Method for preparing dimethylbenzene from oxygen-containing compound and methylbenzene

A xylene and compound technology, applied in the field of preparation of p-xylene, can solve the problem of low yield of xylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

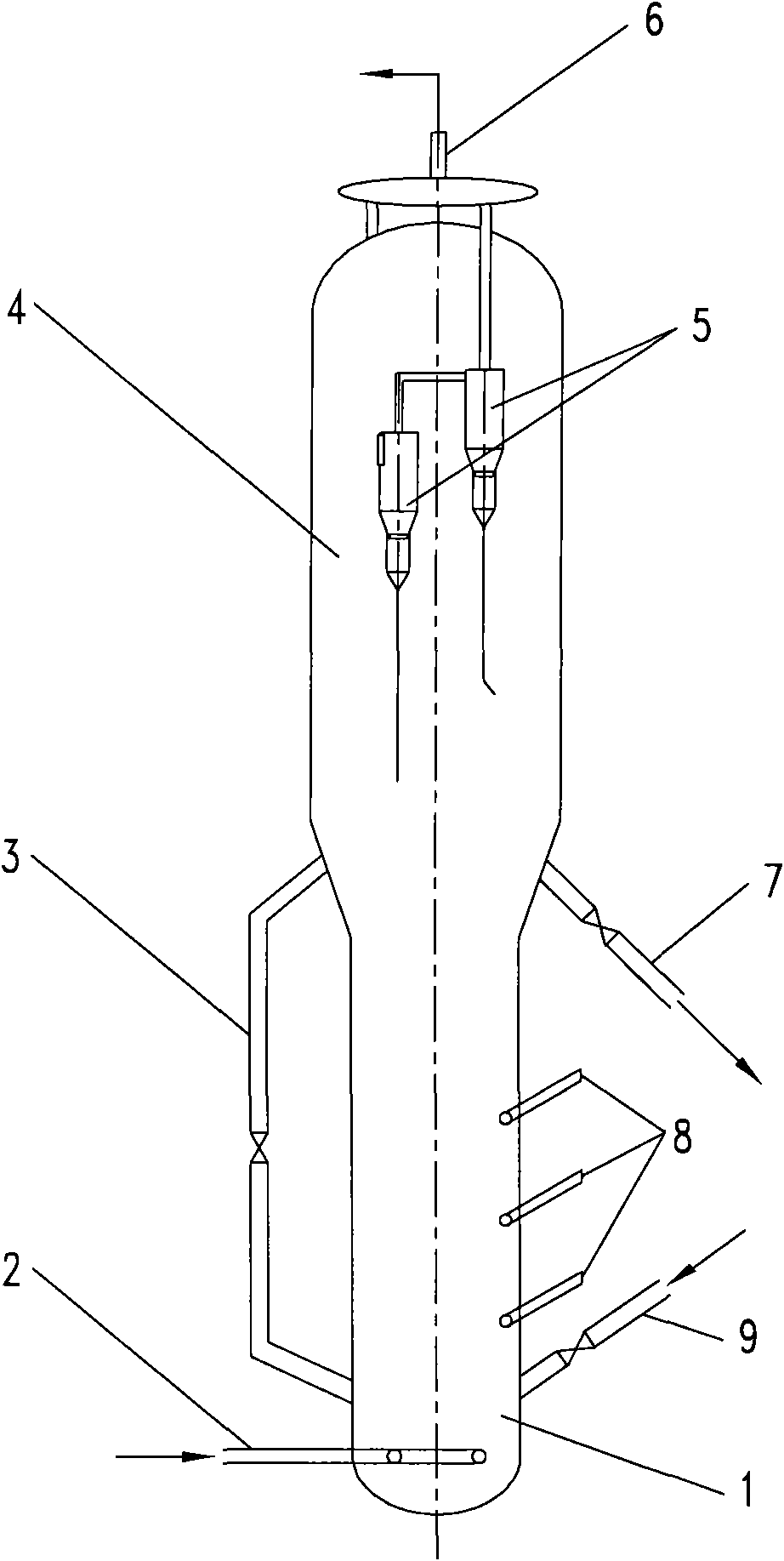

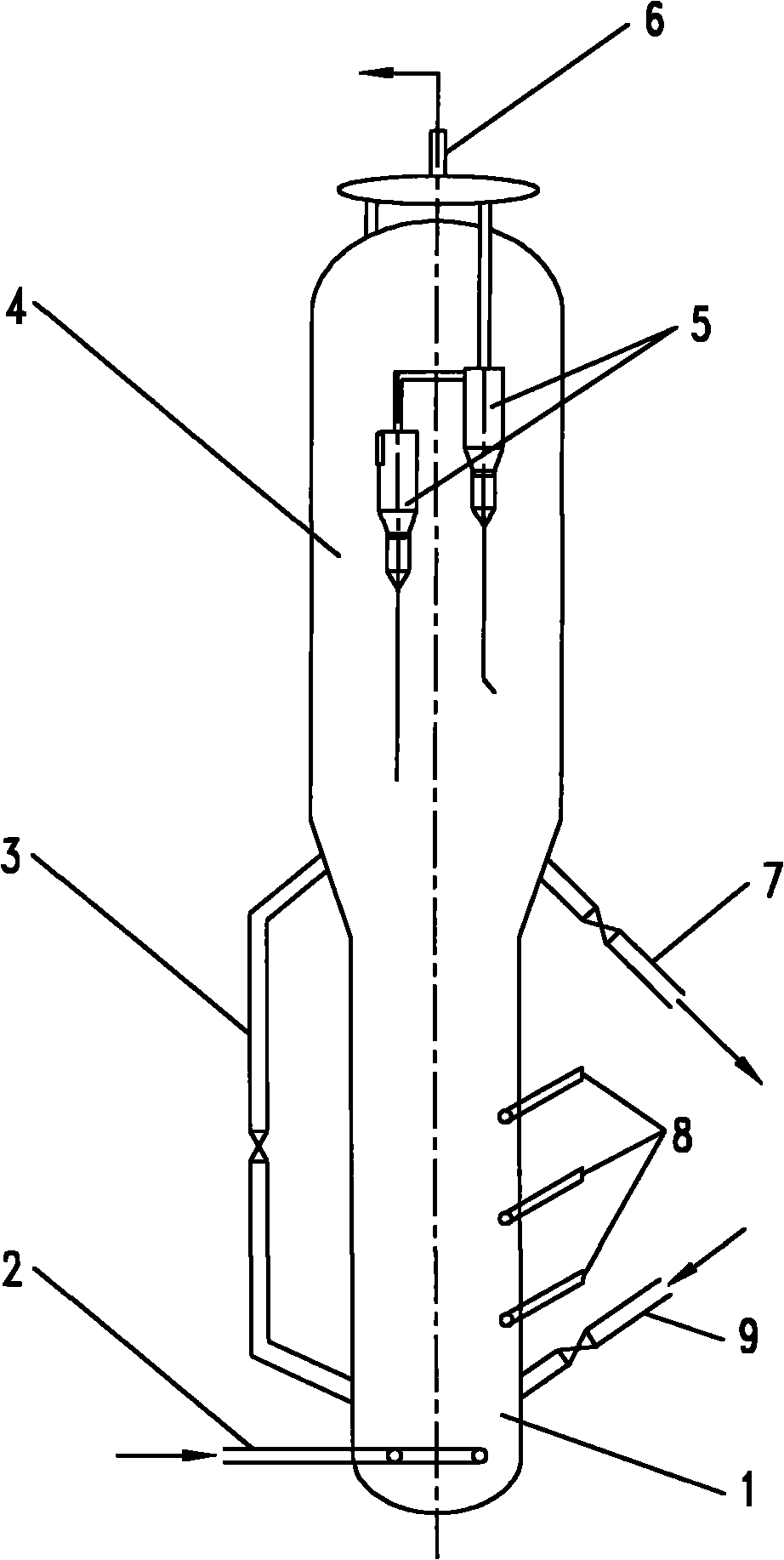

[0024] in such as figure 1 On the reaction device shown, the catalyst is ZSM-5, SiO 2 / Al 2 o 3 The molar ratio is 20, the first part of the raw material enters the reactor from the bottom of the fluidized bed reactor, and the second part of the raw material enters the reactor from a feed port separated in the axial direction of the fluidized bed reactor, and the feed port is located at 1 / 3 of the height of the reaction zone from the bottom of the reaction zone is in contact with the fluidized bed catalyst to generate products including xylene, and the bed density of the fluidized bed reactor is 50 kg / m 3 , the first part of the raw material is toluene and water vapor, the weight ratio of water vapor to toluene is 0.2:1, the second part of the raw material is a mixture of methanol and toluene, and the weight ratio of methanol to toluene is 1:1. The reaction pressure is 0.01MPa in terms of gauge pressure, the reaction temperature is 325°C, the gas phase velocity is 1.8 m / s, ...

Embodiment 2

[0026] According to the conditions and steps described in Example 1, catalyst SiO 2 / Al 2 o 3The molar ratio is 200, the first part of the raw material enters the reactor from the bottom of the fluidized bed reactor, and the second part of the raw material enters the reactor from two inlets separated in the axial direction of the fluidized bed