Combination unit for multilevel heat exchange and gas liquid separation

A technology of gas-liquid separation and combined equipment, which is applied in heat exchange equipment, use of liquid separating agent, lighting and heating equipment, etc. It can solve the problems of increased gas pressure drop, low heat exchange efficiency, and small heat exchange area, and achieves Reduced flow resistance, reduced production energy consumption, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

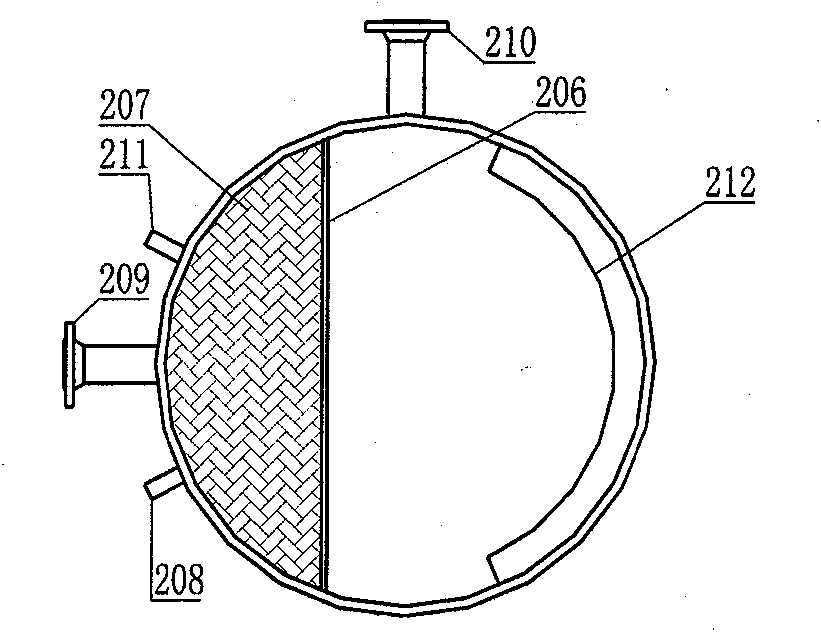

[0027] Example: A stream of distillation gas is extracted from the side line of a distillation tower in a factory, and a "first-stage shell-and-tube condenser + a first-stage gas-liquid separator" is used to extract the first-stage condensate under the conditions of temperature T1 and pressure P1; Shell condenser + secondary gas-liquid separator" extracts the secondary condensate under the conditions of temperature T2 and pressure P2; adopts "three-stage shell-and-tube condenser + three-stage gas-liquid separator" to extract the secondary condensate under the conditions of temperature T3 and pressure P3 Under the extraction of tertiary condensate and non-condensable gas.

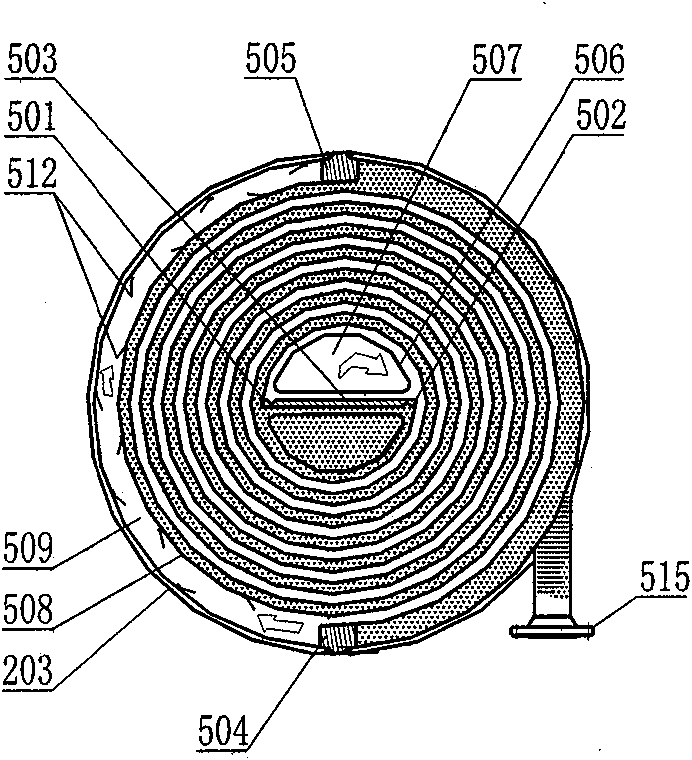

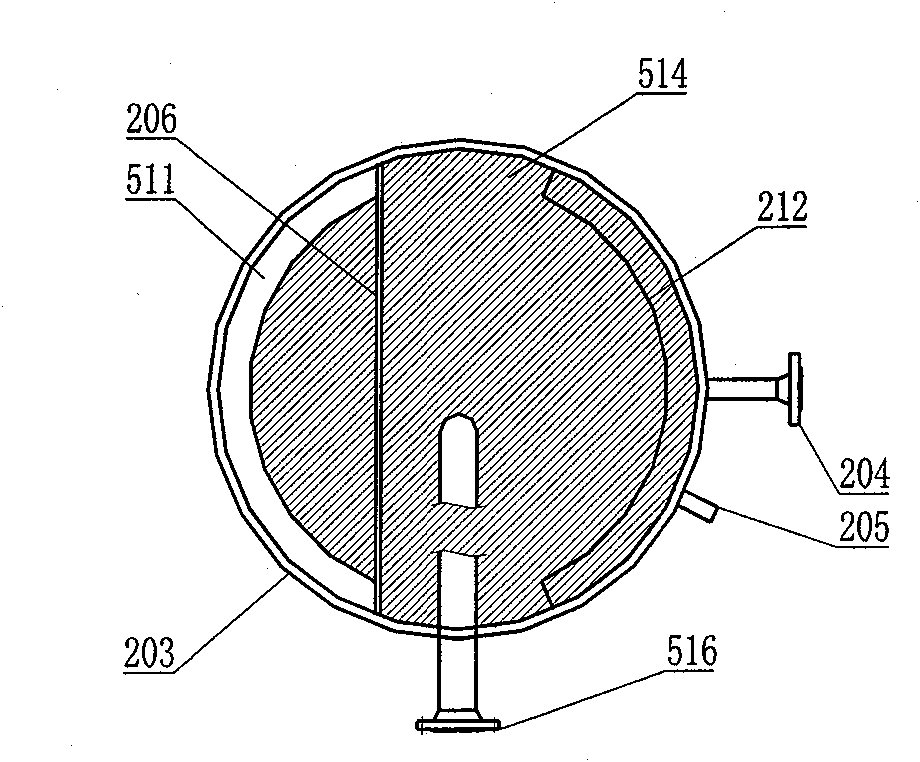

[0028] The preferred implementation mode adopted in the present invention: without changing the process flow and process conditions of the examples, the modular equipment with the functions of heat exchange, gas-liquid separation, and condensate collection are combined into a tower-shaped overall equipment to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com