Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

782results about How to "Reduce entrainment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

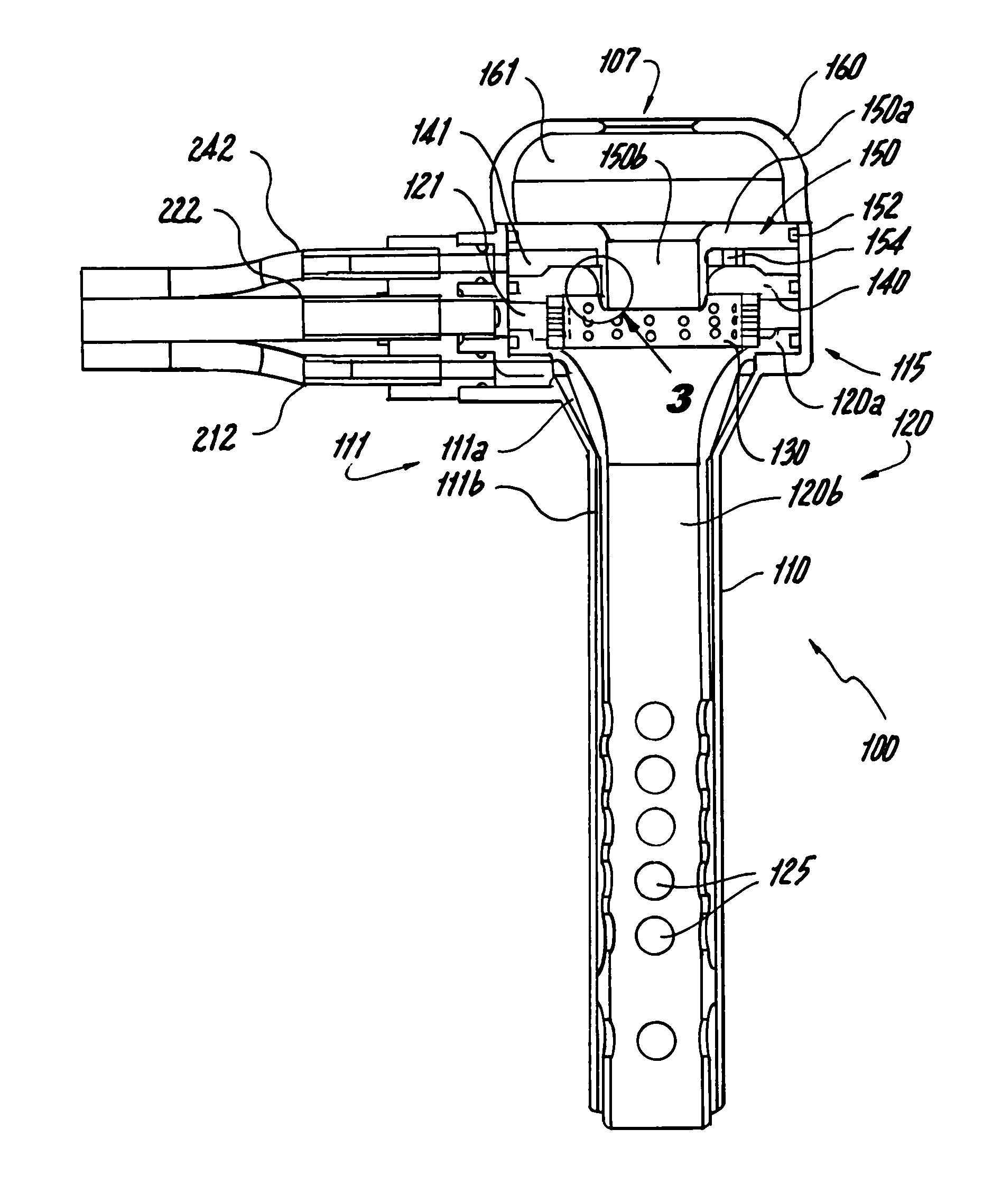

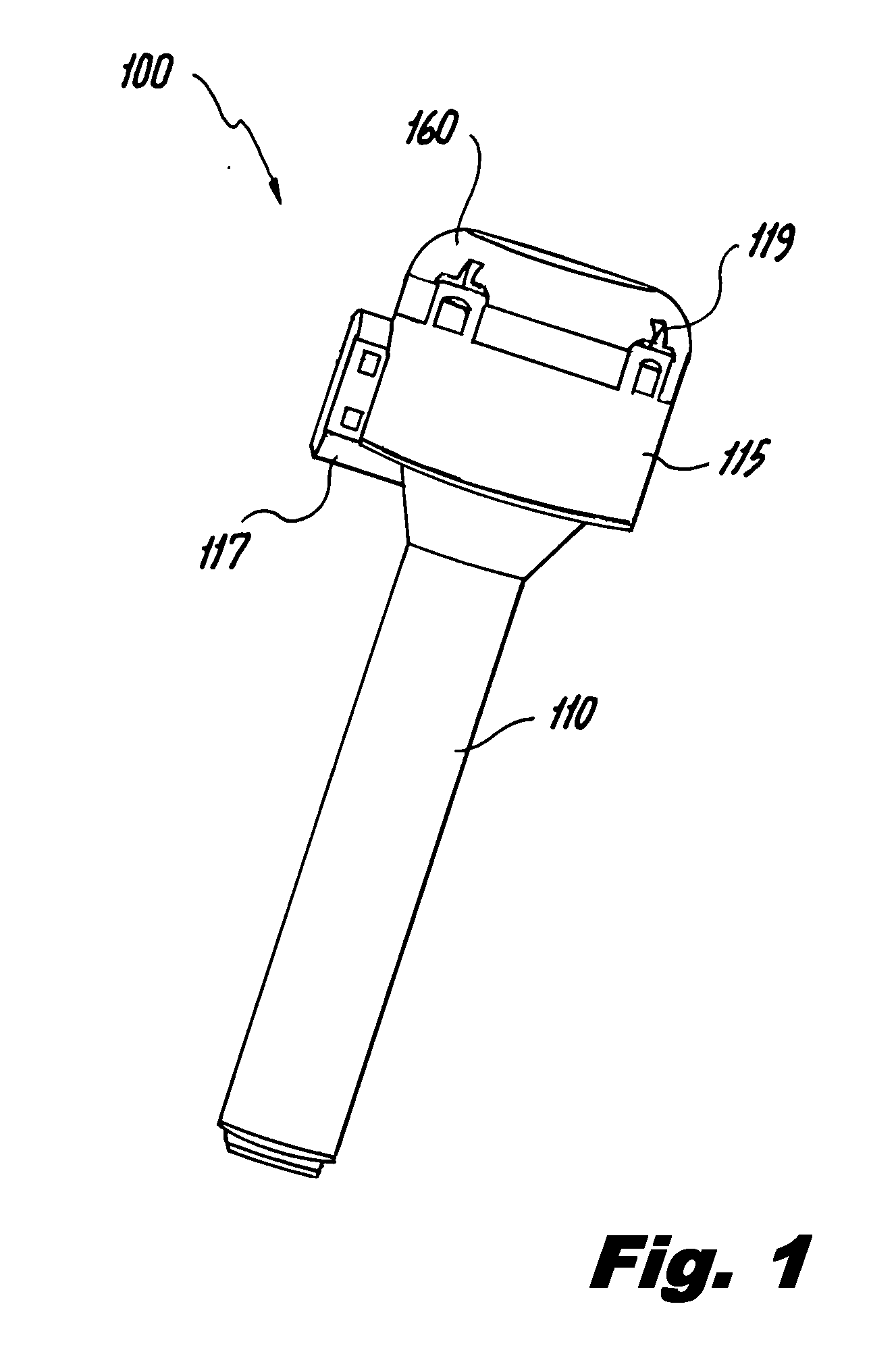

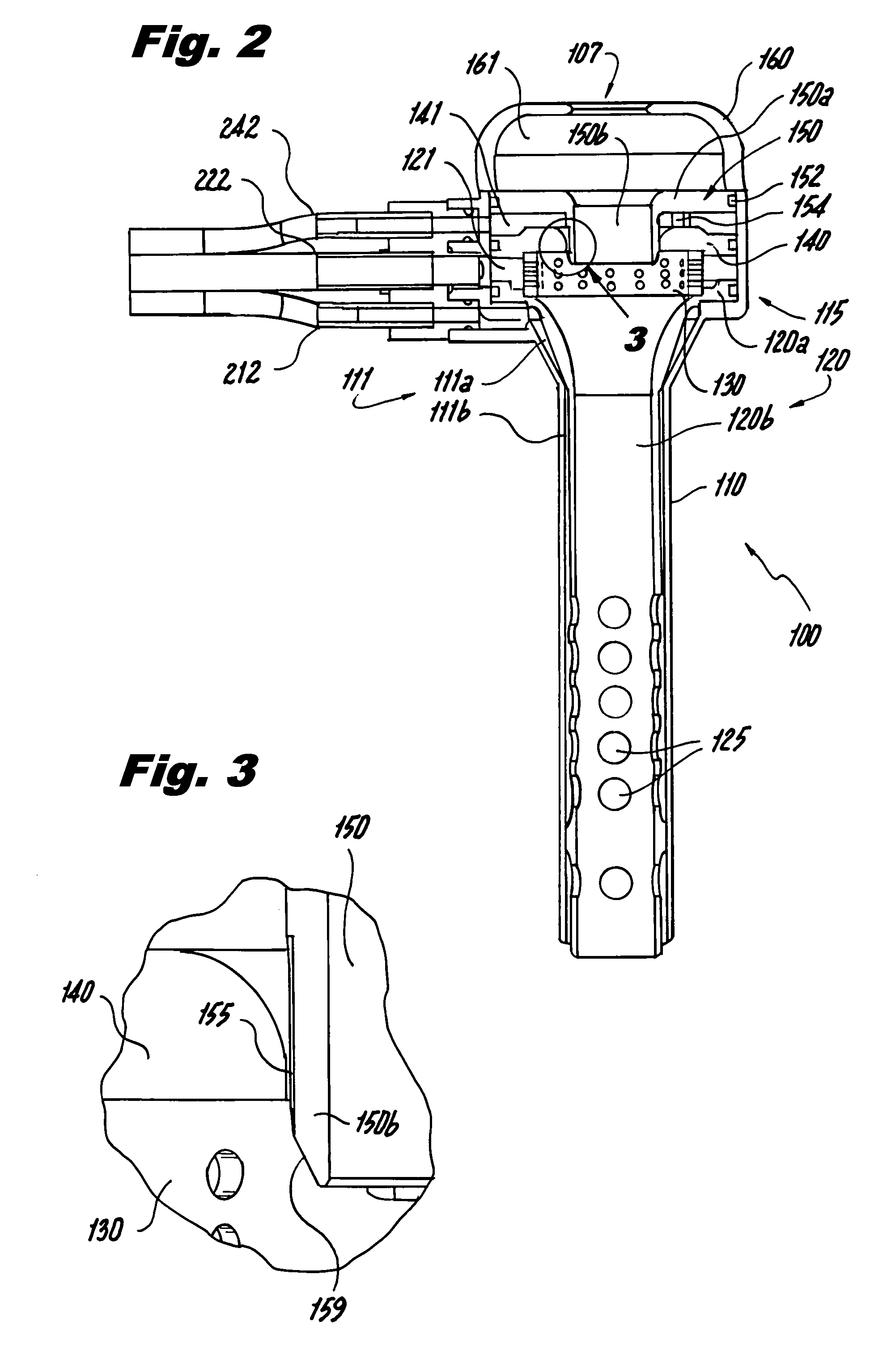

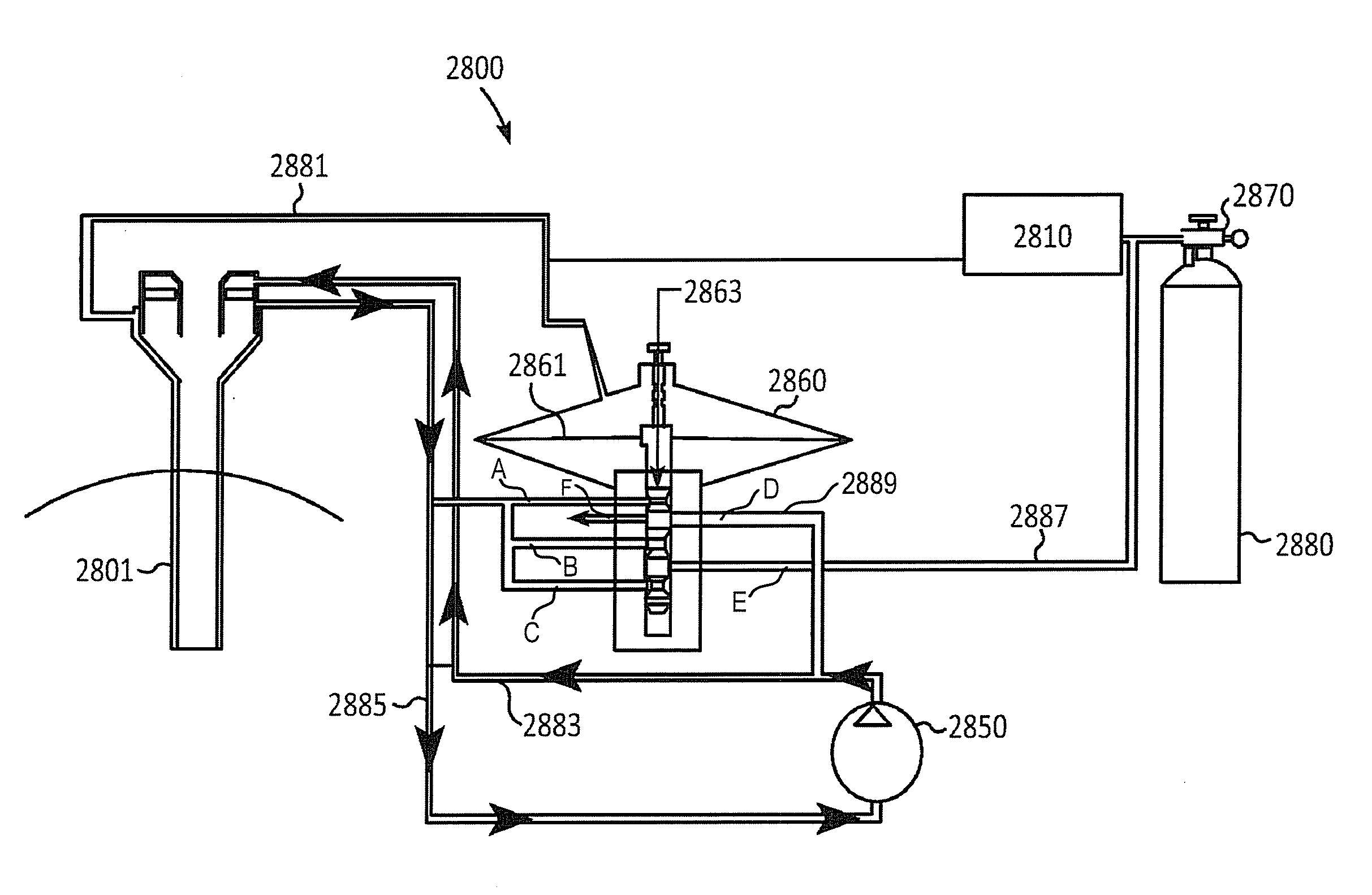

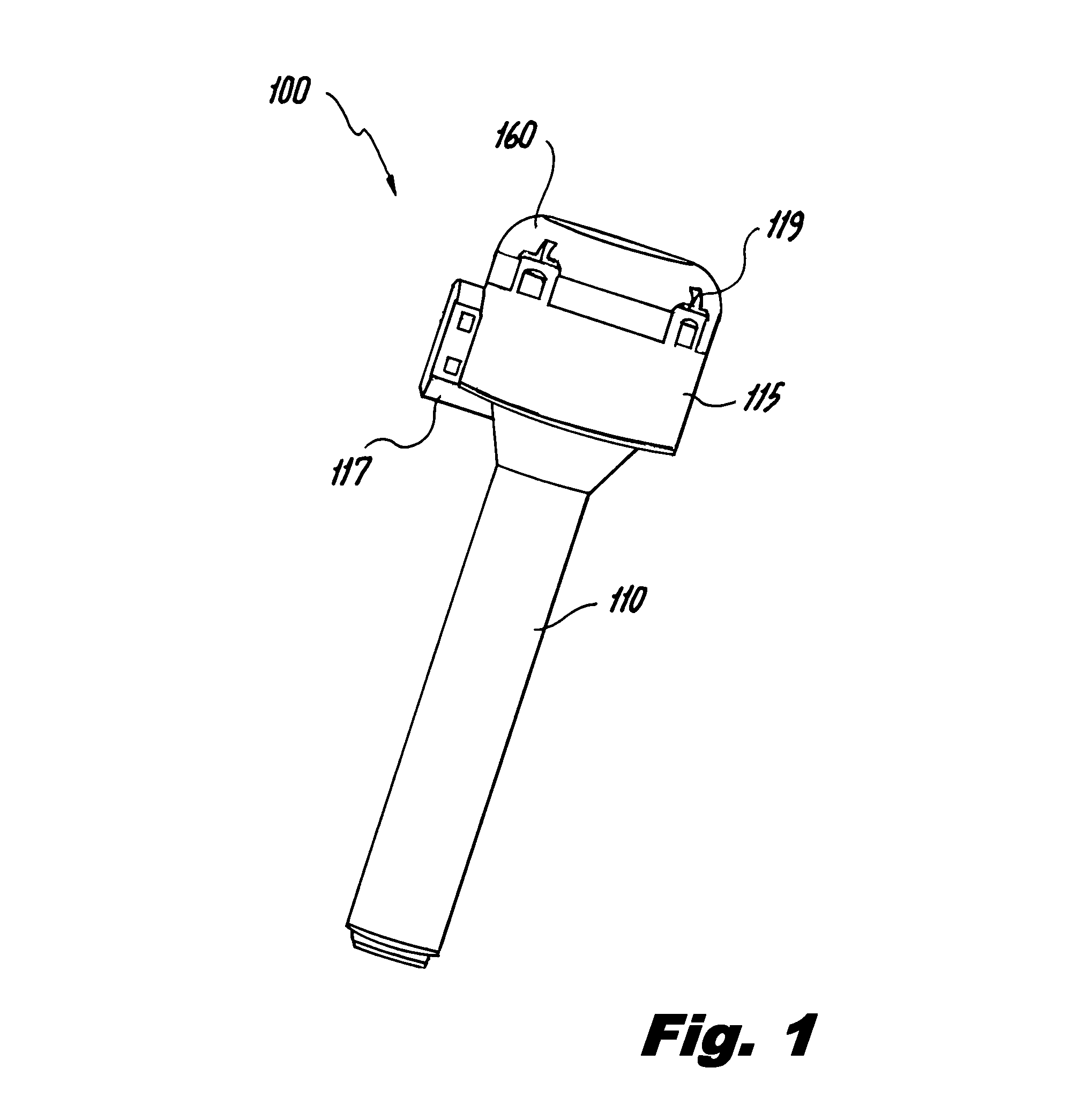

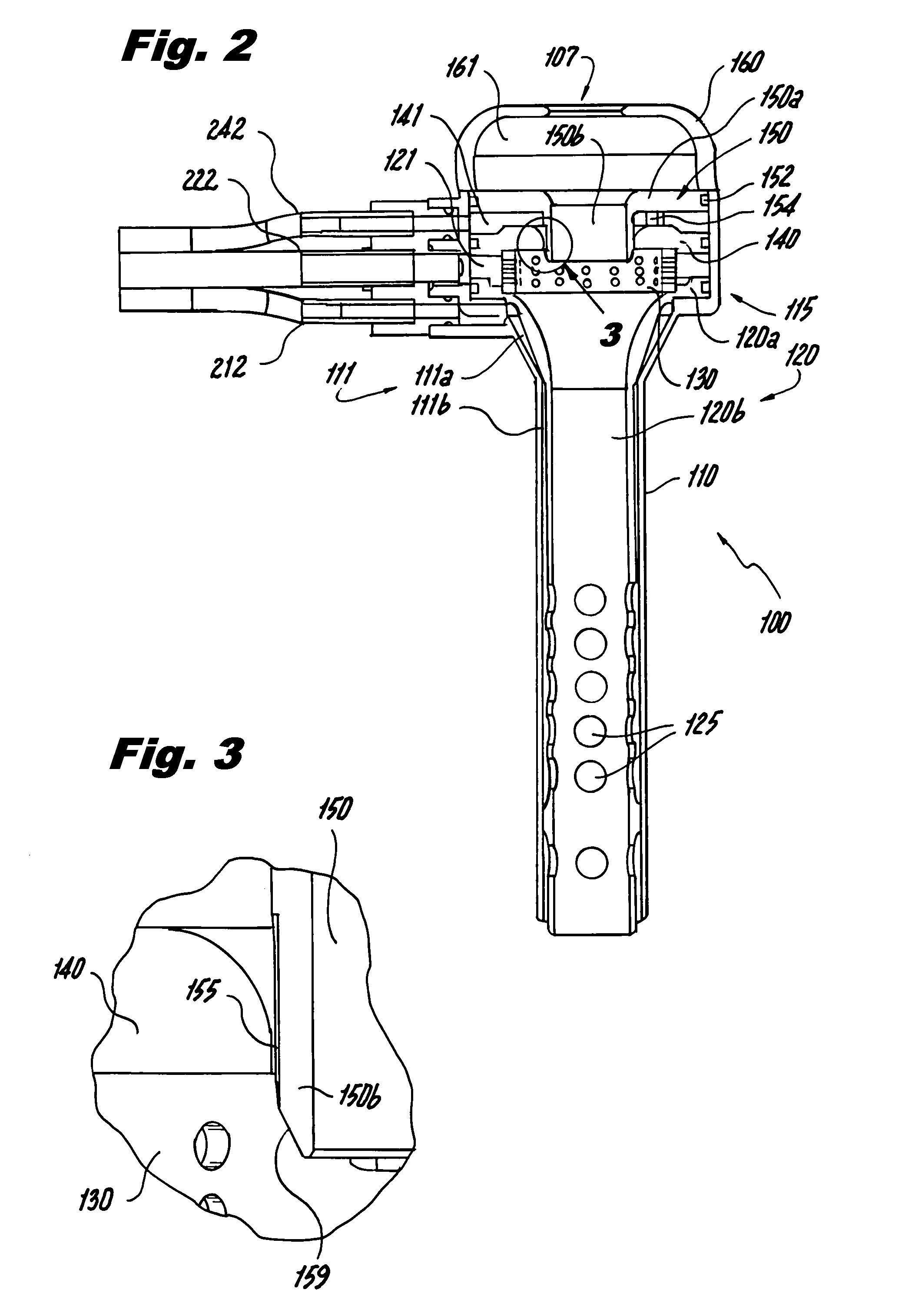

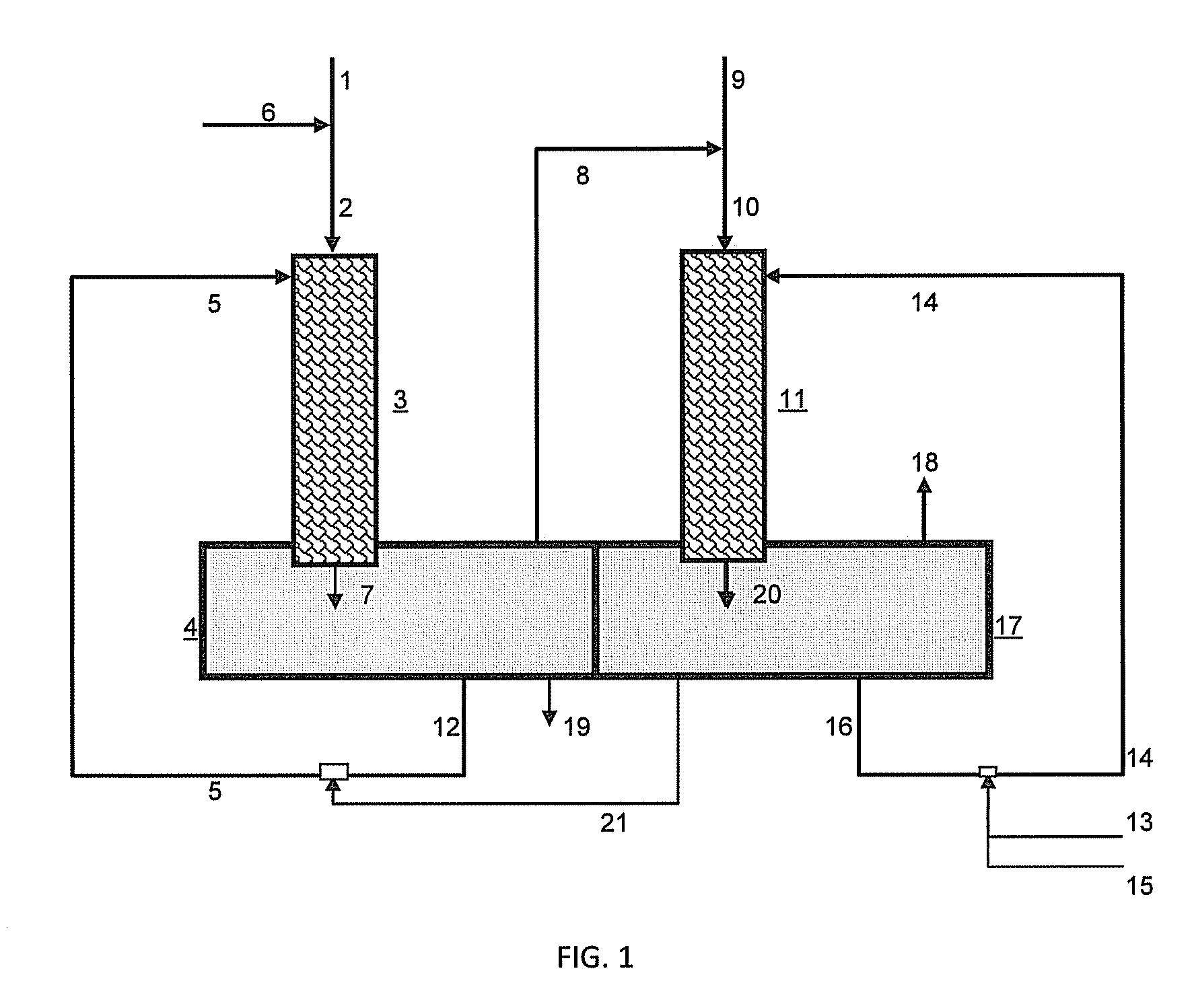

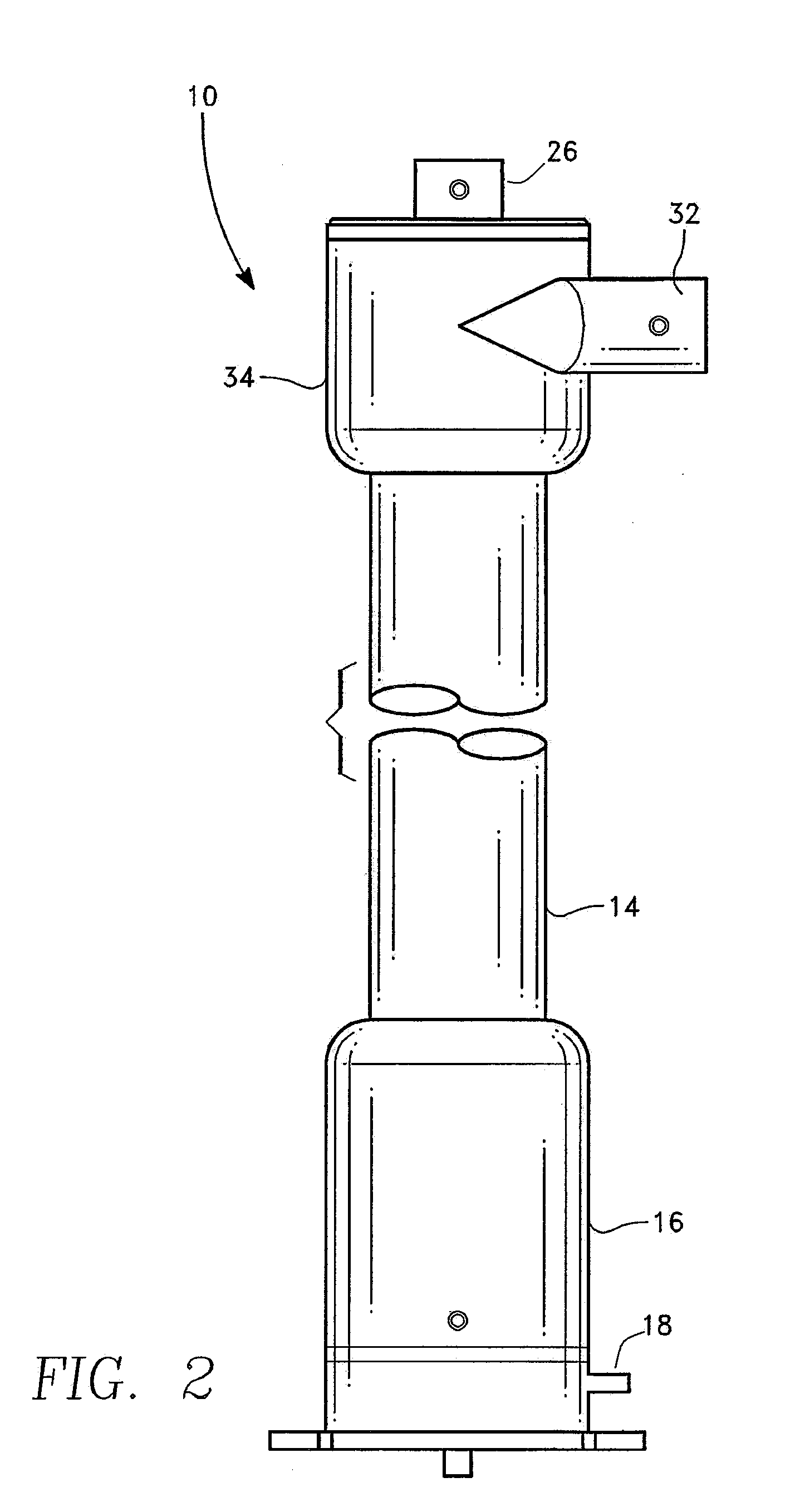

System and method for improved gas recirculation in surgical trocars with pneumatic sealing

Systems for insufflation and recirculation of insufflation fluid in a surgical procedure include a control unit having a fluid pump, a supply conduit, a return fluid conduit and a pressure-controlled valve. The pressure-controlled valve is in fluid communication with an insufflation gas supply, the supply conduit and the return conduit and is adapted and configured to respond to pressure control signals to adjust position and thereby system flow parameters, to reduce entrainment of air from the surrounding environment, and to increase the concentration of insufflation gas in an operative space, and / or to reduce an overpressure condition in the operative space.

Owner:SURGIQUEST

System and method for improved gas recirculation in surgical trocars with pneumatic sealing

Systems for insufflation and recirculation of insufflation fluid in a surgical procedure include a control unit having a fluid pump, a supply conduit, a return fluid conduit and a pressure-controlled valve. The pressure-controlled valve is in fluid communication with an insufflation gas supply, the supply conduit and the return conduit and is adapted and configured to respond to pressure control signals to adjust position and thereby system flow parameters, to reduce entrainment of air from the surrounding environment, and to increase the concentration of insufflation gas in an operative space, and / or to reduce an overpressure condition in the operative space.

