Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

441 results about "Catalyst selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selectivity is the ability of a particular catalyst to favour the desirable reactions rather than the undesirable reactions. For example in the Catalytic Reformer Unit, the aim is to convert the Paraffins & Naphthenes into Iso-Paraffins and Aromatics.

Method for improving the selectivity of a catalyst and a process for the epoxidation of an olefin

A method for improving the selectivity of a supported highly selective epoxidation catalyst comprising silver in a quantity of at most 0.17 g per m2 surface area of the support, which method comprisescontacting the catalyst, or a precursor of the catalyst comprising the silver in cationic form, with a feed comprising oxygen at a catalyst temperature above 250° C. for a duration of up to 150 hours, andsubsequently decreasing the catalyst temperature to a value of at most 250° C.; anda process for the epoxidation of an olefin, which process comprisescontacting a supported highly selective epoxidation catalyst comprising silver in a quantity of at most 0.17 g per m2 surface area of the support, or a precursor of the catalyst comprising the silver in cationic form, with a feed comprising oxygen at a catalyst temperature above 250° C. for a duration of up to 150 hours, andsubsequently decreasing the catalyst temperature to a value of at most 250° C. and contacting the catalyst with the feed comprising the olefin and oxygen.

Owner:SHELL USA INC

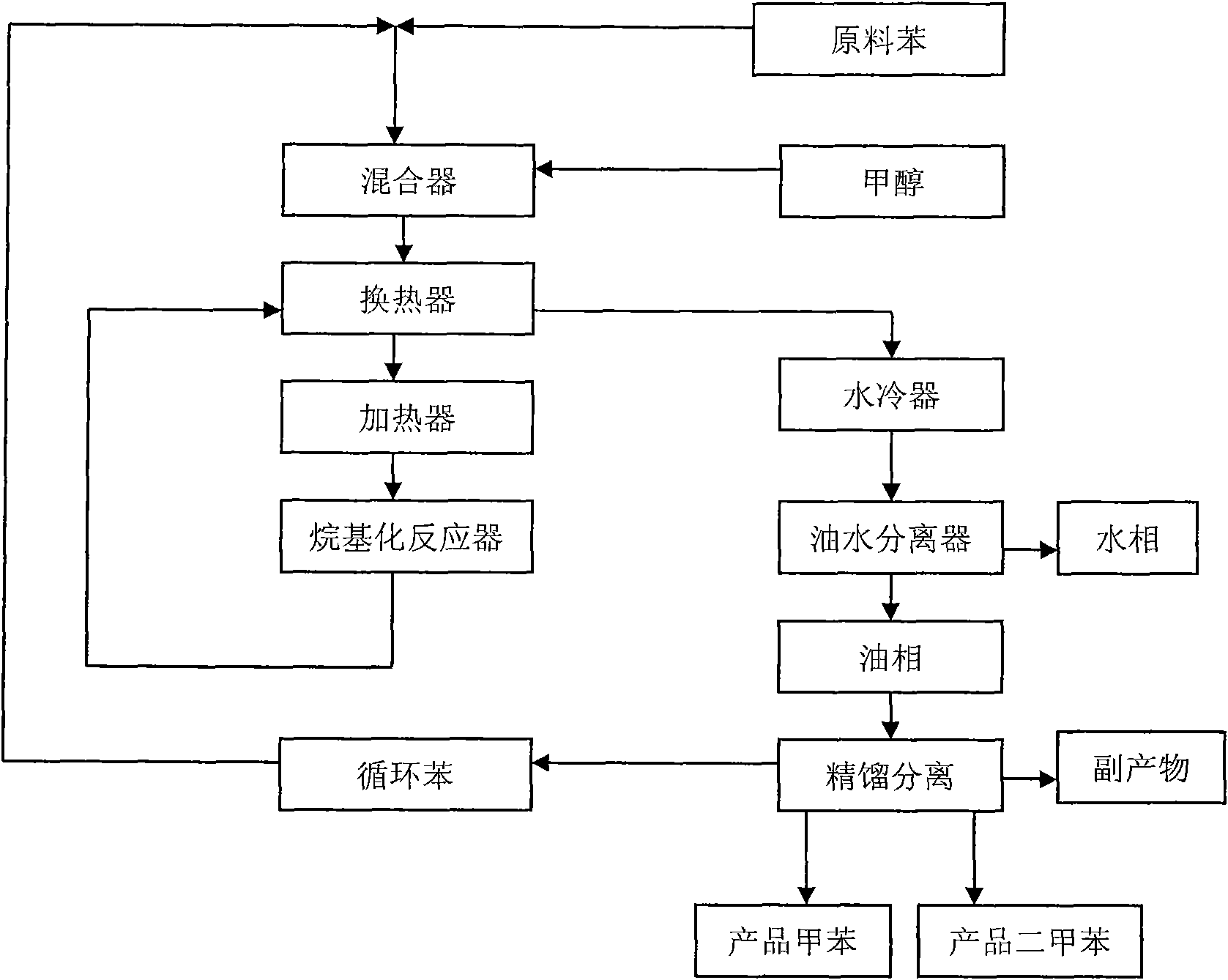

Method for preparing methylbenzene or dimethylbenzene by alkylating benzene with methanol

InactiveCN101624327AHigh selectivityEasy to adjustMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferReaction temperature

The invention relates to a method for preparing methylbenzene or dimethylbenzene by alkylating benzene with methanol, comprising the following steps: raw material benzene and recycle benzene rectified to be recovered are mixed together with the methanol, mixed materials exchange heat with materials on an outlet of an alkylation reactor, and then the mixed materials are heated to achieve alkylation reaction temperature and subject to alkylation reaction to obtain a product under the condition that an acidic catalyst exists; the product is cooled by water to reduce temperature and then subjects to oil-water separation to obtain a water phase and an oil phase, wherein the water phase is purified to be recycled, the oil phase is rectified to be separated to obtain the benzene, the methylbenzene and the dimethylbenzene, and the methylbenzene and the dimethylbenzene are used as target products to separate from a reaction system; and unreacted benzene is returned to be circulated and continuously reacted together with the raw material benzene. The invention has high catalyst selectivity and can conveniently regulate the selectivity of the methylbenzene and the dimethylbenzene.

Owner:山西恒扬科技有限公司 +1

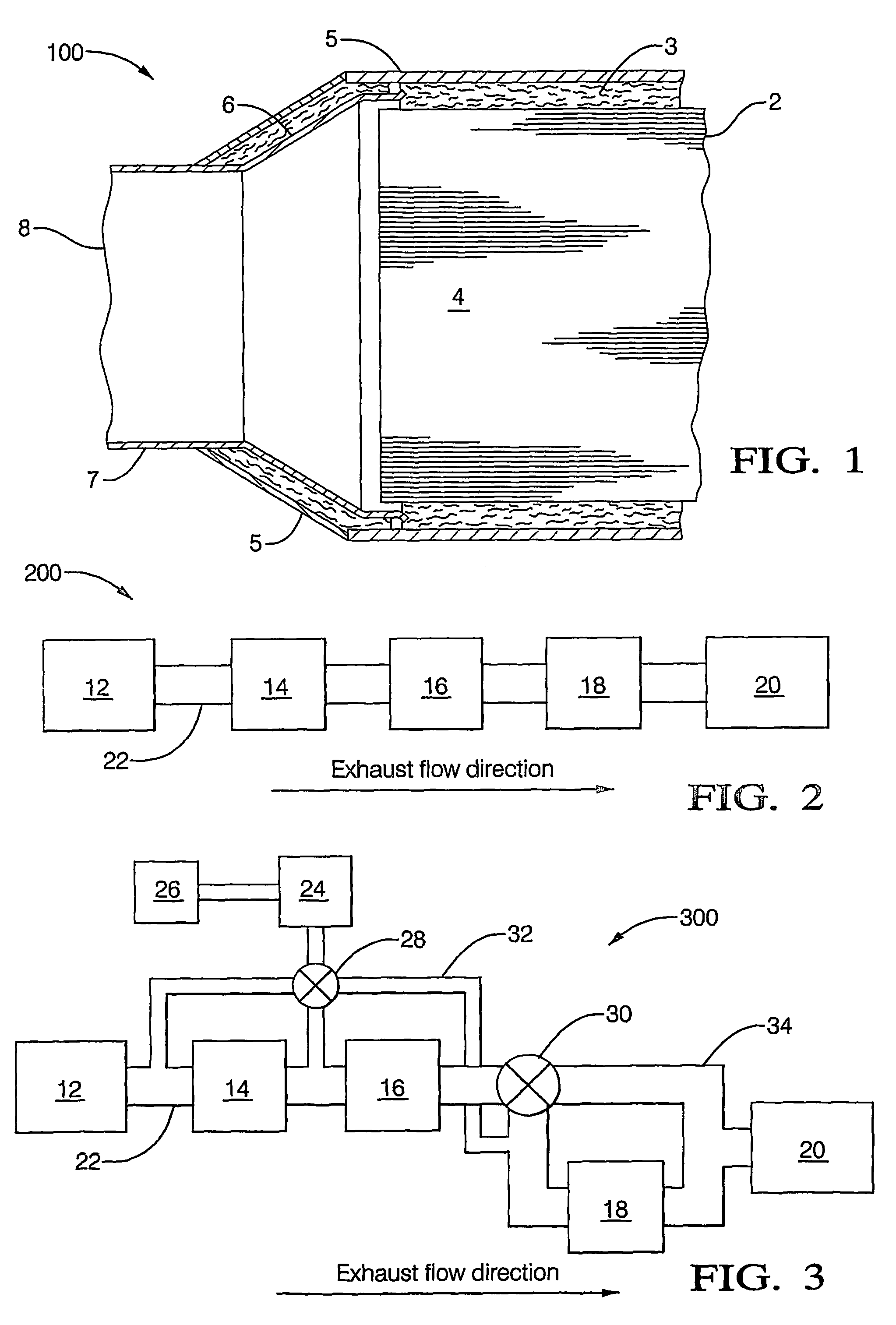

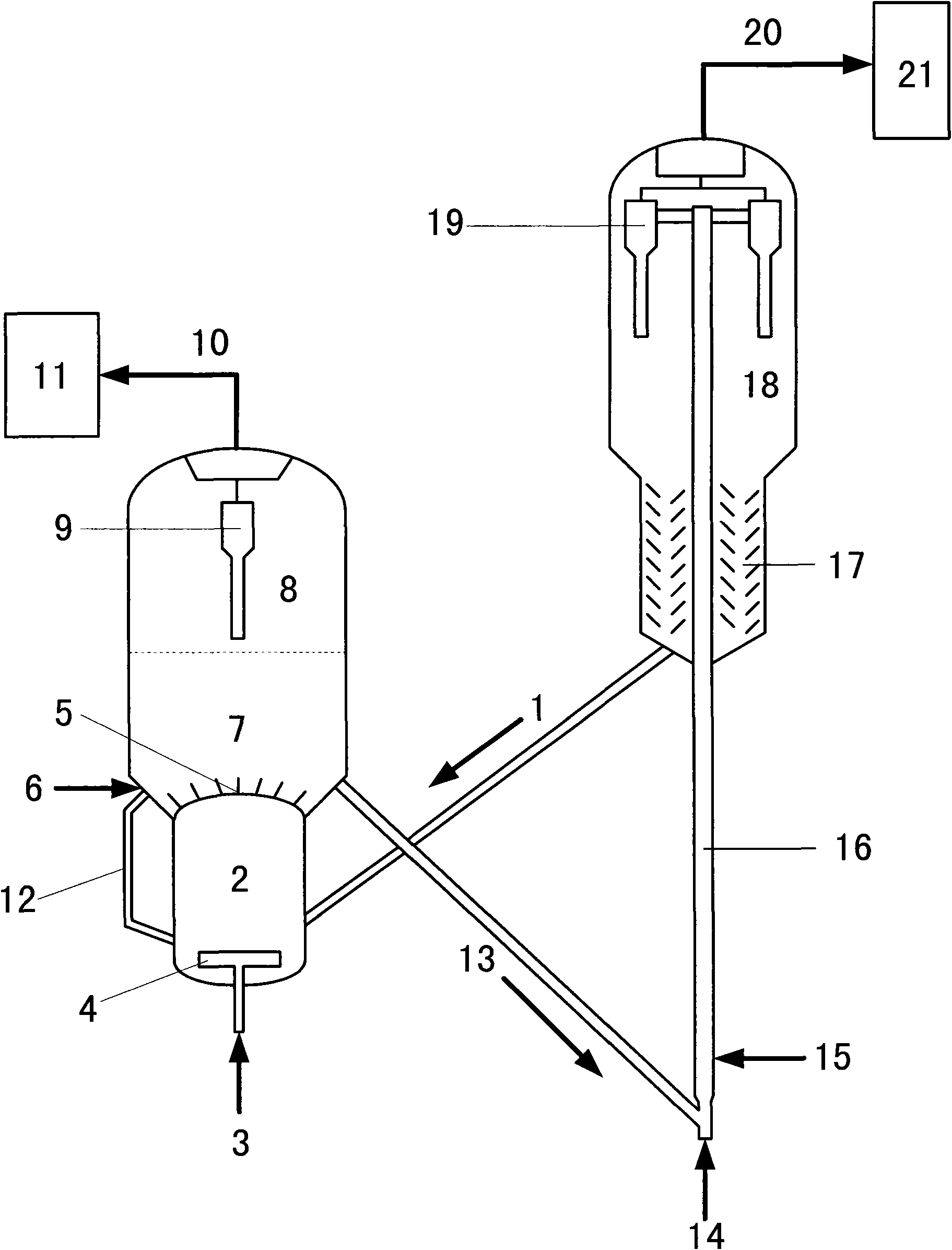

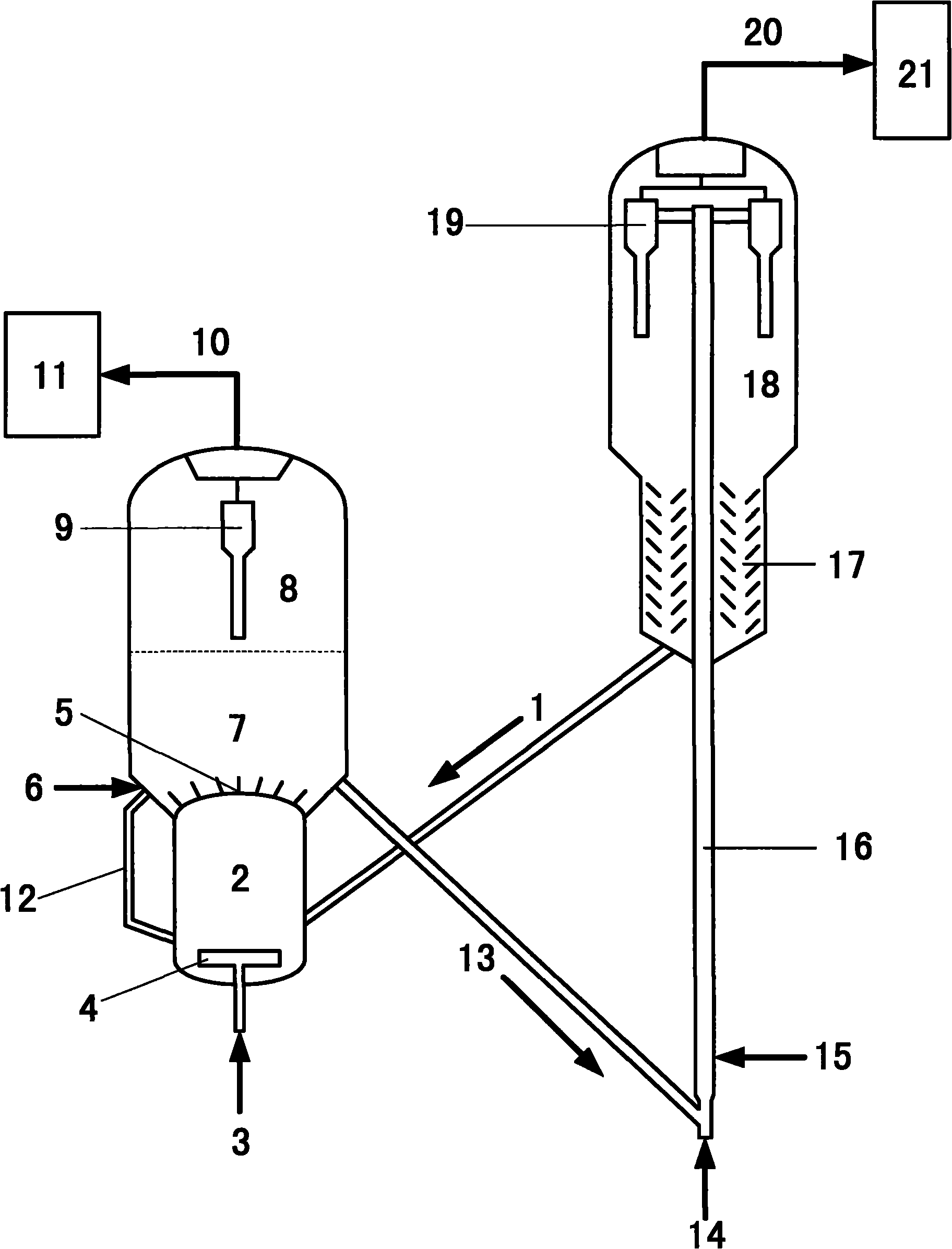

System and method of NOx abatement

A NOX abatement system includes a first NOX adsorber capable of being disposed in-line and downstream of and in fluid communication with an engine. The NOX abatement system further includes a selective catalytic reduction catalyst disposed in-line and downstream of, and in direct fluid communication with, the first NOX adsorber. The selective catalytic reduction catalyst is capable of storing ammonia. An off-line reformer is disposed in selective communication with and upstream of the first NOX adsorber and the selective catalytic reduction catalyst. The reformer is capable of producing a reformate that includes primarily hydrogen and carbon monoxide.

Owner:DELPHI TECH INC

Catalyst for producing dimethylbenzene by alkylation of benzene and methanol

InactiveCN102600887AHigh xylene selectivityHigh catalytic activityMolecular sieve catalystsMolecular sieve catalystBenzeneMolecular sieve

The invention relates to a catalyst for producing dimethylbenzene by alkylation of benzene and methanol. The catalyst mainly overcomes the shortcomings of low utilization rate of methanol alkylation, low conversion rate of benzene and low selectivity of dimethylbenzene in the actual application of the catalyst reported in previous literatures. Through the adoption of the technical scheme of loading alkaline earth and rare-earth metal elements on a hydrogen-type MCM-22 molecular sieve, the problem is well solved. The catalyst provided by the invention is high in selectivity and can be used in the production process of dimethylbenzene by alkylation of benzene and methanol.

Owner:TONGJI UNIV

Three-layer multi-metal oxide catalyst and preparation method thereof

ActiveCN102247863ASolve crackingOrganic compound preparationCatalyst activation/preparationHigh concentrationBULK ACTIVE INGREDIENT

The invention provides a three-layer multi-metal oxide catalyst and a preparation method thereof. The catalyst contains various metal oxides which are taken as active ingredients; and the composition of the active ingredients can be expressed by the following general formulas: MoaBibNieCogSihAiBjCkOx (I), MoaBibNieTifOm (II) and MoaBibSicAldOn (III). The catalyst is applicable to the process of producing corresponding unsaturated aldehyde by selectively oxidizing propylene or isobutene, and can effectively prevent a large number of byproducts from being generated because high-concentration organic substances in feed gas are initially contacted with the catalyst to form higher hot spots, so that the selectivity of catalyst is improved.

