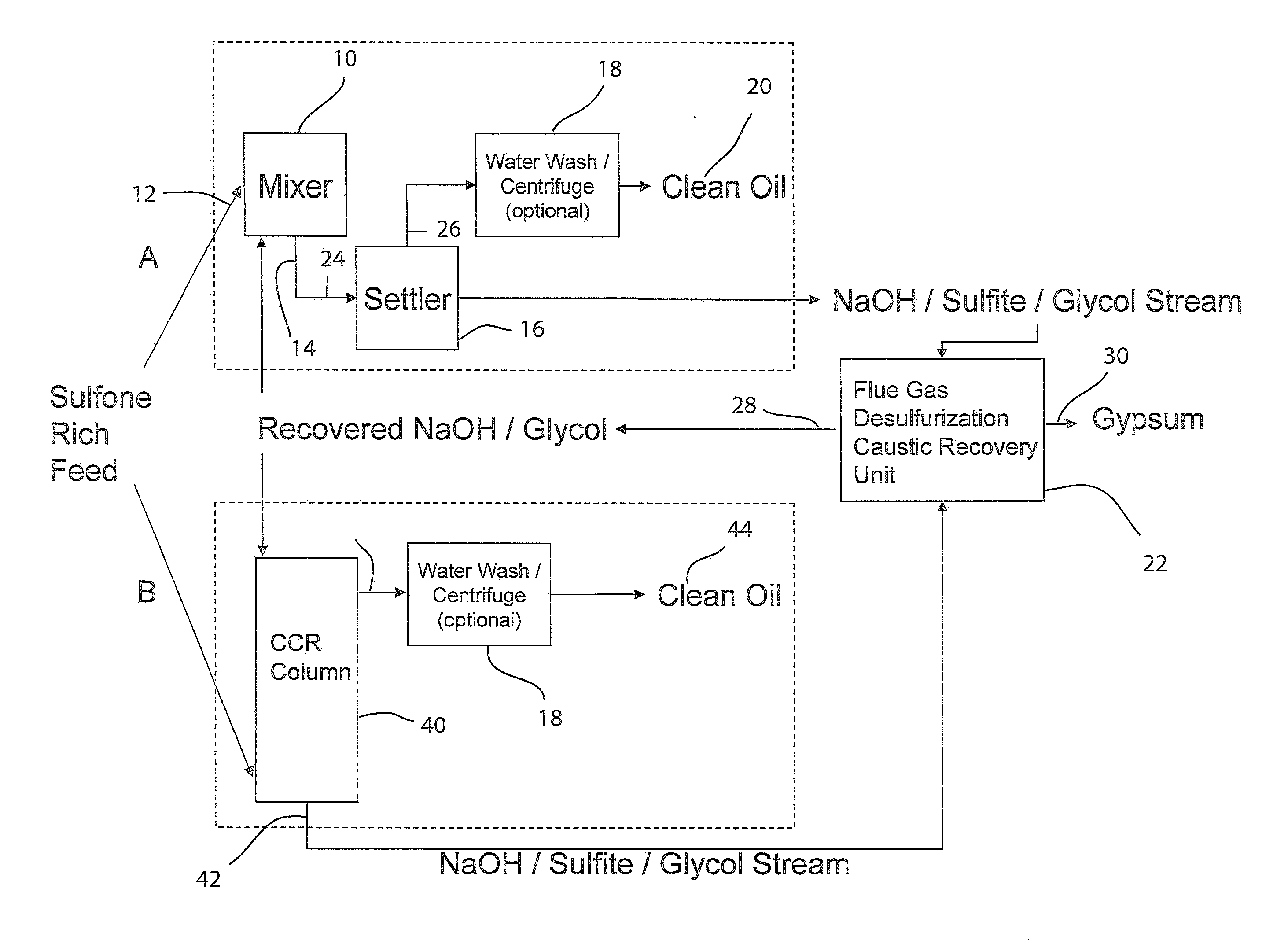

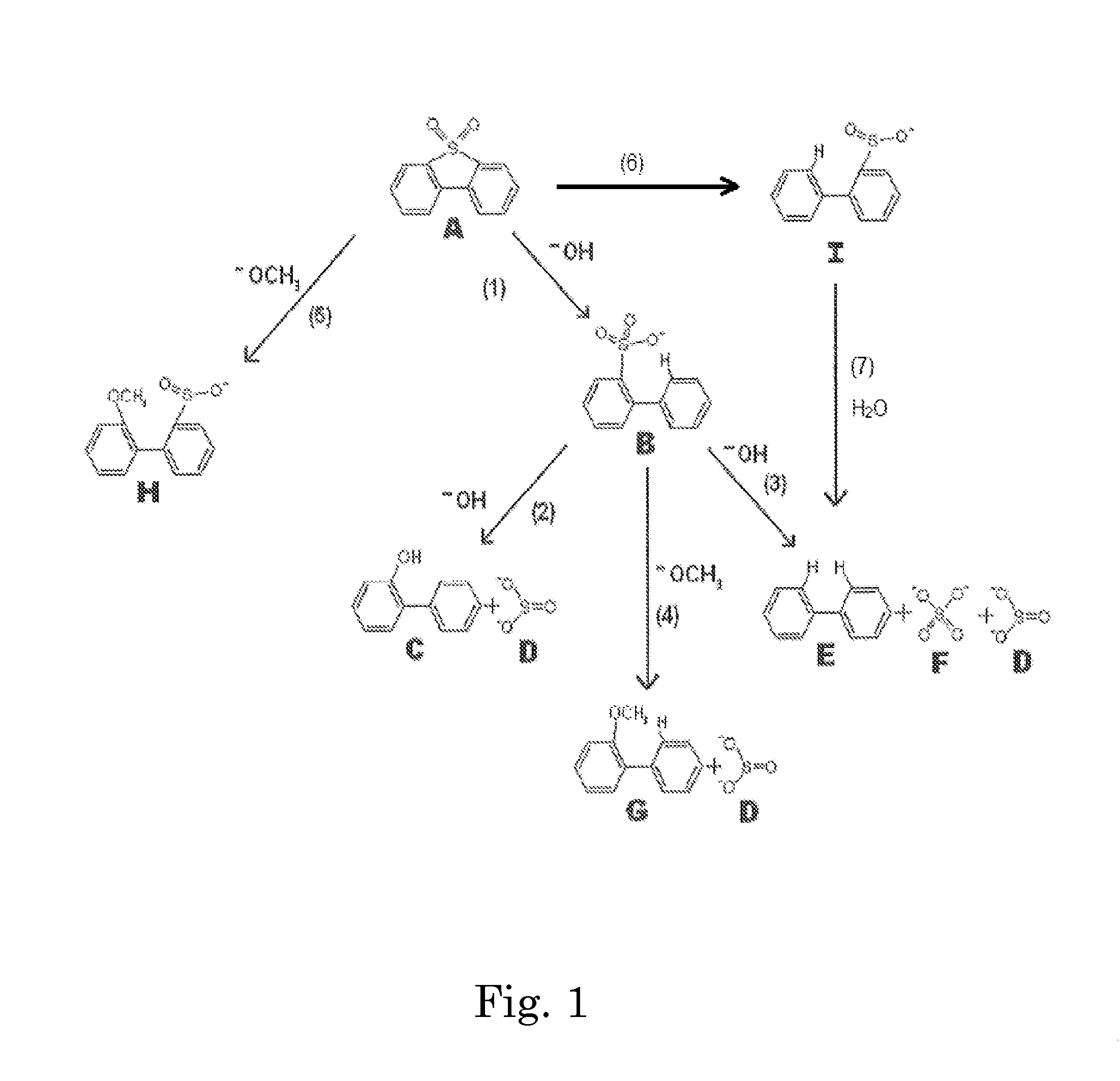

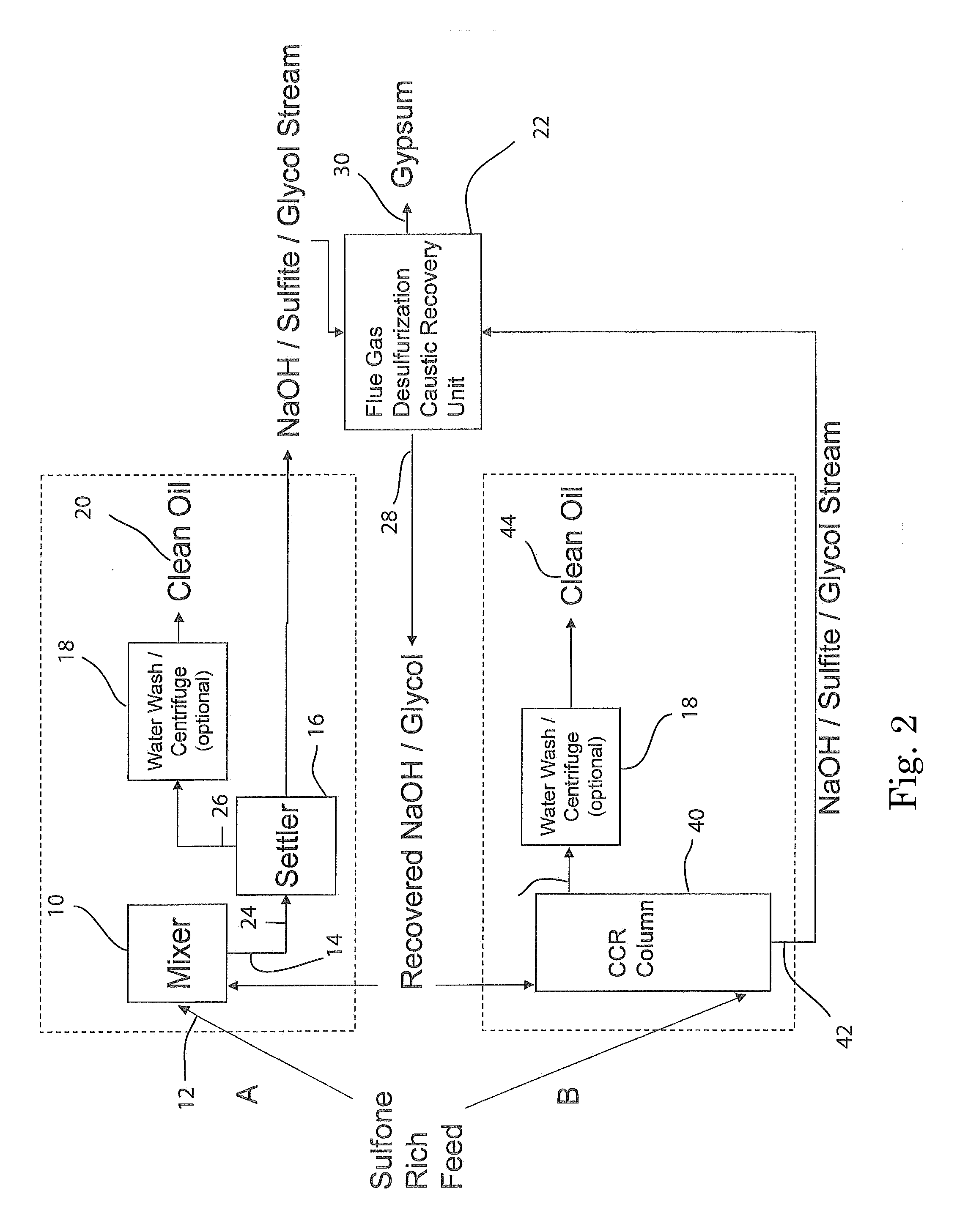

An improved method for desulfurizing a fuel stream such as a diesel stream is disclosed which includes generation of a sulfone oil, the desulfurization of the sulfone oil and the recycling of the resulting biphenyl-rich stream and ultra-low sulfur diesel streams. The method includes combining a thiophene-rich diesel stream with an oxidant to oxidize the thiophenes to sulfones to provide a sulfone-rich diesel stream. Sulfone oil is extracted from the sulfone-rich diesel stream to provide sulfone oil and a first low-sulfur diesel stream The low-sulfur diesel stream is recycled. The sulfone-rich oil stream is combined with an aqueous oxidant-containing stream, such as caustic stream, which oxidizes the sulfones to biphenyls and forms sulfite to provide a second low-sulfur diesel stream

Owner:UOP LLC

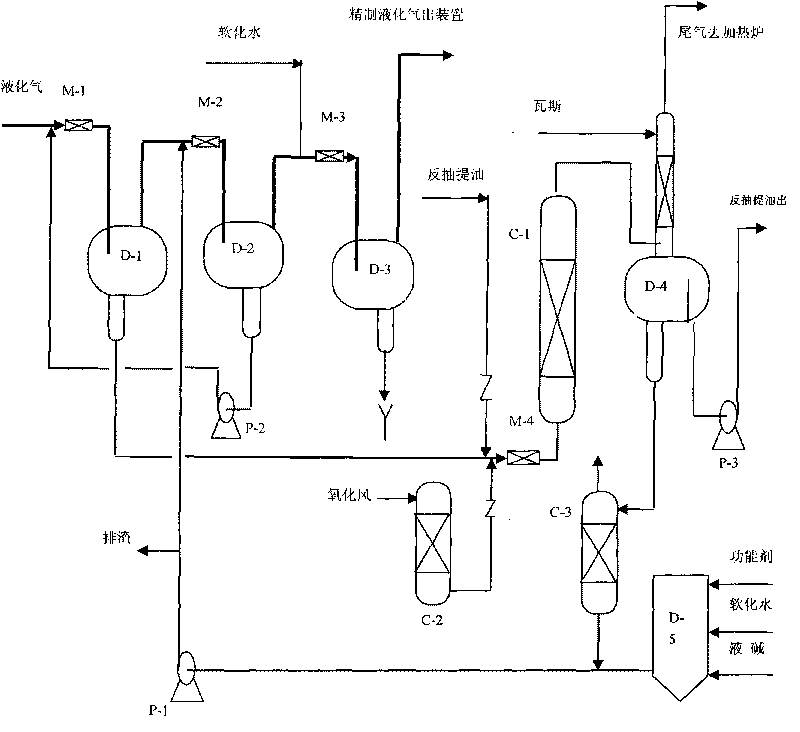

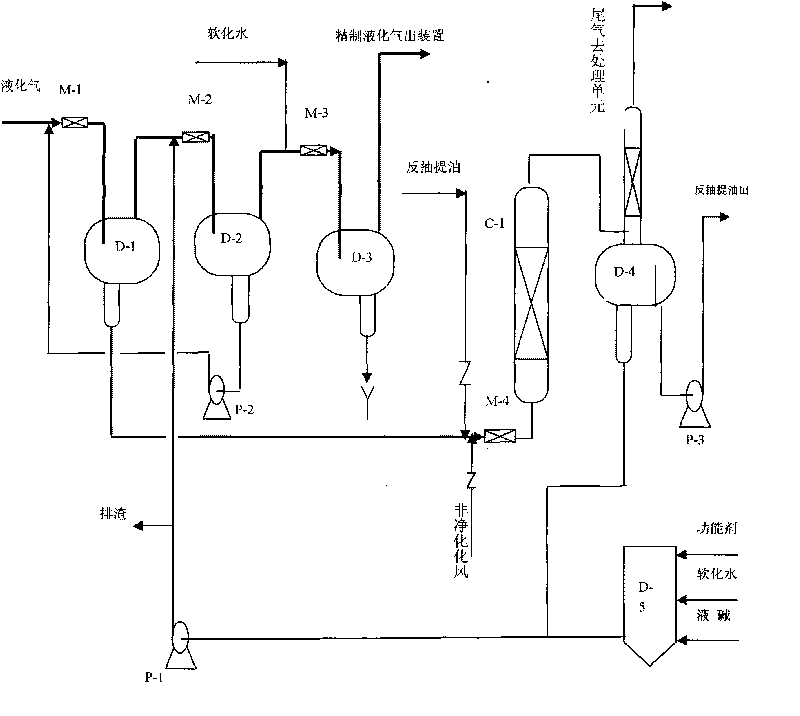

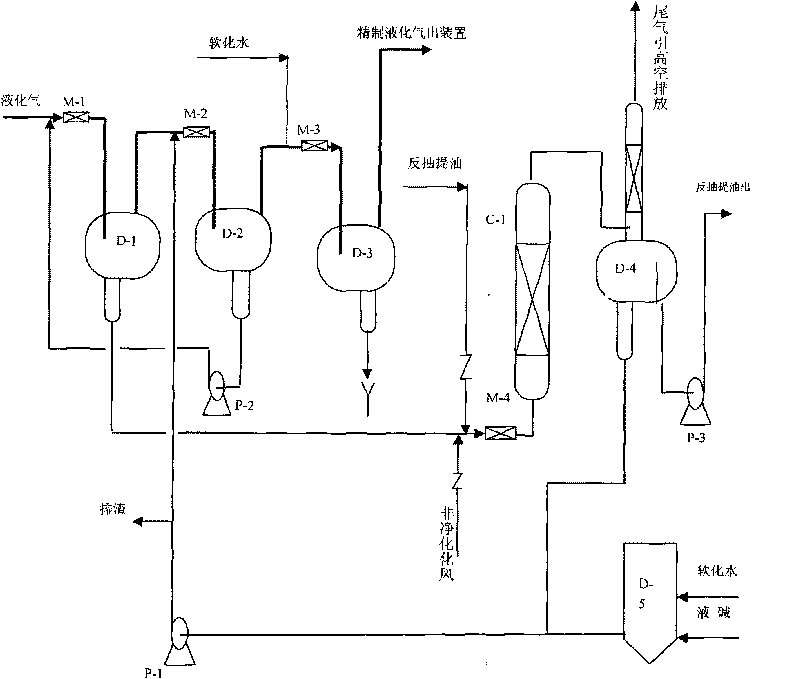

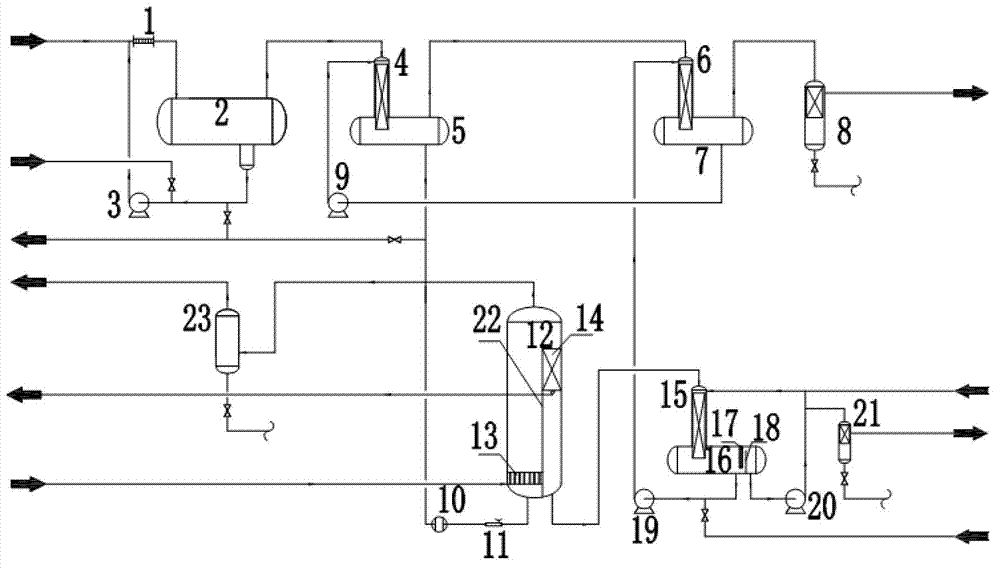

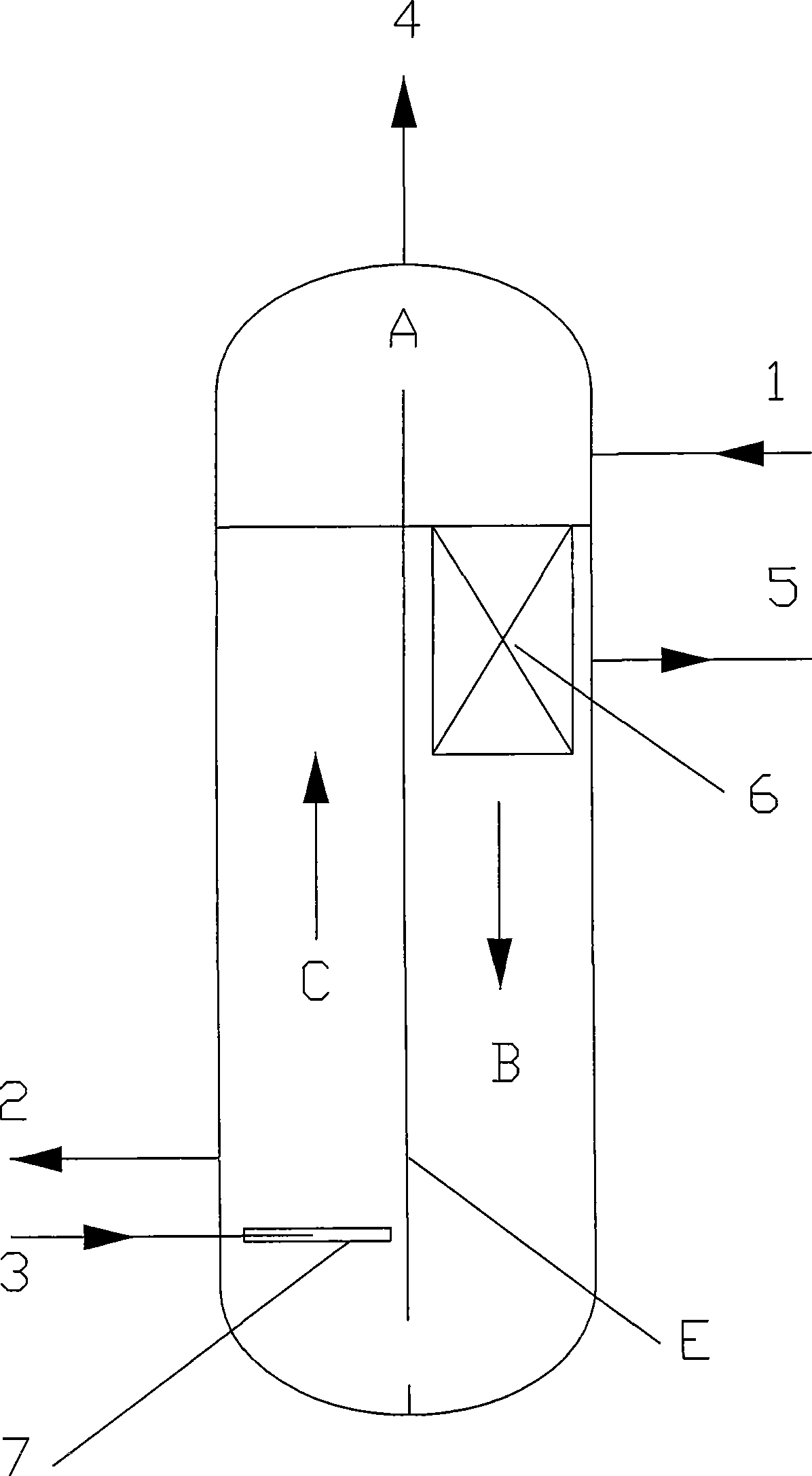

Liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur

ActiveCN101705108AImprove abilitiesHigh activityGaseous fuelsRefining with aqueous alkaline solutionsSlagCarbonyl sulfide

The invention relates to a liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur, in particular to a sweetening technique for liquefied gas in an oil refinery. The oil refining liquid hydrocarbon refers to components of liquefied gas and light gasoline, wherein the liquefied gas is a raw material for producing MTBE, and the light gasoline is a component for producing high-cleanness gasoline. In order to solve the problem of high total sulfur in the oil refining MTBE and the light gasoline, according to the shape and the distribution rule of sulfocompounds in the liquid hydrocarbon, processes such as functional reinforcement of a recycle solvent, three-phase mixed reinforced regeneration, regenerated catalyst and extractant separation and recycle solvent deoxidization and the like are adopted in the conventional process of liquid hydrocarbon extraction, oxidization and mercaptan removal, so the technical effects of reinforcing the mercaptan removal depth, improving carbonyl sulfide removal rate, and avoiding forming disulphide in the extracting, saving energy and reducing emission and the like are achieved. Thus, the liquid hydrocarbon can be deeply desulfurated, the problem of high total sulfur in the oil refining MTBE and the light gasoline is solved and the slag discharging quantity in the conventional process is greatly reduced.

