Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4049 results about "Dieseling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dieseling or engine run-on is a condition that can occur in spark-plug-ignited, gasoline powered internal combustion engines, whereby the engine keeps running for a short period after being turned off, due to the engine kicking back upon shutdown, drawing fuel through the carburetor, into the engine and igniting it without a spark.

Sorbent composition, process for producing same and use in desulfurization

Particulate sorbent compositions comprising a mixture of zinc oxide, silica, alumina and a substantially reduced valence nickel are provided for the desulfurization of a feedstream of cracked-gasoline or diesel fuels in a desulfurization zone by a process which comprises the contacting of such feedstreams in a desulfurization zone followed by separation of the resulting low sulfur-containing stream and sulfurized-sorbent and thereafter regenerating and activating the separated sorbent before recycle of same to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Sorbent composition, process for producing same and use in desulfurization

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

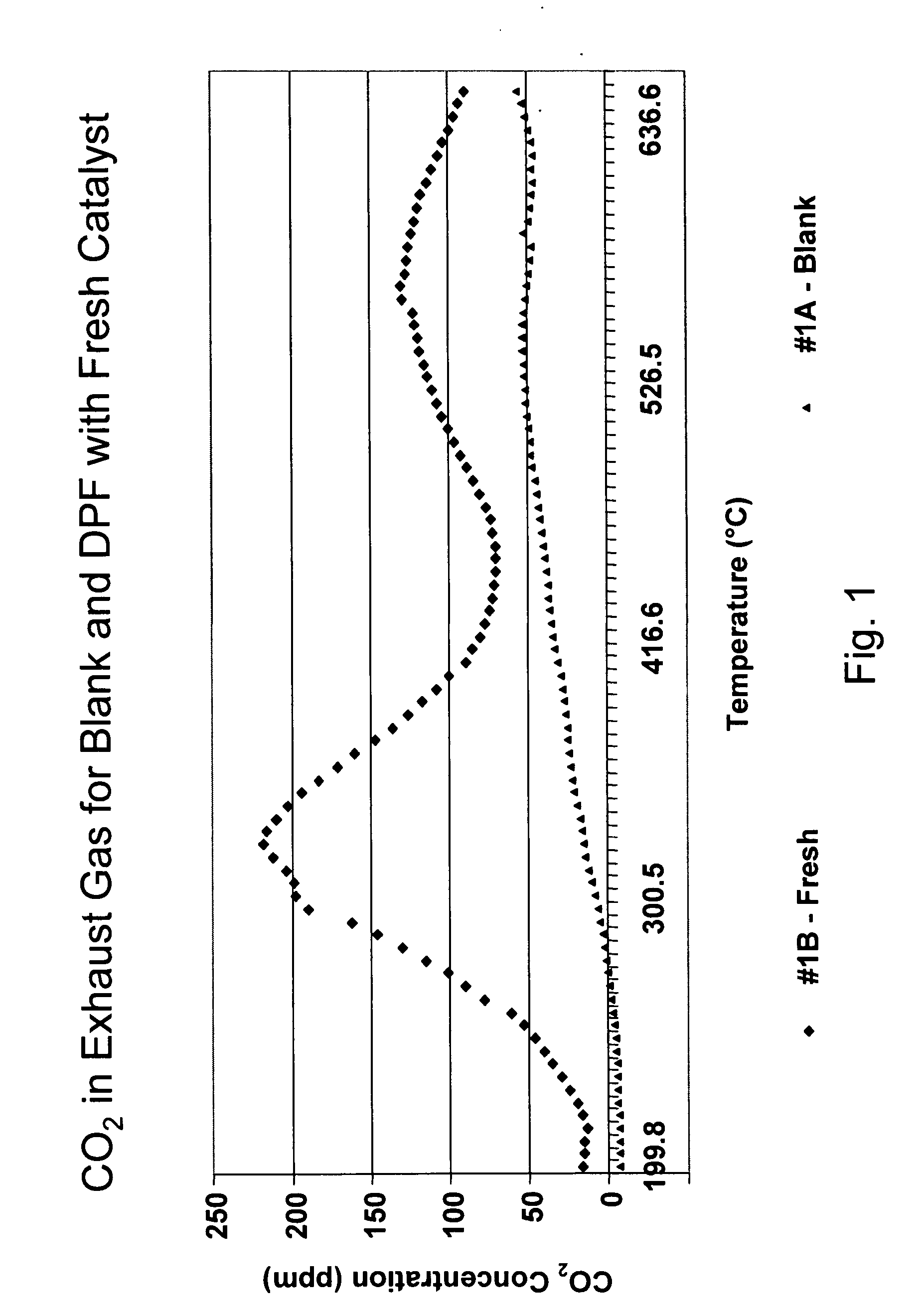

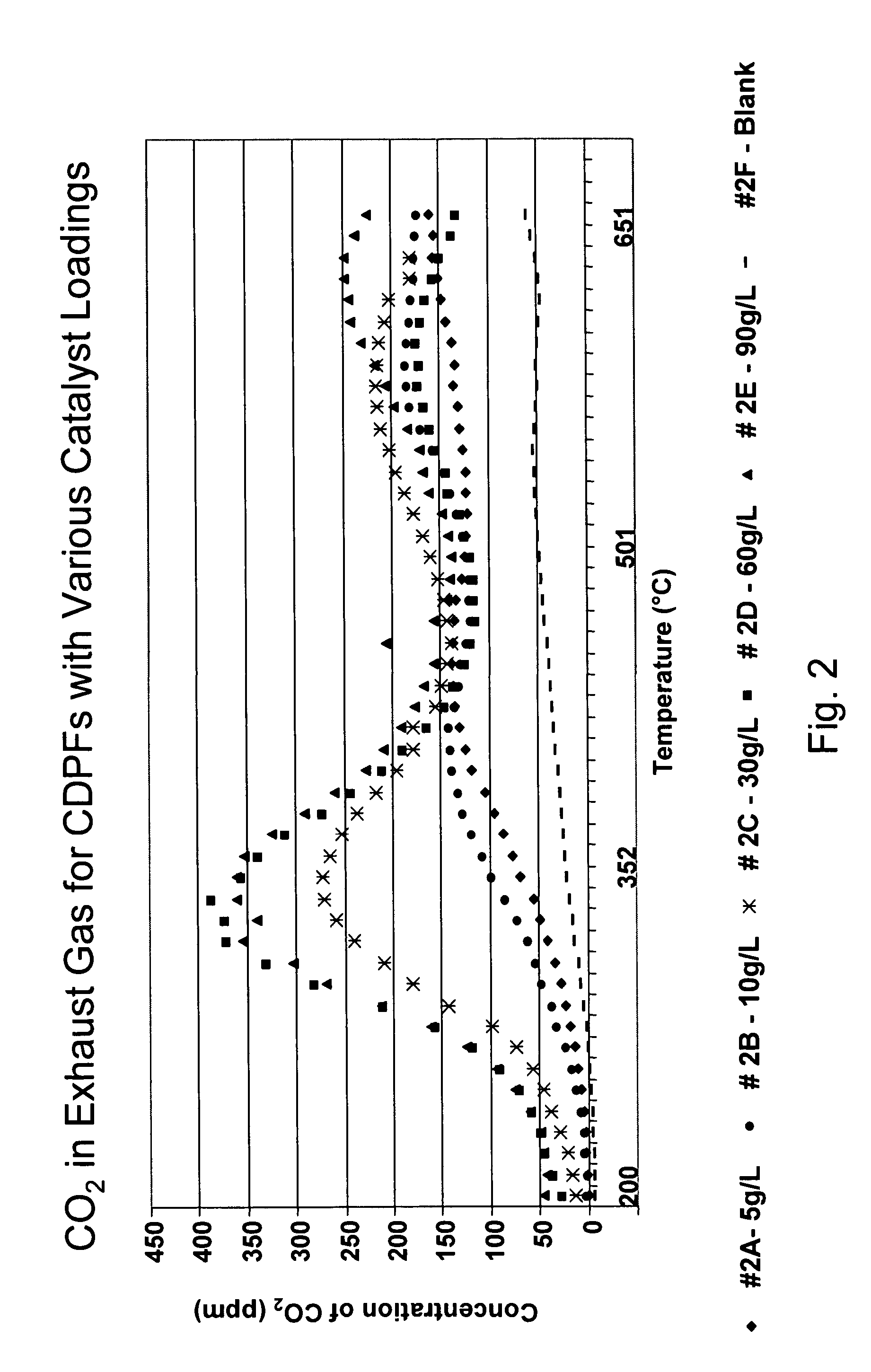

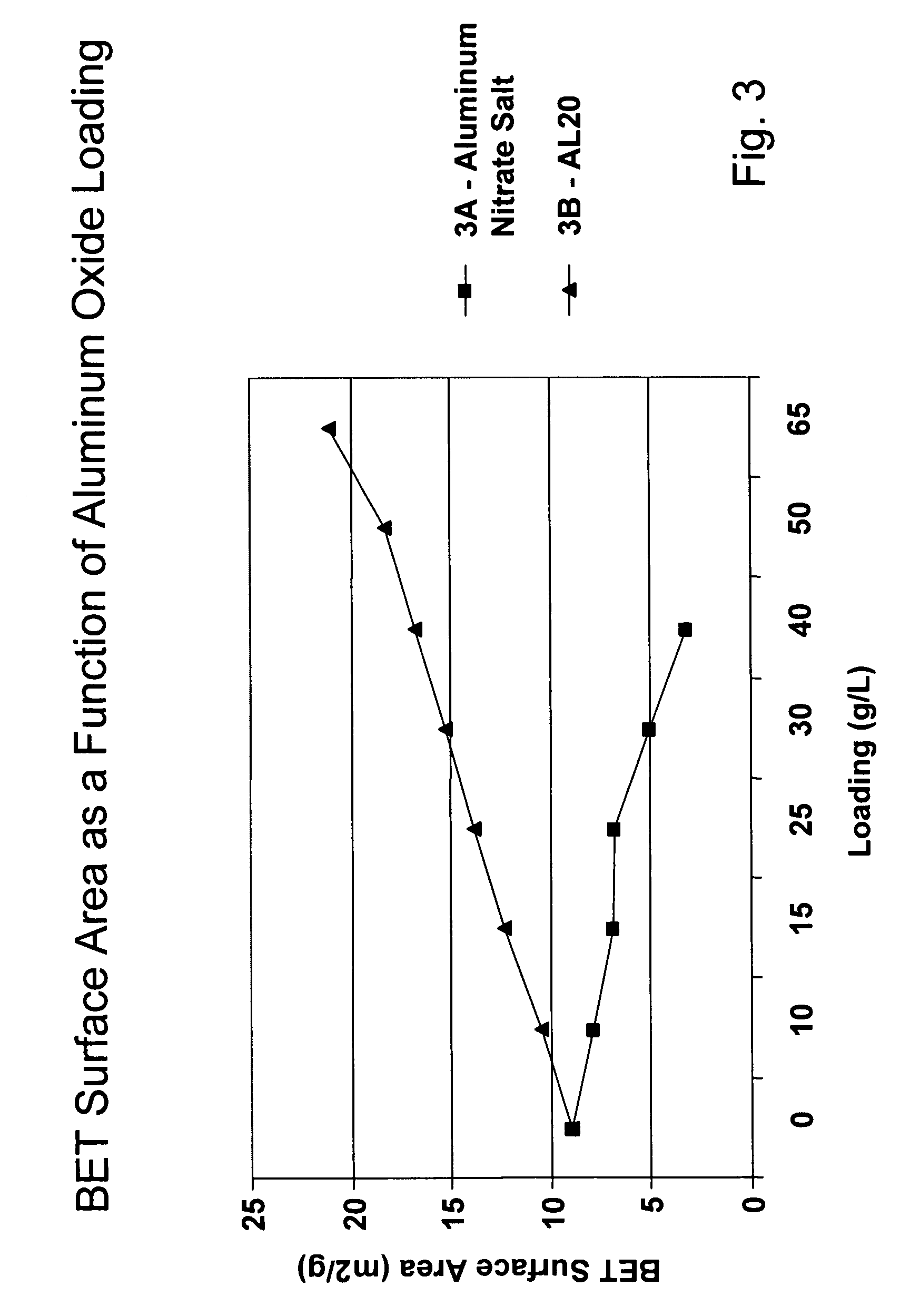

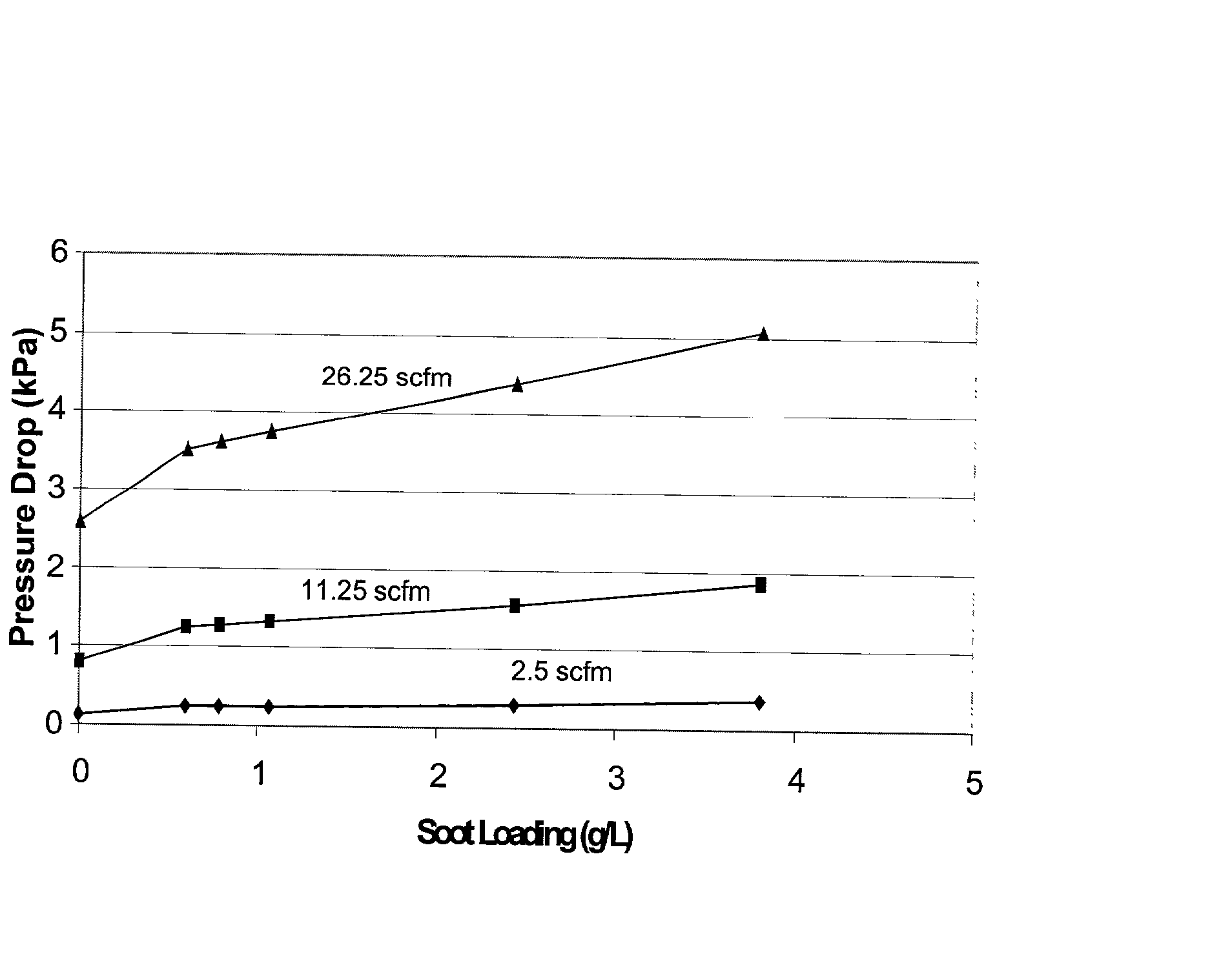

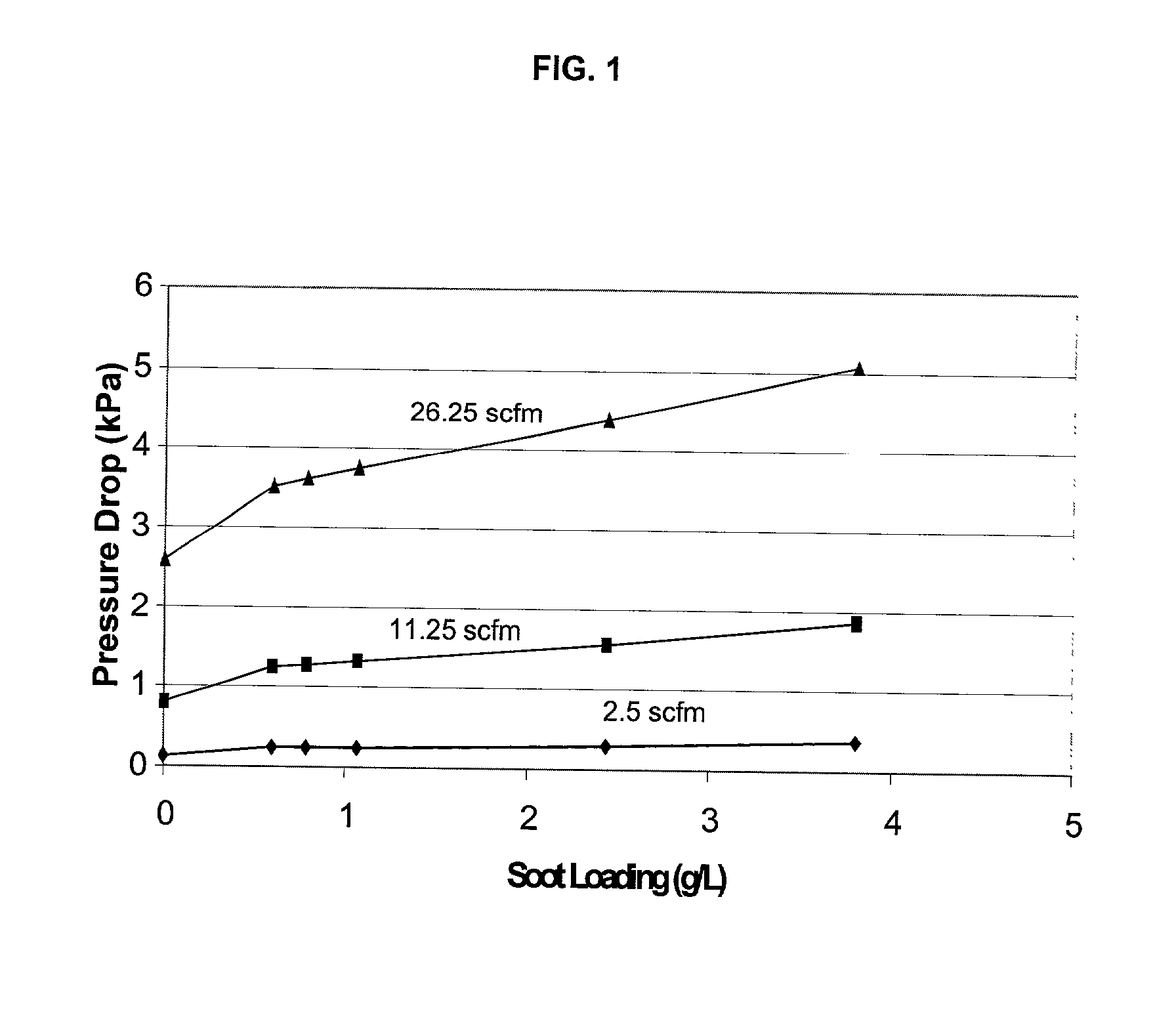

Platinum group metal-free catalysts for reducing the ignition temperature of particulates on a diesel particulate filter

A catalyzed diesel particulate filter (CDPF) and a method for filtering particulates from diesel engine exhaust are provided, where the catalyzed diesel particulate filter includes a substrate and a catalyst composition, where the catalyst composition contains at least one first component, at least one second component, and at least one third component, where the first component is at least one first component selected from the group consisting of cerium and a lanthanide and mixtures thereof, the at least one second component is selected from the group consisting of cobalt, copper, manganese and mixtures thereof; and the third component comprises strontium, where the first component, the second component, and the third component are in an oxide form after calcination. The catalyst on the catalyzed diesel particulate filter lowers the temperature at which particulates are removed from the CDPF by oxidizing the particulates on the filter. The catalyzed diesel particulate filter may also include a washcoat. Washcoats prepared from colloidal aluminum oxide may have higher surface areas and pore volumes loadings than washcoats containing aluminum oxide prepared from aluminum nitrate.

Owner:CATALYTIC SOLUTIONS INC

Lubricating oil composition

ActiveUS20080110799A1Excellent in thermal/oxidation stabilityInhibit of acid numberLiquid carbonaceous fuelsAdditivesInternal combustion engineSoot

The present invention provide a lubricating oil composition suitable for internal combustion engines, which composition is excellent in thermal / oxidation stability and can inhibit the increases of the viscosity and acid number even in the presence of NOx and can be used for a long period of time or provide a lubricating oil composition particularly suitable for diesel or direct injection engines equipped with an exhaust-gas after-treatment device such as DPF or various catalysts, which composition is excellent in high-temperature detergency and base number retention properties and further can achieve the effect of inhibit wear caused by soot contamination in the oil occurring significantly when the content of phosphorus compounds such as ZnDTP is decreased, at a high level and can inhibit the exhaust-gas after-treatment device from being adversely affected. The lubricating oil composition comprises a lubricating base oil containing, a specific amount of a base oil with specific properties, and two or more types of additives selected from specific additives.