Owner:PETROCHINA CO LTD

Self limiting catalyst composition and propylene polymerization process

ActiveUS20070027275A1Poor surfaceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorCarboxylic acid

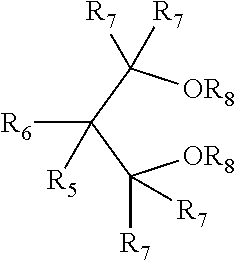

A catalyst composition for the polymerization of propylene comprising one or more Ziegler-Natta procatalyst compositions comprising one or more transition metal compounds and one or more esters of aromatic dicarboxylic acid internal electron donors; one or more aluminum containing cocatalysts; a selectivity control agent (SCA) comprising at least one silicon containing compound containing at least one C1-10 alkoxy group bonded to a silicon atom, and one or more activity limiting agent (ALA) compounds comprising one or more aliphatic or cycloaliphatic carboxylic acids; alkyl-, cycloalkyl- or alkyl(poly)(oxyalkyl)-(poly)ester derivatives thereof; or inertly substituted derivatives of the foregoing.

Owner:WR GRACE & CO CONN

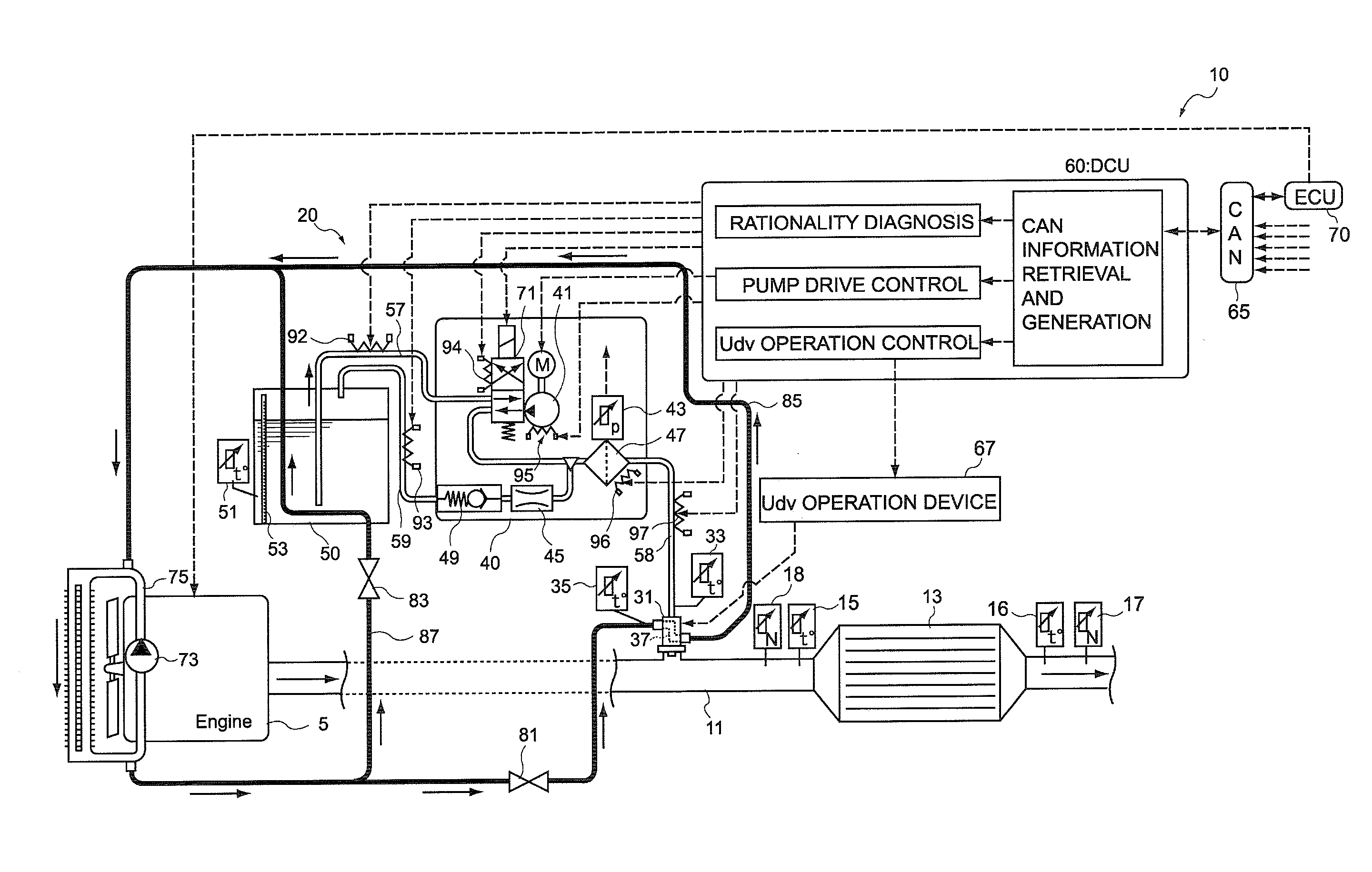

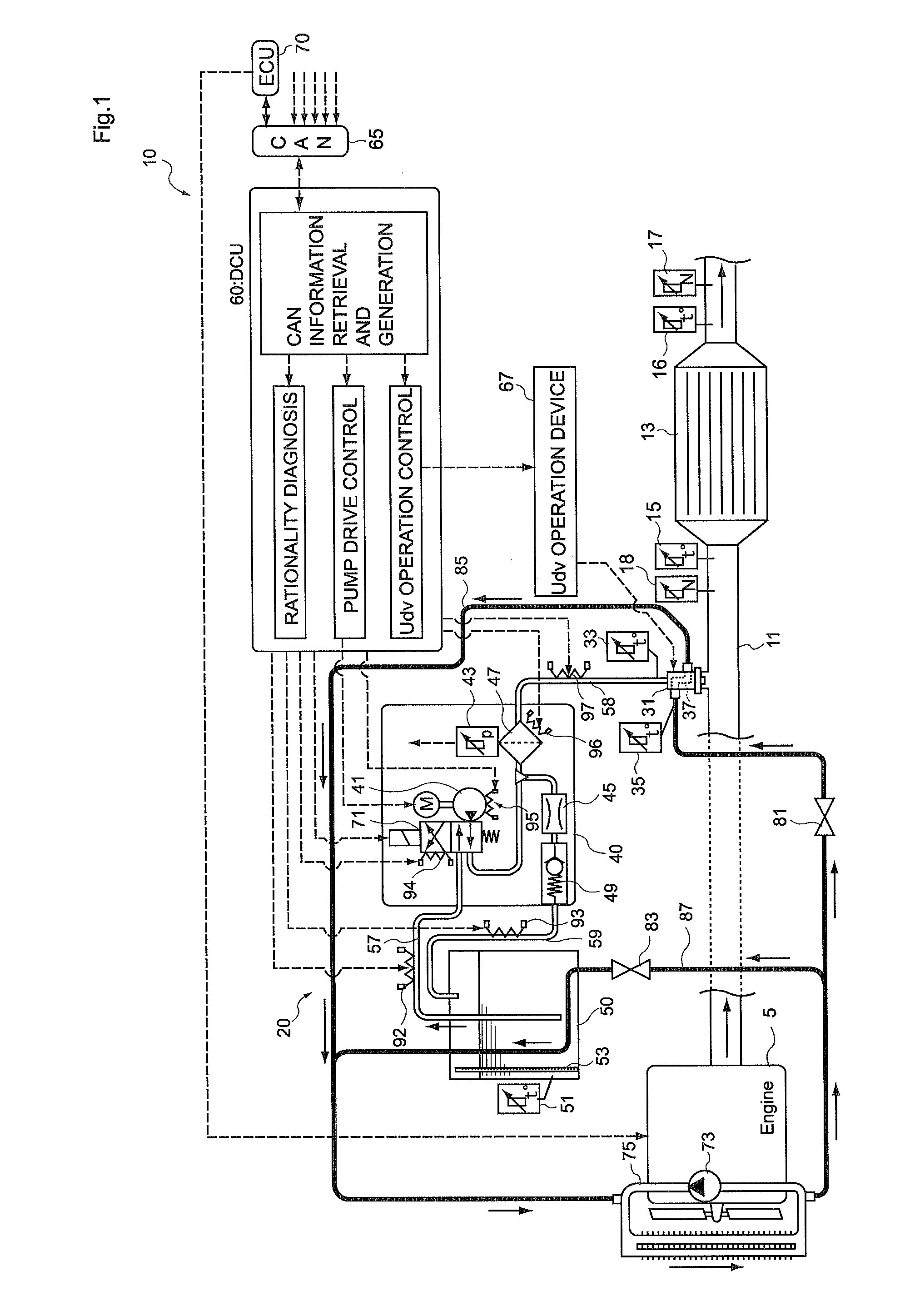

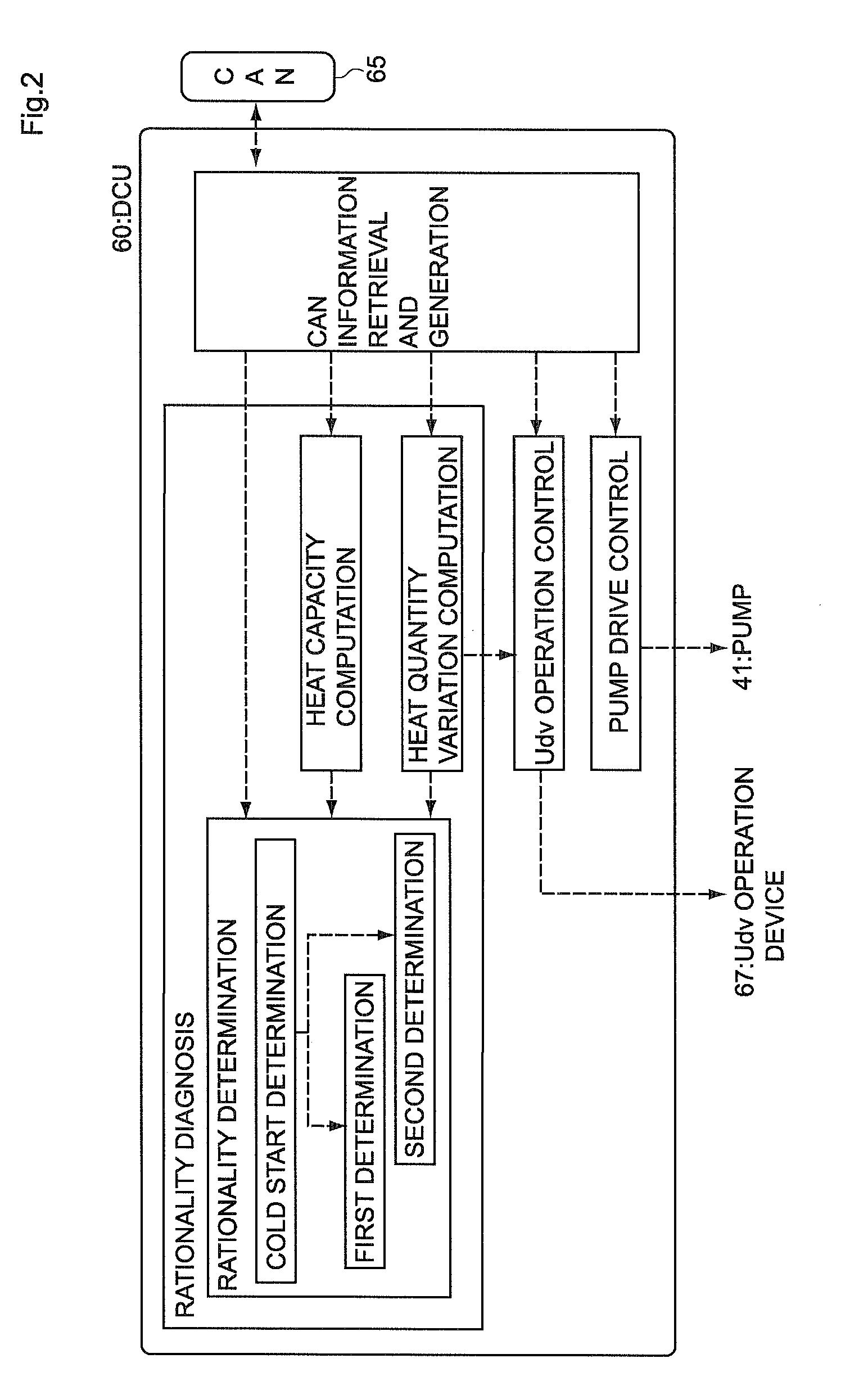

Temperature sensor plausibility diagnosis unit and plausibility diagnosis method and internal combustion engine exhaust purification apparatus

ActiveUS20100319651A1Accurately determineReliability of plausibilityVehicle testingThermometer detailsDiagnosis methodsProcess engineering

To provide a temperature sensor plausibility diagnosis unit and plausibility diagnosis method that can accurately perform plausibility diagnosis of a temperature sensor in a desired timing and an exhaust purification apparatus equipped with the plausibility diagnosis unit.A temperature sensor plausibility diagnosis unit which, in an exhaust purification apparatus of an internal combustion engine that delivers an additive inside a storage tank to an exhaust pipe on the upstream side of a reduction catalyst and selectively reduces and purifies NOx in exhaust with the reduction catalyst, is for performing plausibility diagnosis of a temperature sensor disposed inside the storage tank, the temperature sensor plausibility diagnosis unit being equipped with an additive heat capacity calculating portion that calculates the heat capacity of the additive inside the storage tank, a heat quantity variation calculating portion that calculates an increase or decrease in the quantity of heat that the additive inside the storage tank receives, and a plausibility diagnosing portion that determines the plausibility of the temperature sensor by comparing an estimated temperature course of the additive estimated from the heat capacity of the additive and the increase or decrease in the quantity of heat with a sensor temperature course of the additive detected by the temperature sensor.

Owner:BOSCH CORP

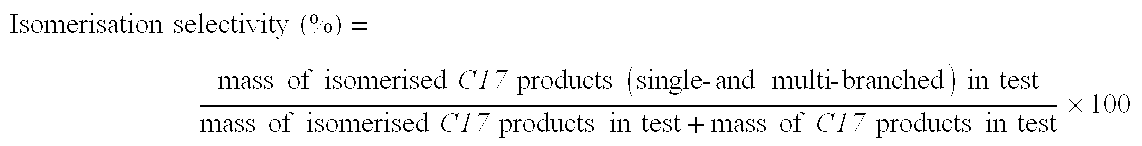

Catalyst based on a molecular sieve and a process for selective hydroisomerisation of long linear and/or slightly branched paraffins using that catalyst

InactiveUS6198015B1Low pour pointHigh viscosity indexHydrocarbon by isomerisationMolecular sieve catalystsAlkaneMolecular sieve

The invention concerns a process for selective hydroisomerization of compounds with an n-alkane chain containing more than 10 carbon atoms, in which the compound to be treated is brought into contact with a catalyst comprising at least one hydro-dehydrogenating element and at least one molecular sieve having a one- or two-dimensional pore network, the accessible pore openings of which are delimited by 10 oxygen atoms, and a distance termed the bridging distance between the pores of less then 0.70 nm, and the zeolite is such that a catalyst which undergoes a standard n-heptadecane isomerization test has, for a conversion of 95%, a selectivity of at least 70% for isomerized products, and the catalyst contains at least 5% by weight of at least one hydro-dehydrogenating element selected from the group formed by non noble GVIII metals, GVIB metals, and niobium, and the catalyst preferably contains phosphorous.The sieve is preferably a NU-10, NU-23, NU-87, EU-13 or Theta-1 zeolite.