Owner:HEBEI REFINING TECH CO LTD

Thermally stable jet prepared from highly paraffinic distillate fuel component and conventional distillate fuel component

InactiveUS6846402B2Improve stabilityReduced deposit formationLiquid organic insulatorsHydrocarbon purification/separationTurbinePetroleum

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in turbine engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component having low to moderate branching and at least one conventional petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

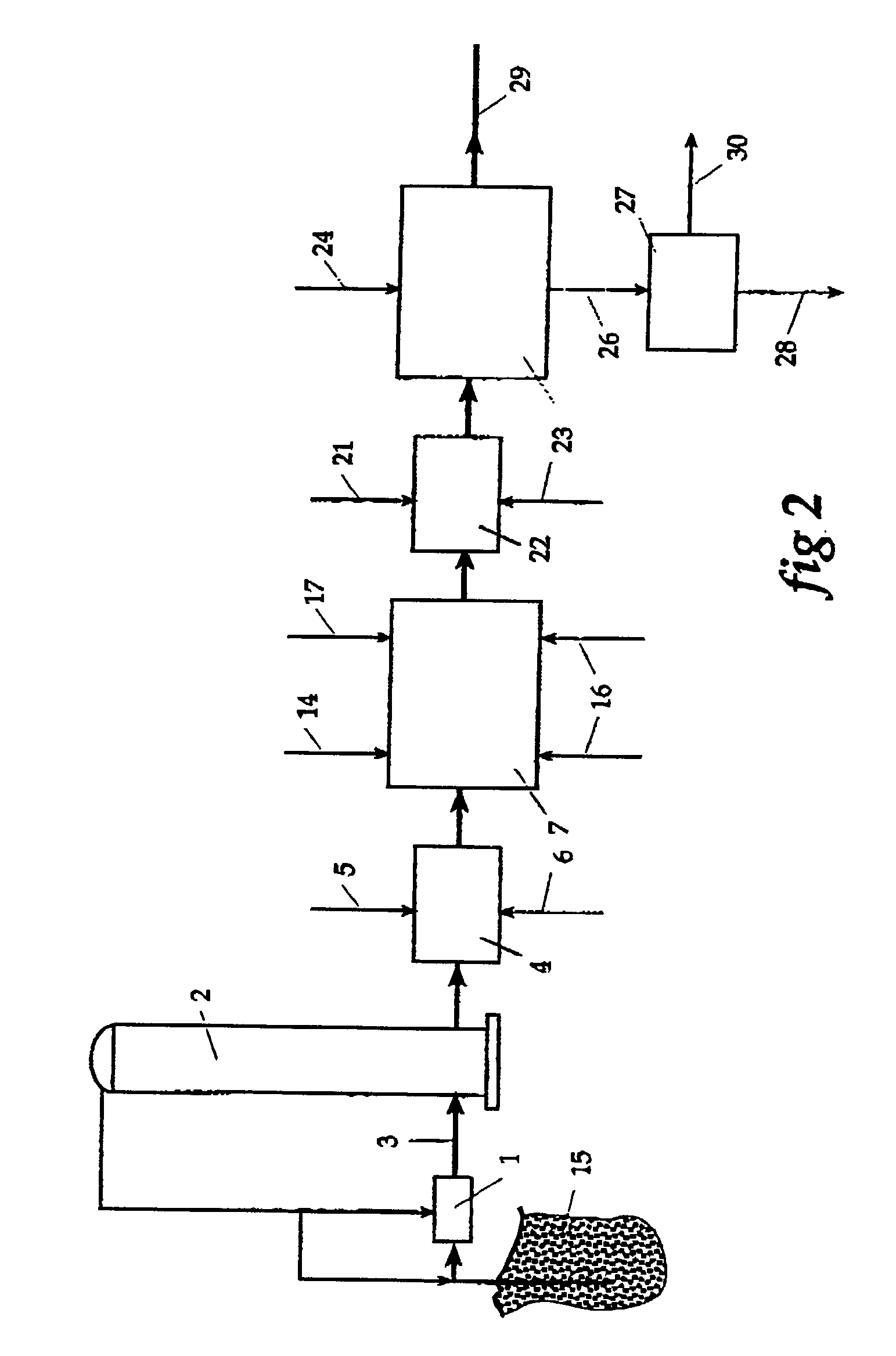

Treatment of crude oils

InactiveUS6955753B1Quality improvementImprove efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionHydrogenPetroleum

A process and apparatus to extract and recover heavy metals and sulfur from crude oil or petroleum fuel products including the steps of emulsifying the crude oil with an emulsifying agent, adding a leach solution to the emulsified crude oil and leaching the emulsified crude oil at elevated temperature and pressure to give a leached emulsified crude oil. The leach solution may be acid or alkali. A proportion of the leach solution is extracted for recovering heavy metals. There can also be a microwave hydro-treating step using hydrogen gas at a temperature below 220° C. to ensure there is no quality degradation in the crude feed to produce a desulfurized crude oil and a hydrogen sulphide by-product and recovering sulfur from the hydrogen sulphide by-product.

