Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

293 results about "Post combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

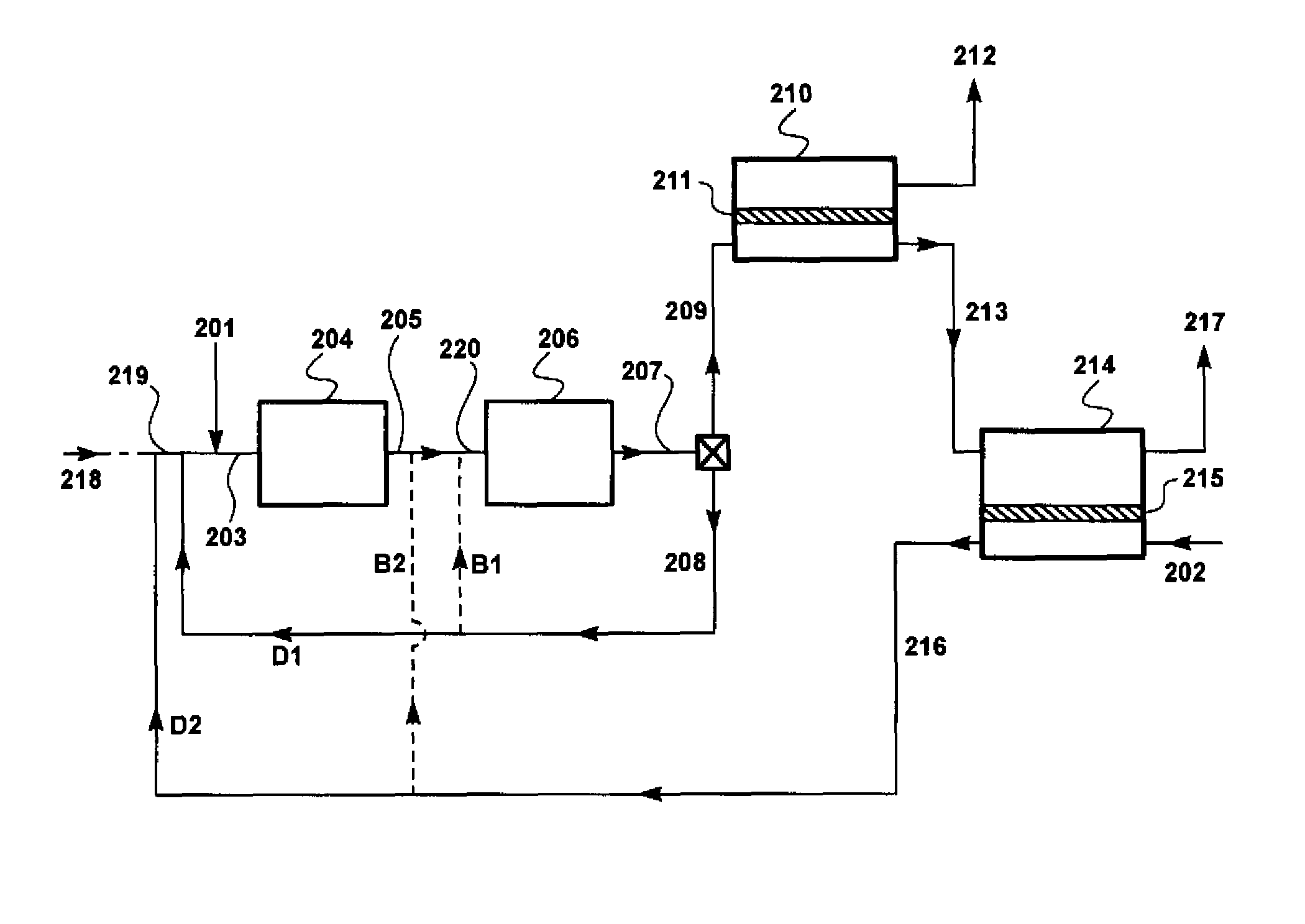

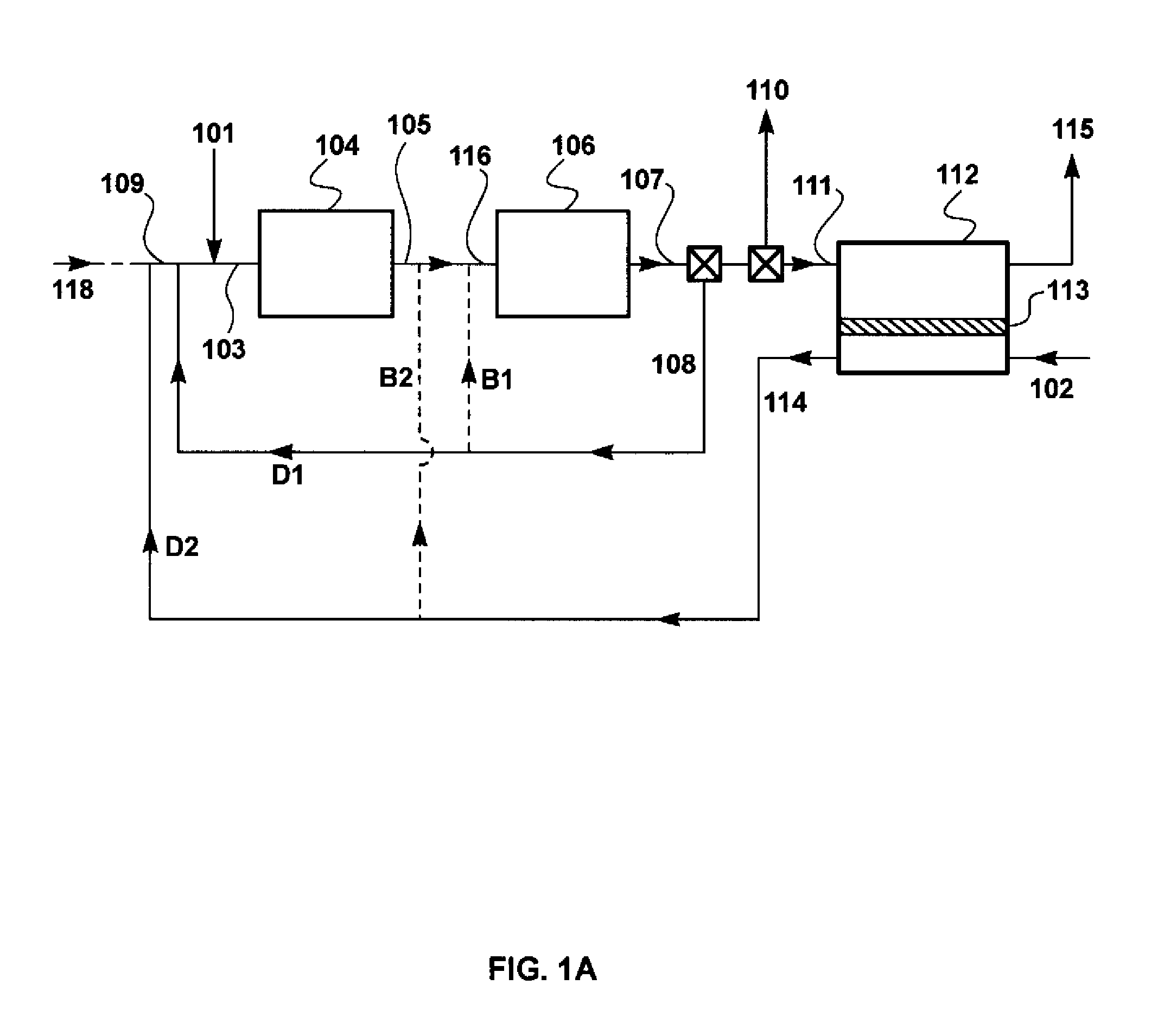

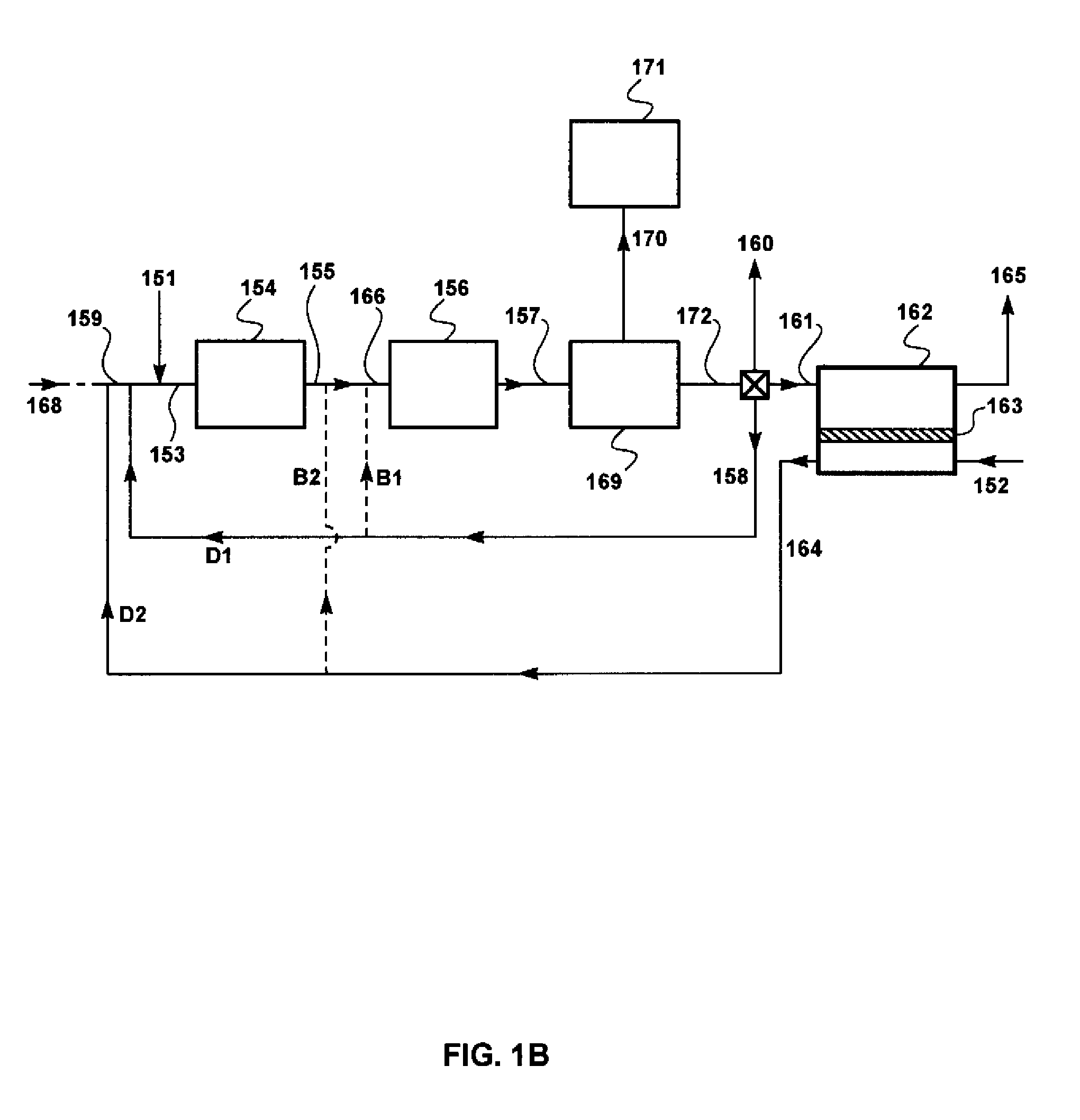

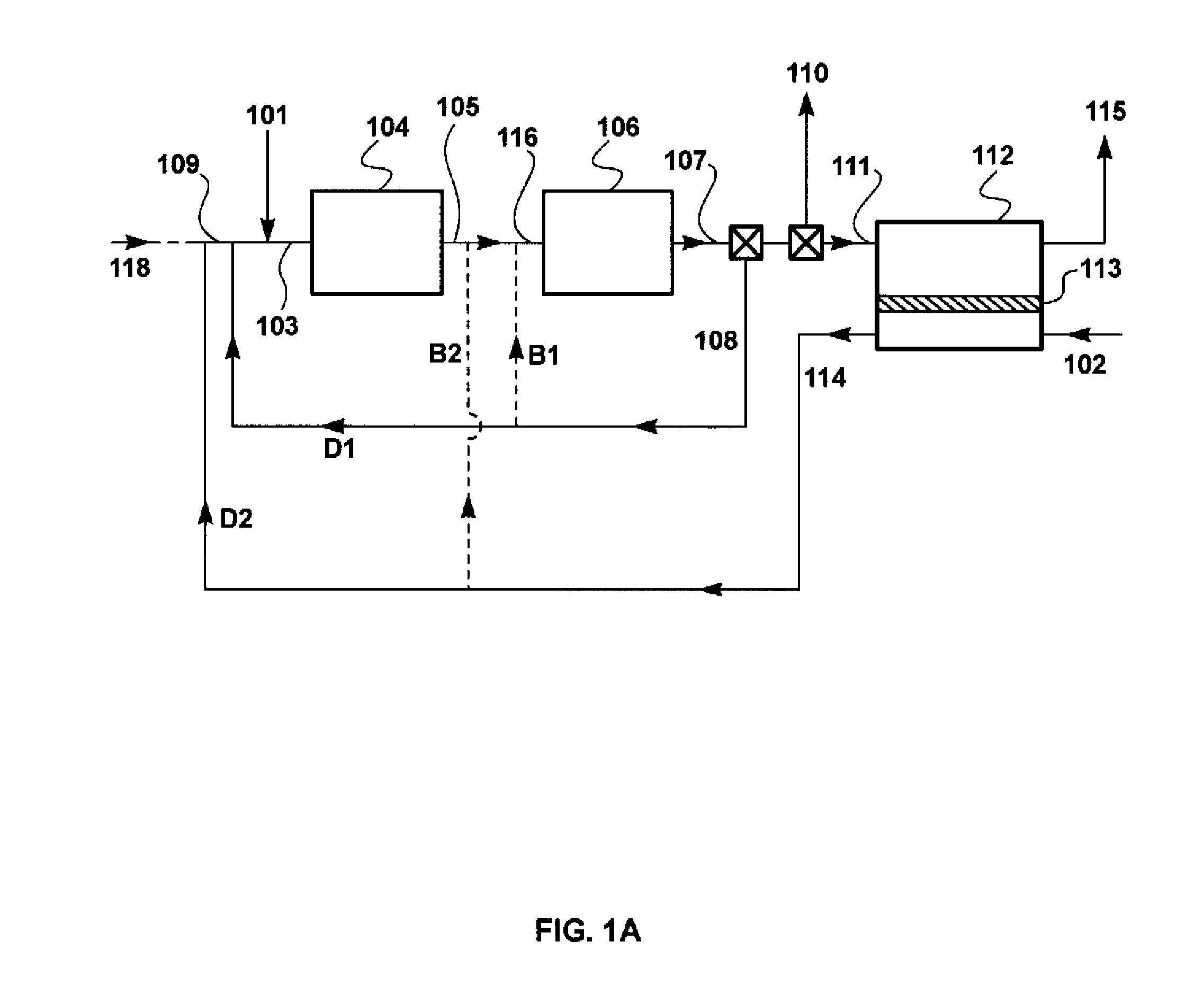

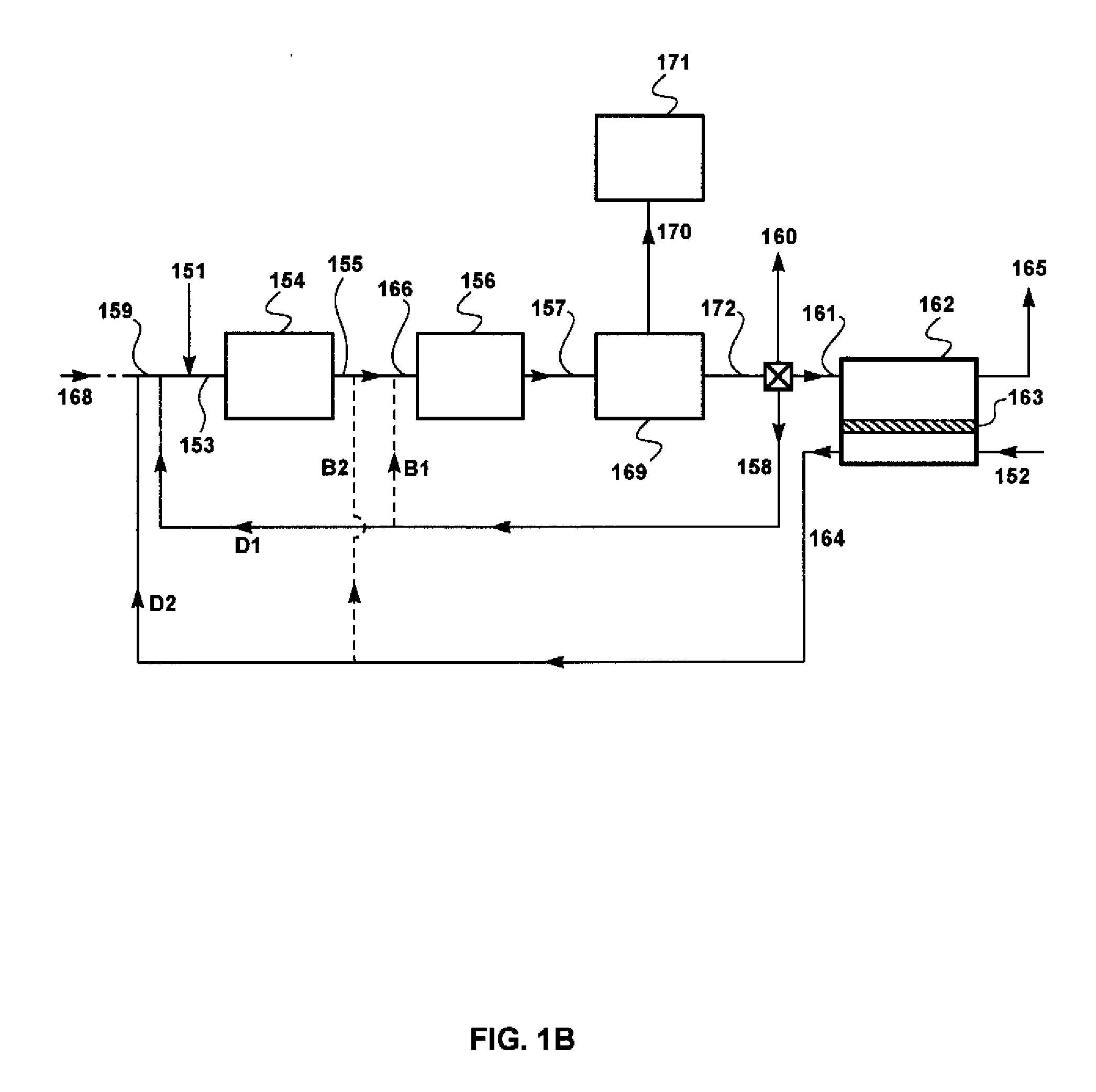

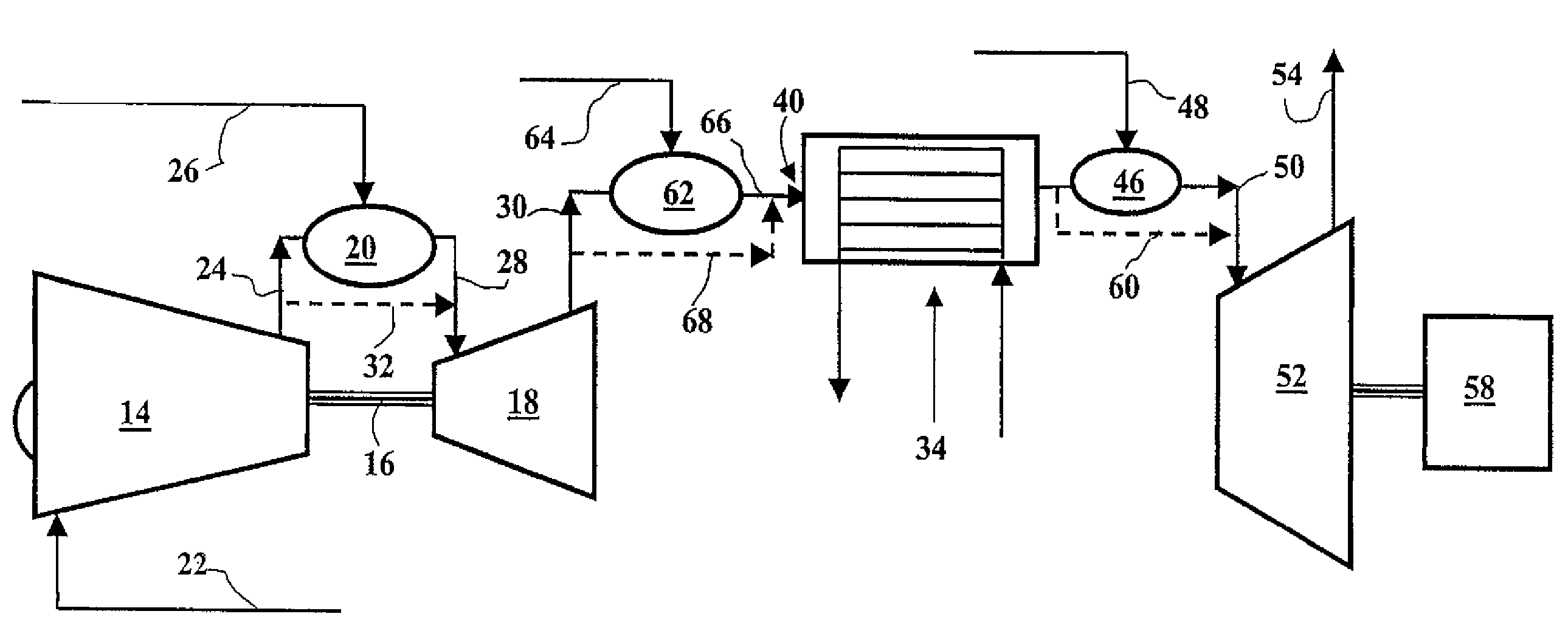

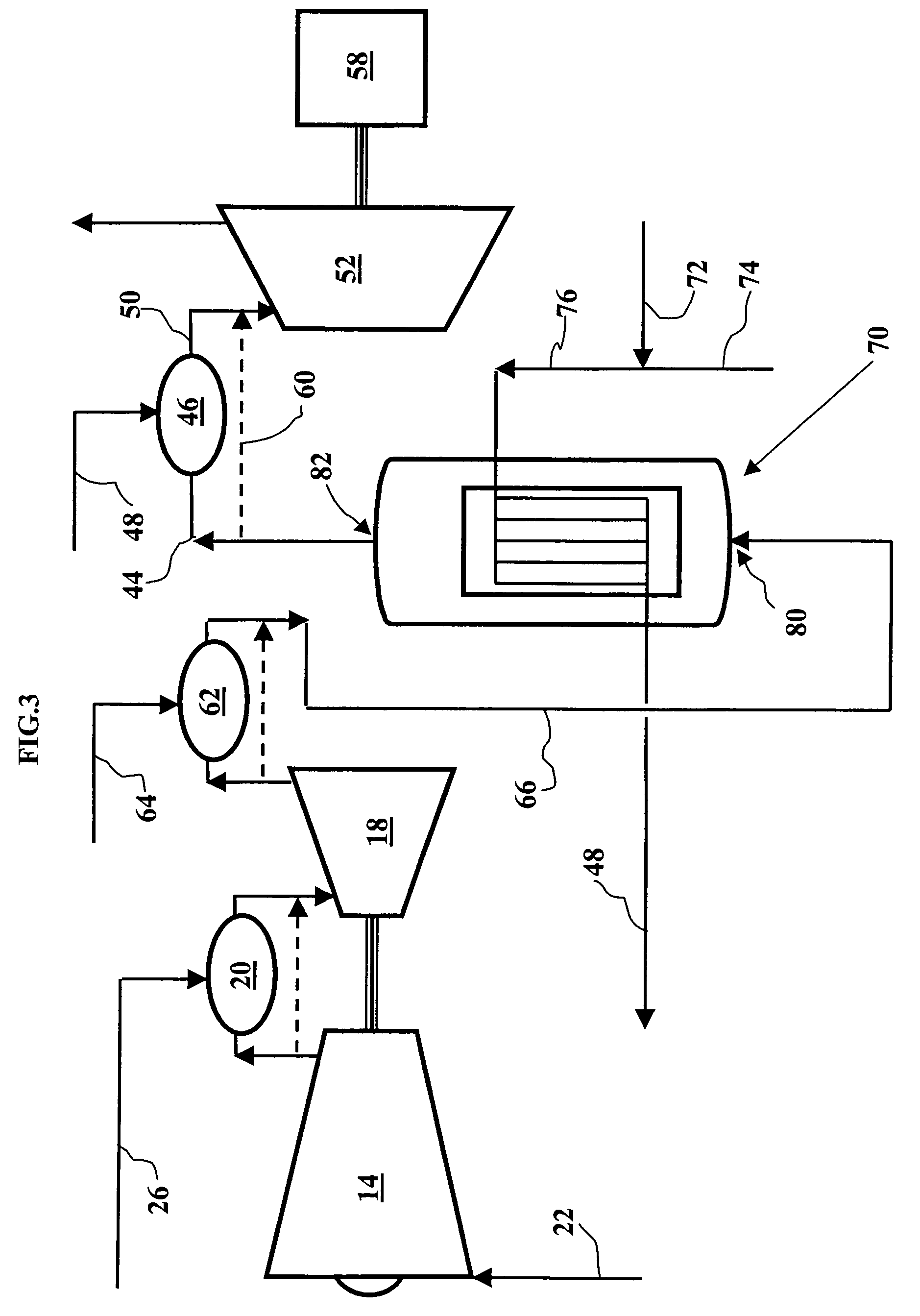

Power generation process with partial recycle of carbon dioxide

ActiveUS8220248B2Inexpensively separatedQuantity minimizationGas treatmentDispersed particle separationElectricityGeneration process