Owner:INST FR DU PETROLE

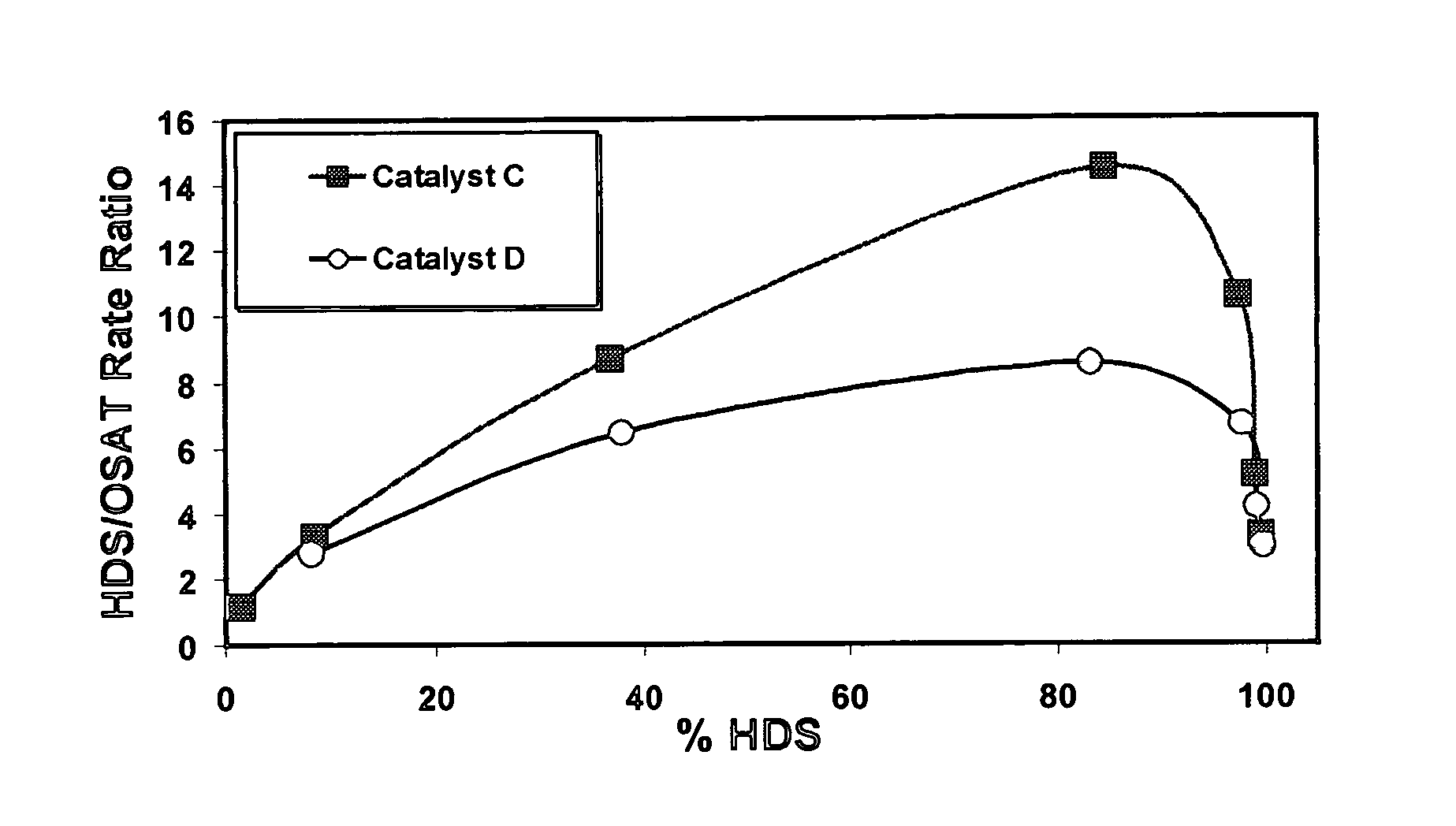

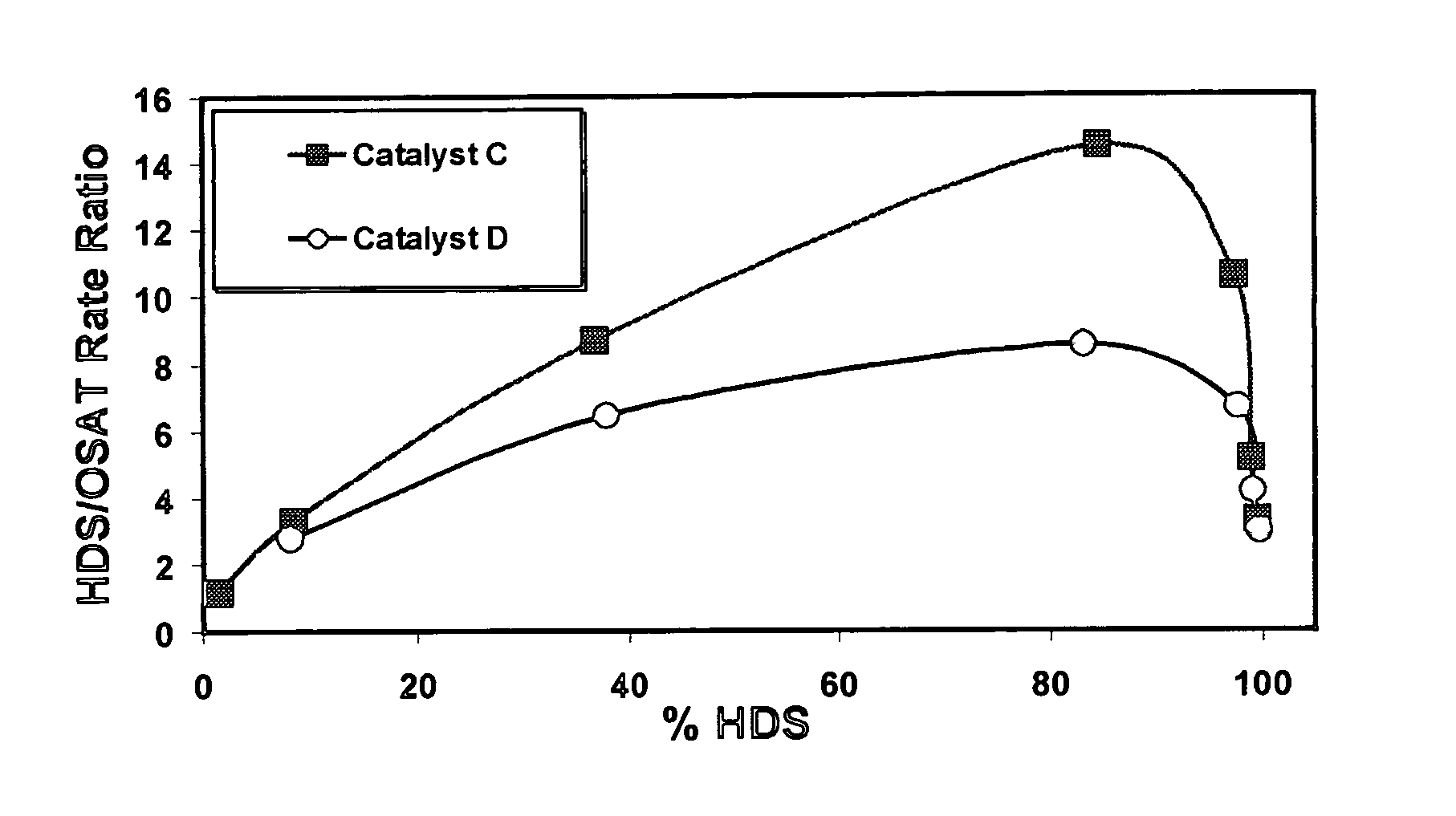

Selective hydrodesulfurization catalyst

ActiveUS20060052235A1Molecular sieve catalystsRefining to eliminate hetero atomsNaphthaHydrodesulfurization

Owner:EXXON RES & ENG CO

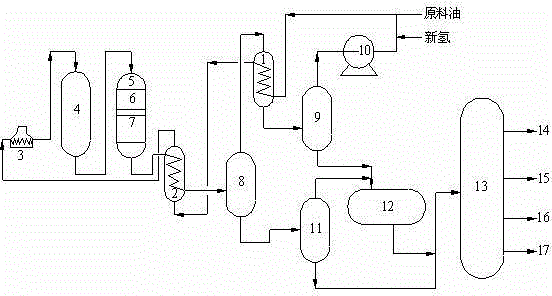

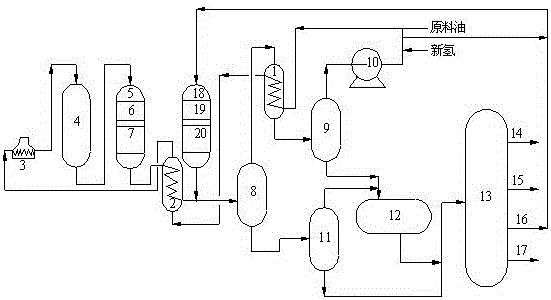

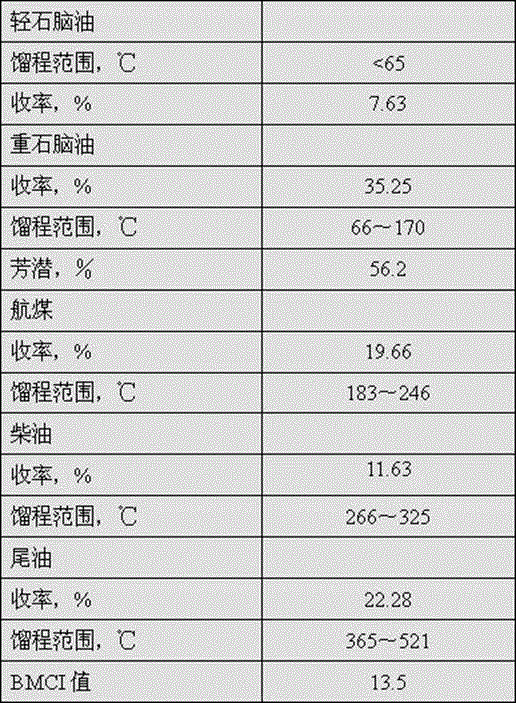

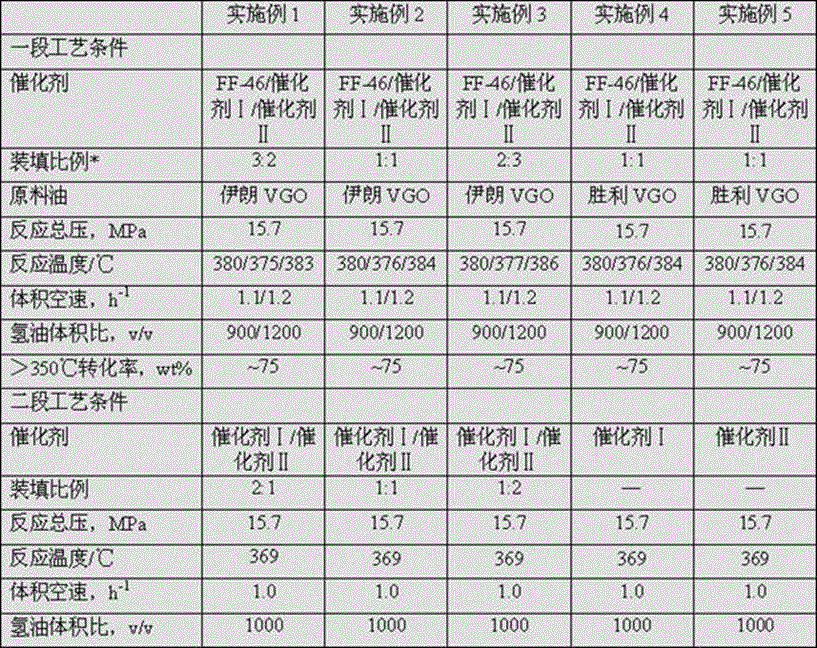

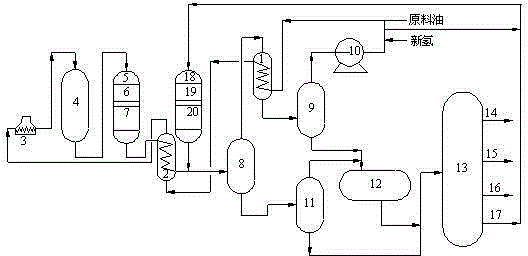

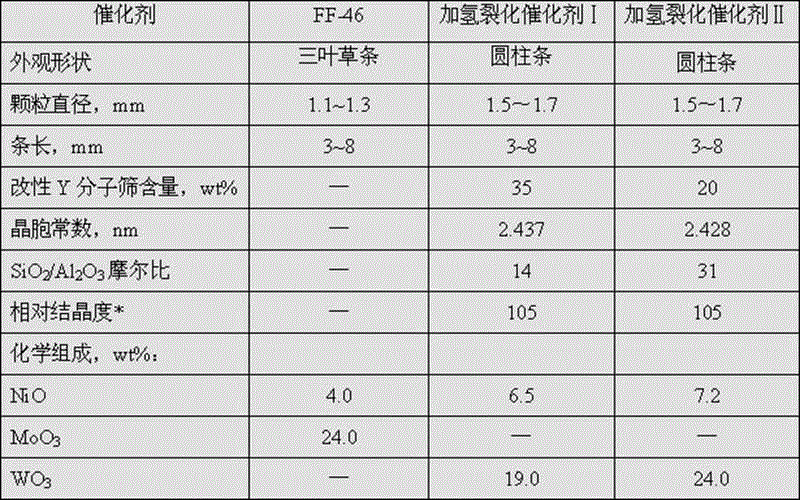

Low energy consumption hydrocracking method for producing high-quality jet fuel

ActiveCN104611019AReduce consumptionSave engineering investmentTreatment with hydrotreatment processesMolecular sieveThermodynamics

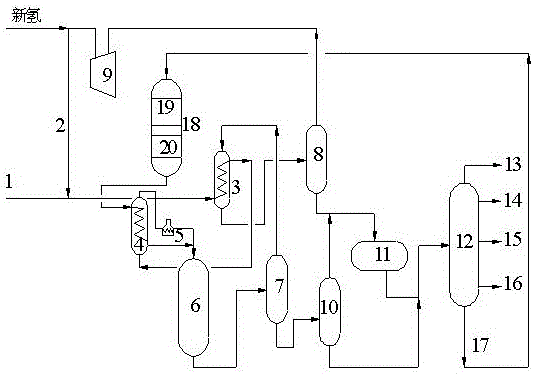

The present invention discloses a low energy consumption hydrocracking method for producing a high-quality jet fuel. According to the method, a raw material oil and hydrogen gas are mixed, then are subjected to heat exchange two times, and then sequentially pass through a hydrorefining reaction zone and a hydrocracking reaction zone, wherein the hydrocracking reaction zone comprises at least two hydrocracking catalysts, the upstream is filled with a catalyst I, the downstream is filled with a catalyst II, the catalyst I contains 15-50 wt% of a modified Y molecular sieve, the catalyst II contains 3-30 wt% of the modified Y molecular sieve, and the modified Y molecular sieve content in the catalyst I is 10-25% higher than the modified Y molecular sieve content in the catalyst II. According to the method of the present invention, the high temperature high pressure countercurrent heat transfer technology and the hydrocracking catalyst grading technology are organically combined, and the hydrocracking reaction heat is comprehensively utilized, such that the characteristics of the two different types of the hydrocracking catalysts are completely provided, and the catalyst selectivity is maintained while the target product quality is improved, and the project investment and the operating energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

