Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1368results about "Thickeners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

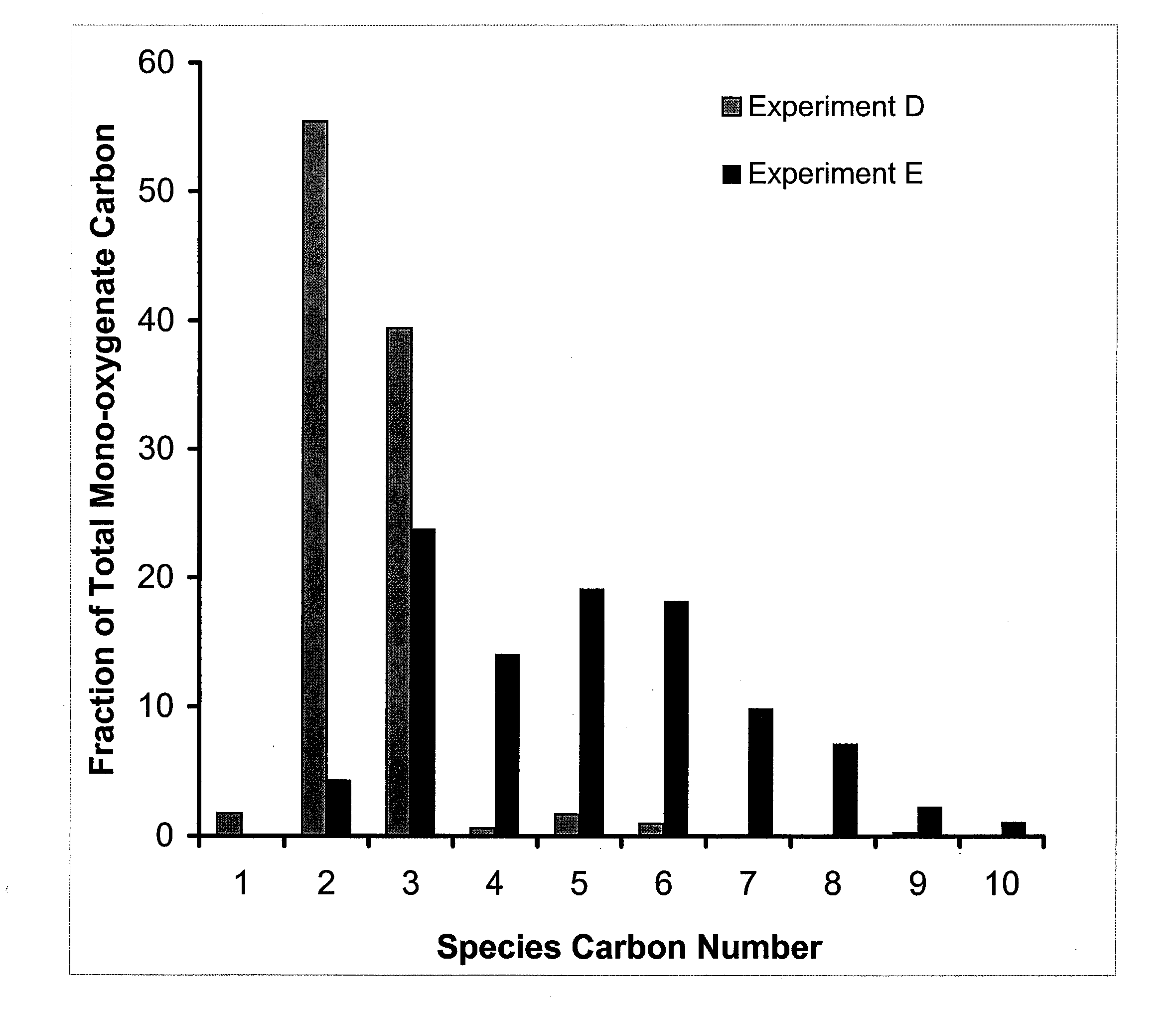

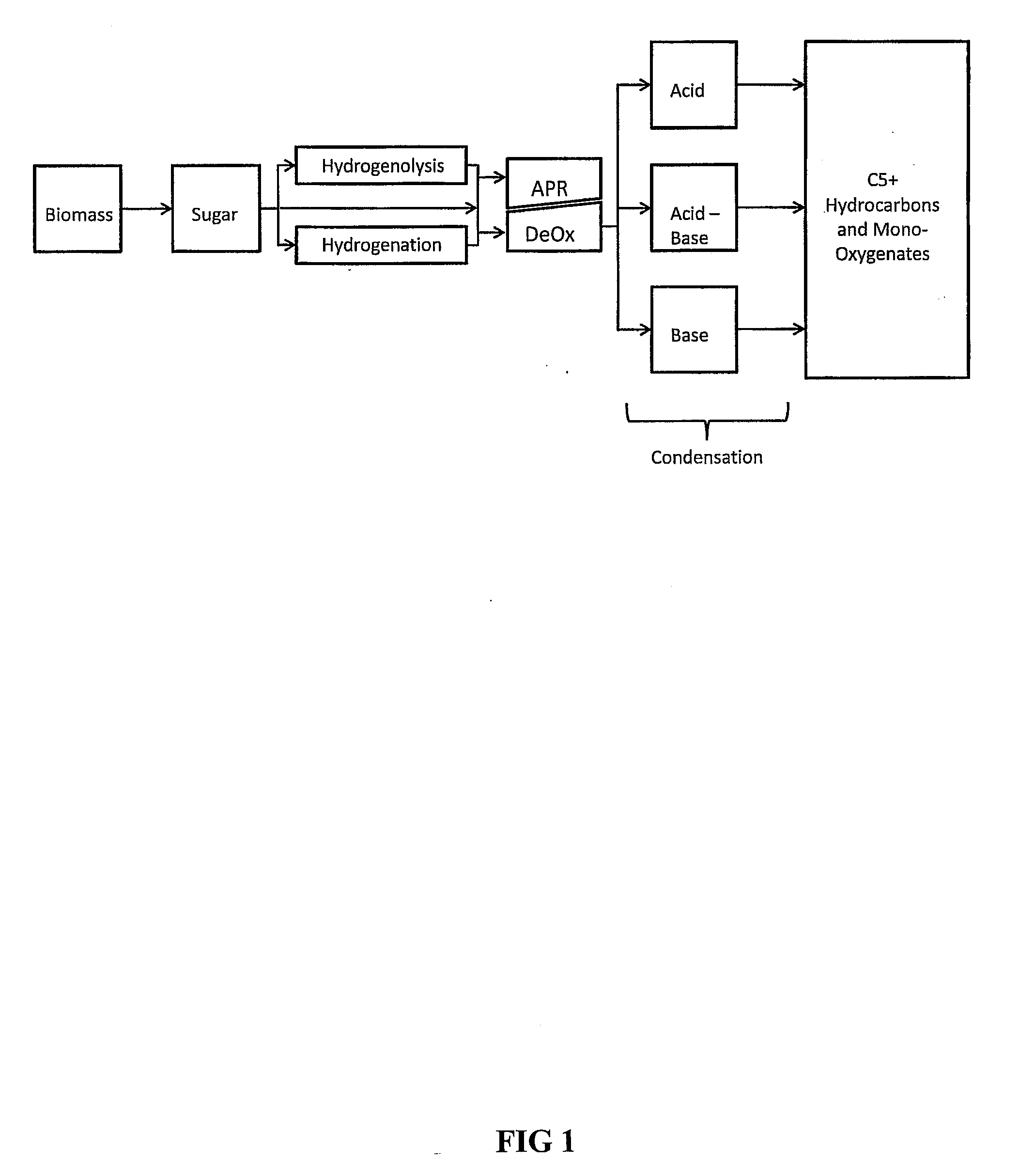

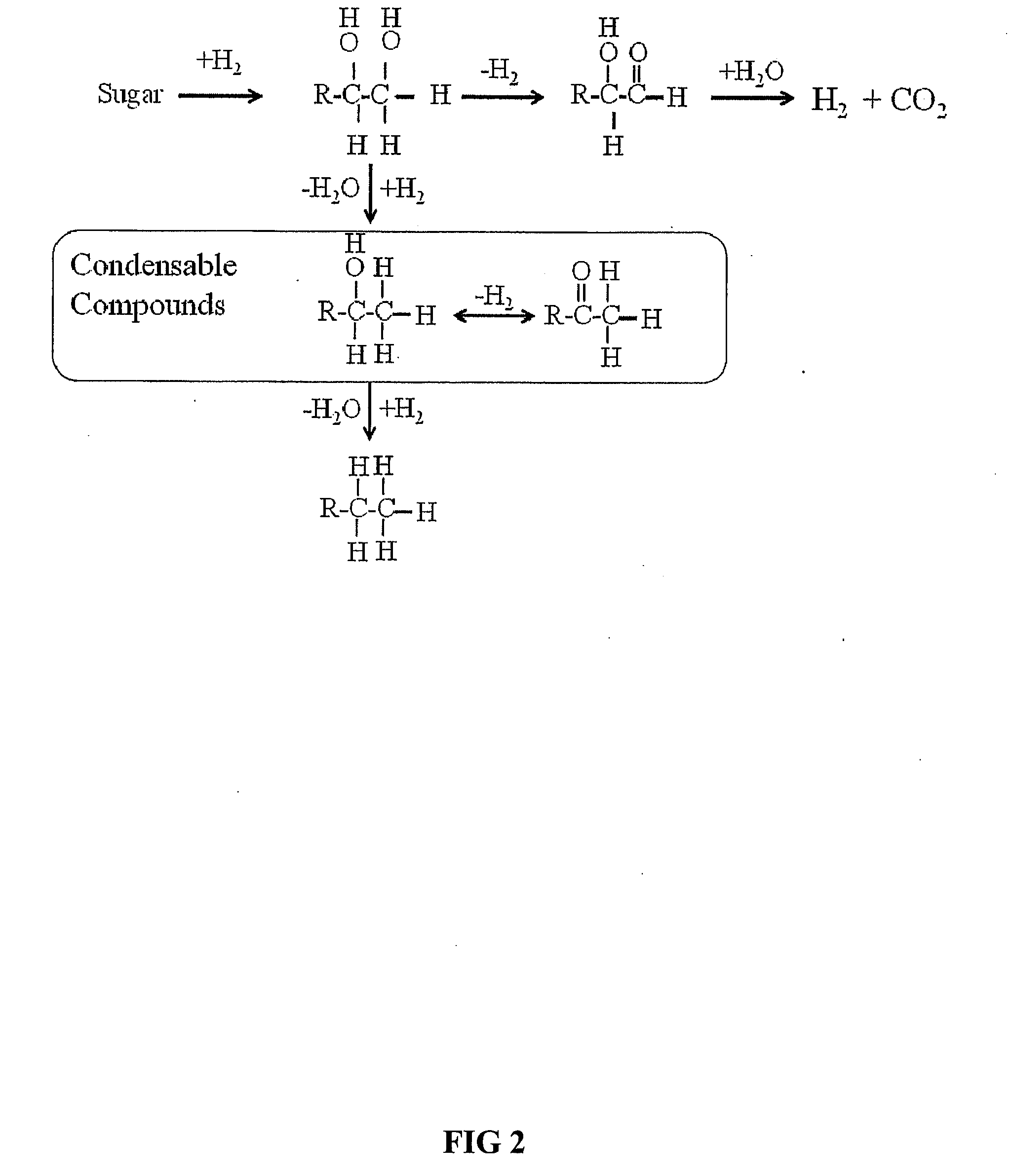

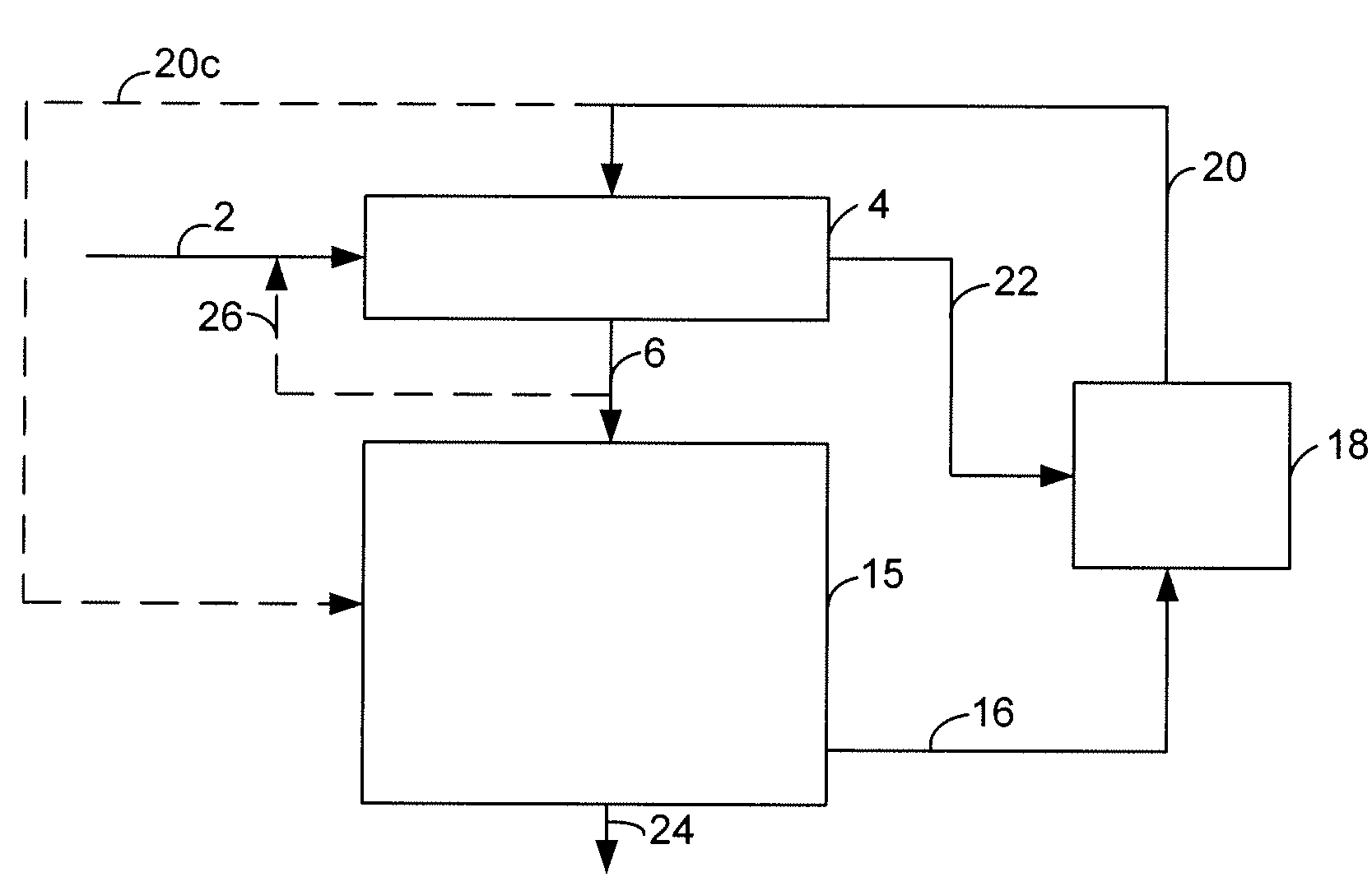

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Premium synthetic lubricants

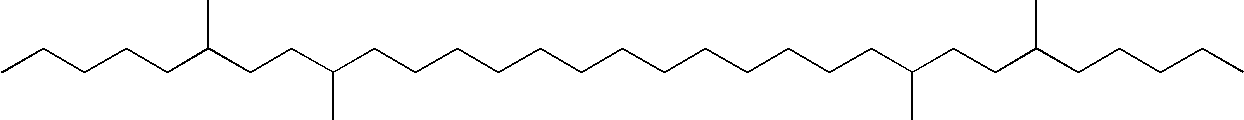

InactiveUS6475960B1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAntioxidantBoiling point

Premium synthetic lubricants comprise a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one, and typically a plurality of lubricant additives such as a detergent, dispersant, antioxidant, antiwear additive, pout point depresant, VI improver and the like. The base stock is derived from a waxy, paraffinic, Fischer-Tropsch synthesized hydrocarbon feed fraction having an initial boiling point in the range of about 650-750° F. and continuously boiling up to at least 1050° F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The waxy feed has a T90-T10 temperature difference of at least 350° F. and is preferably hydroisomerized without any pretreatment, other than optional fractionation. The lubricant may also contain hydrocarbonaceous and synthetic base stock material. Lubricants, such as fully formulated multigrade automotive crankcase and transmission oils formed by adding a suitable additive package to the isoparaffinic base stock have exhibited performance superior to similar fully formulated oils based on both PAO and conventional, petroleum derived base stocks.

Owner:EXXON RES & ENG CO

Production of Aviation Fuel from Biorenewable Feedstocks

ActiveUS20090158637A1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAlkaneVegetable oil

A process has been developed for producing aviation fuel from renewable feedstocks such as plant oils and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide n-paraffins having from about 8 to about 24 carbon atoms. At least some of the n-paraffins are isomerized to improve cold flow properties. At least a portion of the paraffins are selectively cracked to provide paraffins meeting specifications for different aviation fuels such as JP-8.

