Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3559results about "Electrostatic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

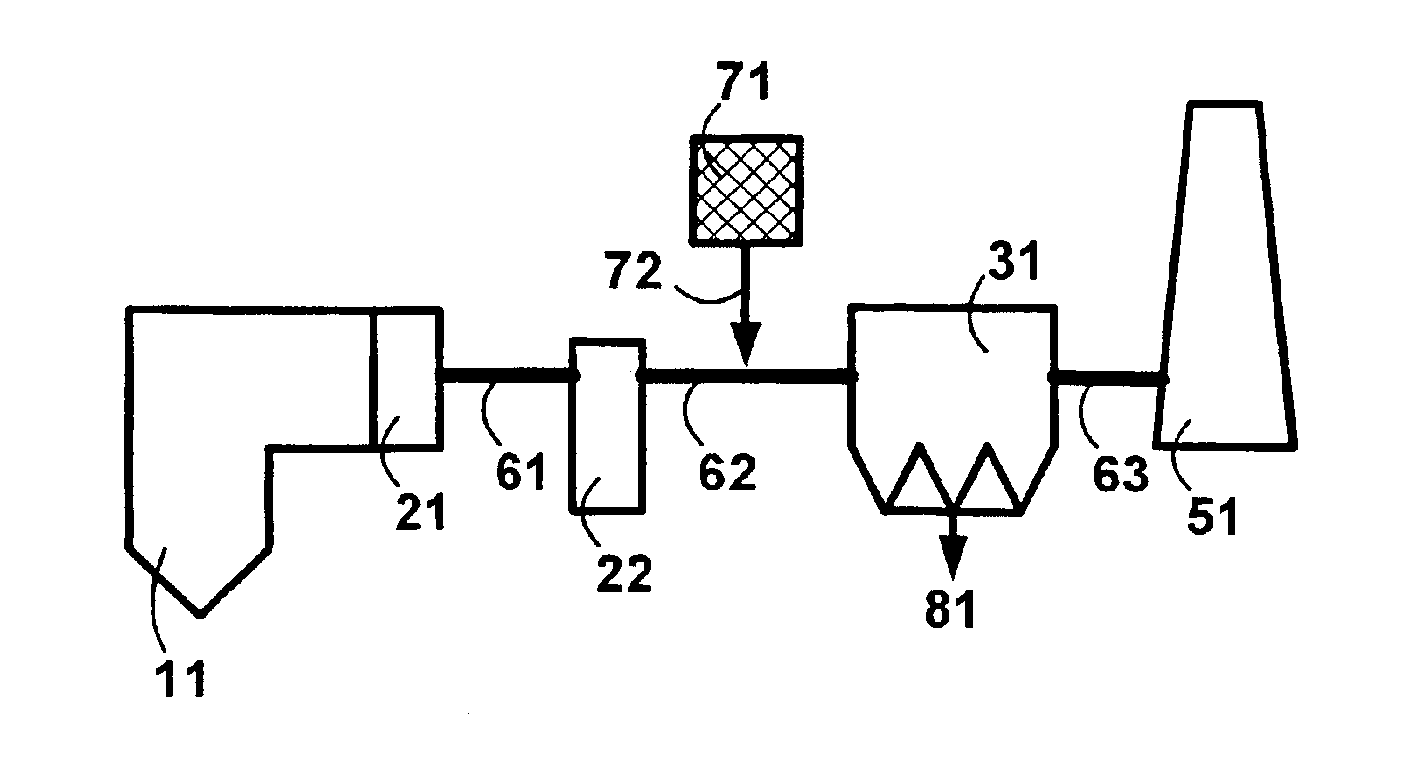

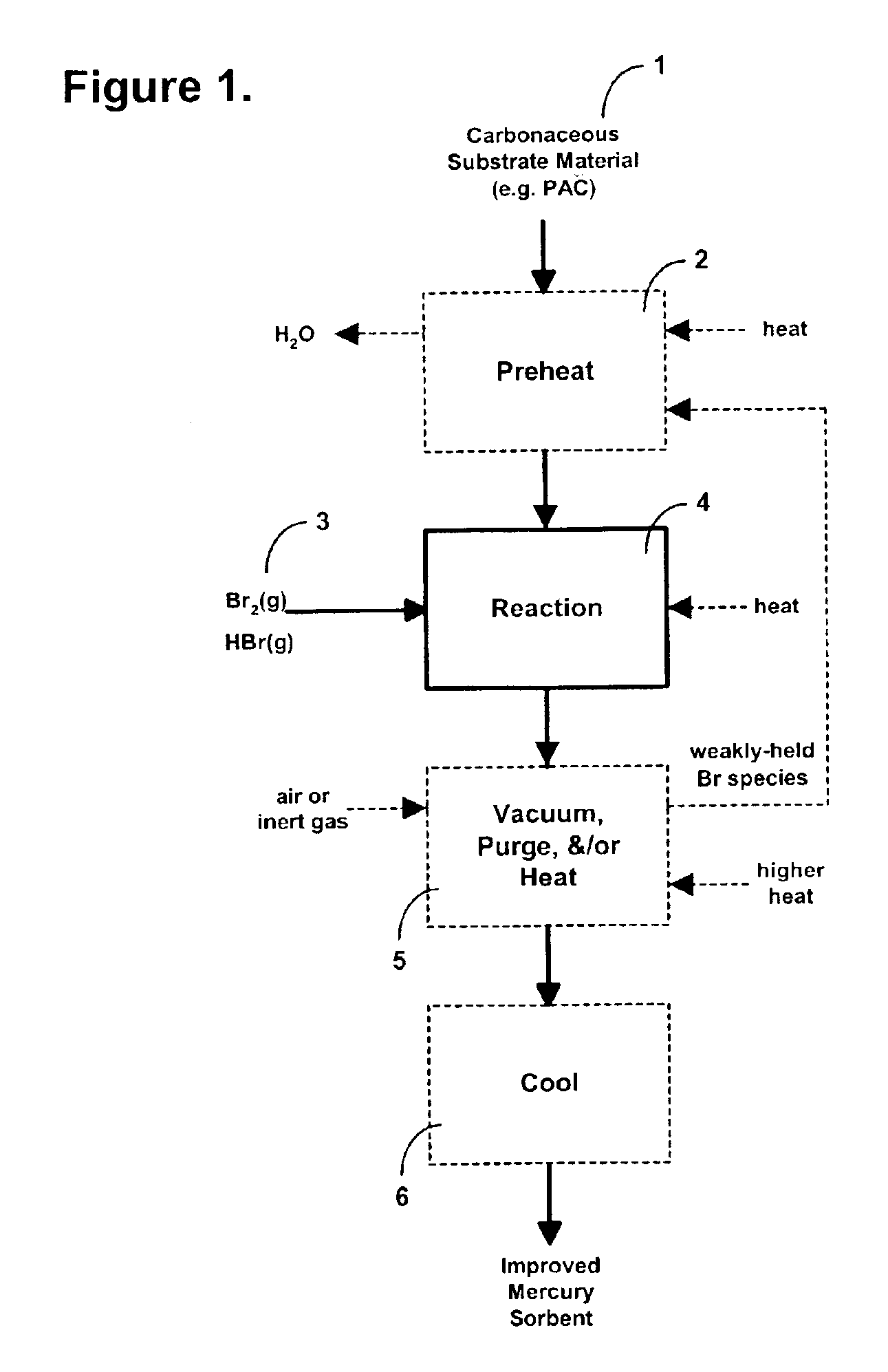

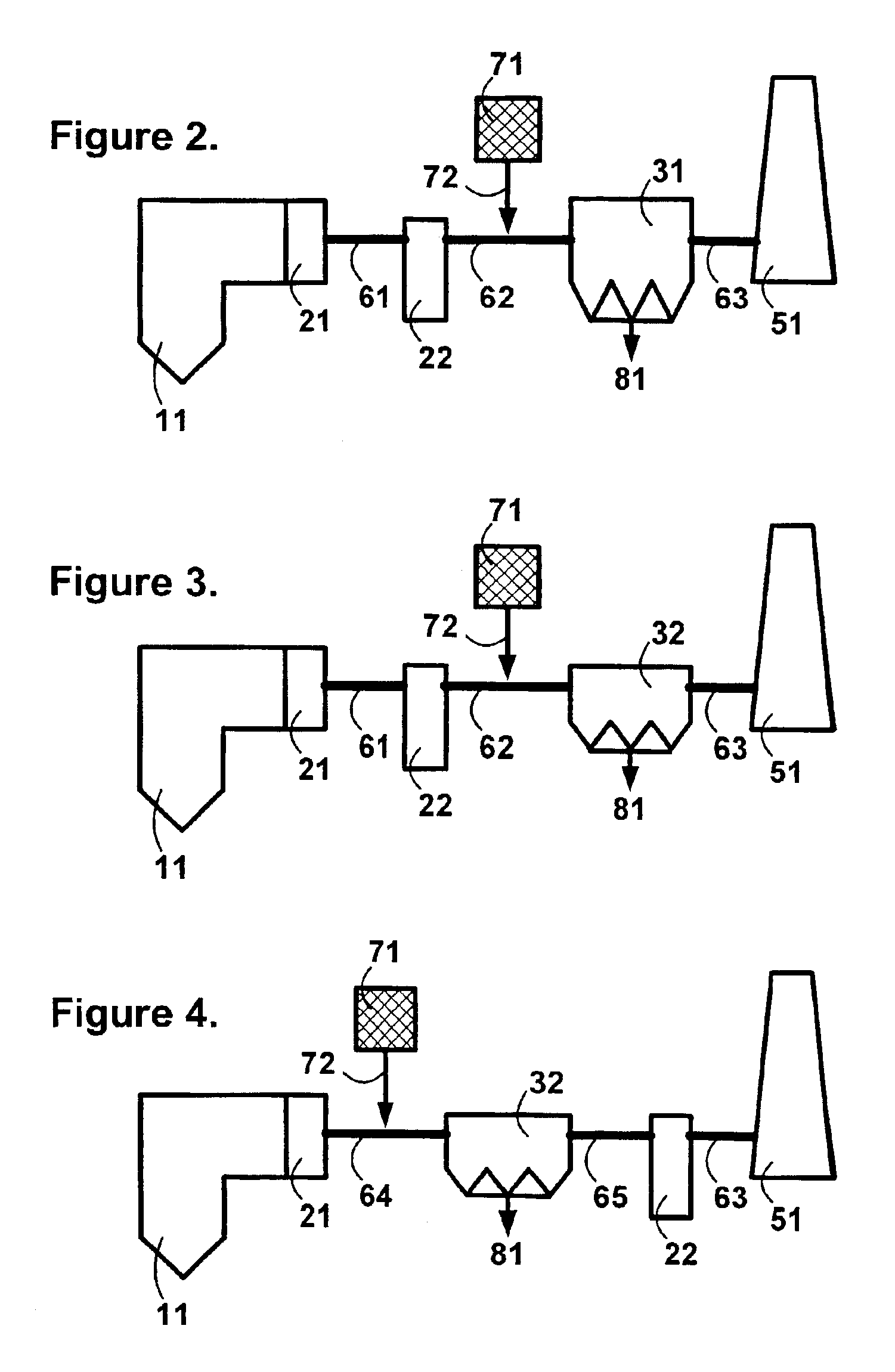

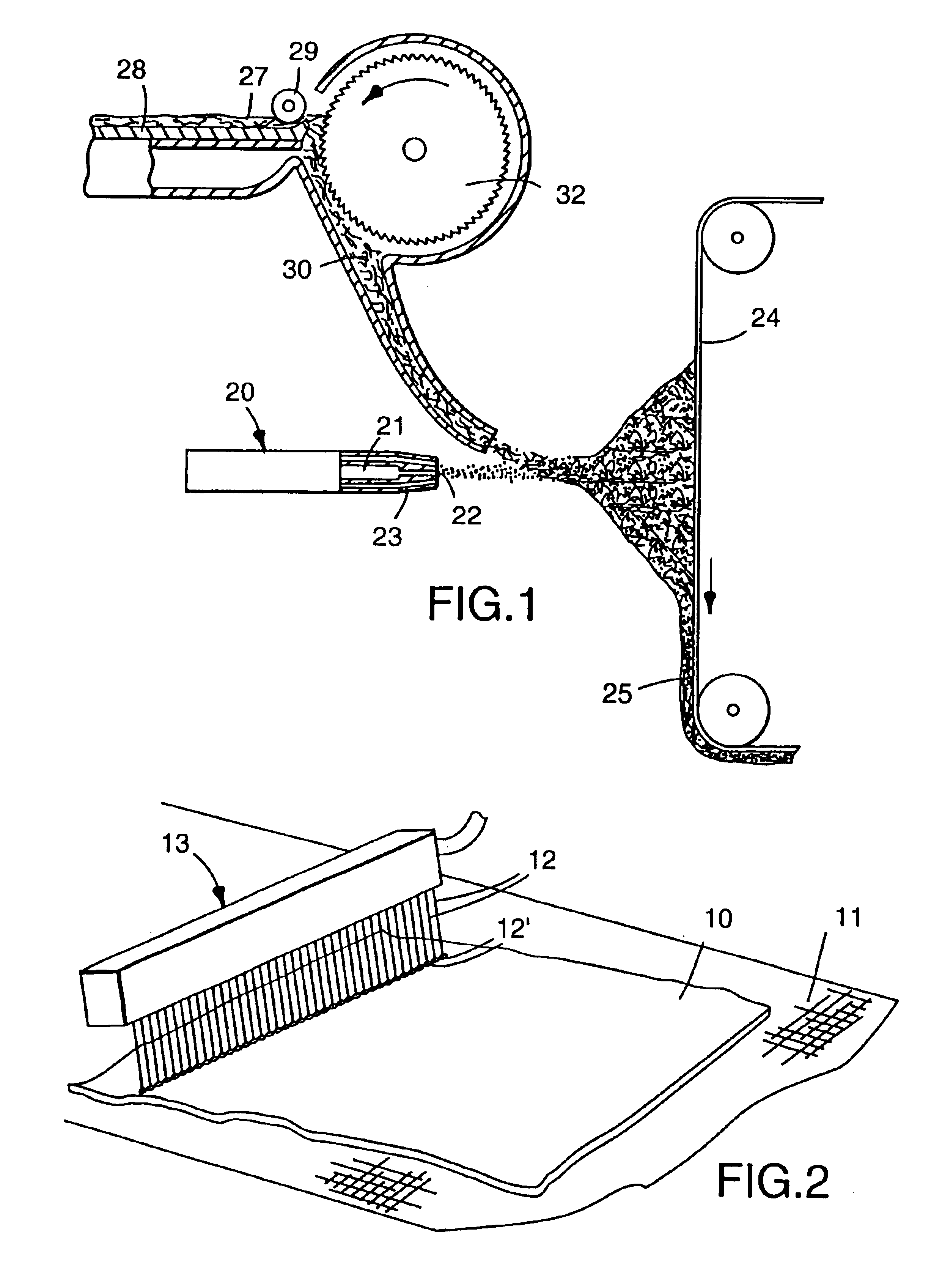

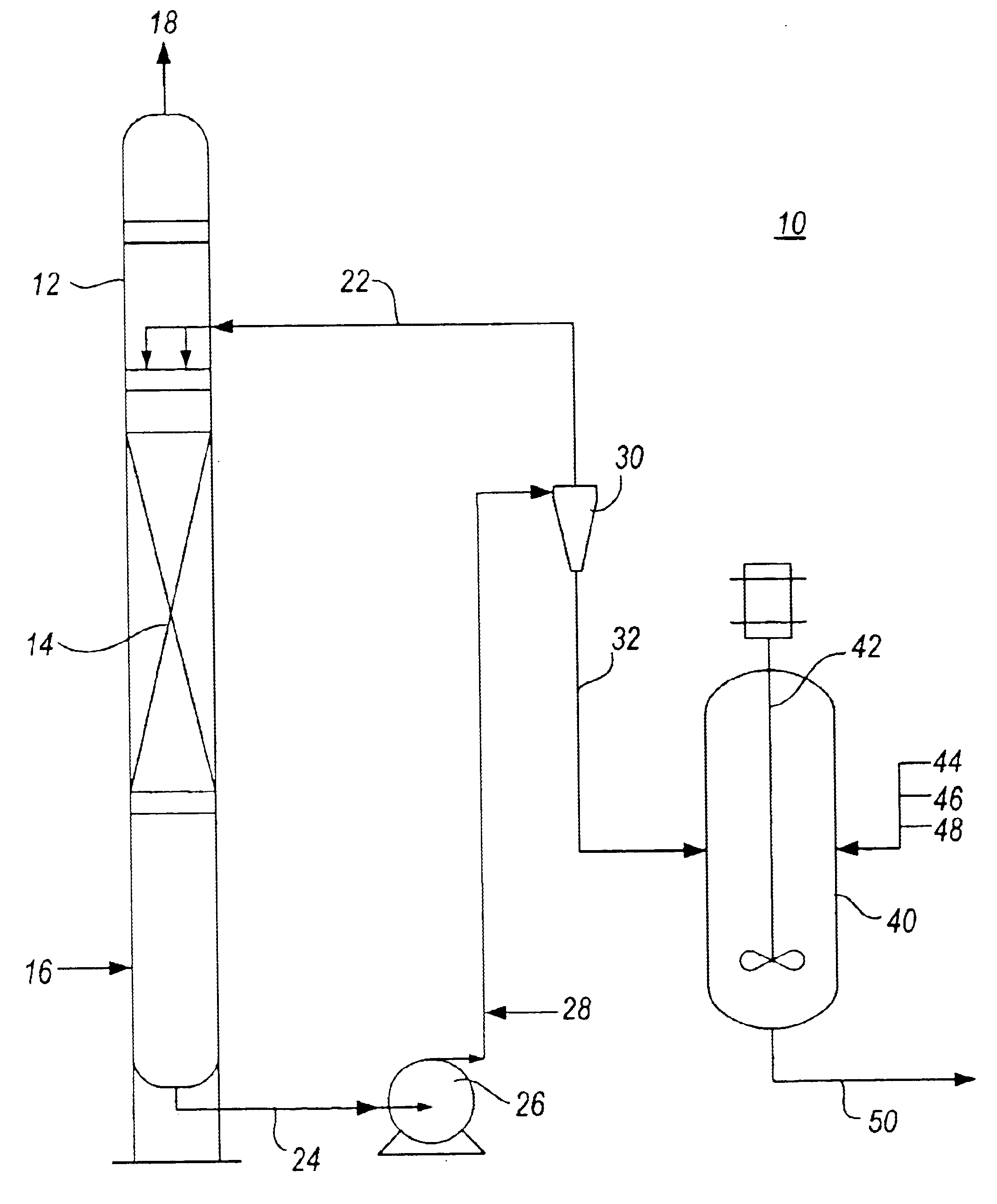

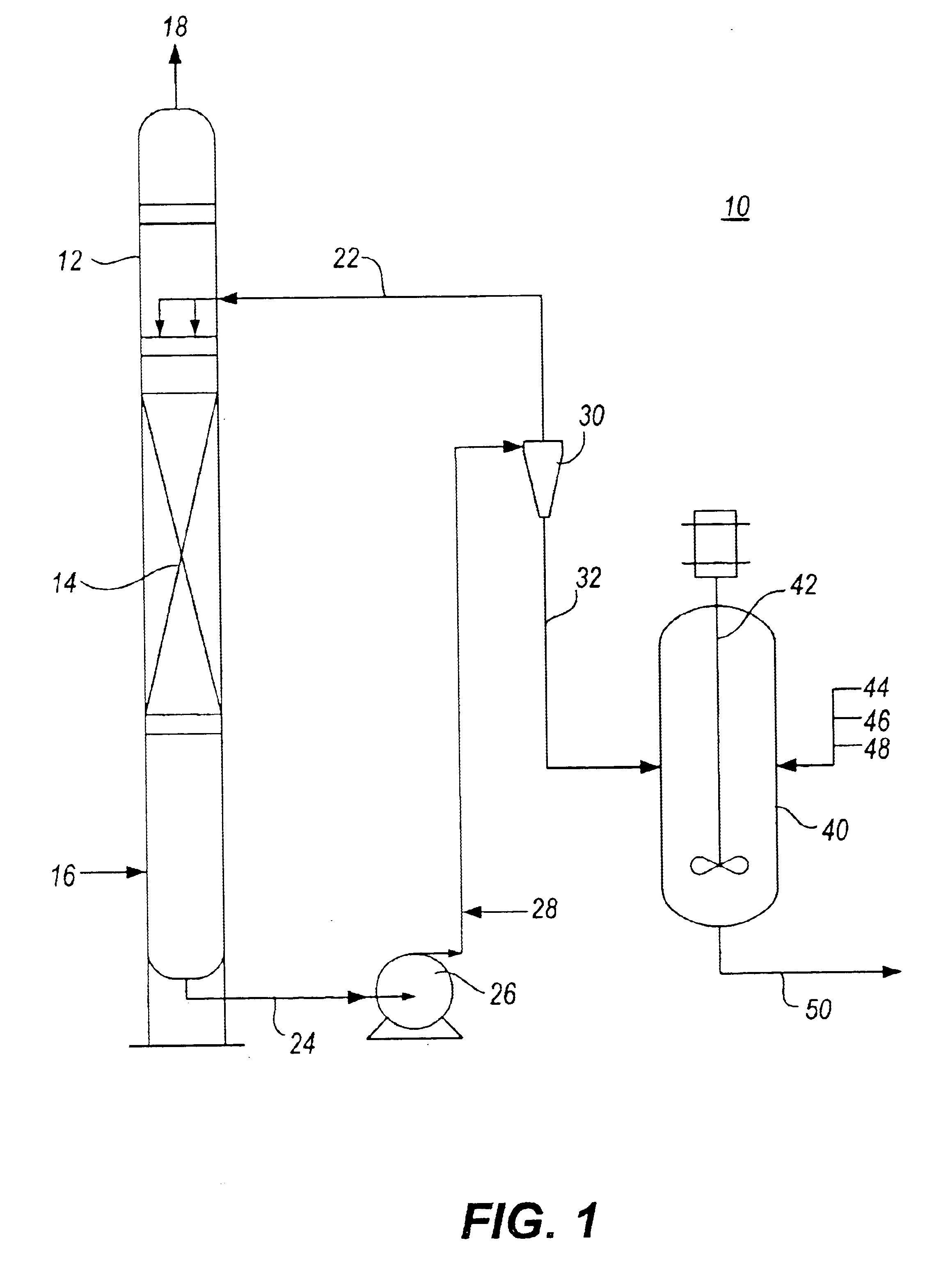

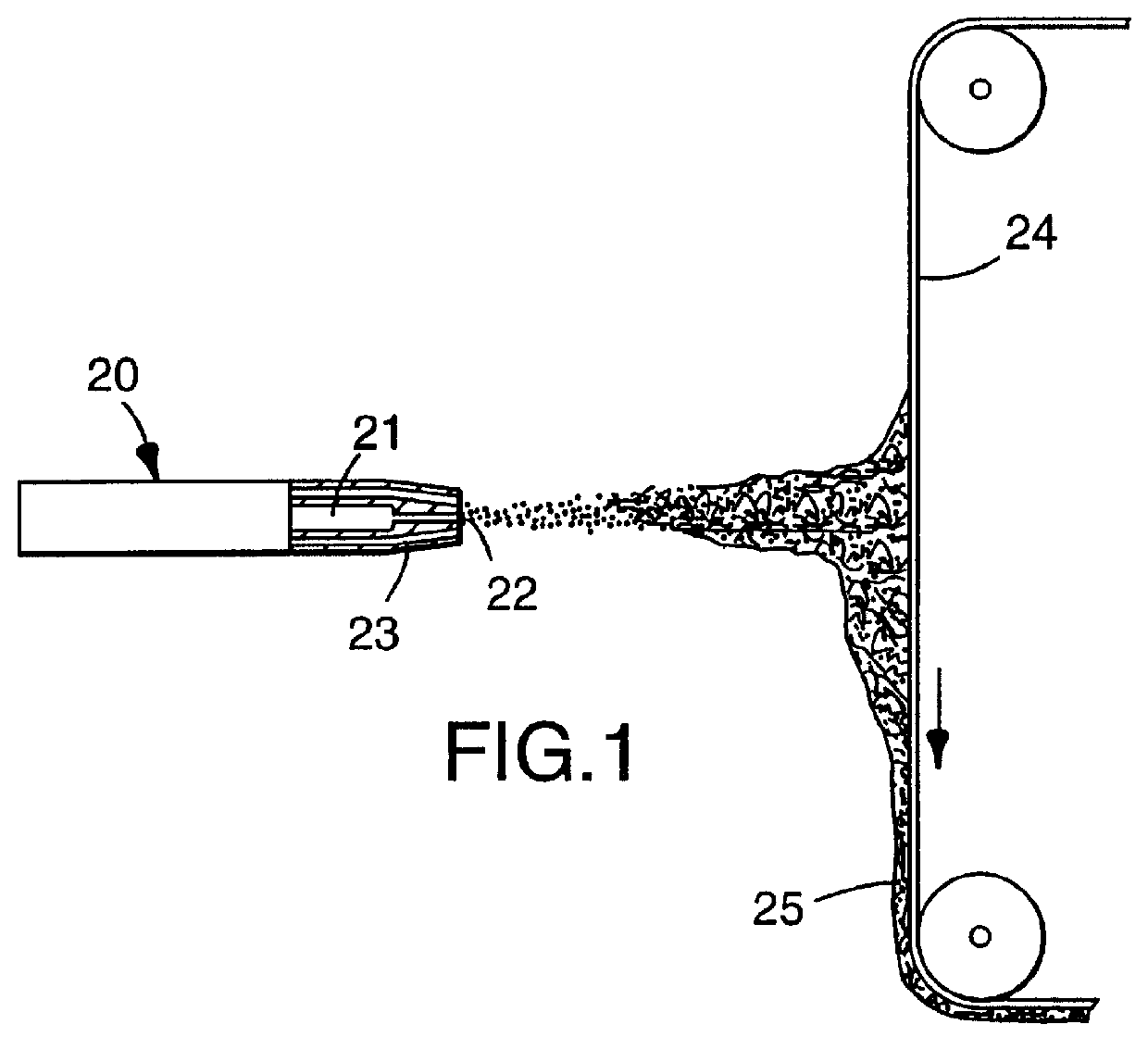

Sorbents and methods for the removal of mercury from combustion gases

InactiveUS6953494B2Improve abilitiesUnified processingGas treatmentOther chemical processesSufficient timeCombustion

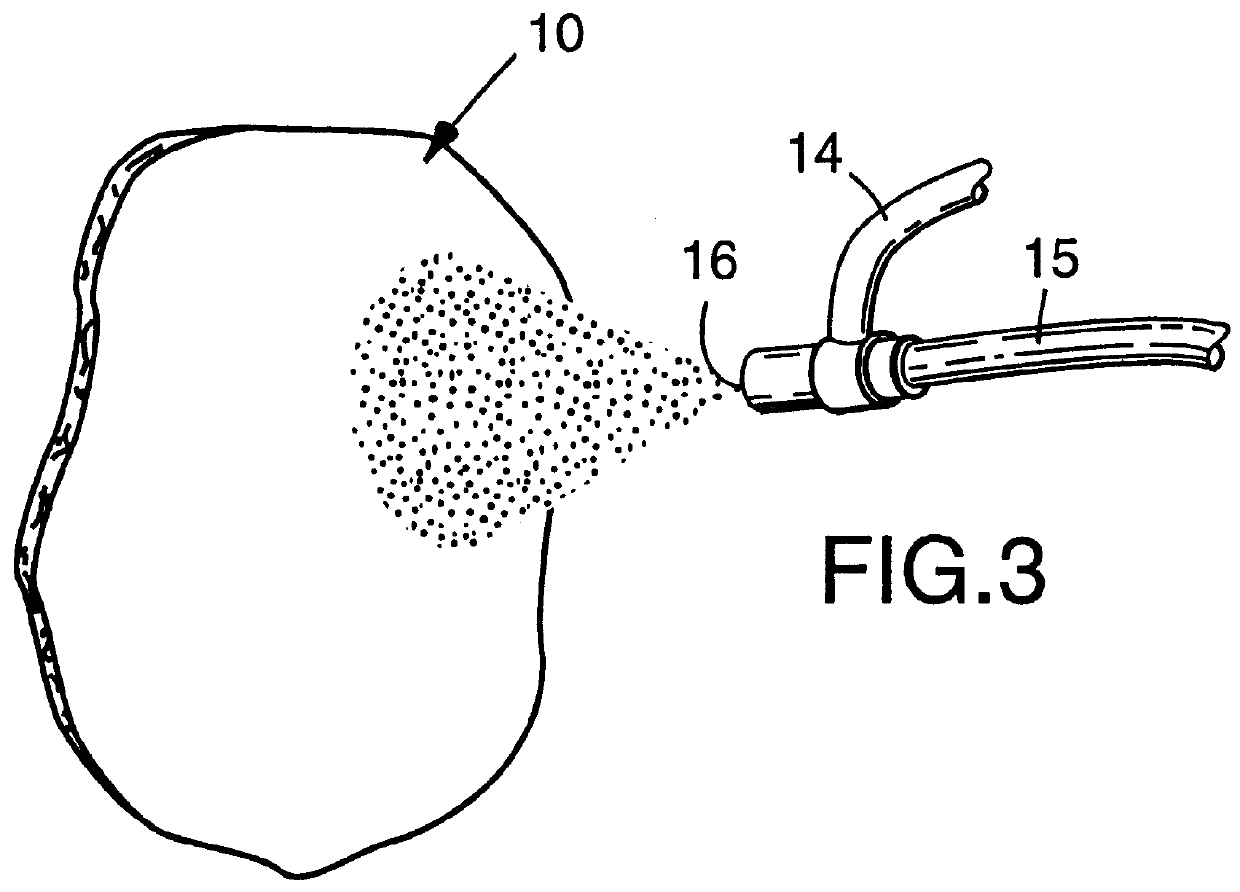

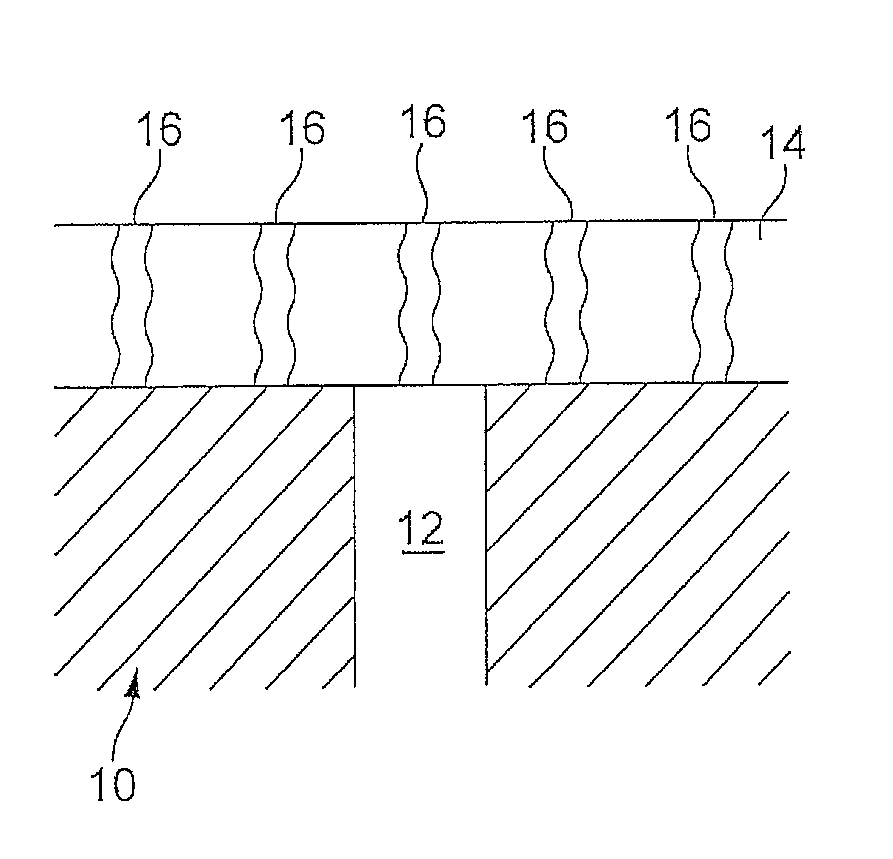

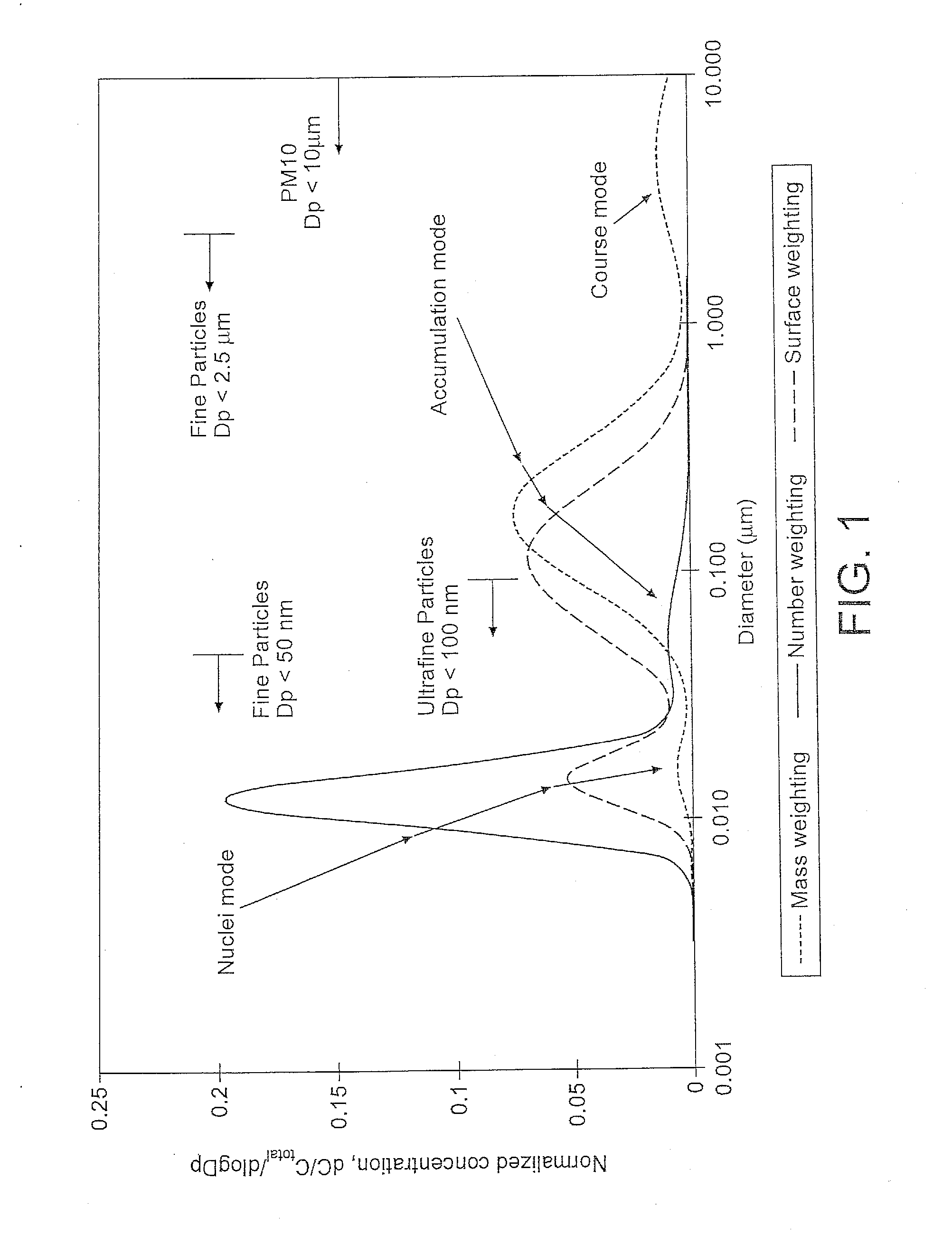

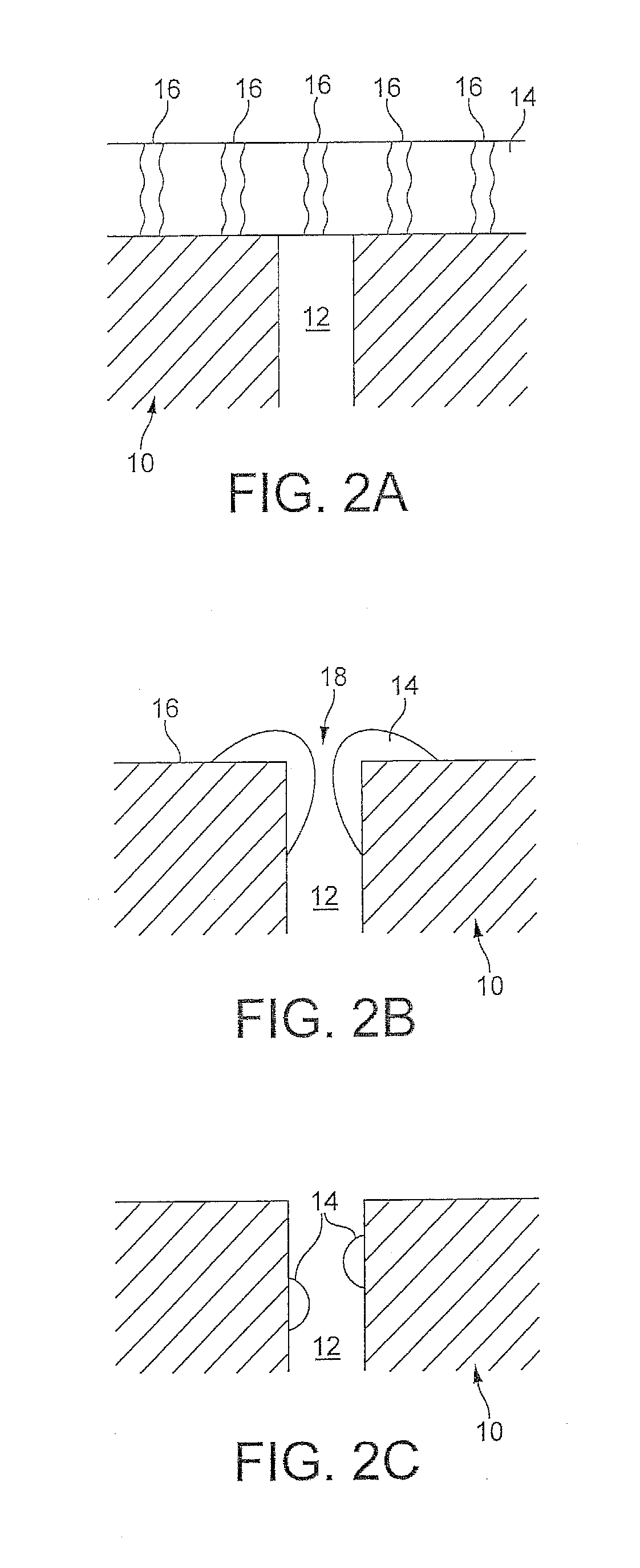

A method for removing mercury and mercury-containing compounds from a combustion gas in an exhaust gas system has the steps of providing a mercury sorbent; injecting the mercury sorbent into a stream of the mercury-containing combustion gas for a sufficient time to allow at least an effective amount of the mercury and mercury-containing compounds in the combustion gas to adsorb onto the mercury sorbent, and collecting and removing the mercury sorbent from the combustion gas stream. The mercury sorbent is prepared by treating a carbonaceous substrate with an effective amount of a bromine-containing gas, especially one containing elemental bromine or hydrogen bromide, for a time sufficient to increase the ability of the carbonaceous substrate to adsorb mercury and mercury-containing compounds. The points of injecting and collecting and removing the mercury sorbent may be varied, depending upon the exact configuration of the exhaust gas system.

