Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1817 results about "Nano sio2" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano Silica NANO Silica (SiO2) allows the plant to build superior defences, meaning pests, moulds and microorganisms find it much harder to infect a plant. NANO is a new method of delivering fertiliser to your plants.

Formula and preparation process of alcohol group nanometer composite and surface modified dry powder mold paint

The invention relates to an auxiliary material for casting and moulding, in particular to a formula of alcohol group dry powder mold paint for sand mold casting. The dry powder mold paint comprises surface modifier, suspending agent, binder and refractory powder, wherein the surface modifier is 0.6-4.2wt% of refractory powder, the suspending agent is 4.0-8.0wt% of refractory powder and the binderis 4.0-6.2wt% of refractory powder. The alcohol group nanometer composite and surface modified dry powder mold paint of the invention adopts nanometer layered clay and nano-SiO2 to form composite suspending agent so that the controllability of operation technological parameters of the alcohol group dry powder mold paint is good and the process performance and operating performance of the obtainedpulp-type paint can both meet the demand of the casting factory.

Owner:深圳市景鼎现代科技有限公司

Fluid bed catalyst in use for oxidizing reaction of olefin ammonia

InactiveCN1600422AImprove wear resistanceHigh activityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedActive component

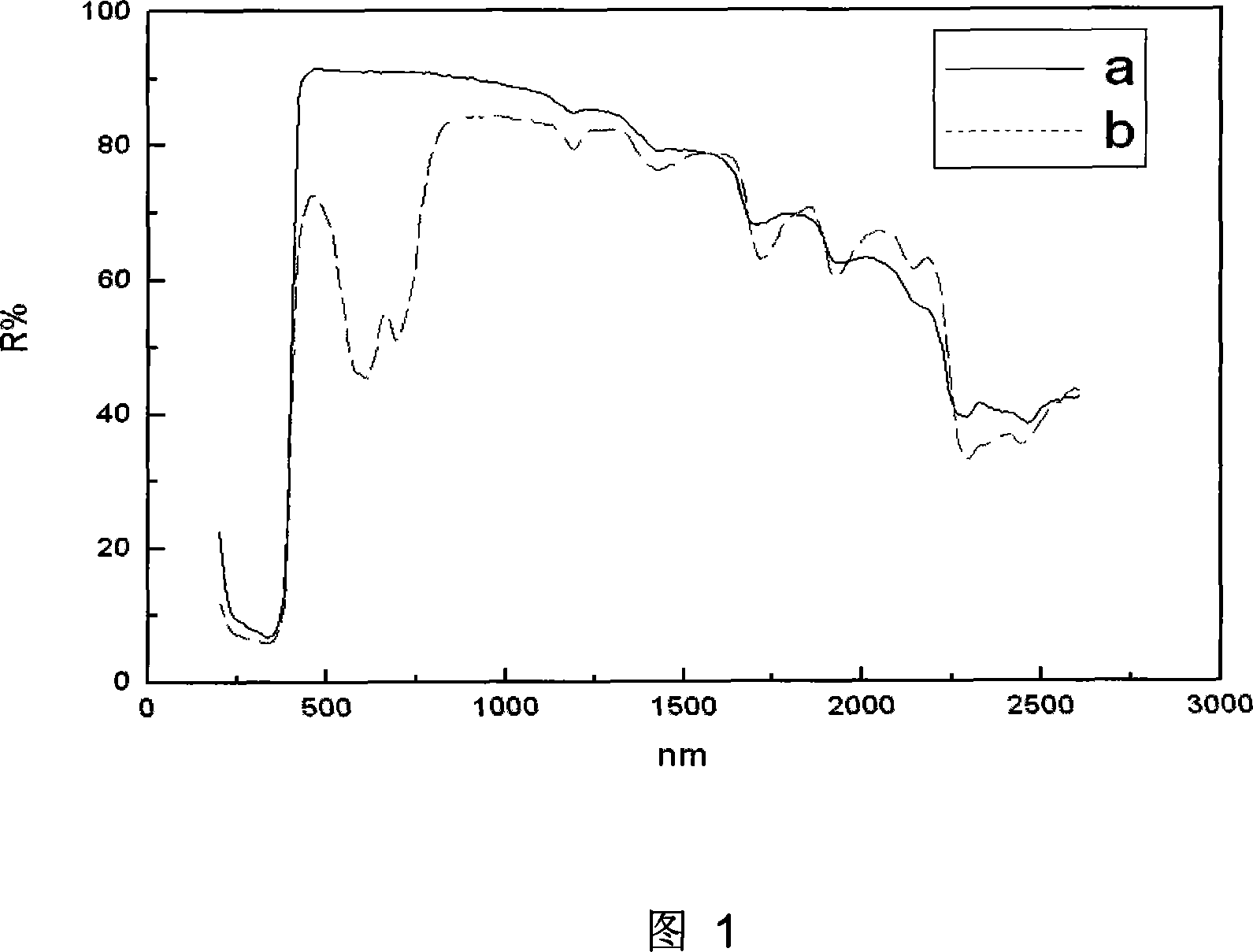

A fluidized-bed catalyst for the ammoxidation reaction of olefin is composed of the carrier consisting of nano-SiO2 and silica sol, and the active component Mo(12-g)BiaFebNicXdZfOgOx, where X is chosen from Mg, Co, Ca, Be, Cu, Zn, Pb, Sb, Mn and Cr, Y is chosen from La, Ce and Sm, Z is chosen from Li, K, Rb, Na and Cs, Q is chosen from B, W, P and V, a=0.1-6, b=0.01-10, c=0.01-10, d=0.01-10, e=0.01-10, g=0-2 and f is more than (0-0.5).

Owner:CHINA PETROLEUM & CHEM CORP

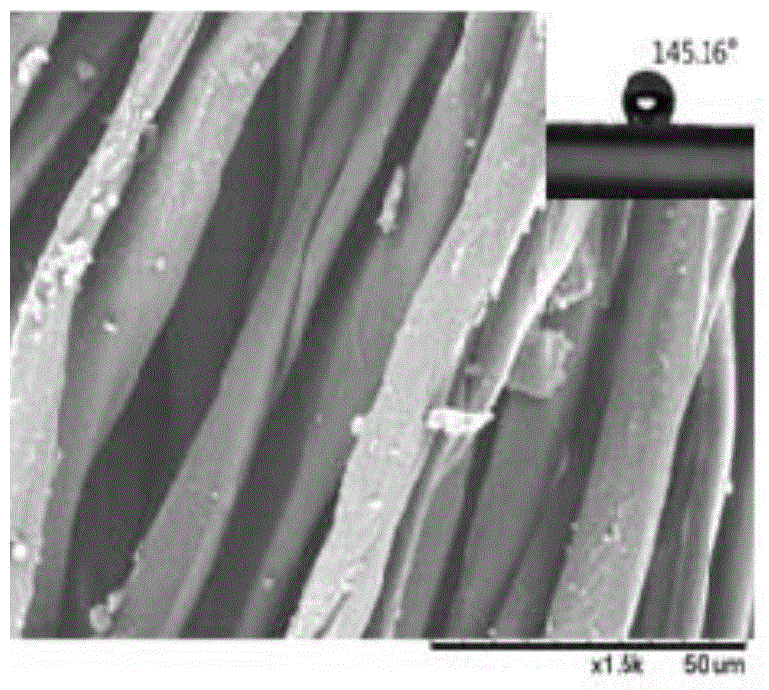

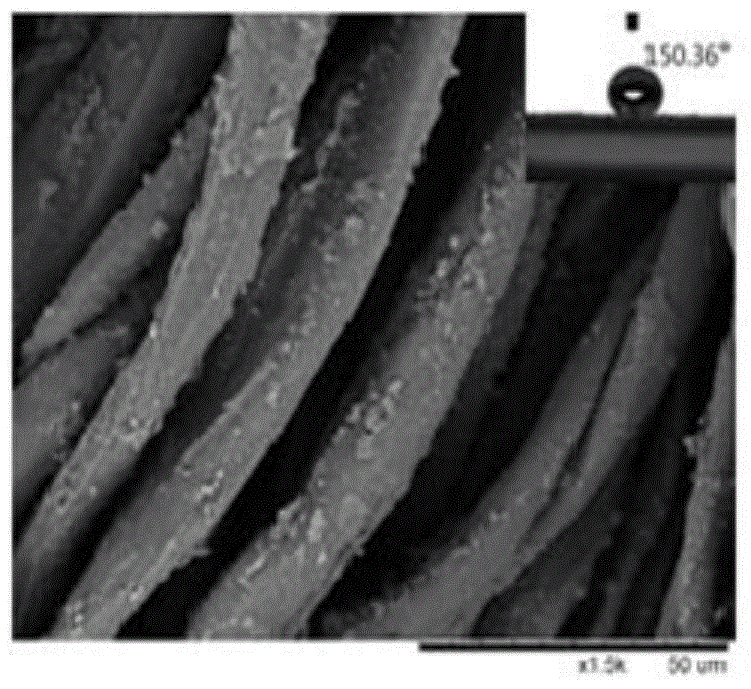

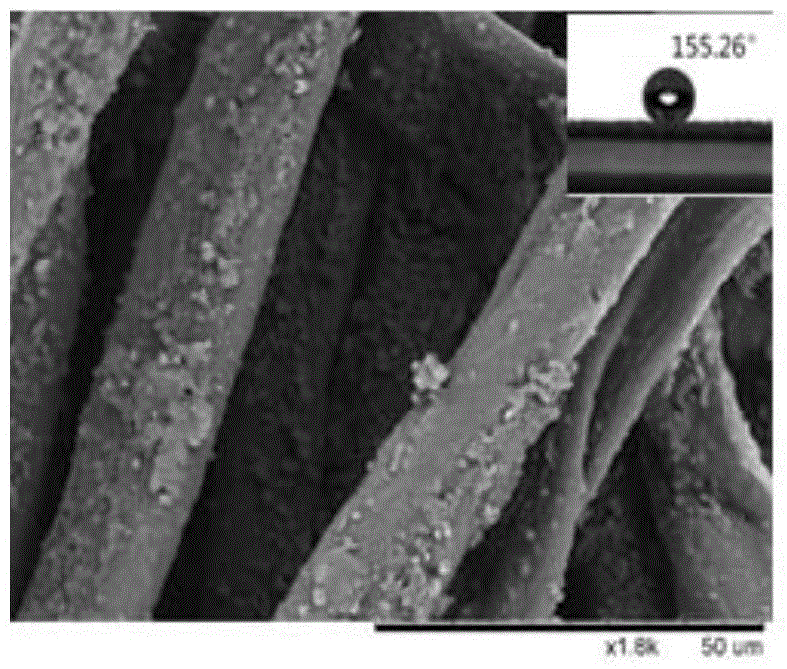

Super hydrophobic cotton fabric and preparation method thereof

The invention belongs to the fabric water-repellent finishing and processing field, in particular relates a super hydrophobic cotton fabric and a preparation method thereof. The preparation method of the super hydrophobic cotton fabric is characterized in that the epoxy-functionalized modification is performed to the cotton fiber of fabric, then aminated nano-SiO2 and epoxy-functionalized nano-SiO2 are used to impregnate the cotton fabric in turn so as to increase the surface roughness of the fabric, finally a low-surface-energy material is adopted to perform hydrophobization treatment to the fabric; the contact angle between the prepared cotton fabric and water drops is more than 150 degrees; the method utilizes the covalent reaction of epoxy groups of cotton fabric, amino groups of nano-SiO2 and epoxy groups of nano-SiO2 to ensure the built rough surface to have good fastness; and the built surface has a large number of Si-OHs and epoxy groups so as to facilitate the chemical combination of the low-surface-energy material and the surface, thus the superhydrophobic property of the prepared fabric has excellent stability.

Owner:SHAANXI UNIV OF SCI & TECH

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for preparing amphiphilic nano silica powder and method for preparing Pickering emulsion using same

InactiveCN101704529AEasy hard reunionHard reunion noNanostructure manufactureSilicaNano sio2Room temperature

The invention discloses a method for preparing amphiphilic nano silica powder and is used for preparing nano silica powder with about 90 degrees of a tri-phase contact angle. The method uses ultrasonic preparation, thus having short preparation process; the invention adopts liquid phase modification, thus avoiding processing means such as grinding, calcining and the like which are easy to cause the powder to generate hard particle agglomeration; the invention can prepare better amphiphilic surface (about 90 degrees of tri-phase contact angle) nano silica powder. The invention also discloses a method for preparing Pickering emulsion by using the amphiphilic nano silica powder under the action of ultrasound or cutting, the nano silica powder stably exists in oil-water interface, thus preventing diffused oil (water) droplets to re-agglomerate into big droplets to split phase and stabilizing emulsion. The prepared emulsion can be stored at room temperature without occurrence of demulsification in three months.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process for preparing nano SiO2 modified carbon fiber emulsion pasting agent

ActiveCN1632217AImprove protectionHigh strengthFibre treatmentFibre chemical featuresCarbon fibersEmulsion

A preparation method of a nano-SiO2 modified carbon fiber emulsion sizing agent, which uses nano-SiO2 as a sizing resin modification material, and the modified material, sizing resin, emulsifier, dispersant, organic solvent and particle-free water are prepared in a certain weight ratio Carbon fiber-forming functional emulsion sizing agent. After the carbon fiber is impregnated with a certain concentration of modified sizing agent for an appropriate time, the strength of the carbon fiber increases by up to 8.7%; the interfacial shear strength (IFSS) of the single fiber composite material can reach up to 43.67MPa; ILSS) up to 98.7MPa.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396AHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

