Degradable polylactic acid diblock copolymer, preparation method and application to modified polylactic acid

A technology of block copolymer and polylactic acid, applied in the field of polymer materials, can solve the problems of high preparation cost, unsuitable for industrialized continuous production, unstable performance of modified polylactic acid, etc., and achieves simple preparation method and guaranteed biodegradability. properties, improving melt strength and melt processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of degradable polylactic acid diblock copolymer comprises the following steps:

[0035] (1) Under the protection of an inert atmosphere, add the polylactic acid A whose terminal group is a hydroxyl group after being fully dried and dehydrated into the reaction device;

[0036] (2) Add diisocyanate B into the reaction device, heat to 185°C-190°C, and stir for 5-8h;

[0037] (3) Adding degradable polymer C containing hydroxyl groups to the reaction device, at 185°C-190°C, and mechanically stirring for 1-2h;

[0038] (4) Add diisocyanate B into the reaction device, stir and react at 185°C-190°C until it is difficult to stir, and obtain a light yellow or light brown elastomer, which is a degradable polylactic acid diblock copolymer.

[0039] In the present invention, the molar ratio of polylactic acid A to the first added diisocyanate B is preferably 1:10-20, and the molar ratio of polylactic acid A to polymer C is preferably 0.01-3:1. The sum of th...

Embodiment 1

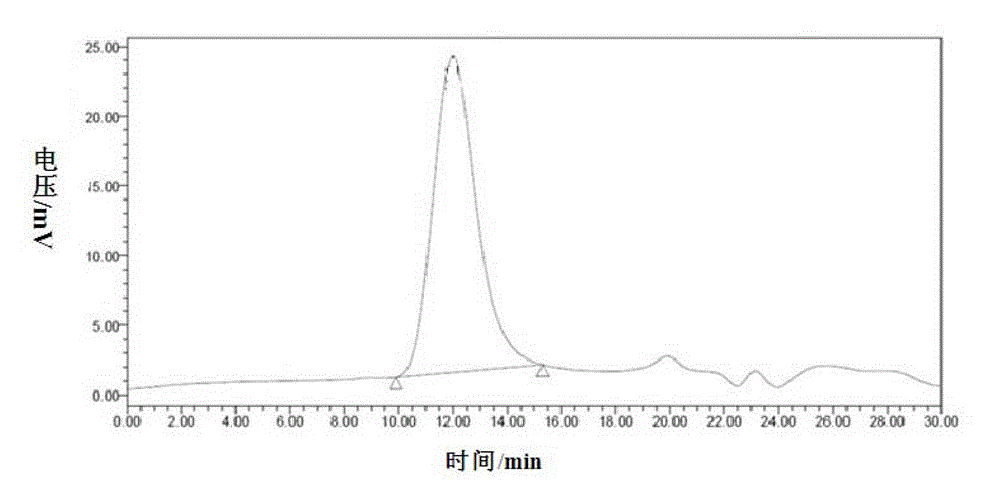

[0066] combine figure 1 Illustrative Example 1

[0067] Preparation of degradable polylactic acid diblock copolymer:

[0068] (1) Under the protection of nitrogen, fully dry 40g of polylactic acid A (molecular weight 15000g / mol) whose terminal group is a hydroxyl group, and put it into a three-necked flask;

[0069] (2) Add 9g of hexamethylene diisocyanate B (168g / mol) into the three-necked flask, heat up to 190°C, and stir for 5h;

[0070] (3) Add 300 g of castor oil (933 g / mol) into the three-necked flask, and mechanically stir at 190 ° C for 1 h;

[0071] (4) Add 45.5 g of hexamethylene diisocyanate B (168 g / mol) into the three-necked flask, and react at 190° C. until it cannot be stirred to obtain a degradable polylactic acid diblock copolymer.

[0072] figure 1 It is the gel permeation chromatogram of the degradable polylactic acid diblock copolymer of Example 1 of the present invention, from figure 1 It can be seen that the peak molecular weight is 86262g / mol, the n...

Embodiment 2

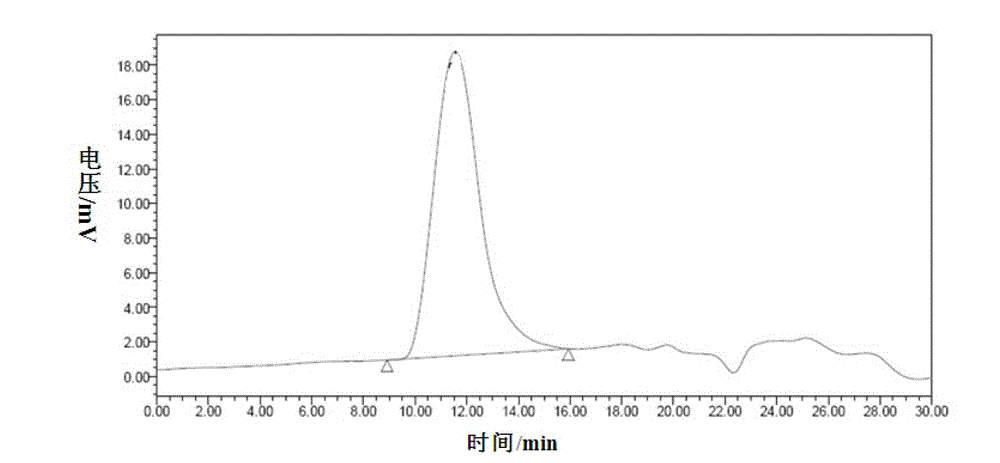

[0074] combine figure 2 Illustrative Example 2

[0075] (1) Under the protection of nitrogen, fully dry 40g of polylactic acid A (molecular weight 15000g / mol) whose terminal group is a hydroxyl group, and put it into a three-necked flask;

[0076] (2) Add 4.5 g of hexamethylene diisocyanate B (168 g / mol) into the three-necked flask, heat up to 190 ° C, and stir for 5 h;

[0077] (3) Add 240 g of castor oil (933 g / mol) into the three-necked flask, and mechanically stir at 190 ° C for 1 h;

[0078] (4) Add 39 g of hexamethylene diisocyanate B (168 g / mol) into the three-necked flask, and react at 190° C. until it cannot be stirred to obtain a degradable polylactic acid diblock copolymer.

[0079] figure 2 It is the gel permeation chromatogram of the degradable polylactic acid diblock copolymer of embodiment 2 of the present invention, from figure 2 It can be seen that the peak molecular weight is 127756g / mol, the number average molecular weight is 83503g / mol, the weight av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com