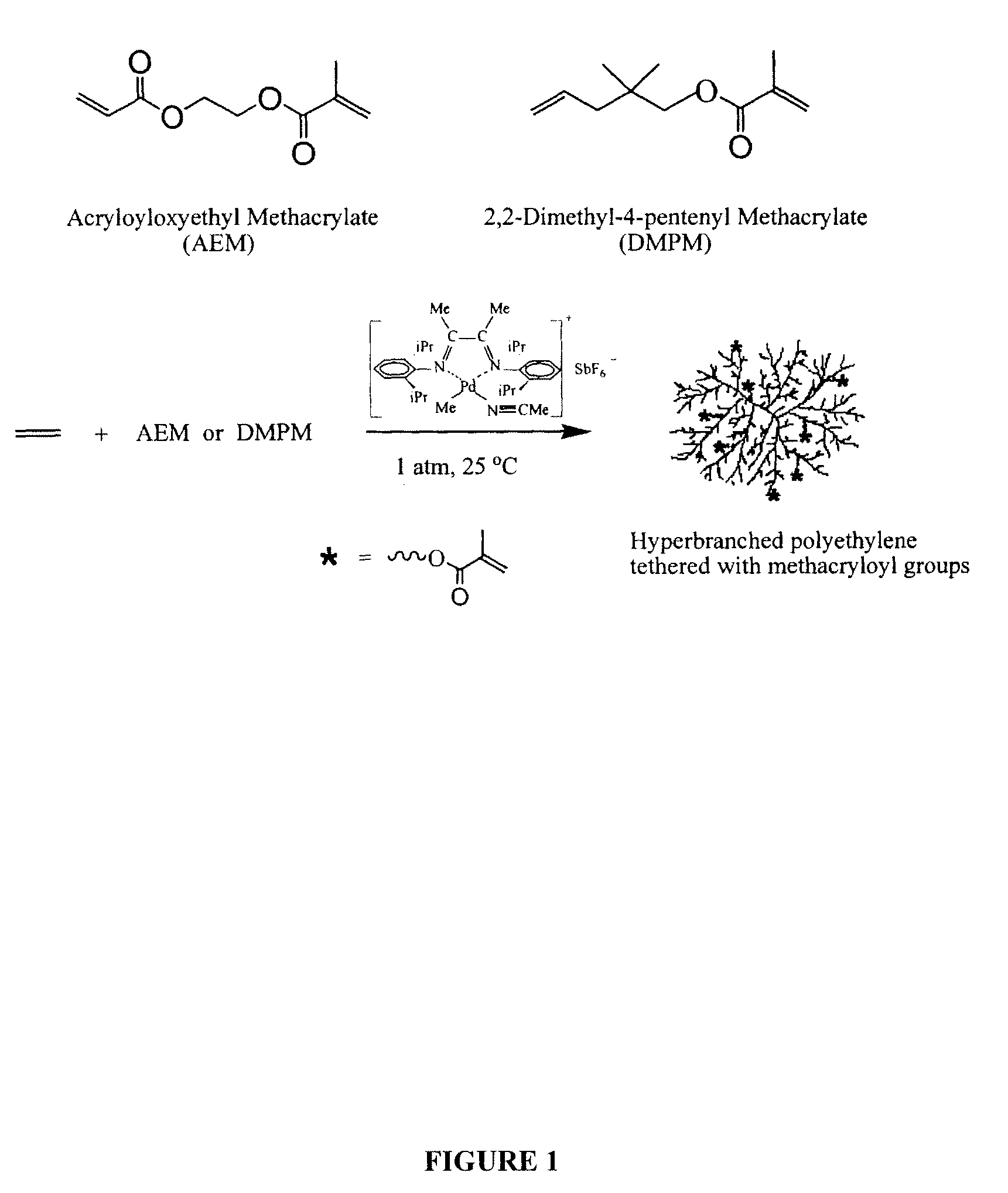

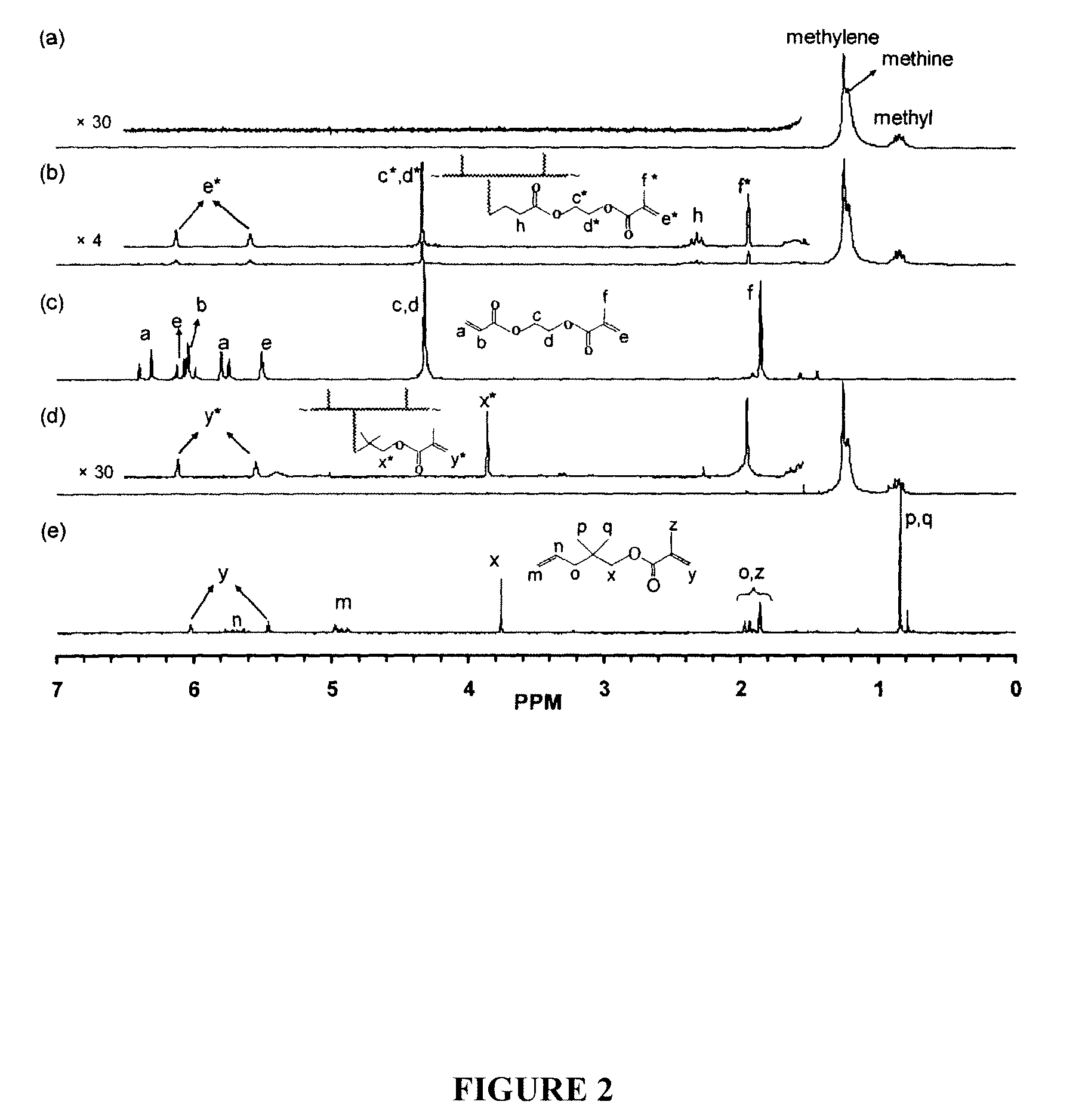

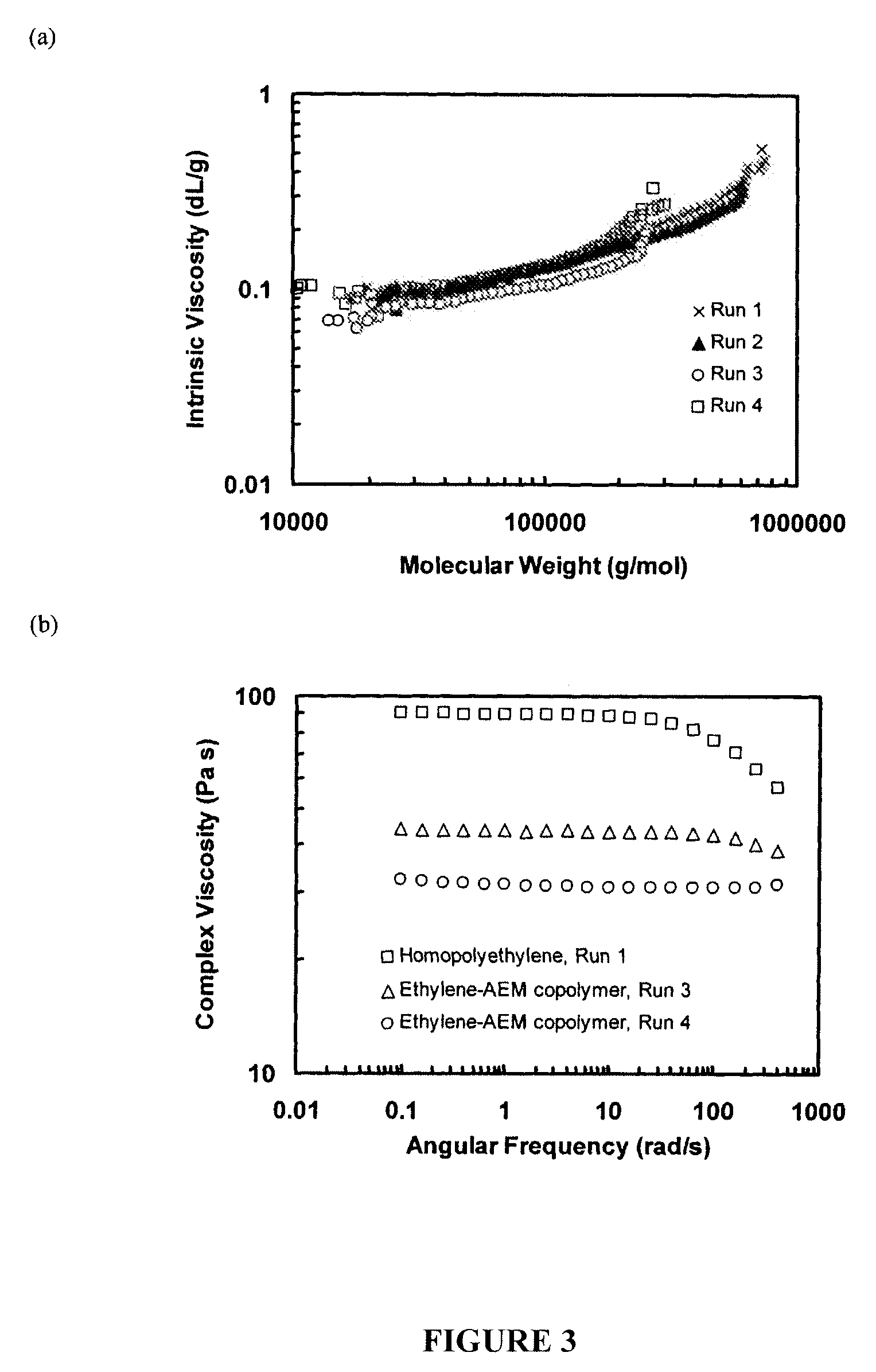

Branched polyolefin polymer tethered with polymerizable methacryloyl groups and process for preparing same

InactiveUS20090253878A1Readily scaled up to industrial scaleSimple and efficientPolyolefinPolyvinyl polymer

A polyolefin polymer comprising one or more terminal polymerizable methacryloyl groups (i.e. tethered to the main body of the polymer) and a novel process for preparing same are herein disclosed. A hyperbranched polyethylene polymer and a process for preparing same are also disclosed. The polymer is prepared by a novel one-pot copolymerization reaction of an olefin, such as ethylene, and a heterobifunctional comonomer comprising a methacryloyl group, catalyzed by a late transition metal α-diimine catalyst which is selectively non-reactive towards methacryloyl groups. The process allows for preparation of polymers with various chain topologies, including linear, branched, and hyperbranched topologies. The terminal methacryloyl groups within the polymer are reactive in further polymerization reactions. Thus, the polymer may be used in materials and applications which require cross-linking or further polymerization, for example, UV / thermal / radical curable crosslinkers for use in thermoset applications.

Owner:YE ZHIBIN +2

Treatment method for improving selectivity of catalytic cracking catalyst

ActiveCN101927199AUniform activityUniform selectivityMolecular sieve catalystsCatalyst activation/preparationWater vaporFluidized bed

The invention discloses a treatment method for improving the selectivity of a catalytic cracking catalyst, which comprises the following steps: filling a fresh catalyst into a phase fluidized bed, contacting the fresh catalyst with aging medium containing water vapor, aging under a certain hydrothermal condition to obtain an aged catalyst; and adding the aged catalyst into an industrial catalytic cracking device. In the method, the activity and selective distribution of the catalyst in the catalytic cracking device are more uniform to obviously improve the selectivity of the catalytic cracking catalyst, thereby obviously reducing dry gas productivity and coke productivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

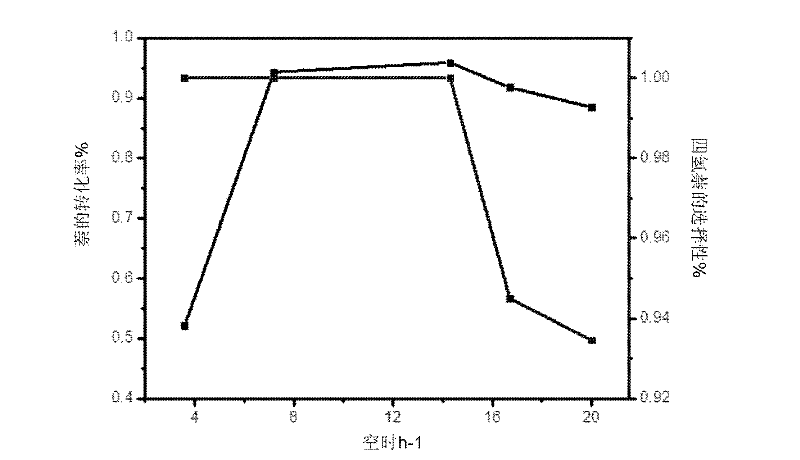

High-selectivity catalyst for naphthalene hydrogenation reaction for preparing tetrahydronaphthalene and preparation method thereof

InactiveCN102600877AHigh selectivityPrevent polymerization and sinteringMolecular sieve catalystsHydrocarbon by hydrogenationMicrowave pyrolysisHydrogenation reaction

The invention discloses high-selectivity carbide catalyst for naphthalene hydrogenation reaction for preparing tetrahydronaphthalene and a quick microwave preparation method thereof, belonging to the technical field of catalyst material application and preparation. The method comprises the steps of: fully grinding complex compounds containing relevant metals and carriers, or supporting the complex compounds containing the relevant metals onto the surfaces of carriers through a solution impregnation method and conducting microwave pyrolysis in inert gas to form the supported carbide catalyst. The invention provides the high-efficiency carbide catalyst with 100 percent selectivity aiming at the naphthalene hydrogenation reaction for preparing the tetrahydronaphthalene and a simple, convenient, quick, environmental-friendly and energy-saving preparation method thereof. The prepared carbide particles are evenly dispersed on the carriers, so that the situation of surface carbon deposition is avoided. The contradiction between high catalyst selectivity and high cost is successfully avoided, and therefore the high-selectivity carbide catalyst and the preparation method thereof have promising industrial application prospect.

Owner:DALIAN UNIV OF TECH

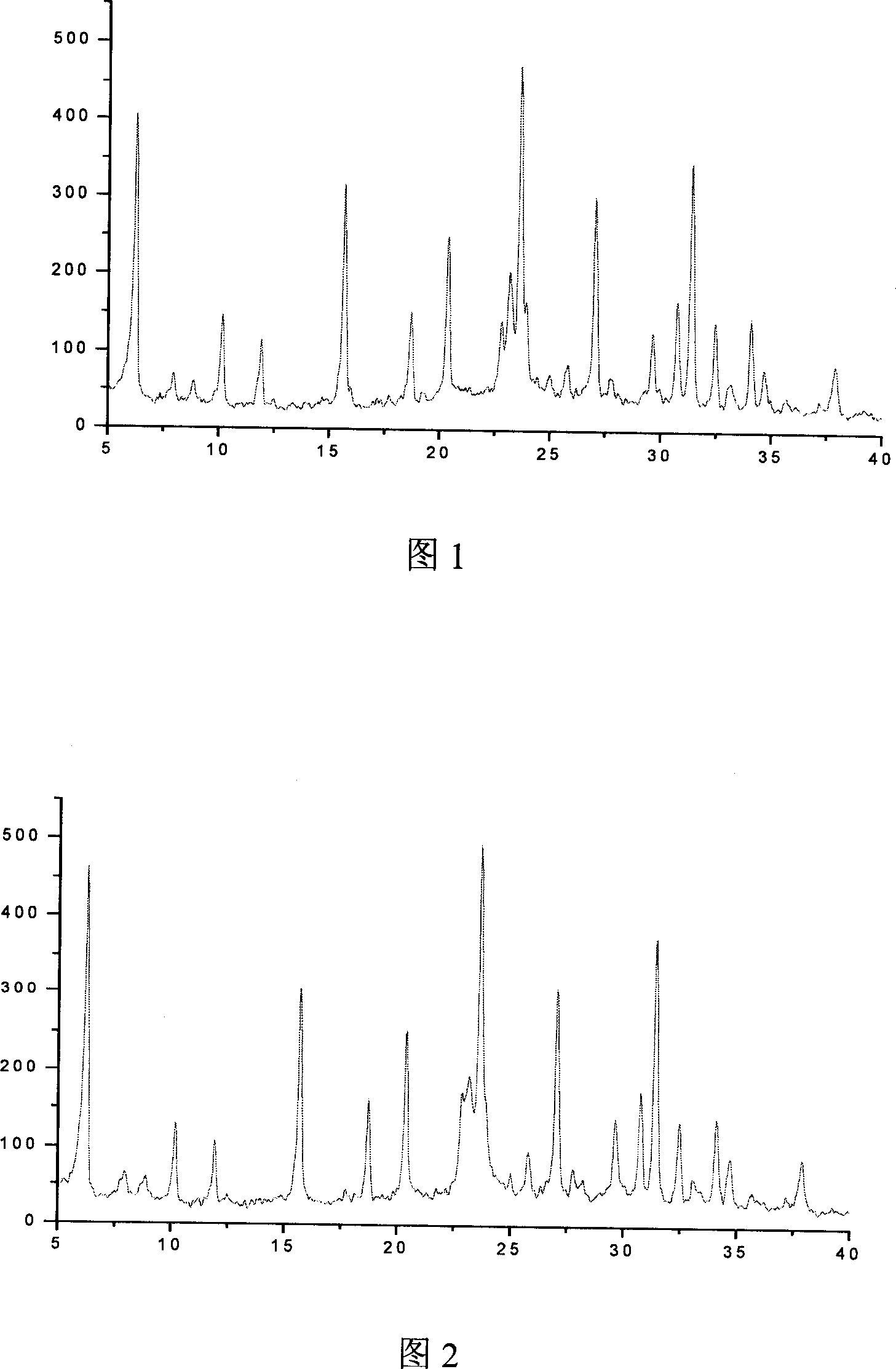

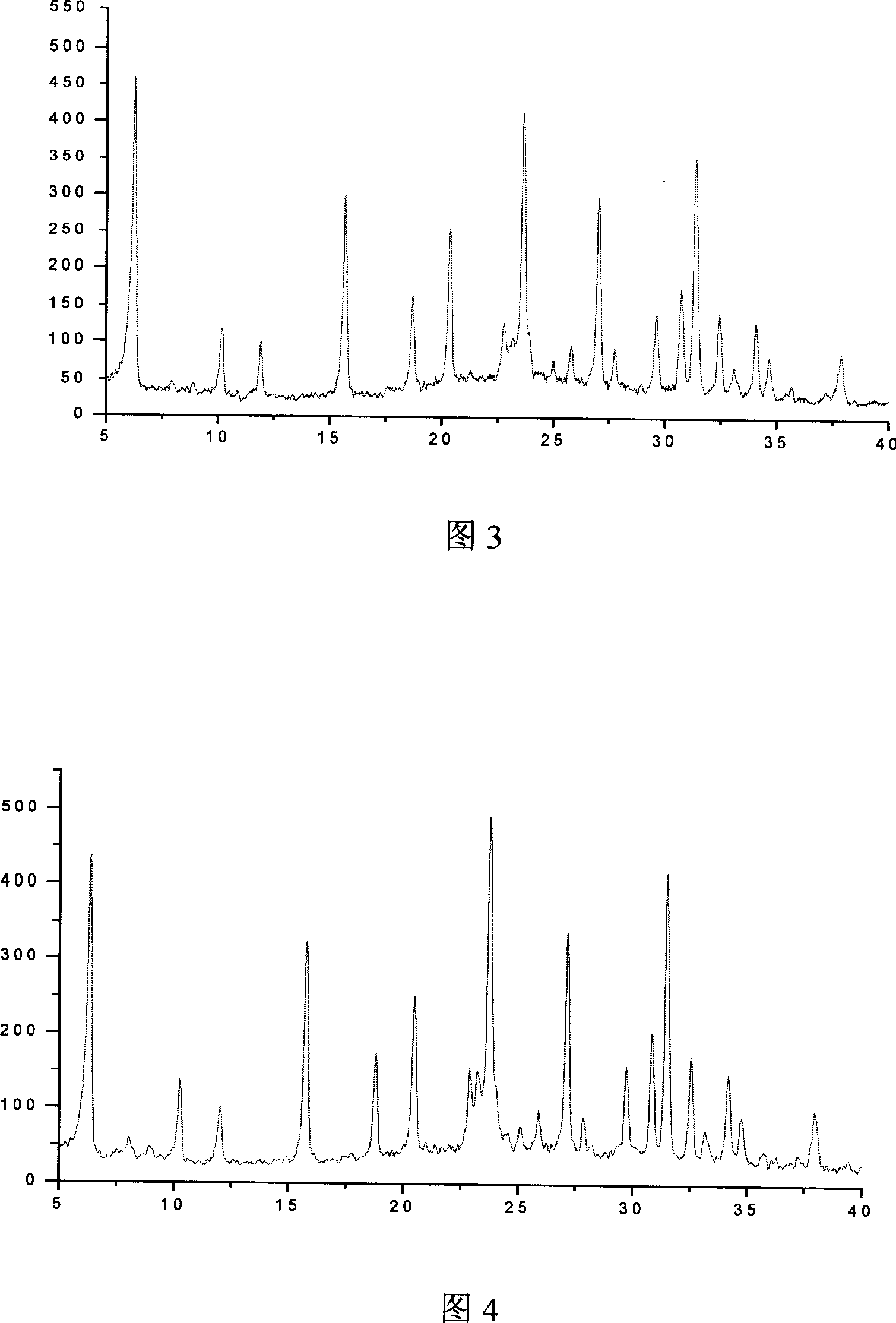

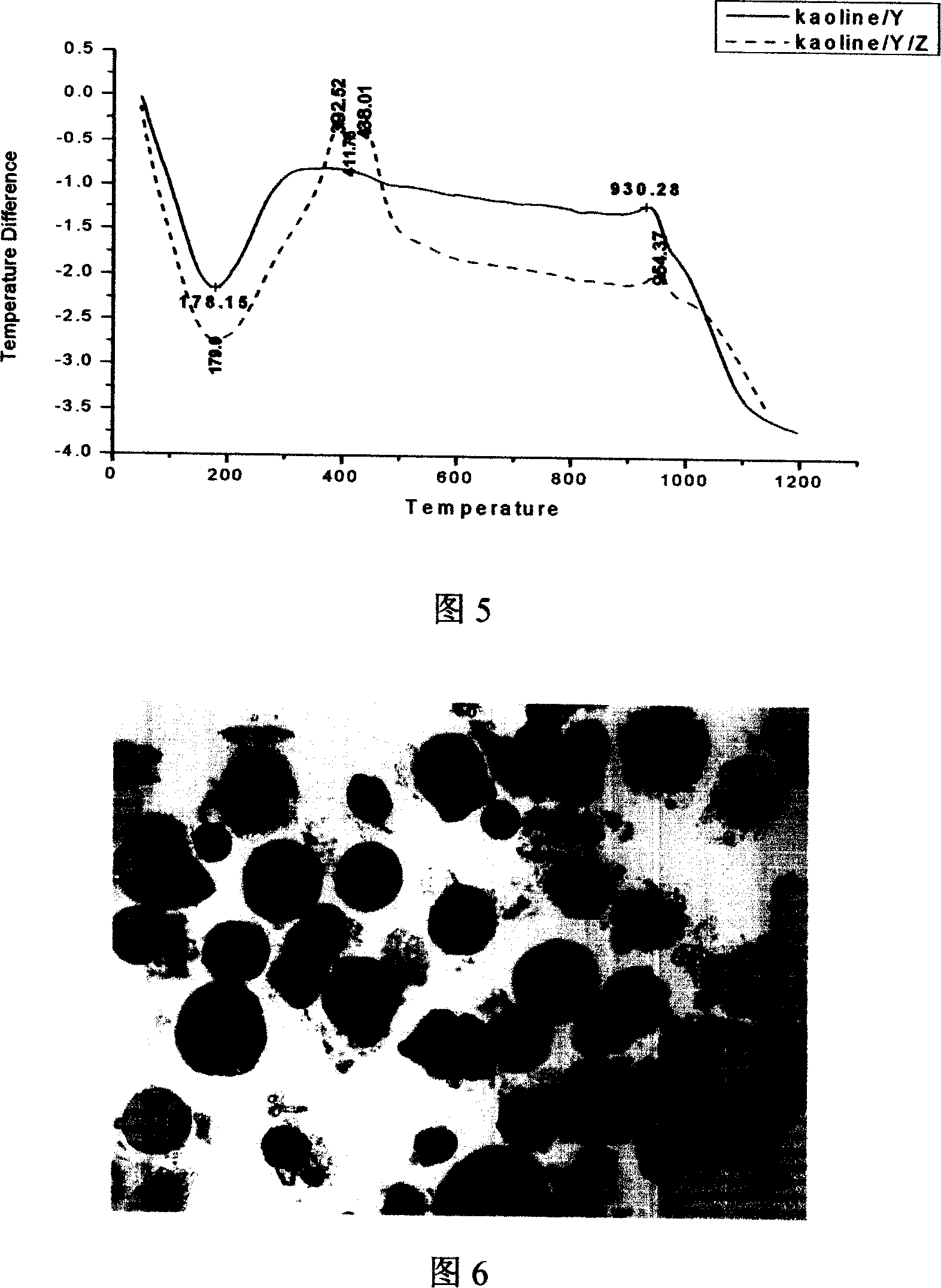

A kaolin based compound molecule sieve and preparation method thereof

ActiveCN1951567AImprove thermal stabilityImprove shape-selective catalytic performanceOrganic chemistryMolecular sieve catalystsMicrosphereThermal stability

The invention relates to a caoline substrate composite molecule screen and relative preparation. Wherein, the invention is characterized in that: on the inner and outer surface of modified caoline micro ball which meets original position crystallization condition, there are Y molecule screen and ZSM-5 zeolite, while the relative content of Y molecule screen is 10-98%, and the ZSM-5 content is 2-90%. The invention leads Y zeolite and second molecule screen (ZSM-5 zeolite) into the inner and outer surface of micro ball, to improve the catalyst selectivity and improve the propone yield. And the invention expresses high thermal stability.