Owner:RODOLFO ANTONIO M GOMEZ

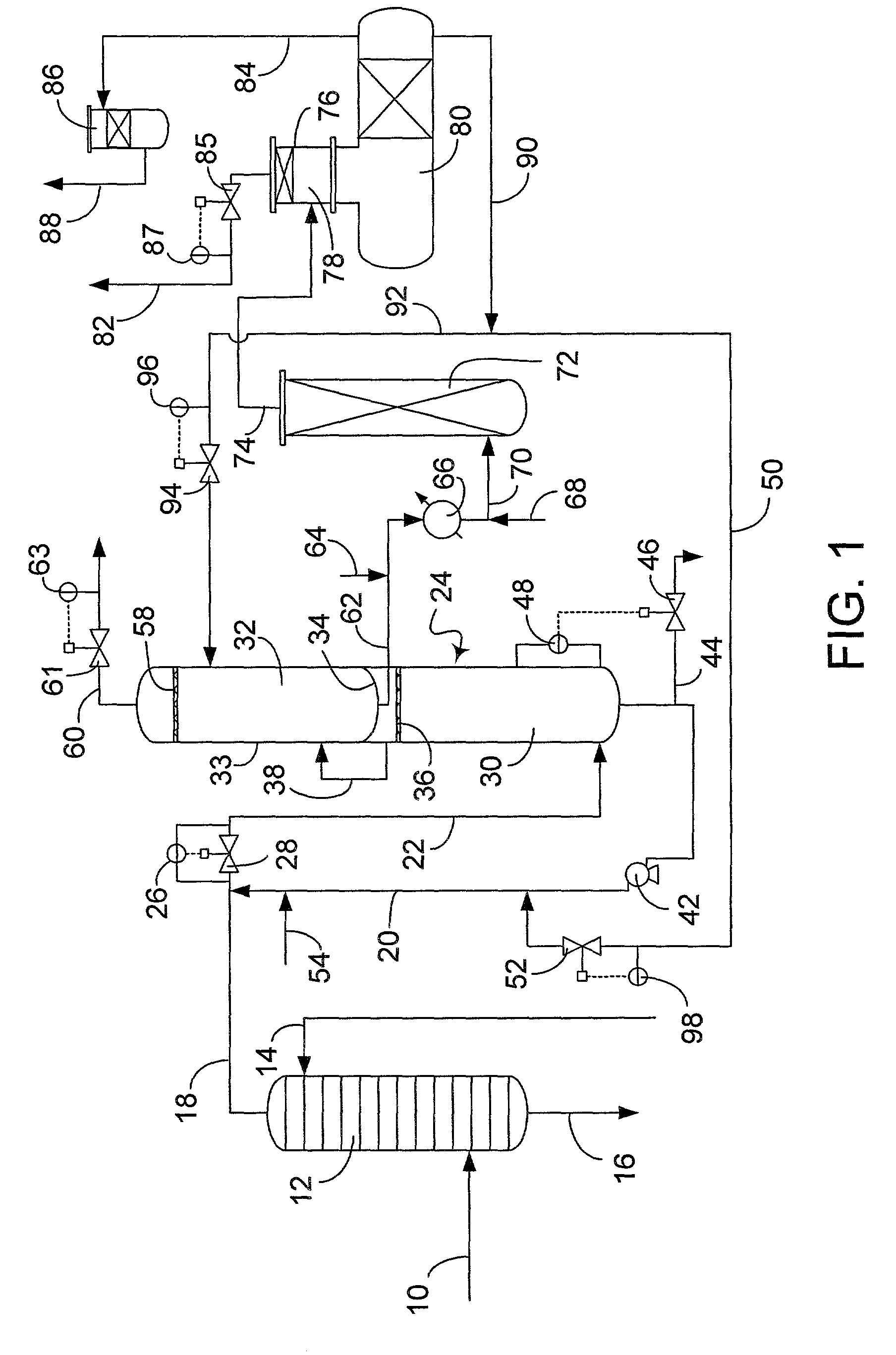

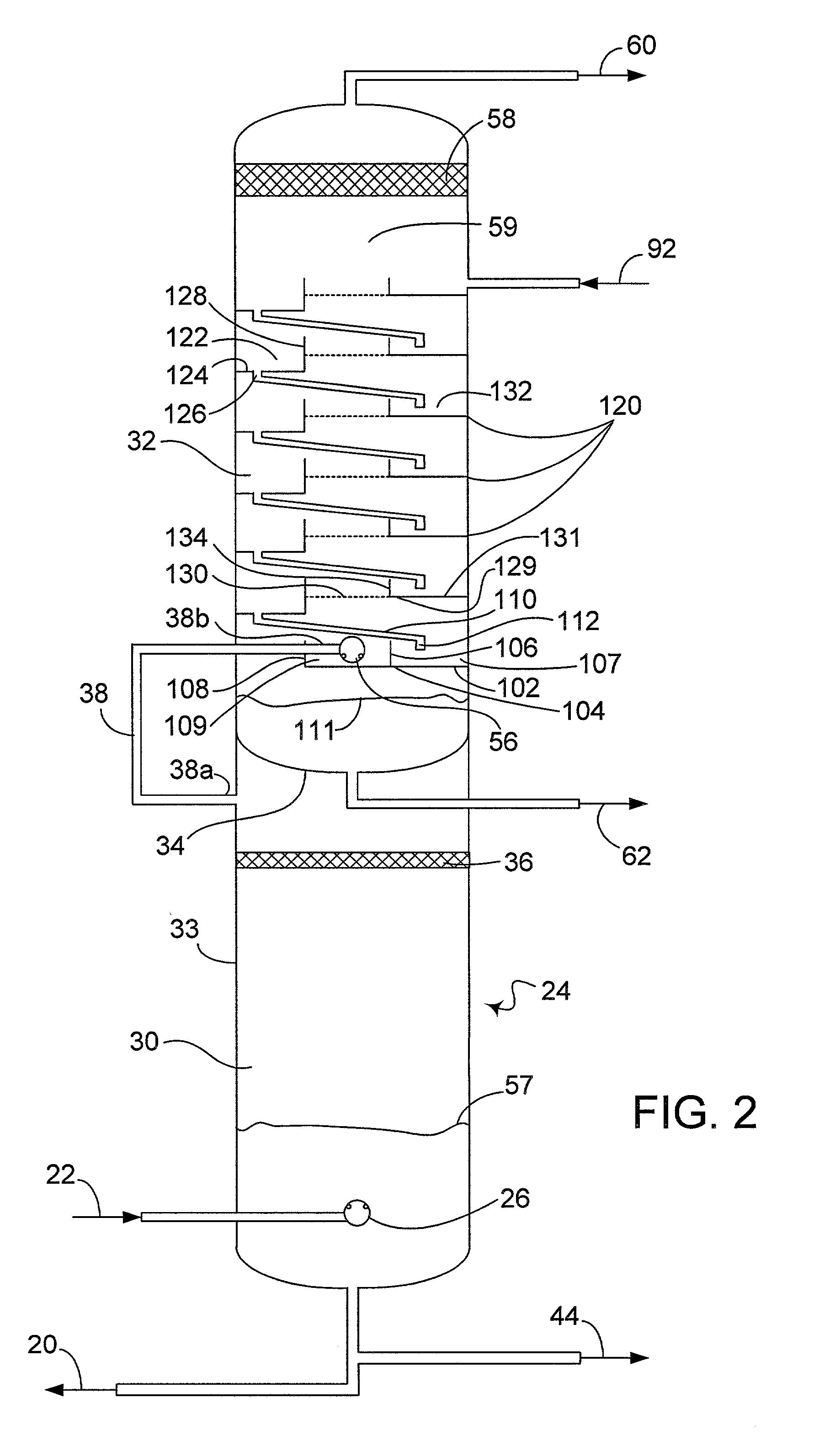

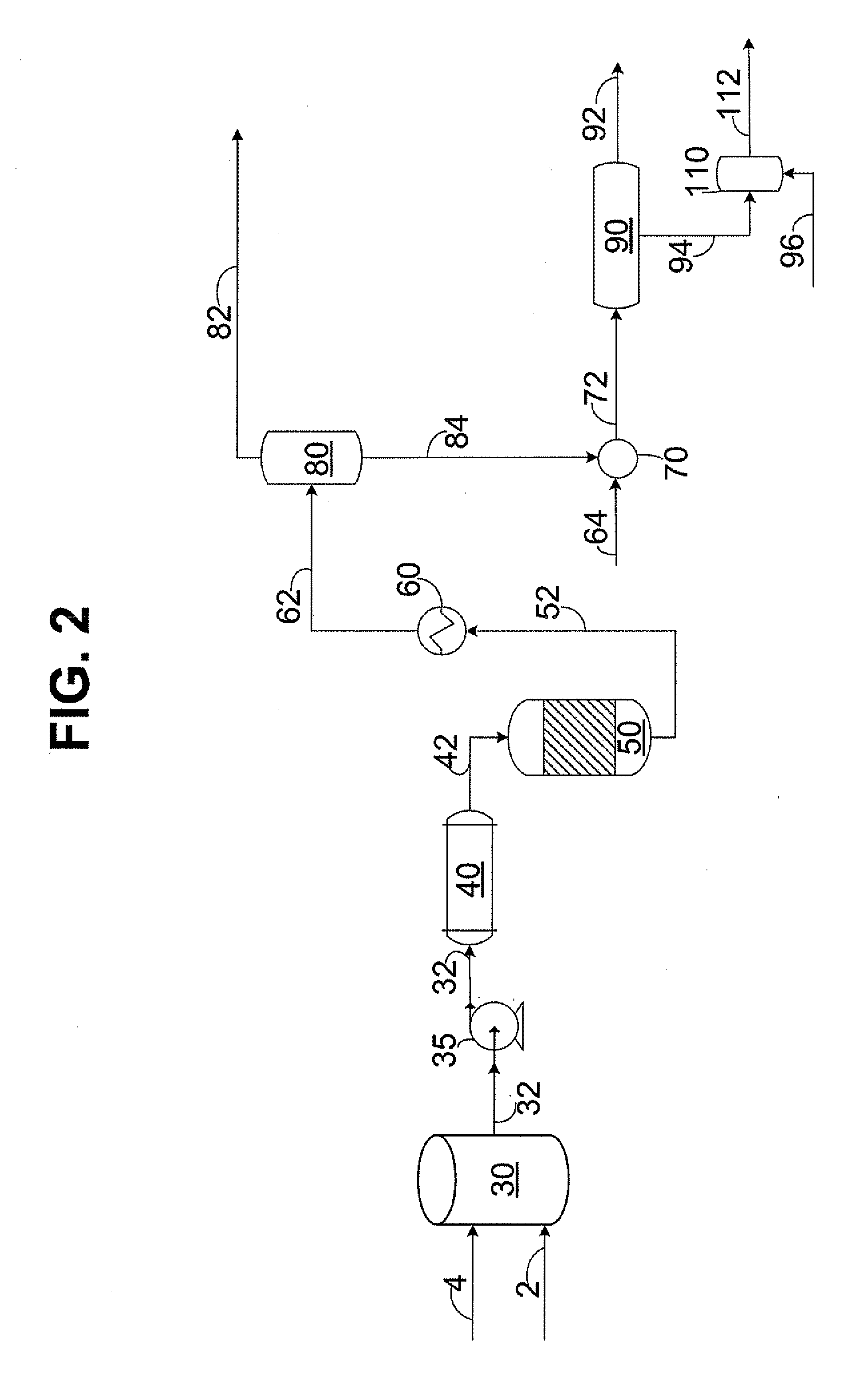

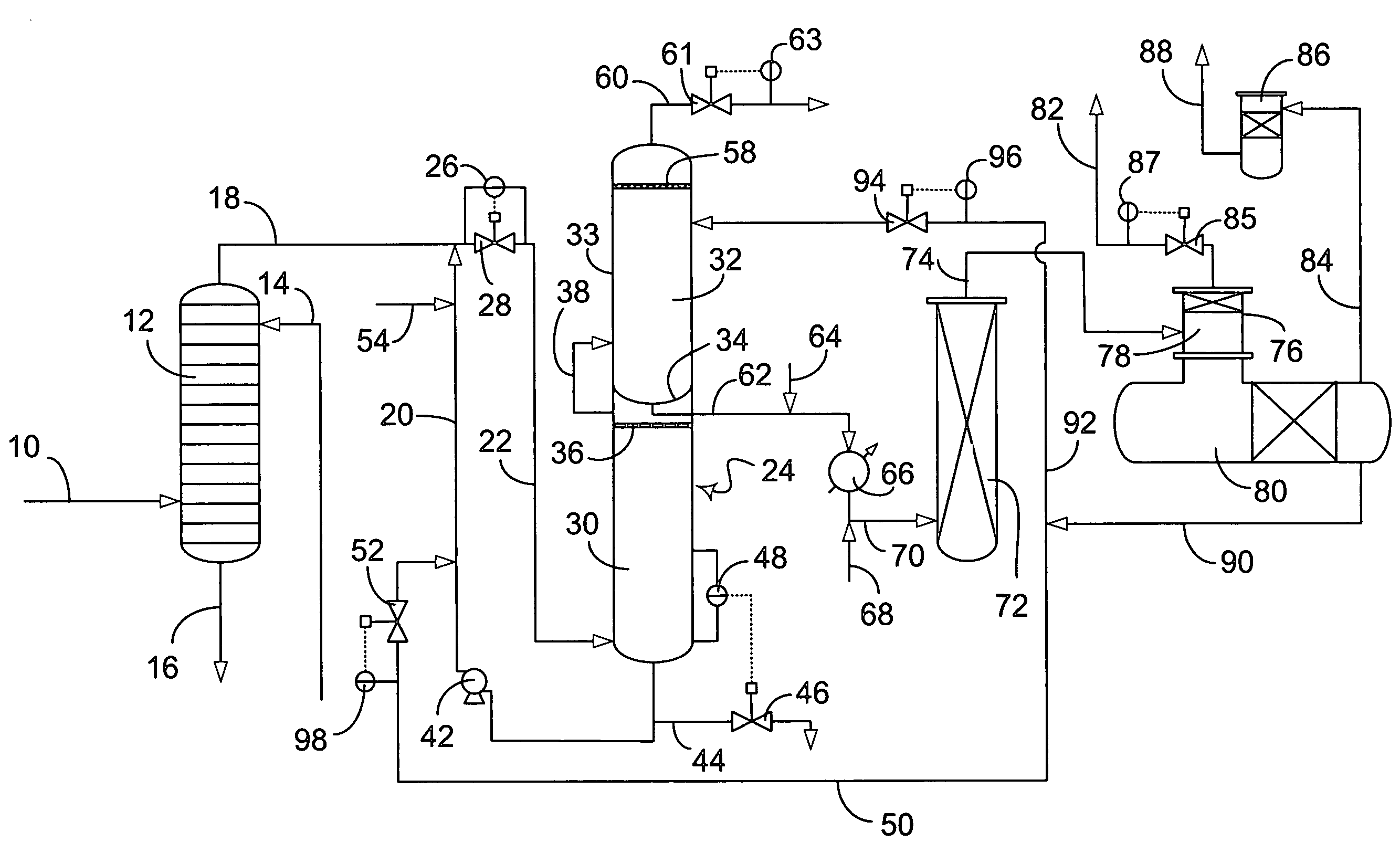

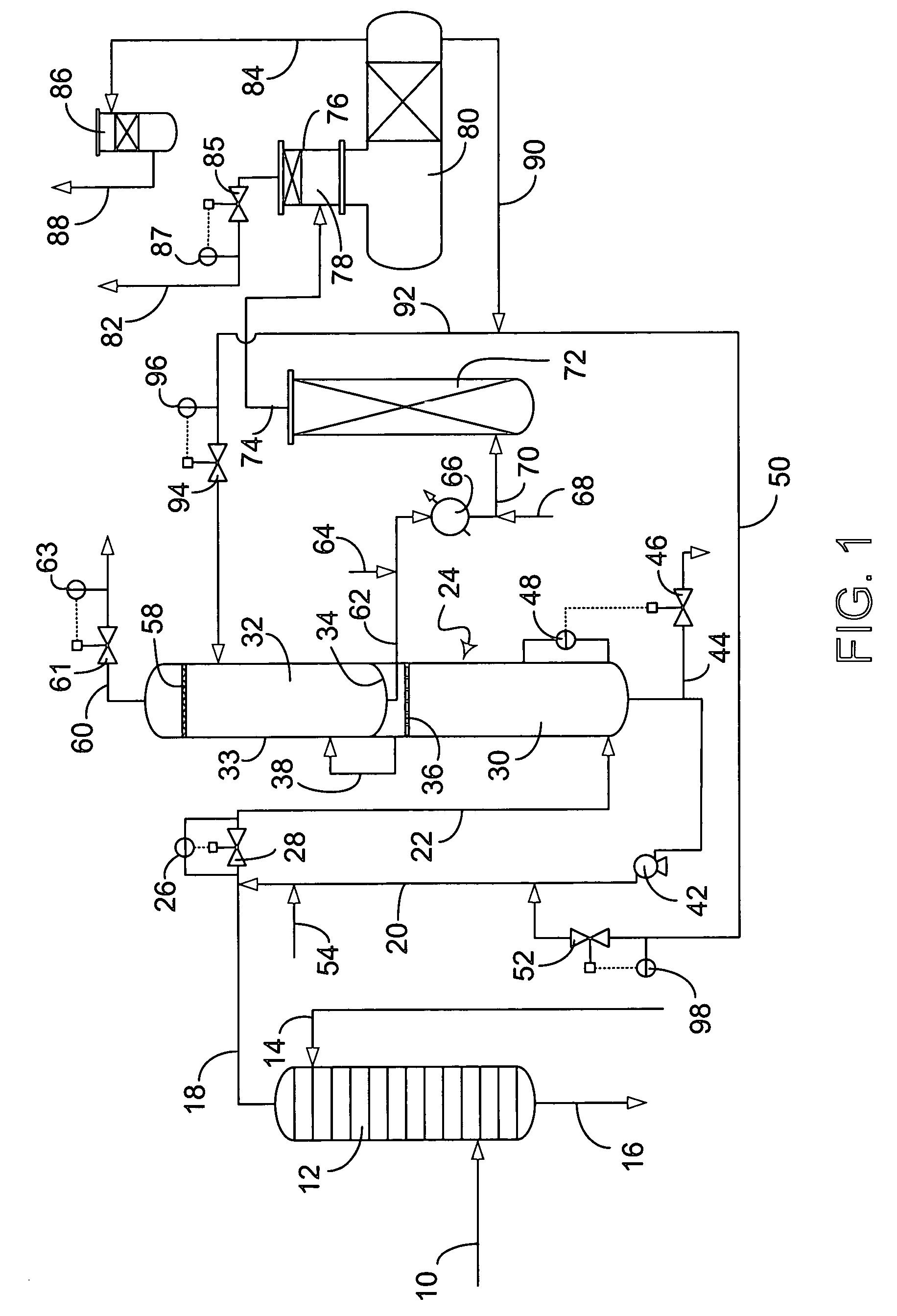

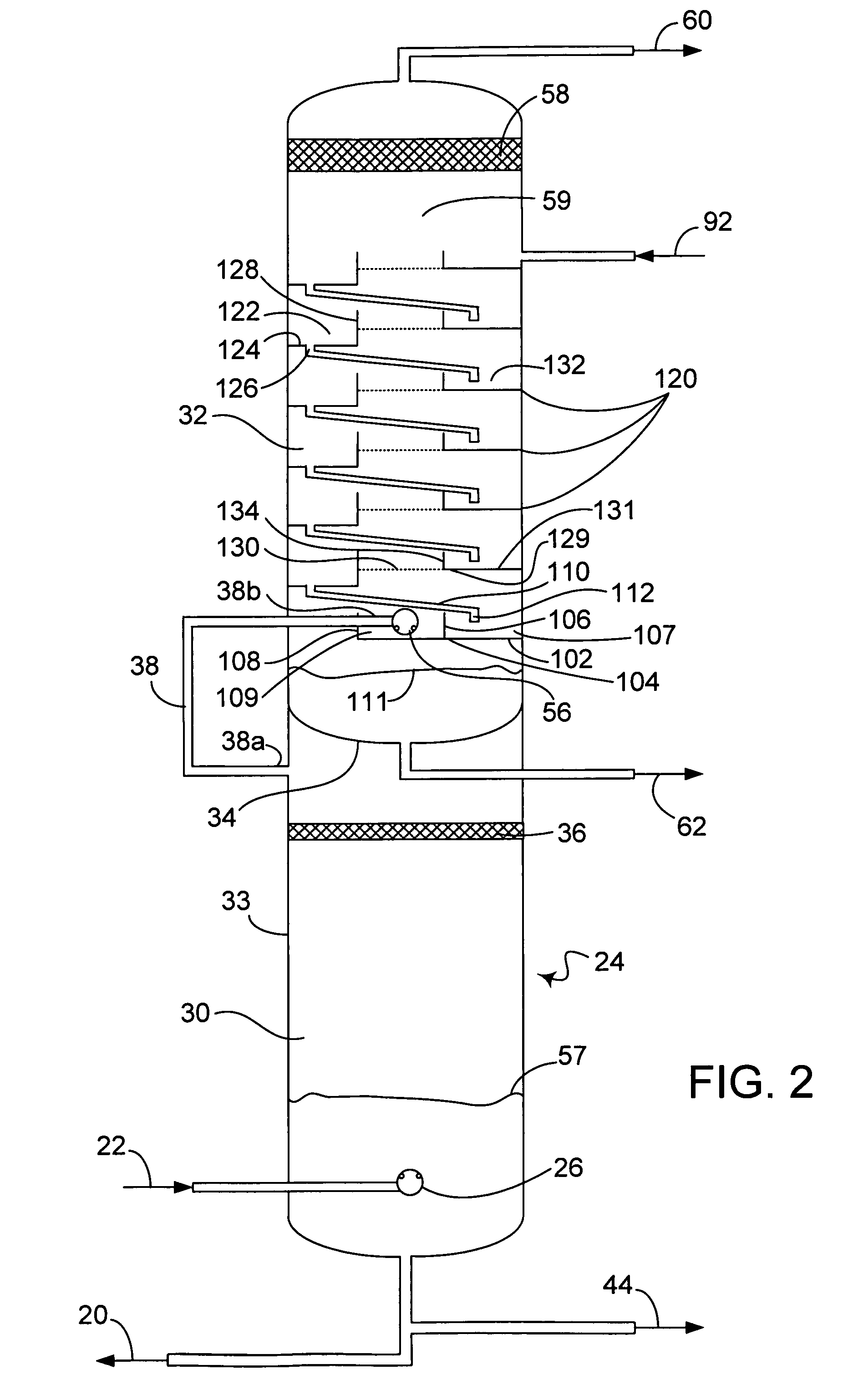

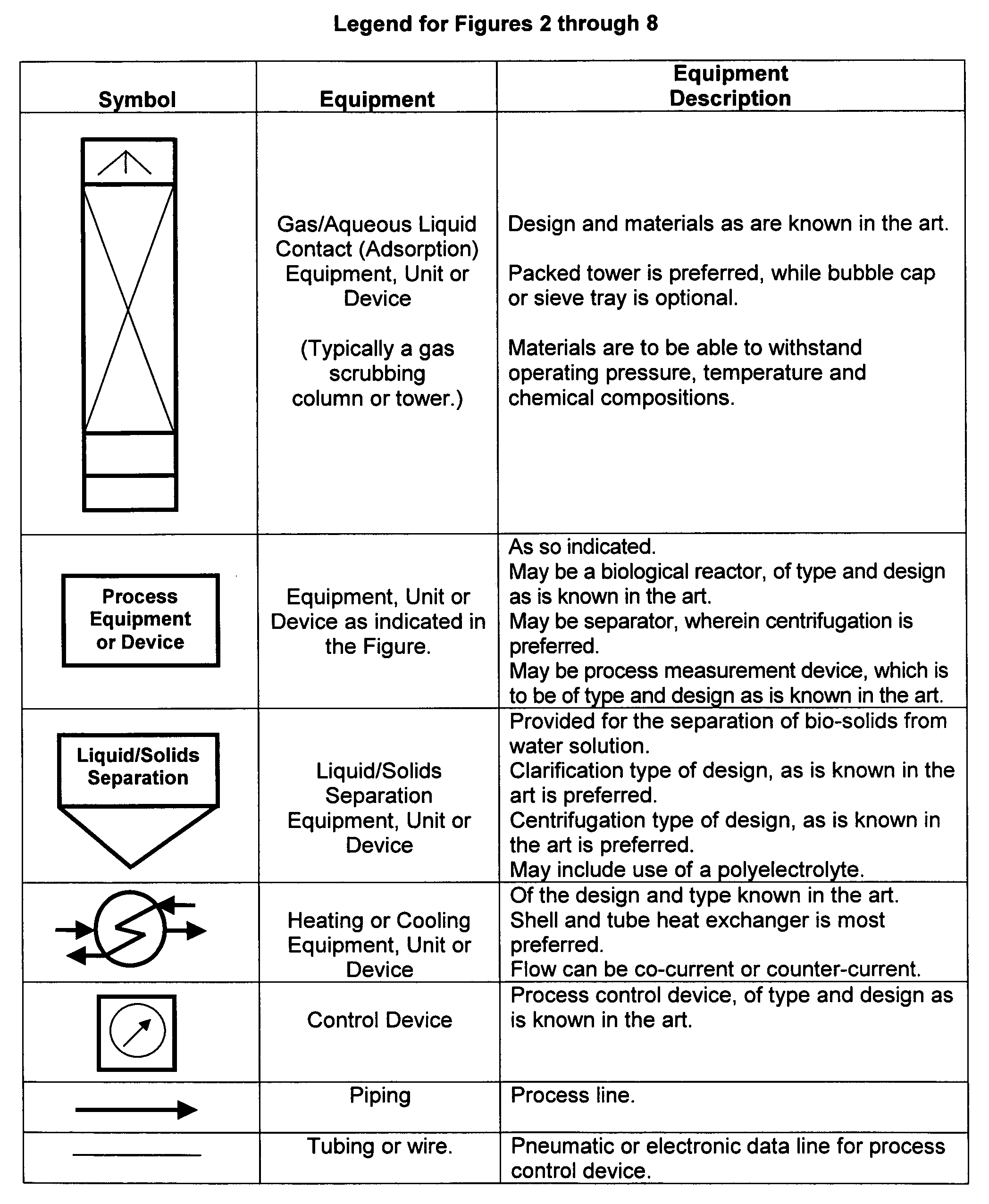

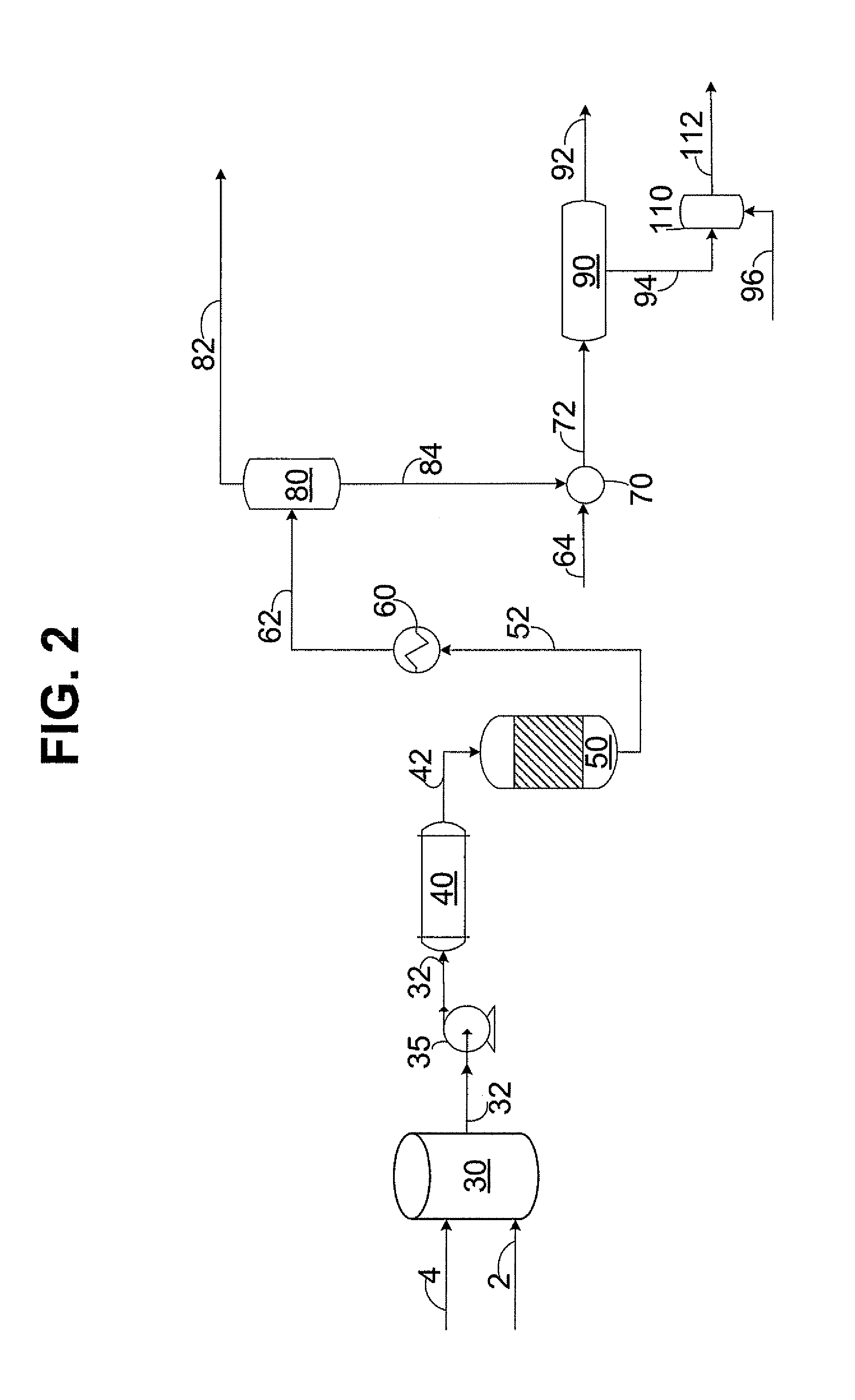

Apparatus and process for extracting sulfur compounds from a hydrocarbon stream

Described is an apparatus and process for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic communicates with an extractor section disposed directly above the prewash section for converting mercaptans to mercaptides by reaction with alkali. Hydrocarbon product exits the extractor section through a coalescer that prevents alkali from exiting with the hydrocarbon product stream.

Owner:UOP LLC

Removal of sulfur compounds from petroleum stream

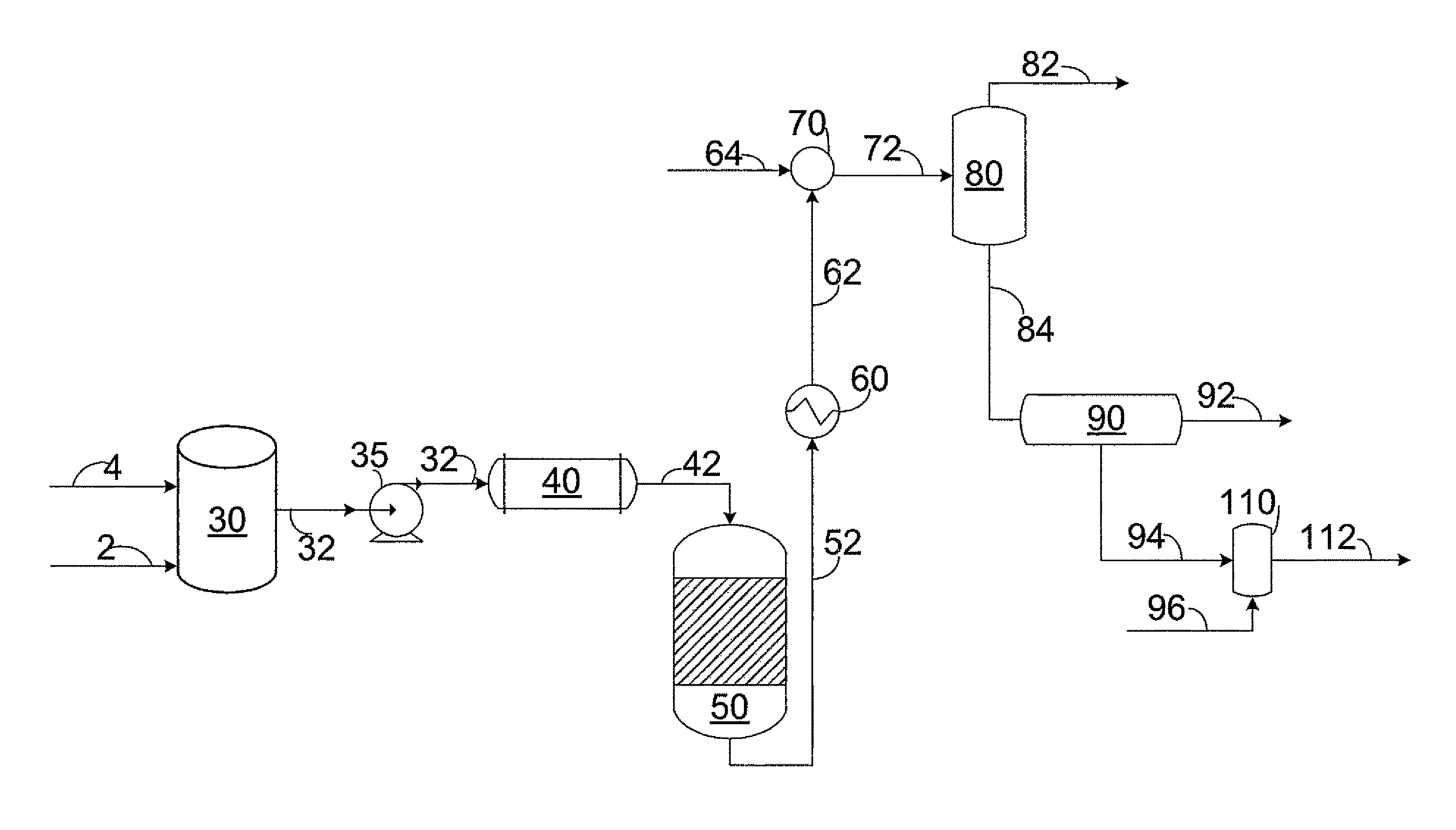

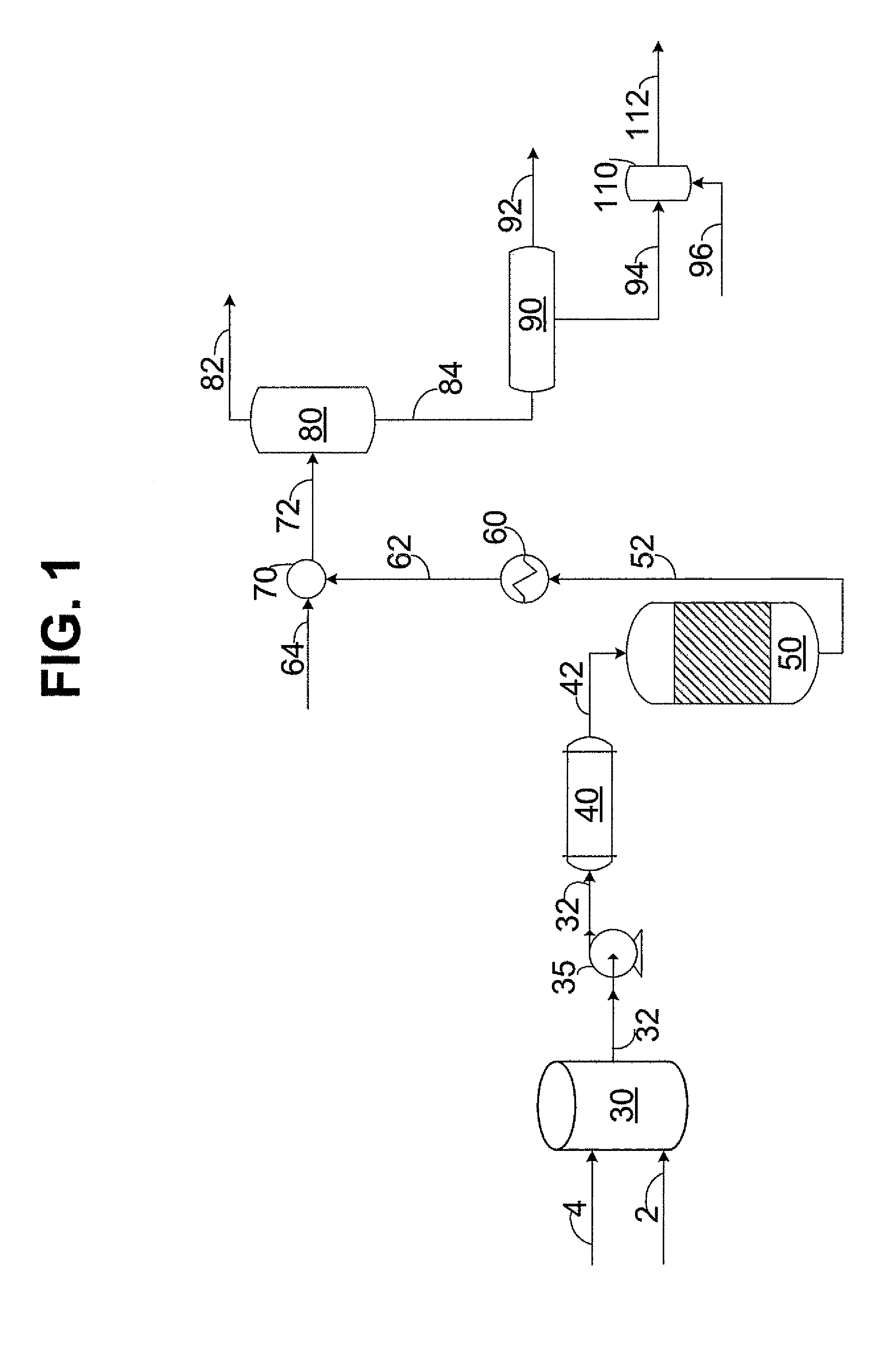

ActiveUS20110315600A1Reduce the amount requiredIncreasing API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyThiolLow nitrogen

A process for upgrading an oil stream by mixing the oil stream with a water stream and subjecting it to conditions that are at or above the supercritical temperature and pressure of water. The process further includes cooling and a subsequent alkaline extraction step. The resulting thiols and hydrogen sulfide gas can be isolated from the product stream, resulting in an upgraded oil stream that is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the oil stream.

Owner:SAUDI ARABIAN OIL CO

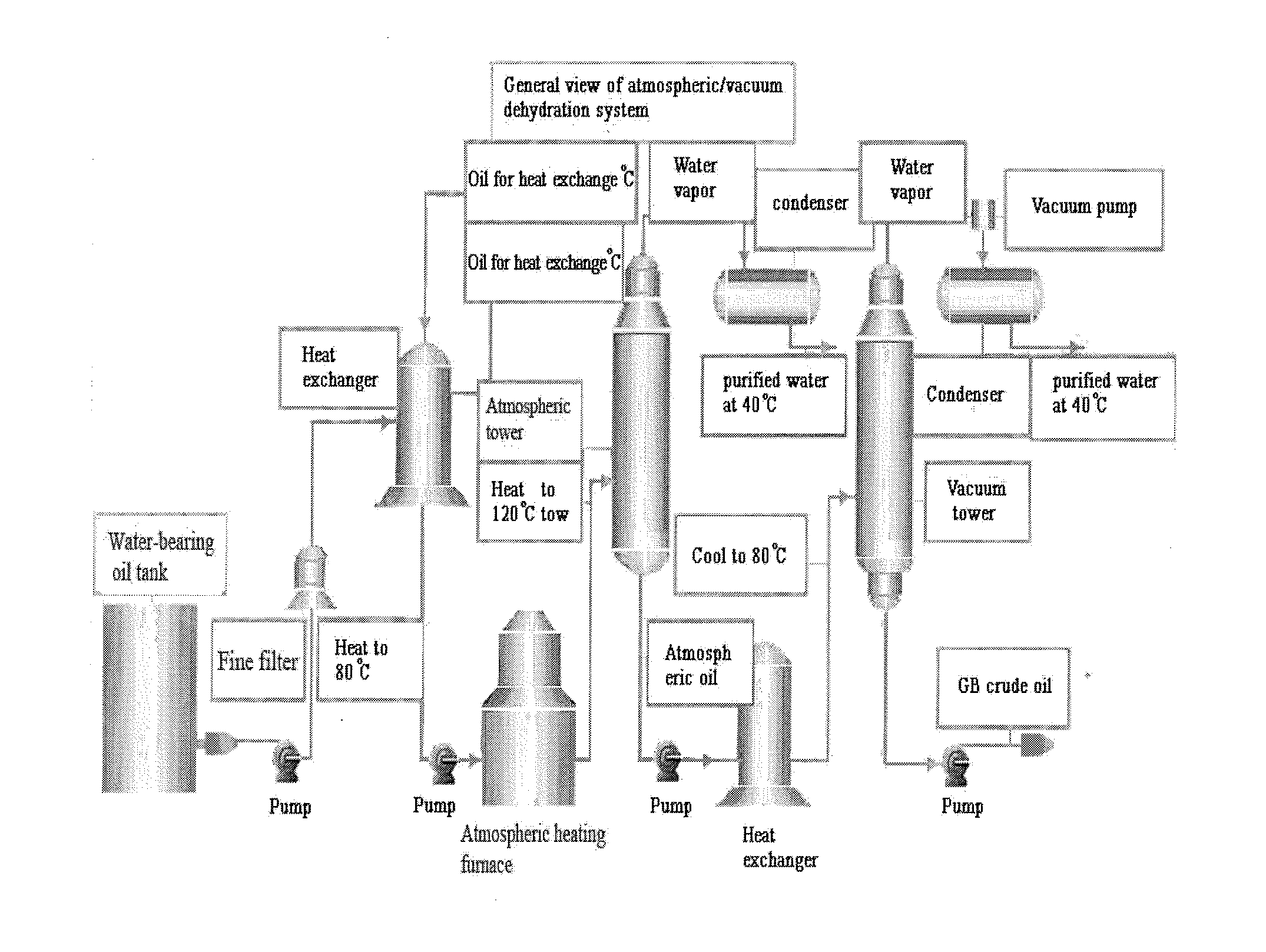

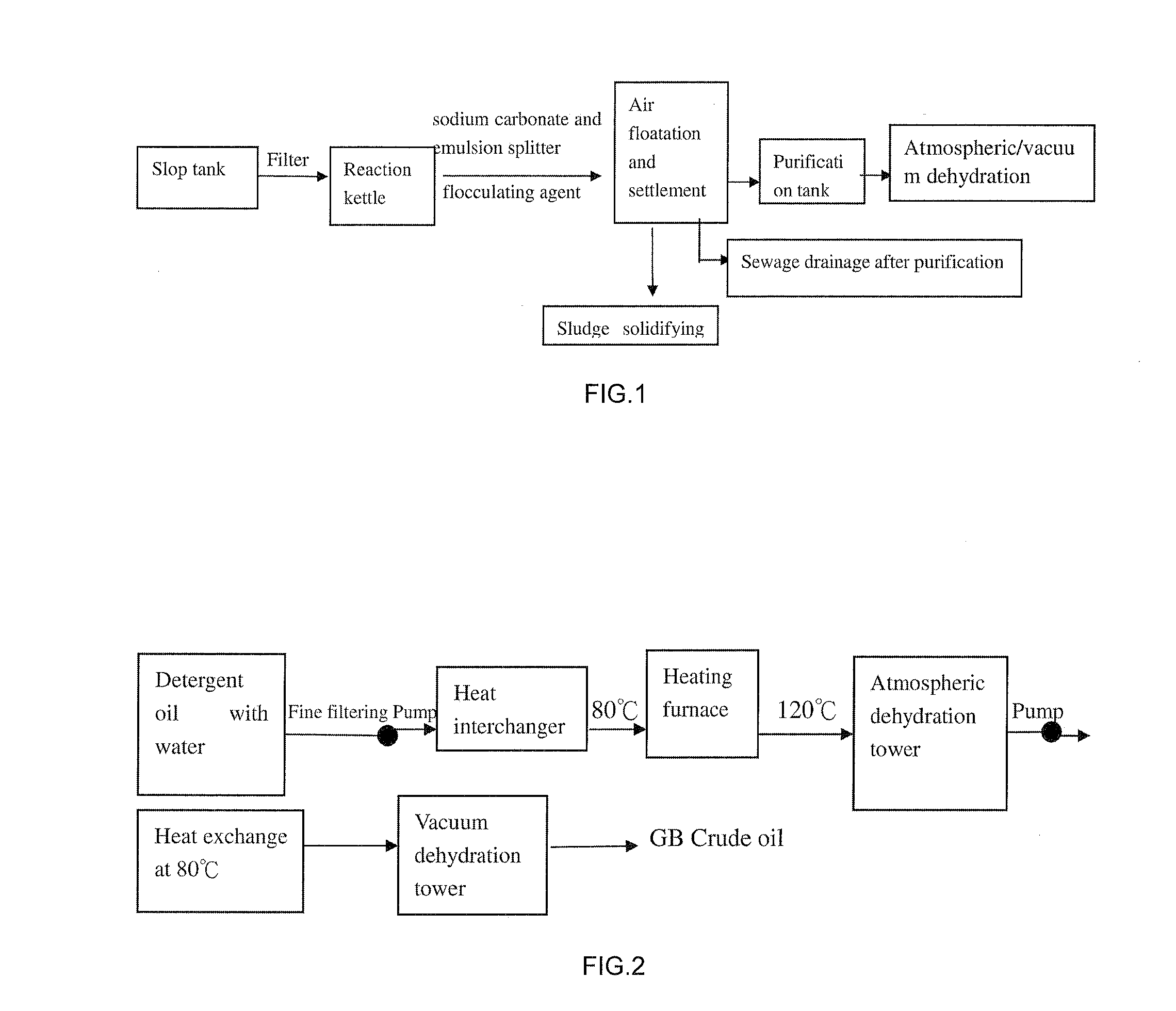

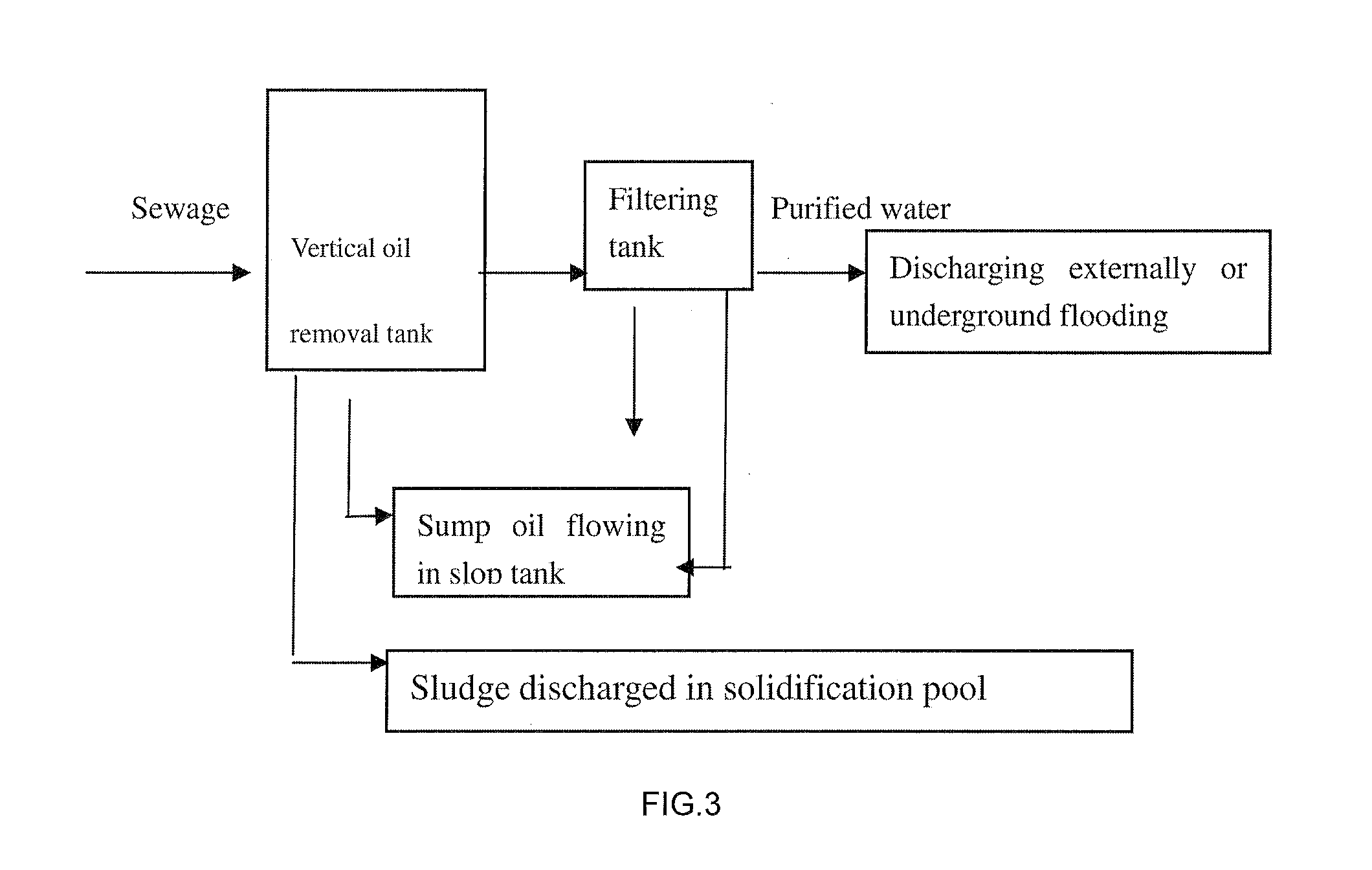

Centralized Sump Oil and Acid Oil treatment process and System

InactiveUS20120103914A1Easy to separateLow cost of treatmentSludge treatmentVacuum distillation separationSludgePollution

