Preparation method for high-activity material

A high-activity, lithium-source technology, applied to electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of cumbersome lithium iron phosphate synthesis process, difficult large-scale production, and irregular product shapes, etc., to achieve good cycle Stability, improvement of high rate charge and discharge performance, and effect of reducing activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

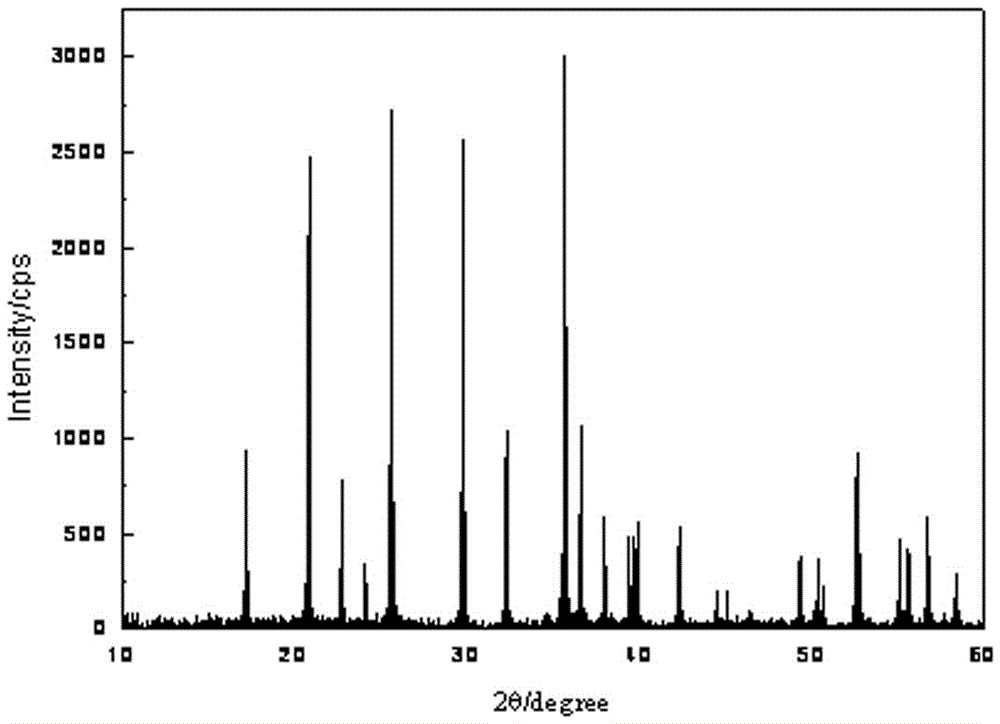

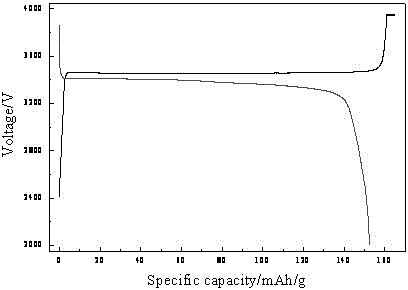

[0030] Weigh 185 g of lithium carbonate, 575 g of ammonium dihydrogen phosphate, 397 g of iron oxide, 1.0 g of magnesium oxide, 60 g of glucose and 15 g of carbon black, use polyethylene glycol as a dispersant, and control the speed of the ultrafine ball mill-sand mill Continuous grinding at 300 r / min for 4 h to obtain the desired slurry. Adjust the inlet and outlet temperatures of the spray drying to 300 and 150°C, respectively, and dry and granulate at a feed rate of 3 L / min to obtain the precursor of lithium iron phosphate. The former body was sintered at a heating rate of 10 °C / min to 700 °C for 5 h in an atmosphere furnace filled with high-purity nitrogen, and then naturally cooled to room temperature. Finally, the sintered product is taken out, pulverized, and mechanically integrated to obtain the lithium iron phosphate positive electrode active material. Using metal lithium sheet as the negative electrode, the charge and discharge voltage is 2.0~3.95 V, 0.05C / 0.1C char...

Embodiment 2

[0032] Weigh 520 g of lithium dihydrogen phosphate, 397 g of iron oxide, 1.0 g of magnesium oxide, 100 g of sucrose and 10 g of acetylene black, use citric acid as a dispersant, and control the speed of the ultrafine ball mill-sand mill to 300 r / min for continuous circulation Grind for 6 h to obtain the desired slurry. Adjust the spray drying inlet and outlet temperatures to 300 and 150°C respectively, and dry and granulate at a feed rate of 2 L / min to obtain the lithium iron phosphate precursor. The body was sintered at 650 °C for 4 h at a heating rate of 10 °C / min in an atmosphere furnace with high-purity nitrogen, and then cooled naturally to room temperature. Finally, the sintered product is taken out, pulverized, and mechanically integrated to obtain the lithium iron phosphate positive electrode active material. The measured tap density of the material is 1.28 g / cm 3 . Using metal lithium sheet as the negative electrode, charge and discharge voltage is 2.0~3.95 V, char...

Embodiment 3

[0034]With 185 g of lithium carbonate, 575 g of ammonium dihydrogen phosphate, 898 g of ferrous oxalate, 0.4 g of titanium oxide, 40 g of glucose and 10 g of carbon black, use absolute ethanol as a dispersant, and control the speed of the ultrafine ball mill-sand mill Continuous grinding at 400 r / min for 5 h to obtain the desired slurry. Adjust the inlet and outlet temperatures of the spray drying to 350 and 150°C, respectively, and dry and granulate at a feed rate of 2 L / min to obtain the precursor of lithium iron phosphate. The body was first heated to 720 °C for 8 h at a heating rate of 10 °C / min in an atmosphere furnace filled with high-purity nitrogen, and then naturally cooled to room temperature. Finally, the sintered product is taken out, pulverized, and mechanically integrated to obtain the lithium iron phosphate positive electrode active material. Using metal lithium sheet as the negative electrode, the charge and discharge voltage is 2.0~3.95 V, 0.05C / 0.1C charge a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com