Completely-biodegradable blown film as well as preparation method and application of completely-biodegradable blown film

A biodegradable and blown film technology, applied in applications, other household appliances, chemical instruments and methods, etc., can solve problems such as increasing the nucleation speed of PLA and hindering the crystallization behavior of PLA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

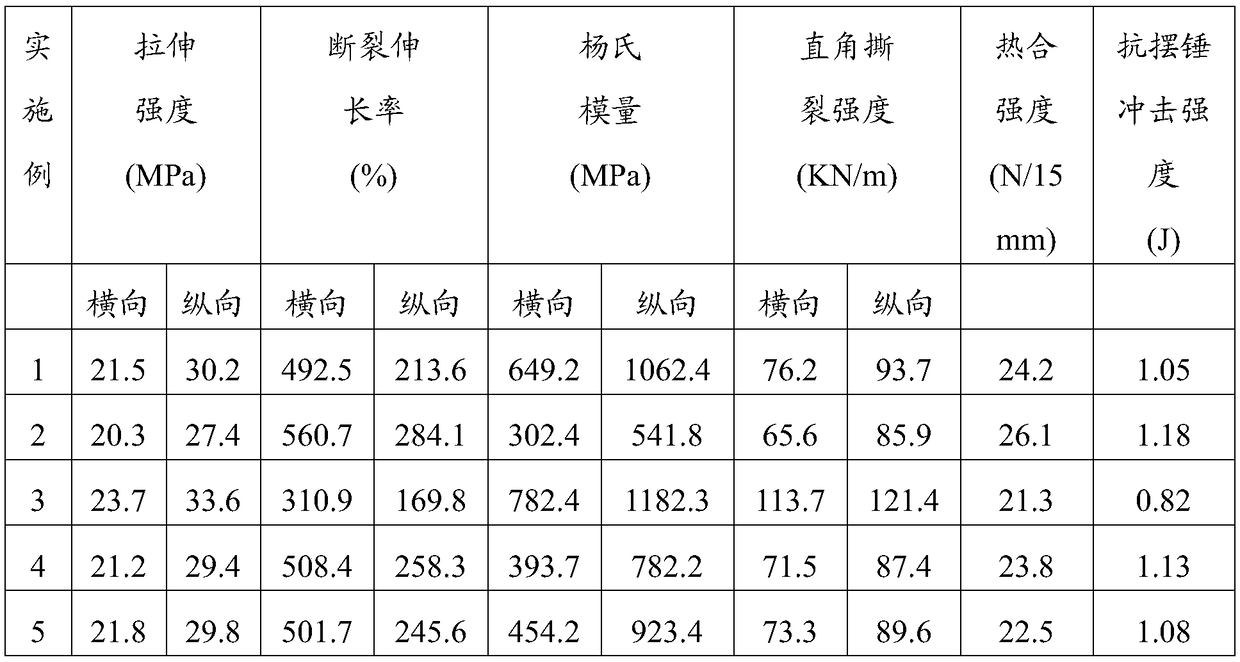

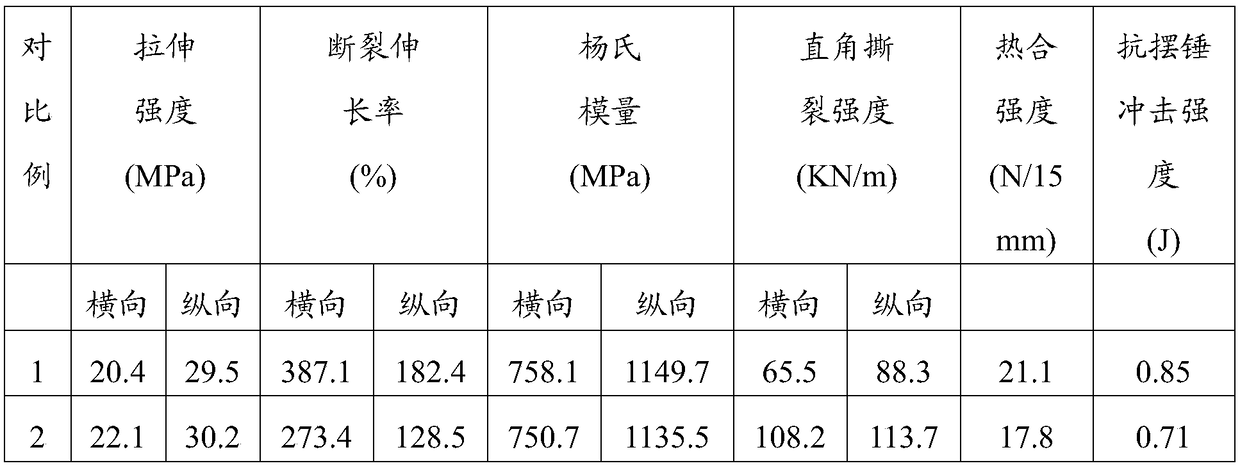

Examples

preparation example Construction

[0054] The present invention provides a method for preparing a fully biodegradable blown film described in the above technical solution, comprising the following steps:

[0055] 10-25 parts of polylactic acid, 61.8-88.95 parts of polyterephthalic acid-adipate-butylene glycol ester, 0.1-2 parts of compatibilizer, 0.1-5 parts of plasticizer, and 0.1-3 parts of nucleating agent , 0.05-0.2 parts of chain extender, 0.1-1 part of anti-blocking agent and 0.2-2 parts of carbon black are mixed, melted, extruded and granulated to obtain the inner layer resin;

[0056] 10-25 parts of polylactic acid, 52.8-83.25 parts of polyterephthalic acid-adipate-butylene glycol ester, 0.1-2 parts of compatibilizer, 0.1-5 parts of plasticizer, 0.1-2 parts of lubricant, 0.05-0.2 parts of chain extender and 6-12 parts of titanium dioxide are mixed, melted, extruded and granulated to obtain middle layer resin;

[0057] 15-30 parts of polylactic acid, 53.8-82.65 parts of polyterephthalic acid-adipate-but...

Embodiment 1

[0075] The present invention provides a completely biodegradable film, the composition and mass parts ratio of the formula are as follows:

[0076] Inner layer resin: 20 parts of PLA; 71.25 parts of PBAT; 0.6 parts of carbon black; 2 parts of compatibilizer GMS; 2 parts of plasticizer ATBC; 1 part of lubricant EBS; 2 parts of nucleating agent talcum powder.