Owner:SURGIQUEST

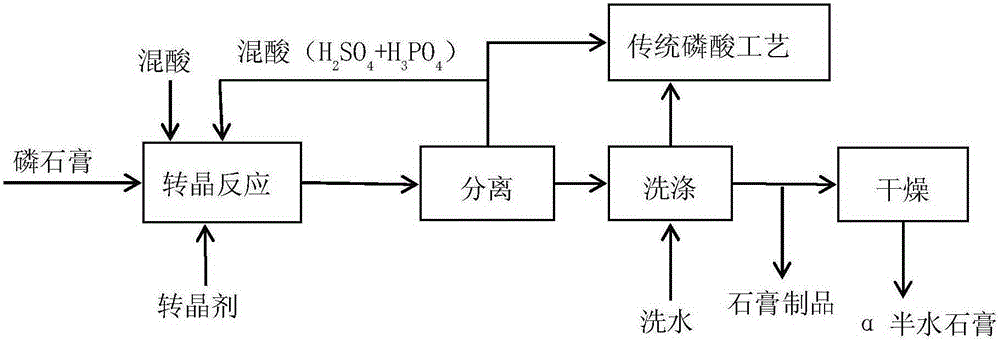

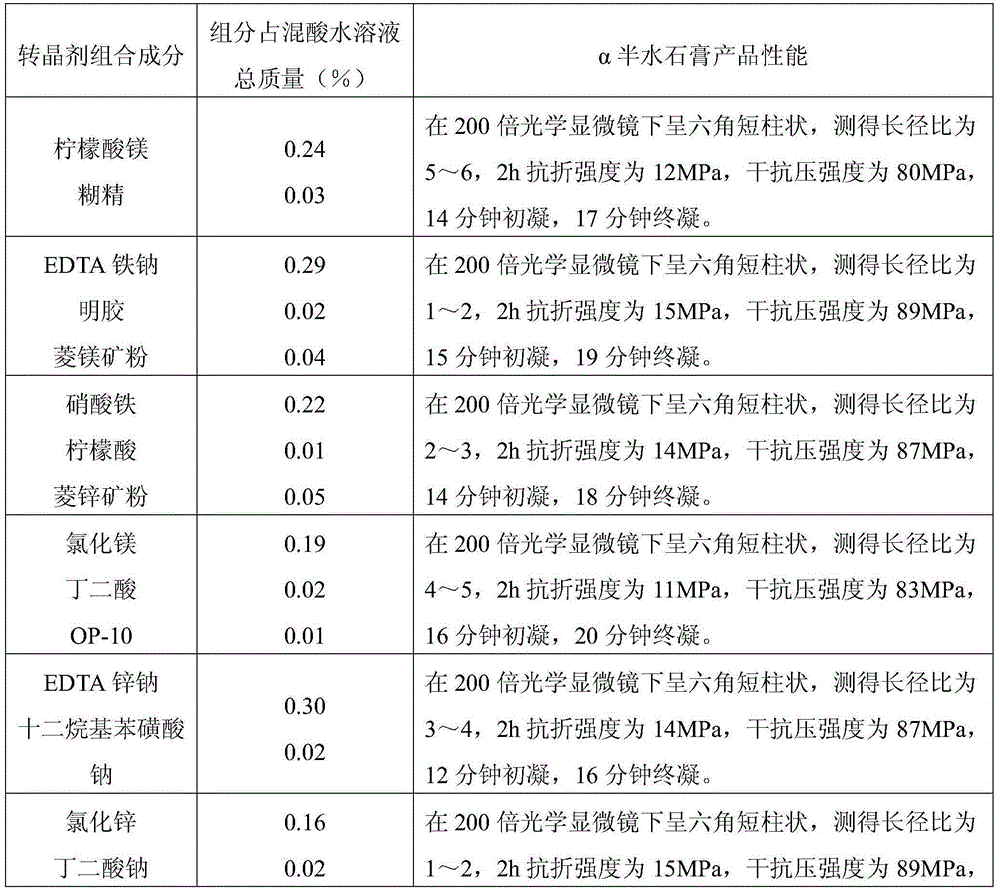

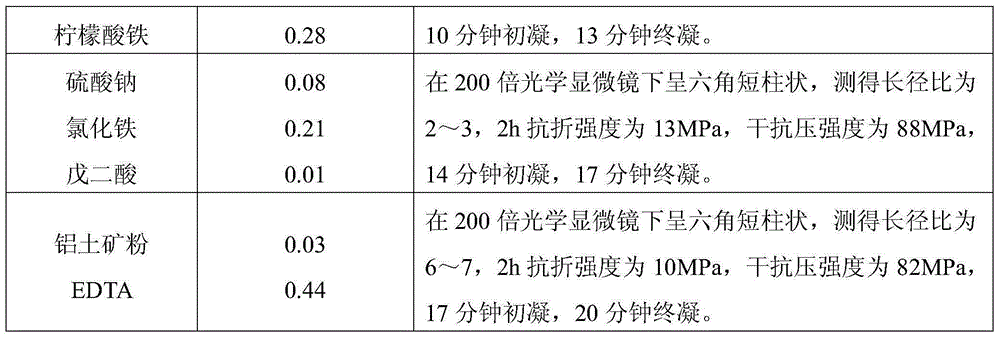

Method for preparing alpha semi-hydrated gypsum from dihydrate gypsum

The invention relates to a method for preparing alpha semi-hydrated gypsum from dihydrate gypsum. The method comprises the following steps: adding dihydrate gypsum and a crystal modifier into a mixed acid water solution containing sulfur acid and phosphoric acid to carry out crystal transformation, carrying out solid-liquid separation, returning a part of liquid phase into a crystal transformation tank for crystal transformation, and conveying another part of liquid phase to an acidolysis tank for use, wherein the acidolysis tank is used for preparing phosphoric acid by decomposing phosphorite by virtue of sulfuric acid; adding washing water to wash a solid phase, and introducing the washing water into the liquid phase for use. The washed solid phase can be prepared into alpha semi-hydrated gypsum powder through drying and can be prepared into gypsum products such as gypsum boards, gypsum blocks, gypsum components and the like by directly adding water without drying. According to the method, the alpha semi-hydrated gypsum is prepared in the mixed acid water solution containing sulfur acid and phosphoric acid, procedures including desulfuration, removal of impurity and the like on raw gypsum can be omitted, furthermore, mixed acid can be recycled, and the obtained alpha semi-hydrated gypsum product is high in strength and stable in quality.

