Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Guaranteed biodegradability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

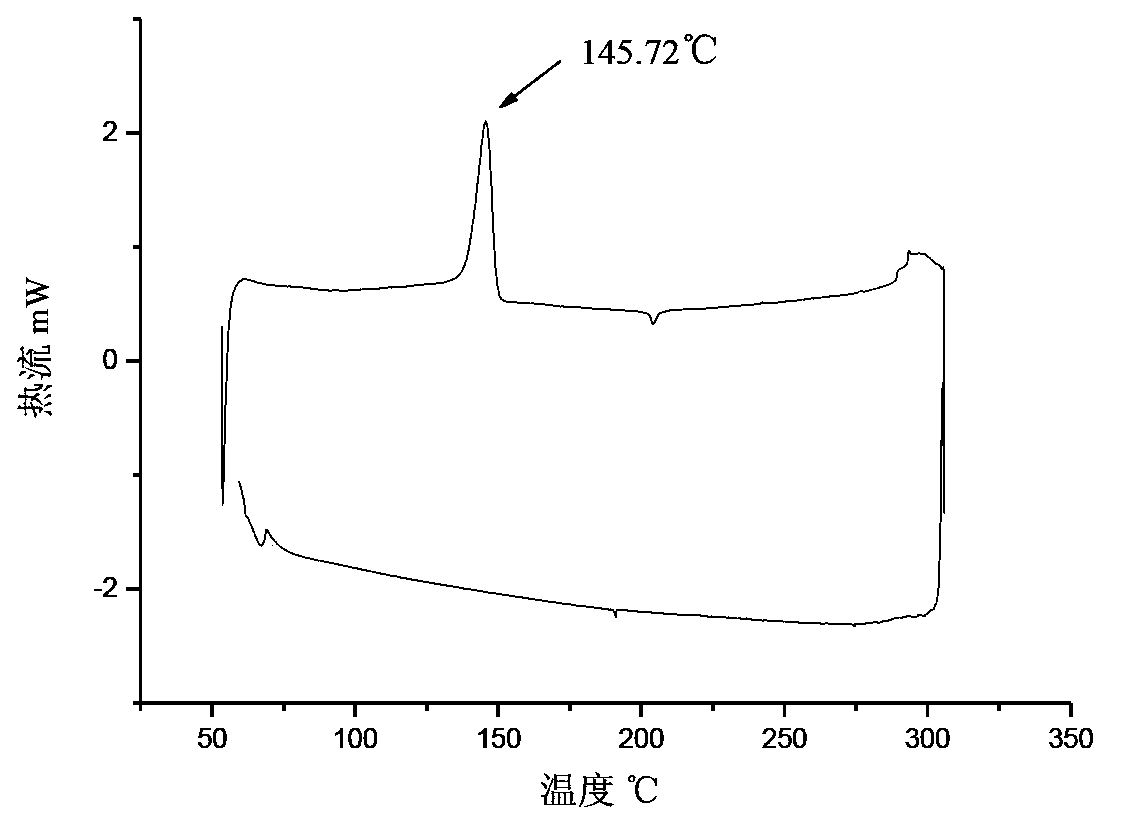

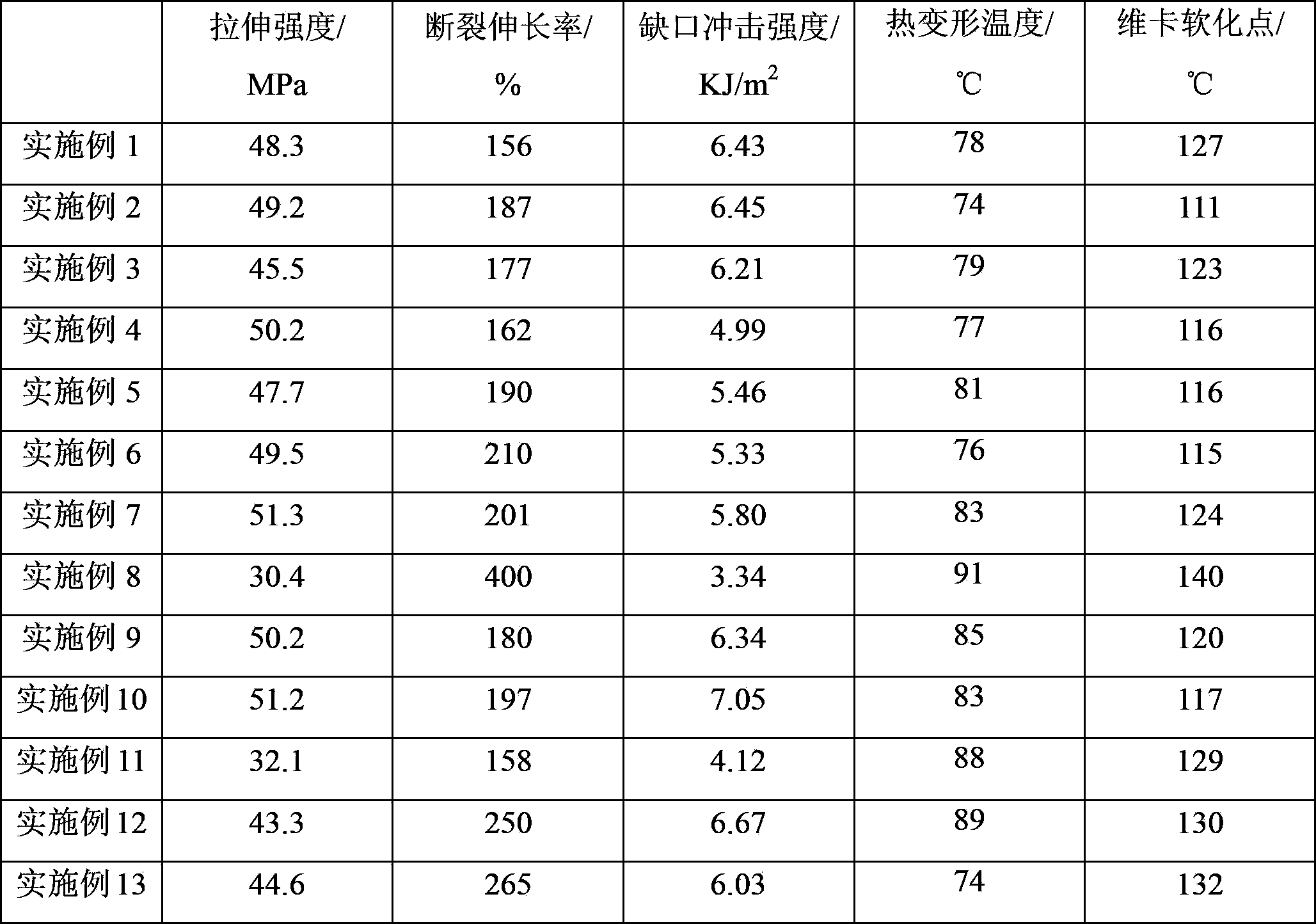

Novel heat-resistant high-toughness polylactic acid composite material and preparation method thereof

InactiveCN103819884AGuaranteed biodegradabilityExcellent mechanical properties and heat resistanceBiodegradable polyesterToughness

The invention belongs to the technical field of composite materials, and relates to a polylactic acid composite material and a preparation method thereof. The polylactic acid composite material is prepared from the following components in percentage by weight: 5 to 90 percent of polylactic acid, 5 to 80 percent of biodegradable polyester and 5 to 80 percent of heat-resistant master batch. The heat-resistant high-toughness polylactic acid composite material is obtained by continuous in-situ reaction extrusion. The composite material simultaneously has the characteristics of high toughness, high temperature resistance, low production cost, full biodegadability and the like.

Owner:SHANGHAI ZAIHE IND INVESTMENT CO LTD

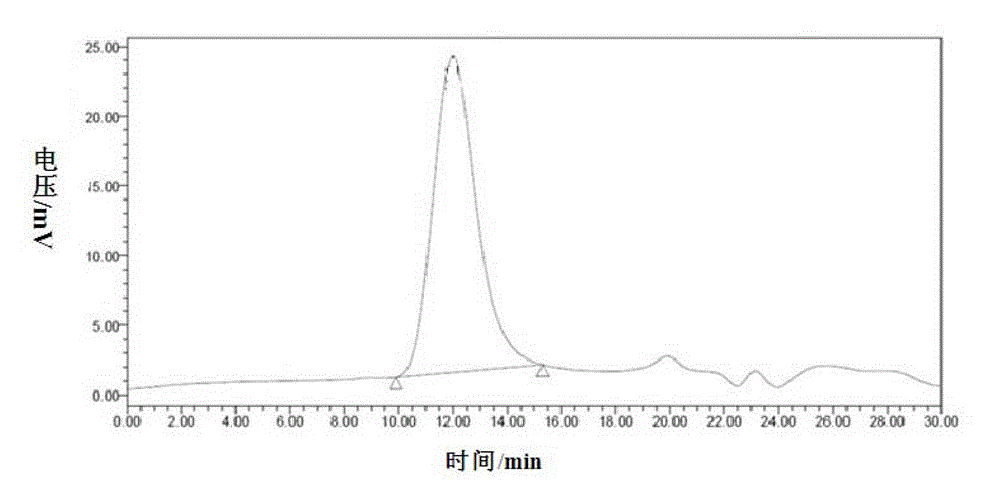

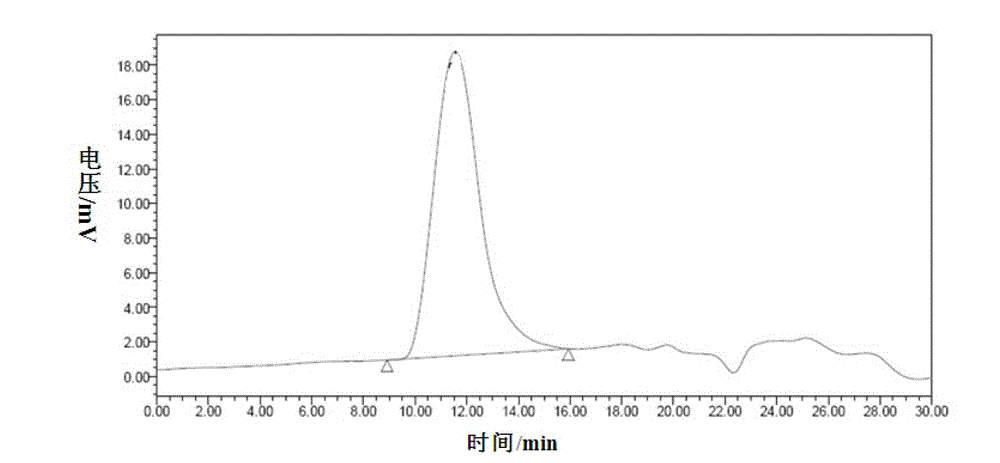

Degradable polylactic acid diblock copolymer, preparation method and application to modified polylactic acid

The invention discloses a degradable polylactic acid diblock copolymer, a preparation method and application to modified polylactic acid, solving the problems of instable performance, high preparation cost and unsuitability for industrialized continuous production of modified polylactic resin in the prior art. The preparation method of the degradable polylactic acid diblock copolymer comprises the following steps of: adding dried and dewatered polylactic acid A with an end group being hydroxy into a reaction device under the protection of an inert atmosphere, adding diisocyanate B, heating to 185-190 DEG C, reacting with stirring for 5-8h, adding degradable high polymer C containing hydroxy, reacting with stirring for 1-2h at the temperature of 185-190 DEG C, adding the diisocyanate B, and reacting at the temperature of 185-190 DEG C until the stirring is difficult to obtain the degradable polylactic acid diblock copolymer. The degradable polylactic acid diblock copolymer disclosed by the invention is good in compatibility with the polylactic resin, is used for modifying the polylactic resin, is capable of remarkably improving processing property and mechanical property of the polylactic resin, and has the elongation at break reaching 60 percent.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