Owner:NIPPON OIL CORP

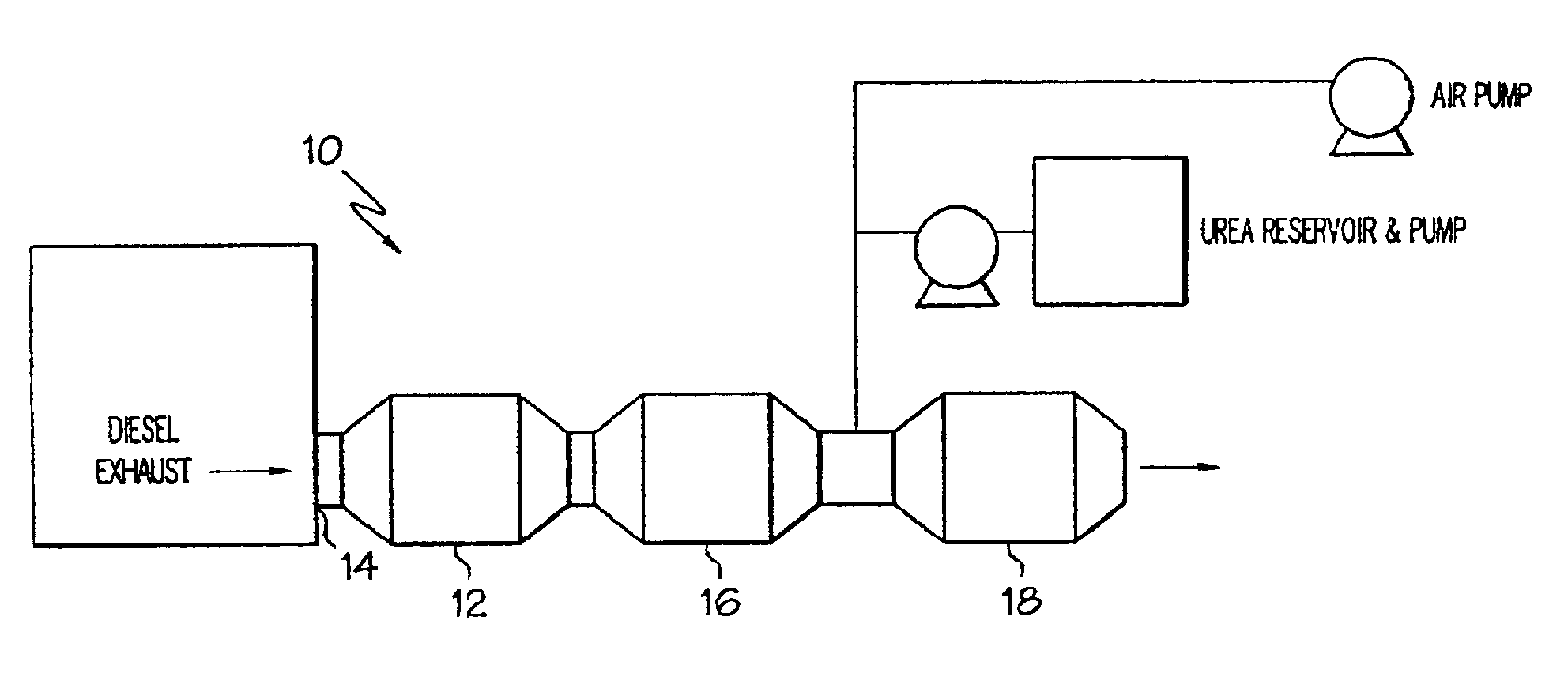

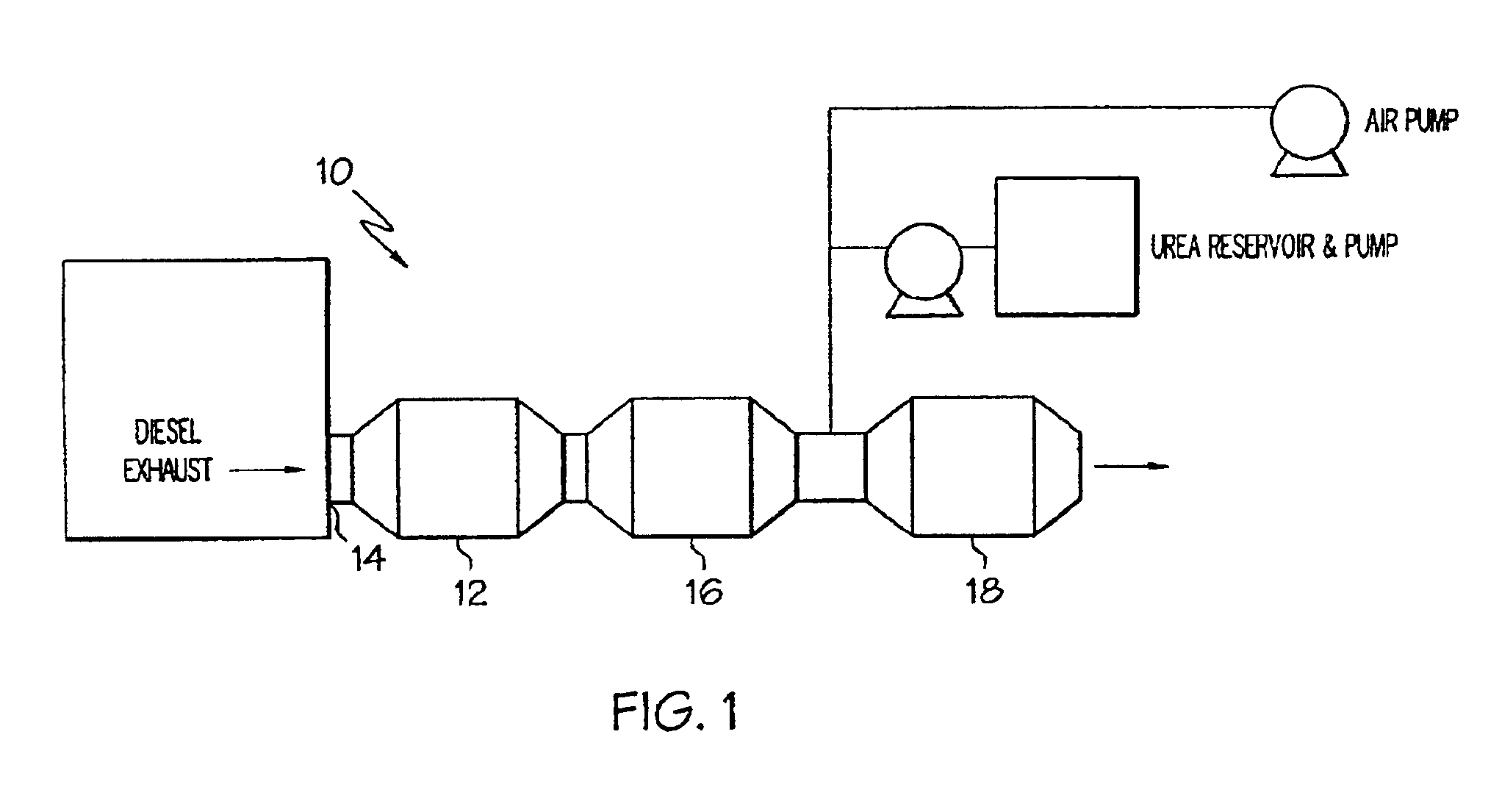

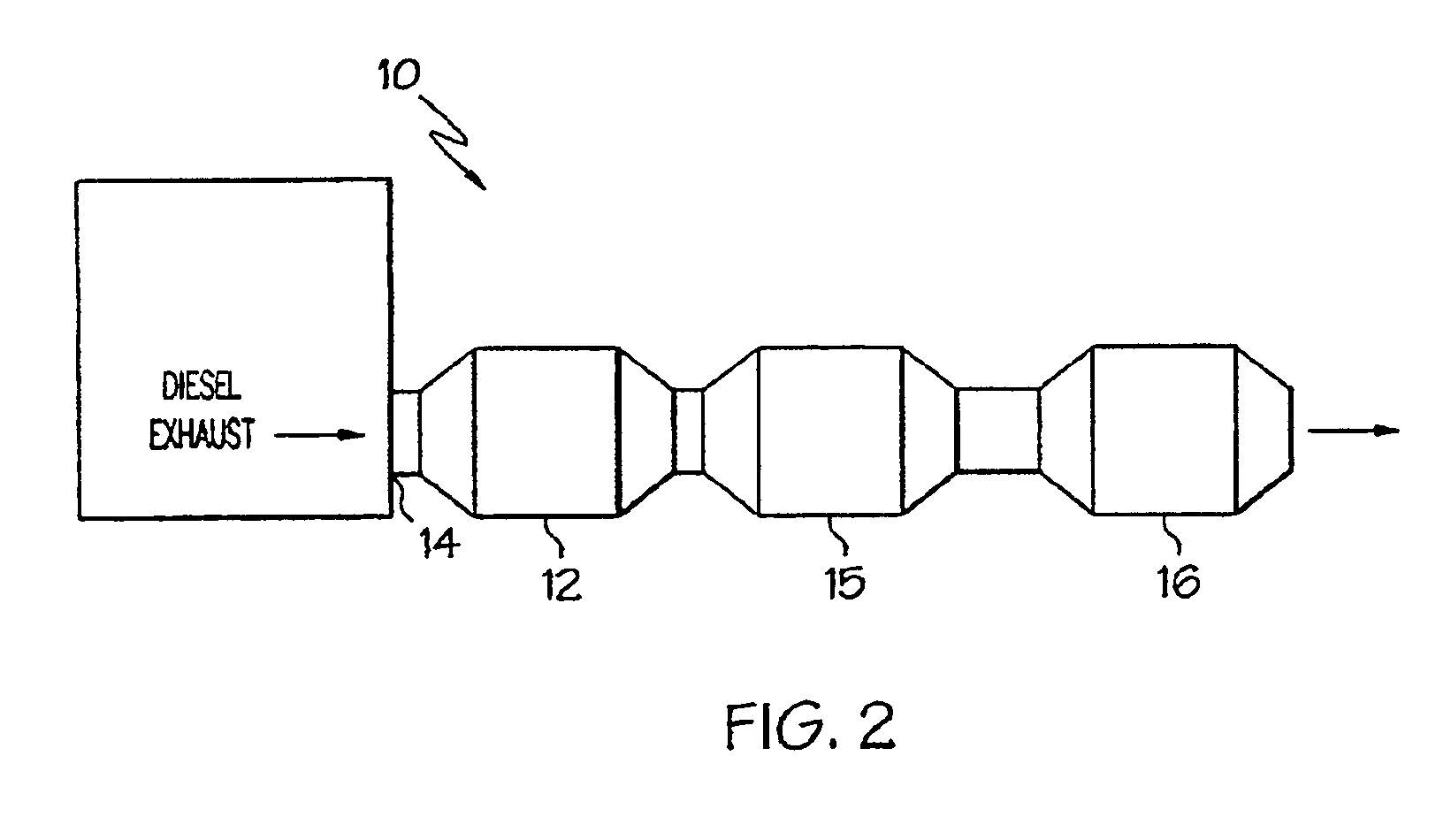

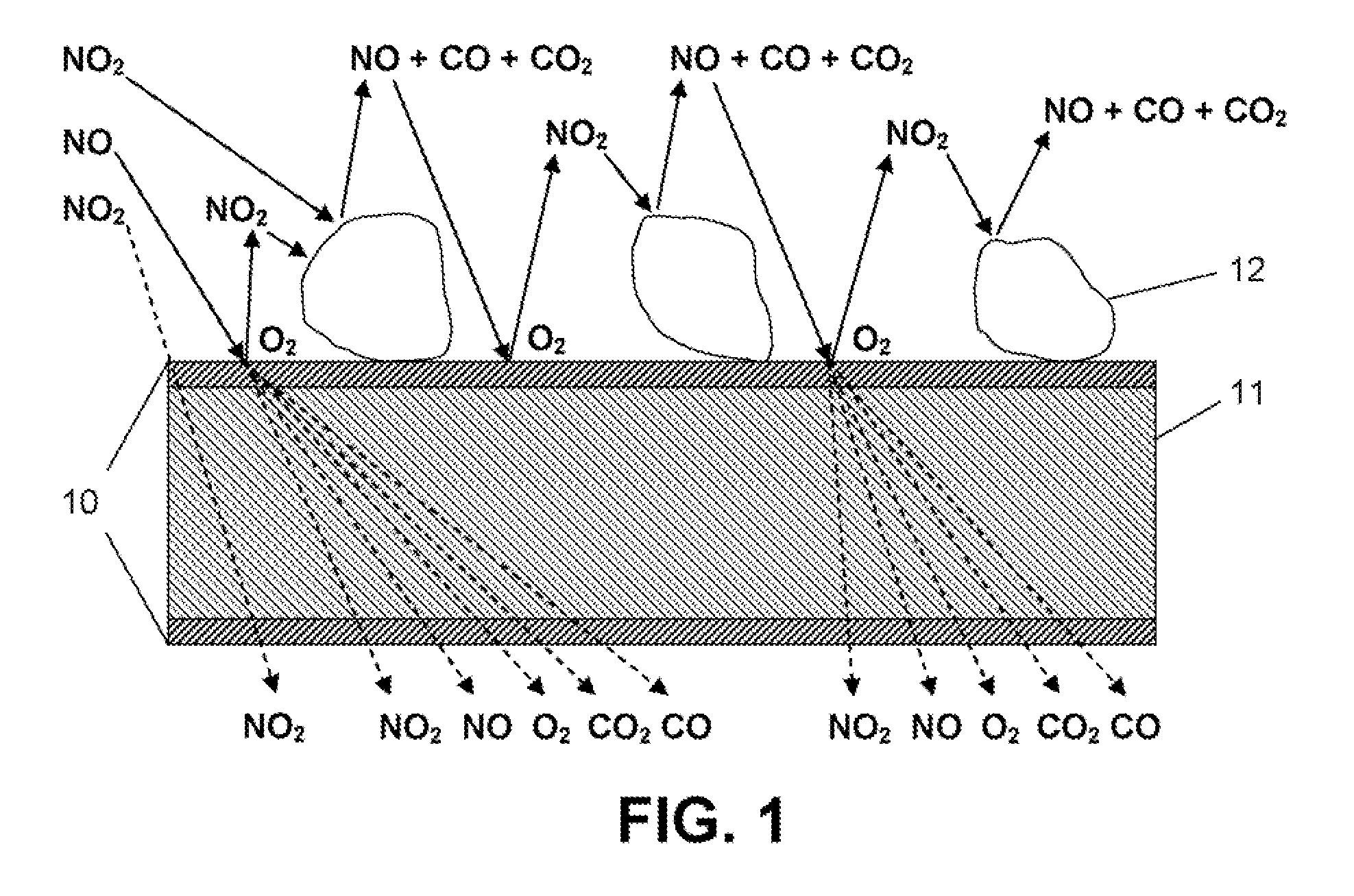

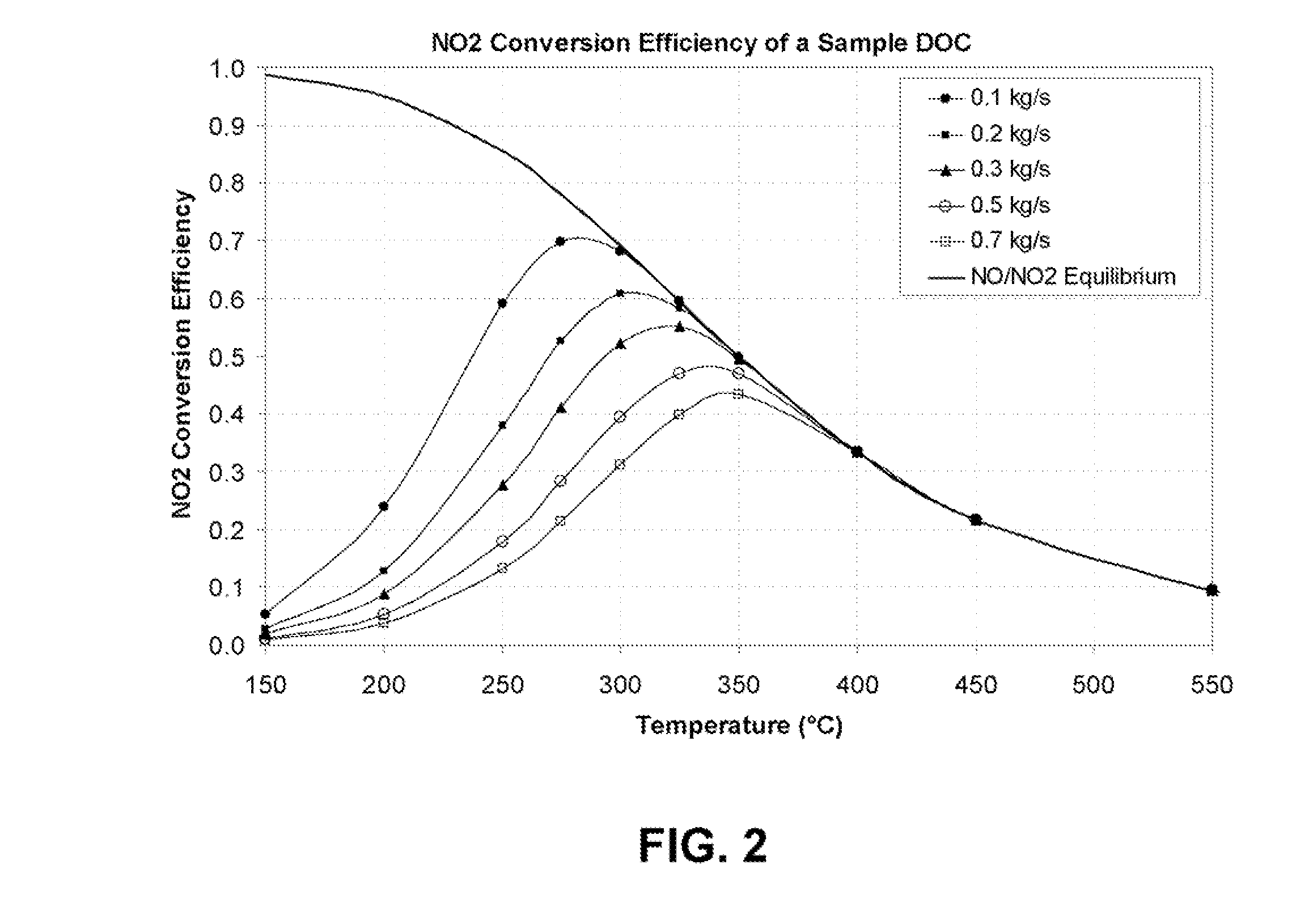

Method of treating diesel exhaust gases

InactiveUS6813884B2Promote regenerationReduce NOxExhaust apparatusDispersed particle separationParticulatesNitrogen

A diesel exhaust treatment system and method of oxidizing NO to NO.sub.2 at low temperatures are provided. The system utilizes a platinum catalyst on a zirconia-stabilized silica support which oxidizes NO in the exhaust gas to NO.sub.2 and uses the NO.sub.2 in an amount sufficient to oxidize particulate trapped on a particulate filter. The catalyst is preferably pre-treated at a temperature of between about 500 to 650.degree. C. in a NO-oxygen-nitrogen mixture to increase conversion at low temperatures. The catalyst preferably includes an additional oxide component selected from the group consisting of TiO.sub.2, P.sub.2 O.sub.5, WO.sub.3, B.sub.2 O.sub.3, and Al.sub.2 O.sub.3. or a heteropolyacid component to further increase activity at low temperatures or to decrease platinum loading at the same level of performance.

Owner:FORD GLOBAL TECH LLC

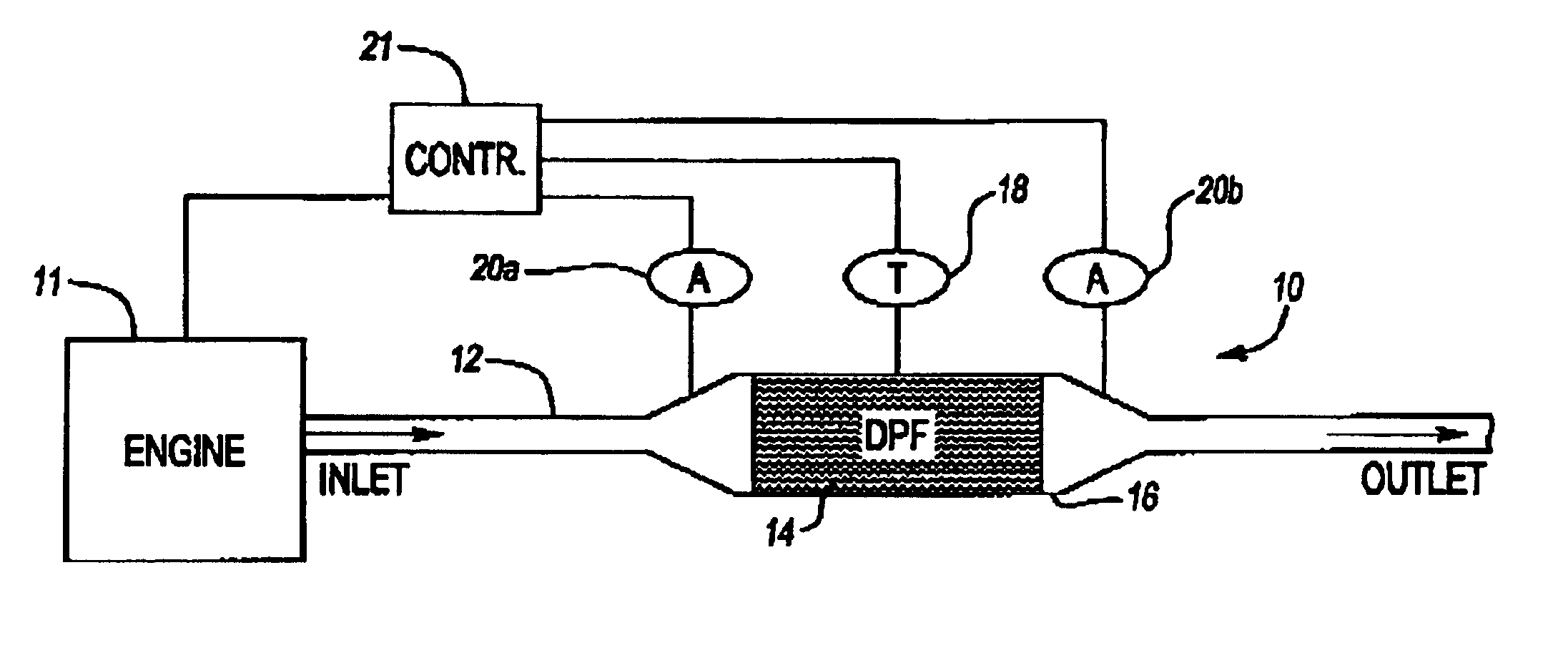

Diesel particulate filter monitoring using acoustic sensing

A particulate filter system is provided including an exhaust system transporting emissions from an engine. A filter such as a diesel particulate filter is disposed in the exhaust system. An acoustic sensor is associated with the exhaust system for detecting one or more frequencies passing through the filter. The frequency corresponds to a filter state indicative of a clean, full, loading, or failed filter. One or more acoustic sensors may fluidly or mechanically coupled to portions of the exhaust system to determine the frequency caused by the exhaust flow through the filter. The acoustic emissions from the filter may be used to compare to a known filter state to determine the present filter state. Alternatively, more sophisticated mathematical approaches may be used in which processed filter information is compared to a known filter state to determine the present filter state.

Owner:AVL NORTH AMERICA

Method of treating diesel exhaust gases

InactiveUS20030140620A1Add supportHigh catalytic activityExhaust apparatusDispersed particle separationParticulatesNitrogen

A diesel exhaust treatment system and method of oxidizing NO to NO2 at low temperatures are provided. The system utilizes a platinum catalyst on a zirconia-stabilized silica support which oxidizes NO in the exhaust gas to NO2 and uses the NO2 in an amount sufficient to oxidize particulate trapped on a particulate filter. The catalyst is preferably pre-treated at a temperature of between about 500 to 650° C. in a NO-oxygen-nitrogen mixture to increase conversion at low temperatures. The catalyst preferably includes an additional oxide component selected from the group consisting of TiO2, P2O5, WO3, B2O3, and Al2O3. or a heteropolyacid component to further increase activity at low temperatures or to decrease platinum loading at the same level of performance.