Owner:贵州正磷科技有限公司

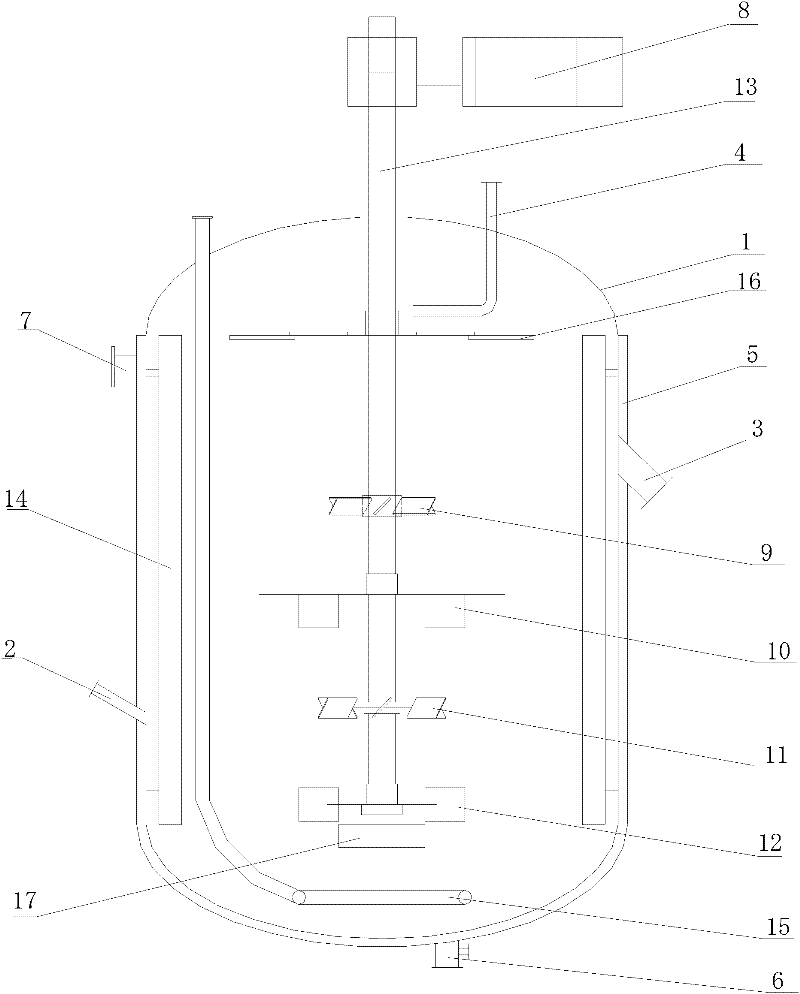

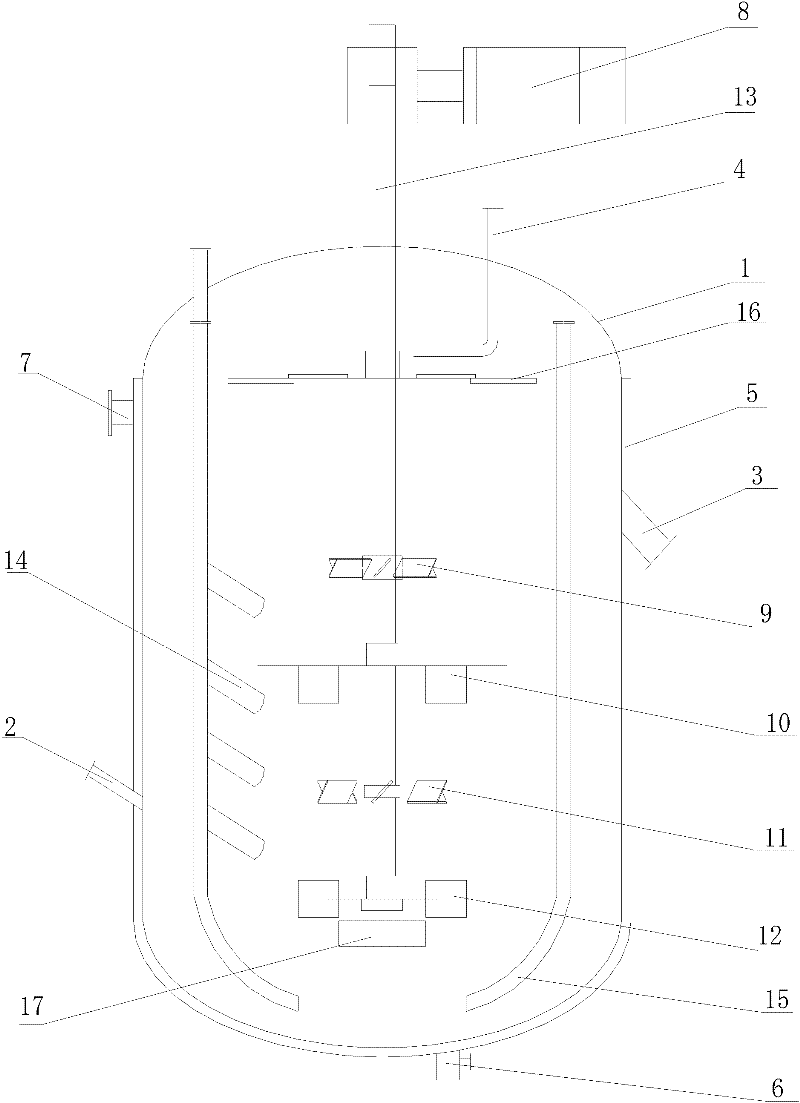

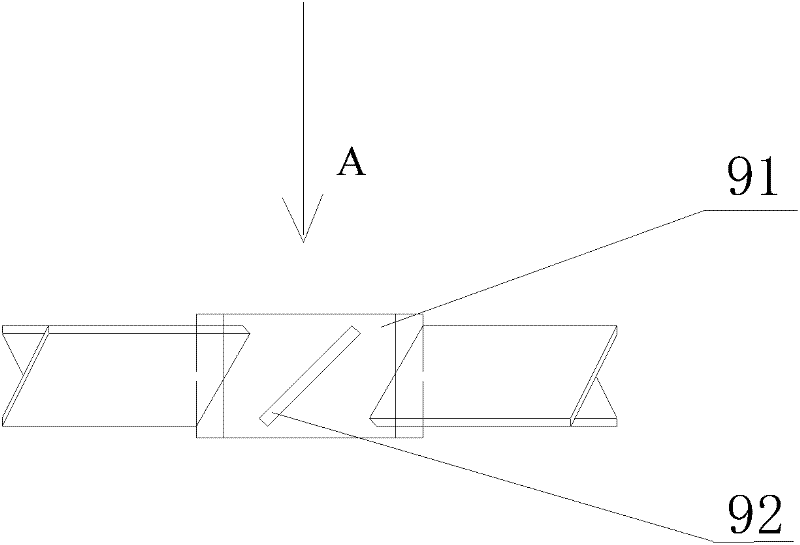

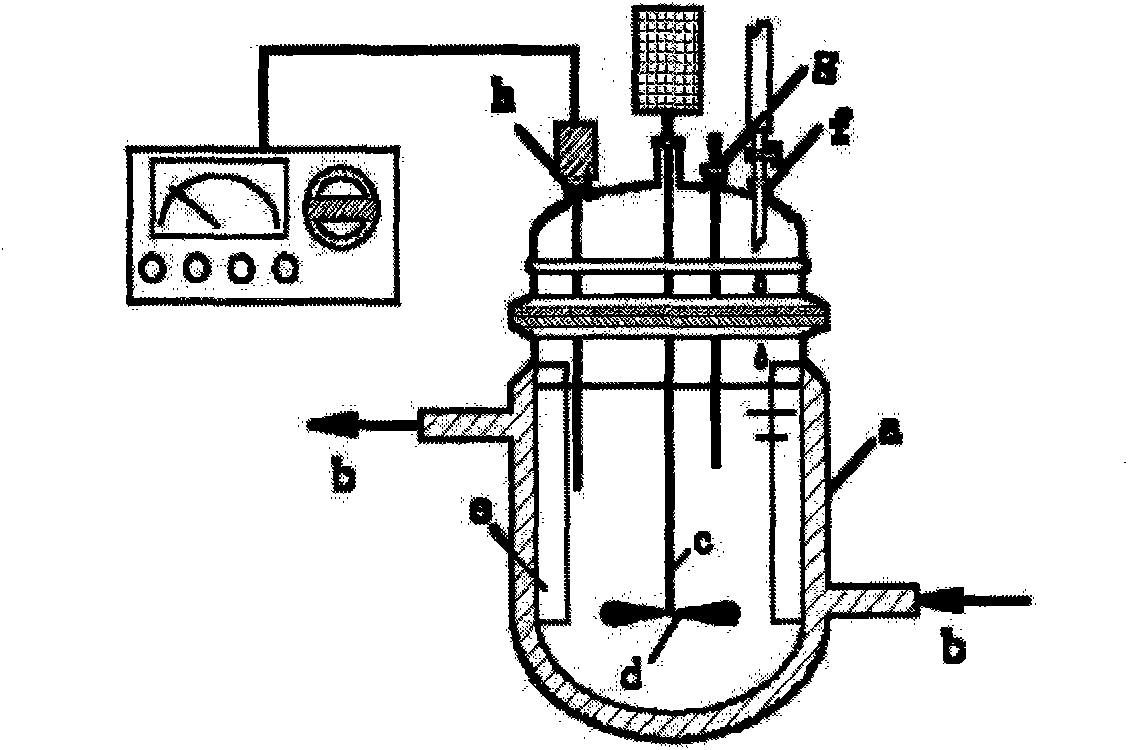

Stirred tank reactor

InactiveCN102358760ALarge circulationShort mixing timeRotary stirring mixersChemical/physical/physico-chemical stationary reactorsSizingProcess engineering

The invention discloses a stirred tank reactor and aims at improving a stirring turbine in the stirred tank reactor by using a four-layer combination stirring turbine. The stirring turbine comprises a first layer turbine, a second layer turbine, a third layer turbine and a fourth layer turbine which are arranged from the middle to the bottom of a stirring shaft sequentially. The first layer turbine is an upward axial flow turbine, the second layer turbine is a disk type turbine, the third layer turbine is an upward axial flow turbine, and the fourth layer turbine is a radial flow turbine. Radial circulation close to a liquid level, radial circulation close to a middle area of a stirred tank and radial circulation in a bottom area of the stirred tank are formed, so that circulation quantity inside the stirred tank is big and mixing time is short. Poor mixing area does not exist, and solid containing rate and gas containing rate are evenly distributed. A mass transfer condition of air and liquid is good, and single transfer efficiency is high. Entrainment quantity of sizing is greatly reduced, fouling of a heat exchanger is reduced, and service life is long. Operation cost is lowered, and production cost is saved.

Owner:ZHEJIANG UNIV

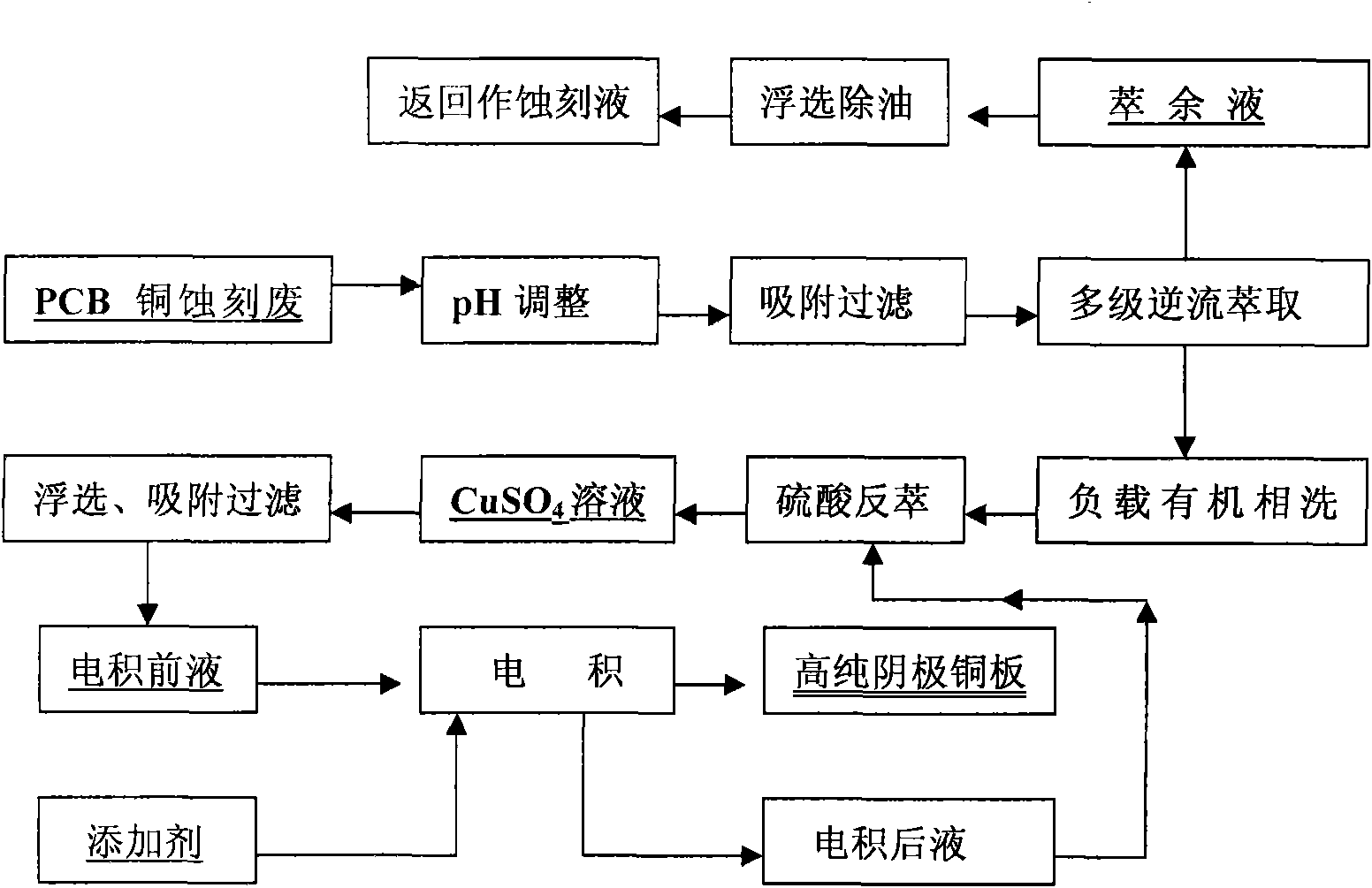

Method of preparing high pure cathode copper by using PCB acid chlorine copper etching solution sewage

InactiveCN101550488AHigh purityReduce entrainmentPhotography auxillary processesProcess efficiency improvementIonRegenerative cycle

The present invention disclose a method of preparing high pure cathode copper by using PCB acid chlorine copper etching solution sewage, the main technical characteristics include applying sewage preprocess procedure to satisfy extraction need better, programming multi-extraction to improve extraction recovery rate of cooper, applying extractant with high selectivity avoid extraction entrainment design, washing procedure etc. to reduce carried impurity and dispel affect of chloride ion to electrodeposition. The electrodeposition applies additive to improve copper crystallinity, simultaneity, utilize residual useful ingredient in raffinate to prepare copper etching solution, arriving the objective of both prepare high pure cathode copper effectively and regenerative cycle use of the etching solution. The purity of the prepared cathode copper reaches 99.99%.

Owner:CENT SOUTH UNIV +1

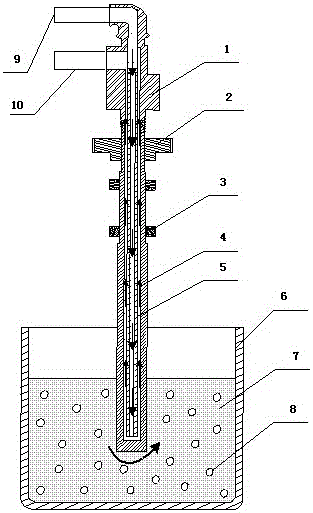

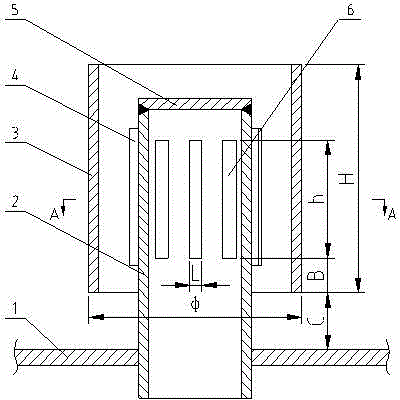

Method and device for preparing semi-solid state slurry through intensive cooling stirring

The invention discloses a method for preparing semi-solid state slurry through intensive cooling stirring. The method comprises the following steps: placing overheated alloy melt in a crucible or a casting ladle, descending a rotary stirring shaft internally introduced with a circular cooling medium in the alloy melt through a lifting device, driving the convection heat exchange of the alloy melt through stirring, continuously cooling the rotary stirring shaft through the circular cooling medium, stirring for a fixed period of time or cooling the melt to a set temperature, raising the rotary stirring shaft to prepare the semi-solid state slurry and form an ingot casting; closing the casting ladle containing the semi-solid state slurry to formation equipment and pouring the semi-solid state slurry into a cavity or material chamber of the formation equipment to take the shape; and taking out a formed part and moving the crucible or the casting ladle back to an original position and filling the overheated alloy melt to perform the next semi-solid state slurry preparation. The invention further provides a device for realizing the above method. Through the adoption of the method and device provided by the invention, large volume of semi-solid state slurry can be prepared once, and the semi-solid state slurry can be continuously produced in batch, and then the rheolytic formed part can be prepared through the combination of pressure casting, rolling, die-forging and other conventional formation equipment.

Owner:SHANGHAI INST OF TECH

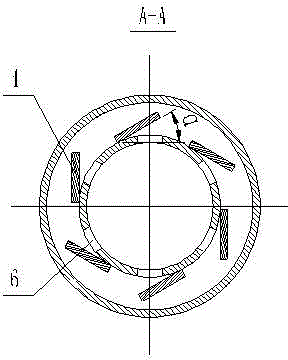

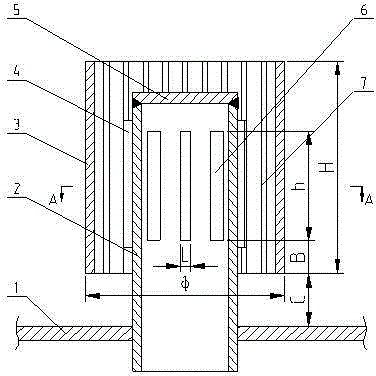

Straight cylinder-shaped flow baffling type demister

ActiveCN104606963AEfficient removalAchieve separationDispersed particle separationChemical industryTower

The present invention discloses a straight cylinder-shaped flow baffling type demister, which comprises a plurality of demisting assemblies, wherein each demisting assembly comprises a gas rising pipe and a straight cylinder, the straight cylinder is arranged on the outer side of the gas rising pipe and is at the same axis line as the gas rising pipe, the gas rising pipe is fixed on a tower disk, the top portion of the gas rising pipe is provided with a sealing cover plate, the circumference of the gas rising pipe is provided with a plurality of seams, and the gas rising pipe circumference close to each seam is provided with tangential diversion wings. According to the straight cylinder-shaped flow baffling type demister, the separation of the liquid droplet and the gas is achieved through the multiple flow baffling during the fluid flowing process; and the straight cylinder-shaped flow baffling type demister has characteristics of simple structure, easy installation and effective gas-liquid separation achieving, and is suitable for the gas-liquid separation process in the fields of chemical industry, environmental protection, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

