Continuous production process and device of benzoic acid

A production process and production device technology, applied in the field of benzoic acid continuous production process and its device, can solve the problems of difficult temperature control, lower work efficiency, prolong working time, etc., achieve temperature and stability, improve production efficiency, and shorten reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

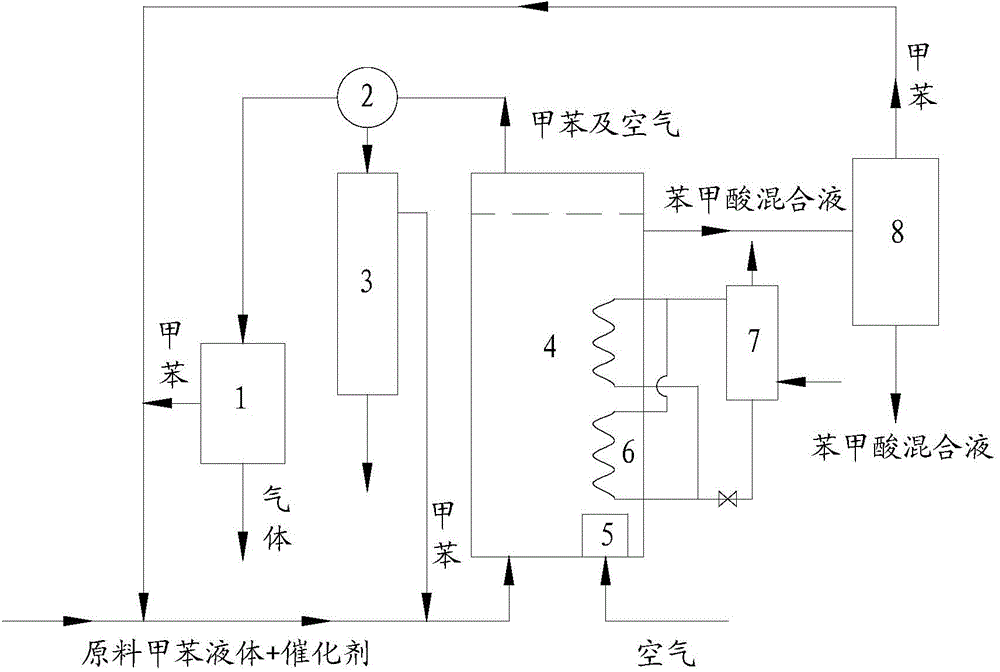

[0059] A continuous production process for benzoic acid, comprising the following steps:

[0060] ⑴. Pass the toluene liquid and the catalyst from the bottom of the reaction tower, the catalyst is mainly octanoic acid metal, and the weight percentage of the metal is: manganese: 1.3%; cobalt: 5%; nickel: 0.3%;

