Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

293results about How to "Good colloidal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

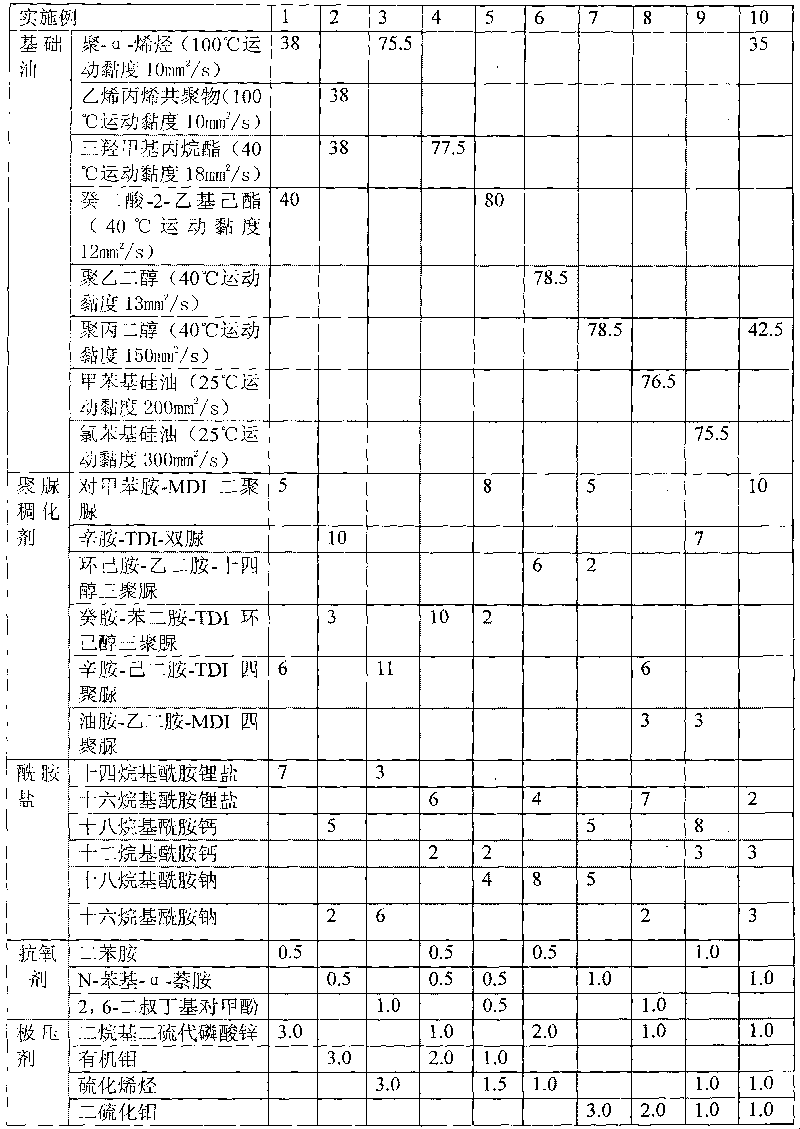

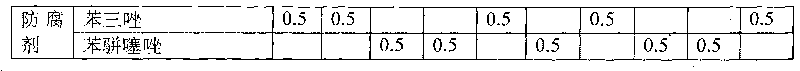

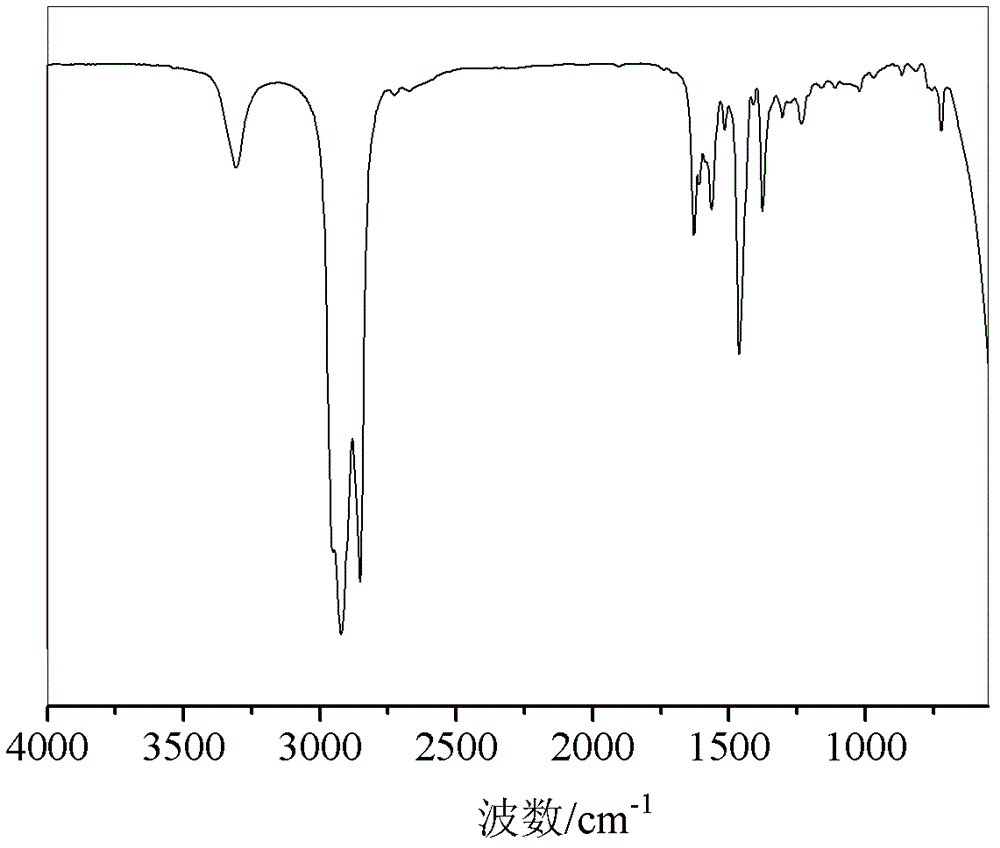

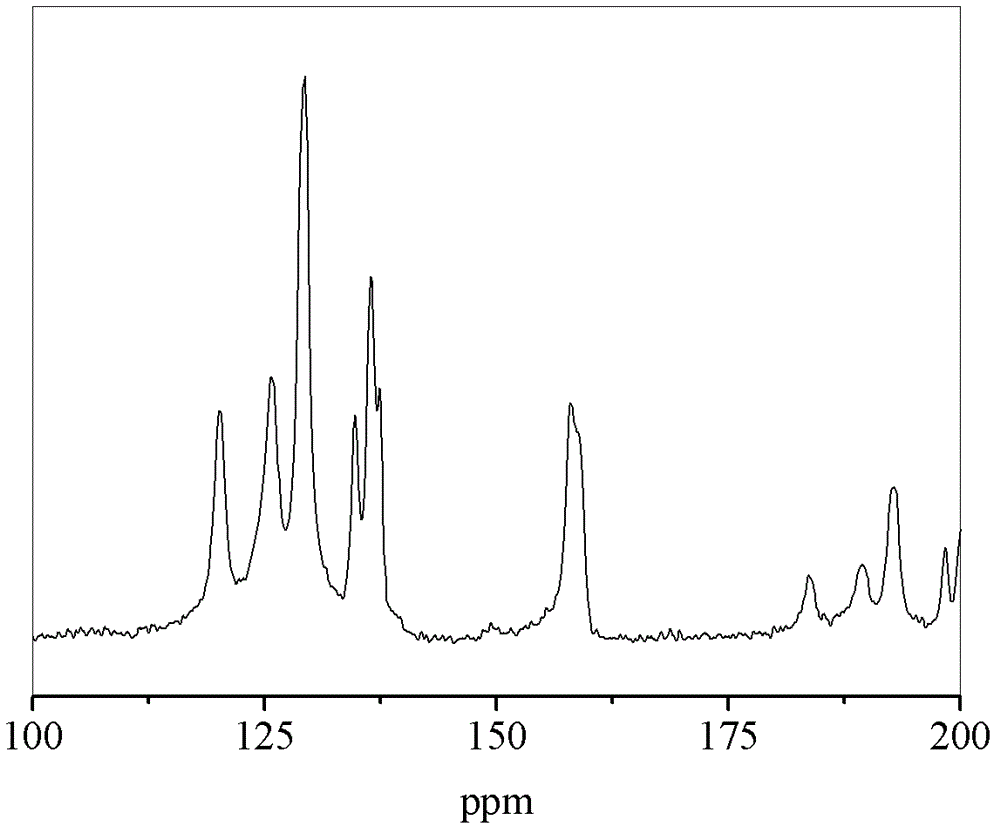

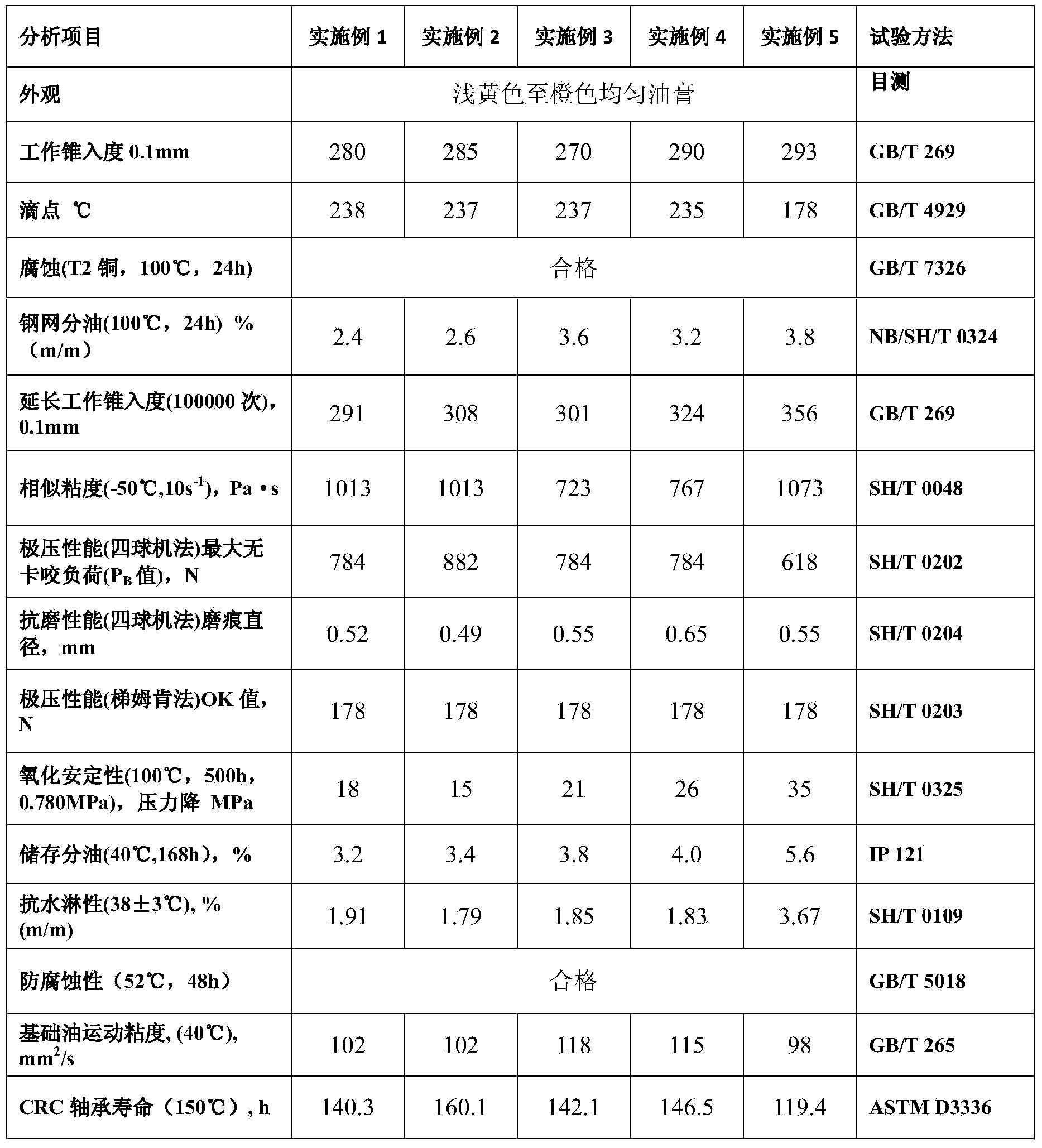

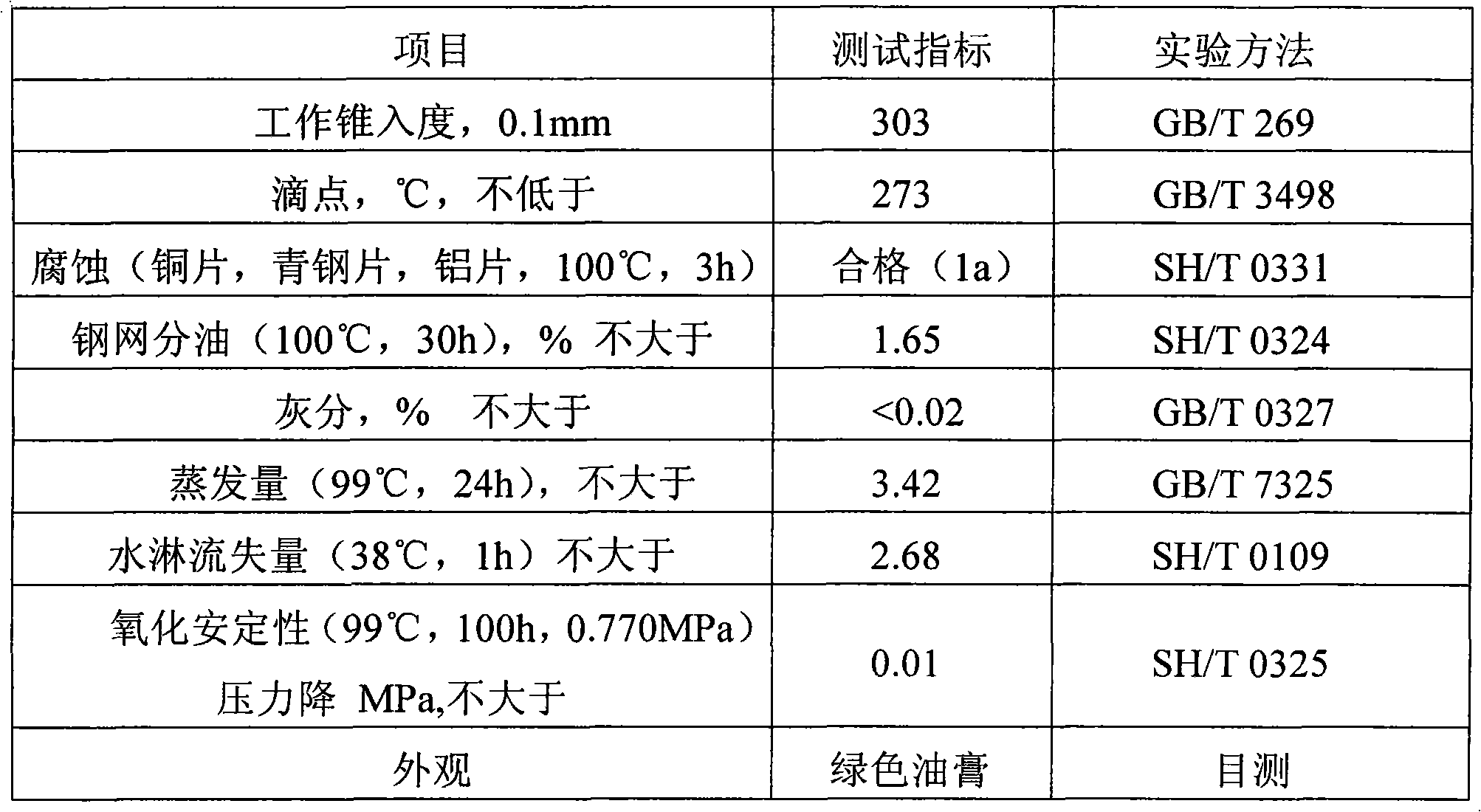

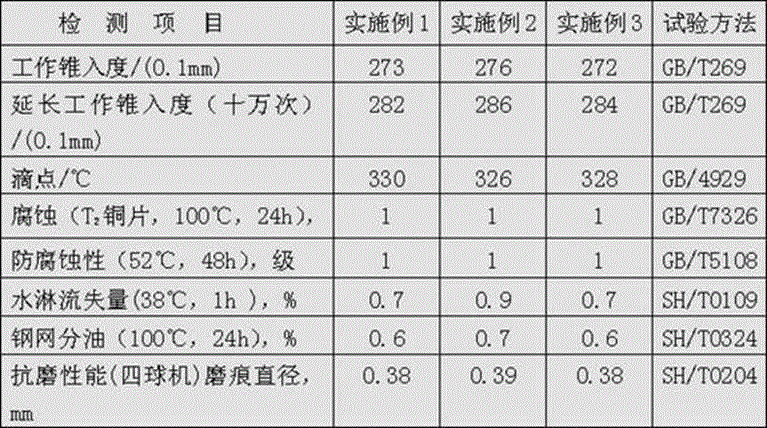

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

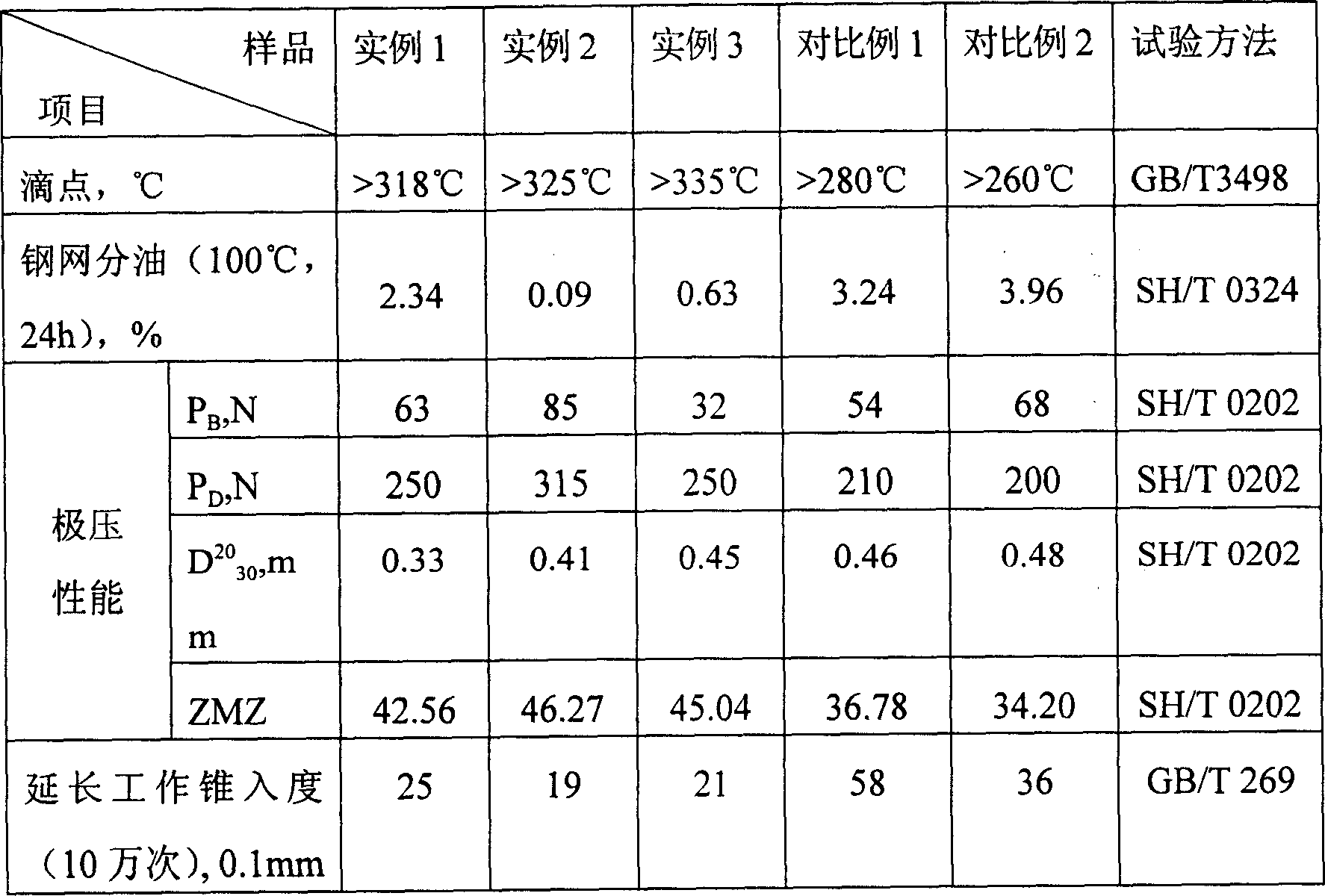

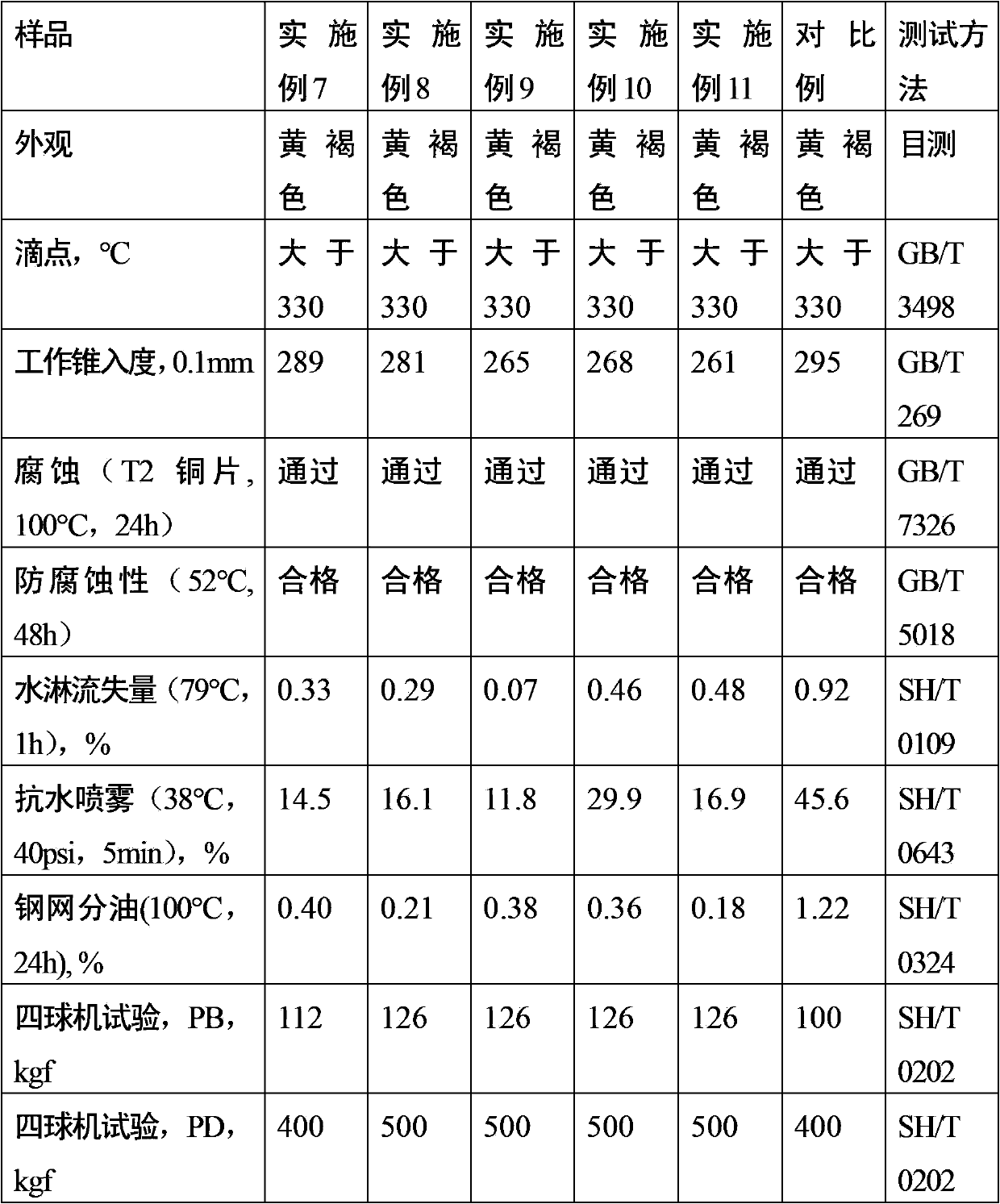

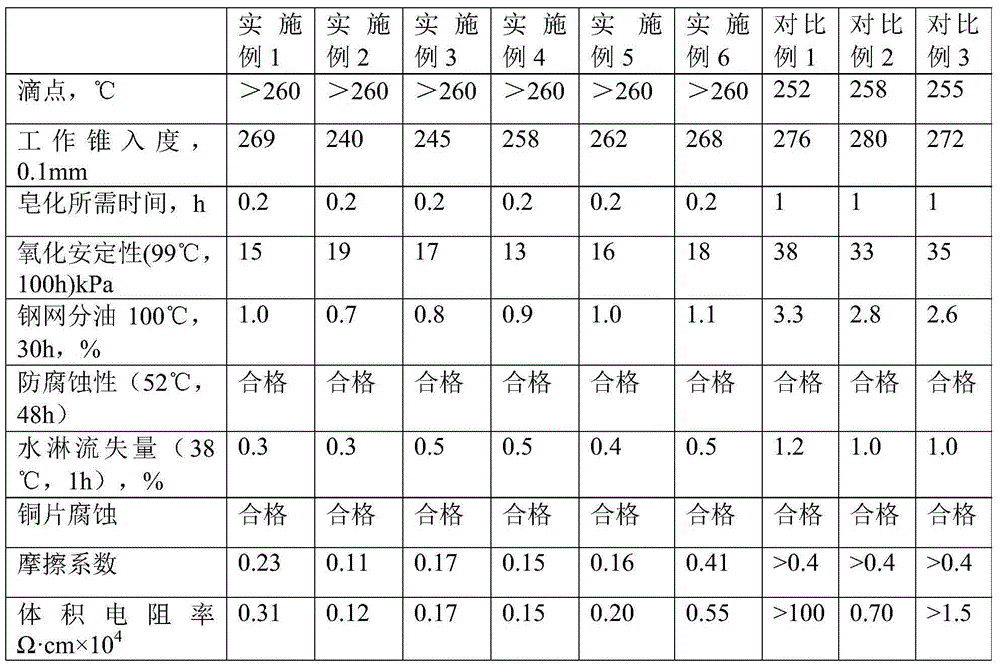

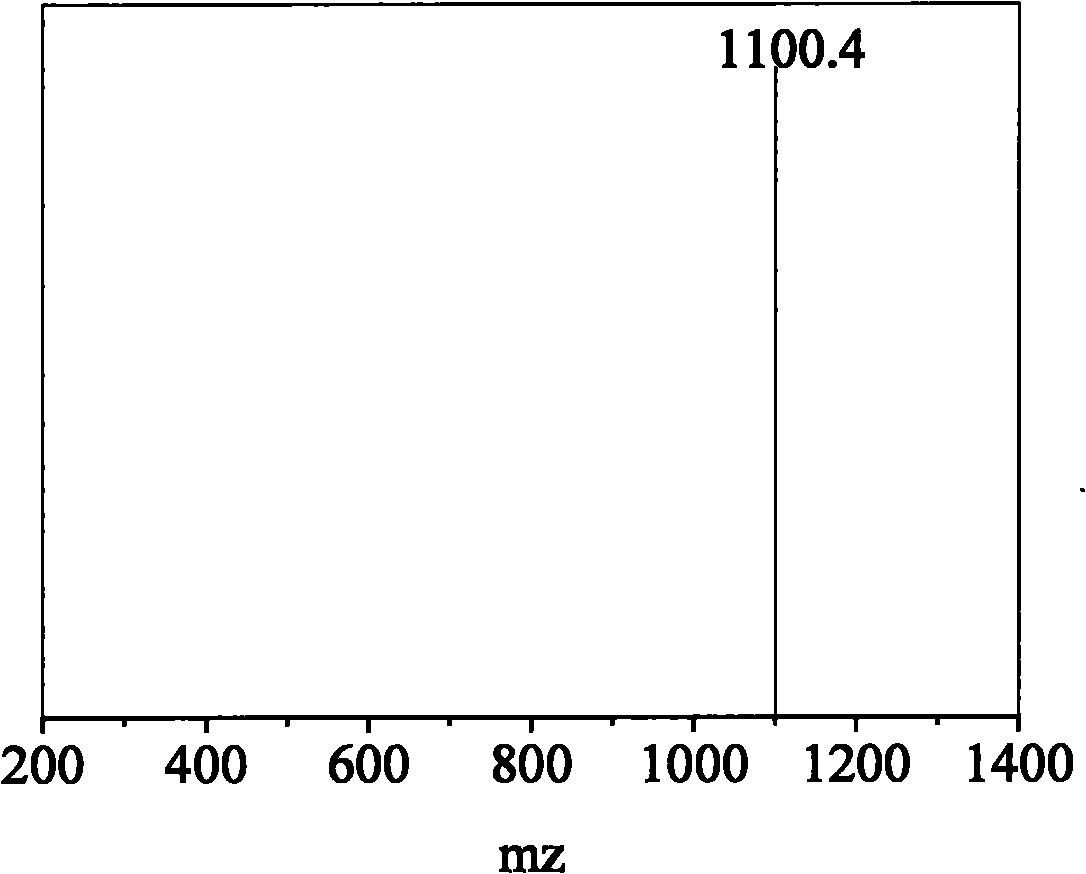

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of octapolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the octapolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polyurea-composite calcium lubricating grease

InactiveCN1493673APrevent volatilizationImprove high temperature performanceAdditivesCalcium hydroxideOrganic acid

A lubricating polyureas-composite calcium grease is prepared through proportionally mixing basic oil, calcium hydroxide (oxide), water and C1-C20 organic acid together, heating to 30-100 deg.C, adding diisocyanate and organic