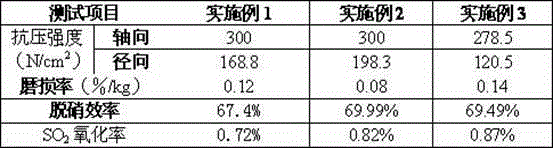

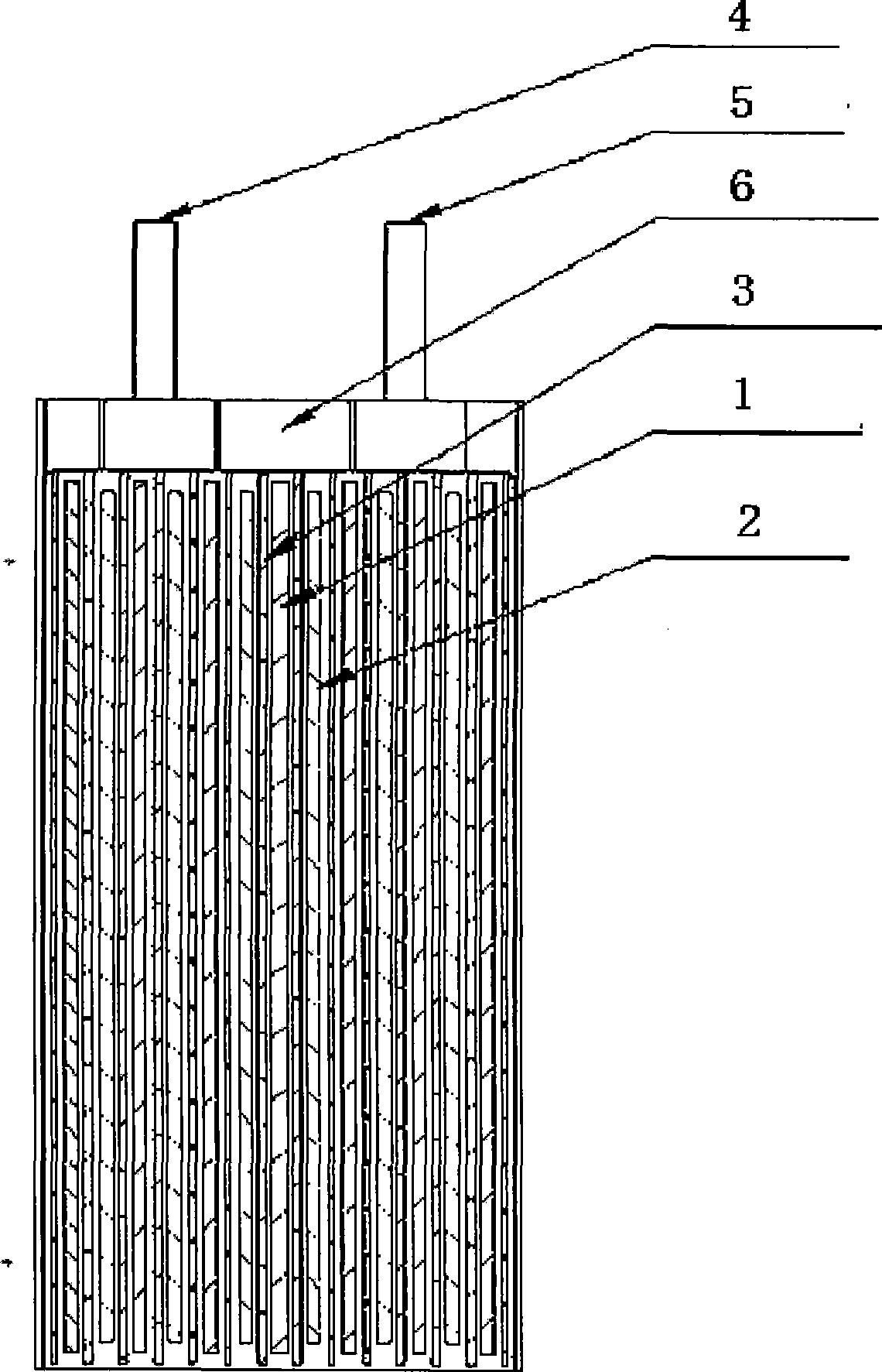

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

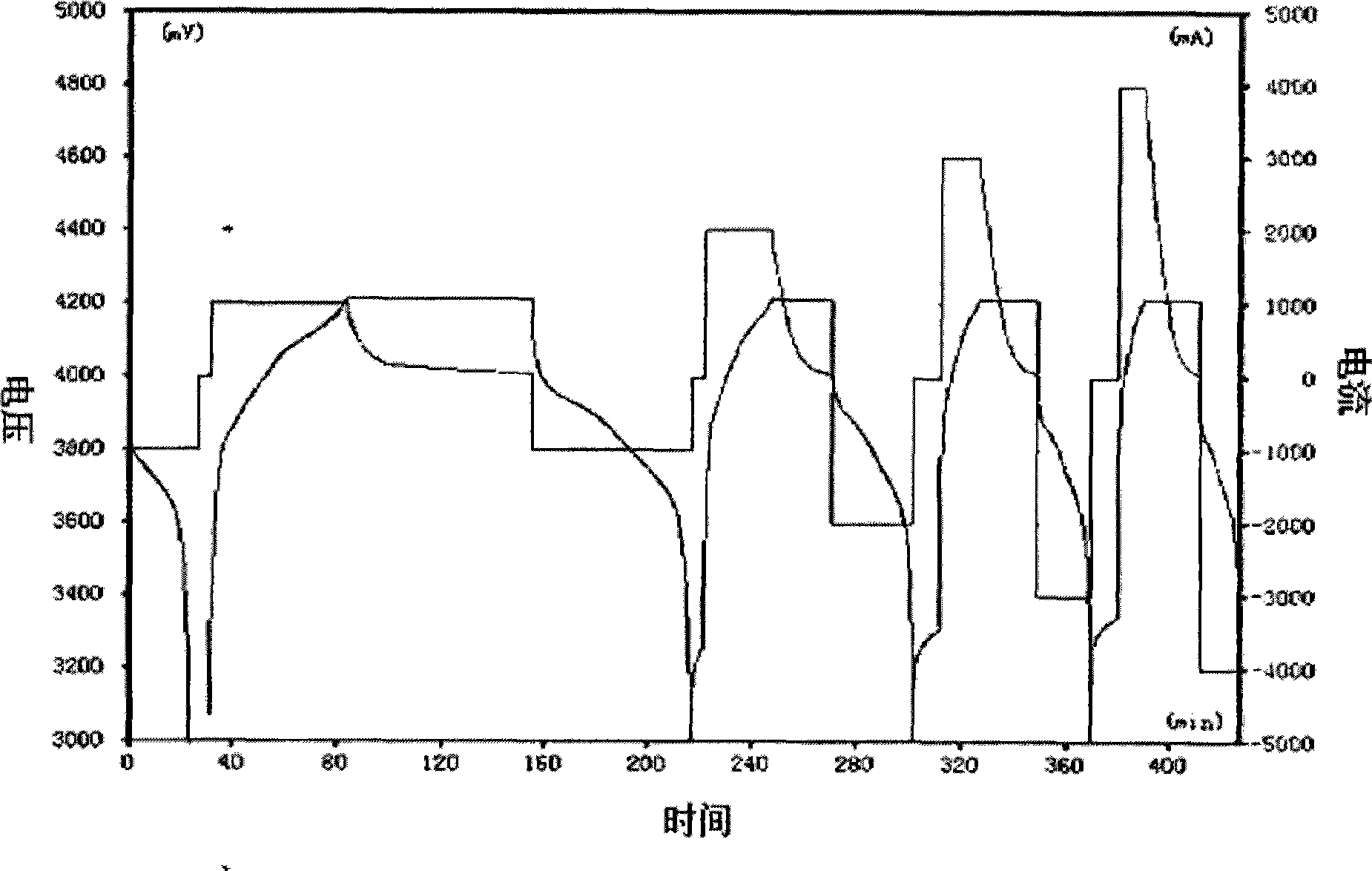

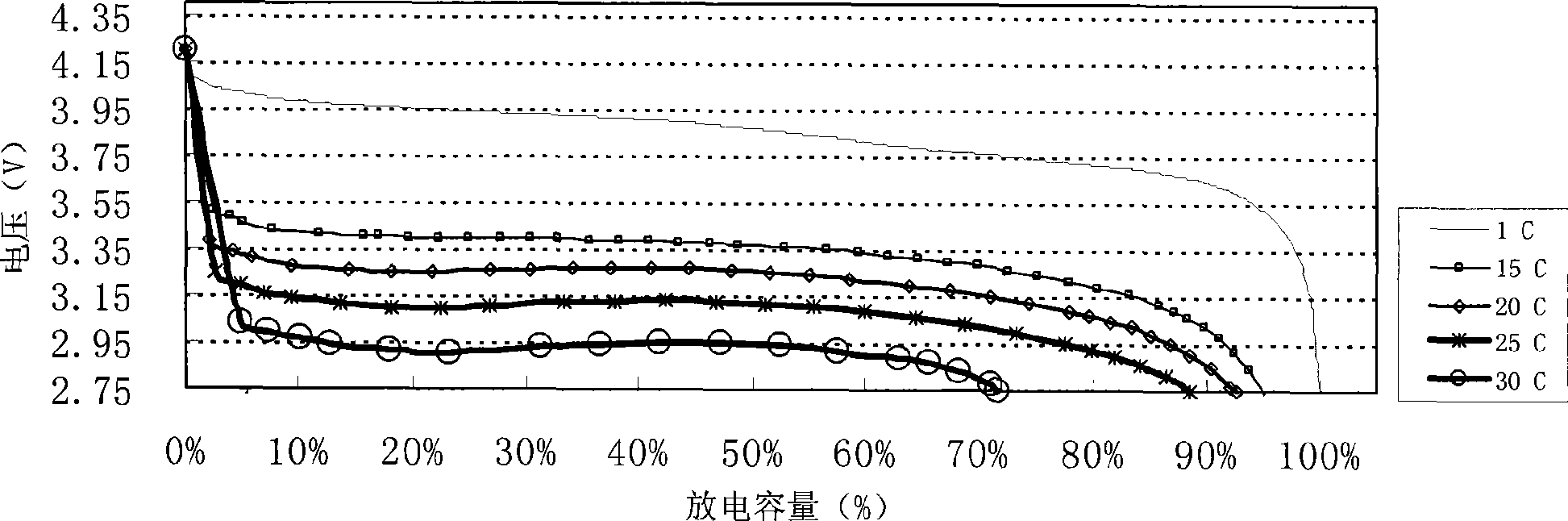

Multi-multiplying power charging-discharging lithium ion battery and method for producing the same

InactiveCN101499530AImprove high rate charge and discharge performanceImprove performanceElectrode manufacturing processesFinal product manufactureHigh rateMicrosphere

The invention provides a high-rate charge-discharge lithium-ion battery and a preparation method thereof. The anode active material of the lithium-ion battery is lithium manganate; the cathode active material is selected from one or more of mesocarbon microbeads, artificial graphite or natural graphite coated by mesophase pitch; a conductive agent is selected from one or more of conductive graphite, conductive carbon black, nano Ag, nano SiO2 or nano Al2O3. The preparation method of the lithium-ion battery comprises the preparation of the anode plate, the parathion of the cathode plate and the assembly of the battery. The lithium-ion battery has the advantages of high-rate charge-discharge performance, long cycle life, high capacity, safe use, environmental protection, low cost and the like. The preparation method has the advantage of simple and easy process operation, and is applicable to the mass production.

