Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160 results about "NOx adsorber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A NOₓ adsorber or NOₓ trap (also called Lean NOₓ trap, abbr. LNT) is a device that is used to reduce oxides of nitrogen (NO and NO₂) emissions from a lean burn internal combustion engine by means of adsorption.

Hybrid catalyst system for exhaust emissions reduction

InactiveUS20060010857A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

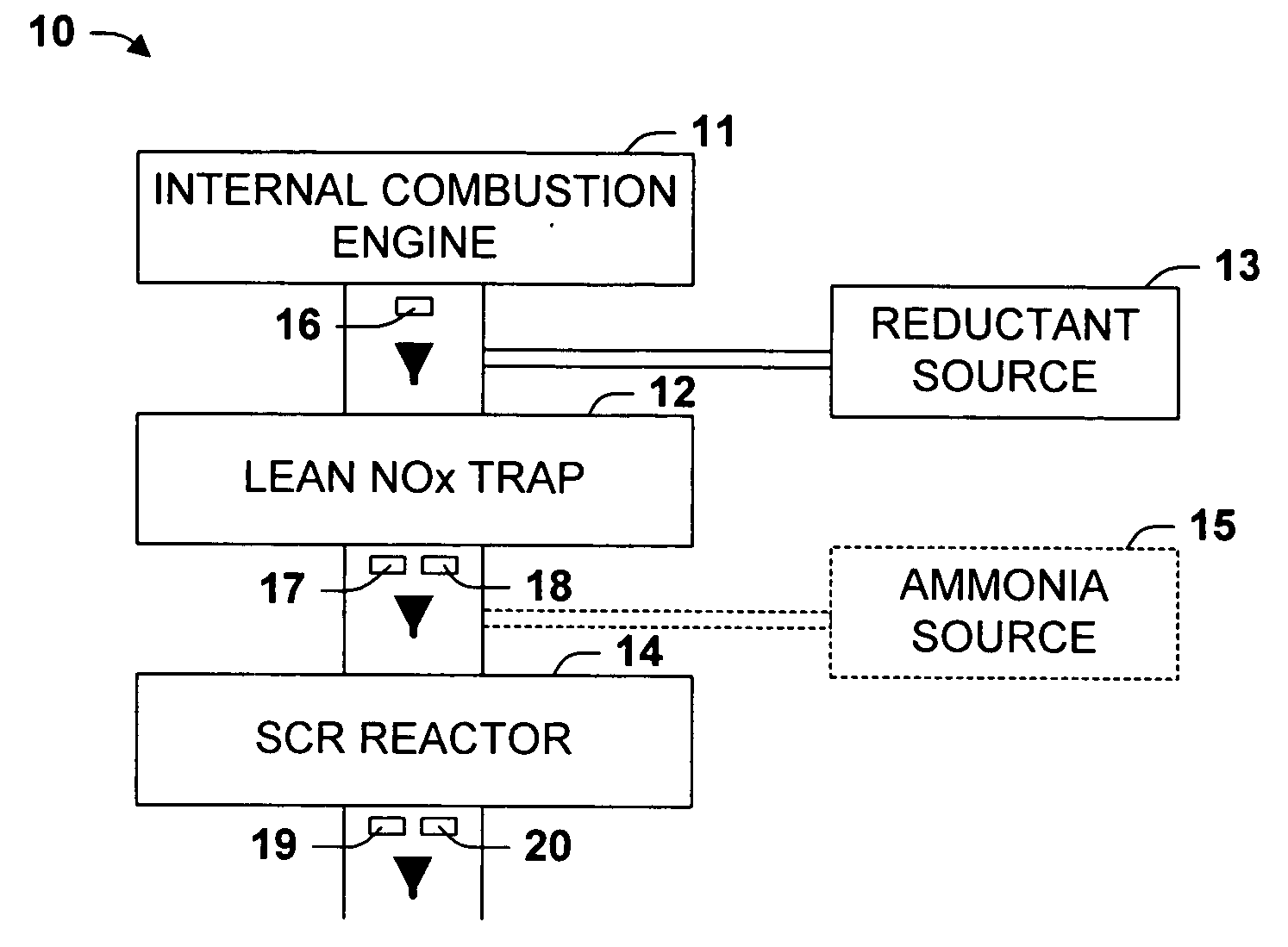

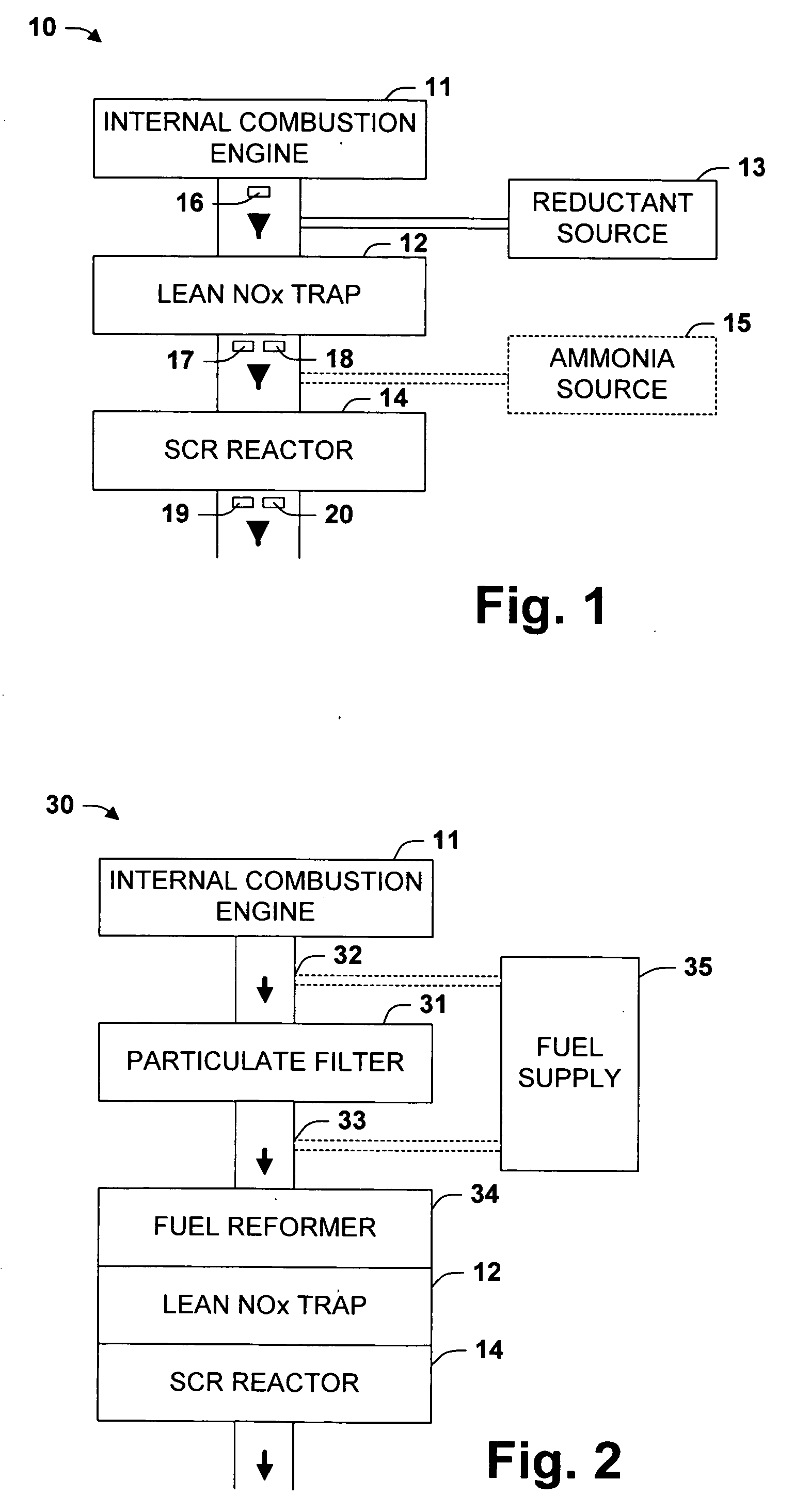

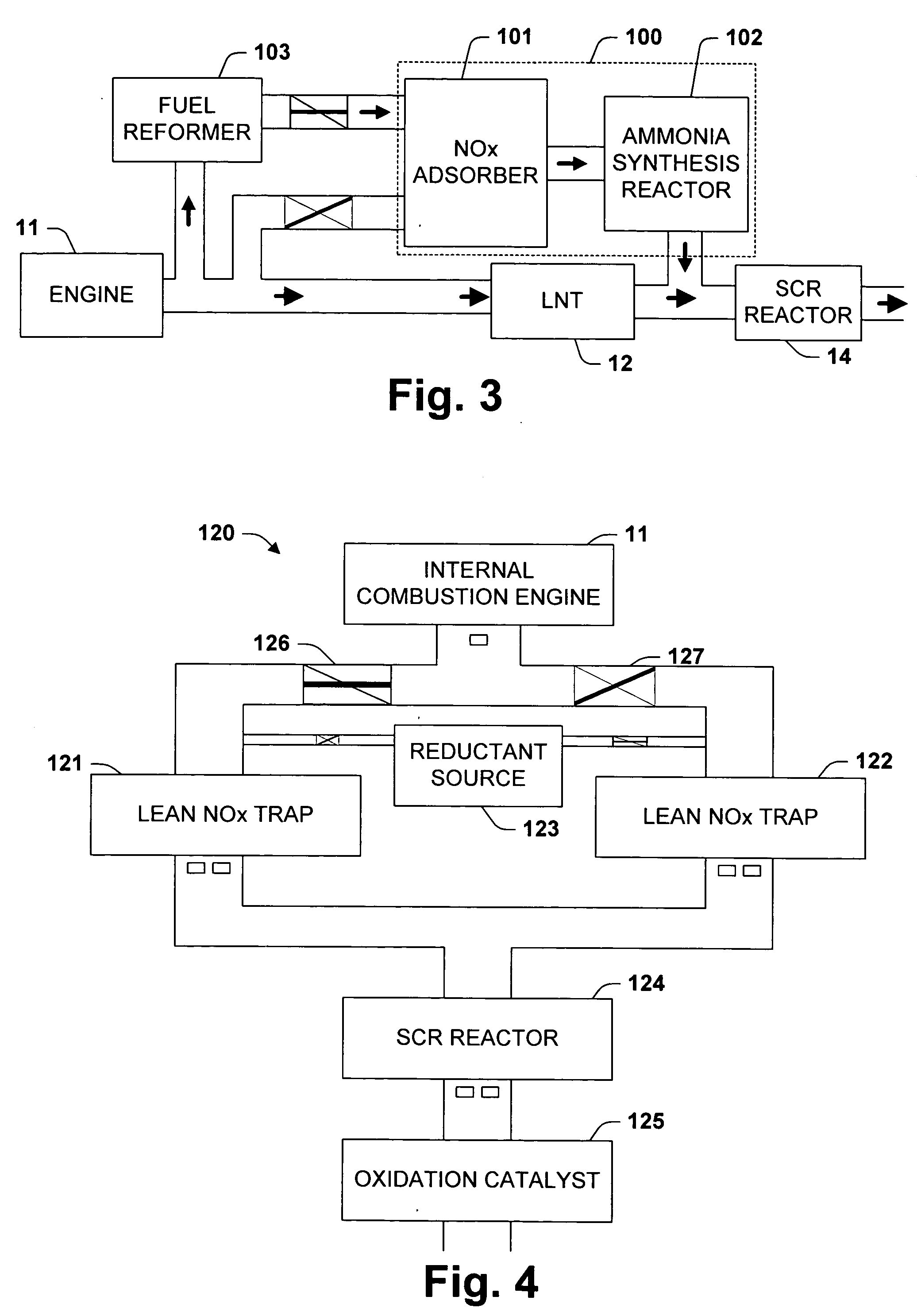

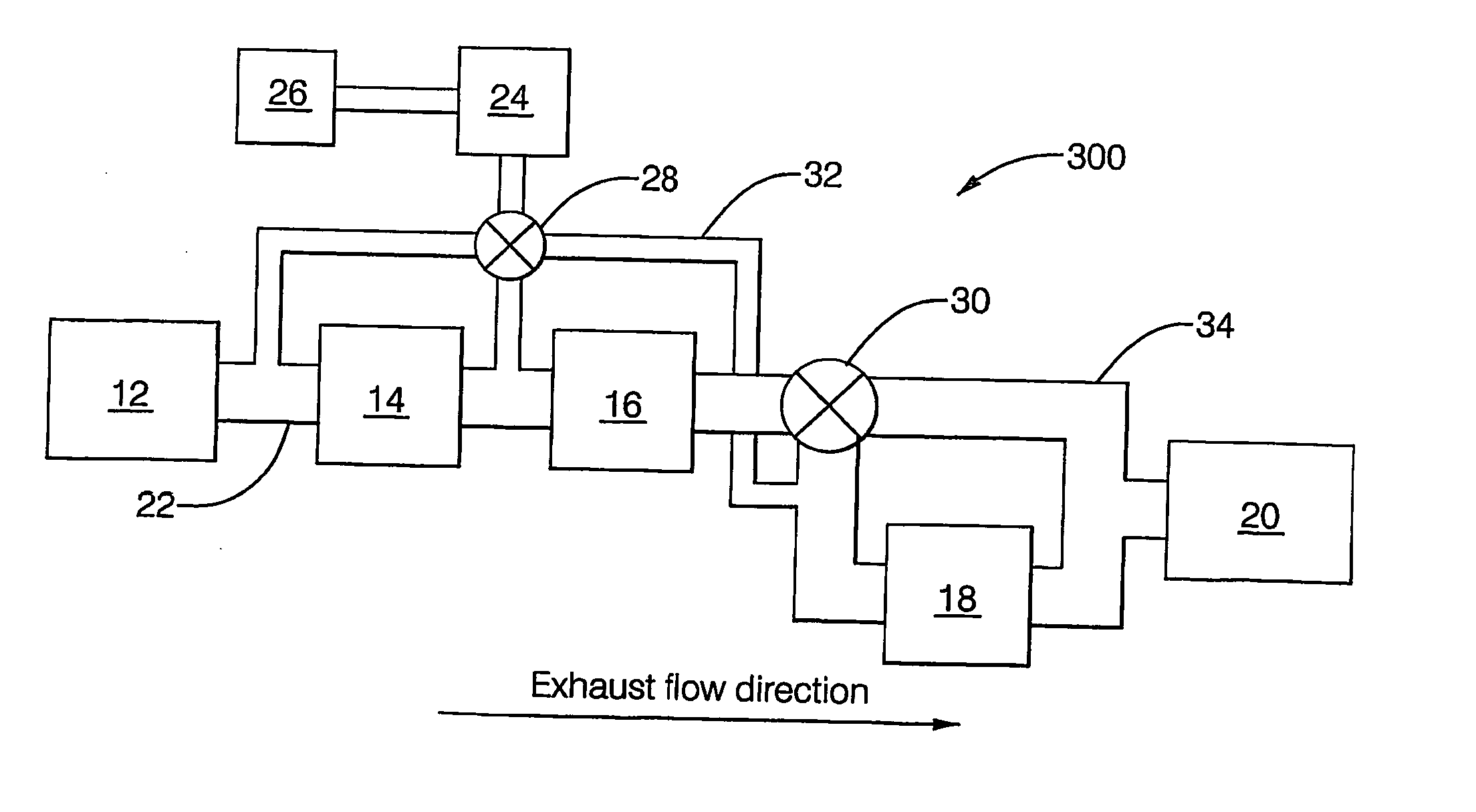

