Composite polyolefin/sio2 nano particle and its prepn

A technology of olefin polymers and nanoparticles, which is applied in the field of olefin polymer/SiO2 composite nanoparticles and its preparation, can solve the problems that the coating layer is easy to fall off, the total reaction yield is high, and the grafting efficiency is low. The effect of low grafting efficiency, low grafting rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

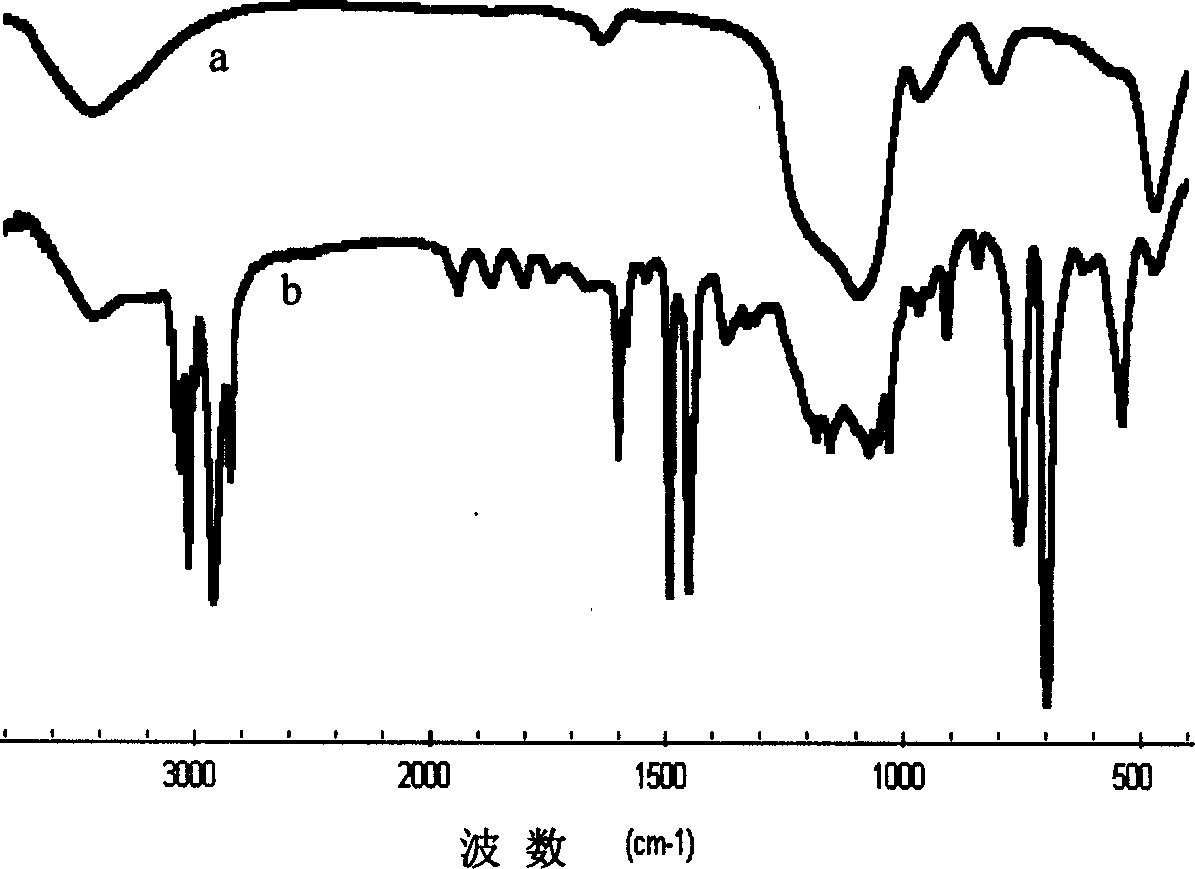

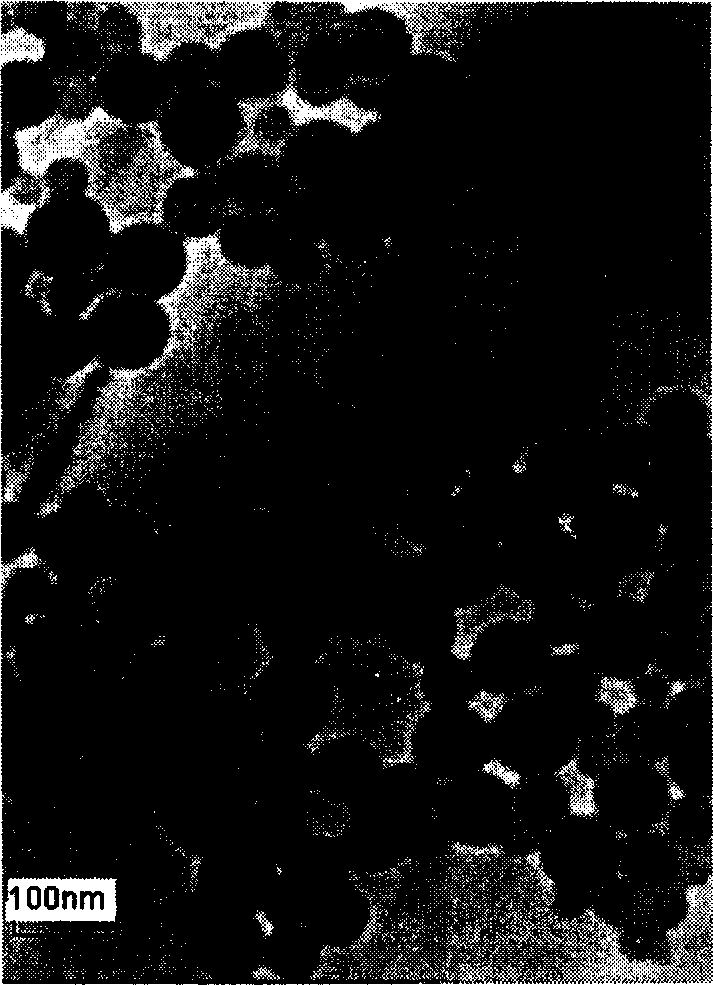

[0049] Example 1: The average particle size of Zhoushan Mingri Company is 10 ± 5nm, and the specific surface area is 640m 2 / g nano-SiO 2 After treating with 5% KH-570 silane-type coupling agent produced by Nanjing Shuguang Chemical Factory, weigh 0.5 g and add it to 15 ml of styrene monomer, and stir evenly. Add 60ml deionized water, 0.75g sodium dodecylsulfonate and 0.1g nonylphenol polyoxyethylene ether (10) in the four-neck flask equipped with mechanical stirring, reflux condenser, nitrogen protection and thermometer, and heat up to 40°C and stirring to dissolve, add monomer and SiO 2 mixture. Then, add an aqueous initiator solution made of 0.068g ammonium persulfate and 10ml deionized water, raise the temperature to 80°C for 1.5hr, then raise the temperature to 90°C, continue the reaction for 0.5hr, then cool and discharge. Part of the emulsion after discharge was demulsified, washed, and dried to obtain a white powder product, and the other part of the emulsion was pl...

example 2

[0050] Example 2: The preparation method is the same as Example 1, with SiO 2 The amount of addition increased from 0.5g to 1.0g. The results obtained are shown in Table 1.

example 3

[0051] Example 3: the preparation method is the same as Example 1, with SiO 2 The amount of addition increased from 0.5g to 2.0g. The results obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com