Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1511 results about "Tributyl citrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tributyl citrate; tributyl citric acid; from MeSH. Depositor-Supplied Synonyms. Chemical names and identifiers provided by individual data contributors and associated to PubChem Substance records. Synonyms of Substances corresponding to a PubChem Compound record are combined.

Polymeric films

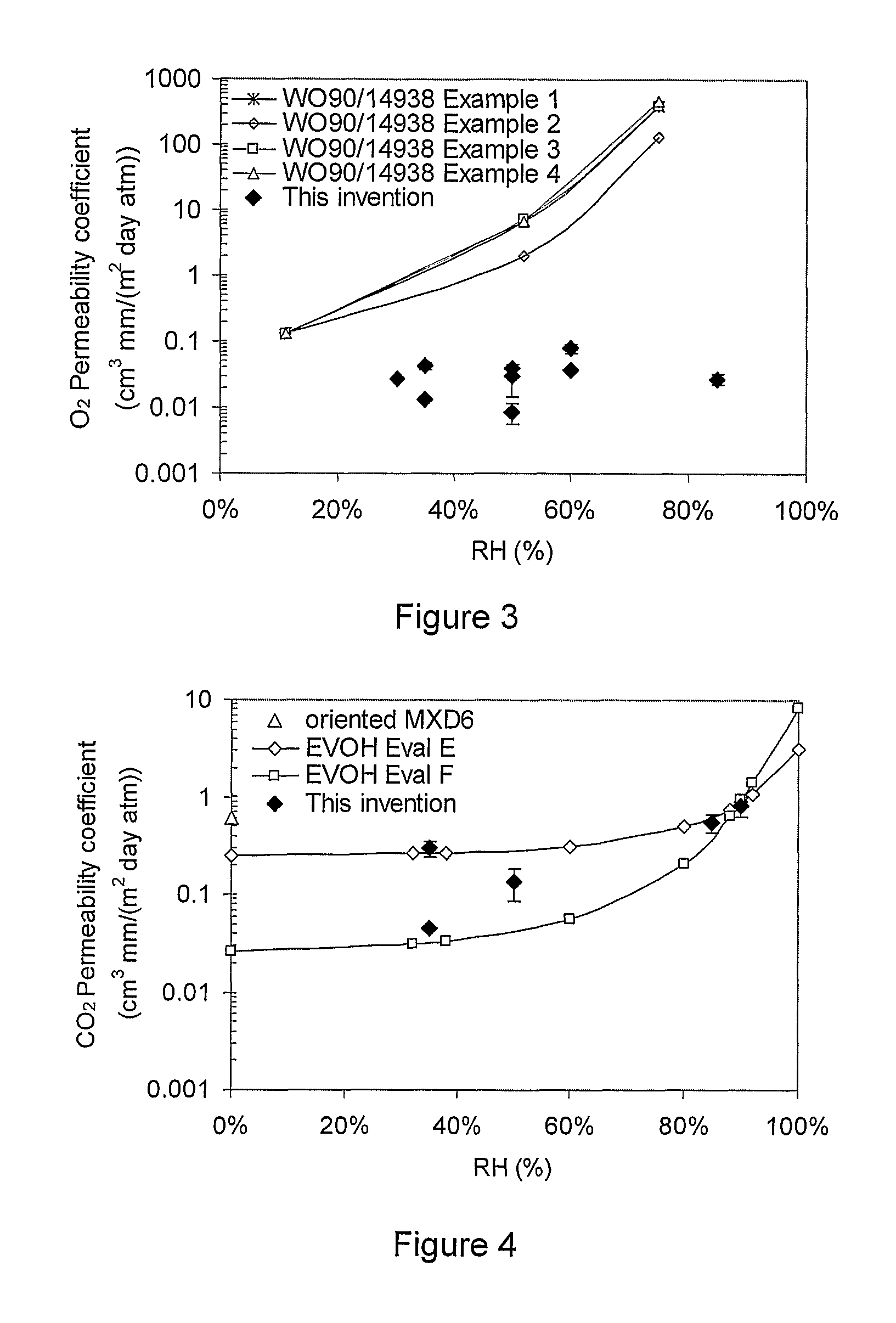

ActiveUS20090312462A1Excellent oxygen barrier propertiesSuitable for usePaper coatingDomestic articlesMolten statePolymer science

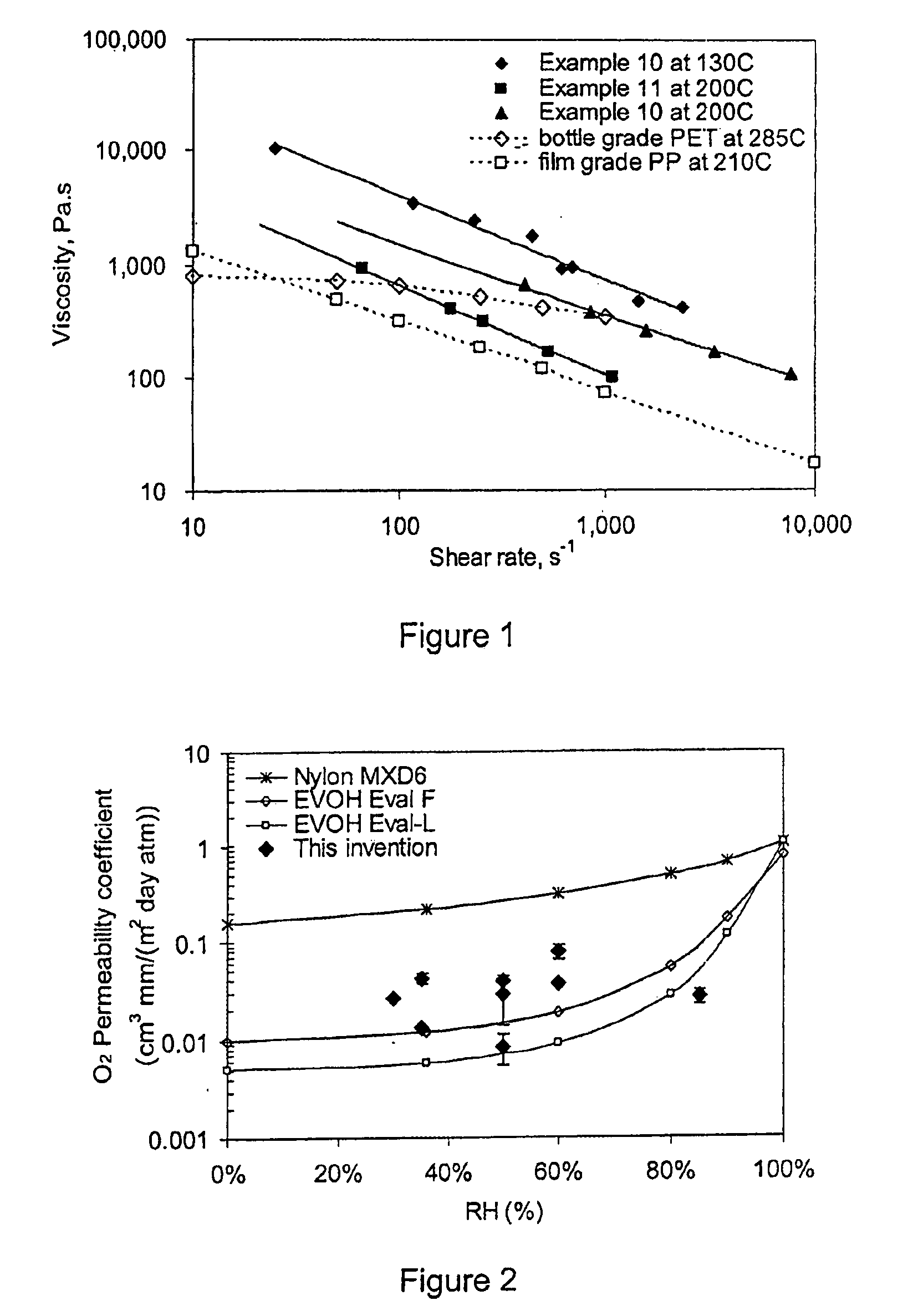

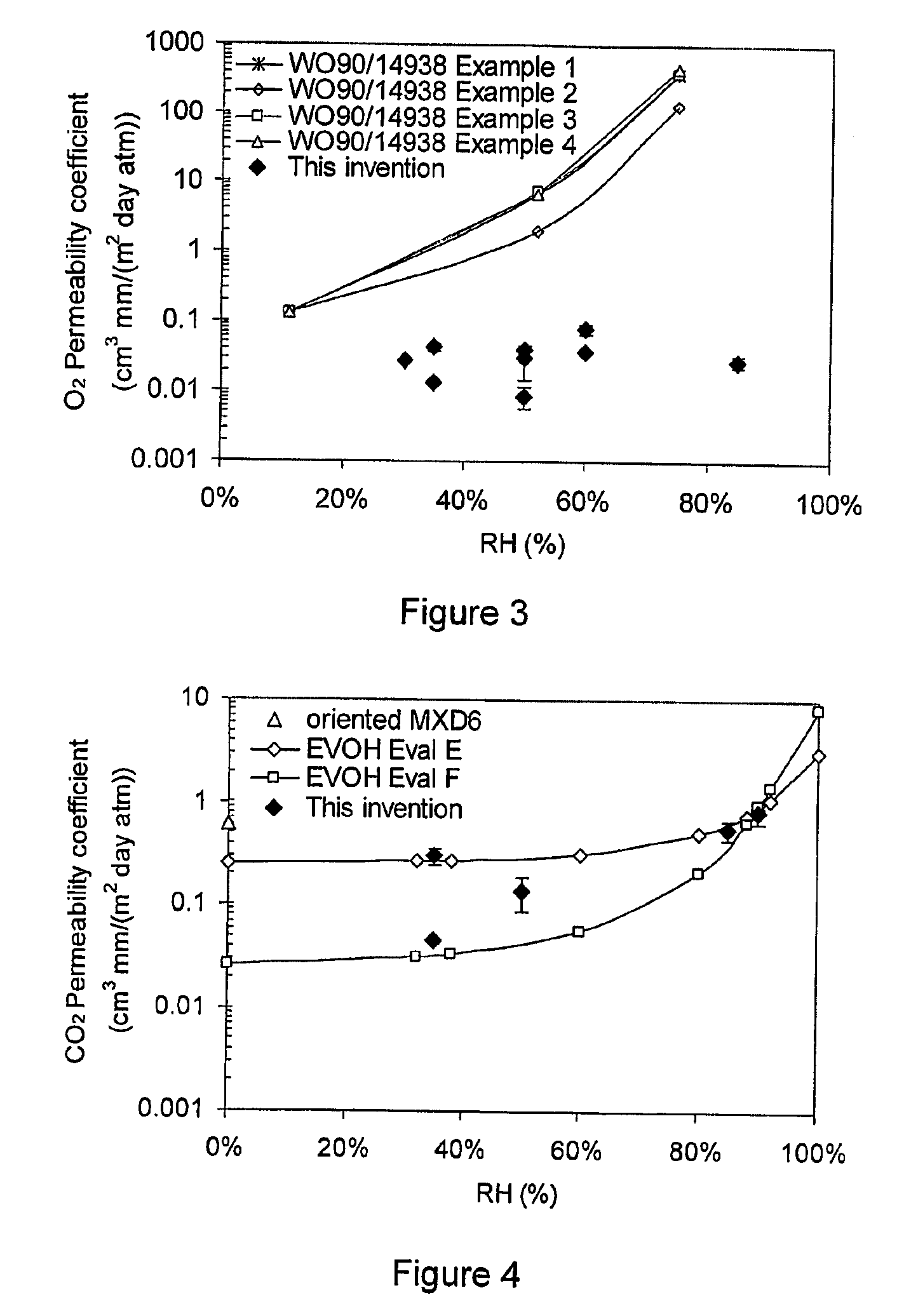

A polymer composition and its use for thin film packaging applications including on a dry basis: a) from 45 to 90% by weight of starch; b) from 0.1 to 15% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch component; and c) from 5 to 45% by weight of one or more plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500 and more preferably still 100-400 and desirably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol.

