Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1479results about "Hydrocarbon by hydrocarbon and non-hydrocarbon condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroalkylation of aromatic hydrocarbons

InactiveUS6037513AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07.

Owner:MOBIL OIL CORP

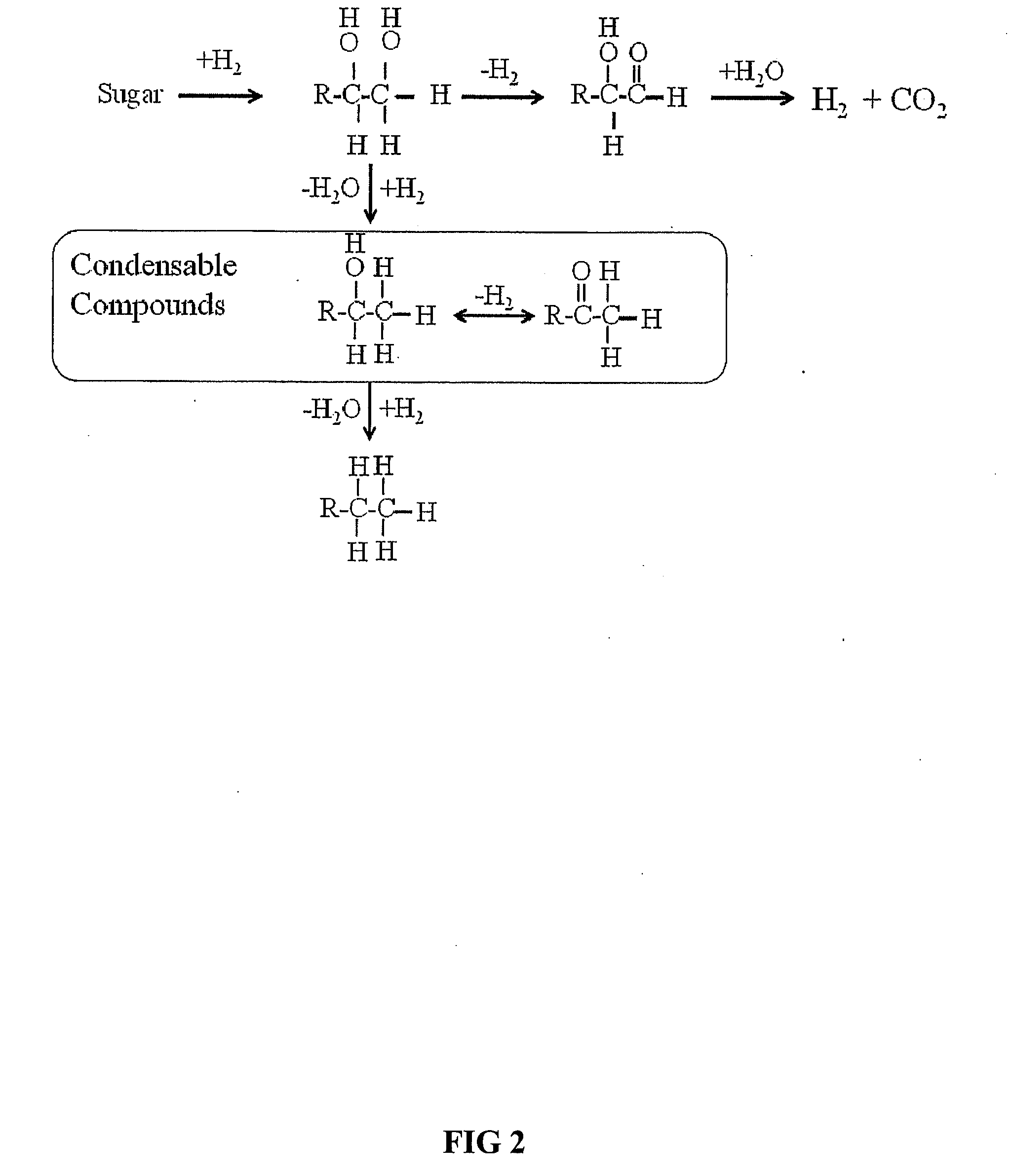

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080216391A1Organic compound preparationHydrocarbon from oxygen organic compoundsFuranLiquid fuel

