Method for preparing anode composite material for lithium sulfur secondary batteries

A lithium-sulfur secondary battery and composite material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the complex and cumbersome preparation of SBA-15, achieve the effects of improved electrochemical performance, simple process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Nano SiO 2 ball preparation

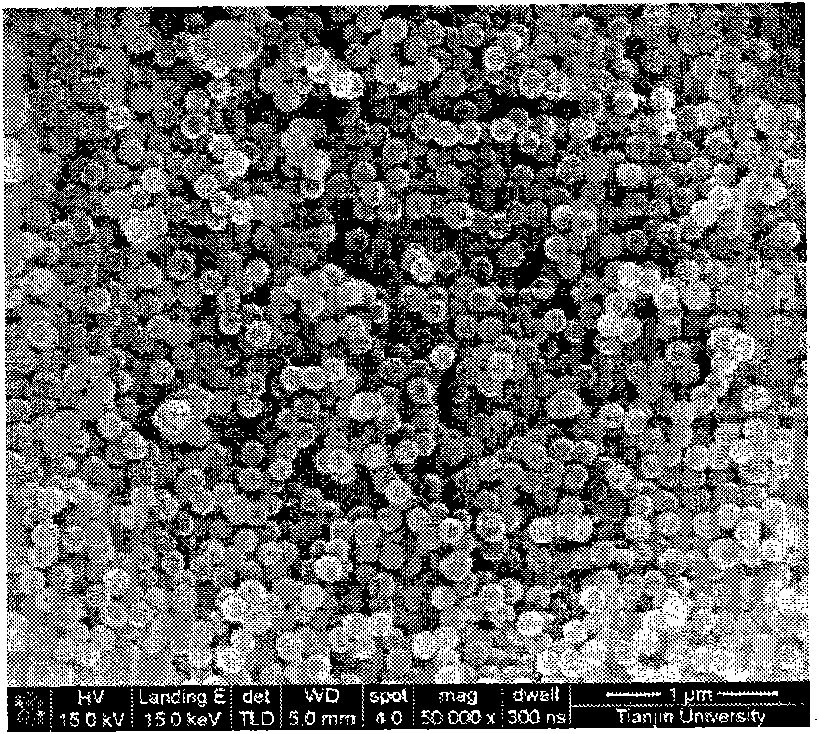

[0028] Add 20ml of deionized water and 20ml of ammonia water to 500ml of absolute ethanol. The mass percentage concentration of ammonia water is 25%. After stirring evenly, add 40ml of ethyl orthosilicate, continue stirring for 48 hours, and then centrifuge and dry to obtain SiO 2 ball. SiO 2 shape of the ball see figure 1 .