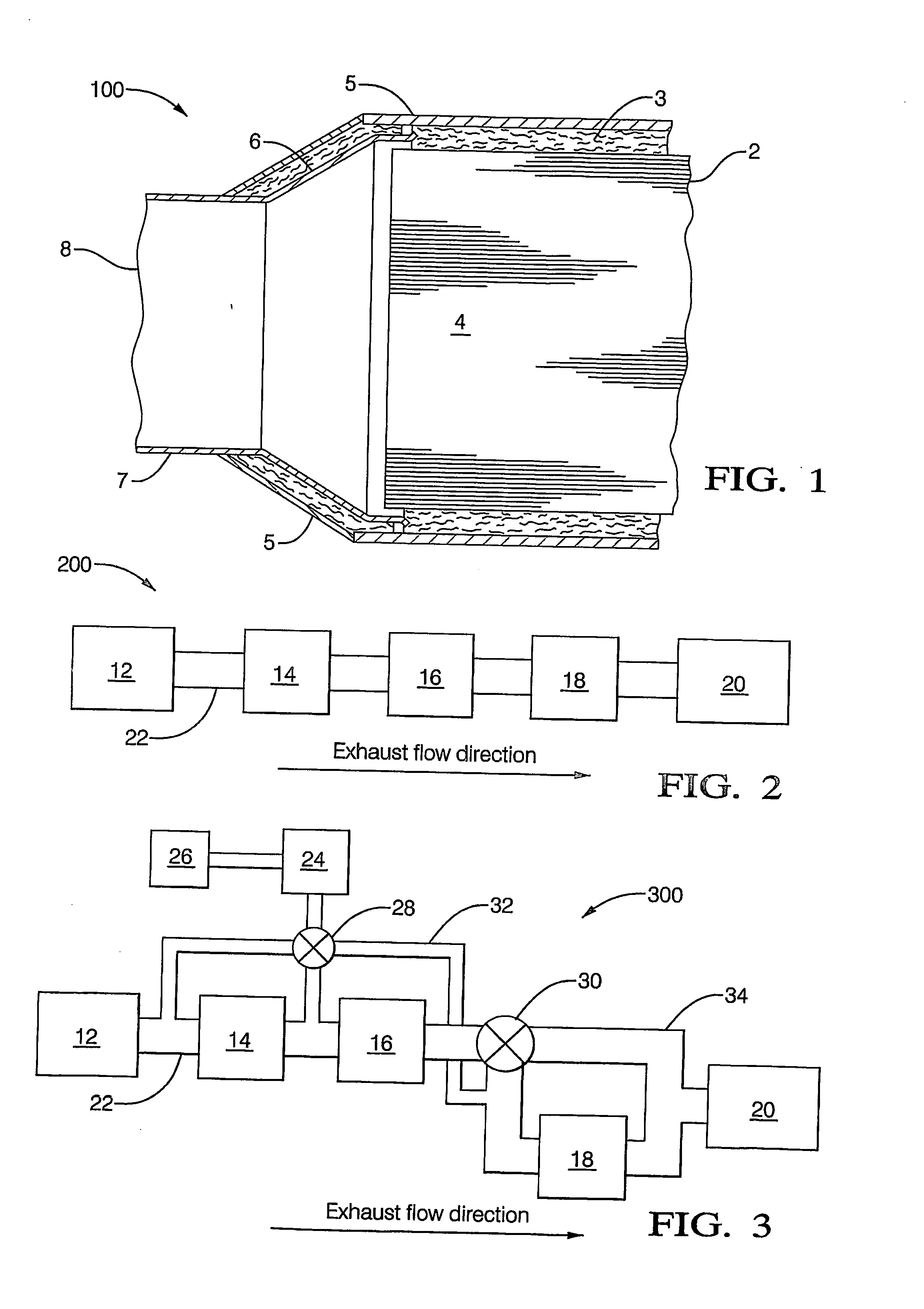

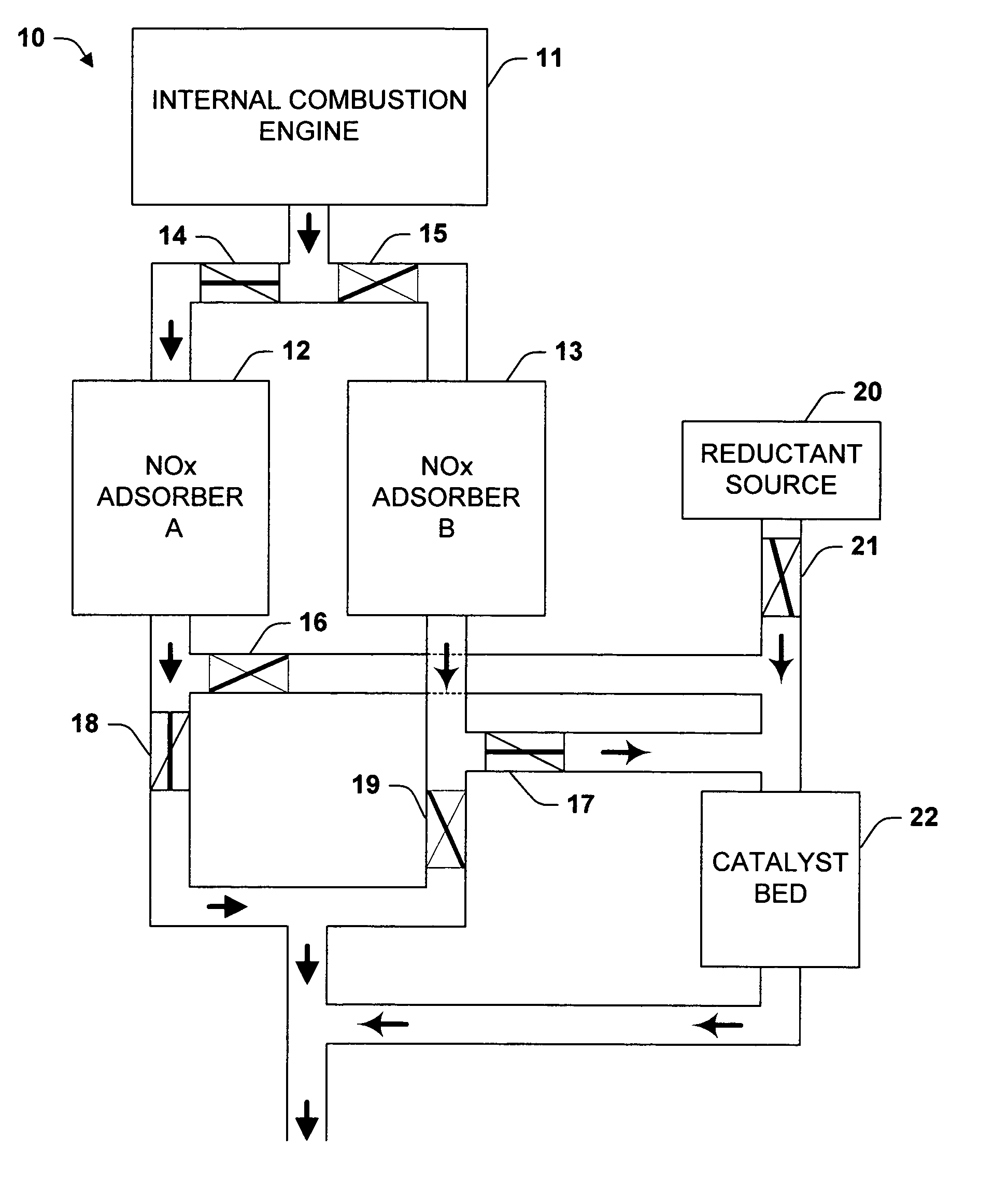

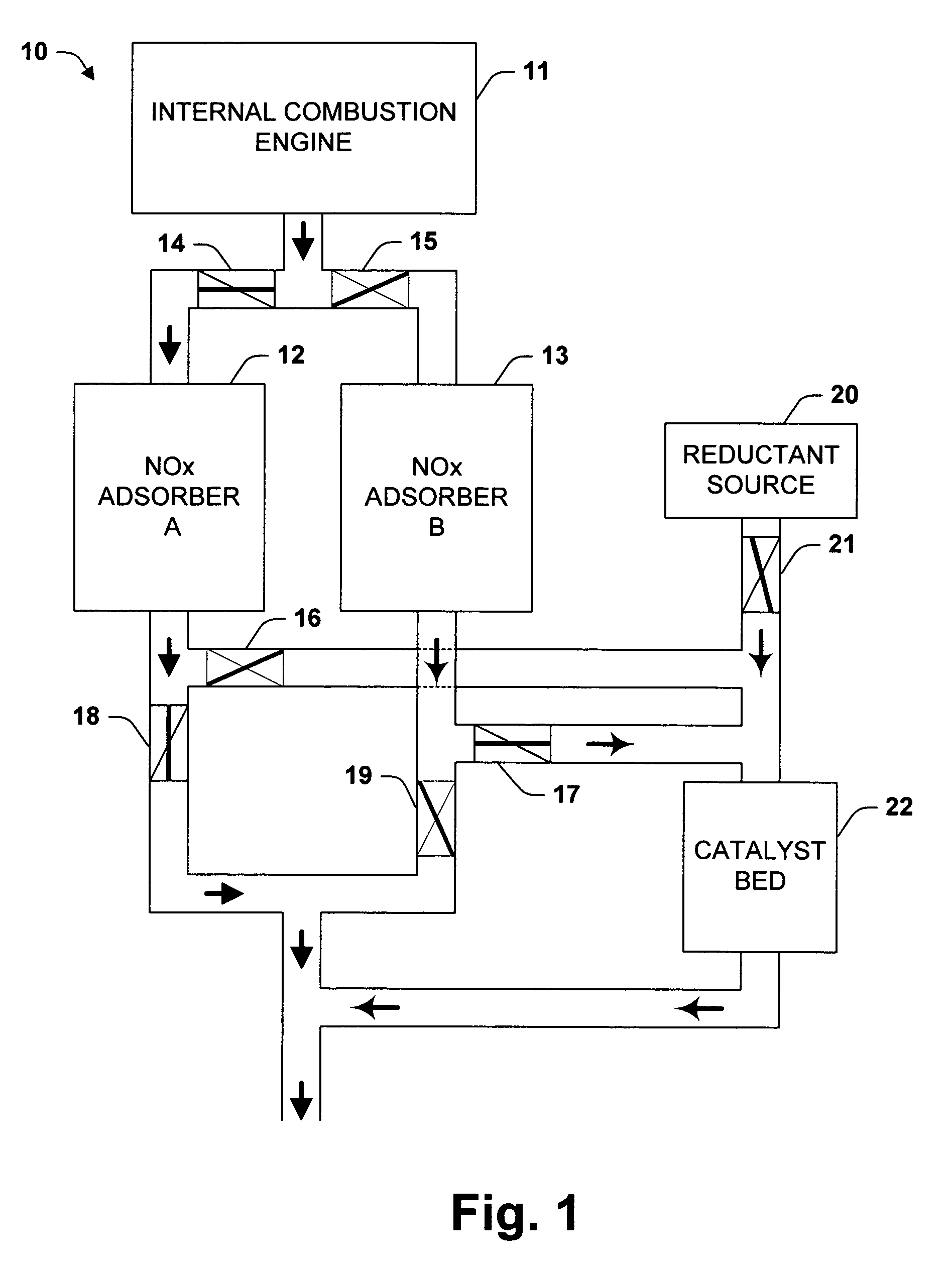

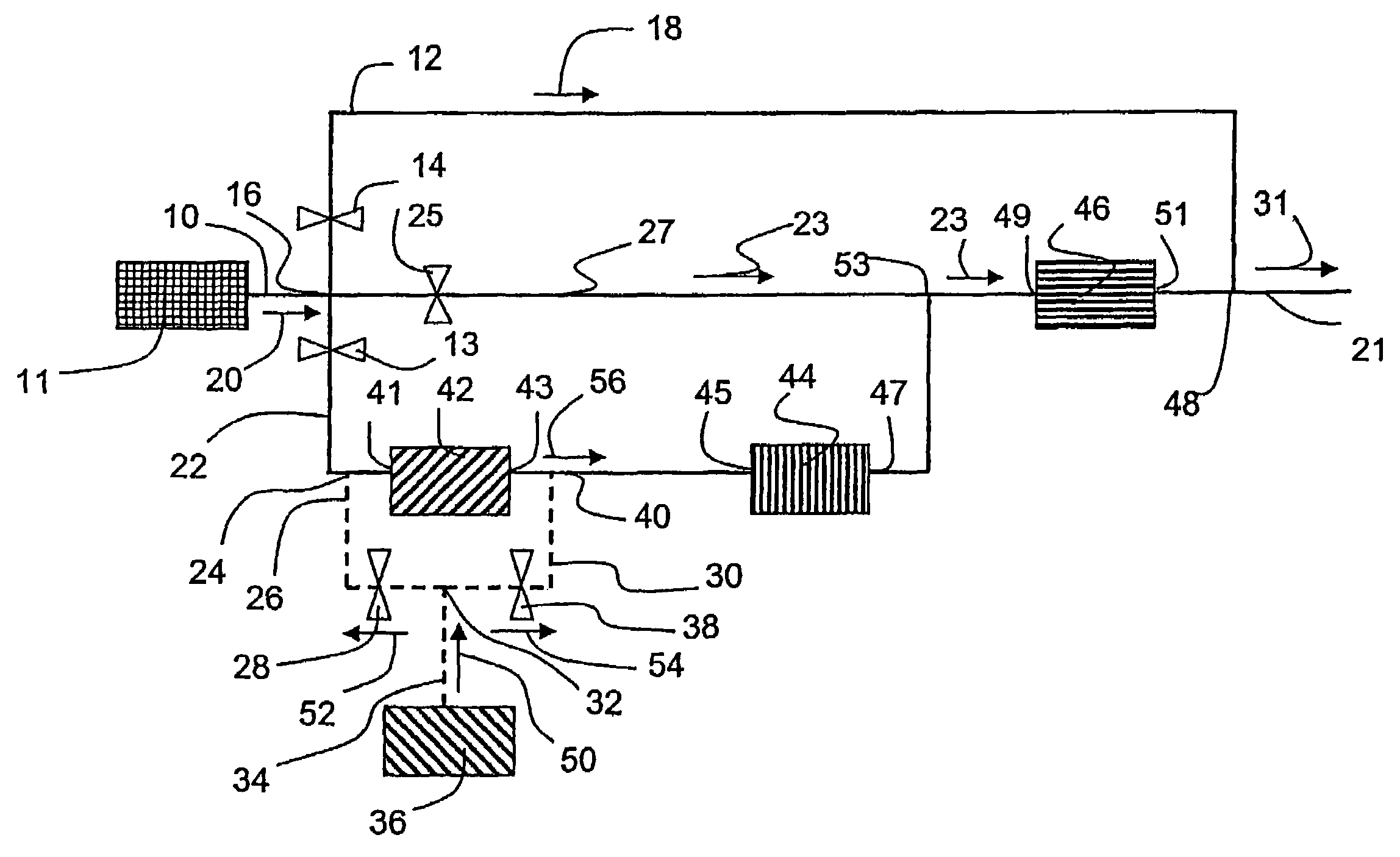

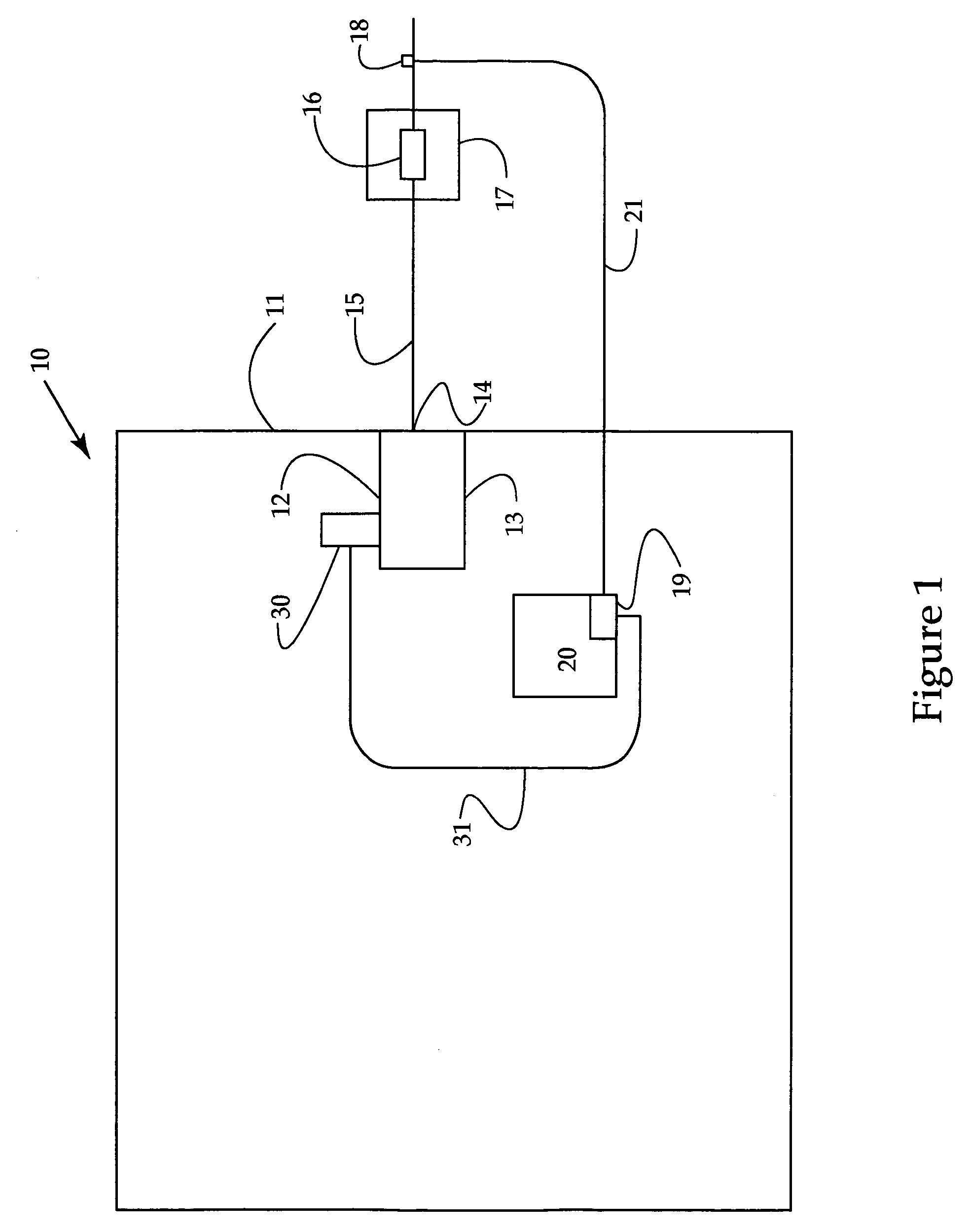

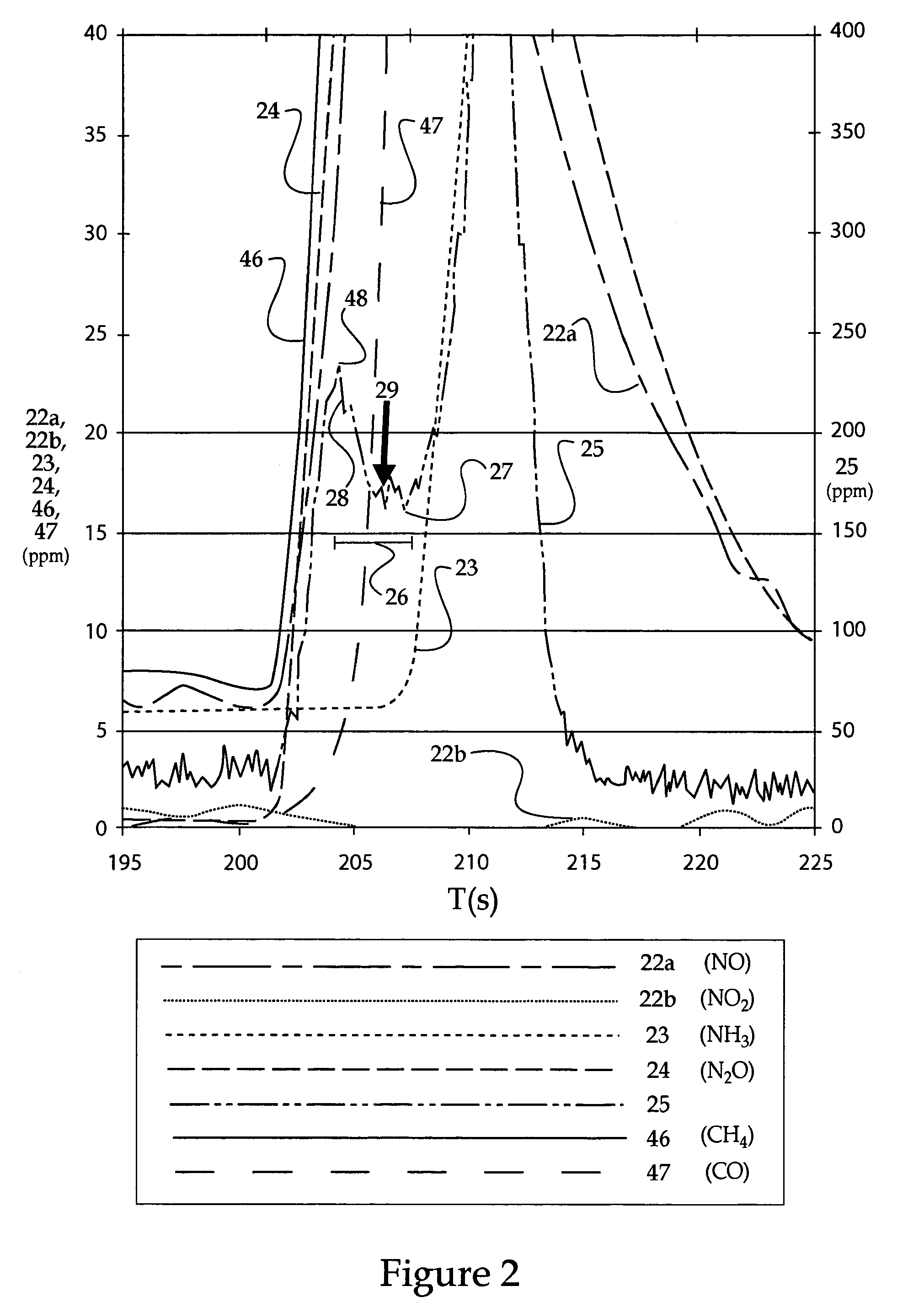

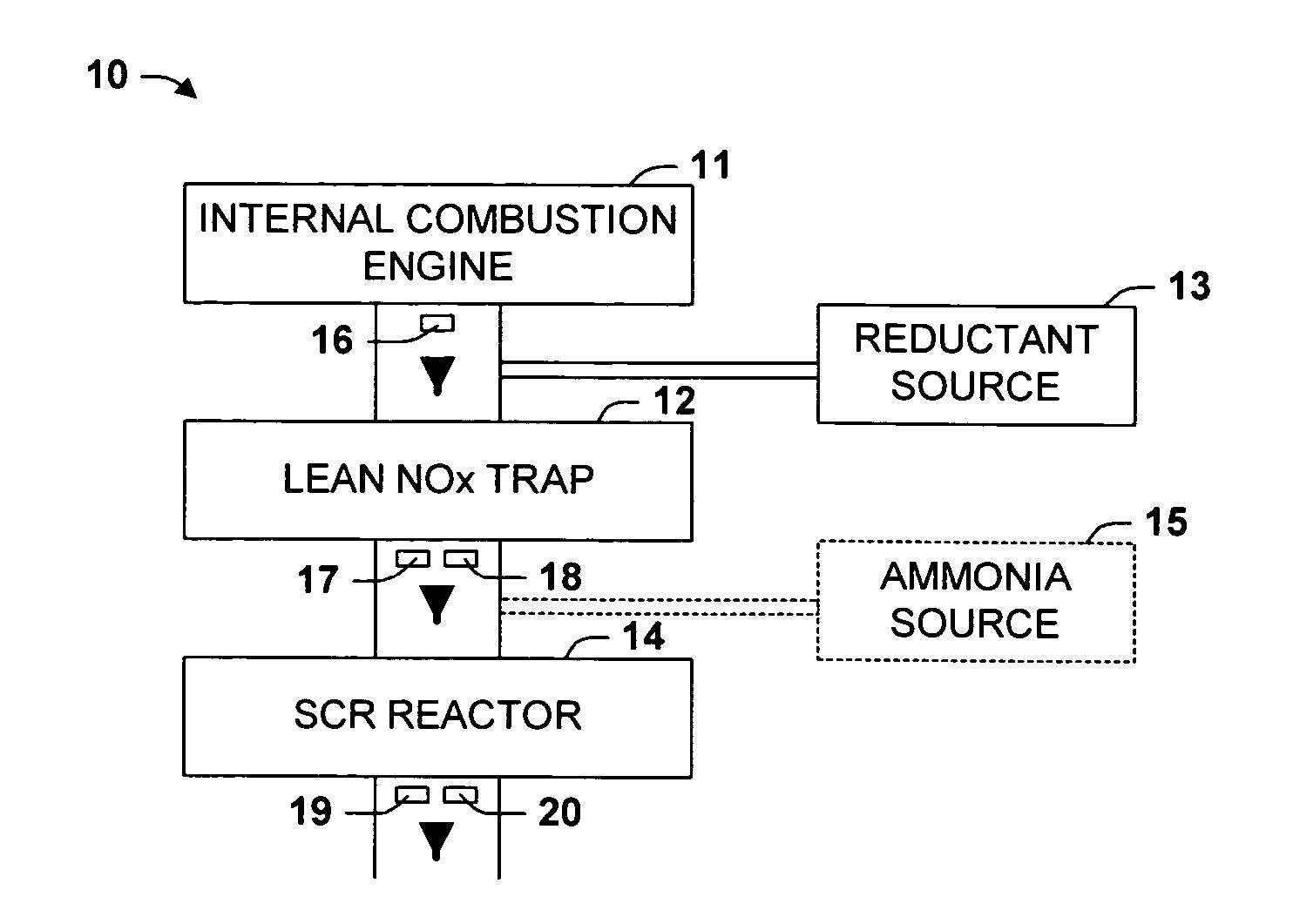

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

System and method of nox abatement

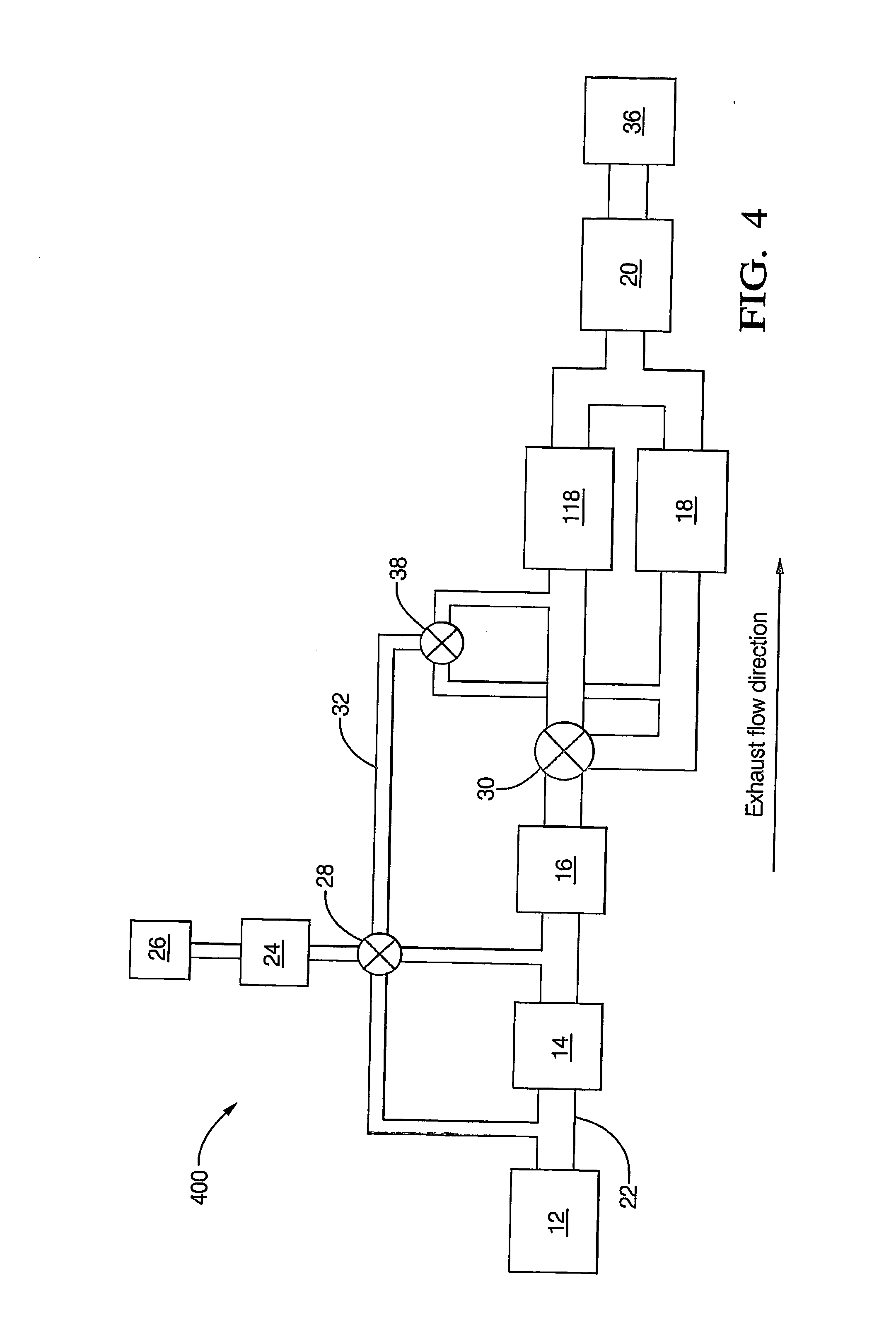

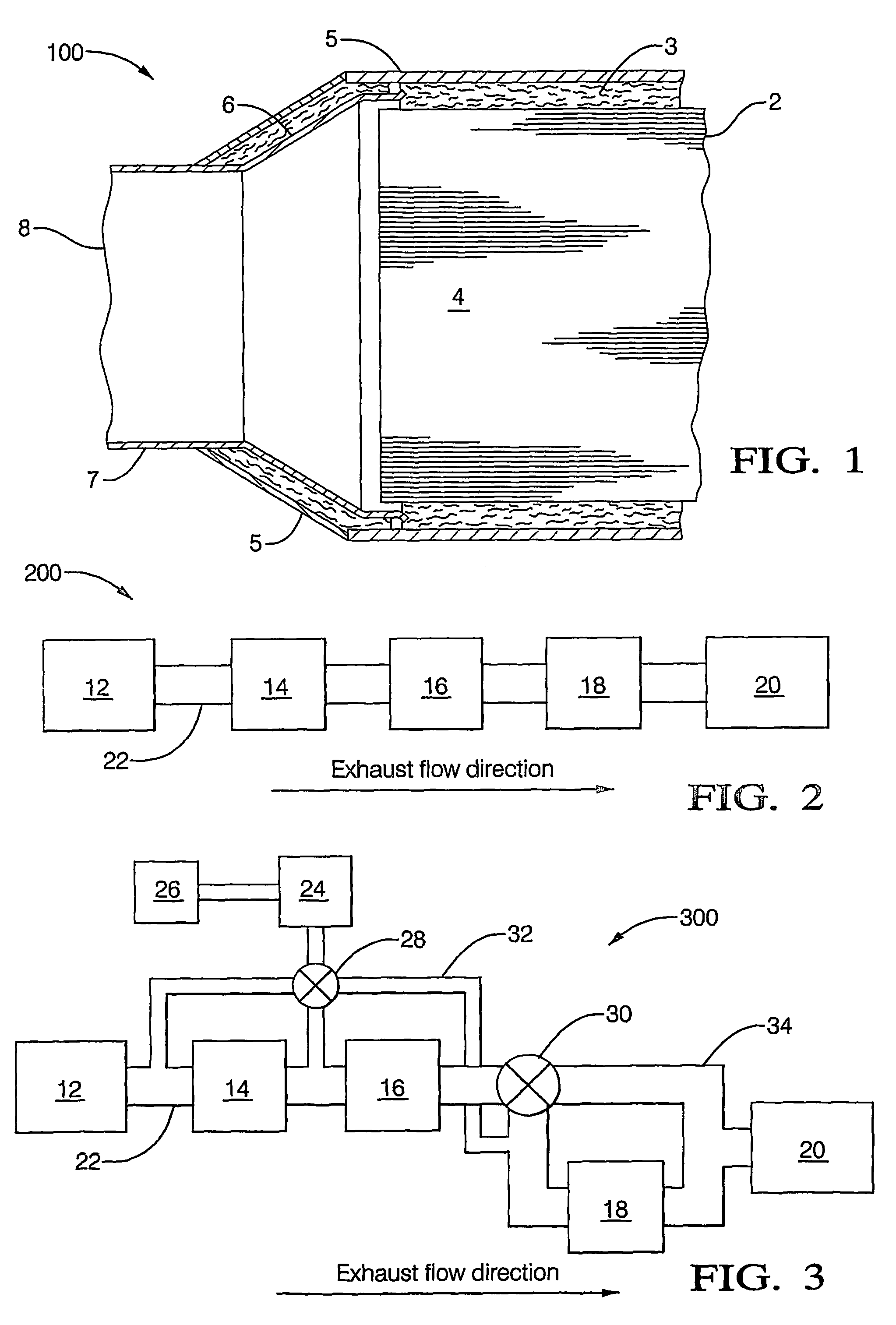

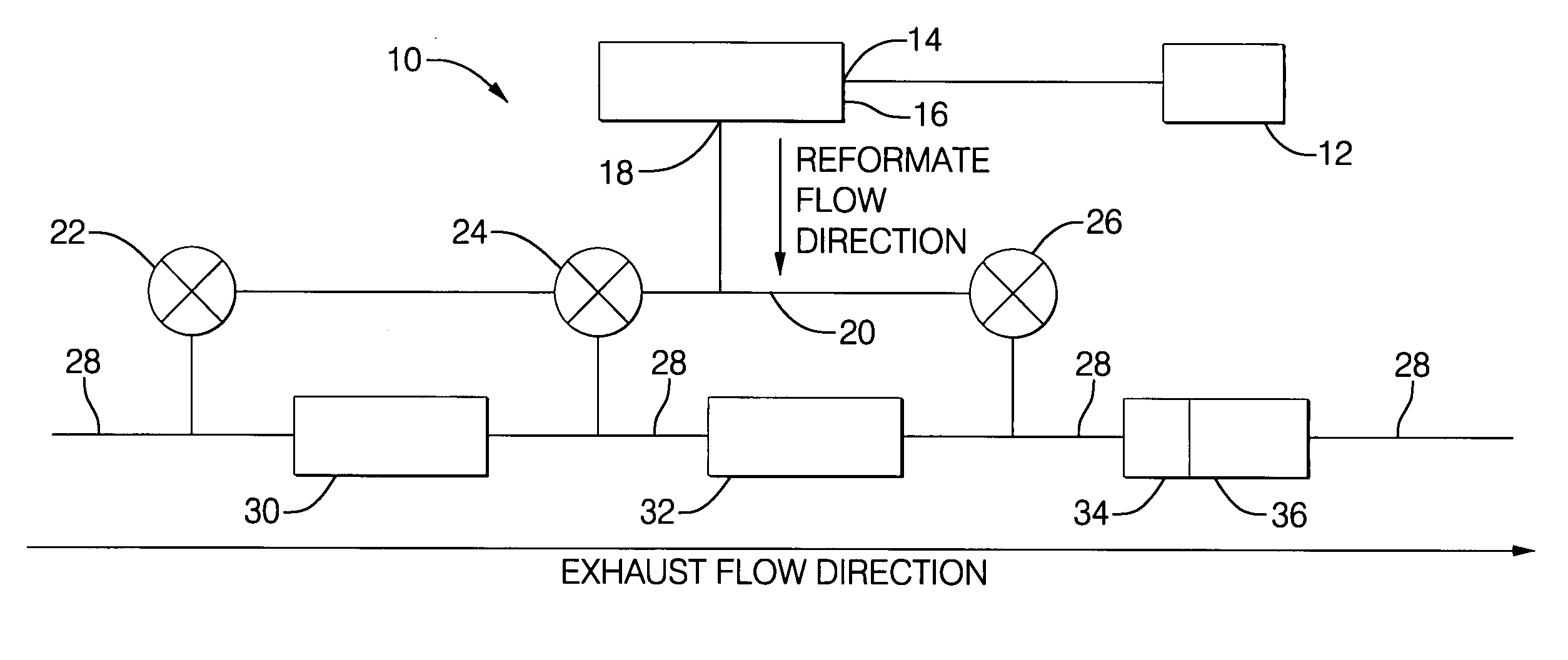

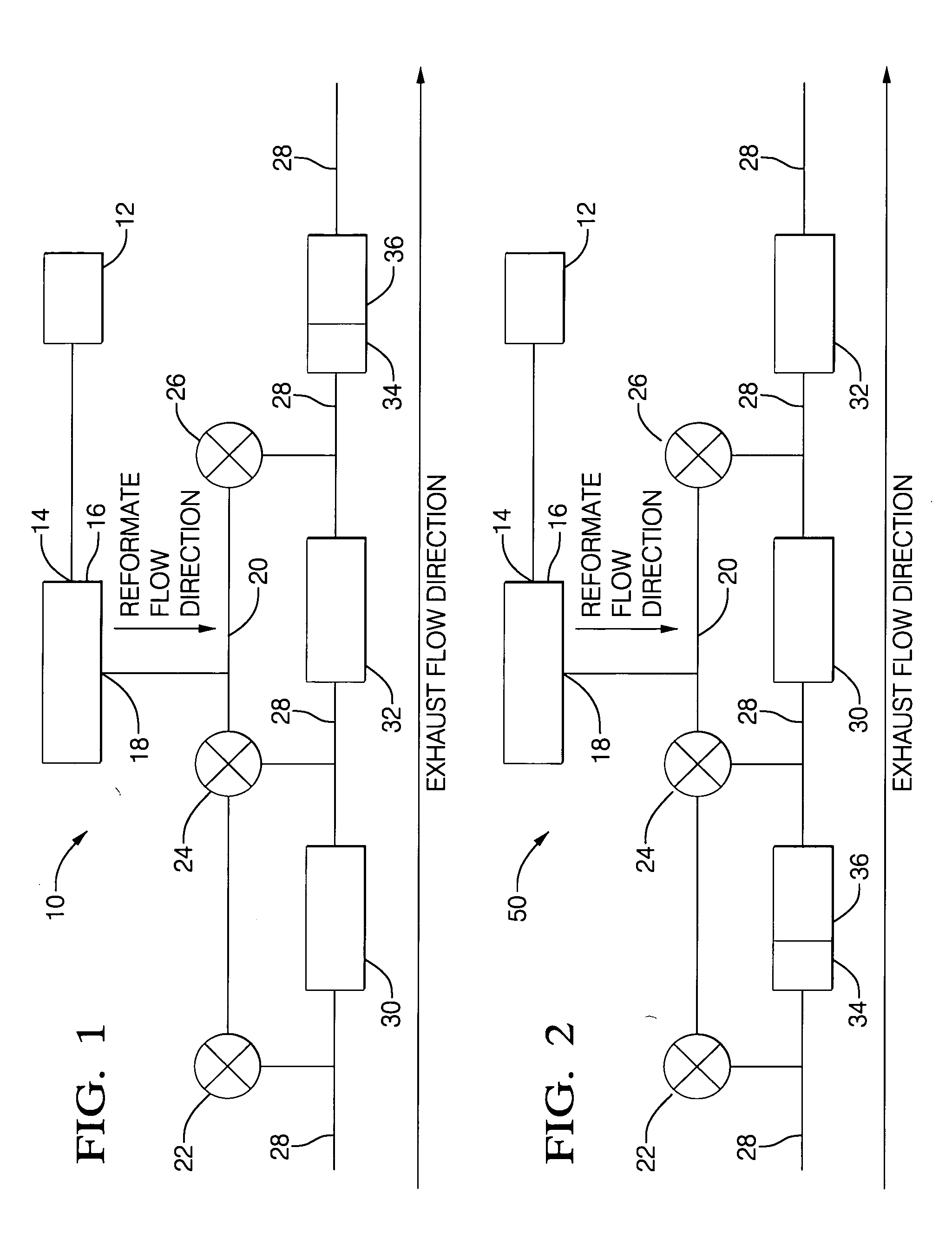

InactiveUS20060213187A1Internal combustion piston enginesExhaust apparatusHydrogenProcess engineering