Owner:UOP LLC

Gelled hydrocarbon compositions and methods for use thereof

InactiveUS6849581B1Improve stabilityAvoid stabilityOrganic detergent compounding agentsSurface-active detergent compositionsOrganic baseOrganic fluid

Gelled organic compositions and methods for using same. The gelled compositions may be liquid organic fluids, such as gelled liquid hydrocarbons, formed from a mixture of an organic-base fluid, a carboxylic acid, and one or more metal source compounds, such as a metal salt of carboxylic acid. The gelled compositions may be used in variety of applications including, but not limited to, oil field, pipeline and processing facility applications.

Owner:BJ SERVICES LLC +1

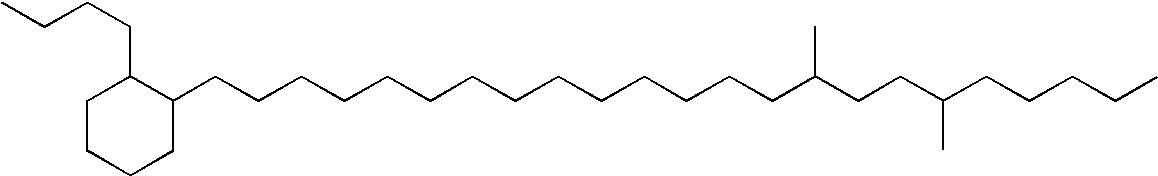

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS7083713B2Improve Oxidation StabilityHigh viscosity indexRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationCycloparaffinsBase oil

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

Premium synthetic lubricant base stock (Law734) having at least 95% noncyclic isoparaffins

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750° F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750° F., from which it continuously boils up to at least 1050° F. and has a T90-T10 temperature difference of at least 350° F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750° F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

Base oil

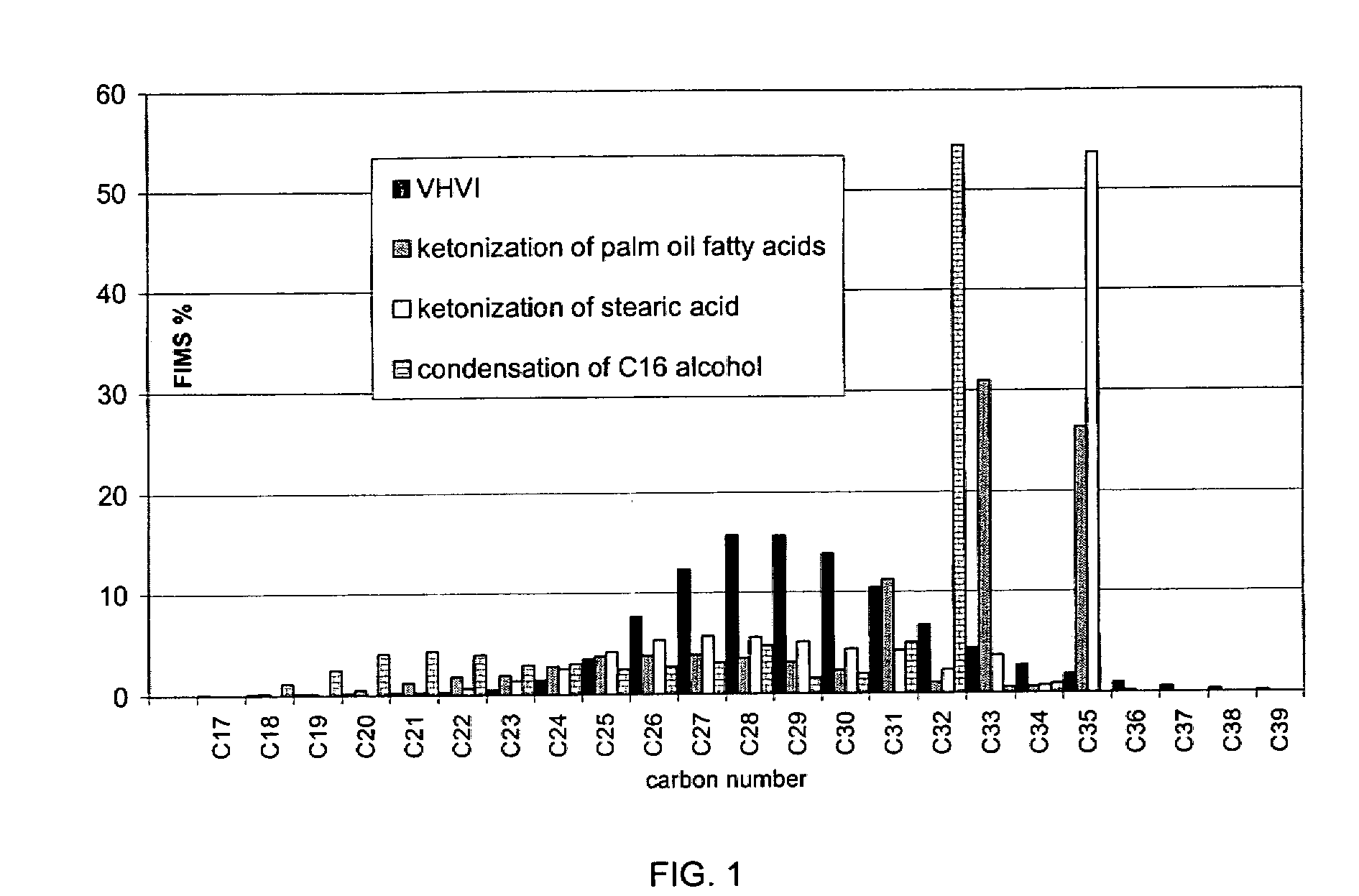

ActiveUS20070135663A1Improve technical effectReduce fuel consumptionHydrocarbon purification/separationLiquid carbonaceous fuelsCarbon numberViscosity index

The invention relates to a new base stock material. Specifically the invention relates to a saturated hydrocarbon composition and particularly to a composition based on biological raw materials, to be used as a high-quality base oil or to be used as a component in the production of a base oil having a high viscosity index and good low temperature properties. The composition contains saturated hydrocarbons and has a narrow carbon number range.

