Laser rotary-cut drilling device

A drilling device and laser technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as incompetence, and achieve the effect of expanding application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

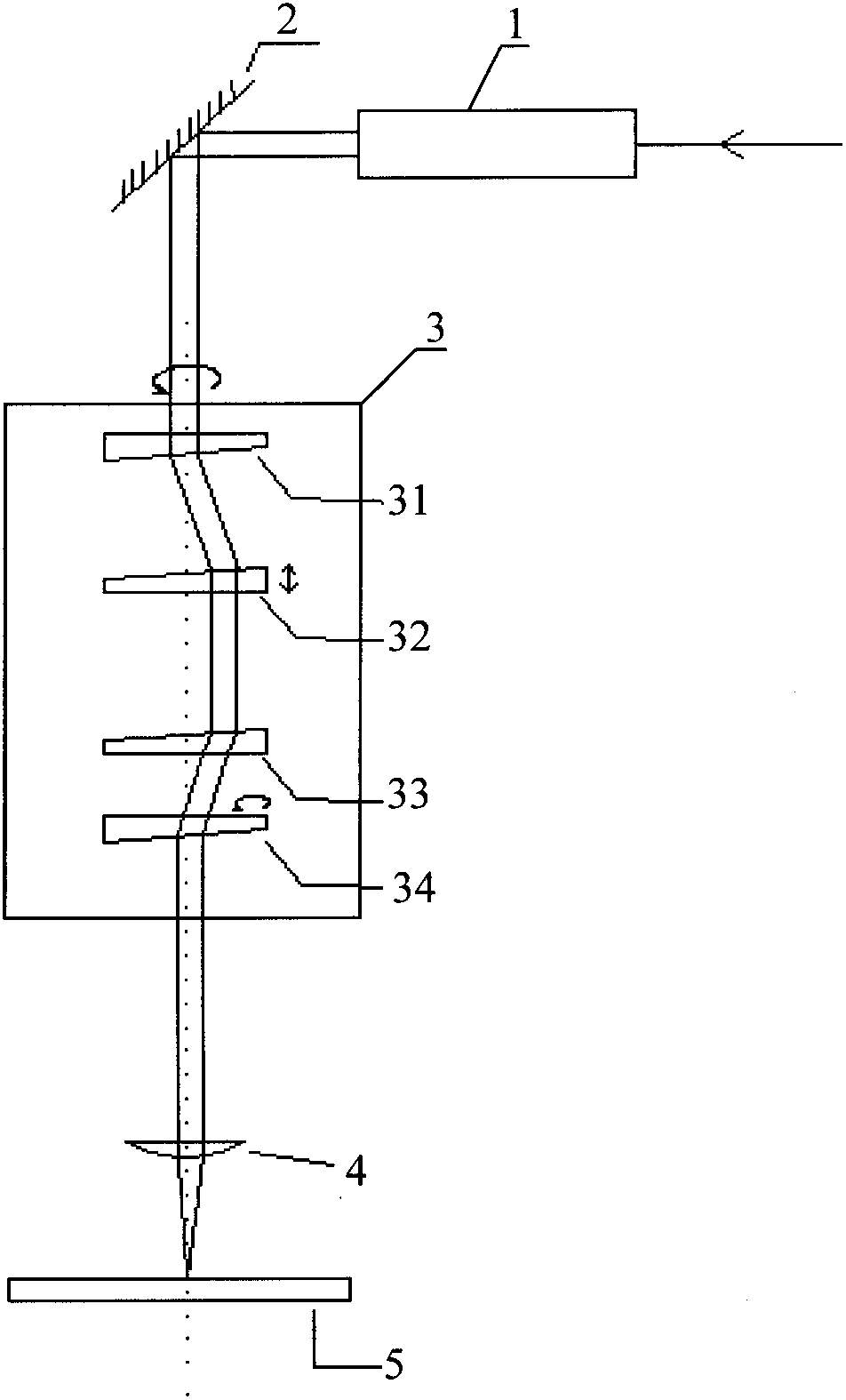

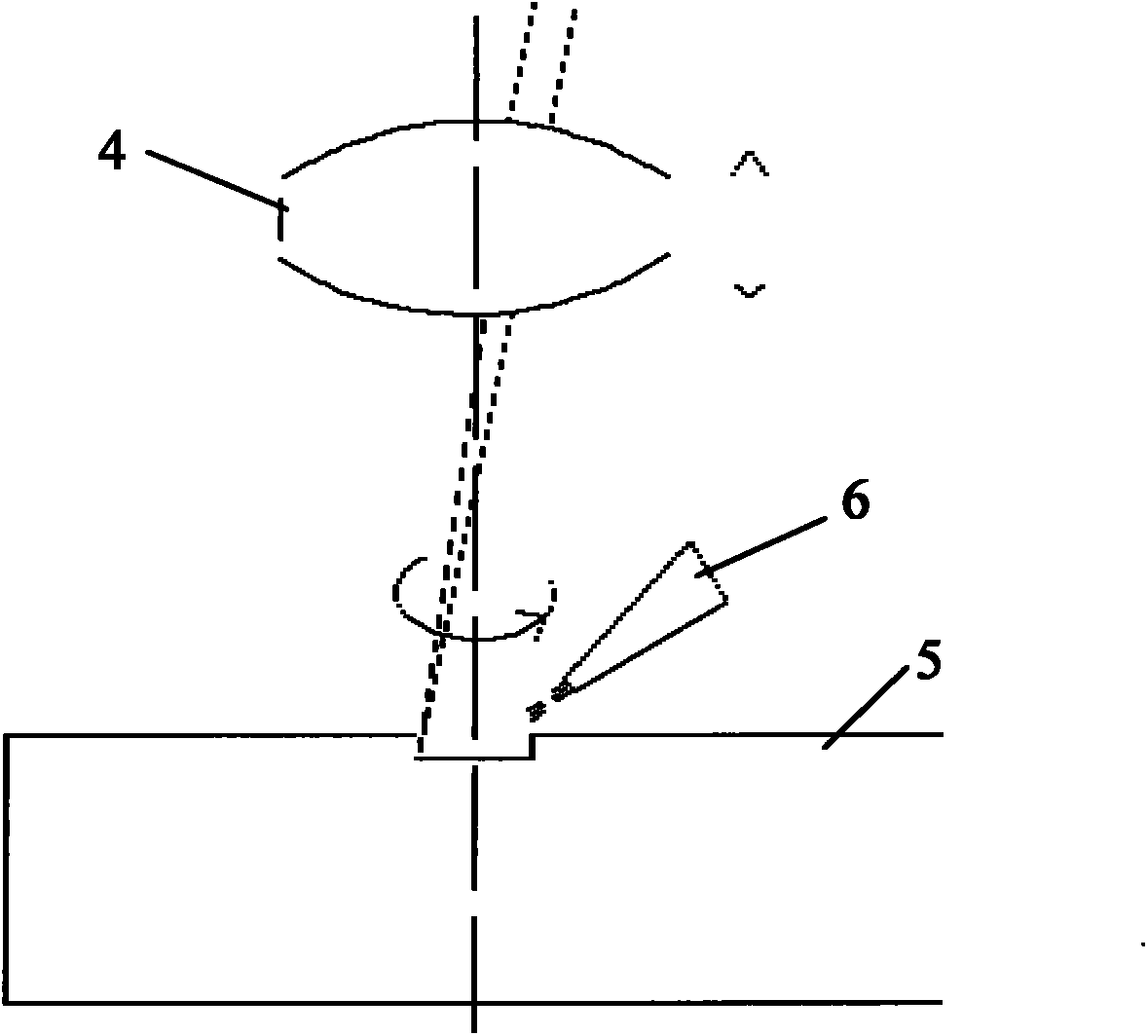

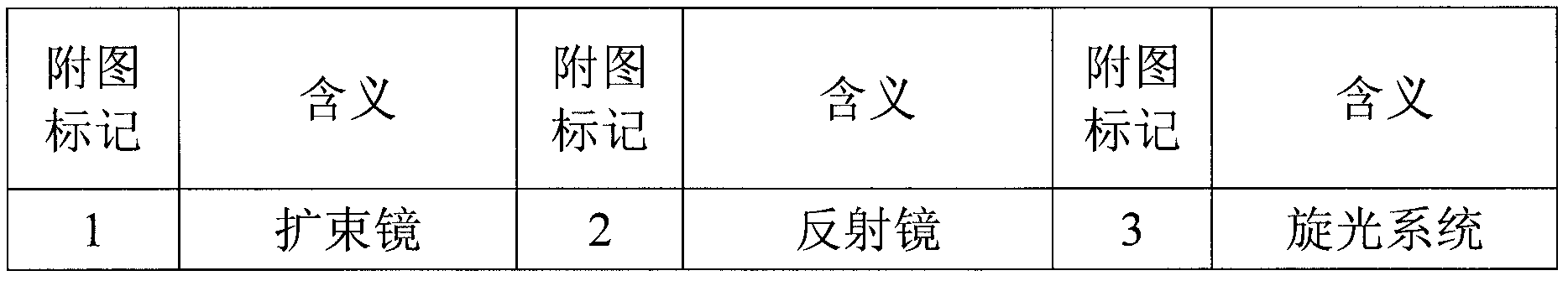

[0017] Such as figure 1 As shown in the laser rotary cutting drilling device, the laser is a Q-switched pulse laser with a pulse width less than 20 ns, the output end of the laser is provided with a beam expander 1, and the output end of the beam expander 1 is arranged with a 45-degree total reflection mirror 2, 45 The output end of the total reflection mirror 2 is arranged with an optical rotation system 3, the optical rotation system 3 includes a first wedge prism 31, a second wedge prism 32, a third wedge prism 33 and a fourth wedge prism 34, the first wedge prism 31 and the second wedge prism The wedge prism 32 is a wedge prism with the same wedge angle. The first wedge prism 31 or the second wedge prism 32 is connected with the up and down linear motion mechanism and can move up and down along the axis. The third wedge prism 33 and the fourth wedge prism 34 have the same wedge angle. The wedge prisms, the third wedge prism 33 or the fourth wedge prism 34 are connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com