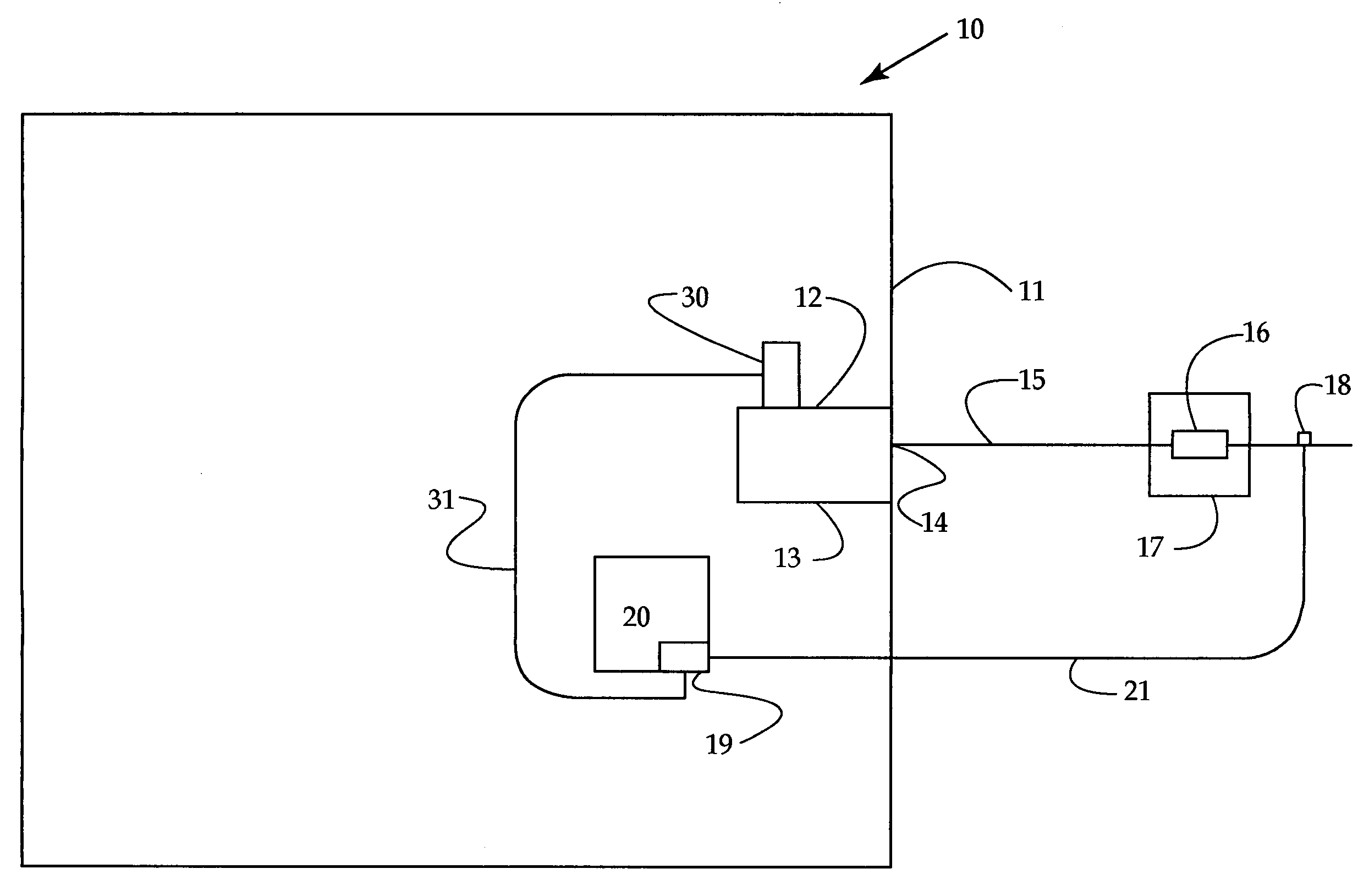

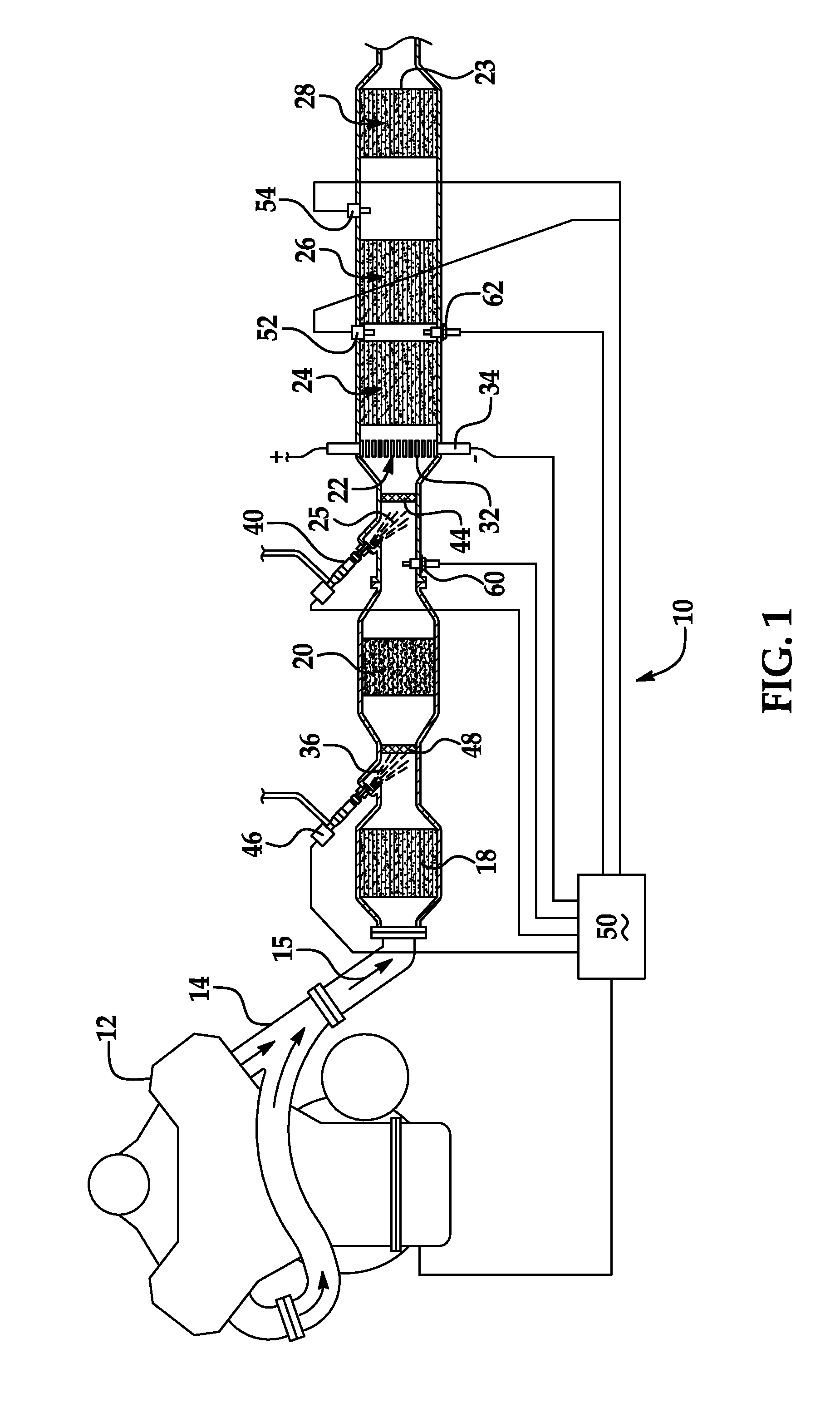

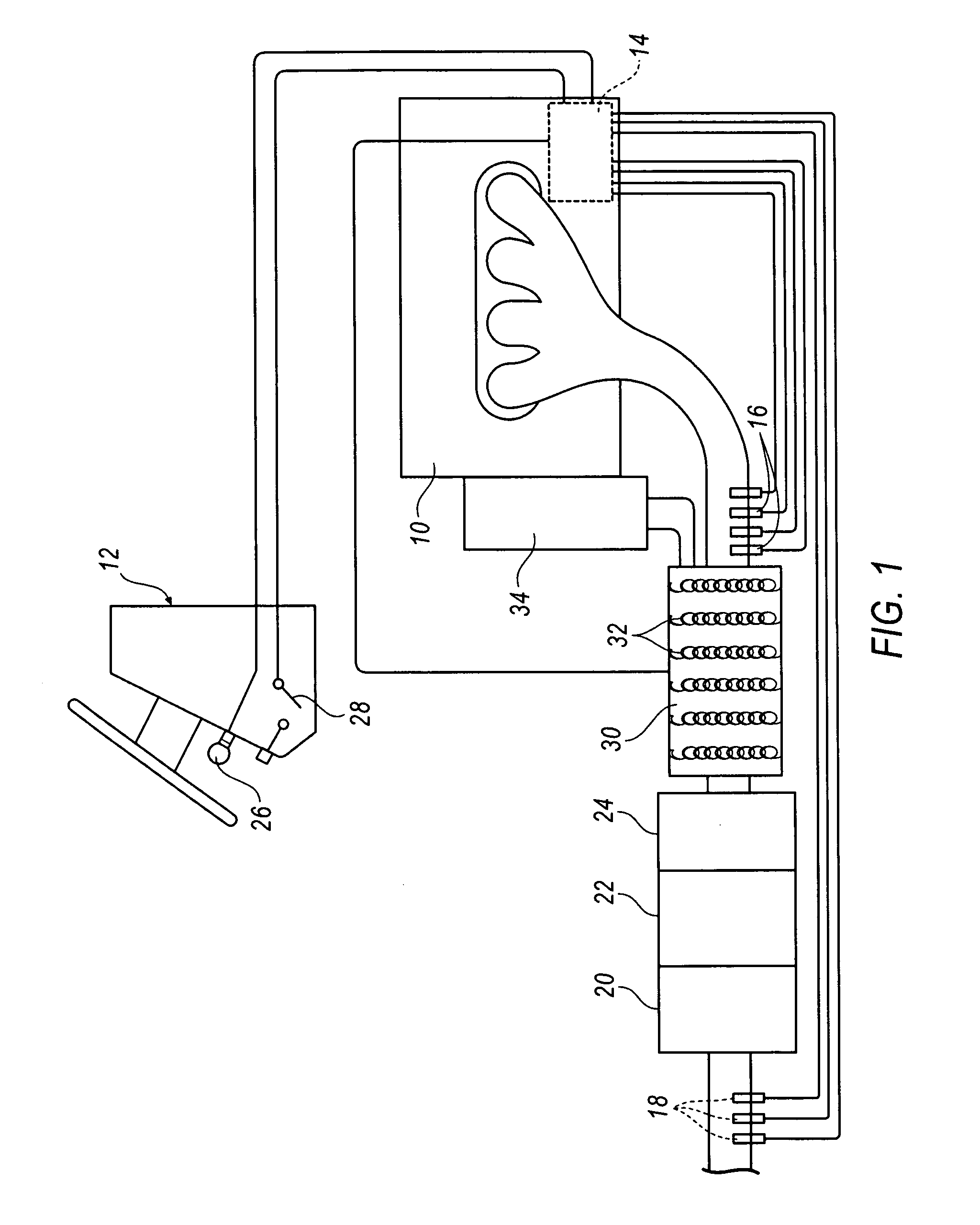

A NOx abatement system comprising: a first NOx adsorber (18) capable of being disposed in-line and downstream of and in fluid communication with an engine (12); a selective catalytic reduction catalyst (20) disposed in-line and downstream of and in direct fluid communication with the first NOx adsorber (18), wherein the selective catalytic reduction catalyst (20) is capable of storing ammonia; and an off-line reformer (24) disposed in selective communication with and upstream of the first NOx adsorber (18) and the selective catalytic reduction catalyst (20), wherein the reformer (24) is capable of producing a reformate comprising primarily hydrogen and carbon monoxide.

Owner:DELPHI TECH INC

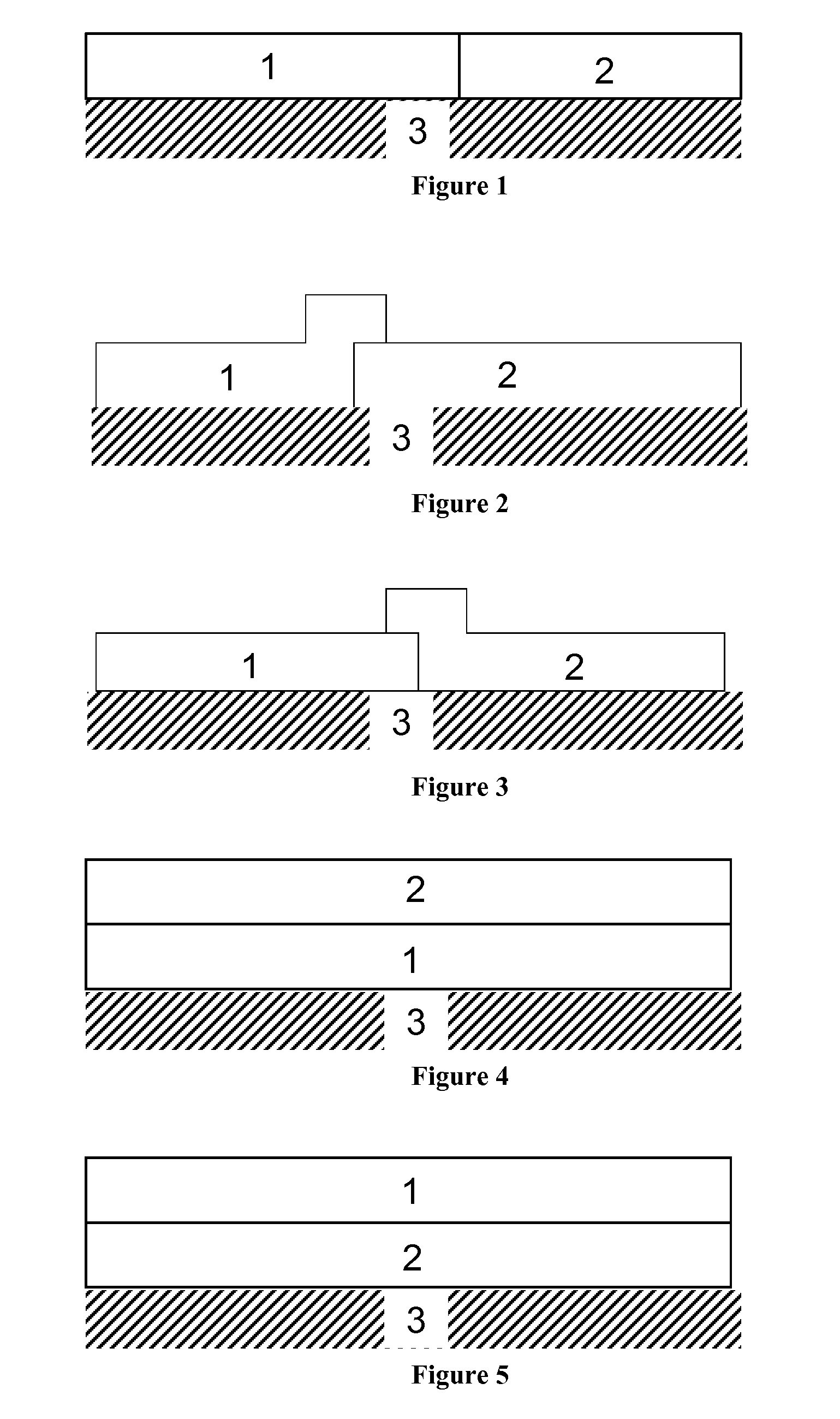

NOx Adsorber Catalyst with Superior Low Temperature Performance

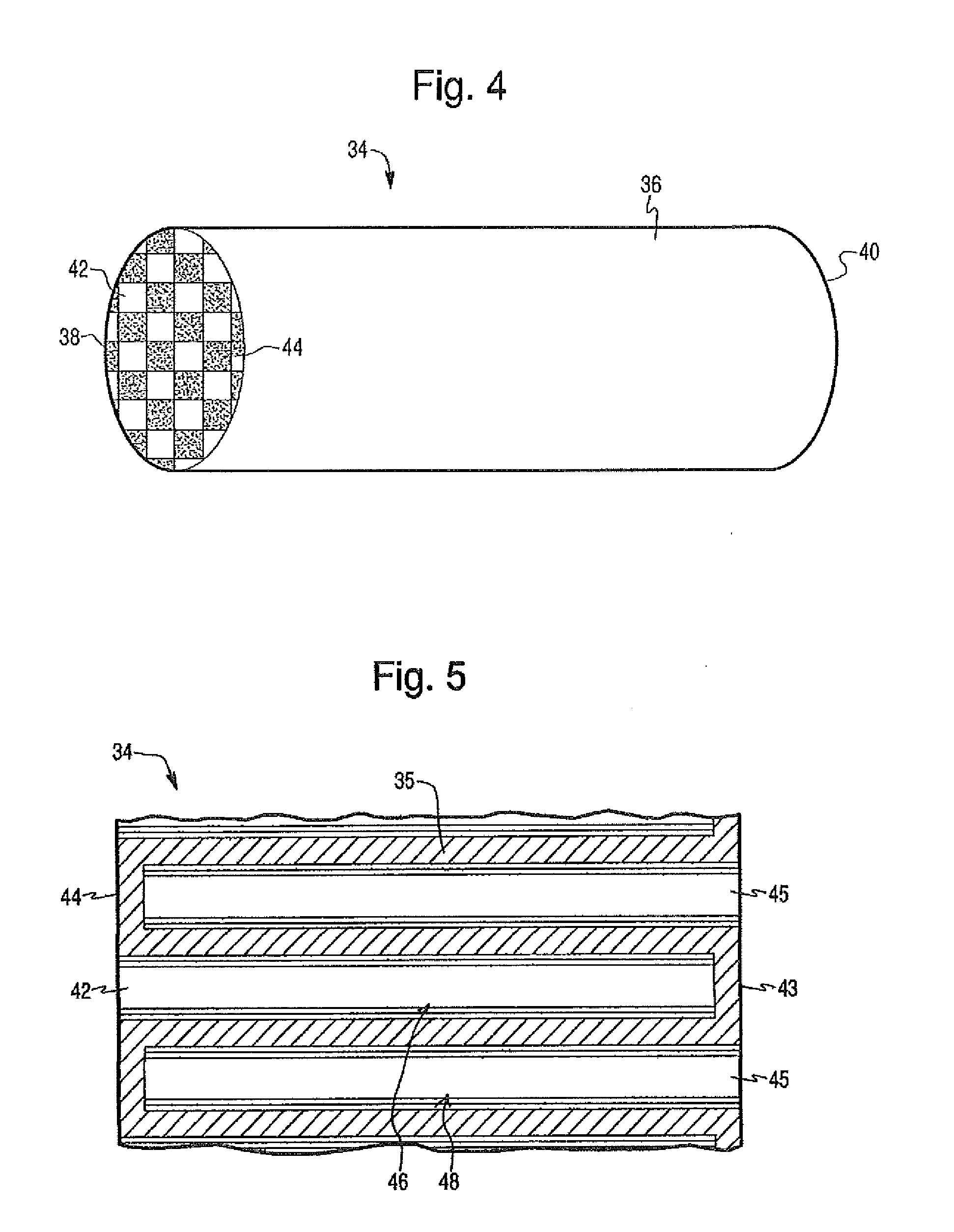

The lean NOx trap catalyst composition of the present invention comprises distinct layers, or zone configuration or multi-brick arrangement. The top layer, front zone or front brick is free of any alkali or alkaline earth NOx trapping components. The under layer, rear zone or rear brick may contain any desirable NOx trapping component in contact with a precious metals group catalyst (e.g., Pt). Catalysts of this invention show wide temperature operation window with superior low temperature performance.

Owner:BASF CORP

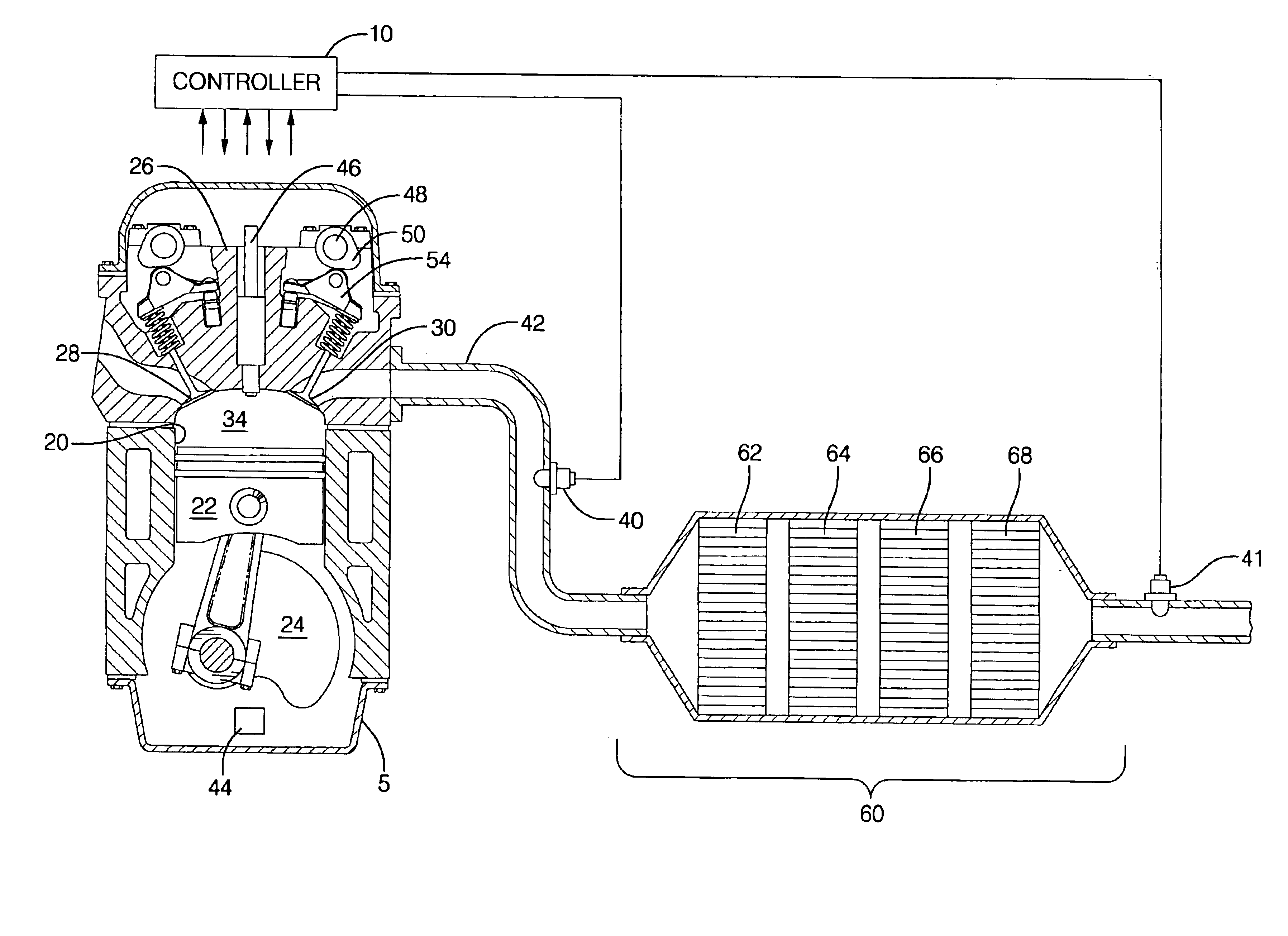

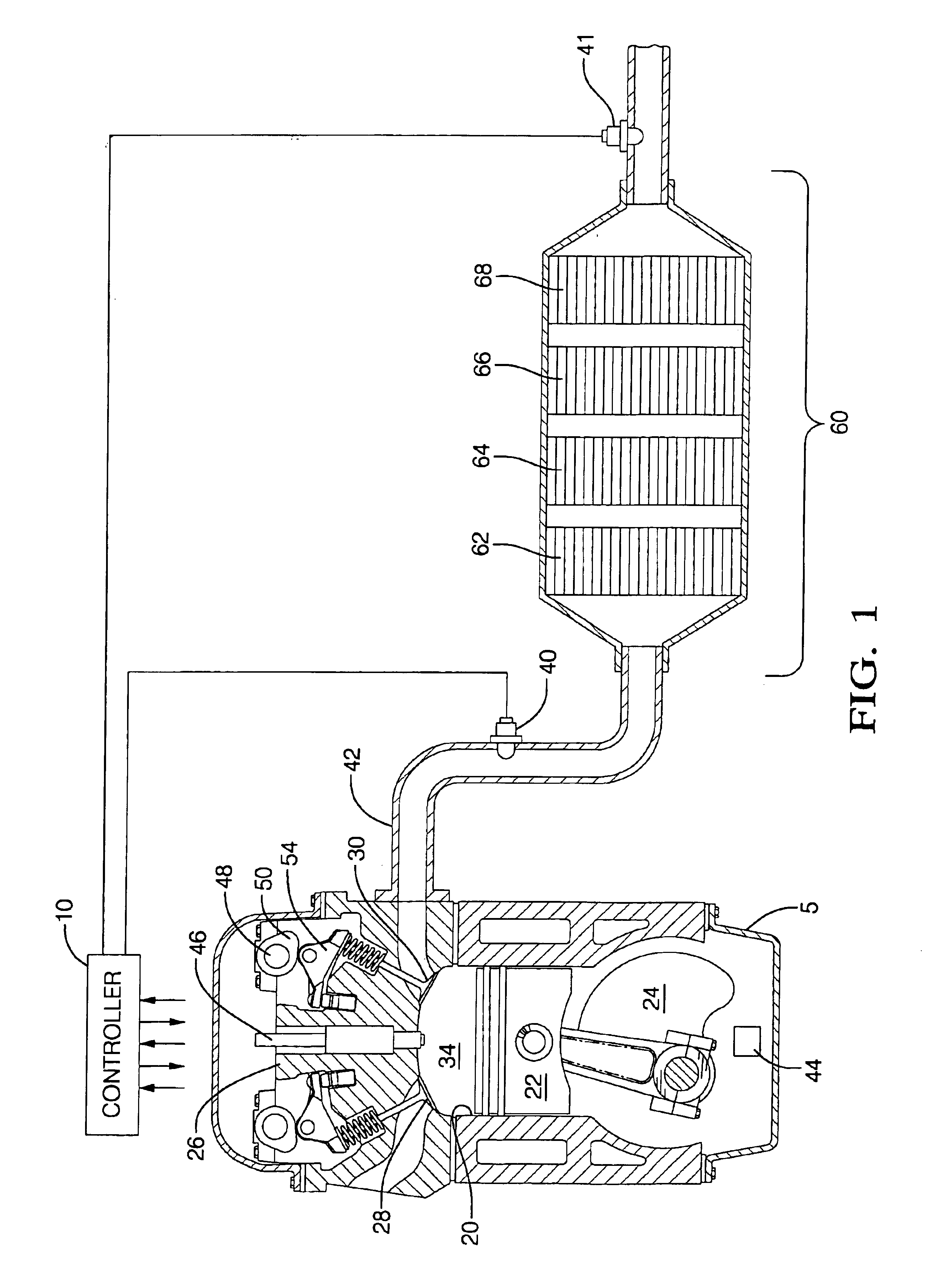

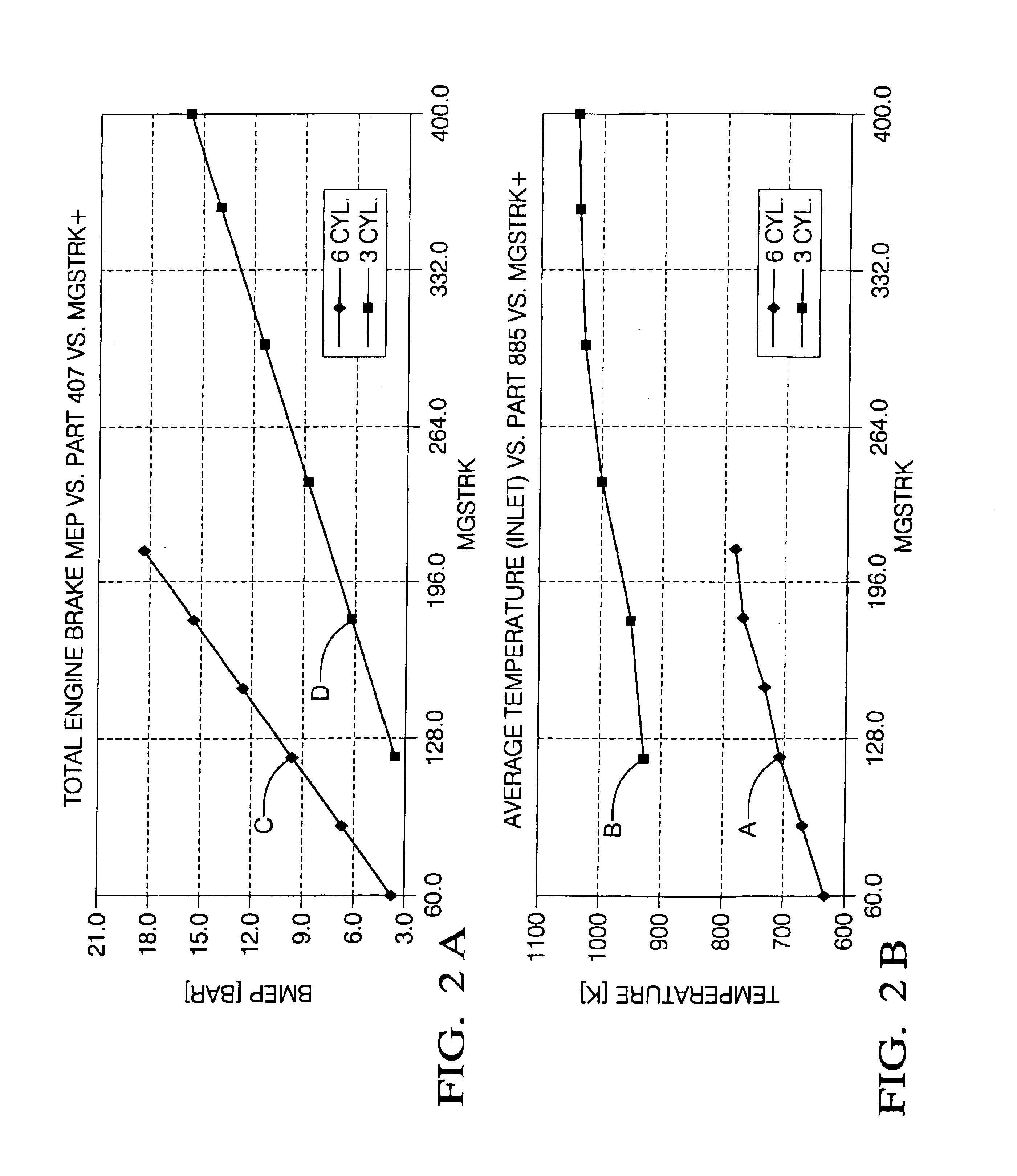

Engine cylinder deactivation to improve the performance of exhaust emission control systems

InactiveUS6904752B2Increase exhaust temperatureIncreases fuel chargeValve arrangementsAir-treating devicesParticulatesControl system

The invention provides a controller and cylinder deactivation system to regenerate an exhaust aftertreatment device for a multicylinder engine that operates primarily at an air / fuel ratio that is lean of stoichiometry. The invention uses the cylinder deactivation system to control temperature and air / fuel ratio of an exhaust gas feedstream going into an aftertreatment device. The invention also increases the amount of fuel delivered to each non-deactivated cylinder by an amount sufficient to maintain operating power of the engine. The regeneration action includes desorbing NOx from a NOx adsorber catalyst, desulfating the NOx adsorber catalyst, and purging a diesel particulate trap.