Owner:PLANTIC TECH

Modified polylactic acid material and preparation method and application thereof

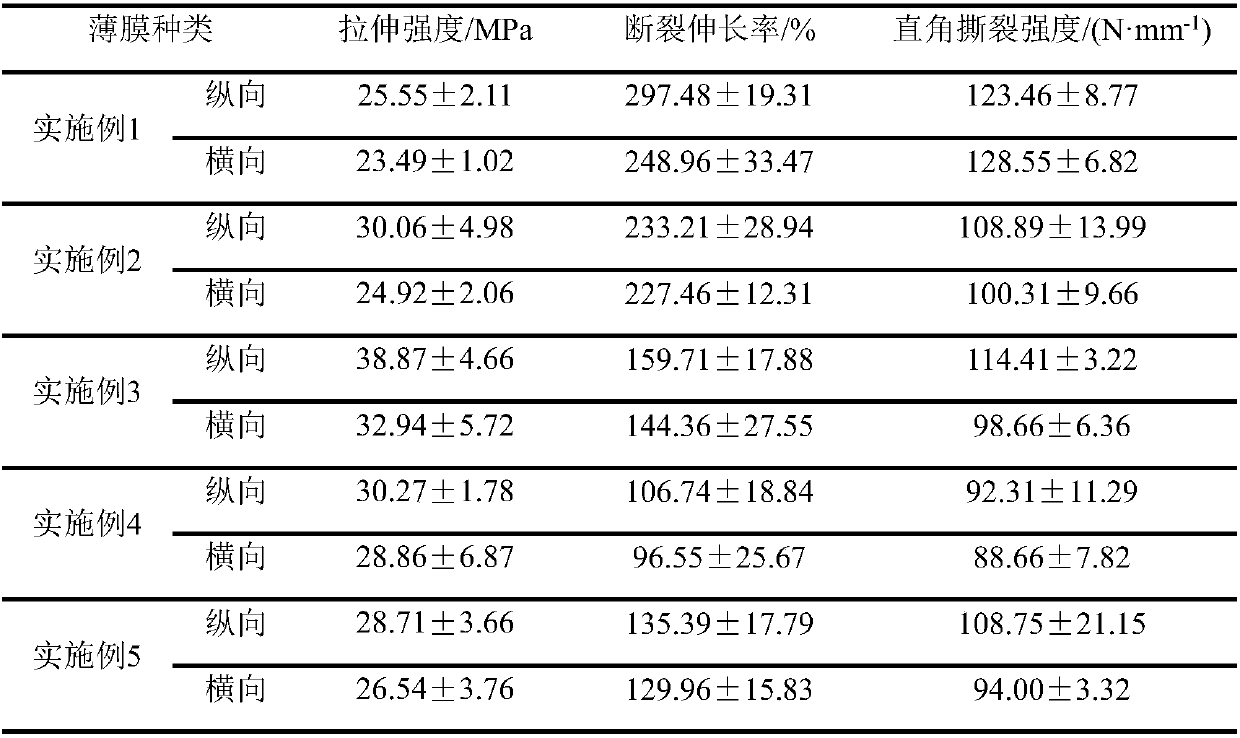

The invention provides a modified polylactic acid material and a preparation method and application thereof. The modified polylactic acid material comprises the following raw materials in part by weight: 40 to 70 parts of polylactic acid, 10 to 20 parts of thermoplastic polyester elastomer, 10 to 20 parts of plasticizer and 10 to 20 parts of organic or inorganic filler, wherein the thermoplastic polyester elastomer is polyester thermoplastic polyurethane; the plasticizer is one or two of tributyl acetocitrate, epoxidized soybean oil, propylene glycol polyester adipate or dioctyl maleate; and the organic or inorganic filler is one or more of starch, talcum powder, calcium carbonate, mica, montmorillonite, clay or titanium dioxide. The modified polylactic acid material has the advantages of improving the flexibility of a polylactic acid material and reducing the cost of a biodegradable material. A mechanical performance test shows that in the modified polylactic acid material, the tensile strength is 15 to 70 MPa and the fracture tensile rate is 20 to 38 percent.

Owner:江苏天仁生物材料有限公司

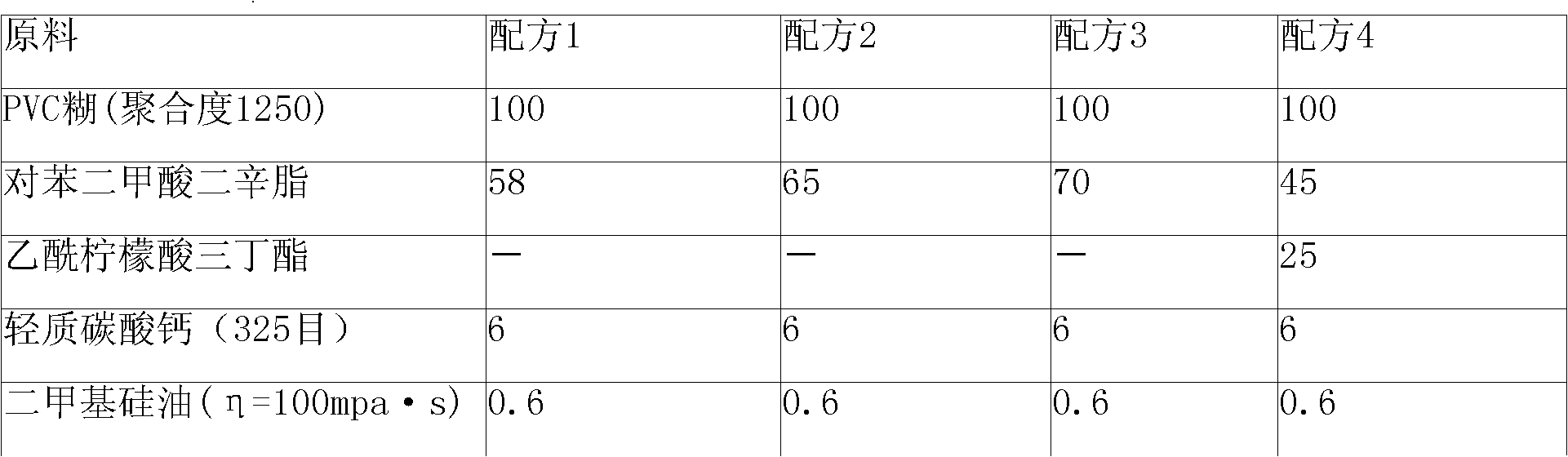

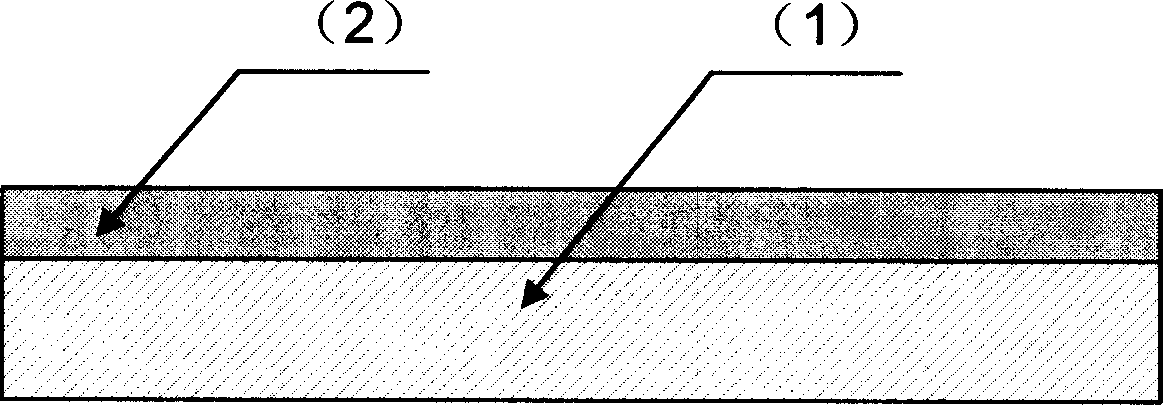

Barrier film

InactiveUS20090110942A1Stable mechanical propertiesImprove homogeneityFireproof paintsFibre treatmentMolten statePolyethylene oxide