Owner:NESTE OIL OY

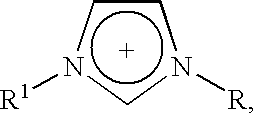

Process for removing polar impurities from hydrocarbons and mixtures of hydrocarbons

InactiveUS7553406B2Improve efficiencyMild process conditionsOrganic compounds purification/separation/stabilisationSolvent extractionHydrocotyle bowlesioidesIonic liquid

This invention relates to a process for removing polarizable impurities from hydrocarbons and mixtures of hydrocarbons using ionic liquids as an extraction medium. By way of extraction, the degree of contamination of the hydrocarbon or mixture of hydrocarbons is reduced to a low or very low level. The specific ionic liquids are compounds of the Formula 1, which are organic salts that are liquid or can be melted to form a liquid and that can form at least a biphasic mixture with a hydrocarbon. The process is suitable for purifying a wide range of hydrocarbons under a wide range of process conditions.

Owner:MERCK PATENT GMBH

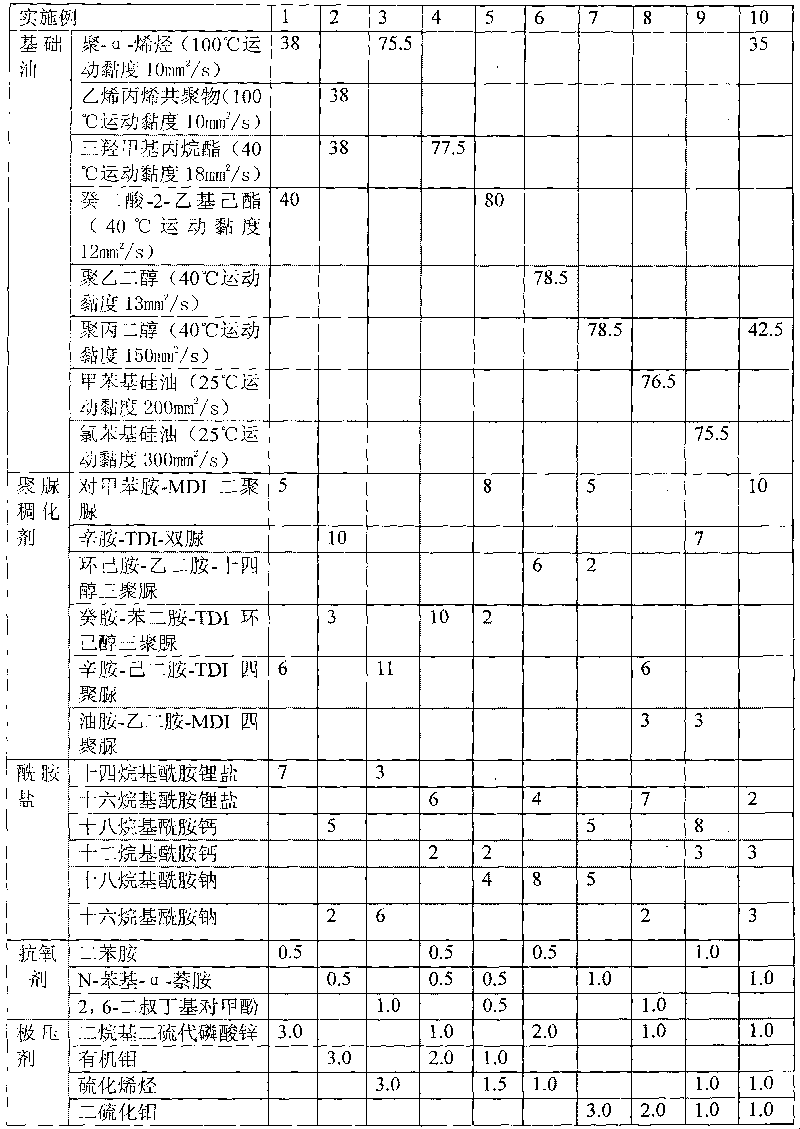

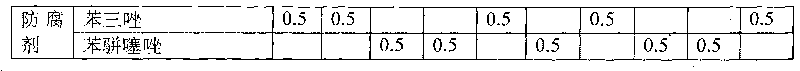

Polyurea grease composite

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

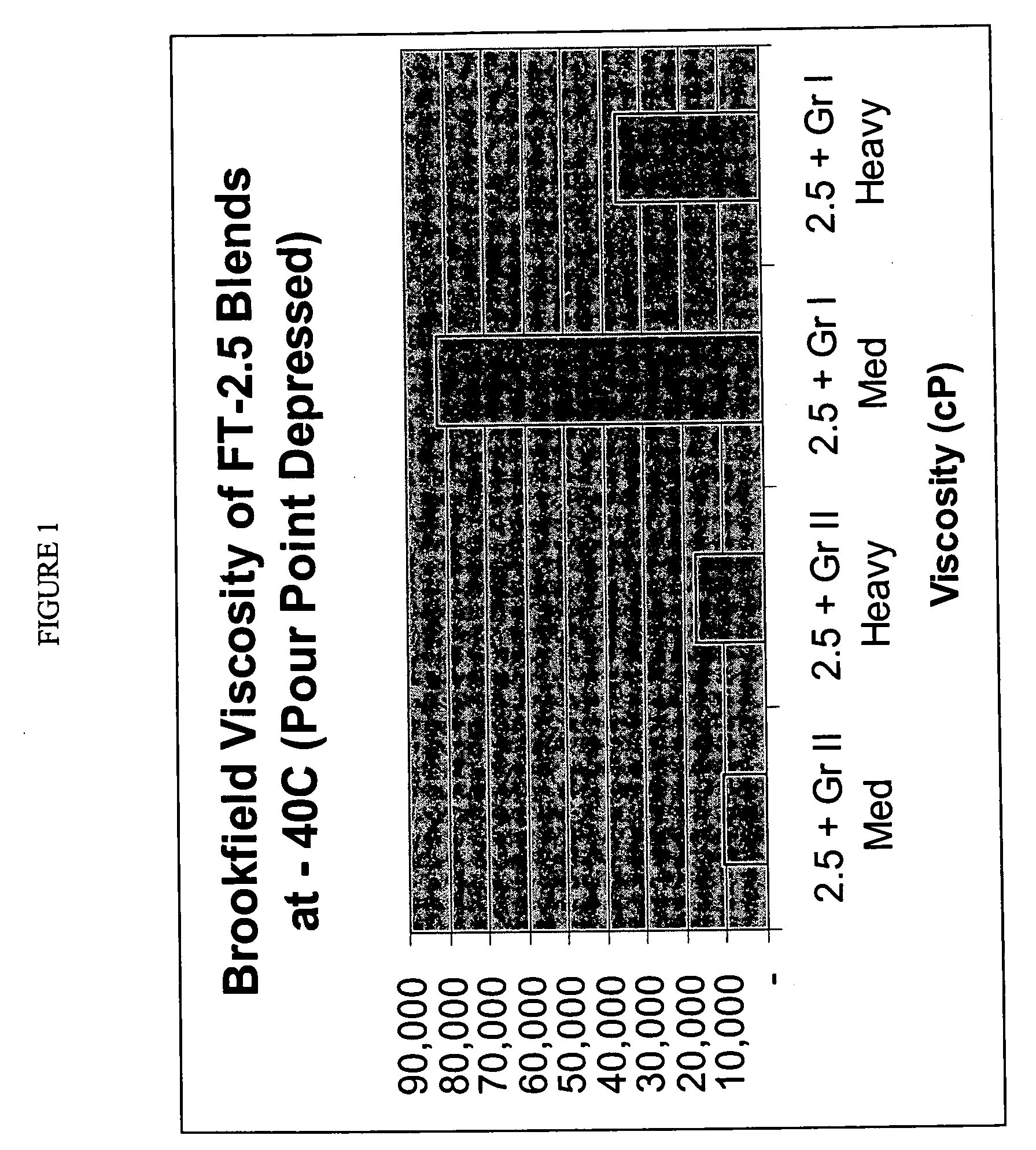

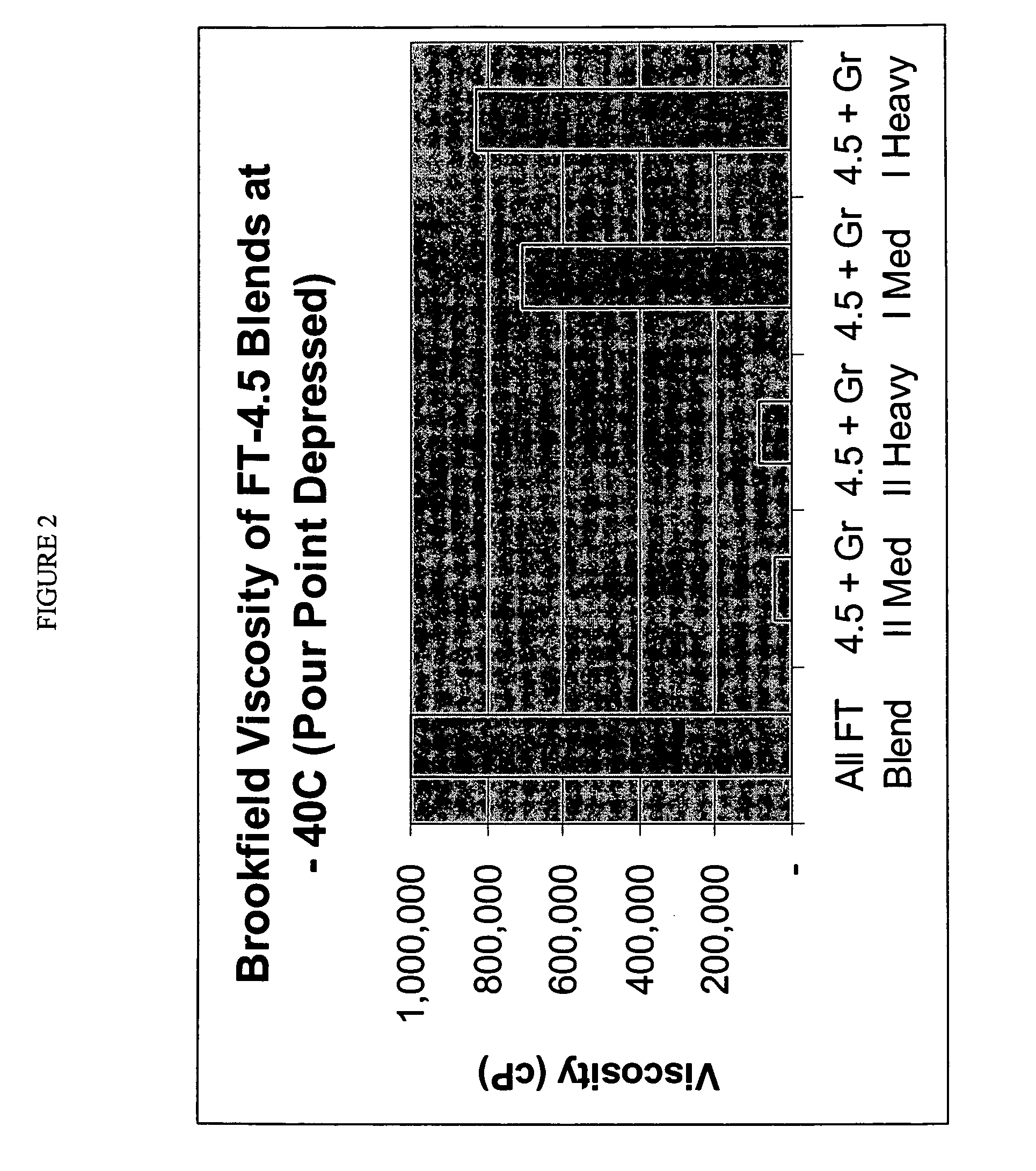

Processes for making lubricant blends with low brookfield viscosities

InactiveUS20050261146A1Improve low temperature performanceLow viscosityRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxSulfur

Lubricant blends and finished gear oils comprising a lubricant base oil fraction derived from highly paraffinic wax, a petroleum derived base oil, and a pour point depressant are provided. The lubricant base oil fraction derived from highly paraffinic wax comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS20050133408A1Improve Oxidation StabilityHigh viscosity indexHydrocarbon purification/separationLiquid hydrocarbon mixture productionCycloparaffinsBase oil

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

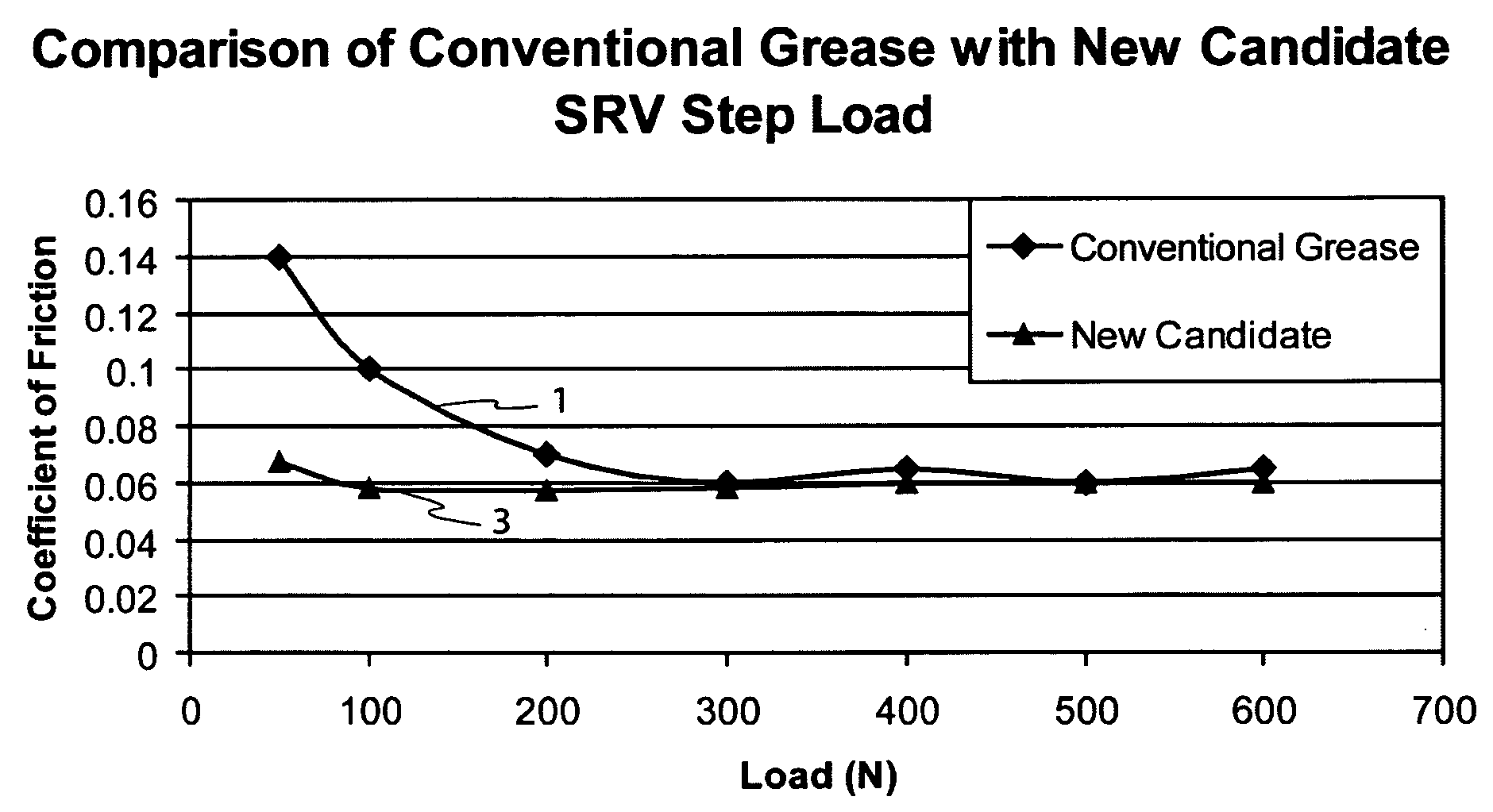

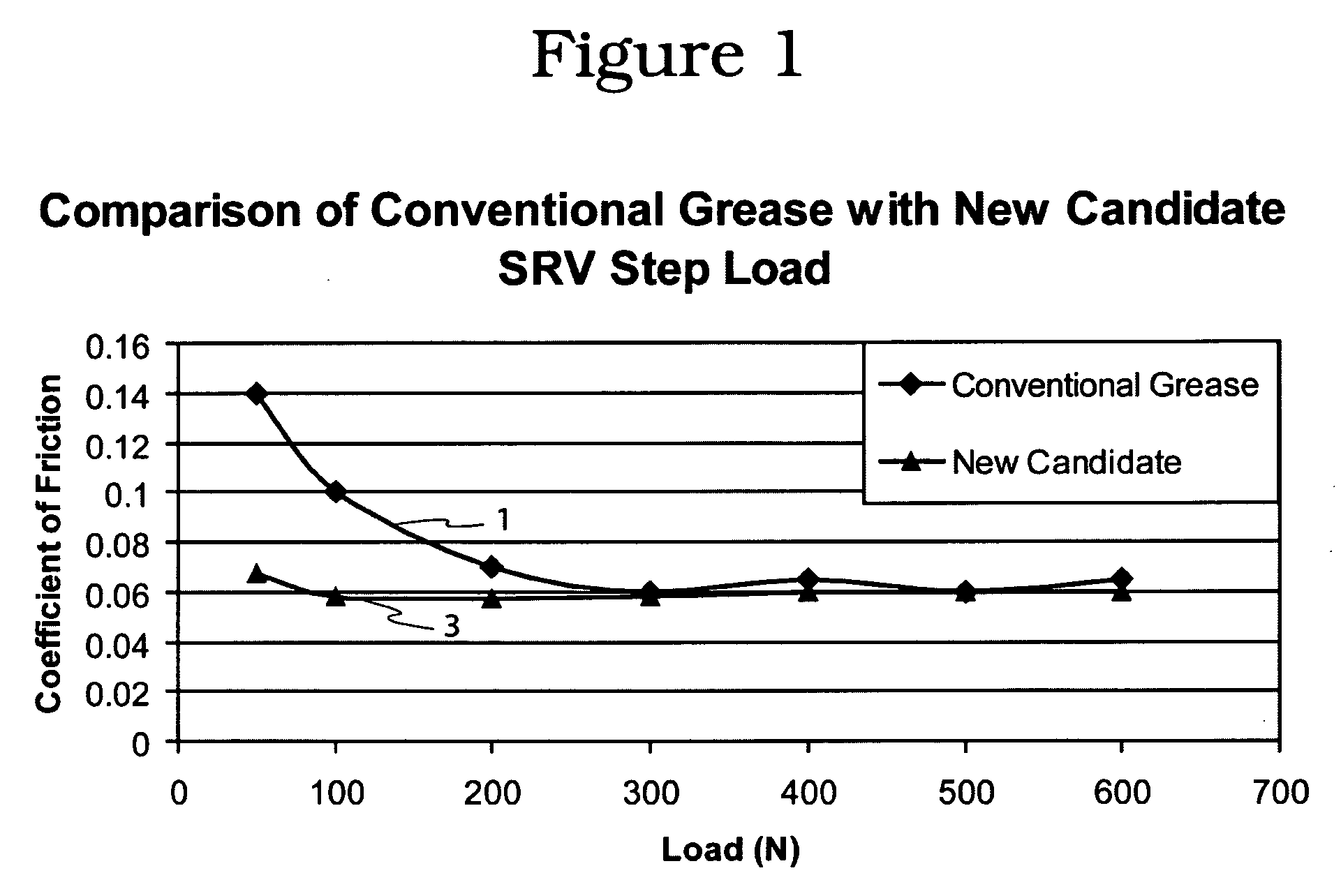

High viscosity index pao with polyurea thickeners in grease compositions

ActiveUS20090247441A1Improve friction performanceHigh indexThickenersAdditivesPolymer scienceBi modal

Owner:EXXON RES & ENG CO

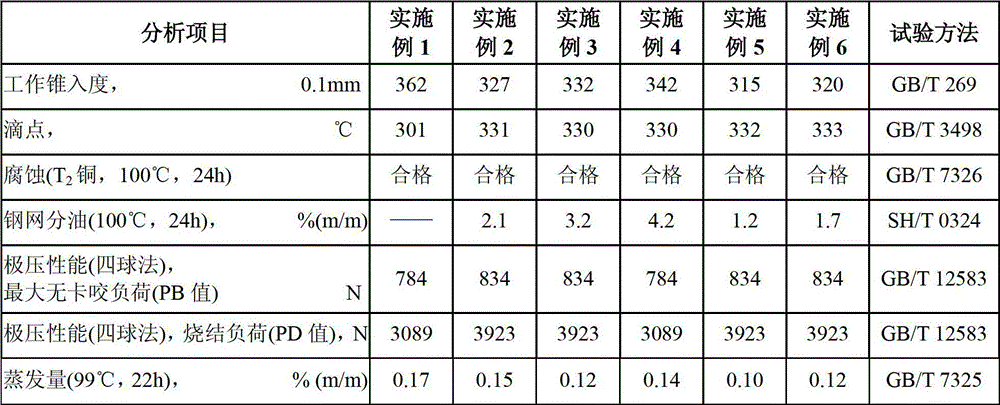

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

Process for improving the lubricating properties of base oils using a Fischer-Tropsch derived bottoms

InactiveUS20050098476A1High viscosityReduce pointsRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationProcess engineeringBase oil