Owner:DELPHI TECH IP LTD

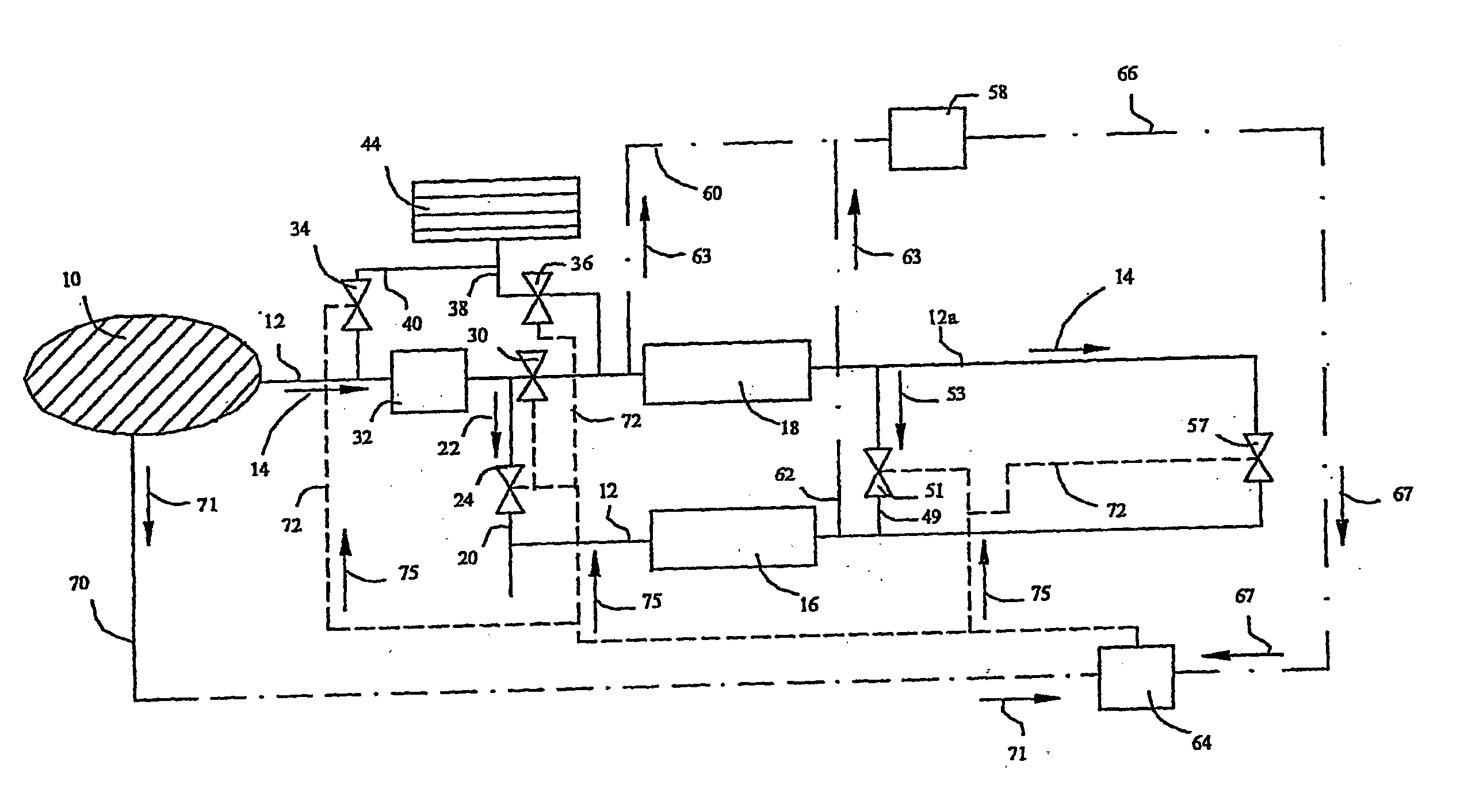

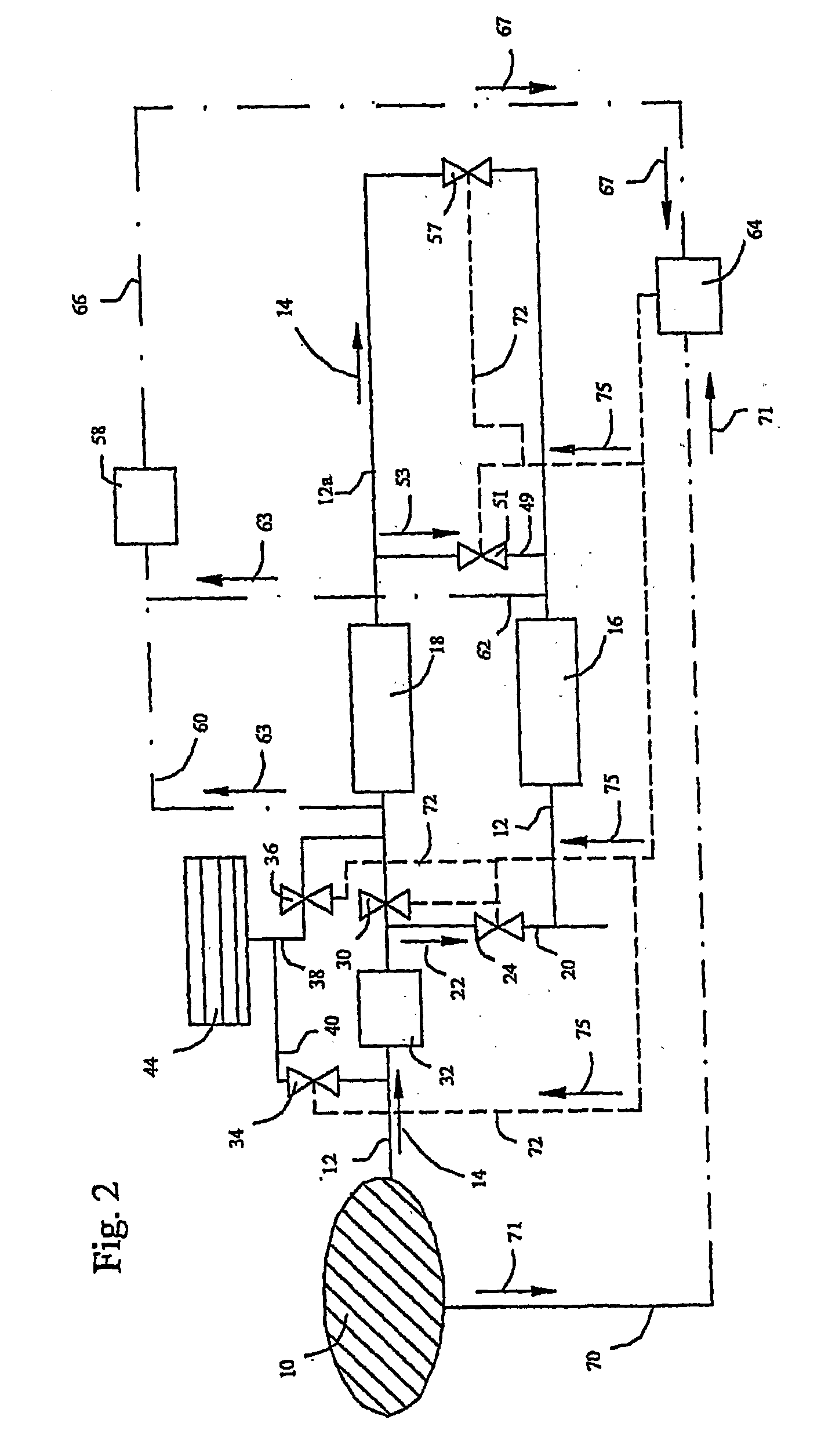

Temperature swing adsorption and selective catalytic reduction NOx removal system

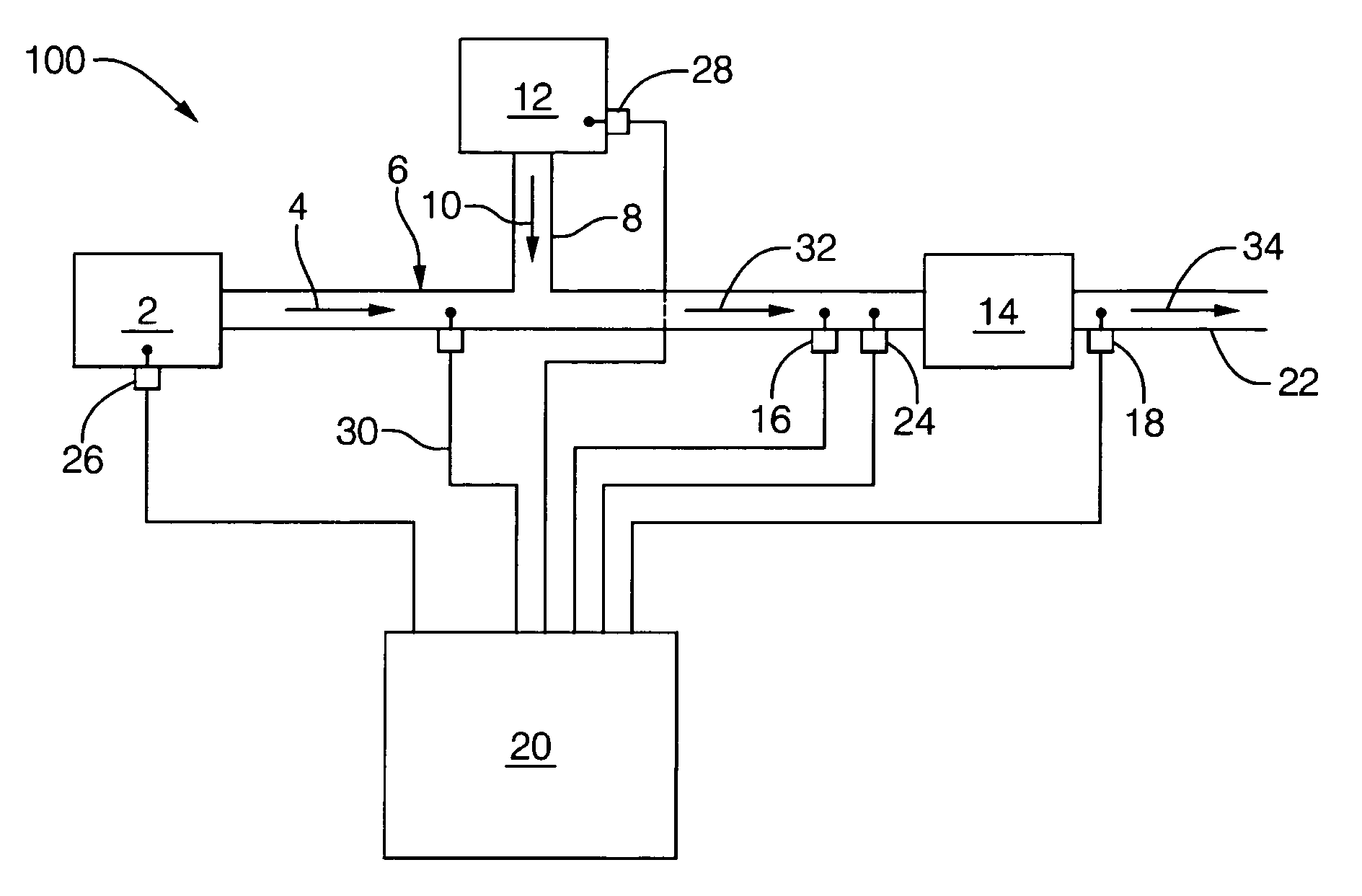

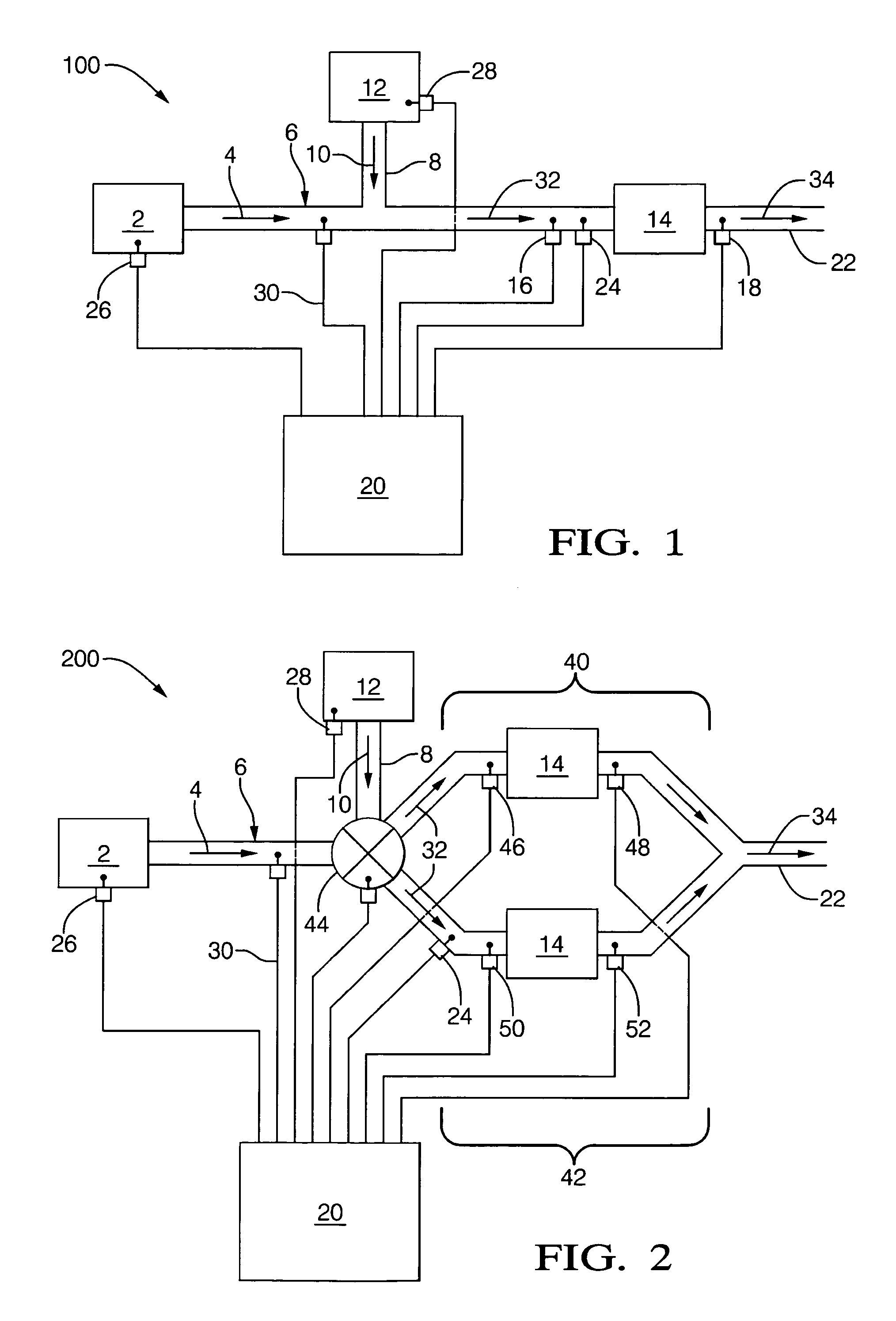

InactiveUS7117669B2Simpler and more replacedEasy to useMolecular sieve catalystsInternal combustion piston enginesSyngasDesorption

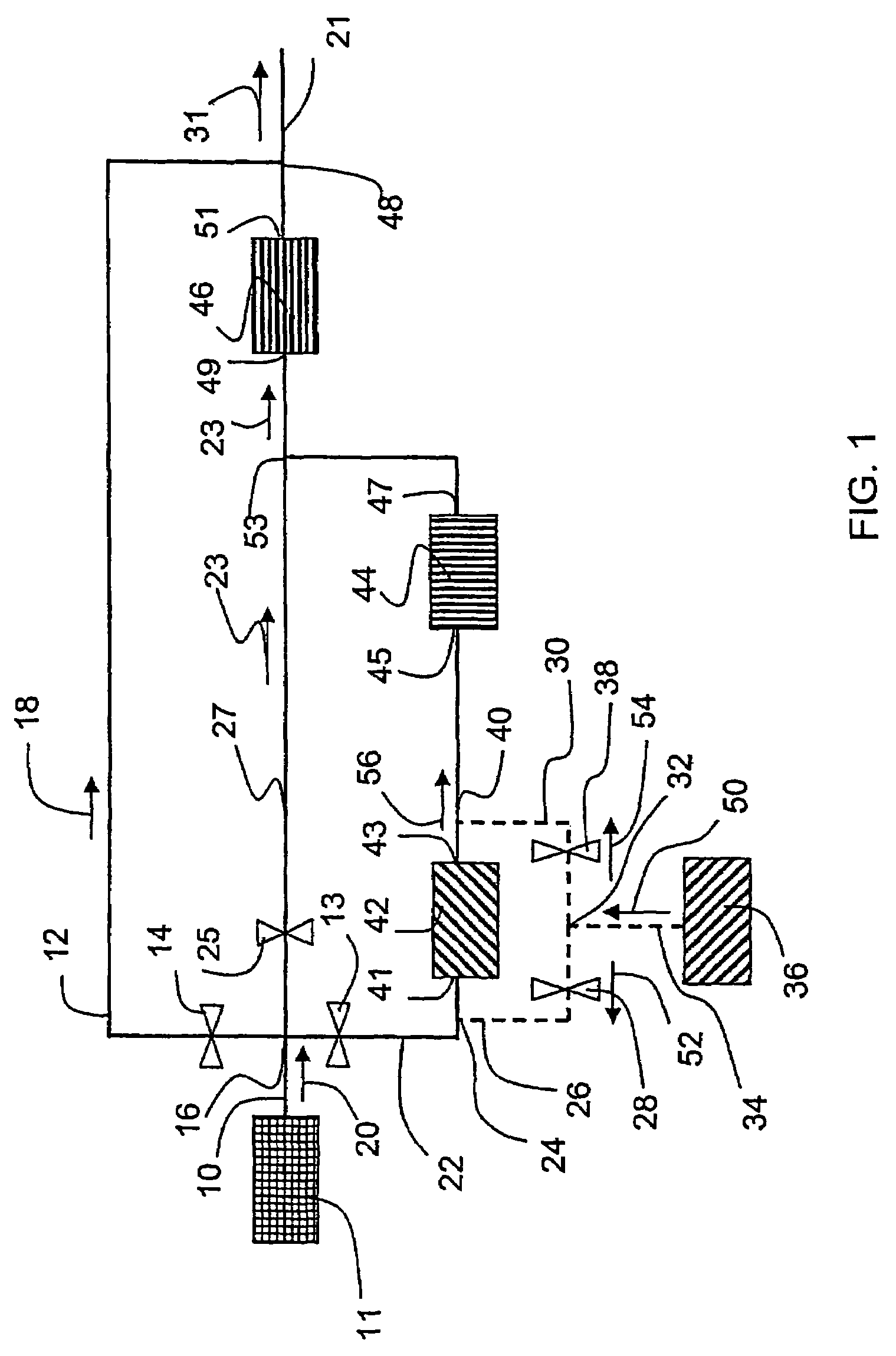

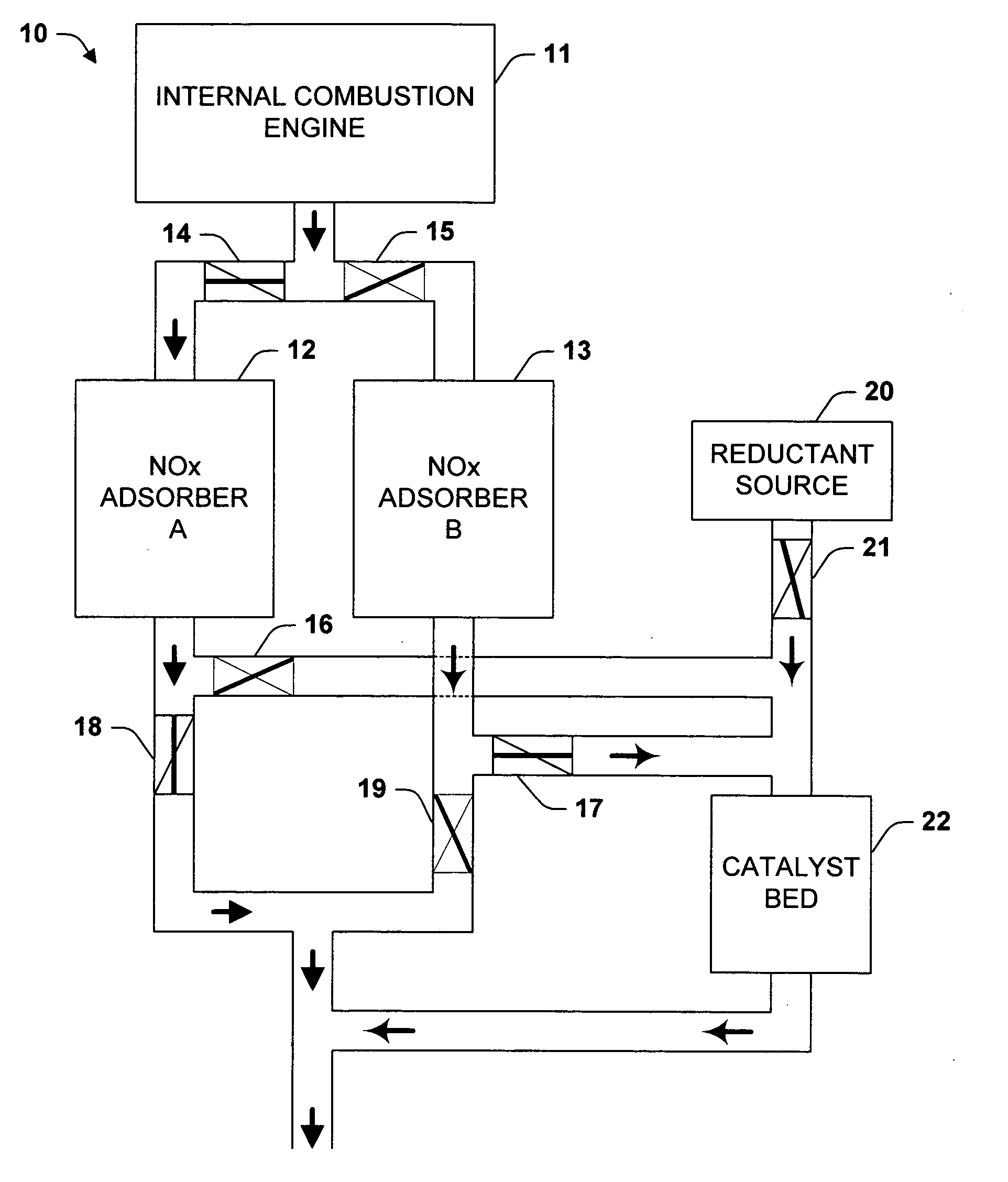

The invention relates to systems for removing NOx from exhaust. In one aspect of the invention, after adsorption, an NOx adsorber is isolated from the main exhaust flow and desorption induced by raising the temperature. The desorbed NOx is combined with a reductant and reduced over a catalyst. Preferably, the reductant is syn gas produced in an on-board reformer. The catalyst need never be exposed to the main exhaust flow, which is particularly advantageous for catalysts sensitive to water, oxygen, or sulfur. In another aspect of the invention, a recirculating flow is induced through an NOx adsorber during a regeneration cycle. Recirculation can induce greater desorption at a given temperature, provide a source of heat for the adsorber, and allow a higher conversion rate with a fixed amount of catalyst. A further aspect of the invention relates to a vehicle-mounted adsorbers with provisions for heating.

Owner:EATON CORP

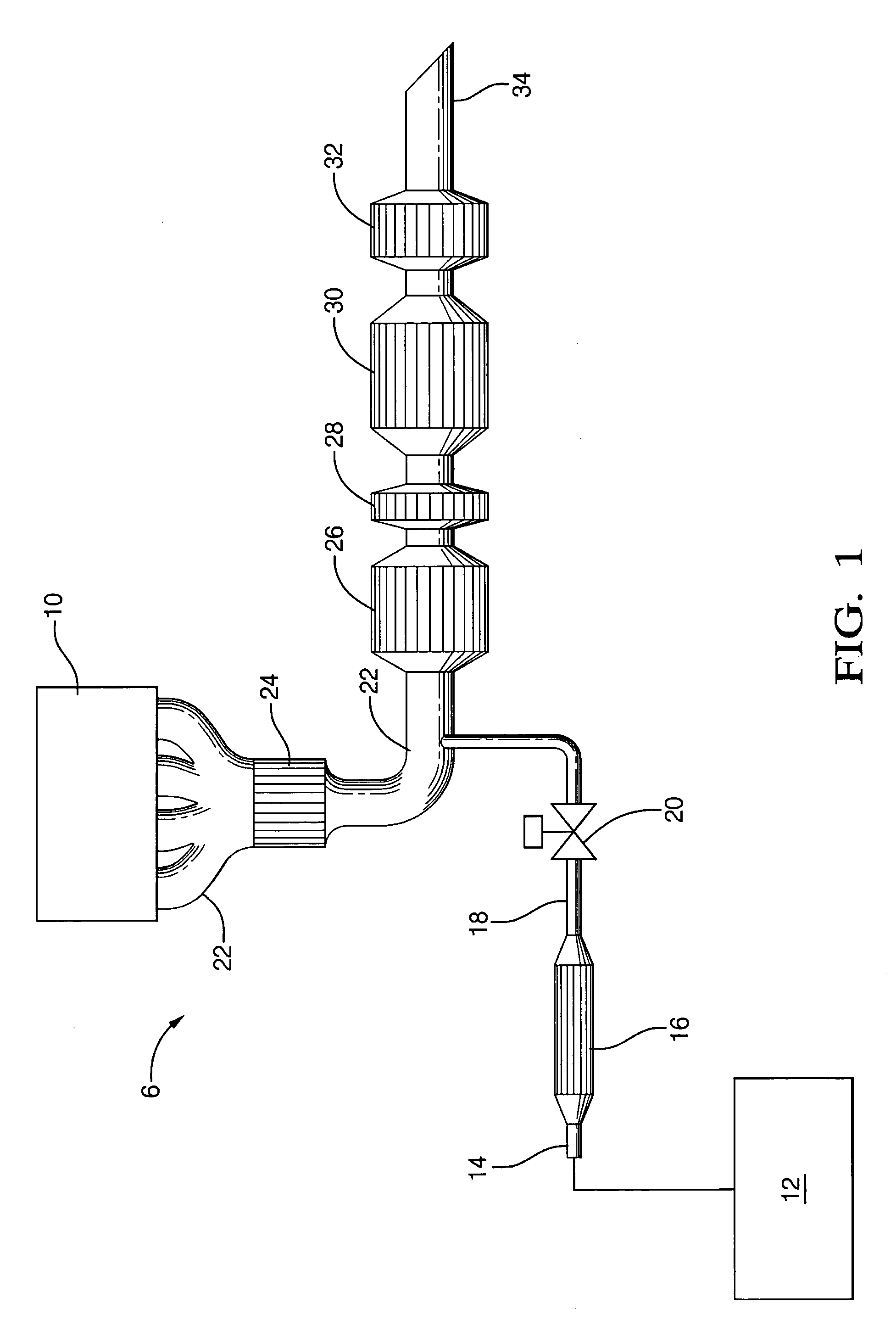

Exhaust system and method of thermal management

An exhaust system can comprise a NOx adsorber, a reformer disposed upstream of a NOx adsorber and in fluid communication with a fuel source, a first valve for controlling the introduction of the fluid to an exhaust conduit; and a particulate filter disposed upstream and in fluid communication with the NOx adsorber and downstream an in fluid communication with the reformer such that the first valve controls introduction of fluid to the exhaust conduit upstream of the particulate filter. The reformer can be designed to generate a fluid comprising sufficient thermal energy, hydrogen, and carbon monoxide. Optionally, the particulate filter can be designed to be regenerated by the thermal energy and to adsorb a sufficient amount of the thermal energy to reduce the temperature of a gas stream comprising the fluid from a first temperature of about 600° C. to about 1,000° C. to a second temperature of less than or equal to about 500° C.