Owner:深圳市崧鼎实业有限公司

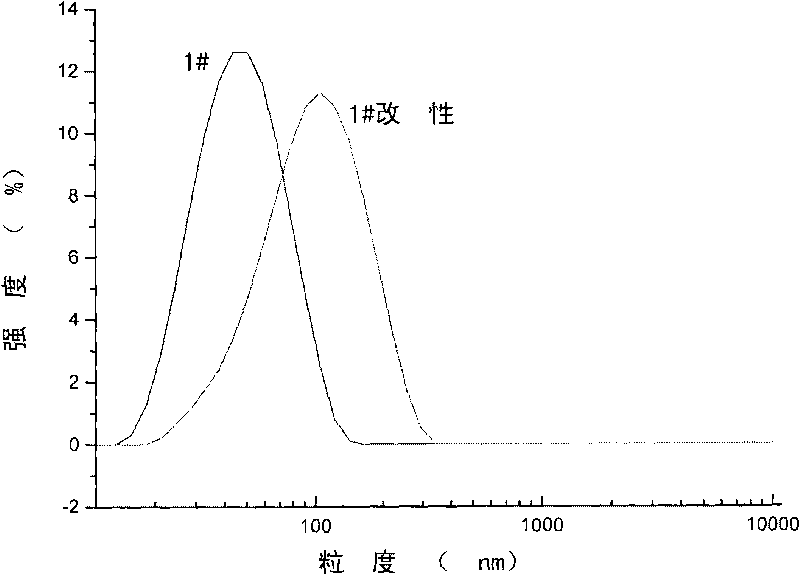

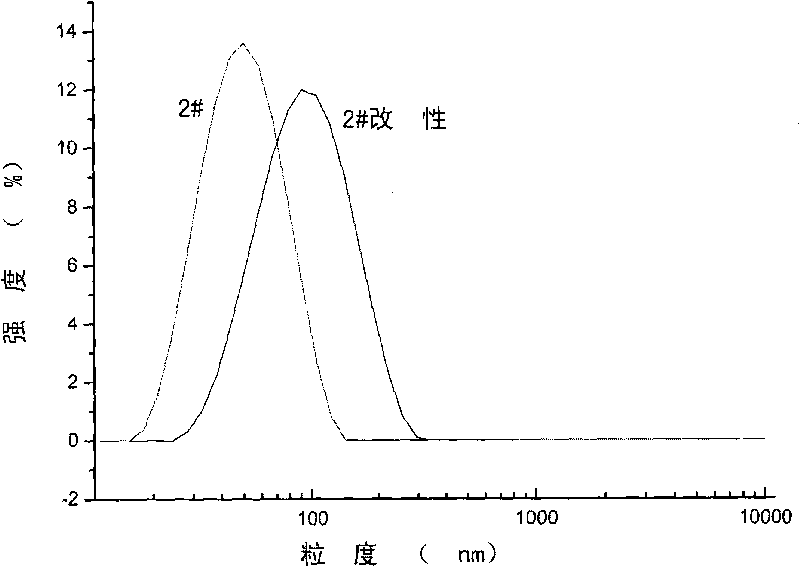

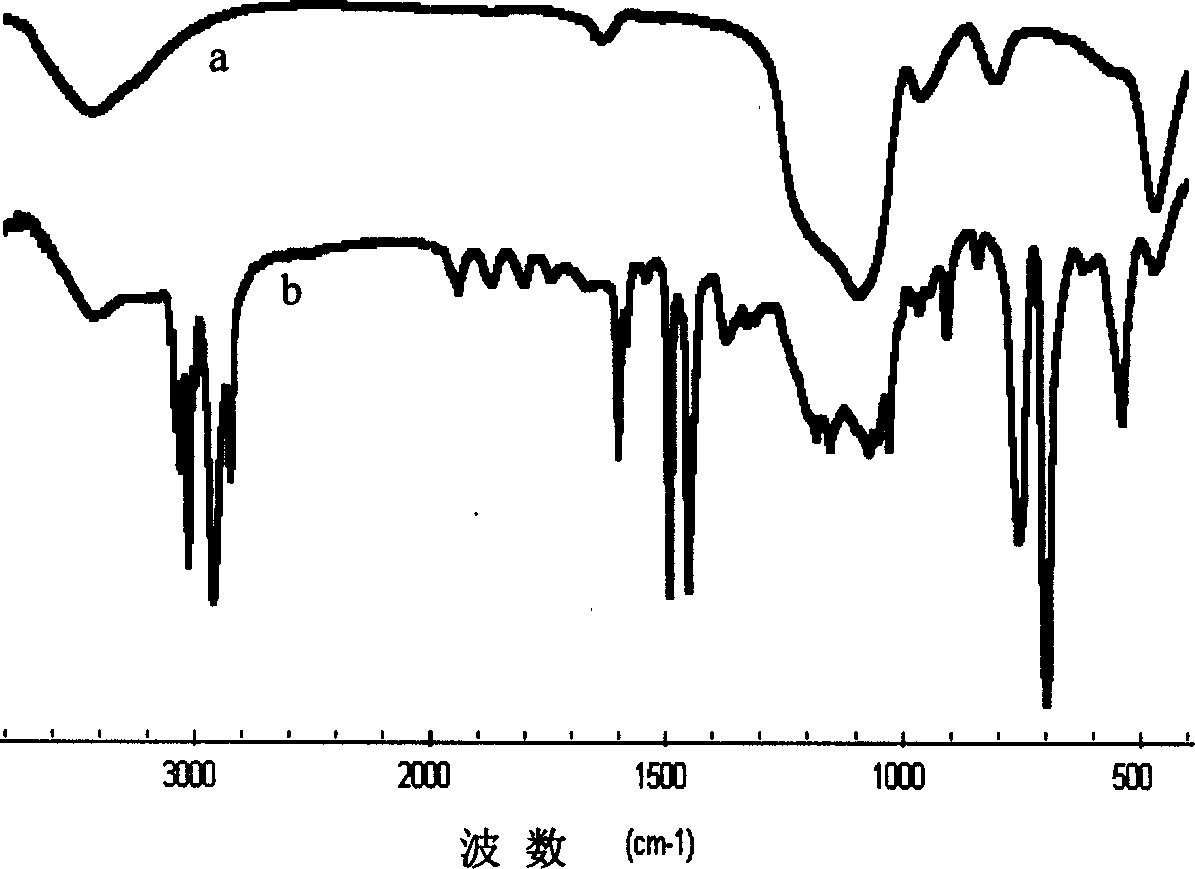

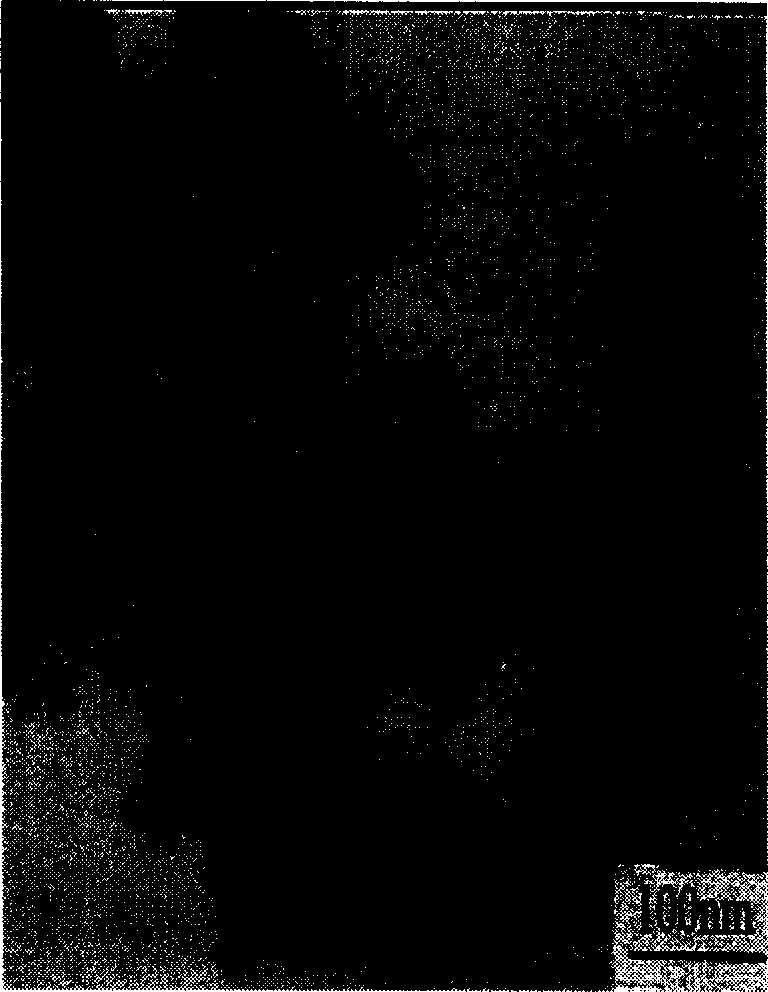

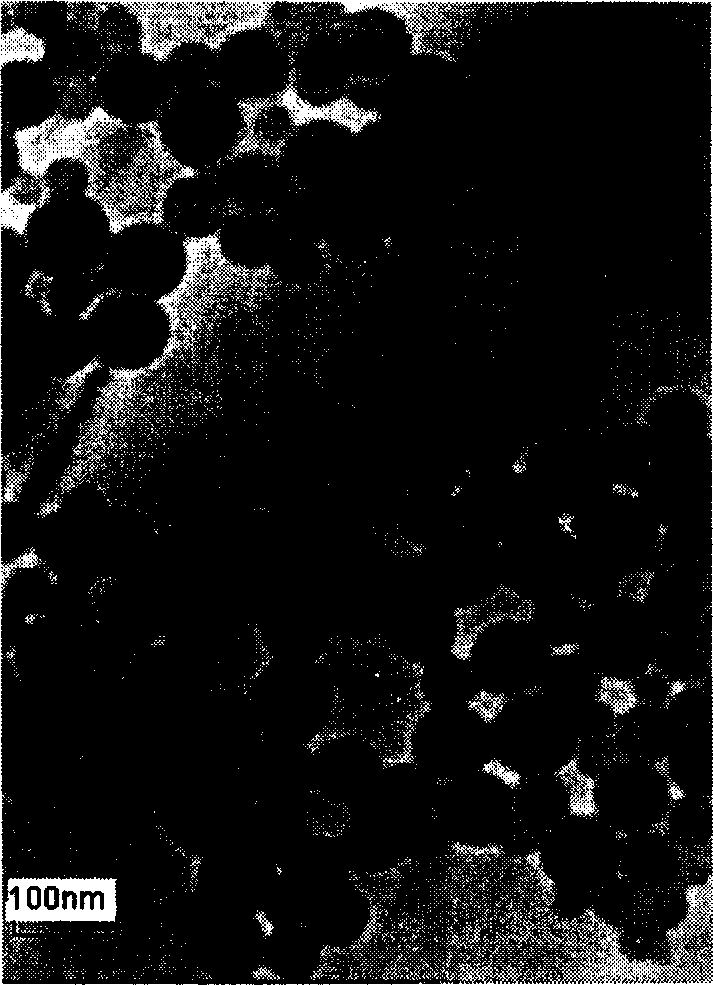

Composite polyolefin/sio2 nano particle and its prepn

The present invention belongs to the field of polymer material technology. Inorganic nano Sio2 partticle, organic olefin monomer and coupler as raw materials are subjected to emulsion polymerization or suspension polymerization in water as medium in the presence of various emulsifiers and initiator, so that the olefine polymer is grafted to the surface of inorganic nano SiO2 particle to form inorganic nano SiO2 particle core-organic olefin polymer shell structure. The composite particle is spherical, has homogeneous particle size smaller than 100 nm, and has high grafting rate and high grafting efficiency. The prepared compoisite olefin polymer / SiO2 particle material has wide application in the development of nano technology.

Owner:TSINGHUA UNIV

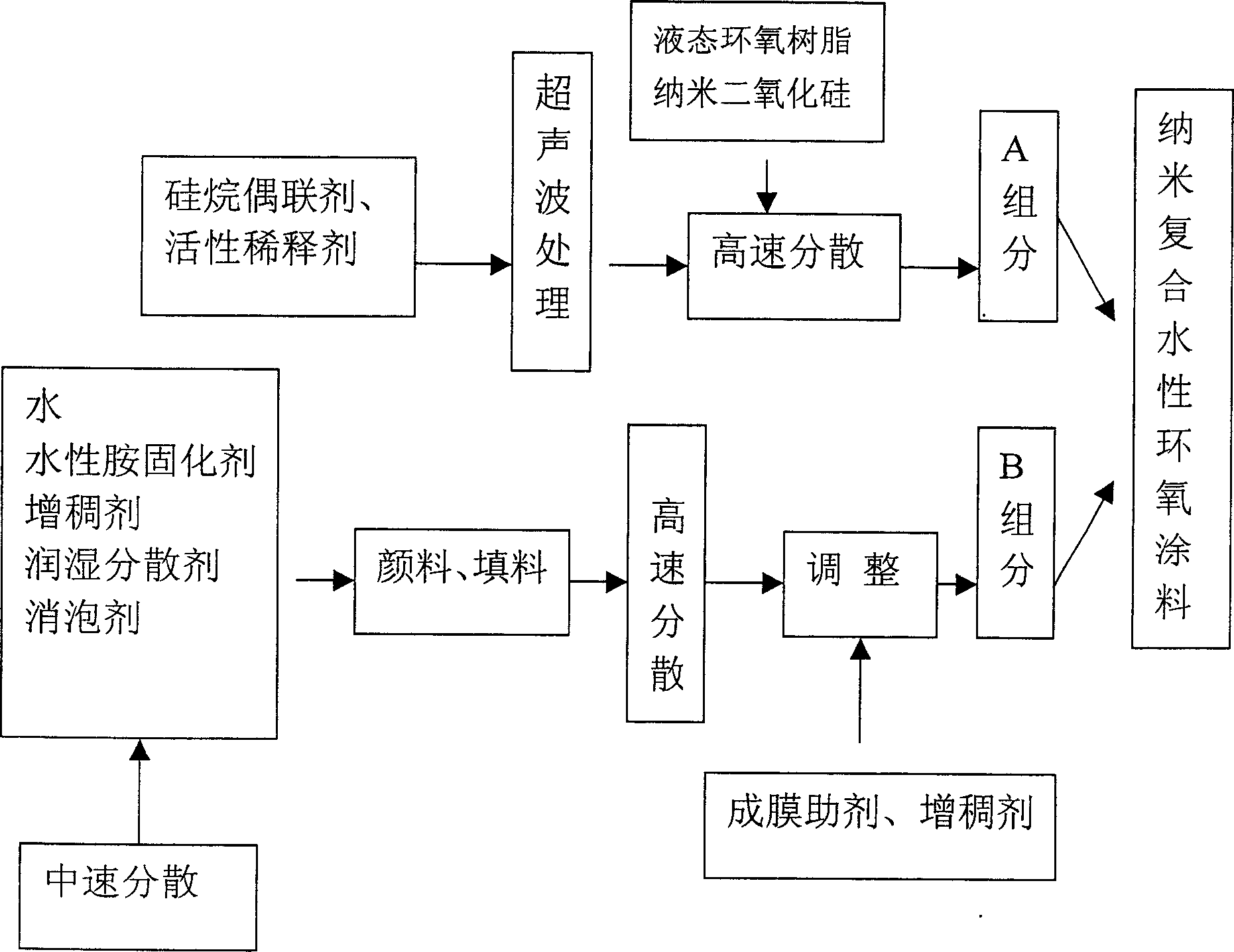

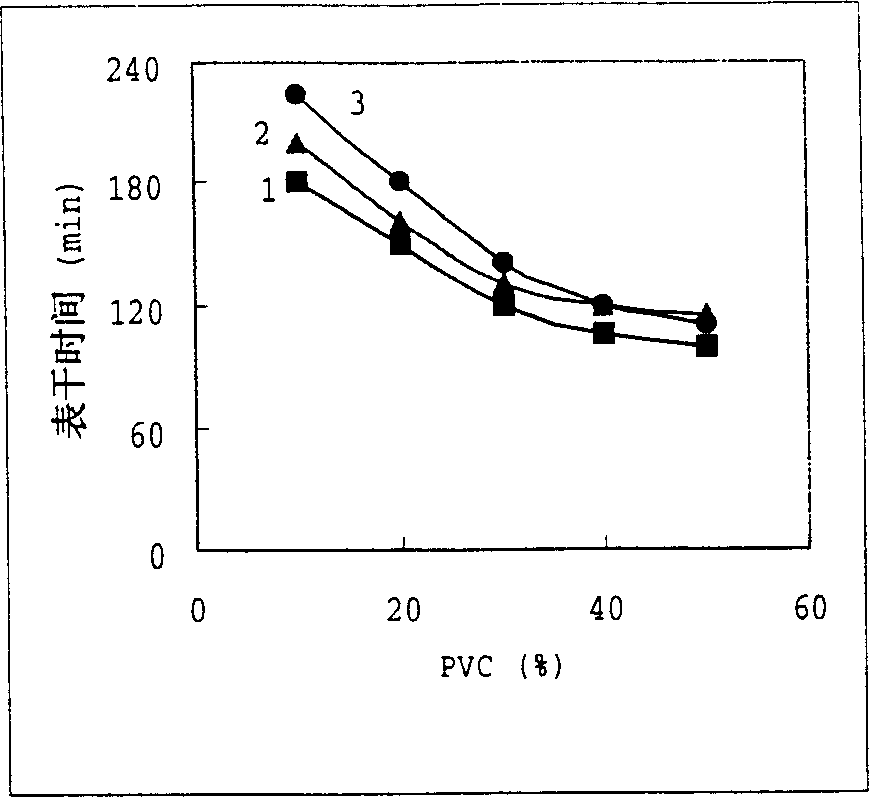

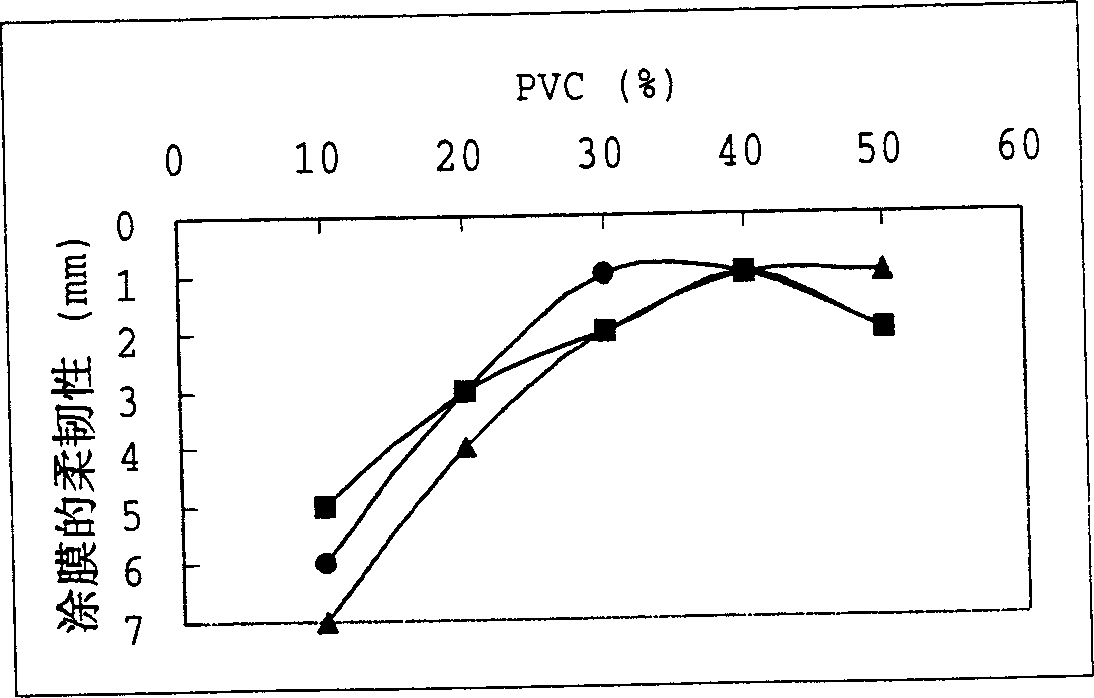

Nano composite aqueous epoxide resin coating material and preparation method

The nano composite water-base epoxy resin coating material comprises: epoxy constituent composed of epoxy resin, active diluent, nano SiO2 particle, and silane coupling agent; and water-base amic curing agent constituent composed of water-base amic curing agent, wet dispersant, defamer, paint, filler, film-forming adjuvant, thickener, and water. This invention also discloses opposite preparation method, improves greatly product properties, and has no pollution.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

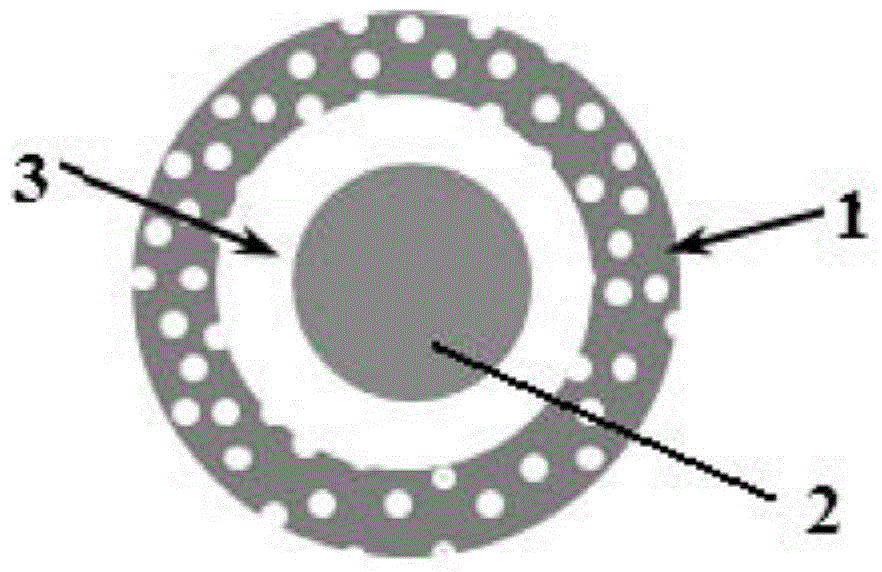

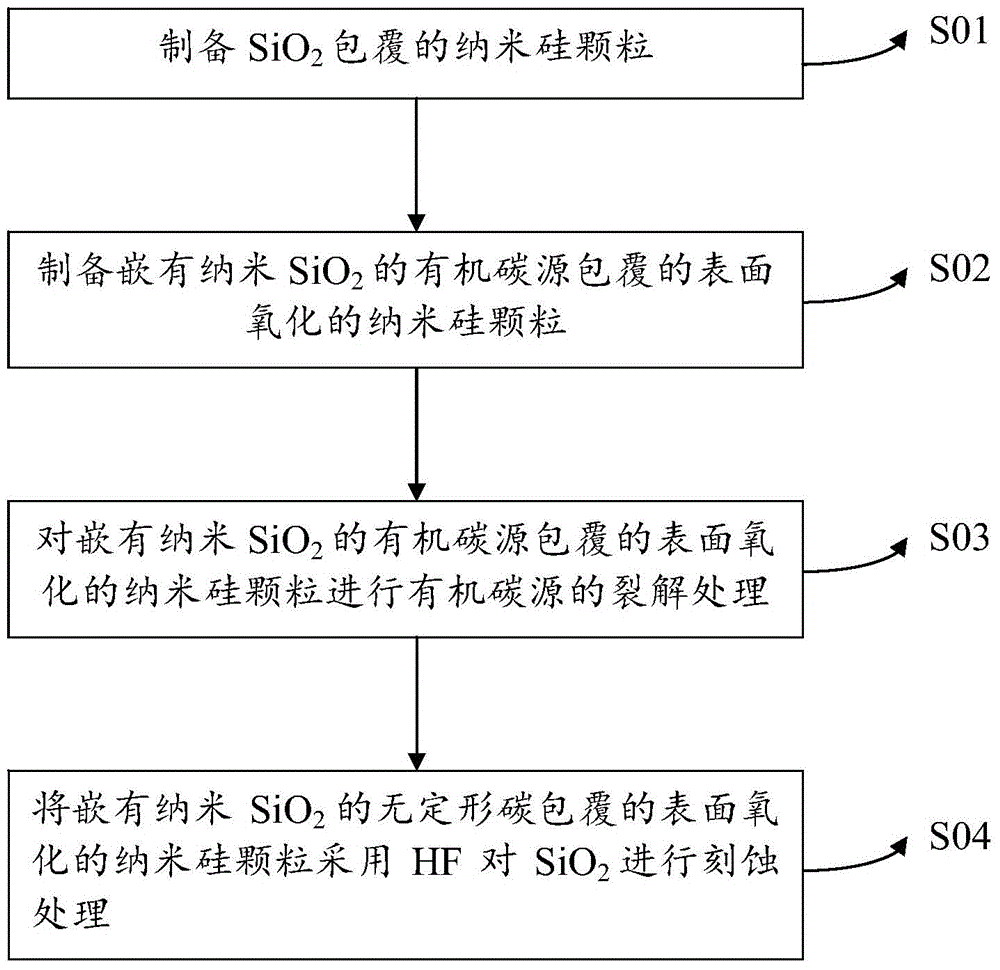

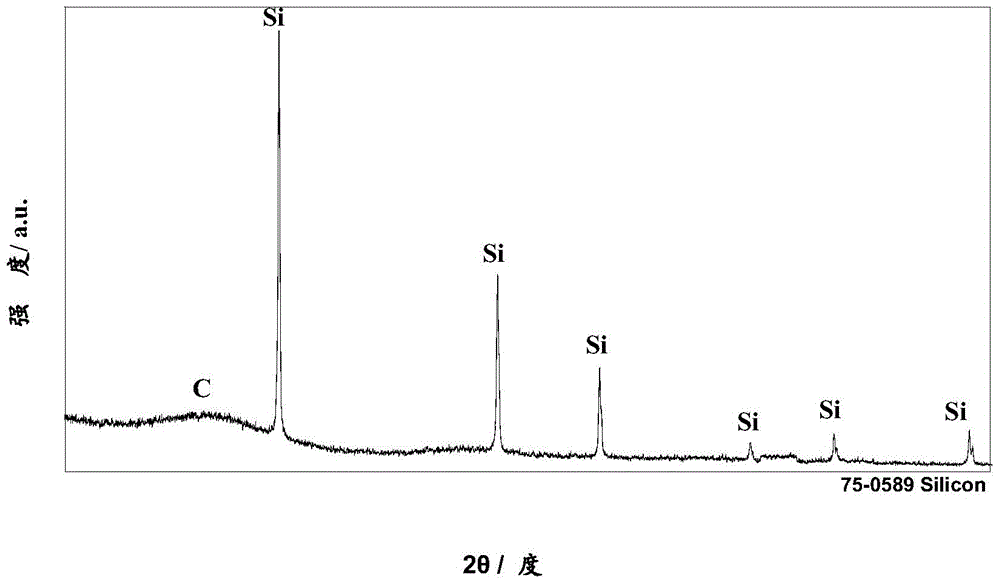

Nanometer silicon and carbon composite negative electrode material and preparation method and lithium ion battery thereof