Owner:FORD GLOBAL TECH LLC

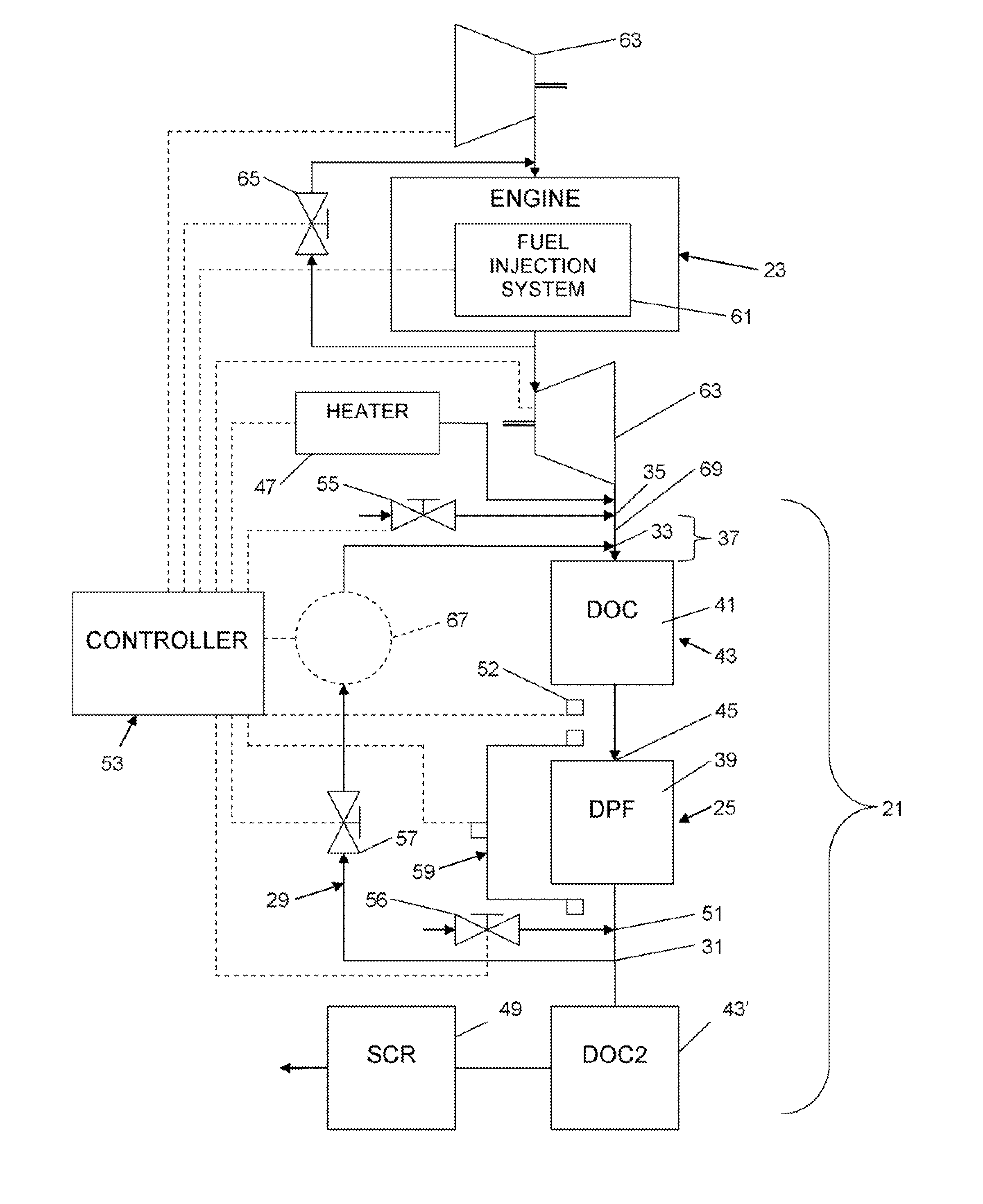

Method and apparatus for no2-based regeneration of diesel particulate filters using recirculated NOX

InactiveUS20110000190A1Lower activation energyElectrical controlExhaust apparatusDiesel particulate filterSoot

In a method for performing NO2-based regeneration of a diese! particulate filter (DPF) using recirculated NOx, the DPF is regenerated by oxidizing soot in the DPF with NO2 so that CO, CO2, and NO are formed, at least some NOx is recirculated from a takeoff point to a point upstream of the takeoff point. NO2 can be formed by reacting the recirculated NO with 02. During regeneration of the DPF, at least some of the NO2 that oxidizes soot in the DPF is recirculated ISI 02 or formed from recirculated NO that is reacted with 02 to form NO2. An exhaust aftertreatment system for performing NO2-based regeneration of a diesel particulate filter (DPF) using recirculated NOx is also disclosed.

Owner:MACK TRUCKS

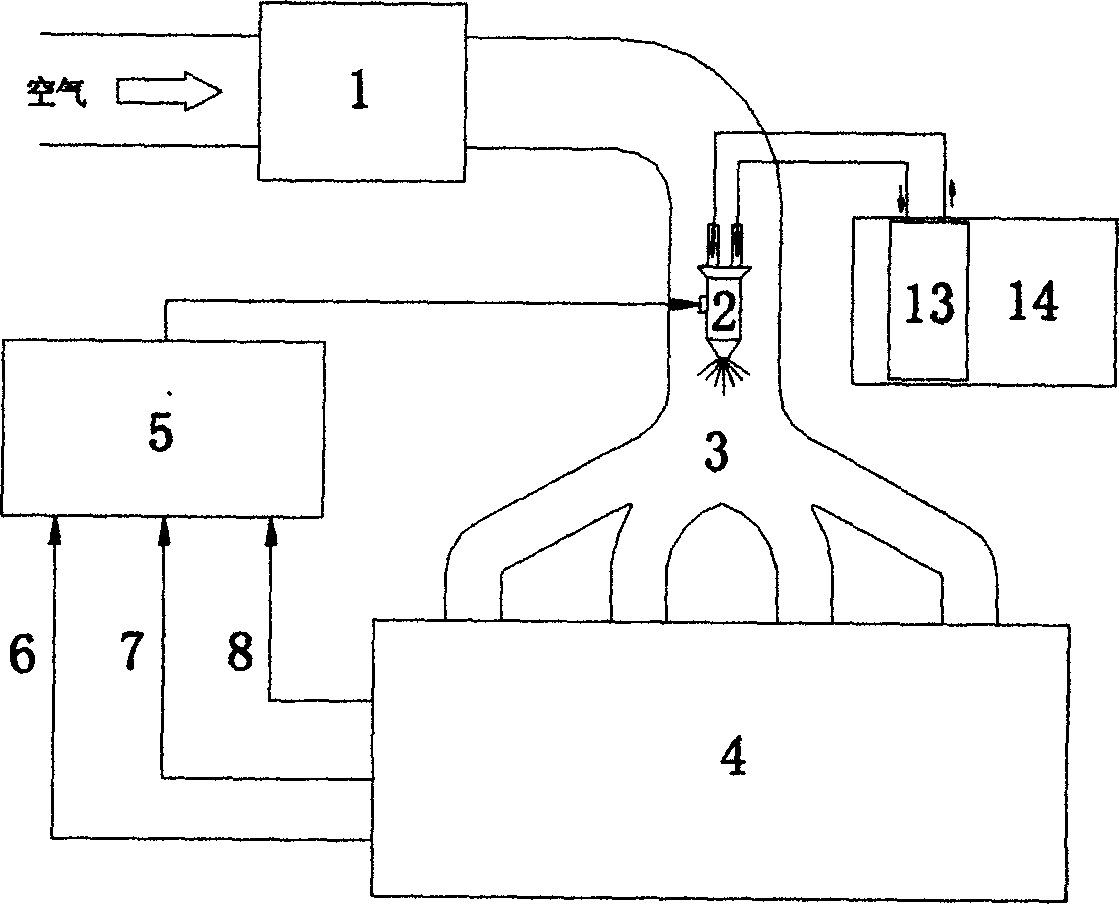

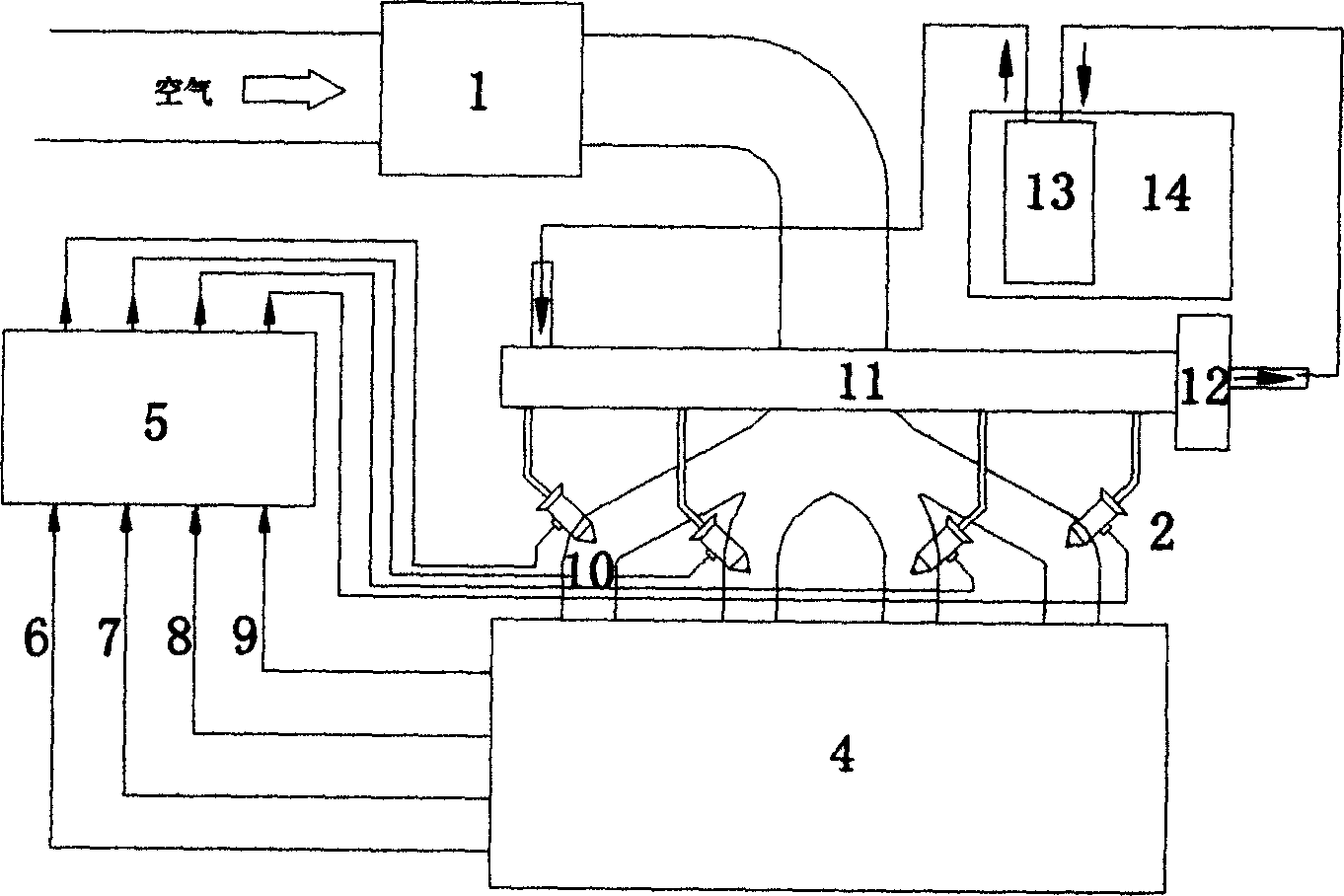

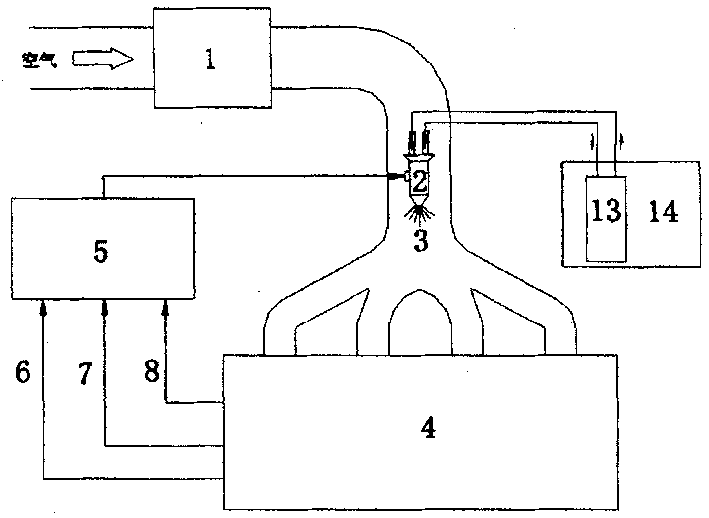

Diesel engine intake alcohol injection apparatus and injection control method

InactiveCN1470752AEmission reductionEasy to modifyElectrical controlMachines/enginesAlcoholInlet channel

The present invention discloses an air-intake alcohol-spraying device of desel engine and its spray control method. Said device is mainly formed from nozzle mounted in the air inlet tube of engine ornozzle mounted in the inlet channel of every cylinder, electric control unit for driving nozzle to open or close it and various sensors of engine load, rotating speed, cam shaft position and cooling water temp. for transferring information to electric control unit. Said invention can substituted diesel oil by partial alcohol fuel, so that the carbon smoke discharge can be reduced by 40%, at the same time the discharge of NOx also can be reduced by above 30%.

Owner:TIANJIN UNIV

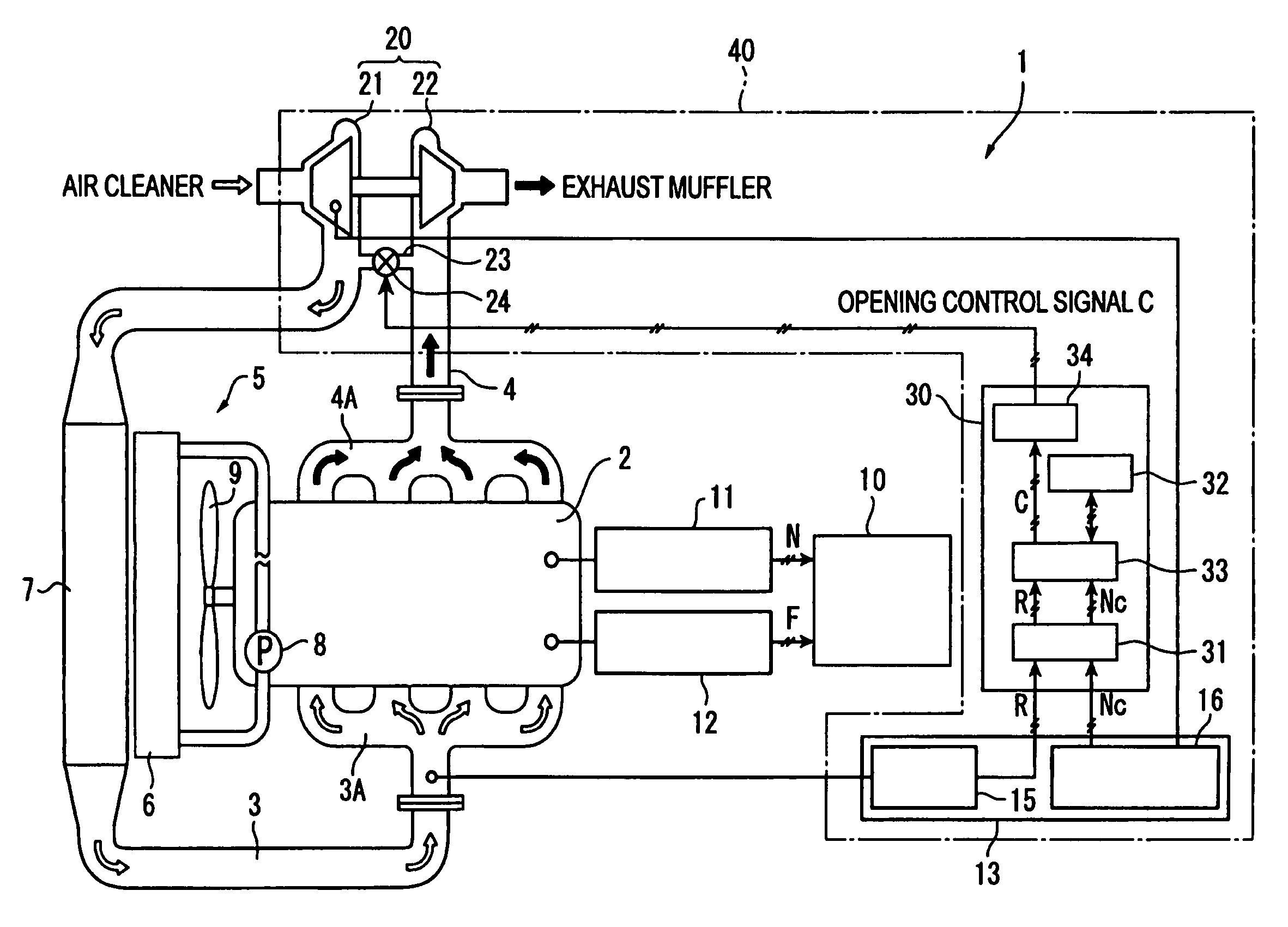

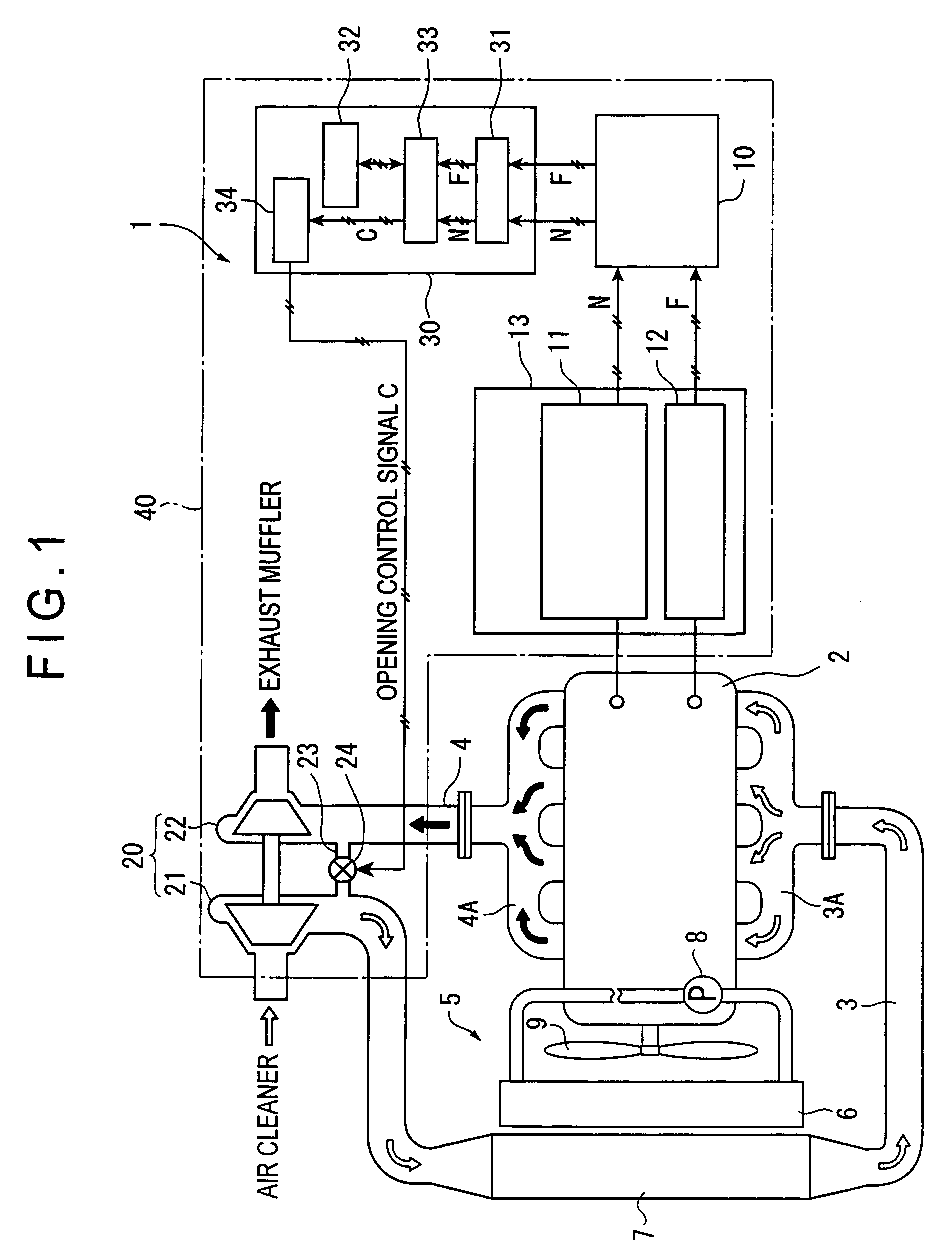

Internal combustion engine provided with intake bypass control device

InactiveUS7032382B2Prevent surgeIncrease pressure ratioElectrical controlInternal combustion piston enginesTurbochargerDieseling

A bypass conduit (23) connects an outlet passage of a compressor (21) of an exhaust gas turbocharger (20) and an inlet passage of an exhaust turbine (22), and a bypass valve (24) is provided therein. When the operating condition of a diesel engine (1) is found to be in a low-speed and high-load region, the bypass valve (24) is controlled by means of a valve controller to adjust the bypass conduit (23) so as to open it. Then, the charge air partly flows into an exhaust conduit (4) to increase the rotational speed of the exhaust turbine (22) and hence the charge air flow rate raises the output of the diesel engine (1). Additionally, as the charge air flow rate is increased, the operating condition of a compressor (21) is prevented from approaching the surging range.

Owner:KOMATSU LTD

Desulfurization and novel sorbents for same

InactiveCN1384770AOctane dropReduce hydrocarbon contentRefining with metalsOther chemical processesAluminateCalcium silicate

Particulate sorbent compositions which are suitable for the removal of sulfur from streams of cracked-gasoline or diesel fuel are provided which have increased porosity, improved resistance to deactivation through the addition of a calcium compound selected from the group consisting of calcium sulfate, calcium silicate, calcium phosphate or calcium aluminate to the support system comprised of zinc oxide, silica and alumina having thereon a promotor wherein the promotor is metal, metal oxide or metal oxide precursor with the metal being selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium or mixtures thereof and wherein the valence of such promotor has been substantially reduced to 2 or less. Process for the preparation such sorbent systems as well as the use of same for the desulfurization of cracked-gasolines and diesel fuels are also provided.