Owner:PETROCHINA CO LTD +1

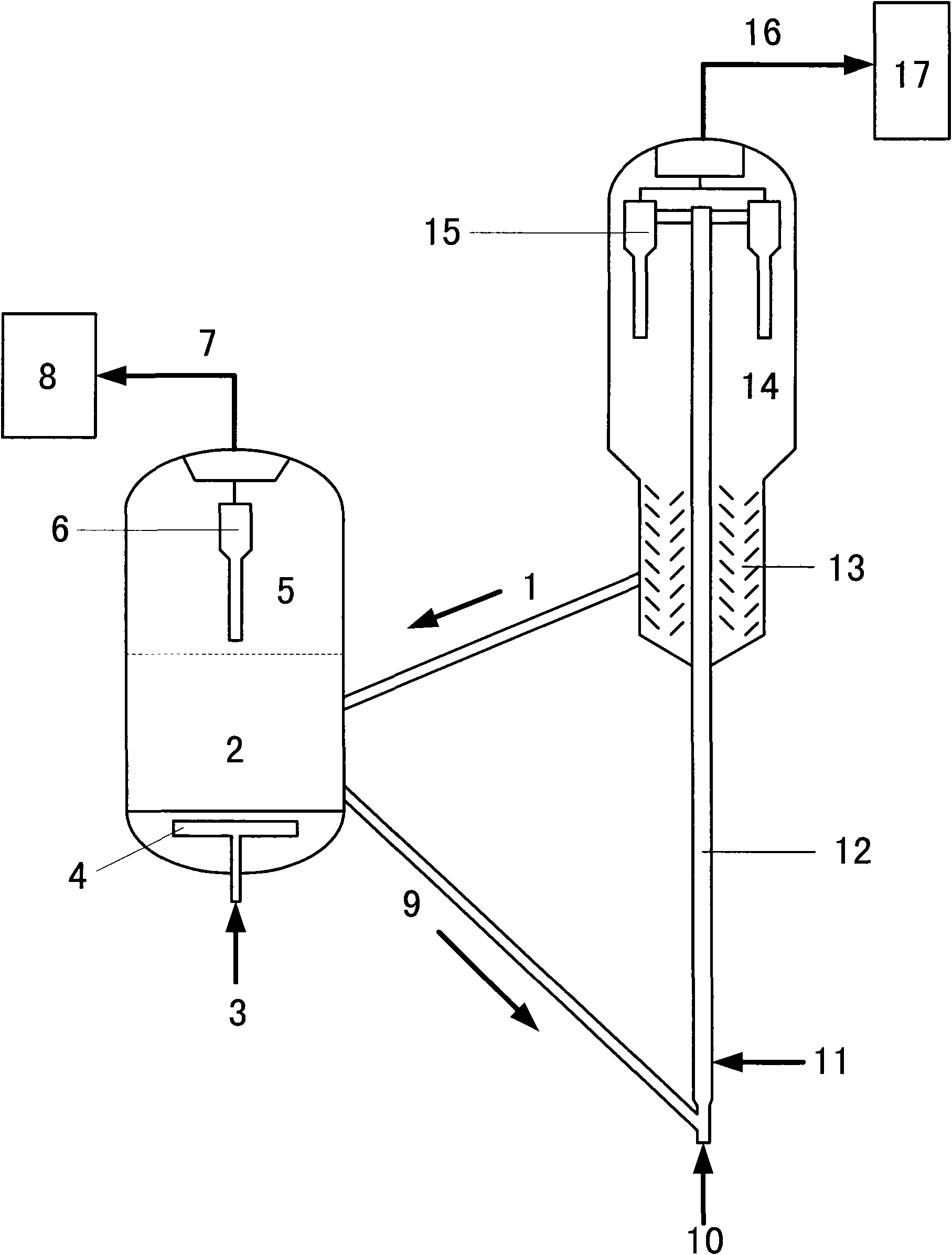

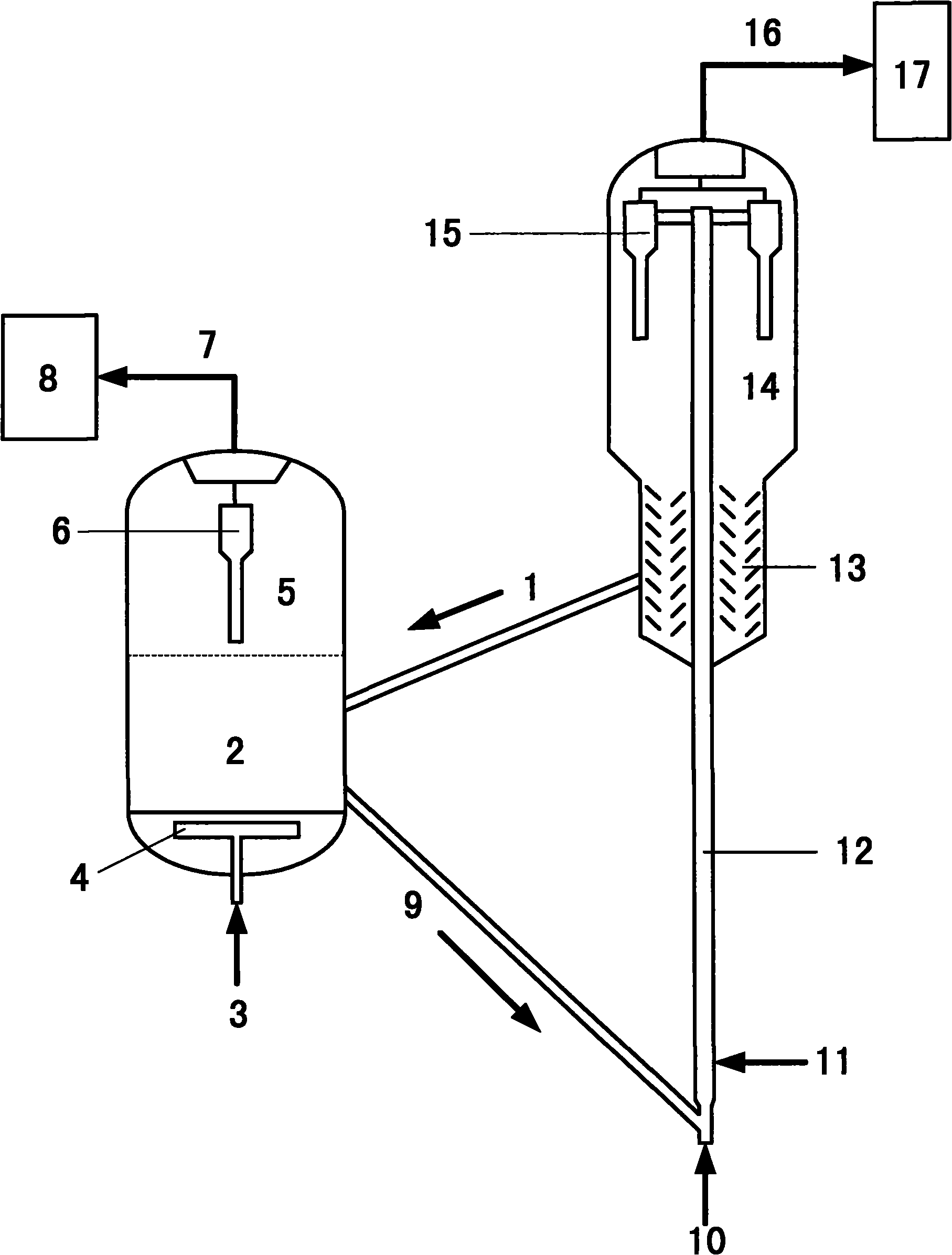

Method for enhancing catalyst selectivity

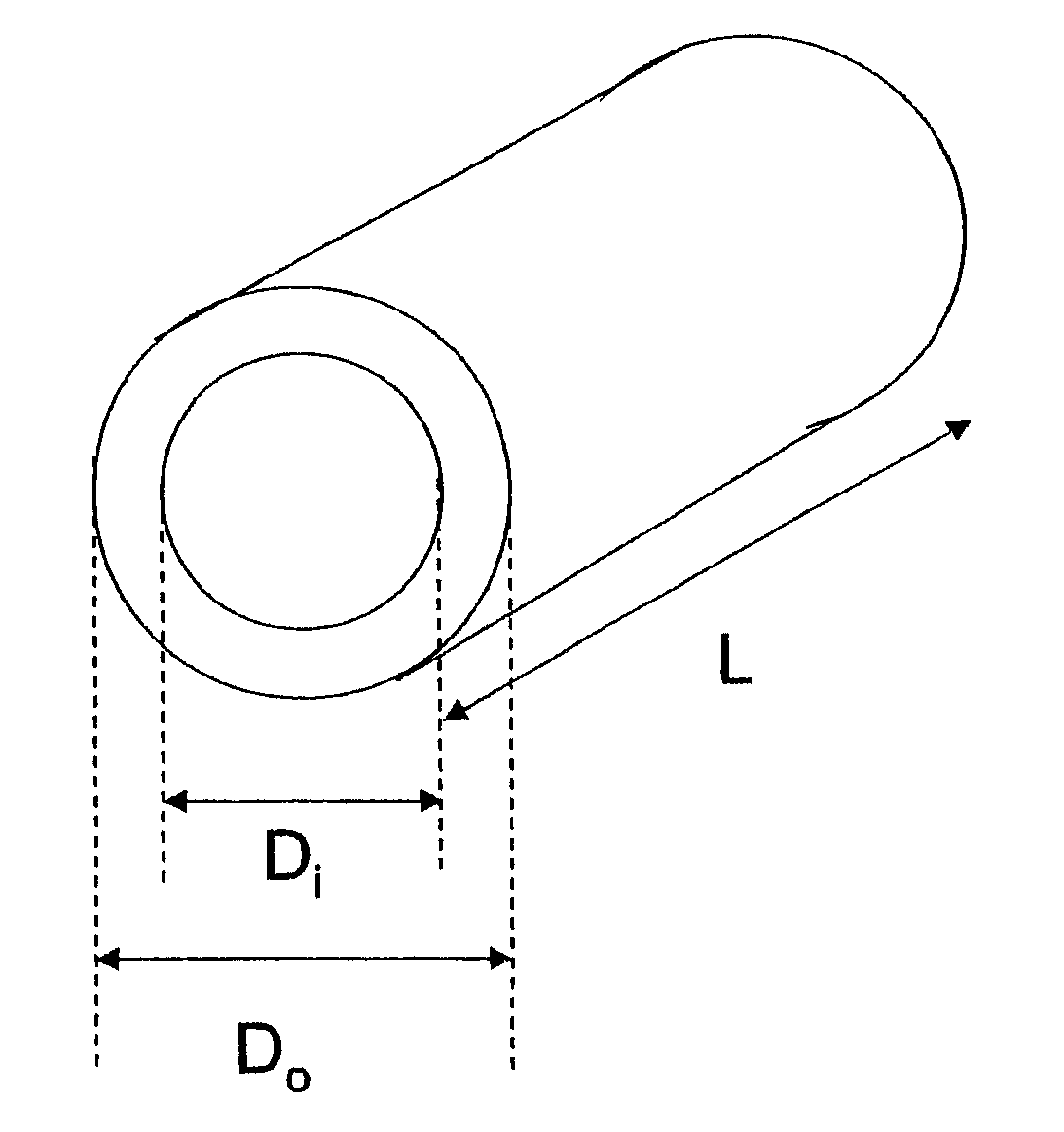

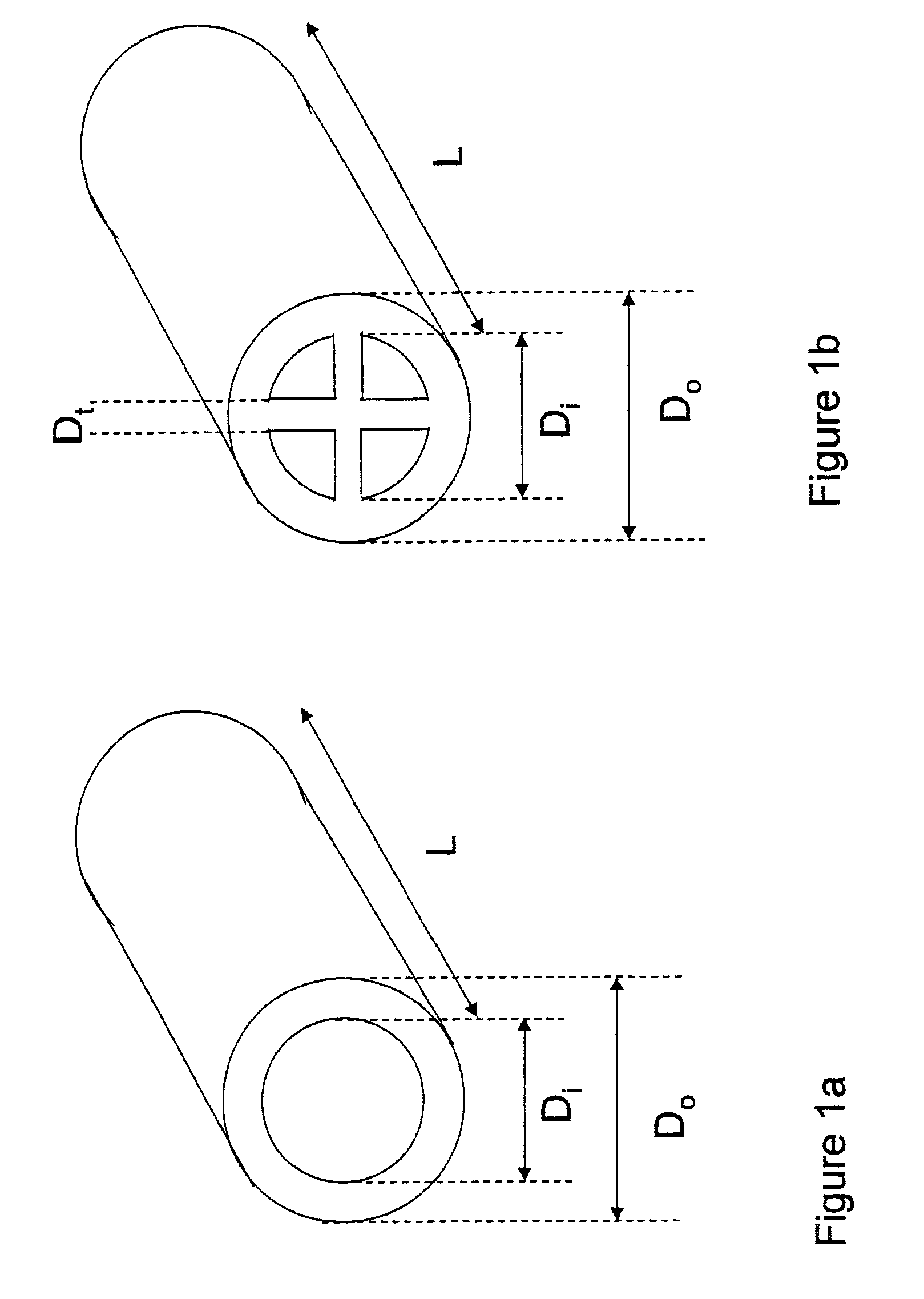

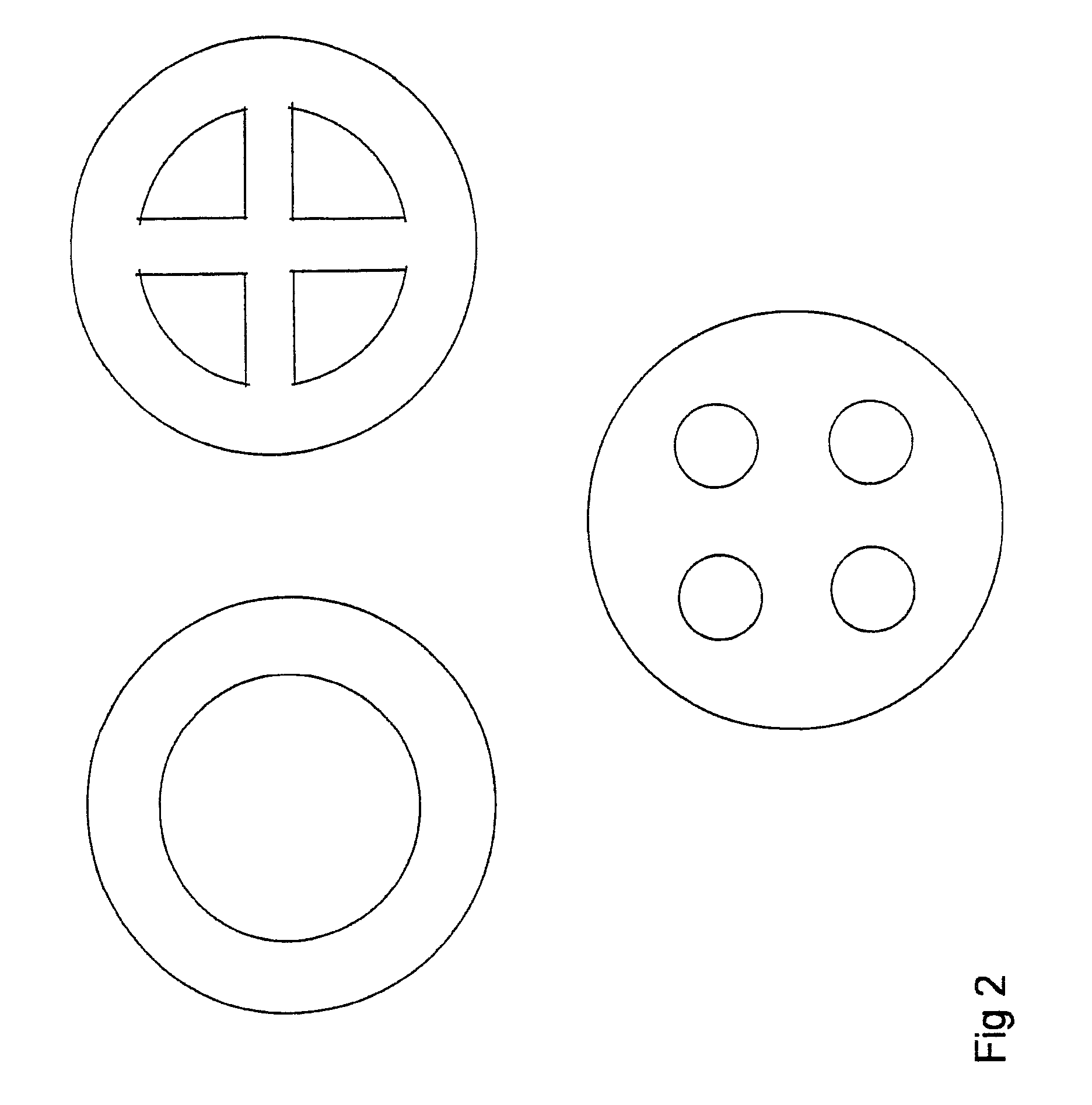

ActiveUS7993599B2Efficient heat transferHigh heat transfer rateGaseous chemical processesOrganic compound preparationPtru catalystDiffusion resistance

A method allowing the efficient conduction of highly exothermic, catalyst initiated reactions, particularly ones in which the product spectrum is highly dependant upon the temperature at which the process is conducted and to diffusional resistances within the catalyst particle matrix. The process occurs in a heat transfer device which consists of at least two channels which have at least one wall in common. Preferably two distinct sets of flow channels exist in which the process proceeds in one set of channels and heat transfer fluid passes through the second. The area of contact between the two sets of channels is sufficiently large to allow the efficient transfer of heat. These dimensions are controlled through the use of hollow catalyst particles through which the process gas can diffuse through either the inside or outside.