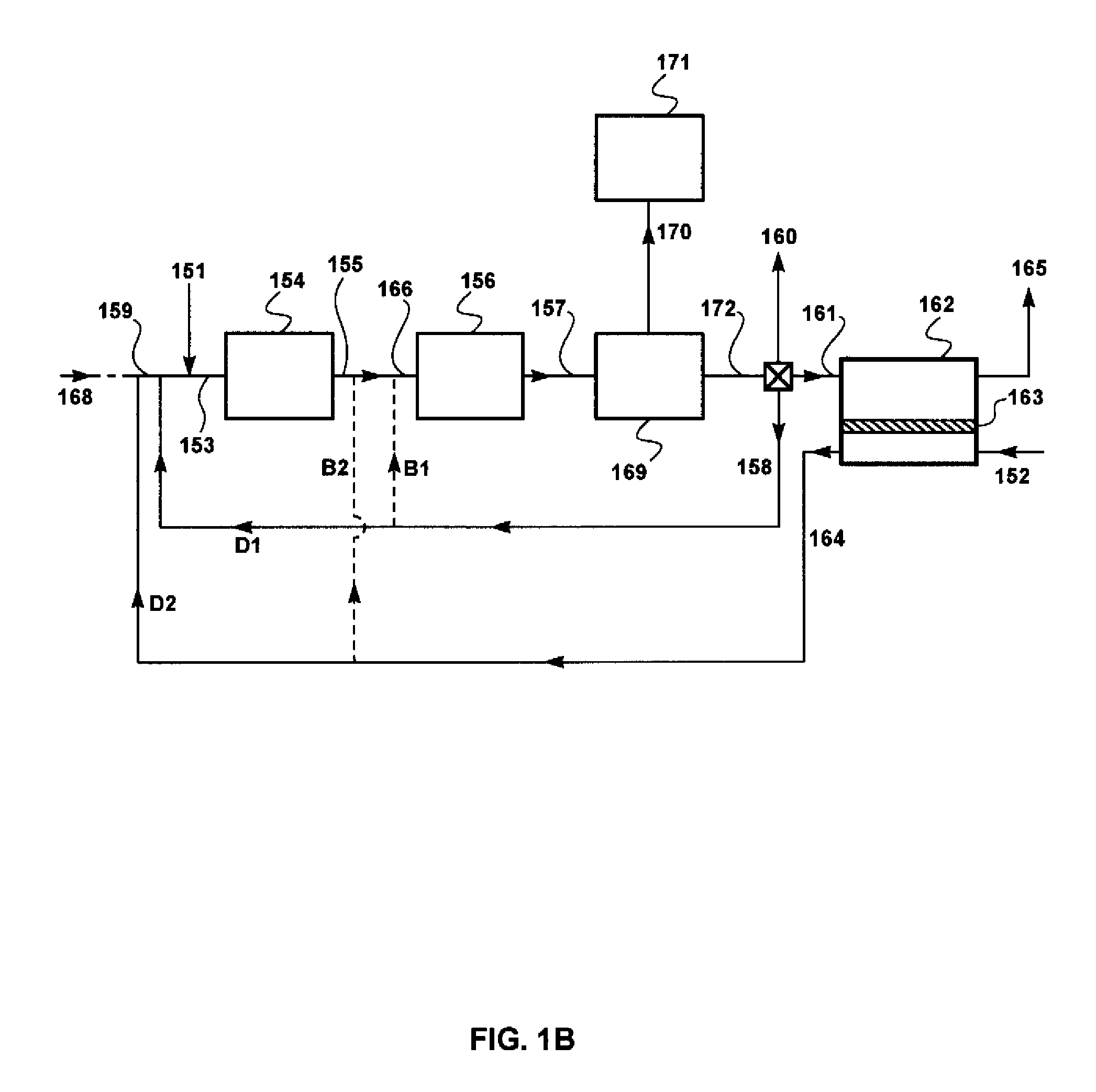

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

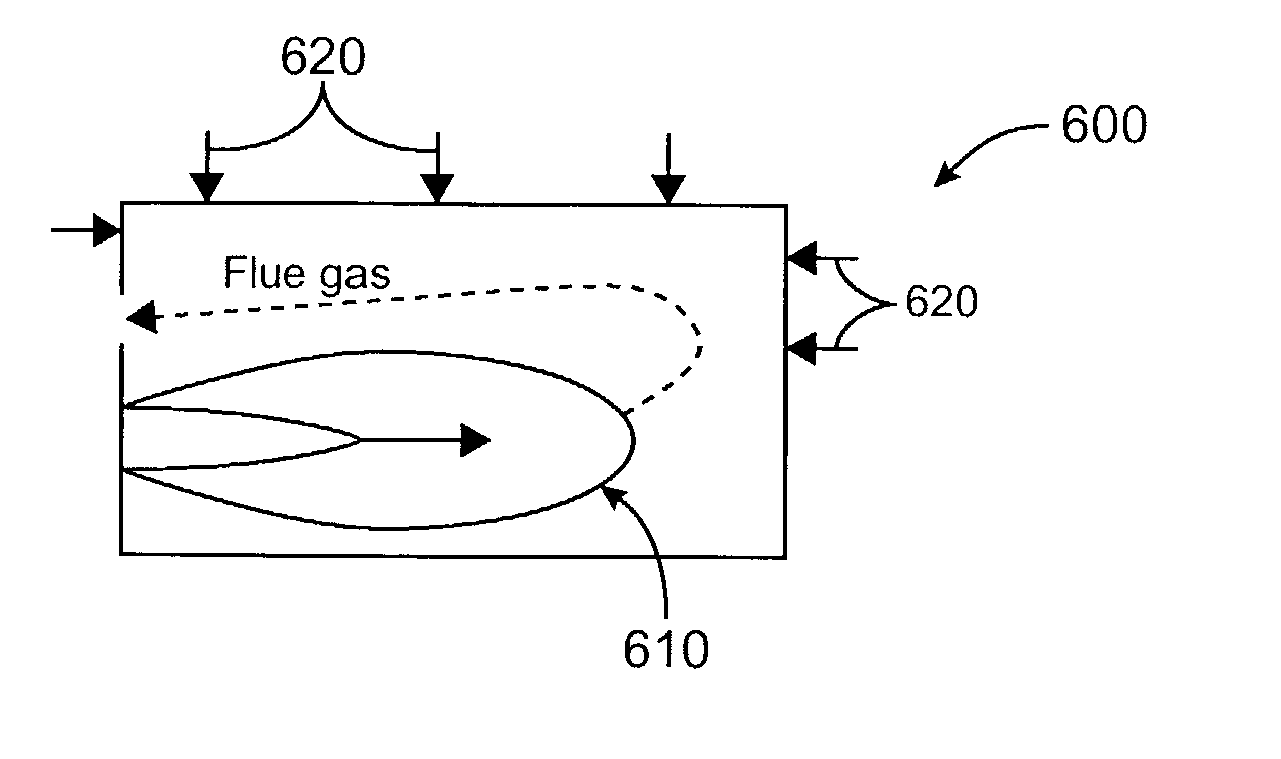

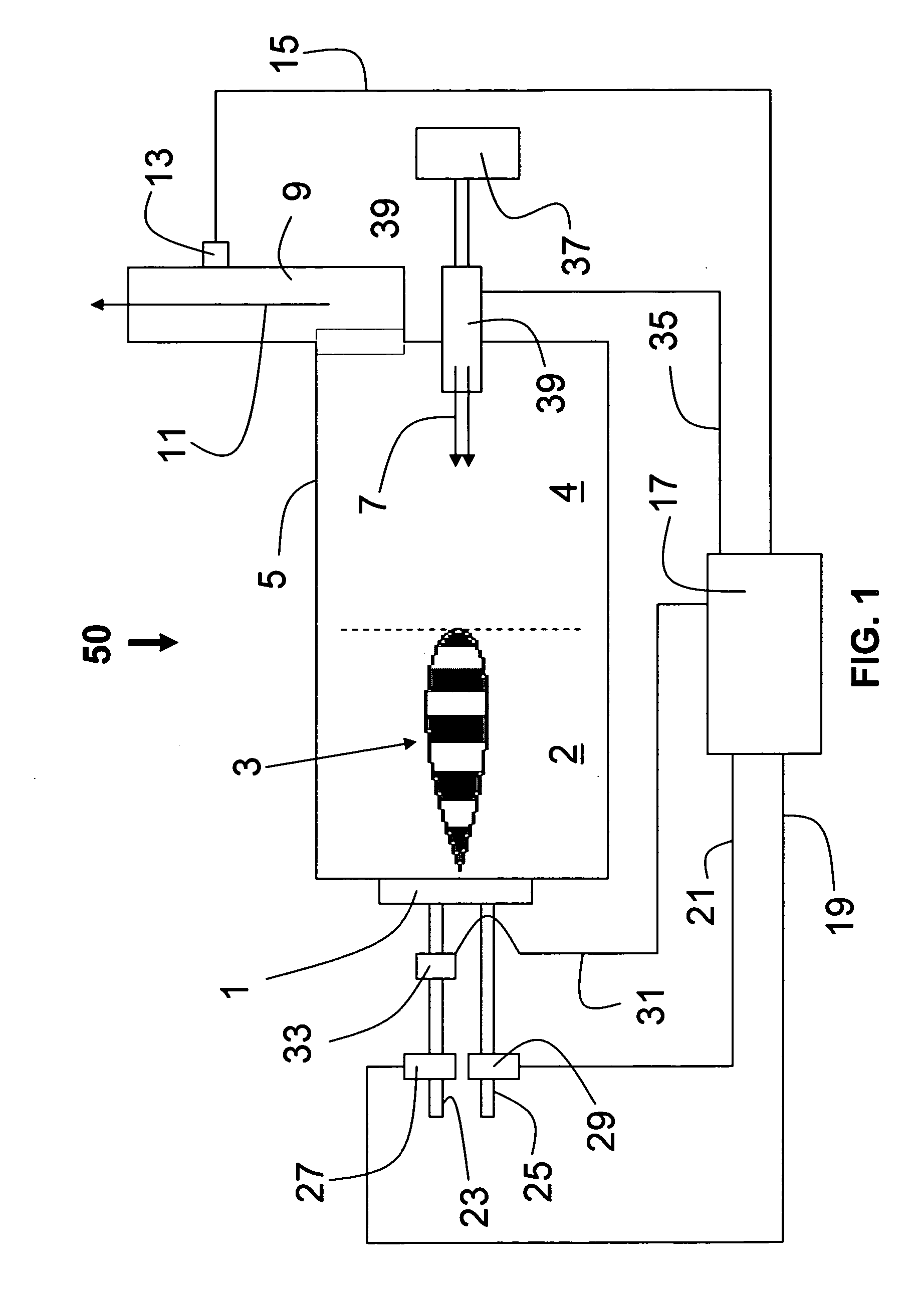

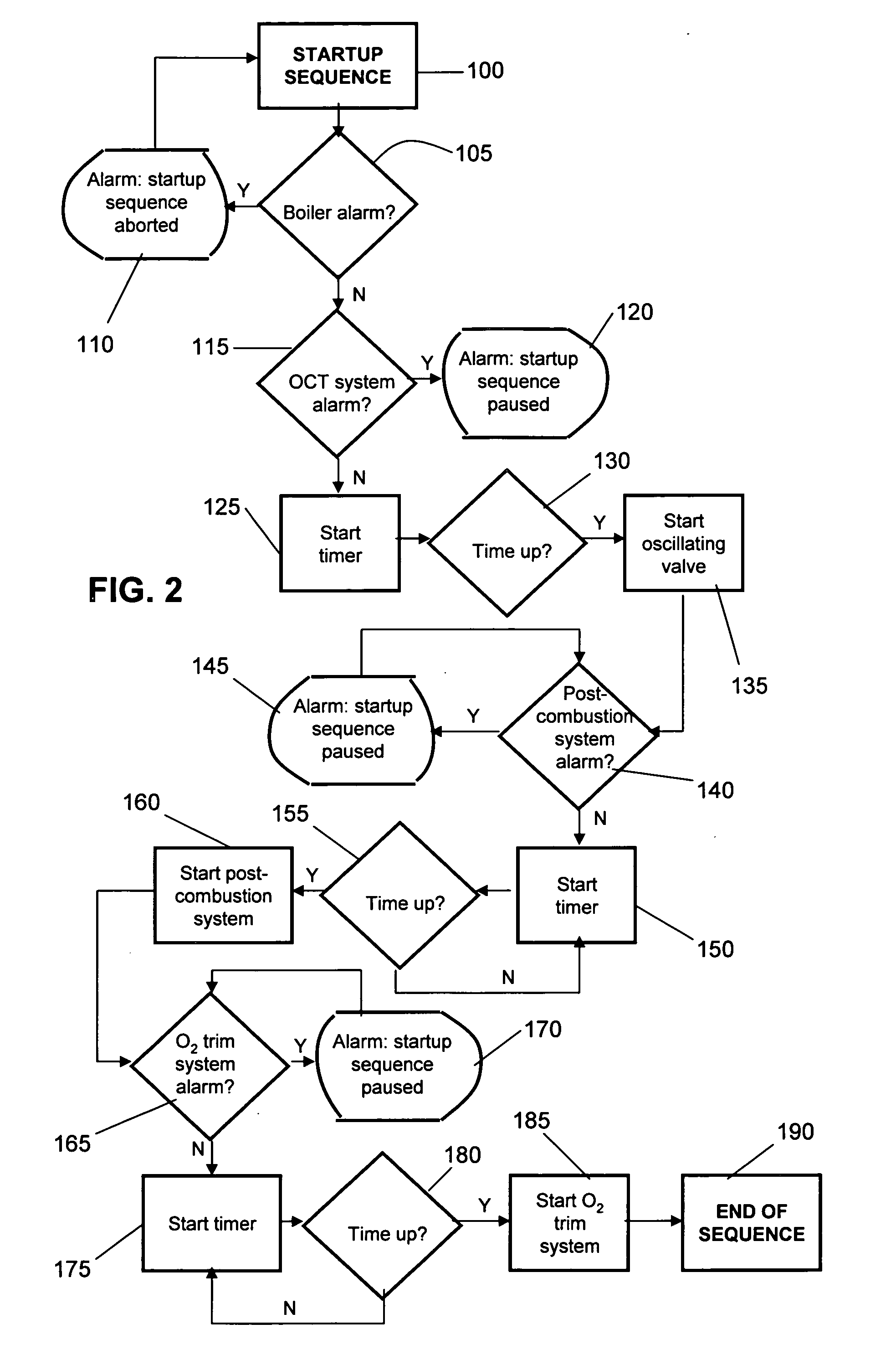

Process and apparatus of combustion for reduction of nitrogen oxide emissions

InactiveUS20030134241A1Special fuel supply arrangementsIndirect carbon-dioxide mitigationNitrogen oxidesControl system

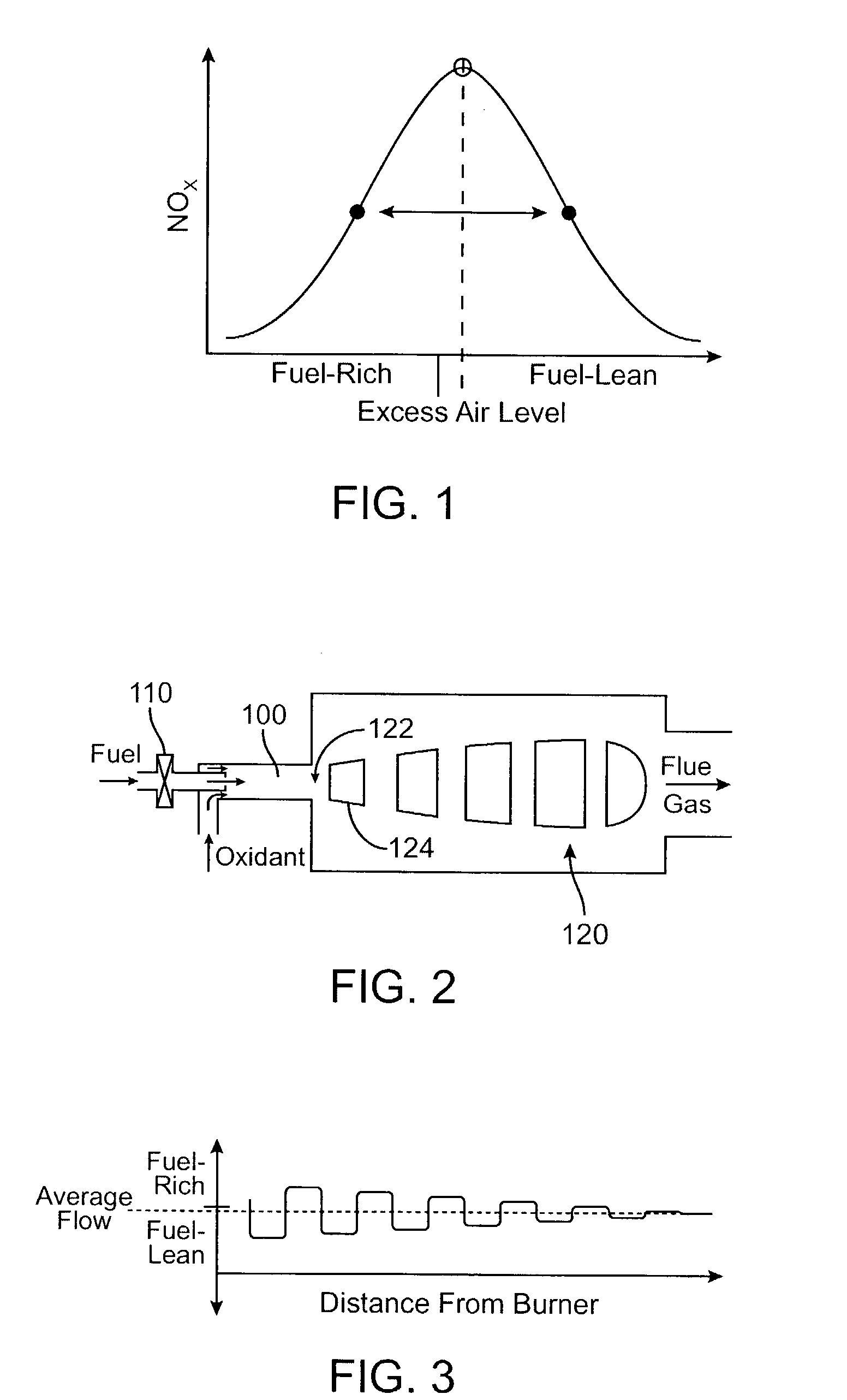

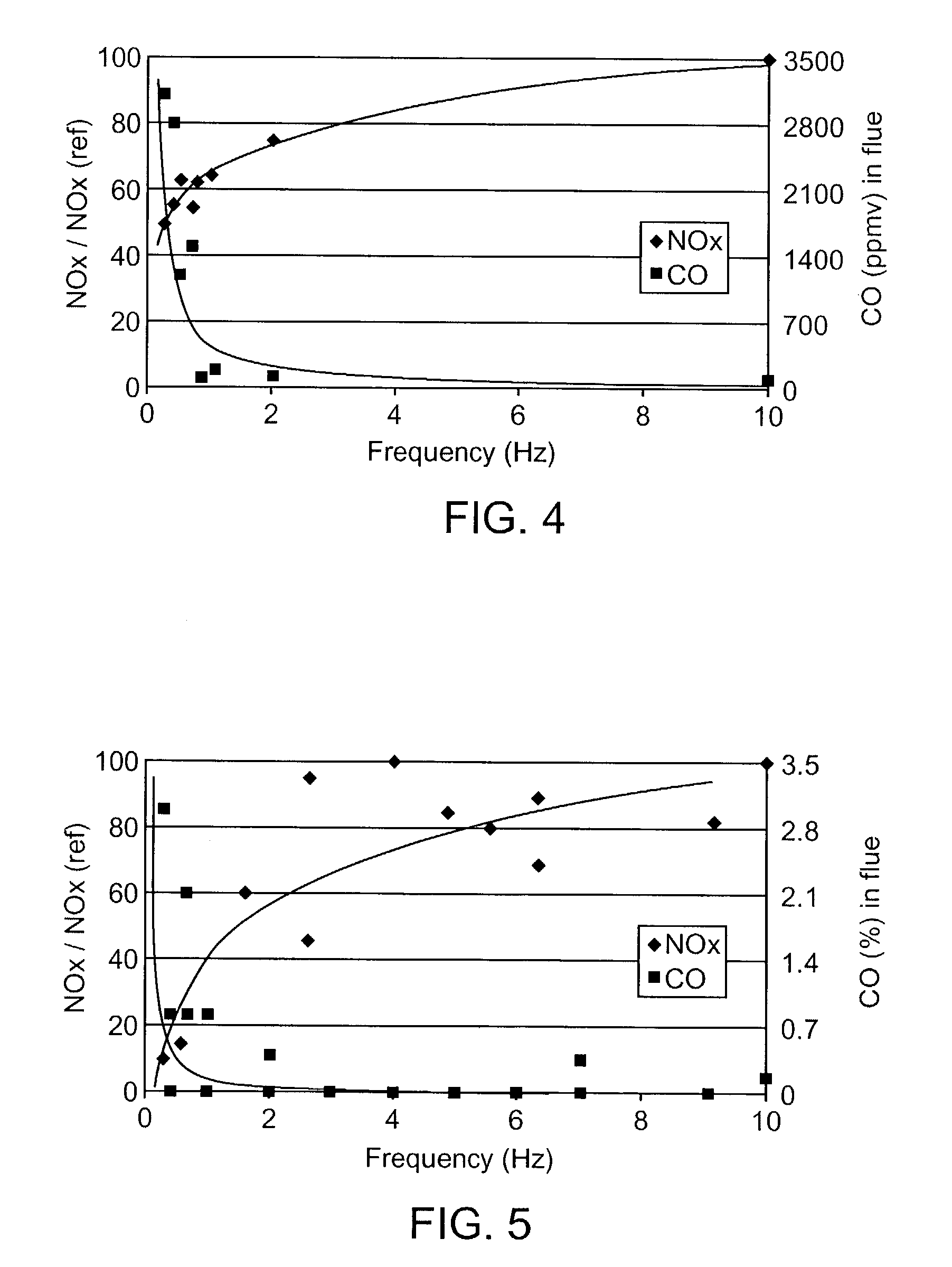

A combustion control system allows the dramatic reduction of NOx emission levels from industrial combustion processes without having recourse to expensive flue gas clean up methods. The system combines the technique of oscillating combustion with an adapted system for post combustion burn out of the excess of CO resulting from the low-NOx combustion zone. A process for fuel combustion includes generating an oscillating combustion zone by oscillating at least one of the fuel flow and the oxidant flow to achieve a reduced nitrogen oxide emission, selecting oscillating parameters and furnace operating parameters to maximize nitrogen oxide reduction efficiency to the detriment of carbon monoxide production, and combusting carbon monoxide downstream of the oscillating combustion zone by injecting a post combustion oxidant.

Owner:MARIN OVIDIU +3

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

Power generation process with partial recycle of carbon dioxide

ActiveUS8220247B2Inexpensively separatedQuantity minimizationGas treatmentDispersed particle separationGeneration processElectricity