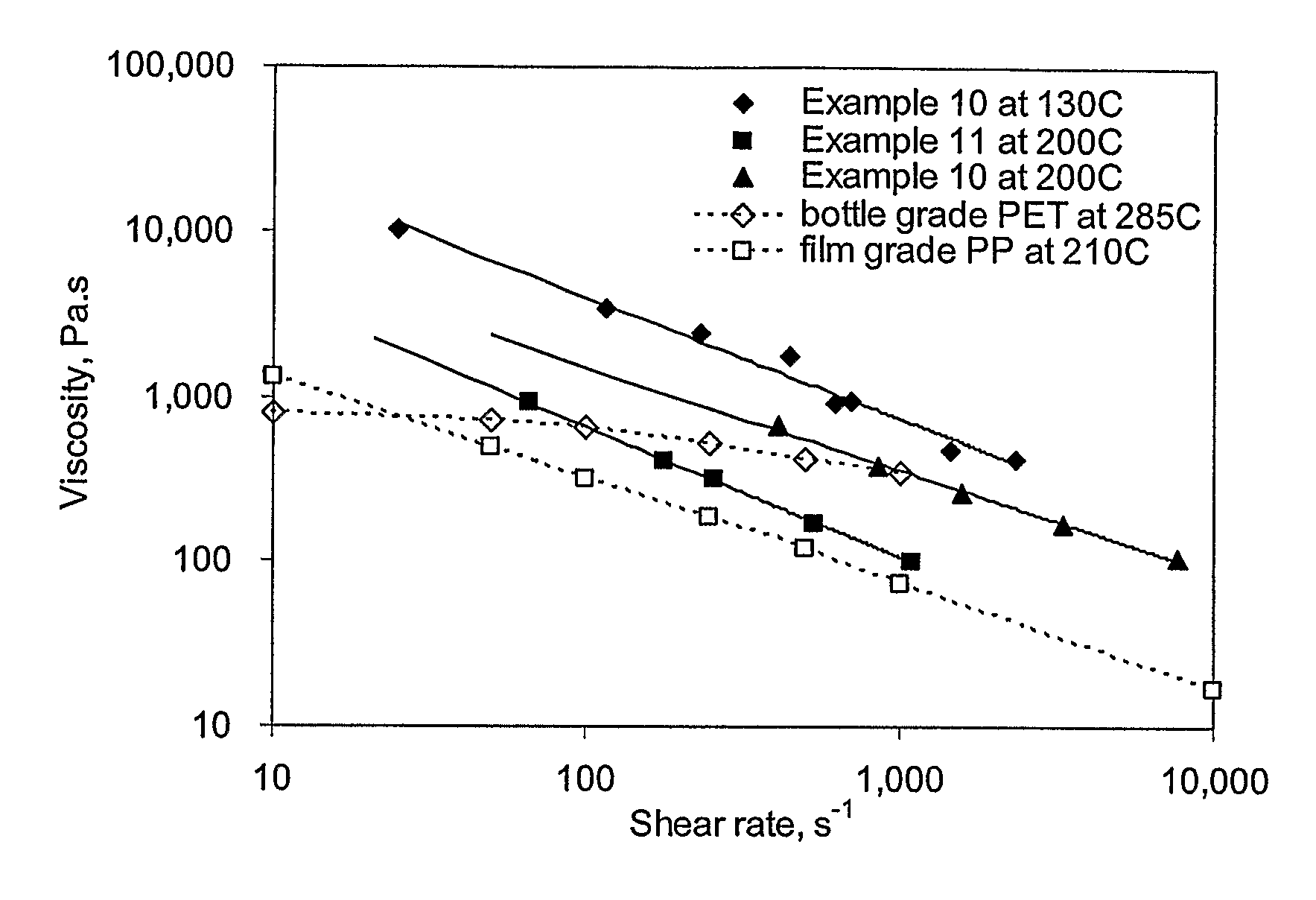

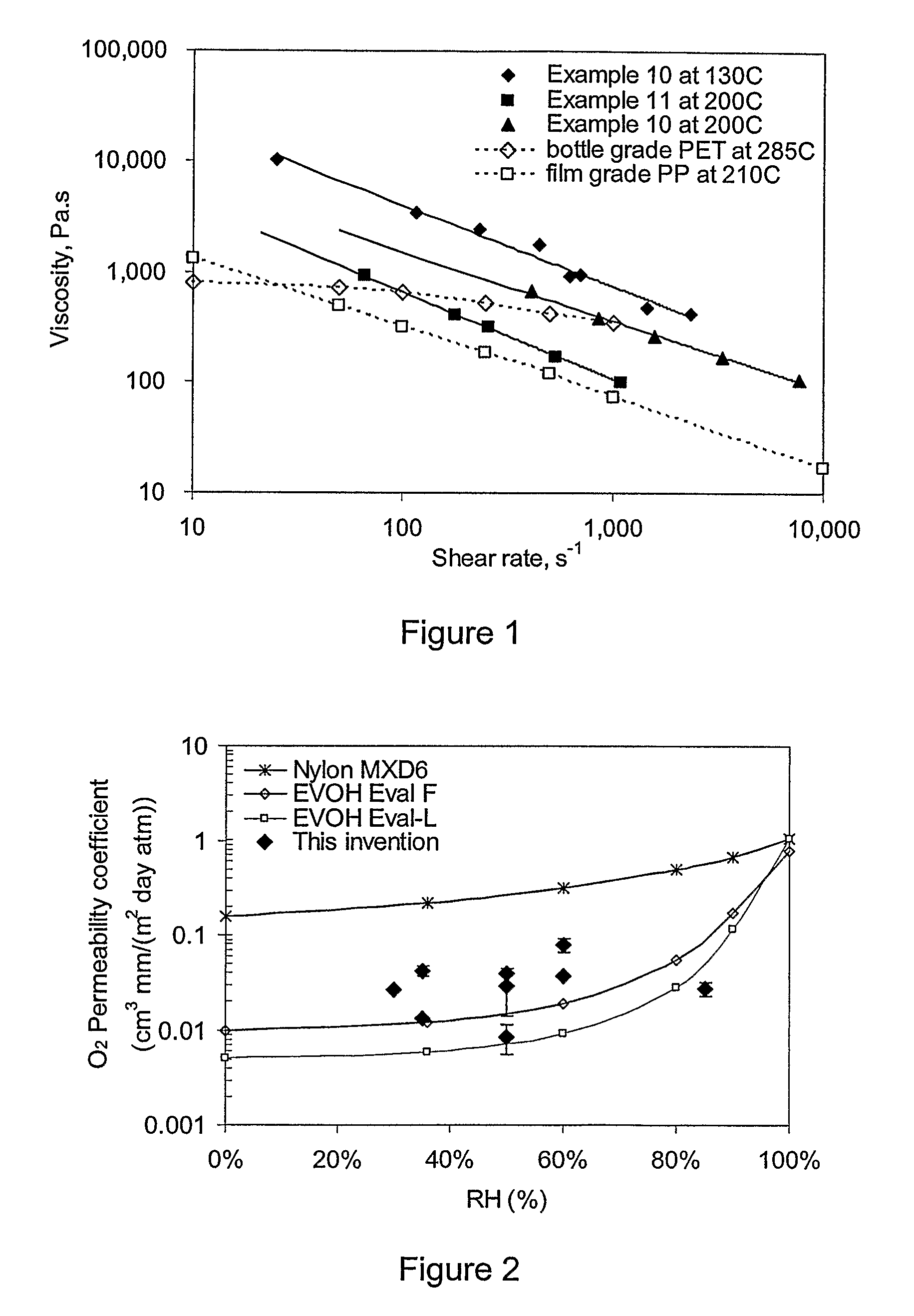

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5 % by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

Barrier film

InactiveUS7854994B2Improve the level ofImprove homogeneityFibre treatmentBottlesPolyethylene terephthalate glycolPolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5% by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

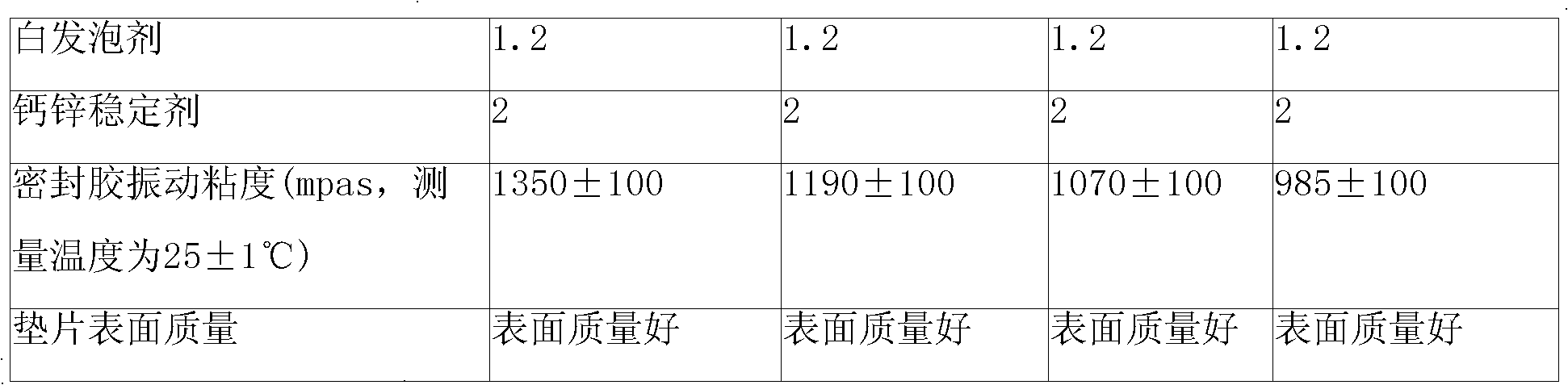

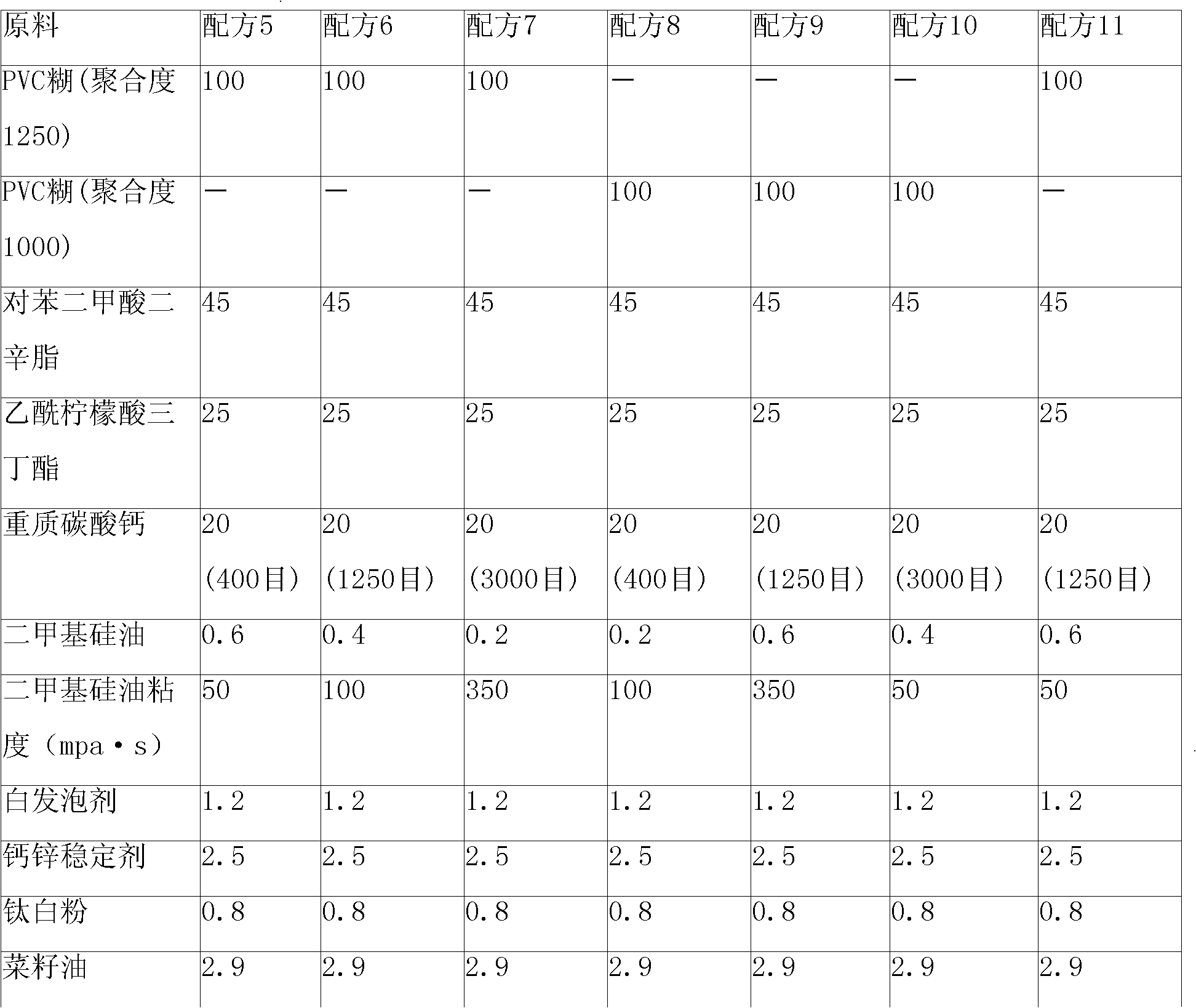

Asepsis environment-protecting polycinyl chloride bottle cap sealant and method for preparing same

InactiveCN101338171ALow priceImprove sealingOther chemical processesAdhesivesPolyvinyl chlorideRapeseed

The invention discloses a nontoxic environment protection polyvinyl chloride sealing gel and a preparation method thereof. The gel is made of pvc paste resin, dioctyl phthalate, acetyl tri-n-butyl citrate, heavy calcium carbonate, calcium-zinc stabilizer, white foaming agent, titanium dioxide, dimethicone and rapeseed oil. Phthalic ester plasticizer is not comprised. The gel meets the requirements of the food safety, and corresponds with the RoHS instruction. The gel is a foot and environmental friendly sealing gel. The using amount of fillings is added. The production cost is lowered. The nontoxic and environmental friendly sealing gel has the advantages of low price, high temperature resistance, good sealing effect and convenient engagement.