Owner:ZEROPOINT CLEAN TECH

A low-energy hydrocracking method for processing inferior raw materials

ActiveCN104611020BReduce consumptionSave engineering investmentTreatment with hydrotreatment processesHydrocarbon oils treatment productsOperating energyFractionation

The present invention discloses a low energy consumption hydrocracking method for processing a poor-quality raw material. According to the method, a raw material and hydrogen gas are mixed, are subjected to heat exchange two times, pass through a heating furnace, and then are subjected to a hydrorefining reaction; the refining effluent is subjected to separation and fractionation; the obtained tail oil enters a hydrocracking reaction zone, wherein the cracking reaction zone comprises at least two cracking catalysts, the upstream is a catalyst I, the downstream is a catalyst II, the catalyst I contains 15-50 wt% of a modified Y molecular sieve, the catalyst II contains 3-30 wt% of the modified Y molecular sieve, and the modified Y molecular sieve content in the catalyst I is 10-25% higher than the modified Y molecular sieve content in the catalyst II; and the hydrocracking effluent and poor-quality raw material oil are mixed and then enter a hydrorefining reaction zone. According to the method of the present invention, the high temperature high pressure countercurrent heat transfer technology and the hydrocracking catalyst grading technology are organically combined, and the hydrocracking reaction heat is comprehensively utilized, such that the catalyst selectivity is maintained while the target product quality is improved, and the project investment and the operating energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrocracking method with low energy consumption and high yield of high-quality chemical raw materials

ActiveCN105018139BReduce consumptionSave engineering investmentTreatment with hydrotreatment processesMolecular sieveHydrogen

The invention discloses a hydrocracking method of low-nergy-onsumption productive high-quality chemical raw materials. After raw oil and hydrogen are mixed, the obtained mixture is subjected to heat transfer for two times and then passes through a heating furnace, the obtained object is sequentially subjected to hydrorefining and then passes through a first cracking reaction area, the obtained product is separated so as to obtain middle distillate, the middle distillate enters a second cracking reaction area to crack, wherein the first cracking reaction area is at least filled with two cracking catalysts, a catalyst I is filled in the upstream part, and a catalyst II is filled in the downstream part; and the catalyst I contains 30-70% of modified Y molecular sieve, the catalyst II contains 15-50% of modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-30% higher than the content of the modified Y molecular sieve in the catalyst II. In the method disclosed by the invention, a high-temperature and high-pressure countercurrent heat transfer technology and a hydrocracking catalyst grading technology are organically combined, and through the comprehensive utilization of hydrocracking reaction heat, while the selectivity of catalysts is maintained, the product quality is enhanced, and the construction investment and the energy consumption of operation are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

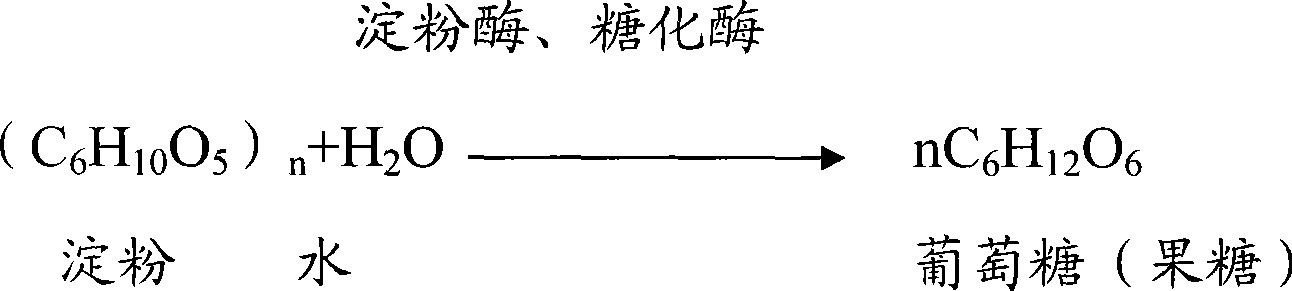

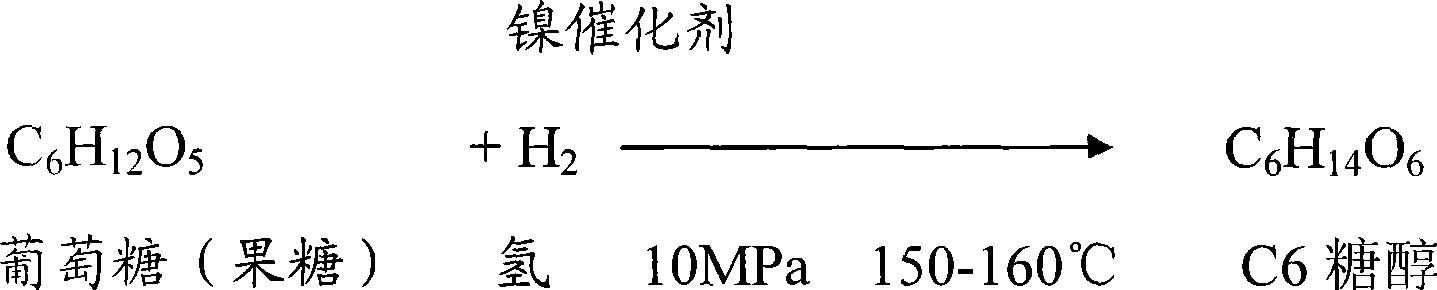

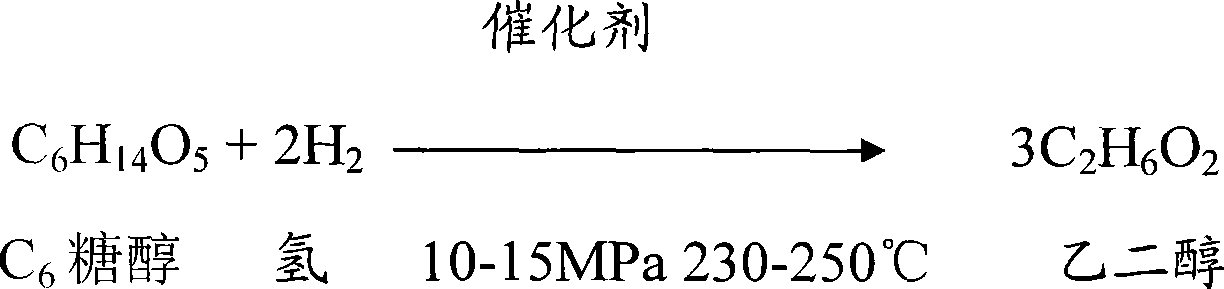

Method for producing low carbon chemical ethanol from C6 sugar alcohol

InactiveCN101544537ANovel production routeUnique process conditionsOrganic compound preparationHydroxy compound preparationAlcohol sugarsHigh pressure

The invention relates to a method for producing low carbon chemical ethanol from C6 sugar alcohol. Chinese patent disclosed number CN1683293A discloses a method for producing dihydric alcohol and andpolyhydric alcohol by cracking sorbierite. The method comprises the steps of converting the sorbierite into glycol, propanediol and glycerin, but process data and a process route as well as products do not achieve good industrial production requirements. The method mainly adopts a continuous process to hydrocrack the C6 sugar alcohol to generate a low carbon ethanol mixture and finally obtains a single (or mixed) product by separating and refining in alkaline environment, in the presence of a nickel chrome catalyst and at high temperature and high pressure. The process route has the advantages of simple process, easy operation, high yield in unit time and variety of the products; and as the catalyst has different selectivities, the composition rate of the produced products can be substantially adjusted.

Owner:西安航天华威化工生物工程有限公司

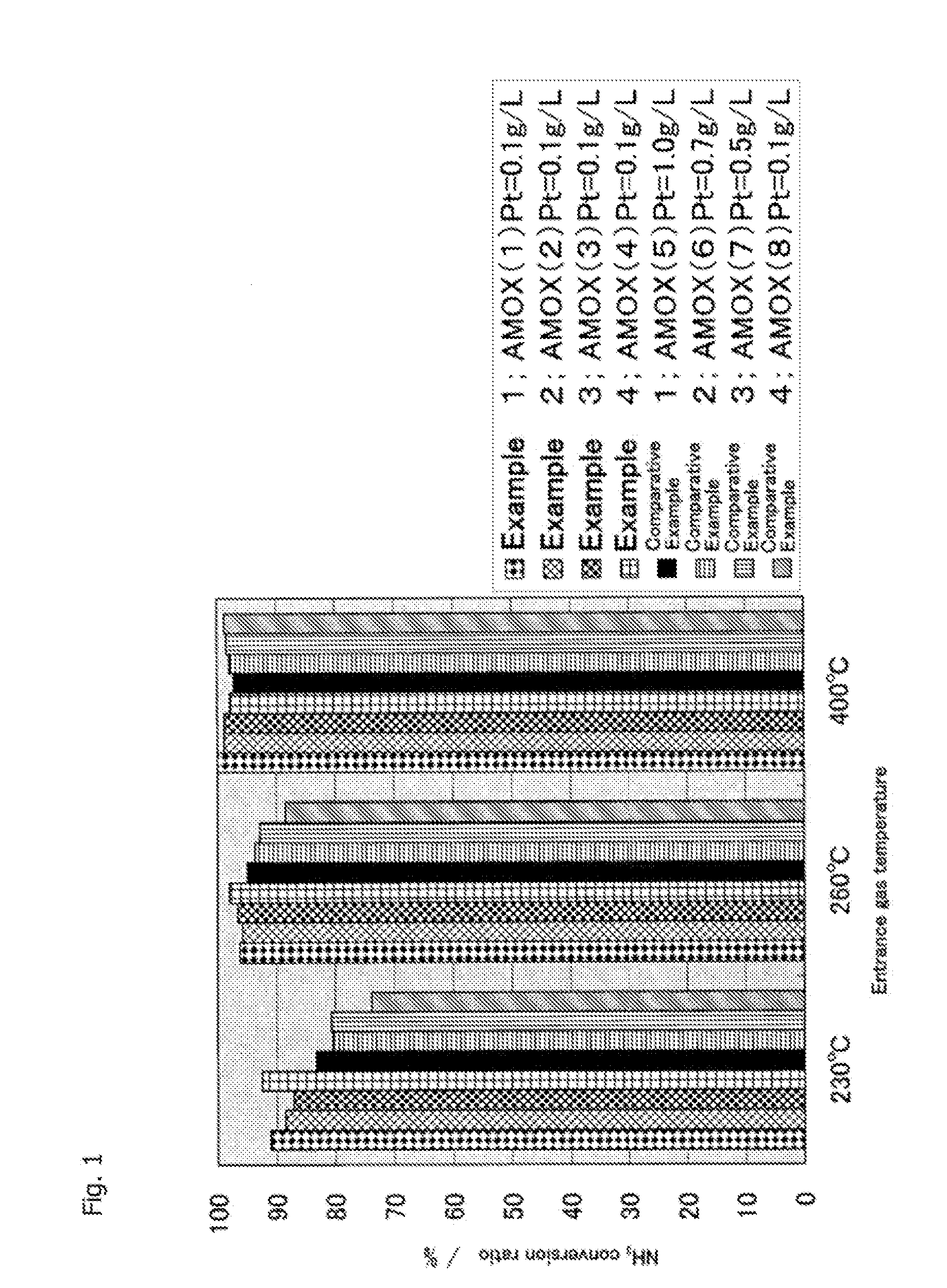

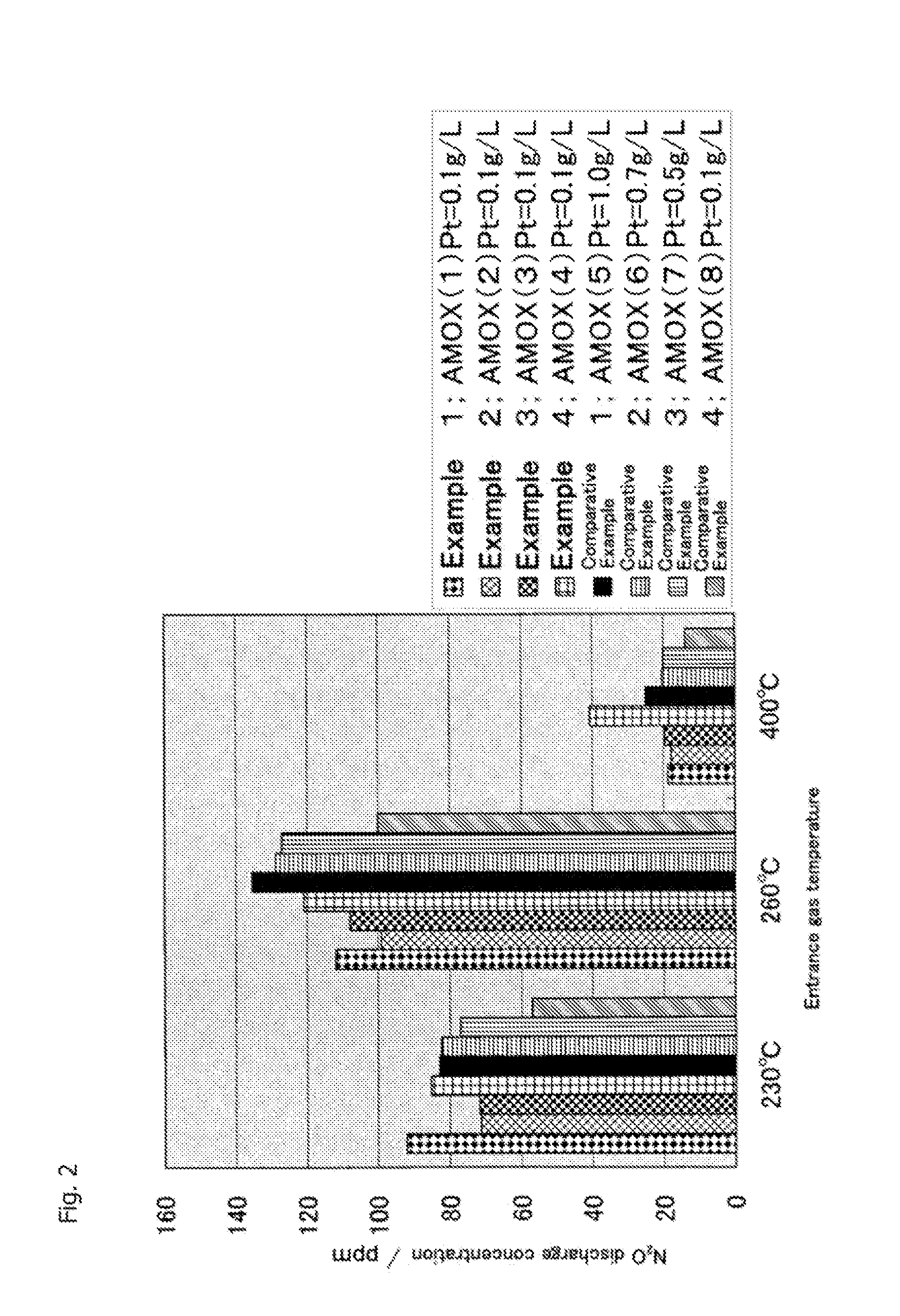

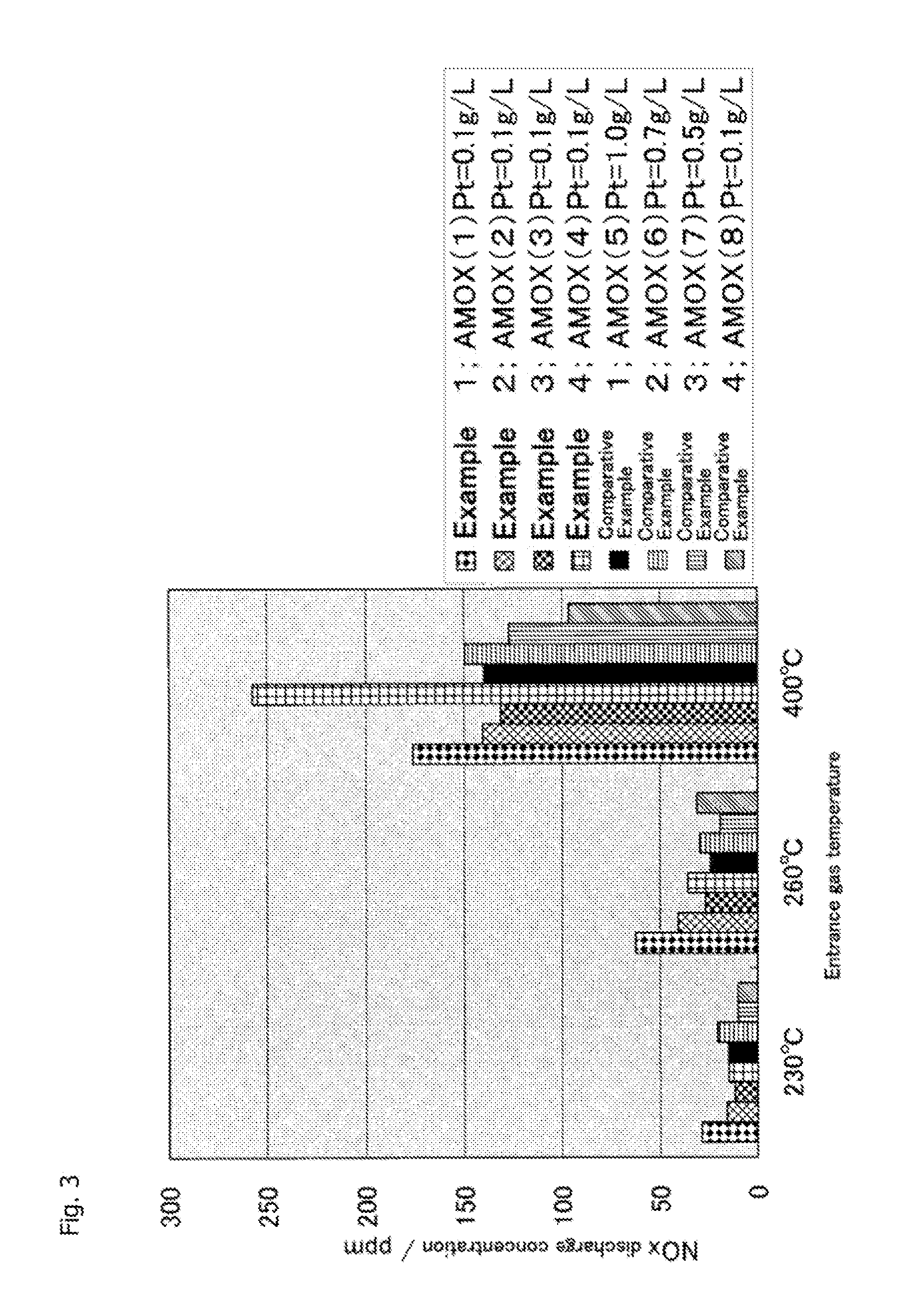

Ammonia oxidation catalyst, exhaust gas purification device using same, and exhaust gas purification method

InactiveUS20140065044A1Avoid by-productsIncrease productionNitrous oxide captureCombination devicesPurification methodsCerium(IV) oxide

Ammonia oxidation catalyst being superior in heat resistance and capable of suppressing by-production of N2O and leakage of ammonia. The ammonia oxidation catalyst (AMOX) removes surplus ammonia, in selectively reducing nitrogen oxides by adding urea or ammonia and using a selective catalytic reduction (SCR) catalyst, into exhaust gas, wherein the ammonia oxidation catalyst is made by coating at least two catalyst layers having a catalyst layer (lower layer) including a catalyst supported a noble metal element on a composite oxide (A) having titania and silica as main components, and a catalyst layer (upper layer) including a composite oxide (C) consisting of tungsten oxide, ceria, and zirconia, at the surface of an integral structure-type substrate, wherein a composition of the composite oxide (C) is tungsten oxide: 1 to 50% by weight, ceria: 1 to 60% by weight, and zirconia: 30 to 90% by weight.

