Liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur

A technology for removing mercaptans and liquid hydrocarbons, which is applied in the refining of hydrocarbon oils, refining with alkaline aqueous solutions, and the petroleum industry. The concentration of , improve the activity, eliminate the effect of regeneration side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

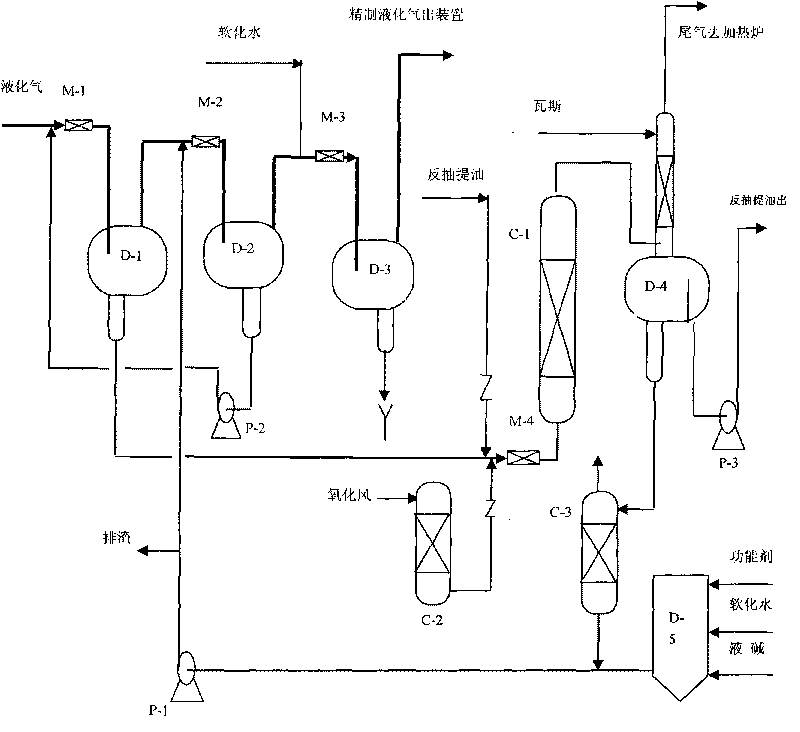

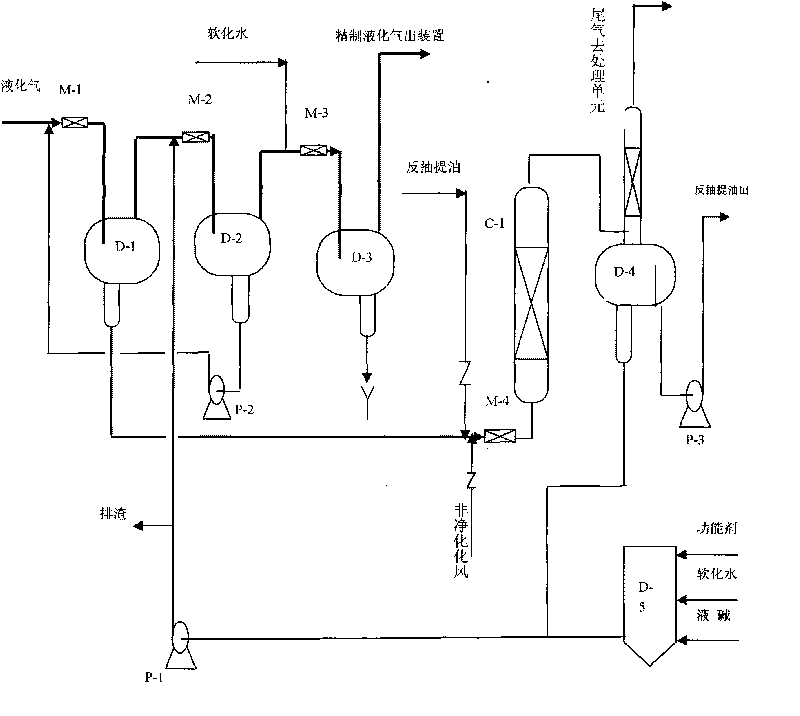

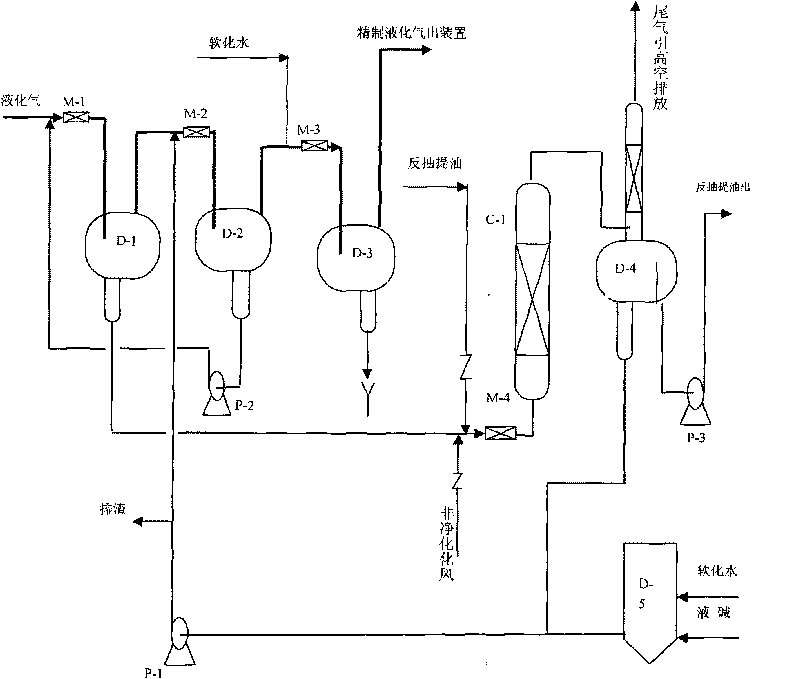

[0053] The present invention will be further described below with reference to the accompanying drawings, and the described embodiments are only used to help those skilled in the art understand the present invention, rather than to limit the scope of application of the present invention.

[0054] In the present invention, the above-mentioned "addition of functional strengthening additives, wind oil three-phase mixed regeneration, fixed bed catalyst, poor solvent deoxidation and oxidative wind deCO 2 Pre-purification” and other processes can be flexibly combined or used alone according to comprehensive factors such as the level of mercaptans contained in the raw material liquid hydrocarbons, the severity of the total sulfur reduction required, the investment amount, and the original equipment.

[0055] Reference manual attached figure 1 , the present invention adopts the flow process that above-mentioned five technological combinations are implemented as follows:

[0056] Extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com