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

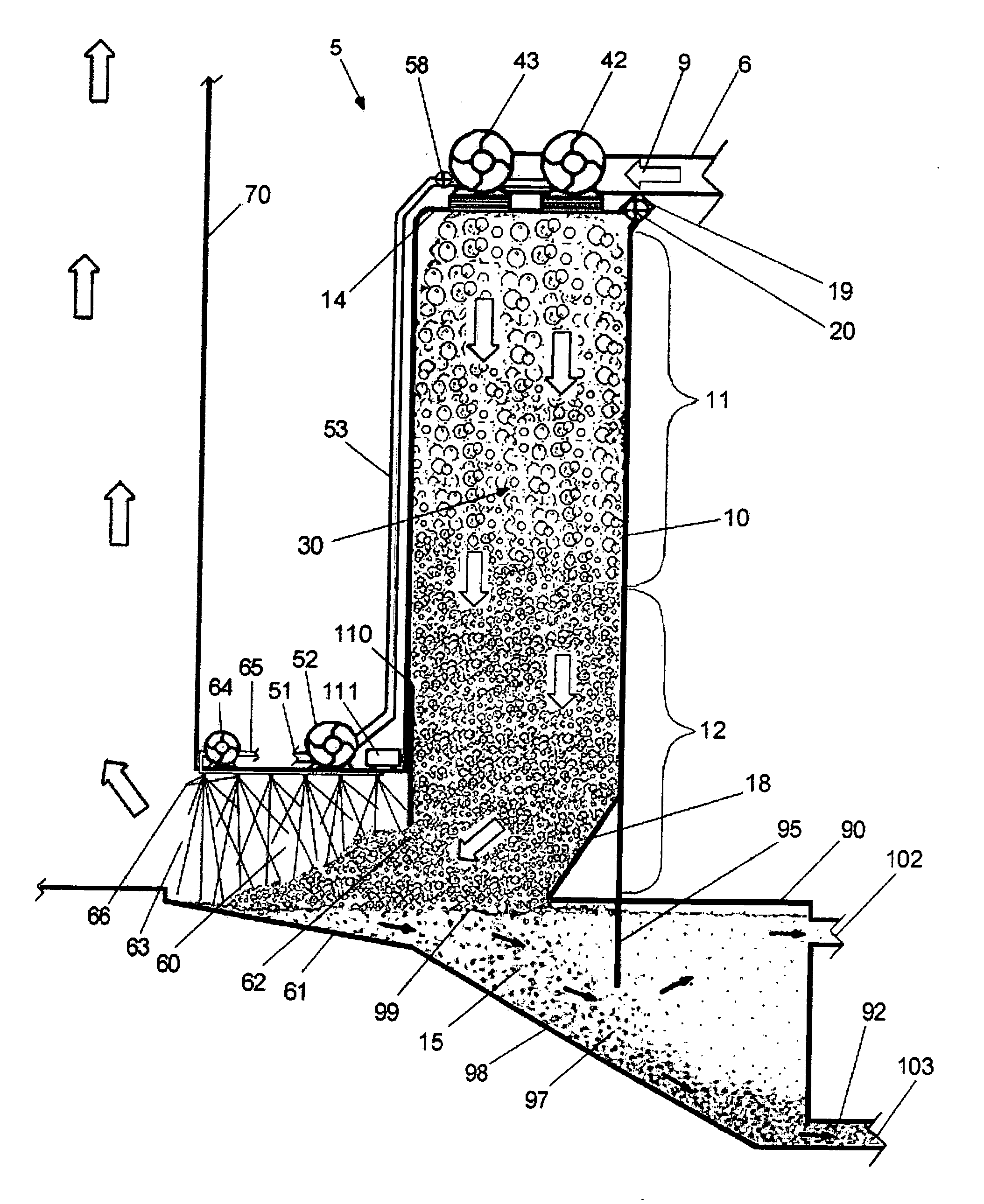

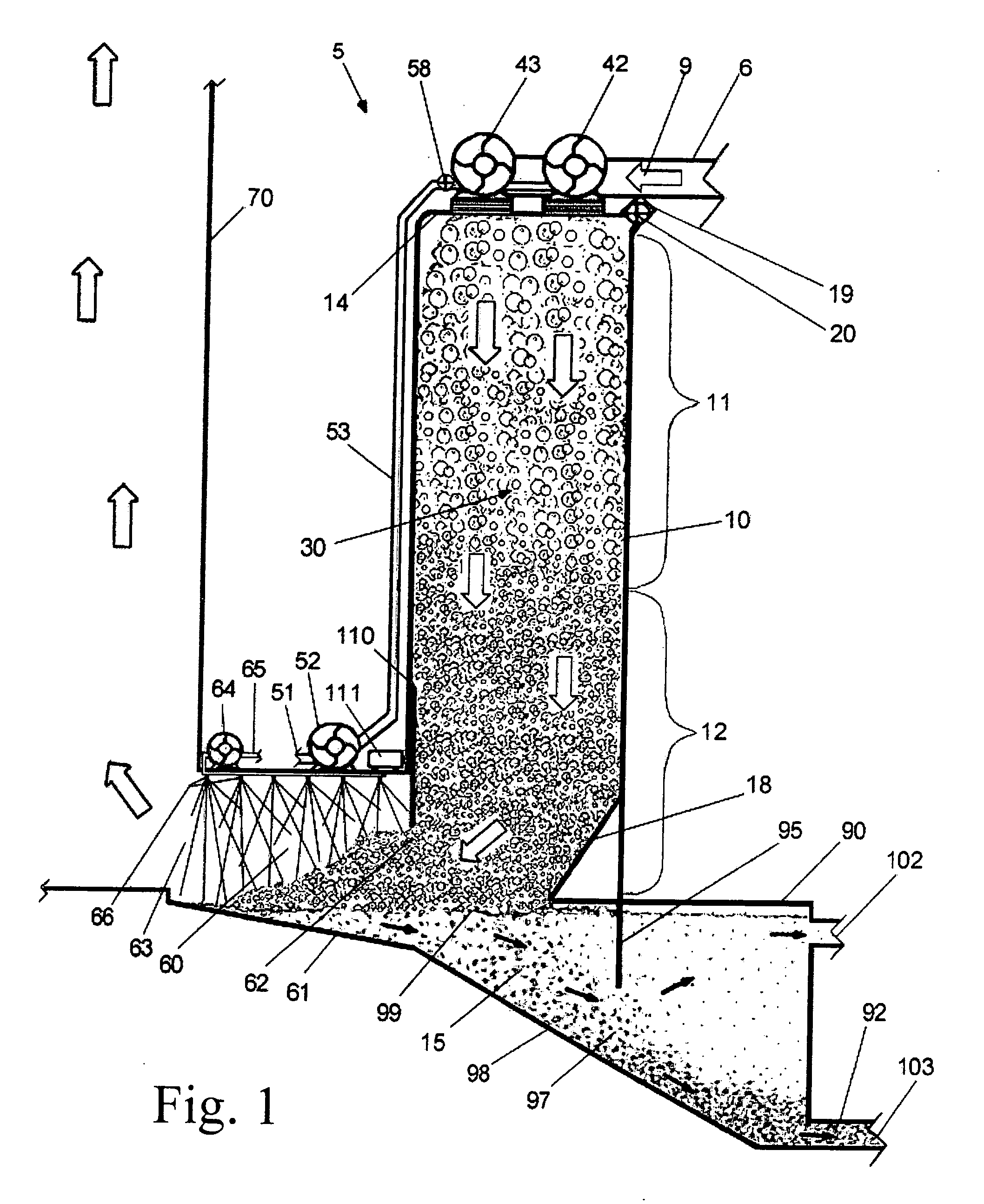

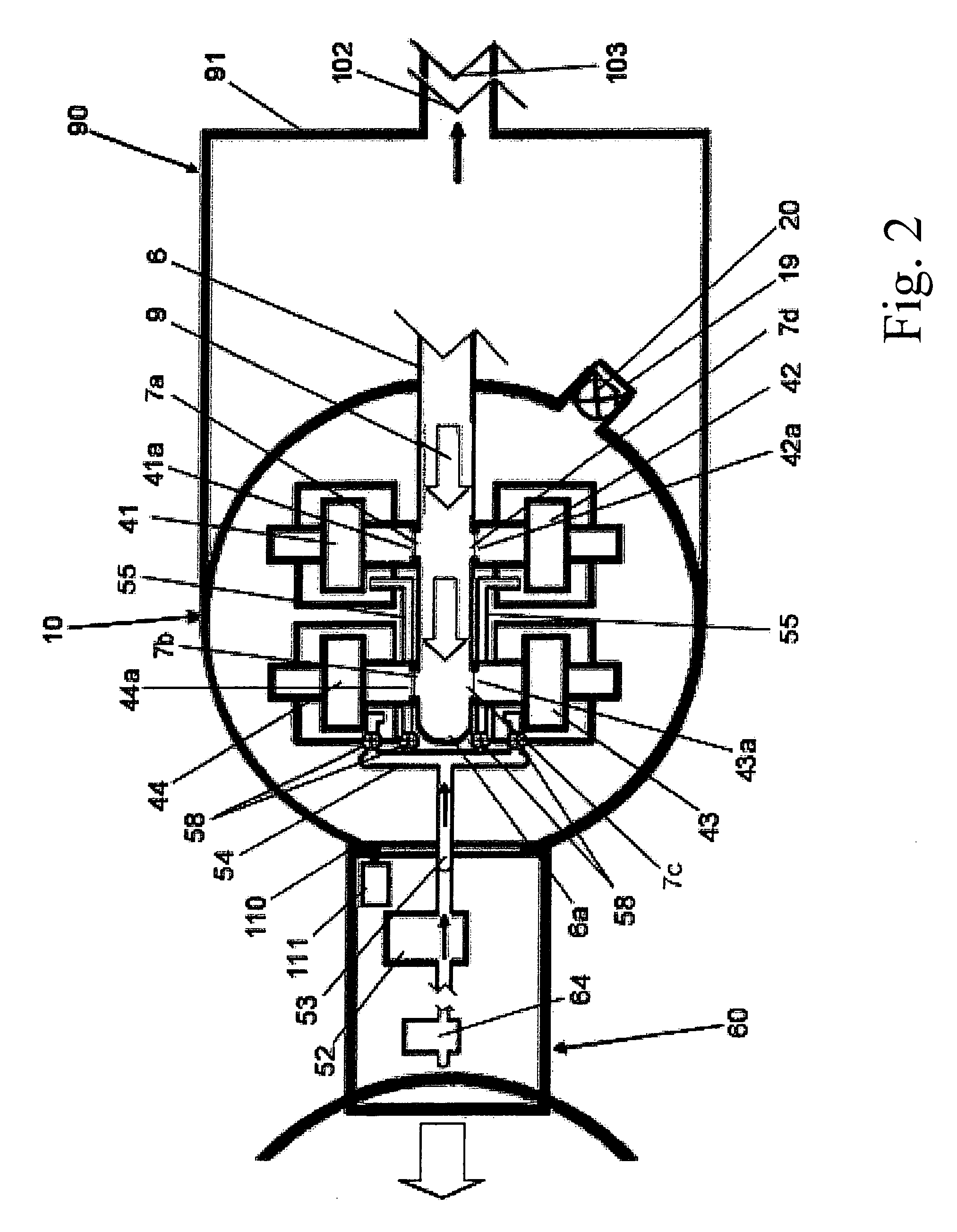

Method and means for capture and long-term sequestration of carbon dioxide

InactiveUS20090081096A1High heat of reactionHigh regeneration energyCombination devicesGas treatmentSolubilityAmbient pressure

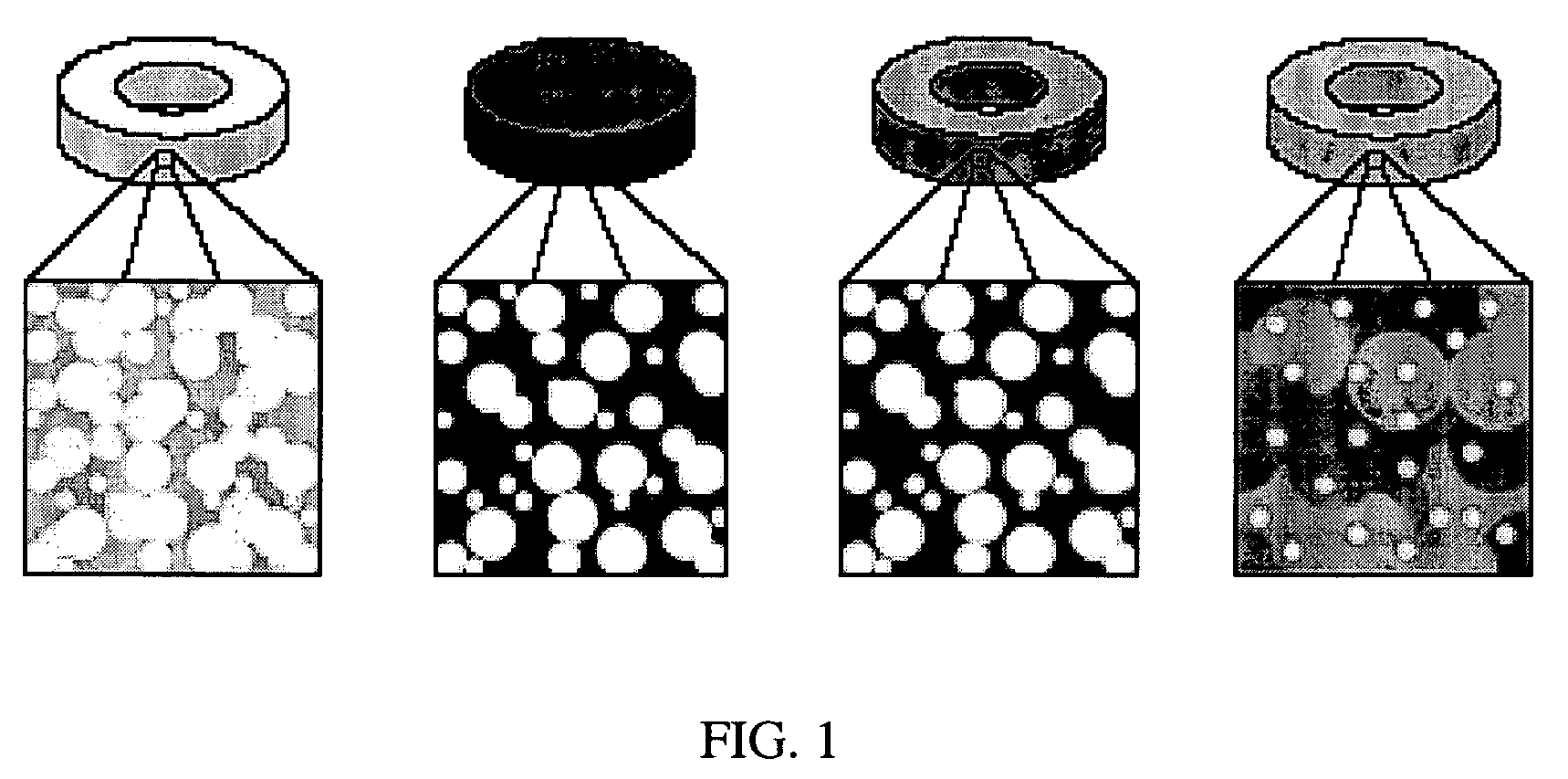

The invention teaches a practical method of recovering CO2 from a mixture of gases, and sequestering the captured CO2 from the atmosphere for geologic time as calcium carbonate and provides a CO2 scrubber for carbon capture and sequestration. CO2 from the production of calcium oxide is geologically sequestered. A calcium hydroxide solution is produced from the environmentally responsibly-produced calcium oxide. The CO2 scrubber incorporates an aqueous froth to maximize liquid-to-gas surface area and time-of-contact between gaseous CO2 and the calcium hydroxide solution. The CO2 scrubber decreases the temperature of the liquid and the mixed gases, increases ambient pressure on the bubbles and vapor pressure inside the bubbles, diffuses the gas through intercellular walls from relative smaller bubbles with relative high vapor pressure into relative larger bubbles with relative low vapor pressure, and decreases the mean-free-paths of the CO2 molecules inside the bubbles, in order to increase solubility of CO2 and the rate of dissolution of gaseous CO2 from a mixture of gases into the calcium hydroxide solution.The CO2 scrubber recovers gaseous CO2 directly from the atmosphere, from post-combustion flue gas, or from industrial processes that release CO2 as a result of process. CO2 reacts with calcium ions and hydroxide ions in solution forming insoluble calcium carbonate precipitates. The calcium carbonate precipitates are separated from solution, and sold to recover at least a portion of the cost of CCS.

Owner:WESTEC ENVIRONMENTAL SOLUTIONS

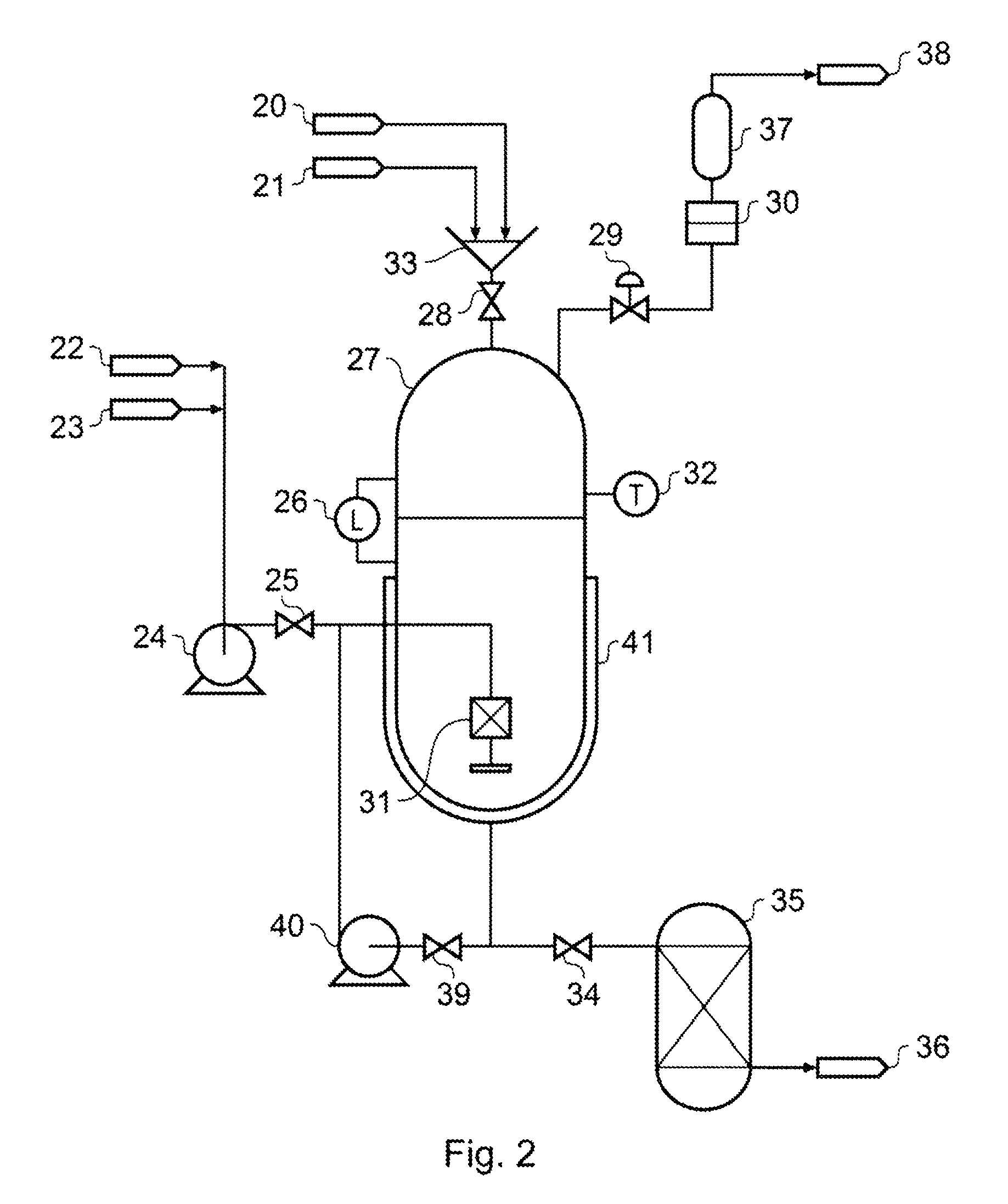

Functional fluid and a process for the preparation of the functional fluid

A functional fluid for the removal of contaminates such as but not limited to, acid causing components in gas, sulfur components and carbon oxides from fluid streams, and removal and treatment of NOX & SOX from post combustion emissions. Also described is the manufacturing process to produce the functional fluid both in a batch atmospheric process system as well as a closed system capable of operating at above or below atmospheric conditions.

Owner:SPECIALIST PROCESS TECH

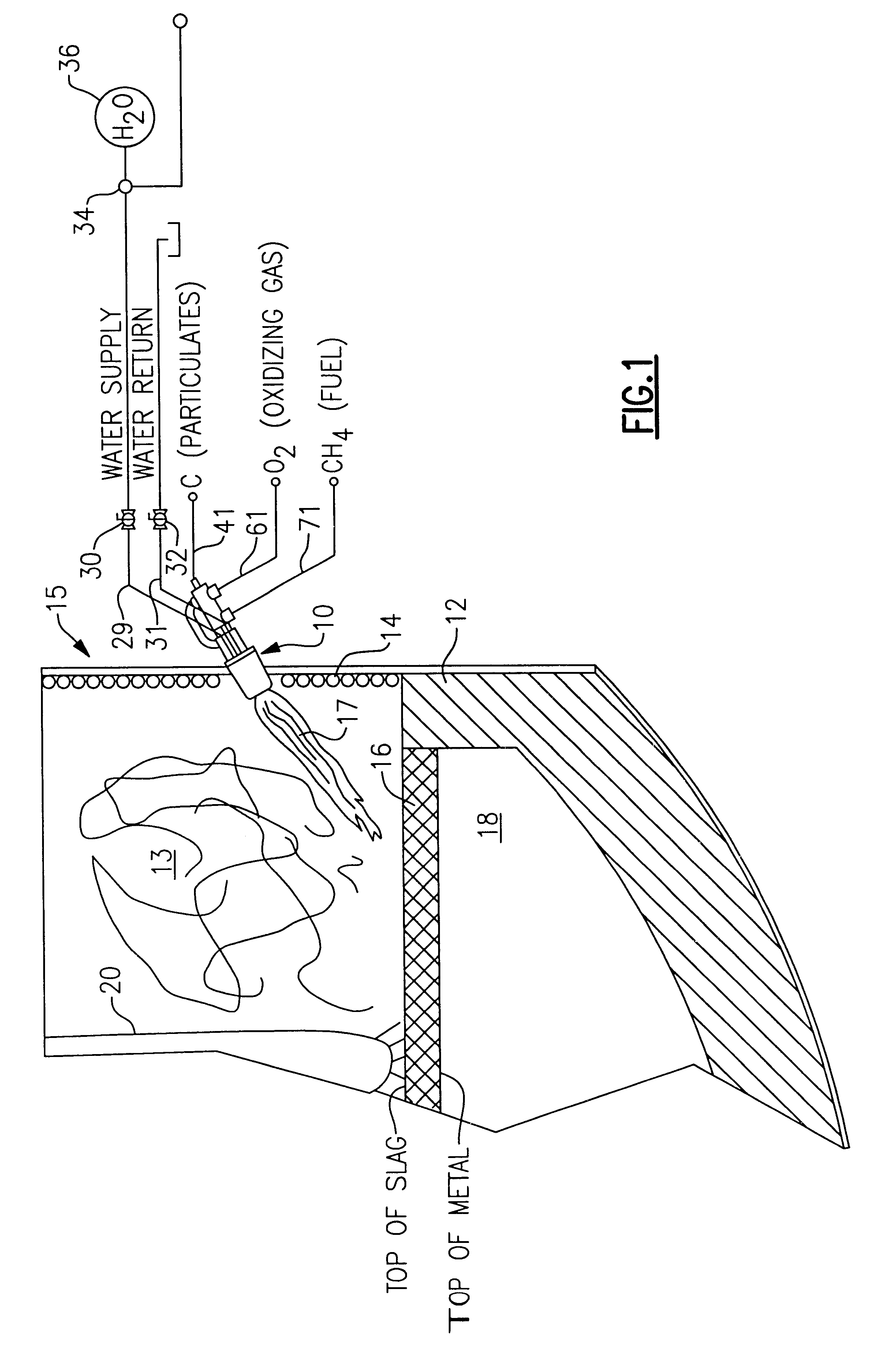

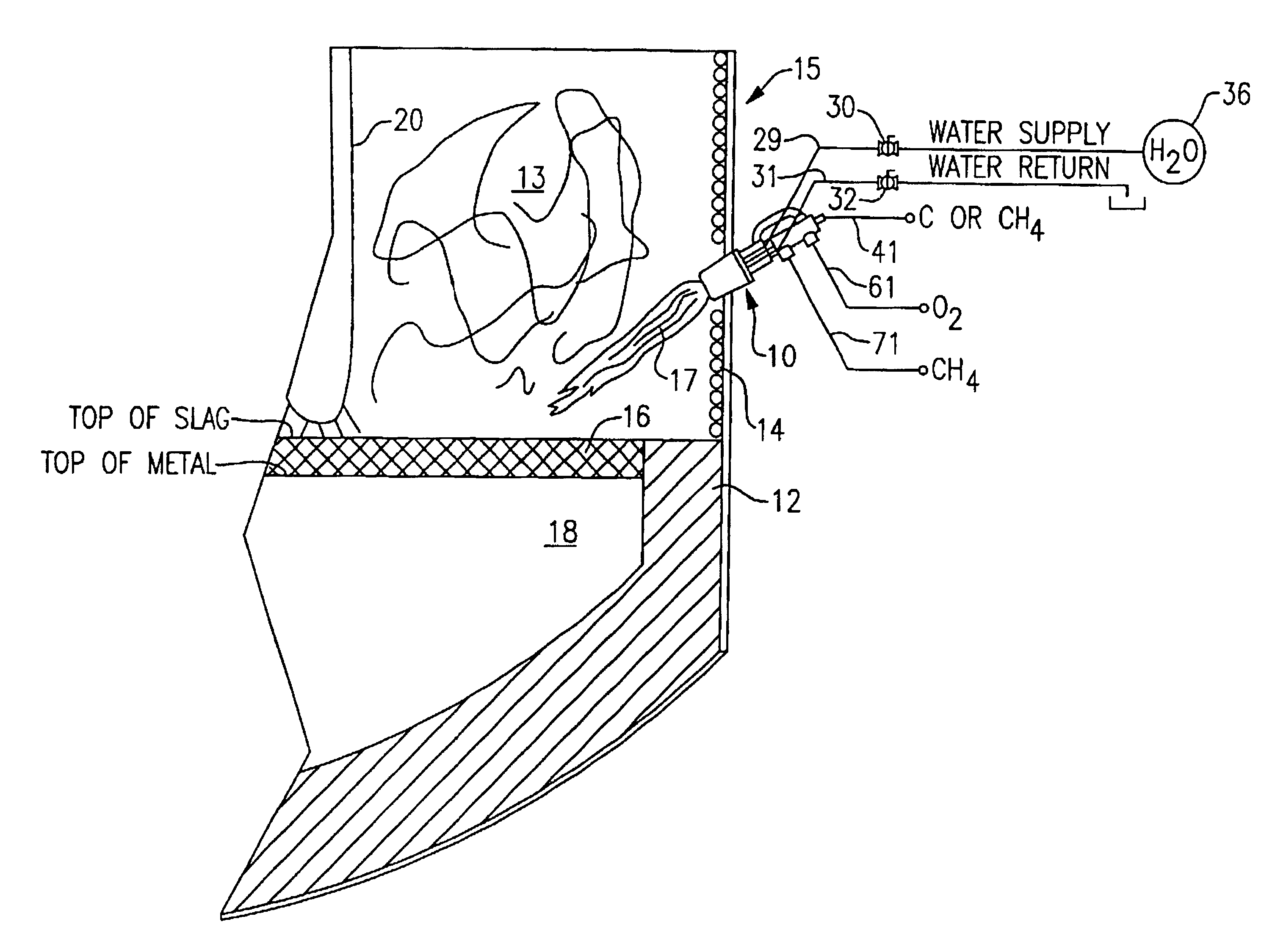

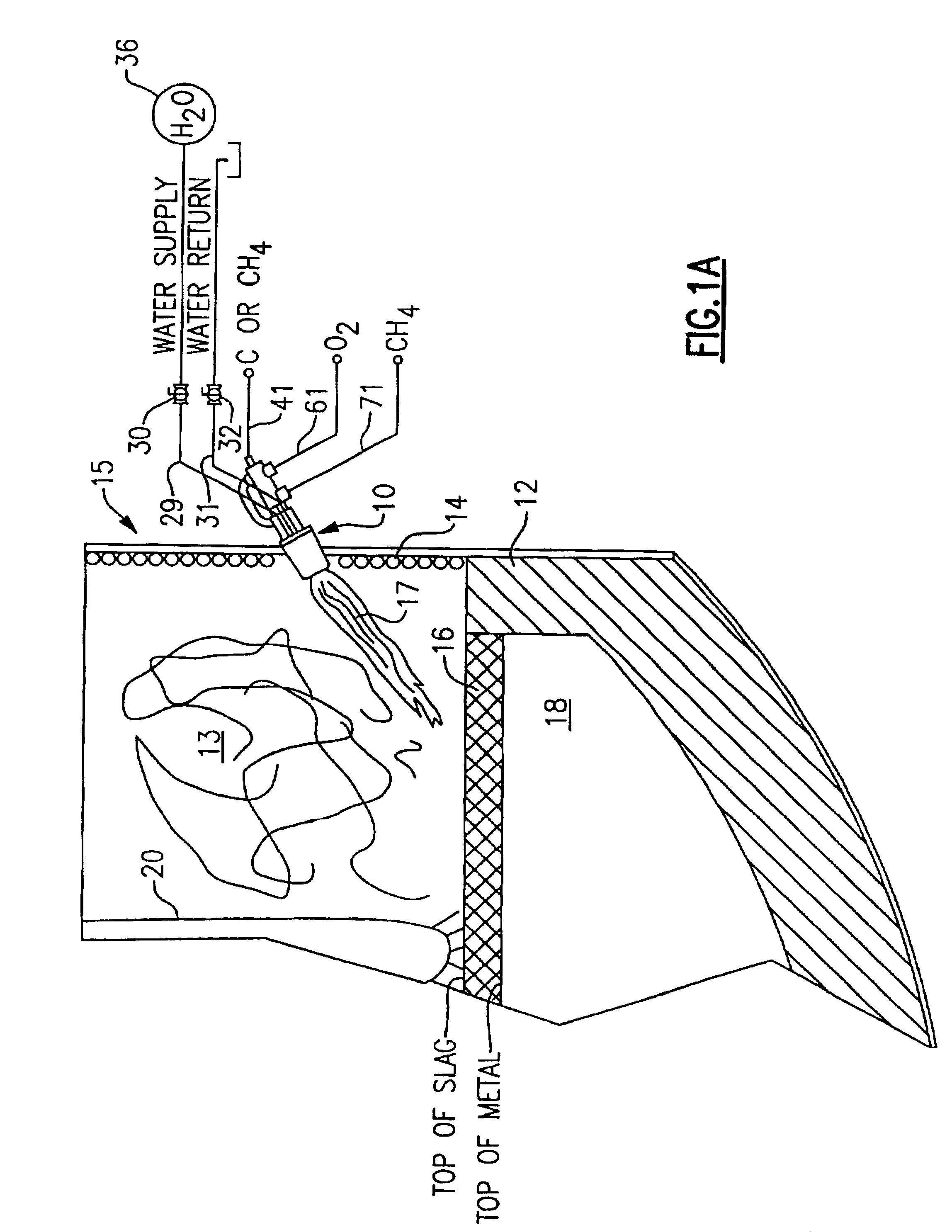

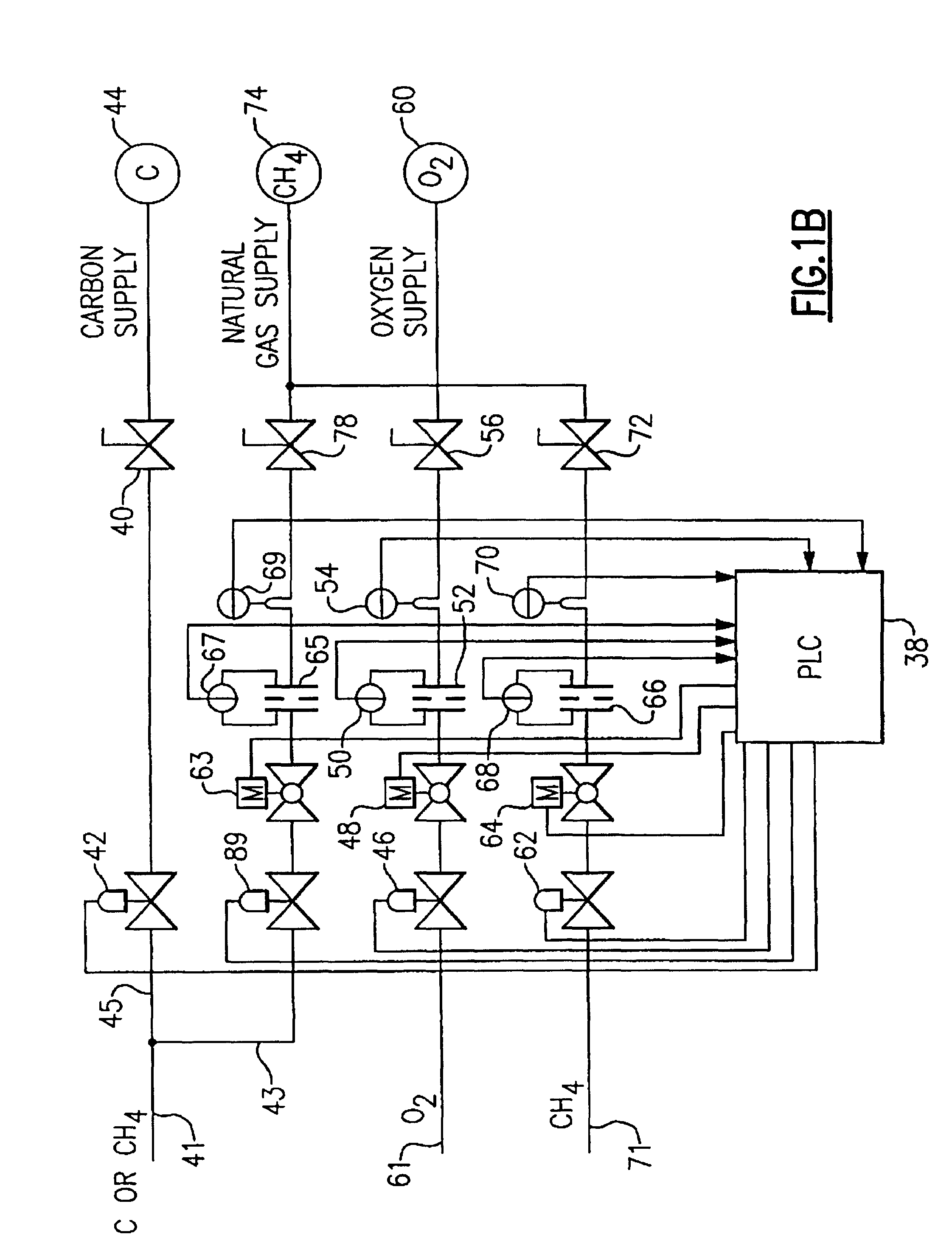

Method for metal melting, refining and processing

An improved method and apparatus for metal melting, refining and processing, particularly adapted to steel making in an electric arc furnace. The method provides auxiliary thermal energy to the steel making process, particulate injection for the formation of slag and foamy slag, and oxygen injection for the decarburization of the melt, for the formation of foamy slag and for post combustion burning of carbon monoxide. The burner includes two injection barrels for providing finely pulverized particles and for providing either a supersonic or a subsonic primary flow of an oxidizing gas. The barrels are positioned side by side in a nozzle at the entrance of a flame shaping chamber of a fluid cooled combustion chamber. The nozzle also contains a plurality of fuel orifices for the providing pressurized fuel to the combustion chamber and a plurality of oxidizing gas orifices for providing a secondary flow of an oxidizing gas around the periphery of the nozzle. Because all of the flows of fuel, oxidizing gas and particulates pass through the flame shaping chamber, they are all substantially directed to the same location in the electric arc furnace. The directionality of the flows allows the burner to heat a localized spot of the slag with thermal energy from the oxidation of the fuel, from the oxidation of oxidizable components in the slag or the melt by the lancing of supersonic oxidizing gas, or from any combination of these. Once a spot in the slag is sufficiently heated, a flow of carbon is directed to the localized hot spot in the slag to reduce the FeO, and other oxides, in the slag to carbon monoxide and produce foamy slag. The particulate carbon introduction can be accompanied by further oxidizing gas injection before, during or after the carbon injection.