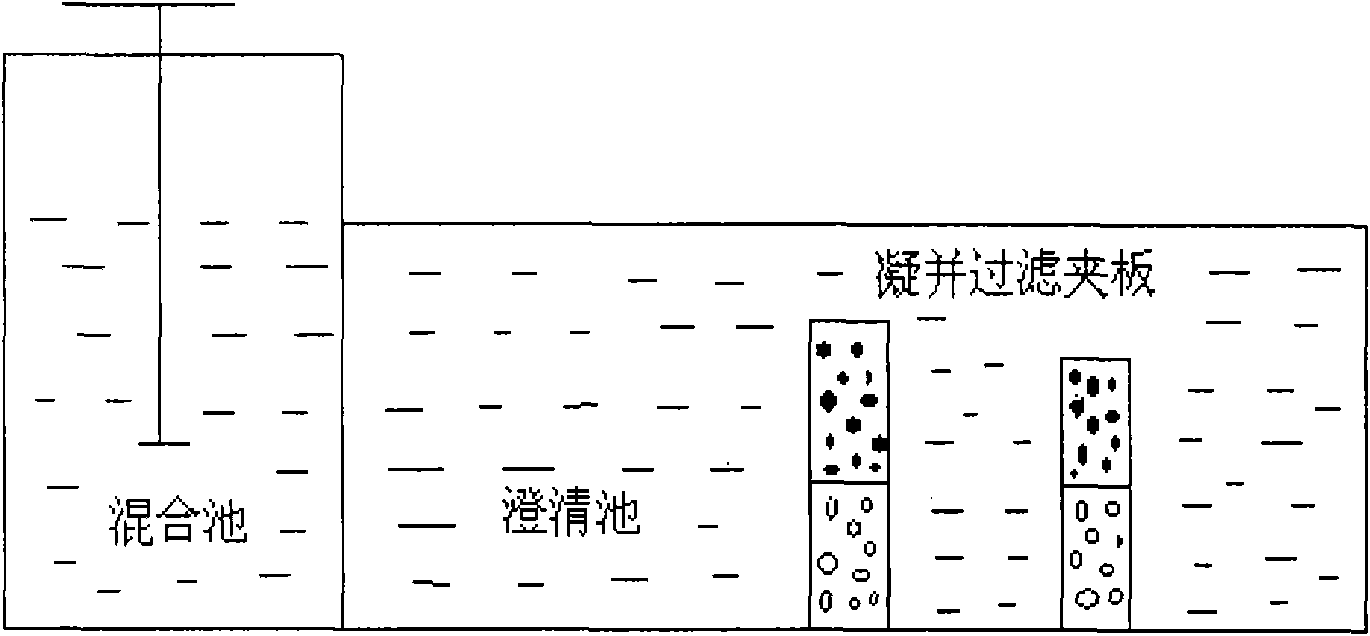

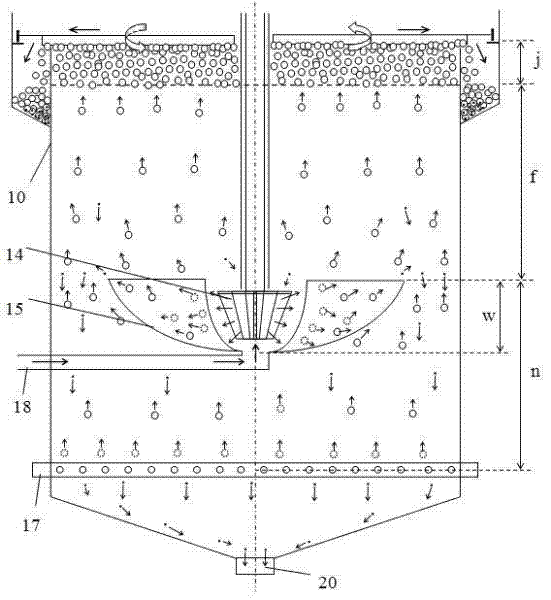

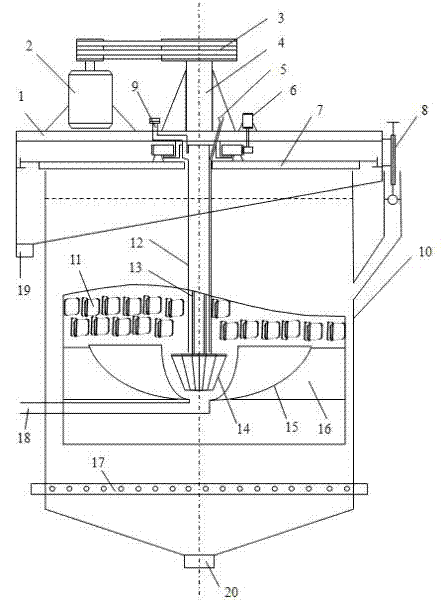

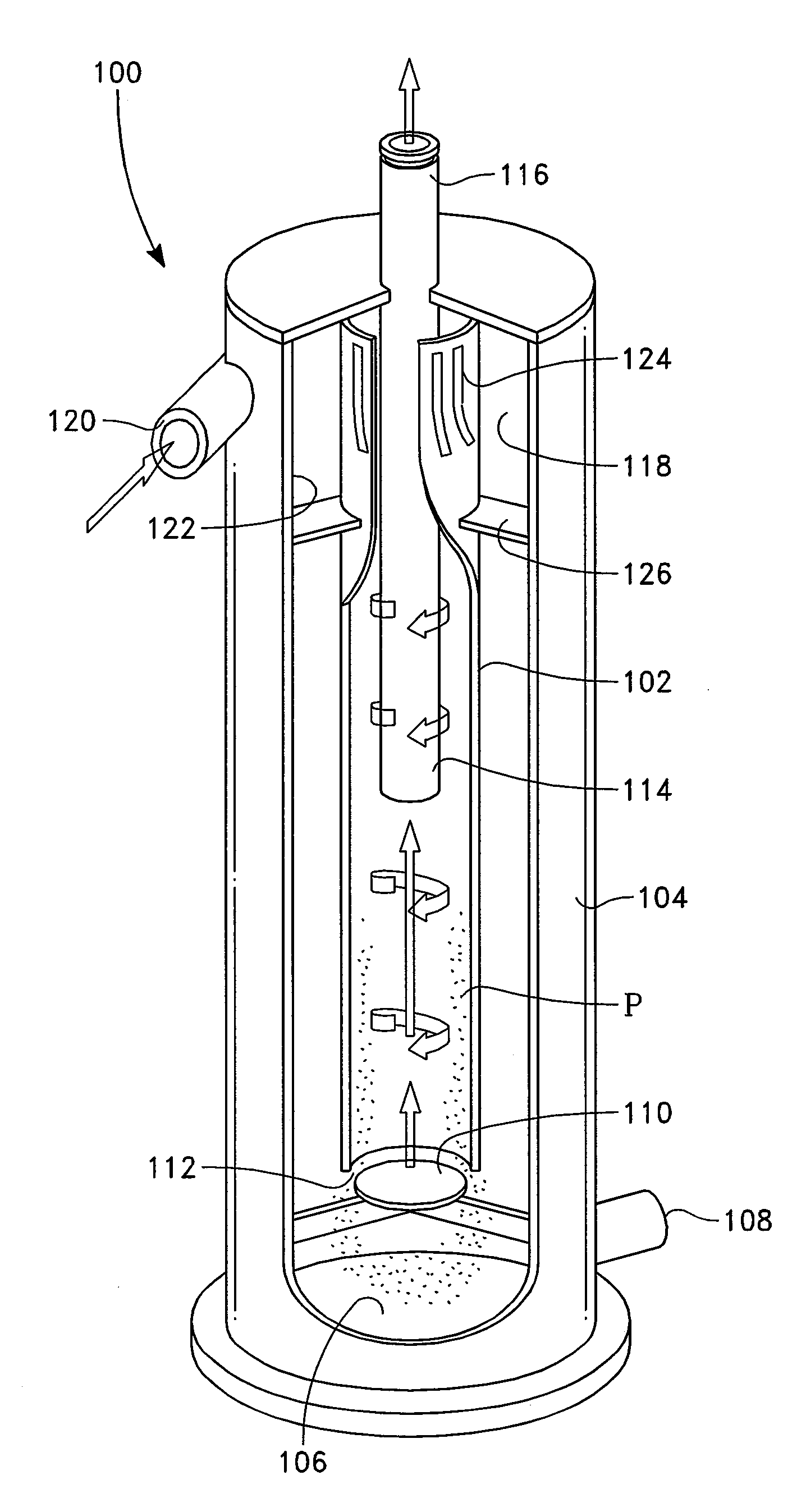

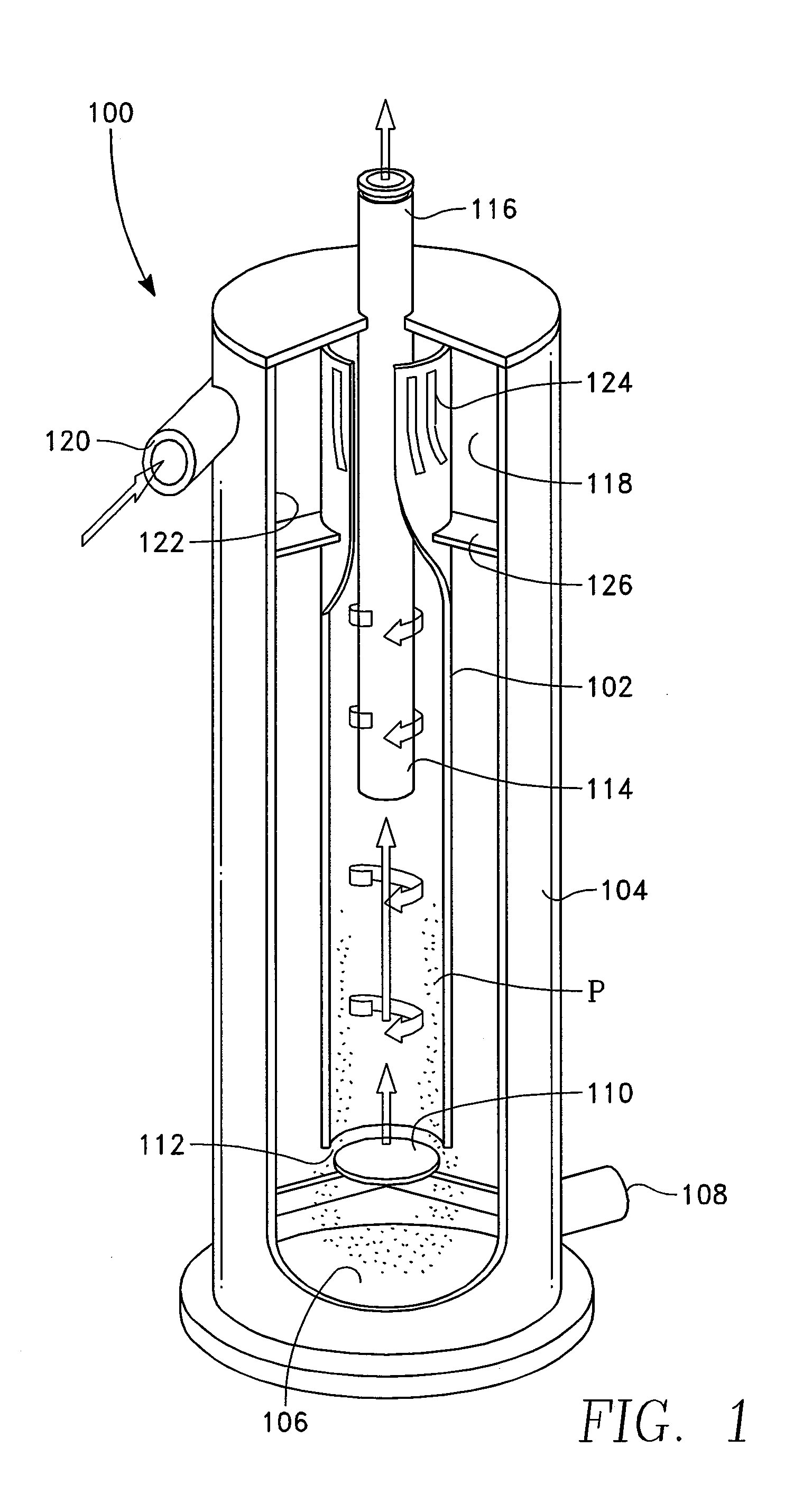

High-efficiency flotation method and its flotation equipment

ActiveCN102284371AAchieve weak turbulence separationImprove mineralization abilityFlotationImpellerEngineering

The invention discloses a column combined reinforced high-efficiency flotation method and flotation equipment thereof. The method comprises four processes, namely strong turbulence mineralization realized by a raw ore through mechanical stirring, static flotation realized by settled sands through counterflow mineralization, weak turbulence separation realized by bubbles through a rectification effect, as well as concentrate secondary enrichment and accurate scraping realization. In the flotation equipment, a bracket is arranged on the top of a cylinder body, a flat scraper is arranged on the lower side of the bracket; a feed pipe is arranged on a position in lower middle of the cylinder body; the outlet end of the feed pipe is connected with the lower end of a false bottom; the false bottom is connected with a rectification plate; an annular inflating pipe is arranged on the lower part of the cylinder body; a monomer rectification plate is connected to the inner wall of the cylinder body; a sleeve is sleeved outside a hollow shaft; and an impeller is connected with the lower end of the hollow shaft. By integrating the advantages of strong mineralization effect of a flotation machine and better separation environment of a flotation column, the defects of high turbulence degree of the traditional flotation machine and insufficient mineralization of the traditional flotation column can be overcome, reinforced high-efficiency flotation is realized, and adaptability to the flotation process is stronger. The column combined reinforced high-efficiency flotation method and the flotation equipment thereof can be applied to separation operation of coals, chemical minerals and the like.

Owner:云南贝凡科技有限公司

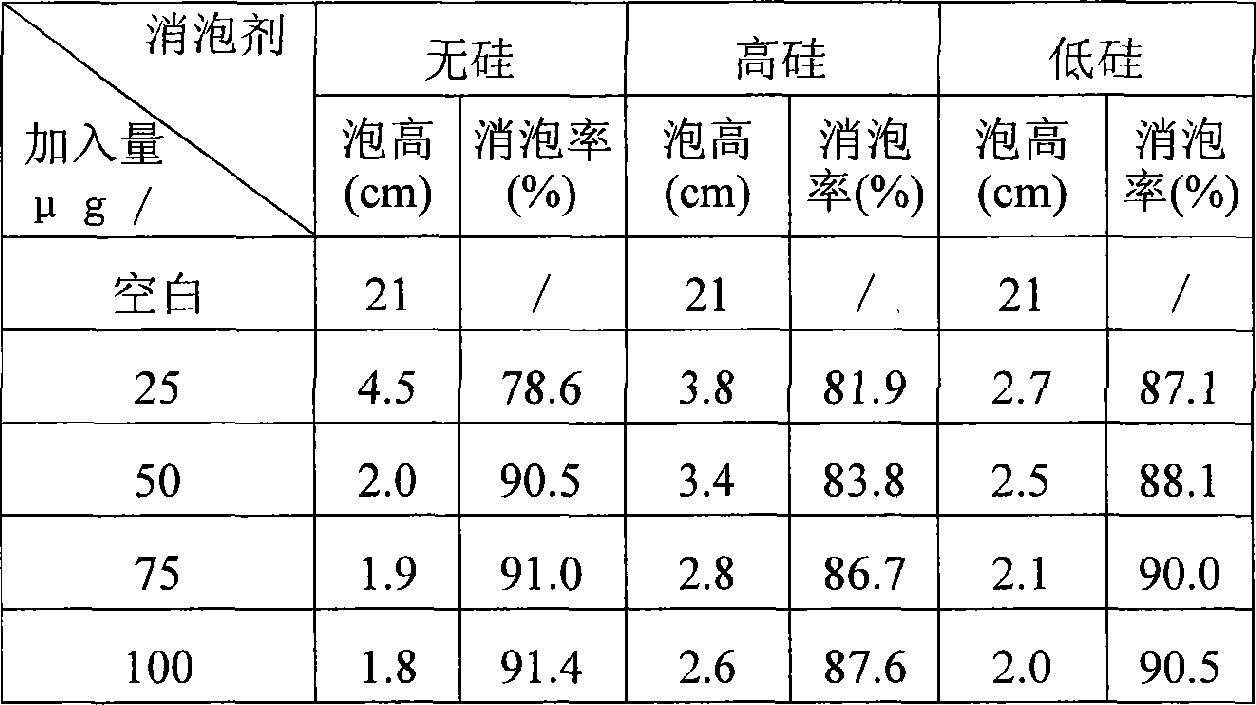

Additive for suppressing and delaying foam generation in coking reaction tower and its prepn process

InactiveCN101045880ASuppress and eliminate generationReduce entrainmentThermal non-catalytic crackingEpoxyHeptyl alcohol

The present invention is additive for suppressing and delaying foam generation in coking reaction tower and its preparation process, and relates to oil refining additive technology. The additive is prepared through compounding high molecular weight block polyether 30-50 wt%, fatty alcohol 20-40 wt% and solvent 20-40 wt%, where, the high molecular weight block polyether is block copolymer of ethylene glycol, epoxy ethane and epoxy propane of molecular weight 10,000-20,000, and the fatty alcohol is isocotanol or 3-enanthol, and the solvent is water solution of alcohol. The preparation process includes the first feeding solvent into reaction kettle and heating slowly to 40-60 deg.c, adding block polyether and fatty alcohol in the ratio via stirring to react for 1-2 hr, cooling and filtering off solid impurity to obtain the product. The additive can suppress and delay foam generation in coking reaction tower effectively.

Owner:SHENYANG POLYTECHNIC UNIV

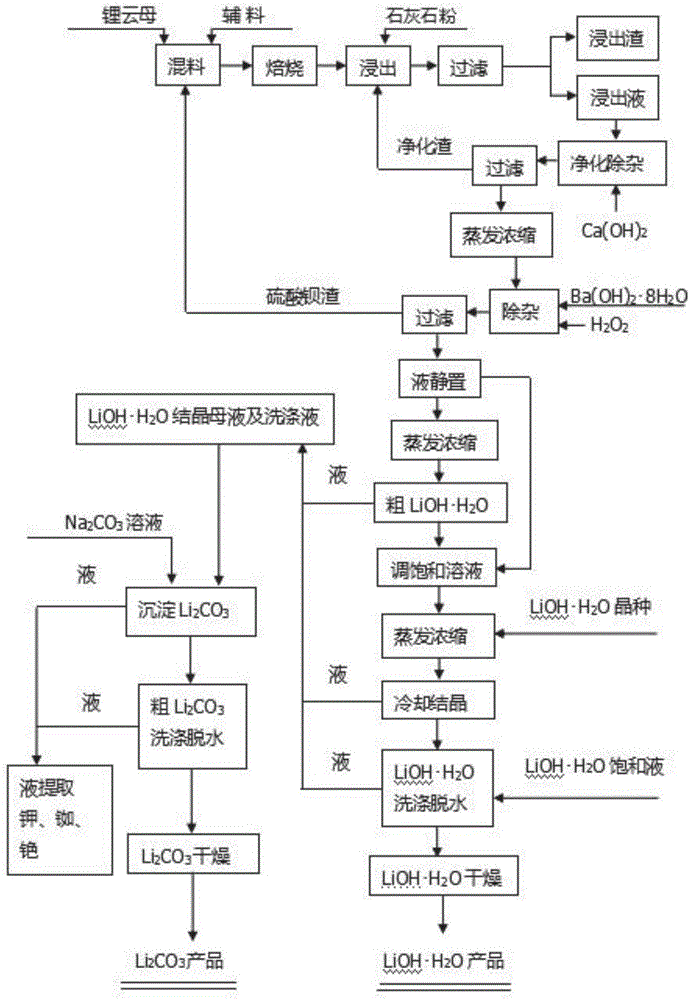

Method for extracting lithium from lepidolite concentrate

ActiveCN106745097AEasy to controlStable productionLithium oxides/hydroxidesLithium carbonates/bicarbonatesResource utilizationLithium hydroxide

The invention discloses a process for extracting lithium hydrate monohydrate and lithium carbonate by performing active roasting and sulfuric acid leaching on lepidolite concentrate. The method comprises the following steps: adding water into the lepidolite concentrate, calcium sulfate, barite powder or barium sulfate return slag and mixing; performing roasting in a preferable roasting furnace at a proper temperature for proper time; grinding and performing sulfuric acid leaching on a roasted material; performing primary purification, concentration and secondary purification on a leaching agent to obtain LiOH finished liquid; performing secondary crystallization and primary saturated liquid washing on the finished liquid to obtain a lithium hydrate monohydrate product; adding sodium carbonate for precipitating the lithium hydrate monohydrate crystallization mother liquor and washing liquid to obtain a lithium carbonate product. By adopting the process, lithium can be separated effectively from the lepidolite concentrate, and qualified lithium hydrate monohydrate and lithium carbonate products are produced. The process has the advantages of low energy consumption, less material flow, low production cost, low discharge capacity, high environmental friendliness, efficient realization of resource utilization, and capability of meeting industrial production.

Owner:谭春波

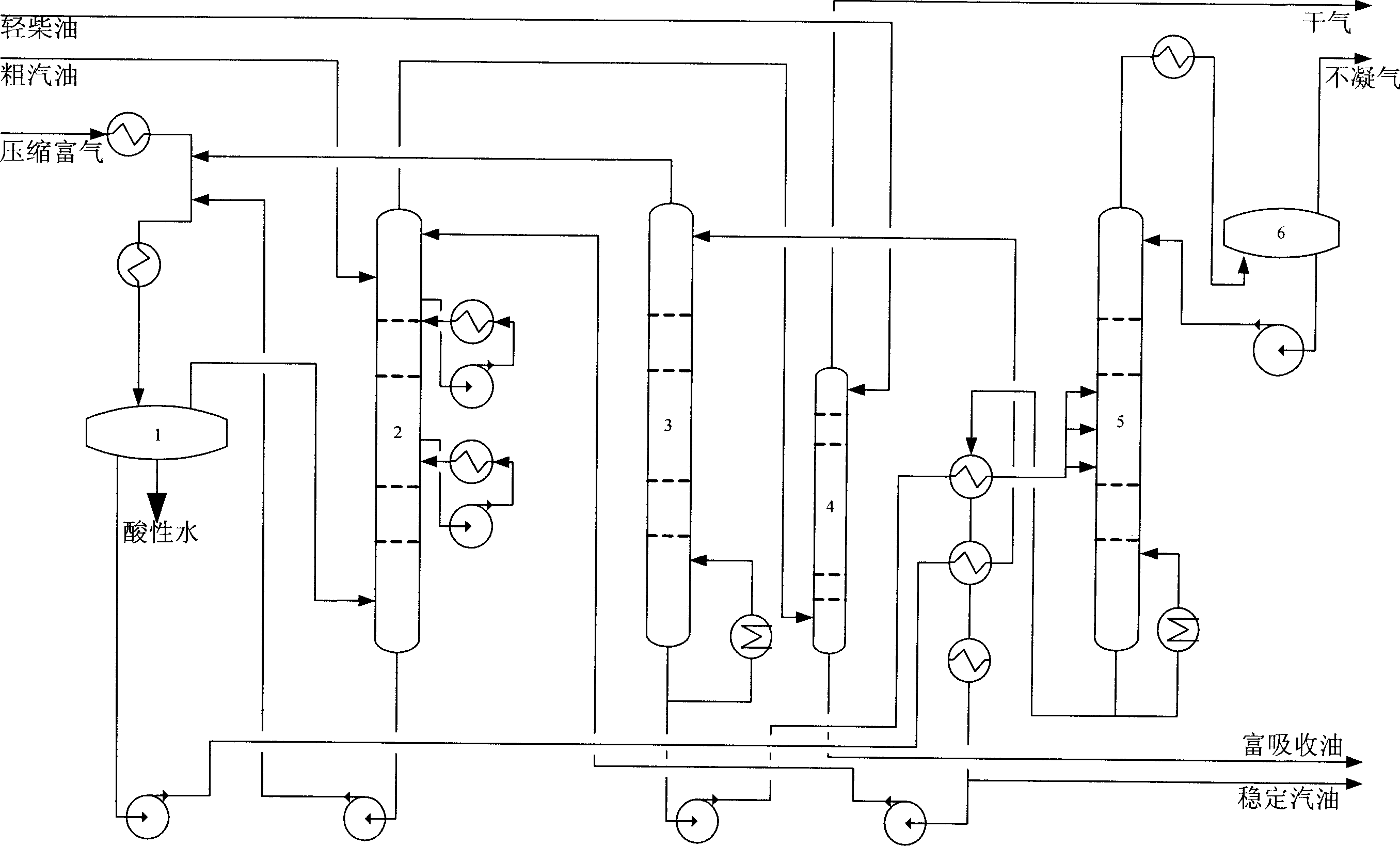

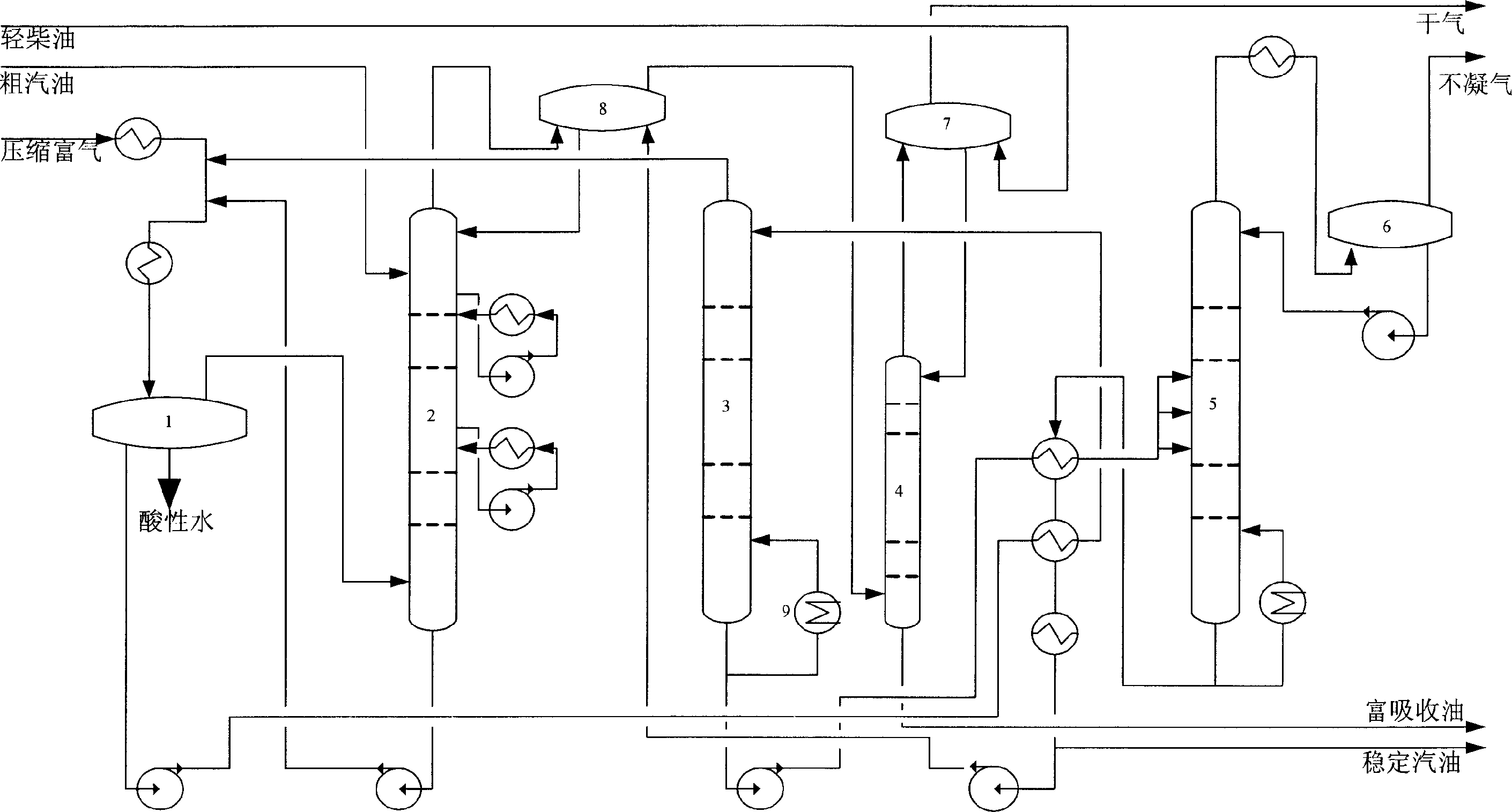

Process for reducing contents of components above C3 in dry gas

ActiveCN1763156AImprove qualityReduce entrainmentLiquid hydrocarbon mixture recoveryHydrocarbon purification/separationProcess engineeringDry gas

The method of lowering the content of C3 and above components in dry gas includes increasing two oil-gas separating tanks and corresponding pipeline to conventional absorbing and stabilizing process. The method can improve the quality of dry gas obviously and lower the entrained C3 and above component amount obviously, and test shows that the method of the present invention can lower the content of C3 and above components in dry gas by over 48 %.