[0029] 2)SiO2 2 Preparation of -C core-shell composites

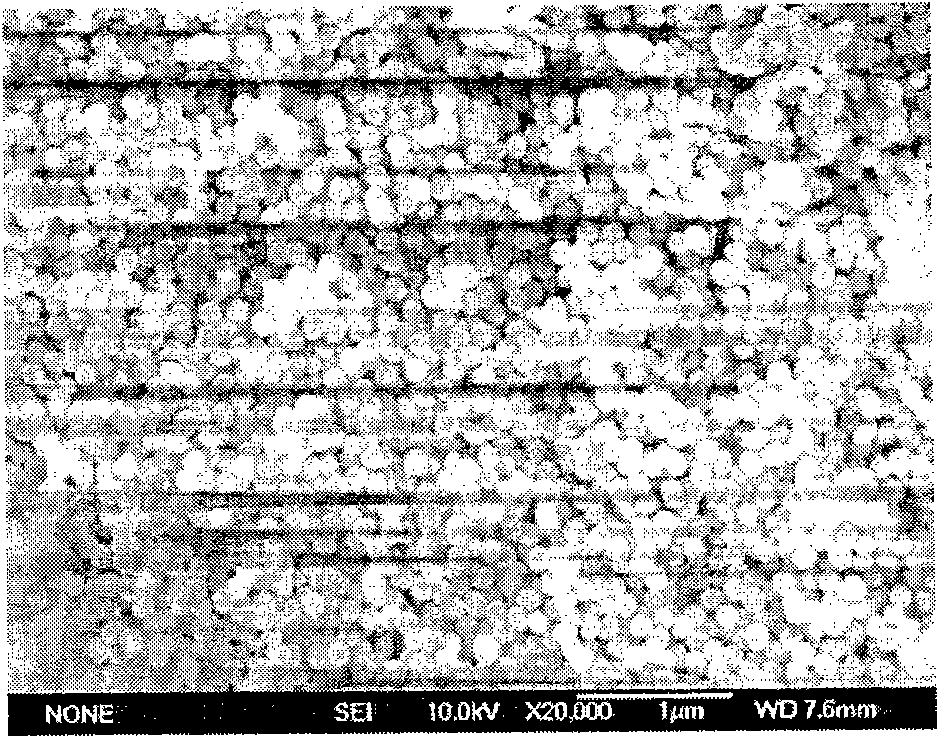

[0030] Mix equal masses of glucose and nano-SiO 2 Mix the balls in 30ml of deionized water and react at 180°C for 10 hours. The reaction product is cooled, centrifuged, dried, and then calcined at 850°C for 5 hours to obtain SiO 2 -C core-shell structure composites. SiO 2 The morphology of -C core-shell composites is shown in figure 2 .

[0031] 3) Preparation of hollow carbon materials

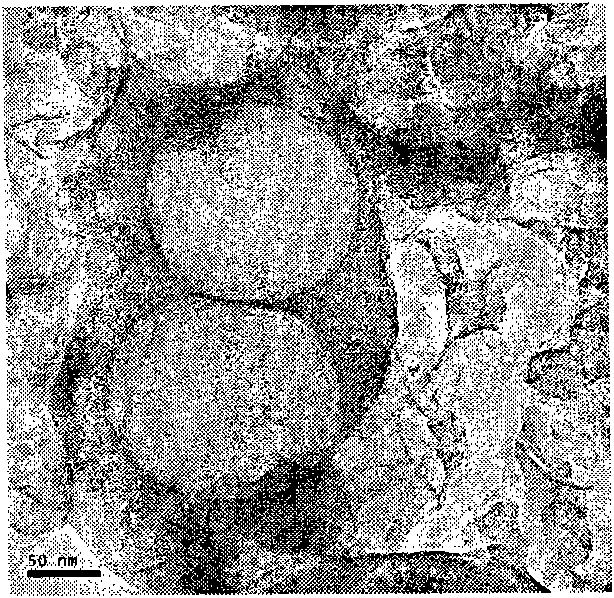

[0032] SiO 2 -C core-shell structure composite material is etched for 24 hours with a mass percent concentration of 8% HF solution to obtain a hollow carbon m...

Embodiment 2

[0039] 1) Nano SiO 2 ball preparation

[0040] Add 15ml of deionized water and 15ml of ammonia water to 500ml of absolute ethanol, the mass percentage concentration of ammonia water is 20%, add 30ml of ethyl orthosilicate after stirring, centrifuge after stirring for 36 hours, and dry to obtain SiO 2 ball. Obtained SiO 2 The shape of the ball and figure 1 resemblance.

[0041] 2)SiO2 2 Preparation of -C core-shell composites

[0042] Equivalent amounts of sucrose and nano-SiO2 Mix the balls in 30ml of deionized water. After reacting at 170°C for 10 hours, the reaction product is cooled, centrifuged, dried, and then calcined at 800°C for 5 hours to obtain SiO 2 -C core-shell structure composites. Prepared SiO 2 Morphology of -C core-shell composites figure 2 resemblance.

[0043] 3) Preparation of hollow carbon materials

[0044] SiO 2 The -C core-shell structure composite material is etched with a KOH solution with a mass percent concentration of 10 mol / L at 60°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Charge and discharge current density | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com