Owner:SORBENT TECH +1

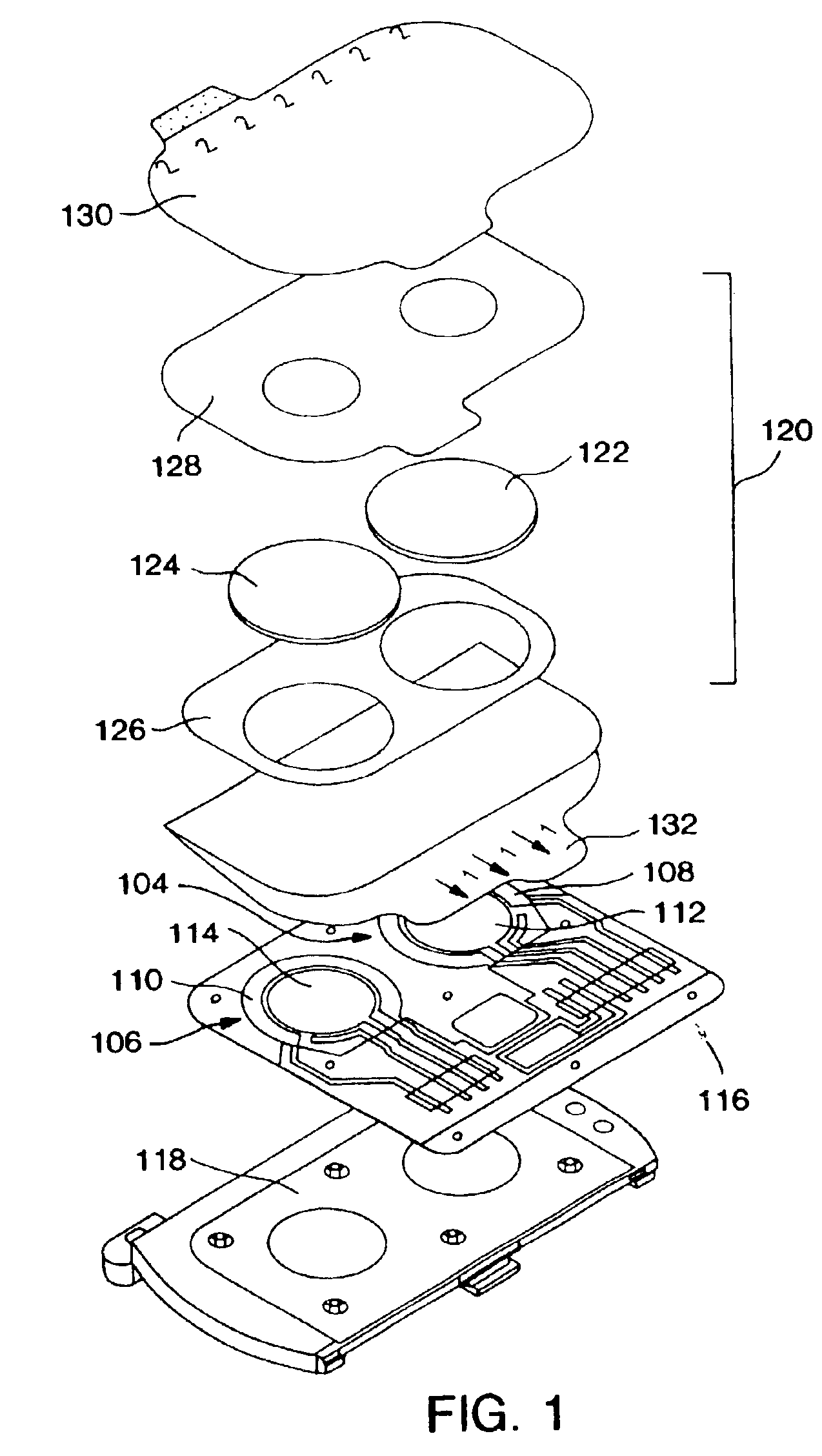

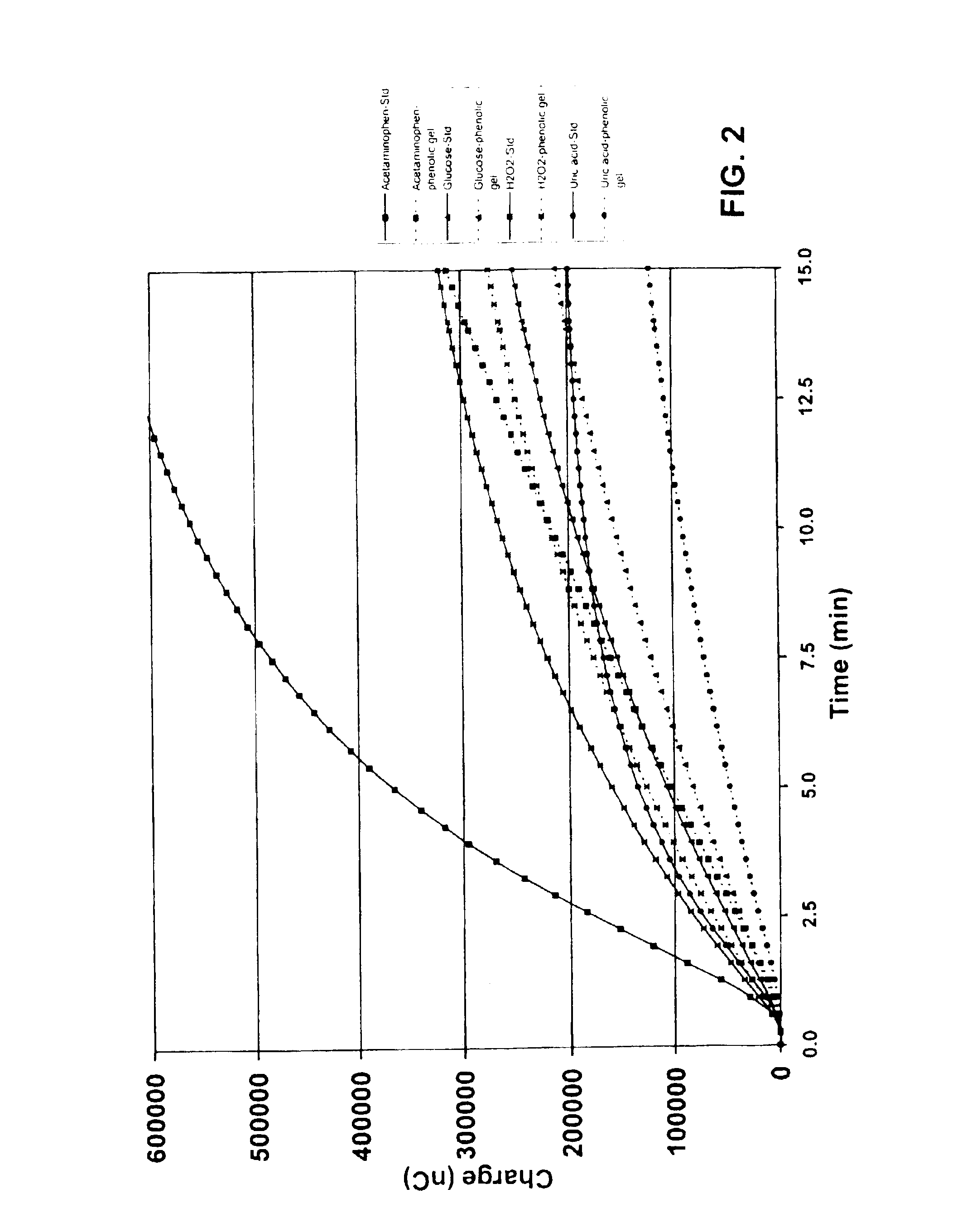

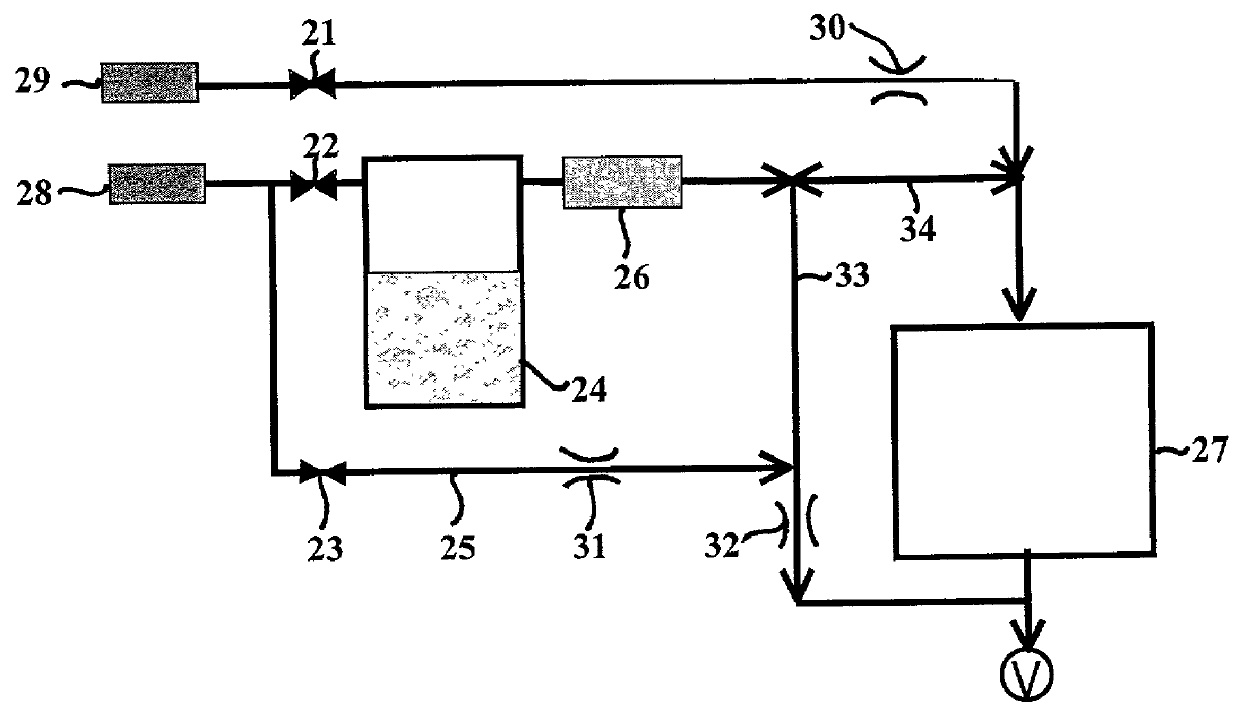

Glucose measuring assembly with a hydrogel

InactiveUS6902905B2Reduce presenceIncrease percentagePowder deliveryElectrotherapyIontophoresis therapyAnalyte

This invention relates to methods for reducing the presence of a compound in an ionically conductive material, e.g., for use in iontophoretic devices, wherein the presence of the compound interferes with detecting a selected analyte. Removal of the compound can typically take place either during or after the manufacture of the ionically conductive material or an assembly comprising this material. Also disclosed are methods for generating selectively permeable barriers on the reactive faces of electrodes. Further, this invention relates to hydrogels comprising one or more biocides, as well as assemblies containing such hydrogels.

Owner:LIFESCAN IP HLDG LLC +1

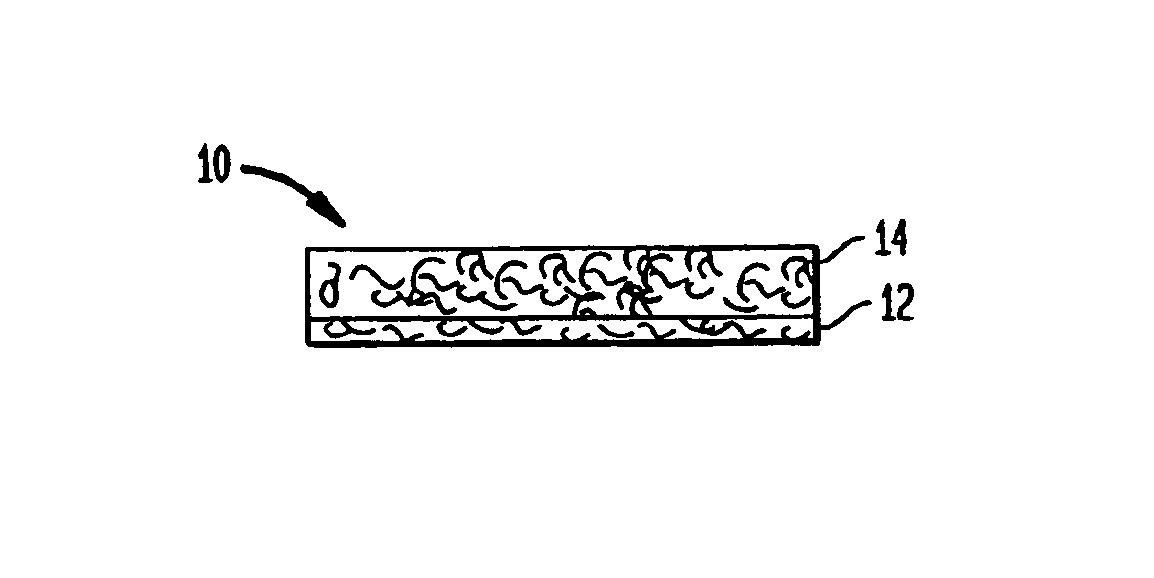

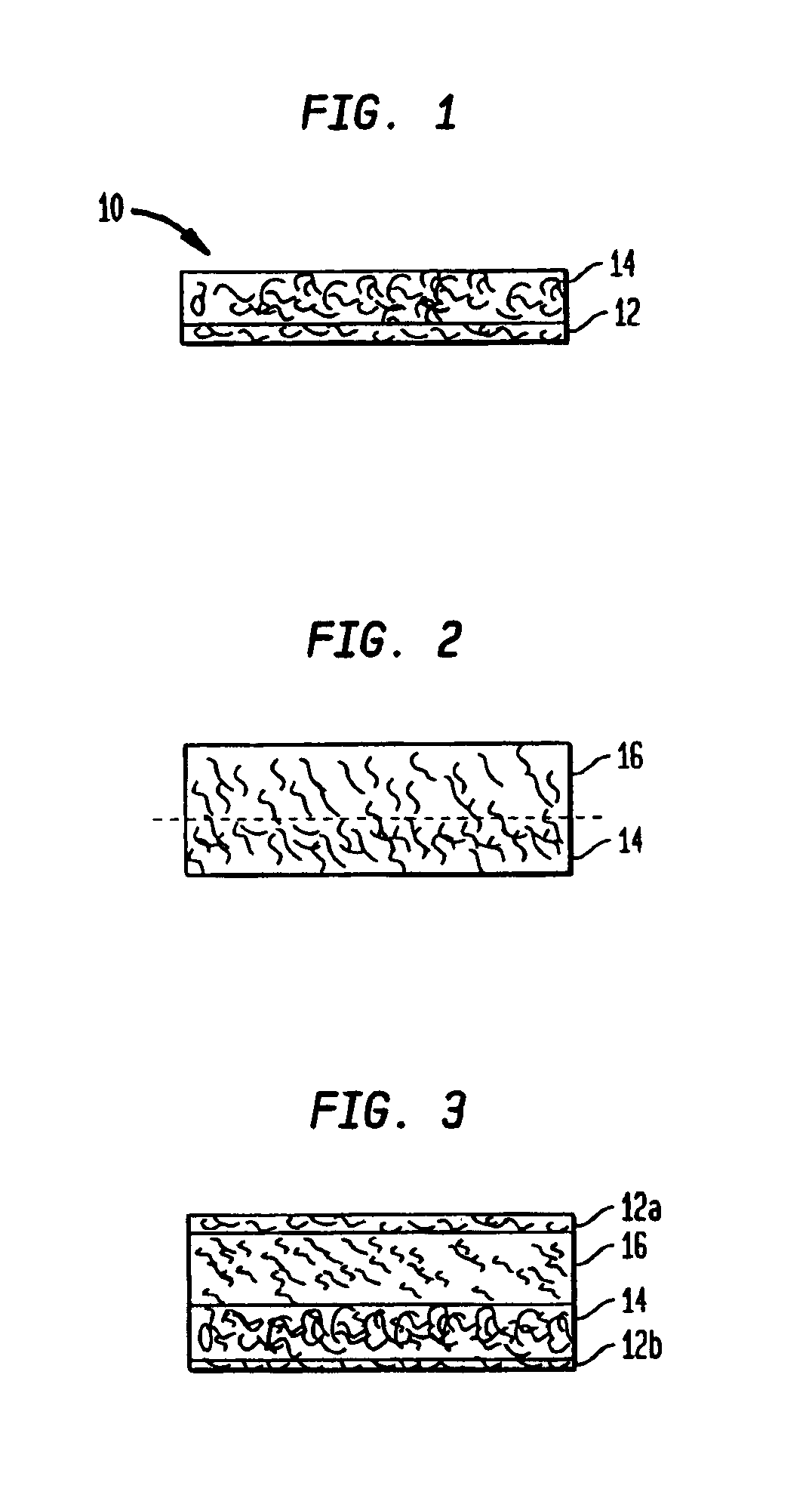

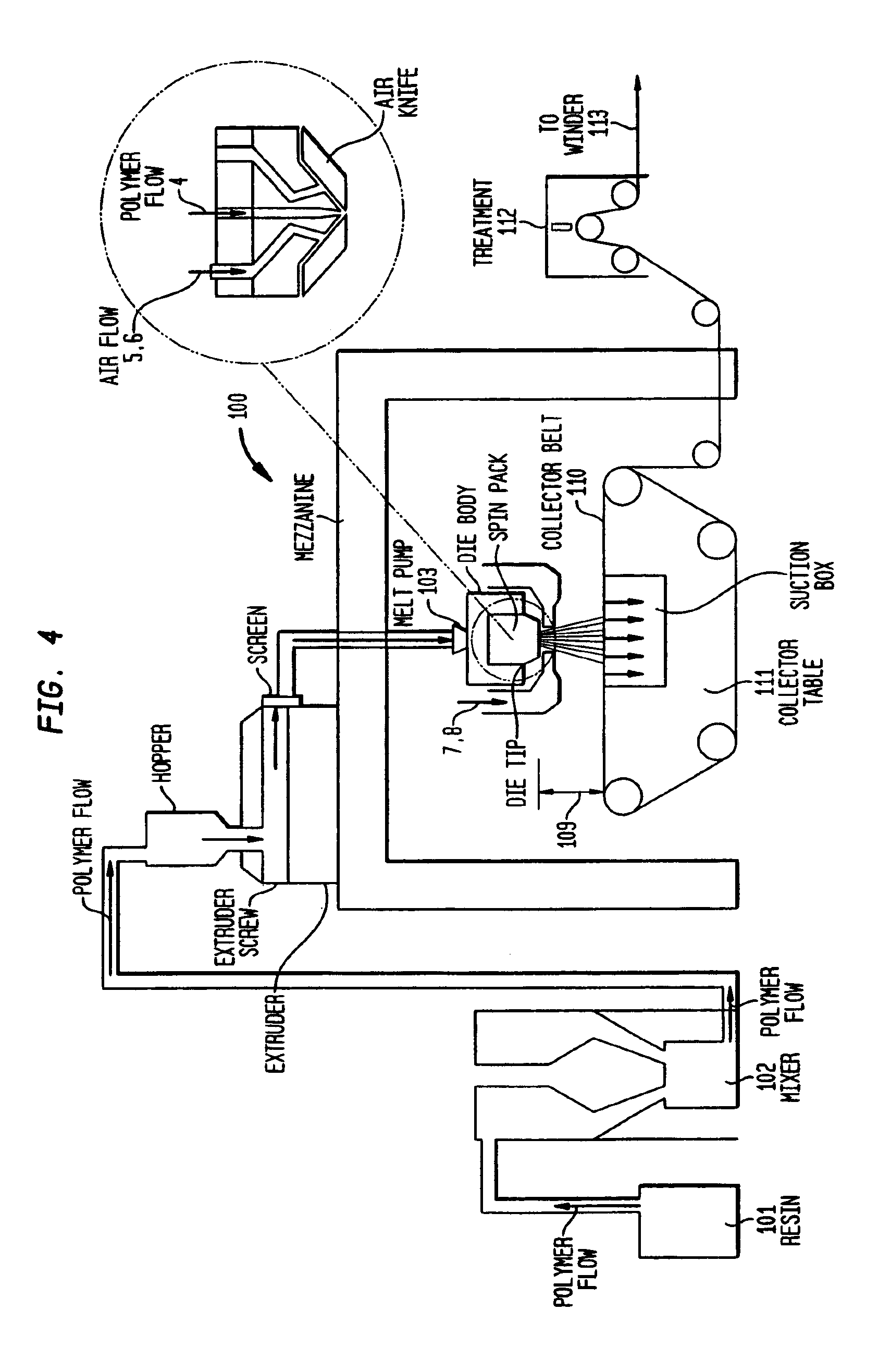

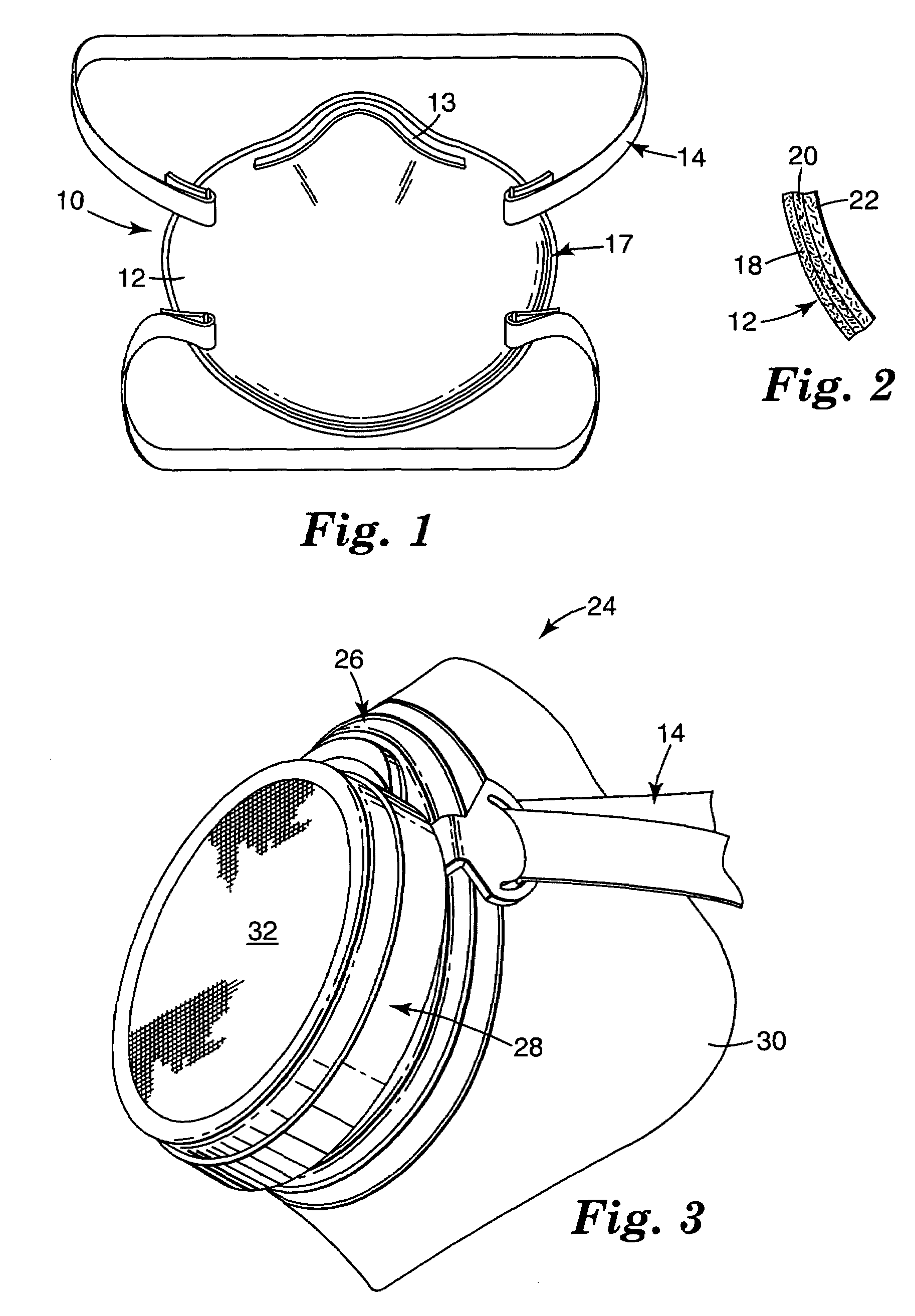

Electret filter media

InactiveUS6119691AReduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersMicrometerFilter media

An electret filter media, and mask, that is made of a nonwoven web of thermoplastic microfibers. The thermoplastic microfibers are of substantially the same composition, are nonconductive, and have an effective fiber diameter less than about 15 micrometers. The nonwoven web also has sufficient unpolarized trapped charge to exhibit an initial filtration quality factor of at least 0.31 when measured under the DOP Penetration and Pressure Drop Test.

Owner:3M CO

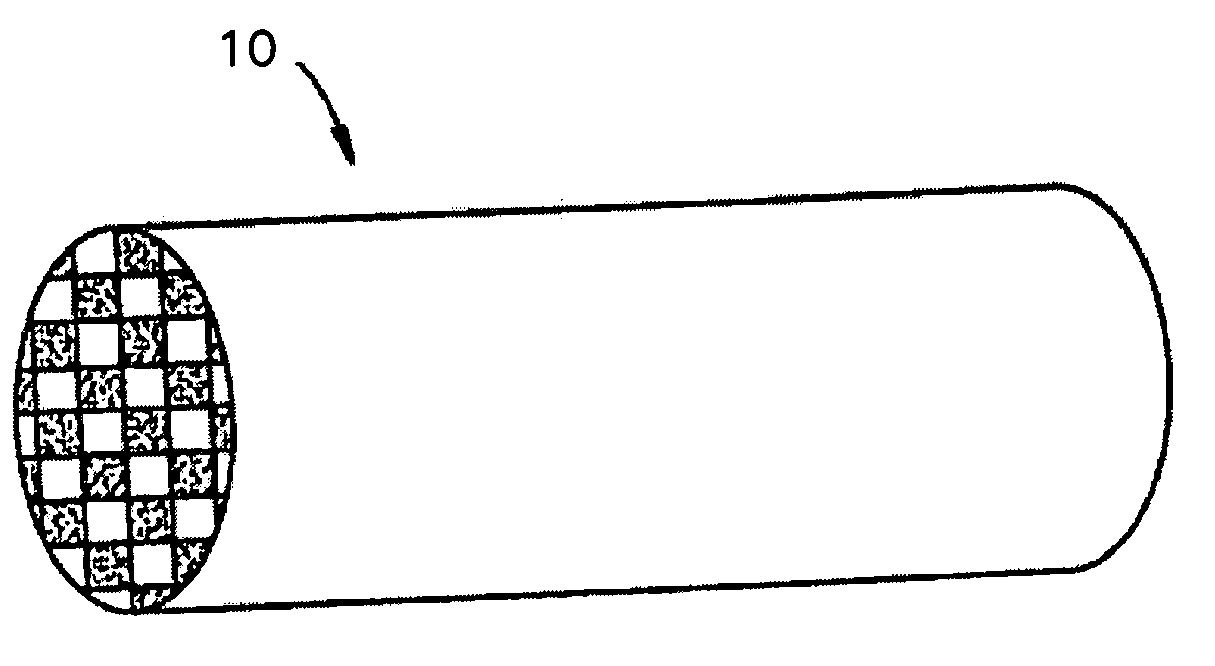

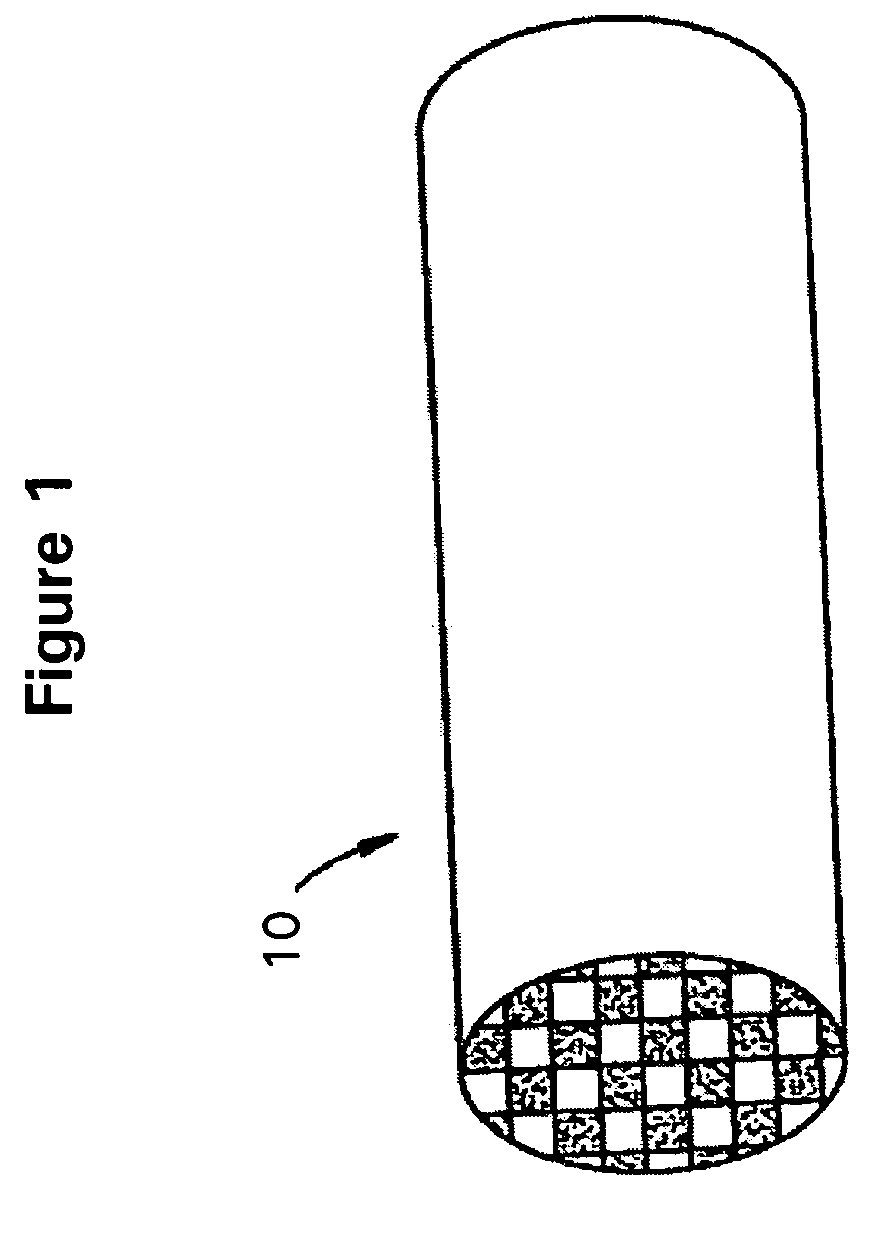

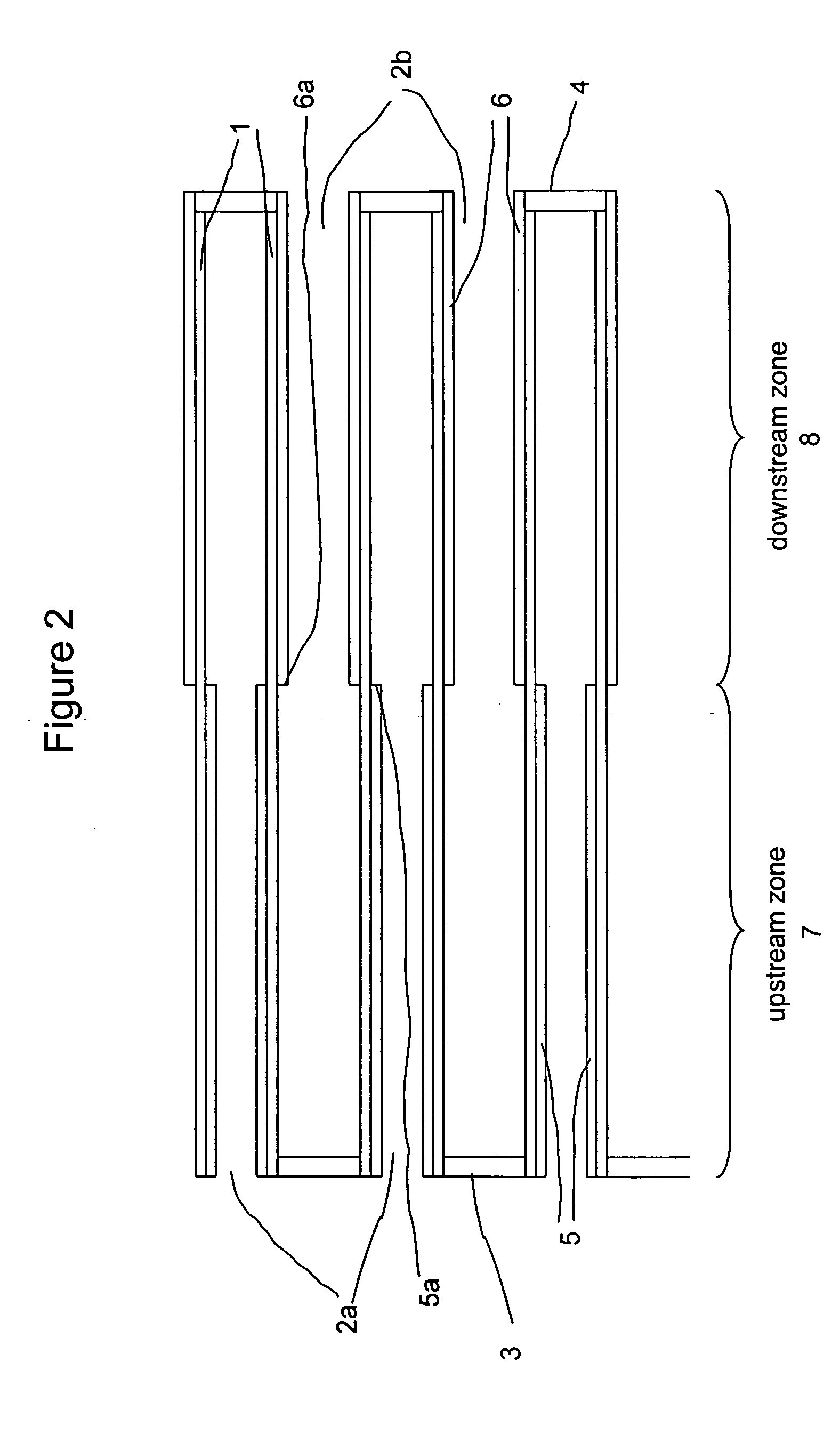

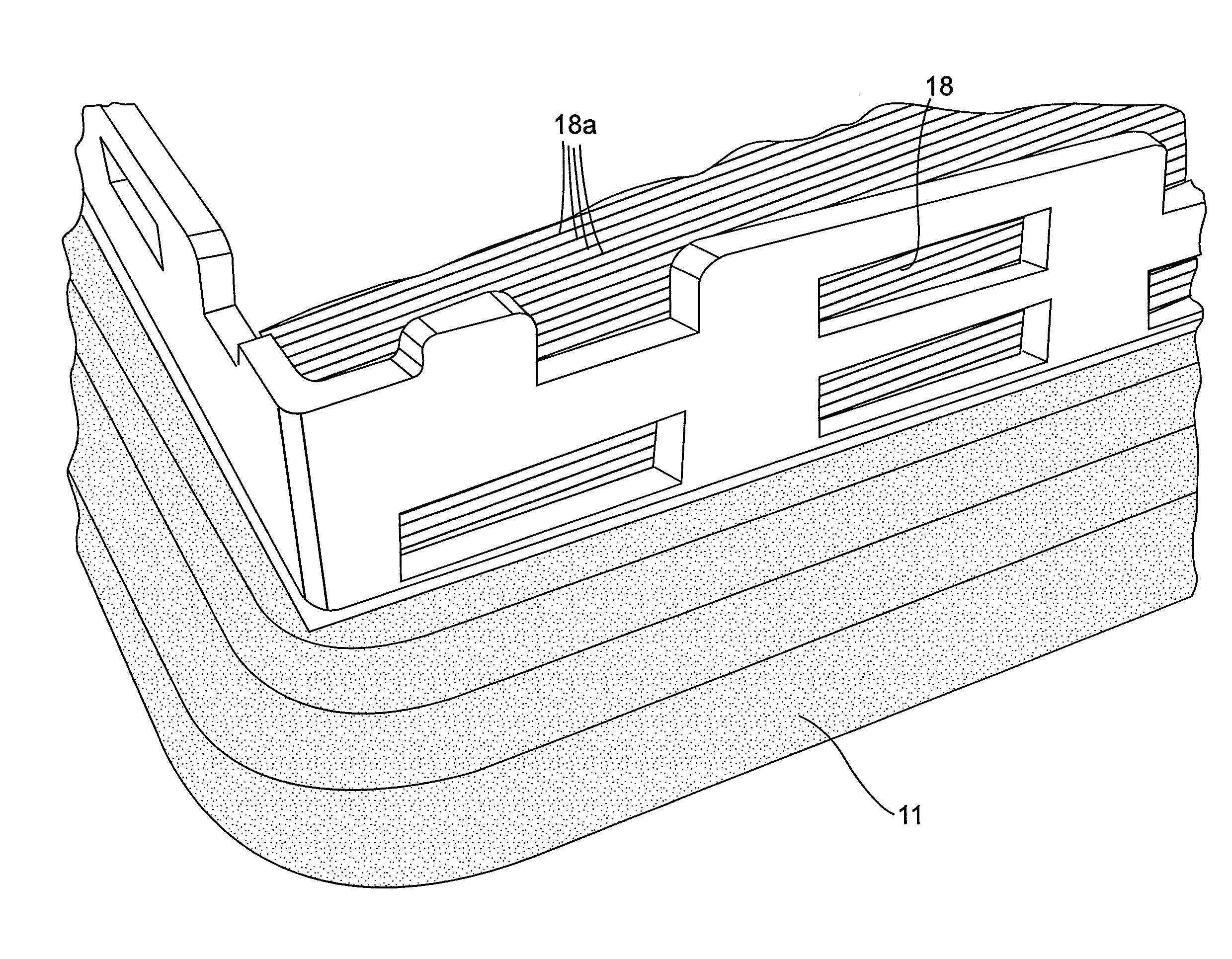

Pressure-balanced, catalyzed soot filter

ActiveUS20060057046A1Minimal overall platinum group metal component material costSpeed up the conversion processCombination devicesMolecular sieve catalystsParticulatesCatalytic function