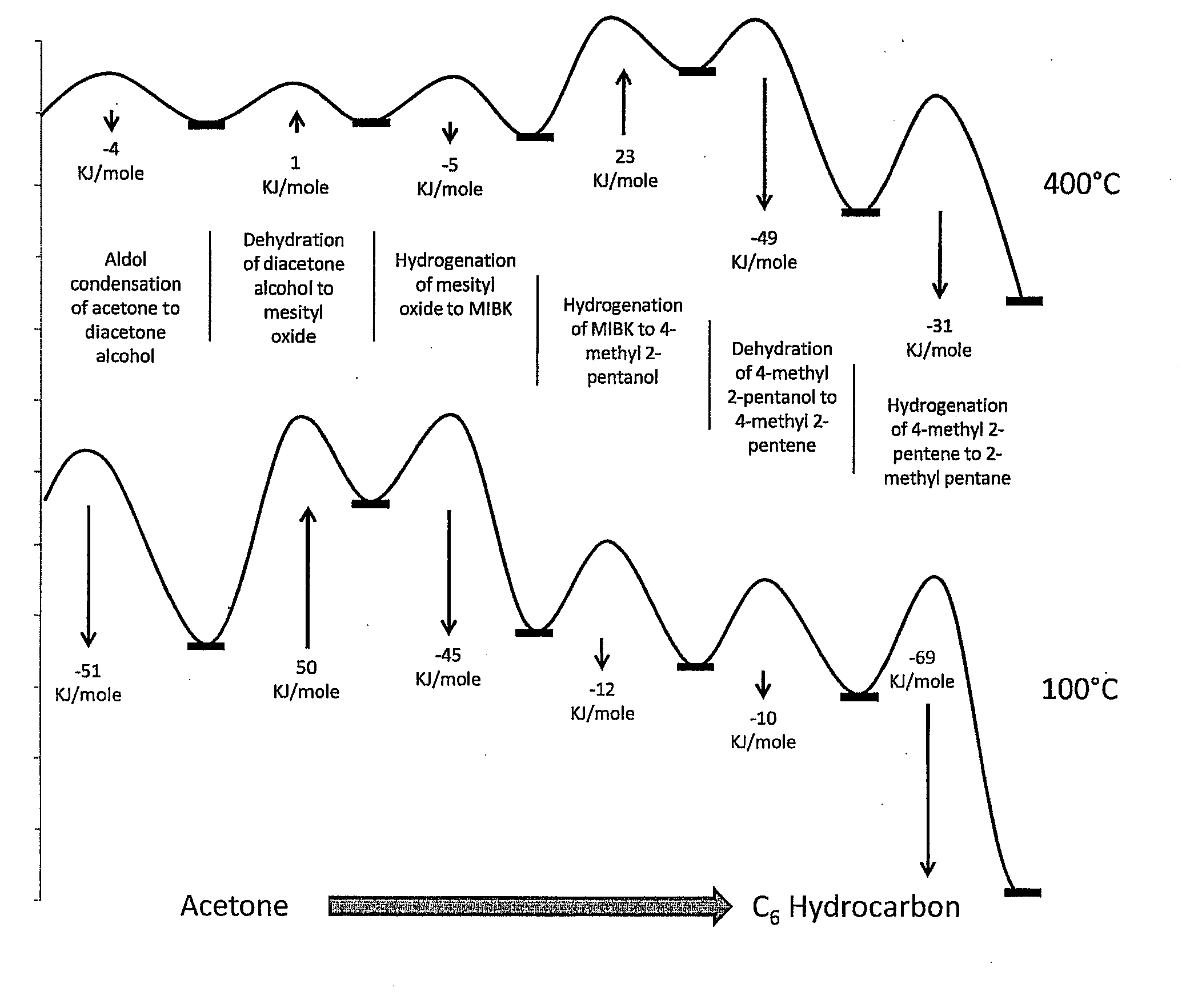

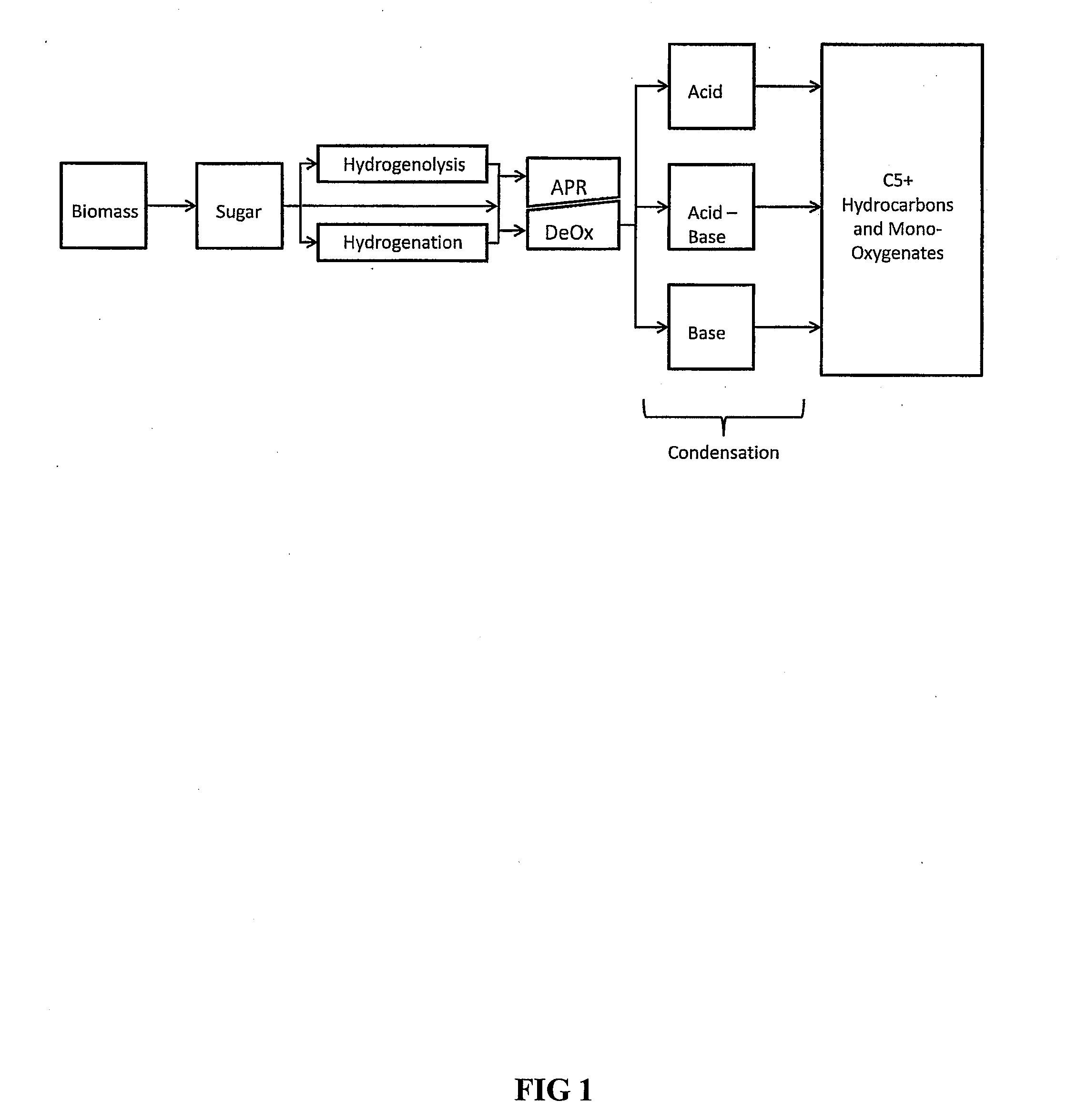

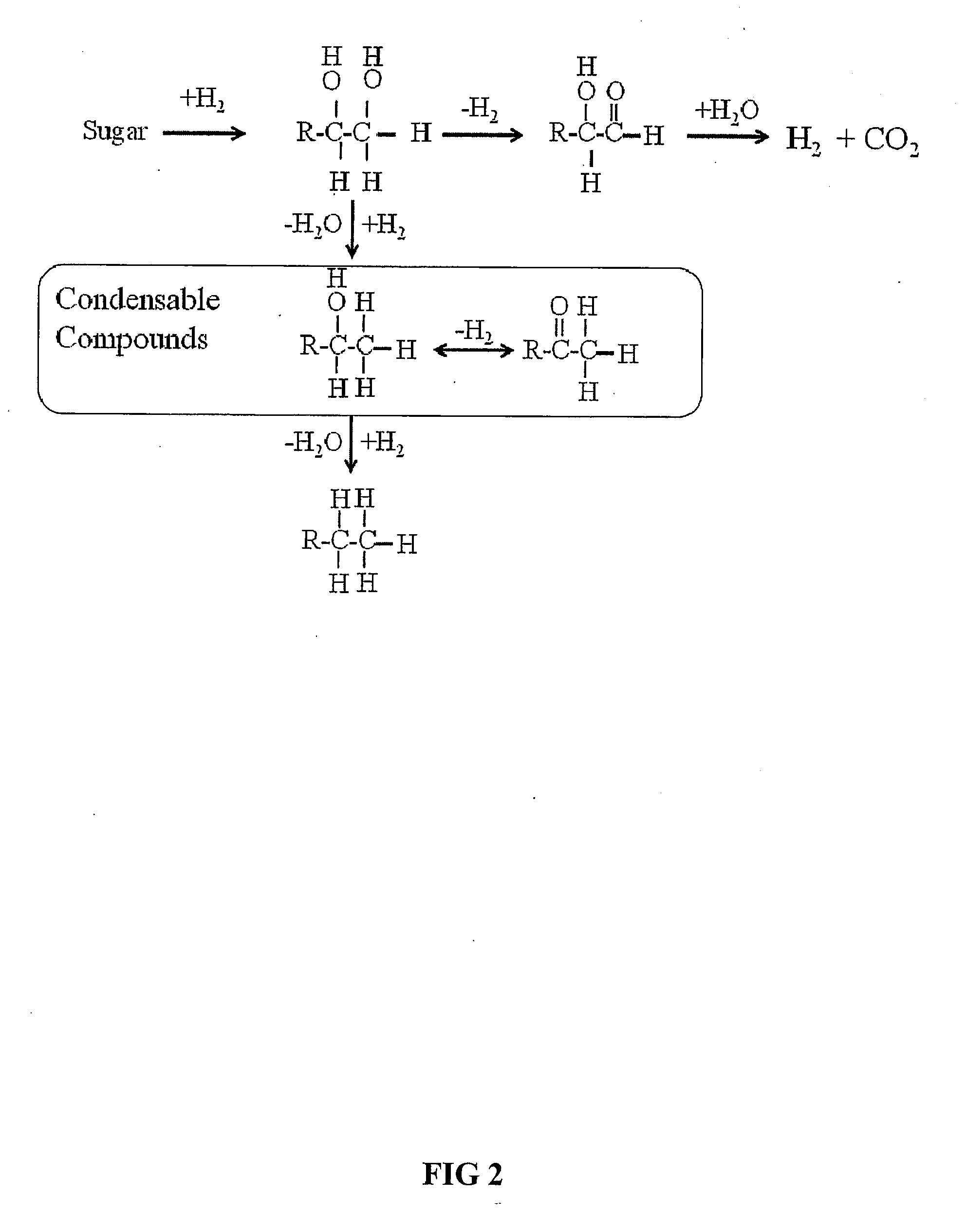

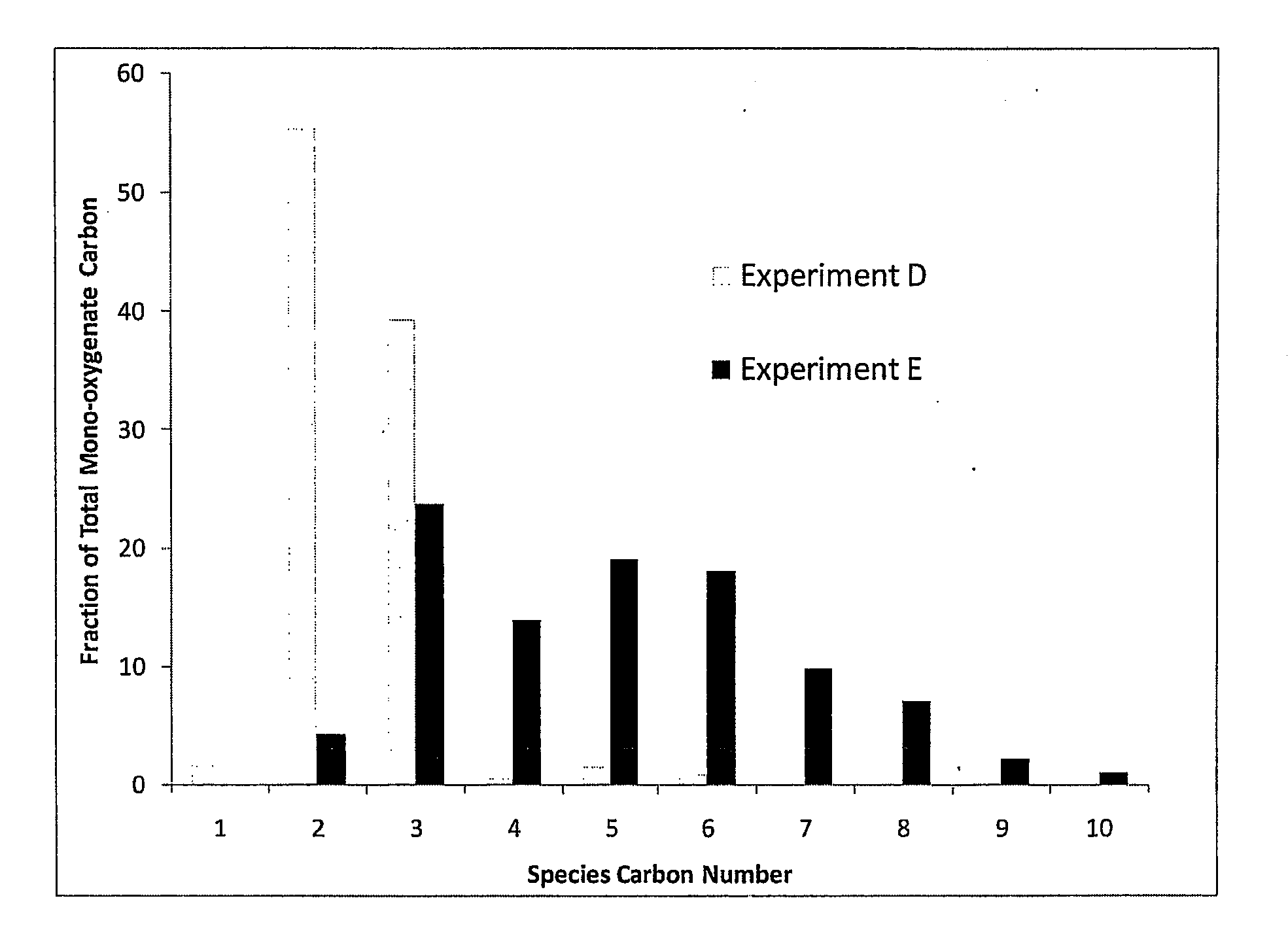

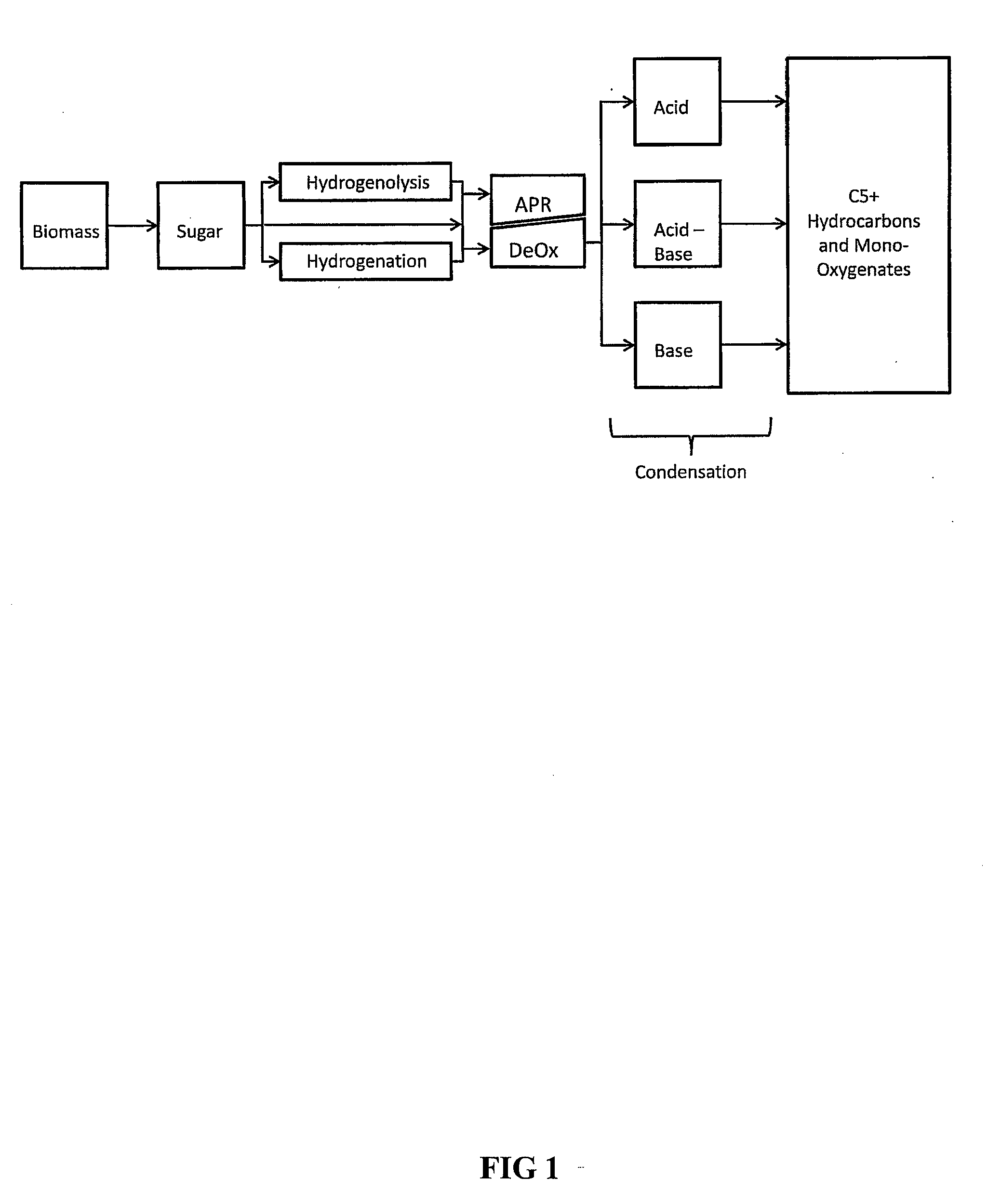

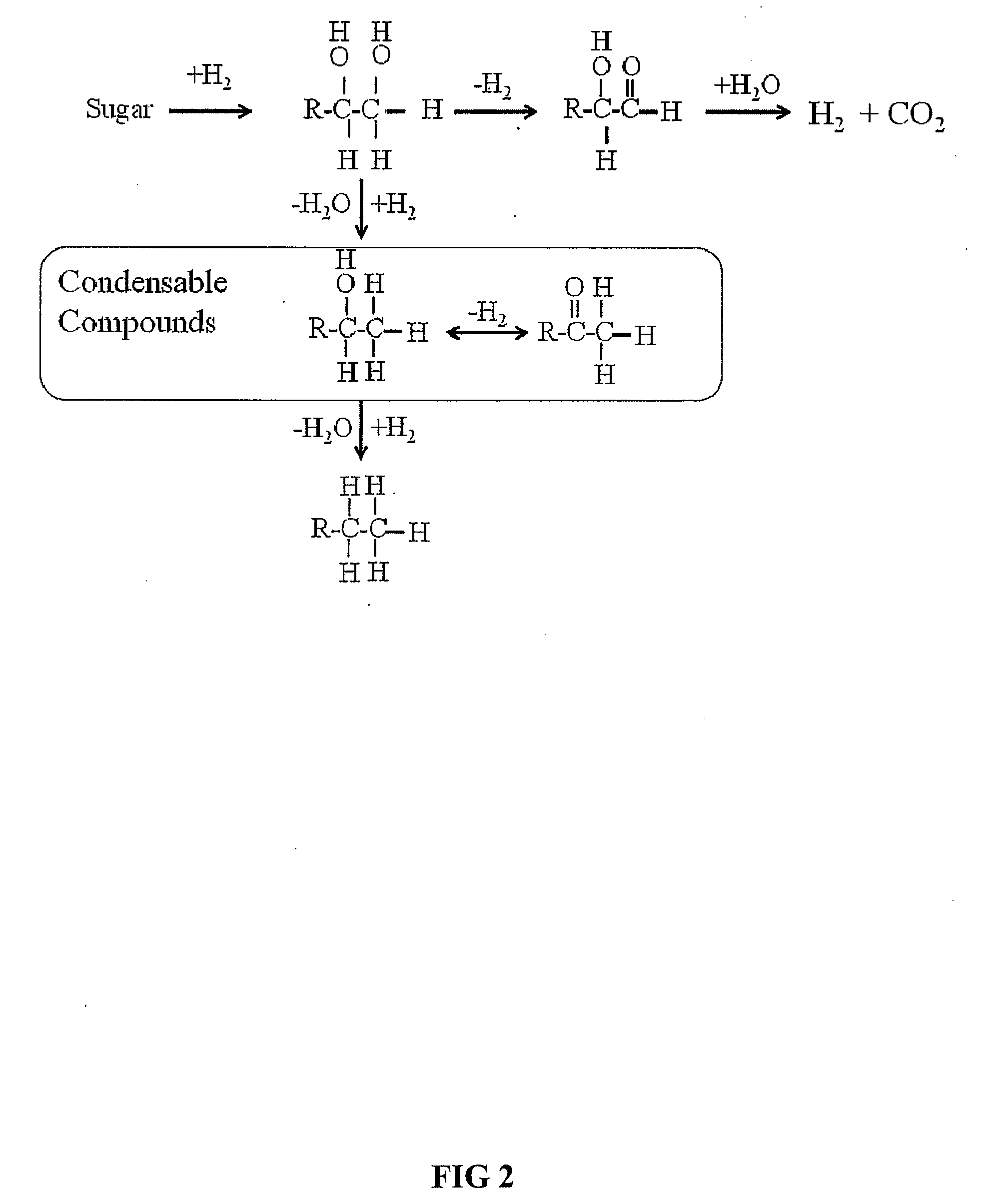

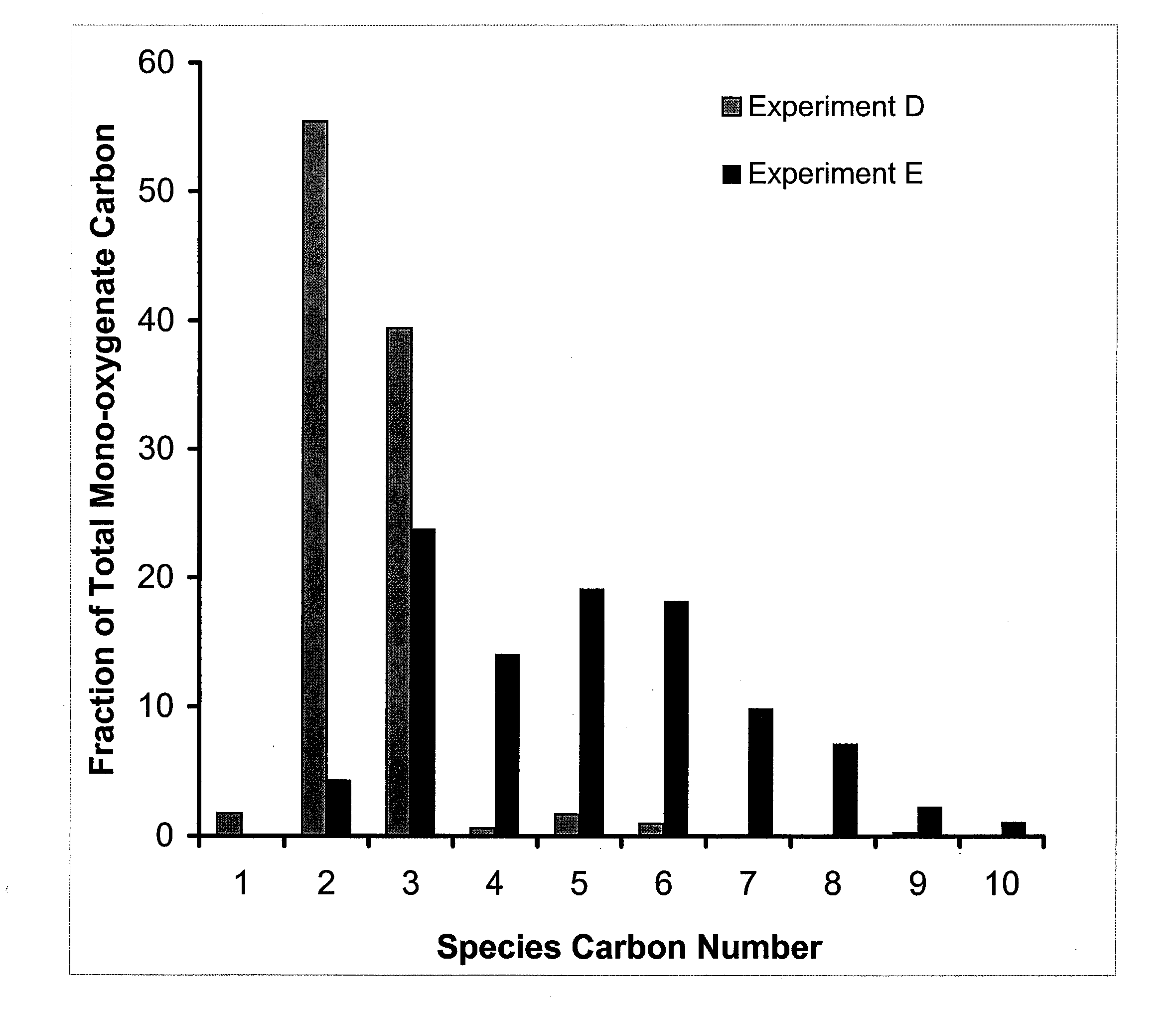

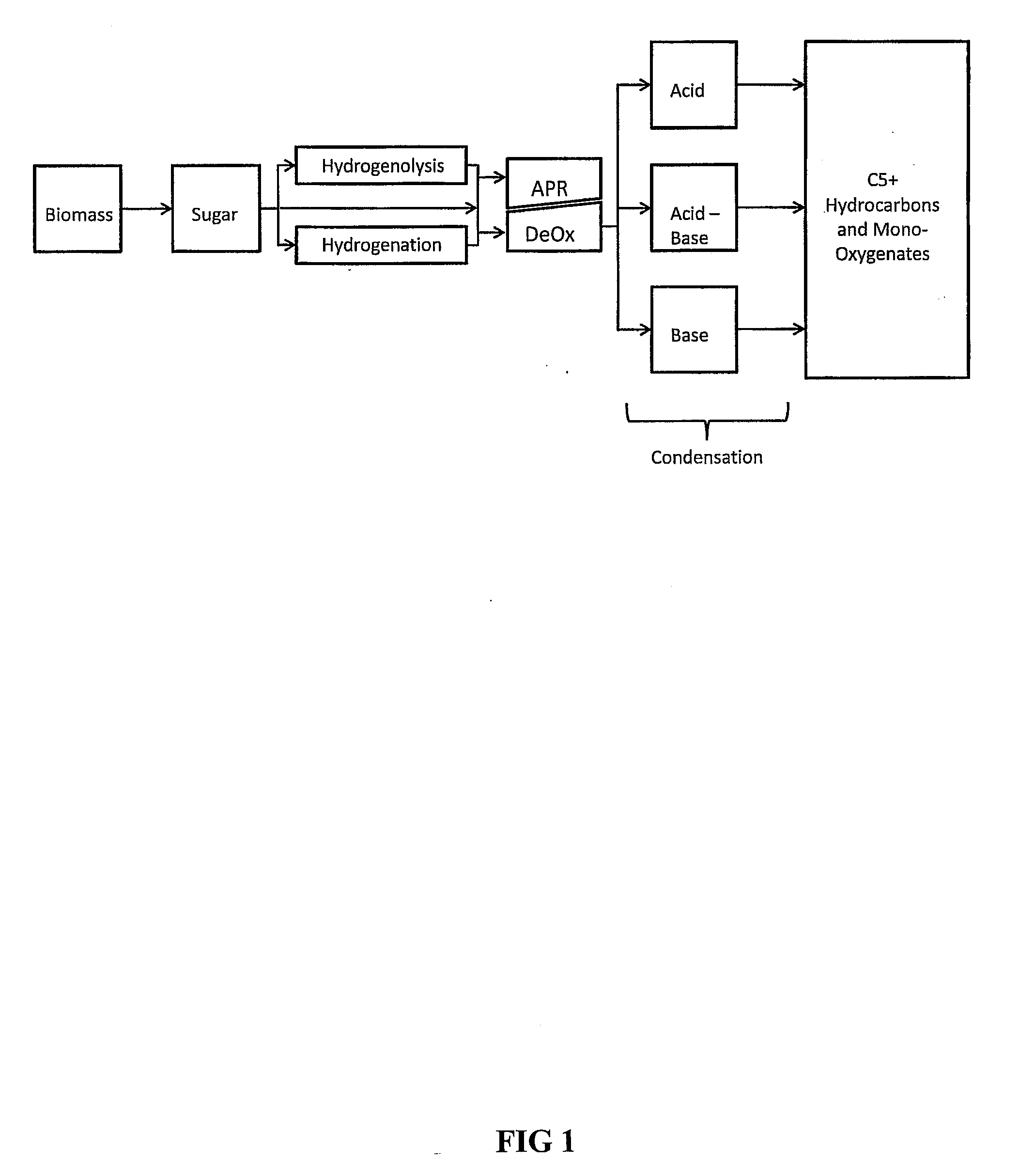

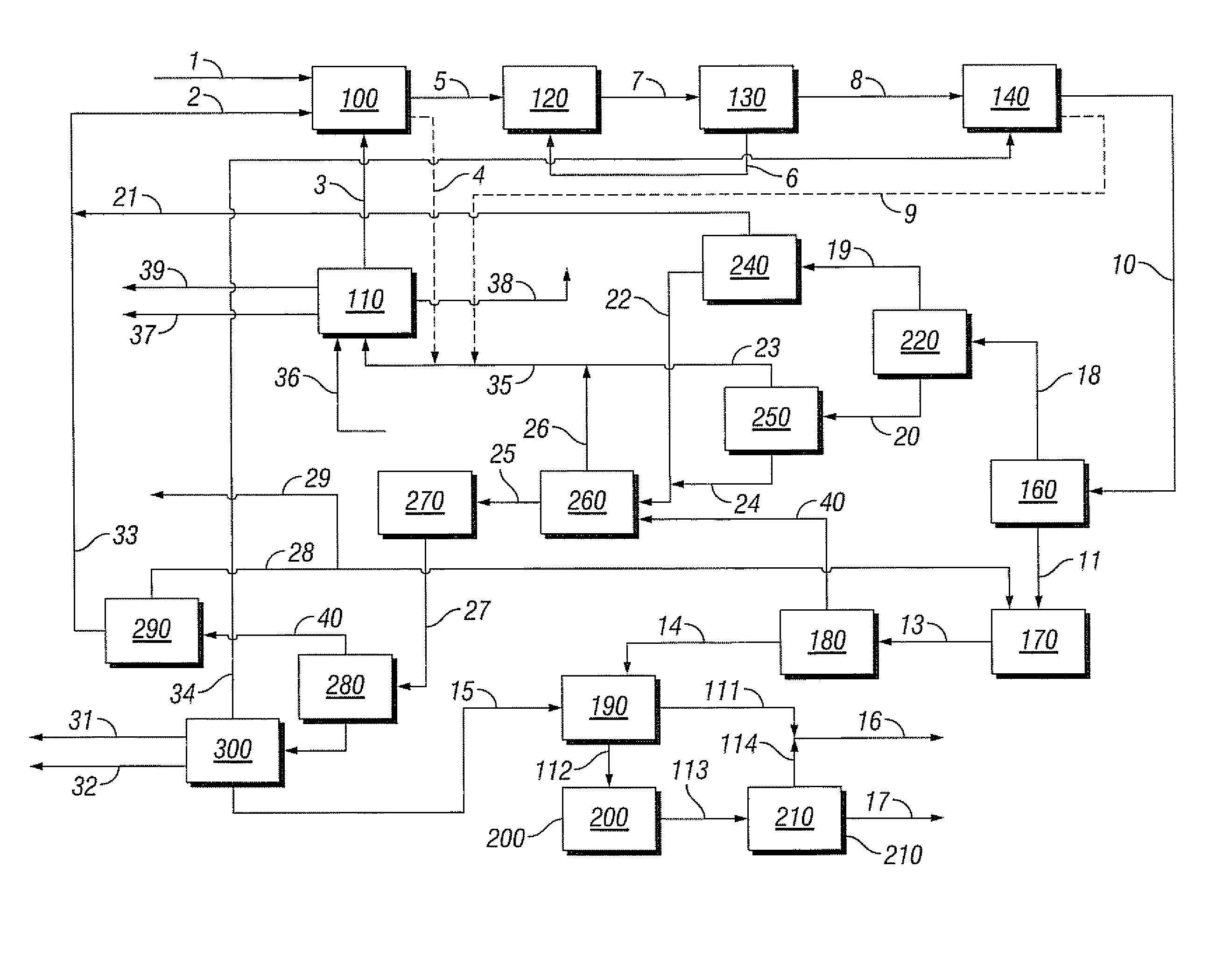

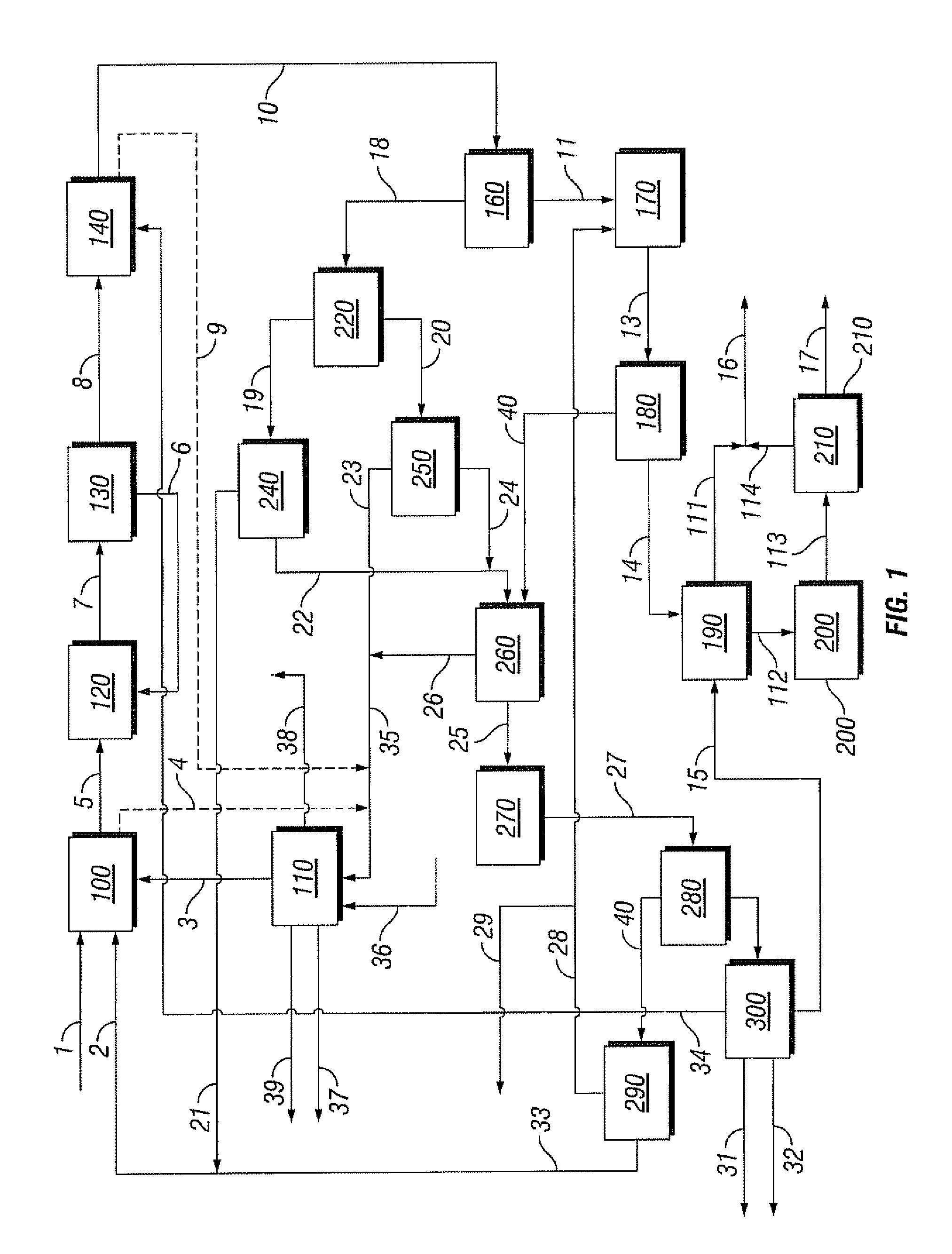

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300435A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionFuranLiquid fuel

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

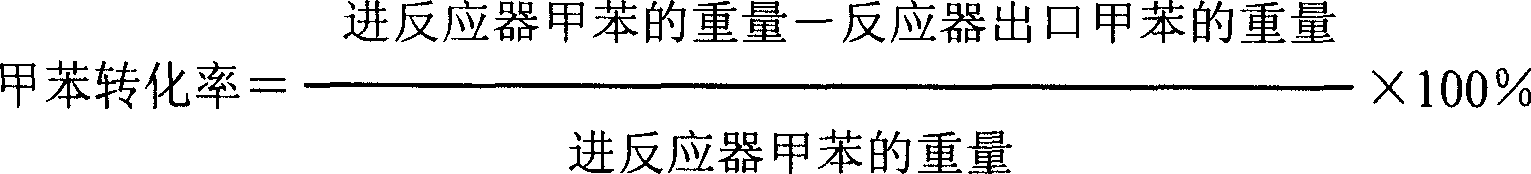

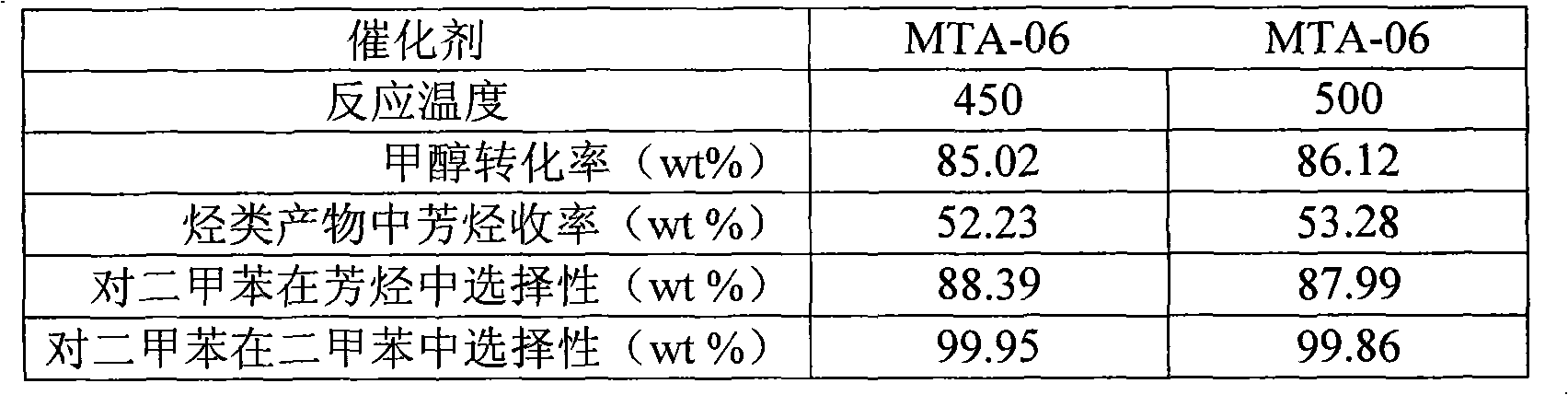

Process for preparing dimethylbenzene by aromatization of methanol

ActiveCN101671226AHigh yieldExtend the life cycleHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAlkyl transfer

A process for preparing dimethylbenzene by aromatization of methanol relates to a process for preparing dimethylbenzene by conducting aromatization reaction in a methanol aromatization reactor with methanol and hydrocarbon as raw materials. The process uses a metal-modified molecular sieve composite material as catalyst and causes the mixture of methanol and one or a plurality of C1-C12 hydrocarbons to conduct aromatization reaction in the methanol aromatization reactor. By adjusting the ratio between methanol and hydrocarbons in the raw material, the process regulates and controls the coordination between aromatization and alkylation reaction and realizes the purposes of effectively improving the yield of the target product dimethylbenzene and prolonging the service cycle of catalyst.

