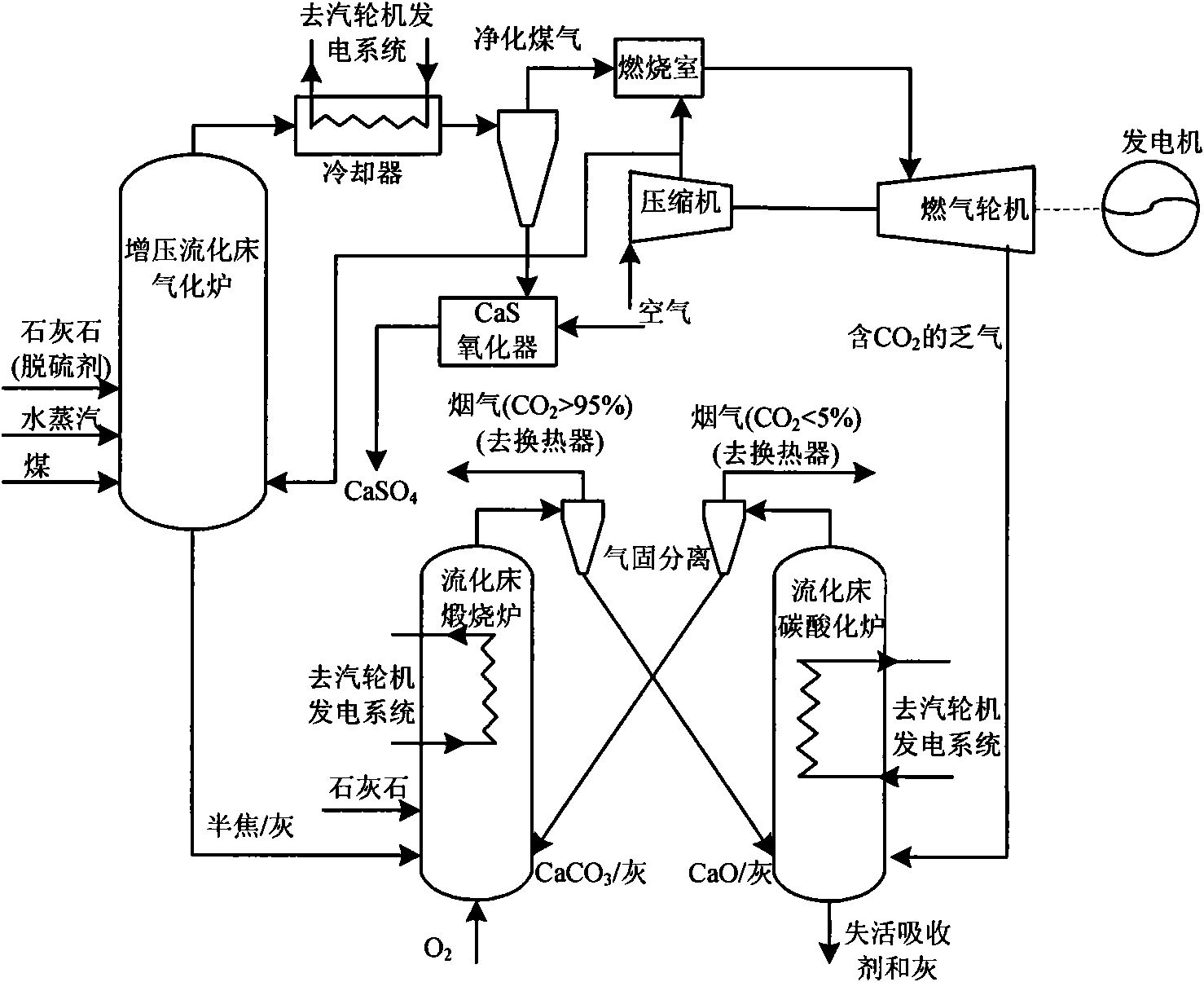

Method for catching carbon dioxide by pressurized fluidized bed combustion combined recycle generating system

A combined cycle power generation and carbon dioxide technology, which is applied in the direction of combined combustion mitigation, gas turbine devices, machines/engines, etc., can solve the problems of gas turbine working capacity limitation, coking in the furnace, etc., to achieve low price, reduce energy consumption, and high system power generation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The coal first enters the pressurized fluidized bed gasifier with air as the gasification agent for partial gasification to generate coal gas and semi-coke. The coal gas is desulfurized by desulfurization agent (limestone) and then filtered to remove dust. The desulfurized product CaS enters the oxidizer. Reacts with air to become CaSO 4 discharge. The air enters the combustion chamber through the compressor, and the purified gas is burned in the combustion chamber to produce high-temperature gas, which enters the gas turbine to generate power. Contains CO 2 The exhaust gas enters the fluidized bed carbonation furnace, where CaO captures the CO in the exhaust gas 2 The carbonation reaction occurs to produce CaCO 3 . Fluidized bed carbonator achieves CaO capture of CO by sensible heat from CaO / ash from fluidized bed calciner and heat from gas turbine exhaust 2 The optimum reaction temperature is 650℃~700℃. CaCO generated in the carbonation furnace 3 Enter the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com