Owner:DELPHI TECH INC

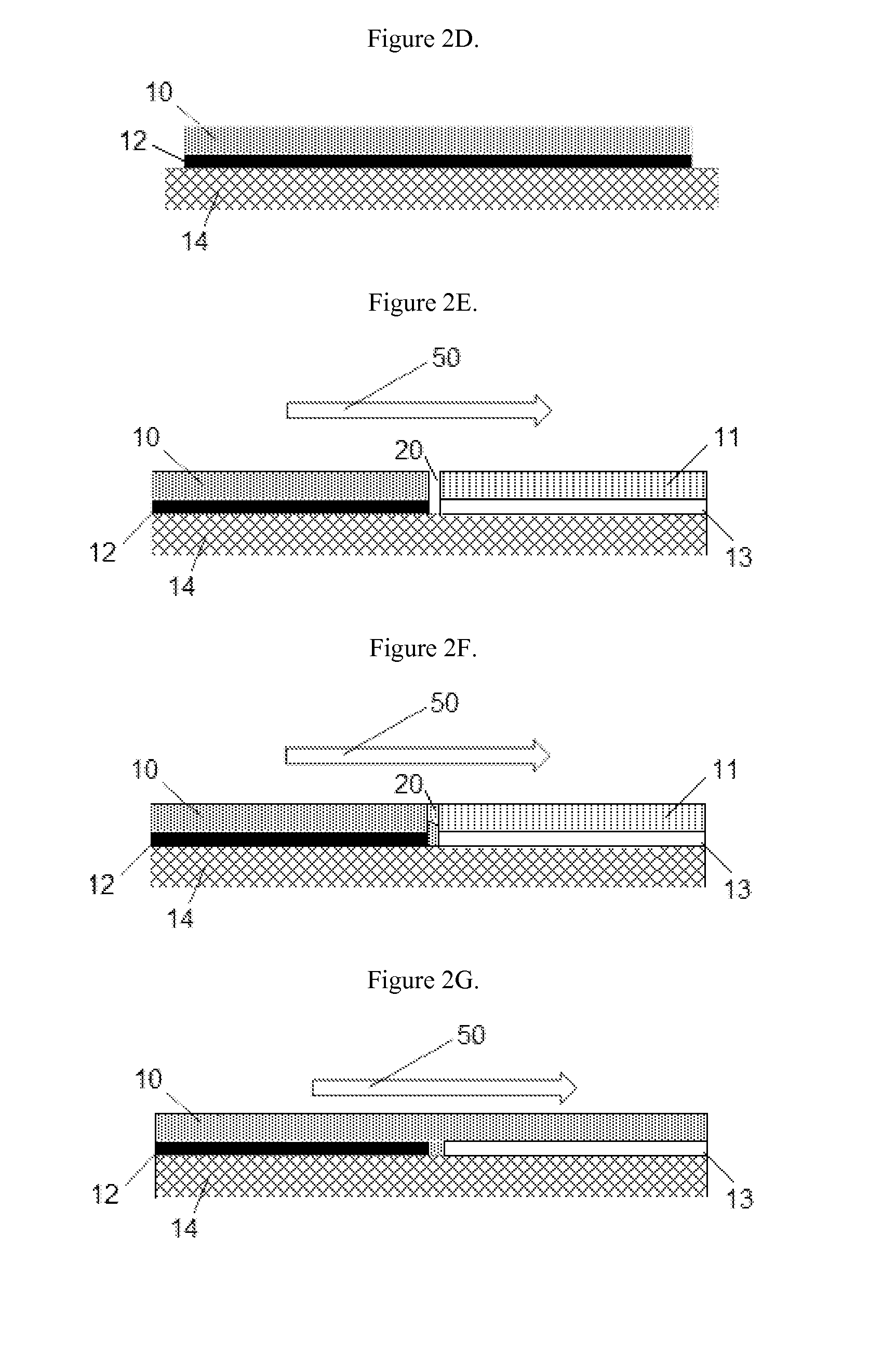

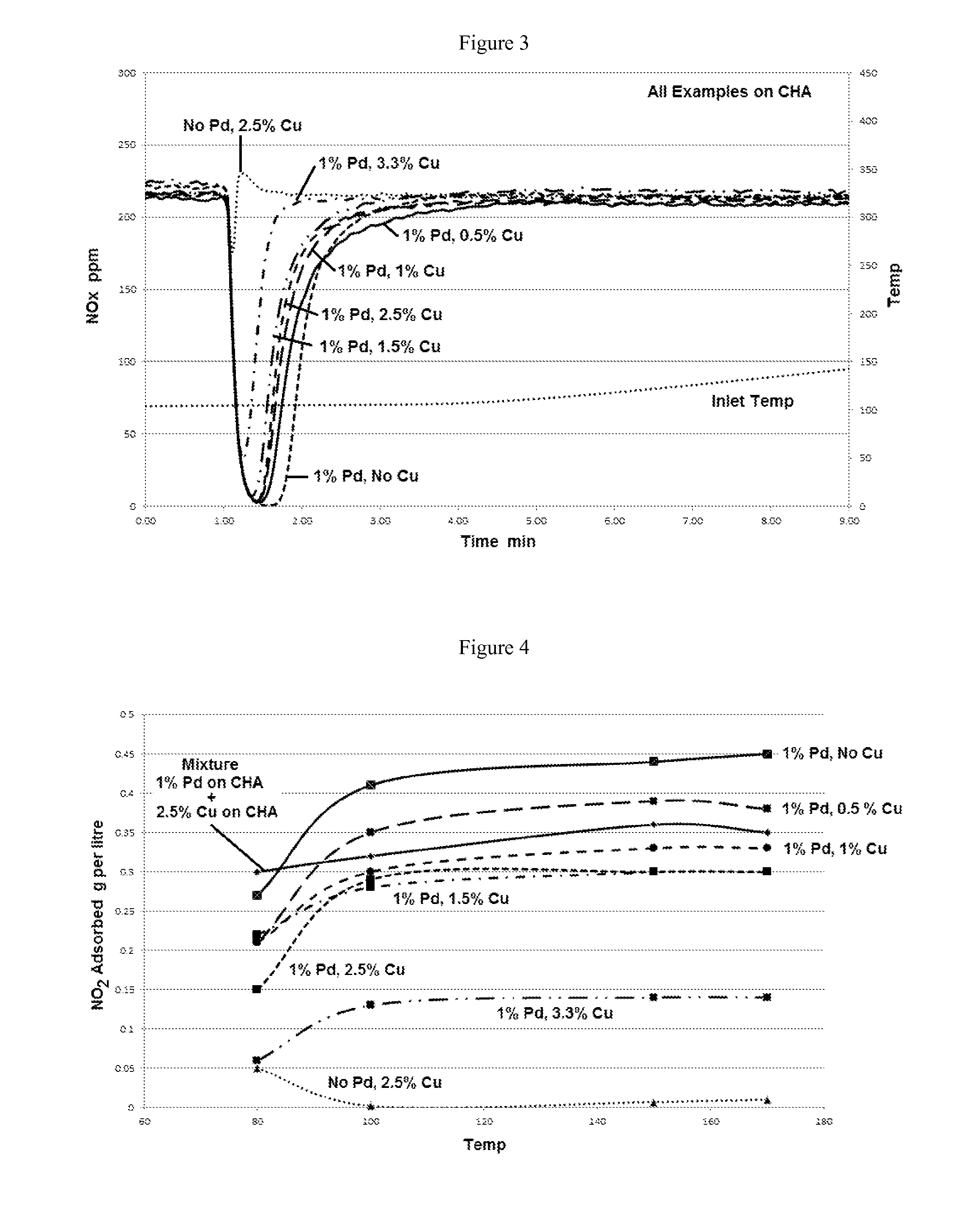

Combining SCR with PNA for Low Temperature Emission Control

ActiveUS20160136626A1Reduce the concentration of nitrogen oxidesReducing stored NOxCombination devicesGas treatmentMolecular sievePtru catalyst

A catalyst article comprises an SCR catalyst and a NOx adsorber catalyst, where each of these catalysts comprise a metal molecular sieve, each with a different metal. The catalyst article can be close coupled with other components to give a NOX performance advantage from cold start to a combined DOC and SCRF system. Higher NOX conversion is also shown in under-floor location due to NOx storage before SCR light off and selective NH3 slip control, allowing higher NH3 fill levels. Systems comprising the catalyst article and methods of using the catalyst article to give improved hydrocarbon and carbon monoxide control, as well as ammonia slip control, are described. The systems can include flow-through or wall-flow monoliths.

Owner:JOHNSON MATTHEY PLC

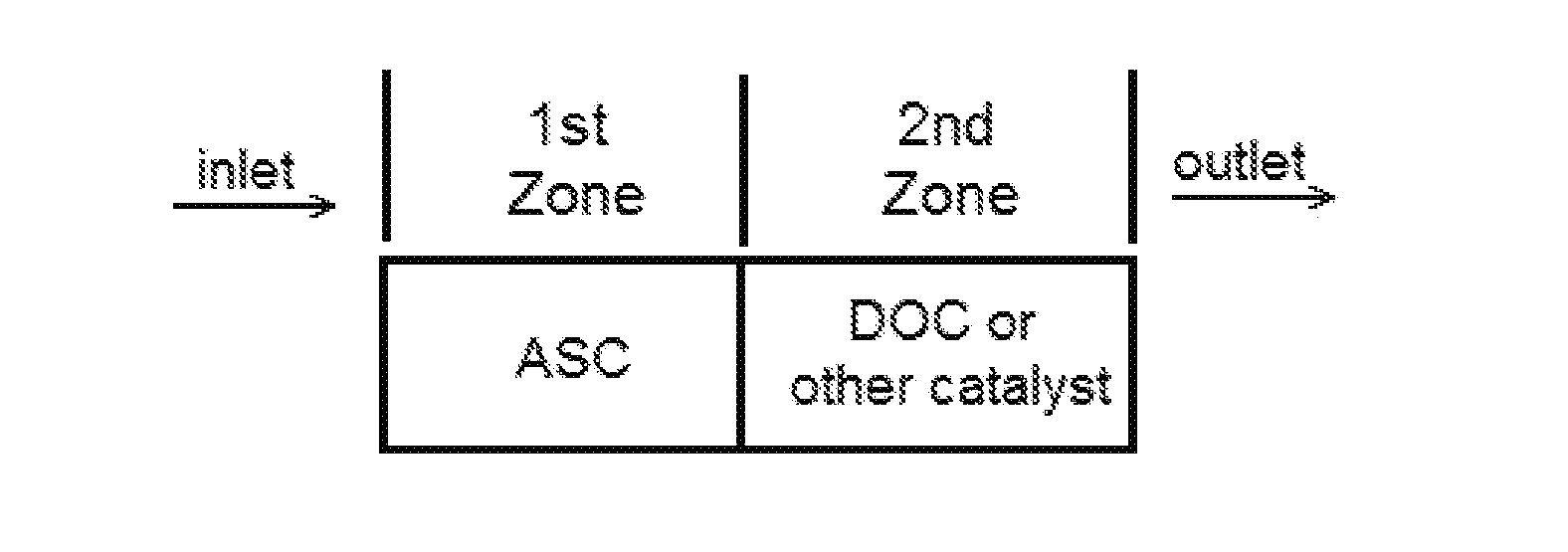

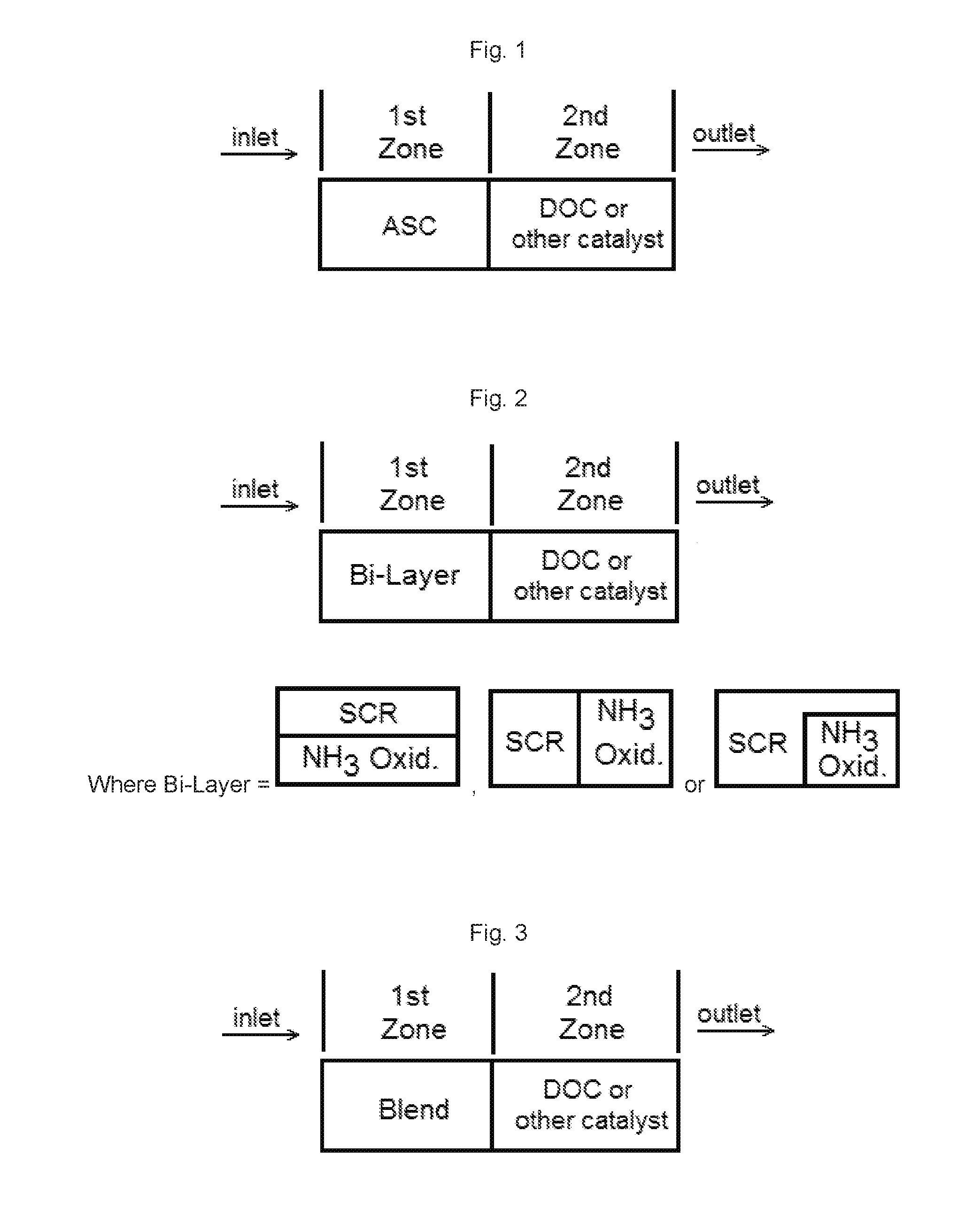

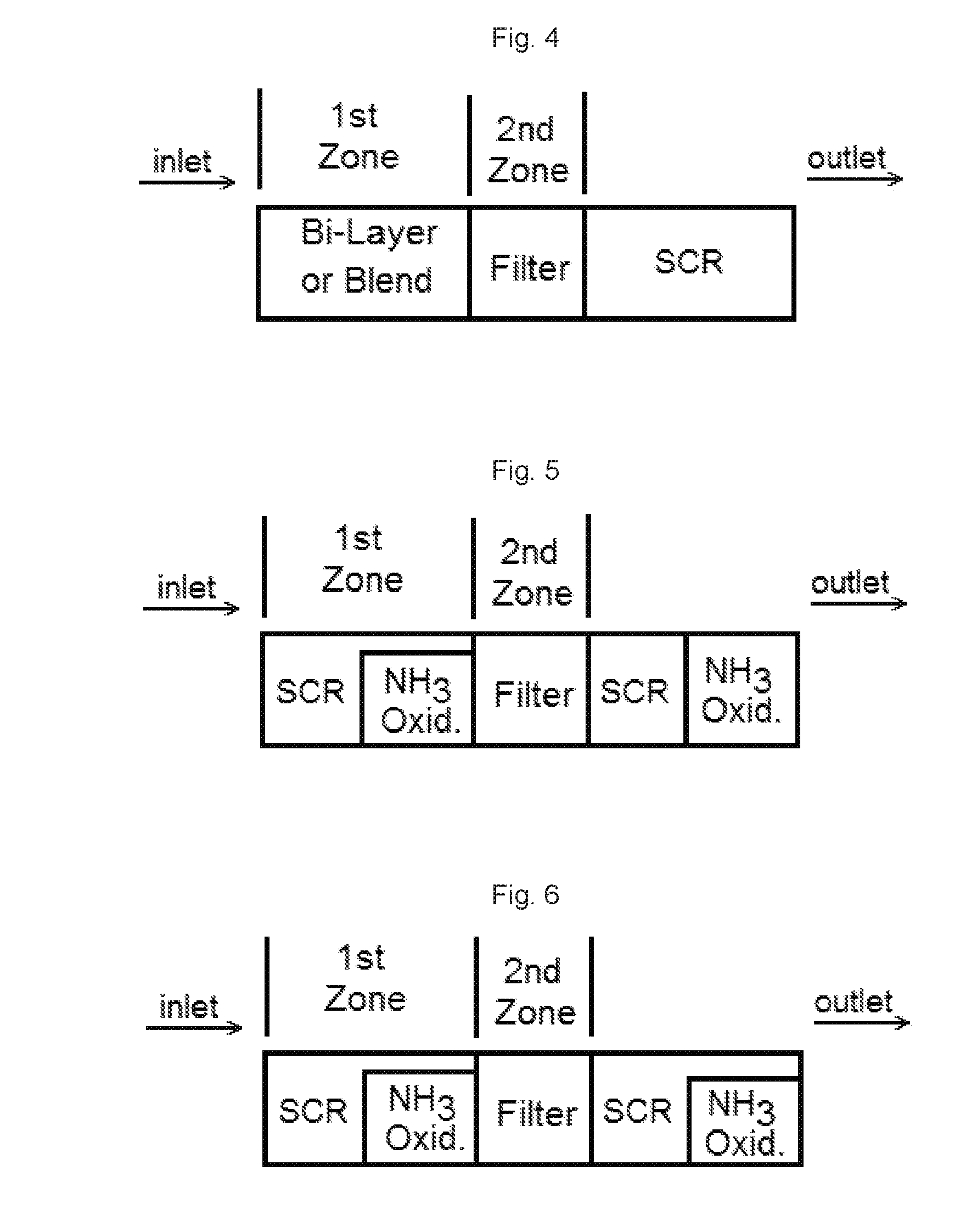

Ammonia slip catalyst designed to be first in an scr system

Catalyst articles having an ammonia slip catalyst (ASC) comprising a blend of platinum on a support with low ammonia storage and a first SCR catalyst, and a second catalyst, such as a diesel oxidation catalyst, a diesel exotherm catalyst (DEC), a NOx absorber, a selective catalytic reduction / passive NOx adsorber (SCR / PNA), a cold-start catalyst (CSC) or a three-way catalyst (TWC) are disclosed. The catalyst articles can also contain one or two additional SCR catalysts. The catalysts can be present in one of various configurations. The catalytic articles are useful for selective catalytic reduction (SCR) of NOx in exhaust gases and in reducing the amount of ammonia slip. Methods of using the catalytic articles in an SCR process, where the amount of ammonia slip is reduced, are also described.

Owner:JOHNSON MATTHEY PLC

Passive NOX adsorber

A passive NOx adsorber is disclosed. The passive NOx adsorber is effective to adsorb NOx at or below a low temperature and release the adsorbed NOx at temperatures above the low temperature. The passive NOx adsorber comprises a noble metal and a small pore molecular sieve. The small pore molecular sieve has a maximum ring size of eight tetrahedral atoms. The invention also includes an exhaust system comprising the passive NOx adsorber, and a method for treating exhaust gas from an internal combustion engine utilizing the passive NOx adsorber.

Owner:JOHNSON MATTHEY PLC

DIESEL OXIDATION CATALYST WITH NOx ADSORBER ACTIVITY

InactiveUS20150273452A1High activityReduction of NO<sub>xCombination devicesNitrogen compoundsPlatinumNitric oxide

An oxidation catalyst for treating an exhaust gas from a diesel engine and an exhaust system comprising the oxidation catalyst are described. The oxidation catalyst comprises: a first washcoat region for adsorbing NOx, wherein the first washcoat region comprises a zeolite catalyst, wherein the zeolite catalyst comprises a noble metal and a zeolite; a second washcoat region for oxidising nitric oxide (NO), wherein the second washcoat region comprises platinum (Pt) and a support material; and a substrate having an inlet end and an outlet end.

Owner:JOHNSON MATTHEY PLC

System and method of NOx abatement

A NOX abatement system includes a first NOX adsorber capable of being disposed in-line and downstream of and in fluid communication with an engine. The NOX abatement system further includes a selective catalytic reduction catalyst disposed in-line and downstream of, and in direct fluid communication with, the first NOX adsorber. The selective catalytic reduction catalyst is capable of storing ammonia. An off-line reformer is disposed in selective communication with and upstream of the first NOX adsorber and the selective catalytic reduction catalyst. The reformer is capable of producing a reformate that includes primarily hydrogen and carbon monoxide.

Owner:DELPHI TECH INC

Method and apparatus for regenerating NOx adsorbers

Owner:WESTPORT POWER

NOx adsorber and method of regenerating same

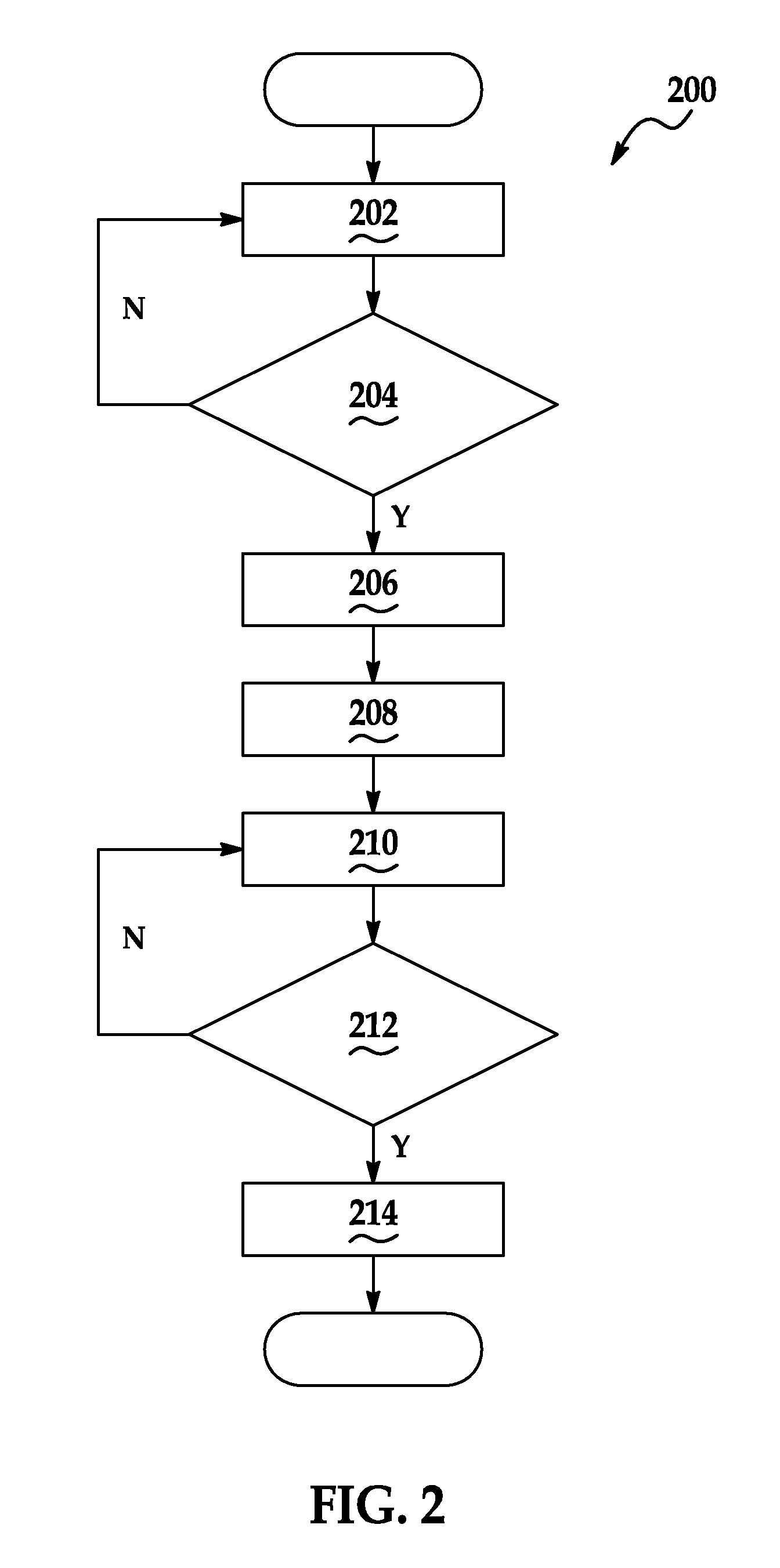

New technologies, such as NOx adsorber catalytic converters, are being used to meet increasingly stringent regulations on undesirable emissions, including NOx emissions. NOx adsorbers must be periodically regenerated, which requires an increased fuel consumption. The present disclosure includes a method of regenerating a NOx adsorber within a NOx adsorber catalytic converter. At least one sensor positioned downstream from the NOx adsorber senses, in the downstream exhaust, at least one of NOx, nitrous oxide and ammonia concentrations a plurality of times during a regeneration phase. The sensor is in communication with an electronic control module that includes a regeneration monitoring algorithm operable to end the regeneration phase when a time rate of change of the at least one of NOx, nitrous oxide and ammonia concentrations is after an expected plateau region begins.