Owner:PROCESS TECH INT

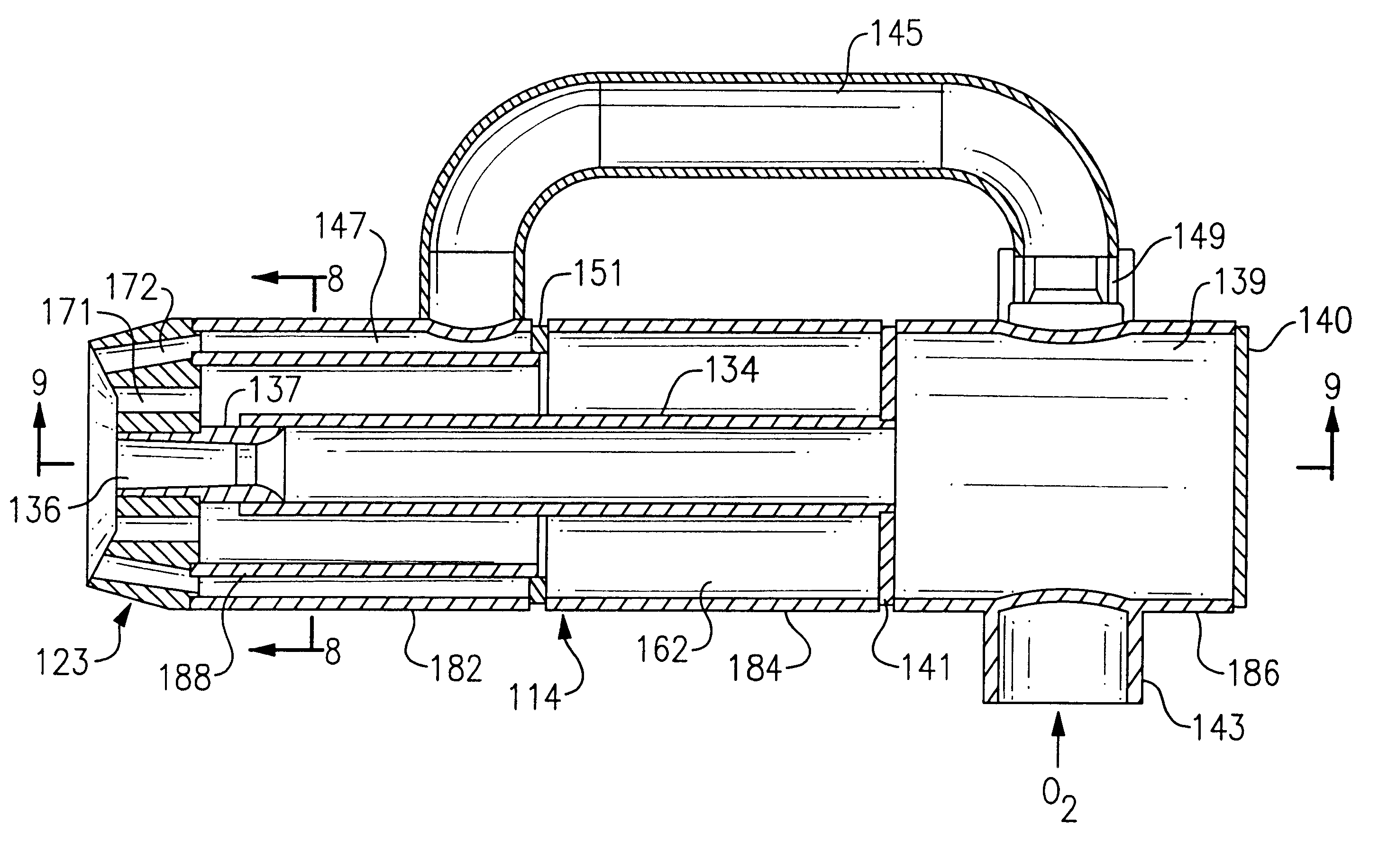

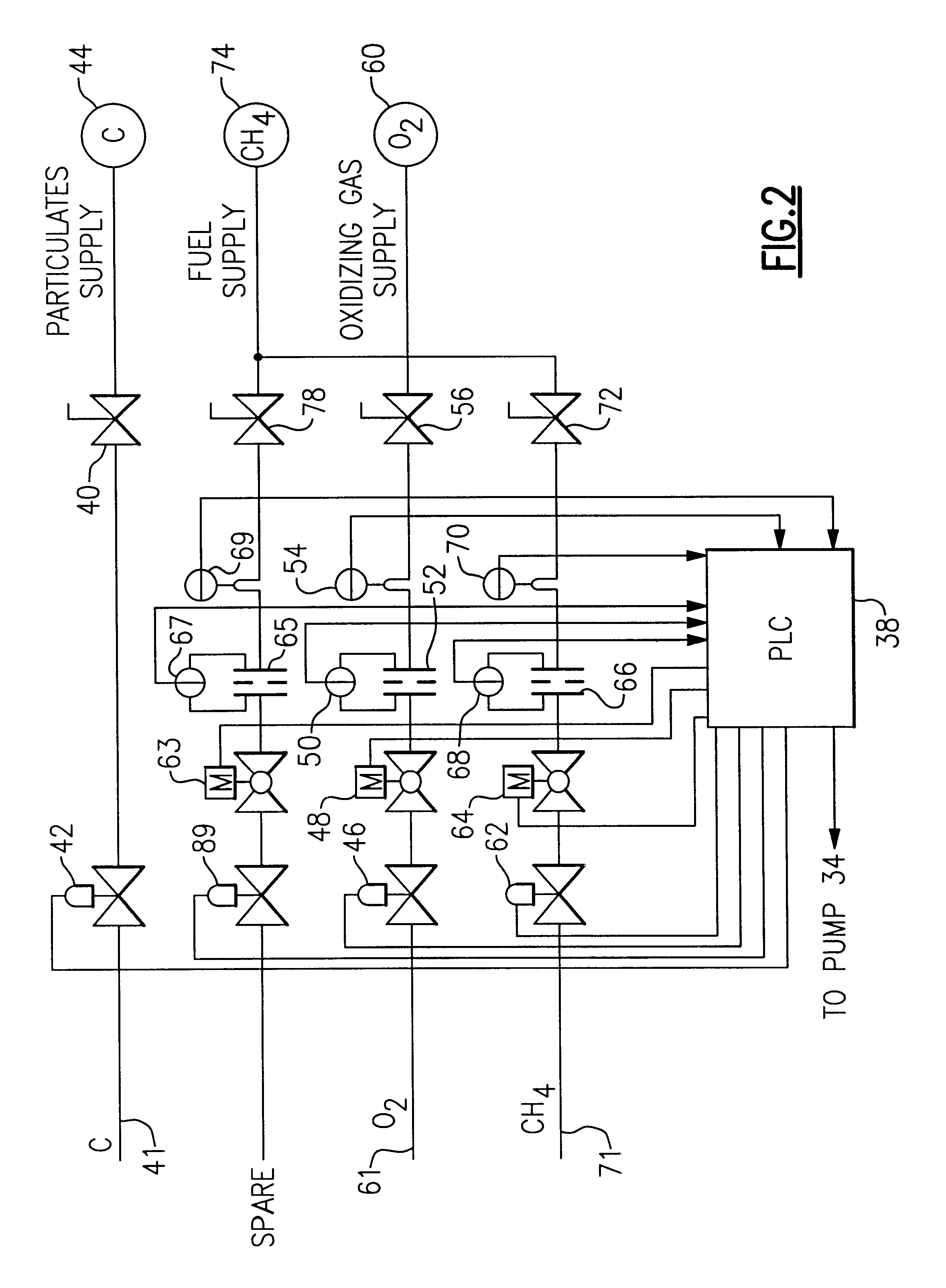

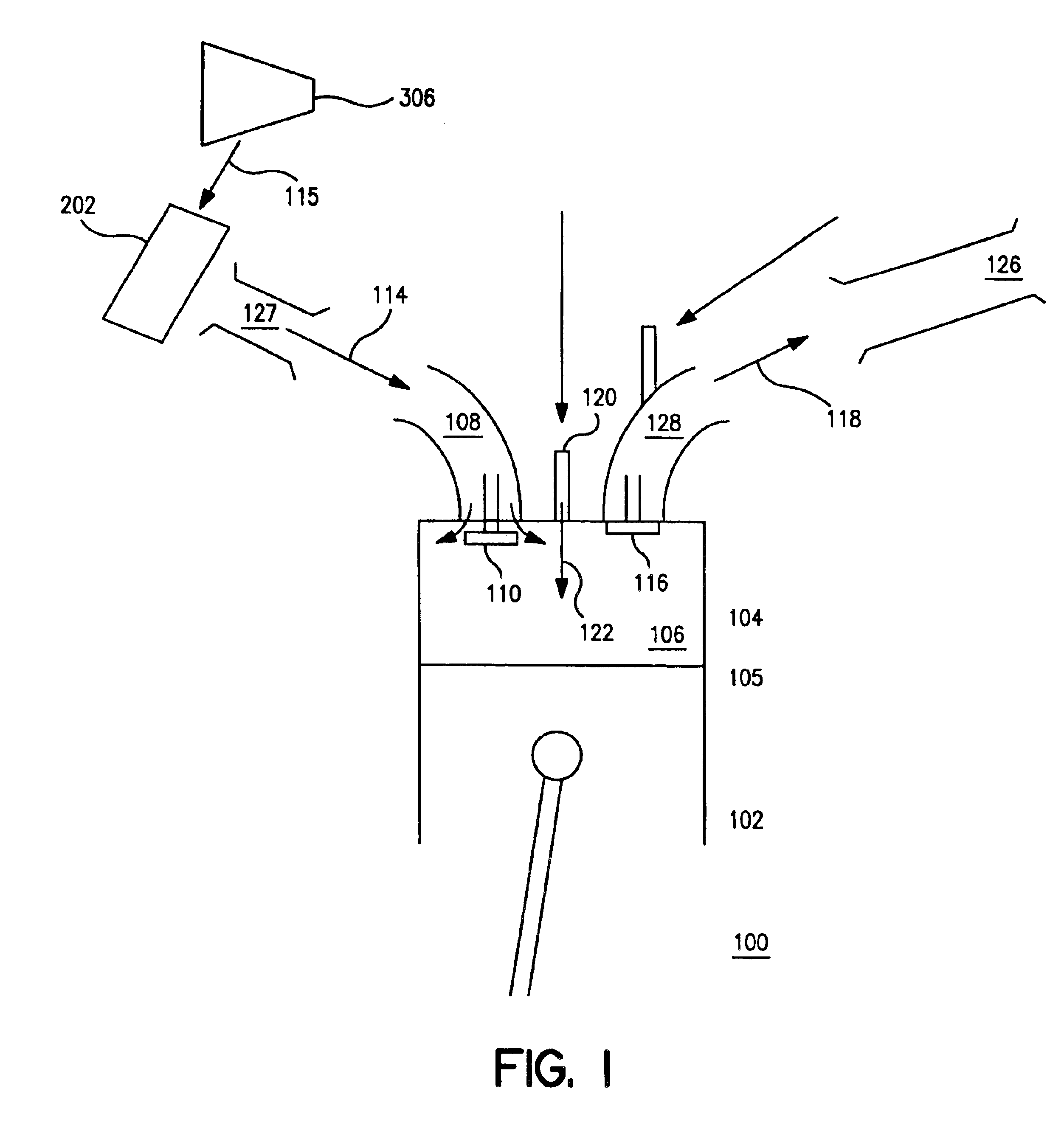

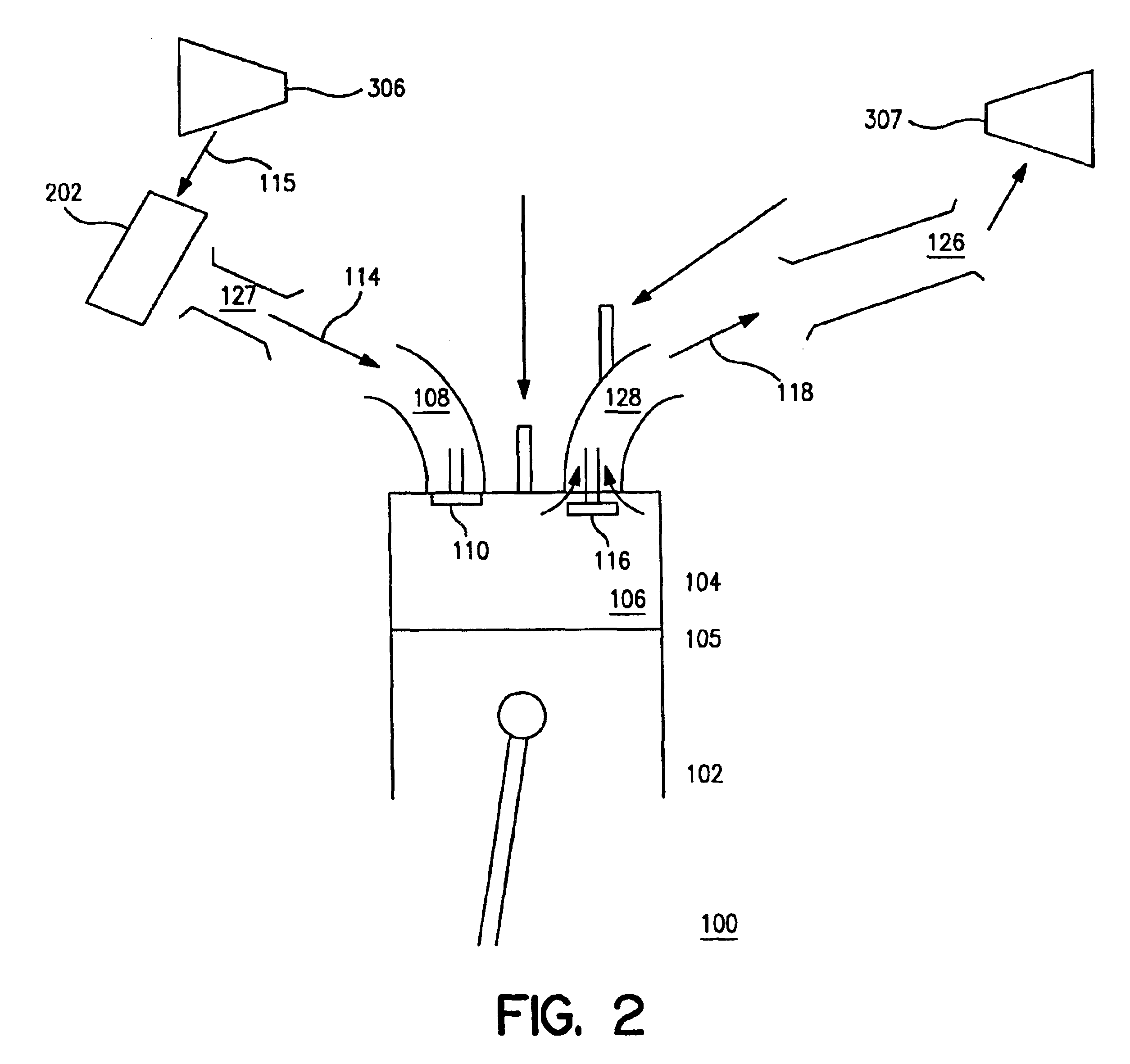

Method and apparatus for improved EAF steelmaking

An improved method and apparatus for EAF steelmaking wherein the method provides additional thermal energy to the steel making process, carbon injection for the formation of foamy slag, and oxygen injection for the decarburization of the melt, the formation of foamy slag and post combustion burning of carbon monoxide. The apparatus comprises a unique burner configuration which has a central conduit for alternatively supplying fluid hydrocarbon fuel or particulate carbon with a carrier gas which are discharged through a exit opening. The fuel or carbon is mixed with a high speed, preferably supersonic, stream of oxidizing gas. The high speed stream of oxidizing gas is provided by an annular supersonic nozzle which causes the oxidizing gas to surround the fuel or the particulates with an annular flow. The annular nozzle design can be adjusted to direct the flows of particulates and oxidizing gases in the areas and shapes desired for efficient management of the steelmaking process. Optionally, the burner can have another conduit for the secondary supply of a pressurized flow of hydrocarbon fluid fuel to a series of apertures which surround the annular flow. Further, optionally, the burner can have another conduit for the supply of a pressurized flow of a secondary oxidizing gas to a series of apertures which surround the annular flow.