Owner:贵州省复合改性聚合物材料工程技术研究中心 +1

Glove made with non-toxic plasticizer ATBC

A combination of materials in a PVC / Nitrile glove fabricated from a conventional manufacturing process comprising approximately 50% Polyvinyl Chloride (PVC) powder, approximately 45% O-Acetyl Tributyl Citrate (ATBC); and approximately 5% TXIB and a stabilizer (CZ-115).

Owner:LIU GUIXI

Low cost bio-based full degradable film and preparation method thereof

The present invention discloses a low cost bio-based full degradable film and preparation method thereof, the ratio of each component in parts by mass of the film is as follows: 15-25 parts of a polyglycolic acid, 25-35 parts of corn starch, 35-55 parts of poly(butylene adipate-co-terephthalate), 5 parts of a compatilizer, 3.75-12.25 parts of a starch plasticizer, 0.5-0.7 part of citric acid, 0.75-1.25 parts of acetyl tributyl citrate, 0.3-0.5 part of maleic anhydride, 0.2 part of antioxidant 164, and 0.2 part of 2-(2″-hydroxyl-5″-methylphenyl)benzotriazole. The low cost bio-based full degradable film provided by the present invention has a bio-based content, which can reach 30% or more, a lower cost, and a tensile strength exceeding a traditional PE thin film, and has very important significance for solving the problem of “white pollution” and promoting the popularization and application of full biodegradable materials.

Owner:JIANGSU JINJU ALLOY MATERIAL

Poly lactic acid composition film and its preparing method and use

The polylactic acid film contains polylactic acid 85-98 wt% and medical plasticizer 2-15 wt%, the polylactic acid may be poly L-lactic acid, poly DL-lactic acid, lactic acid-glycolic acid copolymer or the copolymer of poly L-lactic acid and poly DL-lactic acid with molecular weight of 20-1500 KDa, and the medical plasticizer is tributyl citrate, tributyl acetylcitrate, polyethylene glycol or lactic acid oligomer. The polylactic acid composition of the present invention has excellent flexibility, may be used in introducing the growth of hard and soft tissues in repairing cleft palate or as regenerating film, and introducing the regeneration of bone tissue.

Owner:成都迪康中科生物医学材料有限公司

Concrete with functions of crack resistance and infiltration resistance

InactiveCN104386959AReduce porosityImprove pore structureSolid waste managementCrack resistanceDiethylenetriamine

The invention discloses concrete with the functions of crack resistance and infiltration resistance. The concrete comprises the following raw materials in part by weight: 70-100 parts of cement, 400-500 parts of macadam, 50-70 parts of river sand, 40-50 parts of fly ash, 30-60 parts of mine residues, 5-20 parts of coal slack, 20-50 parts of basalt fibers, 5-15 parts of polypropylene fibers, 5-20 parts of glass fibers, 6-13 parts of expanded perlite, 20-80 parts of nanometer silicon dioxide, 5-15 parts of nano calcium carbonate, 1-3 parts of sodium dodecyl sulfate, 3-6 parts of zinc stearate, 2-5 parts of zinc borate, 3-7 parts of sodium citrate, 0.5-1.4 parts of acetyl tributyl citrate, 0.7-1.3 parts of diethylenetriamine, 3-10 parts of a water reducing agent, and 80-100 parts of water. The concrete disclosed by the invention has the advantages of good crack resistance, excellent infiltration resistance and good durability.

Owner:WUWEI HENGJI COMML CONCRETE

Coloured PVC waterproof roll and its preparation method

InactiveCN1844294AHigh tensile strengthUniform plasticizationOther chemical processesNitrile rubberPolyvinyl chloride

The invention relates to a colored polyvinyl chloride water-proof coiled material, which is prepared from the following constituents (by weight portions): PVC resin 100 parts, phthalandione dioctyl or tributyl citrate 35+-5 parts, powdered nitrile rubber or chlorinated polyethylene 10+-2 parts, calcium carbonate 30+-10 parts, rare earth heat stabilizer 1.5+-0.5 parts, barium stearate0.3+-0.1 part, stearic acid 0.2+-0.1 part. The invention also discloses its preparing process.

Owner:JIANGSU HUAHONG RUBBER & PLASTIC

Completely biological degradable polylactic coating materials

A fully biodegradable polylactic acid coating material for the coated paper consisting of paper substrate and coated plasticizing polylactic acid composition is disclosed. Said plasticizing polylactic acid composition contains proportionally polylactic acid, composite plasticizer chosen from polyethandiol, glucoside triacetate, triethyl citrate, tributyl citrate, triethyl acetylacetate, etc, lipoamide and inorganic filler. The coated paper features high resistance to water, oil and high temp, air tight, and antibacterial effect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