Owner:TSINGHUA UNIV +1

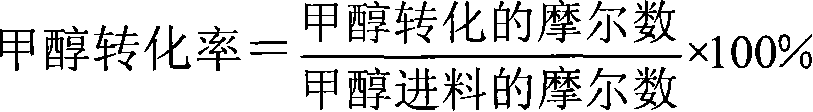

Process for preparing arene selectivity by enhancing methanol aromatizatian and process for preparation of catalyst thereof

ActiveCN101550051AImprove methodHigh yieldMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveFixed bed

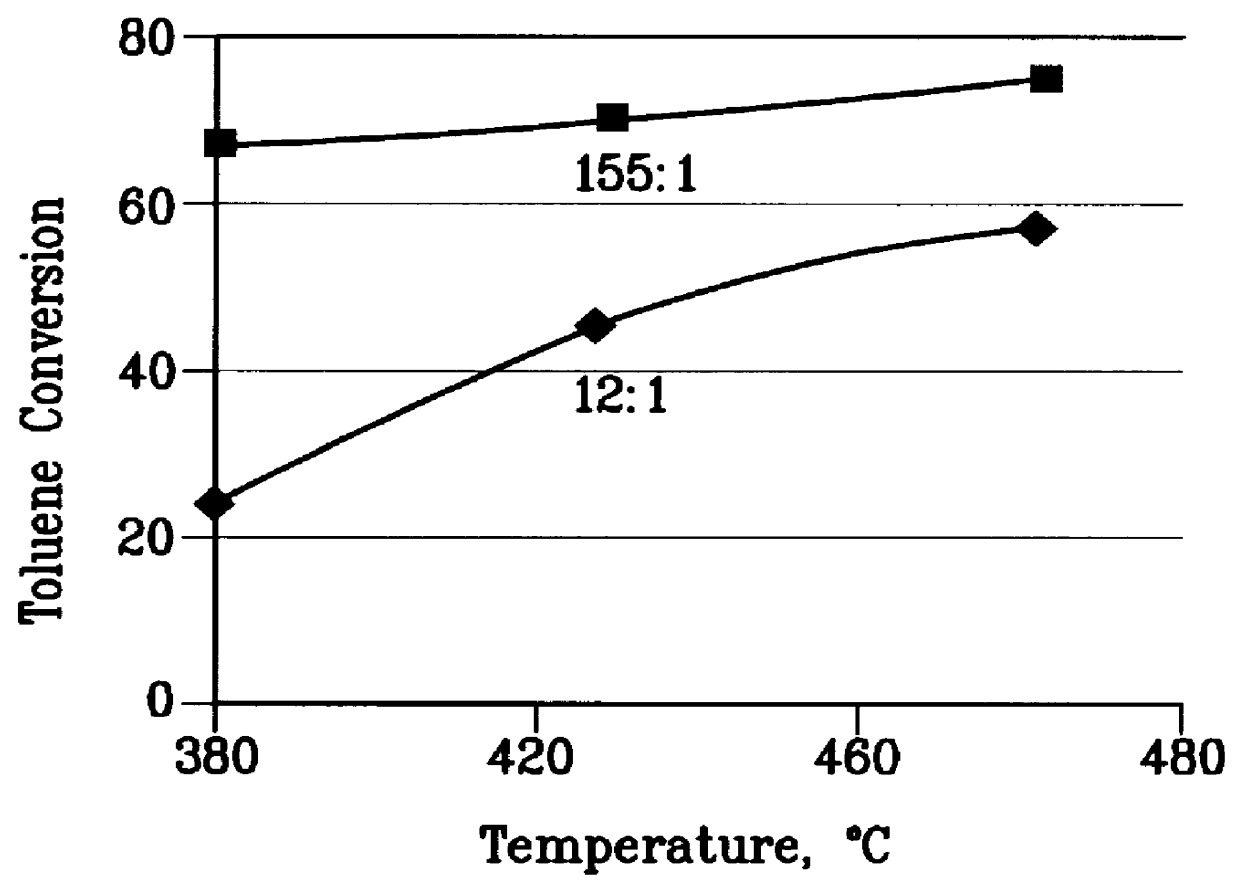

The invention relates to a process for preparing arene selectivity by enhancing methanol aromatizatian. The process uses methanol as raw material, compositely modifies HZSM-5 molecular sieve catalyst by active ions like Ga, Zn, Cu, Cr and Ag for catalyzing methanol aromatizatian, employs the fixed bed continuous process or the floating bed continuous process, wherein the reaction pressure is 0.1-3.5MPa; the reaction temperature is 380-500 DEG C; the space velocity of raw material liquid is 0.1-10.0 h; and N2 space velocity is 120-800 h. The advantages of the invention lie in collocation combination of mixing ion modification, and arene selectivity reaches to 70%.

Owner:TIANJI COAL CHEM IND GROUP +1

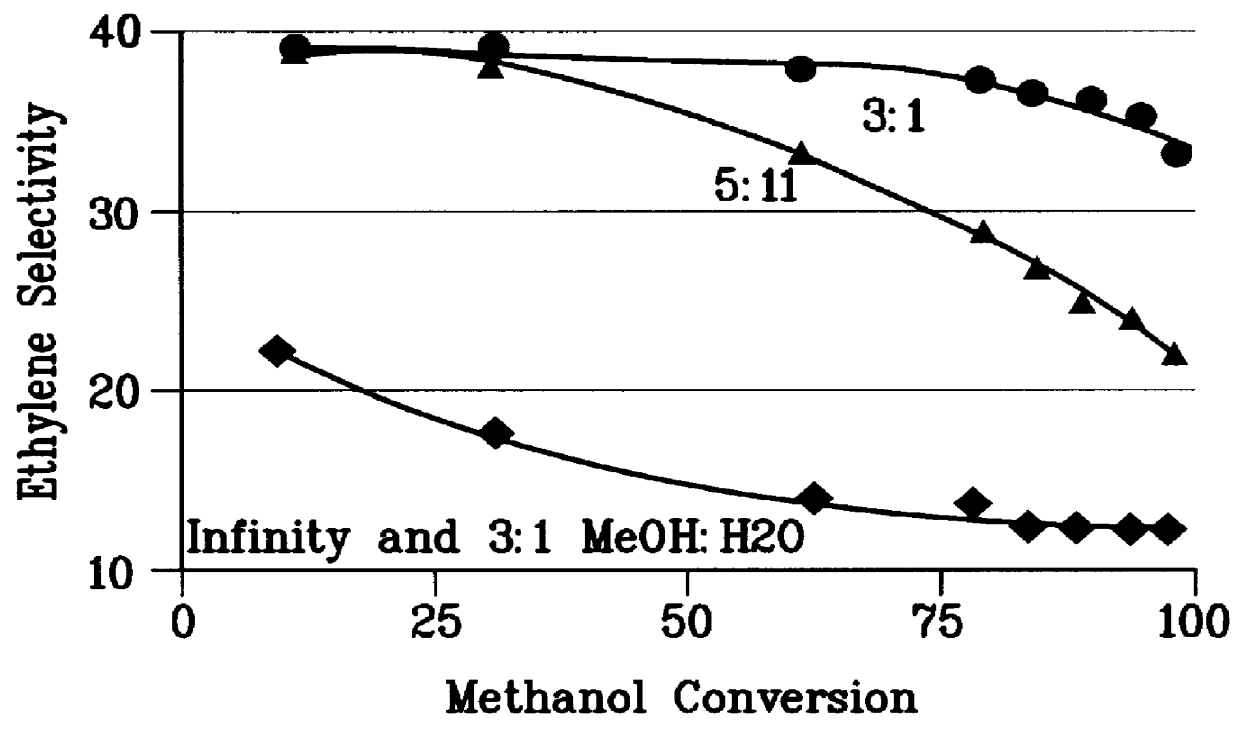

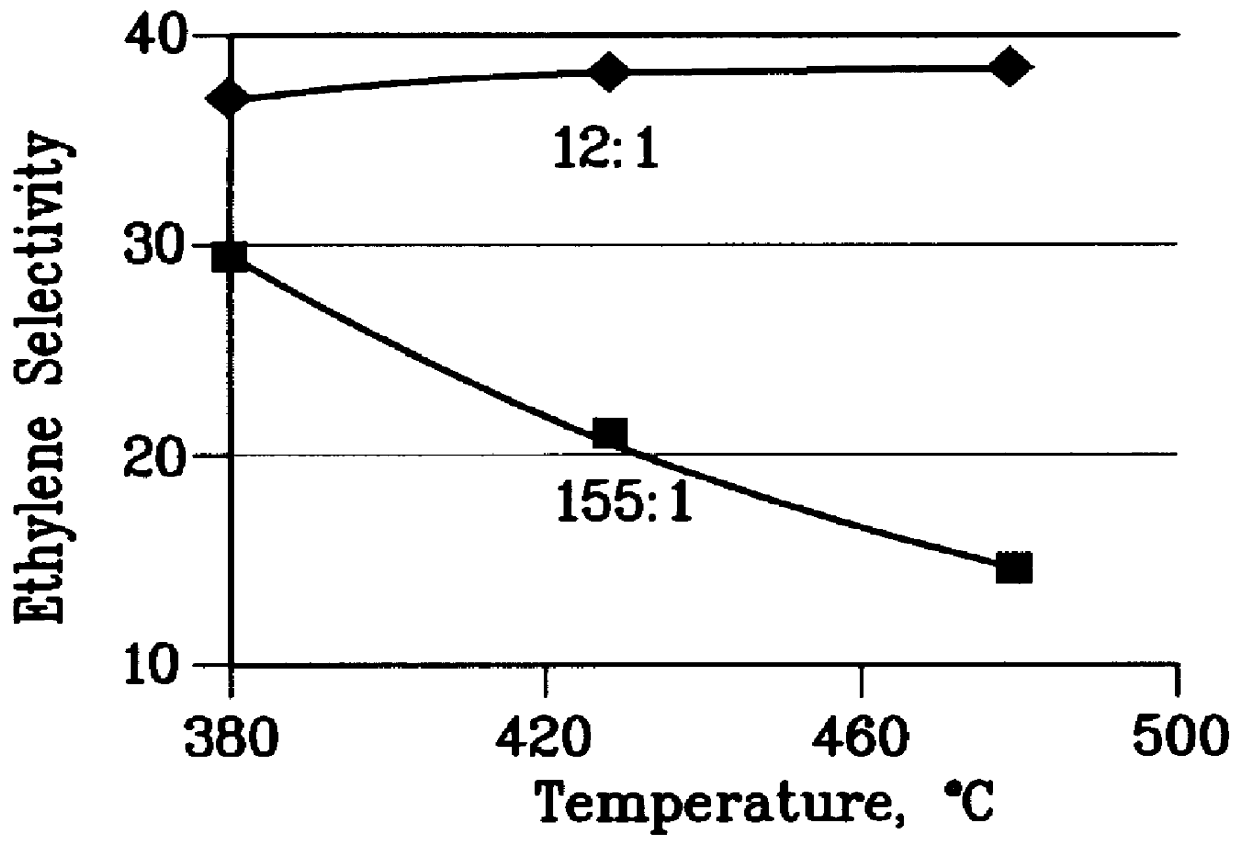

Process for producing light olefins

InactiveUS6046372AMolecular sieve catalystsMolecular sieve catalystAlkyl transferCrystalline materials

There is provided a process for converting methanol and / or dimethyl ether to a product containing C2 to C4 olefins which comprises the step of contacting a feed which contains methanol and / or dimethyl ether with a catalyst comprising a porous crystalline material, said contacting step being conducted in the presence of an aromatic compound under conversion conditions including a temperature of 350 DEG C. to 480 DEG C. and a methanol partial pressure in excess of 10 psia (70 kPa), said porous crystalline material having a pore size greater than the critical diameter of the aromatic compound and the aromatic compound being capable of alkylation by the methanol and / or dimethyl ether under said conversion conditions.

Owner:MOBIL OIL CORP

Catalyst and process for converting methanol to hydrocarbons

InactiveUS6048816AMolecular sieve catalystsMolecular sieve catalystCrystalline materialsDimethyl ether

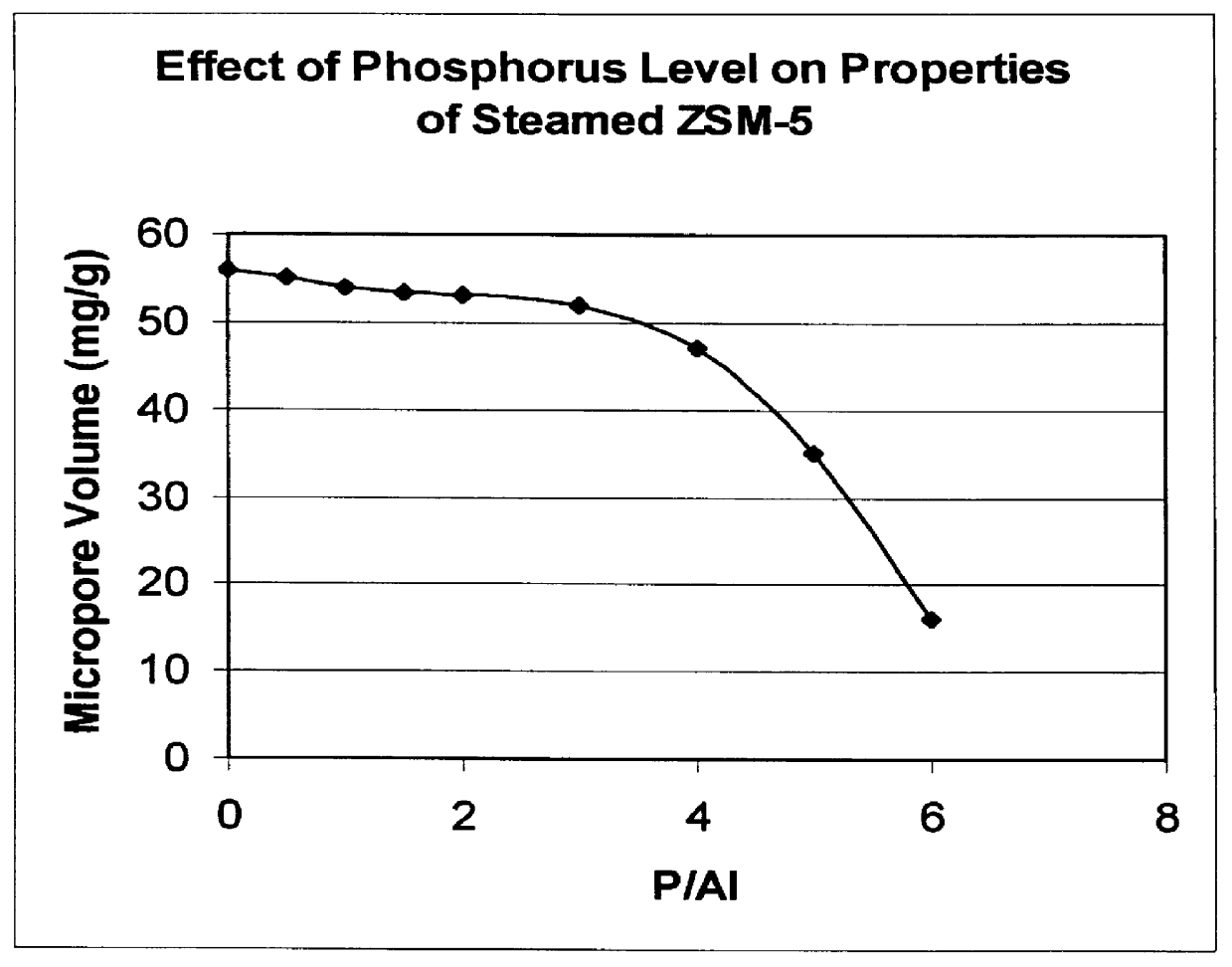

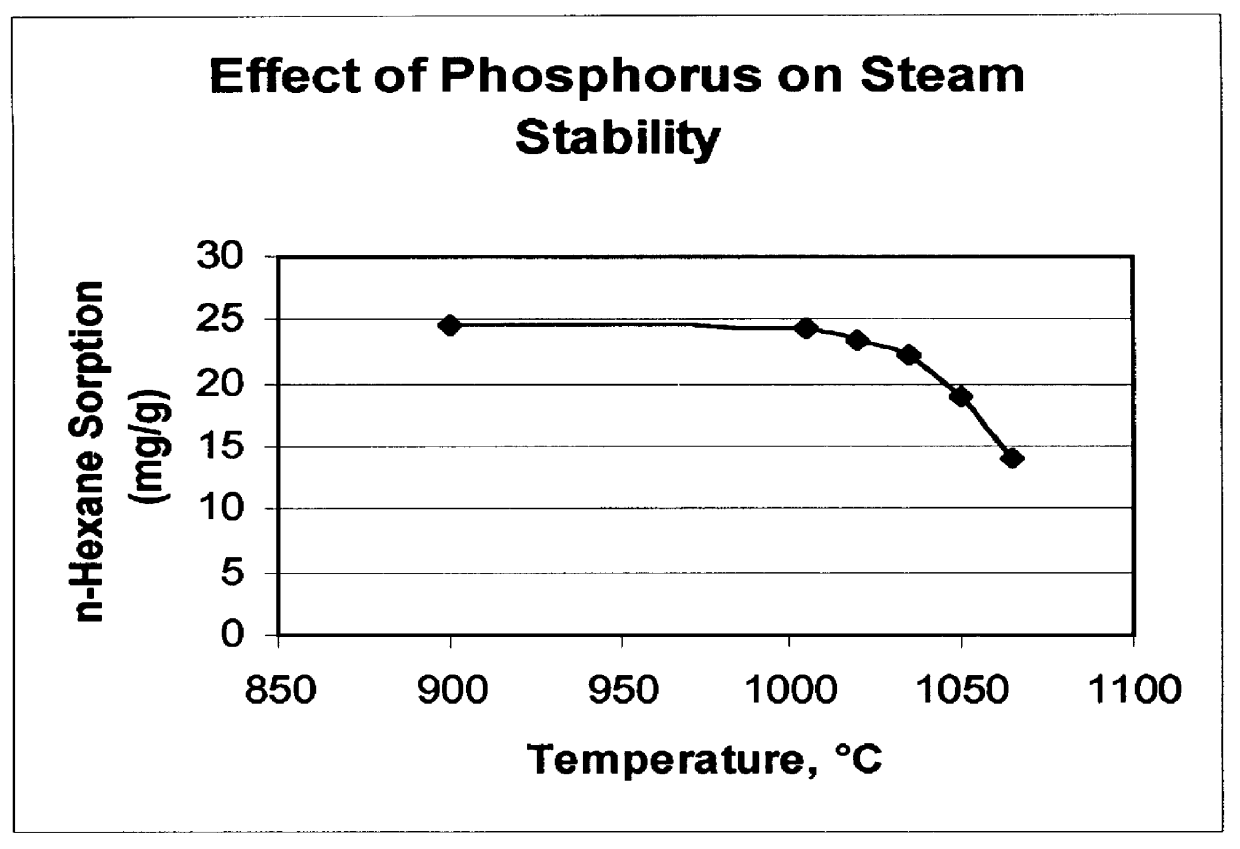

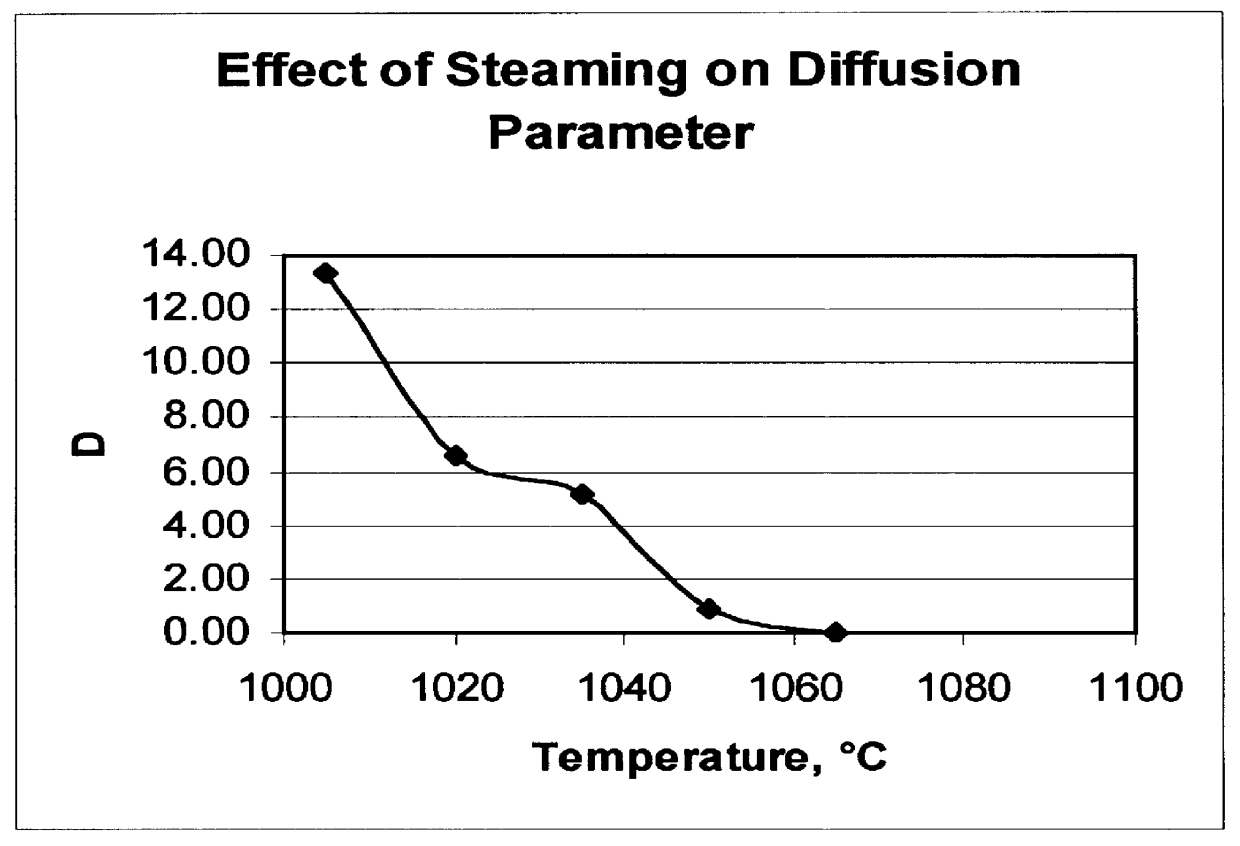

There is provided a catalyst and a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins. The catalyst comprises a porous crystalline material having a Diffusion Parameter for 2,2-dimethylbutane of about 0.1-20 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). In addition, the catalyst is characterized by a hydrothermal stability such that, after steaming the catalyst at 1025 DEG C. for 45 minutes in 1 atmosphere steam, the catalyst exhibits a methanol conversion activity of at least 50% when contacted with methanol at a methanol partial pressure of 1 atmosphere, a temperature of 430 DEG C. and 0.5 WHSV. The porous crystalline material is preferably a medium-pore zeolite, particularly ZSM-5, which contains phosphorus and has been severely steamed at a temperature of at least 950 DEG C.