Owner:PROCESS TECH INT

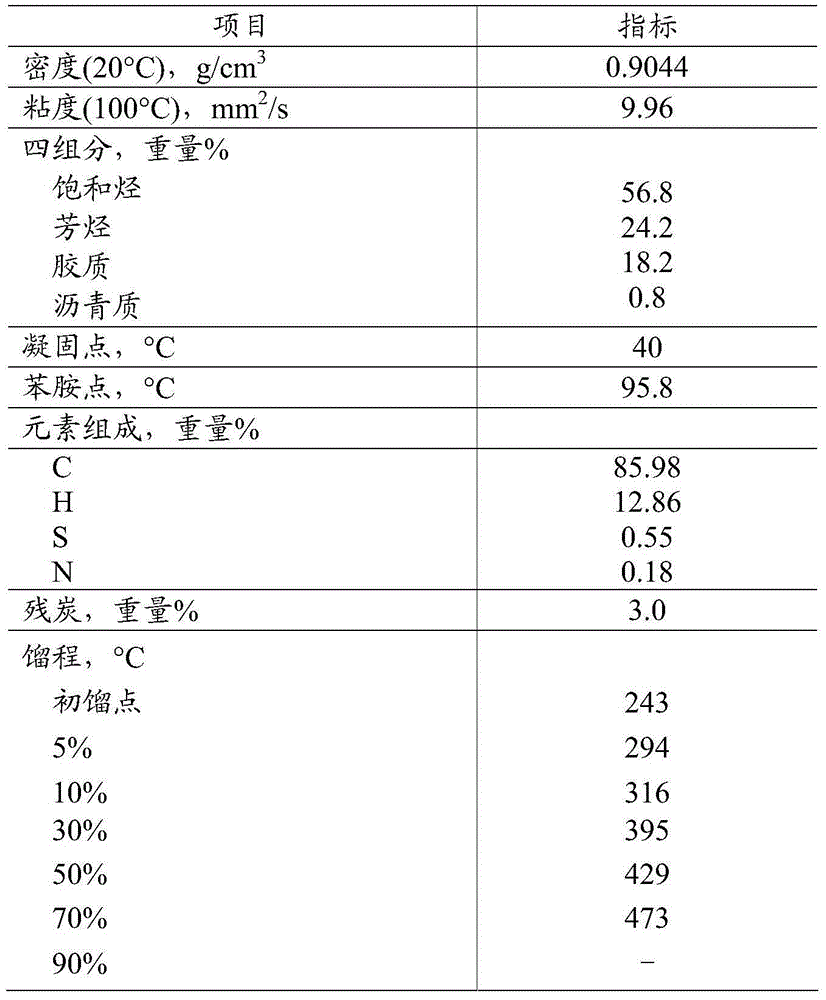

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

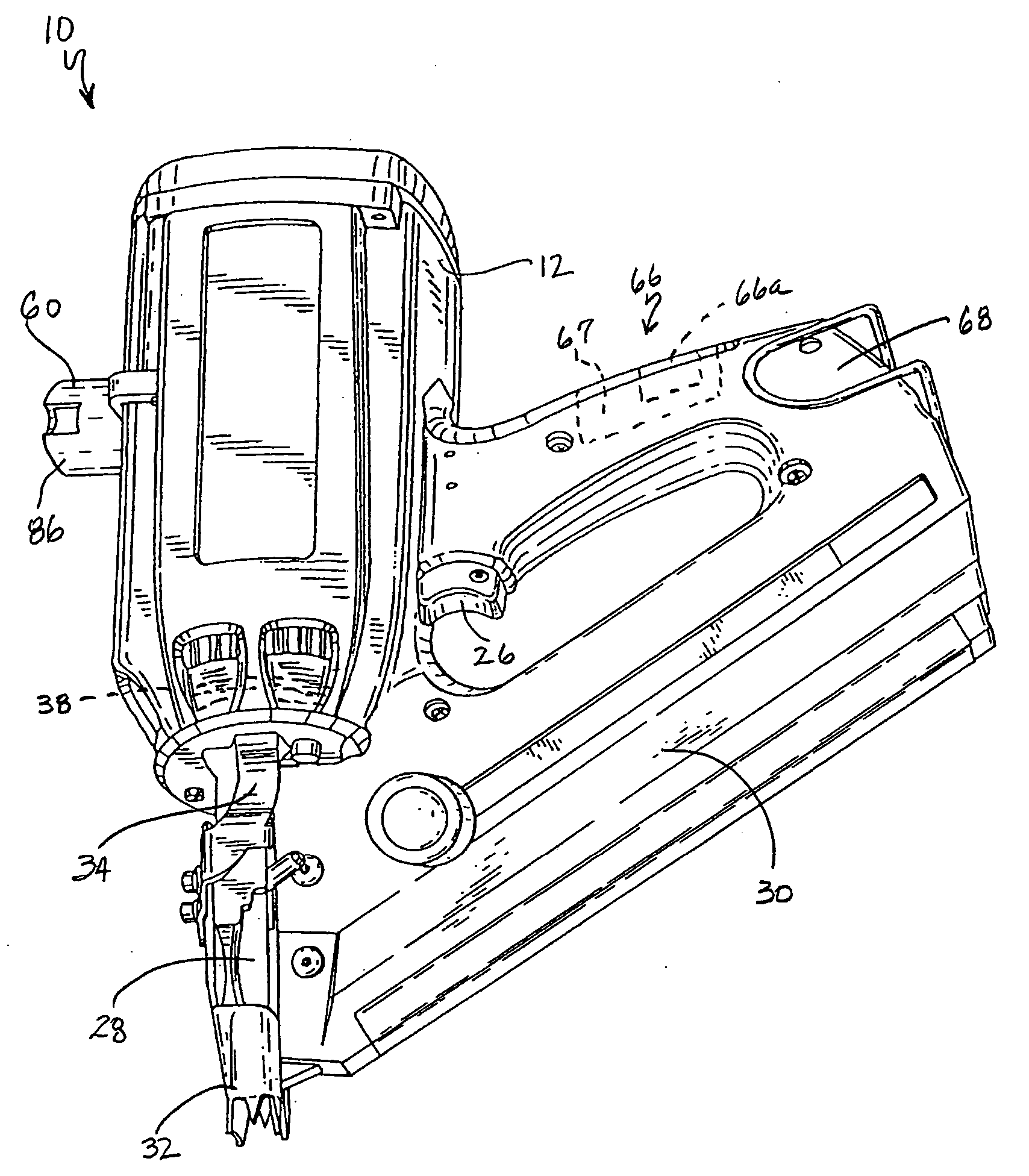

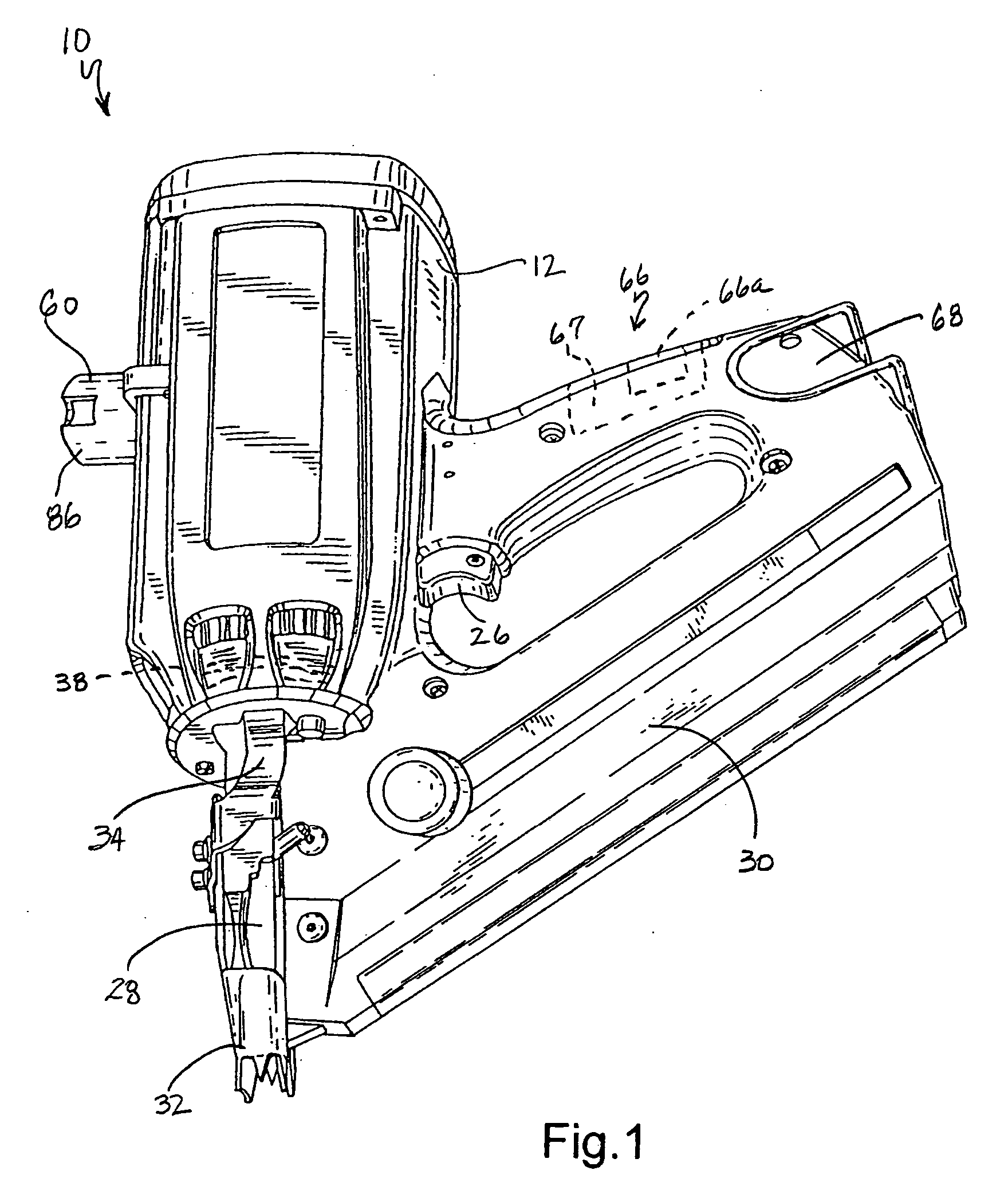

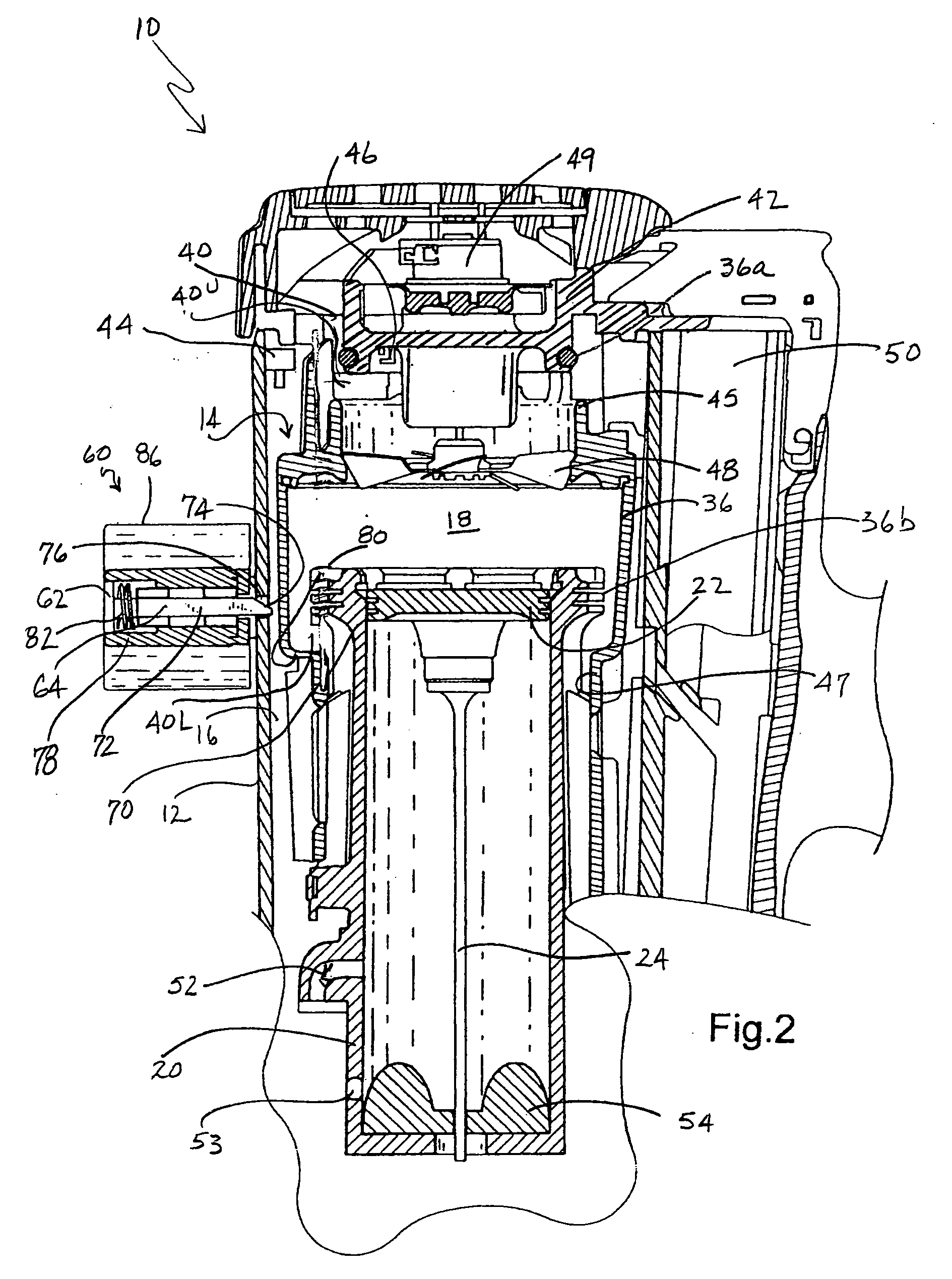

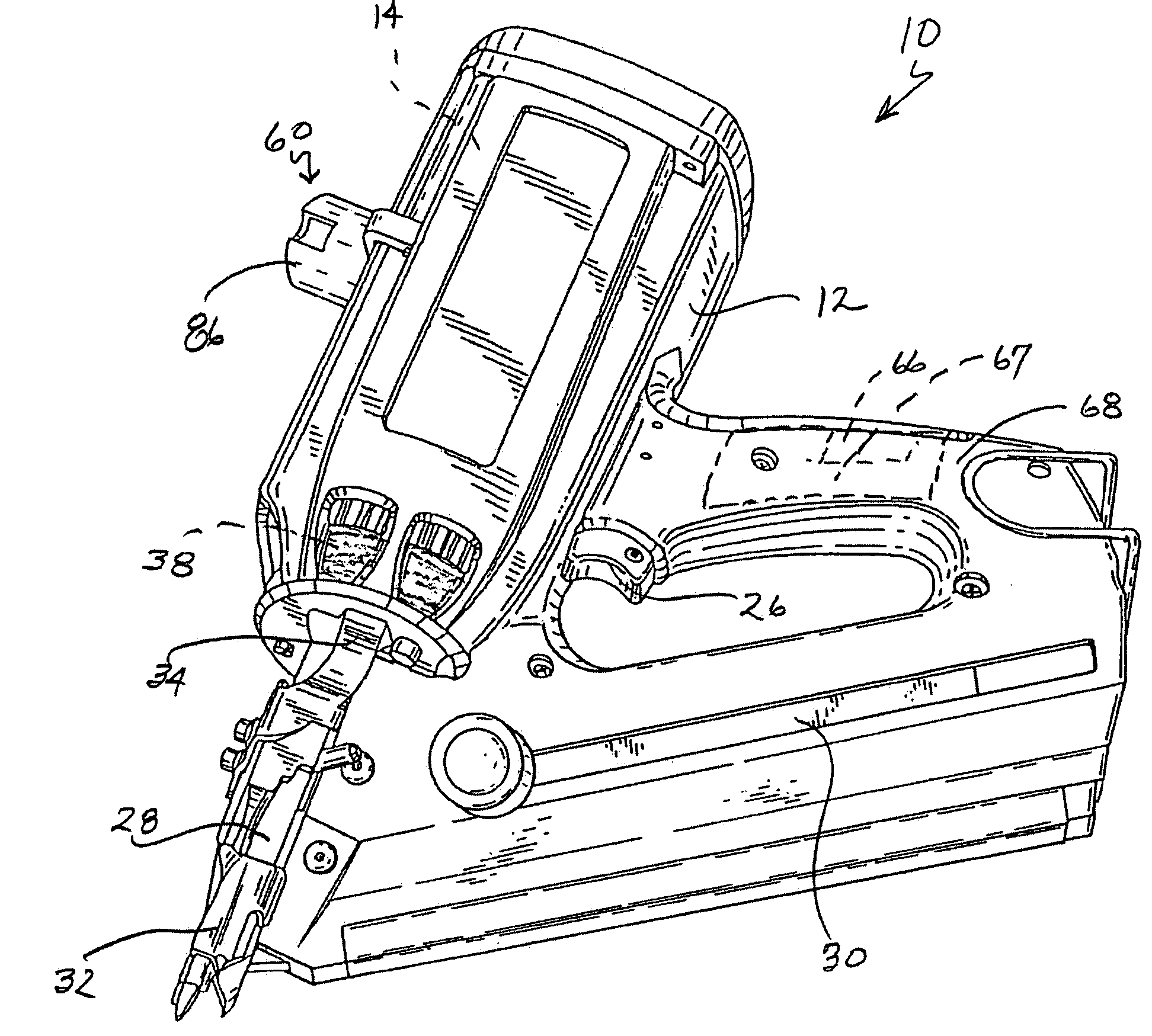

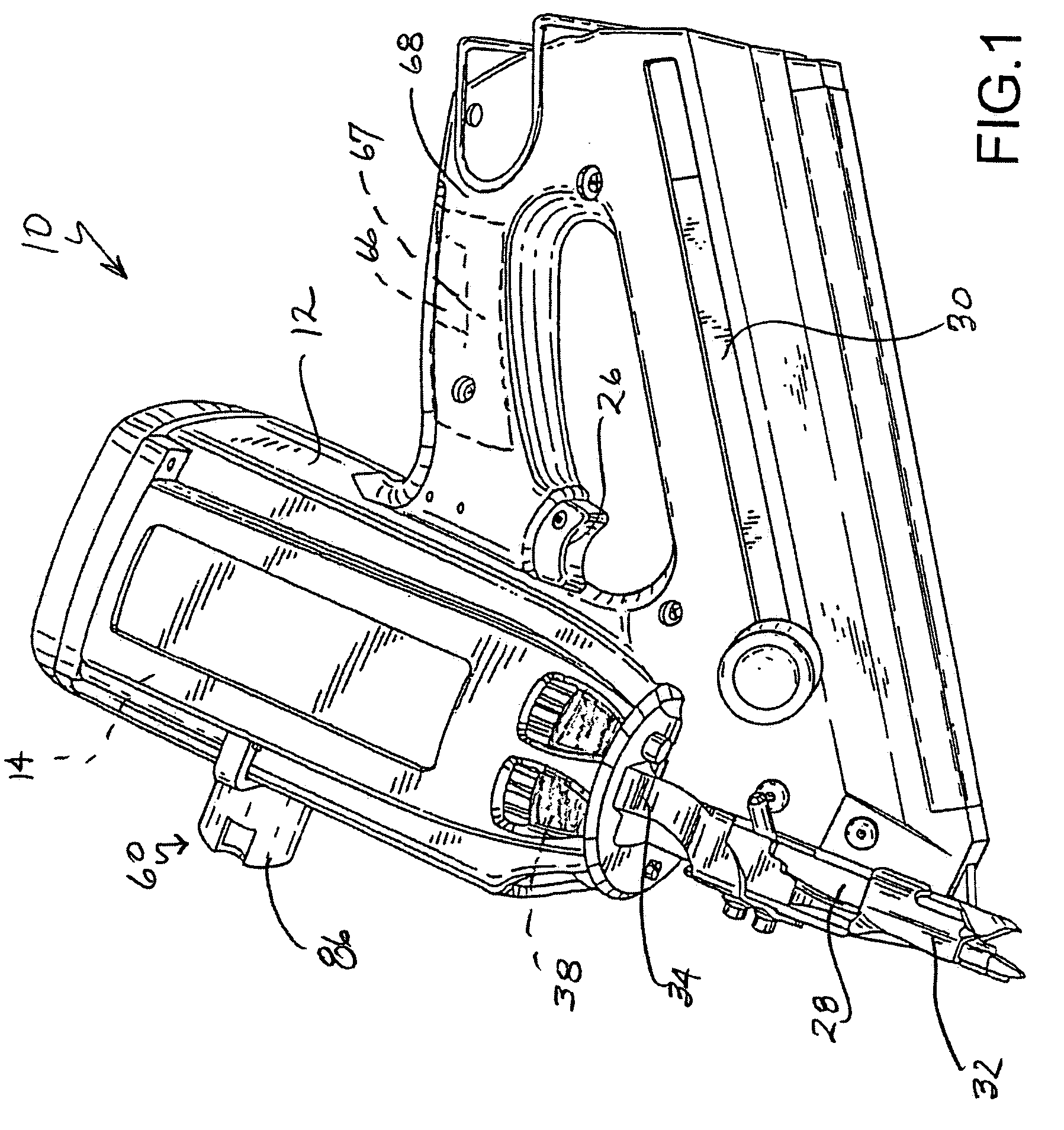

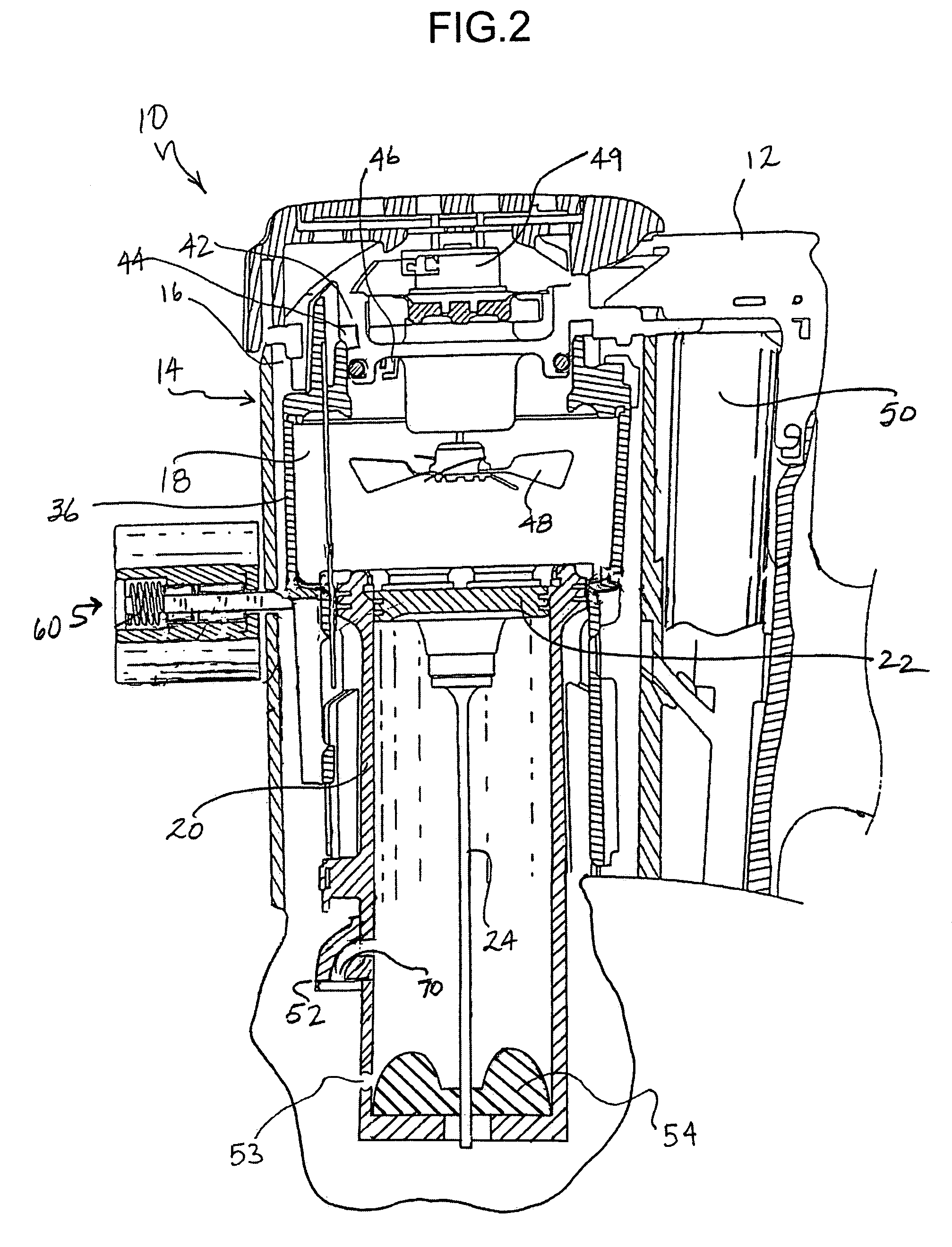

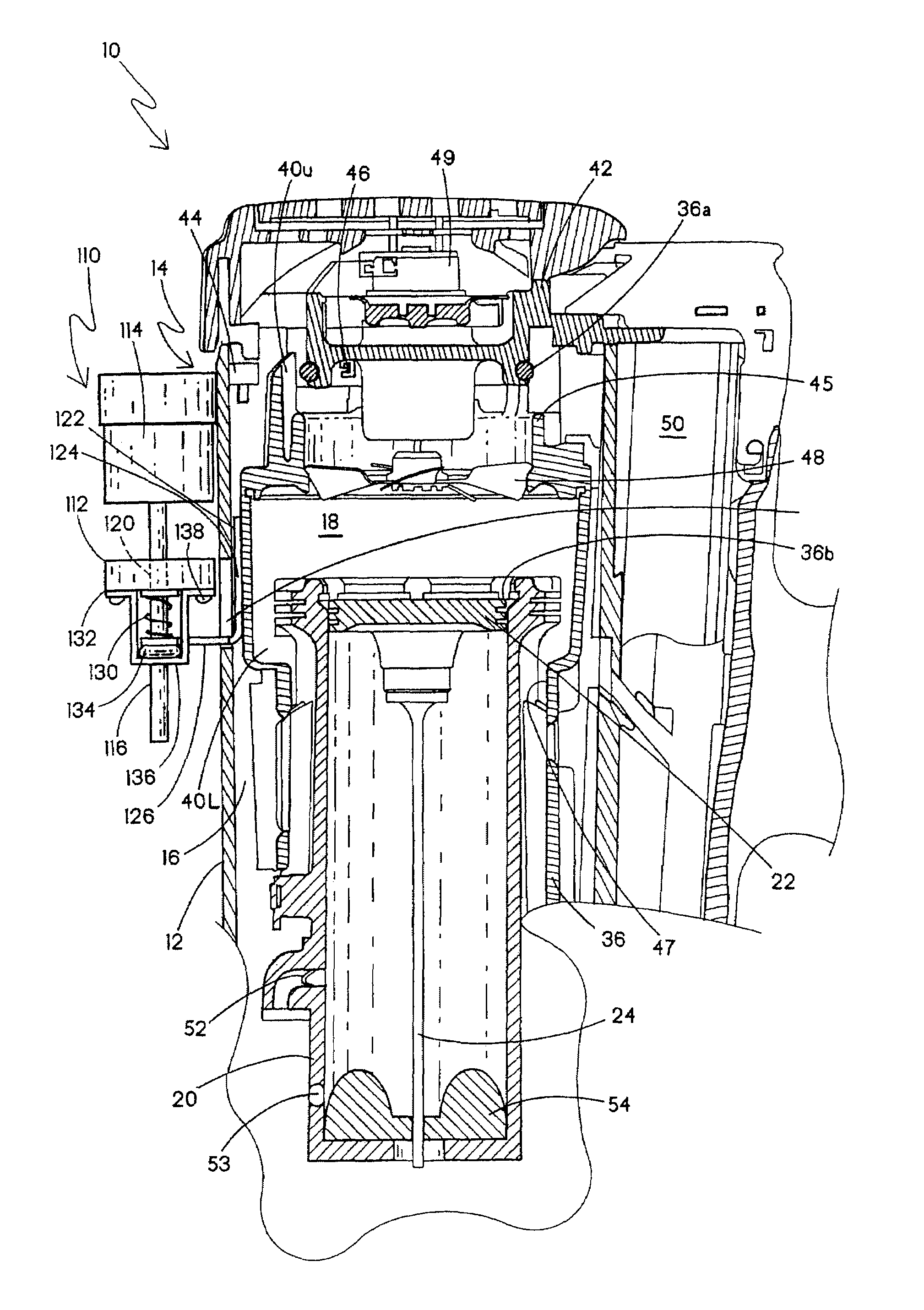

Combustion chamber distance control for combustion-powered fastener-driving tool

ActiveUS20070131731A1Reliable vacuum returnReduce shock-induced damageStapling toolsNailing toolsCombustion chamberRest position

A combustion-powered fastener-driving tool includes a combustion-powered power source including a cylinder head and a combustion chamber defined by the cylinder head, a valve sleeve and an upper surface of a reciprocating piston, the valve sleeve reciprocable relative to the cylinder head between a rest position and a pre-firing position. The valve sleeve has a range of positions between a first sealing position in which the combustion chamber is closed, and said pre-firing position in which the valve sleeve is prevented from further movement. A lockout device is associated with the power source and has an actuated position configured for preventing the reciprocation of the valve sleeve beyond the first sealed position to open the combustion chamber, but permitting movement of the valve sleeve from the first sealed position to the pre-firing position until the piston returns to a piston pre-firing position post combustion.

Owner:ILLINOIS TOOL WORKS INC

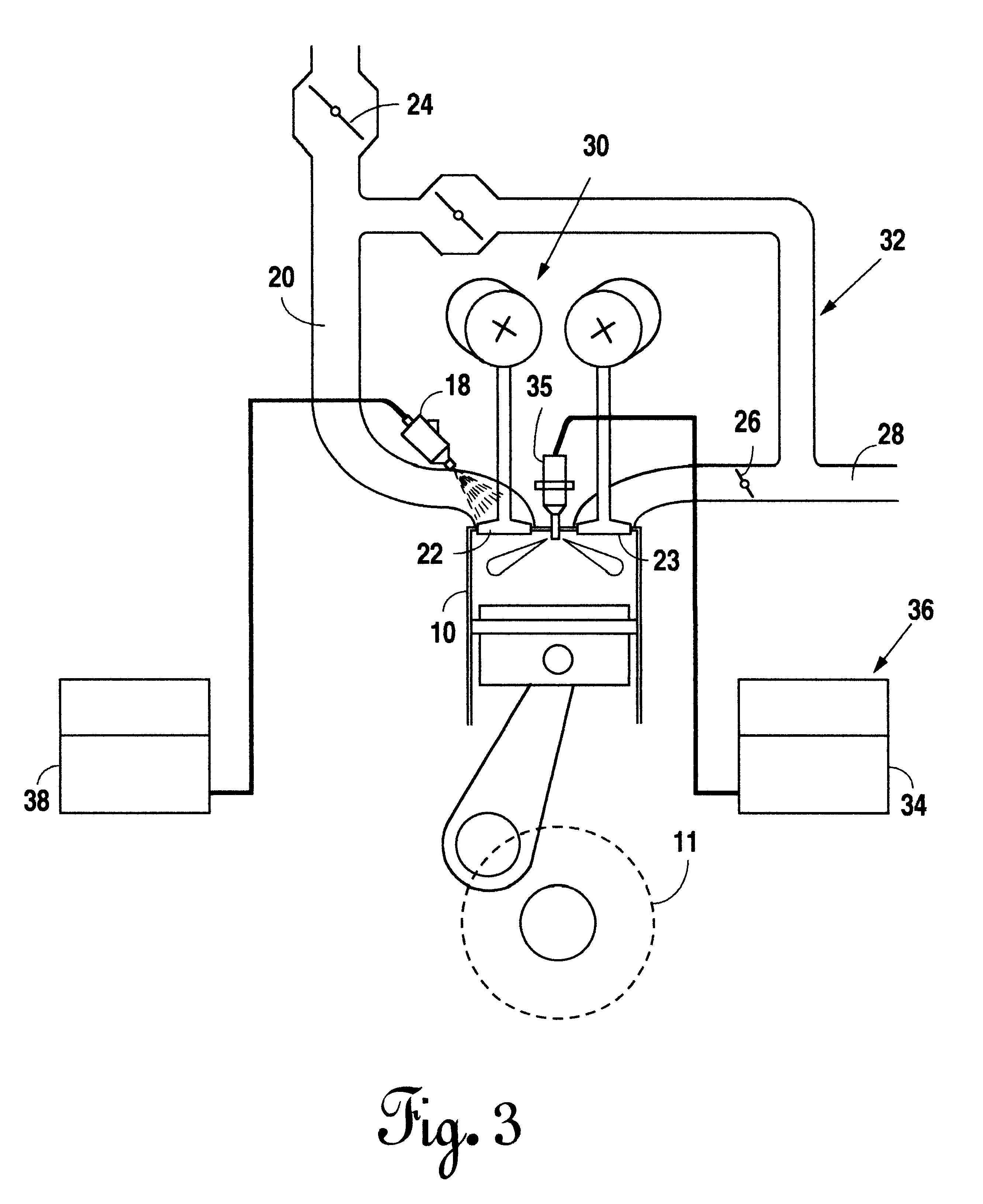

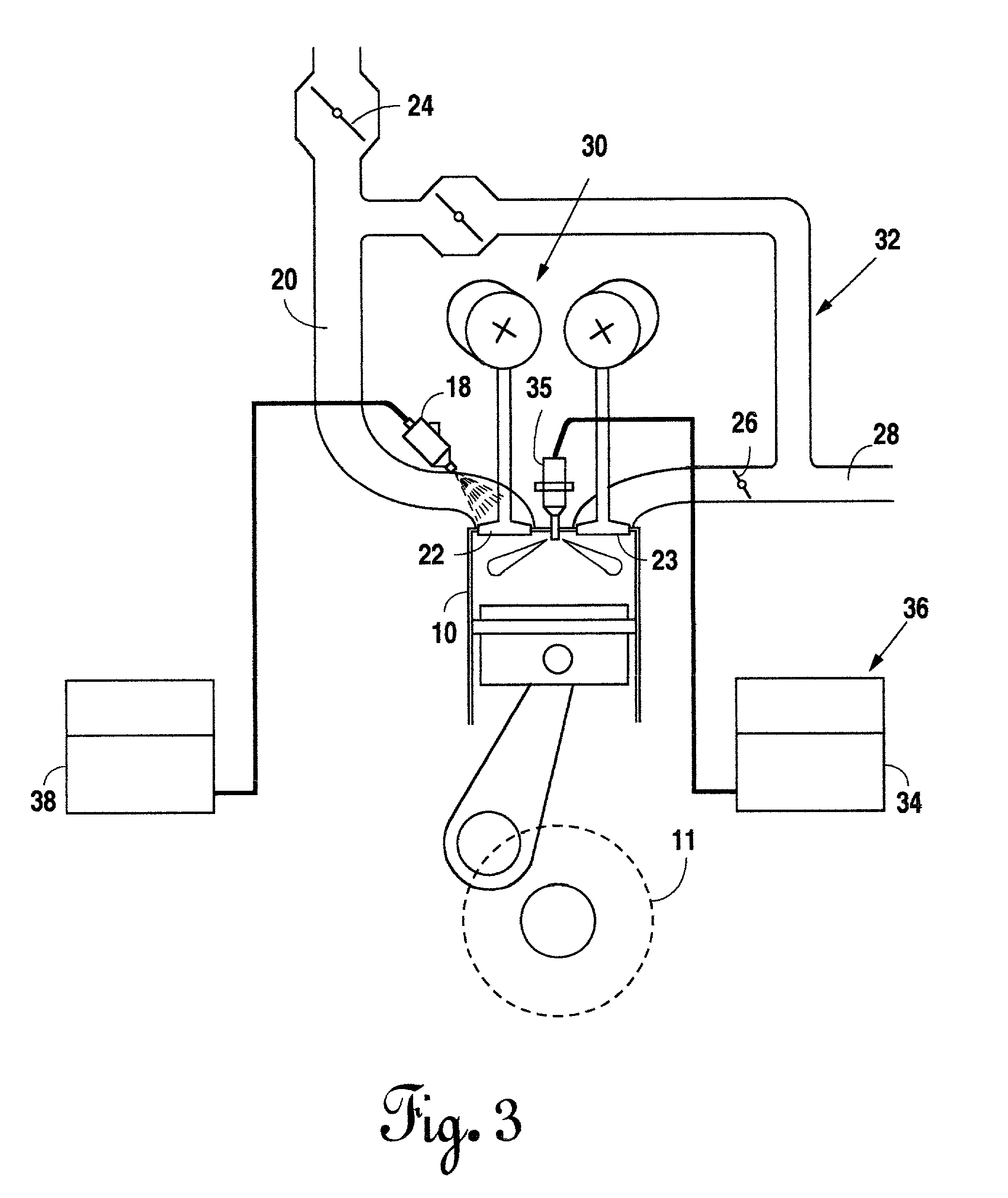

Method and apparatus for operating a diesel engine under stoichiometric or slightly fuel-rich conditions

InactiveUS6679224B2Electrical controlNon-fuel substance addition to fuelParticulatesCombustion chamber

A method and apparatus for operating a diesel engine under stoichiometric or slightly fuel-rich conditions, as is often necessary to maintain effective operation of certain post-combustion emission reduction devices, such as Lean NOx Traps, includes a readily vaporizable fuel injection nozzle disposed in the intake manifold system in communication with a combustion chamber of the diesel engine. The readily vaporizable fuel mixes with the intake air and produces a mixture of pre-mixed air and fuel when introduced into the combustion chamber. A diesel fuel, which is directly injected into the combustion chamber through a conventional diesel fuel injection nozzle. Combustion of the pre-mixed air and readily vaporizable fuel, with controlled injected of the diesel fuel, reduces the particulate matter (soot) emissions when operating the engine under the necessary stoichiometric or slightly fuel-rich conditions.