amine, draining water, saponifying, heating to 210-230 deg.C, cooling and homogenizing. Its advantages are high refractory performance, stability and extreme-pressure antiwear nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of bipolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the bipolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-sulfonate-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN102453599AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersCorrosionSulfonic acid

The invention discloses a composite calcium-sulfonate-based tetrapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 1-10% of higher fatty acid calcium; (3) 1-15% of small-molecule inorganic acid calcium or organic acid calcium; (4) 0.5-30% of tetrapolyurea; and (5) 10-80% of lubricating base oil. According to the lubricating grease, calcium petroleum sulfonate or synthesized calcium sulfonate is adopted as a raw material, and the lubricating oil contains a composite calcium thickening agent and a tetrapolyurea compound. The lubricating grease has excellent extreme pressure wear resistance, ultra-long lubricating life, good adhesion, water resistance, colloid stability, high dropping point, thermal stability, corrosion resistance, and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex lithium base grease and preparation method thereof

The invention relates to complex lithium base grease and a preparation method thereof. The preparation method comprises the following processes of: adding 1 / 4 of base oil and dibasic organic acid into a reaction kettle, heating and melting, and adding monobasic organic acid for reaction; adding 1 / 4 of base oil, cooling the base oil, and adding lithium hydroxide oil solution for saponification andwarming; adding 1 / 4 of base oil, moving materials in the reaction kettle to an intermediate kettle, adding the rest 1 / 4 of base oil into the intermediate kettle, and circulating and cooling; adding an antioxidant, a corrosion inhibitor and an extreme pressure antiwear additive; and uniformly stirring, homogenizing and degassing to obtain the complex lithium base grease. The complex lithium base grease has a simple process, the time for producing the complex lithium base grease with a normal-pressure kettle is short, energy resources are saved, production cost is reduced, the utilization rate of equipment is improved, and the saponification reaction is quick and full.

Owner:无锡中石油润滑脂有限责任公司