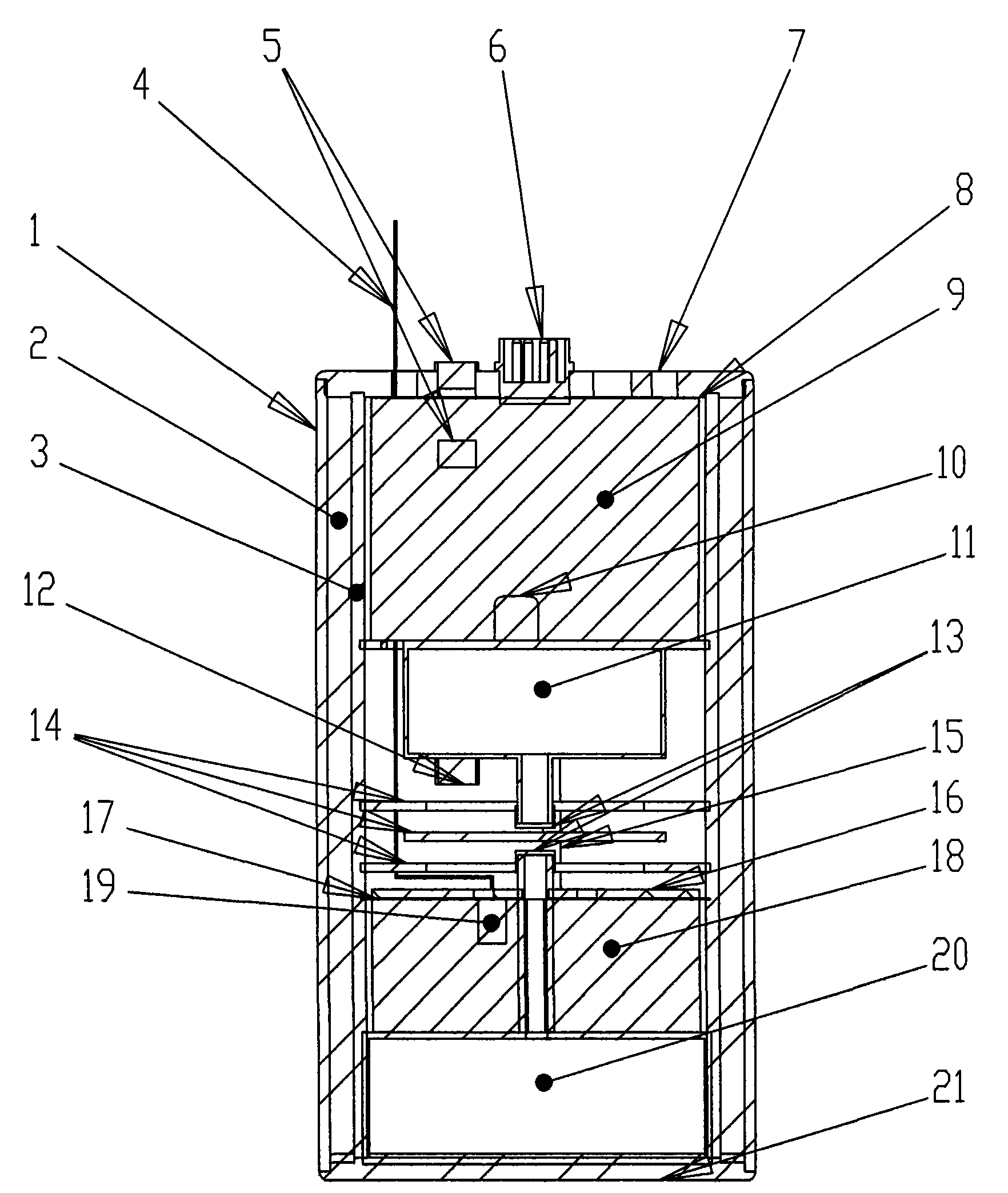

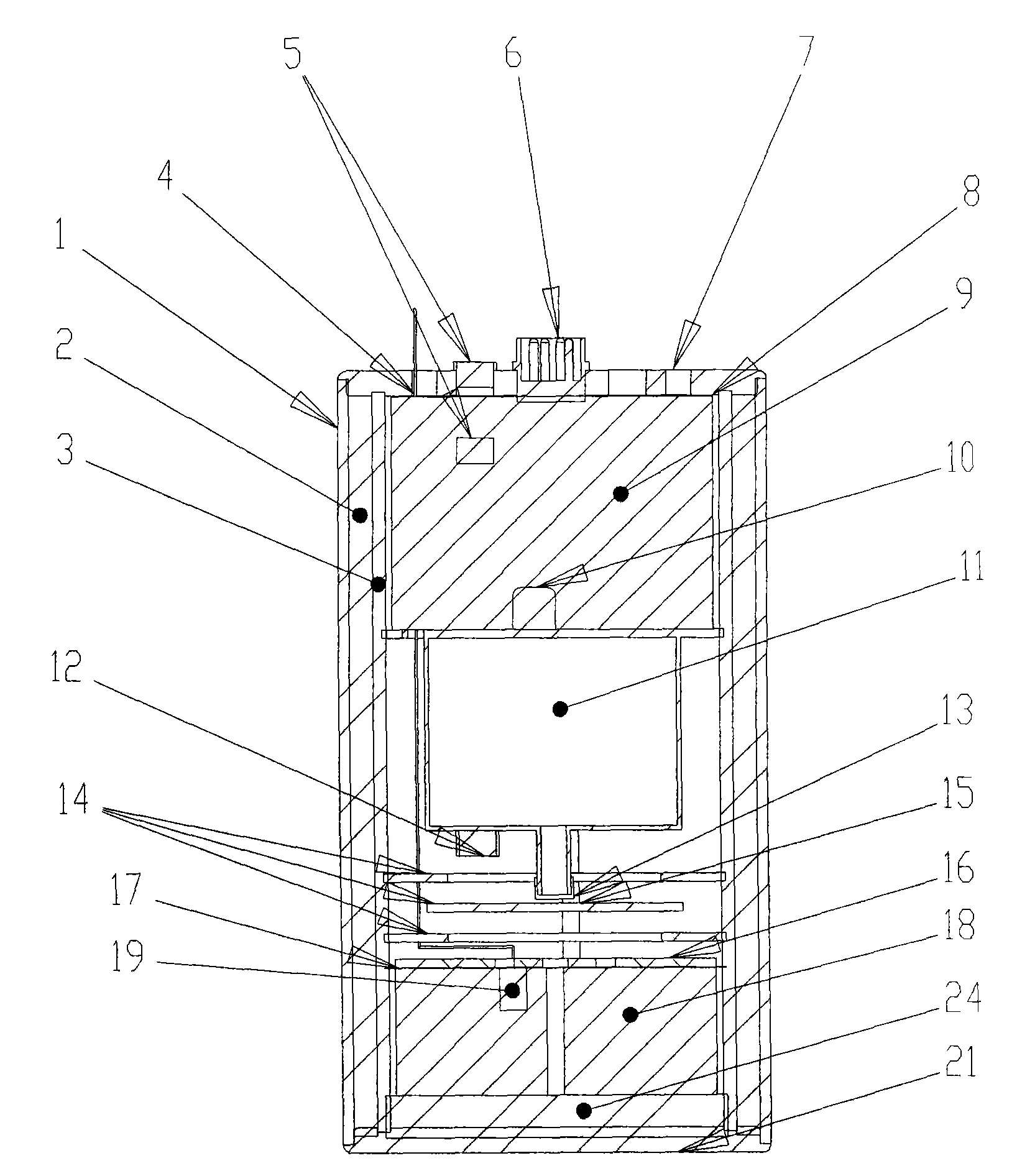

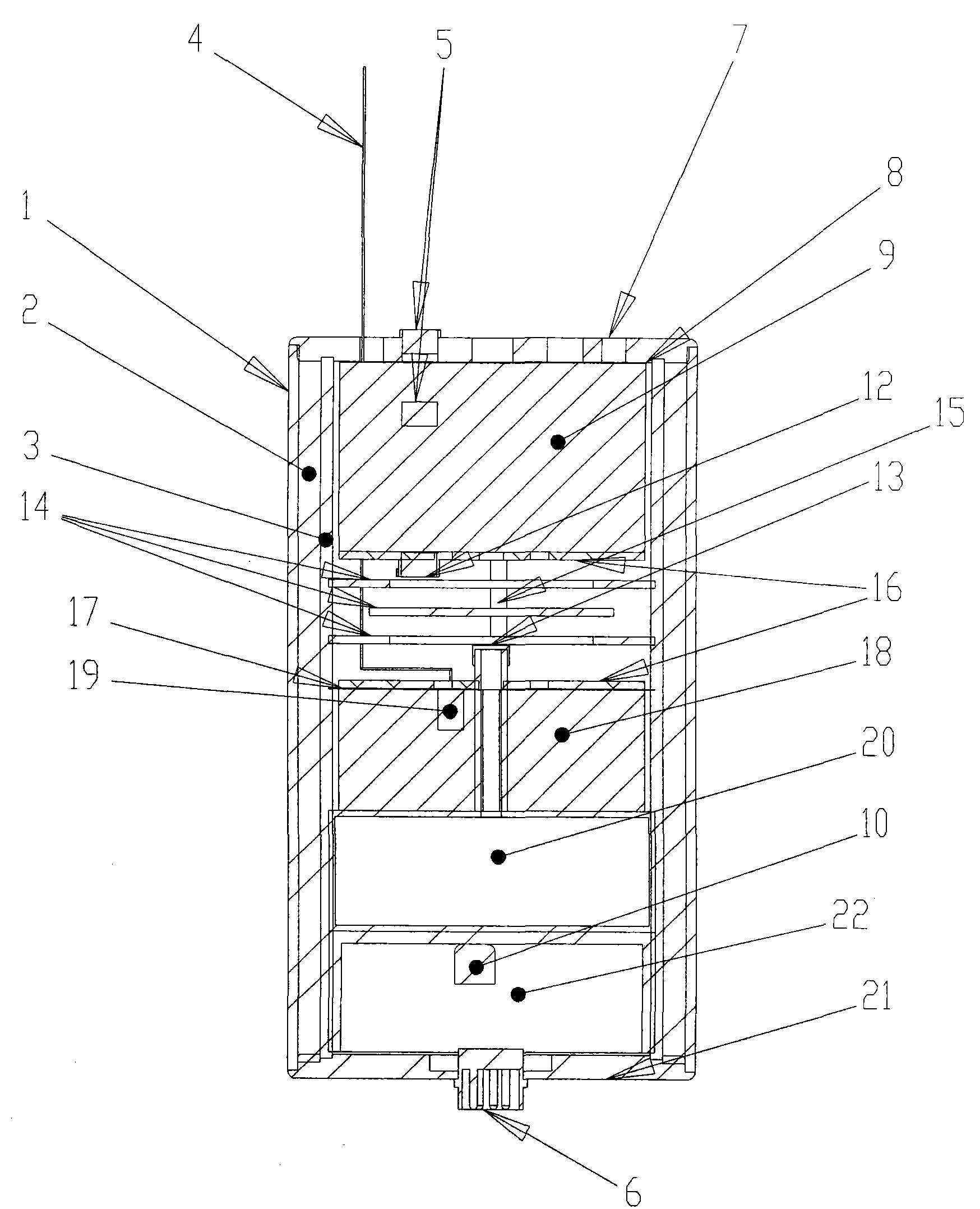

Steam hot aerosol fire-extinguishing composite and application method and fire extinguishing device thereof

ActiveCN101554520AWide variety of sourcesLess corrosiveFire rescueFire extinguisherSodium bicarbonateEpoxy

The invention provides a steam hot aerosol fire-extinguishing composite which contains 30-80wt percent of oxidant, 10-60wt percent of fuel additive and 2-30wt percent of cohesion solidification molding auxiliary agent. The oxidant can be one or more of the following substances: potassium salt, strontium salt, ammonium salt, magnesium salt, nitrocellulose and nitroglycerin; the fuel additive can be one or more of the following substances: azos, azoles, amino-guanidine nitrate, sodium bicarbonate, melamine, cyanoguanidine, carbamide, hexamine, triaminoguanidine nitrate, olefin, saccharose, aluminium powder, magnesite powder and magnesium-aluminium alloy power; the cohesion solidification molding auxiliary agent can be one or more of the following substances: phenol formaldehyde resin, ethoxyline resin, glycidyl azide, urethane rubber, hydroxyl-terminated polybutadiene, polyisobutylene, acetyl tributyl citrate, carboxymethyl cellulose, polyvinyl alcohol phenolic resin and acrylic resin. The invention also provides a fire extinguishing method and a fire extinguishing device adopting the composite. The invention has strong fire extinguishing capacity and fewer hazardous materials and can be applied to different places.

Owner:JIANGXI TSINGHUA IND CO LTD

Dielectric paste for metal aluminum substrate thick film circuit and preparation method thereof

InactiveCN101740160AImprove thixotropyGood anti-sinking effectNon-macromolecular adhesive additivesSolid-state devicesDielectricCITRATE ESTER

The invention discloses dielectric paste for a metal aluminum substrate thick film circuit and a preparation method thereof. The invention aims to prepare the dielectric paste matched with a metal aluminum substrate. The dielectric paste is characterized in that SiO2, Na2O, B2O3, K2O, BaO, CaO, Co2O3, TiO2, P2O5, V2O5, Sb2O3 and Cr2O3 are combined to prepare microcrystalline glass powder; and the microcrystalline glass powder and an organic binder which consists of terpinol, butyl carbitol, butyl carbitol acetate, tirbutyl citrate, 1,4-butyrolactone, nitroncellulose, ethyecellulose, hydrogenated castor oil and lecithin are put in a vessel for stirring and rolling by a three-roll roller mill in a weight ratio of the microcrystalline glass powder to the organic binder of 70-90 parts: 30-10 parts so as to prepare the finished product dielectric paste. The dielectric paste is mainly used as the dielectric paste of the thick film circuit formed by being printed on the metal aluminum substrate.

Owner:湖南利德电子浆料股份有限公司

Mouldable Biodegradable Polymer

InactiveUS20100297458A1Synthetic resin layered productsCellulosic plastic layered productsMolten statePolyethylene oxide

A biodegradable injection mouldable polymer composition including on a dry weight basis from 45-85% w / w by weight of a starch and / or a modified high amylose starch, from 2-15% w / w by weight of a water soluble polymer preferably selected from polyvinyl alcohol, polyvinyl acetate and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch components, and from 5-45% w / w by weight of one or more polyol plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500, and still more preferably 100-400 and preferably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, polyglycerol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol; more preferably glycerol, maltitol, sorbitol, erythritol and xylitol. The composition is preferably substantially soluble in water.

Owner:PLANTIC TECH

Medium temperature sintering type electro-conduction slurry with lead-free glass powder and preparation method of medium temperature sintering type electro-conduction slurry

InactiveCN103903677ALow softening temperatureMeet the requirements of energy saving and environmental protectionNon-conductive material with dispersed conductive materialCable/conductor manufactureMicron scaleAlkali metal oxide

The invention discloses a medium temperature sintering type electro-conduction slurry with lead-free glass powder and a preparation method of the medium temperature sintering type electrocondution slurry. The preparation method is characterized by comprising the steps of preparing an organic carrier, preparing the lead-free glass powder, preparing silver powder and preparing the electro-conduction slurry. The electro-conduction slurry comprises, by mass, 0 to 80% of micron-scale spherical silver powder, 5% to 70% of micron-scale flake silver powder, 2% to 25% of the lead-free glass powder and 0 to 25% of the organic carrier. The lead-free glass powder comprises, by mass, 25% to 75% of Bi2O3, 20% to 60% of B2O3, 0 to 20% of ZnO, 0 to 20% of Sb2O3, 0 to 10% of Al2O3 and 0 to 8% of alkali metal oxide. The organic carrier comprises, by mass, 50% to 80% of terpilenol, 10% to 40% ofbutyl carbitol acetic ester, 0 to 10% of tributyl citrate, 3% to 10% of ethocel, 0 to 2% of hydrogenated castor oil and 0 to 3% of addition agent.

Owner:SHANGHAI INTELLIGENT SENSOR ELECTRONICS TECHCO

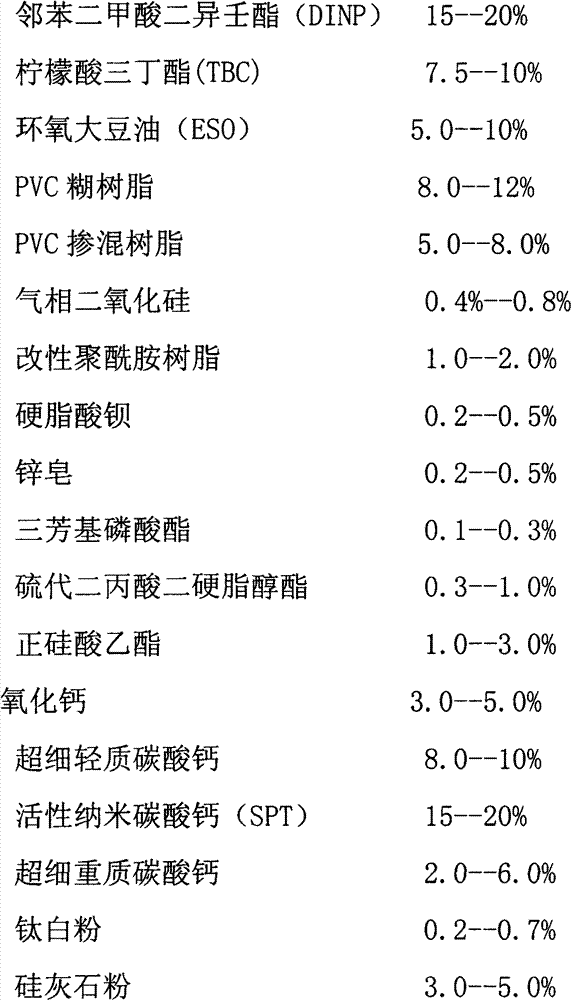

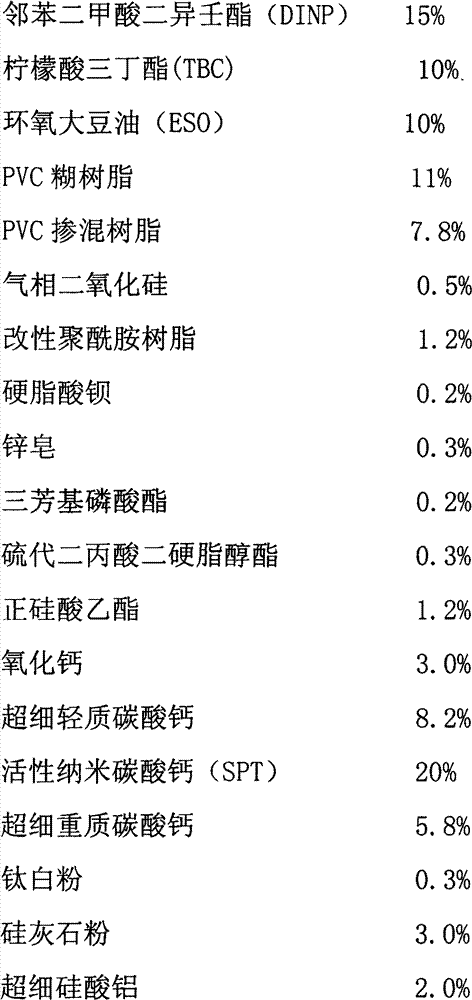

Environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for vehicle

ActiveCN102757746AGood compatibilityReduce usageNon-macromolecular adhesive additivesOther chemical processesPhosphateTributyl citrate