ActiveCN104953122AImprove cycle performanceImproved magnification performanceCell electrodesSecondary cellsCarbon compositesPorous carbon

The invention discloses a nanometer silicon and carbon composite negative electrode material, a preparation method thereof and a lithium ion battery. The nanometer silicon and carbon composite negative electrode material is of a core-shell structure. A gap is formed between the outer wall of a core body and the inner wall of a shell layer, wherein the core body is made of nanometer silicon, and the shell layer is a nanometer porous carbon layer. The preparation method of the nanometer silicon and carbon composite negative electrode material comprises the steps of preparing nanometer silicon particles wrapped by SiO2; preparing nanometer silicon particles, wherein nanometer SiO2 is embedded into the nanometer silicon particles which are wrapped by organic carbon sources, and the surfaces of the nanometer silicon particles are oxidized; performing organic carbon source splitting decomposition on the nanometer silicon particles provided with the embedded nanometer SiO2 and oxidized surfaces and wrapped by the organic carbon sources, performing etching processing on the SiO2 on the nanometer silicon particles provided with the embedded nanometer SiO2 and oxidized surfaces and wrapped by amorphous carbon by adopting HF, and the like. The negative electrode material of the lithium ion battery is the nanometer silicon and carbon composite negative electrode material. The nanometer silicon and carbon composite negative electrode material and the lithium ion battery are excellent in cycling stability, specific capacity, rate capability and safety performance.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Blended yarn weaved fabric based on novel flame retardant viscose, preparation method and application thereof

InactiveCN101538764AIdeal twistImprove flame retardant performanceWeft knittingFlame-proof filament manufactureYarnChemical treatment

The invention relates to a novel flame retardant fabric, a preparation method and an application thereof, particular to a blended yarn weaved fabric based on novel flame retardant viscose, a preparation method and an application thereof. The flame retardant viscose is prepared by blended spinning with nanometer SiO2 and cellulose solution; wherein the blended ratio of the flame retardant viscose and natural fiber is 20:80 to 80:20. The invention also provides the preparation method of the flame retardant blended yarn weaved fabric. As the nanometer SiO2 particles are adopted as inorganic flame retardant, the novel flame retardant blended yarn weaved fabric is good in fire resistance; limited oxygen index is more than 28%, meltdown or dripping can not appear when combusting, only a small quantity of flue gas which is safe and innoxious is produced, and the fabric is washing resistant and chemical treatment resistant. The invention has air and moisture permeability and soft feel. The blended yarn weaved fabric is mainly composed of the flame retardant viscose and cotton fiber, and can be applied to preparation of bedding such as bed sheet, quilt cover, pajamas, etc.

Owner:上海神九纺织科技有限公司

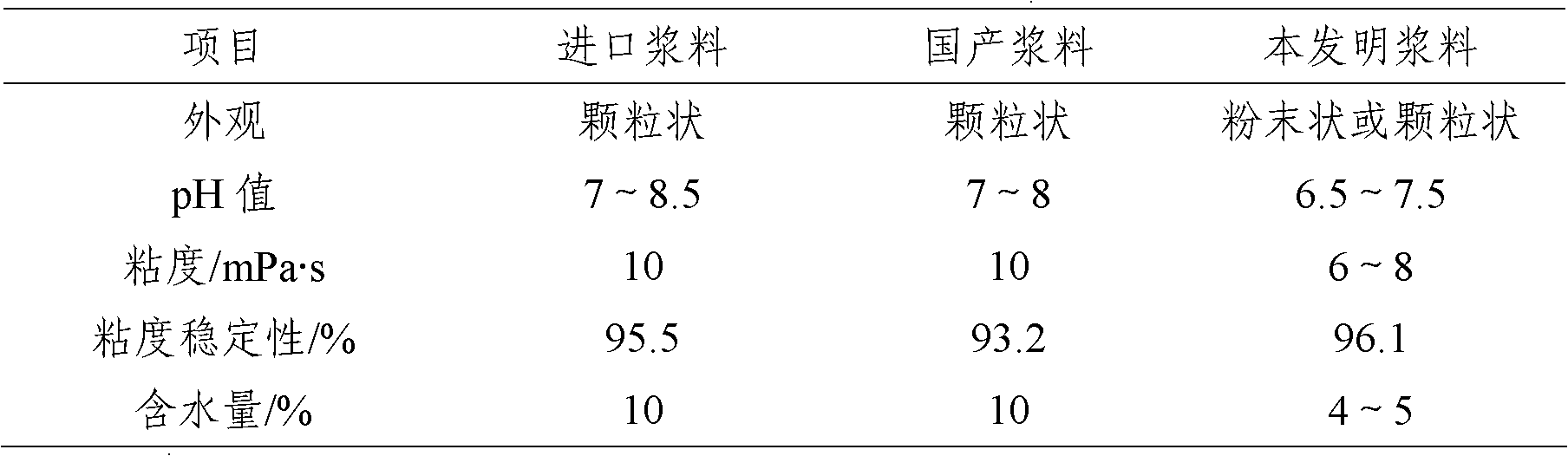

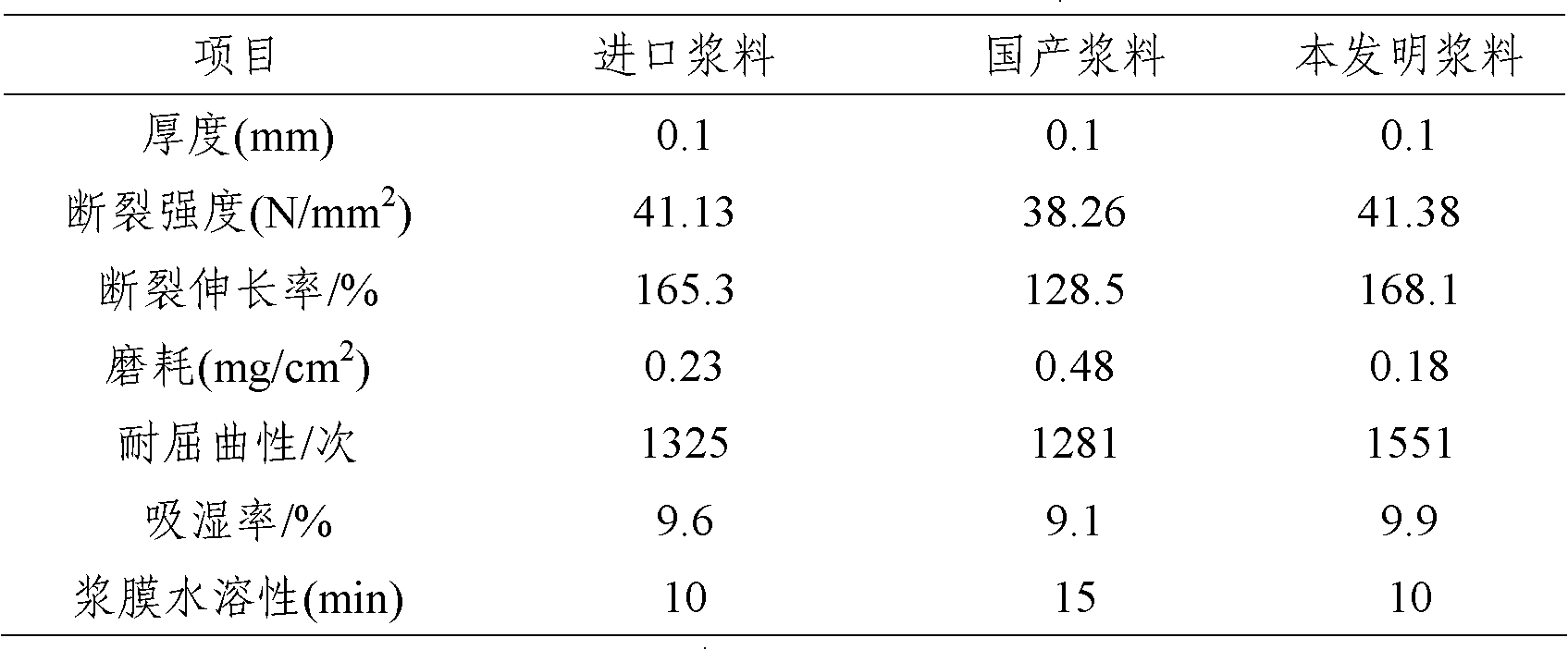

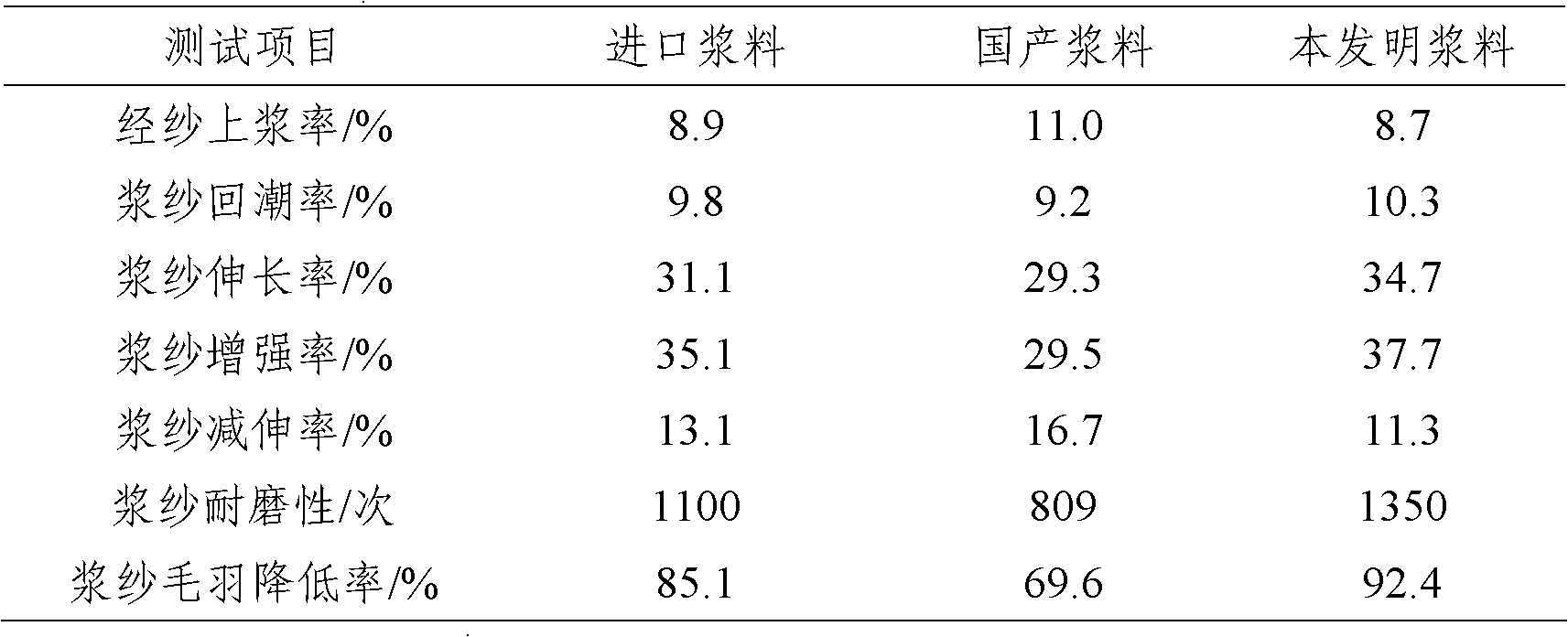

Textile size combination

The invention provides a textile size combination which is prepared by mixing solid acrylate with nano SiO2 compound modified starch in proportion, wherein the solid acrylate is prepared by the following steps: mixing acrylonitrile, methyl acrylate, butyl acrylate, methyl methacrylate, acroleic acid, methacrylic acid with acrylamide in proportion, and enabling the mixed solvent to be subject to internal polymerization under the action of compound initiator and chain transfer agent, neutralizing with sodium hydroxide and drying; and the nano SiO2 compound modified starch is prepared by the following steps: sequentially acidifying, crosslinking and oxidizing starch, introducing surface-modified nano-level SiO2 and carrying out ultrasonic dispersion. The size can obviously improve the warp sizing performance and improve the weaving efficiency, can be completely replace PVA and imported sizes in the same amount or partial amount, and is widely used for the warp sizing of purified cotton, terylens, novel fibers and mixed yarns of various counts.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Method for preparing durable cellulose fiber fabric with super-hydrophobic surface

InactiveCN104594028AExcellent Durability Super Hydrophobic PropertiesMeet functional requirementsVegetal fibresCross-linkState of art

The invention relates to a method for preparing a durable cellulose fiber fabric with a super-hydrophobic surface. The method comprises the following three steps: preparing modified SiO2 composite sol, preparing a modified fabric and performing super-hydrophobic finishing on the fabric. The active groups are introduced into nanometer SiO2 and fiber surface, the fabric is finished by adopting a simple one-step method, the binding force between the fabric and the inorganic nanometer SiO2 is enhanced by virtue of the active groups on the fiber surface and the cross-linking effect on the modified SiO2 surface, the covalent bonding firmness between the modified sol and the surface of the modified cellulose fiber fabric is improved, and the super-hydrophobic interface of a fluoride-free cellulose fiber fabric with certain washing fastness is finally obtained. Compared with the prior art, the preparation method disclosed by the invention is economical and environmentally friendly, and the industrial production is promoted.