reactor, and the two inlets The feed ports are respectively located at 1 / 3 and 1 / 2 height of the reaction zone from the bottom of the reaction zone, and the feed volumes of the two feed ports are equal, and contact with the fluidized bed catalyst to generate products including xylene. The fluidized bed reactor The bed density is 80 kg / m 3 , the first part of the raw material is toluene and water vapor, the weight ratio of water vapor to toluene is 0.1:1, the second part of the raw material is a mixture of methanol and toluene, and the weight ratio of methanol to toluene is 2:1. The reaction pressure is 0.01MPa in terms of gauge pressu...

Embodiment 3

[0028] According to the conditions and steps described in Example 1, catalyst SiO 2 / Al 2 o 3 The molar ratio is 100, the first part of the raw material enters the reactor from the bottom of the fluidized bed reactor, the second part of the raw material enters the reactor from three feeding ports separated in the axial direction of the fluidized bed reactor, and the three feeding ports The feeding ports are respectively located at 1 / 4, 1 / 2, and 2 / 3 of the height of the reaction zone from the bottom of the reaction zone, and the feeding volumes of the three feeding ports are equal, and contact with the fluidized bed catalyst to generate products including xylene, flow The bed density of the chemical bed reactor is 200 kg / m 3 , the first part of the raw material is toluene and water vapor, the weight ratio of water vapor to toluene is 0.01:1, the second part of the raw material is a mixture of methanol and toluene, and the weight ratio of methanol to toluene is 10:1. The reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com