Owner:CHINA PETROLEUM & CHEM CORP

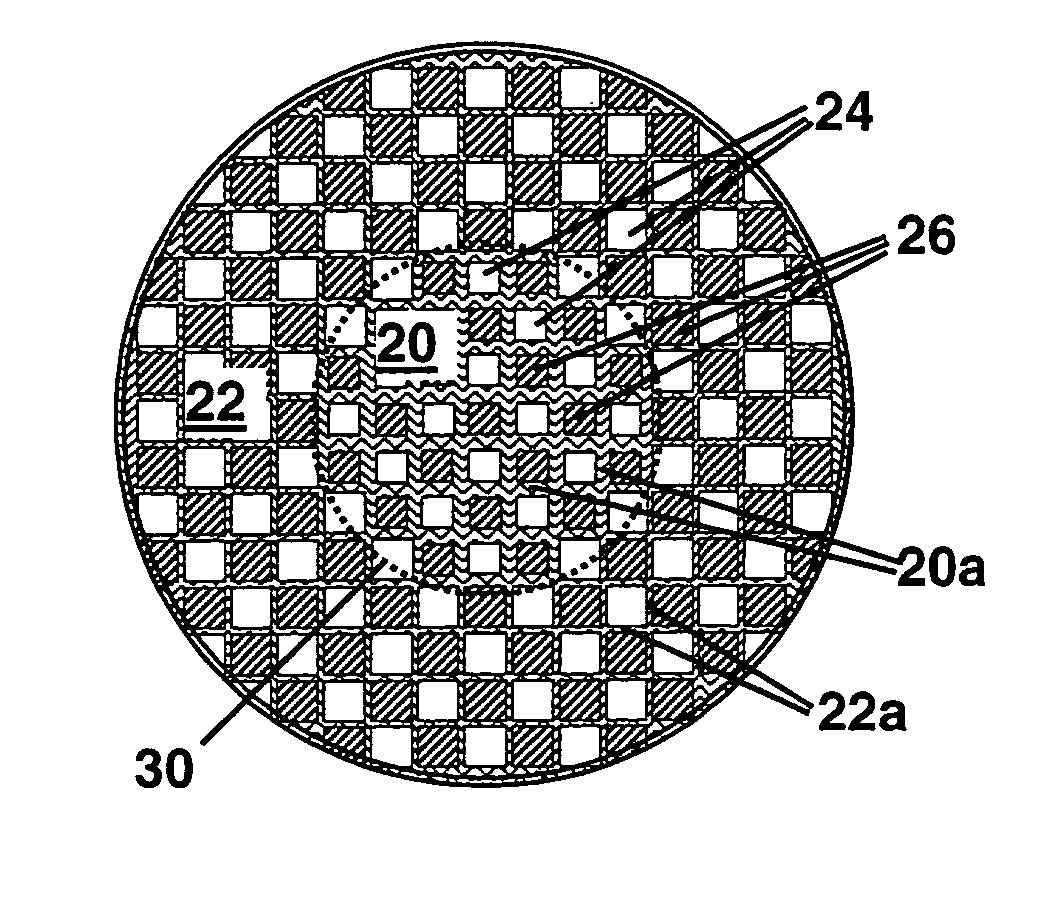

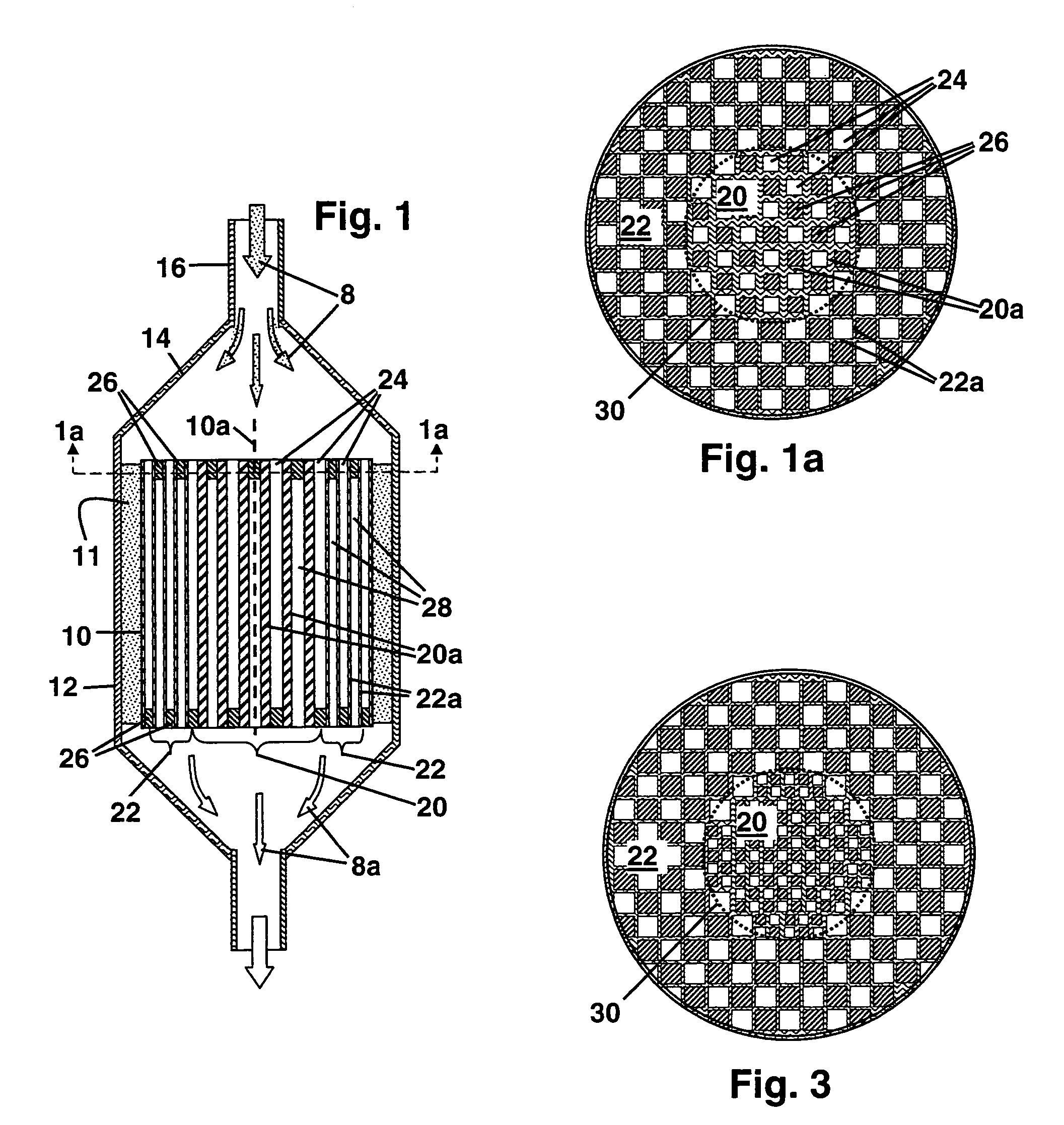

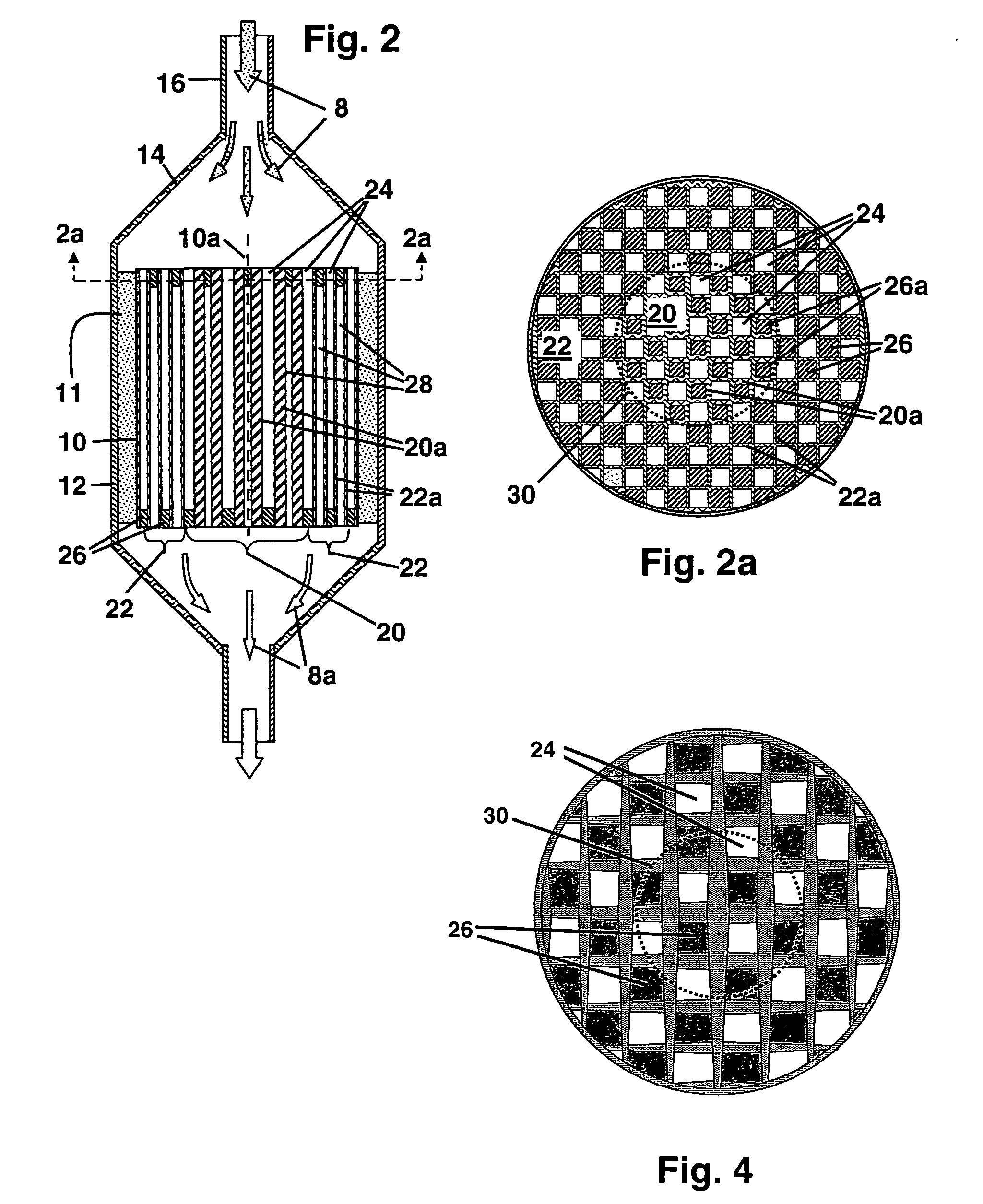

Diesel engine exhaust filters

ActiveUS7238217B2Resist damageSpeed up the processCombination devicesGas treatmentDieselingMechanical engineering

Diesel engine exhaust filtration systems, and ceramic honeycomb wall flow exhaust filters for such systems, wherein the filters comprise axially centralized filter sections having a higher heat capacity and / or a higher gas flow resistance than peripheral filter sections disposed radially outwardly thereof, the filters thereby exhibiting increased resistance to thermal damage from filter regeneration over-heating.

Owner:CORNING INC

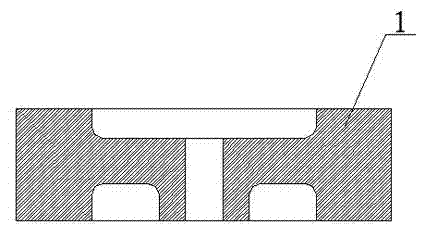

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

Emissions treatment system with ammonia-generating and SCR catalysts

ActiveCN102387851AReduce usageCutting costsGas treatmentInternal combustion piston enginesRare-earth elementParticulates

Provided are emissions treatment systems for an exhaust stream having an ammonia- generating component, such as a NOx storage reduction (NSR) catalyst or a lean NOx trap (LNT) catalyst, and an SCR catalyst disposed downstream of the ammonia-generating catalyst. The SCR catalyst can be a molecular sieve having the CHA crystal structure, for example SSZ- 13 or SAPO-34, which can be ion-exchanged with copper.; The LNT can be layered, having an undercoat washcoat layer comprising a support material, at least one precious metal, and at least one NOx sorbent selected from the group consisting of alkaline earth elements, rare earth elements, and combinations thereof and a top washcoat layer comprising a support material at least one precious metal, and ceria in particulate form, the top washcoat layer being substantially free of alkaline earth components, The emissions treatment system is advantageously used for the treatment of exhaust streams from diesel engines and lean burn gasoline engines.

