Management of thermal fluctuations in lean NOx adsorber aftertreatment systems

a technology of aftertreatment system and thermal fluctuation, which is applied in the direction of exhaust gas recirculation, exhaust treatment, and addition of non-fuel substances to fuels. it can solve the problems of deterioration rate, performance deterioration of current lna washcoats, and interference with the ability of lna to remove nox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

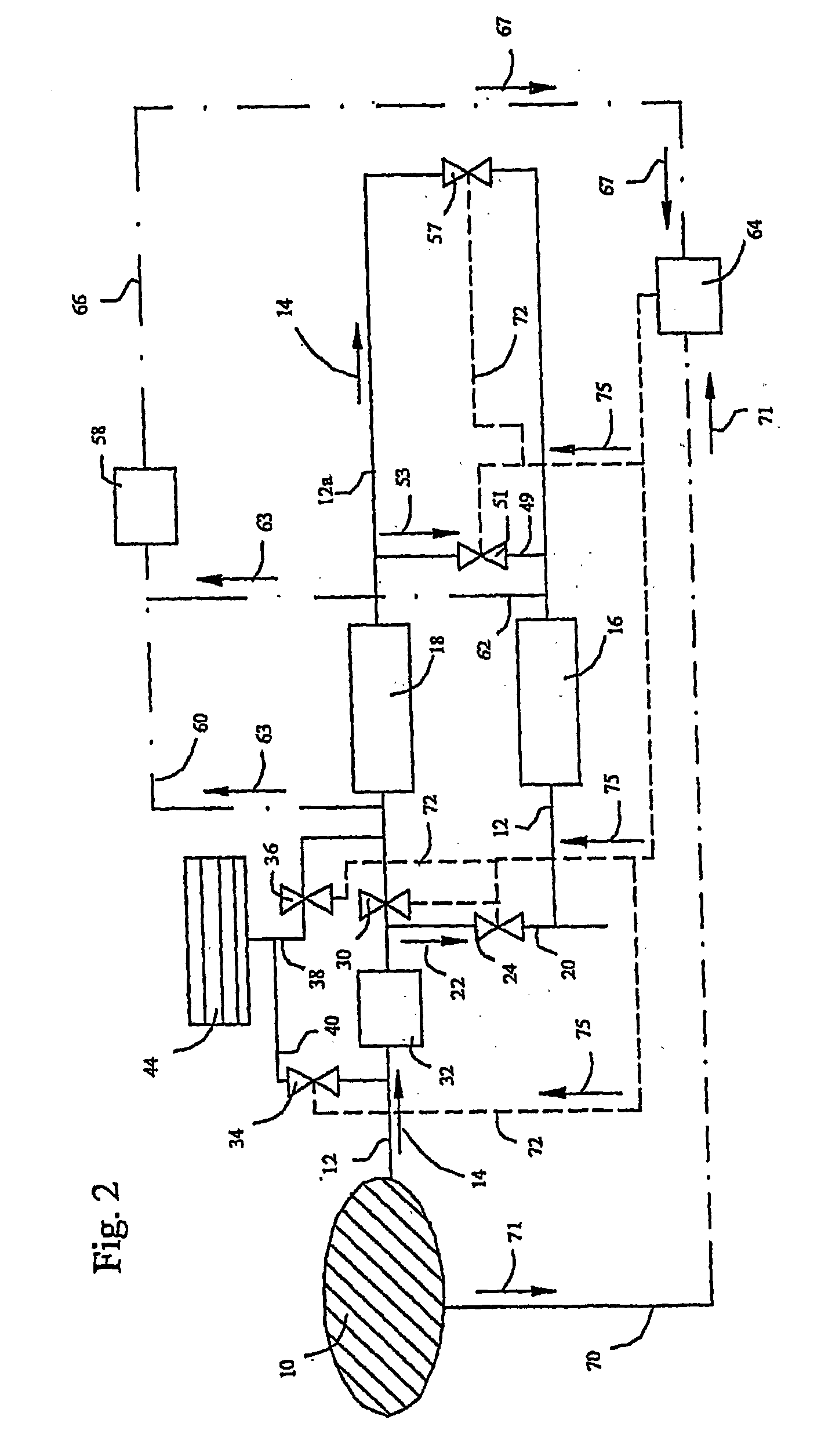

[0066]FIG. 3 shows an aftertreatment system according to the present technique. As in the embodiment shown in FIG. 2, exhaust gas is directed, as indicated by arrow 14, to LNA 16 from engine block 10 through exhaust lines that include lead line 12 and hot line 86. A reductant can be introduced into lead line 12 through line 38 as controlled by valve 36 from store 44. Catalyst 18 is available downstream of the junction of line 38 and lead line 12 to allow for the exhaust gas to be heated and oxidized across catalyst 18 as needed. Exhaust gas temperature is further controlled by turbine-driven blower 82 disposed in lead line 12. Blower 82 accepts exhaust gas, expands and cools the gas to extract energy from the gas, and uses that energy to direct air through line 84 and valve 80 as indicated by arrow 94 (in the embodiment shown) to lead line 12 downstream of turbine-driven blower 82 and upstream of LNA 16.

[0067] The exhaust line includes hot line 86. Flow through hot line 86 is contro...

first embodiment

[0115] Controls, as described above, can also be employed to control embodiments having a turbine-driven blower 82. Here, however, control is needed to monitor the flow of air into lead line 12 through valve 80 during adsorption cycles. During a regeneration or de-sulfation cycle, valve 90 can be opened to direct all or a portion of the flow around turbine driven blower 82, as desired to match the temperature requirement for exhaust gas through LNA 16. Although, not shown in this embodiment, as would be understood by persons skilled in the technology involved here, a bypass could also be employed between catalyst 18 and LNA 16 (upstream of catalyst 18 and downstream of LNA 16). This bypass would be employed in the same manner as described for the first embodiment in FIG. 1.

[0116] In addition to hot line 86, line 91 could also be employed to remove load from turbine driven blower 82 when there is a need to maintain exhaust gas heat.

[0117] For the embodiment shown in FIG. 3 flow sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com