Owner:MOBIL OIL CORP

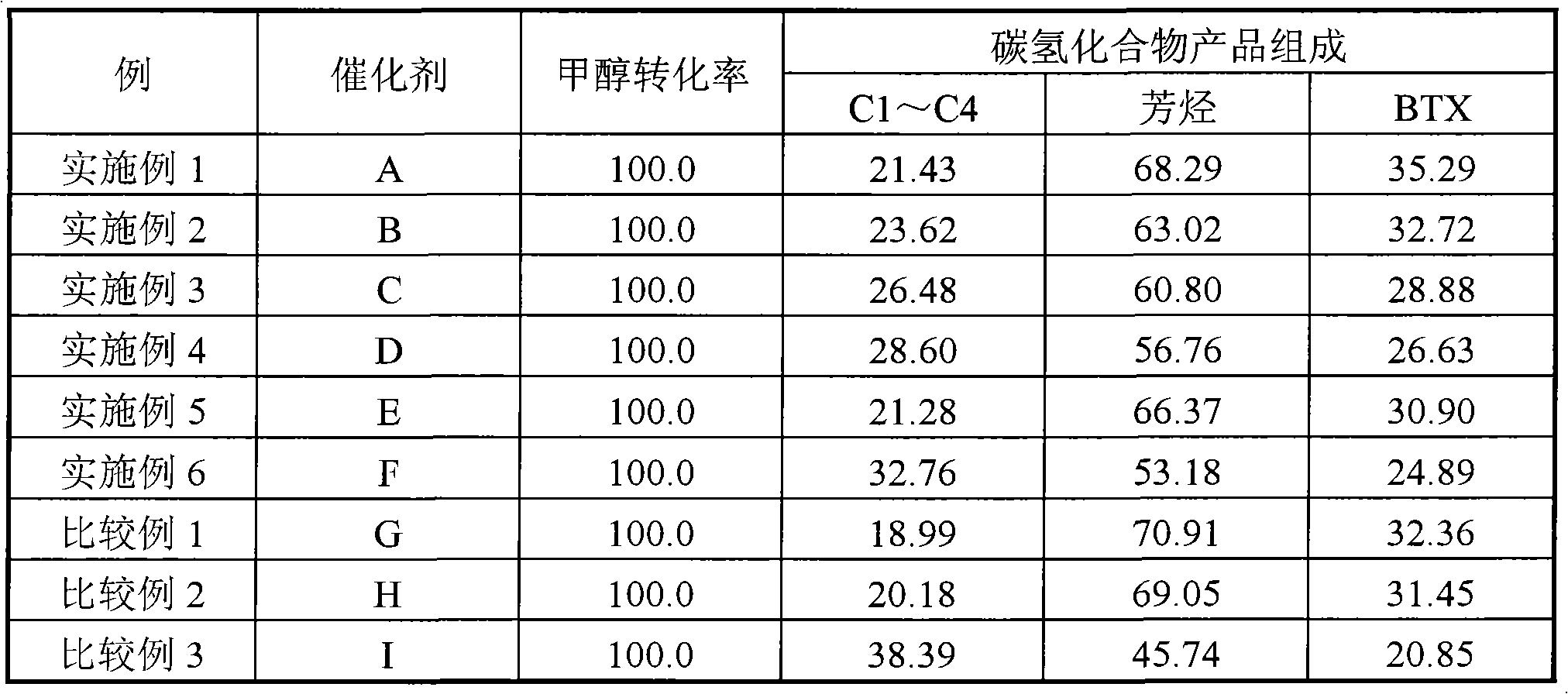

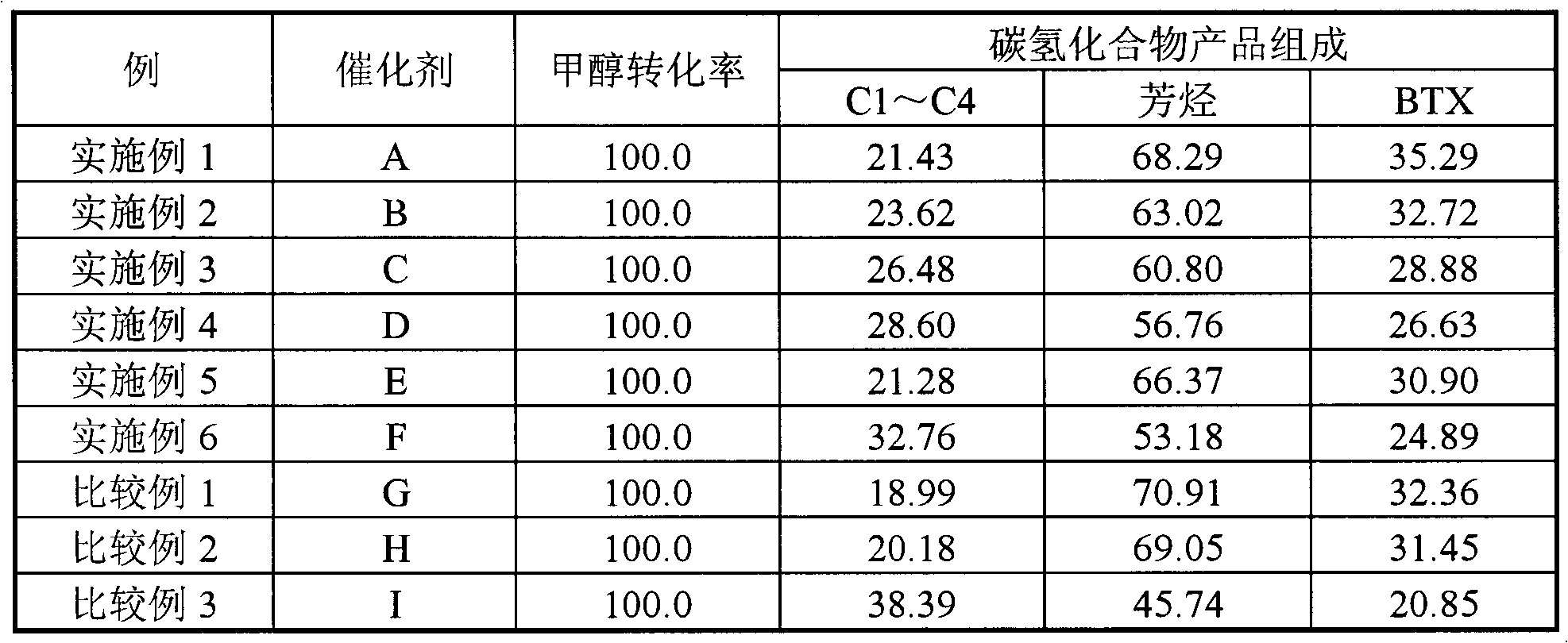

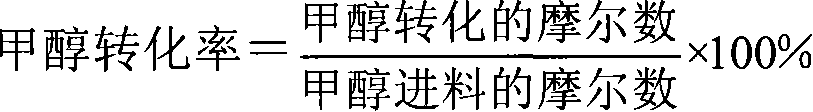

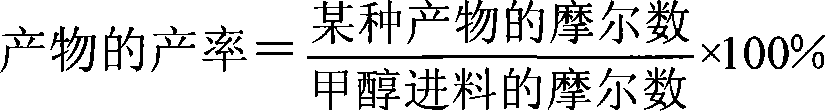

Catalyst for preparing aromatic hydrocarbon through methanol conversion and preparation method thereof

ActiveCN102371176AHigh selectivityHigh activityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sievePhosphor

The invention relates to a catalyst for preparing aromatic hydrocarbon through methanol conversion and a preparation method thereof, and mainly solves the problems of complex technological process and low selectivity of the target product in the prior art. According to the invention, the catalyst comprises the following components of: by weight, a) 20-80 parts of a molecular sieve carrier; b) 0.5-12 parts of lanthanum element or its oxide which is carried on a); c) 0.5-10 parts of phosphor element or its oxide; d) 20-80 parts of a binder, wherein the molecular sieve comprises a mixture of HZSM-5 and at least one component selected from HZSM-11 or Hbeta molecular sieves; and the weight ratio of HZSM-5 to the at least one component selected from HZSM-11 or Hbeta is 0.1-10: 1. The technical scheme provided by the invention greatly solves the problems and can be used in the industrial production of aromatic hydrocarbon through methanol conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing aromatic hydrocarbon through methanol transformation

InactiveCN102372550AHigh selectivityHigh catalytic activityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveRare earth

The invention relates to a method for preparing aromatic hydrocarbon through methanol transformation, and mainly solves the problems of complicated process flow and low selectivity of target products existing in the prior art. The problems are better solved by adopting the technical scheme that the method comprises the step of: reacting by taking methanol as a raw material and a mixture of HZSM-5 containing rare earth metal or oxide thereof and at least one of a HZSM-11 or Hbeta molecular sieve as an active main body of a catalyst under the condition that the reaction temperature is 320 to 480 DEG C, the reaction pressure is 0.1 to 3.0MPa and the weight hourly space velocity of the raw material is 0.5 to 6.0 h<-1>; and the method can be used for the industrial production of the aromatic hydrocarbon through methanol transformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

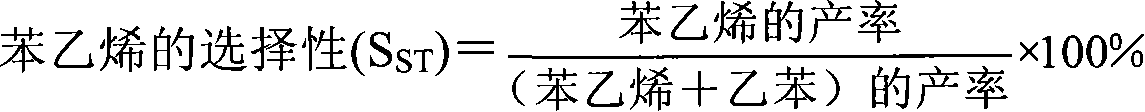

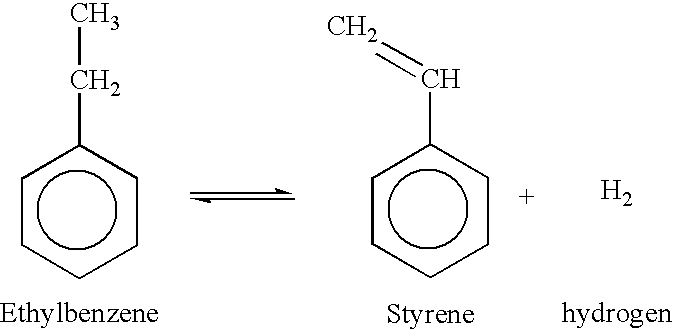

Method for preparing styrene catalyst through toluene-methanol side chain alkylation

ActiveCN101623650AAvoid breakingImprove stabilityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferMolecular sieve

The invention relates to a method for preparing a styrene catalyst through toluene-methanol side chain alkylation, which mainly solves the problem that in the prior art, a catalyst has a vulnerable catalyst structure and poor catalyst stability. Through the technical scheme that an alkali molecular carrier is loaded with elements selected from B, P and at least one of alkali metal and alkaline-earth metal to prepare the catalyst, wherein the carrier is exchanged into an H-type molecular sieve by ammonium salt before loading, roasted, exchanged by alkali metal salt, dried, roasted and dipped with the loaded elements, the method well solves the problem of poor stability and can be used for industrial preparation of the styrene catalyst through toluene-methanol side chain alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for alkylation of toluene methanol

ActiveCN1915512AHigh activityImprove para-selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlkyl transferHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkaline molecular sieve catalyst for preparing styrene

ActiveCN101623649AStrong alkalineImprove stabilityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAlkyl transfer

The invention relates to an alkaline molecular sieve catalyst for preparing styrene, which mainly solves the problems that in the prior art, a catalyst has weak alkalescence, a vulnerable structure and poor stability. Through a technical scheme that an alkaline molecular sieve subjected to alkalis exchange is treated by ammonia under the condition of a temperature between 350 and 900 DEG C, the alkaline molecular sieve catalyst wells solves the problem and can be used in industrial preparation of the styrene catalyst through toluene-methanol side chain alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

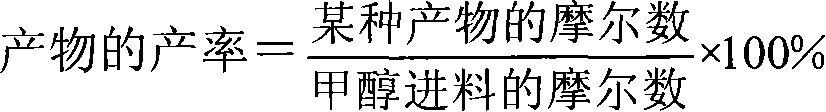

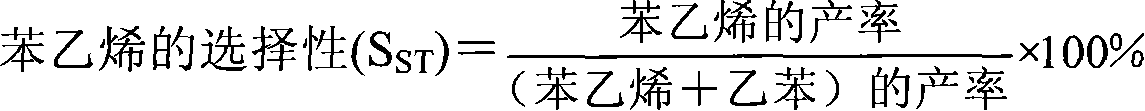

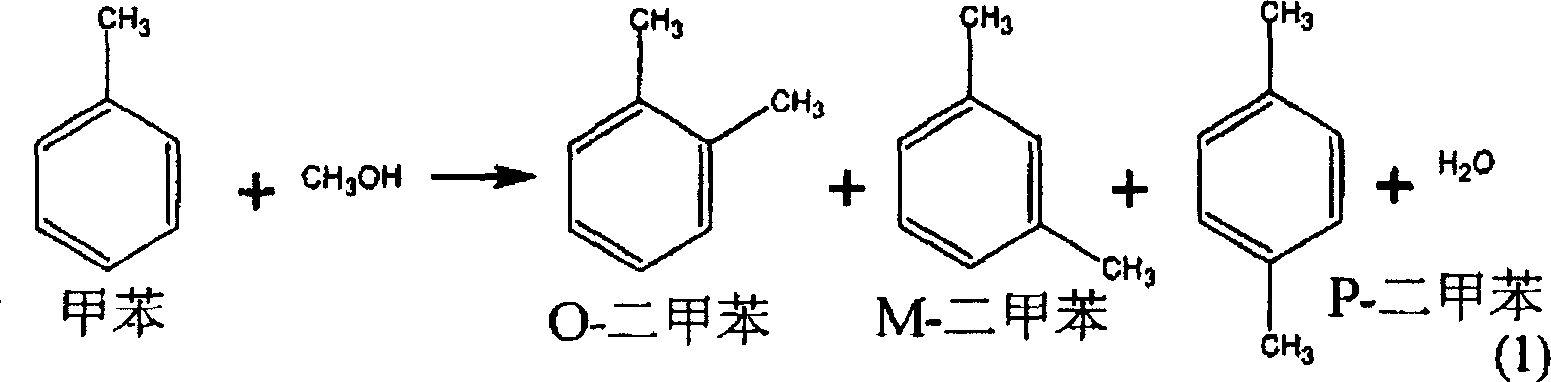

Method for preparing methylbenzene or dimethylbenzene by alkylating benzene with methanol

InactiveCN101624327AHigh selectivityEasy to adjustMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferReaction temperature

The invention relates to a method for preparing methylbenzene or dimethylbenzene by alkylating benzene with methanol, comprising the following steps: raw material benzene and recycle benzene rectified to be recovered are mixed together with the methanol, mixed materials exchange heat with materials on an outlet of an alkylation reactor, and then the mixed materials are heated to achieve alkylation reaction temperature and subject to alkylation reaction to obtain a product under the condition that an acidic catalyst exists; the product is cooled by water to reduce temperature and then subjects to oil-water separation to obtain a water phase and an oil phase, wherein the water phase is purified to be recycled, the oil phase is rectified to be separated to obtain the benzene, the methylbenzene and the dimethylbenzene, and the methylbenzene and the dimethylbenzene are used as target products to separate from a reaction system; and unreacted benzene is returned to be circulated and continuously reacted together with the raw material benzene. The invention has high catalyst selectivity and can conveniently regulate the selectivity of the methylbenzene and the dimethylbenzene.

Owner:山西恒扬科技有限公司 +1

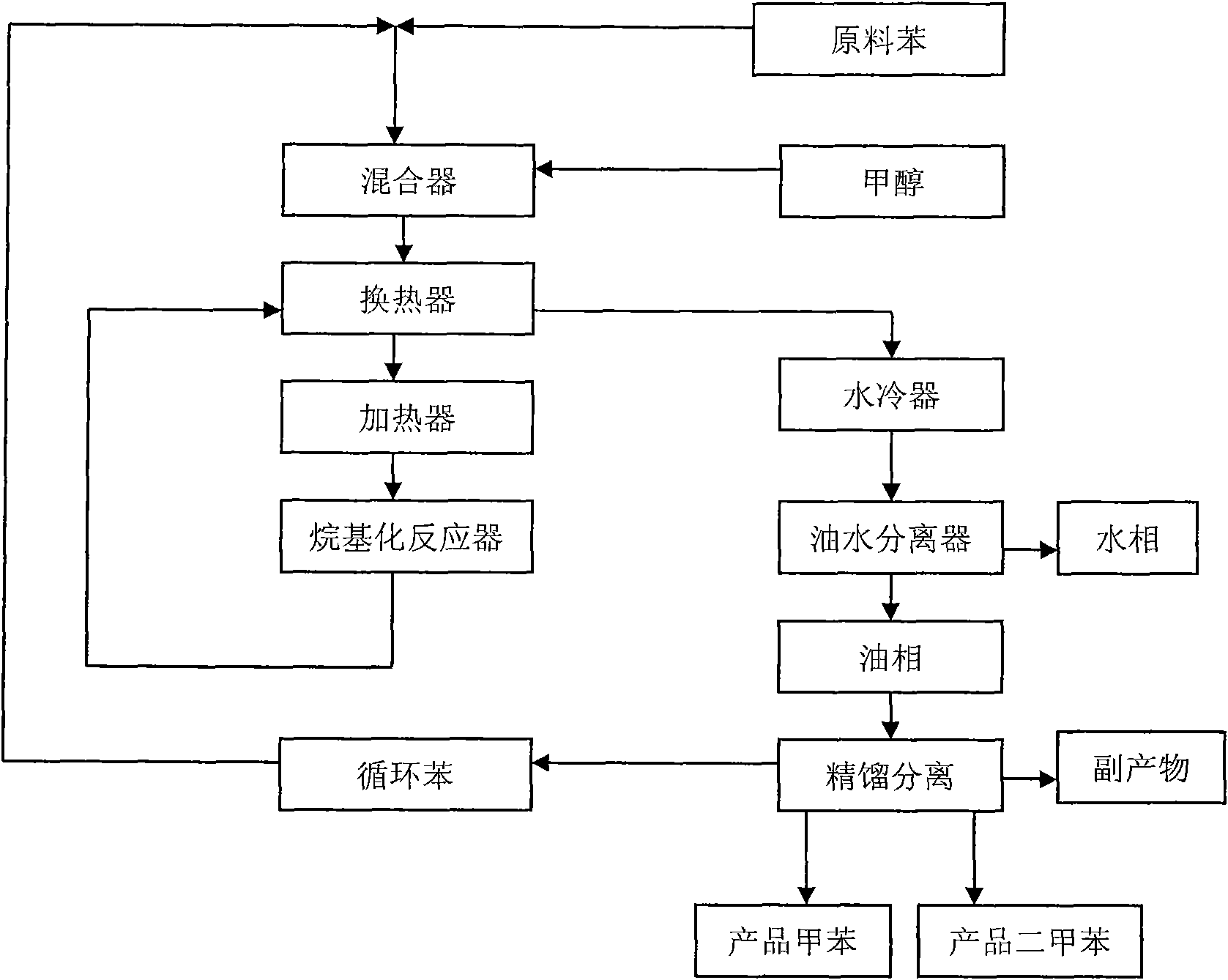

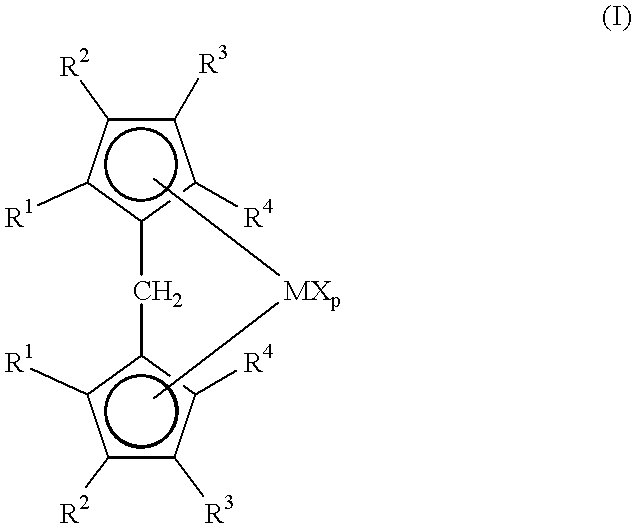

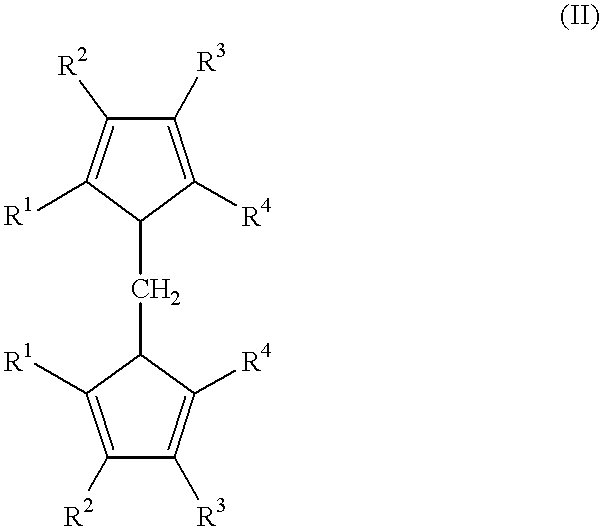

Metallocene compounds and their use in catalysts for the polymerization of olefins

InactiveUS6268518B1Group 5/15 element organic compoundsHydrocarbon by hydrocarbon condensationArylHydrogen

It is disclosed a new class of bridged metallocene compounds of formula (I):wherein R1 and R2 can be hydrogen, alkyl, cycloalkyl, aryl, alkylaryl or arylalkyl radicals; R3 and R4 form a condensed, 5- to 8-membered, aliphatic, aromatic or heterocyclic ring; M is a transition metal of groups 3, 4, 5, lanthanide or actinide; X is hydrogen, halogen, -R, -OR, -OSO2CF3, -OCOR, -SR, -NR2 or PR2, wherein R is an hydrocarbon substituent; and p is 0-3. Furthermore, a catalyst system for olefin polymerization based on the above bridged metallocene compounds and the ligands for their preparation are disclosed.