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

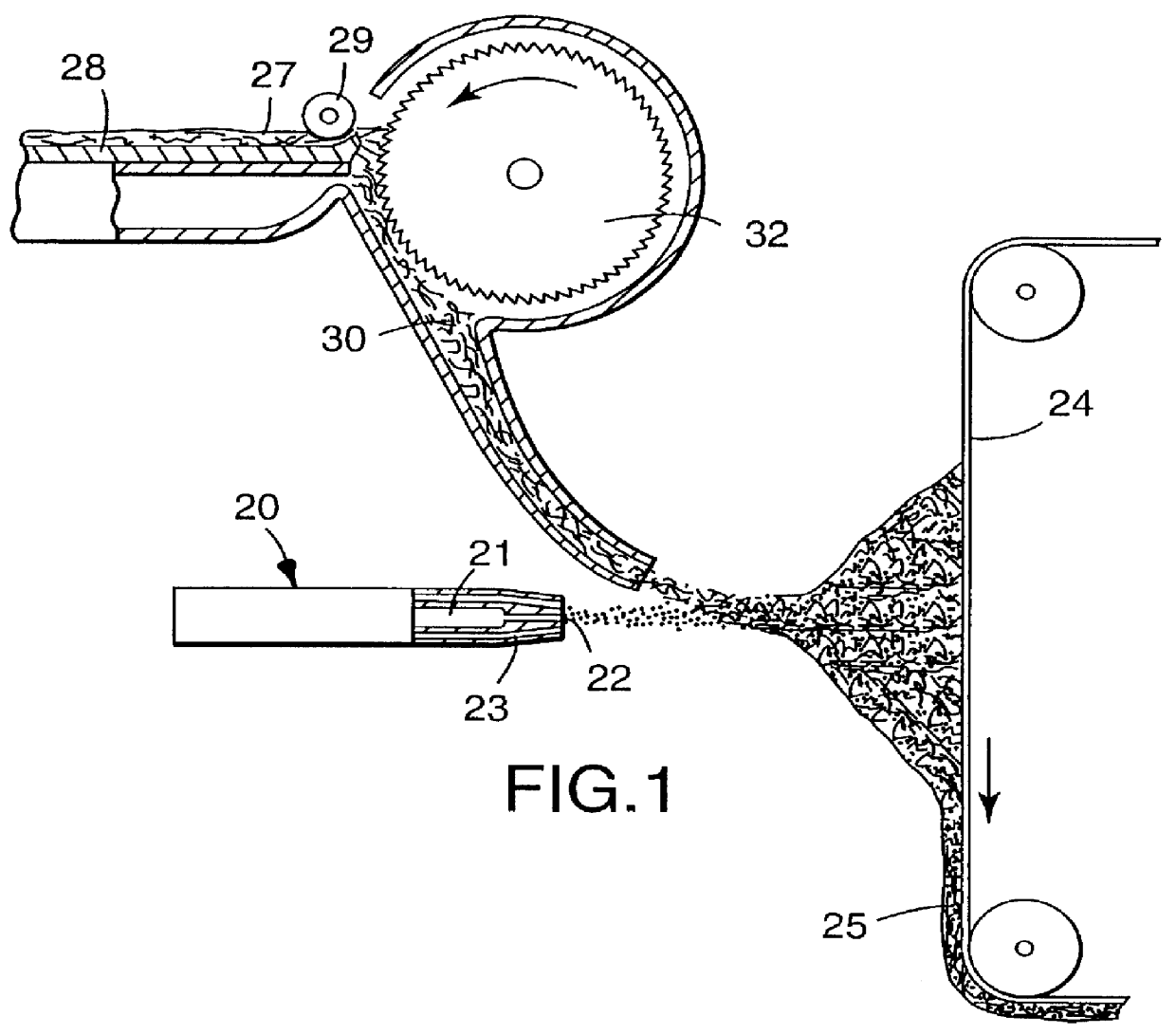

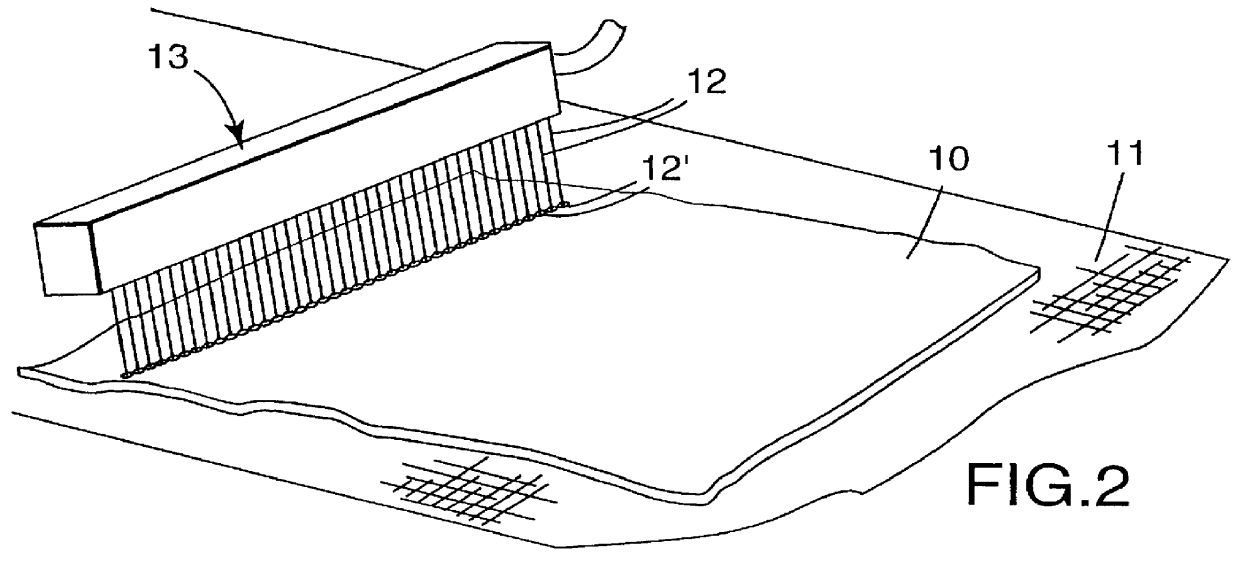

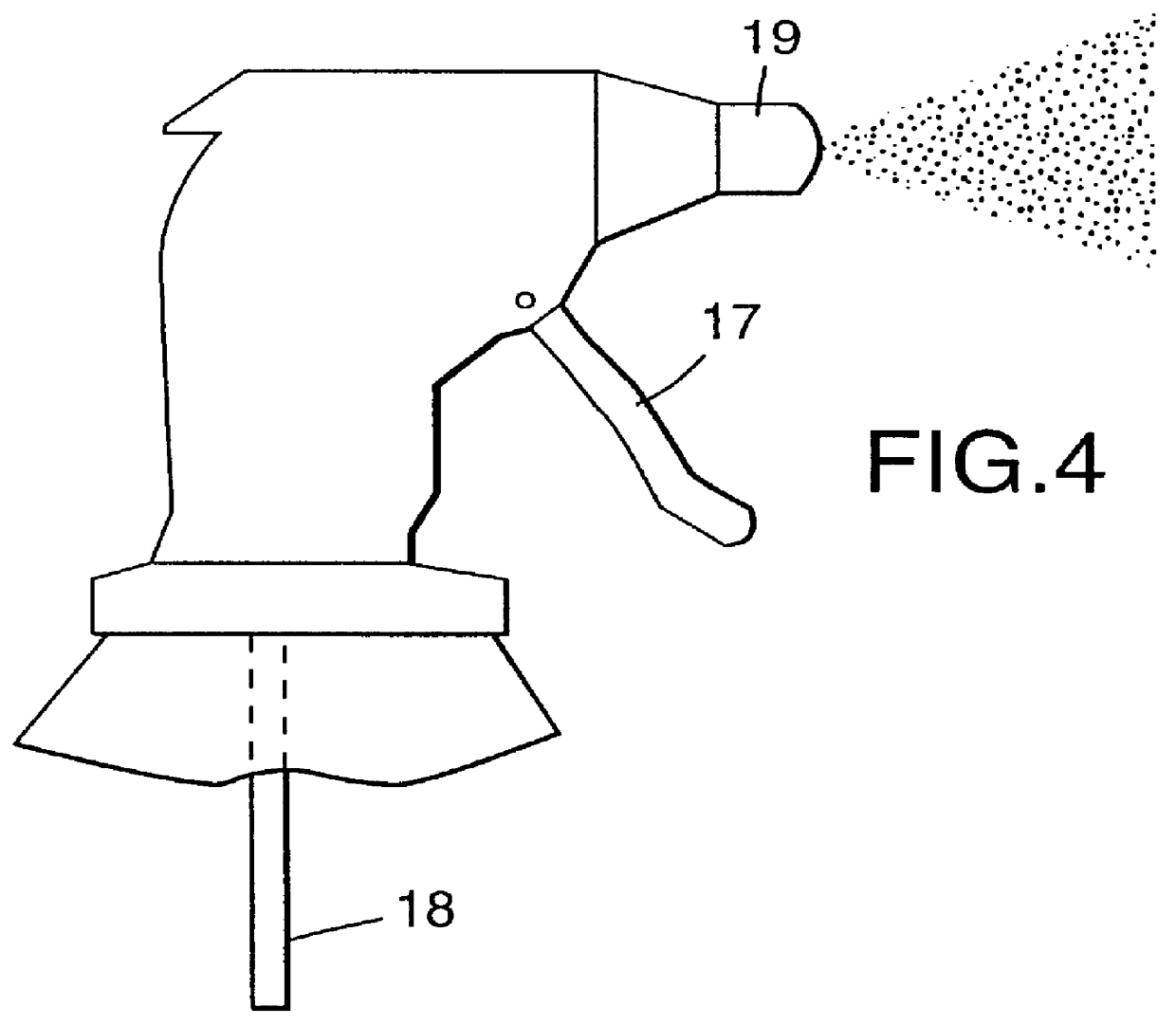

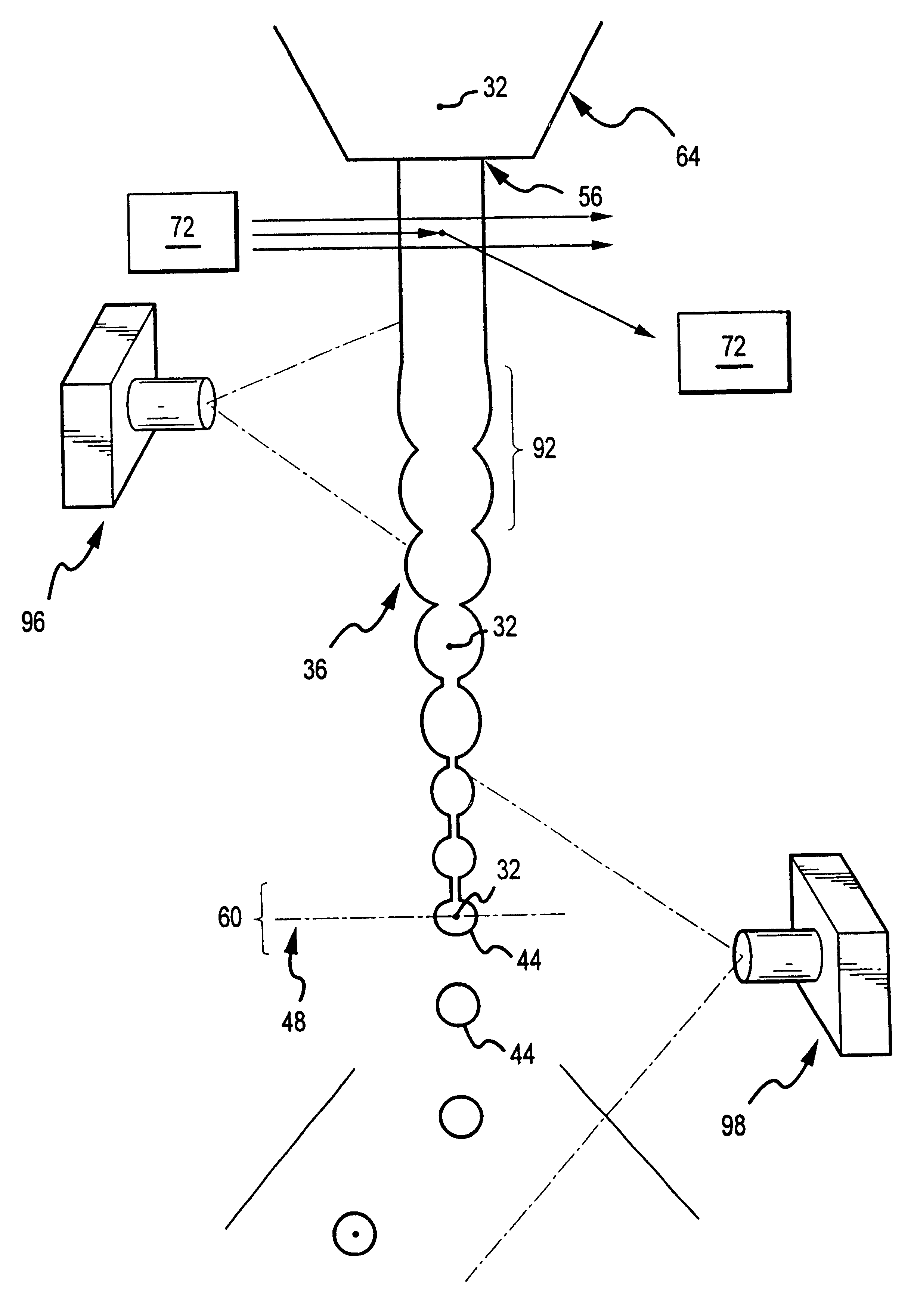

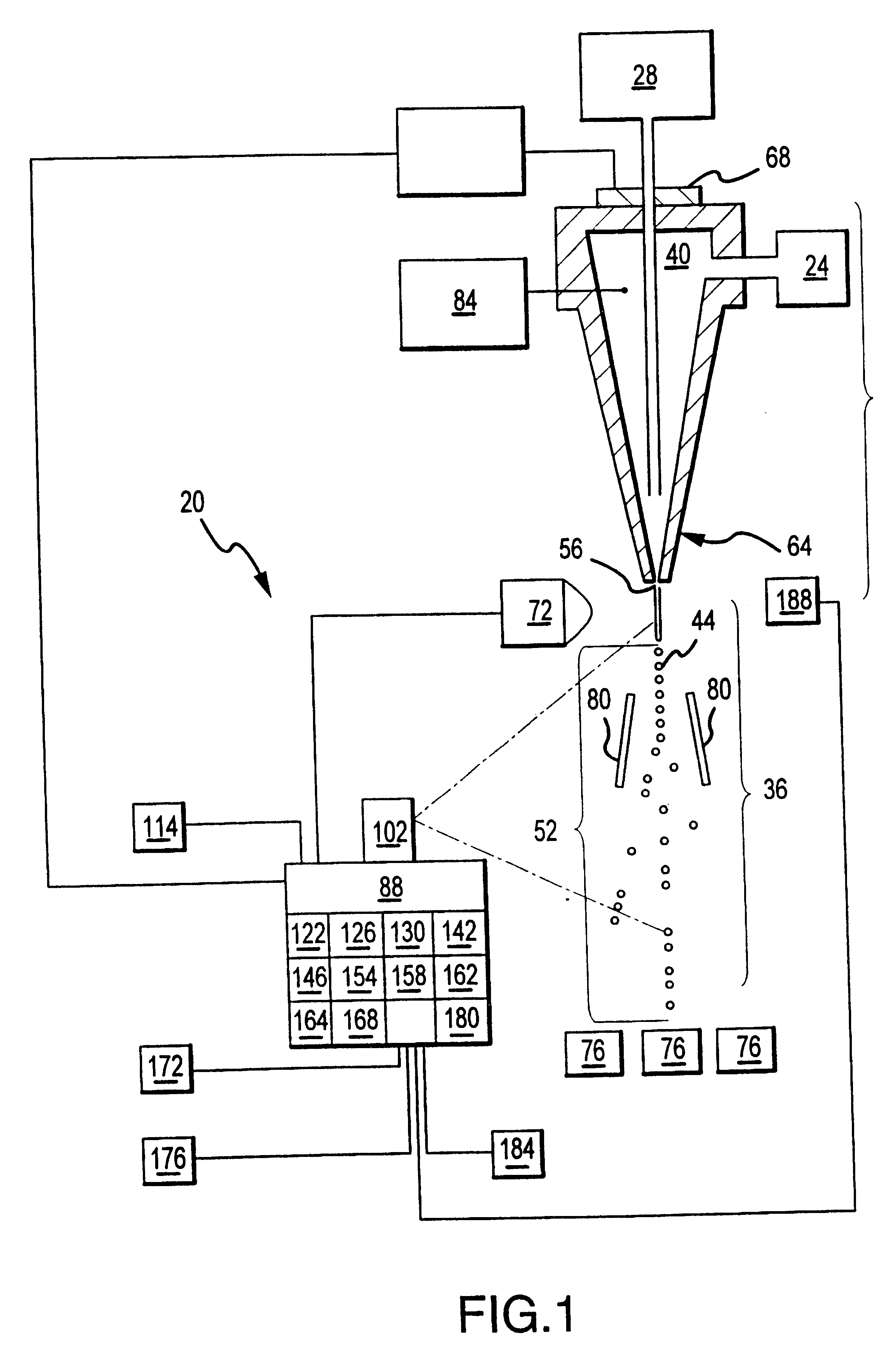

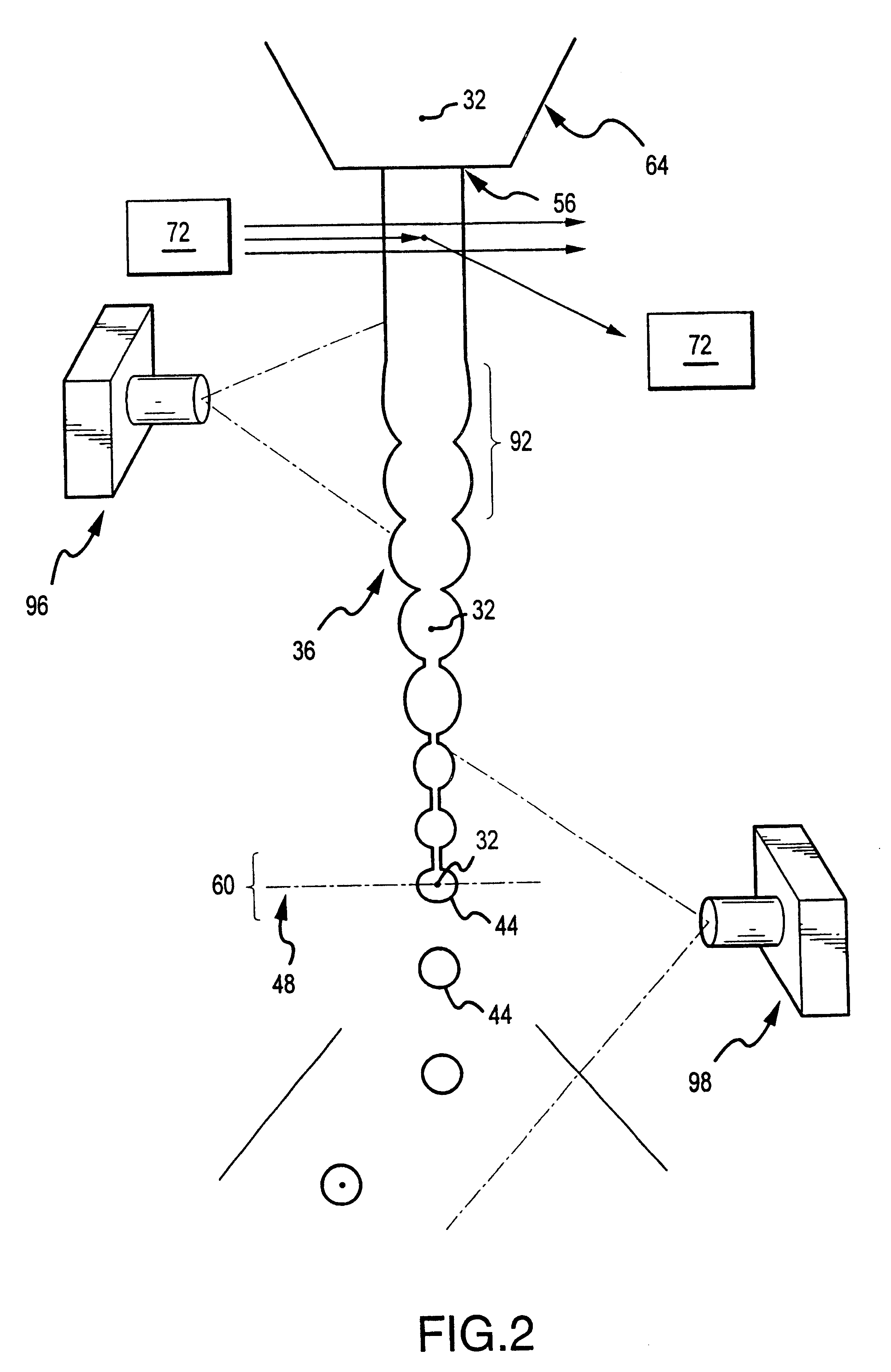

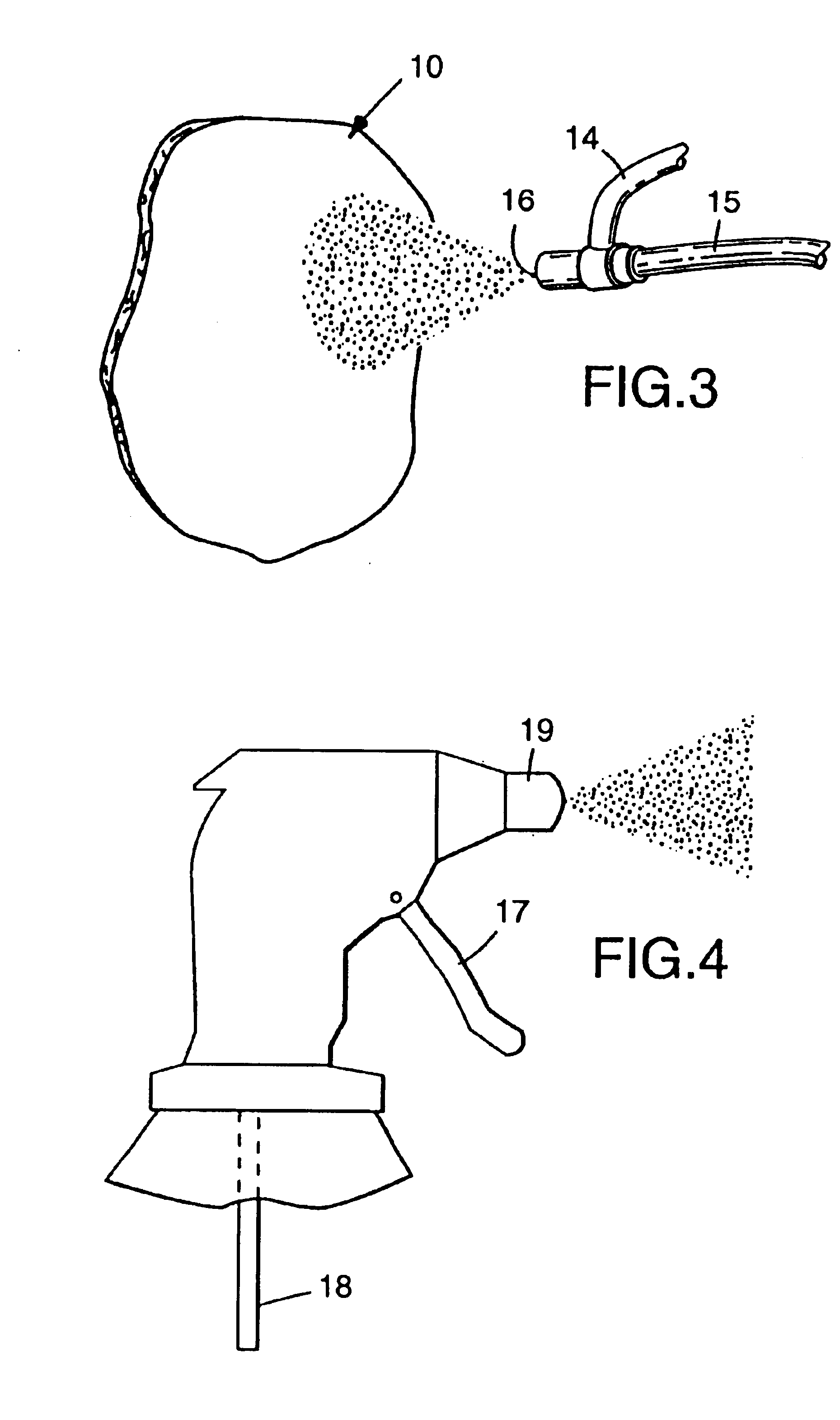

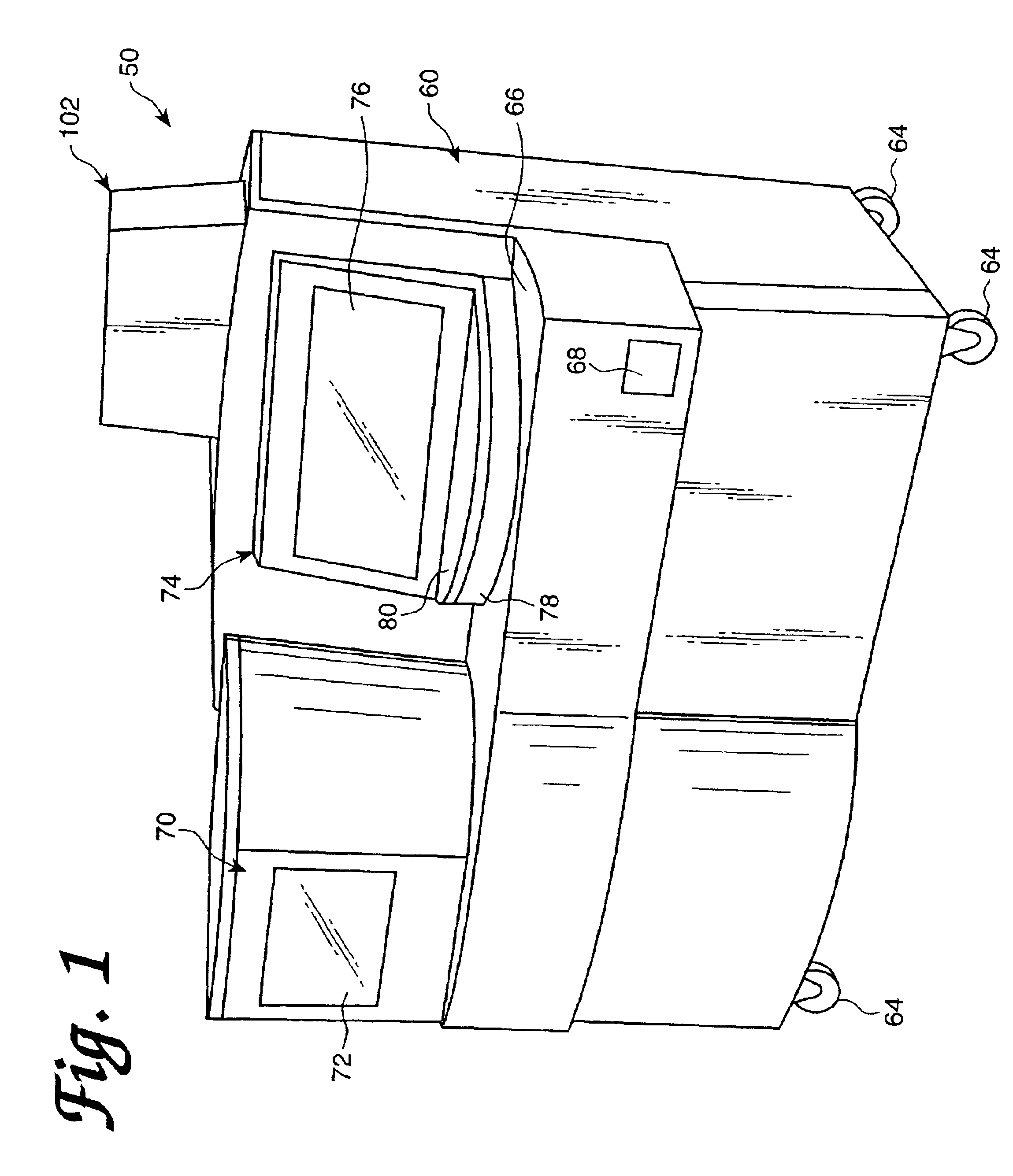

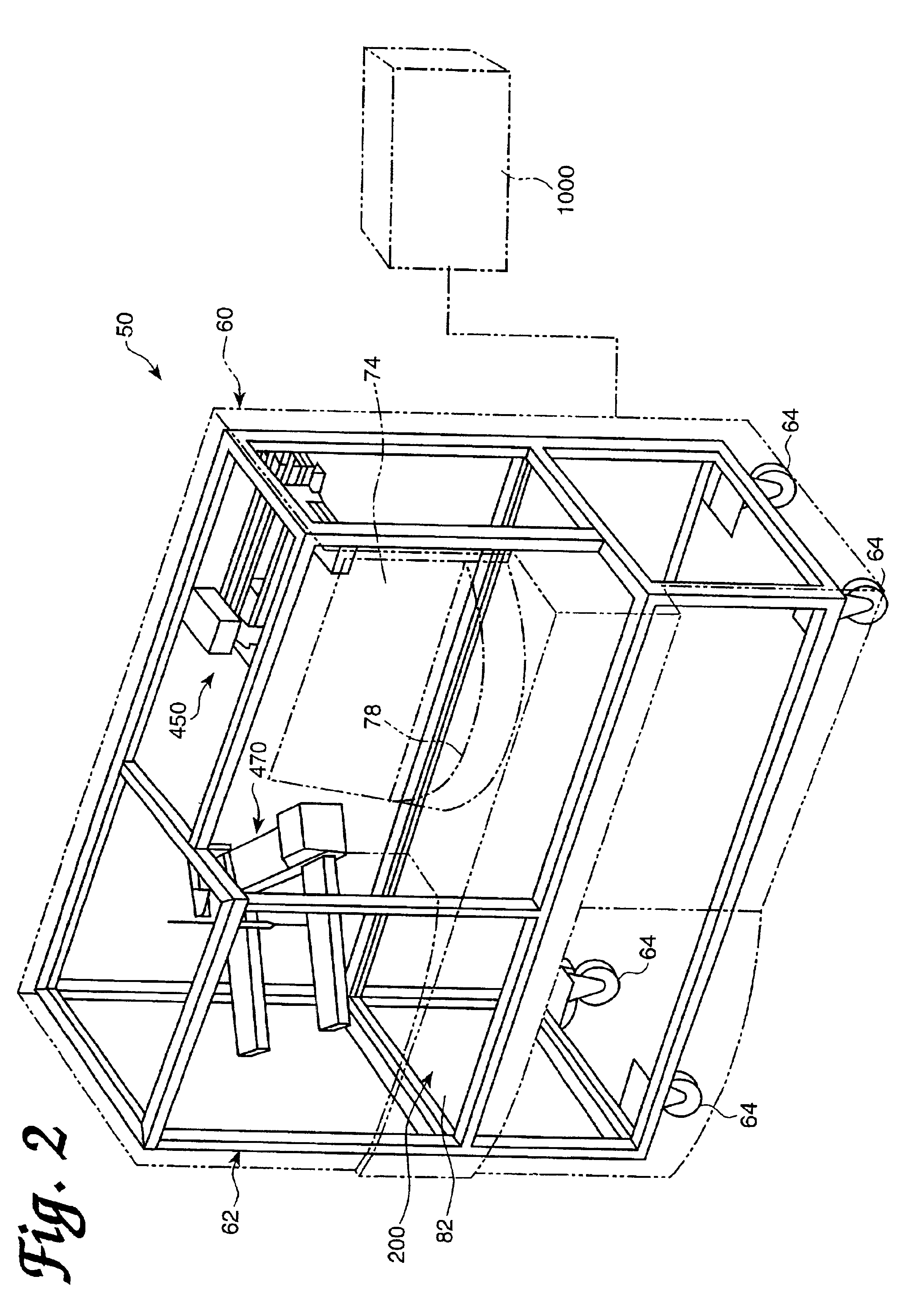

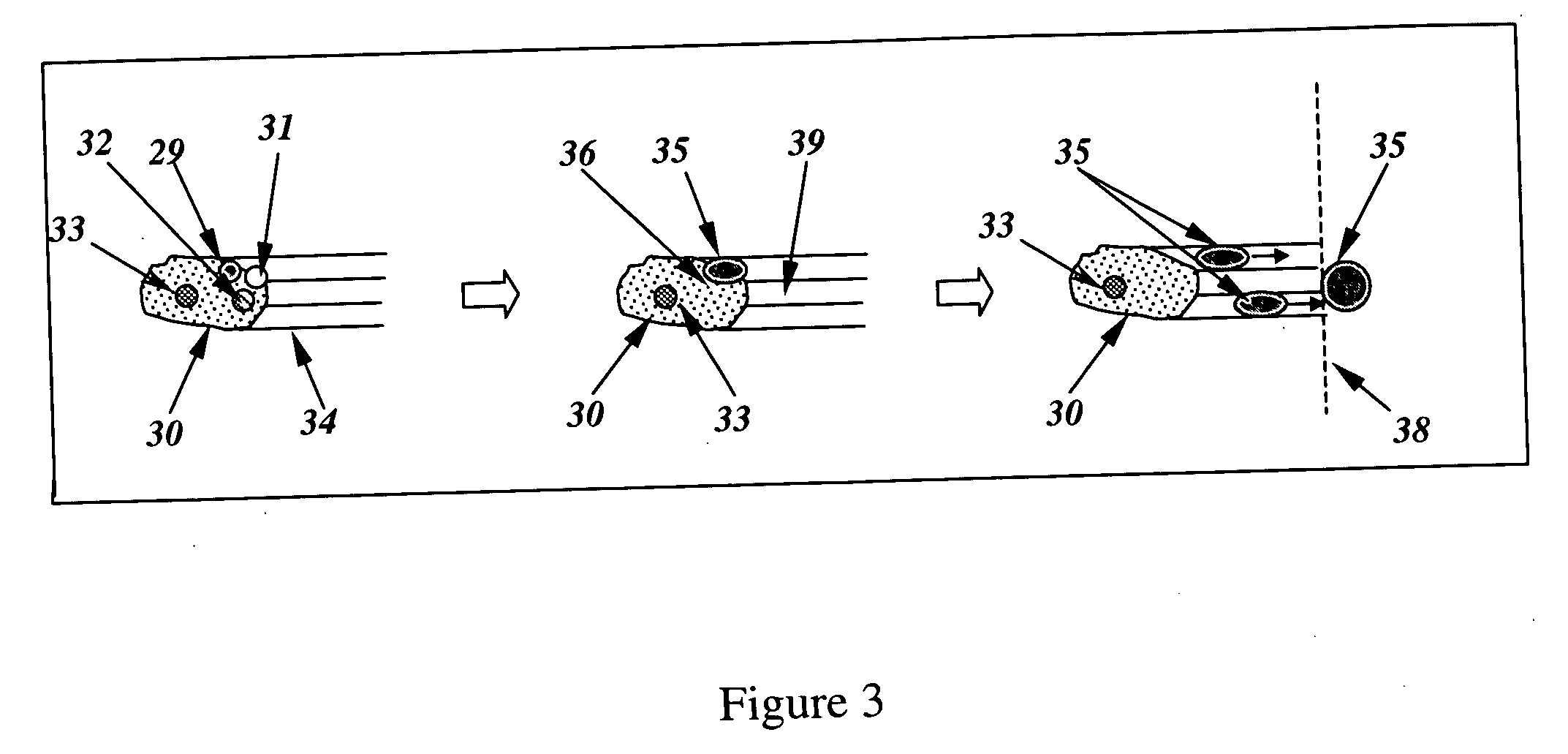

Method and apparatus for flow cytometry

InactiveUS6589792B1Accurately determining a drop delay timeAccurate chargesElectrostatic separationCharacter and pattern recognitionDelayed timeLength wave