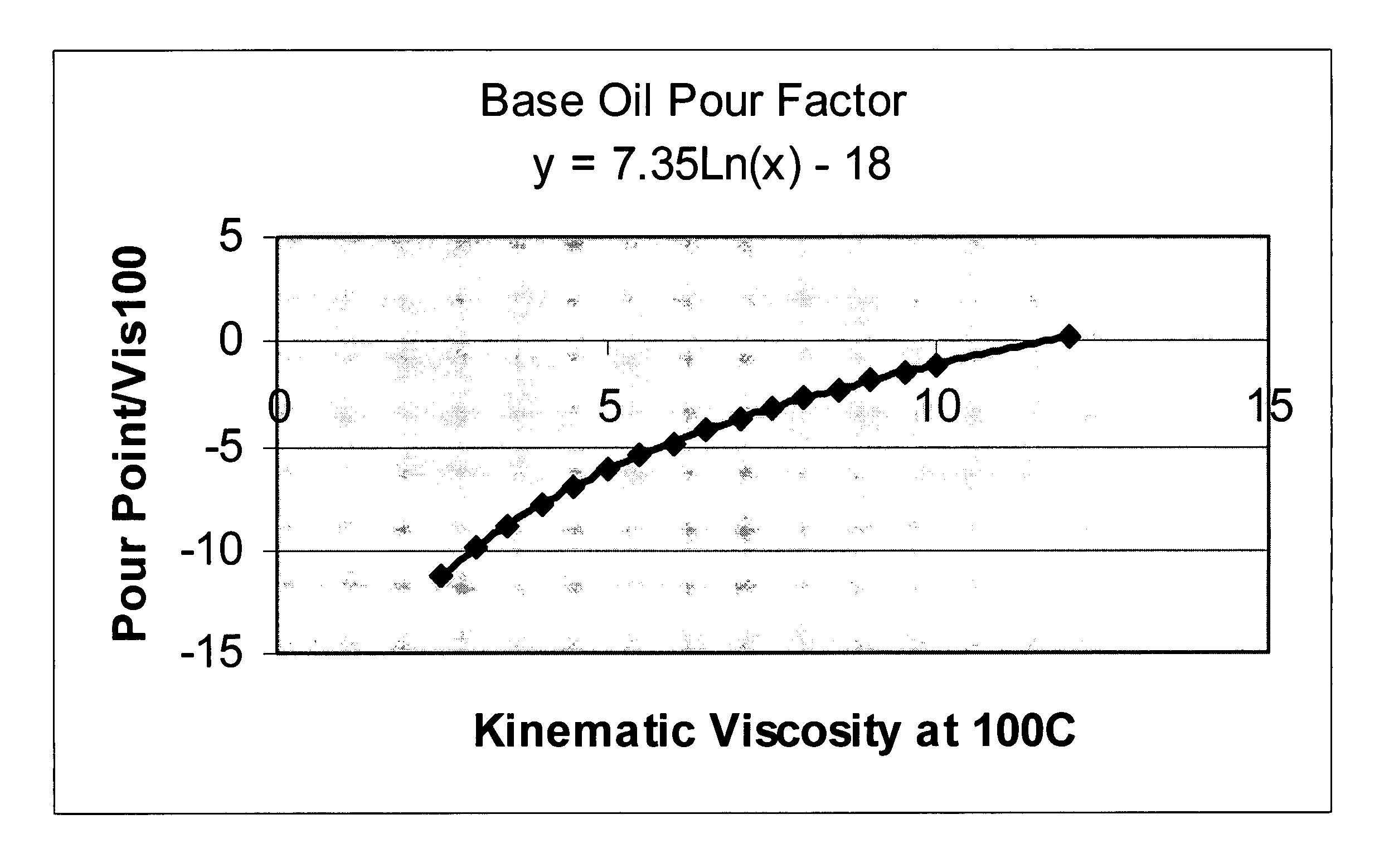

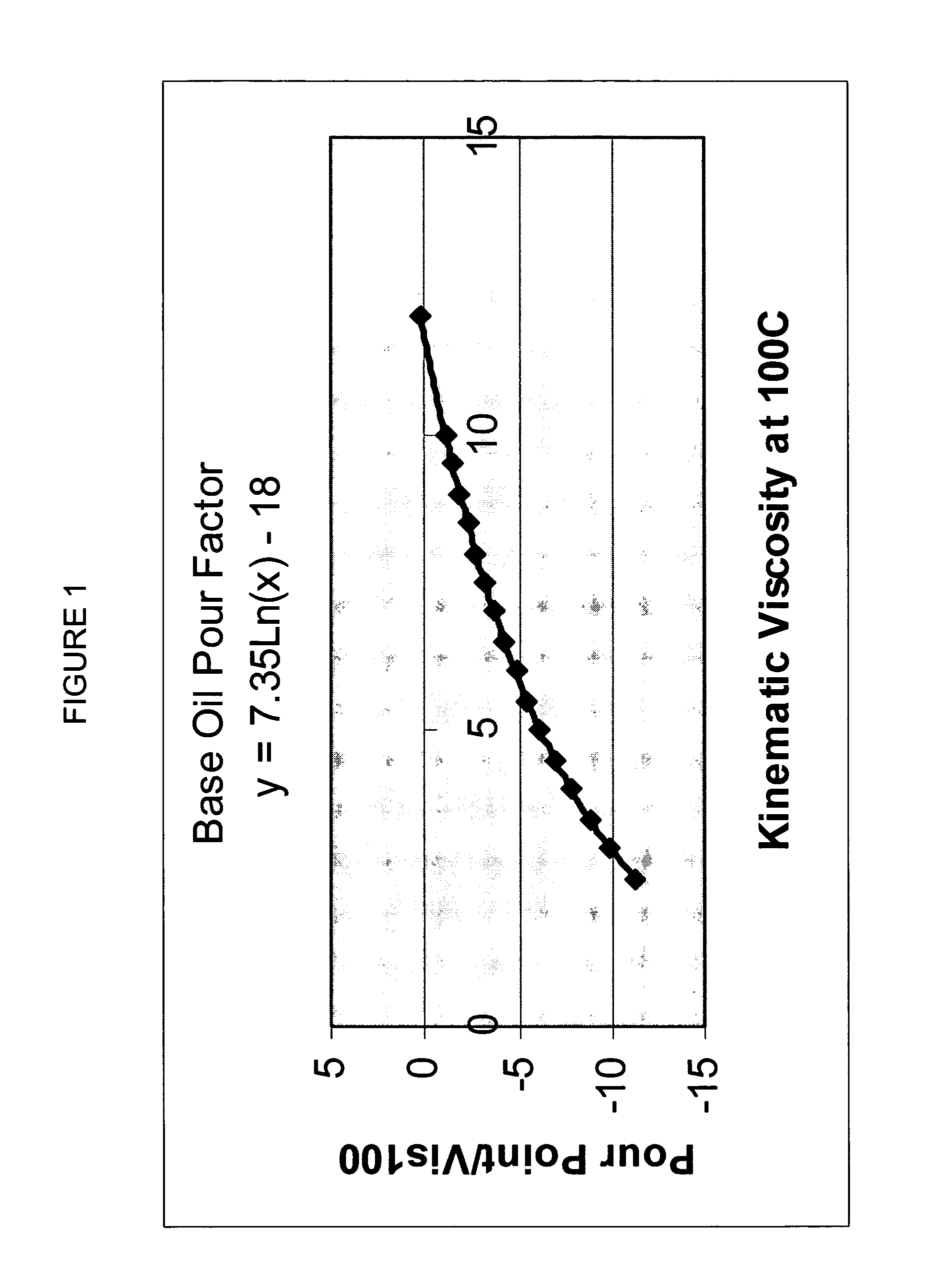

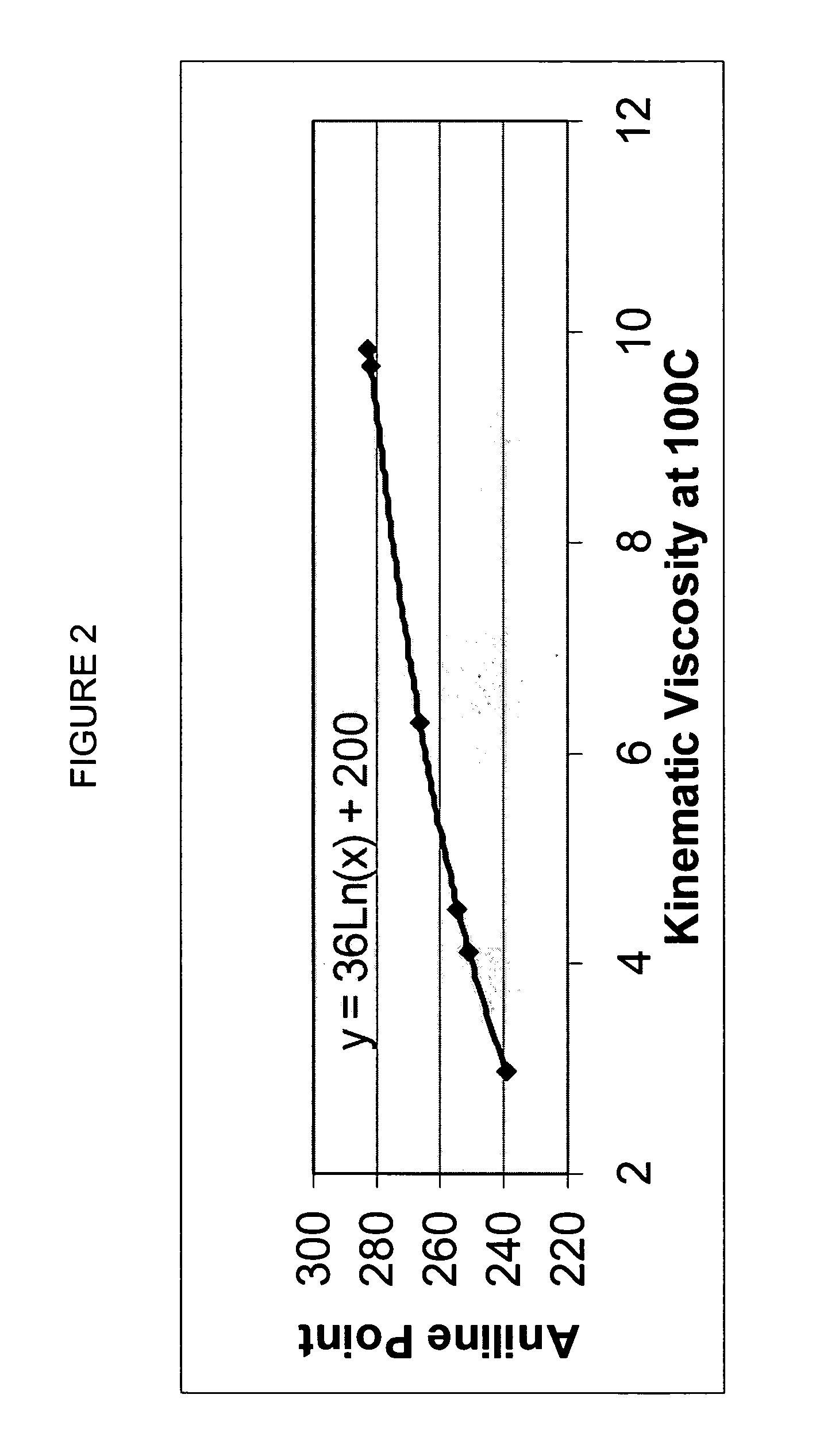

A method for improving the lubricating properties of a distillate base oil characterized by a pour point of 0 degrees C. or less and a boiling range having the 10 percent point falling between about 625 degrees F. and about 790 degrees F. and the 90 percent point falling between about 725 degrees F. and about 950 degrees F., the method comprises blending with said distillate base oil a sufficient amount of a pour point depressing base oil blending component to reduce the pour point of the resulting base oil blend at least 3 degrees C. below the pour point of the distillate base oil, wherein the pour point depressing base oil blending component is an isomerized Fischer-Tropsch derived bottoms product having a pour point that is at least 3 degrees C. higher than the pour point of the distillate base oil.

Owner:CHEVROU USA INC

Open-type gear grease composition

The invention provides an open gear grease composition, which comprises the following components and the weight percentage contents are that gelatinizer 2-6%, mineral oil 20-60%, synthetic oil 20-60%, antioxidant 0.3-1%, oil solubility anti-wear extreme pressure additive 1-15%, solid additive 3-20% and rust inhibitor 1-3%. The open gear grease composition of the invention does not contain dissolvent and bitumen, which has no harmless to environment, and solves the problems that bitumen-type open gear oil has bad pollution and low-temperature performance, and the flowability of open gear grease is bad. The open gear grease composition has outstanding water resistance, adhesiveness and antiwear and extreme pressure property.

