Multi-multiplying power charging-discharging lithium ion battery and method for producing the same

A lithium-ion battery, charging and discharging technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as unfavorable charging and discharging, the influence of electron flow, and easy platinum leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

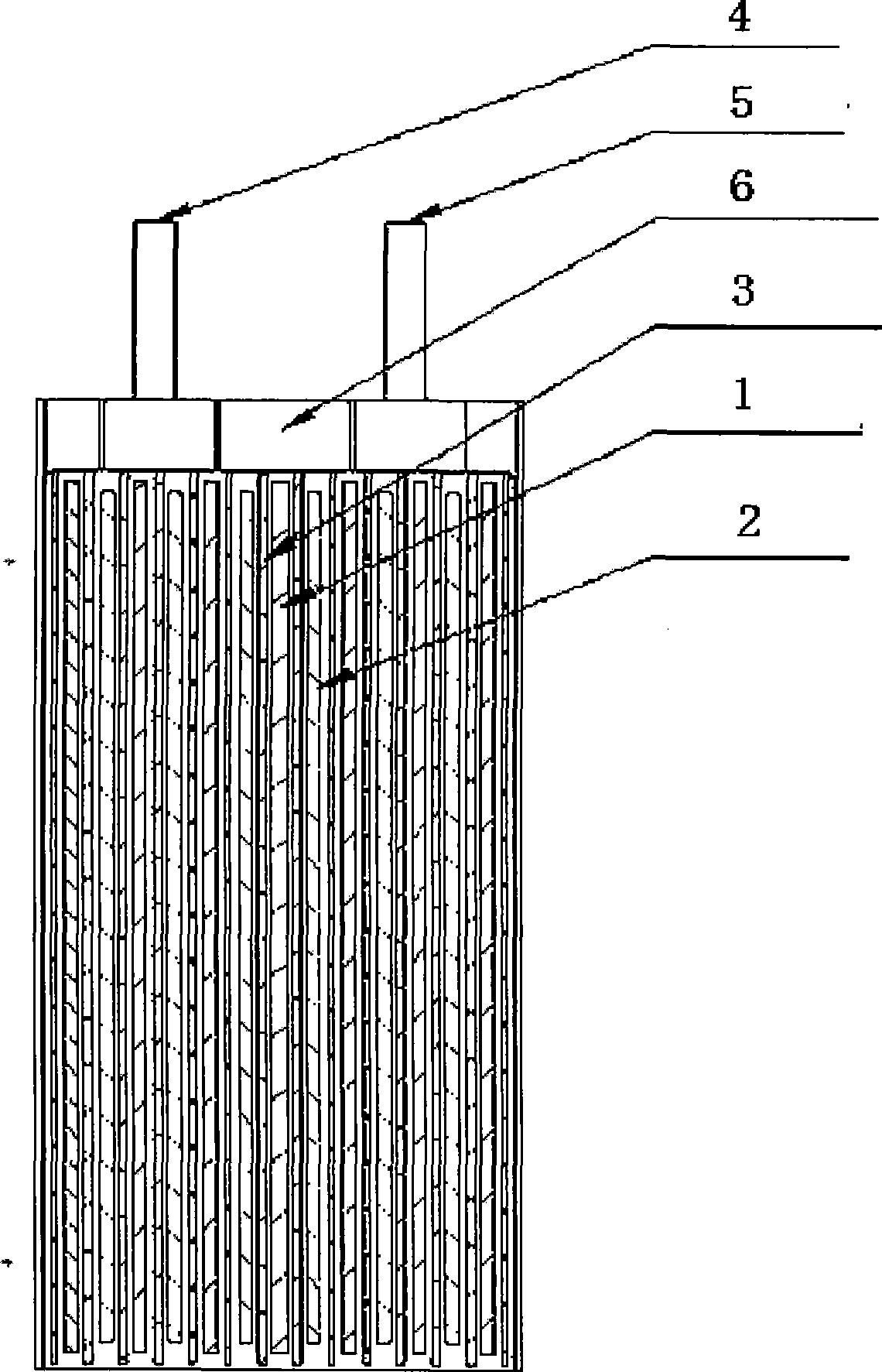

[0060] Dissolve polyvinylidene fluoride-perfluoropropylene (PVDF-HFP) in N-methylpyrrolidone (NMP), the stirring speed is 30r / min for revolution, 300r / min for rotation, and add nano-SiO in stages after stirring evenly 2 and lithium manganate, the weight ratio of each component is lithium manganate: nanometer SiO 2 :PVDF-HFP=90:5:5. Coat the evenly stirred slurry on the aluminum foil current collector. The oven temperature of the coating machine is 75°C. After drying, the coating surface density is 280mg / 10cm 2 , the compacted density is 3.1g / cm 3 . Cut and spot-weld the aluminum lug 4 to obtain the positive pole piece 1 .

[0061] Dissolve sodium carboxymethyl cellulose (CMC) in high-purity deionized water, stir at a speed of 30r / min for revolution and 300r / min for rotation, and add nano-SiO in stages after stirring evenly 2 , mesophase carbon microspheres (CMB) and styrene-butadiene rubber (SBR), the weight ratio of each component is CMB: nano-SiO 2 :SBR:CMC=93:4:1.5:1.5...

Embodiment 2

[0070] Dissolve polyvinylidene fluoride-perfluoropropylene in N-methylpyrrolidone (NMP), and stir at a revolution speed of 30r / min and an autorotation speed of 300r / min. After stirring evenly, add nano-Ag and lithium manganate in stages, each group The weight ratio of parts is lithium manganese oxide:nano Ag:PVDF-HFP=96:2:2. Coat the evenly stirred slurry on the aluminum foil current collector. The oven temperature of the coating machine is 75°C. After drying, the coating surface density is 250mg / 10cm 2 , the compacted density after rolling is 3.15g / cm 3 . Cut and spot-weld the aluminum lug 4 to obtain the positive pole piece 1 .

[0071] Sodium carboxymethylcellulose (CMC) is dissolved in high-purity deionized water, and after stirring evenly, nano-Ag, mesocarbon microspheres (CMB) and styrene-butadiene rubber (SBR) are added in stages, and the weight composition ratio of each component is It is CMB:Nano Ag:SBR:CMC=94:3:1.5:1.5. Coat the evenly stirred slurry on the coppe...

Embodiment 3

[0074] Dissolve polyvinylidene fluoride-perfluoropropylene in N-methylpyrrolidone (NMP), stir at a revolution speed of 30r / min, and rotate at 300r / min, and add nano-Al in stages after stirring evenly 2 o 3 and lithium manganate, the weight ratio of each component is lithium manganate: nanometer Al 2 o 3 :PVDF-HFP=92:3.5:4.5. Coat the uniformly stirred slurry on the aluminum foil current collector. The oven temperature of the coating machine is 75°C. After drying, the coating surface density is 270mg / 10cm 2 , the compacted density after rolling is 3.0g / cm 3 . Cut and spot-weld the aluminum lug 4 to obtain the positive pole piece 1 .

[0075] Dissolve sodium carboxymethylcellulose (CMC) in N-methylpyrrolidone (NMP), stir at a speed of 30r / min for revolution and 300r / min for rotation, and add nano-Al in stages after stirring evenly 2 o 3 , mesophase carbon microspheres (CMB) and styrene-butadiene rubber (SBR), the weight ratio of each component is CMB:nano Al 2 o 3 :SBR:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com