A flow cytometer (20) capable of utilizing an imaging system including a sensor (88) to determine various properties of the flow cytometer (20). Importantly, the imaging allows for determination of a drop delay time (154). Other characteristics that can be determined include at least the width of the stream, pressure of the stream, effect of charged droplets on other droplets (44), trajectory of the stream, resonant frequency, wavelengths, change in position of droplet break-off point (150), and others. An automatic warning system (180) can be used to alert an operator of an anomaly during setup or during normal operation. Furthermore, a mechanical interrupter can be used to shield a sort result from contamination by an incorrectly functioning stream. The cytometer (20) also allows for the disablement of the sort, particularly the charging and deflection systems. In addition, a more accurate system for detecting the speed of the stream can be used. The imaging system including a sensor (88) can allow for the removal of background noise and the monitoring of a change in a stream characteristic.

Owner:BECKMAN COULTER INC

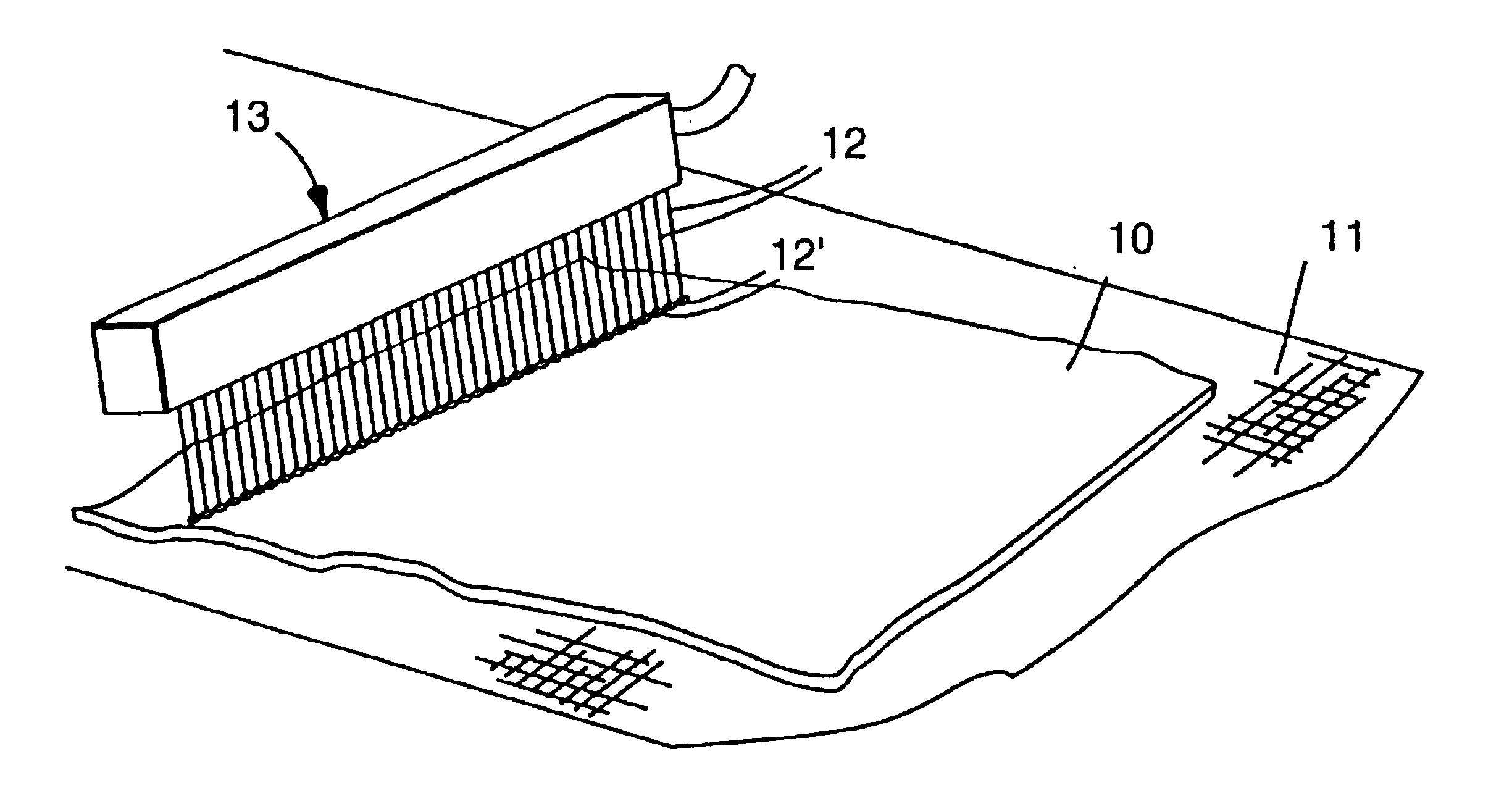

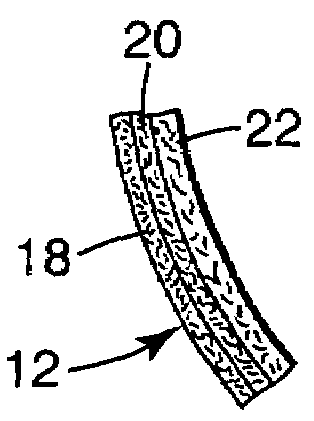

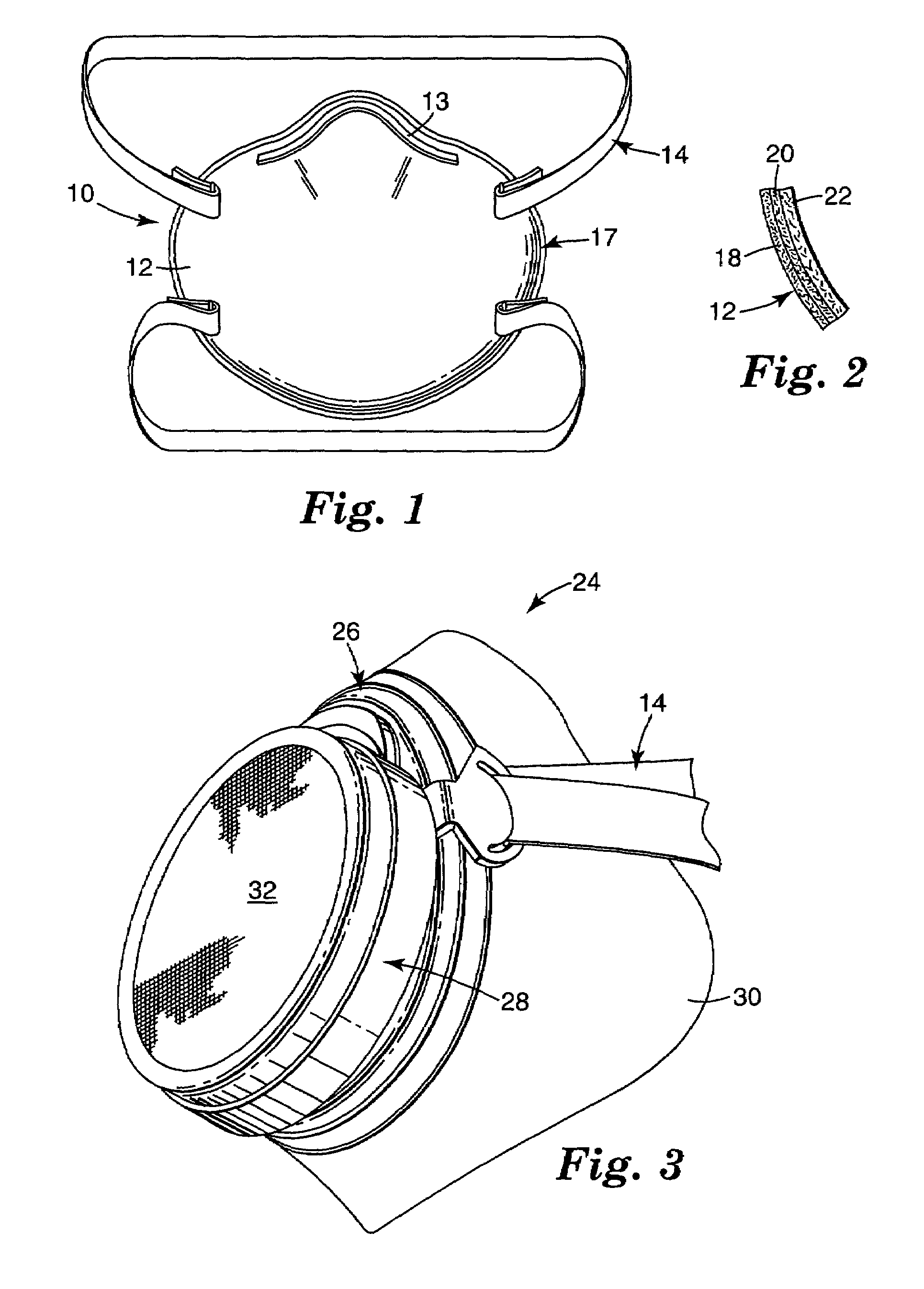

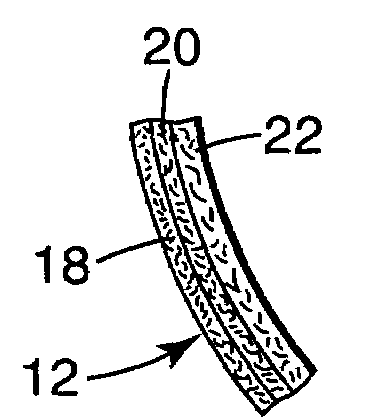

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

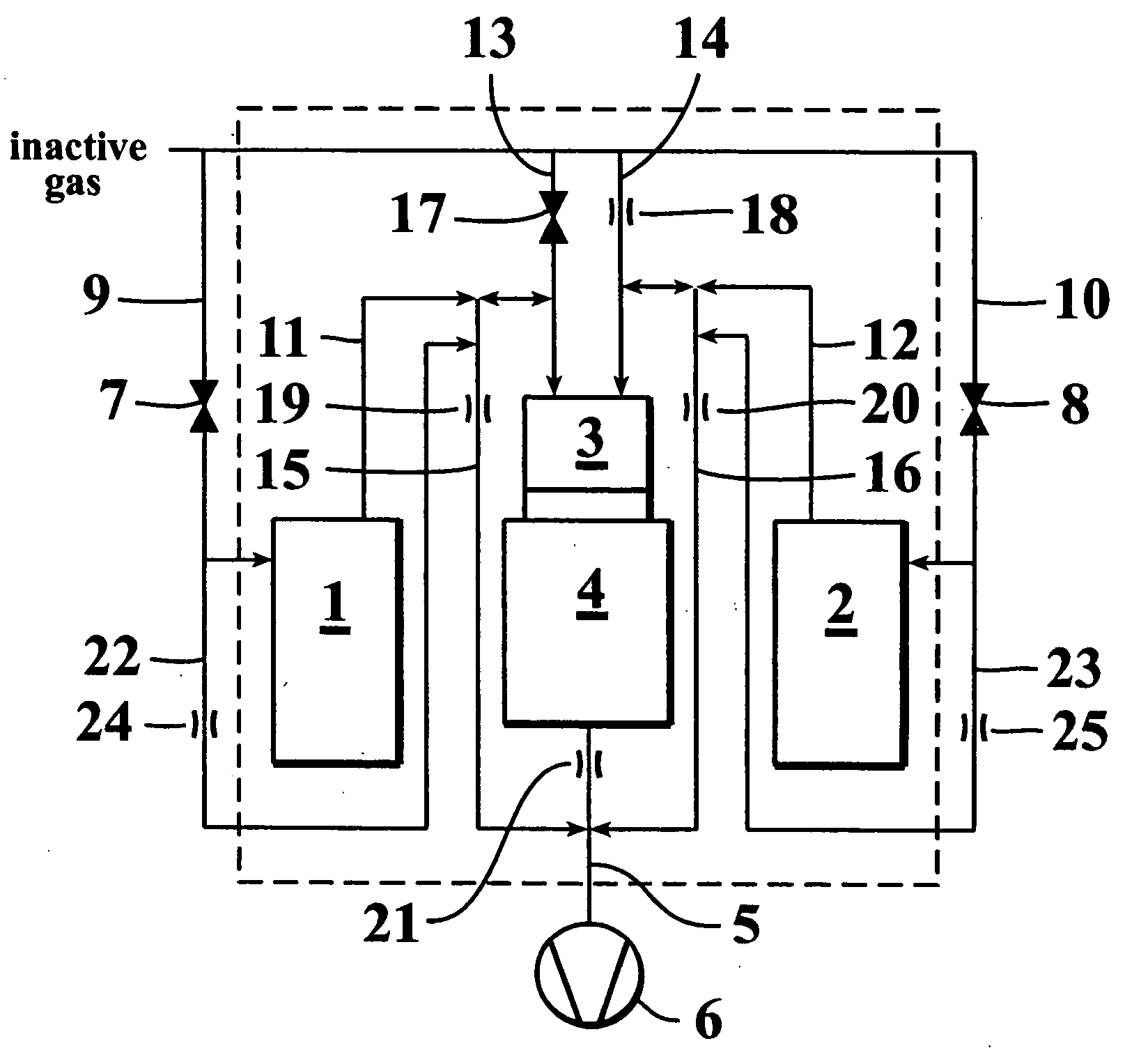

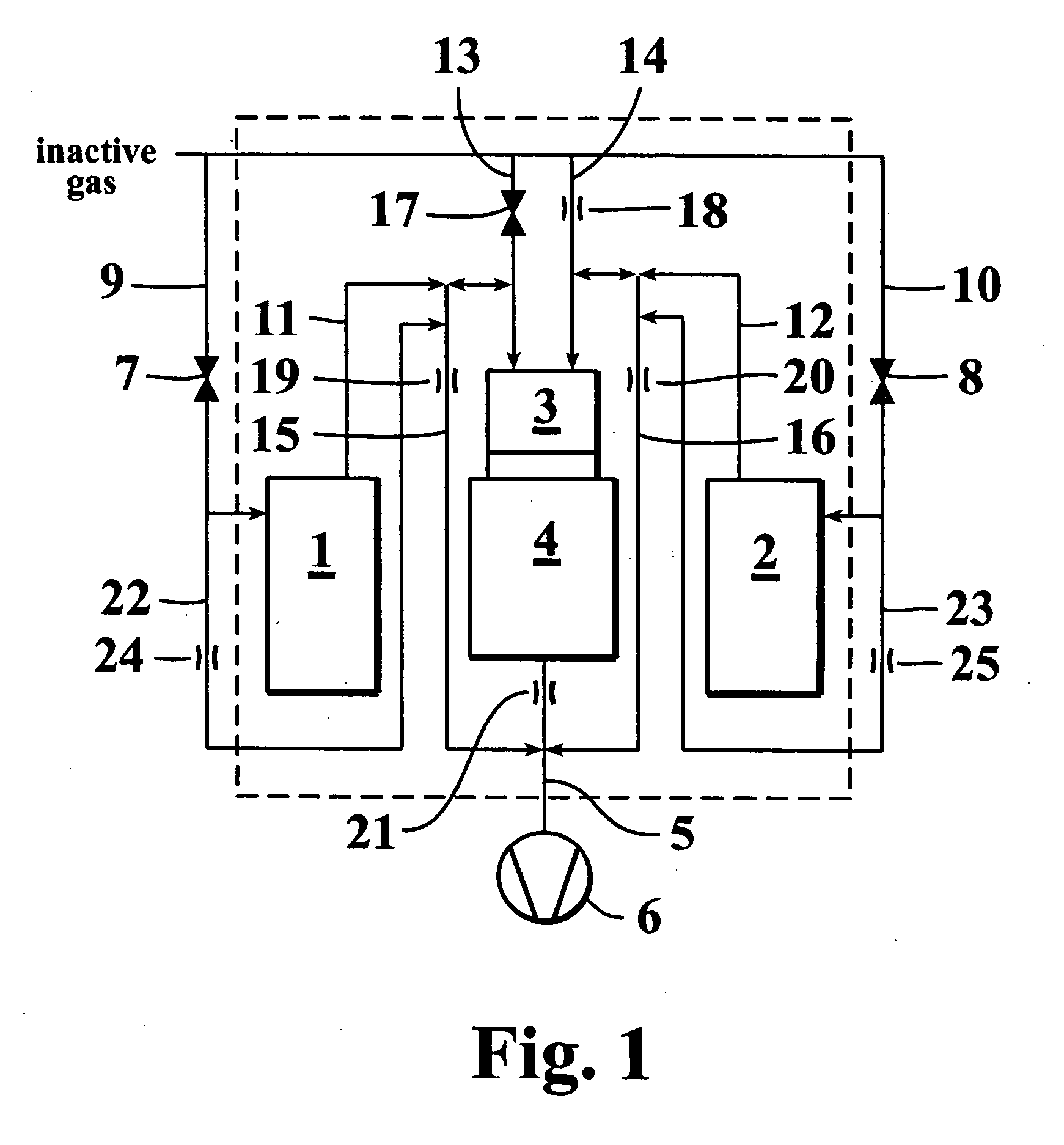

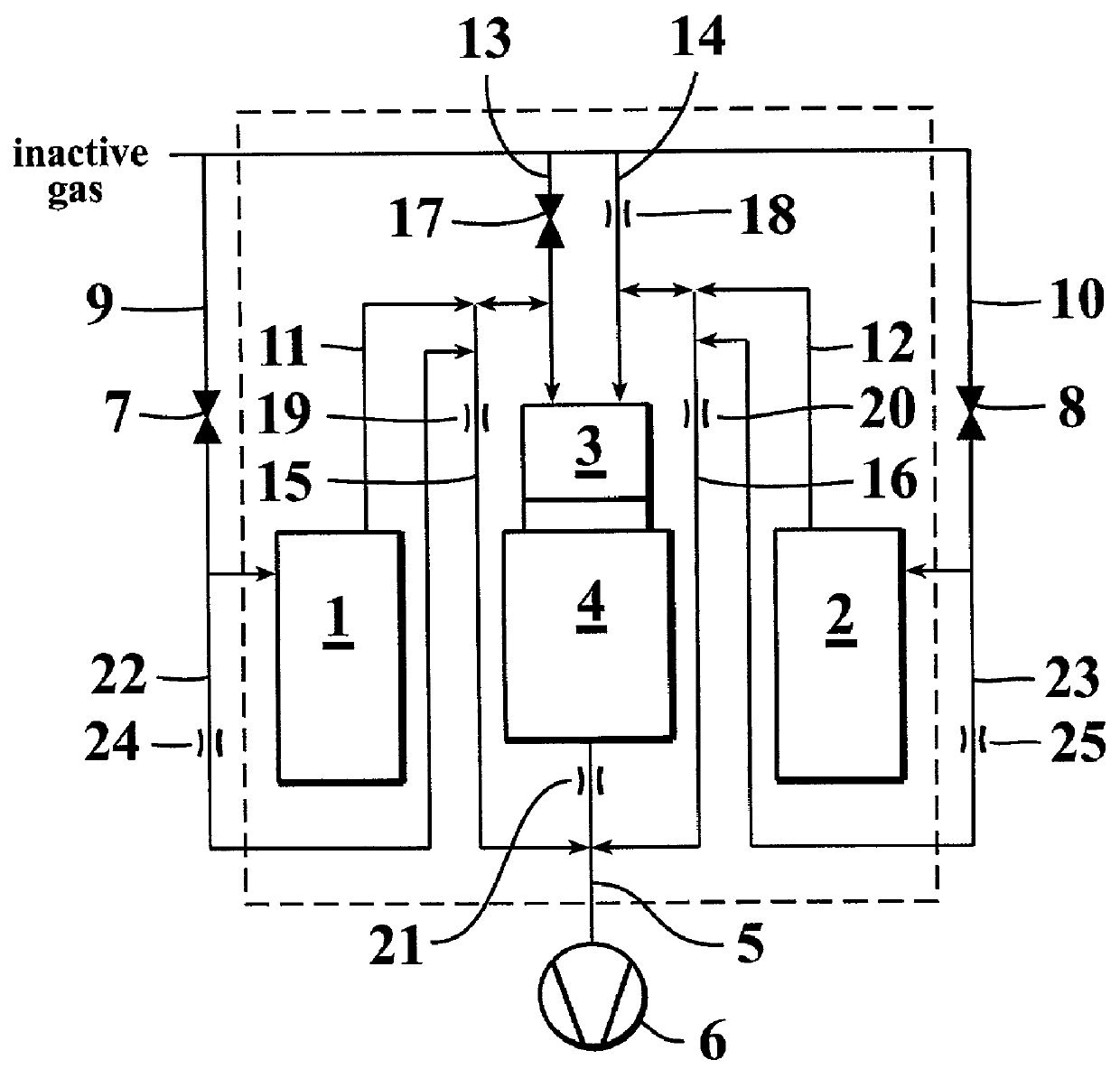

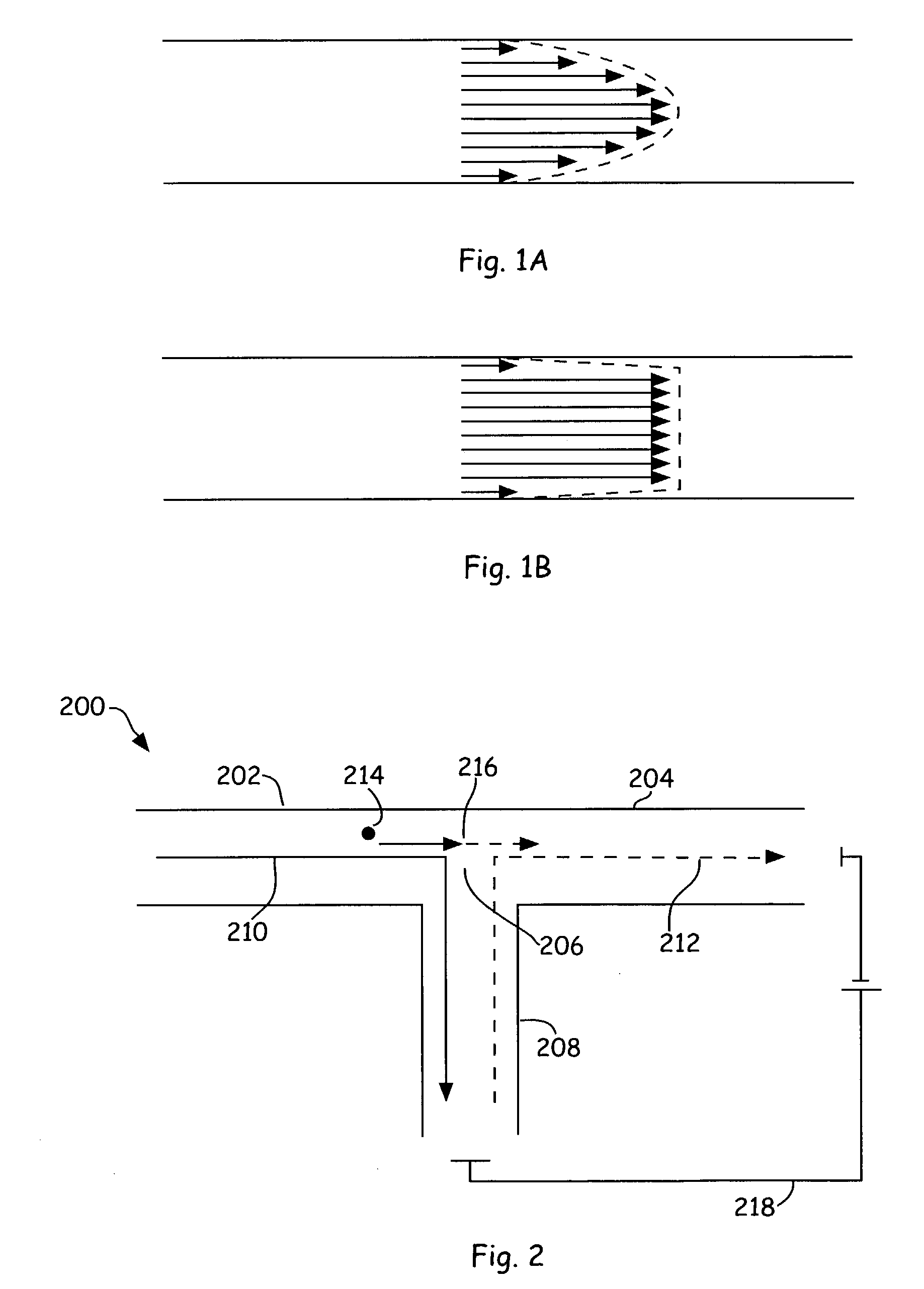

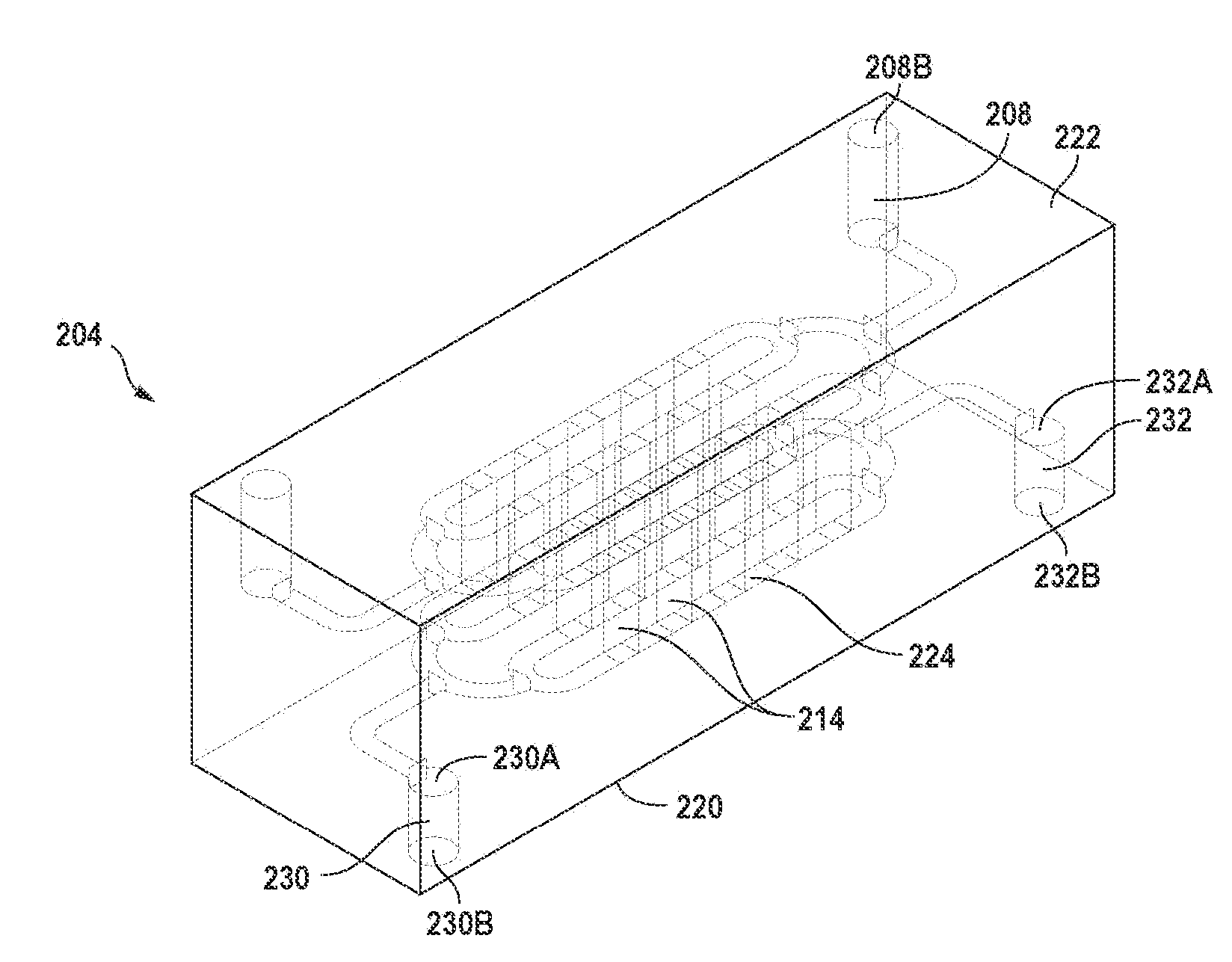

Method of growing a thin film onto a substrate

InactiveUS20040261706A1Uniform smoothnessAvoid it happening againPolycrystalline material growthPressurized chemical processSurface reactionGas phase

A method of growing a thin film onto a substrate placed in a reaction chamber according to the ALD method by subjecting the substrate to alternate and successive surface reactions. The method includes providing a first reactant source and providing an inactive gas source. A first reactant is fed from the first reactant source in the form of repeated alternating pulses to a reaction chamber via a first conduit. The first reactant is allowed to react with the surface of the substrate in the reaction chamber. Inactive gas is fed from the inactive gas source into the first conduit via a second conduit that is connected to the first conduit at a first connection point so as to create a gas phase barrier between the repeated alternating pulses of the first reactant entering the reaction chamber. The inactive gas is withdrawn from said first conduit via a third conduit connected to the first conduit at a second connection point.