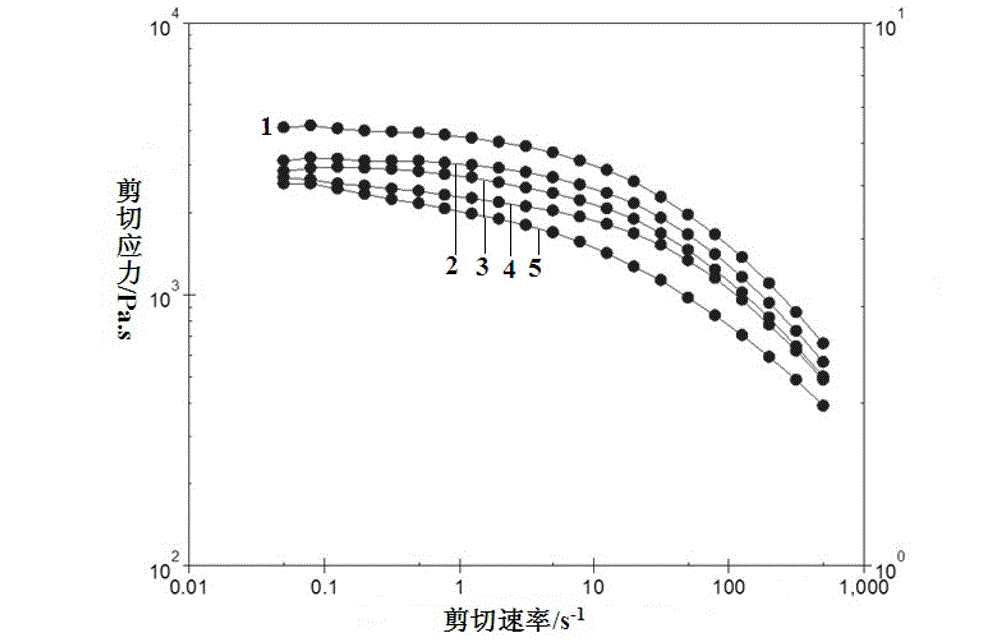

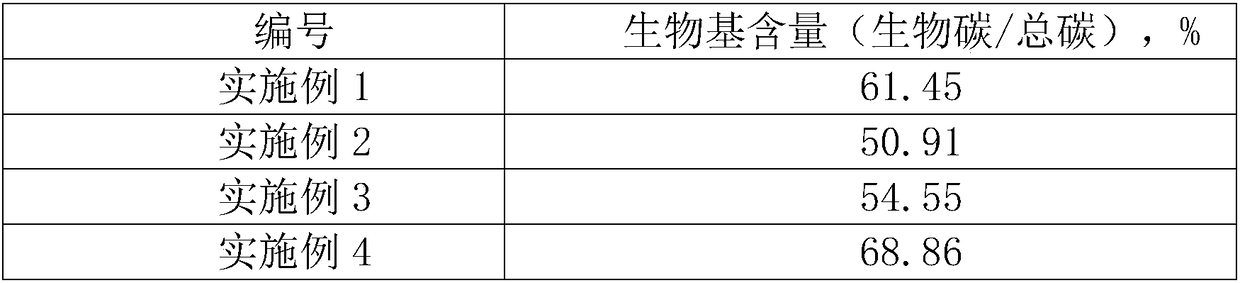

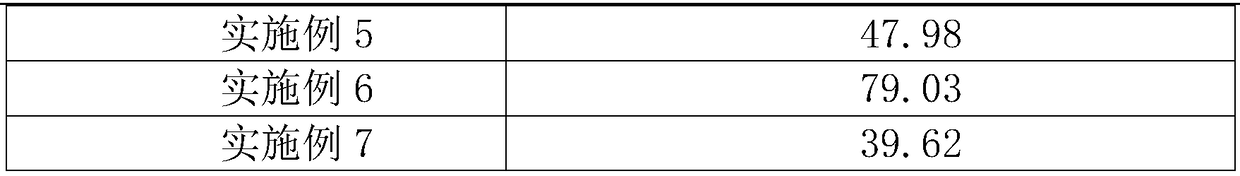

Bio-based biodegradable multi-block copolymer as well as preparation method and application thereof

InactiveCN108192105AGuaranteed biodegradabilitySolve the melting point is too lowFlexible coversWrappersDimer acidMechanical property

The invention discloses bio-based biodegradable multi-block copolymer as well as a preparation method and application thereof. The multi-block copolymer comprises a chain segment A and a chain segmentB; the chain segment A is fat-aromatic coplyester with number average molecular weight of 3000 to 100000, which is obtained by performing esterification (ester exchange) on C2-C36 fatty diacid and derivatives thereof, C6-C20 aromatic diacid and derivatives thereof, C2-C36 divalent alcohol, and 0.0 to 10% by weight of polyhydroxyl or polycarboxyl compound and performing condensation polymerization; the chain segment B is fatty copolyester with number average molecular weight of 3000 to 100000, which is obtained by performing esterification (ester exchange) on dimer acid and derivatives thereof, C2-C12 fatty diacid and derivatives thereof, C2-C36 divalent alcohol as well as 0.0 to 10% of polyhydroxyl or polycarboxyl compound and performing condensation polymerization. The chain segment A and the chain segment B react with a polyfunctional chain extender of polyisocyanate, a polyepoxy compound and carbodiimide which is 0.01 to 10% of the polymer to form the multi-block copolymer. The product prepared by the method has high biodegradability, mechanical property and processing property, and can be widely applied to the fields of packaging, biological medicine, medical treatment and thelike.

Owner:王肖桦

Preparation method for hyperbranched polyurethane, modified polylactic resin, and preparation method for modified polylactic resin

The invention discloses a preparation method for hyperbranched polyurethane. The method comprises the following steps of: mixing castor oil and diisocyanate in a molar ratio of (1-5):1 under the protection of nitrogen, raising temperature to 60 to 90 DEG C, and reacting to obtain the hyperbranched polyurethane. The preparation method for the hyperbranched polyurethane has the characteristics of simplicity, low cost, and adjustable molecular weight. The invention also provides modified polylactic resin and a preparation method thereof. A biomass material castor oil is used as the raw material, the degradable hyperbranched polyurethane prepared by a chemical method is used for modified polylactic acid, and the biodegradability of the modified polylactic acid can be guaranteed. The hyperbranched polyurethane is obtained by polymerizing the caster oil and diisocyanate, and hyperbranched structures, cross-linked structures and a large amount of hydrogen bonds are introduced by the hyperbranched polyurethane in a polylactic acid system in a melt blending process of the polylactic acid, so the mechanical property, the processability and compatibility of the polylactic acid are improved effectively.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Totally degradable foam buffer packaging material and its manufacturing method

The invention provides a complete biodegradable foam cushioning packing material and method for preparation, characterized in that starch over 80% content is used as base-material, ultra-fine polyvinyl alcohol is used as film forming intensifier, water is used as foaming agent, and core forming agent and flow modifier are added, wherein the mixture is amalgamated through blending homogeneous machine and fed into reverse-flighted screw extrusion machine for one-shot extrusion forming. The product can be used to substitute polystyrene foam for filling with no requirement on shapes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