Owner:MONTELL TECH CO BV

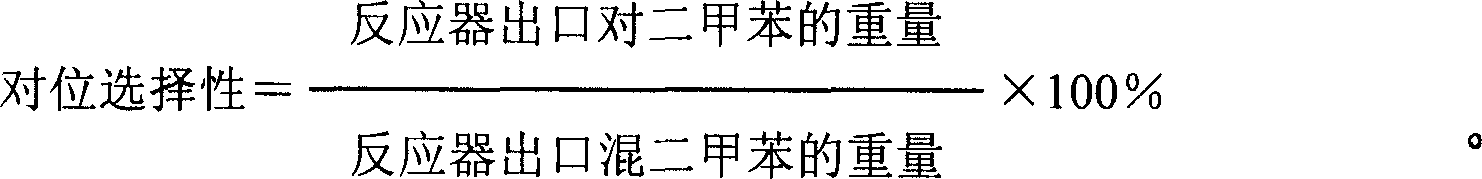

Nano molecular sieve catalyst for synthesizing paraxylene and preparation method thereof

ActiveCN101485994AMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationIridiumRare earth

The invention provides a catalyst for synthesizing a nanometer molecular sieve of para-xylene and a method for preparing the same, and mainly overcomes the defects of poor stability and low selectivity on para-xylene in the prior catalyst. In the method, the nanometer molecular sieve as a mother substance, silicon, phosphorus, magnesium and mixed rare earth are modified so as to adjust acid performance and porous channel structure of the catalyst and improve the selectivity of the catalyst, and the metals with hydrogenation function such as noble metals of platinum, palladium, ruthenium, rhodium, iridium, osmium, and the like or transition metals of iron, cobalt, nickel, and the like are modified so as to inhibit the deactivation of carbon accumulation of the catalyst and greatly improve the stability of the catalyst.

Owner:DALIAN UNIV OF TECH

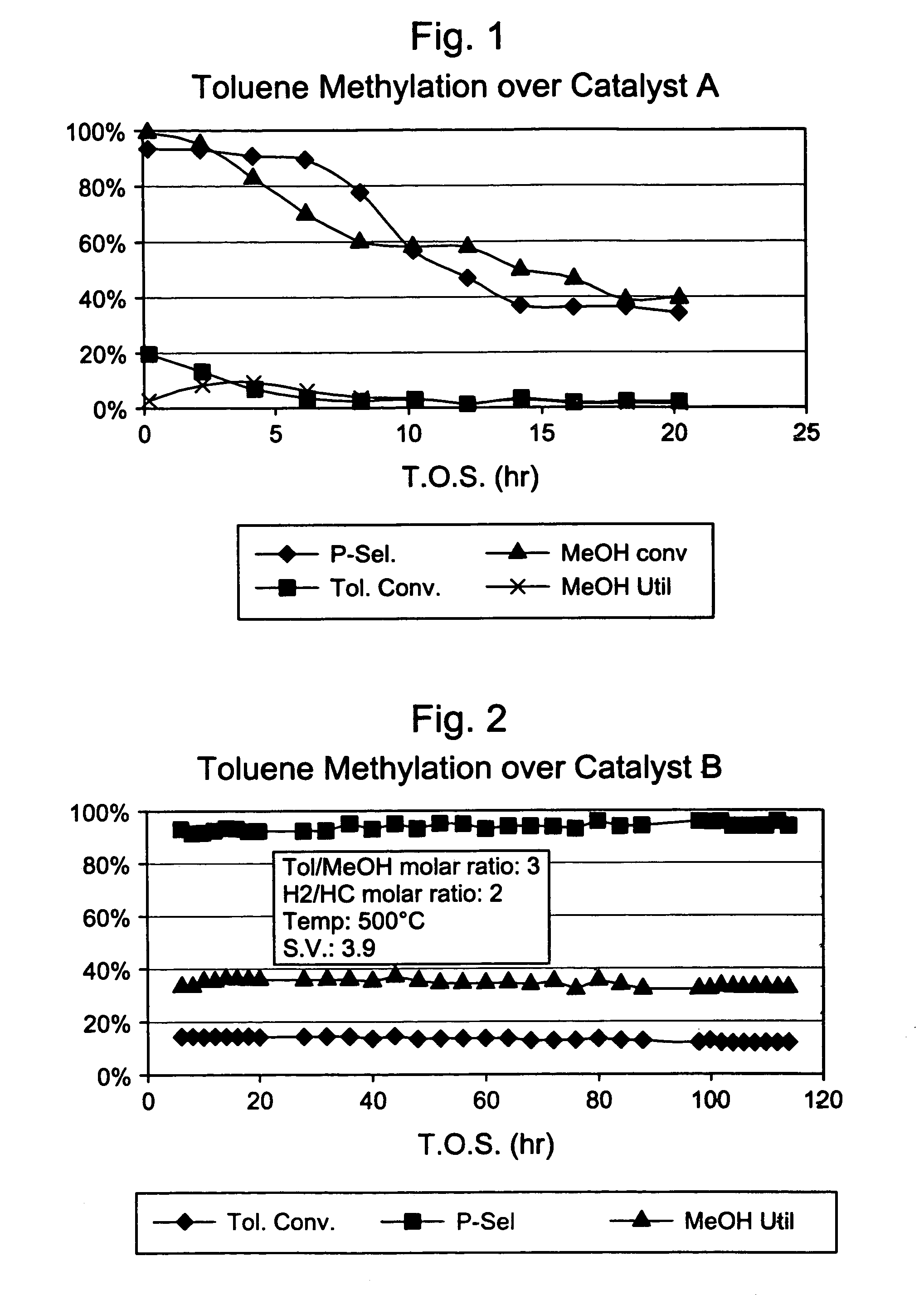

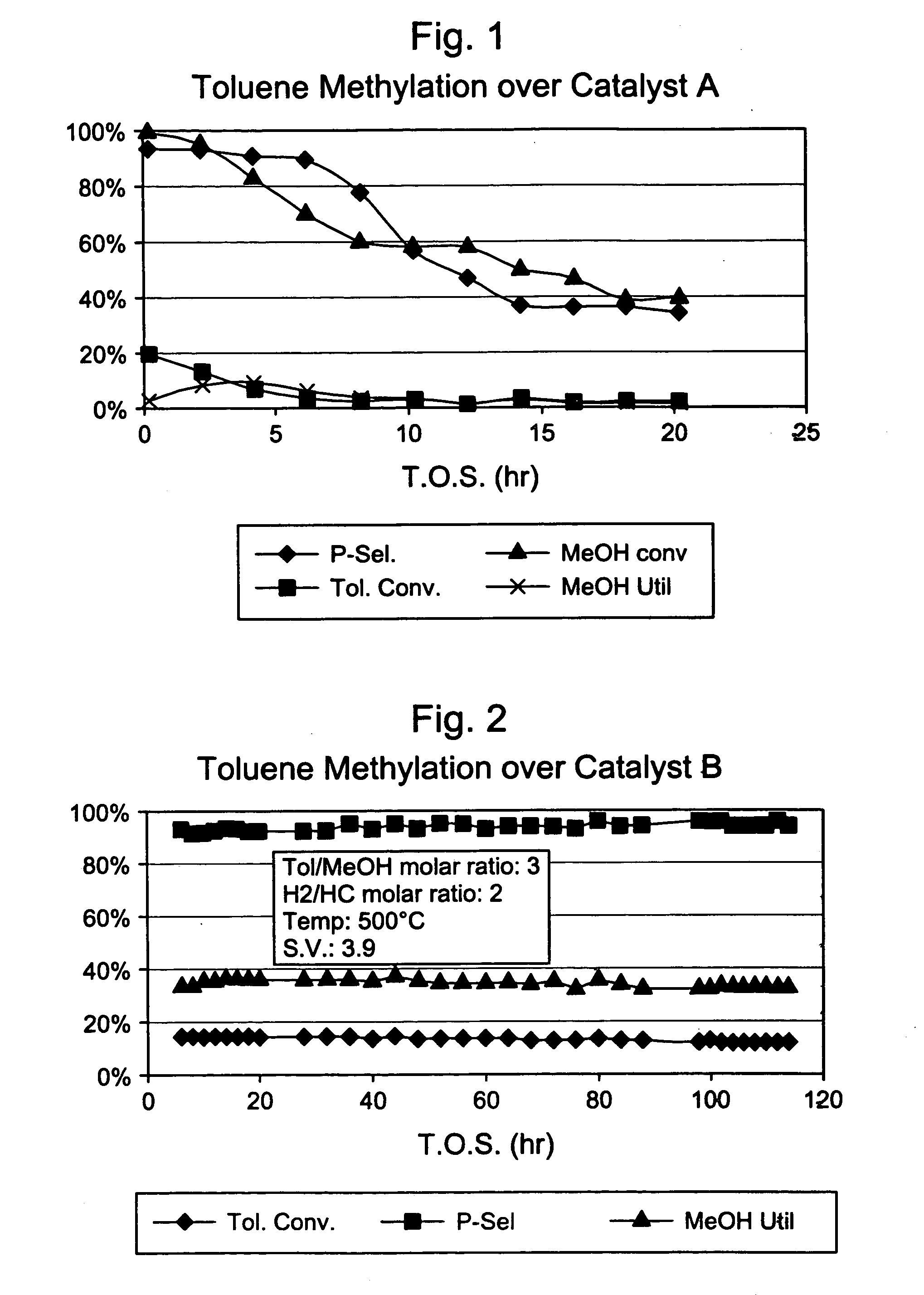

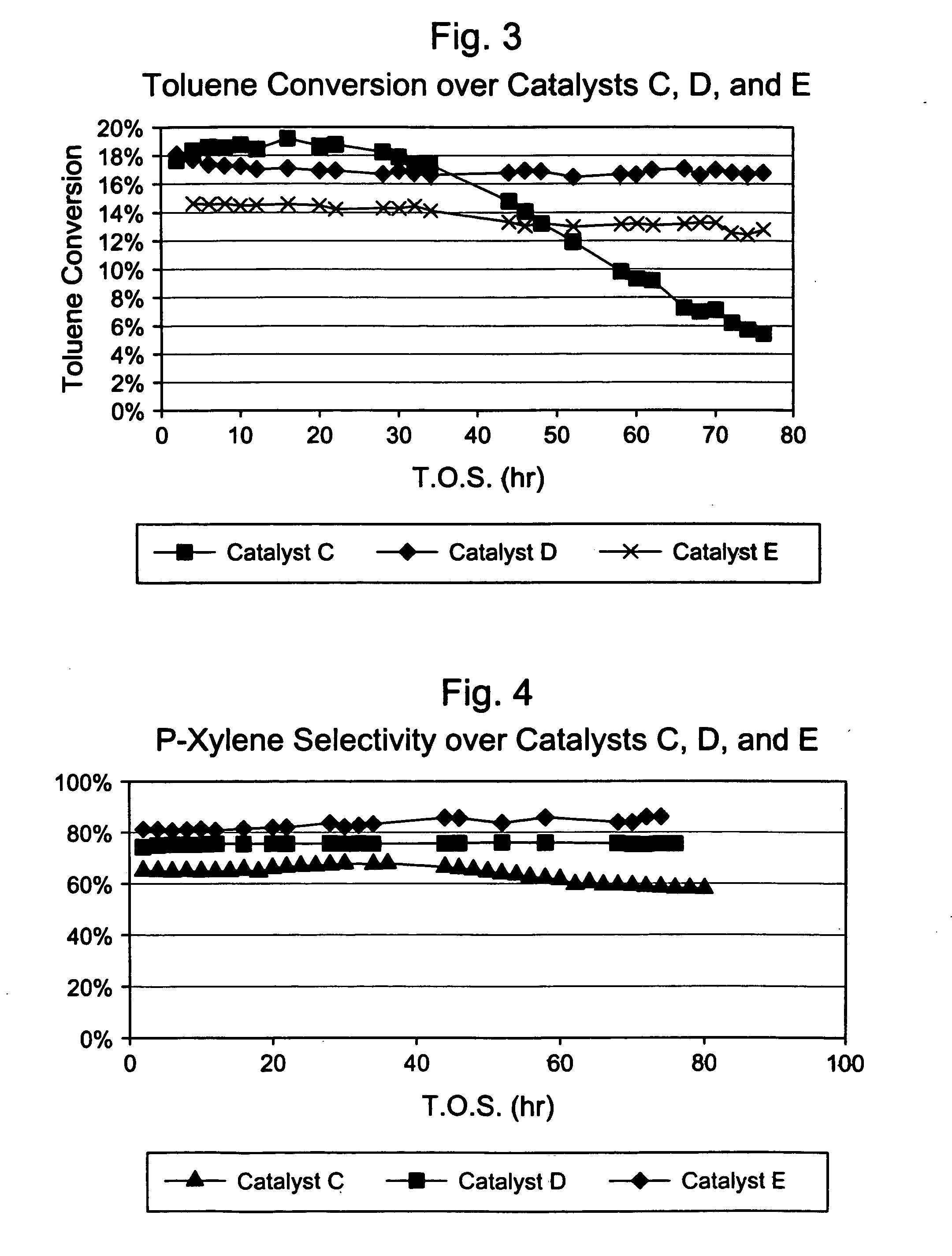

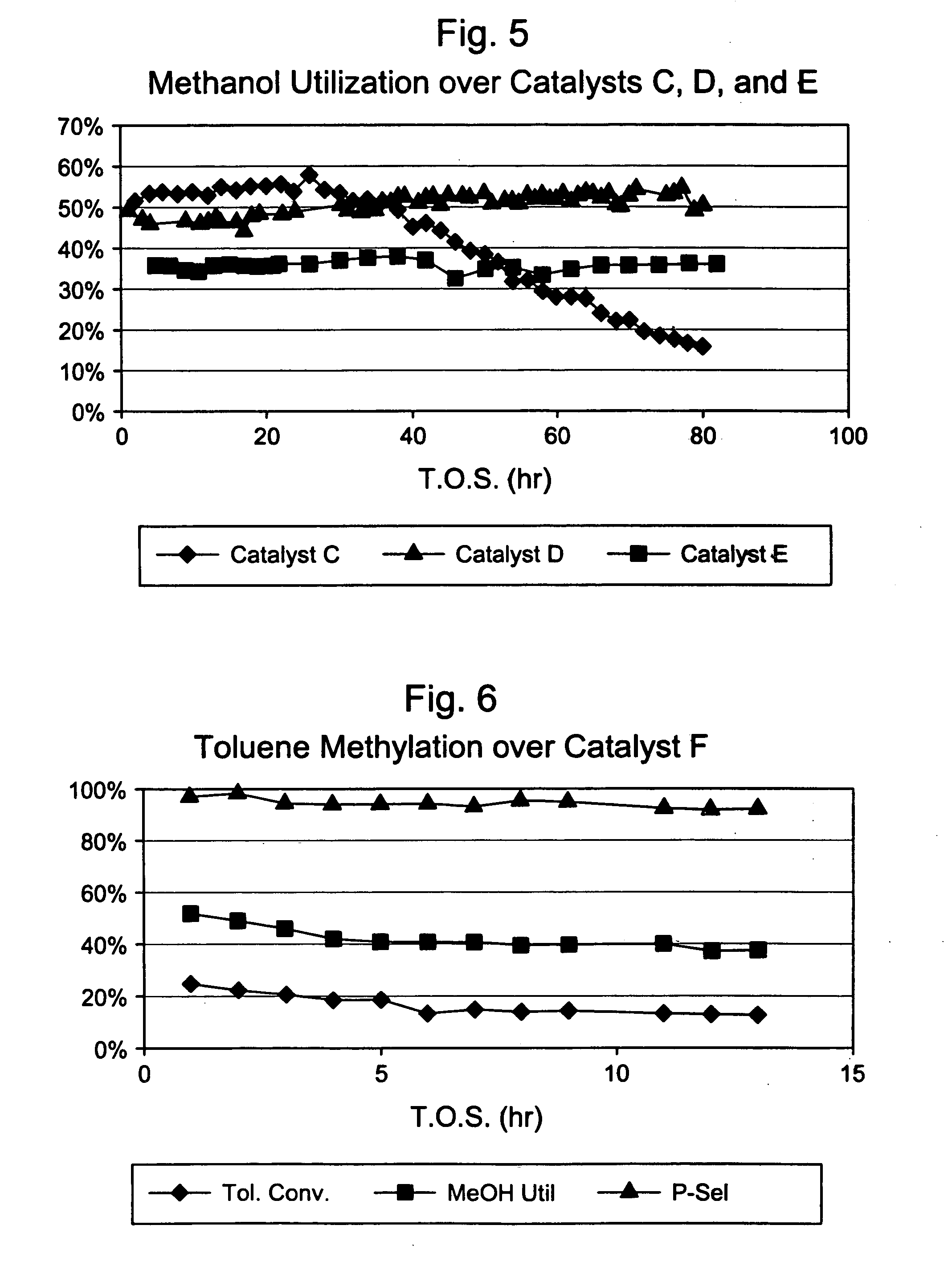

Toluene methylation process

InactiveCN1775715AHigh selectivityMolecular sieve catalystsMolecular sieve catalystHydrogenMethylation