Owner:ASM IP HLDG BV

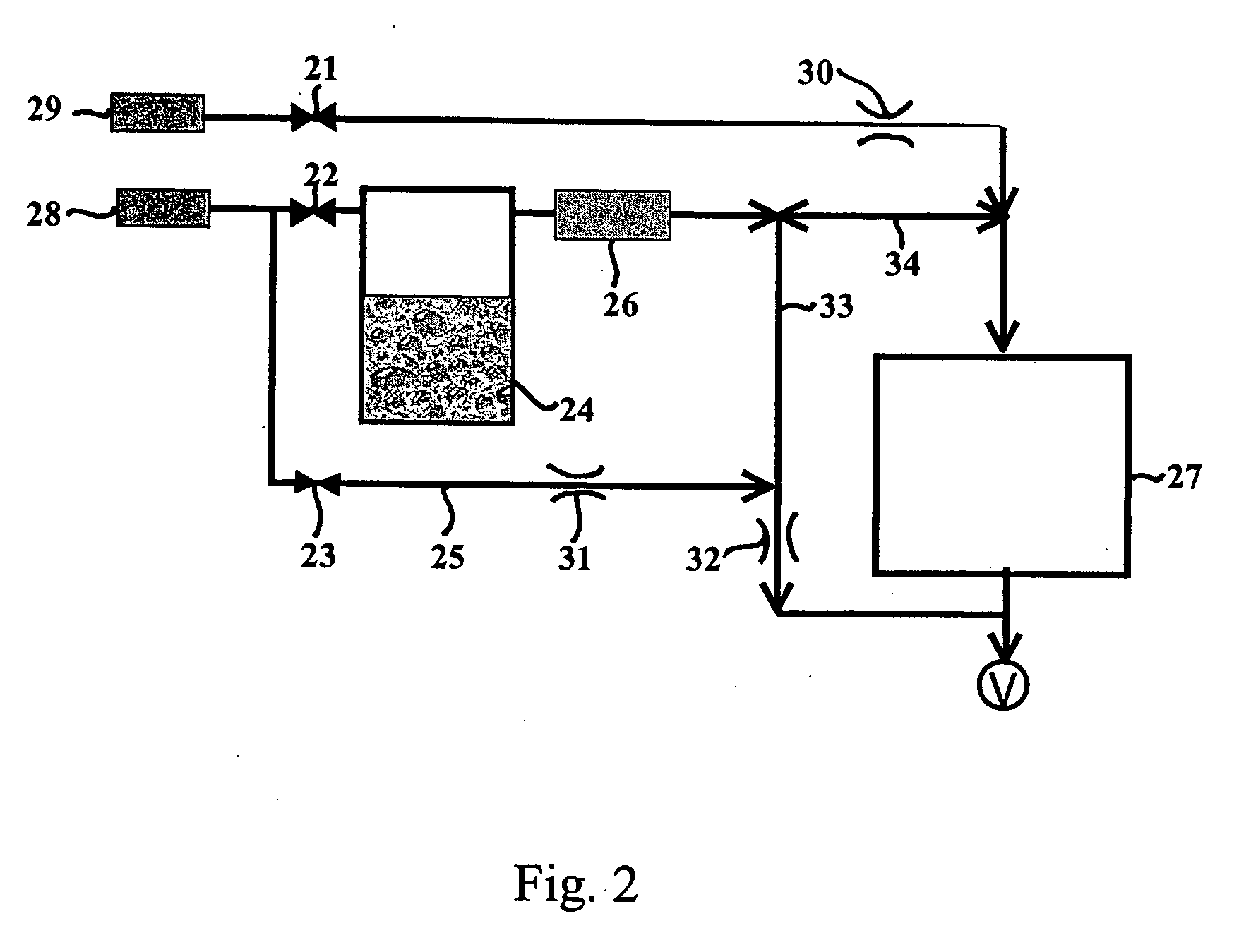

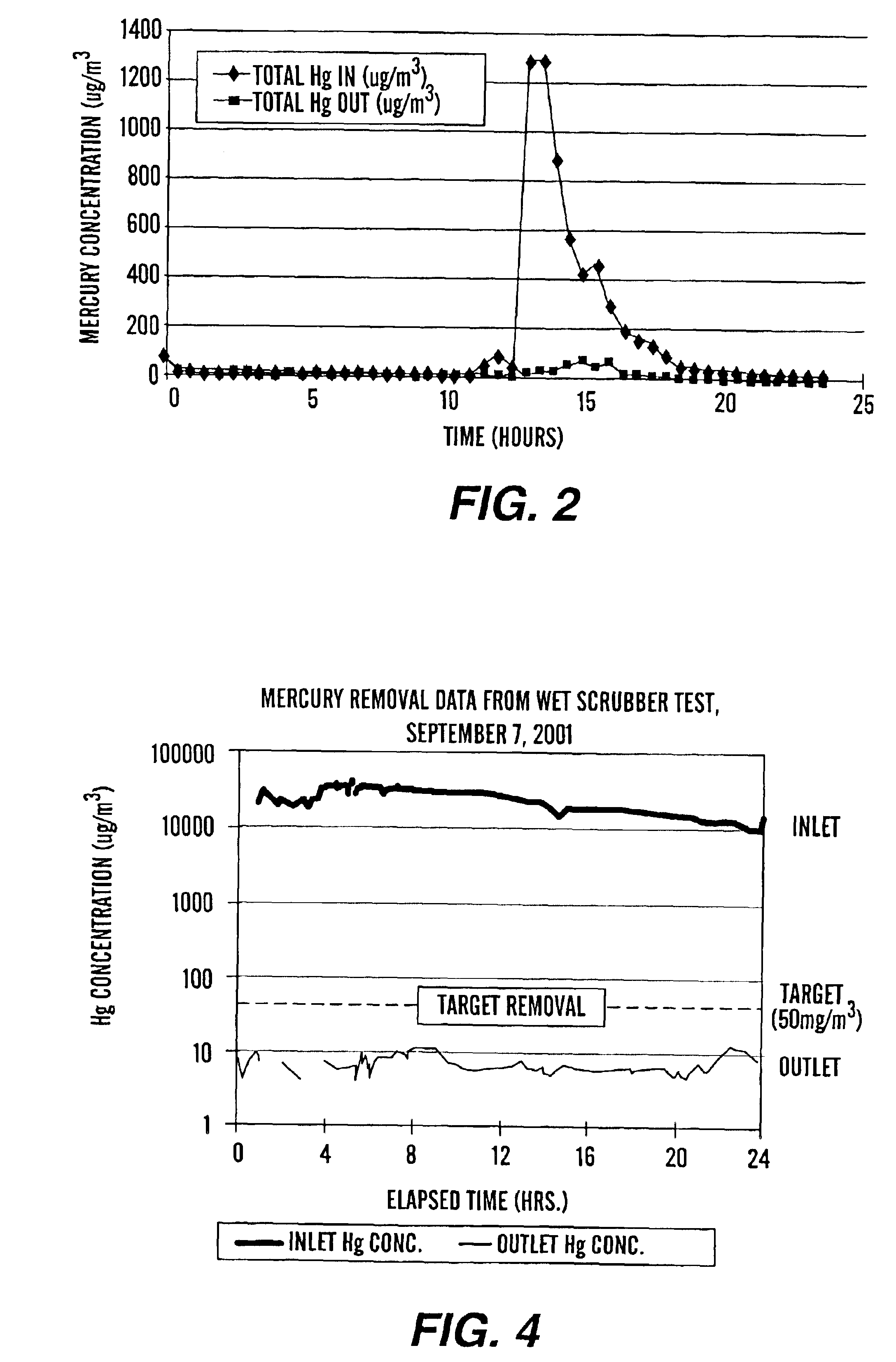

Method for removal and stabilization of mercury in mercury-containing gas streams

InactiveUS6942840B1Improve scalabilityCombination devicesDispersed particle filtrationOxygenVapor phase

The present invention is directed to a process and apparatus for removing and stabilizing mercury from mercury-containing gas streams. A gas stream containing vapor phase elemental and / or speciated mercury is contacted with reagent, such as an oxygen-containing oxidant, in a liquid environment to form a mercury-containing precipitate. The mercury-containing precipitate is kept or placed in solution and reacts with one or more additional reagents to form a solid, stable mercury-containing compound.

Owner:MERCURY CONTROL TECH

Dust filter bag including a highly porous backing material ply

InactiveUS6706086B2Simple and cost-effective productionCleaning filter meansCombination devicesBursting strengthCellulose fiber

A dust filter bag having a highly porous backing material ply and a method for producing the dust filter bag. The dust filter bag includes at least one filter material ply and at least one backing material ply, the backing material ply possessing an air permeability of at least 900 l / m<2 >x s, a burst strength of at least 70 kPa, a rupture strength longitudinally better than 10 and transversely better than 3 N, a flexural rigidity longitudinally better than 0.5 cN cm<2 >and transversely better than 0.25 cN cm<2>, a basis weight of 30-80 g / m<2 >and a droplet sink-in time of less than 10 minimum. The dust filter bag can be produced by the following steps: mixing fibers including cellulose fibers and fusible fibers into a homogenous fiber mix, processing the fiber mix into a fiber web by wet laying, drying the fiber web, curing the dried fiber web by thermofusion into a backing material ply, processing the backing material ply with a filter material ply into a raw bag, and finishing the raw bag into a dust filter bag.

Owner:NEENAH GESSNER GMBH

Filter media

InactiveUS6858057B2Lower performance requirementsEnhanced filtration performance characteristicCombination devicesOther chemical processesFilter mediaEngineering

A filter media comprising a synthetic microfiber polymer fine fiber web wherein the diameter of the fibers is between about 0.8 to about 1.5 microns. The filter media is acceptable for use in ASHRAE applications. Constructions with a low DP backing, support or prefilter layers of coarse fiber provide large area filter webs of high efficiency and a stable and high threshold value of alpha above eleven.

Owner:HOLLINGSWORTH VOSE

Method of growing a thin film onto a substrate

InactiveUS20010054377A1Reduce wasteGuaranteed uptimePressurized chemical processPolycrystalline material growthSurface reactionGas phase

A method of growing a thin film onto a substrate placed in a reaction chamber according to the ALD method by subjecting the substrate to alternate and successive surface reactions. The method includes providing a first reactant source and providing an inactive gas source. A first reactant is fed from the first reactant source in the form of repeated alternating pulses to a reaction chamber via a first conduit. The first reactant is allowed to react with the surface of the substrate in the reaction chamber. Inactive gas is fed from the inactive gas source into the first conduit via a second conduit that is connected to the first conduit at a first connection point so as to create a gas phase barrier between the repeated alternating pulses of the first reactant entering the reaction chamber. The inactive gas is withdrawn from said first conduit via a third conduit connected to the first conduit at a second connection point.

Owner:ASM IP HLDG BV

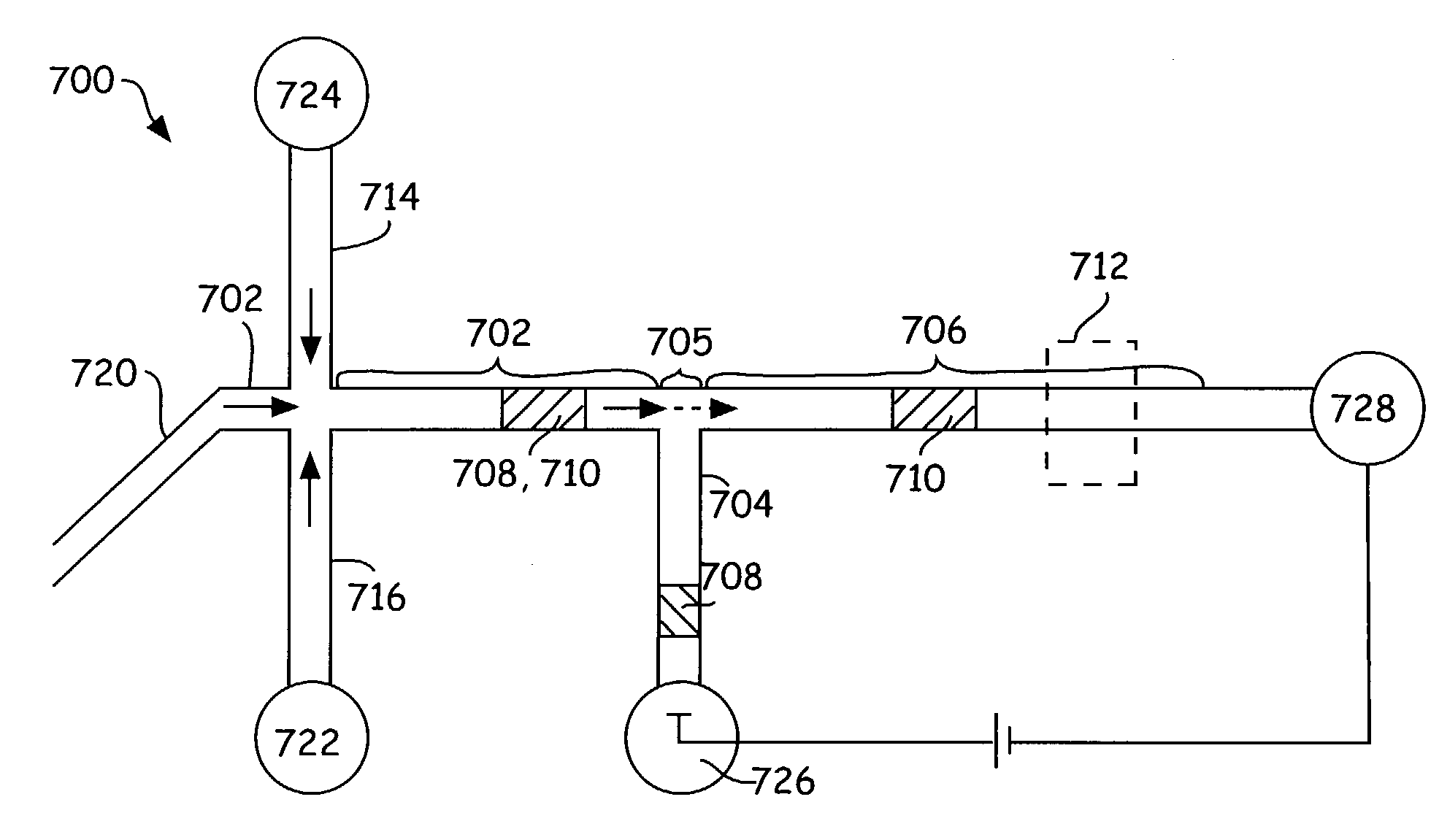

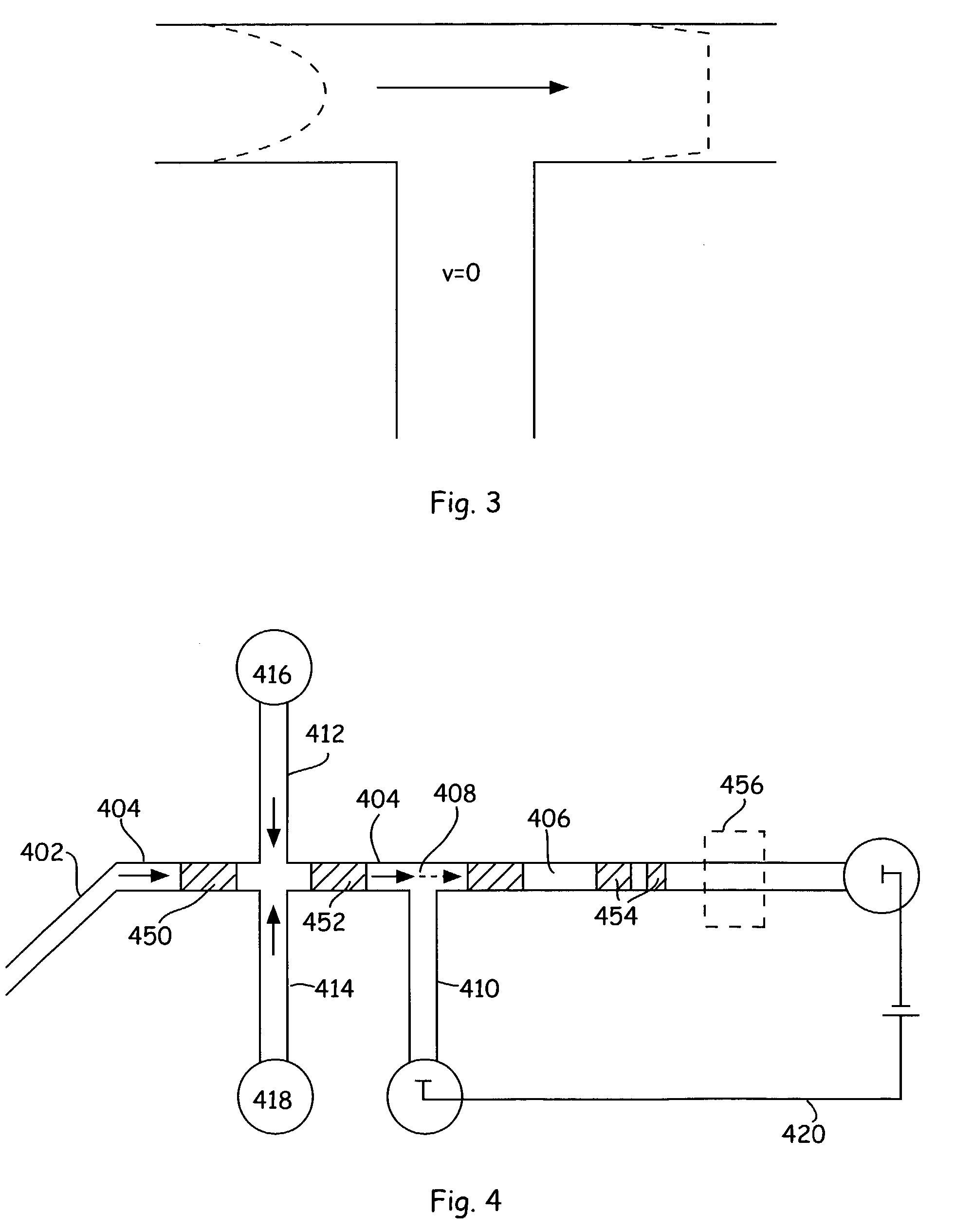

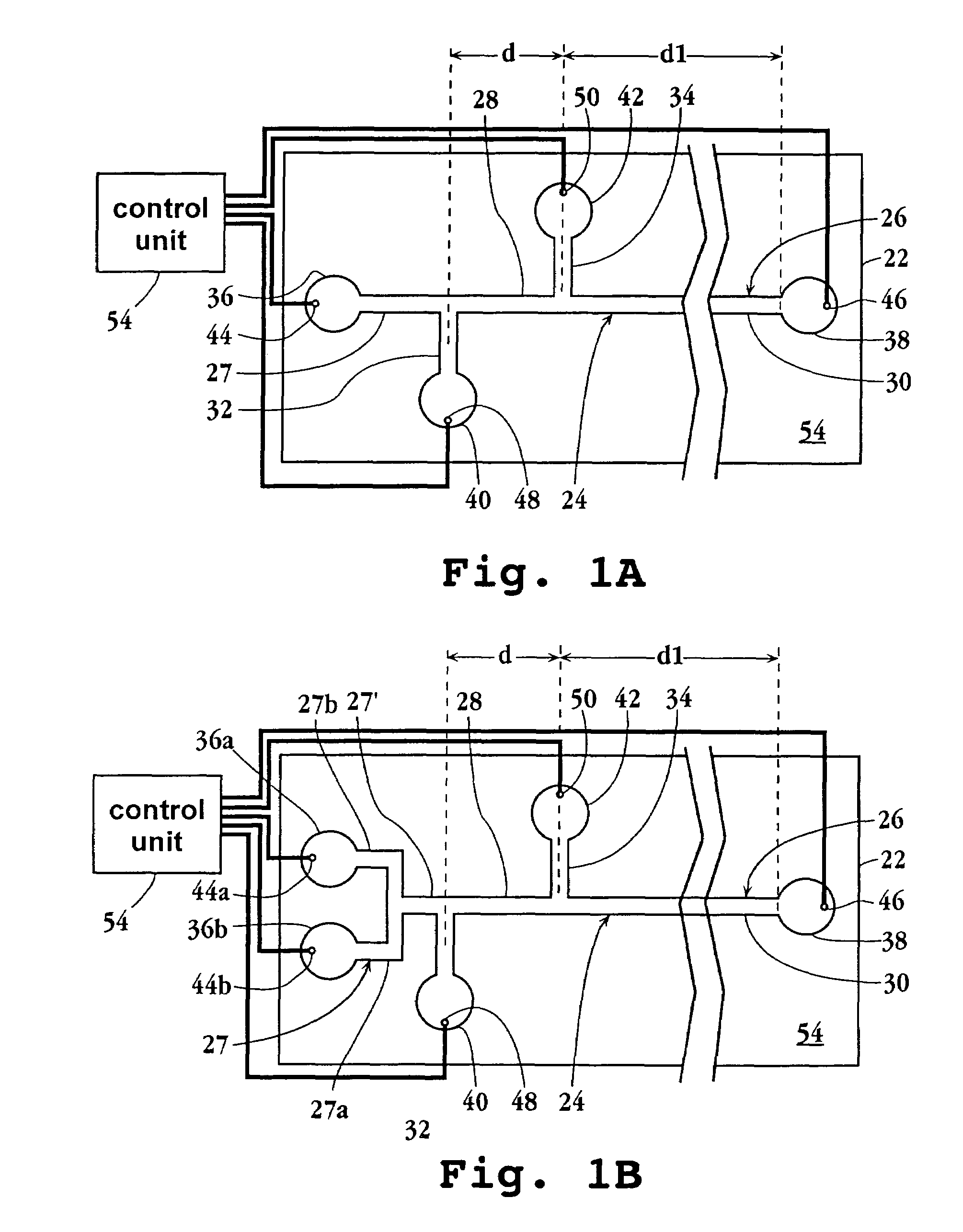

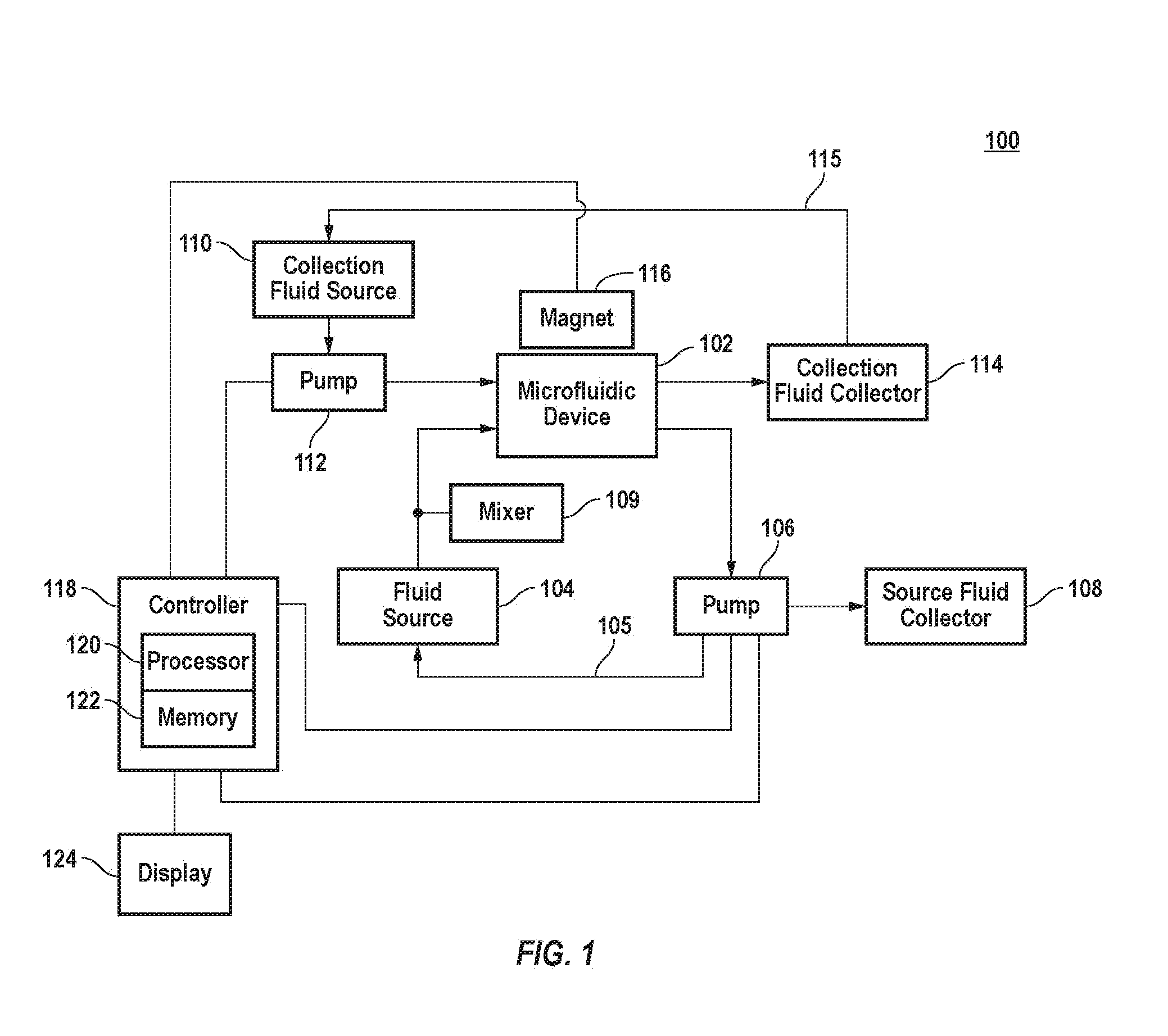

Mixed mode microfluidic systems

ActiveUS7160423B2Minimization requirementsReduce in quantitySludge treatmentElectrostatic separationSection planeChannel network

Methods and systems that employ hybrid fluid flow profiles for optimized movement of materials through channel networks. These systems employ hybrid pressure-based and electrokinetic based flow systems for moving materials through interconnected channel networks while maintaining interconnection among the various channel segments. In particular, the invention is generally directed to channel networks where flow in a first channel segment is driven by pressure flow with its consequent parabolic flow profile, while flow in an interconnected channel segment is dominated by electrokinetic flow with its consequent plug flow profile. The invention also provides channel networks wherein fluid flow in channel segments is driven by both pressure and electric field and the multiple species contained in a fluid plug are separated by altering the applied pressure and electric fields in the various channel segments of the channel networks.

