Liquid oxygen explosive composite and liquid oxygen explosive

A technology of liquid oxygen explosives and compositions, which is applied in the direction of explosives, etc., can solve the problems of paper explosives that are not conducive to static electricity export, mechanical impact contact, and large static electricity of powder particles, so as to reduce the sensitivity of explosives, reduce static electricity, and reduce entrainment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

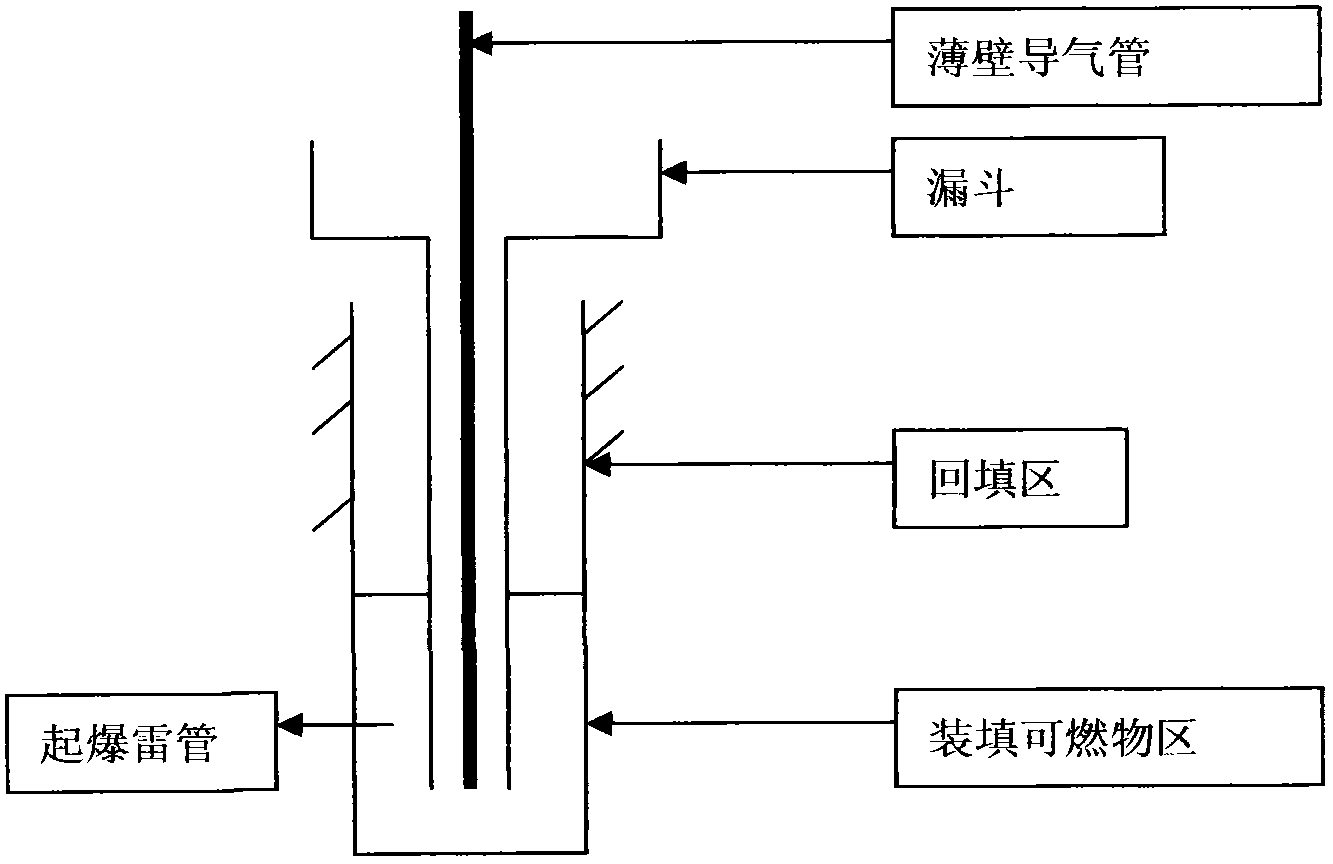

Image

Examples

Embodiment 1

[0033] Example 1: A liquid oxygen explosive composition:

[0034] A liquid oxygen explosive composition consisting of liquid oxygen and combustibles, the combustibles are composed of 50% by mass of coal powder and 50% of wet sawdust or combustible fibers, and the wet sawdust is pre-used at a concentration of 20% The sodium chloride solution is humidified to 5% (that is, the wet sawdust contains 5% sodium chloride solution); the diameter of the coal powder is 20-30 microns; the mass ratio of the liquid oxygen to the combustible is 2: 1; Oxygen in liquid oxygen is 99.00% to 99.80%.

Embodiment 2

[0035] Example 2: A liquid oxygen explosive composition:

[0036] A liquid oxygen explosive composition consisting of liquid oxygen and combustibles, the combustibles are composed of 70% by mass of coal powder and 30% of wet sawdust or combustible fibers, and the wet sawdust is pre-concentrated at a concentration of 20% The sodium chloride solution is humidified to 5%; the diameter of the coal powder is 2030 microns; the mass ratio of the liquid oxygen to combustibles is 2:1; the liquid oxygen contains 99.50% oxygen.

Embodiment 3

[0037] Example 3: A liquid oxygen explosive composition:

[0038] A liquid oxygen explosive composition consisting of liquid oxygen and combustibles, the combustibles are composed of 60% by mass of coal powder and 40% of wet sawdust or combustible fibers, and the wet sawdust is pre-concentrated at a concentration of 20% The sodium chloride solution is humidified to 5%; the diameter of the coal powder is 20-30 microns; the mass ratio of the liquid oxygen to combustibles is 2:1; the liquid oxygen contains 99.00% to 99.80% of oxygen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com