This invention reveals to the public the centralized sump oil and acid oil treatment process and system. The process consist of (1) the filter; (2) entry to reaction kettle, the sodium carbonate solution added at the time of air floatation till PH value keeps about 6.0-8.0; and emulsion splitter and flocculating agent added for further reaction; (3) suspension of air floatation and static settlement; (4) the international crude oil is collected after the detergent oil at the upper level of the reaction kettle is dehydrated under normal and reduced pressure; the wastewater is drained after filtering by the natural oil removal tank and the oil-water filter; the sludge is solidified by the cement and the quick lime and aluminium oxide are used as the coagulant aid for solidifying the sludge. The centralized treatment process of sump oil and acid oil not only greatly lowers the pollution of surroundings of the oilfield and corrosion of equipment, but also changes waste into valuable, reuses a great amount of crude oil and improves the economic benefits of the oilfield. The sludge solidified can be directly used for buildings.

Owner:YUAN GANG

Apparatus for prewashing a hydrocarbon stream containing hydrogen sulfide

Disclosed is an apparatus for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic prepares the hydrocarbon stream for extraction. Spent alkali is continuously withdrawn and regenerated alkali is continuously added to the prewash section.

Owner:UOP LLC

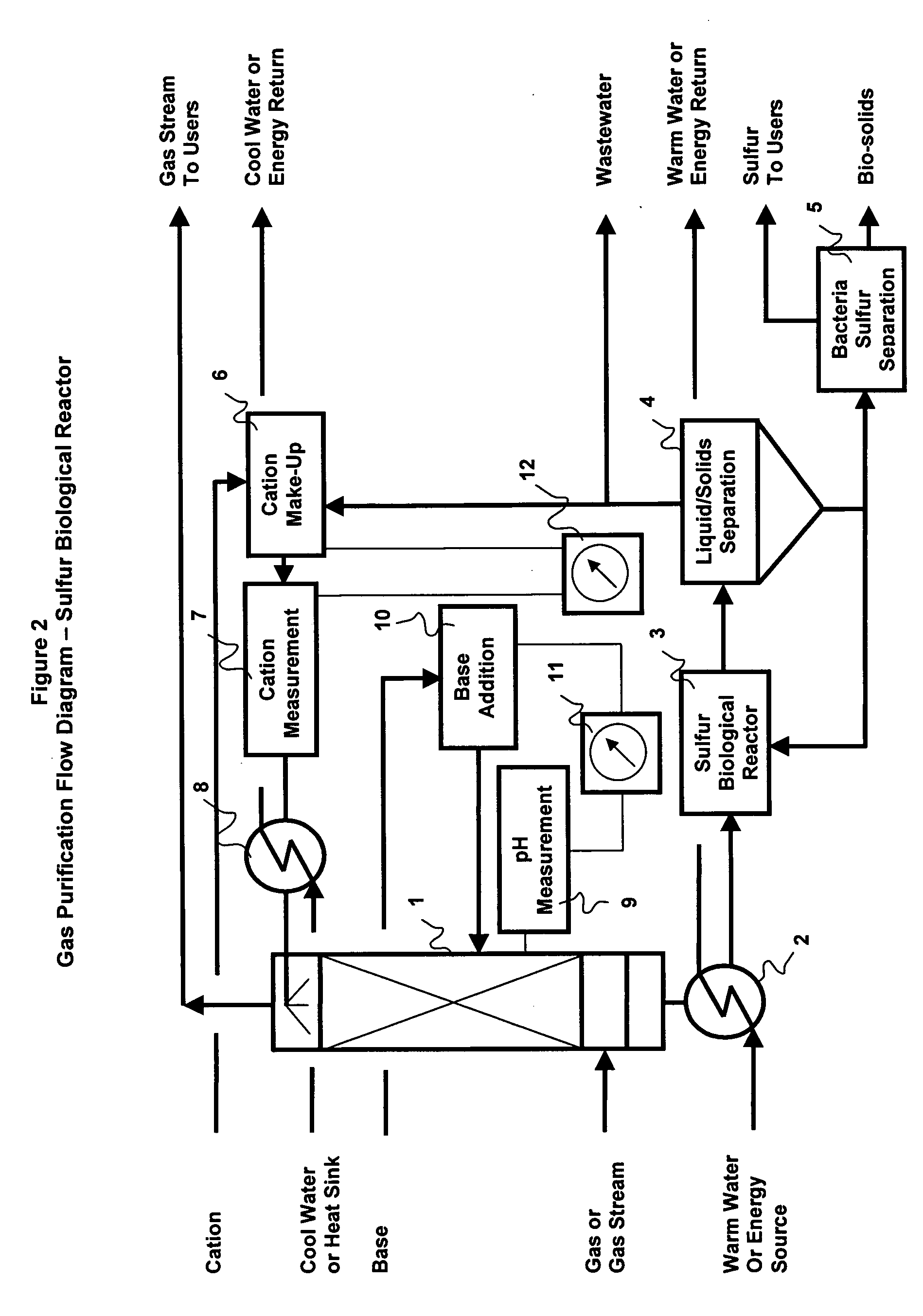

Methods, processes and apparatus for biological purification of a gas, liquid or solid; and hydrocarbon fuel from said processes

InactiveUS20080190844A1Effective and efficient and economically feasibleTreatment using aerobic processesWaste water treatment from gaseous effluentsPresent methodThiobacillus

This invention relates to improved methods, processes and apparatus for the removal of sulfides from a gas, liquid or solid (substance) wherein the substance is contacted with an aqueous solution. The instant invention presents methods and processes wherein at least one of H2S, SO2 and CS2 is chemically converted in an aqueous media to a salt and / or compound comprising sulfur and a cationic moiety. Said salt and / or compound comprising sulfur and a cationic moiety is herein termed a “Sulfur Salt”. After formation of the Sulfur Salt, the Sulfur Salt is converted to elemental sulfur with a bacterium capable of metabolizing sulfur. The preferred bacterium for metabolizing sulfur is a strain from the genus Thiobacillus. The most preferred strain from the genus Thiobacillus is Thiobacillus denitrificans. The instant invention prefers an aqueous operating pH of between 6.0 and 8.0, while the most preferred aqueous pH is between 6.0 and 7.0.

Owner:CLEARVALUE TECH

Mercaptan removal and lye regeneration device and method for gasoline light fractions

Owner:NINGBO ZHONGYI PETROCHEM TECH

Process for removing one or more sulfur compounds from a stream

InactiveUS20120000827A1Lowered disulfide contentReducing and eliminating undesiredRefining with aqueous alkaline solutionsHydrocarbon oils treatmentThiolSulfur

One exemplary embodiment can be a process for removing one or more disulfide compounds from a caustic stream. The process can include passing the caustic stream, previously contacted with a hydrocarbon stream for removing one or more mercaptans, through a column to remove the one or more disulfide compounds downstream of a mercaptan oxidation zone.

Owner:UOP LLC

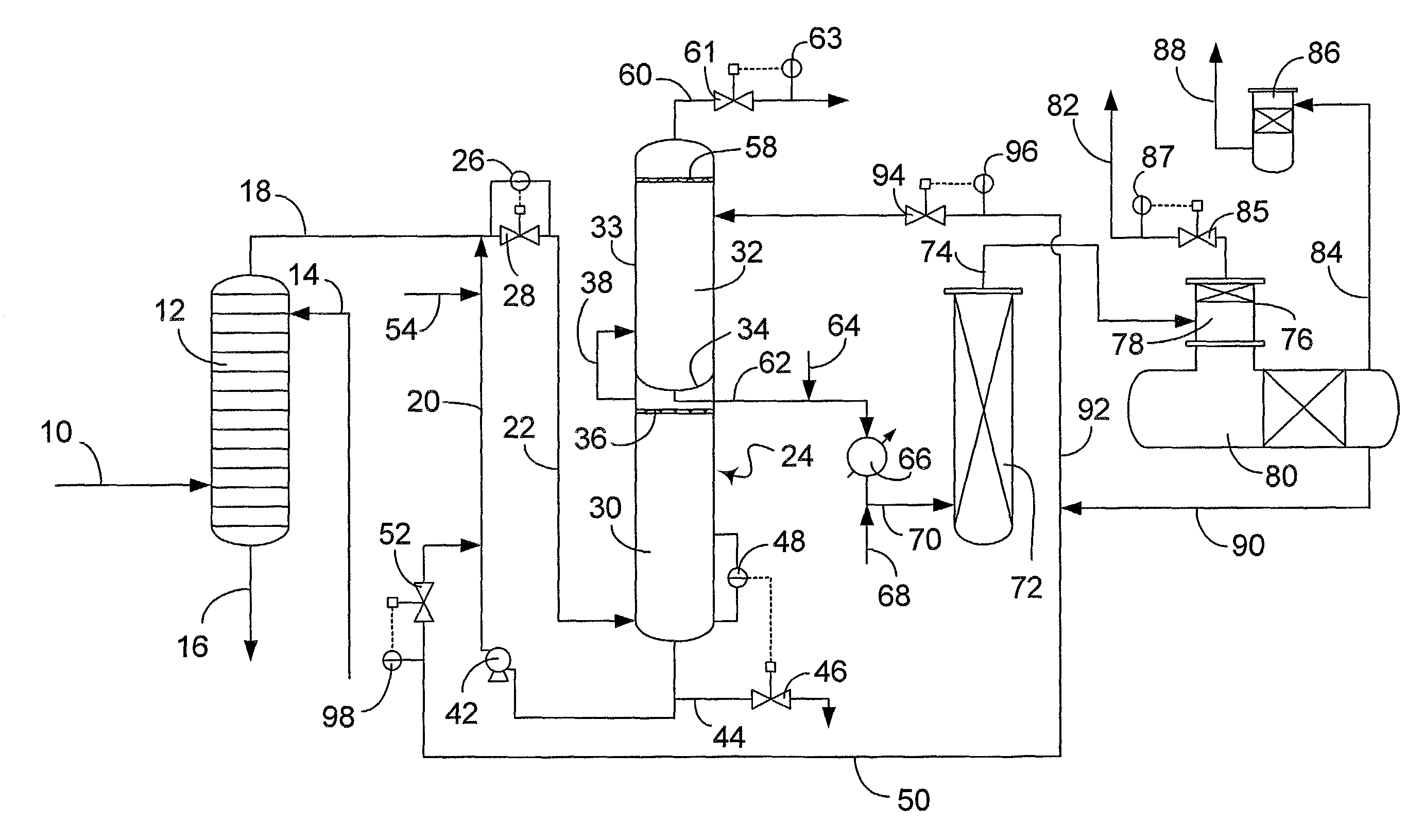

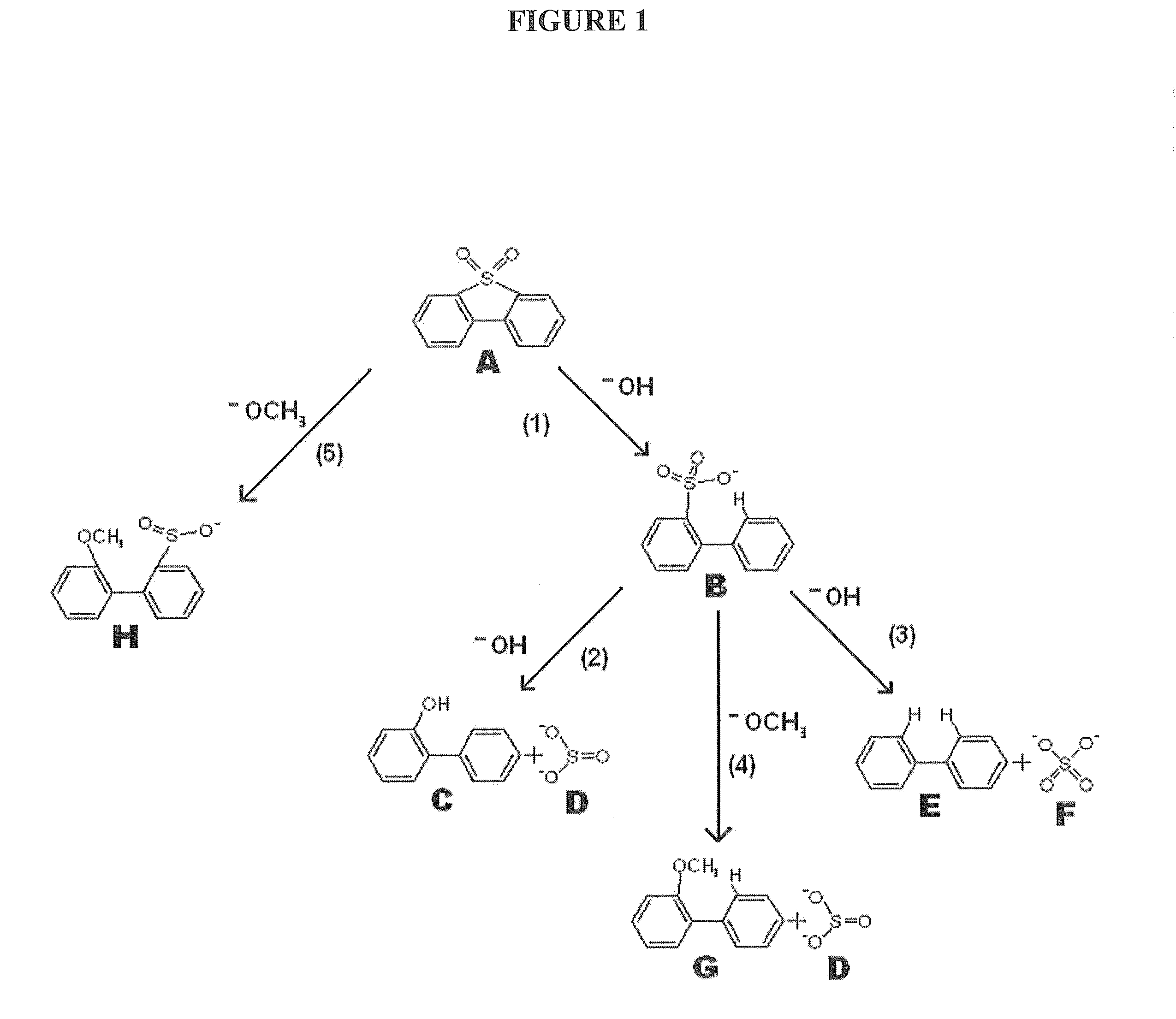

Removal of sulfur-containing compounds from liquid hydrocarbon streams

InactiveUS7790021B2Easy to separateEasy extractionRefining with oxygen compoundsTreatment with plural serial refining stagesLiquid hydrocarbonsSulfite

An improved method for desulfurizing a fuel stream such as a diesel stream is disclosed which includes generation of a sulfone oil, the desulfurization of the sulfone oil and the recycling of the resulting biphenyl-rich stream and ultra-low sulfur diesel streams. The method includes combining a thiophene-rich diesel stream with an oxidant to oxidize the thiophenes to sulfones to provide a sulfone-rich diesel stream. Sulfone oil is extracted from the sulfone-rich diesel stream to provide sulfone oil and a first low-sulfur diesel stream The low-sulfur diesel stream is recycled. The sulfone-rich oil stream is combined with an aqueous oxidant-containing stream, such as caustic stream, which oxidizes the sulfones to biphenyls and forms sulfite to provide a second low-sulfur diesel stream.

Owner:UOP LLC

Naphtha hydroprocessing with mercaptan removal

InactiveUS20050284794A1Increase valueHigh yieldHydrocarbon oil crackingTreatment with hydrotreatment processesNaphthaOrganic chemistry

This invention relates to the hydroprocessing of naphtha with removal of mercaptan from product. Naphtha feedstock is hydrotreated and hydrocracked. Sulfur-containing contaminants, notably C5+ recombinant mercaptans, are then selectively removed from the hydrocracked naphtha by selective extraction or adsorption.

Owner:EXXON RES & ENG CO

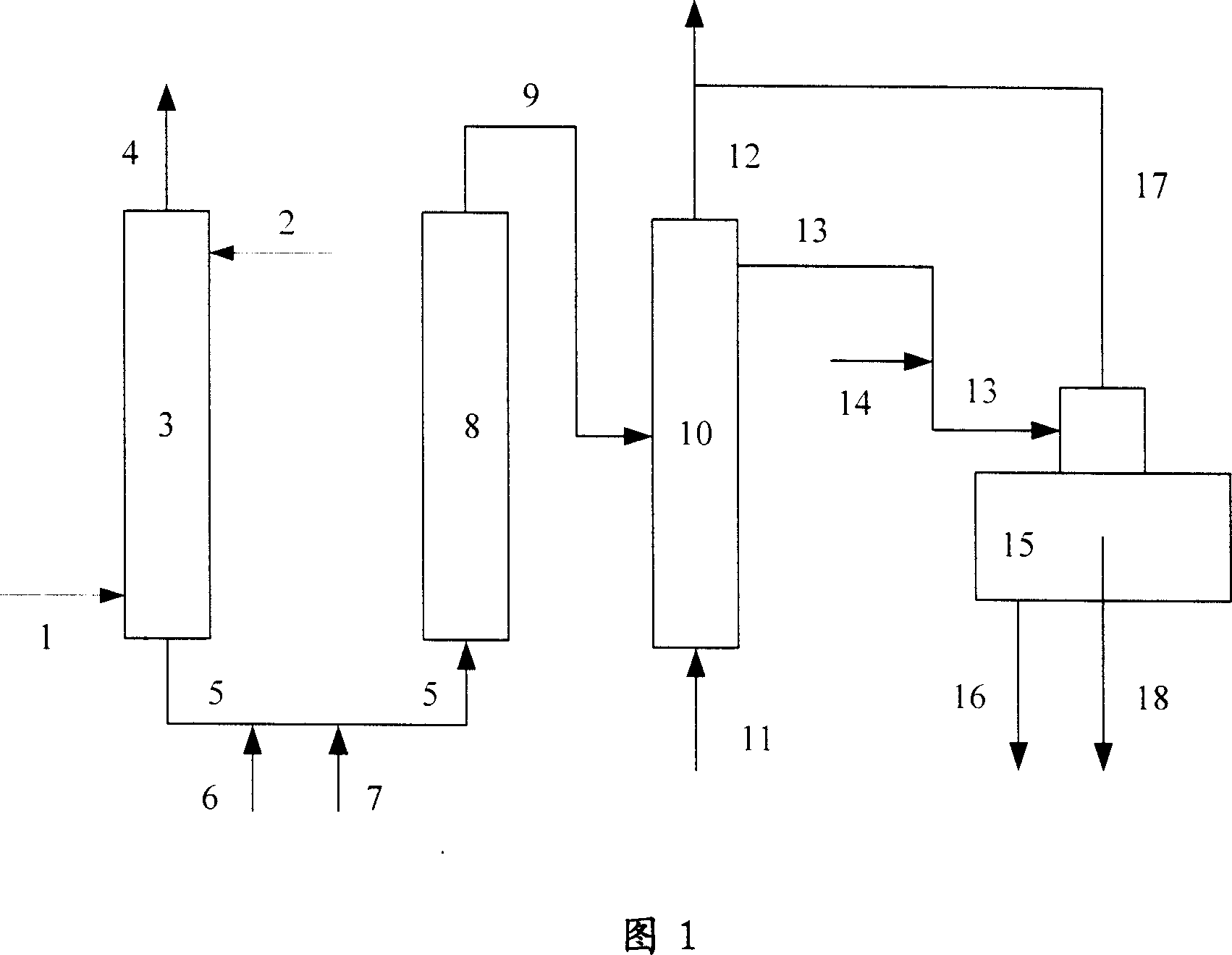

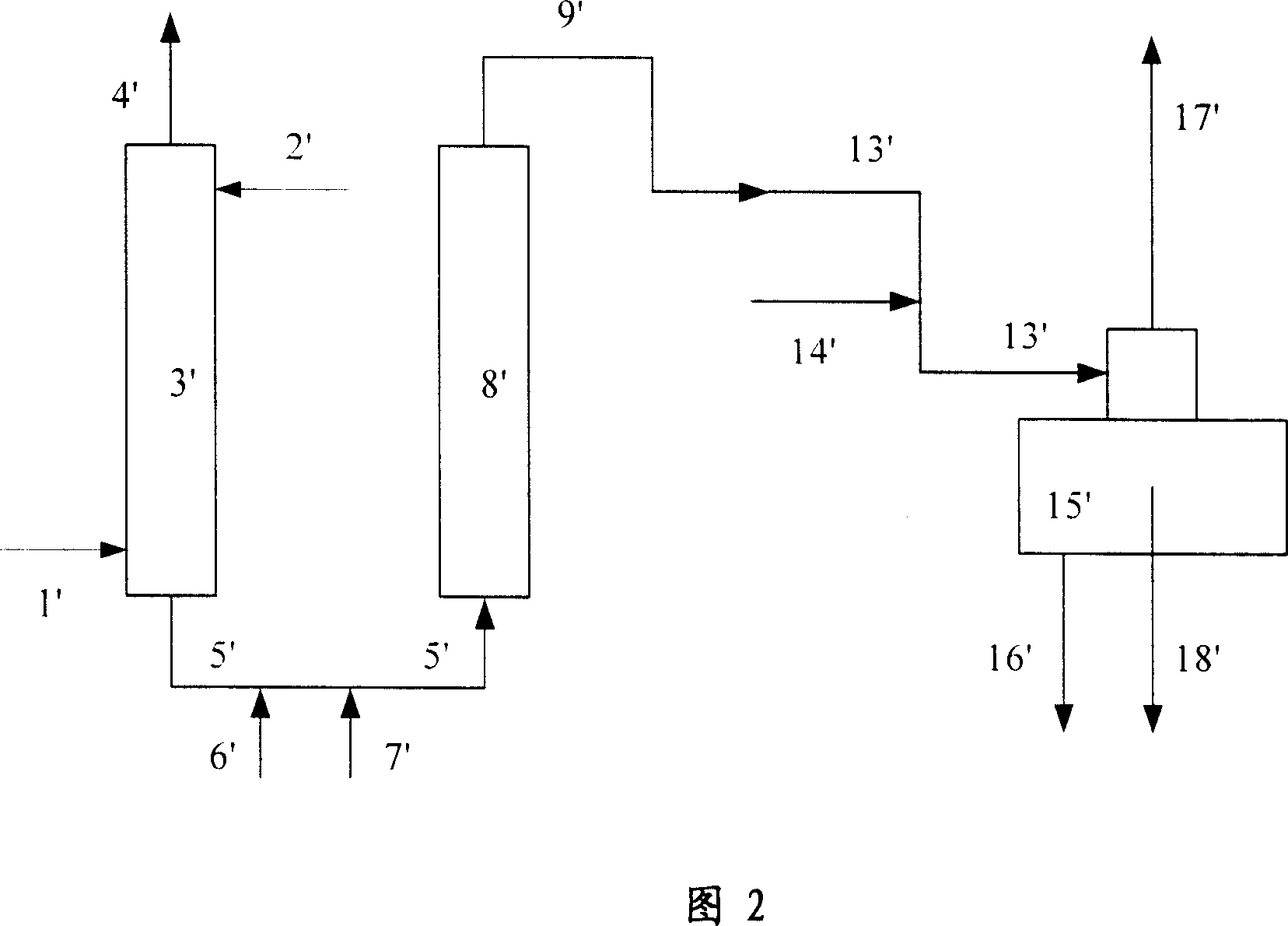

Method and device for lye extraction desulfurization

ActiveCN1990828AExtraction and desulfurization realizedRealize the purpose of extraction and desulfurizationRefining with aqueous alkaline solutionsThiolSolvent

The invention provides a method and device for desulfurization from hydrocarbon flow thorough alkaline liquid suction. It is to add a gas- removal system between oxidation system and phase separation system, and introduce inert gas into gas- removal system to exchange oxidative gas and then effectivelyt promote the separation of sulfur dioxide or sulfur dioxide- containing solvent from regenerative alkaline liquid in phase separation system, and the thiol in hydrocarbon flow can be inhibited from oxidation by oxidative gas in suction system, which enables thorough desulfurization by alkaline liquid suction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Emulsion neutralization of high total acid number (TAN) crude oil

InactiveUS20060054538A1Eliminate needReduce acidityWaste water treatment from quariesWater/sewage treatment by neutralisationOrganic acidAqueous droplet

This invention is a method for reducing the total acid number of organic acid containing petroleum oil comprising forming a water-in-oil emulsion comprising an aqueous Group IIA metal hydroxide solution or slurry in a hydrocarbon oil, said water-in-oil emulsion having an aqueous droplet particle size diameter of from 1 to 25μ, adding the water-in-oil emulsion to the organic acid containing petroleum oil and permitting the mixture to stand for a time sufficient to permit the neutralization of the organic acids in the petroleum oil.