Owner:CHINA PETROLEUM & CHEM CORP

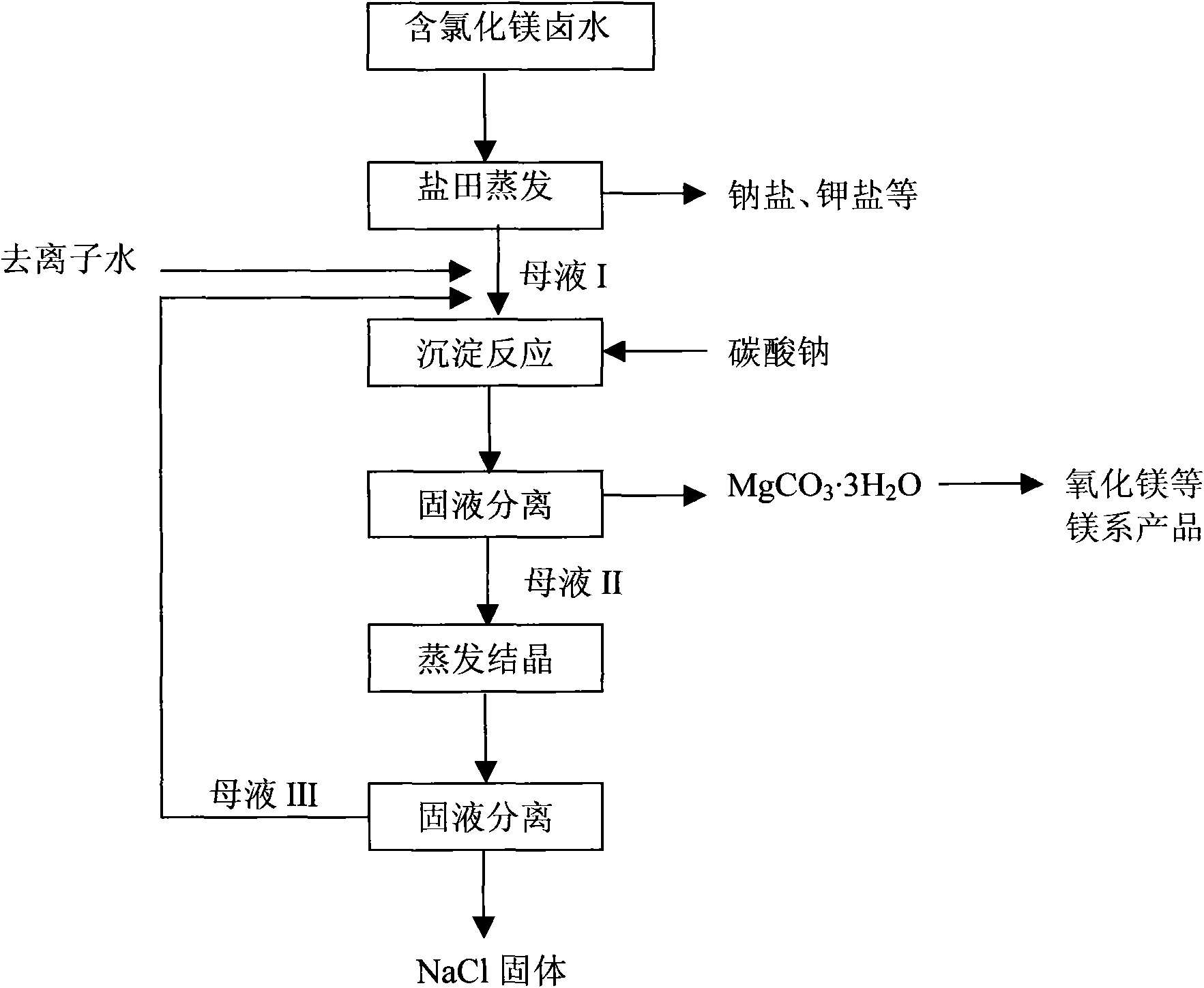

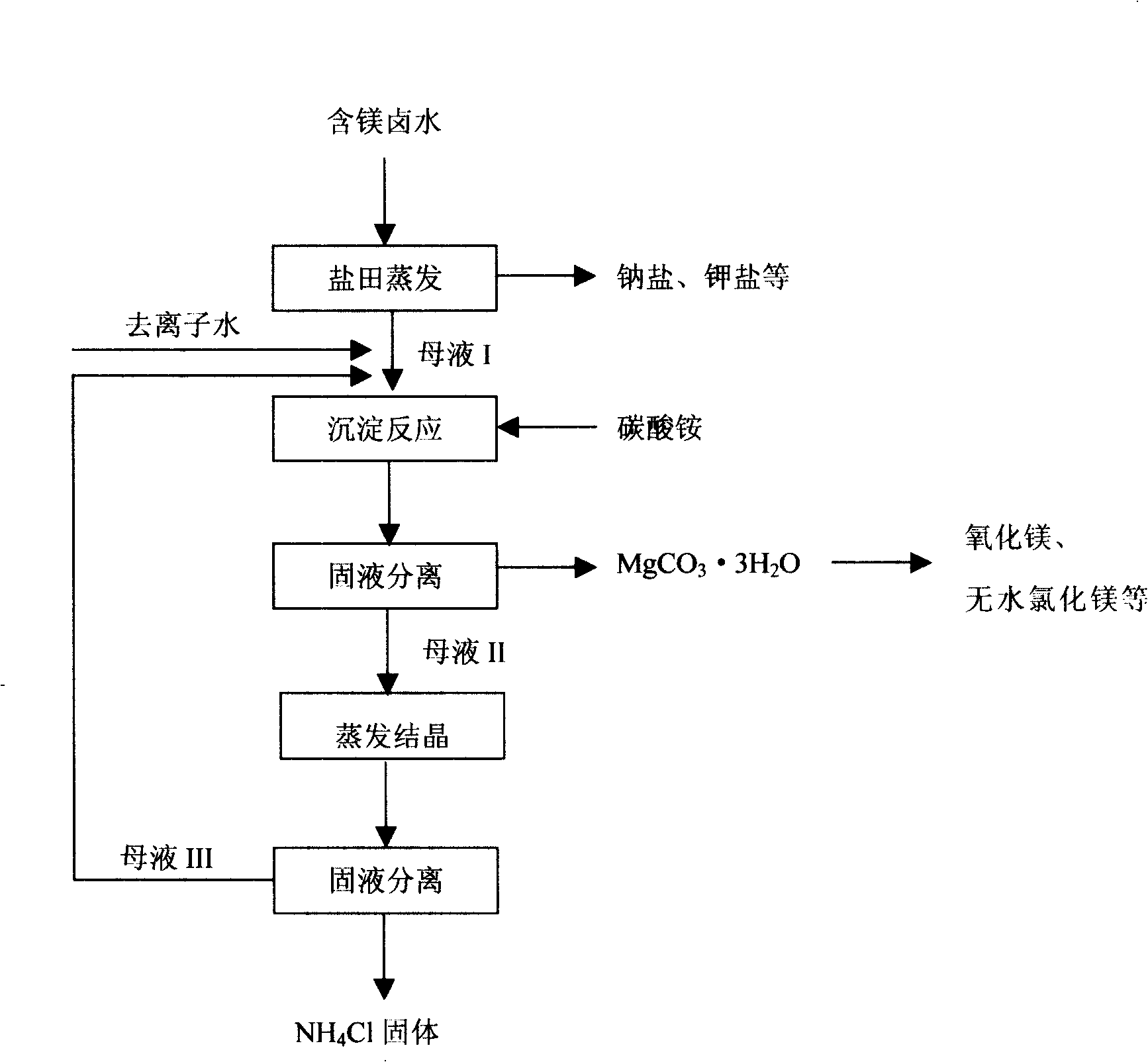

Method for preparing magnesia by taking magnesium chloride containing brine as raw material

The invention belongs to the field of salt chemical engineering, in particular relates to a method for preparing magnesia by taking magnesium chloride containing brine as a raw material. The method comprises the following steps of: obtaining an intermediate (the purity is 99.0 percent) of magnesium carbonate trihydrate with good needle-shaped crystalline form by taking the magnesium chloride containing brine as the raw material and sodium carbonate as a precipitator and controlling the reaction conditions of reaction temperature, stirring rotary speed and charging speed of the sodium carbonate and the like; calcining the obtained intermediate of the needle-shaped magnesium carbonate trihydrate crystal at a high temperature to prepare high-purity magnesium oxide (the purity is 99.4 percent); after reaction, filtering a coarse product of the magnesium carbonate trihydrate to obtainsodium chloride containing crystalline mother liquor; by vaporizing, condensing and crystallizing the crystalline mother liquor, extracting a sodium chloride crystal; and filtering the sodium chloride crystal to obtain a sodium chloride crystal. The method aims to produce the intermediate of the needle-shaped magnesium carbonate trihydrate by rich brine from sea and salt lakes, and further prepares the high-purity magnesia. The method has the advantages of good economic benefits, no environmental pollution, strong operability and easy realization of industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Fume desulfurizing process employing multiple circulation and stable double alkali method and apparatus

ActiveCN1864811APrevent oxidationExtend regeneration reaction timeDispersed particle separationSlagProcess engineering

The invention relates to field of atmosphere pollution control and treatment, especially relates to a process of multiple circulate and stable flue gas desulfurization by means of double aluminium subsulfate. It is characterized in that it comprises: desulfurizing absorption liquid internal cycle, external cycle, internal cycle of desulfurizing slag, internal cycle of desulfurizing agent, and external cycle of desulfurizing salg. The invention also relates to the device for said process. THe invention is characateized by stable process, low investment, high desulfurizing rate and low operating cost.

Owner:广州市天赐三和环保工程有限公司

Phenol-acetone wastewater evaporation desalting pretreatment process

ActiveCN104192927AReduce entrainmentIncrease productivityGeneral water supply conservationNature of treatment waterTarWastewater

The invention relates to a phenol-acetone wastewater evaporation desalting pretreatment process. A process that a falling film evaporator and an OSLO evaporation crystallizer are combined is adopted, cross flow operation is adopted, and a solution is treated according to the following steps: preheating a raw material liquid through a condensate water preheater, passing through a two-effect falling film evaporator, passing through a three-effect falling film evaporator, passing through a four-effect film evaporator, passing through a one-effect OSLO evaporation crystallizer, discharging out concentrated crystal slurry, performing solid-liquid separation, feeding the mother liquid back to the one-effect OSLO evaporation crystallizer for further evaporation, and recycling the solid. The process is reasonable in design, and due to selection of process procedures and equipment, the problems that a phenol-acetone wastewater evaporation desalting device is instable in operation and tubes are blocked by tar are solved, and the production efficiency is improved.

Owner:青岛国标环保有限公司

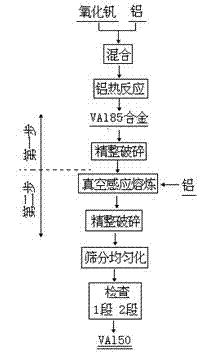

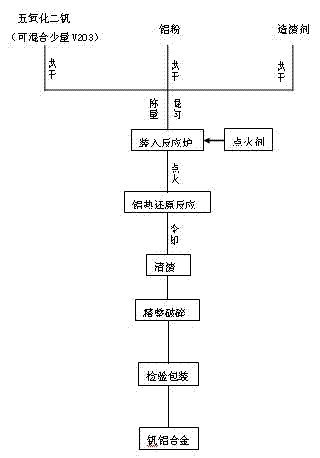

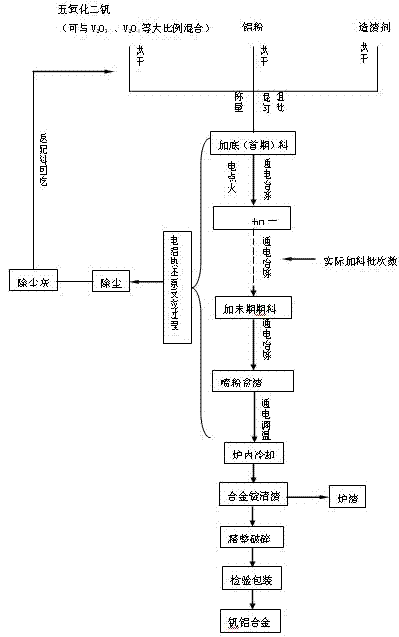

Method for smelting vanadium-aluminum alloy by electro-aluminothermic process

Owner:HEBEI IRON AND STEEL

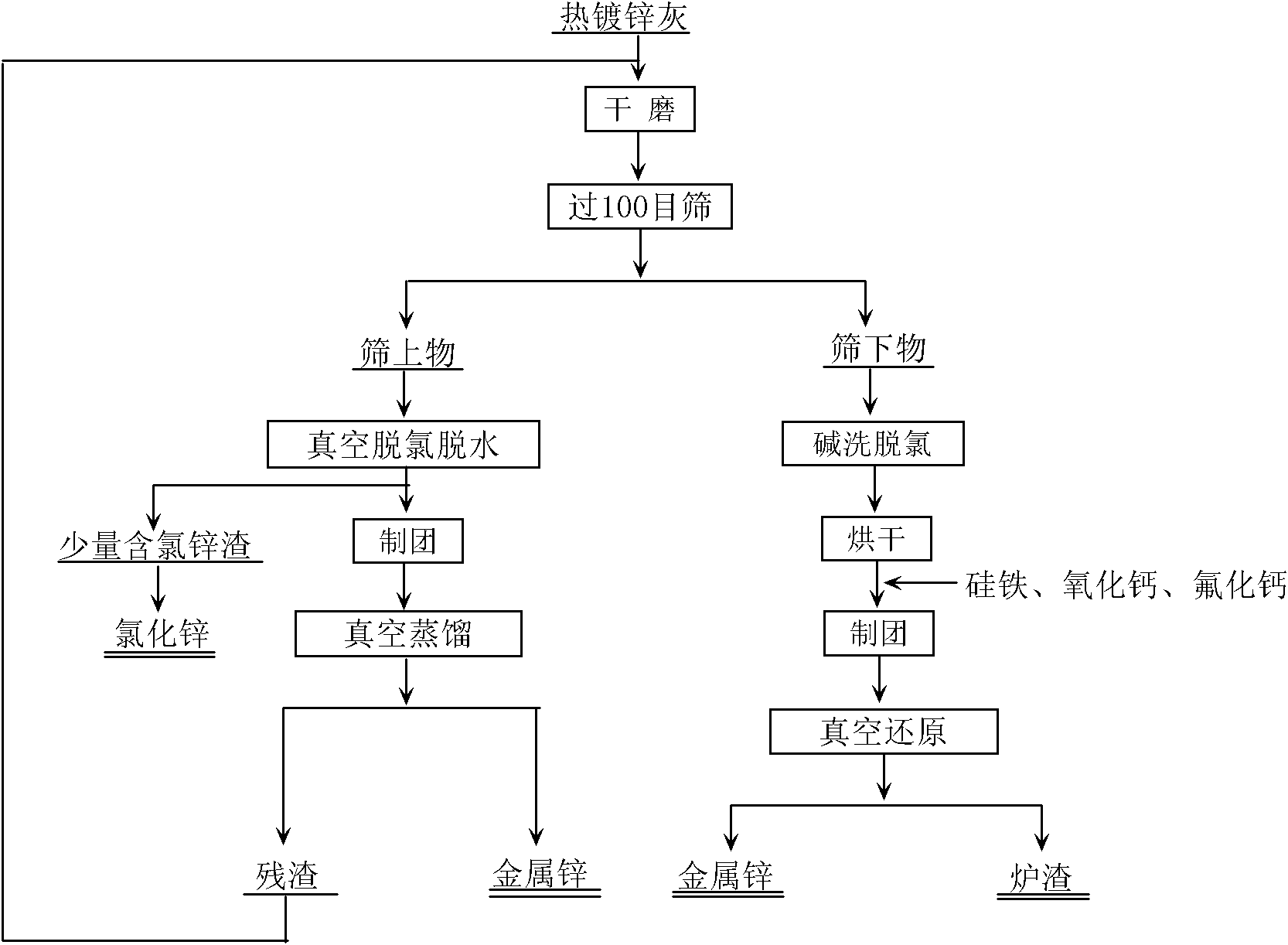

Process for recovering zinc from hot-dip coating zinc ash

InactiveCN101979684AReduce energy consumptionHigh purityProcess efficiency improvementBound waterFerrosilicon

The invention relates to a process for recovering zinc from hot-dip coating zinc ash. The process comprises the following steps of: separating the hot-dip coating zinc ash after dry grinding and screening to obtain an oversize product and an undersize product; removing bound water and a small amount of zinc chloride from the oversize product under the condition that the temperature is between 400 and 500 DEG C and the vacuum degree is 10 to 50 Pa; performing vacuum distillation on the oversize product under the condition that the temperature is between 650 and 800 DEG C and the vacuum degree is 10 to 30 Pa to obtain zinc; and performing alkali cleaning on the undersize product to remove chlorine, and then performing vacuum thermal reduction on the undersize product to obtain the zinc from zinc oxide by using ferrosilicon as a reducing agent and calcium oxide as a slagging agent under the condition that the vacuum degree is 10 to 30 Pa and the temperature is between 1,050 and 1,200 DEG C. The process has a high recovery rate for recovering the zinc from the hot-dip coating zinc ash, and the obtained zinc has a good crystallized shape.

Owner:CENT SOUTH UNIV

Hydrocarbon Treatment Process

InactiveUS20110127194A1Rapid liquid-liquid mass transferReduce entrainmentOther chemical processesRefining with oxygen compoundsBisulfideThiol

In a catalytic treatment process, mercaptans in sour hydrocarbon are oxidized to disulfide oils using an aqueous treatment solution containing a chelated polyvalent metal catalyst, alkali metal hydroxide, and the alkali metal salt of at least one alcohol in a non-dispersive mixing apparatus wherein an upgraded hydrocarbon containing the disulfide oils is produced.