Owner:N E CHEMCAT

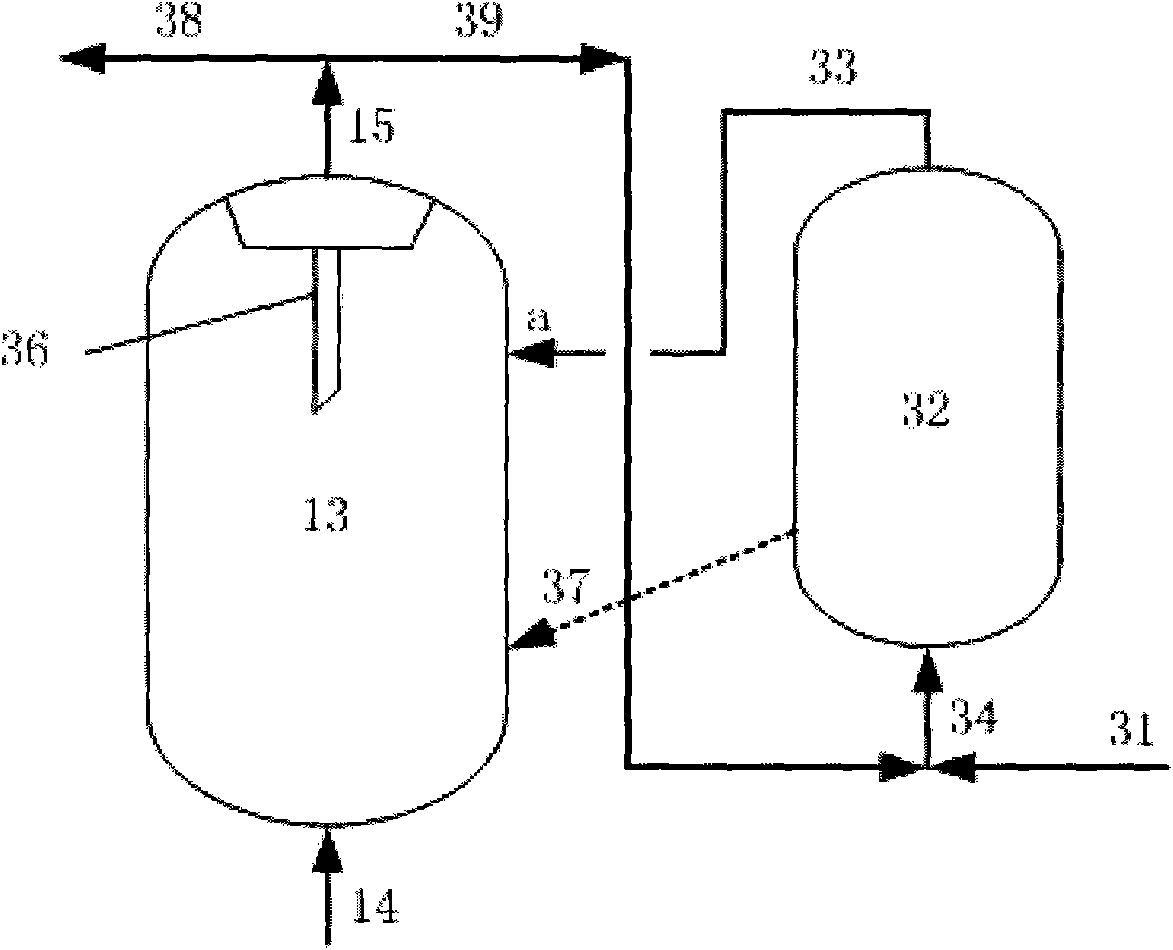

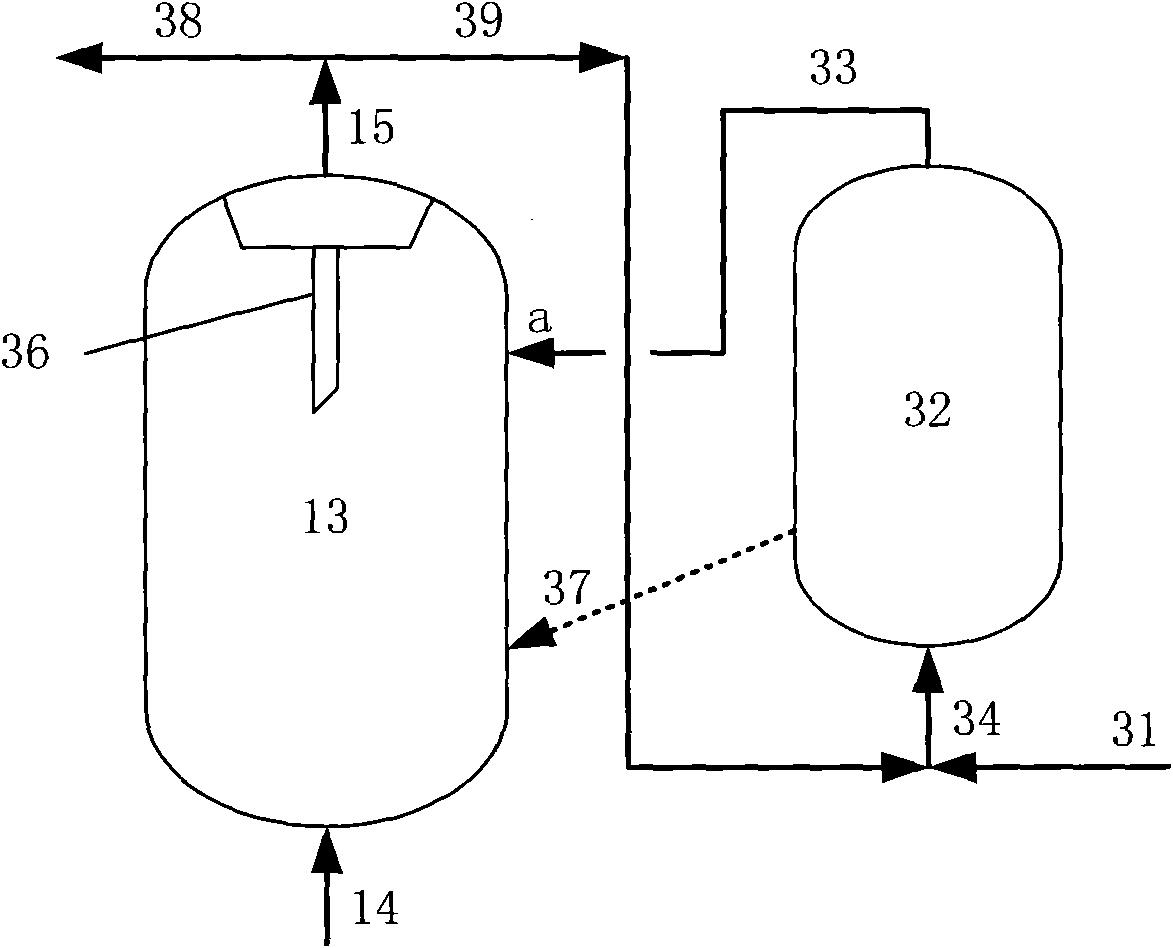

Catalyst regeneration method for improving selectivity of catalyst

ActiveCN101850276AEven distribution of activityReduce yieldCatalytic crackingMolecular sieve catalystsEnergy recoveryOxygen

The invention relates to a catalyst regeneration method for improving the selectivity of a catalyst. A catalyst to be regenerated is contacted with oxygen-containing gas in a first fluidized bed and generates a coke combustion reaction, the mixture of the obtained semi-regenerated catalyst and flue gas enters a second fluidized bed regenerator, is contacted with the optional oxygen-containing gas and generates the coke combustion reaction continuously, the regenerated catalyst enters a reactor, and the flue gas enters an energy recovery system of the flue gas by a cyclone separator. The distribution of the activity of the regenerated catalyst obtained by the method is more uniform, the activity of the regenerated catalyst obtained by the method more approaches to the equilibrium activity of a catalyst, part of heavy metal on the surface of the regenerated catalyst is buried by a substrate under the conditions of low temperature and long-time operation, and the rest part of the heavy metal is passivated. When hydrocarbon carries out a catalytic cracking reaction on the regenerated catalyst, the yields of dry gas and coke are obviously lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

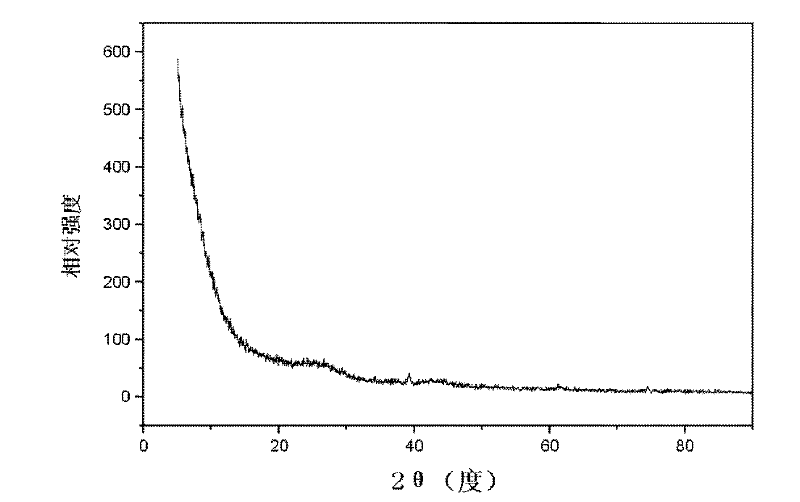

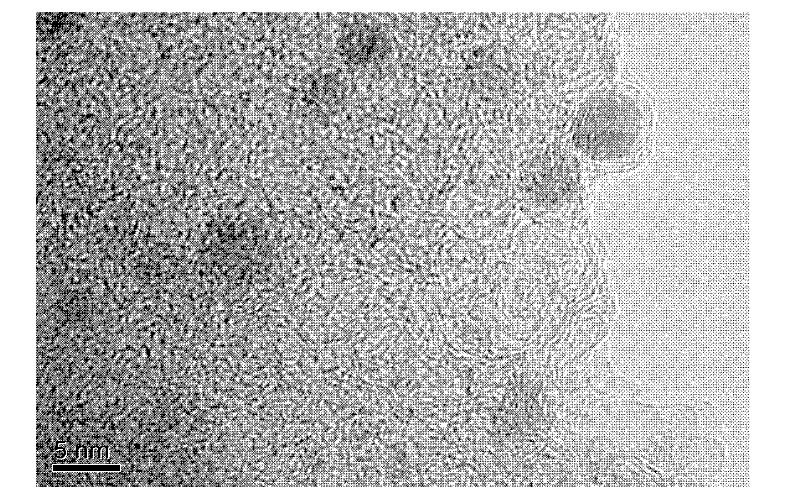

Method for electrocatalytic reduction of carbon dioxide

ActiveCN107447228ALow costEasy to controlMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectricityPlatinum

The invention discloses a method for electrocatalytic reduction of carbon dioxide. The method comprises the following steps: a three-electrode system is put in electrolyte containing carbon dioxide for electrolysis; the three-electrode system comprises a working electrode, a counter electrode and a reference electrode, wherein the counter electrode is a platinum chip electrode; the reference electrode is a saturated calomel electrode; the working electrode is a glassy carbon electrode after electrode modification; the electrode modification process is to modify the glassy carbon electrode by adopting a modifying agent through a chemical deposition method; and the modifying agent contains a ZIF-8 material or a modified ZIF-8 material. The ZIF-8 materials from different start zinc sources or the modified ZIF-8 materials calcined at different temperatures are applied to different electrolyte anions for electrocatalytic reduction of CO2; and the ZIF-8 materials or the modified ZIF-8 materials are used as electrocatalysts to achieve good selectivity, high efficiency and a certain stability.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