Owner:BASF CORP

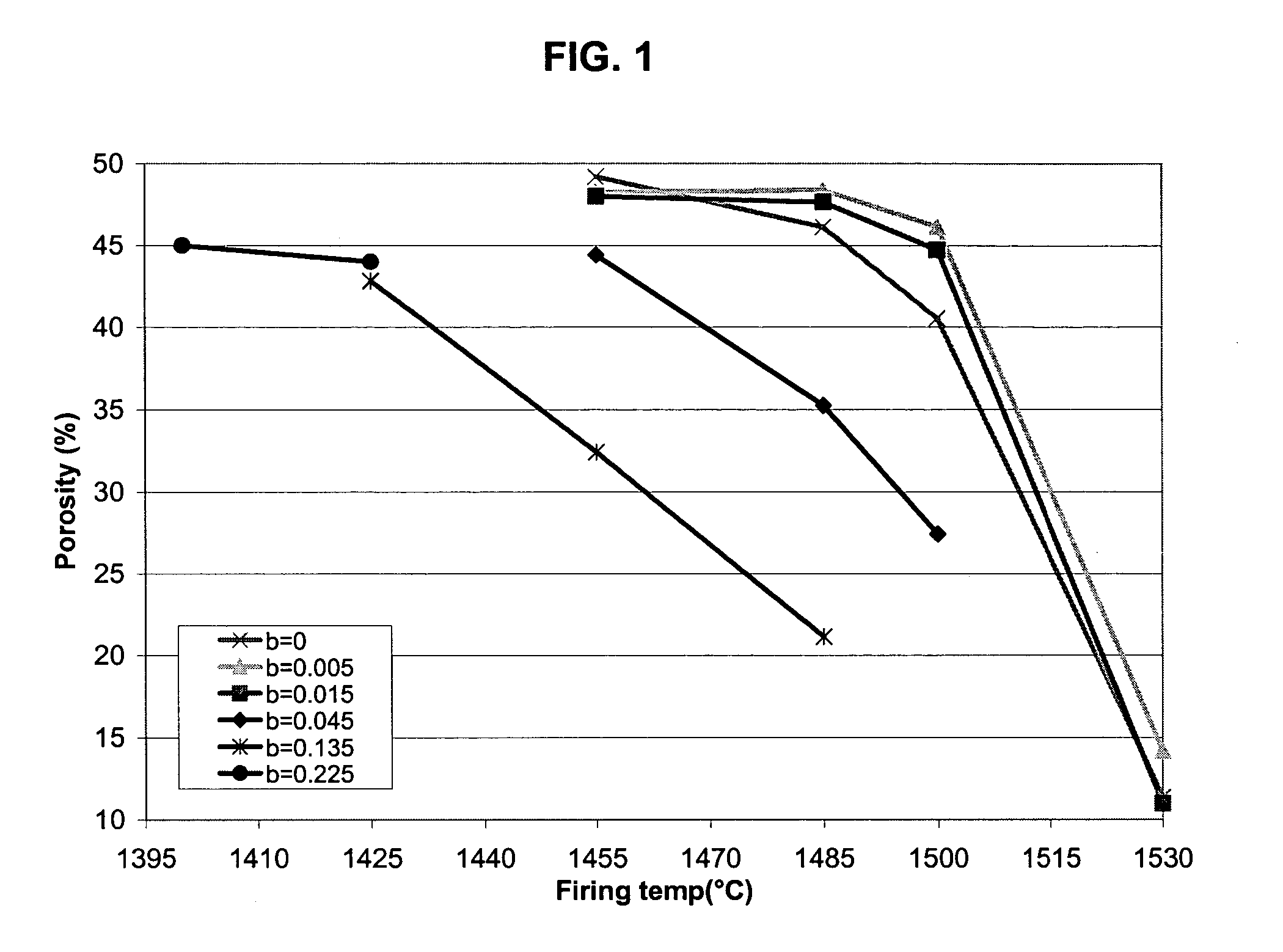

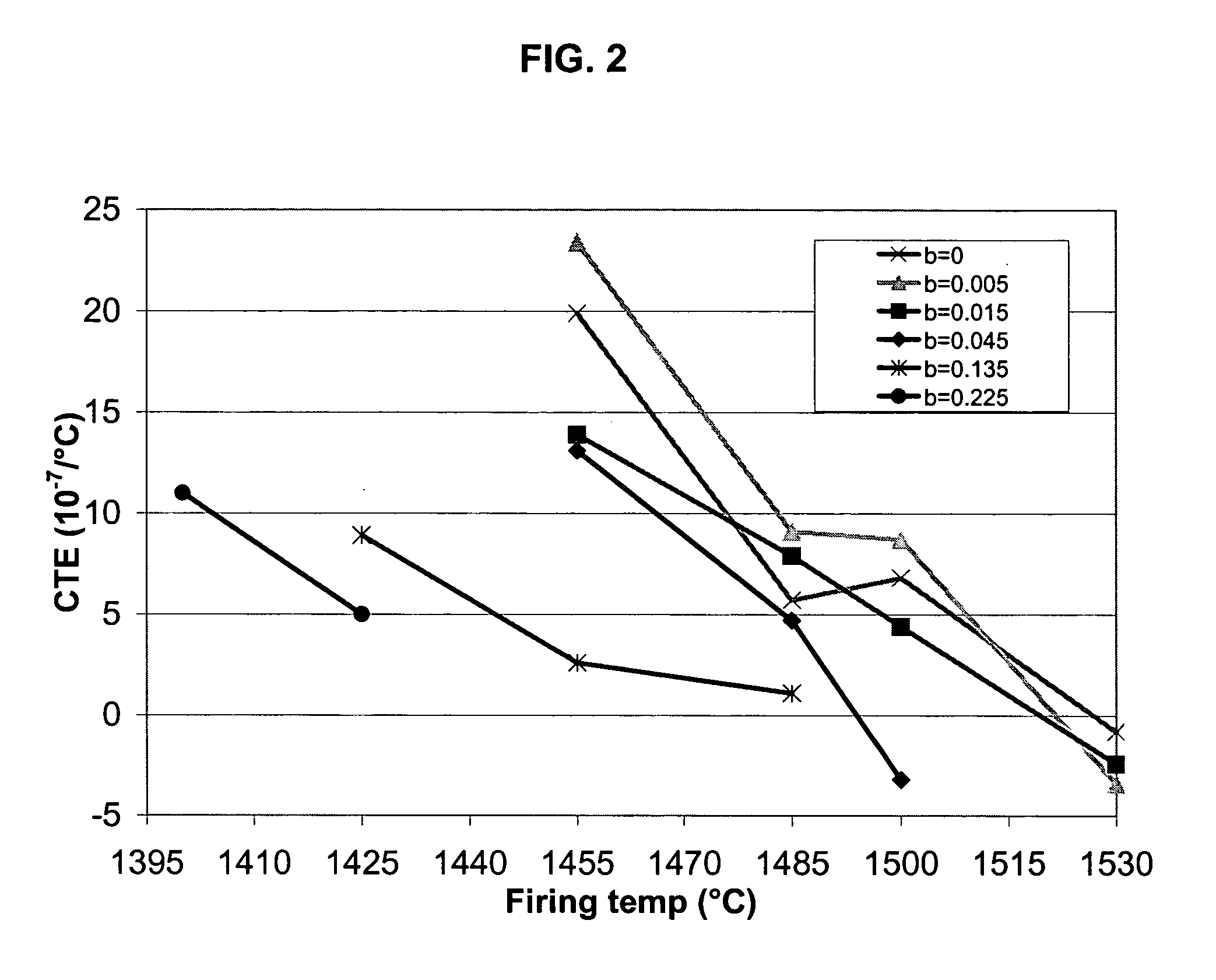

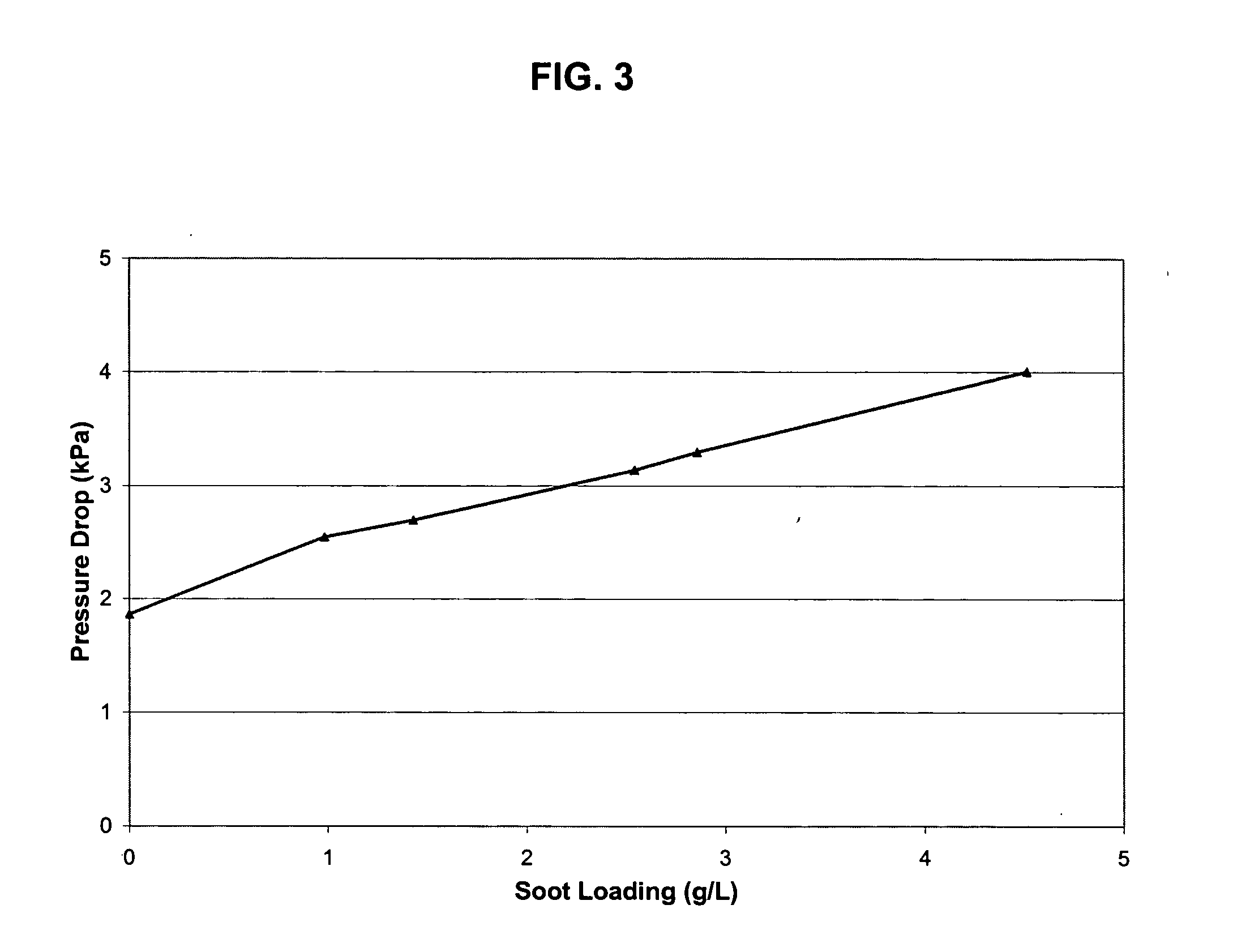

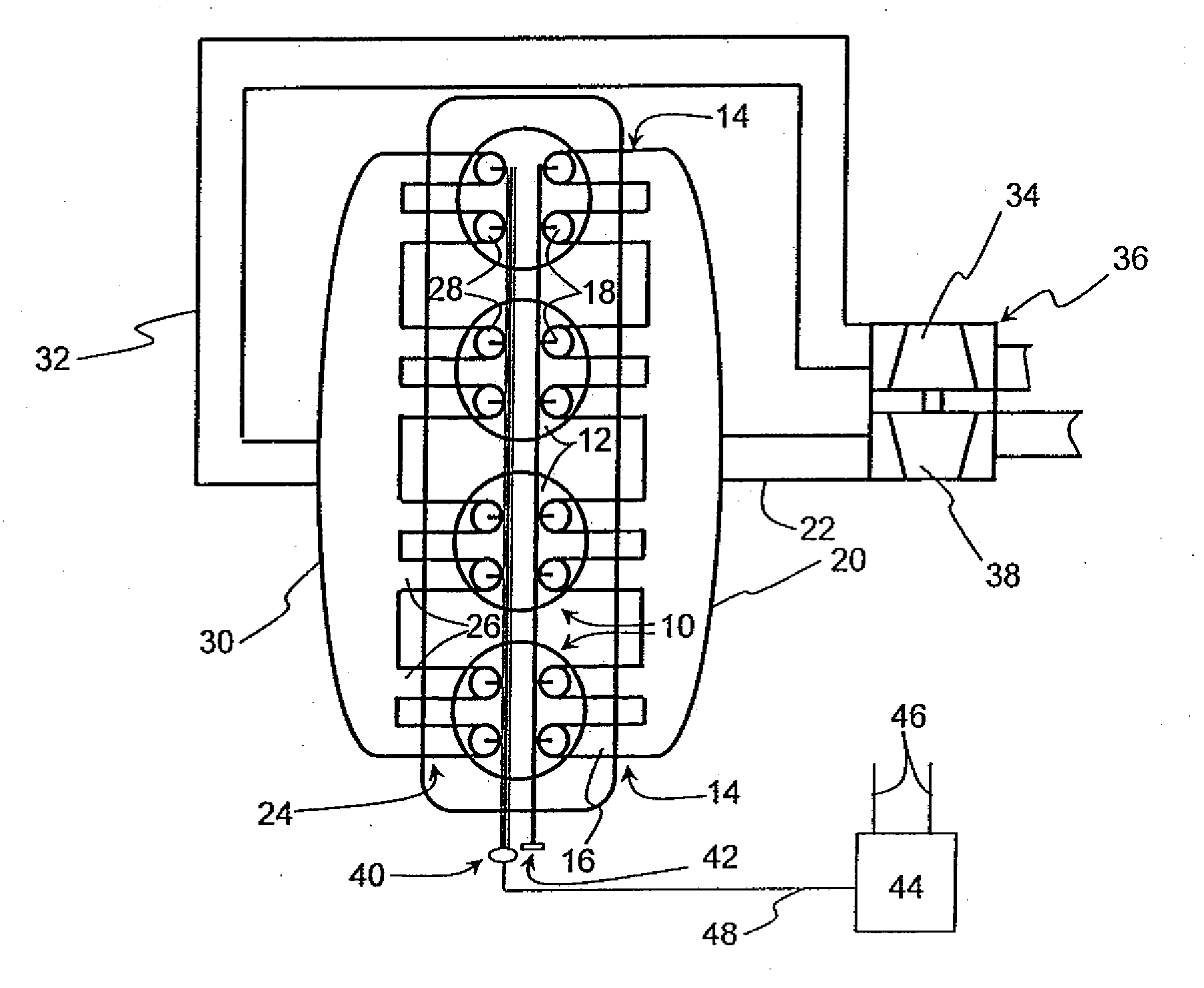

Ceramic body based on aluminum titanate

An aluminum titanate-based ceramic body having a composition a formula comprising a(Al2O3.TiO2)+b(CaO.Al2O3.2SiO2)+c(SrO.Al2O3.2SiO2)+d(BaO.Al2O3.2SiO2)+e(3Al2O3.2SiO2)+f(Al2O3)+g (SiO2)+h(Fe2O3.TiO2)+i(MgO.2TiO2), wherein a, b, c, d, e, f, g, h, and i are weight fractions of each component such that (a+b+c+d+e+f+g+h+i)=1, wherein 0.5<a≦0.95; 0≦b≦0.5; 0≦c≦0.5; 0≦d≦0.5; 0<e≦0.5; 0≦f≦0.5; 0≦g≦0.1; 0≦h≦0.3; 0≦i≦0.3; b+d>0.01. A method of forming the ceramic body is provided. The ceramic body is useful in automotive emissions control systems, such as diesel exhaust filtration.

Owner:CORNING INC

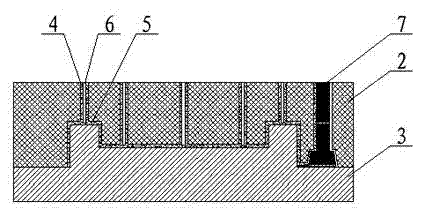

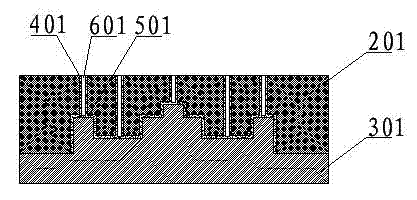

Fuel injection rule measuring device of diesel engine and measuring method thereof

InactiveCN101571090APrecise control of initial pressureEliminate measurement interferenceEngine testingFuel injection apparatusMeasurement deviceData processing

The invention discloses a fuel injection rule measuring device of a diesel engine and a measuring method thereof. The device comprises a pressure vessel, an oil atomizer, an oil pump, a photoelectric encoder, a high pressure connector, a pressure sensor, a charge amplifier, a DSP data acquisition system, a temperature sensor, a safety valve, a feeding disconnecting valve, a pressure meter disconnecting valve, a pressure meter, a volume regulating plunger, a back pressure disconnecting valve, an oil collector and a data processing and display system. The method includes that a measuring rule is obtained by utilizing Soave formula by acquiring the temperature and pressure of the pressure vessel and the angle signal of the oil pump. In the invention, the back pressure disconnecting valve is used for back pressure adjustment, the initial pressure in the pressure vessel is accurately controlled, environment back pressure injected by the oil atomizer is accurately simulated, and the volume adjusting plunger can adjust the volume of the pressure vessel. The invention eliminates that measuring interference between two adjacent injections in one injecting process which probably appears in plunger displacement method and ensures fuel injection rule measuring accuracy.

Owner:BEIHANG UNIV

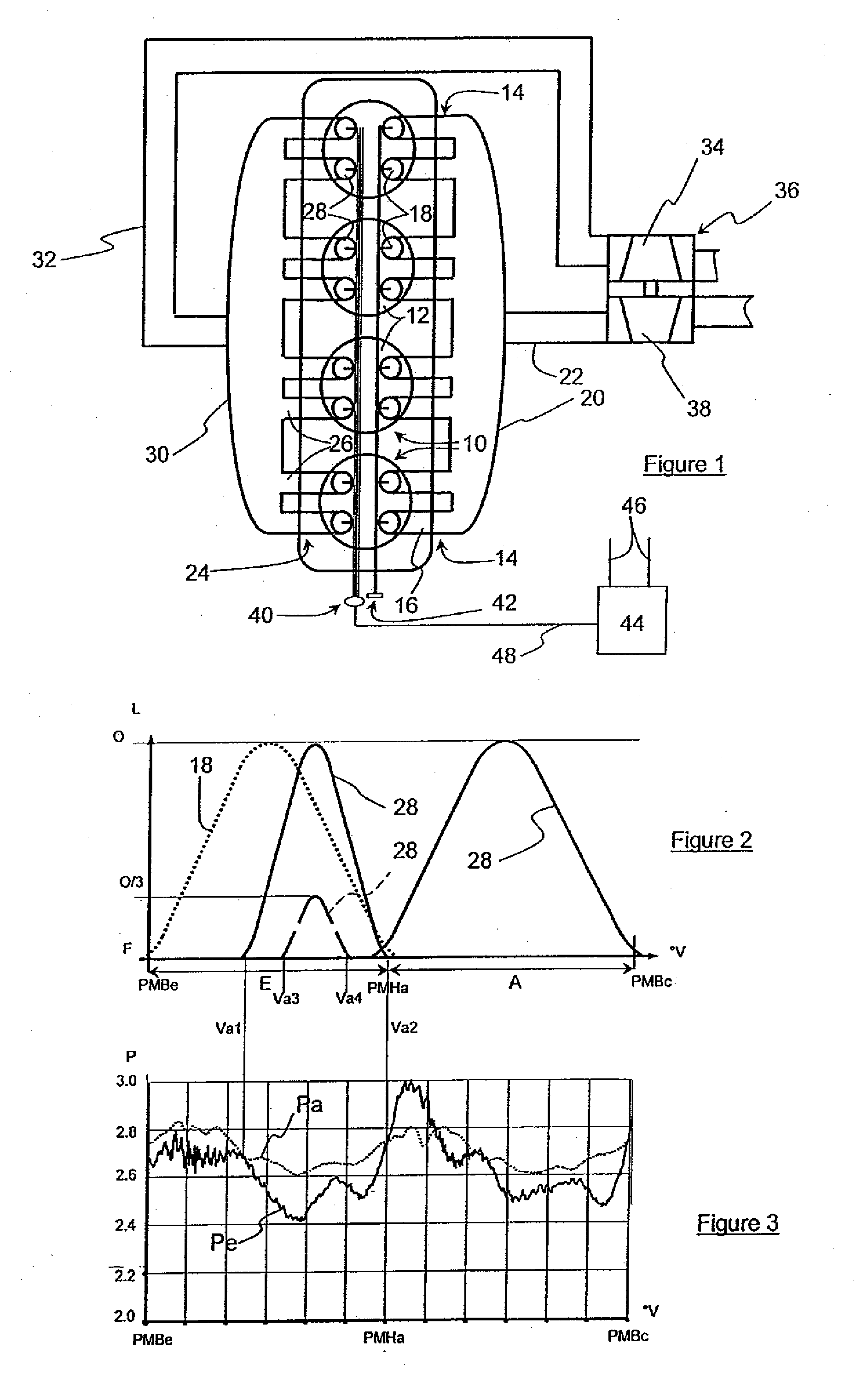

Residual burnt gas scavenging method with double intake valve lift in a direct-injection supercharged internal-combusion engine, notably of diesel type

ActiveUS20090194080A1Reduce the overall heightDecreasing intake valve lift spreadValve arrangementsNon-fuel substance addition to fuelCombustion chamberExhaust valve

The present invention relates to a method of scavenging residual burnt gas of a direct-injection internal-combustion engine, notably of diesel type, comprising at least one cylinder (10) including a combustion chamber (12), at least one exhaust means (14) with an exhaust valve (18) controlled by exhaust control means (42), at least one intake means (24) with an intake valve (28) controlled by intake control means (40) and a processing unit (44) receiving the values relative to the intake pressure (Pa) and to the exhaust pressure (Pe) of the engine.According to the invention, the method consists, when the engine runs under low speed and high load conditions, in:carrying out a sequence of opening / closing of exhaust valves (18) during the exhaust phase of the engine,during this exhaust valve opening / closing sequence, in carrying out at least one sequence of opening / closing of intake valves (28) so as to achieve scavenging of the residual burnt gas.

Owner:INST FR DU PETROLE

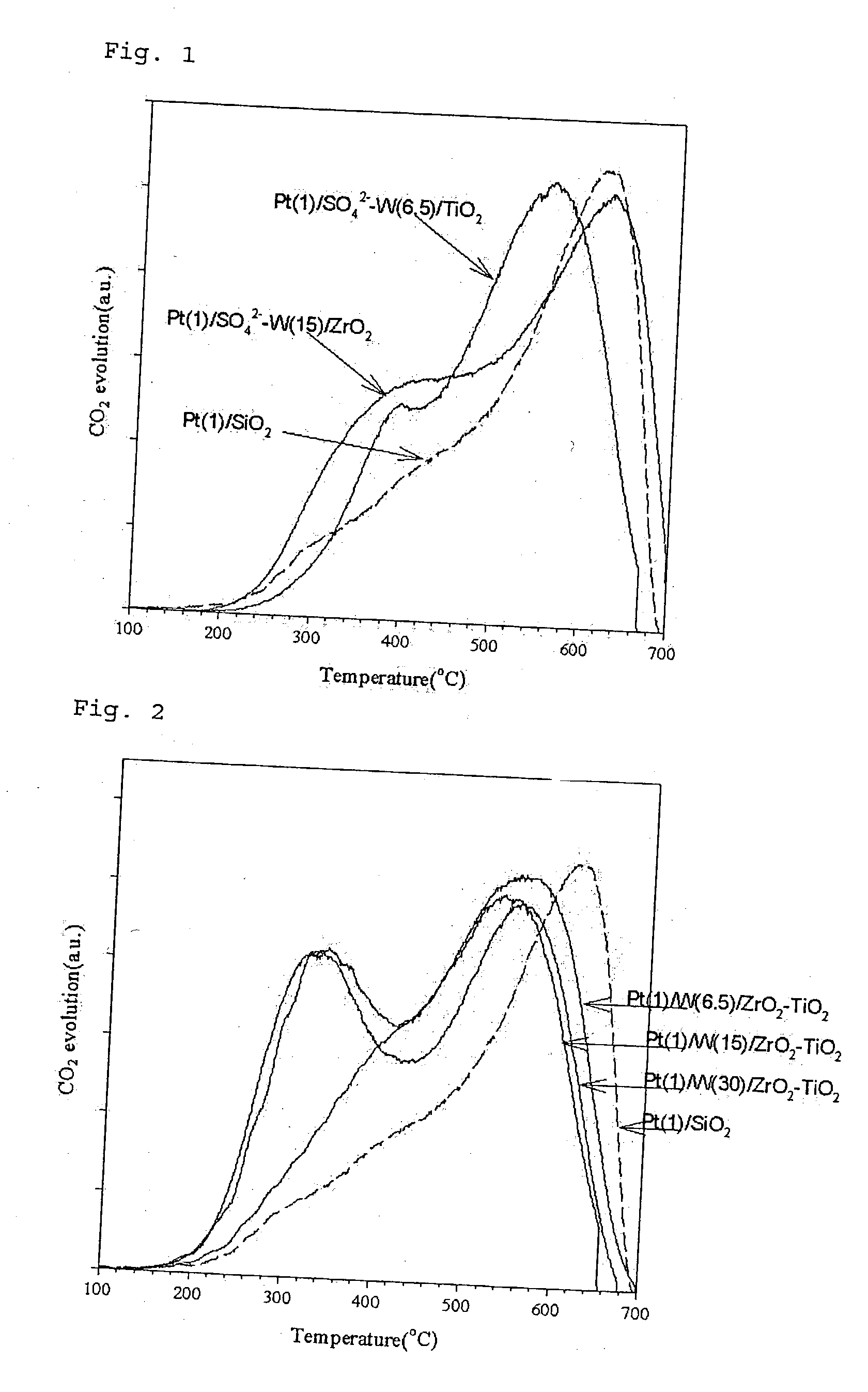

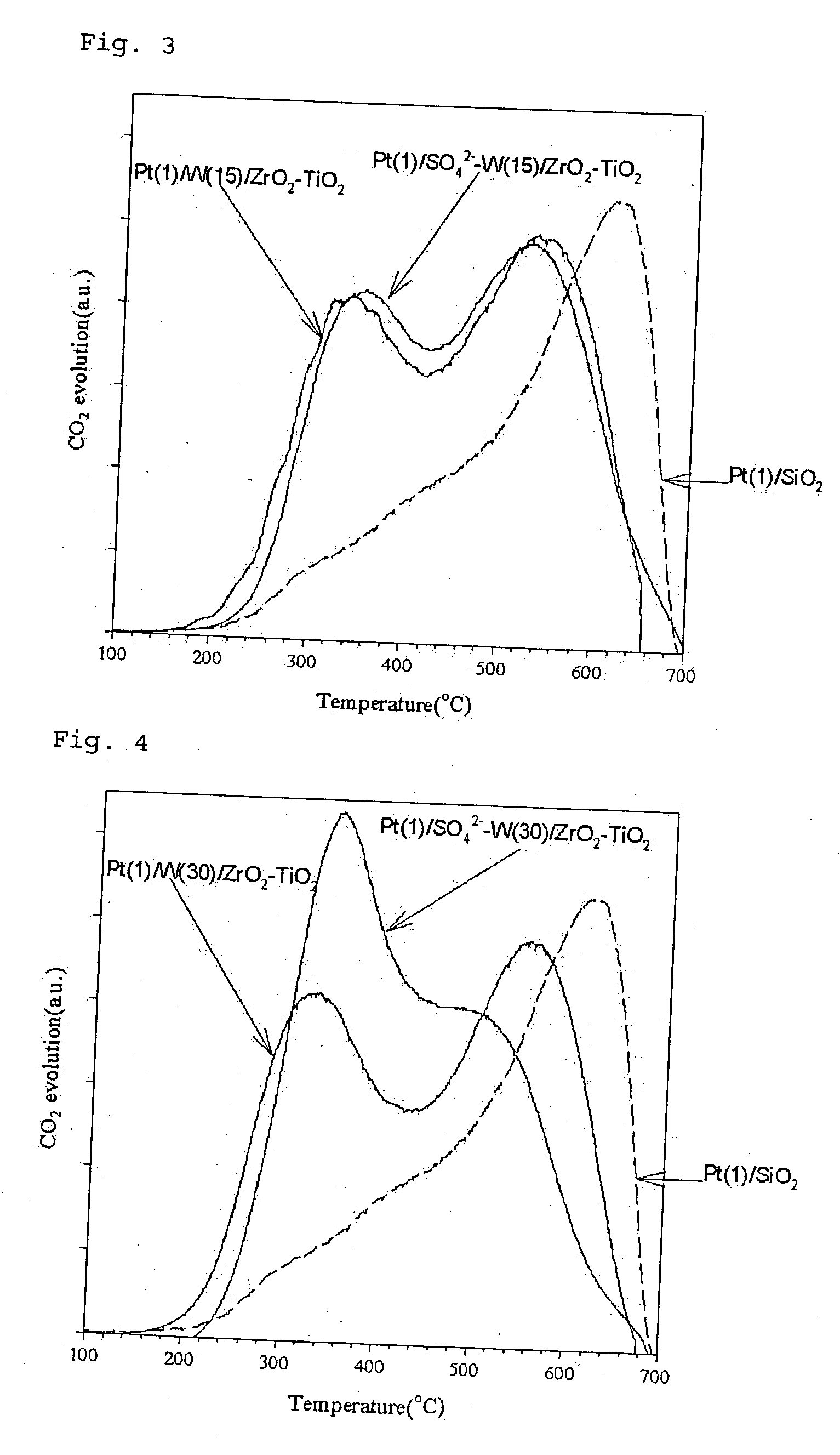

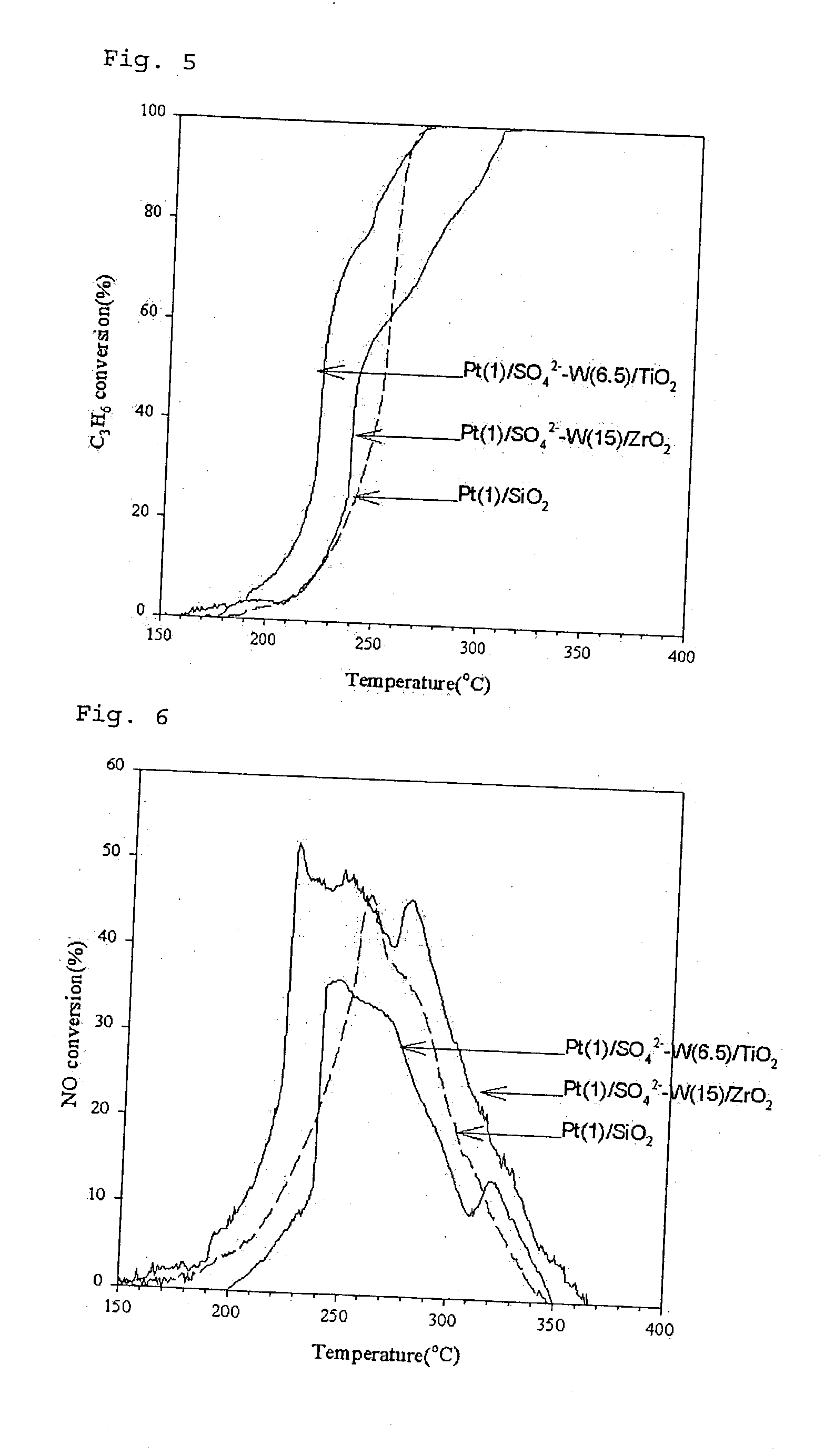

Catalyst for purification of diesel engine exhaust gas

InactiveUS20030104932A1Increase acidityHigh activityAcutation objectsGas treatmentParticulatesNitrogen oxides

This invention provides a new catalyst for purification of diesel engine exhaust gas comprising a carrier of at least one sulfur-resistant refractory oxide and at least one catalytic metal, wherein at least one solid acid and / or sulfuric acid is carried on the carrier by adding at least one precursor of said solid acid and / or sulfuric acid during the preparation of the carrier, and preparation thereof. The catalyst of this invention is thermally and chemically durable and can effectively remove particulate matters, hydrocarbons and nitrogen oxides contained in the diesel engine exhaust gas at low temperatures.