Owner:CATERPILLAR INC

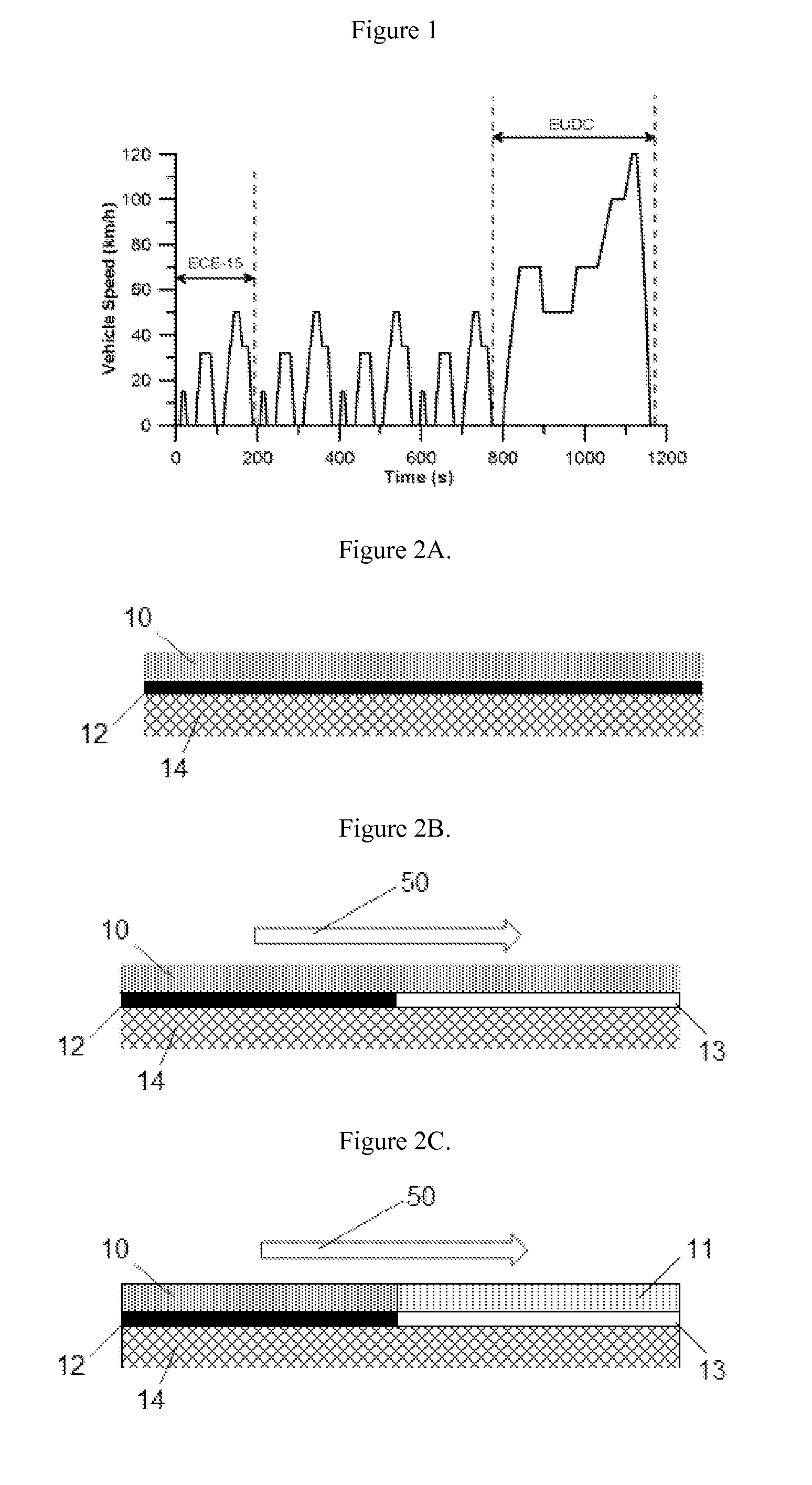

LNT regeneration strategy over normal truck driving cycle

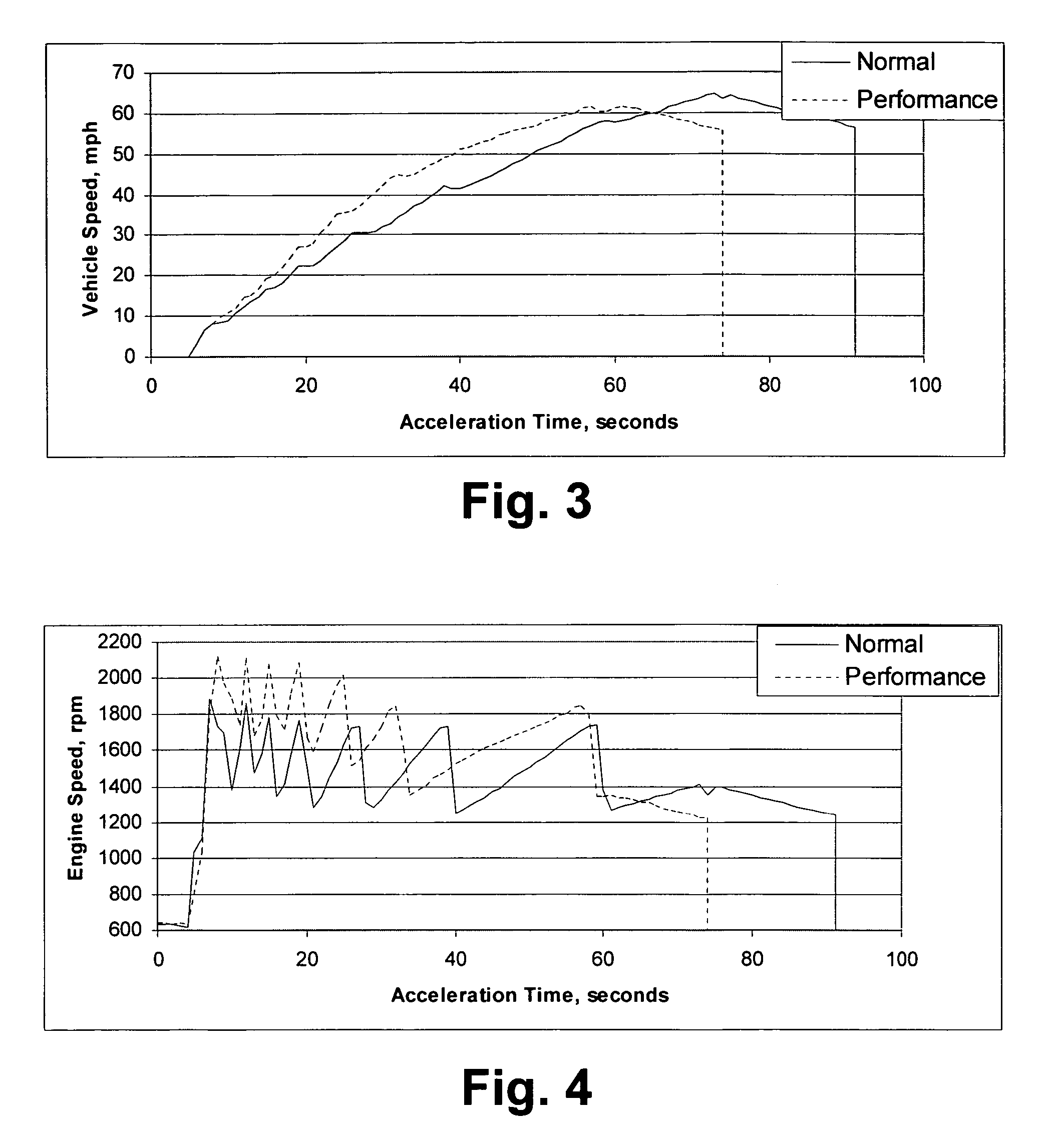

InactiveUS20060277898A1Reduce fuel penaltyReduce the fuel penaltyElectrical controlInternal combustion piston enginesTruckDiesel engine

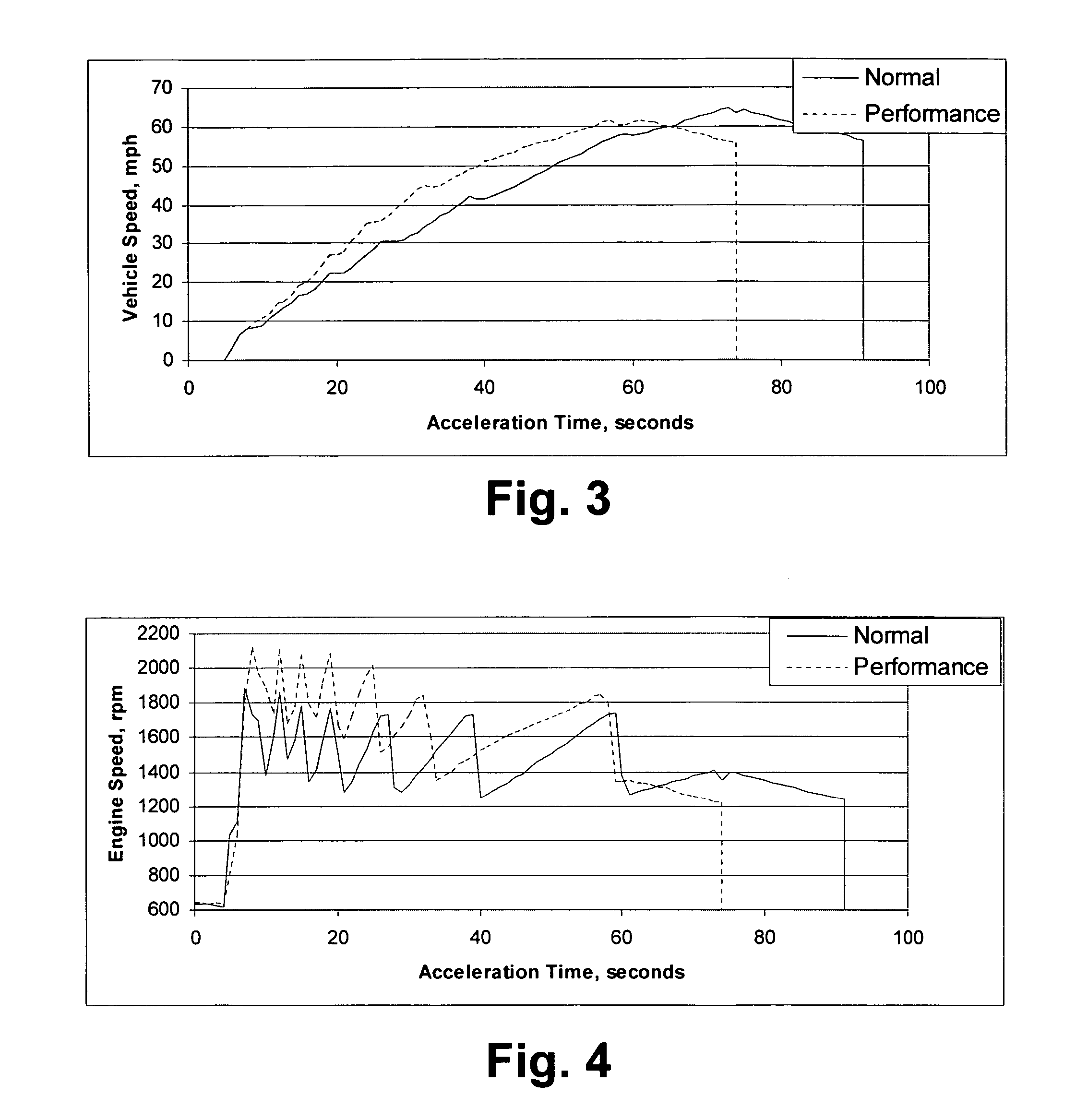

Partial denitrations are made practical by an SCR catalyst placed downstream of a NOx adsorber. The SCR catalyst permits partial denitrations to be extended to where a favorable fuel penalty rate presented by driving conditions can be utilized to a sufficient extent that the benefit of the favorable conditions is not offset by the increased start-up fuel penalty associated with conducting opportunistic partial denitrations. Regenerations, including both denitration and desulfations, can be initiated selectively based on a fuel penalty calculation. Examples of such calculations lead to methods in which opportunistic regenerations are based on low oxygen concentrations, condition existing while shifting gears, and throttling events for a diesel engine with a throttled air supply. The methods flexibly take advantage of driving conditions to reduce fuel penalties associated with regenerations. In one embodiment, driving conditions include future conditions predicted based on GPS and map data.

Owner:INT ENGINE INTPROP CO LLC

Hybrid catalyst system for exhaust emissions reduction

InactiveUS20070033928A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

Nitrogen oxide adsorbent prepared through ion exchange modification of natural zeolite

InactiveCN102049239AReduce manufacturing costLarge adsorption capacityOther chemical processesAluminium silicatesMetal ions in aqueous solutionSorbent

The invention relates to the modification technology of natural zeolite material and aims to provide a nitrogen oxide adsorbent prepared through ion exchange modification of the natural zeolite. The adsorbent is prepared through the following step: adding the natural zeolite after dealumnization processing and ammonium exchange processing into metal salt aqueous solution to be subjected to metal ion exchange; and washing, drying and then roasting at the high temperature of 300-600 DEG C for 1-5 hours to obtain the nitrogen oxide adsorbent of modified natural zeolite containing corresponding metal elements, wherein the metal salt is any one of hydrochloride, nitrate, sulfate or oxalate of Na, Ca, K, Ba, Ti, Mn, Ni or Cu. The nitrogen oxide adsorbent prepared through modification of the natural zeolite can be used as an environment function material for adsorbing and purifying the industrial tail gas, flue gas and automobile exhaust containing nitrogen oxide. The nitrogen oxide adsorbent is low in production cost and large in adsorption quantity, and has a broad market prospect as the environment function material.

Owner:ZHEJIANG UNIV

LNT regeneration strategy over normal truck driving cycle

InactiveUS7685813B2Reduce the fuel penaltyImprove fuel economyElectrical controlInternal combustion piston enginesTruckDiesel engine

Partial denitrations are made practical by an SCR catalyst placed downstream of a NOx adsorber. The SCR catalyst permits partial denitrations to be extended to where a favorable fuel penalty rate presented by driving conditions can be utilized to a sufficient extent that the benefit of the favorable conditions is not offset by the increased start-up fuel penalty associated with conducting opportunistic partial denitrations. Regenerations, including both denitration and desulfations, can be initiated selectively based on a fuel penalty calculation. Examples of such calculations lead to methods in which opportunistic regenerations are based on low oxygen concentrations, condition existing while shifting gears, and throttling events for a diesel engine with a throttled air supply. The methods flexibly take advantage of driving conditions to reduce fuel penalties associated with regenerations. In one embodiment, driving conditions include future conditions predicted based on GPS and map data.

Owner:INT ENGINE INTPROP CO LLC

Electronically Heated NOx Adsorber Catalyst

InactiveUS20130111886A1Internal combustion piston enginesExhaust apparatusSorbentProcess engineering

An exhaust gas treatment system for an internal combustion engine is provided, and includes an exhaust gas conduit, an upstream selective catalytic reduction (“SCR”) device, an electrically heated catalyst (“EHC”) device, an oxidation catalyst (“OC”) device, a downstream SCR device, and a control module. The EHC device is in fluid communication with the exhaust gas conduit and is configured to receive the exhaust gas. The EHC device is located downstream of the upstream SCR device and is selectively activated to produce heat. The OC device is in fluid communication with the exhaust gas conduit, and is selectively heated by the EHC device. At least one of the EHC device and the OC device have a NOx adsorber catalyst disposed thereon for selectively adsorbing NOx below a threshold temperature and substantially releasing NOx above the threshold temperature.