[0077] Weigh PLA, PBAT, carbon black, GMS, ATBC, EA, EBS, ADR and talcum powder according to the above formula, carry out mechanical blending of each component for 5 minutes, put the mixed raw materials into the twin-screw extruder, extrude The conditions for granulation are: the set temperature of the twin-screw extruder is: Zone 1: 120-140 °C, Zone 2: 150-170 °C, Zone 3: 160-180 °C, Zone 4: 170-190 °C, Zone 5: 170~190℃, Zone 6: 170~190℃, Zone 7: 170~190℃, Zone 8: 170~190℃, Head: 170~190℃, Screw speed: 100~300rpm.

[0078] Middle layer resin: 20 parts of PLA; 64.95 parts of PBAT; 10 parts of titanium dioxide; 1 part of...

Embodiment 2

[0094] The present invention provides a completely biodegradable film, the composition and mass parts ratio of the formula are as follows:

[0095] Inner layer resin: 10 parts of PLA; 81.9 parts of PBAT; 0.6 parts of carbon black; 1 part of compatibilizer GMS; 2 parts of plasticizer ATBC; 1 part of lubricant EBS; 2.4 parts of nucleating agent talcum powder.

[0096] Middle layer resin: 10 parts of PLA; 74.9 parts of PBAT; 10 parts of titanium dioxide; 1 part of compatibilizer GMS; 3 parts of plasticizer ATBC; 1 part of lubricant EBS; 0.1 part of chain extender 4368 type ADR.

[0097] Outer resin: 15 parts of PLA; 76.3 parts of PBAT; 4 parts of titanium dioxide; 0.5 parts of compatibilizer GMS; 3 parts of plasticizer ATBC; 1 part of lubricant EBS; 0.2 parts of chain extender 4368 type ADR.

[0098] The mixing and processing conditions of the inner, middle and outer layers of blown film resin are the same as in Example 1.

[0099] The set temperature of the film blowing machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| heat seal strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com