High-efficiency flotation method and its flotation equipment

A high-efficiency, machine-column technology, used in flotation, solid separation, etc., can solve the problems of good mineralization effect, good separation environment, weak mineralization degree of flotation column, etc., to strengthen high-efficiency flotation and overcome turbulence. Large, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

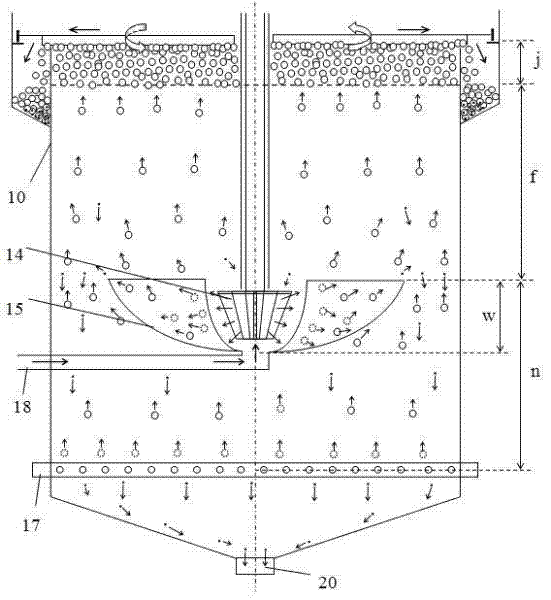

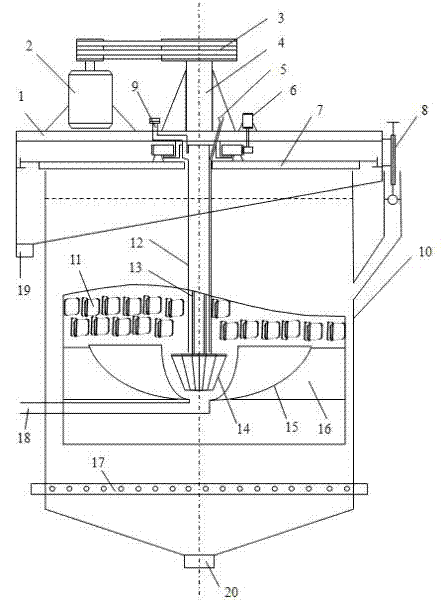

[0023] in figure 1 Among them, the present invention includes raw ore through mechanical agitation to achieve strong turbulent mineralization, sedimentation through countercurrent mineralization to achieve static flotation, bubbles through rectification to achieve weak turbulent separation, and concentrate secondary enrichment to achieve precise scraping. Process:

[0024] ①The raw ore is mechanically stirred to achieve strong turbulent mineralization: in the turbulent mineralization area w in the figure, the raw ore is fed into the flotation machine through the feed port, and the impeller 14 generates negative pressure during the rotation, which can suck in the slurry and a large amount of air , The impeller 14 and the rectifying plate inside the false bottom 15 produce strong turbulence due to the huge shearing force. The pulp is fully dispersed under the strong turbulence, and the inhaled air is broken into small bubbles under agitation and combined with The ore pulp is fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com