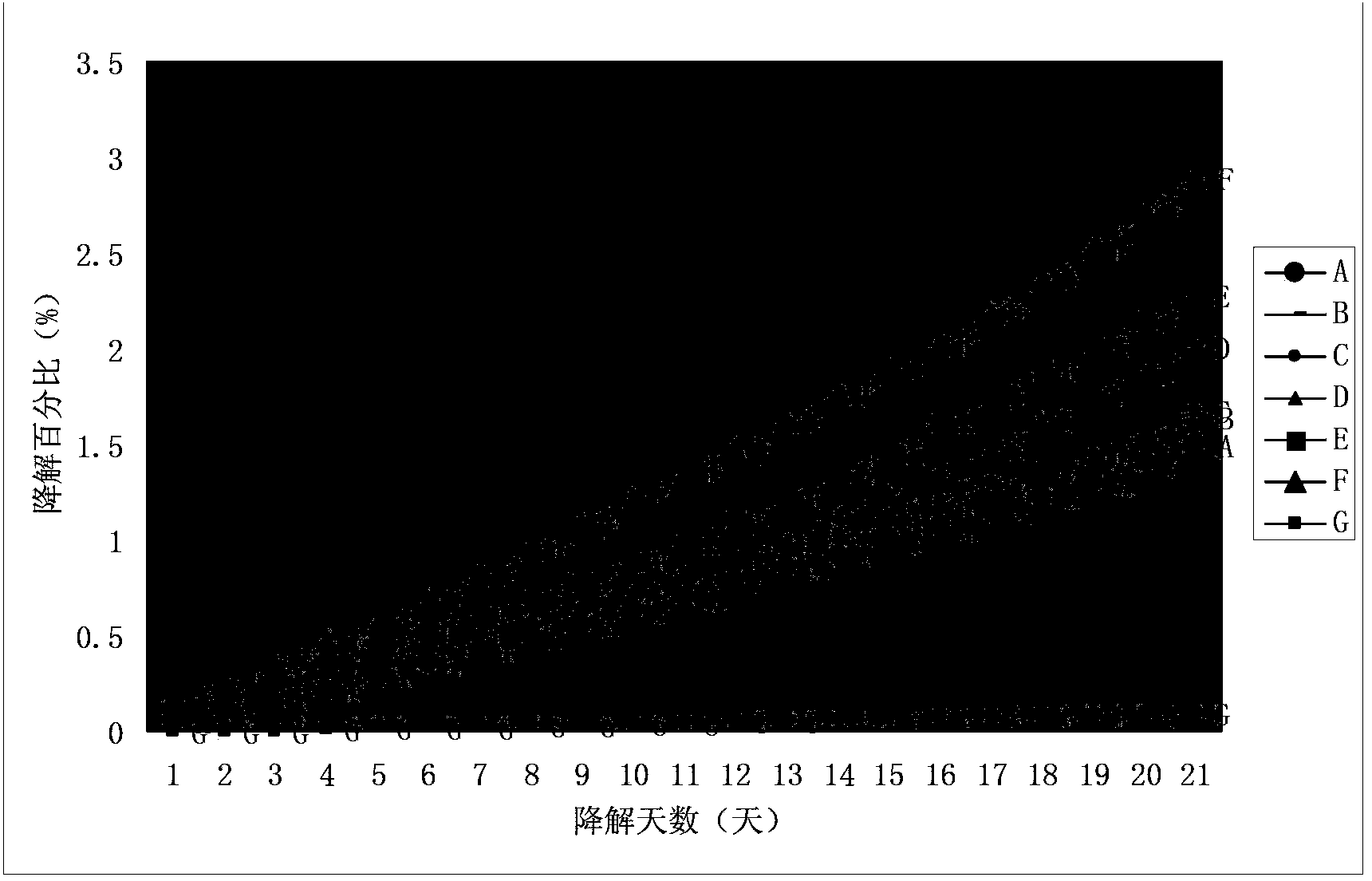

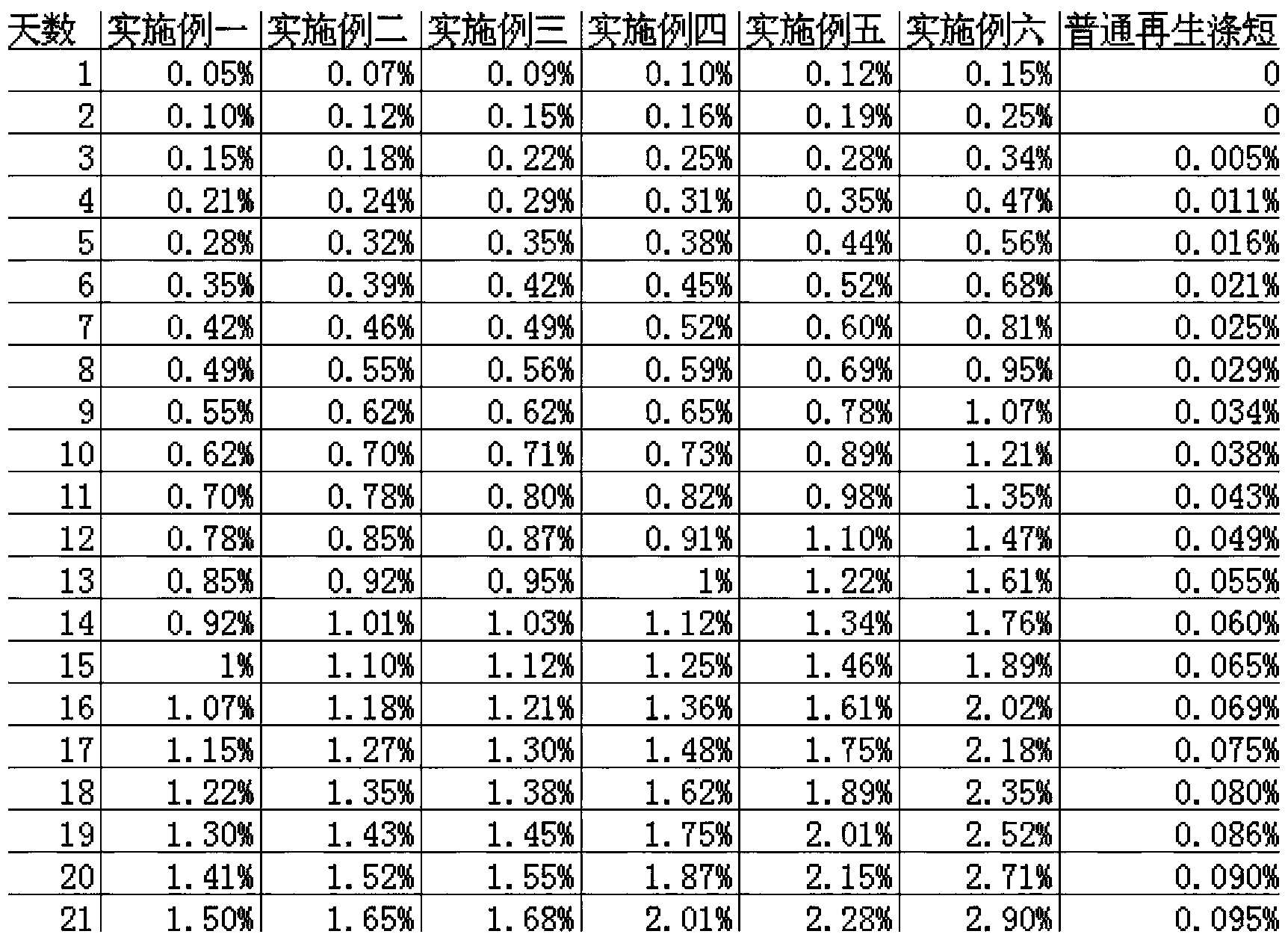

Preparation method of biodegradable regenerated polyester staple fibers

ActiveCN102828276APrevent volatilizationBalanced moistureFilament forming substance formingArtificial filament heat treatmentPolyesterPolymer science

The invention discloses a preparation method of biodegradable regenerated polyester staple fibers, which is characterized by comprising the steps of drying spinning materials by a vacuum drum, mixing with biodegradable master batch dried by a master batch drying system at the feed inlet of a screw extruder; preparing primary fibers after mixing and fusing by the screw extruder and extruding by a spinneret plate; cooling primary fibers by an annular blowing device; successively carrying out winding, falling, bundling and time balancing on the primary fibers in a constant temperature and constant-humidity room; stretching the primary fibers in oil bath and stream respectively; performing curling, relaxation heat setting, cutting and packaging to obtain biodegradable regenerated polyester staple fibers, wherein physical properties and mechanical properties of the biodegradable regenerated polyester staple fibers produced by the method do not change, and therefore, the subsequent processing and usage are not influenced; after being used, the fibers can be decomposed into inert humus, carbon dioxide and water in a microorganism-enriching environments such as refuse landfill or composting site, thereby returning to nature and achieving real biodegradation.

Owner:福建鑫华股份有限公司

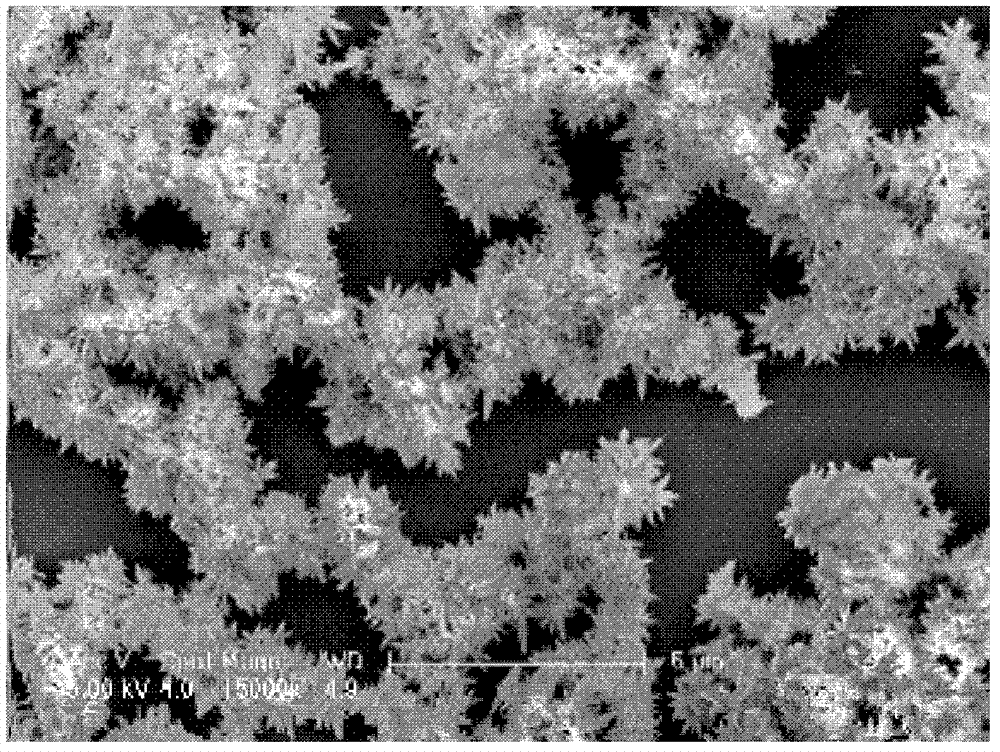

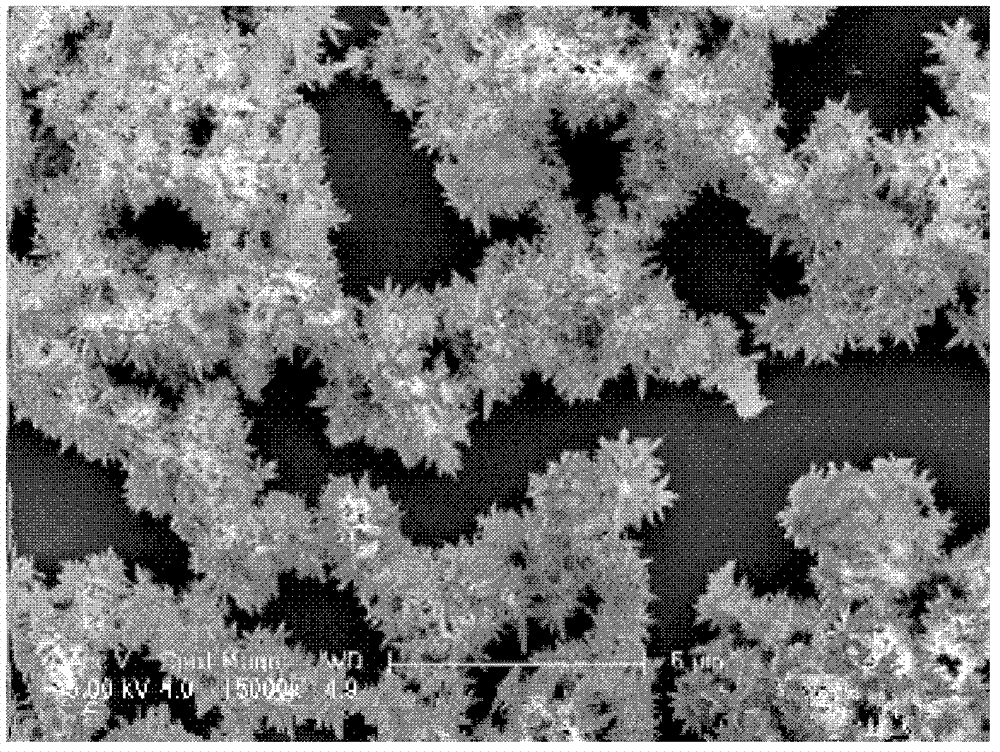

Preparation method of nanometer strontium hydroxyapatite and application thereof

InactiveCN103086337APromote degradationGuaranteed biodegradabilityNanotechnologyPhosphorus compoundsFreeze-dryingDiammonium phosphate

The invention discloses a preparation method of nanometer strontium hydroxyapatite, which comprises the following steps: preparing a strontium nitrate aqueous solution and a diammonium phosphate aqueous solution with certain concentrations, adjusting the pH value of the strontium nitrate aqueous solution, mixing the strontium nitrate and the diammonium phosphate aqueous solutions to generate a nanometer strontium hydroxyapatite precipitate, standing and aging, filtering to remove the upper supernatant, washing and filtering the nanometer strontium hydroxyapatite precipitate to be neutral, performing centrifugal dewatering and freeze drying to finally obtain the nanometer strontium hydroxyapatite. When compared with nanometer hydroxyapatite, the nanometer strontium hydroxyapatite obtained in the preparation method has better biodegradability and better osteoinductivity; meanwhile, the preparation process avoids high temperature process, so the biodegradability is further ensured; The nanometer strontium hydroxyapatite obtained in the preparation method has good prospects in the application of bone repair materials.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Biodegradable LA (lactide) oligomer bonding agent, and preparation method and purpose thereof

The invention relates to a biodegradable bonding agent material prepared from LA (lactide) chemical synthesis products. The LA materials are poured into a reaction container containing solvents according to the proportion of 5 to 50 percent of the mass of the solvents; a reactor has a stirring and control function; the reactor is controlled under the nitrogen gas protection condition; a certain reaction temperature is controlled; meanwhile, the stirring is performed; after the LA is completely fused, catalysts are added; after reacting for a period of time, stirring is stopped; after the materials are taken out, extraction and centrifugation are performed, so that the LA chemical synthesis products are obtained; then, the LA chemical synthesis products are dissolved by acetic ester, so that the biodegradable bonding agent is obtained. The bonding agent has the characteristics that the preparation is simple; the relative molecular weight and the viscosity are controllable; the biodegradable performance is realized. The biodegradable bonding agent material can be used in the fields of adhesive tapes, leather, sticking paper, stationery, office, electronics, automobile edge trimming fixation, shoe industry, handwork ornament pasting and fixation and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