Owner:SHANGHAI UNIV OF ENG SCI

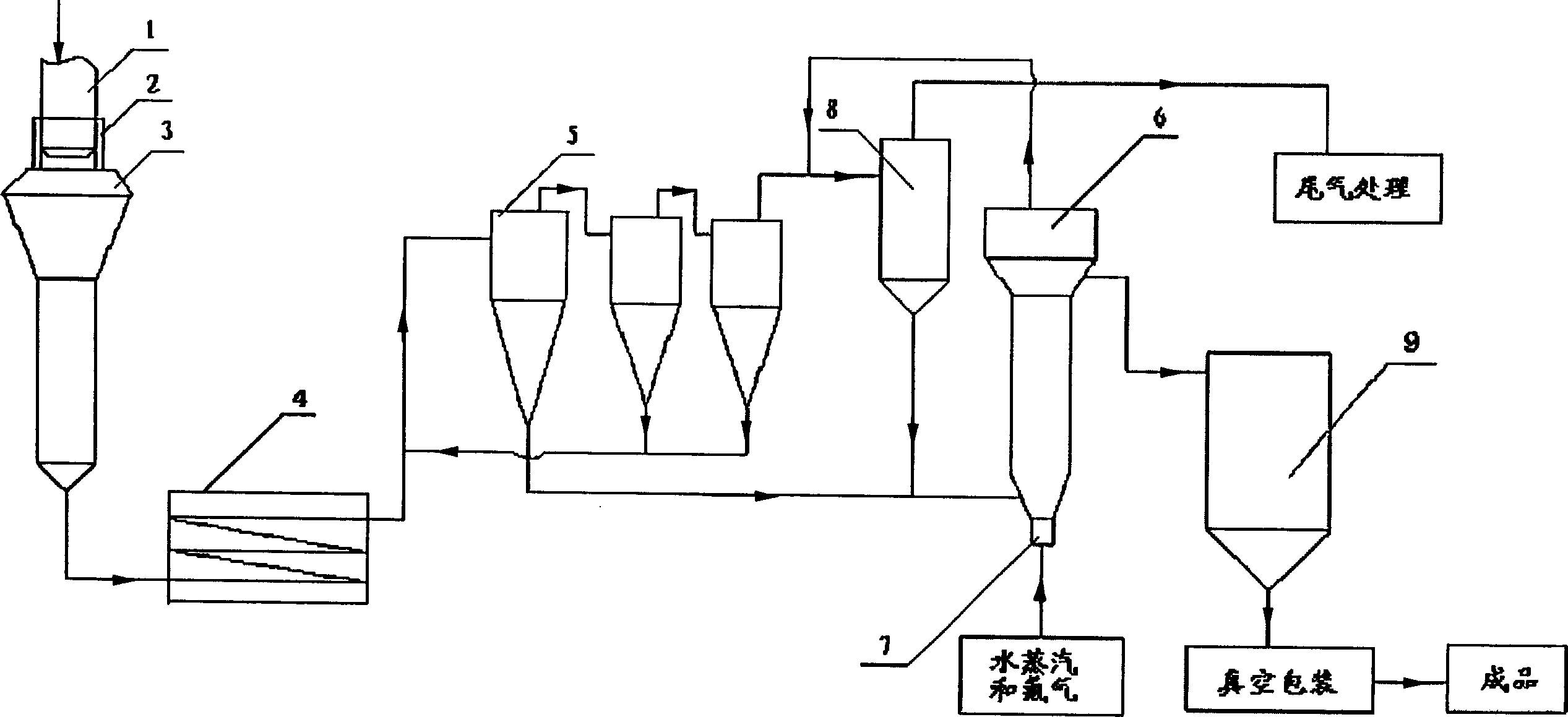

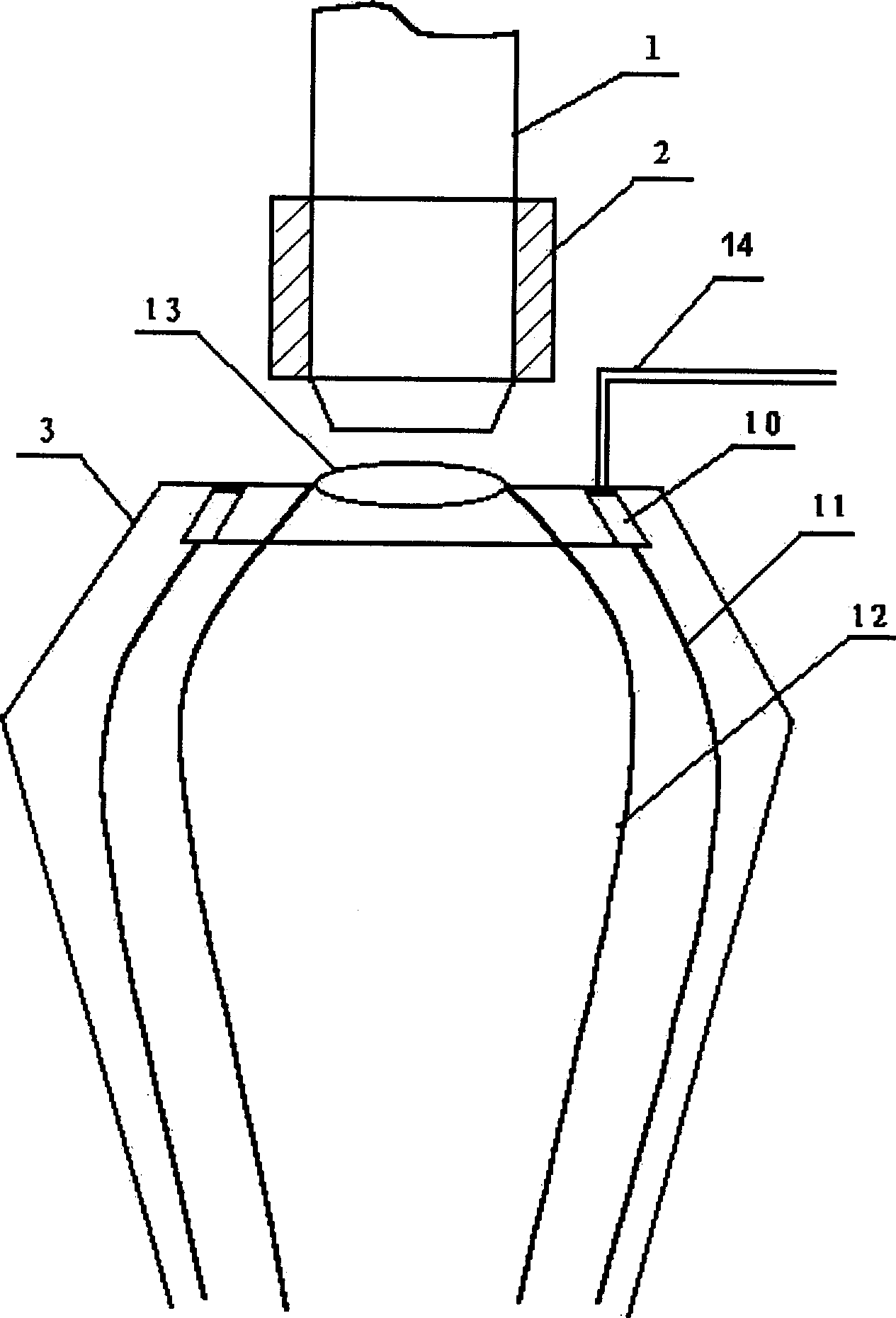

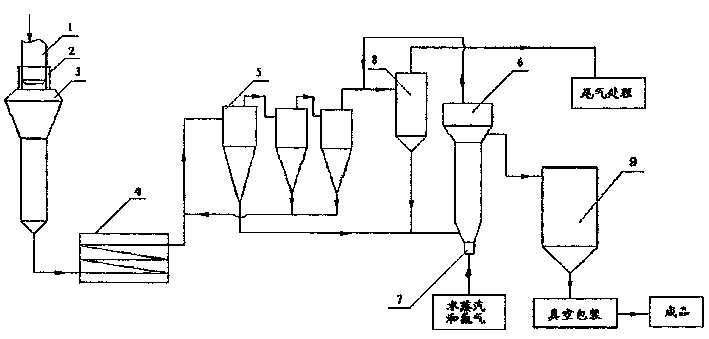

High-dispersion nano silicon dioxide preparation method

InactiveCN1422805AImprove continuityImprove stabilityOxide/hydroxide preparationSilicaWater vaporSilanes

The invention discloses a method to prepare high-disperse nano SiO2, imputting O2-H2 organic halogen silane in a certain proportion into reaction room to make burning reaction, at the same time inputting a protective gas, vapor and inert gases, adopting the produced water and heat to make high-temperature hydrolytic condensation reaction and making the late process such as aggregative gas-solid separation deacidification on the reaction product to obtain it, primary particle dimaeter 7-40 nm, ratio surface area 100-400 m2 / g, pH value 3.8-4.5, SiO2 receiving rate >99%.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL

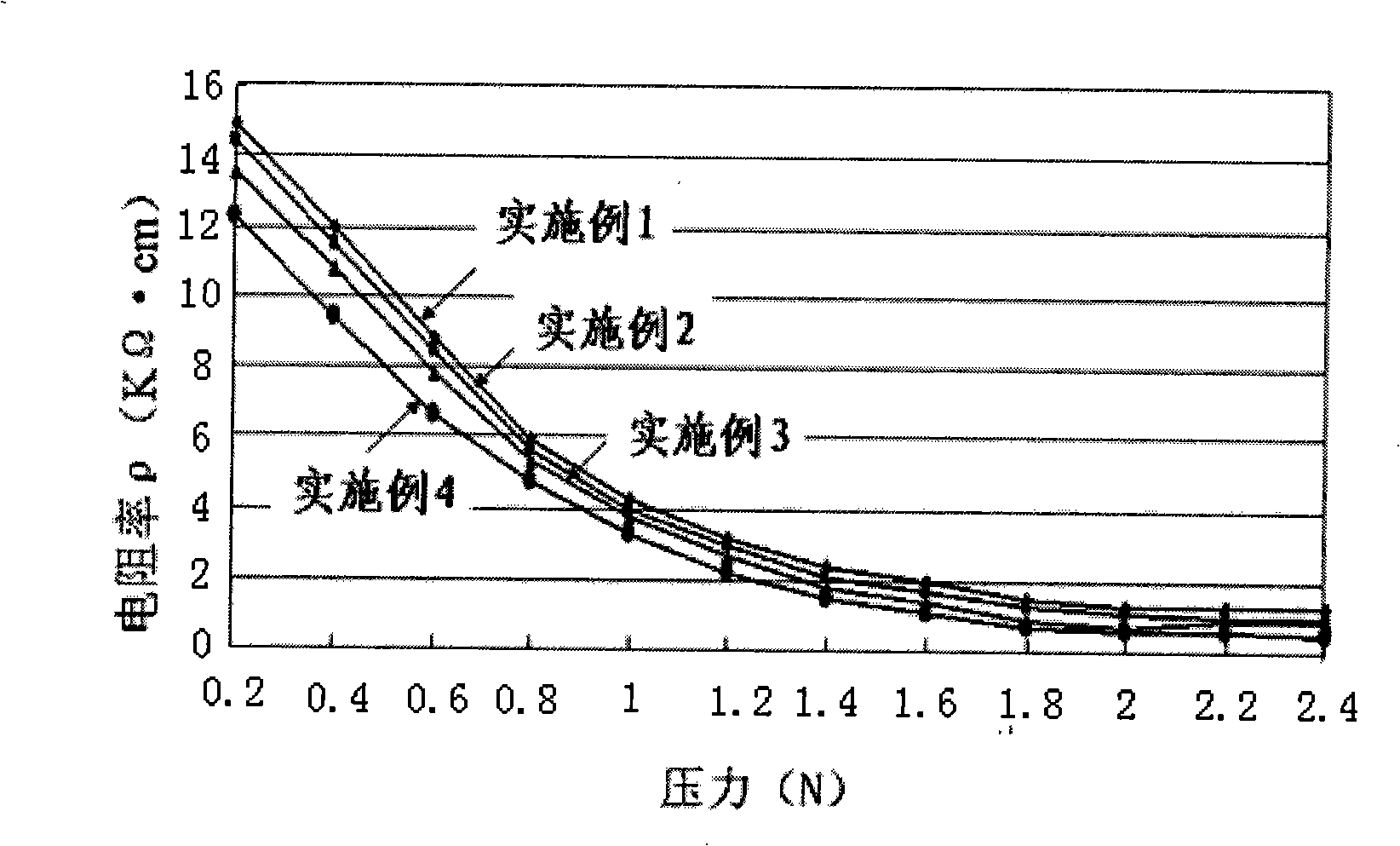

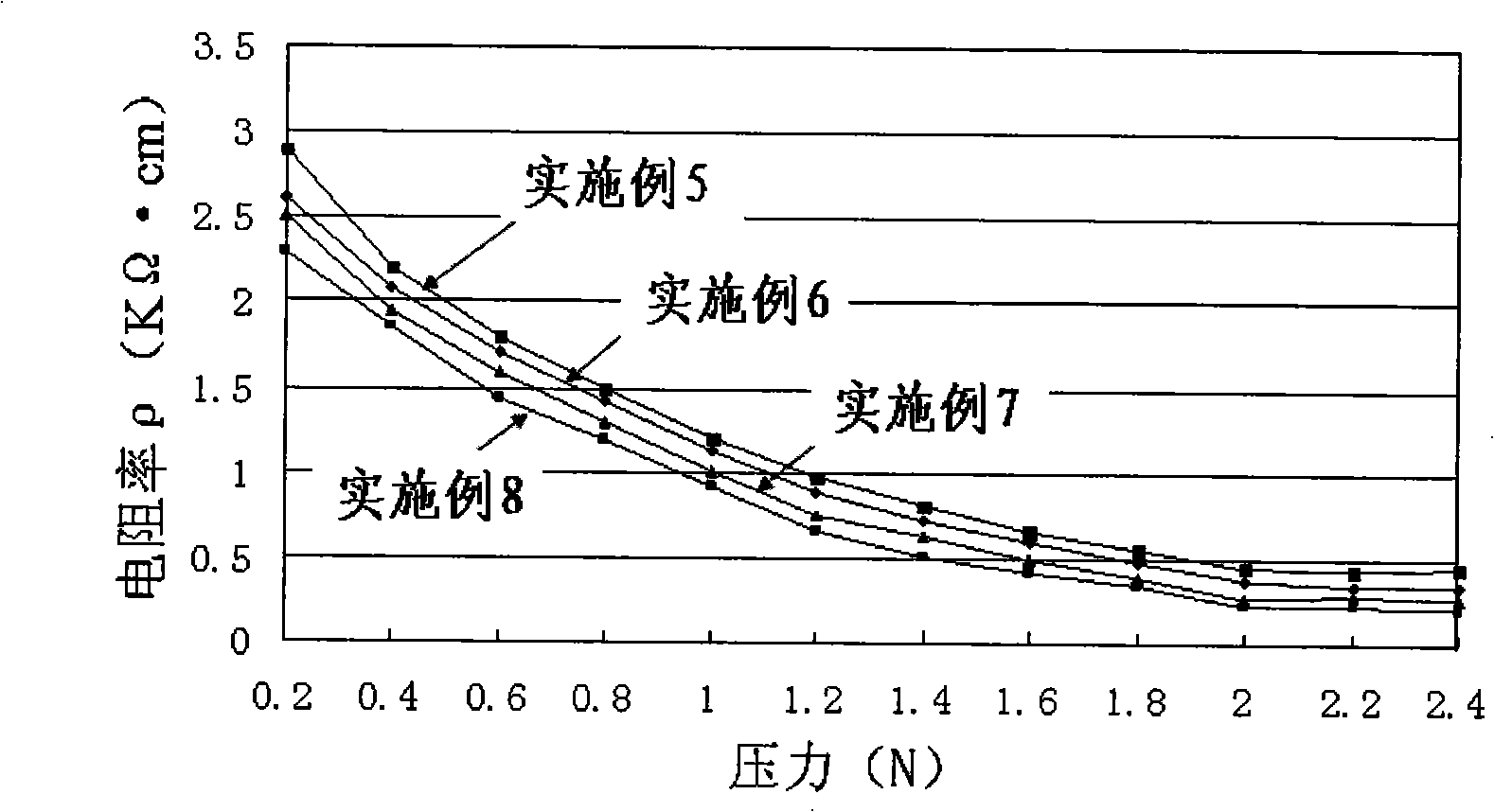

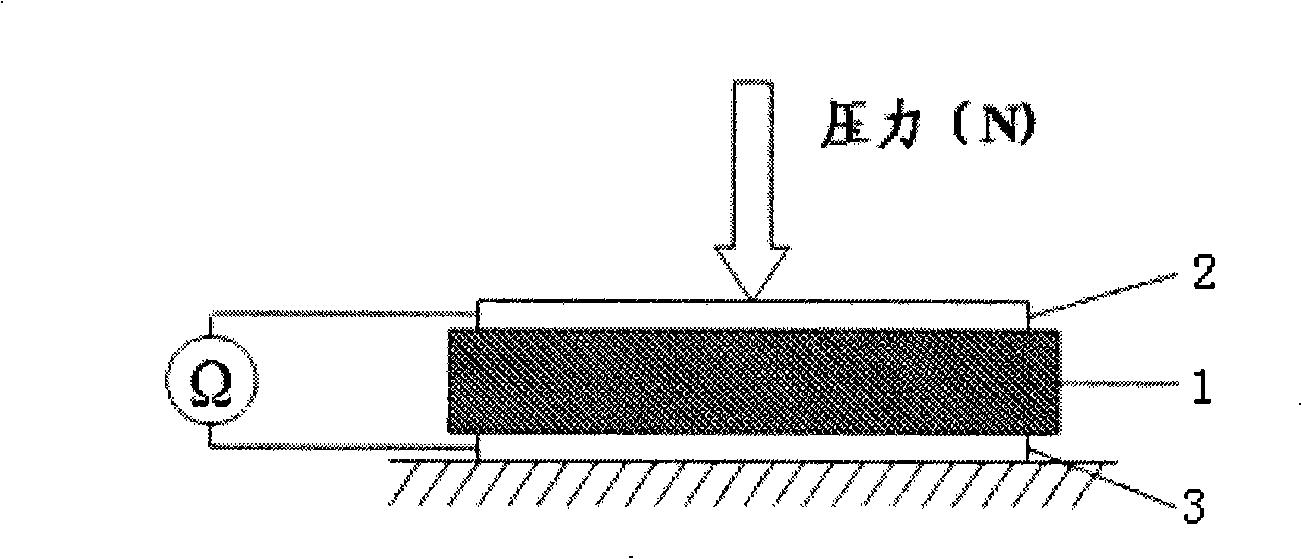

Pressure sensitive material used for flexible touch sensation sensor and preparation method thereof