Owner:益田润石(北京)化工有限公司

High-temperature-resistant extreme pressure type lubricating grease composition and preparation method

The invention relates to a high-temperature-resistant extreme pressure type lubricating grease composition and a preparation method of the high-temperature-resistant extreme pressure type lubricating grease composition. The preparation method comprises steps as follows: mixing high-base-value calcium naphthenate, high-base-value sulfoacid calcium, and 35 to 65% of base oil; agitating; then adding a transforming agent; heating to reach 75 to 105 DEG C; maintaining the temperature for 40 to 120 minutes until the materials are thick; continuously heating the material until the temperature reaches more than 200 DEG C; removing the water completely, wherein the rest base oil is added during heating; continuously heating the materials until the temperature reaches 220 to 240 DEG C; agitating for 5 to 30 minutes at constant temperature until the materials are thick; and cooling and homogenizing to obtain the product as requirements. The lubricating grease prepared by the preparation method is high in comprehensive performance, excellent in high-temperature resistance, and high in extreme-pressure wear resistance, and can be used for lubricating high-temperature equipment with high load; and the requirements on use in high-temperature and high-load lubricating situations in the ferrous metallurgy industry can be met.

Owner:CHINA PETROLEUM & CHEM CORP

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

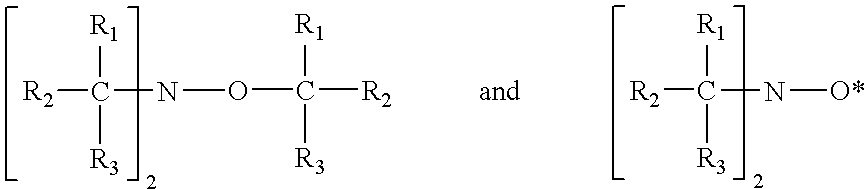

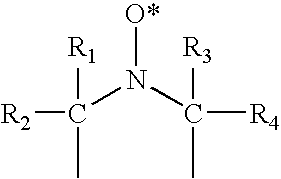

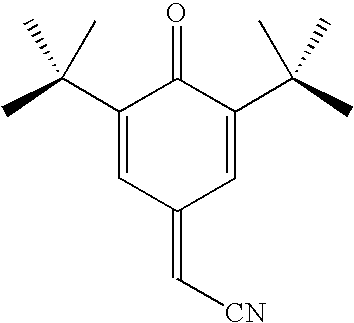

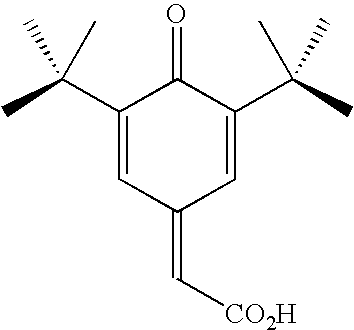

Blends of quinone alkide and nitroxyl compounds and polymerization inhibitors

InactiveUS7045647B2Improve performanceReduce the numberOrganic compounds purification/separation/stabilisationOrganic compound preparationQuinonePolymer science

Disclosed herein is a method for inhibiting the premature polymerization of ethylenically unsaturated monomers comprising adding to said monomers an effective amount of: A) at least one nitroxyl compound, and B) at least one quinone alkide compound having an electron-withdrawing group at the 7-position. Additionally, a composition is disclosed that comprises: A) at least one nitroxyl compound, and B) at least one quinone alkide compound having an electron-withdrawing group at the 7-position.

Owner:DEUT BANK AG NEW YORK BRANCH +1

Thermally stable jet prepared from highly paraffinic distillate fuel component and conventional distillate fuel component

InactiveUS6846402B2Improve stabilityReduced deposit formationLiquid organic insulatorsHydrocarbon purification/separationTurbinePetroleum

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in turbine engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component having low to moderate branching and at least one conventional petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

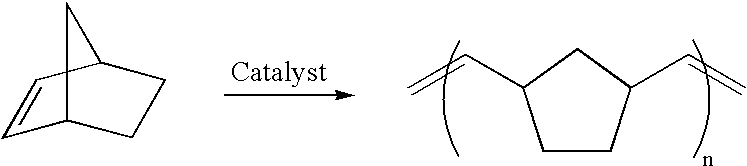

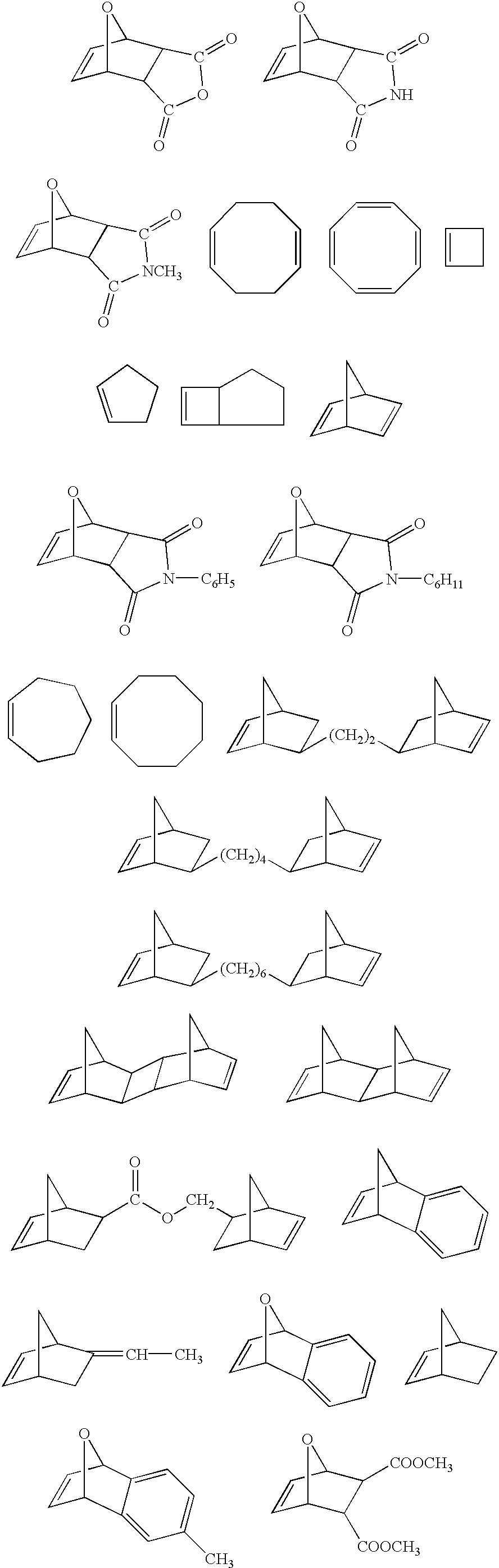

Metathesis polymerization adhesives and coatings

InactiveUS6800170B2Easy to useRemarkable strengthHydrocarbon purification/separationThickenersOligomerCoating system

An adhesive or coating composition prepared by mixing together at least one metathesizable highly-reactive cycloolefin (e.g., a norbornadiene) and a metathesis catalyst. The use of highly-reactive cycloolefins can provide exceptional adherence to a low-surface-tension substrate. Another embodiment is a two-part adhesive or coating system wherein the first part includes at least one first metathesizable material, and the second part includes at least one liquid metathesis oligomer or polymer and a metathesis catalyst.

Owner:LORD CORP

Blending of low viscosity Fischer-Tropsch base oils with conventional base oils to produce high quality lubricating base oils

ActiveUS7144497B2Liquid organic insulatorsHydrocarbon purification/separationCombustionInternal combustion engine

A process for producing a lubricating base oil blend which comprises (a) recovering a Fischer-Tropsch derived distillate fraction characterized by a kinematic viscosity of about 2 cSt or greater but less than 3 cSt at 100 degrees C.; and (b) blending the Fischer-Tropsch derived distillate fraction with a petroleum derived base oil selected from the group consisting of a Group I base oil, a Group II base oil, a Group III base oil, and a mixture of two or more of any of the foregoing conventional base oils in the proper proportion to produce a lubricating base oil blend characterized as having a viscosity of about 3 or greater; also the base oil blends, finished lubricants, and their use in internal combustion engines.

Owner:CHEVROU USA INC

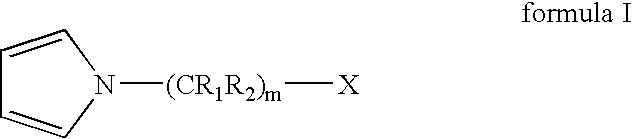

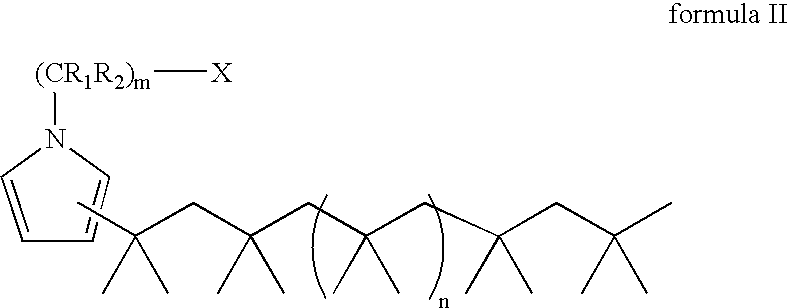

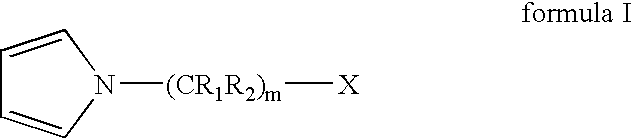

Living and quasiliving cationic telechelic polymers quenched by N-substituted pyrrole and methods for their preparation

InactiveUS6969744B2Organic compounds purification/separation/stabilisationHydrocarbon purification/separationActive polymerChloride

Disclosed is a method of preparing terminally functionalized telechelic polymers using a cationic living polymer product or a terminal tert-chloride chain end of a carbocationic quasiliving polymer product, which comprises quenching the polymer product with an N-substituted pyrrole to thereby functionalize the N-substituted pyrrole at the terminal reactive polymer chain end(s). Also disclosed are the terminal functionalized polyisobuyl N-substituted pyrrole compounds where the polyisobutyl group is substituted at the 2 and 3 position of the N-substituted pyrrole.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