Insulating and heat-conducting silicone grease and preparation method thereof

InactiveCN103709757AImprove colloidal stabilityImprove stabilityHeat-exchange elementsAluminiumAntioxidant

The invention discloses insulating and heat-conducting silicone grease. The insulating and heat-conducting silicone grease consists of the following raw materials in parts by weight: 10-40 parts of organic silicon oil, 50-80 parts of heat-conducting powder, 0.5-4 parts of a structure improver, 0.5-3 parts of rheological aid, 0.5-5 parts of a friction modifier and 0.1-2 parts of an antioxidant. The insulating and heat-conducting silicone grease prepared by the invention is excellent in heat-conducting performance and low in cost, and is widely applicable to heat radiators requiring effective cooling in the industry, such as heat transmission for a gap where a diode and a substrate (aluminum or copper plate) are in contact, and heat conduction and insulation of a rectifier, electric and the like.

Owner:无锡中石油润滑脂有限责任公司

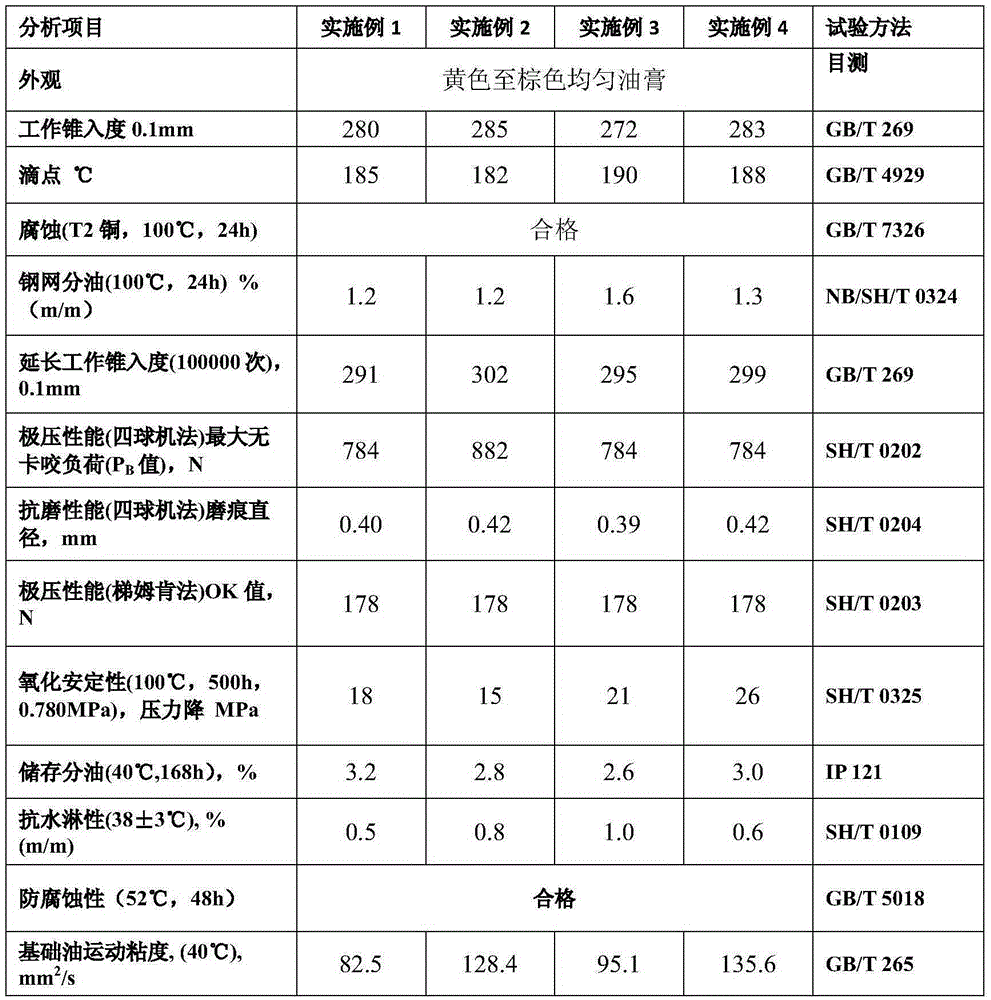

Lithium-calcium complex lubricating grease composition and preparation method

InactiveCN104449983AGood mechanical stabilityGood colloidal stabilityLubricant compositionLithium soapLong chain fatty acid