Owner:CAPLIPER LIFE SCI INC

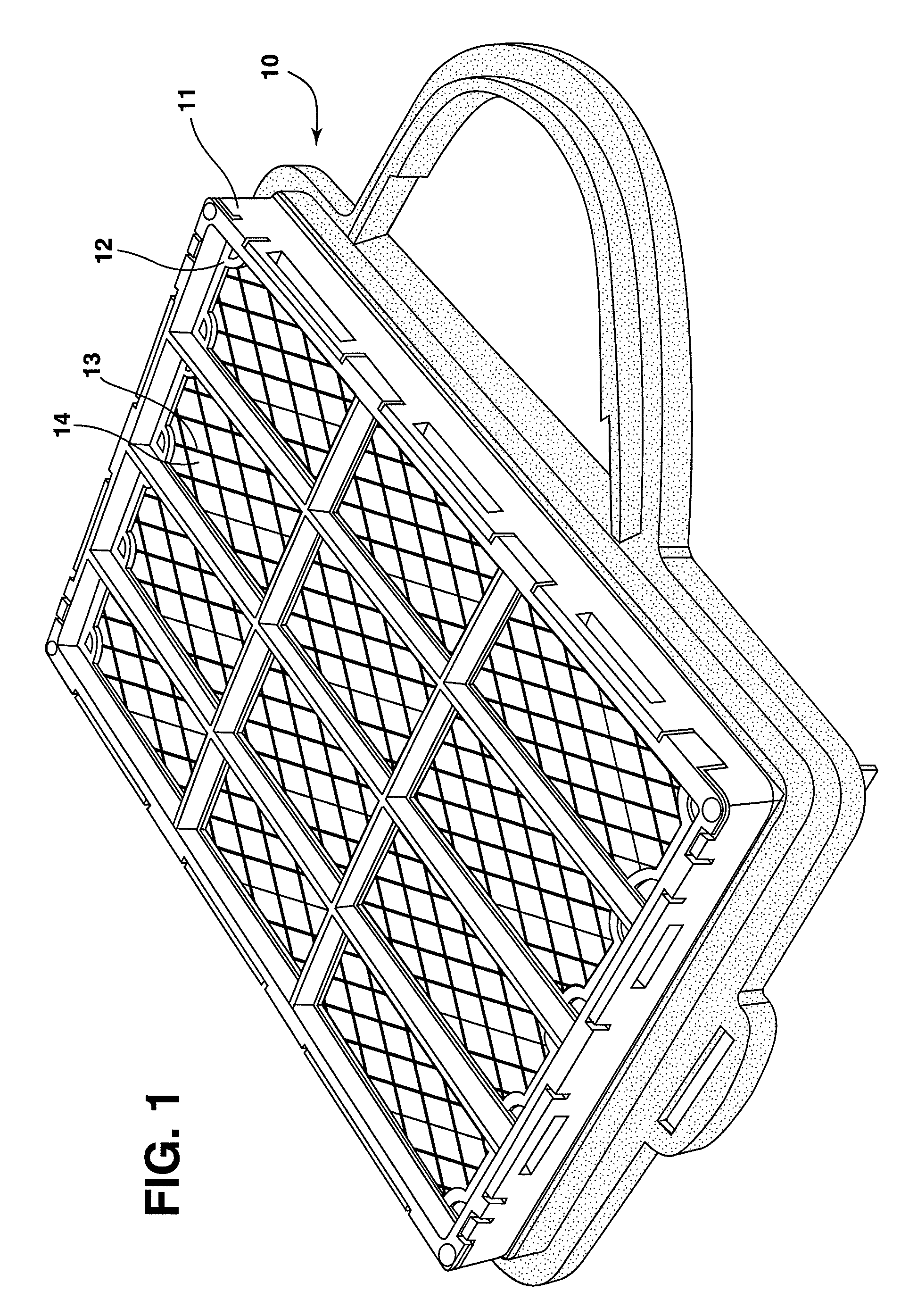

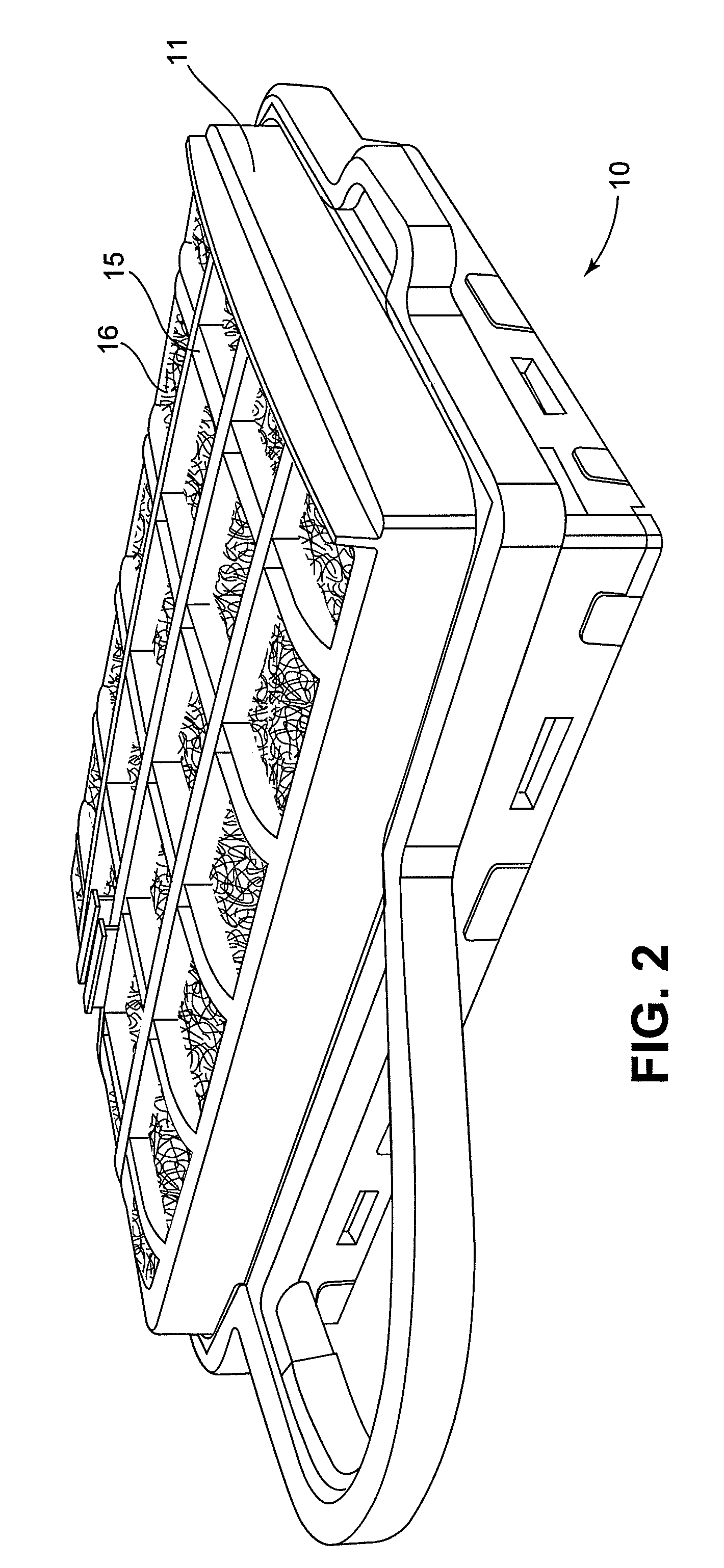

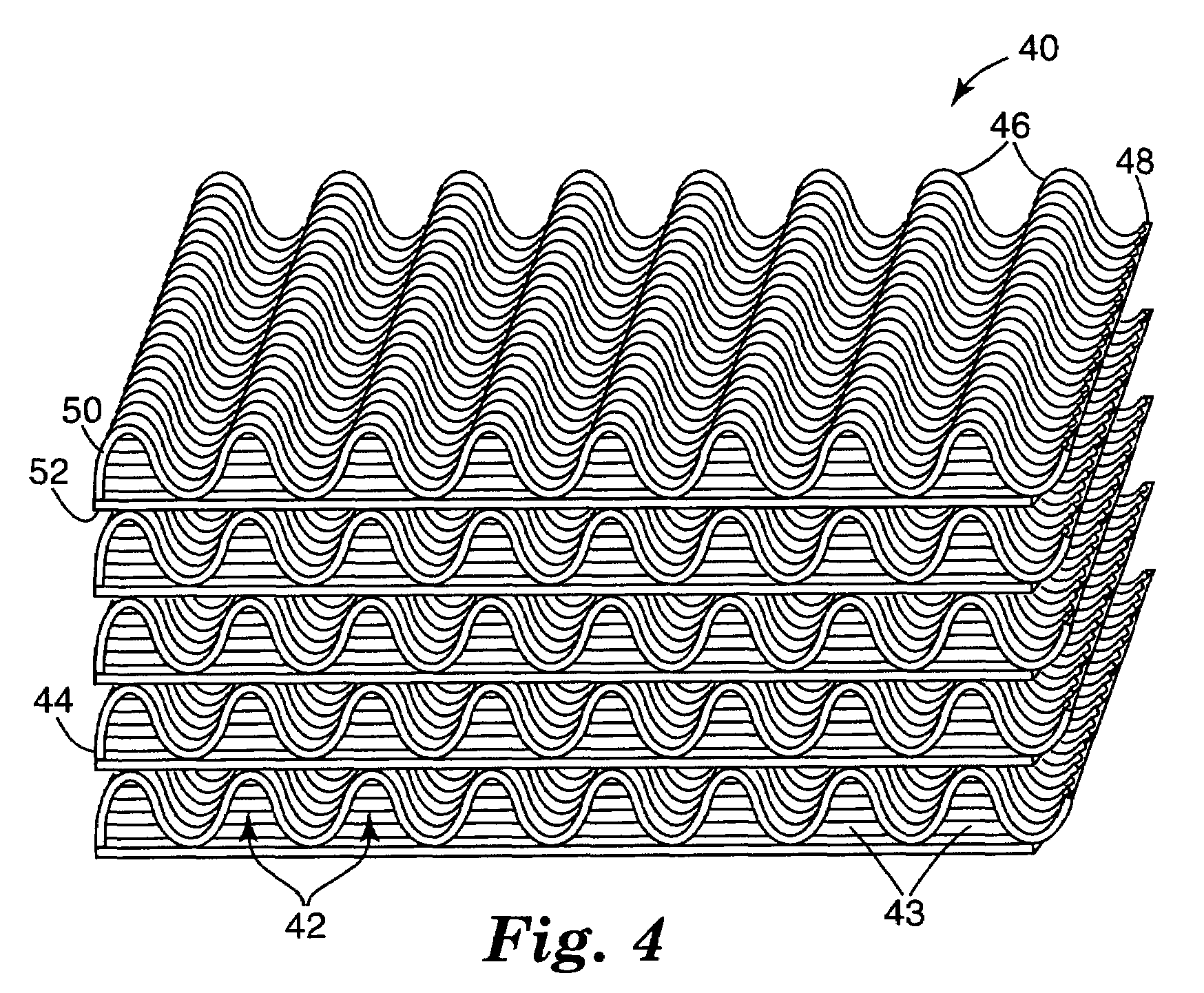

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

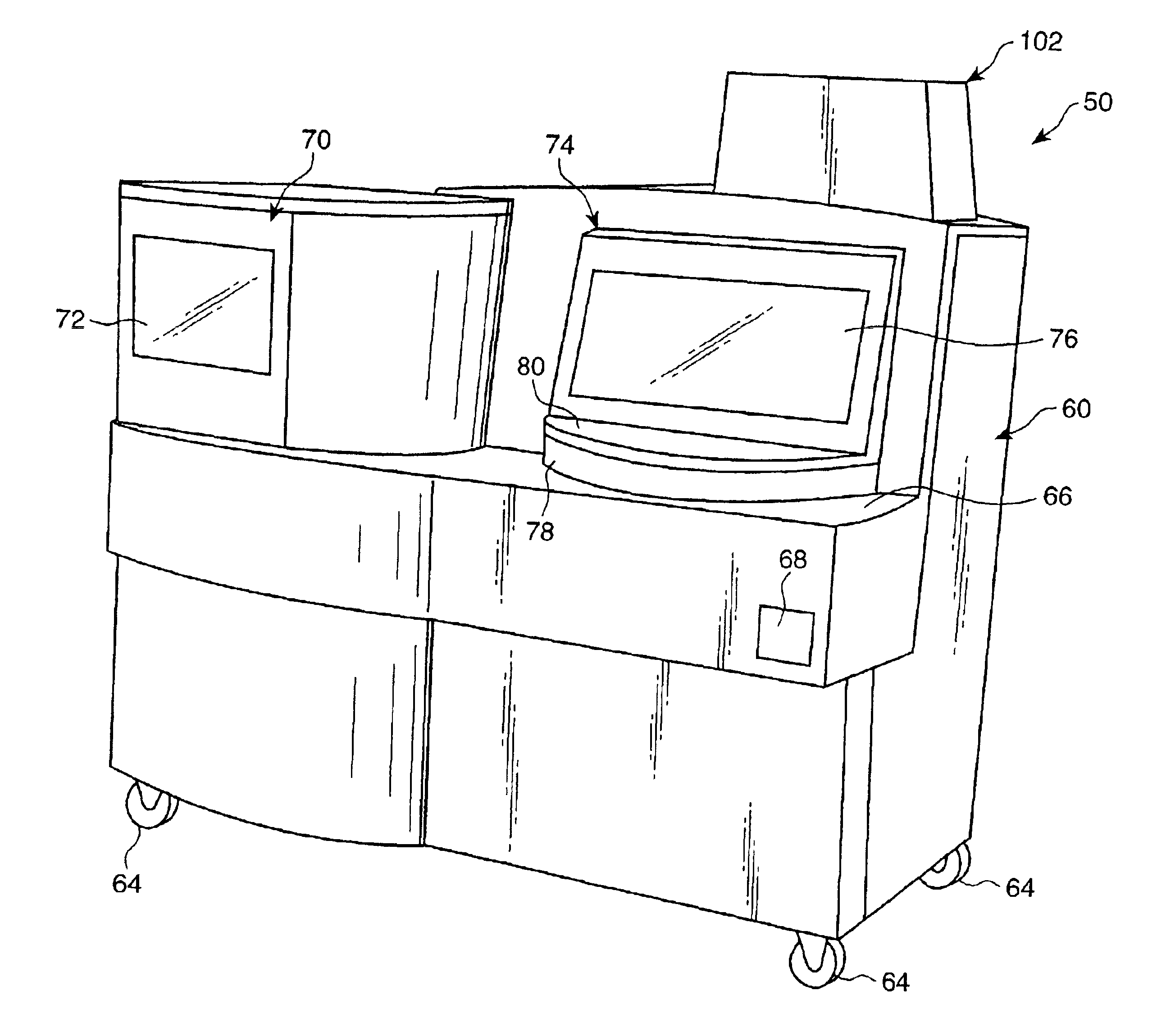

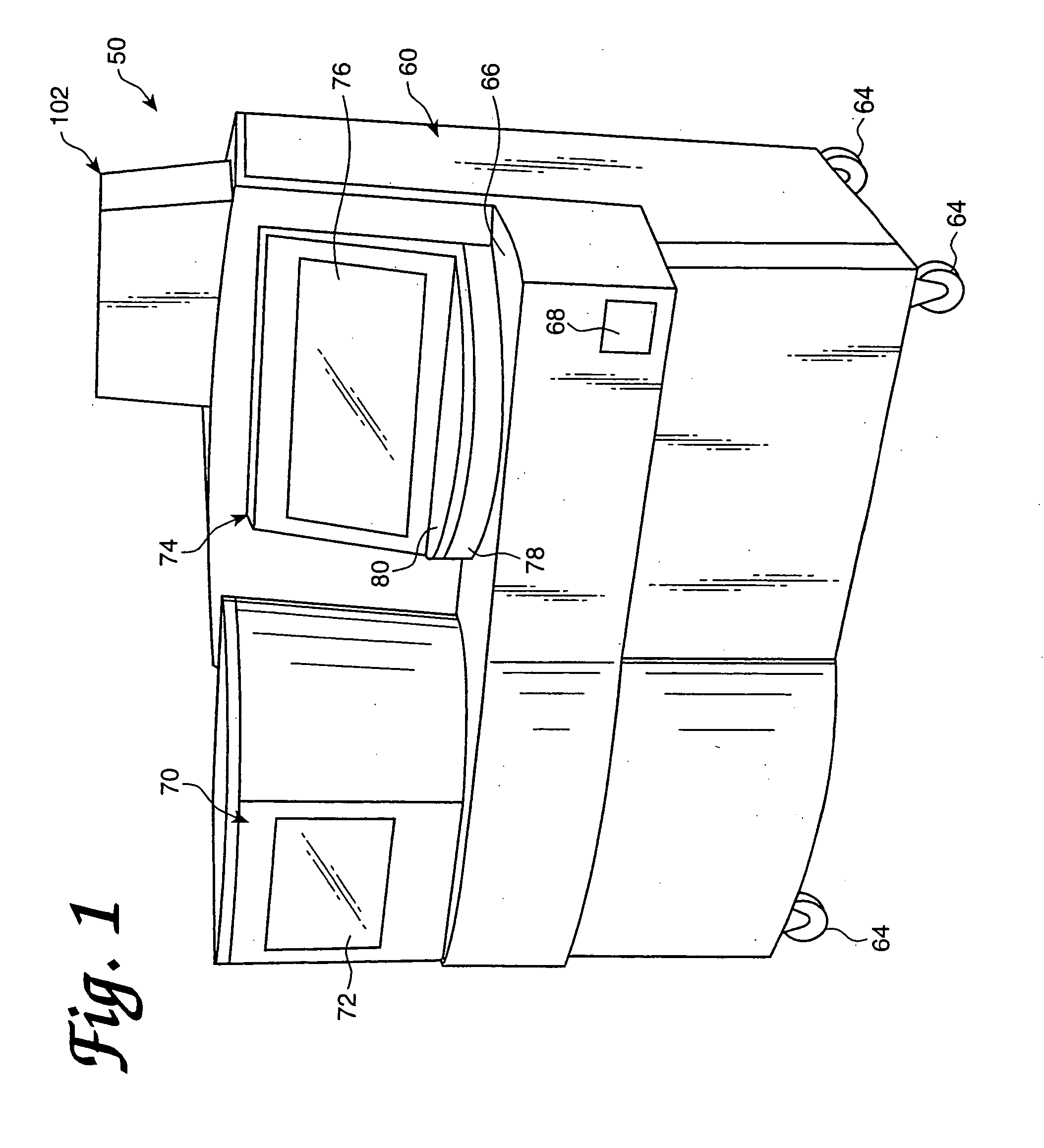

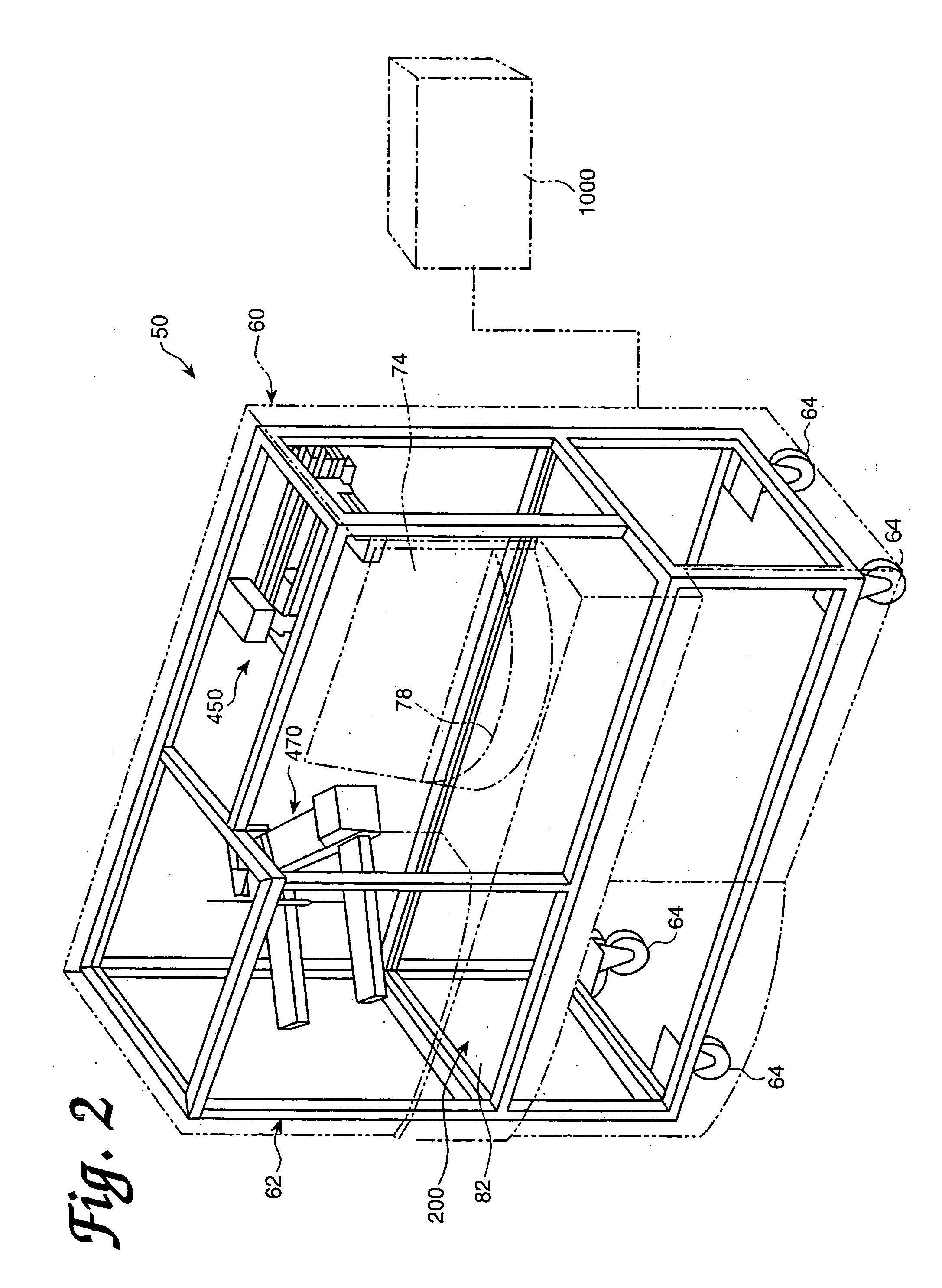

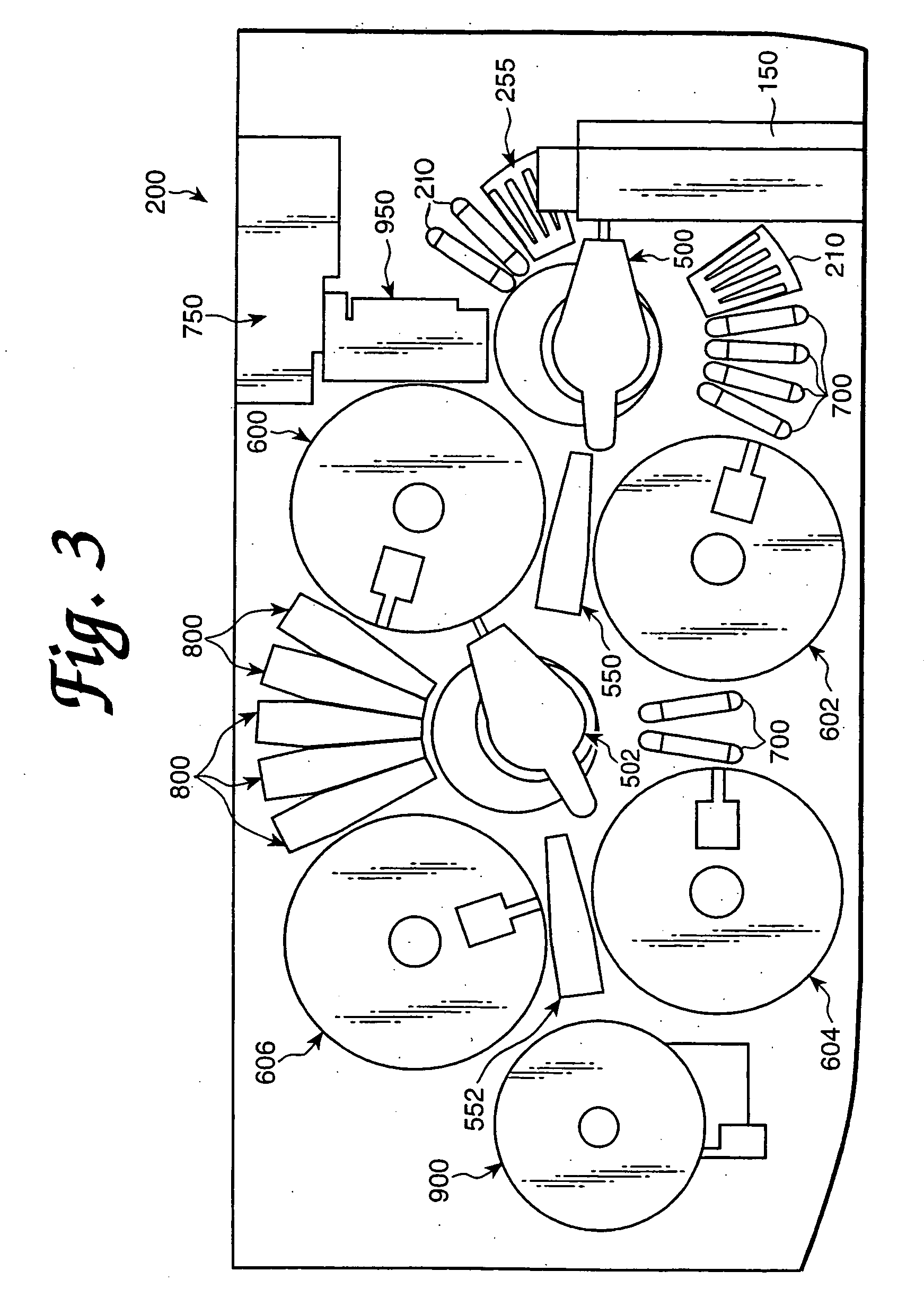

Automated process for isolating and amplifying a target nucleic acid sequence

InactiveUS6890742B2Efficient and high through-put operationEfficient space utilizationBioreactor/fermenter combinationsRotating receptacle mixersIsolation proceduresTemperature control

An automated analyzer for performing multiple diagnostic assays simultaneously includes multiple stations, or modules, in which discrete aspects of the assay are performed on fluid samples contained in reaction receptacles. The analyzer includes stations for automatically preparing a specimen sample, incubating the sample at prescribed temperatures for prescribed periods, preforming an analyte isolation procedure, and ascertaining the presence of a target analyte. An automated receptacle transporting system moves the reaction receptacles from one station to the next. The analyzer further includes devices for carrying a plurality of specimen tubes and disposable pipette tips in a machine-accessible manner, a device for agitating containers of target capture reagents comprising suspensions of solid support material and for presenting the containers for machine access thereto, and a device for holding containers of reagents in a temperature controlled environment and presenting the containers for machine access thereto. A method for performing an automated diagnostic assay includes an automated process for isolating and amplifying a target analyte. The process is performed by automatically moving each of a plurality of reaction receptacles containing a solid support material and a fluid sample between stations for incubating the contents of the reaction receptacle and for separating the target analyte bound to the solid support from the fluid sample. An amplification reagent is added to the separated analyte after the analyte separation step and before a final incubation step.

Owner:GEN PROBE INC

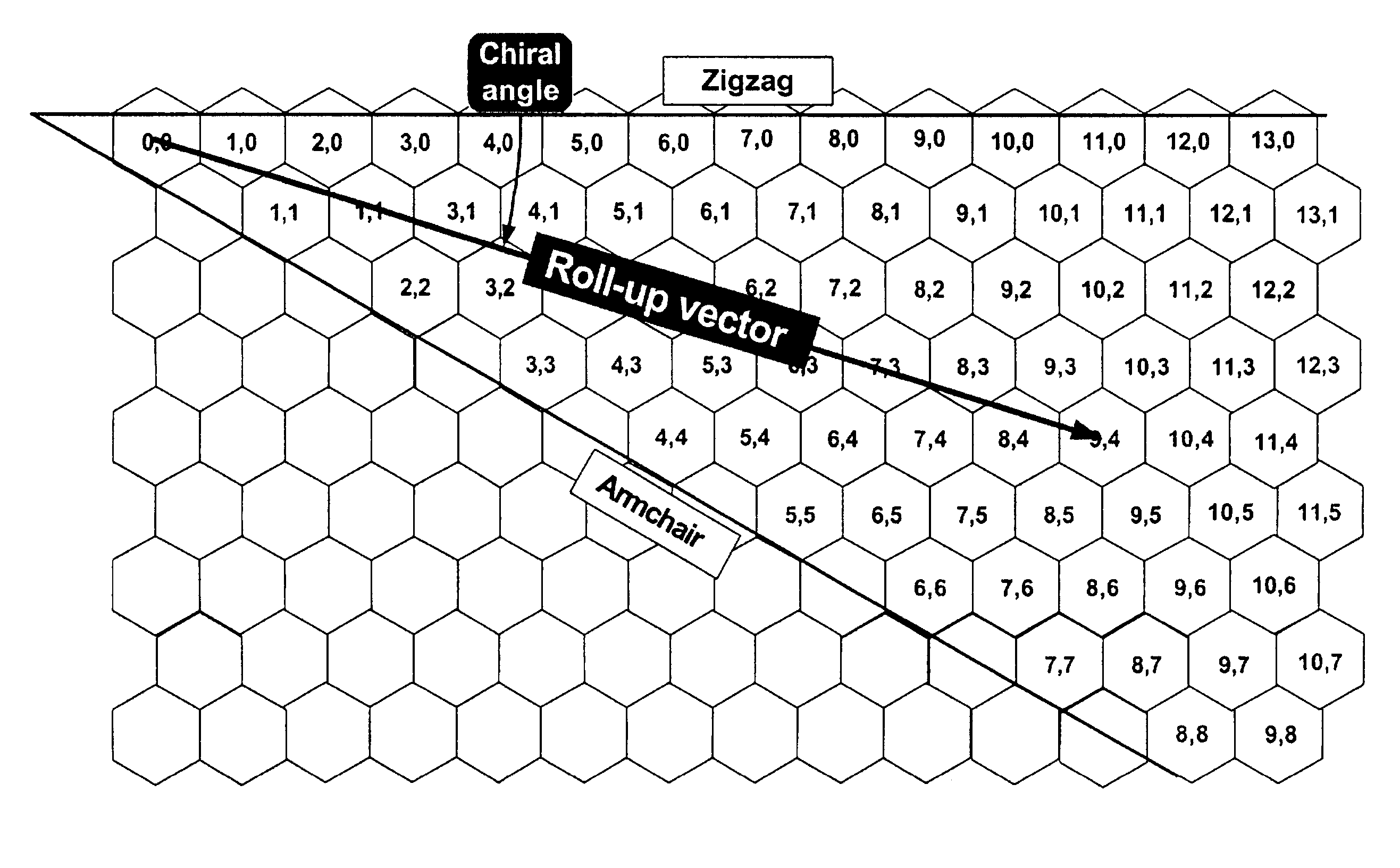

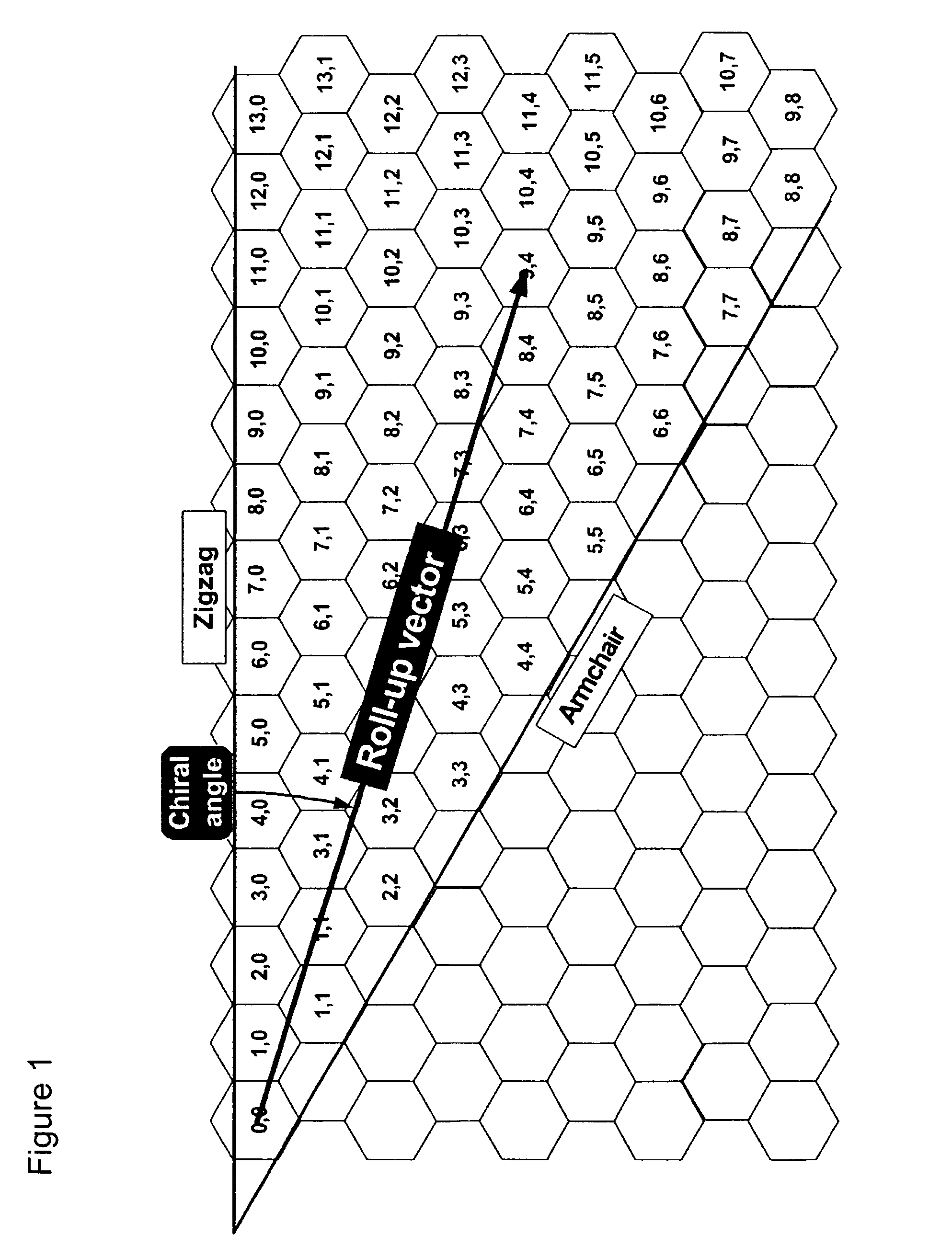

Method for separating single-wall carbon nanotubes and compositions thereof

The invention relates to a process for sorting and separating a mixture of (n, m) type single-wall carbon nanotubes according to (n, m) type. A mixture of (n, m) type single-wall carbon nanotubes is suspended such that the single-wall carbon nanotubes are individually dispersed. The nanotube suspension can be done in a surfactant-water solution and the surfactant surrounding the nanotubes keeps the nanotube isolated and from aggregating with other nanotubes. The nanotube suspension is acidified to protonate a fraction of the nanotubes. An electric field is applied and the protonated nanotubes migrate in the electric fields at different rates dependent on their (n, m) type. Fractions of nanotubes are collected at different fractionation times. The process of protonation, applying an electric field, and fractionation is repeated at increasingly higher pH to separated the (n, m) nanotube mixture into individual (n, m) nanotube fractions. The separation enables new electronic devices requiring selected (n, m) nanotube types.

Owner:RICE UNIV

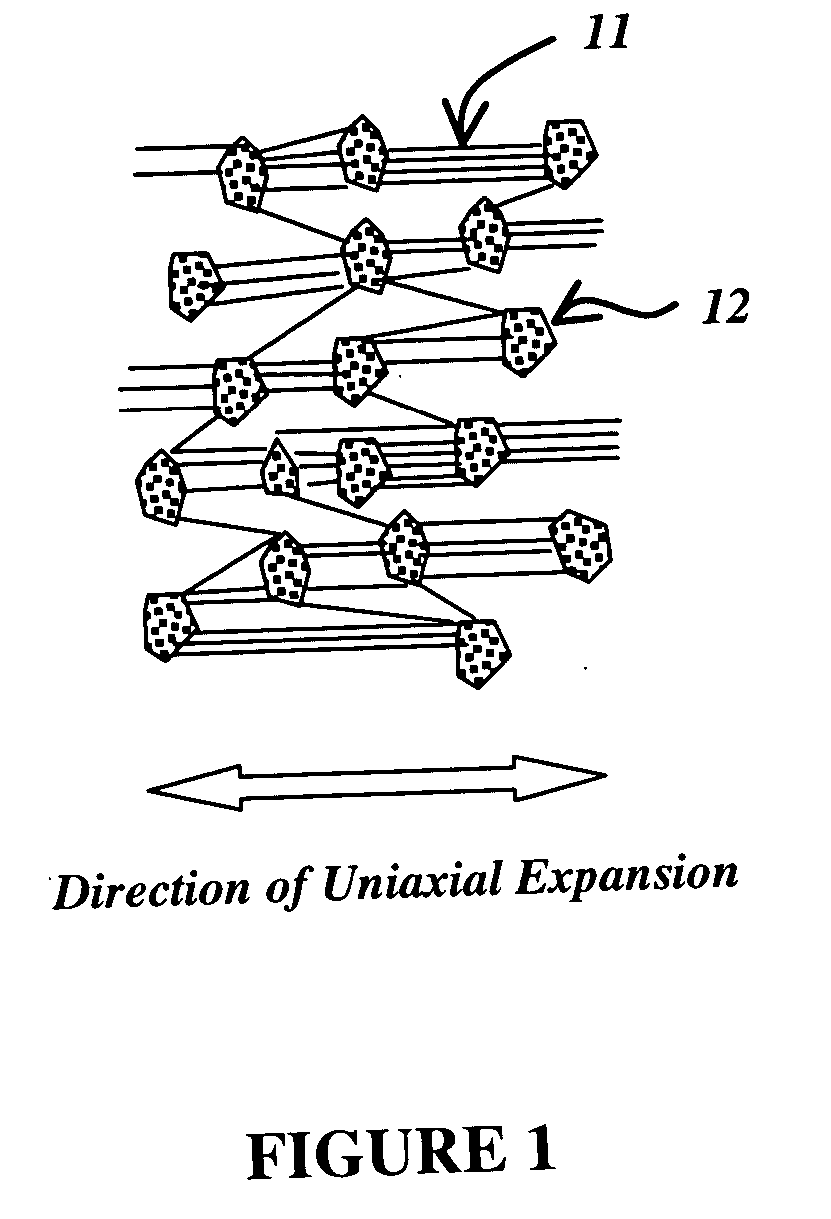

Alignment of carbon nanotubes using magnetic particles

InactiveUS20050239948A1Material nanotechnologyLiquid separation by electricityMagnetite NanoparticlesNanometre

Methods are provided for aligning carbon nanotubes and for making a composite material comprising aligned carbon nanotubes. The method for aligning carbon nanotubes comprises adsorbing magnetic nanoparticles to carbon nanotubes dispersed in a fluid medium to form a magnetic particle-carbon nanotube composite in the fluid medium; and exposing the composite to a magnetic field effective to align the nanotubes in the fluid medium. The method for making a composite material comprising aligned carbon nanotubes comprises (1) adsorbing magnetic nanoparticles to carbon nanotubes to form a magnetic particle-carbon nanotube composite; (2) dispersing the magnetic particle-carbon nanotube composite in a fluid matrix material to form a mixture; (3) exposing the mixture to a magnetic field effective to align the nanotubes in the mixture; and (4) solidifying the fluid matrix material to form a nanotube / matrix material composite comprising the aligned nanotubes which remain aligned in the absence of said magnetic field.

Owner:FLORIDA STATE RES FOUND +1

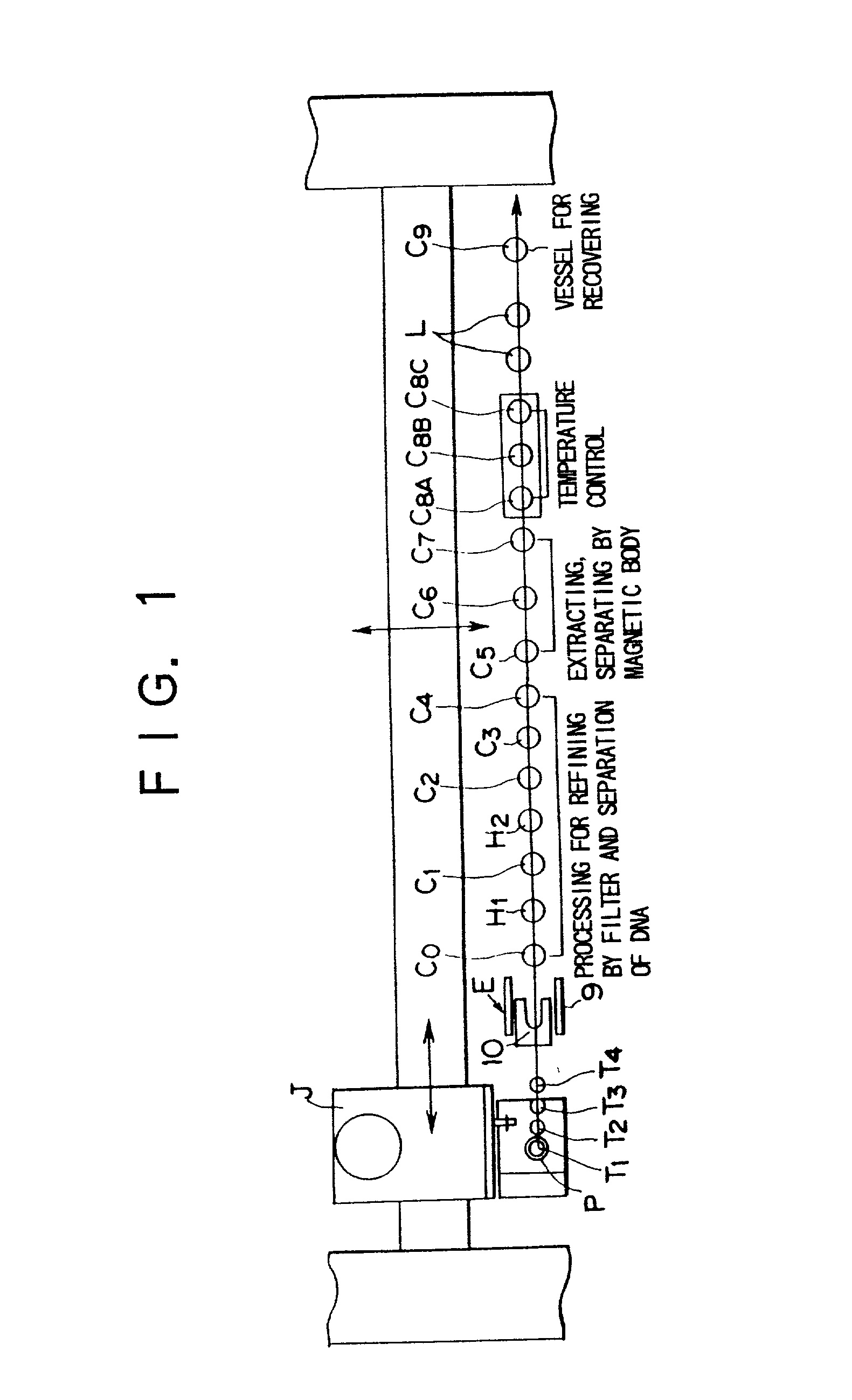

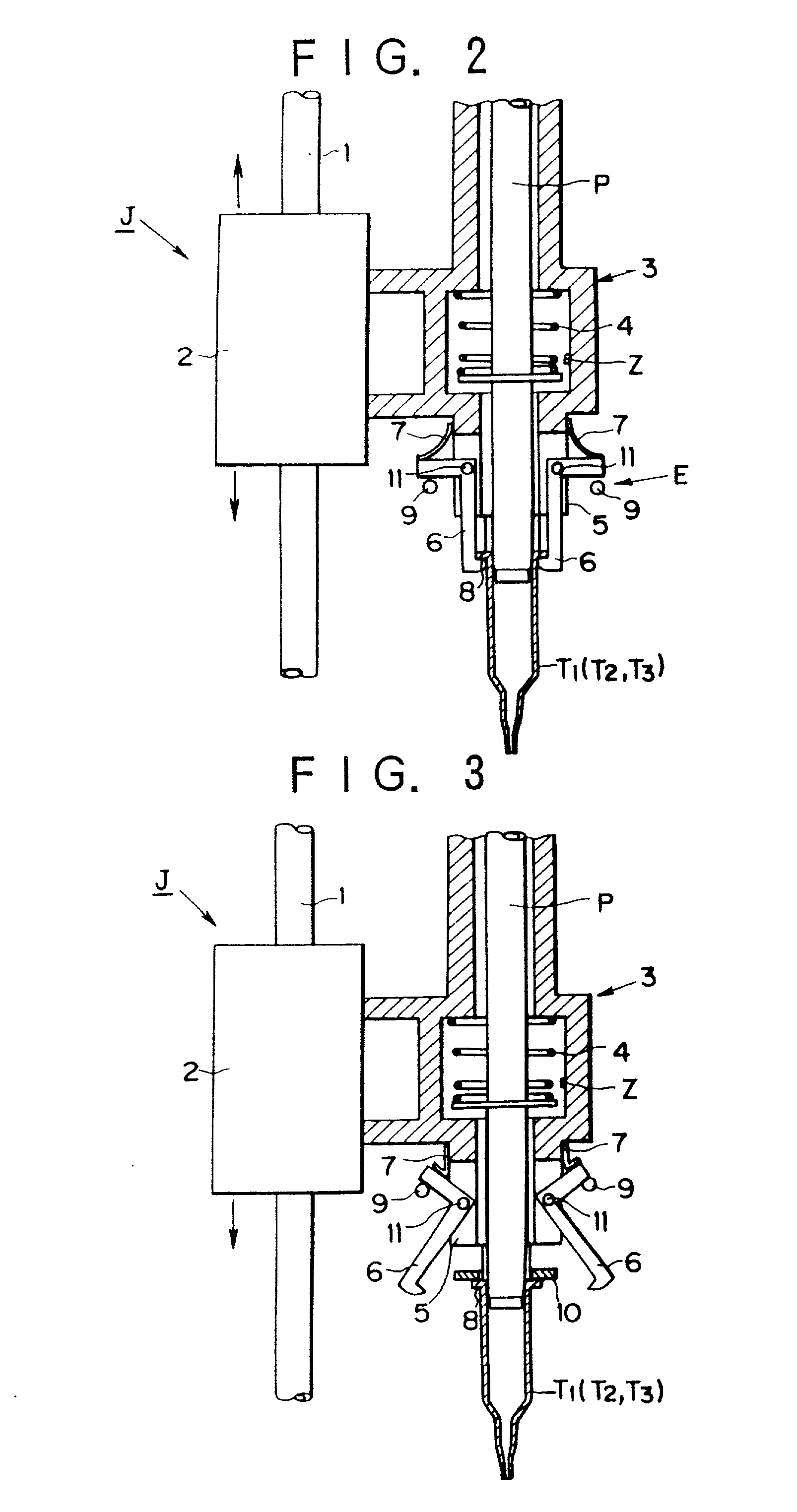

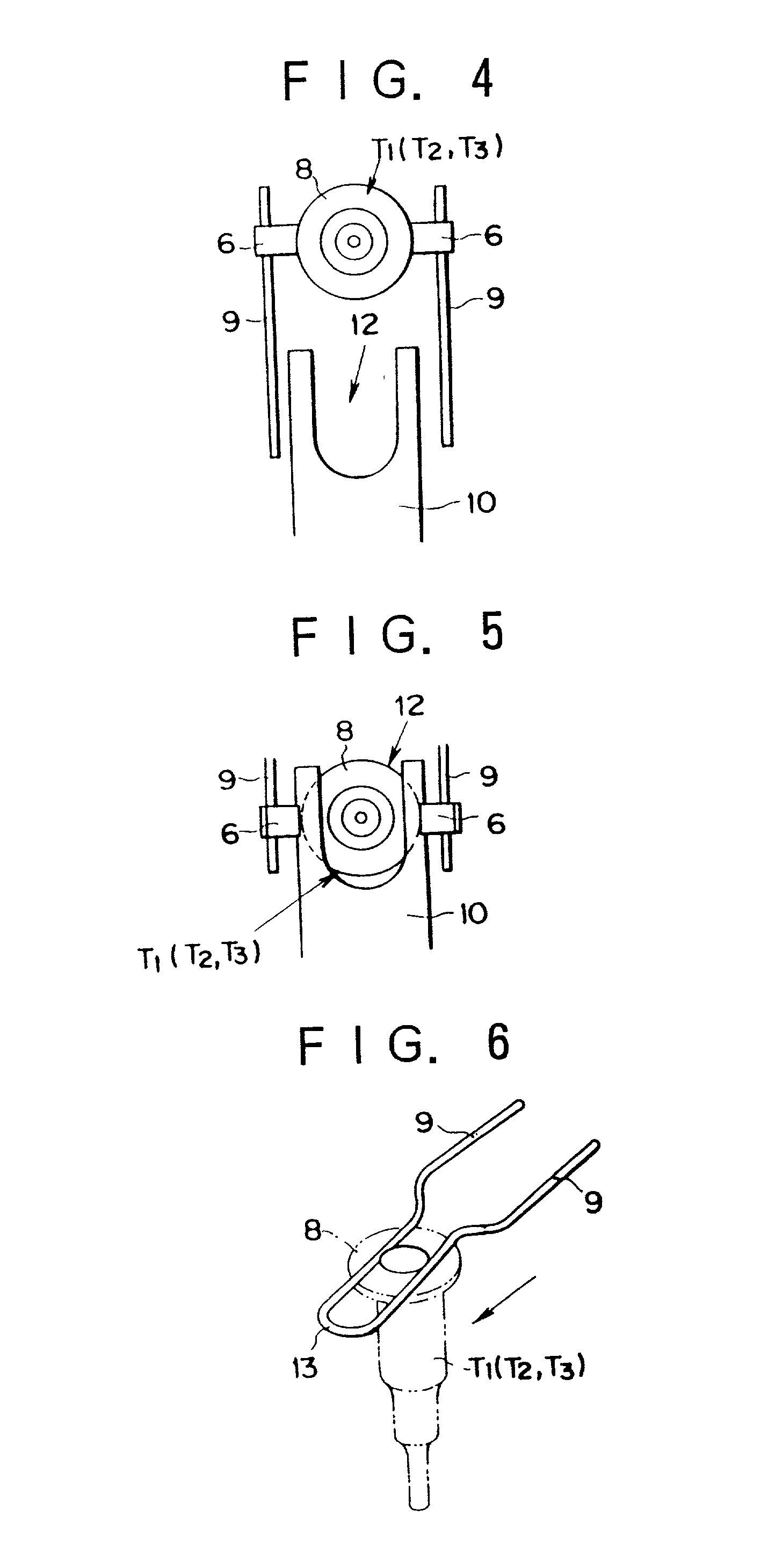

Liquid processing method making use of pipette device and apparatus for same

InactiveUS20020123156A1Improve accuracyBioreactor/fermenter combinationsHeating or cooling apparatusPipetteEngineering

Technological preposition of the present invention is a liquid processing method making use of a pipette device which sucks a liquid containing a target high molecular substance from inside of a vessel through a chip detachably set on a sucking port or a discharging port of a liquid sucking / discharging line and transfers this liquid or target high molecular substance to the next target processing position for the purpose to execute such works as quantifying, separating, taking out, pipetting, cleaning, condensing, and diluting a liquid or a target high molecular substance contained in a liquid and also such works as extracting, recovering, and isolating the target high molecular substance by means of sucking and discharging a liquid with a pipette device and controls by a magnetic body over magnetic particles and / or a filter combined according to the necessity, and the chip can isolate the target high molecular substance by having the substance attracted onto magnetic particles or with a filter set on each chip.