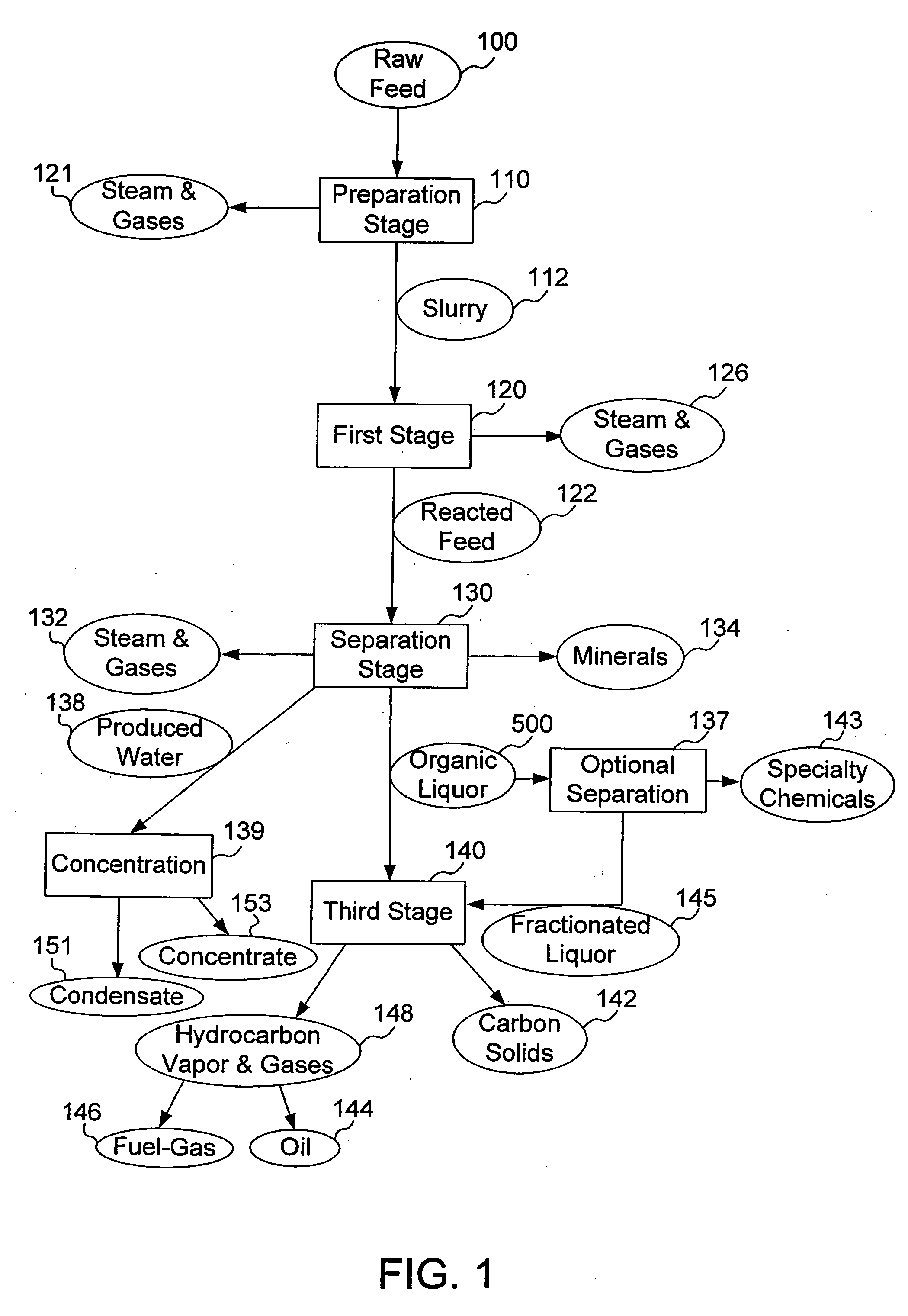

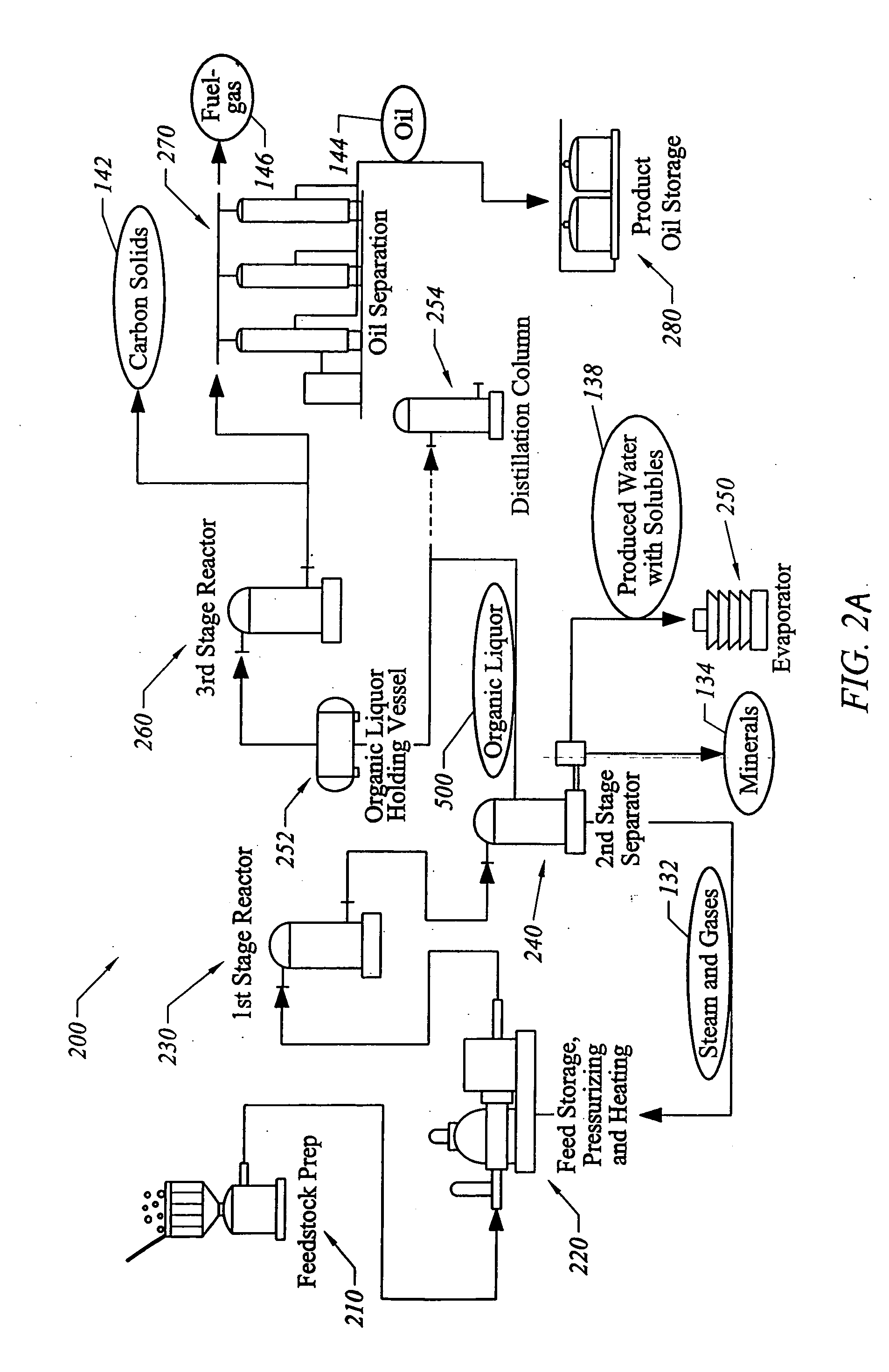

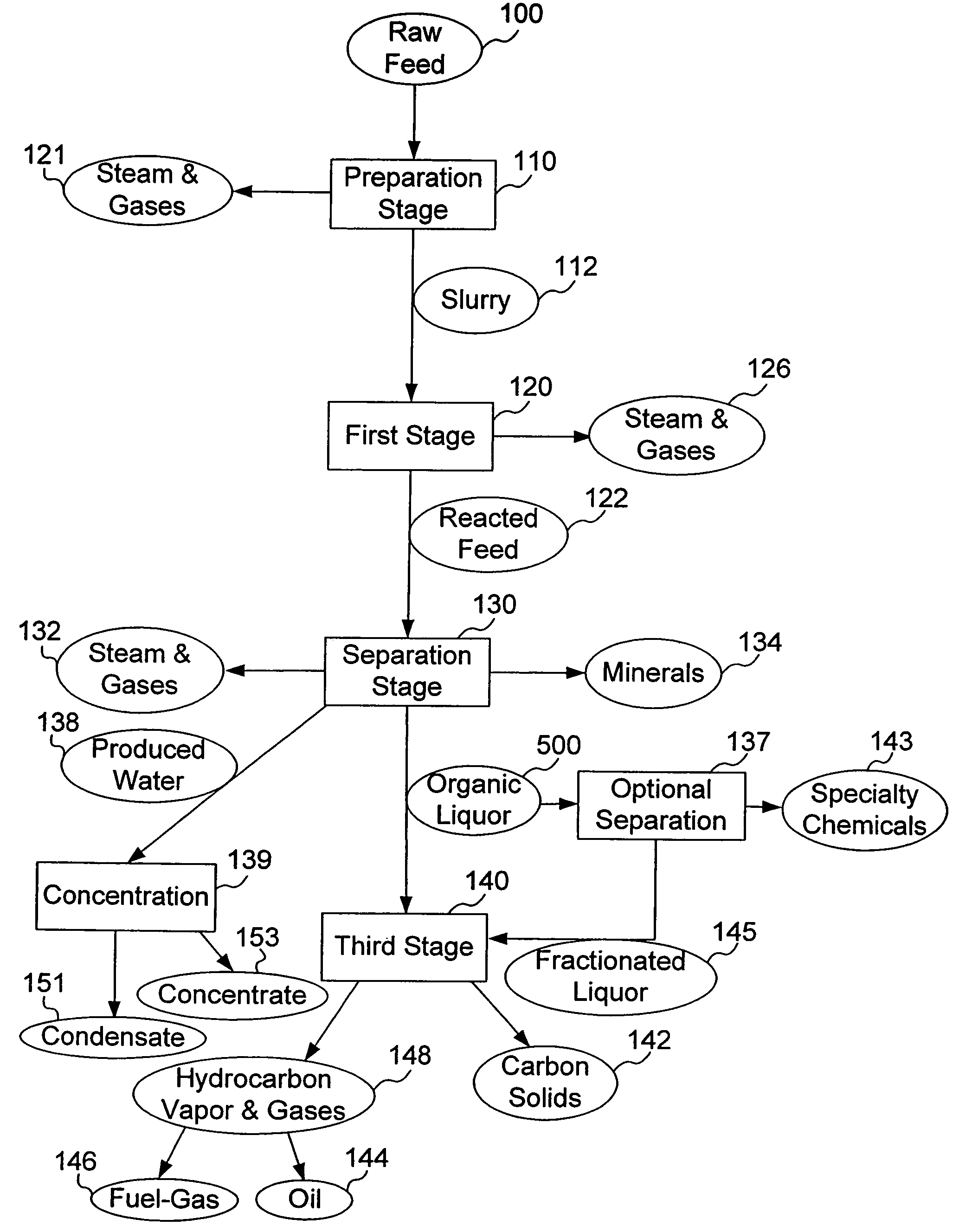

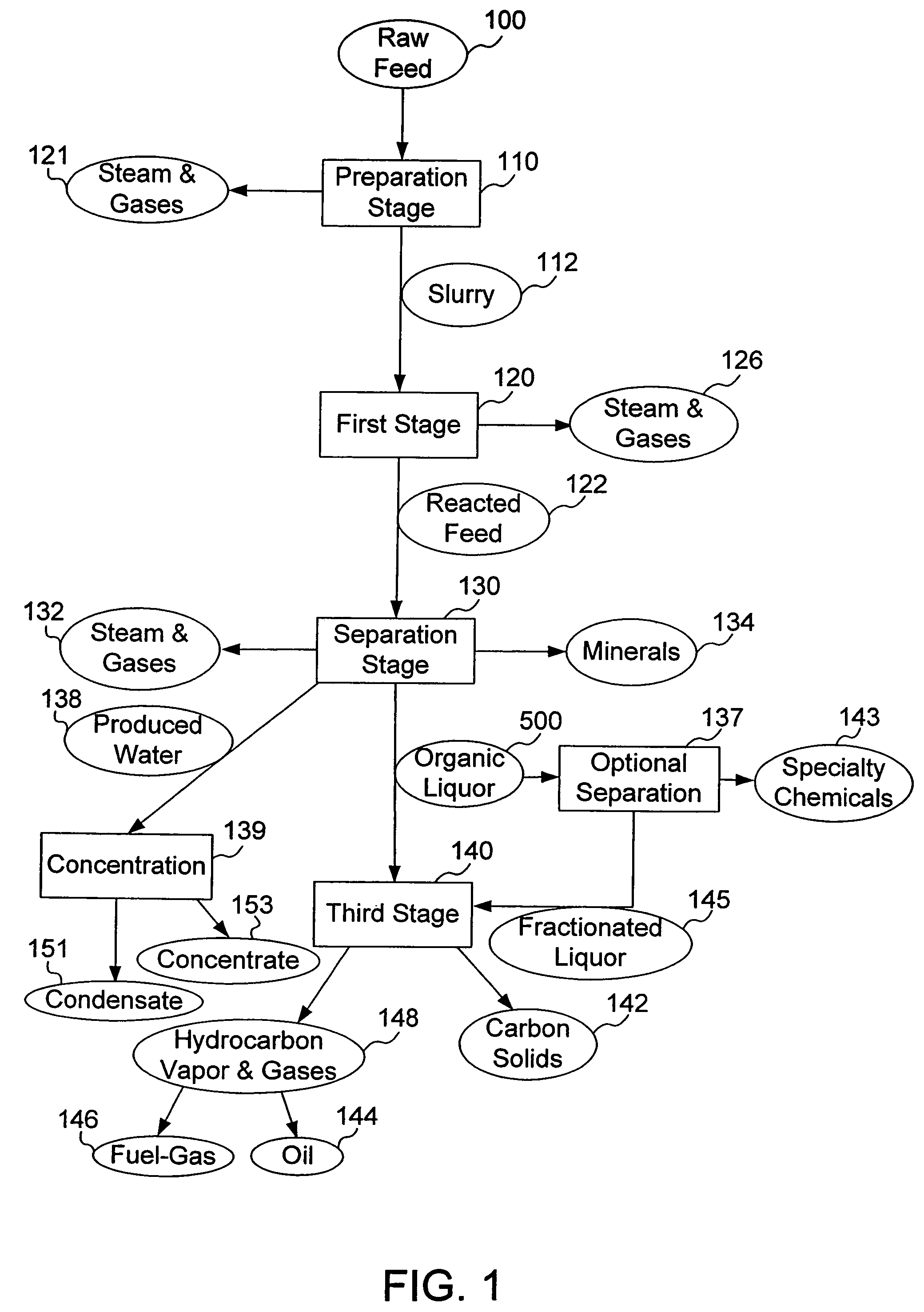

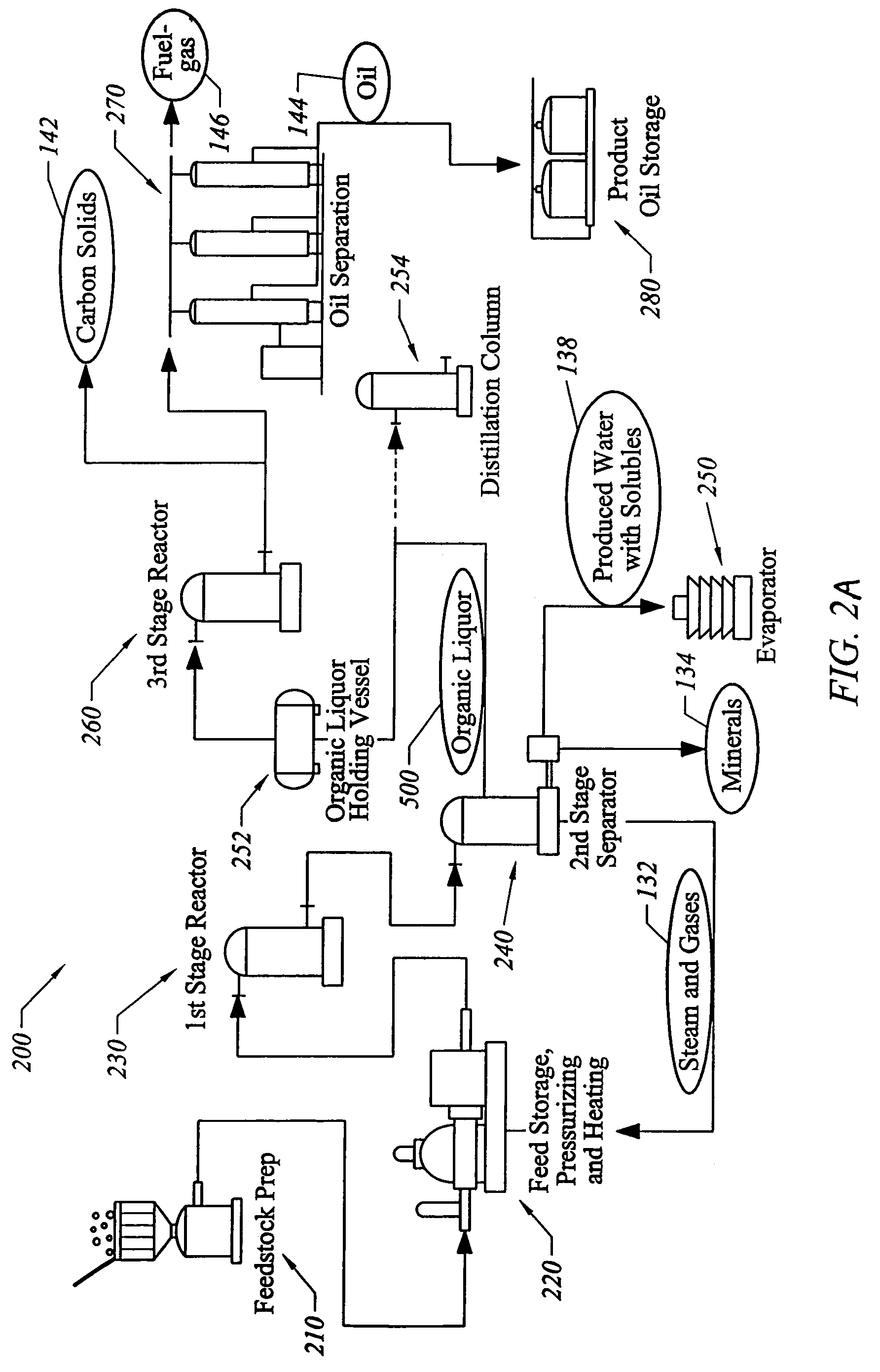

Process for conversion of organic, waste, or low-value materials into useful products

ActiveUS20060004237A1Low viscosityHydrocarbon purification/separationIndirect and direct heating destructive distillationHigh energySulfur

The present invention addresses the processing of waste and low-value products to produce useful materials in reliable purities and compositions, at acceptable cost, and with high energy efficiency. In particular, the invention comprises a multi-stage process that converts various feedstocks such as offal, animal manures, municipal sewage sludge, that otherwise have little commercial value, to useful materials including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure in a reducing environment accomplished by controlled addition of sulfur and sodium, separates out various components, then further applies heat and pressure to one or more of those components. The invention further comprises an apparatus for performing a multi-stage process of converting waste products into useful materials, and at least one oil product that arises from the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

Blending of low viscosity Fischer-Tropsch base oils and Fischer-Tropsch derived bottoms or bright stock

ActiveUS7141157B2High kinematic viscosityLow viscosityHydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon additionBase oilViscosity

A process for preparing Fischer-Tropsch derived lubricating base oils by blending a Fischer-Tropsch distillate fraction having a viscosity of 2 or greater but less than 3 cSt at 100 degrees C. with a Fischer-Tropsch derived bottoms fraction; lubricating base oil compositions having a viscosity between about 3 and about 10 cSt at 100 degrees C. and a TGA Noack volatility of less than about 45 weight percent; and finished lubricants using the aforesaid lubricating base oils.

Owner:CHEVROU USA INC

Calcium Carbonate Based Sulfonate Grease Compositions and Method of Manufacture

ActiveUS20130109602A1Saving expenseShorten the timeThickenersAdditivesCalcium carbonateCalcium hydroxide

An overbased calcium sulfonate grease composition comprising a reduced amount of overbased calcium sulfonate, added calcium carbonate, base oil, one or more converting agents, and one or more complexing acids if a complex grease is desired. The calcium sulfonate grease composition improves thickener yield and expected high temperature utility as demonstrated by dropping point. The calcium carbonate may be used to react with complexing acids when making a complex grease, such that the addition of calcium oxide or calcium hydroxide is not required. A method of making the composition comprising the steps of mixing the overbased calcium sulfonate and base oil, adding the calcium carbonate, adding one or more converting agents, and adding one or more complexing acids. All or a portion of one or more of the complexing acids may be added with or prior to the one or more converting agents.