Owner:SAUDI BASIC IND CORP SA

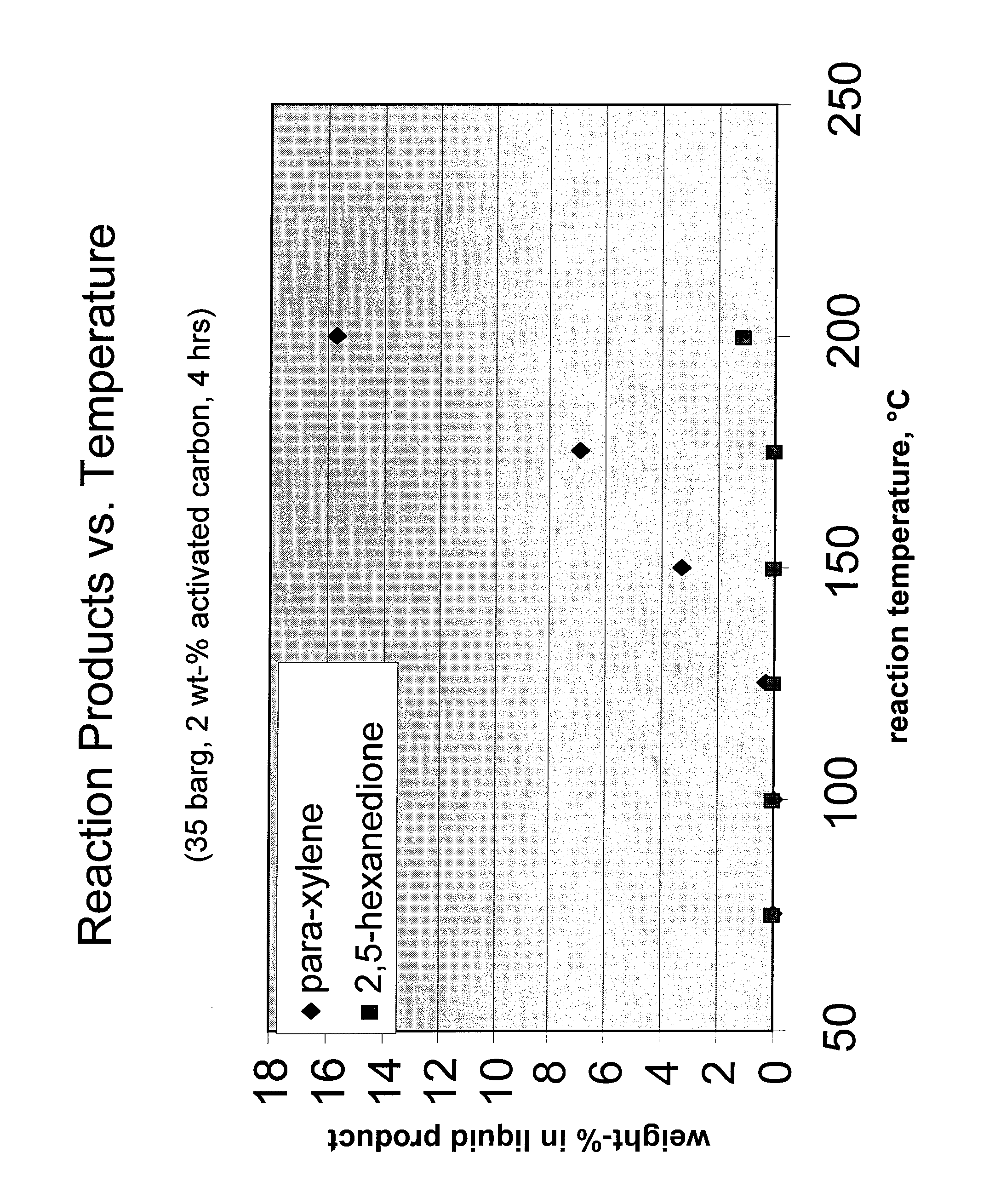

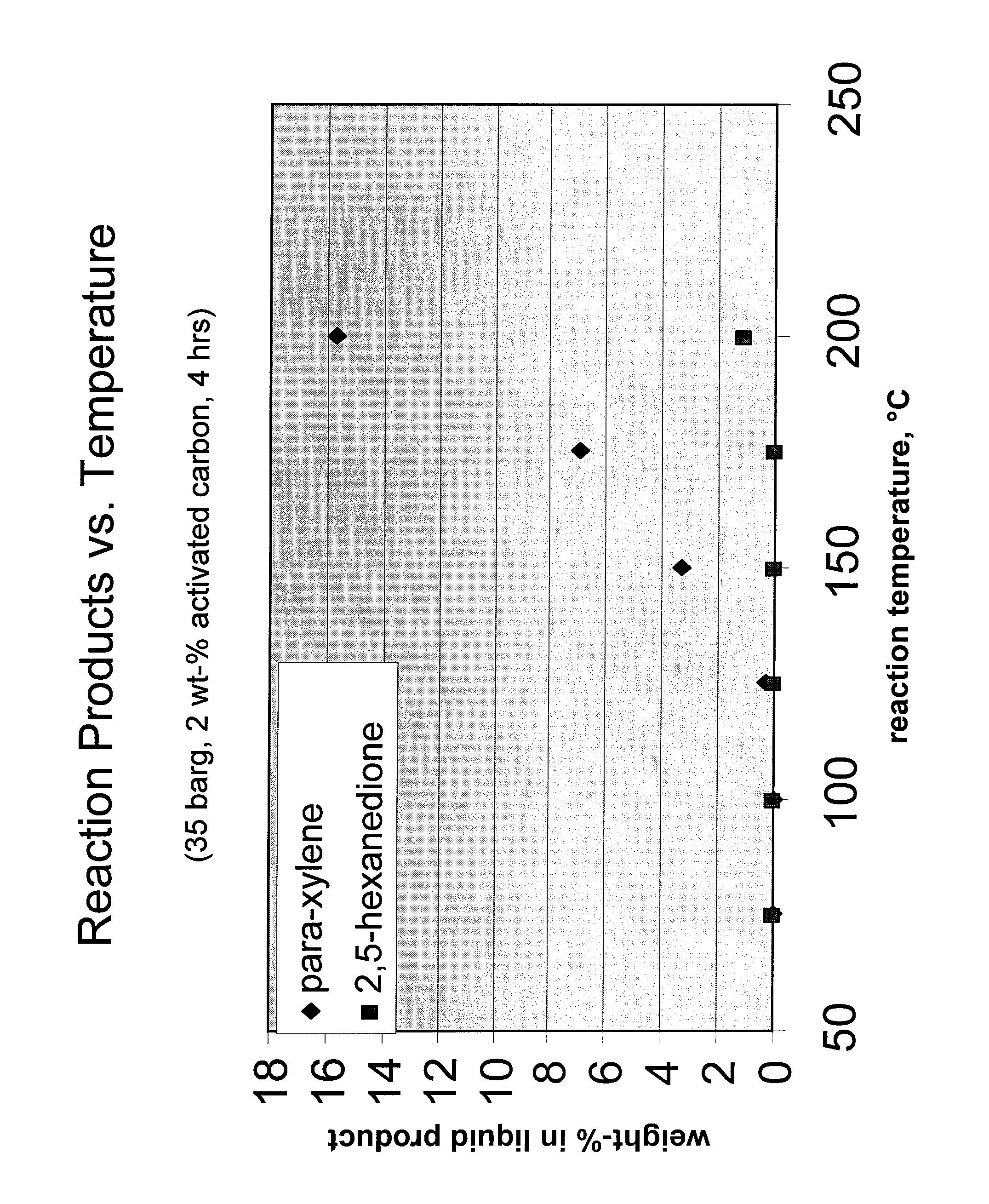

Carbohydrate route to para-xylene and terephthalic acid

Catalytic processes for the conversion of 2,5-dimethyl furan (DMF) to para-xylene are described. Para-xylene is a key product that is currently obtained commercially from petroleum sources. However, it has now been determined that the cycloaddition of ethylene to DMF provides an alternative route to para-xylene. Advantageously, the DMF starting material for the processes may be synthesized from carbohydrates (e.g., glucose or fructose), thereby providing a pathway that relies at least partly, if not completely, on renewable feedstocks.

Owner:UOP LLC

Catalyst for producing dimethylbenzene by alkylation of benzene and methanol

InactiveCN102600887AHigh xylene selectivityHigh catalytic activityMolecular sieve catalystsMolecular sieve catalystBenzeneMolecular sieve

The invention relates to a catalyst for producing dimethylbenzene by alkylation of benzene and methanol. The catalyst mainly overcomes the shortcomings of low utilization rate of methanol alkylation, low conversion rate of benzene and low selectivity of dimethylbenzene in the actual application of the catalyst reported in previous literatures. Through the adoption of the technical scheme of loading alkaline earth and rare-earth metal elements on a hydrogen-type MCM-22 molecular sieve, the problem is well solved. The catalyst provided by the invention is high in selectivity and can be used in the production process of dimethylbenzene by alkylation of benzene and methanol.

Owner:TONGJI UNIV

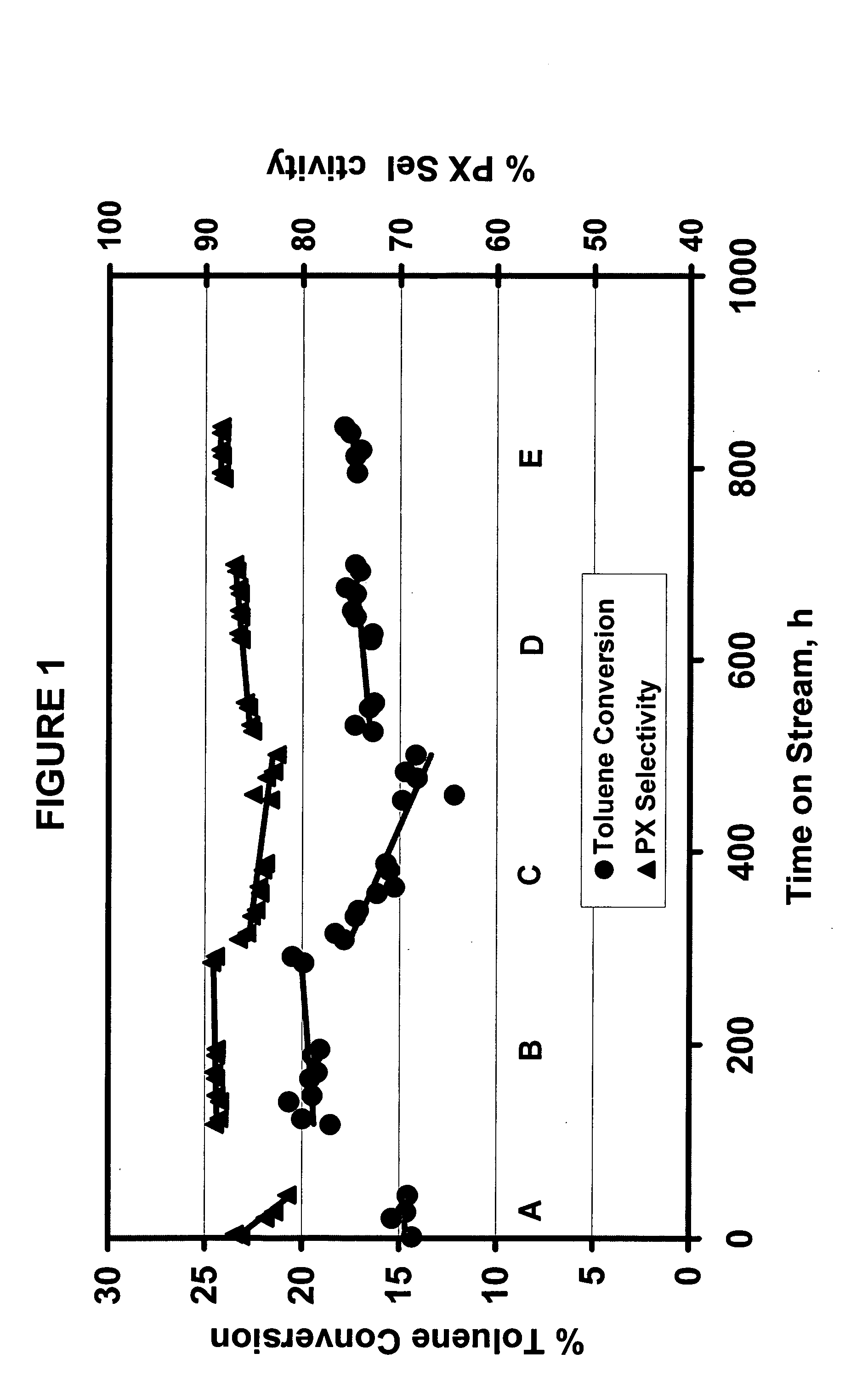

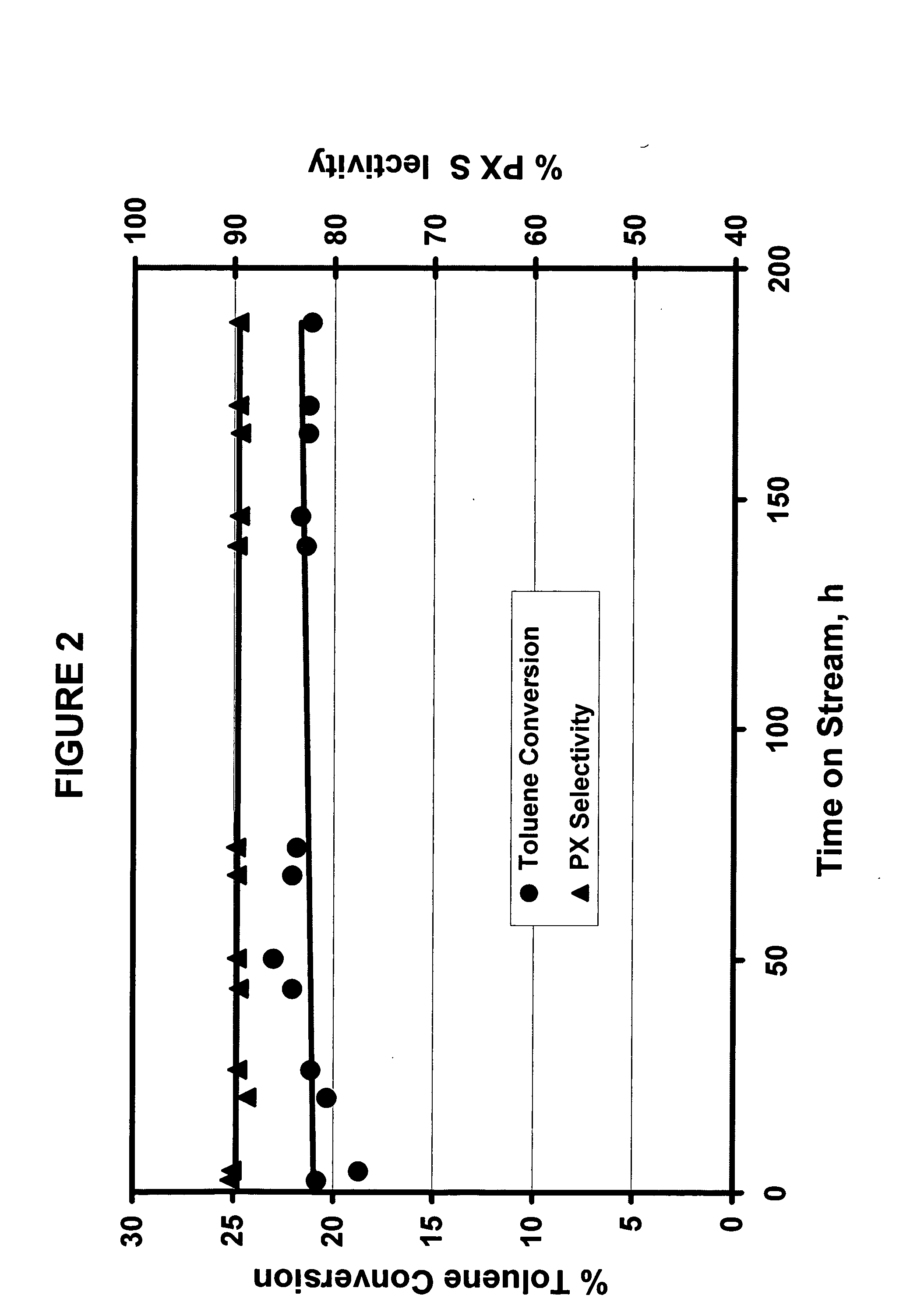

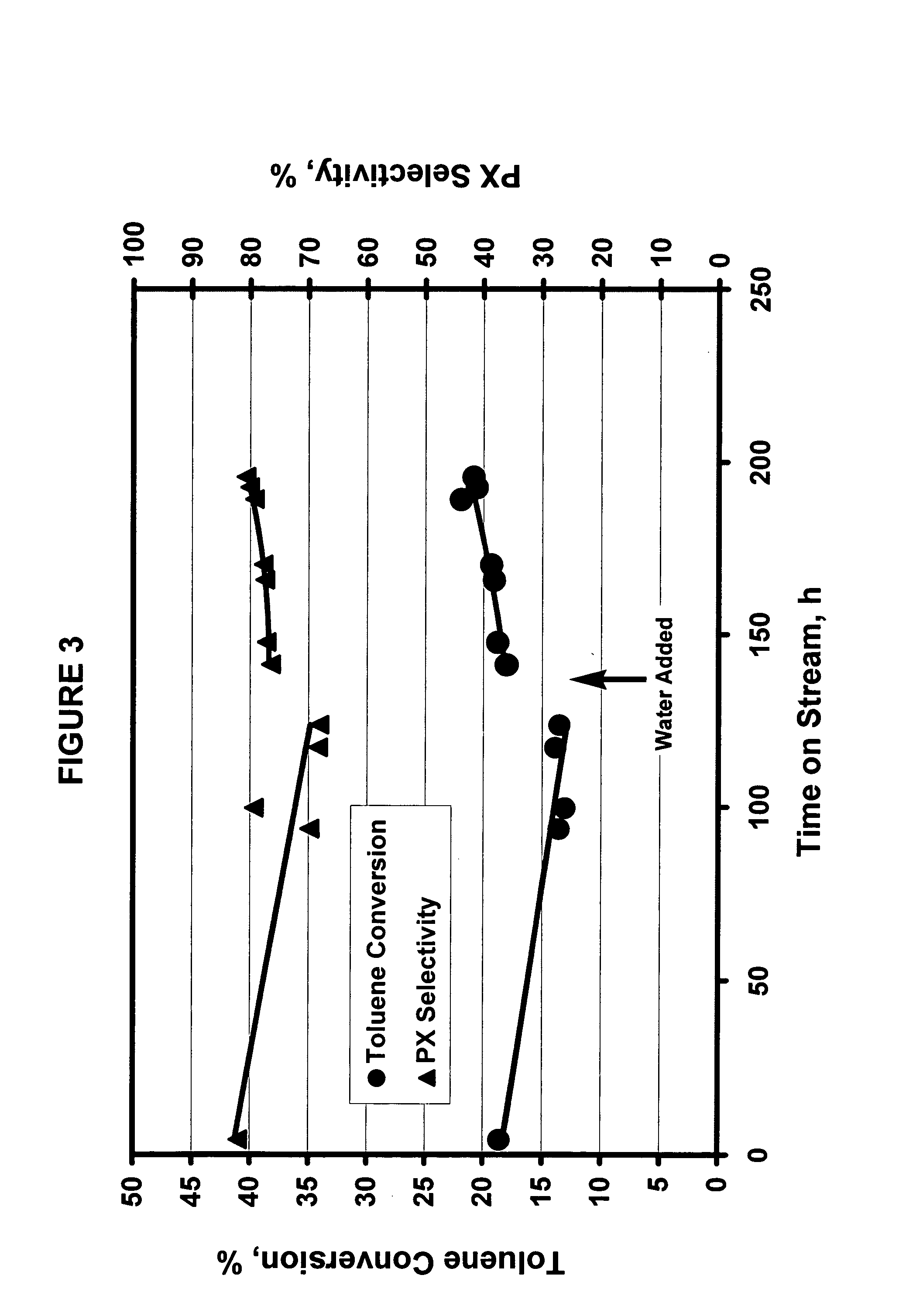

Toluene methylation process

A method of preparing a xylene product is carried out by providing a reactor containing a non-steamed, phosphorus-treated ZSM-5-type zeolite catalyst. The catalyst is contacted with a toluene / methanol feed and a cofeed of hydrogen under reactor conditions suitable for the methylation of toluene. Water is introducing into the reactor during the methylation reaction under conditions that provide substantially no structural aluminum loss of the catalyst from such introduction of water.

Owner:SAUDI BASIC IND CORP SA

Carbohydrate route to para-xylene and terephthalic acid

ActiveUS8314267B2Organic compound preparationHydrocarbon by hydrocarbon and non-hydrocarbon condensationFuranCycloaddition

Catalytic processes for the conversion of 2,5-dimethyl furan (DMF) to para-xylene are described. Para-xylene is a key product that is currently obtained commercially from petroleum sources. However, it has now been determined that the cycloaddition of ethylene to DMF provides an alternative route to para-xylene. Advantageously, the DMF starting material for the processes may be synthesized from carbohydrates (e.g., glucose or fructose), thereby providing a pathway that relies at least partly, if not completely, on renewable feedstocks.

Owner:UOP LLC

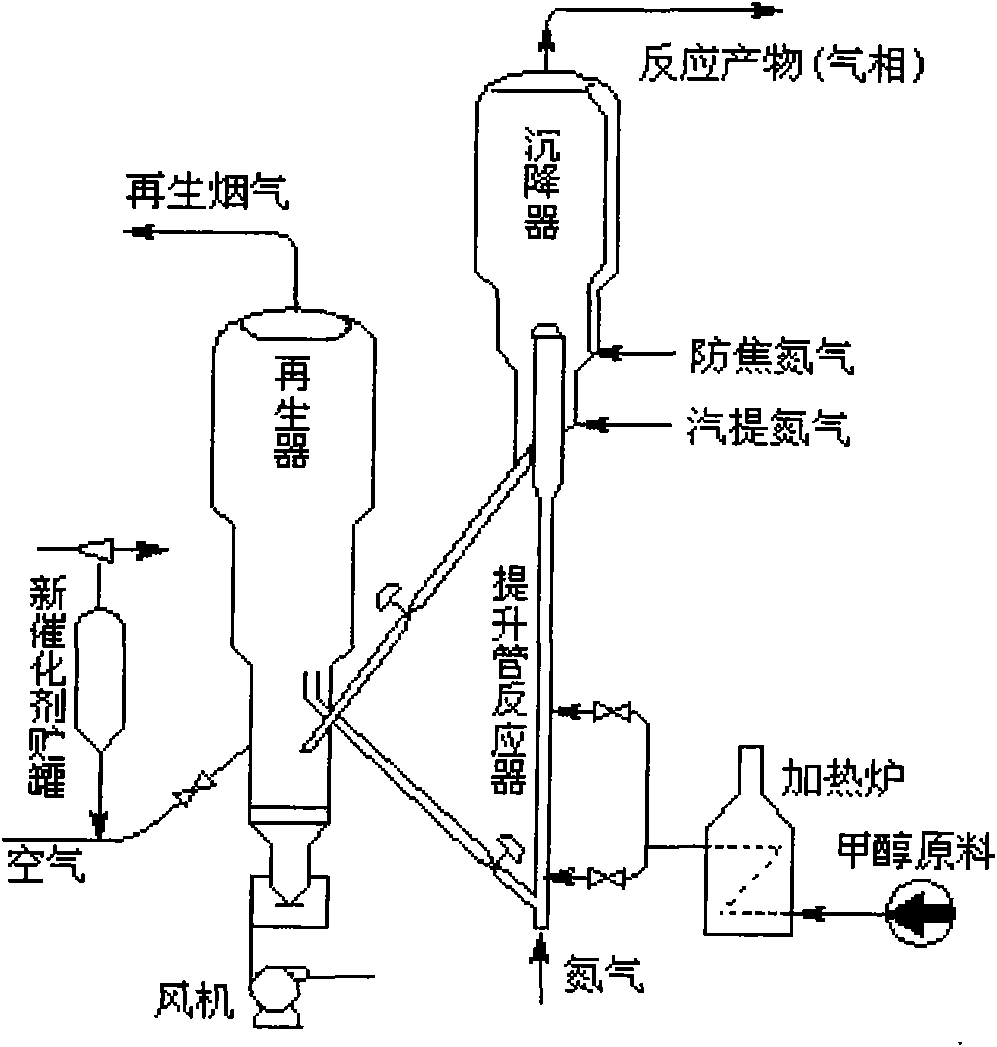

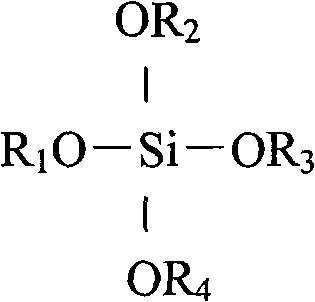

High yield preparation method of paraxylene by methanol/dimethyl ether conversion

InactiveCN101607864AMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveAromatic hydrocarbon

The invention relates to a high yield preparation method of paraxylene by methanol / dimethyl ether conversion and the method can increase the yield of paraxylene in the converted products of methanol / dimethyl ether by adopting molecular sieve based catalyst which is modified with metals or through silylanization and adding aromatic hydrocarbons in the raw materials. The aromatic hydrocarbons is the separated benzene and / or toluene which is generated through the methanol / dimethyl ether conversion reaction and part or whole of aromatic hydrocarbons is recycled in the reaction system; otherwise, additional benzene and / or toluene is added in the raw materials. By adopting the method, the content of aromatic hydrocarbons in the products of the methanol / dimethyl ether conversion reaction can be more than 50wt%; wherein, the content of paraxylene in aromatic hydrocarbons is more than 80wt% and the selectivity of paraxylene in xylene isomers is more than 99wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