Owner:SOUTHWEST RES INST

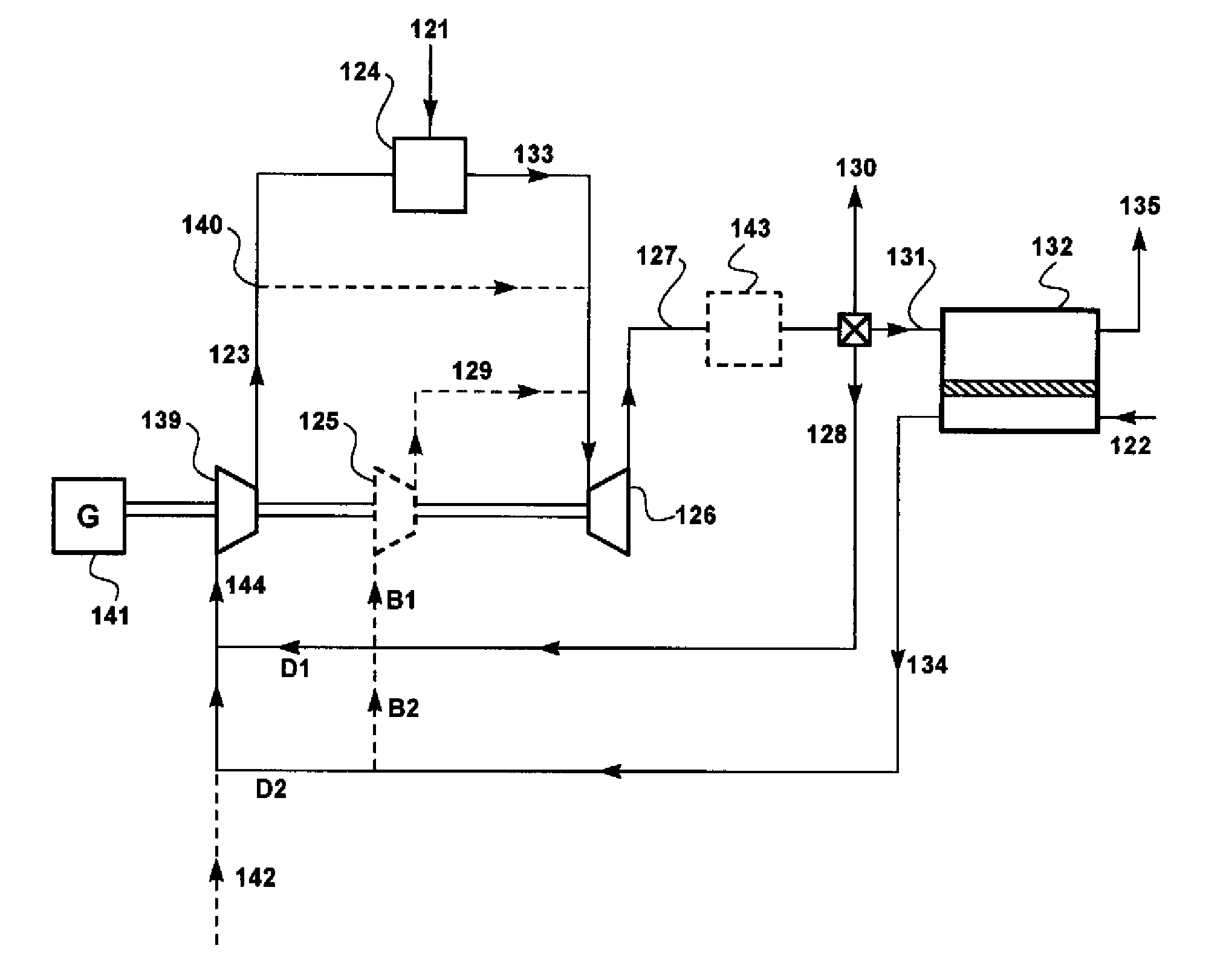

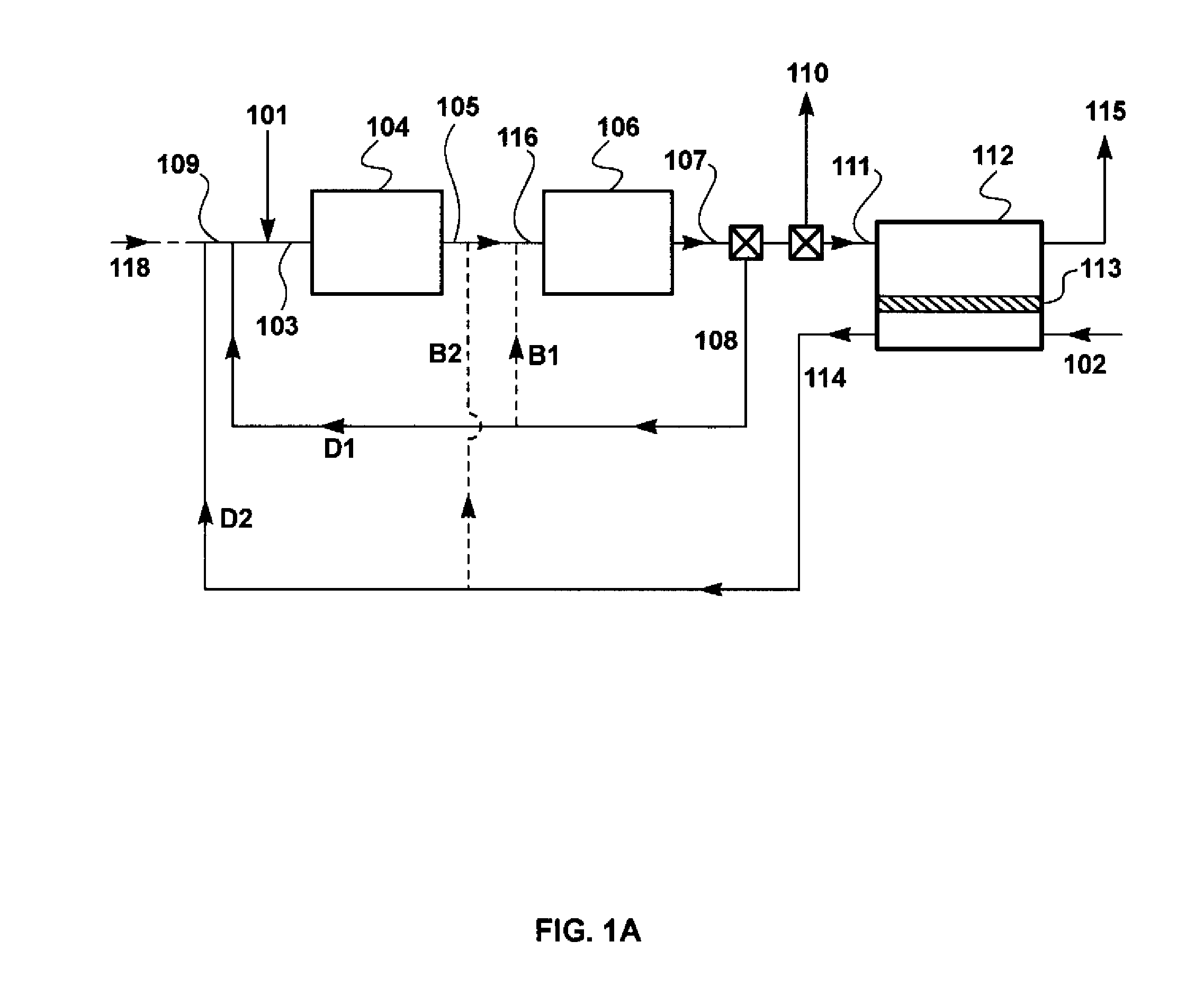

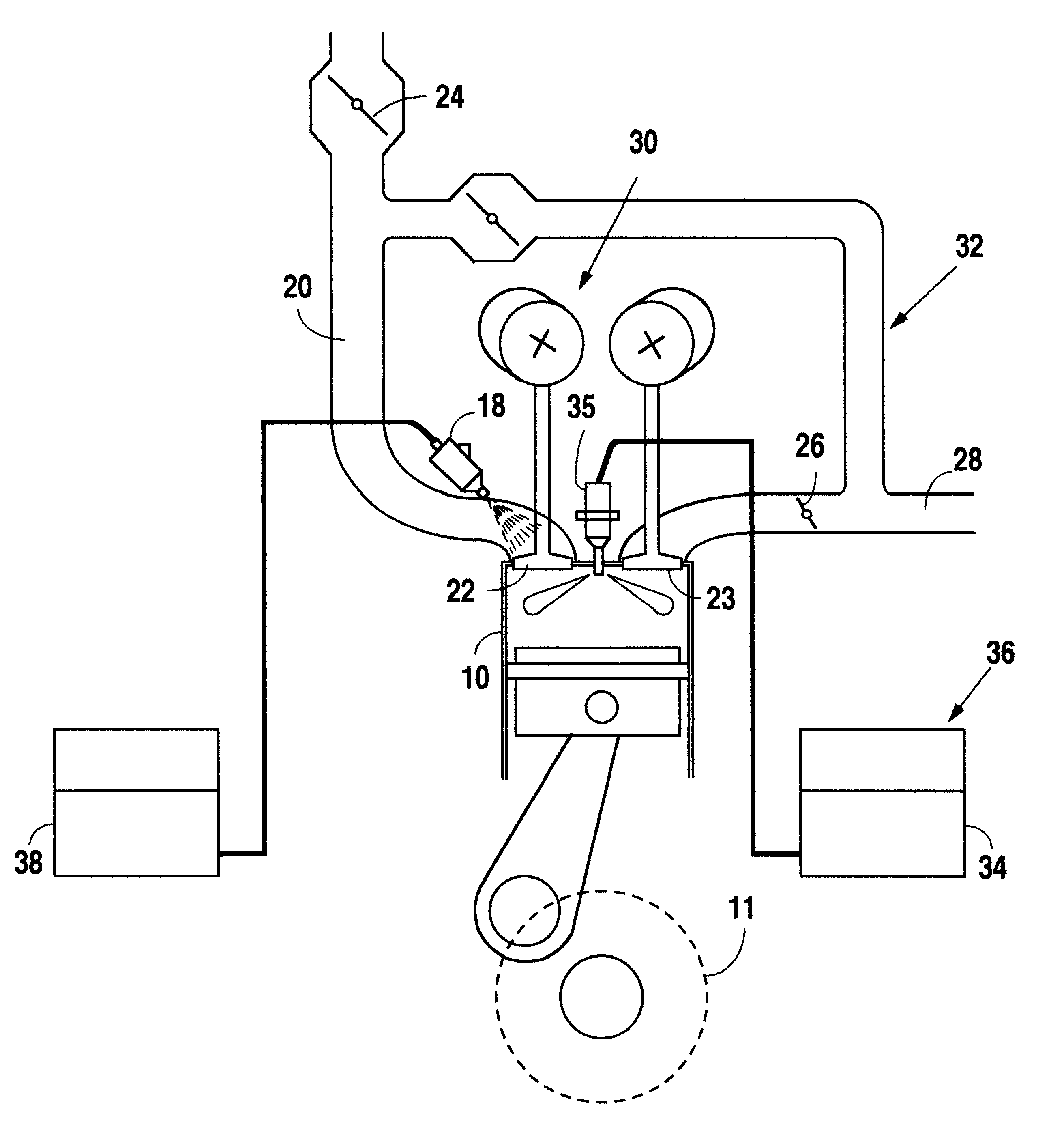

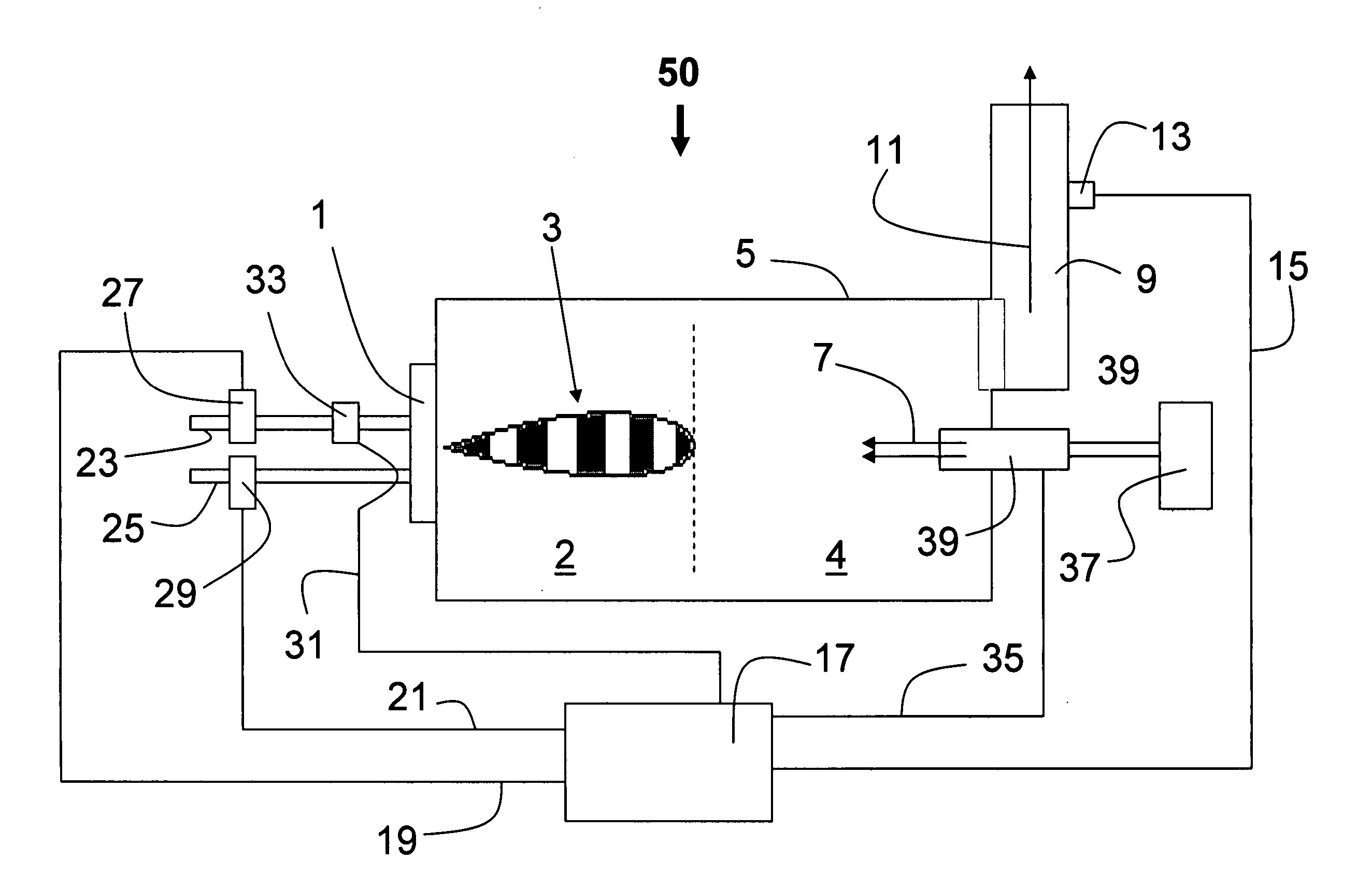

Advanced control system for enhanced operation of oscillating combustion in combustors

InactiveUS20060177785A1Level of optimizationCombustion using gaseous and pulverulent fuelFuel supply regulationCombustion chamberCombustor

Methods for optimizing emission levels from combustion operations, which include a system and process for optimizing levels of NOx and CO during fuel combustion including supplying flows of fuel (which is predetermined) and main oxidant to a burner. Oscillating combustion is generated by oscillating the fuel flow with an oscillating valve and combusting the oscillating fuel with the main oxidant adjacent the burner to produce combustion products. A post-combustion oxidant is injected into the combustion products where it is combusted with the combustion products. A controller is operatively associated with control units for controlling the main oxidant and post-combustion oxidant flow rates and the oscillating valve.

Owner:VARAGANI RAJANI K +2

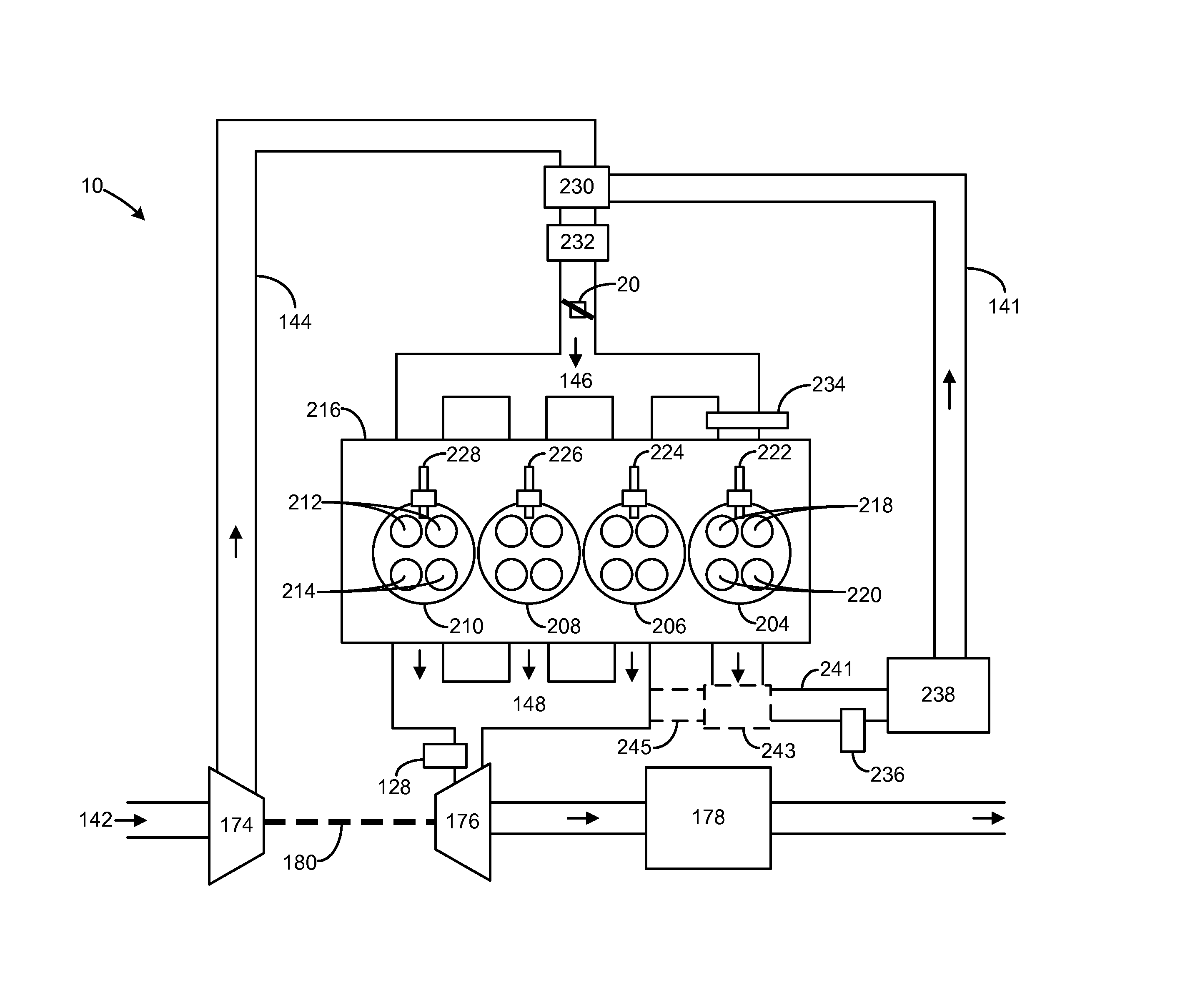

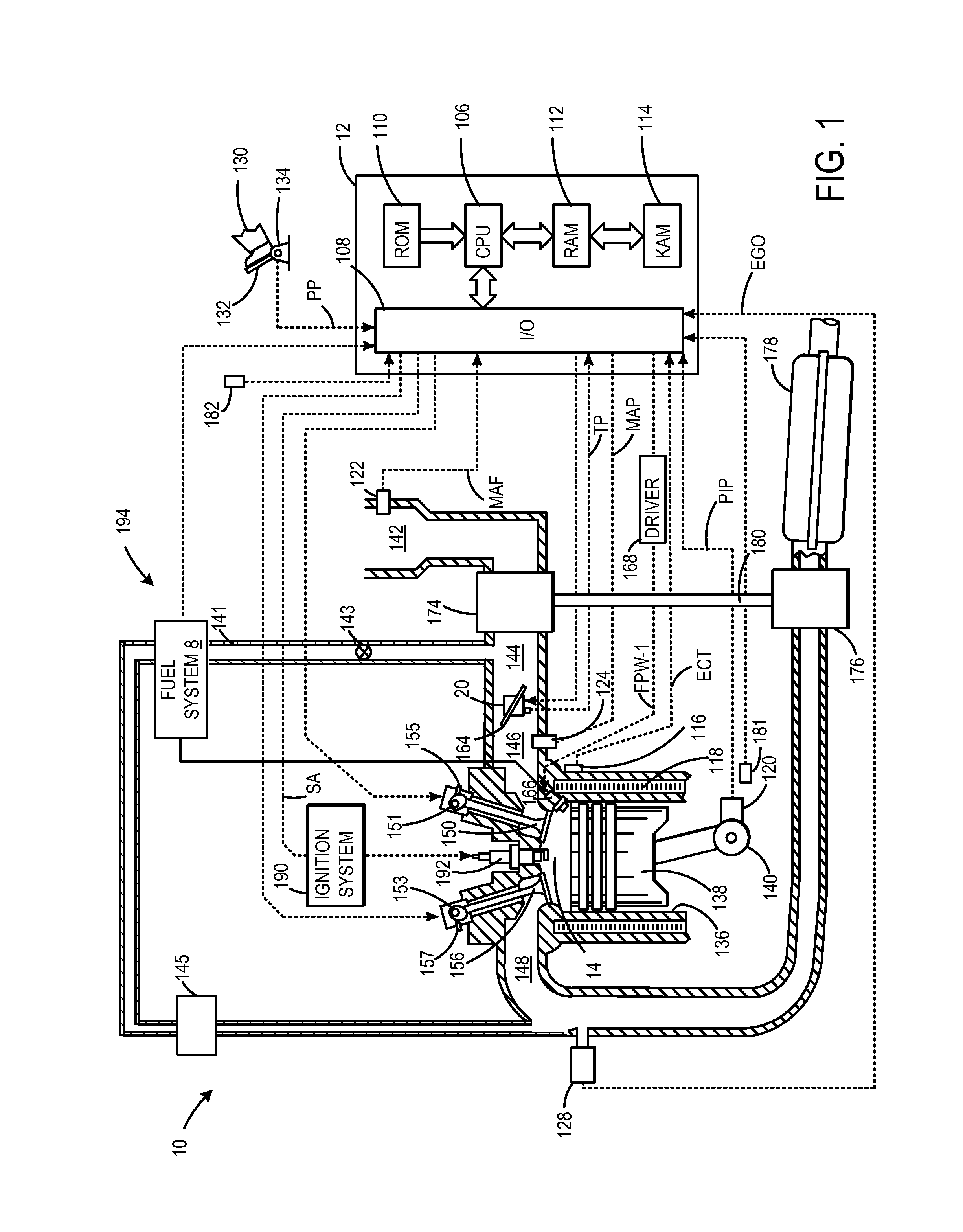

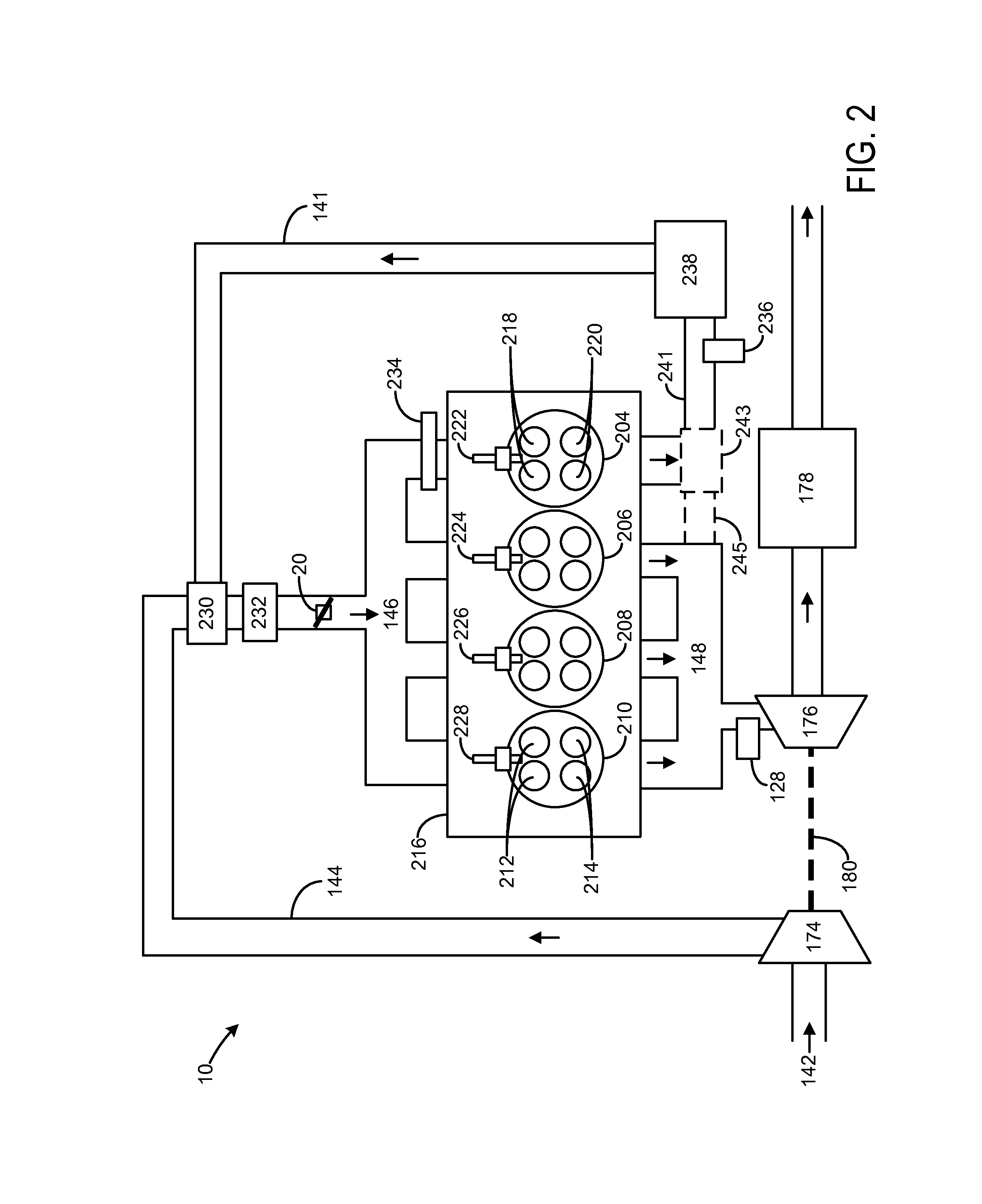

Dedicated egr cylinder post combustion injection

ActiveUS20140360461A1Decrease throttlingReduce nitrogen oxide emissionsNon-fuel substance addition to fuelExhaust gas recirculationExhaust gas recirculationAutomotive engineering

Systems and methods for increasing an amount of fuel injected into a dedicated exhaust gas recirculation (EGR) cylinder in an engine are disclosed. In one example approach, a method comprises, prior to combustion, injecting a first amount of fuel to a dedicated EGR cylinder, and after combustion and during an expansion and / or exhaust stroke, directly injecting a second amount of fuel to the dedicated EGR cylinder.