Owner:PRECISION SYST SCI

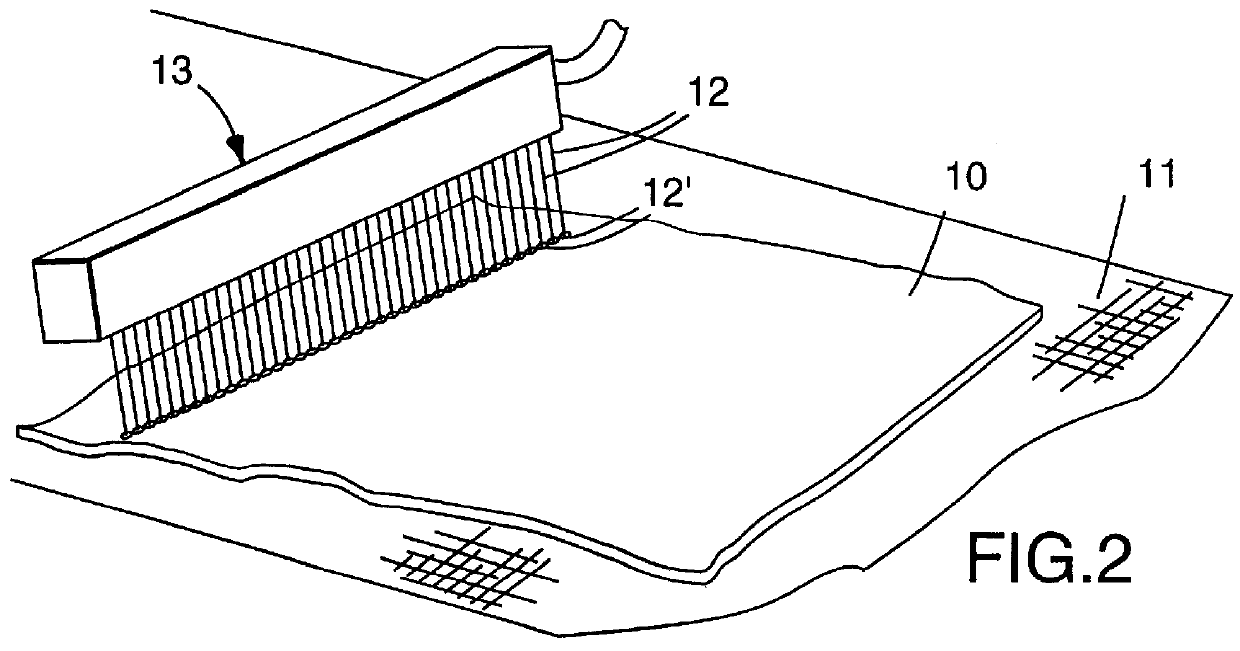

High efficiency synthetic filter medium

InactiveUS6123752AHigh strengthReduce basis weightOther chemical processesElectrostatic separationHEPAGram

A high efficiency filtration medium comprised of a nonwoven filter web of electret charged fibers of a nonconductive thermoplastic resin having a resistivity greater than 1014 ohm-cm, preferably polypropylene. The nonwoven filter web has a basis weight (BW) of less than 60 grams / m2, an effective fiber diameter (EFD) of less than 5 microns and a penetration (PEN) of less than 0.03%, wherein the ratio); BW / (EFD.PEN) is greater than 200. The invention filter medium can be easily used in applications requiring HEPA performance at relatively low pressure drops.

Owner:3M INNOVATIVE PROPERTIES CO

Exhaust system for a vehicular positive ignition internal combustion engine

ActiveUS20110158871A1Reduce frequencyImprove filtering effectCombination devicesCation exchanger materialsParticulatesPorous substrate

Owner:JOHNSON MATTHEY PLC

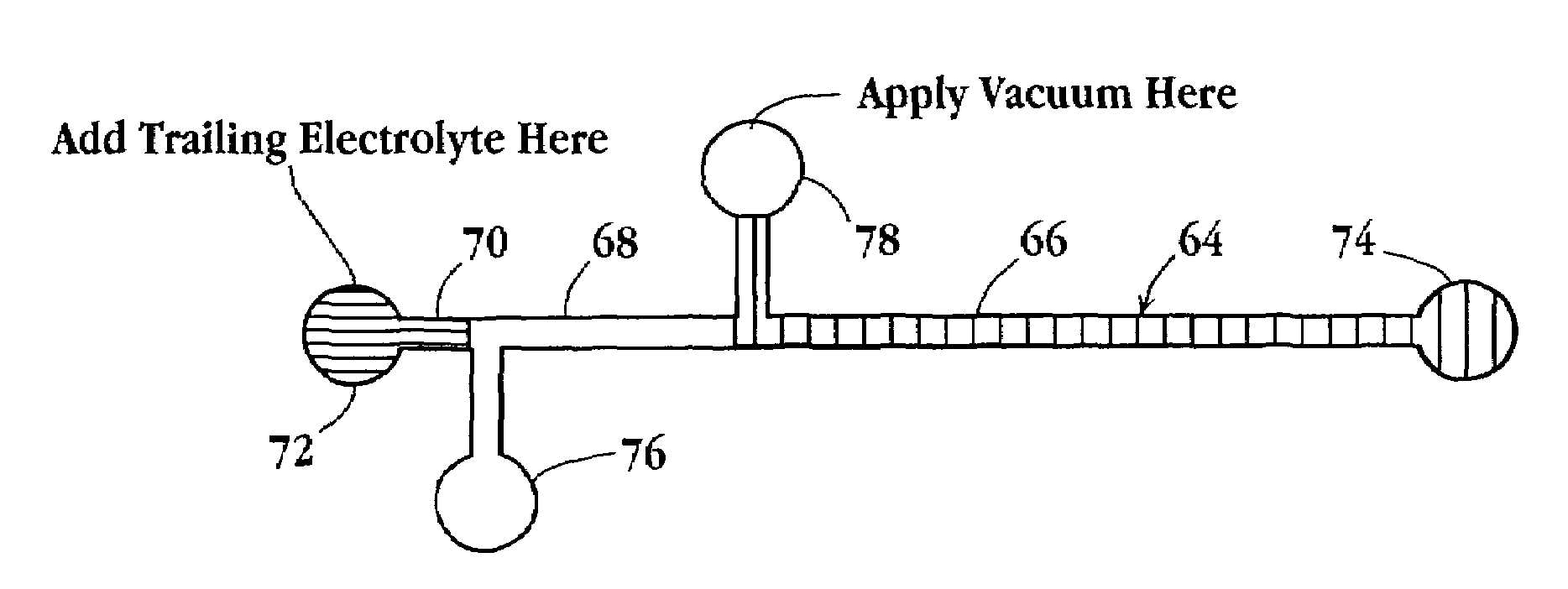

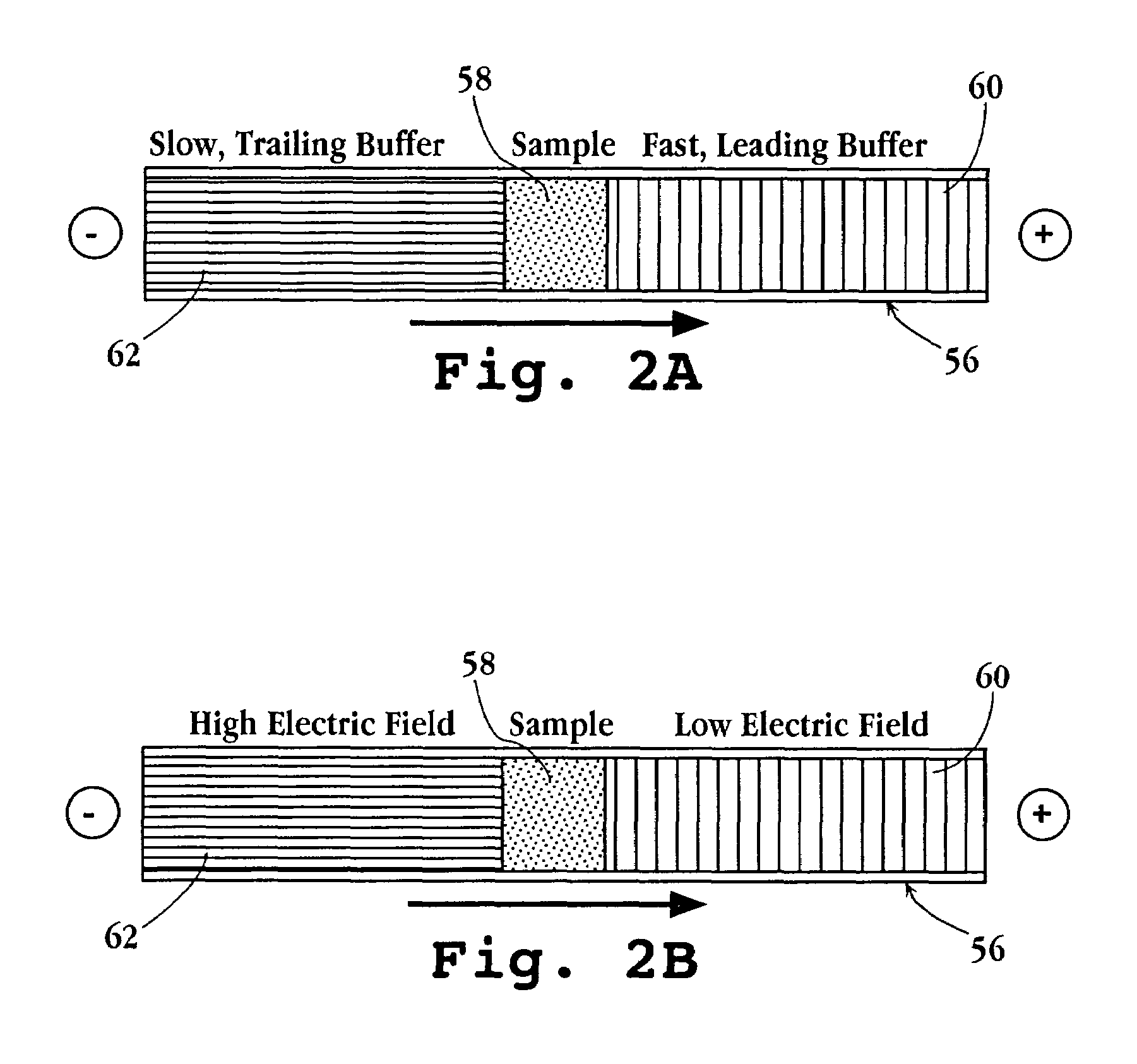

Tandem isotachophoresis/zone electrophoresis method and system

A method of separating components having a given negative or positive charge and contained in a sample is disclosed. The method involves, in one embodiment, loading a microchannel with a sample, placed between a trailing-edge electrolyte having a selected concentration of a titratable species, and a leading-edge electrolyte. With the application of a voltage potential across the microchannel, charged components in the sample stack by isotachophoresis, and electrolytic hydroxyl or hydrogen ions formed by electrolysis at the upstream-end electrode migrate into the trailing-edge ion buffer, titrating the titratable species therein, where the concentration of the titratable species in the trailing-edge electrolyte is selected , in relation to the lengths of the upstream channel region and sample-loading volume, to permit the sample to stack into a relatively small sample volume before electrolytic-ion migration from the upstream electrode into and through the sample-volume region is effective to overtake the charge sample components. With continued application of an electric potential across the channel ends, charged sample components in the stacked sample volume separated by zone electrophoresis.

Owner:MONOGRAM BIOSCIENCES

Flue gas purification process using a sorbent polymer composite material

ActiveUS20050019240A1Easy to fixImprove removal efficiencyGas treatmentNitrogen compoundsSorbentFluoropolymer

This invention provides a process of removing sulfur oxides, mercury vapor, and fine particulate matters from industrial flue gases that contain such pollutants. The pollutants are removed by modules, which contain microporous adsorbent (i.e., sorbent) material that is held within a polymer matrix. The preferred polymers are fluoropolymers. The composite material that contains the microporous absorbent material held within a polymer matrix removes sulfur oxides by converting them into high concentration sulfuric acids. It also removes mercury vapor by chemically adsorbing the mercury into the matrix. It also removes fine particulate matters by surface filtration. The sulfuric acid that is produced inside the composite material is automatically expelled onto the external surfaces of the composite material and is drained into an acid reservoir together with the fine particulate matters which are washed from the external surfaces of the composite material by the constant dripping of the sulfuric acid along the external surfaces of the composite material.

Owner:WL GORE & ASSOC INC

Automated process for isolating and amplifying a target nucleic acid sequence

InactiveUS20050130198A1Efficient and high through-put operationEfficient comprehensive utilizationRotating receptacle mixersBioreactor/fermenter combinationsIsolation proceduresTemperature control

Owner:GEN PROBE INC

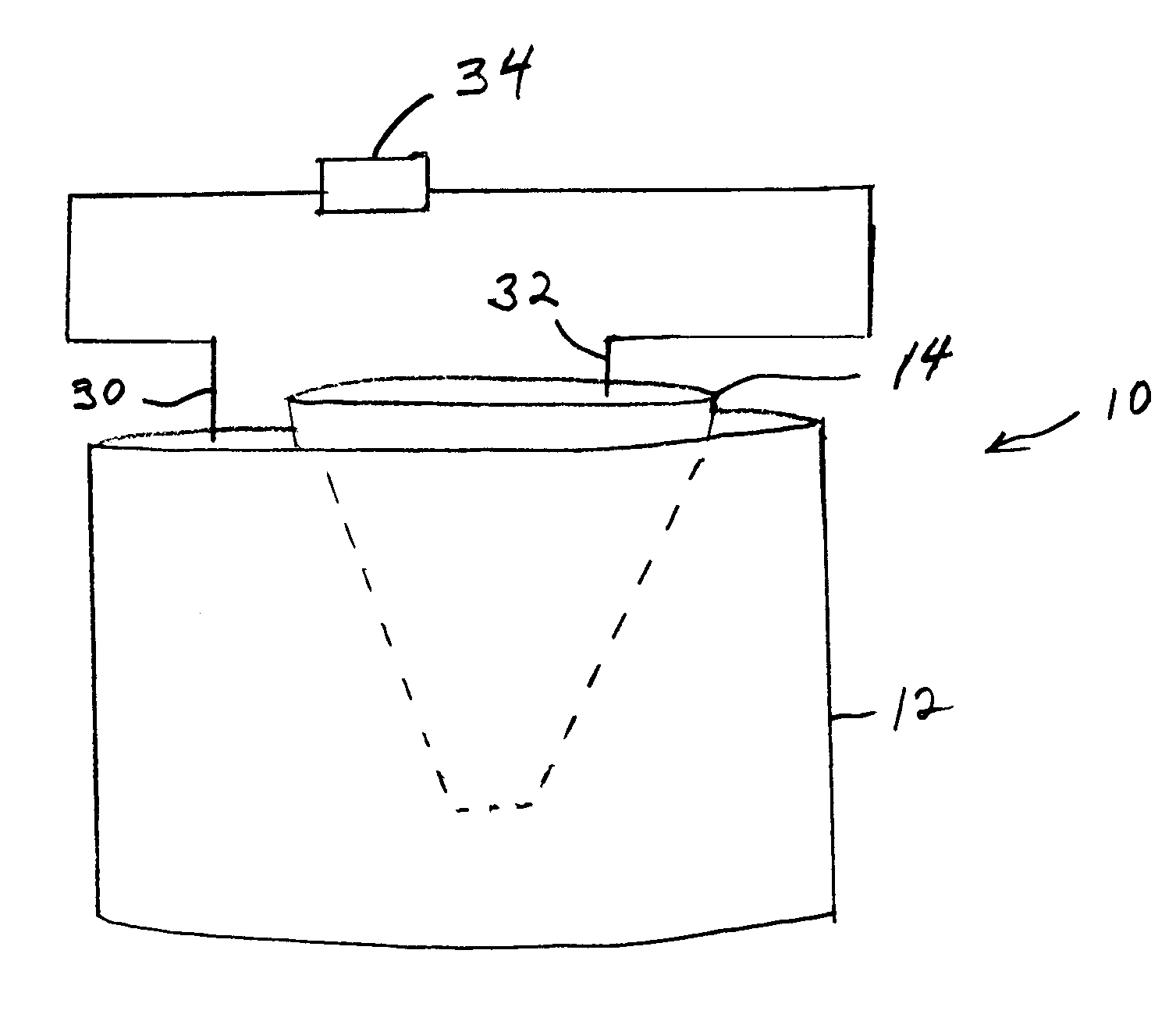

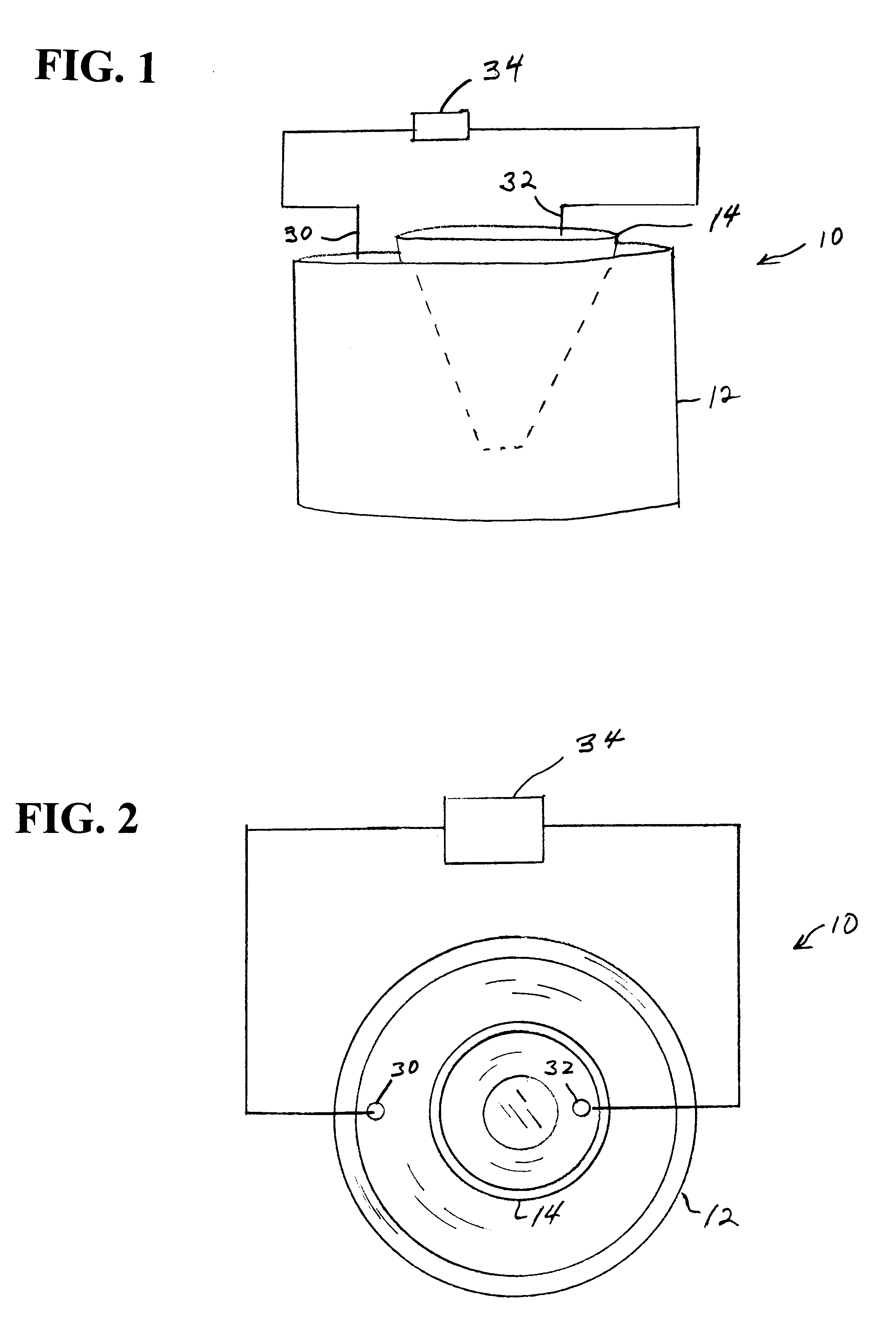

Method and apparatus for protein manipulation

InactiveUS6649419B1Avoid problemsAvoid deformationBioreactor/fermenter combinationsBiological substance pretreatmentsAvidityAnalytical chemistry

A method and apparatus for extracting, identifying, and manipulating proteins or peptides from a solution uses paramagnetic beads having a coating with an affinity for the target component. In one embodiment, paramagnetic beads coated with C18 are used to adsorb proteins and peptides. The beads can be used to purify, immobilize and assay antibodies. By cycling the beads, many times greater molar amount of binding partner may be separated from a solution. A magnetic probe is used to capture the beads and transfer the beads to selected processing stages.

Owner:ANDERSON FORSCHUNG GROUP

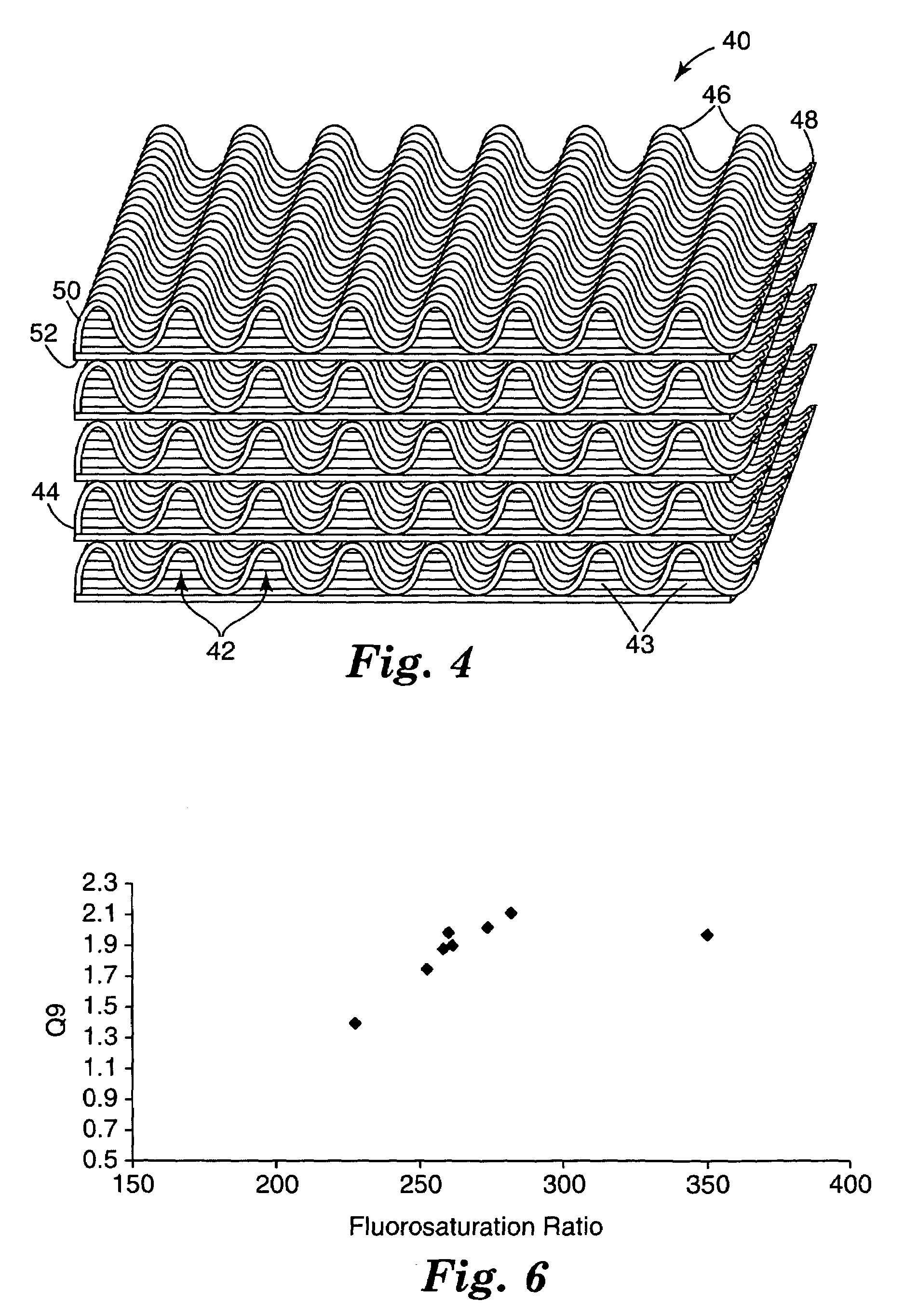

Electret article having high fluorosaturation ratio

ActiveUS7244291B2Improve thermal stabilityIncreased thermal stability—asBreathing filtersElectrostatic separationFiberPolymer chemistry

Owner:3M INNOVATIVE PROPERTIES CO

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

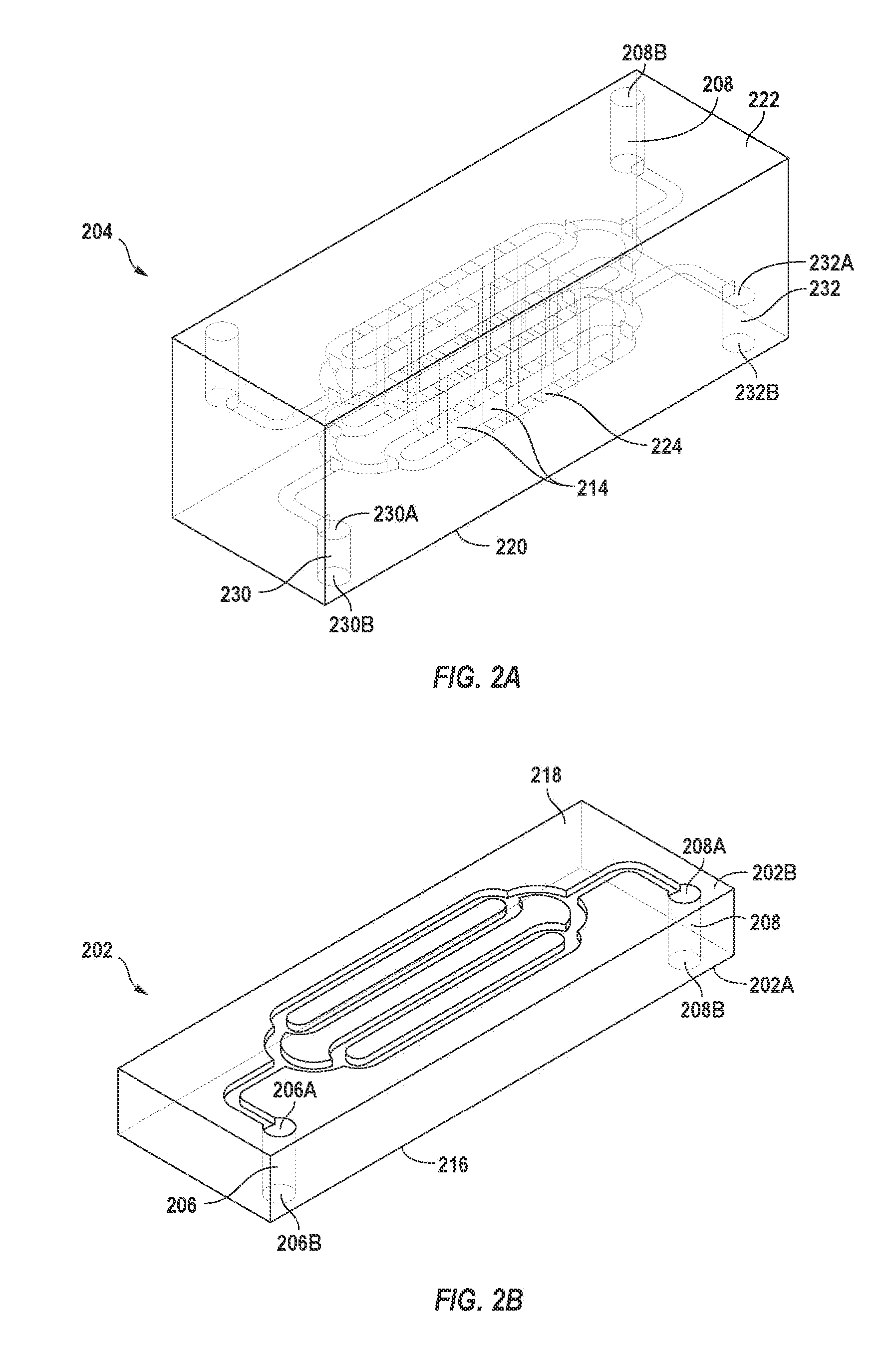

Device for Filtration of Fluids Therethrough and Accompanying Method

ActiveUS20120149021A1Easy to separateEasy to removeBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic field gradientFluid filtration

A microfluidic device for separating target components from a source fluid includes one or more source channels connected to one or more collection channels by one or more transfer channels. The target components of the source fluid can be magnetic or bound to magnetic particles using a know binding agent. A source fluid containing magnetically bound target components can be pumped through the source channel of the microfluidic device. A magnetic field gradient can be applied to the source fluid in the source channel causing the magnetically bound target components to migrate through the transfer channel into the collection channel. The collection channel can include a collection fluid that is stagnant until a predefined volume of source fluid is processed or a predefined volume of target components accumulate in the collection channel, at which point collection fluid can be pumped into the collection channel to flush the target components out of the collection channel. The target components can be subsequently analyzed for detection and diagnosis.

