Catalyst for preparing aromatic hydrocarbon through methanol conversion and preparation method thereof

A methanol conversion and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low selectivity of target product aromatics and complex process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation of this embodiment includes: based on the total weight of the catalyst, 2% P 2 o 5 , 3% La 2 o 3 , 30% HZSM-5, 10% HZSM-11, 25% Hβ, 30% Al 2 o 3 Catalyst A.

[0015] Weigh 30 grams of HZSM-5 molecular sieve, 10 grams of HZSM-11 molecular sieve, 25 grams of Hβ molecular sieve, 30 grams of Al 2 o 3 , 38 grams of scallop powder, mixed evenly, adding 42 grams of nitric acid aqueous solution with a mass concentration of 5%, fully kneaded and extruded into a cylindrical shape with a diameter of 1.5 mm, dried and roasted at 520 ° C for 6 hours to make 2 ~ 3 mm long catalyst support.

[0016] 20 g of the above catalyst carrier was impregnated in 14 ml containing 0.63 g La 2 o 3 In the aqueous solution of lanthanum nitrate, the catalyst intermediate was prepared after standing at room temperature for 24 hours, drying, and calcining at 480°C for 4 hours.

[0017] The above catalyst intermediate was impregnated in 14 ml containing 0.42 g P 2 o 5 In the ...

Embodiment 2

[0020] The preparation of this embodiment includes: based on the total weight of the catalyst, 2% P 2 o 5 , 3% La 2 o 3 , 30% HZSM-5, 18% HZSM-11, 17% Hβ, 30% Al 2 o 3 Catalyst B.

[0021] The preparation method is the same as in Example 1, except that 18 grams of HZSM-11 molecular sieve and 17 grams of Hβ molecular sieve are weighed.

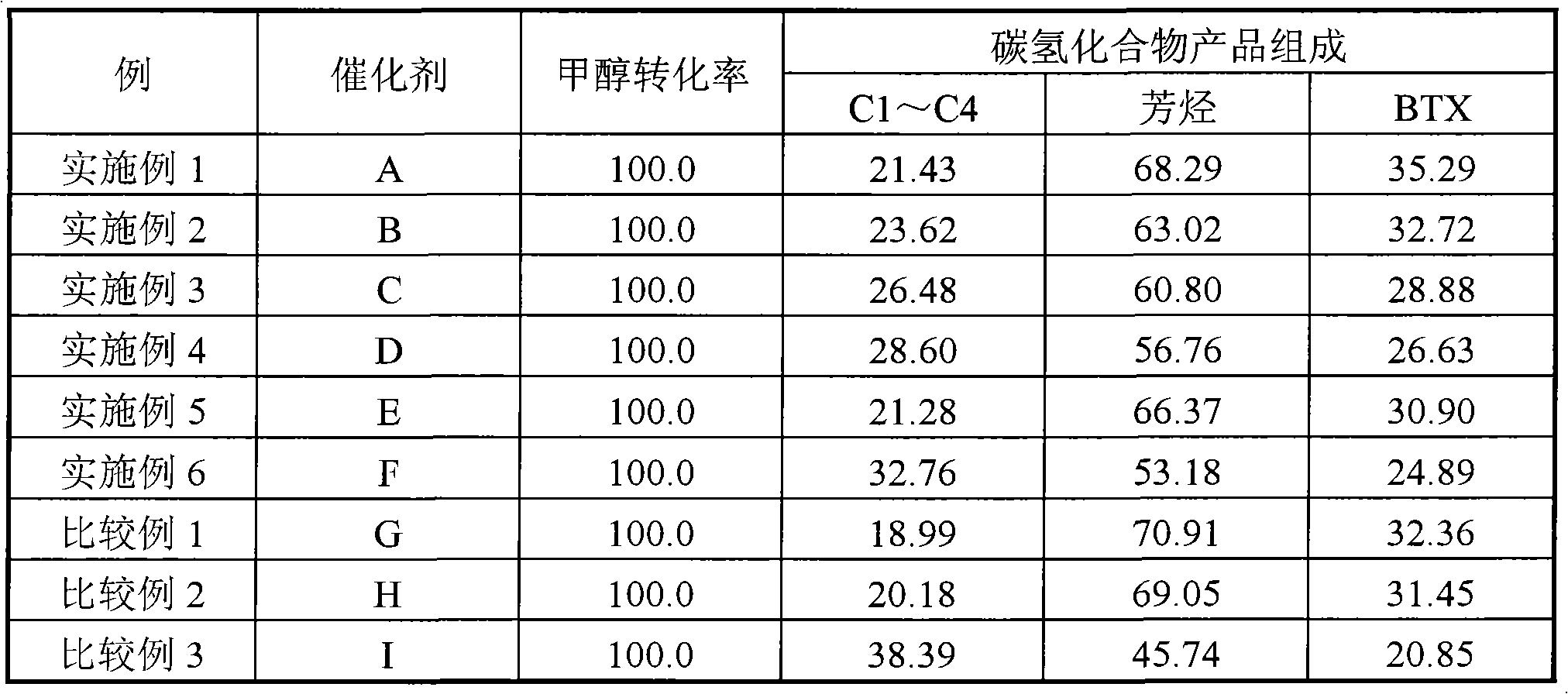

[0022] Catalyst evaluation conditions are the same as in Example 1, and the reaction results are listed in Table 2.

Embodiment 3

[0024] The preparation of this embodiment includes: based on the total weight of the catalyst, 2% P 2 o 5 , 3% La 2 o 3 , 30% HZSM-5, 25% HZSM-11, 10% Hβ, 30% A1 2 o 3 Catalyst C.

[0025] The preparation method is the same as that of Example 1, except that 25 grams of HZSM-11 molecular sieve and 10 grams of Hβ molecular sieve are weighed.

[0026] Catalyst evaluation conditions are the same as in Example 1, and the reaction results are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com