The invention relates to a lithium-calcium complex lubricating grease composition and a preparation method. The lubricating grease comprises the following components: (1) 60%-87% of base oil; (2) 10%-38% of a thickening agent; and (3) 1.5%-11% of an additive, wherein the thickening agent disclosed by the invention is a lithium-calcium complex thickening agent, comprises one or more long-chain fatty acid lithium soap and one or more micromolecular acid calcium soap, and is obtained from the reactants of acid and lithium hydroxide and calcium hydroxide. The lithium-calcium complex lubricating grease prepared by the method has good mechanical stability, colloid stability, water resistance and good extreme pressure antiwear property; and above all, the hardening phenomenon is not generated under room-temperature long-term storage and high-temperature (120 DEG C) conditions on the basis that excellent performances of the original lithium-calcium complex lubricating grease are reserved.

Owner:CHINA PETROLEUM & CHEM CORP

Lithium-based lubricating grease and preparation method thereof

The invention discloses lithium-based lubricating grease and a preparation method thereof. The lithium-based lubricating grease is characterized by being prepared from the following components on the basis of the weight of the lubricating grease: 65-95% of lubricating base oil, 6-20% of lithium-based thickening agent and 0.5-15% of graphene. The lithium-based lubricating grease has excellent properties such as excellent high temperature resistance, water and adhesion resistance, colloidal stability, extreme pressure antiwear property, long lubricating service life, corrosion resistance and salt mist resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-rust extreme pressure lithium lubricating grease composition and preparation method

InactiveCN105331426AImprove extreme pressure performanceImprove shear stabilityLubricant compositionAntioxidantLithium hydroxide

The invention relates to an anti-rust extreme pressure lithium lubricating grease composition and a preparation method thereof. The composition is prepared from 5.5%-12.5% of thickening agents, 72.8%-91.3% of base oil, 0.5%-3.8% of extreme pressure anti-wear agents, 0.28%-1.25% of antioxidants and 0.02%-1.05% of anti-rust anti-corrosion agents, wherein the base oil is high-viscosity mineral oil. The preparation method of the composition comprises the steps that one third of the base oil and 12-hydroxy stearin or a mixture of 12-hydroxy stearin and stearic acid are heated to the temperature ranging from 60 DEG C to 80 DEG C, a lithium hydroxide solution is added, the temperature is raised to range from 180 DEG C to 220 DEG C after a reaction is completed, one third of quenching oil is added, the extreme pressure anti-wear agents, the anti-rust anti-corrosion agents and the rest of the base oil are added after cooling is conducted, and the composition is prepared after grounding is conducted. The novel lubricating grease containing the extreme pressure components and the anti-rust anti-corrosion components has the excellent extreme pressure property and anti-corrosion property and can be widely applied to severer environment conditions with a medium or heavy load and water.

Owner:CHINA PETROLEUM & CHEM CORP

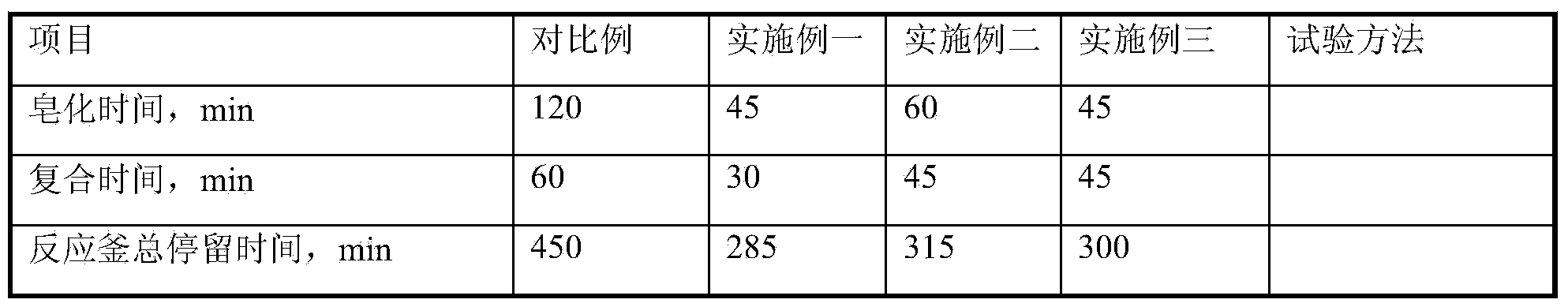

Lubricating grease for hub bearing of heavy load truck and preparation method thereof

InactiveCN103450978AEliminates tendency to overflowSlow dehydration stepThickenersThiocarbamateChemical industry

The invention relates to a lubricating grease and a preparation method thereof, particularly relates to a lubricating grease for a hub bearing of a heavy load truck and a preparation method thereof, and belongs to the technical field of a chemical industry. The lubricating grease is prepared from the following raw materials: (A) base oil which accounts for 60-85% of total weight of the lubricating grease, (B) a thickening agent, which is C12-C22 unitary organic acid which accounts for 7-12% of total weight of the lubricating grease, 0.5-3% of sebacic acid, 0.2-1% of boric acid, and 3-5% of lithium hydroxide oil solution, (C) an additive, which is thiocarbamate which accounts for 0.5-3% of total weight of the lubricating grease, 2-5% of sulfide olefin cottonseed oil, 2-4% of dialkyl dithiocarbamate salt, 0.5-2.5% of molybdenum dialkyl dithiophosphate, 0.3-2% of antirust agent and 0.3-1% of antioxidant. The lubricating grease has the beneficial effects that the production time is shortened; the lubricating grease is more controllable in process, stable in product quality, less in seepage loss of a high-temperature bearing, and prominent in extreme pressure property; lubricating protection can be better provided for hubs of the heavy load truck; the lubricating requirements of the hub bearing of the heavy load truck under various working conditions can be met; the grease exchange period of the hub bearing is prolonged.