Owner:GM GLOBAL TECH OPERATIONS LLC

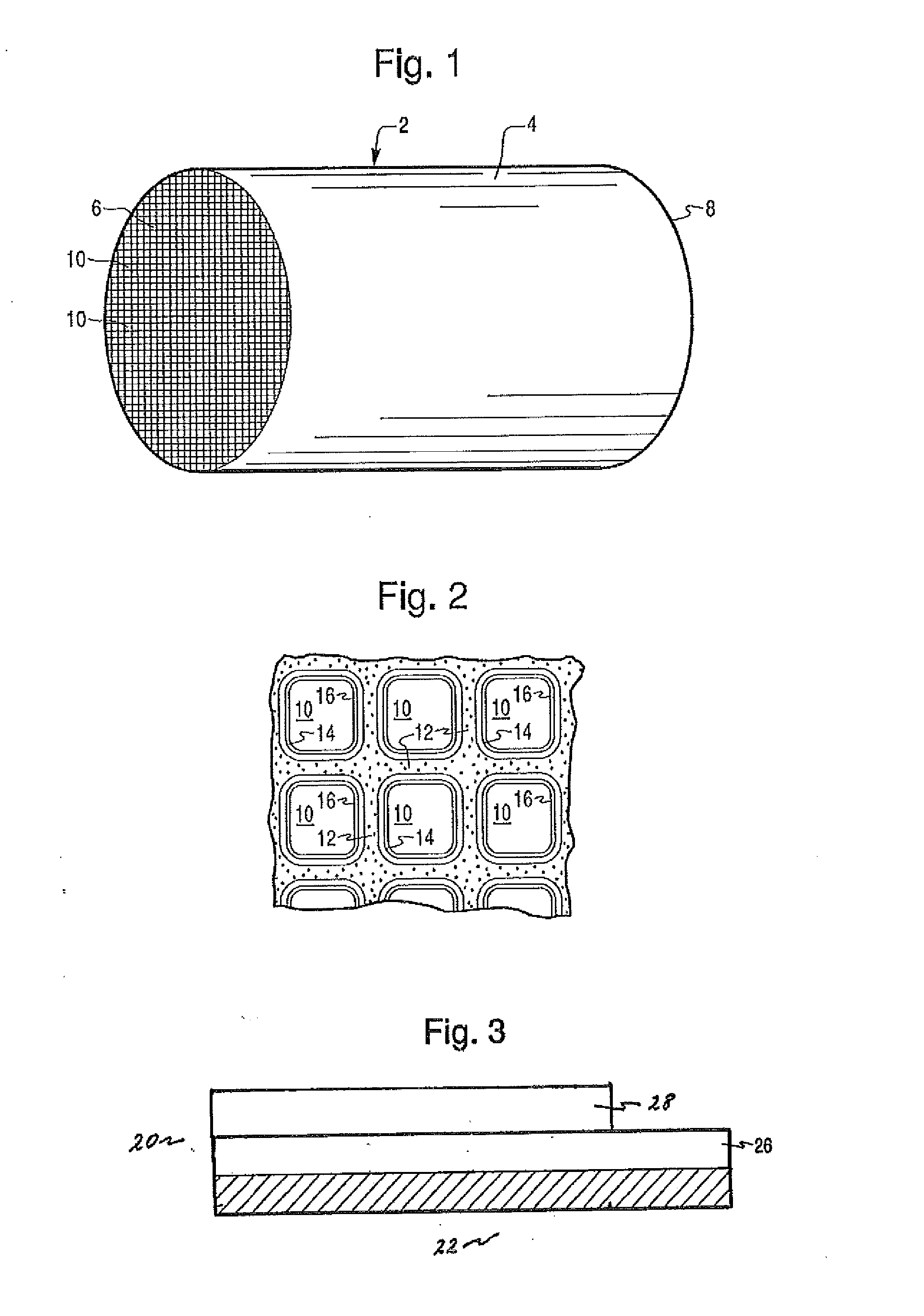

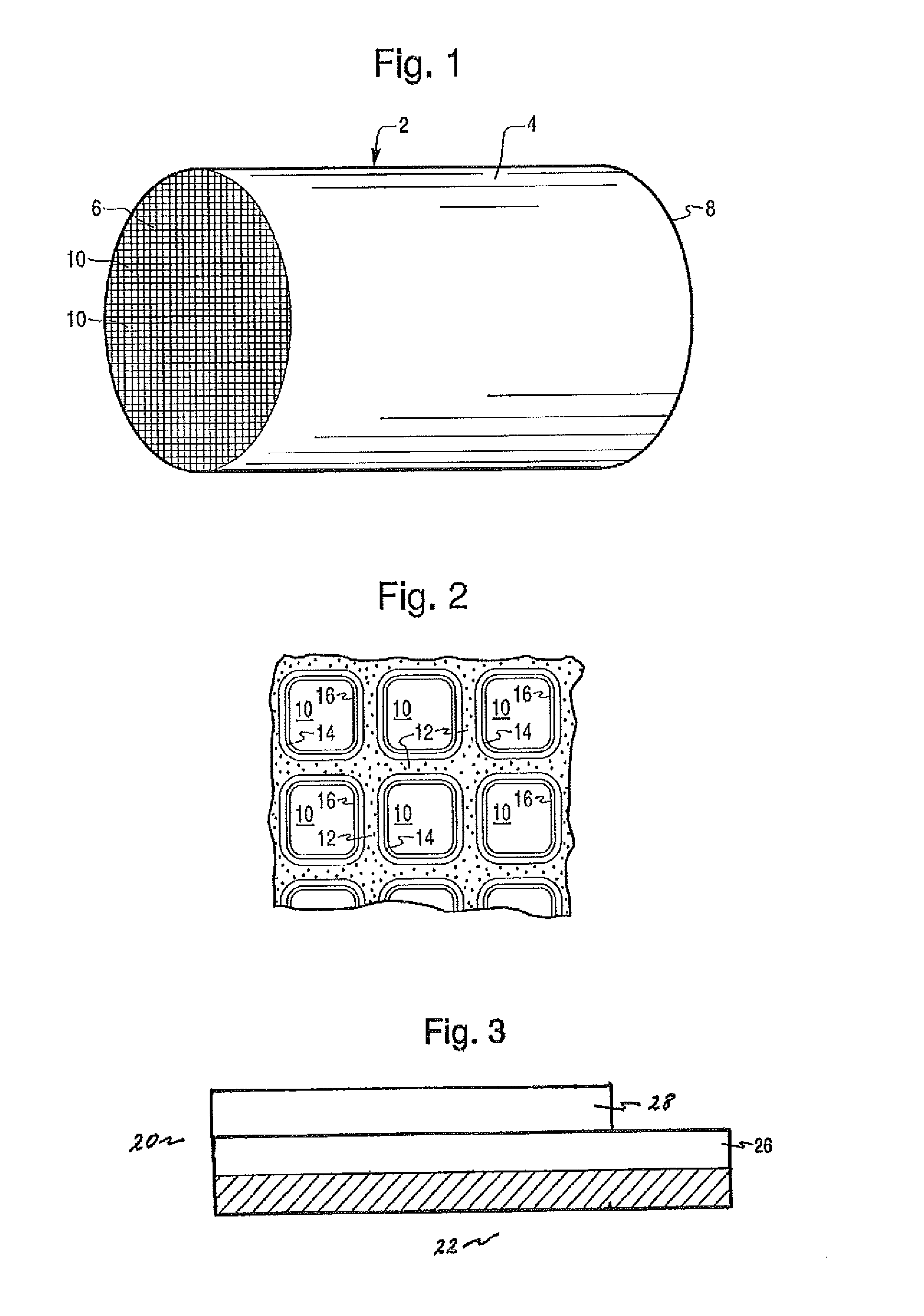

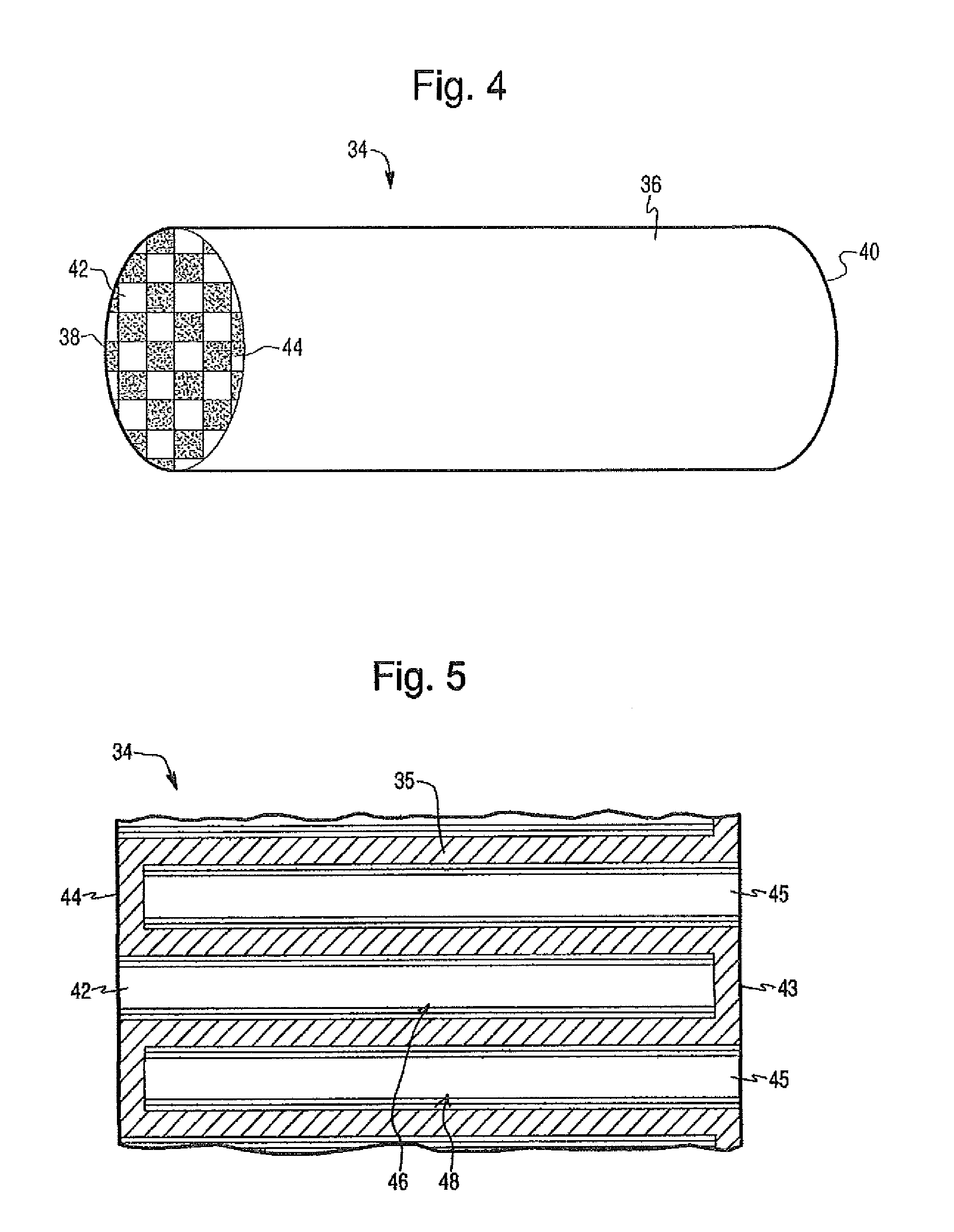

Catalyst support

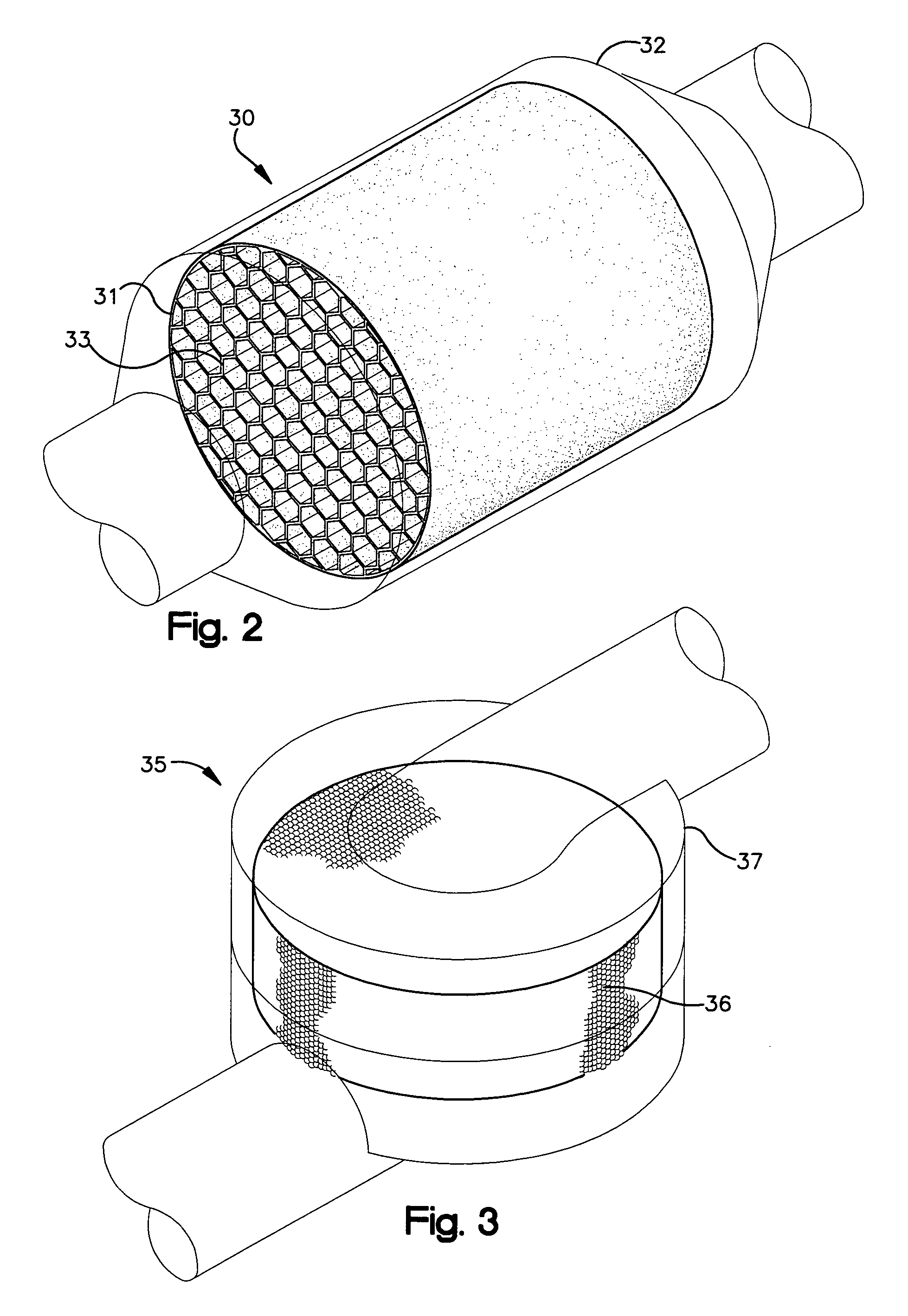

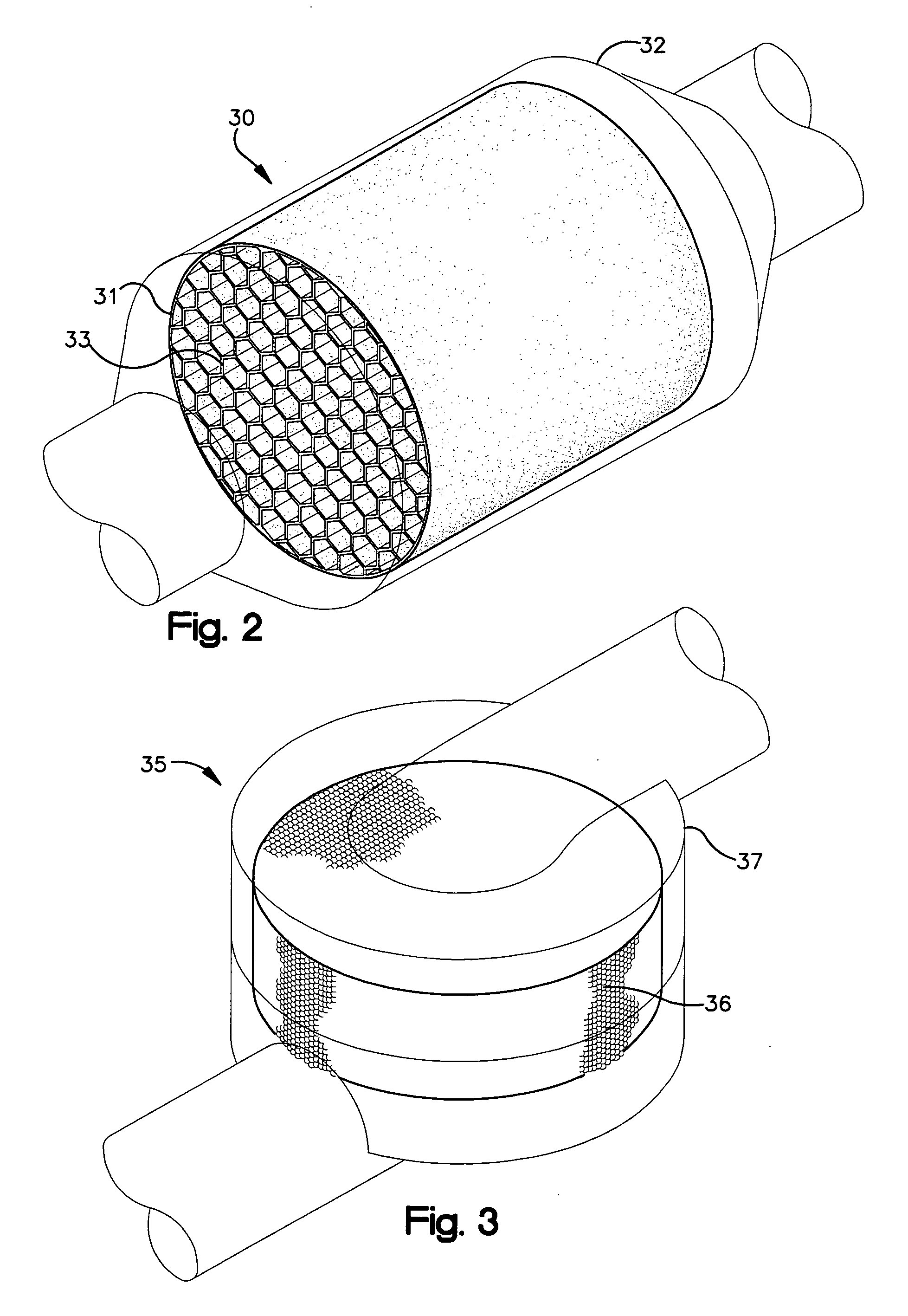

InactiveUS20040152593A1High porosityImprove carrying capacitySilencing apparatusMachines/enginesMicrometerHoneycomb

A catalyst support for use in technologies (i.e., SCR and NOx adsorbers) which address the reduction of NOx from exhaust emissions of diesel and GDI engines. The catalyst support has a honeycomb body composed of a porous ceramic material, and a plurality of parallel cell channels traversing the body from a frontal inlet end to an outlet end thereof. The porous ceramic material is defined by a total porosity greater than 45 vol. %, and a network of interconnected pores with a narrow pore size distribution of pores having a median pore size greater than 5 micrometers but less than 20 micrometers. The catalyst support is capable of attaining higher catalyst loadings without a pressure drop penalty.

Owner:CORNING INC

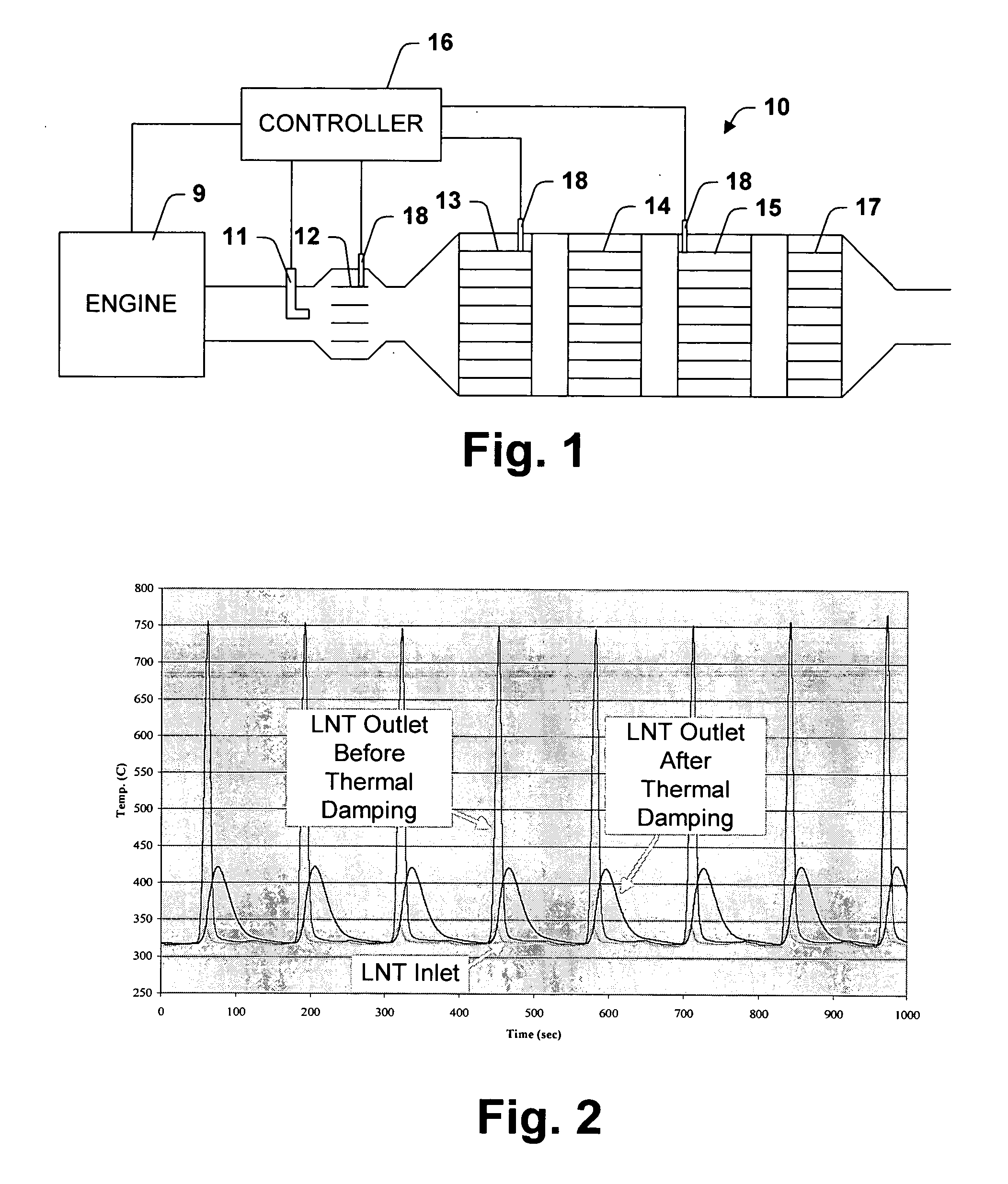

Thermal management of hybrid LNT/SCR aftertreatment during desulfation

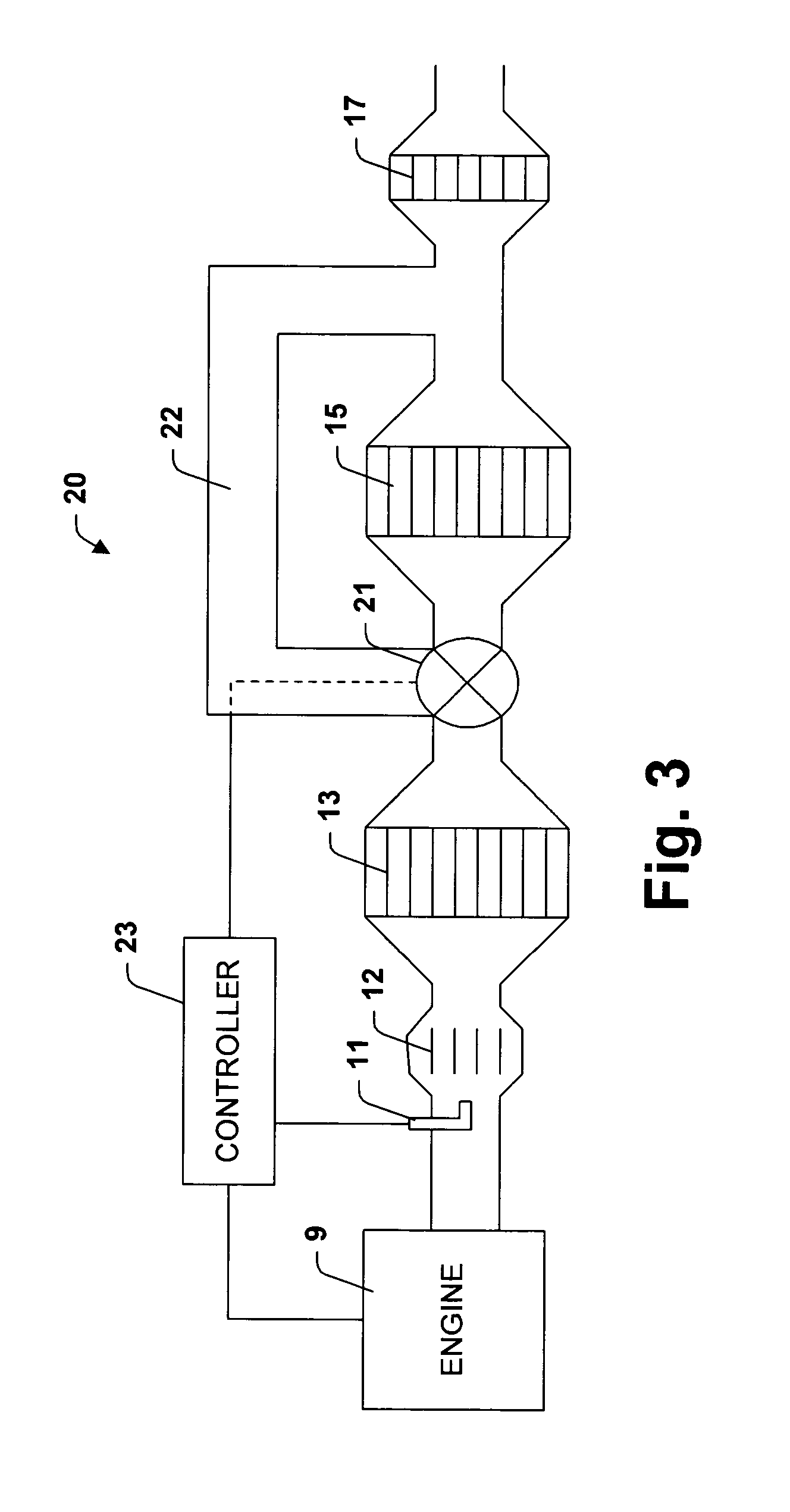

ActiveUS7251929B2Avoid heatLow peakingGas treatmentInternal combustion piston enginesExhaust fumesEngineering

In an exhaust aftertreatment system comprising a NOx adsorber-catalyst followed by an SCR catalyst, means are provided for preventing the SCR catalyst from becoming heated to near the same peak temperatures as the NOx adsorber-catalyst during desulfation. In one embodiment, the means is a thermal mass between the NOx adsorber-catalyst and the SCR catalyst. In another embodiment, the means is a valve configured to selectively divert exhaust leaving the NOx adsorber-catalyst from the SCR catalyst. In a method of the invention, the NOx adsorber-catalyst temperature is cycled during desulfation. The peaks of the cycles are within an appropriate temperature range for desulfating the NOx adsorber-catalyst, but the average temperature is below the temperature range at which the SCR catalyst is damaged. The temperature peaks are damped as they travel from the NOx adsorber-catalyst to the SCR, whereby the SCR experiences much lower peak temperatures than the NOx adsorber-catalyst.

Owner:INT ENGINE INTPROP CO LLC

Temperature swing adsorption and selective catalytic reduction NOx removal system

InactiveUS20050247049A1Simpler and more replacedEasy to useInternal combustion piston enginesExhaust apparatusSyngasDesorption

The invention relates to systems for removing NOx from exhaust. In one aspect of the invention, after adsorption, an NOx adsorber is isolated from the main exhaust flow and desorption induced by raising the temperature. The desorbed NOx is combined with a reductant and reduced over a catalyst. Preferably, the reductant is syn gas produced in an on-board reformer. The catalyst need never be exposed to the main exhaust flow, which is particularly advantageous for catalysts sensitive to water, oxygen, or sulfur. In another aspect of the invention, a recirculating flow is induced through an NOx adsorber during a regeneration cycle. Recirculation can induce greater desorption at a given temperature, provide a source of heat for the adsorber, and allow a higher conversion rate with a fixed amount of catalyst. A further aspect of the invention relates to a vehicle-mounted adsorbers with provisions for heating.

Owner:EATON CORP

NOx adsorber aftertreatment system for internal combustion engines

InactiveUS7117667B2More surface areaMore time areaCombination devicesInternal combustion piston enginesCombustionExhaust fumes

The present invention provides for an NOx adsorber aftertreatment system for internal combustion engines which utilizes a parallel arrangement of an adsorber catalyst and a bypass. The exhaust flow from the engine is routed through the adsorber during lean operation. At a predetermined regeneration time (for example, when the adsorber catalyst is 20% full), the exhaust gas flow is reduced through the parallel leg that contains the adsorber catalyst to be regenerated (e.g., 20% through the catalyst leg, 80% of the flow to the bypass leg). A quantity of hydrocarbon is injected into the reduced-flow catalyst leg in order to make the mixture rich. Since the flow has been reduced in this leg, only a small fraction of the amount of hydrocarbon that would have been required to make the mixture rich during full flow is required. This will result in a substantial reduction in the fuel penalty incurred for regeneration of the adsorber catalyst. Once the leg has been regenerated, the exhaust flow is switched to flow 100% through the adsorber leg.