Owner:KH CHEM CO LTD

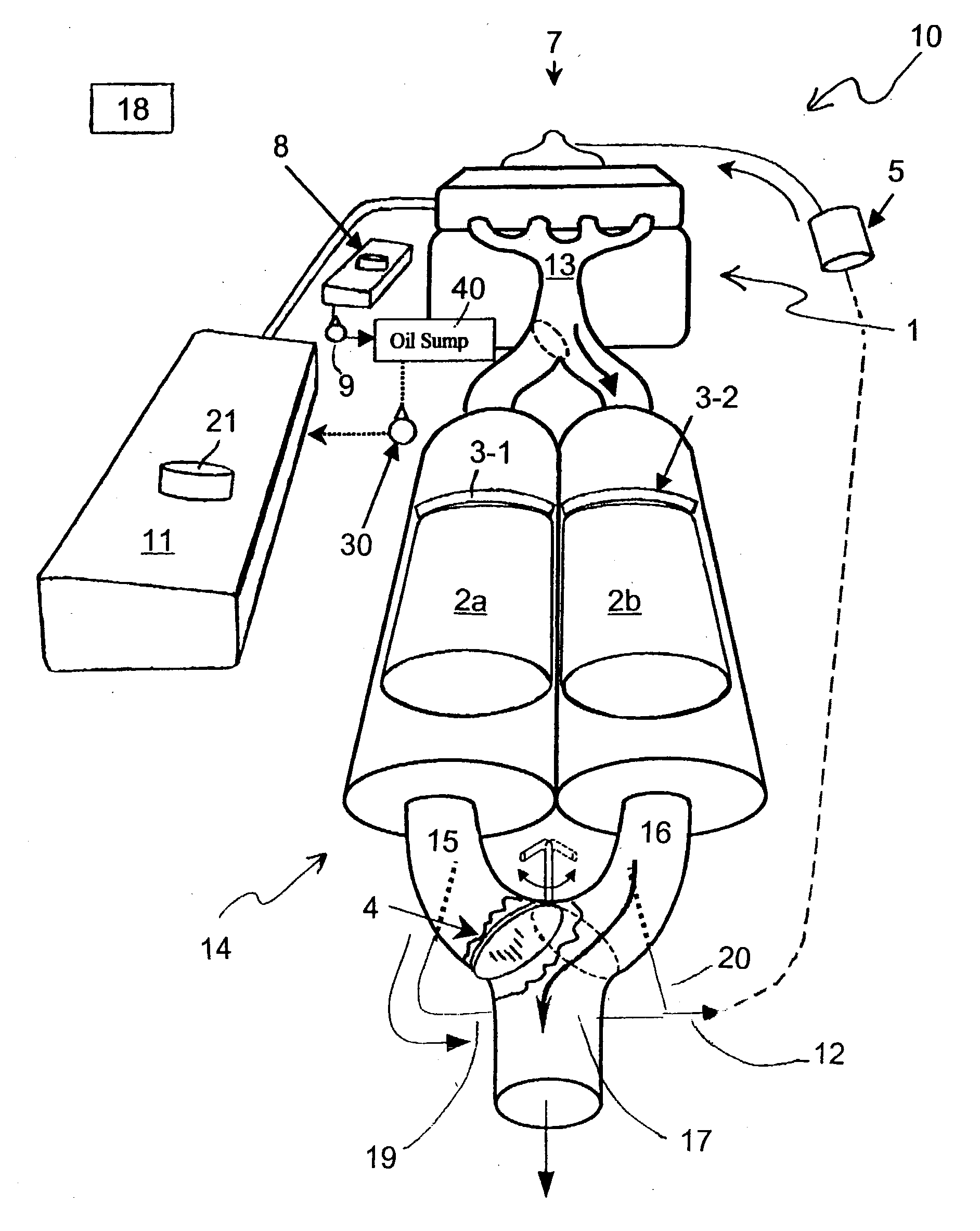

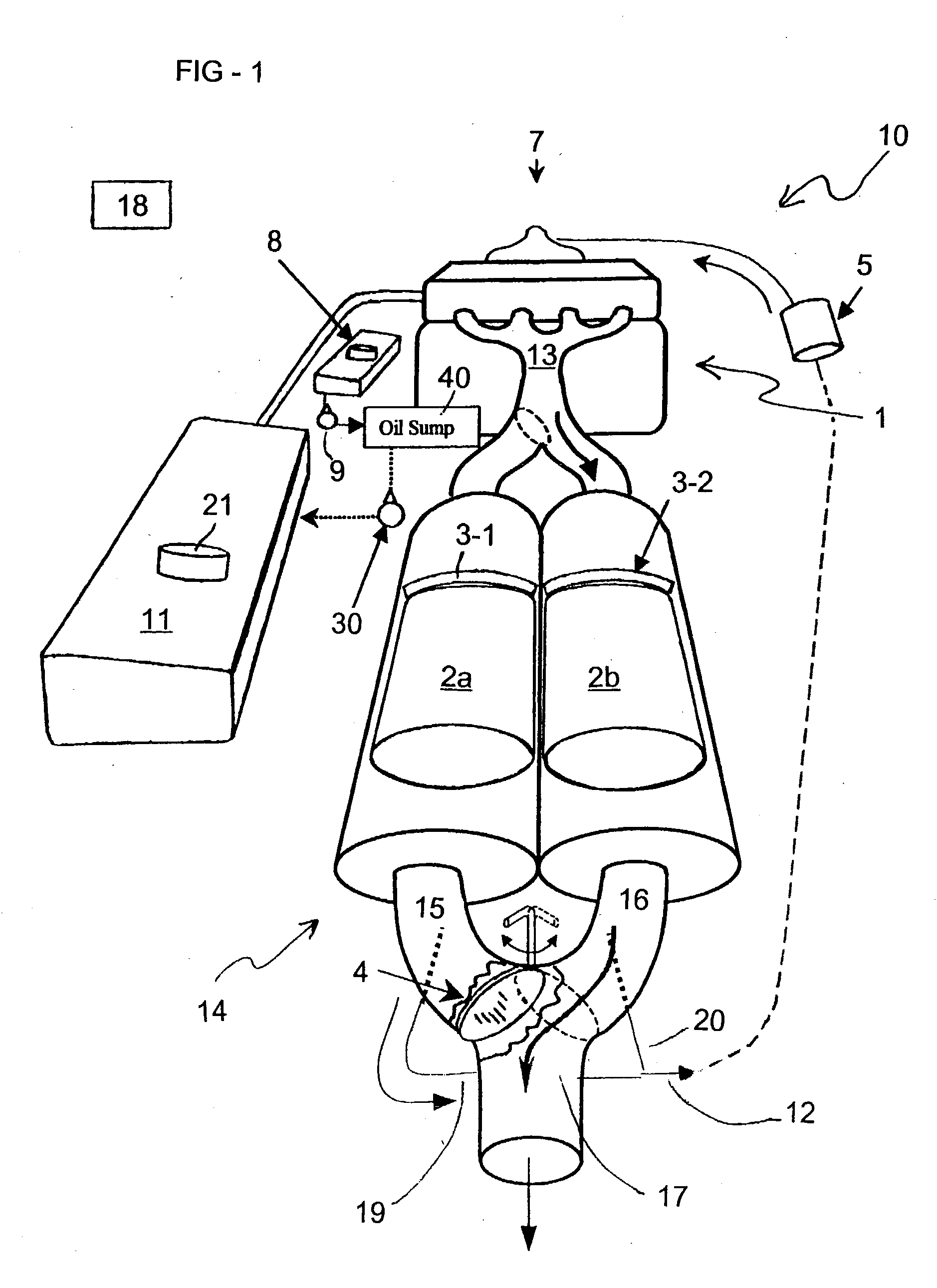

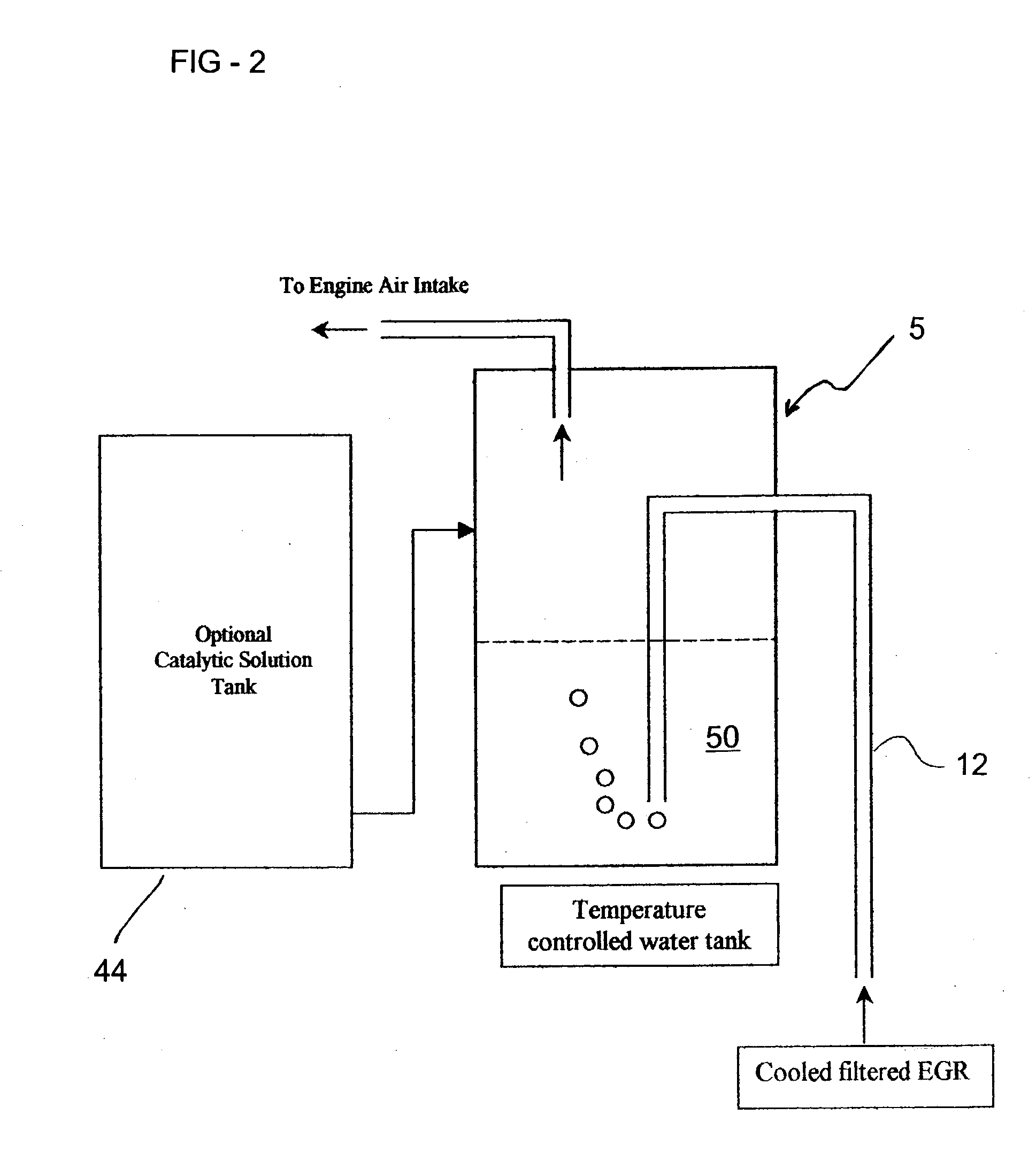

System for and methods of operating diesel engines to reduce harmful exhaust emissions and to improve engine lubrication

InactiveUS20040194454A1Facilitates DPF regenerationAnti-wear propertyInternal combustion piston enginesNon-fuel substance addition to fuelOil additiveExhaust gas emissions

A Diesel engine anti-wear lubricant oil additive composition that includes organo-metallic compounds of Cu, Ce, etc., is used to catalytically bum-off diesel particulate matter (PM) collected by diesel particulate filter (DPF). A fuel borne catalyst (FBC) of Cu,Ce,Fe etc., required for regenerating the DPF is made by blending a predetermined quantity of used engine oil, removed from the engine crankcase oil system, with fuel in the fuel tank of a diesel engine equipped with DPF and EGR systems. A method of fumigating water and catalytic compounds of Cu, Fe, Ce, etc., into the air-intake system of a diesel engine in the EGR gases from the DPF or air, to reduce both PM and NOx emissions from a diesel engine, with improved engine lubrication performance, is also disclosed.