Owner:CHARLES STARK DRAPER LABORATORY +1

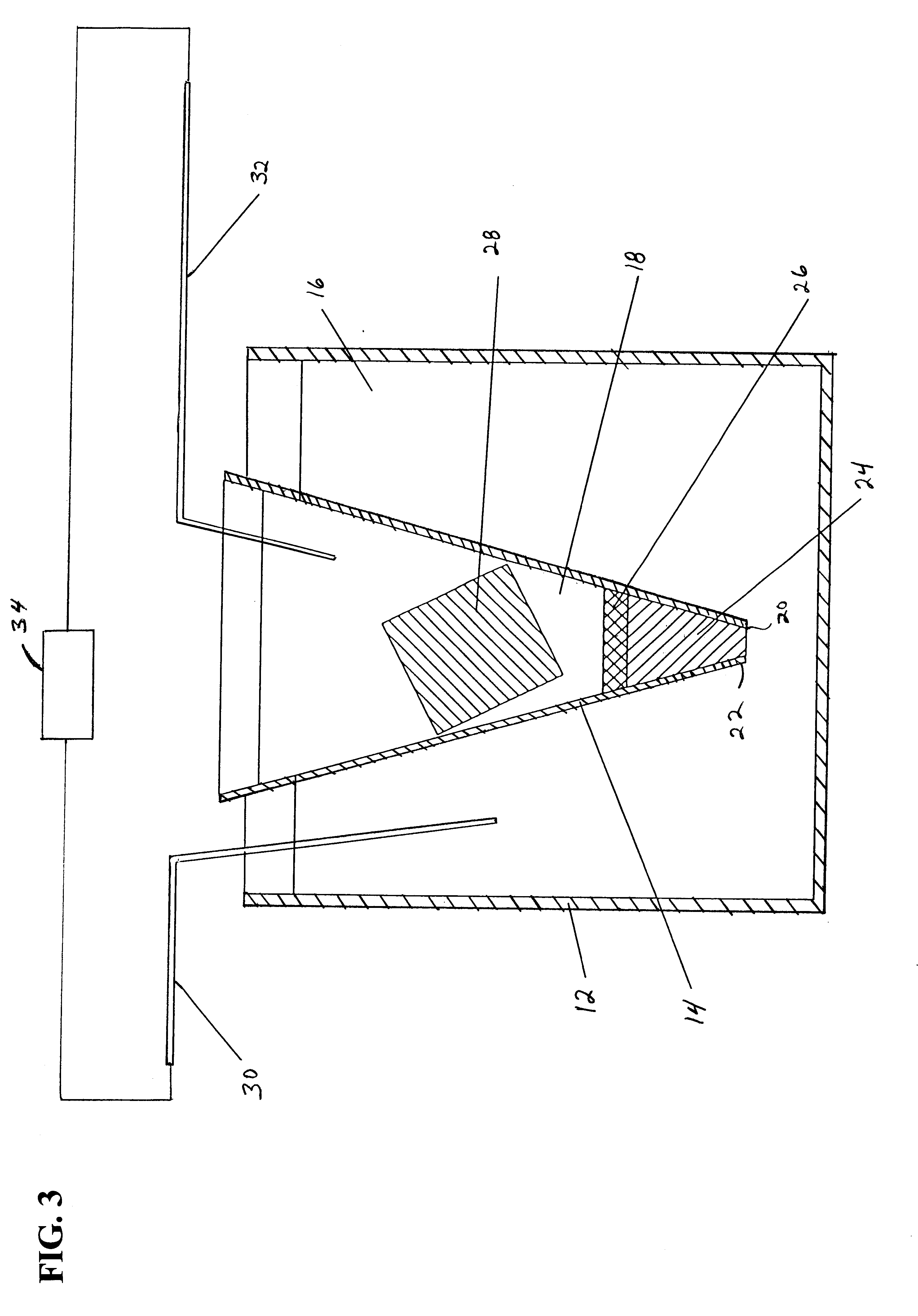

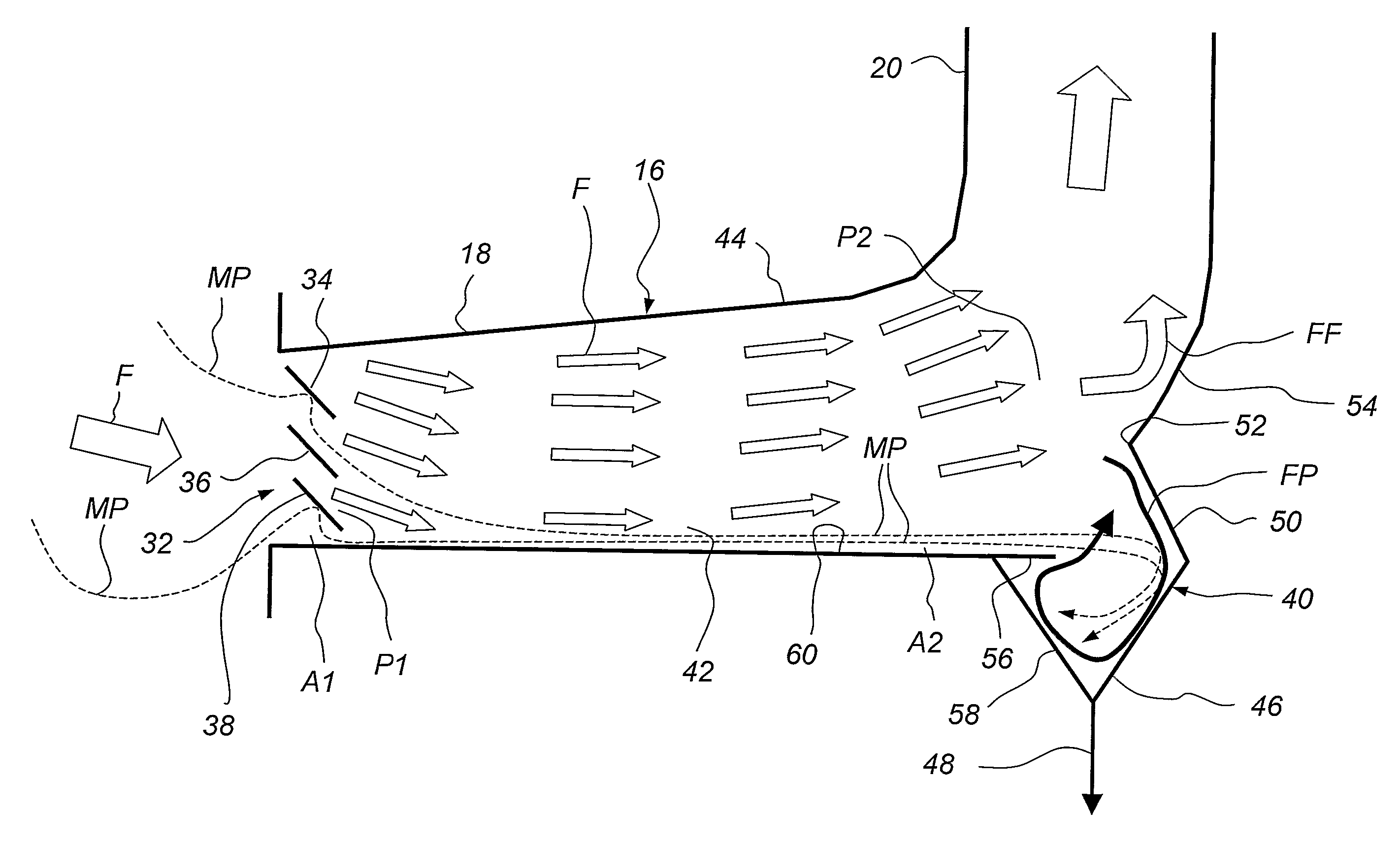

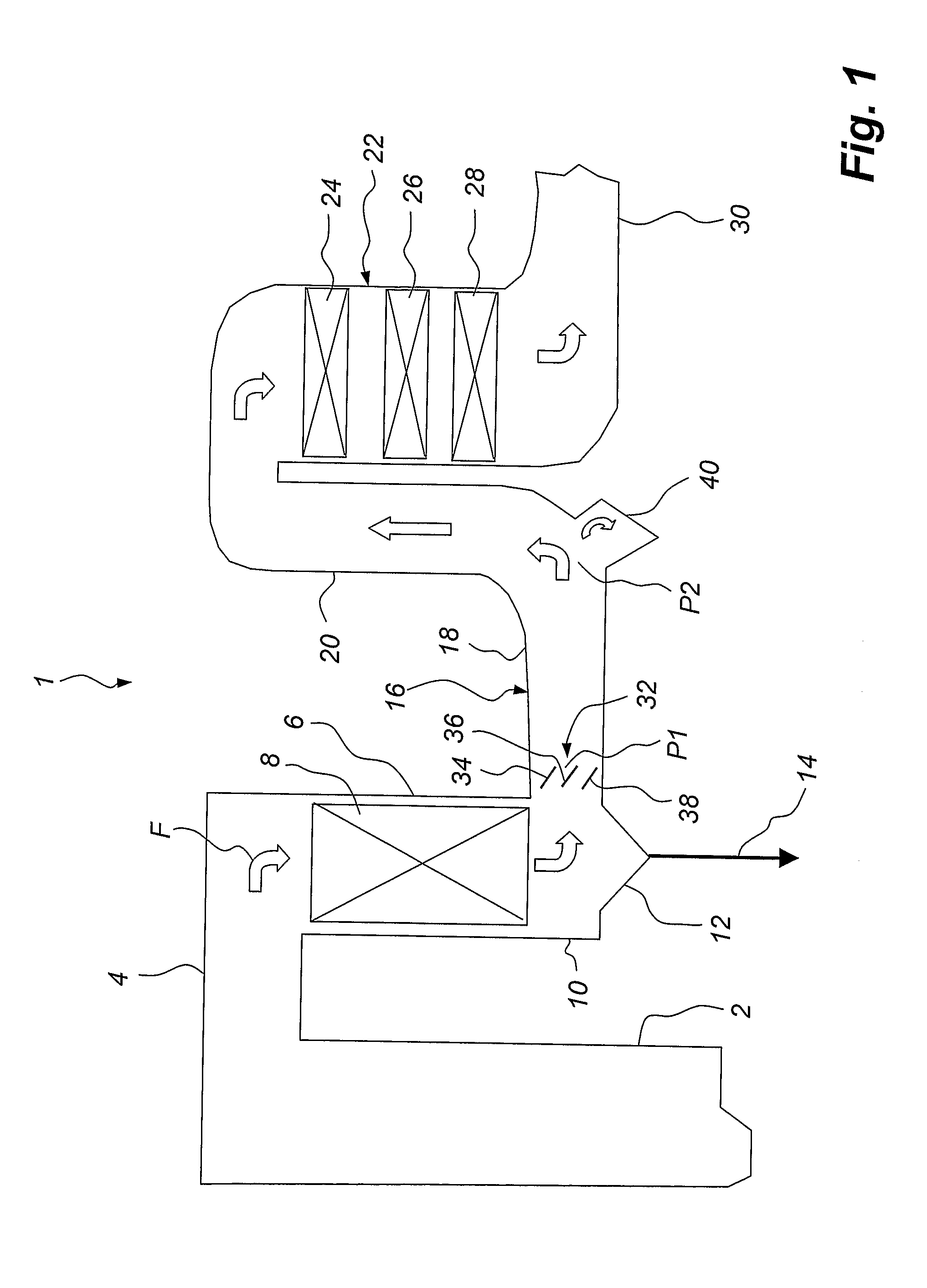

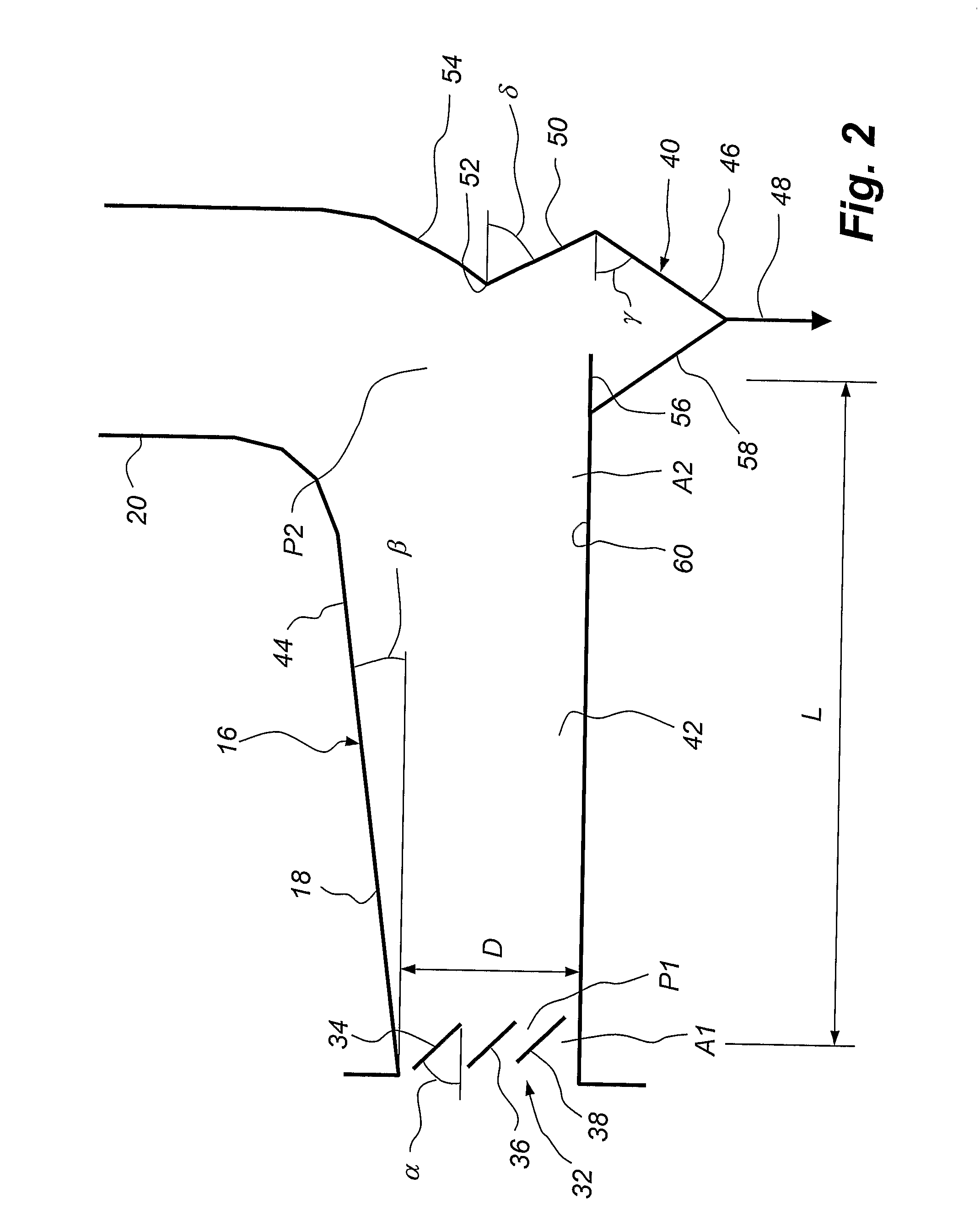

Method and Device for the Separation of Dust Particles

A device (16) for separating particles (MP) from a flue gas flow (F) has a horizontal flue gas duct (18), through which the flue gas flow (F) is passed substantially horizontally from a first position (P1) to a second position (P2). In the first position (P1), the device (16) has a baffle arrangement (32), which comprises at least one plate (34, 36, 38) which is arranged in the flue gas duct (18) and which is inclined so as to deflect particles (MP) down to the lower portion (42) of the horizontal flue gas duct (18). In the second position (P2), the device (16) has a collecting means (40), which is arranged in the lower portion (42) of the flue gas duct (18) to collect the particles (MP) which have been deflected downwards by the plate (34, 36, 38) to the lower portion (42) of the flue gas duct (18).

Owner:GENERAL ELECTRIC TECH GMBH

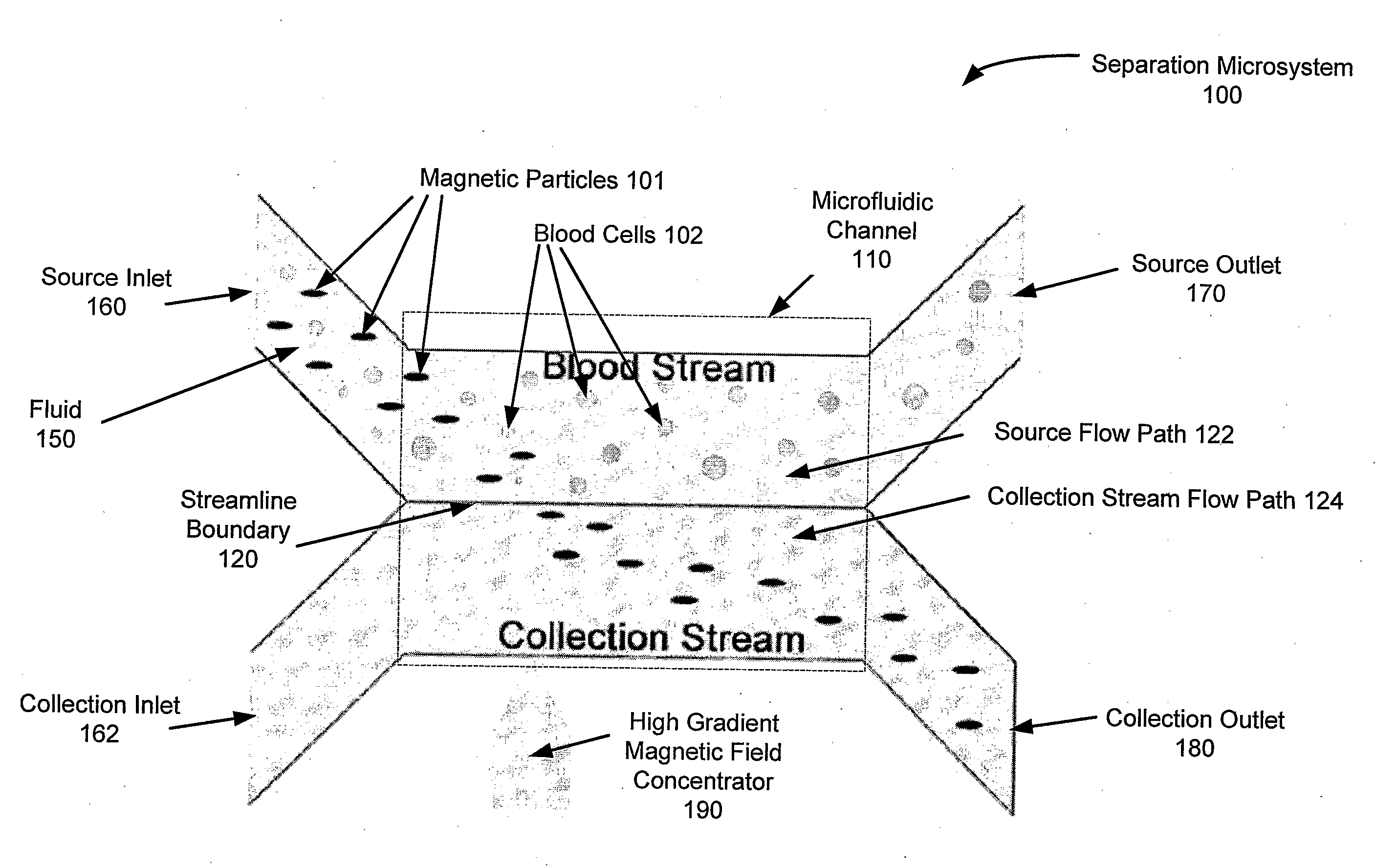

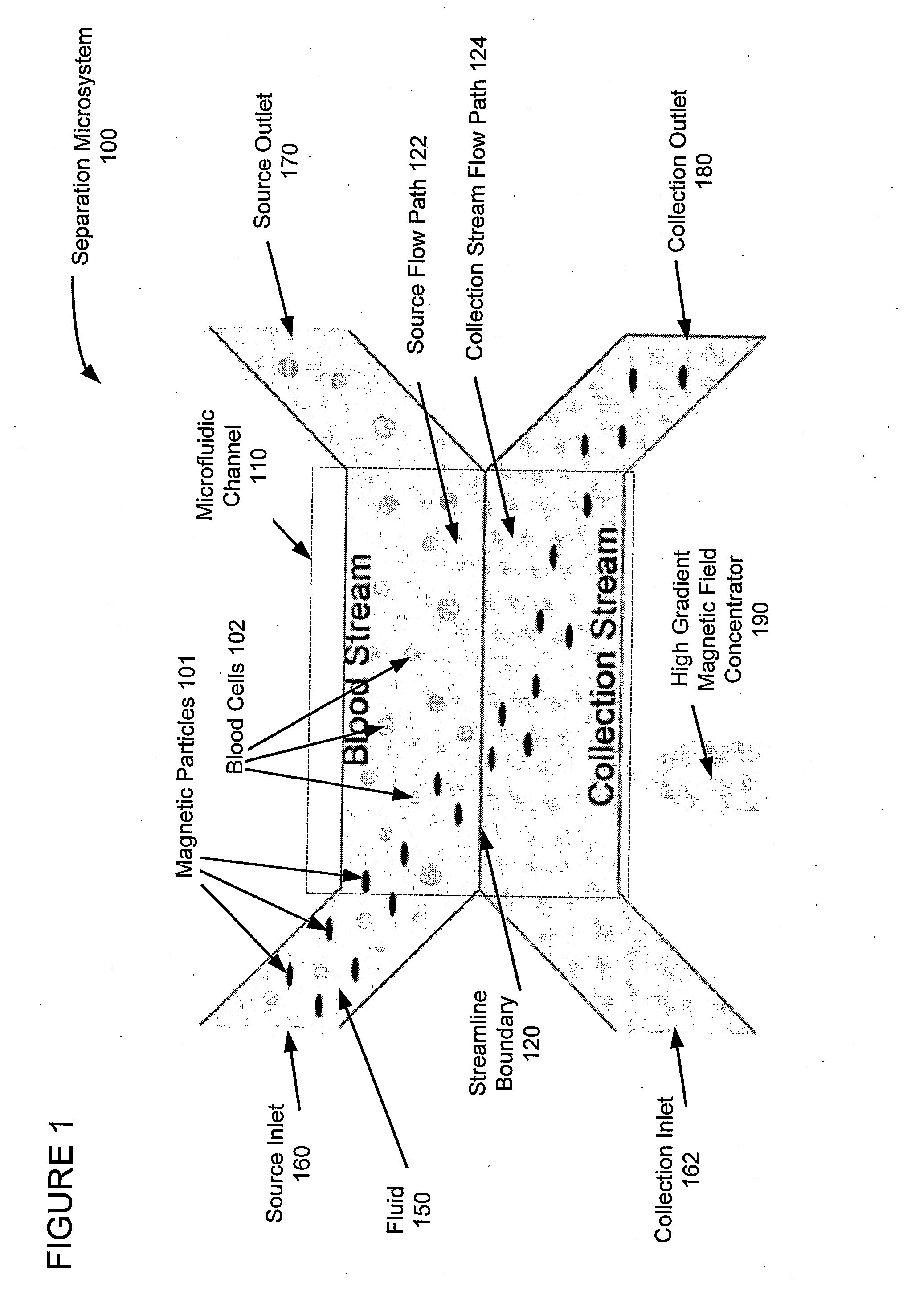

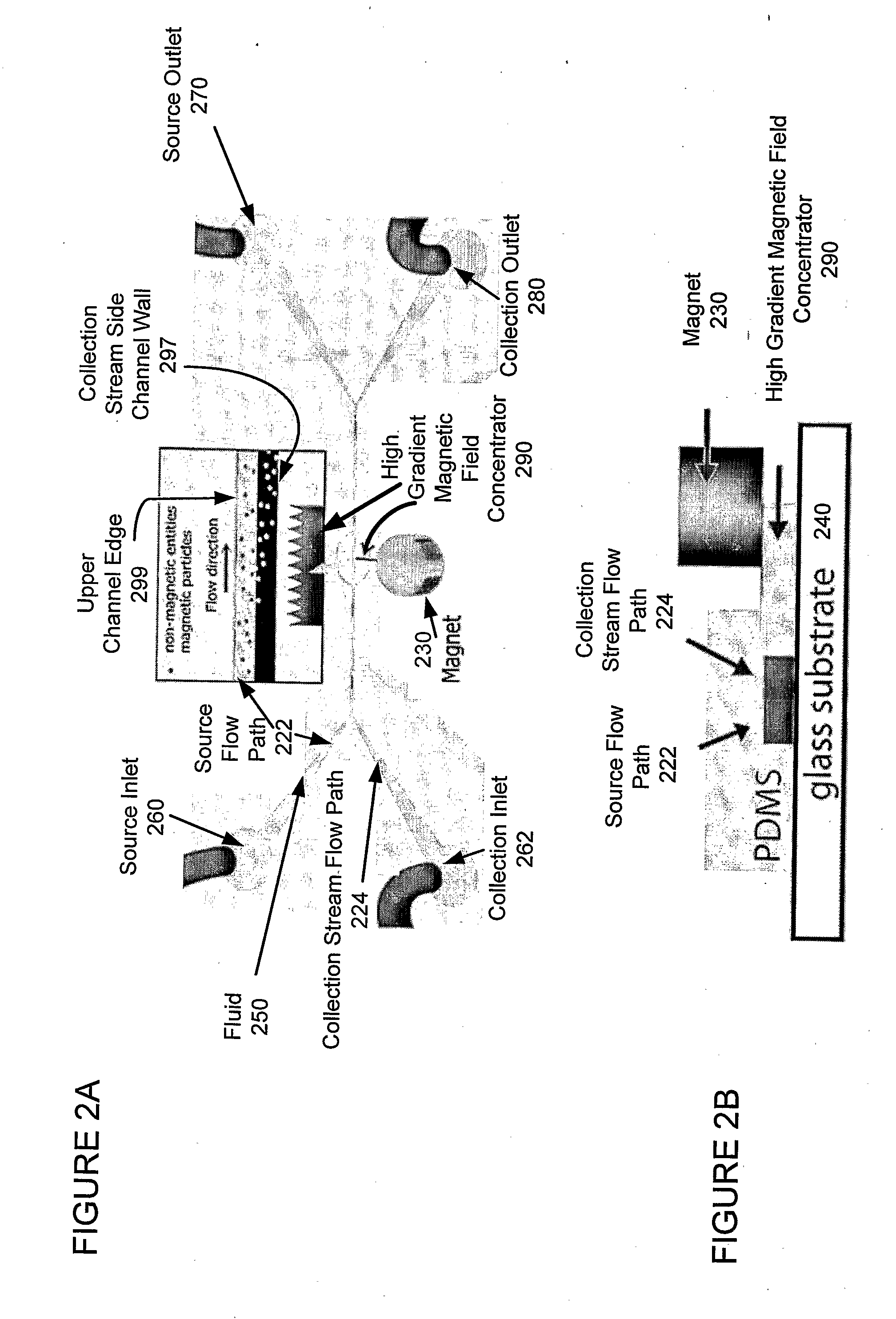

Device and method for combined microfluidic-micromagnetic separation of material in continuous flow

ActiveUS20090220932A1Minimize disturbanceEfficient separationBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic field gradientChemical physics

A miniaturized, integrated, microfluidic device pulls materials bound to magnetic particles from one laminar flow path to another by applying a local magnetic field gradient. The device removes microbial and mammalian cells from flowing biological fluids without any wash steps. A microfabricated high-gradient magnetic field concentrator (HGMC) is integrated at one side of a microfluidic channel. When magnetic particles are introduced into one flow path, they remain limited to that flow path. When the HGMC is magnetized, the magnetic beads are pulled from the initial flow path into the collection stream, thereby cleansing the fluid. The microdevice allows large numbers of beads and materials to be sorted simultaneously, has no capacity limit, does not lose separation efficiency as particles are removed, and is useful for cell separations from blood and other biological fluids. This on-chip separator allows cell separations to be performed in the field outside of hospitals and laboratories.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

Electret article having heteroatoms and low fluorosaturation ratio

An electret article that includes a polymeric material that has electric charge imparted thereto, that has one or more heteroatoms, that has a fluorosaturation ratio of less than 200, and that has an atomic percent fluorine of greater than about 40%. The inventive electret article is resistant to charge degradation upon exposure to high temperatures for prolonged time periods.

Owner:3M INNOVATIVE PROPERTIES CO

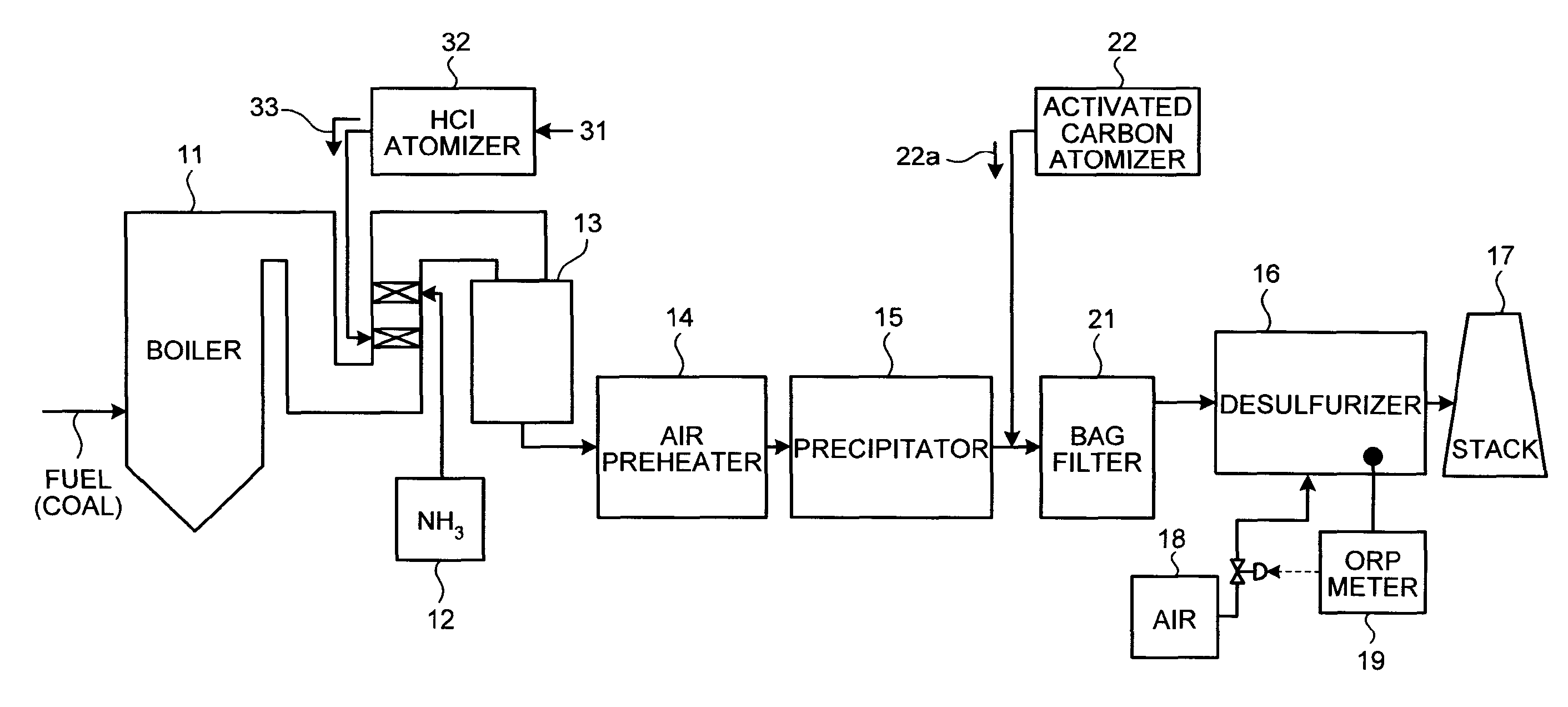

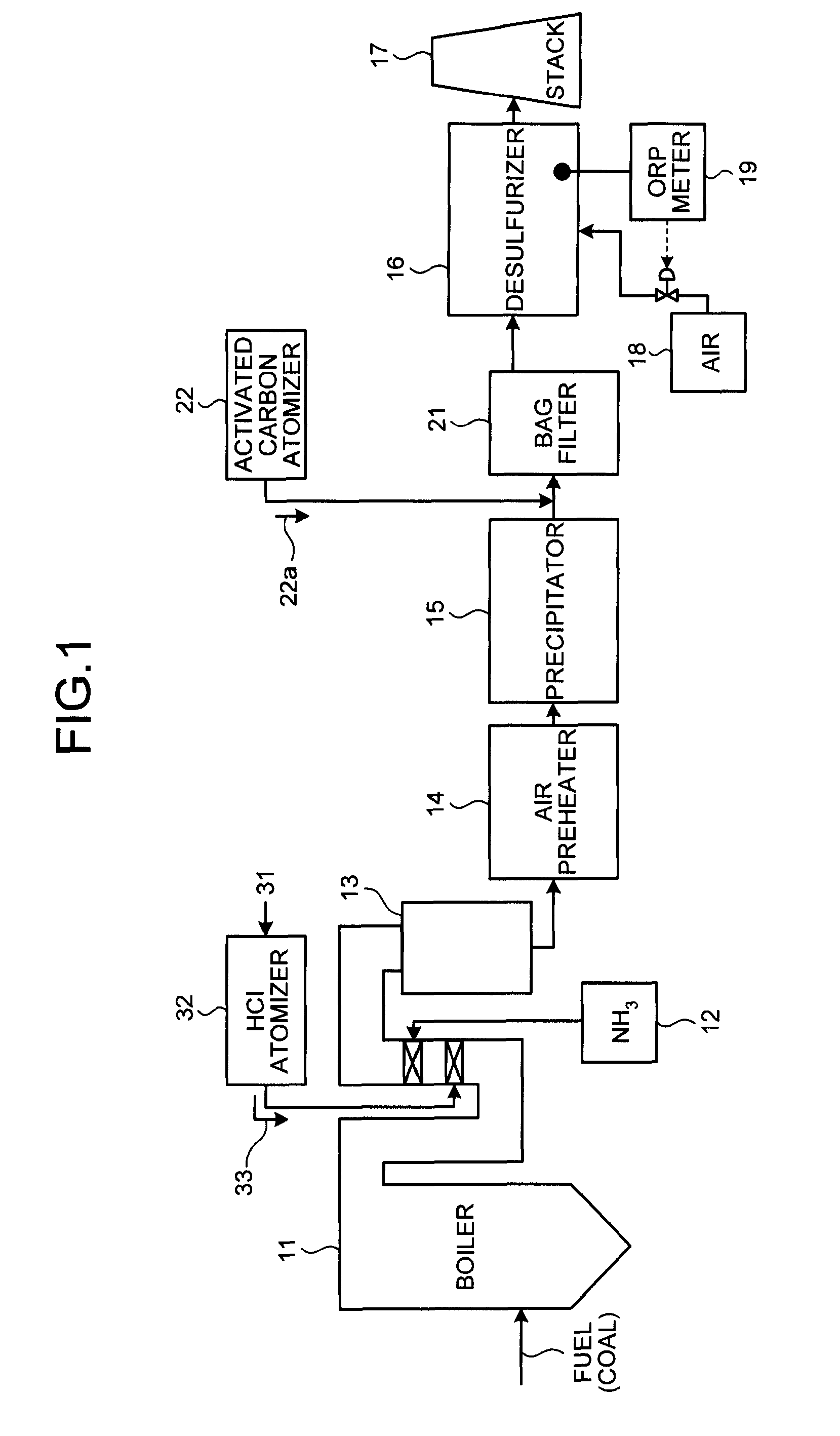

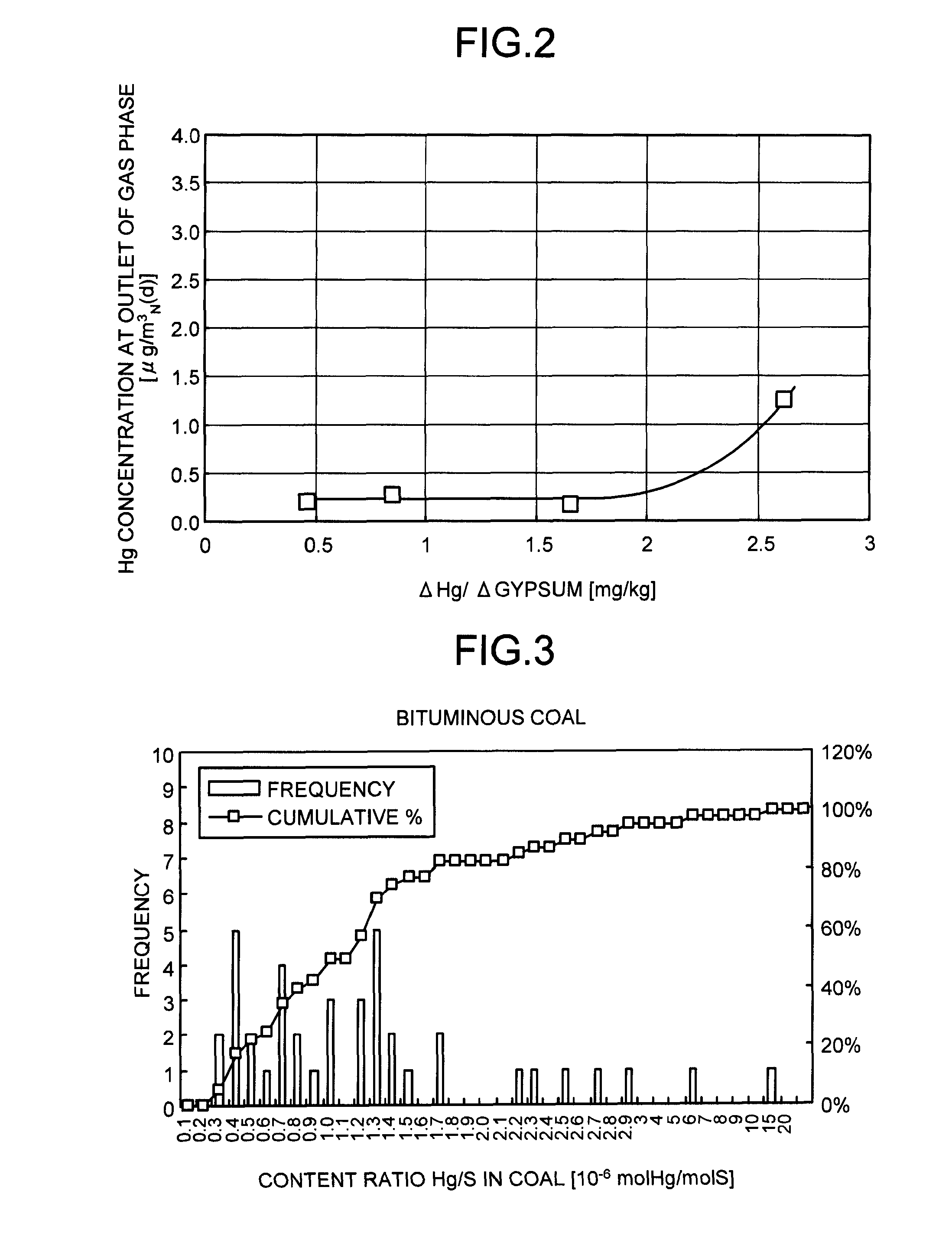

Flue gas control system of coal combustion boiler and operating method thereof

ActiveUS8071060B2Reduce operating costsCombination devicesNitrogen compoundsAir preheaterParticulates

A flue gas control system of a coal combustion boiler comprises an HCl atomizer that sprays hydrogen chloride to flue gas from a coal combustion boiler that uses coal as a fuel; NOx removing apparatus that removes nitrogen oxides by ammonia denitration by adding ammonia to the flue gas after spraying hydrogen chloride and oxidizes mercury; an air preheater that recovers heat in the gas after removal of nitrogen oxides; a precipitator that removes particulates in the gas; an activated carbon atomizer that sprays activated carbon into the gas after particulate collection; a bag filter that collects activated carbon having adsorbed mercury; a desulfurizer that removes sulfur oxides in the flue gas after removal of activated carbon; a stack that discharges the gas which has undergone desulfurization to outside; and an ORP meter that measures an oxidation reduction potential for feeding air to a slurry absorbent in the desulfurizer.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com