The invention relates to an environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for a vehicle. The environment-friendly PVC weld joint sealant mainly comprises the components of diisononyl phthalate (DINP), tributyl citrate (TBC), epoxidized soybean oil (ESO), PVC paste resin, PVC blend resin, fumed silica, modified polyamide resin, barium stearate, zincsoap, triaryl phosphate, thiodipropionic acid distearate alcohol ester, tetraethoxysilane, calcium oxide, ultrathin light calcium carbonate, active nano-calcium carbonate (SPT), ultrathin heavy calcium carbonate, titanium dioxide, wollastonite in powder, ultrathin aluminium silicate and the like. According to the environment-friendly PVC weld joint sealant provided by the invention, the technologies of raw material compounding, nontoxic additive adding and the like are adopted so as to reduce the curing temperature of the sealant; and a 'wet-to-wet' technology is achieved during coating the vehicle. Through the adoption of the environment-friendly PVC weld joint sealant, the energy consumption is reduced, and the volatizing of harmful gases is reduced. The environment-friendly PVC weld joint sealant has the characteristics of nontoxicity, environmental protection, fireproof performance, energy conservation, easiness in construction and the like The environment-friendly PVC weld joint sealant is an energy-conservation environmental-protection PVC weld joint sealant.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

Capacitor film containing modified attapulgite and preparation method thereof

ActiveCN102964664AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethylenePolyvinyl alcohol

The invention discloses a capacitor film containing modified attapulgite and a preparation method thereof. The capacitor film comprises the following raw materials, by weight: 30-40 parts of homogeneous ethylene / alpha olefin copolymer, 25-30 parts of metallocene linear low-density polyethylene resin, 13-18 parts of LDPE low-density polyethylene, 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 1.2-1.5 parts of poly-4-methyl-1-pentene, 7-9 parts of modified attapulgite, 0.8-1.2 parts of an antioxidant DLTP, 0.6-0.8 part of tributyl citrate, 1.4-1.8 parts of dioctyl maleate, 4-6 parts of calcium stearate, 1.4-1.8 parts of vinyl tri (beta-methoxy ethyoxyl) silane and 0.8-1.2 parts of modified wood ash. The preparation method provided by the invention is simple; addition of diatomite, modified attapulgite and modified wood ash enhances resistance and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength and good heat sealing performance.

Owner:ANHUI YIDA ELECTRONICS

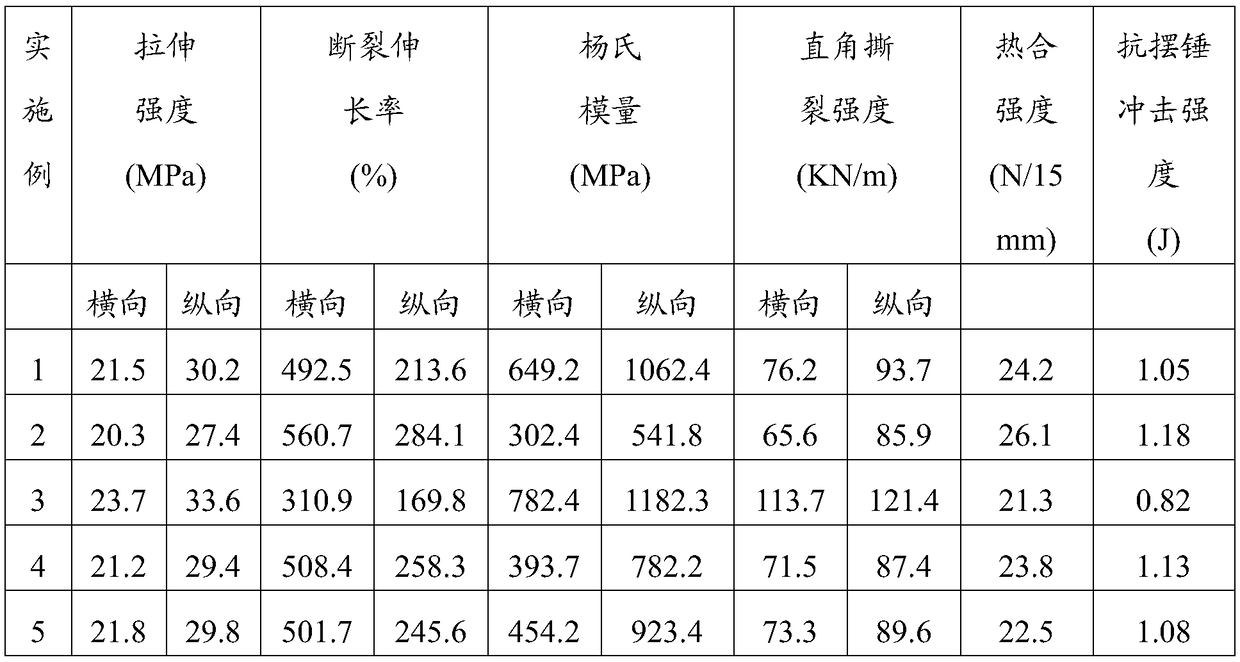

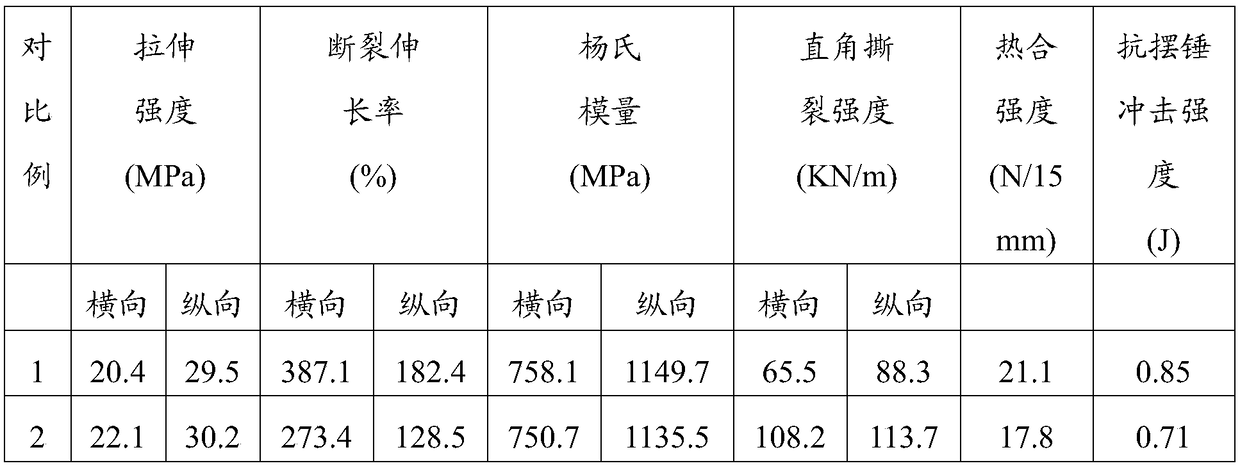

Completely-biodegradable blown film as well as preparation method and application of completely-biodegradable blown film

ActiveCN109177401AImprove melt strengthGood dispersionSynthetic resin layered productsFlat articlesMethacrylatePolymer science

The invention provides a completely-biodegradable blown film as well as a preparation method and application of the completely-biodegradable blown film. The film comprises an inner layer, a middle layer and an outer layer which are in contact in sequence; based on parts by weight, the inner layer comprises polylactic acid, poly(terephthalic acid)-adipic acid-butylene glycol ester, talcum powder, an antiblocking agent and carbon black; each of the middle layer and the outer layer comprises polylactic acid, poly(terephthalic acid)-adipic acid-butylene glycol ester and titanium dioxide; and eachof the three layers further comprises glycerol monooctadecanoate, acetyl tributyl citrate, ethylene bisstearamide and a chain extender; the antiblocking agent is erucylamide or oleamide; and the chainextender is a copolymer of styrene-acrylic acid-propylene oxide methacrylate and / or a copolymer of styrene-maleic anhydride-propylene oxide methacrylate. The film has relatively high tensile elongation at break, pendulum impact strength, tensile strength, Young modulus and heat sealing strength and keeps complete biodegradability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Low-temperature sintering type conductive slurry based on semiconductor chip agglutination and its manufacturing technique

InactiveCN101246760AAvoid crackingVolatile evenlyOil/fat/wax adhesivesSemiconductor/solid-state device manufacturingMetallurgySemiconductor chip

The invention discloses a semiconductor-chip-based low-temperature sintering type conductive slurry for bonding and the preparing technology thereof. The slurry is composed of a solid phase composition and an organic binder, the weigh proportion of which is 70-90:30-10, the solid phase composition is mixed with sheet-like and ball-shaped composite silver powder and glass powder in a weight proportion of 65-90:35-10, wherein the weight proportion of the sheet-shaped silver powder and the ball-like silver powder is 5-15: 95-85, the average grain diameter of the composite silver powder is less than 4mum, the glass powder is PbO-Al2O3-SiO2 glass powder, the main compositions are: PbO: 95%-60%, Al2O3: 2%-30%, SiO2: 1%-20%, TiO2: 0.5%-20%; the main compositions of the organic binder are: terpilenol: 50%-70%, tributyl citrate: 35%-15%, lecithin: 5%-1%, ethyl cellulose: 8%-3%, hydrogenated castor oil: 5%-10% and dimethylbenzene: 2%-10%. The slurry has high thermal conductivity, high conductivity, low-expansion coefficient and high heat dispersion.

