Process for reducing contents of components above C3 in dry gas

A component content, dry gas technology, applied in the field of C4 component content, reducing C3 in dry gas, can solve the problems of reducing oil and gas entrainment, dry gas is not dry, etc., to achieve easy implementation, reduced entrainment, and quality improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

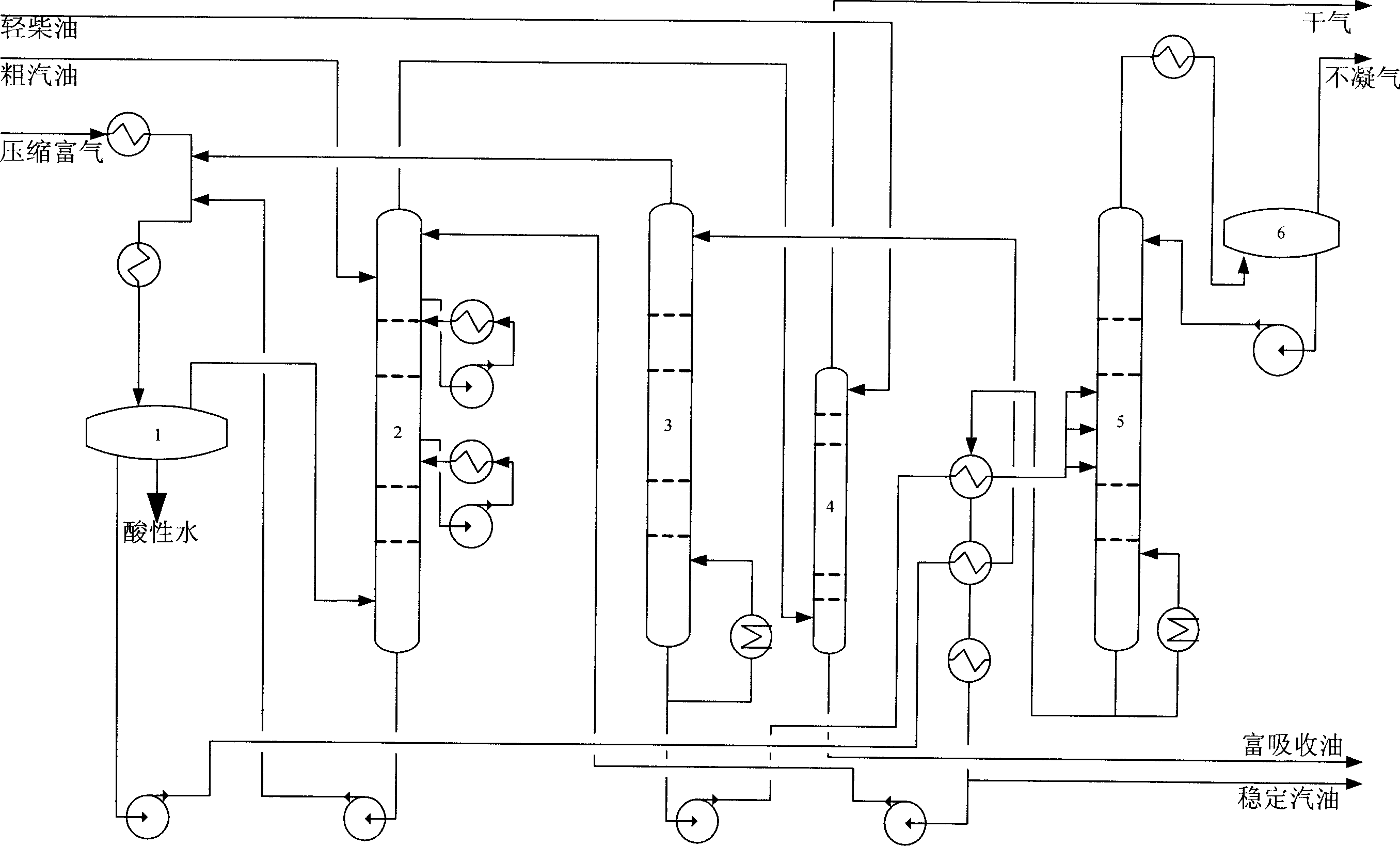

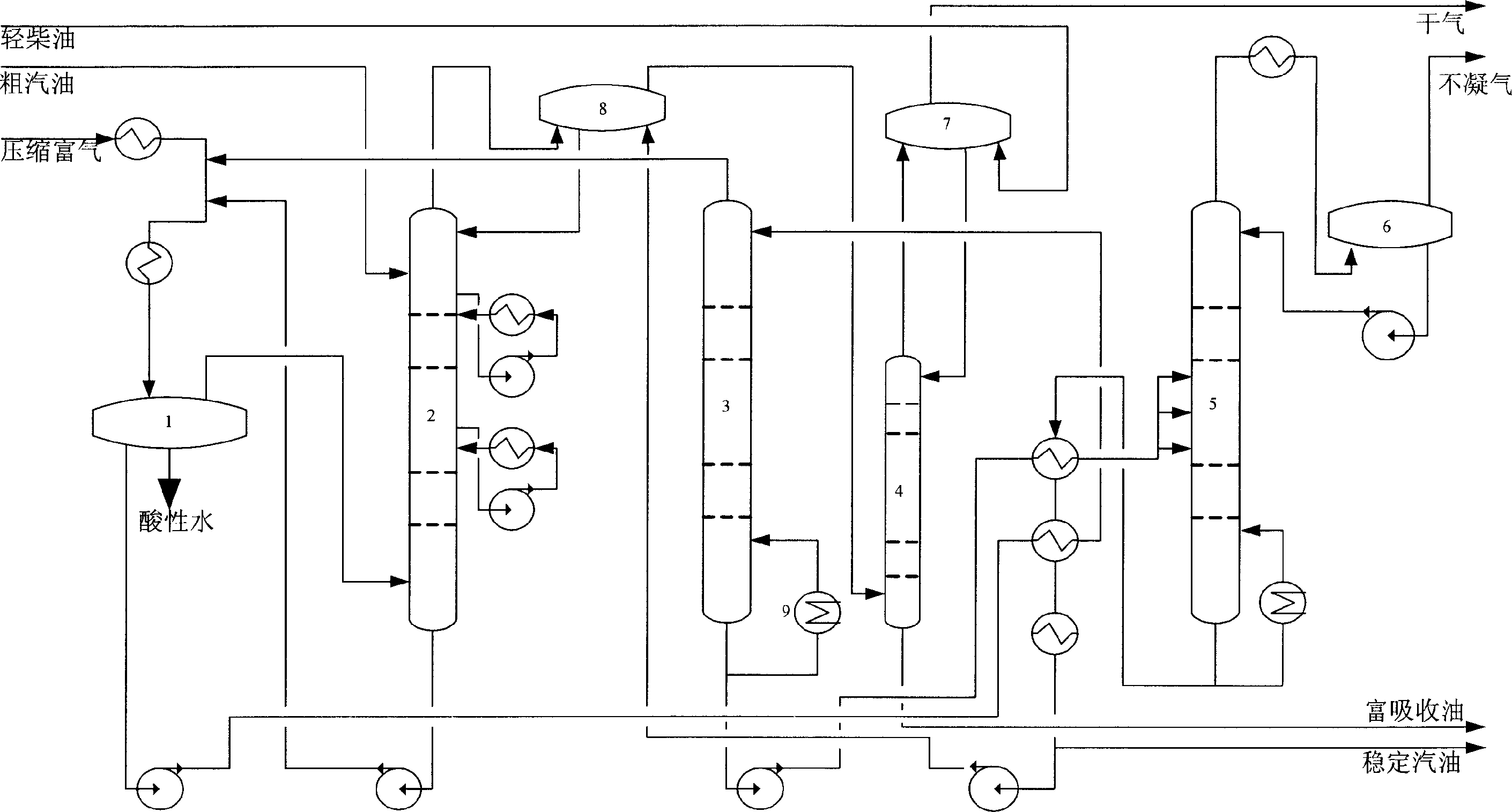

Method used

Image

Examples

Embodiment 1

[0018] This example illustrates that the content of components above C3 in dry gas can be significantly reduced by adopting the absorption stabilization process provided by the present invention.

[0019] Table 1 shows the changes in dry gas composition before and after the application of the present invention in a set of conventional catalytic cracking units. It can be seen from the table that after adopting the present invention, the content of carbon three and above components in the dry gas is reduced from the previous 5.86v% to the current 3.05v%, that is, the reduction range is 48%.

Embodiment 2

[0021] This example shows that the content of components above C3 in dry gas can be significantly reduced by adopting the absorption stabilization process provided by the present invention.

[0022] Table 2 shows the changes in dry gas composition before and after the application of the present invention in a set of catalytic cracking units that produce more liquefied gas. It can be seen from the table that after adopting the present invention, the content of carbon three and above components in the dry gas is reduced from 8.66% by weight before to 1.97% by weight now, that is, the reduction rate is 77%.

[0023] components

[0024] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com