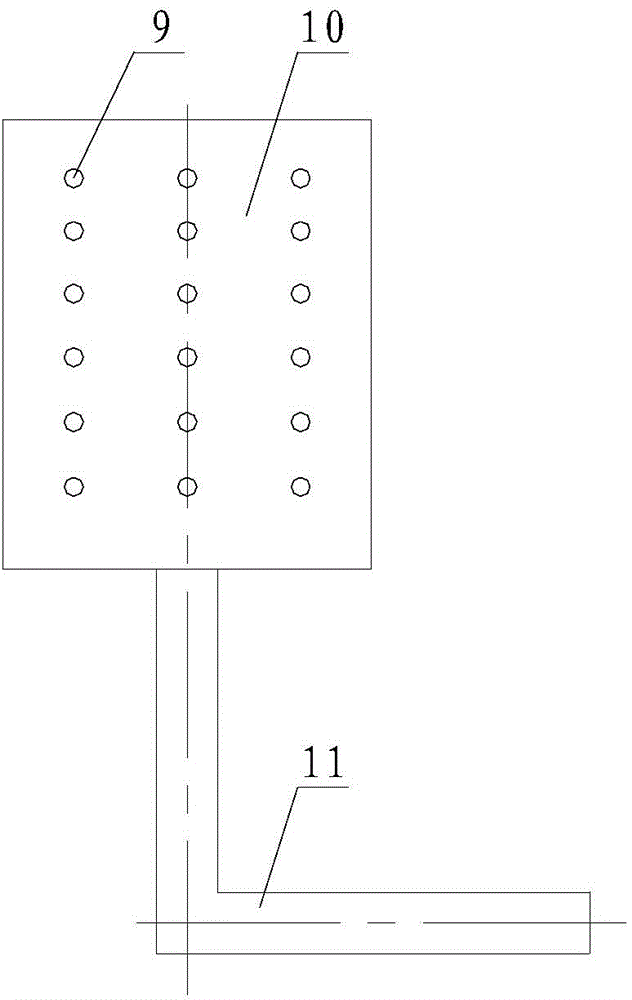

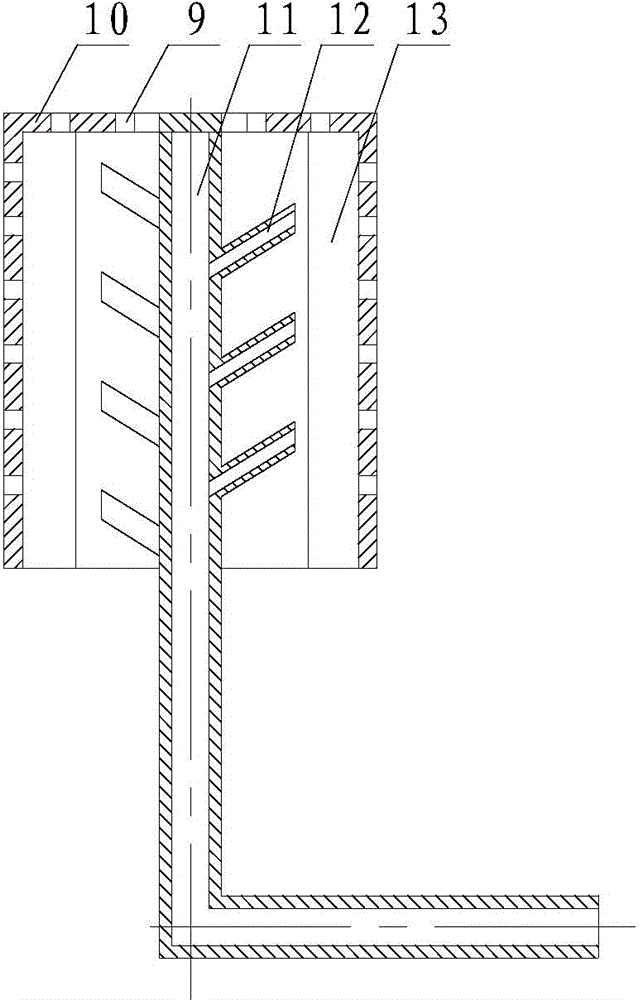

[0061] ⑵. Air is introduced from the bottom of the reaction tower, and the air and toluene liquid react under the action of the catalyst. One or more gas-liquid distributing agitators are installed at the bottom of the reaction tower, and the air is discharged through the distributing agitators, which can fully stir and react with toluene while forming tiny bubbles;

[0062] ⑶. During the reaction process, use a temperature-controlling heat exchanger to control the temperature in the reaction tower, and the temperature range is 160-170°C. The temperature-controlling heat exchanger is two tubular heat exchangers used in series;

[0063] ⑷. After the reaction material pa...

Embodiment 2

[0067] A continuous production process for benzoic acid, comprising the following steps:

[0068] ⑴. Pass the toluene liquid and the catalyst from the bottom of the reaction tower, the catalyst is mainly octanoic acid metal, and the weight percentage of the metal is: manganese: 1.8%; cobalt: 6%; nickel: 0.7%;

[0069] Step (2)-(4) is identical with embodiment 1.

Embodiment 3

[0071] A continuous production process for benzoic acid, comprising the following steps:

[0072] ⑴. Pass the toluene liquid and the catalyst from the bottom of the reaction tower, the catalyst is mainly octanoic acid metal, and the weight percentage of the metal is: manganese: 2.3%; cobalt: 7%; nickel: 1%;

[0073] Step (2)-(4) is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com