InactiveCN101260237AImprove compatibilityGood flexibilityForce measurementSensor arrayTouch sensation

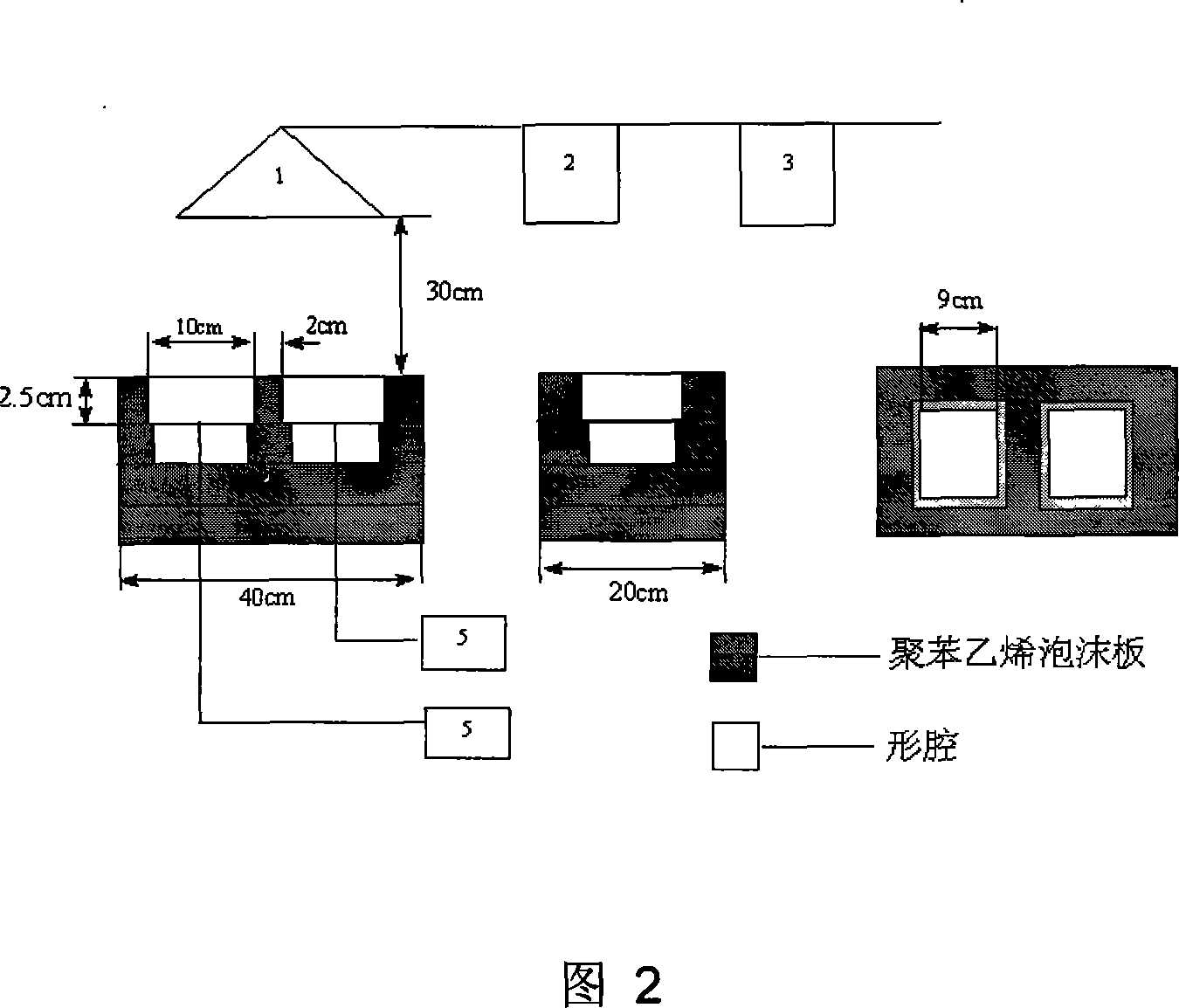

A pressure sensitive material used in a flexible touch sensor and a preparation method thereof are characterized in that: the material adopts carbon black, a silicon rubber composite system and added nano SiO2 or nano Al2O3 as raw materials; according to the preparation method, all raw materials are mixed in turn under normal temperature and normal pressure to obtain mixed solution which is injected into a touch sensor structural model, thereby curing forming is completed at room temperature. The pressure sensitive material, which has excellent touch sensing function and flexility, is suitable to be used in a touch sensor array structure designed at will; moreover, the preparation method has a simple process.

Owner:HEFEI UNIV OF TECH

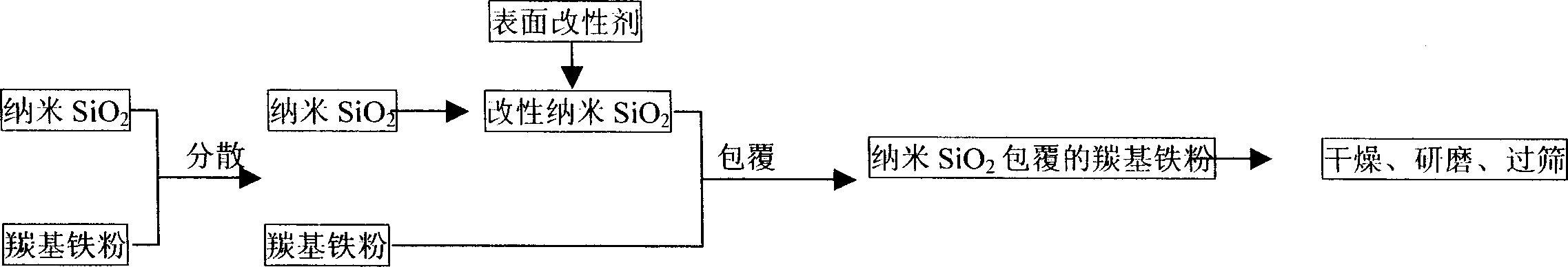

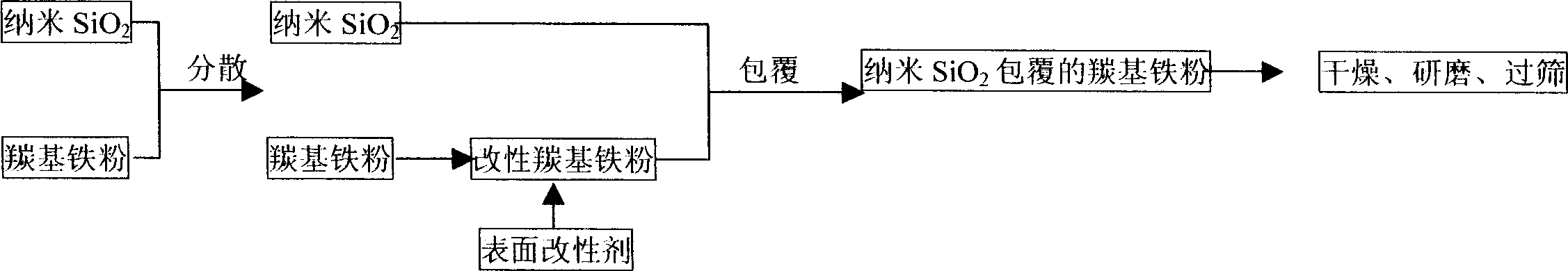

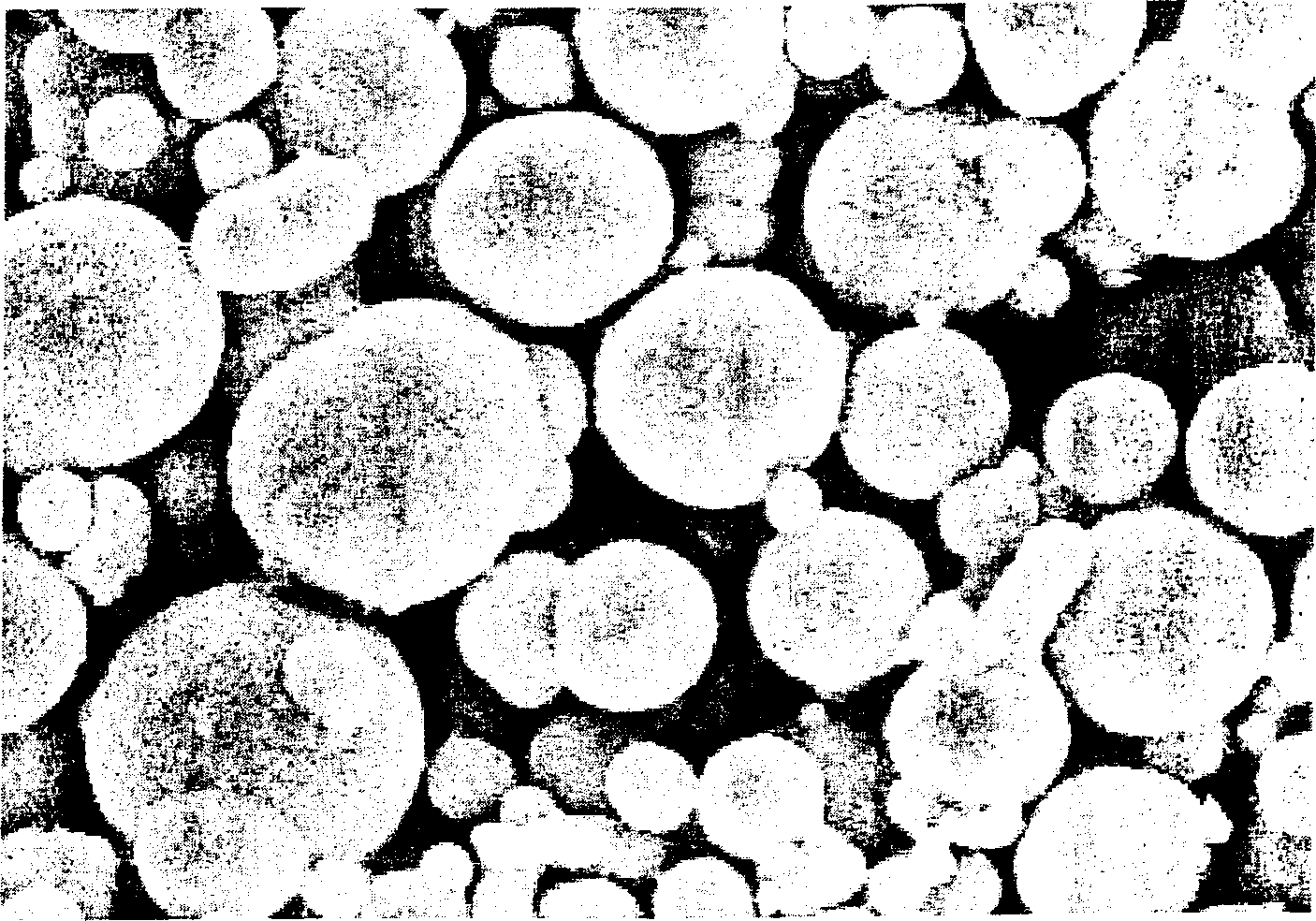

Production of nano-SiO2 for coating carbonyl iron powder

A process for preparing the nano-SiO2 coated carbonyl iron particles includes such steps as dispersing SiO2 nanoparticles and carbonyl iron particles by grinding, modifying the surface polarity of both particles by soluble caustic substance, coating the SiO2 nanoparticles on the surface of each carbonyl iron particle by physical adsorption, backing in vacuum or protective atmosphere, grinding, sieving and packing.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