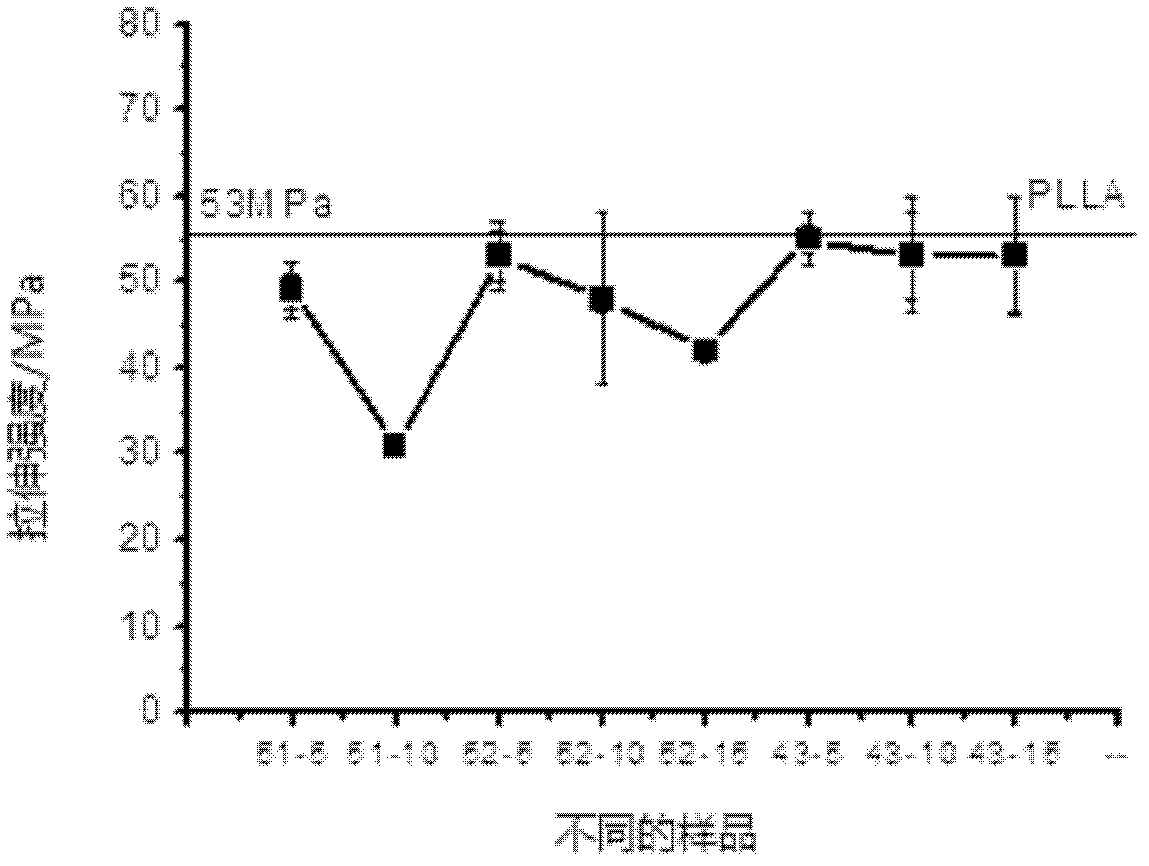

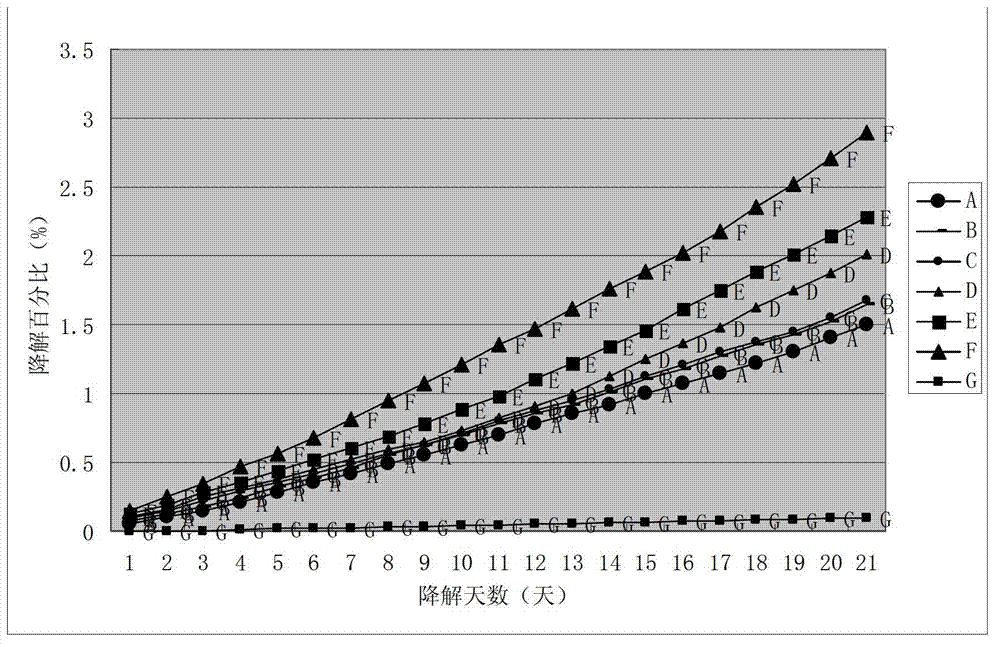

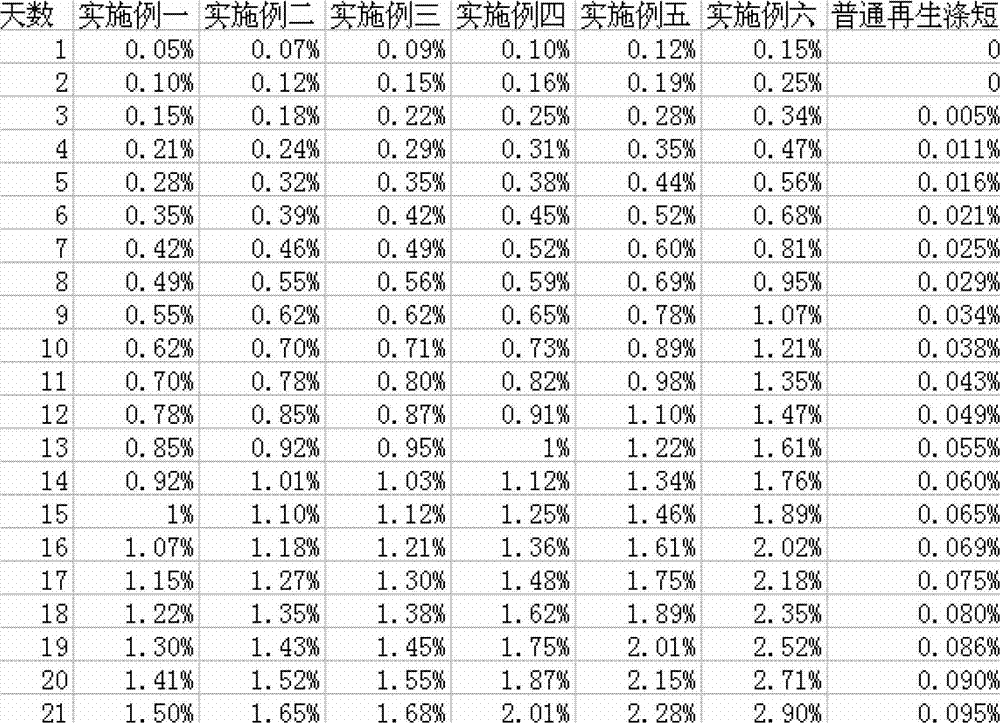

Blended composite material prepared from lactide surface grafted bamboo powder and polylactic acid, and preparation method and applications thereof

The invention relates to a blended composite material prepared from lactide surface grafted bamboo powder and polylactic acid. According to a preparation method, bamboo powder is subjected to lactide surface grafting, wherein at a certain temperature and a certain stirring speed, a mixture of bamboo powder and lactide is reacted with the presence of stannous octoate catalyst so as to obtain lactide surface grafted bamboo powder; the lactide surface grafted bamboo powder (10 to 90 parts), polylactic acid (10 to 90 parts), and a small amount of a heat stabilizer (2 to 5 parts) are subjected to melt blending so as to obtain the blended composite material. The blended composite material can be used for thermoplastic process; is high in thermal decomposition temperature, tensile strength, elasticity modulus, and glossiness; is biodegradable; can be applied to the fields such as household plastic products, packaging, agriculture, furniture, floor, building and decorative material, and sports goods; and possesses a promising application prospect.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

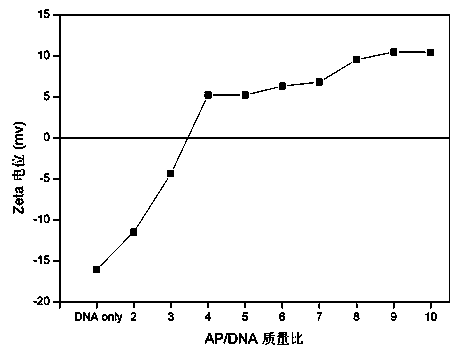

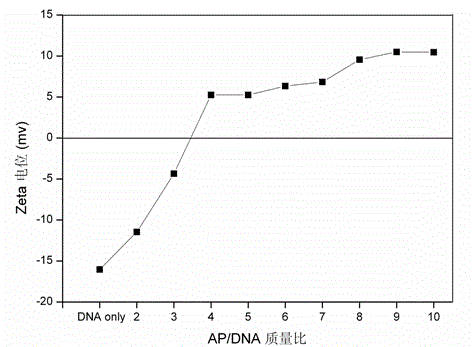

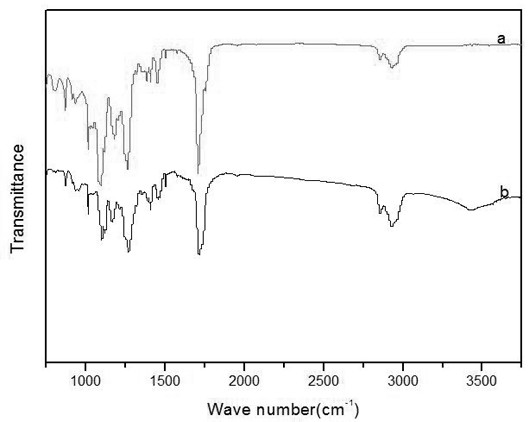

Cationization silk fibroin and preparation method thereof

ActiveCN104119451AGuaranteed biodegradabilityImprove targetingPeptide preparation methodsOther foreign material introduction processesGene deliveryCarboxylic acid

The invention discloses a cationization silk fibroin and a preparation method thereof, and belongs to the technical field of medical high-molecular materials. The cationization silk fibroin is obtained through reaction by coupling protamine sulfate mediated by water-soluble 2-imido thiacyclopentane hydrochloride with silk fibroin activated by sulfo-succinimido-4-[N-maleimide methyl]-cyclohexane-1-carboxylate. The cationization silk fibroin disclosed by the invention has the advantages of good biocompatibility and degradability, controllability in surface charge density, effective DNA (Deoxyribonucleic Acid) compression and protection capacity, higher transfection efficiency and uniqueness in cell targeting and cell nucleus positioning function. The cationization silk fibroin disclosed by the invention can form a cationization silk / gene compound with a gene substance through electrostatic action, and the cationization silk / gene compound is a novel biodegradable cationization silk gene transfer vector with cell targeting and a cell nucleus positioning function.

Owner:SUZHOU UNIV

Biodegradable material containing ladder-like polysilsesquioxane and preparation method of biodegradable material

The invention relates to the technical field of organic silicon materials. In order to solve problems of heat resistance of the existing aliphatic polyester materials, the invention discloses a biodegradable material containing ladder-like polysilsesquioxane and a preparation method of the biodegradable material. The biodegradable material containing the ladder-like polysilsesquioxane is prepared by carrying out polymerization reaction on hydroxyl end-capped ladder-like polysilsesquioxane and aliphatic cyclic ester monomers in the presence of a catalyst. The method disclosed by the invention is used for preparing a biodegradable segmented copolymer by virtue of ring opening polymerization of aliphatic cyclic ester monomers, so that biodegradable performances of the materials are guaranteed, and heat resistance of the aliphatic polyester is improved.

Owner:浙江燧宝新材料技术有限公司

Cationic silk fibroin/gene compound, and preparation method and application thereof

ActiveCN104099372AGuaranteed biodegradabilityHigh transfection efficiencyOther foreign material introduction processesVector-based foreign material introductionChemistryWater soluble

The invention discloses a cationic silk fibroin / gene compound, and a preparation method and application thereof and belongs to the technical field of polymeric biomaterials. The cationic silk fibroin / gene compound, and the preparation method and application thereof are characterized in that a cationic silk gene transmission carrier which has cell targeting and cell nucleus positioning functions and can be biodegraded is established and is obtained through the following steps: protamine sulfate is mediated by a water-soluble 2-imino thiacyclopentane hydrochloride to be in coupled with and react with the silk fibroin activated by sulfo-succunyl imino group-4-[N-maleimide methyl]-cyclohexane-1-carboxylic ester; the combination and a gene matter form the cationic silk fibroin / gene compound through electrostatic interaction. According to the invention, the cationic silk fibroin / gene compound has good biocompatibility and degradability, is controllable in surface charge density, can be effectively compressed and protect DNA, is relatively high in transfection efficiency, and has the particular cell targeting and cell nucleus positioning functions.