Owner:EXXON RES & ENG CO

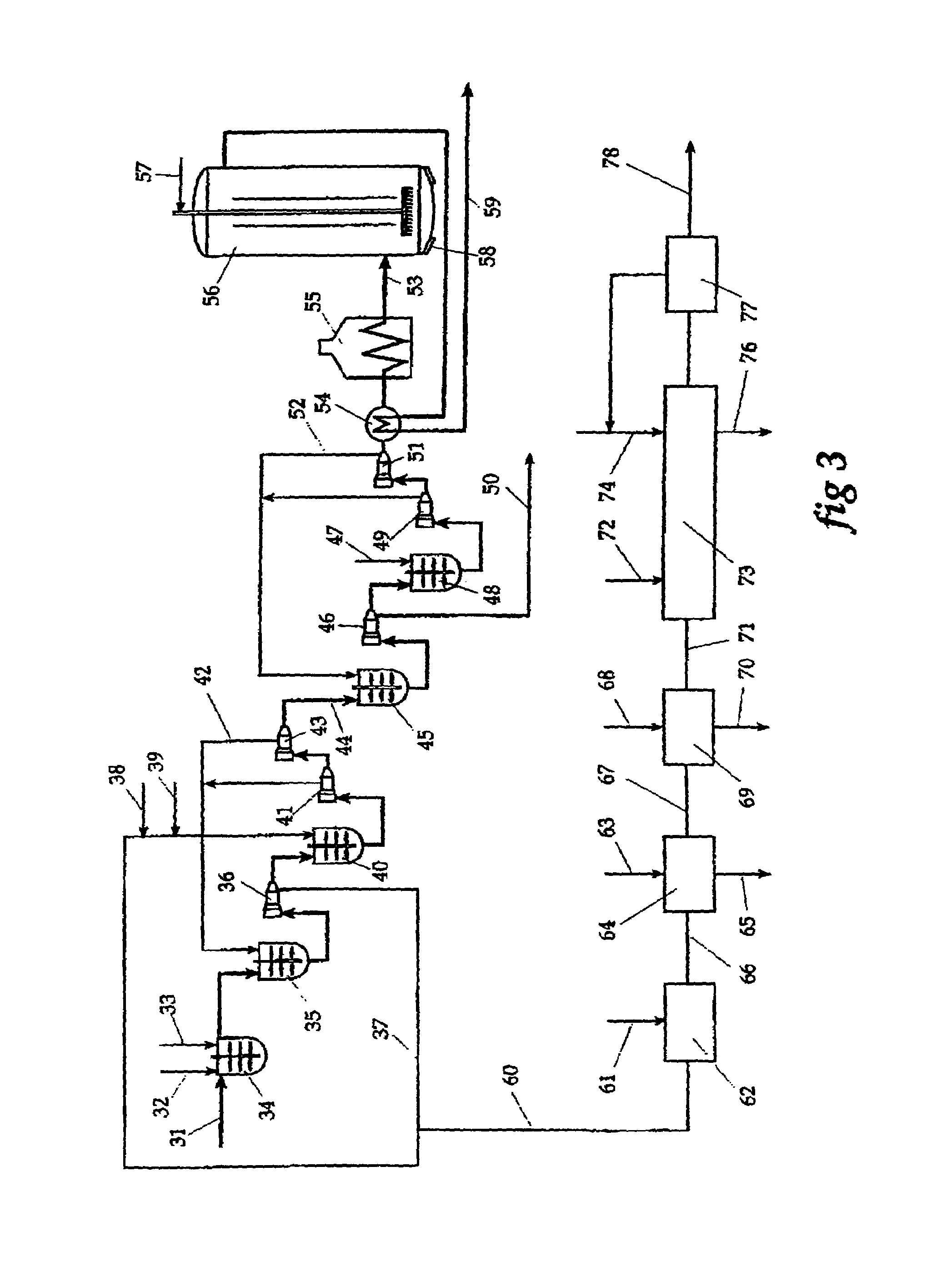

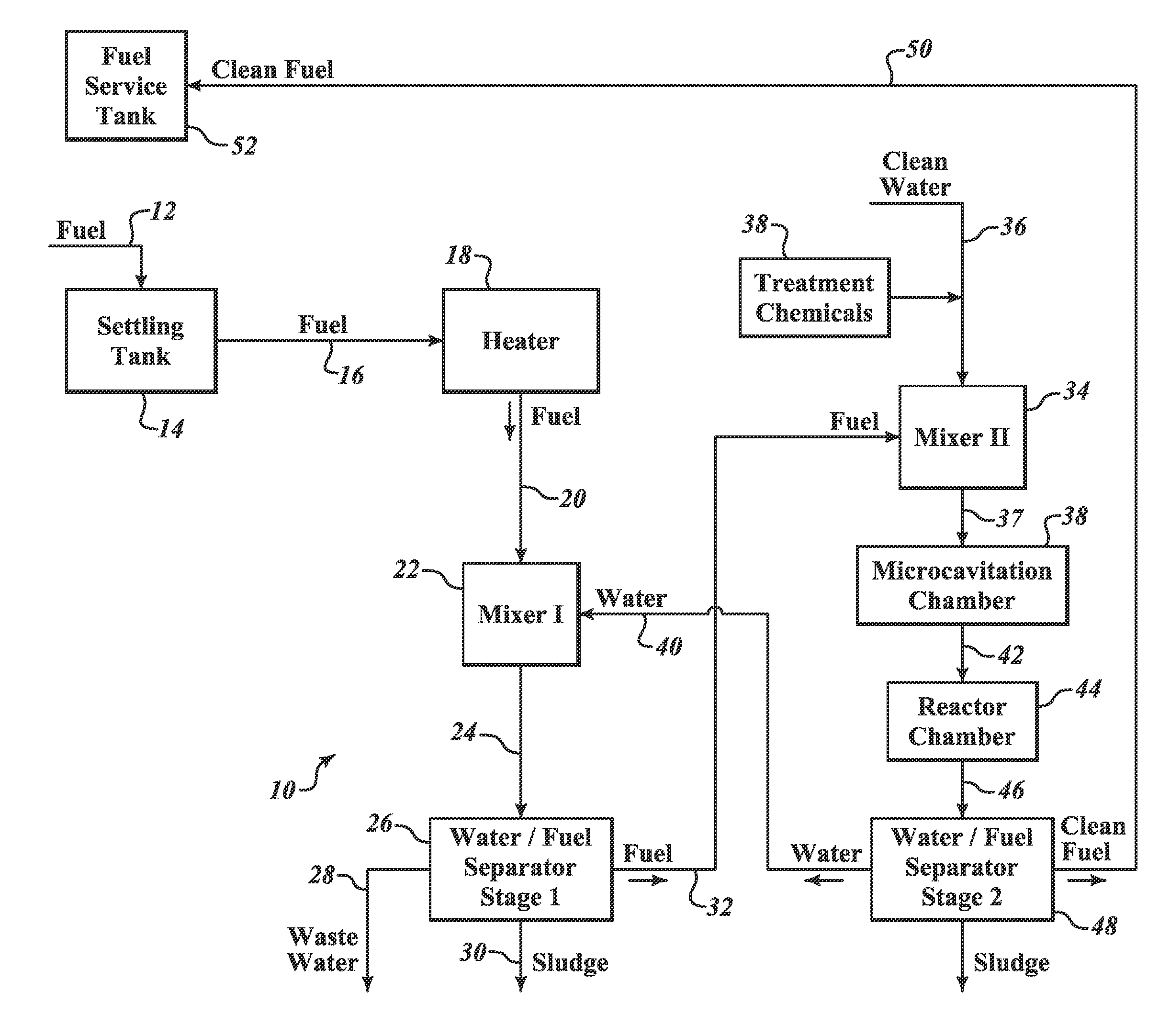

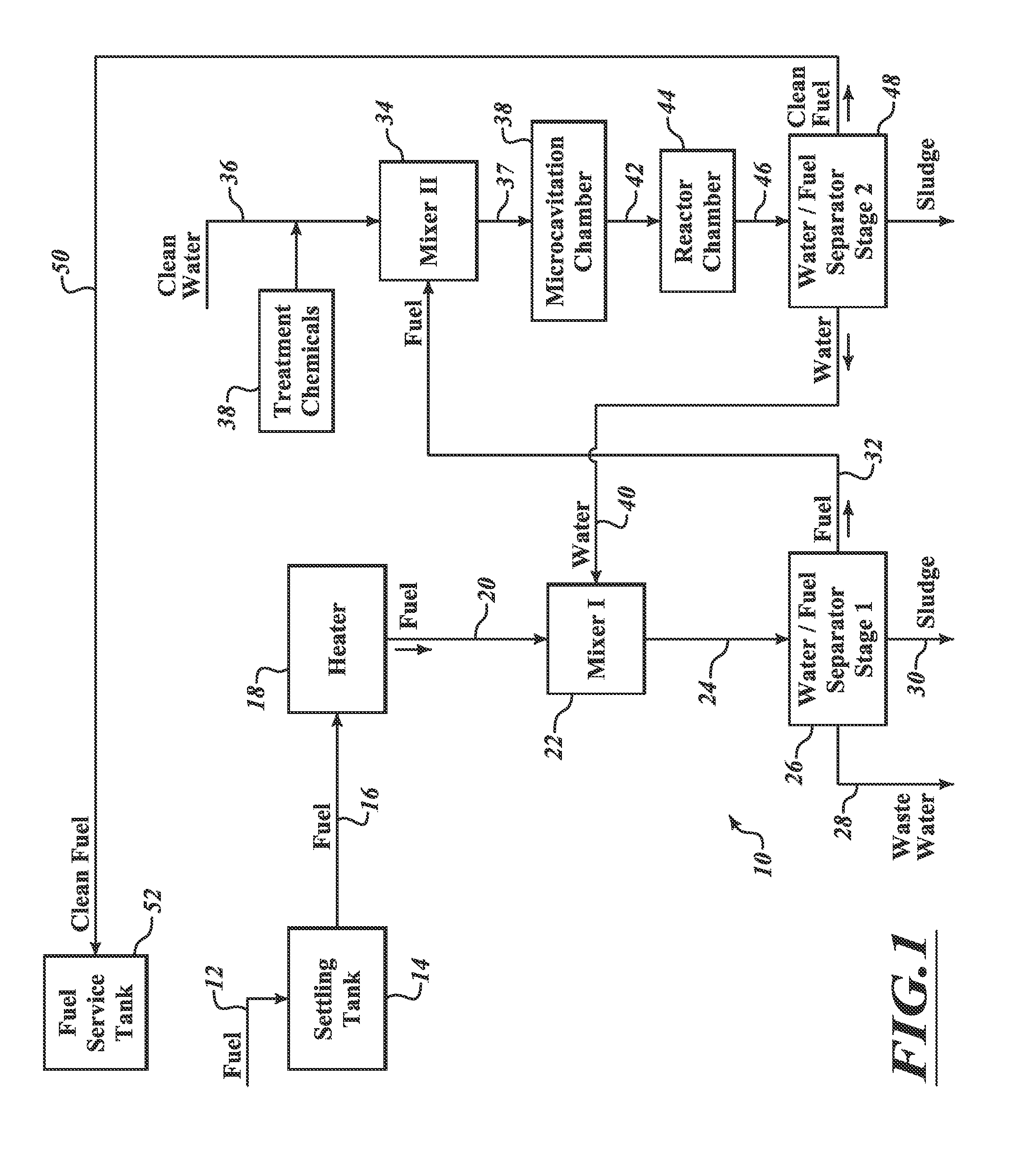

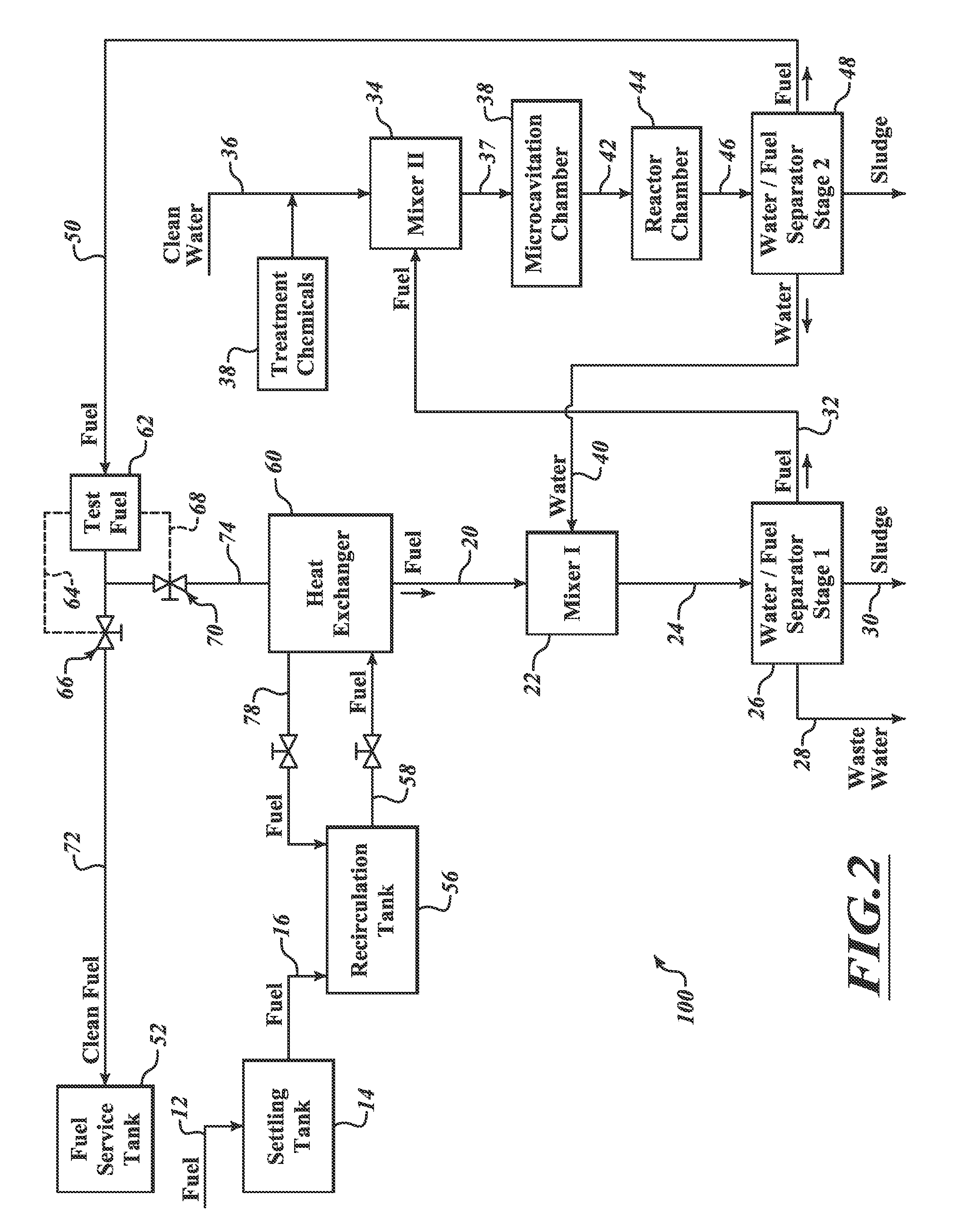

Removal of contaminants from bunker oil fuel

ActiveUS20150217261A1Easy to separateSufficient energyDewatering/demulsification with electric/magnetic meansRefining by heating/coolingElectrolysisEmulsion

A system and method for cleaning sulfur and other pollutants from bunker oil to be used for fuel in large cargo ships is described. Preferably, the system includes two or more stages having a mixer to create an emulsion of oil and water. One or more treatment chemicals are added to the water before it is mixed with the oil in order to assist in separating the sulfur from the oil and freeing it up so that it can combine with various other molecules present in the water or be dissolved in the water. The emulsion may pass through a microcavitation chamber as well as an electrolysis reactor chamber in order to further clean the fuel oil by removing additional sulfur content. The clean fuel is sent to a fuel service tank for use in a diesel engine combustion cycle.