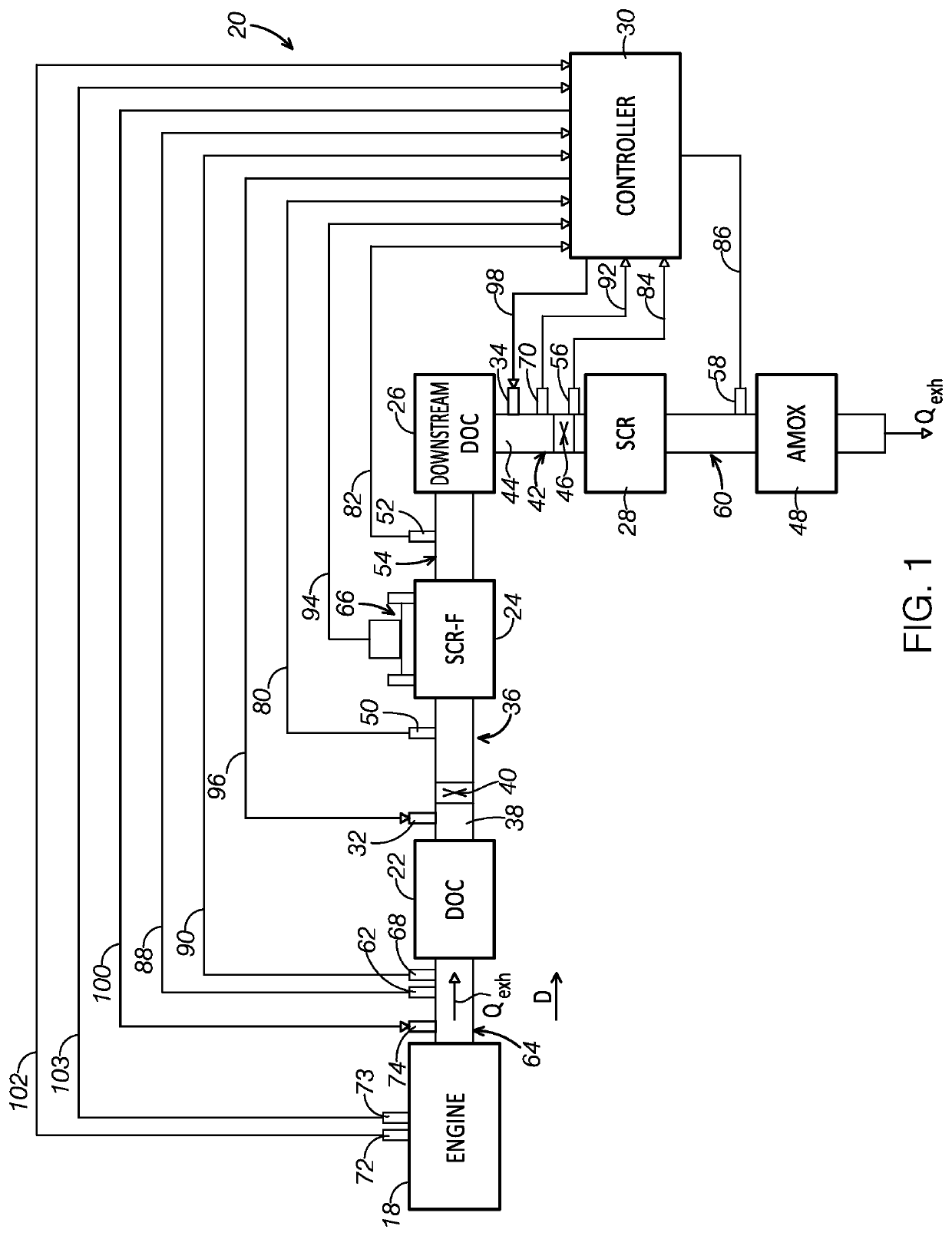

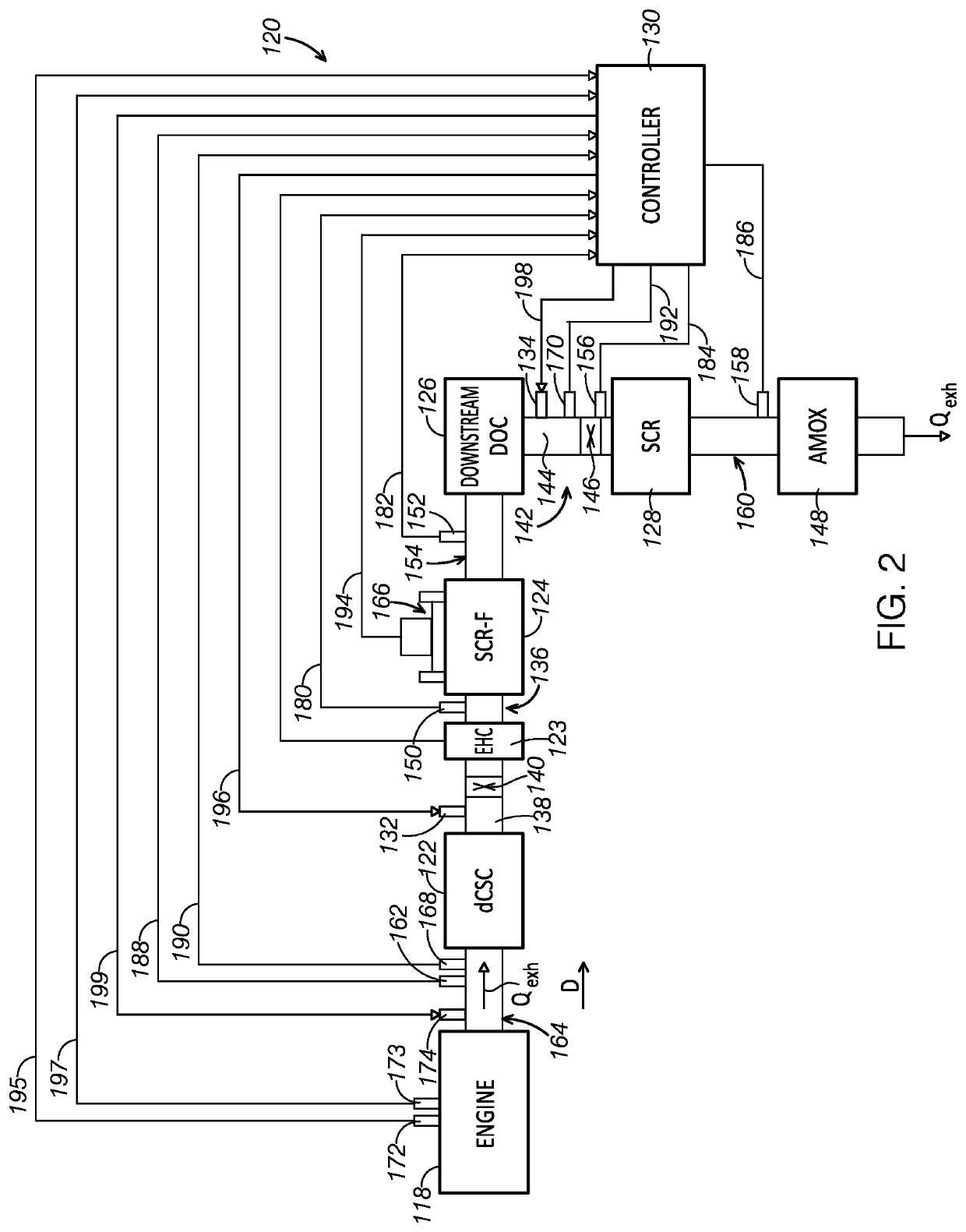

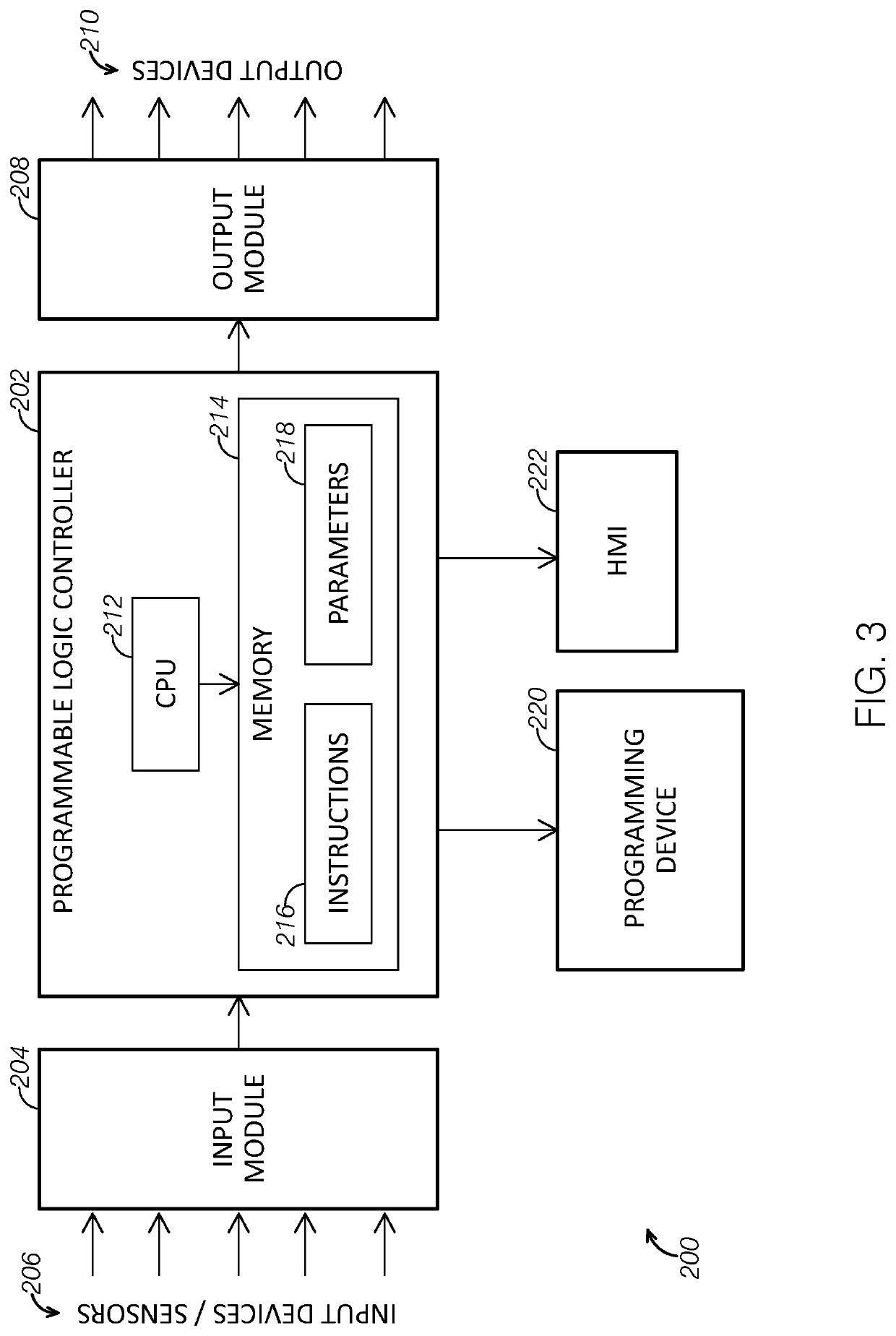

Aftertreatment systems and methods for treatment of exhaust gas from diesel engine

An aftertreatment system to treat exhaust gas from a diesel engine is provided. The aftertreatment system comprises a selective catalytic reduction catalyst on a diesel particulate filter (SCR-F); a first reductant injector connected to an exhaust gas passage upstream of the SCR-F; a downstream diesel oxidation catalyst (DOC) disposed downstream of the SCR-F; a selective catalyst reduction catalyst (SCR) disposed downstream of the downstream DOC; a second reductant injector coupled to an exhaust gas passage positioned between the downstream DOC and the SCR; and a controller to determine a desired particulate matter (PM) oxidation in the SCR-F and a desired system NOx conversion based on engine conditions, and to control a first reductant flowrate from the first reductant injector and a second reductant flowrate from the second reductant injector based on the desired PM oxidation in the SCR-F and the desired system NOx conversion.

Owner:JOHNSON JOHN H +2

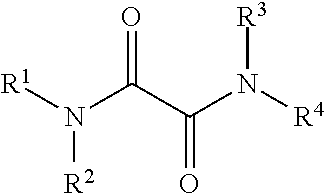

Catalyst System for Olefin Polymerization and Method for Producing Olefin Polymer

ActiveUS20170240667A1High activityEnhanced hydrogen responseOrganic-compounds/hydrides/coordination-complexes catalystsElectron donorPolymer chemistry

A phthalate-free catalyst component for olefin polymerization comprising titanium, magnesium, a halogen, diether, and oxalic acid diamides represented by the following formula (I):and an olefin polymerization catalyst system consisting of the solid catalyst component, an organoaluminum compound, and an optional external electron donor compound. The present catalyst compositions improve diether-based catalyst selectivity while maintaining excellent catalyst activity and hydrogen response. An olefin polymer that has a moderate molecular weight distribution while maintaining higher stereoregularity (isotacticity) over diether-based catalyst, and better than or equal to phthalate-based catalyst can be produced by utilizing the inventive catalyst component.

Owner:FORMOSA PLASTICS USA

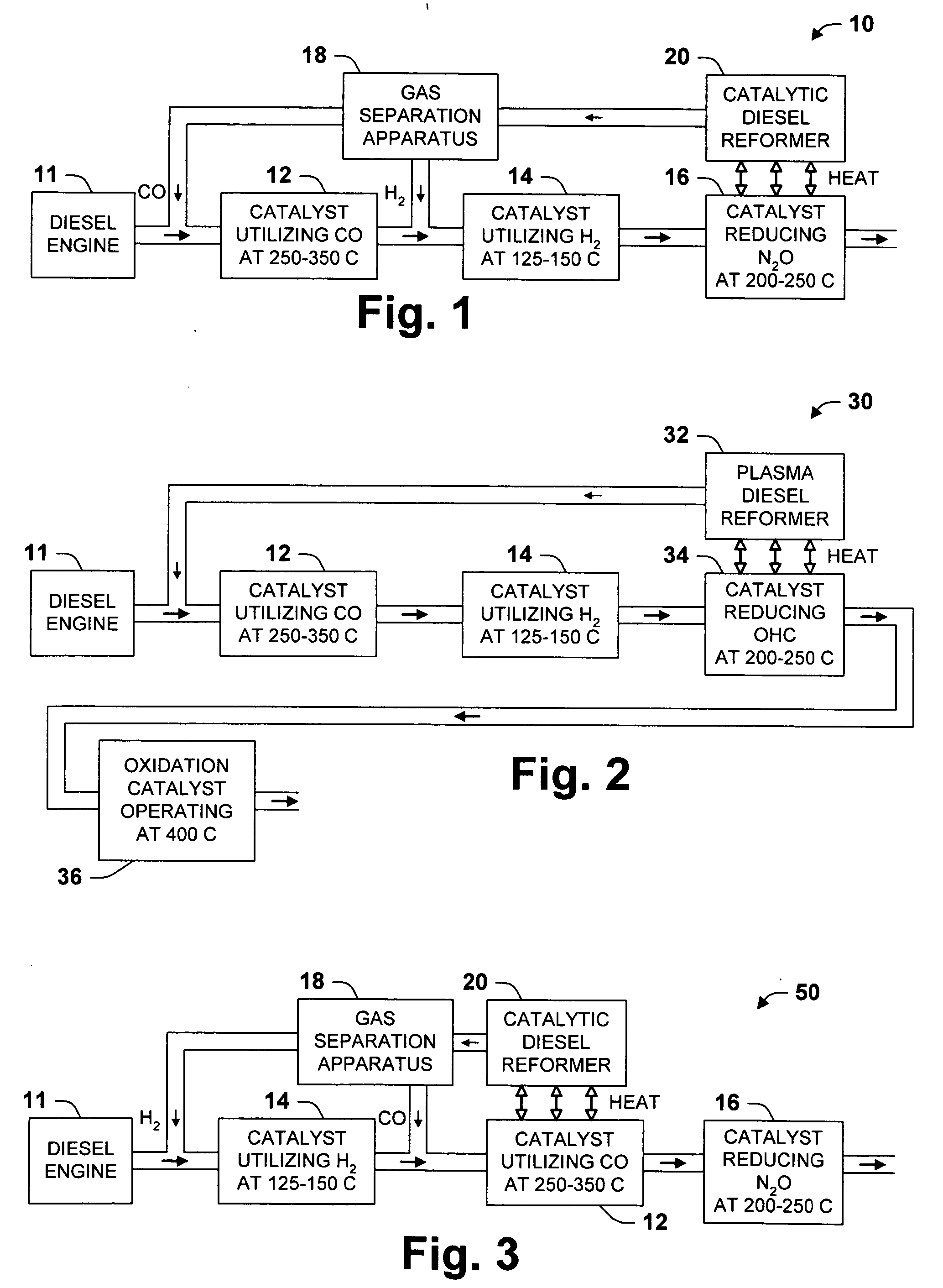

Multiple reactant multiple catalyst selective catalytic reduction for NOx abatement in internal combustion engines

InactiveUS20060112678A1Promote conversionReduce the concentration of nitrogen oxidesNitrous oxide captureGas treatmentCombustionInternal combustion engine

The invention relates to systems and methods for treating oxygen-rich NOx-containing exhaust. The systems and methods comprise using first and second NOx reducing catalysts. According to one aspect of the invention, the first catalyst reduces NOx in oxygen-rich exhaust primarily through reaction with a first reductant species and the second catalyst reduces NOx in oxygen-rich exhaust primarily through reaction with a second reductant species. Collectively, the two catalysts are substantially more effective than either of the catalysts individually in reducing the concentration of NOx in the exhaust. According to another aspect of the invention, an exhaust system is configured to inject a first reductant species primarily at a first location upstream of the first NOx reducing catalyst, and is configured to inject a second reductant species primarily at a second location downstream of the first NOx reducing catalyst, but upstream of the second NOx reducing catalyst.

Owner:EATON CORP

Selective hydrodesulfurization catalyst

ActiveUS7285512B2Molecular sieve catalystsRefining to eliminate hetero atomsNaphthaHydrodesulfurization

Owner:EXXON RES & ENG CO

Hydrocracking method of low-energy-consumption, productive and high-quality jet fuel

ActiveCN105018137AReduce engineering investmentReduce operating energy consumptionTreatment with plural serial stages onlyMolecular sieveHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

Molecular sieve catalyst for synthesizing methanol into durene and its prepn and application

InactiveCN1421271ASimple manufacturing methodHigh selectivityMolecular sieve catalystsCatalyst activation/preparationHydrogenToluene

The molecular sieve catalyst for synthesizing methanol into durene is ZSM-5 type with molar Si / Al ratio of 13-50, strong / weak acid ratio of 1.03-1.30, adsorption amount to cyclohexane of 5.95-6.25 wt%, said adsorption amount to n-hexane of 8.95-9.15 wt%. The hydrogen-type molecular sieve, assistant and nitric acid are mixed and kneaded, and the mixture is formed, stoved, crushed, roasted, soakingin acid solution, stoved and roasted to obtain the catalyst. The present invention has the advantages of simple preparation process, high selectivity of the catalyst, and the durene content in the product as high as 20%.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

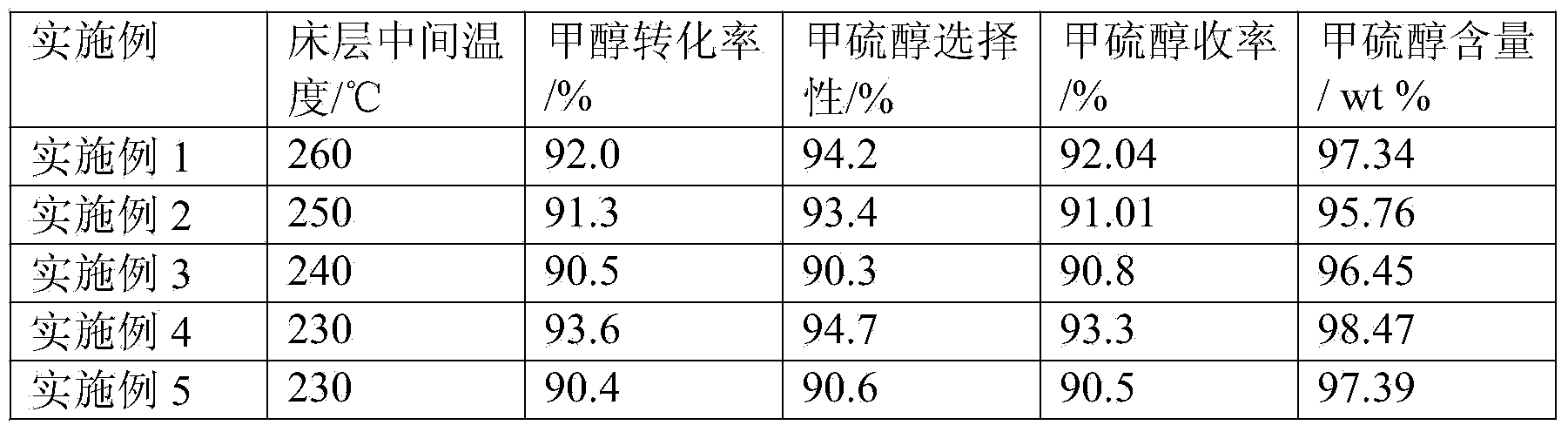

Catalyst for synthesizing methyl mercaptan and preparation method of catalyst

ActiveCN103506130AGood choiceLow activation temperatureThiol preparationMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideReaction temperature

The invention discloses a catalyst for synthesizing methyl mercaptan and a preparation method of the catalyst. The catalyst comprises a carrier, an active component and an assistant, wherein the carrier is gamma-Al2O3, the active component is one or more of Fe2O3, MoO3, ZnO and NiO, and the assistant is alkali metal oxide or alkaline earth metal oxide. The catalyst is prepared as follows: impregnating a precursor of the assistant on the carrier by using a secondary equivalent-volume impregnation method, loading the precursor containing the active component by using the impregnation method again after roasting for one time, and obtaining a target product namely the catalyst for synthesizing the methyl mercaptan after the secondary roasting. According to the catalyst provided by the invention, methyl alcohol and sulfuretted hydrogen are used as raw materials to synthesize the methyl mercaptan, the selectivity of the catalyst is good, the active temperature of the catalyst is lower than that of the prior art, the reaction temperature is between 230-260 DEG C, the yield of the methyl mercaptan is more than 90%, in addition, no dimethyl sulfide is produced in the target product, so that subsequent separation is not needed.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Catalyst regeneration method for improving selectivity of catalyst

ActiveCN101850274AEven distribution of activityReduce yieldCatalytic crackingMolecular sieve catalystsEnergy recoveryOxygen

The invention relates to a catalyst regeneration method for improving the selectivity of a catalyst. A catalyst to be regenerated is contacted with oxygen-containing gas in a dense-phase fluidized bed regenerator, is regenerated under the conditions that the temperature is 550 to 750 DEG C and the mean detention time of the catalyst is 4 to 30 minutes, and generates a coke combustion reaction, the regenerated catalyst enters a reactor, and flue gas enters an energy recovery system of the flue gas by a cyclone separator. The distribution of the activity of the regenerated catalyst obtained by the method is more uniform, the activity of the regenerated catalyst obtained by the method more approaches to the equilibrium activity of a catalyst, part of heavy metal on the surface of the regenerated catalyst is buried by a substrate under the conditions of low temperature and long-time operation, and the rest part of the heavy metal is passivated. When hydrocarbon carries out a catalytic cracking reaction on the regenerated catalyst, the yields of dry gas and coke are obviously lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for improving the selectivity of a catalyst and a process for the epoxidation of an olefin

A method for improving the selectivity of a supported highly selective epoxidation catalyst comprising silver in a quantity of at most 0.19 g per m<2> surface area of the support, which method comprises - contacting the catalyst, or a precursor of the catalyst comprising the silver in cationic form, with a feed comprising oxygen at a catalyst temperature above 250 DEG C for a duration of up to 150 hours, and - subsequently decreasing the catalyst temperature to a value of at most 250 DEG C; and a process for the epoxidation of an olefin, which process comprises - contacting a supported highly selective epoxidation catalyst comprising silver in a quantity of at most 0.19 g per m<2> surface area of the support, or a precursor of the catalyst comprising the silver in cationic form, with a feed comprising oxygen at a catalyst temperature above 250 DEG C for a duration of up to 150 hours, and - subsequently decreasing the catalyst temperature to a value of at most 250 DEG C and contacting the catalyst with the feed comprising the olefin and oxygen.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com