Owner:MERICHEM CO

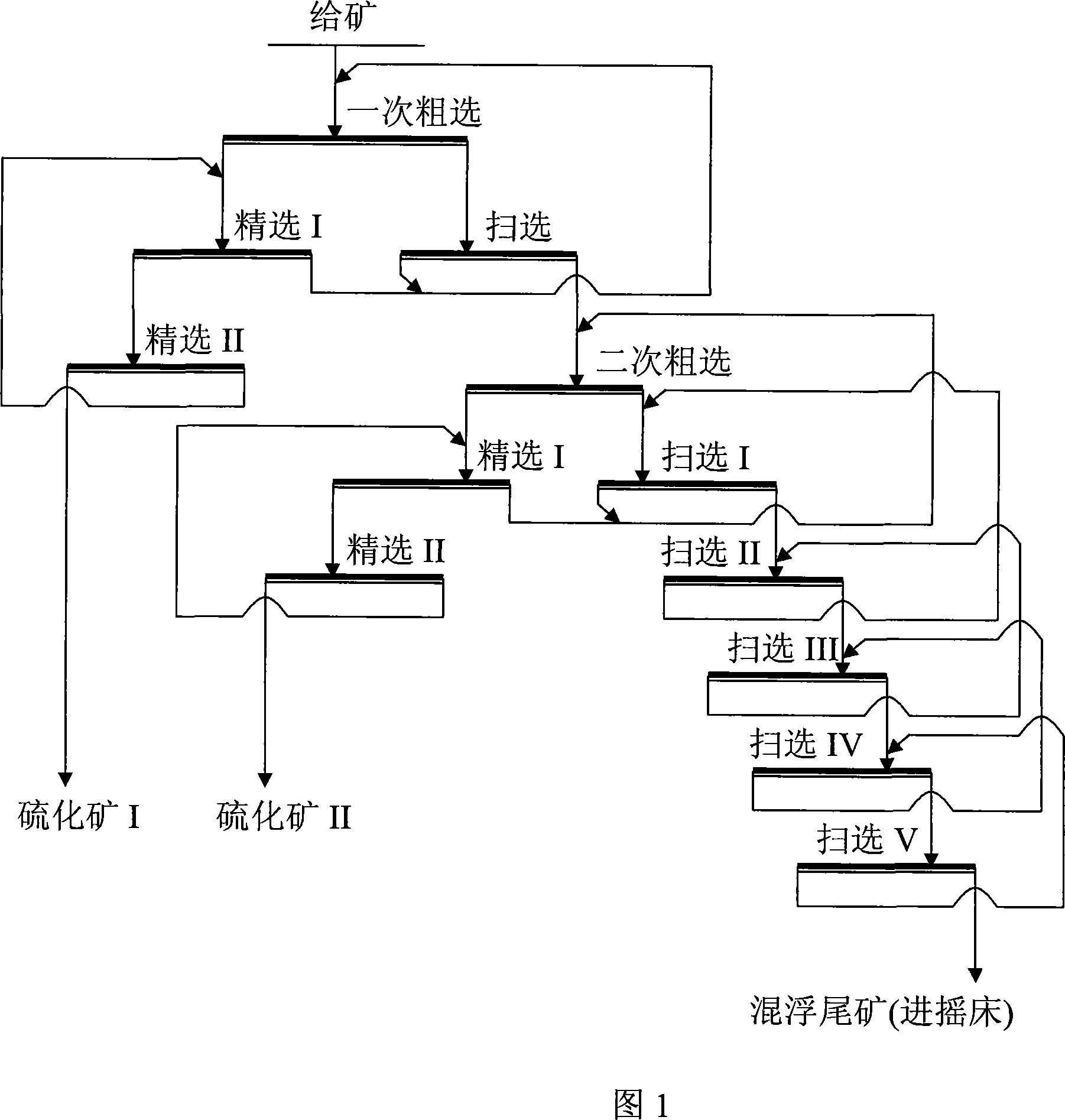

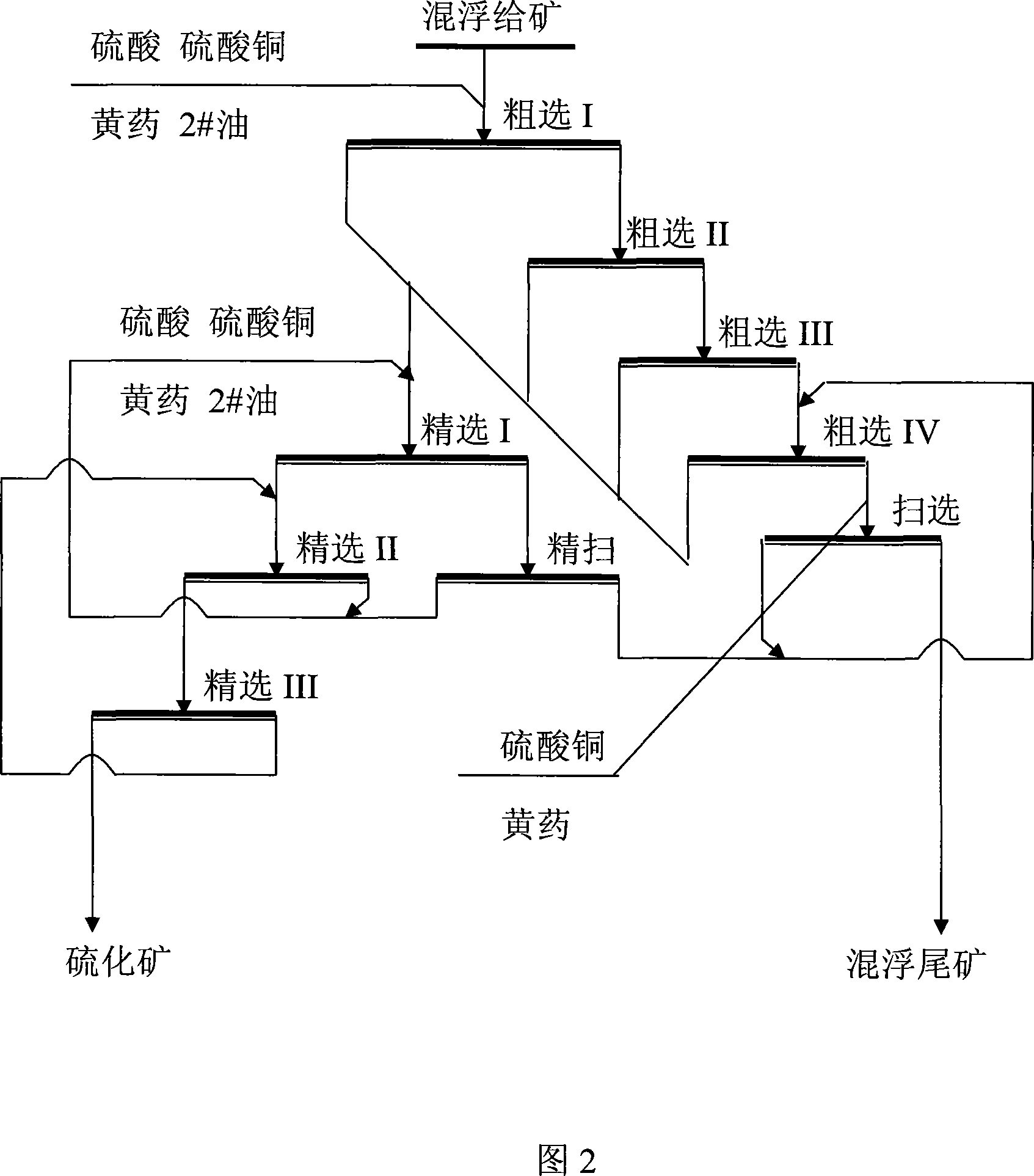

Novel technics of rough-flotation high concentration high-efficient flotation

The present invention relates to bulk floatation process of different kinds of sulfide mineral. The bulk floatation process includes four times of roughing to separate out the floatation tailing, collecting the foamed concentrate from the four times of roughing and concentrating. During the four times of roughing, the floatation strength, the floatation agent amount and the floatation period are increased gradually, so as to float out different floatable minerals in different floatation steps. The bulk floatation process has enhanced separation between the sulfide minerals and the oxide minerals, raised metal sulfide mineral recovering rate, raised floatation efficiency and capacity of ensuring the recovery of cassiterite in the post operation. The foamed concentrate are further separated in three times of concentration and once scavenging to decrease the entrained cassiterite in the sulfide minerals and raise the quality of sulfide concentrate.

Owner:广西华锡矿业有限公司铜坑矿业分公司

Magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating soil

InactiveCN105983569AFast temperature controlFast control timeContaminated soil reclamationElectromagnetic heatingThermal desorption

The invention provides a magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating contaminated sites. The method is characterized in that ferromagnetic materials, such as reducing iron powder, are doped into contaminated soil in an ex-situ mixing and stirring manner, the contaminated soil spirally stirred is heated by using electromagnetism, and a thermal desorption heat transfer gasifying effect is improved through the in-situ electromagnetic eddy heating of the ferromagnetic materials; the reaction activity and oxidation reduction capability of the ferromagnetic materials are improved when the ferromagnetic materials produce heat; after thermal desorption is finished, the ferromagnetic materials of which the surfaces react and adsorb pollutants can be separated from the contaminated soil through magnetic separation, recycled and reutilized; and the continuous remediation of contaminated soil is realized. The device also can be used for the in-situ remediation of contaminated soil. After the ferromagnetic materials are added to the soil in situ through a ploughing stirring device, the soil is heated in situ by utilizing an electromagnetic induction coil to carry out excitation eddy heating in the contaminated soil, pollutants are desorbed, and at the same time, the reaction activity of the magnetic materials(for example, reducing iron powder) can be improved; and after reaction is finished, the iron powder can be separated from the contaminated soil through a magnetic separation technology. The device also can be placed in soil to realize in-situ oxidation reduction degradation. The method and device are suitable for the in-situ thermal desorption remediation of circumjacent large area of low-concentration contaminated soil.

Owner:李泽唐

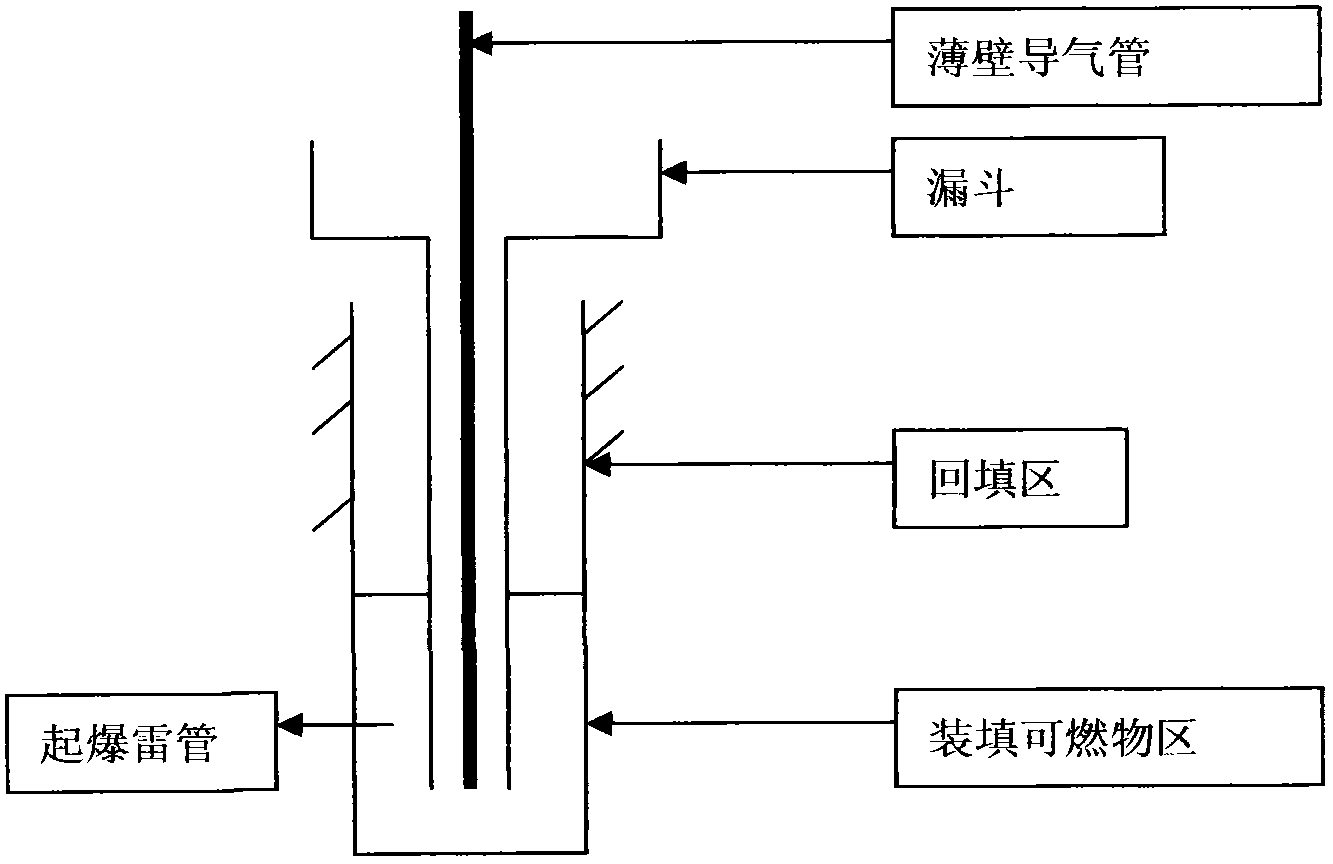

Liquid oxygen explosive composite and liquid oxygen explosive

The invention discloses a liquid oxygen explosive composite and liquid oxygen explosive, belonging to the technical field of liquid oxygen explosive materials containing fuel and enough oxidants to generate high-speed chemical changes after being exploded to generate substances used for detonation. A liquid oxygen explosive composite comprises liquid oxygen and a combustible, wherein the combustible is composed of 50-70% by mass of pulverized coal and 30-50% by mass of wet sawdust or combustible fiber, and the wet sawdust is prepared by humidifying sawdust to 5% by using a sodium chloride solution with concentration of 20%. The liquid oxygen explosive composite and liquid oxygen explosive disclosed by the invention have the advantages of preventing generation of static electricity and explosion possibility, reducing the explosive sensitivity and ensuring the explosive to be safer.

Owner:乔新明

Centrifugal Separator

InactiveUS20110294643A1Reduce generationTrend downWater/sewage treatment by centrifugal separationReversed direction vortexEngineeringSpin structure

A centrifugal separator having a separation chamber and a collection chamber utilizes an axially-oriented structure which extends from the spin structure, or spin plate, up and into the vortex finder. The axially-oriented structure decreases turbulence within portion of the separator in axial adjacency with the spin structure, including the separation chamber in which the solids are collected. The reduction of turbulence substantially reduces the entrainment of solids in the rising stream of liquid flowing to the vortex finder, and thus increases the efficiency of the separator. The spin structure may comprise a truncated cone mounted with a portion of the truncated cone in the separation chamber and the remainder in the collection chamber.

Owner:CLAUDE LAVAL

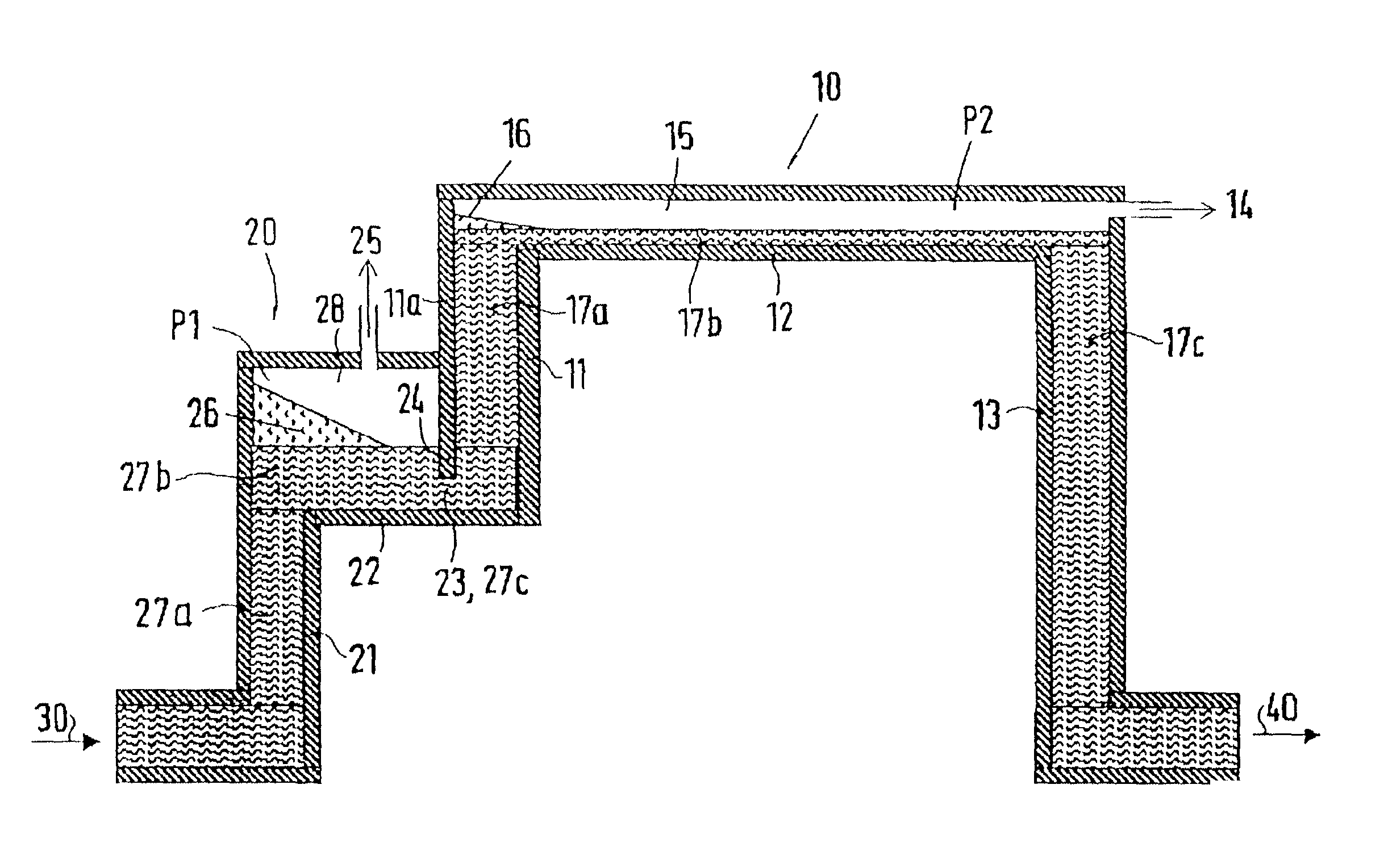

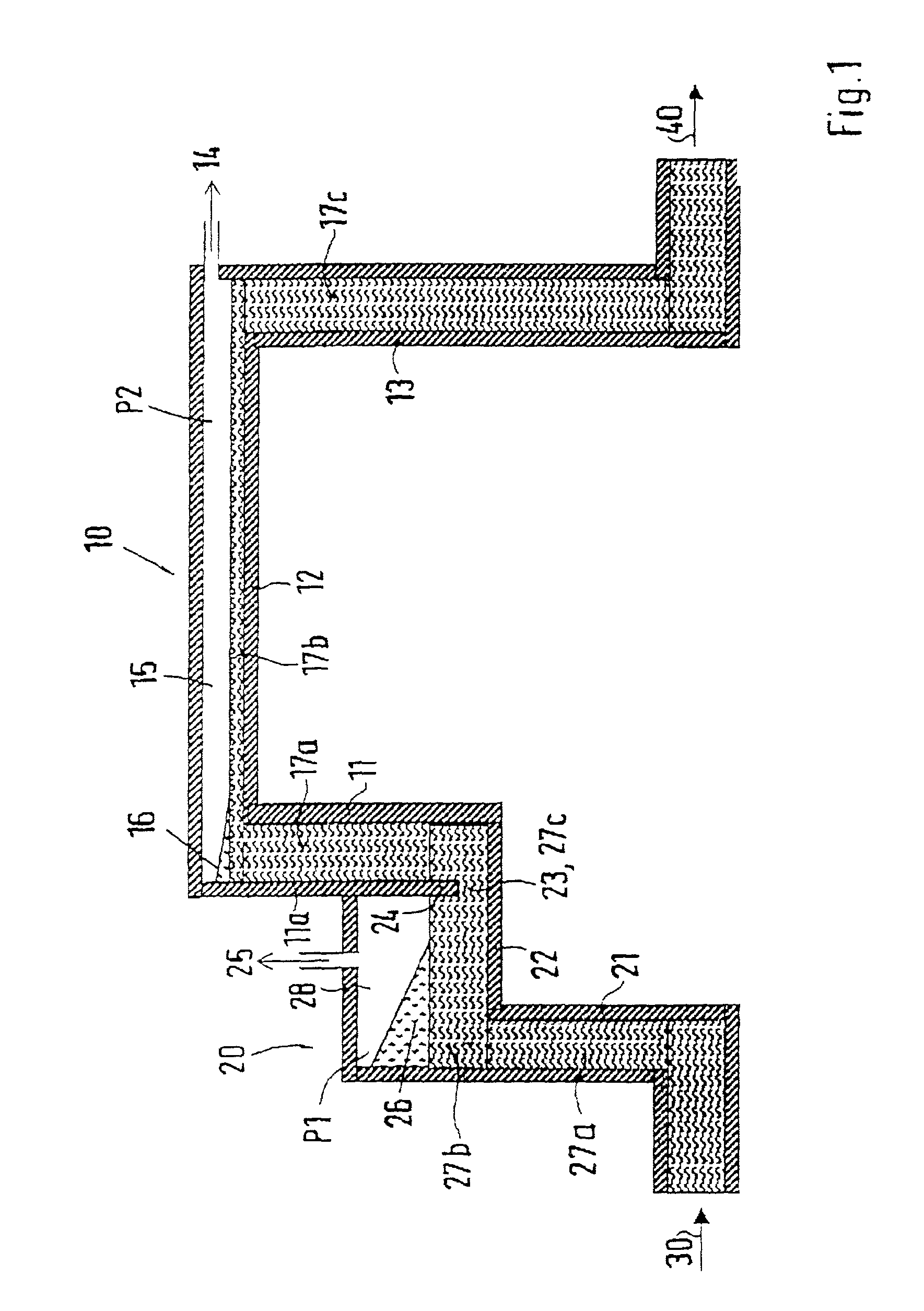

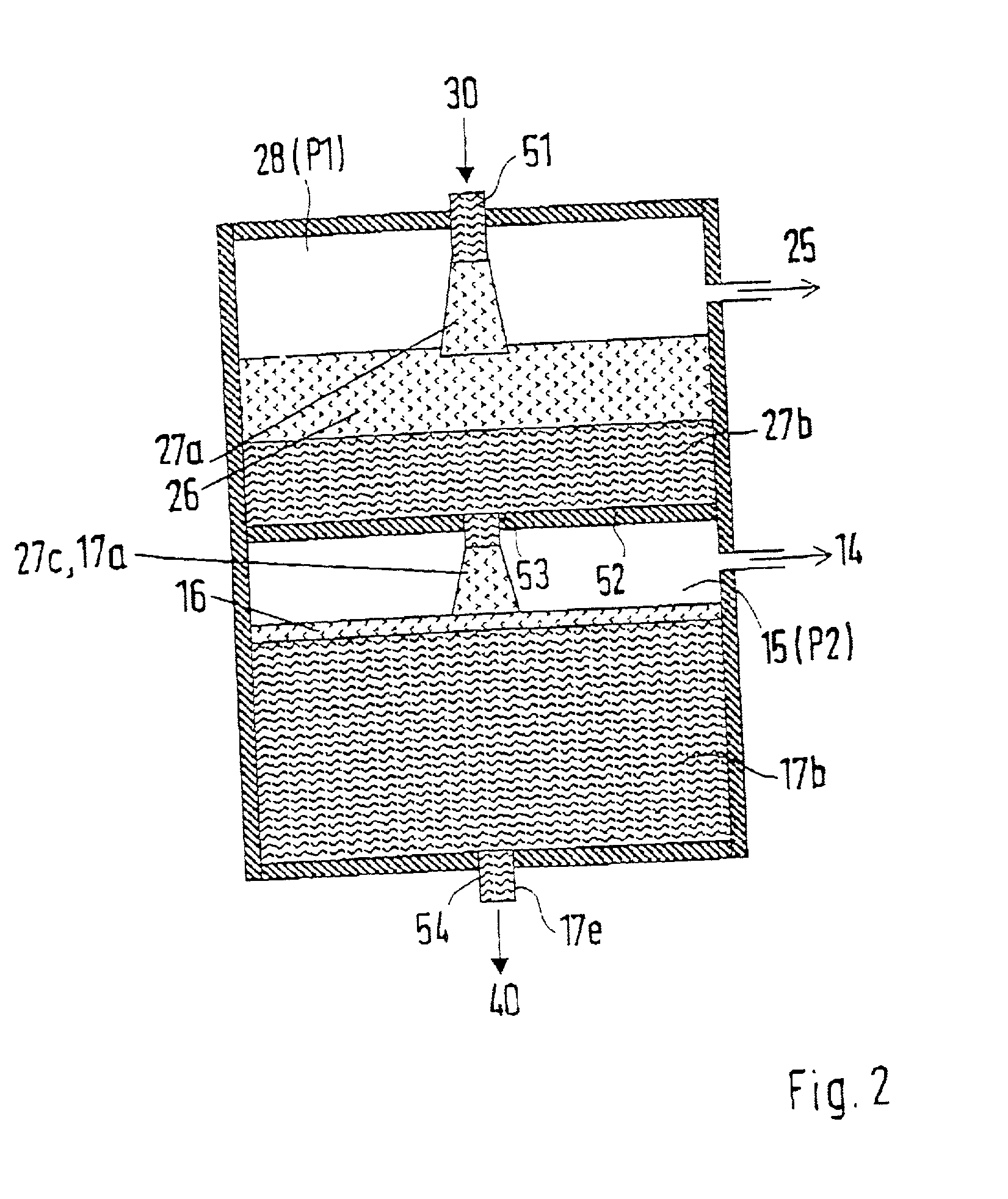

Method and device for refining a glass melting

InactiveUS20020062664A1Small volumeAvoid dangerGlass furnace apparatusGlass meltingAtmospheric pressure

A method and apparatus for refining a glass melting with a vacuum generated above a surface of a glass flux. Refinement is improved because the glass flux is conducted sequentially through several vacuum chambers, and the pressure in the successive vacuum chambers is reduced more and more relative the atmospheric pressure.