Owner:RIM JULIUS J

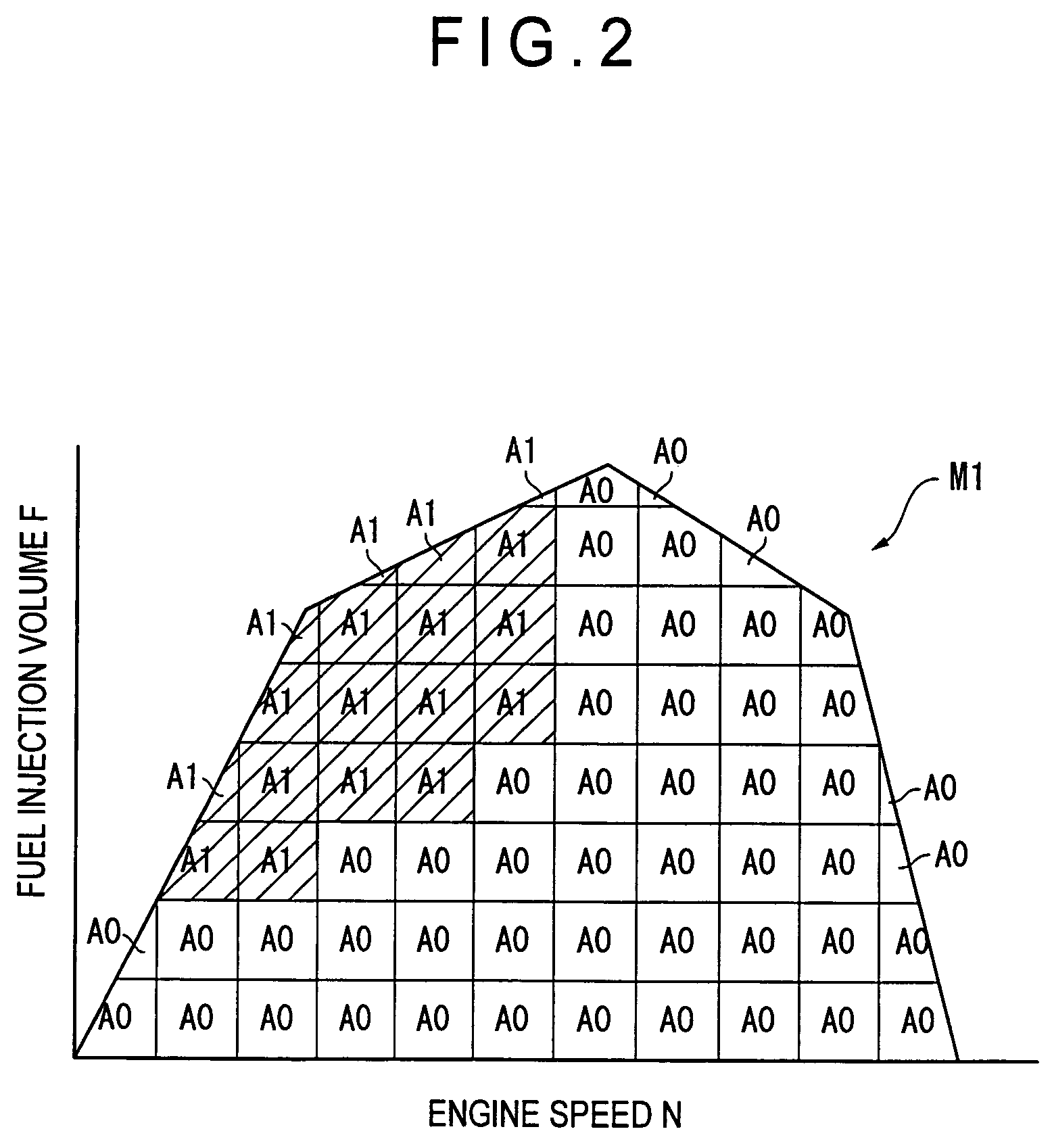

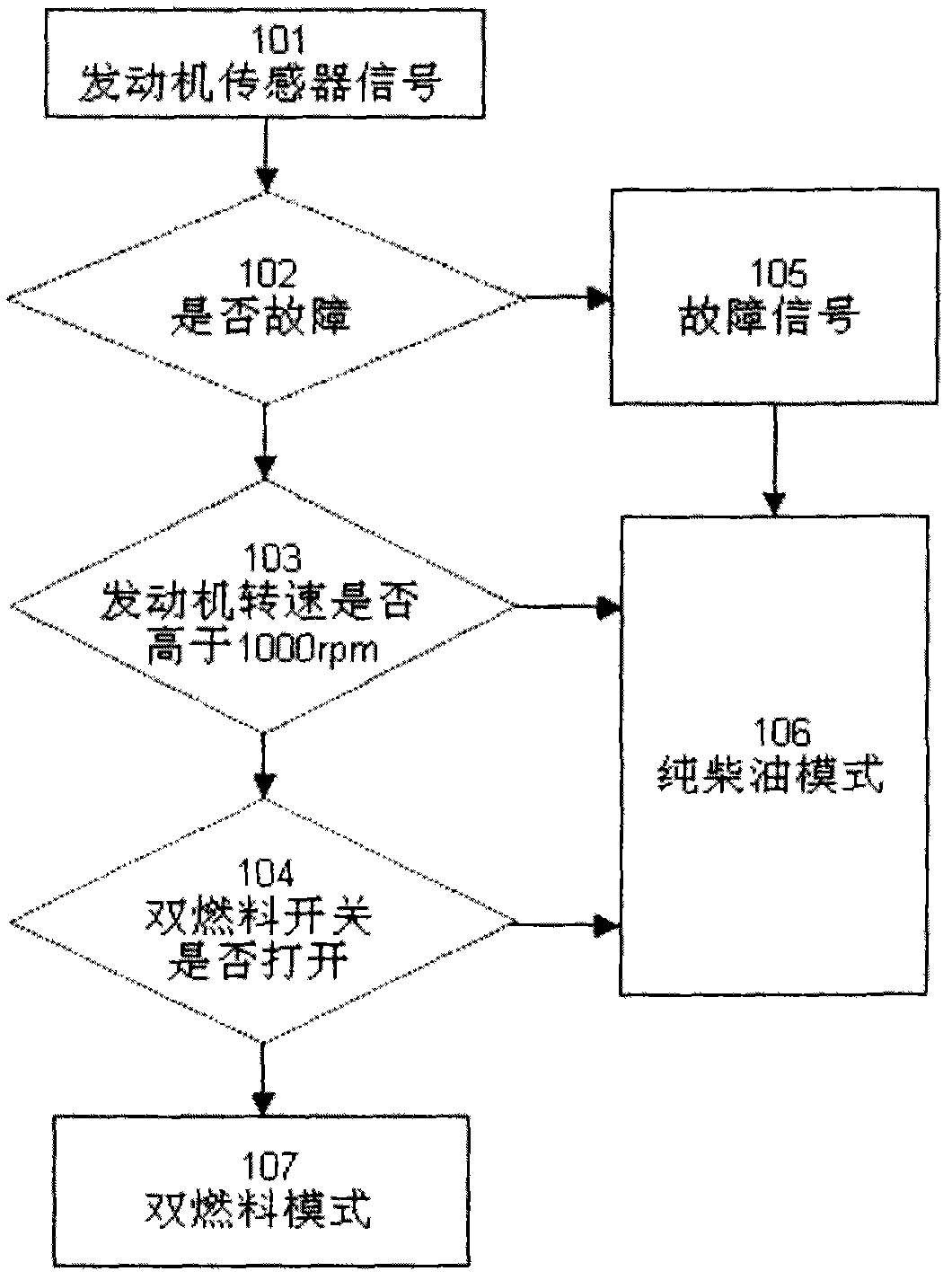

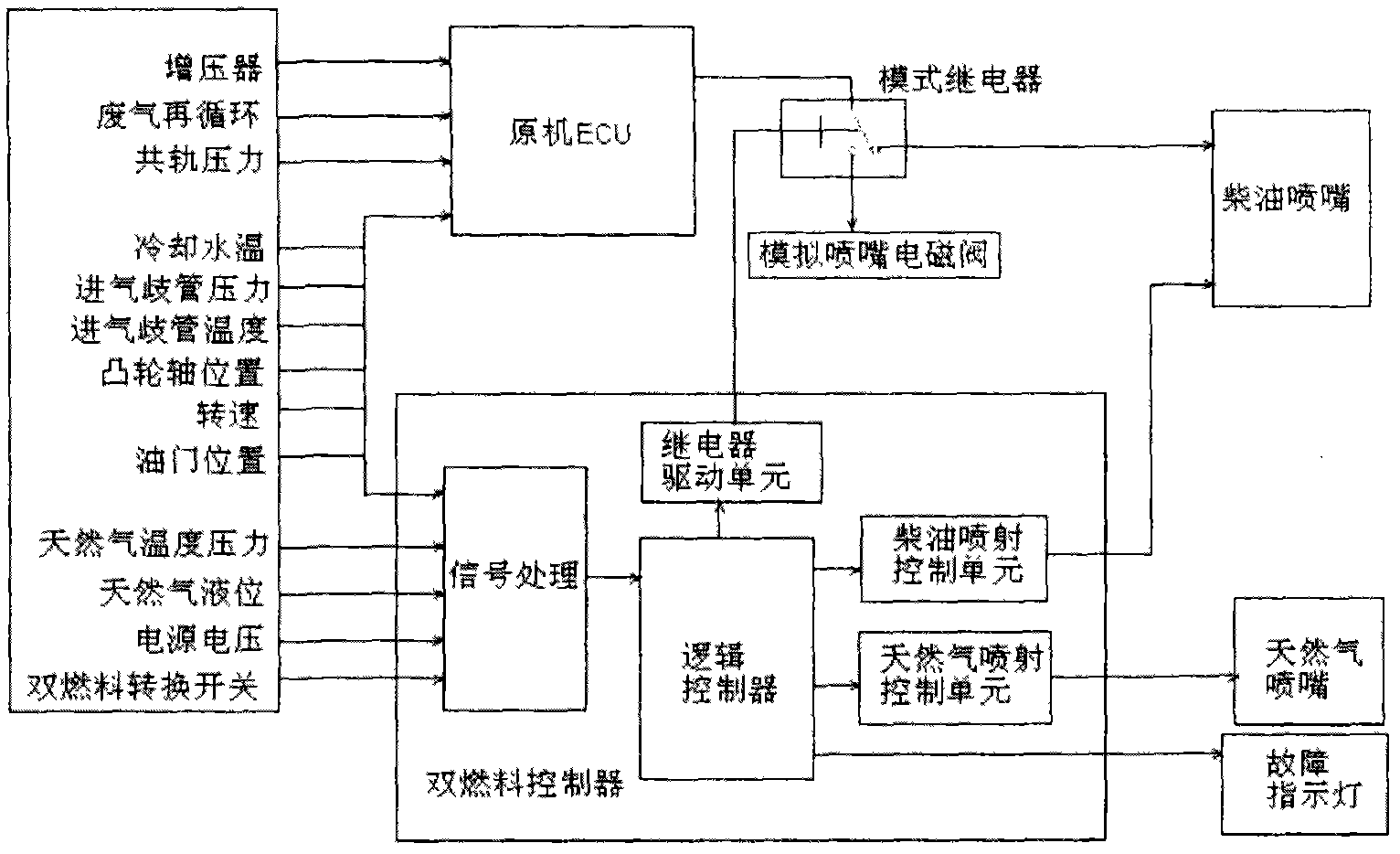

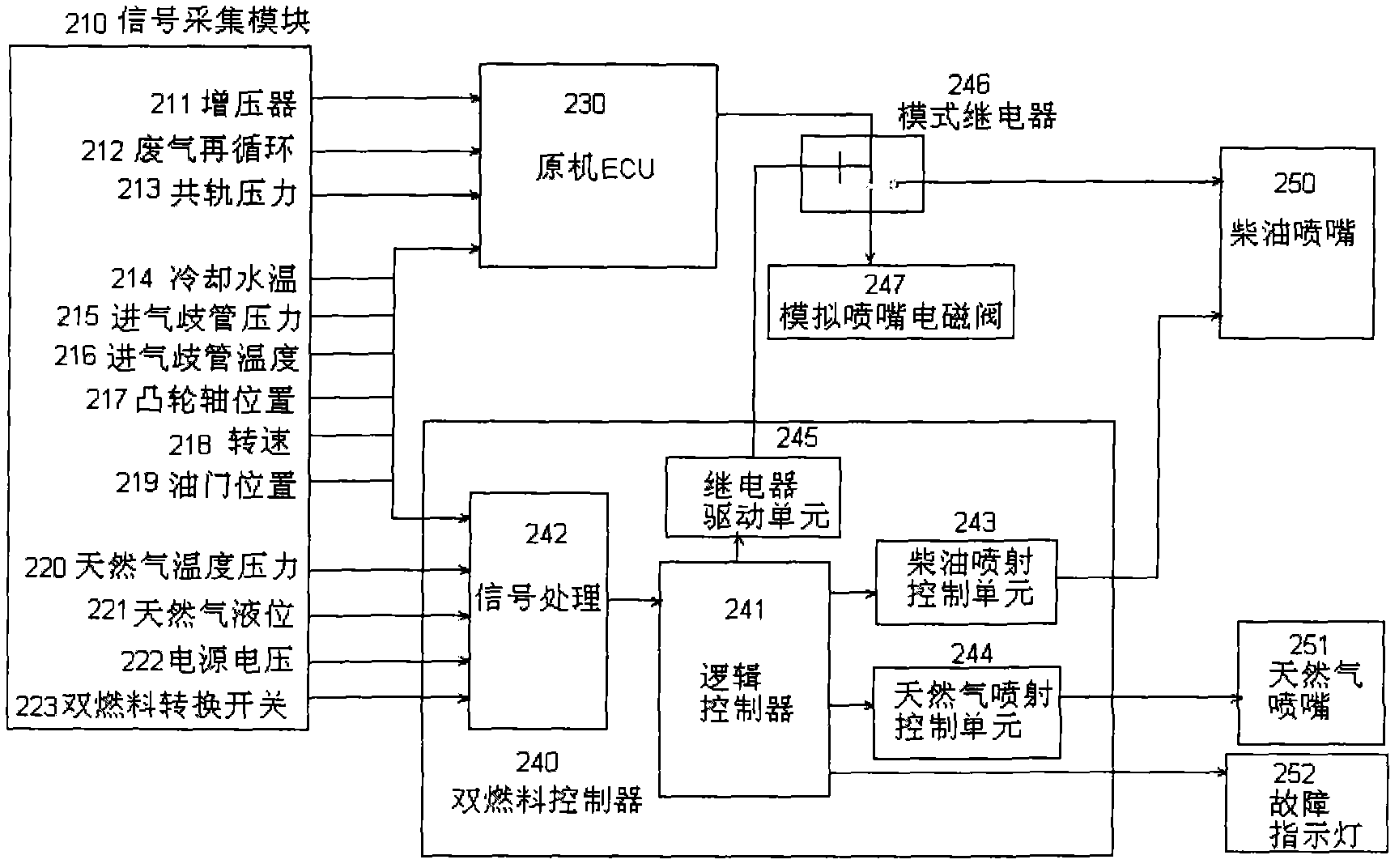

Diesel engine/natural gas dual-fuel engine electric control system

InactiveCN103016168AGuaranteed to workElectrical controlInternal combustion piston enginesFuel control unitControl system

The invention discloses a control method and a control device of a diesel / natural gas dual-fuel engine. The method is characterized in that that on the basis of maintaining an original engine control system, a diesel and gas control unit is added. Signals of all sensors of the original machine are shared by the dual-fuel control system and an electric control system of the original machine. The added dual-fuel control unit can control the injection of the diesel and an additionally-installed gas injection system (including a gas nozzle electromagnetic control, a gas switch valve control, gas liquid level or pressure monitoring and the like), and the added dual-fuel control unit can also process signals which are associated to the gas system. The injection volume and the oil injection moment of the diesel can be precisely controlled according to different working states of a diesel engine, and the injection time and the injection duration of the natural gas can also be controlled. The duel-fuel engine can be enabled to run safely and stably, the fuel consumption can be reduced, and the emission of tail gas can be reduced.

Owner:BEIJING YIKONG LINGBO AUTOMOBILE ELECTRONICS TECH

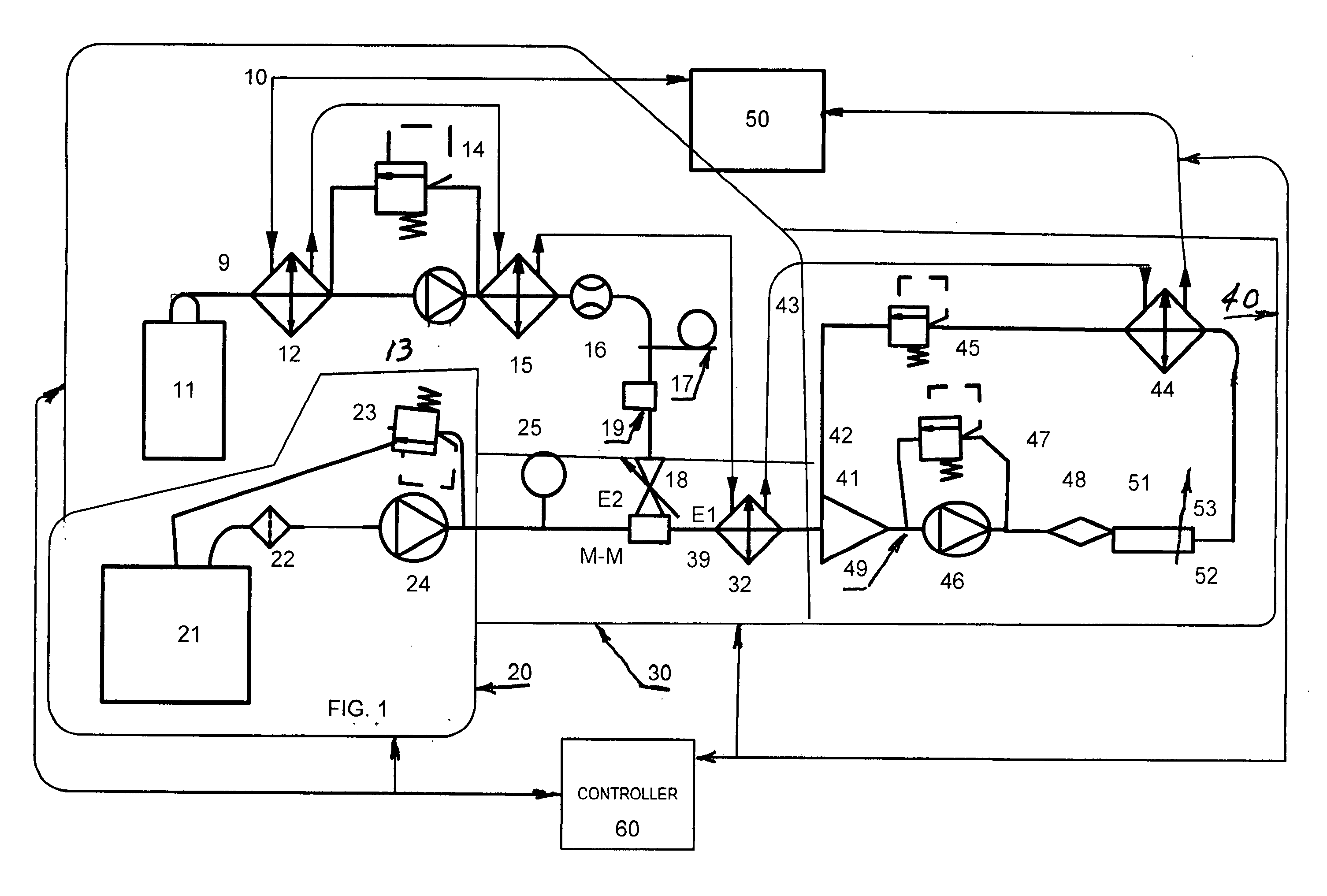

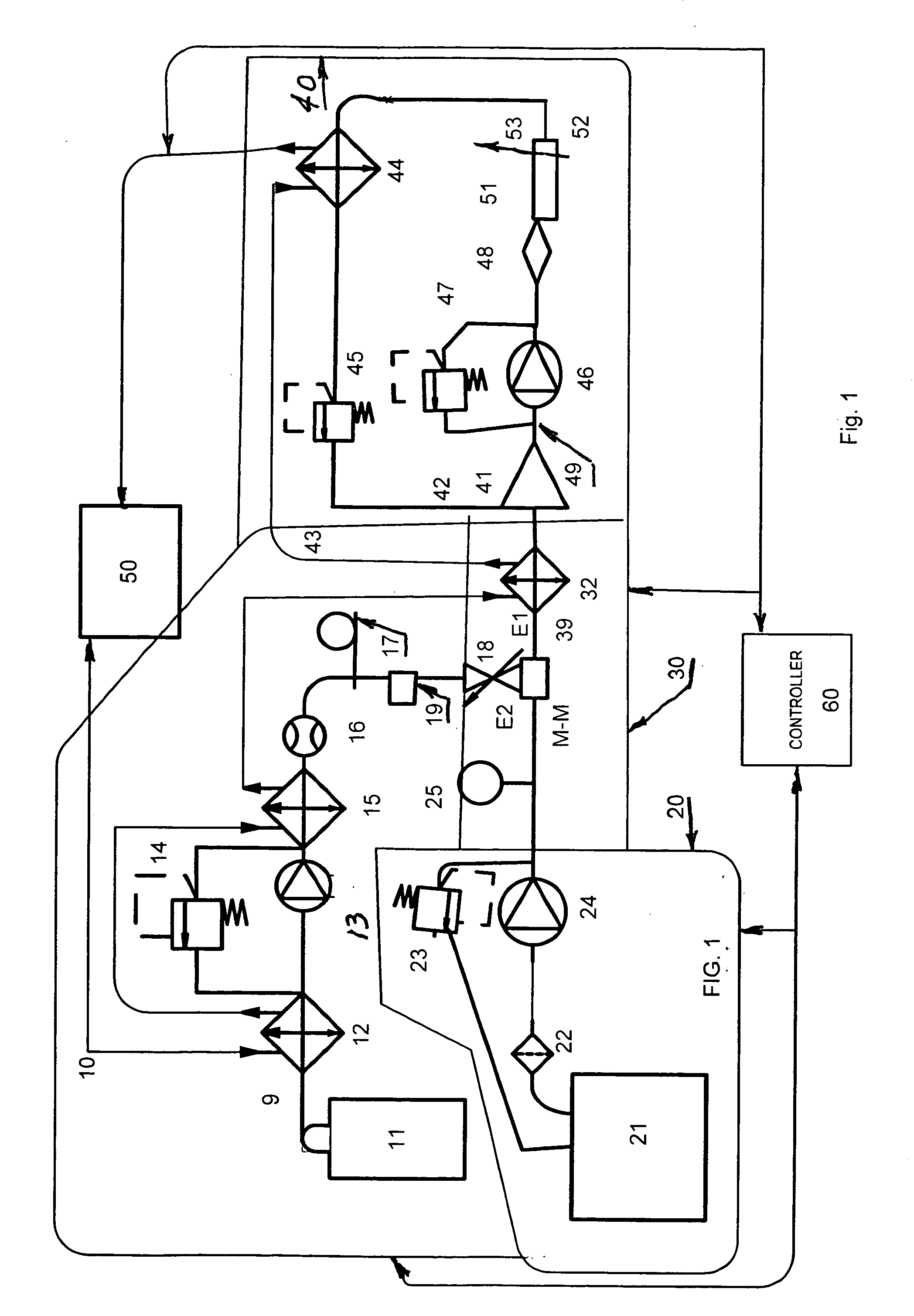

Fuel system and method for burning liquid ammonia in engines and boilers

ActiveUS20100288211A1Easy to igniteImprove combustion characteristicsElectrical controlControlling ratio of multiple fluid flowsCombustion chamberEngineering

A process and apparatus is provided for burning liquid ammonia in an energy device such as a diesel engine, boiler or gas turbine. In particular, the process and apparatus include mixing a renewable fuel with a low flame speed and high ignition temperature, e.g., ammonia, with a combustible liquid fossil or bio-fuel and supplying the mixture into a closed fuel loop where part is efficiently burned in an engine combustion chamber, and part is used to cool the engine and returned by the loop for mixture with fresh incoming fuel mixture. The invention provides for the mixing and emulsifying in such a way that vapour lock is avoided. In the loop, the mixture is emulsified into a disperse distribution of fuel droplets such that upon injection of a portion into the combustion chamber, the renewable fuel in an emulsified droplet evaporates, mixes with the air and forms a small combustion cell surrounding the liquid fuel droplet. The fuel droplet burns and then serves as an ignition kernel for the gas mixture in the small combustion cell producing efficient and rapid combustion of the renewable fuel. The fuel loop allows the fuel system to automatically scale for engines varying in power output from 1 to 35,000 horsepower.

Owner:CAHN RICHARD C +1

Medium speed diesel engine oil

A lubricating oil having a CCS viscosity at −15° C. less than 7000 cP, good shear stability, and a TBN between 8 and 20 comprising: a) a lubricating base oil made from a waxy feed, b) an engine oil additive package formulated to protect silver bearings, and c) less than 2.0 wt % viscosity index improver. Also a process to make a lubricating oil having a CCS viscosity at −15° C. less than 7000 cP, good shear stability, and a TBN between 8 and 20. Additionally, a lubricating oil having low CCS viscosity comprising specified amounts of lubricating base oil made from a waxy feed, engine oil additive package formulated to protect silver bearings, up to 55 wt % bright stock with a VI greater than 120, and no viscosity index improver or conventional pour point depressant additives. Also, a method for operating a railroad engine using the lubricating oil of this invention.

Owner:CHEVROU USA INC

Diesel engine oil test bed system

ActiveCN102012318AMeet the test requirementsEasy to useInternal-combustion engine testingTest requirementsDiesel engine

The invention relates to a diesel engine test system, in particular to a diesel engine oil test bed system, which comprises a return oil filter tank, a cleaning oil tank, a cleaning oil pump, a first engine oil filter, a lubricating feedback pump, an engine oil filter, a heat exchanger, a secondary engine oil filter, a first engine oil inlet / outlet filter, a heating water pump, a diesel engine oil bottom shell and an engine oil preheating water tank. The diesel engine oil test bed system has favorable use effect, safety and reliability, is simple and convenient for operation and can meet the test requirement of the diesel engine, and the advancement of the automatic regulation property and the control technology, of the system, is worth of popularization and adoption.

Owner:CRRC QISHUYAN CO LTD

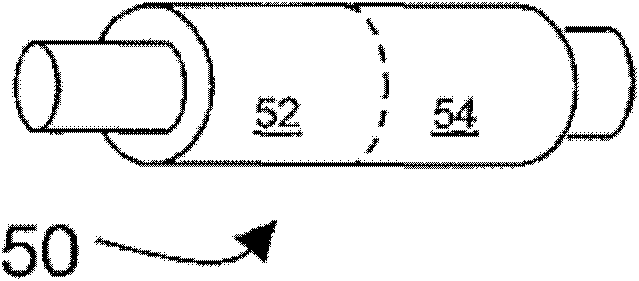

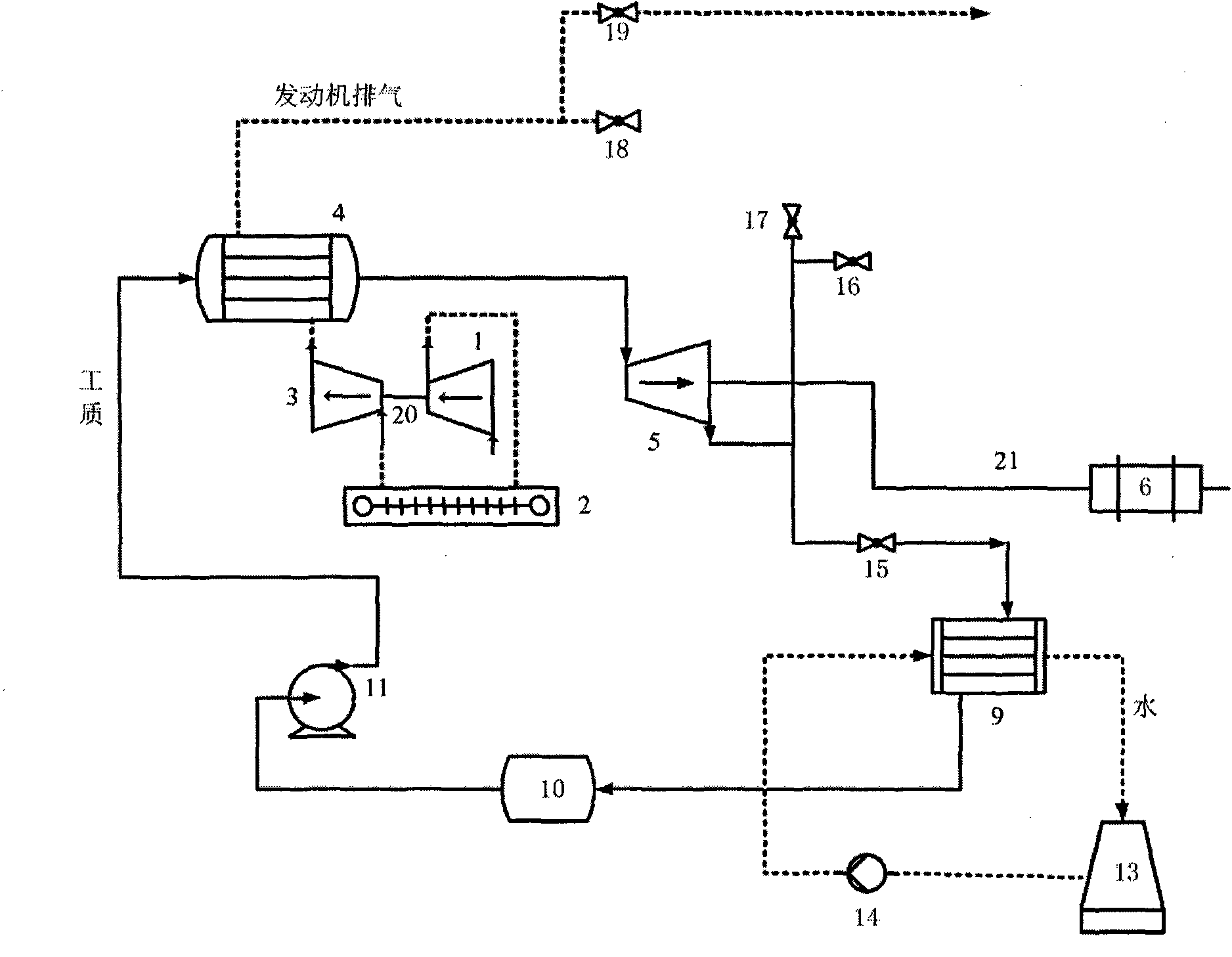

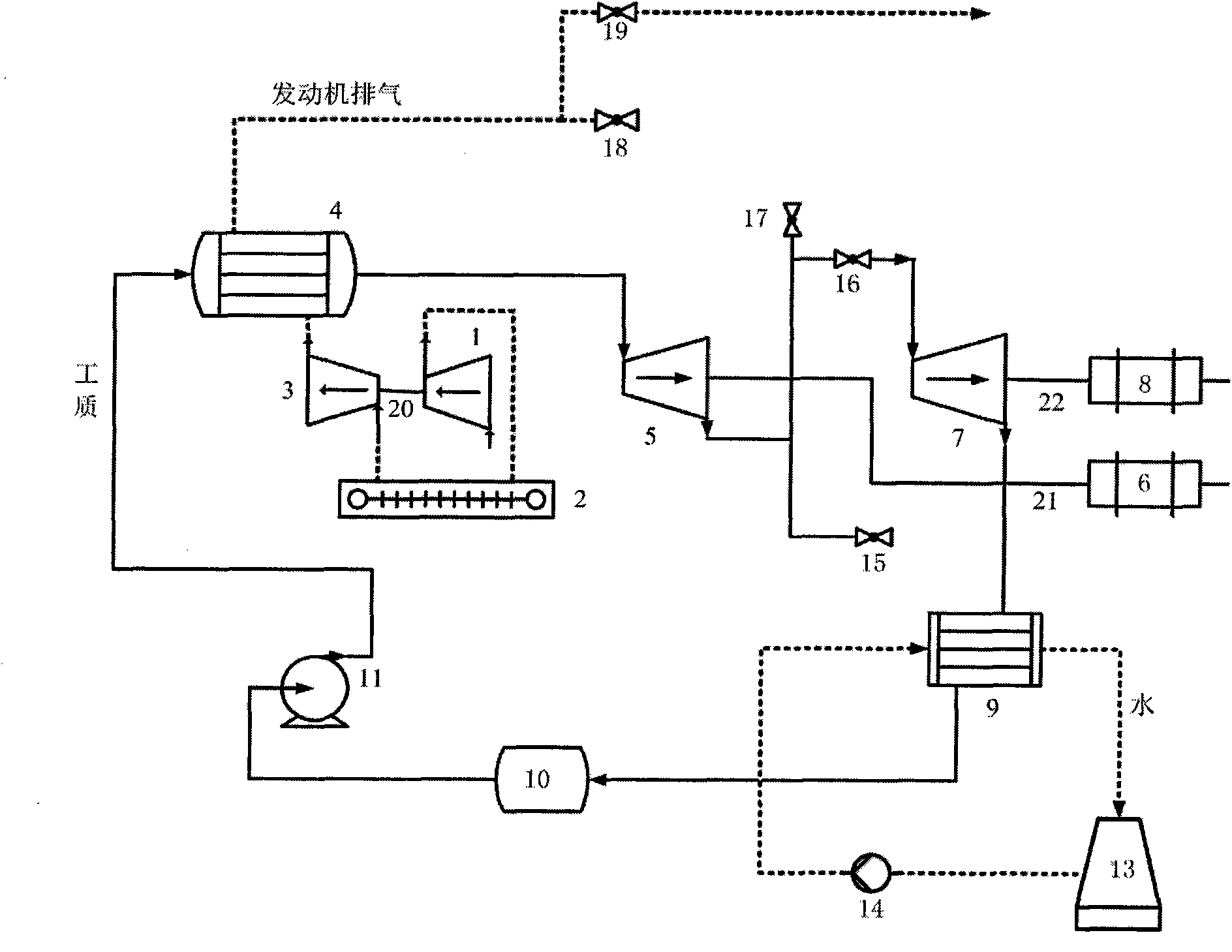

Organic Rankine cycle diesel engine tail gas and waste heat utilization system using two-stage single-screw expanding machine