Owner:SUZHOU UNIV

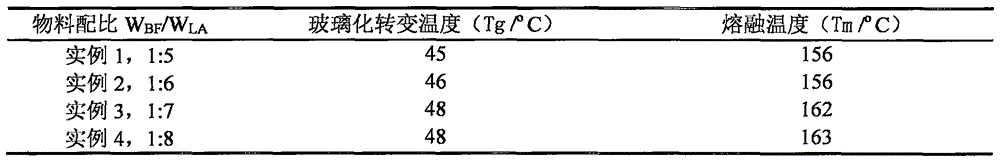

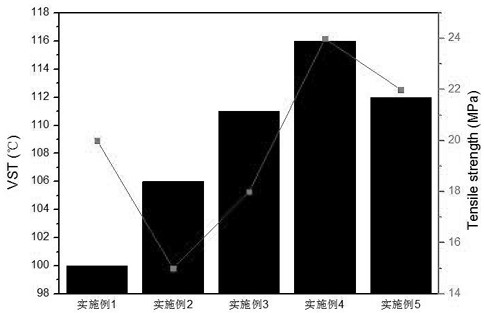

Preparation method of degradable heat-resistant copolyester

ActiveCN112280013AImprove thermodynamic performanceImprove mechanical propertiesBio-packagingPolymer sciencePtru catalyst

The invention relates to the field of high polymer material synthesis, in particular to a preparation method of degradable heat-resistant copolyester. The method comprises the following steps: addingterephthalic acid, sebacic acid, 1, 4-butanediol and an esterification catalyst into a reaction kettle for esterification reaction, entering a polycondensation stage after the reaction reaches an esterification end point, adding the polycondensation catalyst, heating while reducing the vacuum degree of a system, reacting until the torque of a motor does not rise to the polycondensation end point,stopping the vacuum of the system, and blowing nitrogen for cooling, then adding polylactic acid, melting, then starting to dropwise add a chain extender hexamethylene diisocyanate, and carrying out chain extension to the maximum value of the motor torque, thus obtaining the block degradable heat-resistant copolyester PBSeT-HDI-PLA. According to the invention, PBSeT is used as a matrix, and the heat resistance of a sample is controllably adjusted by changing the mass ratio of PBSeT to PLA and the content of a chain extender. While the biodegradability is ensured, the thermodynamic property ofthe product is improved, and the mechanical strength of the product is high. The vicat softening point is increased by 16 DEG C compared with the vicat softening point before modification, and the heat resistance is greatly improved.

Owner:ZHONGBEI UNIV

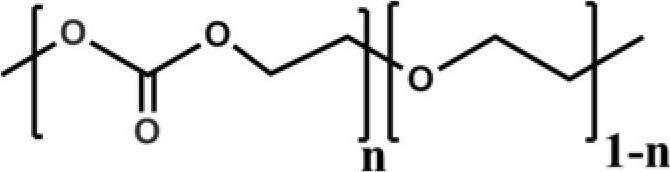

Thermal response poly-(carbonate-ether) capable of being biologically degraded and preparation method thereof

The invention discloses thermal response poly-(carbonate-ether) capable of being biologically degraded and a preparation method thereof. The method comprises a step of implementing co-polymerization reaction for carbon dioxide and ethylene oxide under a catalytic action of a composite catalyst of a duplex-metal-cyanide-rare-earth complex to obtain the poly-(carbonate-ether). Because the rare earth complex can accelerate the ring-opening reaction of the ethylene oxide, so that the method can adopt the composite catalyst of the duplex-metal-cyanide-rare-earth complex to accelerate the co-polymerization reaction, can ensure that the contents of the carbonic ester of the poly-(carbonate-ether) can be adjusted within 4% and 45%, and can ensure that the prepared poly-(carbonate-ether) has thermal response performance while being biologically degraded. The test result shows that the poly-(carbonate-ether) prepared by using the method has a thermal response behavior in water liquid and can be dissolved in water at low temperature. The polymer cannot be dissolved and separated out from water while the temperature is higher than the critical dissolving temperature. The transition temperature is 10 DEG C to 90 DEG C. Especially the poly-(carbonate-ether) has the thermal response behavior at 35 DEG C to 37 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

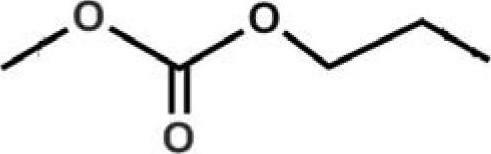

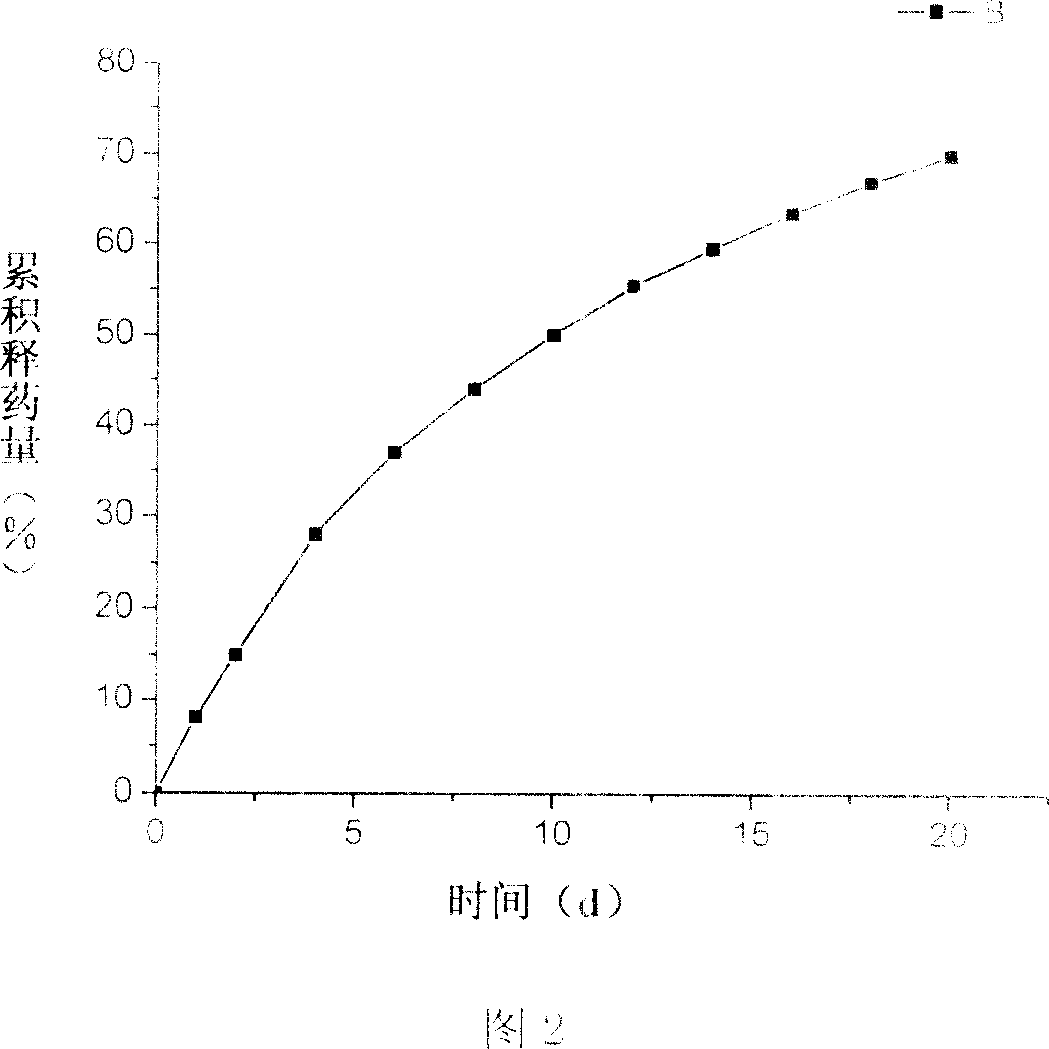

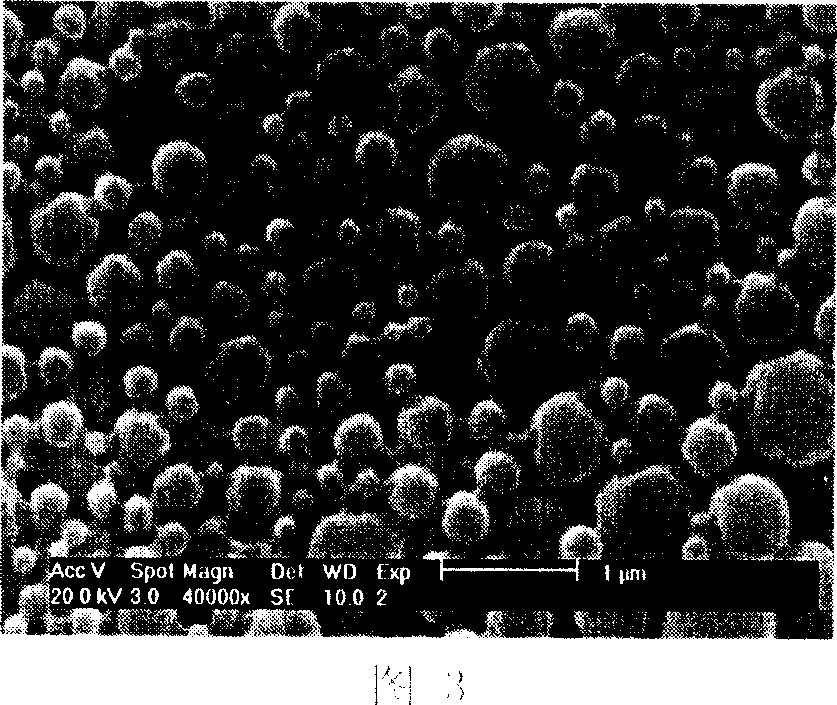

Method for preparing epirubicin slow-release prepn

ActiveCN1947721AHigh encapsulation efficiencyGood sustained release effectOrganic active ingredientsPharmaceutical non-active ingredientsFreeze-dryingMicrosphere

A slow-release epidoxorubicin-polylactic acid microball is prepared through dissolving epidoxorubicin hydrochloride in DMF, adding triethylamine, adding polylactic acid, adding water, dialyzing in water while stirring and exchanging water every 1-3 hr, centrifugal dewatering, ultrasonic treating, water washing, removing uncoated epidoxorubicin, and freeze-drying of deposit.