Owner:SCHOTT GLAS INNOVATION & TECH MANAGEMENT

Method for preparing trihydrated magnesium carbonate from magnesium chloride-containing bittern by using ammonium carbonate

InactiveCN101259968AImprove the environmentSolve the use problemMagnesium carbonatesChemical industryHigh concentration

The invention belongs to the salt chemical industry technical field, in particular to a method for producing trihydrated magnesium carbonates and ammonium chlorides from magnesium chloride containing brine water by utilizing ammonium carbonates. The invention adopts the technical proposal that: the trihydrated magnesium carbonates are produced by taking the magnesium chloride containing brine water with high concentration as materials and the ammonium carbonates as precipitating agents. The trihydrated magnesium carbonate crystals with desirable shapes can be obtained by controlling technological conditions, so that the adsorption of impurities is reduced, and the products have relatively high purity; the trihydrated magnesium carbonate crystals obtained by reaction are big in volume and easy to filter, thereby lowering the energy consumption of filtering; moreover, the method of the invention has the advantages of strong operability, easy realization of industrialization, good economic benefits of byproducts and no environmental pollution, and realizes the comprehensive utilization of salt lake resources.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

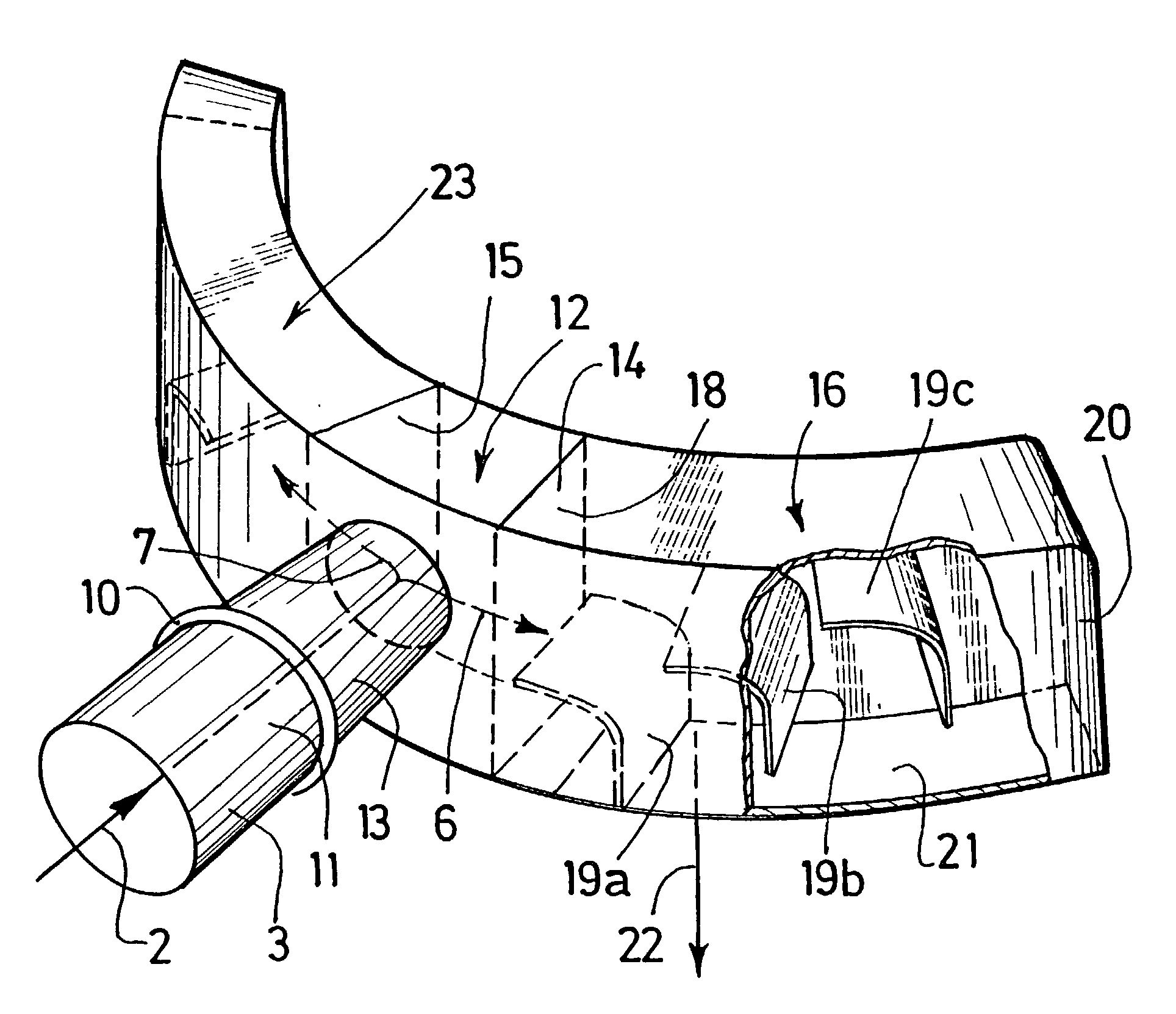

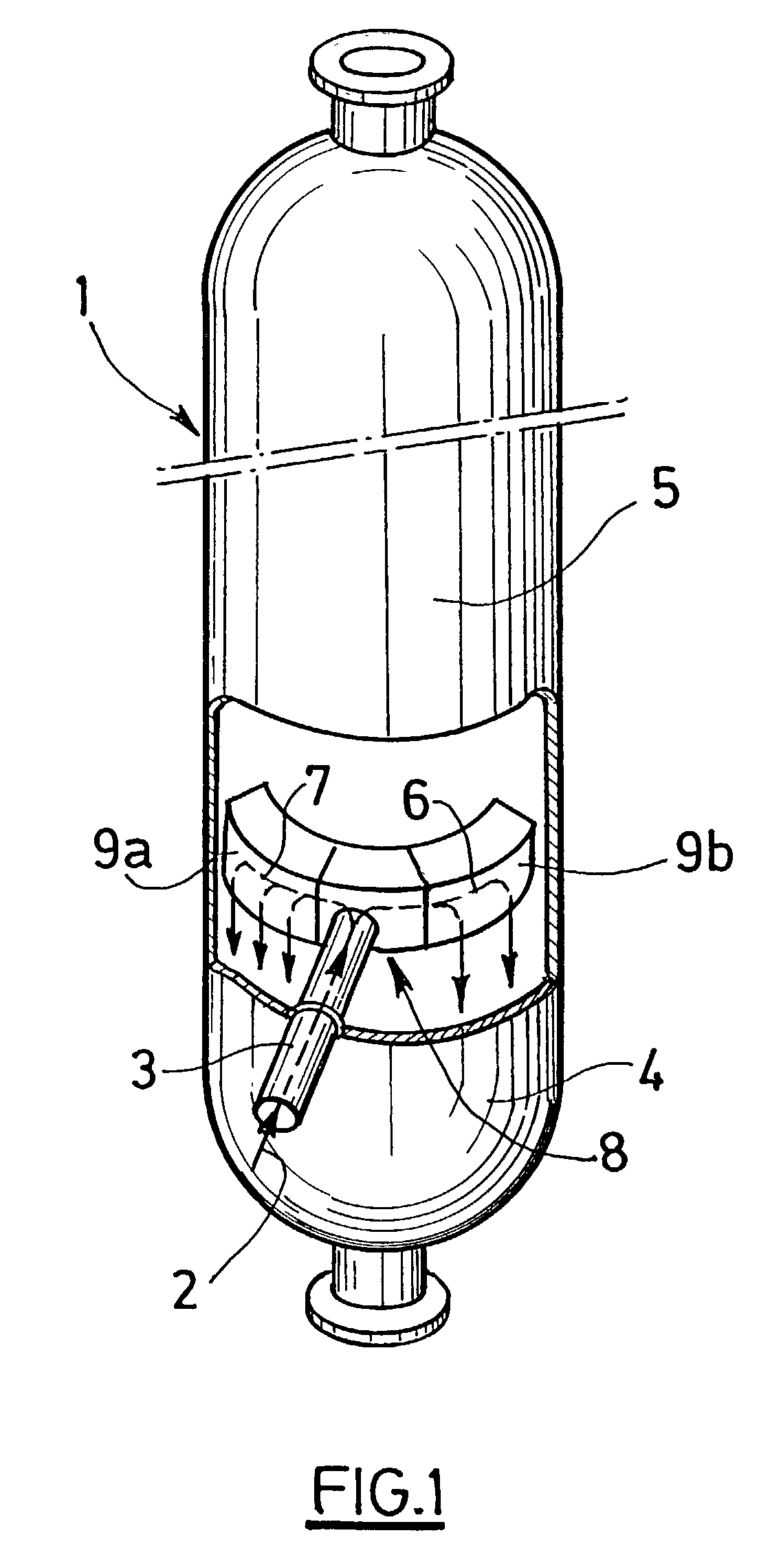

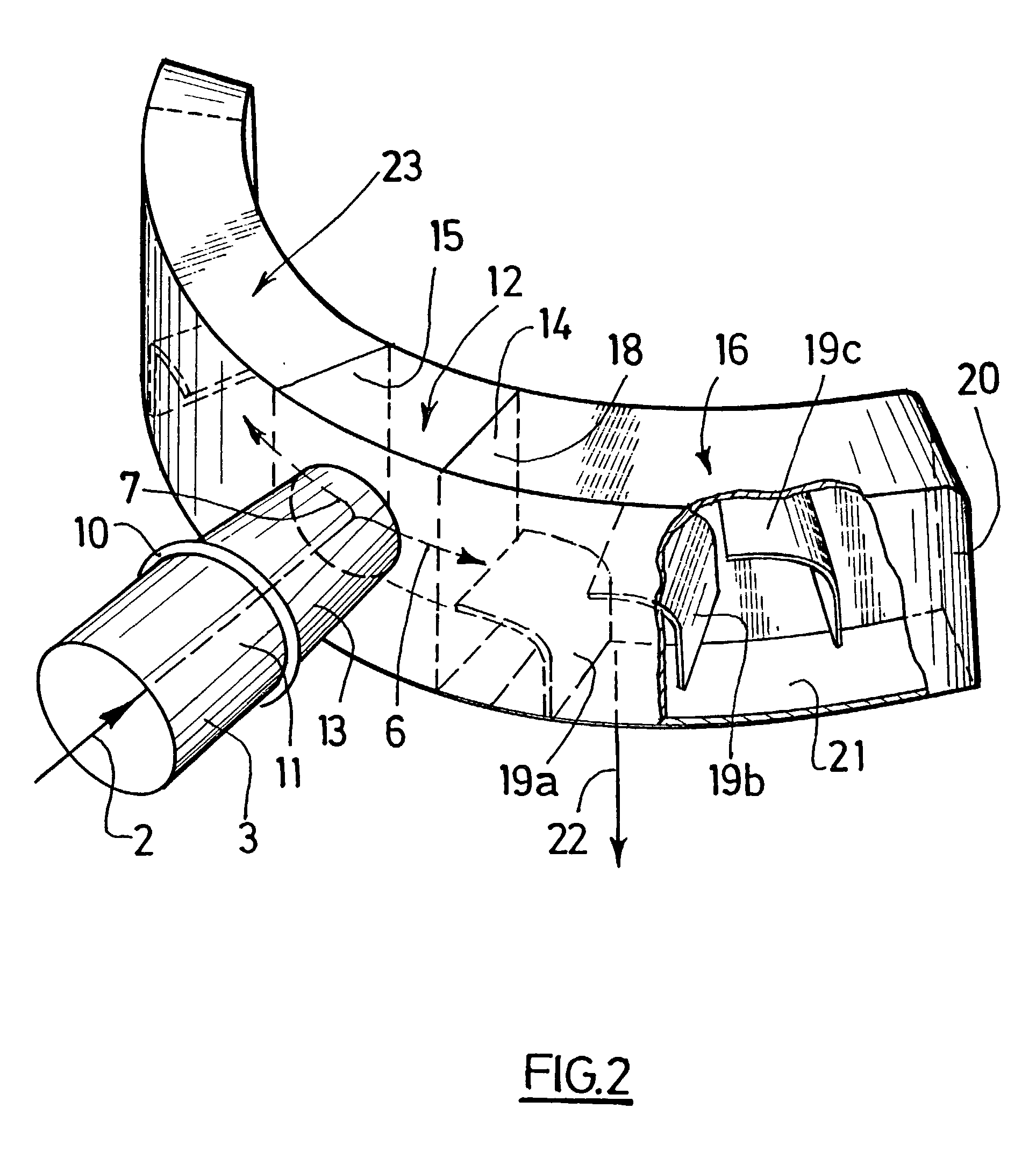

Method and device for introducing a liquid-vapor mixture into a radial feed cylindrical fractionating column

InactiveUS6997445B2Reduce entrainmentEqually distributedCarburetting airMixing methodsFractionating columnPetroleum

A method and device for introducing a liquid-vapor mixture into a radial feed cylindrical fractionating column (1). The method includes separating the liquid-vapor mixture into two opposite and horizontal flows (6, 7), and directing the flows toward the lower part (4) of the column (1) to reduce the entrainments of liquid toward the upper part (5) of the column. The device includes elements (9a, 9b) for separating the liquid-vapor mixture into two opposite and horizontal flows and elements for directing the flows toward the lower section of the column. The elements cooperate to reduce the entrainment of liquid toward the upper section of the column. The method and device can be applied in the oil industry, namely in crude oil refineries as well as in chemistry and petrochemistry.

Owner:TOTAL RAFINAGE DISTRIBUTION SA

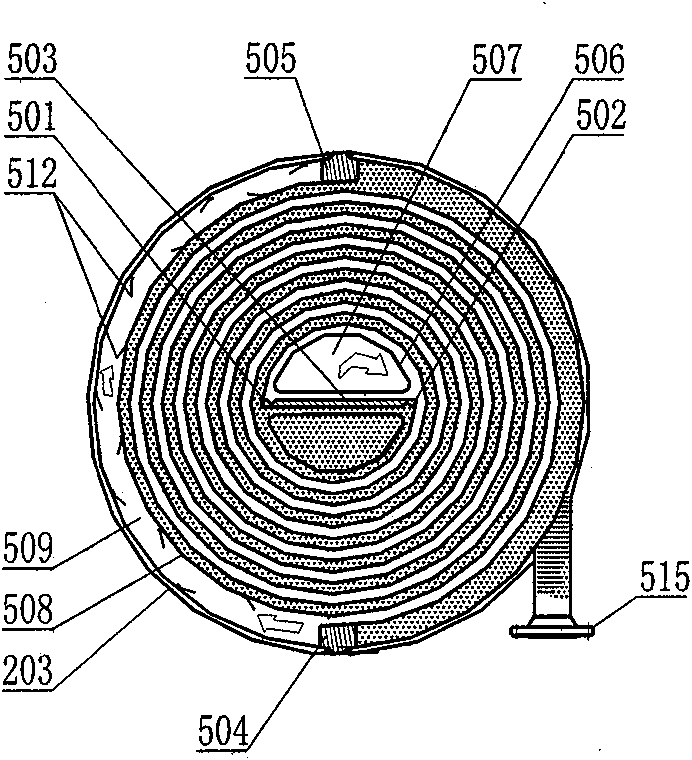

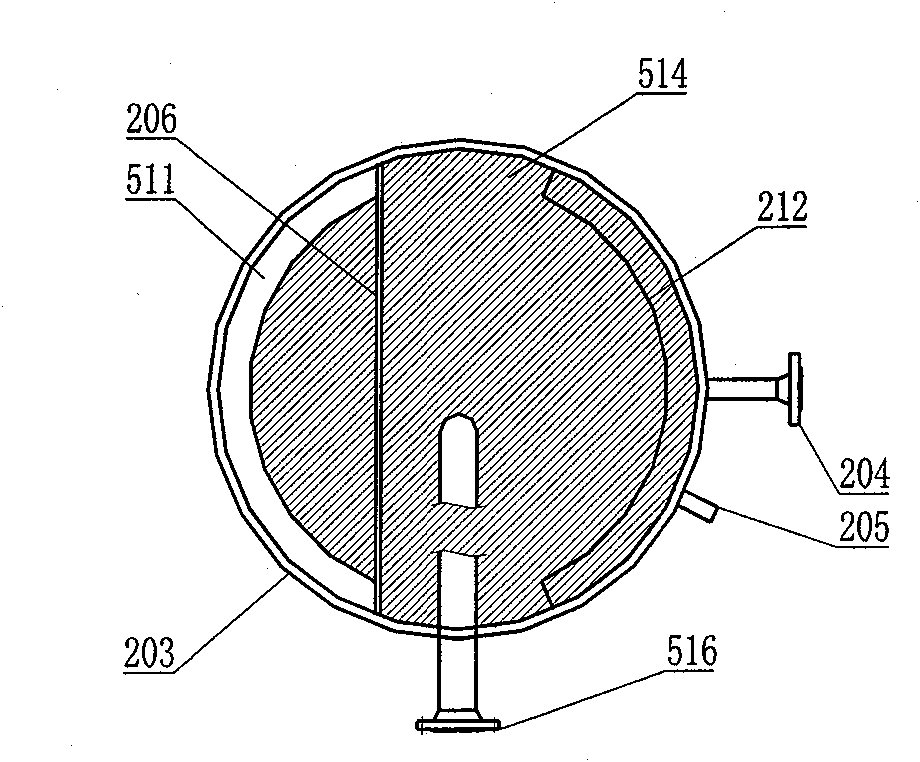

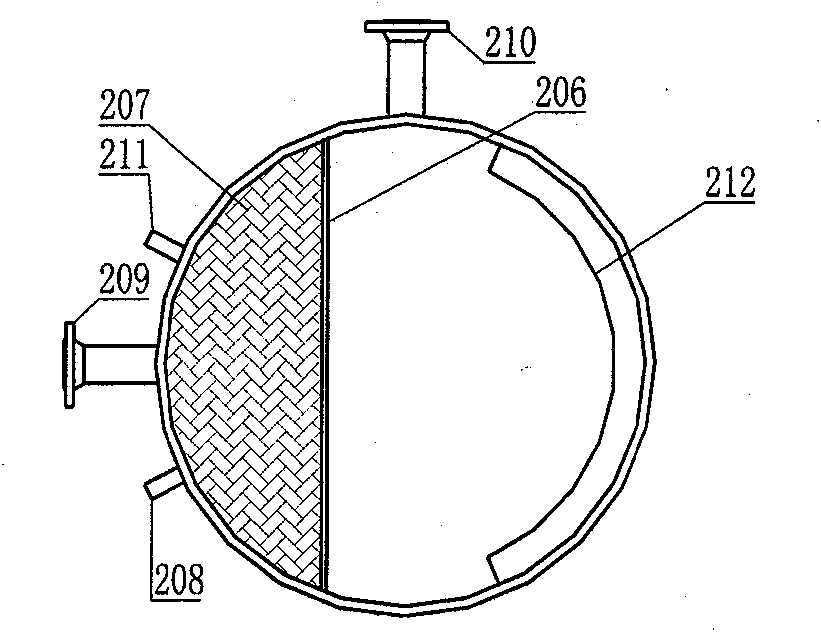

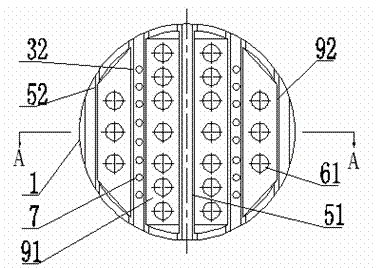

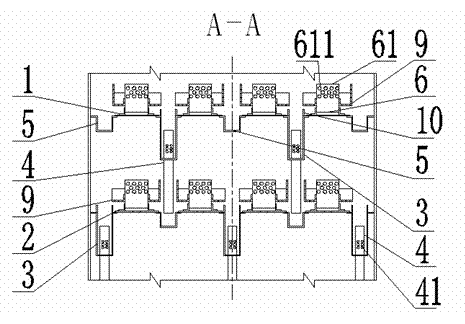

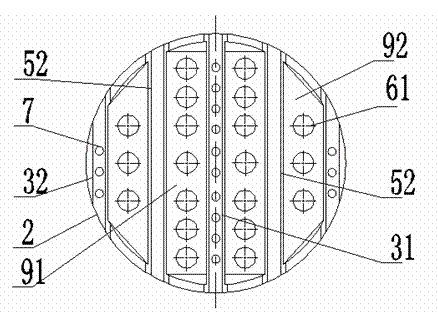

Combination unit for multilevel heat exchange and gas liquid separation

ActiveCN102059042AImprove sealingImport and export area increasedUsing liquid separation agentHeat exchanger casingsAutomatic controlEngineering

The invention discloses a combination unit for carrying out segmented control on heat exchange temperature and pressure of a multi-component gas, gas liquid separation, and staged recover of condensate. The combination unit is tower-shaped equipment, and is divided into upper, middle and lower parts, wherein the three parts are connected by flanges. The gas flows in the tower from bottom to top; the lower part of the tower body is used for removing the entrained liquid of a gas which enters into the tower, and collecting the condensate generated by upper heat-exchange equipment; the middle part of the tower body is formed by multiple sections of modular equipment; a heat exchanger of the modular equipment at each section is a spiral-plate exchanger; the modular equipment at each section is used for automatically controlling the heat exchange temperature and pressure of a gas and gas liquid separation, and is used for collecting condensate produced by the modular equipment at the previous section; and the upper part of the tower body is used for primarily and automatically controlling the heat exchange temperature and pressure of a gas and gas liquid separation. The combination unit is characterized in that the section number of the modular equipment can be freely and flexibly selected so as to be combined with the upper part and the lower part of the lower into the whole equipment, thus meeting the production requirements for progressive heat exchange of the gas, gas liquid separation and staged recover of the condensate.