Owner:CENT SOUTH UNIV

A kind of low-temperature sintering nano-silver paste and preparation method thereof

ActiveCN102290117ALower sintering temperatureHigh thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPolyvinyl alcoholAlloy

The invention discloses a low temperature-sintered nano silver paste and a preparation method thereof. The invention is characterized in that: by weight percent, the components of the nano silver paste are as follows: 78.5 to 89.5 percent of nano silver powder with the average grain size of 20nm to 50nm; 5.0 percent to 10.0 percent of polyvinyl alcohol as organic carrier; 5.0 percent to 10.0 percent of tributyl citrate as organic solvent; and 0.5 percent to 1.5 percent of abietic acid as surfactant. The nano silver paste preparation method sequentially includes the following steps: ethanol solution water heating, component adding and mixing, ultrasonic dispersion under zero DEG C, mechanical stirring and vacuum drying. The sintering temperature of the silver paste is notably decreased, and does not need to reach the softening temperature of glass, moreover, the silver content of the sintered material is at least 98 percent, the nano silver paste has high heat conductivity and high reliability, and the heat conductivity of the nano silver paste is three to four times higher than the heat conductivity of alloy solder, and thereby the heat-dissipating problem of packaging is effectively solved. The low temperature-sintered nano silver paste is particularly suitable for use as novel thermal interface material for the interconnection between power type chips in the field of electronic packaging.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

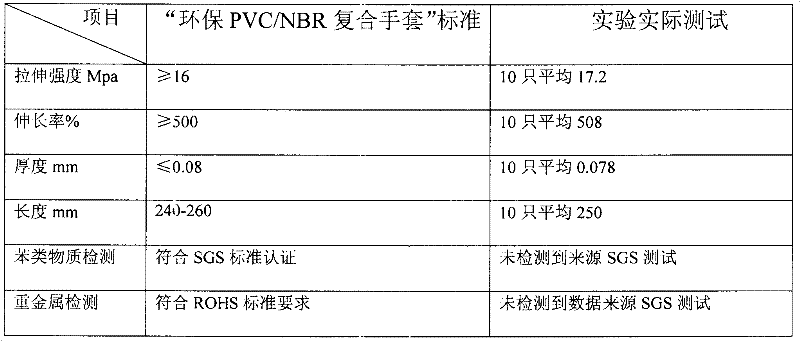

Environmentally-friendly polyvinyl chloride/nitrile butadiene rubber (PVC/NBR) composite gloves

InactiveCN102336988AReduced ability to migrateReduce volatilityCoatingsProtective garmentPolyesterPolymer science

The invention discloses environmentally-friendly polyvinyl chloride / nitrile butadiene rubber (PVC / NBR) composite gloves. The composite gloves are prepared from the following raw materials: PVC paste resin powder, plasticizer, heat stabilizer, NBR, accelerant, vulcanizing agent and color paste in a ratio of 100:(40-60):(0.9-1.8):(25-40):(0.5-1):(0.5-1):(2-5), wherein the plasticizer is ATBC (acetyl tributyl citrate) / polyester plasticizer; the heat stabilizer is phenol-free environmentally-friendly calcium-zinc heat stabilizer; the accelerant is tetramethyl thiuram disulfide / N-cyclohexyl-2-benzothiazole sulfonamide (TMTD / CZ); and the vulcanizing agent is sulfur. The composite gloves have the advantages that the mobility and volatility of the materials in the raw materials are reduced, the energy consumption is lowered, the wearing comfort is improved at the same time, and harm to human bodies is completely avoided.

Owner:江苏尤佳手套有限公司

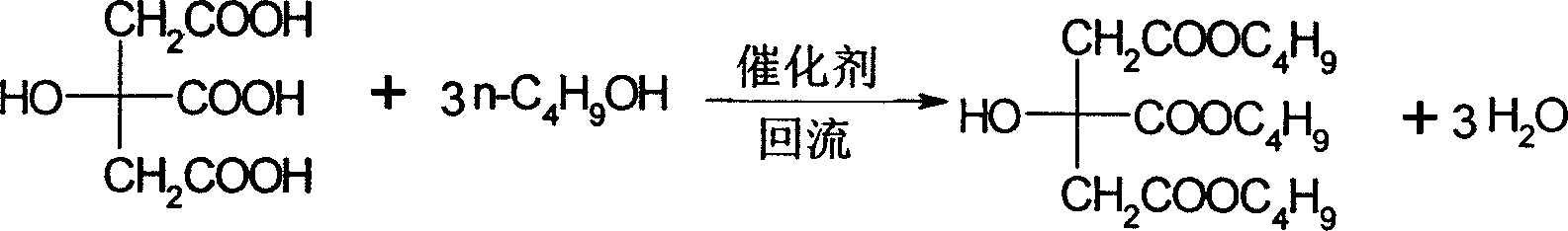

Method for preparing tributyl citrate using mesoporous molecular sieve as catalyst

InactiveCN1762969AReduce dosageNo pollution in the processMolecular sieve catalystsOrganic compound preparationMolecular sieveDistillation

The tributyl citrate preparing process features using mesoporous molecular sieve as catalyst for the synthesis of tributyl citrate, filtering out the catalyst from the reacted product after reaction for reuse, and treating the filtrate through distillation, water washing, alkali washing, and re-distillation to obtain tributyl citrate. The catalyst has relatively high catalytic activity on the esterification of citric acid and n-butanol. The present invention has the advantages of high yield, cheap catalyst, small catalyst consumptlion, mild reaction condition, short reaction period, reusability of the catalyst, no environmental pollution, direct use of non-toxic reactant n-butanol as water entrainer, etc.

Owner:EAST CHINA NORMAL UNIV

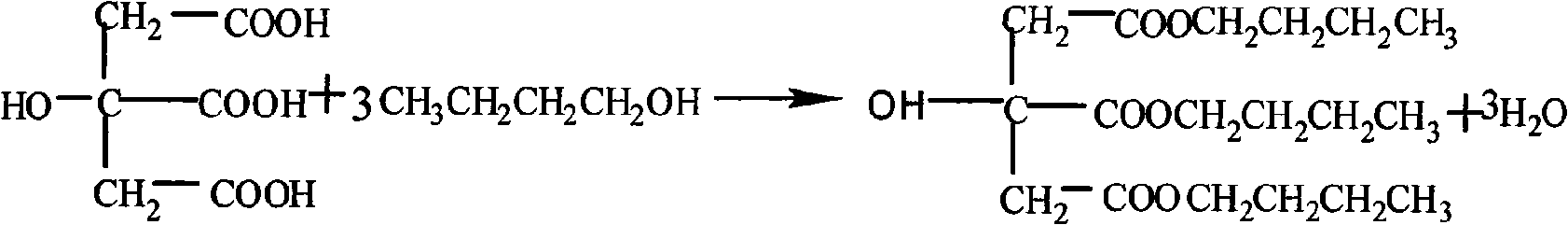

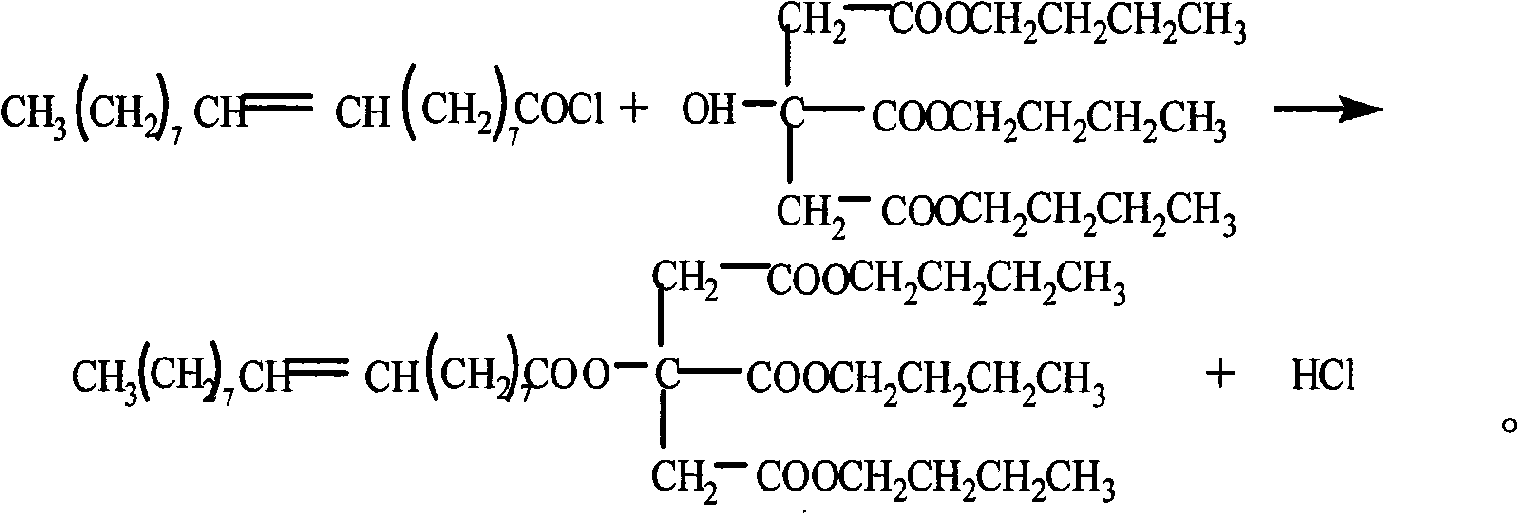

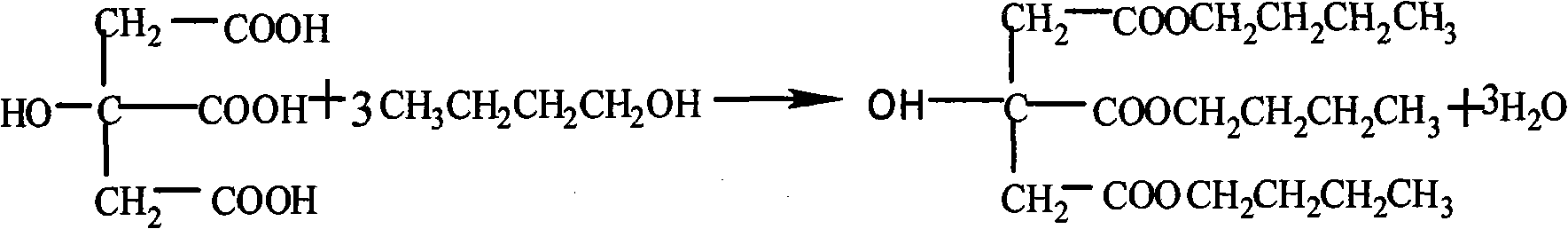

Method for preparing oleoyl tributyl citrate plasticizer

InactiveCN101255114AOrganic compound preparationCarboxylic acid esters preparationRoom temperatureChloride

The invention provides a method for preparing oleoyl tributyl citrate plasticizer, comprises: adding citric acid, n-butanol, water-carrying agent and catalytic agent into a reactor, stirring and heating up, controlling the temperature for reaction at 96 degree C until no water is generated again, and obtaining tributyl citrate; adding oleate into the reactor, stirring and heating up, dropping phosphorus trichloride into the reactor, reacting for 3h at 60 degree C, cooling to room temperature, standing for 2h, and separating to obtain; and a step 3, synthesizing oleoyl tributyl citrate; adding tributyl citrate and a catalytic agent into the reactor, stirring and heating up to 70 degree C, dropping oleoyl chloride, absorbing the generated hydrogen chloride by introducing the drier into base, stopping the reaction until the pH value of base has no change, and obtaining oleoyl tributyl citrate by neutralizing with sodium carbonate solution, water washing, and vacuum filtrating.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Low-cost biology base full degradation thin film and preparation method thereof

The invention discloses a low-cost biology base full degradation thin film and a preparation method thereof. The thin film is prepared from the following ingredients in parts by mass: 15 to 25 parts of polyglycollide, 25 to 35 parts of corn starch, 35 to 55 parts of poly(butyleneadipate-co-terephthalate), 5 parts of compatilizers, 3.75 to 12.25 parts of starch plasticizers, 0.5 to 0.7 part of citric acid, 0.75 to 1.25 parts of acetyl tributyl citrate, 0.3 to 0.5 part of maleic anhydride, 0.2 part of antioxidants 164 and 0.2 part of 2-(2'-hydroxyl-5'-methyl phenyl)benzotriazole. The low-cost biology base full degradation thin film provided by the invention has the advantages that the biology base content can reach 30 percent or higher; the cost is lower; the stretching intensity exceeds that of a conventional PE thin film; very important significance is realized on solving the problem of white pollution and promoting the popularization and the application of a full biodegrade material.