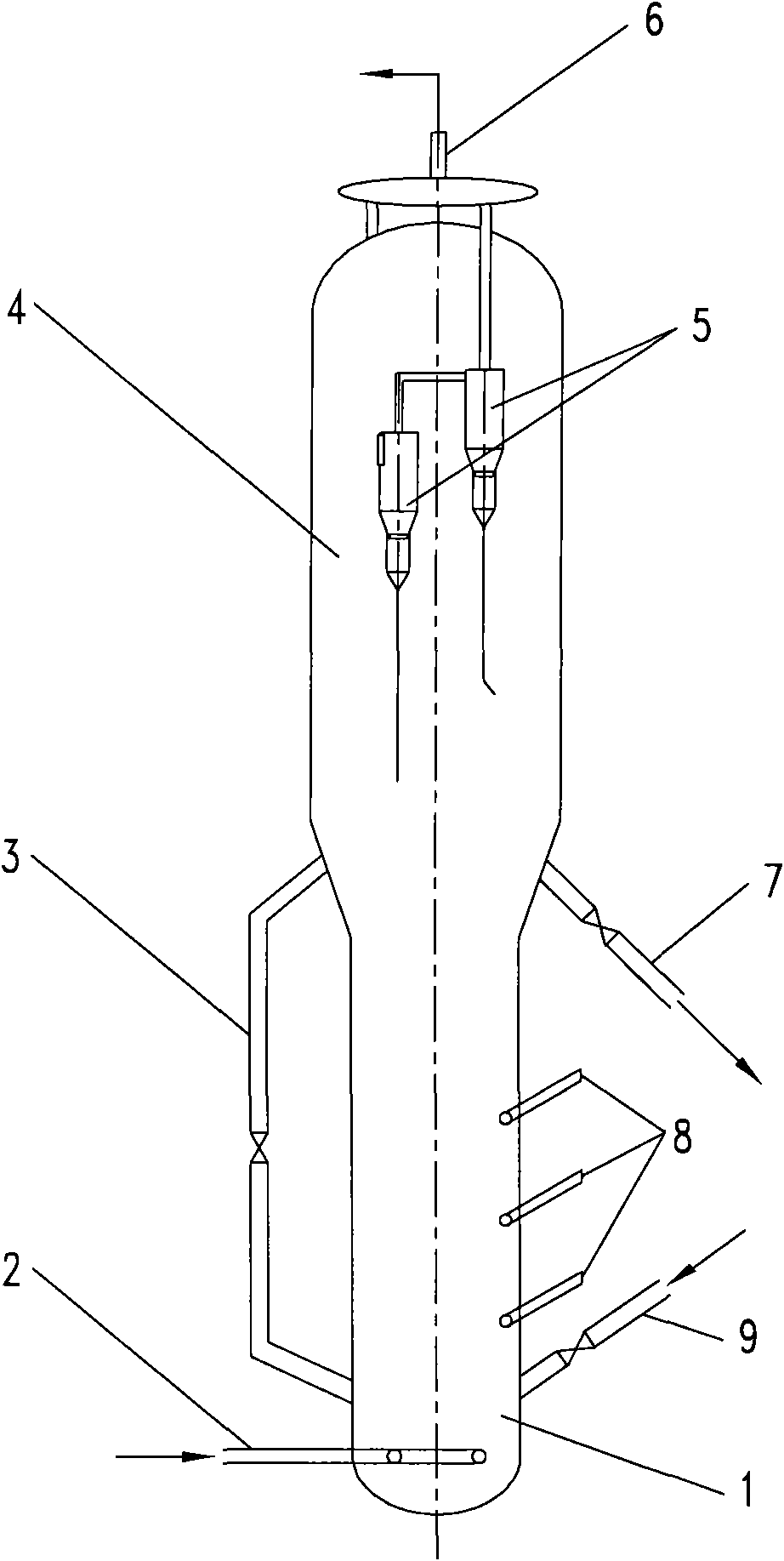

Method for preparing dimethylbenzene from oxygen-containing compound and methylbenzene

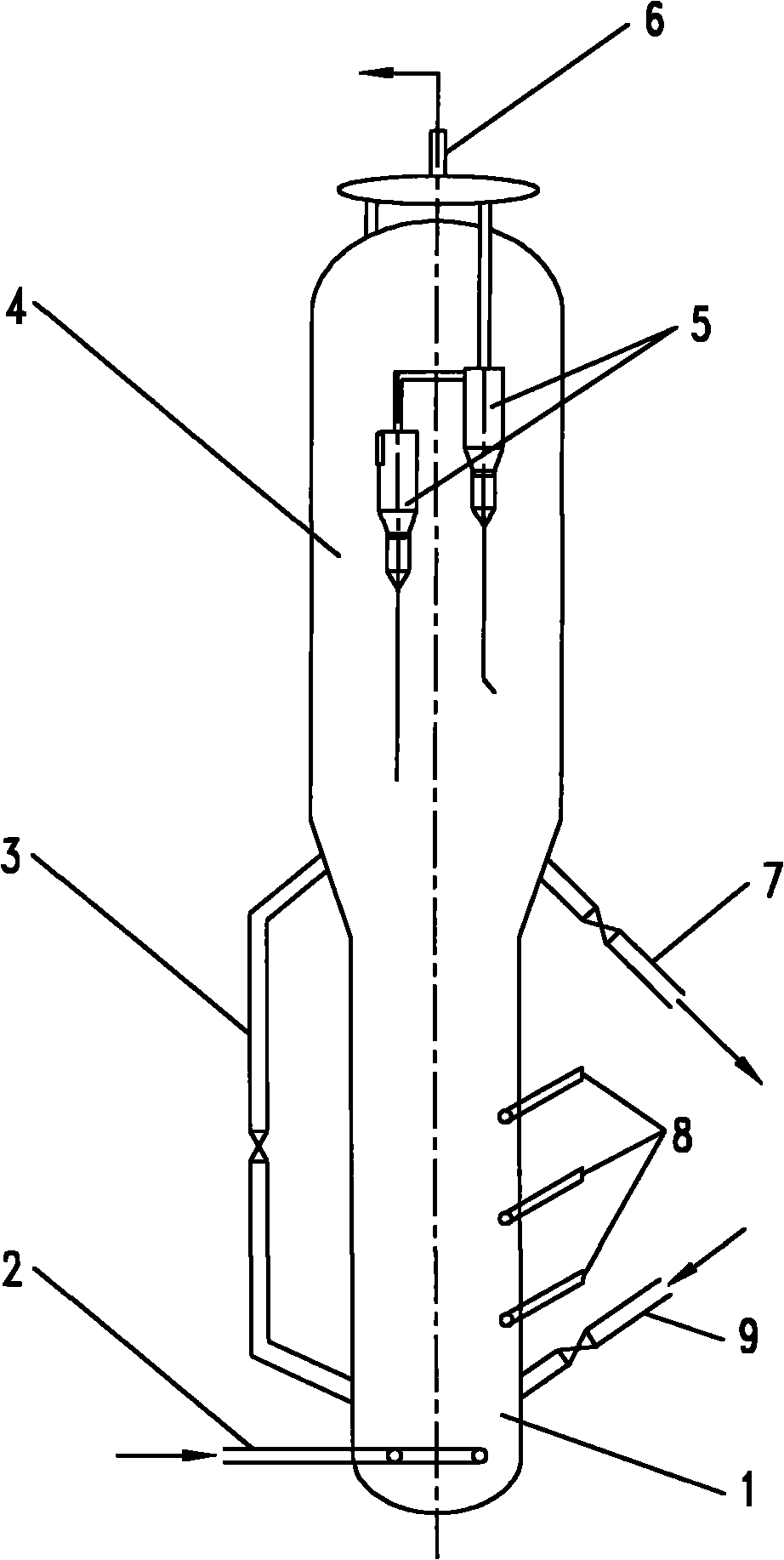

ActiveCN102464557AImprove technical effectHydrocarbonsHydrocarbon by hydrocarbon and non-hydrocarbon condensationFluidized bedWater vapor

The invention relates to a method for preparing dimethylbenzene from oxygen-containing compound and methylbenzene. The problem that the yield of the dimethylbenzene is lower in the prior art is solved. The method comprises the following steps that: a first part of raw material enters a reactor from the bottom of a fluidized bed reactor, and a second part of raw material enters the reactor from at least one material inlet isolated in the axial direction of the fluidized bed reactor to be in contact with a fluidized bed catalyst to generate a product containing the dimethylbenzene under an effective condition, wherein the density of the bed layer of the fluidized bed reactor is 50 to 500kg / m<3>, the first part of raw material is methylbenzene and water vapor, the weight ratio between the water vapor and the methylbenzene is (0.01-0.2):1, the second part of raw material is a mixture of methanol or dimethyl ether and methylbenzene, and the weight ratio between the methanol or dimethyl ether and the methylbenzene is (1-10):1. The problem is better solved through the technical scheme and the method can be applied to the industrial production of the dimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic metal framework supported palladium, preparation method and application thereof

InactiveCN101733162AImprove stabilityHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryN dimethylformamide

The invention discloses an organic metal framework supported palladium in the technical field of chemical industry, a preparation method and application thereof. The organic metal framework supported palladium is prepared by the method comprising the steps of: dissolving terephthalic acid and zinc nitrate hexahydrate into N, N-dimethylformamide, dripping triethylamine with the stirring, continuing stirring the obtained solution, filtering the obtained solution, and washing a precipitate to obtain a solid, namely MOF-5; and dissolving Na2PdC14 into the N, N-dimethylformamide to obtain solution, adding the MOF-5 into the solution, and then dripping hydrazine hydrate to obtain Pd@MOF-5 through stirring, filtration, washing and vacuum drying. The invention also relates to the method for preparing the organic metal framework supported palladium, application thereof taken as a catalyst in a Sonogashira reaction, and the method for preparing diaryl acetylene. The organic metal framework supported palladium in the invention has good stability, can catalyze the reaction with high selectivity and high efficiency under rather low loading of the catalyst, and can be repeatedly used.

Owner:SHANGHAI JIAO TONG UNIV

Modified ZSM-5 molecular sieve catalyst, preparation method and application in toluene methanol alkylation reaction

InactiveCN102716763AHigh selectivityHigh activityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationHigh activityLarge particle

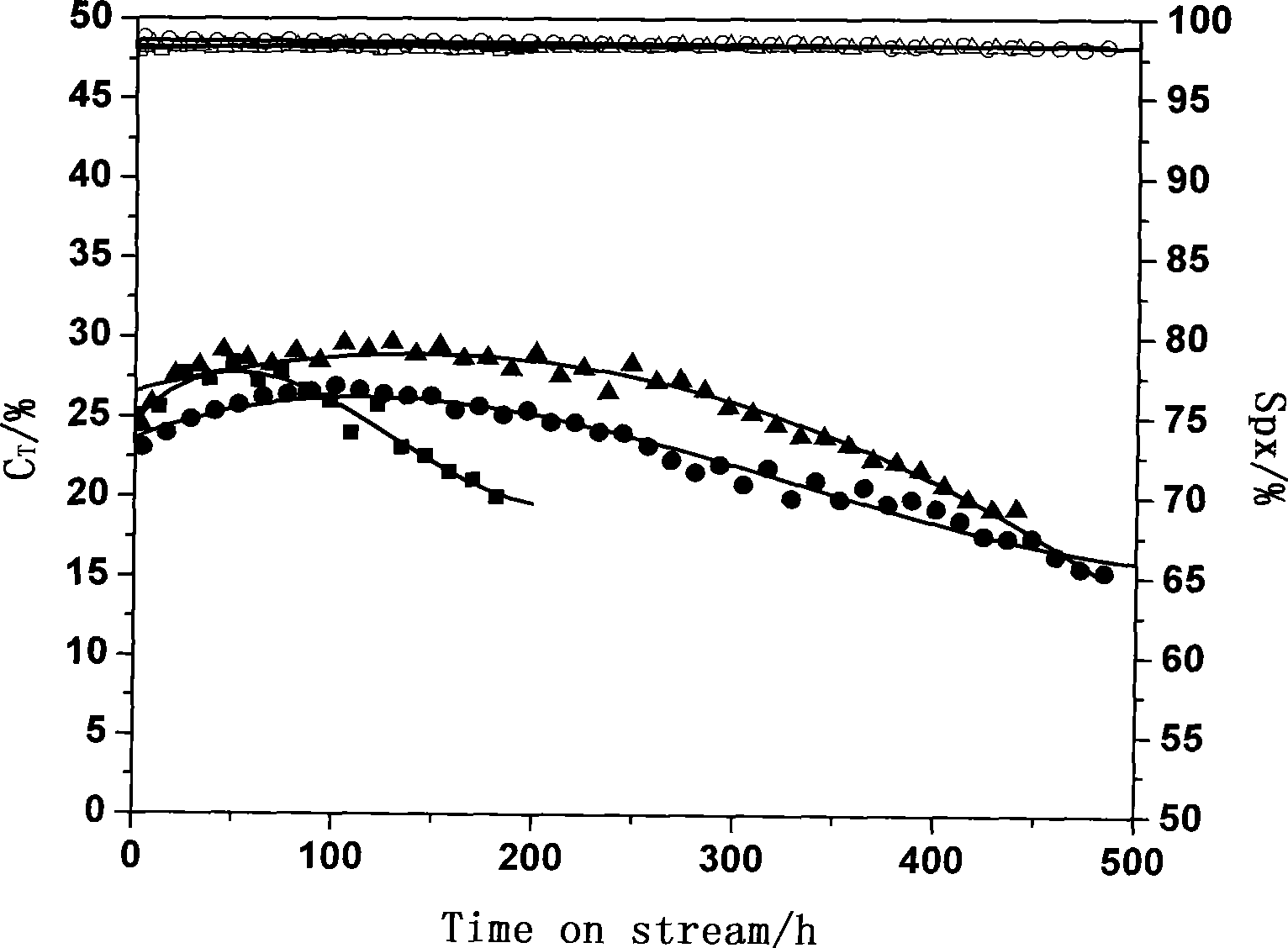

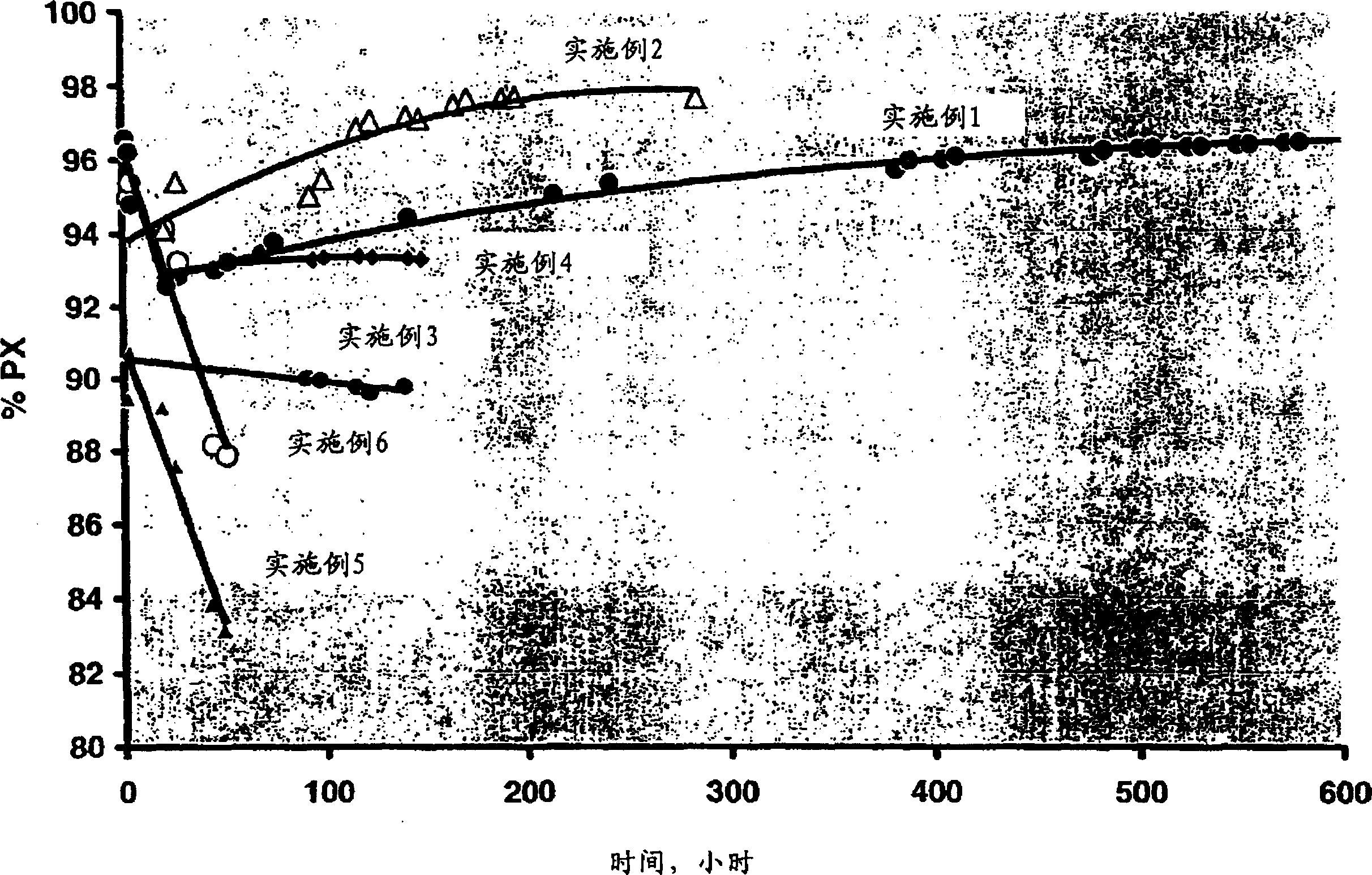

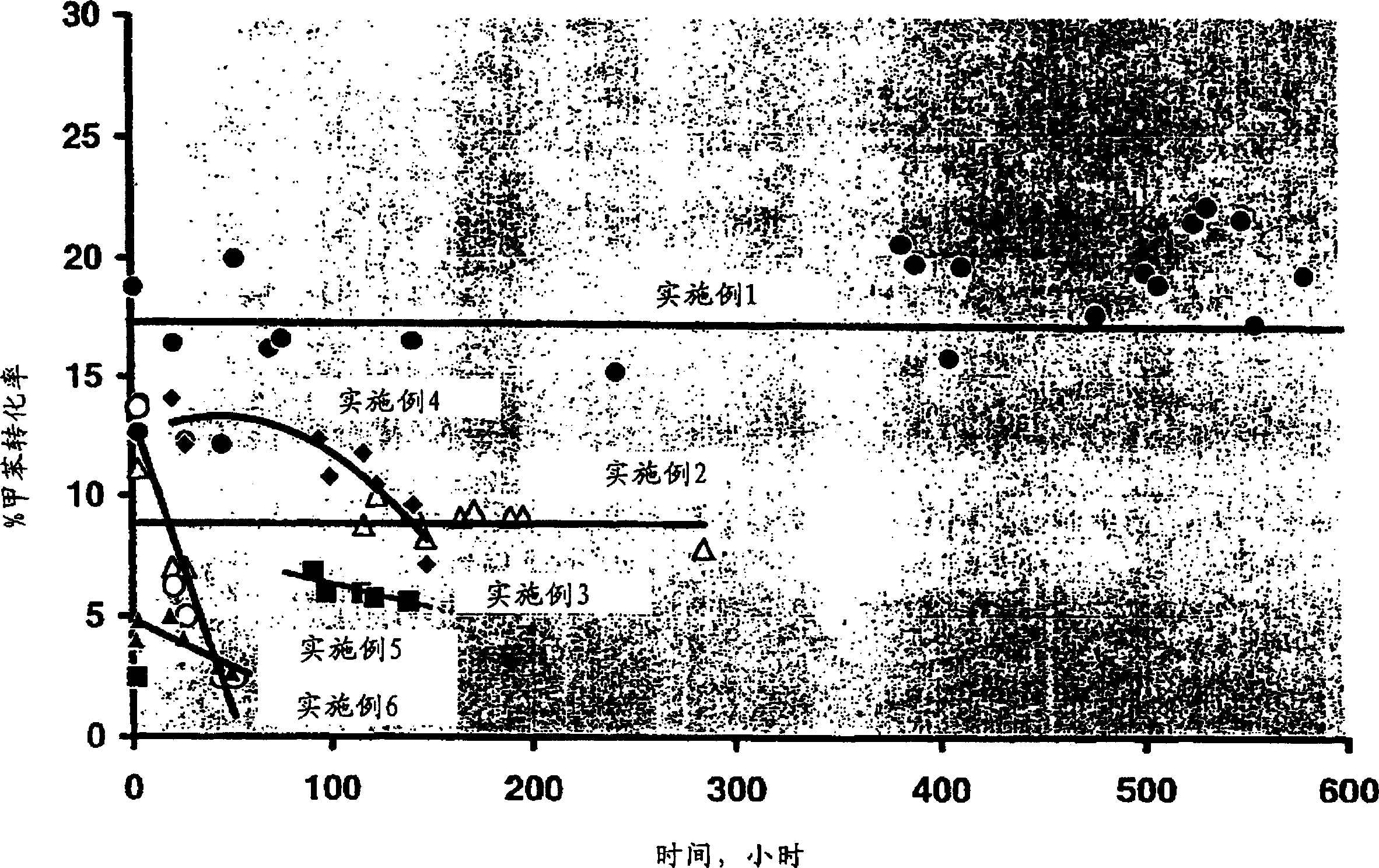

The invention relates to a modified ZSM-5 molecular sieve catalyst used for toluene methanol alkylation, which takes a ZSM-5 molecular sieve as a matrix, molecular sieve raw powder is taken as a commodity reagent, its scaled silica-alumina ratio (nSiO2 / nAl2O3) is 25, the particle sizes can be divided into two types, the primary particle size of the large particle size (or conventional particle size) ZSM-5 belongs to the micron order, the primary particle size of the small particle size ZSM-5 is about 200 nanometers, tetraethoxysilane (TEOS) is taken as a silicon source, an external surface and hole opening of the molecular sieve can be modified through chemical liquid phase deposition, the SiO2 deposition amount is between 3% and 25%, or chemical modification of Ni and P elements is employed, and the contents of Ni and P elements are 0-1% and 0-8%. According to the invention, the modified ZSM-5 molecular sieve catalyst can be used for preparing xylene by the toluene methanol alkylation with high catalytic activity, the conversion for per pass of toluene can reach more than 30%, in three types of xylene products, the selectivity on xylene is higher than 90%, and the modified ZSM-5 molecular sieve catalyst of the invention is the catalyst possessing high activity and high selectivity.