Owner:FORD GLOBAL TECH LLC

Method and apparatus for operating a diesel engine under stoichiometric or slightly fuel-rich conditions

InactiveUS20030084876A1Electrical controlNon-fuel substance addition to fuelParticulatesCombustion chamber

A method and apparatus for operating a diesel engine under stoichiometric or slightly fuel-rich conditions, as is often necessary to maintain effective operation of certain post-combustion emission reduction devices, such as Lean NOx Traps, includes a readily vaporizable fuel injection nozzle disposed in the intake manifold system in communication with a combustion chamber of the diesel engine. The readily vaporizable fuel mixes with the intake air and produces a mixture of pre-mixed air and fuel when introduced into the combustion chamber. A diesel fuel, which is directly injected into the combustion chamber through a conventional diesel fuel injection nozzle. Combustion of the pre-mixed air and readily vaporizable fuel, with controlled injected of the diesel fuel, reduces the particulate matter (soot) emissions when operating the engine under the necessary stoichiometric or slightly fuel-rich conditions.

Owner:SOUTHWEST RES INST

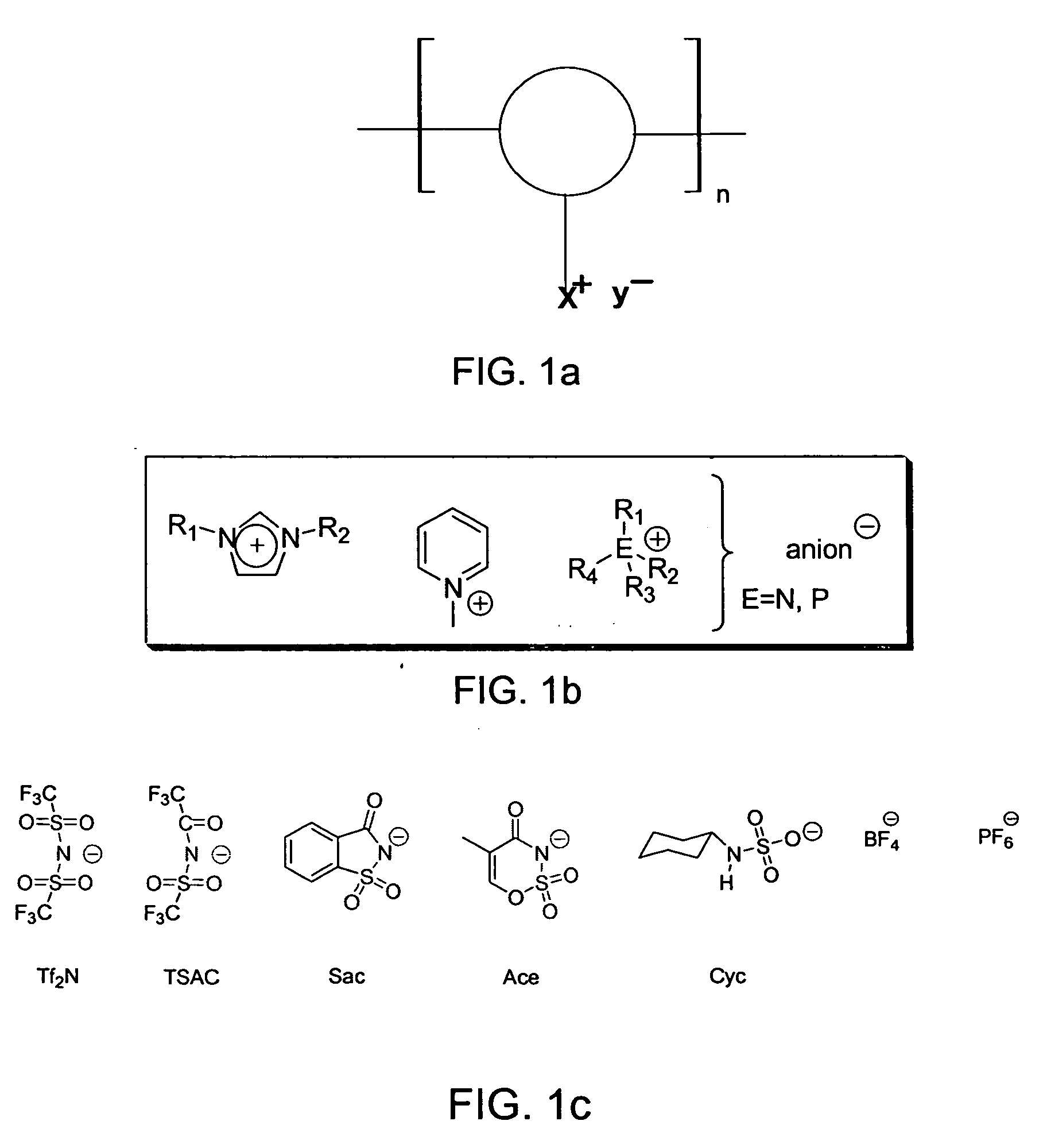

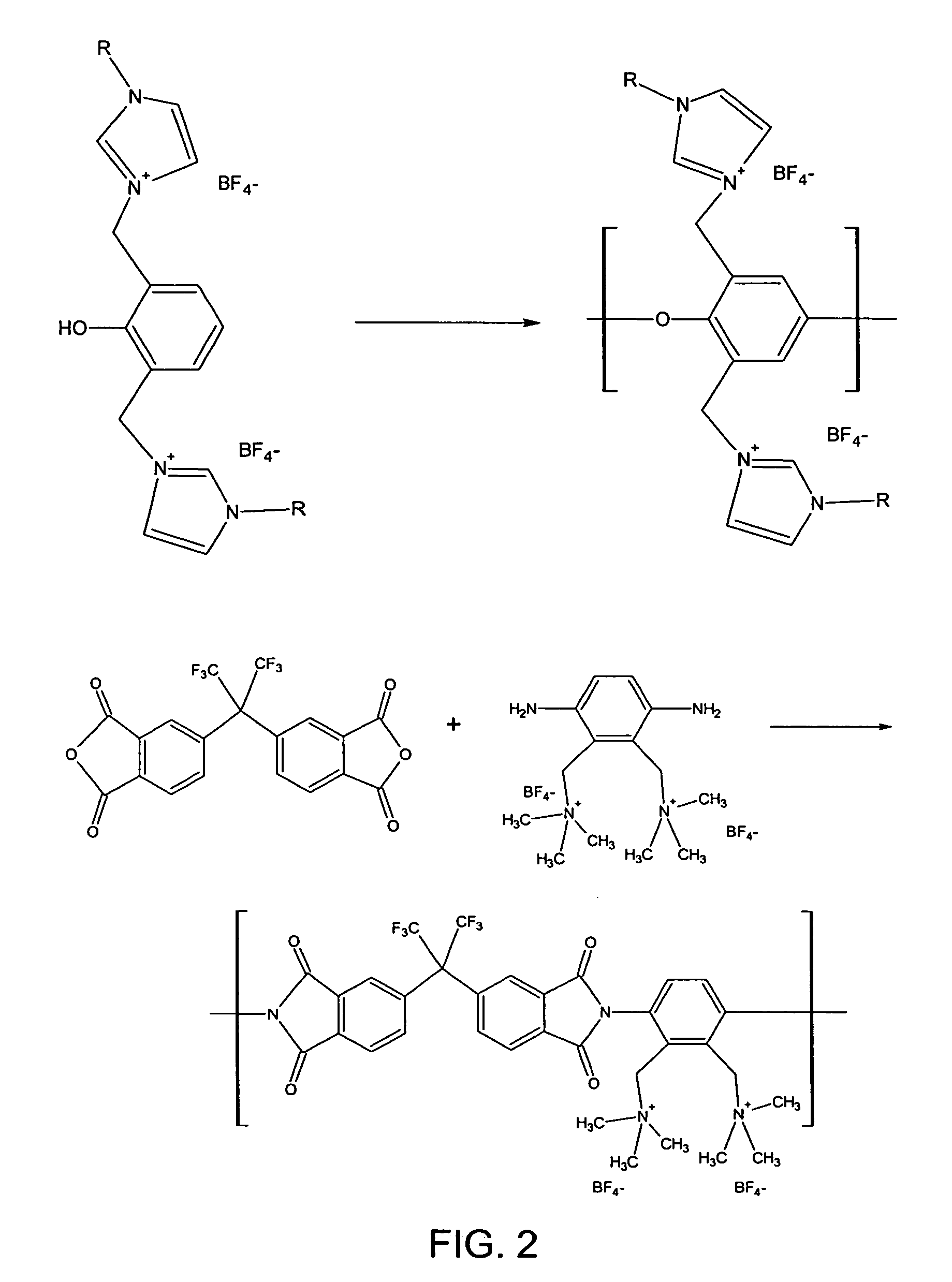

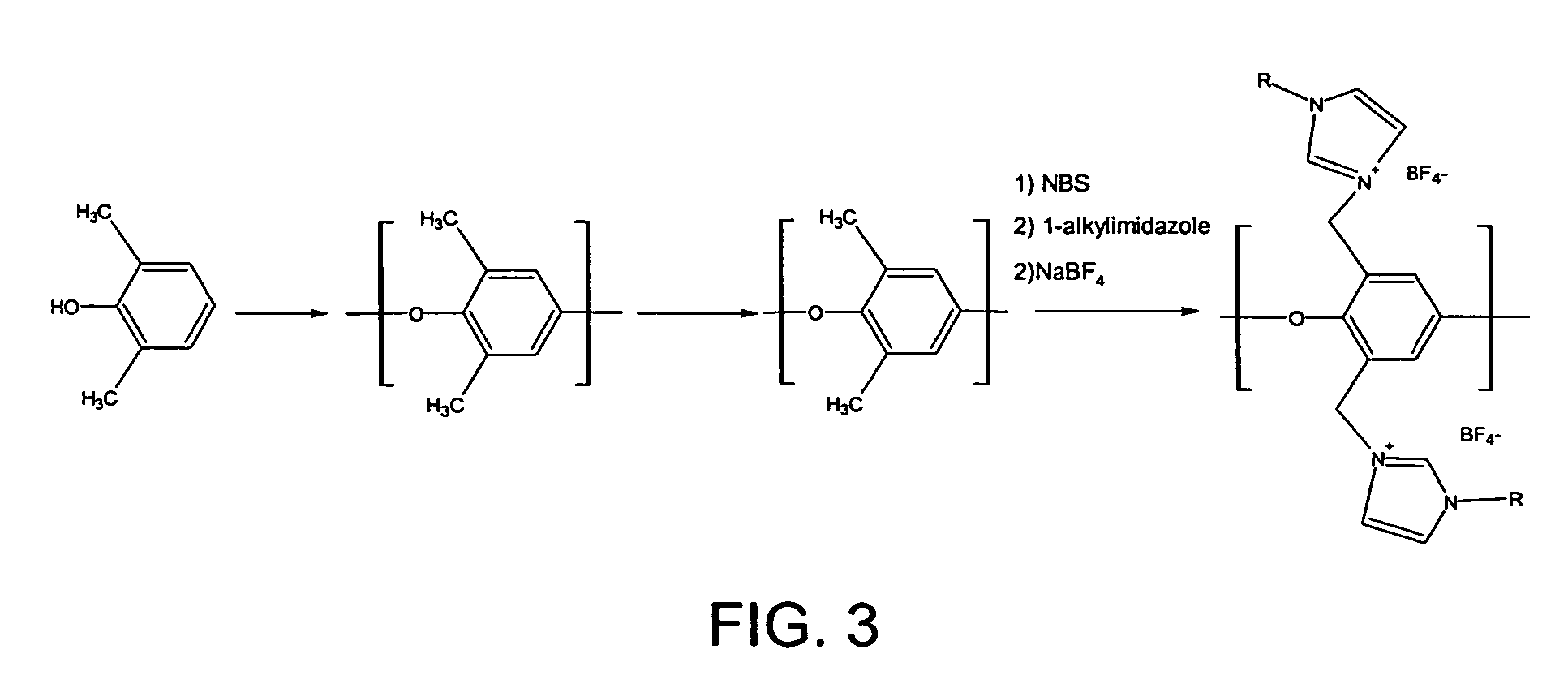

Polymers containing ionic groups for gas separation and storage

Polymeric materials containing ionic groups, which can be used as membranes and sorbents for separating gas components, for example, separating CO2 from flue gas streams and from natural gas streams, and sorbents for storing gas components. Such separation materials are used for pre-combustion separations, post-combustion separations, and natural gas separations, and are alternatives to the conventional amine absorption process.

Owner:UNIVERSITY OF WYOMING

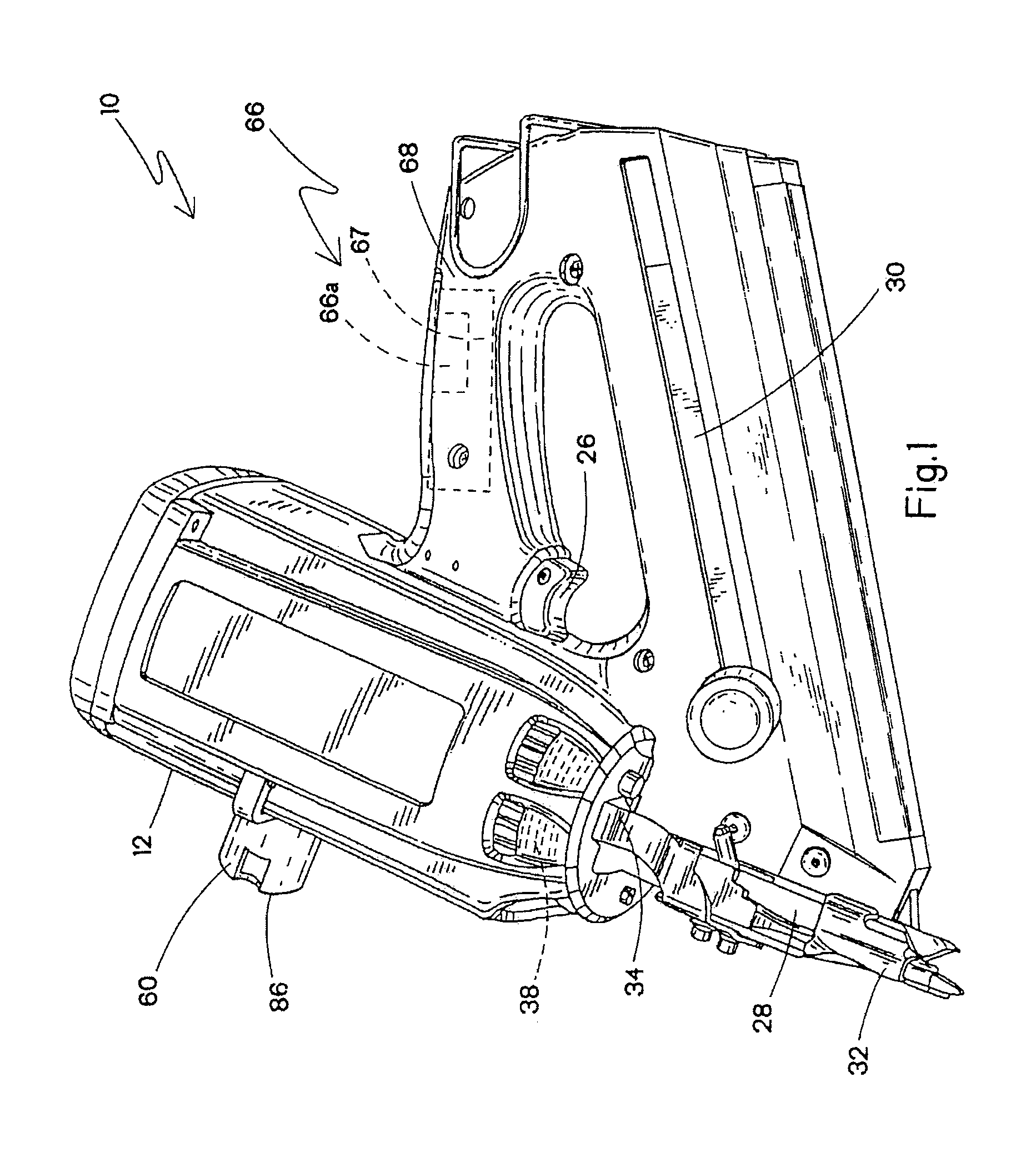

Exhaust system for combustion-powered fastener-driving tool

ActiveUS7201301B2Enhancing piston returnOvercome limitationsStapling toolsFree piston enginesExhaust valveCombustion

A combustion-powered fastener-driving tool includes a combustion-powered power source including a cylinder defining a path for a reciprocating piston and an attached driver blade, the piston reciprocating between a pre-firing position achieved prior to combustion and a bottom out position. Upon combustion in the power source, the cylinder includes at least one exhaust valve configured for releasing combustion gases from the cylinder. The at least one exhaust valve is dimensioned so that sufficient gas is released to reduce post-combustion pressure in the cylinder to approximately one atmosphere in the time available for the piston to travel past the at least one exhaust valve and return to the at least one exhaust valve.

Owner:ILLINOIS TOOL WORKS INC

Composition for reducing emission of CO and NOx of FCC regeneration flue gas and preparation method of composition

InactiveCN105363444AReduce emission activityReduce yieldCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlkaline earth metal

The invention discloses a composition for reducing emission of CO and NOx of FCC regeneration flue gas and a preparation method of the composition. The composition is prepared from 0.5-30 wt% of rare earth elements, 0.01-0.15 wt% of precious metal elements and the balance inorganic oxide carriers basically containing no alkali metal or alkaline-earth metal according to oxide. In the preparation method, the composition where precious metal is introduced is processed by an alkaline solution before being dried and / or calcinated. The composition is used for fluid catalytic cracking, post-combustion caused by too high regeneration flue gas CO concentration can be effectively avoided, the emission concentration of CO and NOx in regeneration flue gas can be effectively controlled, and emission of smoke NOx is remarkably reduced, and basically no adverse influences are caused to distribution of FCC products.

Owner:CHINA PETROLEUM & CHEM CORP +1

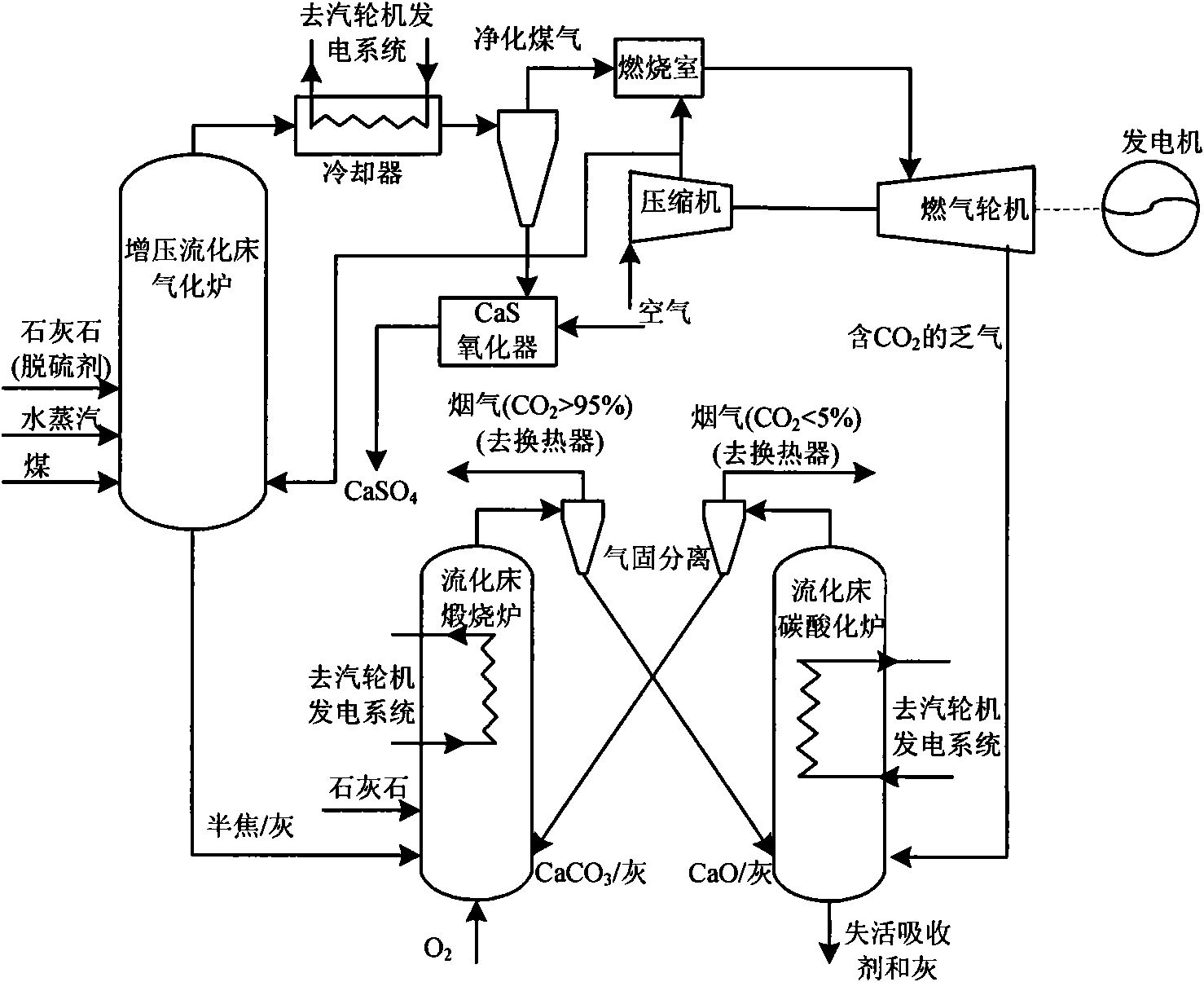

Method for catching carbon dioxide by pressurized fluidized bed combustion combined recycle generating system

InactiveCN101539037AReasonable realization of graded conversionRaise the inlet temperatureGas turbine plantsSteam engine plantsEngineeringCarbonatation

The invention relates to a method for catching carbon dioxide by a pressurized fluidized bed combustion combined recycle generating system, which is a method for catching the carbon dioxide by using CaO generated by calcining limestone or dolomite aiming at a gasification / semi-coking pressurized fluidized combustion combined recycle generating system of a coal pressurized part, coal enters into a pressurized fluidized bed gasification furnace using air as gasifying agent so as to be gasified to generate coal gas and semicoke, the coal gas is combusted after being purified to produce high-temperature fuel to enter a combustion turbine for applying work and generating electricity. Exhaust gas containing CO2 enters into a carbonatation furnace and a calciner double fluidized system, CO2 in the exhaust gas is catched by using circulation carbonatation / calcining reaction of CaO. Steam produced by a coal gas cooler and the double fluidized bed system enters into the turbine system for applying work and generating electricity, therefore, a fuel gas / steam combined recycle generating system catching CO2 is formed. The system has high generating efficiency and low energy consumption, and can realize near-zero exhaust of a plurality of pollutants of SO2, CO2 and the like.

Owner:SOUTHEAST UNIV

Power generation process with partial recycle of carbon dioxide

ActiveUS20110219777A1Reduce environmental impactDecrease in carbon dioxide contentGas treatmentDispersed particle separationGeneration processElectricity

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

Combustion chamber distance control combustion-powered fastener-driving tool

ActiveUS7673779B2Reliable vacuum returnReduce harmStapling toolsFree piston enginesCombustion chamberRest position

A combustion-powered fastener-driving tool includes a combustion-powered power source including a cylinder head and a combustion chamber defined by the cylinder head, a valve sleeve and an upper surface of a reciprocating piston, the valve sleeve reciprocable relative to the cylinder head between a rest position and a pre-firing position. The valve sleeve has a range of positions between a first sealing position in which the combustion chamber is closed, and said pre-firing position in which the valve sleeve is prevented from further movement. A lockout device is associated with the power source and has an actuated position configured for preventing the reciprocation of the valve sleeve beyond the first sealed position to open the combustion chamber, but permitting movement of the valve sleeve from the first sealed position to the pre-firing position until the piston returns to a piston pre-firing position post combustion.

Owner:ILLINOIS TOOL WORKS INC

Cogeneration method and device using a gas turbine comprising a post-combustion chamber

A cogeneration method and device by turbine, particularly by gas turbine, uses a compression section, at least one expansion section, and a combustion chamber. A combustion agent including oxygen is compressed in the compression section; in the combustion chamber, one combustion step is carried out under pressure with a mixture of combustion agent compressed with a fuel; at least some of the hot gases obtained by pressurized combustion are used to effect an exchange with an external facility; and at least one postcombustion step is carried out of a mixture of hot gases coming from combustion with a fuel, prior to the exchange, and at least one other postcombustion step of a mixture of hot gases, coming from the exchange, with a fuel, in order to obtain hot gases that are sent to the expansion section.

Owner:INST FR DU PETROLE

Power generation process with partial recycle of carbon dioxide

ActiveUS20110219778A1Reduce environmental impactDecrease in carbon dioxide contentGas treatmentDispersed particle separationGeneration processElectricity

Disclosed herein is a power generation process in which a portion of the carbon dioxide generated by gaseous fuel combustion is recycled back to the power generation process, either pre-combustion, post-combustion, or both. The power generation process of the invention may be a combined cycle process or a traditional power generation process. The process utilizes sweep-based membrane separation.