Owner:TRITON EMISSION SOLUTIONS

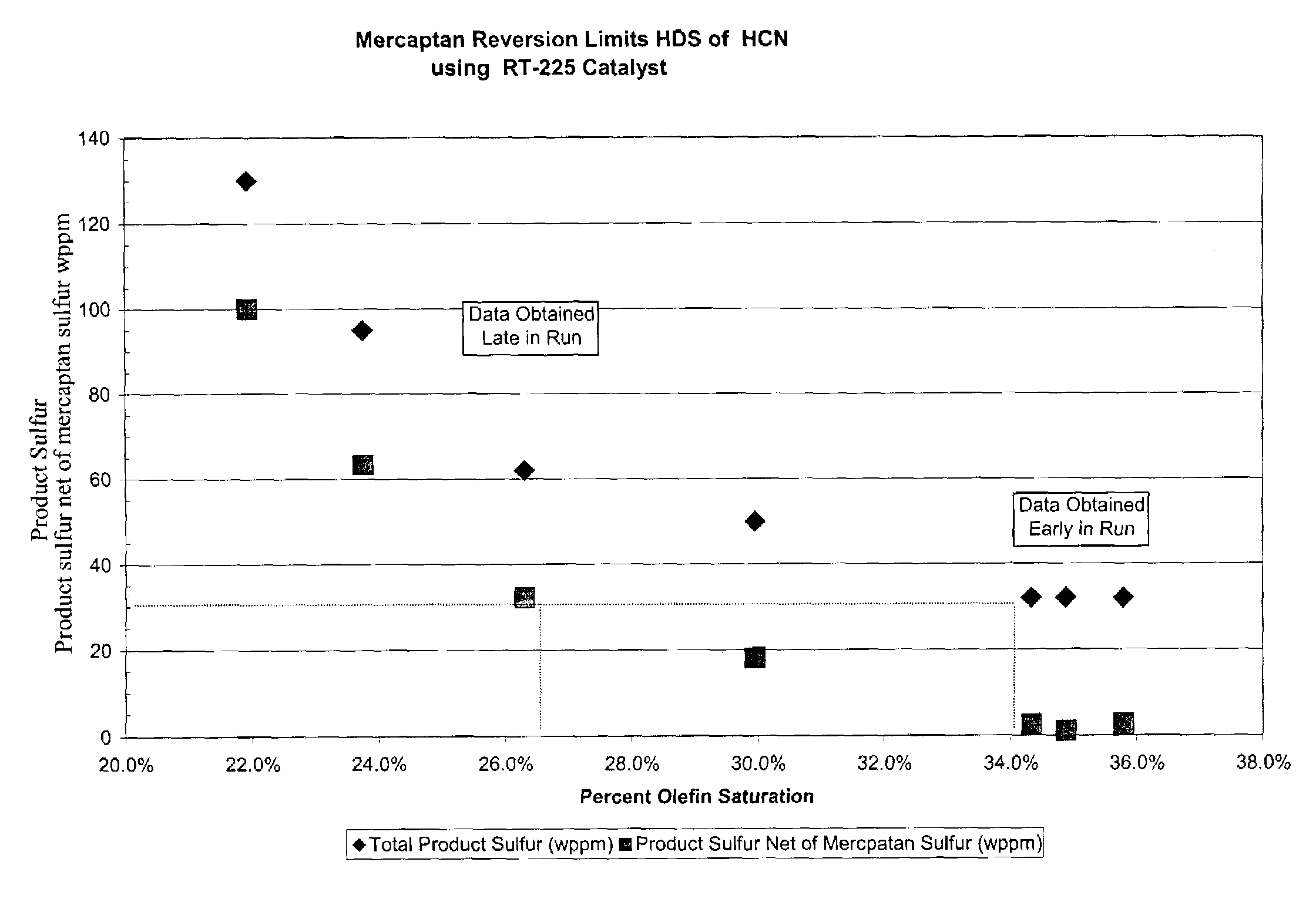

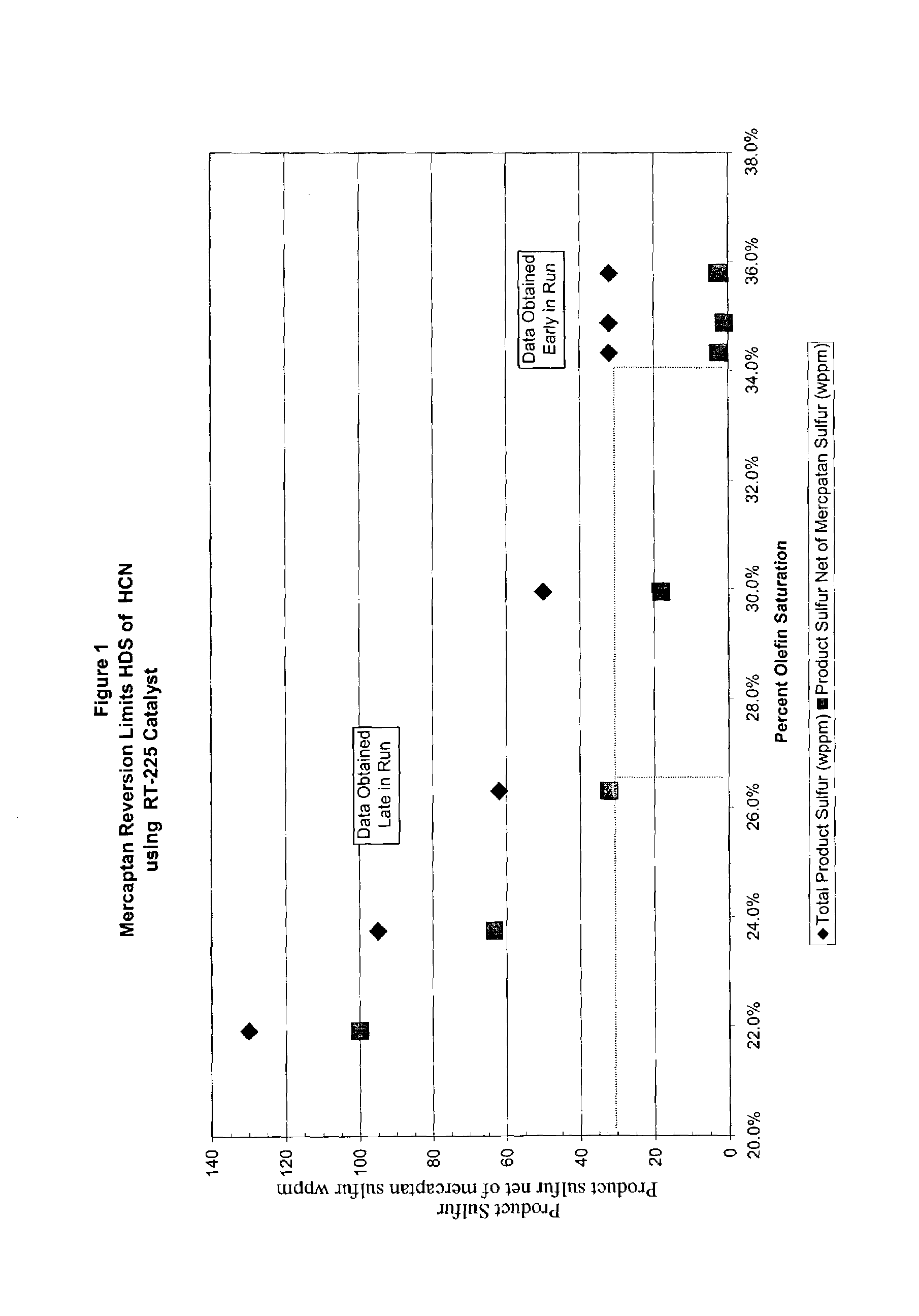

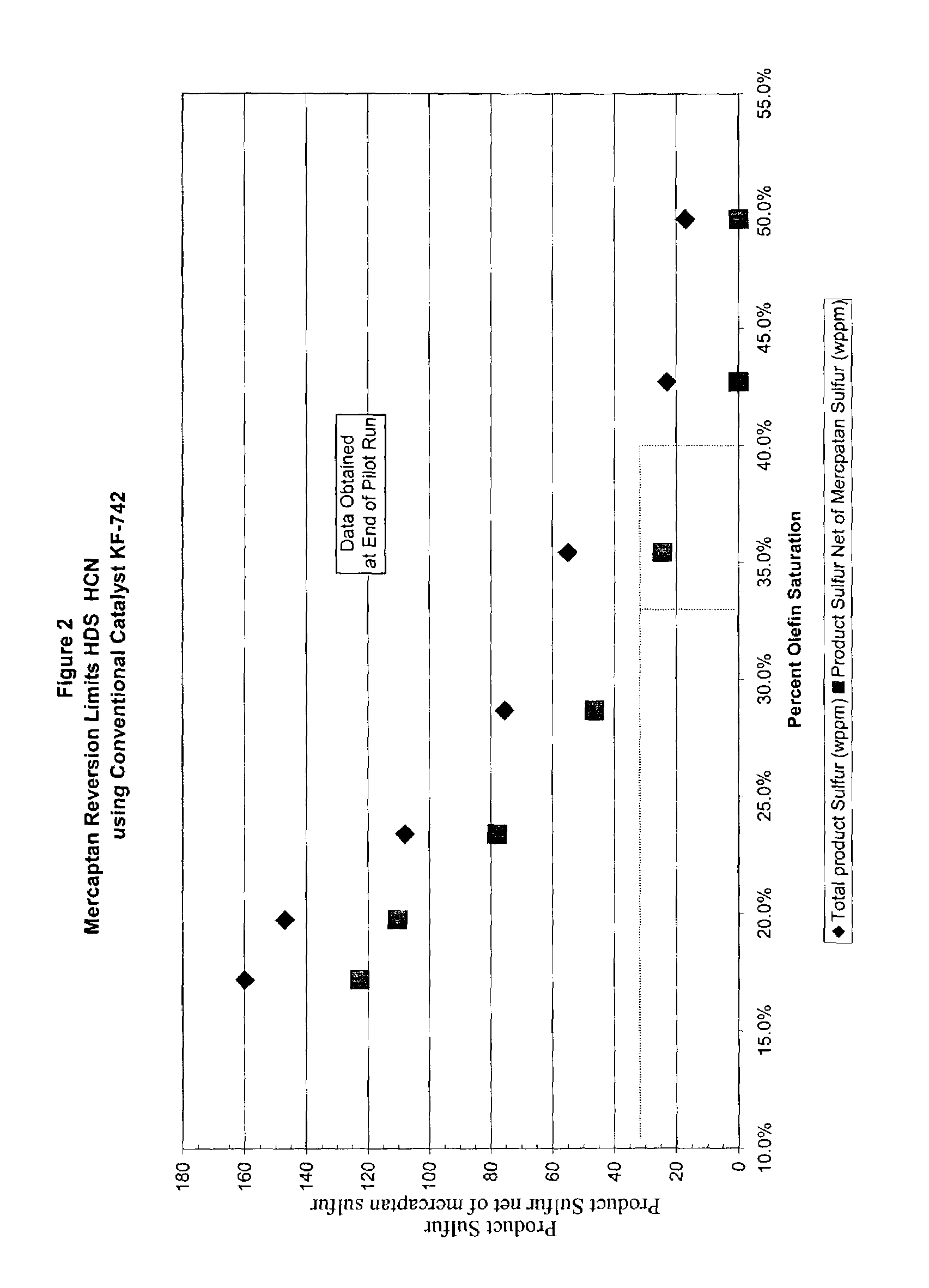

Selective hydroprocessing and mercaptan removal

InactiveUS7244352B2Reduce the amount requiredCatalytic crackingLiquid carbonaceous fuelsNaphthaThiol

A process for producing a naphtha having a decreased amount of sulfur by selective hydroprocessing a petroleum feedstream comprising cracked naphtha to reduce its sulfur content with minimum loss of octane. The reduced sulfur naphtha stream contains mercaptan sulfur reversion products that are removed preferably by use of an aqueous base solution containing a catalytically effective amount of a phase transfer catalyst.

Owner:EXXON RES & ENG CO

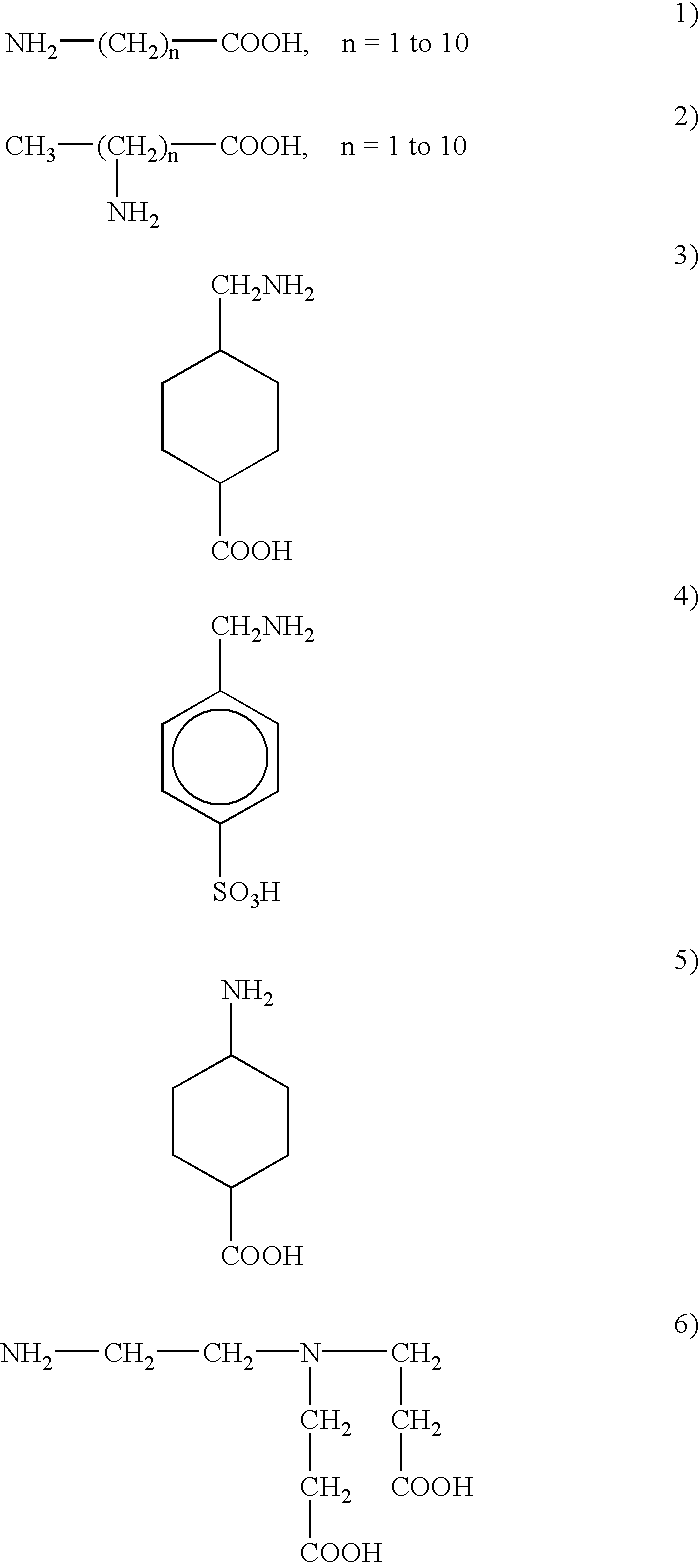

Method for prevention of fouling in basic solution by inhibiting polymerization and solubilizing deposits using amino acids

InactiveUS6986839B2Prevent scalingRemoving polymeric depositThermal non-catalytic crackingDistillation corrosion inhibitionHydrolysisCaproic Acid

A method for inhibiting and dissolving the deposits formed on caustic or alkaline scrubbers used in scrubbing acidic gases such as carbon dioxide, hydrogen sulfide, which are formed during the pyrolytic cracking of naphtha, ethane, and propane. The cracking operations produce certain oxygenated compounds such as vinyl acetate or acetaldehyde, which undergo polymerization under alkaline condition. The vinyl acetate on hydrolysis releases acetaldehyde under alkaline conditions. Amino acids such as 6 amino caproic acid and lactams such as epsilon caprolactam not only prevent but also dissolve the polymers formed by aldol condensation.

Owner:DORF KETAL CHEM (I) PTE LTD

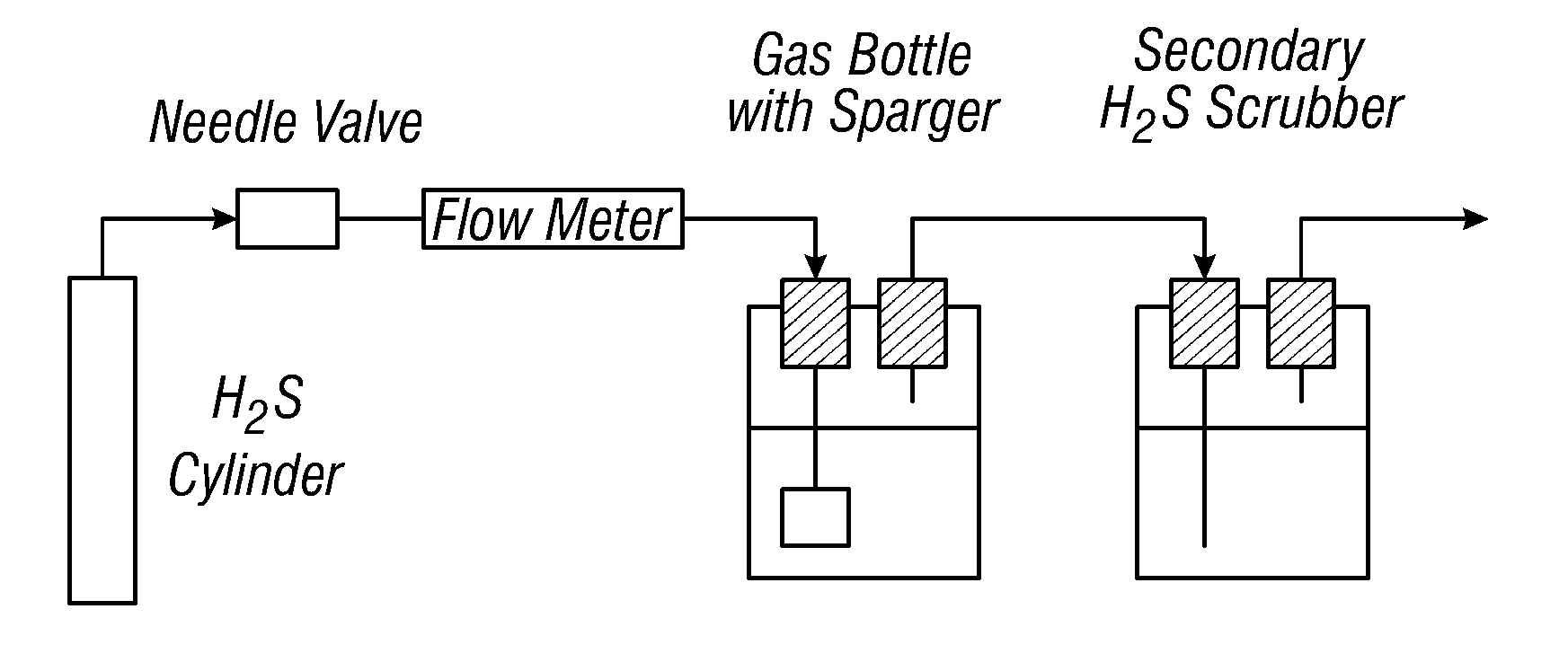

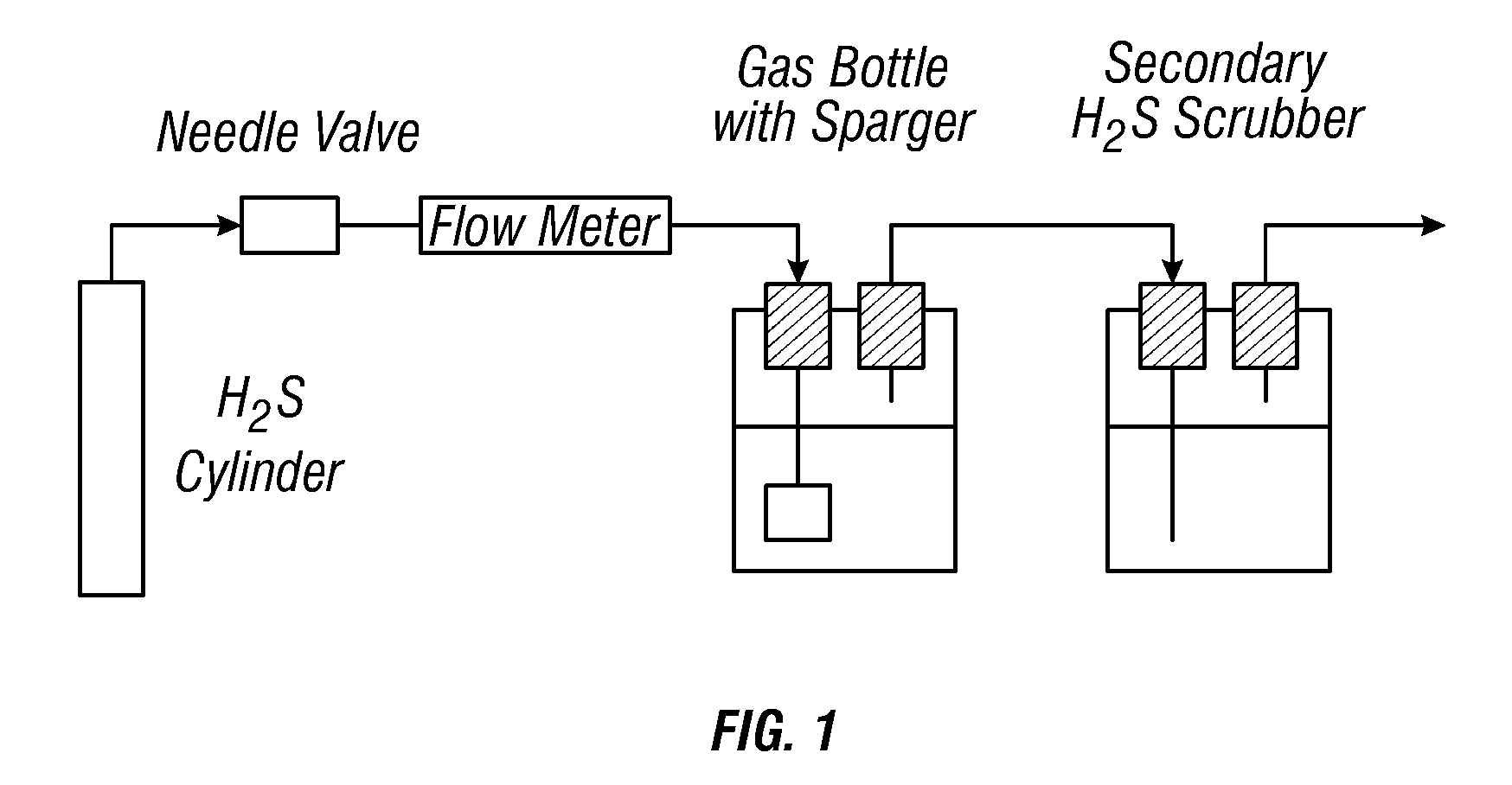

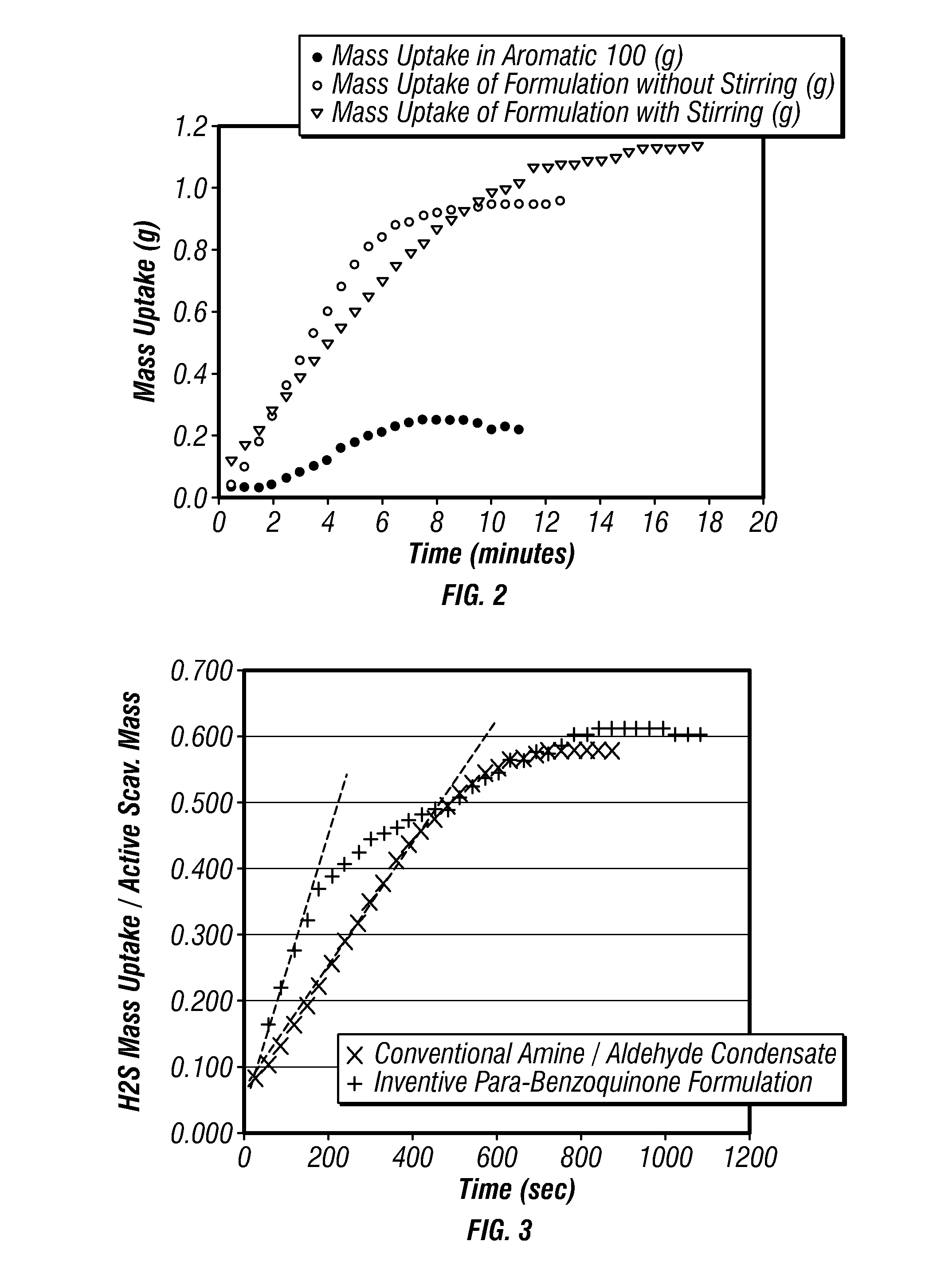

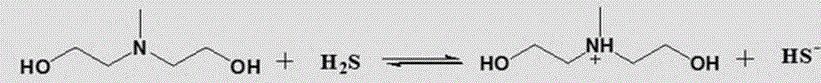

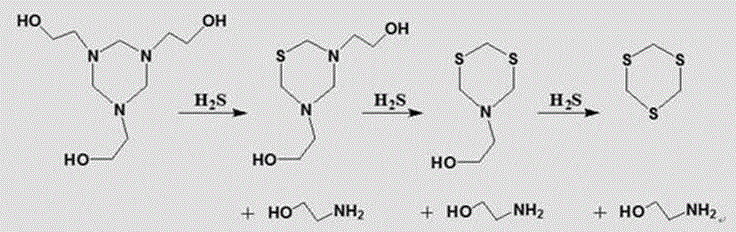

Water-Based Formulation of H2S/Mercaptan Scavenger for Fluids in Oilfield and Refinery Applications

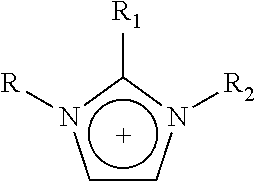

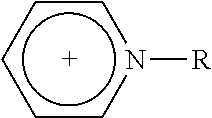

Hydrogen sulfide (H2S) and / or mercaptan scavengers are chemicals that remove H2S and / or mercaptans from gas, oil and water. Water-based formulations may be made and used employing scavenging compounds having the formulae:wherein each R1, R2, R3, and R4 are the same or different and are selected from the group consisting of hydrogen, an alkyl, an alkenyl, an aryl, an acyl, a halogen, a hydroxyl, a nitro, an alkyl ester, an aryl ester, an alkyl ether, an aryl ether, a hydroxymethyl, an anhydride group, an amino, and a sulfide. In one non-limiting embodiment the compounds (A) and (B) do not contain nitrogen atoms. Water-based formulations, such as those using a protic solvent with the above compounds, work well as H2S scavengers.