Owner:瀚晖制药有限公司

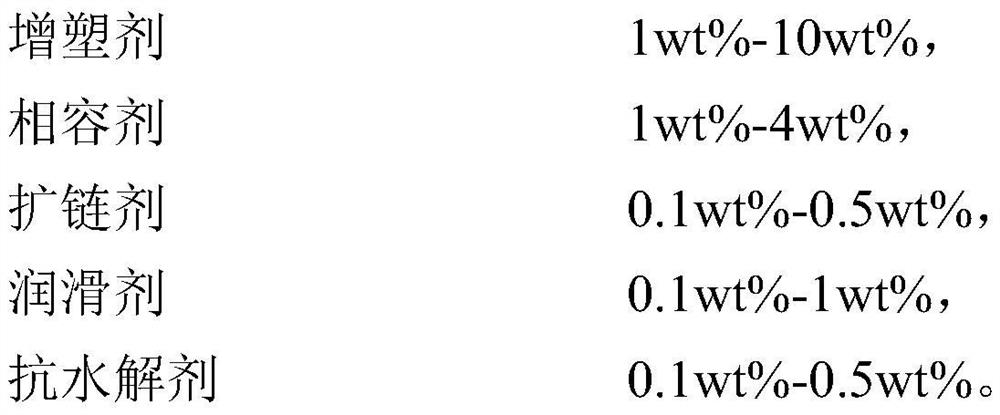

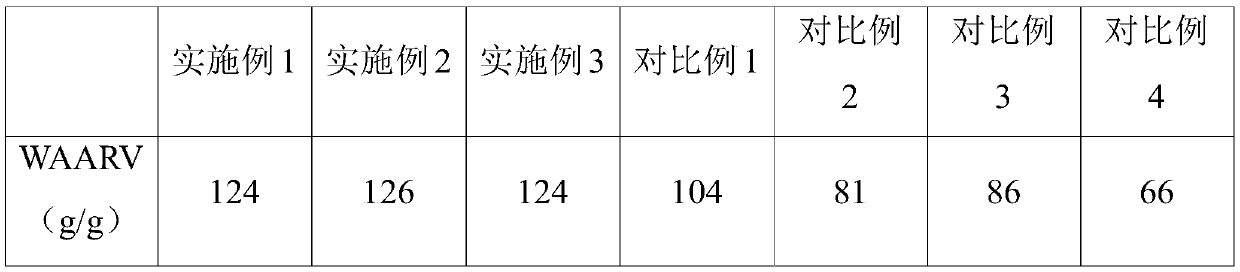

PBAT/PHA/wood powder composition suitable for preparing thin film and preparation and application of PBAT/PHA/wood powder composition

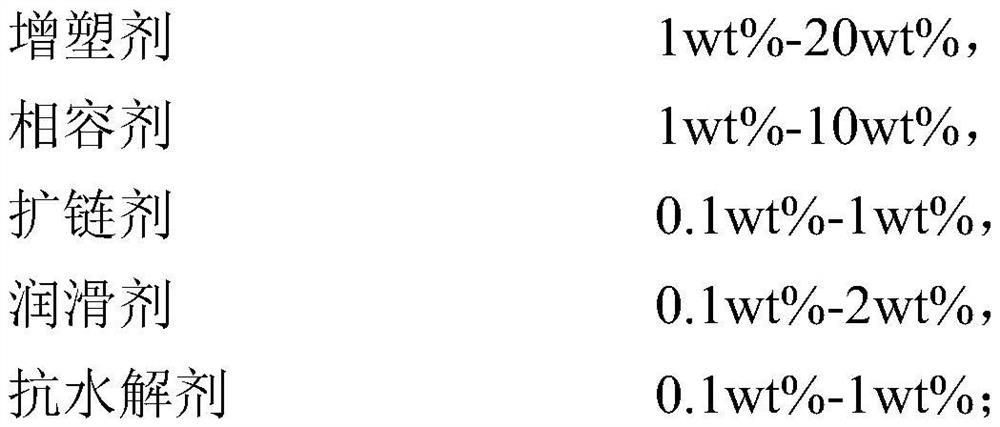

The invention discloses a PBAT / PHA / wood powder composition suitable for preparing a thin film, preparation of the PBAT / PHA / wood powder composition and application of the PBAT / PHA / wood powder composition in preparation of the thin film. The composition comprises the following raw materials: basic components and additional components. The basic components comprise the following components in parts by weight: 30-80 parts of PBAT, 5-30 parts of PHA and 5-40 parts of wood flour. Based on the total weight of the basic components, the additional components comprise 1 wt%-20 wt% of a plasticizer, 1 wt%-10 wt% of a compatilizer, 0.1 wt%-1 wt% of a chain extender, 0.1 wt%-2 wt% of a lubricant and 0.1 wt%-1 wt% of an anti-hydrolysis agent. The preparation method comprises the following steps: uniformly mixing the above raw materials in proportion, adding the formed mixture into a twin-screw granulating unit, and carrying out extruding and granulating to obtain PBAT / PHA / wood flour particles, wherein the temperature of each section of the double-screw granulating unit is in a range of 45-200 DEG C, and the rotating speed of screws is 200-450 rpm.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Preparation method of nanometer strontium hydroxyapatite and application thereof

InactiveCN103086337BPromote degradationGuaranteed biodegradabilityNanotechnologyPhosphorus compoundsFreeze-dryingDiammonium phosphate

The invention discloses a preparation method of nanometer strontium hydroxyapatite, which comprises the following steps: preparing a strontium nitrate aqueous solution and a diammonium phosphate aqueous solution with certain concentrations, adjusting the pH value of the strontium nitrate aqueous solution, mixing the strontium nitrate and the diammonium phosphate aqueous solutions to generate a nanometer strontium hydroxyapatite precipitate, standing and aging, filtering to remove the upper supernatant, washing and filtering the nanometer strontium hydroxyapatite precipitate to be neutral, performing centrifugal dewatering and freeze drying to finally obtain the nanometer strontium hydroxyapatite. When compared with nanometer hydroxyapatite, the nanometer strontium hydroxyapatite obtained in the preparation method has better biodegradability and better osteoinductivity; meanwhile, the preparation process avoids high temperature process, so the biodegradability is further ensured; The nanometer strontium hydroxyapatite obtained in the preparation method has good prospects in the application of bone repair materials.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Air-permeable and water-proof aquatic product fresh-keeping bag and preparation method thereof

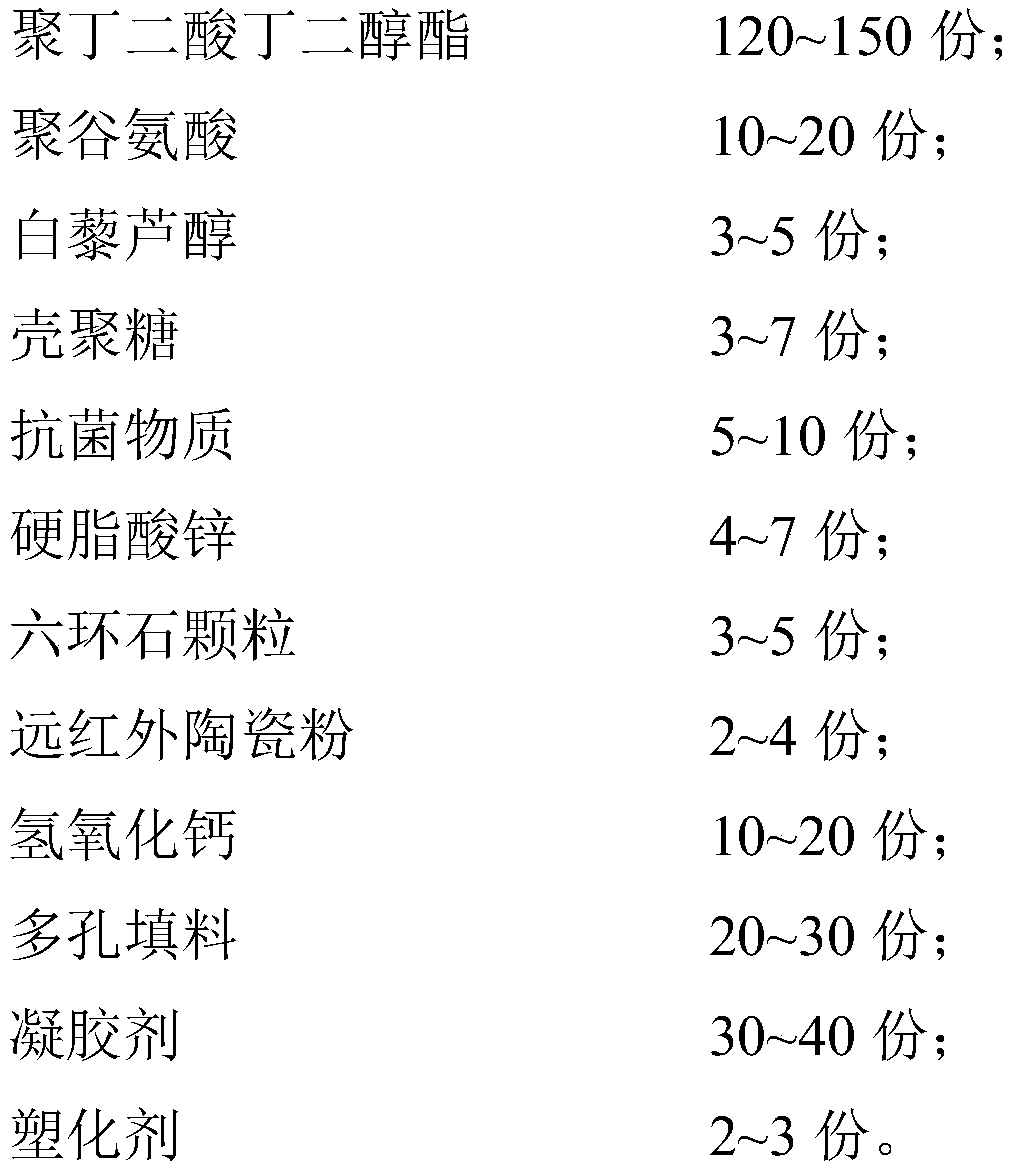

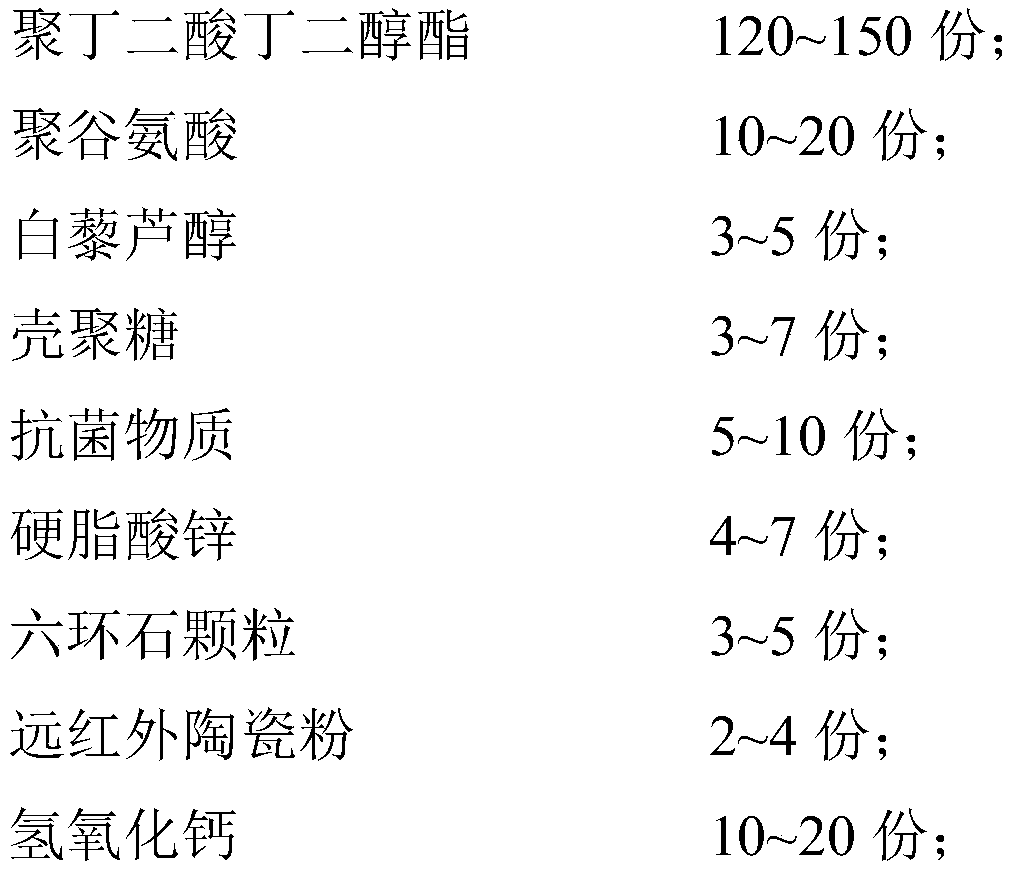

The invention provides an air-permeable and water-proof aquatic product fresh-keeping bag and a preparation method thereof. The aquatic product fresh-keeping bag has excellent air permeable and water-proof performance as well as good mechanical strength, resveratrol and antibacterial substances enable the fresh-keeping bag to have antibacterial performance, and it is guaranteed that bacteria failto breed in the fresh-keeping bag for a long time; calcium hydroxide can absorb water permeating the inside and the outside of the fresh-keeping bag, so that the fresh-keeping bag is made to have a water-proof function; porous packing can guarantee that the fresh-keeping bag has an air-permeable and water-proof function; and poly butylene succinate and polyglutamic acid enables the fresh-keeping bag to have a biodegradation function, pollution is reduced, and environment protection is facilitated. The air-permeable and water-proof aquatic product fresh-keeping bag is safe and innoxious, has noadverse influence on aquatic products and can be fully utilized, in addition, the aquatic products are not prone to rotting, the fresh-keeping bag is suitable for fresh-keeping of the aquatic products, and the fresh-keeping period of the aquatic products is prolonged.