Owner:MEMBRANE TECH & RES

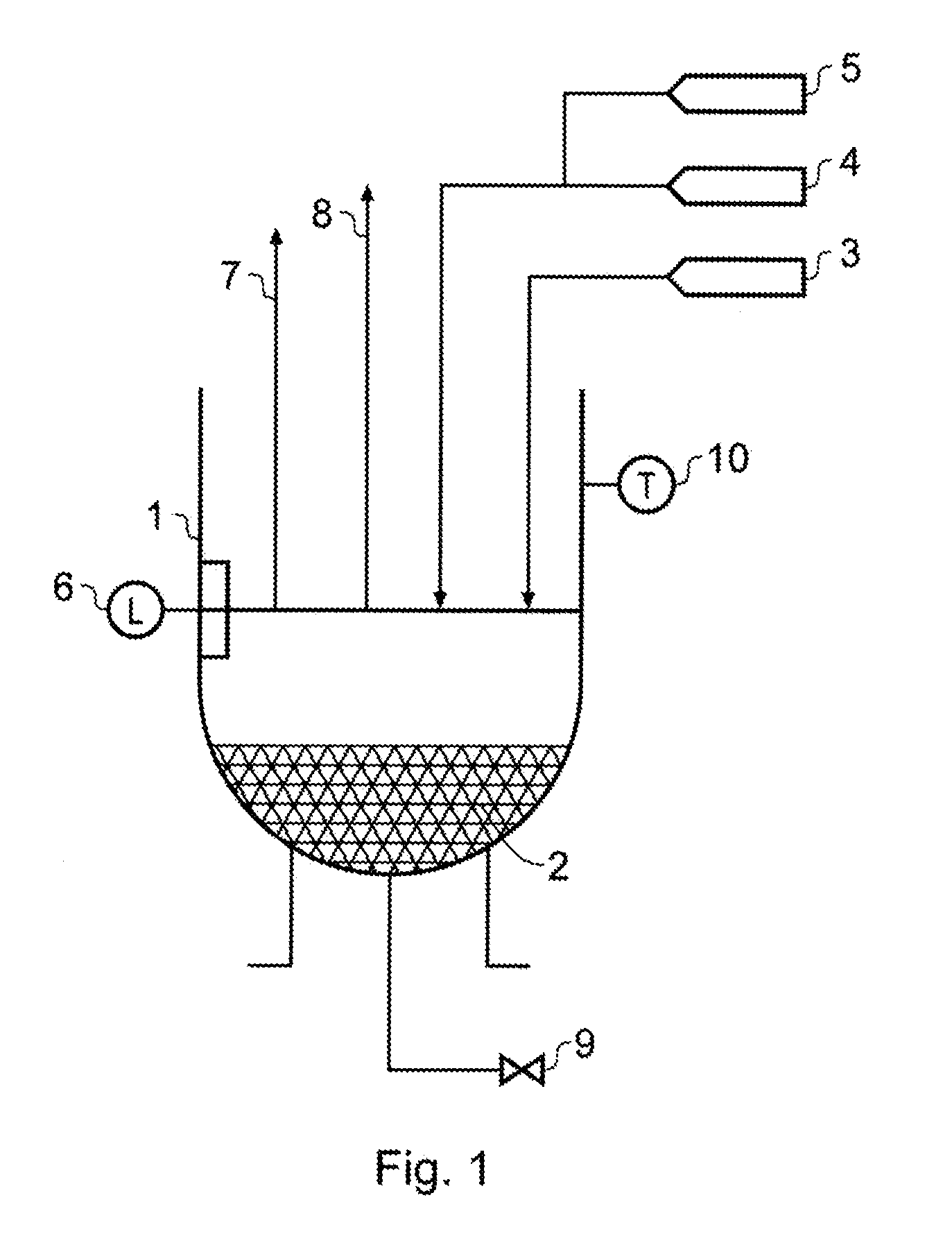

Method for treatment of hazardous fluid organic waste materials

InactiveUS20030171635A1Atomization fastImprove decomposition efficiencyDispersed particle separationOrganic decompositionPlasma torchWater content

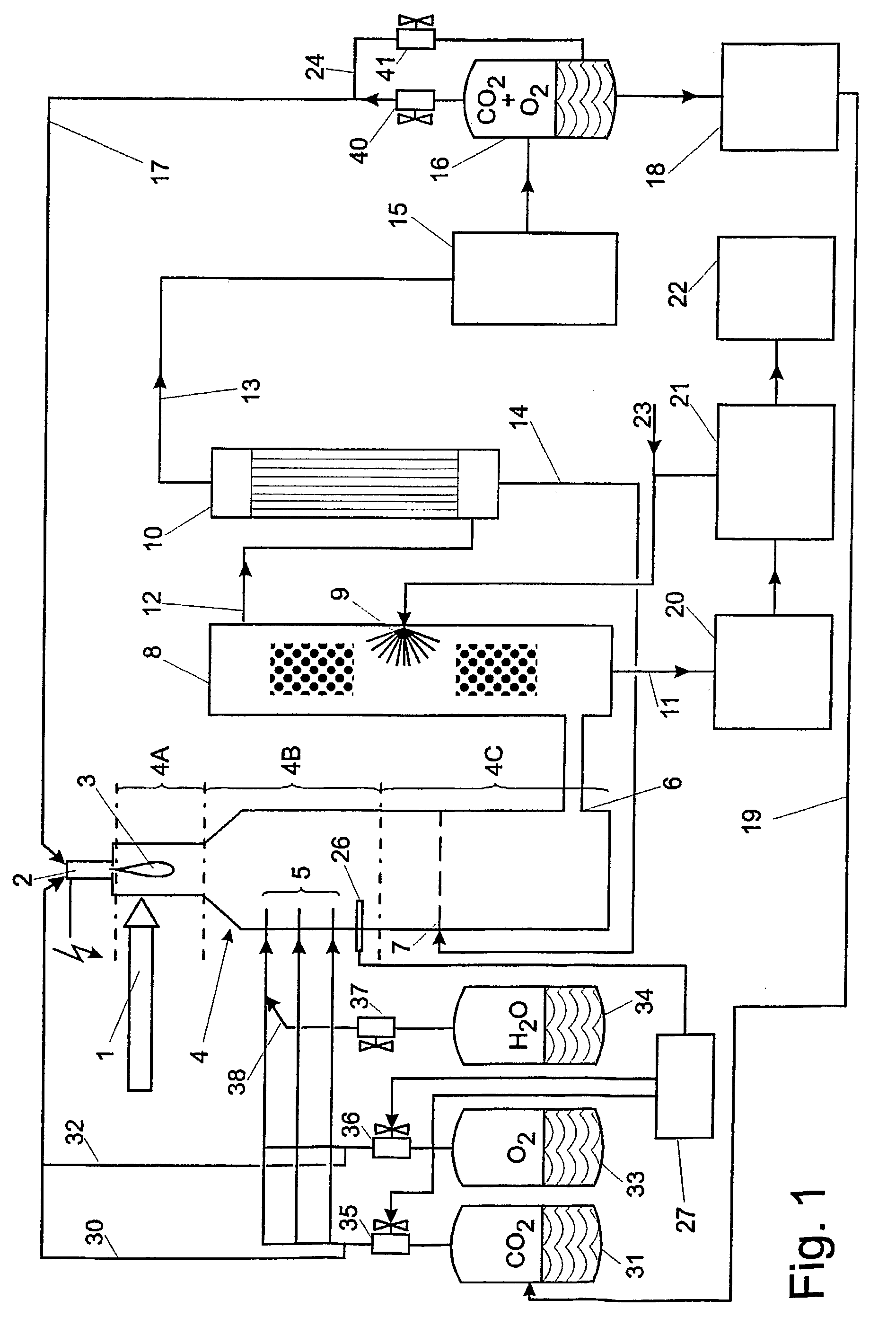

Method for treatment of fluid hazardous, organic waste materials, where a plasma of 2000-5000° C. temperature is generated by means of an electric arc in a plasma generator, the plasma torch is directed into a reactor, the reactor consists of three zones (4A, 4B, 4C), the plasma torch being introduced downwards into the uppermost first zone (4A), the fluid waste (1) being sprayed into the plasma torch in the first zone (4A), where it is heated to a temperature range of 1300-1600° C., the mixture of the plasma and the waste is introduced into the second zone (4B) of the reactor, where an oxidizing material is added (5) to the mixture, the combustion gas produced in the second zone (4B) is then led into the third zone (4C) of the reactor, where it is cooled rapidly by water spraying to a temperature range of 120-160° C., the cooled combustion gas is removed from the third zone (4C) of the reactor is led into a cooler. The plasma torch is generated from the mixture of carbon dioxide and oxygen, the oxidizing material introduced into the second zone (4B) of the reactor is a mixture of carbon dioxide and oxygen. Subsequently the water content of the combustion gas is separated by condensing and is removed and the residual combustion gas is removed.

Owner:BERECZKY TAMAS +4

Method and device for heat supply of rotary hearth furnace

ActiveCN102062534ABreakthrough in heating methodsRestoration of economic rationalityIncreasing energy efficiencyFurnace typesCombustion chamberEngineering

The invention discloses a method and a device for the heat supply a rotary hearth furnace. Smoke afterheat generated by the rotary hearth furnace is firstly heated up through a rear combustion chamber to 1300 DEG C and then respectively introduced into a ball-type hot blast furnace and a fire tube-type rotary dryer which are interconnected in parallel, double preheating and staged heat exchange of the fuel for gas generator and the combustion-supporting air are realized by means of the coordinative operation of combined afterheat utilization devices which are mutually connected, such as ball-type hot blast furnace, heat pipe exchanger, fire tube-type rotary dryer and the like, thus the temperature of combustion flame at a combustion nozzle of the rotary hearth furnace is guaranteed to be not less than 2200 DEG C and drying iron ore powder is performed while high temperature reduction is implemented. The novel high-temperature smoke afterheat recycling technology of the rotary hearth furnace is especially suitable for plants in the area without natural gas and coke-oven gas which require coal-based direct reduction rotary hearth furnace to generate high reduction temperature ranging from 1300 to 1400 DEG C, the technology is advanced, the economical benefit is considerable, the top-quality fuel is saved, the expenditure for cooling high temperature smoke is avoided, and the CO2emission and the production cost are lowered.

Owner:SICHUAN LOMON MINING & METALLURGY

Turbo-charged internal combustion engine with in-cylinder EGR and injection rate shaping

InactiveUS6968831B2Improve efficiencyImprove transient responseInternal combustion piston enginesCylinder headsExhaust valveExternal combustion engine

A turbo-charged internal combustion cylinder assembly includes a combustion chamber which may be communicably connected to a compressor via an intake port through an intake manifold and aftercooler so the compressor may provide pre-combustion gases to the combustion chamber when the intake valve is open. An exhaust port communicably connects the combustion chamber to an exhaust manifold. An exhaust valve may open to exhaust post-combustion gases to the exhaust manifold while an intake valve is substantially closed, and the exhaust valve may open to admit post-combustion gases to the combustion chamber while the intake valve is substantially open and an exhaust port pressure in the exhaust port is higher than a combustion chamber pressure in the combustion chamber. A fuel injector may admit fuel to the combustion chamber. A spill valve may control a rate of fuel injection to the combustion chamber, the spill valve having a first position providing a maximum fuel injection rate, a second position providing a substantially zero fuel injection rate, and at least one intermediate position providing an intermediate fuel injection rate between the maximum fuel injection rate and the zero fuel injection rate.

Owner:VOLVO LASTVAGNAR AB

Titanium aluminide intermetallic composites

An intermetallic composite and method of making an intermetallic composite is disclosed comprising a porous titanate preform of the formula εxTiyOz, where ε represents an element reduceable by molten aluminum to form an aluminate of the formula εiAjOk. Adding aluminum and heating the preform sufficient to melt the aluminum results in formation of a post-combustion intermetallic composite comprising both titanium aluminide and 68 -aluminate.

Owner:SAFFIL AUTOMOTIVE

System and method for incineration treatment of saliferous waste residue, saliferous waste water and stink waste gas

The invention discloses a system and a method for incineration treatment of saliferous waste residue, saliferous waste water and stink waste gas and relates to the technical field of unharmful resourceful treatment of industrial three wastes. The system and the method aim at resolving the problem that the existing three water treatment method is large in device investment, high in treatment cost, salt cannot be separated to obtain purified salt, and no device can be used for treating the three wastes simultaneously. The system for treatment comprises a pretreating chamber, a incineration device, a waste heat recycling device and a tail gas purifying device which are sequentially connected. The upper portion of the pretreating chamber is connected with a waste liquid injection port, the lower portion of the pretreating chamber is connected with a waste slag input port, and a salt discharge port is arranged at the bottom end of the pretreating chamber. The incineration device comprises a main combustion chamber and a post-combustion chamber which are sequentially connected in the smoke flowing direction. The method for treatment includes a. pretreating: delivering waste liquid, high temperature smoke and waste residue into the pretreating chamber to be combusted; b. high temperature incineration: placing the gasified waste liquid and the stink waste gas into the incineration device to be incinerated; c. waste heat recycling; and d. tail gas purification. The system and the method are especially suitable for treatment of industrial three wastes.

Owner:季栋梁

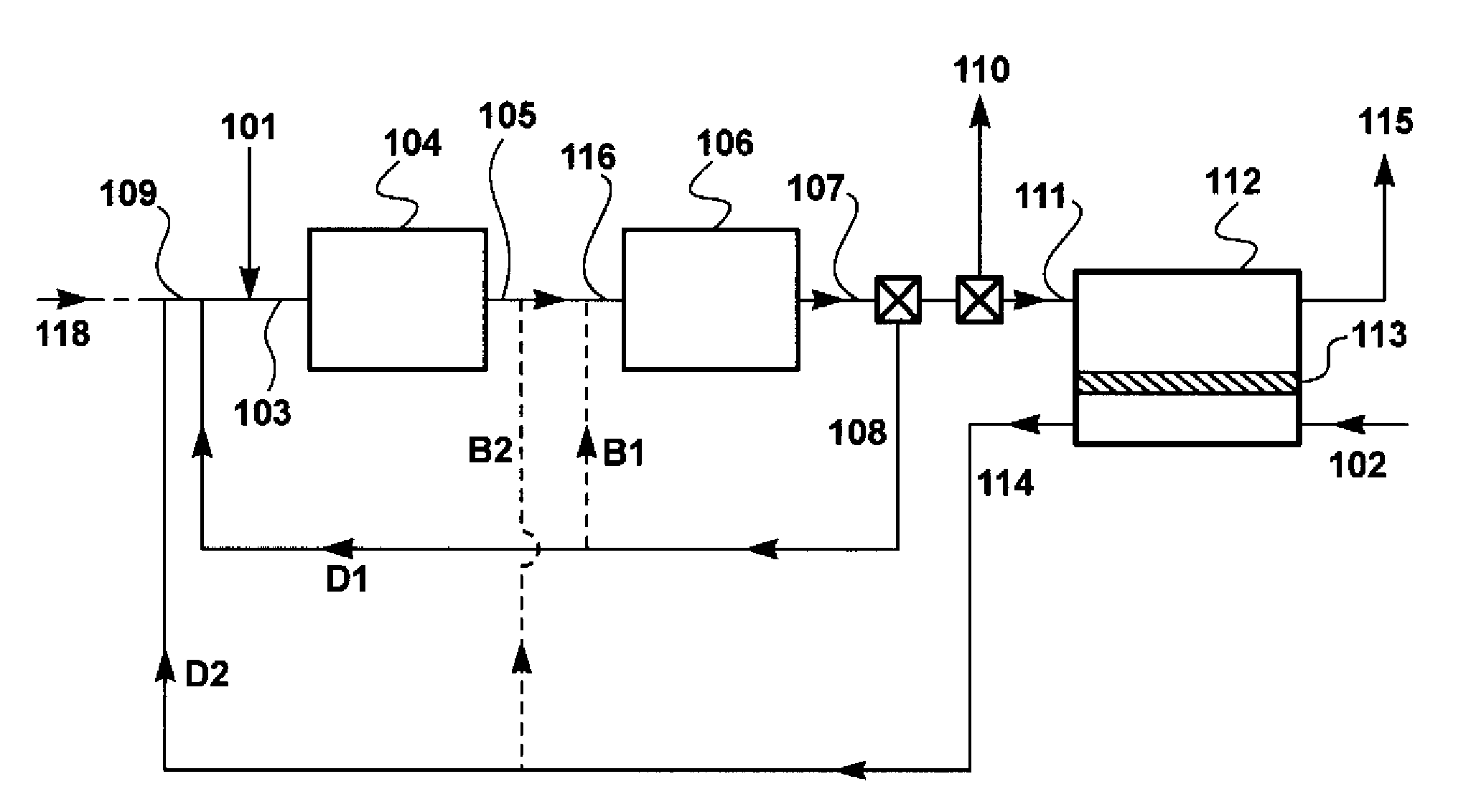

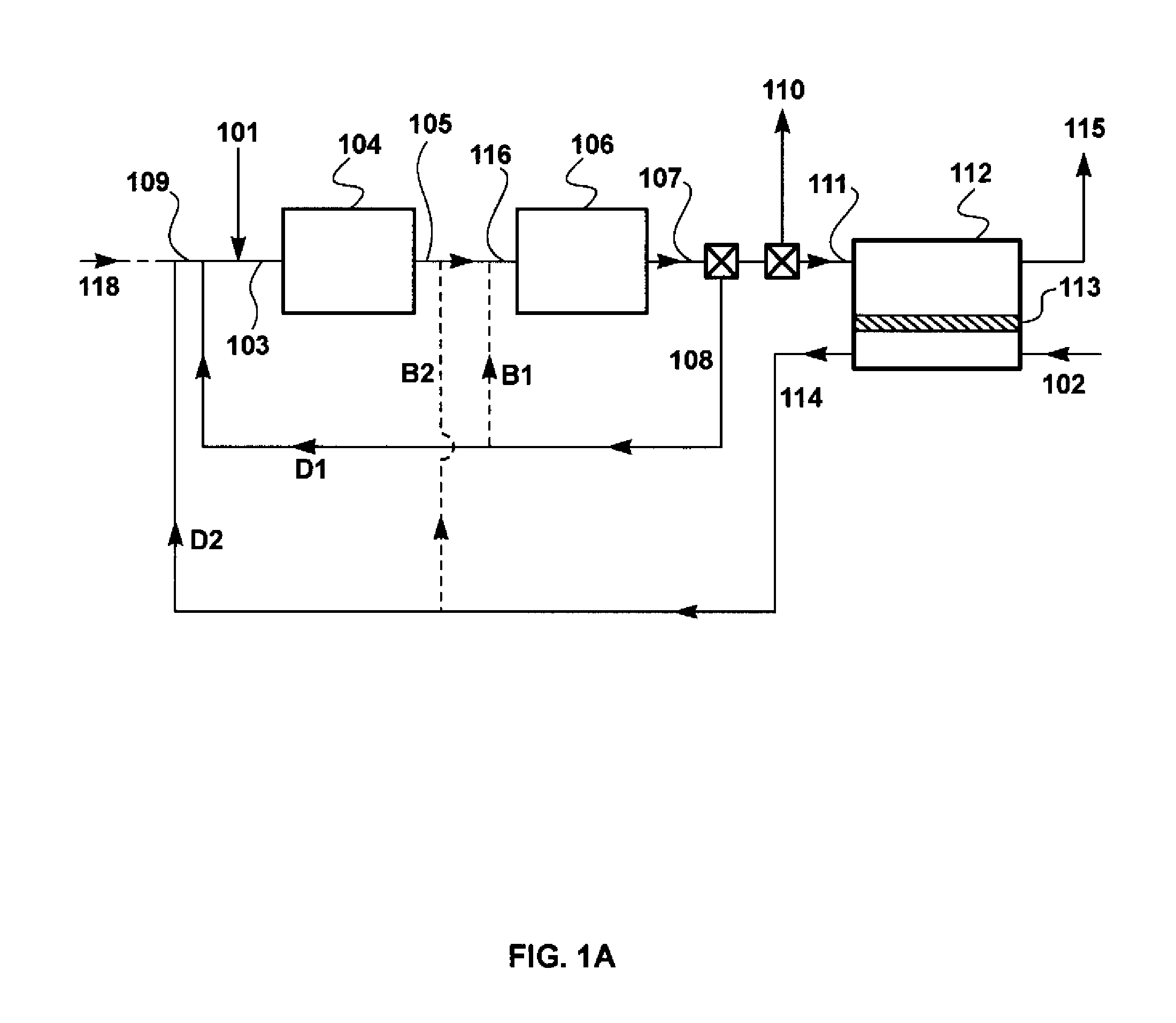

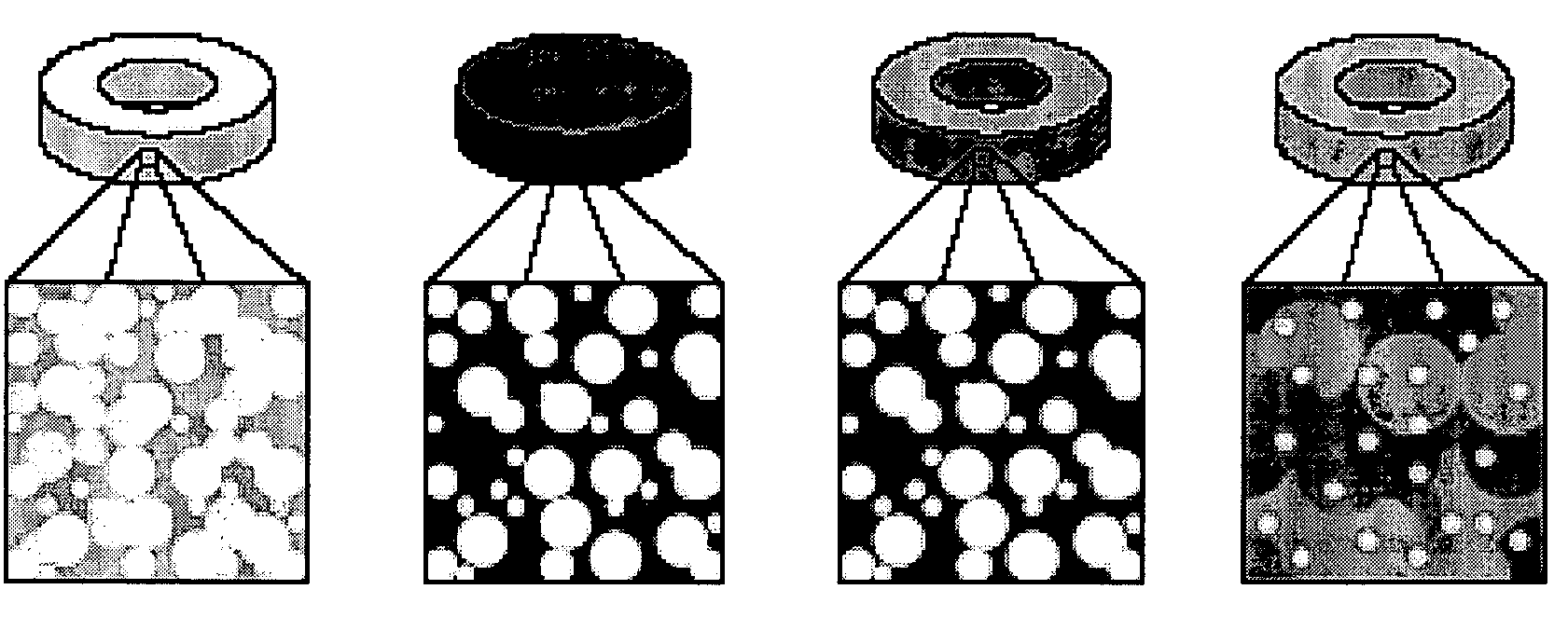

Ultra-thin co2 selective zeolite membrane for co2 separation from post-combustion flue gas

InactiveUS20110094380A1Superior thermal and mechanical and chemical stabilityImprove corrosion resistanceSemi-permeable membranesMembranesOxygenPost synthesis

A method for producing a crystalline silicoaluminophosphate (SAPO) membrane in which a porous support is contacted with SAPO seed crystals to form a SAPO seeded porous support. The SAPO seeded porous support is filled with an aqueous SAPO synthesis gel including a mixture of sources of aluminum, phosphorus, silicon, oxygen, water, and a templating agent, forming a gel-filled porous structure which is then heated to form a SAPO layer of SAPO crystals on a surface of and / or within pores of the porous support. The SAPO layer is calcined, thereby removing the templating agent and forming a supported porous SAPO membrane layer, which is then subjected to a pore size reduction post-synthesis treatment process, producing a reduced pore size supported porous SAPO membrane layer having an average pore size of less than about 0.38 nm.

Owner:GAS TECH INST

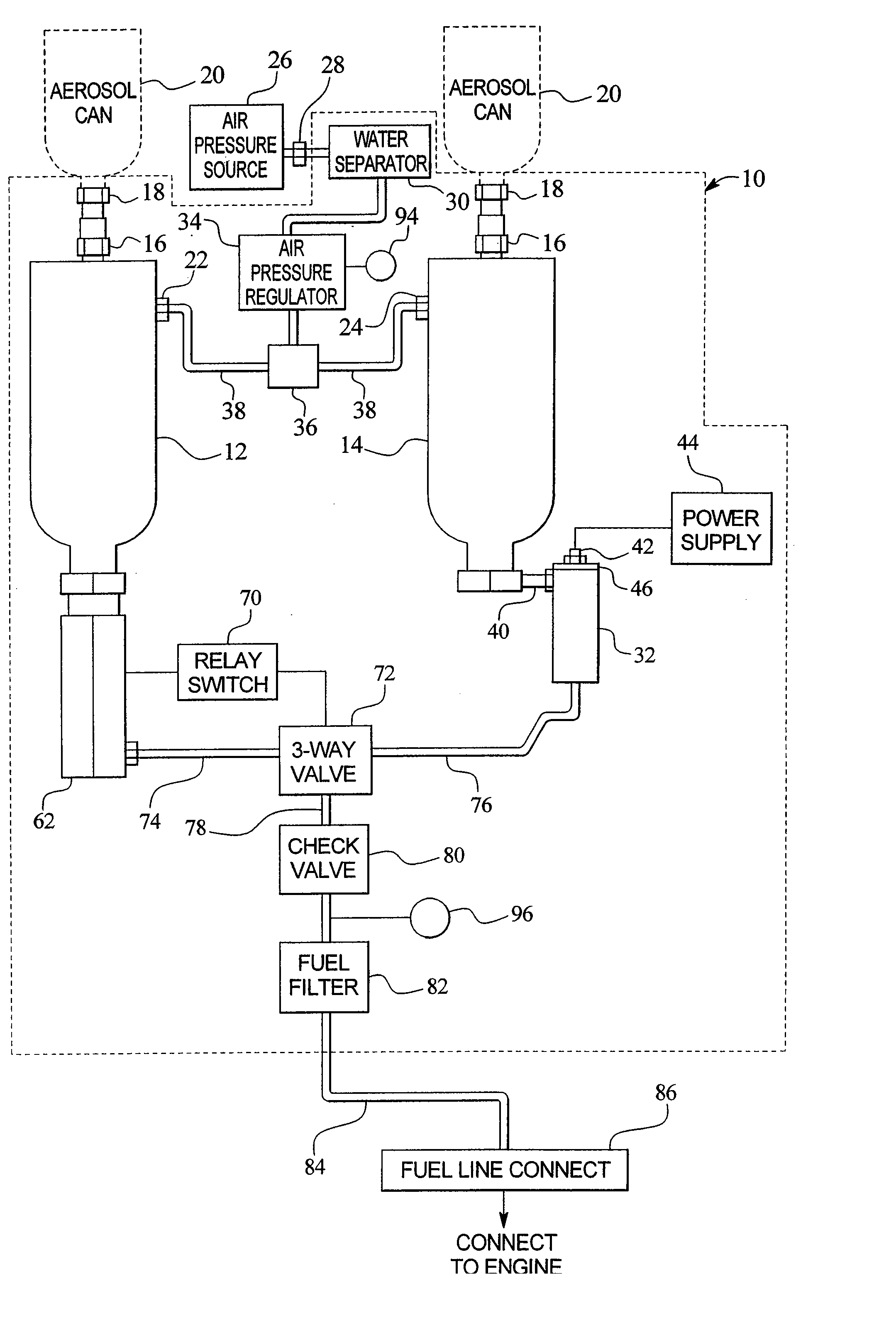

Apparatus and methods for cleaning combustion systems

ActiveUS20070012342A1Emission reductionHollow article cleaningFuel injection apparatusCombustion systemOxygen sensor

The invention provides compositions and methods for more thoroughly cleaning internal combustion engines, fuel systems and emission systems and that operate with reduced toxic emissions. The invention provides an apparatus that contains at least one vessel for receiving a cleaning fluid and an electrode in a cleaning fluid flow path configured to apply a charge to a cleaning fluid. The cleaning fluids are unique fuel derived products which do not contain detergents. The apparatus is unique in that it can provide any of several cleaning processes including a pre-combustion cleaning process, a post-combustion cleaning process or a combined pre-combustion and post-combustion cleaning process. The method is particularly effective at cleaning oxygen sensors in exhaust systems.

Owner:CPS PROD CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com