Owner:BAKER HUGHES INC

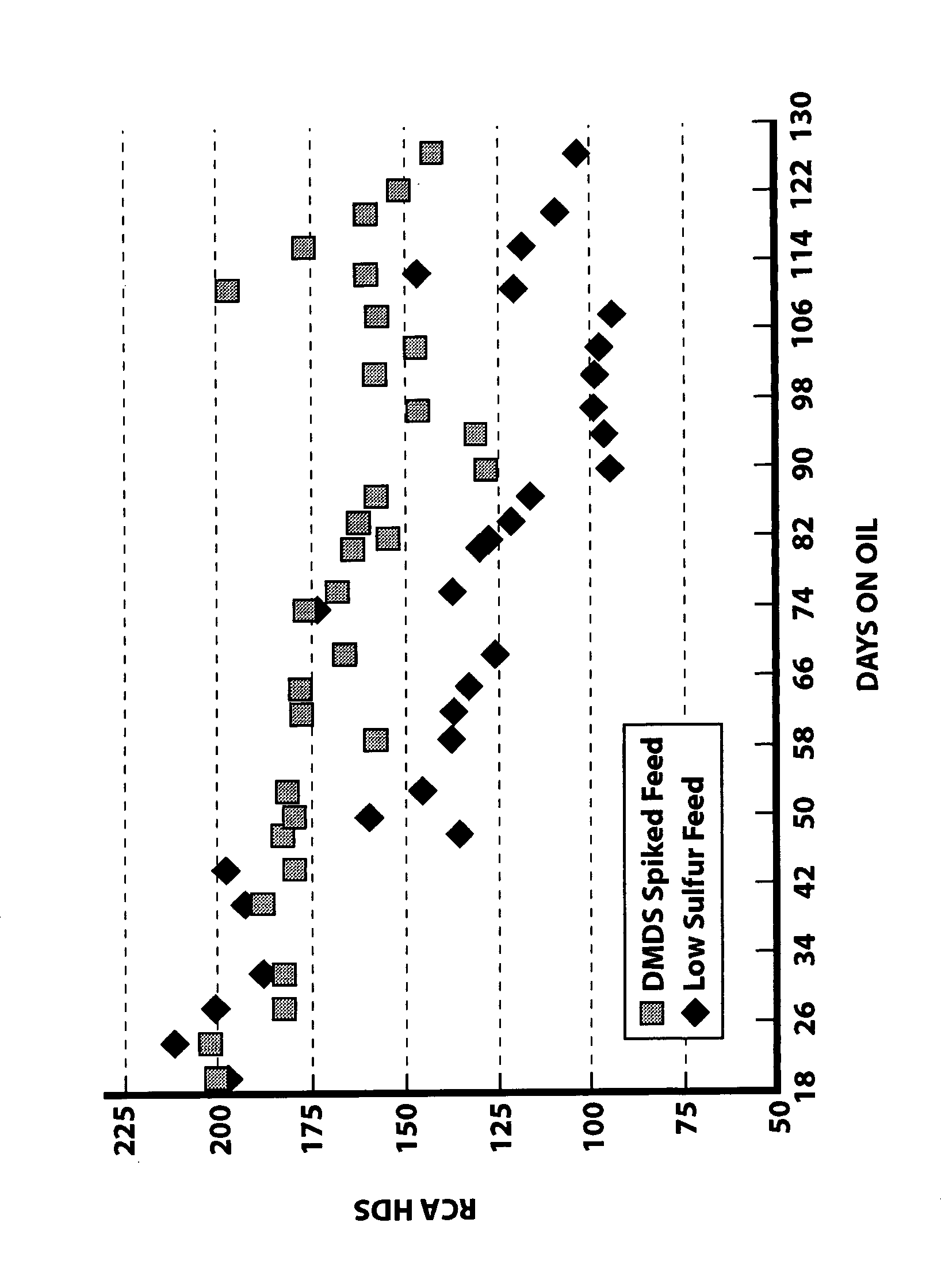

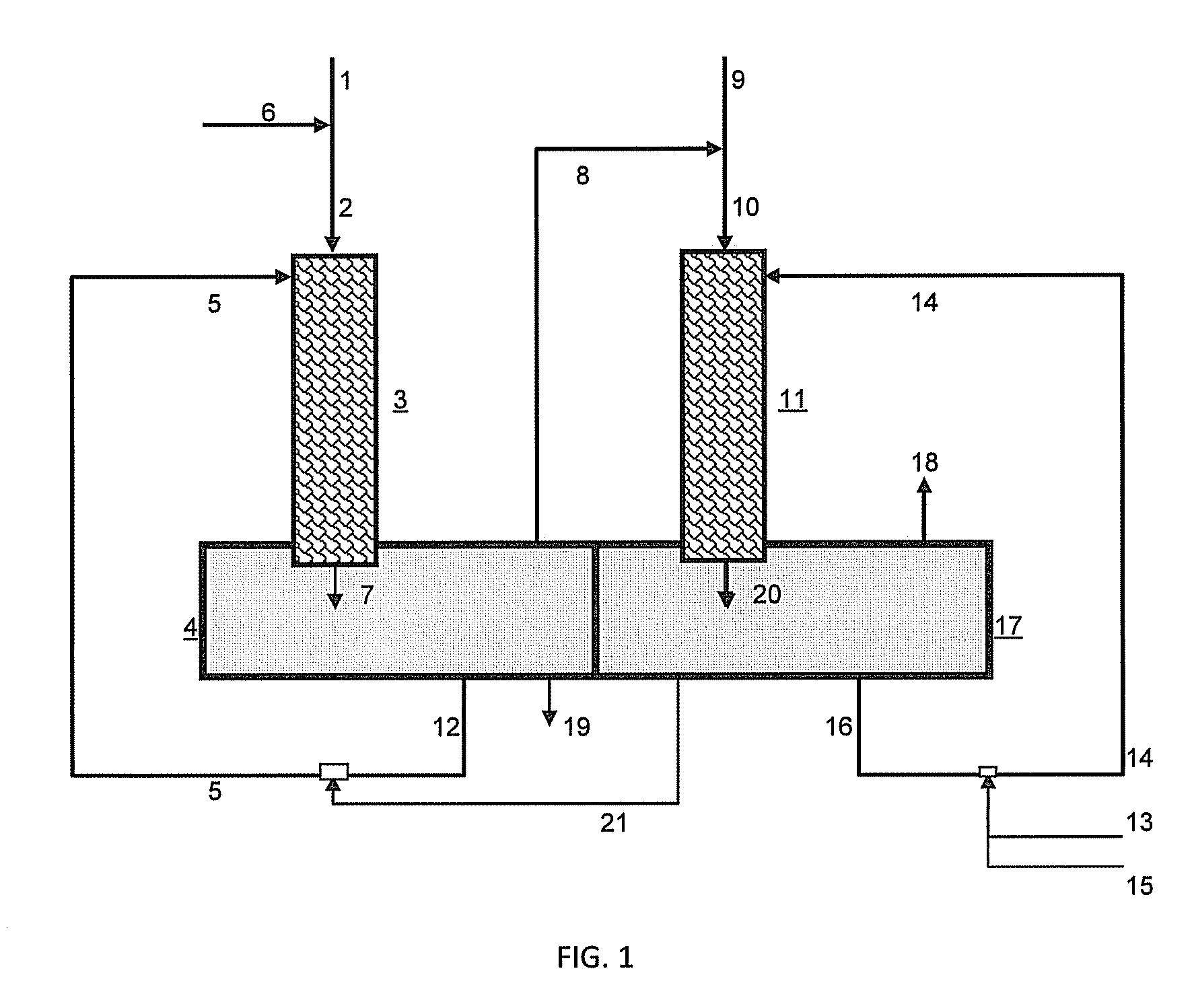

Naphtha desulfurization process

InactiveUS20060151359A1Catalyst activation/preparationTreatment with hydrotreatment processesNaphthaHydrogen

This invention relates to a process for selectively desulfurizing naphtha. More particularly, a low sulfur naphtha feed containing less than 500 wppm sulfur is hydrodesulfurized using a hydrodesulfurization catalyst and a hydrogen treat gas containing at least about 50 vppm hydrogen sulfide followed by mercaptan removal or conversion.

Owner:EXXON RES & ENG CO

Hydrocarbon Treatment Process

InactiveUS20110127194A1Rapid liquid-liquid mass transferReduce entrainmentOther chemical processesRefining with oxygen compoundsBisulfideThiol

In a catalytic treatment process, mercaptans in sour hydrocarbon are oxidized to disulfide oils using an aqueous treatment solution containing a chelated polyvalent metal catalyst, alkali metal hydroxide, and the alkali metal salt of at least one alcohol in a non-dispersive mixing apparatus wherein an upgraded hydrocarbon containing the disulfide oils is produced.

Owner:MERICHEM CO

Process of recovery of exhausted ionic liquids used in the extractive desulfurization of naphthas

InactiveUS20110215052A1Low toxicitySedimentation separationDifferential sedimentationOrganic solventHalogen

A process for recovering ionic liquids comprising the steps of: providing a first ionic liquid mixture, the first ionic liquid having a halogen metallate anion, the mixture containing an organic solvent; adjusting the pH of the mixture to pH 7-10 by the addition of a base to form a first precipitate; separating the first precipitate from the mixture; removing the organic solvent from the first mixture to form a second precipitate and separating the second precipitate from the first mixture; acidifying the resulting mixture to pH 2-7 by the addition of an acid; and drying the mixture to obtain a second ionic liquid having a halogen anion.

Owner:INST MEXICANO DEL GASOLINEEO

Removal of sulfur compounds from petroleum stream

ActiveUS9005432B2Reduce the amount requiredIncrease gravityThermal non-catalytic crackingMolecular sieve catalystsThiolLow nitrogen

A process for upgrading an oil stream by mixing the oil stream with a water stream and subjecting it to conditions that are at or above the supercritical temperature and pressure of water. The process further includes cooling and a subsequent alkaline extraction step. The resulting thiols and hydrogen sulfide gas can be isolated from the product stream, resulting in an upgraded oil stream that is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the oil stream.

Owner:SAUDI ARABIAN OIL CO

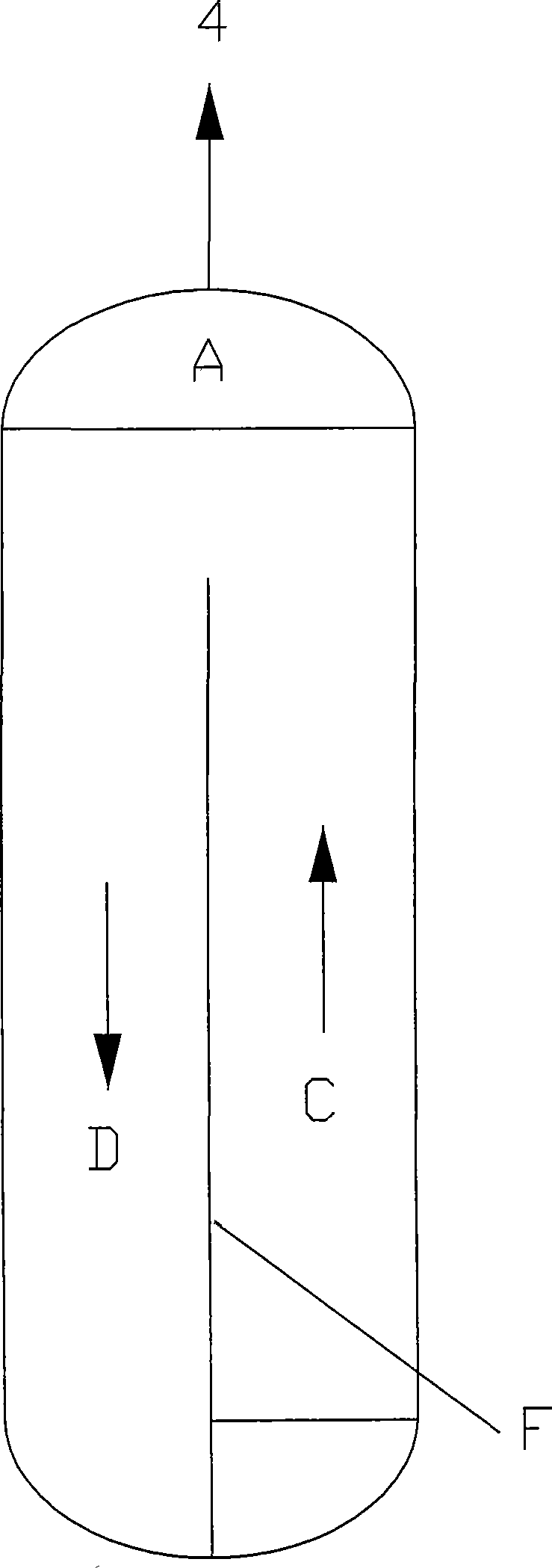

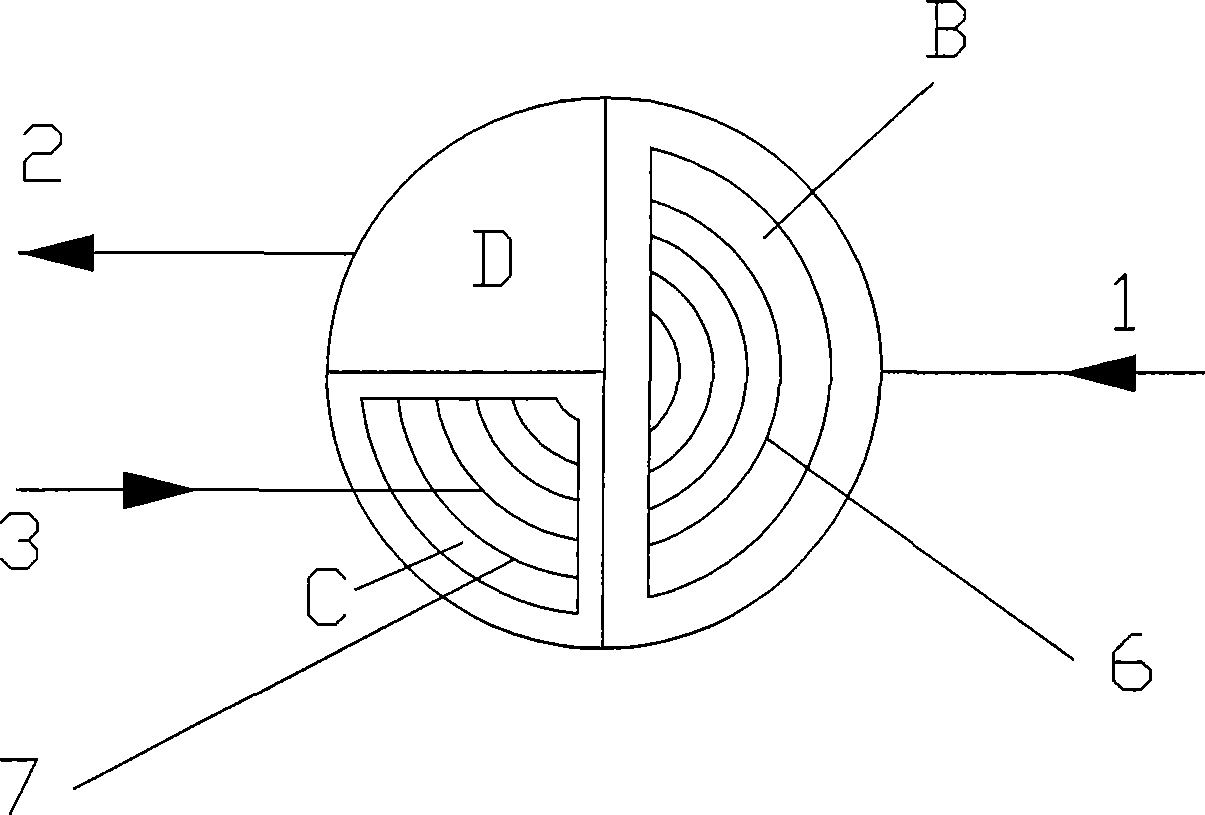

Oil-containing alkali liquor separation apparatus and method

ActiveCN101469276AImprove cleanlinessReduce contentLiquid separationRefining with aqueous alkaline solutionsBisulfidePhase separation process

The invention relates to an oil-contained lye separating device, which at least comprises a device shell and is characterized in that the upper space of the device shell is a tail gas separation zone provided with a tail gas outlet, and the circumferential surface of the middle-lower space of the device shell is at least distributed with an oil-alkali separation zone provided with an oxidized lyeinlet and a gas stripping separation zone, wherein an oil phase aggregation separating device and an oil phase outlet are arranged in the oil-alkali separation zone which is communicated with the bottom of the gas stripping separation zone; a gas distributor and a gas stripping gas inlet connected therewith are arranged in the gas stripping separation zone; and the device shell is provided with aregenerated lye outlet. A method comprises the following steps: adopting the oil phase aggregation separating device to perform oil-alkali separation on the oxidized lye in the oil-alkali separation zone, and then using the gas distributor to perform gas stripping in the gas stripping zone so as to obtain the regenerated lye through a lye stabilization zone, wherein the tail gas zone is communicated with other zones so as to exhaust the tail gas after the treatment. The oil-contained lye separating device integrates the separation processes of the three phases including the tail gas generatedin the lye regeneration process, the lye and disulphide into a whole; the cleanliness of the lye obtained through separation is improved, the content of the disulphide is low, and the separation effect is good; besides, the oil-contained lye separating device has the advantages of more compact structure, small volume, and reasonable and practical process.

Owner:NINGBO ZHONGYI PETROCHEM TECH

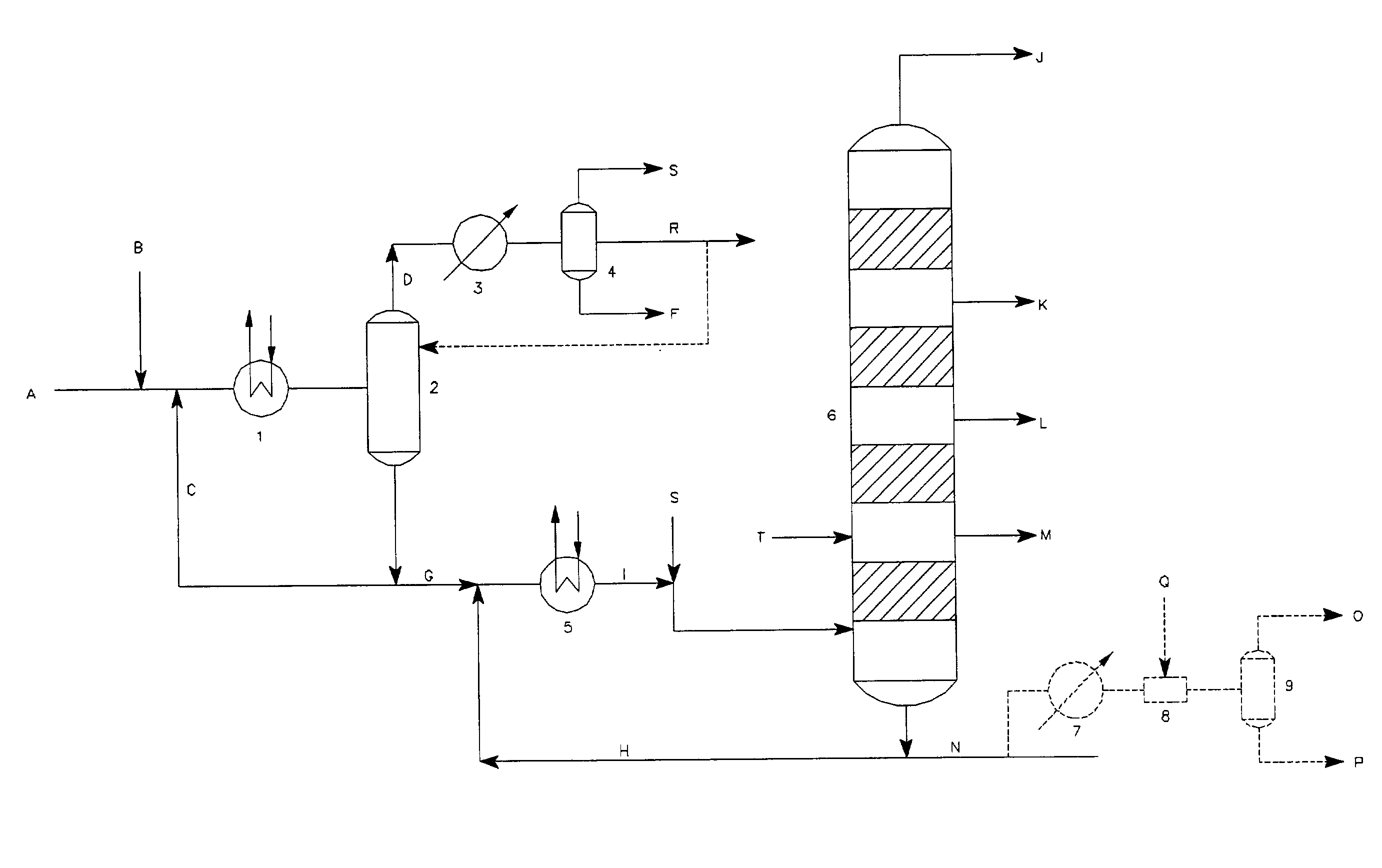

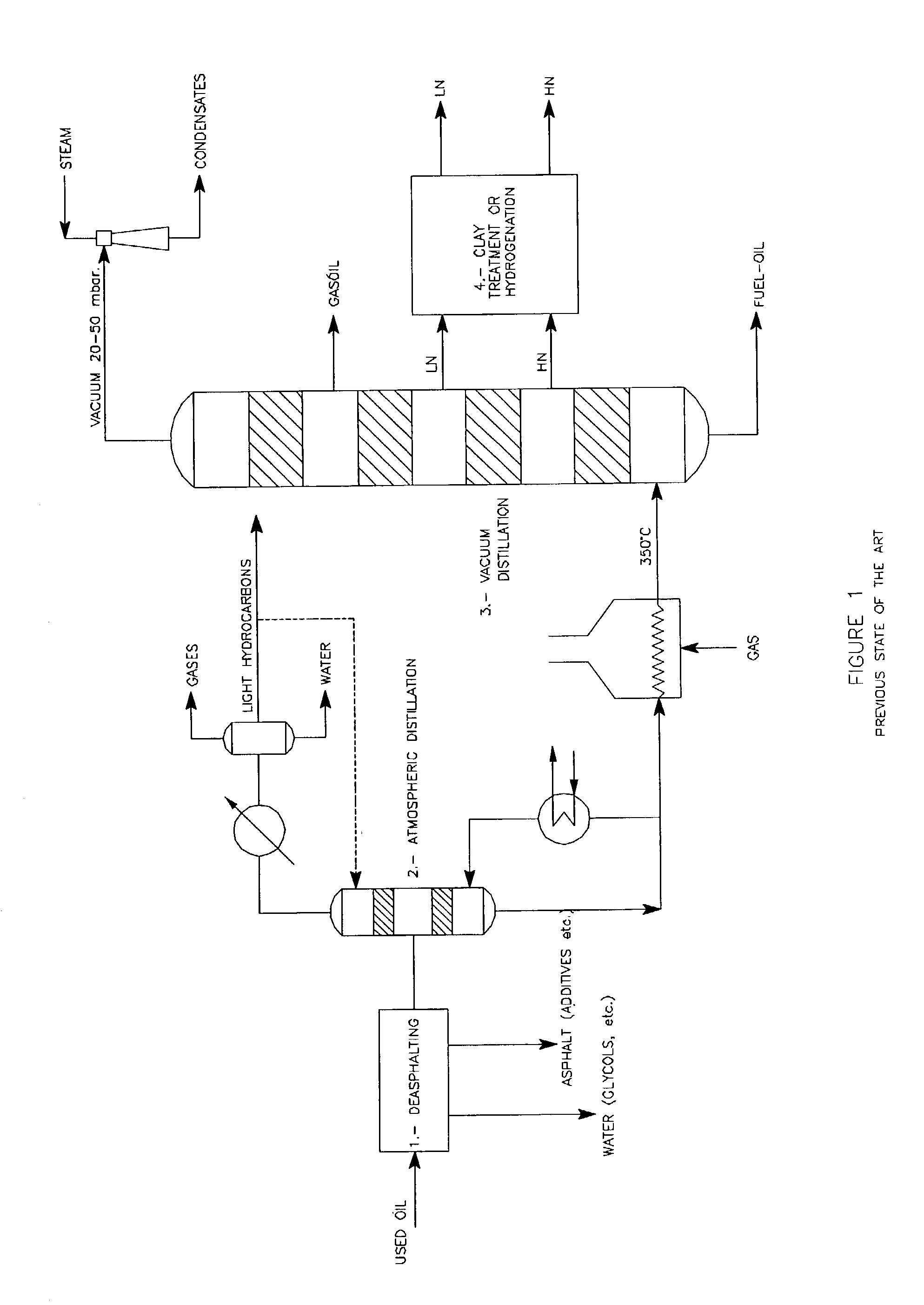

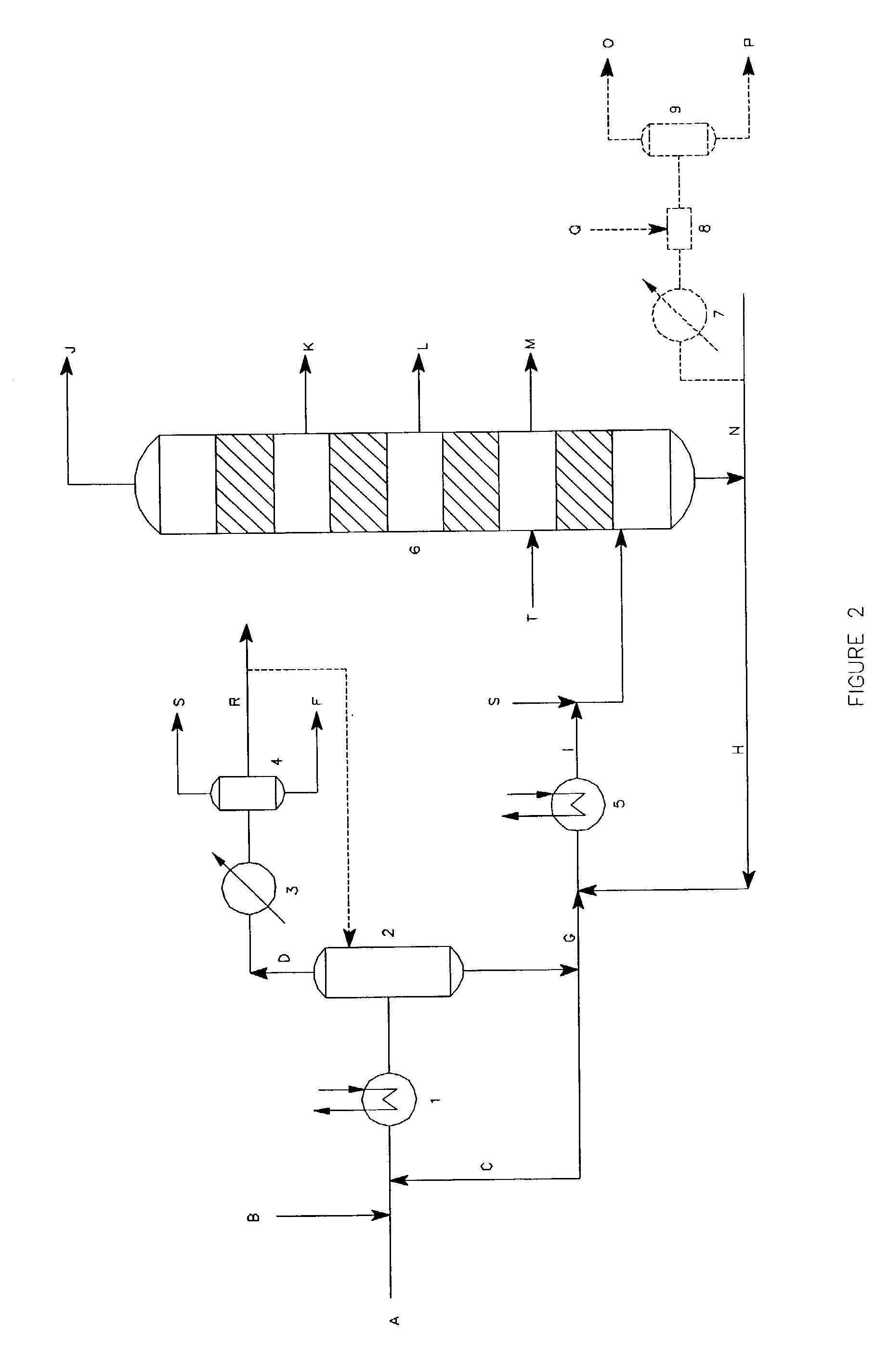

Process for re-refining used oils by solvent extraction

InactiveUS7226533B2No corrosionExpedited distillationWorking-up pitch/asphalt/bitumenTreatment with plural serial refining stagesWaste oilFuel oil

A process to re-refine used petroleum oils by extraction with aliphatic solvents, wherein after eliminating the extract solvent, the process consists of the following treatments, (a) flash, continuous vaporization, at atmospheric pressure or near atmospheric pressure, to separate the light fractions, in the presence of small amounts of a basic compound or a reducing agent or a combination of both and (b) continuous distillation, in a fractionating column, of the bottom liquid obtained in stage (a), under vacuum and moderate temperatures, in the presence of a basic compound or a reducing compound or a combination of both, with recirculation from the bottom of the column to its feed; separating, as lateral extractions, the vacuum gas-oil or spindle oil and the lubricant bases and, as bottom product, a fuel-oil or asphaltic component.