Owner:CUMMINS FILTRATION INC

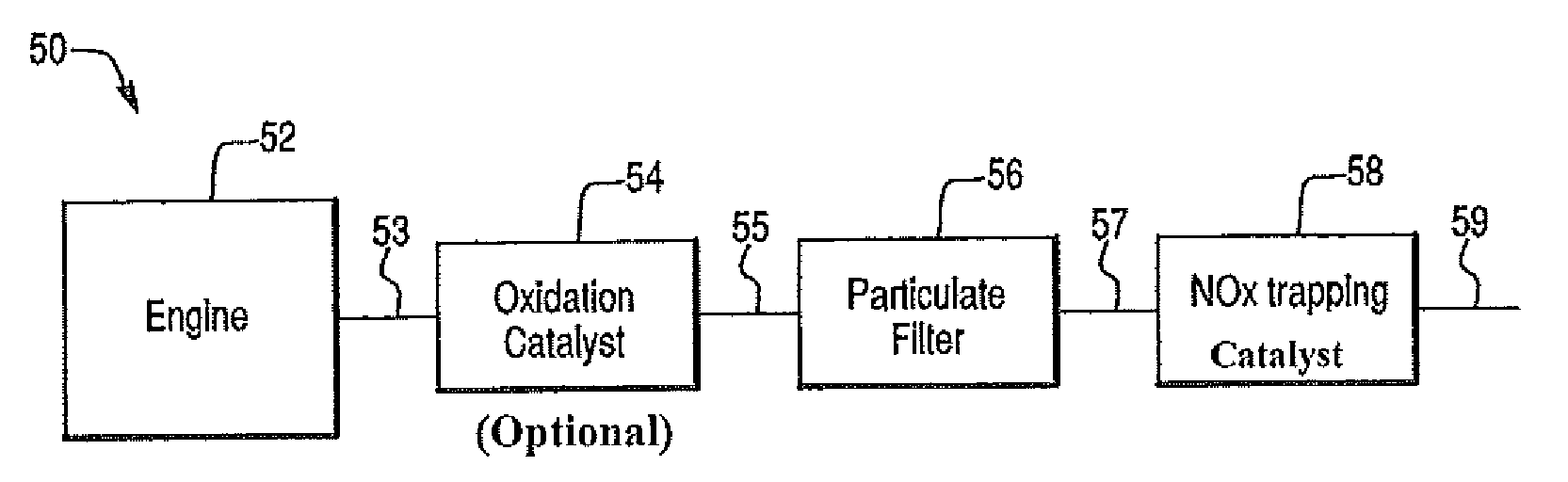

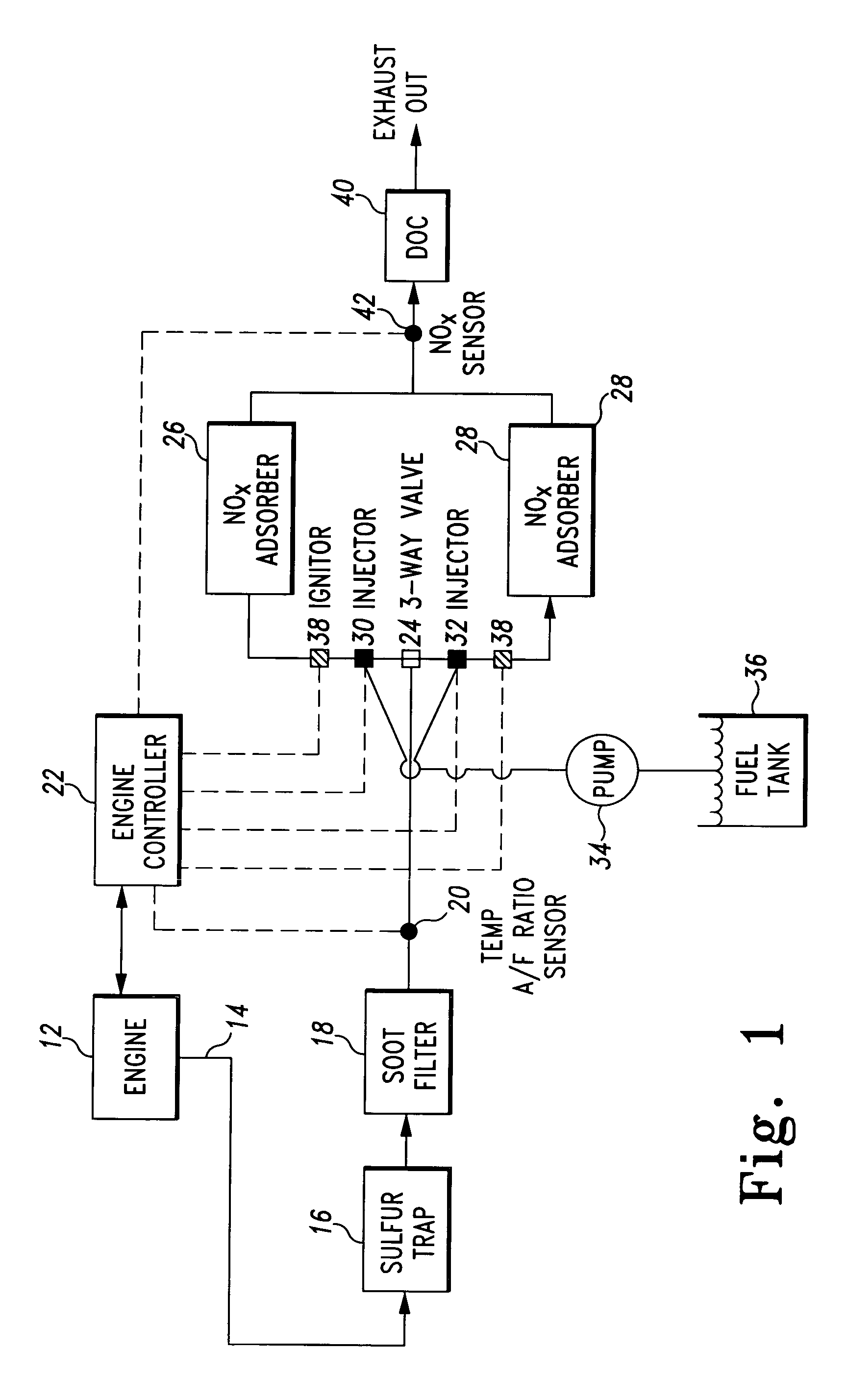

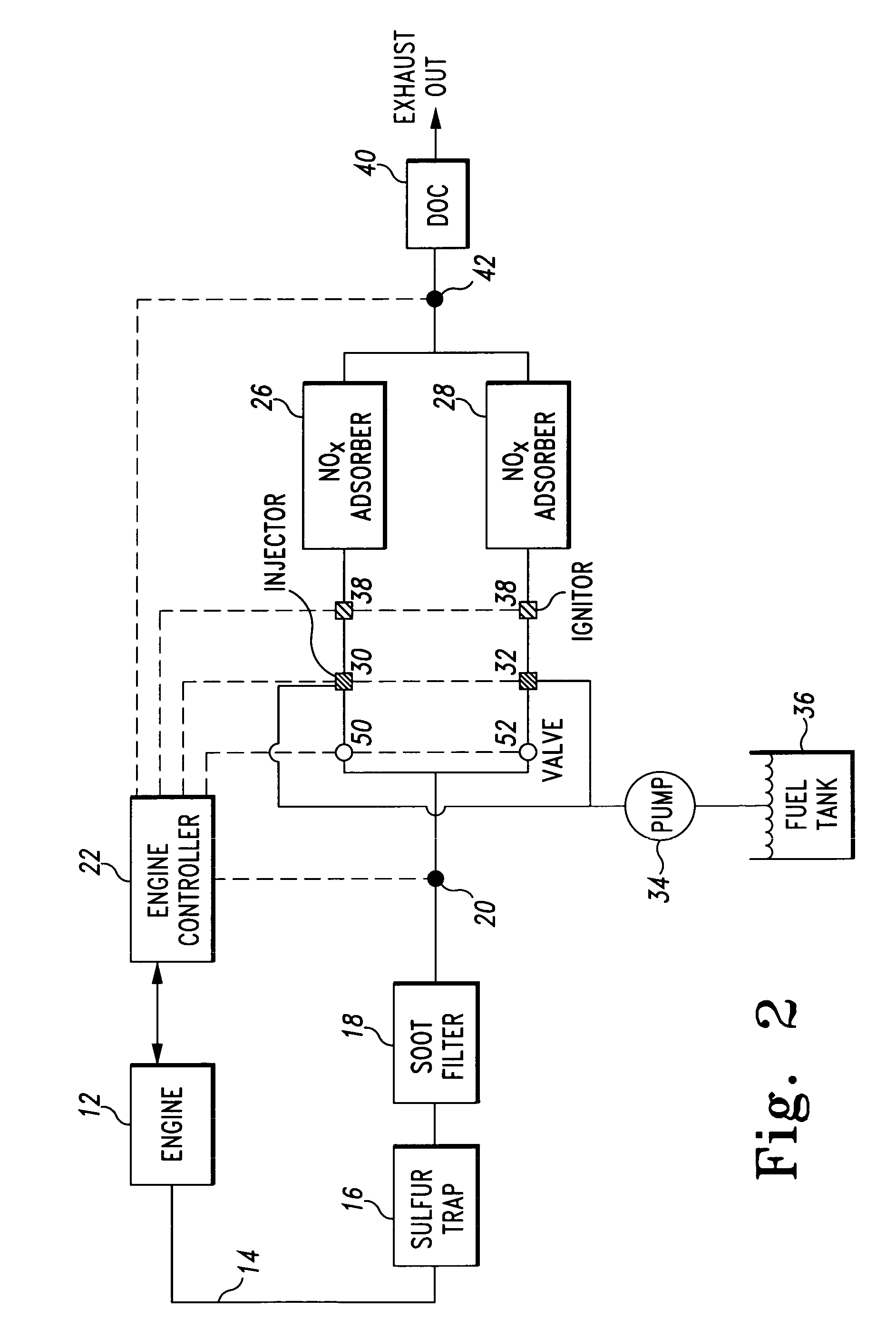

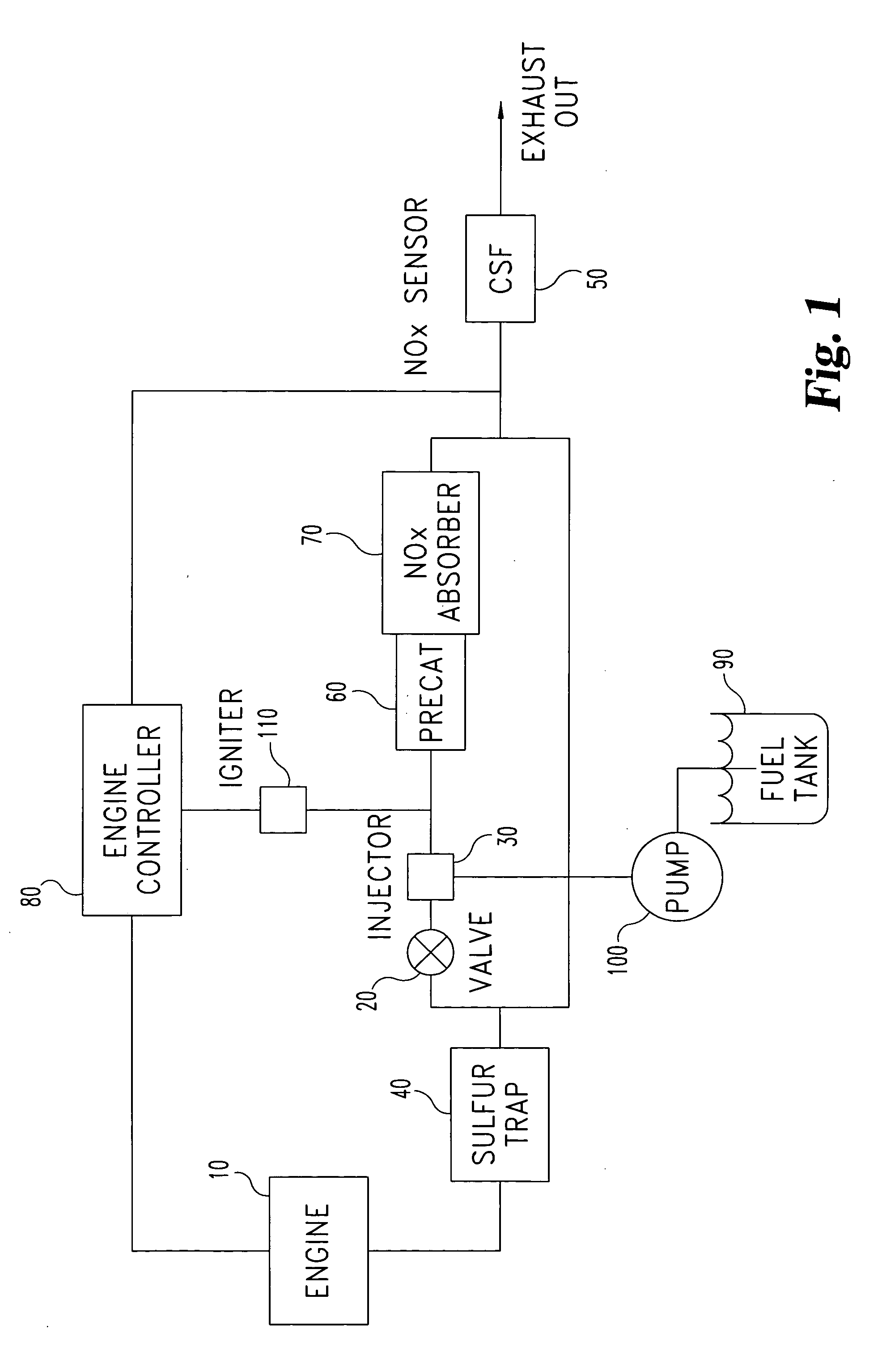

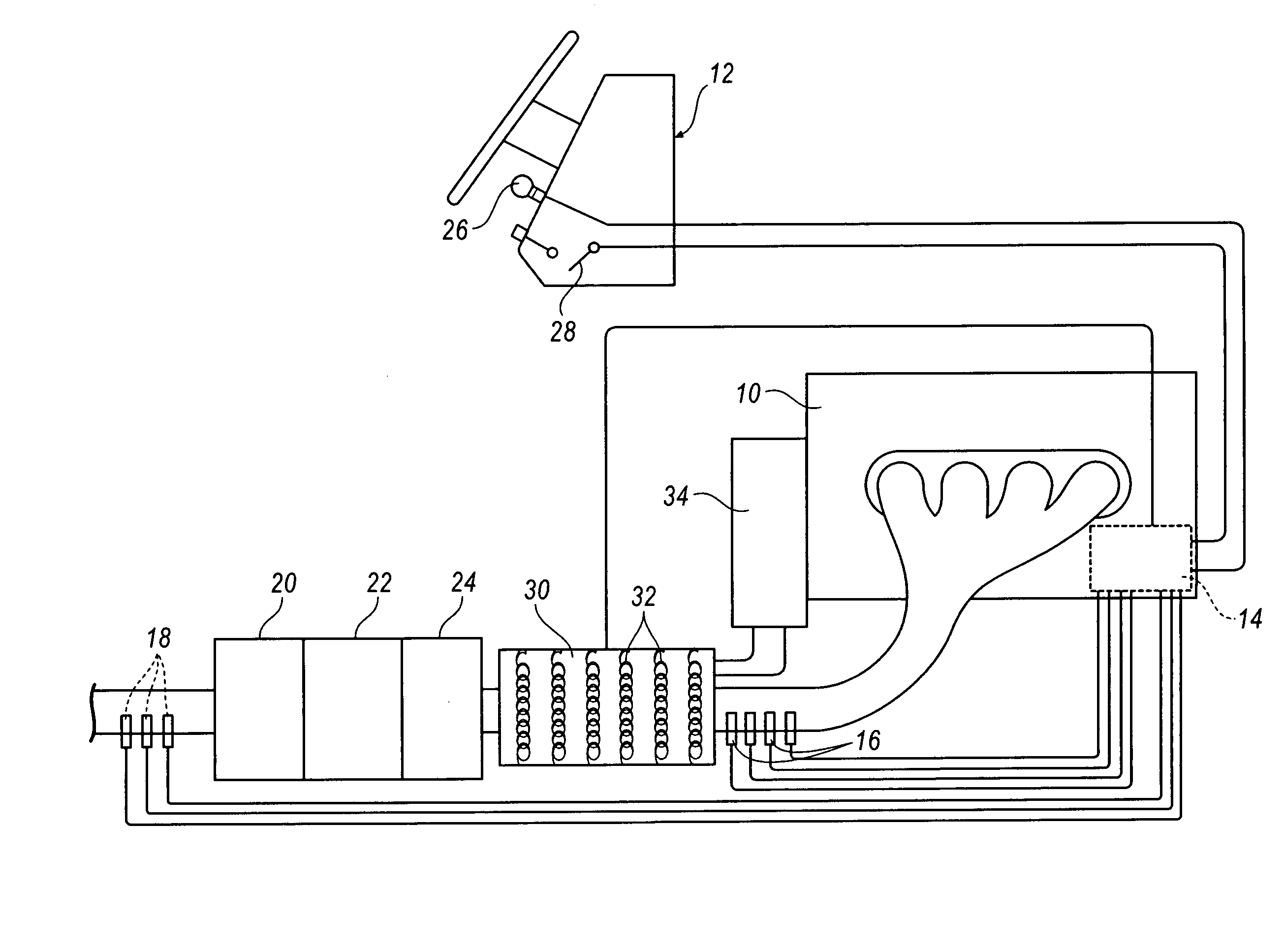

Precat-NOx adsorber exhaust aftertreatment system for internal combustion engines

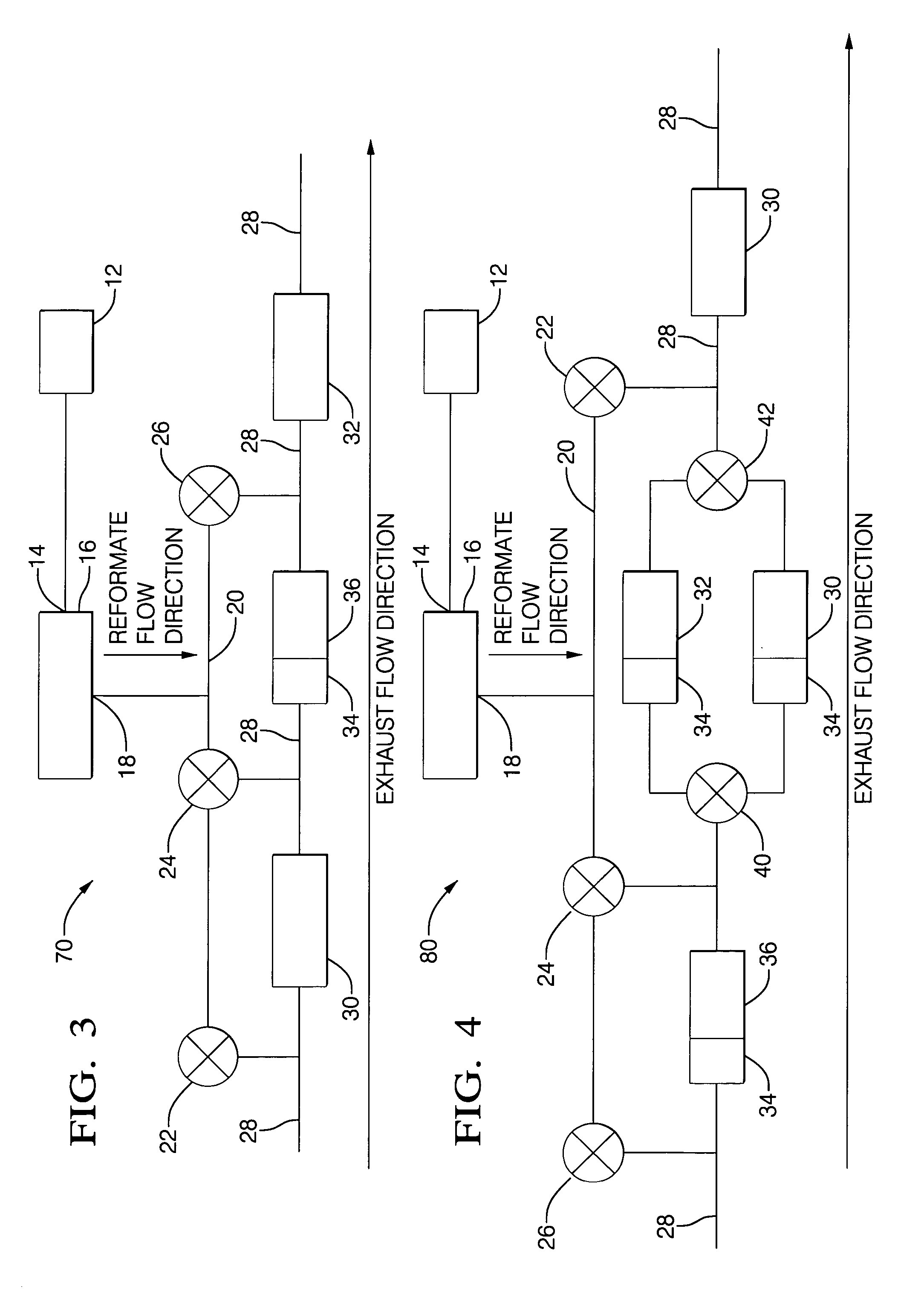

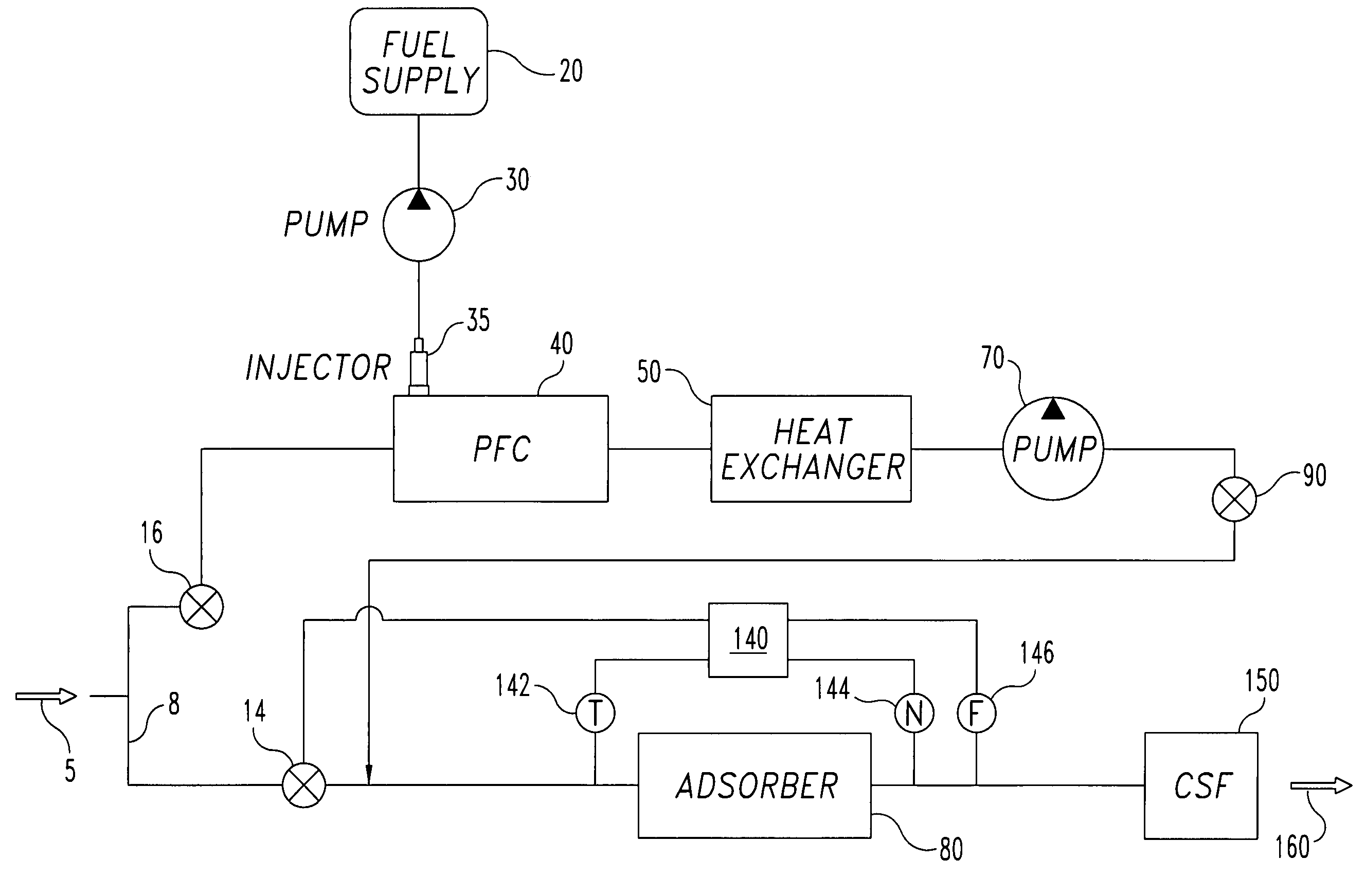

ActiveUS20050178110A1Efficiently regenerate the NOx adsorber/reducerInternal combustion piston enginesSilencing apparatusCombustionControl system

The invention provides a NOx adsorber aftertreatment system for internal combustion engines which utilizes at least one precat operatively coupled to at least one NOx adsorber to aid in the regeneration of the NOx adsorber. Fuel is injected into a precat located upstream of a NOx absorber producing heat, H2O, and reductants such as CO, HC, and volatile hydrocarbons, which are input into the NOx absorber. The combination of heat, water, and reductants help to efficiently regenerate the NOx Adsorber which in turn releases exhausts products such as CO2 and N2. Regeneration of a NOx adsorber can be performed during periods of reduced exhaust gas flow lowering the fuel penalty associated with NOx adsorber regeneration. The pre-cat, NOx adsorber regenerating aftertreatment system of the present invention may be used with any suitable control system.

Owner:CUMMINS FILTRATION INC

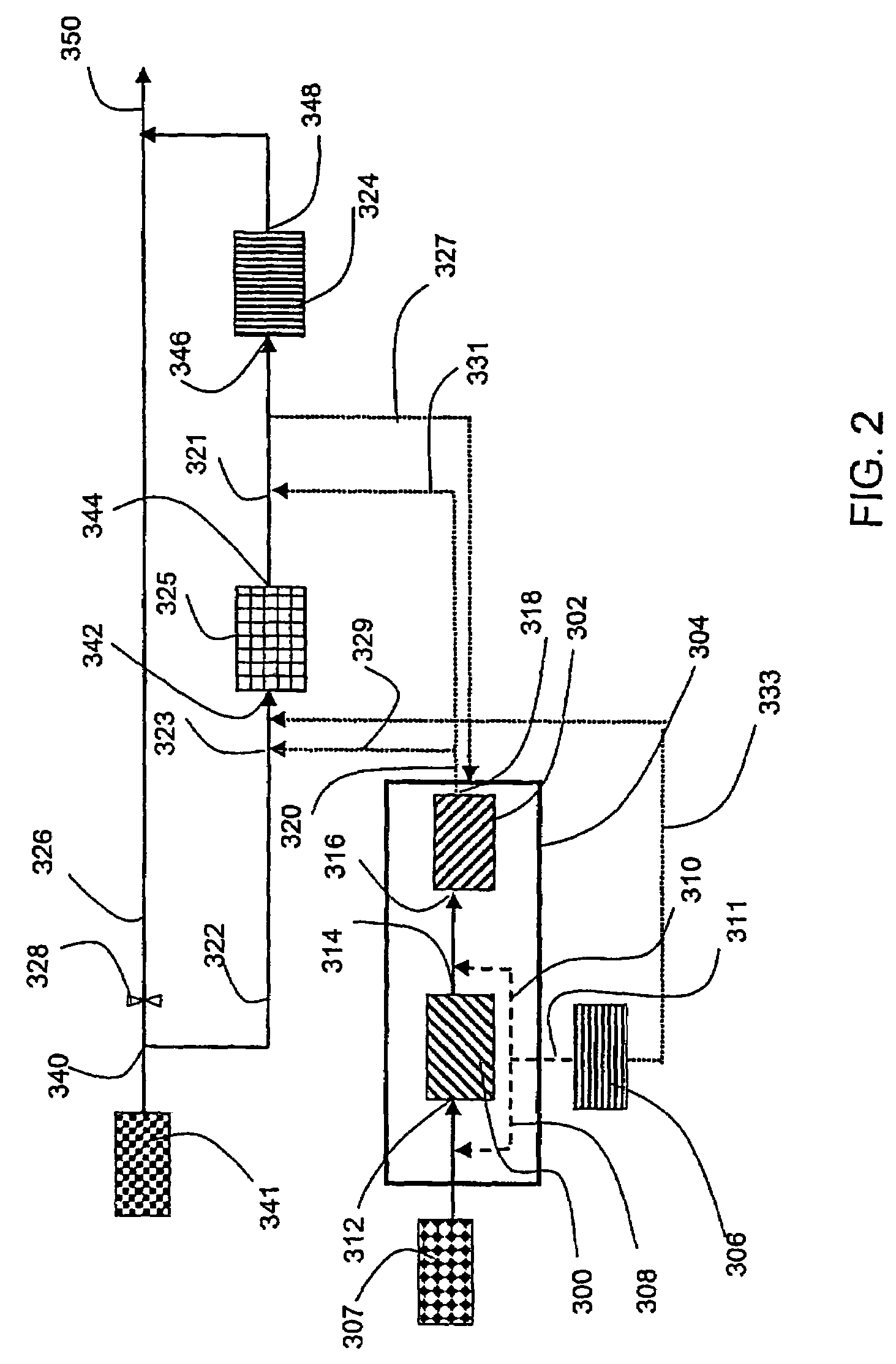

Method and system for regenerating NOx adsorbers and/or particulate filters

An active system for regenerating a NOX adsorber and a particulate filter, the system comprising a fuel source, a reformer for generating hydrogen and carbon monoxide in fluid communication with the fuel source, a first valve, a second valve, and a third valve in fluid communication with the reformer, an oxidation catalyst, a NOX adsorber located downstream from the oxidation catalyst, a particulate filter located downstream from the NOX adsorber; and wherein the first valve, the second valve, and the third valve control fluid flow from the reformer to the oxidation catalyst, the NOX adsorber, and the particulate filter.

Owner:DELPHI TECH IP LTD

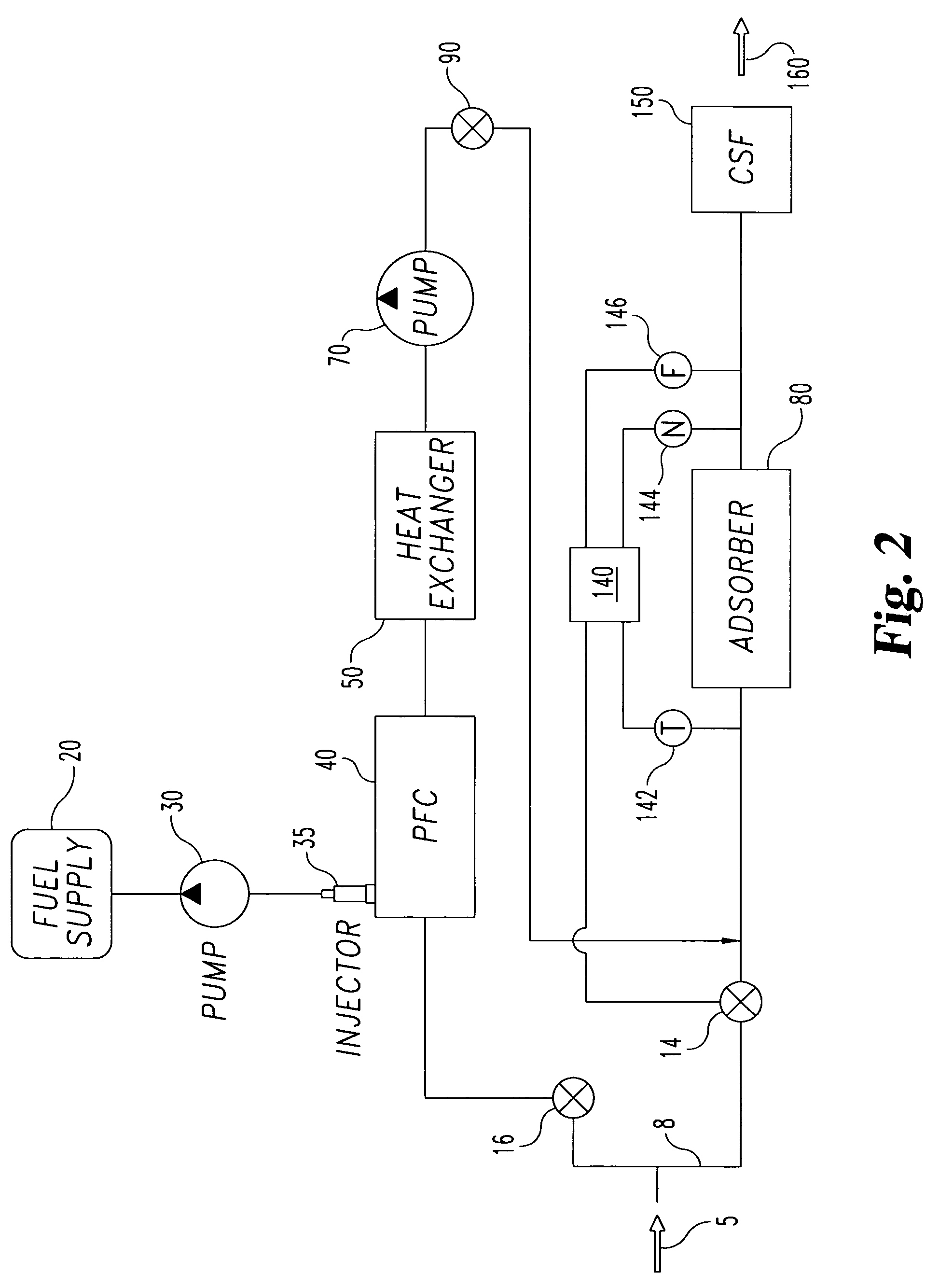

Plasma fuel converter NOx adsorber system for exhaust aftertreatment

InactiveUS7377101B2Increase production and deliveryChange trafficExhaust apparatusSilencing apparatusControl systemExhaust fumes

The invention provides a NOx adsorber aftertreatment system for internal combustion engines which utilizes a plasma fuel converter operatively coupled to at least one NOx adsorber to aid in the regeneration of the NOx adsorber. Fuel and engine exhaust is injected into a plasma fuel converter upstream of a NOx absorber producing reductant such as H2, and CO, which are inlet into the NOx absorber. Reductants such as H2 and CO acting along and together help to efficiently regenerate the NOx Adsorber which in turn releases exhausts products such as CO2 and N2. Using the reductants generated by the plasma fuel converter NOx adsorbers, catalytic soot filter, and the like can be regenerated at exhaust temperatures less than 250° C. The plasma fuel converter, NOx adsorber regenerating aftertreatment system of the present invention may be used with any suitable control system.

Owner:CUMMINS FILTRATION INC

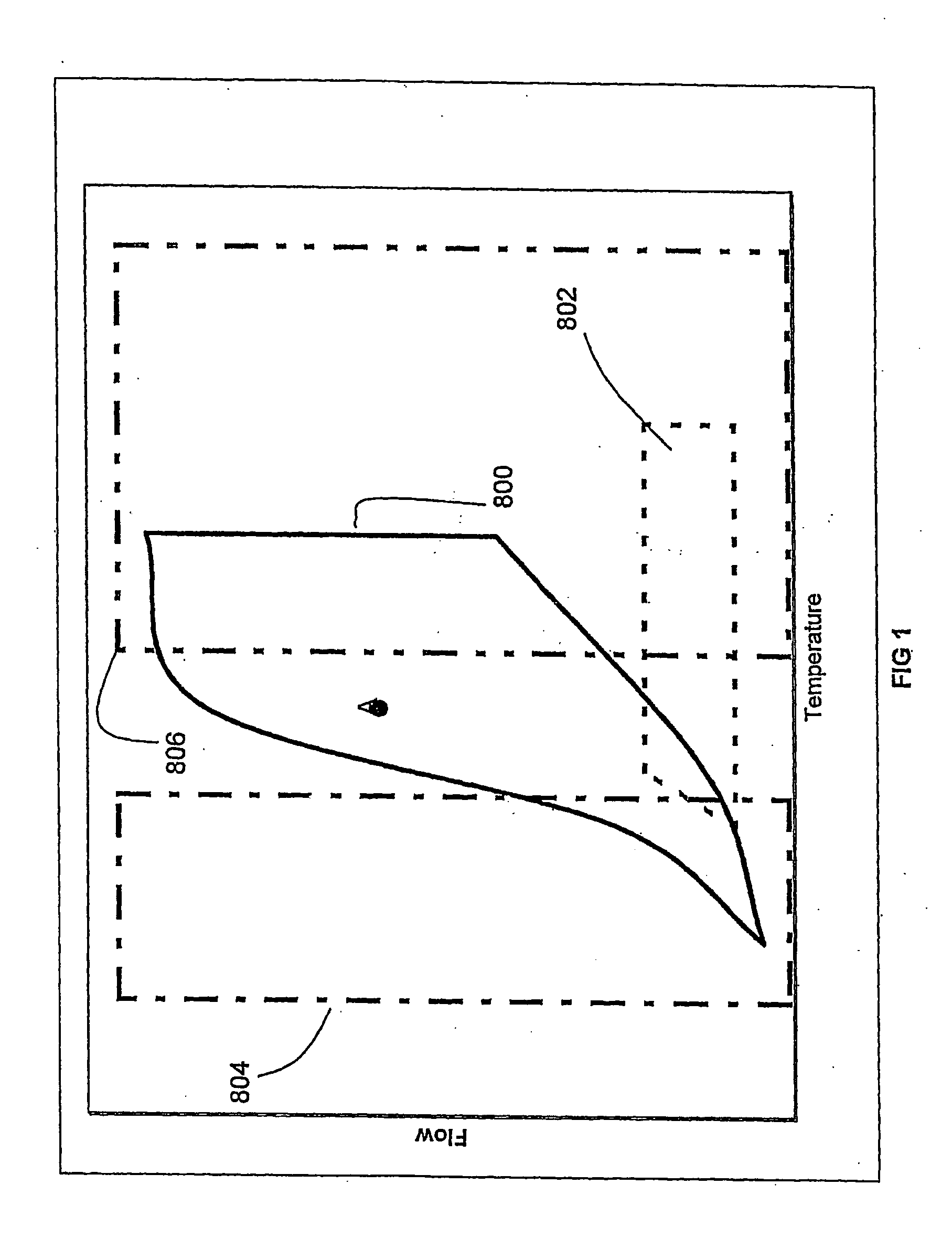

Management of thermal fluctuations in lean NOx adsorber aftertreatment systems

InactiveUS20060053776A1Nitrous oxide captureNon-fuel substance addition to fuelSulfationCompound (substance)

A method and apparatus manage heat in exhaust gas in an aftertreatment system that employs a lean NOx adsorber. A de-sulfation hot line and cooling line are employed to control exhaust gas temperatures for adsorption, regeneration and de-sulfation cycles of the aftertreatment system where each cycle can require different chemical and exhaust gas temperatures independent of the engine operation. The method and apparatus include a SOx adsorber to provide greater system durability.

Owner:WESTPORT POWER

Exhaust system and methods of NOx adsorber desulfation

ActiveUS7036489B1Increase temperatureInternal combustion piston enginesExhaust apparatusCombustionHydrogen

Owner:DELPHI TECH IP LTD

Thermal management of hybrid LNT/SCR aftertreatment during desulfation

ActiveUS20070006573A1Avoid heatLow peakingGas treatmentInternal combustion piston enginesEngineeringNOx adsorber

In an exhaust aftertreatment system comprising a NOx adsorber-catalyst followed by an SCR catalyst, means are provided for preventing the SCR catalyst from becoming heated to near the same peak temperatures as the NOx adsorber-catalyst during desulfation. In one embodiment, the means is a thermal mass between the NOx adsorber-catalyst and the SCR catalyst. In another embodiment, the means is a valve configured to selectively divert exhaust leaving the NOx adsorber-catalyst from the SCR catalyst. In a method of the invention, the NOx adsorber-catalyst temperature is cycled during desulfation. The peaks of the cycles are within an appropriate temperature range for desulfating the NOx adsorber-catalyst, but the average temperature is below the temperature range at which the SCR catalyst is damaged. The temperature peaks are damped as they travel from the NOx adsorber-catalyst to the SCR, whereby the SCR experiences much lower peak temperatures than the NOx adsorber-catalyst.

Owner:INT ENGINE INTPROP CO LLC

Method and system for passive regeneration of compression ignition engine exhaust filters

A method and system for passively regenerating particulate filters, catalyze soot filters and NOx adsorber catalysts for a vehicle having a compression ignition engine having an engine control module (ECM) including an integrated engine and emission system map, and an integrated starter / alternator / flywheel / retarder assembly, comprising sensing the condition of the particulate filters, catalyzed soot filters, and NOx adsorber catalysts and generating an initiate cleaning cycle signal upon sensing that the filters and catalysts require cleaning, monitoring operation of the engine and vehicle to determine the engine speed and vehicle speed and generating an engine speed / vehicle speed operating signal, receiving the initiate passive cleaning engine cycle signal and the engine speed vehicle speed operating signal, and initiating engine control parameter adjustments to modify engine operation to promote passive regeneration of the filters.

Owner:DETROIT DIESEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com