Owner:JIANGSU LOPALTECH

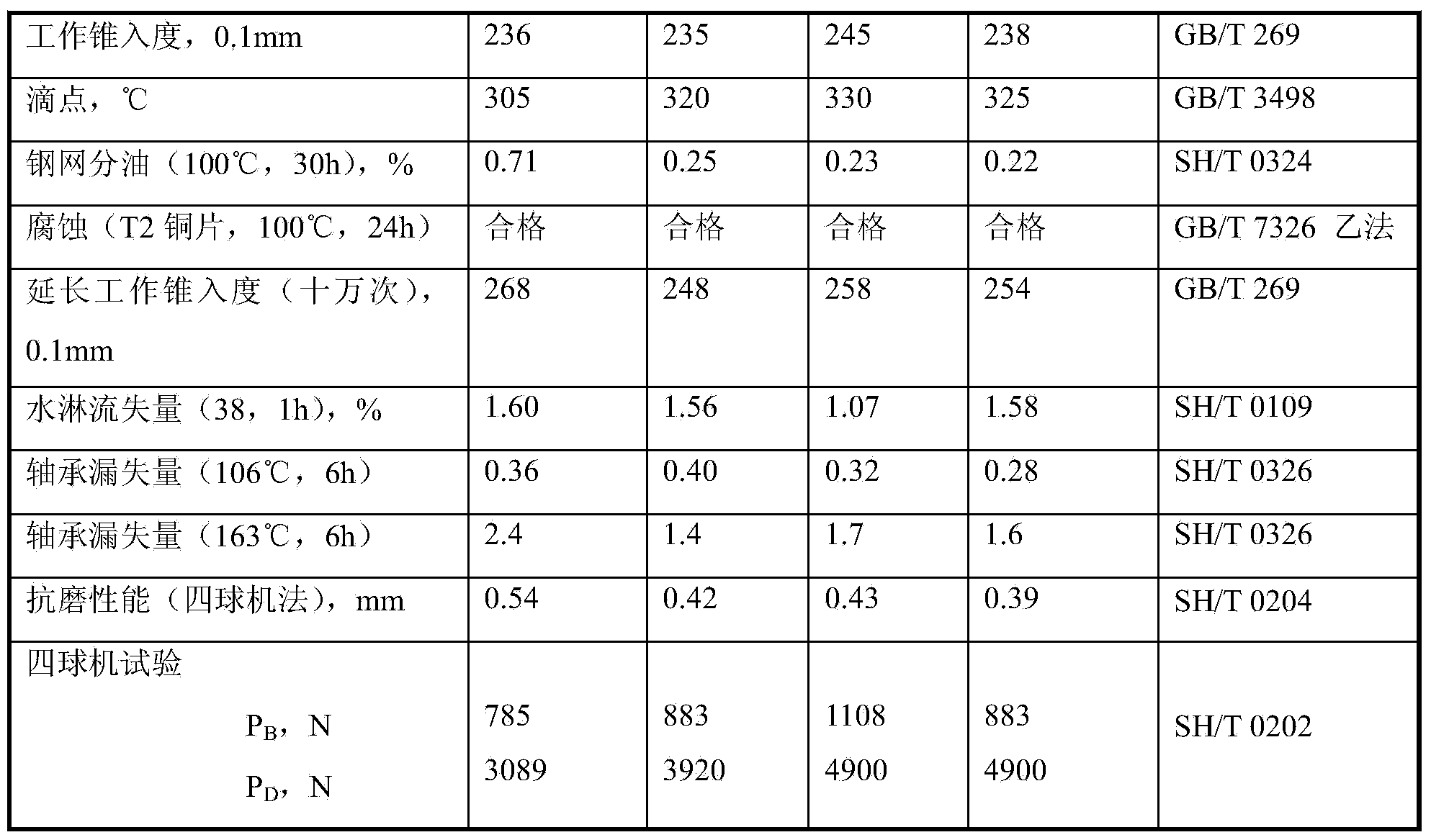

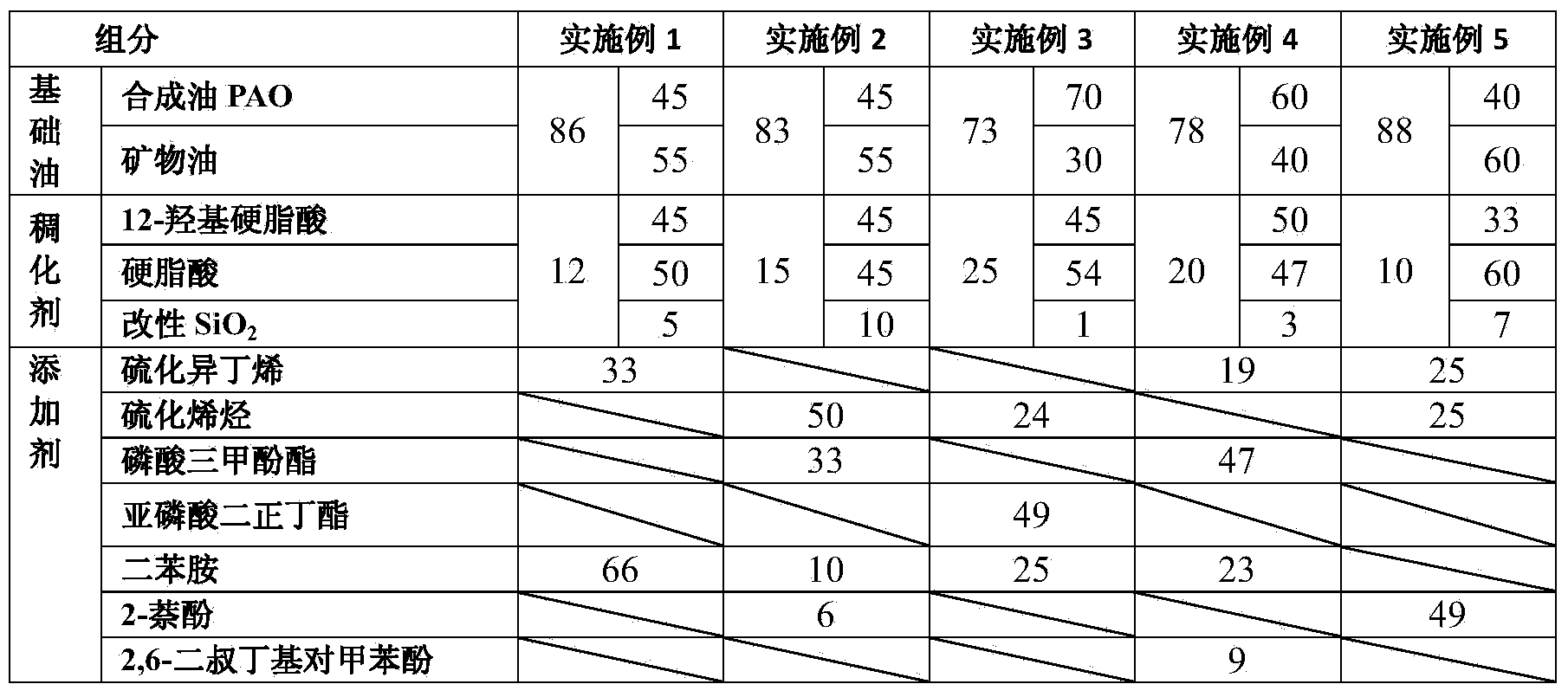

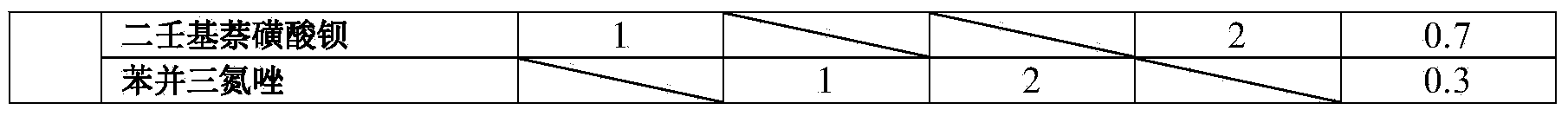

Lubricating grease containing modified silica component and preparation method of lubricating grease

ActiveCN103484204AImprove shear stabilityLittle change in cone penetrationPigment treatment with organosilicon compoundsLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to lubricating grease containing a modified silica component and a preparation method of the lubricating grease. The excellent properties of silicone grease and lithium lubricating grease are well combined through modified SiO2. With total weight of a composition as benchmark, the lubricating grease provided by the invention comprises the following components: a thickening agent accounting for 10-25% of the total weight and including 12-hydroxystearic acid, stearic acid and the modified SiO2; base oil accounting for 73-88% of the total weight and consisting of synthetic oil and mineral oil; and additives mainly including the following three types: (a) 0.6-1.8% of anti-wear reagent at extreme pressure, (b) 0.32-1.32% of antioxidant, and (c) 0.02-0.04% of antirust preservative. The novel lubricating grease containing modified SiO2 has excellent shear stability and storage stability and is a kind of SiO2-containing lithium lubricating grease in which high and low temperature, colloid stability and water resistance are greatly improved. The lubricating grease is especially suitable for application under harsh environmental conditions of high temperature and heavy load.

Owner:CHINA PETROLEUM & CHEM CORP

Compound lithium base grease composite and preparation method thereof

ActiveCN101838580AGood colloidal stabilityGood mechanical stabilityAdditivesLithiumMechanical stability

The invention discloses a compound lithium base grease composite, which comprises the following materials in percentage by weight: 70-89% of grease base oil, 10-25% of densifier, 0.02-2% of additive, and 0.01-5% of bismuth oxide. In the compound lithium base grease composite, micron-level bismuth oxide powder is added as an extreme-pressure additive, and the prepared compound lithium base grease composite has good colloidal stability and mechanical stability, and better high temperature performance and extreme pressure resisting performance.

Owner:SUN YAT SEN UNIV

Composite zirconium-based urea bipolymer grease and preparation method thereof

ActiveCN102952604AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersHeat stabilityBase oil

The invention provides composite zirconium-based urea bipolymer grease and a preparation method thereof. The composite zirconium-based urea bipolymer grease comprises: by weight, 1) 1 to 59% of composite zirconium which is produced by a reaction of at least one higher fatty acid, at least one aromatic acid, and an oxide and / or a hydroxide of zirconium, wherein a mole ratio of the at least one aromatic acid to the at least one higher fatty acid is (0.5 to 7): 1, 2) 1 to 59% of a urea bipolymer, and 3) 40 to 95% of lubrication base oil. The composite zirconium-based urea bipolymer grease contains the composite zirconium as a densifier and the urea bipolymer. The composite zirconium-based urea bipolymer grease has excellent extreme pressure wear resistance, a long lubrication life, good water resistance, colloid stability, a high dropping point and good heat stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease composition and preparation method thereof

ActiveCN102604723AGood high and low temperature performanceStrong antioxidantLubricant compositionNano sio2Antioxidant

The invention discloses a lubricating grease composition and a preparation method of the lubricating grease composition. The lubricating grease composition consists of the following materials by weight: 70-85% of lubricating grease base oil, 12-27% of a double thickening agent and 0.1-3% of an additive, wherein the lubricating grease base oil is silicone oil. The preparation method adopts silicone oil with good high-temperature and low-temperature performance as the lubricating grease base oil, is simple in process, and effectively reduces the energy consumption relative to a two-step method.In the lubricating grease composition of the invention, nano-SiO4 is used as a thickening agent and the additive simultaneously. The additive also comprises such solid additives as an antioxidant, a rust protection agent and the like. The lubricating grease composition of the invention has good colloid stability, mechanical stability and high and low temperature performance, and can be suitable for an extreme operating condition.

