Polylactic acid composition and polylactic acid product

A technology of polylactic acid and composition, which is applied in the field of polylactic acid composition and polylactic acid products, can solve the problems of low elongation at break, no improvement in blow molding processability, low melt strength, etc., and achieve good comprehensiveness Mechanical properties, the effect of improving blow molding processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

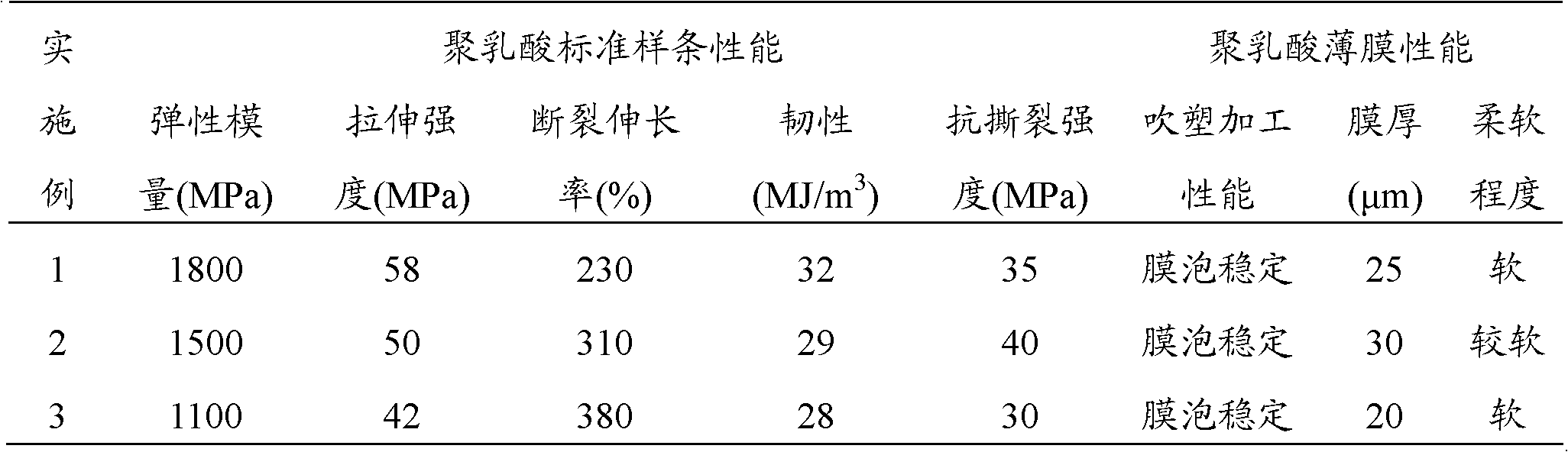

Examples

preparation example Construction

[0065] The present invention provides a polylactic acid product, which is made of polylactic acid resin comprising the polylactic acid composition described in the above technical solution or the polylactic acid composition obtained by the preparation method described in the above technical solution and additives. The present invention uses the polylactic acid composition described in the above technical solution or the polylactic acid composition obtained by the preparation method described in the above technical solution as the main raw material, adds additives therein, and processes it into polylactic acid products. The present invention has no special restrictions on the preparation process of polylactic acid products, and the technical solution for the preparation of polymer material products well-known to those skilled in the art can be used. For example, polylactic acid plastic products can be obtained by molding methods, or blown film The film preparation method is used...

Embodiment 1

[0077] In parts by weight, 60 parts of polylactic acid, 20 parts of polybutylene adipate-terephthalate, 10 parts of polybutylene succinate, 4 parts of tributyl citrate, 5 parts of calcium carbonate , 0.1 part of benzoyl peroxide, 0.1 part of polyepoxy methyl acrylate, 0.1 part of zinc stearate, 0.4 part of niacinamide, 0.1 part of light stabilizer GW540, 0.1 part of antioxidant 1010 and 0.1 part of monolaurin After the acid glyceride is dried, the above components are fully mixed in a mixer, and then the obtained mixture is pelletized in a twin-screw extruder to obtain polylactic acid resin pellets. The parameters of the twin-screw extruder are set to: feed The mouth temperature is 165°C, the temperature of the first heating zone is 171°C, the temperature of the second heating zone is 171°C, the temperature of the third heating zone is 172°C, and the temperature of the die head is 171°C.

[0078] In the present invention, the obtained polylactic acid resin pellets are prepared...

Embodiment 2

[0082] In parts by weight, 65 parts of polylactic acid, 5 parts of polybutylene adipate-terephthalate, 25 parts of polybutylene succinate, 4 parts of polyethylene glycol, 0.2 parts of benzene peroxide Formyl, 0.1 part of polyepoxy methyl acrylate, 0.4 part of nicotinic acid amide, 0.1 part of light stabilizer GW540, 0.1 part of antioxidant 1010 and 0.1 part of glyceryl monolaurate are dried and fully mixed in a mixer Mixing, and then granulating the obtained mixture in a twin-screw extruder to obtain polylactic acid resin pellets, the parameters of the twin-screw extruder are set as follows: the temperature of the feeding port is 165°C, the temperature of the first heating zone is 171°C, The temperature of the second heating zone is 171°C, the temperature of the third heating zone is 172°C, and the temperature of the die head is 171°C.

[0083] In the present invention, the obtained polylactic acid resin pellets are prepared in an injection molding machine for standard splines...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com