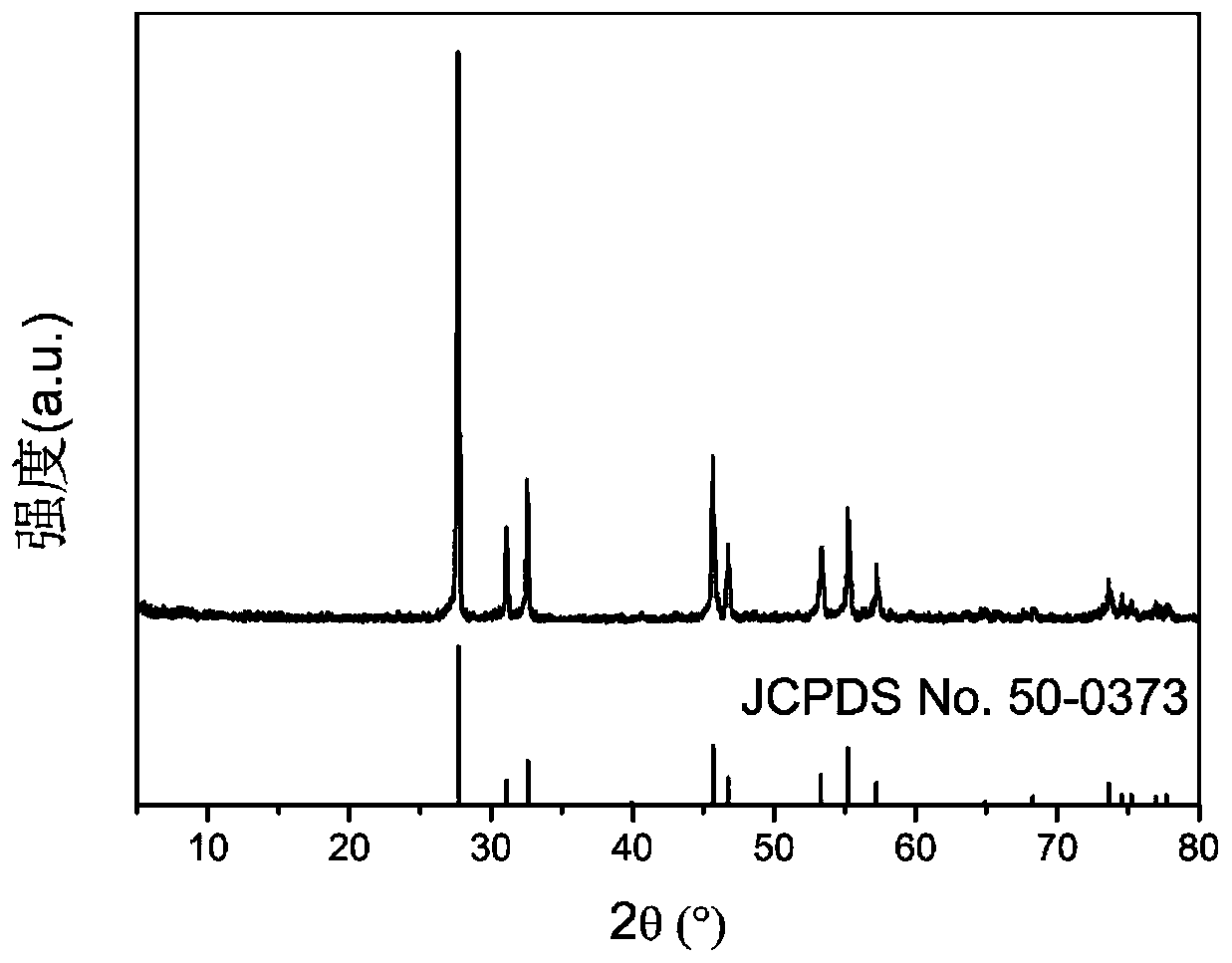

Preparation method and application of a kind of highly active bismuth chromate nano photocatalyst

A nano-photocatalyst and photocatalyst technology, applied in the field of nanomaterials, can solve the problems of narrow light absorption range, poor light stability, low efficiency, etc., and achieve the effects of wide light absorption range, strong mineralization ability, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the highly active bismuth chromate nano photocatalyst that the present invention proposes comprises the following steps:

[0038] (1) Dissolve bismuth nitrate pentahydrate and chromium nitrate nonahydrate in aqueous mannitol solution at room temperature to obtain a lavender transparent solution, wherein the concentration of bismuth nitrate pentahydrate is 0.02 to 0.08 mol / L, and bismuth nitrate pentahydrate The molar ratio to chromium nitrate nonahydrate is 12:1, and the concentration of mannitol solution is 0.5-5mol / L;

[0039] (2) Add 1 to 5 ml of saturated sodium carbonate aqueous solution dropwise to the solution of the above step (1), and continuously stir to obtain a lavender emulsion;

[0040] (3) Transfer the emulsion in the above step (2) to a hydrothermal reaction kettle, react at 130-180°C for 6-12 hours, and after natural cooling, a gray-green precipitate is obtained;

[0041] (4) Filter the precipitate in the above step (3), colle...

Embodiment 1

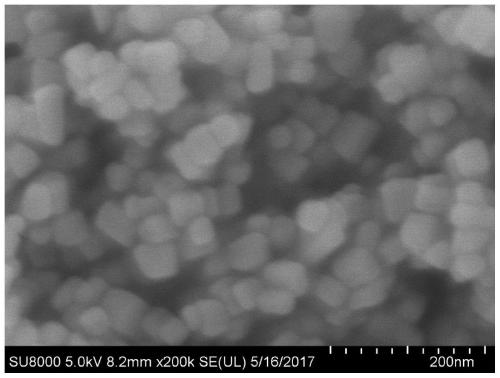

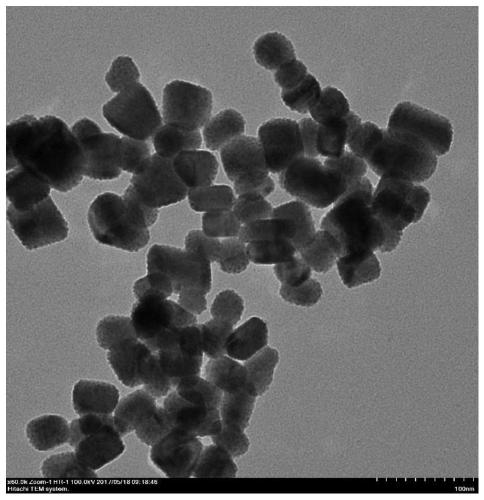

[0052] Embodiment 1, preparation bismuth chromate photocatalyst

[0053](1) At room temperature, bismuth nitrate pentahydrate and chromium nitrate nonahydrate are dissolved in mannitol aqueous solution to obtain a lavender transparent solution, wherein the concentration of bismuth nitrate pentahydrate is 0.04mol / L (bismuth nitrate pentahydrate and chromium nitrate nonahydrate The mol ratio of chromium nitrate hydrate is 12:1), and the concentration of mannitol solution is 0.15mol / L;

[0054] (2) In the solution of above-mentioned step (1), add 5ml saturated sodium carbonate aqueous solution dropwise, stir continuously to obtain the lavender emulsion;

[0055] (3) Transfer the emulsion in the above step (2) to a hydrothermal reaction kettle, react at 150° C. for 12 hours, and after natural cooling, a gray-green precipitate is obtained;

[0056] (4) Filter the precipitate in the above step (3), collect the solid, fully wash the solid with deionized water, and vacuum-dry the sol...

Embodiment 2

[0059] Embodiment 2, preparation bismuth chromate photocatalyst

[0060] (1) At room temperature, bismuth nitrate pentahydrate and chromium nitrate nonahydrate are dissolved in mannitol aqueous solution to obtain a lavender transparent solution, wherein the concentration of bismuth nitrate pentahydrate is 0.08mol / L (bismuth nitrate pentahydrate and chromium nitrate nonahydrate The mol ratio of chromium nitrate hydrate is 12:1), and the concentration of mannitol solution is 0.2mol / L;

[0061] (2) In the solution of above-mentioned steps (1), add 2ml saturated sodium carbonate aqueous solution dropwise, stir continuously to obtain the lavender emulsion;

[0062] (3) Transfer the emulsion in the above step (2) to a hydrothermal reaction kettle, react at 180° C. for 6 hours, and after natural cooling, a gray-green precipitate is obtained;

[0063] (4) Filter the precipitate in the above step (3), collect the solid, fully wash the solid with deionized water, and vacuum-dry the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com