Owner:SUN YAT SEN UNIV

Composite sodium-based lubricating grease and preparation method thereof

ActiveCN104560315AImprove antioxidant capacityImprove high drop pointThickenersSalt resistanceGraphene

The invention discloses composite sodium-based lubricating grease and a preparation method thereof. By the weight of the lubricating grease, the compound sodium-based lubricating grease comprises the following components: 65-95% of lubricating base oil, 5-30% of a composite sodium-based thickener and 0.2-15% of graphene. The composite sodium-based lubricating grease disclosed by the invention has excellent properties such as high temperature resistance, water resistance, adhesivity, colloid stability, extreme pressure antiwear property, long lubricating life, corrosion resistance and salt fog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lithium lubricating grease and preparation method thereof

ActiveCN109810748AGood mechanical stabilityLong mechanical stabilityAdditivesBase-materialsLithiumAntioxidant

The invention discloses lithium lubricating grease. The lithium lubricating grease is prepared from raw materials in parts by weight: 75-88 parts of base oil, 0.5-2.5 parts of an anti-wear agent, 0.1-1.5 parts of an anti-rust agent, 0.1-1.5 parts of an antioxidant, 5-25 parts of a lubricating agent, 5-15 parts of a thickening agent and 0.6-2.0 parts of a saponifying agent. The lithium lubricatinggrease has the advantages of good colloid resistivity, superior mechanical resistivity and the like of traditional lithium lubricating grease, and meanwhile, the anti-wear property of the lithium lubricating grease is greatly improved. Furthermore, the lithium lubricating grease has a superior anti-oxygen property, can significantly shorten the saponifying reaction time, reduce the saponifying reaction temperature, and greatly improve the resistivity, stability and the wear-resistant property of basic lithium lubricating grease, and the lithium lubricating grease can be qualified for the severworking conditions of high temperature, high speed, high load, excessive water and the like.

Owner:GUANGXI LIUGONG MASCH CO LTD

Leakage-proof speed reducer lubricating grease composition and preparation method thereof

ActiveCN102433192AGood colloidal stability and thixotropyHigh yield stressLubricant compositionCooling temperatureAntiwear additive

The invention relates a speed reducer lubricating grease composition and a preparation method thereof. The composition comprises 69 to 80 percent of mineral base oil, 12 to 23 percent of ester base oil, 3.2 to 6 percent of thickening agent, 0.6 to 2 percent of dinonyl sulfonate or zinc naphthenate, and 1 to 2.8 percent of solid wear-resistance additive. The preparation method comprises: adding the mineral base oil into a reaction kettle, adding fatty acid, mixing, raising temperature to 80 to 85 DEG C, adding an aqueous solution of lithium hydroxide, heating to 90 to 100 DEG C, and performingsaponification for 1 to 2 hours; raising temperature to 210 DEG C, adding the mineral base oil into the reaction kettle, and quenching, wherein the quenching temperature is kept between 140 to 190 DEG C, and the quenching oil accounts for 14 to 43 percent of the total amount of the base oil; adding the ester base oil, and cooling; when the temperature is below 100 DEG C, adding the dinonyl sulfonate or zinc naphthenate, cooling to a temperature below 80 DEG C, and adding the solid wear-resistance additive; and cooling to a temperature below 60 DEG C, rolling oil by a three-roll machine for three times and filling to obtain finished speed reducer lubricating grease composition. In the invention, the lubricating grease is prepared by one-step direct reaction, the process and equipment are simple and energy-saving, and the quality of the product produced by the process is stable.

Owner:CHINA PETROLEUM & CHEM CORP

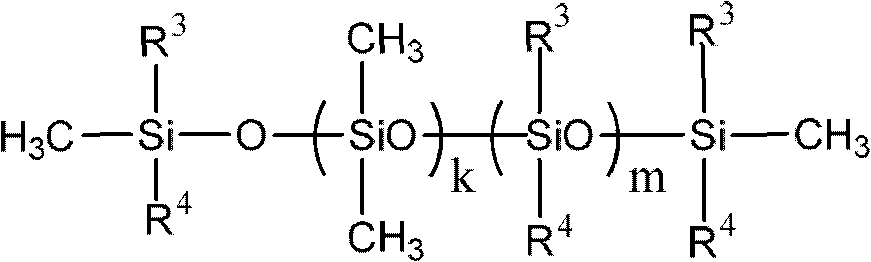

Grease special for plastic and preparation method thereof

InactiveCN101880578AStable colloidal stabilityStrong high temperature resistanceBase-materialsTemperature resistanceLubrication

The invention discloses grease special for plastic and a preparation method thereof. The grease comprises the following components: organopolysiloxane, an additive, a heat stabilizer, a colloid stabilizer and a thickener, wherein the additive improves lubrication of dropping points and interfaces. The grease not only has the performance of common grease, but also has the advantages of stable colloid stability, strong high temperature resistance, and a special plastic protective function.

Owner:福州三辰新材料有限公司

Calcium-sulfonate-based hexapolyurea lubricating grease and preparation method thereof

ActiveCN102417856AGood extreme pressure and anti-wear propertiesImprove adhesionThickenersHeat stabilityLubrication

The invention provides a calcium-sulfonate-based hexapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of, by weight: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 0.5-30% of hexapolyurea; and (3) 10-80% of lubrication base oil. According to the invention, Newtonian fluid calcium sulfonate is converted and is subject to a reaction with diisocyanate, diamine and monoamine, such that the calcium-sulfonate-based hexapolyurea lubricating grease is obtained, the lubricating grease provided by the invention has excellent extreme pressure anti-wear capacity, ultra-long lubricating life, good adhesion, good water resistance, good colloid stability, high dropping point, good heat stability, good corrosion resistance, good salt spray resistance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

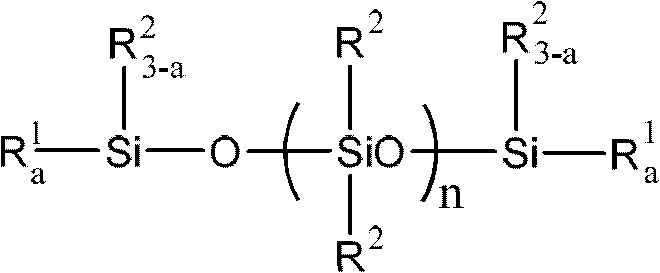

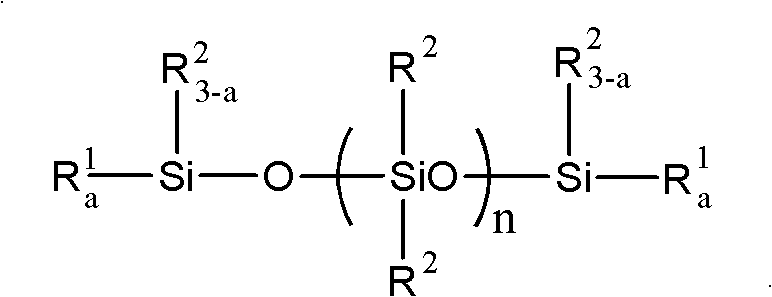

Lithium base grease and preparation method thereof

ActiveCN110317669APromote degradationGood colloidal stabilityGroup 5/15 element organic compoundsLubricant compositionLithiumMechanical stability

The invention provides lithium base grease and a preparation method thereof. The lithium base grease comprises a lubricating base oil, a lithium base thickener and a phosphorous compound, and a structure of the phosphorous compound is described in the specification. The lithium base grease has excellent biodegradability, colloid stability, mechanical stability and oxidation resistance, is suitablefor severe working conditions such as high temperature, high speed, high load, wateriness, and is environmental-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