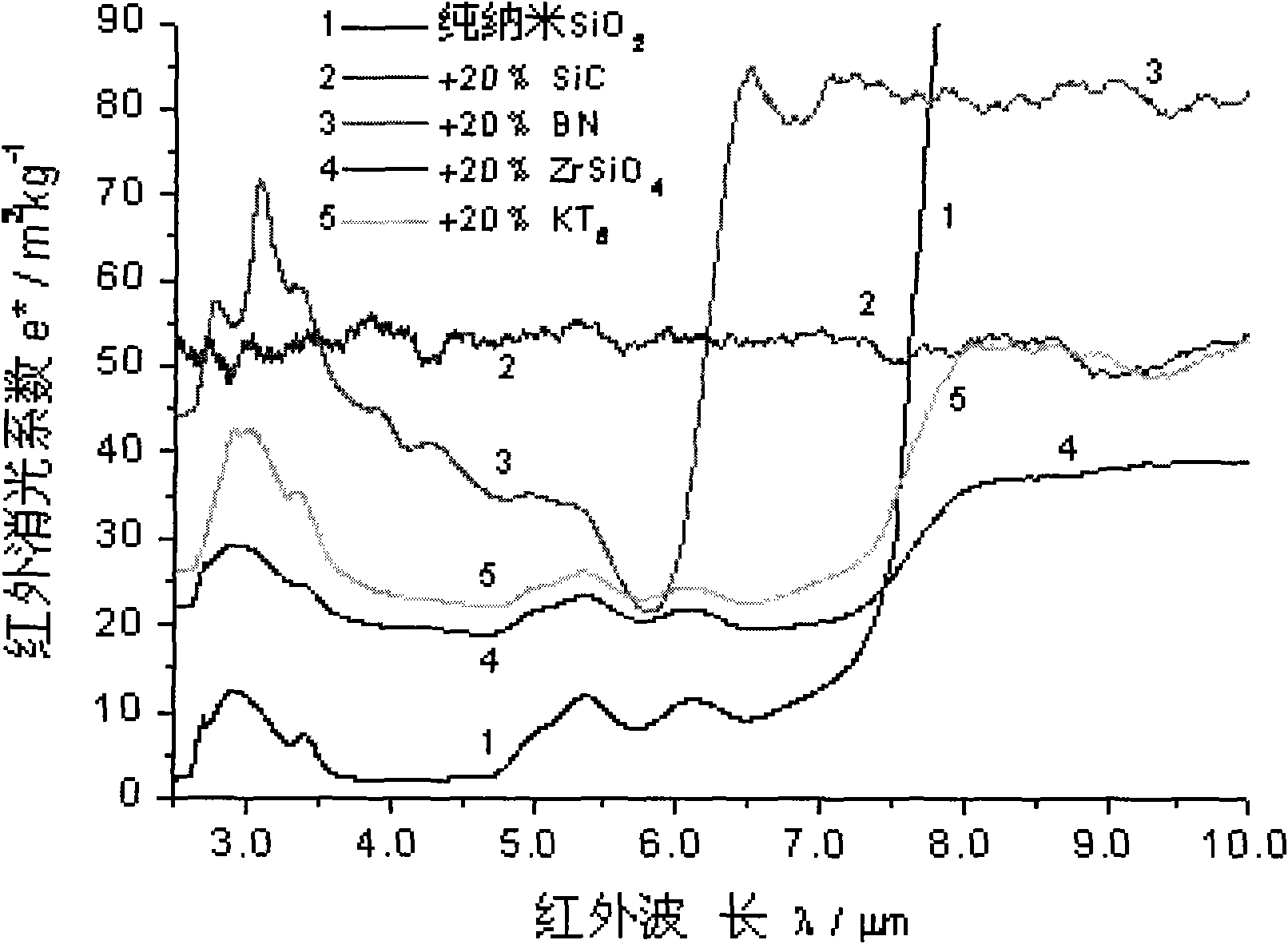

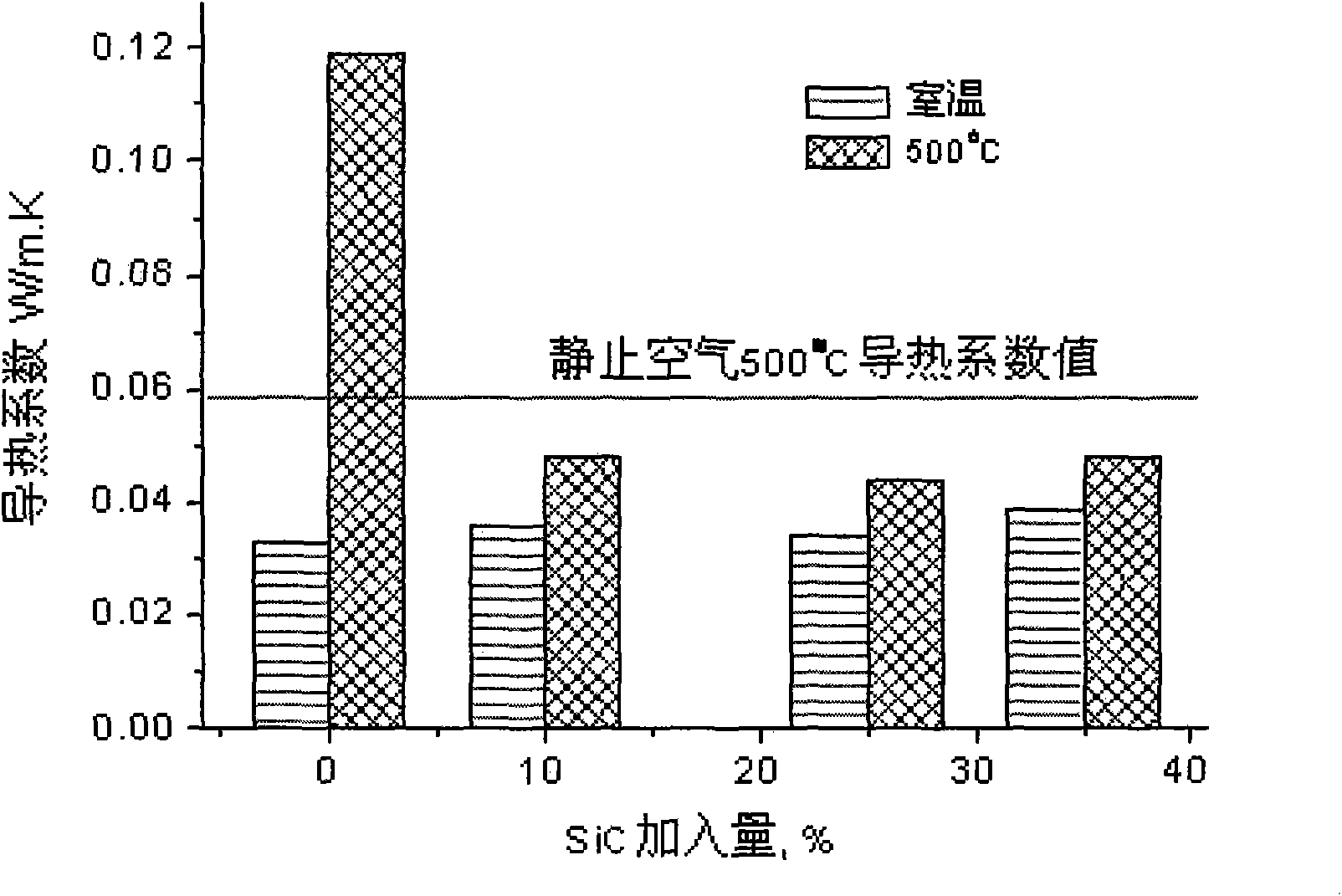

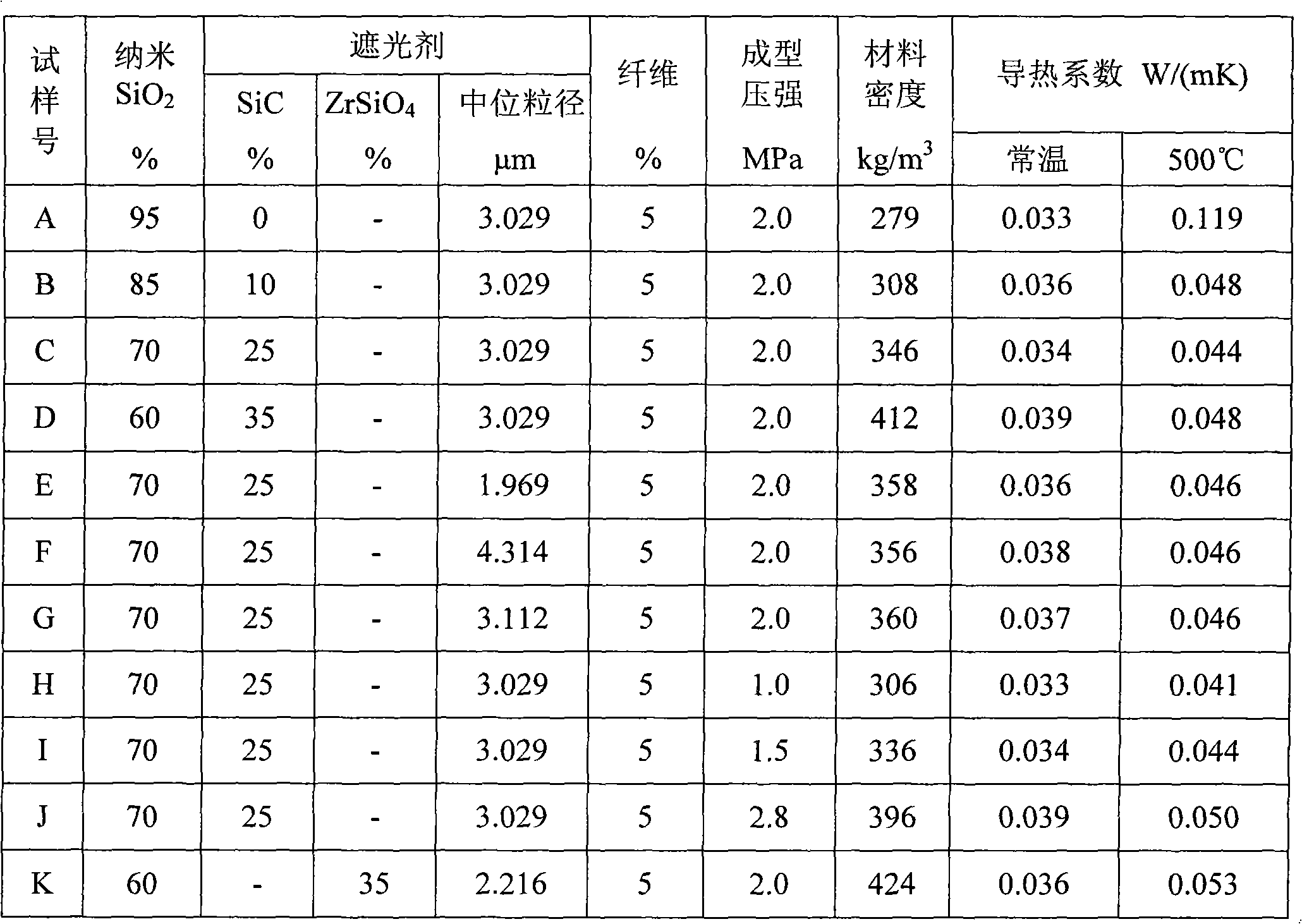

High-efficiency insulating material used for high-temperature pipeline and preparation method thereof

ActiveCN101671157AReduced heat transfer ratioEnhanced inhibitory effectThermal insulationPipe protection by thermal insulationSupercritical dryingFiber

The invention discloses a high-efficiency insulating material capable of being used for a high-temperature pipeline with insulation requirements. The high-efficiency insulating material comprises thefollowing mixed raw materials by weight percentage: 40 to 80 percent of nano SiO2 powder, 5 to 40 percent of infrared opacifier and 0 to 25 percent of reinforcing fiber. The high-efficiency insulatingmaterial is formed by adopting a drying method and overcomes the defect that the sol-gel method for preparing an aerogel-based material needs supercritical drying. The high-efficiency insulating material is designed by a microstructure, carries out full restriction on heat conduction, convection and radiant heat transfer at high temperature simultaneously and leads the heat-conducting coefficientof material under the use temperature to be lower than that of static air.

Owner:NAVAL UNIV OF ENG PLA

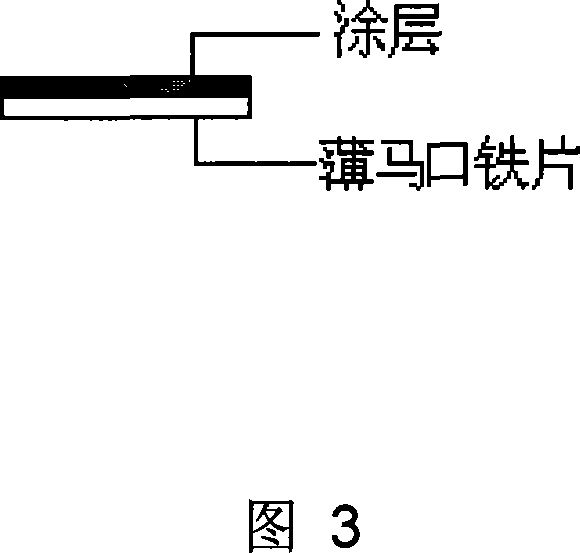

Insulating composite paint of nanometer inorganic matter and polymer and its prepn

The present invention relates to one kind of nanometer inorganic matter / polymer composite insulating paint for electric power apparatus and protecting equipment and its preparation process, and belongs to the field of chemical paint technology and electric insulating technology. The paint consists of one to three kinds of nanometer inorganic materials, including SiO2, TiO2, Al2O3, ZnO, CuO and Fe2O3; one polymer of epoxy resin, polyimide and organopolysiloxane; and coupling agent, in the weight ratio of (1-8) to 100 to (0.02-0.08). Its preparation process includes mixing the nanometer particle with coupling agent, adding the polymer, adding organic solvent, ultrasonic dispersing at 50-100 deg.c to obtain stable suspension, and vacuum treatment at 80-120 deg.c to eliminate solvent and gas to obtain the composite insulating paint. The composite insulating paint may be cured at 120-300 deg.c for 5-18 hr to obtain insulating coating.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Graphene oxide modified compound type heat conducting silicone rubber and preparation method thereof

ActiveCN103937259AFlexibility does not affectImprove thermal conductivityHeat conductingCoordination complex

The invention discloses graphene oxide modified compound type heat conducting silicone rubber and a preparation method thereof. According to the preparation method, the compound type silicon resin with high heat conduction property and low expansion factor is prepared by using 0.5-1 part of graphene oxide as heat conducting stuffing and an inorganic crosslinking agent, 10-50 parts of nanometer SiO2 as the heat conducting stuffing, 5-30 parts of compound of two MQ silicone resin containing hydroxyl and vinyl and different in viscosity as a special bonding modifying agent, 1-10 parts of organic hydrogen polysiloxane as an organic crosslinking agent, 0.1-2 parts of platinum complex as a catalyst, 0.01-0.001 part of alkynol substance as an inhibitor and 60-100 parts of polysiloxane resin as base rubber and adopting a nanometer compounding method, wherein the graphene oxide is partially modified by a silane coupling agent, and the nanometer SiO2 is prepared by a sol-gel method. The compound type silicon resin can be widely applied to encapsulation of various electronic components and plays a role in shock absorption and heat dissipation.

Owner:东莞九天量子科技有限公司

Preparation method of acrylic resin finishing agent modified by nano silicon dioxide (SiO2)-coated multi-walled carbon nanotubes

ActiveCN102786644AOvercome the defect of "hot sticky and cold brittle"Good compatibilityCoatingsAcrylic resinCarbon nanotube

The invention relates to a preparation method of an acrylic resin finishing agent modified by nano silicon dioxide (SiO2)-coated multi-walled carbon nanotubes (MWCNTs). The acrylic resin emulsion has excellent film-forming property, mechanical stability and adhesion, but the characteristic of a linear structure of polyacrylate cause the problems of ''stickiness when heated and brittleness when cooled'' of the coating, poor solvent resistance, unstable adhesion of the coating and the like. The method provided by the invention comprises the steps of preparing MWCNTs / SiO2 nano composite particles through a sol-gel process of tetraethoxysilane, modifying the MWCNTs / SiO2 nano composite particles with a silicane coupling agent, and bonding the MWCNTs / SiO2 nano composite particles modified by the silicane coupling agent into the polyacrylate chains through an in-situ emulsion polymerization. The method provided by the invention uses water as a reaction medium, which is environment-friendly and can achieve continuous operation easily; and excellent characteristics of MWCNTs and SiO2 are introduced into acrylic resin, which can overcome the drawback of ''stickiness when heated and brittleness when cooled'' of the acrylic resin and can further increase the intensity, water resistance, heat resistance, gas permeability, yellowing resistance and flame resistance of the coating.

Owner:SHAANXI UNIV OF SCI & TECH

Organic sillicon modified acrylic ester/inorganic nano composite emulsion and its preparation

A composite organosilicon modified acrylatel inorganic nano emulsion features that the nano-class inorganic phase (SiO2, TiO2, ZnO and CaCo3) is contained in the particles of organosilicon modified acrylate emulsion, and is prepared through reverse emulsion polymerizing and in-situ emulsion polymerizing. Its advnatages are high mechanical, self-cleaning and antistatic performance and high stability. It can be used for paint, adhesive, polishing agent and cement modifier.

Owner:上海华实纳米材料有限公司

Method for preparing anode composite material for lithium sulfur secondary batteries

The invention discloses a method for preparing an anode composite material for lithium sulfur secondary batteries, which comprises the following steps: 1) hydrolyzing ethyl orthosilicate to obtain nano SiO2 spheres; 2) mixing solution of a carbon source with the nano SiO2 spheres and heating the mixture to react the solution of the carbon source with the nano SiO2 spheres; 3) cooling, centrifuging, drying, calcining and carbonizing the product obtained by the previous step to obtain a SiO2-C core-shell structure material; 4) etching the SiO2-C core-shell structure material by using solution of HF, NaOH or KOH to obtain a hollow carbon sphere material; and 5) grinding and mixing sulfur and the hollow carbon sphere material, placing the mixture in a sealed container filled with an Ar gas, heating the mixture and casting the melt to obtain a S-C composite material. The method has the advantages that: 1) the process is simple; 2) the raw material is cheap and readily available and the production cost is low; and 3) the composite material has a special core-shell structure and therefore inhibits the loss of active materials, improves the conductive performance of the material and obviously improves the electrochemical performance of electrodes.

Owner:NANKAI UNIV

Method for preparing Nano SiO2 fire retardant viscose fiber, and film

ActiveCN101050559ASimple processEasy to operateFlame-proof filament manufactureArtificial filaments from viscoseFire retardantSodium sulfate

The present invention relates to a preparation method of nano SiO2 fire-retardant viscose fiber and film, specially, it relates to a preparation method of fire-retardant viscose fiber formed from cellulose and SiO2 and organic-inorganic polymer nano composite membrane made of cellulose and SiO2. Said method includes the following steps: adding silicone sol with a certain mass into a viscose solution whose composition contains alpha-cellulose whose mass percentage content is 6-9% and sodium hydroxide whose mass percentage content is 5-6%; fully stirring and mixing them at 10-50 deg.C, deforming so as to obtain viscose-silicone sol solution, then adding said viscose-silicone sol into a coagulation acid bath prepared by using sulfuric acid, sodium sulfate, zinc sulfate and water, coagulating at 10-100 deg.C, spinning so as to obtain nano SiO2 fiber-retardant viscose fiber, utilizing coating process so as to obtain organic-inorganic polymer nano composite membrane of cellulose / SiO2.

