Composition for reducing emission of CO and NOx of FCC regeneration flue gas and preparation method of composition

A technology for regenerating flue gas and composition, applied in chemical instruments and methods, air quality improvement, chemical/physical processes, etc., can solve the problems of cracking catalyst cracking activity and adverse effects on selectivity, and achieve high reduction of NOx in regenerated flue gas. Effects of emission activity, high activity and stability, high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

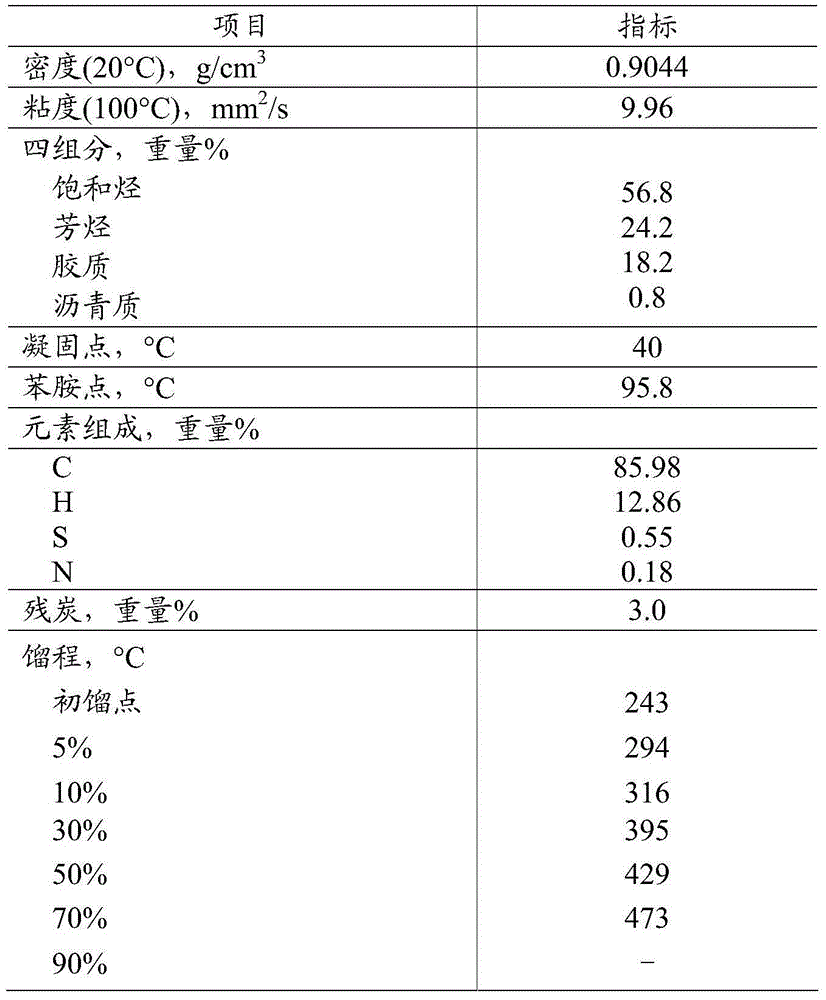

Image

Examples

Embodiment approach

[0023] Provided by the present invention is used to reduce catalytic cracking regeneration flue gas CO and NO xThe discharged composition may also contain no more than 5% by weight, such as 0.1 to 5% by weight, of one or more metal additive components selected from the non-rare earth elements of Groups IB to VIIB, based on oxides, usually the metal The content of the additive component is no more than 2% by weight, the metal is preferably one or more of Ti, Zr, V, Cr, Mo, W and Mn, more preferably the metal additive component is a compound of Cr, and Based on the weight of the composition, the Cr content is not more than 2% by weight, for example, 0.2-2% by weight. One embodiment, the described method for reducing catalytic cracking regenerated flue gas CO and NO x The discharged composition is calculated by oxides: (1) 0.5-30% by weight of rare earth elements, (2) 0.01-0.15% by weight of noble metal elements, (3) 0-5% by weight of the metal additive components and (4) the r...

Embodiment 1

[0039] This embodiment illustrates that the present invention is used to reduce FCC regeneration flue gas CO and NO x Preparation of Emission Composition S1.

[0040] Weigh 4kg of pseudo-boehmite, add it to 16kg of deionized water for beating and disperse, add 250mL of hydrochloric acid to acidify for 20min, add CeO 2 1136mL of cerium nitrate solution with a mass content of 240g / L was beaten and dispersed, and then added with Cr 2 o 3 239 mL of chromium nitrate solution with a mass content of 57 g / L was continuously beaten, spray-dried, and calcined at 600° C. for 1 h to obtain the composition carrier M1. Weigh 100g (by weight on a dry basis) of carrier M1, add it to 400mL of water, add PdCl with a mass content of 12.5g / L in terms of PdO 2 Solution 4.8mL, stirred for 20min, filtered to obtain the composition filter cake impregnated with precious metals, the filter cake was rinsed with 80mL ammonia solution with a concentration of 2mol / L, and dried to obtain the composition ...

Embodiment 2

[0042] This embodiment illustrates the reduction of FCC regeneration flue gas CO and NO according to the present invention x Preparation of Emission Composition S2.

[0043] Weigh 4kg pseudo-boehmite, add it to 16kg deionized water for beating and disperse, add 250mL hydrochloric acid for acidification for 20min, add the mass content (in terms of CeO 2 1386 mL of 240 g / L cerium nitrate solution was beaten and dispersed, spray-dried, and calcined at 600° C. for 1 h to obtain the composition carrier M2. Weigh 100g (by weight on a dry basis) of carrier M2, add it to 500mL of water, and add PdCl with a mass content (calculated as PdO) of 12.5g / L 2 The solution was 4.8 mL, stirred for 20 min, filtered to obtain the composition filter cake impregnated with precious metals, the filter cake was rinsed with 100 mL of ammonia solution with a concentration of 2 mol / L, and the filter cake was roasted at 400 ° C for 2 h to obtain the composition S2 of the present invention ( where CeO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com