Owner:SENER GRUPO DE ING SA

Desulfurizer used for extraction of crude oil containing hydrogen sulfide and treatment of sewage containing hydrogen sulfide

ActiveCN105112087AGet rid of usabilityGet rid of performance constraintsWater/sewage treatment by degassingRefining with aqueous alkaline solutionsSodium acetateNuclear chemistry

The invention discloses a desulfurizer used for extraction of crude oil containing hydrogen sulfide and treatment of sewage containing hydrogen sulfide. The desulfurizer comprises, by mass, 25 to 40% of hydroxyethyl-hexahydro-s-triazine, 5 to 10% of micro-molecular alcohol, 1 to 2% of an osmotic agent sodium sulfosuccinate, 1 to 2% of acetic acid, 0.1 to 0.2% of sodium acetate and 0.02 to 0.04% of an antifoaming agent, with the balance being water, wherein the micro-molecular alcohol is methanol, or ethanol or a mixture of methanol and ethanol, and the antifoaming agent is a water-soluble polyether or silicone oil antifoaming agent. The desulfurizer provided by the invention has a simple formula, is intermiscible with water in any ratio and can effectively reduce hydrogen sulfide in crude oil or sewage; the desulfurizer rapidly reacts with hydrogen sulfide and a reaction product is soluble in water and does not block a pipeline; moreover, an s-triazine main agent has good scale-inhibition, anti-scale and sterilization properties; and the hydrogen sulfide removing agent in the invention overcomes the problems that an alcamine desulfurizer has rapidly reduced desulphurization efficiency at high temperature and hydrogen sulfide removed through reaction may be reversibly released again, and has a temperature application range of 0 to 120 DEG C.

Owner:新疆天普石油天然气工程技术有限公司

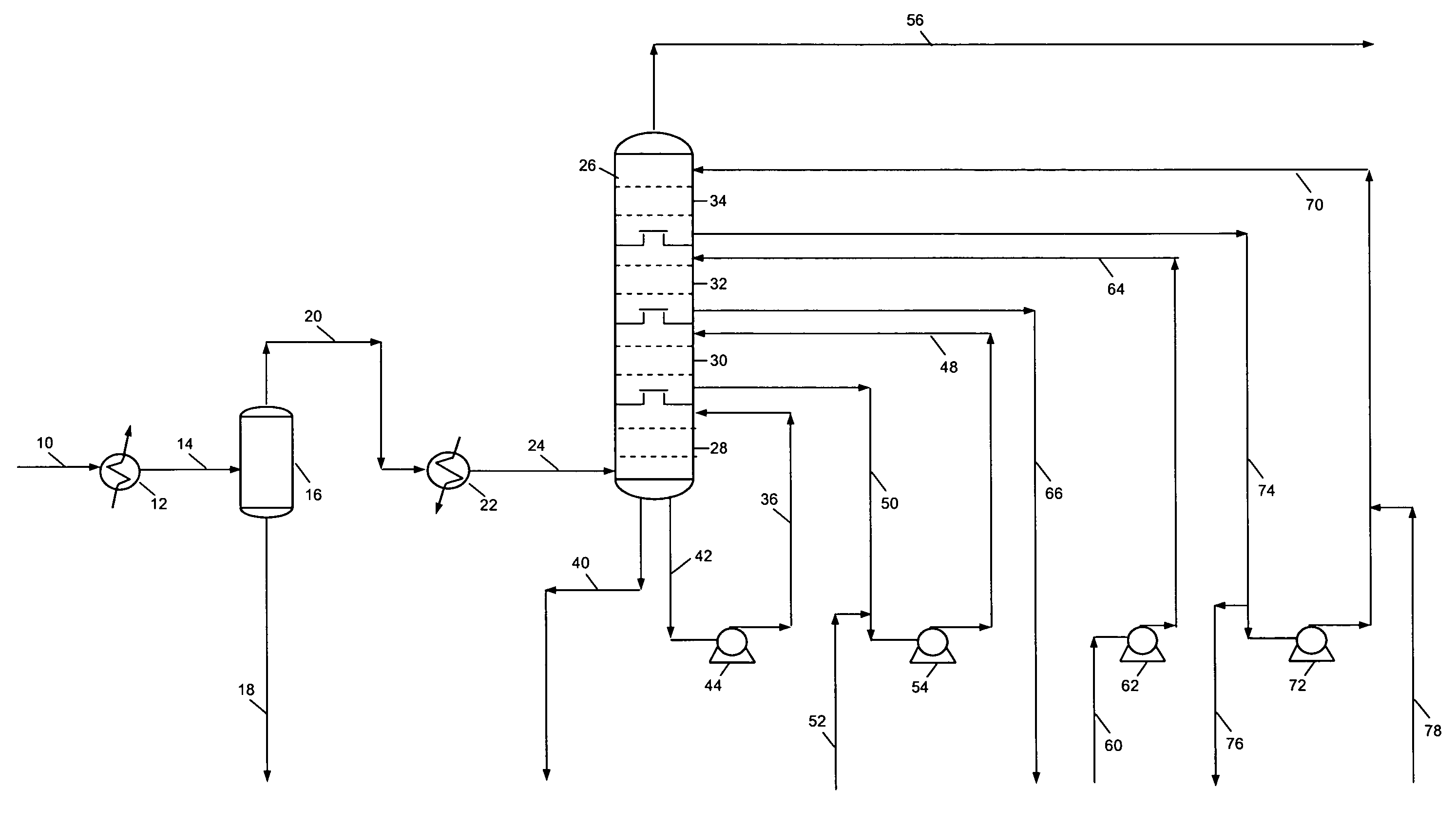

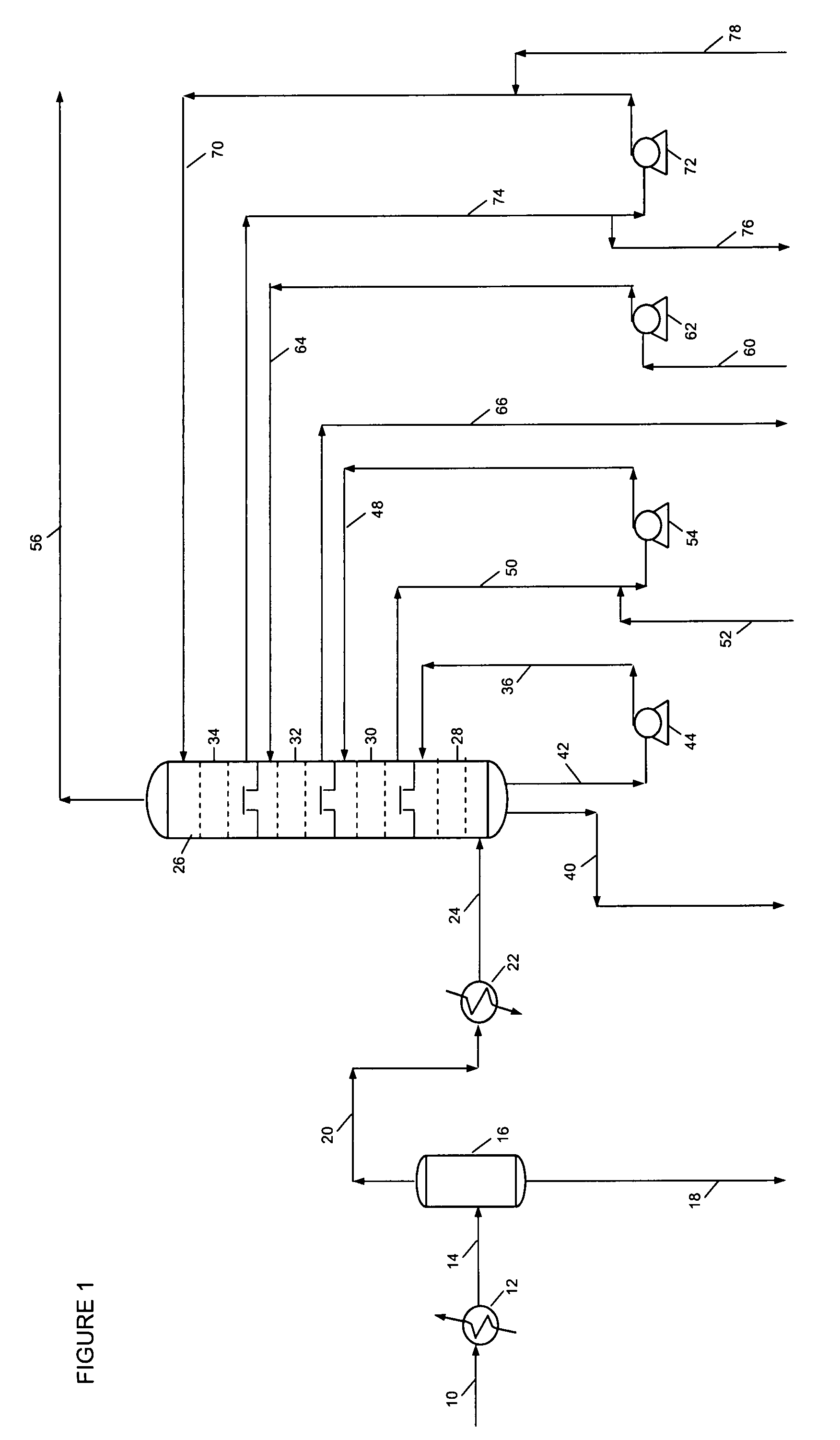

Removal of acid gases and sulfur compounds from hydrocarbon gas streams in a caustic tower

ActiveUS20090036727A1Avoid poisoningFully removedThermal non-catalytic crackingCatalytic crackingThiolSulfur

The present invention provides a process for treating a hydrocarbon feed gas stream containing acid gases (CO2, H2S and mercaptans) by contacting the feed gas stream in a multi-section caustic tower, the bottom sections employing a recirculating caustic solution to remove the CO2 and H2S down to low single digits parts per million concentration and the upper sections employing a stronger caustic solution on a once-through basis to produce a mercaptans depleted gas stream.

Owner:STONE & WEBSTER PROCESS TECH

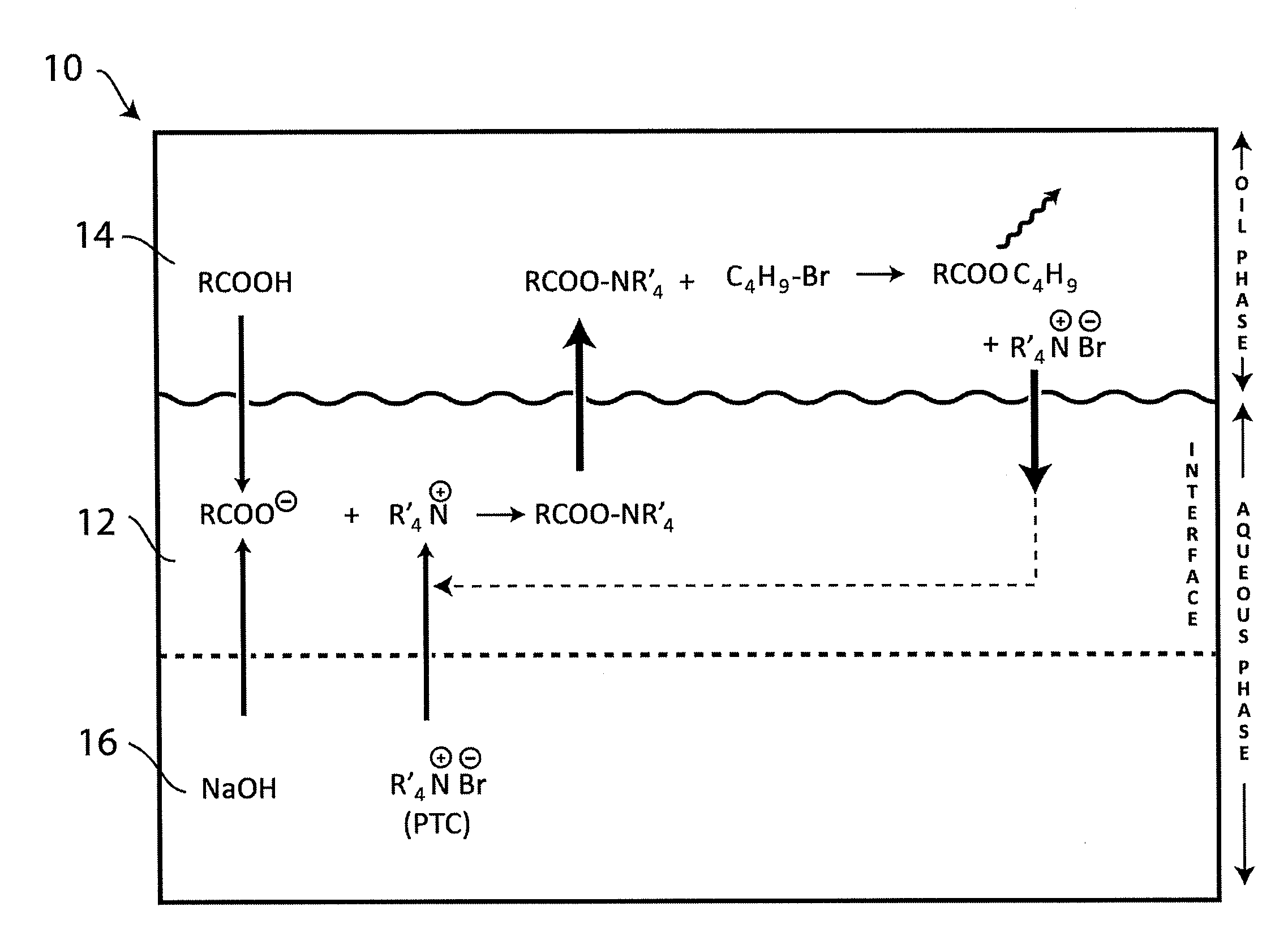

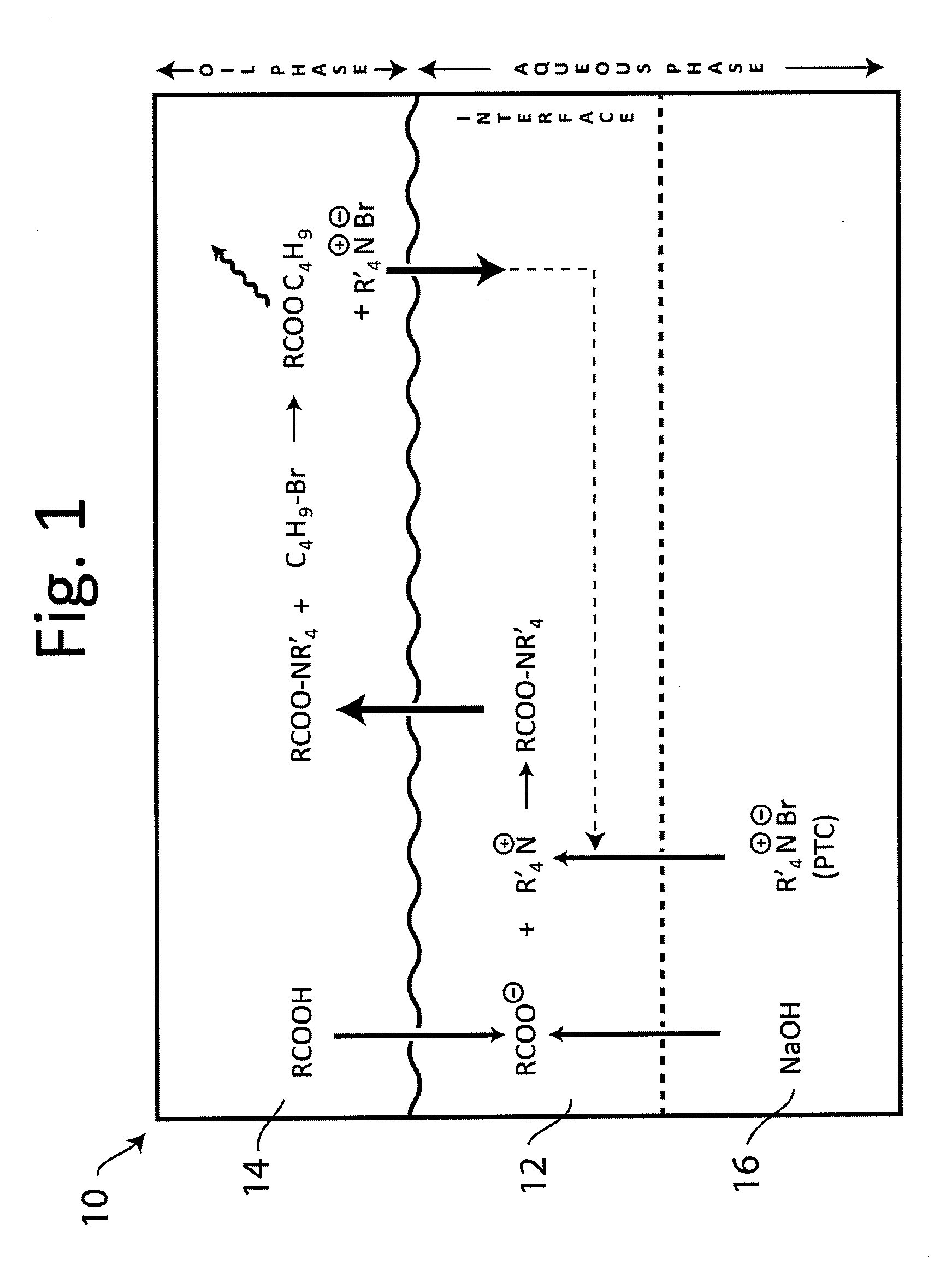

Treatment of hydrocarbons containing acids

InactiveUS20100155304A1Easy to operateMinimizes eliminates corrosionRefining with aqueous alkaline solutionsTreatment apparatus corrosion/fouling inhibitionLiquid hydrocarbonsCorrosive acid

The invention relates to a method of treating a liquid hydrocarbon (e.g. heavy oil, bitumen, etc.) containing naphthenic acids or other corrosive acids in order to partially or fully convert such acids into non-corrosive compounds. The method comprises adding an alkylating agent to the hydrocarbon, bringing the hydrocarbon into contact with an aqueous liquid containing an alkaline compound and a phase transfer catalyst to form an immiscible two-phase system, maintaining the contact to allow conversion of the naphthenic acids to non-corrosive oil-soluble esters, and separating the aqueous phase from the liquid hydrocarbon. Naphthenic acids are highly corrosive to plant and equipment and the method enables them to be converted to non-corrosive compounds in an economic manner.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

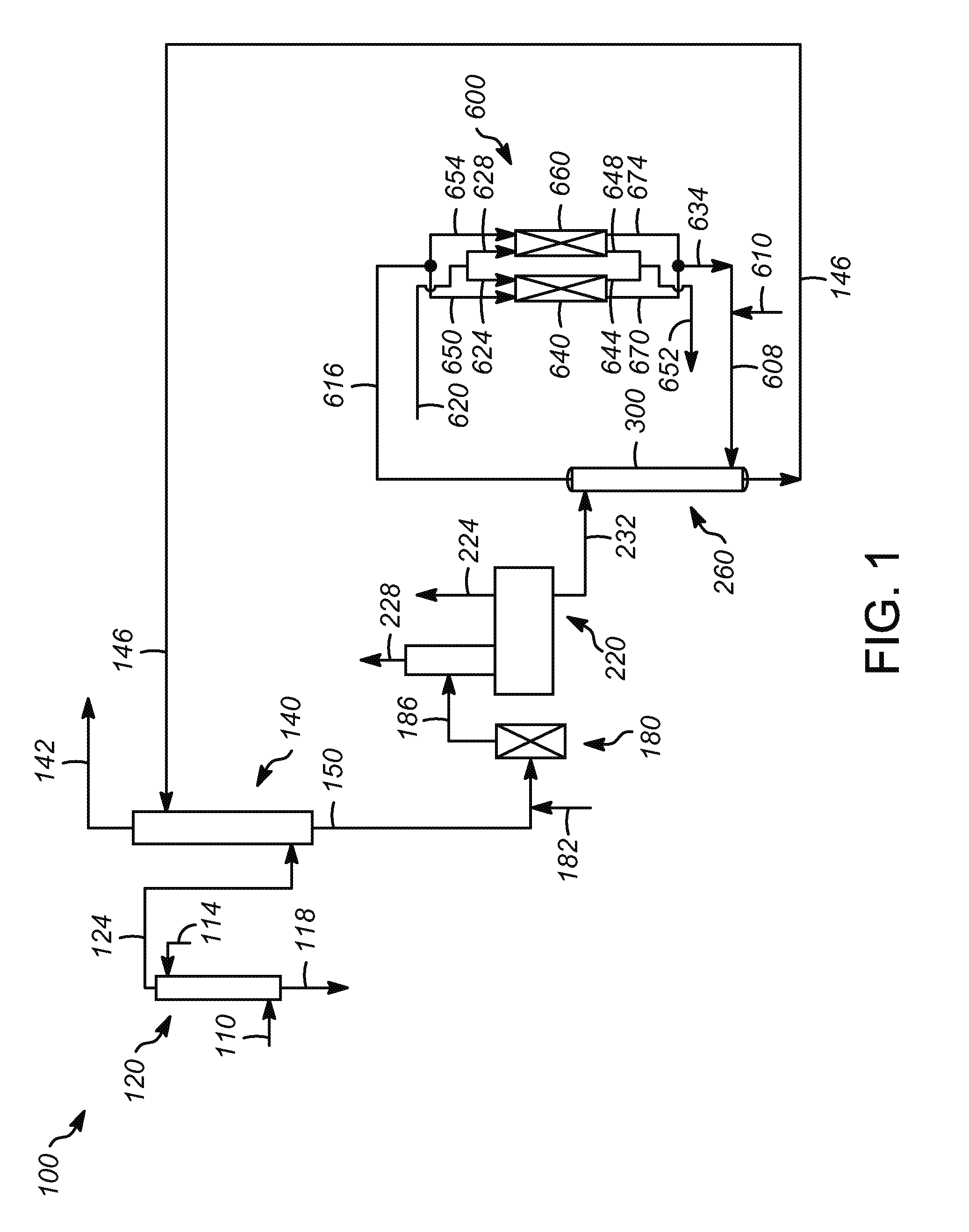

Reaction system and products therefrom

ActiveUS20120067777A1Decreasing heteroatom contentIncreasing API gravityRefining with oxygen compoundsDispersed particle separationHeteroatomReaction system

A reaction system and method for removing heteroatoms from oxidized-heteroatom-containing hydrocarbon streams and products derived therefrom are disclosed. An oxidized-heteroatom-containing hydrocarbon feed is reacted in a reaction system thereby forming non-ionic hydrocarbon products. The products derived therefrom are useful as transportation fuels, lubricants, refinery intermediates, or refinery feeds.

Owner:AUTERRA INC

Reaction system, methods and products therefrom

ActiveUS20150184086A1Decreasing heteroatom contentIncreasing API gravityLiquid separation by electricityElectrostatic separationHeteroatomReaction system

A reaction system and method for removing heteroatoms from oxidized-heteroatom-containing hydrocarbon streams and products derived therefrom are disclosed. An oxidized-heteroatom-containing hydrocarbon feed is reacted in a reaction system thereby forming non-ionic hydrocarbon products. The products derived therefrom are useful as transportation fuels, lubricants, refinery intermediates, or refinery feeds.

Owner:AUTERRA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com