Owner:安徽民祯活性包装材料有限公司

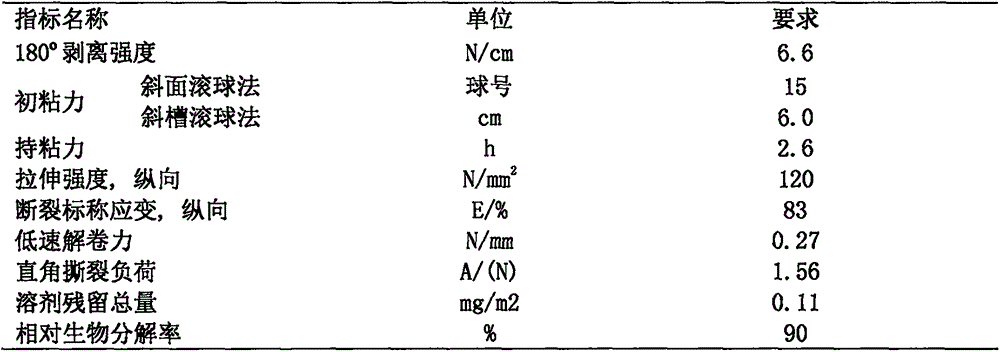

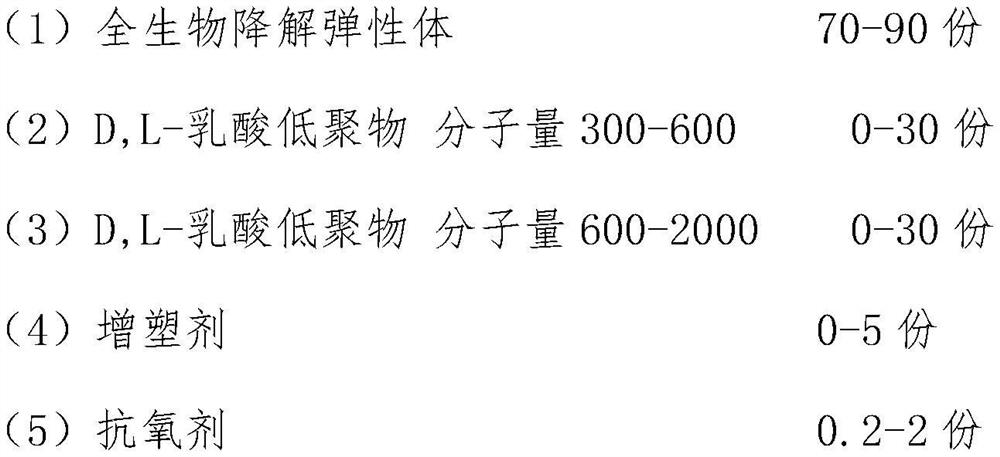

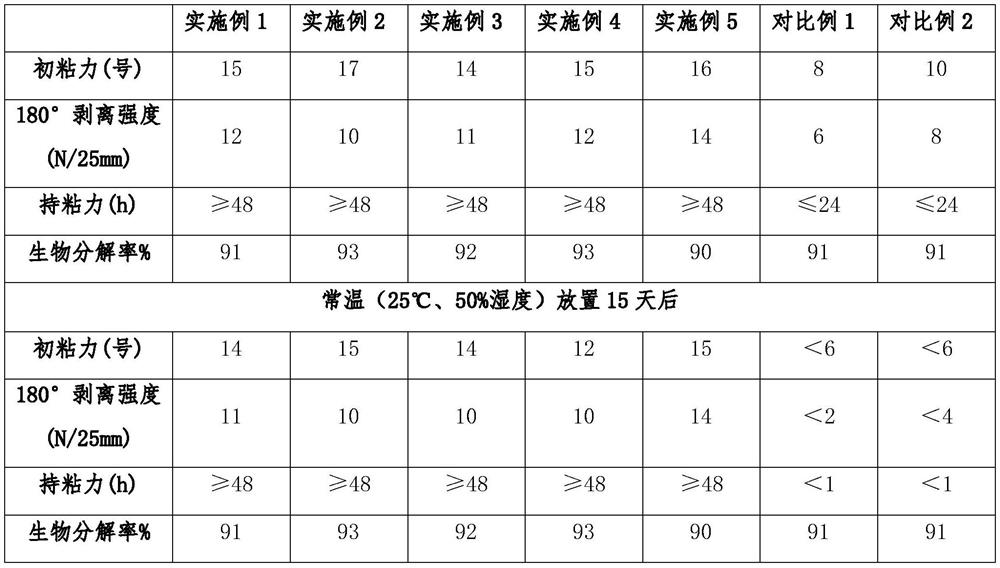

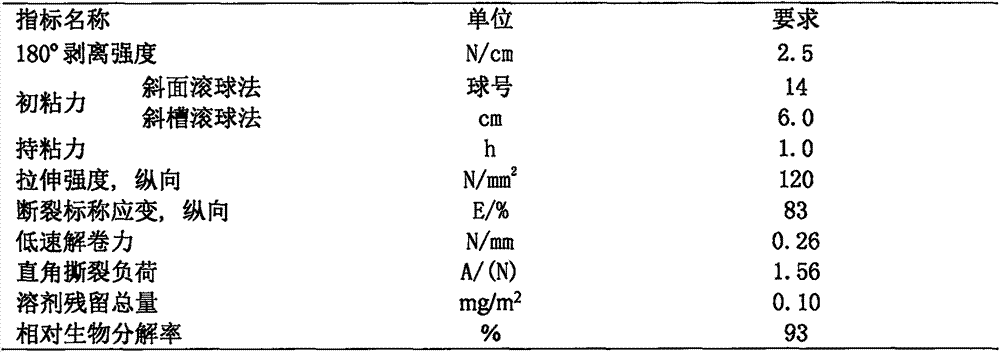

Full-biodegradable pressure-sensitive adhesive and preparation method thereof

ActiveCN112812725AHigh mechanical strengthImprove initial tackMacromolecular adhesive additivesElastomerPolymer science

The invention discloses a full-biodegradable pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared by mixing a full-biodegradable elastomer, a D, L-lactic acid oligomer with the molecular weight of 300-600, a D, L-lactic acid oligomer with the molecular weight of 600-2000, a plasticizer and an antioxidant. The pressure-sensitive adhesive has the characteristics of simple and pollution-free preparation process, no solvent, convenience in industrialization and the like. The biodegradable pressure-sensitive adhesive tape prepared from the pressure-sensitive adhesive has the advantages of large initial adhesion, high peel strength, good permanent adhesion, good biodegradability and the like.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

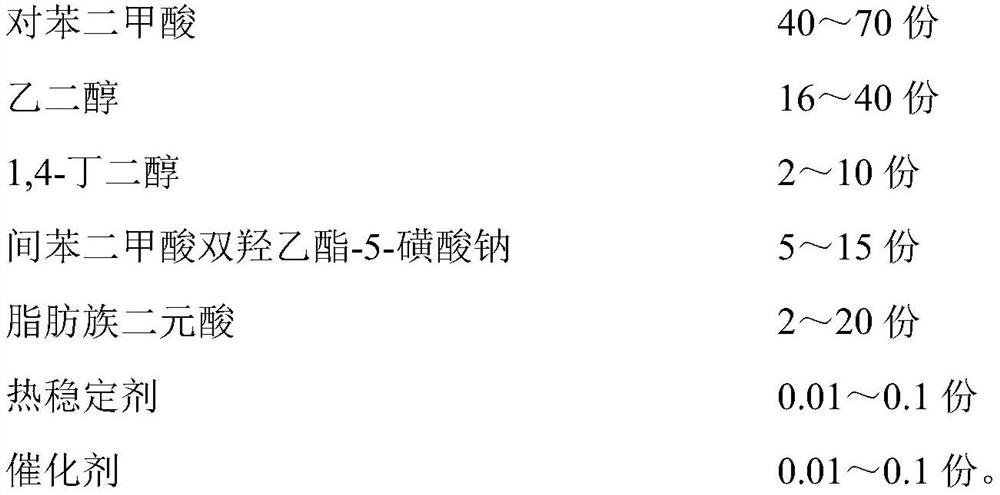

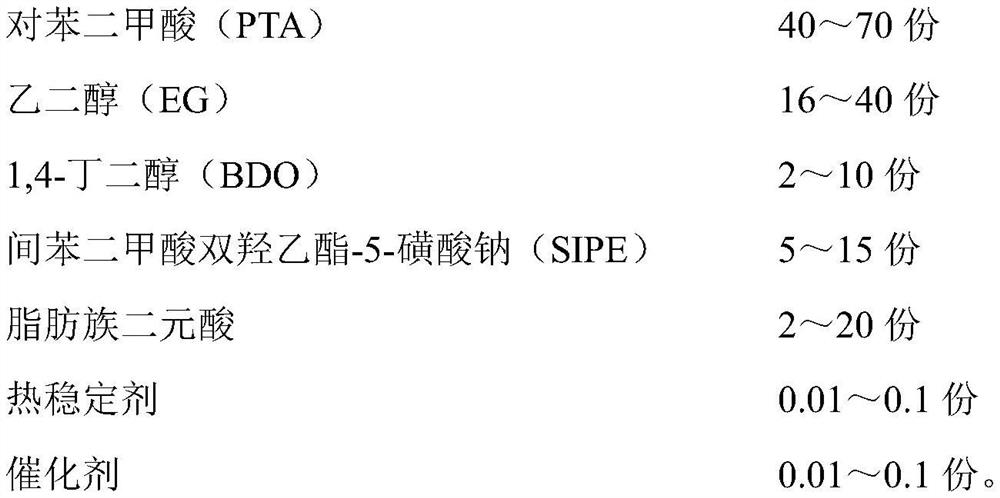

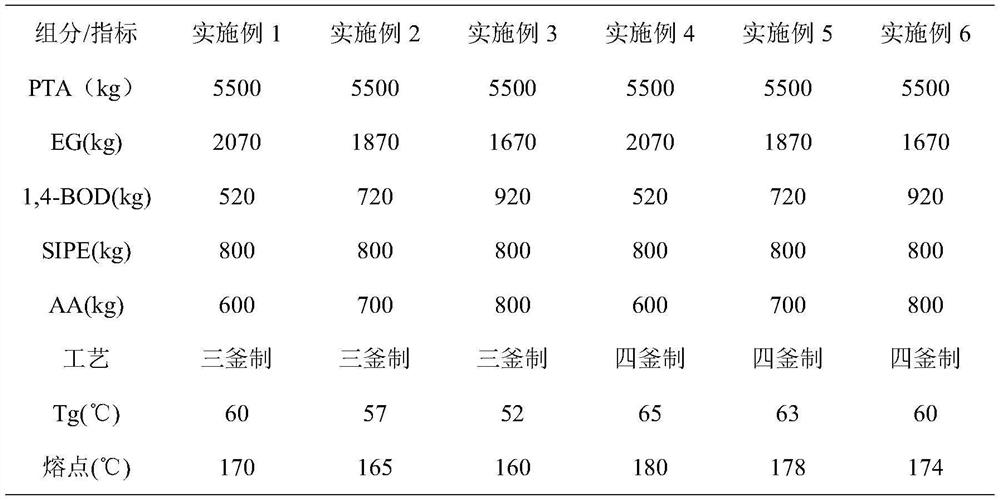

Easily biodegradable water-soluble polyester and preparation method thereof

PendingCN111777752AImprove the uniformity of copolymerizationOptimizing Process ParametersFibre typesEthyl esterYarn

The invention discloses an easily biodegradable water-soluble polyester and a preparation method thereof. According to the present invention, terephthalic acid, sodium bis(2-hydroxyethyl)isophthalate-5-sulfonate, ethylene glycol, 1, 4-butanediol, an aliphatic dibasic acid modified monomer and other components are subjected to copolymerization modification to successfully prepare the high BOD5 / CODcr type water-soluble polyester with excellent biochemical degradability, meanwhile, an intermittent four-kettle process is adopted, a step-by-step polymerization process is realized, process parameters are optimized, a final product has the characteristics of easiness in sizing, easiness in desizing, high glass-transition temperature and the like, and the use requirements of efficient sizing and green desizing of polyester chemical fiber filaments, short fibers and polyester-nylon composite yarns are met.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

Surgical dressing bandage

Provided is a surgical dressing bandage. The surgical dressing bandage is characterized in that one face of a surgical dressing is coated with a medical adhesive and bonded with release paper, and when used, the surgical dressing bandage adheres to the surface of a wound after the release paper is torn off; the dressing is made of sodium alginate fiber, and biodegradability and high water absorption are achieved.