Owner:NCH CORP

Olefin Oligomerization

A process for producing a hydrocarbon composition that comprises contacting a feed stream, that comprises at least one C3 to C8 olefin, and an olefinic recycle stream, that comprises a first olefinic recycle stream and no more than 10 wt % of C10+ non-normal olefins, with a molecular sieve catalyst in a reaction zone under olefin oligomerization conditions producing an oligomerization effluent stream; separating the oligomerization effluent stream to produce a first olefinic stream, that has a weight ratio of C4− / (C5-C8) molecules from about 0.8 to about 1.2 times the weight ratio of C4− / (C5-C8) molecules found in the oligomerization effluent stream, and a first hydrocarbon product stream, that comprises at least 1 wt % and no more than 30 wt % of C9 non-normal olefin; and splitting the first olefinic stream to produce the first olefinic recycle stream and a first purge stream.

Owner:EXXONMOBIL CHEM PAT INC

Composition and method for inhibition of formation of gas hydrates

InactiveUS6596911B2Using liquid separation agentDistillation purification/separationSolventOnium compound

A method and a composition used therein are disclosed for inhibiting formation of hydrocarbon hydrates. The composition comprises an onium compound, an amine salt and, optionally, a solvent. The method and composition are particularly useful for oil and gas production

Owner:BAKER HUGHES INC

Process for conversion of organic, waste, or low-value materials into useful products

ActiveUS7301060B2Low viscosityHydrocarbon purification/separationIndirect and direct heating destructive distillationSpeciality chemicalsHigh energy

Owner:SYNPET TEKNOLOJI GELISTIRME

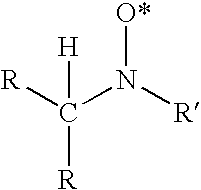

Polymer inhibition of vinyl aromatic monomers using a quinone methide/alkyl hydroxylamine combination

ActiveUS7651635B1Other chemical processesDistillation purification/separationHydroxylamineQuinone methide

The invention provides a composition of matter and a method of its use in preventing unwanted polymerization reactions. The composition comprises an inhibitor and a retarder. The inhibitor is highly effective. The retarder is reliable under extreme and emergency situations. The inhibitor can be an alkylhydroxylamine. The retarder can be a 7-cyano-quinone methide. The combination of the inhibitor and retarder has been found to be far more effective than expected.

Owner:ECOLAB USA INC

Popular searches

Hydrocarbons Treatment with hydrotreatment processes Base-materials Petroleum wax recovery Hydrocarbon oils treatment products Preparation by OH group elimination Bio-feedstock Hydrocarbon by hydrocarbon and non-hydrocarbon condensation Preparation from heterocyclic compounds Hydrocarbon from oxygen organic compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com