Owner:QINGDAO UNIV

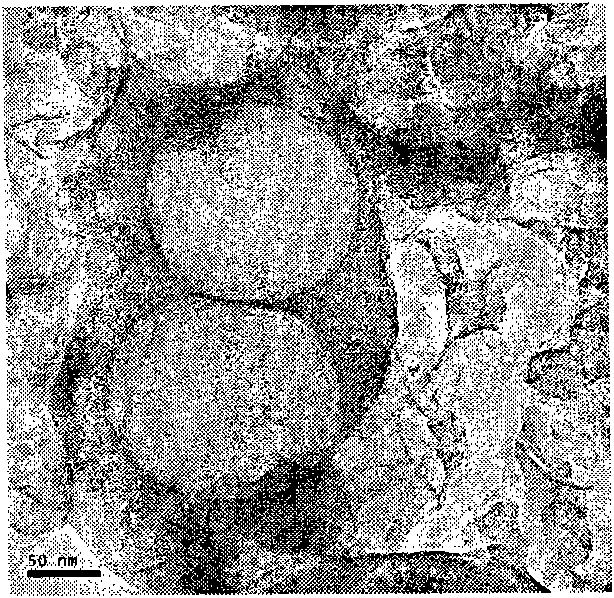

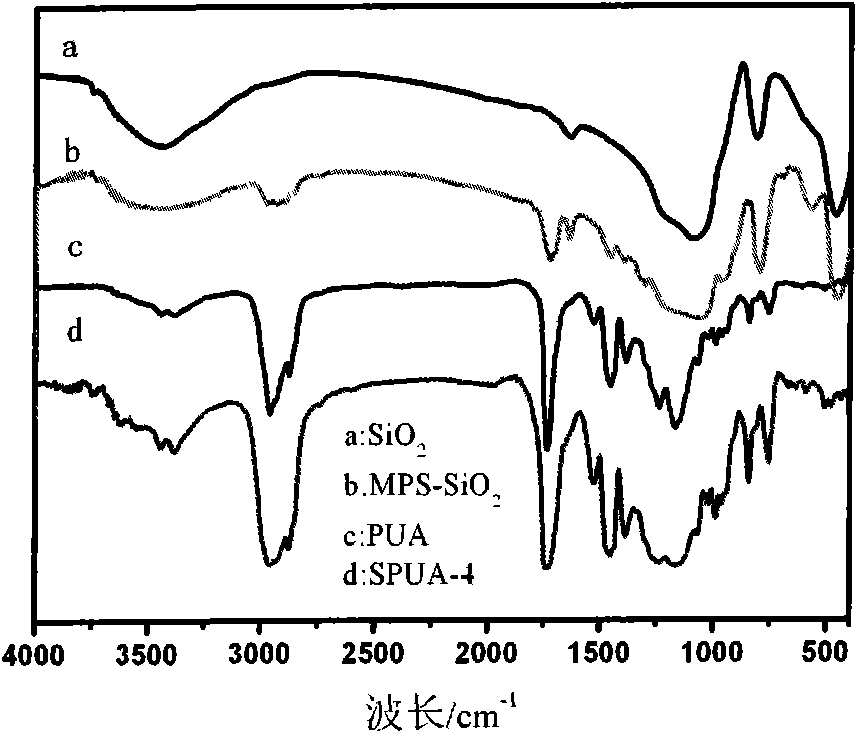

Method for preparing nano SiO2/polyurethane/acrylic ester composite emulsion and miniemulsion polymerization

InactiveCN102010486AGood dispersionHigh strengthPigment treatment with organosilicon compoundsPolymer scienceEmulsion

The invention relates to a method for preparing nano silicon dioxide (SiO2) / polyurethane / acrylic ester composite emulsion and miniemulsion polymerization. The method is characterized in that: the acrylic ester composite emulsion modified by the nano SiO2 and the polyurethane jointly is prepared by a miniemulsion polymerization method. According to the method, SiO2 is modified by using a silane coupling agent KH-570 under an alkaline condition, so that a hydrophilic surface of the composite emulsion is changed into a hydrophobic surface, and the dispersibility of the composite emulsion is improved greatly; stable nano SiO2 / polyurethane / acrylic ester composite emulsion can be prepared by a miniemulsion polymerization process; after the emulsion is formed into a film, the strength of a glue film is greatly improved, the glue film has soft handfeel, and the disadvantage that acrylic ester polymer is sticky in a hot state and is crisp in a cold state is overcome; and the decomposition mechanism of the composite emulsion is not changed.

Owner:ANHUI UNIVERSITY +1

Polysilsesquioxane-polyacrylate-nano SiO2 composite emulsion and preparation method and application thereof

ActiveCN103626933AIncrease contentHigh hardnessNon-macromolecular adhesive additivesCoatingsPolymer scienceAdhesive

The invention relates to the field of high molecule synthesis. In order to solve the problems that the content of nano SiO2 in an acrylate polymer emulsion system is lower and the modifying process on the surface of SiO2 is tedious and the like, the invention provides a polysilsesquioxane-polyacrylate-nano SiO2 composite emulsion which consists of 20-60 parts of a polysilsesquioxane emulsion, 15-35 parts of alkyl methacrylate, 15-35 parts of alkyl acrylate, 1-5 parts of hydroxyl alkyl acrylate, 0.1-1 part of an initiator, 40-80 parts of water, 30-60 parts of a silica sol and 5-15 parts of a cosolvent. The emulsion has good appearance and storage stability. The film is high in transparency, the hardness reaches 6H, the adhesive force is level 1, and the content of silicon based on SiO2 reaches over 25%. The high silicon content polysilsesquioxane-polyacrylate-nano SiO2 composite emulsion integrates advantages of organic and inorganic materials, and the film has excellent performances such as ageing resistance, heat resistance, scratch resistance, wear resistance and high hardness. The emulsion has a wide application prospect in the fields of coatings and adhesives.

Owner:HANGZHOU NORMAL UNIVERSITY

Modified nano-drilling fluid treating agent for restraining mud shale expansion

The invention relates to a modified nano-drilling fluid treating agent for restraining mud shale expansion in petroleum and natural gas drilling. The treating agent can form a dense mud cake at the mouth of an underground porous channel so as to effectively protect a well wall. The technical scheme is that: the treating agent comprises the following raw materials by gram: 5 to 10 g of nano-SiO2, 8 g of acrylamide, 0.8 g of silane coupling agent KH-550, 0.2 g of ammonium persulfate, 300 g of toluene and 500 g of distilled water, wherein nano-SiO2 has the density of 2.33, the specific surface area of 150m<2> / g and the particle size of 20 to 40 nm; and the acrylamide has the molecular weight of 71.08. The silane coupling agent is grafted on the nano-SiO2 by using the silane coupling agent and the acrylamide is grafted and polymerized to form long-chain grafted nano-SiO2 which is called as modified nano-SiO2; and nano-SiO2 particles are uniformly and stably dispersed in the drilling fluid to form the modified nano-drilling fluid. The treating agent has the advantages of higher mud cake quality, thinner mud cake, good toughness, capability of remarkably reducing filtration loss and remarkable mud shale expansion preventing effect, and is used as the treating agent in the field of drilling.

Owner:SOUTHWEST PETROLEUM UNIV

Preparing method of composite styrene-acrylic emulsion containing silicon dioxide

The invention aims at the shortcomings that inorganic nanometer particles are easy to conglomerate and poor in compatibility with a polymer, a polymer emulsion is unstable, and directional conglomerating of emulsion bundles is easy to appear and residues are easy to generate during the polymerization process in a traditional inorganic or organic composite emulsion, and provides a preparing method of a composite styrene-acrylic emulsion containing silicon dioxide. The preparing method includes: using an in situ sol-gel method to produce nanometer silicon dioxide particles which are uniformly dispersed in monomer, and controllable in particle morphology and particle diameters; then preparing a seed emulsion containing the silicon dioxide particles after obtaining a styrene-acrylic pre-emulsion by using mixed type emulsifiers; and finally preparing the composite styrene-acrylic emulsion by adopting a seed emulsion polymerization method. By adopting the preparing method, the styrene-acrylic emulsion of which silicon dioxide is high in filling volume, and uniformly and stable dispersed in the emulsion is obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

High temperature carbon dioxide adsorbent containing silicon nano calcium oxide, its preparation process and application in hydrogen production process

InactiveCN1762572AReduce energy consumptionLarge adsorption capacityProductsOther chemical processesSteam reformingWater vapor

The invention discloses a silicon-containing nano calcium oxide as adsorbent to hot carbon dioxide, which is prepared by: coating the nano CaCO3 with 2-10 SiO2 with gel-sol method or mixing directly them to prepare nano CaCO3 powder contained silicon; mixing with plasticizer to shape, and calcining at 600-80Deg. It also discloses the application of this product in methane water vapor reforming and making hydrogen industry. This adsorbent reduces regeneration temperature and energy consumption greatly, and has well thermal stability.

Owner:ZHEJIANG UNIV

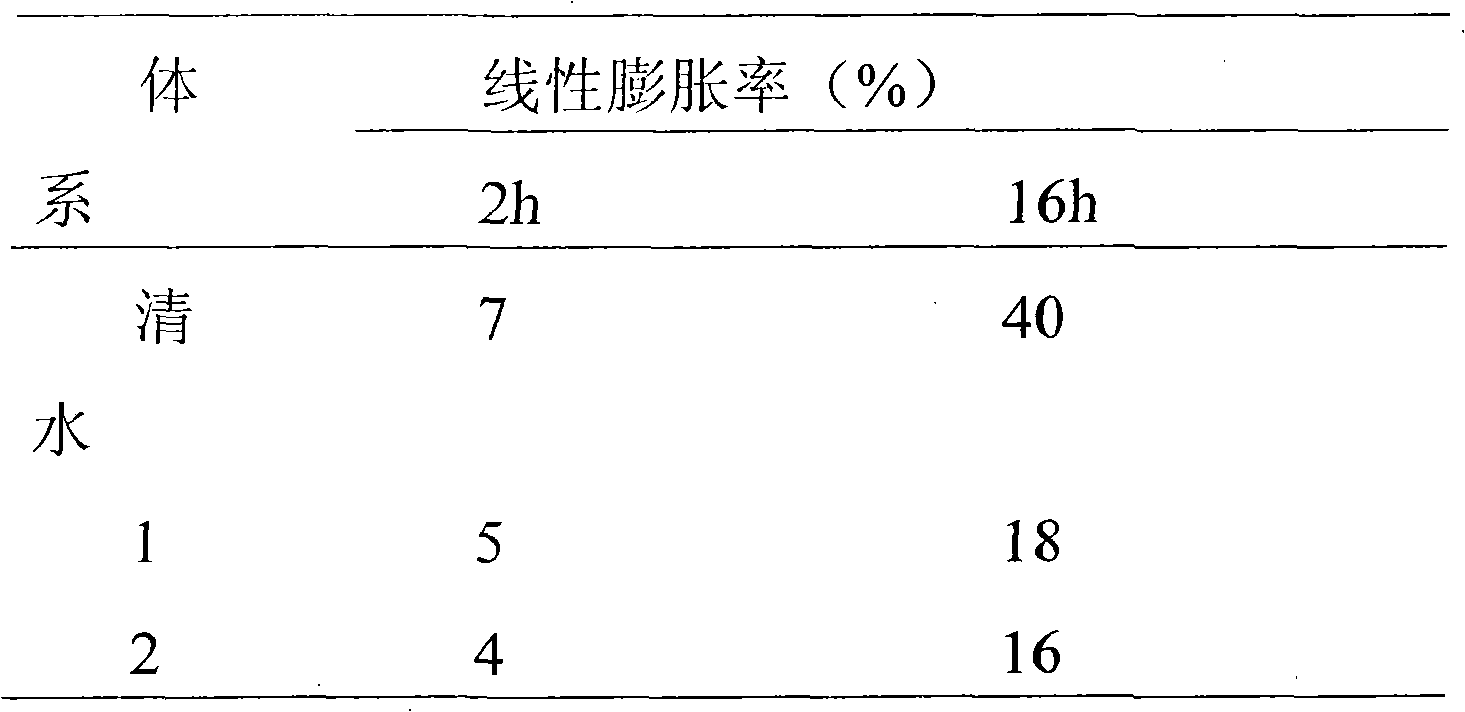

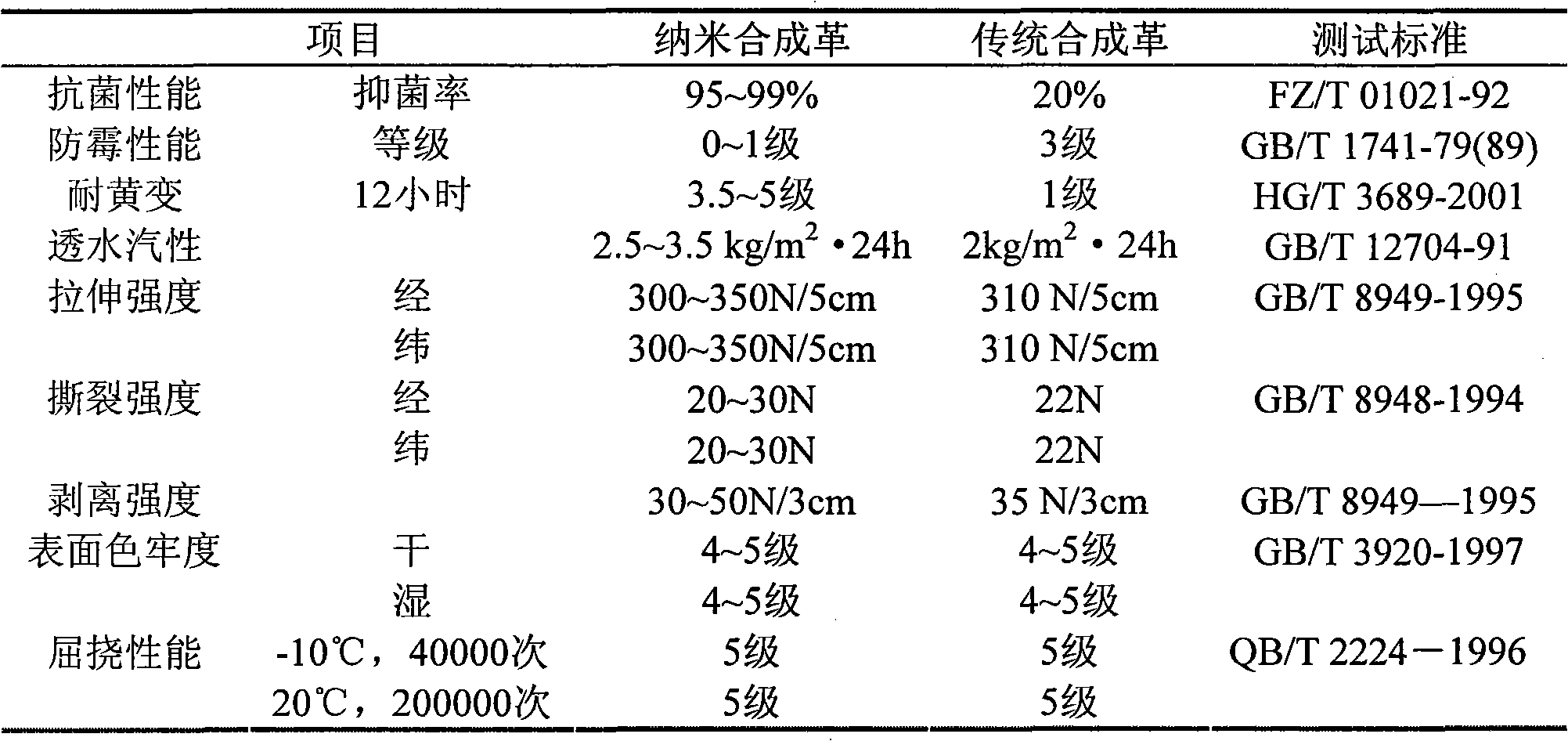

Water-based nano synthetic leather slurry and method for manufacturing nano synthetic leather

InactiveCN101858039ASolve the technical bottleneck problem that is easy to reuniteAvoid reunionFibre treatmentWater basedEmulsion

The invention discloses water-based nano synthetic leather slurry and a method for manufacturing nano synthetic leather. The method is characterized by comprising the following steps of: uniformly mixing 100 weight parts of water-based polyurethane / nano SiO2 or TiO2 emulsion with solid content of 25 to 40 weight percent, 15 to 22 weight parts of filler, 0.1 to 0.5 weight part of leveling agent, 0.1 to 0.5 weight part of antifoaming agent and 0.1 to 0.3 weight part of thickening agent to prepare nano composite slurry; uniformly scraping the water-based polyurethane / nano SiO2 or TiO2 emulsion on release paper by using a transfer method, drying the release paper in a blowing dry box at the temperature of between 100 and 130 DEG C, and cooling the release paper by using a cooling roller at a linear speed of between 15 and 20m / min; scraping a second layer of the water-based polyurethane / nano SiO2 or TiO2 emulsion on the release paper, drying and cooling the second layer under the same conditions; scraping a third layer of the water-based polyurethane / nano SiO2 or TiO2 emulsion, and drying the third layer in the blowing dry box at the temperature of between 100 and 110 DEG C; laminating base cloth on the coating layer of the release paper in a semi-dry state at the linear speed of between 15 and 20 m / min; drying the coating in the blowing dry box at the temperature of between 100 and 130 DEG C at the linear speed of between 15 and 20m / min; and separating the paper from the leather and rolling up the paper and the leather respectively to prepare the nano synthetic leather.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com