Owner:SHAOXING RUIKAI PROTECTION PROD CO LTD

Starch-based degradable straw material and preparation method thereof

PendingCN114031909ALow costIncrease the rate of crystallizationTubular articlesPolymer sciencePlasticizer

The invention discloses a starch-based degradable straw material and a preparation method thereof, and belongs to the technical field of high polymer materials, the starch-based degradable straw material comprises the following components by weight: 60-80 parts of PLA, 3-7 parts of PBAT, 5-30 parts of starch, 3-10 parts of a plasticizer, 0.5-1 part of a nucleating agent, 0.5-1 part of erucyl amide, and 0.5-2 parts of a hyperbranched auxiliary agent; the preparation method of the starch-based degradable straw material comprises the following steps: carrying out high-speed melt blending on PLA, PBAT, starch, a plasticizer, a nucleating agent, erucyl amide and hyperbranched resin, and carrying out extrusion processing to obtain the starch-based degradable straw material. The starch-based degradable straw material has high heat resistance, high toughness and biodegradability.

Owner:浙江通力新材料科技股份有限公司

Degradable appliance dental cast resin for SLA 3D printing and preparation method of same

PendingCN111171241AProne to photopolymerizationImprove formation efficiencyAdditive manufacturing apparatusCellulosePolymer science

The invention discloses degradable appliance dental cast resin for SLA 3D printing. The degradable appliance dental cast resin is prepared by mixing hydroxyl acrylate, urethane acrylate, cellulose modified polylactic acid ester, an acrylate monomer, a photoinitiator, an inorganic filler and a defoaming agent; wherein the acrylate monomer and the photoinitiator enable the mixture to be subjected toa photopolymerization reaction very easily, so that the photocuring efficiency is improved; the cellulose modified polylactic acid ester enables the dental cast resin to have the advantage of high degradation speed; the added defoaming agent can effectively eliminate bubbles in the resin liquid, so that the quality and the success rate of printed products are improved; the added inorganic fillerdoes not influence the biodegradability, enhances the hardness, compressive strength and notch impact strength of the material, and satisfies the use requirements in the field of oral appliances. Thematerial cost is equivalent to that of a traditional material, and the material has the advantages of being high in degradation speed, high in hardness, high in compressive strength, small in shrinkage rate, convenient to manufacture and low in manufacturing cost.

Owner:SHANDONG HUGE DENTAL MATERIAL CO LTD

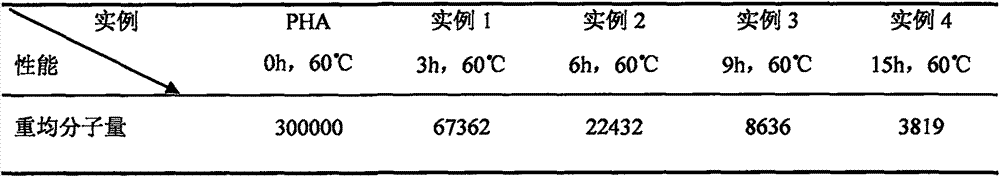

Biodegradable adhesive as well as preparation method and application thereof

ActiveCN107418492AAvoid exceeding the standard of volatile harmful gasesSimple processing technologyAdhesivesChemistryWater soluble

The invention relates to a biodegradable adhesive material prepared by using a chemical degradation product of a polyhydroxyalkanoate (PHA) alkali liquor and belongs to the field of adhesives. The method comprises the steps of firstly pouring a PHA material into a reaction container with an alkali solution at the ratio of 5-30% of the mass of the alkali solution, wherein a reactor has stirring and temperature control functions; controlling the reactor at a certain reaction temperature while stirring, stopping stirring after reacting for a period of time and obtaining a PHA alkaline chemical degradation product; and diluting the PHA alkaline chemical degradation product by using distilled water to obtain the biodegradable adhesive. The adhesive is a water-soluble adhesive, has the characteristics of being simple in preparation, controllable in relative molecular weight and viscosity and biodegradable, can be applied to the fields of adhesive tape, leather, sticker, stationery, office, electrons and automotive trim fixation, footwear industry and handmade jewelry pasting and fixation.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

High-water-absorption aerogel packaging material prepared from reed waste residues and preparation method thereof

ActiveCN111592680AWon't happenAchieve the purpose of enrichmentBio-packagingPaper material treatmentGlycineFreeze-drying

The invention discloses a high-water-absorption aerogel packaging material prepared from reed waste residues and a preparation method thereof. The method comprises the following steps: (1) crushing reed waste residues, soaking in a sodium hydroxide solution for 4-8 hours, filtering, and collecting and cleaning a solid-phase product; (2) putting the solid-phase product into a mixture of lactic acidand glycine betaine, uniformly stirring, filtering, and collecting a solid-phase product; (3) grinding the product obtained in the step (2), and heating at 60-75 DEG C for 2-5 hours; (4) stirring andmixing a starch-acrylic acid graft copolymer and phosphate, cooling to 60-75 DEG C, adding the product obtained in the step (3), and continuing stirring for 2-6 hours; and (5) carrying out freeze drying. The aerogel packaging material prepared by the invention has excellent degradation performance and water absorption performance, and is non-toxic, harmless, environment-friendly and safe.

Owner:QILU UNIV OF TECH

Biodegradable heat shrink film and processing technology thereof

PendingCN114015185AOptimized Strength and Heat ShrinkageGuaranteed biodegradabilityAnoxomerPolymer chemistry

The invention discloses a biodegradable heat shrink film and a processing technology thereof, and relates to the technical field of heat shrink films. The biodegradable heat shrink film is prepared from the following raw materials by weight: 100 parts of modified polylactic acid, 0.5-5 parts of an anti-static agent, 0.5-5 parts of a lubricant, 0.5-5 parts of an antioxidant, and 0.5-5 parts of a light stabilizer. The polylactic acid is used as a processing raw material of the heat shrink film, and the green and environment-friendly heat shrink film is prepared by using the excellent biodegradability of the polylactic acid, so that the problem of environmental pollution caused by discarding of a conventional heat shrink film is relieved.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

A kind of fully biodegradable pressure-sensitive adhesive and preparation method thereof

ActiveCN112812725BHigh mechanical strengthImprove initial tackMacromolecular adhesive additivesElastomerPolymer science

The invention discloses a fully biodegradable pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is composed of a fully biodegradable elastomer, a 300-600 molecular weight D,L-lactic acid oligomer, and a 600-2000 molecular weight D,L-lactic acid oligomer. It is prepared by mixing lactic acid oligomers, plasticizers and antioxidants. The pressure-sensitive adhesive has the characteristics of simple and pollution-free preparation process, no use of solvent, convenient industrialization and the like. The biodegradable pressure-sensitive adhesive tape prepared by the pressure-sensitive adhesive has the advantages of high initial adhesion, high peeling strength, good holding force, good biodegradability and the like.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

Totally degradable foam buffer packaging material and its manufacturing method

The invention provides a complete biodegradable foam cushioning packing material and method for preparation, characterized in that starch over 80% content is used as base-material, ultra-fine polyvinyl alcohol is used as film forming intensifier, water is used as foaming agent, and core forming agent and flow modifier are added, wherein the mixture is amalgamated through blending homogeneous machine and fed into reverse-flighted screw extrusion machine for one-shot extrusion forming. The product can be used to substitute polystyrene foam for filling with no requirement on shapes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

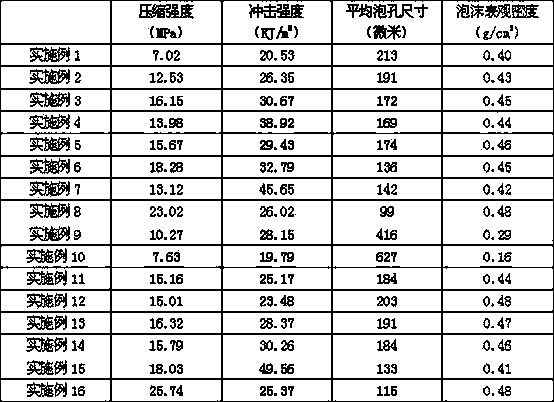

Hollow microsphere reinforced polylactic acid (PLA)-based composite foaming material and preparation method thereof

The invention discloses a hollow microsphere reinforced polylactic acid (PLA)-based composite foaming material and a preparation method thereof. The foaming material has the apparent density of 0.15 to 0.8g / cm<3>, the compressive strength of 7 to 25MPa, the impact strength of 20 to 50KJ / m<2> and the average cell size of 90 to 630mu m and consists of the following raw materials in part by weight: 50 to 93 percent of PLA, 1 to 20 parts of hollow glass microspheres, 1 to 30 parts of biodegradable toughening agent, 1 to 3 parts of nano-nucleating agent, 0.5 to 3 parts of cross-linking agent, 1 to 10 parts of foaming agent, 0.1 to 1 part of foaming aid, 1 to 3 parts of antioxidant, 1 to 2 parts of lubricating agent and 0.5 to 1.5 parts of surfactant. The method comprises the following steps of: extruding and granulating the raw materials at the temperature of between 100 and 190 DEG C, and performing foam forming on a foaming masterbatch on a flat vulcanizing machine at the temperature of between 120 and 200 DEG C. Composite foamed plastic with high mechanical property and surface quality can be prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of biodegradable regenerated polyester staple fibers

ActiveCN102828276BPrevent volatilizationBalance internal stressFilament forming substance formingArtificial filament heat treatmentPolyesterPolymer science

The invention discloses a preparation method of biodegradable regenerated polyester staple fibers, which is characterized by comprising the steps of drying spinning materials by a vacuum drum, mixing with biodegradable master batch dried by a master batch drying system at the feed inlet of a screw extruder; preparing primary fibers after mixing and fusing by the screw extruder and extruding by a spinneret plate; cooling primary fibers by an annular blowing device; successively carrying out winding, falling, bundling and time balancing on the primary fibers in a constant temperature and constant-humidity room; stretching the primary fibers in oil bath and stream respectively; performing curling, relaxation heat setting, cutting and packaging to obtain biodegradable regenerated polyester staple fibers, wherein physical properties and mechanical properties of the biodegradable regenerated polyester staple fibers produced by the method do not change, and therefore, the subsequent processing and usage are not influenced; after being used, the fibers can be decomposed into inert humus, carbon dioxide and water in a microorganism-enriching environments such as refuse landfill or composting site, thereby returning to nature and achieving real biodegradation.

Owner:福建鑫华股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com