Owner:ANHUI SHIHUA ENG & TECH

Method for resourceful treatment garbage incineration fly ash by plasma torch

ActiveCN106984633AEasy curingAchieve reductionConstruction waste recoveryWaste processingReduction treatmentSludge

The invention provides a method for resourceful treatment garbage incineration fly ash by a plasma torch. Raw materials are pretreated through adding such other silicon-contained wastes as household garbage incineration bottom slag, cullet and construction wastes and high-heat-value liquid dangerous wastes into fly ash by a forming method; the treated raw materials are fed in a transfer arc plasma torch melting furnace with oxygen as working gas through a feeding unit; a molten fly ash melt is cooled by air cooling to form a glass body; tail gas generated in the furnace firstly removes chlorine salt by a salts collecting and purifying unit, and enters an acid recovery unit to recover HCl and enters an SO2 recovery unit to recover SO2, so that the tail gas is harmlessly treated; sludge generated in the treatment process is returned into the furnace; waste water is reused; heat is recovered; and when the harmless reduction treatment is performed for dioxin in the fly ash and cured heavy metal, no waste water and no waste slag are discharged.

Owner:JIANGSU TIANYING PLASMA TECH CO LTD +1

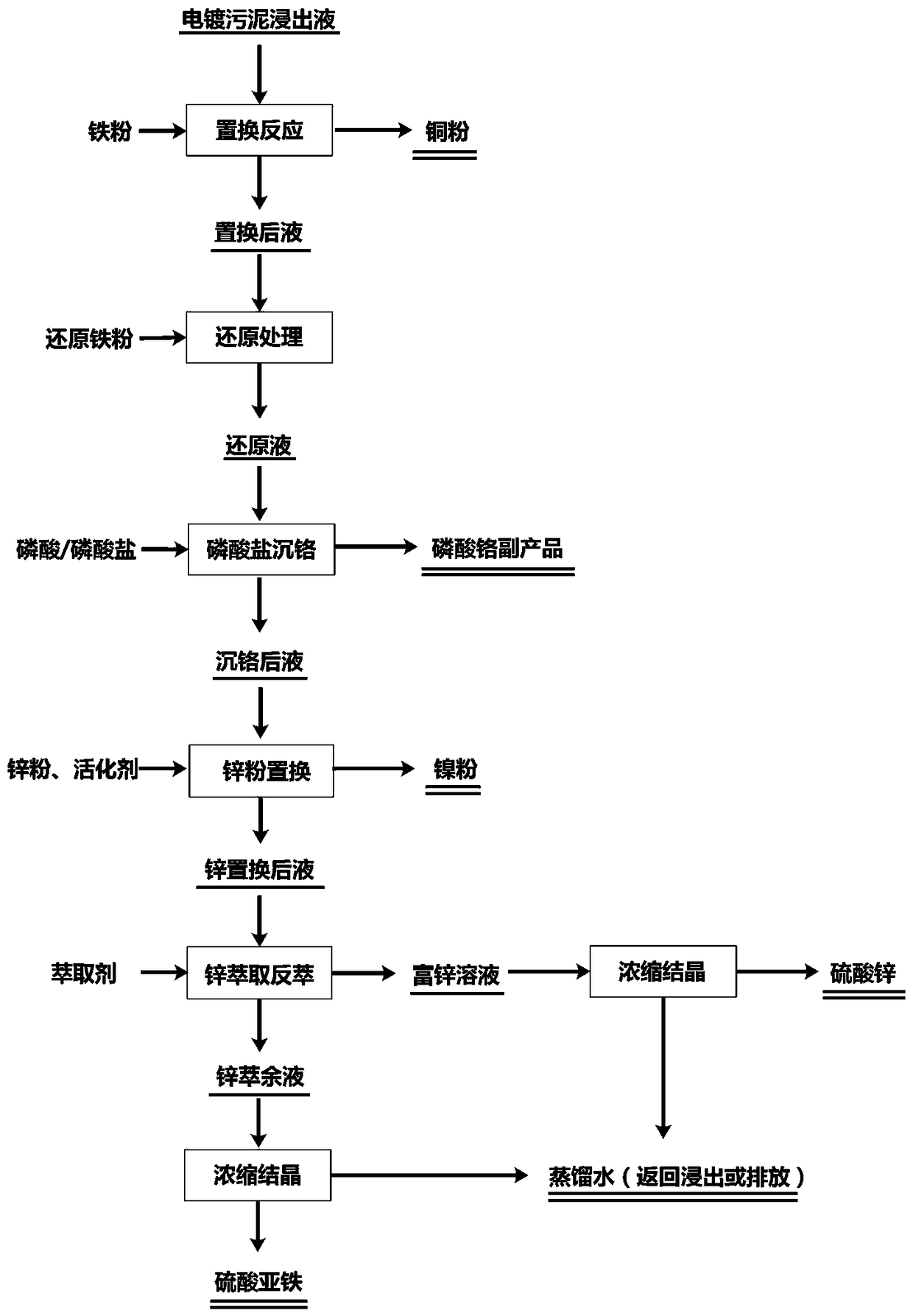

Method for separating iron, chromium, nickel, copper and zinc from high-iron high-chromium electroplating sludge leachate

The invention provides a method for separating iron, chromium, nickel, copper and zinc from high-iron high-chromium electroplating sludge leachate. The method comprises the following steps: (1) addingiron powder into the leachate to obtain a copper powder product and replaced liquid; 2) adding iron powder into the replaced liquid to obtain reduced liquid; (3) adding a chromium precipitating agentinto the reduced liquid, and carrying out filtering to obtain chromium-precipitated liquid and a chromium precipitate; (4) adding the activator antimony salt and zinc dust into the chromium-precipitated liquid, carrying out a reaction, and then carrying out filtering to obtain nickel powder and nickel-removed liquid; (5) adding an acidic phosphate extraction agent into the nickel-removed liquid to extract zinc, then carrying out reextraction by using dilute sulfuric acid, subjecting a zinc-rich solution to concentration and crystallization to prepare a zinc salt product, and subjecting zinc raffinate to subsequent treatment; and (6) subjecting the zinc raffinate to concentration and crystallization to prepare ferrous sulfate heptahydrate, and returning distilled water for leaching. The separation method of the invention has the advantages of short process and high efficiency, and can effectively solve the problem difficulties in separate separation of chromium, iron, nickel, copper and zinc metals in the high-iron high-chromium electroplating sludge leachate.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for synthesizing diatomic alcohol ether acid ester

InactiveCN101475469ALow toxicityEasy to useOrganic compound preparationCarboxylic acid esters preparationSolubilityReaction temperature

The invention relates to a method for synthesizing glycol ether ester. The method comprises the following steps that: glycol ether and fatty acid as raw materials are directly esterified and synthesized into glycol ether acetic ester at a temperature of between 80 and 180 DEG C in the presence of an acidic catalyst and an azeotropic dehydrating agent; and the acidic catalyst is paratoluenesulfonic acid or methanesulfonic acid, and dosage of the catalyst is 0.05 to 1 percent of total weight of reaction materials. The method is characterized in that the mol ratio of the fatty acid to the glycol ether is 1.0:0.8-1.5; and the azeotropic dehydrating agent is isobutyl acetate or 2-butanol acetate, and dosage of the azeotropic dehydrating agent is 5 to 30 percent of the total weight of the reaction materials. The method has the advantages that compared with butyl acetate, the azeotropic dehydrating agent used in the reaction has a lower boiling point and a lower azeotropic point, smaller solubility and lower hydrolysis speed, so that energy consumption during reacting and reclaiming the azeotropic dehydrating agent can be reduced, the reaction speed is improved, and water entrainment of a side product is reduced.

Owner:NANJING FORESTRY UNIV +1

Flow-separation back-mixing-free spraying tower disc

ActiveCN102961888AStrong anti-blockingLess foamingDispersed particle separationDistillation separationSpray towerMechanical engineering

The invention discloses a flow-separation back-mixing-free spraying tower disc. The tower disc is formed by combining an upper-layer tower disc and a lower-layer tower disc; and each tower disc comprises liquid descending grooves, liquid descending pipes, liquid accepting grooves, three-dimensional spraying and mass transferring units and liquid guide grooves. The flow-separation back-mixing-free spraying tower disc is characterized in that the long-strip-shaped liquid accepting grooves are formed in the horizontal position of the center of the tower disc; each long-strip-shaped liquid descending groove is arranged between each two adjacent liquid accepting grooves; liquid descending openings are designed in the bottoms of the liquid descending grooves; each liquid descending opening corresponds to one liquid descending pipe, and each liquid descending pipe stretches and is fixed in each liquid descending groove; the three-dimensional spraying and mass transferring units are arranged among the liquid descending grooves and the liquid accepting grooves; the liquid guide grooves, which are flow-separation-plate-type liquid guide grooves, are arranged on the peripheries of cap covers of the three-dimensional spraying and mass transferring units; one liquid guide groove corresponds to one three-dimensional spraying and mass transferring unit; the shapes and the structures of the upper and lower tower discs are the same basically; and one set of liquid descending pipes on the lower edge of one liquid descending groove of the upper-layer tower disc correspond to one liquid accepting groove of the lower-layer tower disc in a staggered manner, so that the upper-layer tower disc and the lower-layer tower disc are combined into the double-layer flow-separation back-mixing-free spraying tower disc.

Owner:TIANJIN CHUANGJU TECHNOLGOY

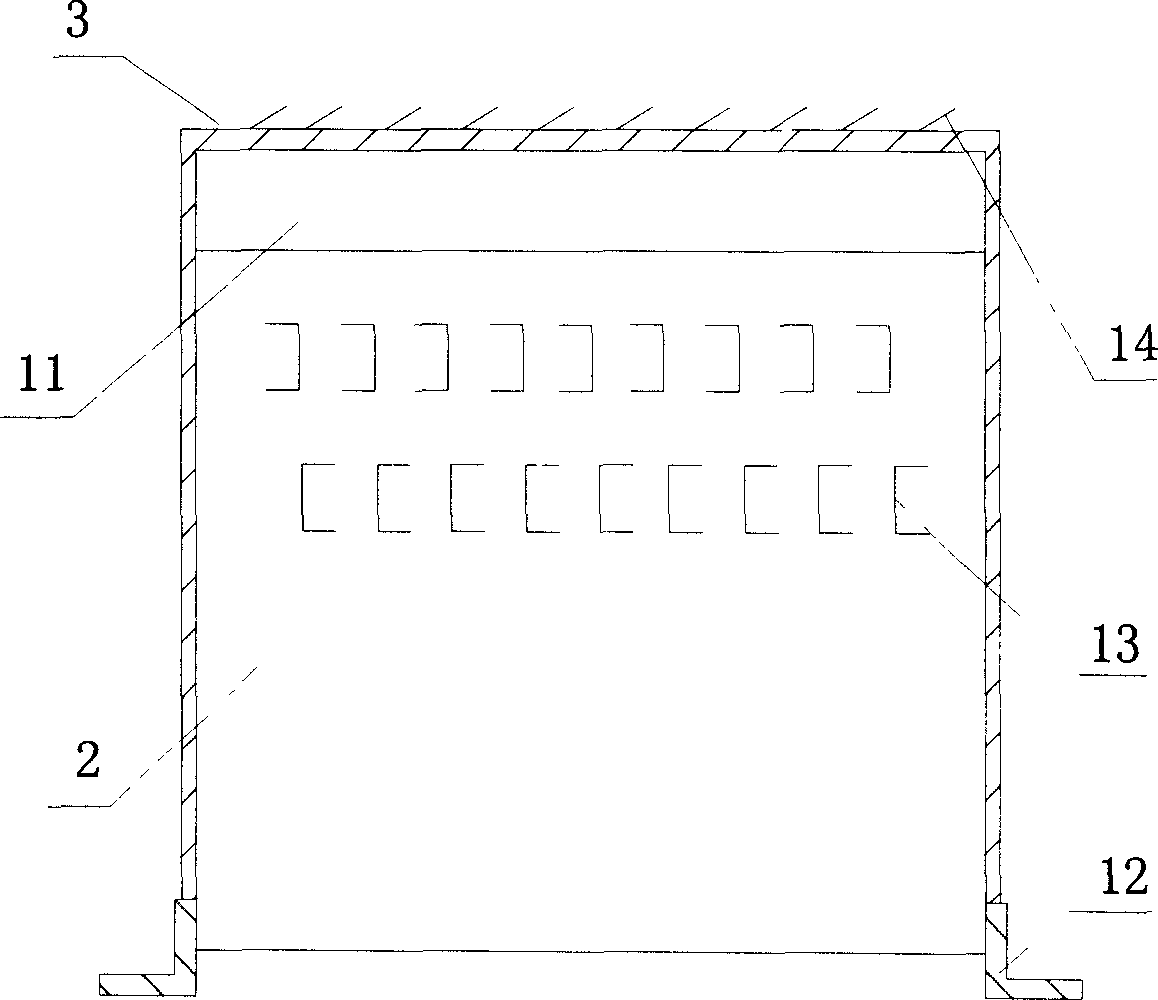

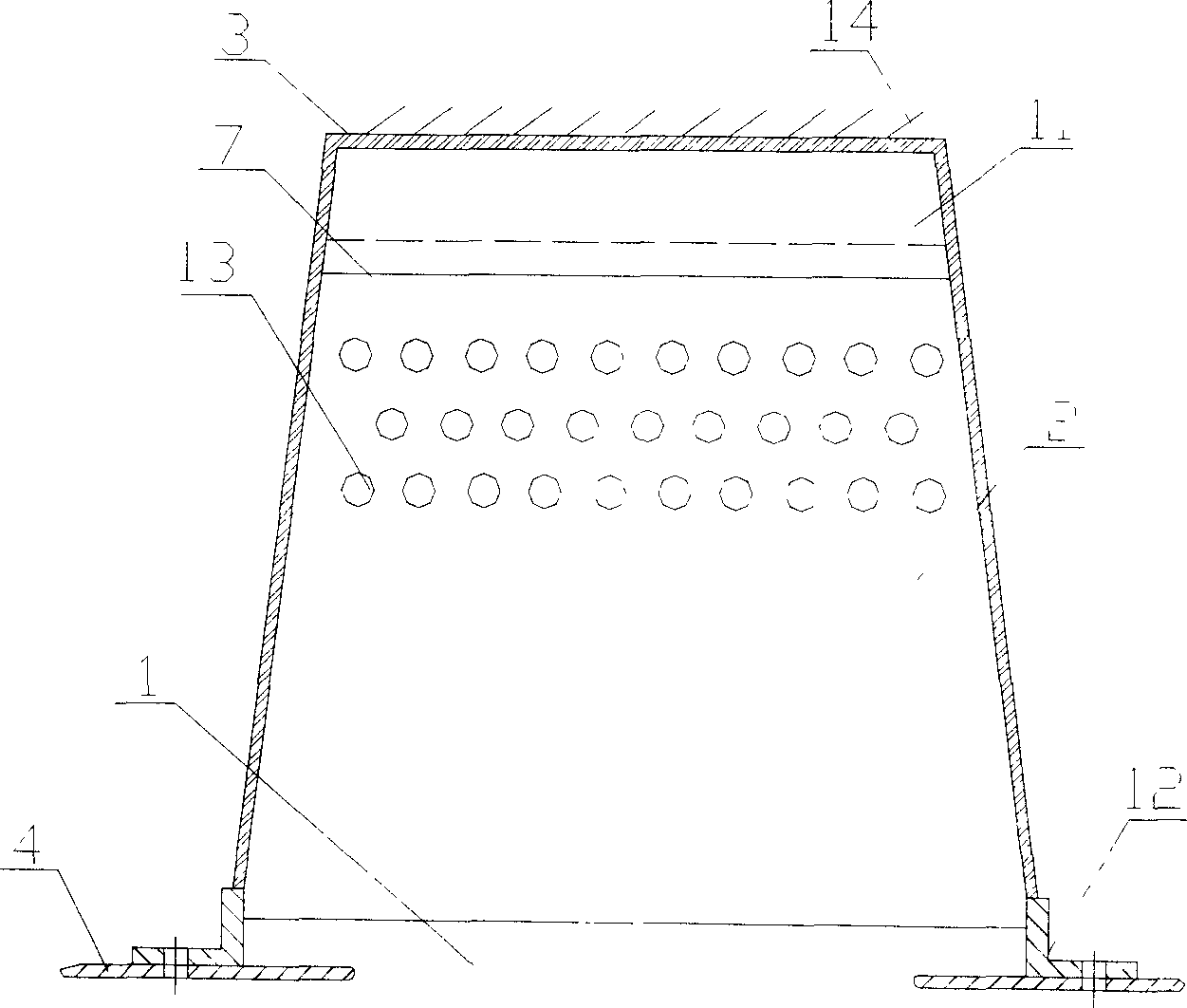

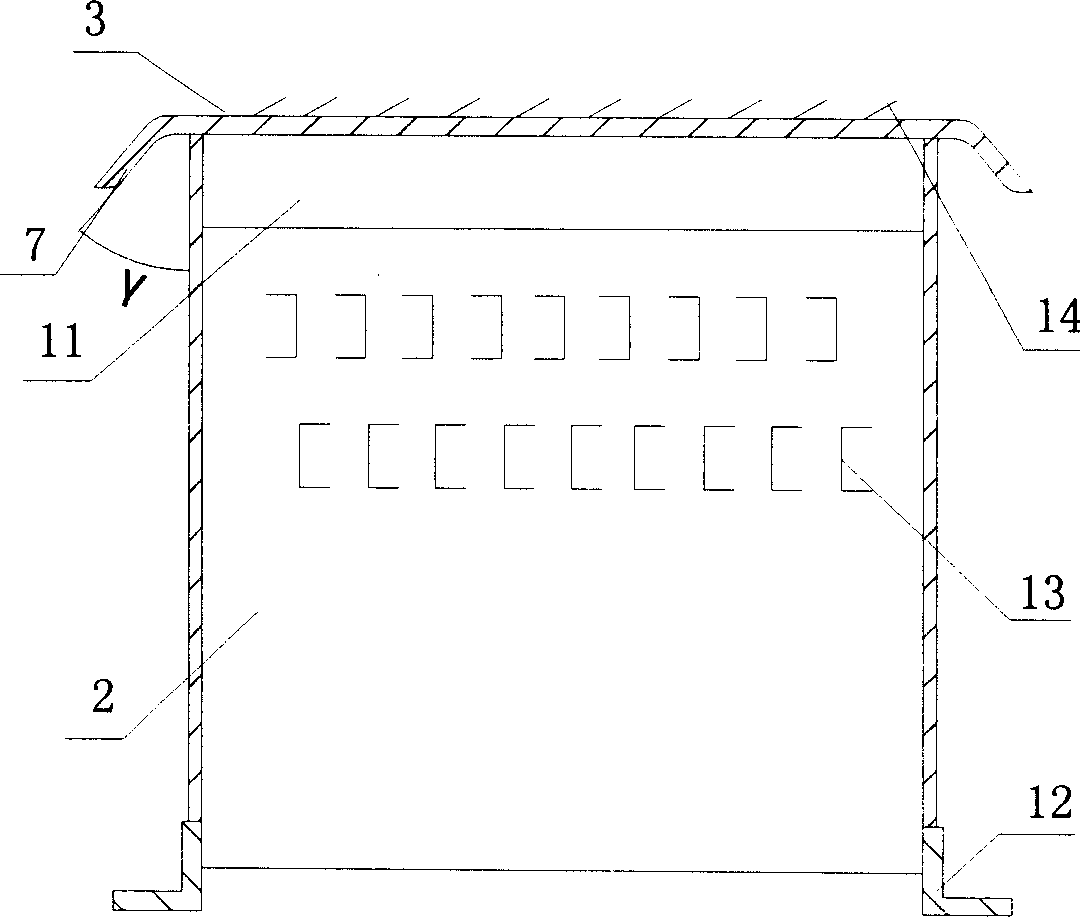

Subassembly between gas-liquid contacting and in use for knockout tower for mass transfer

InactiveCN1660463AHigh porosityReduced sprayDistillation separationChemical/physical/physico-chemical processesProduct gasEngineering

A gas-liquid contact unit for the mass-transfer separation tower in order to increase the efficiency of tower plate is composed of a cylindrical or truncated conic spray hood with uniformly distributed spray holes, a circular top plate with uniformly distributed guide holes and installed to top edge of said spray hood with a window between them, and 3-4 supporting legs for installing it at the flow-up air hole on tower plate.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com