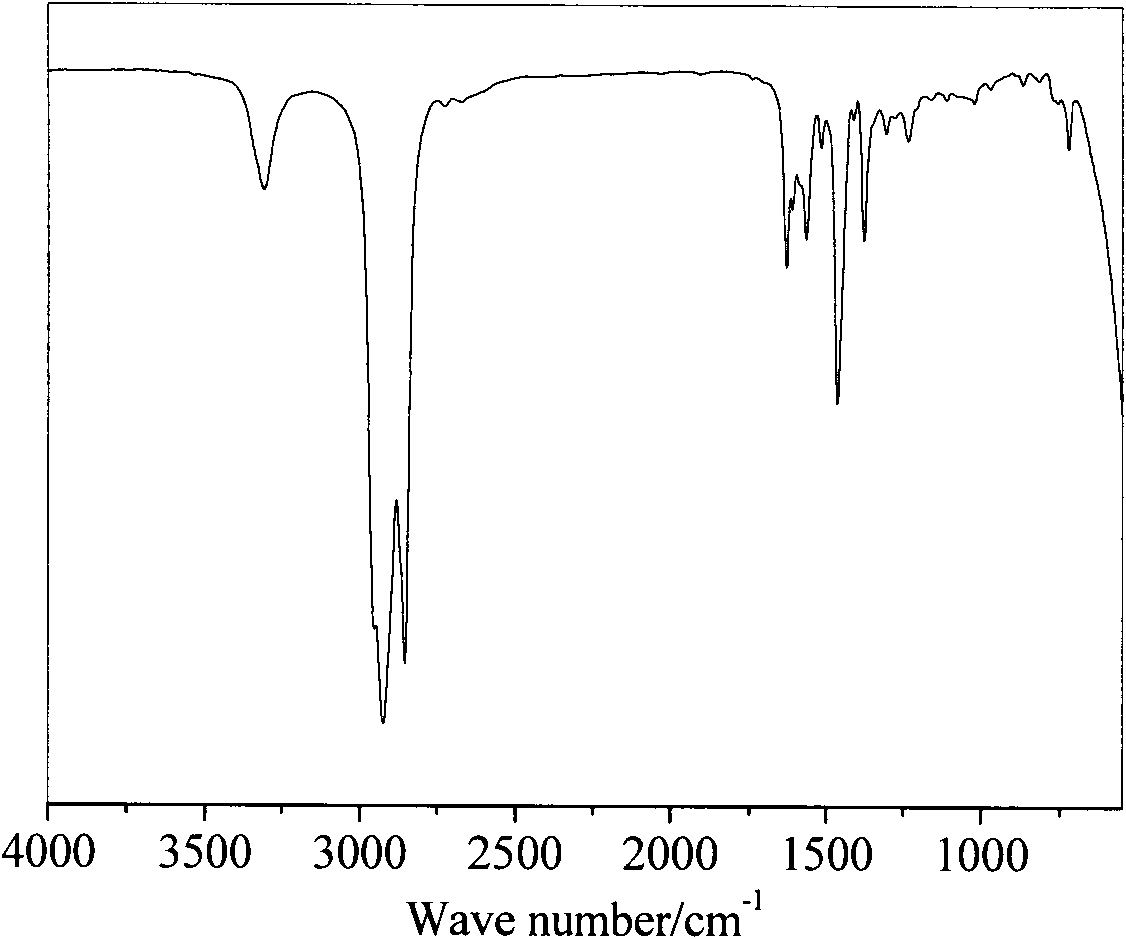

Functional urea-based lubricating grease and preparation method thereof

ActiveCN101886018AImprove antioxidant capacityImproved colloidal stabilityThickenersAntioxidantReaction temperature

The invention discloses functional urea-based lubricating grease and a preparation method thereof. According to the functional urea-based lubricating grease, furfural refined oil of naphthenic crude oil is used as lubricating grease base oil, and a substance synthesized by the reaction of organic amine mixture and diisocyanate is used as urea-based thickening agent; and the functional urea-based lubricating grease composition also comprises at least one of the following additives: antioxidant and pigment. Because the furfural refined oil of a mineral source is used as the base oil, the urea-based lubricating grease has good anti-oxidation property and high colloid stability; and meanwhile, the addition of oxidant improves the oxidation stability of the urea-based lubricating grease and the addition of a little amount of pigment endows the urea-based lubricating grease with special appearance. In the preparation method of the invention, the initial reaction temperature of the thickening agent is controlled to be between 60 and 100 DEG C, so the energy consumption is effectively reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +2

High/low-temperature-resistant lubricating crease and preparation method for same

InactiveCN105087108AGood high and low temperature performanceImprove Oxidation StabilityLubricant compositionSulfonatePolyolefin

The invention discloses high / low-temperature-resistant lubricating crease, which is prepared from the following raw materials in parts by weight: 10 to 15 parts of glyceride, 45 to 50 parts of poly-R olefin, 0.5 to 1 part of an extreme-pressure agent, 0.3 to 0.6 part of an antioxidant, 20 to 30 parts of synthetic sulfonate, 1 to 2 parts of an anti-wear agent, 5 to 7 parts of fatty acid, 3 to 5 parts of low molecular weight alcohol, 0.5 to 1 part of a water-soluble inorganic base and 3 to 5 parts of water. The invention also discloses a preparation method for the high / low-temperature-resistant lubricating crease. The product prepared by the method has high high / low-temperature stability, anti-oxidation stability, extreme pressure resistance, anti-rusting performance and water resistance, the life cycle of the lubricating grease is prolonged, frictional resistance is effectively reduced, wear is reduced, and energy resources are saved.

Owner:LUOHE BEIJIA BILL SCI & TECH CHEM

Composite calcium naphthenate-based lubricating grease and preparation method therefor

ActiveCN103627496AGood extreme pressure and anti-wear propertiesLong lubrication lifeLubricant compositionHeat stabilityBase oil

The invention provides a kind of composite calcium naphthenate-based lubricating grease and a preparation method therefor. With the weight of the lubricating grease as a reference, the lubricating grease comprises the following ingredients: 10%-70% of non-Newtonian calcium naphthenate, 1%-10% of calcium salts of high fatty acids, 1%-15% of calcium salts of micromolecule inorganic acids or fatty acids and 10%-80% of lubrication base oil. The lubricating grease employs petroleum calcium naphthenate or synthesized calcium naphthenate as a raw material, and contains composite calcium densifiers. The lubricating grease has good anti-water-spray properties and anti-water spray loss properties, and has good performances of adhesion, extreme pressure antiwear property, colloid stability, high dropping point, heat stability, anti-corrosion and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex aluminum-base lubricating grease and preparation method thereof

ActiveCN104560314AImprove antioxidant capacityImprove high drop pointLubricant compositionSalt resistanceGraphene

The invention discloses complex aluminum-base lubricating grease and a preparation method thereof. On a lubricating grease weight basis, the complex aluminum-base lubricating grease comprises the following components: 65-95 percent of lubricating base oil, 5-30 percent of complex aluminum-base thickening agent and 0.2-15 percent of graphene. The complex aluminum-base lubricating grease provided by the invention has excellent properties such as high-temperature resistance, water resistance, adhesivity, colloid stability, extreme pressure wearability, lubricating life, corrosion resistance and salt fog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tetra-urea lubricating grease and preparation method thereof

The invention provides a tetra-urea lubricating grease and a preparation method thereof. The tetra-urea lubricating grease comprises lubricating oil basic oil and a tetra-urea thickening agent, and does not contain di-urea thickening agent and fatty acid metal salt. In the preparation method, the tetra-urea lubricating grease is obtained by the reaction of diisocyanate, diamine and monoamine. Compared with the di-urea lubricating grease, the tetra-urea lubricating grease has higher dropping point, better extreme pressure property, colloid stability and shearing stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite barium-based lubricating grease composition and preparation method thereof

The invention discloses a composite barium-based lubricating grease composition and a preparation method thereof. By taking the weight of the lubricating grease as a benchmark, the composite barium-based lubricating grease composition comprises the following components: 65-95% of lubricating base oil, 5-30% of a composite barium-based thickening agent and 0.2-15% of graphene. The composite barium-based lubricating grease has excellent high temperature resistance, water resistance, adhesion, colloidal stability, extreme pressure antiwear property, anti-corrosion property, salt and spray resistance and the like and long lubricating life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thixotropic optical fiber filling paste for ribbon optical cable and preparation method thereof

ActiveCN102207594AStrong paste skeletonHigh thixotropic indexFibre mechanical structuresWeather resistanceOil separation

The invention relates to thixotropic optical fiber filling paste for a ribbon optical cable, which mainly comprises base oil, an oil separation inhibitor, a pour point depressant, an antioxidant, an organic gelling agent, an inorganic gelling agent and a thixotropic agent. The invention also provides a preparation method for the thixotropic optical fiber filling paste for the ribbon optical cable. The thixotropic optical fiber filling paste for the ribbon optical cable is mainly characterized in that: the thixotropic optical fiber filling paste has excellent colloid stability and oxidation stability, heat resistance, weather resistance, non separation of oil in a system, low acid value, high thixotropic index, high water resistance, no emulsification, good high-temperature trickle-down property, high temperature resistance and low temperature resistance, is mainly used to be filled in a loose tube of the ribbon optical cable so as to prevent water or other fluid from flowing into or moving into the optical cable, and provides excellent effects of resisting water, buffering and the like for the optical cable.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

Lubricating grease for wheels of airplanes and its preparing method

A lubricating grease for the wheels of airplane contains composite Li or Ca soap as thickening agent (3-20 wt.%), graphite powder (2-20%), phosphate (0.1-5.0%), arylamine as antioxidizing agent (0.01-3%), phenyltriazole salt of fatty acid as antirust agent (0.01-3.0%), and poly-alpha-olefine oil (rest). Its advantages are better high and low temp nature, high stability, extreme pressure performance and antirust nature, and good compatibility to rubber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com