Owner:JIANGSU JINJU ALLOY MATERIAL

Waterproof liquid bandage for wound surface protection and preparation method thereof

The invention relates to a waterproof liquid bandage for wound surface protection and a preparation method thereof. The waterproof liquid bandage comprises the following components in the terms of 100g of liquid bandage: 60g-90g of absolute ethyl alcohol, 1g-10g of ethyl acetate, 5g-15g of nitrated cellulose, 0.5g-2g of tributyl acetocitrate, 1g-5g of isopropyl palmitate and 0.1g-2g of vitamin E acetate. The waterproof liquid bandage for wound surface protection is a novel liquid bandage with dual functions of physical containment and wound healing enhancement, is safe and environment-friendly, is high in film-forming speed, simple and convenient to use and good in comfort and is mainly used for prevention of superficial skin wound surfaces such as scratching and incised wound and the like.

Owner:山东颐诺生物科技有限公司

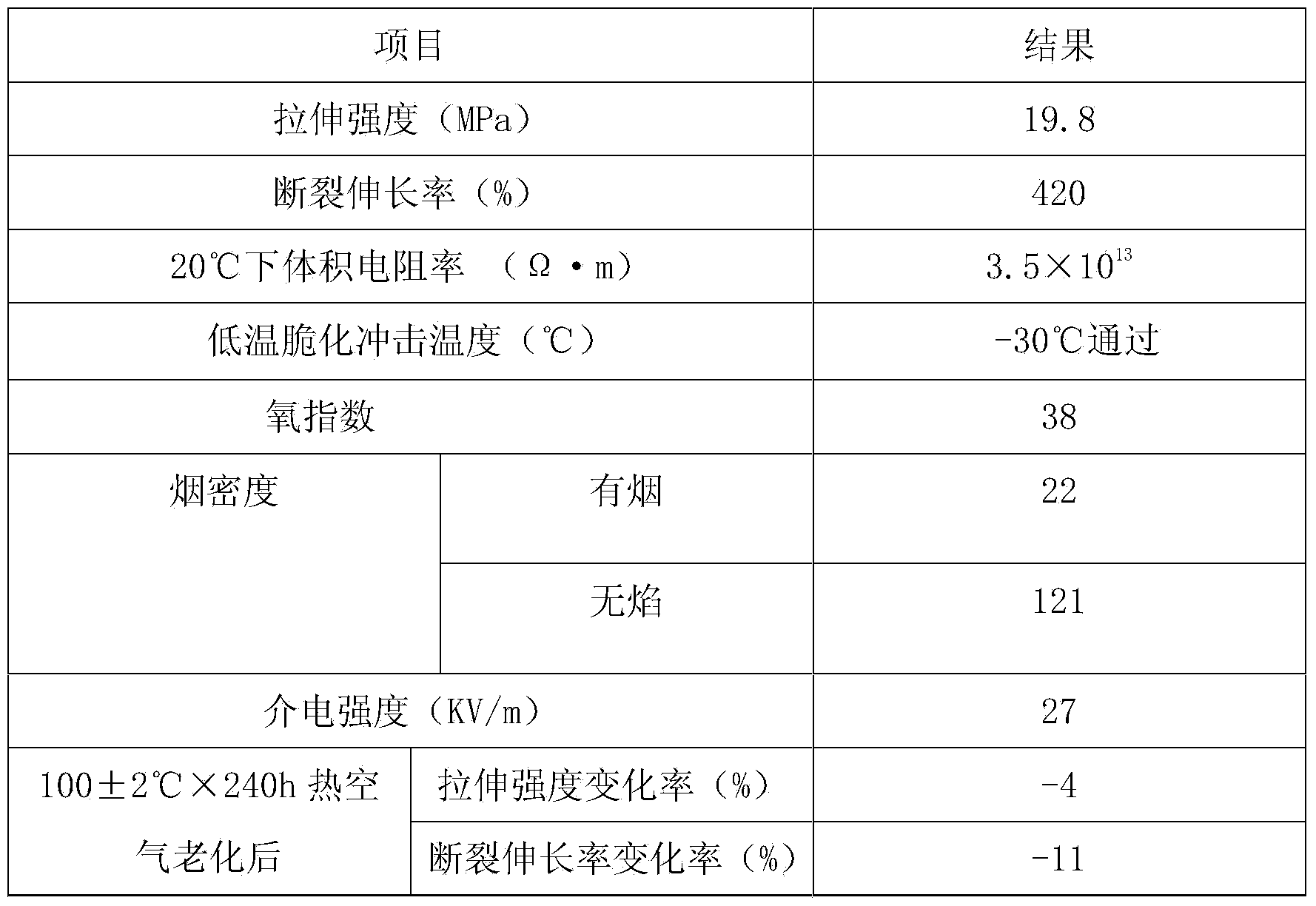

Environment-friendly heat-proof composite elastic cable material for cables and cords

Owner:SHANDONG HUANENG CABLE

Wear-resistant halogen-free flame-retardant cable material

ActiveCN103524938AImprove wear resistanceImprove mechanical propertiesPlastic/resin/waxes insulatorsCalcium silicateWear resistant

The invention provides a wear-resistant halogen-free flame-retardant cable material. The wear-resistant halogen-free flame-retardant cable material is prepared by using the following raw materials, by weight, 30-40 parts of a PVC resin, 20-30 parts of a PVDF resin, 10-20 parts of a PEEK resin, 0.1-0.3 parts of calcium silicate, 2-10 parts of tributyl citrate, 0.2-0.5 parts of nanometer silicon carbide, 30-40 parts of magnesium hydroxide, 10-20 parts of antimonony oxide, 3-5 parts of zinc borate, 1-3 parts of zine stearate, 0.4-1.2 parts of a coupling agent, 5-10 parts of aluminum hypophosphite, 1-2 parts of calcium stearate, 1-2 parts of 4-methylguaiacol, 0.1-0.5 parts of an antioxidant 168, 0.1-1 part of a toner and 8-10 parts of a modification filler. Wear resistant resins and surface wear resisting agents are added, so good mechanical properties of the wear-resistant halogen-free flame-retardant cable material are maintained, and the wear resistance of the cable material is greatly improved.

Owner:桐乡市永成线缆有限公司

Method for synthesizing acetyl tributyl citrate by using ion type catalyst

ActiveCN101125814AEasy to makeLow pricePhysical/chemical process catalystsOrganic compound preparationAcetic anhydrideSodium bisulfate

The invention relates to a method for synthesizing acetyl tributyl citrate through electrophoretic catalyst. The method comprises the steps: step one: citric acid, butanol and sodium bisulfate monohydrate are added into a reactor, and the catalyst is recycled and filtered after the cooling of the stirring reflux reaction, filtrate is neutralized by adding alkaline solution and rinsed till neutral state, then the butanol is distilled and recycled under normal pressure, and the residual water is steamed under reduced pressure to acquire crude tirbutyl citrate, and the compound decolurant of acticarbon and aluminum oxide is added into the crude tirbutyl citrat for decoloring treatment, thereby, the finished tirbutyl citrat is acquired; step two: the finished tirbutyl citrate, acetic anhydride and the sodium bisulfate monohydrate are added into the reactor, and the catalyst is filtered , cooled and recycled after 1.0-3.0 hours of stirring reaction under the temperature of 50-90 DEG C; filtrate is neutralized by adding alkaline solution and rinsed till neutral state; acetyl tributyl citrate is acquired after water phase is separated and n-butyl acetate is distilled under reduced pressure and recycled. The catalyst of the method of the invention is easily separated and recycled, the esterification process is not easily influenced by by-product, emulsification is not easy during the rinsing process and the product yield is high.

Owner:李祥庆

Novel starch-polyvinyl alcohol blend fully-degradable plastic film and preparation method thereof

InactiveCN104927093AScientific and reasonable particle sizeSmall particle sizeEnvironmental resistanceTert butyl

The invention discloses a novel starch-polyvinyl alcohol blend fully-degradable plastic film. The novel starch-polyvinyl alcohol blend fully-degradable plastic film is characterized by being prepared from the following raw materials in parts by weight: 60-65 parts of corn starch, 7-9 parts of nano montmorillonite, 0.6-0.7 part of peanut oil, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 30-35 parts of polyvinyl alcohol, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 4-6 parts of nano titanium dioxide, and 1-1.5 parts of 2,6-di-tert-butyl-4- methyl phenol. The product disclosed by the invention is produced by a safe formula, and can be used for manufacturing a food packaging bag and the like; in use, the product is high in strength, waterproof, oil-resistant and durable in use, beneficial to realizing large-scale industrial production, easy to grasp, and convenient to popularize; and under the action of oxygen enrichment and microorganisms, the wasted product is automatically degraded and finally generates carbon dioxide and water, so that the novel starch-polyvinyl alcohol blend fully-degradable plastic film is ecological and environmentally-friendly.

Owner:TONGLING FOUNDER PLASTICS TECH

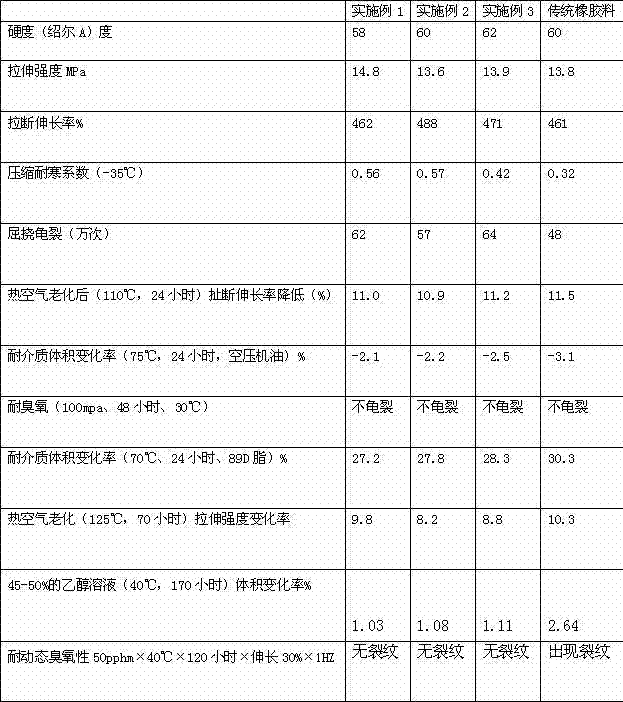

Butyl rubber for wrapping capacitor case

The invention discloses a butyl rubber for wrapping a capacitor case, which is prepared from the following raw materials: butyl rubber (BBK232), LANXESS Deutschland 9650 ethylene propylene diene monomer, poly-4-methyl-1-pentylene, zinc oxide, nano fluorite powder, nano bentonite, attapulgite, anti-aging agent NBC, anti-aging agent OD, polyamide wax micropowder, accelerator TMTD, accelerator CZ, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, isopropyl tri(dioctylpyrophosphate)titanate, antioxidant 1035, carbon black N339, N660 carbon black 15-25, dibasic lead phosphite, tributyl citrate, stearic acid, coumarone, propanediol sebacate polyester, benzenesulfonyl hydrazide, ferrocene and modified kieselguhr. According to the reasonable raw material formula, the produced rubber has favorable comprehensive properties and strong binding property with metal; and the rubber has high mechanical properties, fatigue resistance, dynamic ozone resistance, aging resistance and the like, thereby providing a high-intensity protective function for the capacitor.

Owner:江苏南翔橡胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com