Owner:NANJING UNIV

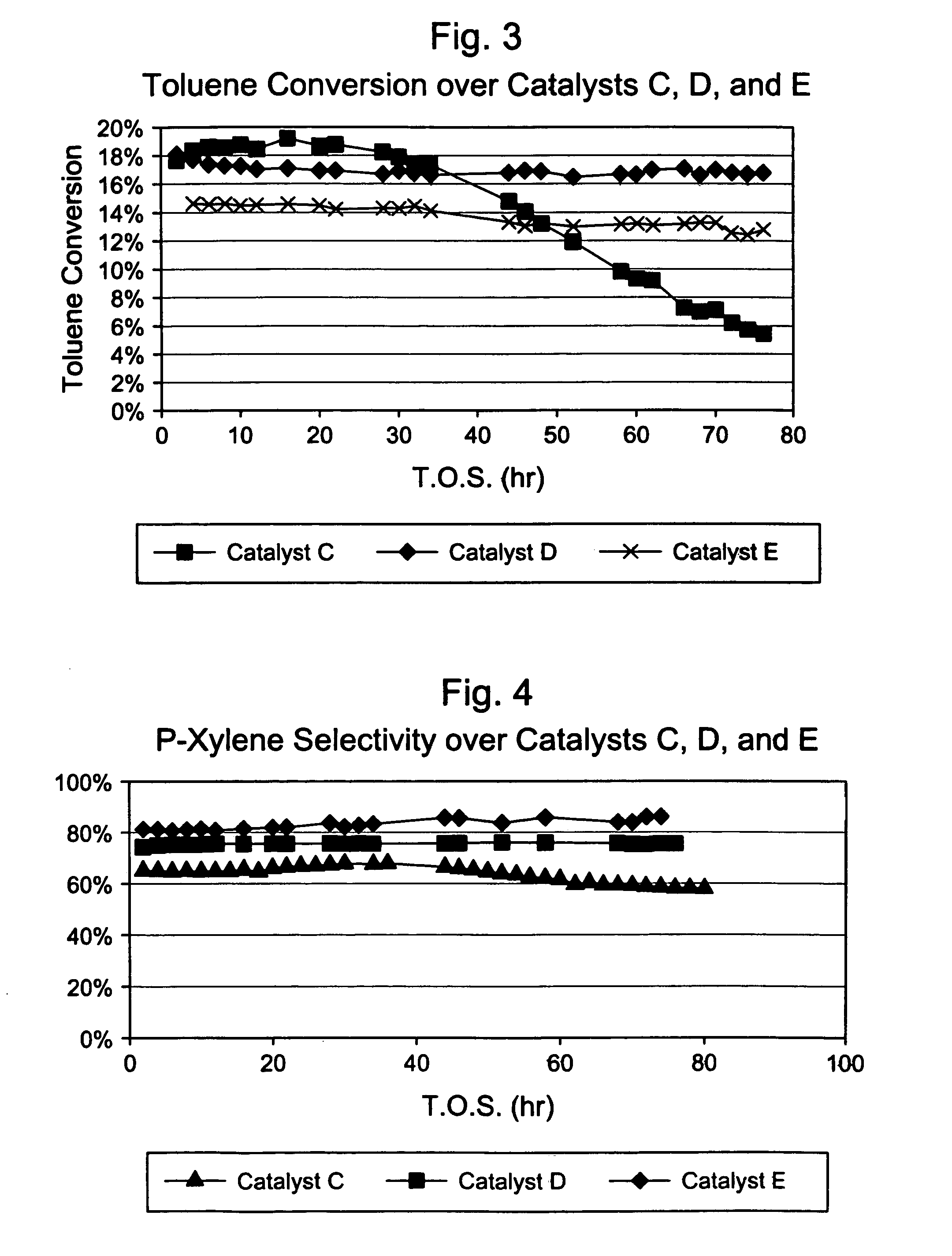

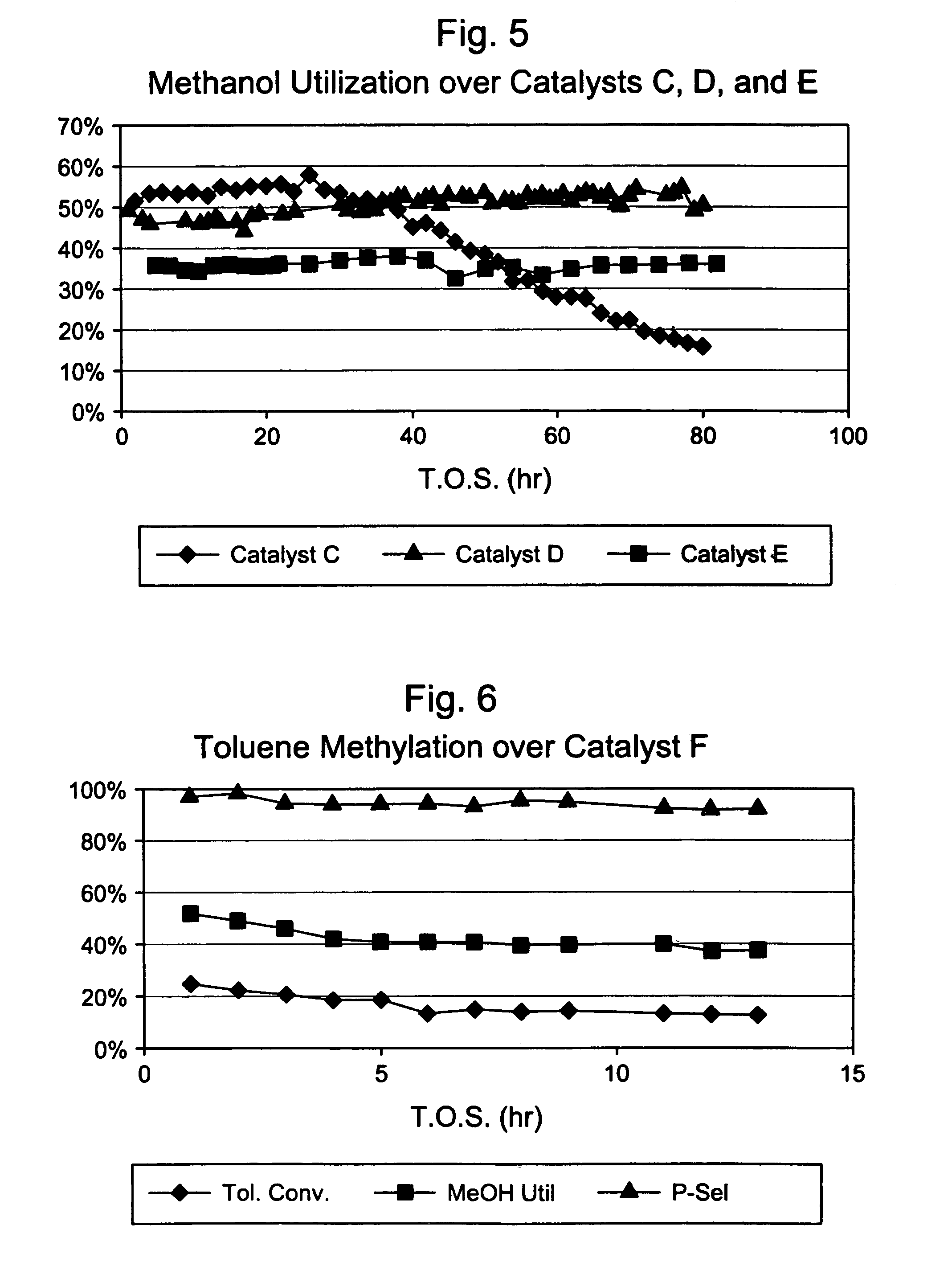

Process for aromatic alkylation

This invention relates to a process for the selective alkylation of toluene and / or benzene with an oxygen-containing alkylation agent. In particular, the process uses a selectivated molecular sieve which has been modified by the addition of a hydrogenation component, wherein at least one of the following conditions is met: (a) the selectivated molecular sieve has an alpha value of less than 100 prior to the addition of the hydrogenation component, or (b) the selectivated and hydrogenated catalyst has an alpha value of less than 100. The process of this invention provides high selectivity for the alkylated product while reducing catalyst degradation.

Owner:EXXONMOBIL CHEM PAT INC

Metal-organic framework materials with magnetic cores and preparation and application thereof

InactiveCN103521269APromote rapid formationShorten the timeMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMetal-organic framework

The invention provides metal-organic framework materials with magnetic cores and preparation and application thereof, and belongs to the technical field of magnetic metal-organic framework materials. FeCl3 6H2O is adopted for preparing superparamagnetic Fe3O4 cores, cetyl trimethyl ammonium bromide is used as a template agent, sodium silicate is used as silicon sources of SiO2 shell layers, mesoporous SiO2 shell layers are formed on the surfaces of the Fe3O4 cores by adopting an ultrasonic wave method, the template agent is removed by roasting under protection of N2 after drying, and magnetic SiO2@Fe3O4 nanospheres are prepared. The SiO2@Fe3O4 nanospheres are used as cores, an in-situ self-assembly mesh structure IRMOFs is carried out on the surfaces of the SiO2@Fe3O4 cores through Zn metal ions and organic carboxylic acid ligands by adopting the ultrasonic wave method. The novel MOFs materials can be used as catalysts of liquid phase catalysis reaction, and also have application values in the aspects of adsorption, separation, biological medicine and the like.

Owner:BEIJING UNIV OF CHEM TECH

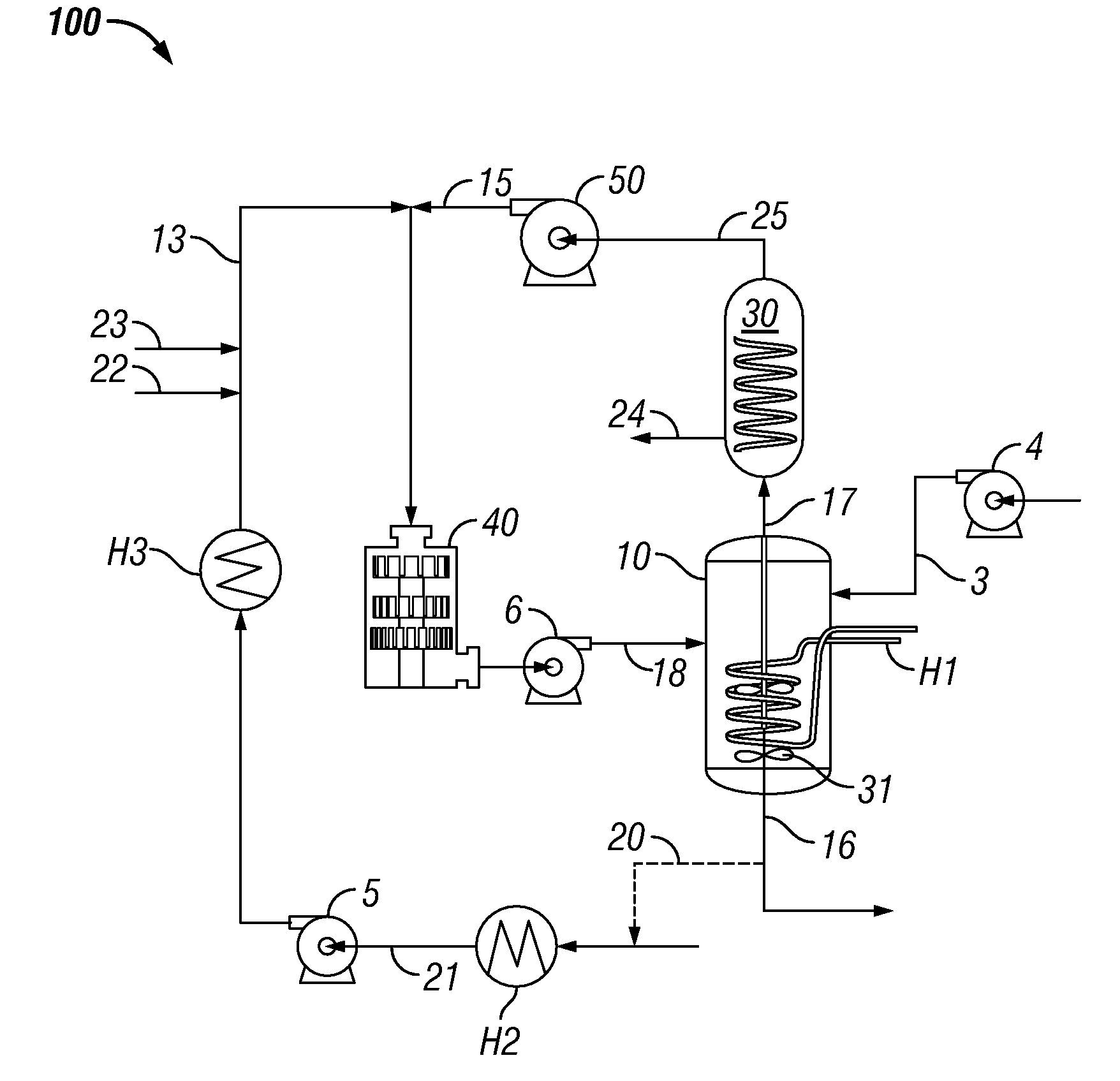

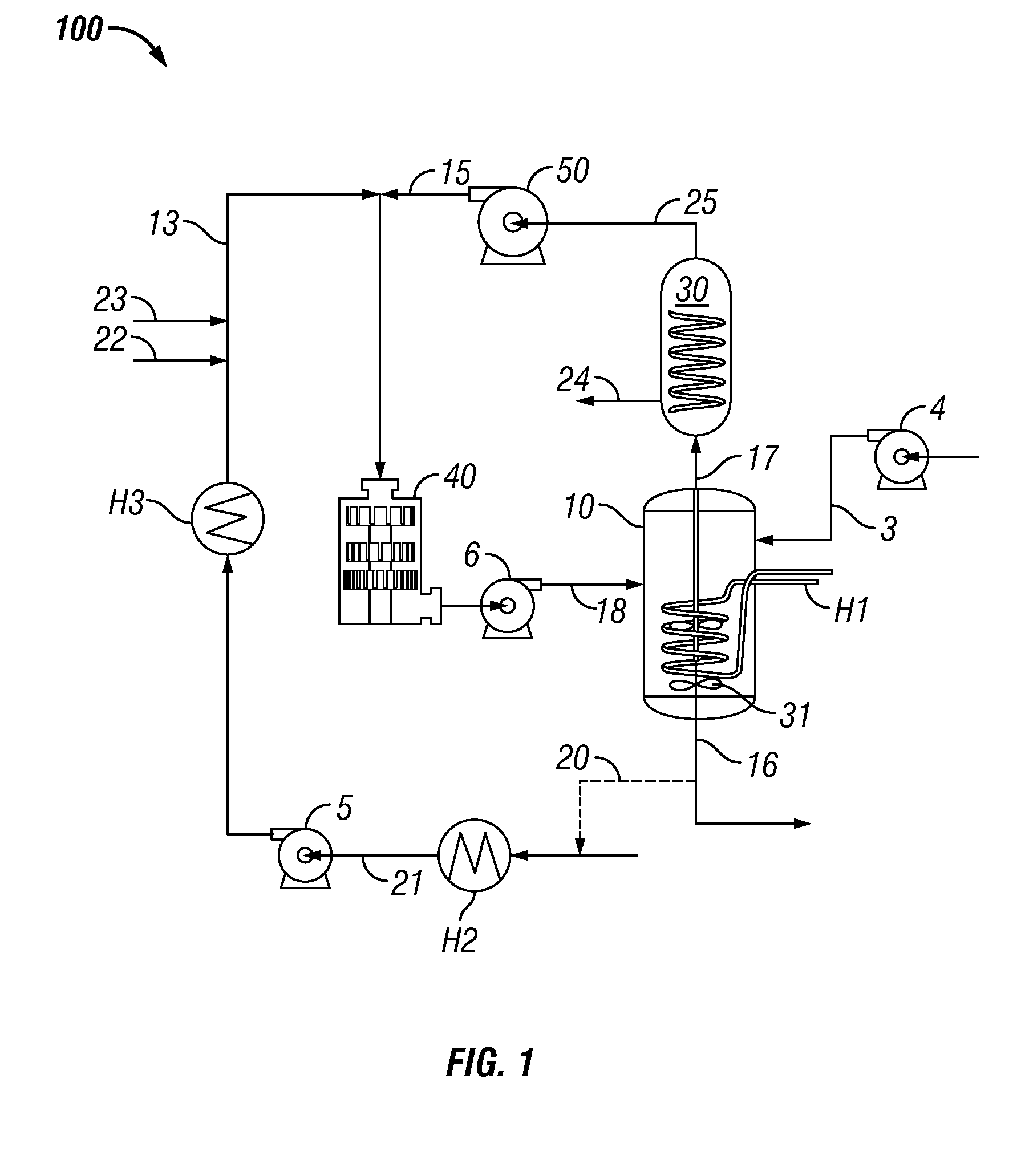

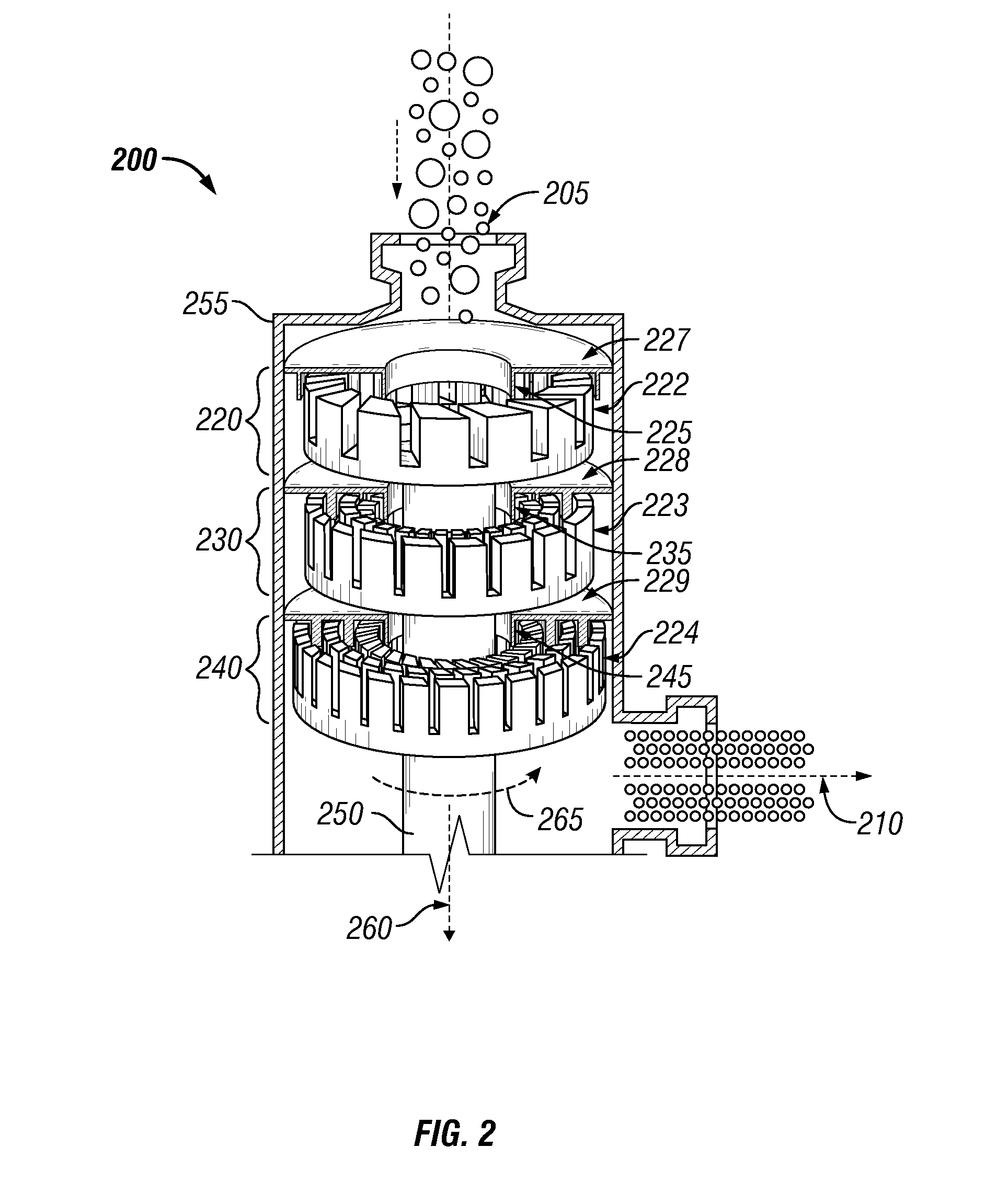

System and process for production of liquid product from light gas

InactiveUS20090001316A1Increase ratingsLow costTransportation and packagingRotary stirring mixersLiquid productHydrogen

A method for producing a product comprising at least one selected from C2+ hydrocarbons, oxygenates, and combinations thereof from light gas comprising one or more of carbon dioxide, methane, ethane, propane, butane, pentane, and methanol by forming a dispersion of light gas in a liquid feed, wherein the dispersion is formed at least in part with high shear forces and wherein at least one of the liquid feed and the light gas is a hydrogen source. A system for carrying out the method is also presented.

Owner:HRD CORP

Integrated process to coproduce aromatic hydrocarbons and ethylene and propylene

InactiveUS20100087686A1Handling is also issueAvoid security issuesOrganic compound preparationChemical industryHalogenBromine

An integrated process for producing aromatic hydrocarbons and ethylene and / or propylene and optionally other lower olefins from low molecular weight hydrocarbons, preferably methane, which comprises: (a) contacting at least one low molecular weight alkane, preferably methane, with a halogen, preferably bromine. under process conditions sufficient to produce a monohaloalkane, preferably monobromomethane, (b) reacting the monohaloalkane in the presence of a coupling catalyst to produce aromatic hydrocarbons and C2+ alkanes, (c) separating the aromatic hydrocarbons from the product mixture of step (b) to produce aromatic hydrocarbons, and (d) cracking at least part of the C2+ alkanes in an alkane cracking system to produce ethylene and / or propylene and optionally other lower olefins.

Owner:SHELL OIL CO

Process for aromatic alkylation

This invention relates to a process for the selective alkylation of toluene and / or benzene with an oxygen-containing alkylation agent. In particular, the process uses a selectivated molecular sieve which has been modified by the addition of a hydrogenation component, wherein at least one of the following conditions is met: (a) the selectivated molecular sieve has an alpha value of less than 100 prior to the addition of the hydrogenation component, or (b) the selectivated and hydrogenated catalyst has an alpha value of less than 100. The process of this invention provides high selectivity for the alkylated product while reducing catalyst degradation.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com