InactiveCN102022221AReduce exhaust temperatureLower evaporation temperatureInternal combustion piston enginesEngine componentsCooling towerOrganic Rankine cycle

The invention relates to an organic Rankine cycle diesel engine tail gas and waste heat utilization system using a two-stage single-screw expanding machine, belonging to the field of energy conservation and emission reduction, and mainly comprising a gas compressor, an engine, a turbomachine, a tube bundle type evaporator, a single-screw expanding machine I, a magnetic powder dynamometer I, a single-screw expanding machine II, a magnetic powder dynamometer II, a plate type condenser, a liquid storage tank, a working medium pump, an intermediate heater, a cooling tower, an adjustable flow pump, a flow divider valve I of an expanding machine outlet, a flow divider valve II of the expanding machine outlet, a flow divider valve III of the expanding machine outlet, an exhaust control valve I, an exhaust control valve II, a turbomachine and compressor coupling shaft, a coupling shaft I, a coupling shaft II and various connecting pipelines. According to the conditions of different rotating speeds and different loads of a diesel engine, by utilizing the invention, the opening and closing of the flow divider valves of the expanding machine outlet and the exhaust control valves are adjusted, waste heat recoveries at different levels are realized and the energy taken away by the tail gas of the diesel engine is furthest recovered and utilized.

Owner:中投亿星新能源投资有限公司

Composite cordierite filters

InactiveUS20030110744A1Improved thermalImprove mechanical propertiesCombination devicesAuxillary pretreatmentBoridePorosity

Composite cordierite honeycomb structures especially suitable for diesel exhaust filtration applications comprise a non-oxide polycrystalline phase constituting 10-70% by weight, with the remainder of the ceramic material constituting a cordierite phase, the non-oxide polycrystalline phase being selected from the group consisting of carbides, nitrides, and borides. Preferably the non-oxide phase is either polycrystalline silicon carbide or polycrystalline silicon nitride and has a particle aspect ratio of less than 3. Inventive ceramic bodies are porous with an open porosity of at least 30%, preferably between 40% and 60%, and a median pore size of at least 5 micrometers, more preferably greater than 8 micrometers and less than 12 micrometers.

Owner:CORNING INC

Carboxylated detergent-dispersant-containing compositions having improved properties in lubricating oils

A lubricant additive composition comprising (a) a carboxylated detergent-dispersant obtained by (i) neutralizing alkylphenols using an alkaline earth base in the presence of at least one carboxylic acid that contains from one to four carbon atoms but in the absence of alkali base, dialcohol, and monoalcohol, forming an intermediate product, then (ii) carboxylating the intermediate product using carbon dioxide so that at least 20 mole percent of the original alkylphenol starting material has been converted to single aromatic-ring hydrocarbyl salicylate; and (b) an overbased, non-sulfonate-containing detergent such as, for instance, a hydrocarbyl phenate-carboxylate; a medium overbased salicylate having a total base number of about 50 to 170; a high overbased salicylate having a total base number greater than 170; or an overbased sulfurized hydrocarbyl phenate of alkaline earth metals; and combinations and mixtures thereof. Also provided for are additive packages and finished lubricating oil compositions comprising the same. The compositions of this invention reduce sludge and contaminant formation, especially in low and medium speed diesel engines and in marine diesel engines.

Owner:CHEVROU USA INC

Control strategy for HCCI-CD combustion in a diesel engine using two fuel injection phases

ActiveUS7021276B2Easy to useReduce generationElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionControl system

Owner:INT ENGINE INTPROP CO LLC

System and method for a load anticipation feature and its tuning method for a generating set

A method, system and computer software for providing a load anticipation feature for a diesel generating set including a diesel engine, a generator, a speed governor, and an automatic voltage regulator generator in a power system and computer data processor apparatus and computer executable instructions for ascertaining an equivalent linear speed control system whose response approximately matches the non-linear speed response of the diesel generating set; ascertaining at least one programmable parameter of the load anticipation feature based on a real power load applied to the diesel generating set and a desired speed response of the linear speed control system; generating a control output based on a measured real power load and at least one programmable parameter of the load anticipation feature; the speed governor receiving the control output and adjusting the speed of the diesel engine based on the control output.

Owner:BASLER ELECTRIC

Particulate matter oxidation catalyst and filter

InactiveUS20070105715A1Increased durabilityReduce the amount requiredCombination devicesGas treatmentStructural formulaDiesel particulate filter

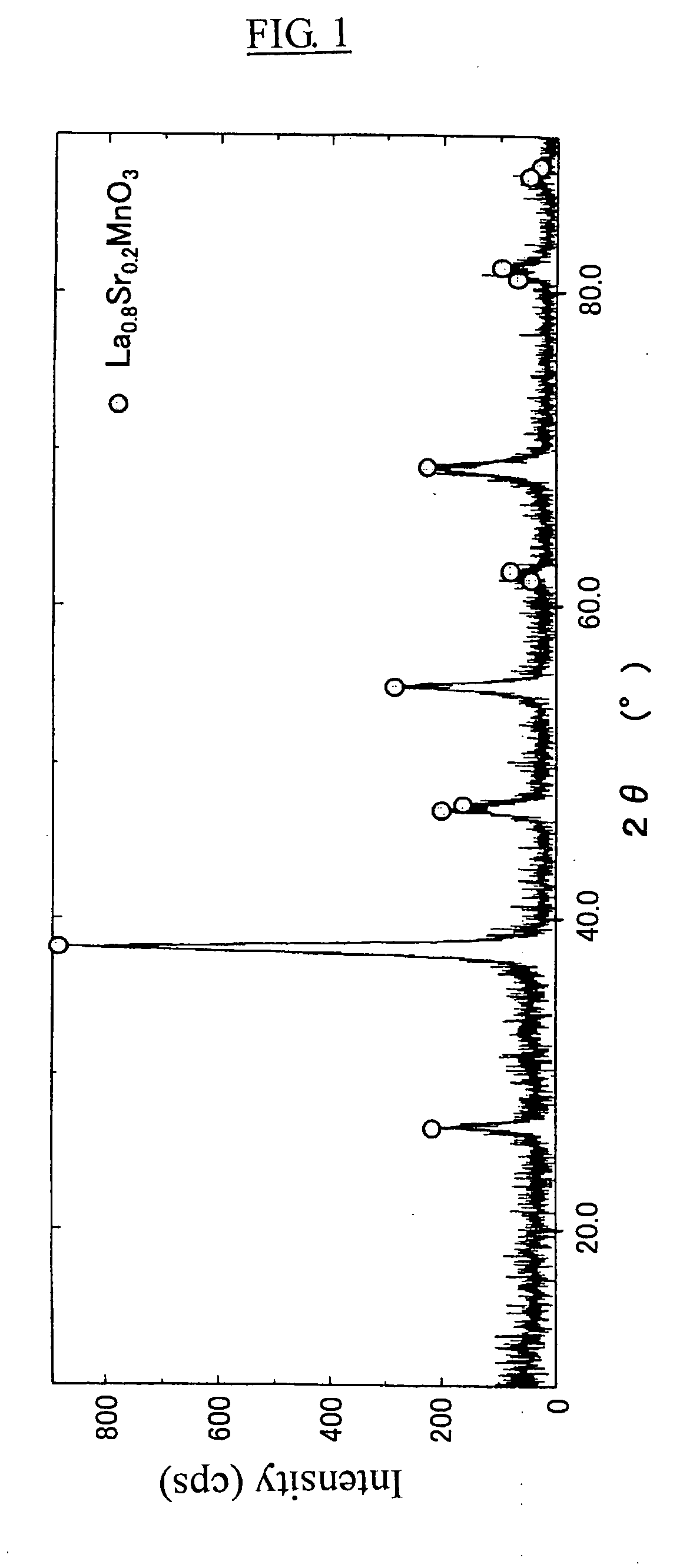

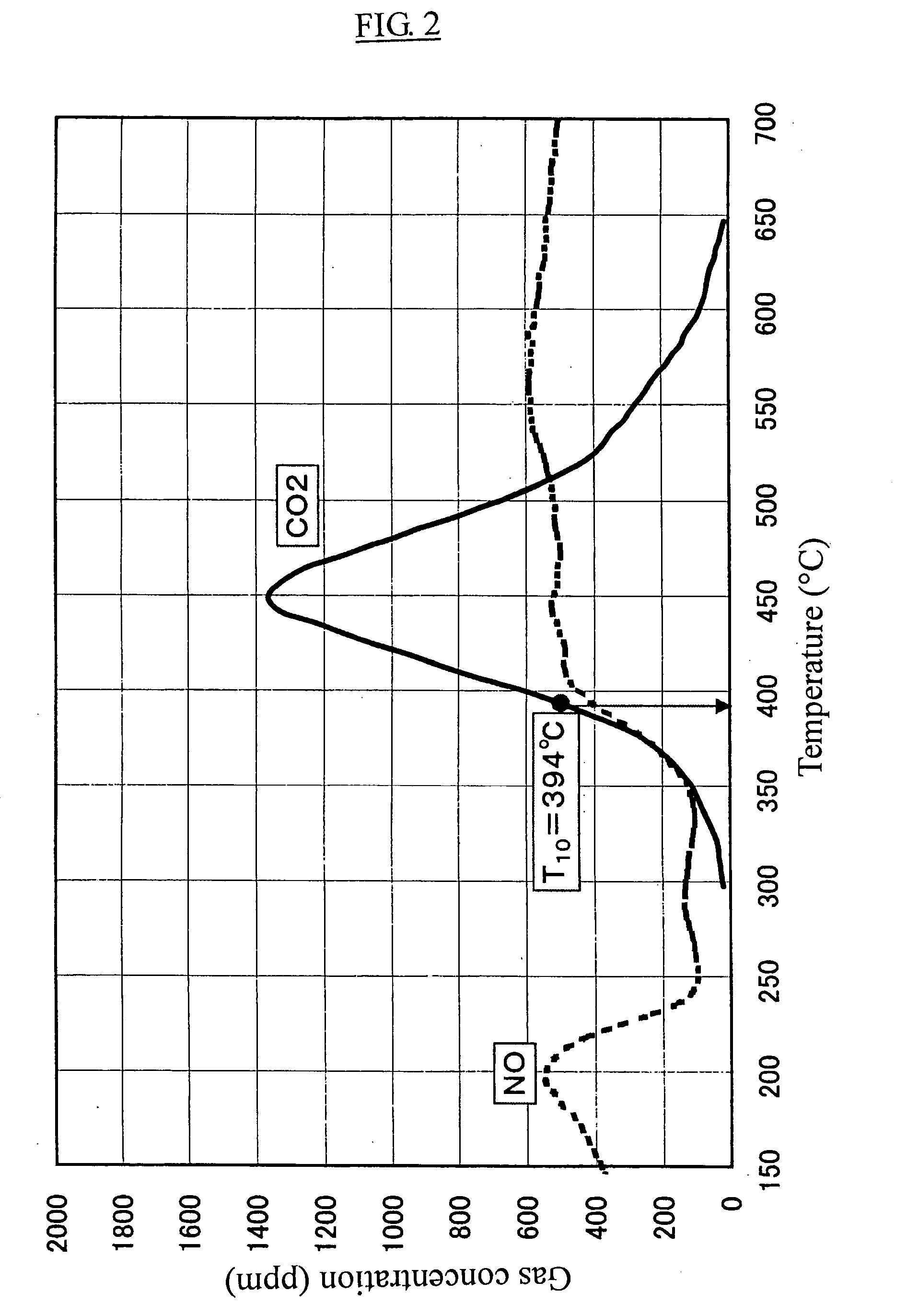

This is a catalyst suitable for a diesel particulate filter (DPF) that traps particulate matter (PM) present in diesel engine exhaust, being a diesel engine exhaust gas particulate matter oxidation catalyst using a perovskite-type composite oxide that has an NO adsorption domain over the range of 200-450° C. This catalyst induces low-temperature combustion of PM but does not use noble metals so it is inexpensive and its constituent materials are not volatile at exhaust gas temperatures so it has superior durability. The perovskite-type composite oxide contains essentially no Na and is represented by the structural formula RTO3, where R comprises one or more elements selected from a group made up of La, Sr, Ba, Ca and Li, and T comprises one or more elements selected from a group made up of Mn, Fe, Co, Cu, Zn, Ga, Zr, Mo, Mg, Al and Si.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

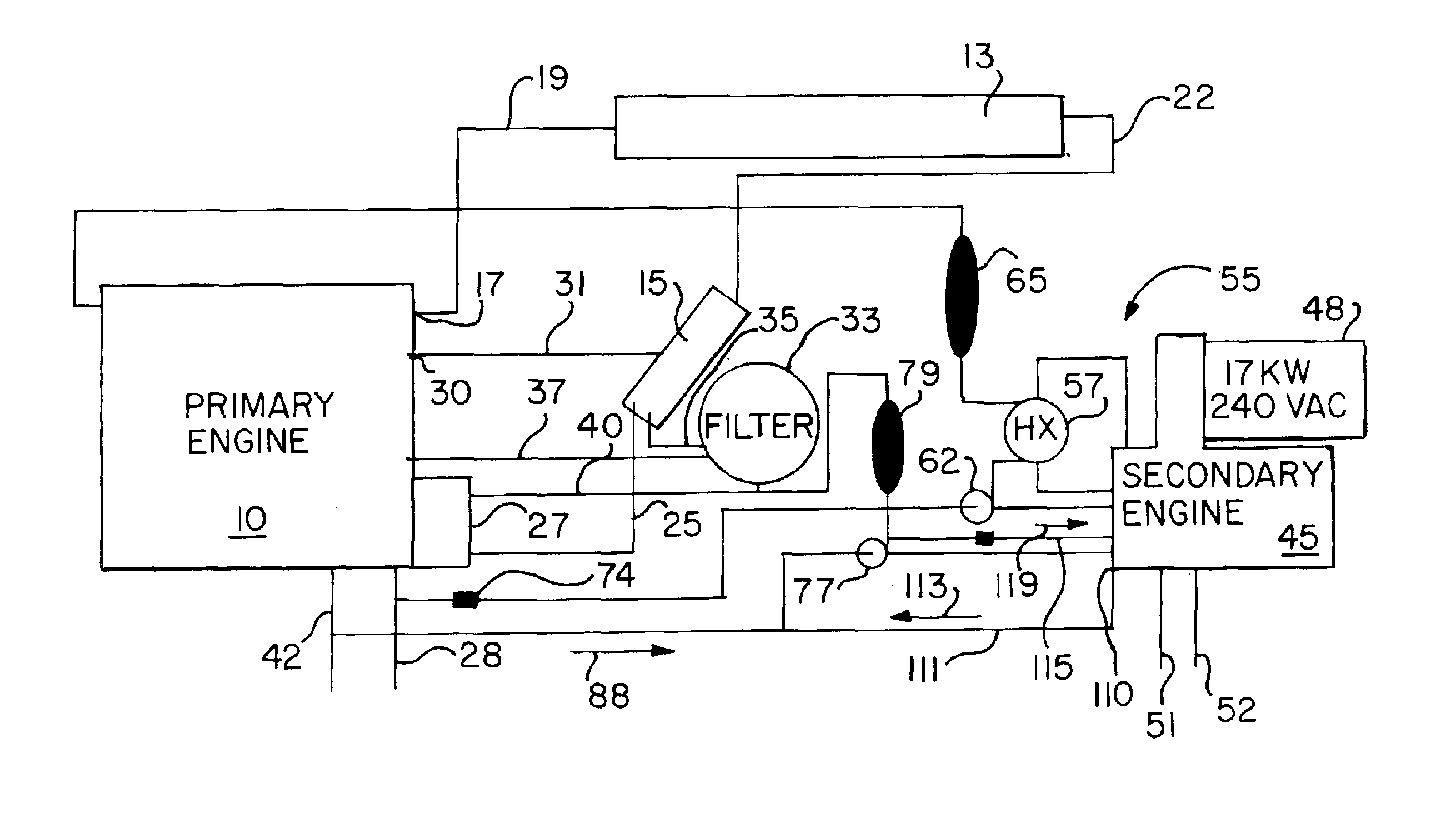

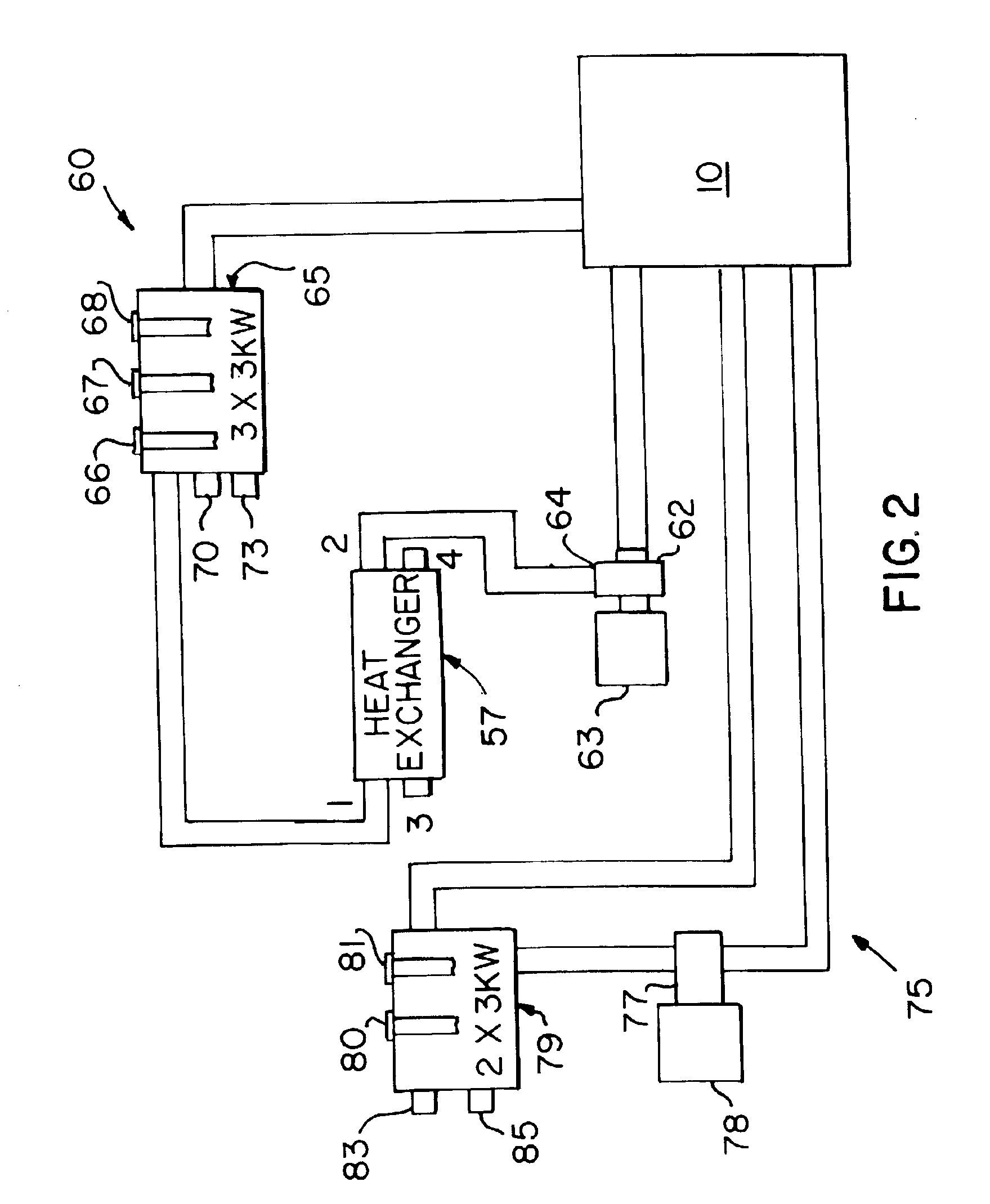

System and method for supplying auxiliary power to a large diesel engine

A system and method for providing auxiliary power to a large diesel engine allowing shutdown of such large engine in all weather conditions. An auxiliary power unit made up of a secondary engine coupled to an electrical generator is provided. An automatic control system shuts down the primary engine after a period of idling and the auxiliary power unit provides electrical power for heating and air conditioning. In cold weather, the auxiliary power unit maintains the primary engine coolant and lube-oil warm to facilitate engine restart. The coolant system is kept warm using a heat exchanger and electrical heaters. The lube-oil system is kept warm using a recirculating pump and electrical heaters. In warm weather, the auxiliary power unit provides electrical power for air conditioning and other hotel loads. The auxiliary power unit isolates the primary engine batteries during operation and provides electrical power for hotel and non-vital loads.

Owner:CSXT INTPROP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com